Blast furnace gas prediction balancing and scheduling system and method

A blast furnace gas and scheduling system technology, which is applied in forecasting, manufacturing computing systems, data processing applications, etc., can solve the problem that it is difficult to ensure accuracy, does not consider the difference between the gas generation process and the gas consumption process, and does not consider the gas generation process. It can improve the timeliness and accuracy, reduce the amount of emission, and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

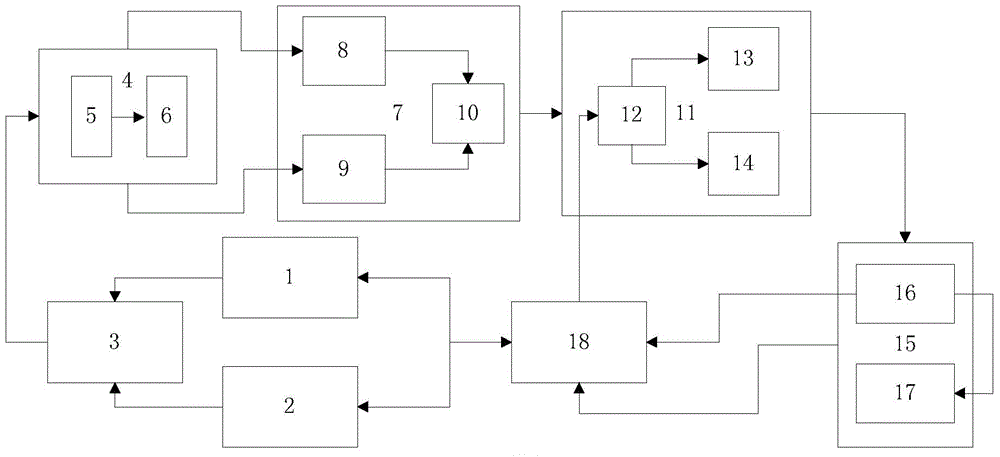

[0029] Depend on figure 1 It can be seen that the blast furnace gas prediction and balance scheduling system of the present invention is mainly composed of blast furnace gas generating equipment 1, blast furnace gas consumption equipment 2, system history database 3, data acquisition and processing module 4, data analysis module 7, blast furnace gas prediction module 11, blast furnace gas The balance scheduling module 15 and the gas control center 18 are composed.

[0030] The data acquisition and processing module 4 is composed of a data acquisition sub-module 5 and a data de-interference sub-module 6. The data analysis module 7 is composed of a gas generation calibration sub-module 8, a gas consumption calibration sub-module 9 and a calibration data storage sub-module 10. The blast furnace The gas prediction module 11 is composed of a plan and emergency submodule 12 , an occurrence prediction submodule 13 and a consumption prediction submodule 14 , and the blast furnace gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com