Patents

Literature

40results about How to "Process time saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

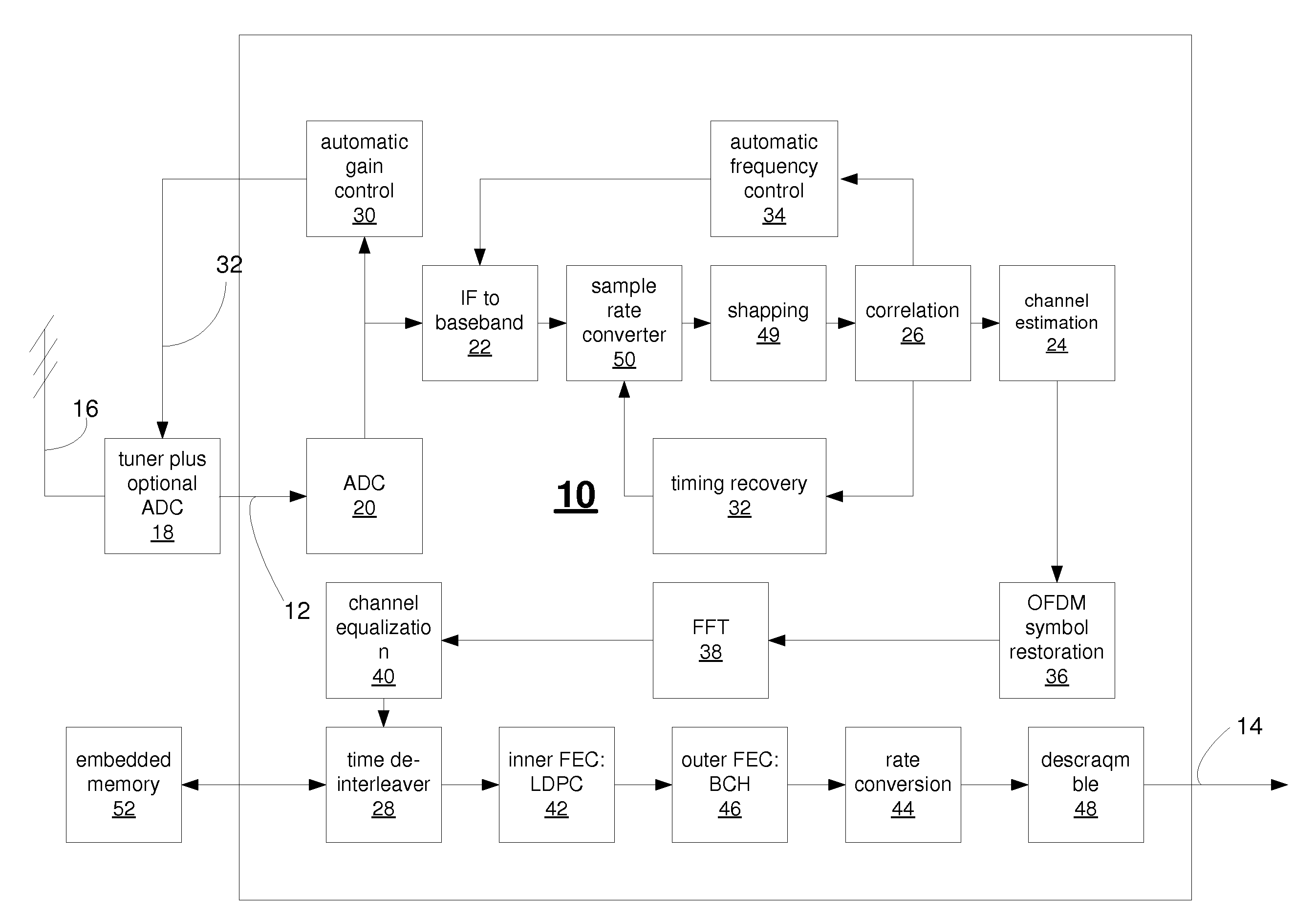

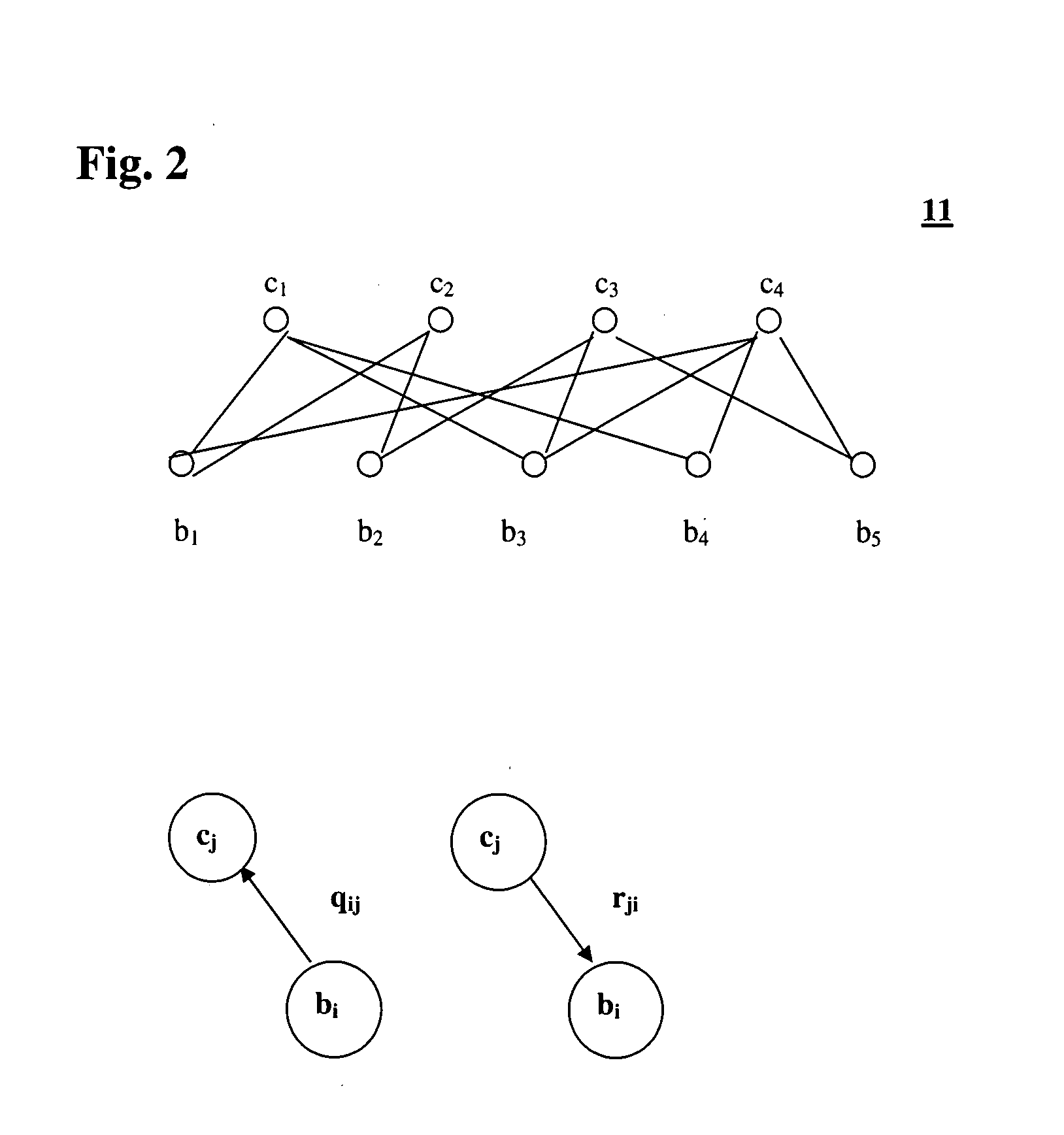

LDPC decoder with an improved llr update method using a set of relative values free from a shifting action

InactiveUS20090070659A1Reduce memory requirementsFast decodingModulated-carrier systemsError detection/correctionTheoretical computer scienceParity-check matrix

In a decoder having an improved LLR (log-likelihood-ratio) update method is provided. The method comprising the steps of: providing a parity check matrix; and using merely a set of parameters on a row of the parity check matrix instead of data of the whole non-zero elements of the parity check matrix free from at least one shifting action after each row updating; thereby saving memory space and process time.

Owner:LEGEND SILICON

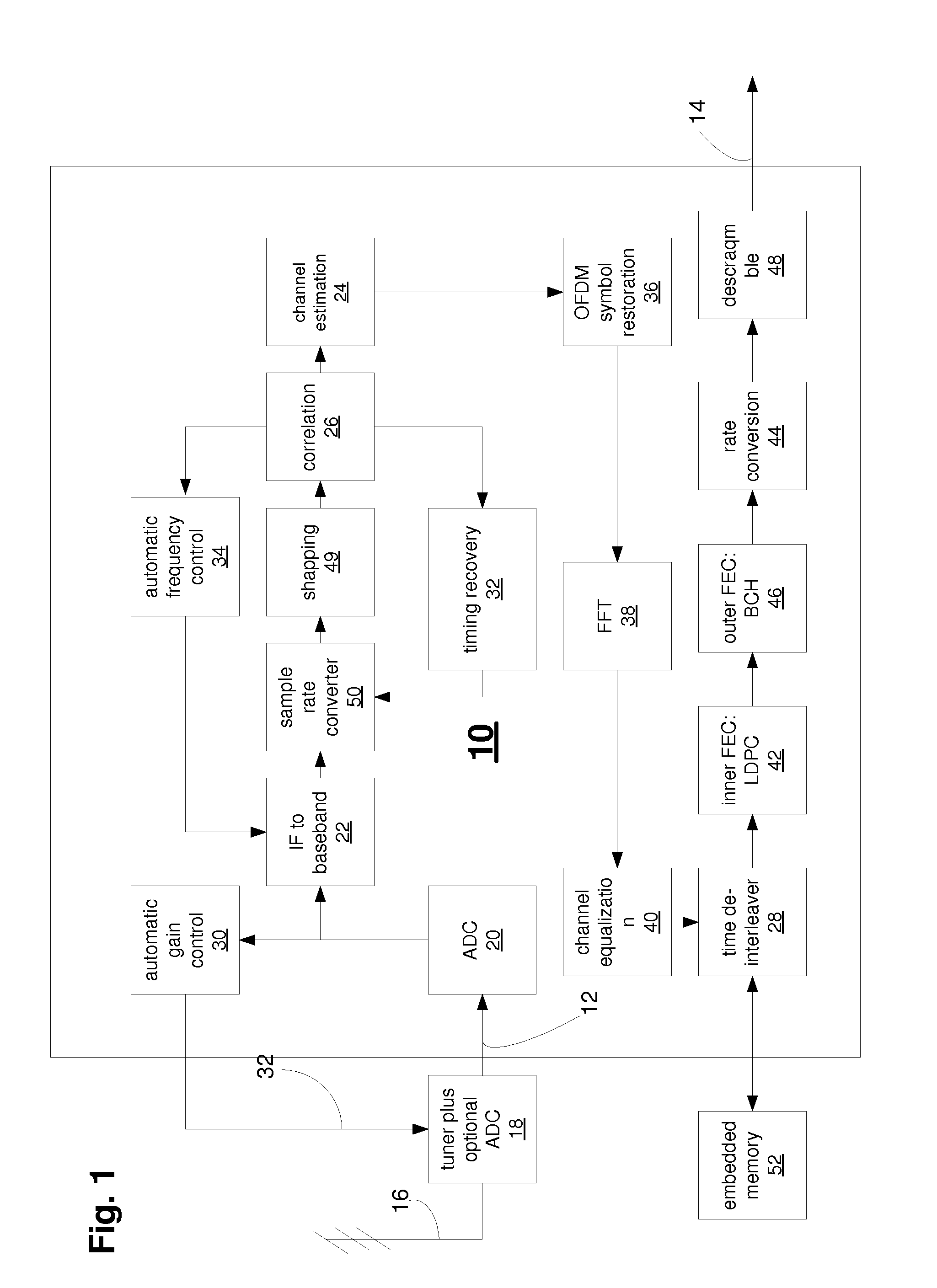

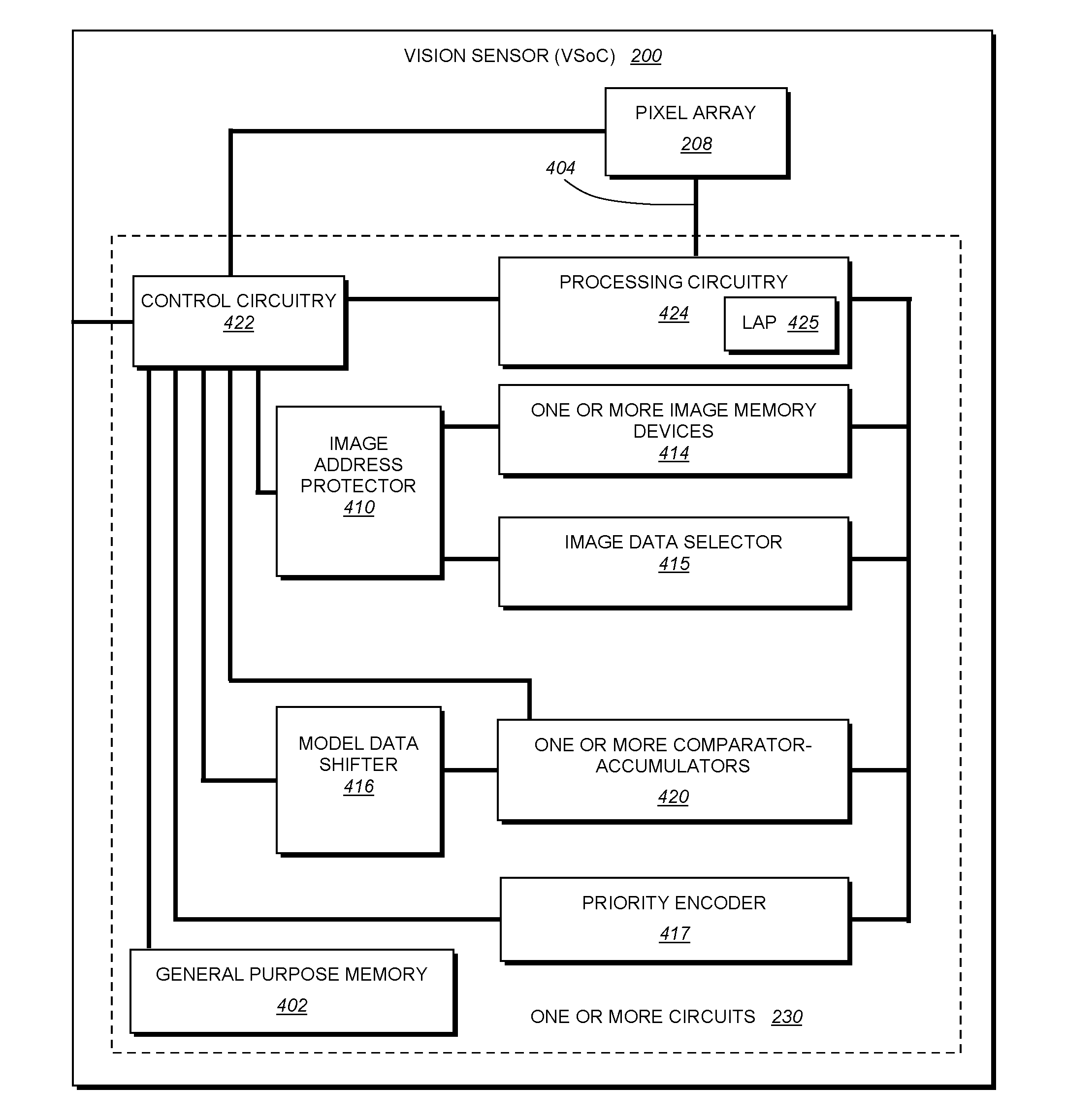

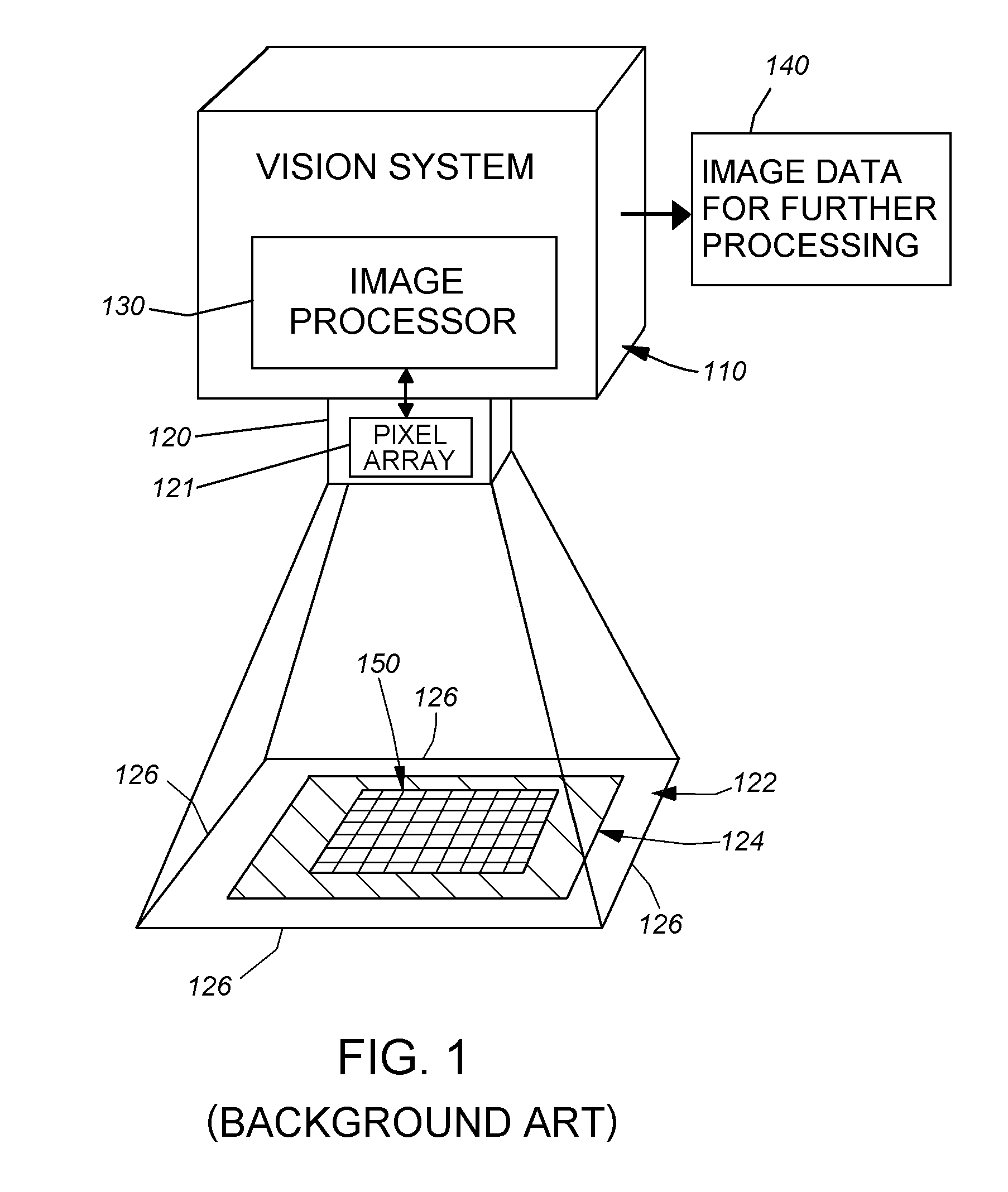

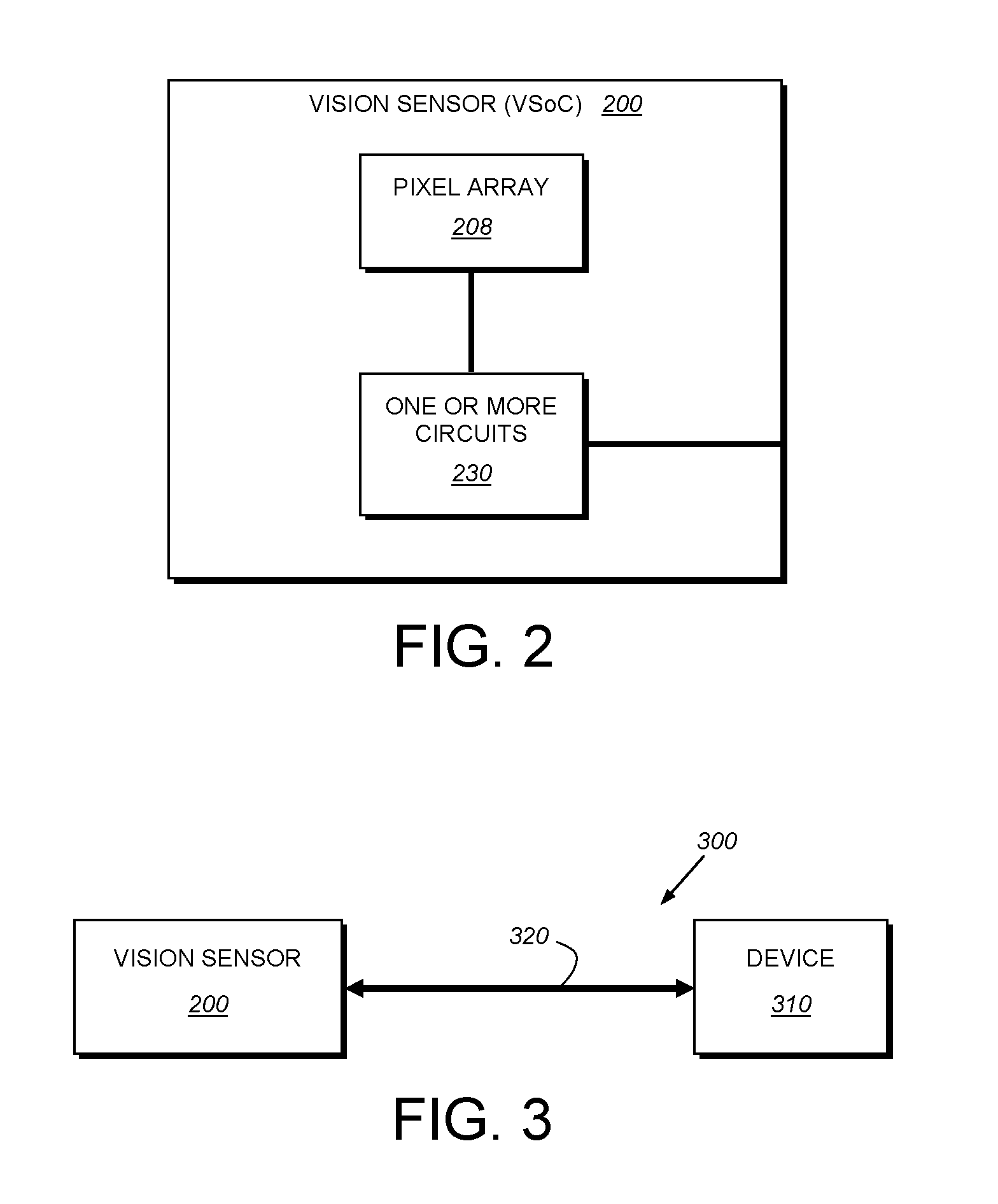

System and method for processing image data relative to a focus of attention within the overall image

InactiveUS20110211726A1Process time savingSave data storage overheadTelevision system detailsProgram control using wired connectionsSensor arrayDigital data

This invention provides a system and method for processing discrete image data within an overall set of acquired image data based upon a focus of attention within that image. The result of such processing is to operate upon a more limited subset of the overall image data to generate output values required by the vision system process. Such output value can be a decoded ID or other alphanumeric data. The system and method is performed in a vision system having two processor groups, along with a data memory that is smaller in capacity than the amount of image data to be read out from the sensor array. The first processor group is a plurality of SIMD processors and at least one general purpose processor, co-located on the same die with the data memory. A data reduction function operates within the same clock cycle as data-readout from the sensor to generate a reduced data set that is stored in the on-die data memory. At least a portion of the overall, unreduced image data is concurrently (in the same clock cycle) transferred to the second processor while the first processor transmits at least one region indicator with respect to the reduced data set to the second processor. The region indicator represents at least one focus of attention for the second processor to operate upon.

Owner:COGNEX CORP

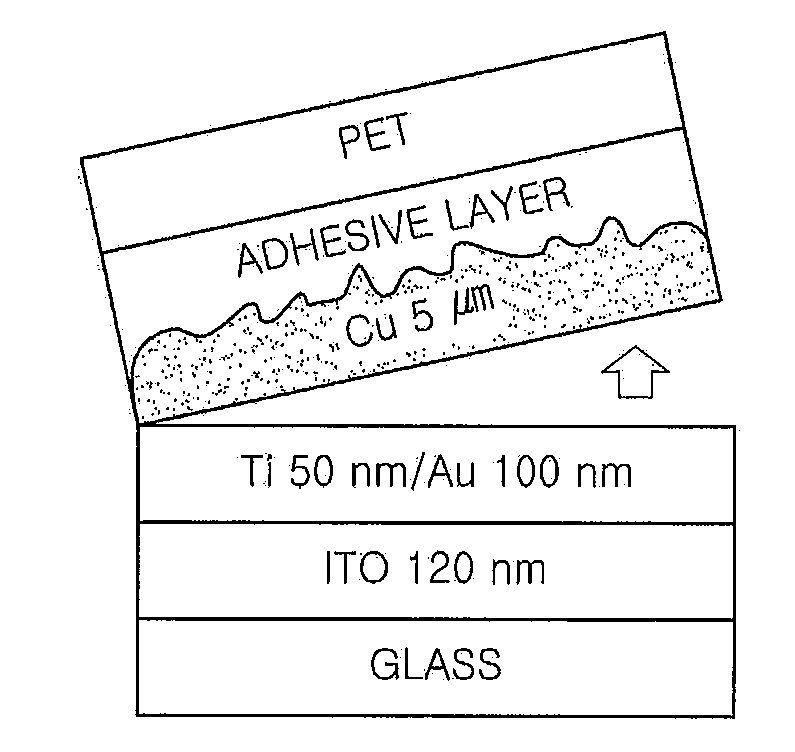

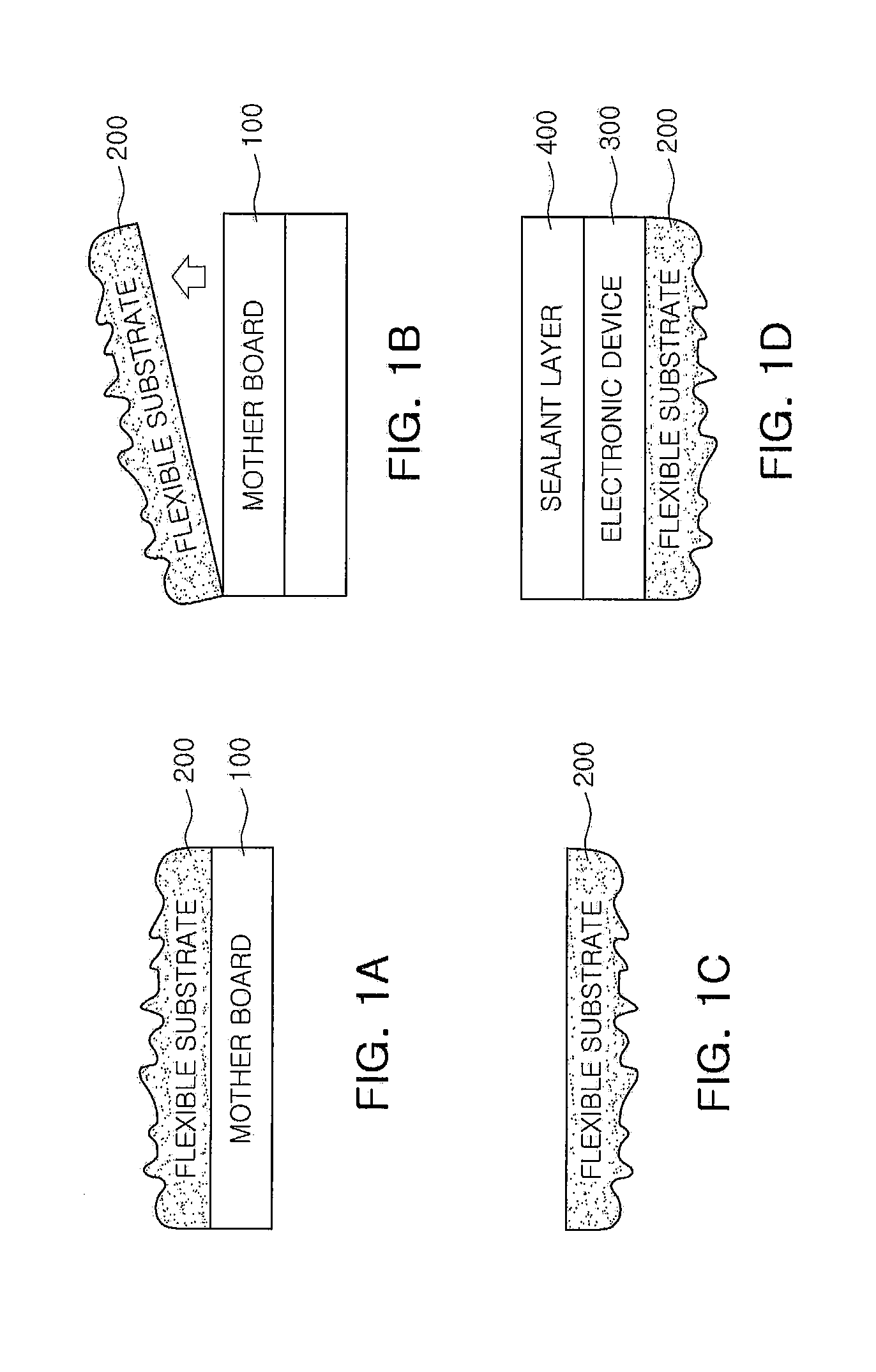

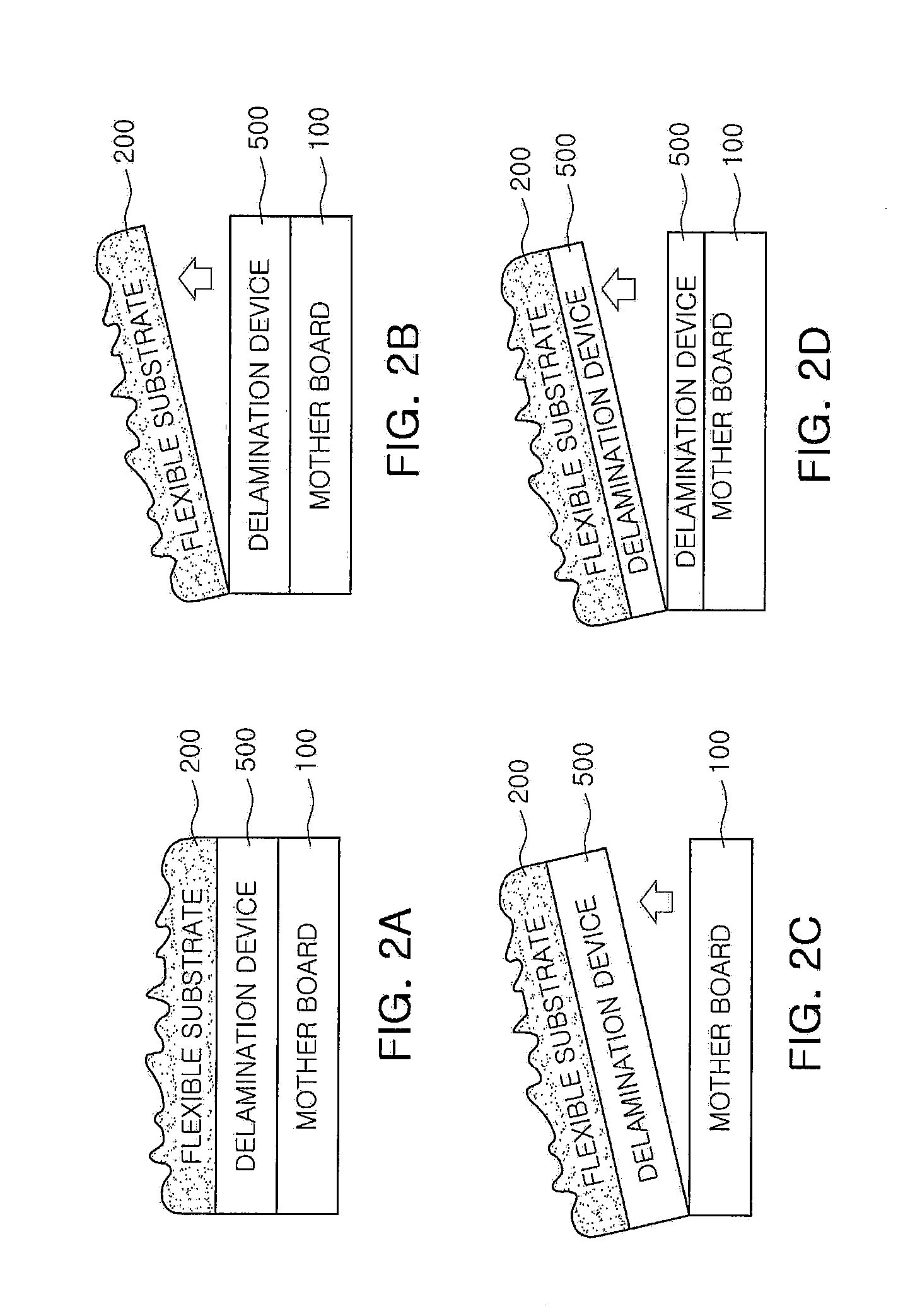

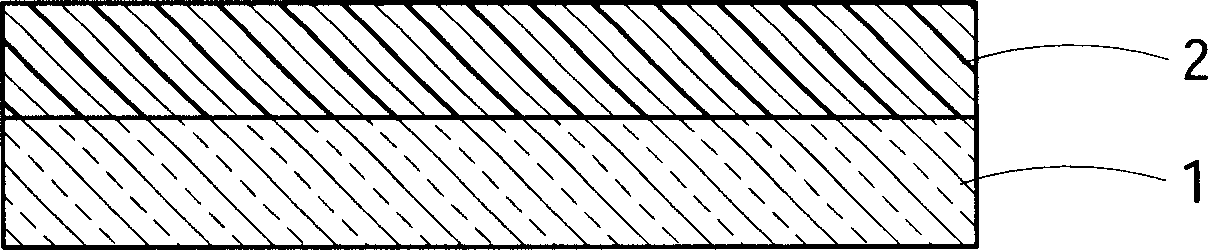

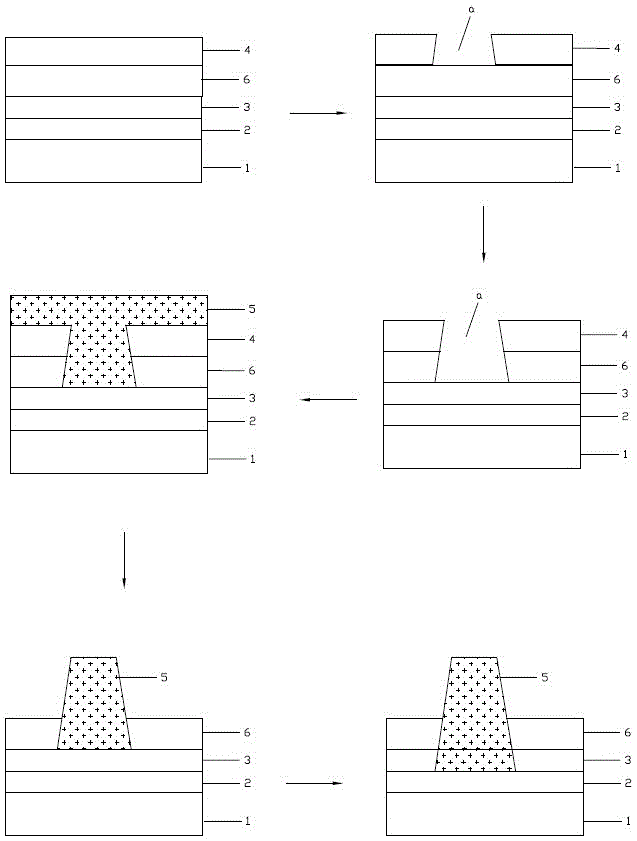

Flexible electronic device, method for manufacturing same, and a flexible substrate

InactiveUS20130105203A1Improve performanceLow costPrinted circuit assemblingCircuit bendability/stretchabilitySurface roughnessThermal expansion

The present invention relates to resolving issues concerning deterioration in the performance and yield of a flexible electronic device, caused by low manufacturing temperatures, high degrees of surface roughness, a high thermal expansion coefficients, and bad handling characteristics of typical flexible substrates. The method for manufacturing a flexible electronic device according to the present invention includes: forming a flexible substrate on a motherboard while physically separating the interface therebetween so that the interfacial bonding therebetween has a yield strength less than that of the flexible substrate; and forming an electronic device on the separated surface of the flexible substrate which had previously been in contact with the motherboard.

Owner:POHANG IRON & STEEL CO LTD

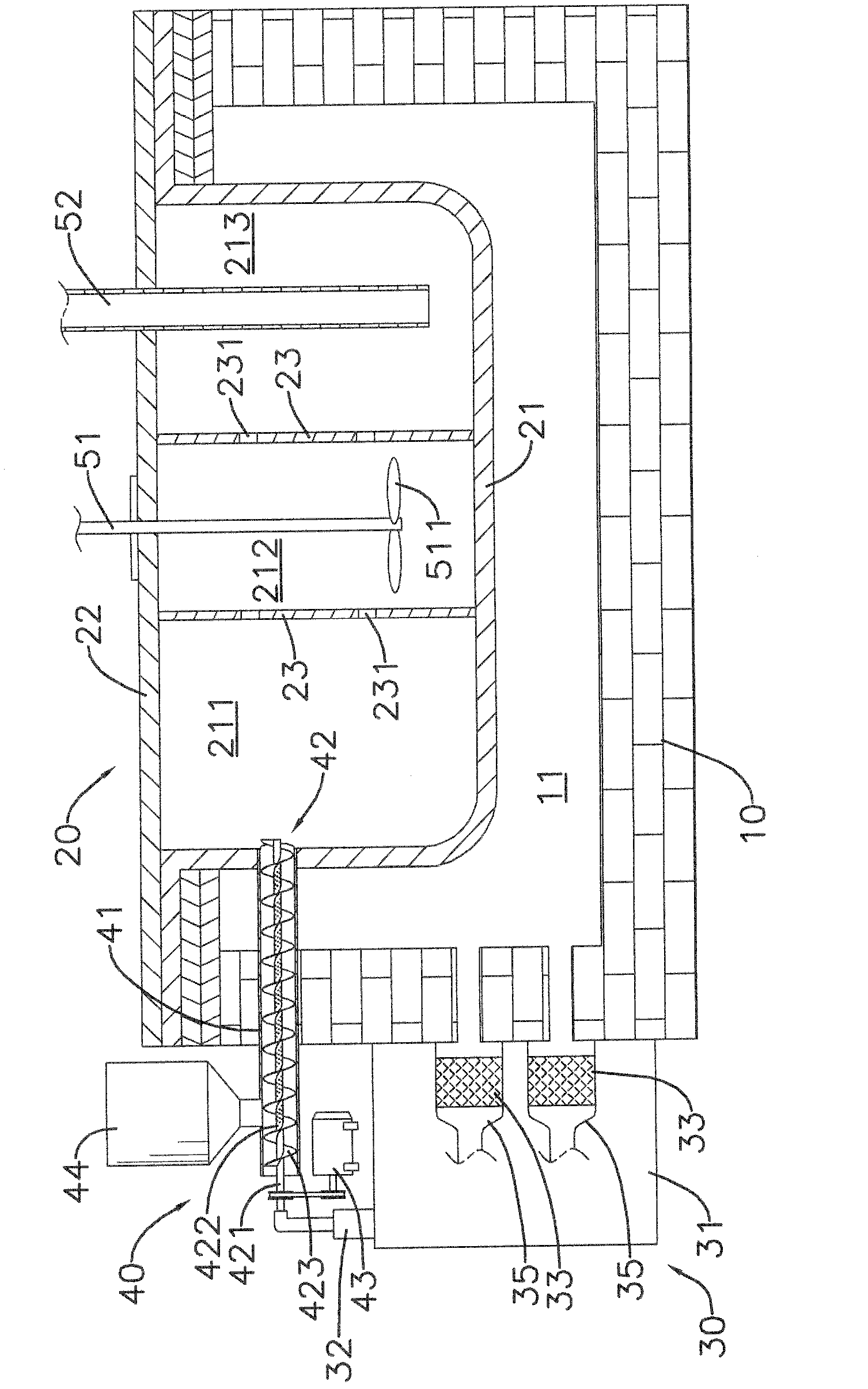

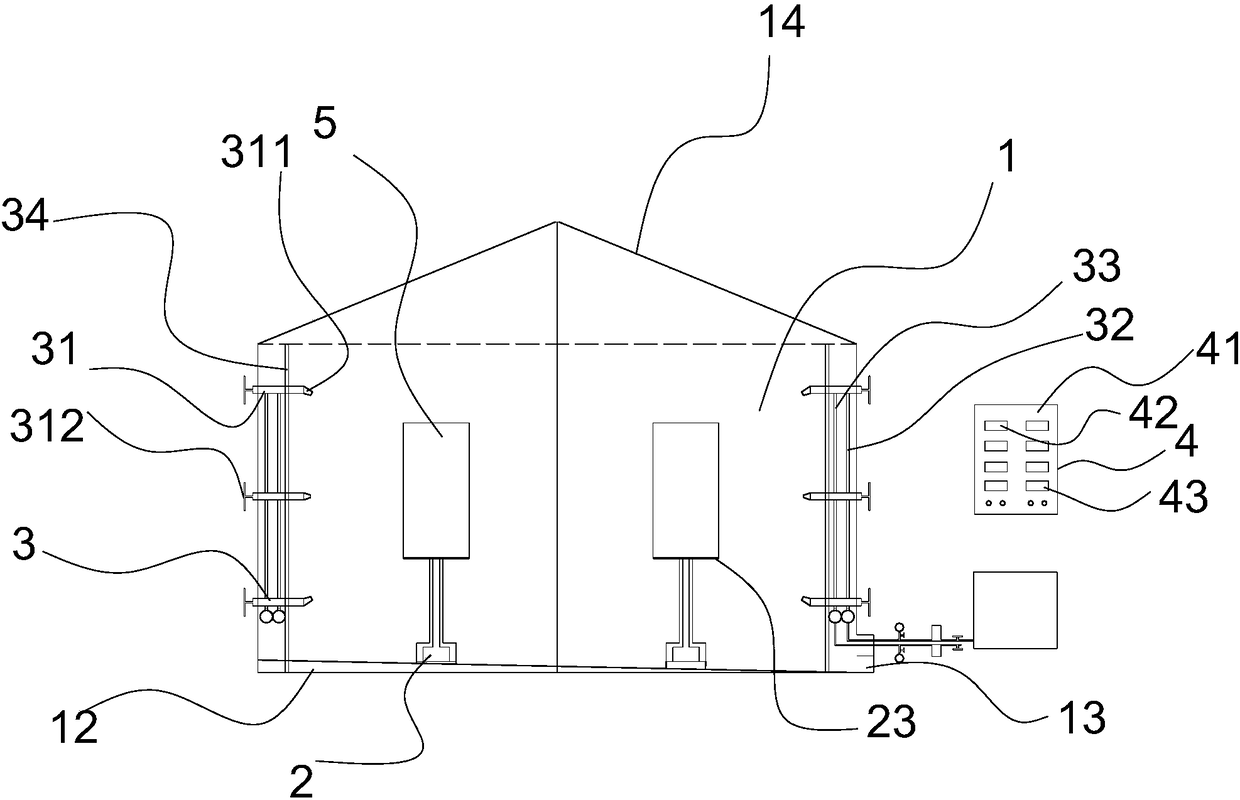

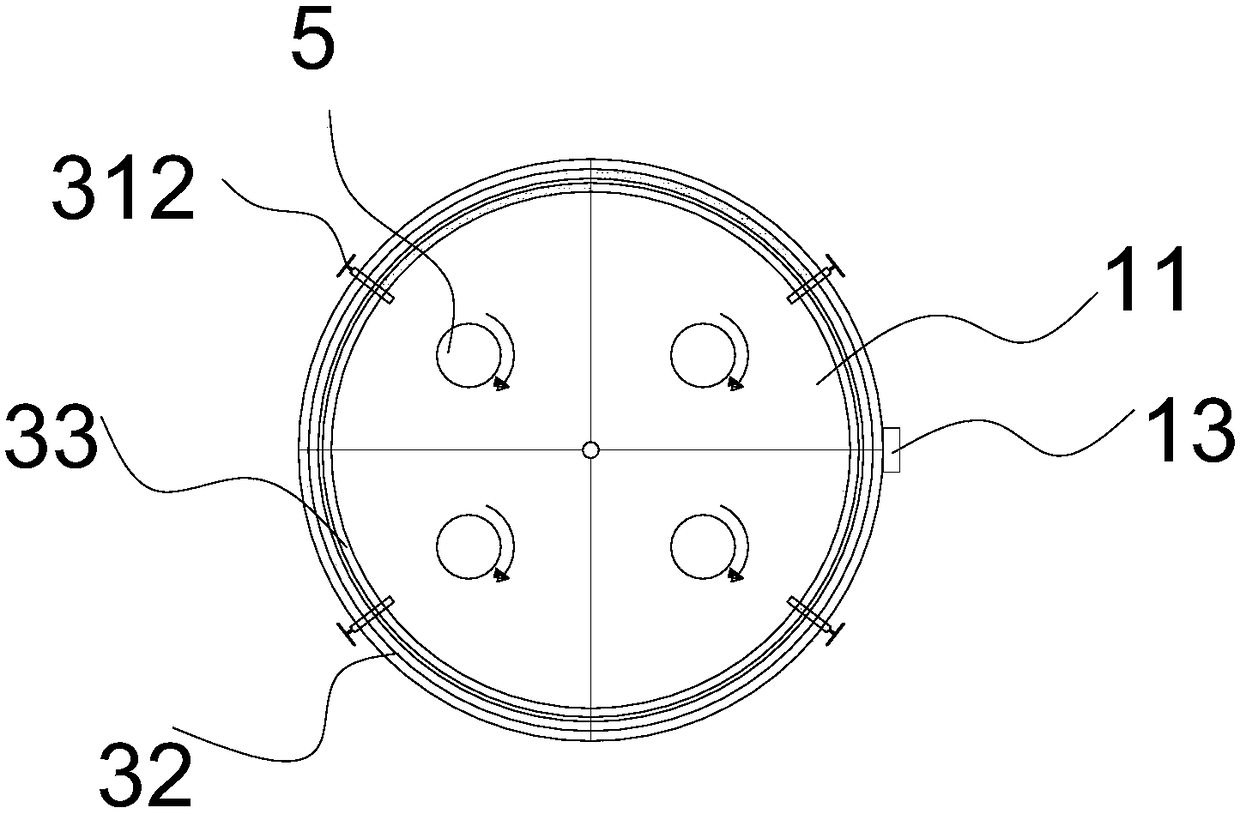

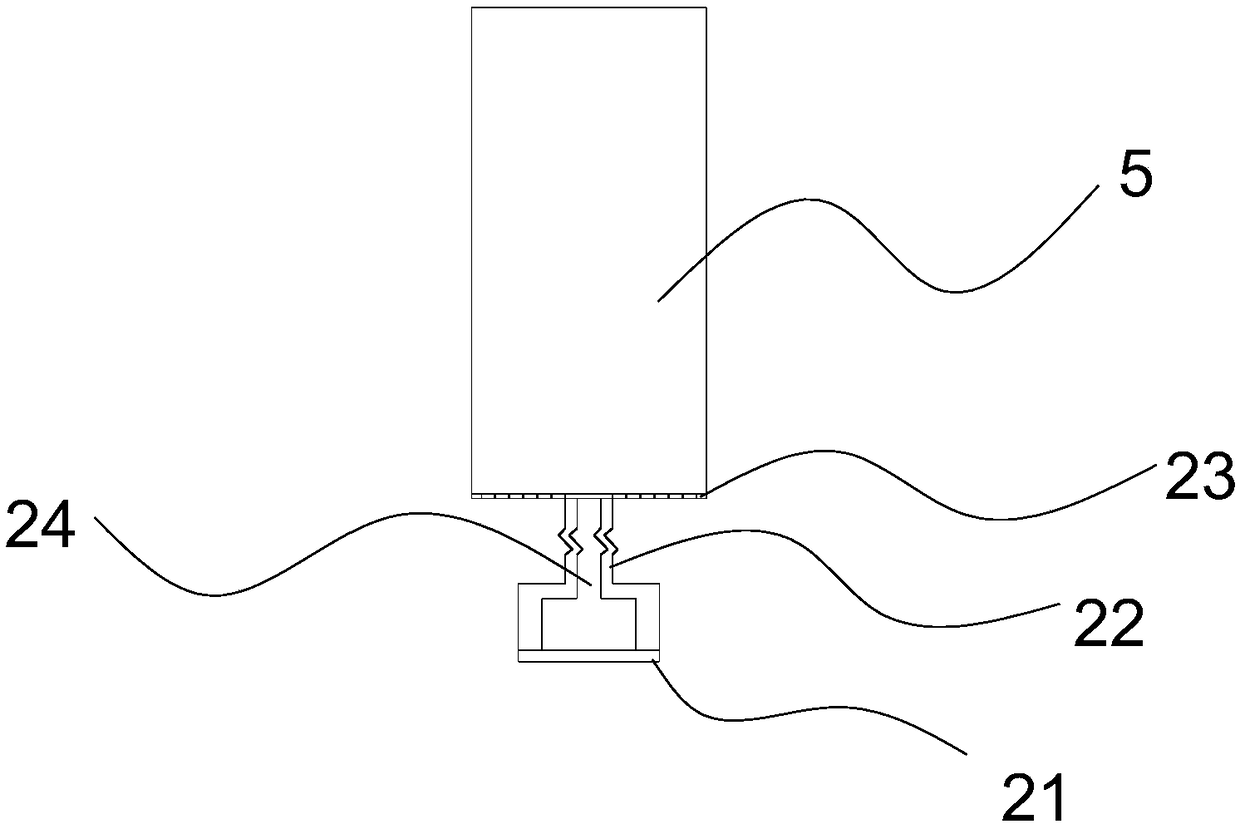

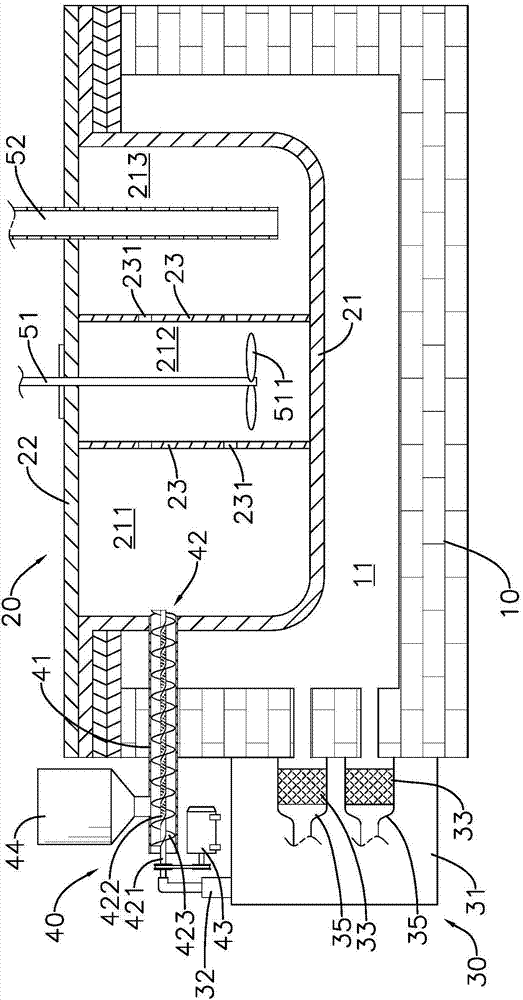

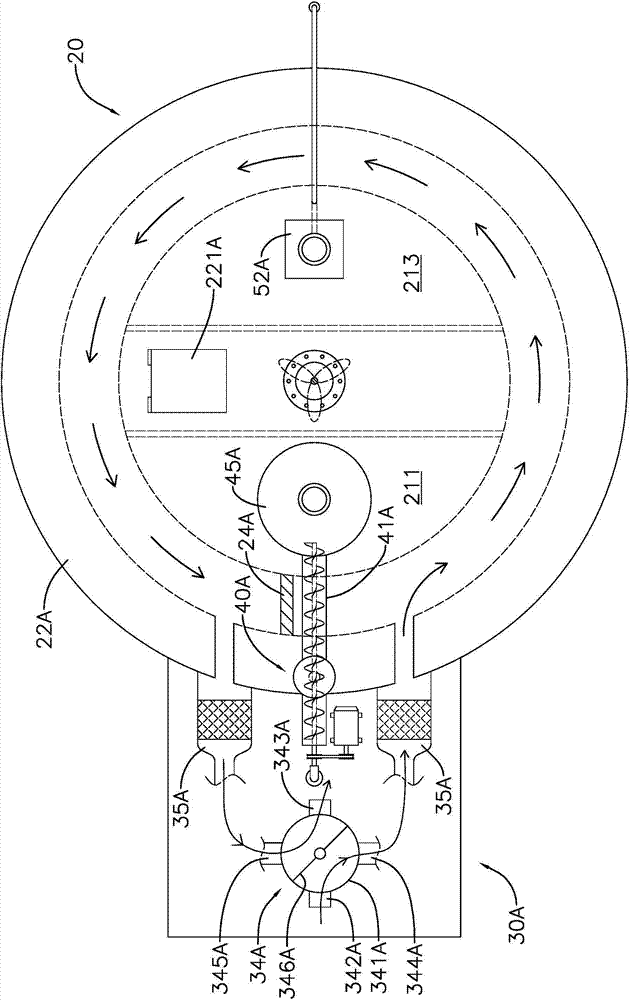

Metal melting furnace and metal melting method

ActiveCN103017518AShorten the timeProcess time savingPreheating chargesCrucible furnacesCombustion systemMetallic materials

The invention relates to a metal melting furnace and a metal melting method. The metal melting furnace comprises a heating furnace, a melting furnace erected on the heating furnace, a heat accumulating type combustion system, a feeding device and a circulating melt pumping and supply device erected on the melting furnace. The heat accumulating type combustion system not only can heat the heating furnace, but also can store high-temperature gas in the heating furnace on a heat accumulator, so that the heating efficiency of the heating furnace is increased. The residual heat of the heat accumulator is led to the feeding device and is used for heating granular or flaky metal materials thrown in the feeding device. Waste heat can be sufficiently recovered, and the preheated metal materials can be further pushed into the melting furnace by the feeding device, and heated and melted into liquid. Therefore, heat energy can be fully recovered, time spent on the sequent procedure of melting the metal materials into the liquid can be largely shortened, the heat energy (fuels) can be largely saved, and the whole process for preheating, heating and melting the metal materials and filling the liquid metal into a die is time-saving, fluent and successive and the metal melting furnace has high safety.

Owner:PINDA TECH

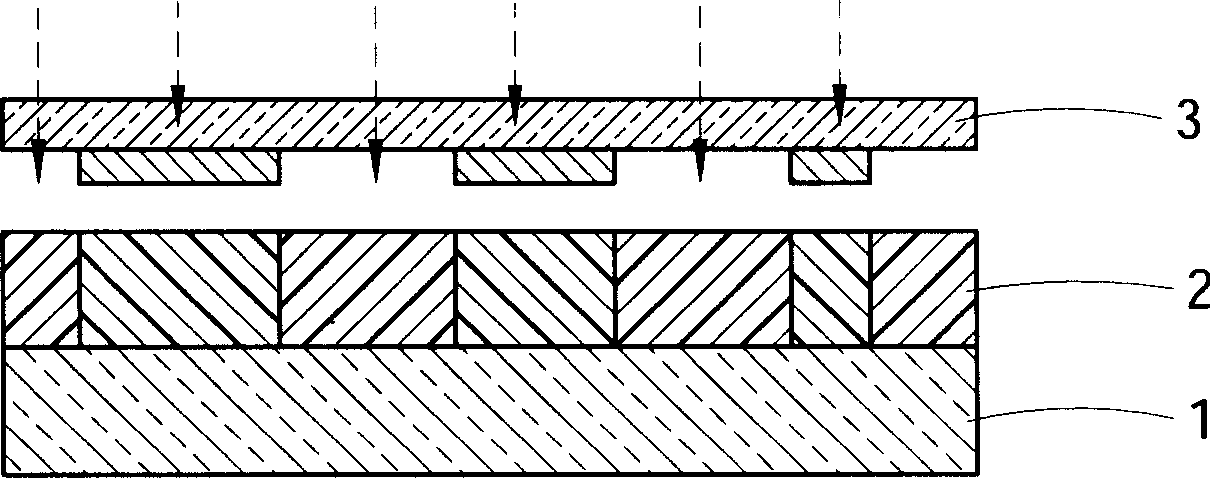

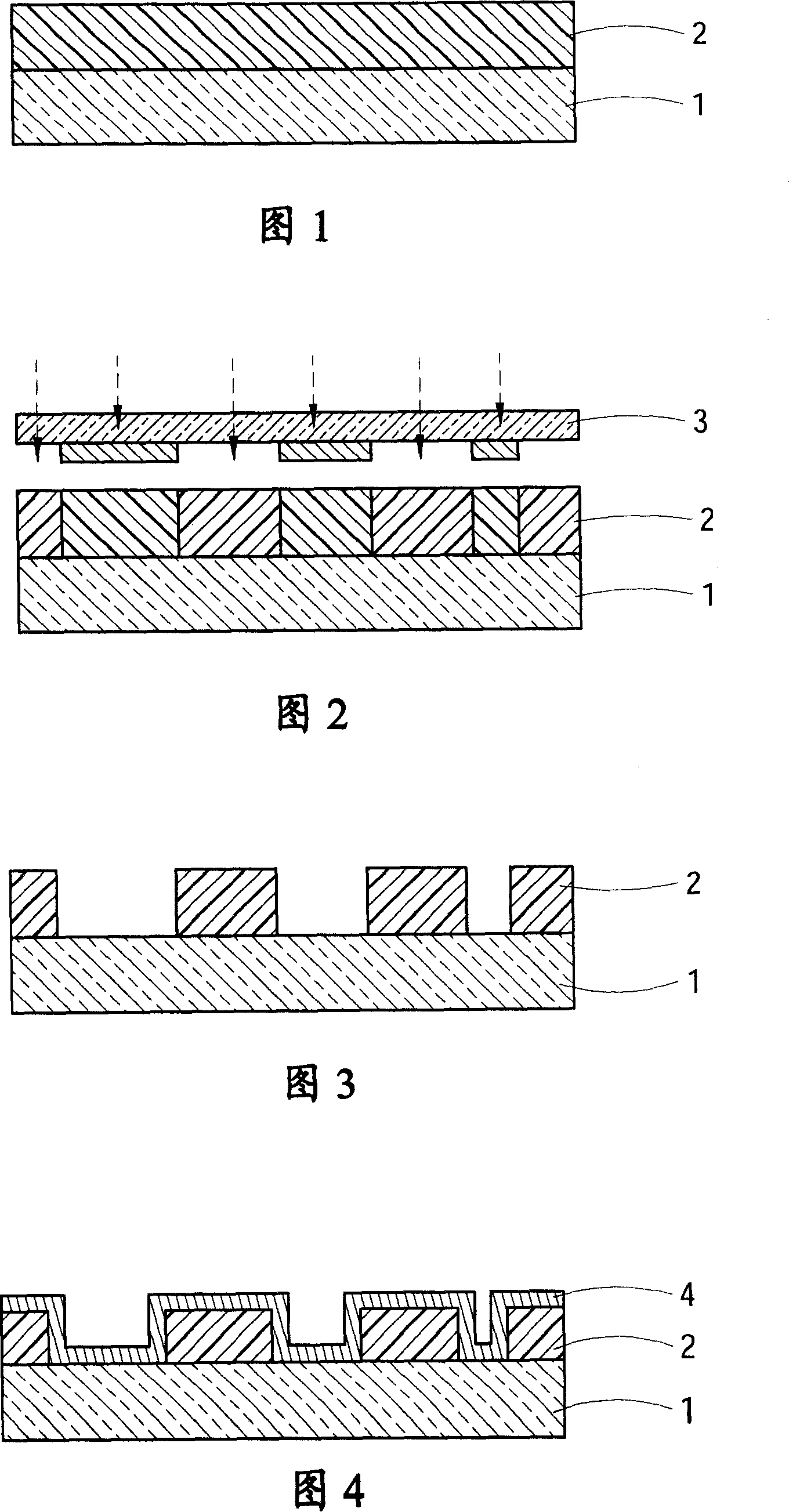

Method for fabricating super fine set of die for guiding light plate

InactiveCN1696782ASimple processProcess time savingPhotomechanical exposure apparatusMicrolithography exposure apparatusLight guideHeight difference

A method for preparing light guide plate forms a patterned metal layer on a metal baseplate by utilizing the microimaging process, and then coats a Ni - P alloy layer on surface of the patterned metal layer which has height difference.

Owner:CORETRONIC

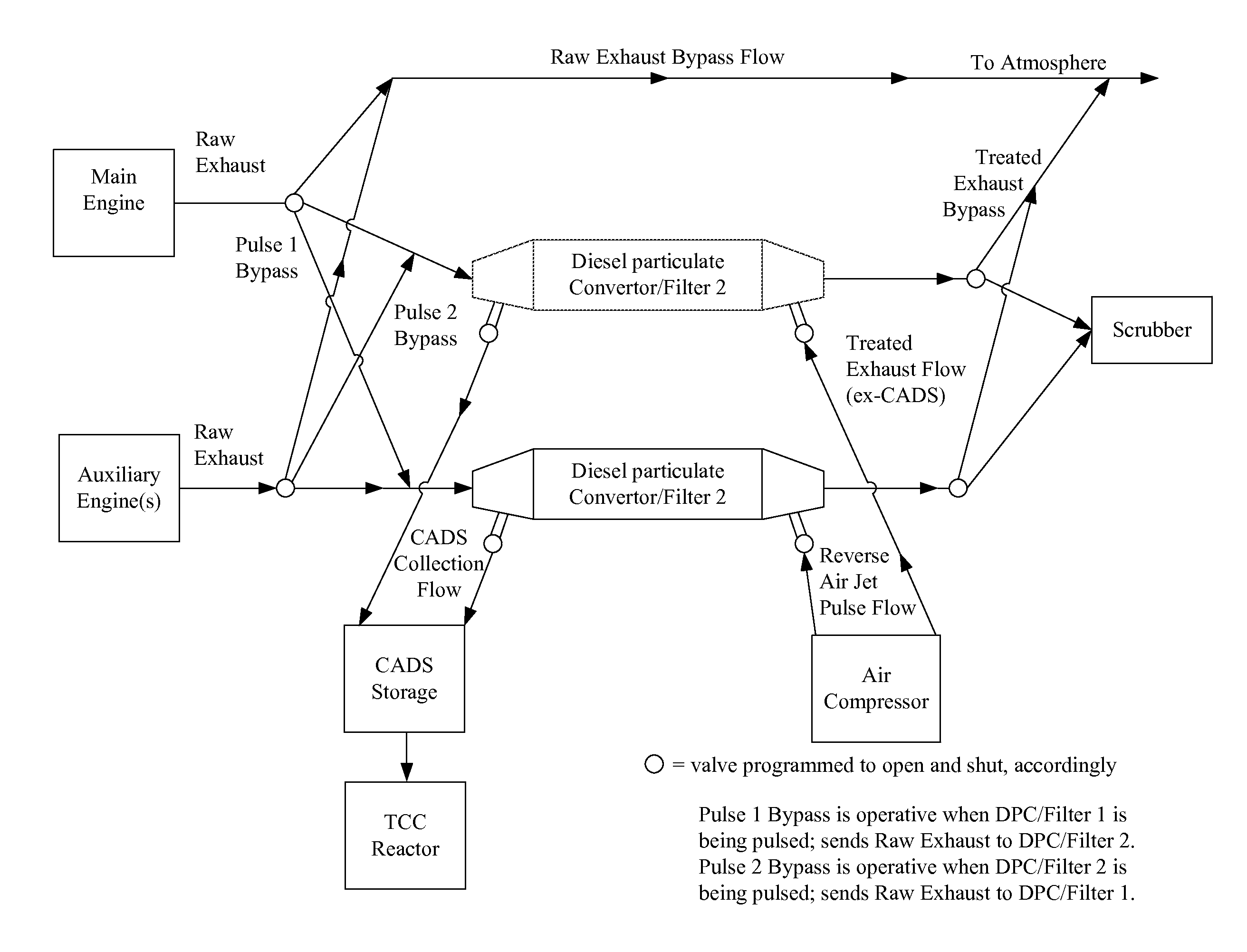

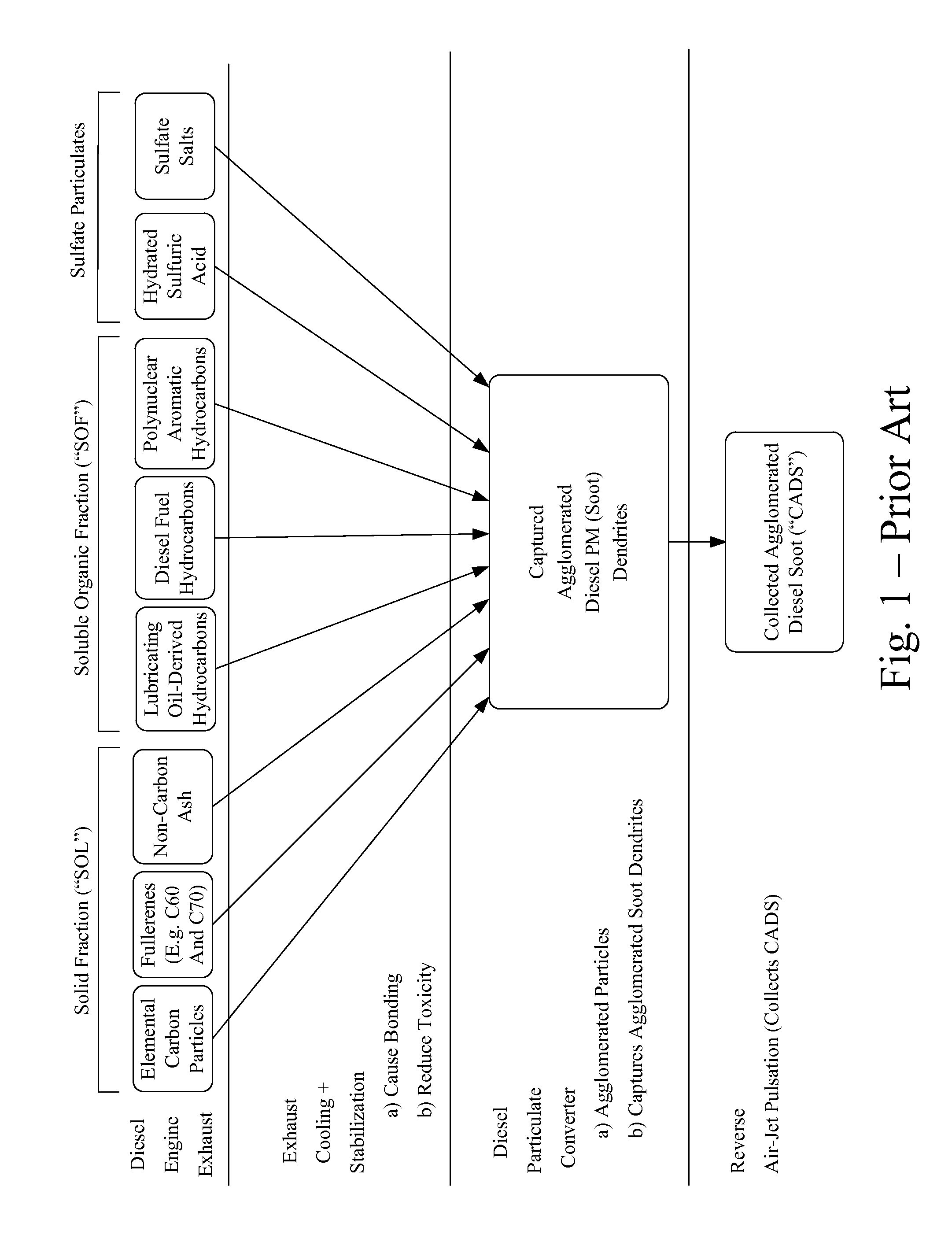

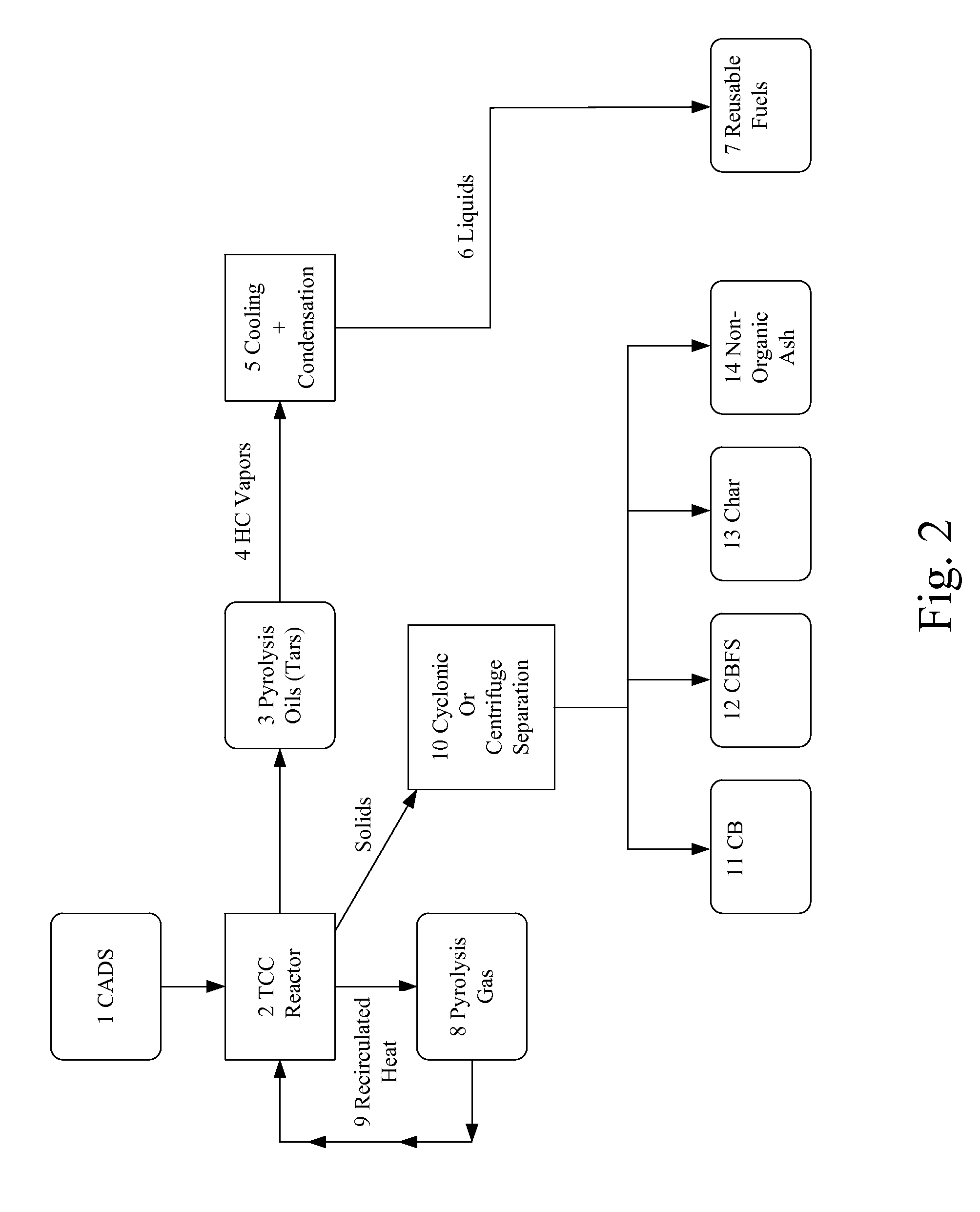

System for recycling captured agglomerated diesel soot and related method

ActiveUS20130055699A1Process time savingSave logisticsInternal combustion piston enginesExhaust apparatusTarProcess engineering

A method of recycling captured agglomerated soot captured by and collected from a diesel emission control after-treatment (DECAT) system, the method comprising collecting captured agglomerated diesel soot (CADS) as a feedstock, loading the CADS into a controlled thermochemical conversion (TCC) process reactor, employing time-phased heat and pressure in the controlled TCC process reactor until the CADS sufficiently decompose to reclaim solids, liquid fuels and gases, piping pyrolysis oils (tars) and vapors produced in the controlled TCC process reactor to chambers, cooling and condensing the pyrolysis oils and vapors into a liquid form, and recirculating a pyrolysis gas produced in the controlled TCC process reactor for use as a source of heat and power.

Owner:DEARBORN FINANCIAL

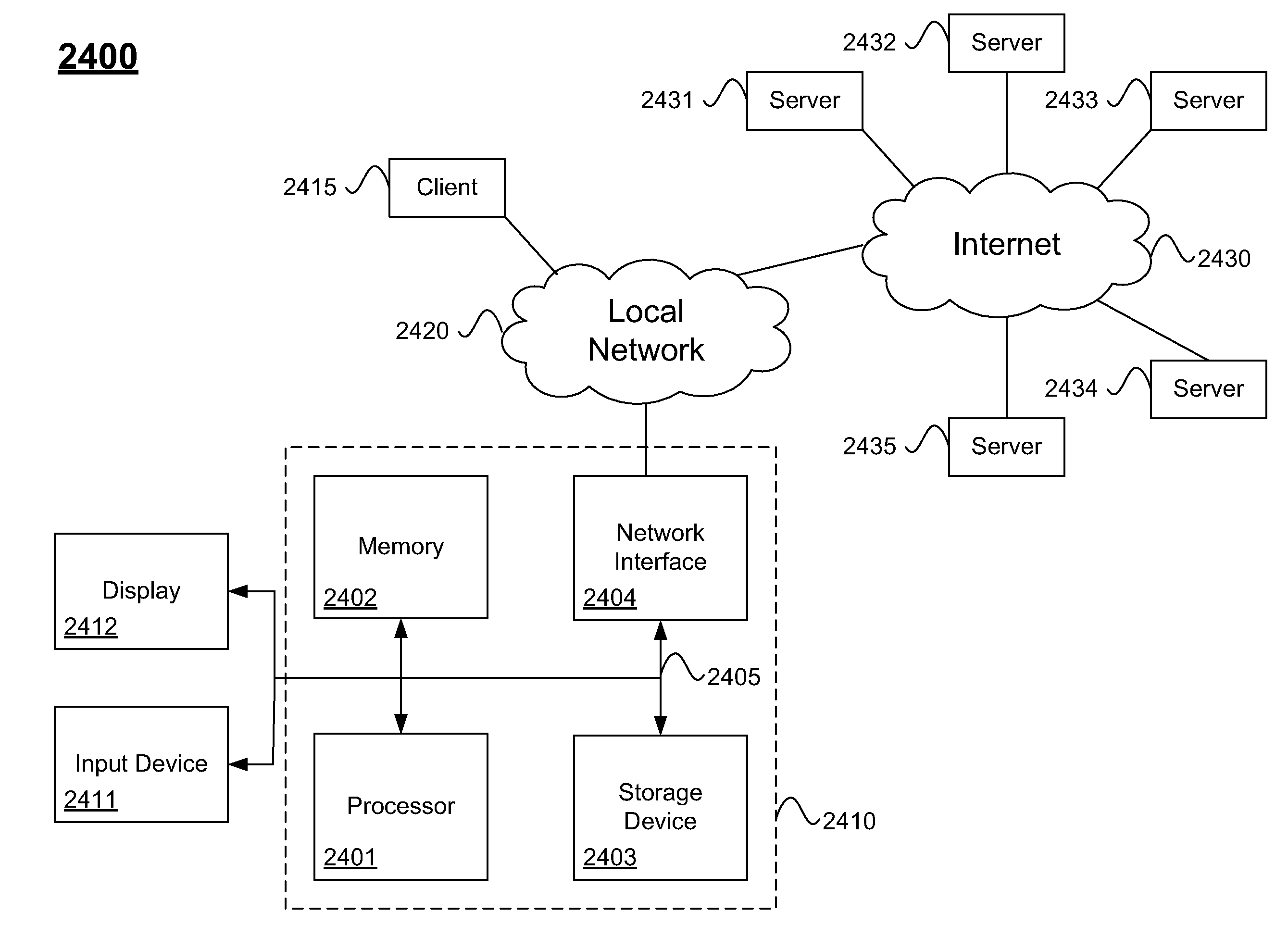

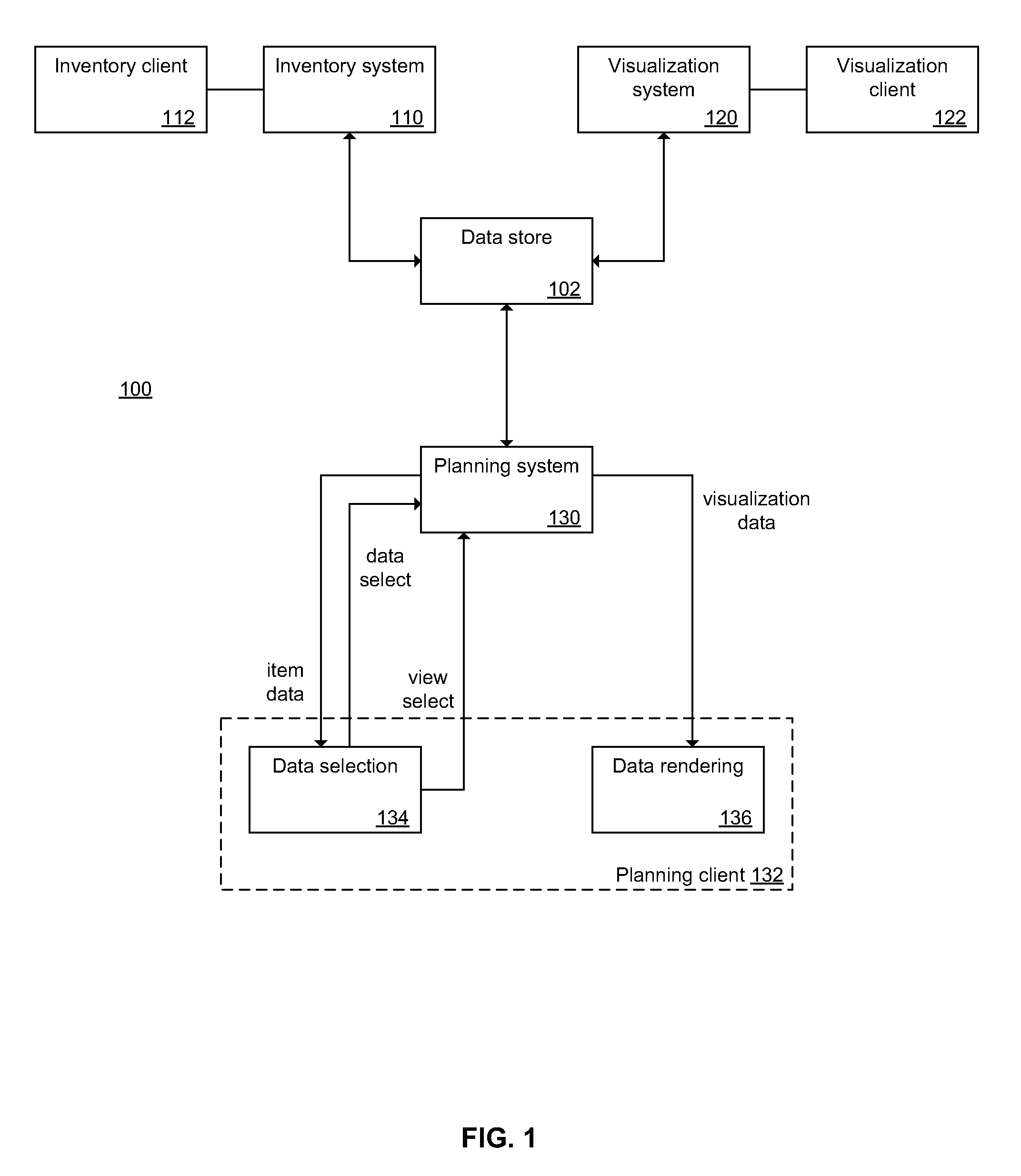

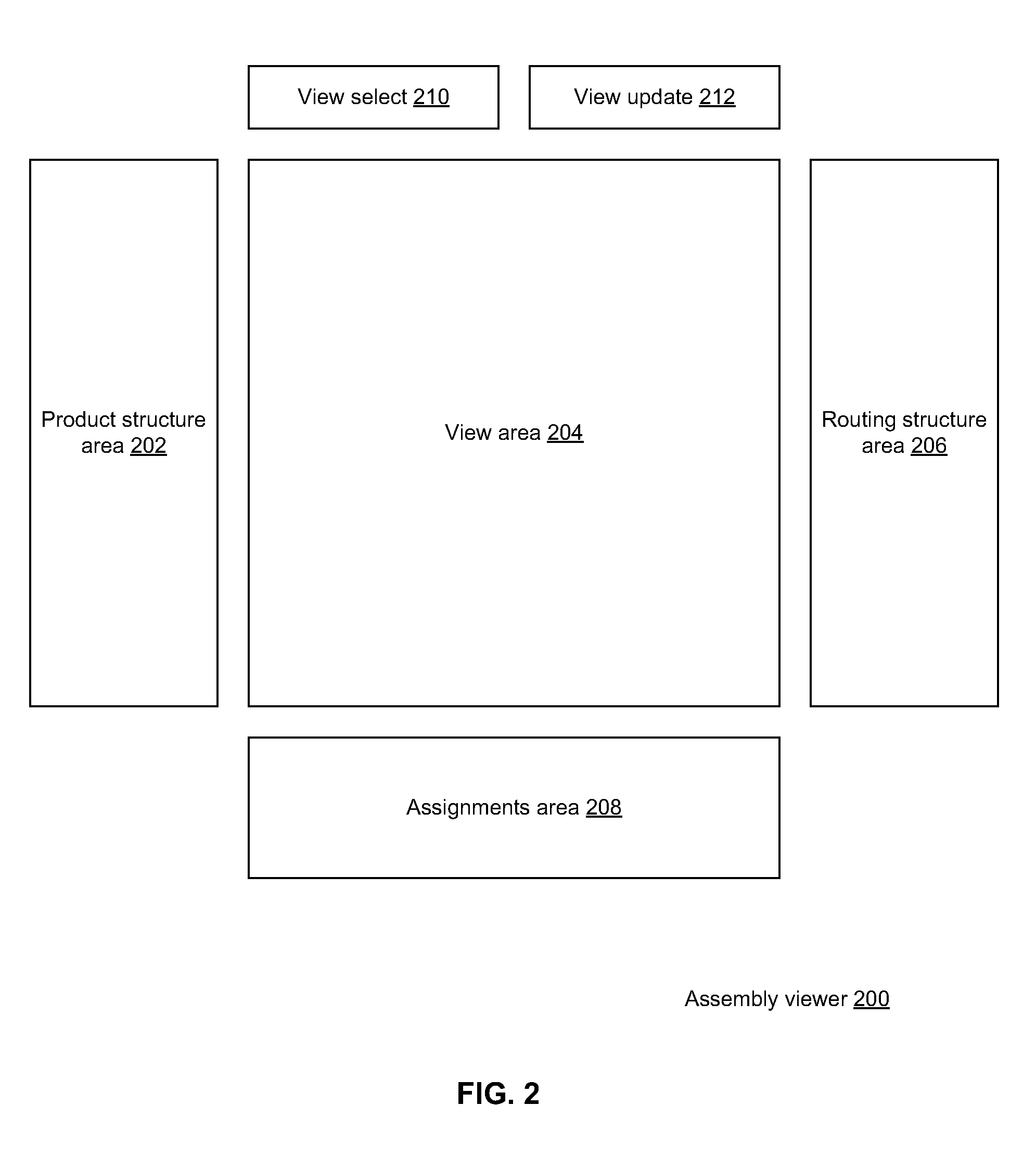

System and Method of Viewing Updating for Planning Item Assemblies

A system and method of displaying item lists and item views for a product assembly process. The method includes storing item data and visualization data, displaying the item data, receiving a first user input that selects a subset of the item data, receiving a second user input that selects a viewing mode, and, in response to a third user input, reading a subset of the visualization data that corresponds to the first user input and displaying the subset of the visualization data according to the viewing mode. In this manner, downloading time and display processing time is saved as compared to other systems.

Owner:SAP AG

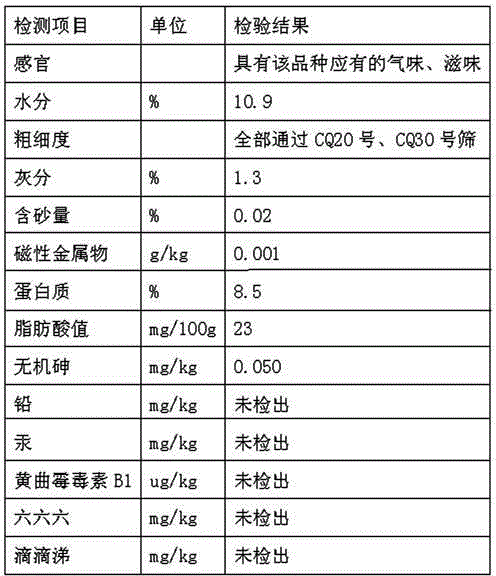

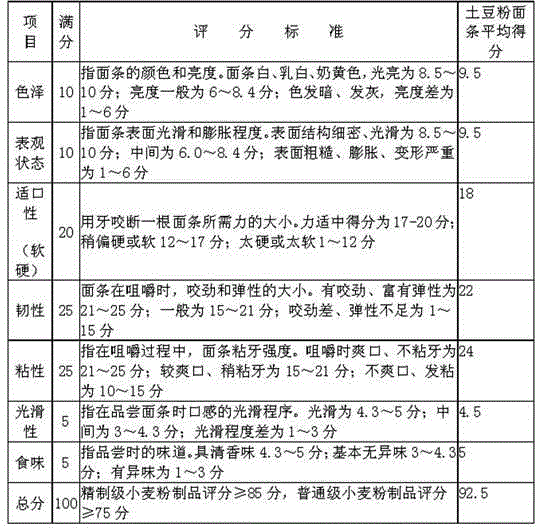

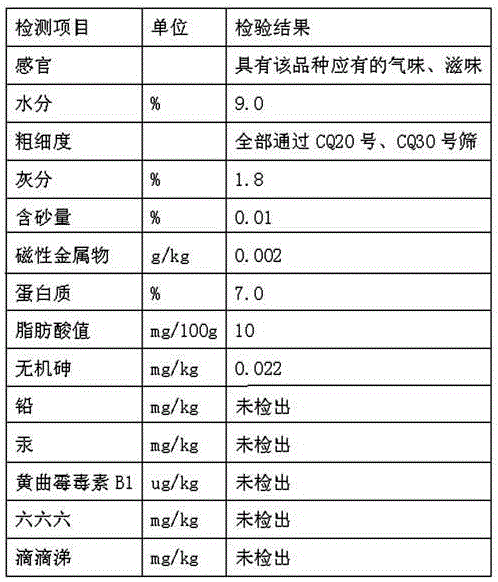

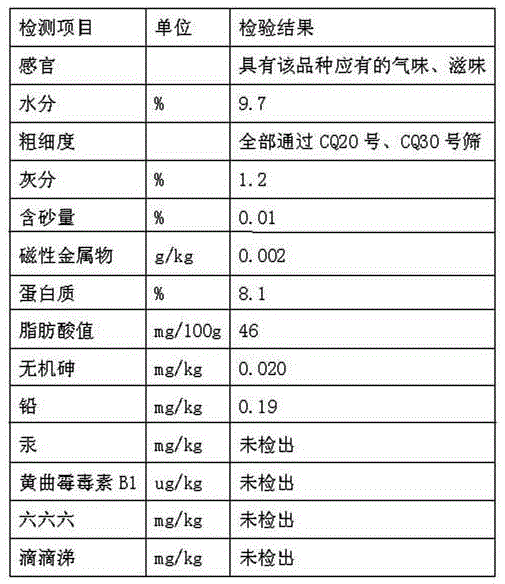

Special potato noodle type powder for using potatoes as staple food

InactiveCN104905180ARealize large-scale factory productionGreat tasteFood preparationFood additivePotato starch

The invention belongs to the technical field of food processing. In order to solve the problems that the processing cost of conventional potato whole flour is higher, the processing procedures are complex, during making staple food products with the conventional potato whole flour, the forming is difficult, the hardness is high, the staple food products are not resistant to boiling, the content of the potato whole flour is low, the cost of making cooked potato food is high and the like, the invention provides special potato noodle type powder for using potatoes as staple food. A preparation method of the potato whole flour comprises the following steps: choosing raw materials, cleaning the chosen raw materials, removing skins of the potatoes, selecting the potatoes of which the skins are removed, cutting the selected potatoes into slices, blanching the potato slices, cooling the blanched potato slices, drying the cooled potato slices and milling the dried cooled potato slices; mixing the potato whole flour, wheat flour and potato starch to be made into noodles. The preparation process is time-saving, simple and convenient, the noodles are popular and suitable for people to eat, the popularization is facilitated, and the quality is steady; the noodles are easy to form, tenacious, comprehensive in nutrition and good in taste; the content of the potato whole flour is more than 50%, any food additive is not added, safe, healthy environment-friendly food is ensured, the situation that the potatoes are consumed as the staple food is facilitated, the sustainable development of agriculture of China is facilitated, and the special potato noodle type powder is good for nutrition and health of people.

Owner:SHANXI SHUYAN FOOD

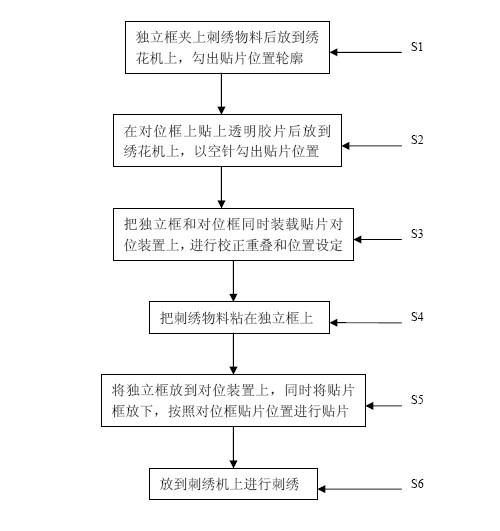

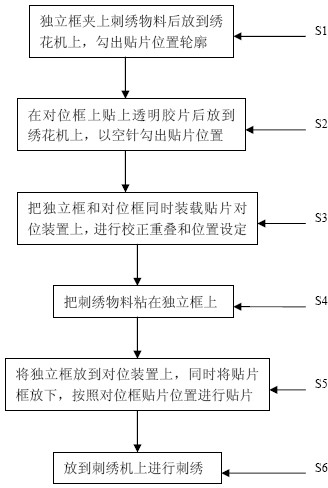

Counterpoint method of applique embroidery surface mounting

ActiveCN102182025ABeautiful appearanceSolve the disadvantages of misalignmentAutomatic machinesSurface mountingEngineering

The invention discloses a counterpoint method of applique embroidery surface mounting. By the method, the defect that the surface mounting counterpoint for multiple times is irregular is overcome. A surface mounting process is convenient to operate, quick, precise, simple in operation, practical and reliable. The operation flow comprises the following steps of: firstly, clamping an embroidery material on an independent embroidery frame, placing the embroidery frame on an embroidery machine, and embroidering the outlines of the embroidery material and a placing position of surface mounting through weaving with a single needle; secondly, sticking a transparent adhesive sheet on a counterpoint frame of a counterpoint device, correcting and superposing the embroidering independent embroidery frame and the surface mounting position of the surface mounting counterpoint frame, and setting the position; and finally, sticking the material required to be embroidered onto the independent embroidery frame, sticking surface mounting sheets onto the material required to be embroidered according to the surface mounting position of the counterpoint frame, and placing the independent embroidery frame on the embroidery machine to embroider. The whole pattern can be embroidered at one time, so the counterpoint time of surface mounting is reduced, the production efficiency of the embroidery machine is improved, mass production can be realized, and the manufacturing cost of applique embroidered clothes is greatly reduced.

Owner:HUI ZHOU SHENTIAN PRECISION MACHINES

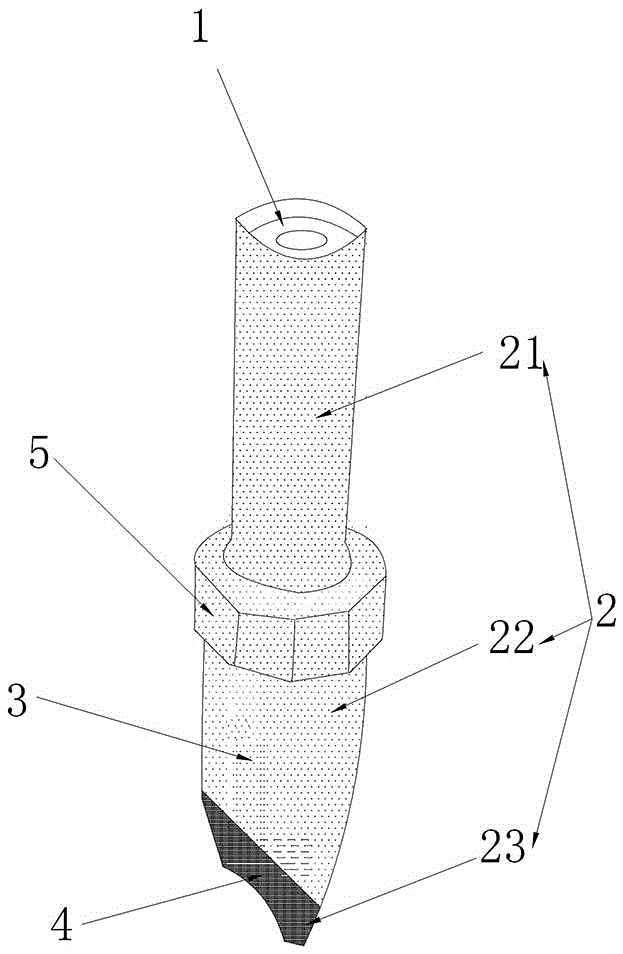

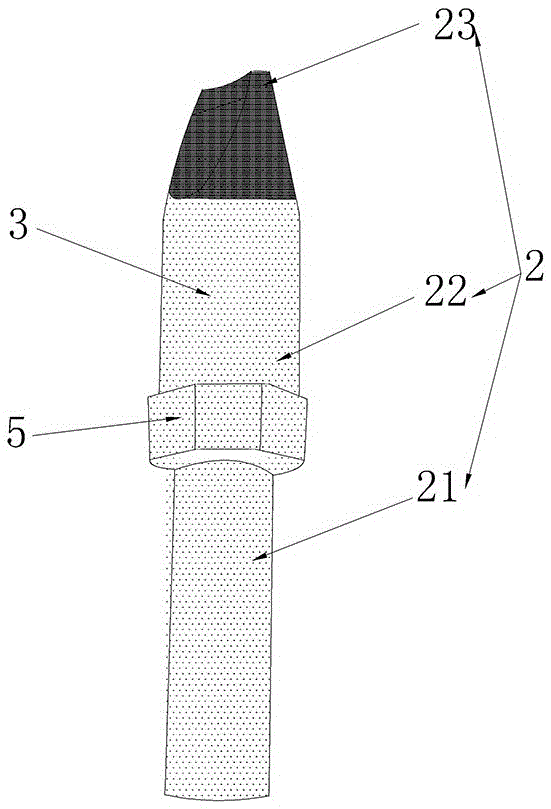

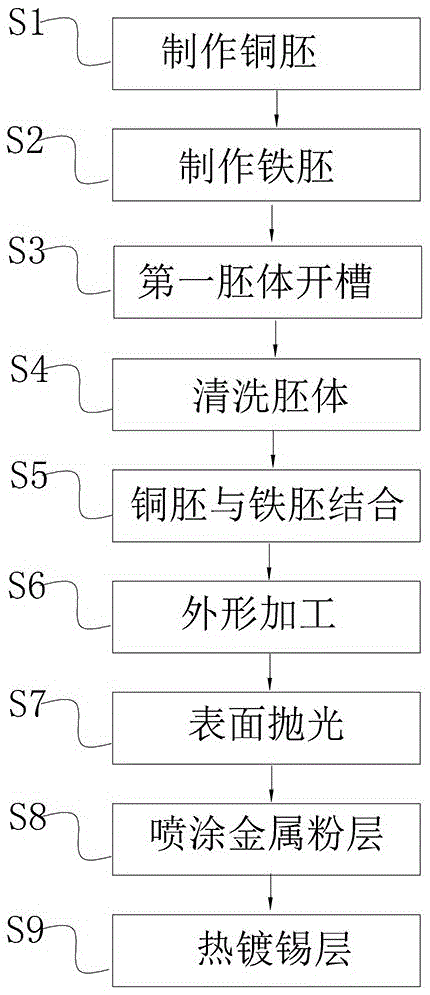

Energy-saving and environment-friendly solder tip and production process thereof

InactiveCN106670614AExtended service lifeSolve the problem of uneven life spanSoldering bitsSoldering ironCopperProtection layer

The invention discloses an energy-saving and environment-friendly solder tip and a production process thereof. During production of the solder tip, copper billet manufacturing, iron billet manufacturing, copper billet and iron billet combination, shape processing, surface polishing, spraying of an anti-corrosion metal layer, hot galvanizing of a molten tin protection layer and the like are sequentially conducted to finally form a copper billet, an iron billet, the anti-corrosion metal layer and a tin layer, wherein the iron billet comprises a first billet body and a second billet body which are integrally formed; a copper billet groove for fixing and accommodating the copper billet is formed in the first billet body; a working end for tin soldering operation is arranged at the second billet body; the anti-corrosion metal layer is sprayed to cover the outer surface of the second billet body; and the tin layer covers a solder tip on the outer surface of the working end. The process is simple, the cost is low, the environment is protected, a produced product is stable in performance, the production period is short, and automatic production can be realized.

Owner:深圳市吉美电子设备有限公司

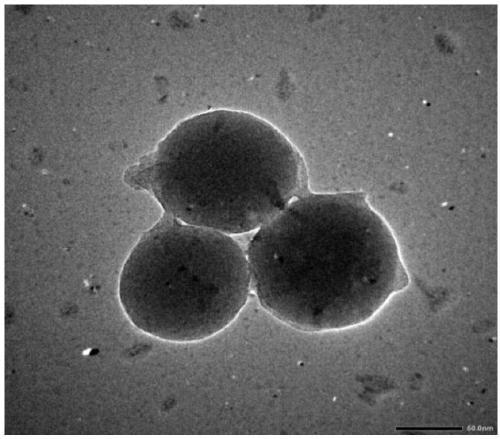

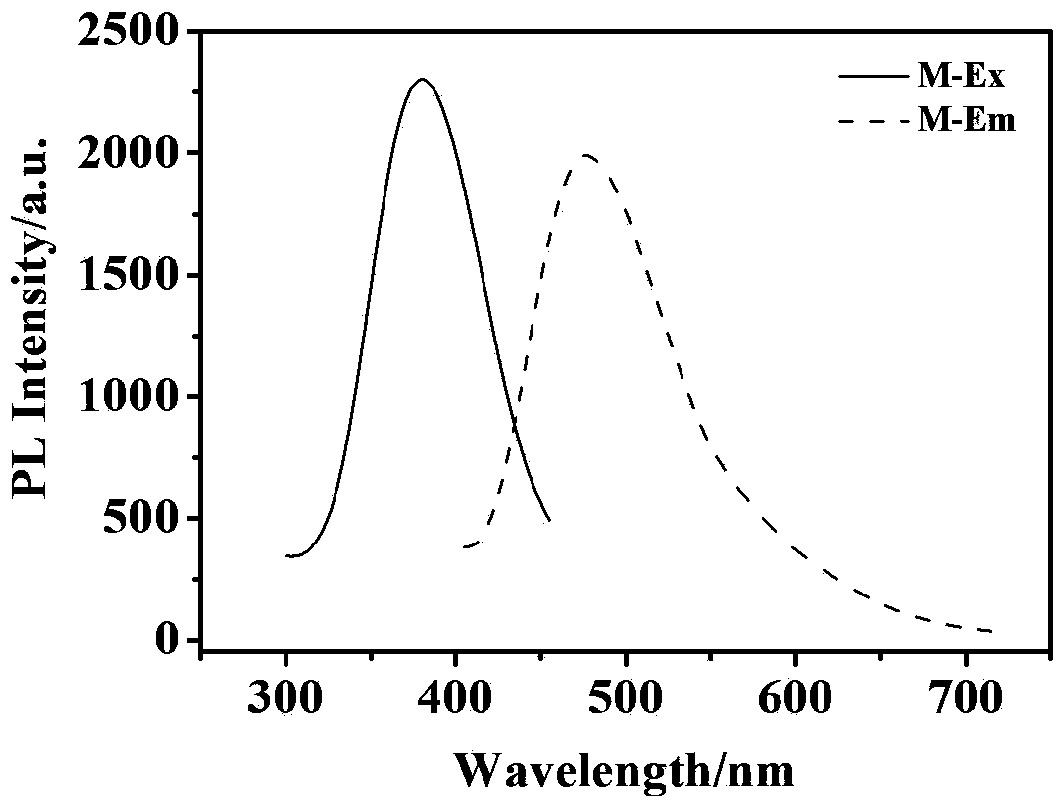

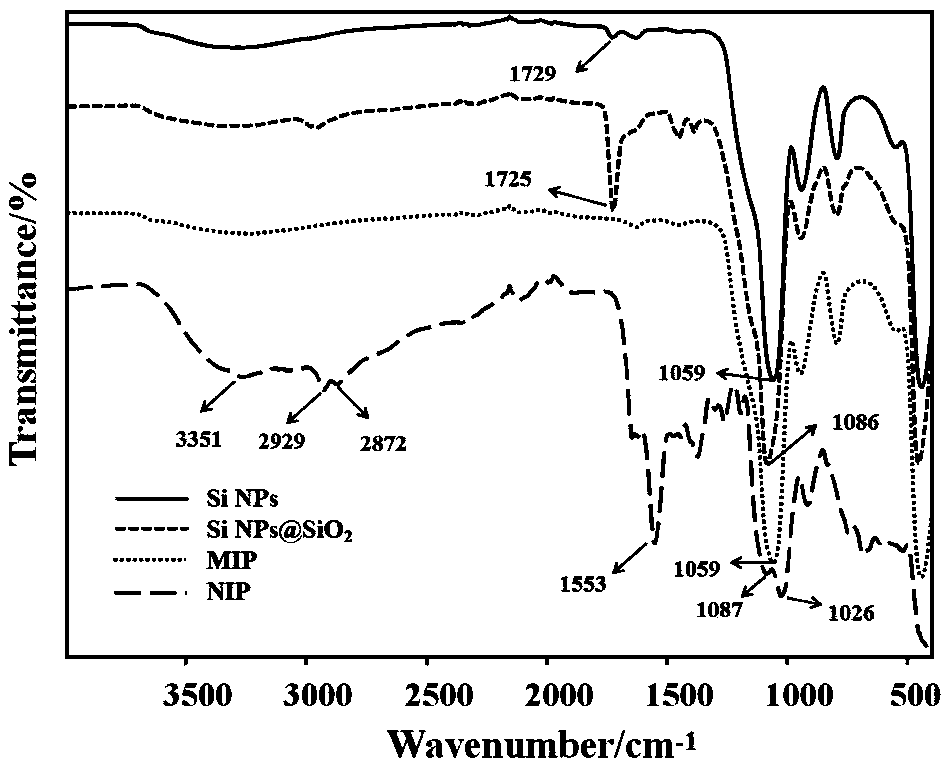

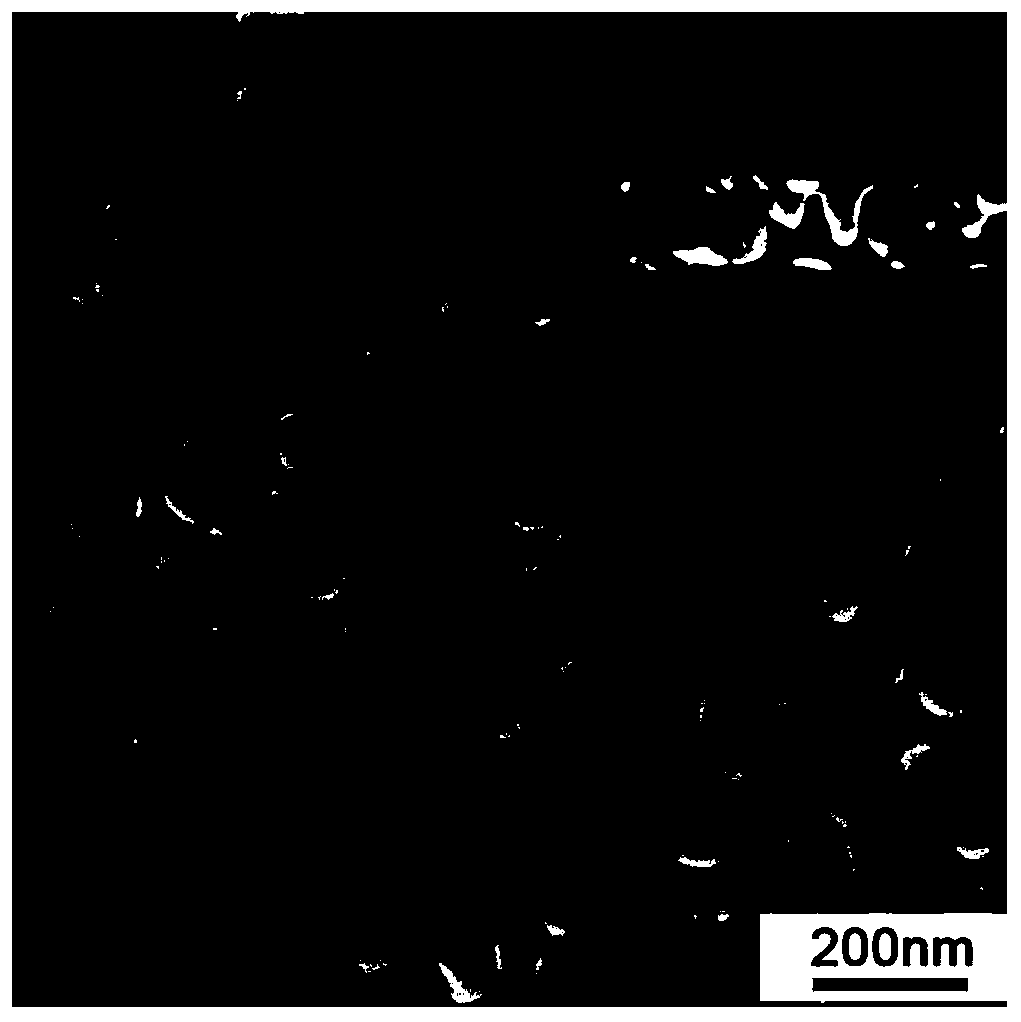

Preparation method of fluorescent double-template antigenic-determinant imprinted polymer based on silicon nanoparticles

InactiveCN109608572AFunctional DiversificationSimple and fast operationOrganic active ingredientsInorganic non-active ingredientsAntigenFunctional monomer

The invention relates to a preparation method of a fluorescent double-template antigenic-determinant imprinted polymer based on silicon nanoparticles. The fluorescent nanoparticles are taken as a carrier, and linear nonapeptide and adriamycin of an extracellular region where HER2 is over expressed are used as double templates to synthesize the imprinted polymer. The method comprises the followingsteps: preparing fluorescent silicon nanoparticles (Si NPs), carrying out silanization on the Si NPs; and preparing the fluorescent double-template antigenic-determinant imprinted polymer based on thesilicon nanoparticles. According to the method, the imprinted polymer is synthesized by combining antigenic-determinant imprinting, double-template imprinting and a surface imprinting method, the operation is simple and convenient, the process saves time, and the material has a targeting imaging function and a targeted therapy function. Zinc acrylate and acrylamide are adopted as functional monomers, and the templates are jointly fixed through metal chelating and action of hydrogen bonds, so that the specific recognition effect of the material on a target object can be effectively improved, and controlled release of medicines can be realized by utilizing an acidic pH value. The synthesized fluorescent imprinted polymer efficiently combines high sensitivity of fluorescence and high selectivity of a molecular imprinting technology.

Owner:NANKAI UNIV

Preparation method for transistor ohmic contact electrode

InactiveCN106683993AImprove thermal stabilitySufficient diffusion depthSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactControllability

The invention discloses a preparation method for a transistor ohmic contact electrode. The method comprises the steps of providing a semiconductor substrate containing a heavy doping P type GaAs layer and an InGaP layer; coating photoresist on the InGaP layer and forming at least one display area through exposure and development; depositing metal in the display area to form a metal layer; peeling off the photoresist; and at the temperature of 385-430 degrees centigrade, alloy 60-180 s, under the condition that the thickness of the P type GaAs layer is not smaller than 50 nm, the thickness of the InGaP layer is 30-50 nm, and the bottom of the metal layer at least comprises 20-50 nmPt, spreading the bottom of the metal layer to pass through the InGaP layer, thereby realizing the ohmic contact with the P type GaAs layer. The whole production process is simple, the time is saved, the controllability is greatly improved, and the yield of the products and the production efficiency are improved.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

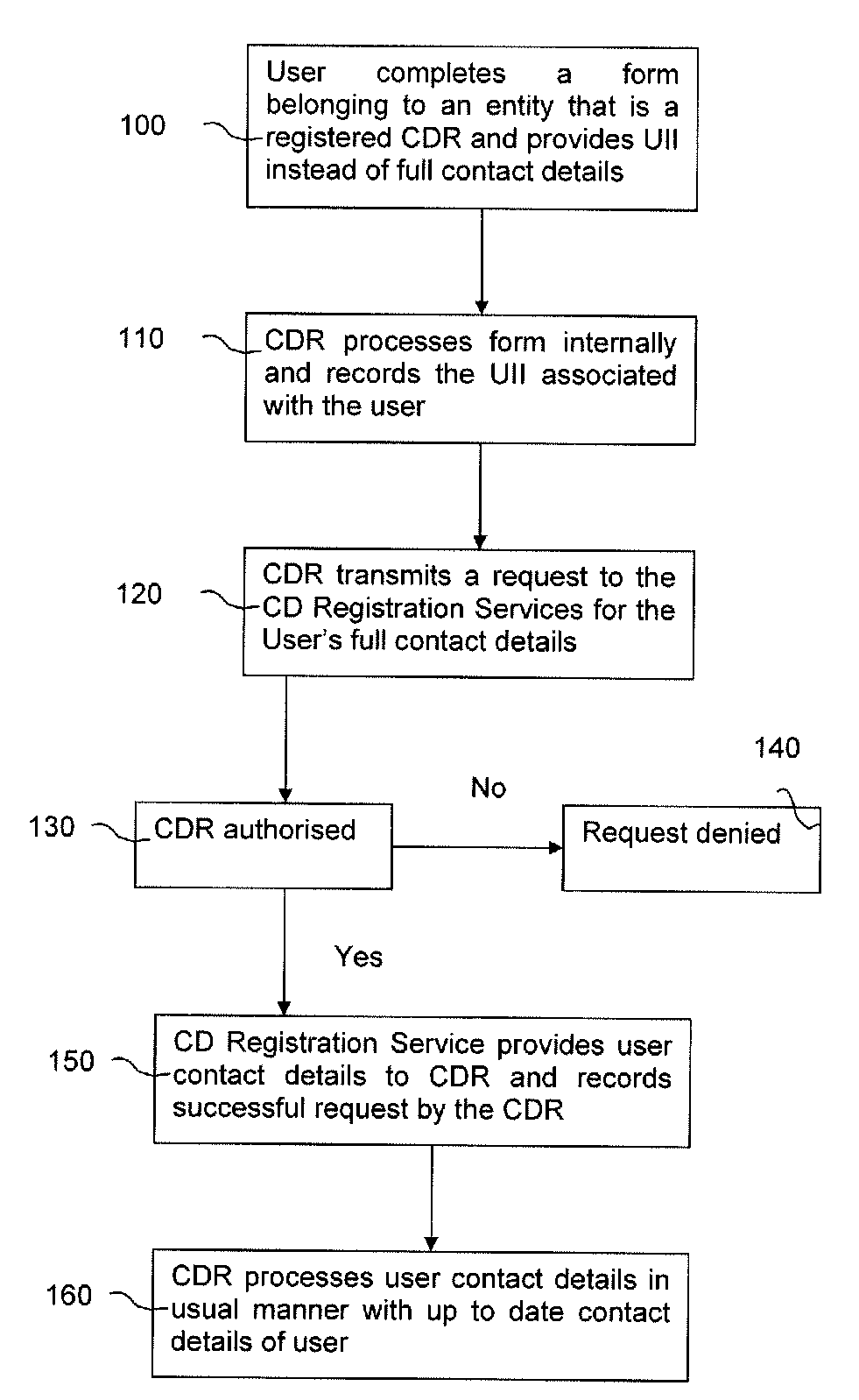

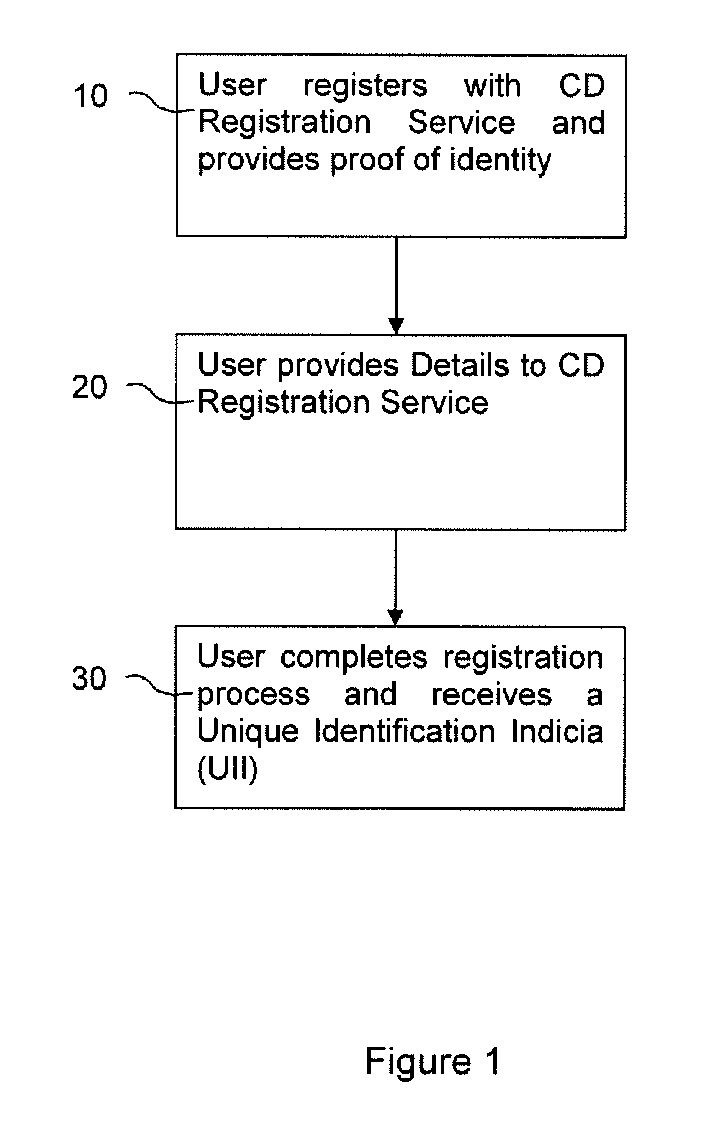

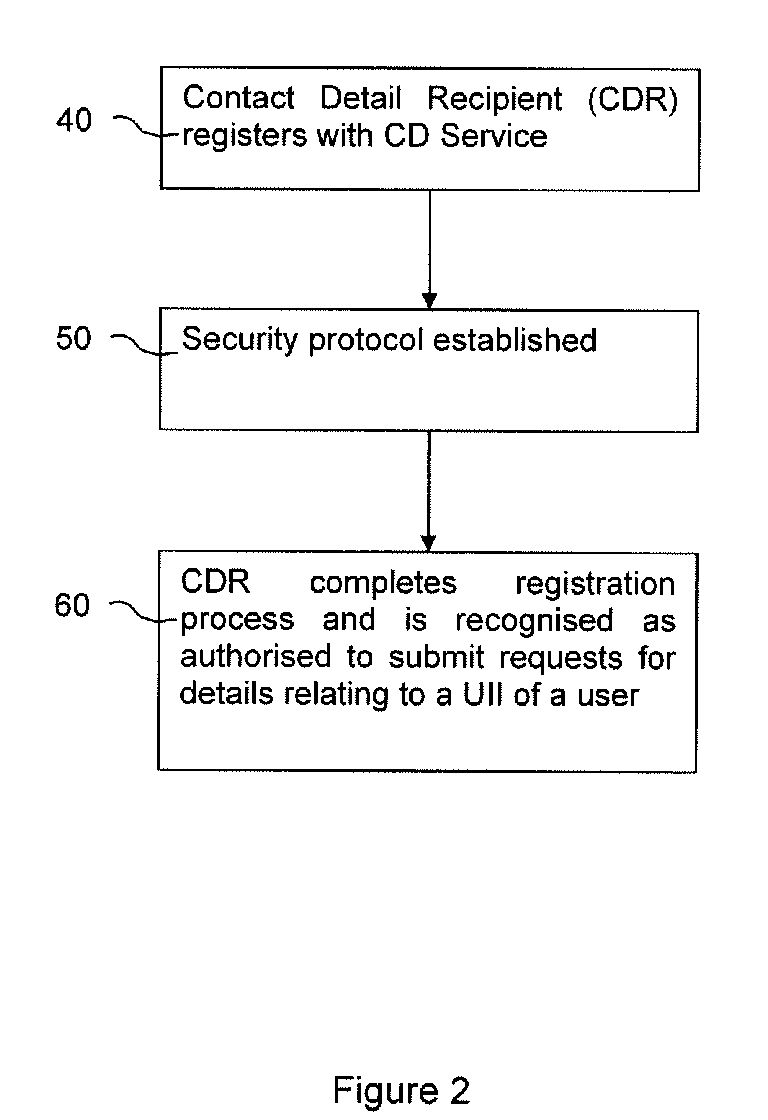

Contact Details Service

ActiveUS20100115115A1Shorten the timeReduce errorsMultiple digital computer combinationsOffice automationContact methodWorld Wide Web

A method for a user to advise related entities with respect to a consumer service of their contact details wherein the user submits data to a Contact Details Registration Service to register their use of the consumer service; the Contact Details Registration Service allocating the user with a unique identification indicia and transmitting same to the user for subsequent use in communications with the Contact Details Registration Service and / or any related entities of the consumer service registered with the Contact Details Registration Service; the data submitted by the user including their contact details and having at least an address to which correspondence is to be sent, the contact details being associated with the unique identification indicia of the user by the Contact Detail Registration Service and stored in a database; and the user's contact details being accessible to the consumer service, or related entities thereof, upon provision of the user's associated unique identification identifier to the Contact Details Registration Service database, wherein the Contact Details Registration Service database maintains a record of related entity requests for the contact details of the user.

Owner:ACCENTURE GLOBAL SERVICES LTD

Device capable of adjusting saturation degree of soil sample and application method of device

PendingCN108303303ASimple structureEasy to usePreparing sample for investigationSpray nozzleEngineering

The invention provides a device capable of adjusting the saturation degree of a soil sample. The device comprises a saturation container, a weighing system, a pressure spraying system and a control system which is in wireless connection with the weighing system and the pressure spraying system; the weighing system is arranged in the saturation container and comprises an electronic scale, a supportfixedly connected with the upper end of the electronic scale and a water permeable plate arranged at the upper end of the support, and the water permeable plate can rotate relative to the axis wherethe support is located; the pressure spraying system comprises an atomizing sprayer arranged on one side of the water permeating plate, a water guide hose and an air guide hose, and the water guide hose and the air guide hose are communicated with the atomizing sprayer; the atomizing sprayer is arranged on a guide rail and can move up and down along the guide rail to be positioned; a nozzle with an adjustable angle is arranged at the front end of the atomizing sprayer and extends in the direction of the water permeating plate; an atomizing degree adjusting valve is arranged at the rear end ofthe atomizing sprayer. The invention further provides an application method of the device capable of adjusting the saturation degree of the soil sample. The device has the advantages of being simple in structure, convenient to use, capable of saving time and labor and capable of reducing the damage to the sample in the testing process on the basis that the saturation degree is adjusted according to requirements.

Owner:河南省文物建筑保护研究院 +1

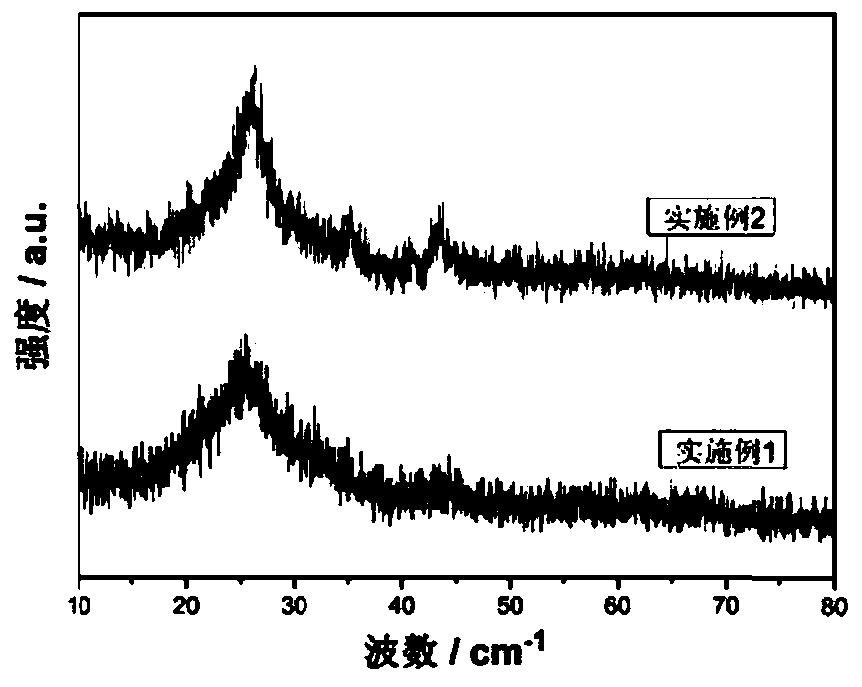

Preparation method of graphene, graphene and application of graphene

InactiveCN110980701ACheap and easy to getUniform thicknessGrapheneOrganic solventFunctional composite

The invention discloses a preparation method for preparing graphene based on a primary solution of graphite oxide, and belongs to the technical field of nano materials. The method comprises the following steps: by taking a primary solution of graphene oxide as a raw material, firstly adding a proper amount of metal to control partial reduction of graphite oxide, washing and drying to obtain powdery partially reduced graphite oxide, and then realizing rapid reduction and expansion of the partially reduced graphite oxide by utilizing microwave heating to finally obtain graphene. The process is simple and efficient in preparation process, no organic solvent harmful to the human body is introduced in the preparation process, and the prepared graphene is high in carbon-oxygen ratio, low in costand easy to realize large-scale production, and has a wide application prospect in the fields of functional composite materials and anticorrosive coatings.

Owner:DALIAN UNIV OF TECH

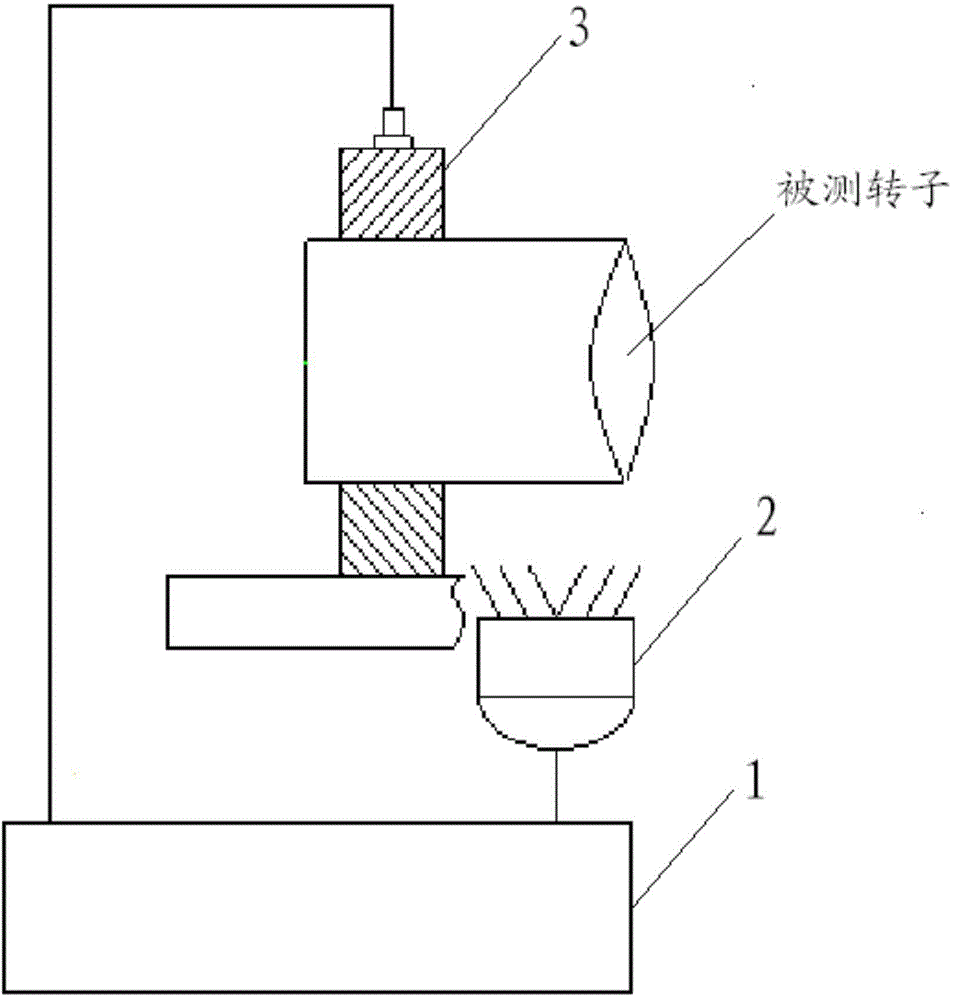

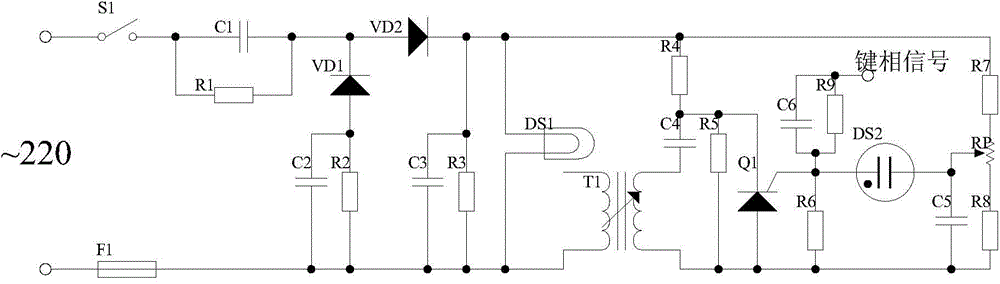

Phase test device

An embodiment of the invention discloses a phase test device. The device comprises a vibration sensor data collector, a stroboscope and a vibration sensor. A first input terminal of the vibration sensor data collector is connected to an output terminal of the stroboscope and a second input terminal is connected to an output terminal of the vibration sensor. The stroboscope is used for outputting a key phase signal whose rotation frequency is the same with a rotation frequency of a detected rotation device to the vibration sensor data collector. The vibration sensor is used for detecting and outputting a vibration sensor signal of the detected rotation device to the vibration sensor data collector. When the above scheme is used to detect a phase of the detected rotation device which is operated, the operation of the detected rotation device does not need to be stopped and a sign position of the detected rotation device can be checked; and through the vibration sensor data collector, a vibration high point phase of the detected rotation device and a phase of the sign position can be measured. A whole process is time-saving and labor-saving and cost is low.

Owner:FUJIAN NINGDE NUCLEAR POWER

Process for after-finishing biological enzymes of ramie yarn and bast fiber cloth

InactiveCN101713149AProcess time savingImprove product qualityBiochemical fibre treatmentVegetal fibresChemistryEnzyme

The invention relates to a process for after-finishing biological enzymes of ramie yarn and bast fiber cloth. The process comprises the following steps of: (1) placing a composite enzyme ingredient in a material cylinder, controlling the pH value, raising the temperature to 50 to 60 DEG C and running the cloth under a liquid level for 30 to 60 minutes; (2) guiding the solution to a main cylinder, controlling the pH value, raising the temperature to 50 to 60 DEG C, running the cloth under the liquid level for 30 to 60 minutes, raising the temperature to 70 to 85 DEG C and running the cloth under the liquid level for 10 to 20 minutes; and (3) placing a film-forming ingredient in the main cylinder, controlling the pH value, raising the temperature to 50 to 60 DEG C to obtain the solution and running the cloth under the liquid level for 30 to 60 minutes. Compared with the prior art, the process for after-finishing the biological enzymes of the ramie yarn and the bast fiber cloth saves energy consumption, simplifies a technological process, prevents the production of toxic substances, remarkably enhances the product quality, achieves a top-quality product rate of over 98 percent and greatly reduces the production cost.

Owner:上海龙之杰企业发展有限公司 +2

A specific flour for potato dough skin and dumpling wrappers to make potatoes as a staple food

The present invention belongs to the technical field of food processing and provides a specific flour for potato dough skin and dumpling wrappers to make potatoes as a staple food and solves the problems that the existing potato full flour has higher processing costs and more complex processing steps, the staple food products manufactured by the existing potato flour are difficult to mold, have high hardness, are not able to endure boiling, have low content of potato full flour and higher costs to make potato pasta. The preparation method of potato full flour comprises the following steps: selecting materials, cleaning and peeling, picking, slicing, blanching, cooling and oven-drying, milling, and mixing potato full flour and potato starch to make dough skin and dumpling wrappers. The manufacturing processes are time-saving, simple and convenient, the products are suitable for mass consumption and beneficial for promoting, the industrialized production of potato flour can be realized, and the products have stable quality; the specific flour for potato dough skin and dumpling wrappers is easy to mold, have good tenacity, full nutrition and good mouthfeel. All raw materials are from potatoes, do not add any food additive, can ensure food to be safe, healthy and green, and promote the consumption of the potatoes as a staple food. The specific flour for potato dough skin and dumpling wrappers to make potatoes as a staple food promotes China's sustainable development of agriculture and benefits people's nutrition and health.

Owner:SHANXI SHUYAN FOOD

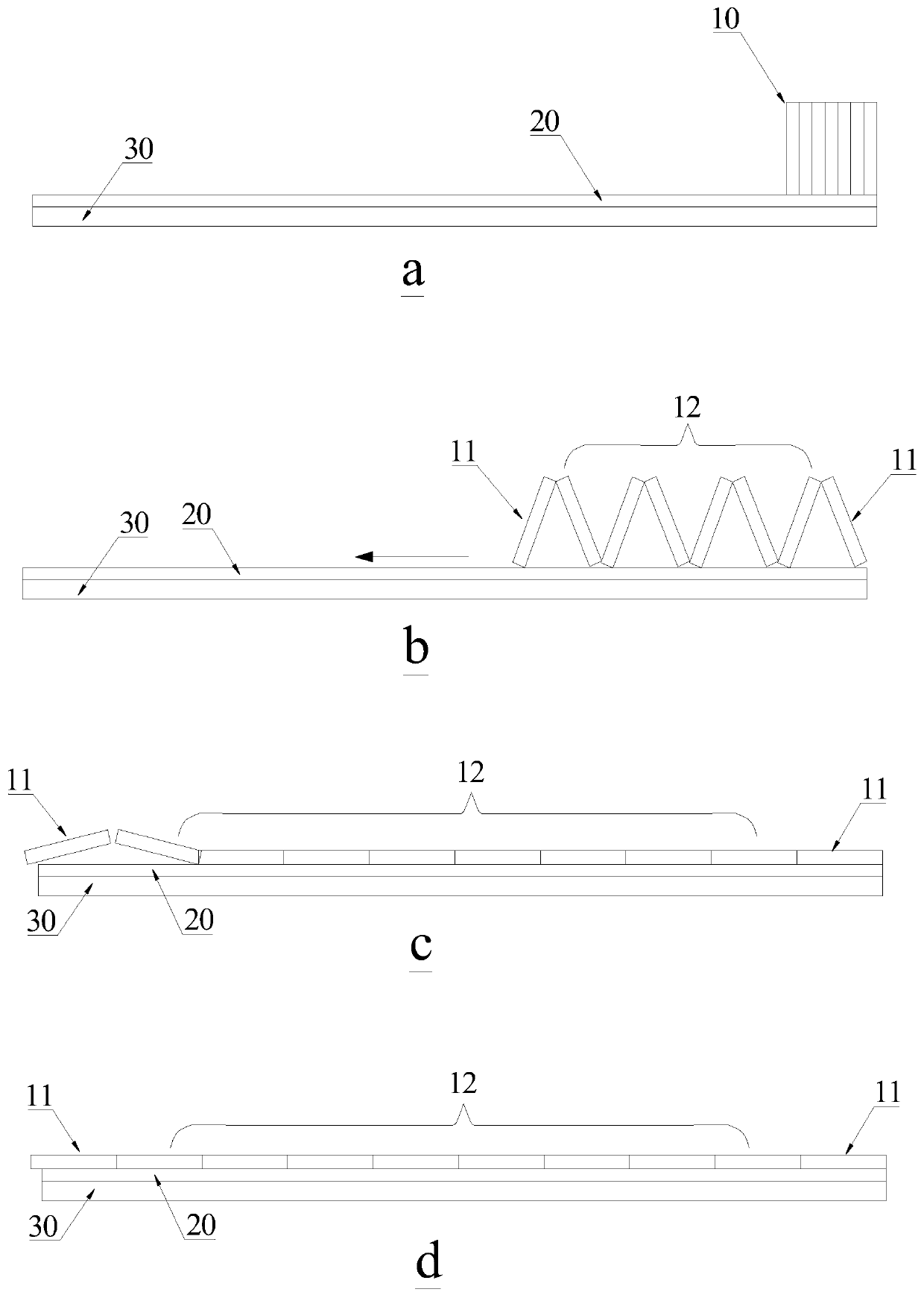

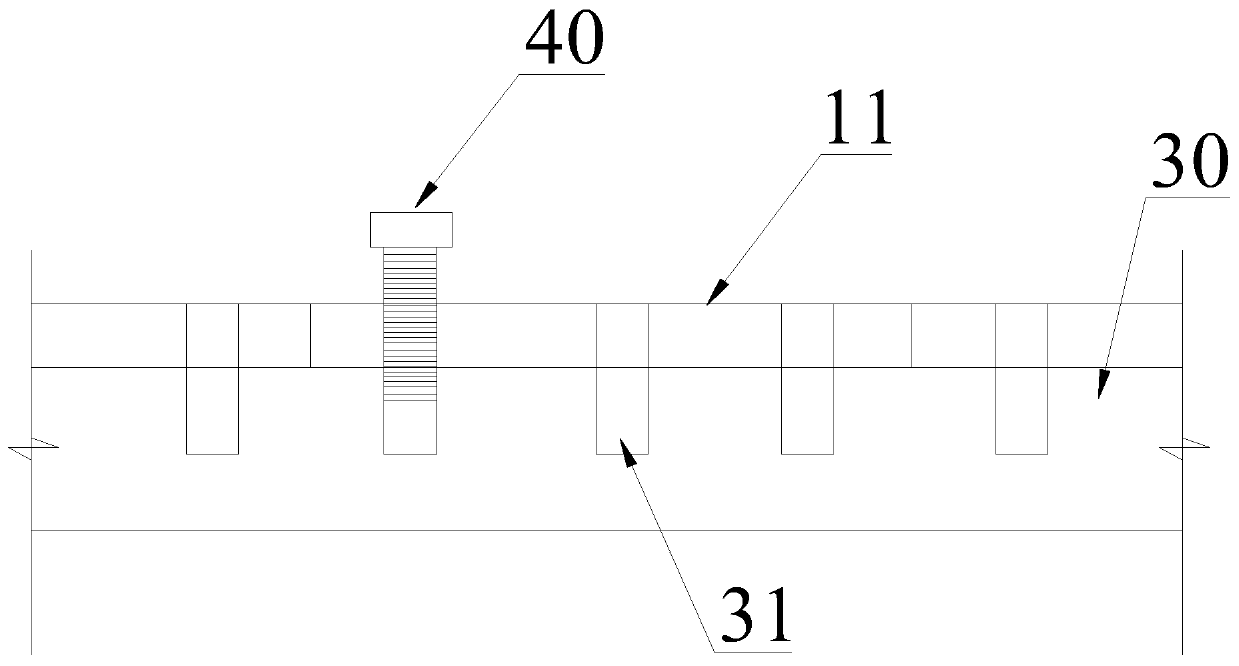

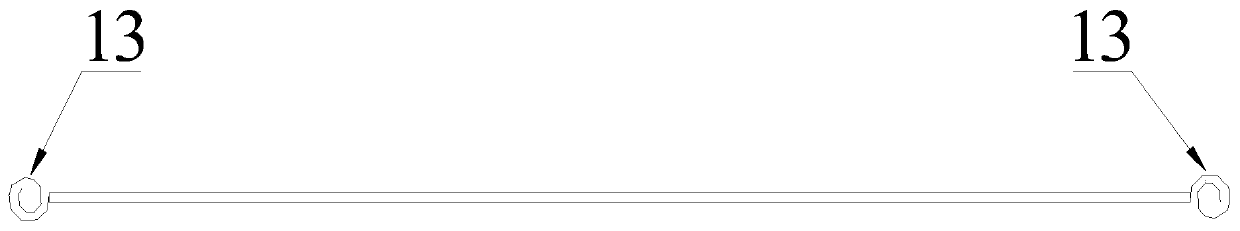

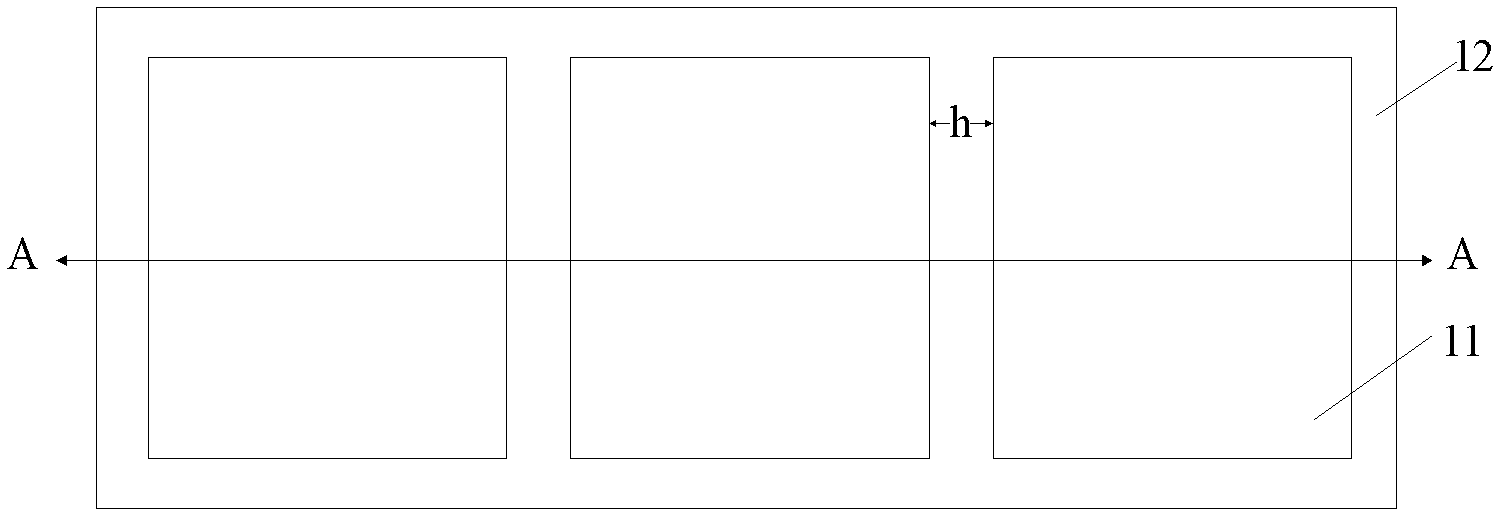

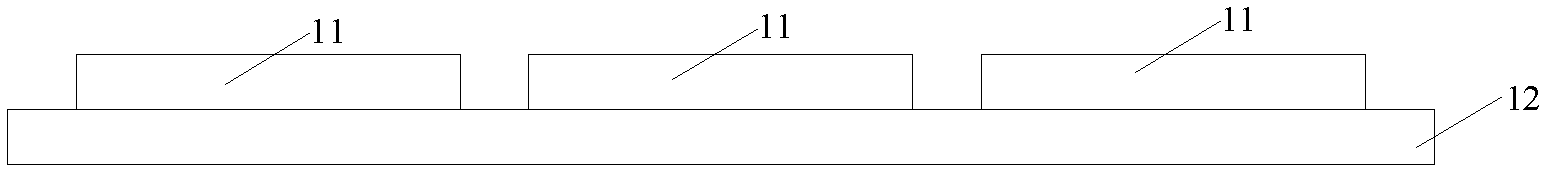

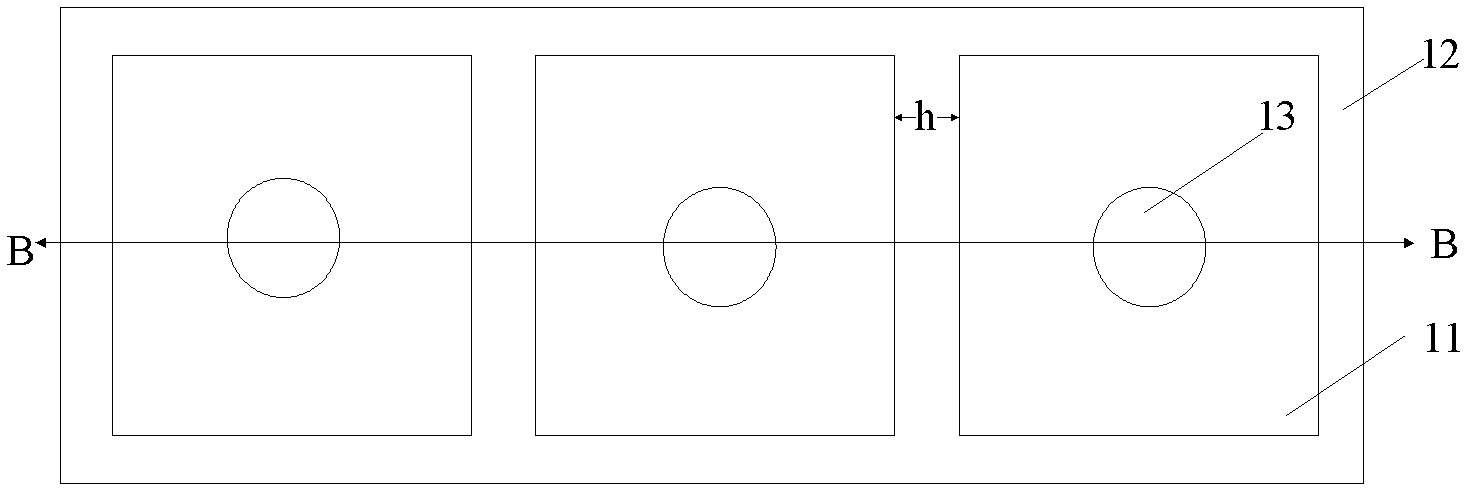

Roof panel assembly and construction method thereof

PendingCN110670782AFast construction and installationReduce in quantityBuilding roofsArchitectural engineeringStructural engineering

The invention discloses a roof panel assembly and a construction method thereof. The roof panel assembly comprises a plurality of single roof panels; the roof panels comprise the first roof panels andthe second roof panel, the first roof panels are roof panels at the two ends of the roof panel assembly, and the second roof panel is a roof panel at the middle part of the roof panel assembly; and one end of each first roof panel is rotatably connected with the end of the adjacent roof panel, and the two ends of the second roof panel are rotatably connected with the ends of the adjacent roof panels. The construction method comprises the steps of assembling, slide rail installation, hoisting, paving and fixing. The roof panel assembly can be conveyed to the roof through one-time hoisting, andthe hoisting cost is saved; and in addition, installation and construction of the roof panel can be quickly completed, the procedure is simple, time-saving and convenient, the construction time and manpower are greatly saved, the construction difficulty is reduced, the number of needed constructors is greatly reduced, and potential safety hazards existing in aerial work are avoided.

Owner:GUANGZHOU JISHI CONSTR GRP

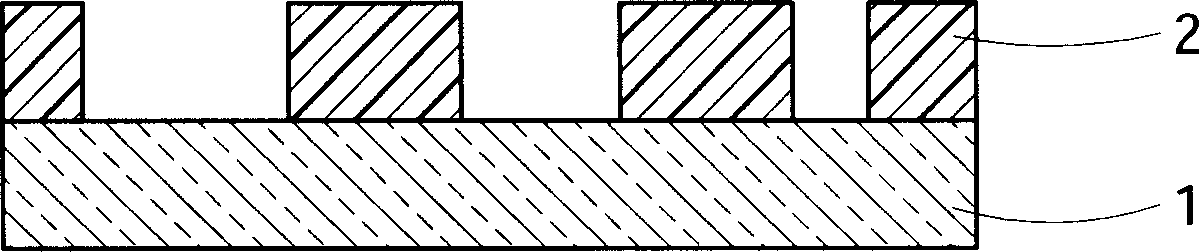

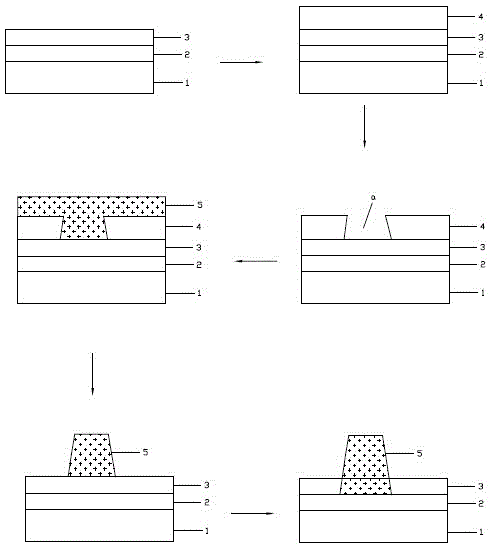

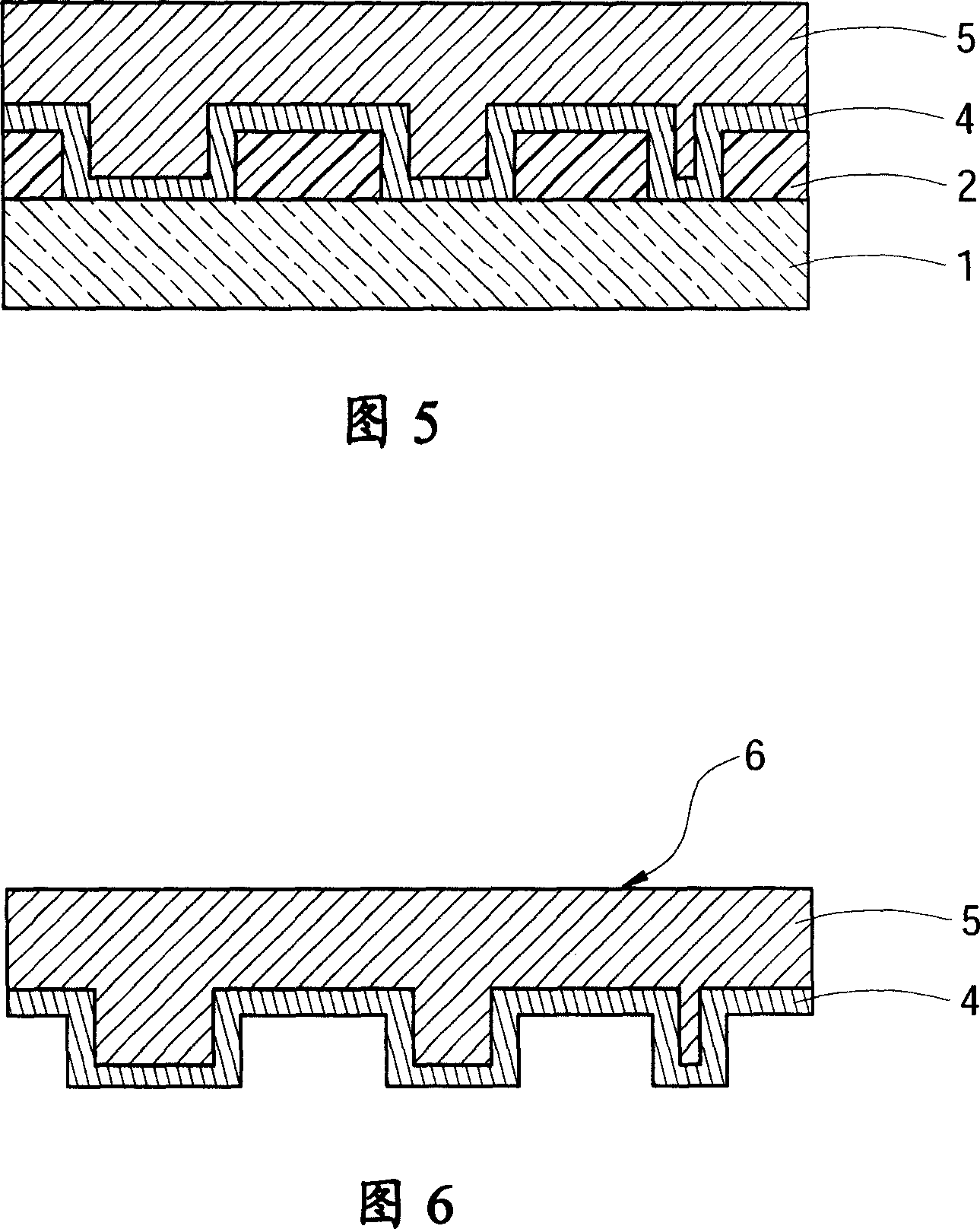

Method for forming pad structure

ActiveCN102931145ASimple processProcess time savingSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

The invention provides a method for forming a pad structure. The method comprises the following steps of: providing a substrate, wherein the substrate is provided with a first protection layer and pads exposed from the first protection layer; forming a second protection layer on the first protection layer and the pads; forming first openings on the second protection layer to expose the pads, wherein the bottoms of the first openings are positioned on the pads; and filling the first openings with a solder material to form new pads. By the method for forming the pad structure, the requirement of flip chip bonding on the pads can be met, the process is simple, time is saved, and production cost is low.

Owner:SEMICON MFG INT (SHANGHAI) CORP

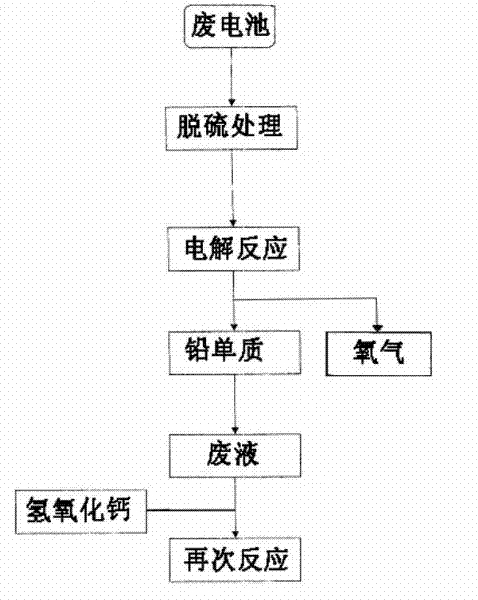

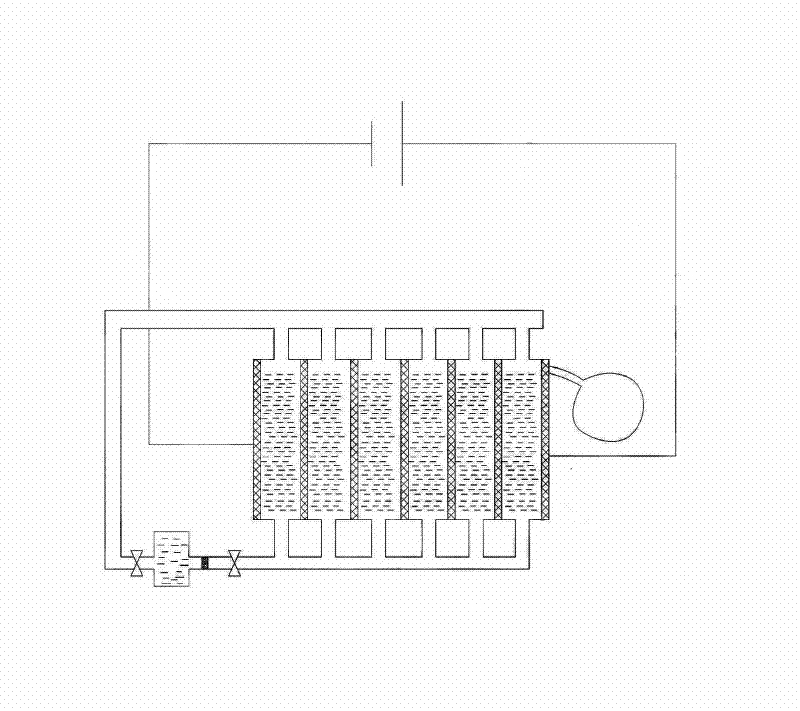

Technology for reclaiming lead from waste lead storage batteries by using pulse power supply

InactiveCN102420344AAchieving zero emissionsReduce workloadPhotography auxillary processesWaste accumulators reclaimingElectricityLow voltage

The invention discloses a technology for reclaiming lead from waste lead storage batteries by using a pulse power supply, and belongs to the technical field of reclamation and reprocessing of waste lead storage batteries. The pulse direct-current power supply is adopted in electrolysis treatment, the pulse direct-current power supply is connected with an electrolytic bath, 3 to 7 electrode partition plates are arranged in the electrolytic bath, the electrode partition plates partition the electrolytic bath into 4 to 8 independent areas, and each independent area forms a micro electrolysis field in a power-on state; and a liquid inlet pipe is arranged at the upper end of the electrolytic bath, and a liquid outlet pipe is arranged at the lower end of the electrolytic bath. The technology has the advantages of power saving in the whole process flow, low voltage, pulse polarization prevention, short time, low power consumption and no pollution.

Owner:ZHEJIANG HUITONG POWER

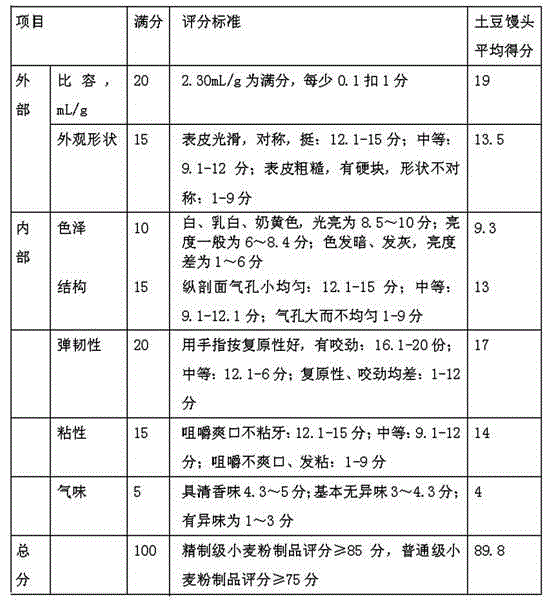

Special flour for potato steamed bun for taking potatoes as staple food

The invention belongs to the technical field of food processing. In order to solve the problems that the existing potato whole flour is relatively high in processing cost and relatively complex in processing step while the existing potato whole flour which is used for manufacturing staple food products is hard to mold, is great in hardness and is not resistant to cooking, the potato whole flour is low in content, the cost for manufacturing a potato food made of flour is high and the like, the invention provides special flour for a potato steamed bun for taking potatoes as staple food. The preparation method of the potato whole flour comprises the following steps: choosing raw materials; cleaning and peeling the raw materials; selecting the raw materials; cutting the raw materials into slices; blanching the raw materials; cooling and drying the raw materials; and pulverizing the raw materials. The potato whole flour is mixed with oat flour to prepare the steam bun. The staple food preparation process is time-saving, simple and convenient and the prepared bun is suitable for the public to eat, the popularization is facilitated, and the potato flour is industrially produced and is stable in quality; the staple food is easy to mold, is tenacious, is complete in nutrition and is good in taste. In the potato steamed bun, the content of the potato whole flour reaches over 50% and the potato steamed bun is free of any food additives, so that the safety, health and greenness of the food are guaranteed, the consumption of potatoes as the staple food is promoted, the agricultural sustainable development of China is promoted, and the nutrition and health of people are facilitated.

Owner:SHANXI SHUYAN FOOD

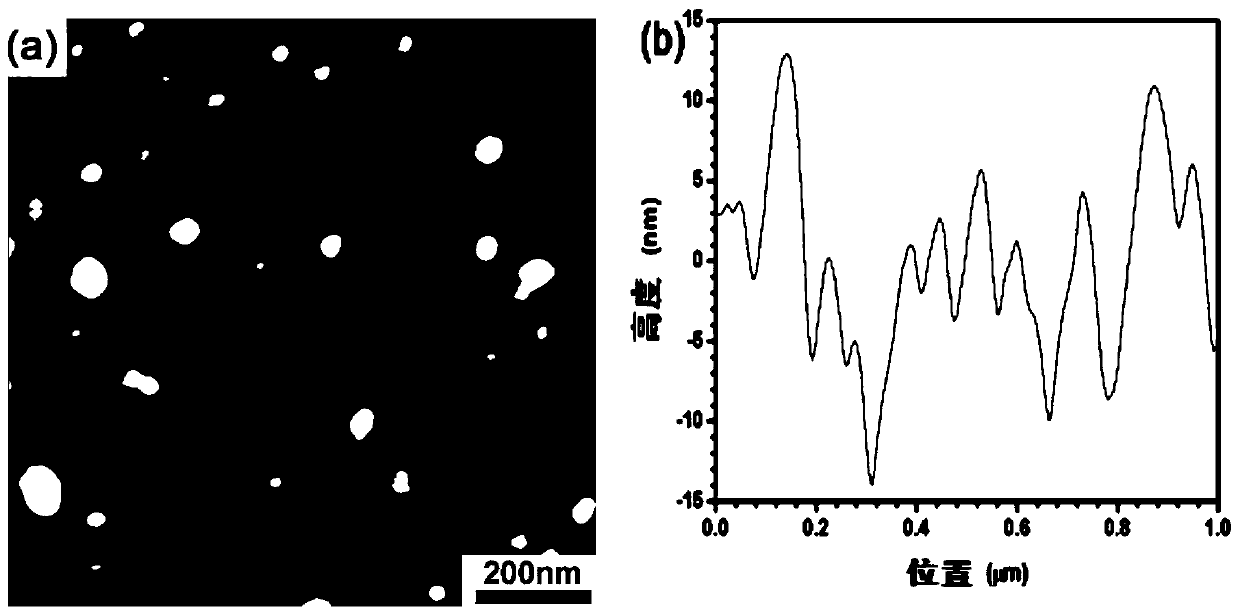

Hydrogen peroxide electrochemical sensor electrode, preparation method and sensor

InactiveCN110220953AImprove detection linear rangeHigh detection sensitivityMaterial electrochemical variablesPrussian blueDetection limit

The invention relates to a hydrogen peroxide electrochemical sensor electrode, a preparation method and a sensor. The sensor comprises a hydrogen peroxide sensor electrode, wherein the hydrogen peroxide sensor electrode comprises a substrate, a gold film on the substrate and a modifying layer formed on the gold film; the gold film is of a porous structure, and is 20 to 50nm in mean pore size; andthe modifying layer is made of Prussian blue. The hydrogen peroxide sensor has a hydrogen peroxide detection limit of 0.25[mu]m or less, and has linear response within a range of 1 to 10000[mu]m.

Owner:NINGBO UNIV +1

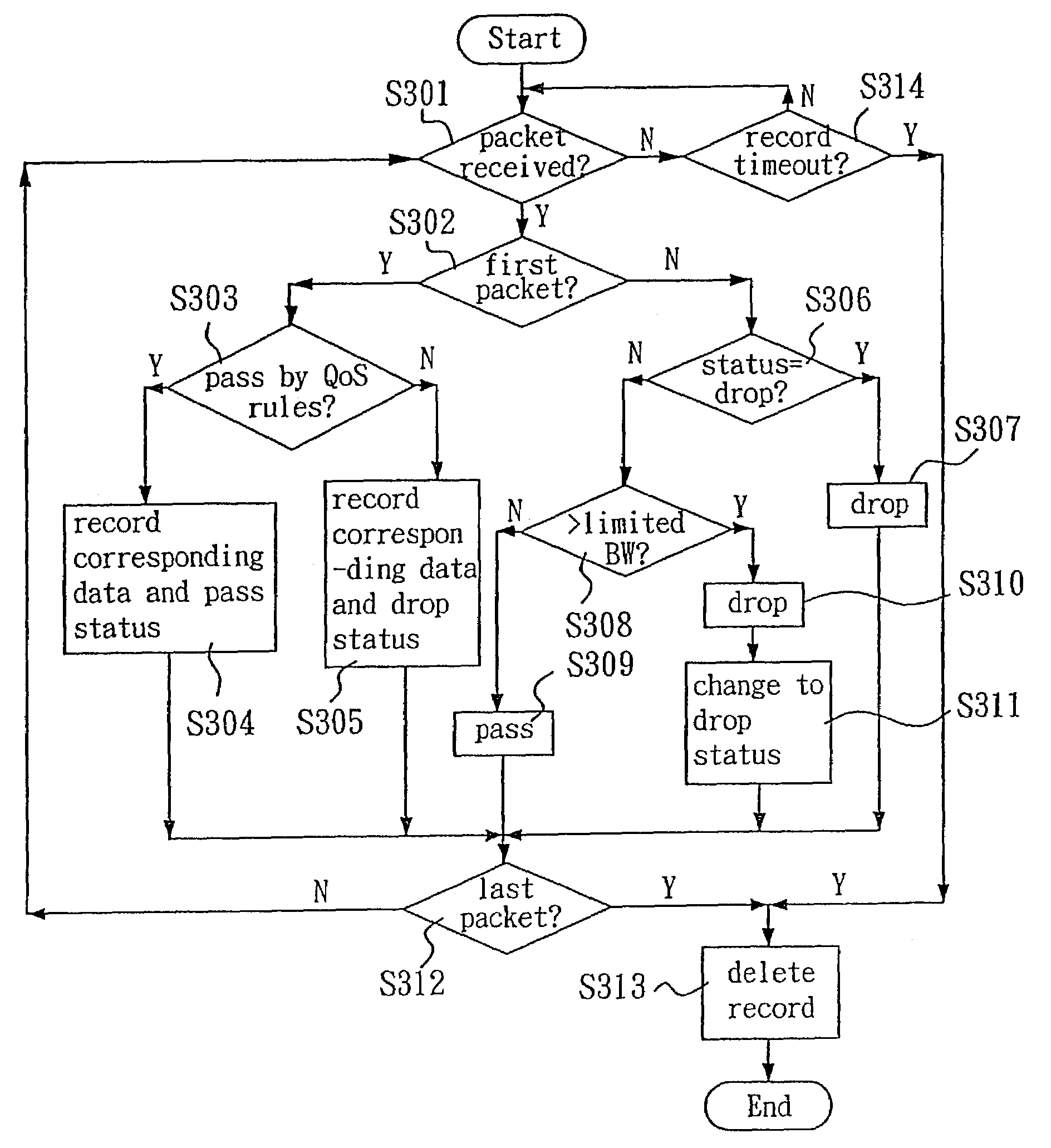

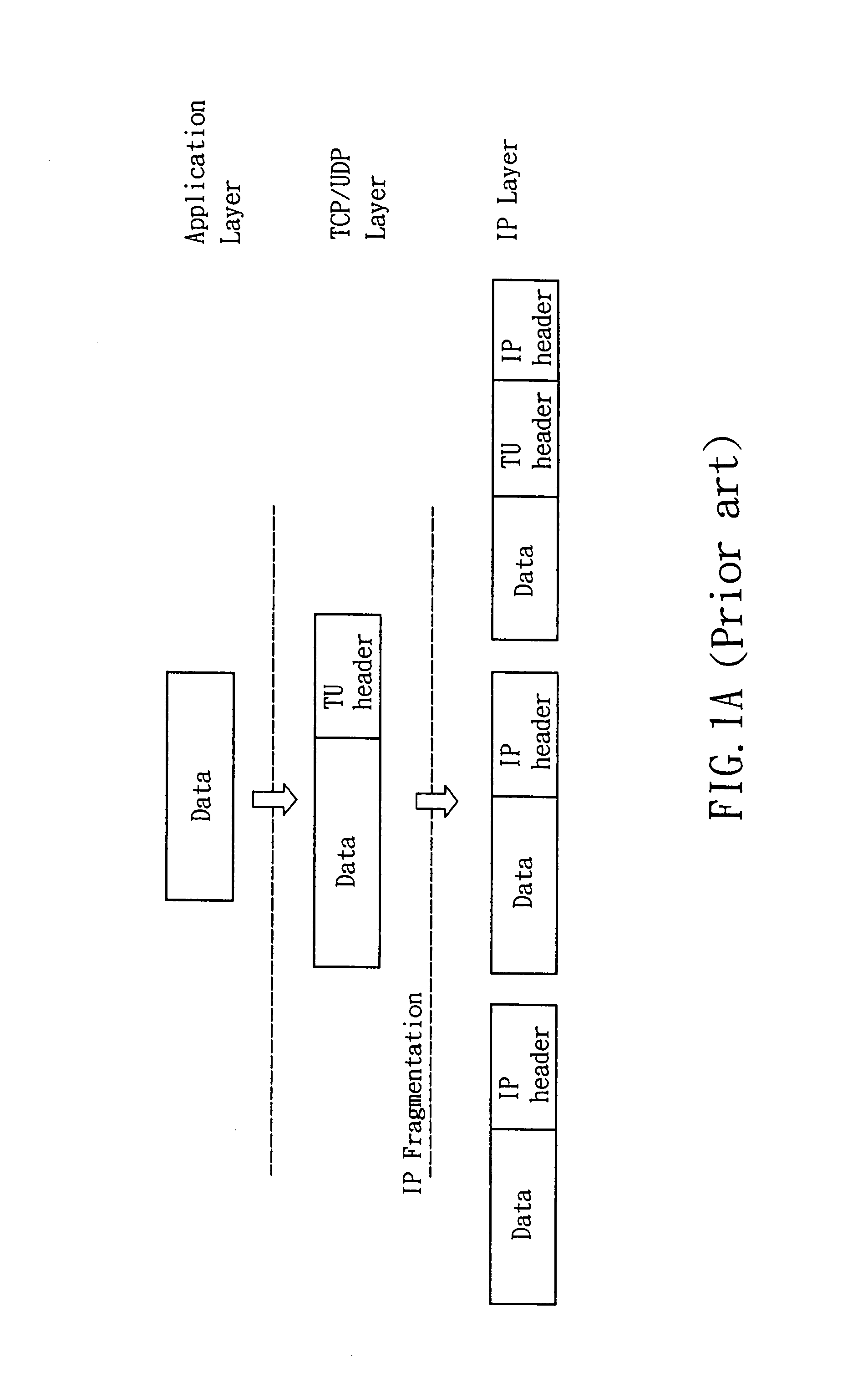

QoS router system for effectively processing fragmented IP packets and method thereof

ActiveUS7272112B2Saving channel bandwidthProcess time savingError preventionTransmission systemsNetwork packet

QoS router system and method are provided for effectively processing fragmented IP packets transmitted over a network. When receiving a first fragmented IP packet of a set from a flow, a router determines whether to allow the first packet to pass or to drop by according to predefined QoS rules. A pass status is recorded in a record if the packet is allowed to pass. A drop status is recorded in the record if the packet is dropped. When receiving other fragmented IP packet of the same set, the router determines whether to allow the fragmented packet to pass or to drop by according to the previous record. If the record is drop status, the packet is dropped, and if the record is pass status, the packet is allowed to pass when the used bandwidth of the flow does not exceeds a predetermined bandwidth.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

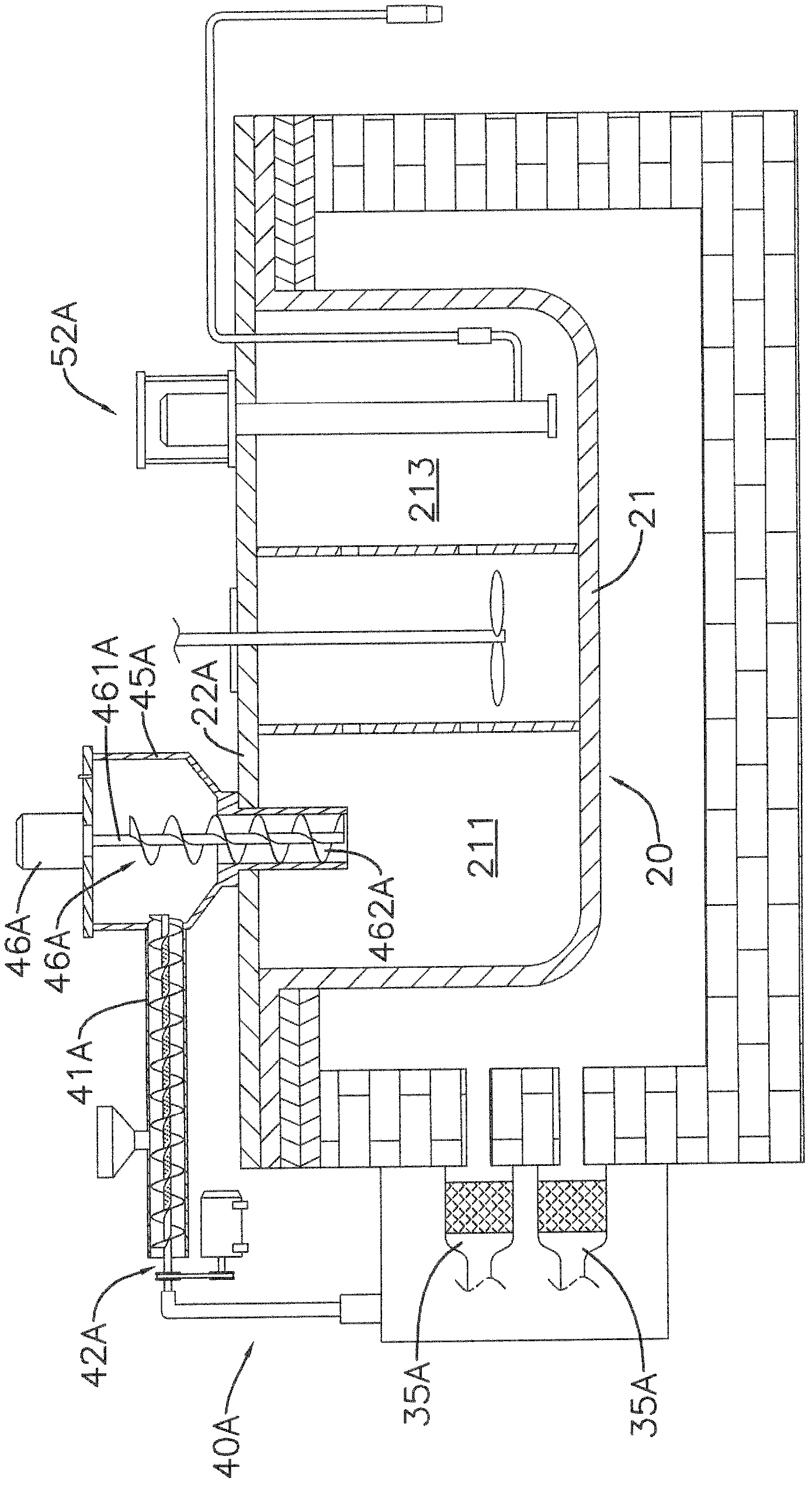

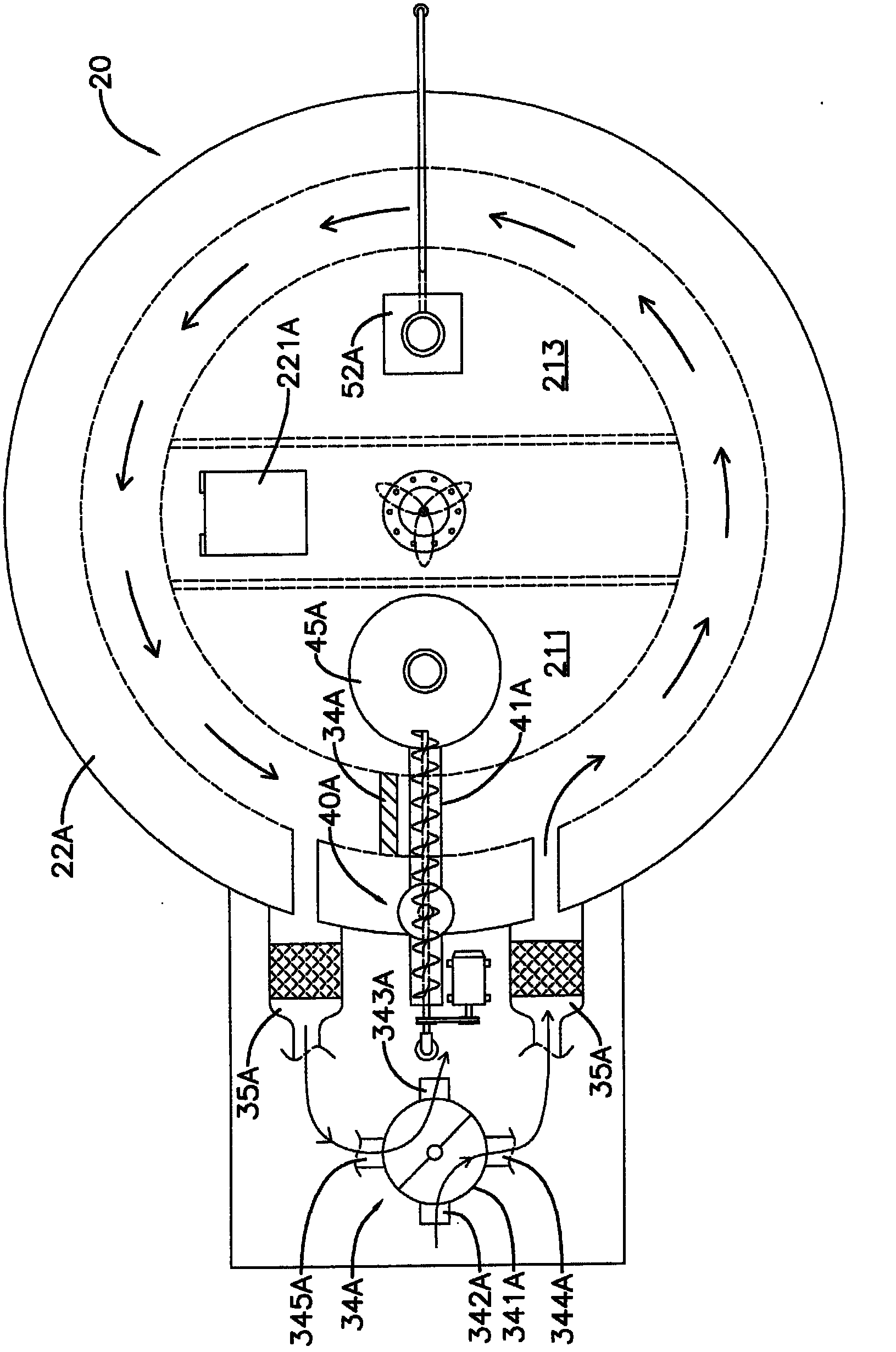

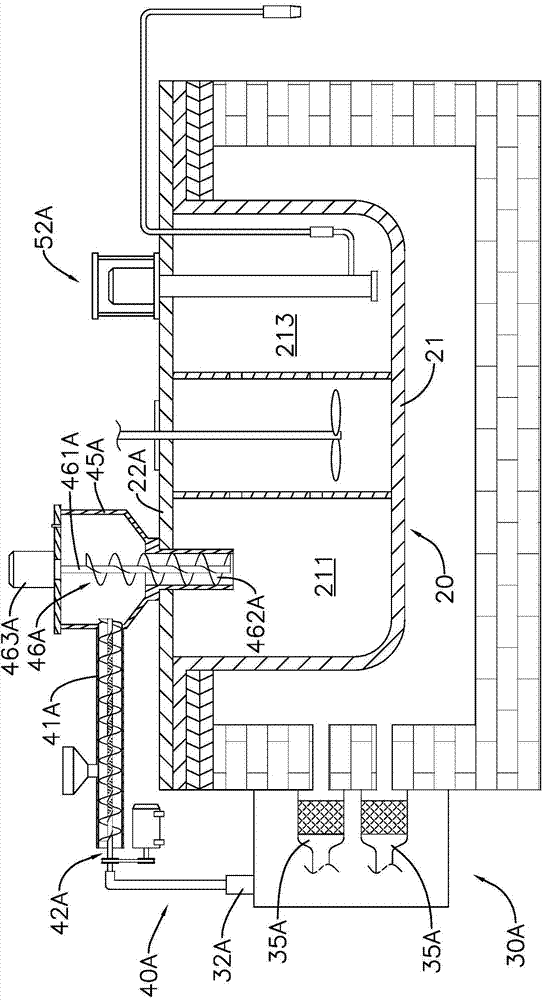

Metal melting method

InactiveCN105300115AShorten the timeProcess time savingEnergy industryPreheating chargesCombustion systemMetallic materials

The invention relates to a metal melting method. A heating furnace, a smelting furnace erected on the heating furnace, a checker chamber combustion system, a feeding device and a cycle slurry pumping and fluid feeding device erected on the smelting furnace are included in the method. The checker chamber combustion system can heat the heating furnace, store high-temperature gas in the heating furnace into a regenerator, improve the efficiency of heating the heating furnace, guide waste heat of the regenerator into the feeding device and heat granular or sheet-like metal materials charged into the feeding device; as a result, the waste heat can be fully recycled, and the preheated metal materials can be further pushed into the smelting furnace by the feeding device and heated and melted into liquid. Thus, heat energy can be fully recycled, the time and heat energy (fuel) required for subsequently melting the metal materials into liquid can be substantially decreased, and the metal materials are overall preheated, heated and melted; time is shortened in the process that liquid metal is injected into the mould, and the process is smooth and can be conducted continuously, and high safety is realized.

Owner:丁春燕

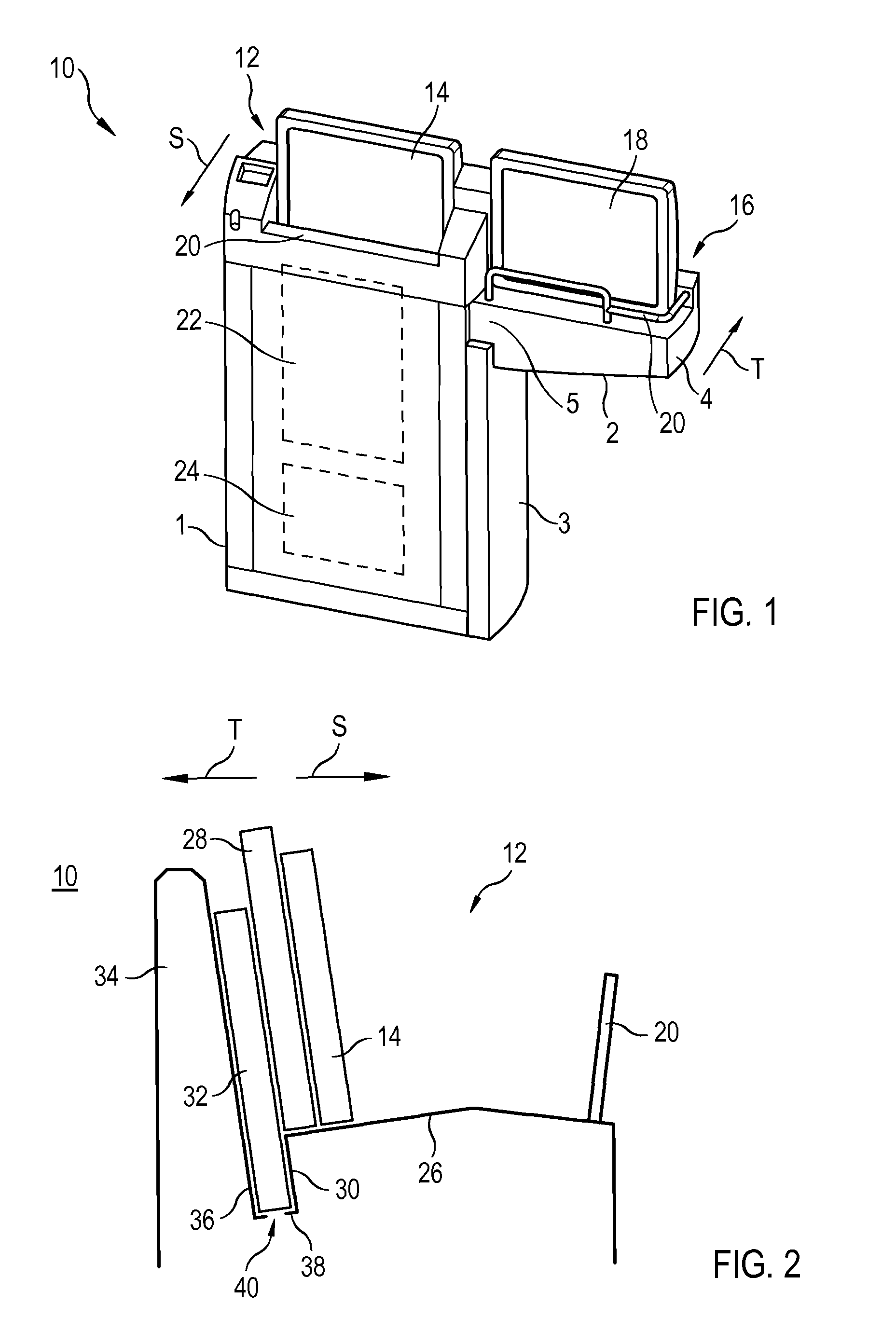

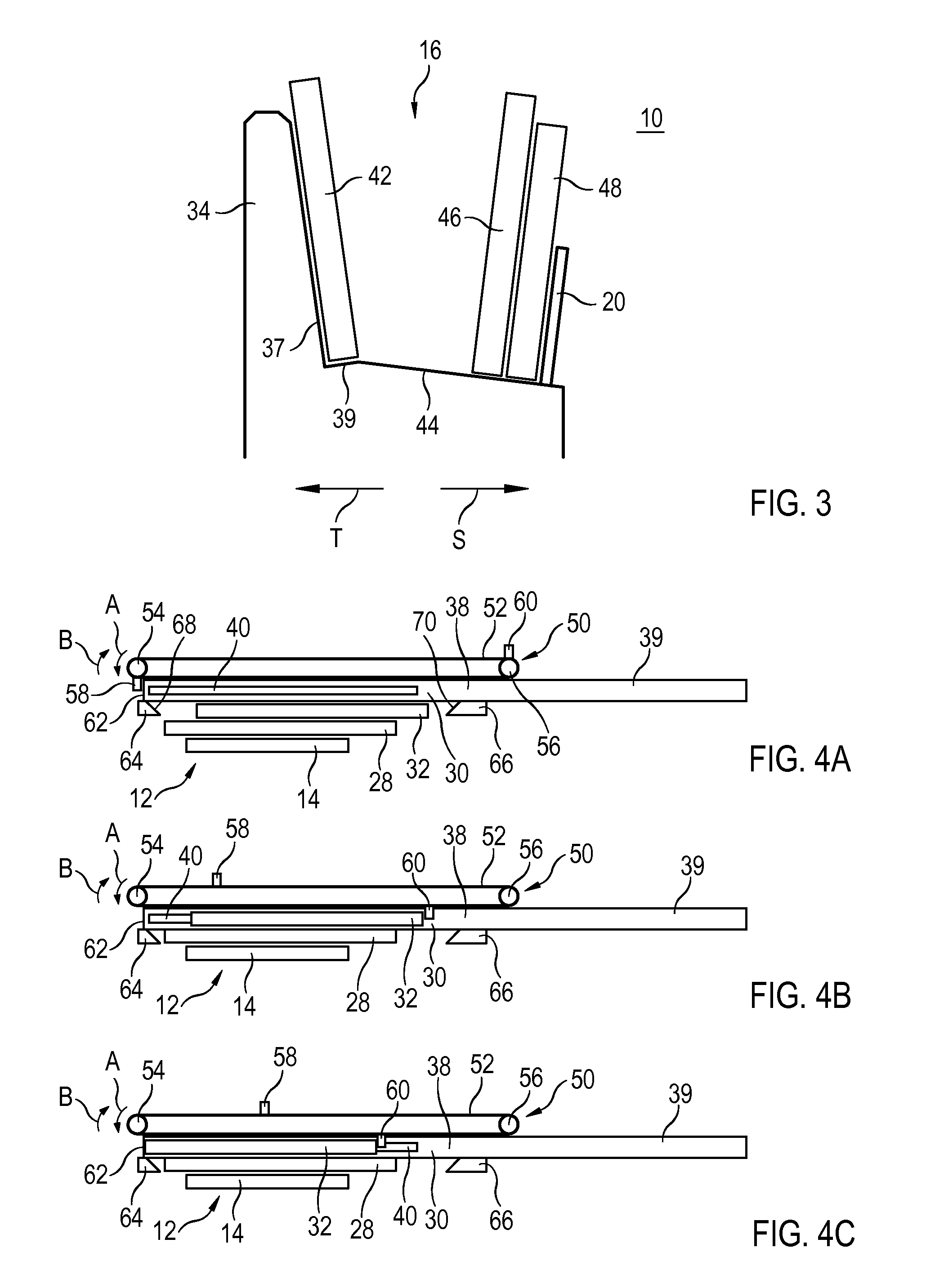

Apparatus for reading out X-ray information stored in storage phosphor plates

ActiveUS8049195B2Process time savingMaterial analysis by optical meansStereoscopic photographyX-rayEngineering

An apparatus (10) for reading out, in a time-saving and reliable way, X-ray information stored in storage phosphor plates with an input unit (12) in which a plurality of cassettes (14) in which a storage phosphor plate to be read out is respectively located, can be input. A read-out unit (22) is located beneath the input unit (12) and in which storage phosphor plates can be read out, it being possible to remove a storage phosphor plate from a cassette (14) located within the input unit (12) and to convey it to the read-out unit (22) located beneath the input unit (12) in order to read out the storage phosphor plate, and to convey it back into the cassette located within the input unit (12) after having read out the storage phosphor plate, an output unit (16) which is adjacent to the input unit (12) and in which cassettes (18) can be output, and a moving device for moving the cassette (14) located within the input unit (12) the storage phosphor plate of which has been read out in the read-out unit (22) located beneath the input unit (12) along a substantially horizontal path of movement to the output unit adjacent to the input unit (12).

Owner:AGFA NV

Metal melting furnace and metal melting method

ActiveCN103017518BShorten the timeProcess time savingPreheating chargesCrucible furnacesCombustion systemMetallic materials

Owner:PINDA TECH

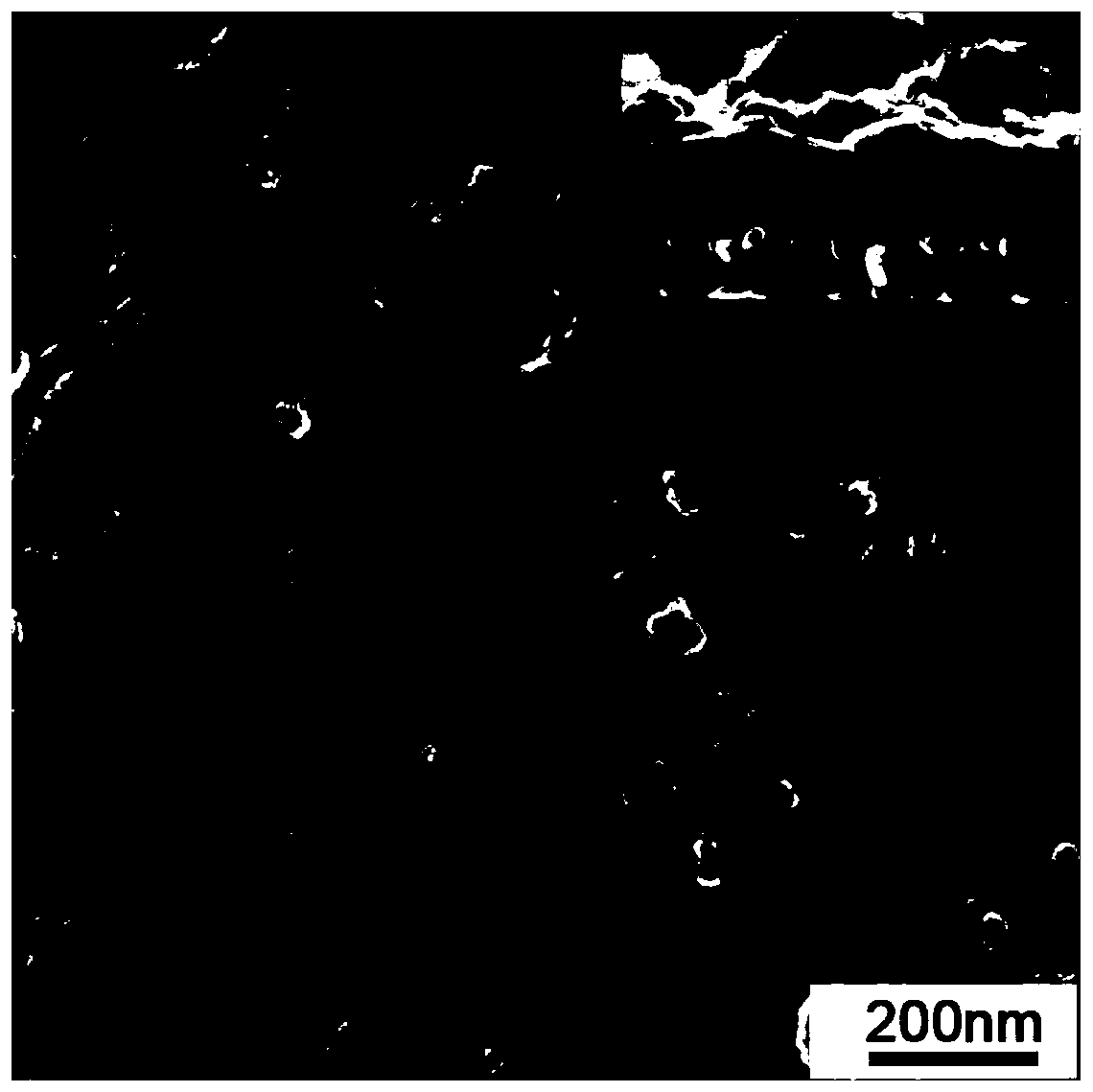

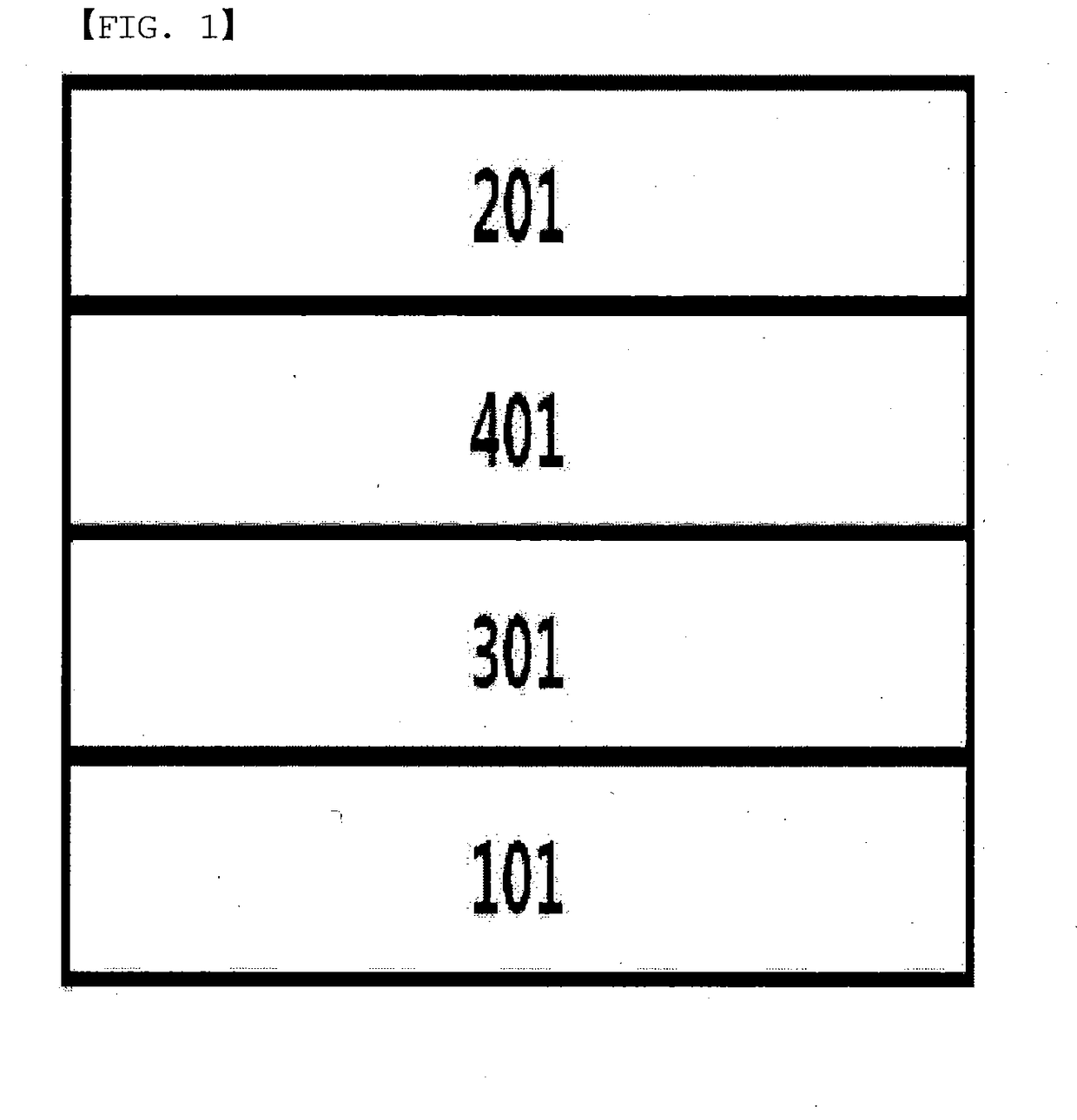

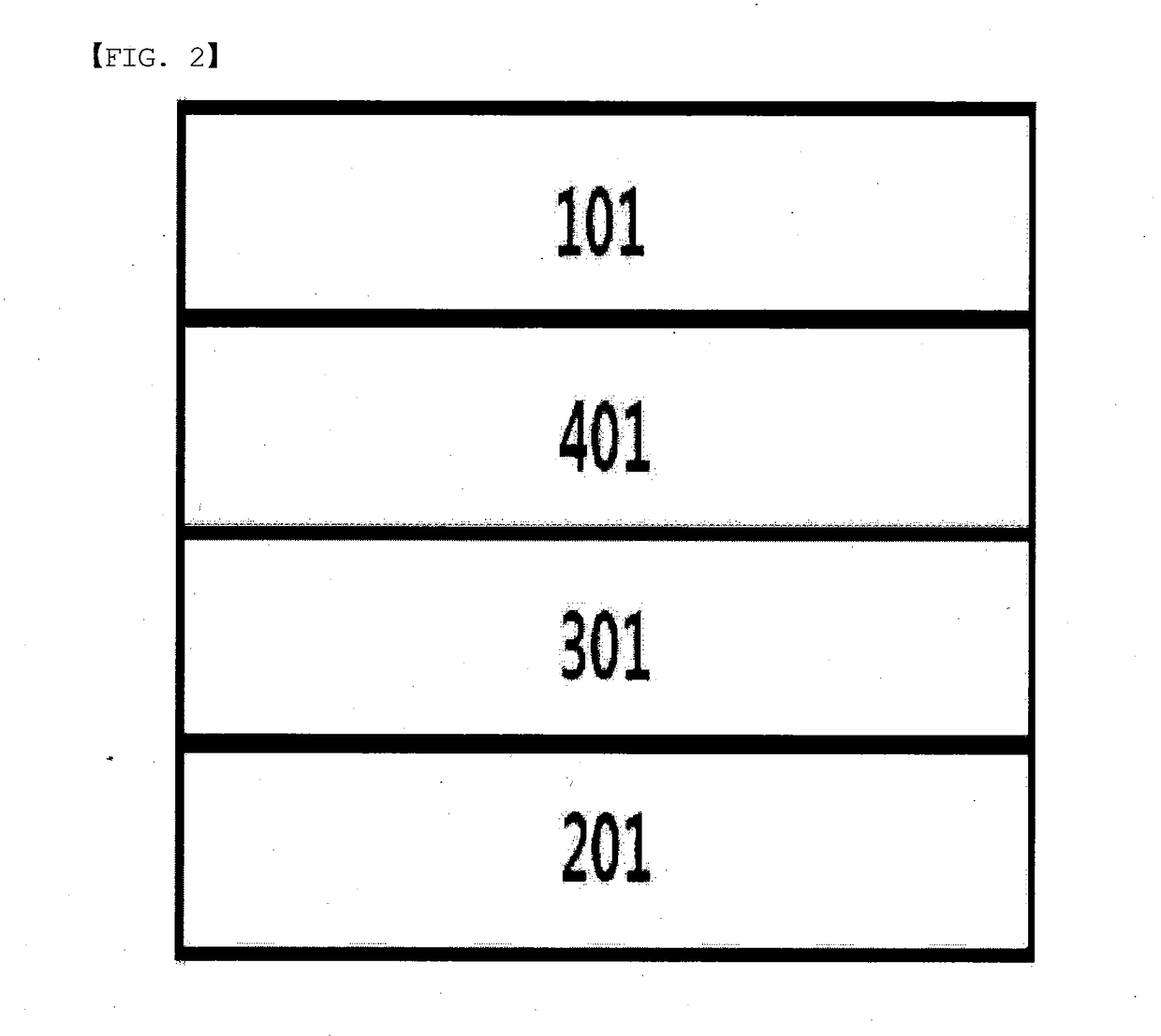

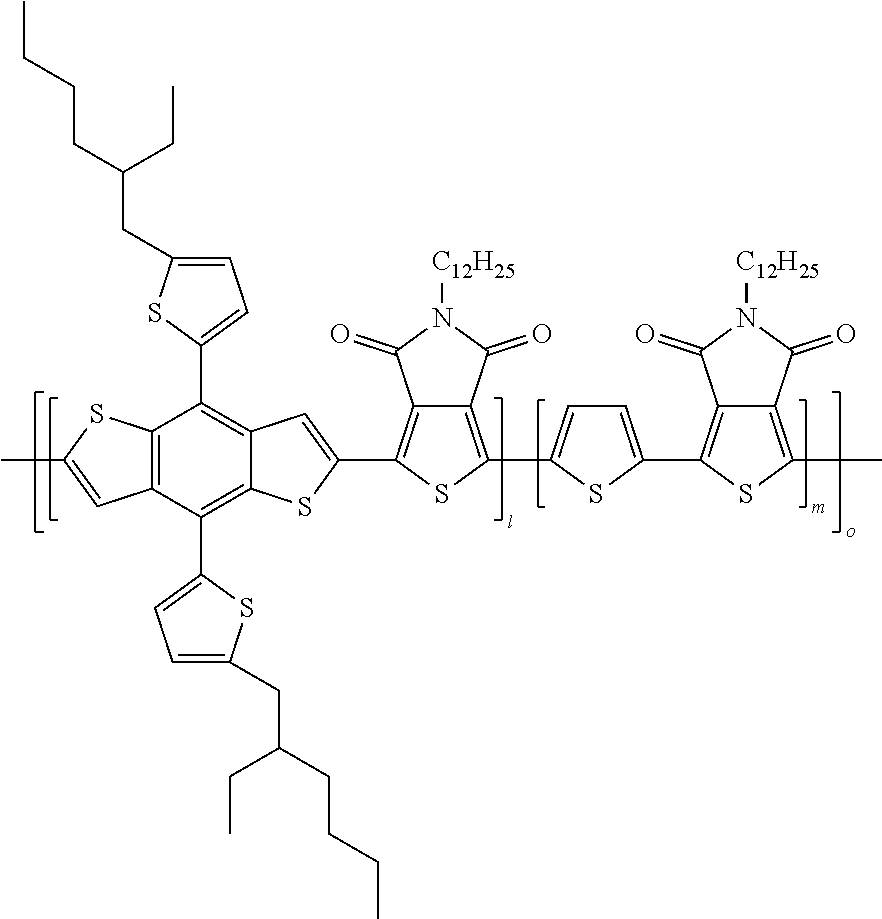

Organic solar cell and method for manufacturing same

ActiveUS20190074443A1Evenly layeredHigh light conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellEngineering

Owner:LG CHEM LTD

Affixed cloth embroidered embroidery fabric and affixed cloth embroidered method thereof

InactiveCN112575431ACounterpoint SimplifiedDoes not affect machine efficiencyMulti-ply fabricsYarnPolymer scienceBatch manufacturing

The invention relates to the technical field of affixed cloth embroidery, and discloses an affixed cloth embroidered (or applique) embroidery fabric. The affixed cloth embroidered embroidery fabric comprises inner warp and weft yarns and surface warp and weft yarns which are interwoven; the inner warp and weft yarns comprise inner warp yarns and inner weft yarns which are interwoven; and the surface warp and weft yarns comprise surface warp yarns and surface weft yarns which are interwoven. According to an affixed cloth embroidered method, the defect that patches are not aligned for many timesis overcome; therefore the patching process is convenient, fast, time-saving, labor-saving, accurate, simple in operation, and practical and reliable; the affixed cloth embroidered efficiency and quality are highly improved, patch alignment time is reduced, affixed cloth embroidered patches of the same pattern are kept beautiful in appearance, batch production can be realized, and the affixed cloth embroidered garment manufacturing cost is highly lowered; and in addition, the working requirements of an embroidery machine can be met, patching can be performed without stopping the embroidery machine, the whole embroidery process can be completed at a time, and the production efficiency of the embroidery machine is improved.

Owner:浙江兰乔圣菲家纺有限公司

Method for fabricating super fine set of die for guiding light plate

InactiveCN100359378CSimple processProcess time savingPhotomechanical exposure apparatusMicrolithography exposure apparatusLight guideHeight difference

A method for preparing light guide plate forms a patterned metal layer on a metal baseplate by utilizing the microimaging process, and then coats a Ni - P alloy layer on surface of the patterned metal layer which has height difference.

Owner:CORETRONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com