An efficient loading method and system for automatically identifying goods

A technology of automatic identification and goods, applied in the field of mechanical control, can solve the problems of many steps, large hidden dangers of production safety, and inability to solve the problem of inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

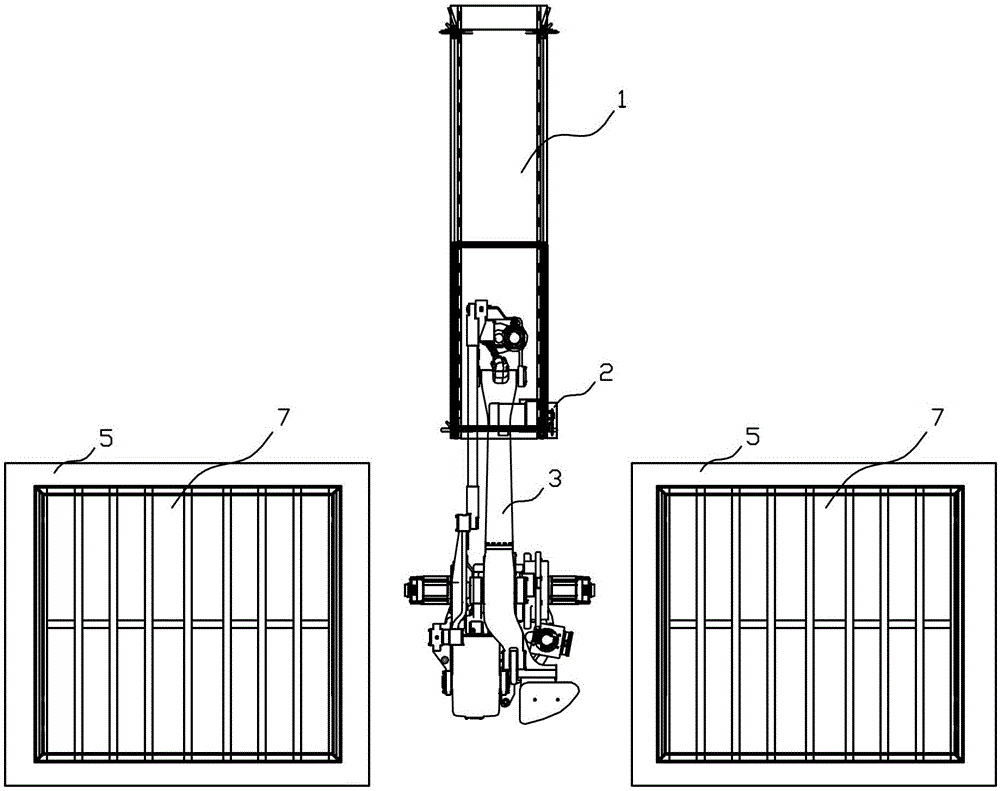

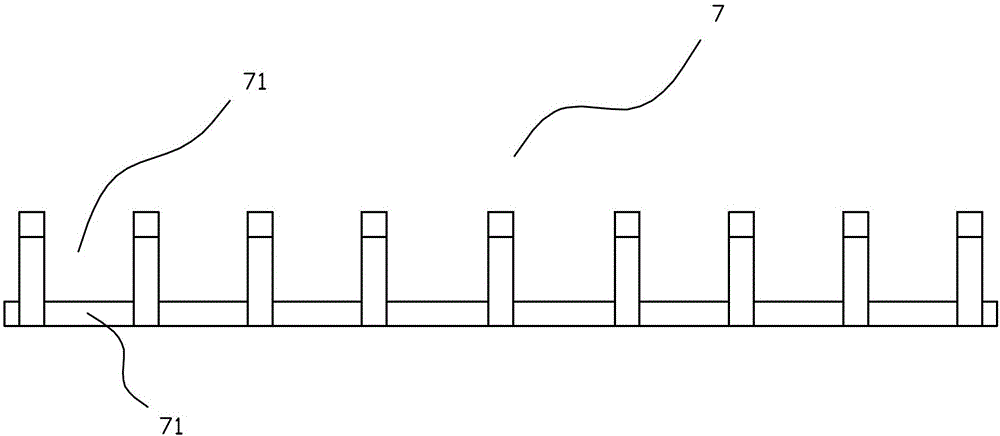

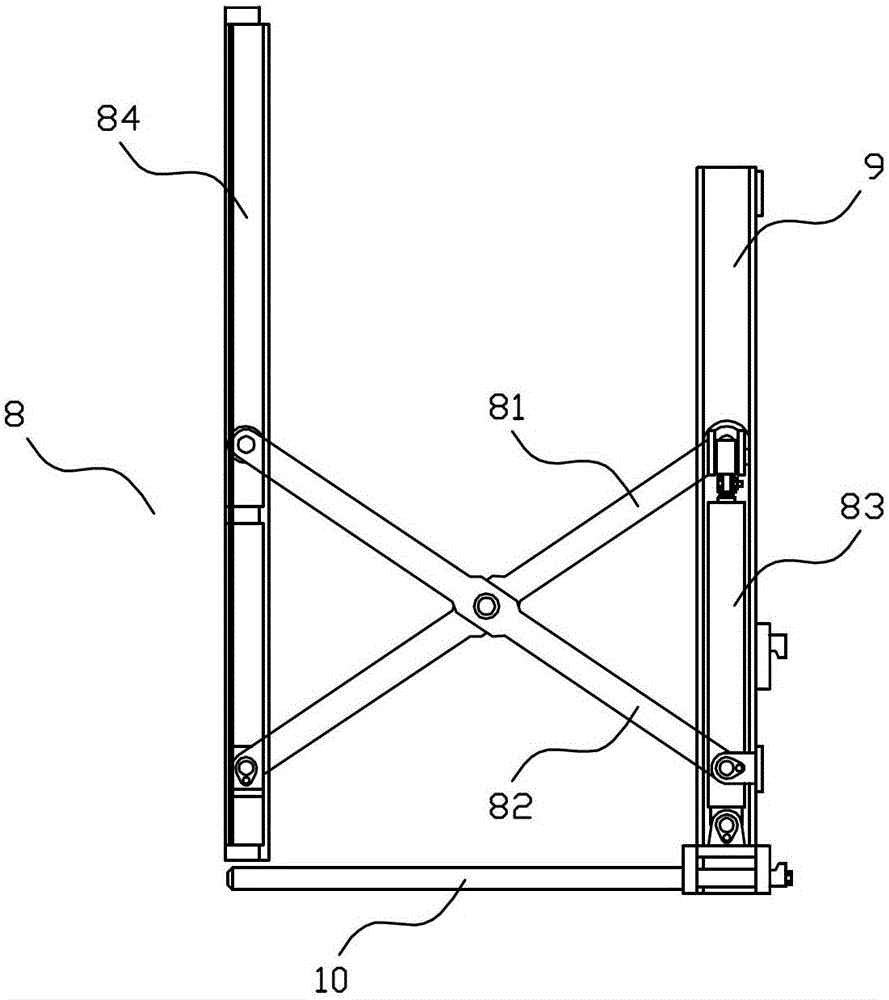

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] The invention provides an efficient loading method for automatically identifying goods, the steps are as follows:

[0035] 1) Define the cargo identification code and the cargo parameters corresponding to the identification code (including the length, width, height, and weight of the cargo); preset compartment size and total loading weight;

[0036] 2) The cargo identification code reading device identifies the cargo identification code, and reads the cargo parameters corresponding to the cargo identification code from the database;

[0037] 3) Calculate the total number of pieces loaded according to the parameters of the goods and the total weight of the load;

[0038] 4) According to the total number of pieces loaded, the size of the carriage, and the parameters of the goods, the stacking model of the goods in the carriage is establi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com