Sludge drying and incinerating integrated zero-discharge treatment system and treatment process

A sludge drying and sludge incineration technology, applied in dewatering/drying/concentrating sludge treatment, incinerators, indirect carbon dioxide emission reduction, etc. The effect of mature equipment structure and reasonable and compact system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

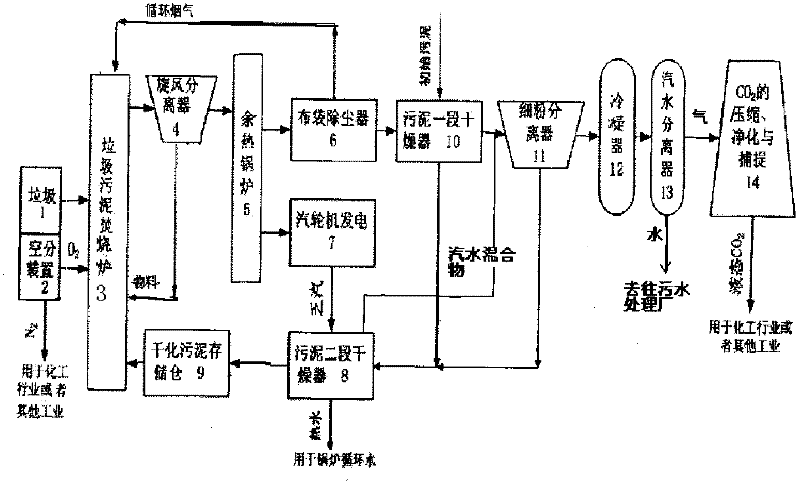

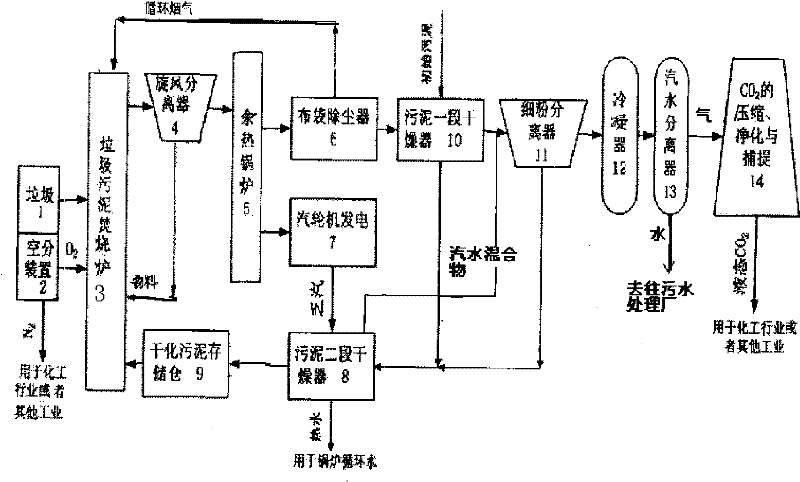

[0028] The invention provides a zero-emission treatment system and treatment process integrating sludge drying and incineration. Be described below in conjunction with accompanying drawing.

[0029] figure 1 Shown is a schematic diagram of the structure and process flow of an integrated sludge treatment process with zero discharge of flue gas pollutants. In the figure, the waste-sludge drying and incineration integrated zero-emission treatment system shown in the figure is connected as a waste storage pit 1, a waste-sludge incinerator 3, a cyclone separator 4, a waste heat boiler 5 and a steam turbine generator set 7 The air separation unit 2 is connected to the garbage-sludge incinerator 3; the waste heat boiler 5 is connected to the bag filter 6, and the bag filter 6 has two flue gas outlets, which are respectively connected to the garbage-sludge incinerator 3 and sludge The first-stage dryer 10 is connected; the sludge first-stage dryer 10 is followed by a fine powder sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com