Patents

Literature

972 results about "Transfer station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A transfer station is a building or processing site for the temporary deposition of waste, often called Waste Transfer Stations, or Material Recycling Facilities (MFU). Transfer stations are often used as places where local waste collection vehicles will deposit their waste cargo prior to loading into larger vehicles. These larger vehicles will transport the waste to the end point of disposal in an incinerator, landfill, or hazardous waste facility, or for recycling.

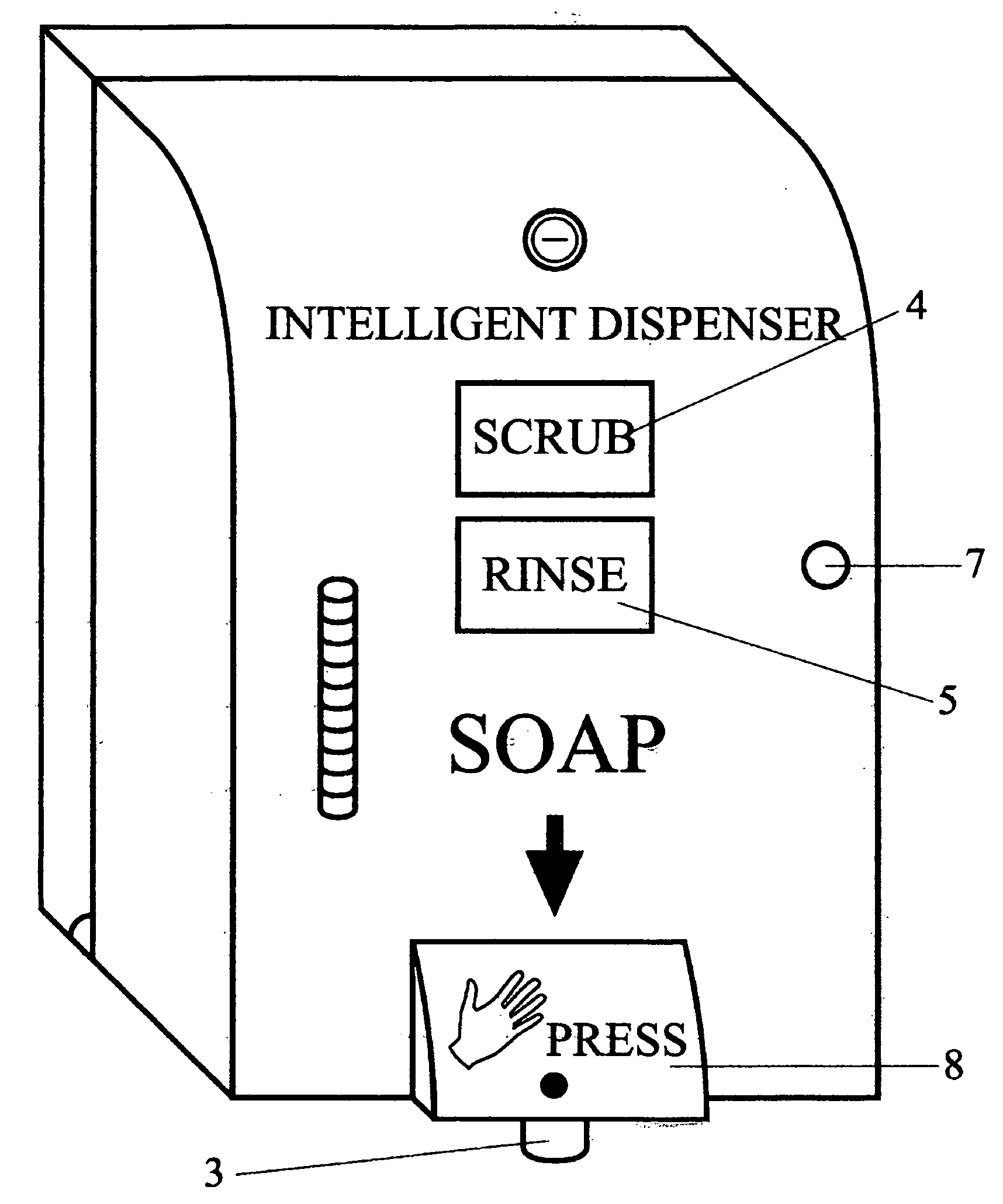

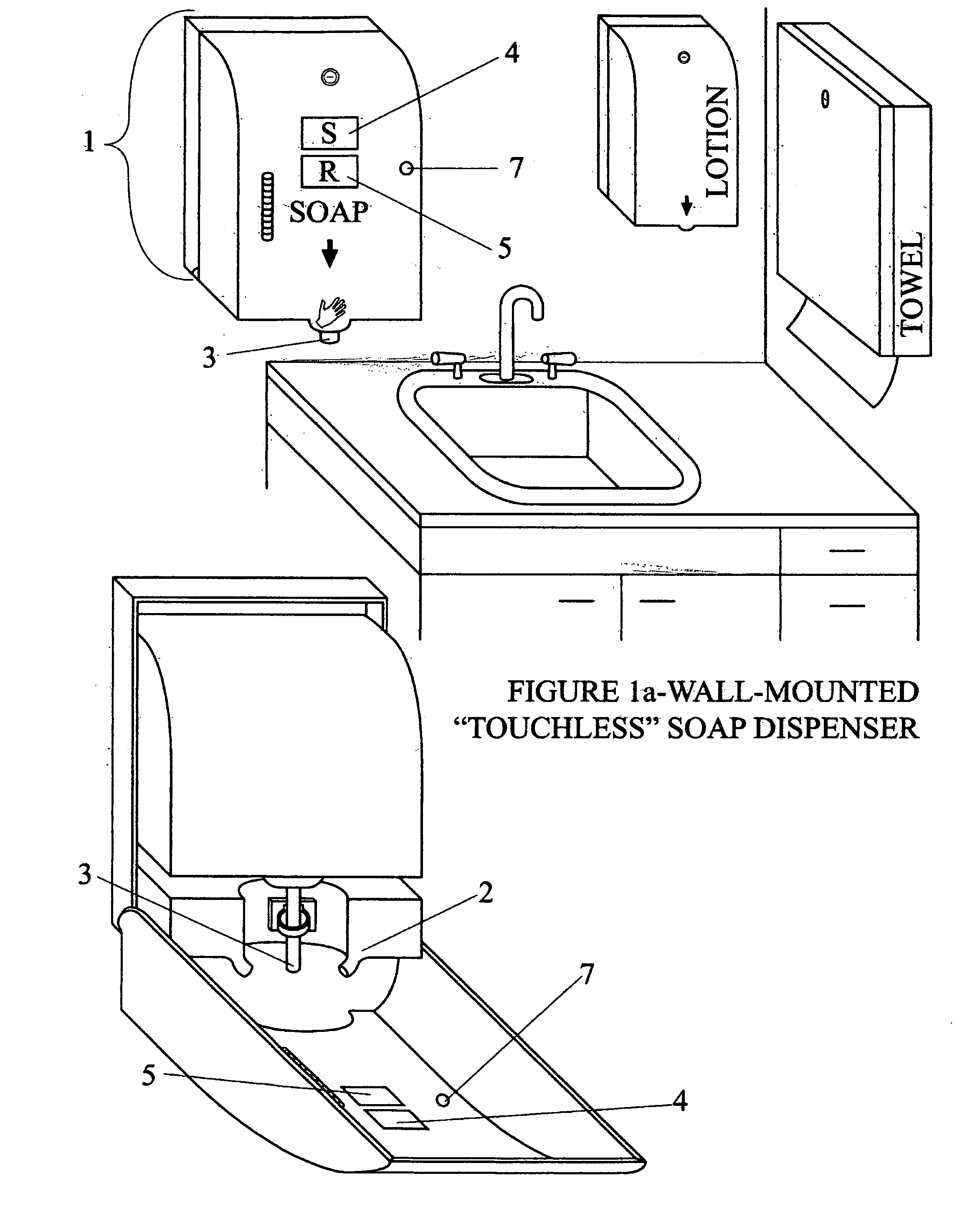

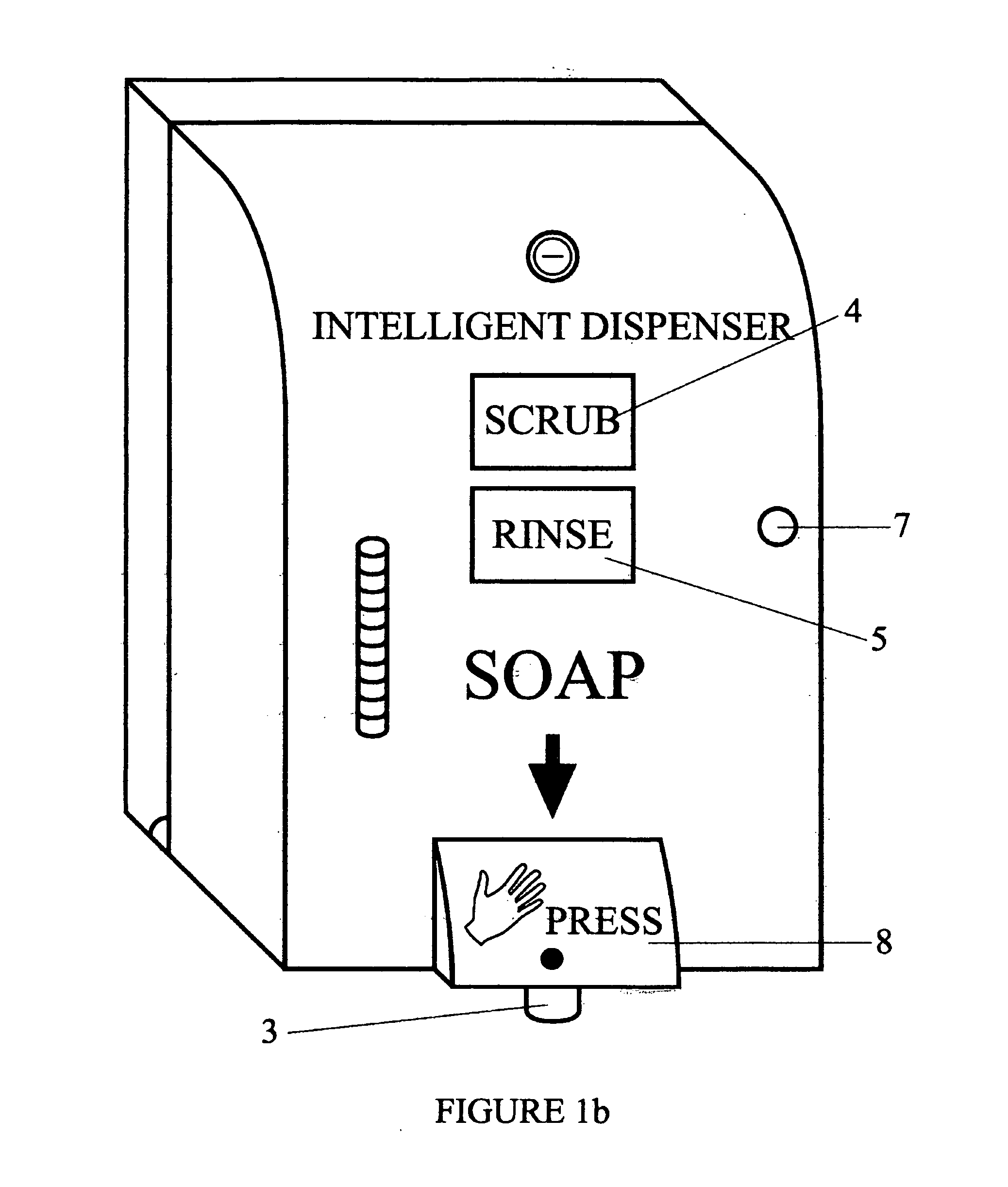

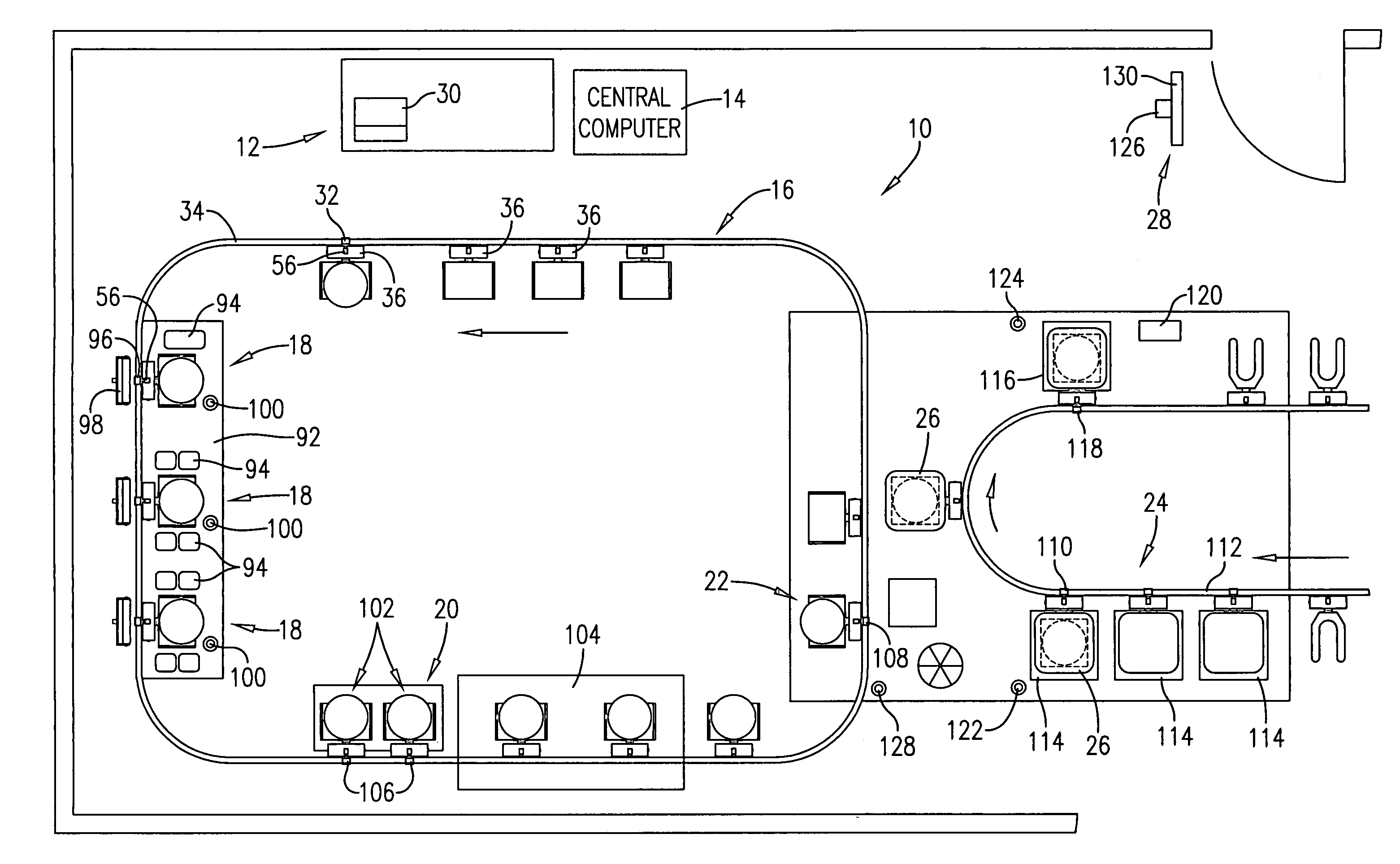

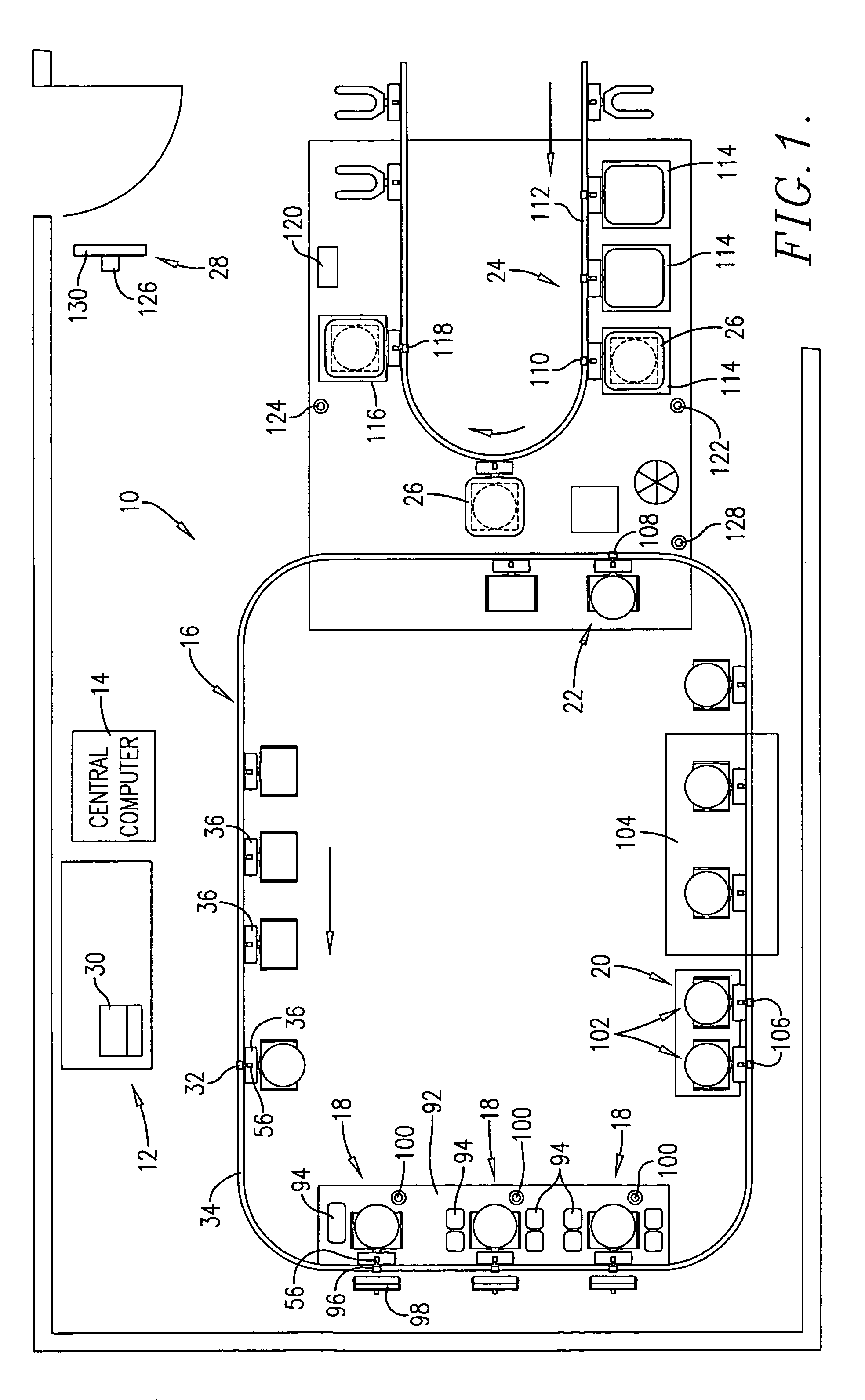

Proactive hand hygiene monitoring system

InactiveUS20090195385A1Absolute accuracyMinimize cross infectionHospital data managementHealthcare resources and facilitiesData transmissionEntry exit

A system consists of remote identification tag (in the form of wristband) for personnel who must undergo hand hygiene frequently during a day's work, programmed soap and rinse-free disinfectant dispensers, entry-exit sensors for controlled access areas and data transfer stations is used to monitor and record every handwashing procedure along with its thoroughness as well as every hand cleaning event with rinse-free disinfectant. The system will further prompt each worker's identification tag at an appropriate place to examine its record to see whether a hand hygiene procedure is required before proceeding to his / her next task. The recorded data with time-date of each event will be transferred to a central computer for statistical analysis and presentation as a daily and / or periodic hand hygiene compliance report on each staff, department, shift and the entire institution.

Owner:HUANG CHING CHING +2

Method for preparing high-concentration biological deodorant

The invention relates to a method for preparing a high-concentration biological deodorant. The method uses natural plants and extracts thereof with deodorizing function, a carbon source, a nitrogen source, trace elements and the like as raw materials, screens special beneficial microbial strains, and ferments the strains to obtain the high-concentration deodorant containing active components of the plants, beneficial microbe and metabolic products by adopting modern bioengineering technology. After being diluted by clear water which is 2,000 times of the deodorant, the deodorant is directly sprayed; and by decomposing smelly substances such as ammonia, hydrogen sulfide, methyl mercaptan, trimethylamine and the like, the growth of harmful microbe generating bad smell in rubbish and smell sources is suppressed so as to achieve the purposes of removing bad smell, repelling flies and reducing disease spreading risk. The deodorant is used for deodorizing in rubbish transfer stations, landfill sites, breeding farms, public toilets, toilets and other rotten places. The deodorant breaks through the defect of low dilution factor of the conventional deodorant, and implements the diluting use of 2,000 times. The cost is reduced while achieving the first level of deodorizing effect, and the acute oral toxicity test shows that the deodorant belongs to a practical non-toxic deodorant product.

Owner:北京普仁生态技术有限公司

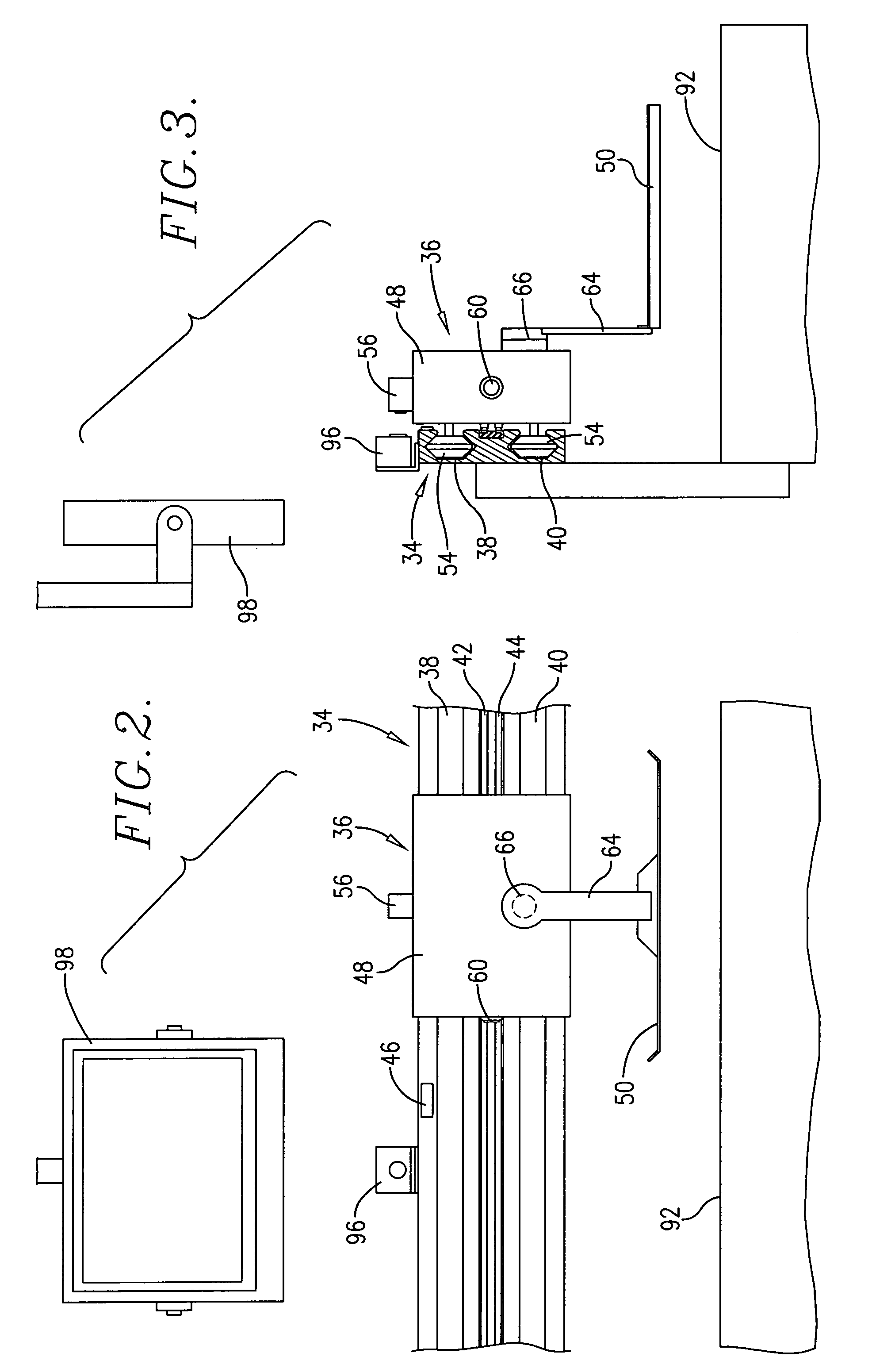

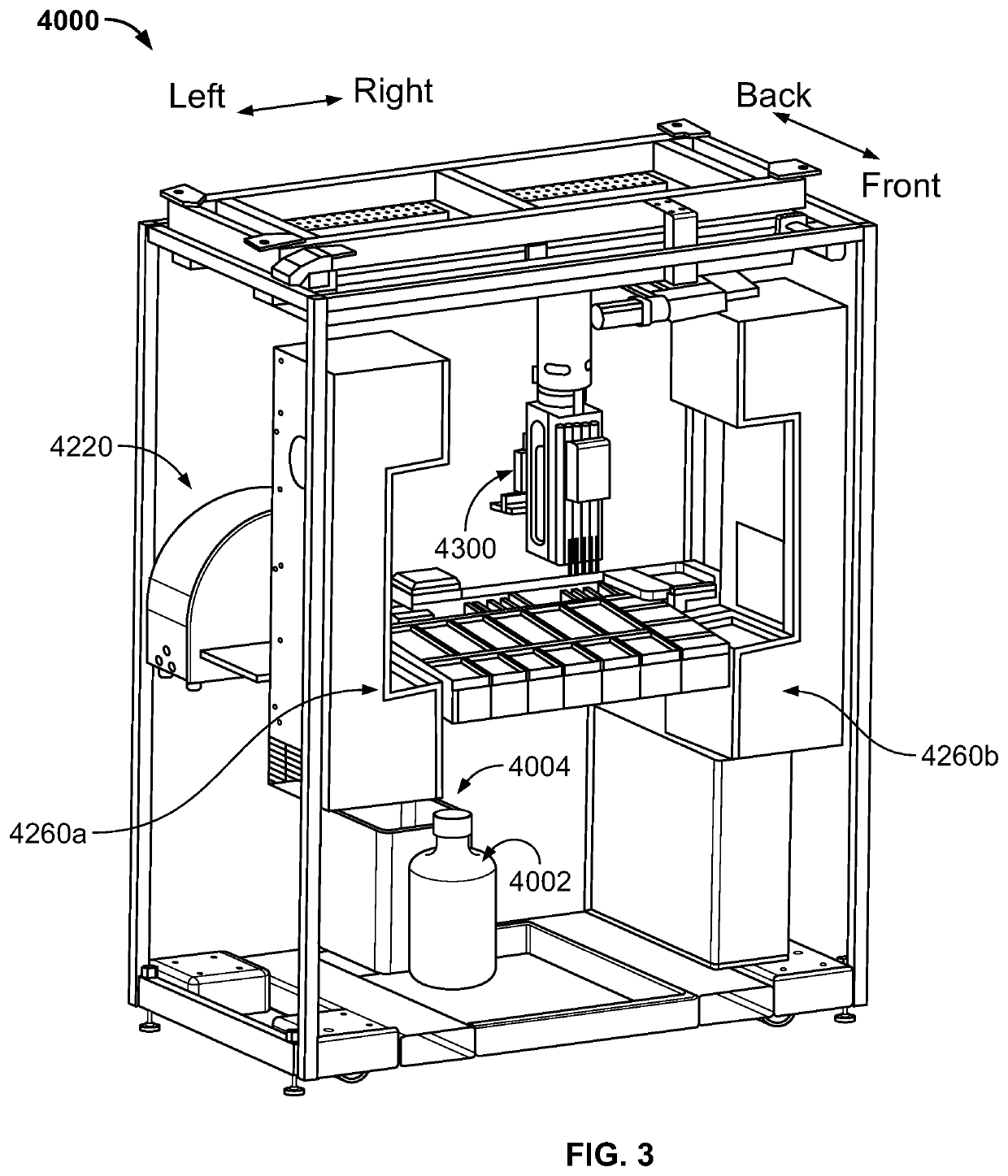

Food preparation system

InactiveUS20050256774A1Reduces and even eliminates human mistakeEfficient solutionLiquid transferring devicesNon-mechanical conveyorsEngineeringDelivery system

A food preparation system and method that partially automates the ordering, preparation, and delivery of food items such as pizza. The food preparation system broadly comprising an ordering or point-of-sale station, a computing device, a conveyor system, at least one food preparation station, at least one heating station, a transfer station, a delivery station including at least one delivery device, and an entry / exit station.

Owner:TSI TECH

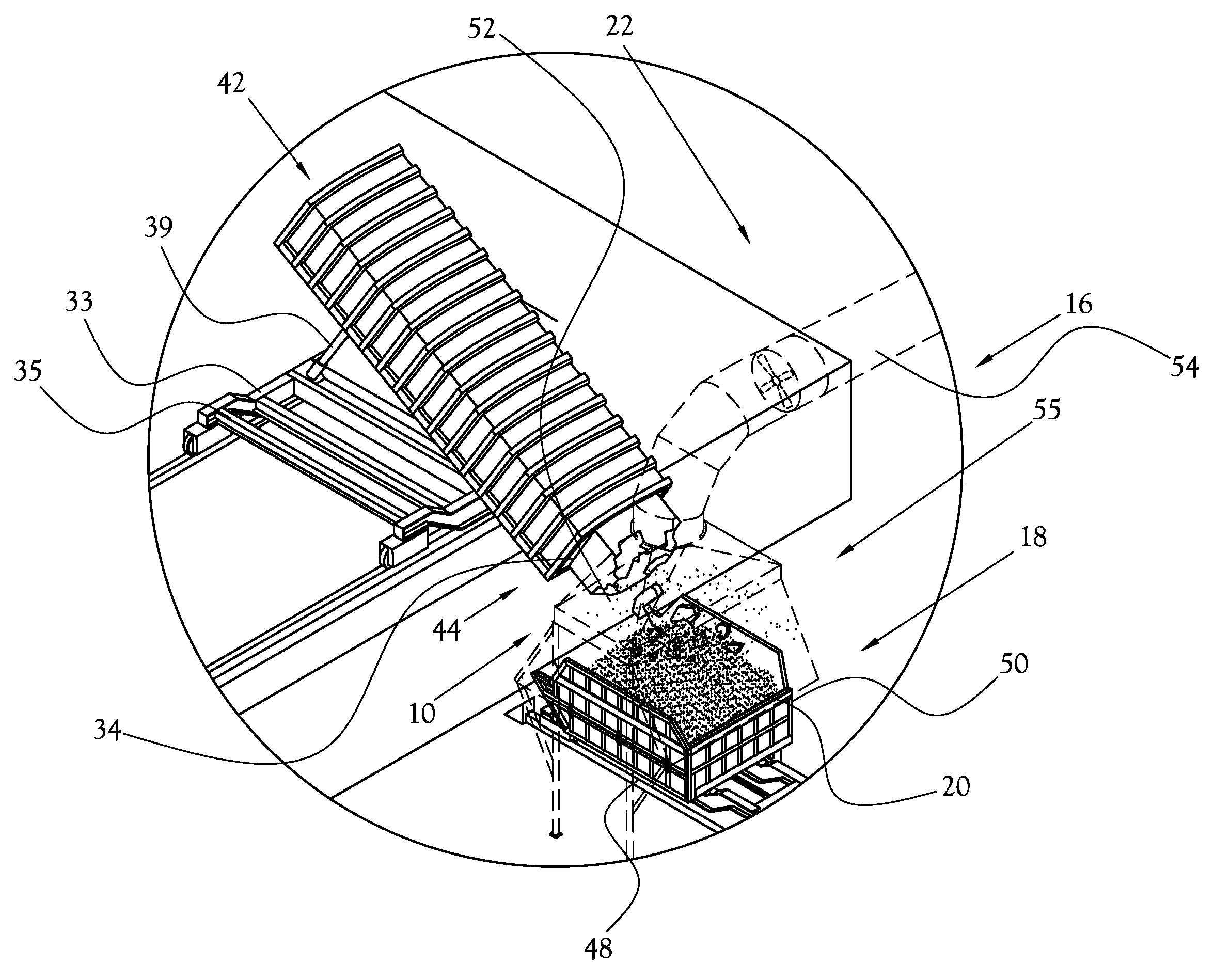

Process for transporting and quenching coke

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

Wave Motion Power Generator

InactiveUS20110121572A1Effective contactEasy to transportEngine fuctionsMachines/enginesOpen waterHydraulic motor

A power generation system is provided that can capture and convert kinetic energy from waves in open water into hydraulic or electrical energy. The system includes one or more platforms that include buoyant arms which extend outwardly from the platform for interaction with waves passing around and beneath the platform. The arms are pivotally secured to the platform and are capable of moving between points above and below the still water level in order to more effectively contact, i.e., float on, the waves as they pass. Opposite the waves, the arms are operably connected to a hydraulic system in order that the fluid in the hydraulic system is effectively pumped by the motion of the arms as a result of the movement of arms resulting from their interaction with the waves. In turn, the hydraulic fluid pumped by the arms serves to operate a hydraulic motor that drives an electric power generator that provides an easily transportable source of power that can be directed to any suitable power transfer station.

Owner:COASTAL HYDRO

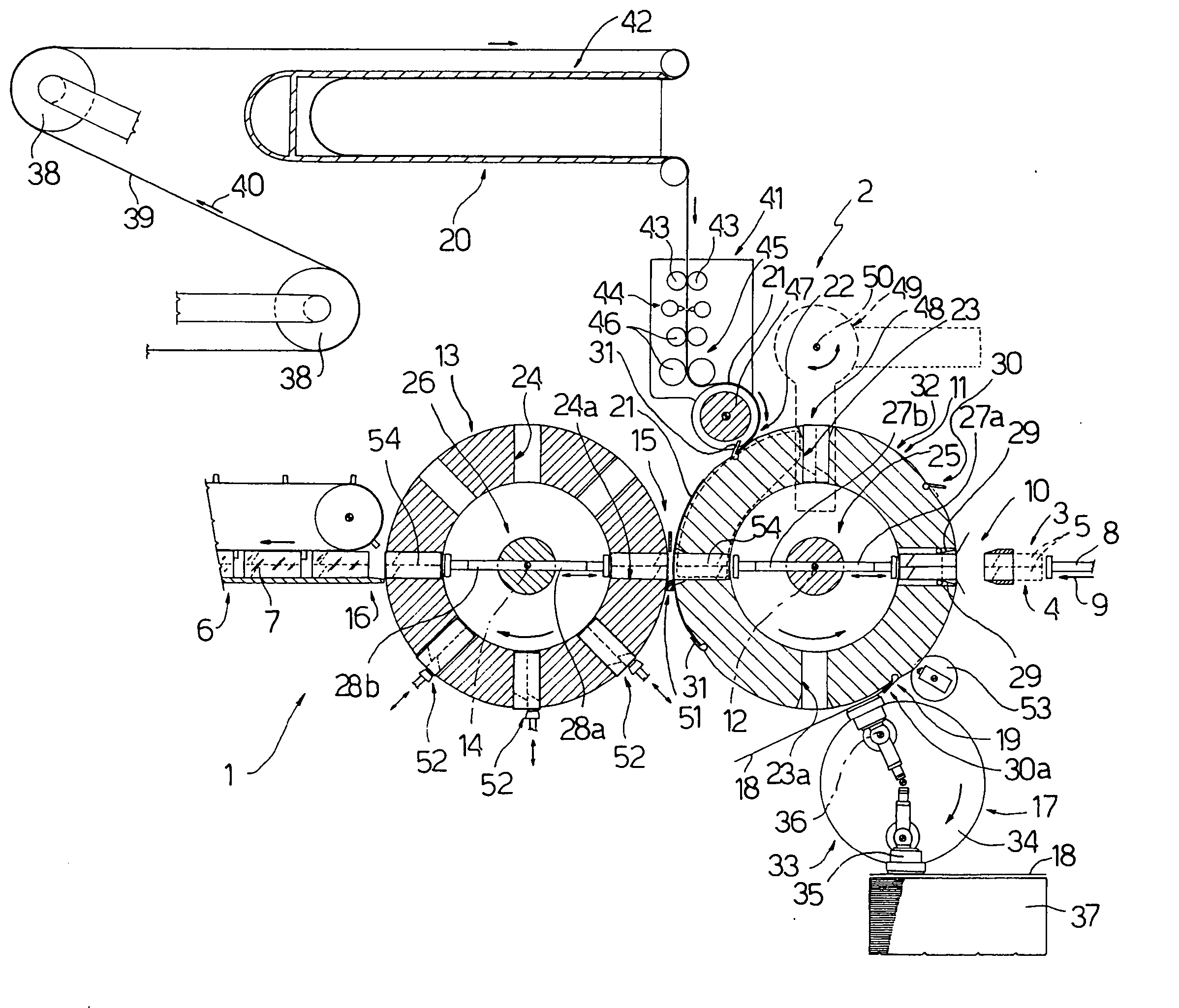

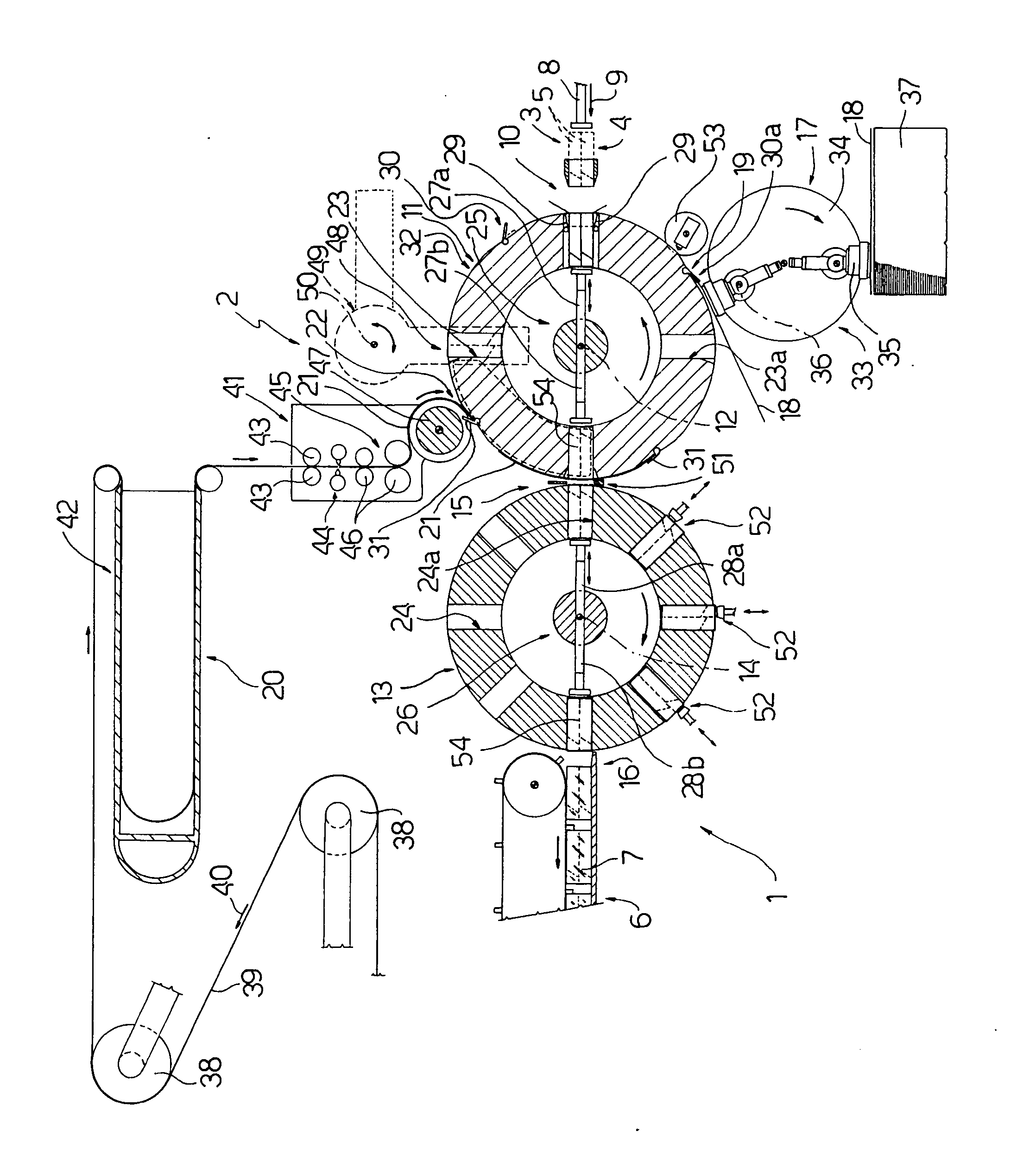

Method and unit for packing groups of products

InactiveUS20050005580A1Drawback can be obviatedPackaging cigaretteWrapper folding/bending apparatusMechanical engineeringPinch grip

A method and unit for packing groups of products, whereby each group is fed, at a loading station, to a respective radial first seat of a first wheel, together with a relative blank, which is first folded into a U and then completely about the relative group to form a packed group, which is transferred, at a transfer station, to a respective radial second seat of a second wheel, together with a relative sheet of overwrapping material, which is first folded into a U and then completely about the relative packed group to form an overwrapped group; the blank and the sheet of overwrapping material both being fed successively to a respective same gripper associated with the relative first seat and fitted to the first wheel, downstream from the first seat.

Owner:GD SPA

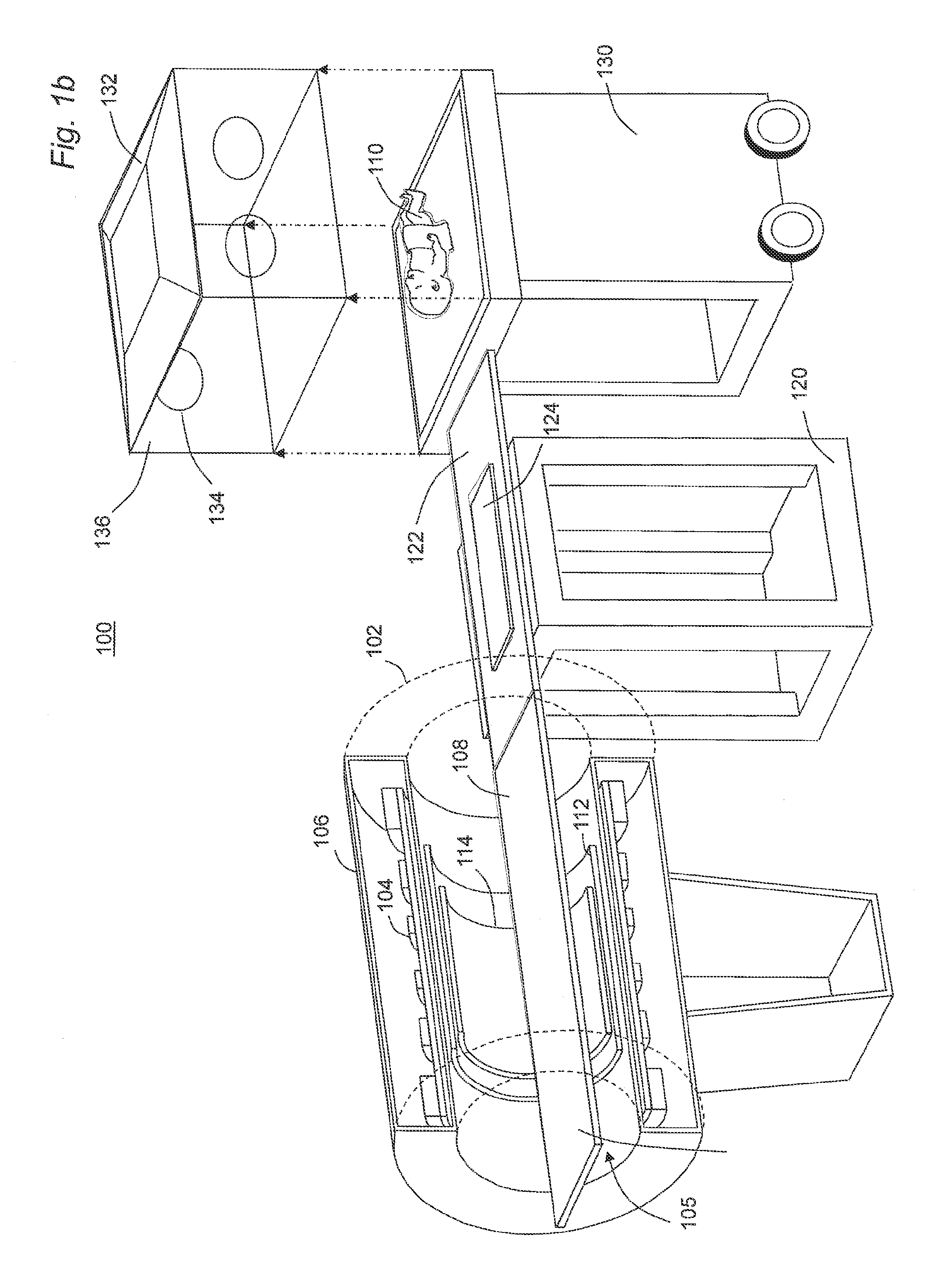

Air lock for introducing substrates to and/or removing them from a treatment chamber

InactiveUS6196154B1Simple designAvoid introducingPressurized chemical processSpraying apparatusEngineeringAirlock

Owner:APPLIED MATERIALS GMBH & CO KG

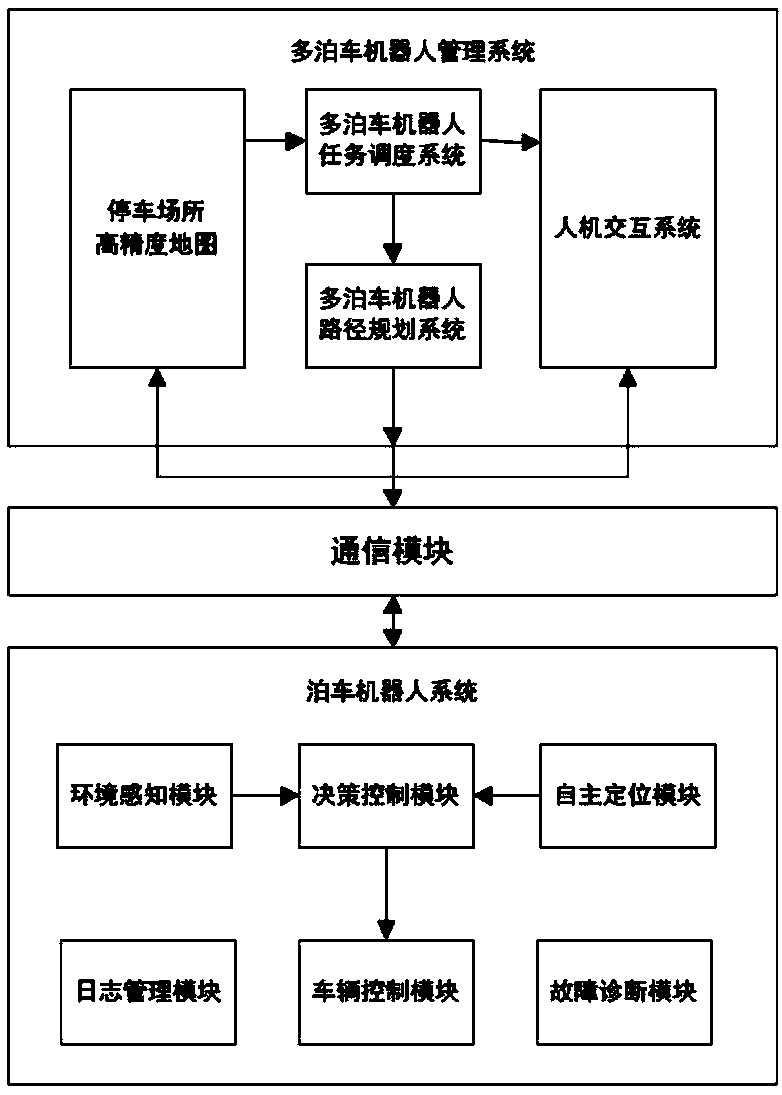

Automatic vehicle carrying and transferring method and system, and application

InactiveCN109403690AExcellent input costEnsure the cost of waitingParkingsTransfer systemSoftware system

The invention discloses an automatic vehicle carrying and transferring method and system. The automatic vehicle carrying and transferring method comprises the following steps that the interactive relation is established with a user; the parking request of the user is obtained, and a loading and transporting device for loading and transporting a vehicle of the user is dispatched to the parking position of the user; the loading and transporting device automatically loads and transports the vehicle of the user to be parked on a designated parking position; the pick-up request of the user is obtained, and the loading and transporting device for loading and transporting the vehicle of the user is dispatched to the designated parking position; and the loading and transporting device automatically loads and transports the vehicle of the user to be parked on a designated pick-up position. The automatic vehicle carrying and transferring system comprises the loading and transporting device, a multiple loading and transporting device task scheduling system, a loading and transporting device vehicle-mounted automatic navigation hardware platform and software system, a vehicle transferring station system and a man-machine interaction subsystem, wherein the loading and transporting device is a parking robot. The comfort of vehicle parking and picking-up of the user is improved, the operationefficiency is improved, the space utilization rate is increased, the construction cost is lowered, and complicated and tedious operation and maintenance are relatively avoided.

Owner:TONGJI UNIV

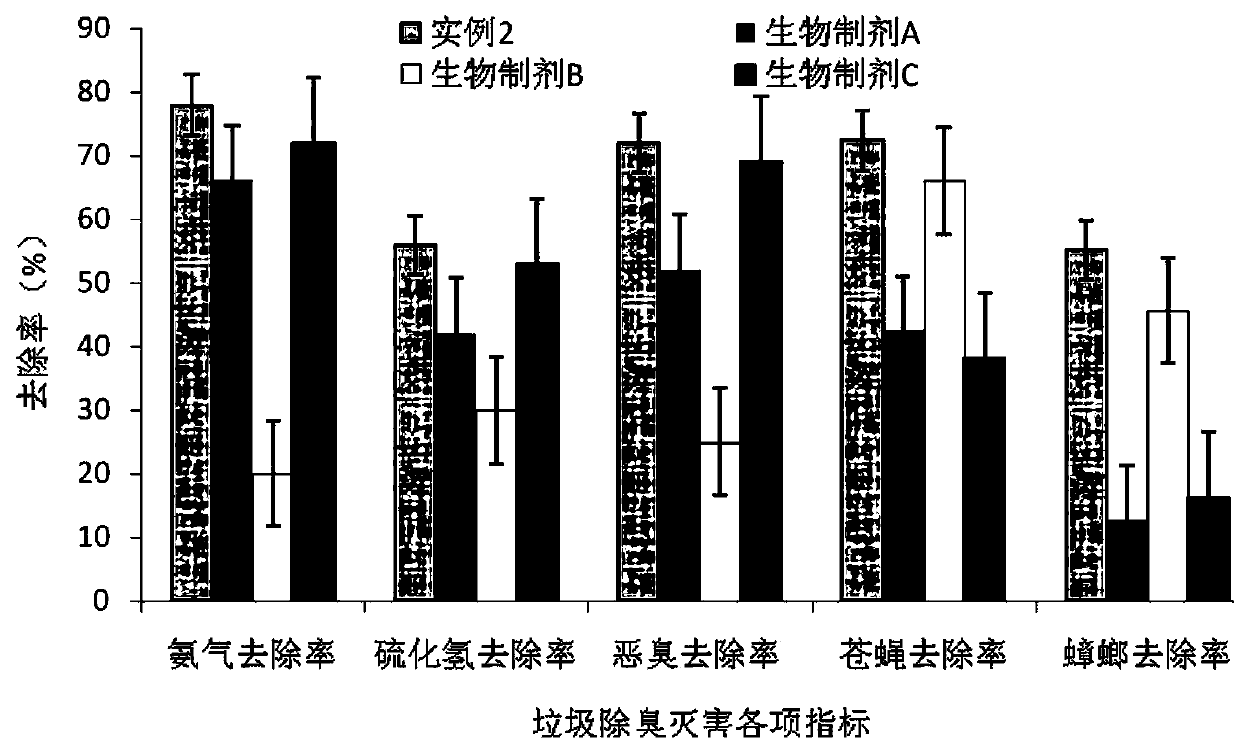

Household garbage deodorizing and sterilizing composite inoculant and preparation method thereof

ActiveCN103992968AAvoid the risk of secondary pollutionInhibition of reproductionFungiBacteriaBiotechnologyEcological environment

The invention belongs to the technical field of environment protection, and especially relates to a composite microbial preparation for garbage deodorizing and sterilization and a preparation method thereof. The microbial preparation comprises beauveria bassiana, saccharomyces cerevisiae, lactobacillus plantar, rhodopseudomonas palustris, and bacillus thruingiensis. The comprehensive composite inoculant provided by the invention can remove the garbage odor and kill insects such as mosquito, fly, cockroach, and the like; and can be used in locations such as rubbish transfer station, digestion tank, public lavatory, landfill, etc. to remove odors and kill insects. The stinky odors given off by the garbage can be rapidly degraded under the cooperation of five microorganisms, furthermore, the bacterium proliferation is inhibited, the insects in the garbage piles such as mosquito, fly, cockroach, and the like can be killed, and the microecological environment of garbage piles can be improved, so the composite inoculant has a very important economic and environment-protection meaning.

Owner:ANHUI QINGMING ENVIRONMENTAL PROTECTION TECH CO LTD

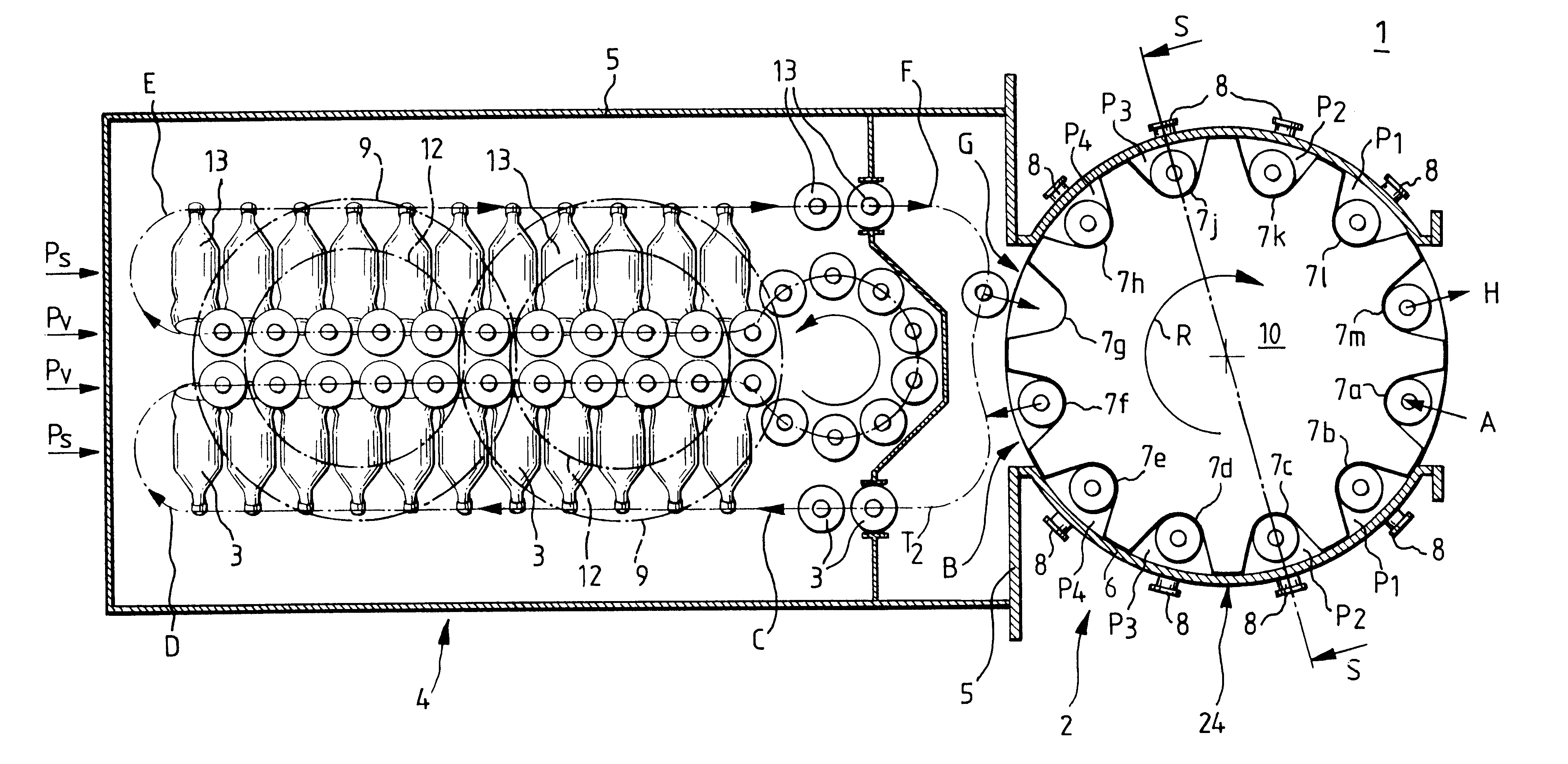

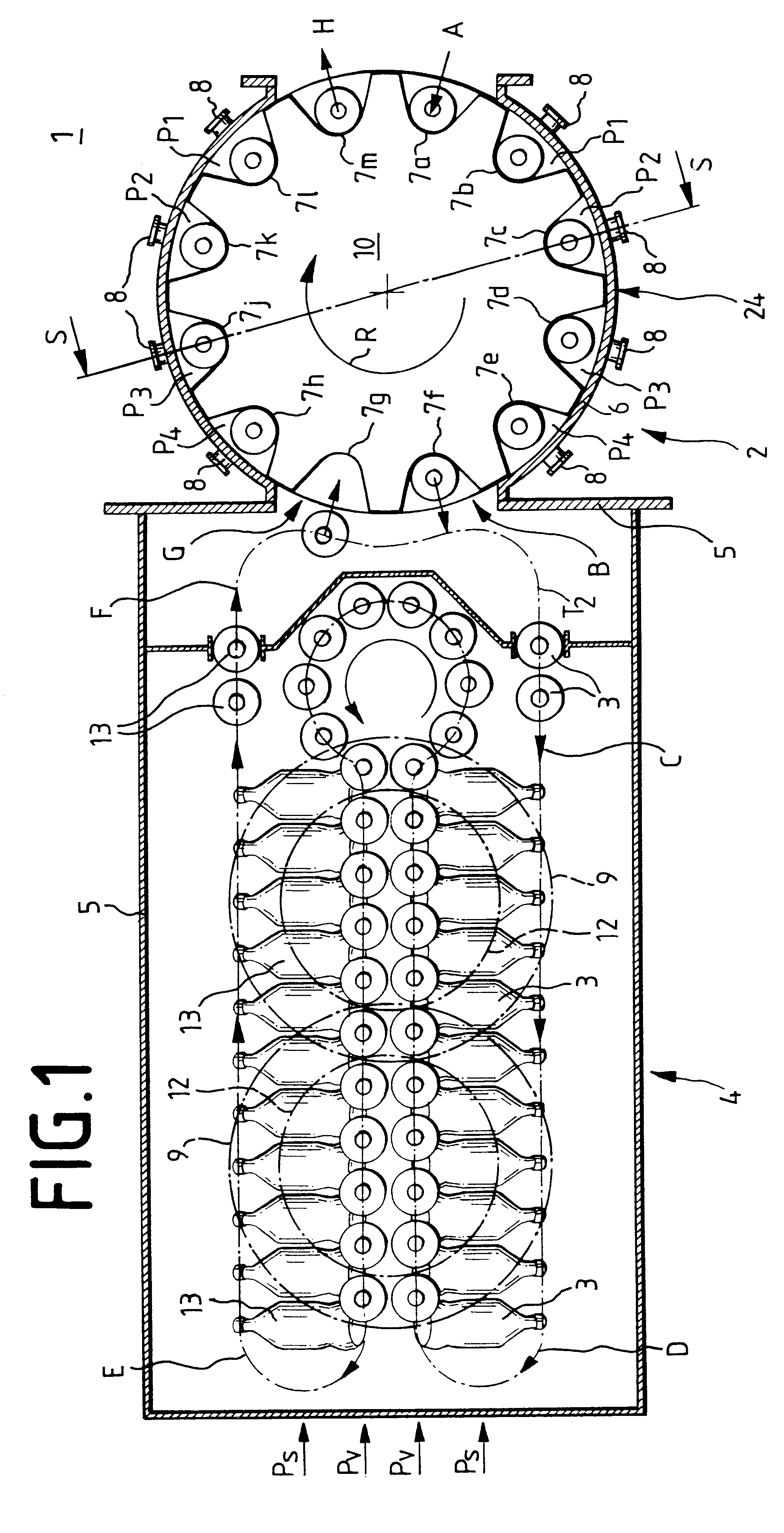

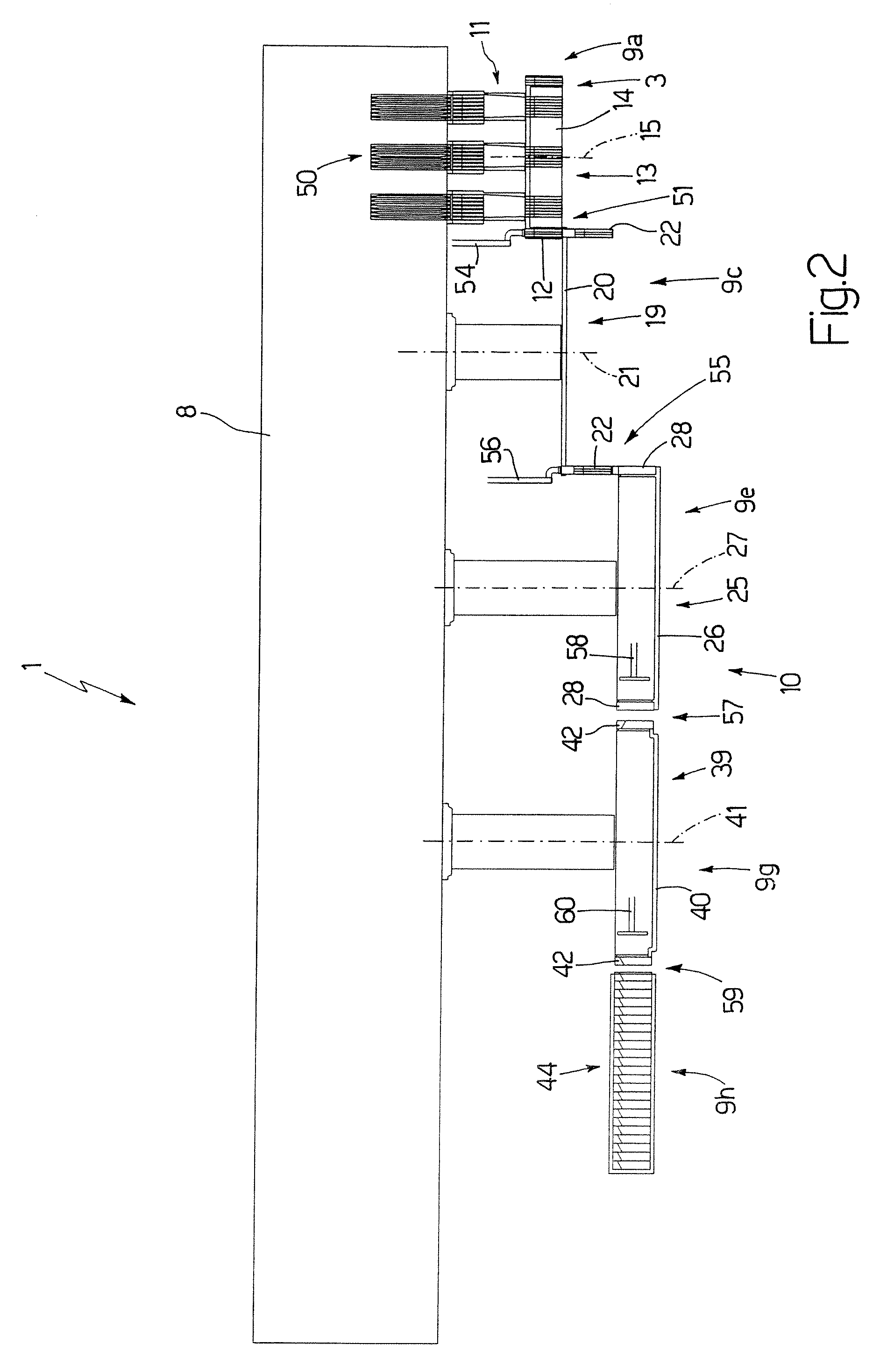

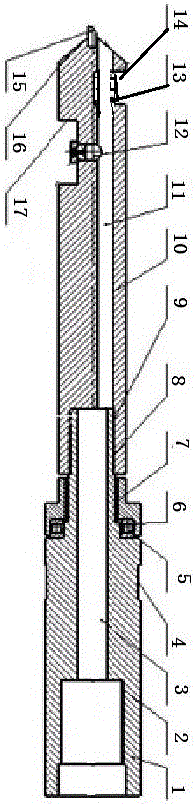

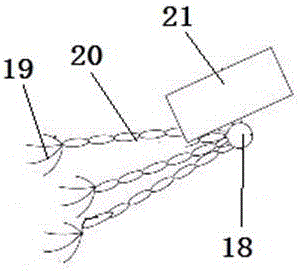

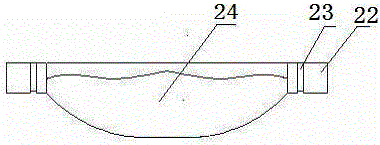

Method and transfer terminal for transferring semi-trailers from railway to roadway, and vice versa and for transporting semi-trailers by rail, as well as traction vehicle for semi-trailers and tractor trailer unit

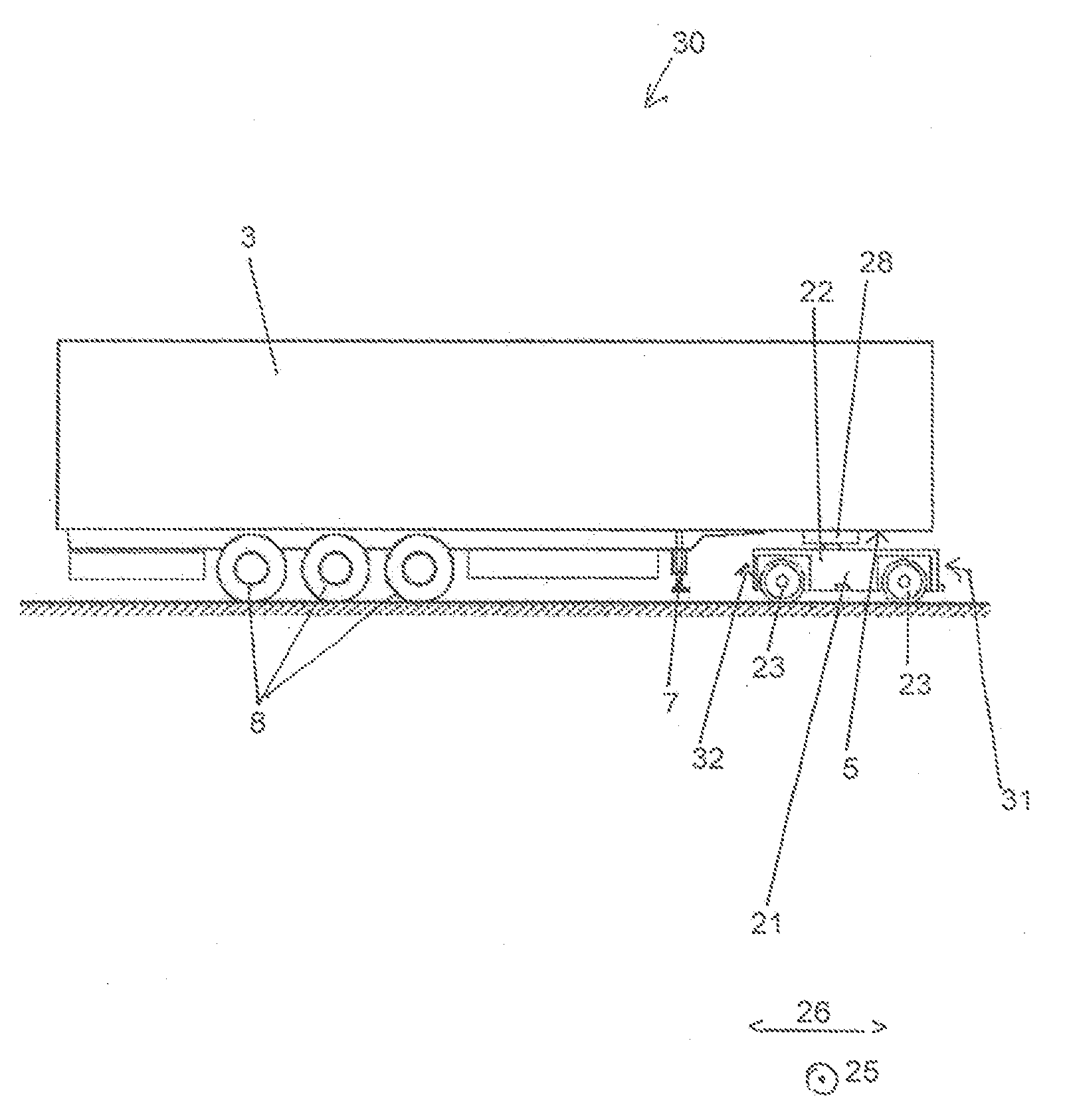

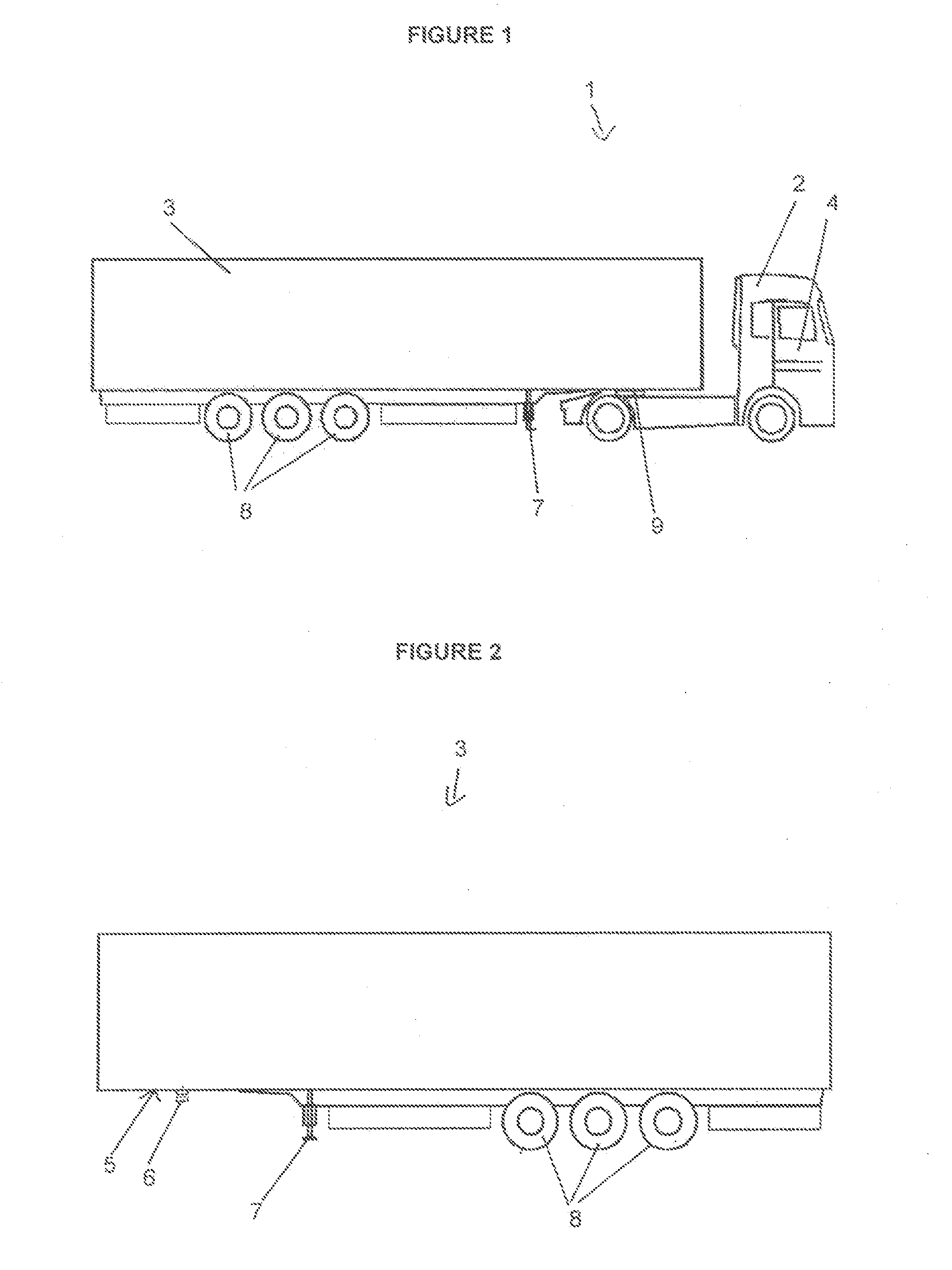

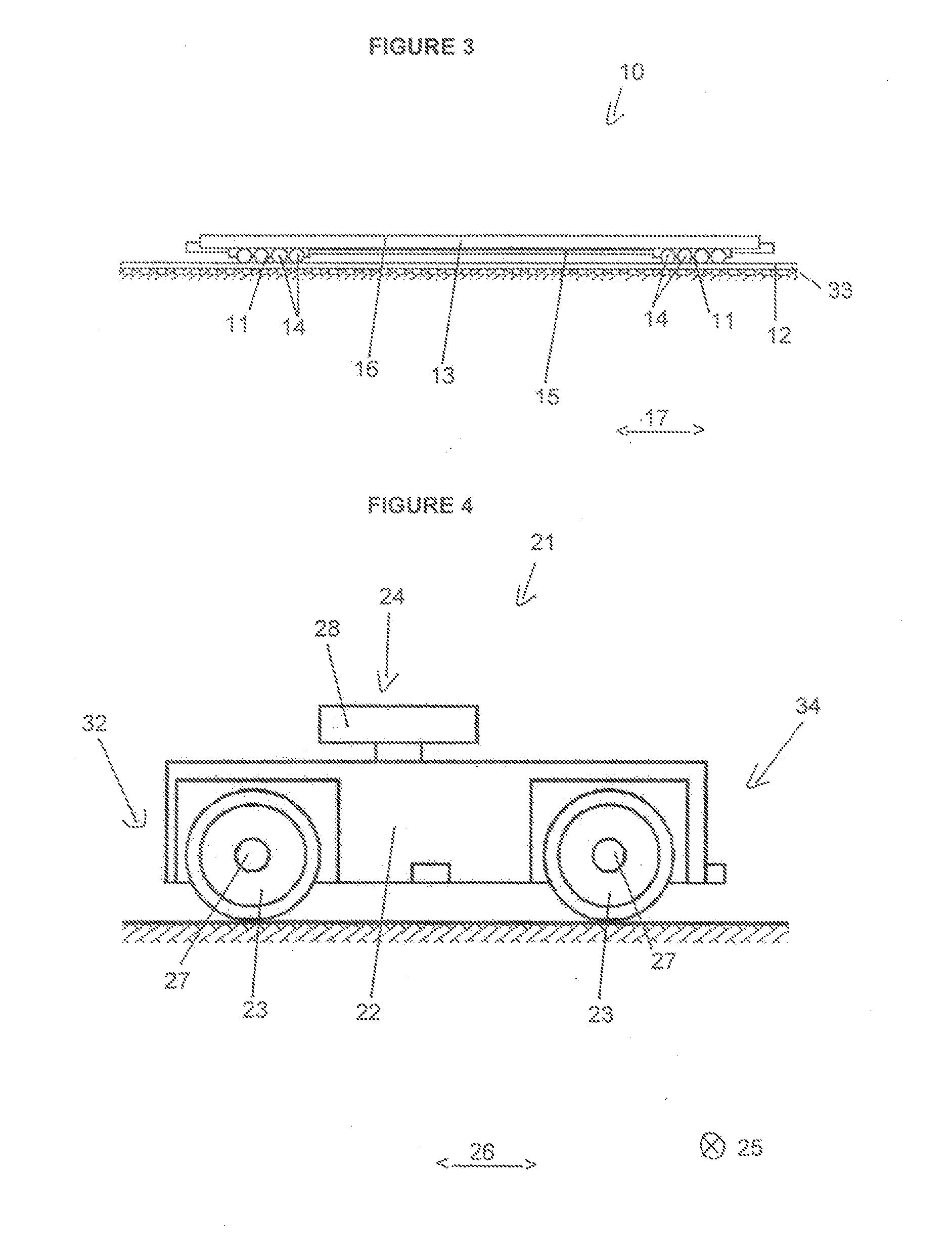

The invention relates to a traction vehicle (21) for semi-trailers (3), preferably for loading and unloading the semi-trailers (3) onto and off of a freight train (18), in particular, as part of the rolling highway, wherein the freight train (18) comprises several freight cars coupled to one another, in particular low-floor railcars (10), and a continuous driving lane in the longitudinal direction (20) of the train for moving the semi-trailers (3) on the freight train (18), wherein the traction vehicle (21) is unmanned and self-propelled, as well as a tractor-trailer unit (30) formed from the traction vehicle (21) and a semi-trailer (3), a method for transferring semi-trailers (3) from the railway (12) to the roadway and vice versa, as well as a freight transfer terminal thereto, and a method for transferring semi-trailers (3) from the railway (12) to the roadway and vice versa and for transporting the semi-trailers (3) on the railway (12).

Owner:CARGOBEAMER

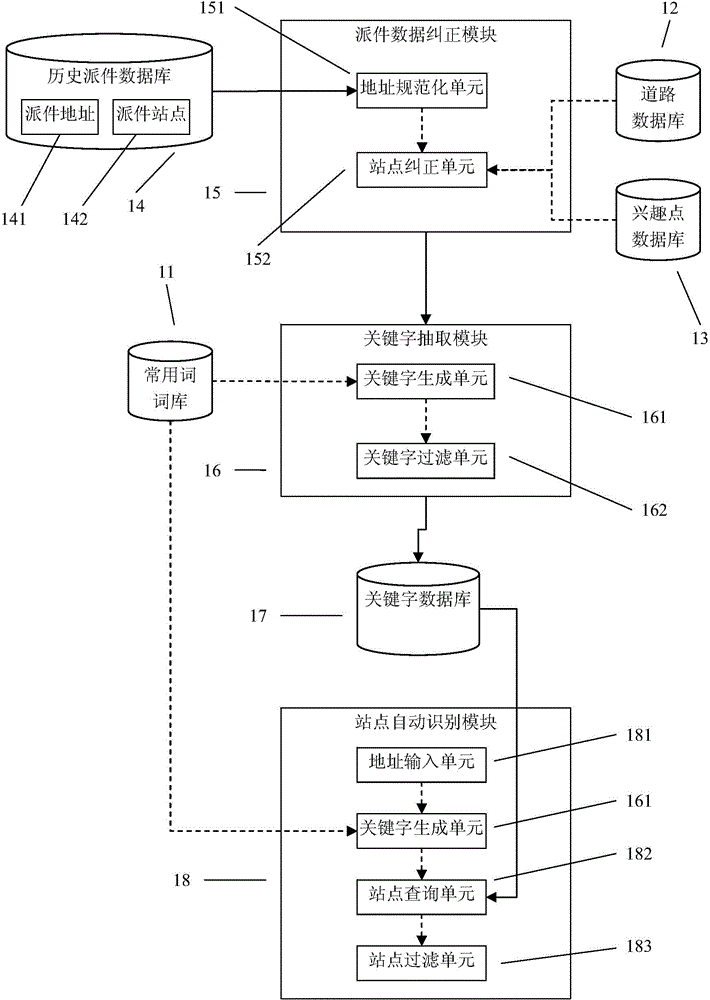

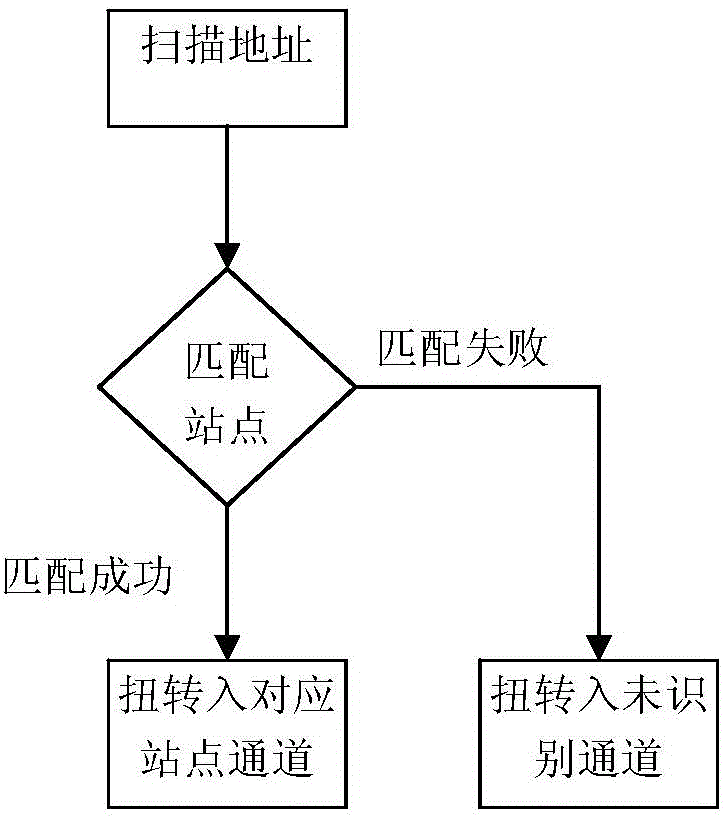

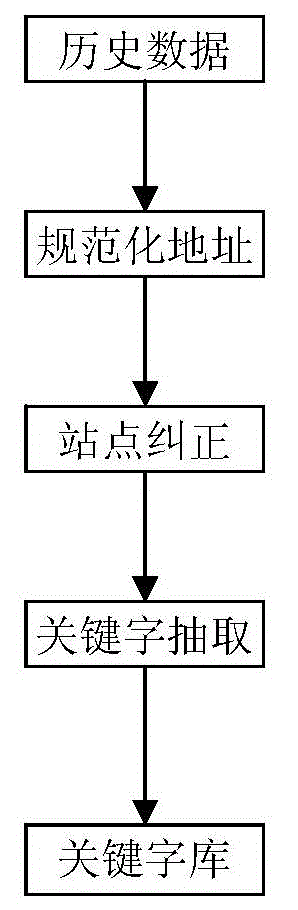

Automatic sorting system and automatic sorting method for express delivery

ActiveCN104624509AAutomatic sorting automatically realizedAutomatic sortingSortingSpecial data processing applicationsSemi automaticComputer module

The invention relates to an automatic sorting system, and discloses an automatic sorting system and an automatic sorting method for express delivery. The automatic sorting system for the express delivery comprises a common word library, a road database, an interest point database, a history delivery database, a delivery data correcting module, a keyword extracting module, a keyword database and an automatic station identifying module. The automatic sorting method comprises the following main steps: keyword database modelling, address scanning and station matching. The invention provides the automatic sorting system and the automatic sorting method for the express delivery, wherein by adopting the automatic sorting system, the identification of delivery stations of the express delivery can be automatically completed without manual interference, sorting of transfer stations and terminal stations of the express delivery can be realized, very high accuracy can be ensured, the problems of easy error occurrence, misoperation, time and labor wasting and the like in a traditional manual sorting method or a semi-automatic sorting method in the express delivery industry are solved, automatic sorting by computers and machines is realized, and the sorting efficiency of the express delivery industry is greatly improved.

Owner:ZHEJIANG BAISHI TECH

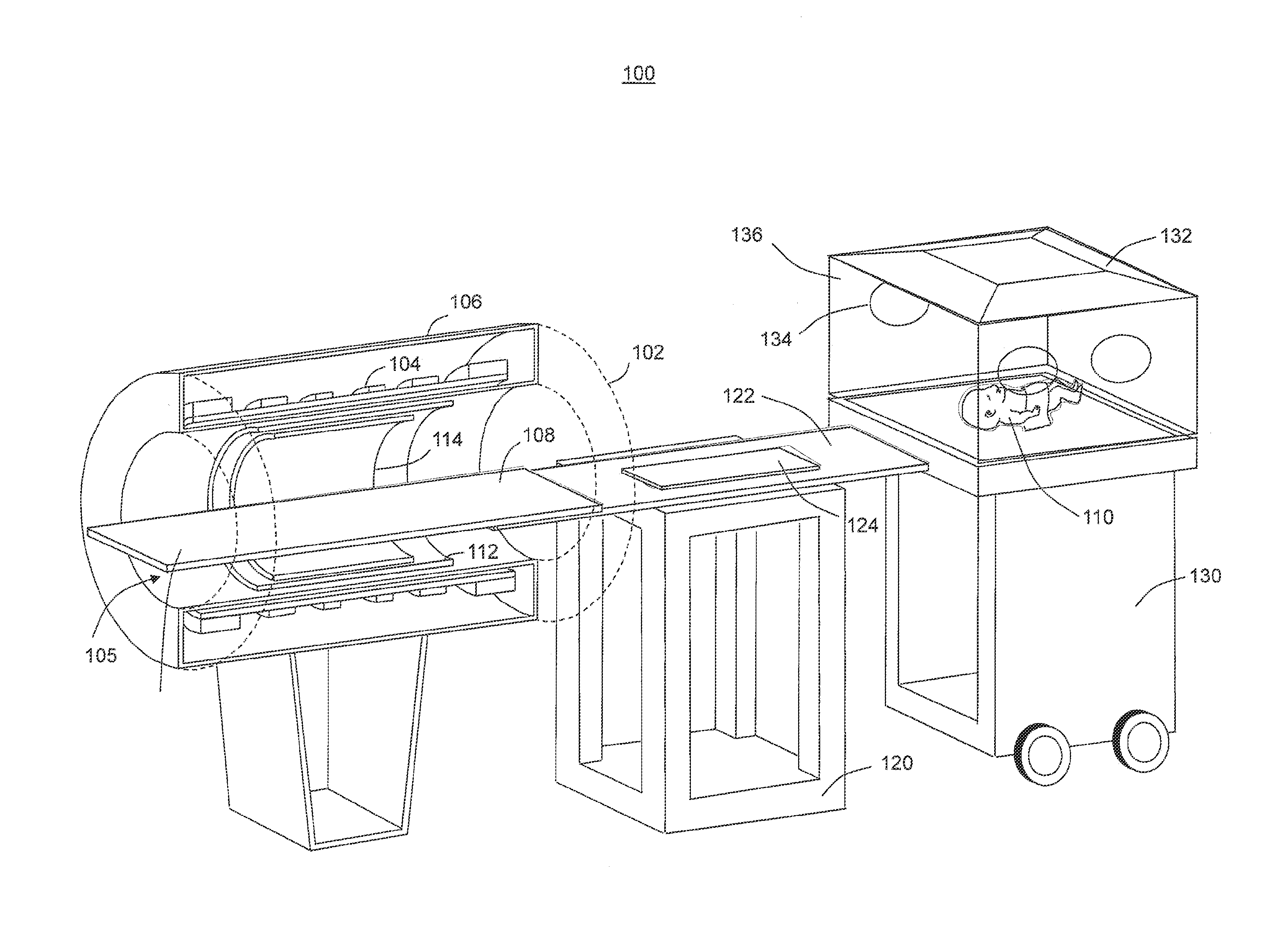

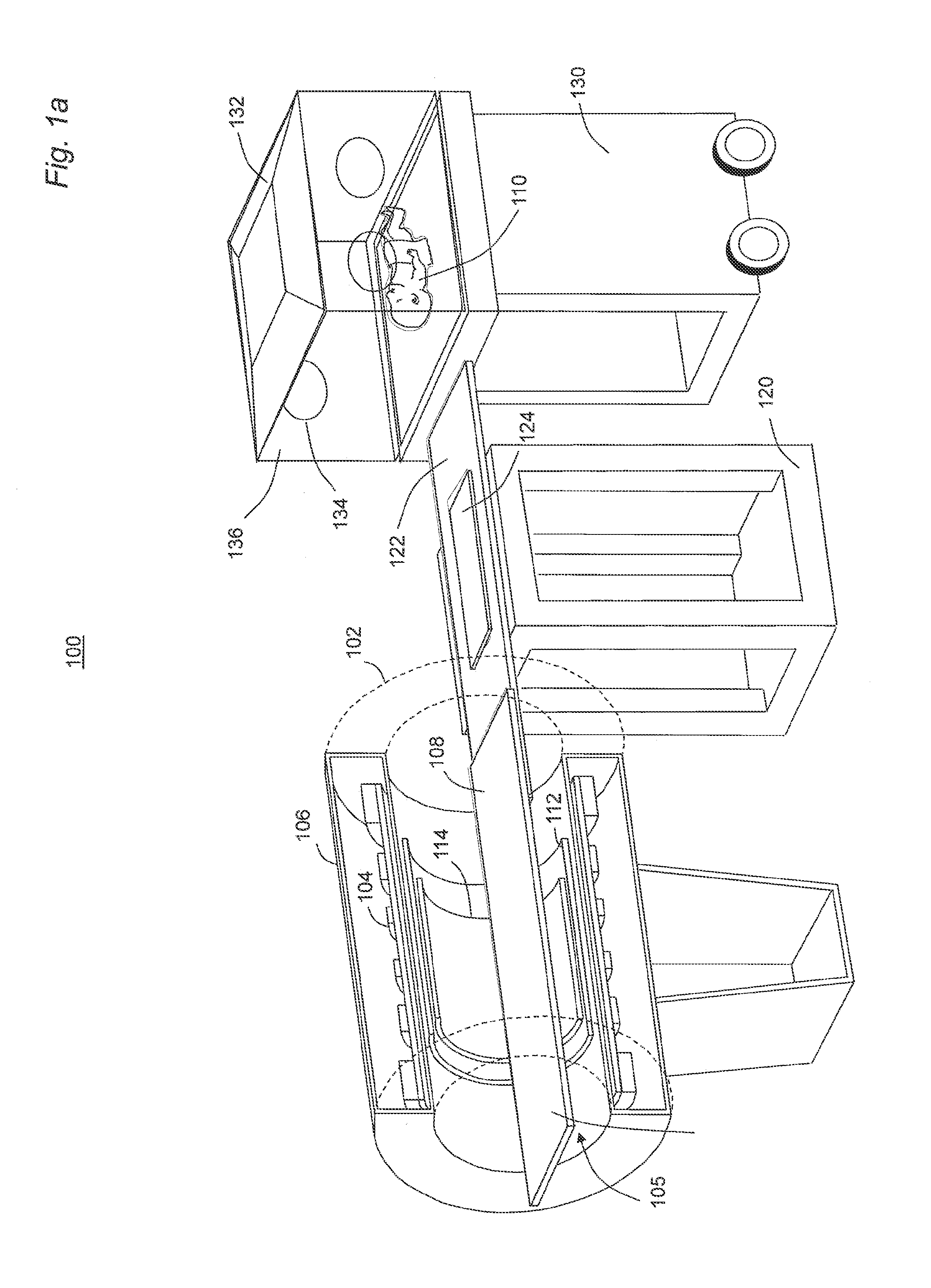

MRI Transfer Station

A transfer station is provided that is suitable for use in association with an incubator and an MR scanner for neonatal infants. The transfer station may include a transfer station platform attached atop a transfer station base. The transfer station may be placed between and an incubator and an MR scanner and may include mechanisms for engaging the incubator and the MR scanner. The transfer station may include a movable bed for a patient that may be placed in the MR scanner.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

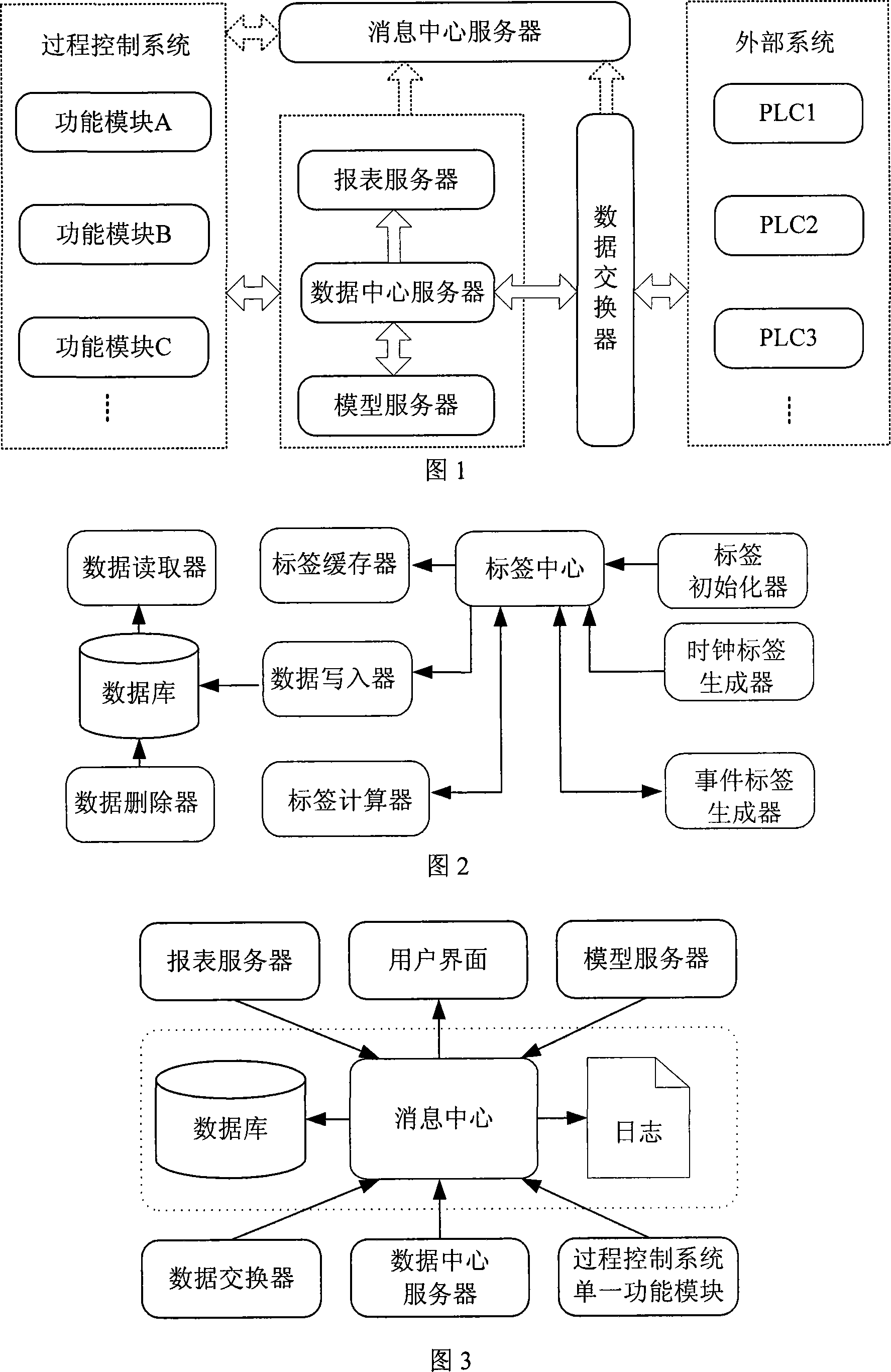

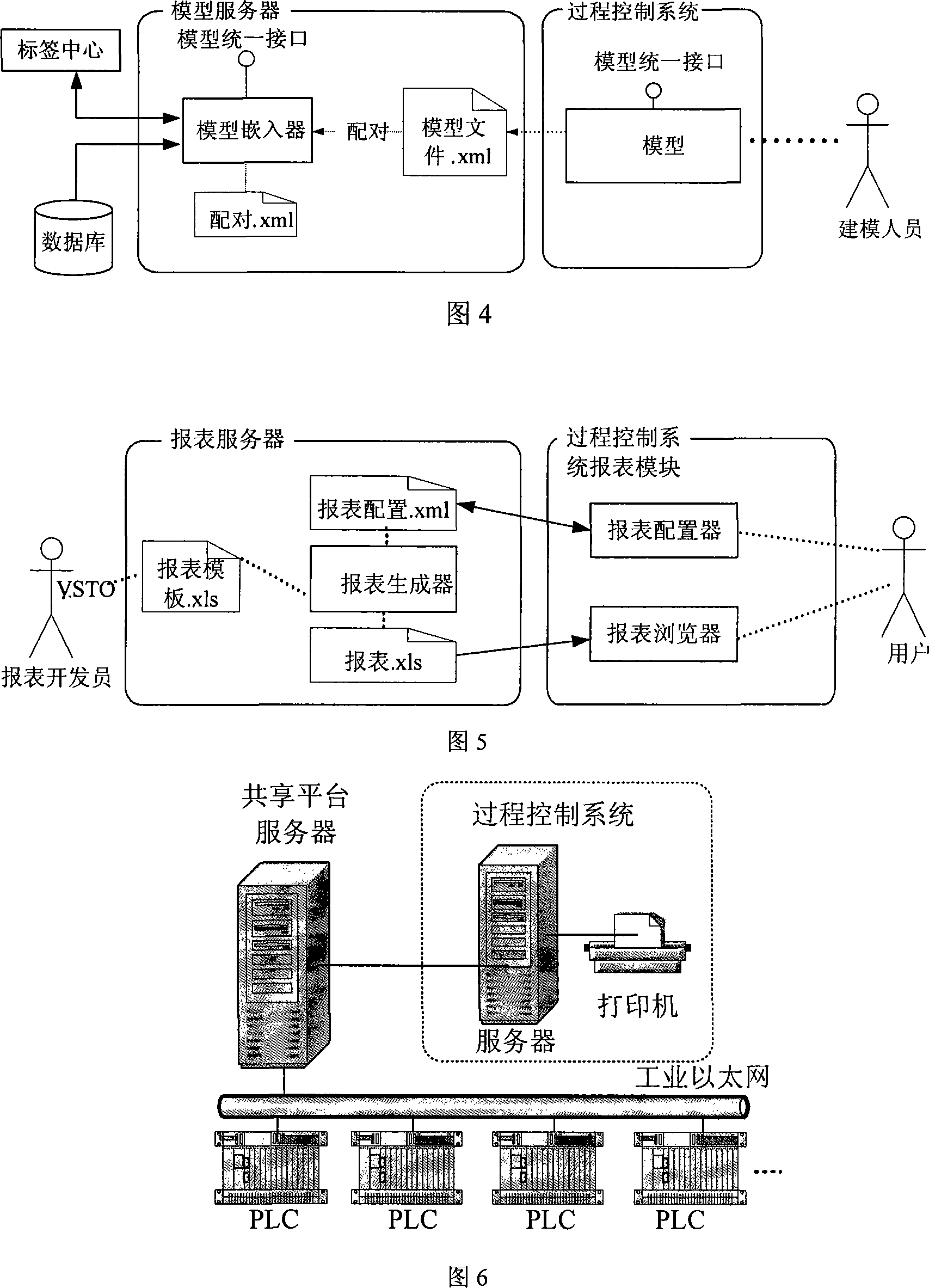

Sharing platform applied to process flow industry process control system

InactiveCN101183263ADecouplingImprove developmentTotal factory controlProgramme total factory controlData streamMessage flow

The invention relates to a sharing platform applied to process control systems in process industry, belonging to the technical field of sharing platforms of process control systems, comprising a process control system, a data exchanging machine, a model server, a report server, a data center server, and a message center server. The invention is characterized in that: the process control system is divided into a plurality of single function modules according to system functions; the data exchanging machine enables the data exchange between the PLC in an external system and the data center server; the model server provides model service to the process control system; the report server provides report service to the process control system; the data center server is the transfer station of data streams, which provides data sharing service to the model server, the report server and the process control system; the message center server is the transfer station for massage flows, which receives the messages of the other modules of the sharing platform and the process control system; all the messages can be seen on the user interface of the process control system. The invention has the advantages that: the development process of process control systems in process industry is simplified, and data service, message service, report service and model service are provided to the process control system.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Method and machine for packing a product in at least one sheet of packing material

InactiveUS20070130888A1Cheap and easy to implementIncrease productivityPackaging cigaretteWrapper folding/bending apparatusPack materialMachine

A machine for packing a product in at least one sheet of packing material has a number of conveyors, each of which has a number of pockets, each for receiving and conveying a respective product; the products are transferred from each conveyor to the next conveyor at a transfer station defined between the two conveyors; the pockets on each conveyor are divided into a first number of groups, each containing an equal second number, greater than one, of pockets; and, at each transfer station, a second number of products are transferred simultaneously from the pockets in a group of pockets on the releasing conveyor to the pockets in a group of pockets on the receiving conveyor.

Owner:GD SPA

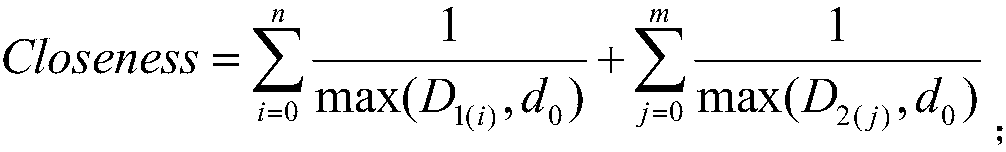

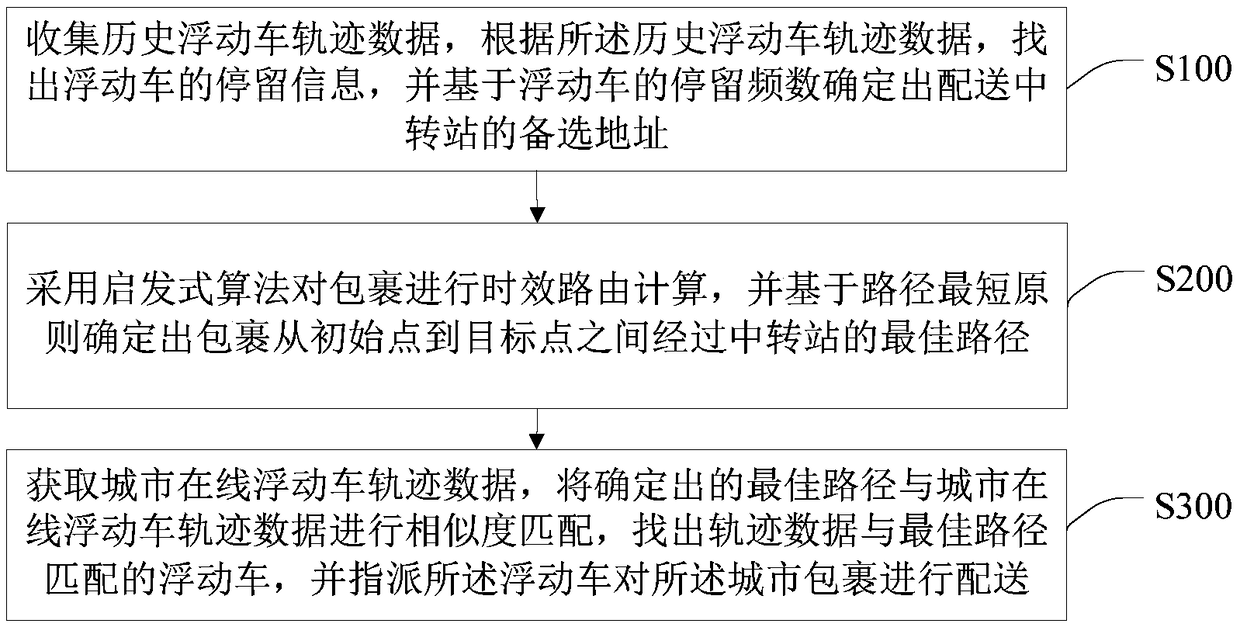

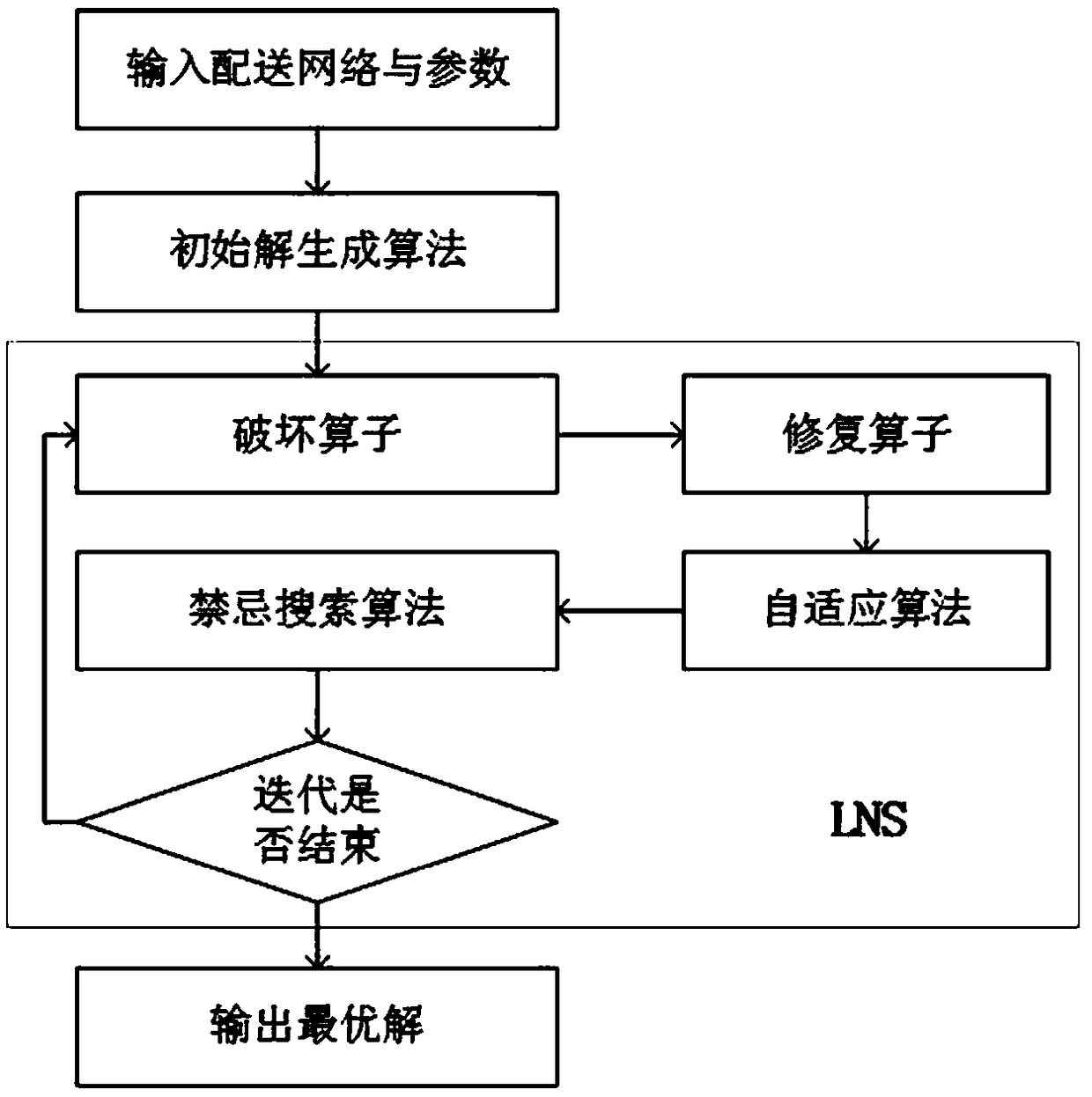

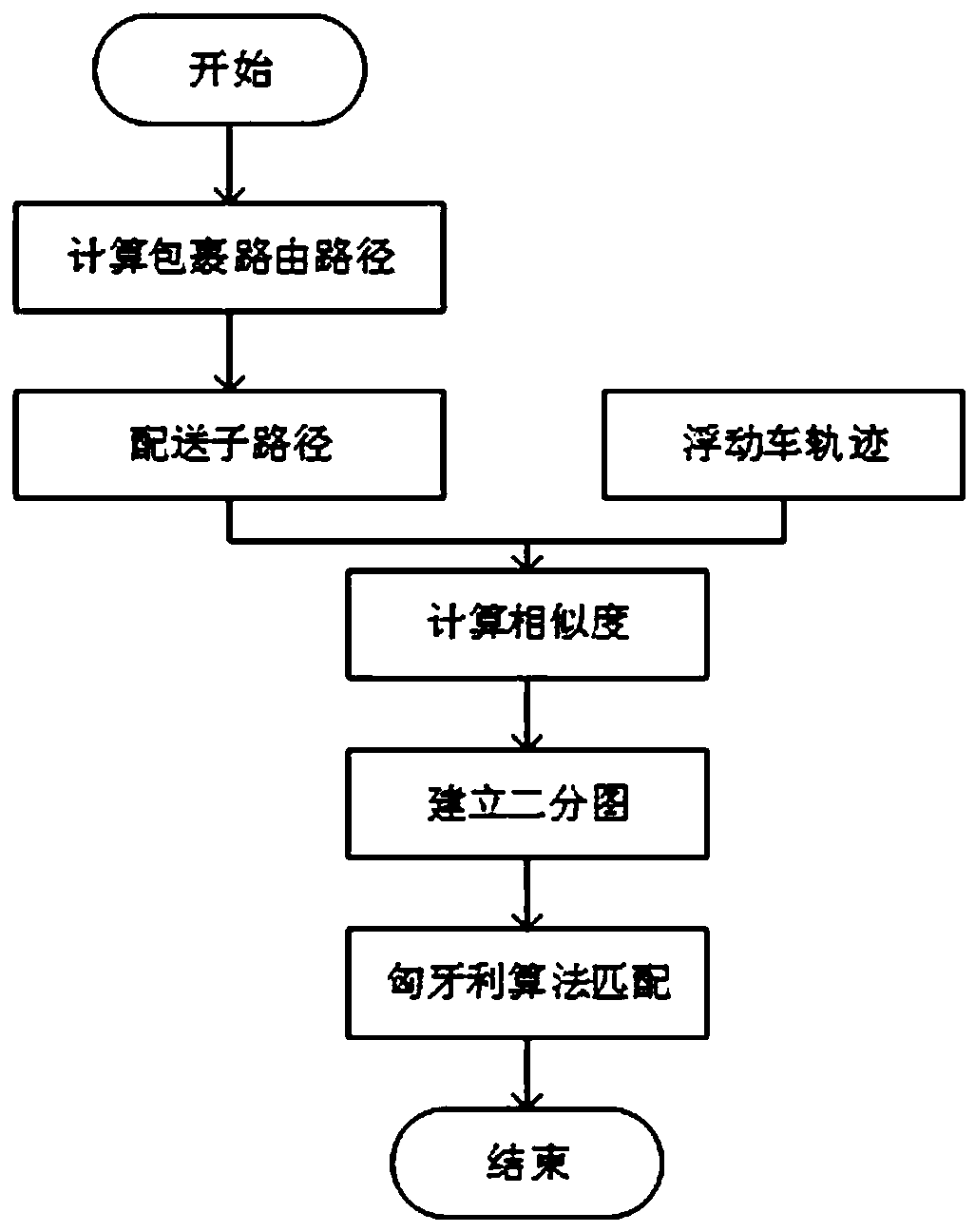

Crowd-sourcing logistics distribution route planning method and system based on track big data

The invention discloses a crowd-sourcing logistics distribution route planning method and system based on track big data. The method comprises: collecting historical floating vehicle track data, finding out the parking information of the floating vehicle, and determining the alternative address of the distribution transfer station. A heuristic algorithm is used to compute the time-dependent routing of packages, and the optimal route of packages passing through the distribution transfer station from the initial point to the target point is determined. The method comprises the following steps: acquiring the urban online floating vehicle trajectory data, matching the determined best path with the urban online floating vehicle trajectory data by similarity degree, finding out the matching floating vehicle, and assigning the floating vehicle to distribute the urban package. The invention obtains the real and effective traffic network data from the traffic trajectory big data, and provides the decision support for the location selection of the logistics distribution transfer station. In addition, the invention matches the on-line floating vehicle trajectory data with the logistics distribution data, thereby realizing the new mode of crowd-sourced logistics distribution by the floating vehicle, and effectively saving the logistics cost.

Owner:SHENZHEN UNIV

Compound biological deodorizer as well as preparation method and application thereof

ActiveCN104548175AUniversally adaptableGood deodorizing effectFungiBacteriaBiotechnologyPichia pastoris

The invention relates to a compound biological deodorizer as well as a preparation method and application thereof. The compound biological deodorizer comprises a plant extract, pichia pastoris, pediococcus pentosaceus, pediococcus acidilactici, candida mycoderma and bacillus megatherium. Through the utilization of compound biological deodorizer to treat a waste transfer station, a livestock and poultry farm and a composting site, the NH3 removal rate can respectively reach 65.2-71.6%, 63.4-73.7% and 53.42-75.77%, and the H2S removal rate can reach 53.5-60.1%, 35.5-45.9% and 47.2-53.8%, so that the odor concentration is obviously reduced, the environment of the periphery of the waste transfer station, the livestock and poultry farm and the composting site is effectively improved, and the improvement of both economic benefits and environment-friendly benefits is facilitated.

Owner:北京沃土天地生物科技股份有限公司

Preparation method of plant extracting solution deodorant

The invention discloses a preparation method of a plant extracting solution deodorant. The deodorant uses Chinese herbal medicine as raw materials, a volatile oil extractor is adopted for extraction to obtain water extracting solution and volatile oil, the water extracting solution is subjected to separation and refining processes to obtain water extracts, then, the water extracts, the volatile oil, de-ionized water and essence are mixed for emulsification, and finally, the plant extracting solution deodorant disclosed by the invention is prepared through filtering. The plant extracting solution deodorant disclosed by the invention has the characteristics that the use is safe and convenient, the environmental-friendly effect, no toxicity and no harm are realized, through field experiment detection in a garbage transfer station, the ammonia gas removal rate can reach about 63 percent, the odor concentration inside and outside the garbage transfer station after deodorization can be much lower than the national standard, the peripheral air quality and the work condition in the garbage transfer station are greatly improved, in addition, the use cost of the deodorant is very low, and the deodorant is suitable for being used for deodorization in the garbage transfer station of urban communities.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

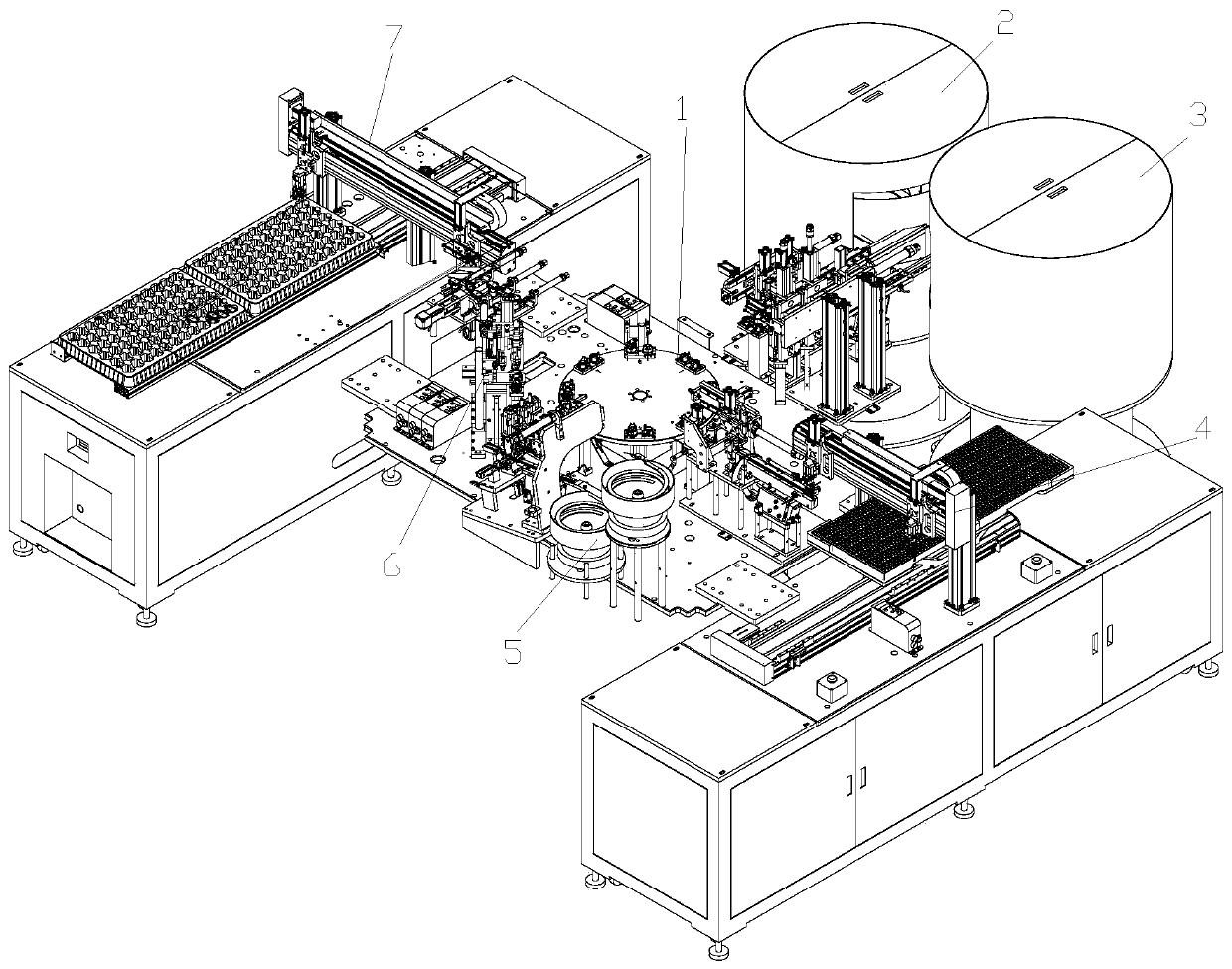

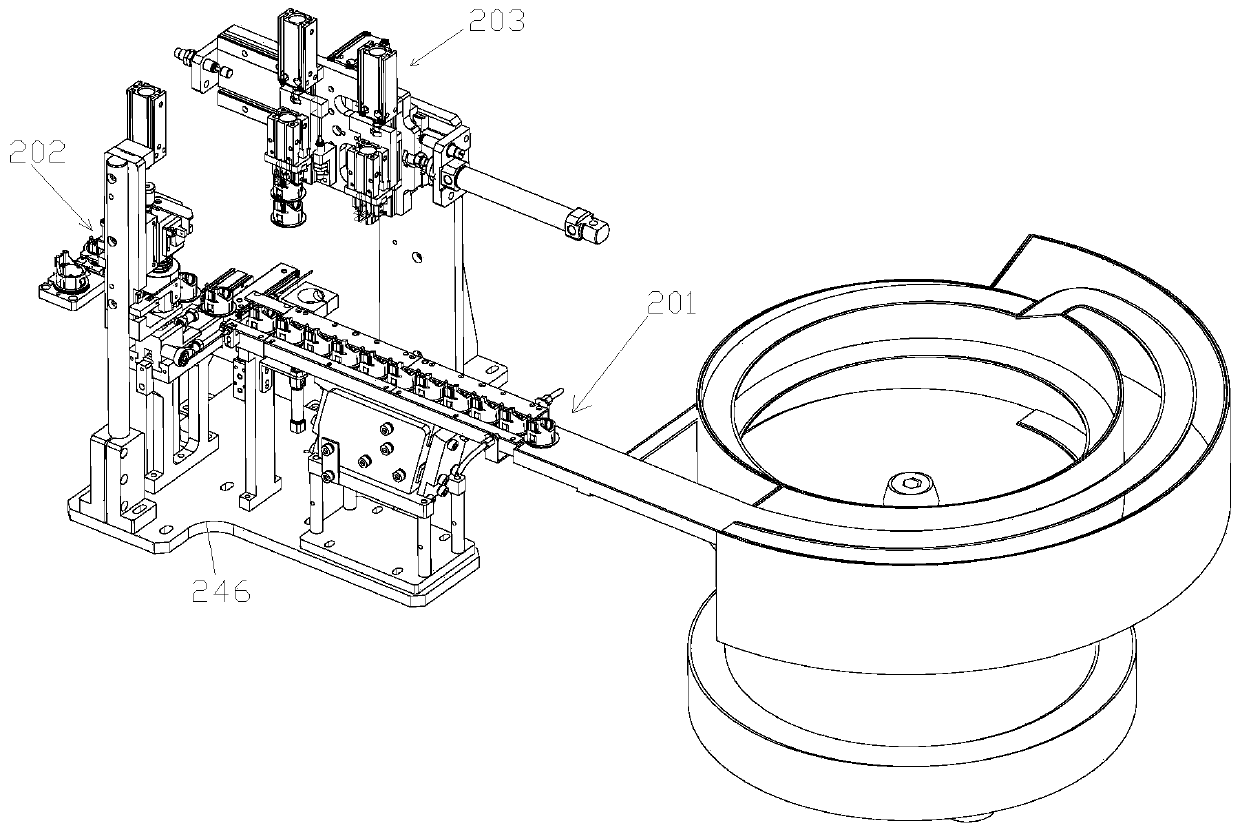

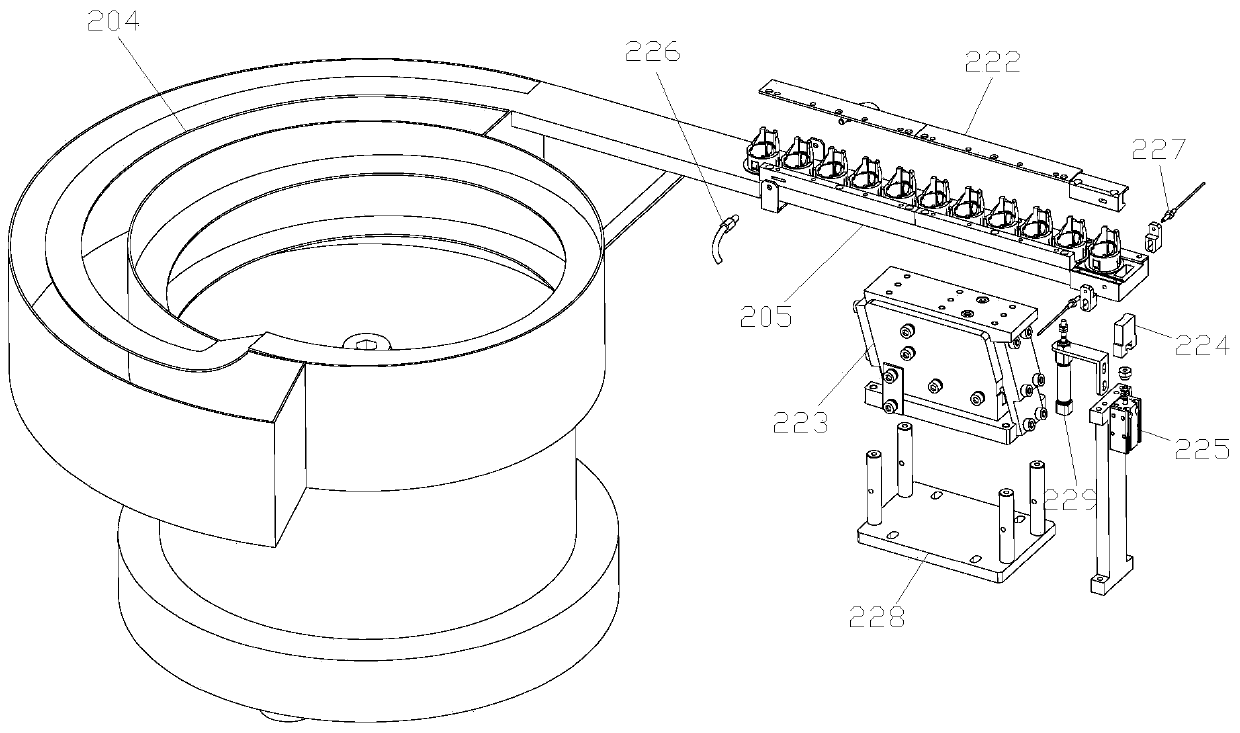

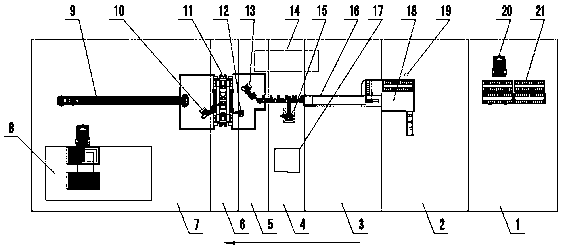

Automatic assembling machine for automobile cigar lighter

PendingCN110842554ARealize fully automatic assemblyQuality improvementAssembly machinesEngineeringStructural engineering

The invention provides an automatic assembling machine for an automobile cigar lighter. The automatic assembling machine comprises turning plate jigs which are distributed in annular arrays; a clamping sleeve assembling mechanism, a clamping sleeve ring assembling mechanism, a clamping sleeve cover assembling mechanism, a torsional spring and shaft assembling mechanism, an integrated assembling mechanism and a finished product discharging mechanism are arranged in a manner of surrounding the outer side of the turning plate jigs; the clamping sleeve assembling mechanism comprises a clamping sleeve feeding device, a clamping sleeve detecting device and a clamping sleeve manipulator; the clamping sleeve ring assembling mechanism comprises a clamping sleeve ring feeding device, a transfer station jig and a transfer assembling manipulator; the clamping sleeve cover assembling mechanism comprises a clamping sleeve cover feeding device and a transfer assembling device; the torsional spring and shaft assembling mechanism comprises a torsional spring and shaft feeding device, a torsional spring and shaft manipulator and a torsional spring and shaft press-mounting device; and the integratedassembling mechanism comprises a total assembly manipulator and a torsional shaping device. The automatic assembling machine can realize full-automatic assembly of a cigar lighter, is high in assemblyefficiency, also has a detection function and realizes high quality of an assembled finished product.

Owner:沈阳益川科技有限公司

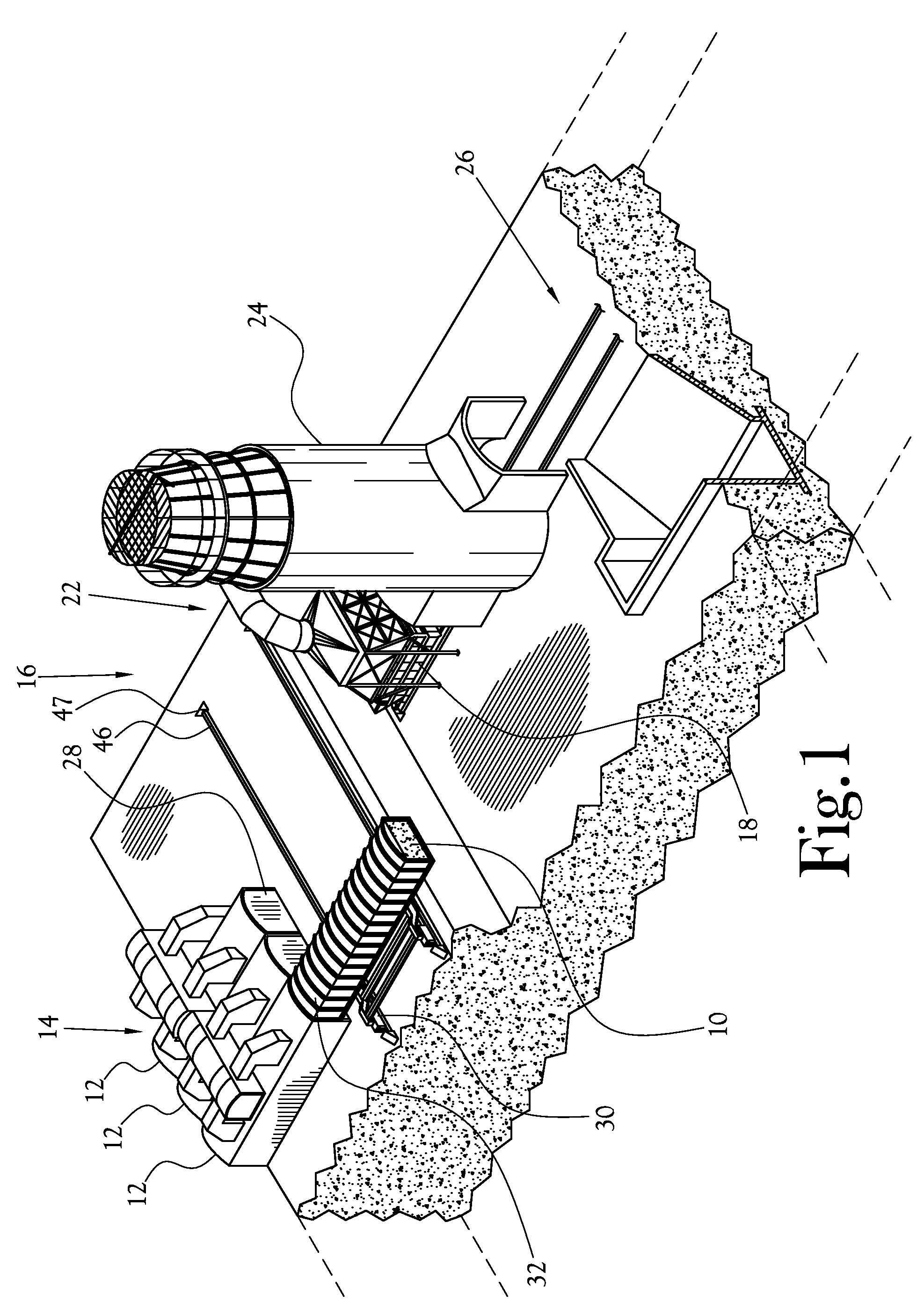

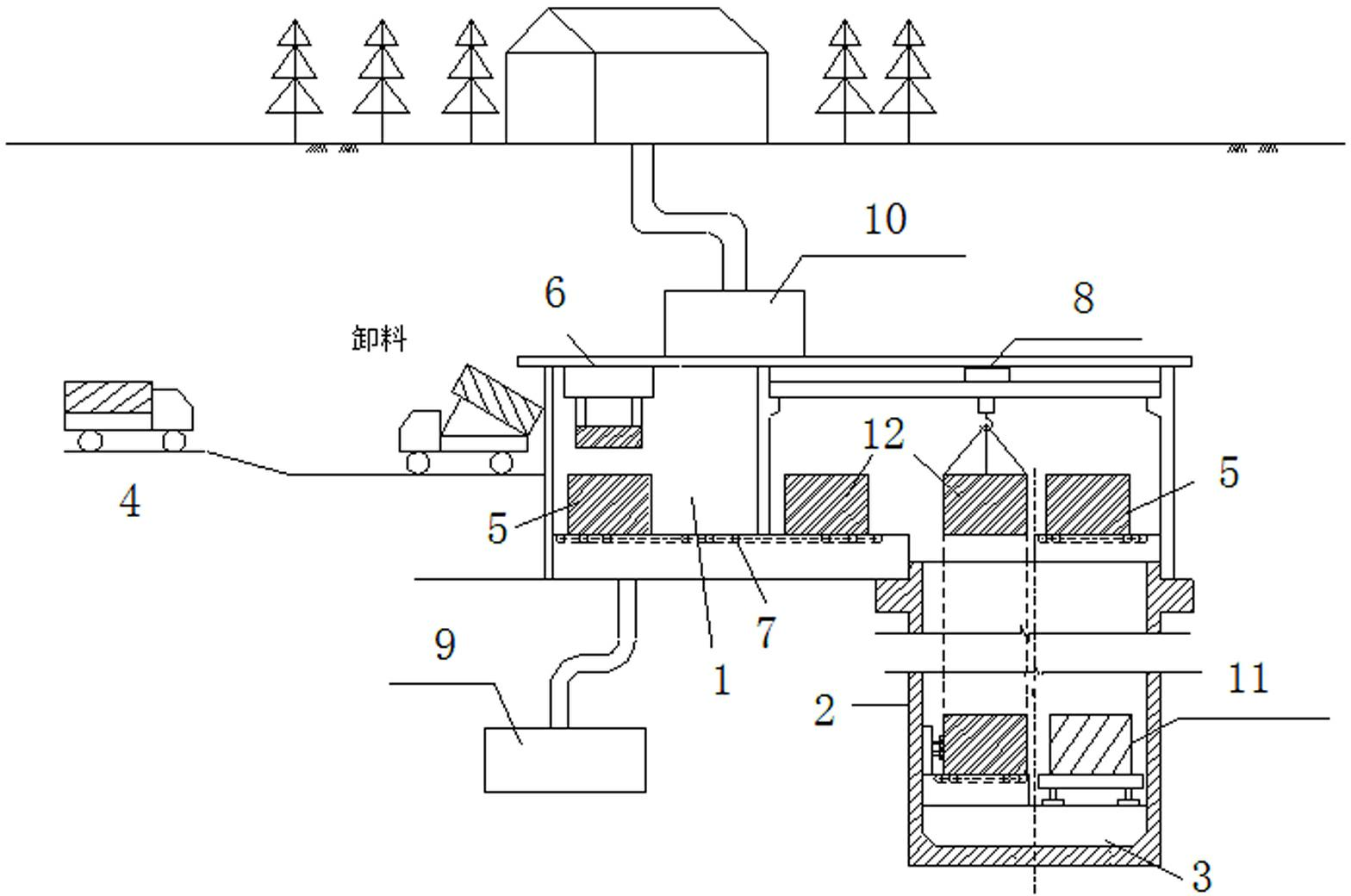

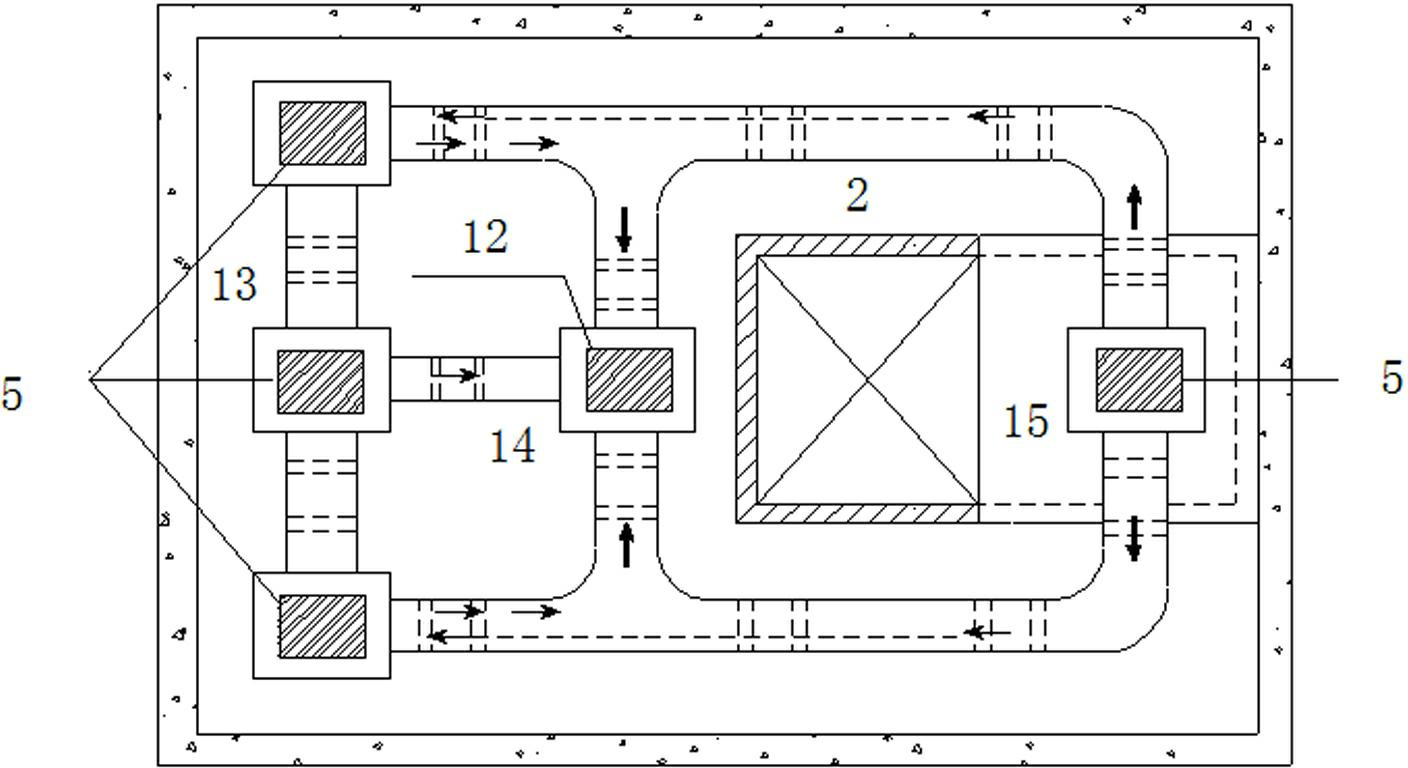

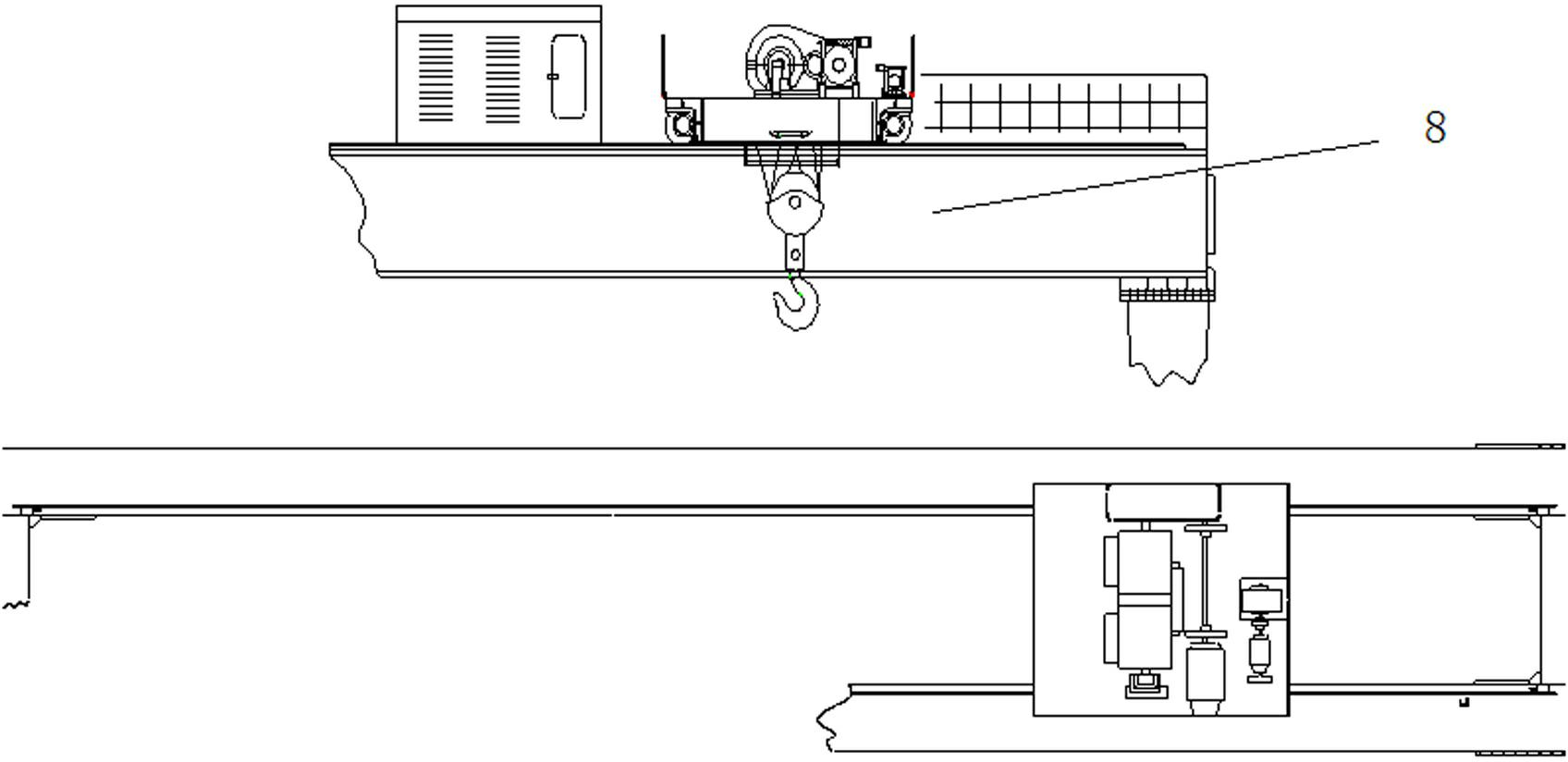

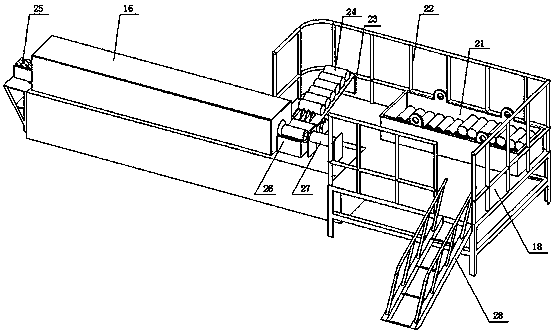

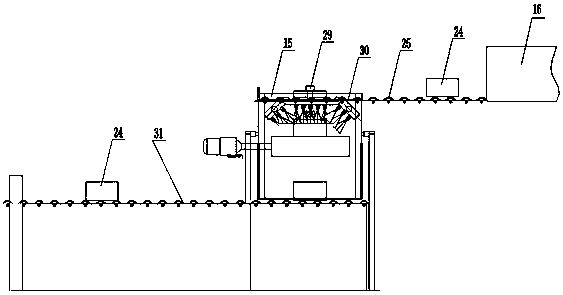

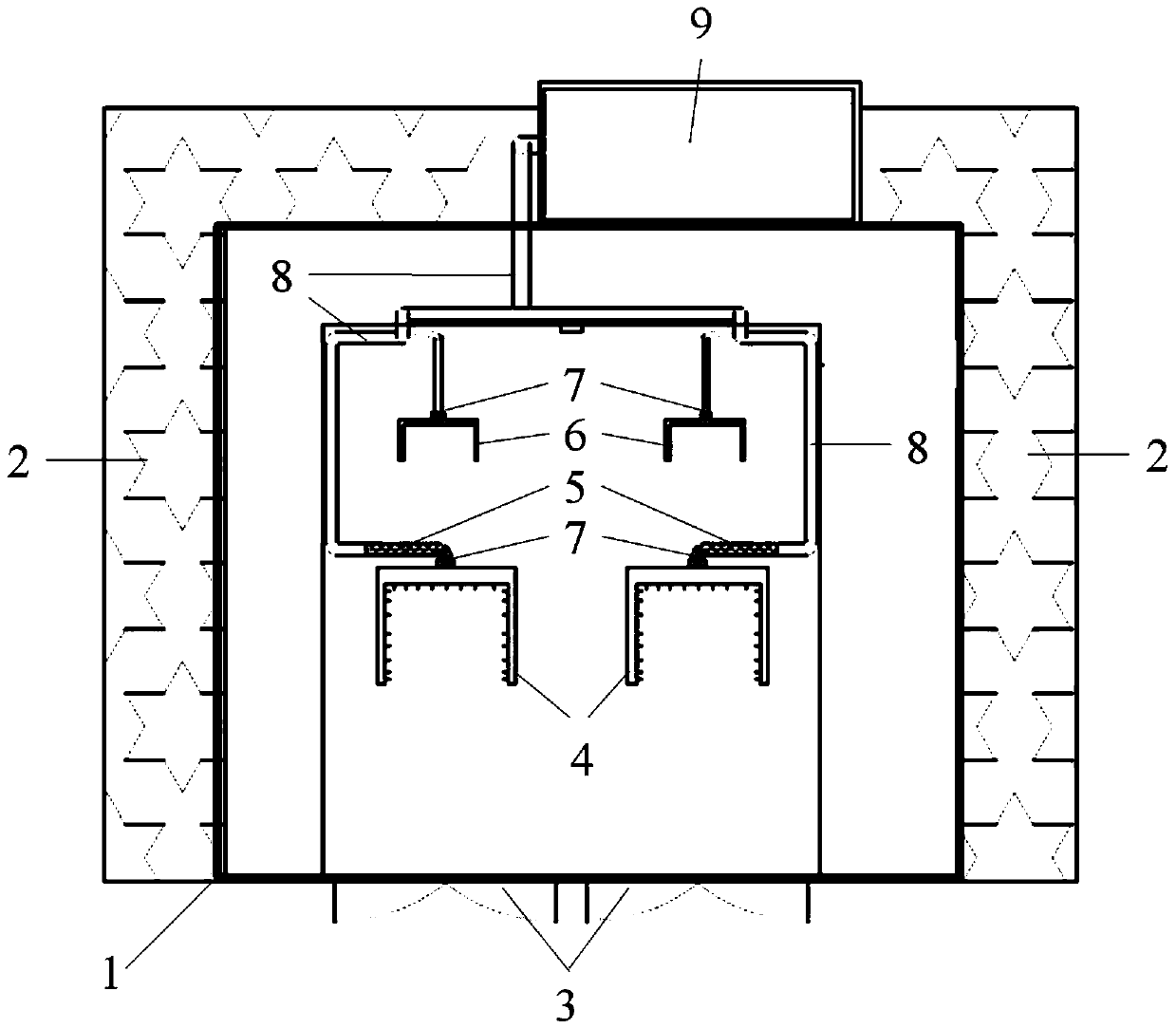

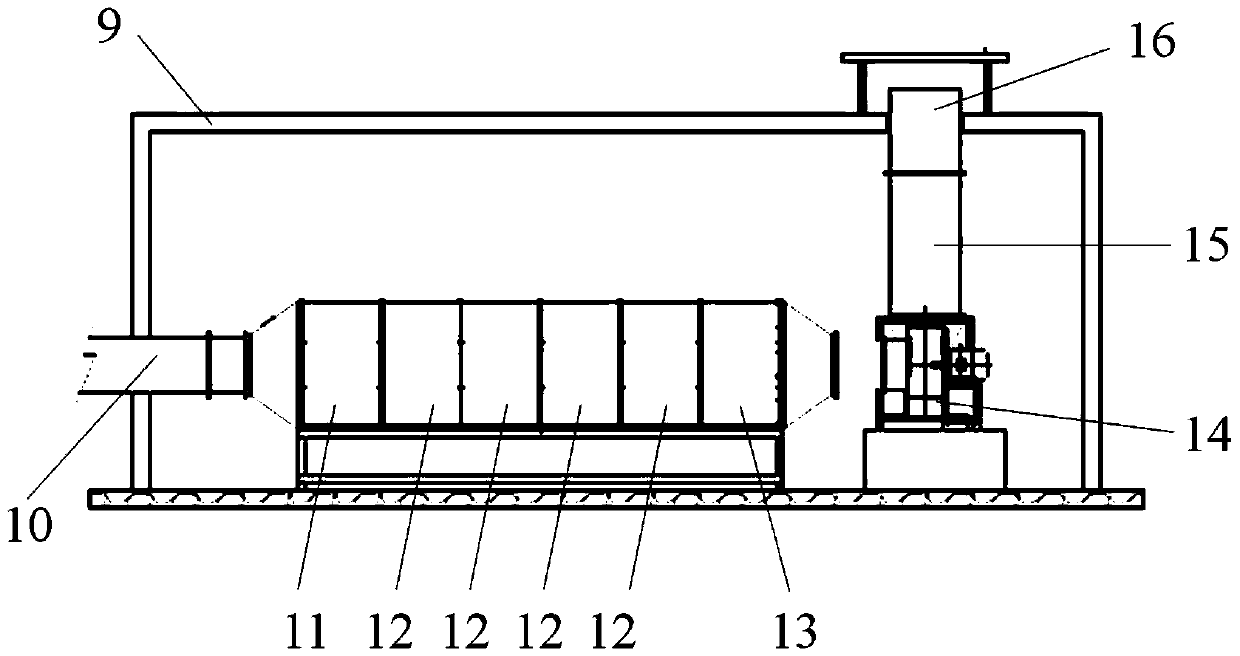

Waste transfer station for urban underground logistics system and transfer method of waste transfer station

ActiveCN102602631AAchieve sustainable developmentRaise the gradeRefuse transferringLoading/unloadingLogistics managementTransport system

The invention discloses a waste transfer station for an urban underground logistics system and a transfer method of the waste transfer station. The waste transfer station is composed of an underground waste compression station, an ultra-deep transfer shaft and an underground transportation station, wherein the waste compression station located in an underground shallow layer space is connected with the transportation station located in an underground deep layer space by the transfer shaft; and the transportation station is connected with an interval tunnel of the underground logistics system. In the waste transfer station, urban household waste is discharged in the underground waste compression station and compressed into containers, the containers fully filled with the urban household waste are transferred to the underground transportation station through the ultra-deep transfer shaft by a gantry crane, and after the containers are placed in transportation box bodies, the transportation box bodies are output by an underground transportation pipeline. According to the waste transfer station, in combination with the process features of waste compression, boxing, storage, lifting and underground transportation, according to the waste compression transfer process, the underground logistics transportation capability and the storage requirement, the layout and the size of the waste transfer station are determined, and the complete underground intensification of an urban household waste collecting and transporting system is realized.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

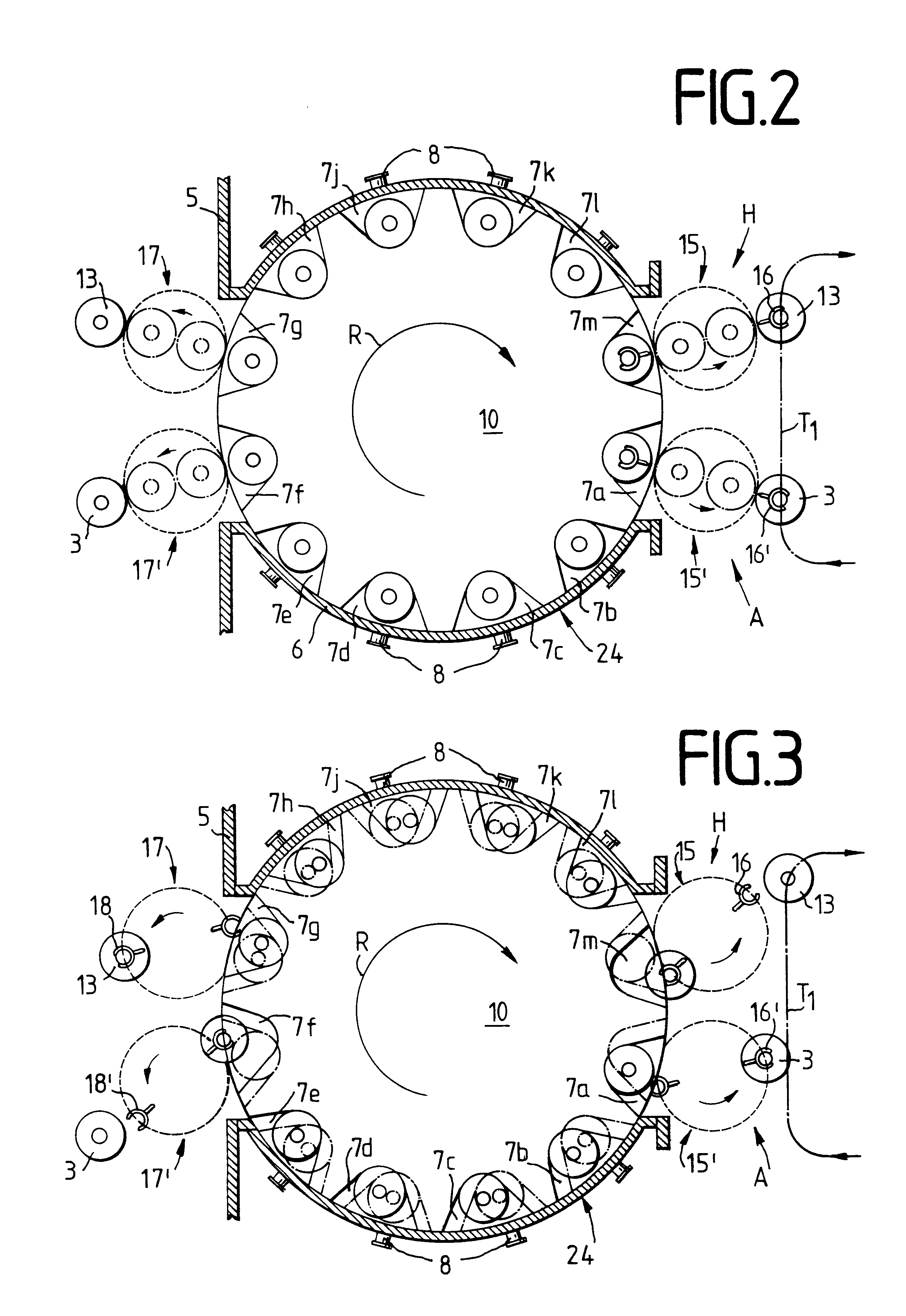

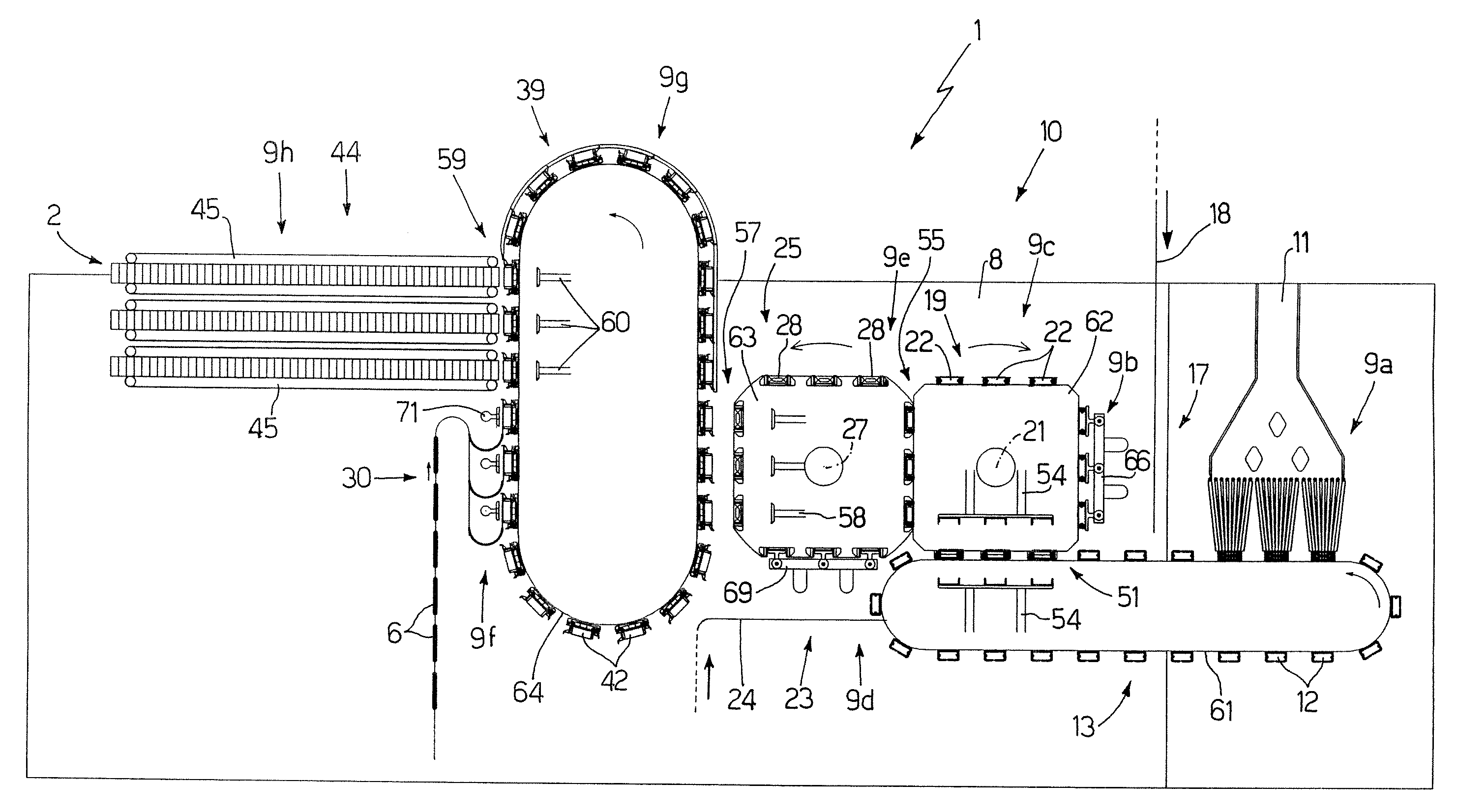

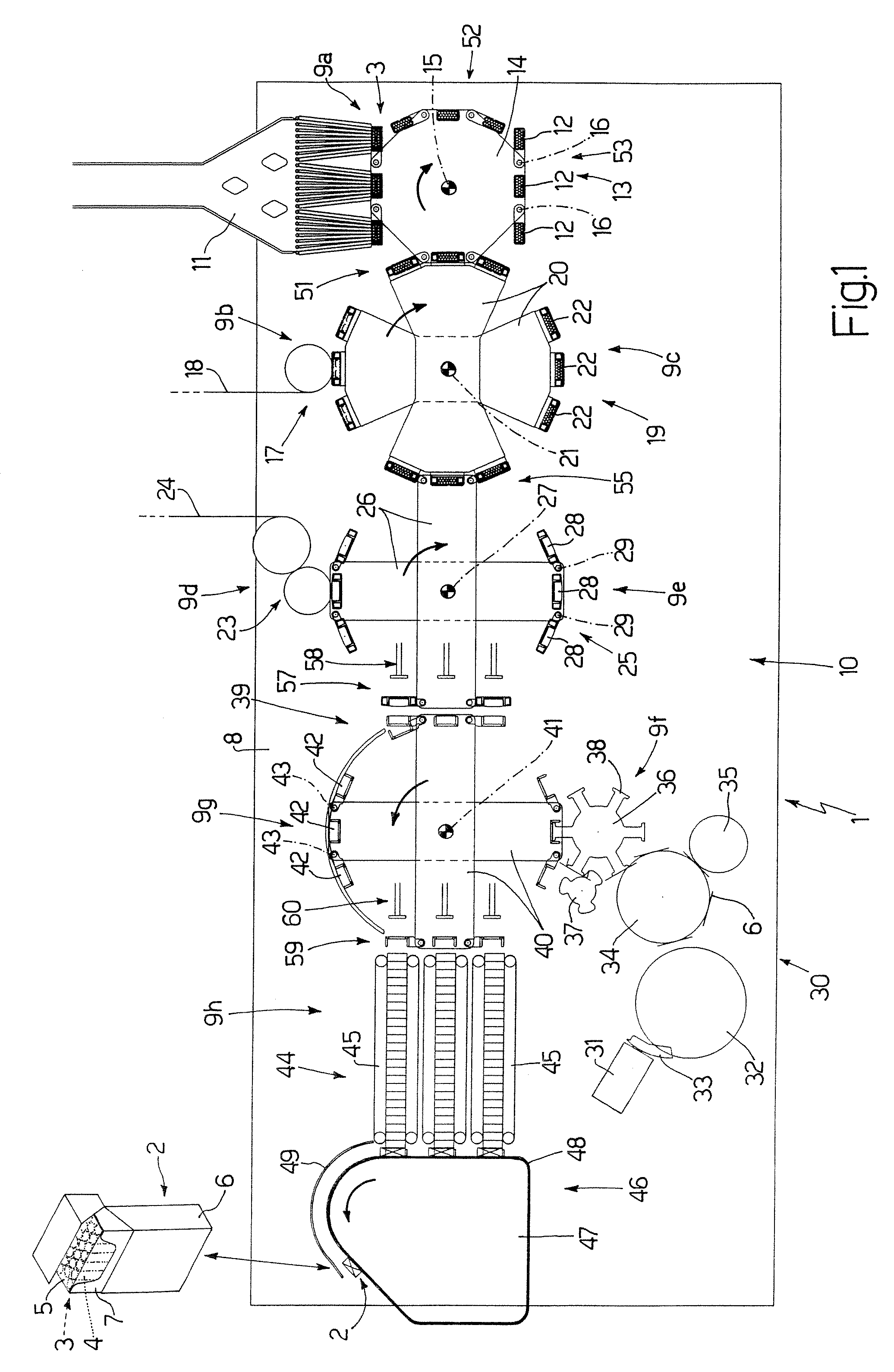

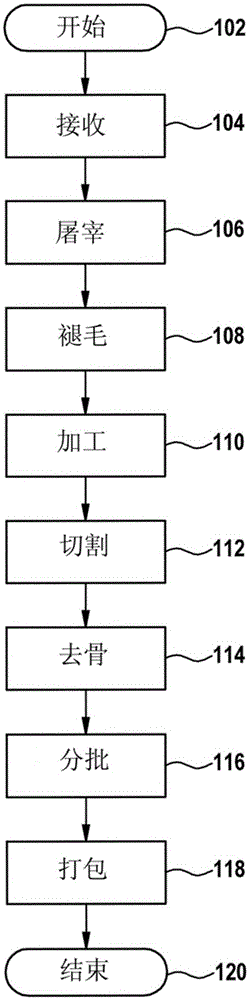

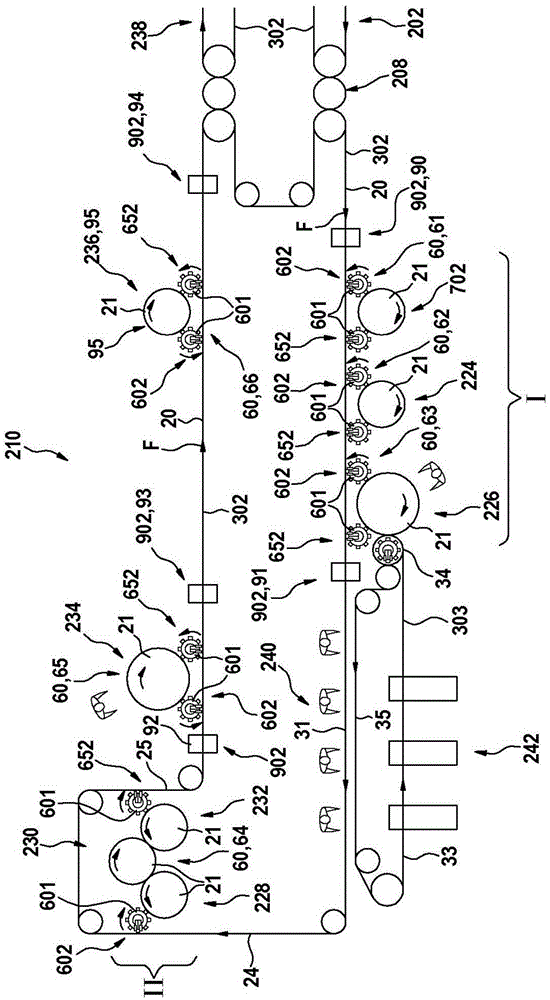

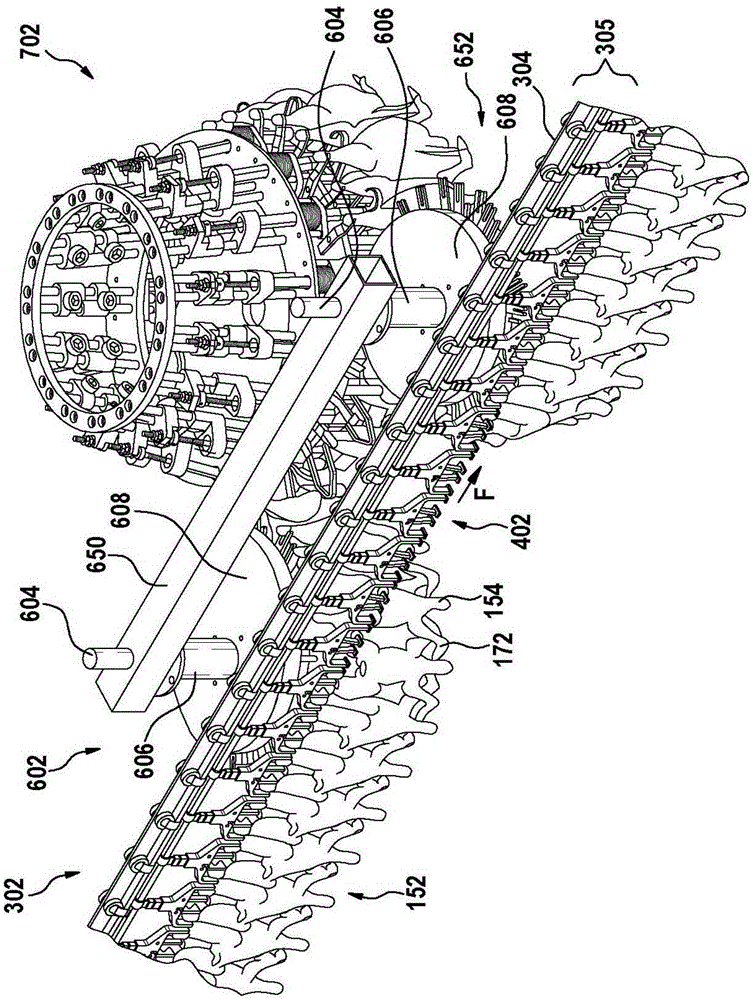

Processing device for processing slaughtered and plucked poultry carcasses, comprising poultry-support devices and poultry-processing devices

ActiveCN105307959AConveyorsPoultry eviscerating devicesEngineeringElectrical and Electronics engineering

The invention relates to a processing device (210) for processing slaughtered and plucked poultry carcasses (152), having multiple processing devices (21) that are equipped to transport poultry carcasses (152) separately from a main conveying device (302) for processing purposes using a processing retaining means (820) which can be moved on a circumferential path. The processing device (210) has transfer stations (60; 51-66) which are arranged in a row along a main conveying line (20) in which the poultry carcasses (152) are conveyed in a suspended manner using support devices (402). Each processing device (21) is paired with a transfer station (60; 61-66) formed by a transfer pair (601) which has two rotational transferring devices (602, 652). The first rotational transferring device (602) removes poultry carcasses (152) from the support devices (402) and transfers the poultry carcasses to the processing retaining means (820) of the processing device (21). The second rotational transferring device (652) removes the processed poultry carcasses (152) from the processing retaining means (820) and transfers the poultry carcasses to the support devices (402). Each support device (402) has a pair (401) of supports (41, 42) with receiving portions (40.1, 40.2) for limbs (11, 12) of the poultry carcasses (152) and comprises a support controller (410). Each support (41, 42) is equipped with a controllable retaining device (403; 405) which is connected to the support controller (410) via a control element (444, 454) that controls a retaining part of the limb receiving portion (40.1, 40.2). In an open position of the controllable retaining part, the limb receiving portion (40.1, 40.2) is open so that the poultry carcass limbs (11, 12) are inserted and removed without being clamped, and the limb receiving portion contacts the poultry carcass limbs (11, 12) only in a closed position of the retaining part. The poultry processing device (21) has a processing controller to which the processing retaining means (820) is connected and by means which the processing retaining means can be moved into different positions along the retaining means circumferential path, namely a starting position for receiving the poultry carcasses, at least one processing position, and an end position for removing the poultry carcasses.

Owner:BAADER FOOD SYST DENMARK AS

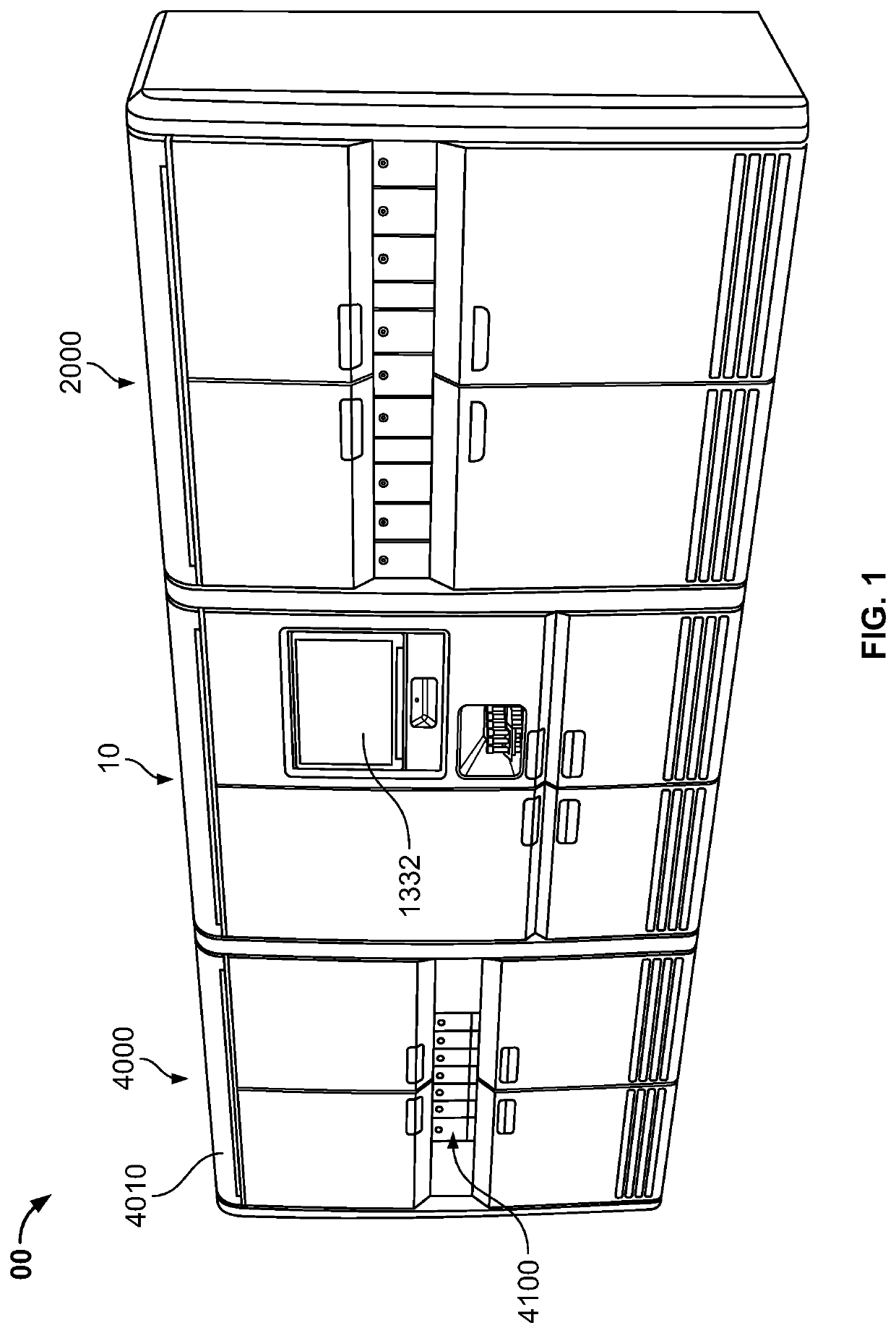

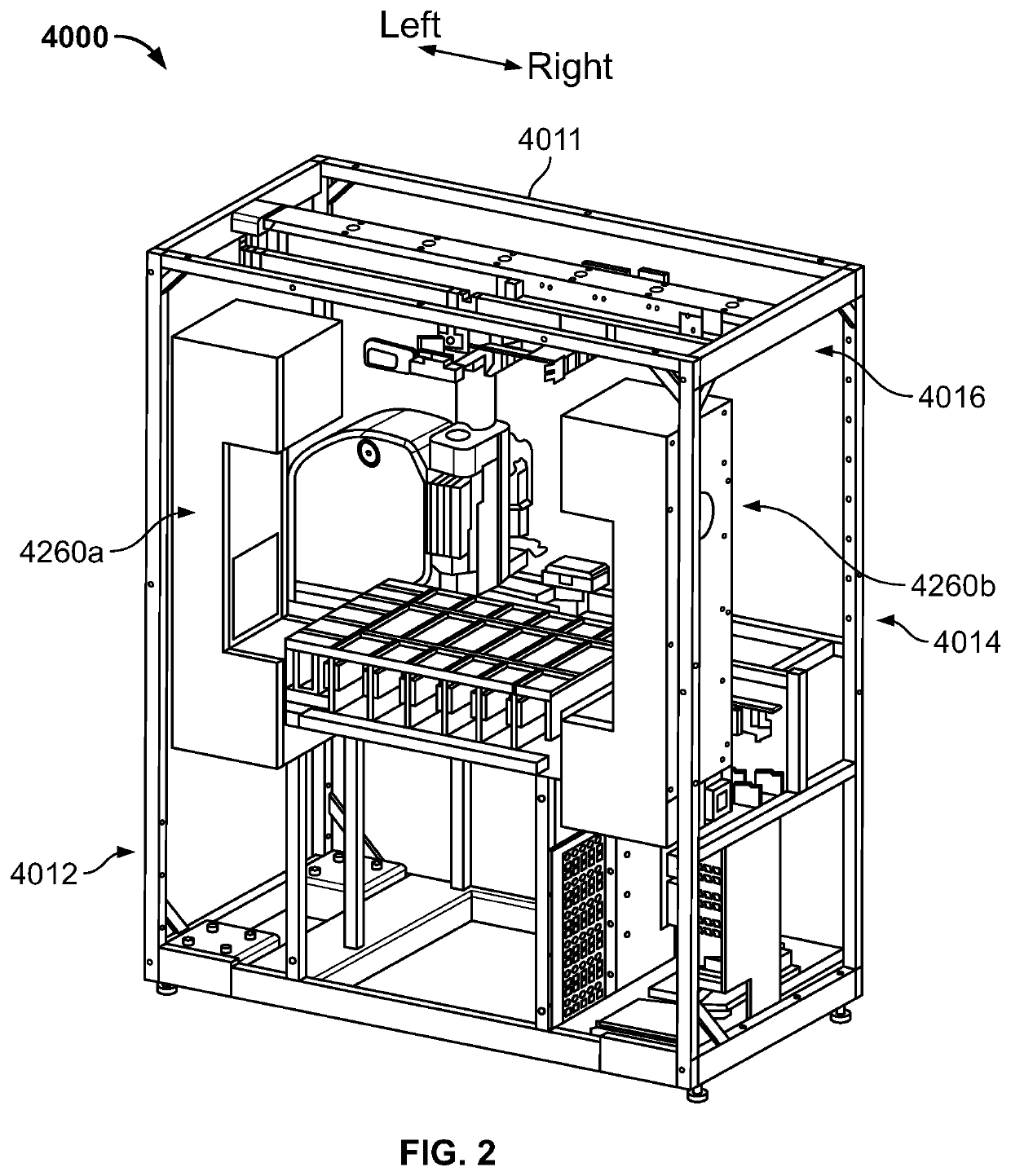

Automated diagnostic analyzer and method for its operation

An automated analyzer that receives samples prepared for analysis in an automated pre-analytical module and a method of operation of such automated analyzer. The automated analyzer includes a shuttle transfer station that receives a shuttle carrier from the automated pre-analytical system. The shuttle transfer station has a clamping assembly for the shuttle. The clamping assembly has jaws that advance engagement members into contact with a bottom portion of sample containers disposed in the shuttle. The clamping assembly secures the sample containers in the shuttle when sample is aspirated from the sample containers. The automated analyzer also has a multichannel puncture tool that is adapted to be carried by a robotic gripper mechanism. The multichannel puncture tool has multiple puncture members that each defines a channel. Each channel is in communication with a different trough in the consumable. A pipette can pass through the channel in the puncture tool.

Owner:BECTON DICKINSON & CO

Narrow site deep foundation pit excavation supporting construction method

The invention relates to a narrow site deep foundation pit excavation supporting construction method, and belongs to the field of building construction. The construction method includes the following contents that the depth of a foundation pit is 12.1 m; the depth of underground water in a the foundation pit is 30 m; the depth of underground water outside the foundation pit is 30 m; and the coefficient for importance of a supporting structure is 1.0. The construction method comprises the steps that (1) a soil nailing and anchor spraying method is adopted for slope supporting of the foundation pit; (2) a support pile and anchor cable method is adopted for non-sloping space supporting of a forwarding station and a gallery; and (3) the support pile and anchor cable method is adopted for foundation pit supporting. According to the narrow site deep foundation pit excavation supporting construction method, it is guaranteed that surface water outside the foundation pit does not flow into the foundation pit, accumulated water inside the foundation pit and on a slope face is drained out of the foundation pit in time, and stagnantblocked water on a shallow layer of the side wall of the foundation pit can be smoothly drained out; and a retention wall is arranged on the periphery of the foundation pit, it is guaranteed that rainwater cannot wash the slope, and it is guaranteed that the accumulated water can be drained out in time.

Owner:CHINA CHEM ENG SECOND CONSTR

Network type LNG (liquefied natural gas) industrial chain integrated prediction and scheduling method

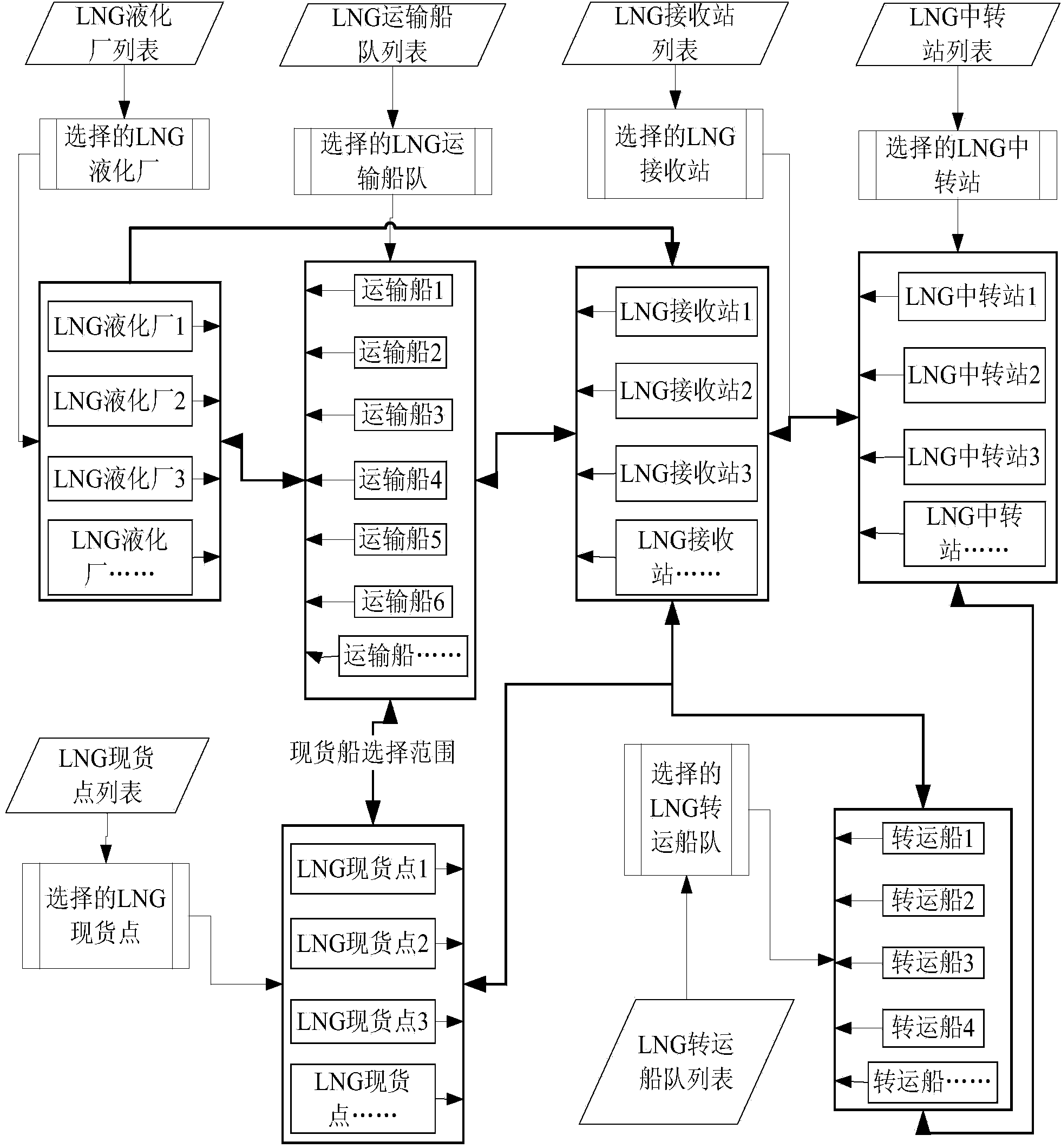

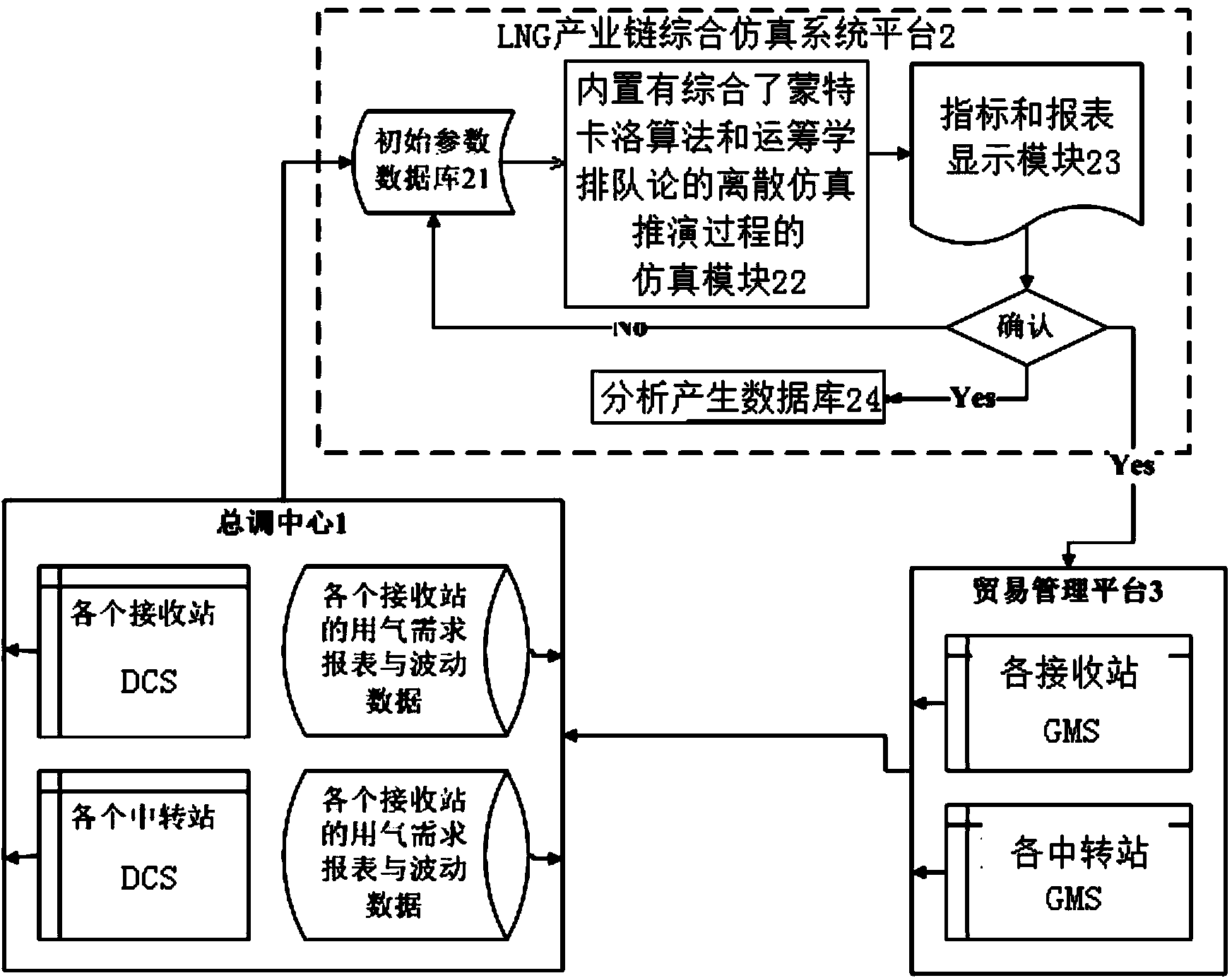

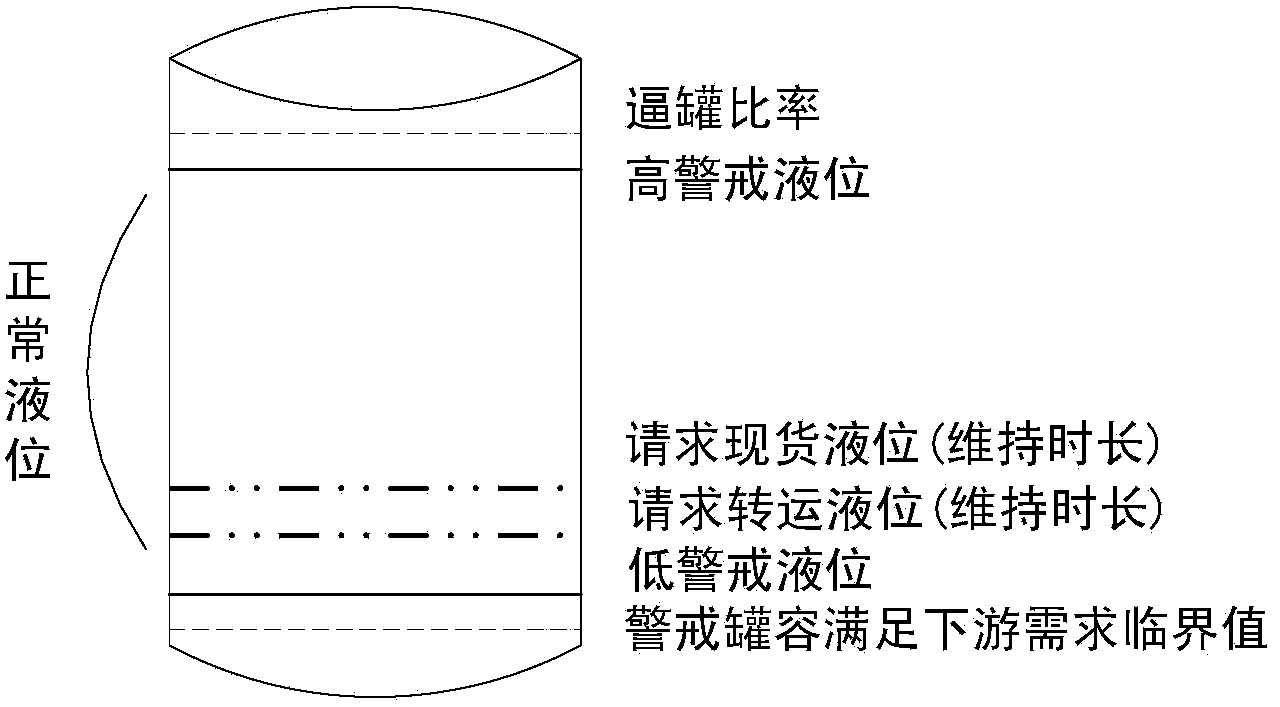

ActiveCN103632234AImprove predictive dispatch speedImprove accuracyResourcesAnalysis dataDistribution control

The invention relates to a network type LNG (liquefied natural gas) industrial chain integrated prediction and scheduling method which includes the steps of (1) setting a network type LNG industrial chain integrated prediction and scheduling system, (2) inputting various original data to an initial parameter database of a simulation system platform in advance, (3) by the simulation system platform, collecting and updating data information of the initial parameter database through DCS (distribution control system) of various receiving stations and transfer stations, (4) starting a simulation module by the simulation system platform to perform simulation deduction, (5) displaying the simulation deduction results by index and report display modules, (6) transmitting the simulation deduction results to a trade management platform by the simulation system platform, and then sending the results to GMS(gas management system) terminals of the receiving stations and the transfer stations via the trade management platform so as to generate the scheduling plan of the home station. The network type LNG industrial chain integrated prediction and scheduling system comprises a master scheduling center, the simulation system platform and the trade management platform; the master scheduling center is connected with the DCS of the receiving stations and the transfer stations, the trade management platform is connected with the GMS of the receiving stations and the transfer stations; the simulation system platform comprises an initial parameter database, the simulation module, the index and report display module and an analysis database.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Multidirectional die forging production line

PendingCN107717484ASet compactIncrease productivityMetal-working apparatusOther manufacturing equipments/toolsProduction lineHeating furnace

The invention relates to the technical field of forging, in particular to a multidirectional die forging production line. The multidirectional die forging production line comprises a raw material blanking station, a blank feeding station, an induction heating station, a water phosphorous removal station, a spraying-lubricating station, a forging station and a forge part transfer station which arearranged in sequence, wherein a saw cutting device and a material storage frame are arranged at the raw material blanking station, a hoisting device and an operating platform are arranged at the blankfeeding station, a medium-frequency induction heating furnace is arranged at the induction heating station, a V-shaped groove and a first material pushing air cylinder are arranged at a feeding portof the medium-frequency induction heating furnace, a phosphorous removal box is arranged at the water phosphorous removal station, a positioning roller and a phosphorous removal ring located above thepositioning roller are arranged in the phosphorous removal box, a feeding manipulator and a spraying manipulator are arranged at the spraying-lubricating station. The forging station is provided witha multidirectional die forging hydraulic press and a die, the forge part transfer station is provided with a blanking manipulator, a conveying chain and a blank forge part storage zone. The stationsof the multidirectional die forging production line are tight in arrangement, various forge parts can be continuously produced, unattended automatic control can be achieved, and the production efficiency is high.

Owner:22MCC GRP PRECISION FORGING

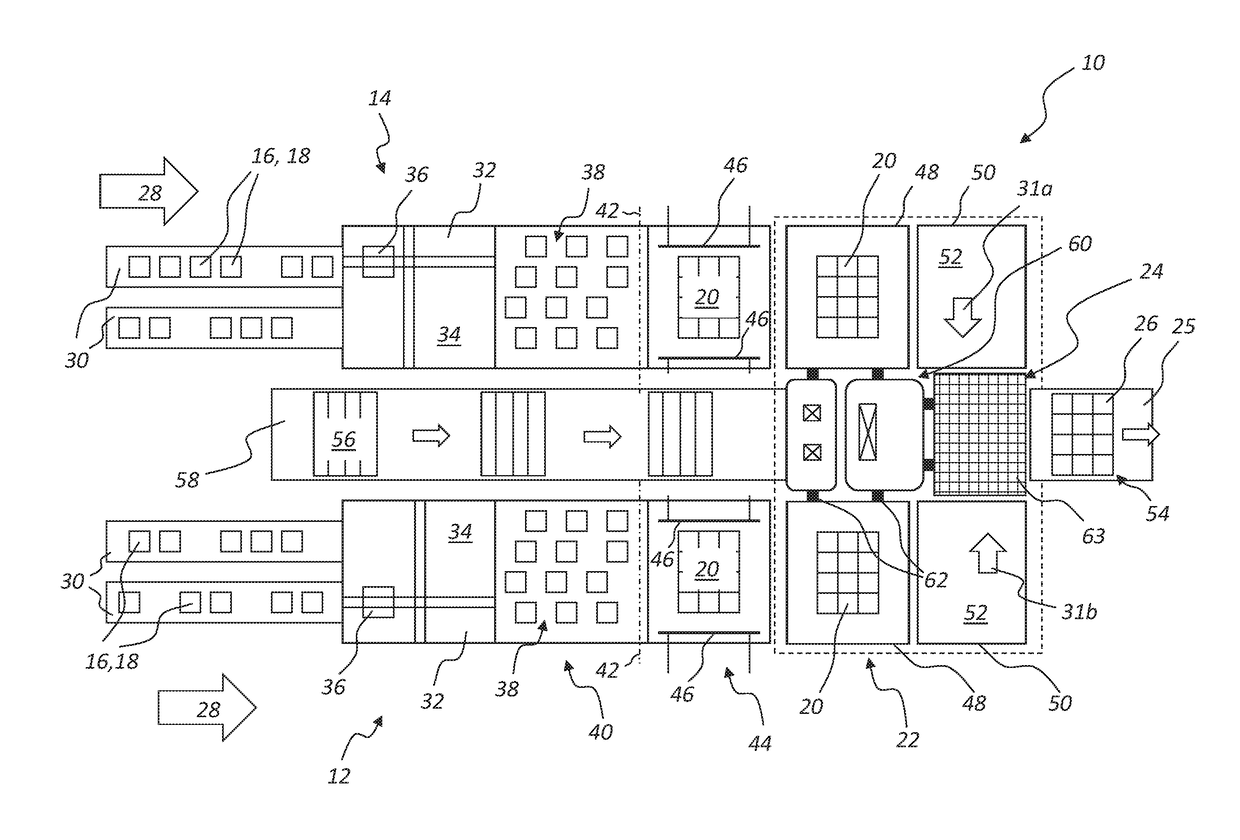

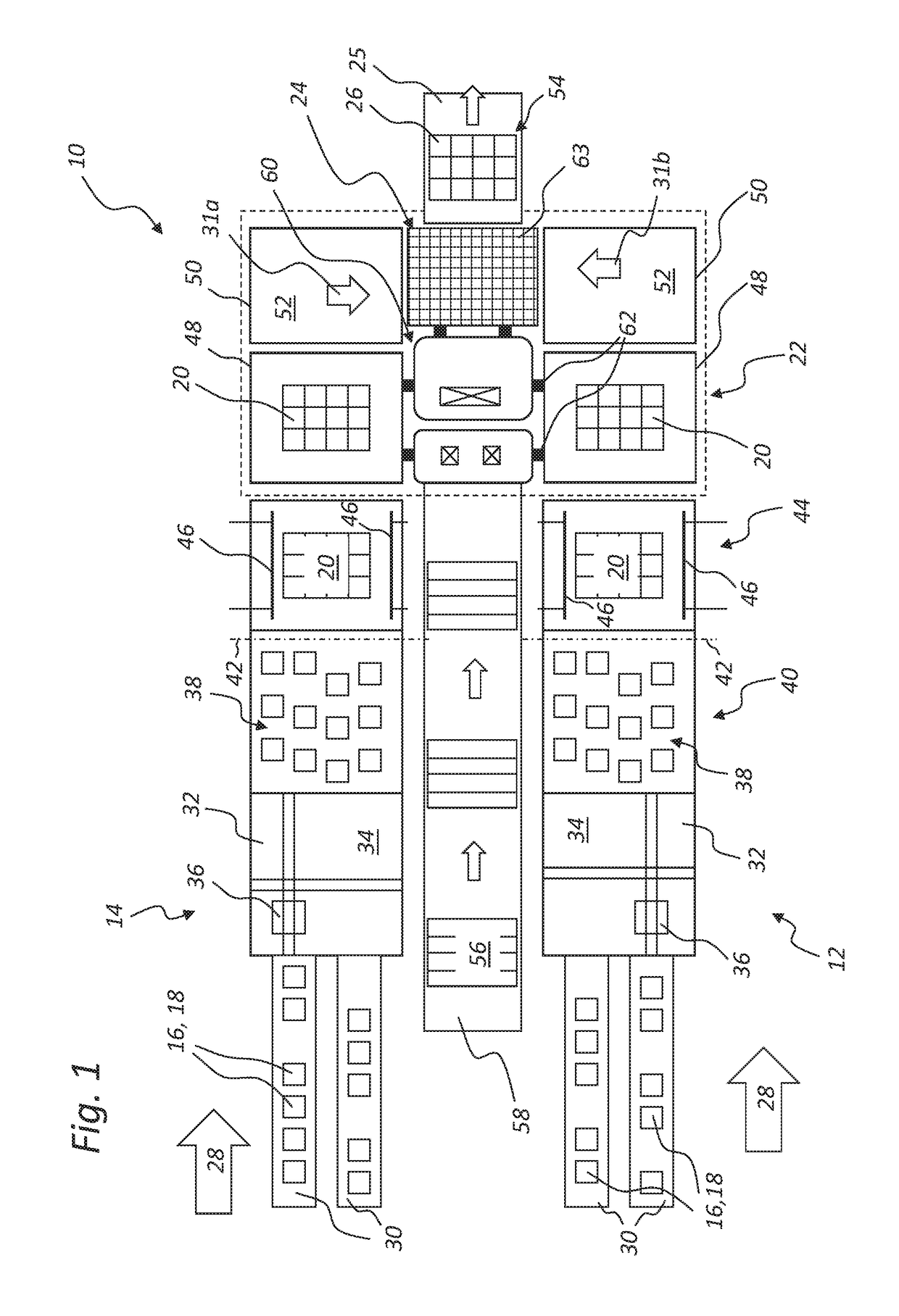

Method and apparatus for conveying articles, piece goods and/or containers within at least two conveying path sections

ActiveUS20180229948A1The process is compact and efficientEasy to slideConveyorsPackagingTransfer lineSupport surface

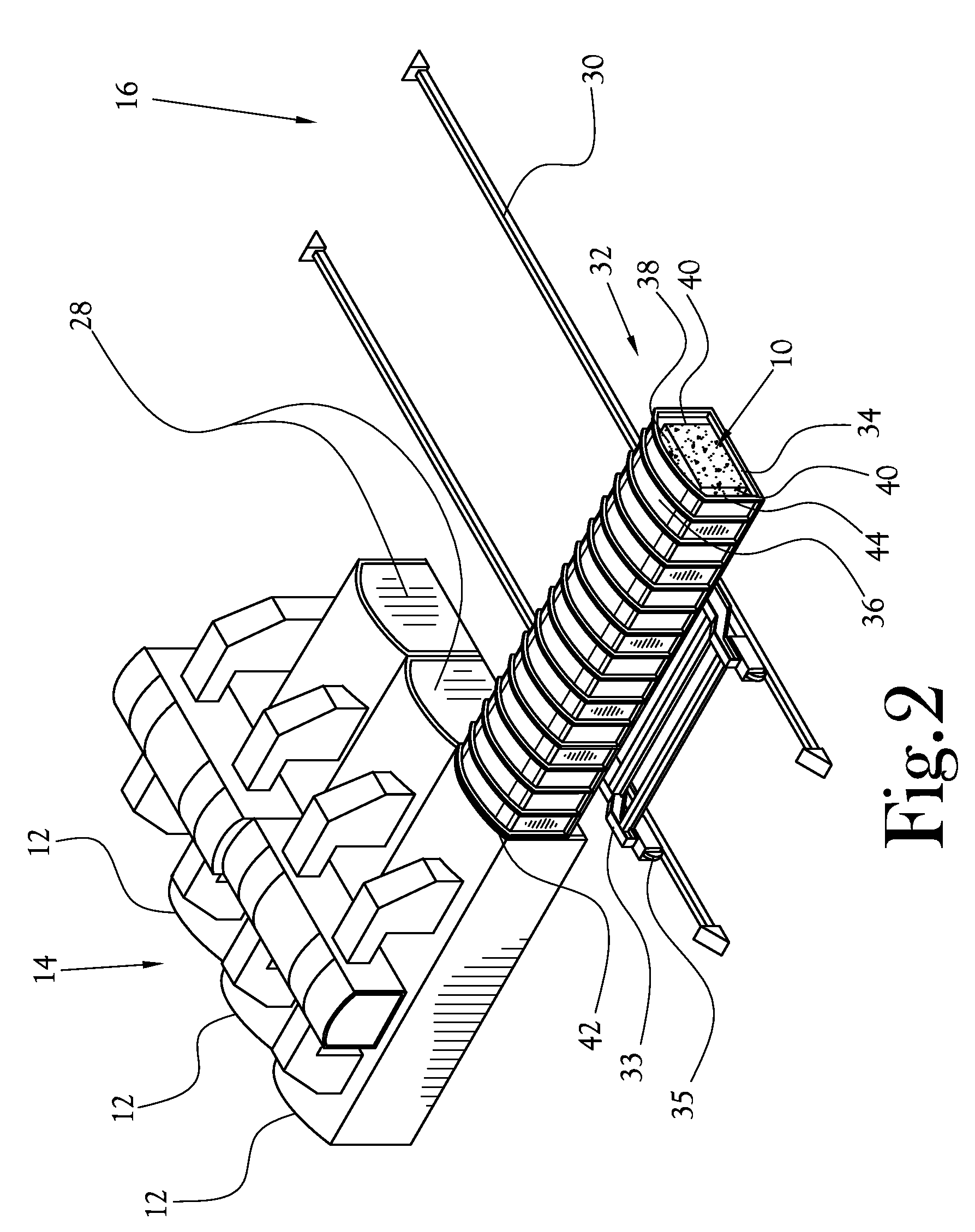

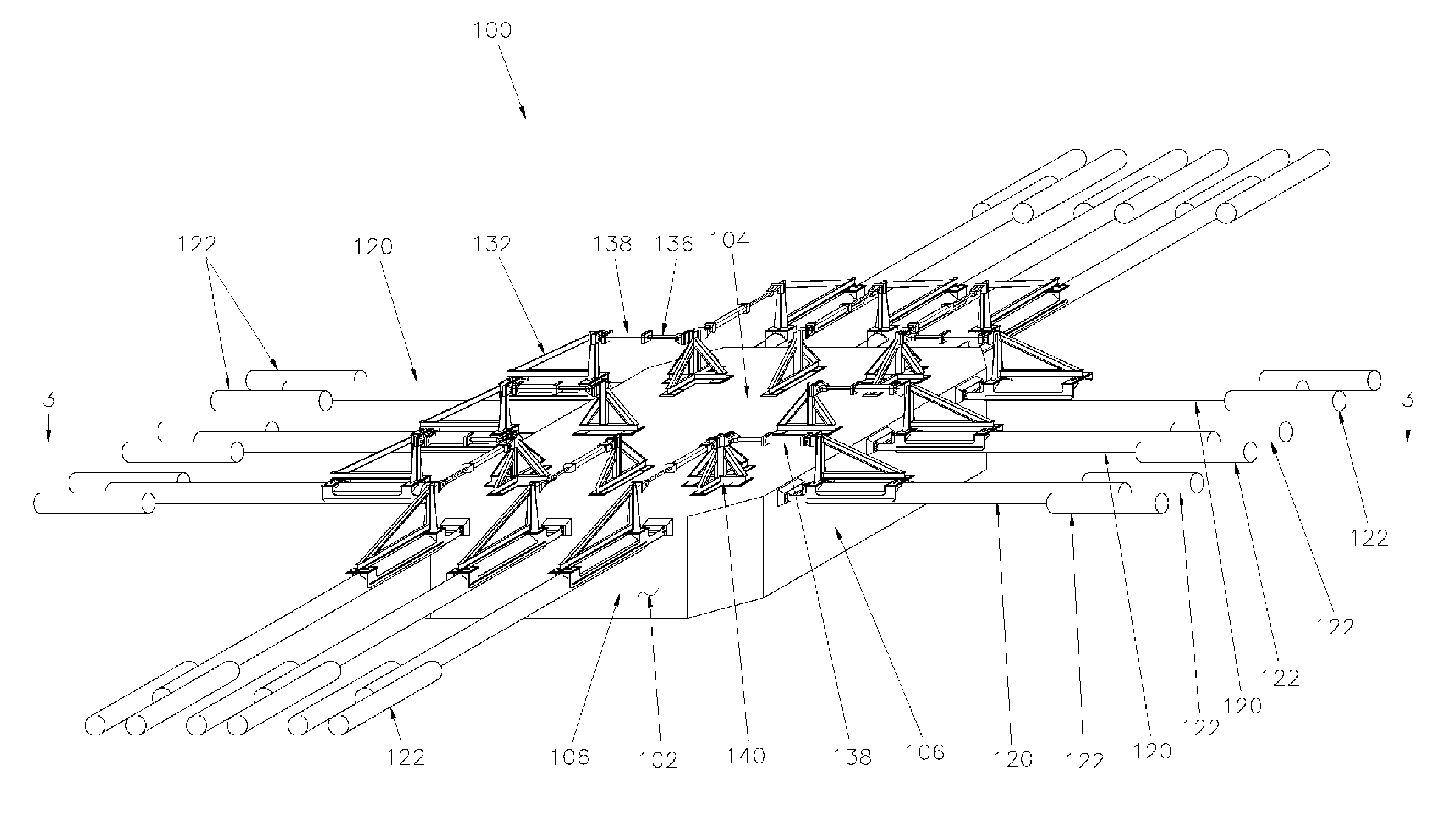

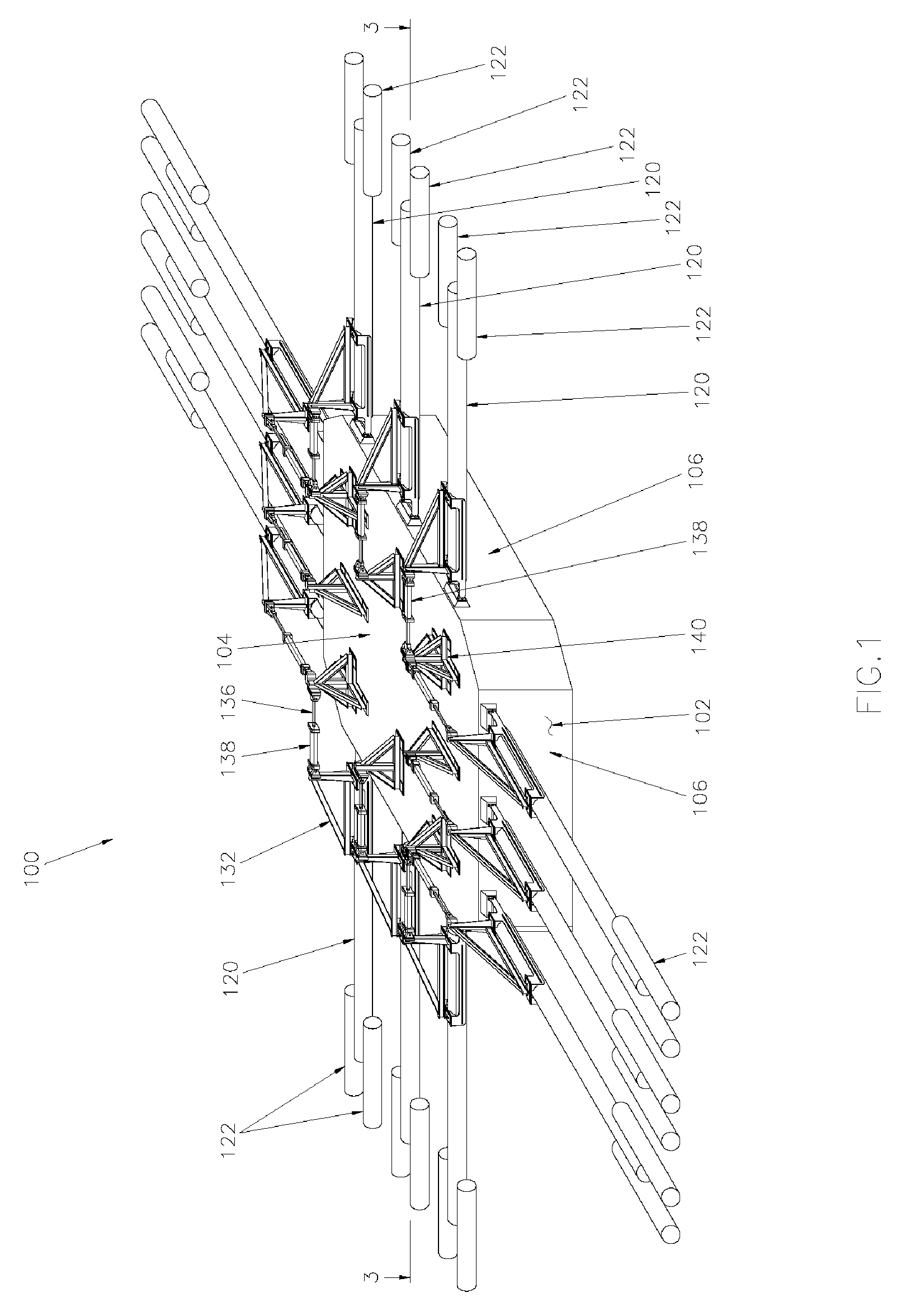

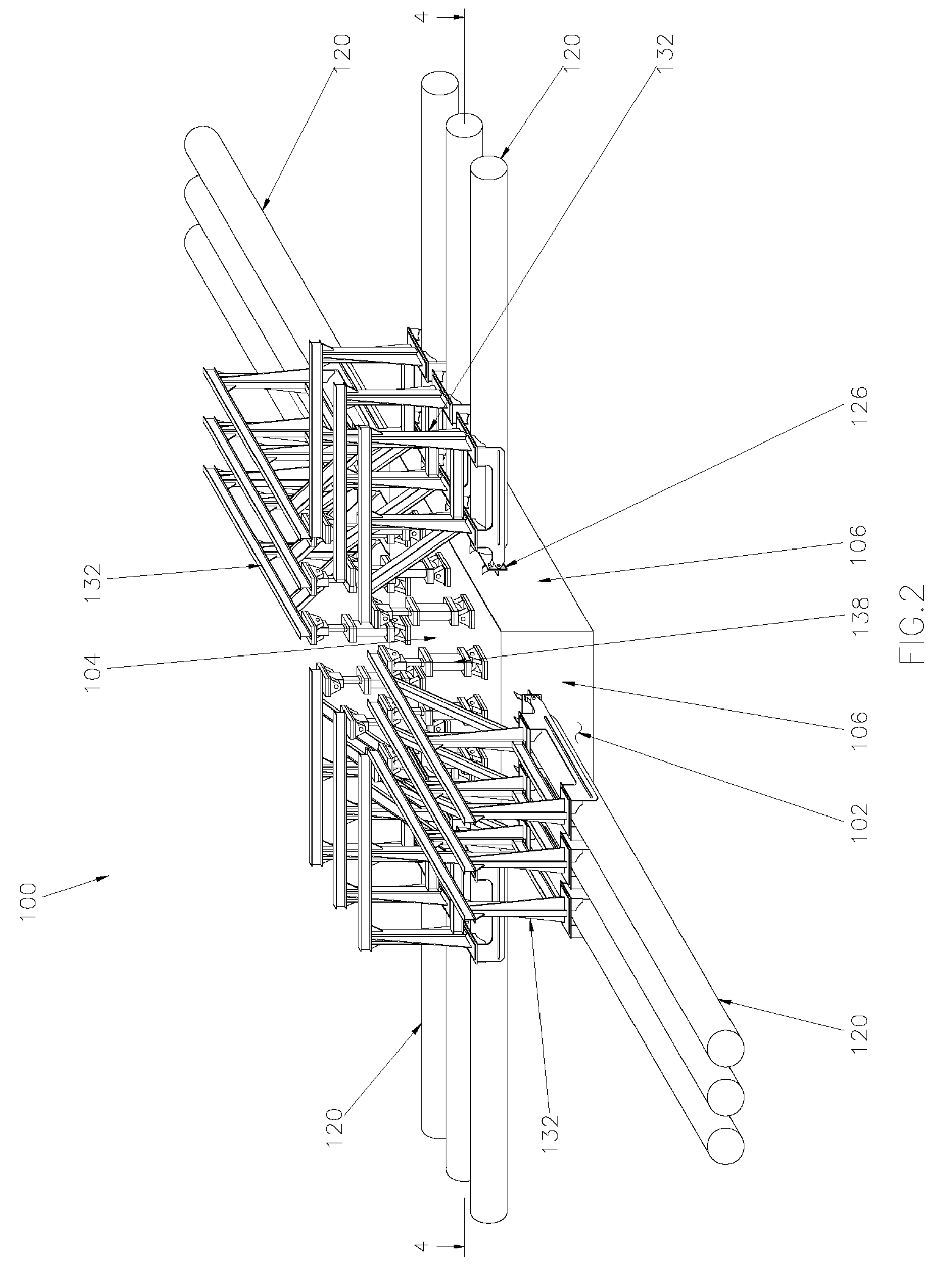

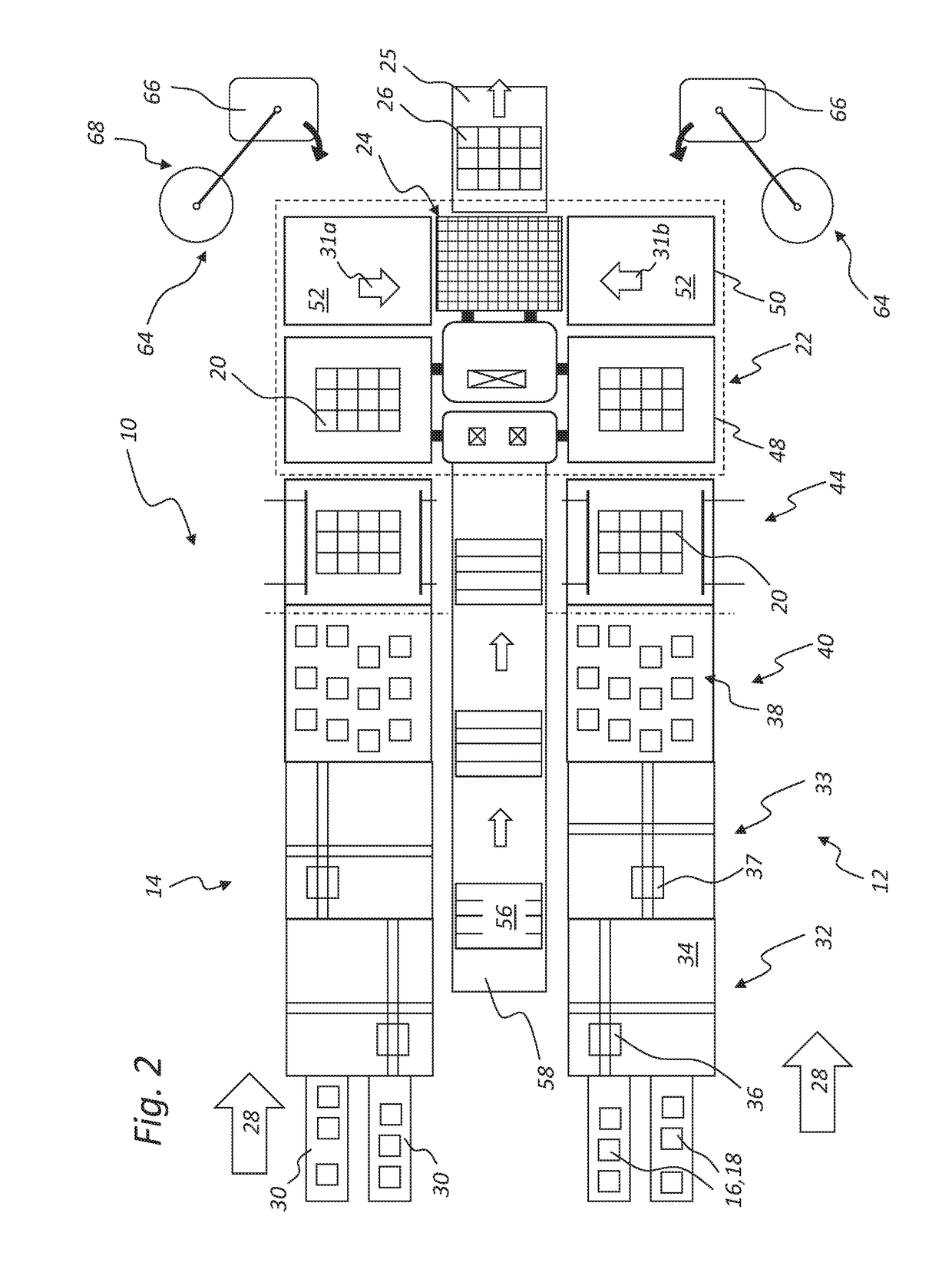

The invention relates to a palletizing apparatus (10) and a method for conveying articles (16), piece goods, and / or bundles (18) and / or palletizable article layers, piece good layers, and / or bundle layers (20) with at least two conveyor line sections (12, 14), each in a particular conveying direction (28, 29). Each conveyor line sections include consecutive handling stations, grouping stations, and / or transfer stations (32, 33, 40, 44, 48, 50), which lead to a central loading station (24), where the article layers, piece good layers, and / or bundle layers (20) are stacked on top of each other and / or palletized in a common loading place (25). The loading station (24) is located between at least two vertically adjustable support surfaces and / or conveying surfaces (52). The common loading place (25) is supplied with article layers, piece good layers, and / or bundle layers (20).

Owner:KRONES AG

Leachate treatment method for garbage transfer station

PendingCN111762970AUniform water qualityImprove processing efficiencyFatty/oily/floating substances removal devicesSludge treatmentReverse osmosisAnaerobic reactor

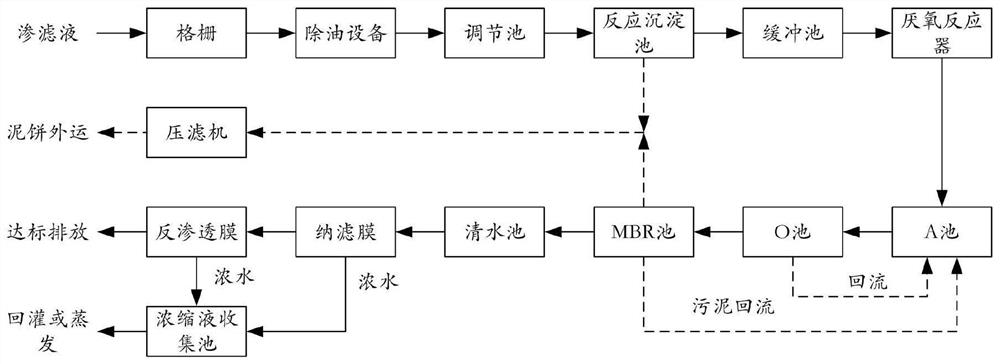

The invention discloses a leachate treatment method for a garbage transfer station. The method comprises the steps of S1, enabling leachate to pass through a grating well, blocking large impurities byutilizing grating in the grating well, enabling the leachate passing through the grating well to enter oil removal equipment, conveying floating oil at the top of the leachate to an oil collection storage tank through an oil-water separator, removing most of the floating oil, and enabling the leachate to enter an adjusting tank after the oil removal process is completed. The invention relates tothe technical field of sewage treatment. According to the leachate treatment method for the garbage transfer station, the oil removal device, the adjusting tank, a reaction sedimentation tank, a buffer tank, an anaerobic reactor, a tank A (denitrification tank), a tank O (nitrification tank), an MBR tank, a clean water tank, a nanofiltration membrane and a reverse osmosis membrane are arranged. Inallusion to the characteristics of landfill leachate, especially the difficulties of high COD content and high ammonia nitrogen content, the scheme design adopts oil removal, coagulating sedimentation, a salt-tolerant anaerobic technology, a nitrification-denitrification biochemical treatment technology and an RO membrane system to ensure that the effluent reaches the limit standard.

Owner:武汉环联环境工程有限公司

Non-water conservation method of aquatic product and industrialization implement system

InactiveCN102823523APreserve nutritional valueNo side effectsClimate change adaptationPisciculture and aquariaAnesthetic AgentFishery

The invention relates to a non-water conservation method of an aquatic product and also relates to an industrialization implement system of the method. The non-water conservation method of the aquatic product comprises the following steps: carrying out cultivating, temporary rearing, domesticating, packaging, transferring and butt awakening on the aquatic product in the non-water conservation industrialization implement system of the aquatic product composed of a cultivating workshop, a temporary rearing workshop, a domestication workshop, a packaging workshop, a transfer station and a butt awakening base. The non-water conservation method has the advantages that a chemical substance such as anesthetics is not adopted in the conservation process of the aquatic product, so that the aquatic product has no side effect on a human body; the potential safety hazard is reduced, and the nutritive value of the aquatic product is also preserved to the greatest extent. The method and system are low in cost; the conservation time of the aquatic product is long and can be up to 60-80 hours, and the survival rate is more than 98%. The method and system disclosed by the invention are simple, high in automatic degree, and easy to operate, and mass transportation can be achieved.

Owner:SHANDONG INST OF COMMERCE & TECH

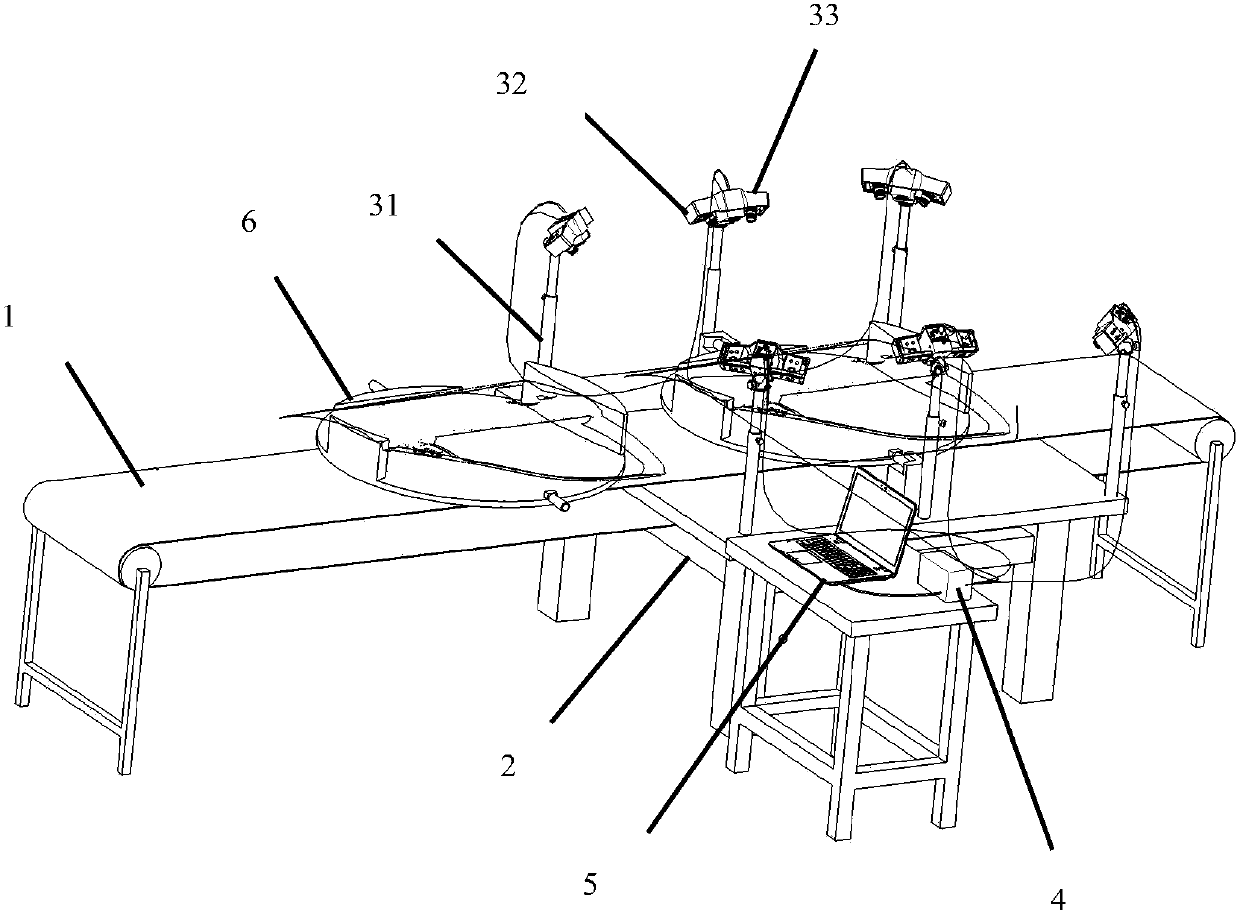

Industrial automatic three-dimensional detection system and method

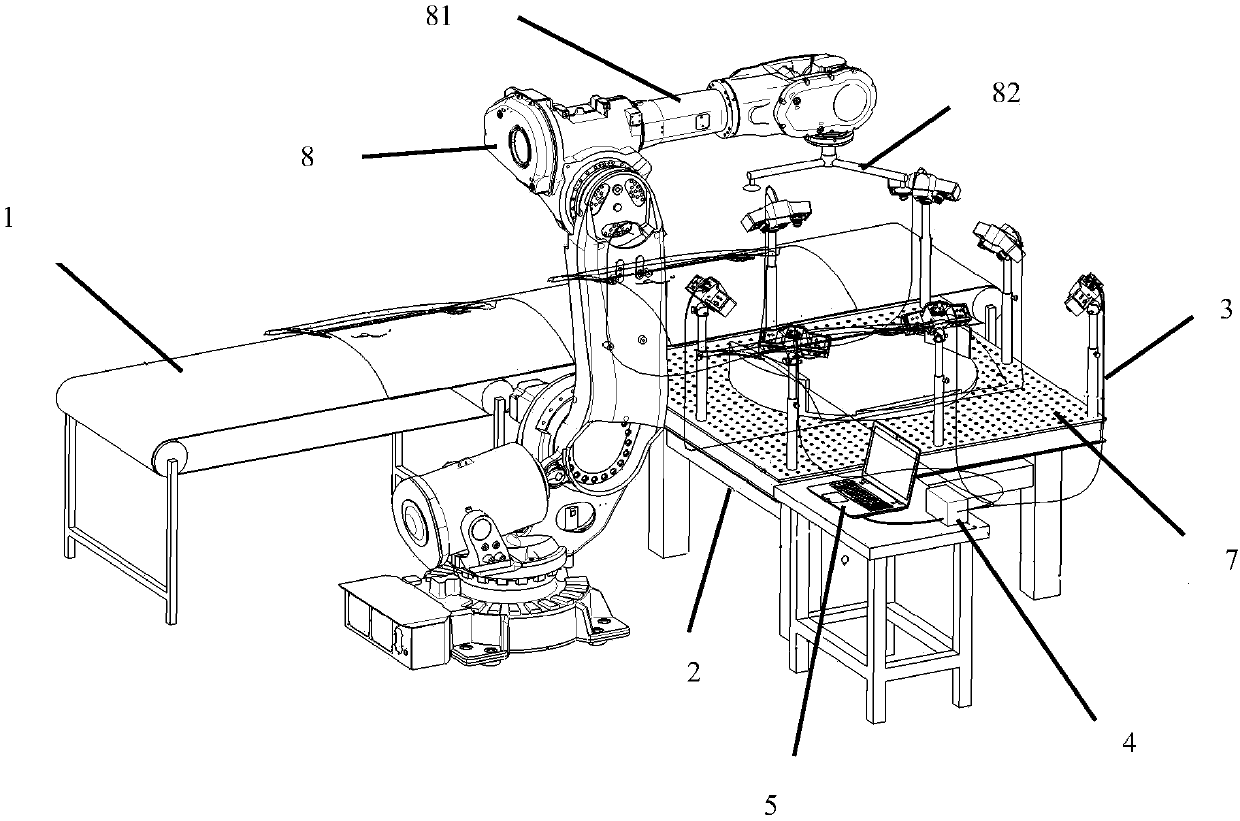

The invention provides an automatic three-dimensional detection system and method. The system comprises a workpiece conveying system, a working platform, one or more three-dimensional optical scanningdevices, a data transfer station and a computer terminal. The system has the advantages that the system is applied to the industrial automatic shape detection of a plurality of production-line objects and the automatic shape scanning and detection of a non-production-line single object, a detection mode using a robot to grab a workpiece and place the workpiece on the scanning working platform ora stop and detection working mode, which does not need robot grabbing, on a production-line conveying belt is adopted, a coordinated detection mode using one or more three-dimensional optical scanningdevices arranged on the periphery of a production line is used to lower the use difficulty, maintenance cost and manpower cost of three-dimensional scanners, and detection efficiency is greatly improved.

Owner:张宇航

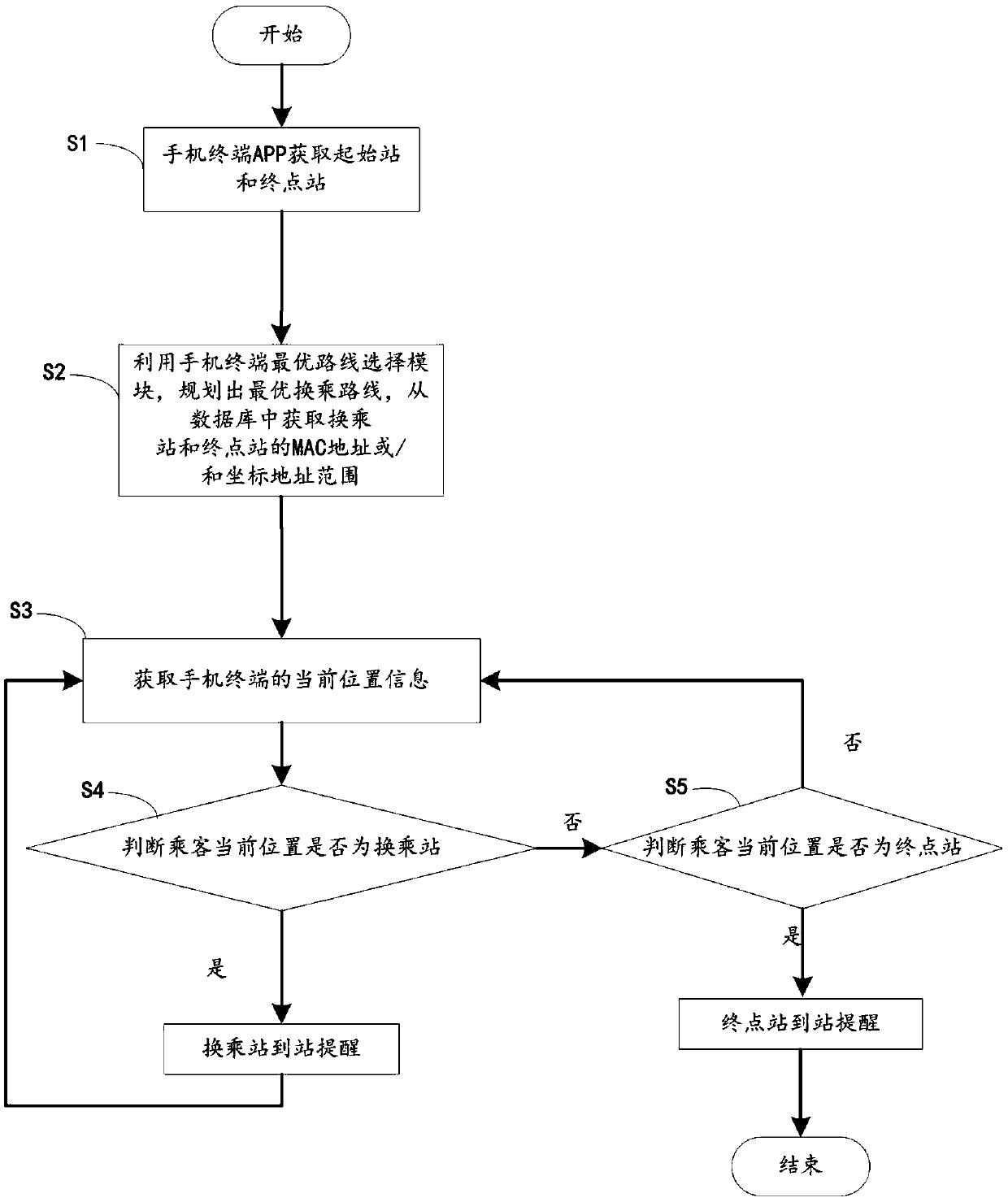

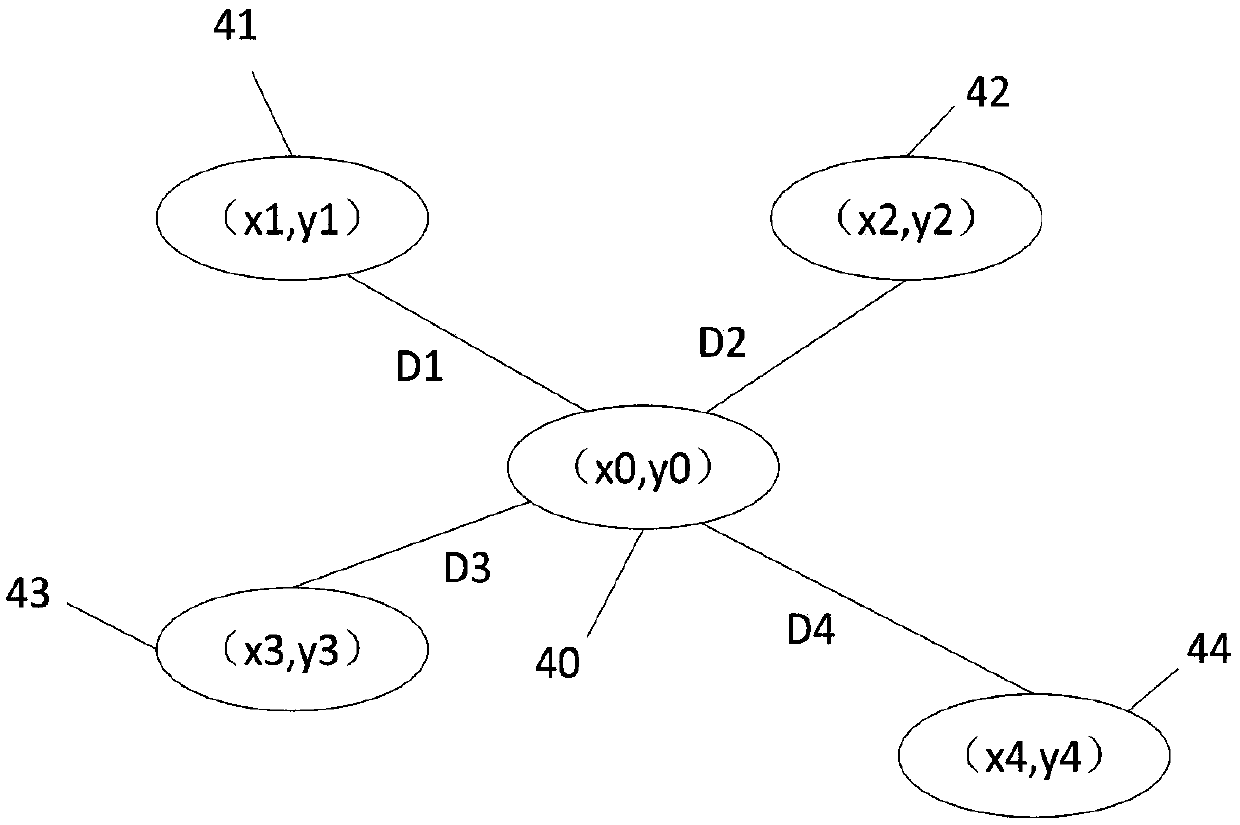

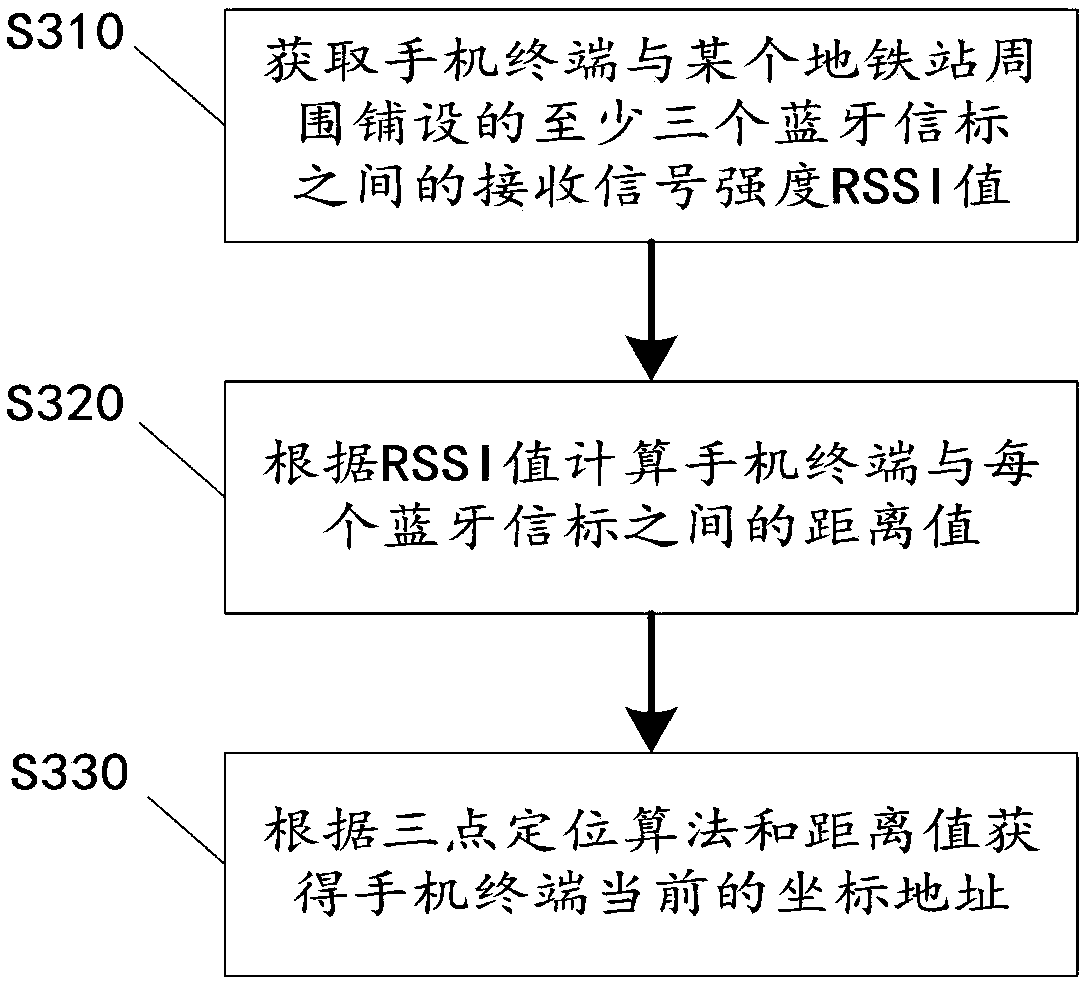

Intelligent arrival reminding method and system

InactiveCN109525733ASolve the situation where the current location cannot be obtainedSubstation equipmentLocation information based serviceMobile phoneTransfer line

The invention discloses an intelligent arrival reminding method and system, relates to the technical field of intelligent traffic, and solves the problems that a user misses a station, a transfer station is missed, a riding line is unclear and the like. The intelligent arrival reminding method comprises the following steps of S1, acquiring a starting station and a terminal station by a mobile phone terminal APP; S2, planning an optimal transfer line by an optimal line selection module of a mobile phone terminal according to the starting station and the terminal station; S3, acquiring current position information of the mobile phone terminal; S4, judging whether the current position of a passenger is the transfer station or not, and if yes, reminding the user to arrive at the transfer station in a predetermined reminding mode by the mobile phone terminal and then executing the step S3, otherwise, executing the step S5; and S5, judging whether the current position of the passenger is theterminal station or not, and if yes, reminding the user to arrive at the terminal station by the mobile phone terminal and ending the process, otherwise, executing the step S3.

Owner:JIANGSU HENGBAO INTELLIGENT SYST TECH CO LTD

Malodorous gas collecting and purifying integrated equipment and method thereof

InactiveCN103990363AAvoid distributingEfficient collectionDispersed particle filtrationDirt cleaningPhotocatalytic reactionFiltration

The invention discloses a malodorous gas collecting and purifying integrated equipment and a method thereof for malodorous gas in a municipal refuse transfer station. The integrated equipment is composed of a waste gas collecting system and a waste gas purifying system, wherein a waste gas purifying treatment method comprises the following steps: (1) carrying out pre-filtration on waste gas by a filtering screen of the waste gas collecting system; (2) uniformly distributing waste gas by a flow equalizing box in the waste gas purifying system; (3) degrading a great amount of malodorous gas by a low-temperature plasma purifying module in the waste gas purifying system; (4) removing residual malodorous gas molecules and generated intermediate micromolecules from waste gas by a photo-catalytic reactor in the waste gas purifying system, and sterilizing and disinfecting; and (5) removing ozone remained in the low-temperature plasma purifying module and the photo-catalytic reactor by an ozone decomposition reactor in the waste gas purifying system to reduce secondary pollution. The integrated equipment and the method have the beneficial effects of collecting malodorous gas with high efficiency, sterilizing and disinfecting, and thoroughly treating the malodorous gas without secondary pollution.

Owner:SHANGHAI RUIJIN ENVIRONMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com