Technology for reclaiming lead from waste lead storage batteries by using pulse power supply

A lead-acid battery and pulse power supply technology, which is applied in the field of recycling waste batteries by pulse capacitor technology, can solve the problems of generating large heat, low current density, and evaporation of electrolyte water, and achieves the effects of short time, low power consumption and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

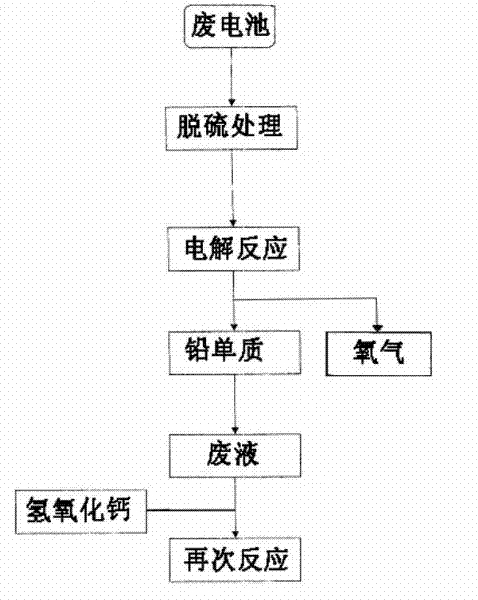

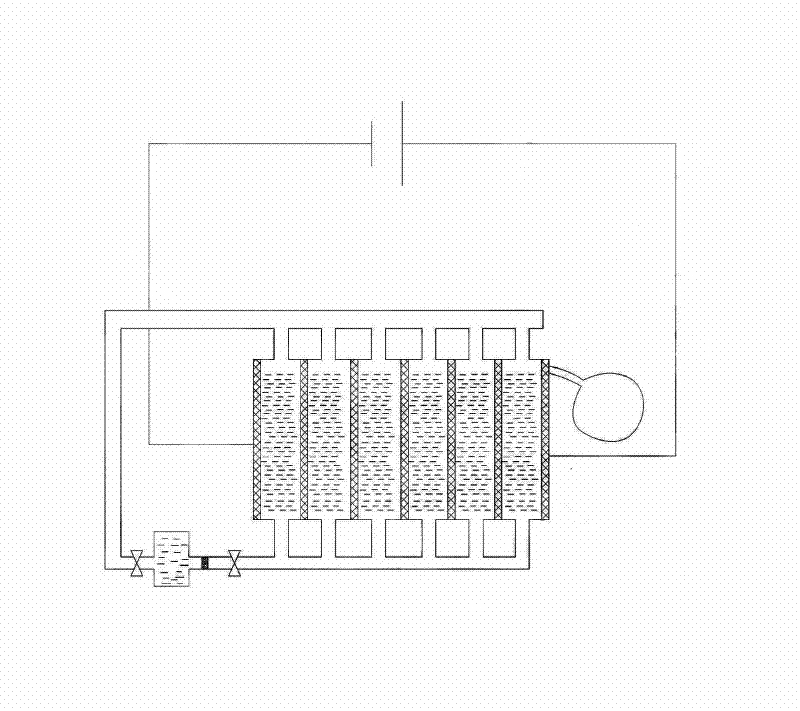

[0019] Embodiment 1 A kind of process of recycling lead in waste lead-acid storage battery by pulse power supply Use the lead plaster made of waste lead-acid storage battery as raw material, first carry out desulfurization treatment to the lead plaster, use the solution of sodium nitrate and sodium nitrite to prepare the lead plaster Perform 5 to 7 times of filtration, apply the lead paste on the electrode separator, and carry out in a closed electrolytic cell, which is divided into 4 to 8 mutually independent areas by 3 to 7 fast electrode separators , the sodium hydroxide solution as the electrolyte is provided in the mutually independent areas, and the concentration of hydroxide ions in the sodium hydroxide solution is 15% to 30%; the upper end of the electrolytic cell is provided with a liquid inlet pipe, and the lower end A liquid outlet pipe is provided for supplementing sodium hydroxide and water to maintain the concentration of free hydroxide ions during the electrolysi...

Embodiment 2

[0021] Embodiment 2 A process of recycling lead in waste lead-acid storage batteries with pulse power supply. Using the lead paste made from waste lead-acid storage batteries as raw material, first desulfurize the lead paste, and use the solution prepared by sodium nitrite to process the lead paste for 5~ 7 times of filtration; the pulse power supply adopts a trigonometric function waveform, and the cycle is 4s; calcium hydroxide is used as the electrolyte in the electrolytic cell, and the concentration of hydroxide ions in the calcium hydroxide is 15% to 30%, and others are the same as those in the examples One is the same.

Embodiment 3

[0022] Embodiment 3 A kind of technique of recycling lead in waste lead-acid storage battery with pulse power supply, pulse power supply adopts triangular wave, cycle is 2s; Connect a container after the liquid outlet pipe, the liquid after reaction in the electrolytic cell is recovered in the described container, in Calcium hydroxide solution is added in the container, and the temperature is lowered so that there are enough hydroxide ions in the solution; others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com