Patents

Literature

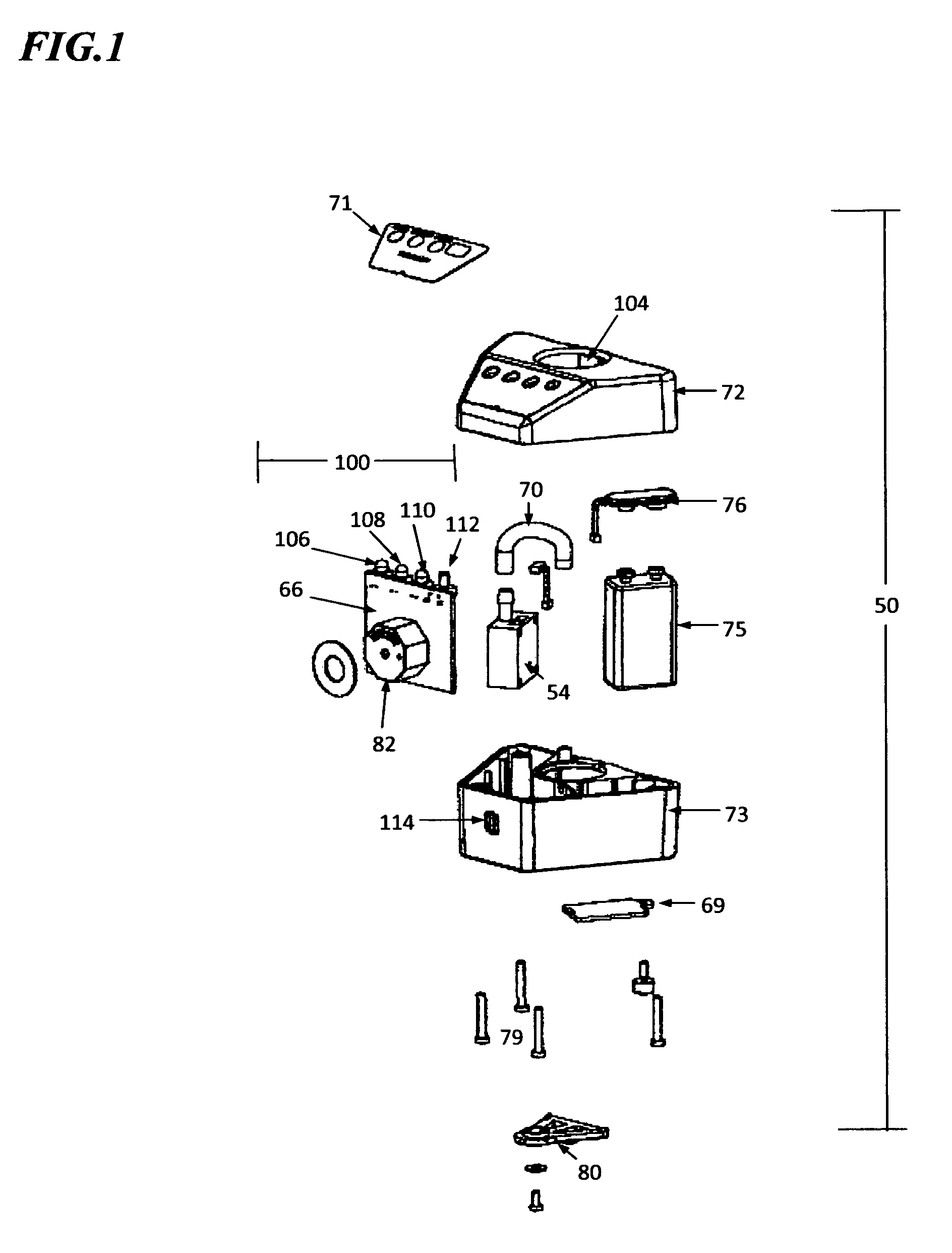

175 results about "Gas management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

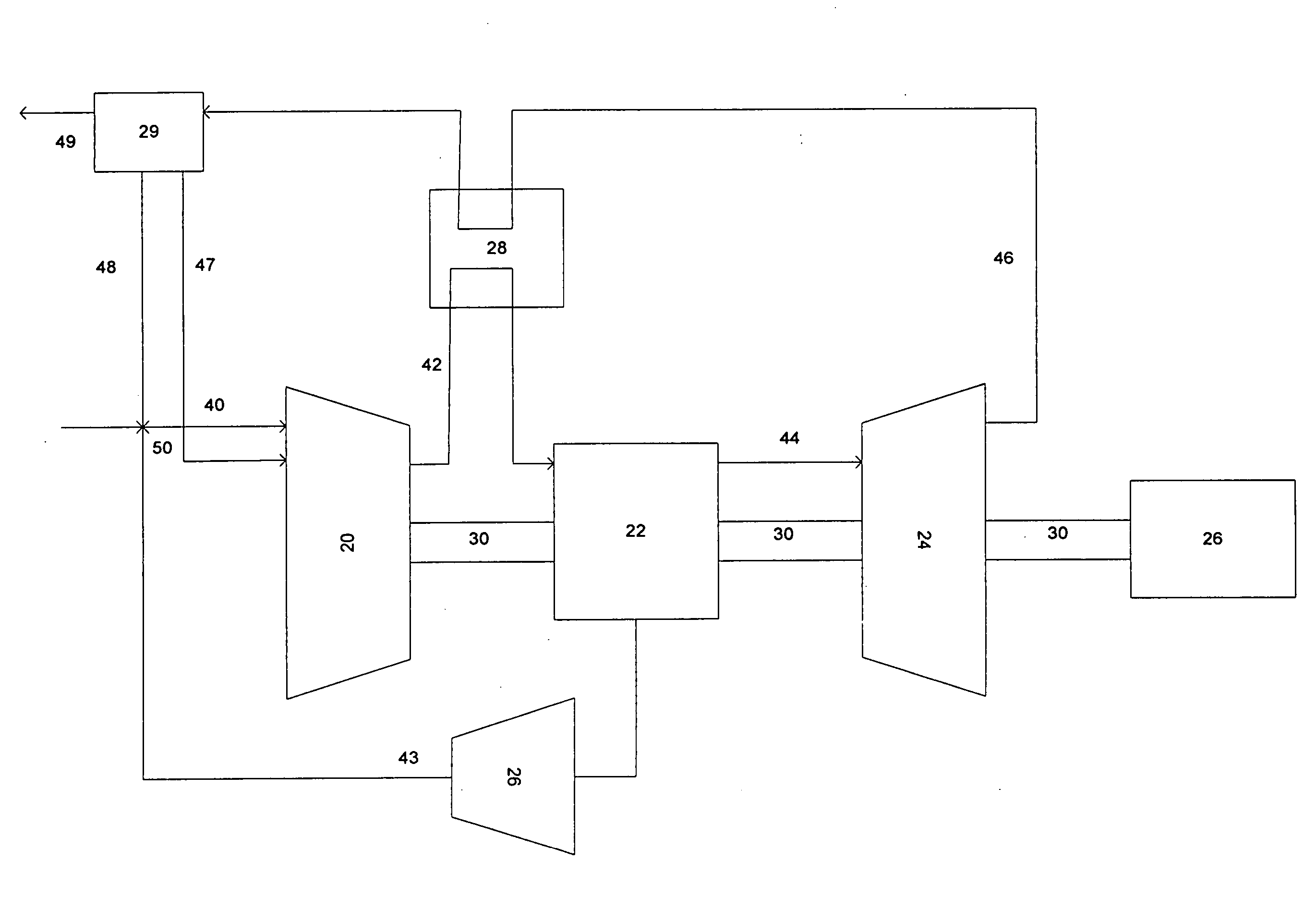

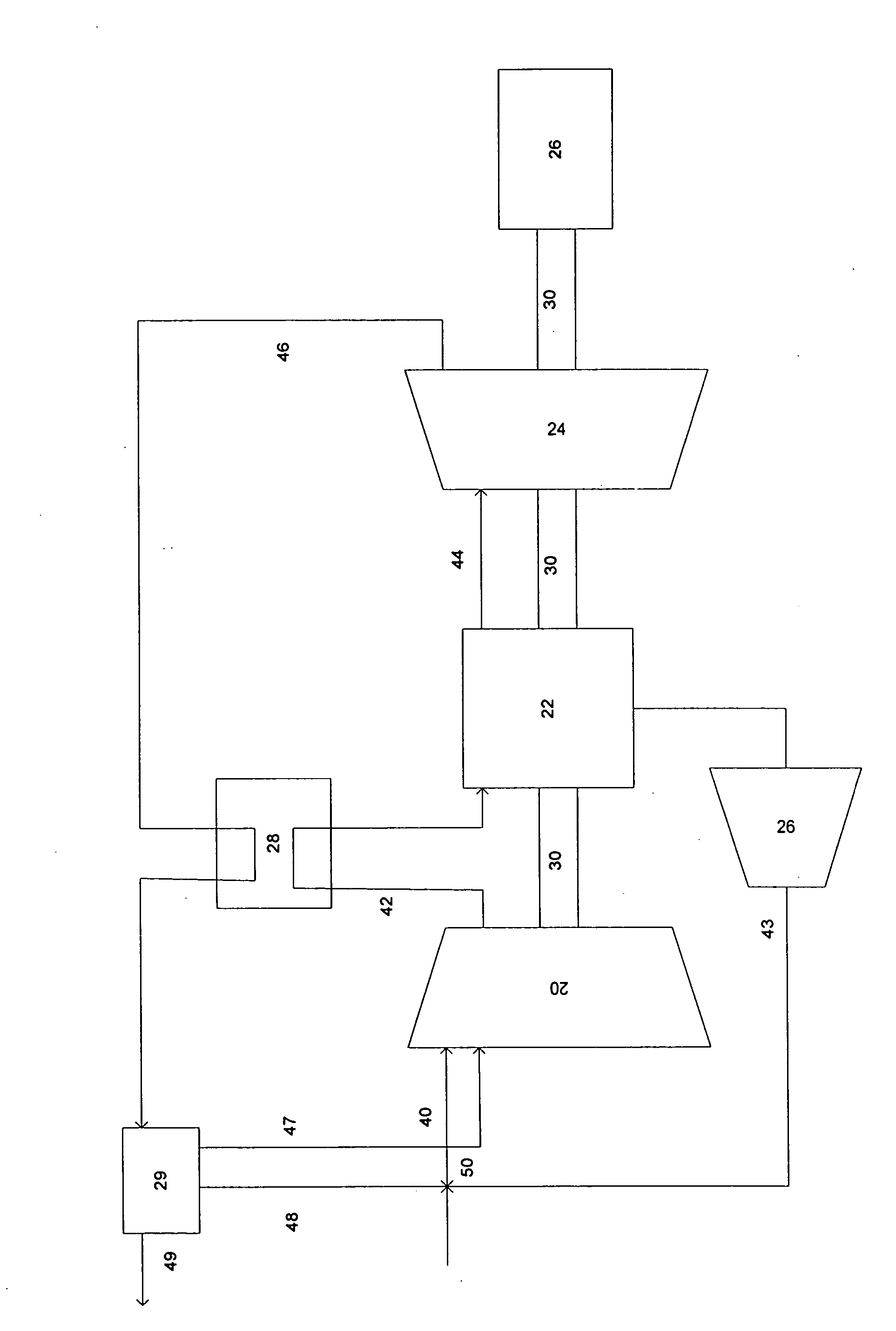

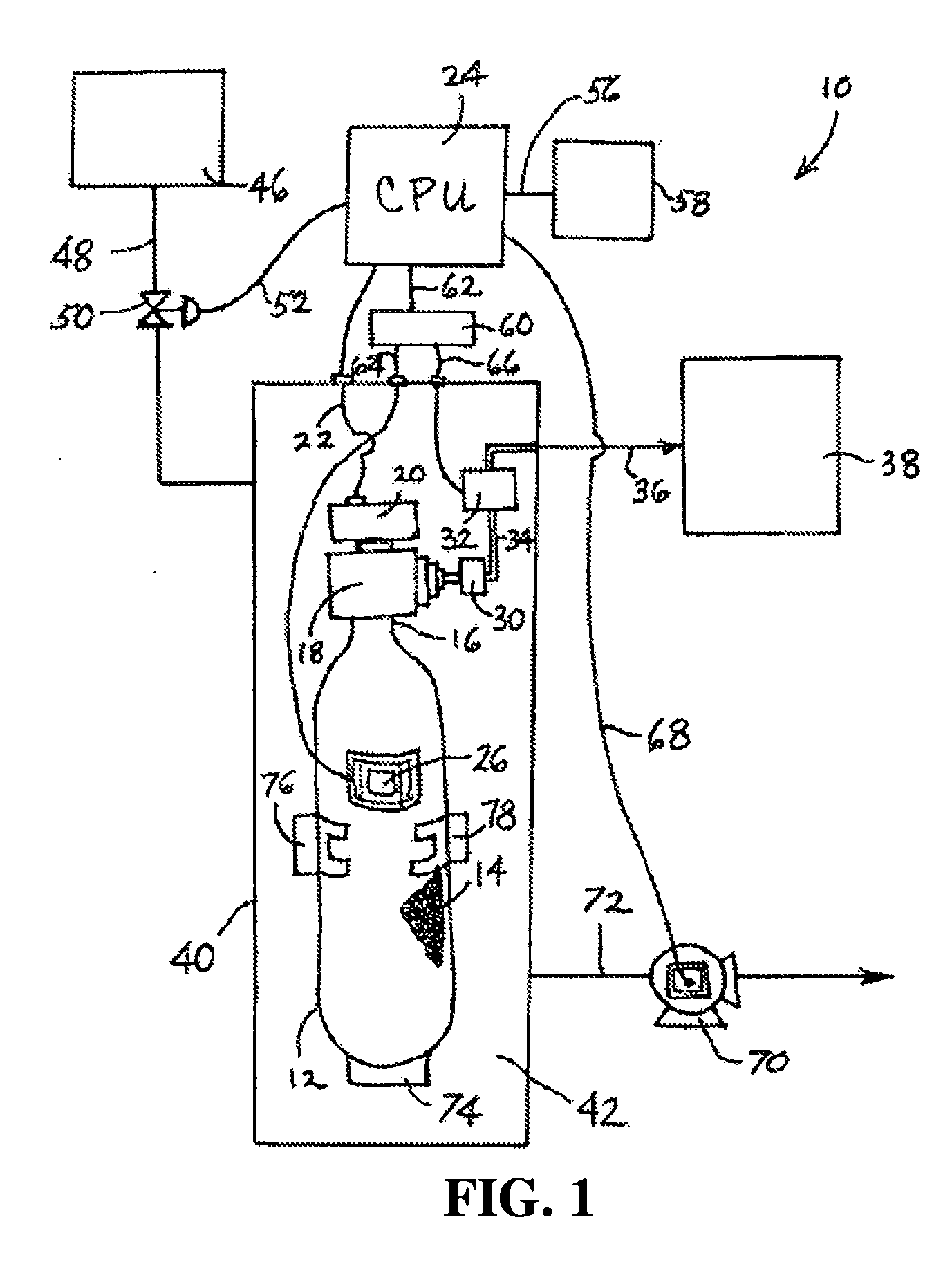

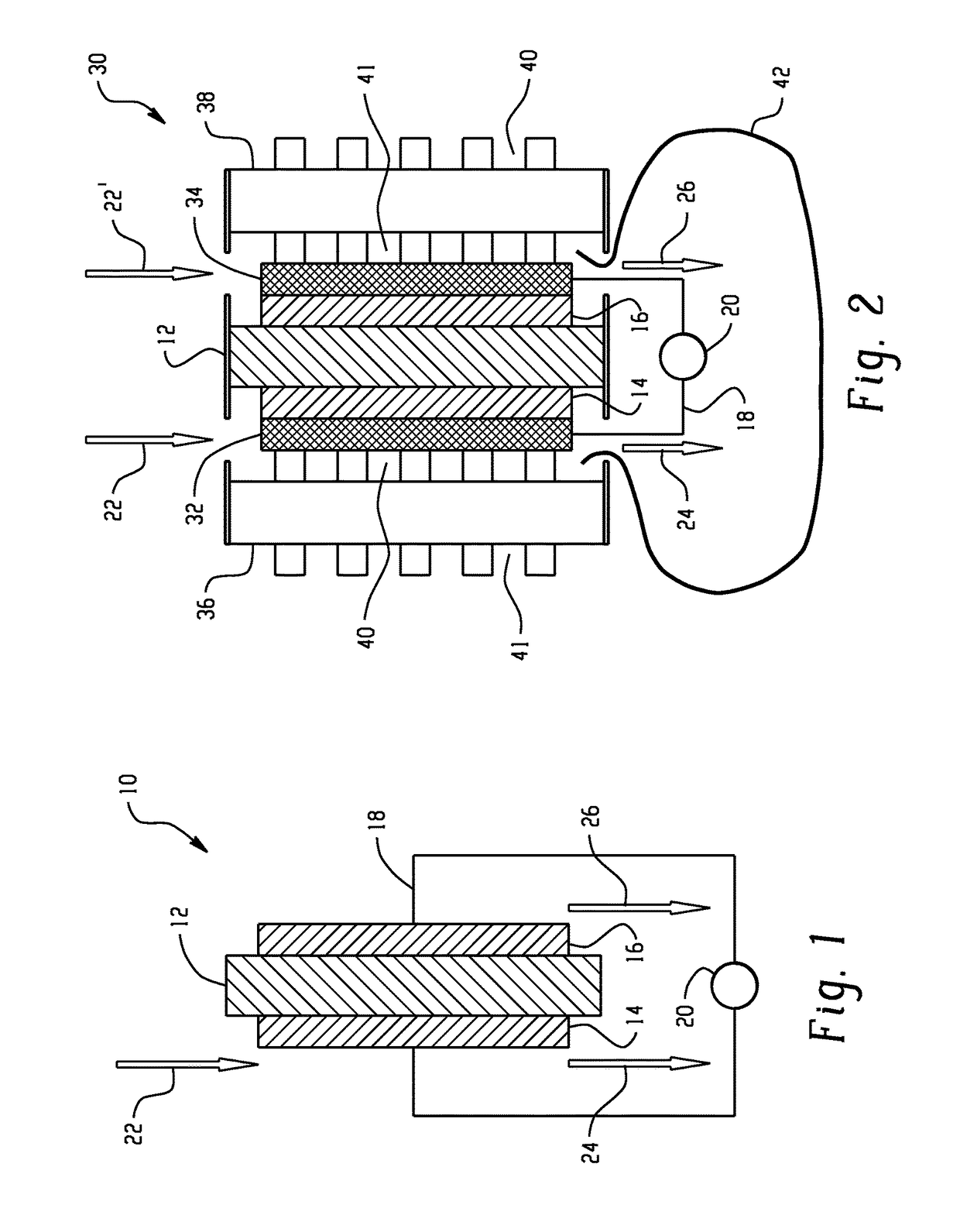

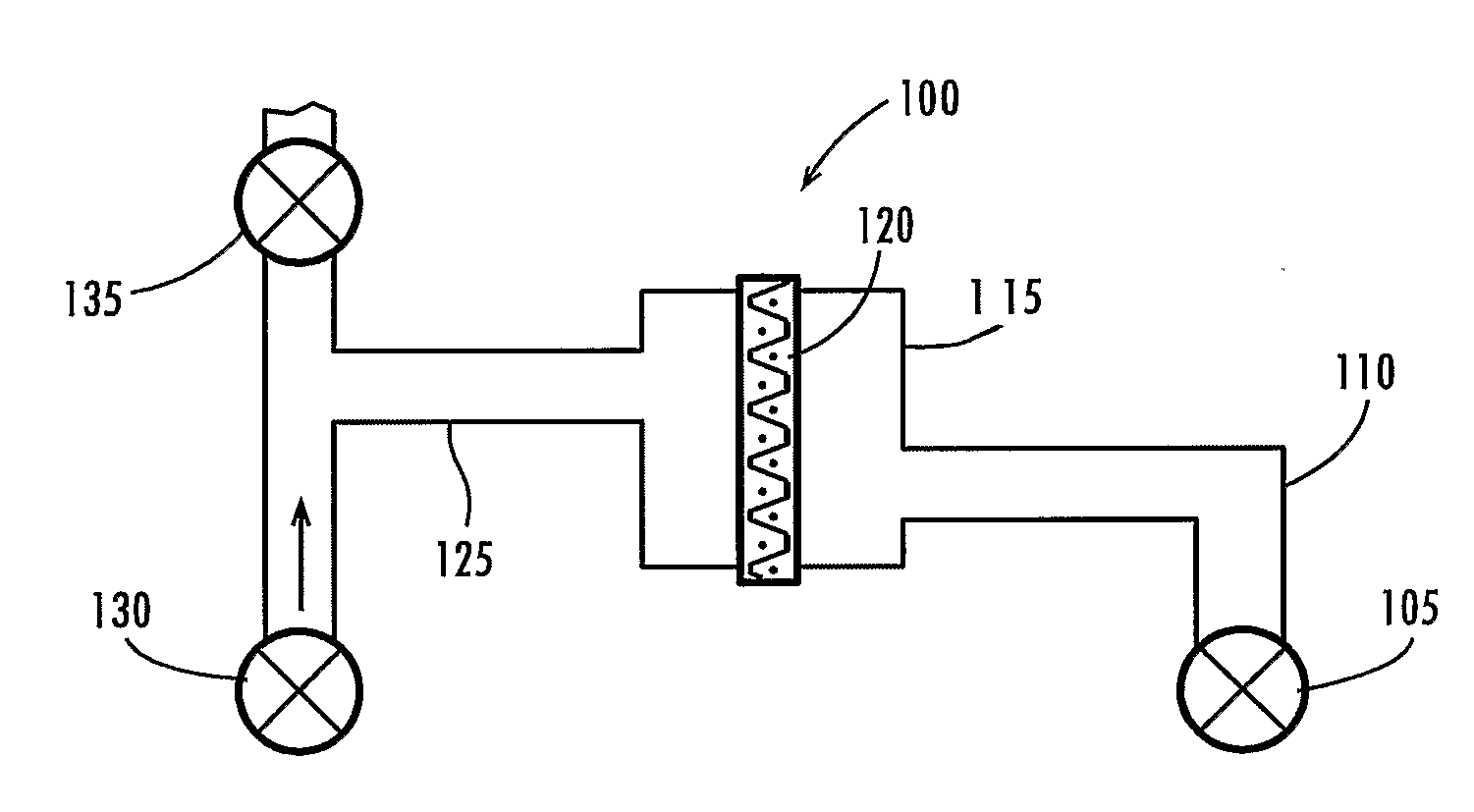

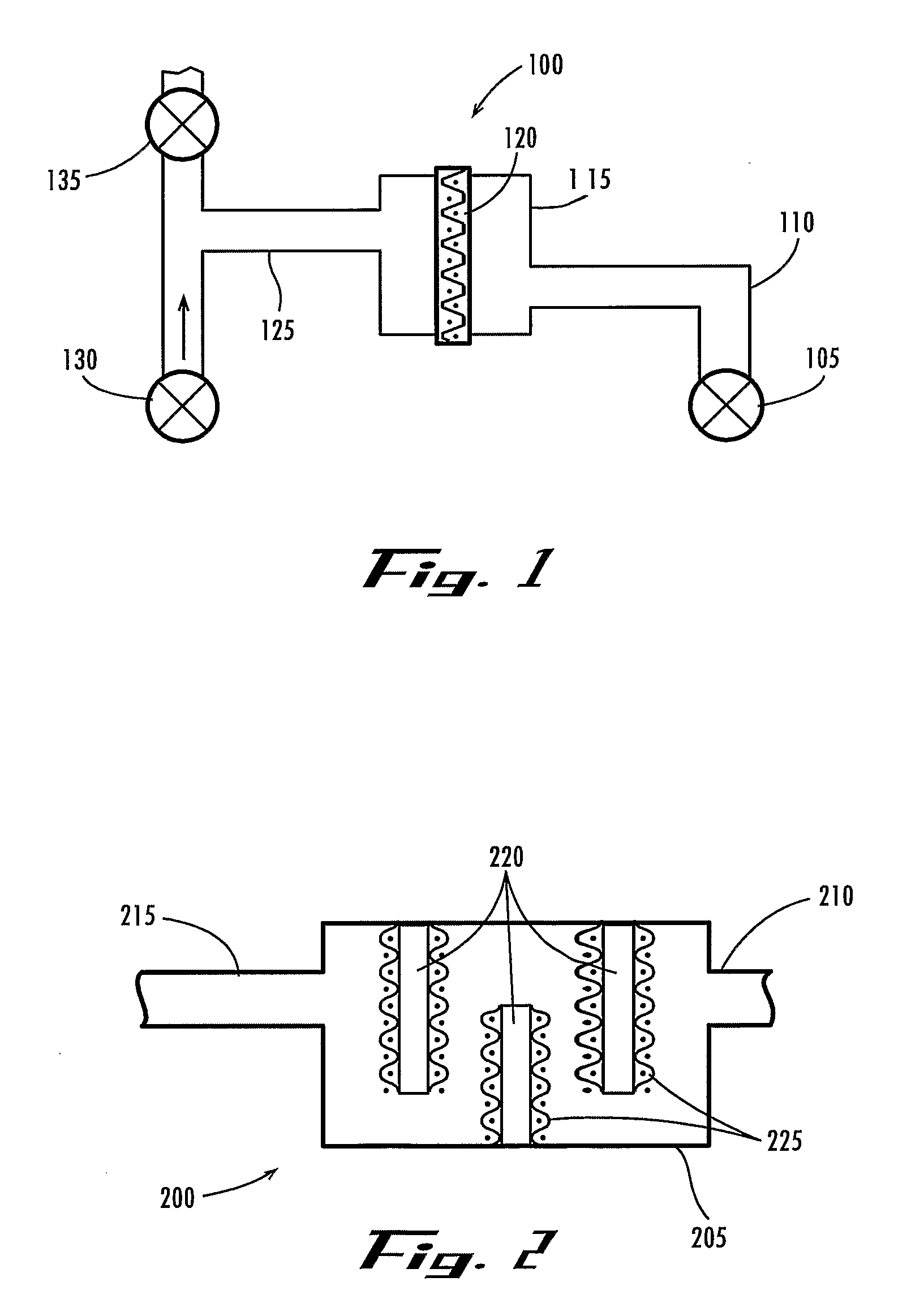

Fuel cell gas management system

InactiveUS6013385AImprove battery efficiencyMinimize the possibilityFuel cell heat exchangeFuel cell controlIonEnthalpy

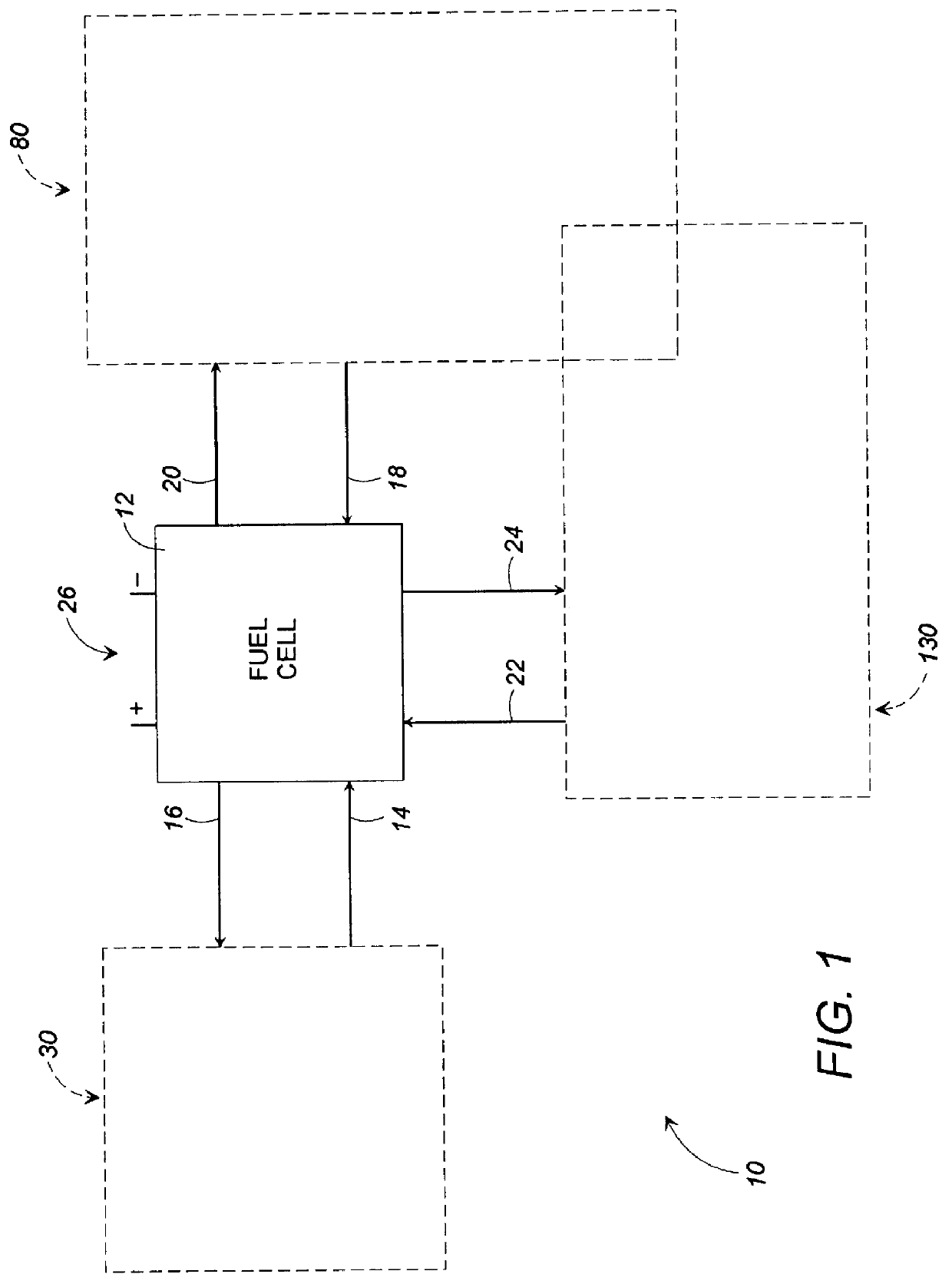

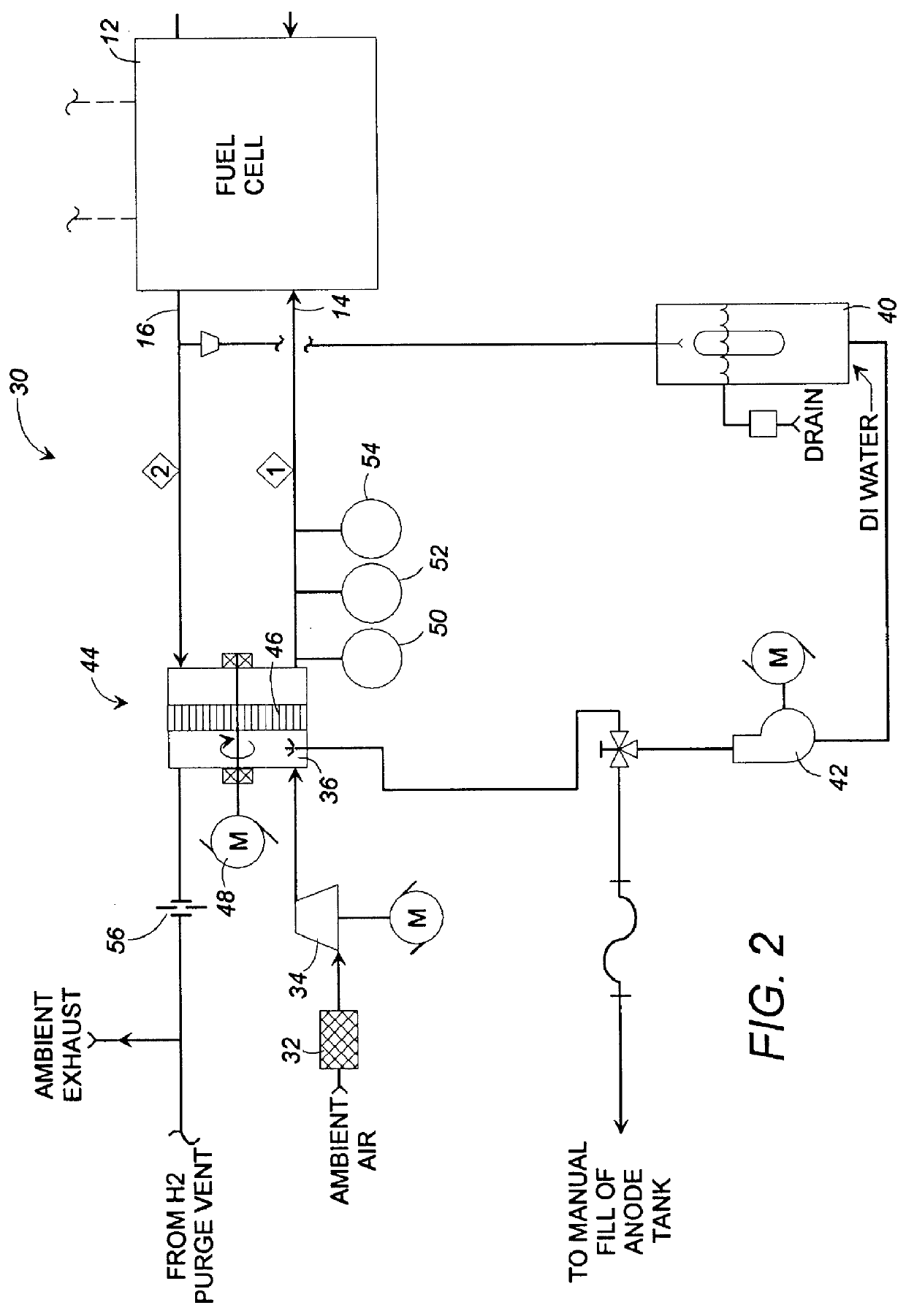

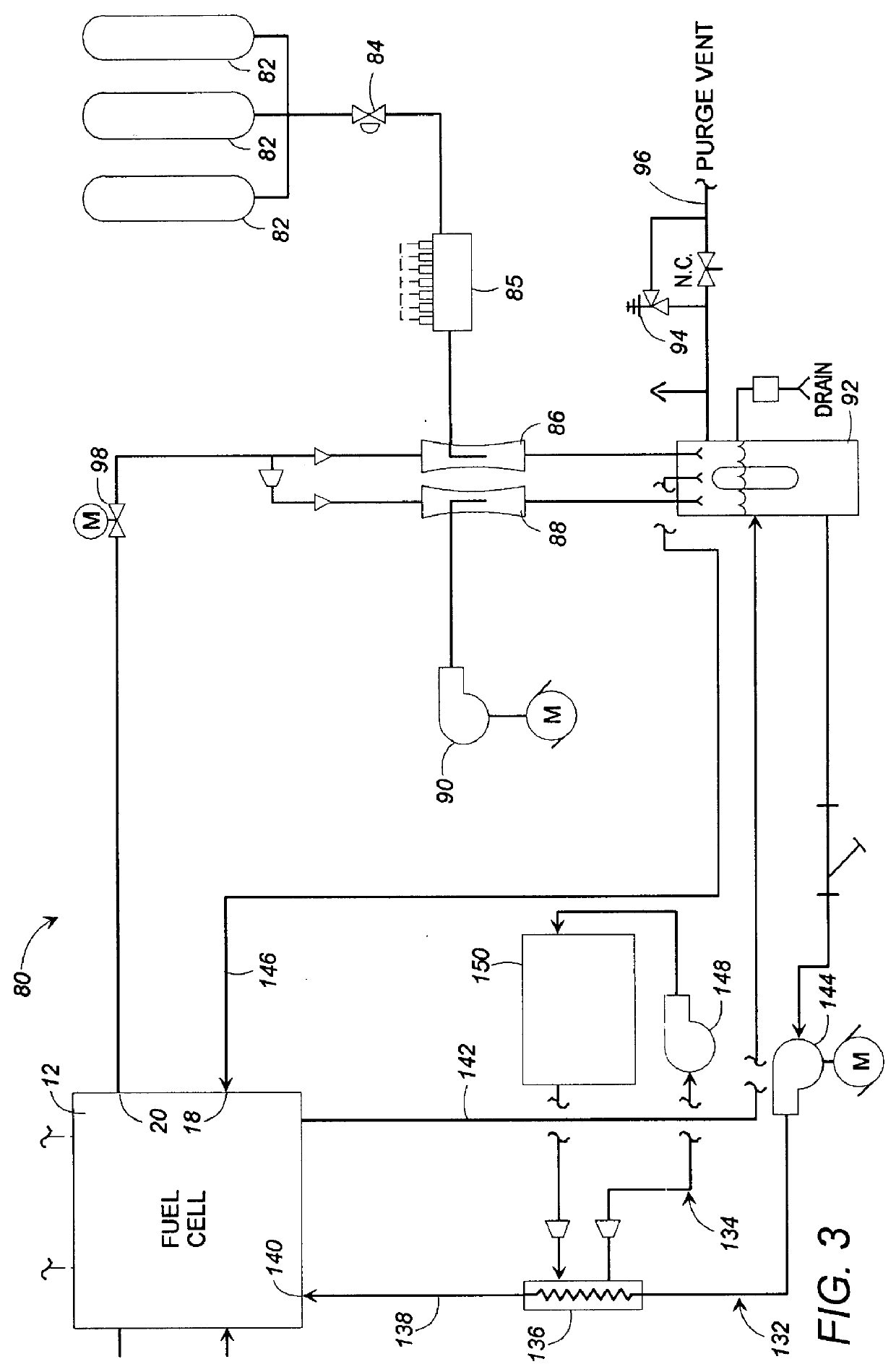

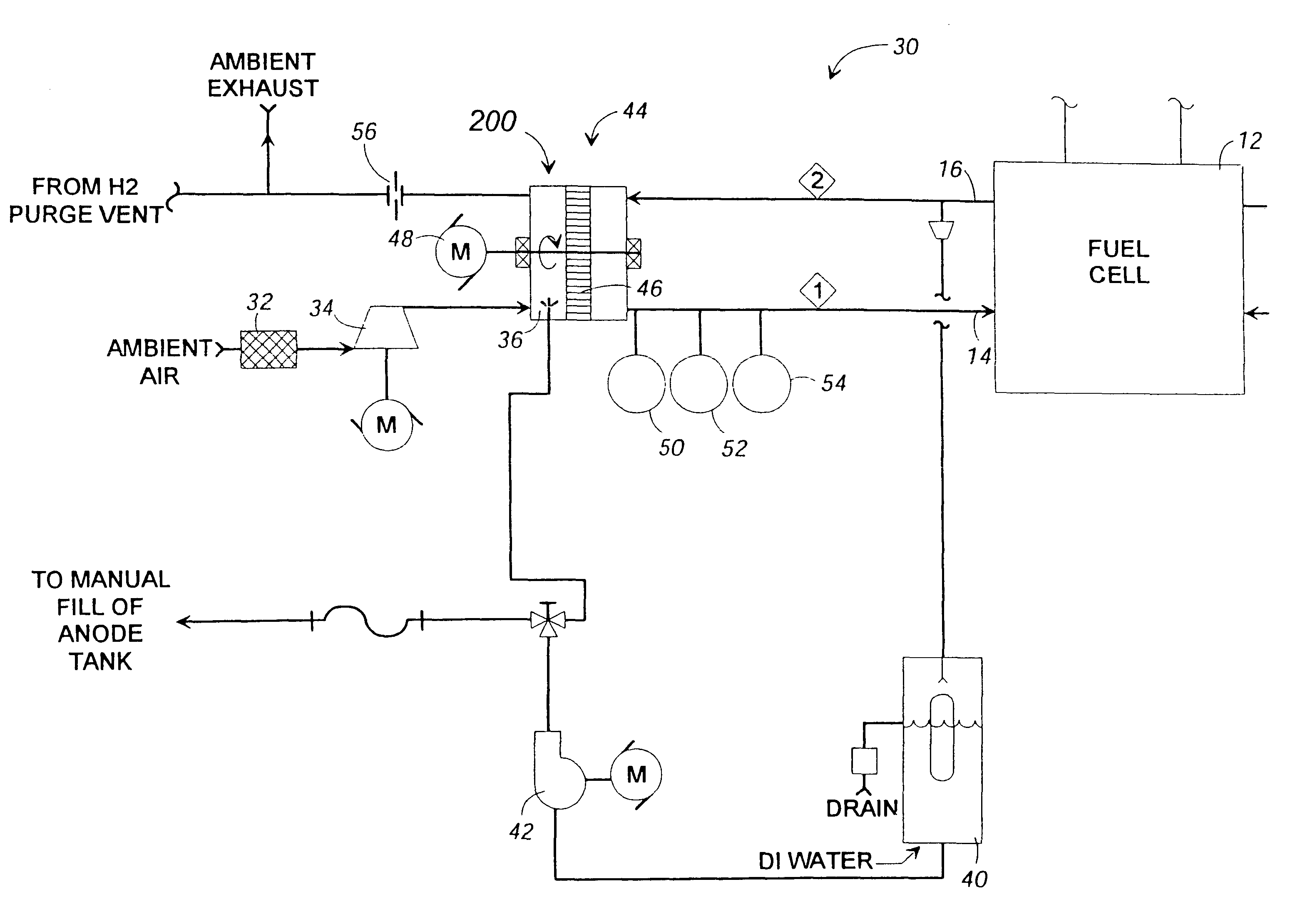

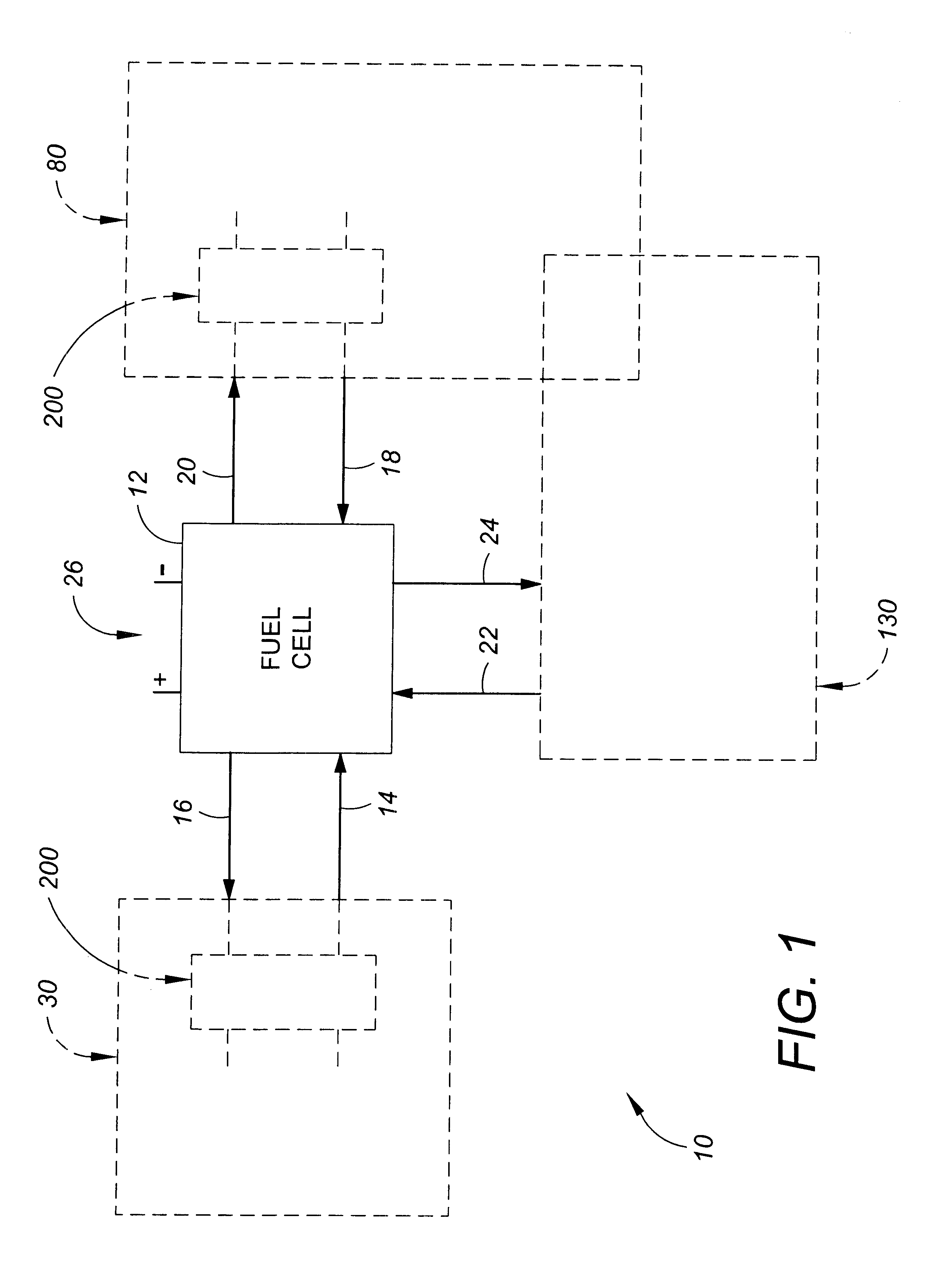

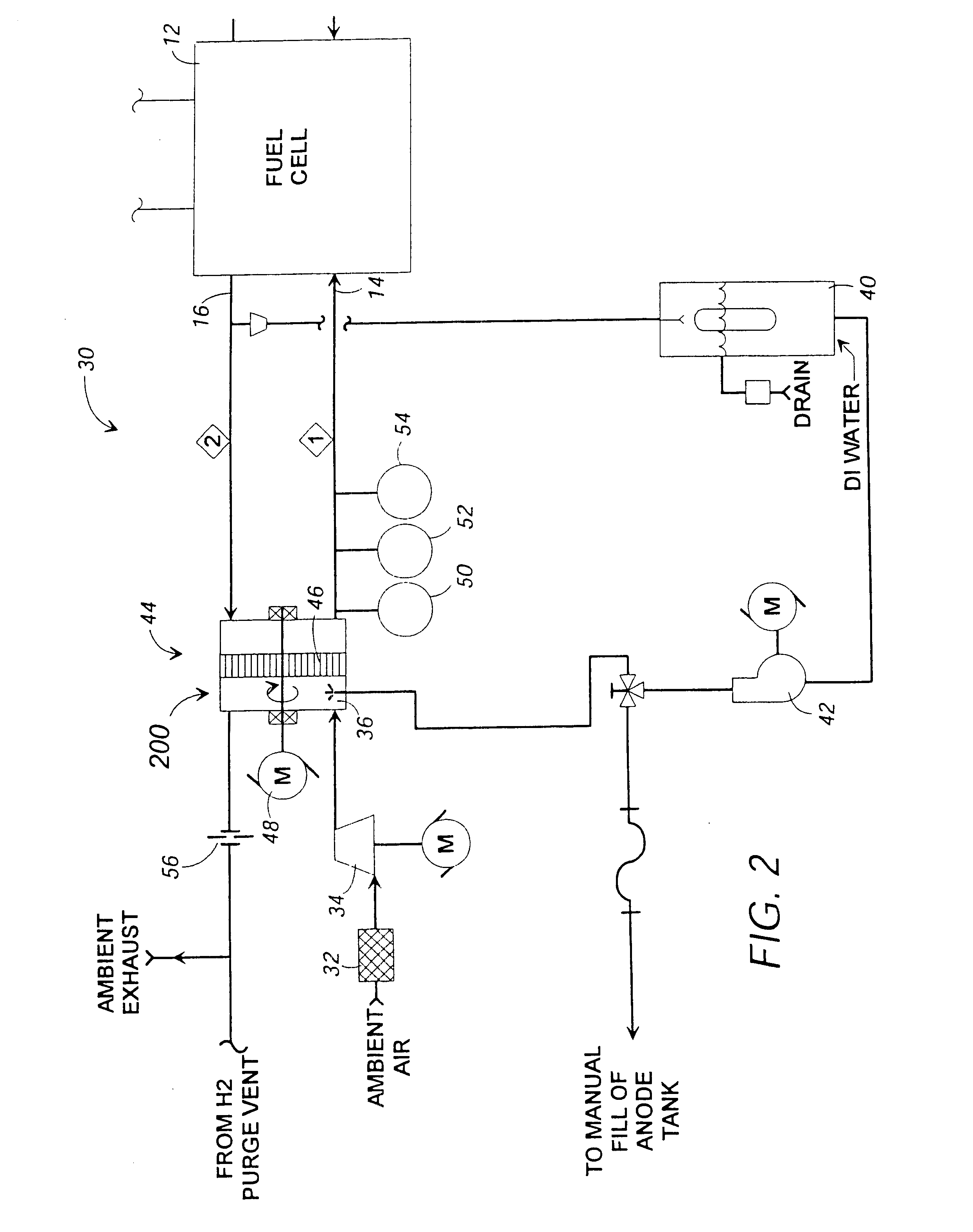

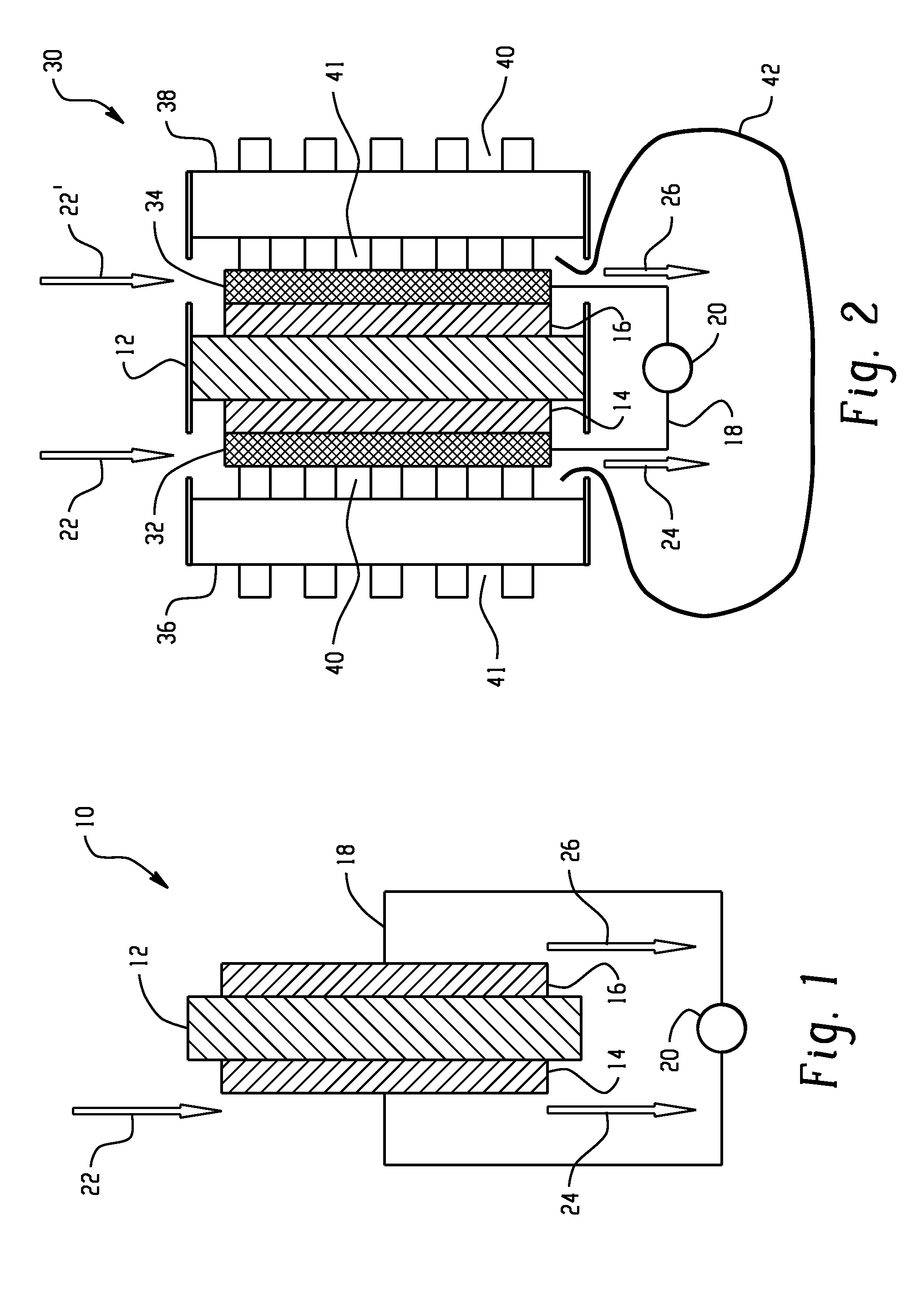

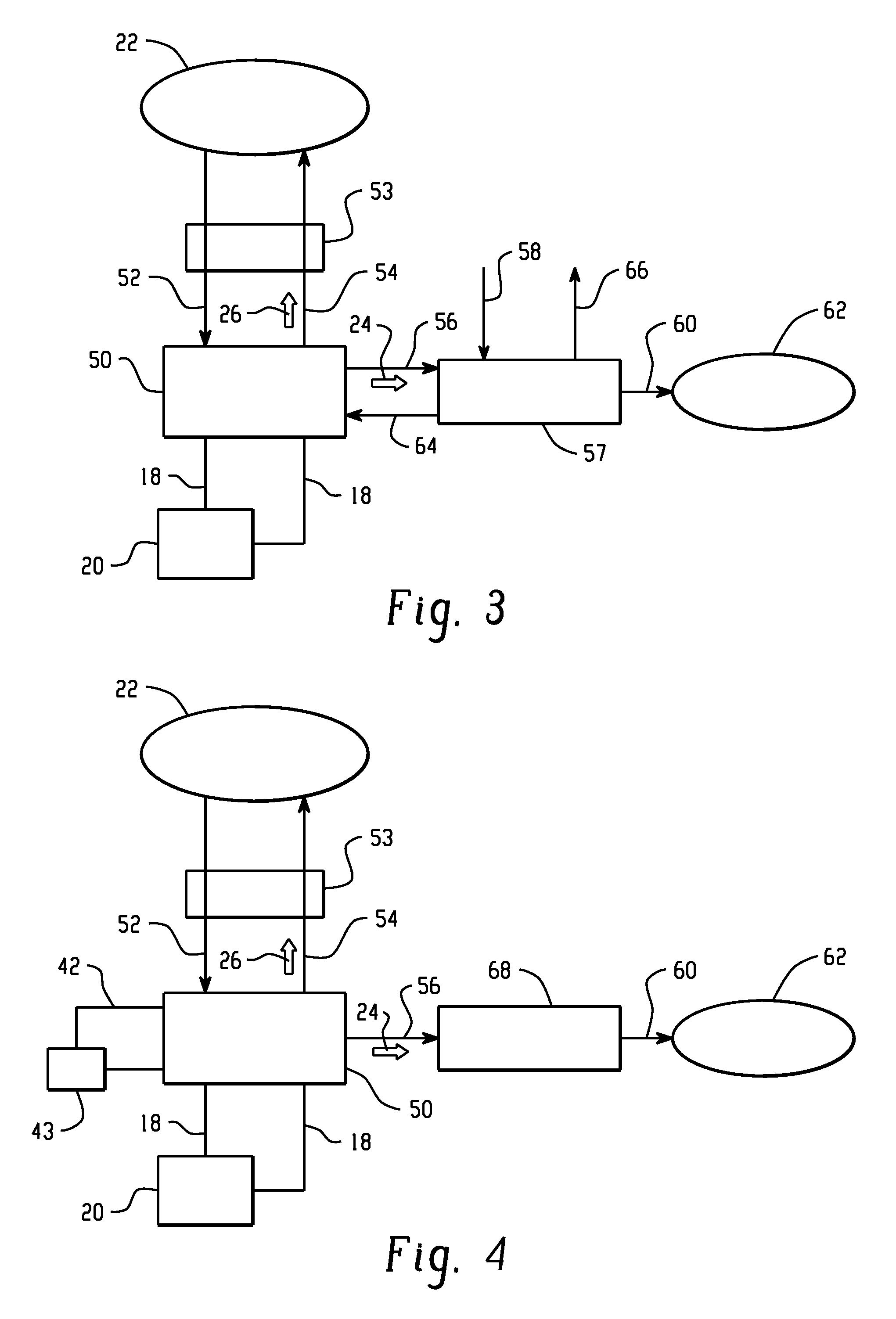

A fuel cell gas management system including a cathode humidification system for transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell equal to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

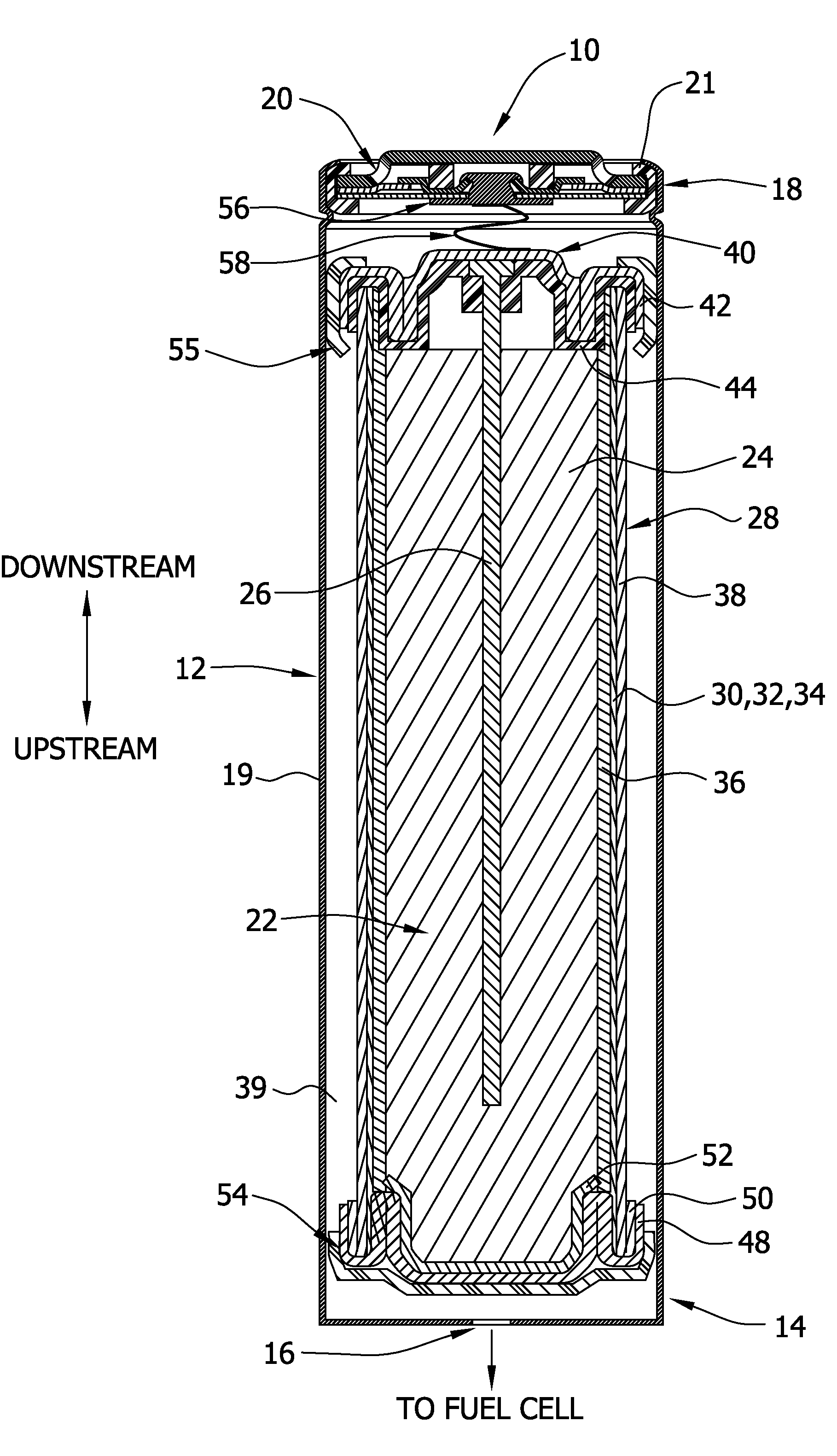

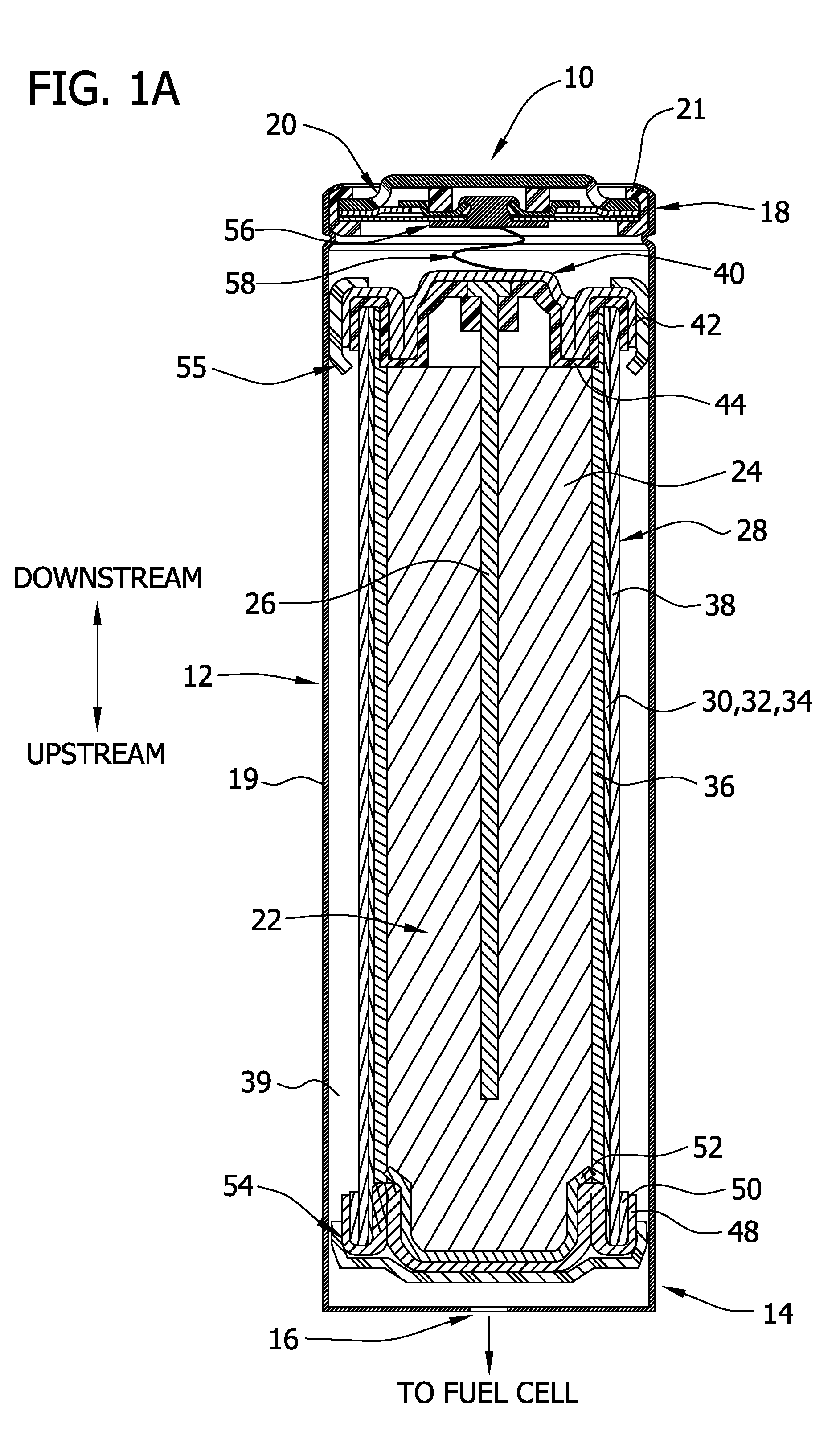

Fuel-cell engine stream conditioning system

A stream conditioning system for a fuel cell gas management system or fuel cell engine. The stream conditioning system manages species potential in at least one fuel cell reactant stream. A species transfer device is located in the path of at least one reactant stream of a fuel cell's inlet or outlet, which transfer device conditions that stream to improve the efficiency of the fuel cell. The species transfer device incorporates an exchange media and a sorbent. The fuel cell gas management system can include a cathode loop with the stream conditioning system transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell related to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

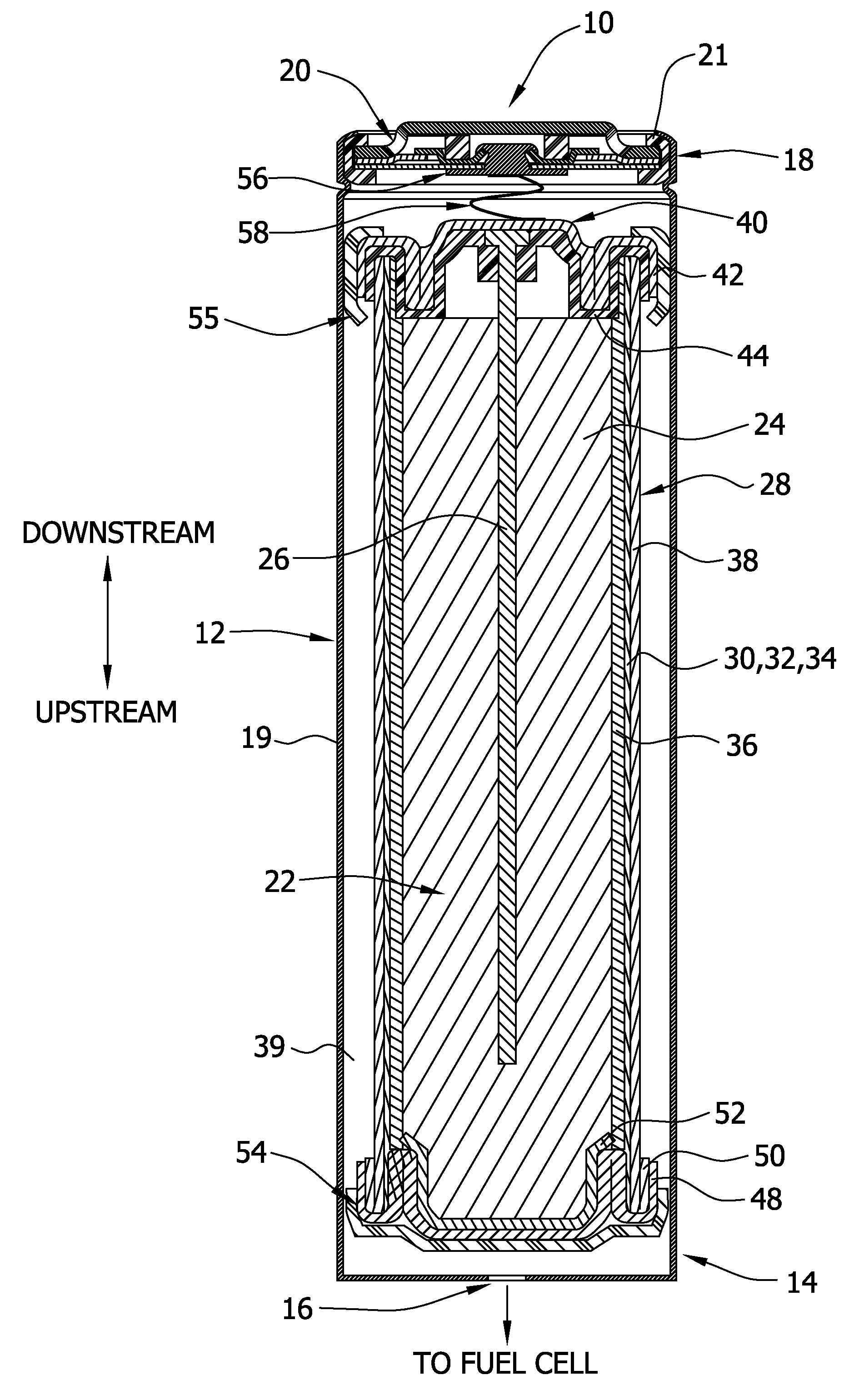

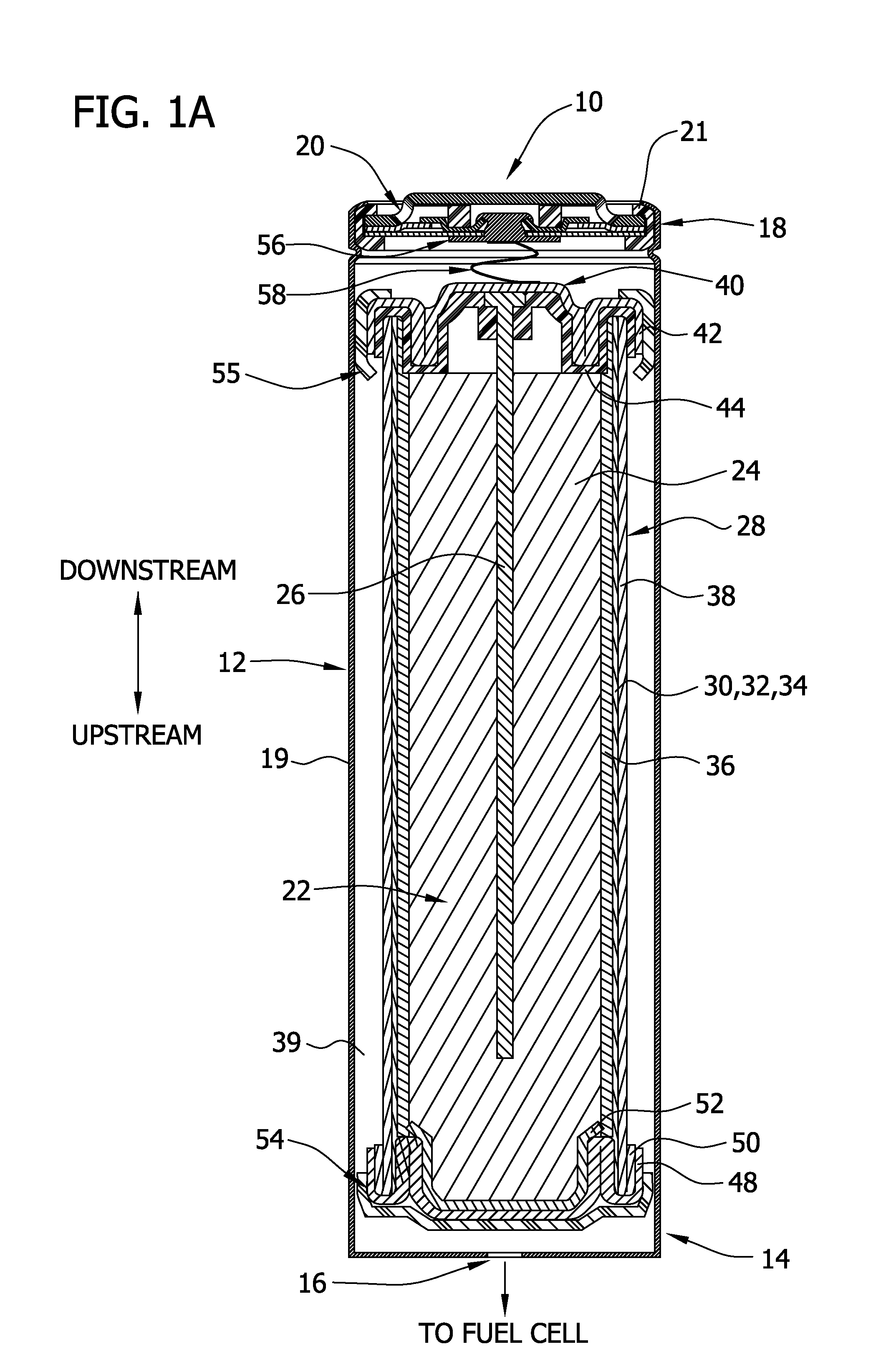

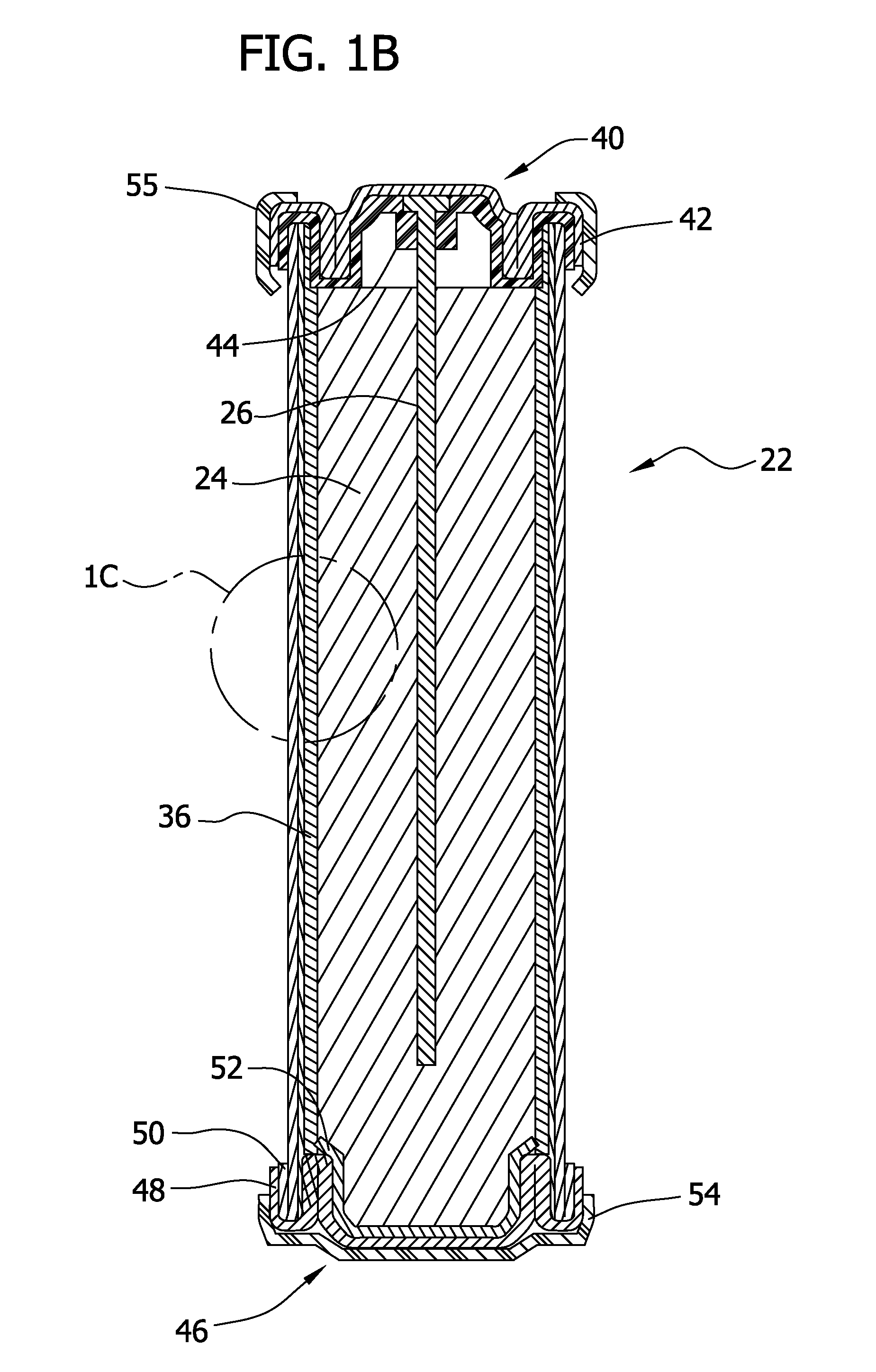

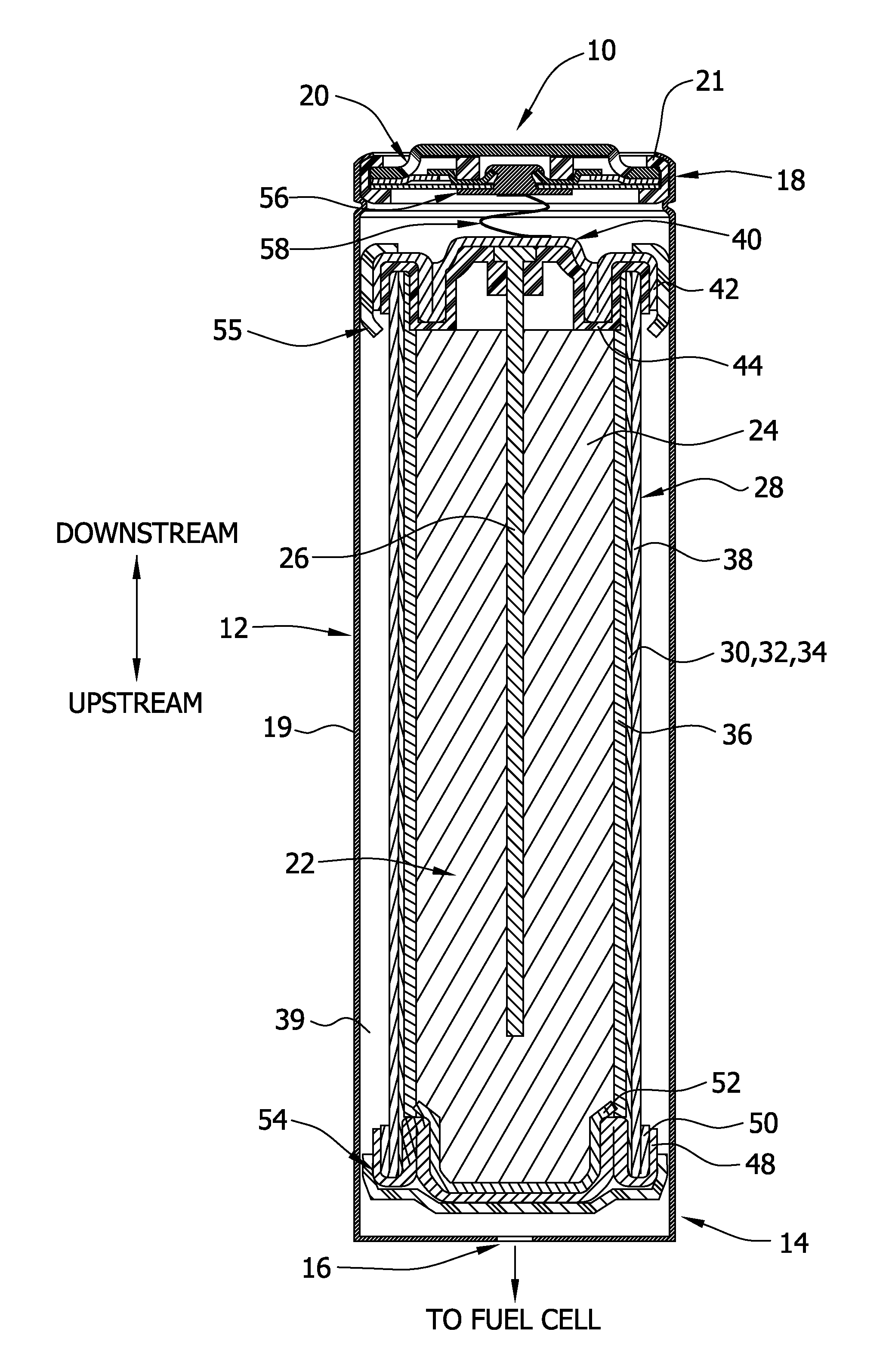

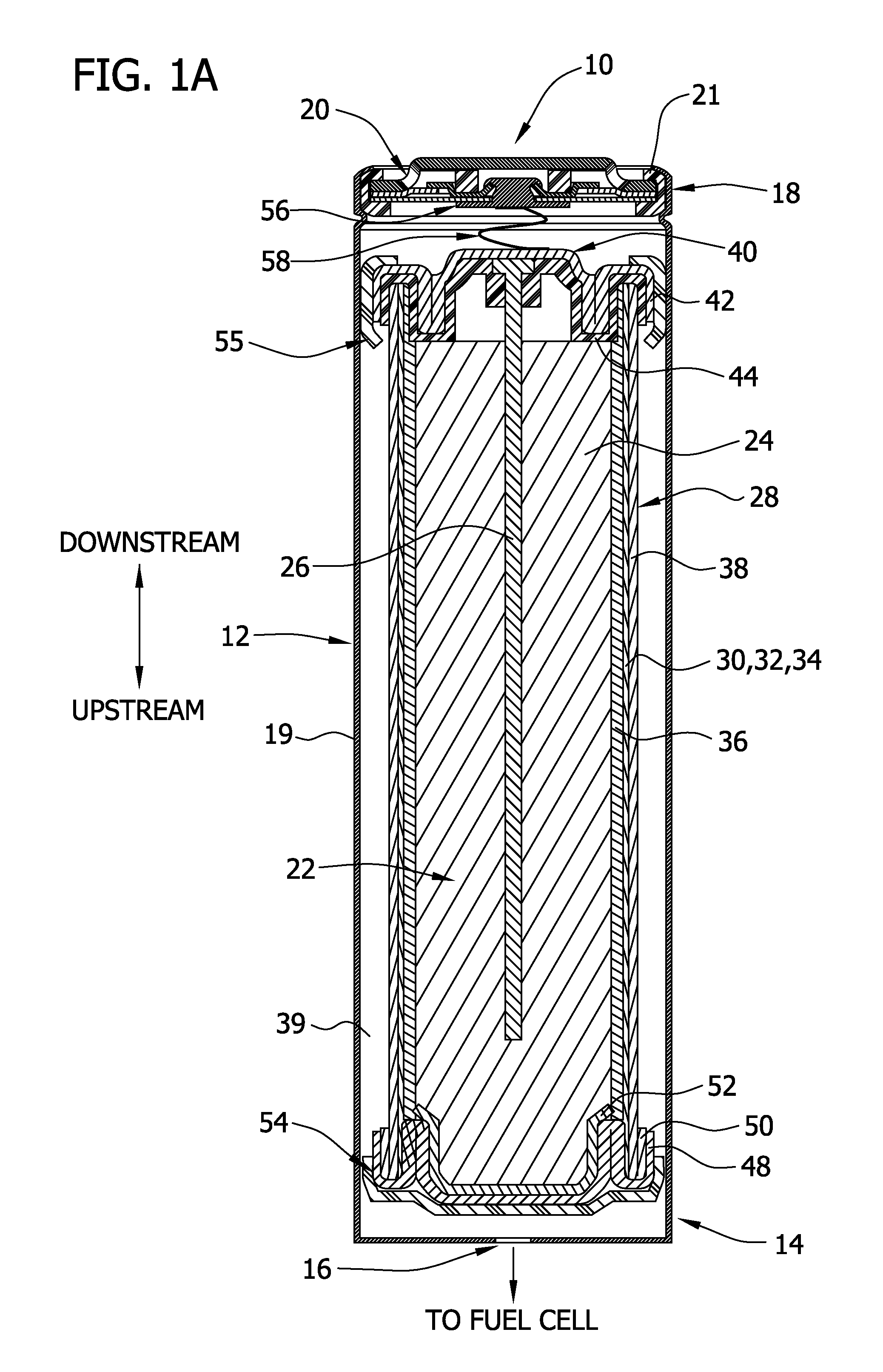

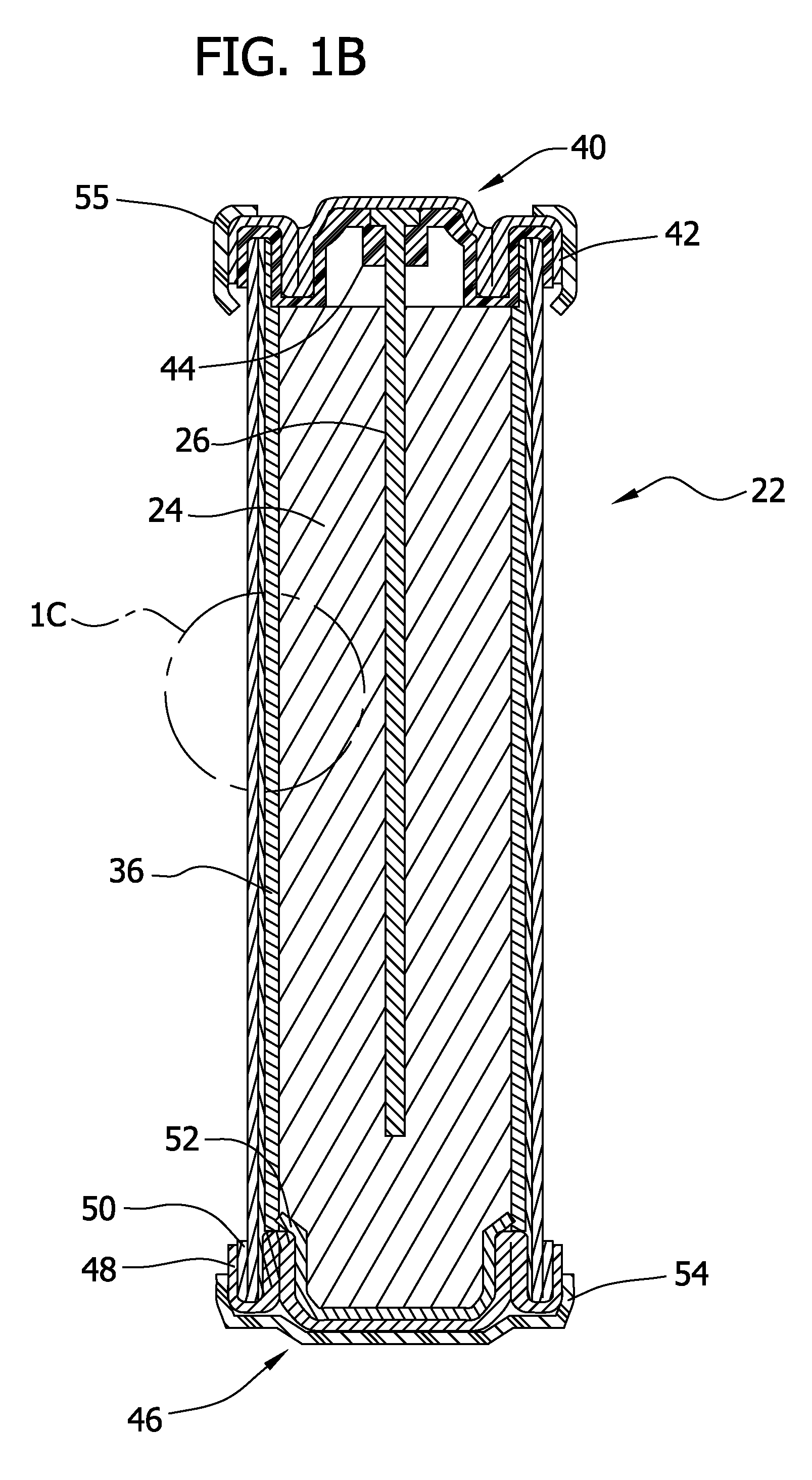

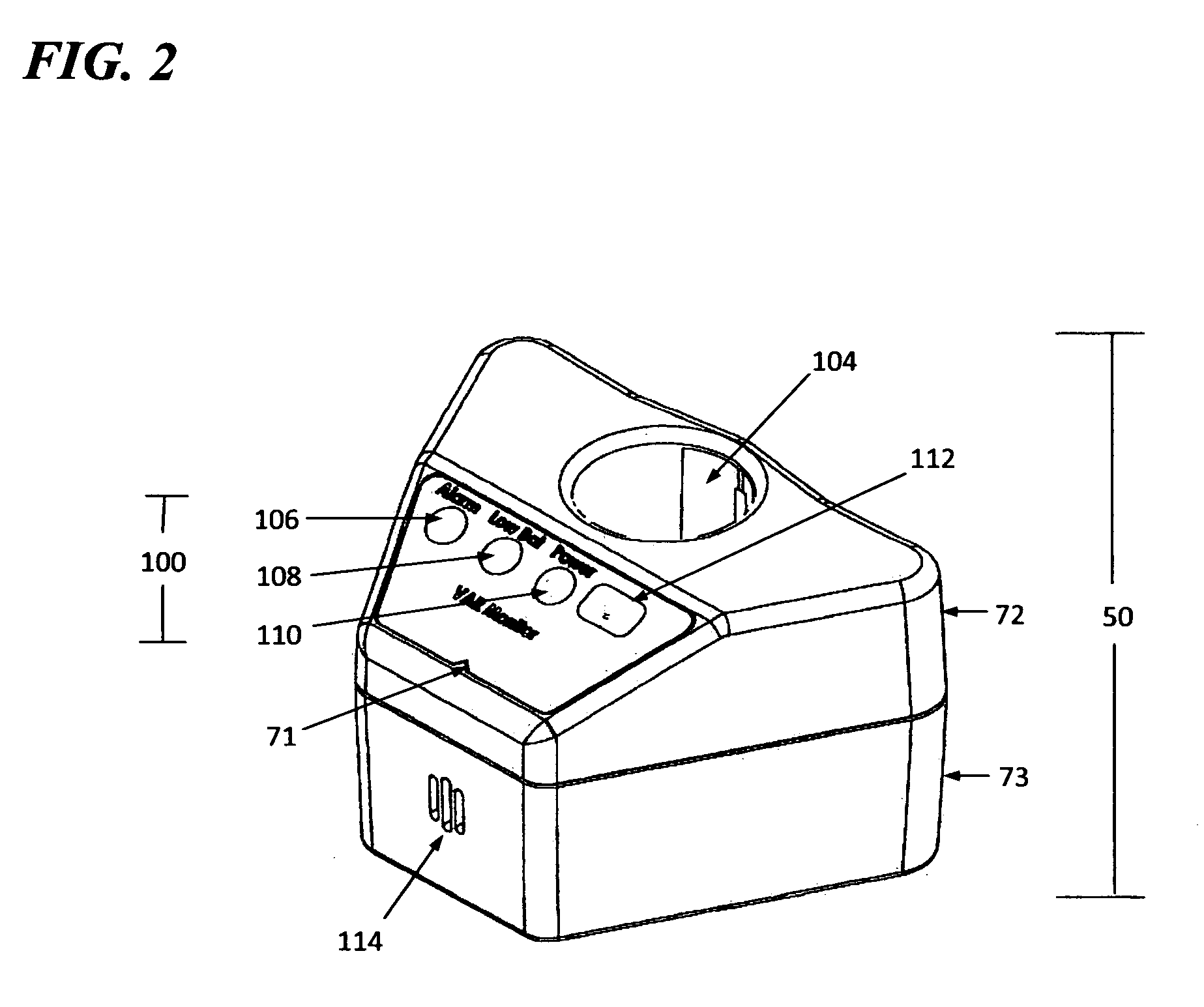

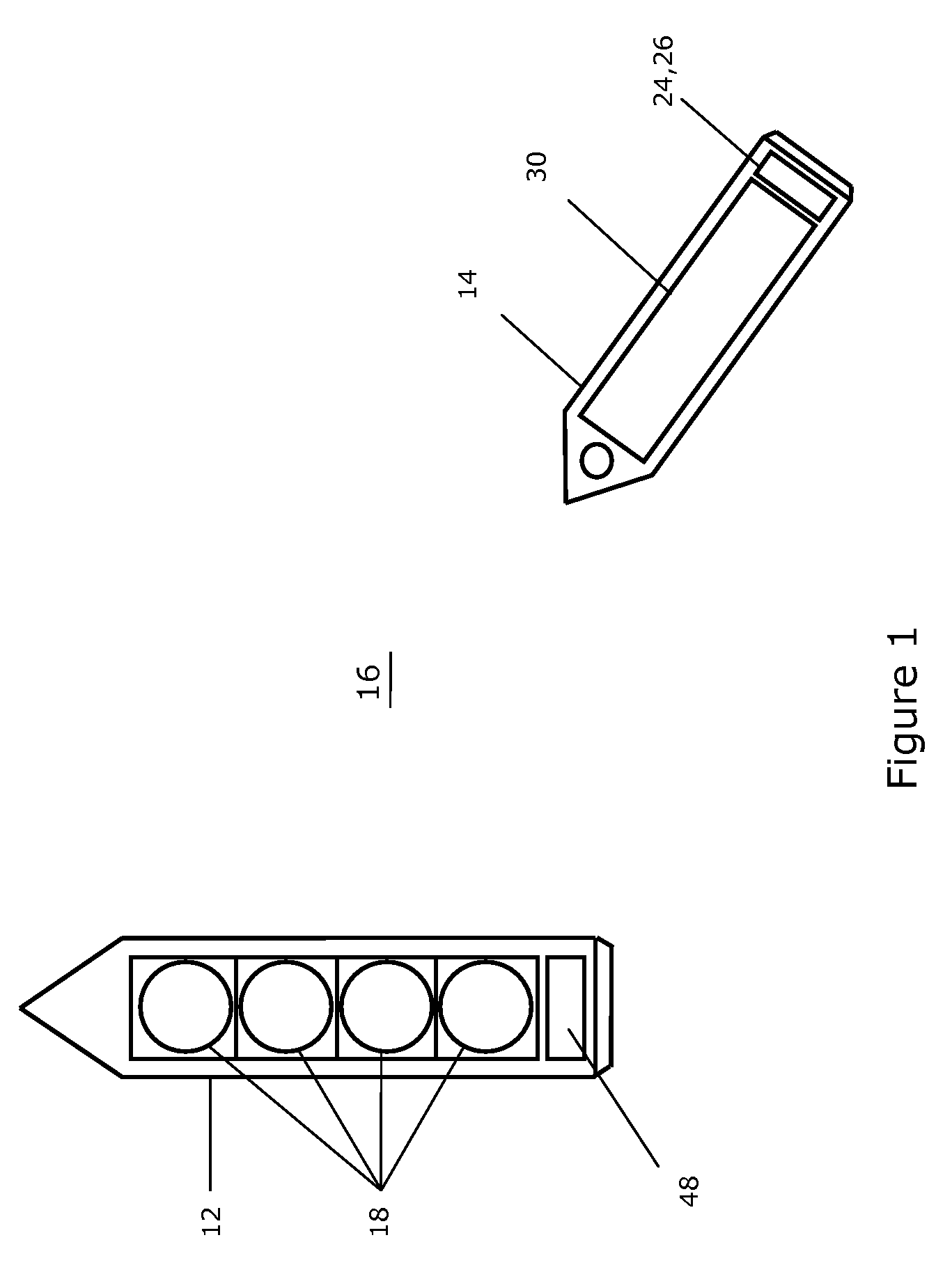

On-demand hydrogen gas generation device having gas management system

The present disclosure generally relates to an on-demand hydrogen gas generation device, suitable for use in a fuel cell, which utilizes water electrolysis, and more particularly galvanic cell corrosion, and / or a chemical hydride reaction, to produce hydrogen gas. The present disclosure additionally relates to such a device that comprises a switching mechanism that has an electrical current passing therethrough and that repeatedly and reversibly moves between a first position and a second position when exposed to pressure differential resulting from hydrogen gas generation, in order to (1) alter the rate at which hydrogen gas is generated, such that hydrogen gas is generated on an as-needed basis for a fuel cell connected thereto, and / or (2) ensure a substantially constant flow of hydrogen gas is released therefrom. The present disclosure additionally or alternatively relates to such an on-demand hydrogen gas generation device that comprises a gas management system designed to maximize the release or evolution of hydrogen gas, and in particular dry hydrogen gas, therefrom once it has been formed, thus maximizing hydrogen gas output. The present disclosure is still further directed to a fuel cell comprising such an on-demand hydrogen gas generation device, and in particular a fuel cell designed for small-scale applications.

Owner:ROVCAL

Toroidal intersecting vane gas management system

InactiveUS20060260308A1Improve matchReduced Power RequirementsNon-fuel substance addition to fuelInternal combustion piston enginesInternal combustion engineManagement system

The invention relates to the discovery that employing a toroidal intersecting vane machine (TIVM) within the internal combustion engine provides substantial improvements in controlling pressure, air pressure and air flow into an engine, while maintaining a simplified mechanical system and providing a compressor with little or no parasitic load on the engine. This invention covers the use of the TIVM for the purpose of providing this control.

Owner:MECHANOLOGY INC

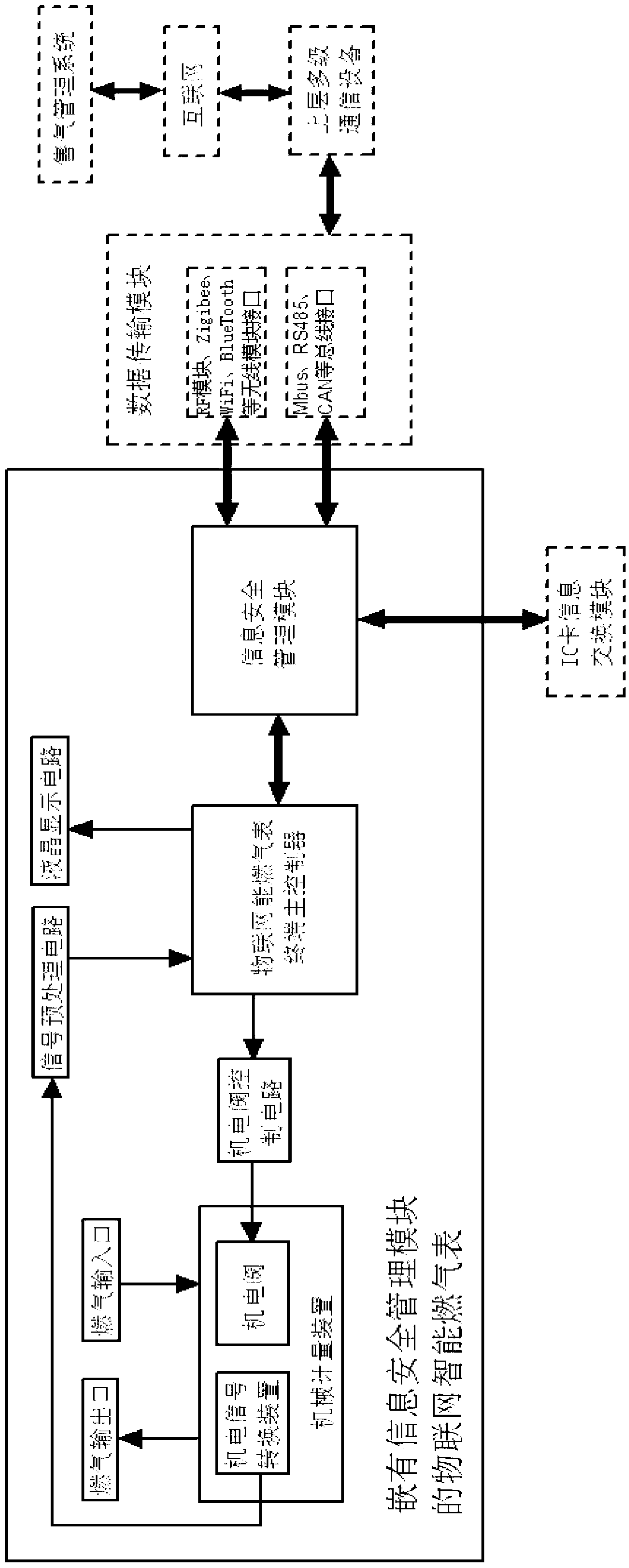

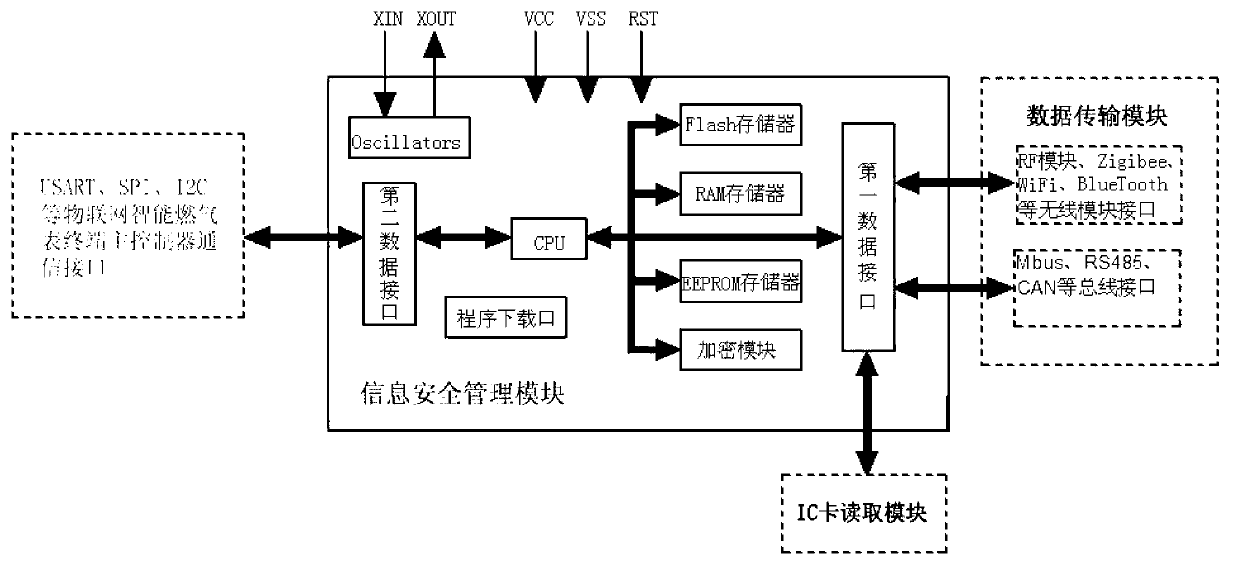

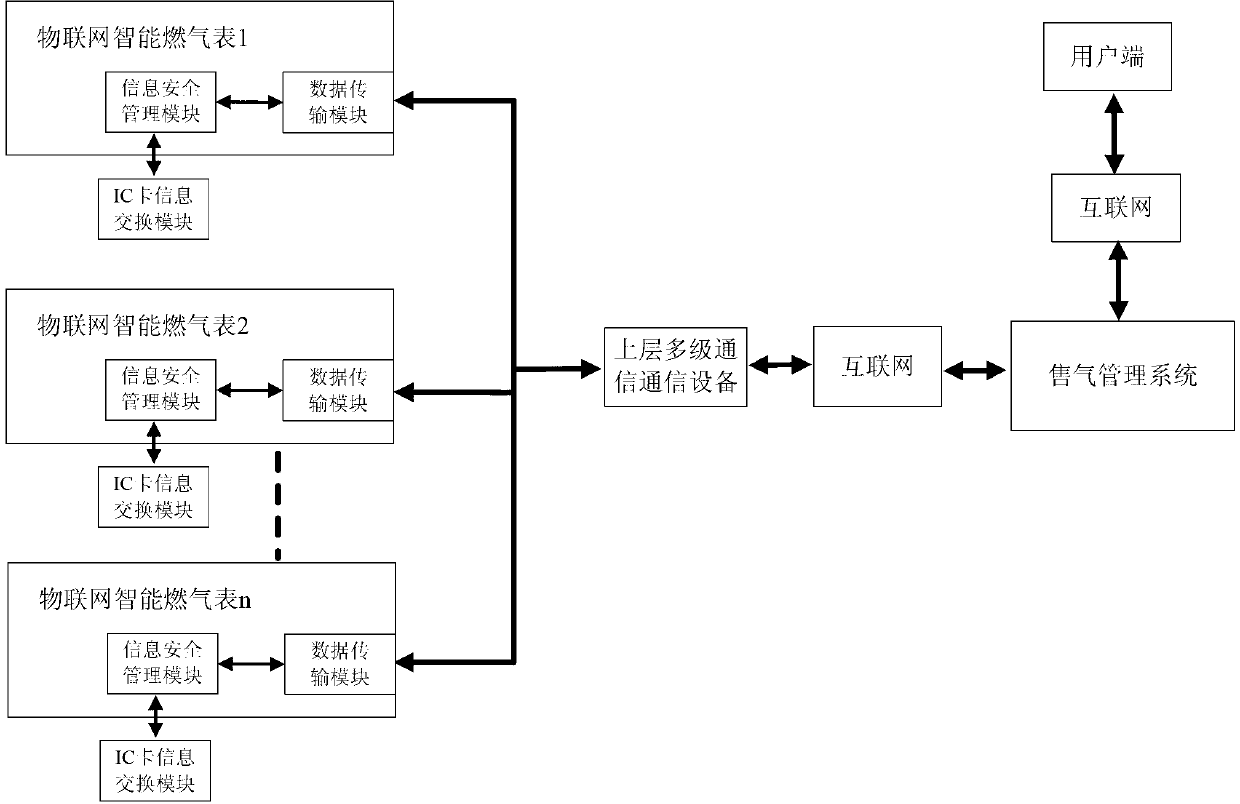

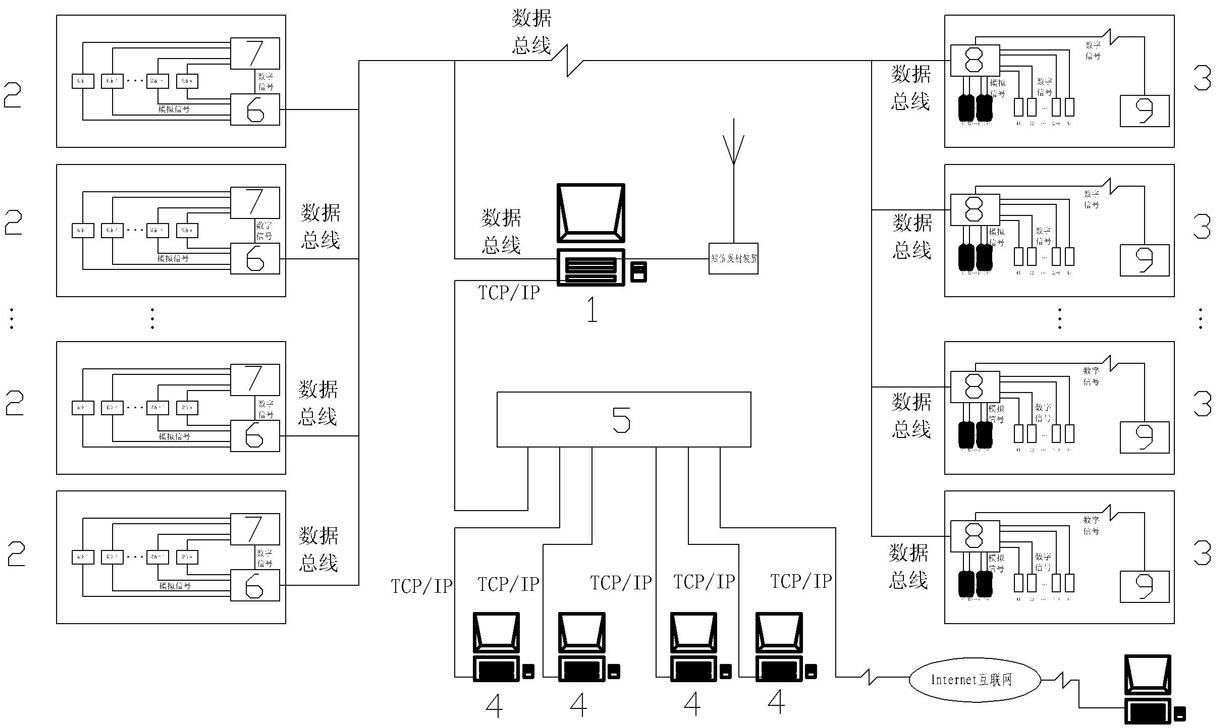

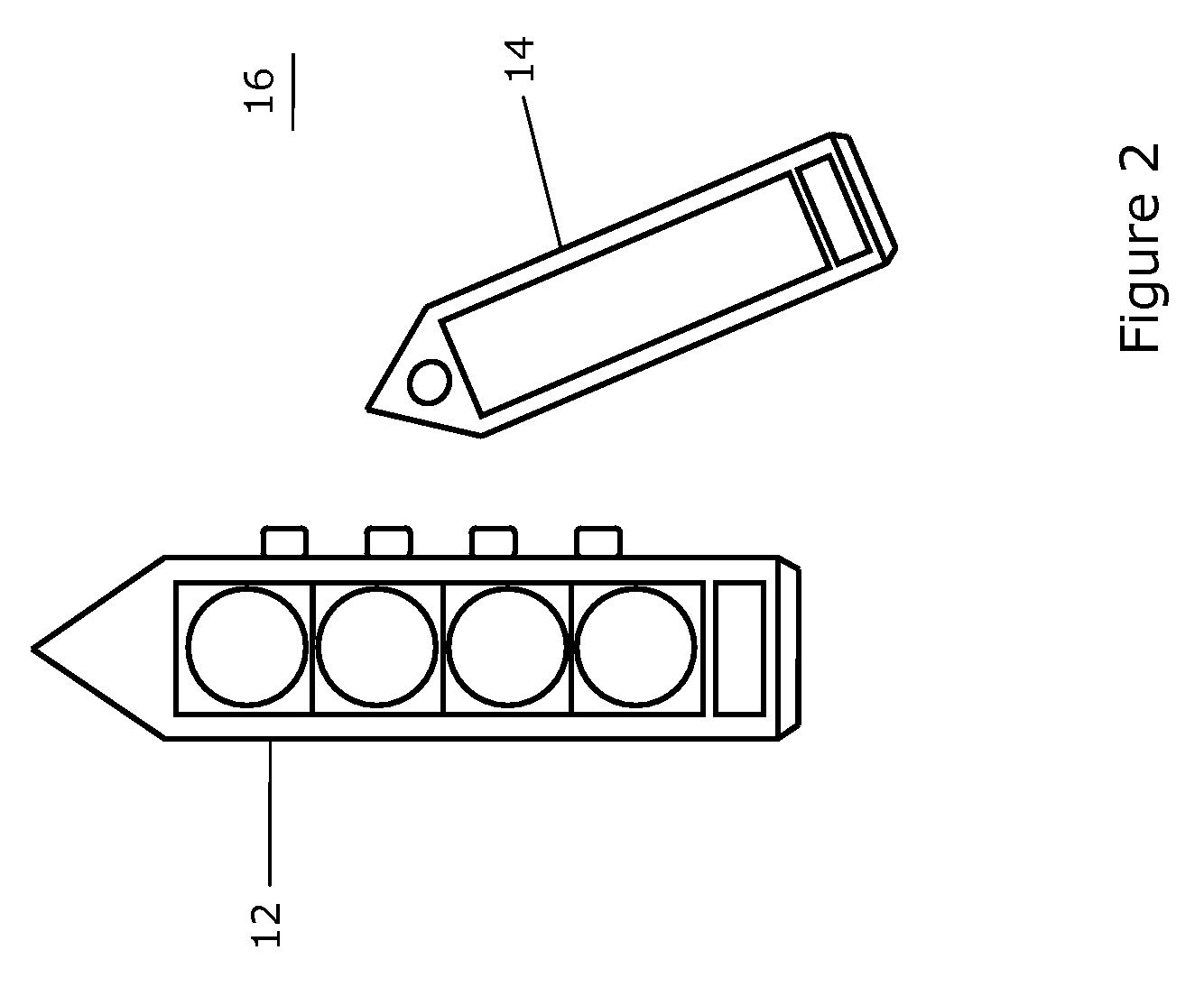

Internet of things intelligent gas meter embedded with information security management module

ActiveCN103106744ASimple structureGuaranteed independenceApparatus for hiring articlesRemote controlThe Internet

The invention discloses an internet of things intelligent gas meter embedded with an information security management module. The information security management module comprises a processor, a first data interface, a second data interface and a flash storer, wherein the processor is respectively connected into the first data interface, the second data interface and the flash storer. When the information security management module exchanges data with an internet of things remote control terminal, identity authentication is conducted, and the communicating validity of the information security management module and the internet of things remote control terminal is ensured. A terminal master controller of the internet of things intelligent gas meter can be communicated with the outside only through the information security management module. The internet of things intelligent gas meter embedded with the information security management module is simple in structure of module, can be connected into a gas management system in a seamless mode through the internal information security management module, achieves dispersion manufacture and unified management of the internet of things intelligent gas meter, and is wide in range of application.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

On-demand hydrogen gas generation device

The present disclosure generally relates to an on-demand hydrogen gas generation device, suitable for use in a fuel cell, which utilizes water electrolysis, and more particularly galvanic cell corrosion, and / or a chemical hydride reaction, to produce hydrogen gas. The present disclosure additionally relates to such a device that comprises a switching mechanism that has an electrical current passing therethrough and that repeatedly and reversibly moves between a first position and a second position when exposed to pressure differential resulting from hydrogen gas generation, in order to (1) alter the rate at which hydrogen gas is generated, such that hydrogen gas is generated on an as-needed basis for a fuel cell connected thereto, and / or (2) ensure a substantially constant flow of hydrogen gas is released therefrom. The present disclosure additionally or alternatively relates to such an on-demand hydrogen gas generation device that comprises a gas management system designed to maximize the release or evolution of hydrogen gas, and in particular dry hydrogen gas, therefrom once it has been formed, thus maximizing hydrogen gas output. The present disclosure is still further directed to a fuel cell comprising such an on-demand hydrogen gas generation device, and in particular a fuel cell designed for small-scale applications.

Owner:ROVCAL

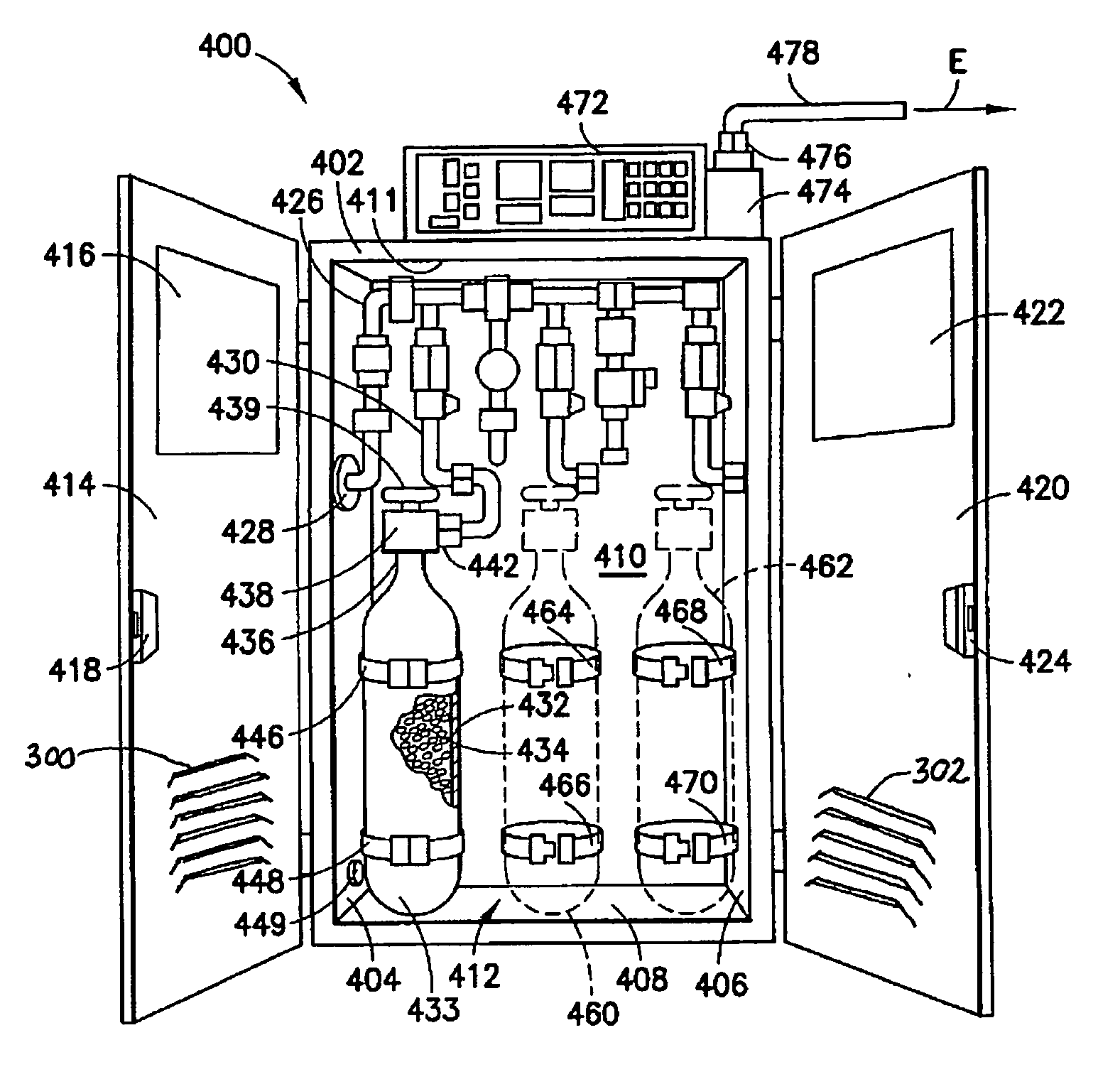

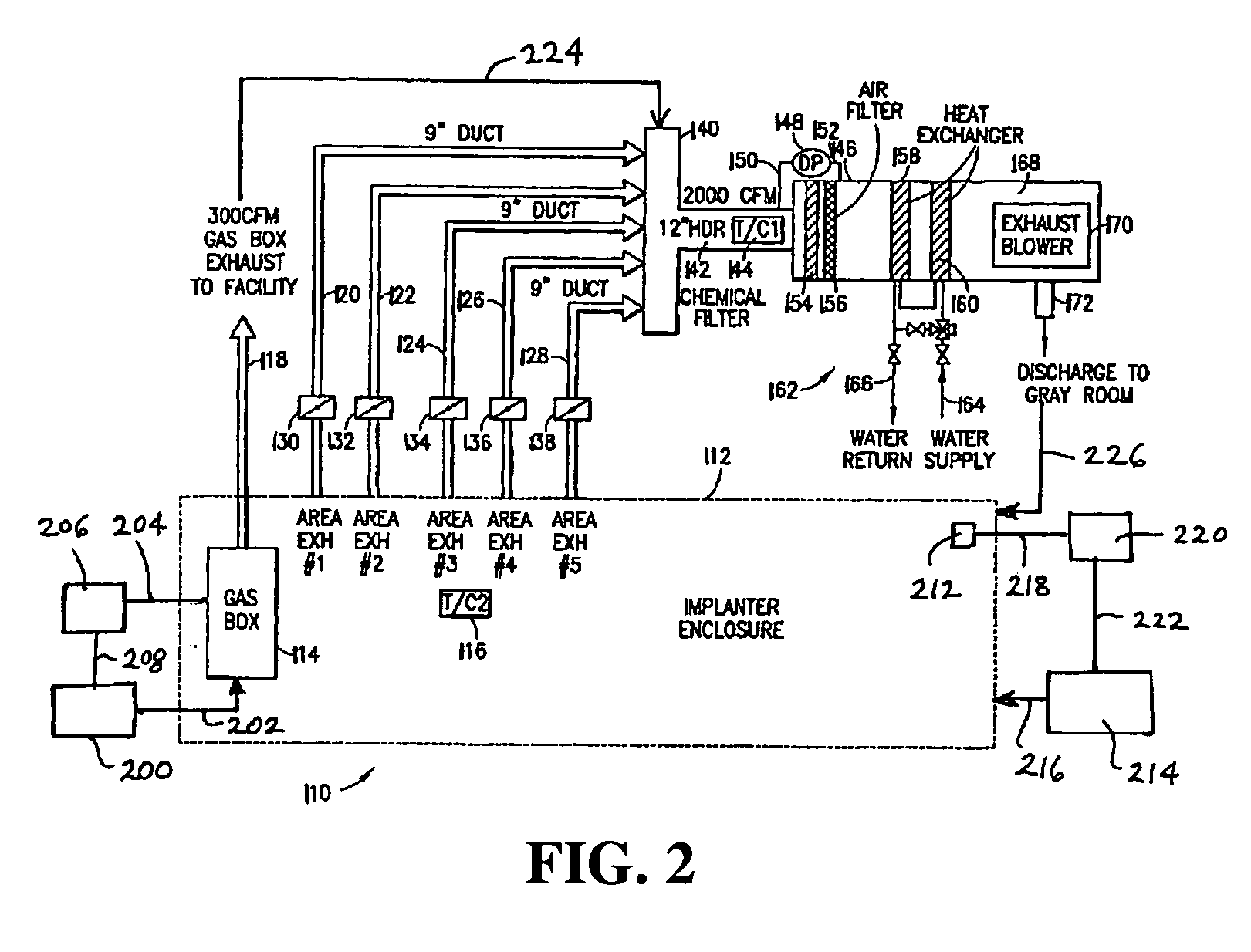

Ventilation gas management systems and processes

ActiveUS20120315837A1Lighting and heating apparatusContainer filling methodsThermodynamicsProcess engineering

A ventilation gas management system and process for an enclosure adapted to contain fluid supply vessel(s) and through which ventilation gas is flowed to provide safe operation in the event of leakage of fluid from a vessel. Ventilation gas flow is modulated to accommodate various hazard levels associated with the deployment and operation of such enclosure containing fluid supply vessel(s), e.g., a gas box or gas cabinet in a semiconductor manufacturing facility, thereby achieving reduction in ventilation gas requirements otherwise required for such deployment and operation.

Owner:ENTEGRIS INC

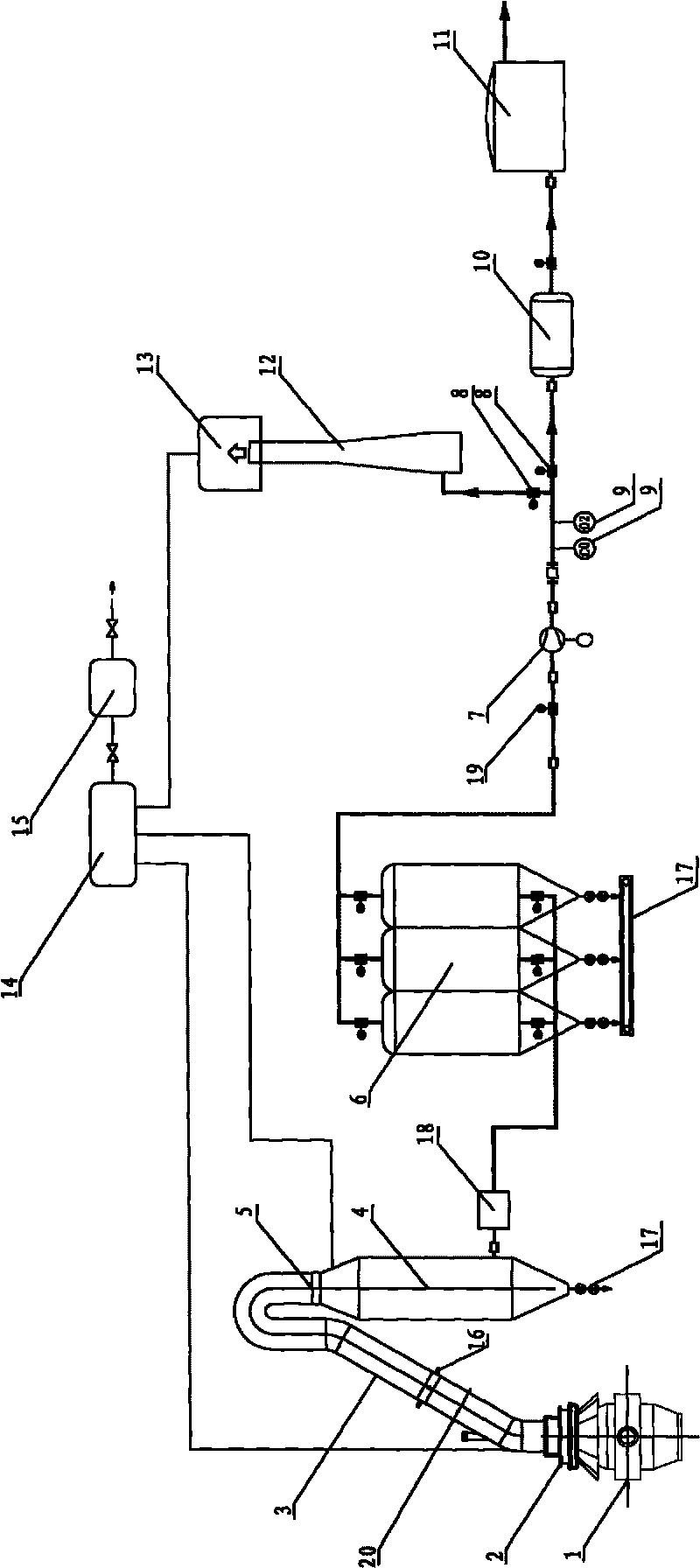

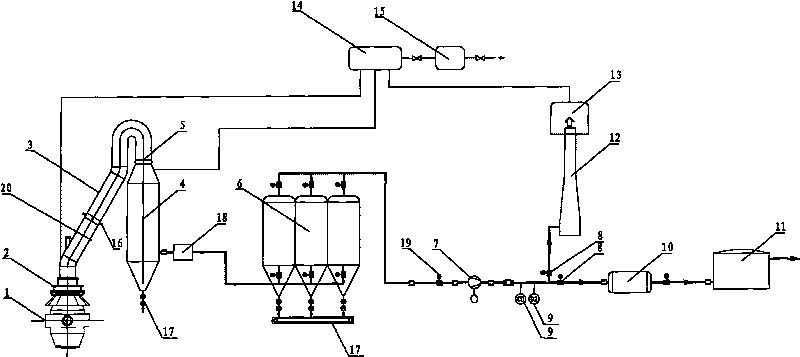

Purifying and recovering process of absolute dry bag-type converter gas negative energy

ActiveCN101691624AHigh heat recovery valueSolve water consumptionIncreasing energy efficiencyManufacturing convertersFiltrationDust control

The invention relates to a gas management process and discloses a purifying and recovering process of absolute dry bag-type converter gas negative energy, comprising the following process steps: gathering gas, lowering the temperature of high-temperature gas, recovering waste heat, lowering the temperature of low-and-medium temperature gas, purifying gas, recovering gas and spreading; by adopting the core processes of waste heat temperature reduction and bag-type filtering, the invention solves the existing defects of large water consumption, high discharging concentration, big energy consumption, low safety factor and high control difficulty by natural cycling temperature reduction and static physical filtration for removing dust, and has the characteristics of water and electricity saving, low discharging concentration, stable and safe discharge, high gas recovering heat value and favourable dust removal effect.

Owner:无锡市东方环境工程设计研究所有限公司

On-demand hydrogen gas generation device with pressure-regulating switch

The present disclosure generally relates to an on-demand hydrogen gas generation device, suitable for use in a fuel cell, which utilizes water electrolysis, and more particularly galvanic cell corrosion, and / or a chemical hydride reaction, to produce hydrogen gas. The present disclosure additionally relates to such a device that comprises a switching mechanism that has an electrical current passing therethrough and that repeatedly and reversibly moves between a first position and a second position when exposed to pressure differential resulting from hydrogen gas generation, in order to (1) alter the rate at which hydrogen gas is generated, such that hydrogen gas is generated on an as-needed basis for a fuel cell connected thereto, and / or (2) ensure a substantially constant flow of hydrogen gas is released therefrom. The present disclosure additionally or alternatively relates to such an on-demand hydrogen gas generation device that comprises a gas management system designed to maximize the release or evolution of hydrogen gas, and in particular dry hydrogen gas, therefrom once it has been formed, thus maximizing hydrogen gas output. The present disclosure is still further directed to a fuel cell comprising such an on-demand hydrogen gas generation device, and in particular a fuel cell designed for small-scale applications.

Owner:ROVCAL

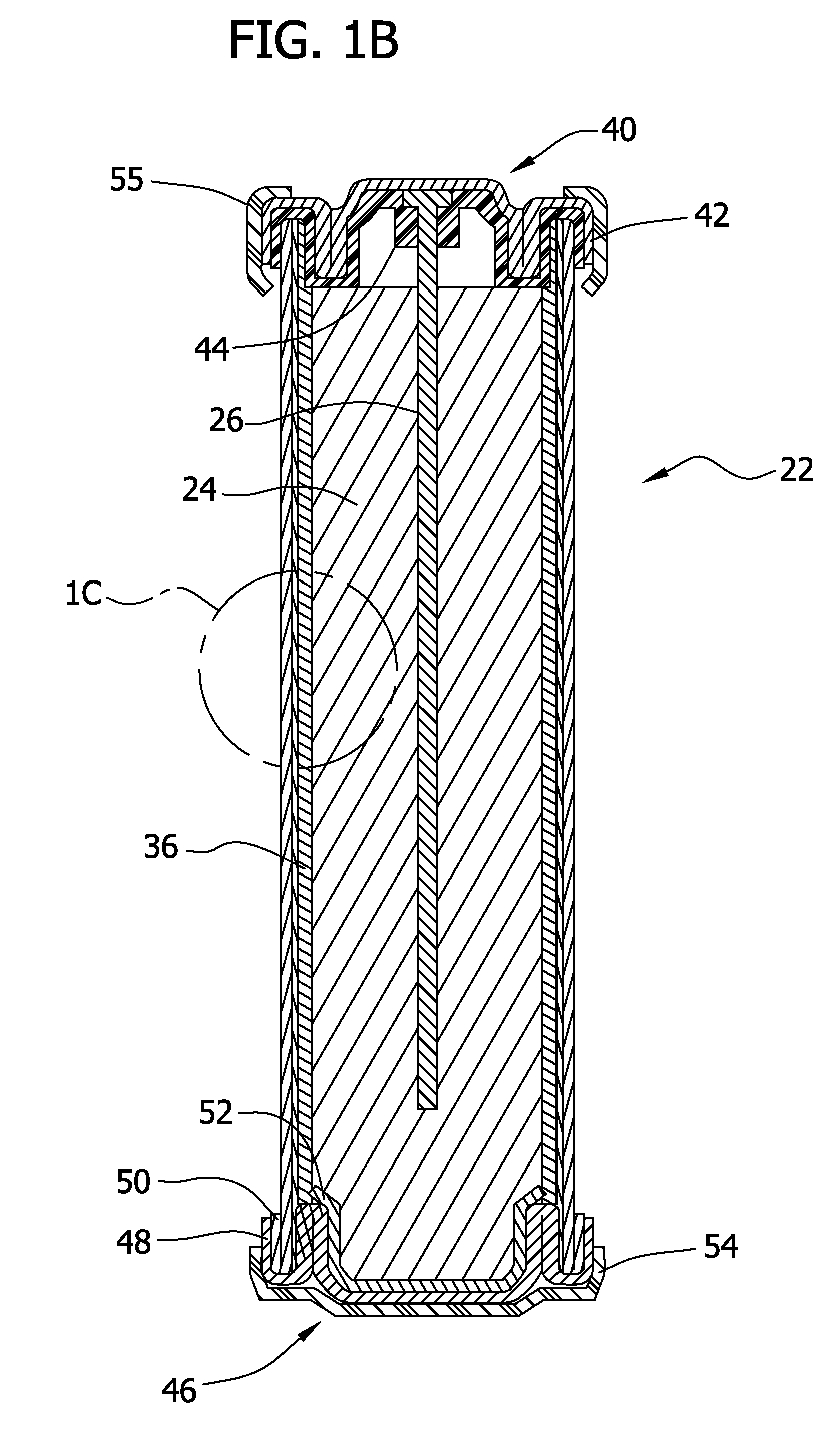

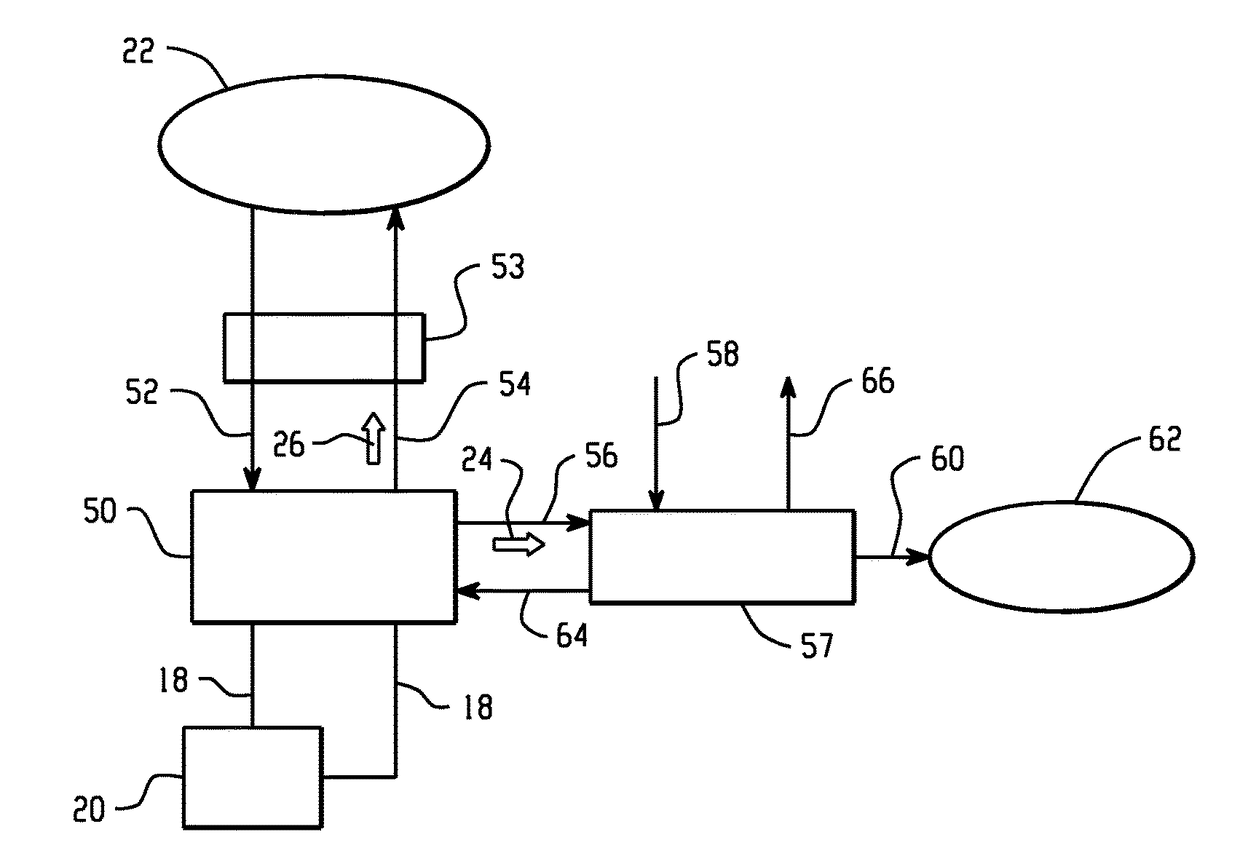

Monitor for automatic resuscitator with primary and secondary gas flow control

The present invention pertains generally to a monitoring system for a resuscitator which detects operation of the resuscitator and a controller unit for a supply of therapeutic gas to a resuscitator, and more specifically, a flow controller for a supply a therapeutic gas to an automatic resuscitator which is triggered by a single point pressure signal provided by the cycling of the automatic resuscitator from a controlled inhalation phase to a controlled exhalation phase. The monitoring aspect of the system detects single point low pressure signals which are sequentially compared against a time clock. Failure of the resuscitator system itself to generate a low pressure signal against the integrated time clock causes an alarm condition. Further, gas management is effected by a flow controller integrated into the monitor, a gas management system which responds to the single point low pressure signal and operate a primary gas control valve attached between a gas supply and an automatic resuscitator such that gas is allowed to flow to the resuscitator when the resuscitator is in an inhalation mode and gas flow is interrupted when the resuscitator is in an exhalation mode. A secondary gas control valve is integrated into the gas management system in parallel to the primary gas control valve. The flow controller includes a low threshold pressure sensor which is actuated by means of a recurrent low pressure pulse generated by the automatic resuscitator itself through the cycling of the resuscitator and remains essentially unaffected by the respiratory cycling of the patient, thus preventing false triggers and greatly simplifying the flow controller operation and format. The low threshold pressure sensor is coupled to a processor wherein the processor reads the occurrence of a pressure event at the pressure sensor and which then closes the primary gas control valve and starts a clock. As the pressure is decreased in the gas management system resulting from the primary gas control being moved to a closed position, the secondary gas control valve moves to open state, thus allowing the gas management system to vent to atmosphere during exhalation, reducing the pressure of the system to an operator defined positive level. Once the clock reaches a pre-defined duration, the primary gas control valve is reopened, the pressure in the gas management system increases thus closing the secondary gas control valve, the automatic resuscitator continues into an inhalation mode, and the process repeats.

Owner:VORTRAN MEDICAL TECH 1

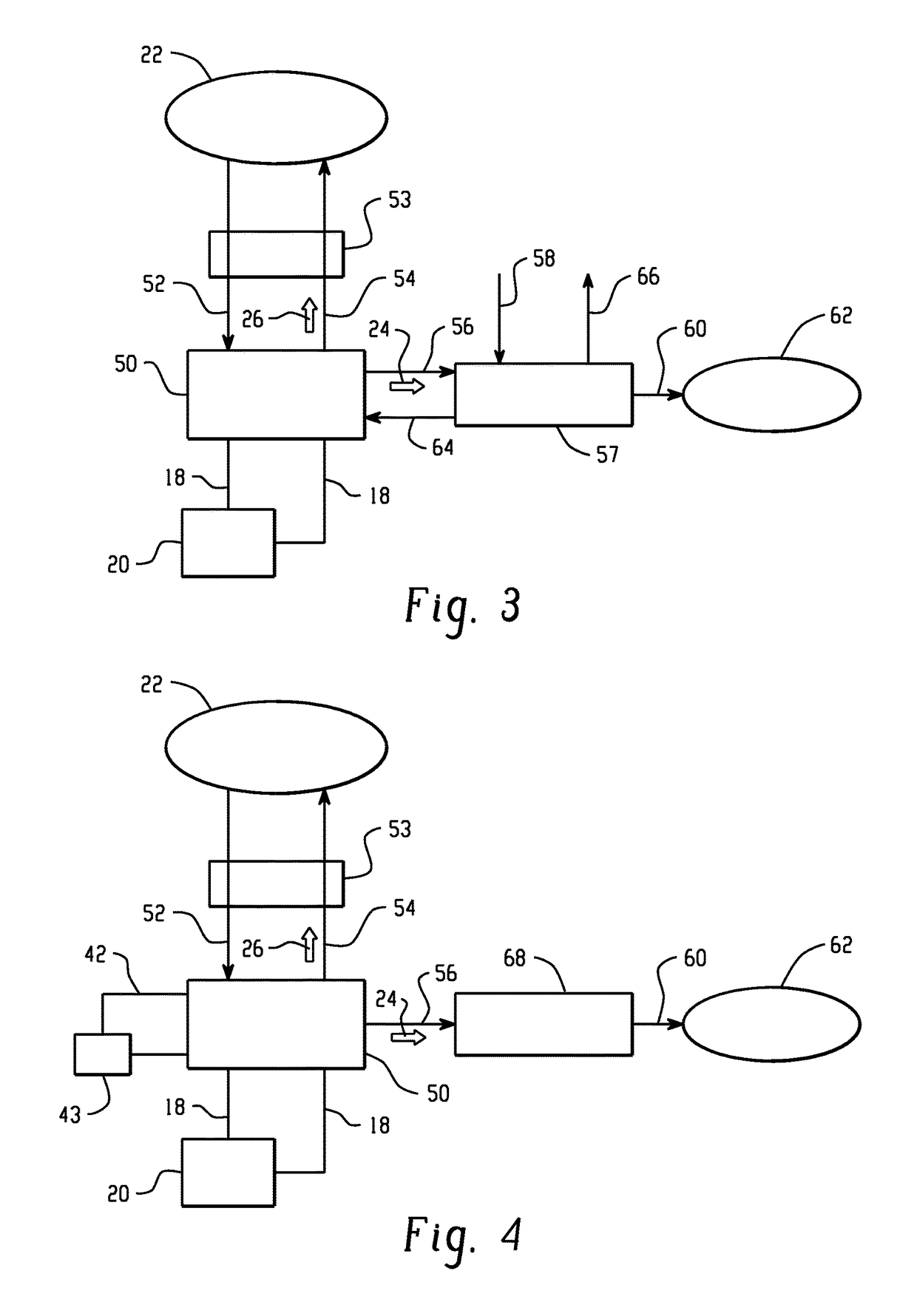

Aircraft fuel tank ullage gas management system

Owner:HAMILTON SUNDSTRAND CORP

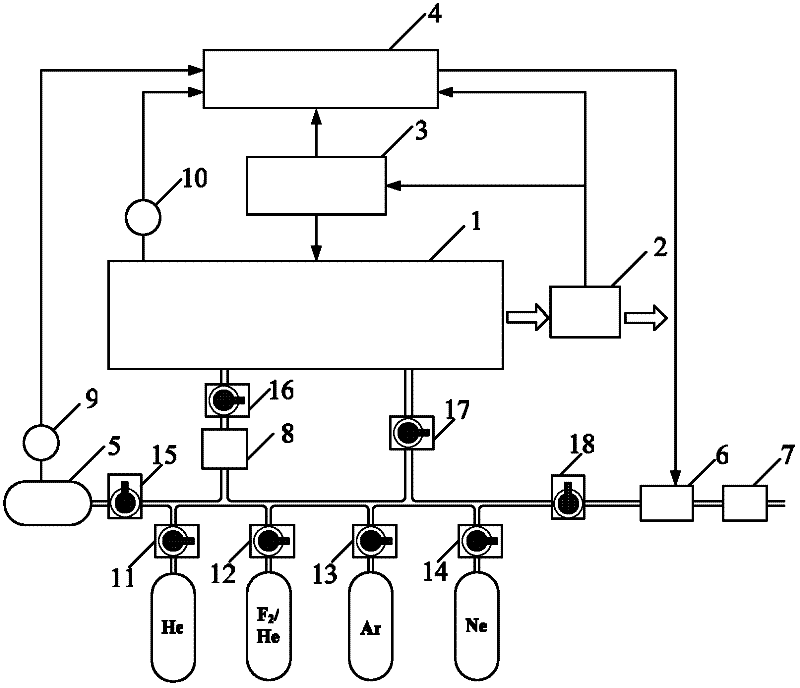

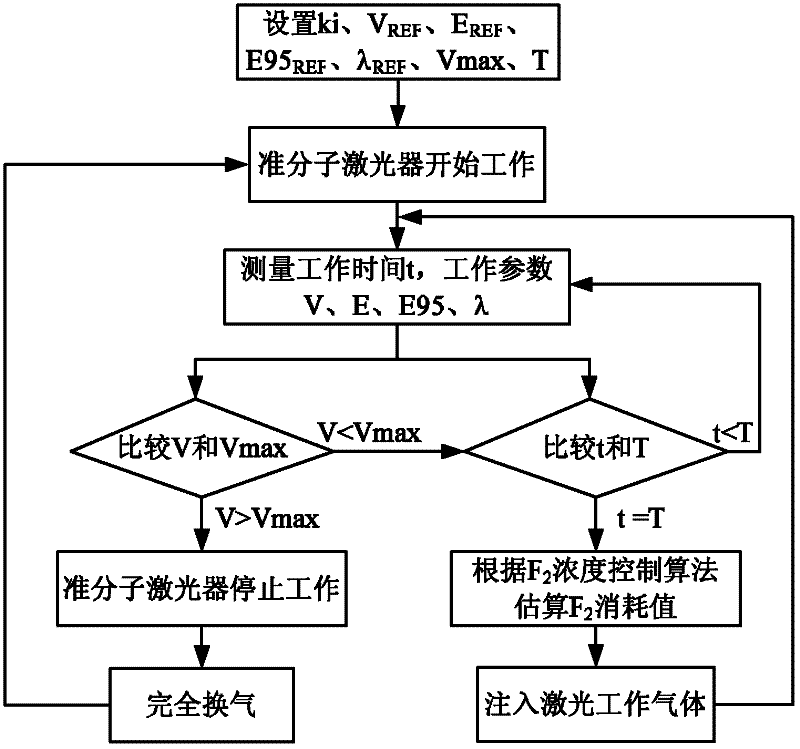

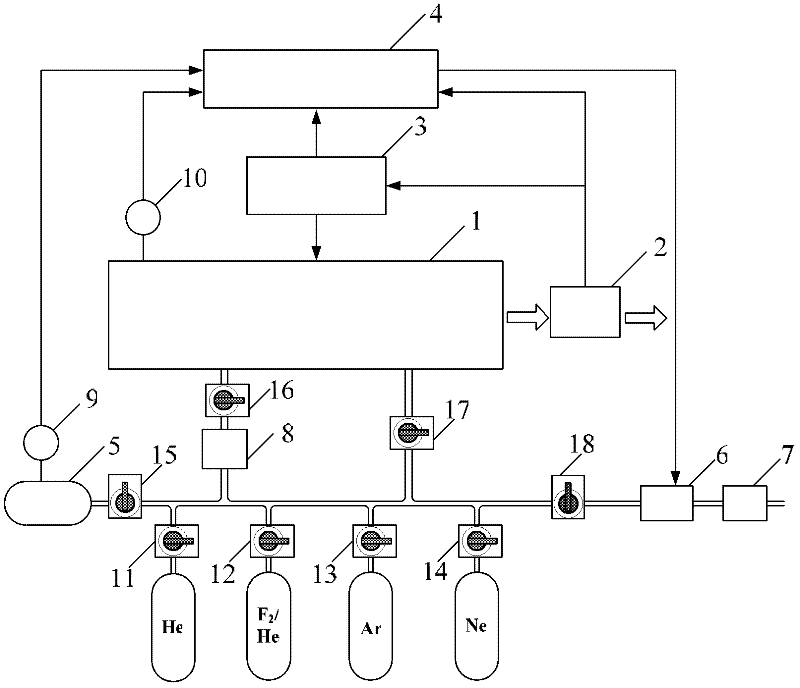

Gas management apparatus and method for excimer laser

The invention relates to a gas management apparatus and a method for an excimer laser. The apparatus comprises: an excimer laser; a monitoring and controlling module; controllable electromagnetic valves that are used for controlling flow directions of laser working gases; gas injection tank that is used for matching laser working gases with different concentrations; a halogen gas processing apparatus and a vacuum pump that are used for discharging laser working gases; and a pressure transducer that is used for monitoring pressure intensities of the laser working gases. According to the invention, working parameters of an excimer laser are monitored, wherein the working parameters include a working voltage, pulse energy, a width of a spectral line, and a wavelength; consumption of laser working gas is estimated according to quantitative relations between the working parameters of the excimer laser and the concentration of the laser working gas, wherein the working parameters are measured by an experiment; changes of pressure intensity of the laser working gas within a laser cavity as well as openings and closures of the controllable electromagnetic valves are controlled by employing pressure monitoring and signal feed back methods, so that the laser working gas is injected with an accurate value into the laser cavity. According to the invention, stability for outputting laser pulse by an excimer laser can be improved; life of laser working gas can be effectively prolonged; and a gas change rate of the laser can be reduced.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

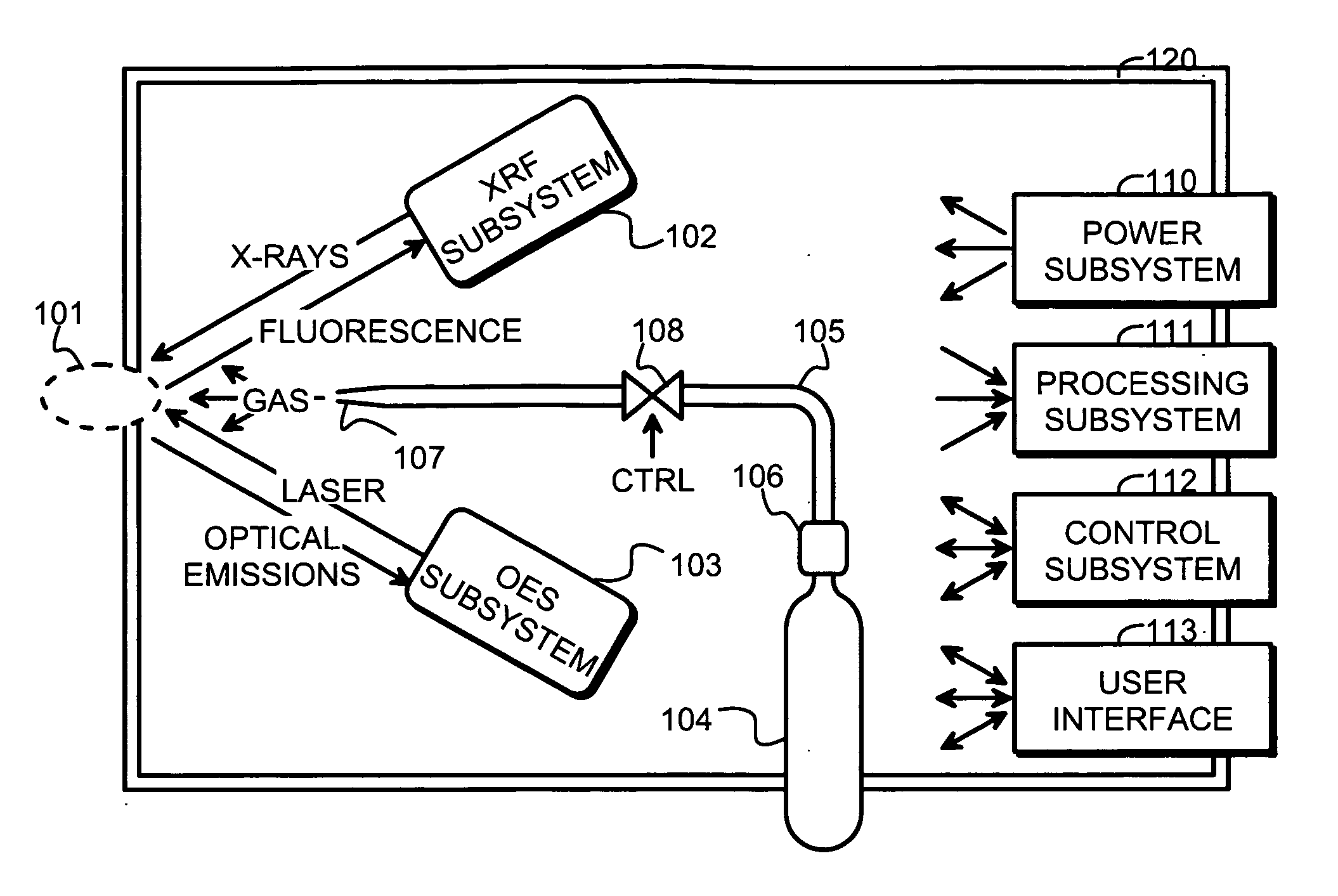

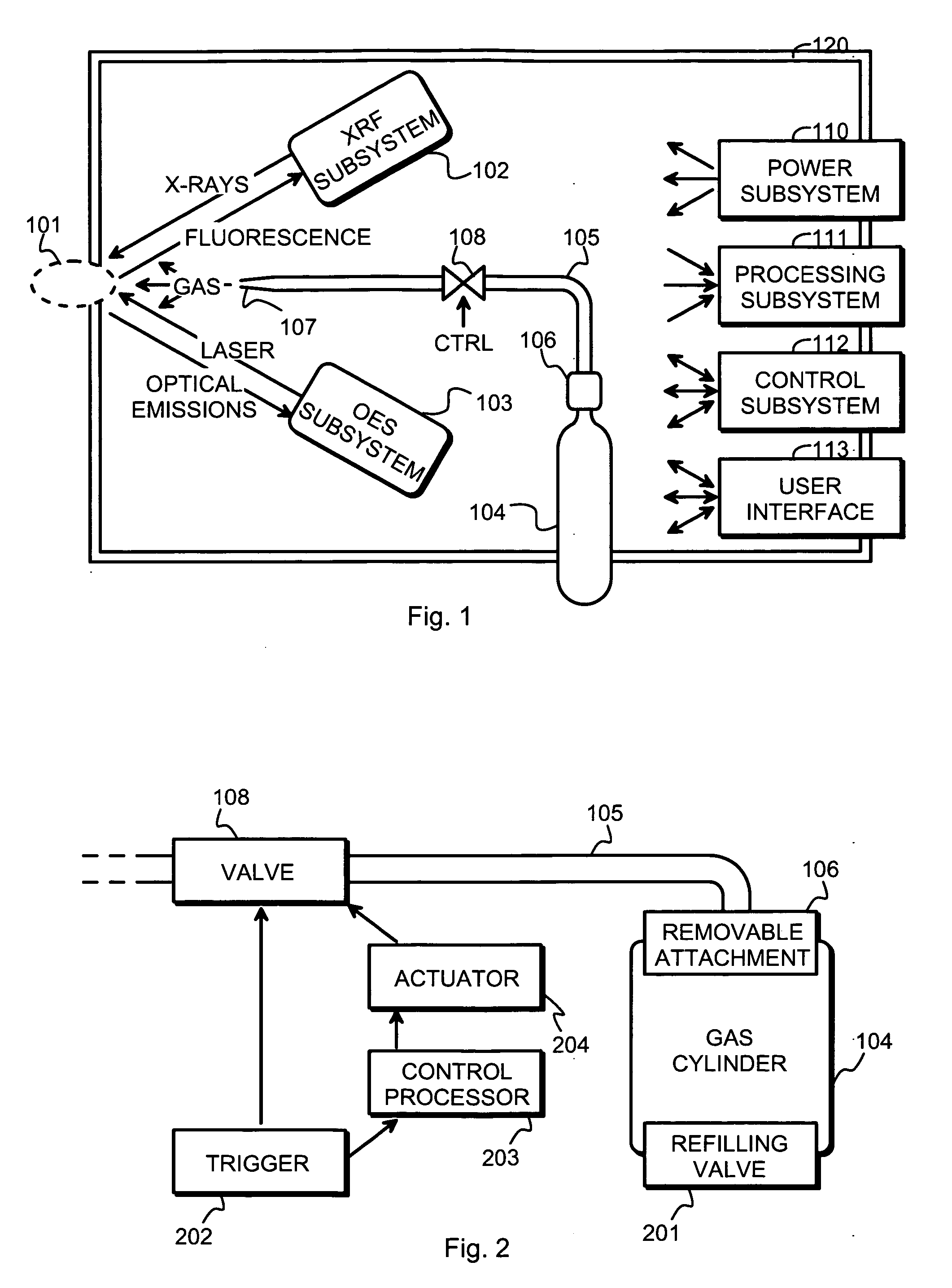

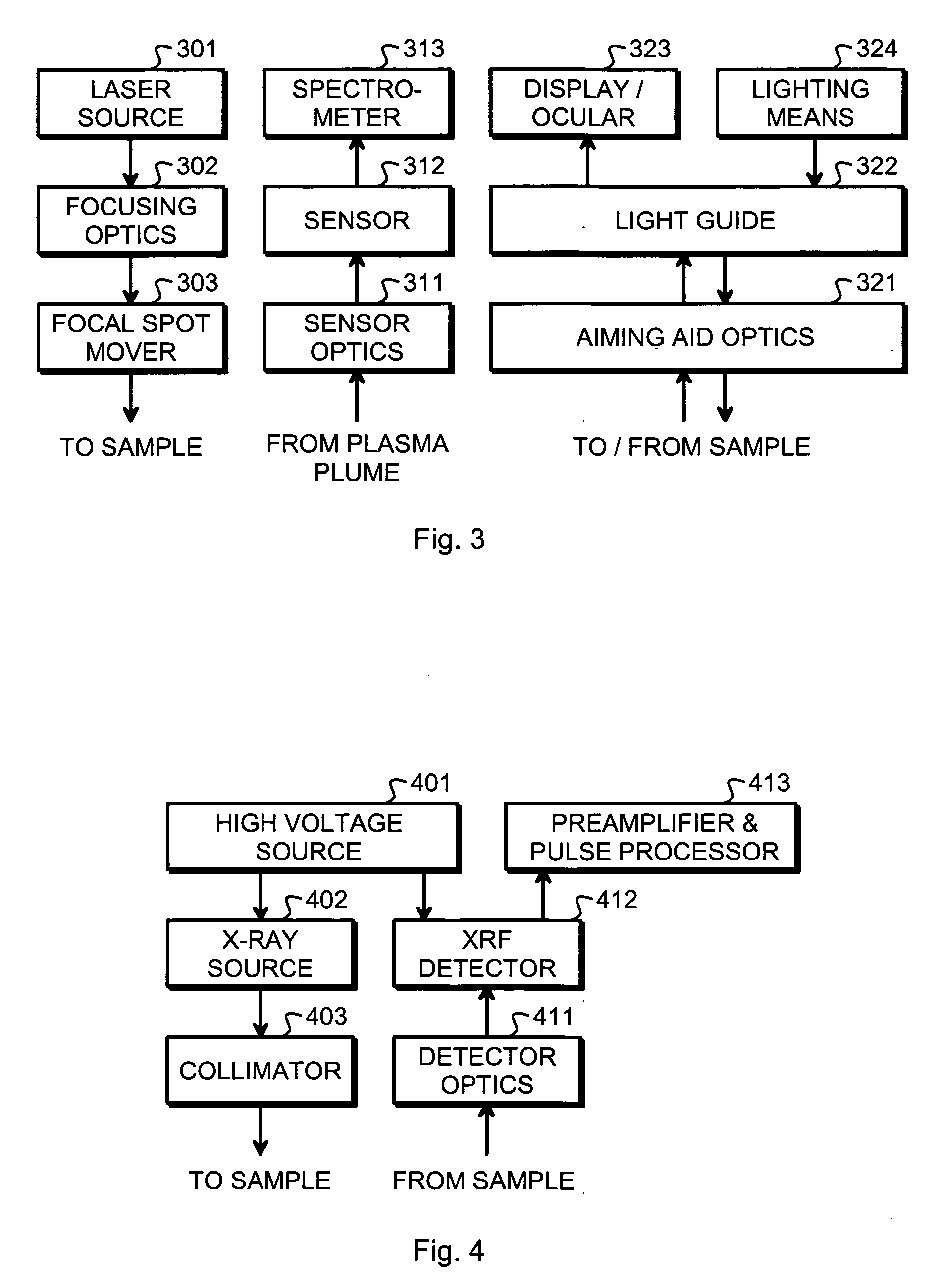

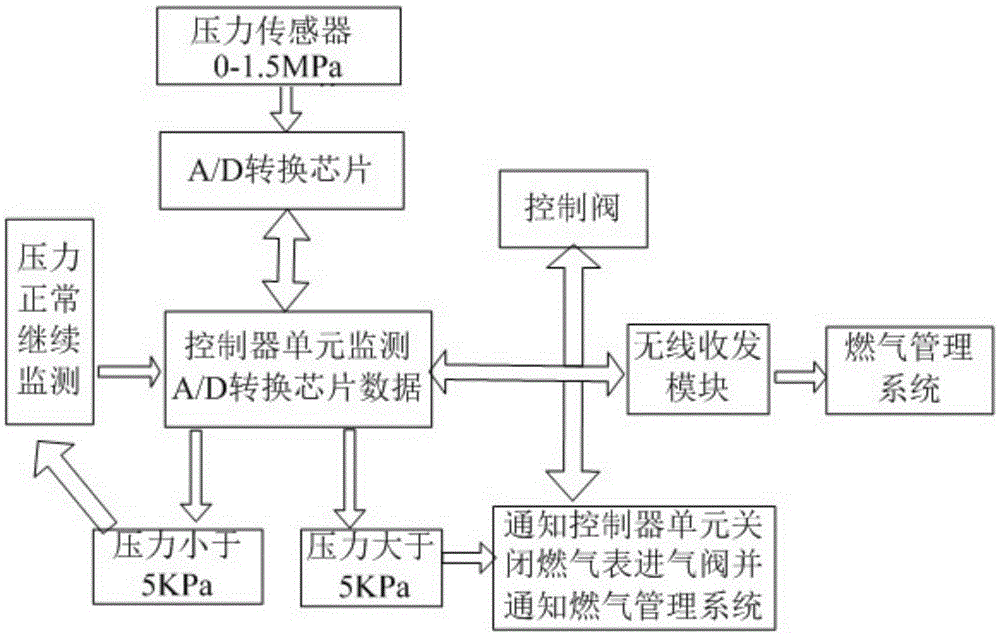

Measurement apparatus and method for determining the material composition of a sample by combined X-ray fluorescence analysis and laser-induced breakdown spectroscopy

ActiveUS20060262900A1Improve reliabilityReduce usageMaterial analysis using wave/particle radiationX-ray spectral distribution measurementMeasurement deviceX-ray

A measurement apparatus and method are provided for determining the material composition of a sample. An X-ray fluorescence detector (412) detects fluorescent X-rays coming from said sample under irradiation with incident X-rays. A laser source (301) is adapted to produce a laser beam. Focusing optics (302) focus said laser beam into a focal spot on a surface of said sample. An optical sensor (312) detects optical emissions coming from particles of said sample upon being exposed to said laser beam at said focal spot. A gas administration subsystem (104, 105, 106, 107, 108) is adapted to controllably deliver gas to a space (101) around said focal spot.

Owner:HITACHI HIGH TECH ANALYTICAL SCI FINLAND OY

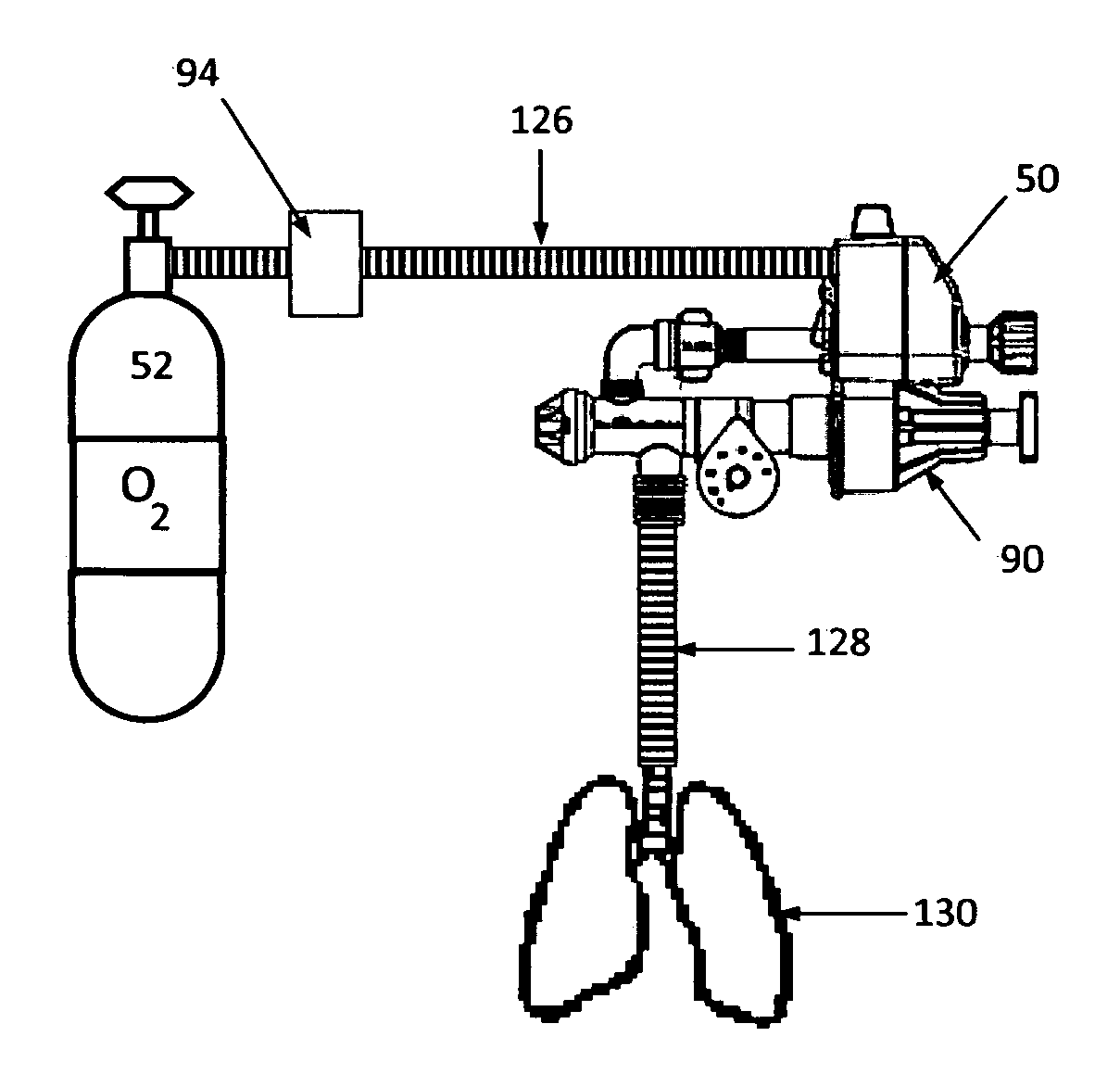

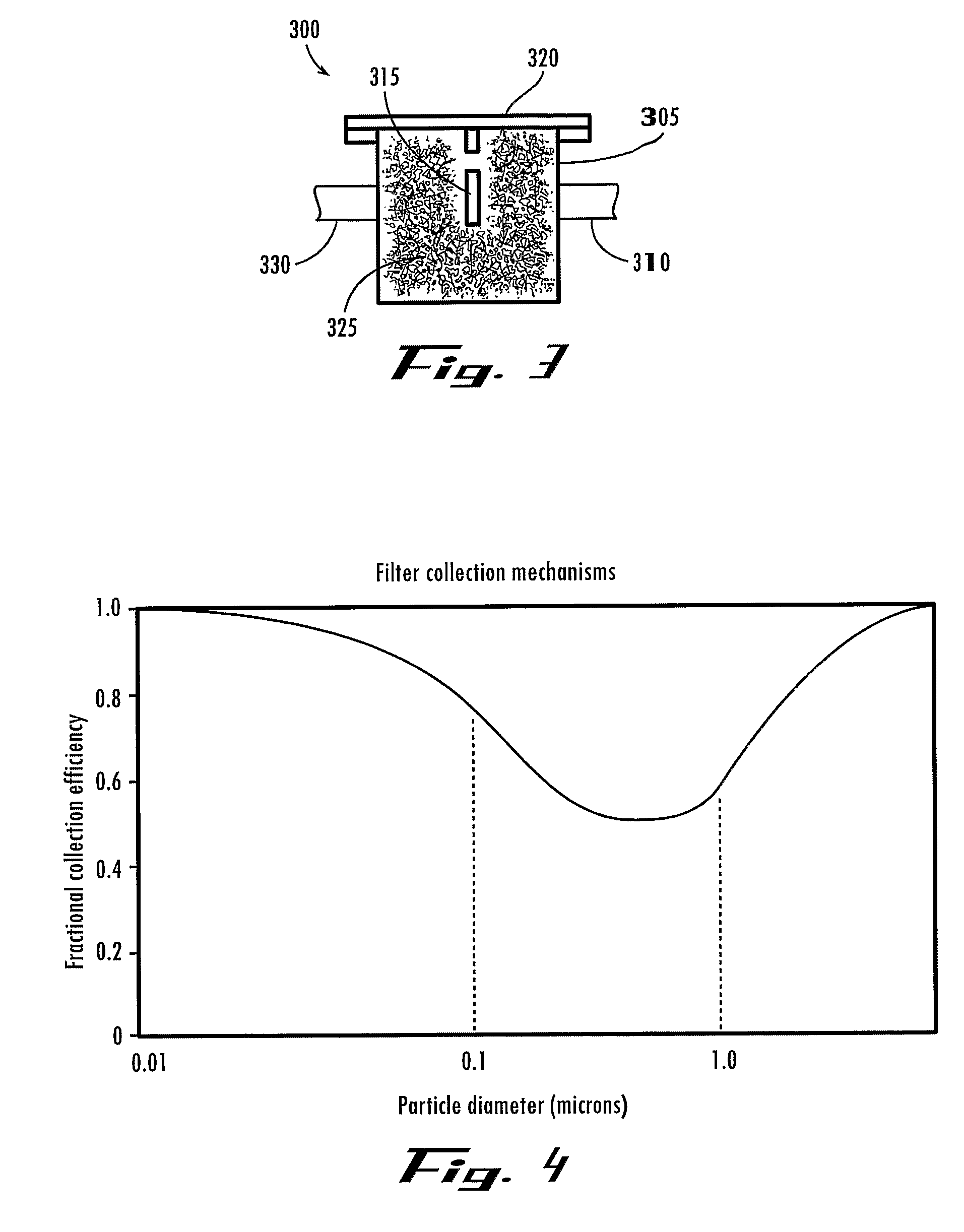

Filter Device for Administration of Stored Gases

InactiveUS20080034967A1Prevent inadvertent transmissionFor quick replacementRespiratorsGas treatmentProduct gasRespiratory support

This invention relates to the field of connectors used to connect gas sources to apparatus for the administration or other use of gas or mixtures of gases, and more specifically to filters used to remove biological contaminants that might be colonized with the pressurized containers used in gas administration for respiratory support of a user or patient or other applications where biological contamination is not desired.

Owner:BOC GRP INC

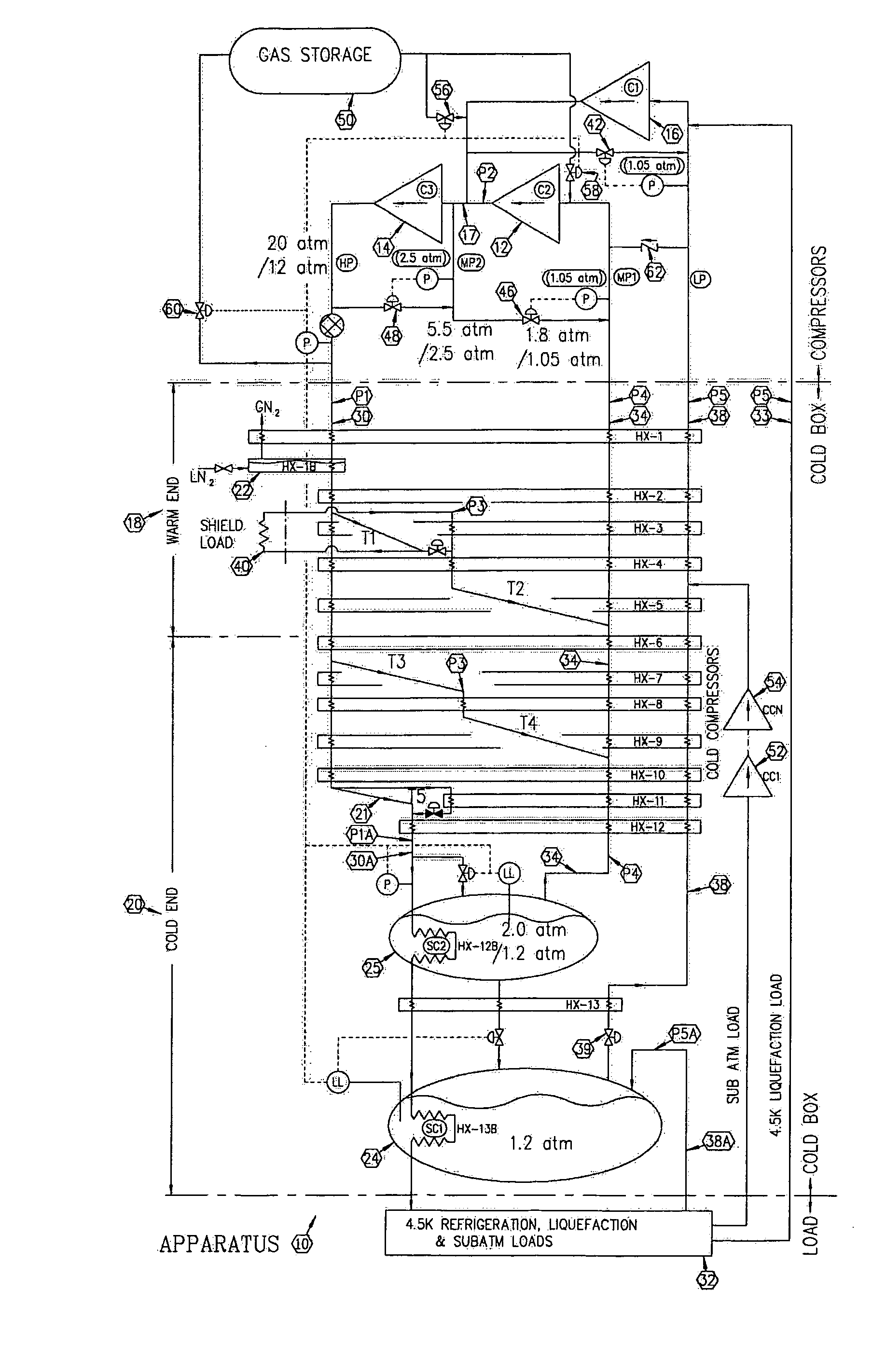

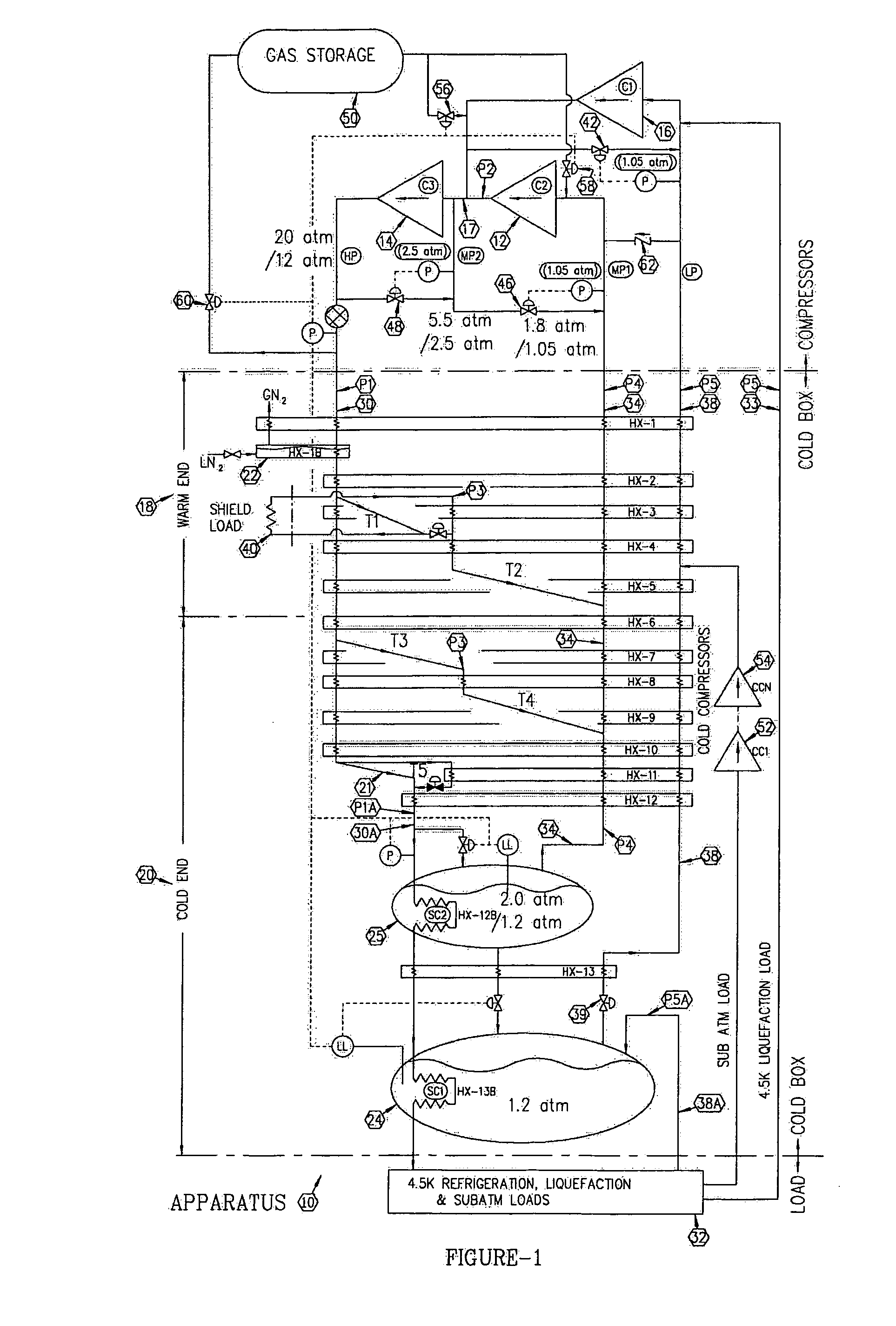

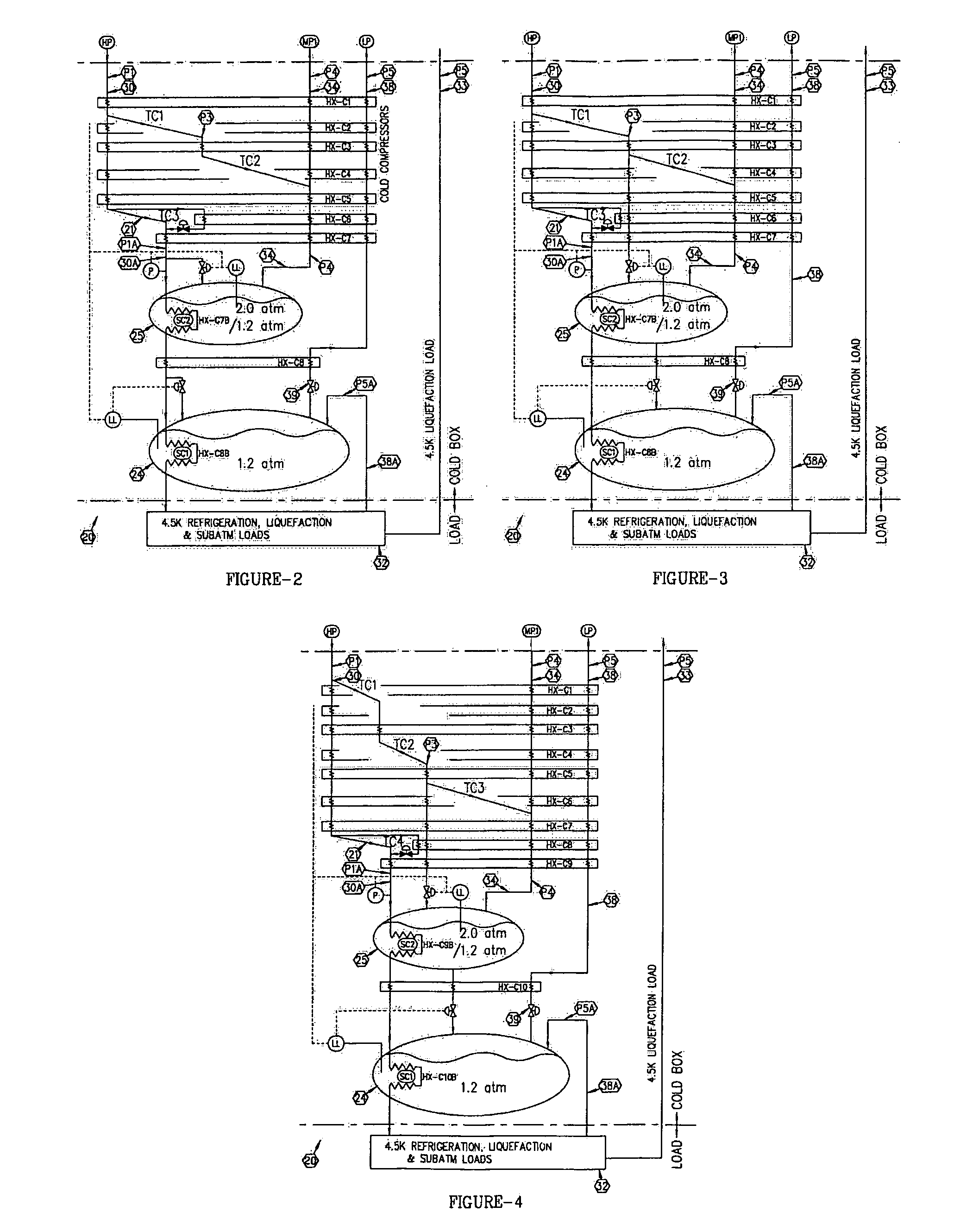

Helium process cycle

ActiveUS7278280B1Operation efficiency is highEffective maintenanceSolidificationLiquefactionOff designProcess engineering

A unique process cycle and apparatus design separates the consumer (cryogenic) load return flow from most of the recycle return flow of a refrigerator and / or liquefier process cycle. The refrigerator and / or liquefier process recycle return flow is recompressed by a multi-stage compressor set and the consumer load return flow is recompressed by an independent consumer load compressor set that maintains a desirable constant suction pressure using a consumer load bypass control valve and the consumer load return pressure control valve that controls the consumer load compressor's suction pressure. The discharge pressure of this consumer load compressor is thereby allowed to float at the intermediate pressure in between the first and second stage recycle compressor sets. Utilizing the unique gas management valve regulation, the unique process cycle and apparatus design in which the consumer load return flow is separate from the recycle return flow, the pressure ratios of each recycle compressor stage and all main pressures associated with the recycle return flow are allowed to vary naturally, thus providing a naturally regulated and balanced floating pressure process cycle that maintains optimal efficiency at design and off-design process cycle capacity and conditions automatically.

Owner:JEFFERSON SCI ASSOCS LLC

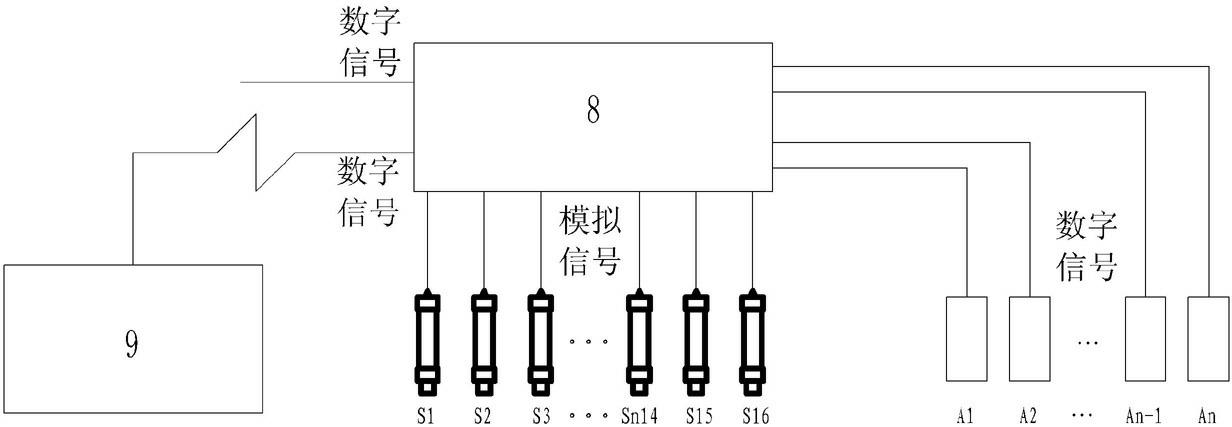

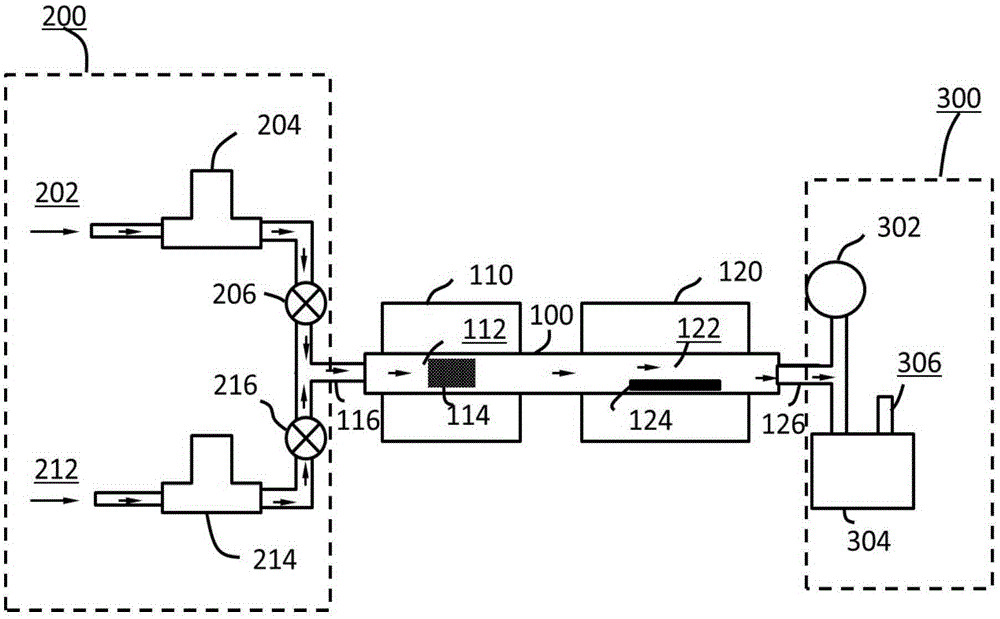

Medical gas management system

InactiveCN102591311AReduce labor intensityEasy cost managementProgramme total factory controlThe InternetMonitoring system

The invention discloses a medical gas management system, which is convenient for remote monitoring management, improves the gas supply safety performance, is timely and convenient for maintenance, and provides the basis for the cost management. The medical gas management system includes a monitoring center (1), a gas source station building system (2), a gas utilization area monitoring system (3) and a plurality of monitoring stations (4), wherein the monitoring center (1) is connected with the gas source station building system (2) and the gas utilization area monitoring system (3) in data bus mode, and is connected with the monitoring stations (4) through a network switch (5) in TCP / IP protocol; and the network switch (5) is connected into the Internet.

Owner:珠海智领医疗科技有限公司

Aircraft fuel tank ullage gas management system

An aircraft fuel tank ullage gas management system is disclosed. The system includes an electrochemical cell having a membrane electrode assembly that includes a cathode and anode separated by an electrolyte separator. A cathode fluid flow path is in fluid communication with the cathode, and receives the flow of cabin air from the cabin air fluid flow path and discharges nitrogen-enriched air. An anode fluid flow path is in fluid communication with the anode, and discharges oxygen or oxygen-enriched air. The electrochemical cell also includes water in fluid communication with the anode. The system includes an electrical power source and electrical connections to the anode and cathode for providing an electric potential difference between the anode and cathode. An ullage flow path receives nitrogen-enriched air from the cathode fluid flow path and delivers it to the fuel tank. An optional flow path delivers humidified oxygen-enriched air back to the cabin.

Owner:HAMILTON SUNDSTRAND CORP

Solid oxide fuel cell with transitioned cross-section for improved anode gas management at the open end

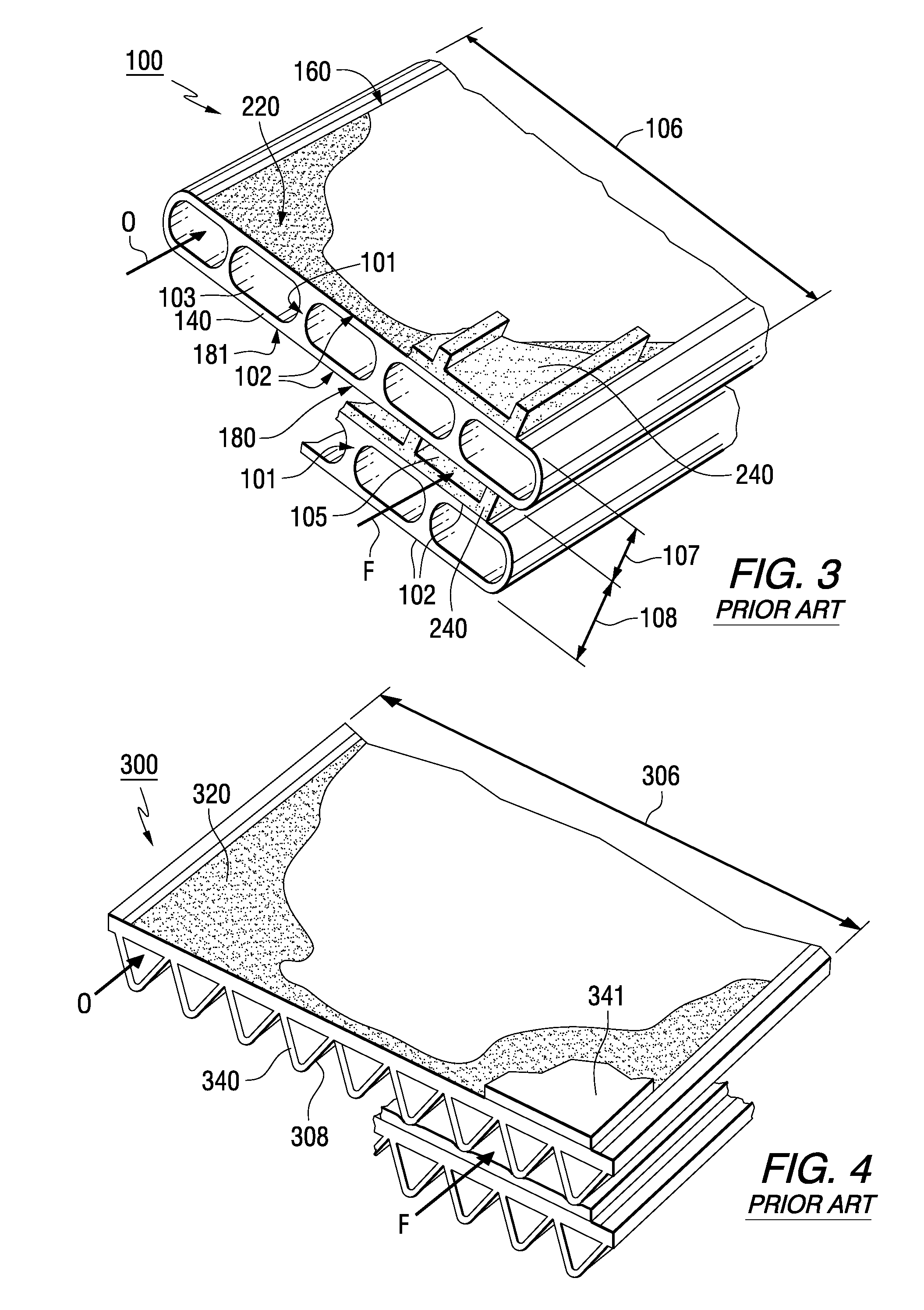

InactiveUS20100009228A1High current density designImprove sealingFuel cells groupingCell component detailsFuel cellsEngineering

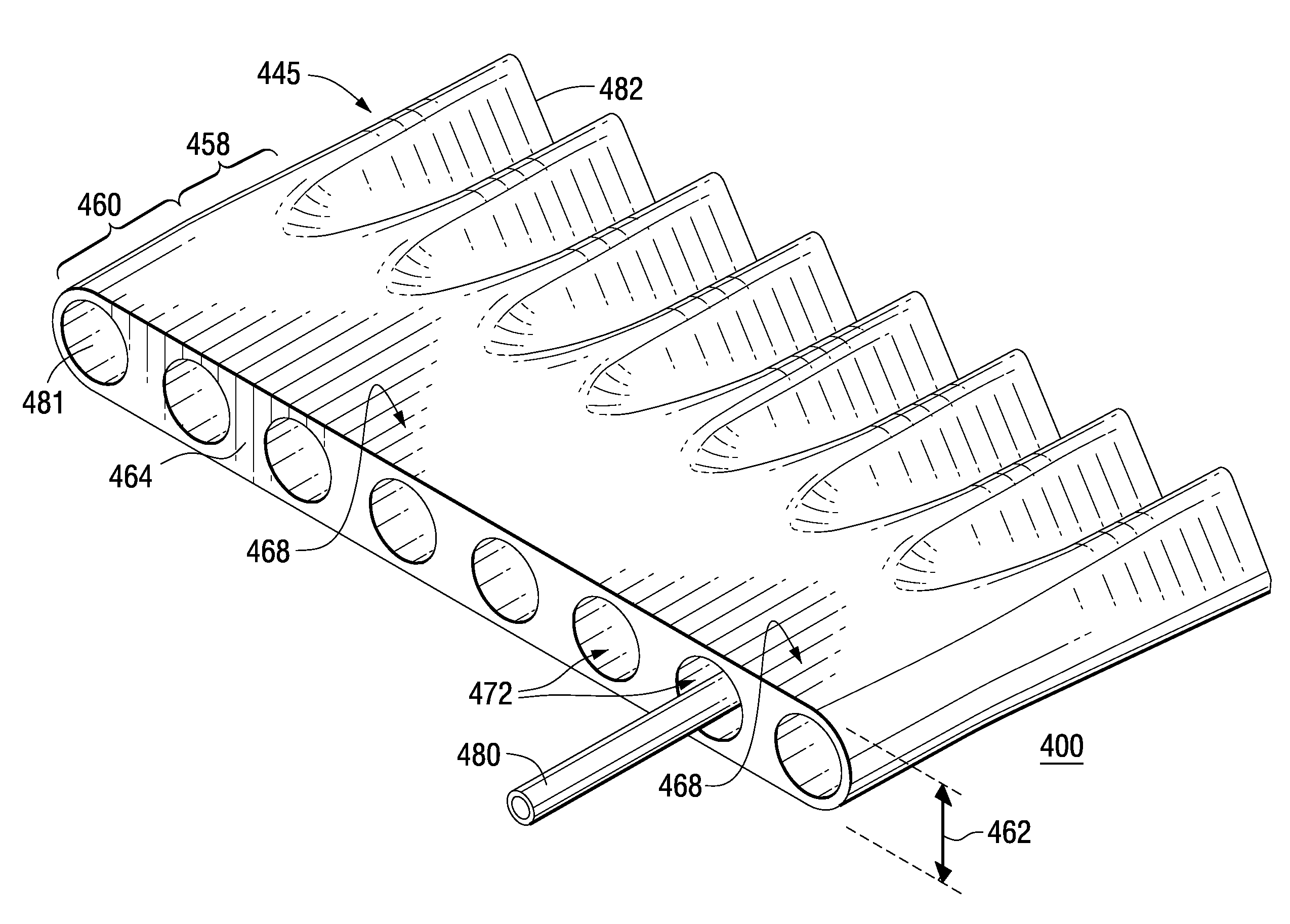

A solid oxide fuel cell (400) is made having a tubular, elongated, hollow, active section (445) which has a cross-section containing an air electrode (452) a fuel electrode (454) and solid oxide electrolyte (456) between them, where the fuel cell transitions into at least one inactive section (460) with a flattened parallel sided cross-section (462, 468) each cross-section having channels (472, 474, 476) in them which smoothly communicate with each other at an interface section (458).

Owner:SIEMENS ENERGY INC

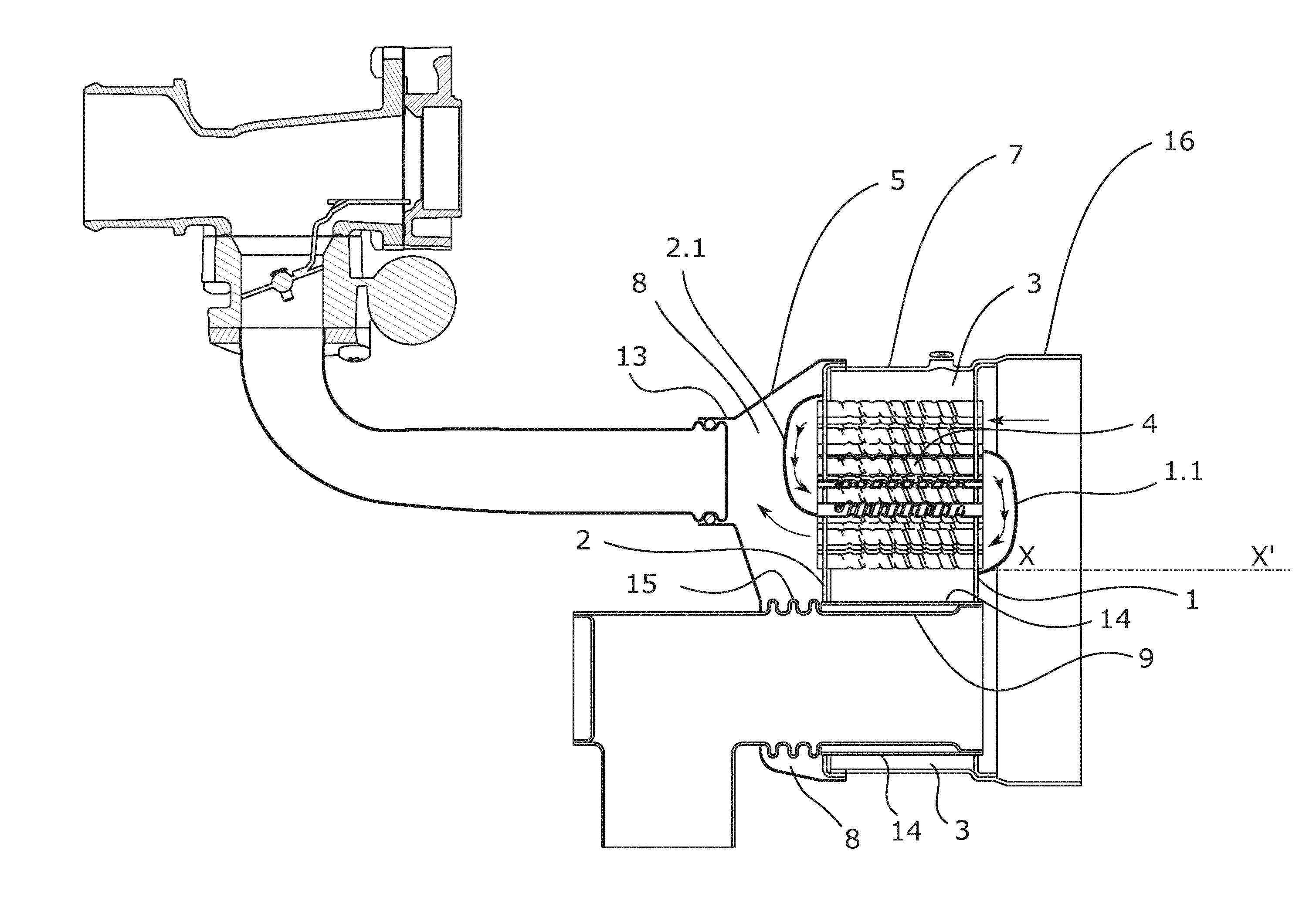

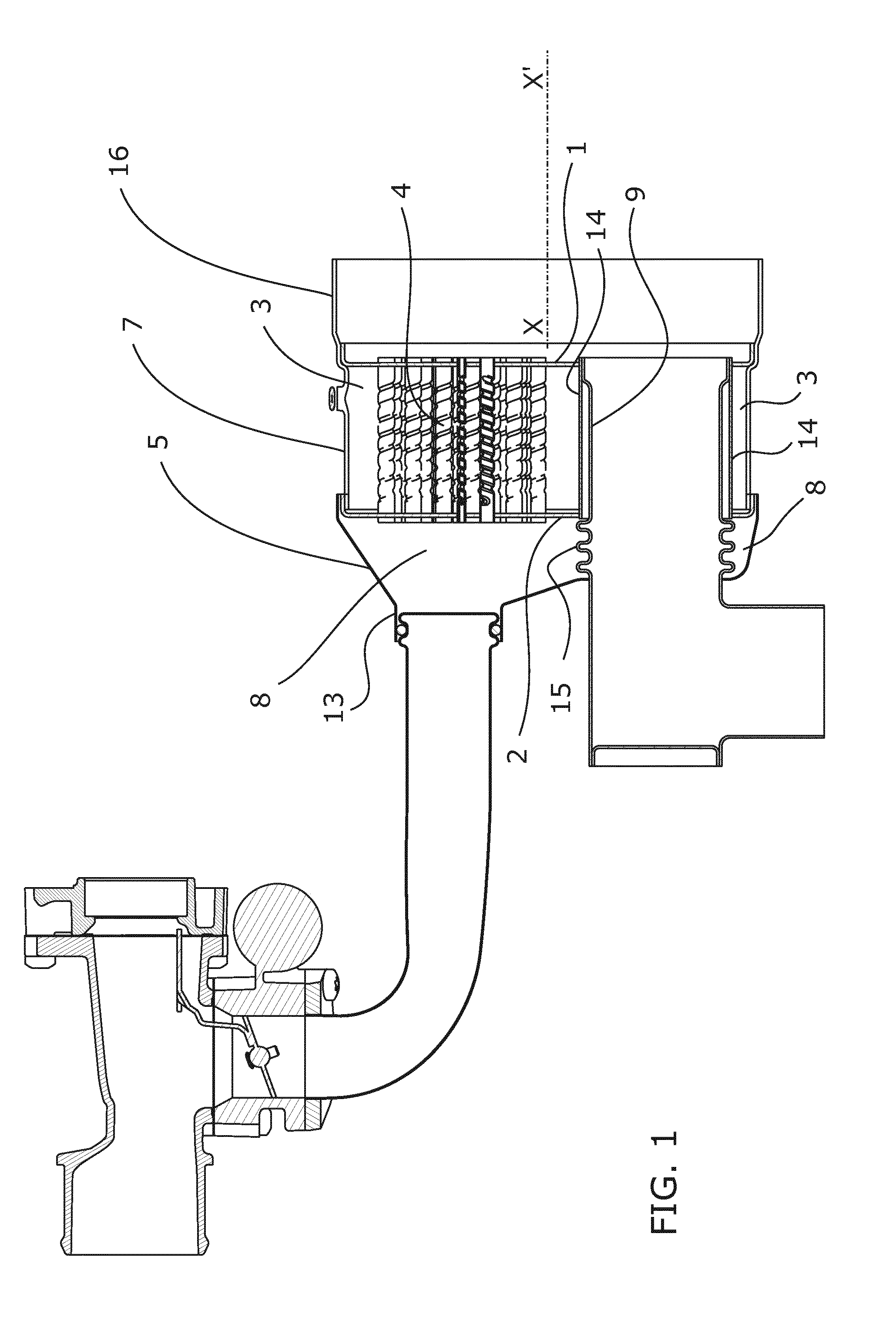

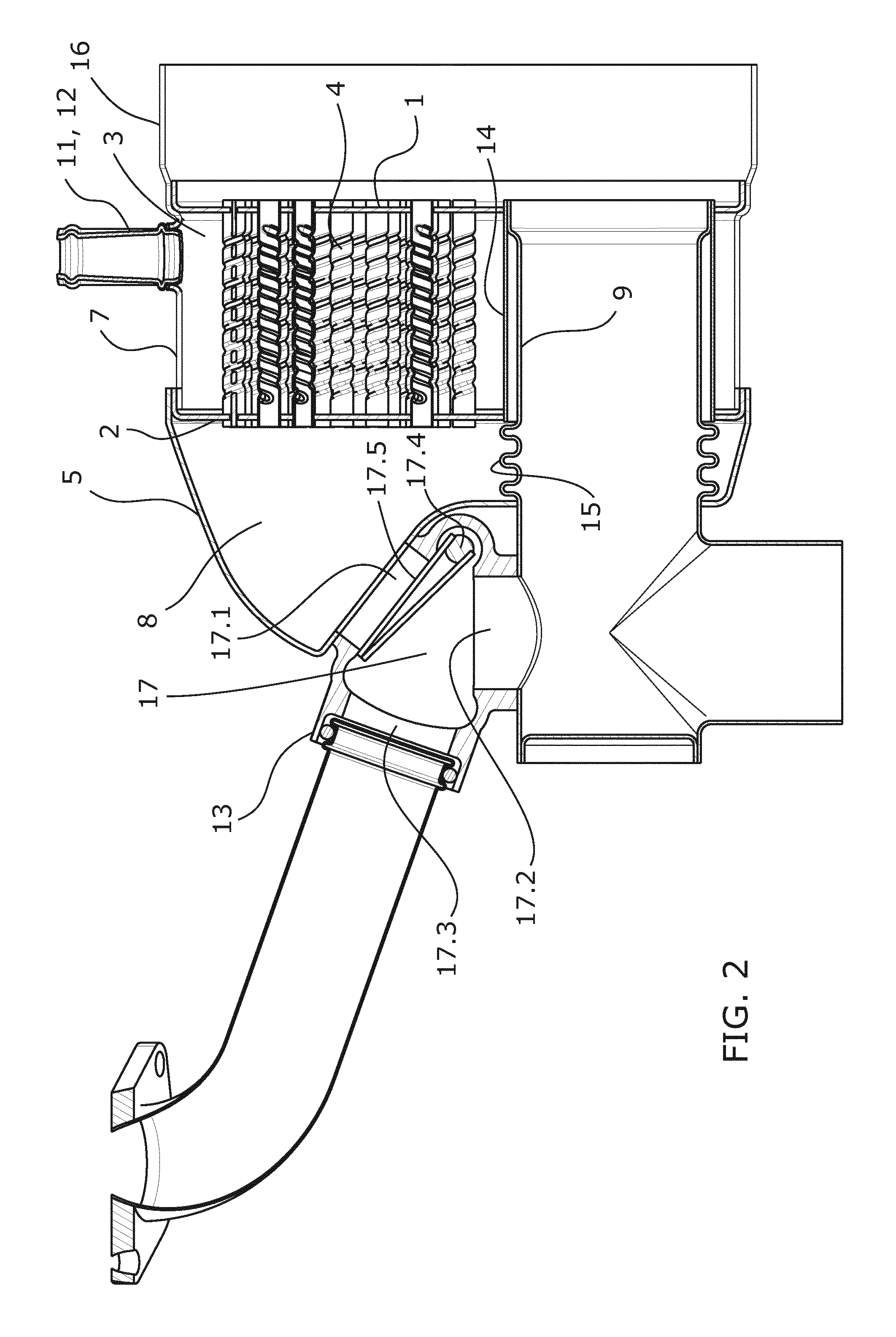

Built-In Exhaust Gas Maintenance Device

InactiveUS20150308388A1High degree of packagingNon-fuel substance addition to fuelEngine operationsConvertersExhaust gas emissions

The present invention relates to a gas management device suitable for being installed at the outlet o fa particle filter or of a catalytic converter. This device is characterized by a very compact configuration having at least the heat exchanger for an EGR (Exhaust Gas Recirculation) system, particularly suitable for a low pressure system, and an exhaust gas discharge pipe which is part of the exhaust line. According to one embodiment, the device also allows integrating a bypass valve for the EGR heat exchanger. According to another embodiment, the device allows integrating a heat recovery unit participating in the EGR system. According to another embodiment, the device also allows both including a bypass and including a heat recovery unit. The degree of integration with the particle filter of the catalytic converter is maintained in all cases.

Owner:BORGWARNER EMISSIONS SYST SPAIN S L U

Method of combined mining caving face using false dipping after high drainage roadway treating gas in beginning mining

The present invention provides a method that the comprehensive surface utilizes a fake inclined rear high pumping lane to manage the gas in the initial period to solve the problem of gas on the comprehensive surface in the initial mining period. The present invention is characterized in that a slope is made in a return airway arranged at the corner of a work surface; the opening of the return airway is arranged in a tangent lane along the working surface and climbs the slope with a certain angle, thus excavating a fake inclined lane with a small cross section communicated with the rail of the rear high pumping lane and then discharging the gas adjacent to the working surface under the pumping negative pressure of the high pumping lane; the key is to arrange the lane on the rim zone when the top plate is in initial caving and gradually discard section by section from up to down along the caving of the top plate, thus the pumping negative pressure moving upwards and the gas density gradually increasing until the caving height of the top plate is communicated with the high pumping lane and connected with an underground gas pumping system; through arranging the lane, the gas gushing out from the adjacent coal layer and the local layer. The present invention with the advantages of security, reliability, low cost, convenient construction and good effect is particularly applicable to the gas management in coal mine.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

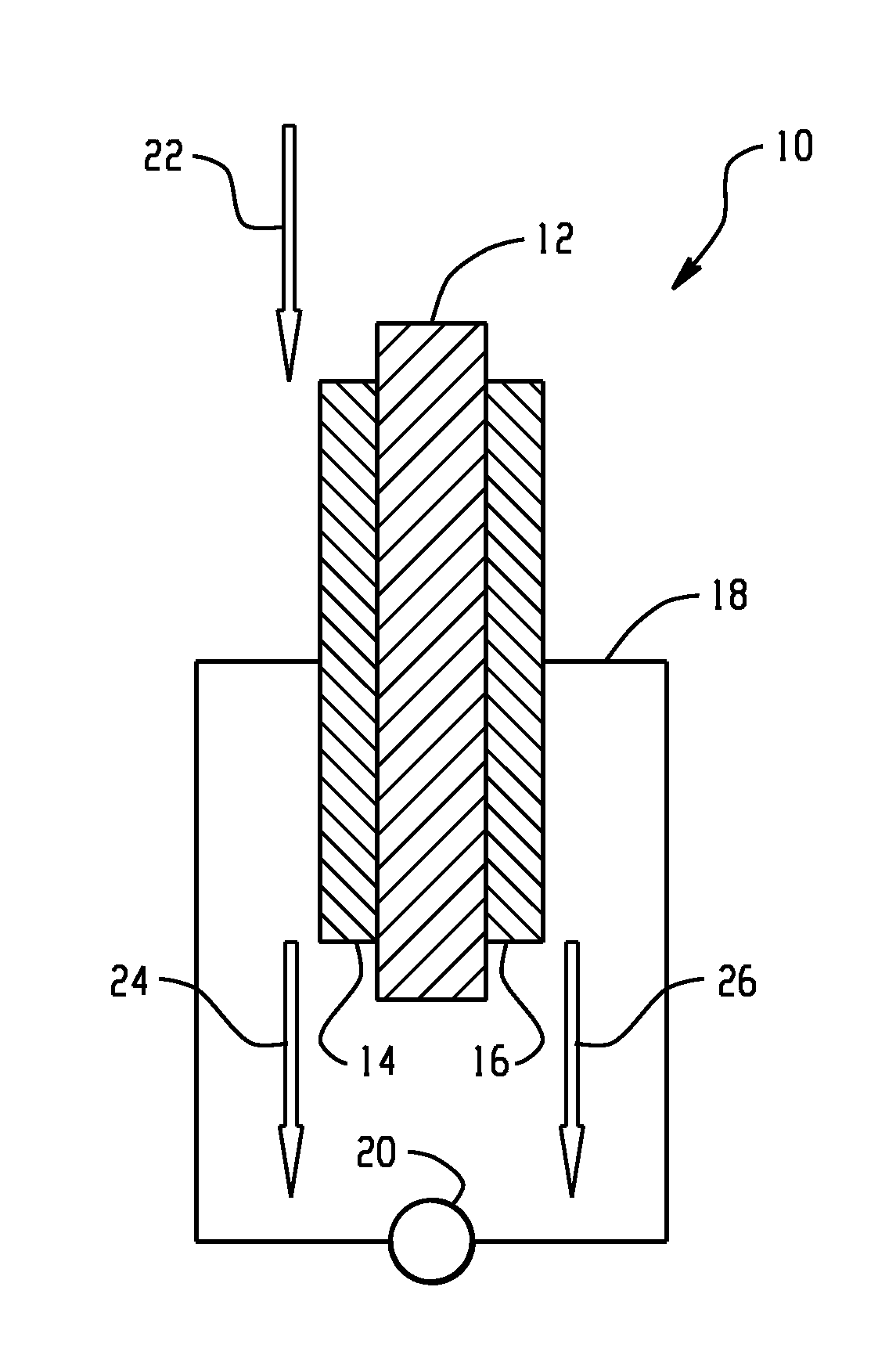

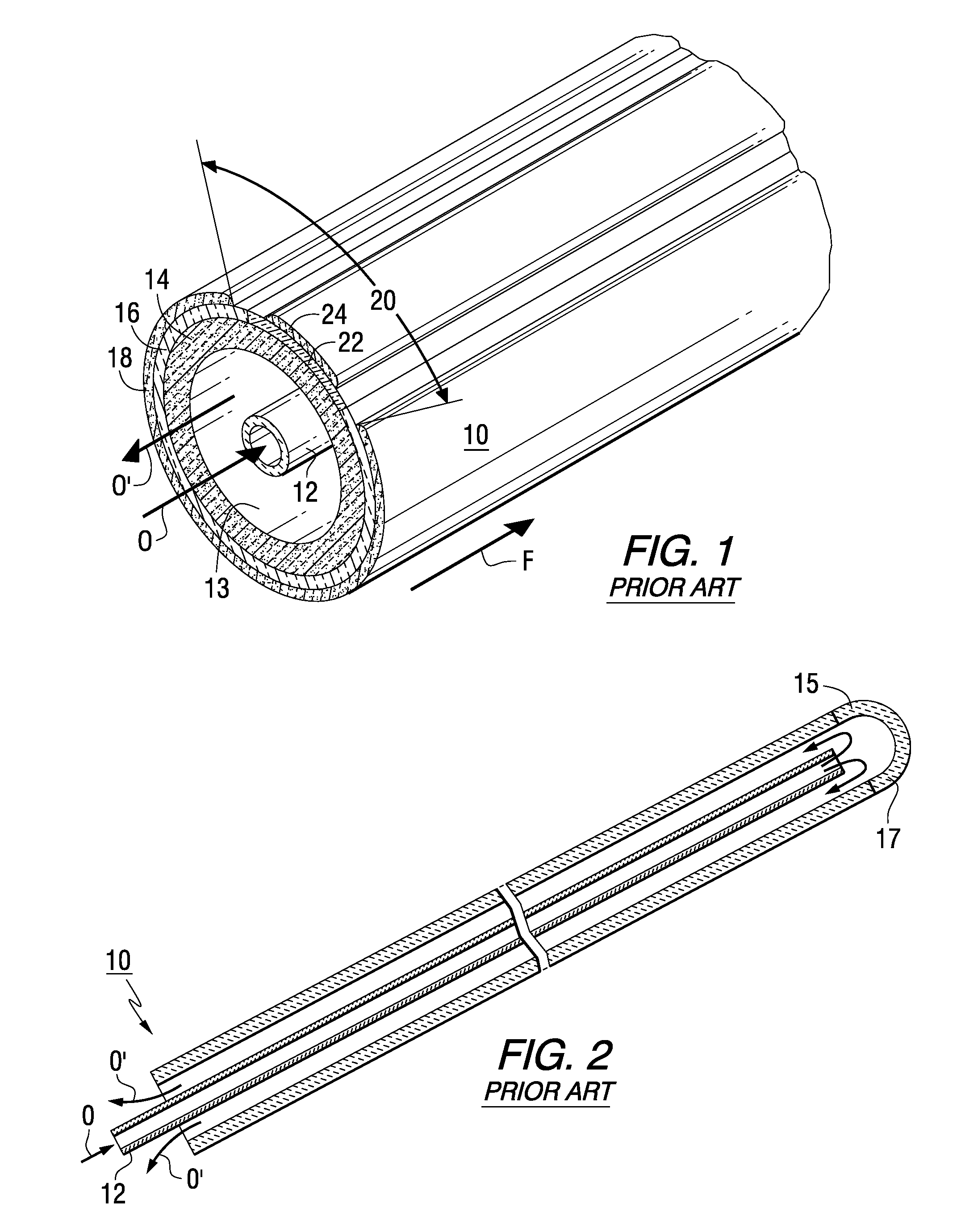

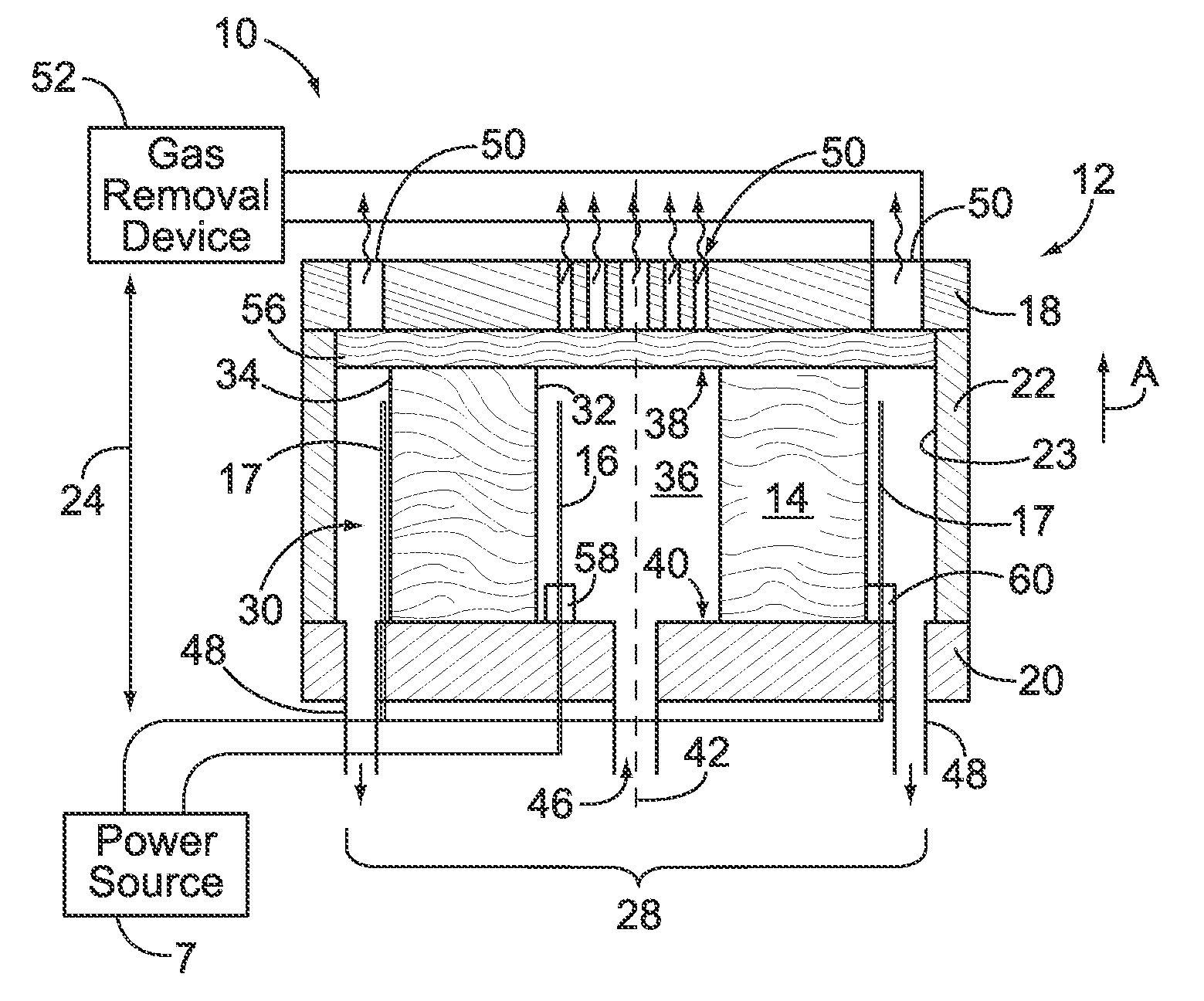

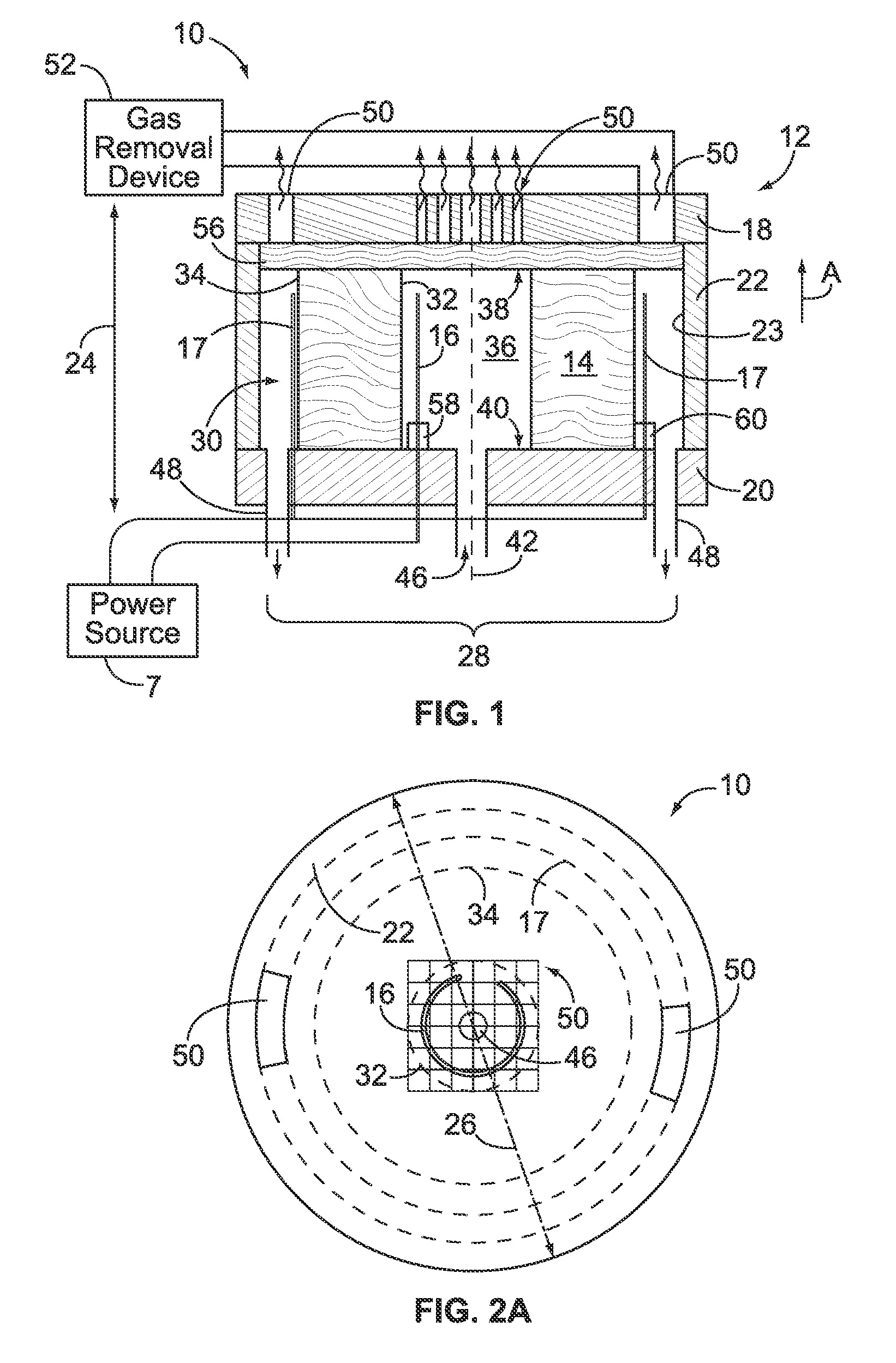

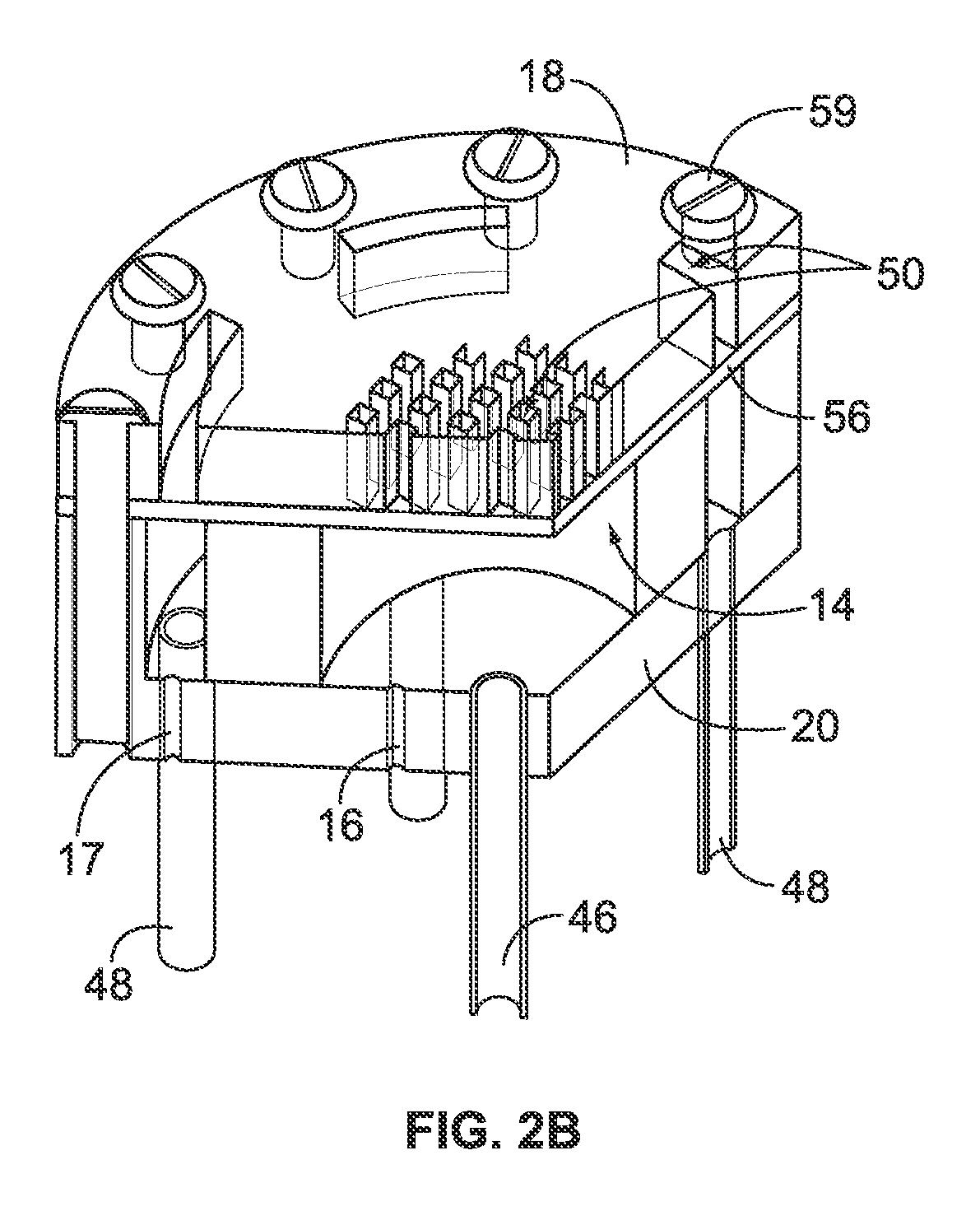

Electroosmotic pump with improved gas management

An electroosmotic (EO) pump is provided that includes a housing having a pump cavity, a porous core medium and electrodes. The porous core medium is positioned within the pump cavity to form an exterior reservoir that extends at least partially about an exterior surface of the porous core medium. The porous core medium has an open inner chamber provided therein. The inner chamber represents an interior reservoir. The electrodes are positioned in the inner chamber and are positioned proximate the exterior surface. The electrodes induce flow of a fluid through the porous core medium between the interior and exterior reservoirs, wherein a gas is generated when the electrodes induce flow of the fluid. The housing has a fluid inlet to convey the fluid to one of the interior reservoir and the exterior reservoir. The housing has a fluid outlet to discharge the fluid from another of the interior reservoir and the exterior reservoir. The housing has a gas removal device to remove the gas from the pump cavity.

Owner:ARIZONA STATE UNIVERSITY +1

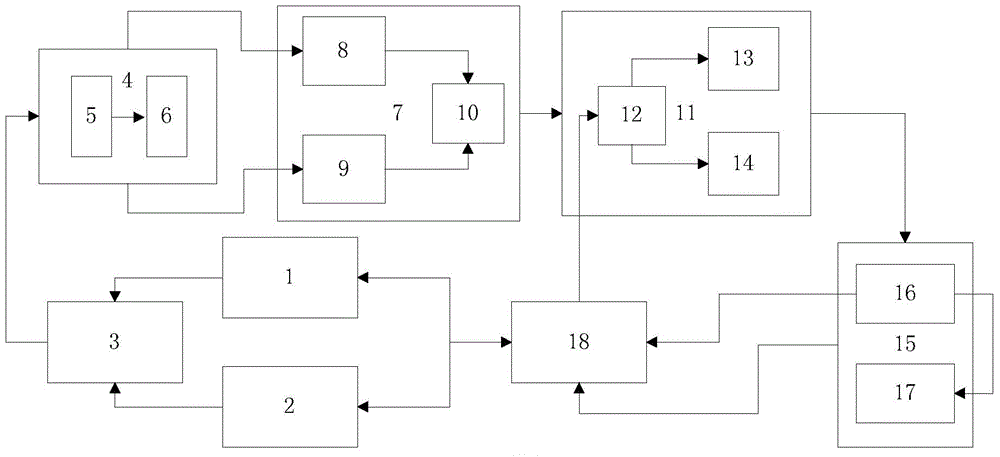

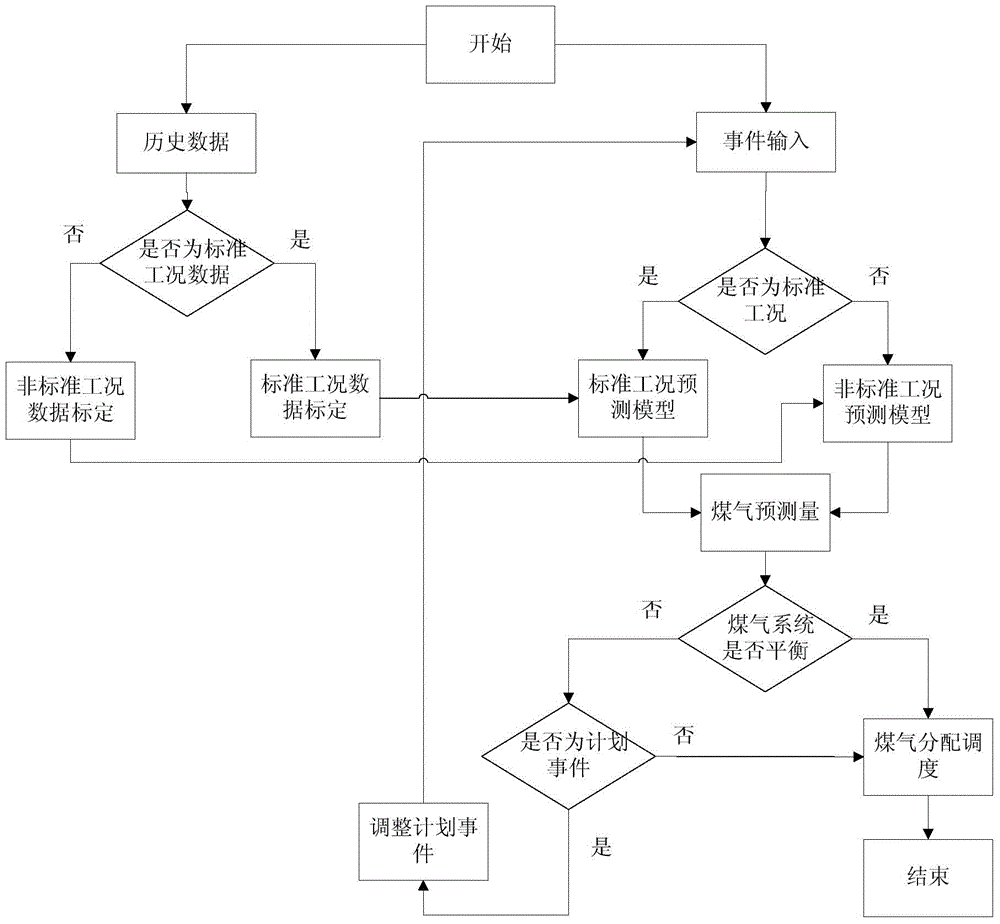

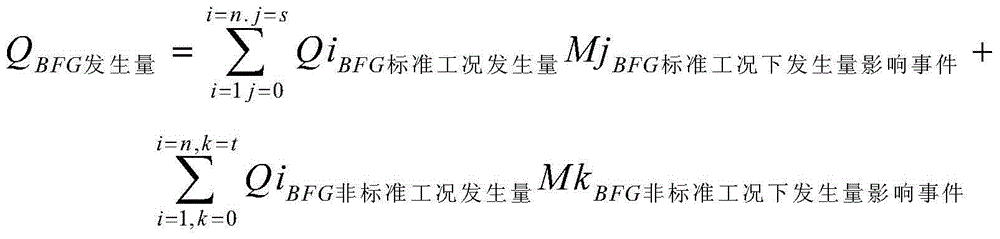

Blast furnace gas prediction balancing and scheduling system and method

ActiveCN105303243AEmission reductionImprove timelinessForecastingManufacturing computing systemsData acquisitionHot blast

The present invention provides a blast furnace gas prediction balancing and scheduling system and method. The system comprises: a blast furnace gas generation and consumption device, a system history database, a data collection and processing module, a data analysis module, a blast furnace gas prediction module, a blast furnace gas balancing and scheduling module, and a gas management and control center. The blast furnace gas generation and consumption device transmits related data and parameter to the system history database; after the data collection and processing module reads and processes the data and parameter, the data and parameter is stored to a calibration data storage sub-module after classification and calibration of the data analysis module. The blast furnace gas prediction module predicts a blast furnace gas generation amount and consumption amount within a planed event time or an emergent event time; the blast furnace gas balancing and scheduling module balances a prediction amount and optimizes a predicted gas volume; and the gas management and control center provides a scheduling solution to the blast furnace gas generation and consumption device. According to the blast furnace gas prediction balancing and scheduling system and method provided by the present invention, timeliness and accuracy of a gas prediction result may be significantly improved, and an emission amount of the blast furnace gas is reduced, thereby lowering energy consumption.

Owner:ANGANG STEEL CO LTD

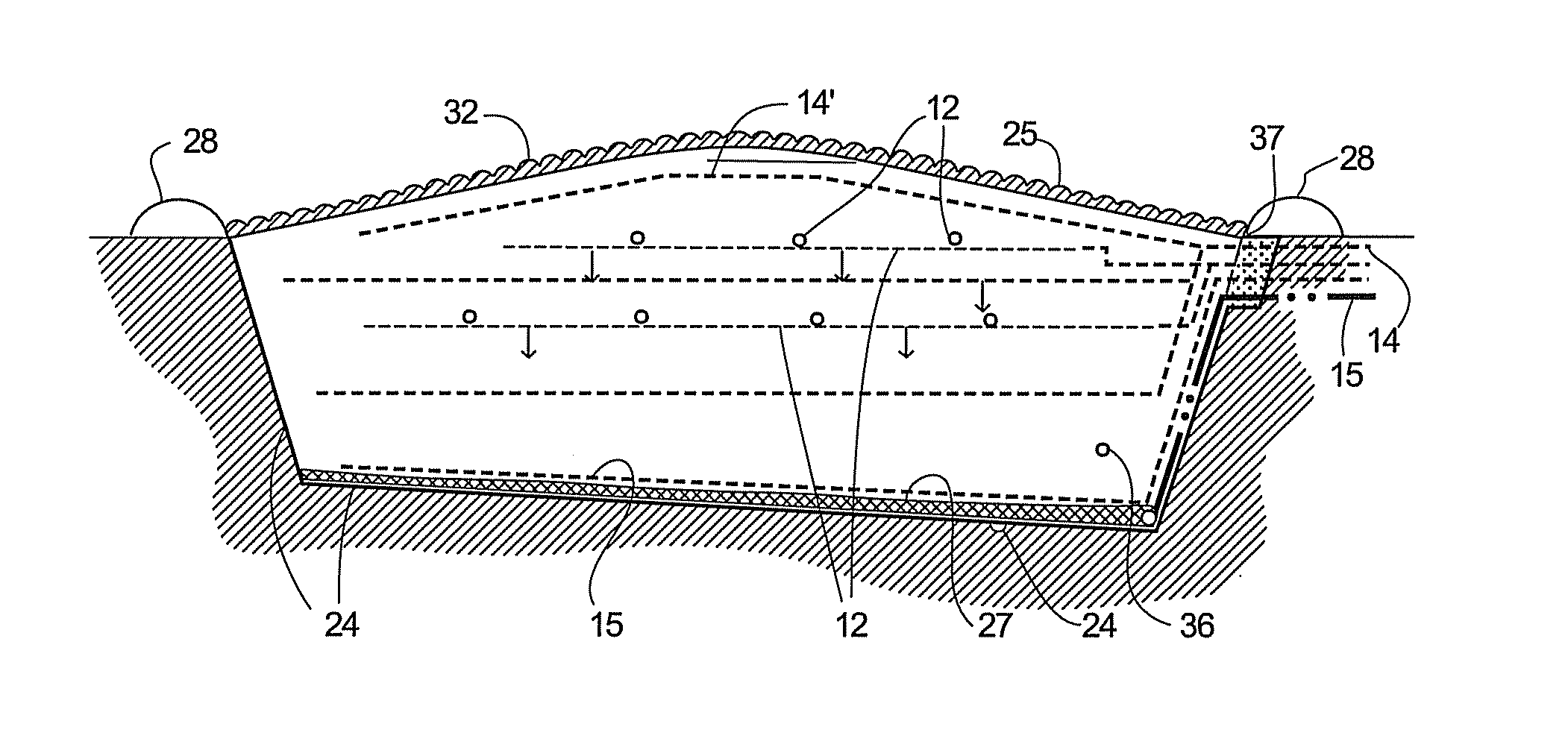

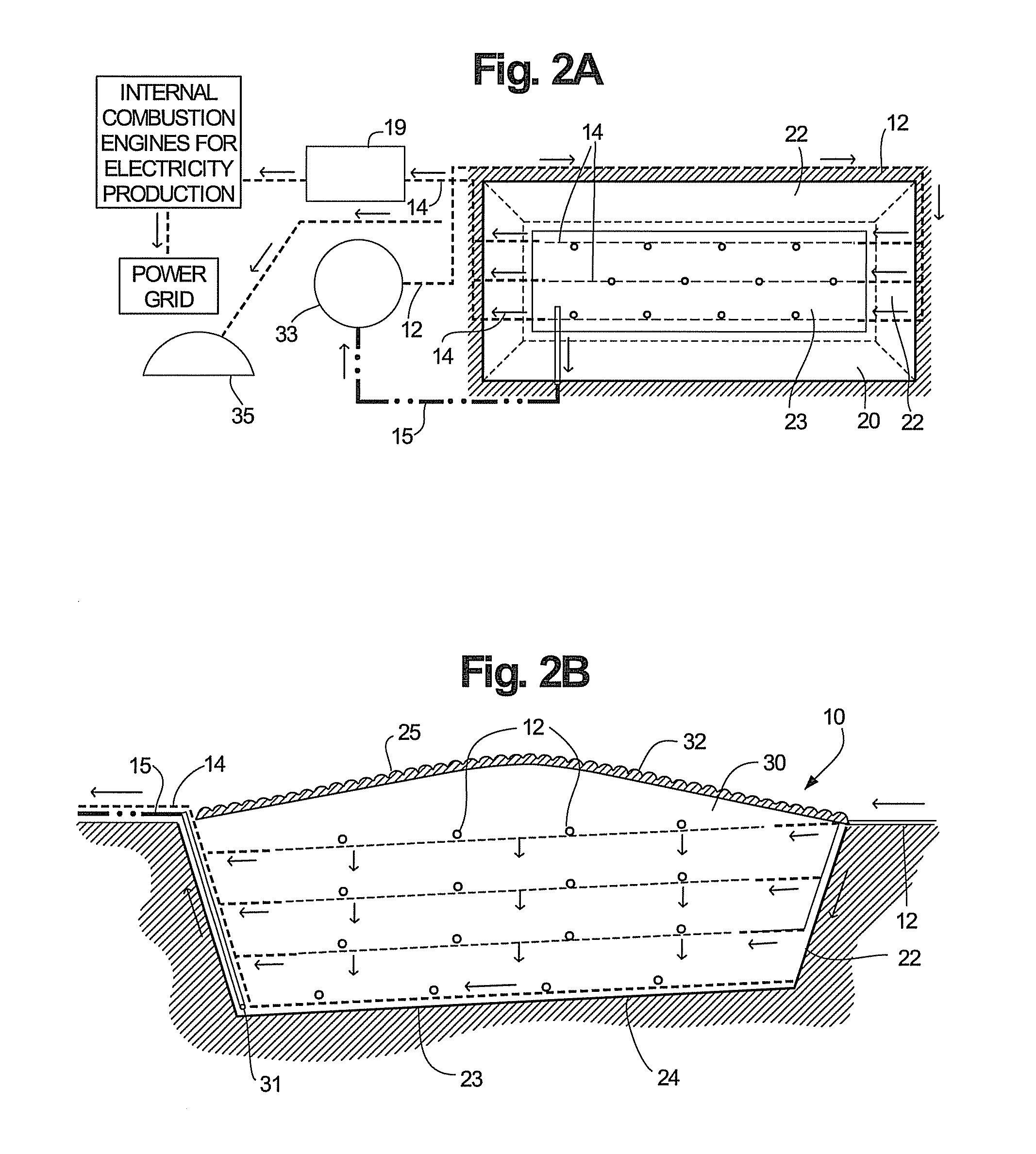

In-Situ Reclaimable Anaerobic Composter

InactiveUS20110045580A1Lower cost of capitalEconomically feasibleBioreactor/fermenter combinationsBio-organic fraction processingAnaerobic decompositionWaste management

An in-situ dry anaerobic composter containing 40% to 75% by weight solids and located in a section of ground including a pit having side walls and a bottom, an essentially impervious liner located in the pit such that the liner abuts the pit side walls and bottom to form a lined pit, a compostable material located in the lined pit and a gas management system for extracting a gaseous anaerobic decomposition product from the compostable material as well as methods for operating the anaerobic composter.

Owner:WASTE MANAGEMENT INC

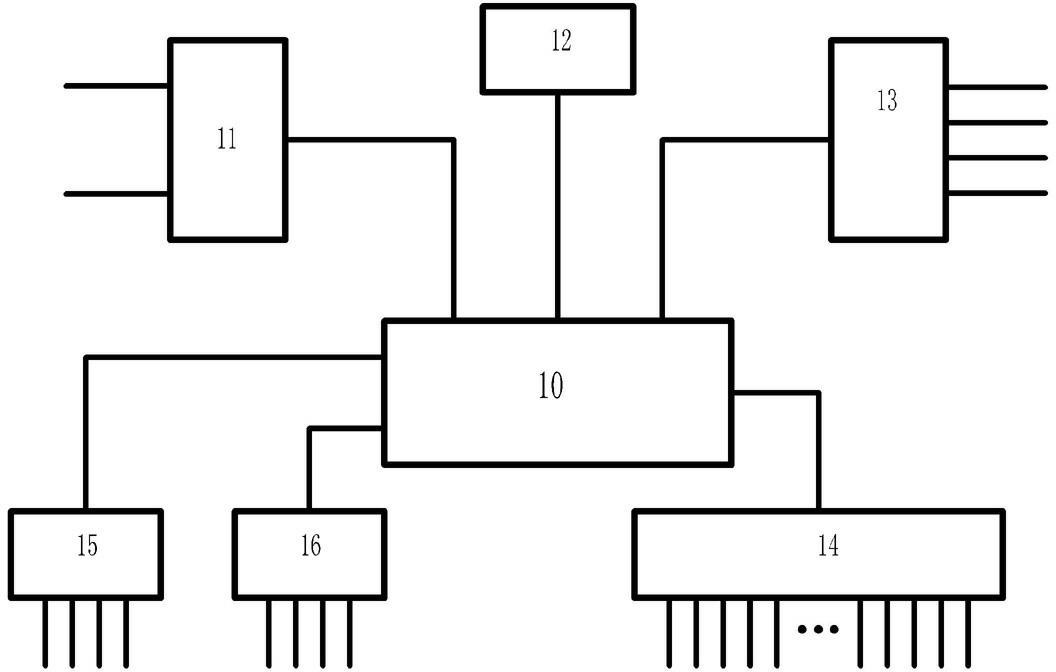

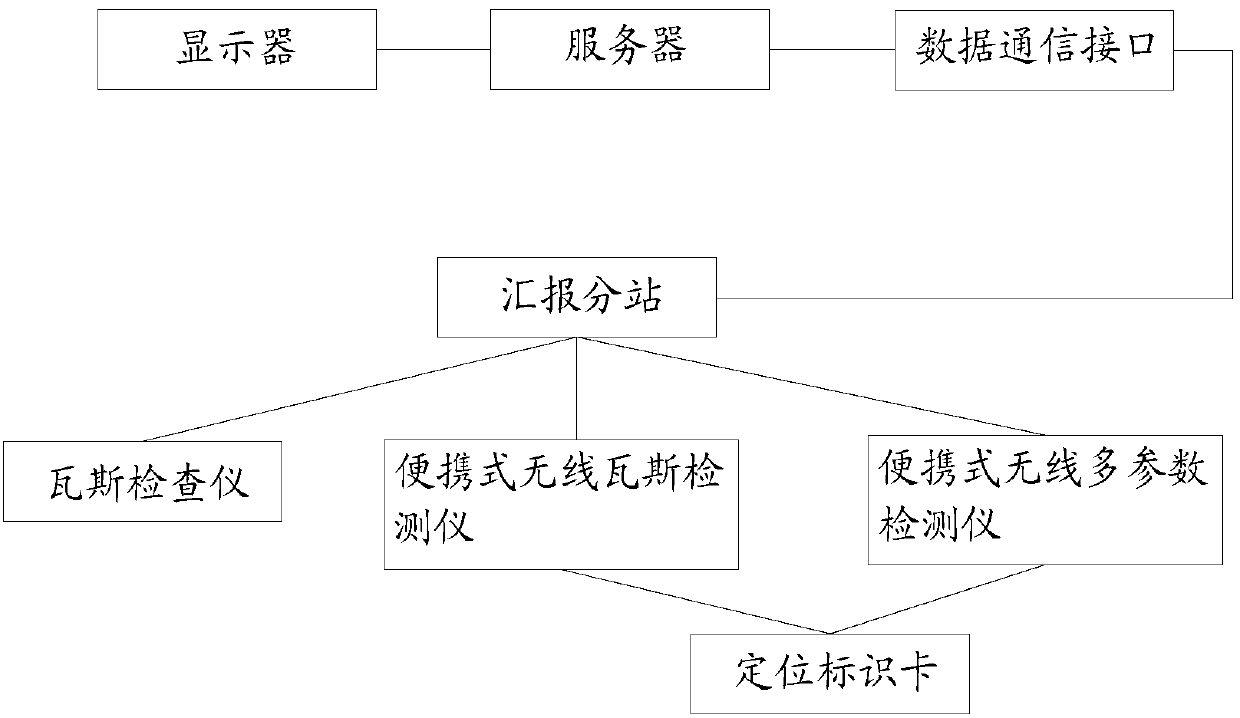

Auxiliary management system for coal mining gas

InactiveCN103277138AEliminate empty shiftsEliminate missing detectionMining devicesGas detectorEngineering

The invention discloses an auxiliary management system for coal mining gas. The auxiliary management system comprises a server disposed on the ground, a report substation located underground, a positioning marking card placed on a key gas management area, a gas inspection tester carried by a full-time gas inspector, a portable wireless gas detector and a wireless multi-parameter detector; and the portable wireless gas detector and the wireless multi-parameter detector are carried by a task managing operator. Inspection data are recorded by the gas inspection tester in distributed areas and input to the report substation. The portable wireless gas detector and the wireless multi-parameter detector communicate with the positioning marking card wirelessly. Address codes of the location of the positioning marking card and data parameters bound with the address codes are recorded and wirelessly transmitted to the substation when passing through the report substation. Real-time monitoring can be performed by the auxiliary management system, monitoring effect is good, and out-of-duty, missing inspection and weak responsibility of the gas inspector are avoided thoroughly fundamentally.

Owner:王珂

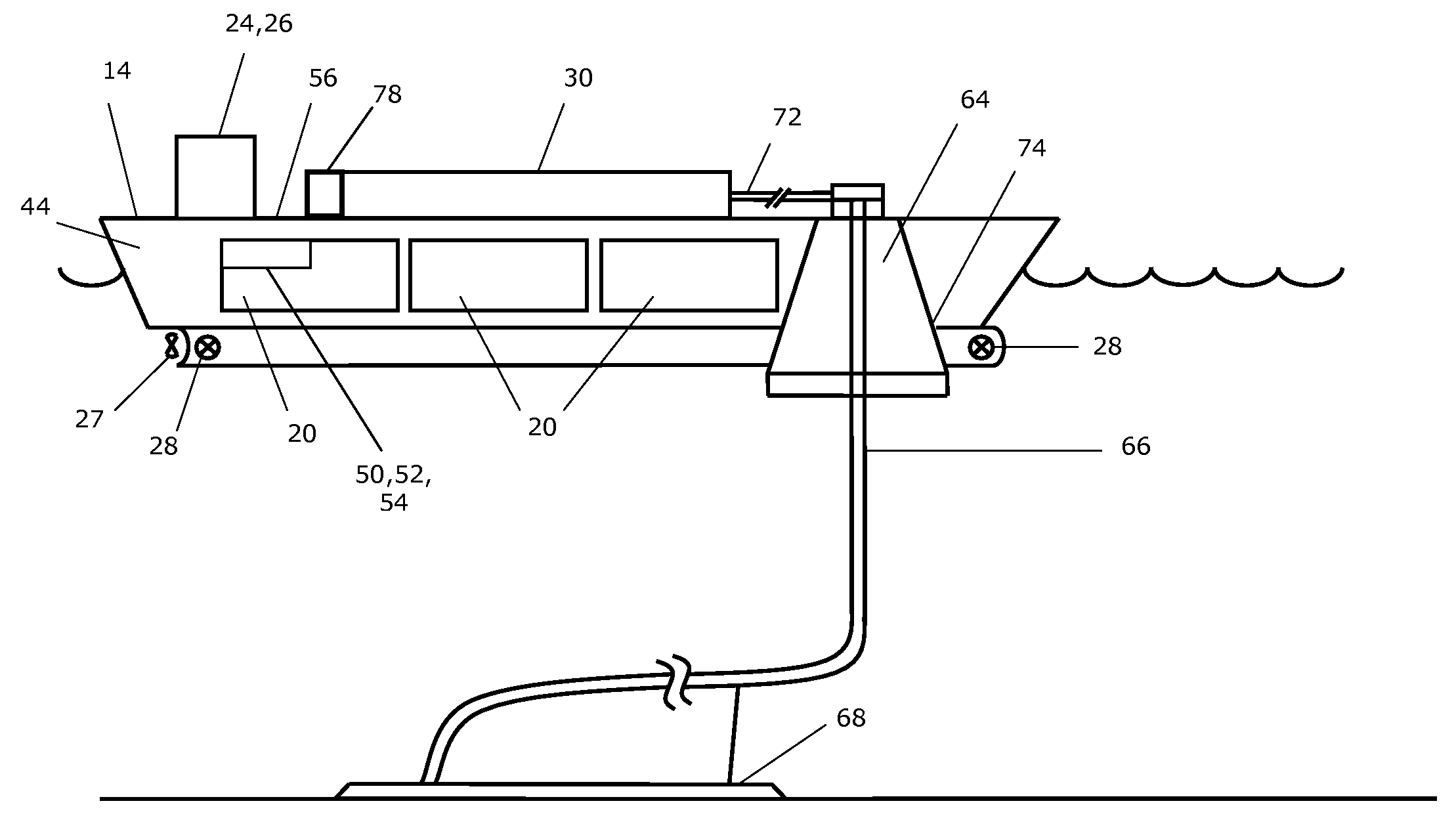

Boil off gas management during ship-to-ship transfer of LNG

InactiveUS20090199575A1Reduce pressureReduce environmental impactAuxillariesGas handling applicationsMarine engineeringStorage tank

The present invention relates to a process and system for managing boil-off gas generated during ship-to-ship transfer of LNG at sea. The LNG is transferred from a storage tank onboard a delivery vessel to a storage tank onboard a receiving vessel. The process includes the steps of a) operating the receiving vessel storage tank at a pressure greater than the operating pressure of the delivery vessel storage tank; and, b) transferring a portion of the boil-off gas from the receiving vessel storage tank to the delivery vessel storage tank onboard.

Owner:WOODSIDE ENERGY

Intelligent gas meter with water inlet detection function

The invention discloses an intelligent gas meter with a water inlet detection function. A terminal computer is arranged outside the intelligent gas meter. The intelligent gas meter comprises a base meter body, wherein a controller unit, an A / D conversion chip, a pressure sensor, a wireless transceiver module and a control valve are arranged inside the base meter body. The input end of the A / D conversion chip is connected with the pressure sensor, and the output end of the A / D conversion chip is connected with the input end of the controller unit. The information of pressure inside the base meter body generated when gas passes through is acquired by the pressure sensor, and the pressure information is converted into a corresponding detection signal which is then input into the terminal computer through the controller unit. The abnormal condition threshold ranges of pressure and periodical service life corresponding to the base meter body are preset in the terminal computer to be used for being compared with the pressure information contained in the pressure detection signal from the pressure sensor, and the control valve is controlled to be opened or closed through a valve driving circuit according to the comparison result so that a gas inlet valve of the gas meter can be opened or closed. When it is detected that water enters the gas meter, the gas meter gives an alarm or feeds the information back to a gas management system, so that loss is avoided.

Owner:四川鹏翔电子科技有限责任公司

Chemical vapor deposition equipment and method for preparing graphene film

The invention discloses chemical vapor deposition equipment for preparing a graphene film. The equipment comprises an incoming gas management system, a gas conversion chamber, a graphene film growing chamber, a vacuum system and a graphite rod arranged in the gas conversion chamber which are in sequential and sealed series connection, wherein a gap between the graphite rod and the inner wall of the gas conversion chamber is 0.5-2mm. According to the equipment disclosed by the invention, with the graphite rod in the gas conversion chamber, the non-flammable and non-explosive gases such as carbon dioxide gas are reduced into carbon monoxide gas which can grow into a graphene film at high temperature; and after that, a graphene film is deposited and grown on a metal substrate in the graphene film growing chamber. In the invention, the non-flammable and non-explosive gases are adopted as the reaction gas and carrier gas for graphene film preparation; and compared with the existing graphene film preparation method adopting flammable and explosive hydrocarbon and hydrogen as the reaction gas and carrier gas, the safety of the technology is remarkably improved, the production cost is reduced, and large-scale production can be realized.

Owner:李雪松

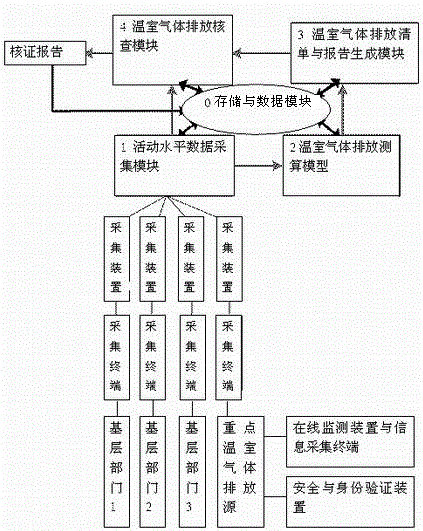

Greenhouse gas management system

InactiveCN104616094ARealize remote online verificationLow costTechnology managementResourcesThird partyEnvironmental resource management

The invention belongs to the technical field of environmental protection and greenhouse gas control, and relates to a greenhouse gas management system which comprises a storage and data module, a movable horizontal data acquisition module, a greenhouse gas emission measurement and calculation module, a greenhouse gas emission list and report generation module and a greenhouse gas emission inspection module. A greenhouse gas movable horizontal data acquisition device based on internal organization departments can remotely inspect organization greenhouse gas emission online, greenhouse gas emission inspection cost is reduced, acquiring greenhouse gas emission of internal organization departments, measuring and calculating, generating lists and reports and performing third party inspection can be integrated by the aid of the bottommost original data, and automation and efficiency of organization greenhouse gas emission management are improved.

Owner:宁夏清洁发展机制环保服务中心(有限责任公司)

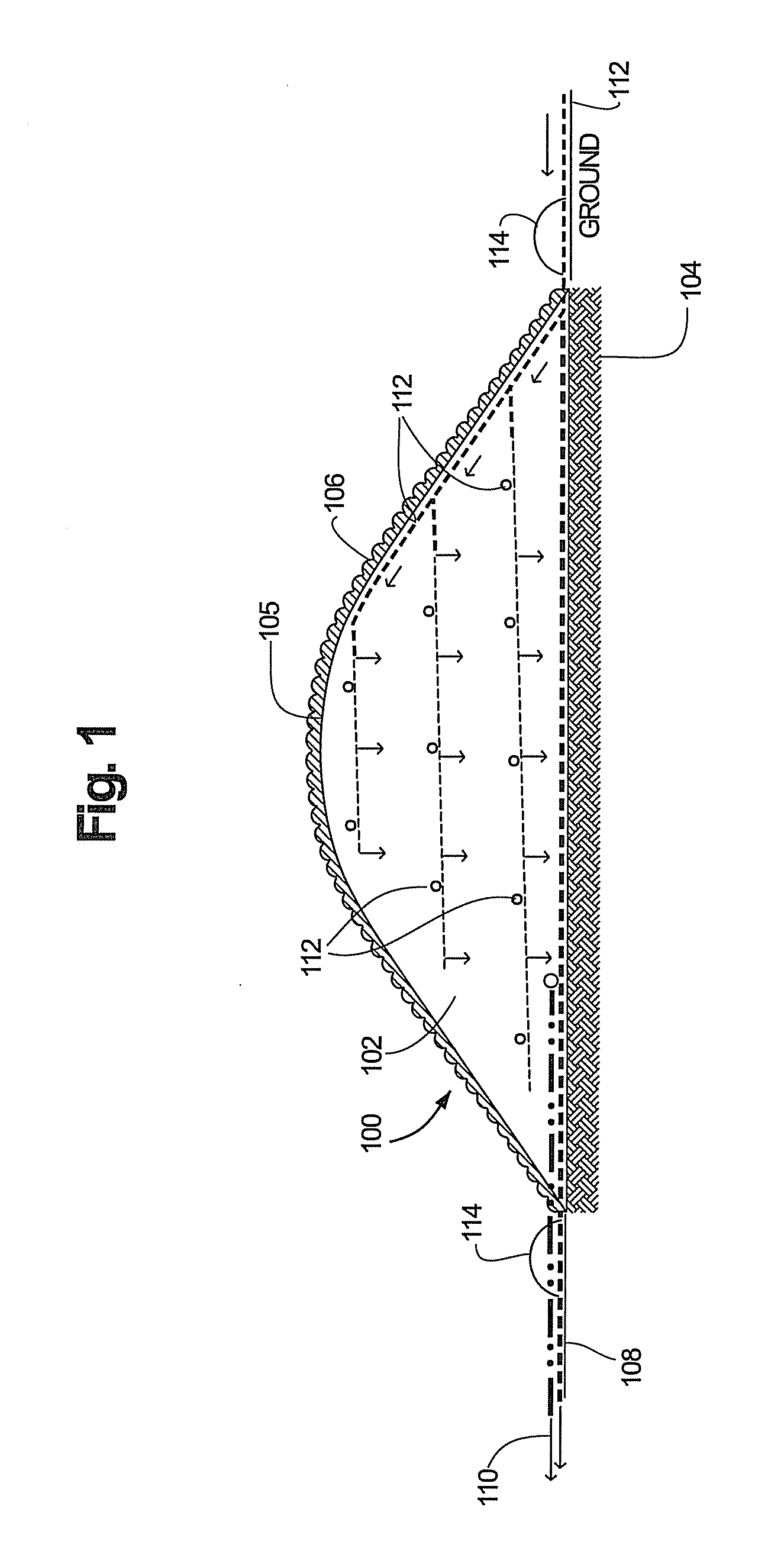

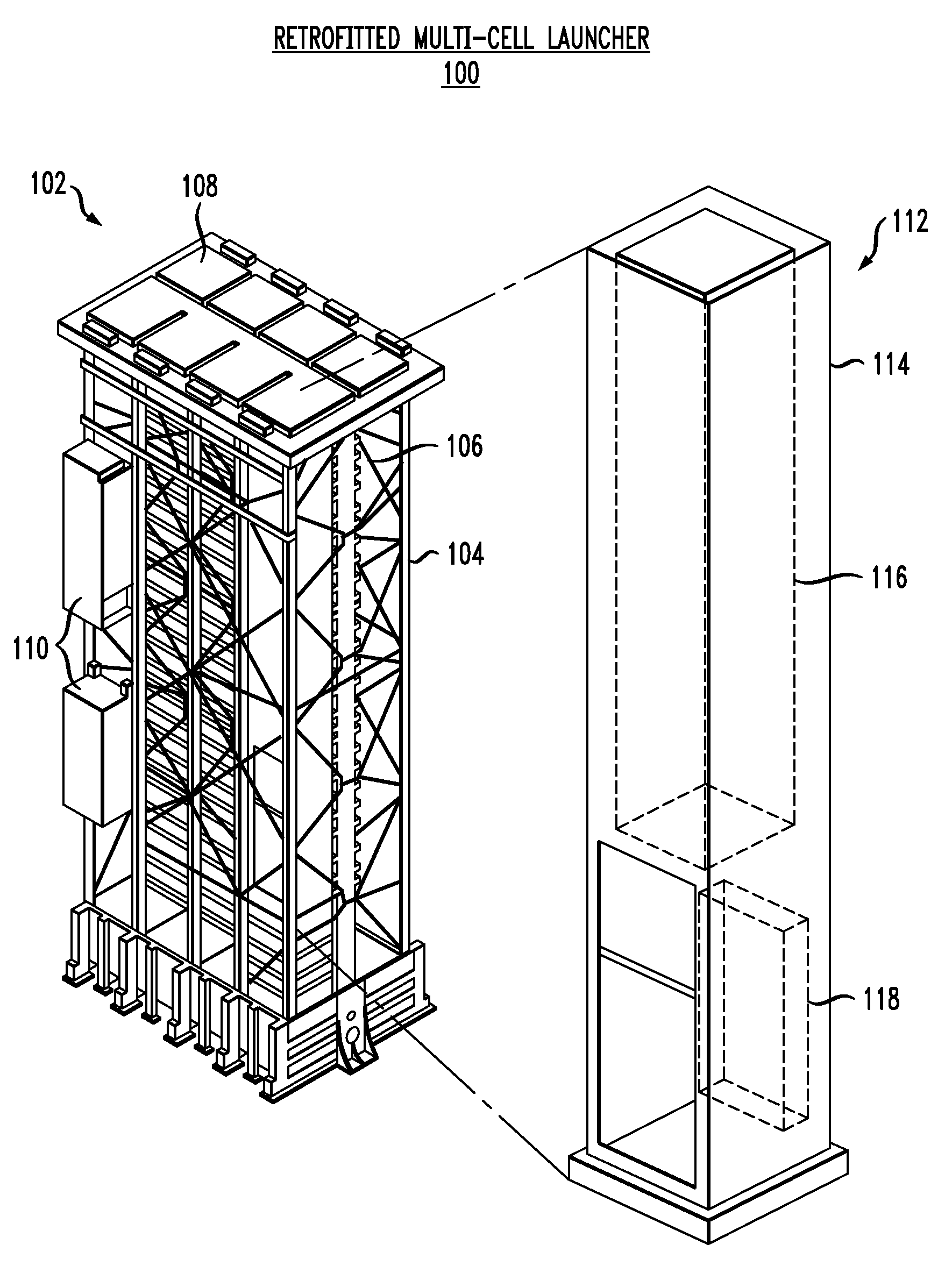

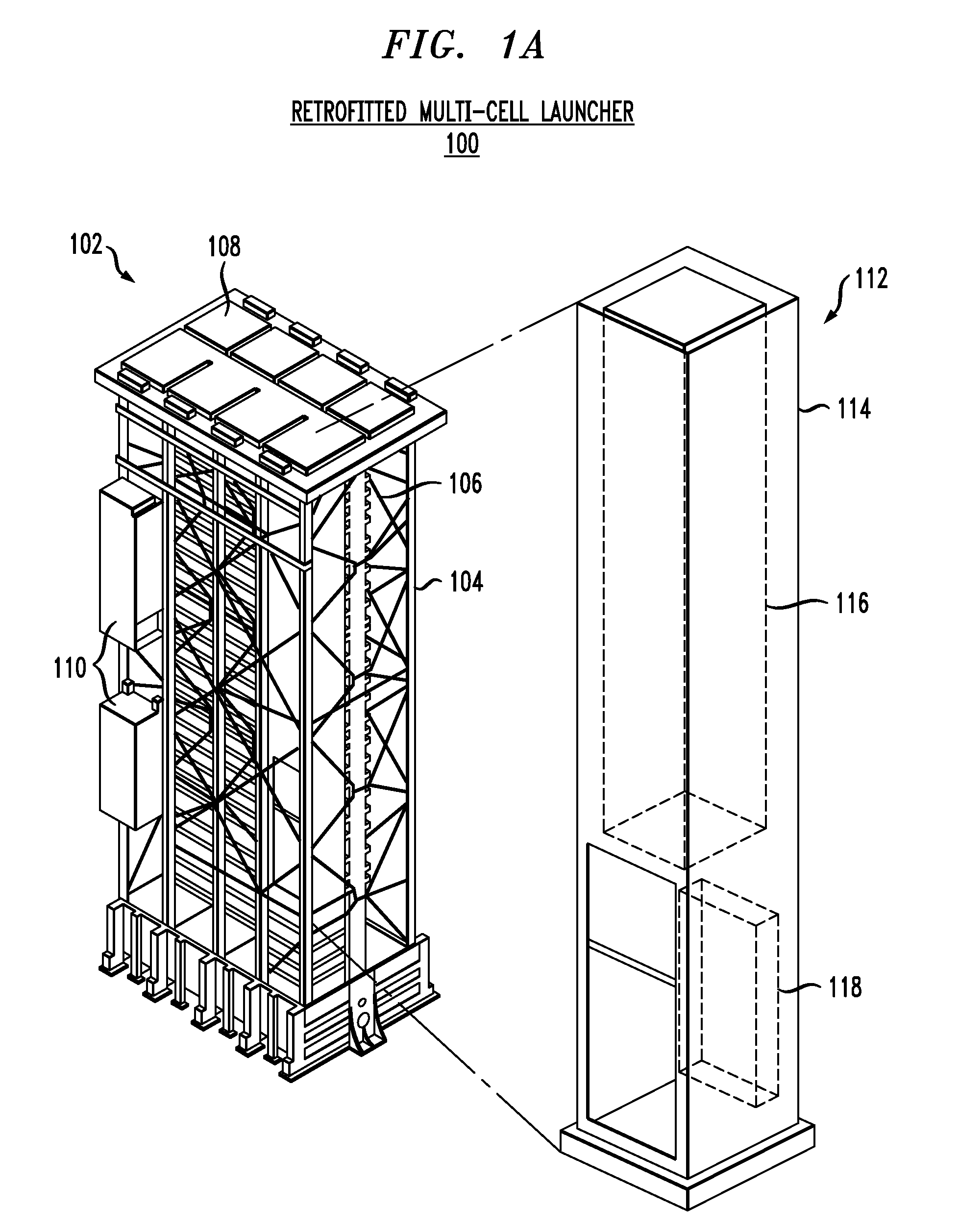

Self-Contained Munition Gas Management System

An apparatus is disclosed that is a self-contained gas management system (hereinafter “GMS”) that accommodates individual canisters of highly energetic small munitions, but is not so limited. By decoupling the gas management system for a given munition from an adjacent munition, the risk of downing a multi-pack launcher or munition adapter is reduced. Thermal wear, overheating, restrained firing and aft closure debris can be isolated through the separation of gas management systems. In addition, the GMS allows for ease of replenishment and maintenance of a given sub-cell of a multi-pack system. The GMS works with existing munitions and canisters without the need to modify them. Each GMS is dimensioned to fit the canistered munition it receives as well as the launch system with which it is used. The illustrative GMS comprises a plenum, and a first and a second uptake structure. The plenum receives the exhaust from the canistered munition when the munition fires. The plenum is fluidically coupled to the first and second uptake structures. The uptake structures in the illustrative embodiment receive the missile exhaust from the plenum and vent the exhaust to the atmosphere. In the illustrative embodiment, the first and second uptake structures are disposed along opposite sides of the canistered munition, flanking it.

Owner:LOCKHEED MARTIN CORP

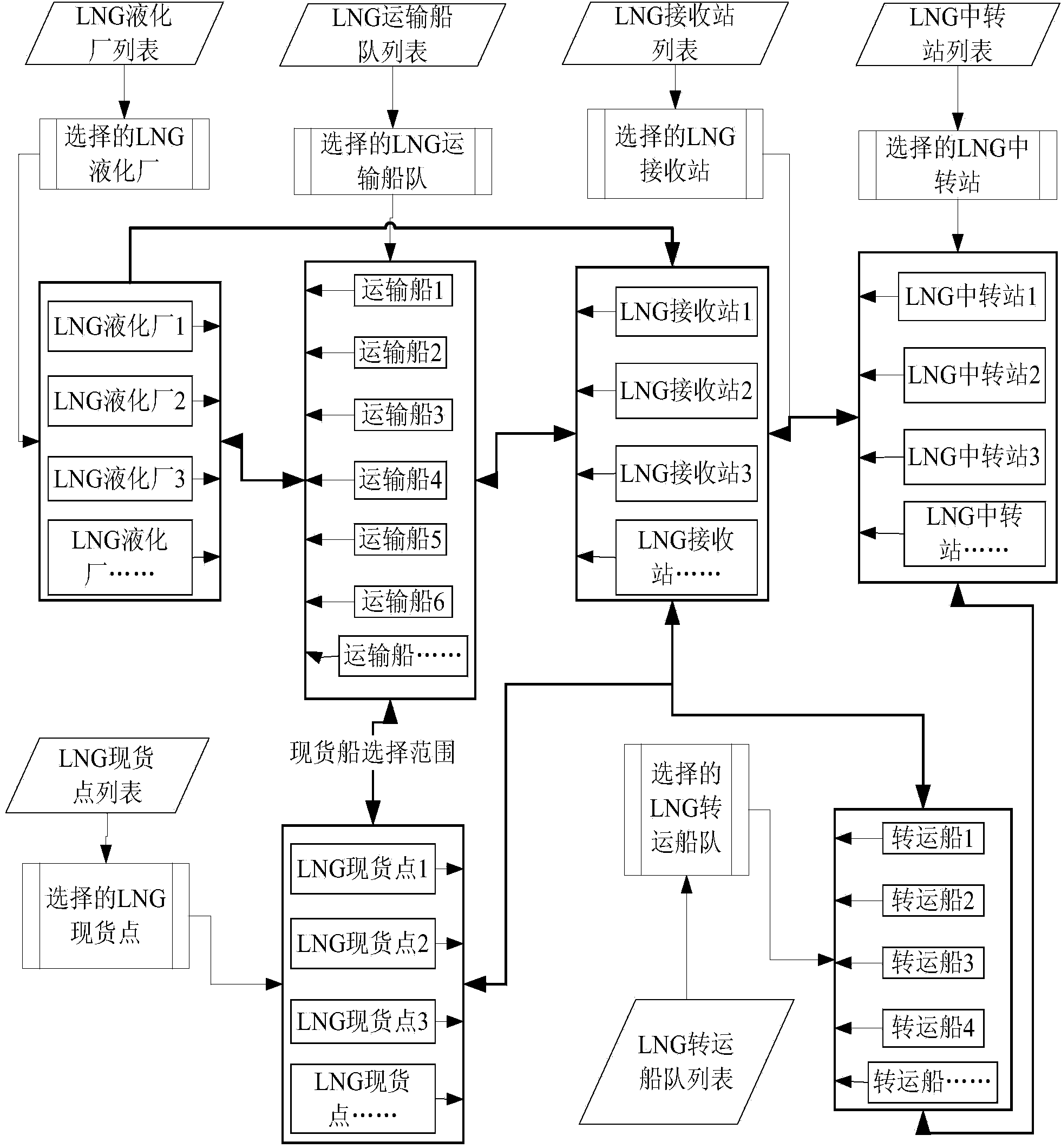

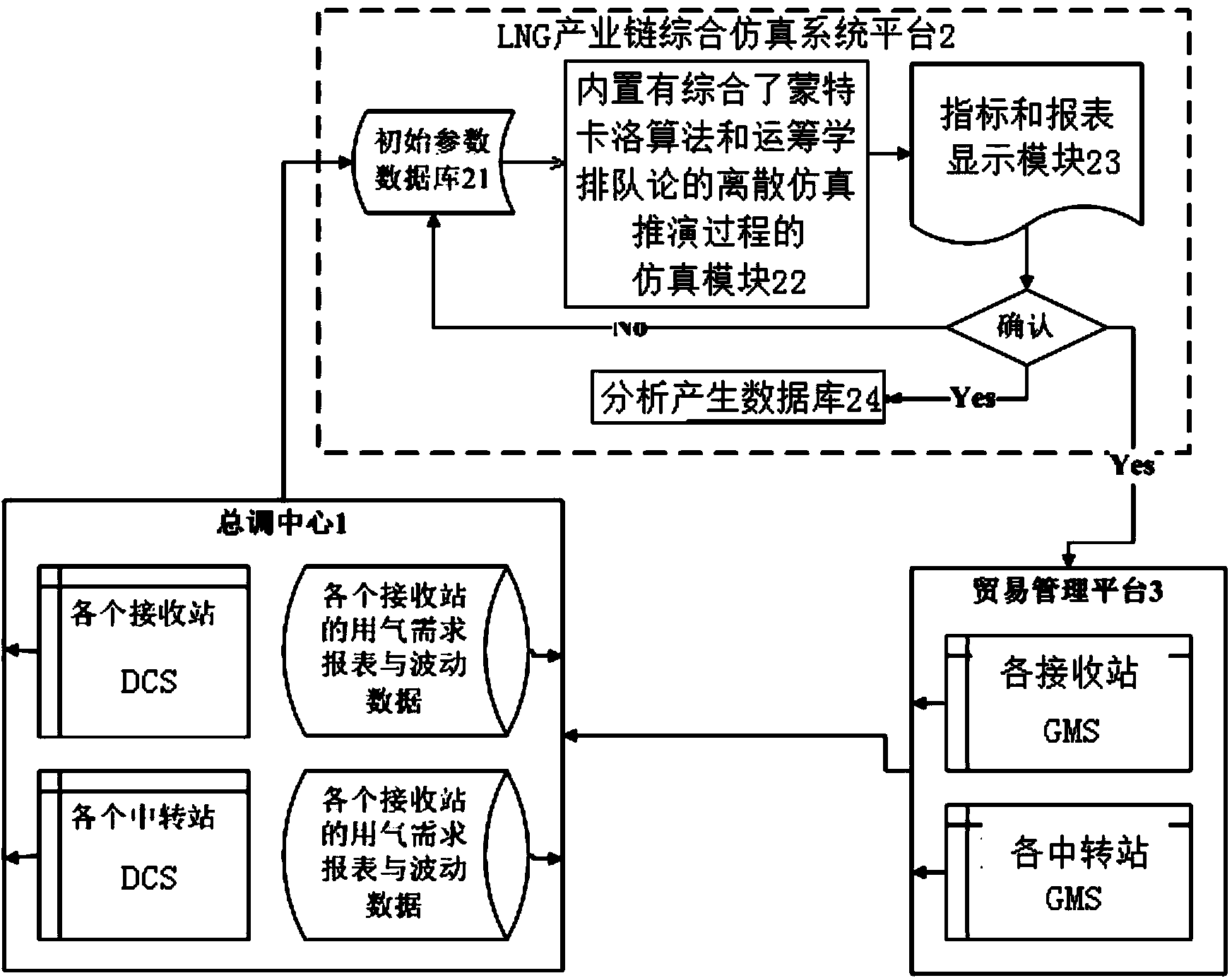

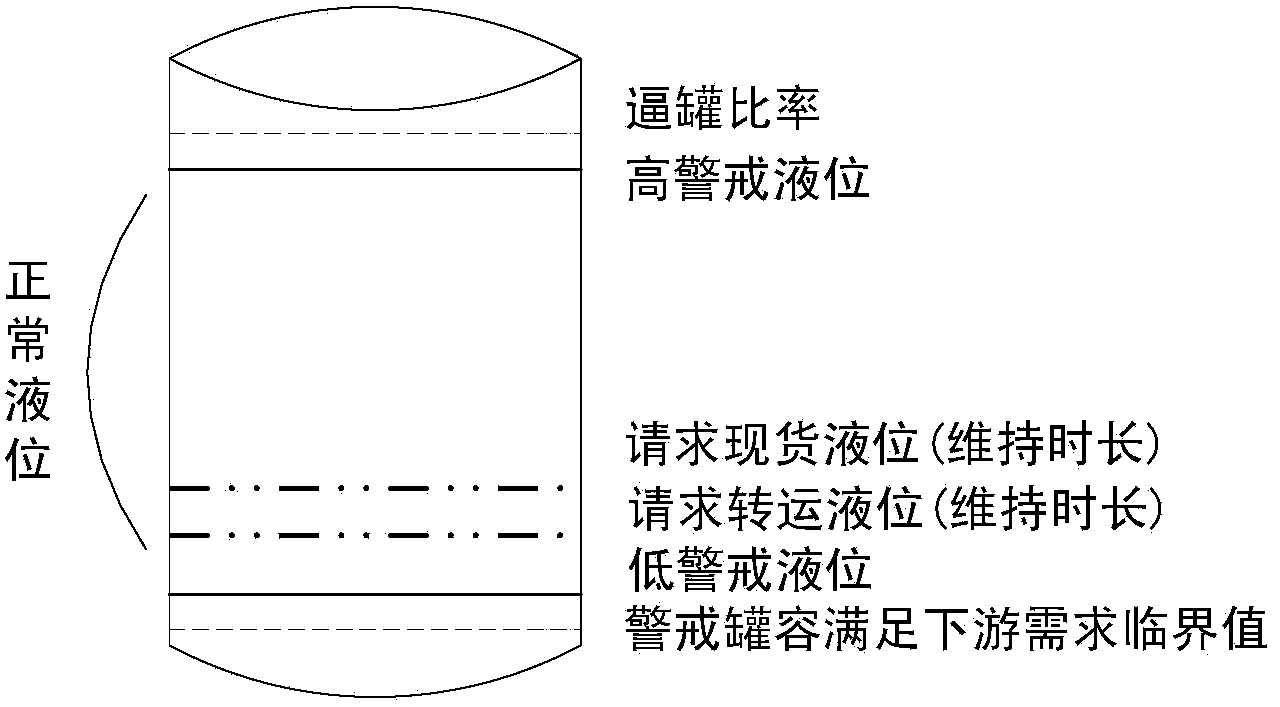

Network type LNG (liquefied natural gas) industrial chain integrated prediction and scheduling method

ActiveCN103632234AImprove predictive dispatch speedImprove accuracyResourcesAnalysis dataDistribution control

The invention relates to a network type LNG (liquefied natural gas) industrial chain integrated prediction and scheduling method which includes the steps of (1) setting a network type LNG industrial chain integrated prediction and scheduling system, (2) inputting various original data to an initial parameter database of a simulation system platform in advance, (3) by the simulation system platform, collecting and updating data information of the initial parameter database through DCS (distribution control system) of various receiving stations and transfer stations, (4) starting a simulation module by the simulation system platform to perform simulation deduction, (5) displaying the simulation deduction results by index and report display modules, (6) transmitting the simulation deduction results to a trade management platform by the simulation system platform, and then sending the results to GMS(gas management system) terminals of the receiving stations and the transfer stations via the trade management platform so as to generate the scheduling plan of the home station. The network type LNG industrial chain integrated prediction and scheduling system comprises a master scheduling center, the simulation system platform and the trade management platform; the master scheduling center is connected with the DCS of the receiving stations and the transfer stations, the trade management platform is connected with the GMS of the receiving stations and the transfer stations; the simulation system platform comprises an initial parameter database, the simulation module, the index and report display module and an analysis database.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com