Patents

Literature

34results about How to "Economically feasible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

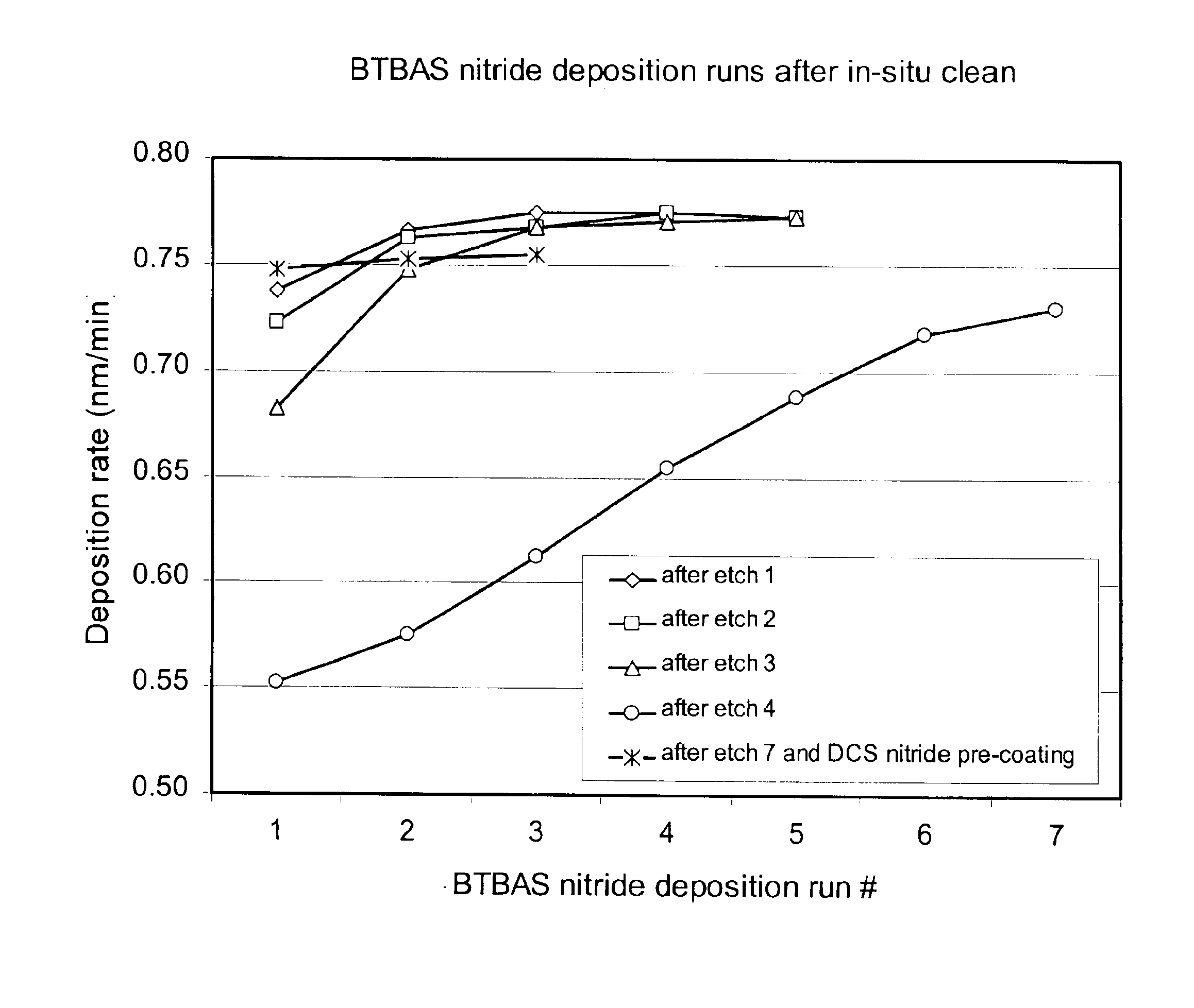

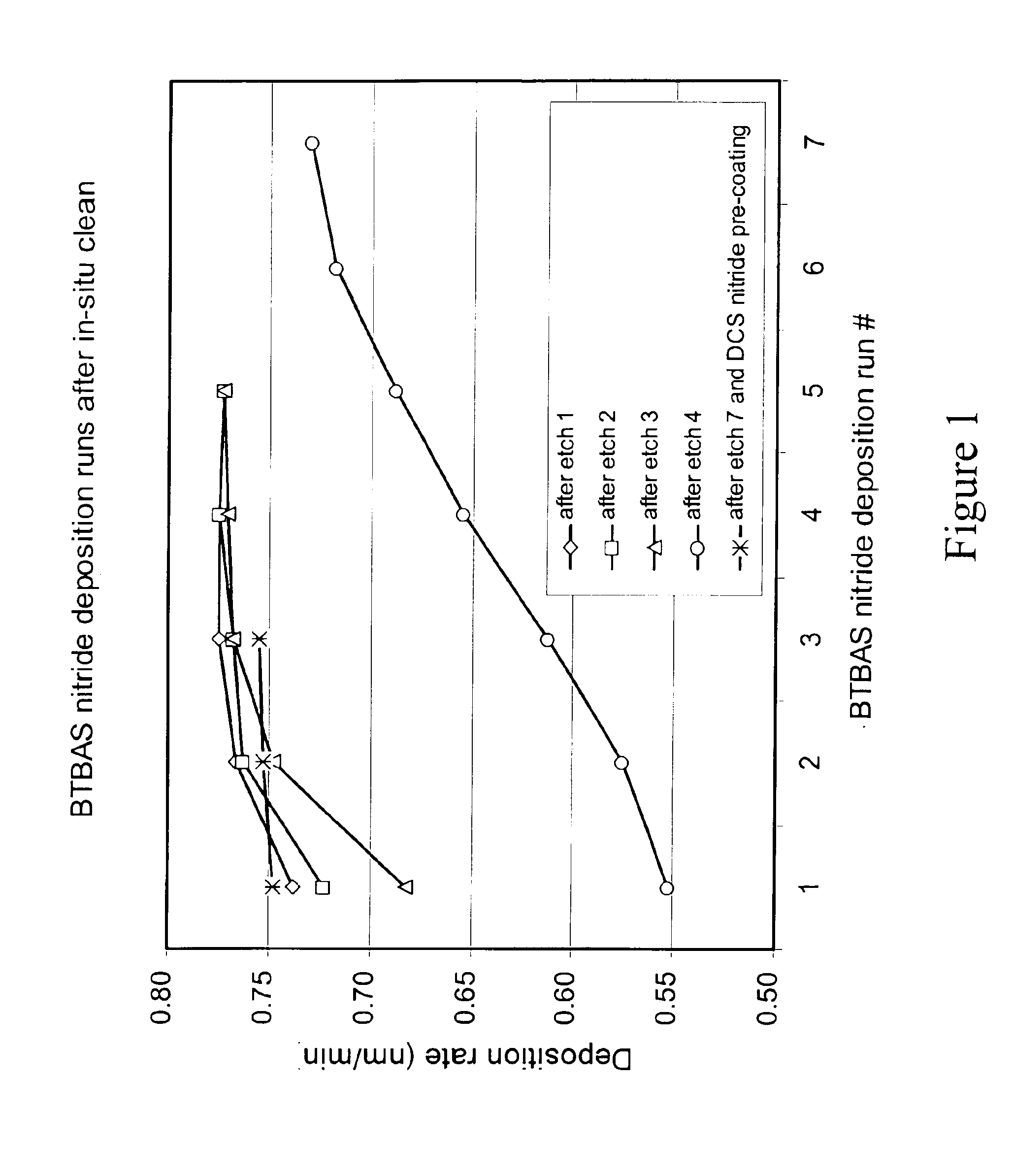

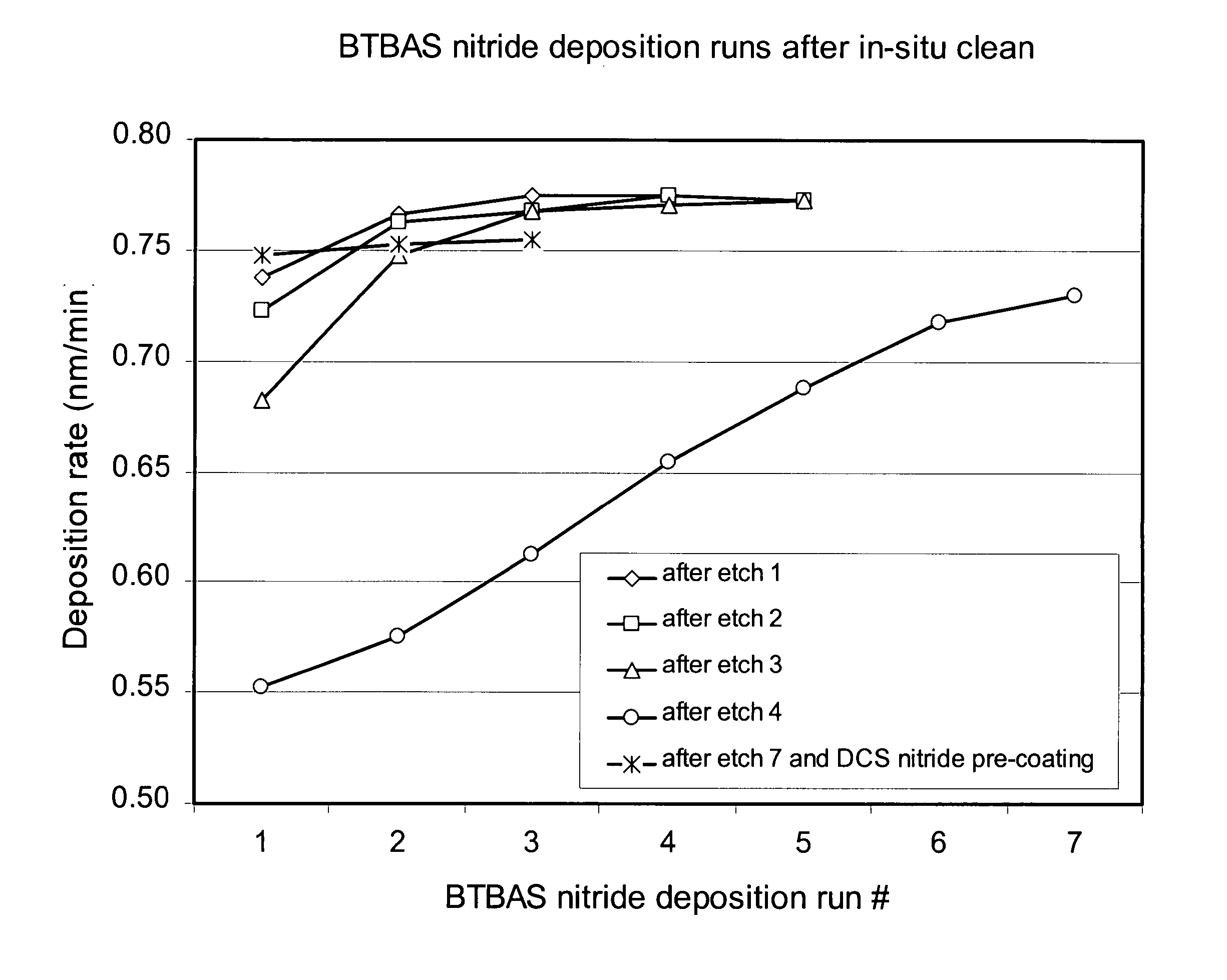

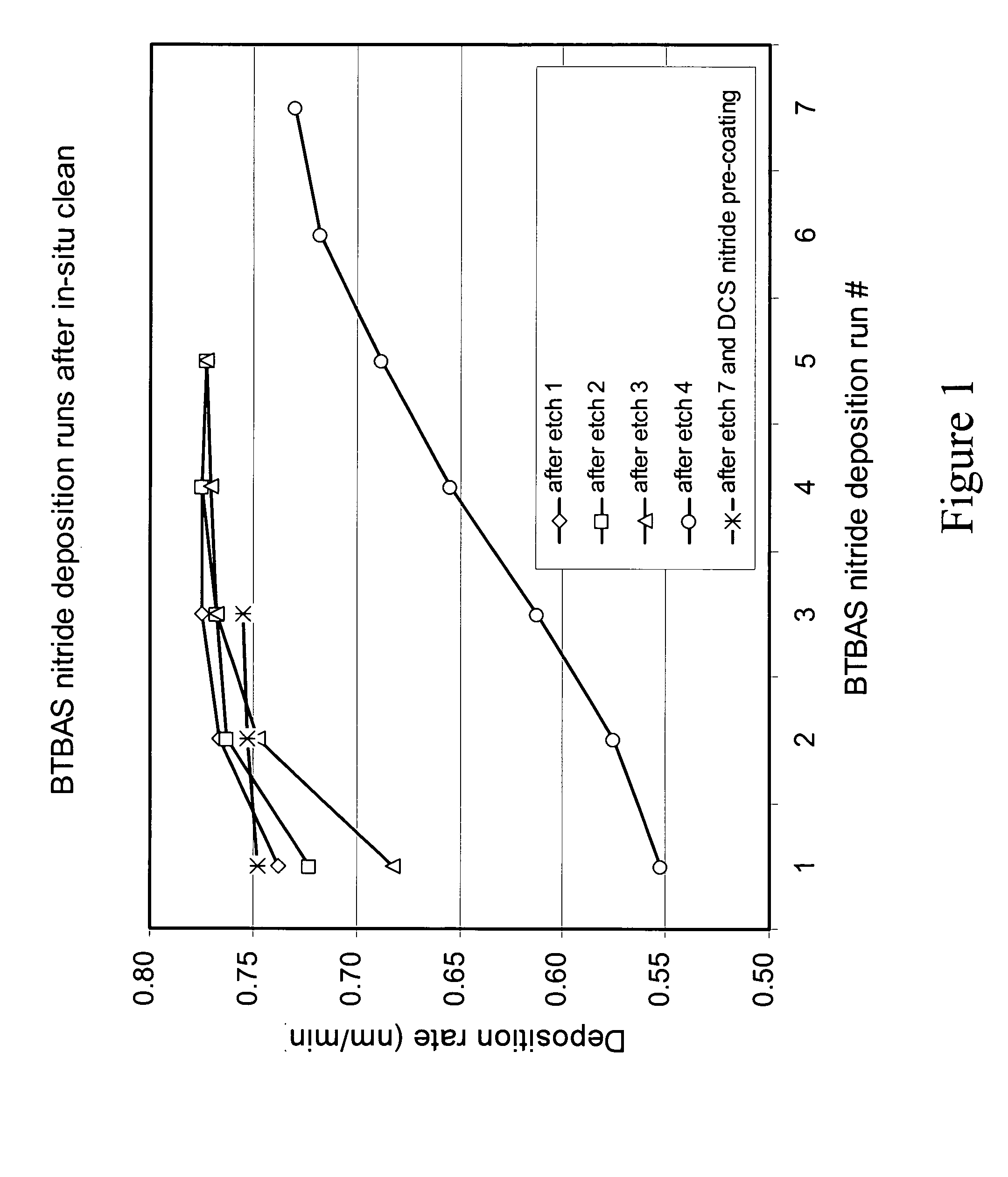

Reactor precoating for reduced stress and uniform CVD

InactiveUS6974781B2Reduce the probability of depositionIncreasing and maintaining deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingInorganic compositionOrganic layer

Owner:ASM INTERNATIONAL

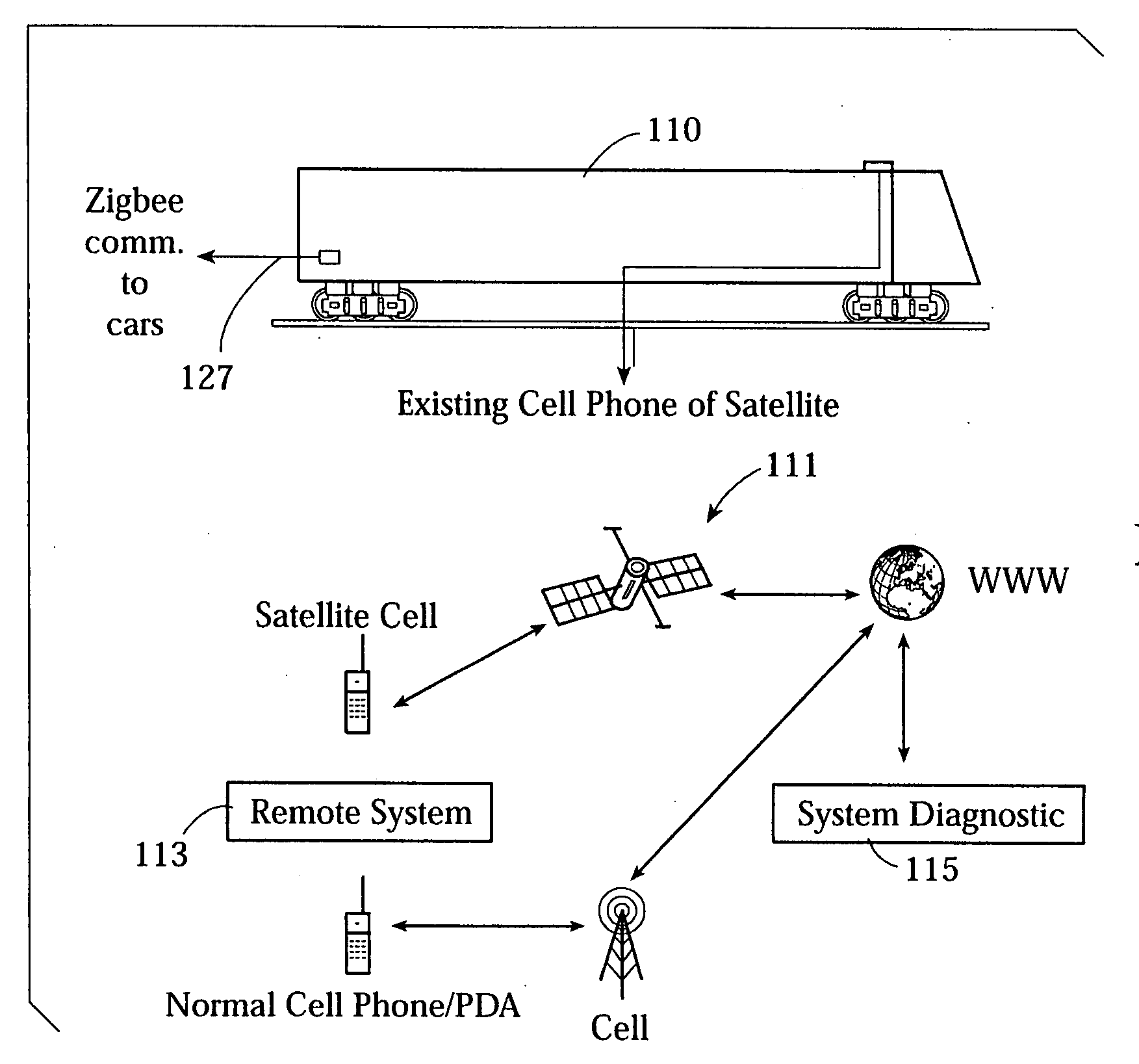

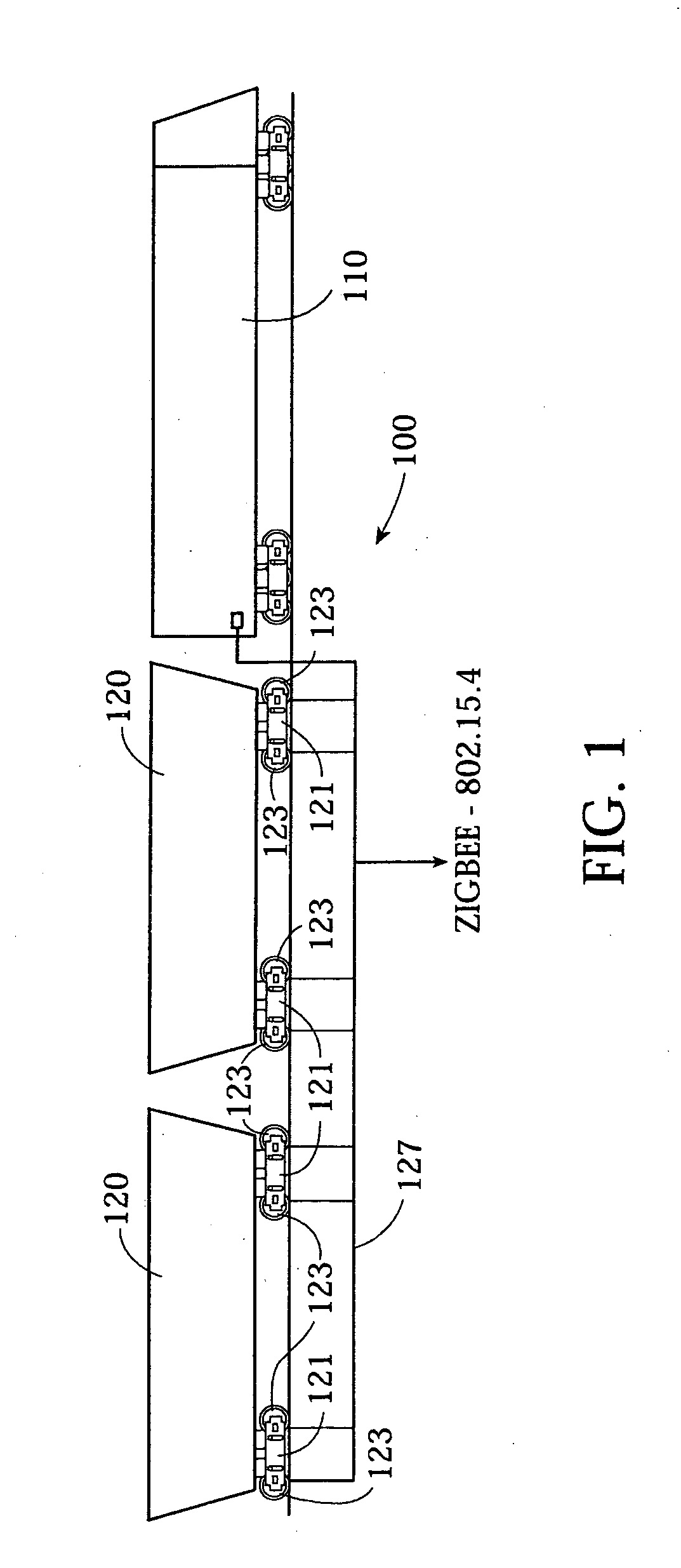

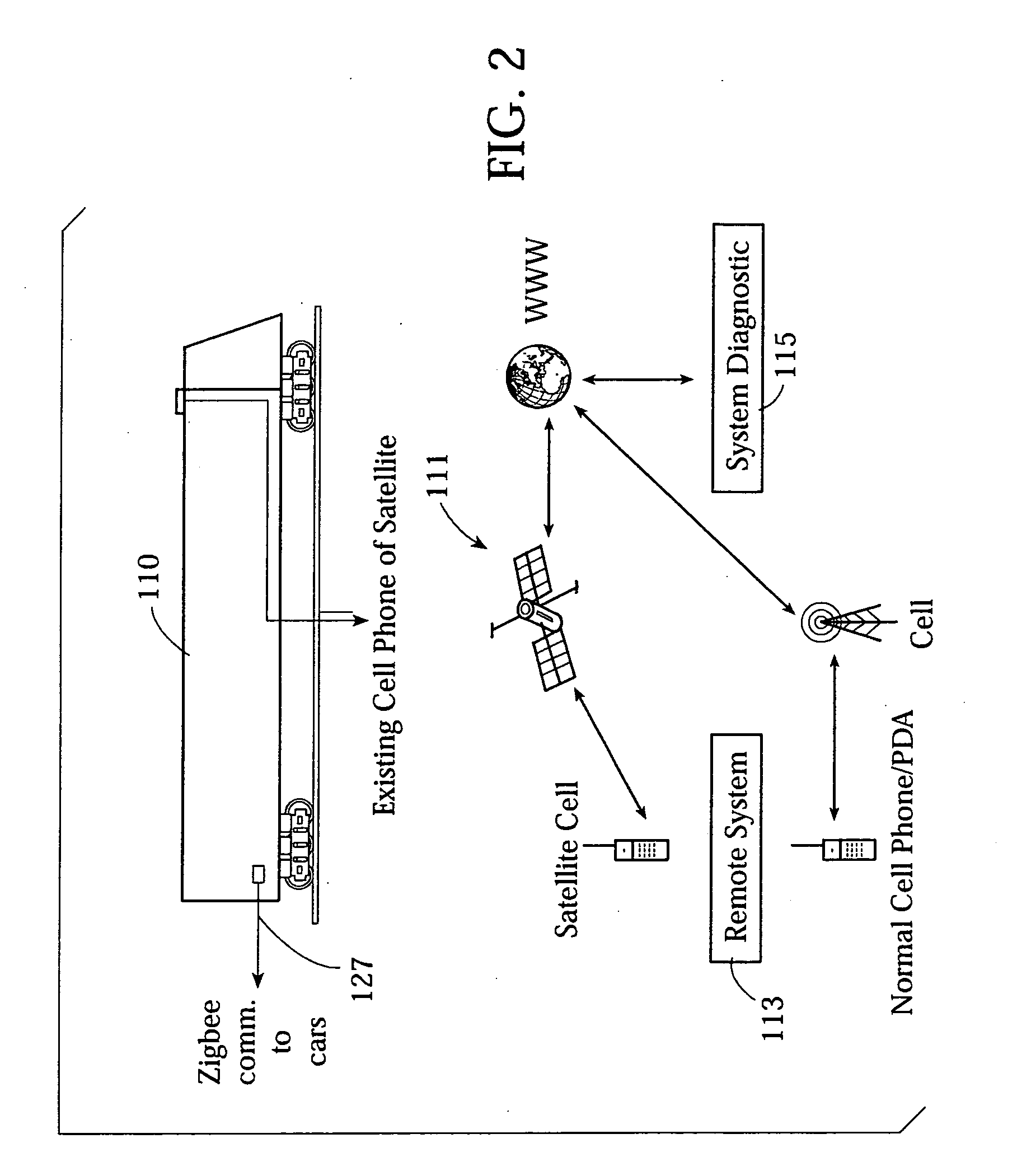

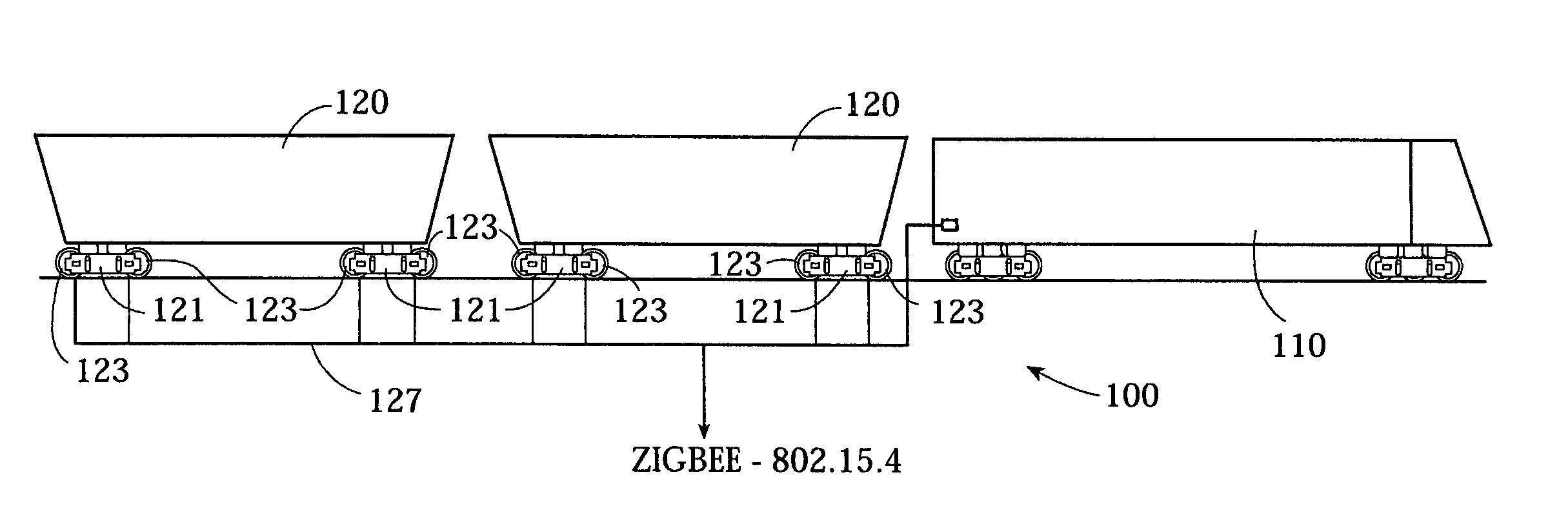

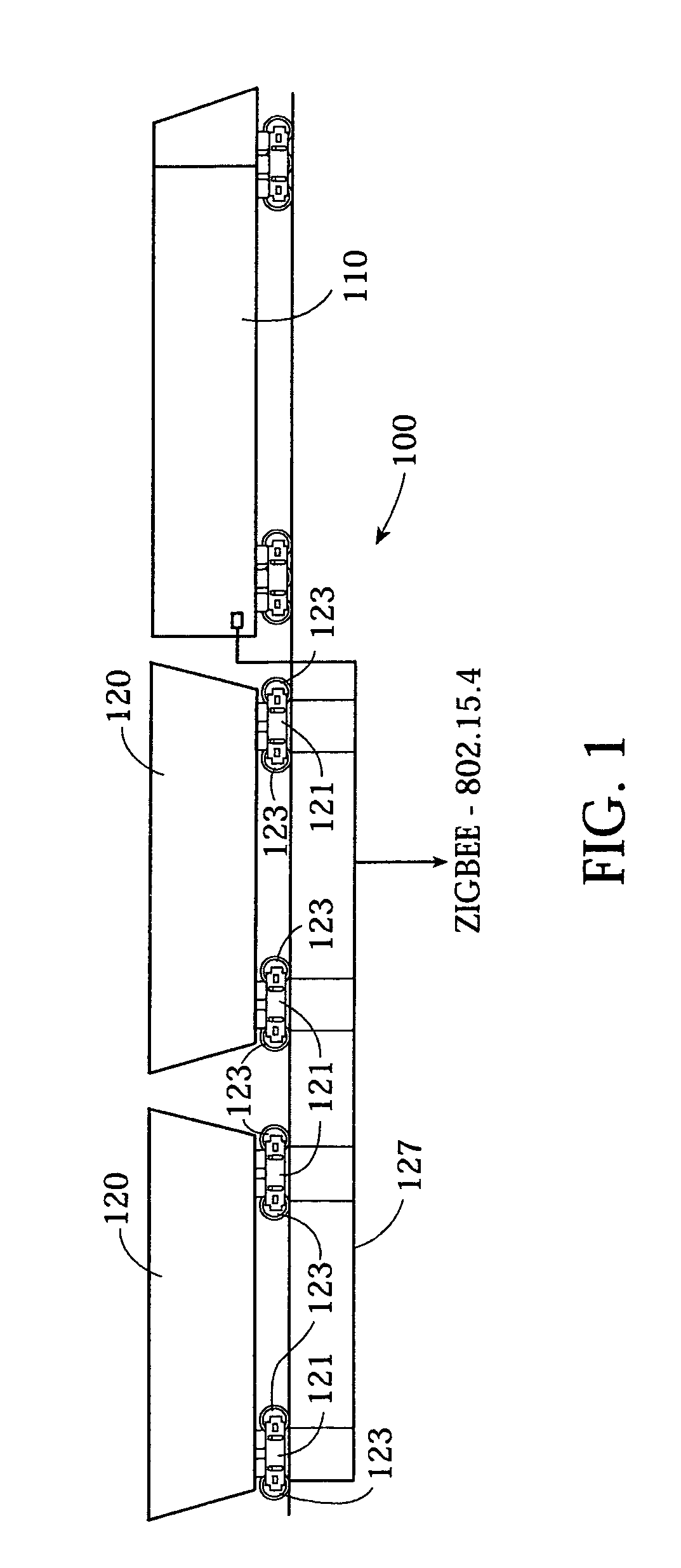

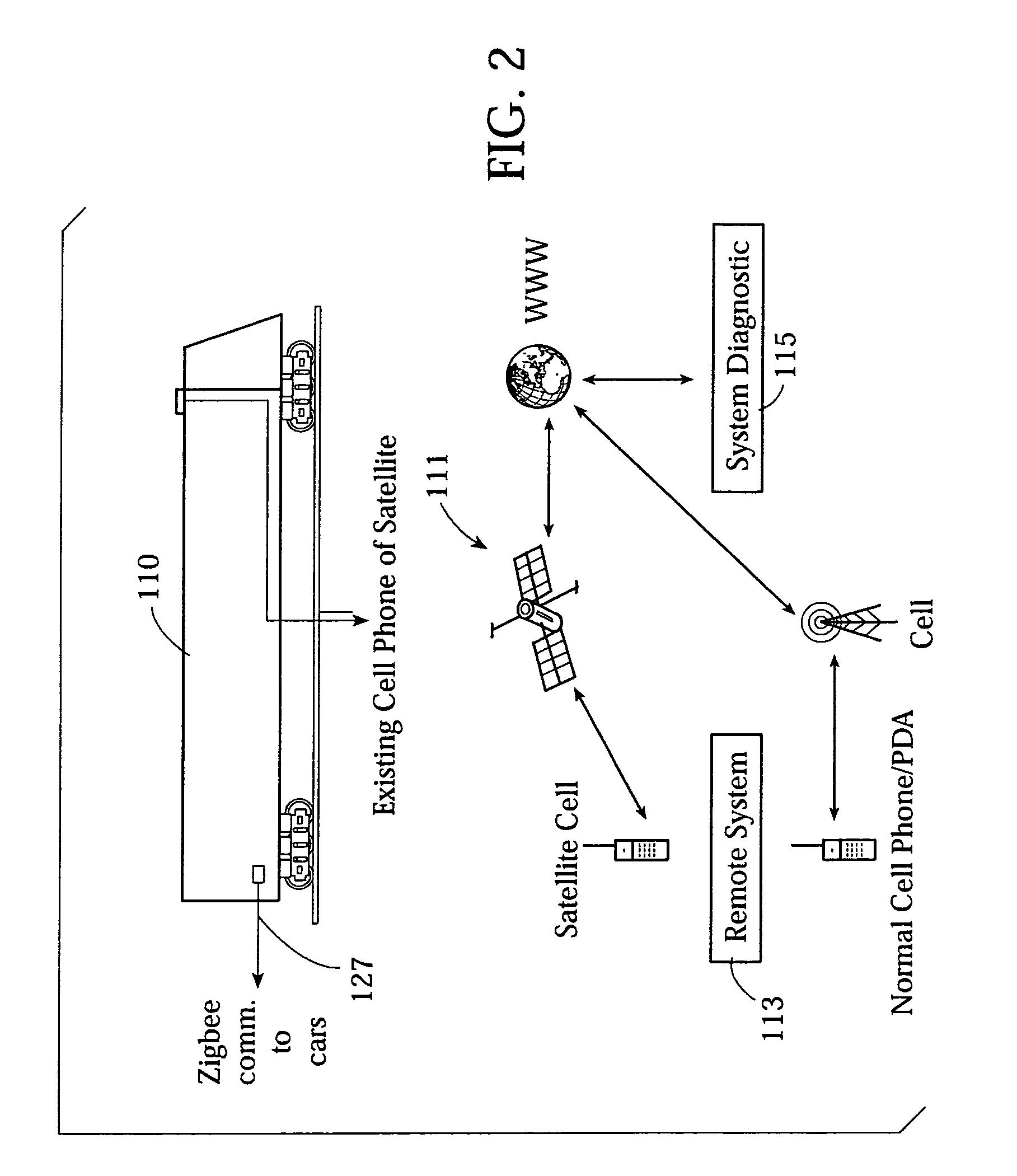

Self-assembling wireless network, vehicle communications system, railroad wheel and bearing monitoring system and methods therefor

ActiveUS20070208841A1Continuous monitoringAccurate data analysisRolling contact bearingsMeasurement devicesWireless mesh networkCommunications system

A low power self-organizing network is made up of a plurality of wireless communication nodes communicating wirelessly with each other. The nodes each have a sensor providing a respective sensor data value indicative of a physical parameter in the environment of that node. The wireless network discontinues communication with any nodes in which the sensor data value is outside a range of network sensor data values. The network is preferably a group of vehicles moving together, especially a train in which each node is associated with a respective wheel of a railroad car. The nodes are low-power devices that communicate using wireless communications according to a Zigbee protocol. The nodes each have an additional sensor sensing a physical parameter the respective wheel thereof and determines from said electrical signal a degree of degradation of a bearing of the wheel, and transmits data of the degree of degradation to the main node. The main node communicates with another computer system using a higher power communication system and transmits thereto data indicative of degradation of said bearings.

Owner:CONVEY INC

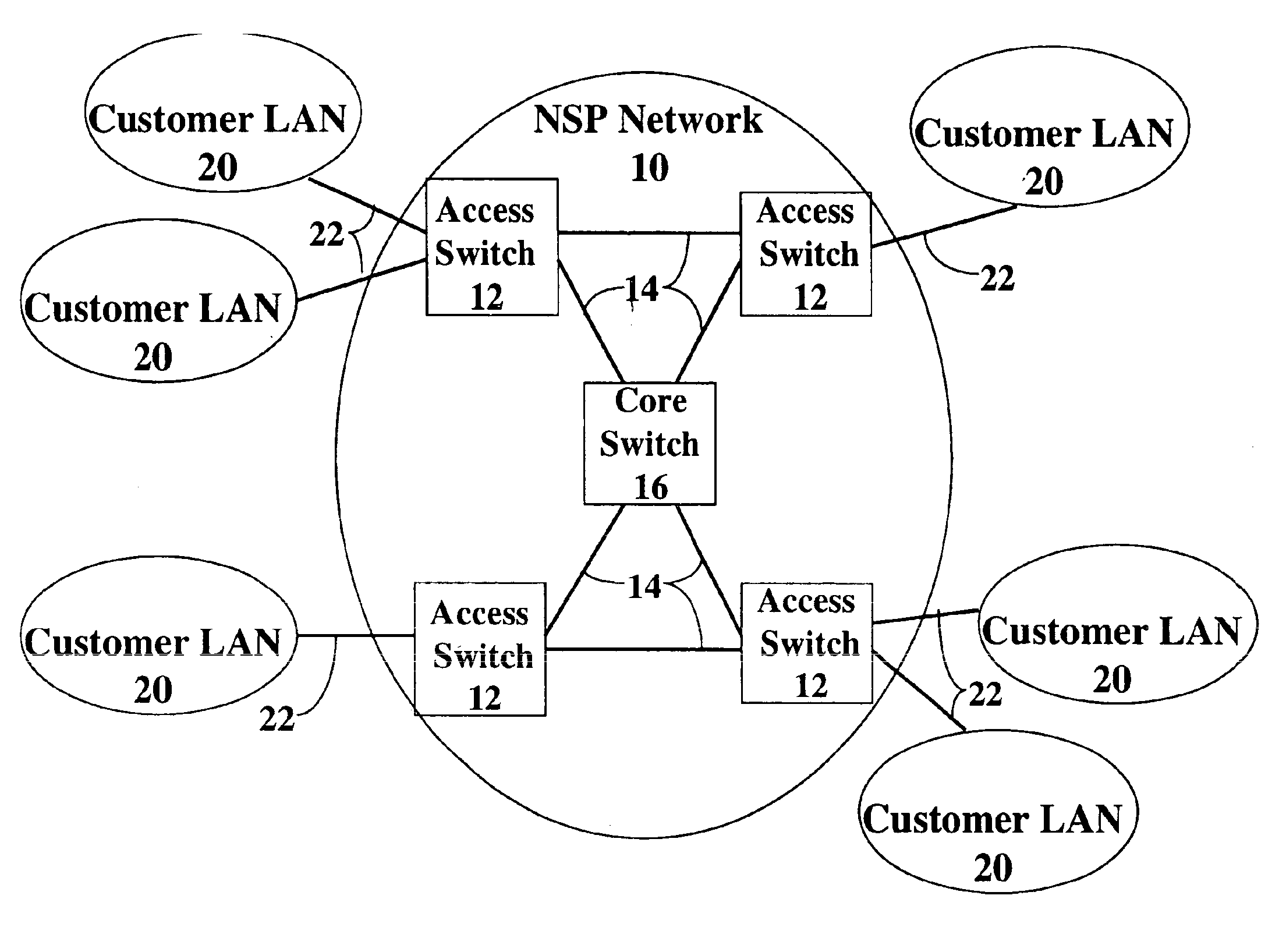

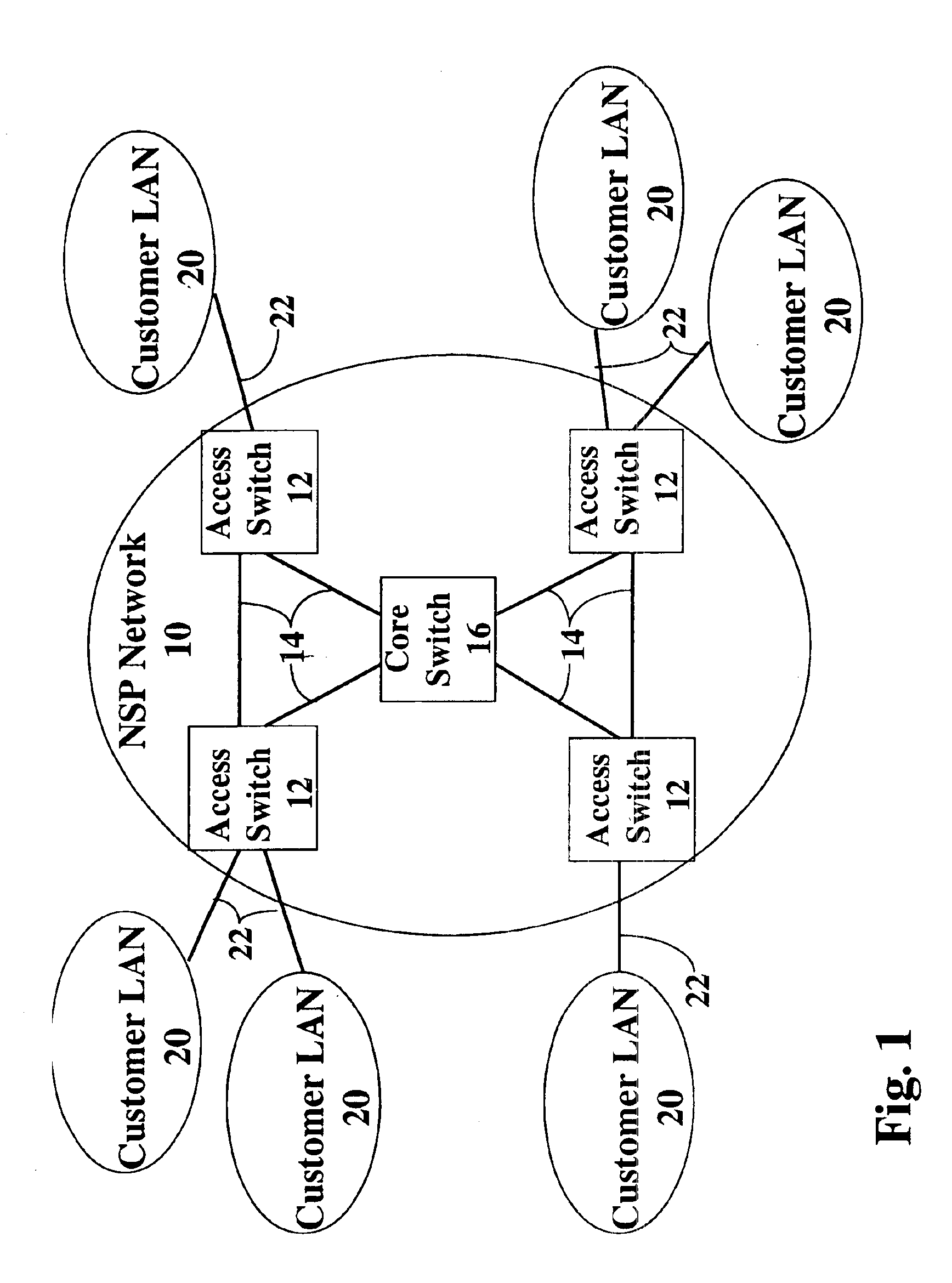

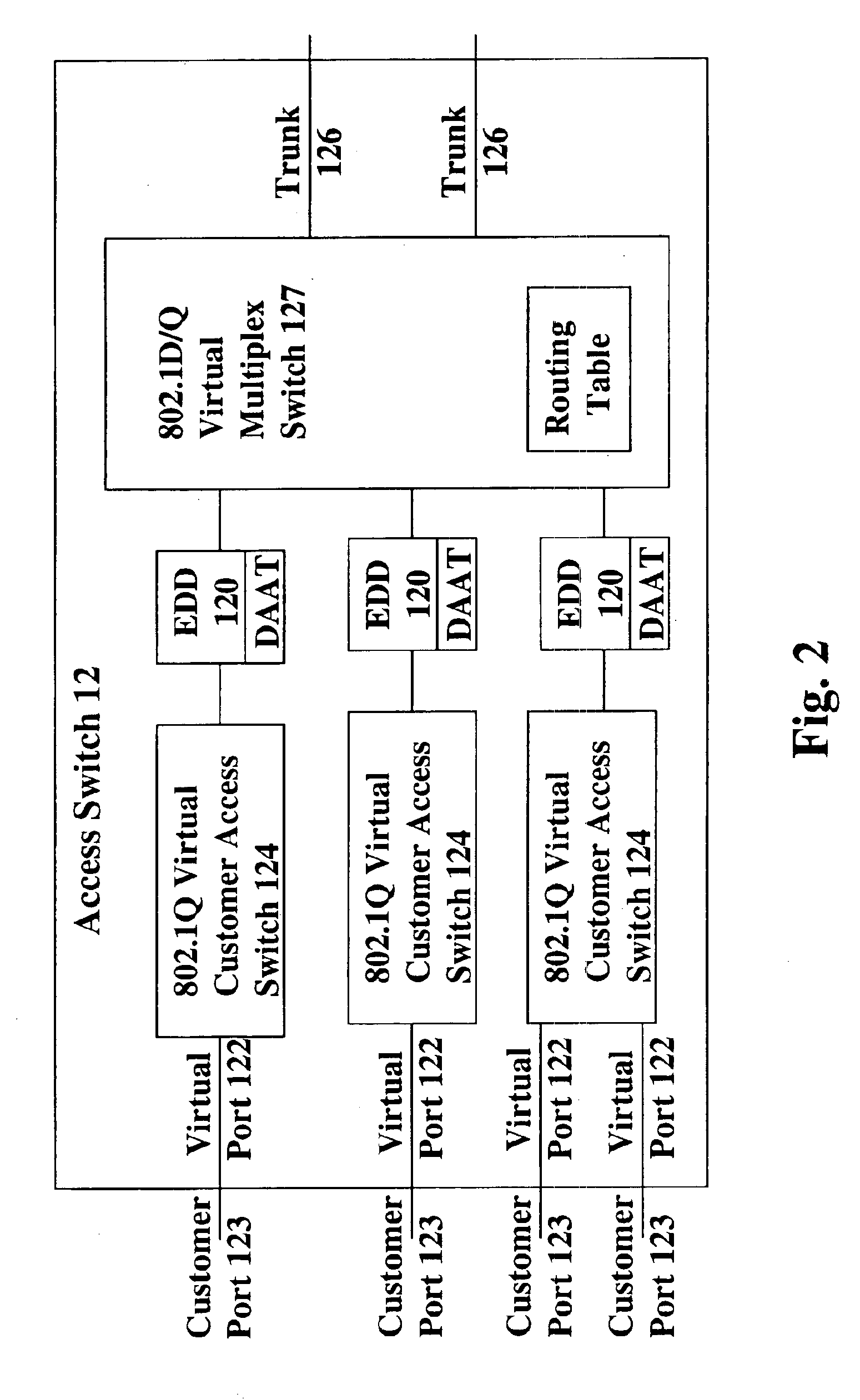

Virtual private networks and methods for their operation

InactiveUS6937574B1Economically feasibleLower acquisition costsNetworks interconnectionPrivate networkPhysical address

In methods and apparatus for routing packets through a communications network, a respective distinct broadcast address is assigned to each of a plurality of distinct sets of virtual ports. No virtual port belongs to more than one of the distinct sets. A respective egress address is assigned to each packet entering the network via an ingress virtual port. The respective egress address corresponds to a respective destination address of the entering packet when a correspondence between the destination address and an egress address is known. When no correspondence between the destination address and an egress address is known, the respective egress address is a broadcast egress address corresponding to the set comprising the ingress virtual port. The packet is routed according to the respective egress address. The routing is restricted to virtual ports belonging to the distinct set of virtual ports that includes the ingress virtual port. The distinct sets of virtual ports and their associated broadcast addresses define isolated virtual private networks within the network. Each physical port of the network may map one-to-one onto a corresponding virtual port, or may map onto a corresponding plurality of virtual ports, in which case the each virtual port of the plurality is associated with a respective distinct combination of a physical address of the physical port and a respective virtual network identifier.

Owner:RPX CLEARINGHOUSE

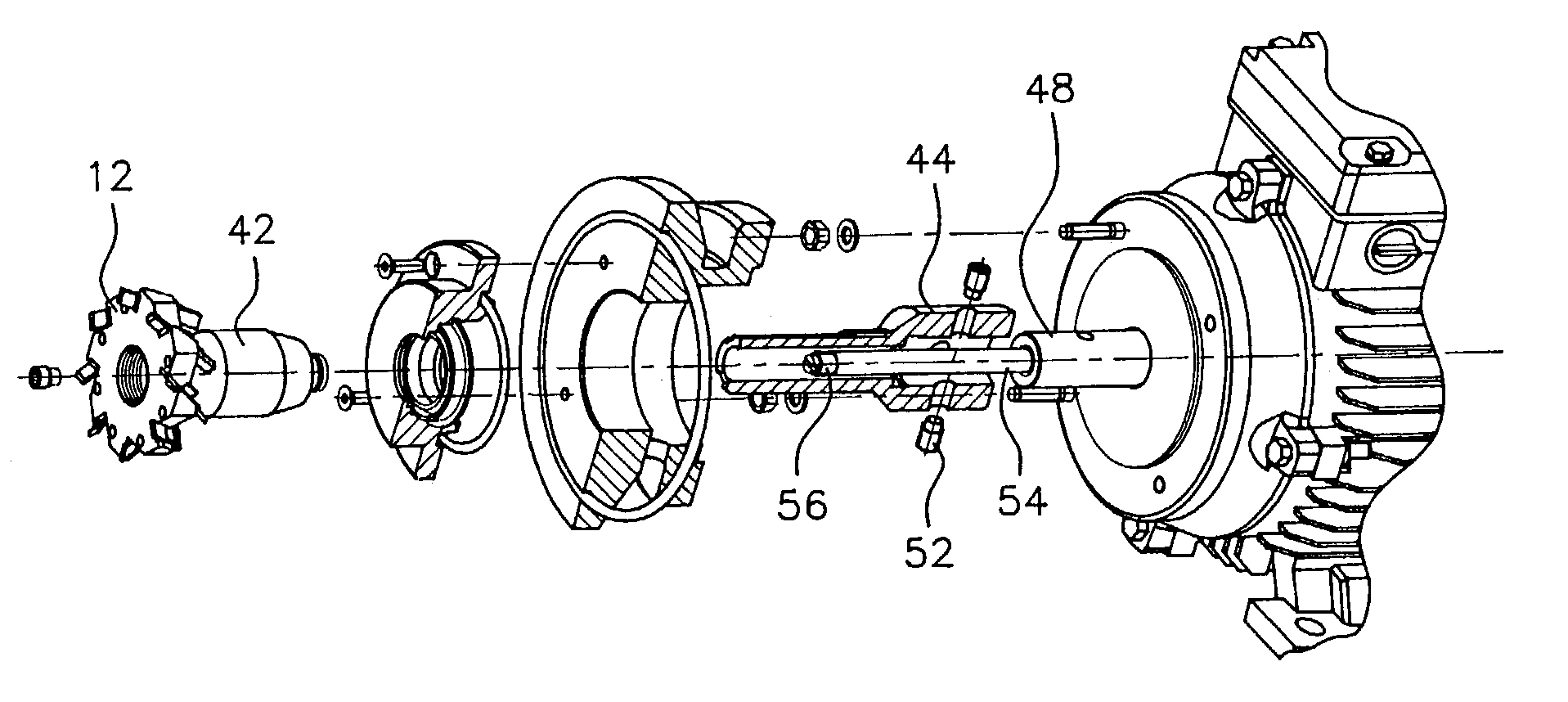

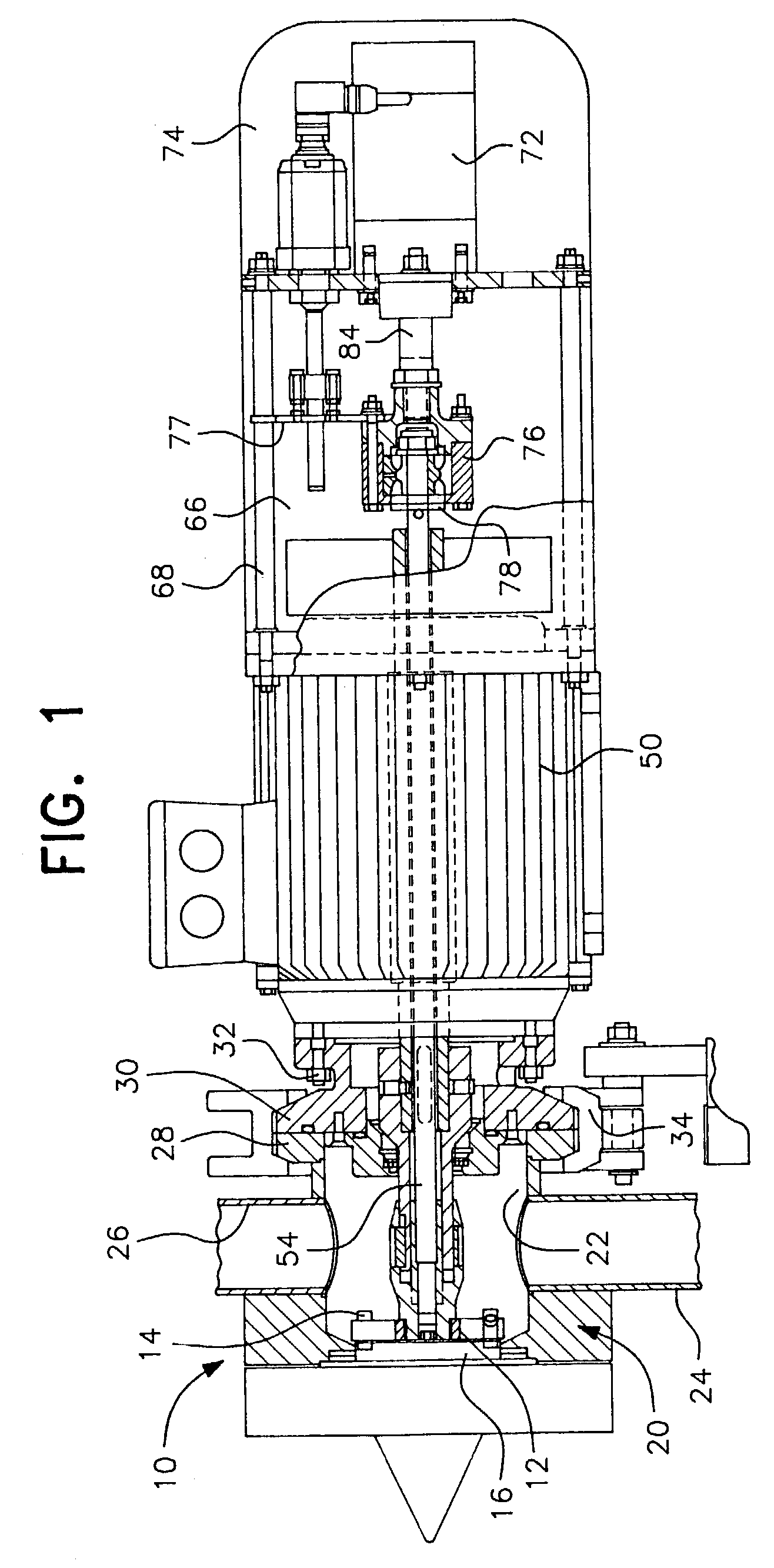

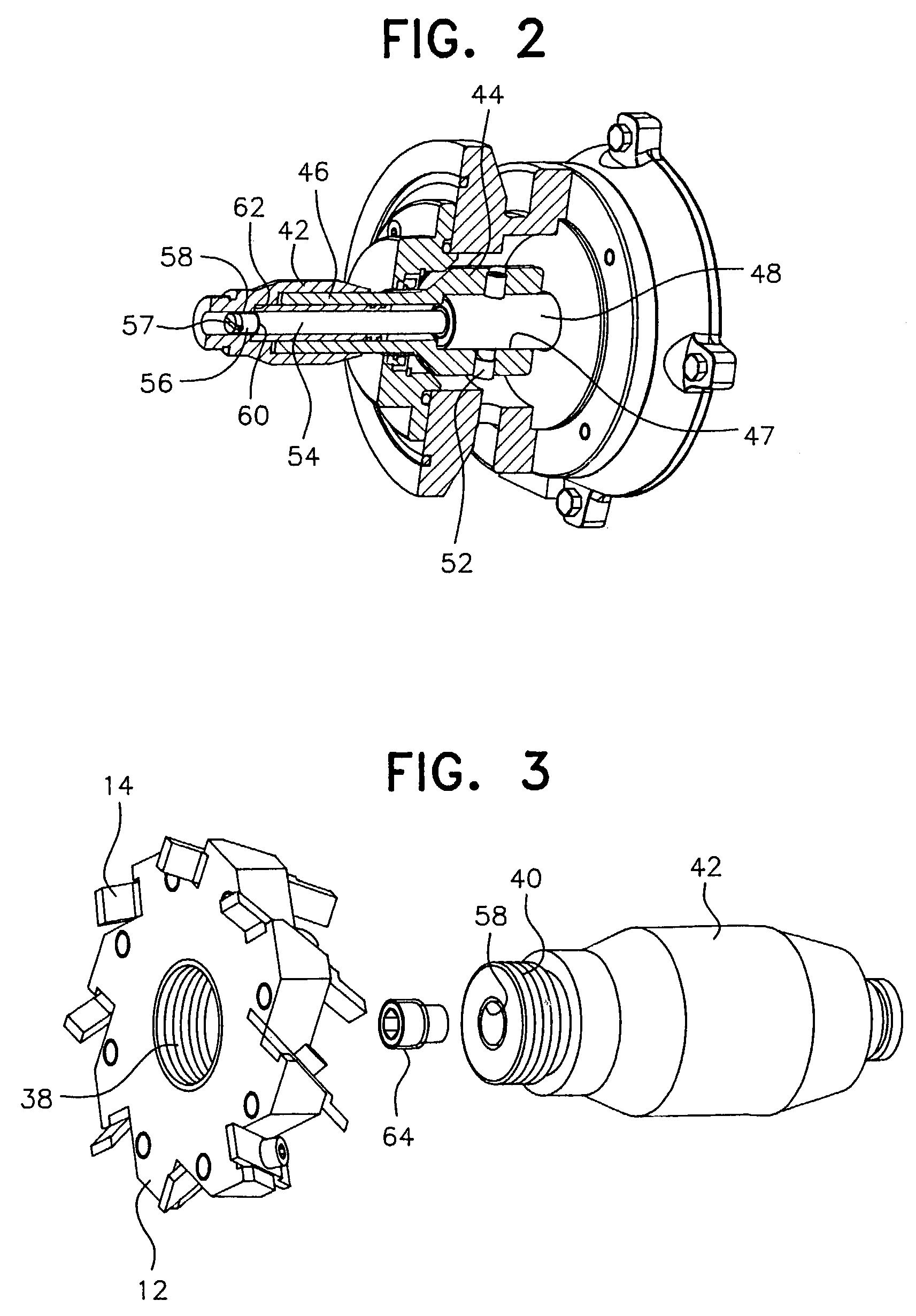

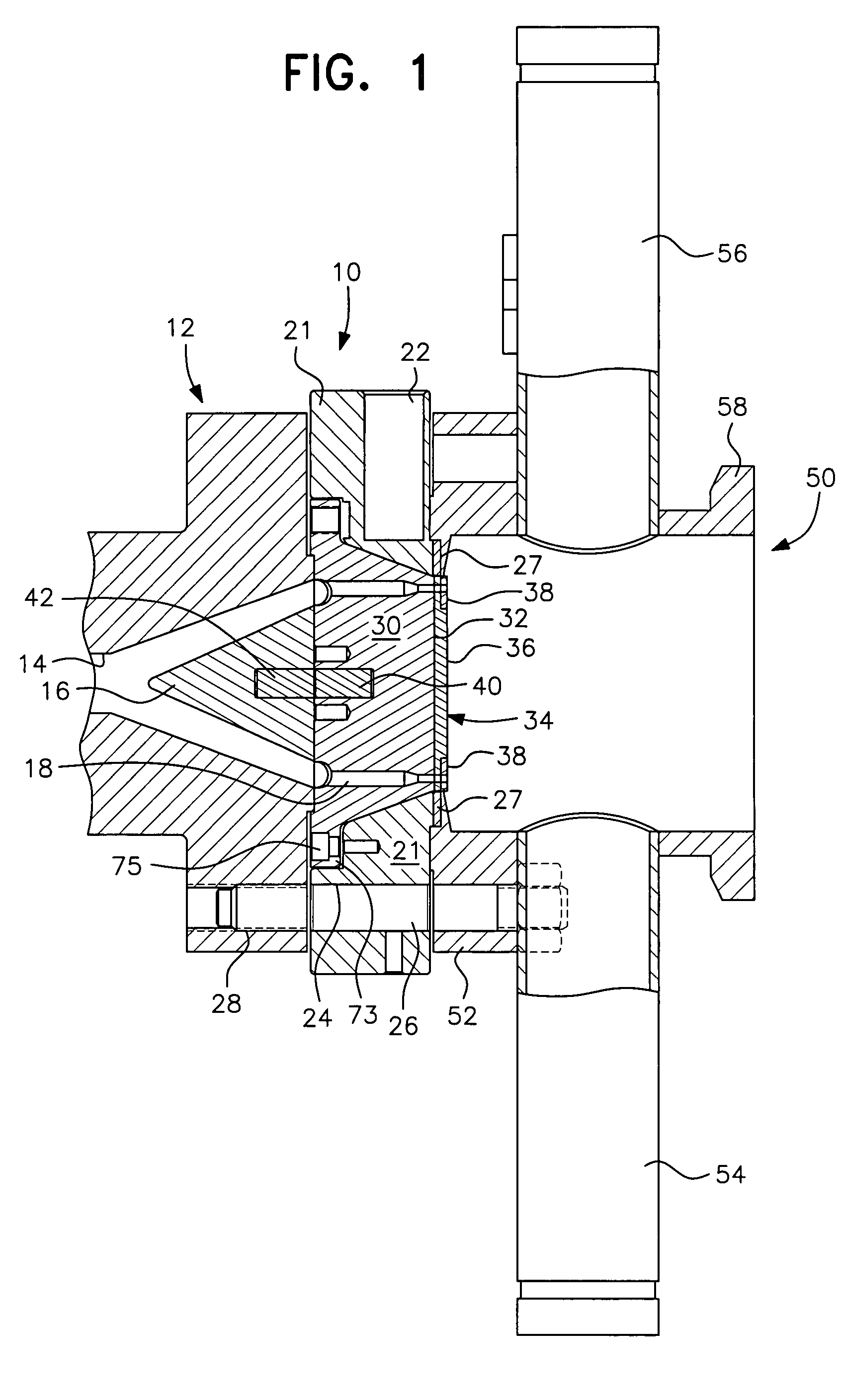

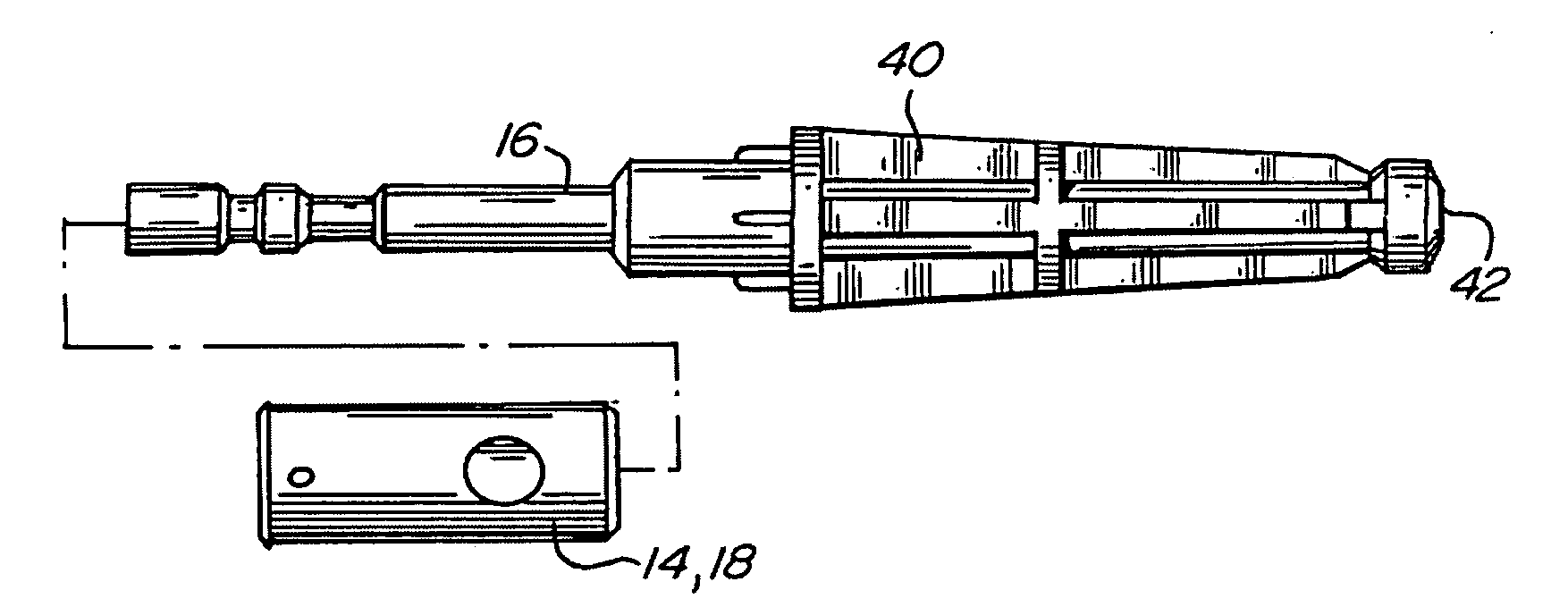

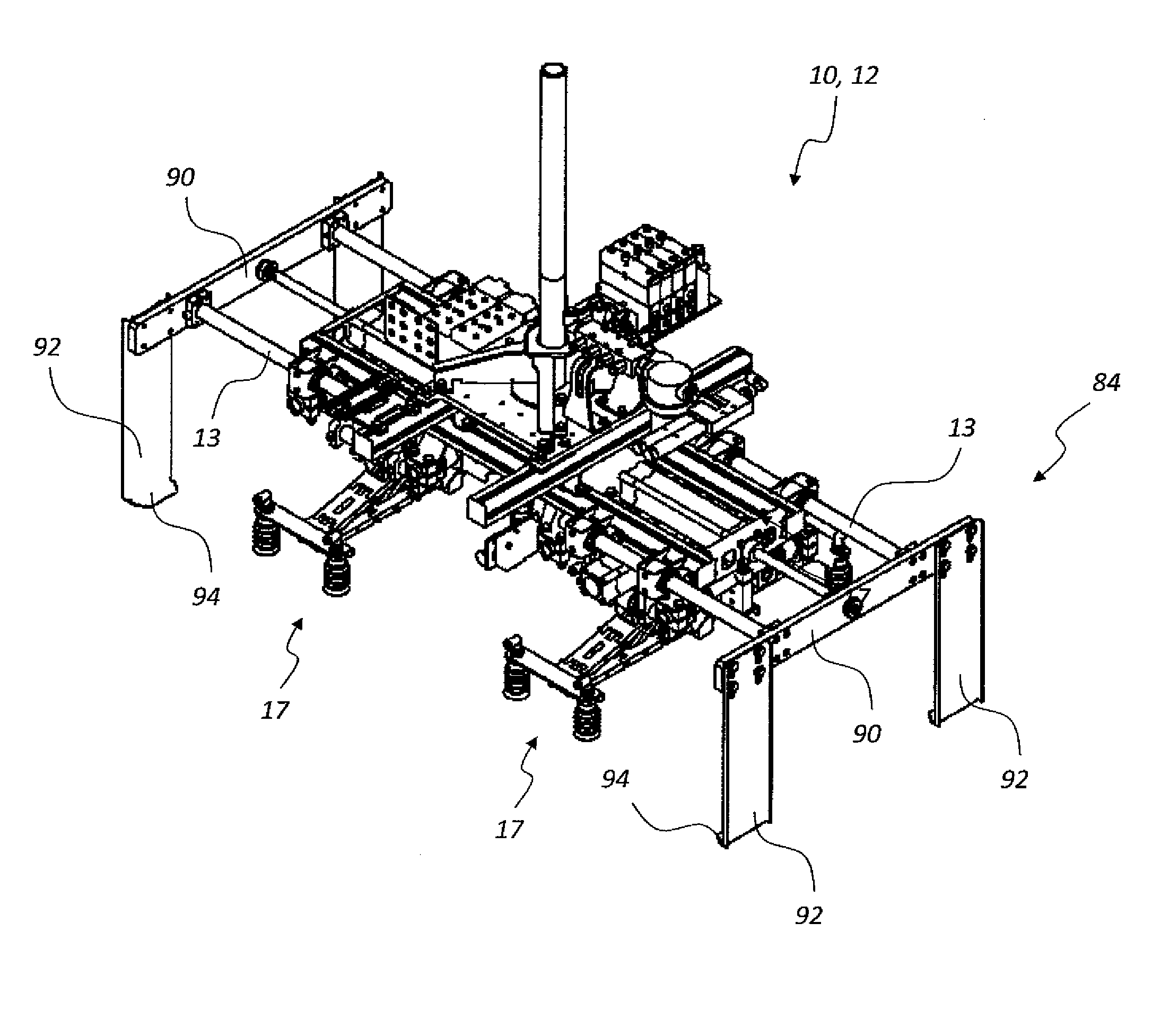

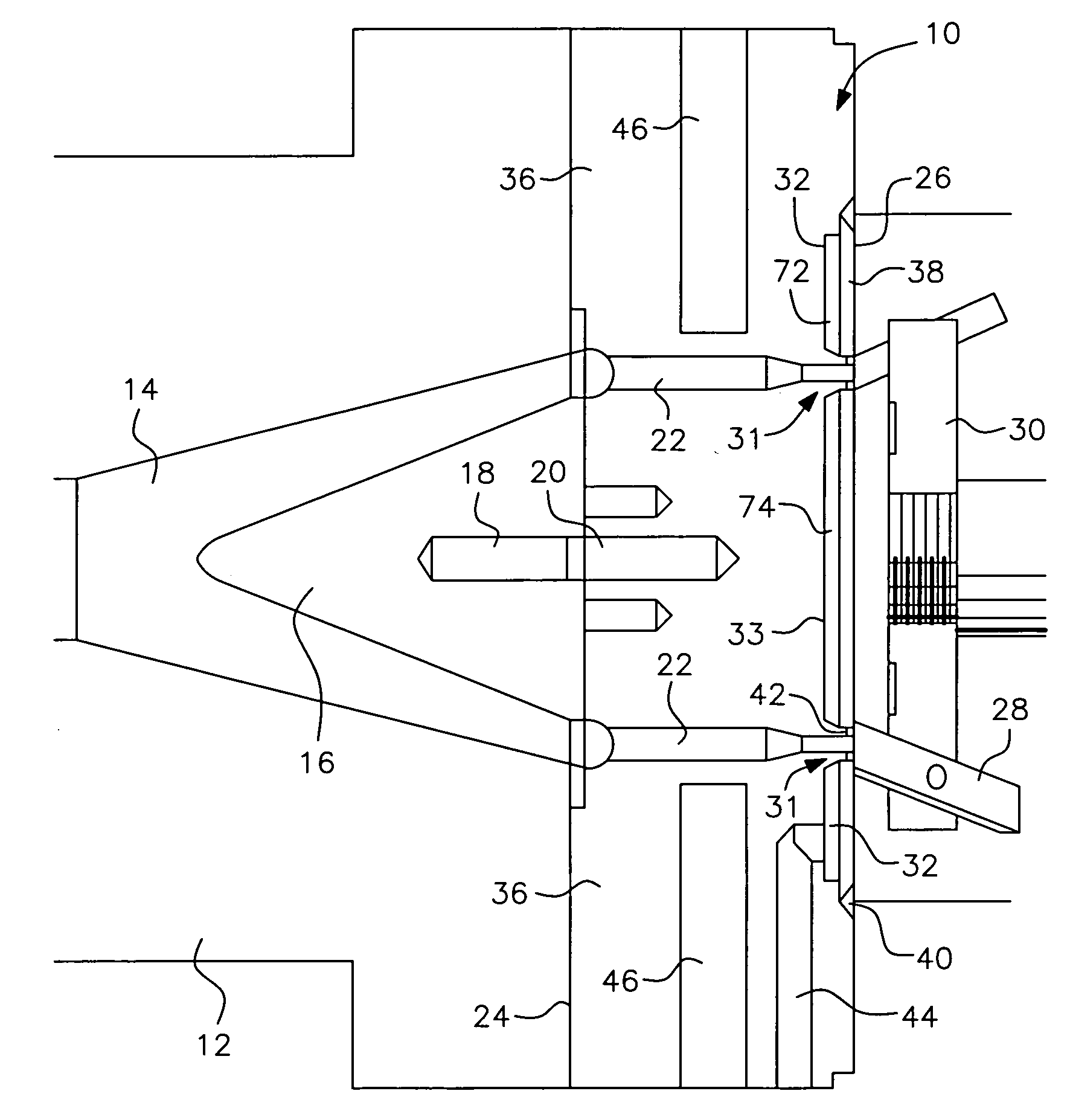

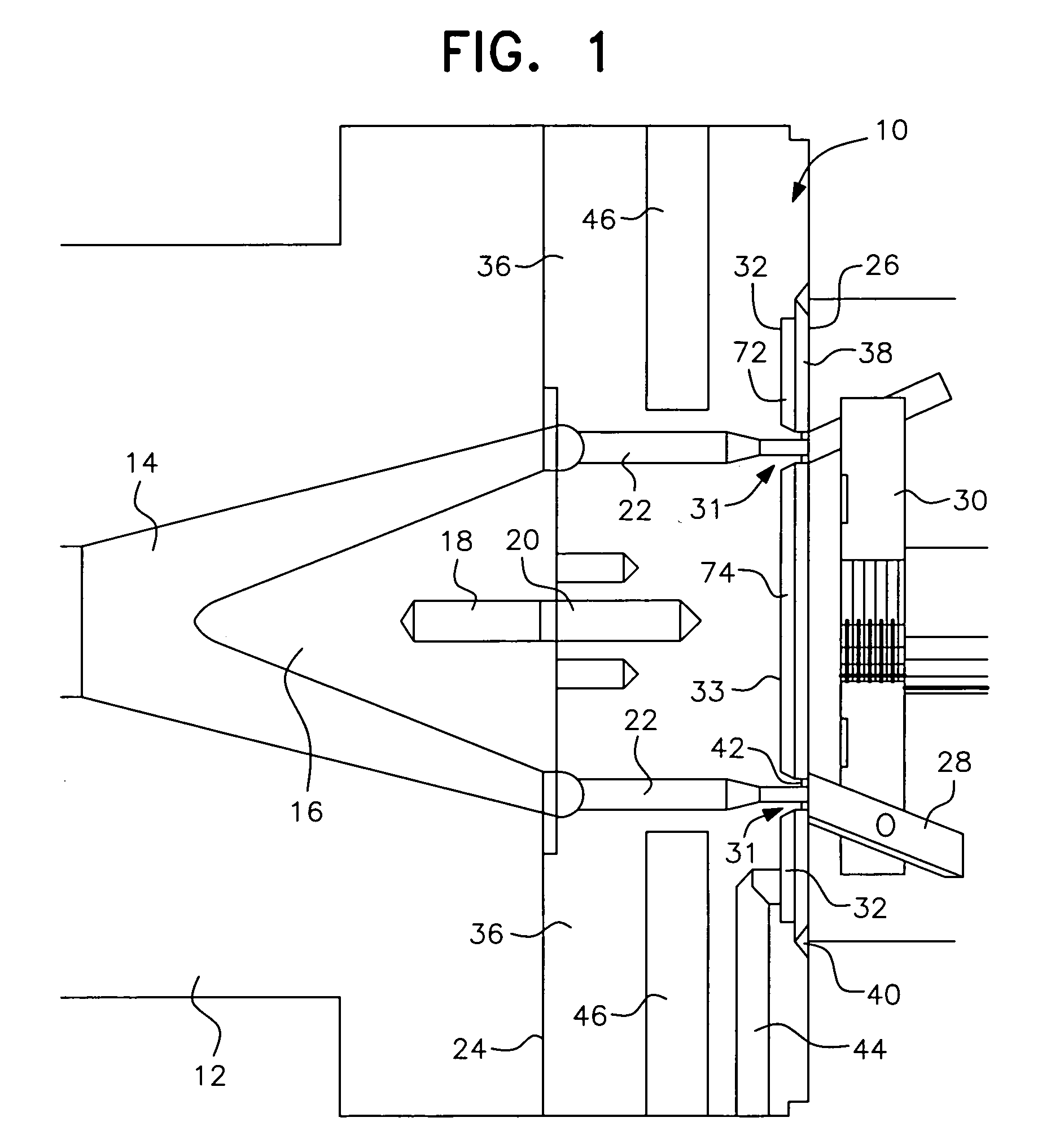

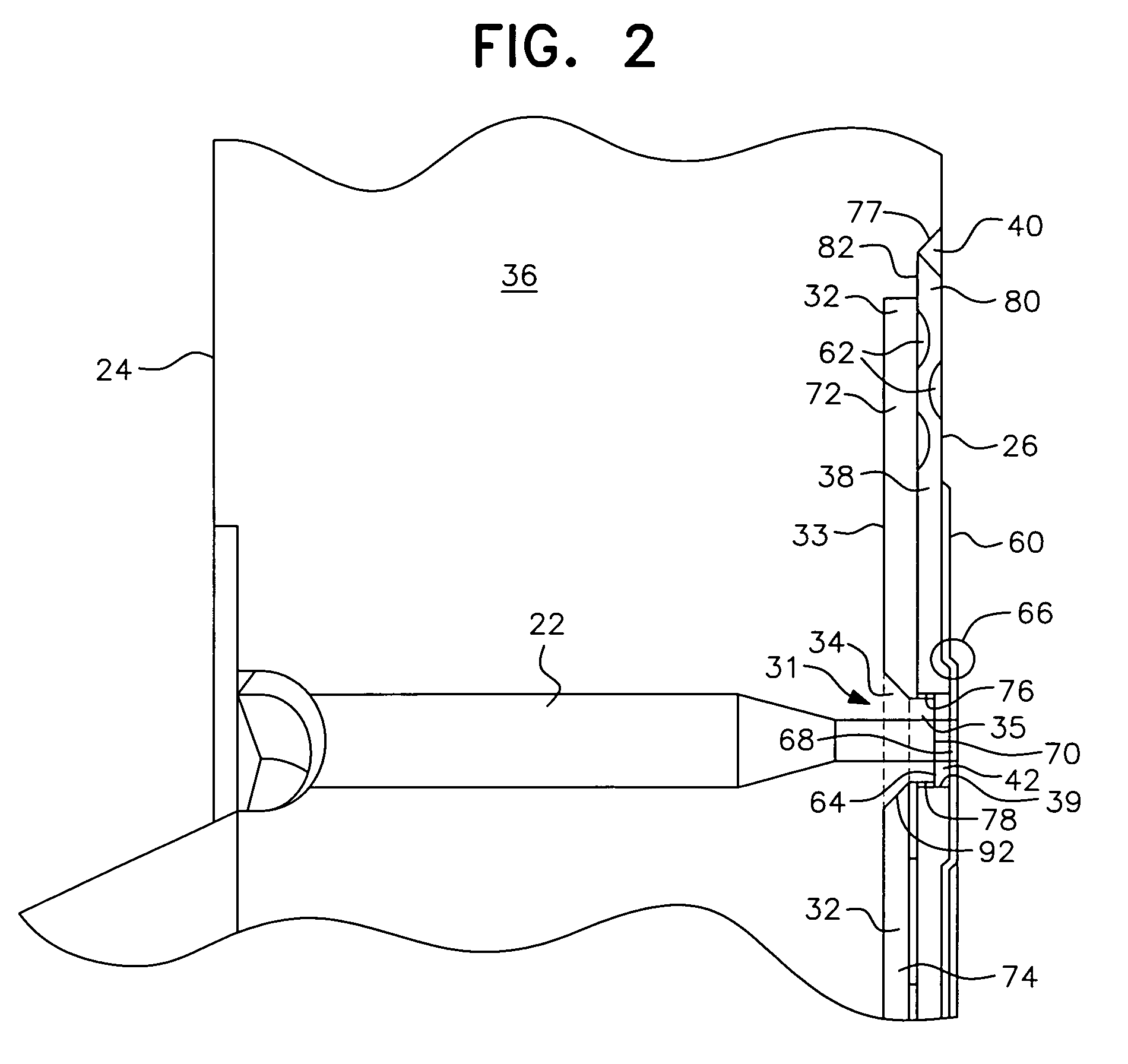

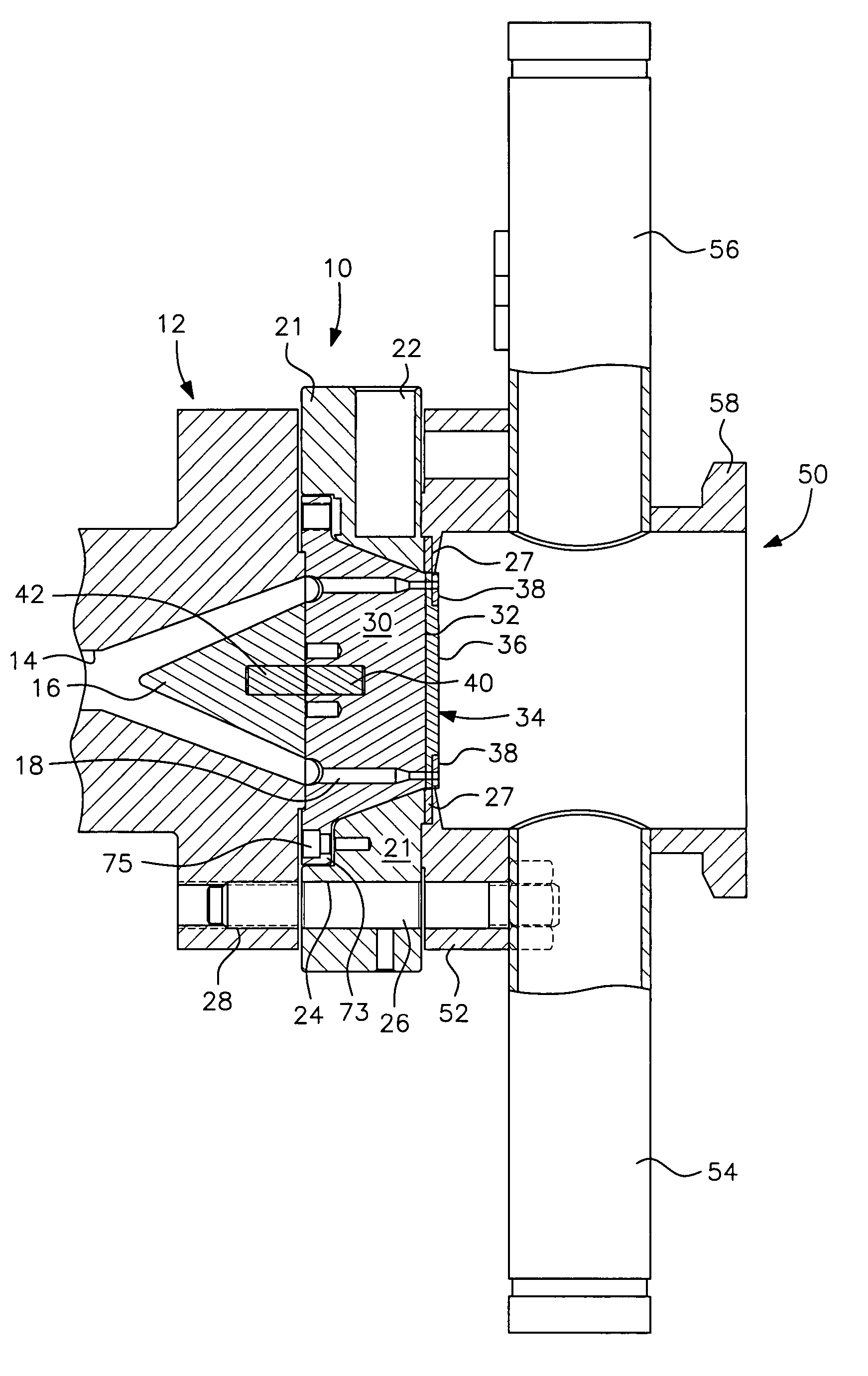

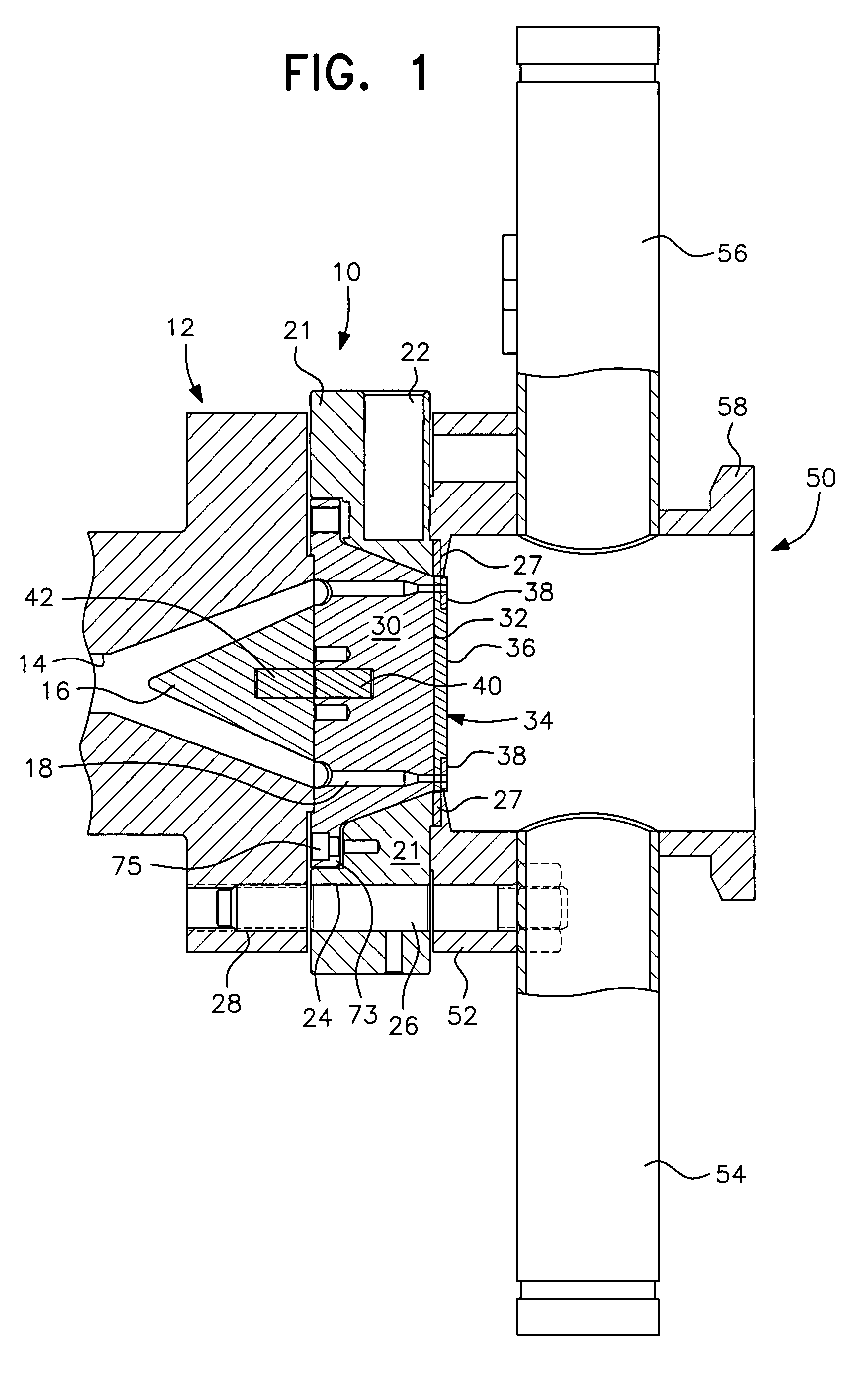

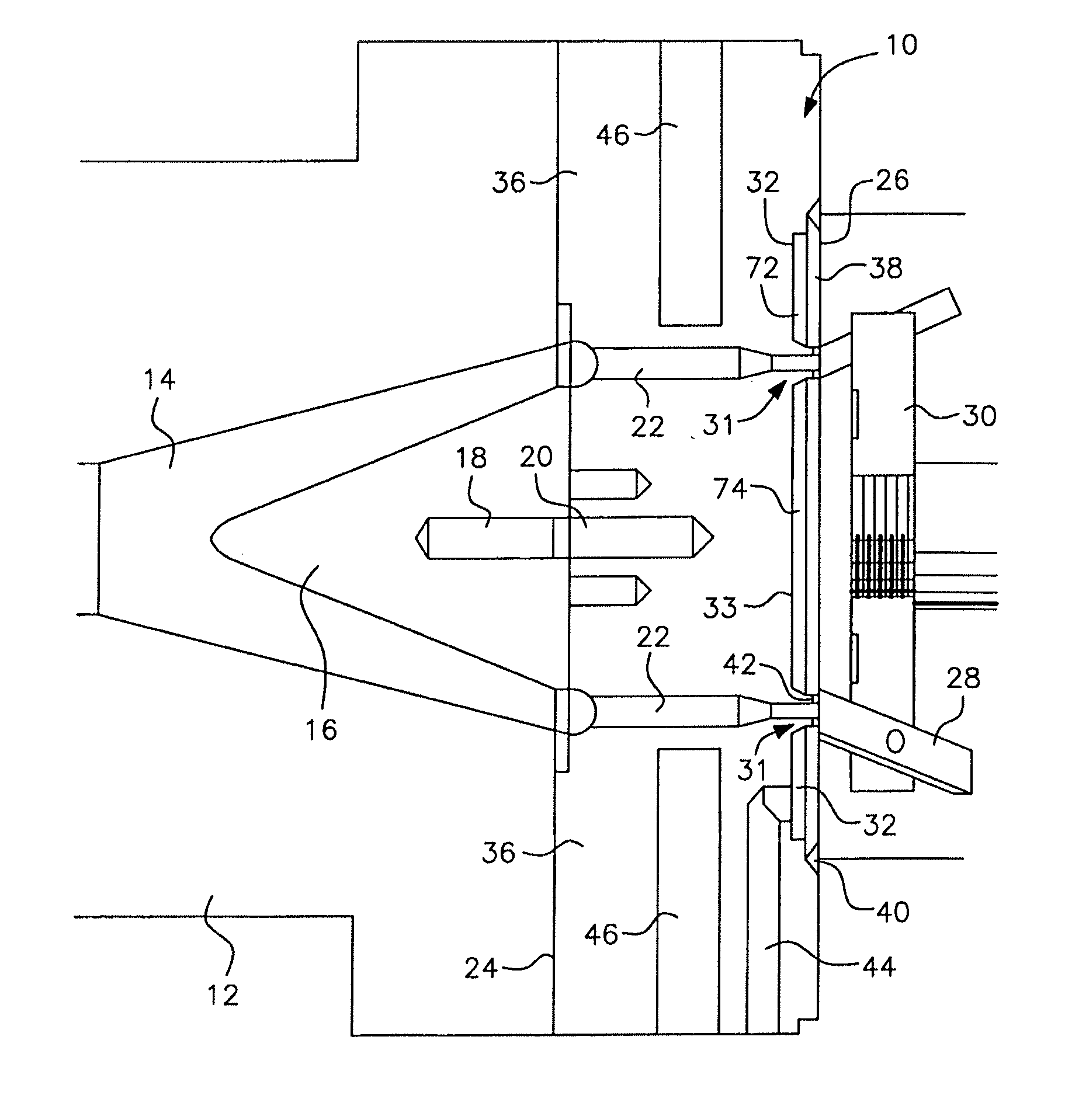

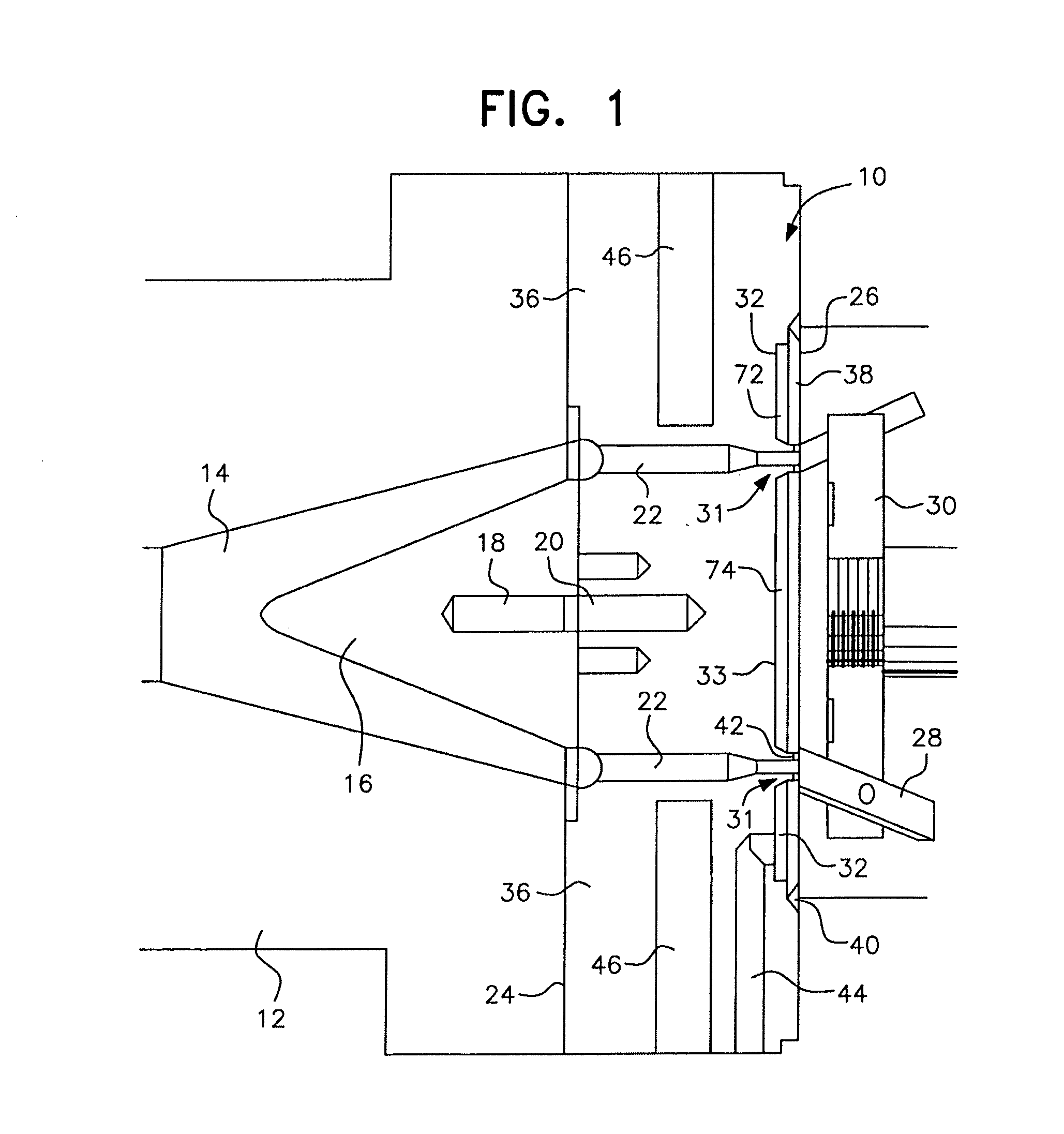

Underwater pelletizer with positively controlled cutter HUB

A cutter hub and blade assembly supported and driven for rotational and axial movement in relation to the die face of a die plate in an underwater pelletizer including a positive control of such axial movement to obtain and maintain optimal axial position of the cutter hub and blades during the pelletizing operation and to minimize wear of the mechanical components involved. Positive control of the axial movement of the cutter hub and blades is obtained by a hydraulic / pneumatic actuation system controlling an elongated motion rod that extends through a driven hollow motor shaft. One end of the motion rod is connected with a hydraulic / pneumatic control and the other end of the rod is connected to a cutter hub holder that supports the cutter hub and blades for axial movement toward or away from the die face.

Owner:GALA INDUSTRIES INC

Self-assembling wireless network, vehicle communications system, railroad wheel and bearing monitoring system and methods therefor

ActiveUS7705743B2Increase power consumptionWide bandwidthRolling contact bearingsMeasurement devicesCommunications systemMonitoring system

A low power self-organizing network is made up of a plurality of wireless communication nodes communicating wirelessly with each other. The nodes each have a sensor providing a respective sensor data value indicative of a physical parameter in the environment of that node. The wireless network discontinues communication with any nodes in which the sensor data value is outside a range of network sensor data values. The network is preferably a group of vehicles moving together, especially a train in which each node is associated with a respective wheel of a railroad car. The nodes are low-power devices that communicate using wireless communications according to a Zigbee protocol. The nodes each have an additional sensor sensing a physical parameter the respective wheel thereof and determines from said electrical signal a degree of degradation of a bearing of the wheel, and transmits data of the degree of degradation to the main node. The main node communicates with another computer system using a higher power communication system and transmits thereto data indicative of degradation of said bearings.

Owner:CONVEY INC

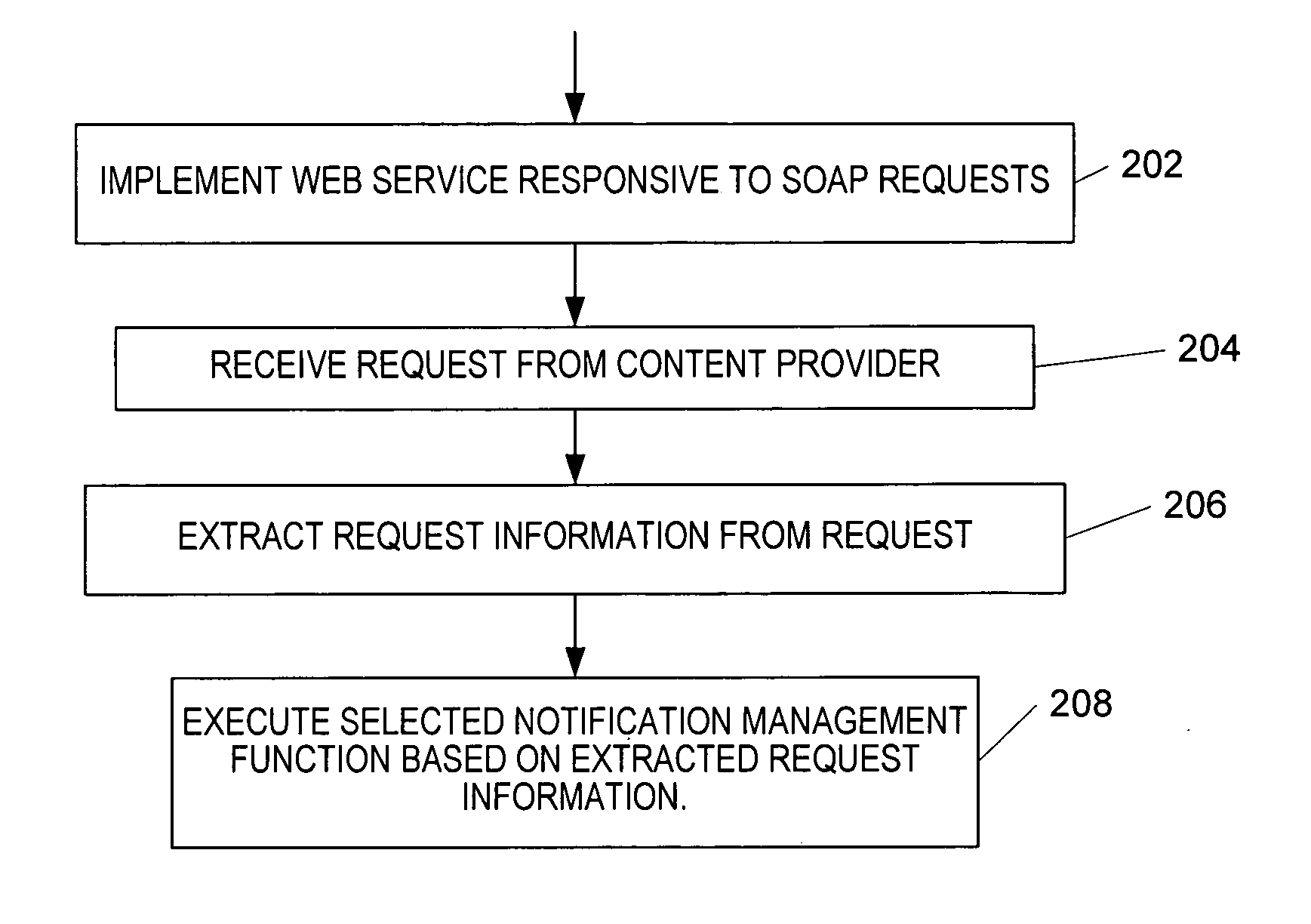

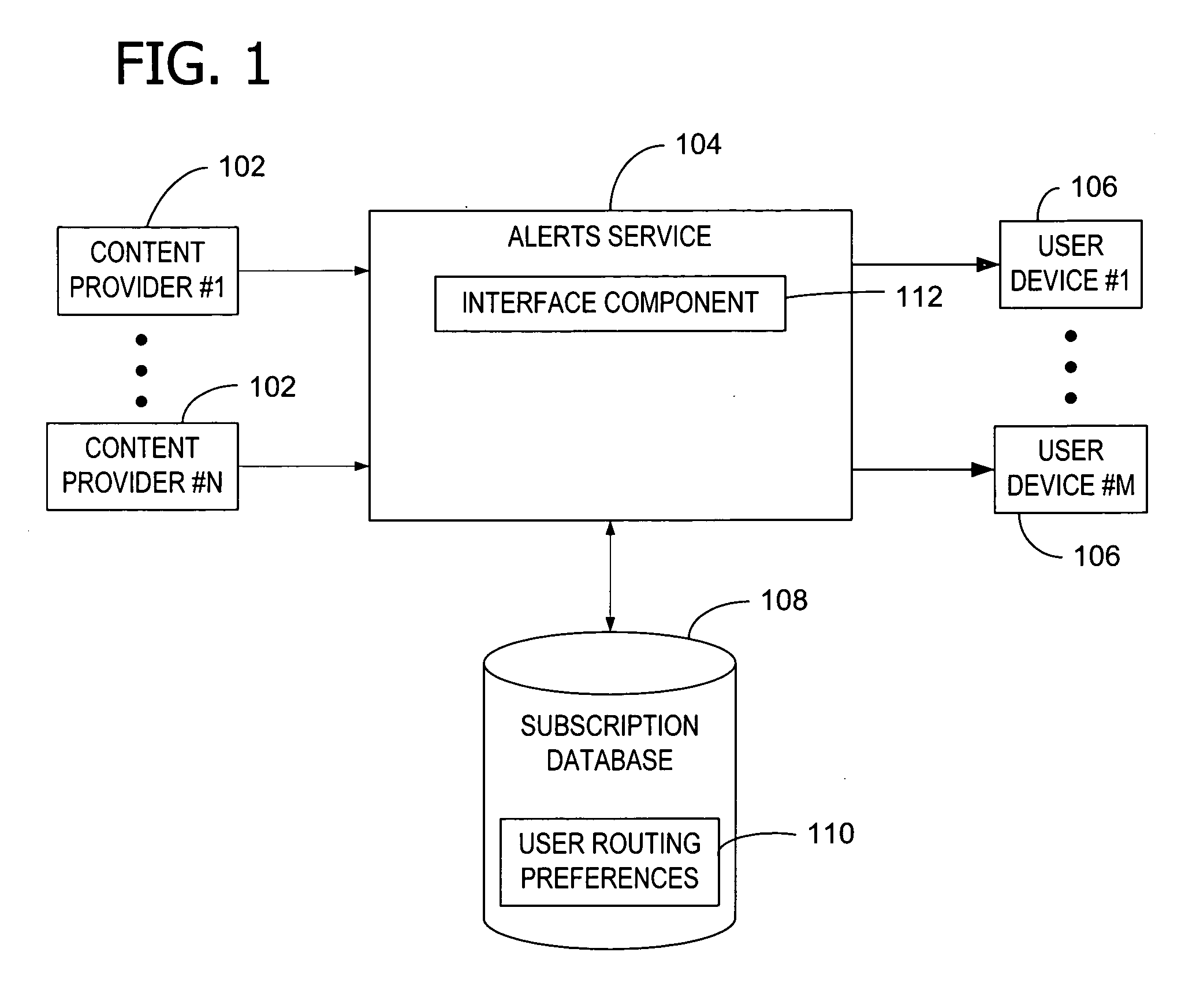

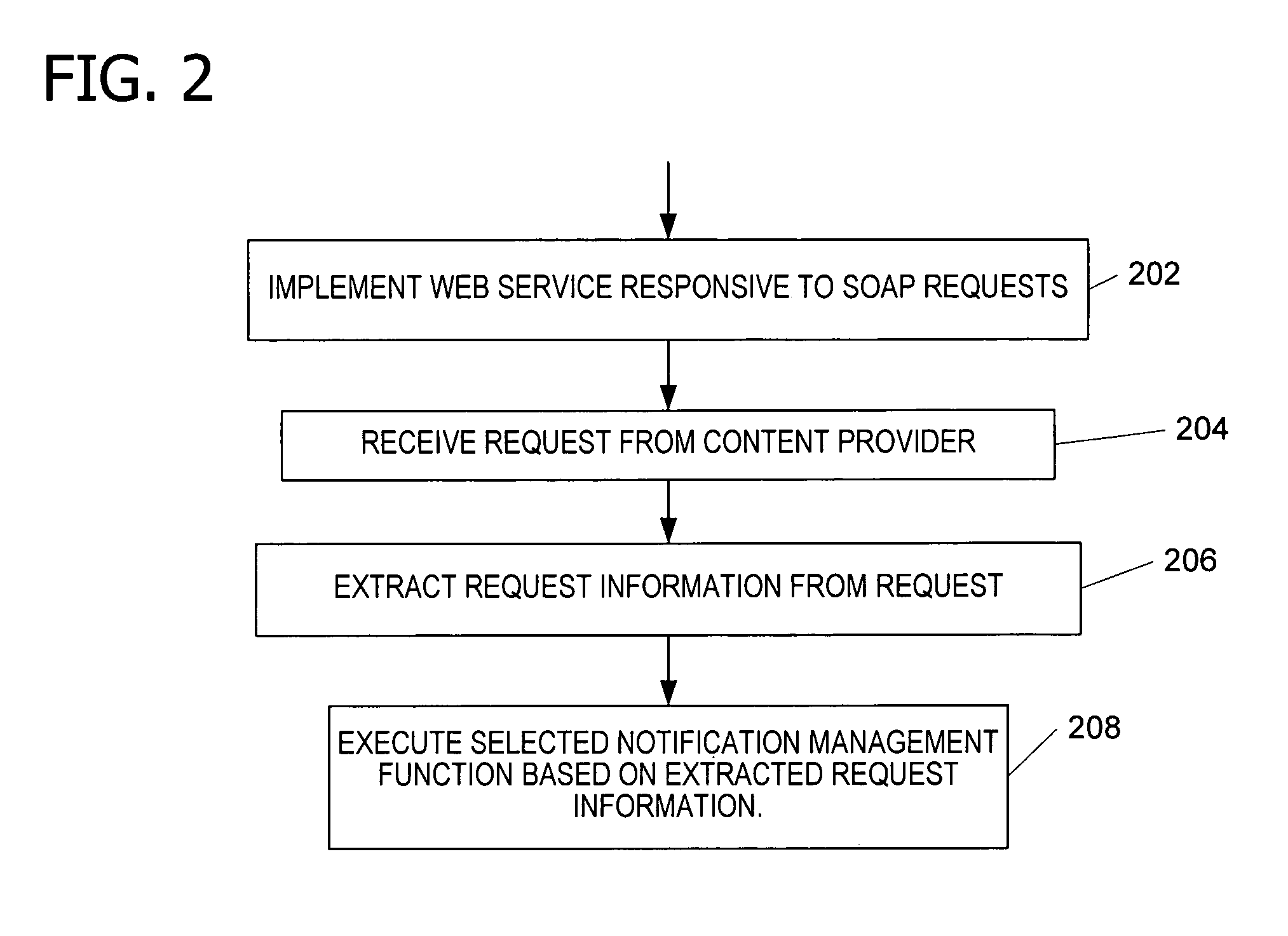

Topic-based notification service

InactiveUS7685265B1Improve interoperabilityEasily program their systemMultiple digital computer combinationsWebsite content managementWeb serviceSubject Identifier

Methods and systems for managing notifications. A web service embodying aspects of the invention is responsive to requests structured according to an extensible messaging framework and extracts request information, including at least a content provider identifier and a topic identifier, from the request to execute a selected notification management function.

Owner:MICROSOFT TECH LICENSING LLC

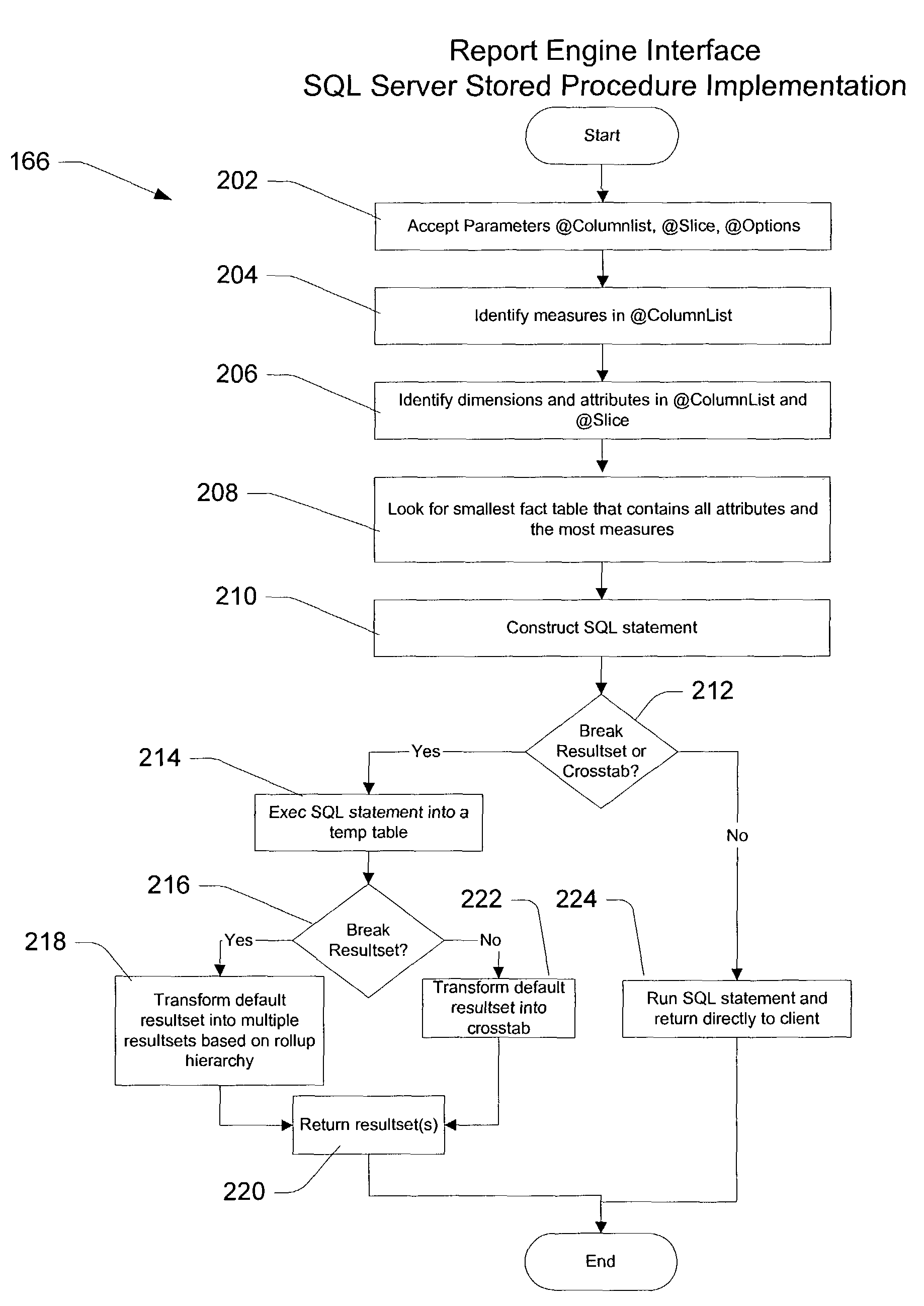

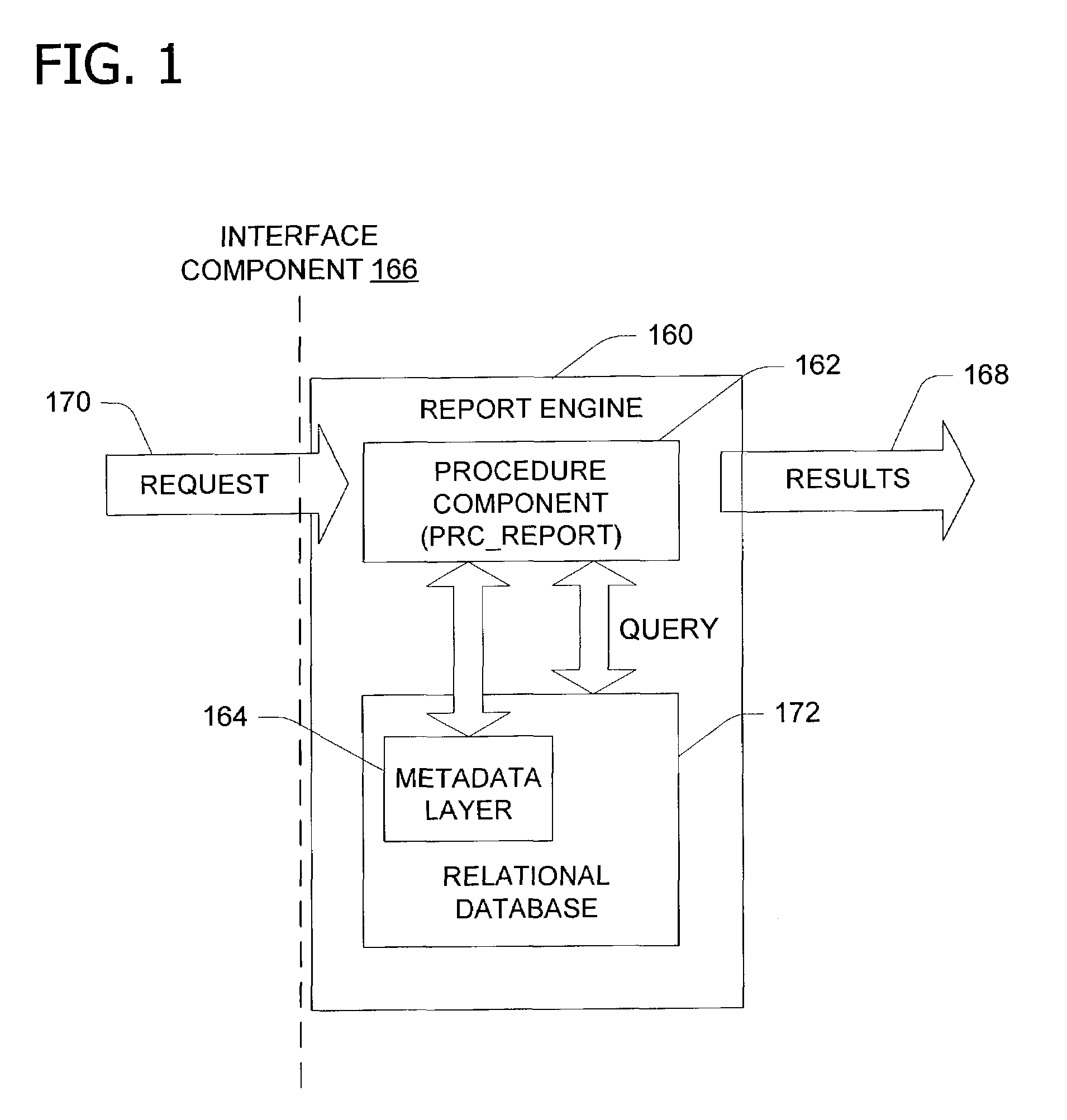

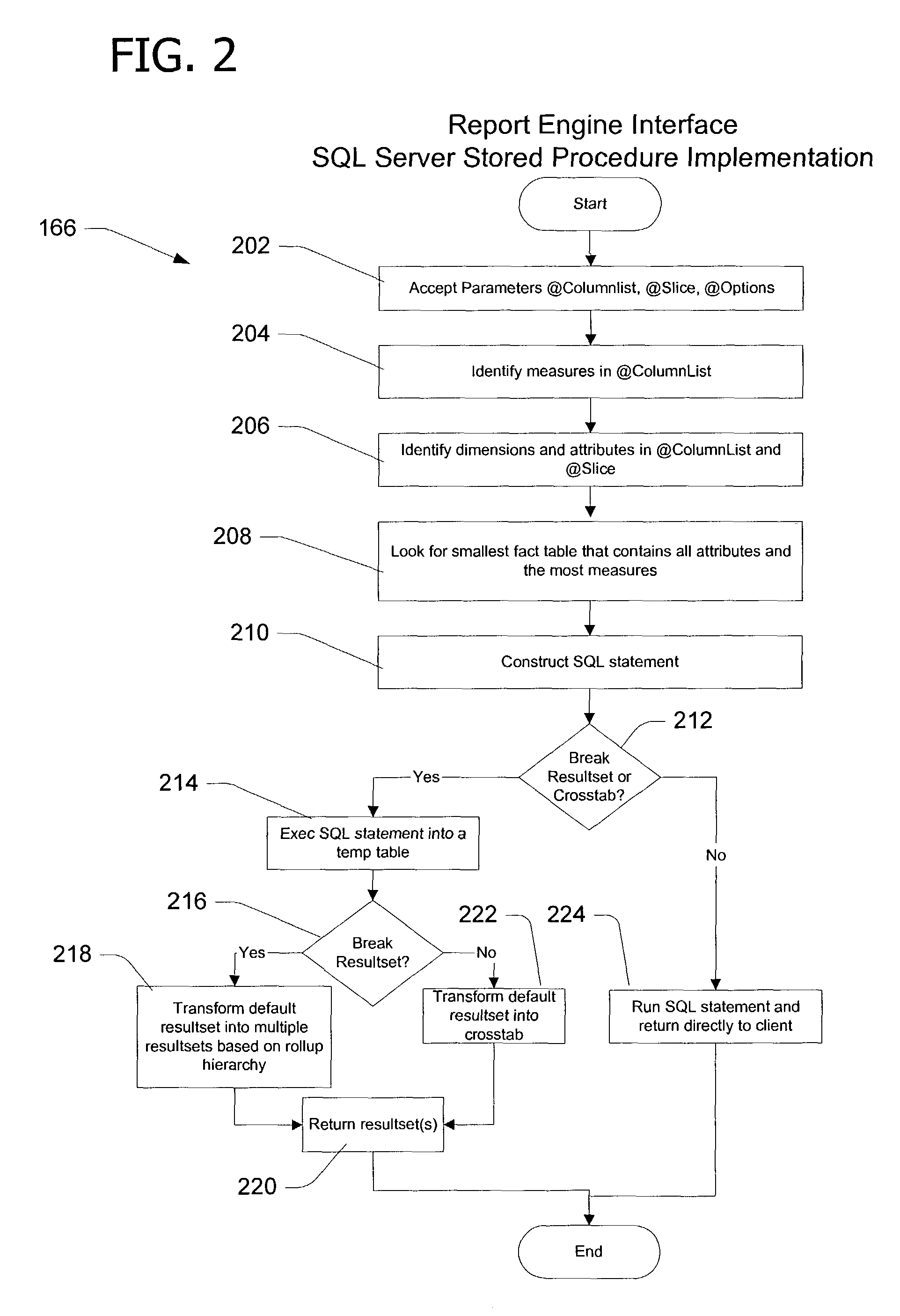

Reporting engine for data warehouse

InactiveUS7143107B1Simple query syntaxWithout sacrificing performanceData processing applicationsDigital data information retrievalData warehouseData storing

A reporting engine for generating customized reports from relational data stored in a database. Metadata associated with the data in the database describes the data according to one or more characteristics of the data. One or more of tables organizing the metadata is exposed as a dimension having at least one column of attributes. The reporting enging compares search criteria, specified by a request from a user, to the metadata attributes, and executes a predefined procedure for retrieving selected data from the database. The procedure constructs a query as a function of the comparison between the search criteria and the metadata attributes for implementing the query to optimize retrieval of the selected data from the database. Other aspects of the invention are directed to computer-readable media for use in connection with the reporting engine.

Owner:MICROSOFT TECH LICENSING LLC

Method for the deposition of silicon nitride films

ActiveUS20050085098A1Reduce the probability of depositionIncreasing and maintaining deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingInorganic compositionPhysical chemistry

A method is provided for obtaining stable and elevated deposition rates in a reaction chamber, following the cleaning of the chamber. The method involves cleaning of the chamber, pre-coating the interior surfaces of the reaction chamber with an inorganic composition, and then, using the pre-coated chamber to deposit an organic layer onto a workpiece.

Owner:ASM INTERNATIONAL

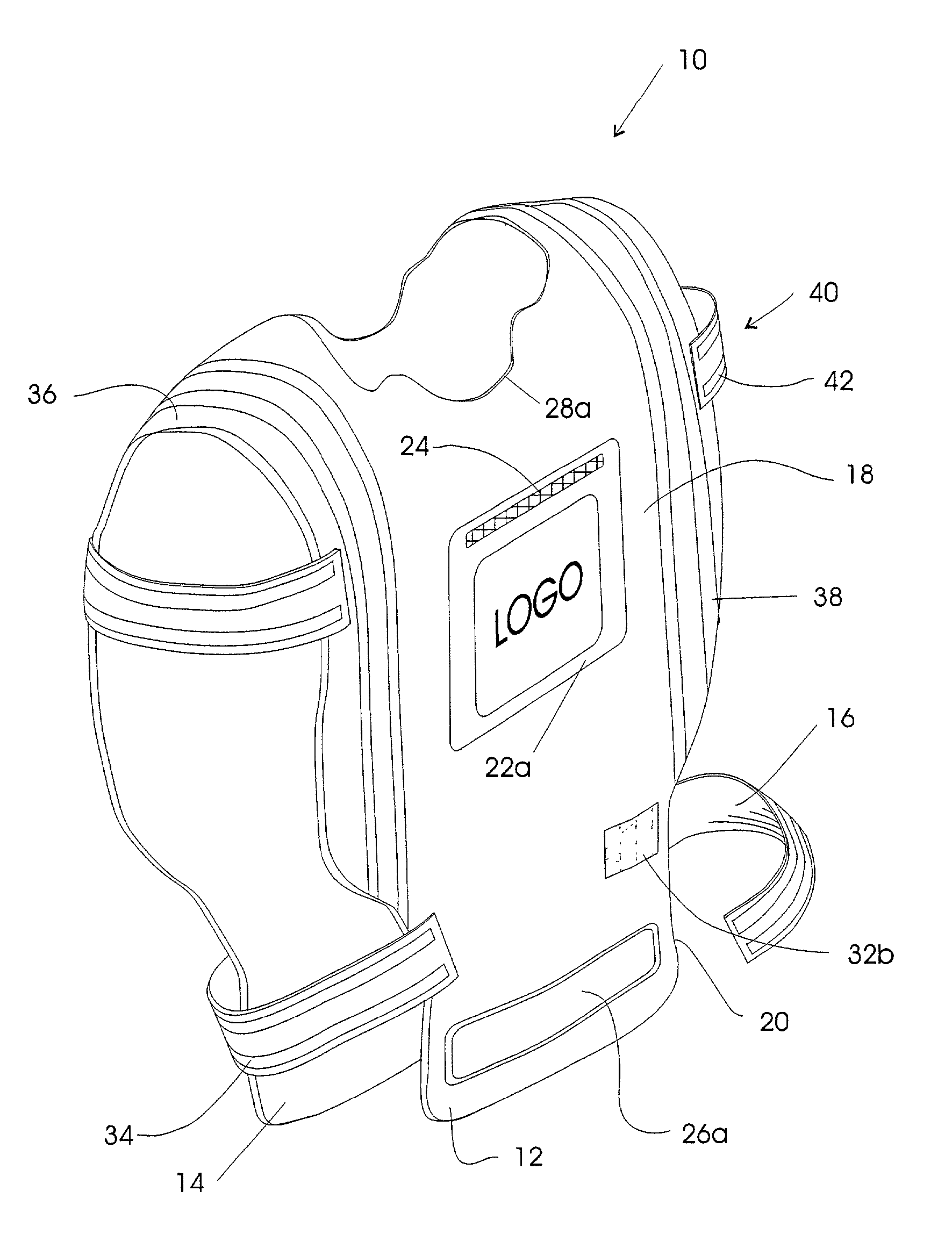

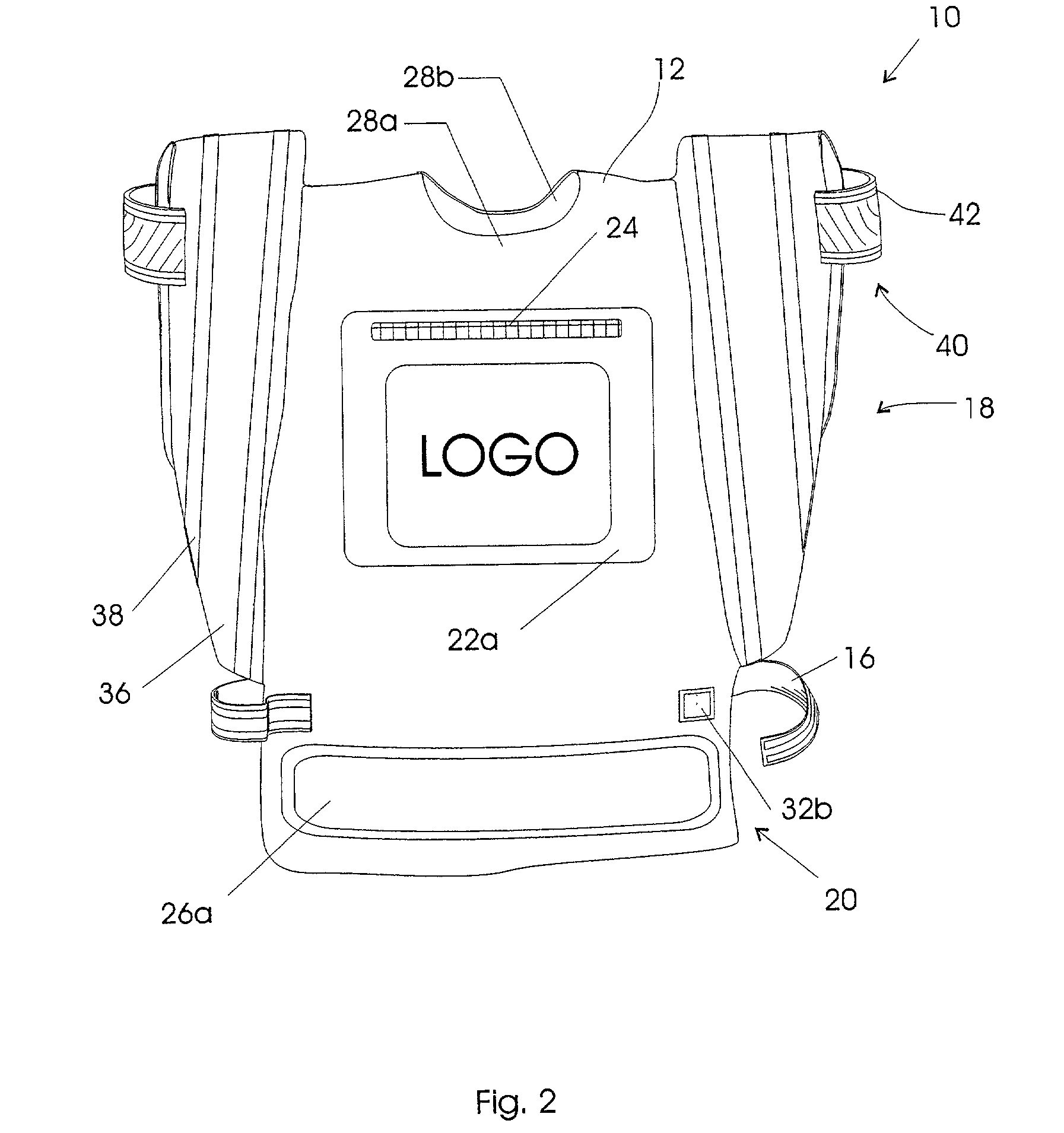

Reflective safety garment

InactiveUS20020145805A1Adjustable sizeSimple designLighting support devicesVehicle interior lightingFront panelEngineering

A safety garment including a vest configuration having a front panel and a rear panel is disclosed. Centrally located on said rear panel is a reflective patch. Surrounding the patch is a mesh material having elastic properties. Extending outwardly from the sides of the vest are protrusions fabricated from a rigid material. Located on these protrusions are reflective patches. A hood can be removably secured to the vest.

Owner:HALL EUGENE C

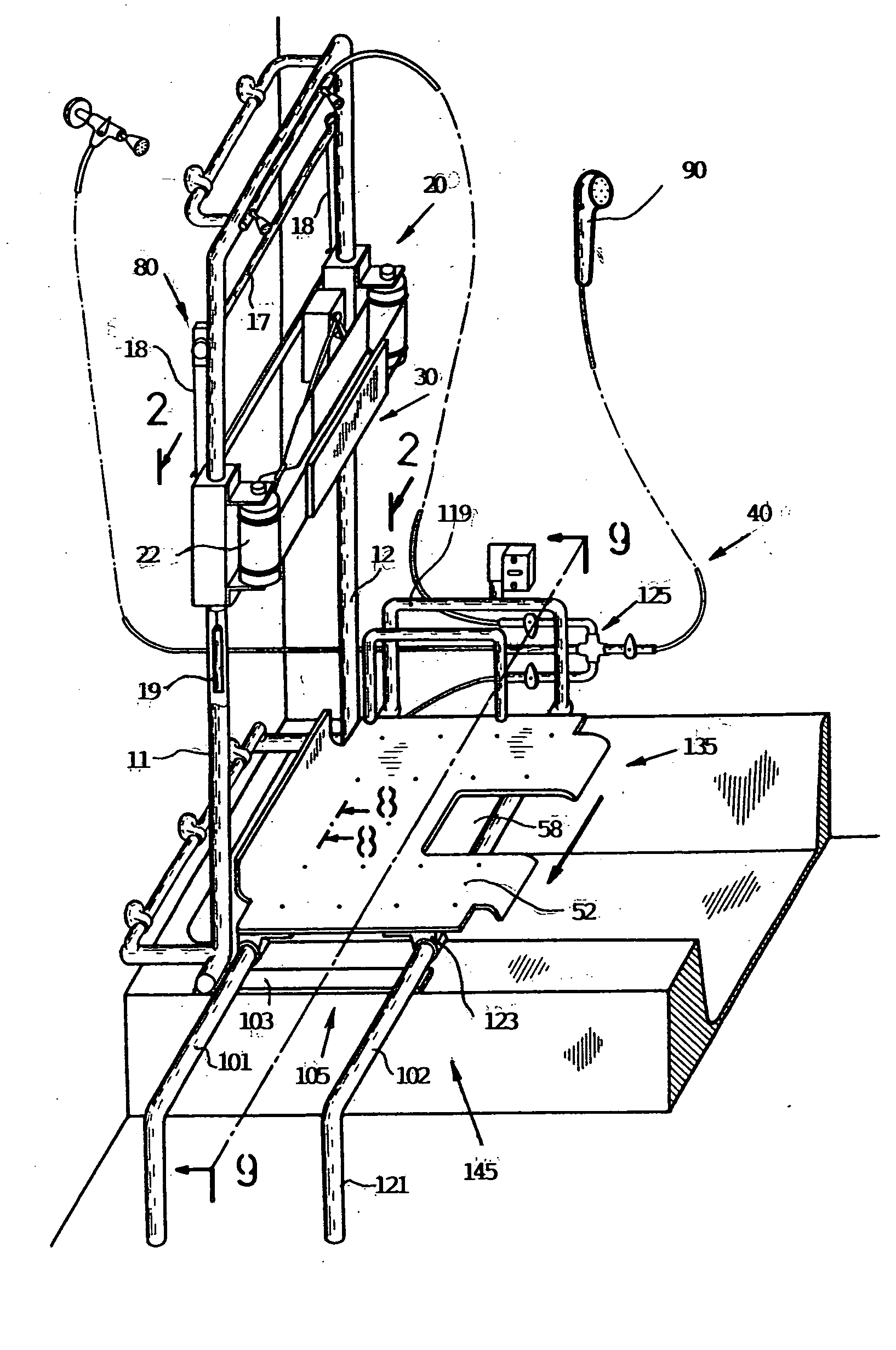

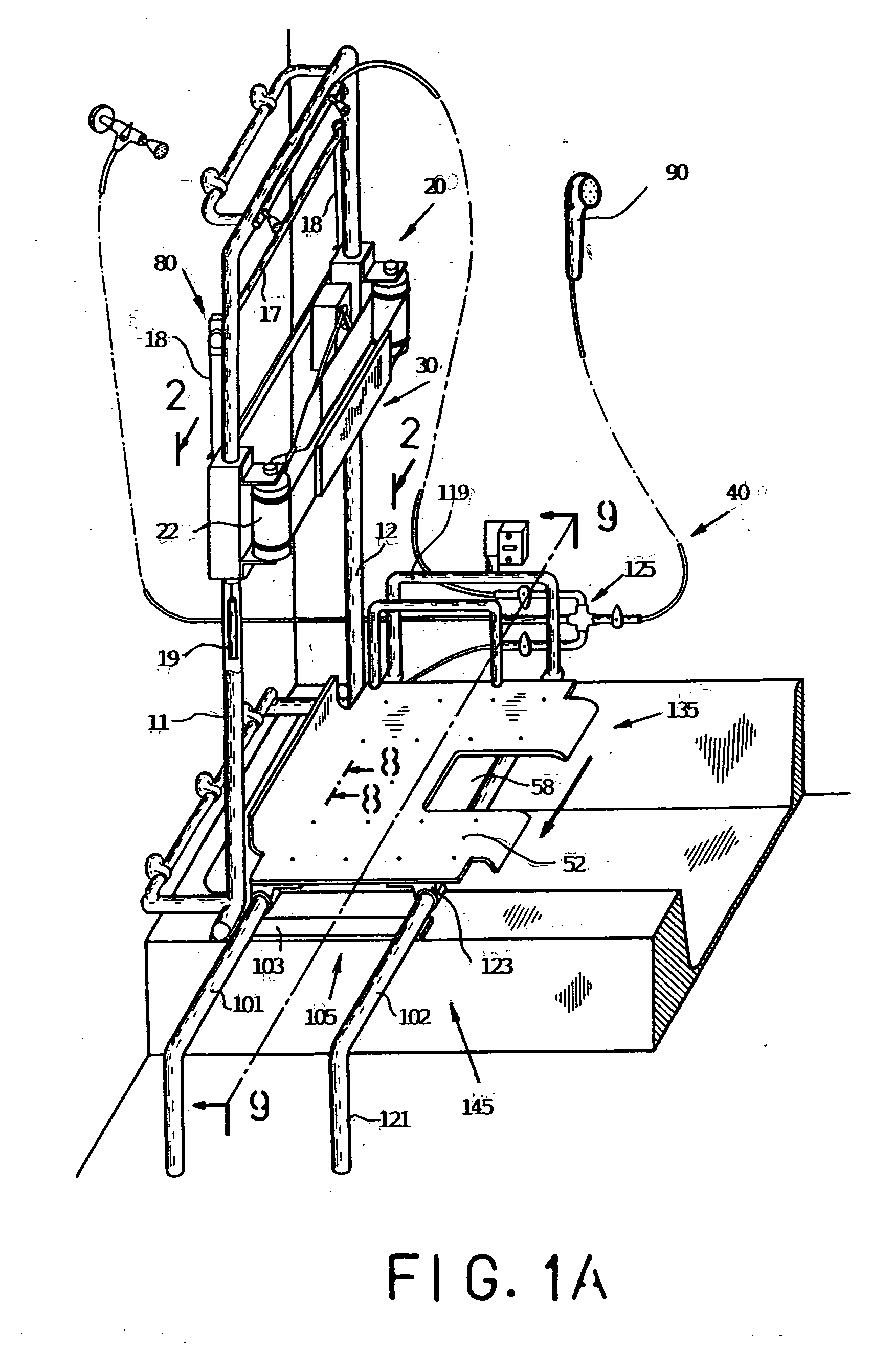

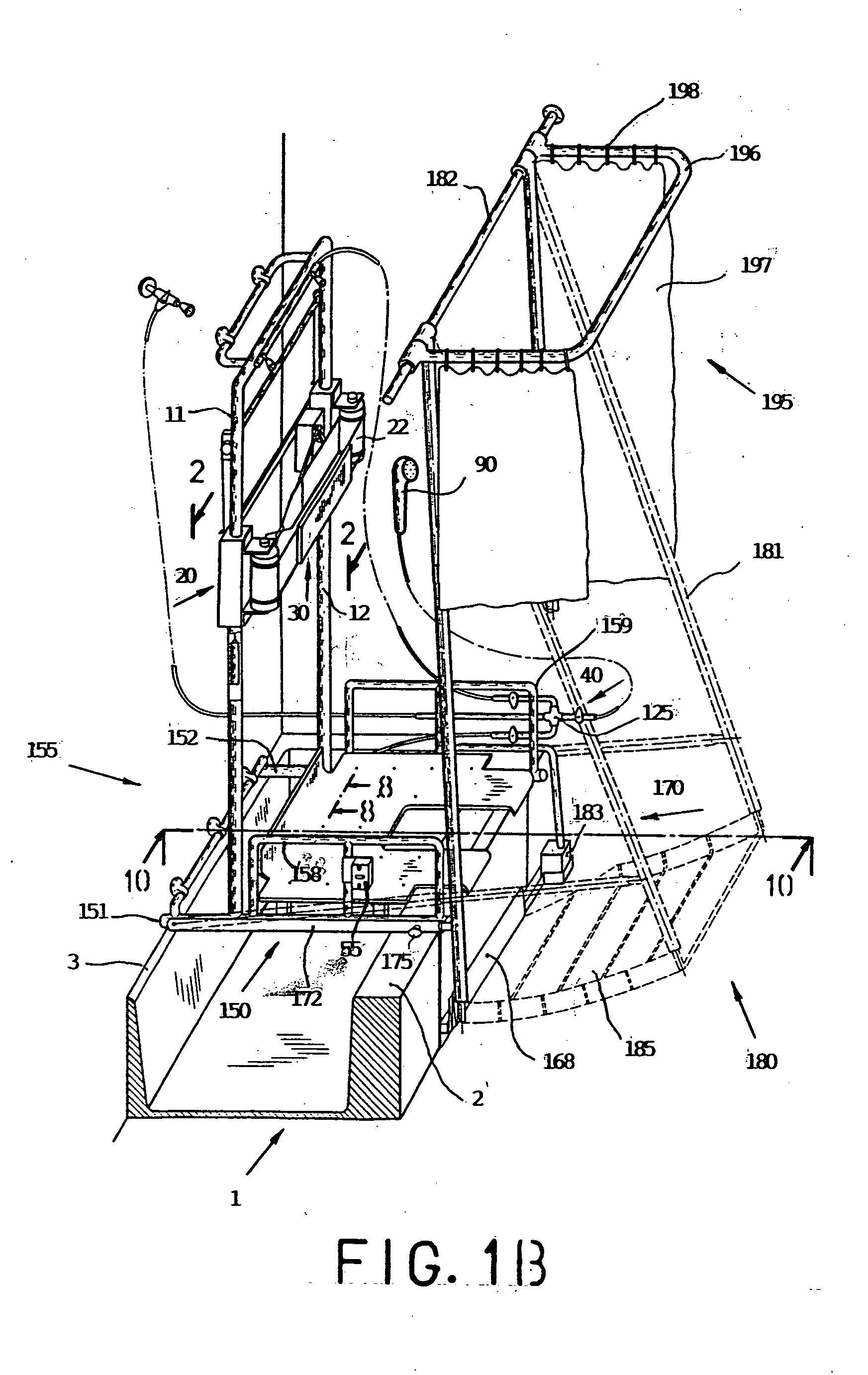

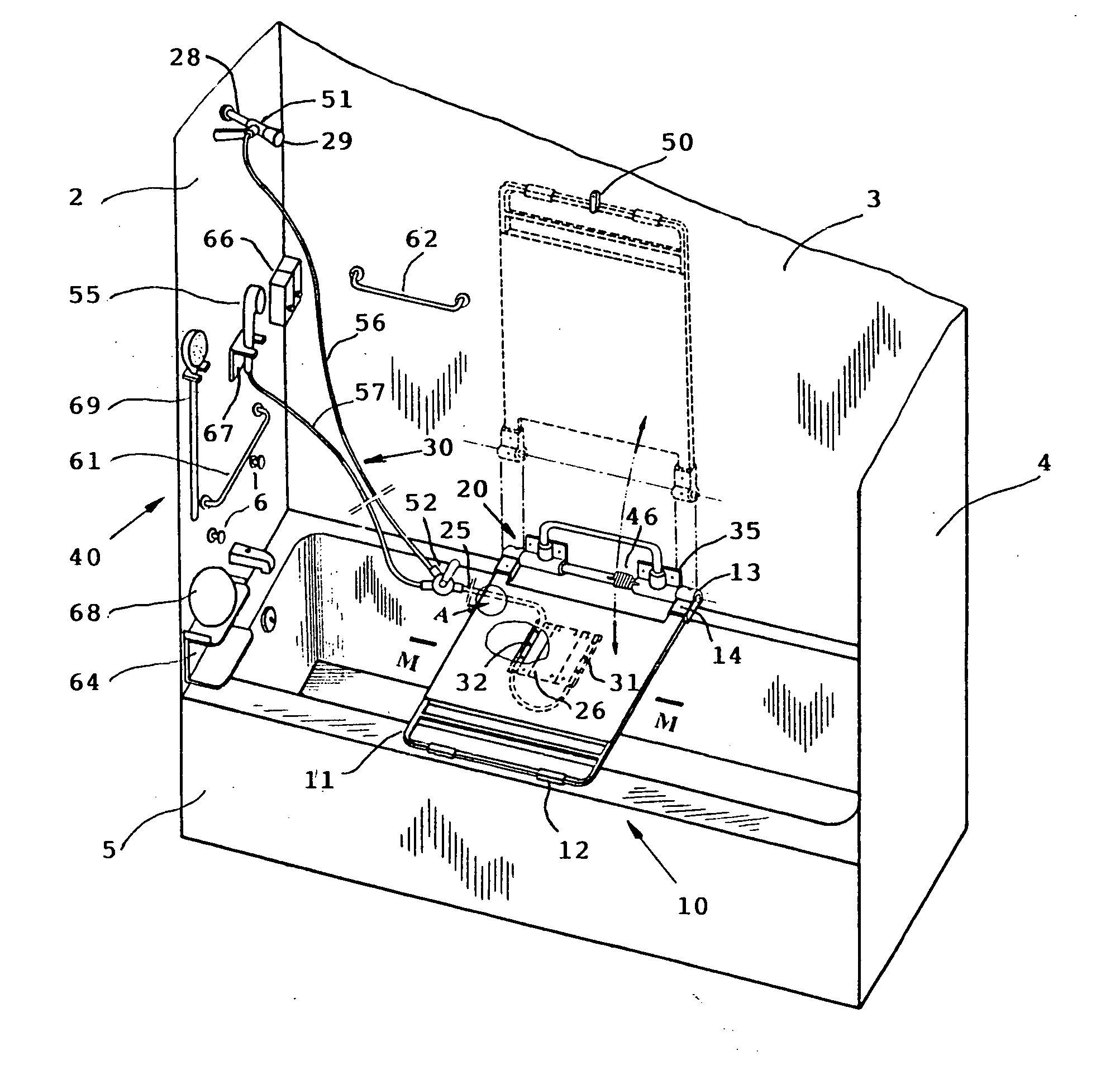

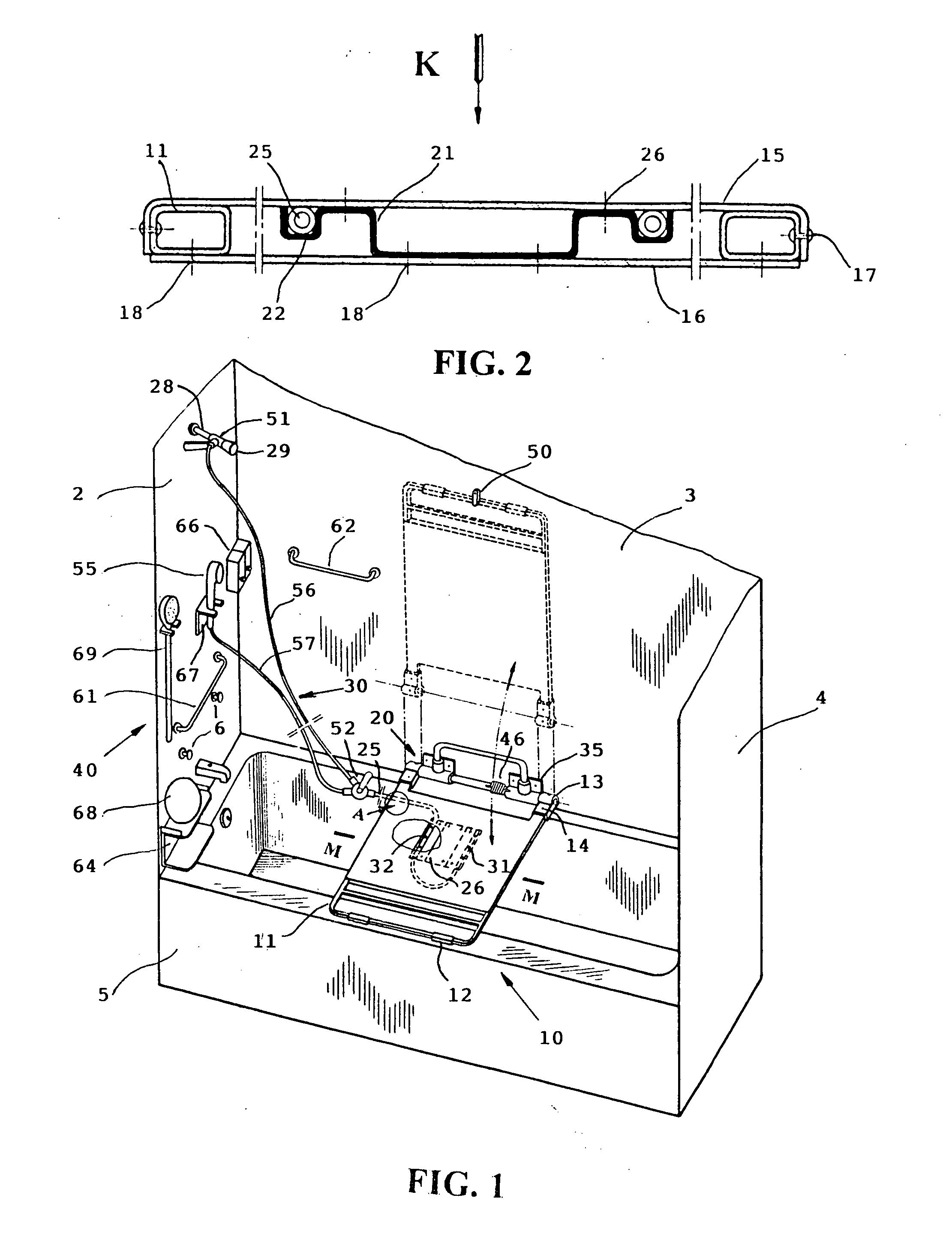

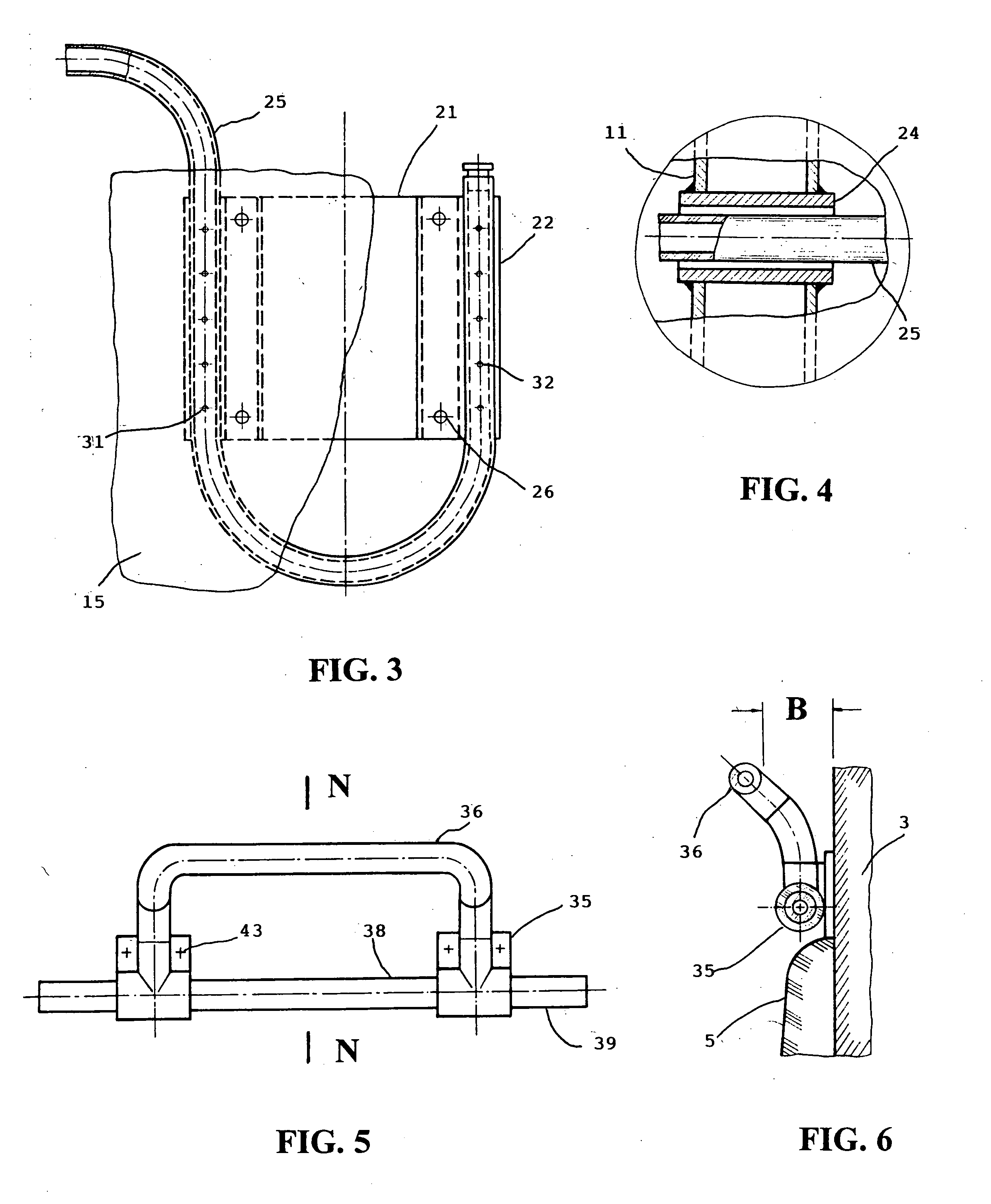

Apparatus for completely bathing onself by users of wheelchair and an elderly, infirm people

Two versions of apparatus for completely bathing oneself by users of wheelchair and elderly, infirm people are disclosed. Both versions includes a slidable up and down carriage with reciprocating belt for soaping and showering bathers back, a chair with coil under the seat for washing bottom parts of the body, a hand shower, and an appliance for washing the feet. For users of wheelchair the chair is designed for sliding with the bather from exterior of the bathtub to the interior of the bathtub. In version for elderly, infirm people the chair seat is fixed in position over the longitudinal lip of the bathtub to let the user to sit down on this chair as well as he sat on a standard chair or toilet. The users back in this case will be in area of the bathtub, while the feet will be out and the water, which coming out will be gathered by curtain in folding tray and pumped back in the bathtub.

Owner:FAINBERG ABRAM

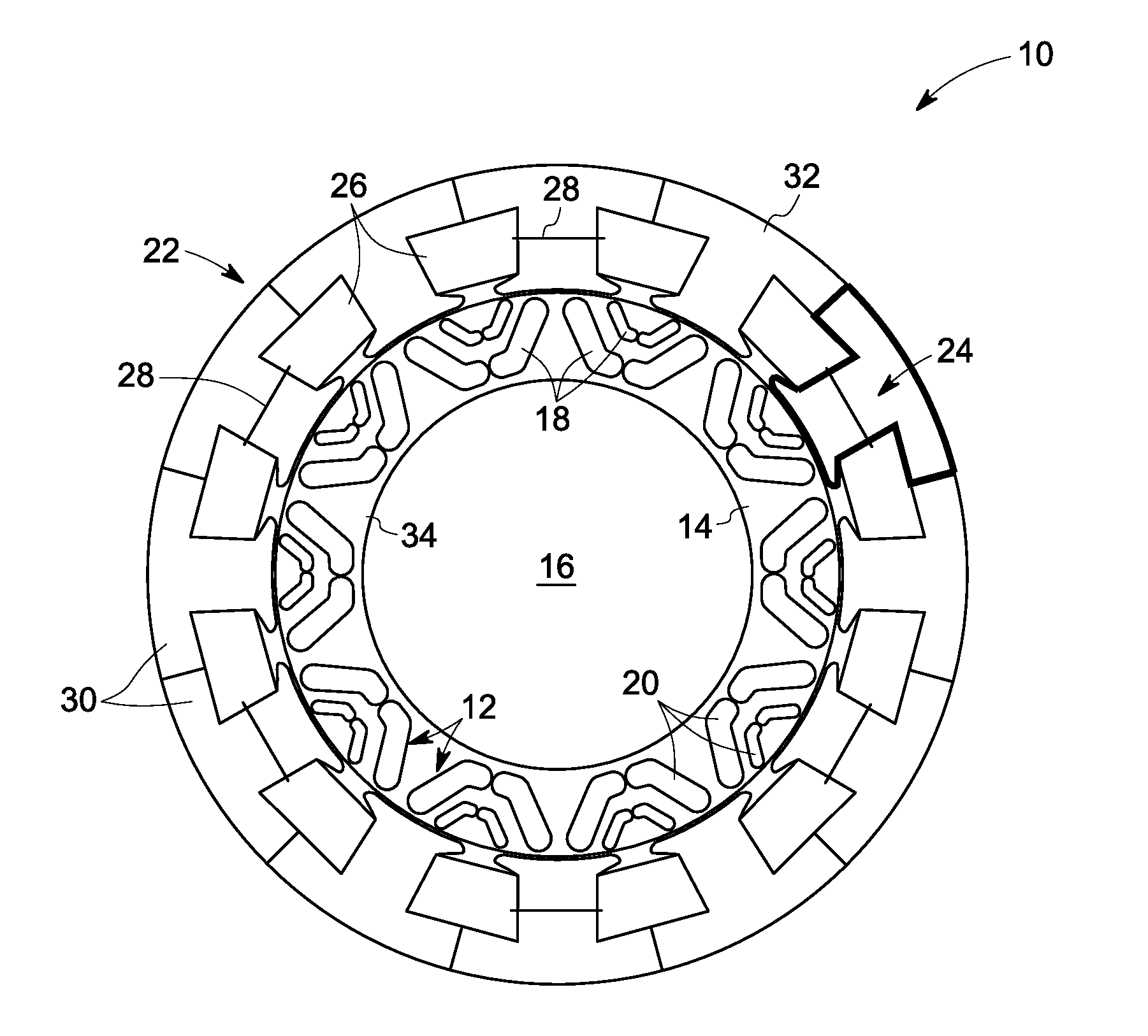

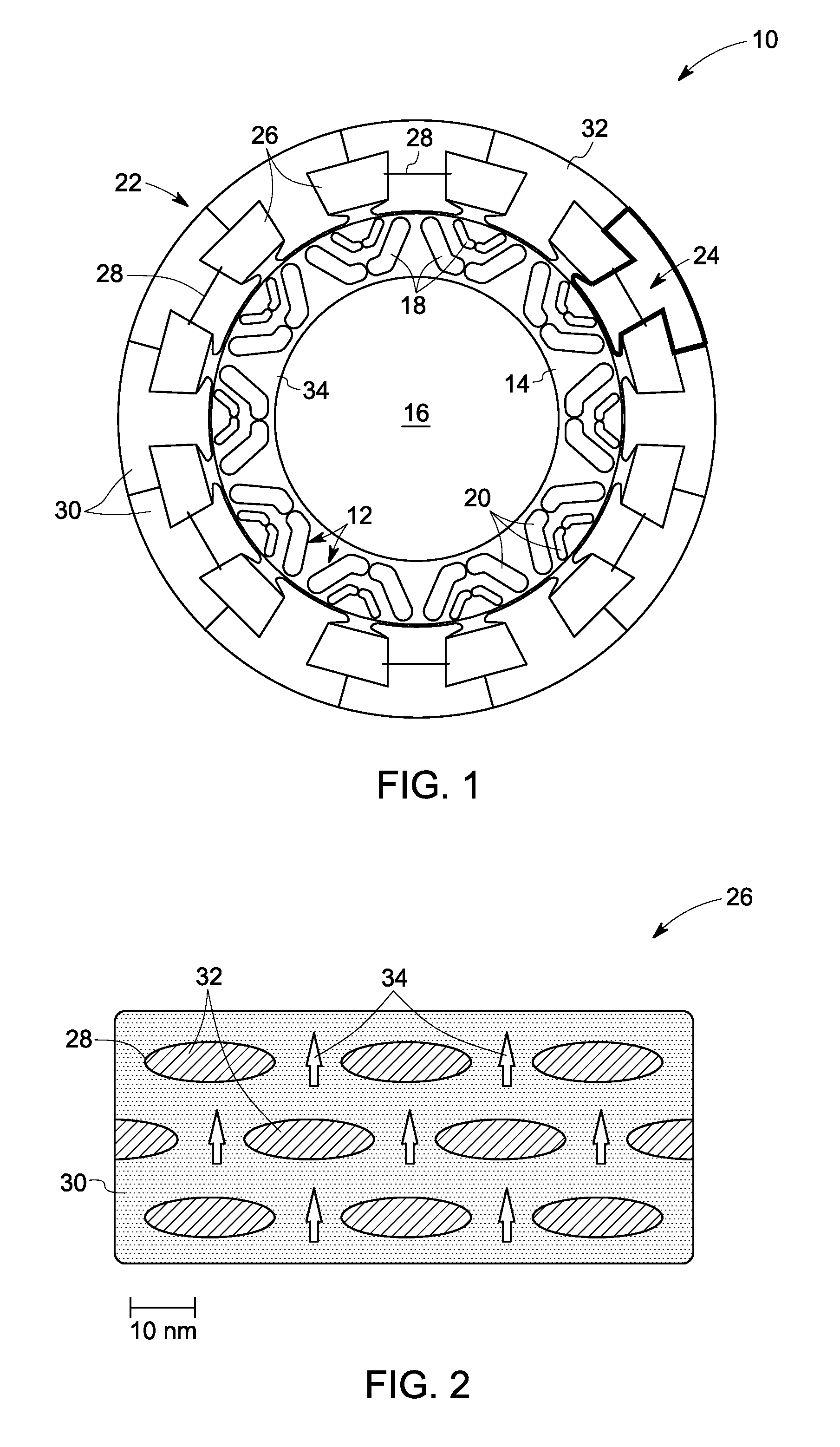

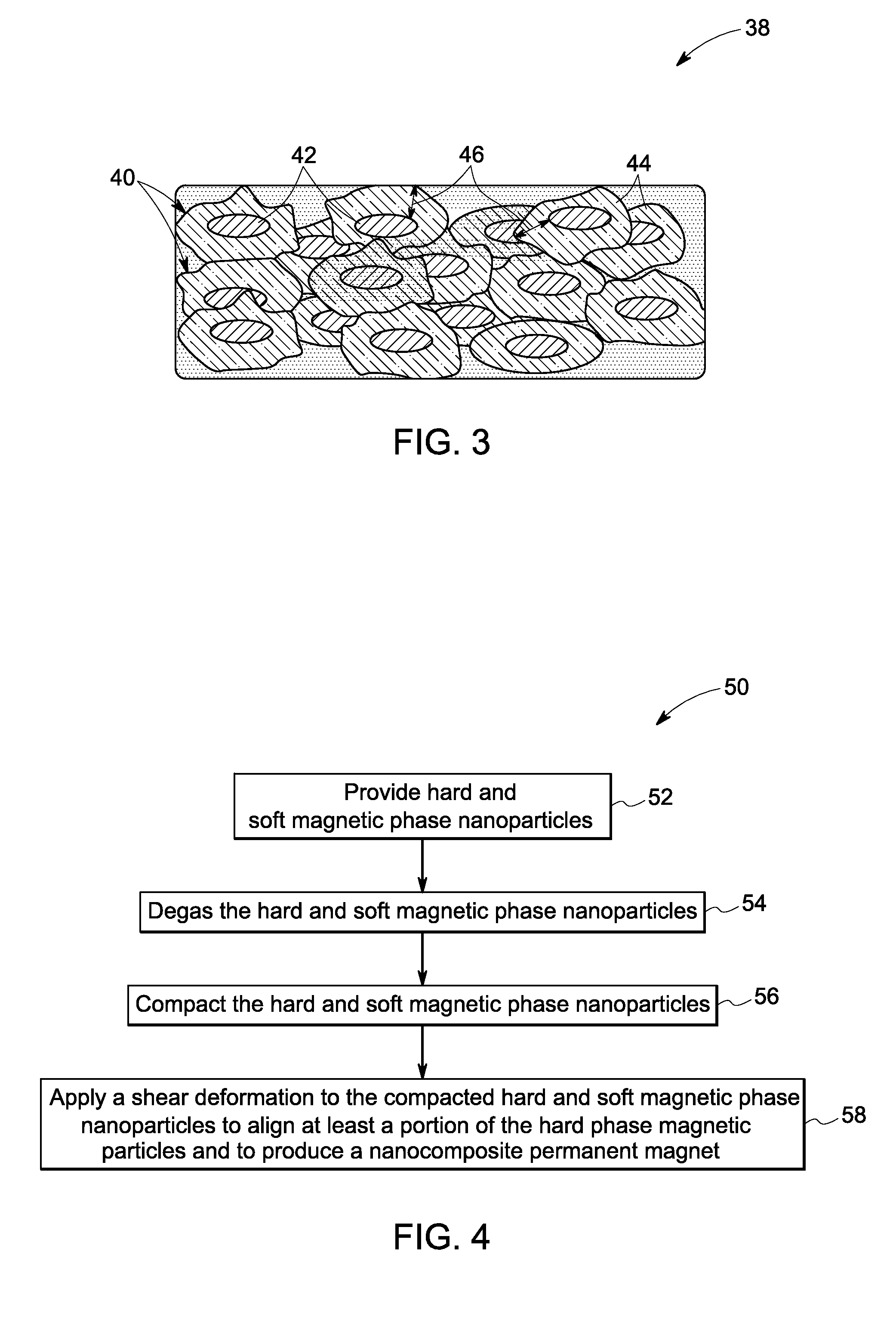

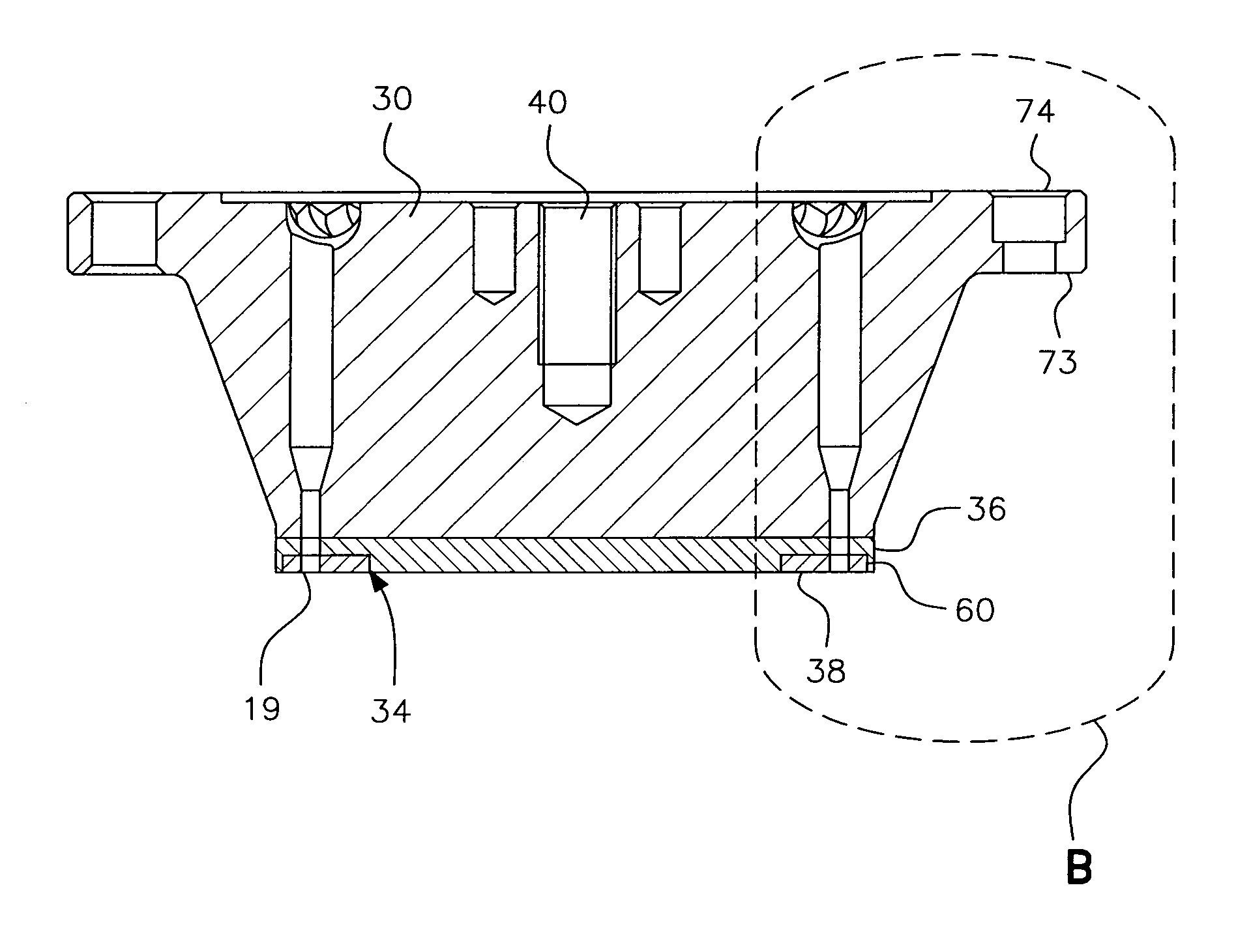

Nanocomposite permanent magnets and methods of making the same

ActiveUS20140002220A1Reduce amountEconomically feasiblePermanent magnetsInorganic material magnetismShearing deformationMagnetic phase

A method of making a nanocomposite permanent magnet is provided. The method comprises applying an extreme shear deformation to hard magnetic phase nanoparticles and soft magnetic phase nanoparticles to align at least a portion of the hard phase magnetic particles and to produce a nanocomposite permanent magnet.

Owner:GENERAL ELECTRIC CO

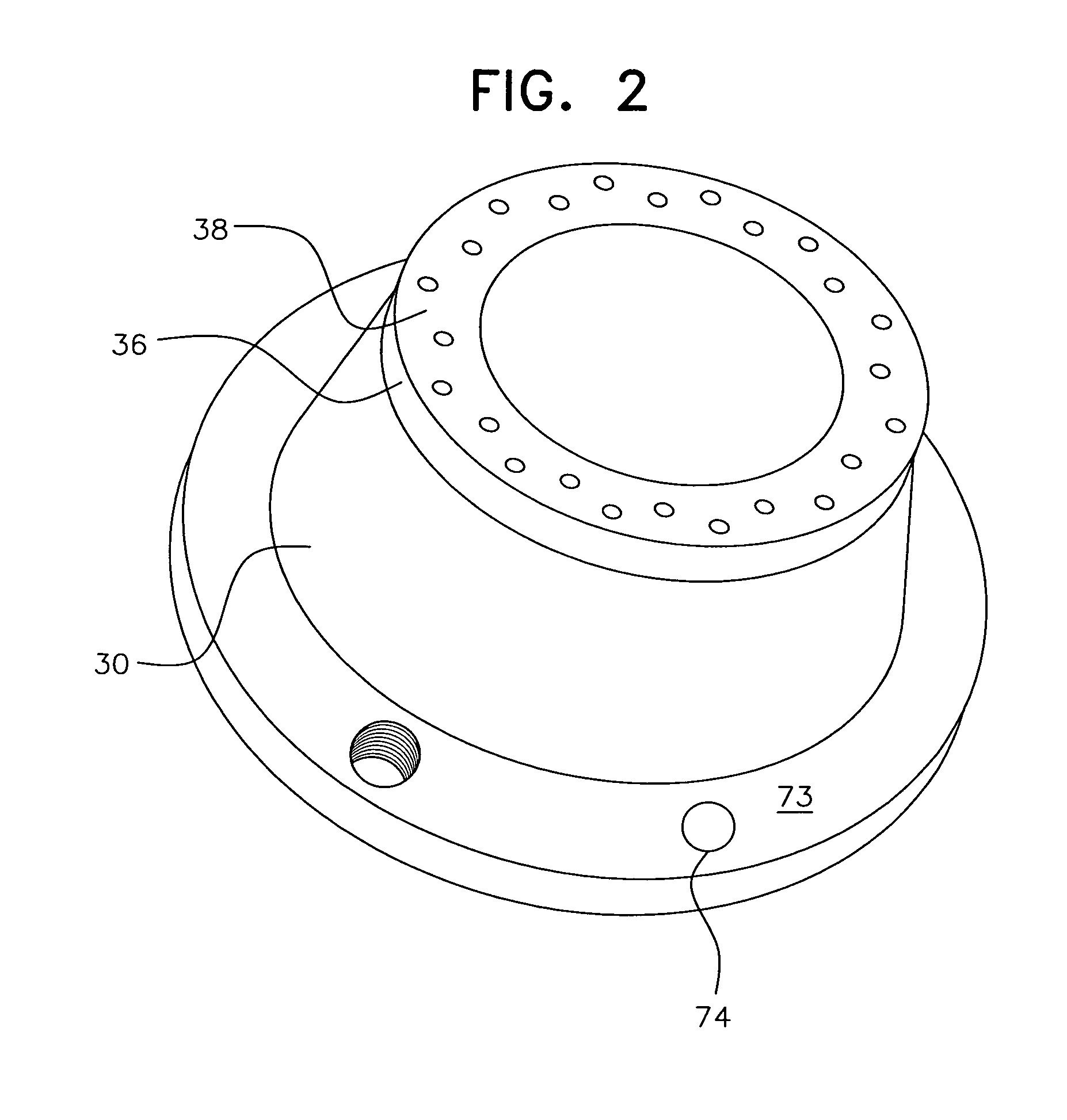

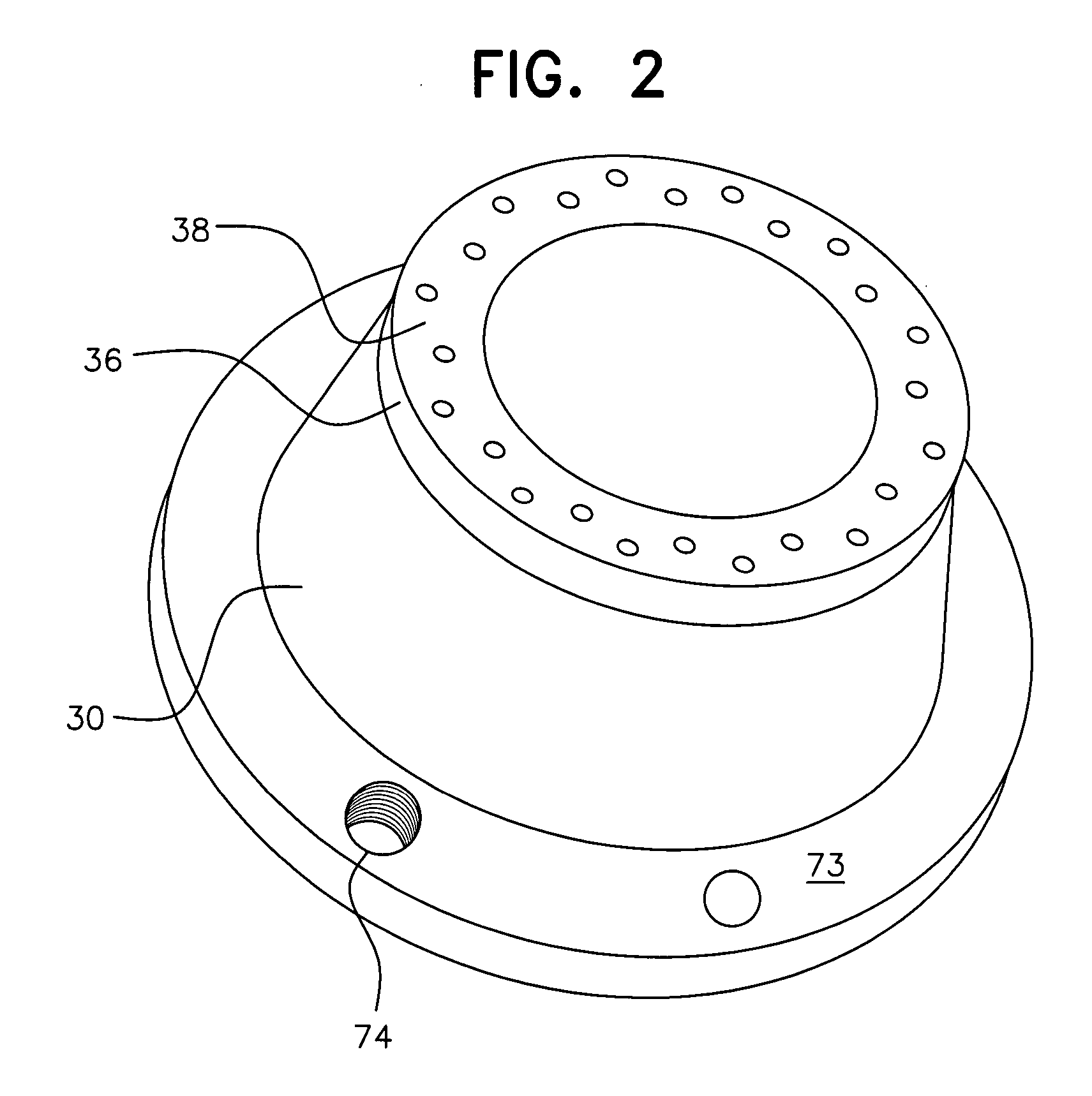

Solid face die plate

A solid face die plate for an underwater pelletizer includes a carrier or holding plate having a circular slot for holding a hard anti-wear element of highly wear-resistant material through which the extrusion orifices open for extruding polymer. The solid face die plate eliminates the need for insulation or plugging material in the center of the die plate and, by embedding the hard anti-wear element within the carrier, protects the edges of the hard anti-wear element for longer wear life.

Owner:GALA INDUSTRIES INC

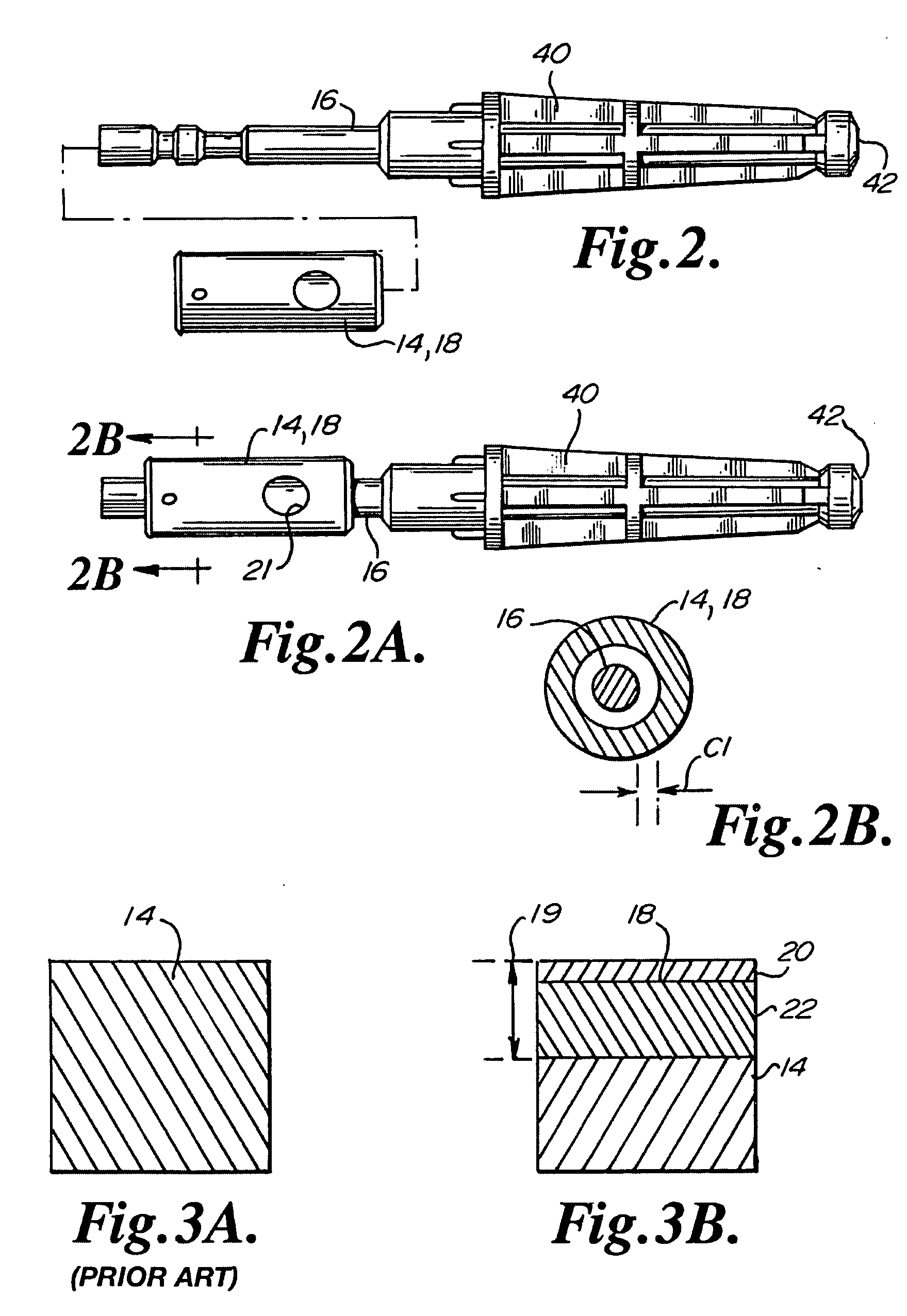

Airless sprayer with hardened cylinder

InactiveUS20070131109A1Less costEconomically feasibleCylindersLiquid spraying apparatusPistonElectric drive

An airless sprayer for paint or the like consists of an electric drive unit connected to a piston. Driven by the electric drive unit, the piston reciprocates within the cylinder, thus spraying the paint or the like. Because of the close tolerance between the piston and cylinder (typically about 0.0002 to about 0.0003 inches), the sprayed liquid provides a seal between the piston and cylinder. To prevent this tolerance from increasing to the point of failure, the cylinder is manufactured from nitride hardened steel. A process for manufacturing the airless sprayer is also disclosed.

Owner:DIVERSIFIED DYNAMICS

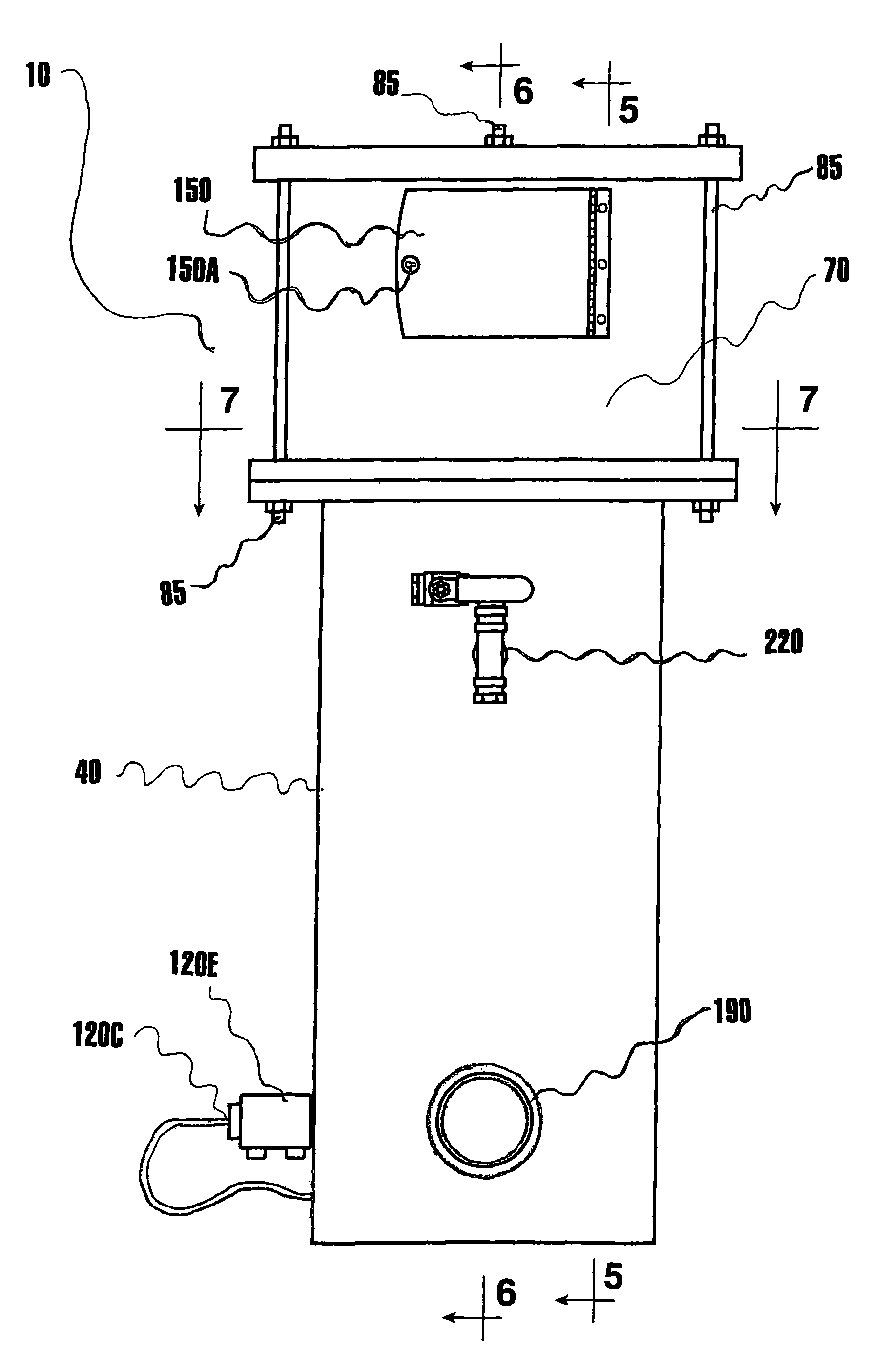

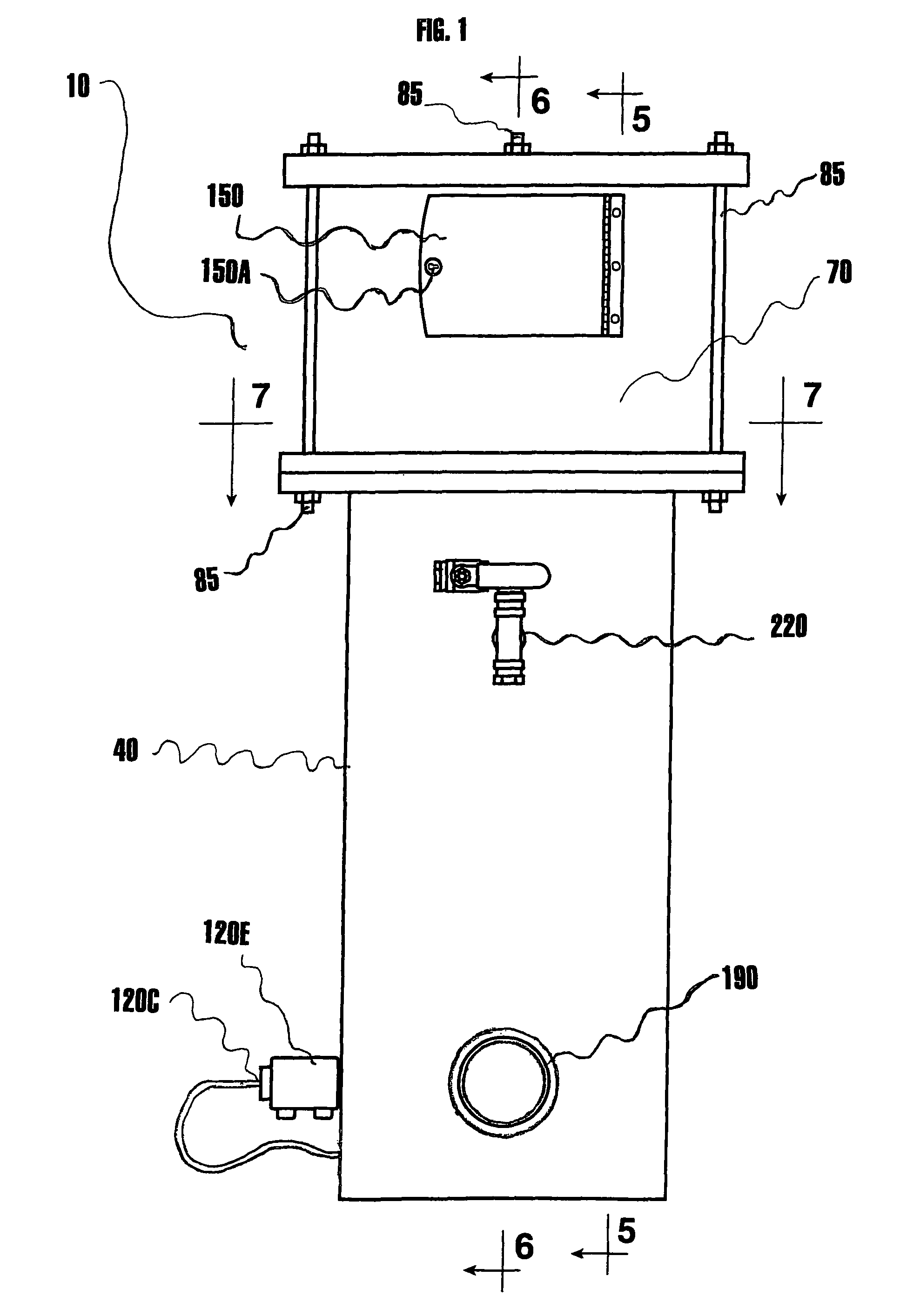

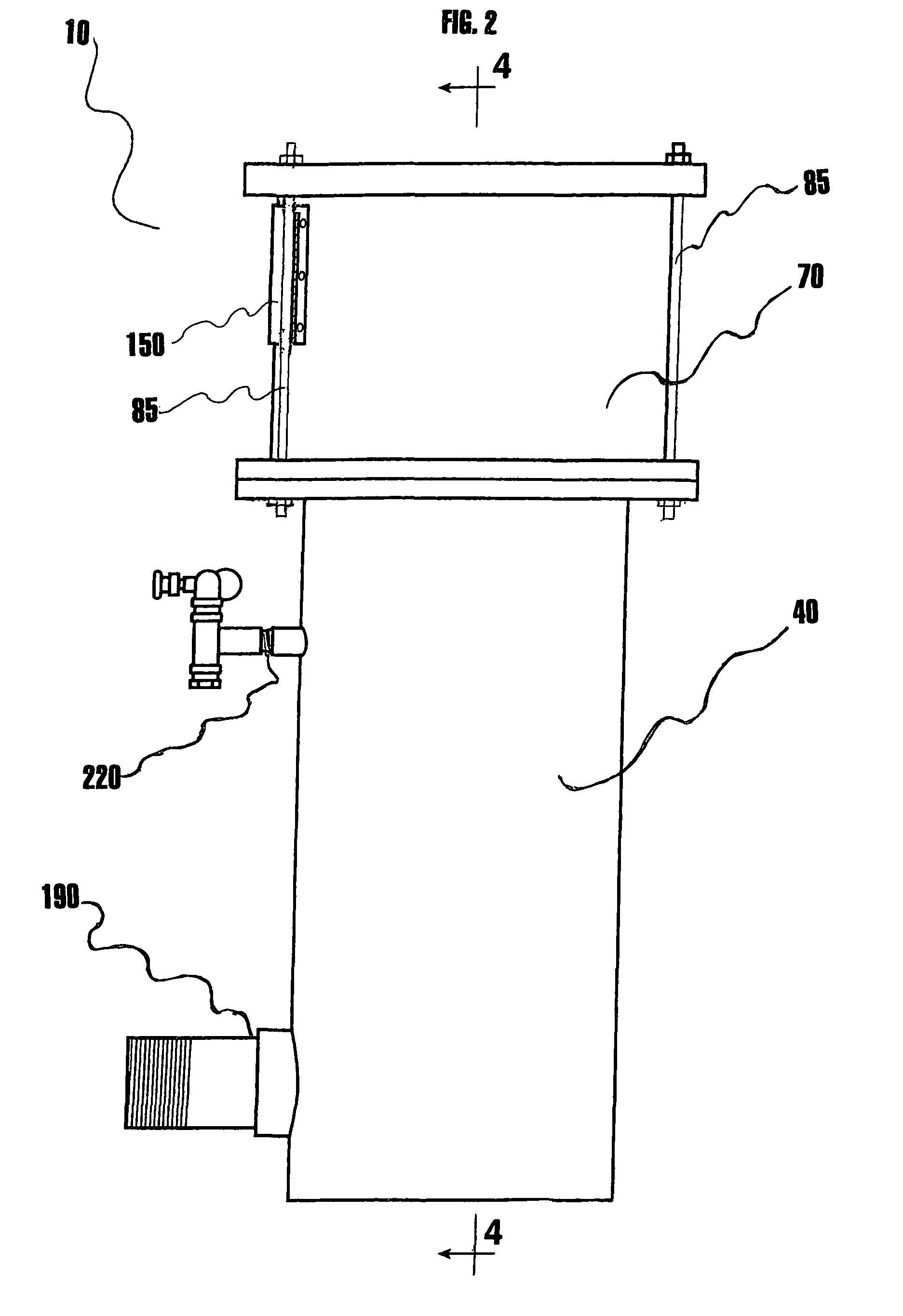

Riser assembly for use with fluid sprinkler

ActiveUS7832659B1Easily and efficiently instalStability , ease and simplicitySelf-acting watering devicesWatering devicesEngineeringGuide tube

The invention is riser assembly for use with a fluid dispenser particularly a sprinkler. The assembly includes: (1) a container partially circumscribing a reservoir for containing a pressurized fluid, the container having a fluid inlet and a fluid outlet disposed therethrough, and (2) a conduit circumscribing a channel occupiable by a signal carrier, the conduit including an intermediate conduit portion disposed within the reservoir, a first conduit portion disposed through the container to a signal carrier entry area outside the container and a second conduit portion disposed through the container to a signal carrier exit area outside the container. The assembly may include a cover connectable to the container, the cover having an aperture for containing the fluid dispenser disposed therethrough, a protective cavity being formed between the cover and the container.

Owner:COLLINS WADE E

Bath collapsible seat

A bath collapsible seat for persons requires bathing in sitting position and for persons, which takes a regular shower or bath comprises: a wall mounting unit rigidly attached to a bathroom wall, a seat assembly pivotally attached to said wall mounting unit to provide moveable between vertical and horizontal positions, where said seat assembly in vertical position not prevented the bather to take regular shower or bath, a water supply means, and means for bathing accessories.

Owner:FAINBERG ABRAM

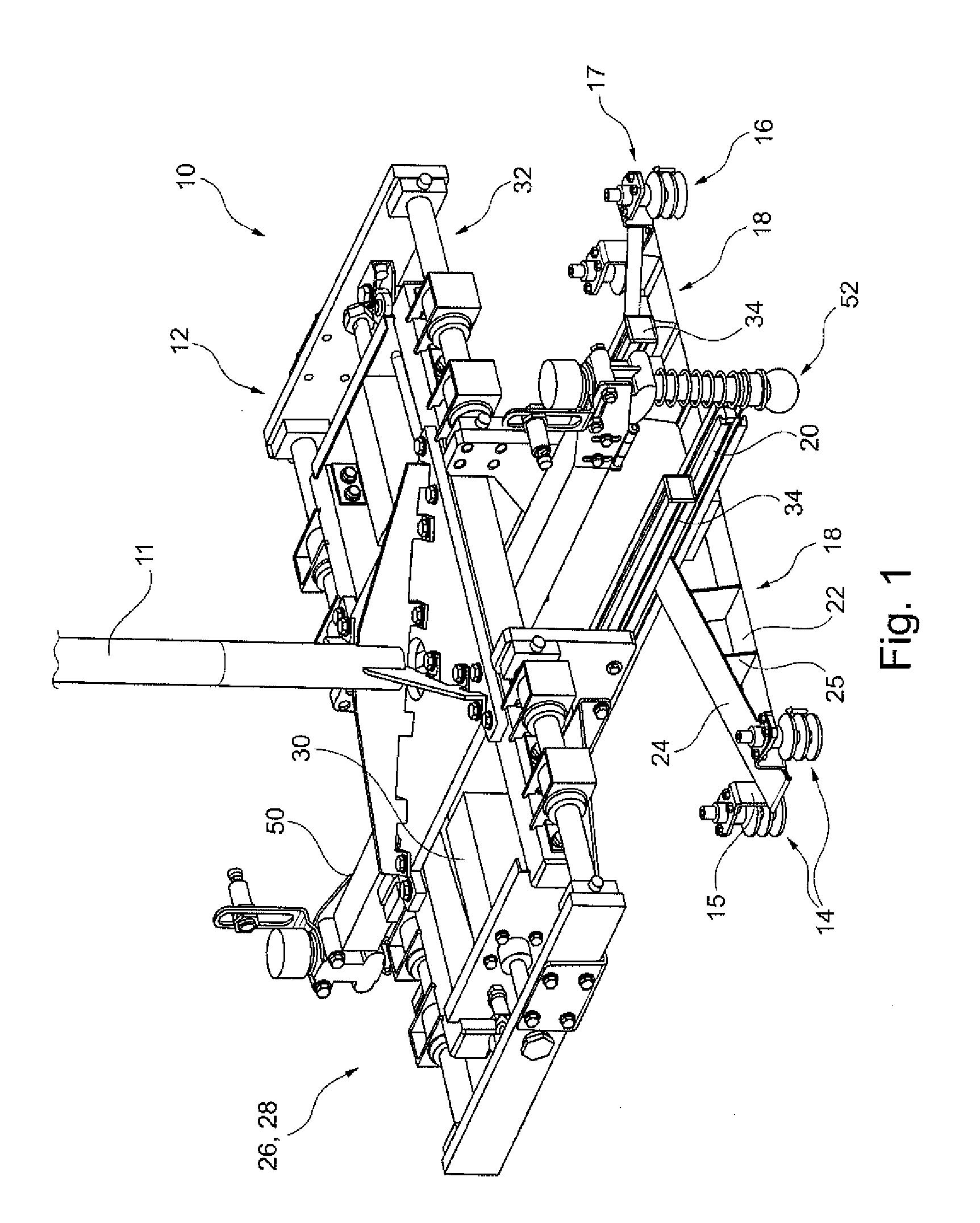

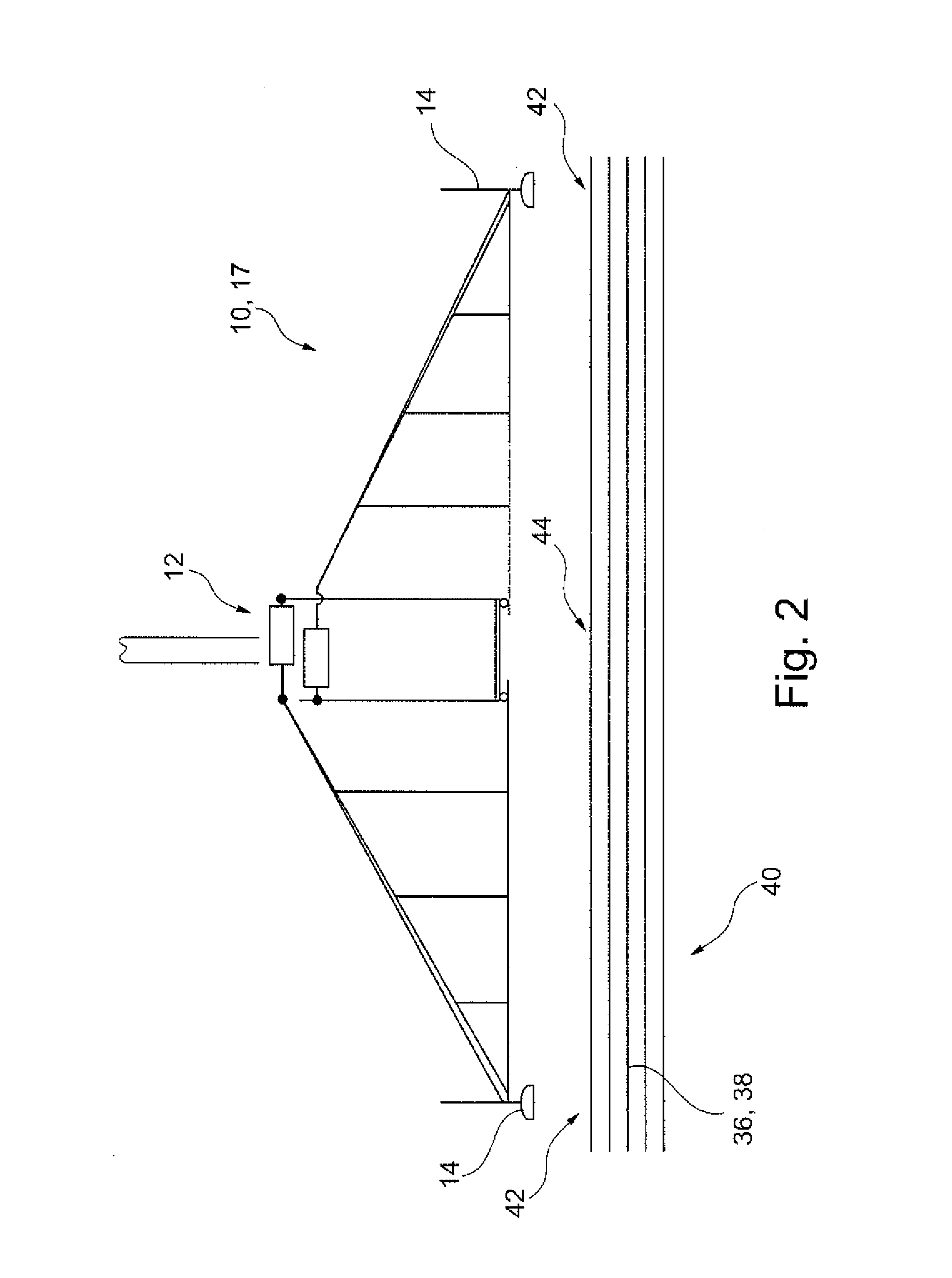

Device and method for receiving, holding and/or handling two-dimensional objects

A receiving, holding and / or handling device for two-dimensional objects, with at least two controllable suction grippers. The suction grippers are arranged and connected to free ends of movable cantilever arms, which are elastically deformable at least in some sections. The cantilever arm are mounted and supported on a bridge. The cantilever arms each include at least one lower pull and one upper pull which meet at the free end of the cantilever arm and are connected there. An actuating device is assigned to the upper pull. The actuating device generates a pulling force with at least one horizontal direction component which is approximately parallel to the longitudinal extension direction of the cantilever arm. A method is also disclosed.

Owner:KRONES AG

Thermally insulated die plate assembly for underwater pelletizing and the like

InactiveUS20100040716A1Maintain temperatureImprove robustnessAuxillary shaping apparatusAtmospheric airUnderwater

An insulated die plate assembly for use in underwater pelletizing and other granulation processes includes a thin, continuous air chamber formed across the plate assembly generally parallel to the die face such that the heated upstream portion of the die plate assembly is thermally insulated from the downstream portion. The air chamber is atmospherically equilibrated by venting the air chamber to the atmosphere. The plurality of extrusion orifices, either individually or in groups, are formed in extrusion orifice extensions that extend through the insulation chamber so that the process melt to be granulated can pass therethrough. The orifice extensions and the components forming the air chamber around the orifice extensions are specially configured to channel heat along said extensions to maintain the process melt therein at a desired temperature, to help rigidify the die plate assembly and to better seal the air chamber.

Owner:GALA INDUSTRIES INC

Solid face die plate

A solid face die plate for an underwater pelletizer includes a carrier or holding plate having a circular slot for holding a hard anti-wear element of highly wear-resistant material through which the extrusion orifices open for extruding polymer. The solid face die plate eliminates the need for insulation or plugging material in the center of the die plate and, by embedding the hard anti-wear element within the carrier, protects the edges of the hard anti-wear element for longer wear life.

Owner:GALA INDUSTRIES INC

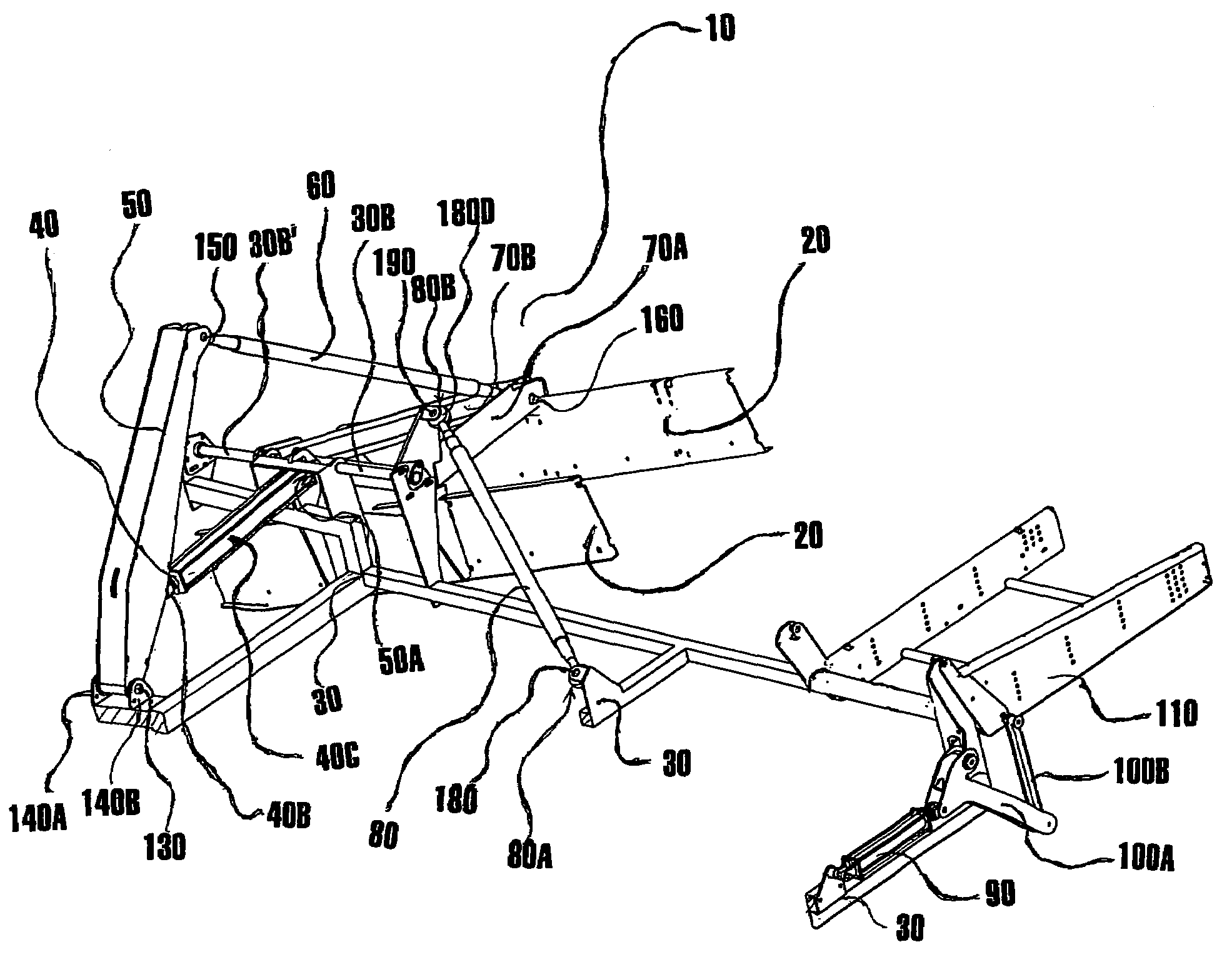

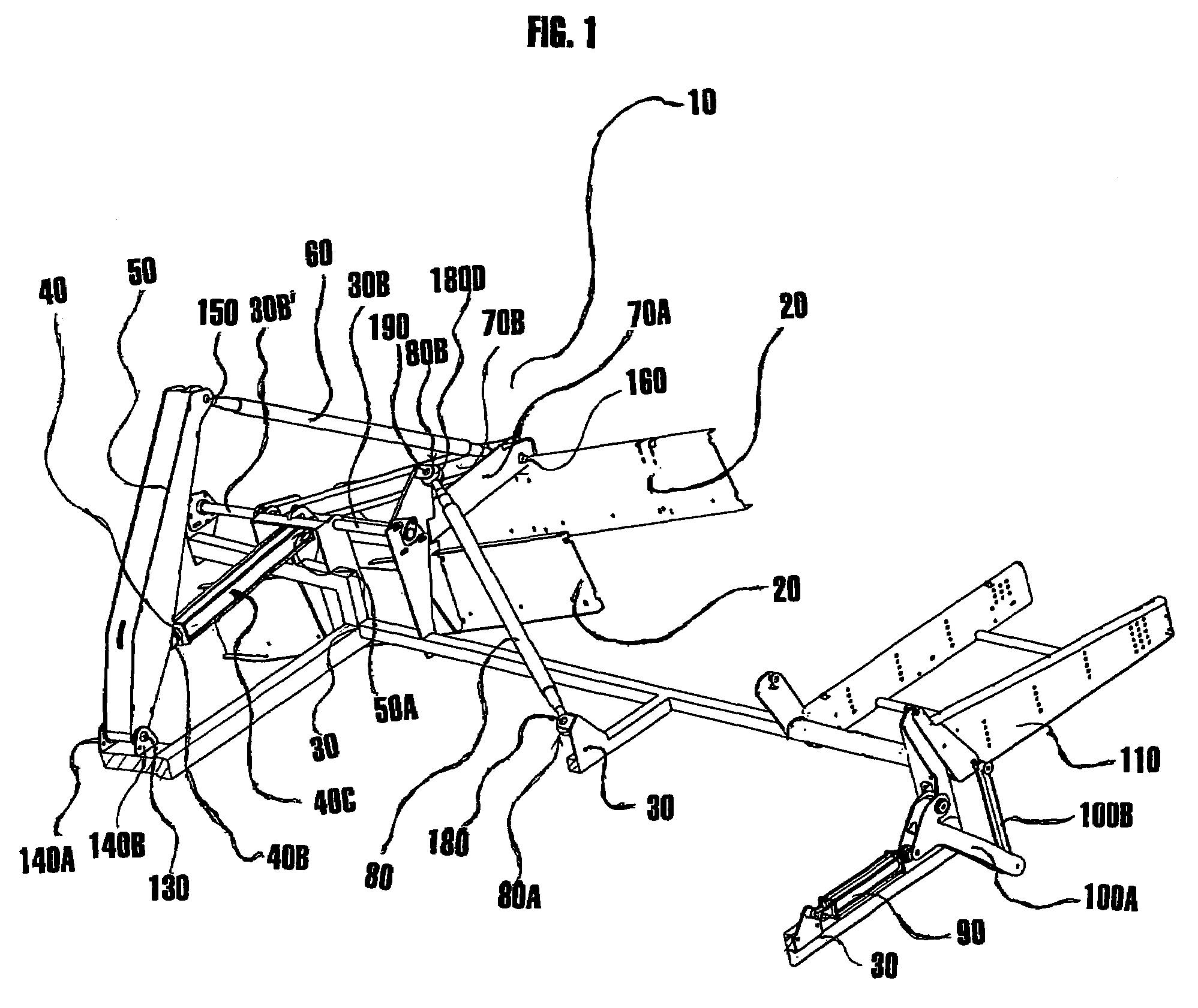

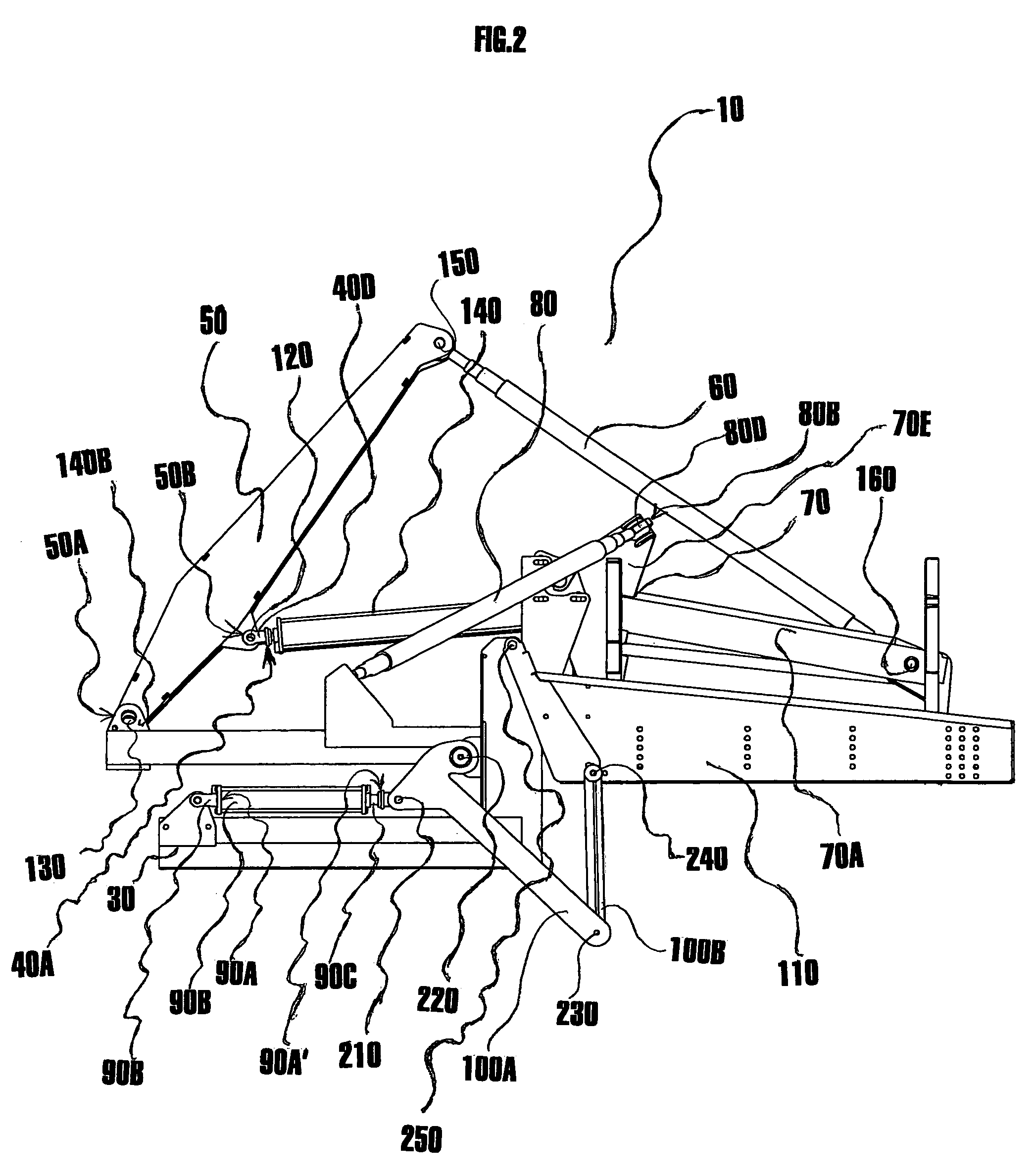

Assembly for moving and rotating conveyor

InactiveUS7261200B1Rapidly and efficiently rotateClear pathDiggersSupporting framesEngineeringActuator

The invention is an assembly for moving and rotating a conveyor from a operational orientation to a transport orientation. The assembly includes: an actuator operatively connecting to a first frame; an arm operatively connecting to the actuator and pivotally connecting to a first frame; a support sub-assembly operatively connected to the first frame and selectively rotatable around an axis and moveable forward and rearward along the axis, the support assembly operatively connecting to a conveyor frame; a first turnbuckle pivotally connected to the arm and to the support sub-assembly; and a second turnbuckle pivotally connected to the first frame and to the support sub-assembly. The assembly may further include a second actuator operatively connected to the first frame and operatively connected through a plurality of pivotally attached connection arms to a hopper.

Owner:SPUDNIK EQUIP

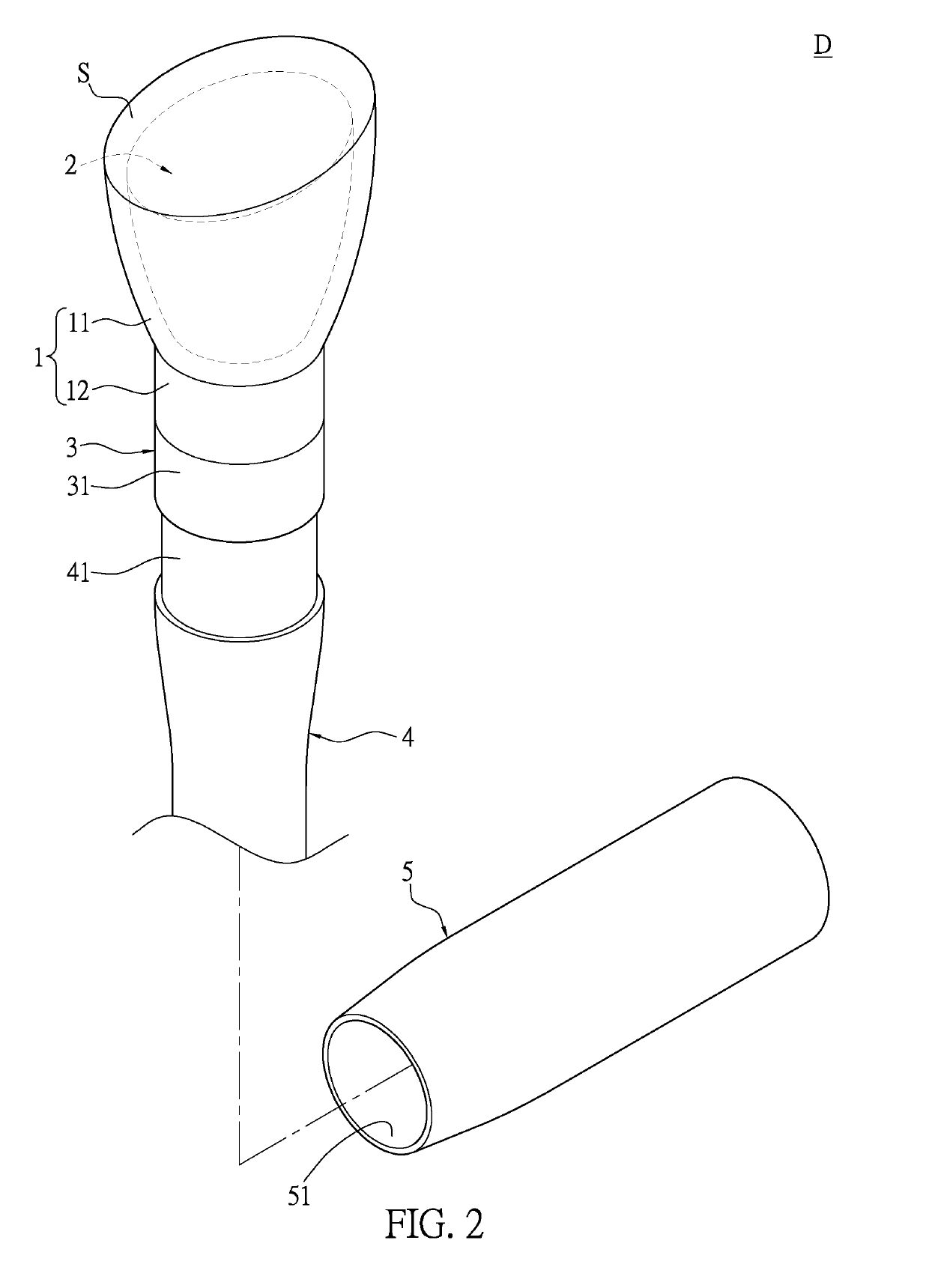

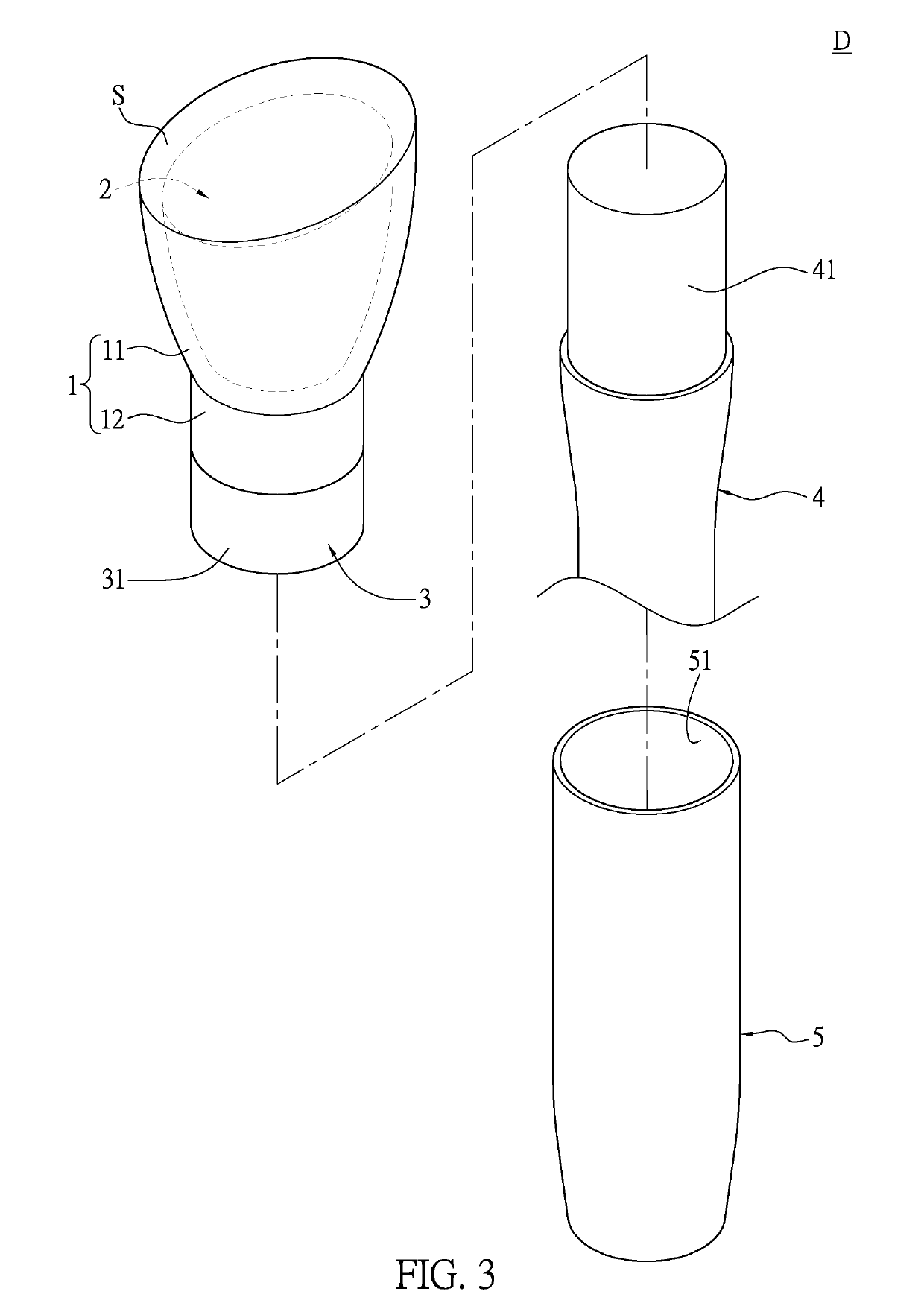

Assembly-type application device and method for using the same

InactiveUS20190216201A1Improve convenienceGood flexibility in usePackaging toiletriesPackaging cosmeticsEngineeringMechanical engineering

An assembly-type application device for a cosmetic product and a method for using the same are disclosed. The assembly-type application device includes a hollow application member, an elastic body, a sealing member, and a holding member. The elastic body is filled in the hollow application member and the hollow application member becomes resilient in the presence of the elastic body. The sealing member is in sealing contact with the hollow application member to maintain the elastic body in the hollow application member. The holding member is coupled with the hollow application member via the sealing member. Every time the assembly-type application device is used, a usage amount of the cosmetic product can be reduced, and the assembly-type application device is easily cleaned after being used.

Owner:HUANG TSUNG REY

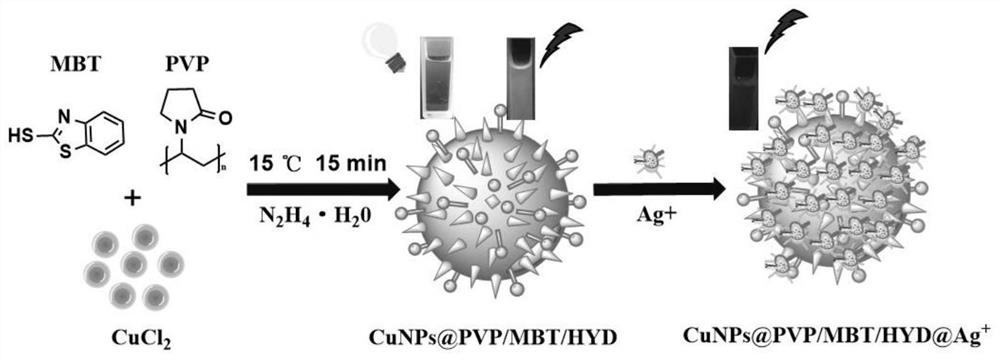

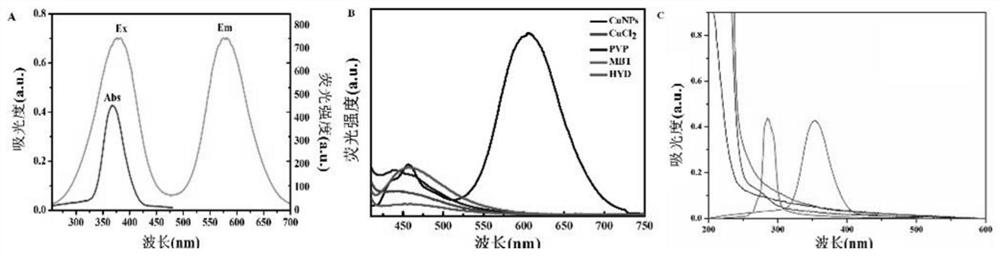

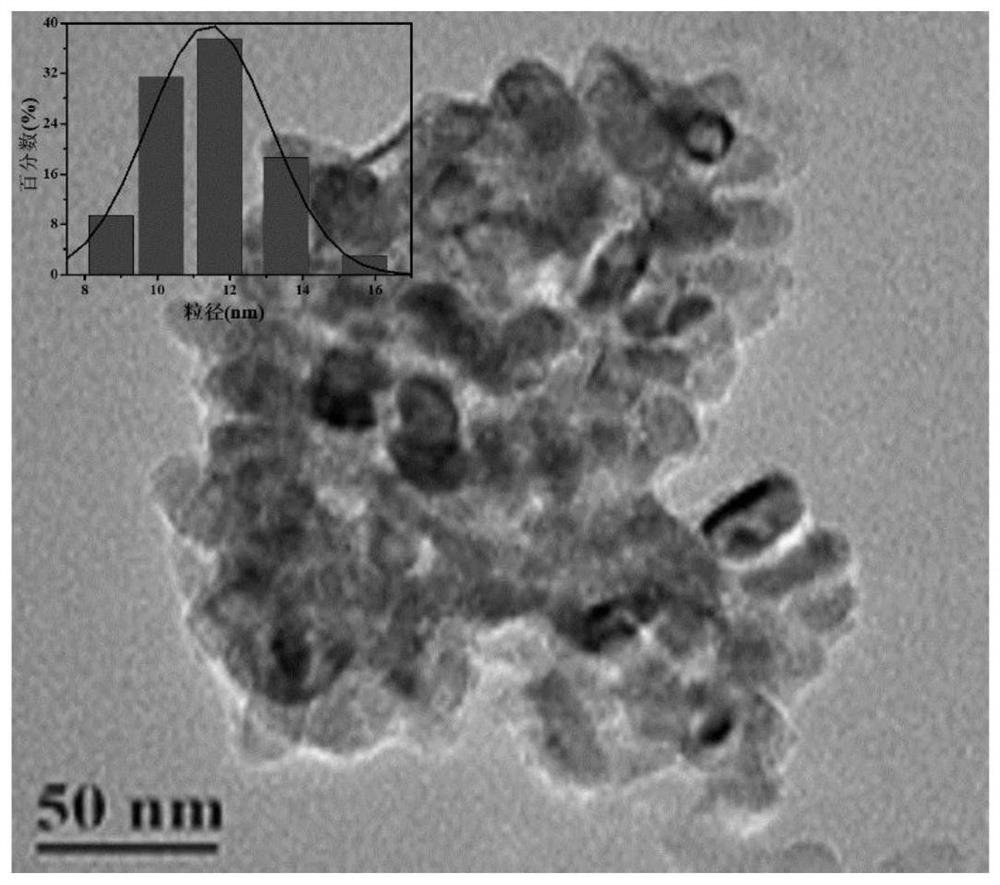

Copper nanoparticle solution as well as preparation method and application thereof

PendingCN111715891AEasy to operateHighly selective detectionNanoopticsFluorescence/phosphorescencePoly ethyleneDyeing

The invention discloses copper nanoparticle solution as well as a preparation method and application thereof. The preparation method of the copper nanoparticle solution comprises the following steps that aqueous solutions of copper chloride, 2-mercaptobenzothiazole and polyvinylpyrrolidone are respectively prepared, then the aqueous solutions are mixed and added with hydrazine hydrate, and finallythe solution is stand at 10-20 DEG C to obtain the strong orange fluorescence emission copper nanoparticle solution. The prepared copper nanoparticle solution probe is high in stability, can be usedfor detecting silver ions and is applied to silver ion detection test paper, and detection of the silver ions is visualized. The copper nanoparticle solution can also be used for pattern dyeing and manufacturing.

Owner:TAIYUAN NORMAL UNIV

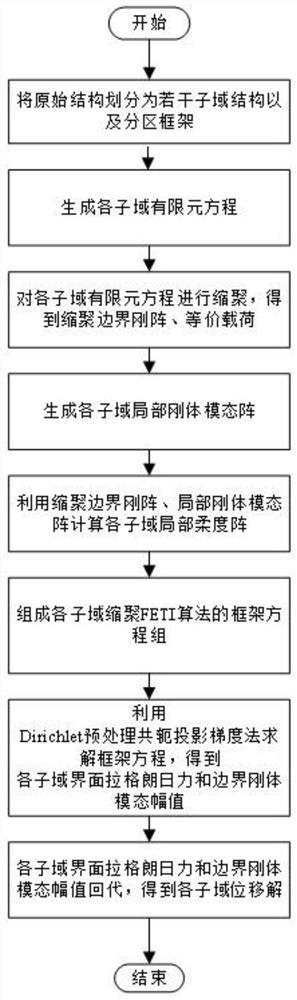

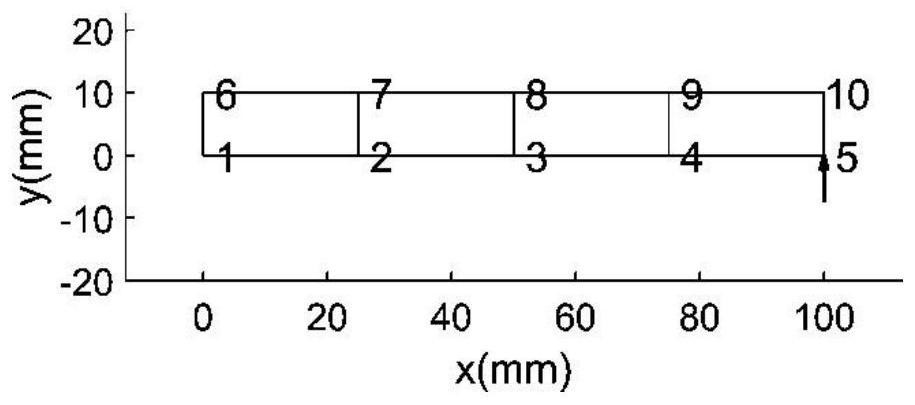

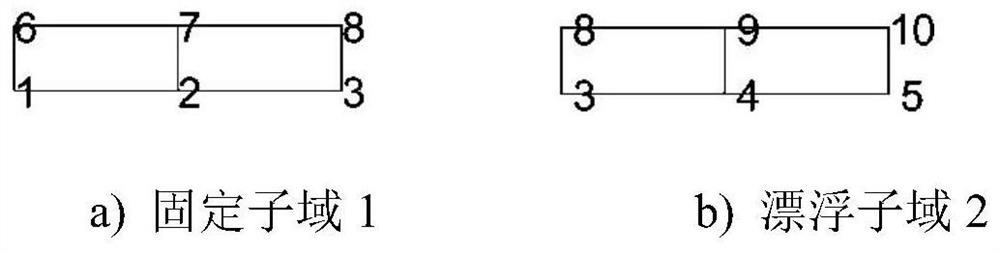

Method for condensing FETI engineering numerical values based on regional decomposition

ActiveCN113779831AEconomically feasibleImprove efficiency of triangular decomposition solutionSustainable transportationDesign optimisation/simulationHat matrixNumerical methodology

The invention discloses a method for condensing FETI engineering numerical values based on regional decomposition. The method comprises the steps of solving a generalized flexibility matrix and a boundary flexibility matrix through constructing a rigid matrix only related to the boundary freedom degree of a floating sub-domain and a rigid body modal matrix of the rigid matrix. The formed new 'hat' matrix can fully utilize and maintain the sparsity of the floating sub-domain rigid matrix, and the order of the new 'hat' matrix is equal to the number of floating sub-domain boundary degrees of freedom and is far smaller than the scale of the original 'hat' matrix, so that the storage space is greatly reduced, and the triangular decomposition solving efficiency of the generalized stiffness matrix is improved; and the calculation of the local flexibility matrix becomes economical and feasible. Meanwhile, an intermediate result of the new 'hat' matrix calculation just provides a Dirichlet preprocessor with a better convergence characteristic for PCPG iterative solution of a frame equation set.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

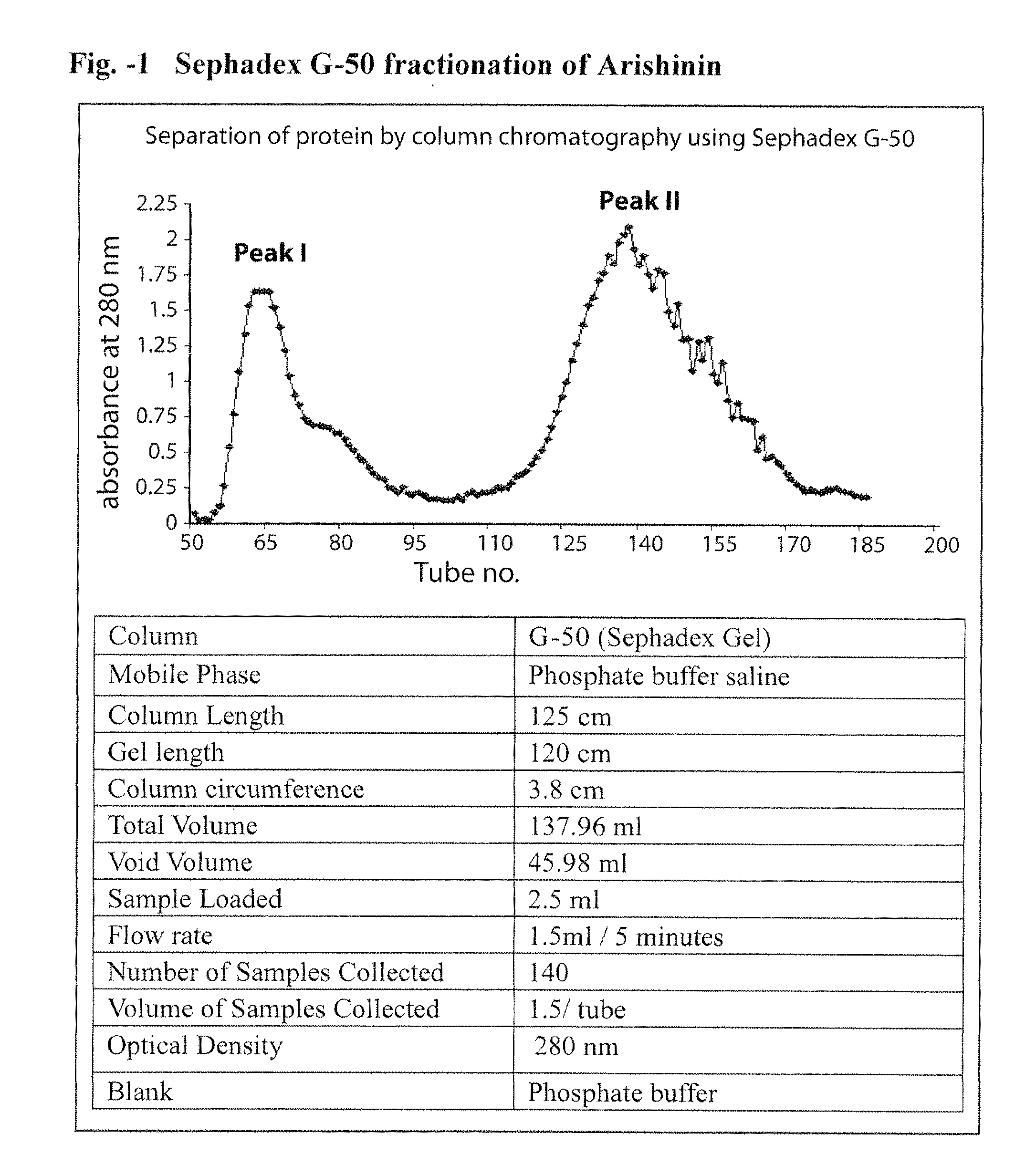

Antioxidant polypeptide and a process for isolation and purification of the same

ActiveUS20110184146A1Reduce molecular weightEasily soluble in waterPeptide/protein ingredientsDepsipeptidesAntioxidative stressNeuro-degenerative disease

A polypeptide is isolated from Turmeric (Curcuma longa Linn) having molecular weight of about 8,000 Daltons. The polypeptide is highly water-soluble and absolutely non-toxic antioxidant, which is isolated using boiling water extraction. The polypeptide is an excellent antioxidant working at low concentration (of about 80 nM) to quench lipid peroxidation up to 90%. The polypeptide is highly effective against oxidative stress related diseases like arthritis, atherosclerosis, cardiovascular diseases, neurodegenerative diseases, cancer, cataract, malaria, bacterial and fungal infectious diseases.

Owner:ADICHUNCHANAGIRI BIOTECH & CANCER RES INST

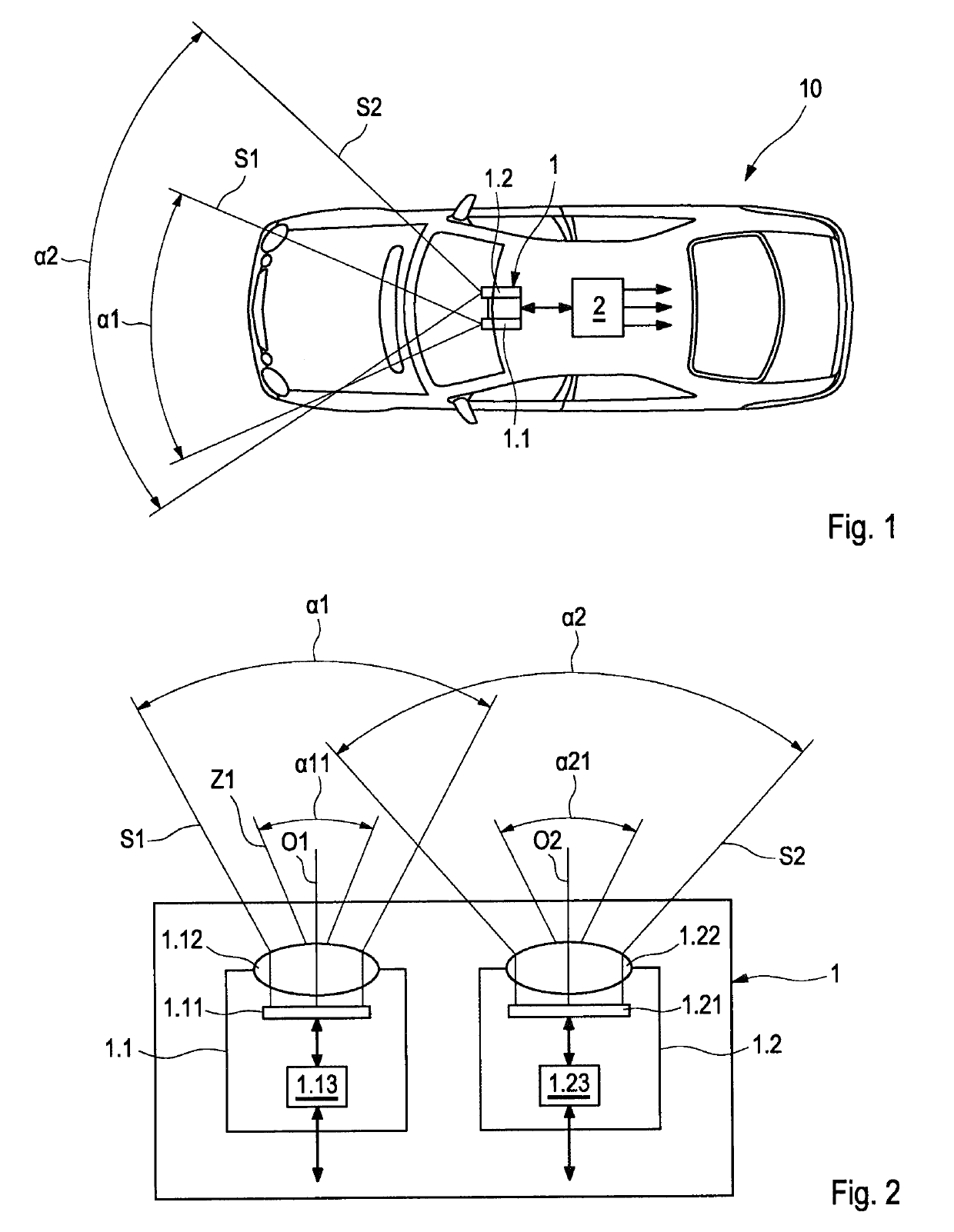

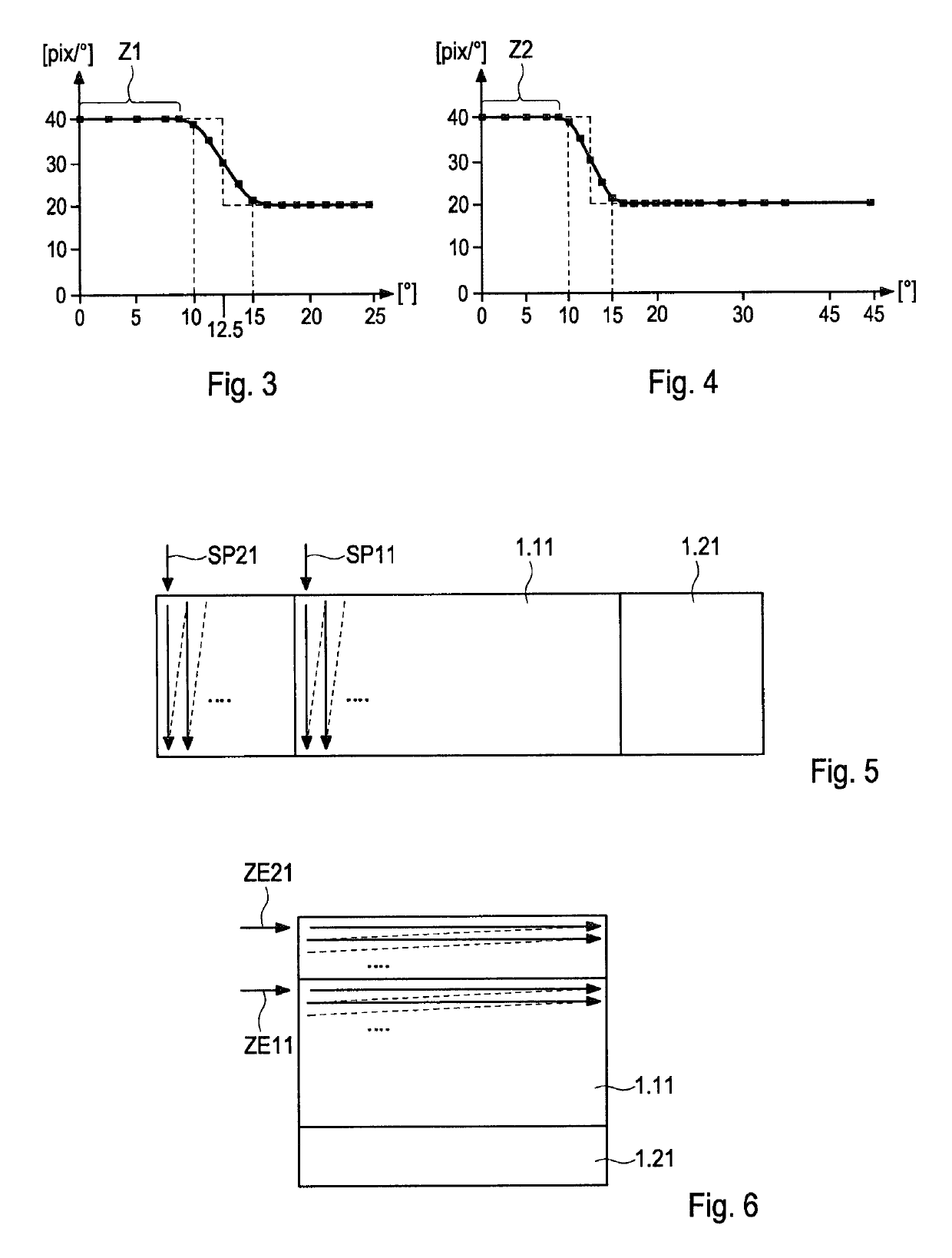

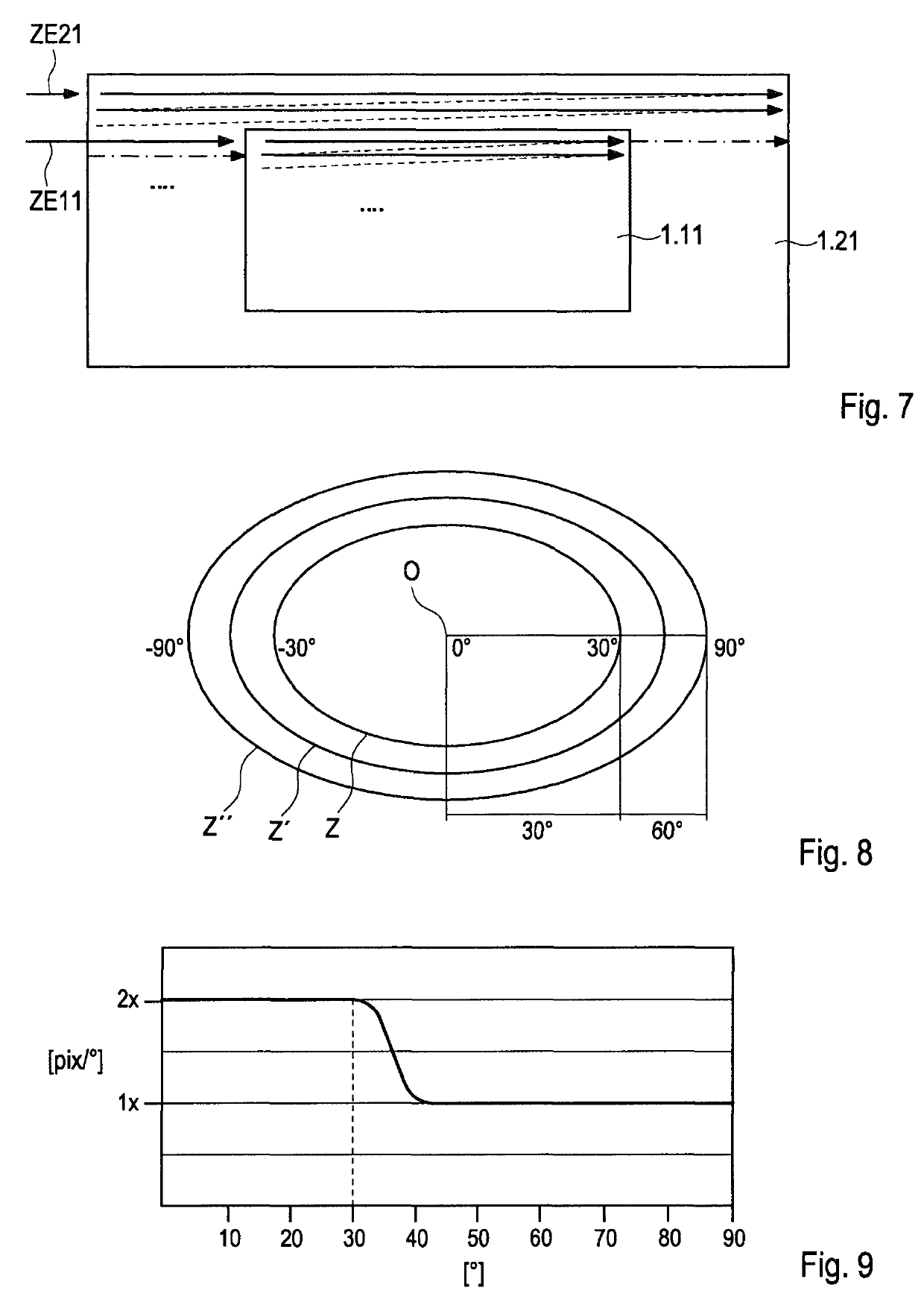

Stereo camera for vehicles

ActiveUS10334234B2High resolutionEconomically feasibleTelevision system detailsColor television detailsImage resolutionOptical axis

A stereo camera (1) for a vehicle includes a first camera (1.1), which has a first image sensor (1.11) and the camera field of vision (S1) of which has a first opening angle (α1), and a second camera (1.2), which has a second image sensor (1.21) and the camera field of vision (S2) of which has a second opening angle (α2). The second opening angle (α2) is greater than the first opening angle (α1). The first camera (1.1) has a first lens optical unit (1.12) and the second camera (1.2) has a second lens optical unit (1.22), which both have an angular resolution that is higher in a central region (Z1, Z2) of the field of vision (S1, S2) lying in the angular range (α11, α21) around the optical axis (O1) than outside of the central region. The cameras are arranged so that the fields of vision (S1, S2) overlap.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

Thermally insulated die plate assembly for underwater pelletizing and the like

ActiveUS20120207864A1Maintain temperatureImprove robustnessConfectioneryFilament/thread formingEngineeringExtrusion

An insulated die plate assembly for use in underwater pelletizing and other granulation processes includes a thin, continuous air chamber formed across the plate assembly generally parallel to the die face such that the heated upstream portion of the die plate assembly is thermally insulated from the downstream portion. The air chamber is atmospherically equilibrated by venting the air chamber to the atmosphere. The plurality of extrusion orifices, either individually or in groups, are formed in extrusion orifice extensions that extend through the insulation chamber so that the process melt to be granulated can pass therethrough. The orifice extensions and the components forming the air chamber around the orifice extensions channel heat along said extensions to maintain the process melt therein at a desired temperature, to help rigidify the die plate assembly and to better seal the air chamber.

Owner:GALA INDUSTRIES INC

Re-useable offset printing plate and method for producing the printing plate

InactiveUS20080026145A1Economically feasibleEconomically feasible for the printing industryMounting boardsPlate printingThermal conductivityMetal substrate

An offset printing plate for sheet fed offset printing, the offset printing plate contains a metal substrate and a top layer having low thermal conductivity. The metal substrate is an aluminum substrate having a thickness between 0.05 and 2 mm. An intermediate layer having low thermal conductivity and formed of anodized aluminum is provided on top of the metal substrate in a thickness of between 1 and 25 μm. A top layer formed of titanium and / or molybdenum, or an alloy thereof, is provided on the intermediate layer in a thickness of between 1 and 10 μm, particularly between 1 and 10 μm.

Owner:HEIDELBERGER DRUCKMASHINEN AG

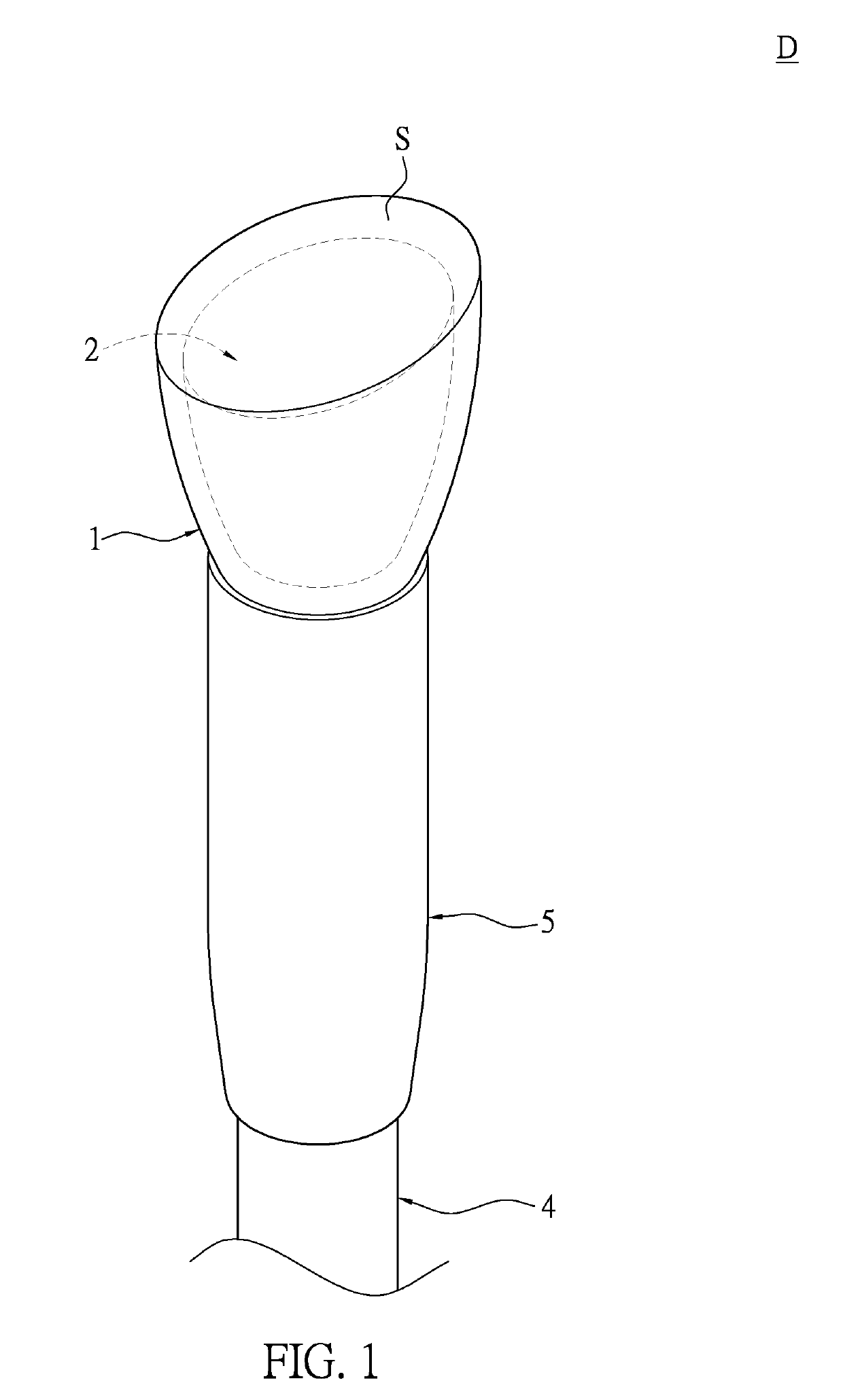

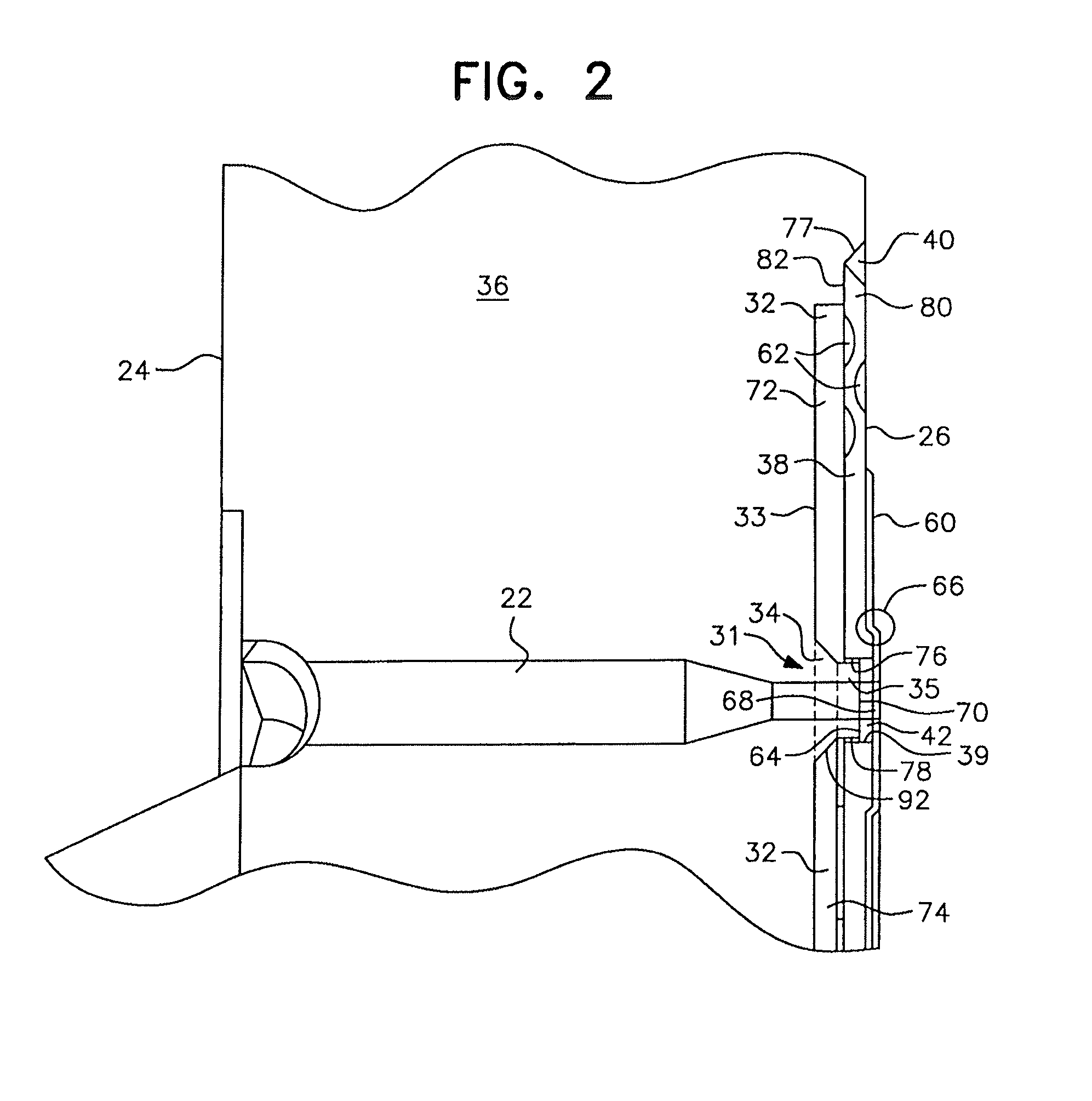

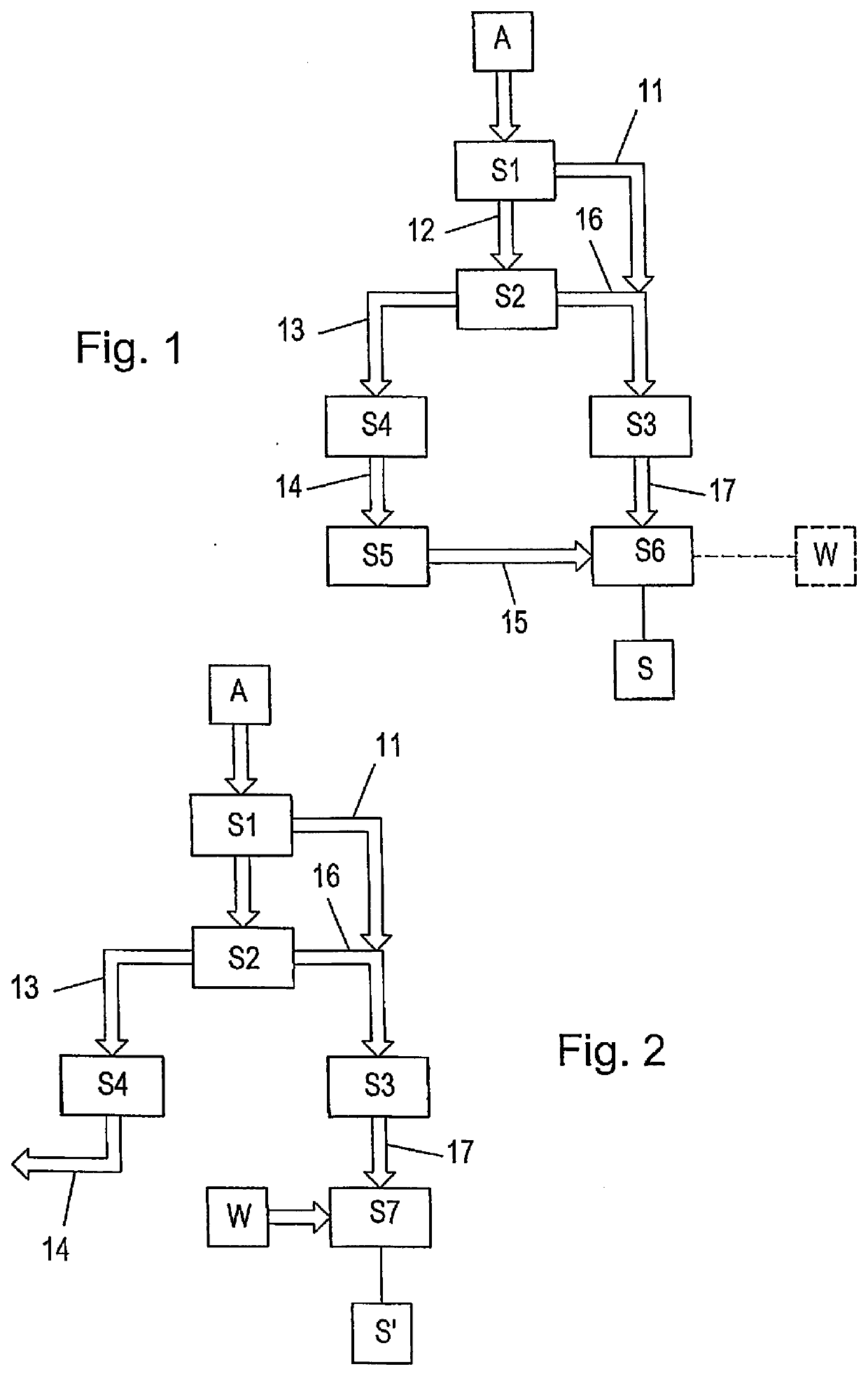

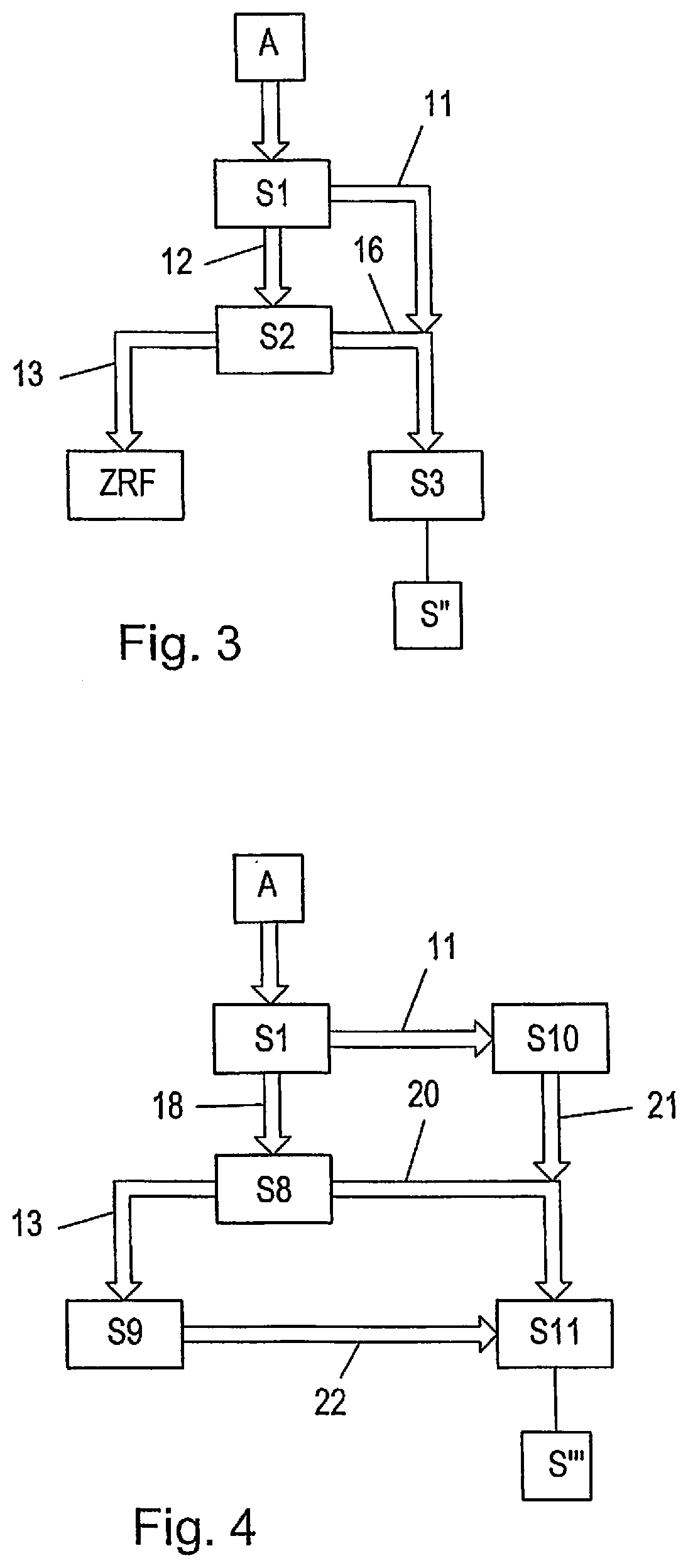

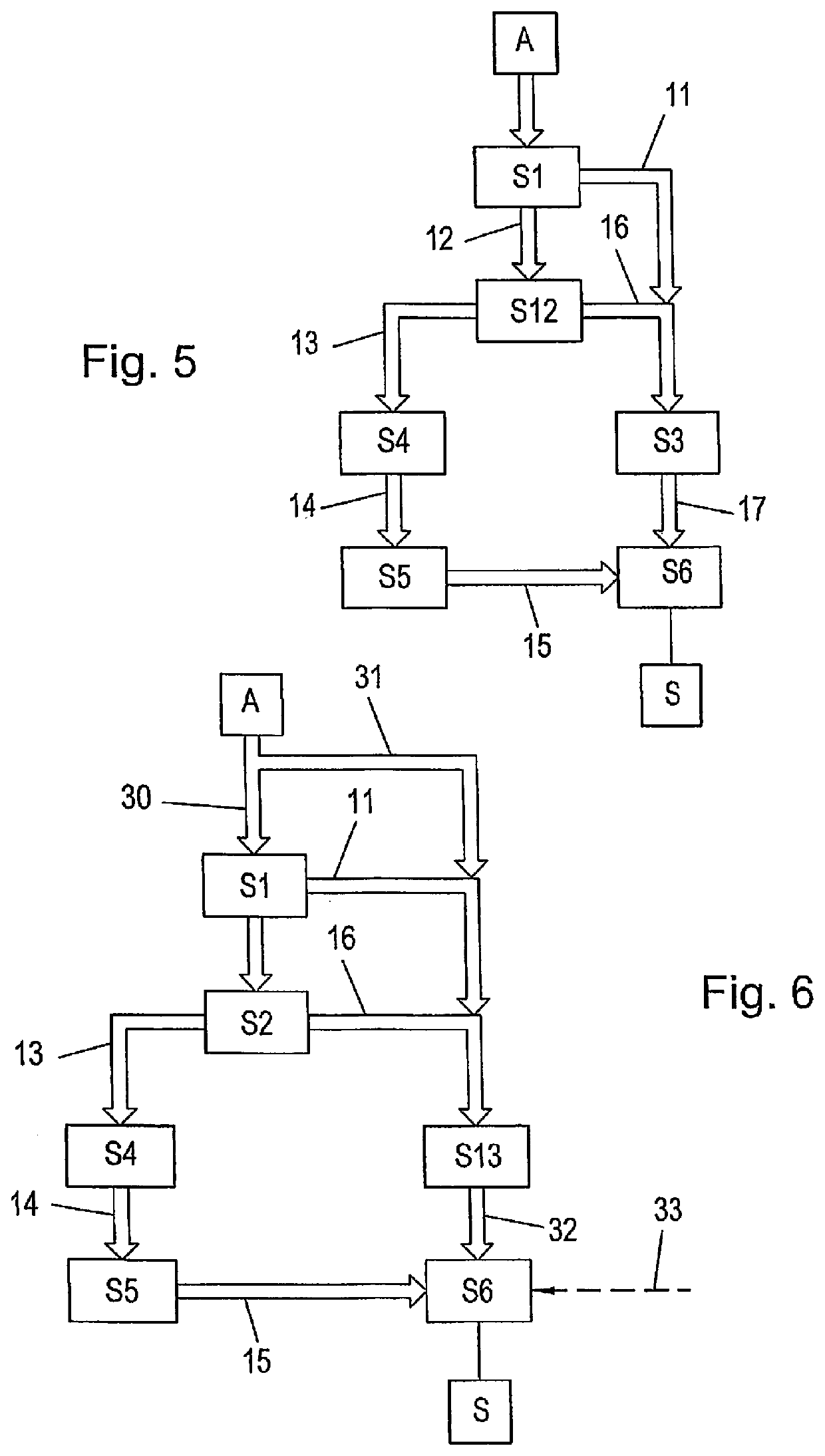

Method for producing a sugar-reduced fruit juice, in particular apple juice

InactiveUS20200305469A1Economically feasibleEconomically simpleSugar food ingredientsJuice extractionBiotechnologyFruit juice

A method for producing a sugar-reduced fruit juice (S), in particular apple juice, wherein components of the fruit (A) are pressed after an at least partial comminution or fractioning process for obtaining the fruit juice. Prior to the pressing process using solely one part (16) of the fruit flesh; at least one part of the juice (14) obtained from the pressed fruit flesh is subjected to an at least partial sugar-removal method (S5); and the juice (15) obtained from the sugar-removal method is combined or mixed with the juice from the pressing process of the rind (11) and optionally the juice (17) from the remaining part of the fruit flesh, whereby the production of a sugar-reduced fruit juice (S) is made possible while retaining as much of the secondary plant contents as possible.

Owner:GRADIENT PROCESS TECH

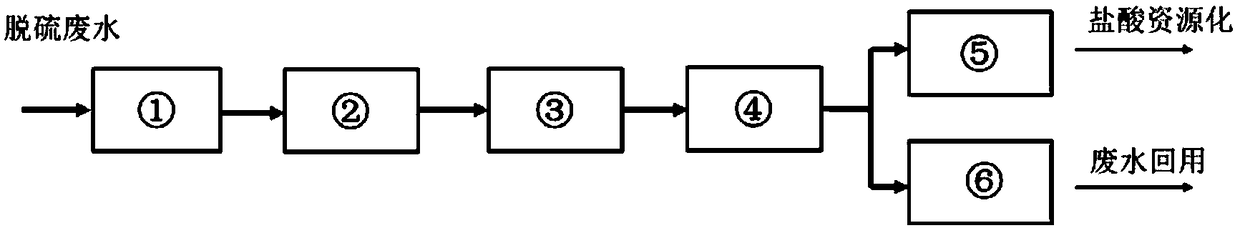

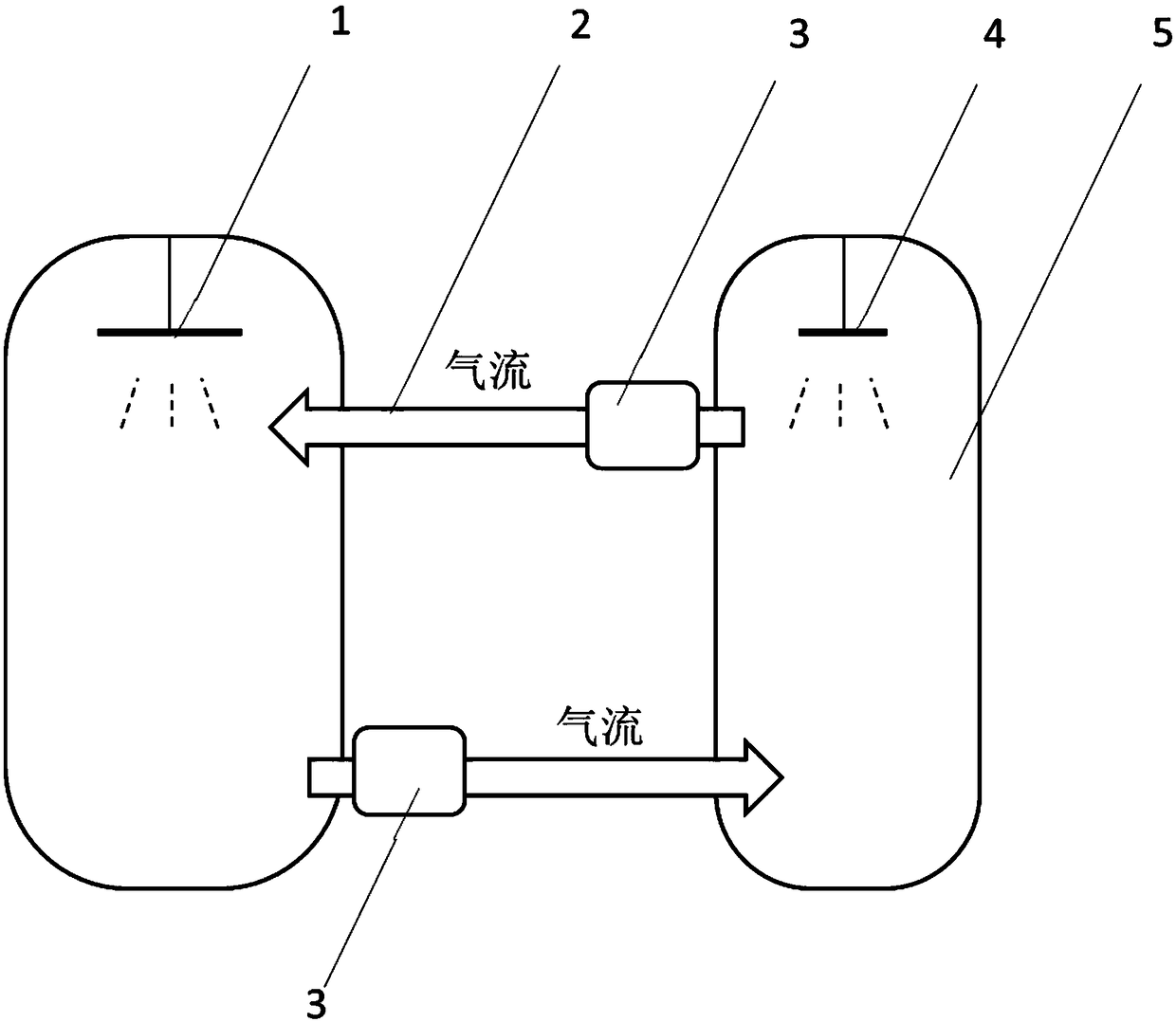

Desulfurization wastewater recycling process and implementation device

InactiveCN109081492AReduce Chloride ContentAccelerate evaporationChlorine/hydrogen-chloride purificationWater contaminantsIndustrial effluentStrong acids

The invention belongs to the field of industrial wastewater treatment. A desulfurization wastewater recycling process includes: pretreating desulfurization wastewater discharged from a desulfurizationtower, mixing pretreated desulfurization wastewater with strong acid, performing gas-liquid mass transfer process treatment, collecting gas generated in gas-liquid mass transfer process treatment, adding lime milk into desulfurization wastewater after gas-liquid mass transfer process treatment to adjust pH to a certain fixed value, and returning wastewater reaching conditions of serving as replenishing water for a desulfurization process into the desulfurization tower to realize recycling. The implementation device of the desulfurization wastewater recycling process comprises a gas-liquid mass transfer device and a wastewater pH adjusting device. A pretreatment tank, an acid adjustment tank and the gas-liquid mass transfer device are in sequential connection, and a first spray tower and asecond spray tower are connected with a tail gas collection device and the wastewater pH adjusting device respectively. The process has advantages that by the engineering design, the process is slightly affected by desulfurization wastewater fluctuation, lower in investment and operating cost than similar processes, free of secondary pollutant solid wastes and the like, easiness in automatic operating of engineering and the like.

Owner:SHENGFA ENVIRONMENT PROTECTION TECH XIAMEN CO LTD +1

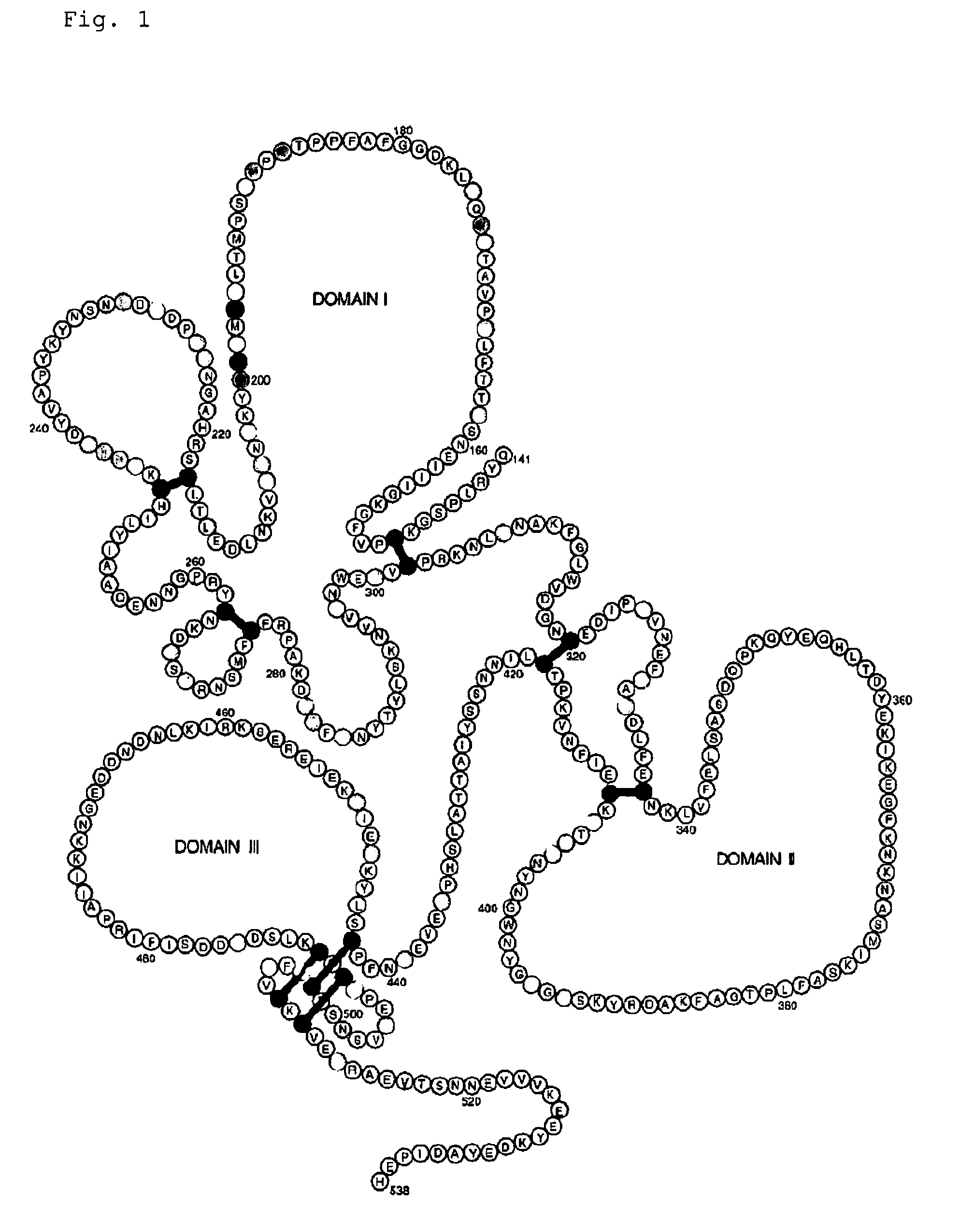

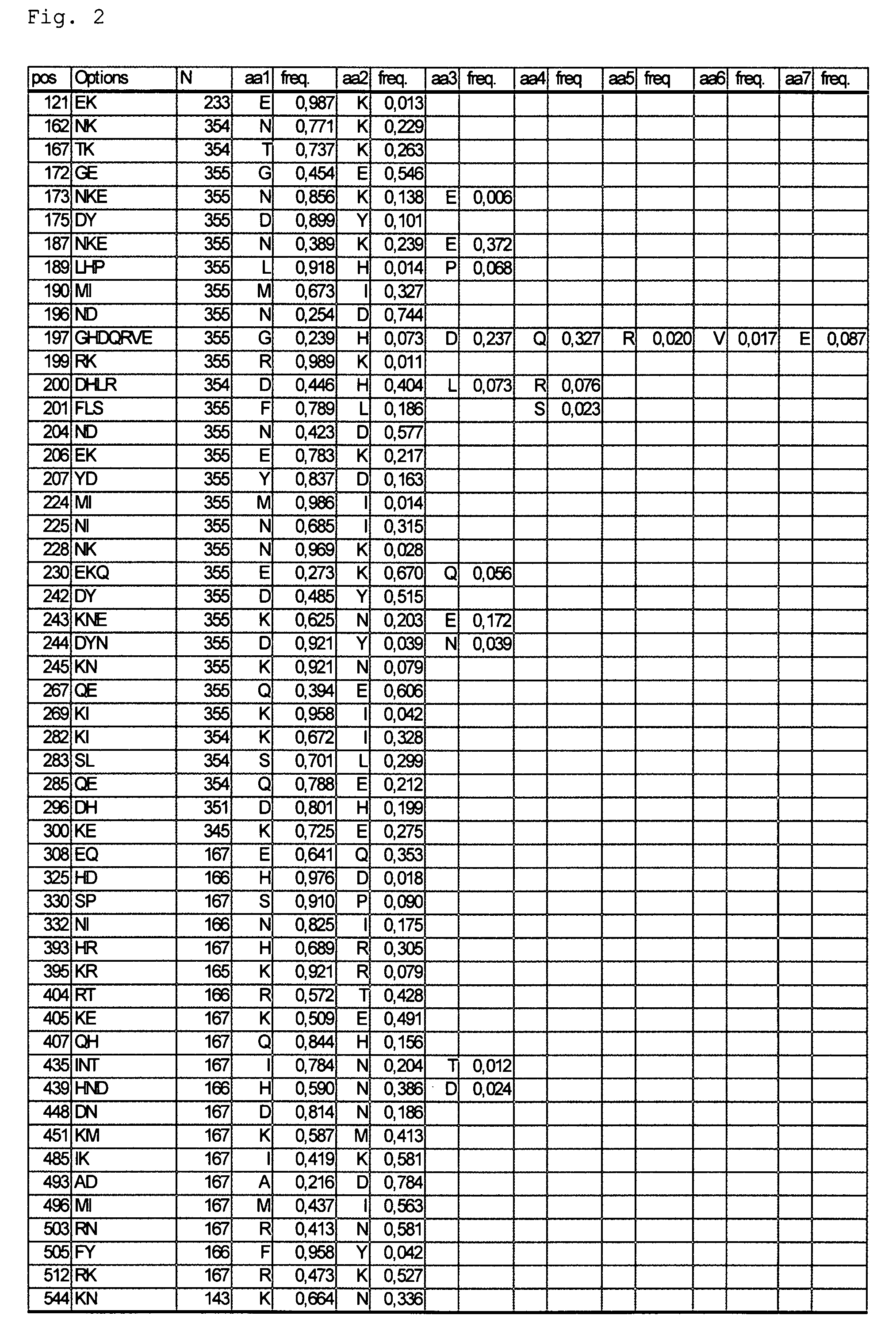

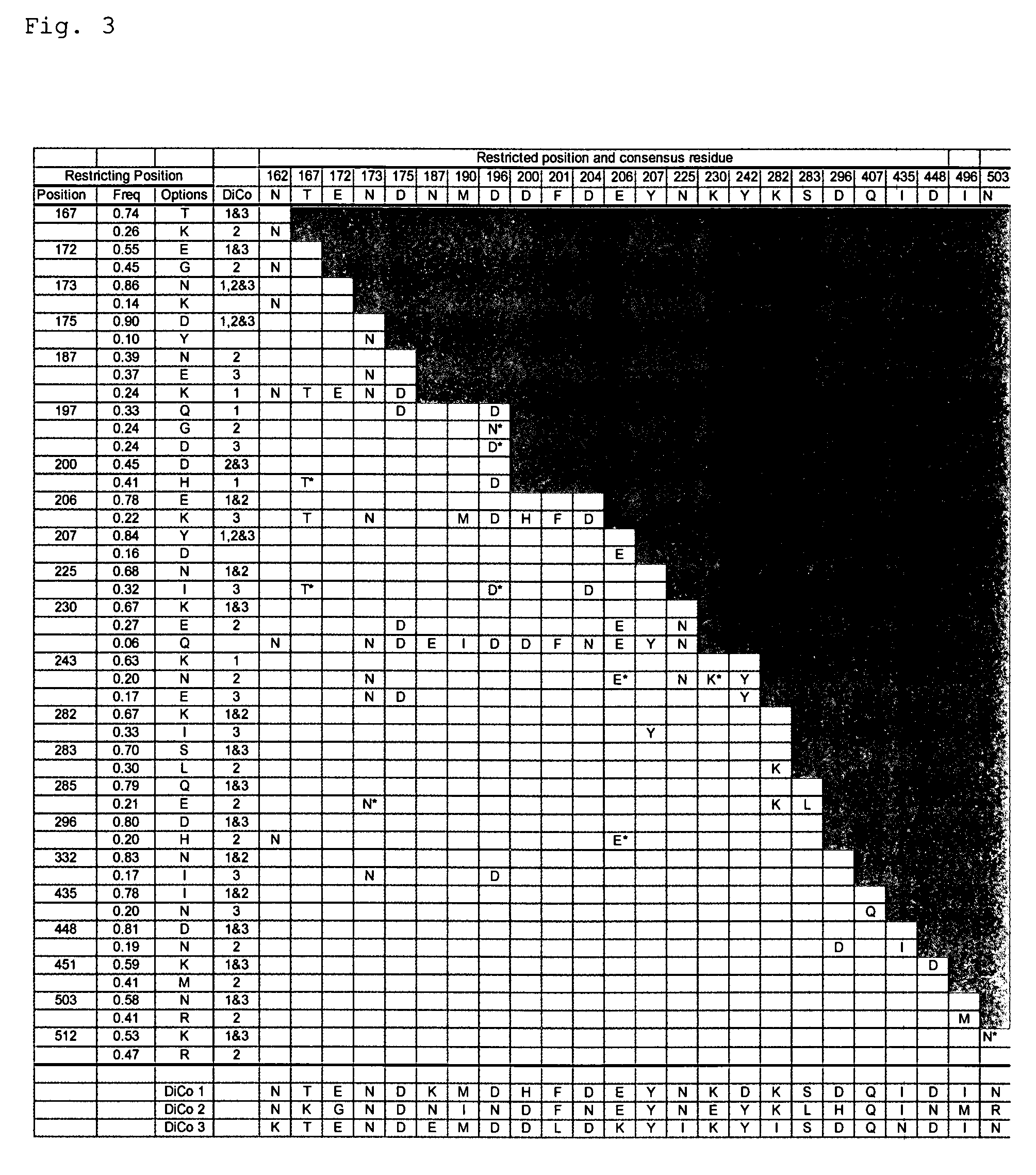

Protein composition for inducing an immune response in a vertebrate comprising a plurality of protein variants covering the heterogeneity of a single antigen, AMA1

InactiveUS8741305B2Easy to produceLow costBacterial antigen ingredientsProtozoa antigen ingredientsAntigenProtein formation

The present invention relates to a protein composition suitable for inducing an immune response in a vertebrate comprising 2 to 10 protein variants of a single antigen, which is the APICAL MEMBRANE ANTIGEN 1 (PfAMA1 OR AMA1) of a Plasmodium species. The antigen comprises a plurality of variable amino acid positions, wherein the amino acid sequences of said protein variants, in combination, represent both the frequency of occurrence of each amino acid at said variable amino acid positions and the linkage between the variable amino acid positions, and wherein said frequency of occurrence is at least between 10% to 20% such as 10%, 11%, 12%, 13%, . . . , 20% in the single antigen, and wherein at least 75% of the linkages between the variable amino acid position is presented by the combination of protein variants.

Owner:STICHTING BIOMEDICAL PRIMATE RES CENT

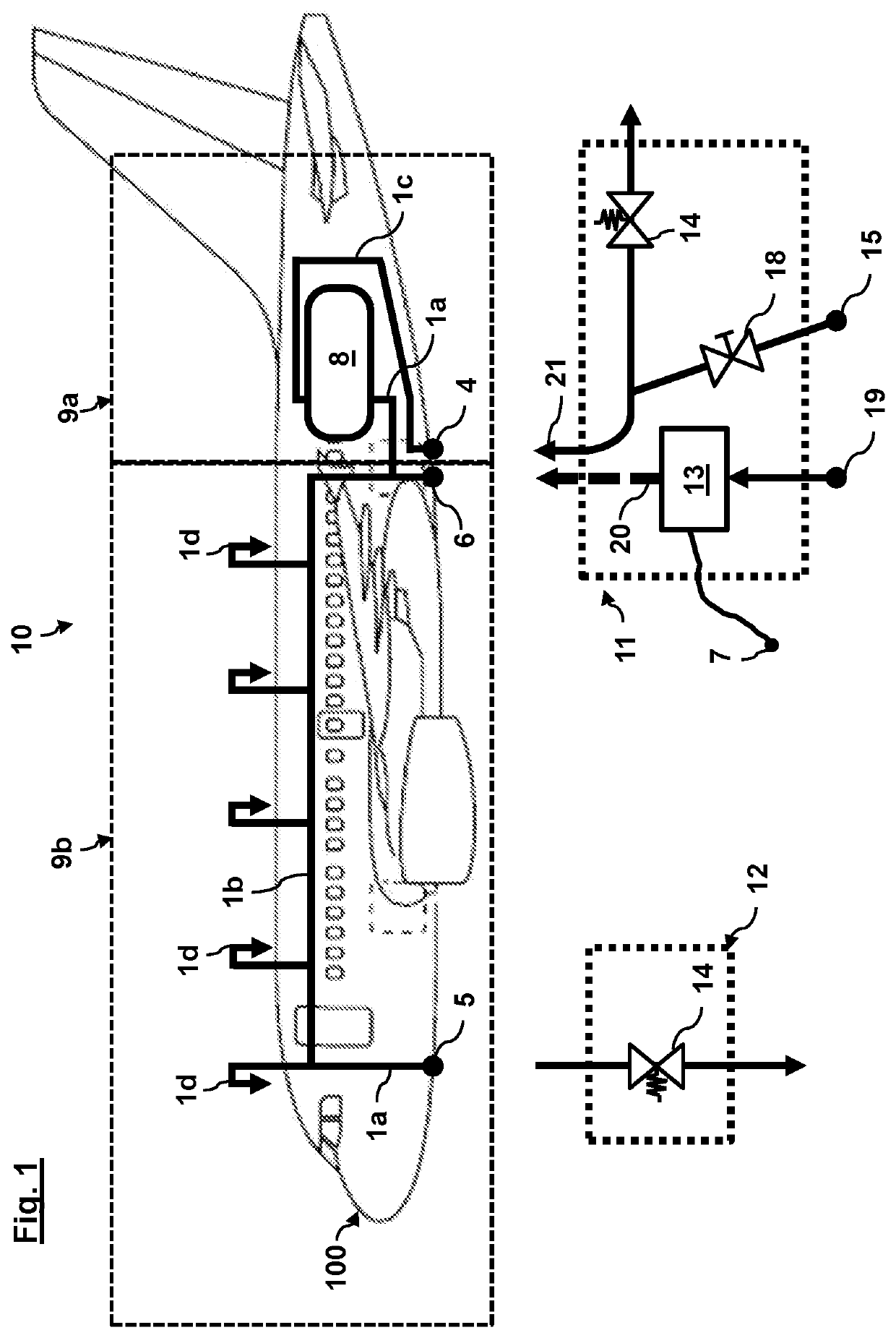

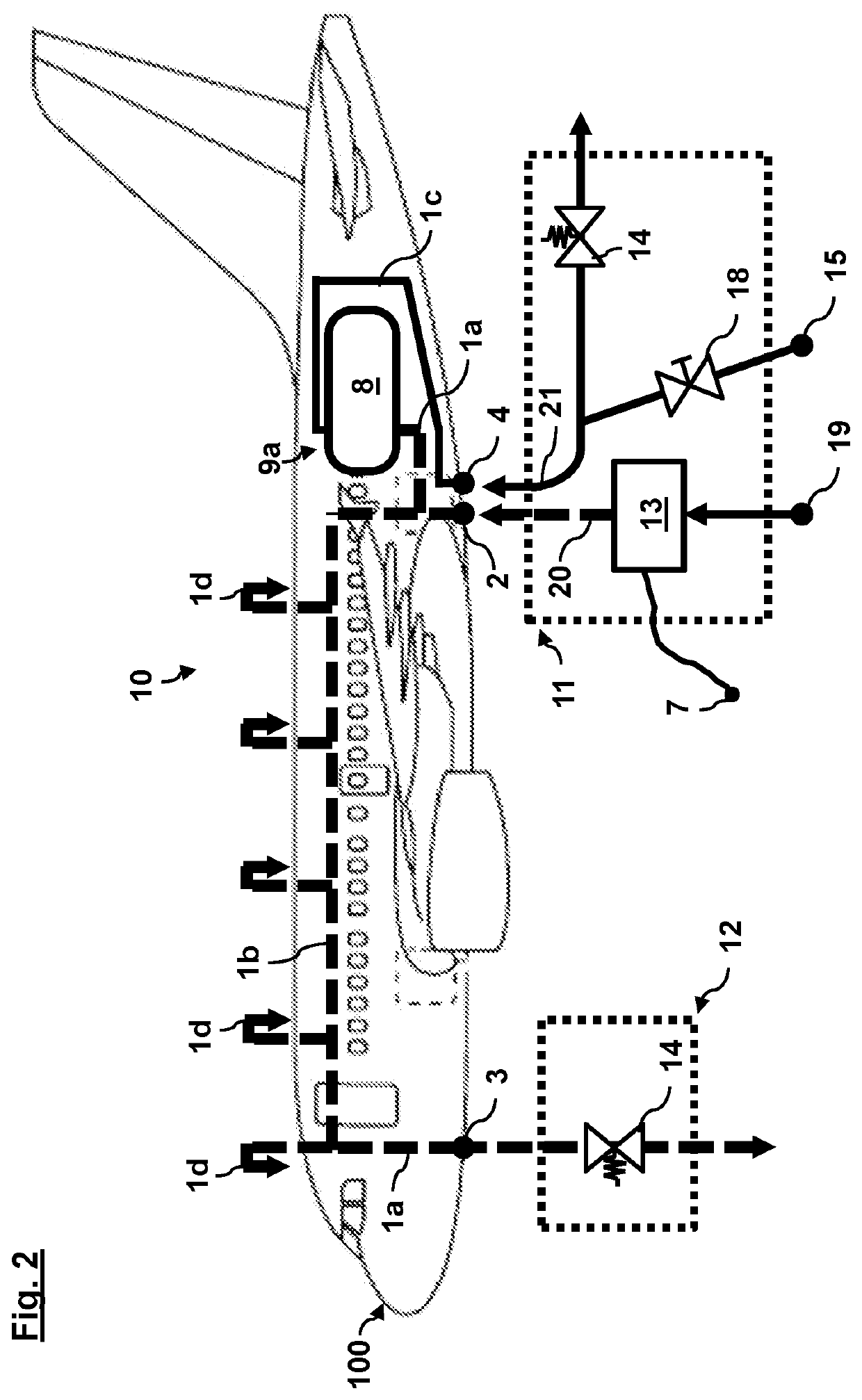

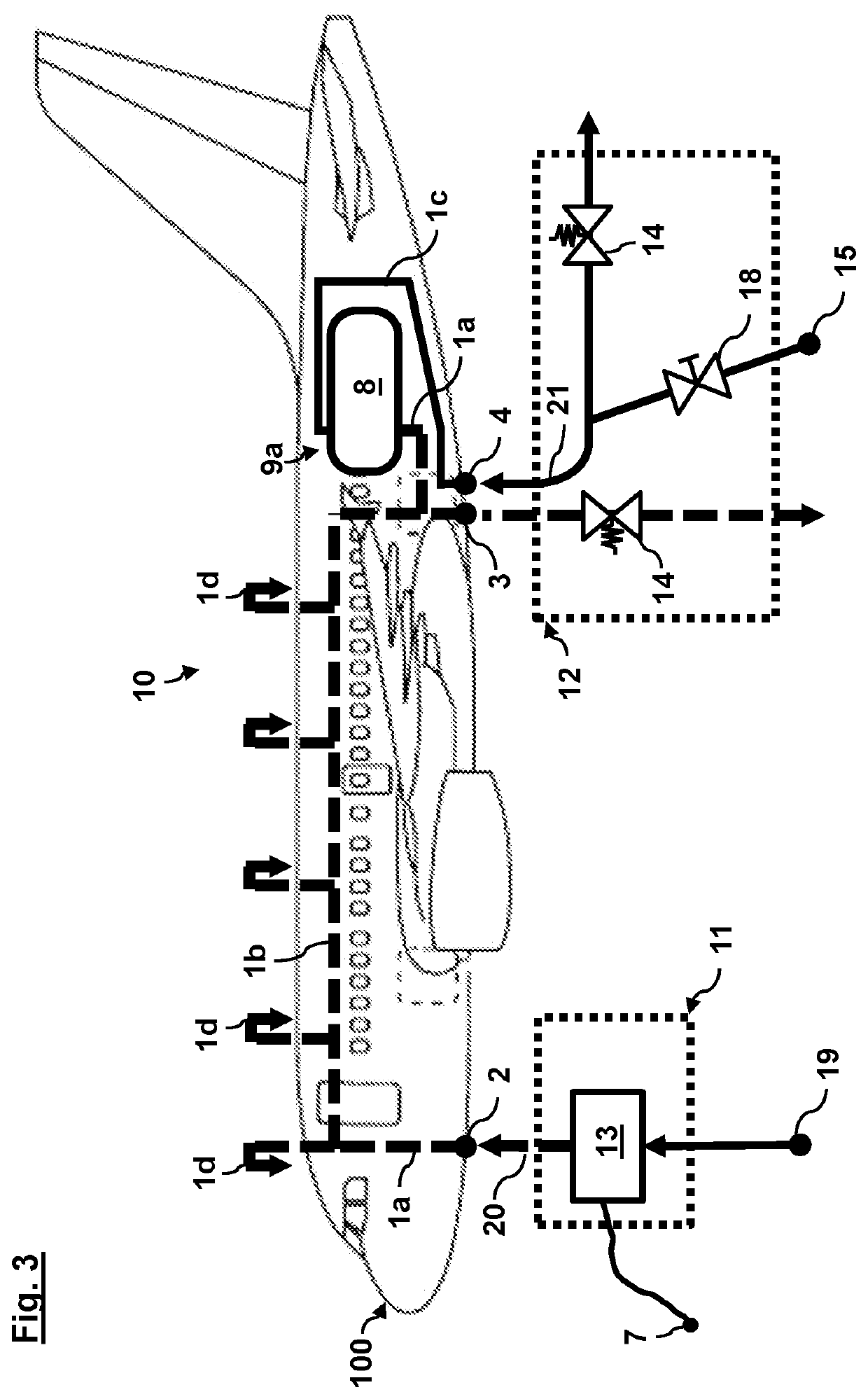

Method For Disinfecting A Water System Of An Aircraft

ActiveUS20190365936A1Small sizeImprove energy consumptionWater treatment parameter controlSpecific water treatment objectivesEngineeringContinuous flow

A method for disinfecting a water system of an aircraft includes letting-in of hot water at an inlet of the water system by a first ground service unit; flushing the hot water from the inlet, through water pipes of the water system, to an outlet of the water system; and letting-out of the hot water at the outlet, by the first ground service unit or a second ground service unit; the hot water being flushed into the inlet and out of the outlet over a predefined disinfection period; and the hot water being provided at the inlet via a continuous-flow heater of the first ground service unit.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com