Method for fabricating super fine set of die for guiding light plate

A manufacturing method and light guide plate technology, applied in optics, nonlinear optics, microlithography exposure equipment, etc., can solve the problems of low pass rate, time-consuming and complicated process of depositing metal base 5, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

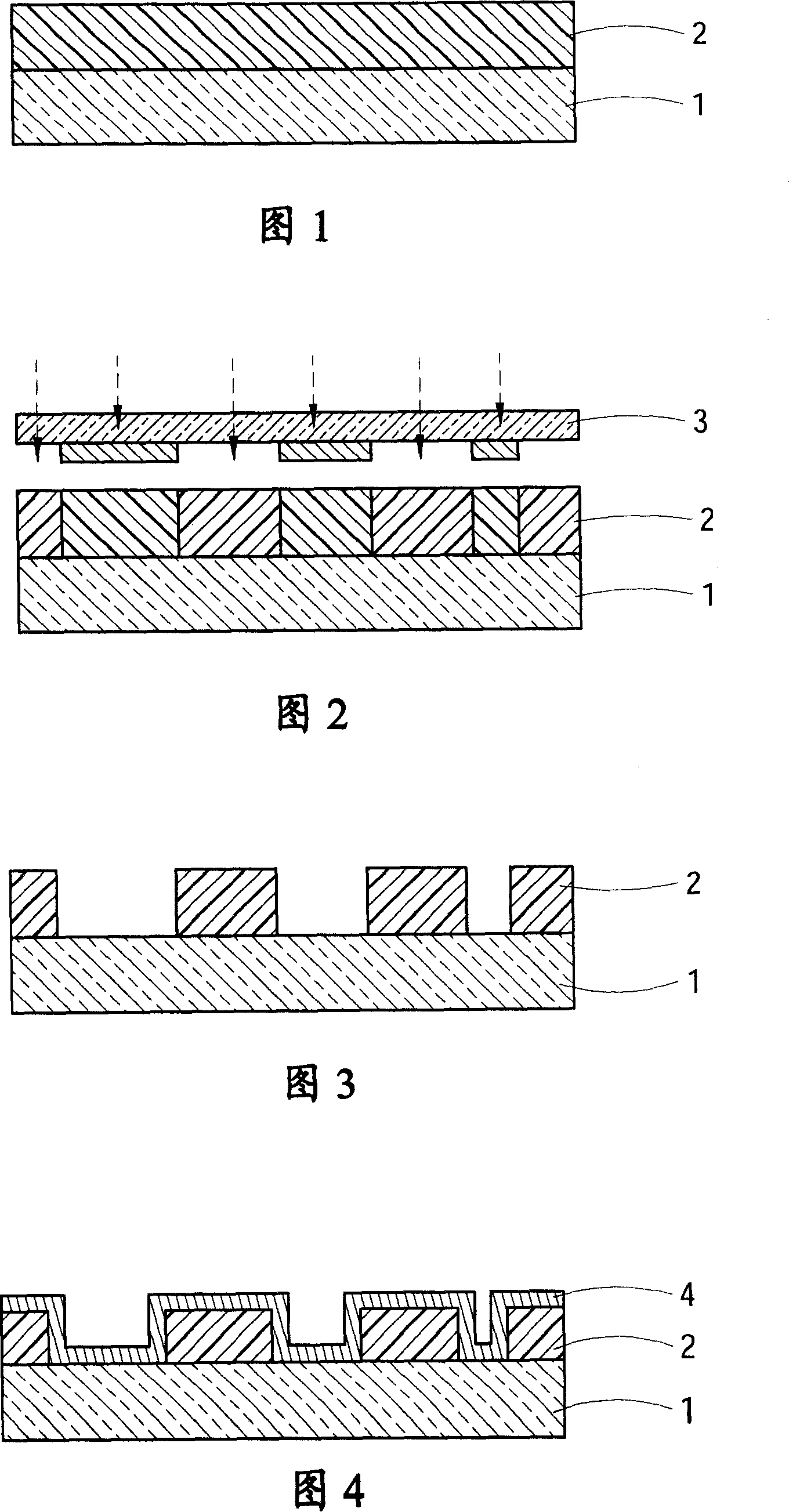

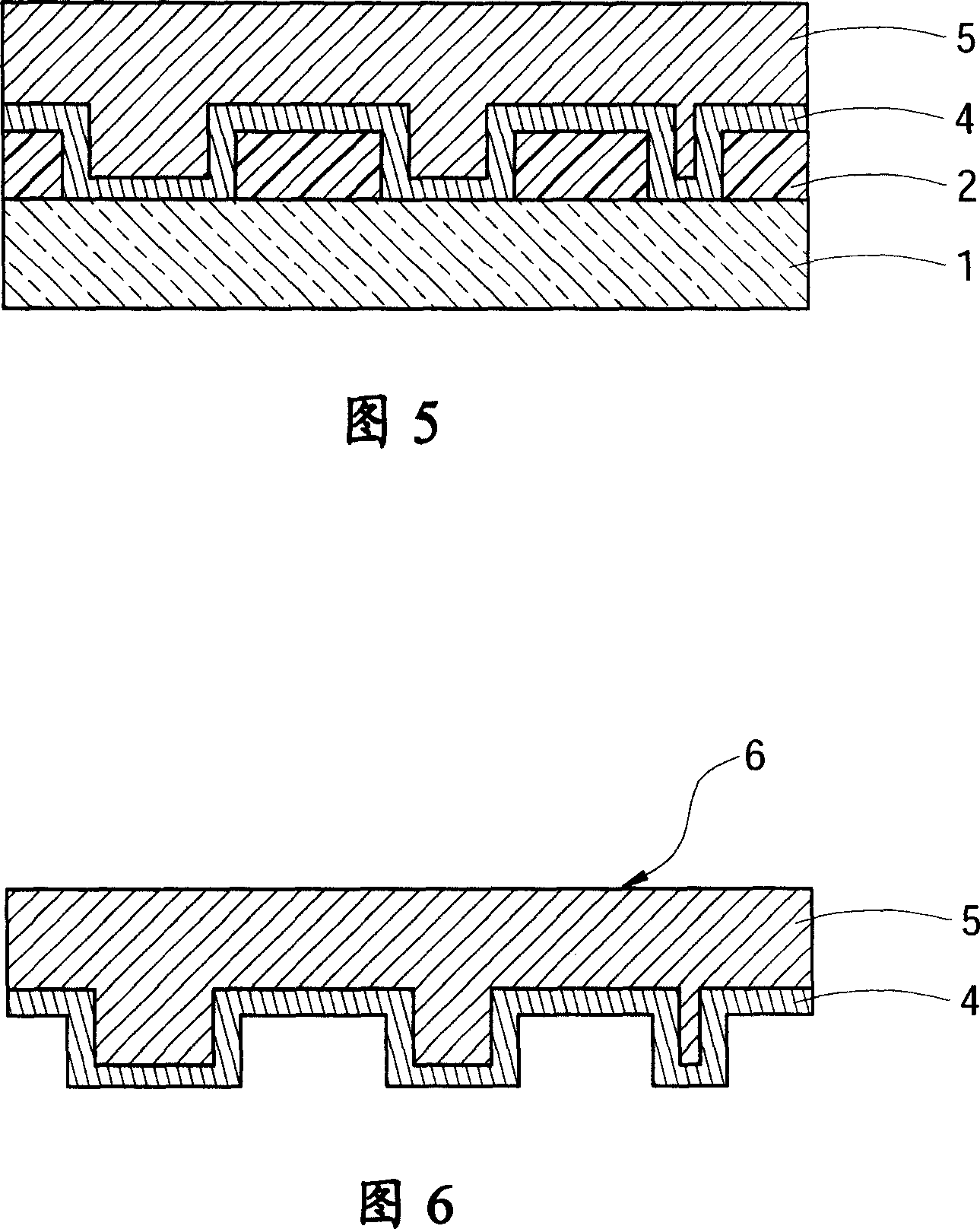

[0019] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

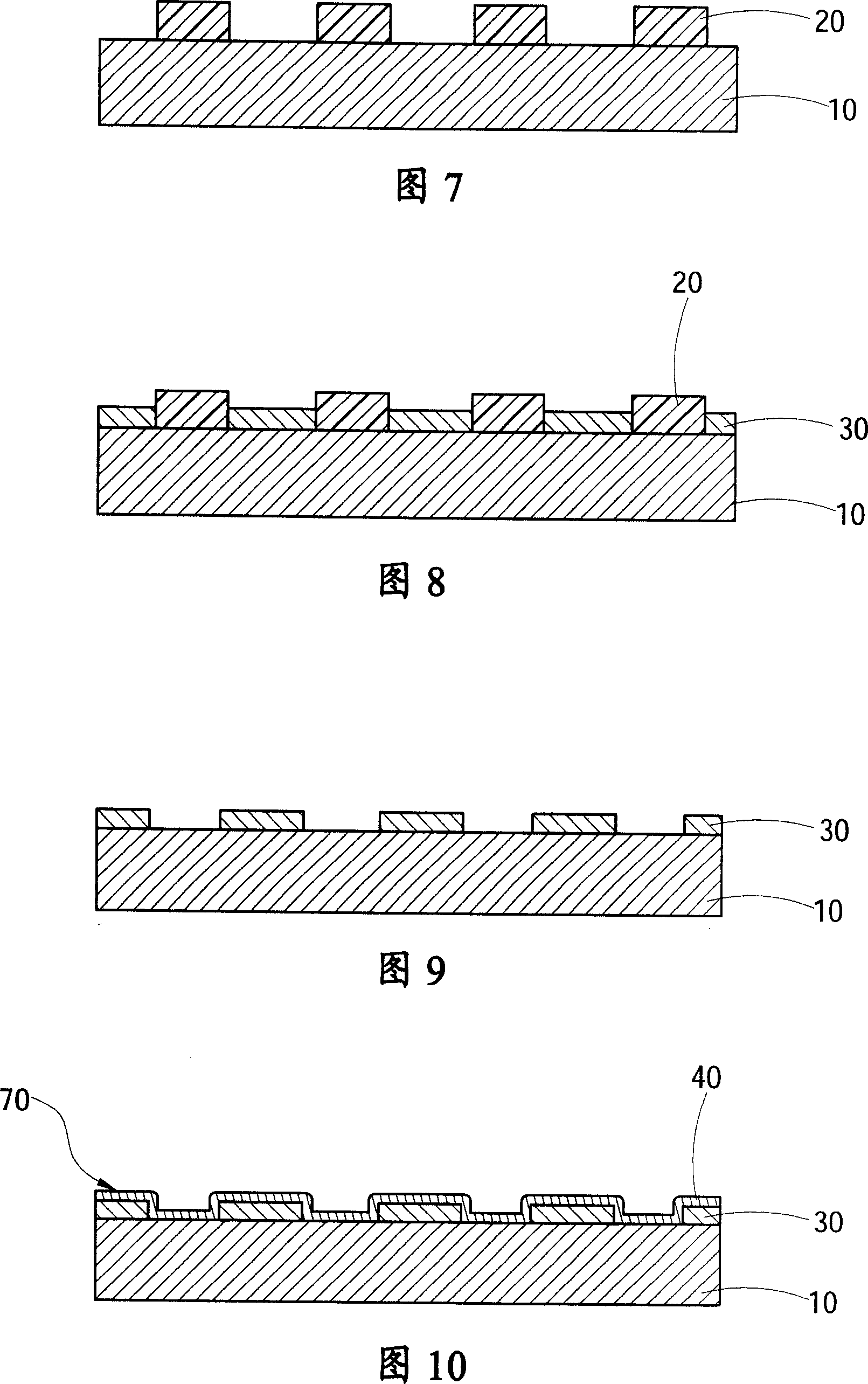

[0020] Please refer to FIG. 7 to FIG. 10 , which are cross-sectional views of making the mold core of the light guide plate at different steps according to the method of the present invention. The steps of the present invention include:

[0021] a. Form a non-metallic layer 20 with a specific pattern on the surface of a metal substrate 10 (as shown in FIG. 7 ), which is fabricated by a lithography process.

[0022] b. On the surface area of the metal substrate 10 that is not covered by the non-metallic layer 20, a metal layer 30 with a thickness not greater than the thickness of the non-metallic layer 20 is plated by electroplating or electroless plating (as shown in Figure 8) ; Due to the characteristics of electroplating or electroless plating process, it can only deposit metal on the surface of metal, so it can only depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com