Near zero emission process of salt-containing waste water

A salty wastewater, near-zero discharge technology, applied in adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high investment and operation cost, low water recovery rate, etc. , to achieve the effect of reducing the cost of water treatment per ton, increasing the discharge and high water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

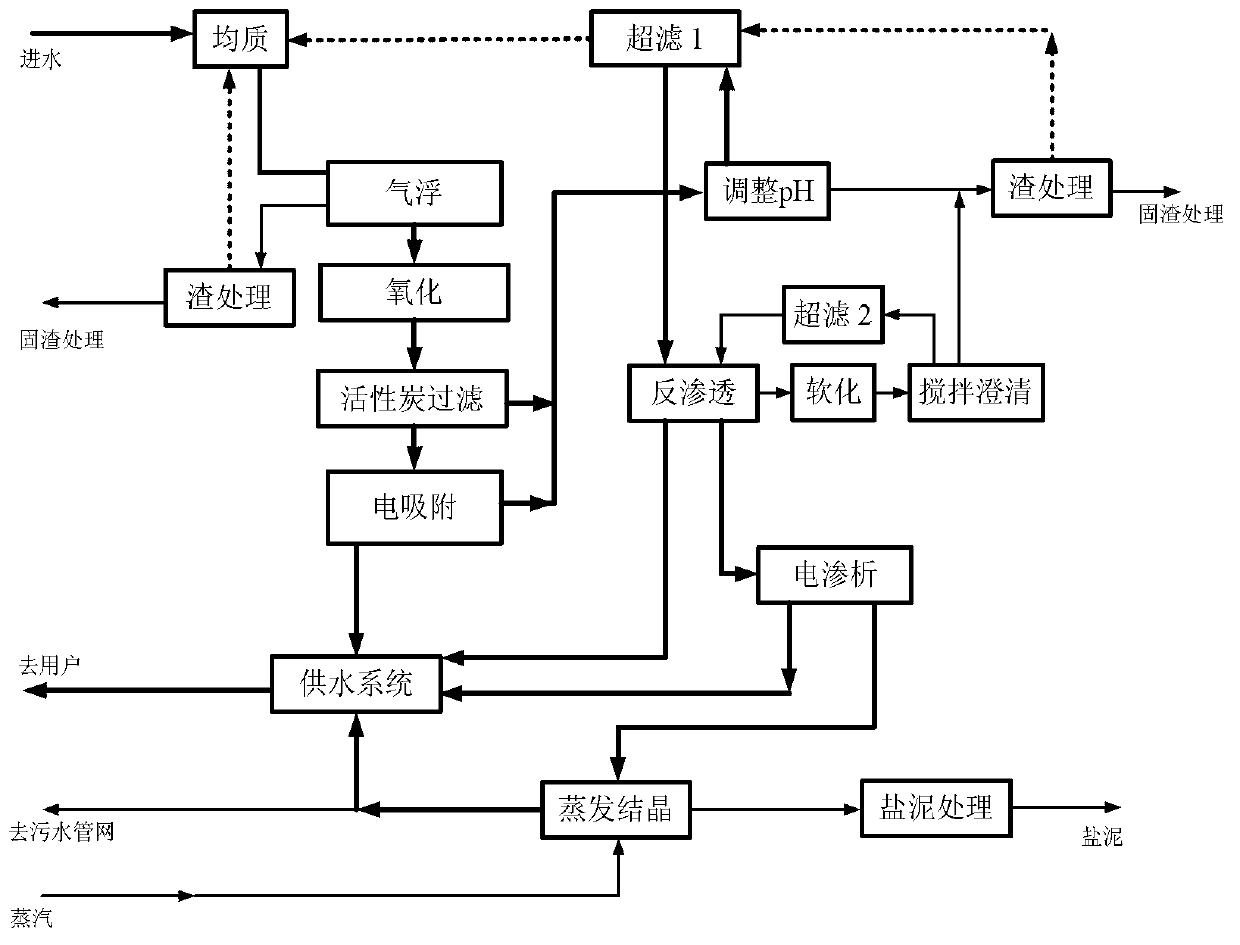

[0026] Pulping tail water is reused as industrial circulating cooling water, the process flow chart is as follows figure 1 . The raw water quality before homogenization is TDS is 2684mg / L, COD Cr 90mg / L, SO 4 2- Concentration is 682mg / L, Cl - Concentration is 797mg / L, SS is 30mg / L, water inflow is 400m 3 / d. After homogenization, the water inflow is 419.4m 3 / d. After air flotation treatment, the water quality is TDS 2648mg / L, COD Cr 54mg / L, SO 4 2- Concentration is 682mg / L, Cl - The concentration is 797mg / L, and SS is 5mg / L. All the water produced by air flotation is oxidized, and a small amount of concentrated water enters the slag treatment process at the same time. After ozone oxidation and granular activated carbon filtration, the wastewater TDS is 2640mg / L, COD Cr 46mg / L, SO 4 2- Concentration is 682mg / L, Cl - The concentration is 797mg / L, Ca 2+ The concentration is 132mg / L, Mg 2+ The concentration is 15mg / L. 40% of the volume fraction of the ozone prod...

Embodiment 2

[0028] Advanced treatment and reuse of printing and dyeing wastewater, the process flow chart is as follows figure 1 . Raw water TDS is 1860mg / L, COD Cr 115mg / L, SO 4 2- Concentration is 306mg / L, Cl - Concentration is 559mg / L, water inflow is 2000m 3 / d. COD after air flotation Cr down to 75mg / L. The process produces concentrated water 22m 3 / d Return to the water inlet part for homogenization, and the concentrated water is discharged 2m 3 / d. COD after deep oxidation of potassium permanganate and filtration of powdered activated carbon Cr down to 60mg / L. After oxidation, 65% of the volume fraction of wastewater enters the electro-adsorption treatment, and the rest of the wastewater enters the ultrafiltration system for treatment. Ultrafiltration 1 and ultrafiltration 2 both use hollow fiber membranes with a membrane pore size of 10nm; the TDS of electro-adsorption produced water is 760mg / L, COD Cr 56mg / L, SO 4 2- The concentration is 102mg / L, Cl - Concentratio...

Embodiment 3

[0030] Deep purification of coal-to-oil saline wastewater, the process flow is as follows figure 1 . Raw water TDS is 4500mg / L, COD Cr 140mg / L, SO 4 2- The concentration is 910mg / L, Cl - Concentration is 1250mg / L, water inflow is 200m 3 / h. After air flotation, the water quality of the produced water is TDS 4400mg / L, COD Cr 77mg / L, SO 4 2- Concentration is 895mg / L, Cl - The concentration is 1190mg / L. The water produced by air flotation is oxidized by chlorine gas and then filtered by granular activated carbon. This part is mainly to reduce the COD of the influent water in the subsequent process. After oxidation, the COD Cr 30mg / L. All the oxidized water enters the ultrafiltration treatment. The water quality of the ultrafiltration process is 4300mg / L TDS and 4300mg / L COD Cr 26mg / L, SO 4 2- Concentration is 870mg / L, Cl - The concentration is 1220mg / L, and ultrafiltration 1 adopts a hollow fiber organic membrane with a membrane pore size of 20nm. The ultrafiltrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com