Patents

Literature

603 results about "Copper nanoparticle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A copper nanoparticle is a copper based particle 1 to 100 nm in size. Like many other forms of nanoparticles, a copper nanoparticle can be formed by natural processes or through chemical synthesis. These nanoparticles are of particular interest due to their historical application as coloring agents and their modern-day biomedical ones.

Metallic ink

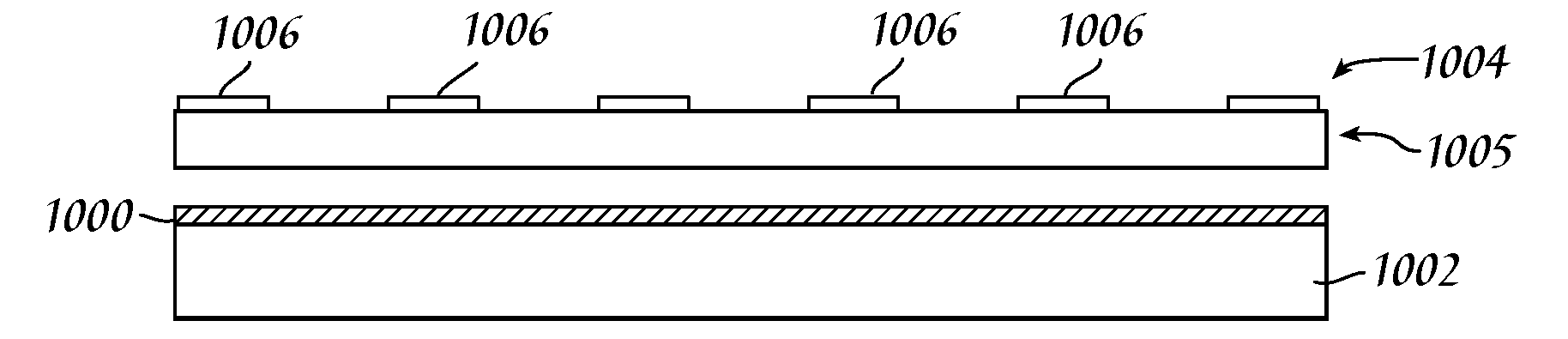

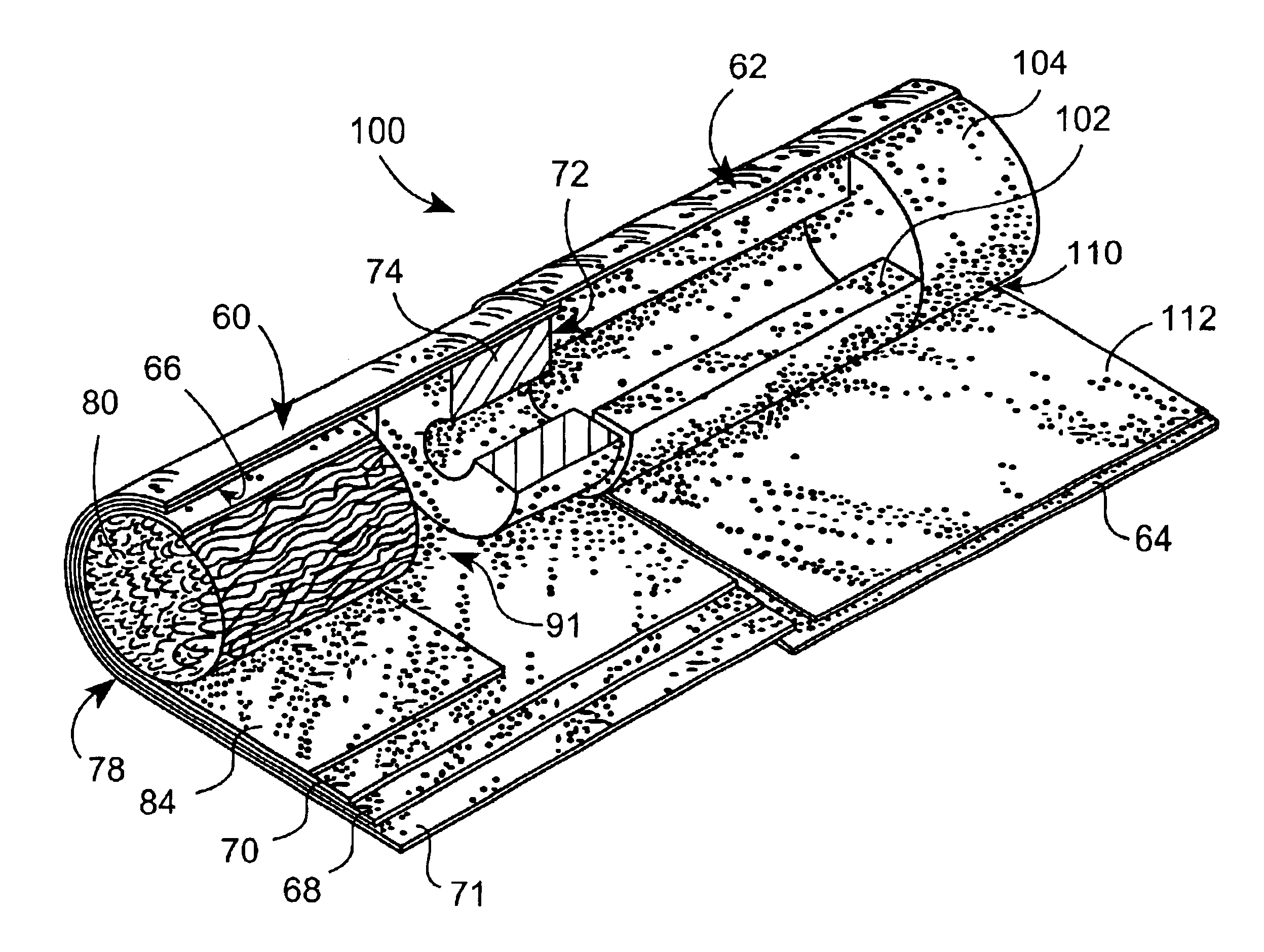

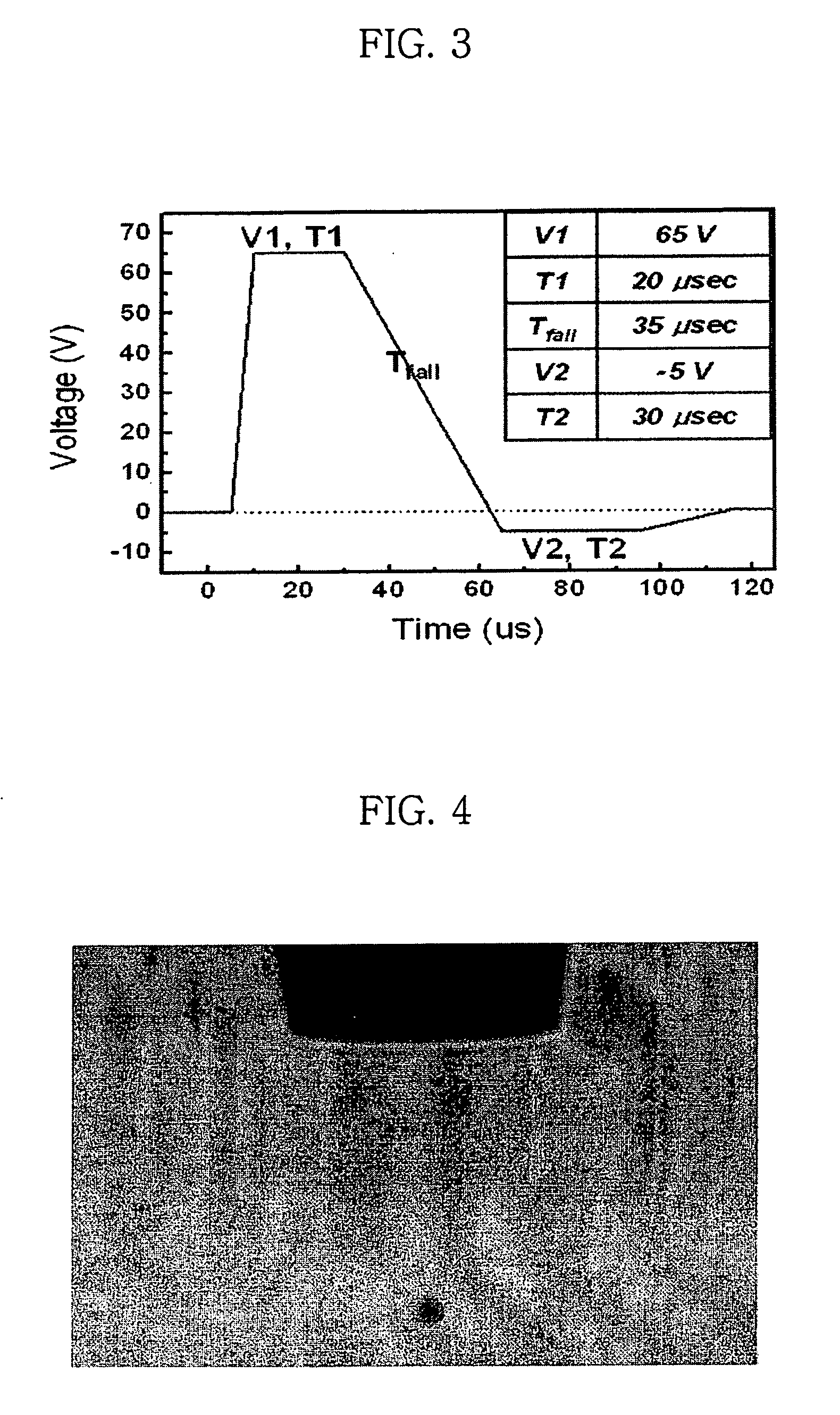

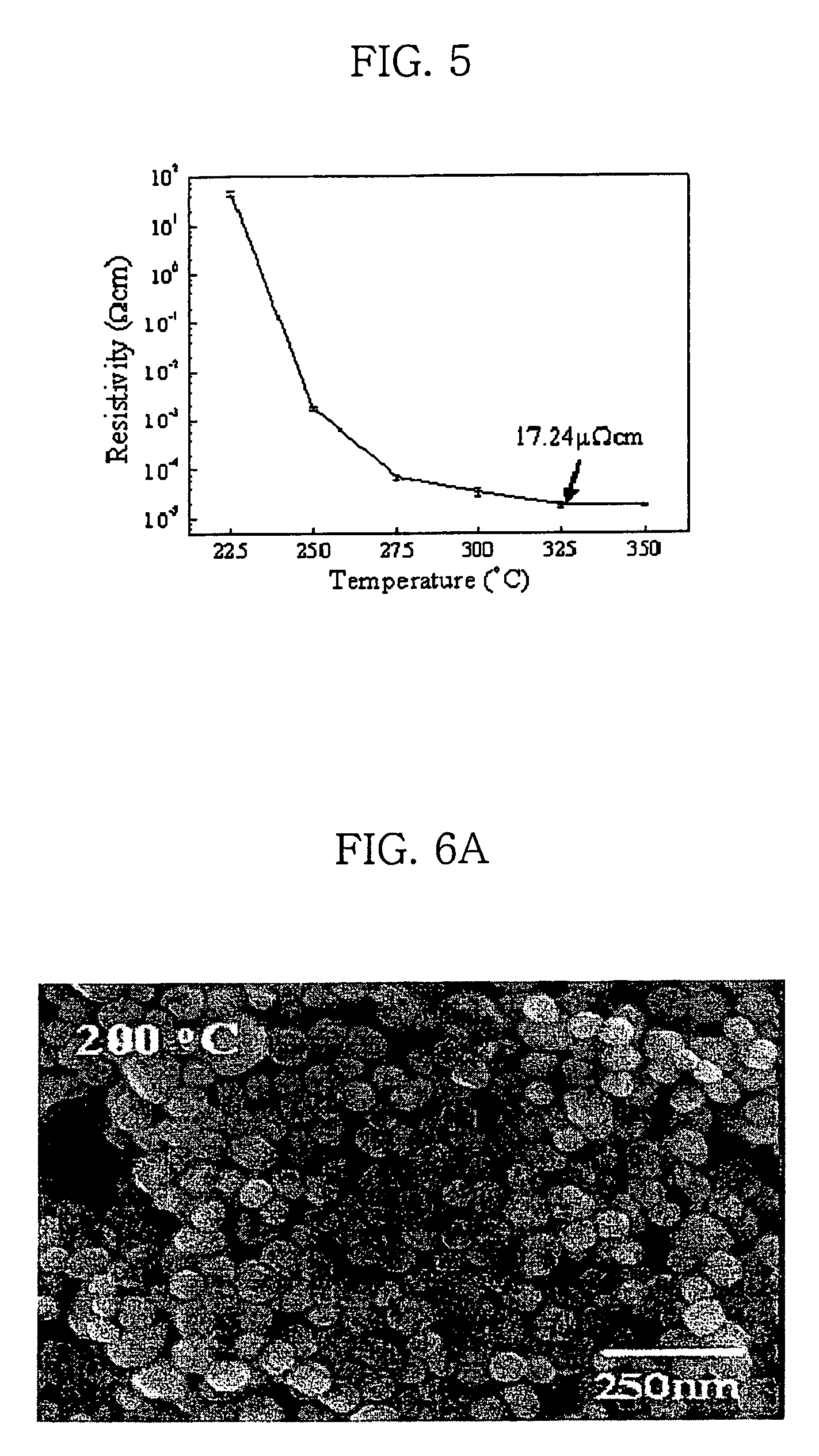

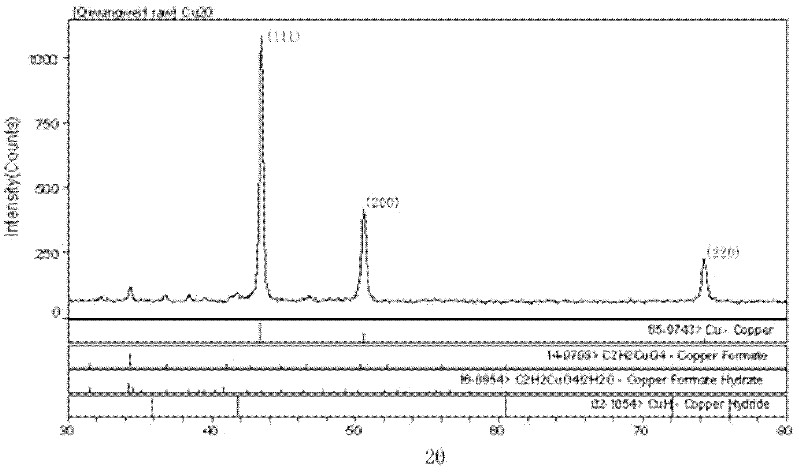

ActiveUS20090274833A1High volume loadGood dispersionMaterial nanotechnologyTransportation and packagingElectrical conductorCopper nanoparticle

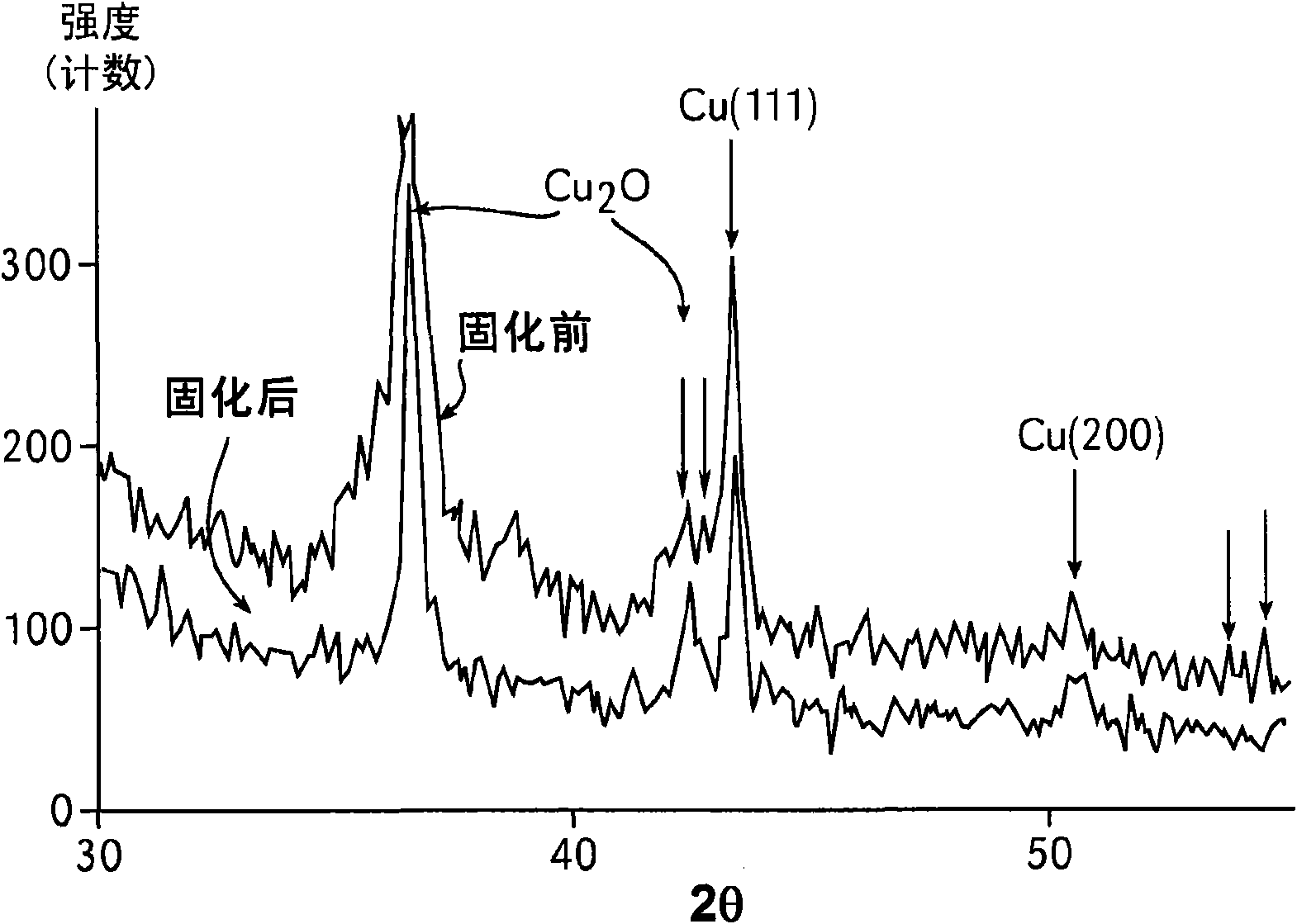

A metallic ink including a vehicle, a multiplicity of copper nanoparticles, and an alcohol. The conductive metallic ink may be deposited on a substrate by methods including inkjet printing and draw-down printing. The ink may be pre-cured and cured to form a conductor on the substrate.

Owner:ISHIHARA CHEM +1

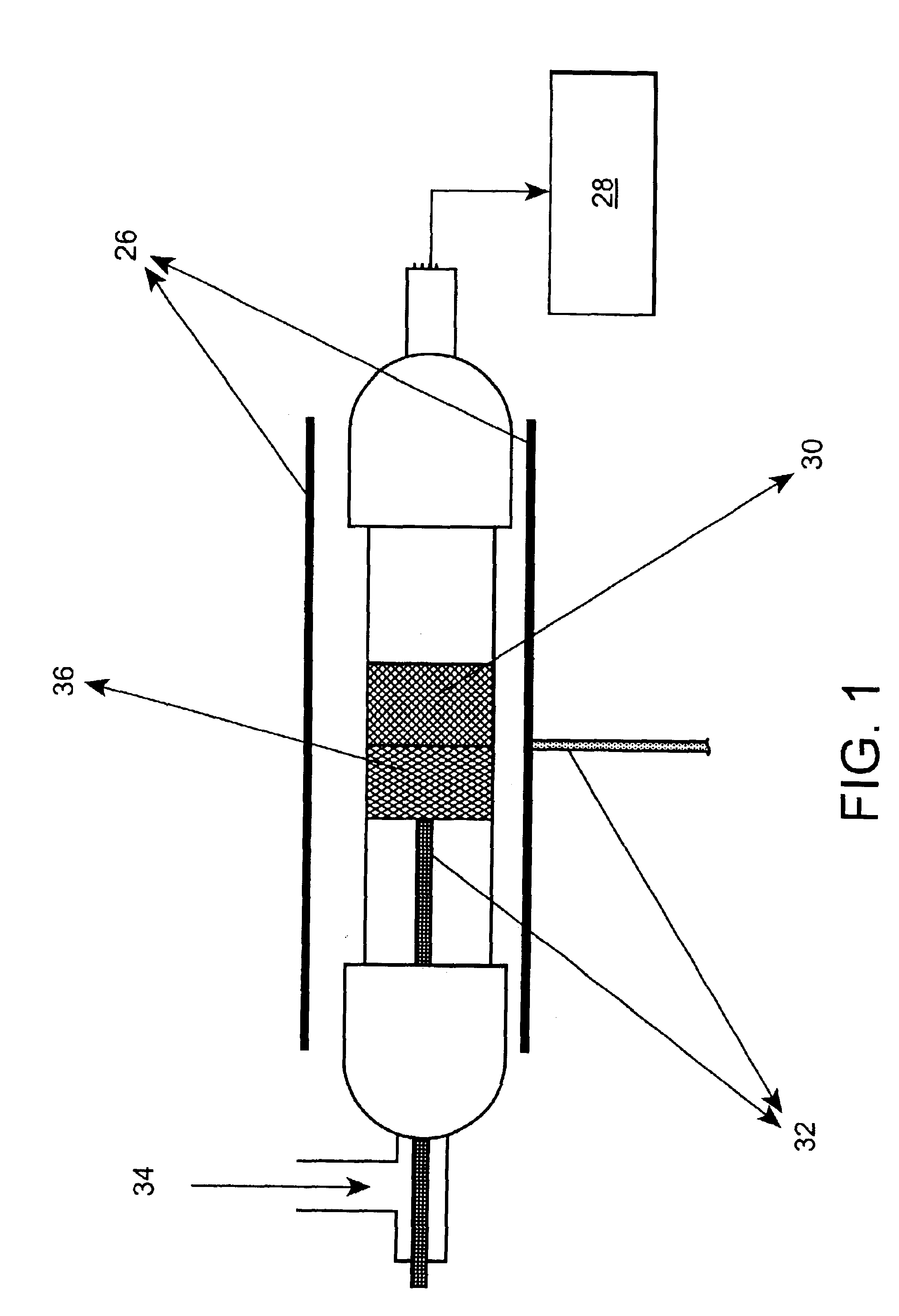

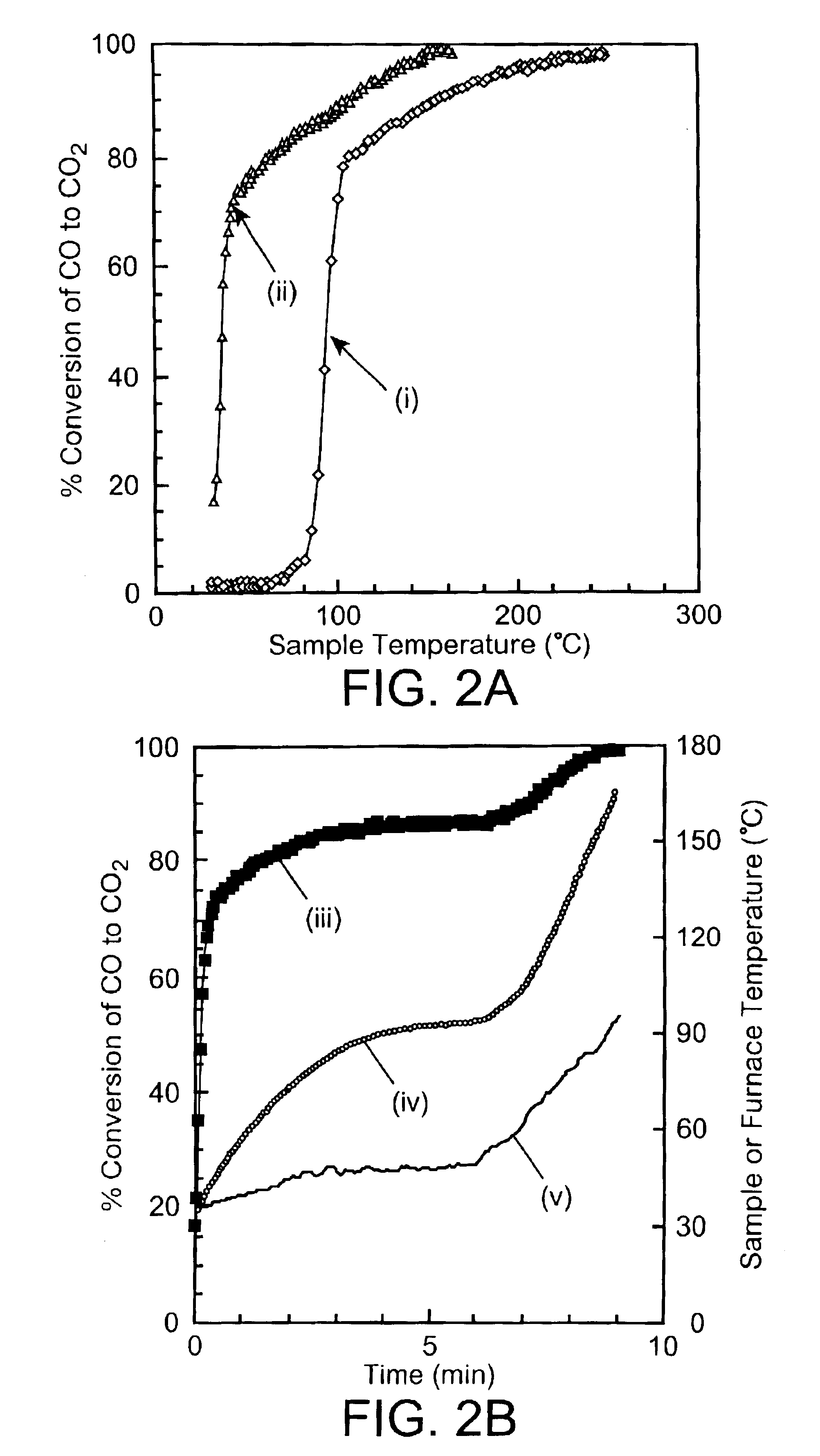

Nanocomposite copper-ceria catalysts for low temperature or near-ambient temperature catalysis and methods for making such catalysts

InactiveUS6857431B2Reduce the amount requiredTobacco preparationNon-fibrous pulp additionPtru catalystHydrocotyle bowlesioides

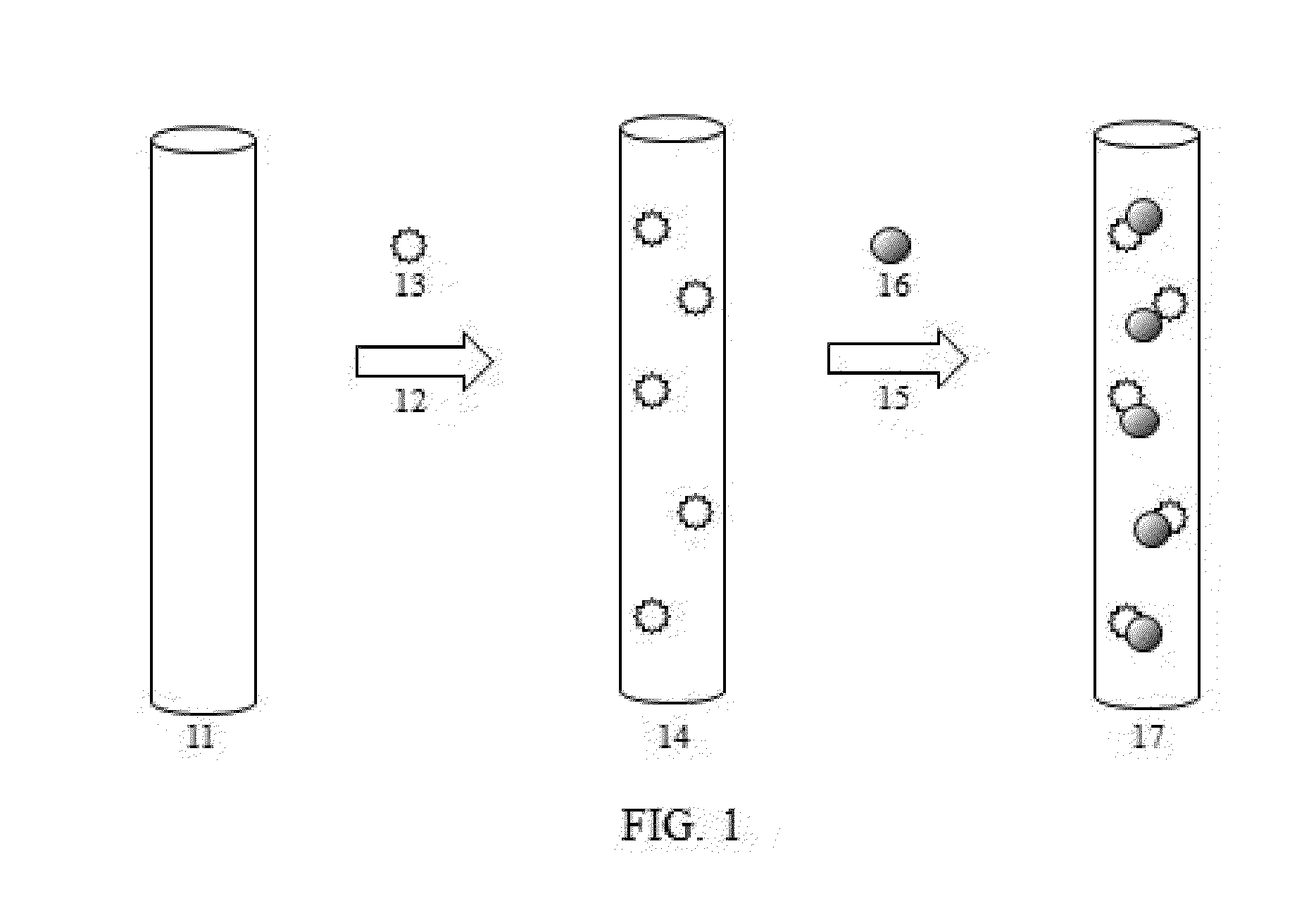

Nanocomposite copper-ceria catalysts are provided, which comprise copper oxide nanoparticles, copper nanoparticles, or a mixture thereof combined with ceria nanoparticles. Methods for making such catalysts are also provided, which involve the steps of (i) combining ceria nanoparticles in an aqueous suspension with copper 2,4-pentanedionate to form a slurry; (ii) heating the slurry formed in step (i) under an inert gas atmosphere or an oxygen-argon atmosphere, at a temperature and for a time sufficient to cause decomposition of the copper 2,4-pentanedionate to form copper nanoparticles and / or copper oxide nanoparticles that are combined with the ceria nanoparticles; and (iii) optionally, subjecting the product formed in step (ii) to a heat treatment process under conditions effective to convert at least some of the copper nanoparticles to copper oxide nanoparticles. The nanocomposite copper-ceria catalysts are useful for low-temperature and near-ambient temperature catalysis, such as the oxidation of carbon monoxide, the reduction of nitric oxide and the conversion of hydrocarbons. The nanocomposite copper-ceria catalysts have a variety of potential applications, for example, in vehicle exhaust emission systems of automobiles and diesel engines, cold starting of automobile engine, fuel cells, lasers, hydrocarbon conversion reactors, air filters for the conversion of carbon monoxide and / or indoor volatile organic compounds, and smoking articles.

Owner:PHILIP MORRIS USA INC

Method for Making Nanoparticles

InactiveUS20080264205A1Cheap methodEasily reduces metalNanotechElectrolysis componentsOxidation-Reduction AgentRedox

A method for making nanoparticles includes the steps of dipping a metal element in a solution that contains metallic ions or ions with a metal, wherein the metal element has a lower electronegativity or redox potential than that of the metal in the ions, and rubbing the metal element to make nanoparticles. Another method for making nanoparticles includes the steps of dipping a metal element in a solution that contains metallic ions or ions with a metal, wherein the metal element has a lower electronegativity or redox potential than that of the metal in the ions, and applying sonic energy to at least one of the metal element and solution. A further method for making copper nanoparticles includes the step of adding ascorbic acid to a copper salt solution.

Owner:ZENG TAOFANG

Metallic ink

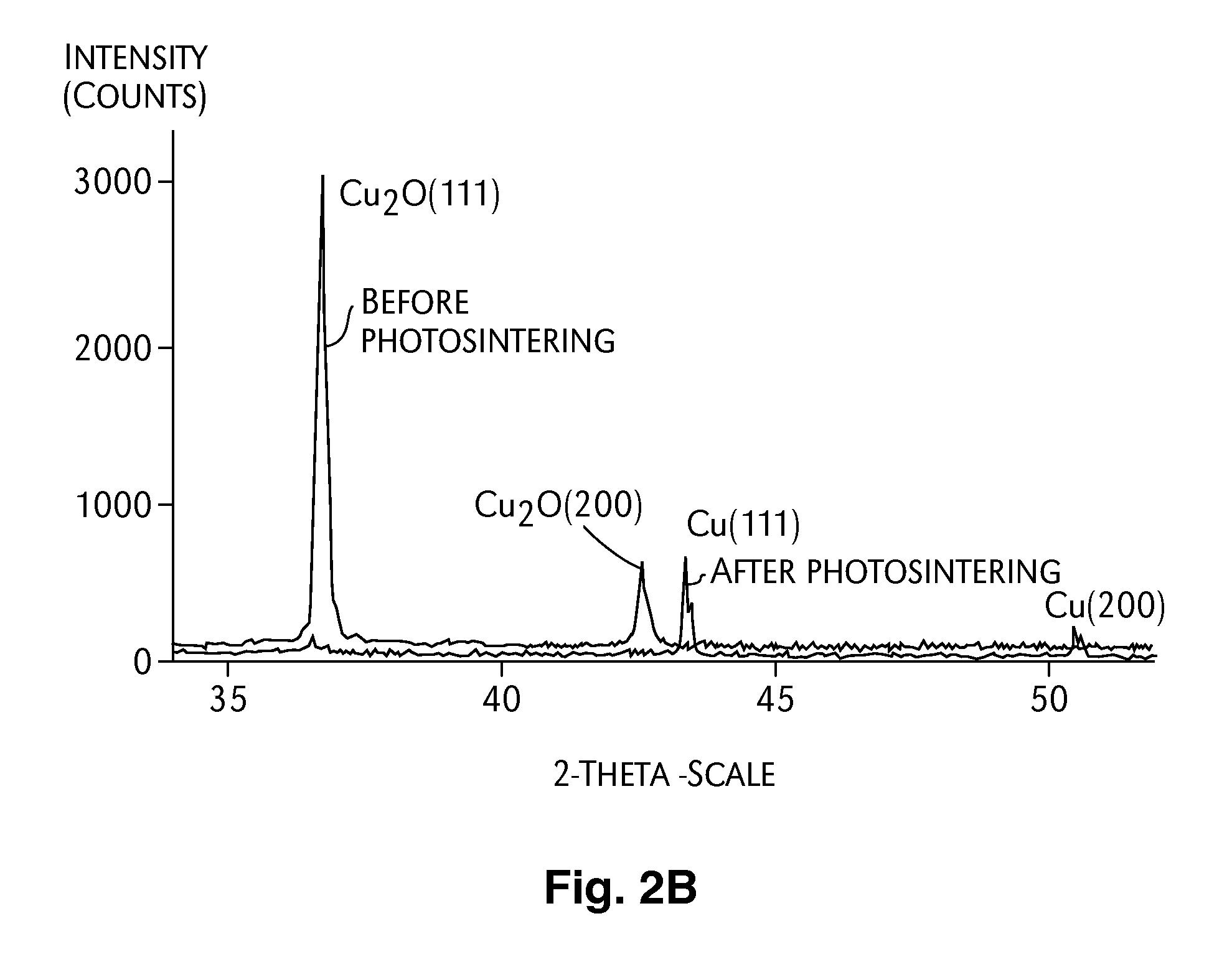

ActiveCN101801674AMaterial nanotechnologyTransportation and packagingOptoelectronicsCopper nanoparticle

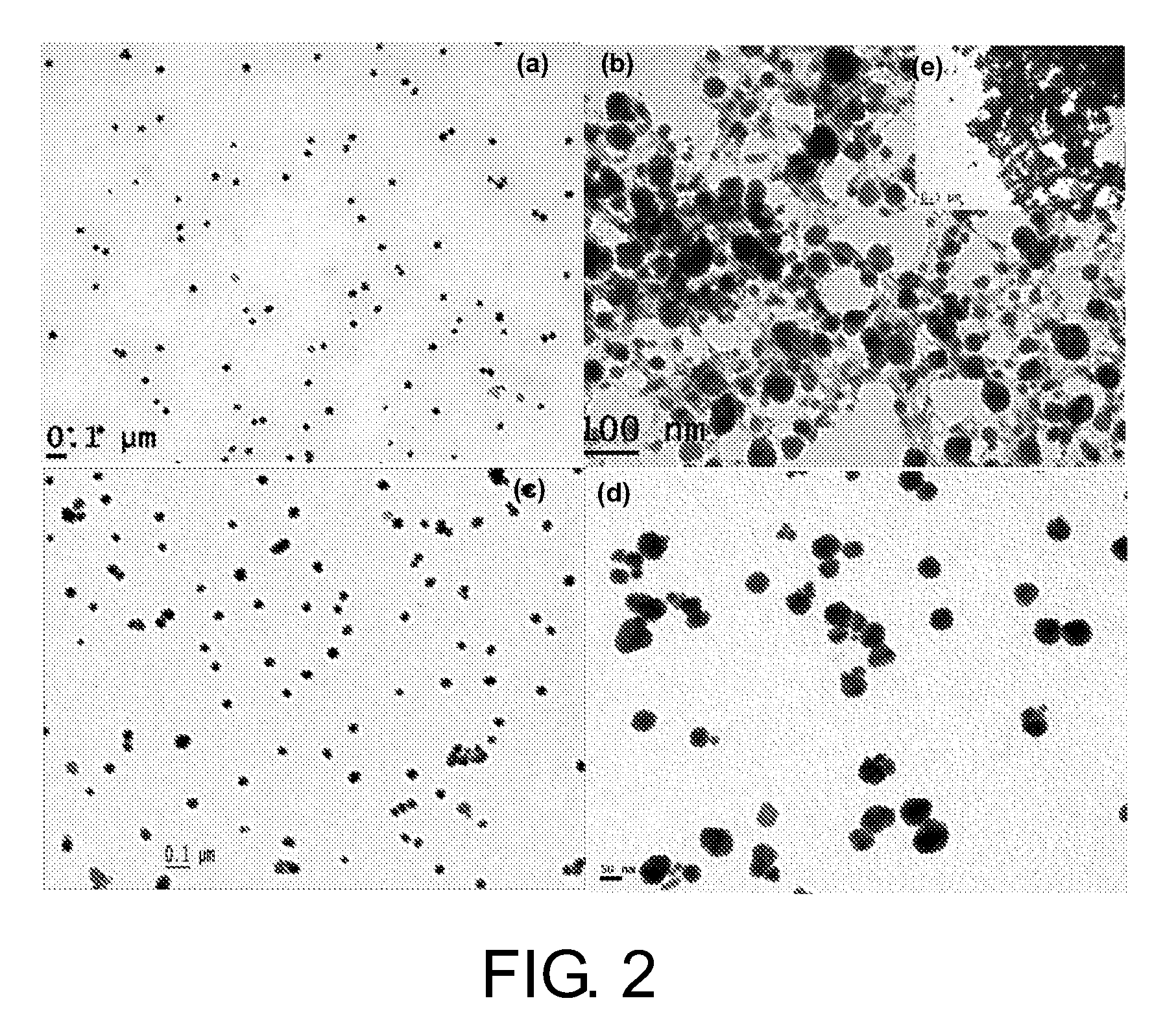

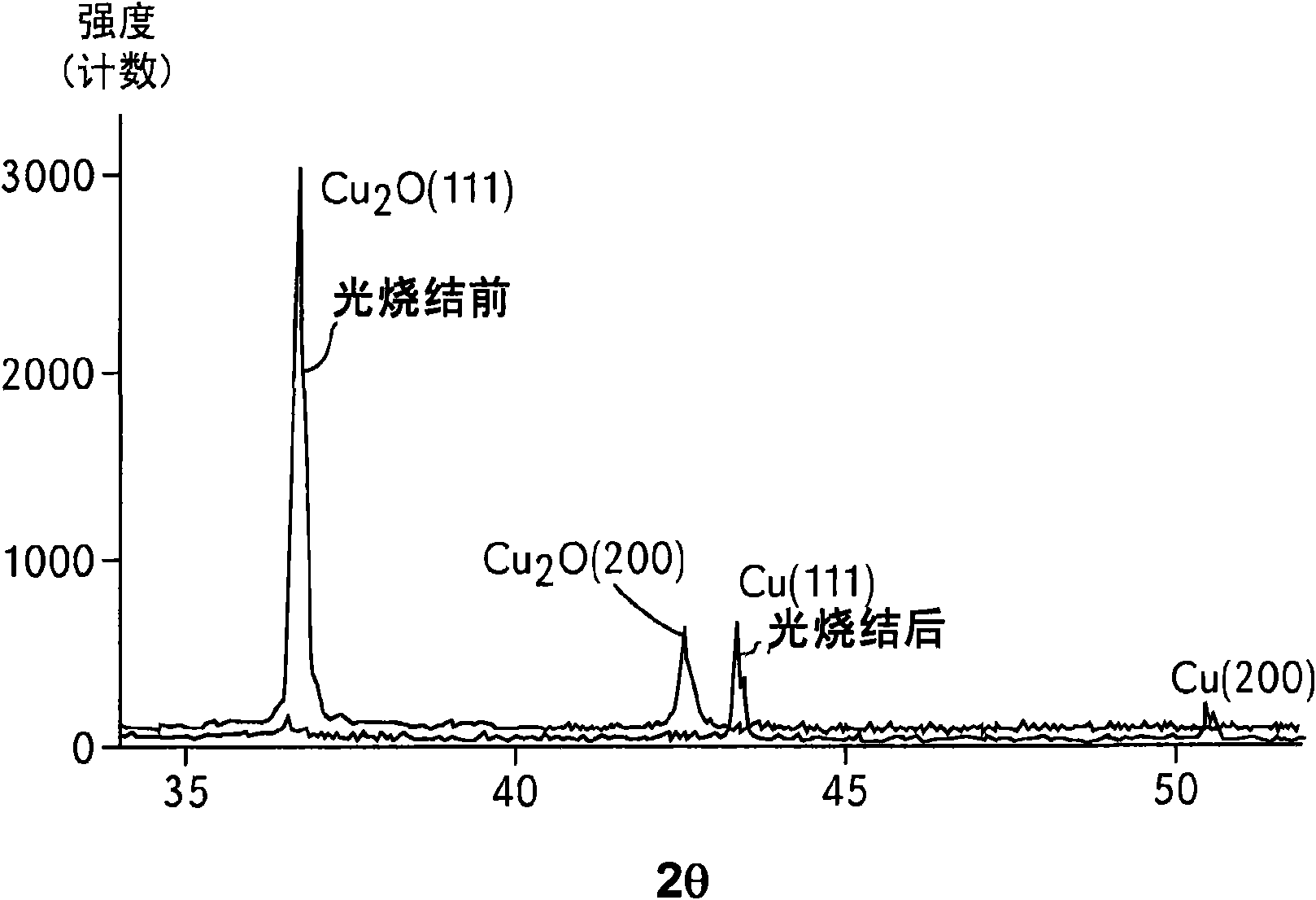

Forming a conductive film comprising depositing a non-conductive film on a surface of a substrate, wherein the film contains a plurality of copper nanoparticles and exposing at least a portion of the film to light to make the exposed portion conductive. Exposing of the film to light photosinters or fuses the copper nanoparticles.

Owner:ISHIHARA CHEM

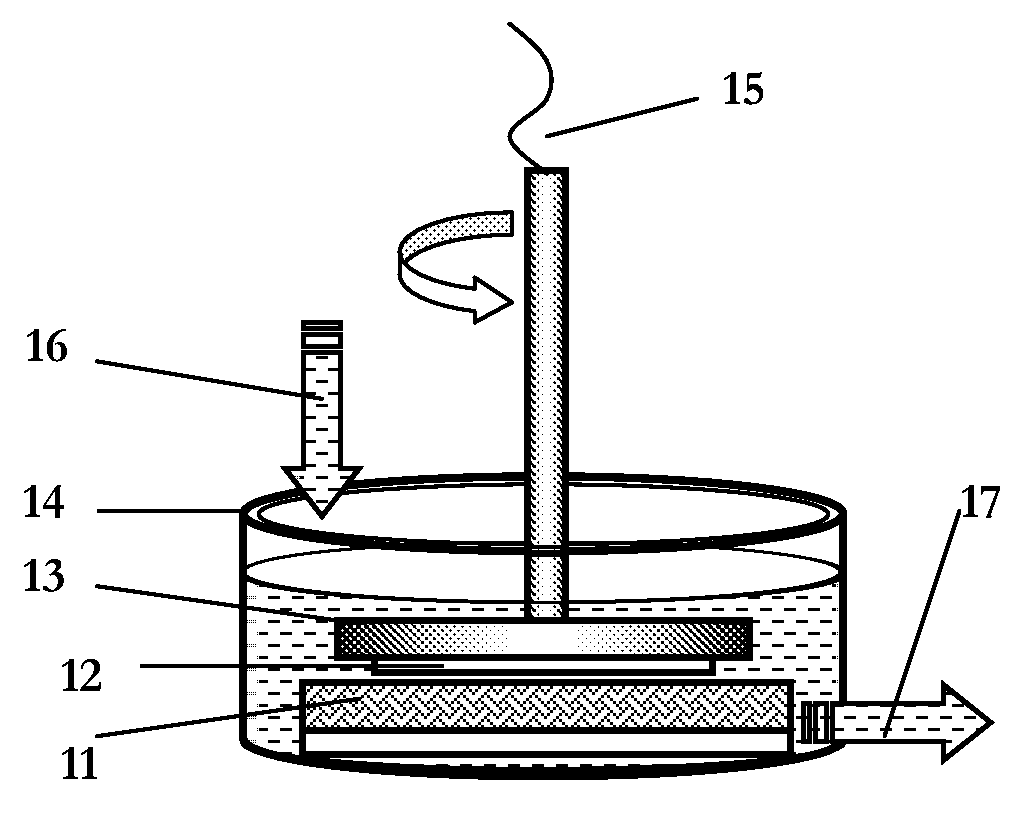

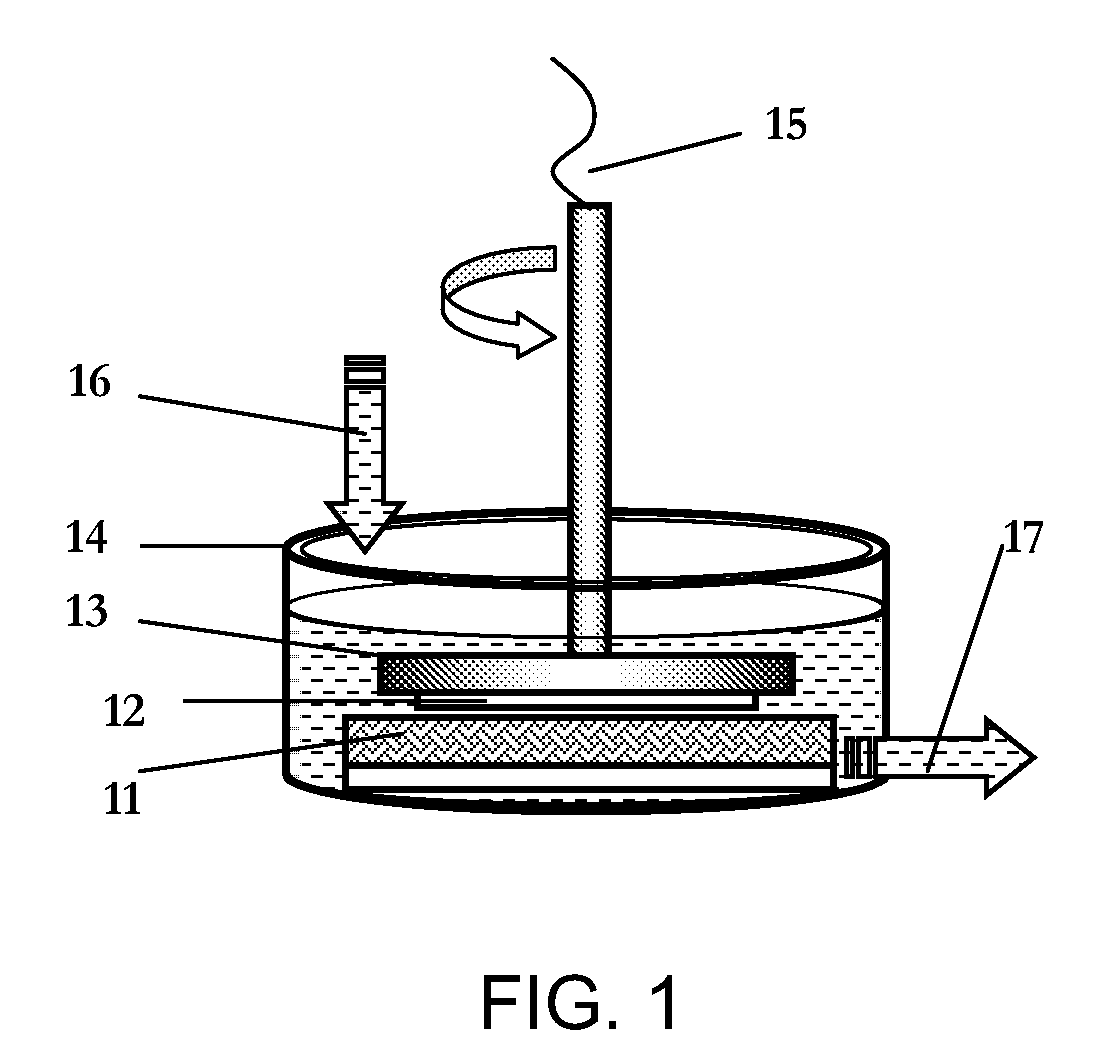

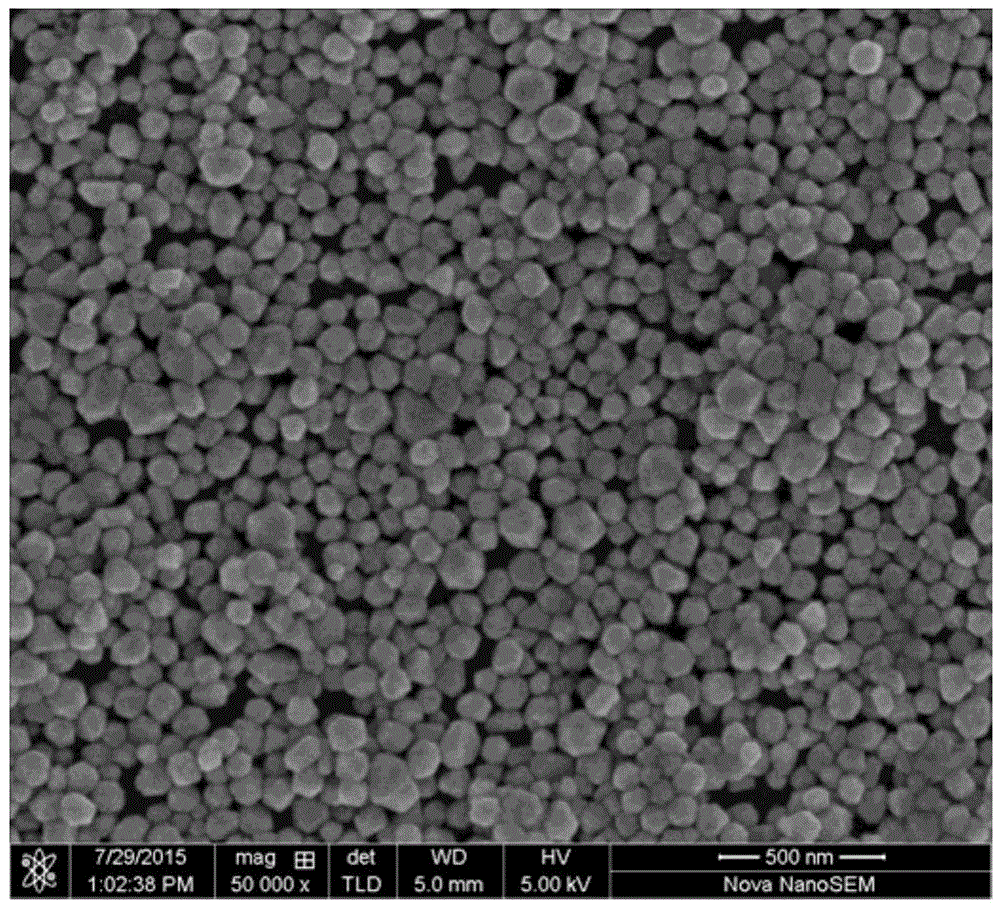

Method for manufacturing copper nanoparticles using microwaves

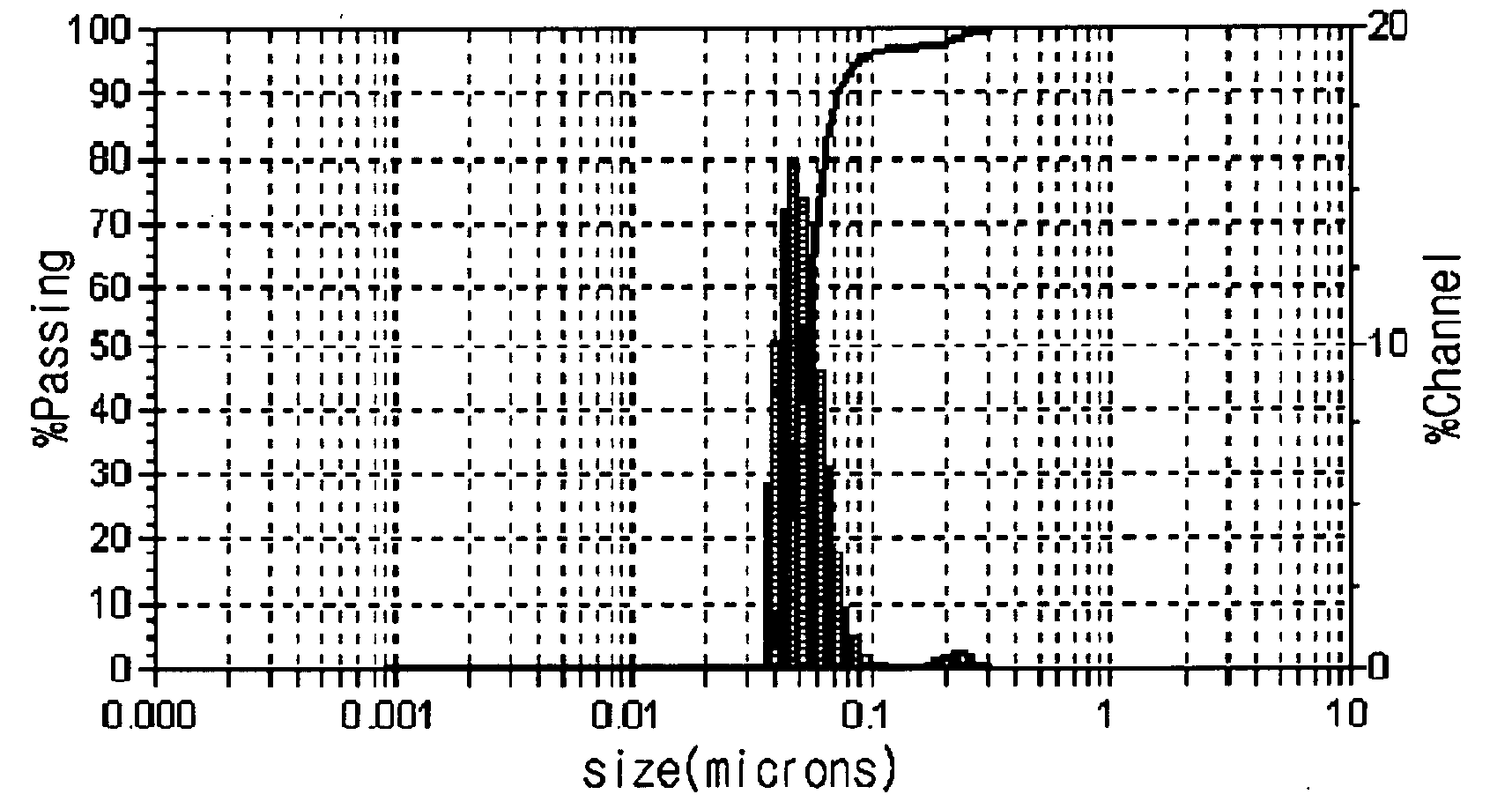

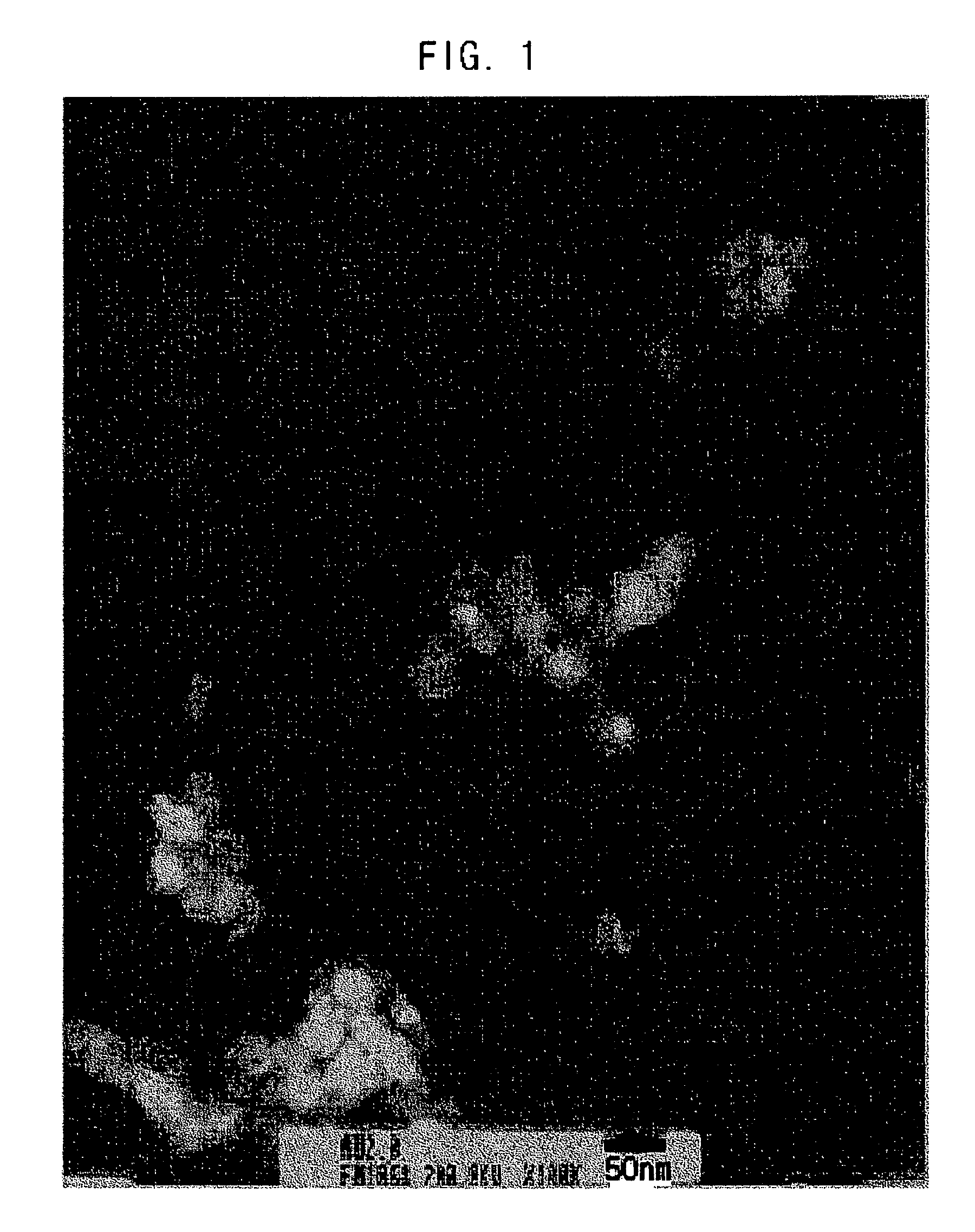

InactiveUS20080072706A1Good dispersionNarrow particle size distributionMaterial nanotechnologyPolycrystalline material growthMicrowaveOrganic solvent

The present invention relates to a method for manufacturing copper nanoparticles, in particular, to a method for manufacturing copper nanoparticles, wherein the method includes preparing a mixture solution including a copper salt, a dispersing agent, a reducing agent and an organic solvent; raising temperature of the mixture solution up to 30-50° C. and agitating; irradiating the mixture solution with microwaves; and obtaining the copper nanoparticles by lowering temperature of the mixture solution.According to the present invention, several tens of nm of copper nanoparticles having a narrow particle size distribution and good dispersibility can be synthesized in mass production.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

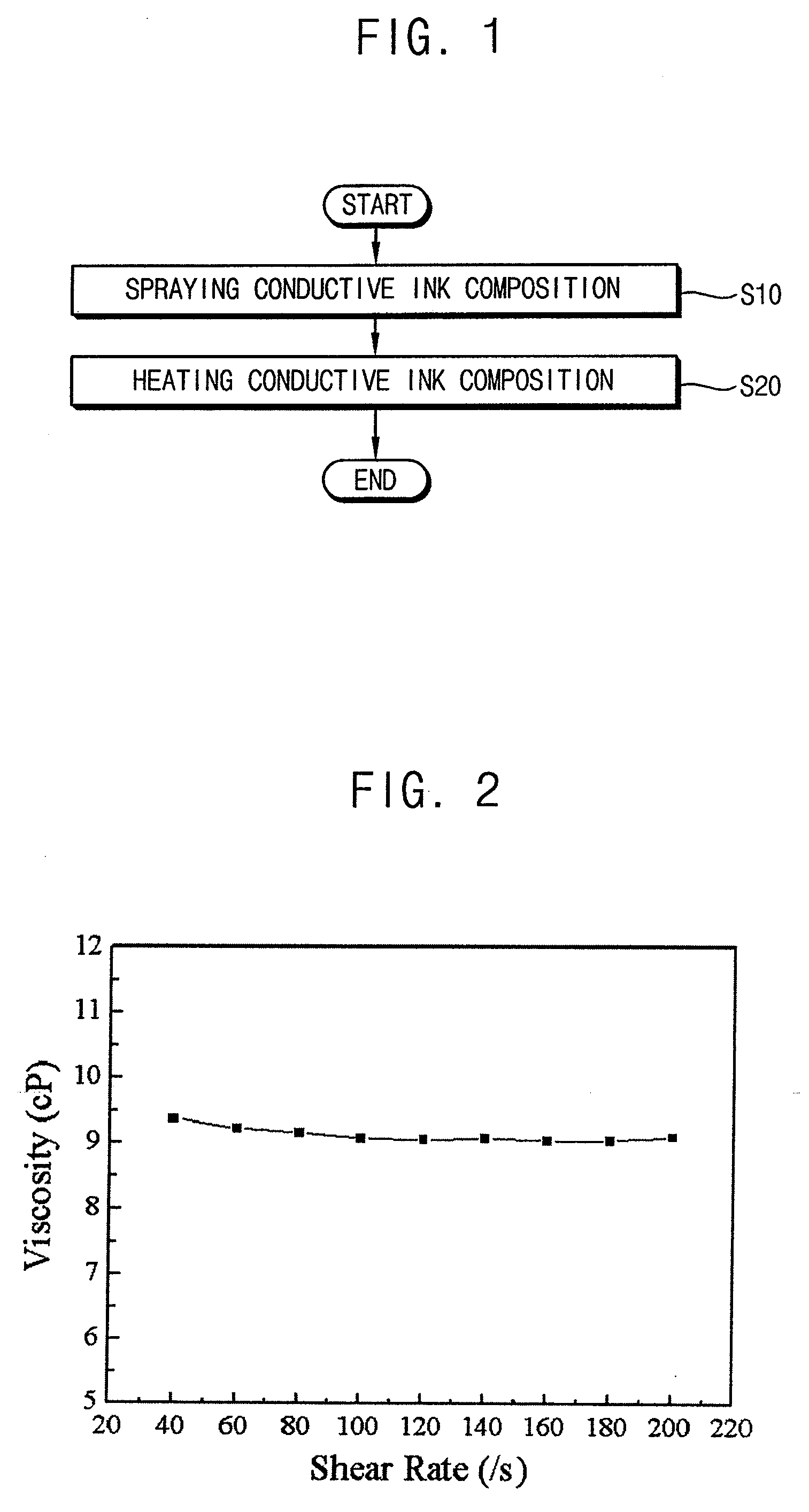

Conductive ink composition and method of forming a conductive pattern using the same

InactiveUS20080241414A1Reduce manufacturing costImprove Oxidation StabilityConductive materialSemiconductor/solid-state device manufacturingSolventCopper nanoparticle

A conductive ink composition includes about 15% to about 50% by weight of copper nanoparticles, about 40% to about 80% by weight of a non-aqueous solvent mixture, about 0.01% to about 5% by weight of a dispersion agent and about 1% to about 20% by weight of a wetting agent. A conductive pattern may be formed with use of the conductive ink composition and an inkjet printer.

Owner:SAMSUNG DISPLAY CO LTD

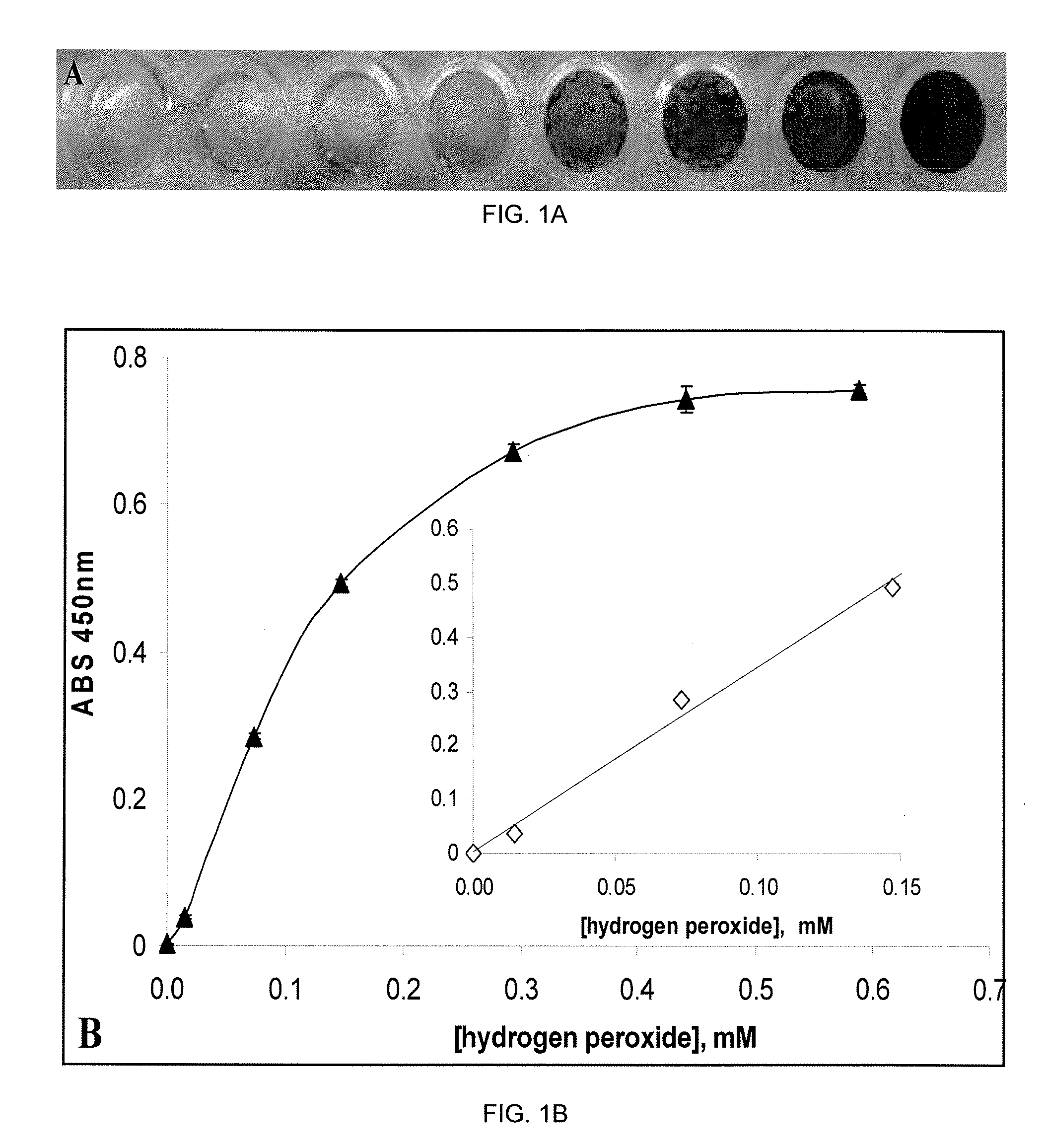

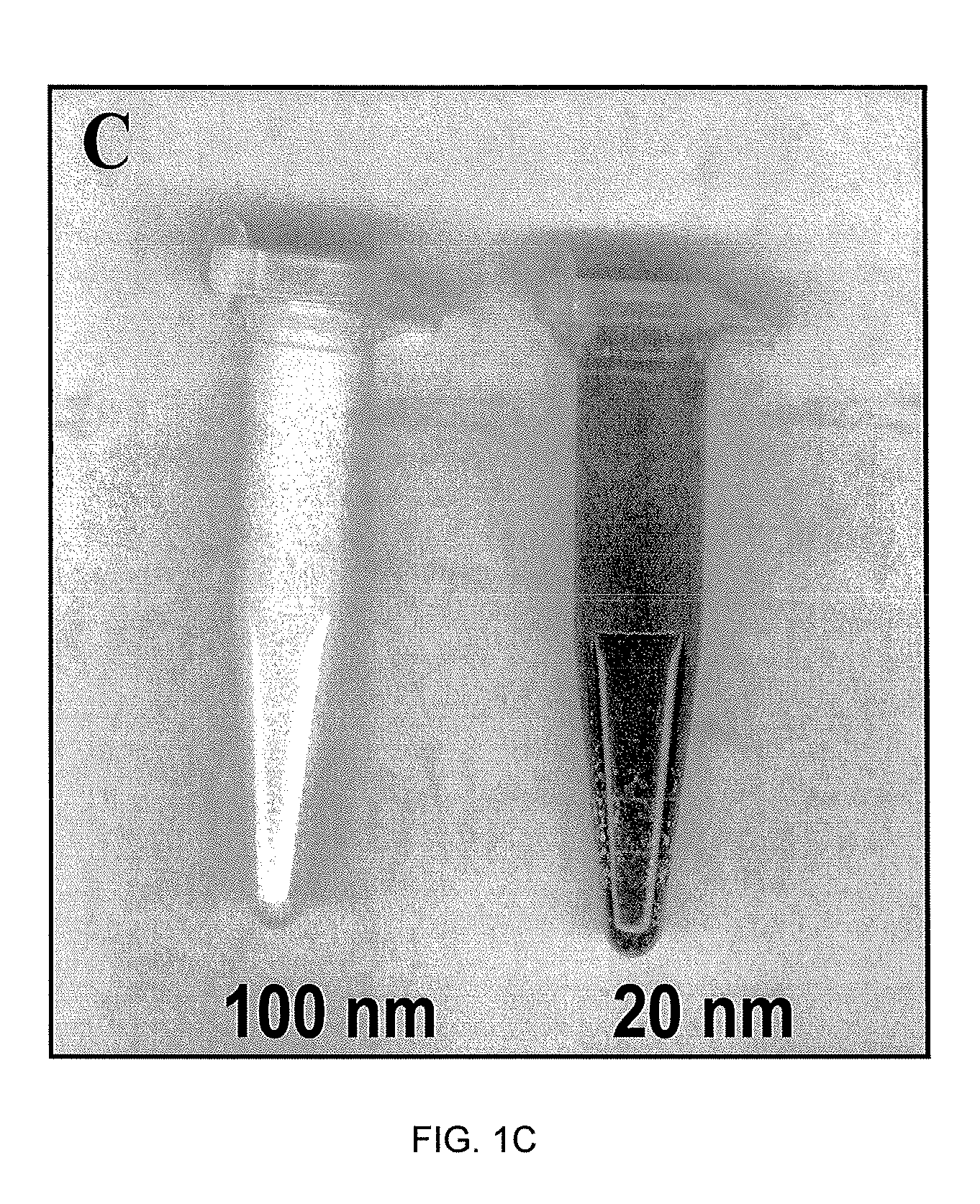

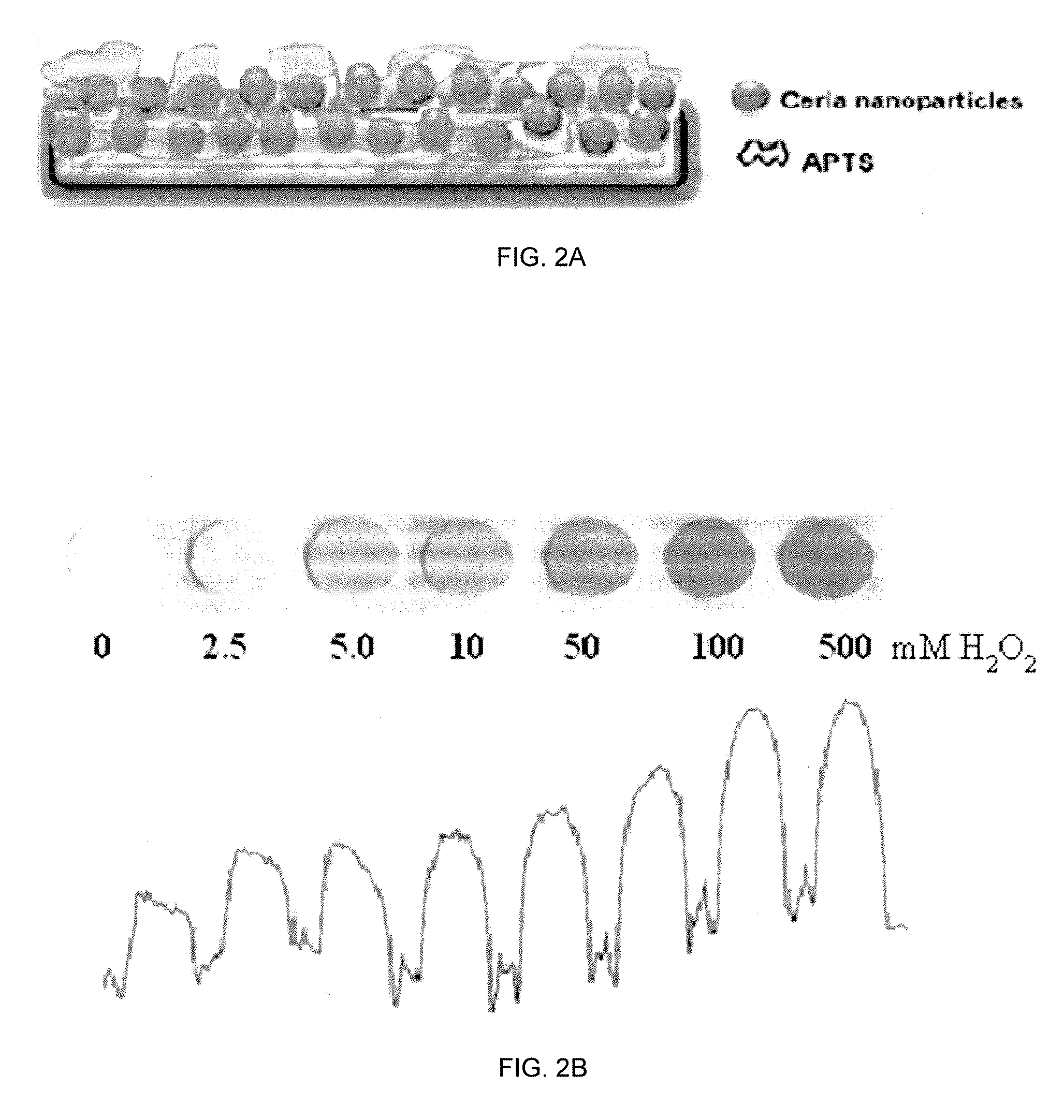

Reagentless Ceria-Based Colorimetric Sensor

ActiveUS20120315659A1Possible to detectIncrease rangeMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementDelivery vehicleIn vivo

A colorimetric reagent in the form of nanoparticles, composite nanoparticles, and nanoparticle coatings, including methods of use, methods of preparation, deposition, and assembly of related devices and specific applications. The colorimetric reagent comprises cerium oxide nanoparticles which are used in solution or immobilized on a solid support, either alone or in conjunction with oxidase enzymes, to form an active colorimetric component that reacts with an analyte to form a colored complex. The rate of color change and the intensity of the color are proportional to the amount of analyte present in the sample. Also described is the use of ceria and doped ceria nanoparticles as an oxygen storage / delivery vehicle for oxidase enzymes and applications in biocatalytic processes in anaerobic conditions of interest in biomedicine and bioanalysis. Further described are a variety of related applications of the disclosed technology including clinical diagnosis, in vivo implantable devices, food safety, and fermentation control.

Owner:CLARKSON UNIVERSITY

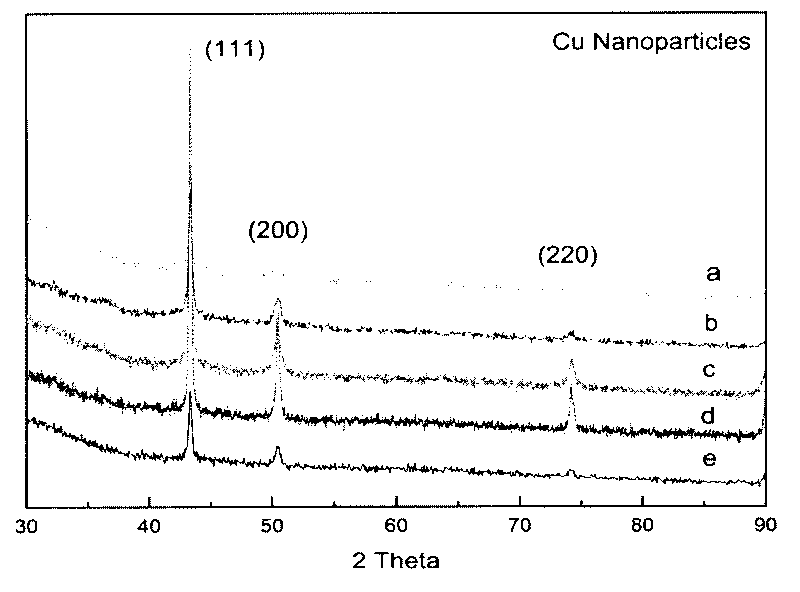

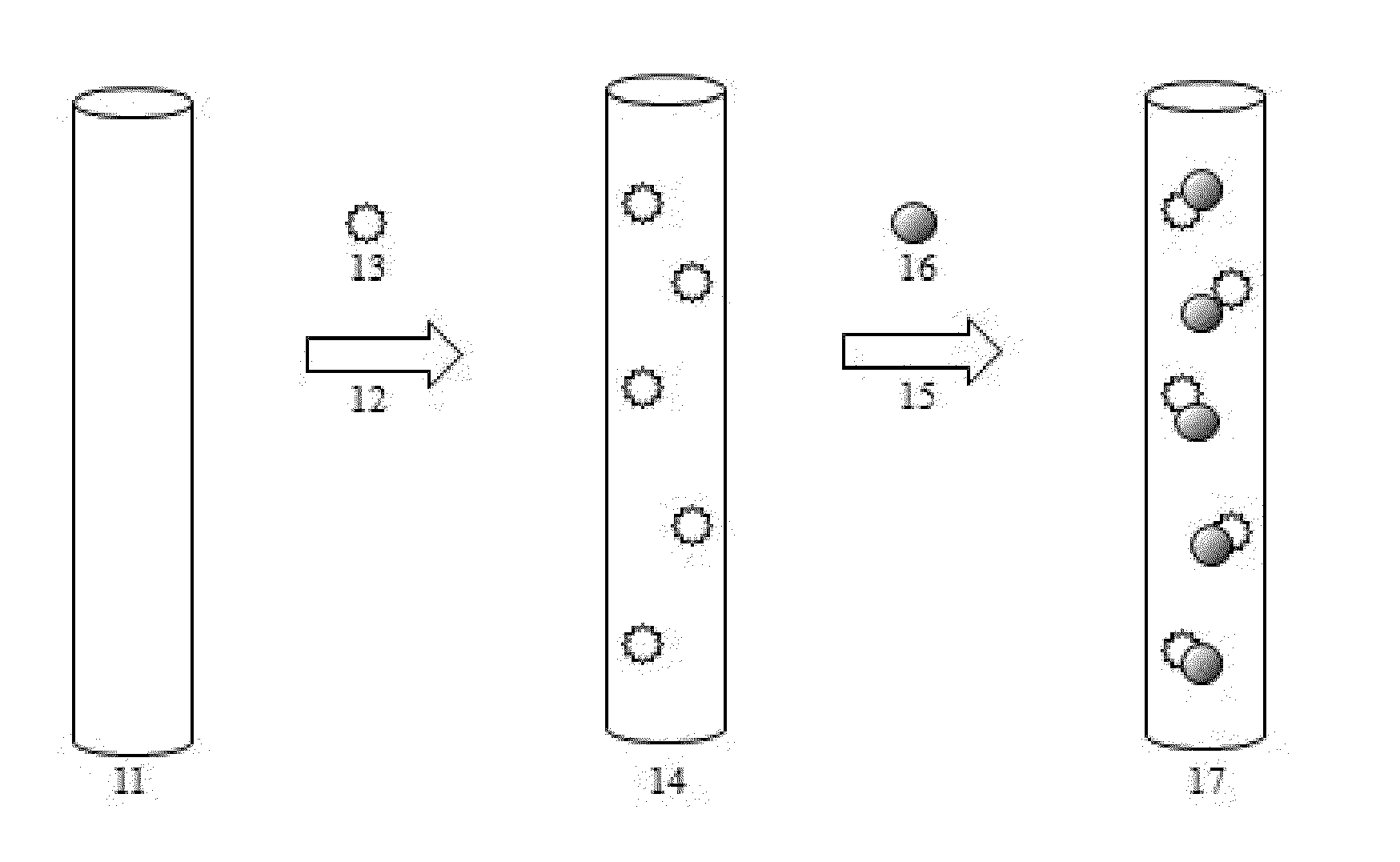

Preparation method of copper nanoparticles with different particle diameters

The invention discloses a preparation method of copper nanoparticles with different particle diameters and relates to a metal nanoparticle. The invention provides a preparation method of copper nanoparticles with different particle diameters, which has simple, economic, environment-friendly process. The preparation method comprises the following steps: adding metal salt of copper chloride or copper acetate, a solvent, a protective agent, a complexing agent and a surfactant in a vessel in sequence, and stirring to obtain a mixture, wherein the protective agent is polyvinylpyrrolidone, polyvinyl alcohol, polyacrylic acid, or the like, the complexing agent is oleic acid, hexadecylamine, oleamide, or the like, and the surfactant is hexadecyl dimethyl ammonium bromide, sodium dodecyl benzene sulfonate or the like; adding a reducing agent in the mixture for reacting, wherein the reducing agent is ascorbic acid, sodium formaldehyde sulphoxylate, sodium borohydride, or the like; cooling the reactant till the temperature is below 40 DEG C, then adding a precipitating agent, mixing, and centrifugally separating; then washing with the organic solvent, centrifugating, and extracting the precipitate; and then drying the precipitate to obtain red powder copper nanoparticles with different particle diameters.

Owner:XIAMEN UNIV

Nanoparticle-enhanced phase change materials (NEPCM) with great potential for improved thermal energy storage

InactiveUS20090236079A1Increased heat release rateFunction increaseMaterial nanotechnologyHeat storage plantsThermal energyThermal energy storage

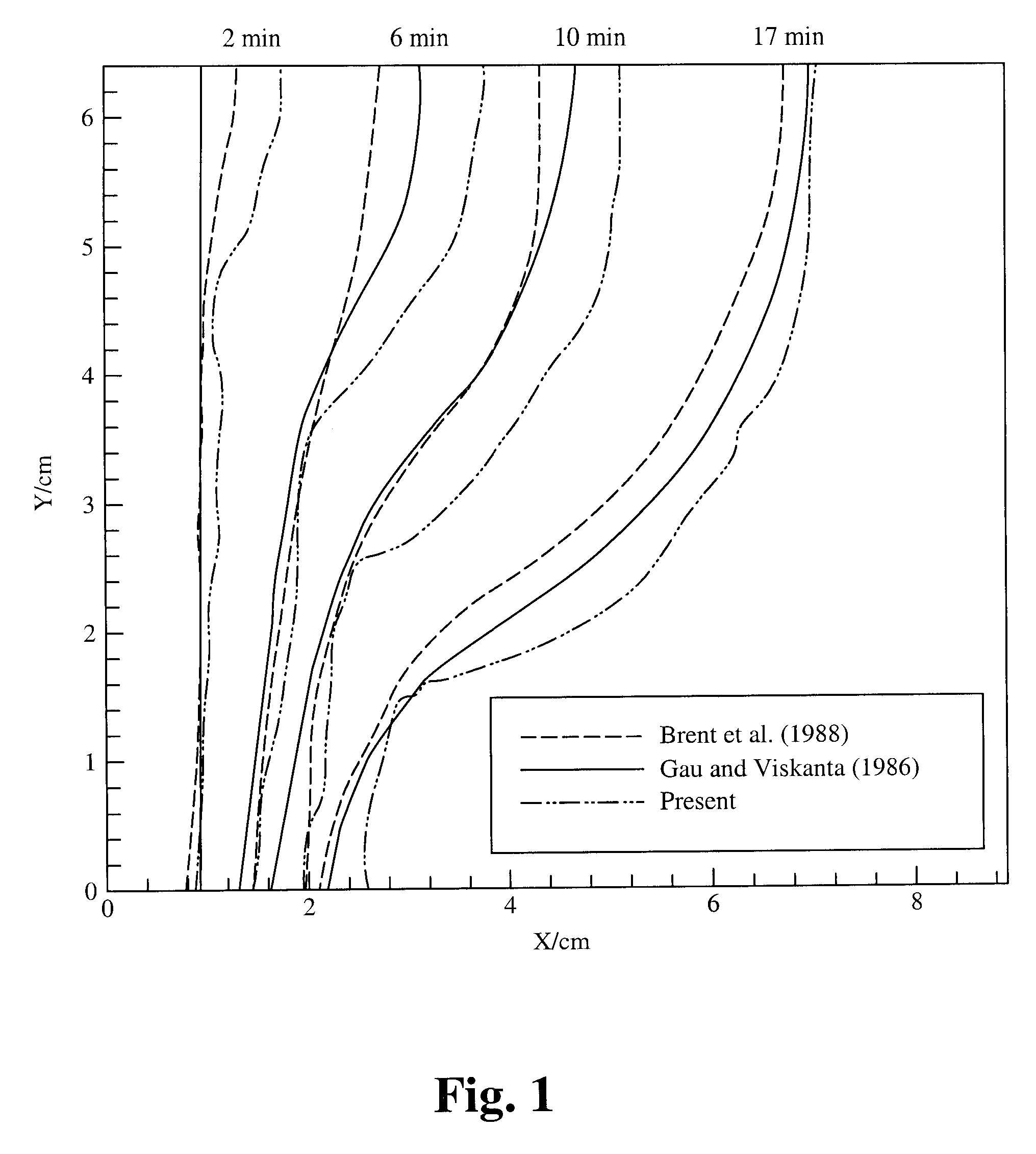

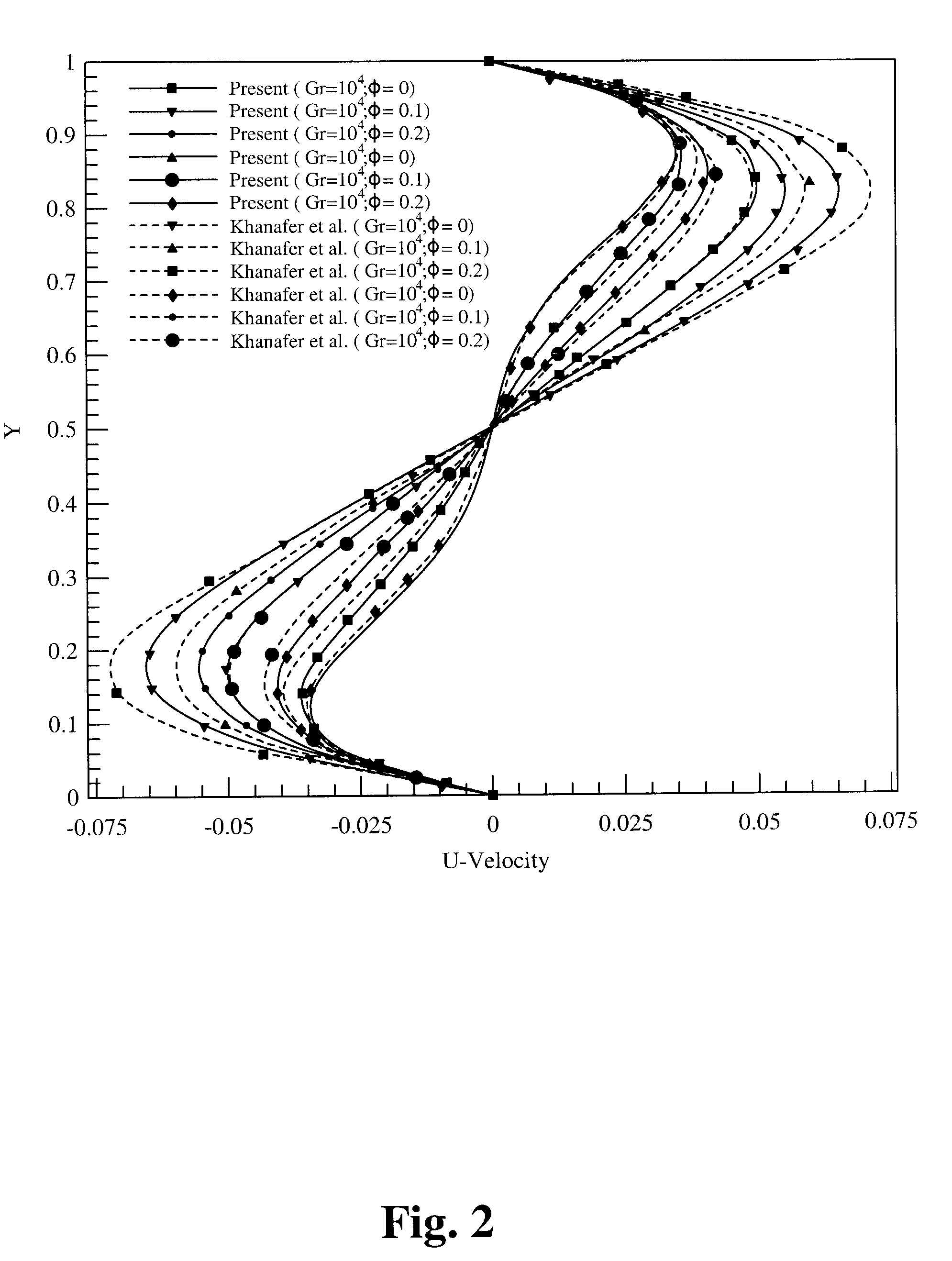

Improved functionality of phase change materials (PCM) through dispersion of nanoparticles is described. The resulting nanoparticle-enhanced phase change materials (NEPCM) exhibit enhanced thermal conductivity in comparison to the base material. Starting with steady state natural convection within a differentially-heated square cavity that contains a nanofluid (water plus copper nanoparticles), the nanofluid is allowed to undergo solidification. Partly due to increase of thermal conductivity and also lowering of the latent heat of fusion, higher heat release rate of the NEPCM in relation to the conventional PCM is observed. The predicted increase of the heat release rate of the NEPCM is a clear indicator of its great potential for diverse thermal energy storage applications.

Owner:AUBURN UNIV

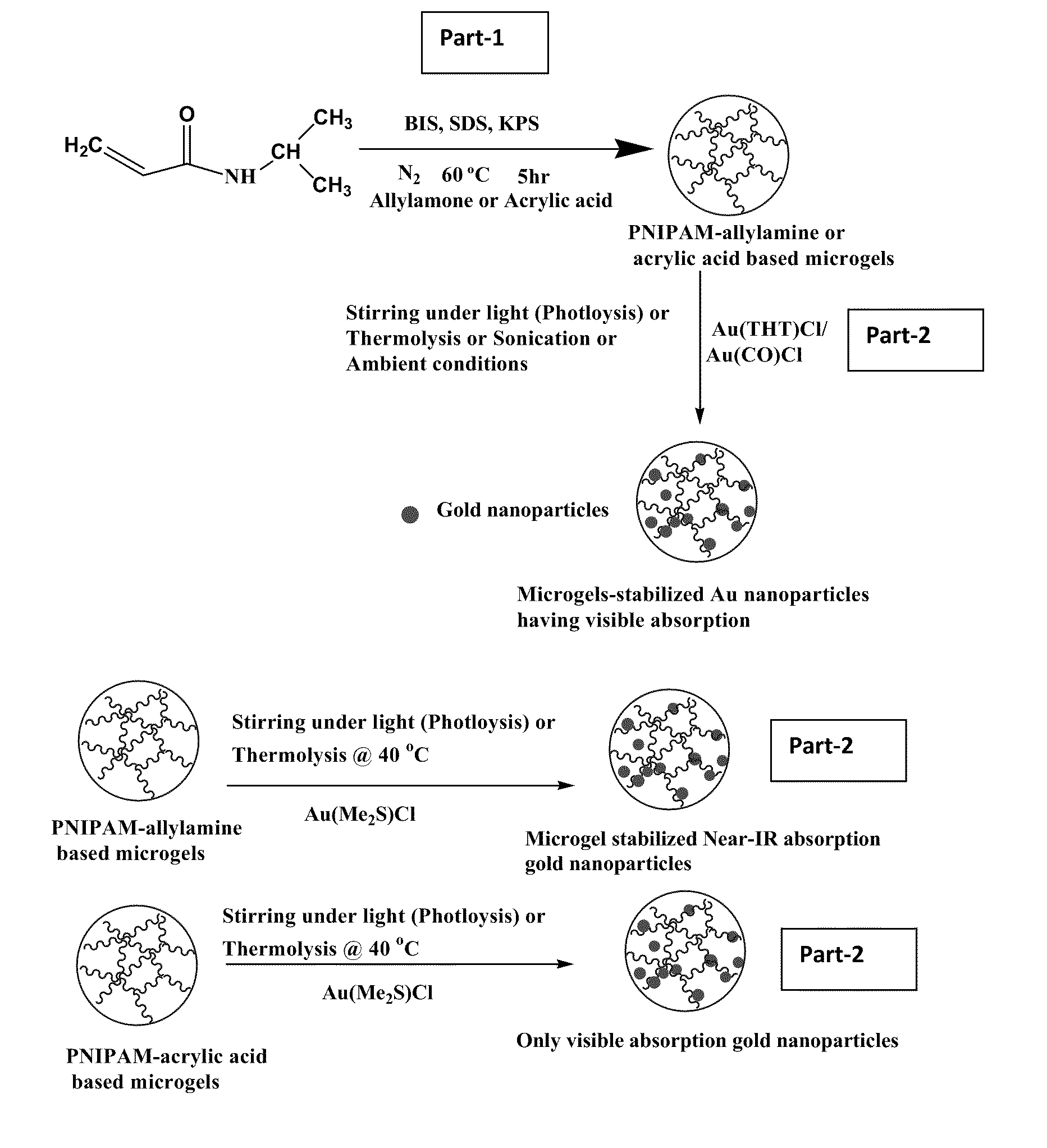

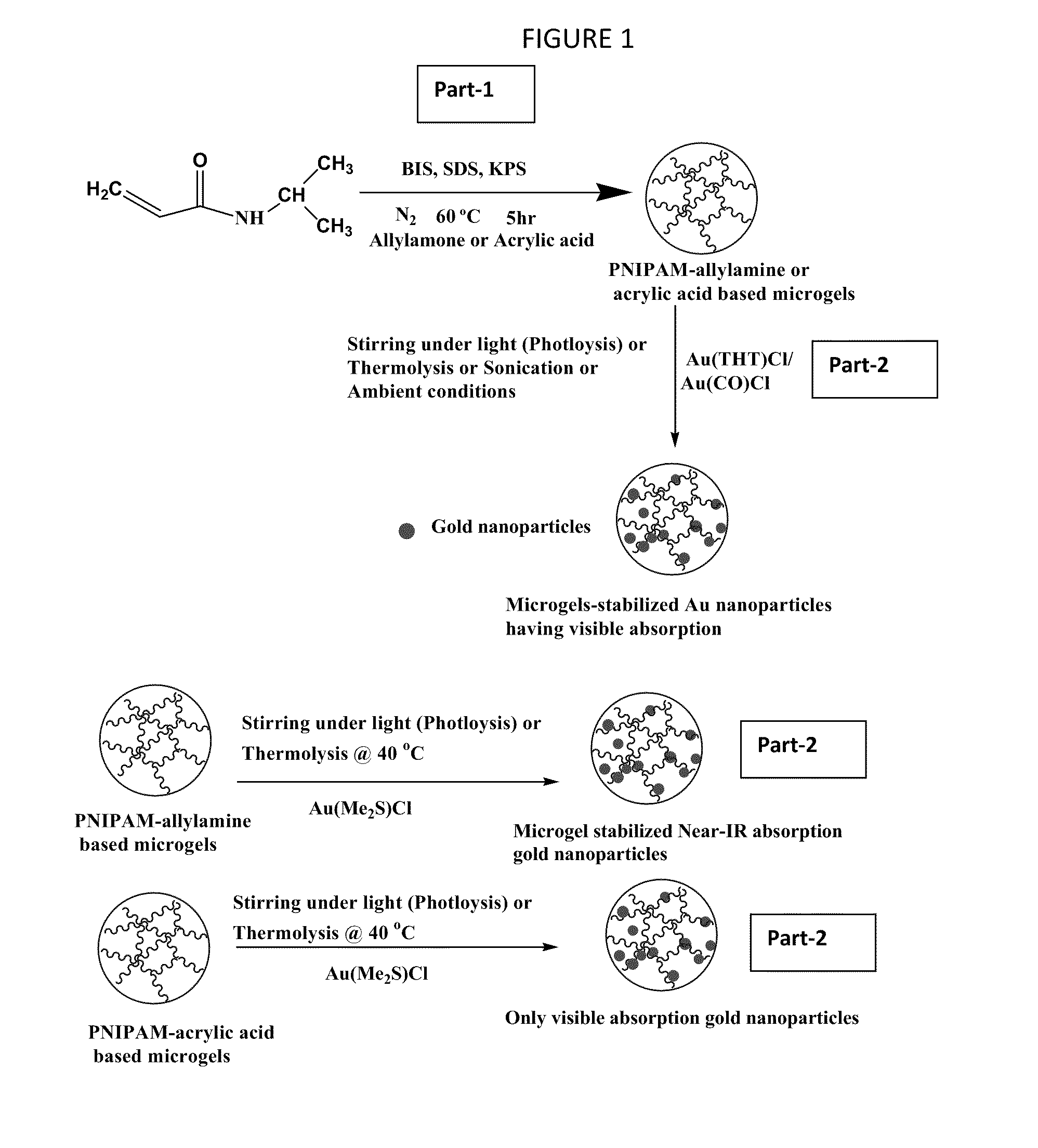

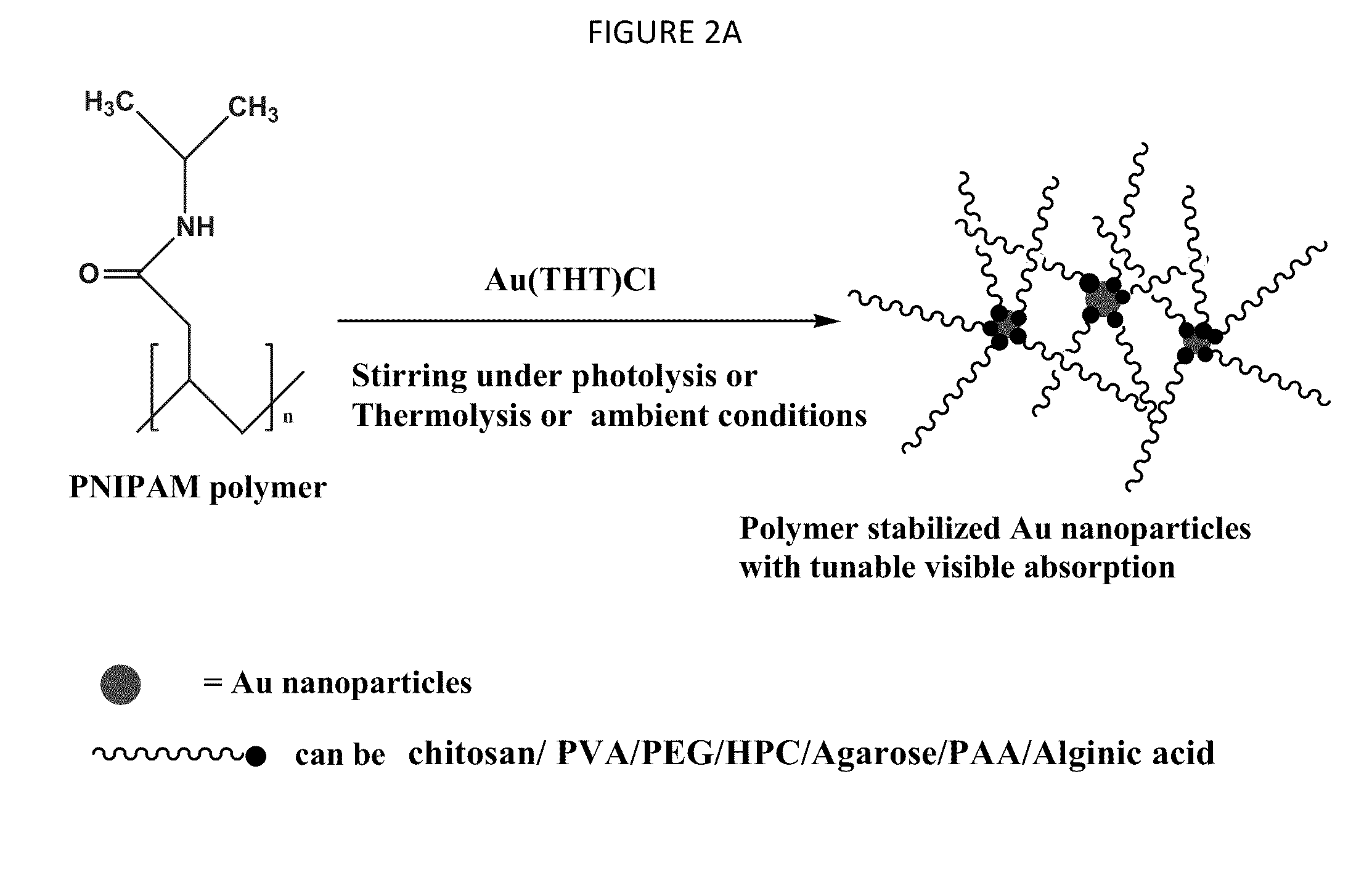

Gold, silver, and copper nanoparticles stabilized in biocompatible aqueous media

InactiveUS20100172997A1Enhance all biological applicationLess chemicalsMaterial nanotechnologyPowder deliveryParticle compositionCopper nanoparticle

The present invention includes metal nanoparticles composition and methods of making and using the same by converting a metal (I) to a metal (0) and forming one or more metal nanoparticles from the metal (0). The one or more metal nanoparticles are stabilized with one or more biocompatible stabilizers to prevent agglomeration and make them amenable for biomedical applications.

Owner:UNIVERSITY OF NORTH TEXAS

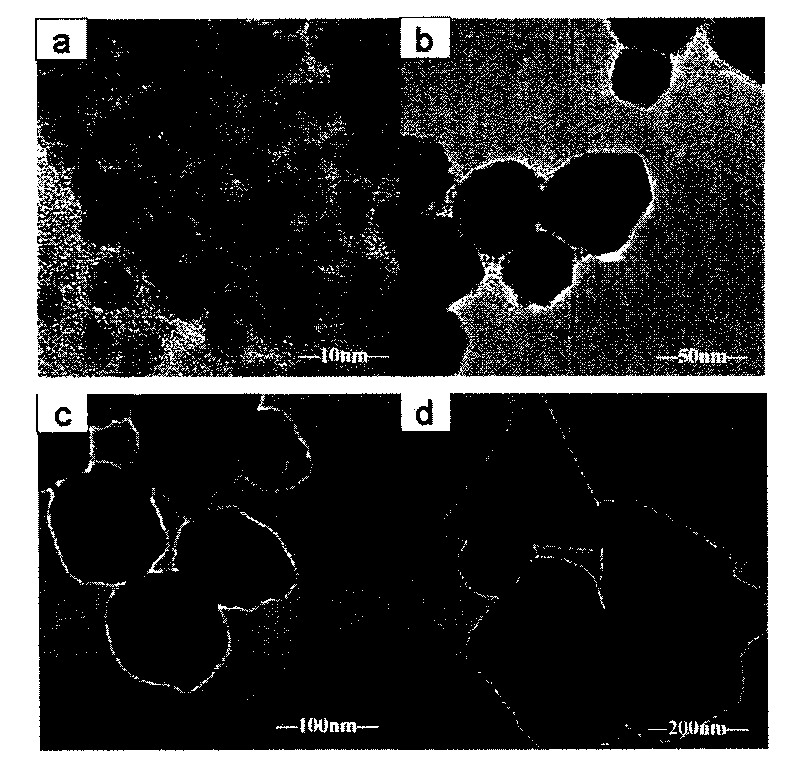

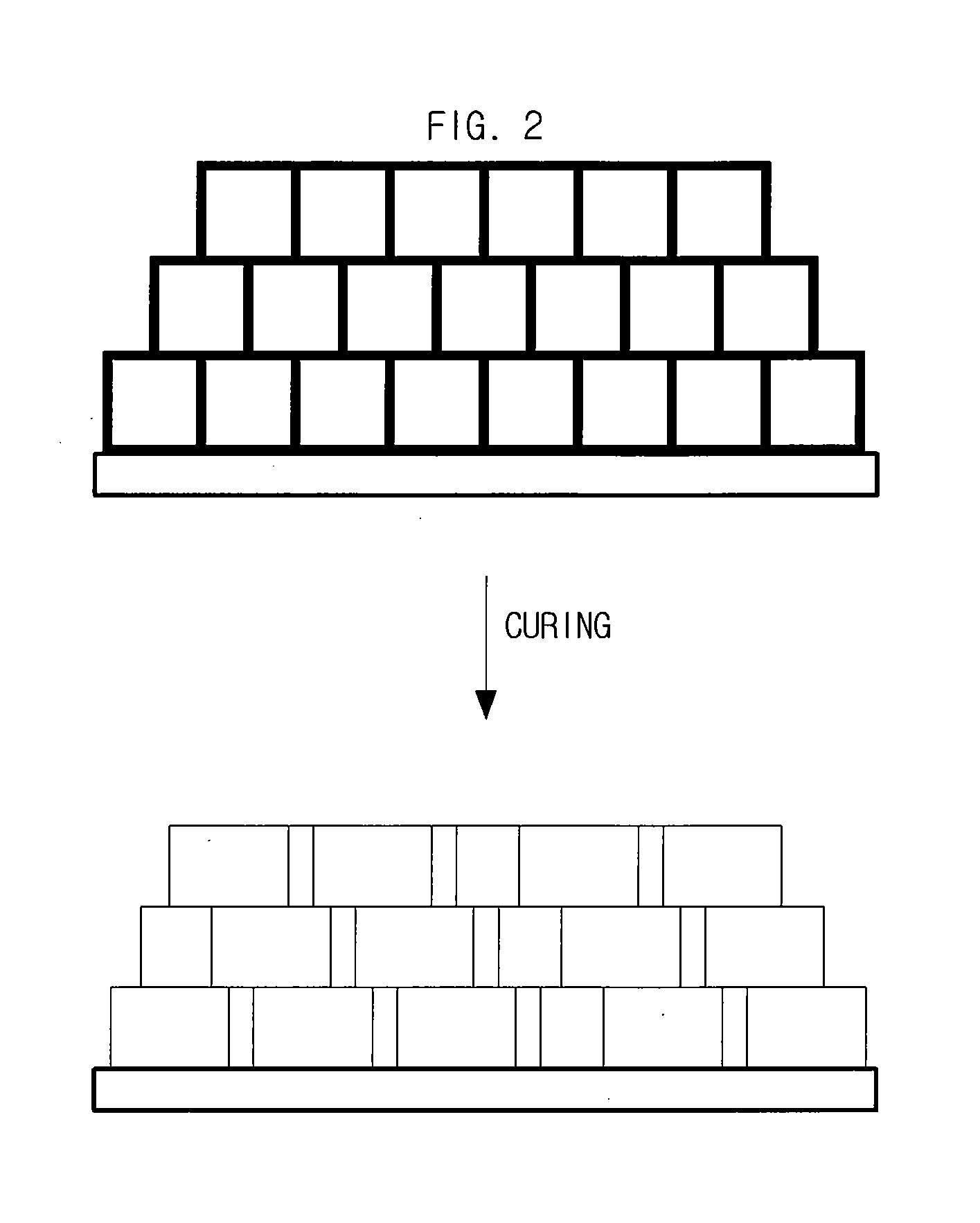

Method for manufacturing cubic copper or copper oxide nanoparticles

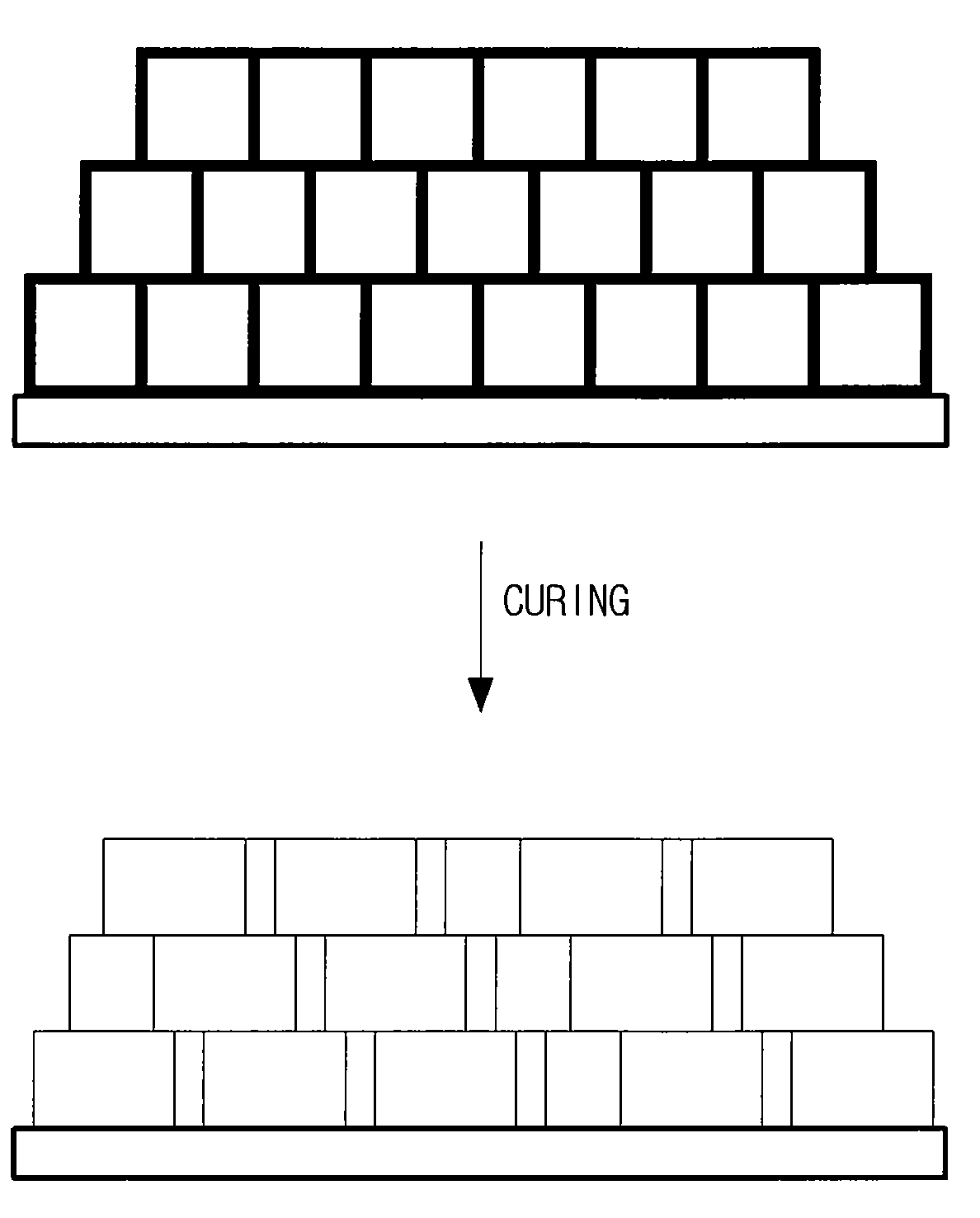

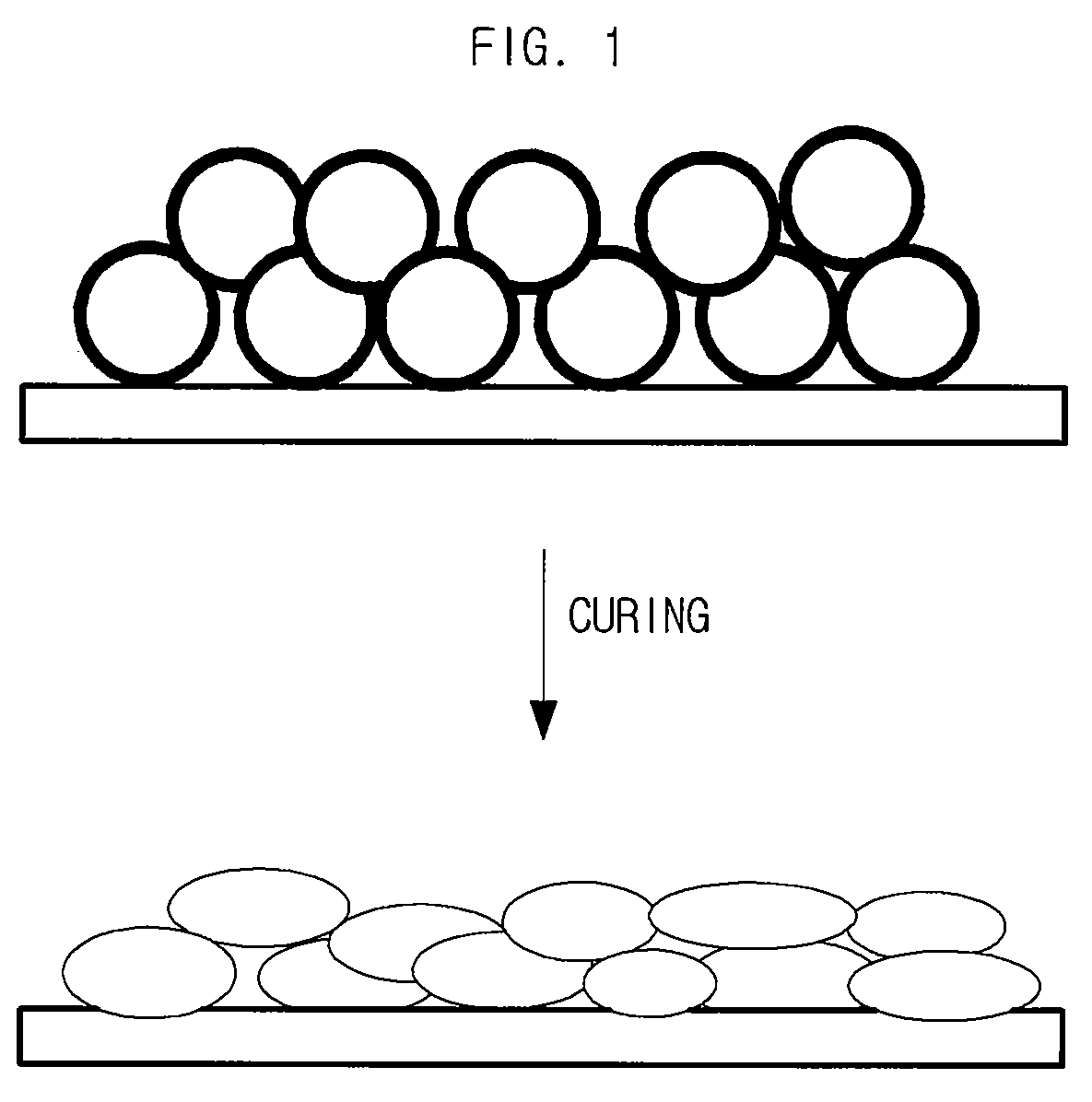

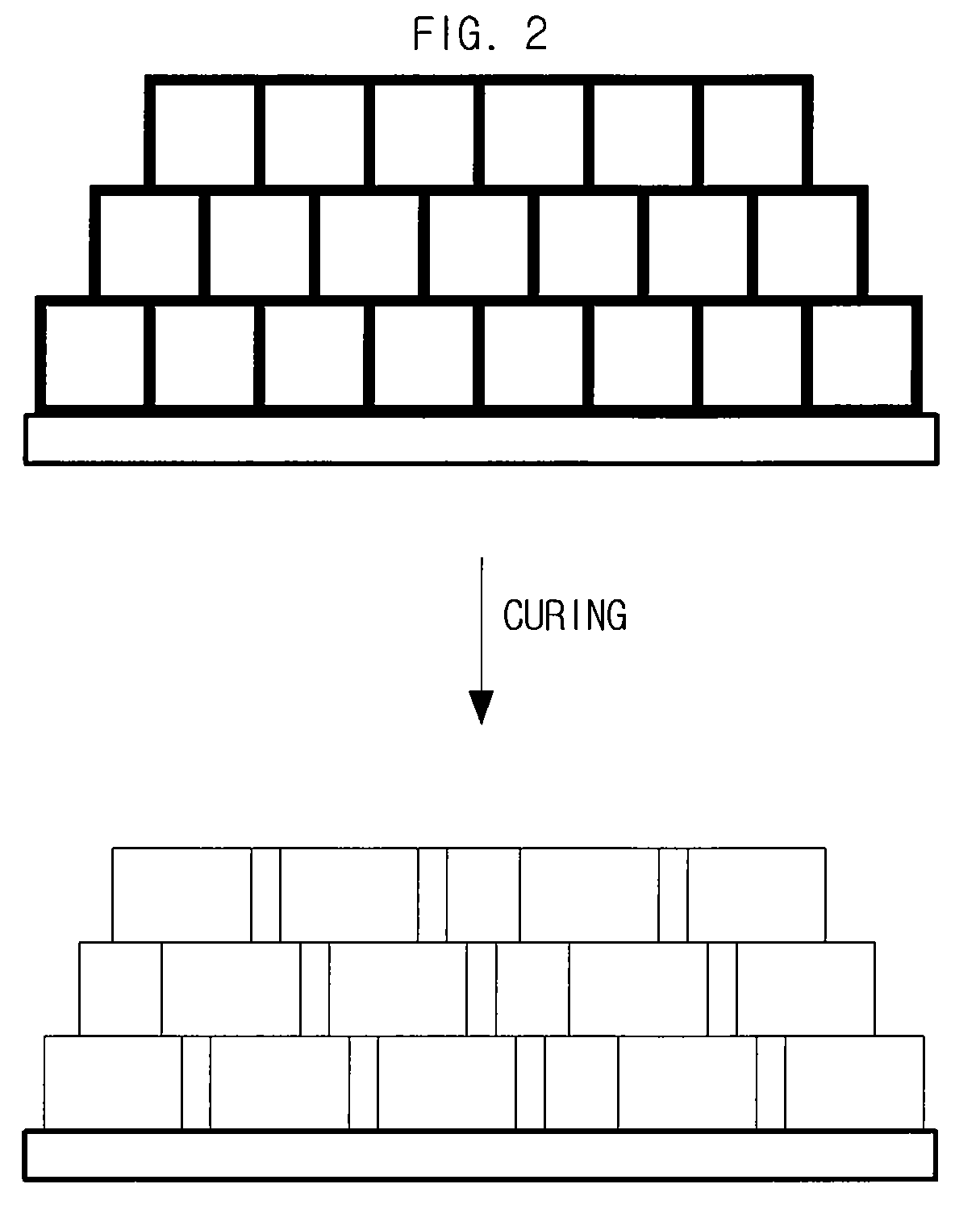

InactiveUS20080159902A1Increase heightEffectively eliminate voidMaterial nanotechnologyNanostructure manufactureAlcoholCopper oxide nanoparticles

The present invention relates to a method of manufacturing cubic copper nanoparticles, and in particular, to a method including (a) mixing and agitating a copper precursor and an amine compound; (b) raising the temperature of the mixed solution up to 90-170° C. and reacting it at the same temperature; (c) adding the mixture to nonaqueous solvent to lower the temperature of the solution to 20-50° C. when the incubation completes; and (d) precipitating and obtaining the nanoparticles by adding an alcohol solvent to the mixture. According to the invention, while conductive wiring is formed metal nanoparticles can be manufactured not in sphere but in cubic shape so that void between particles can be efficiently removed and the height of wiring can be raised.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

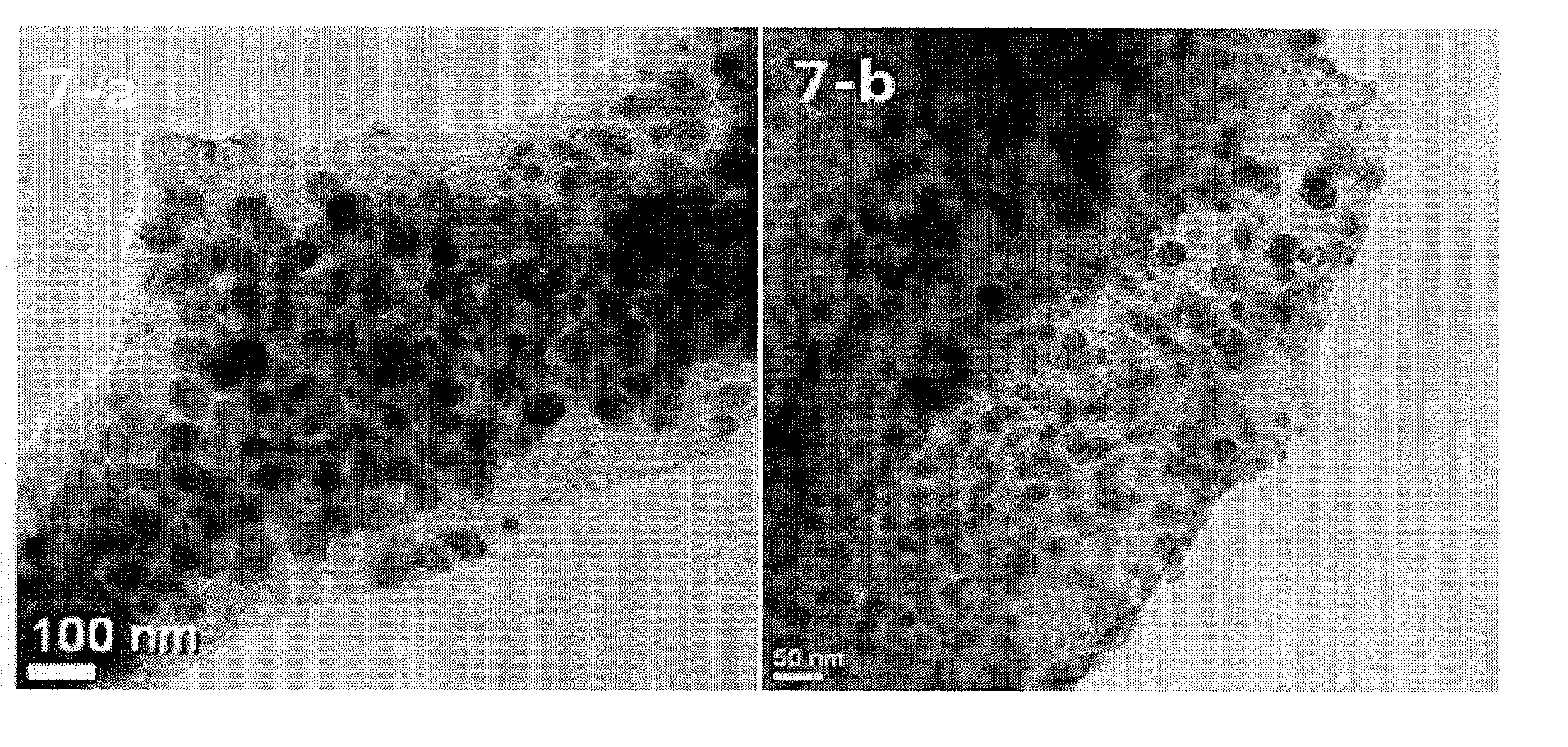

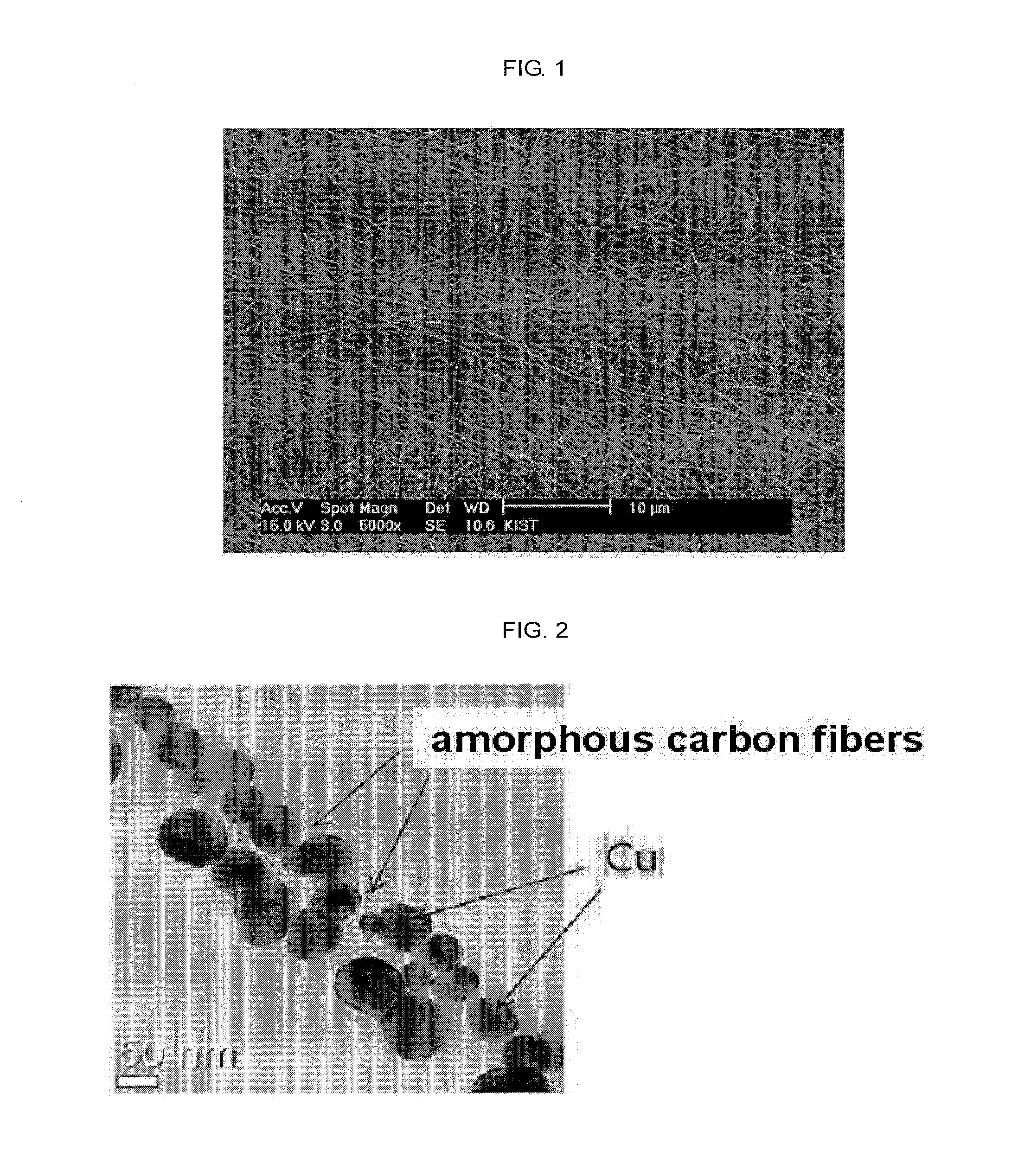

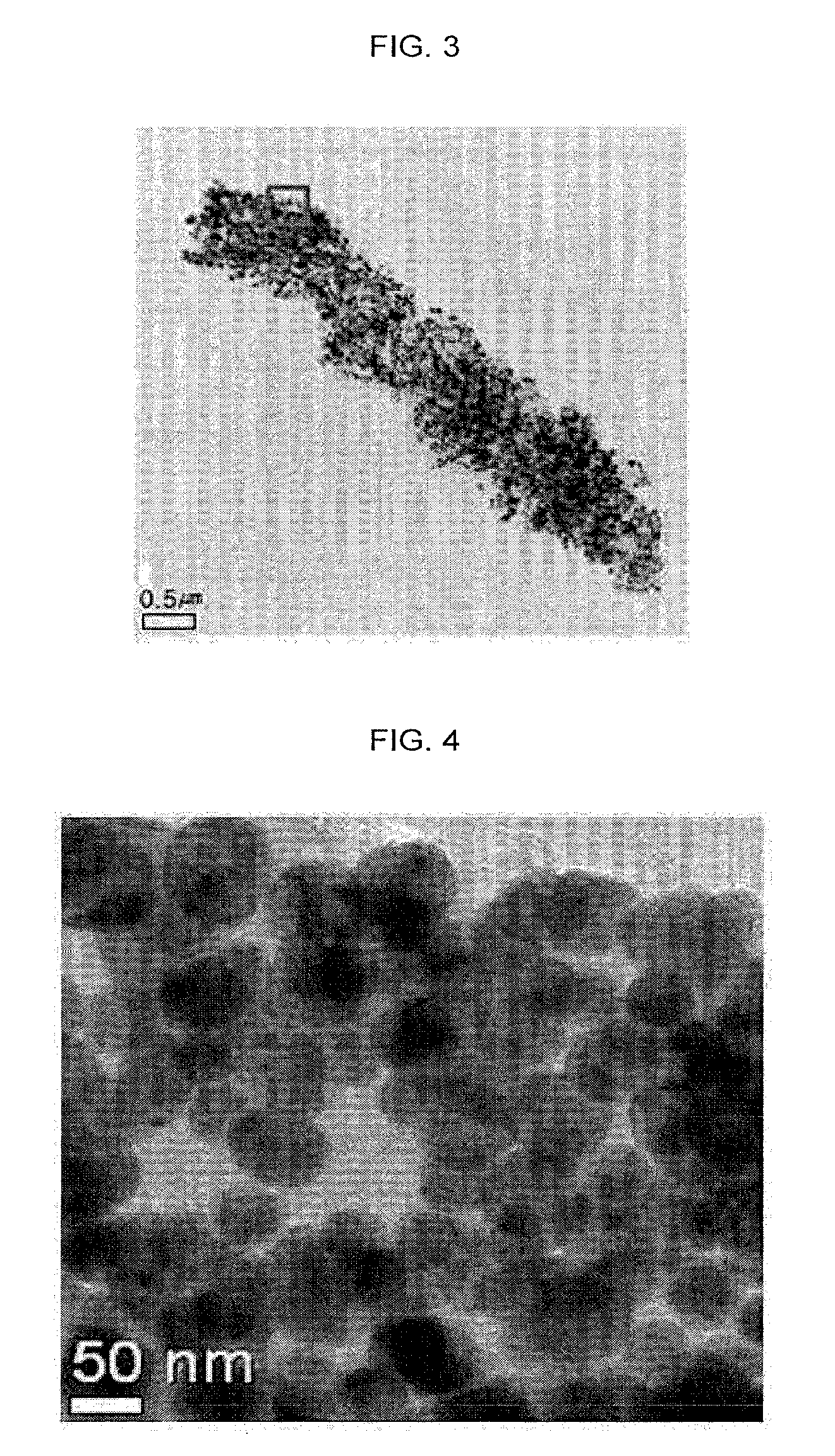

Carbon nanofiber including copper particles, nanoparticles, dispersed solution and preparation methods thereof

ActiveUS20120100303A1Improve conductivityUniform particle sizeMaterial nanotechnologyRadiation applicationsFiberNanofiber

Disclosed are amorphous carbon nanofibers including copper nanoparticles or copper alloy nanoparticles, copper composite nanoparticles prepared by grinding the amorphous carbon nanofibers and implemented as surfaces of Cu-included particles are partially or wholly coated with amorphous carbons, a dispersed solution including the copper composite nanoparticles, and preparation methods thereof and the amorphous carbon nanofibers include nanoparticles including copper, copper nanoparticles or copper alloy nanoparticles, and, the copper composite nanoparticles are implemented as surfaces of Cu-included particles are partially or wholly coated with amorphous carbons.

Owner:KOREA INST OF SCI & TECH

Oxidation-resistant, ligand-capped copper nanoparticles and methods for fabricating them

InactiveUS20080278181A1Shape highlySize highlySemiconductor/solid-state device manufacturingPretreated surfacesOxidation resistantCopper nanoparticle

The present invention is directed toward oxidation-resistant, ligand-capped nanoparticles, each comprising one or more capping ligands on a copper-containing core. Methods of making and using these nanoparticles are also disclosed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

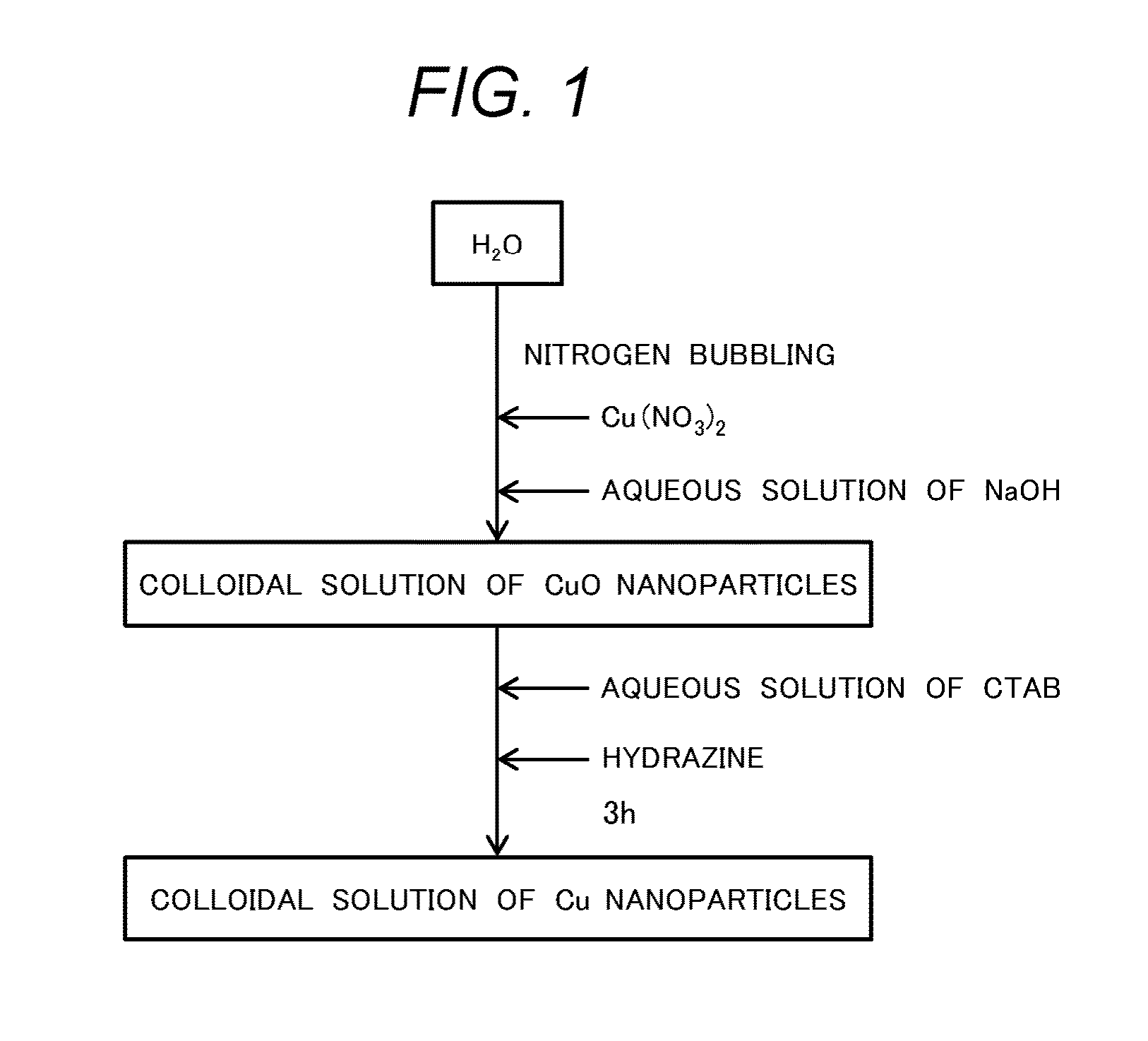

Process for producing copper nanoparticles

ActiveUS20060053972A1Improve stabilityGood dispersionMaterial nanotechnologyTransportation and packagingHydrazine compoundReducing agent

The present invention provides a process for producing copper nanoparticles, comprising steps of: a) reacting an aqueous solution containing a reductant with an aqueous solution of a copper salt while stirring for 1-8 min, wherein the reductant being one or more selected from a group consisting of hydrazine hydrate, sodium borohydride and sodium hypophosphite; b) adding an apolar organic solution containing the extracting agent and continuing the stirring for 0.5-1.5 hrs, said extracting agent being one or more selected from the group consisting of alkyl dithiocarbonic acid and salts thereof, O,O′-dialkyl dithiophosphoric acid and salts thereof, and dialkylamino dithioformic acid and salts and said apolar organic solution being one selected from the group consisting of benzene, toluene and straight or branched alkanes having 6-12 carbon atoms, wherein the alkyl having 6-20 carbon atoms; and c) post-treating the reaction product to obtain copper nanoparticles.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-soluble nano-copper and preparation method thereof

ActiveCN102554217AEffective dispersionSimple preparation processMaterial nanotechnologyNano copperMicroparticle

The invention belongs to the technical field of nanometer materials, and particularly relates to water-soluble nano-copper and a preparation method of the water-soluble nano-copper, wherein the water-soluble nano-copper is nano-copper clusters which are surface-modified by stable organic single molecules formed in a way that organic compound surface modifier containing sulfydryl is bonded on the surface of copper nanoparticles. The invention can obtain copper nanoparticles which can be effectively dispersed in water phases and can exist stably, and is simple in preparation process and preparation devices, low in raw material cost, low in the production cost, high in yield, and suitable for large-scale industrial production, and the raw materials are easily accessible.

Owner:HENAN UNIVERSITY

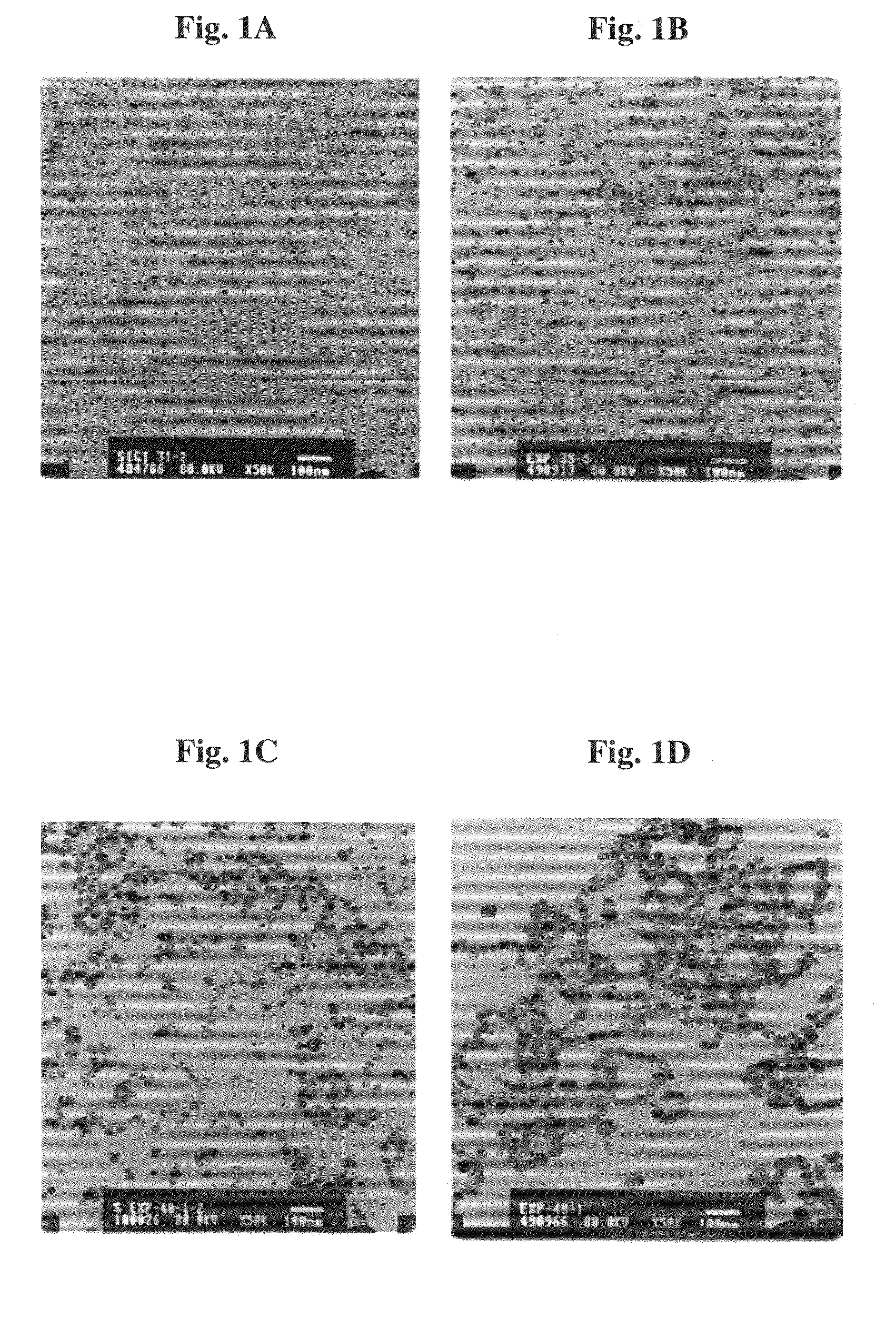

Synthesis of polymer coated ceria nanoparticles for biomedical applications

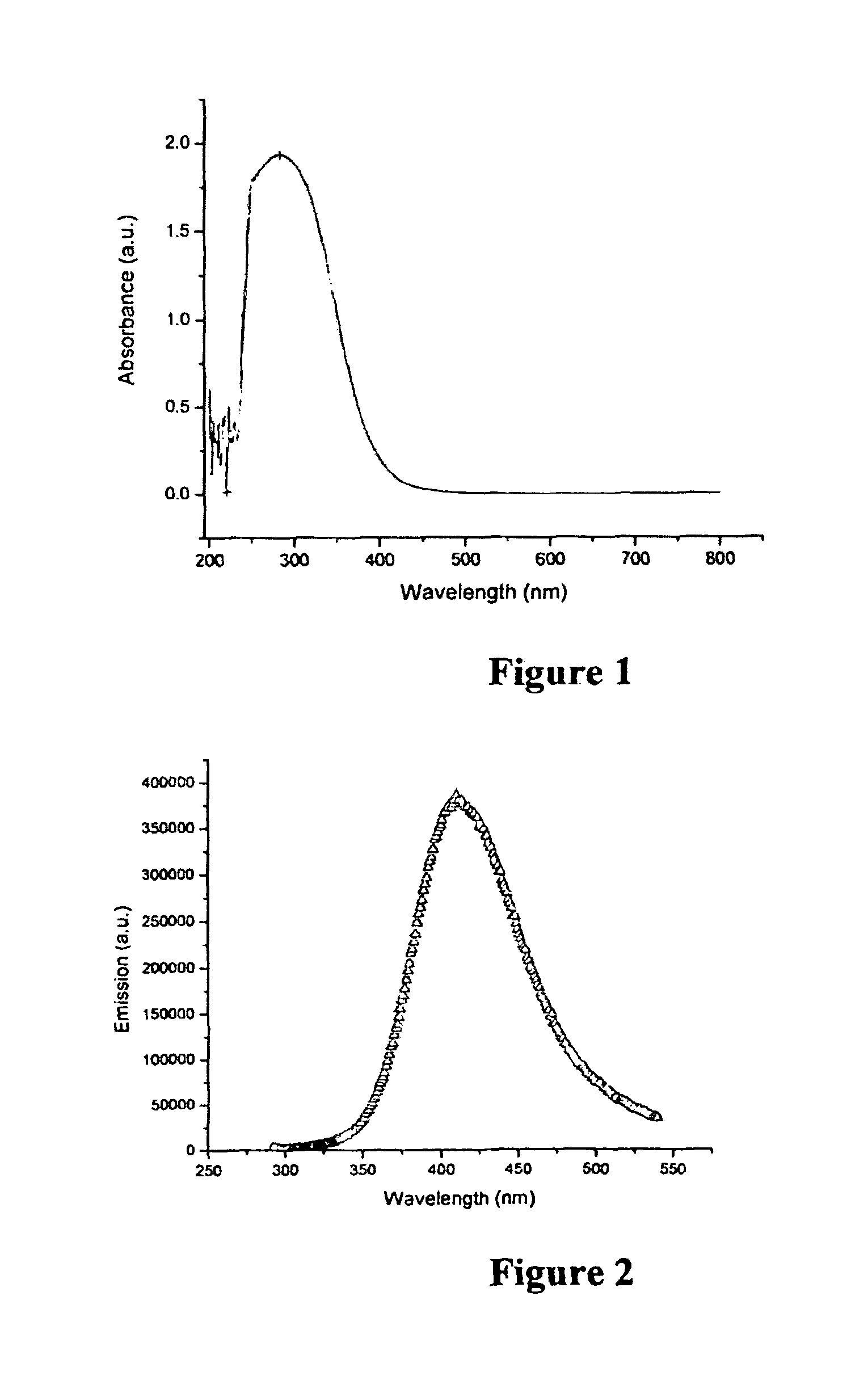

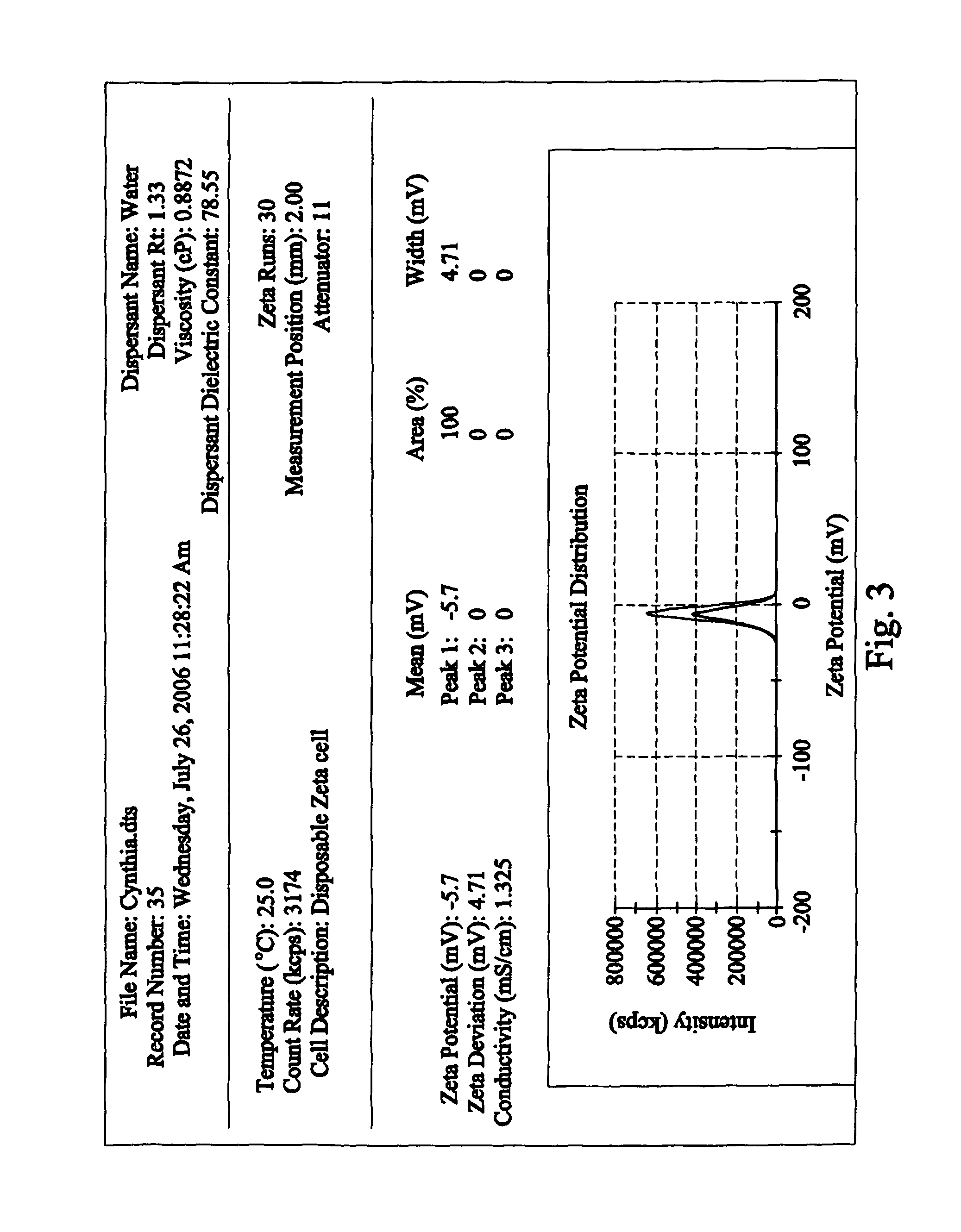

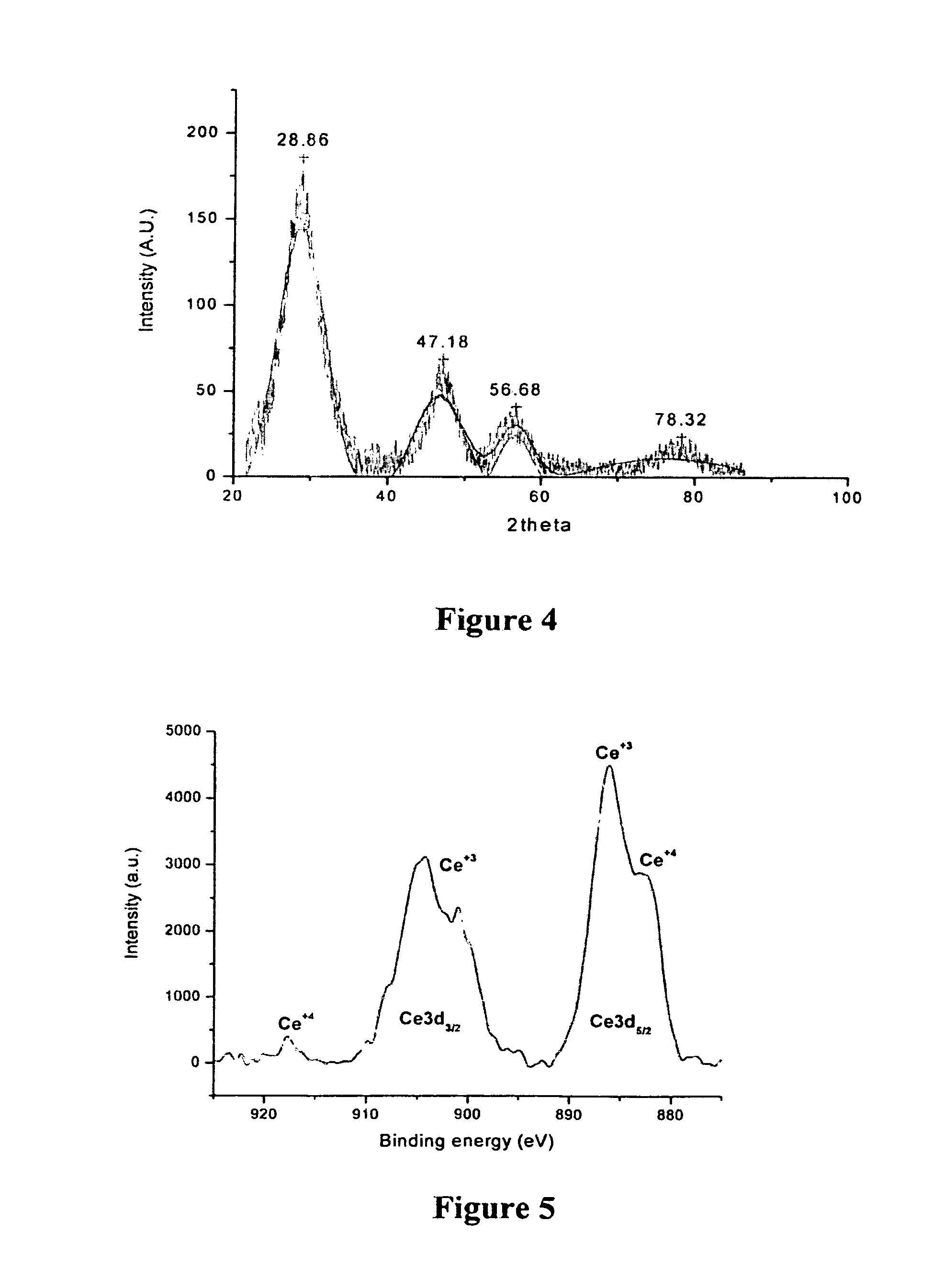

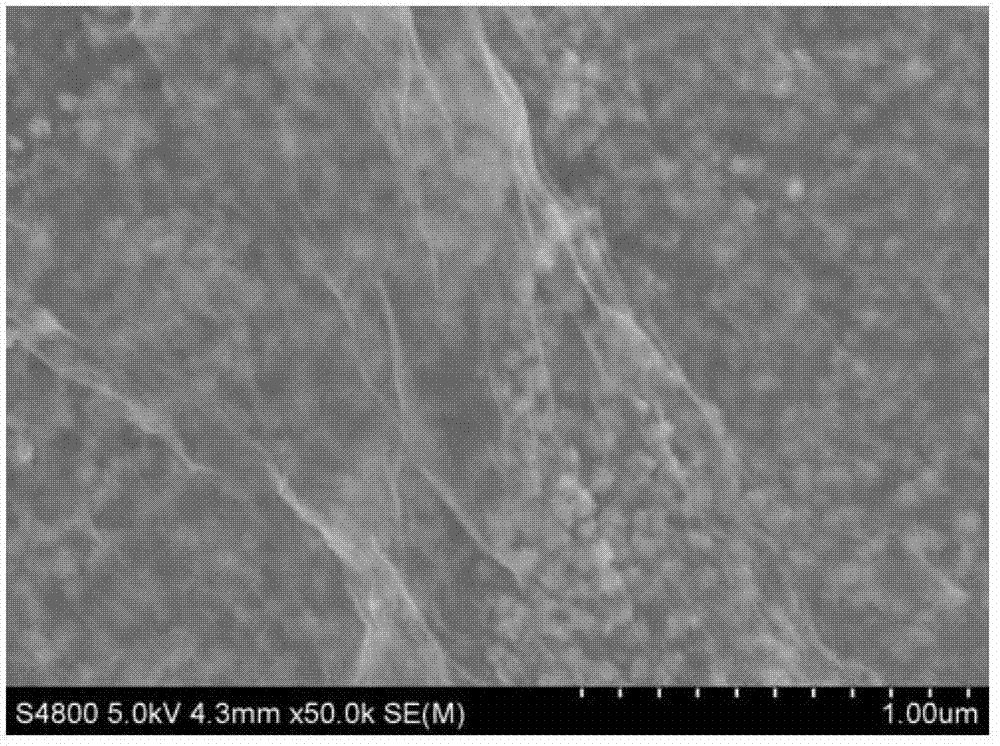

ActiveUS8333993B1Eliminate needImprove solubilityPowder deliveryInorganic active ingredientsSynthesis methodsPhosphate

Procedures and methods for synthesizing biodegradable polymer coated nanoceria result in stable nanoparticle preparations in aqueous systems and physiological relevant colloidal solutions, such as phosphate buffer saline. The coated nanoceria preparations increase the nanoparticle concentration in aqueous or colloidal solutions as most needed for antioxidant, free-radical scavenger, and autocatalytic biomedical applications, including, biological, pharmacological and potential clinical use. To meet this need, a facile synthetic procedure for preparation of a biodegradable polymer-coated nanoceria is disclosed; the preferred biodegradable polymer is dextran. The synthesis method occurs under ambient conditions in an aqueous phase without the use of surfactants and results in a monodispersed preparation that is dextran-coated as determined by dynamic light scattering (DLS). Preliminary characterization of polymer coated nanoceria by XPS, TEM, XRD, and the like shows that these nanoparticles have the necessary physical properties for the desired biological potency, such as Ce+4 / Ce+3 mixed valence state.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

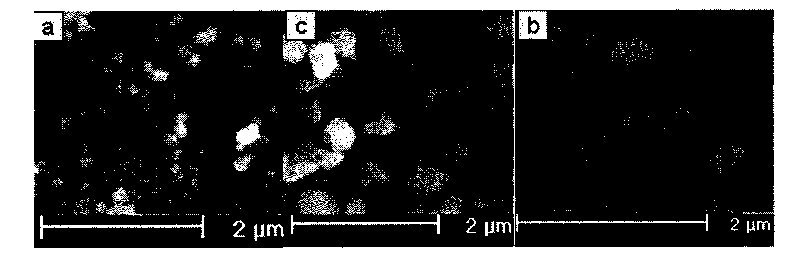

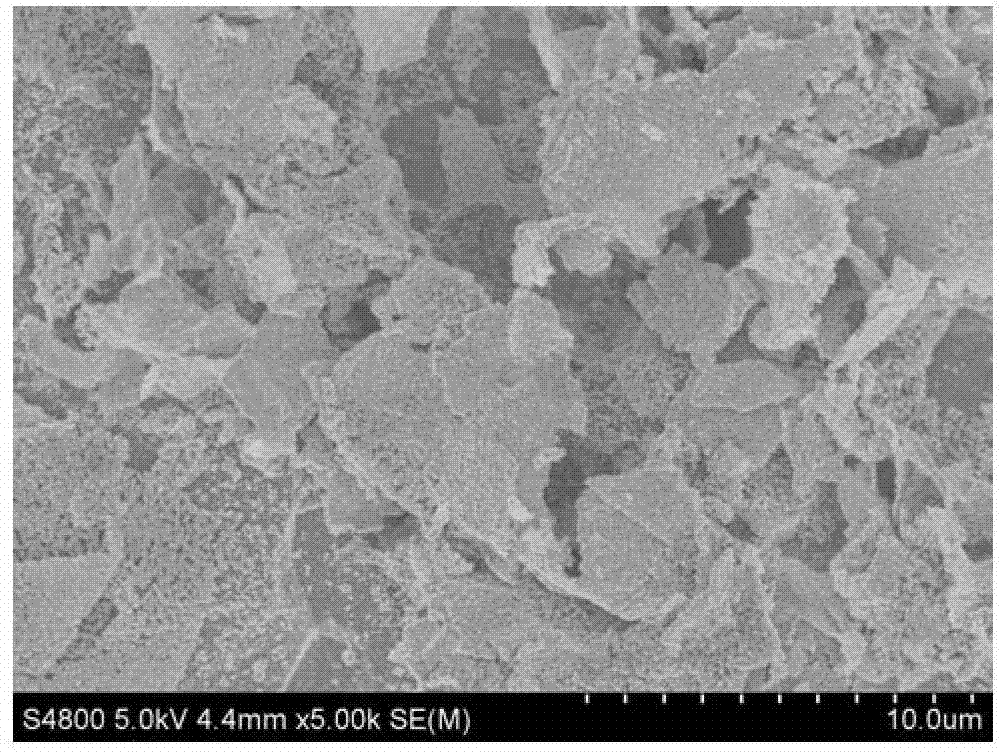

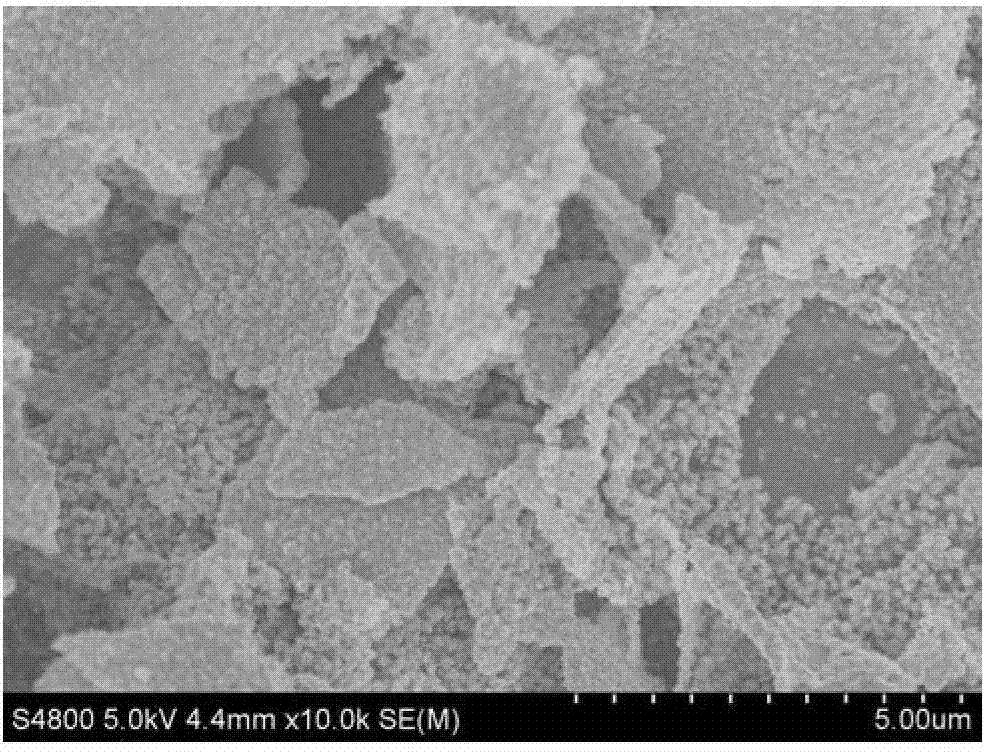

Graphene-copper nanoparticle composite, and preparation and application thereof

InactiveCN102896834AReduced defects with reduced surface areaEasy to operateElectrolytic coatingsMaterial electrochemical variablesTitaniumCvd graphene

The invention discloses a graphene-copper nanoparticle composite, and preparation and application thereof, and is characterized in that three-dimensional irregular multistage overlapped graphene sheet layers are formed on a grinded glassy carbon electrode or a dry pure titanium piece subjected to the surface treatment, the graphene sheet layers are in different sizes and are overlapped at different directions, and some graphene sheet layers are tilted; copper nanoparticles are densely compounded on the graphene sheet layers. The invention further provides a preparation method of the graphene-copper nanoparticle composite, the method is simple and easy, green and environmental friendly, and the glassy carbon electrode decorated by the graphene-copper nanoparticle composite prepared by the method has good application in the aspect of an electrochemical sensor.

Owner:HUNAN UNIV

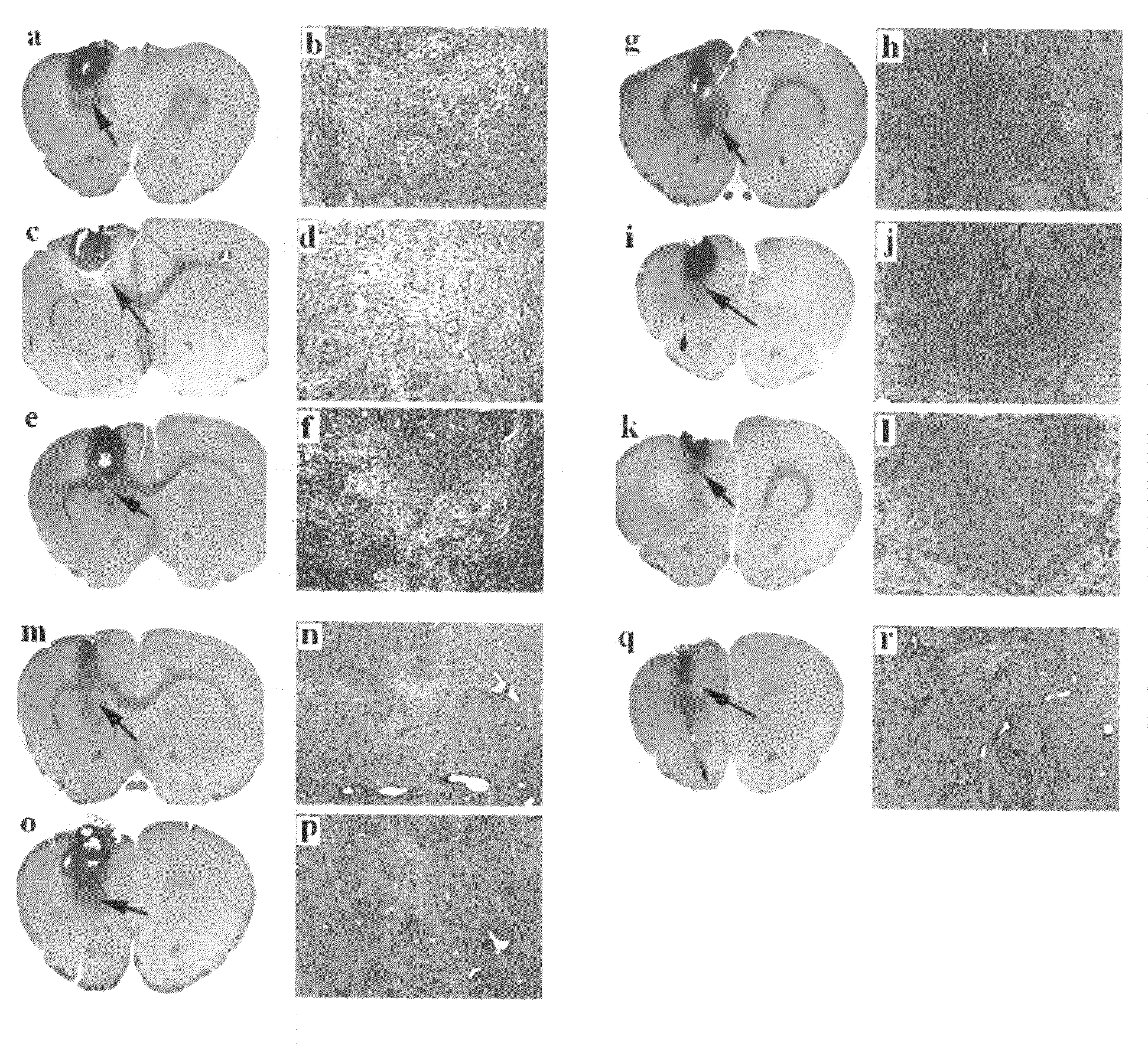

Polymer nanoparticles coated by magnetic metal oxide and uses thereof

InactiveUS20090110644A1Reducing and inhibiting growth of tumorReducing and inhibiting growth of tumor cellUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsActive agentCopper nanoparticle

The invention provides nanoparticles consisting of a polymer which is a metal chelating agent coated with a magnetic metal oxide, wherein at least one active agent is covalently bound to the polymer, said nanoparticles may optionally further comprise at least one active agent physically or covalently bound to the outer surface of the magnetic metal oxide. Pharmaceutical compositions comprising these nanoparticles may be used, inter alia, for detection and treatment of tumors and inflammations.

Owner:HENRY FORD HEALTH SYST +1

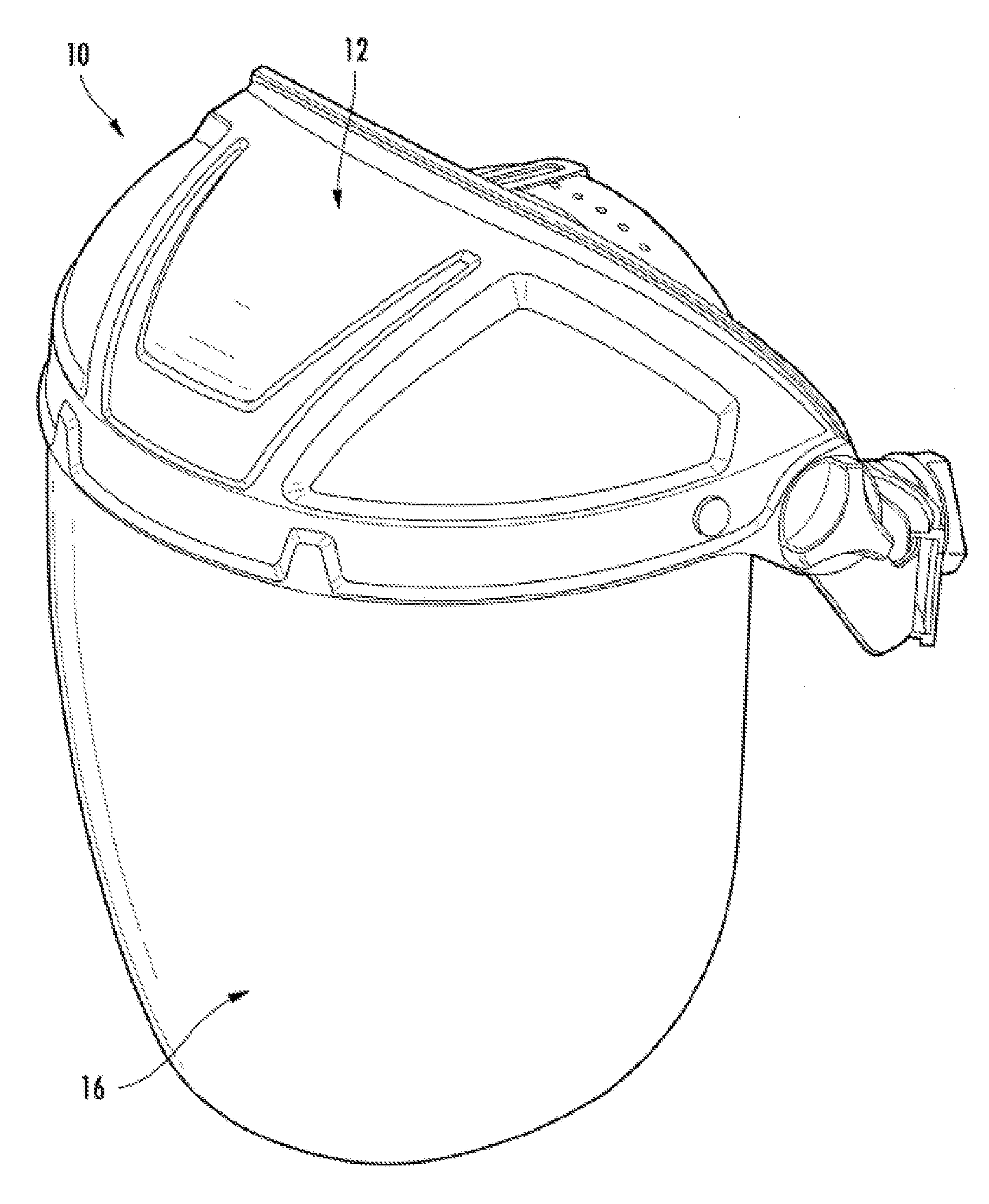

Electric-arc resistant face shield or lens including ir-blocking inorganic nanoparticles

A transparent electric-arc resistant composition is produced by preparing crystalline tungsten bronze nanoparticles and homogenously dispersing the nanoparticles in a transparent plastic matrix. The crystalline tungsten bronze nanoparticles are prepared by homogeneously mixing an aqueous solution of soluble tungsten and cesium salts and then drying the solution. The dried solution is then heated in a reducing gas or inert gas atmosphere to form crystalline tungsten bronze nanoparticles. Thereafter, a dispersion agent is added and the nanoparticles are dispersed in a liquid solvent medium by wet milling to form a dispersion mixture. The dispersion mixture is then mixed with polymer pellets to form a polymer mixture, and the polymer mixture is then extruded to yield polymer pellets containing highly homogeneously dispersed inorganic nanoparticles. During or after dispersion, additional particles, dyes, heat stabilizers or UV absorbers, may be added. A lens or shield is then molded from the polymer pellets.

Owner:HONEYWELL INT INC

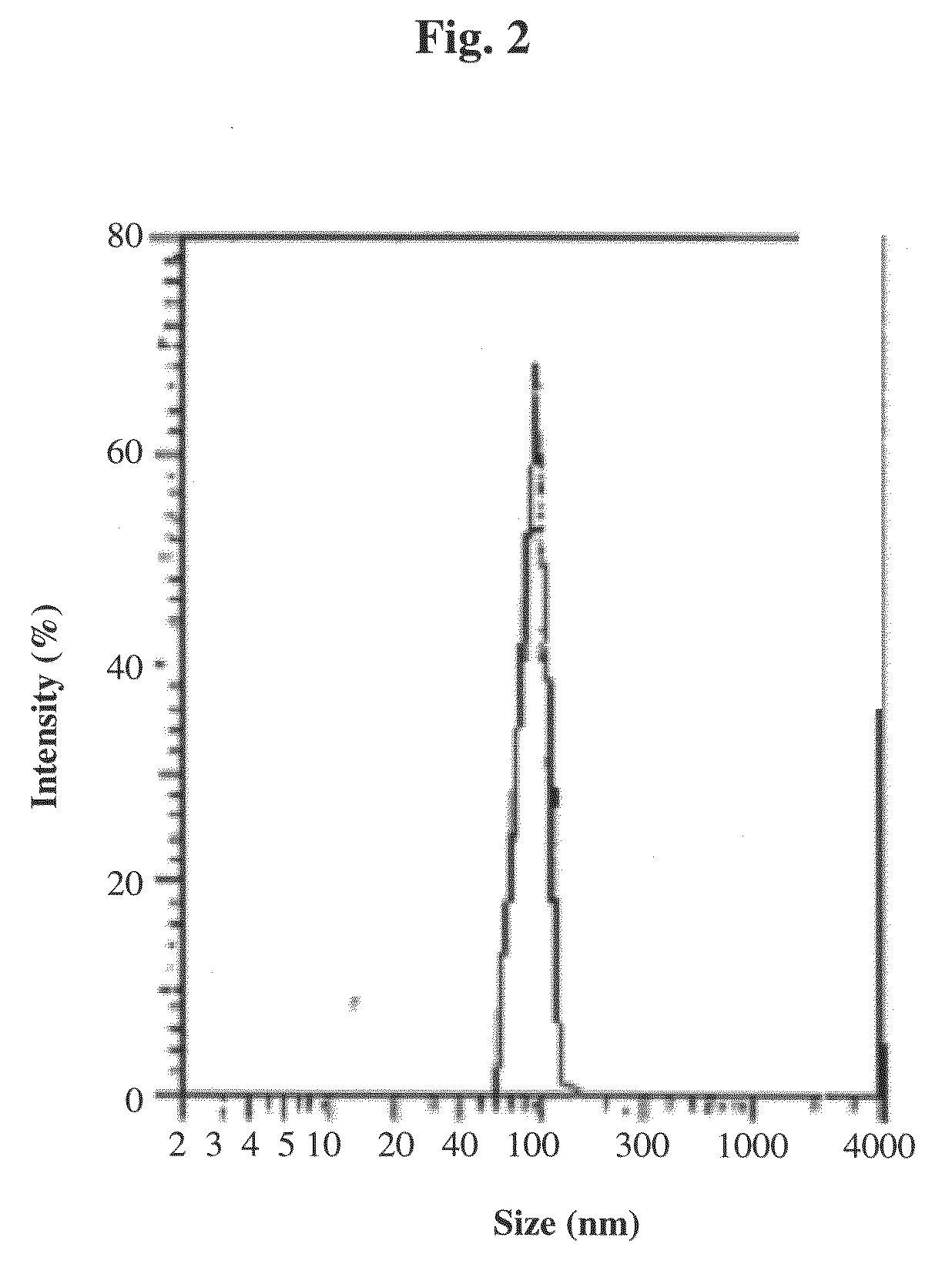

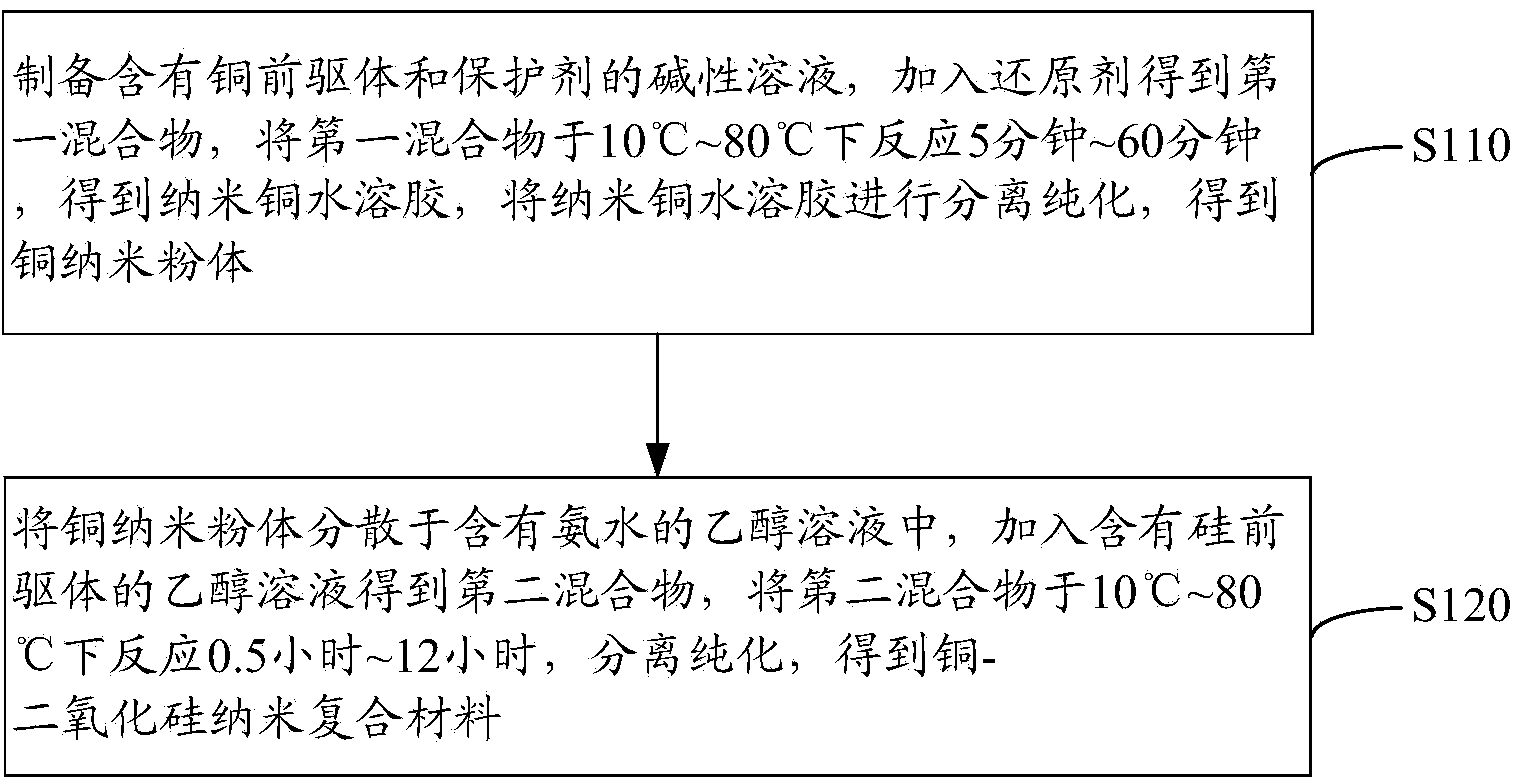

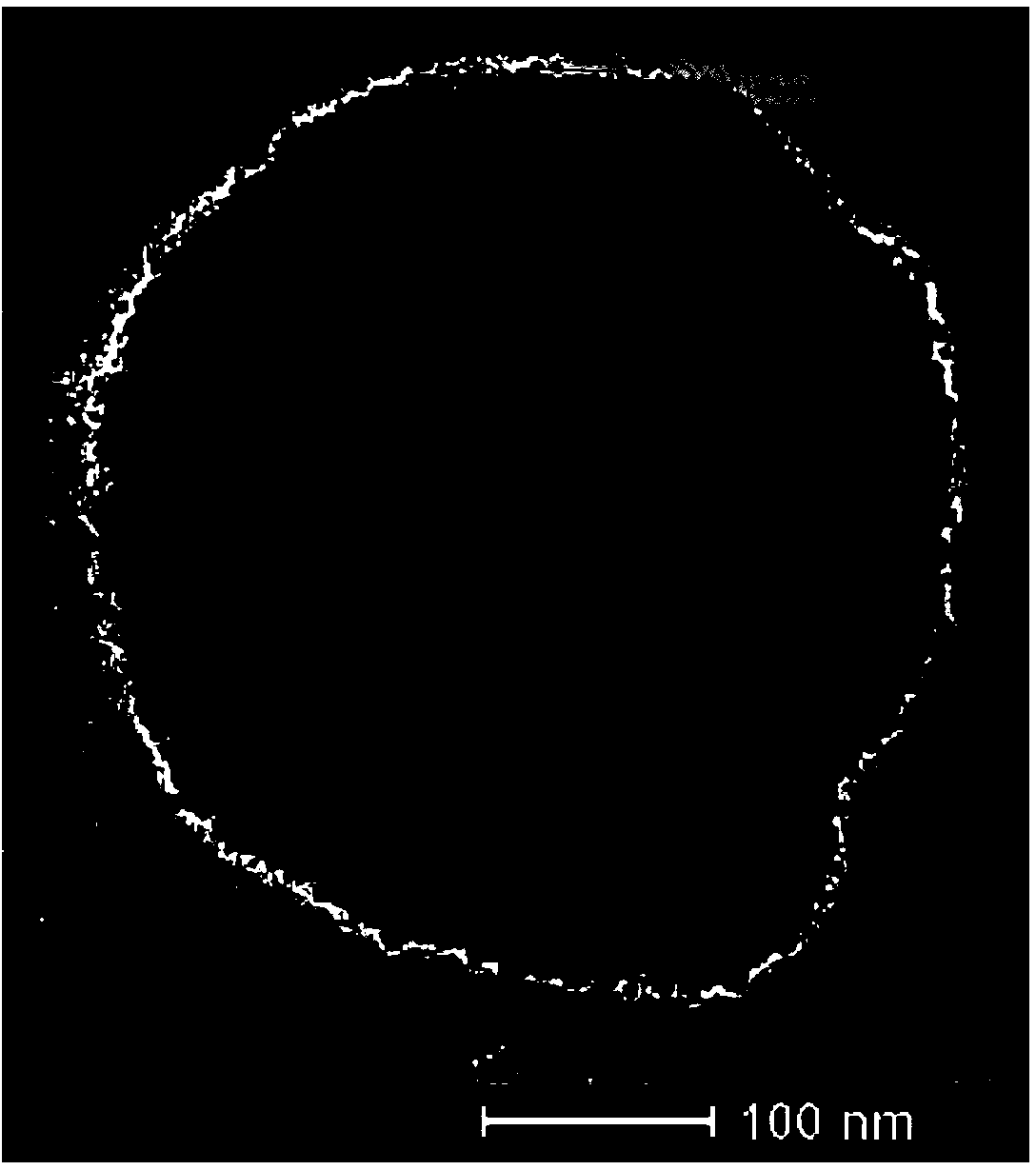

Core-shell structure copper nanoparticle and preparation method thereof

The invention relates to a core-shell structure copper nanoparticle and a preparation method thereof. The core-shell structure copper nanoparticle comprises a copper core and a silicon dioxide shell covering the surface of the copper core, wherein the grain diameter of the copper core is 40-450 nanometers; the thickness of the silicon dioxide shell is 5-50 nanometers. The silicon dioxide shell is capable of effectively preventing oxygen in air from permeating, the oxidation of the copper core is prevented, and the core-shell structure copper nanoparticle has excellent oxidation resistance.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

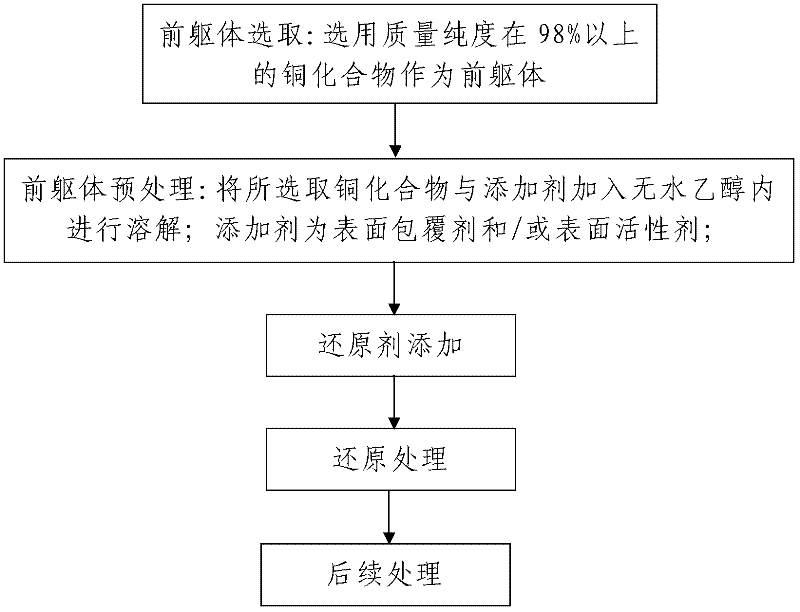

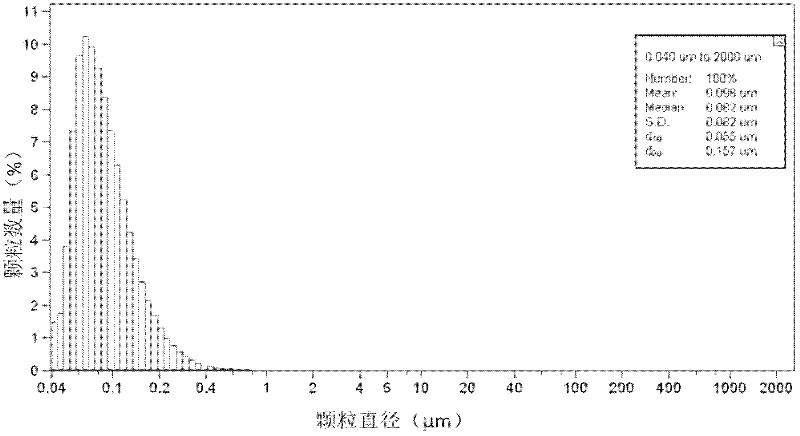

Industrial production method of copper nanoparticle

ActiveCN102407344AIncrease concentrationSimple and fast operationMaterial nanotechnologyReduction treatmentHydrazine compound

The invention discloses an industrial production method of a copper nanoparticle. The industrial production method comprises the following steps of: firstly, selecting a precursor: selecting a copper compound with the purity of over 98 percent as the precursor; secondly, pretreating the precursor: adding the copper compound selected in the first step and an additive into absolute ethyl alcohol for dissolving and uniformly stirring to obtain an ethanol mixed solution, wherein the additive is a surface coating agent and / or a surfactant; thirdly, adding a reducing agent: adding the reducing agent into the ethanol mixed solution and obtaining a mixed solution in which the reducing agent is added, wherein the reducing agent is hydrazine hydrate; fourthly, carrying out reducing treatment; and fifthly, carrying out subsequent treatment. The invention has the advantages of simple process steps, short production flow, simpleness and convenience for operation and low input cost; the produced copper nanoparticle has high quality; and the actual problems of complex process flow, high input cost and poorer stability of the produced copper nanoparticle and the like in a traditional production method of the copper nanoparticle can be effectively solved.

Owner:西安坤德新型材料有限公司

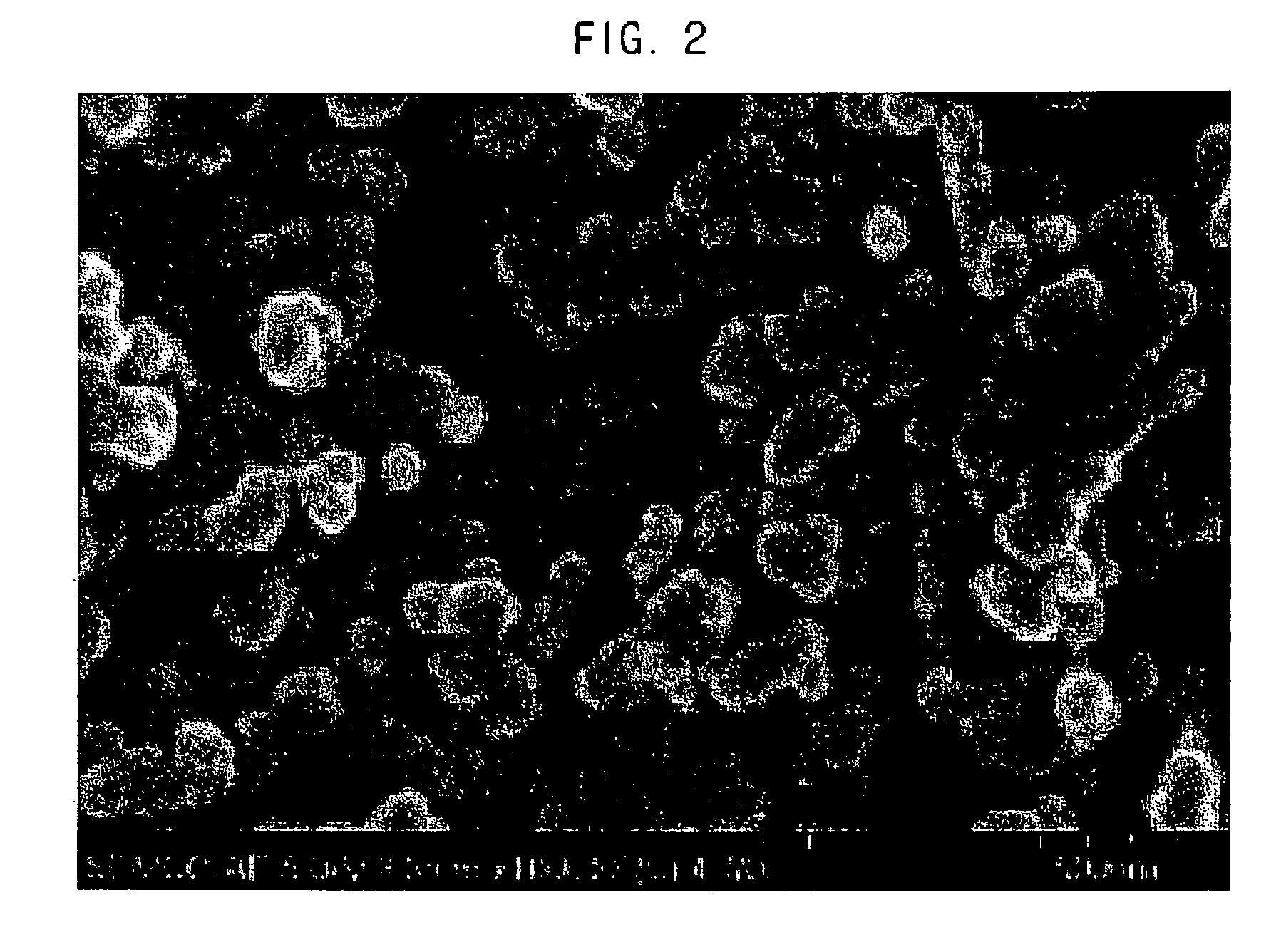

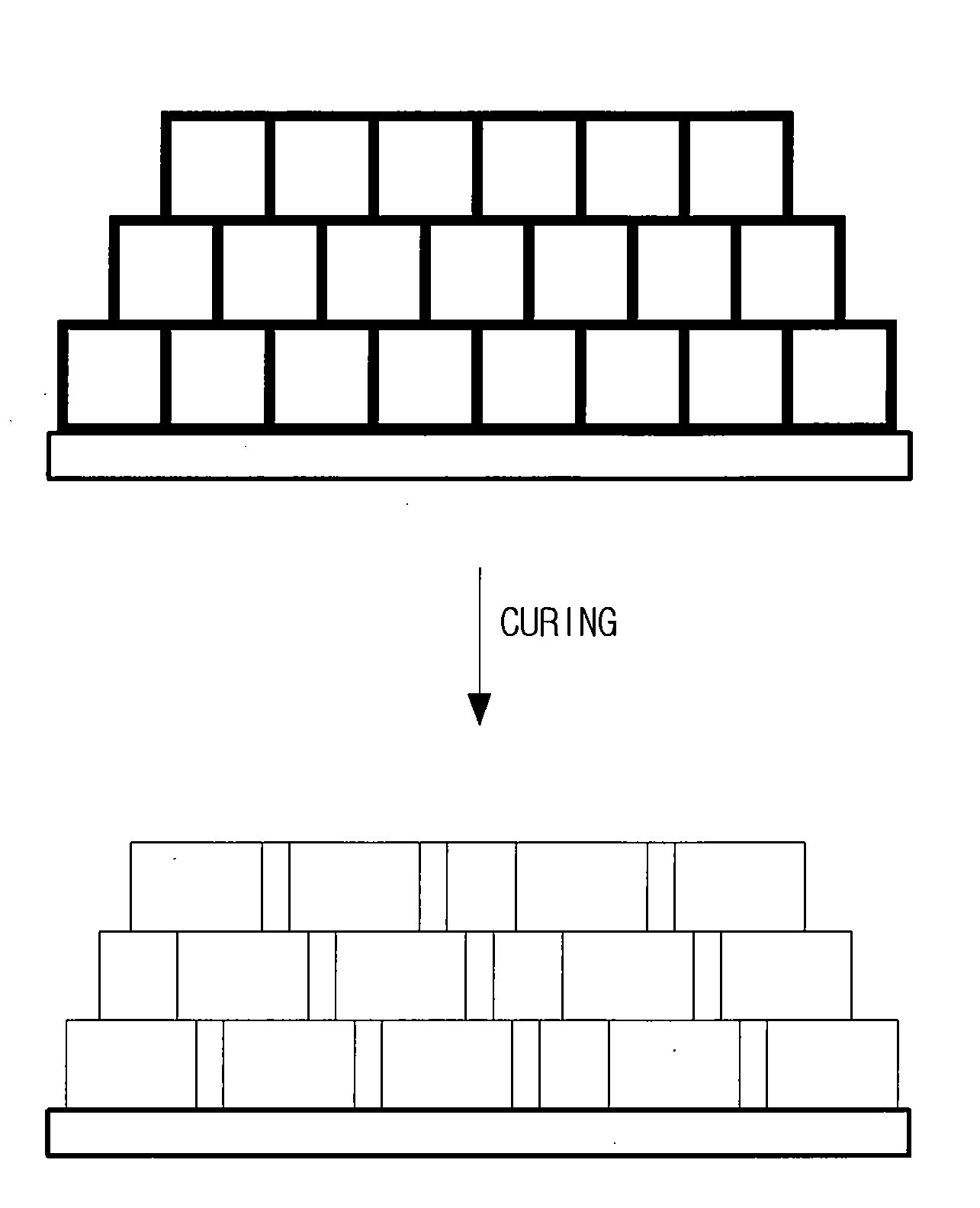

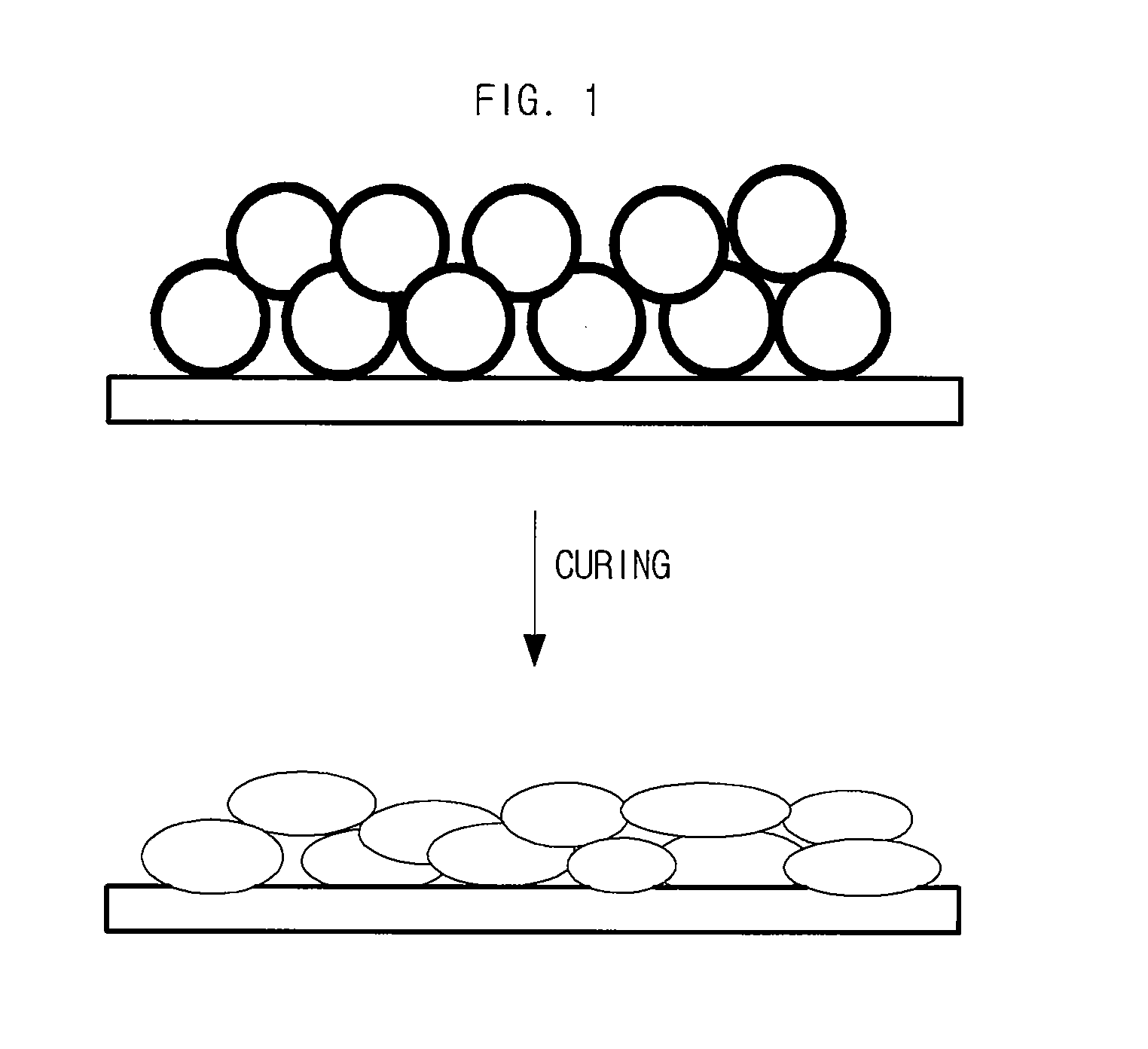

Method for manufacturing cubic copper or copper oxide nanoparticles

InactiveUS7858025B2Increase heightEffectively eliminate voidMaterial nanotechnologyNanostructure manufactureAlcoholCopper oxide nanoparticles

The present invention relates to a method of manufacturing cubic copper nanoparticles, and in particular, to a method including (a) mixing and agitating a copper precursor and an amine compound; (b) raising the temperature of the mixed solution up to 90-170° C. and reacting it at the same temperature; (c) adding the mixture to nonaqueous solvent to lower the temperature of the solution to 20-50° C. when the incubation completes; and (d) precipitating and obtaining the nanoparticles by adding an alcohol solvent to the mixture. According to the invention, while conductive wiring is formed metal nanoparticles can be manufactured not in sphere but in cubic shape so that void between particles can be efficiently removed and the height of wiring can be raised.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

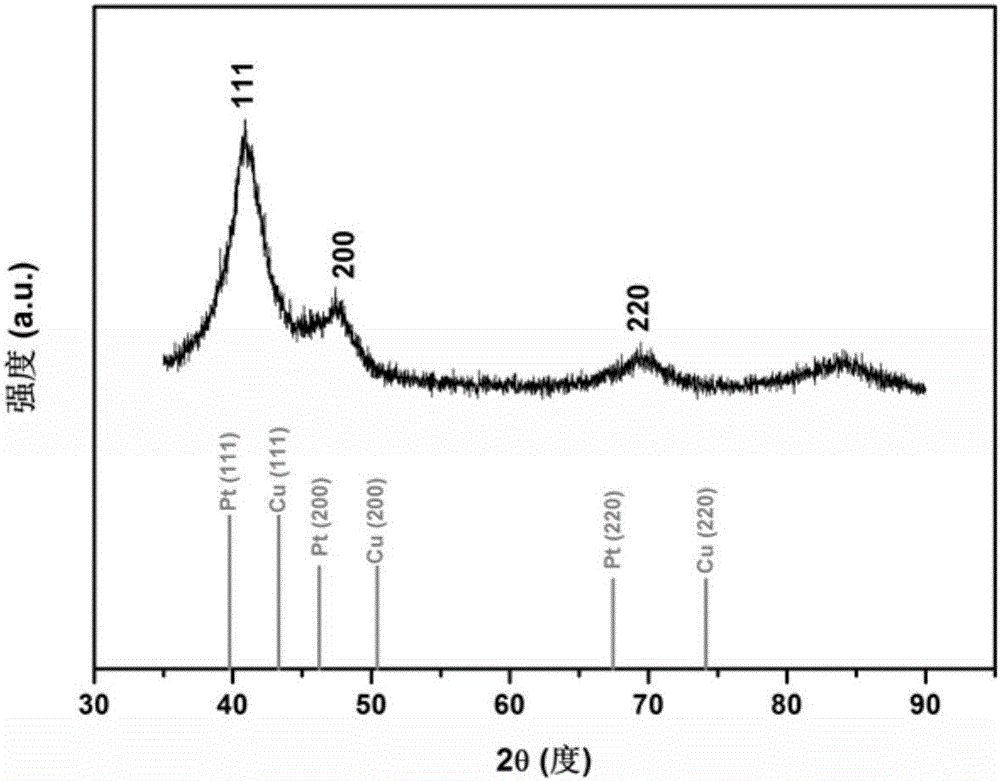

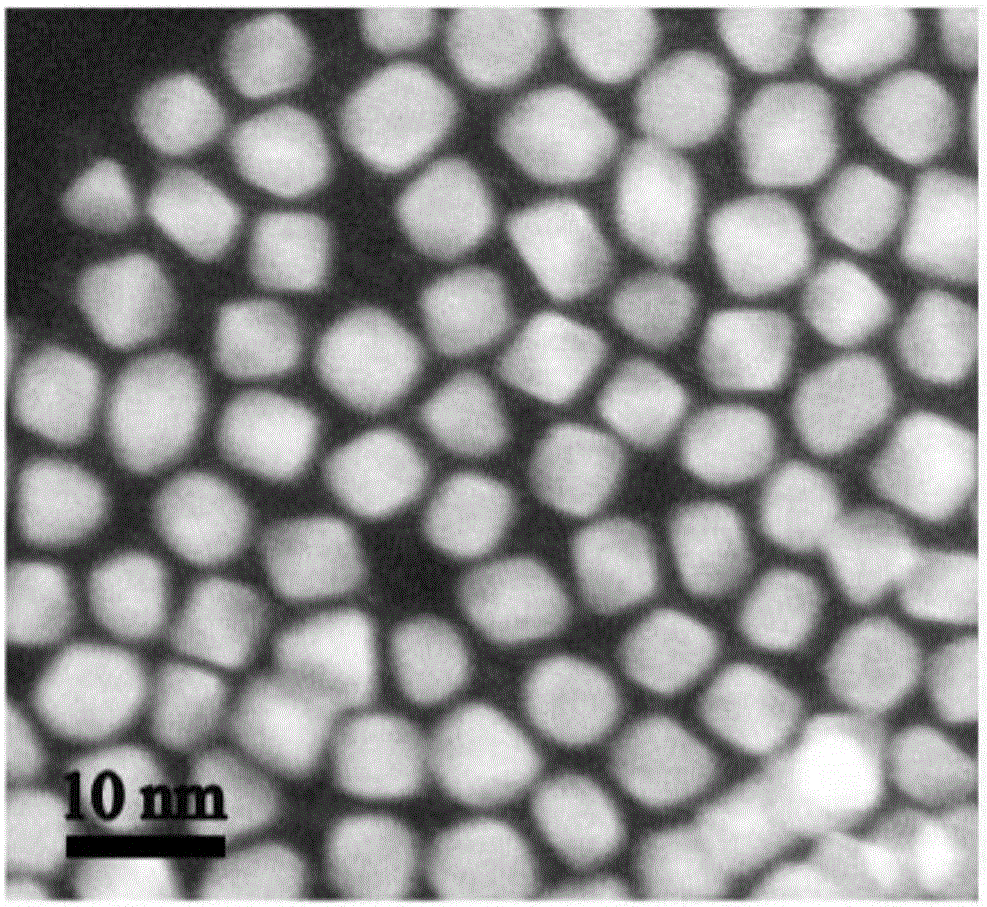

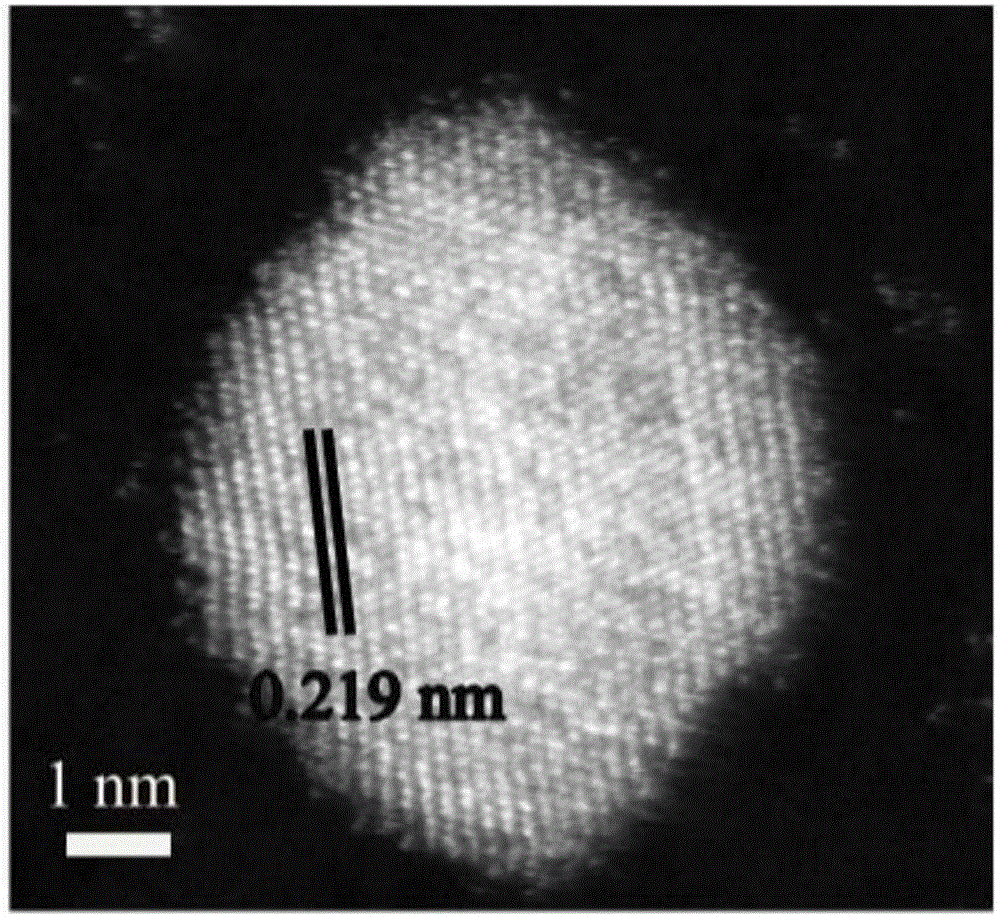

Preparation method for platinum-copper nano-particles with controllable morphologies

ActiveCN106670503ASmall particle sizeUniform sizeMaterial nanotechnologyTransportation and packagingOrganic solventCopper nanoparticle

The invention discloses a preparation method for platinum-copper nano-particles with controllable morphologies. The preparation method comprises the following steps: 1) mixing a reductive organic solvent, a platinum source and a copper source to obtain a mixed solution A; 2) heating and stirring the mixed solution A at 80-130 DEG C and under the condition of inert atmosphere protection until all solid reagents are completely dissolved to obtain a solution B; 3) stopping charging the inert gas, and charging a gas C in the solution B; and 4) heating the solution B to 210-250 DEG C and insulating heat to obtain a suspension D, cooling the suspension D to room temperature, centrifuging, taking bottom precipitates, and centrifugally washing the bottom precipitates by virtue of an organic solvent to obtain black precipitates, that is, the platinum-copper nano-particles. The method is simple and practicable, and the octahedral platinum-copper nano-particles are obtained through controllable synthesis; and moreover, the platinum-copper nano-particles obtained by the method are monolayer-dispersed and uniform in dimension, and have an average particle diameter of less than 10nm. The platinum-copper nano-particles can be used as a nano-catalytic material.

Owner:BEIJING UNIV OF CHEM TECH

ELECTROLESS DEPOSITION OF Bi, Sb, Si, Sn, AND Co AND THEIR ALLOYS

InactiveUS20150221930A1Short reaction timeImprove scalabilityElectrode manufacturing processesLiquid/solution decomposition chemical coatingAlloyElectroless deposition

The present invention relates to production of composite materials utilizing an electroless deposition method for coating substrates with bismuth, antimony, tin, silicon, cobalt and their various compositional alloys. Substrates may be materials comprised of copper, brass, carbon, and silicon. These substrates are immersed in aqueous or ethylene glycol based solutions containing soluble ions of the desired coating material. The present invention generates desired coatings at room temperature during a period of immersion of one hour or less. In one exemplary embodiment, the method provides the electroless deposition of silicon onto copper nanoparticles in a room temperature solution of ethylene glycol. The coated nanoparticles may then be processed to form a battery electrode. In another exemplary embodiment, the method provides electroless deposition of tin onto brass foil in a room temperature aqueous solution. Battery electrodes may then be punched from the coated sheet.

Owner:MANIVANNAN AYYAKKANNU +1

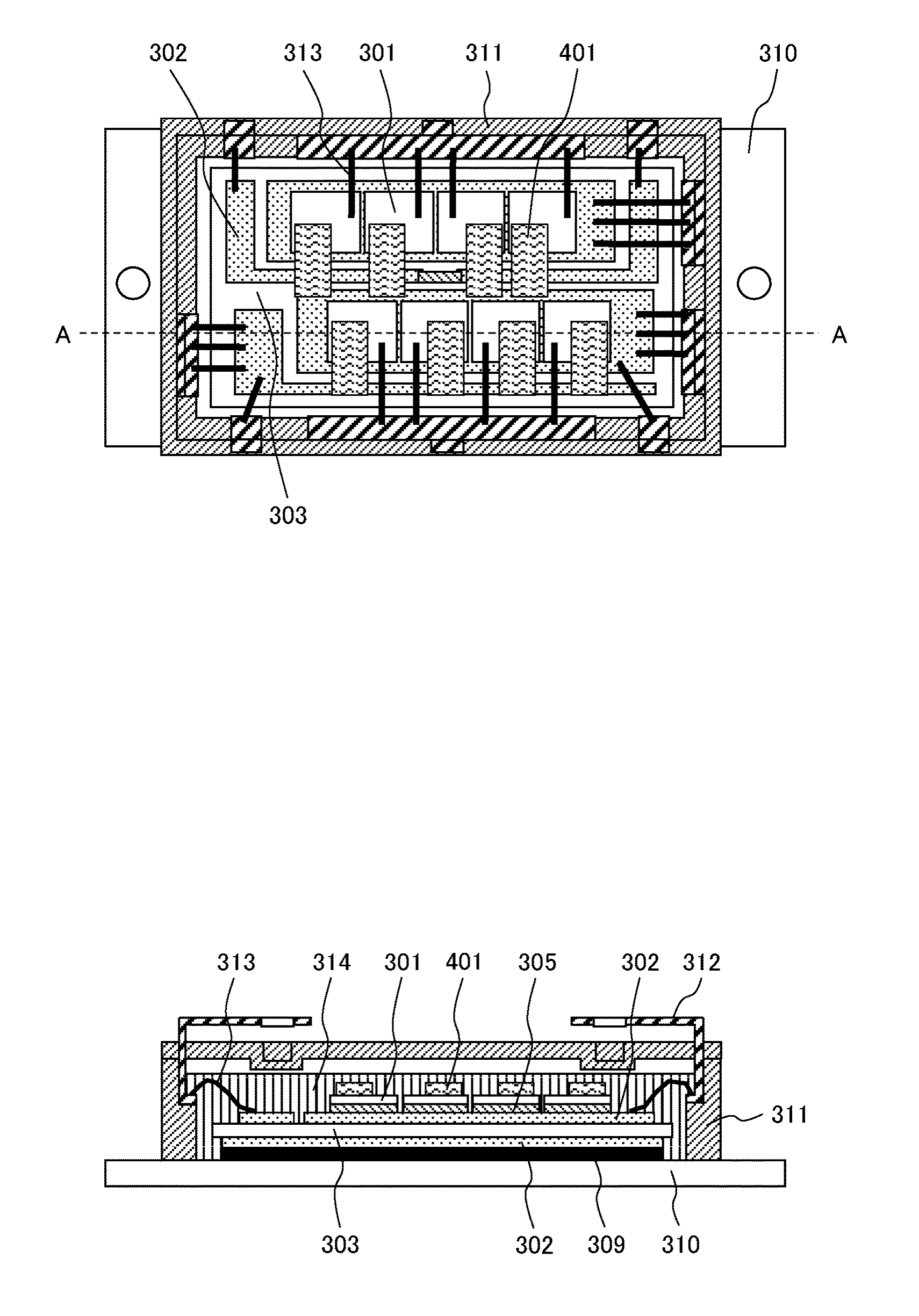

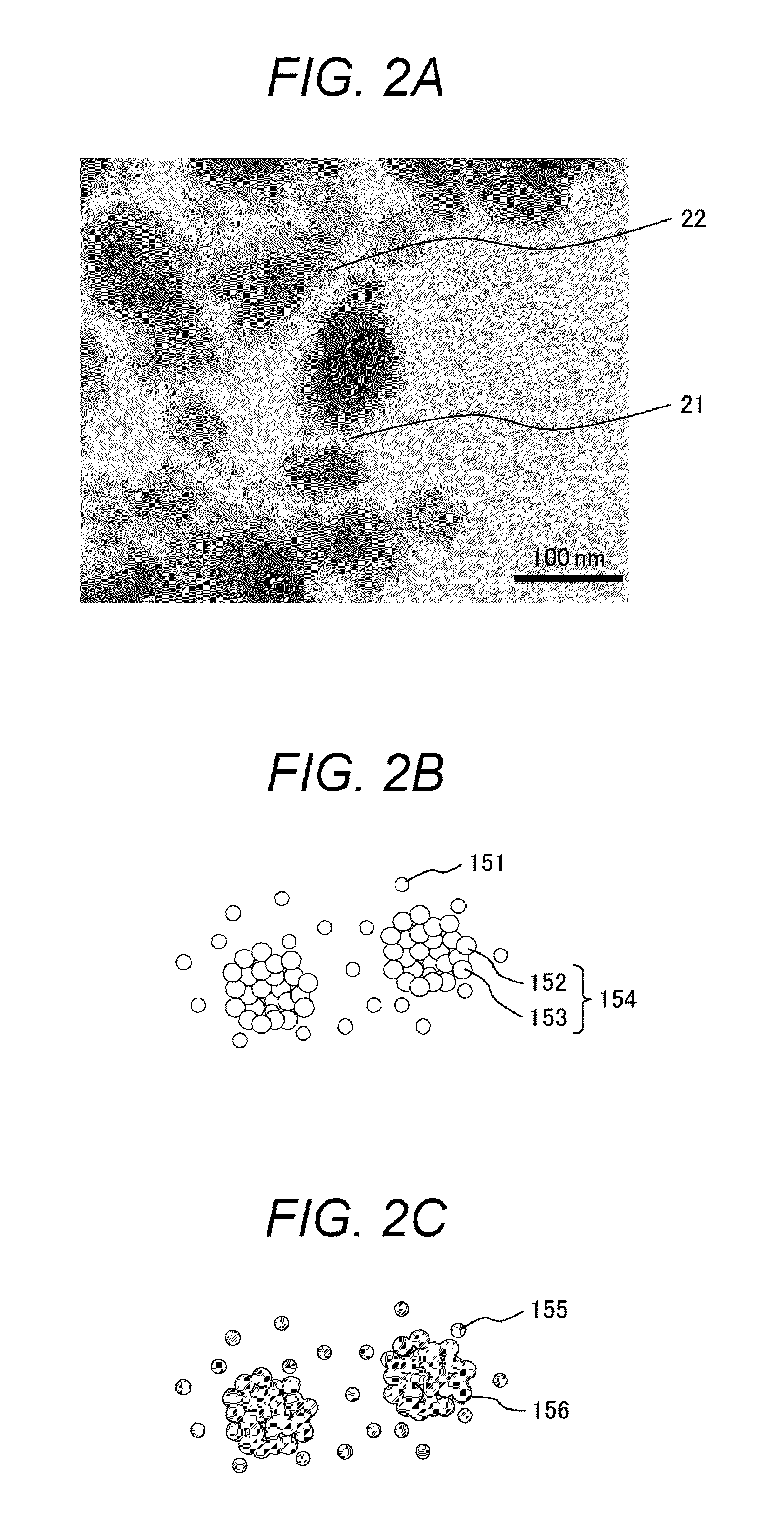

Sinterable bonding material using copper nanoparticles, process for producing same, and method of bonding electronic component

InactiveUS20130105980A1Printed circuit assemblingMaterial nanotechnologyElectronic componentCopper nanoparticle

Disclosed is a sinterable bonding material which is a liquid or a paste containing copper nanoparticles having a particle diameter of 1,000 nm or less, in which the copper nanoparticles have one or more particle diameter peaks of a number-based grain size distribution within a class of particle diameter of 1 to 35 nm and within a class of particle diameter of more than 35 nm and 1,000 nm or less respectively, and in which the copper nanoparticles include individual particles (primary particles) and secondary particles, each of the secondary particles being a fused body of the primary particles. Thus, oxidation resistance and bondability are made compatible in a sinterable bonding material using copper nanoparticles, and ion migration is suppressed in a bonded portion of a semiconductor device, etc. manufactured by using the sinterable bonding material.

Owner:HITACHI LTD

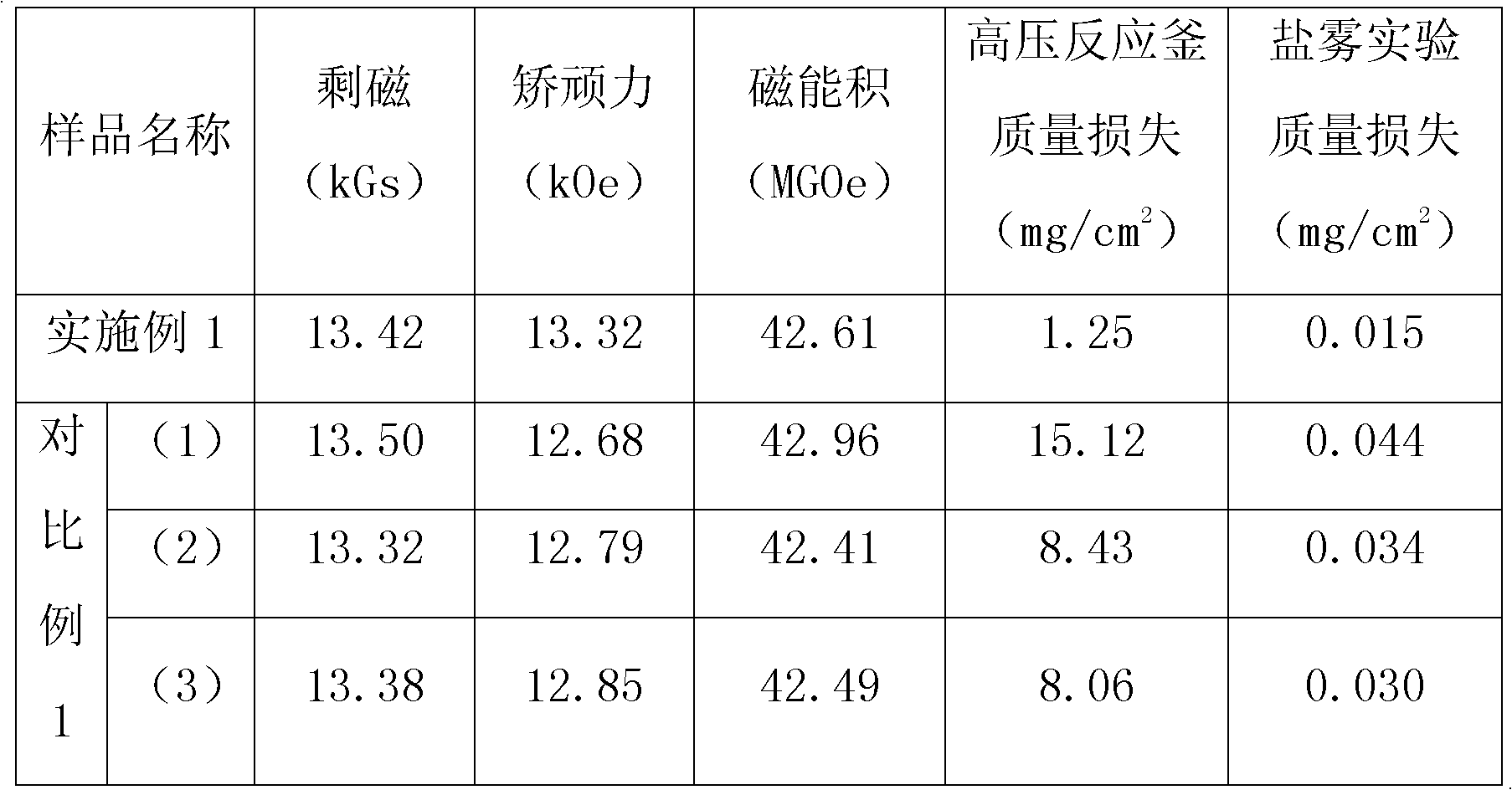

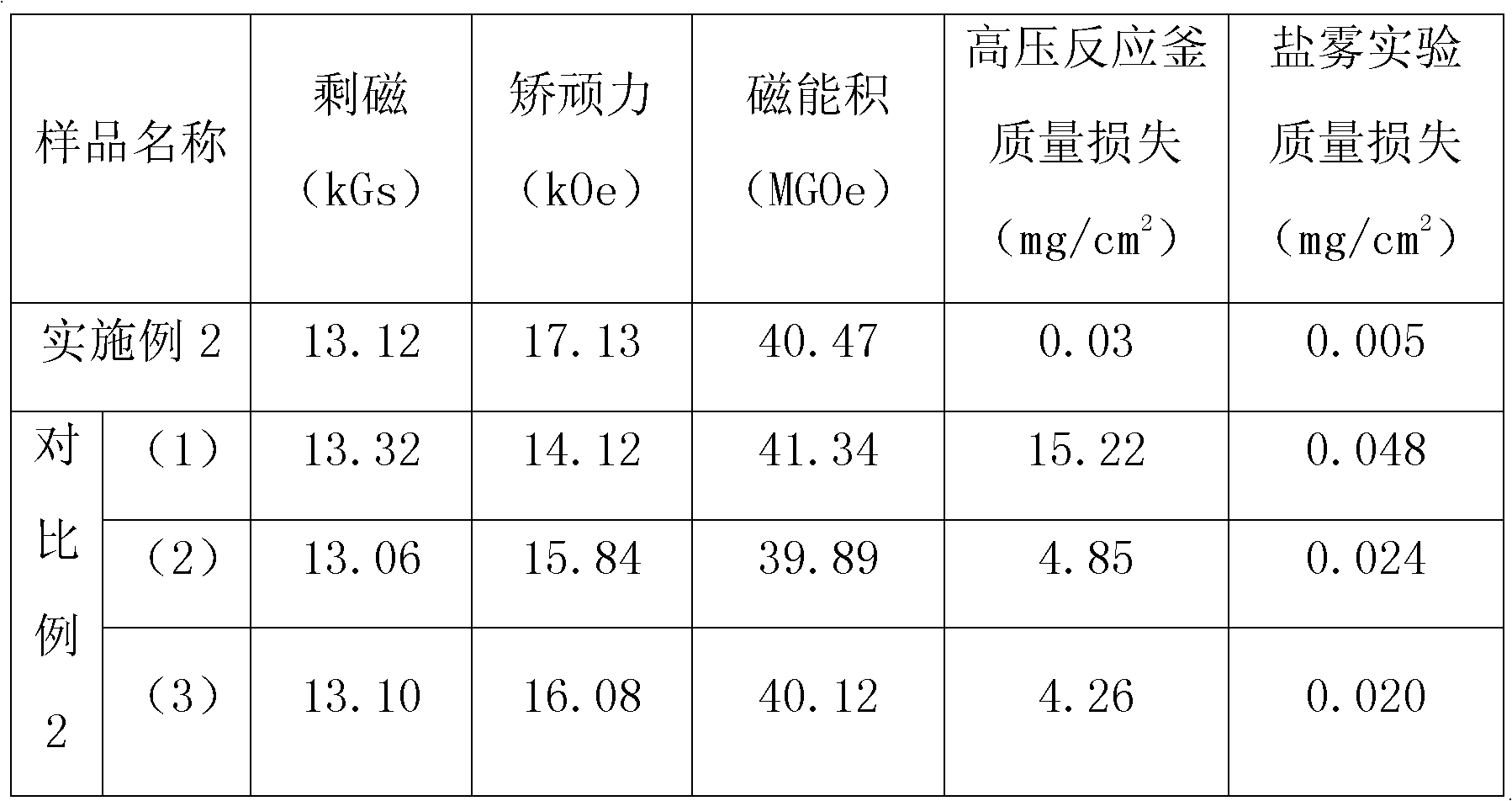

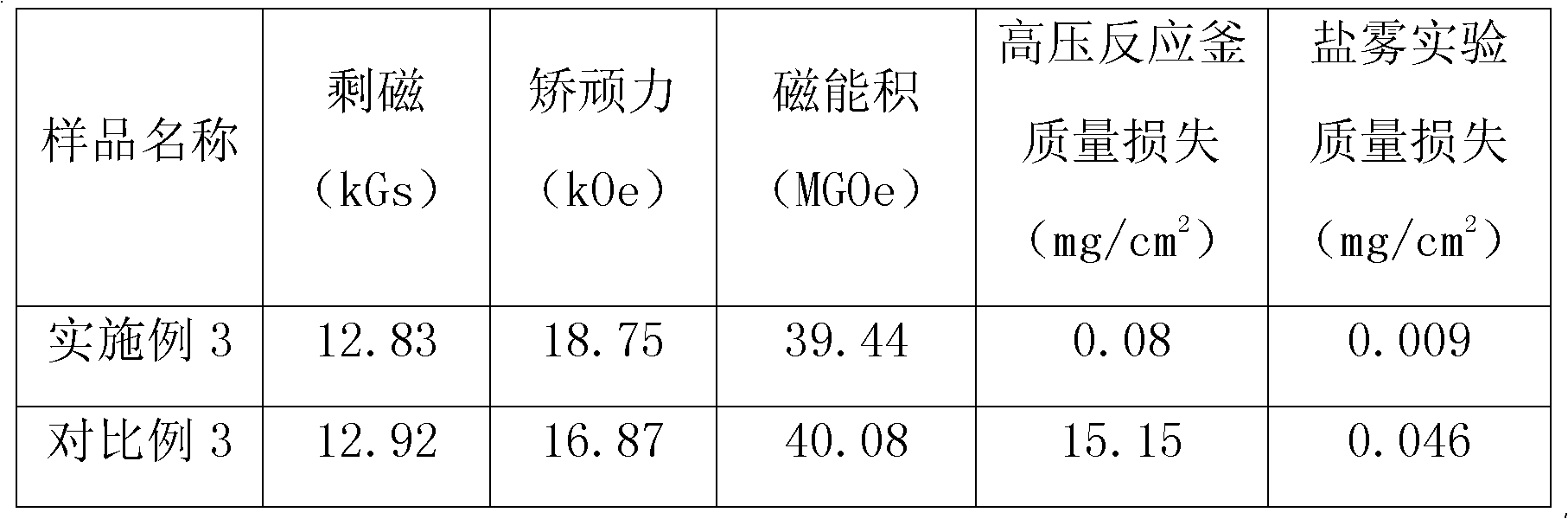

Sintered neodymium-iron-boron-based permanent magnet material with high coercive force and high corrosion resistance, prepared by doping copper nano-particles, and preparation method thereof

ActiveCN102543342AGood magnetic decouplingImprove coercive forceMagnetic materialsCopper nanoparticleHeat treated

The invention relates to a sintered neodymium-iron-boron-based permanent magnet material with high coercive force and high corrosion resistance, prepared by doping copper nano-particles, and a preparation method thereof, belonging to the technical field of magnetic materials. The preparation method comprises the following steps of: adding Cu nano-powder with average particle size of 100-500nm into neodymium-iron-boron-based powder which is of 3-5 mu m, and uniformly mixing, wherein the adding proportion of the Cu nano-powder is 0.2-2.5% of the weight of the neodymium-iron-boron-based powder; performing orientation and press-forming in a 2.5T magnetic field; placing into a vacuum sintering furnace, then increasing the temperature to 1020-1120 DEG C for sintering for 2-4 hours, and finally performing two-stage heat treatment to get the sintered neodymium-iron-boron magnetic material, wherein the temperature of first-stage heat treatment is 830 DEG C-930 DEG C, and the time is 1-3 hours; and the temperature of second-stage heat treatment is 480 DEG C-630 DEG C and the time is 1-3 hours. The coercive force and the corrosion resistance of the neodymium-iron-boron-based permanent magnet material can be greatly improved through the process of adding the nano-Cu powder, sintering and performing the heat treatment.

Owner:浙江爱智机电有限公司

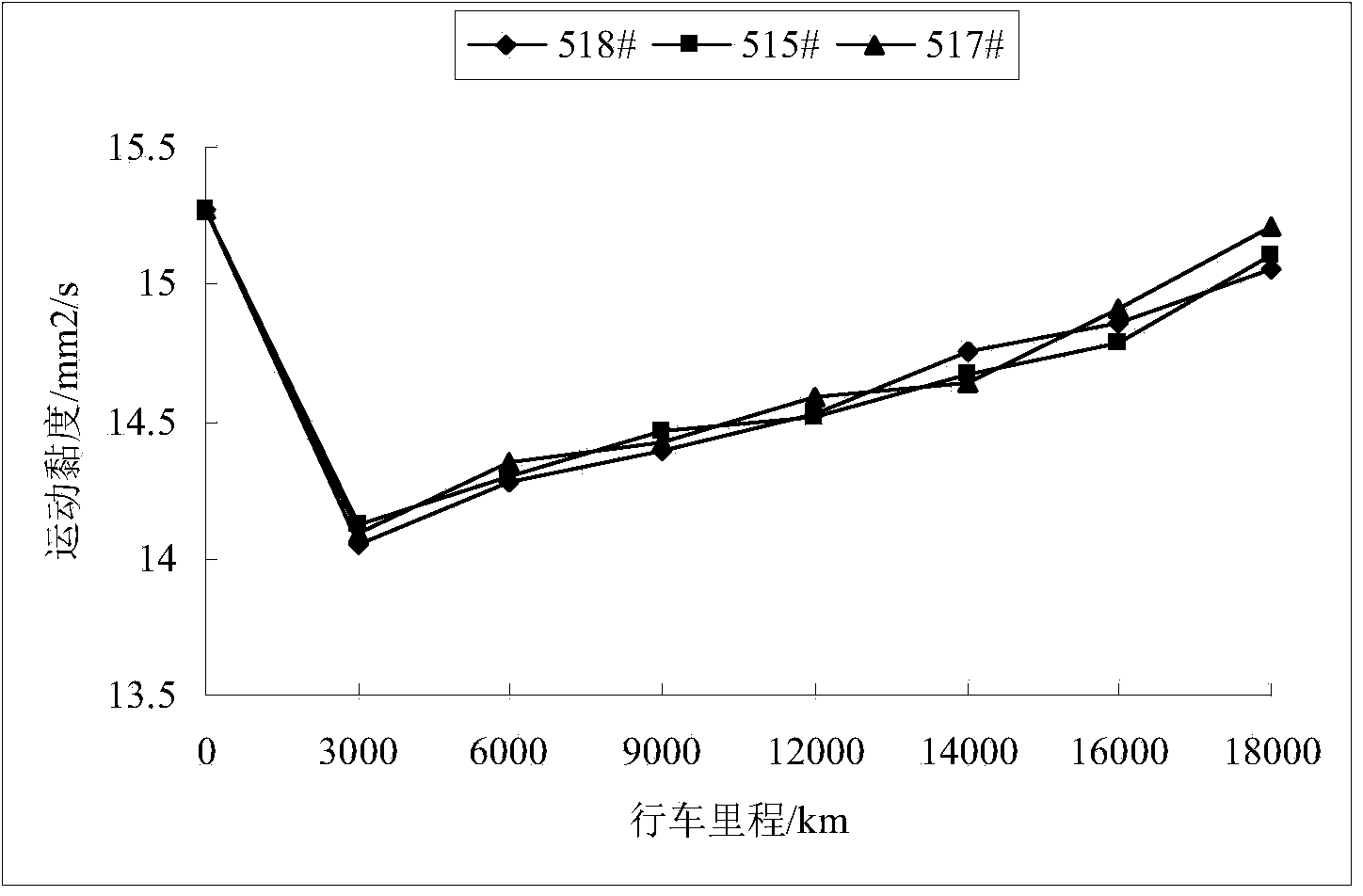

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

Method for manufacturing copper nano granule and copper nano granule produced thereby

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

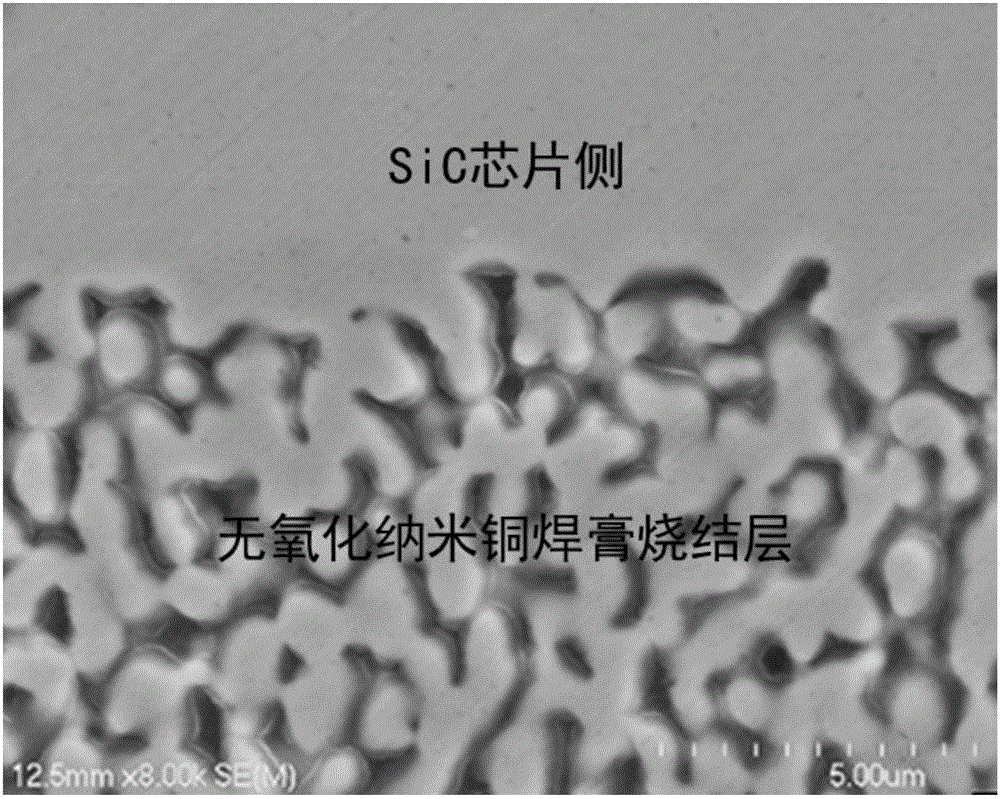

Non-oxidized nano copper soldering paste for high-power chip packaging and preparation method of soldering paste

ActiveCN106825998AEasy to prepareProcess time savingWelding/cutting media/materialsSoldering mediaOrganic solventNano copper

The invention provides non-oxidized nano copper soldering paste for high-power chip packaging and a preparation method of the soldering paste. Copper nanoparticles with the non-oxidized surfaces with the particle size being 30-60 mu m and an organic solvent are mixed in the mass ratio of 2:1-5:1, mechanical stirring and planet type gravity stirring are performed, and the nano copper soldering paste is obtained. The invention further provides the preparation method of the copper nanoparticles with the non-oxidized surfaces. The non-oxidized nano copper soldering paste prepared with the method has higher conductivity and better mechanical properties than common nano copper soldering paste and tin-lead solder. The preparation method is simple and practical and causes no environmental pollution and industrial popularization and application can be realized.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

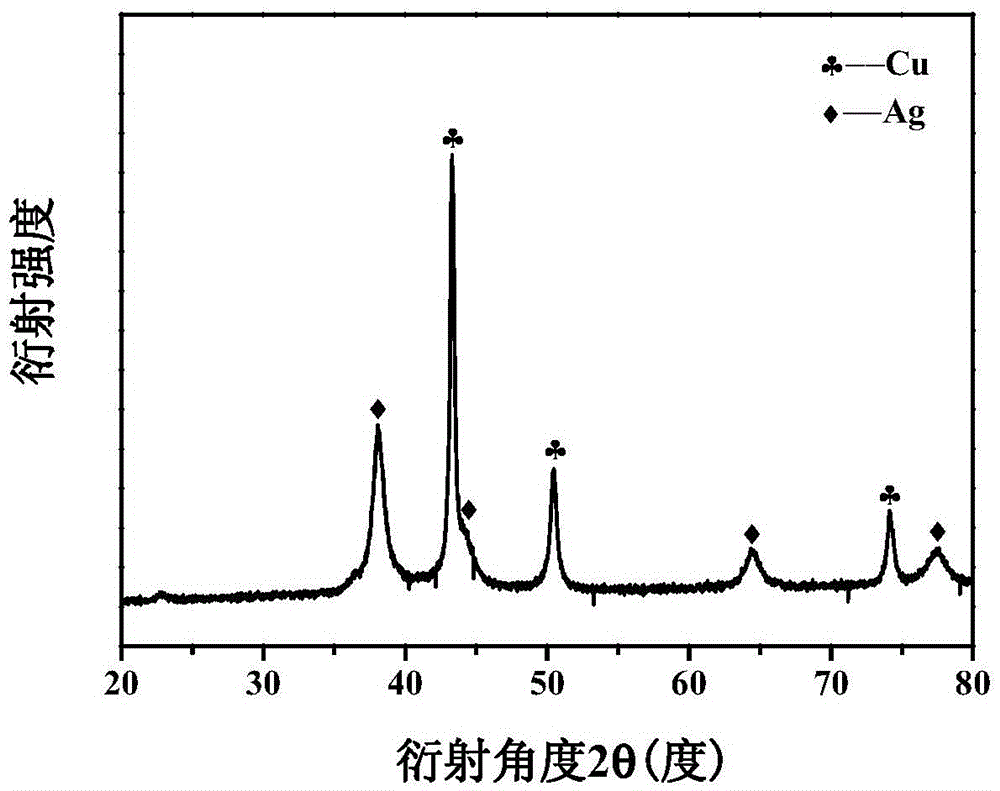

Preparation method of silver coated copper nanoparticles capable of being used for conductive ink

ActiveCN105598468AGood dispersionHigh monodispersityTransportation and packagingMetal-working apparatusDispersityBiological activation

The invention relates to a preparation method of silver coated copper nanoparticles capable of being used for conductive ink. The method comprises the steps that a copper precursor, a protective agent and a reducing agent are dissolved in an organic solvent, the mixture is heated, and a nanocopper solution is obtained; a silver nitrate solution is added into the nanocopper solution, then cooling, centrifugation and drying are carried out, and the silver coated copper nanoparticles capable of being used for the conductive ink are obtained. The silver coated copper nanoparticles capable of being used for the conductive ink are prepared through a continuous reduction and replacement method. In the preparation process, no complex chelating agent is added, the intermediate processes of separation and purification, activation and sensitization and the like are not needed, and the reaction conditions are free of pollution and mild. In addition, the silver coated copper nanoparticles prepared through the preparation method are good in dispersity, high in monodispersion degree, high in oxidation resistance and capable of being produced in a large scale and applied to the field of the conductive ink.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com