Patents

Literature

4330 results about "Zero emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero emission refers to an engine, motor, process, or other energy source, that emits no waste products that pollute the environment or disrupt the climate.

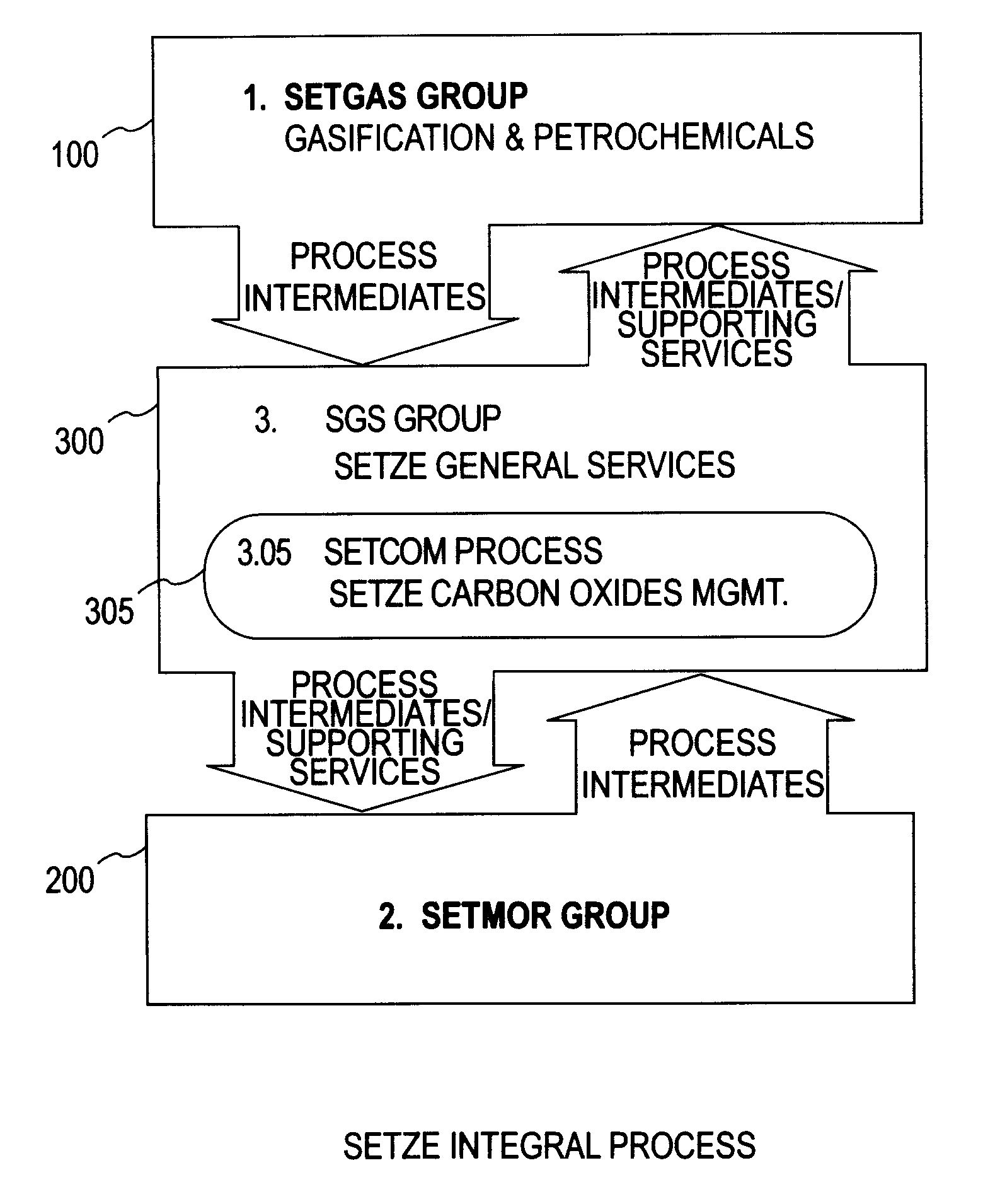

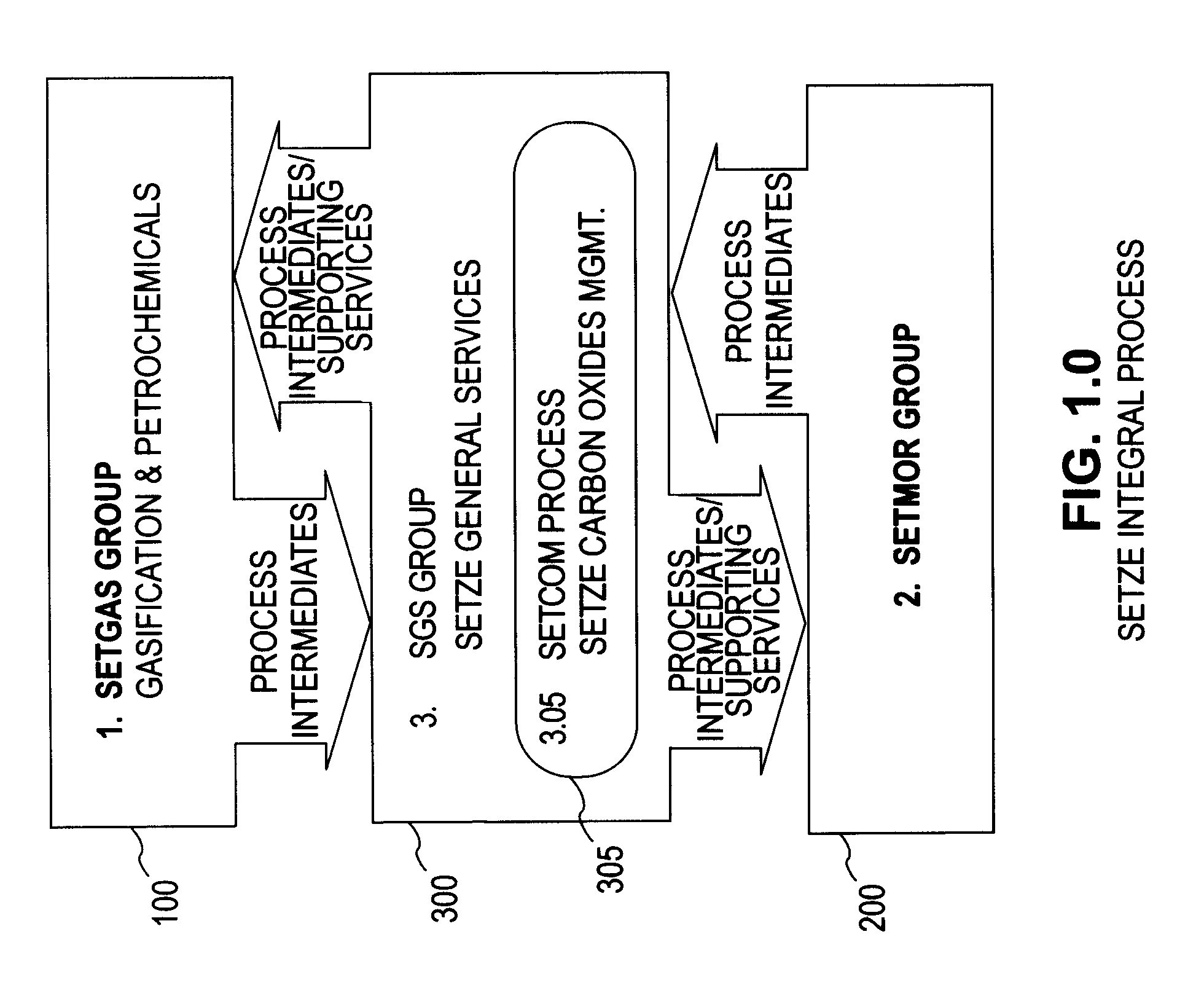

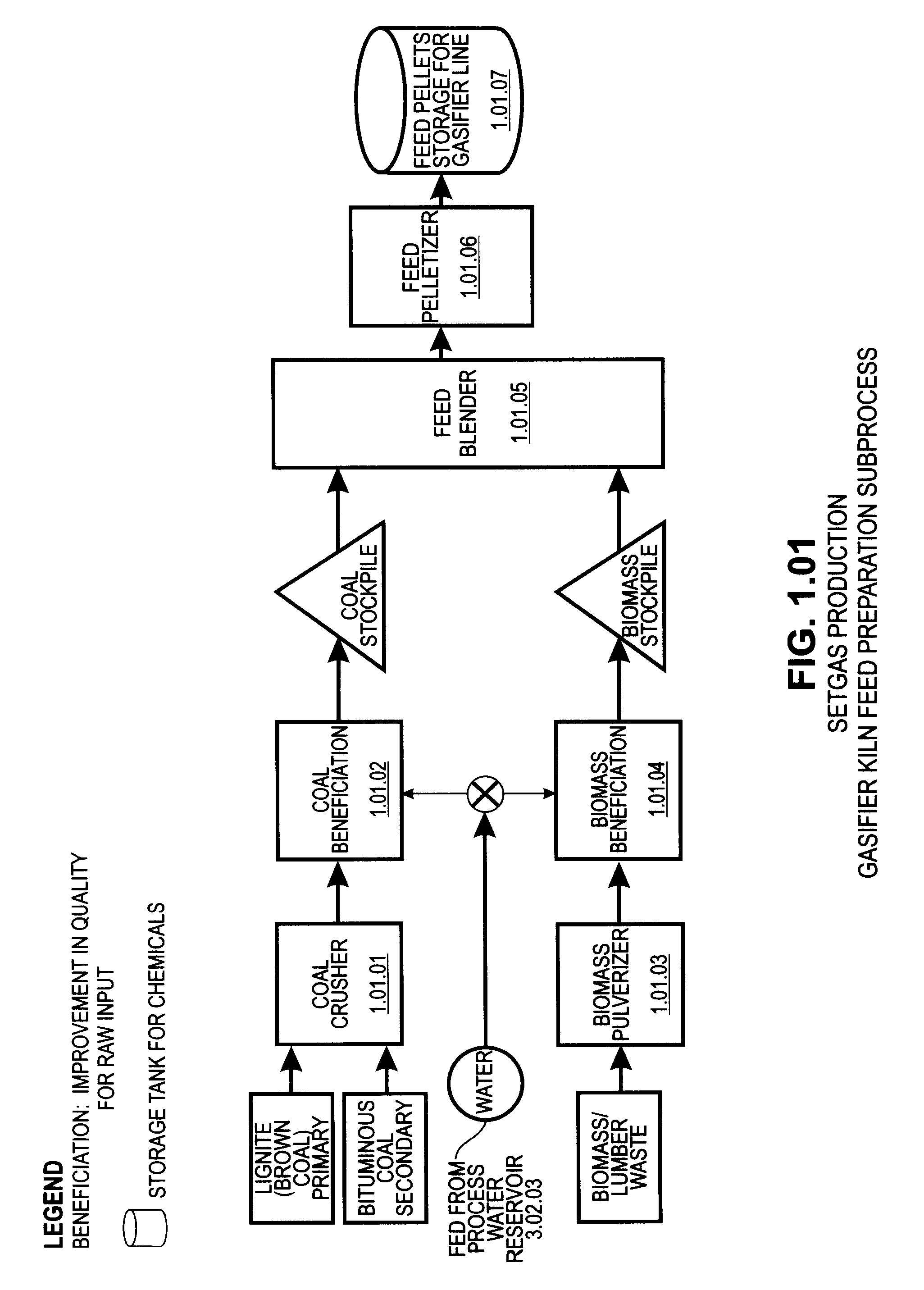

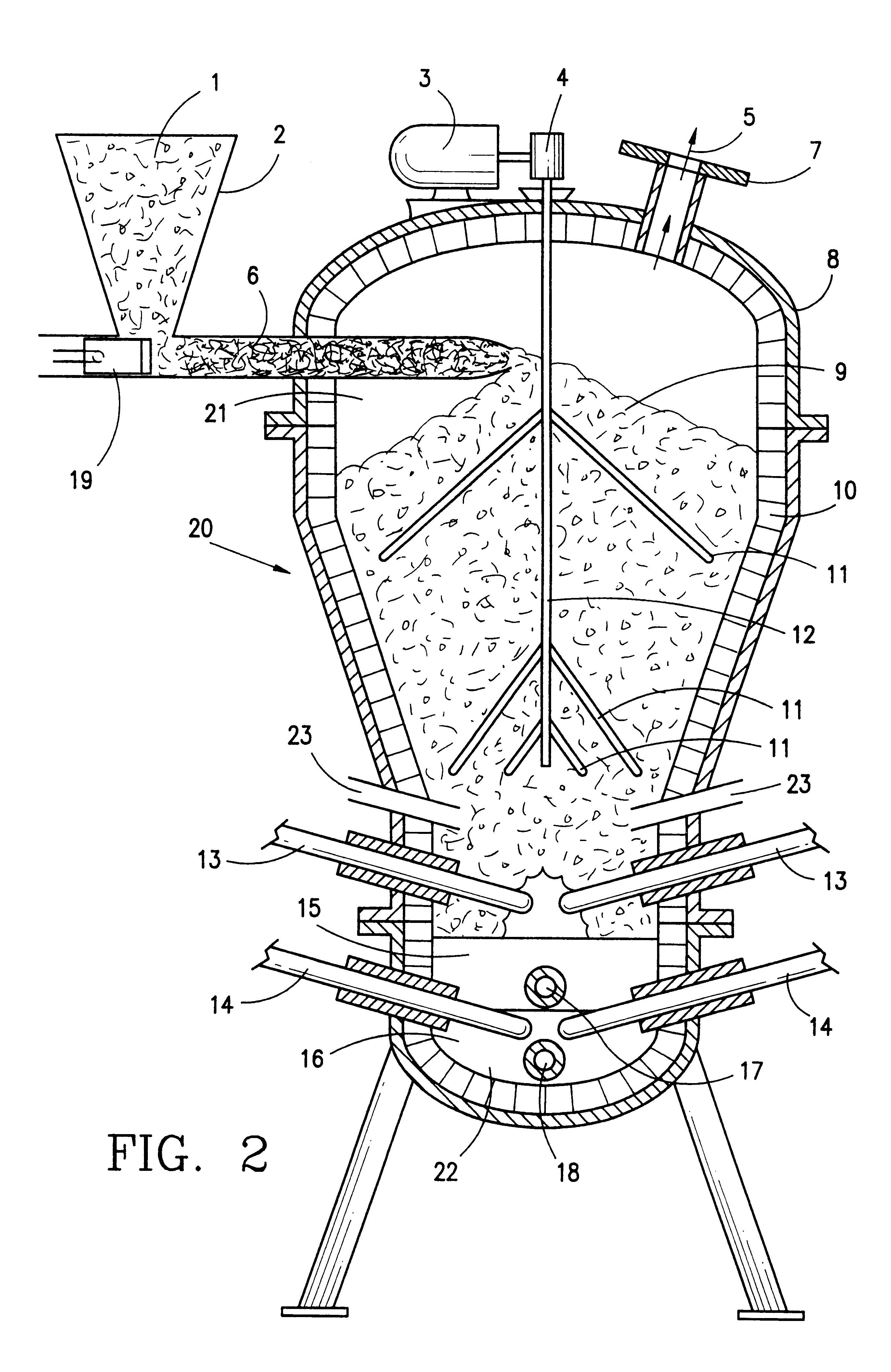

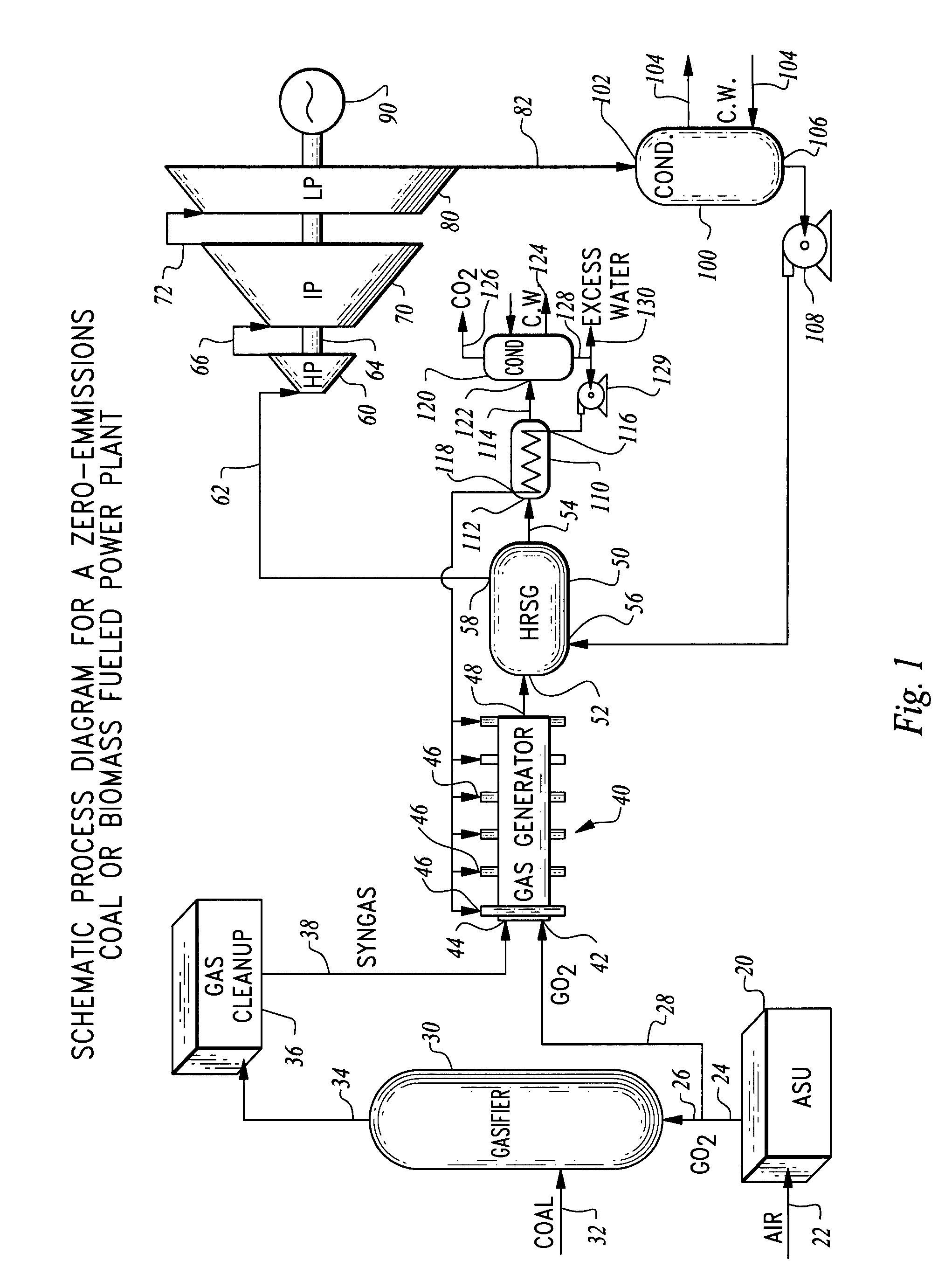

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

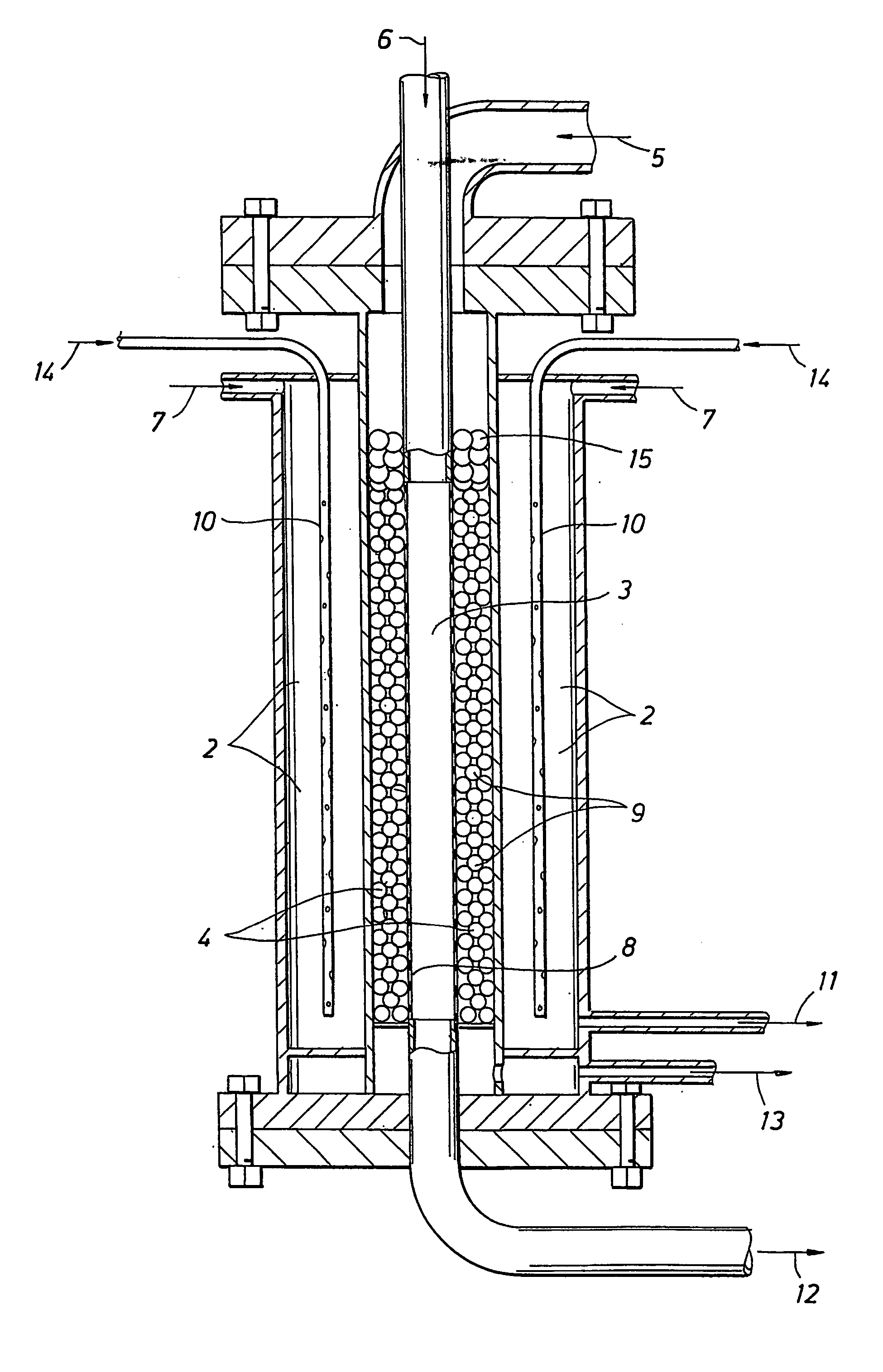

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

Apparatus and process for production of high purity hydrogen

InactiveUS20060248800A1High purityEnhanced overall recoveryCarbon compoundsIndirect carbon-dioxide mitigationSteam reformingCombustion chamber

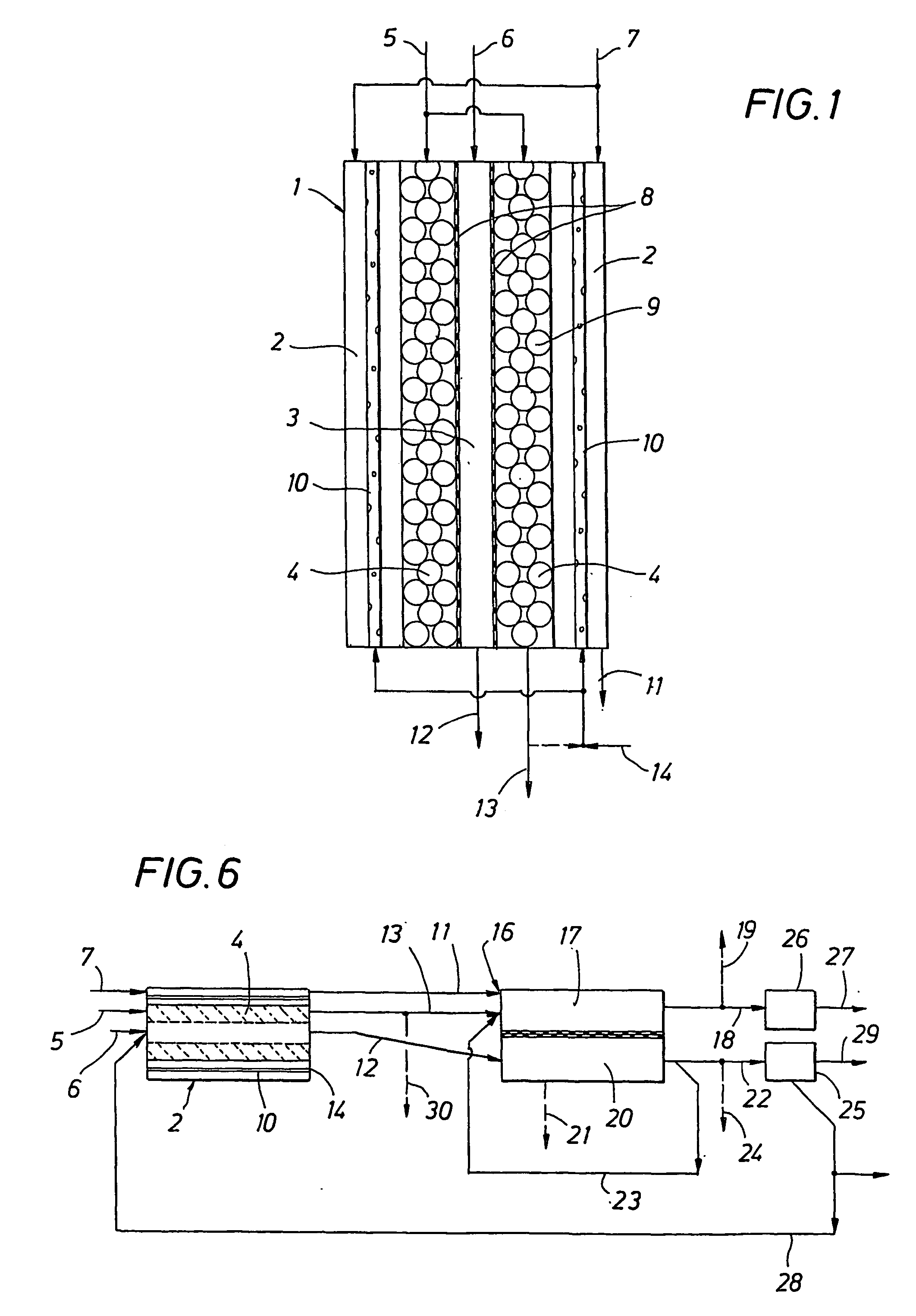

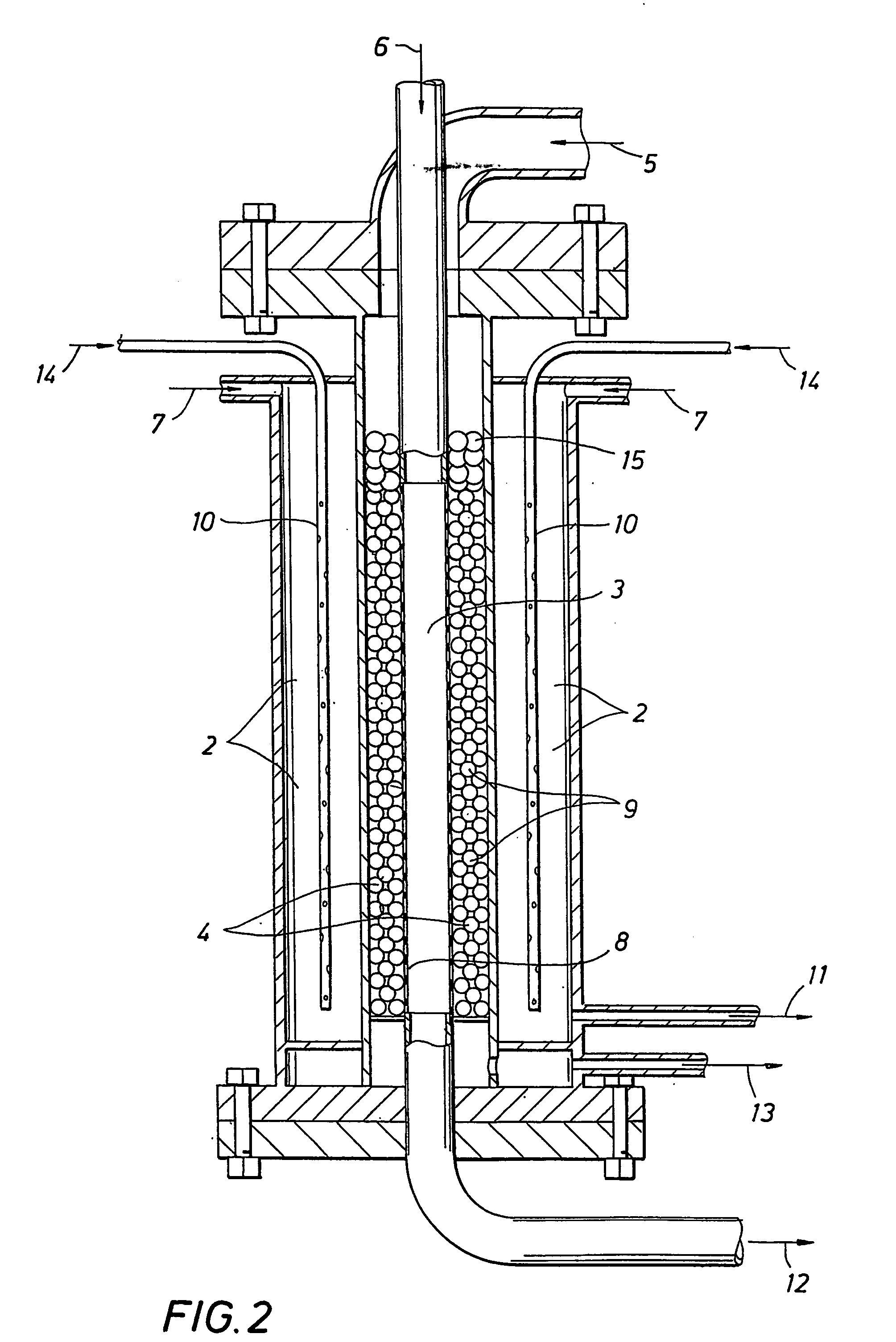

The invention relates to a new and improved process and apparatus for the production of high purity hydrogen by steam reforming. The apparatus is an integrated flameless distributed combustion-membrane steam reforming (FDC-MSR) or reactor for steam reforming of a vaporizable hydrocarbon to produce H2 and CO2, with minimal CO, and minimal CO in the H2 stream. The flameless distributed combustion drives the steam reforming reaction which pro-vides great improvements in heat exchange efficiency and load following capabilities. The reactor may contain multiple flameless distributed combustion chambers and multiple hydrogen-selective, hydrogen-permeable, membrane tubes. The feed and reaction gases may flow through the reactor either radially or axially. A further embodiment of the invention involves producing high purity hydrogen by dehydrogenation using an integrated FDC-membrane de-hydrogenation reactor. A still further embodiment of the invention involves a zero emission hybrid power system wherein the produced hydrogen is used to power a high-pressure internally manifolded molten carbonate fuel cell. In addition, the design of the FDC-SMR powered fuel cell makes it possible to capture good concentrations of CO2 for sequestration or use in other processes.

Owner:SHELL OIL CO

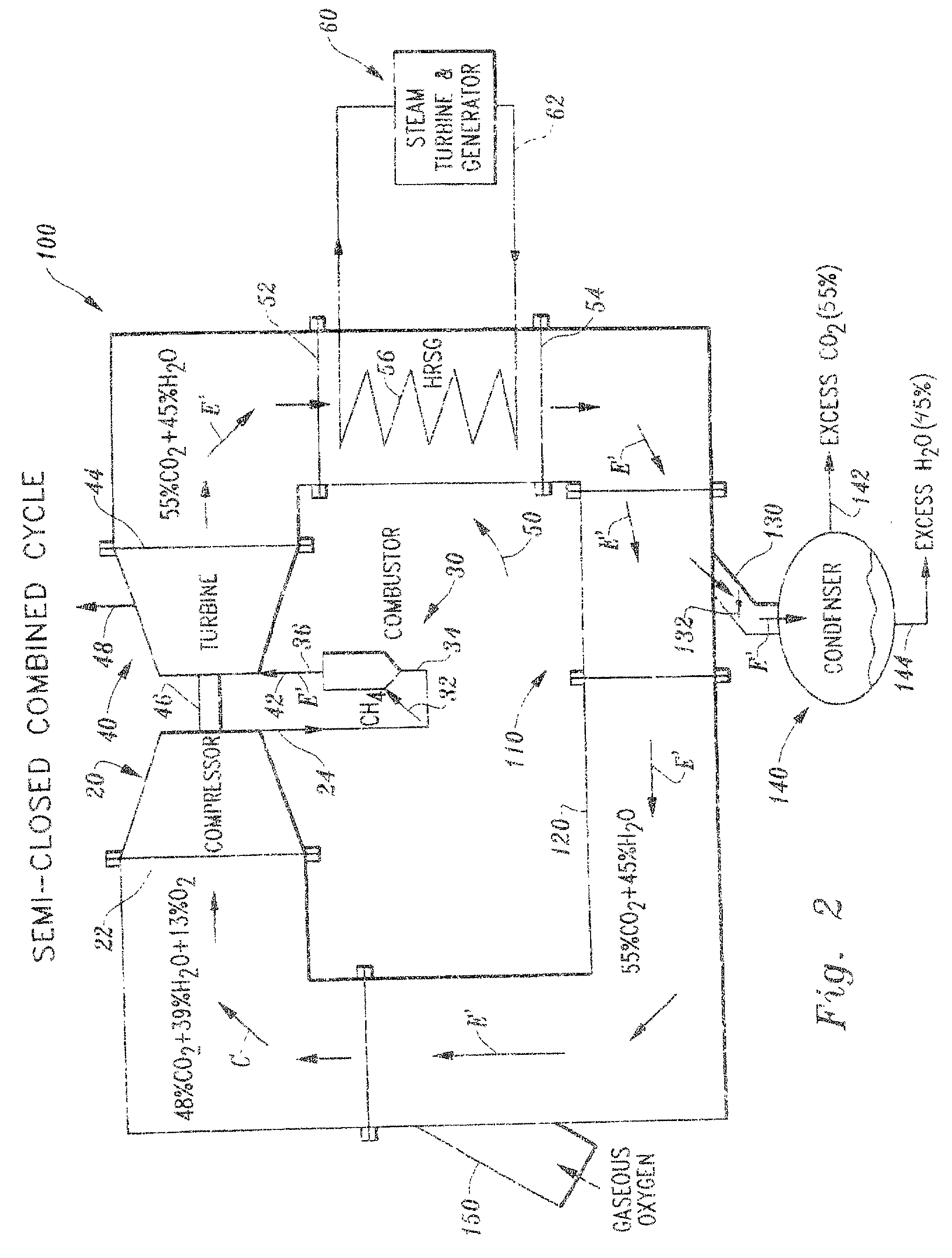

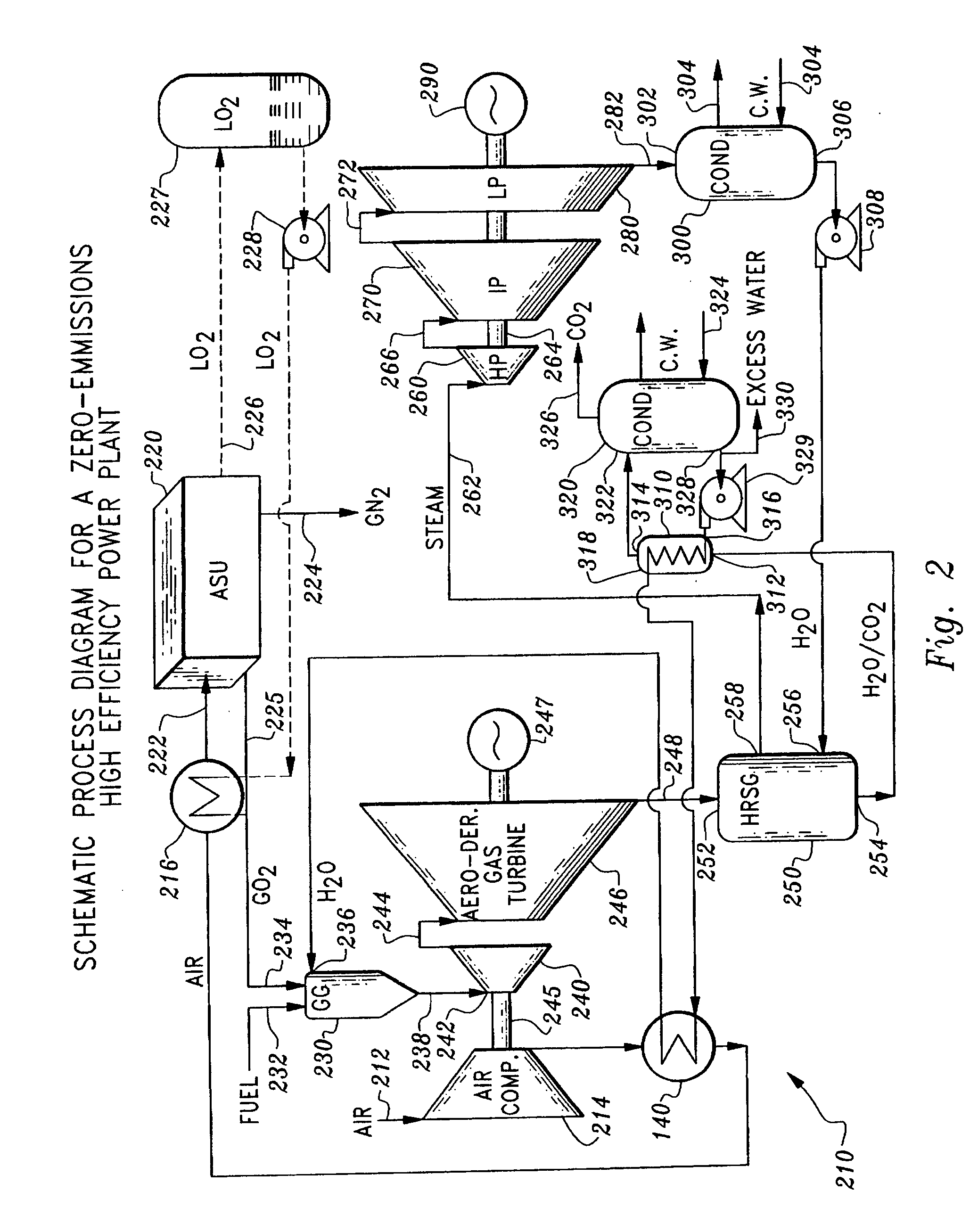

Semi-closed brayton cycle gas turbine power systems

InactiveUS20020023423A1Efficient collectionEliminate emissionsEnergy industryEfficient propulsion technologiesAtmospheric airElectric power system

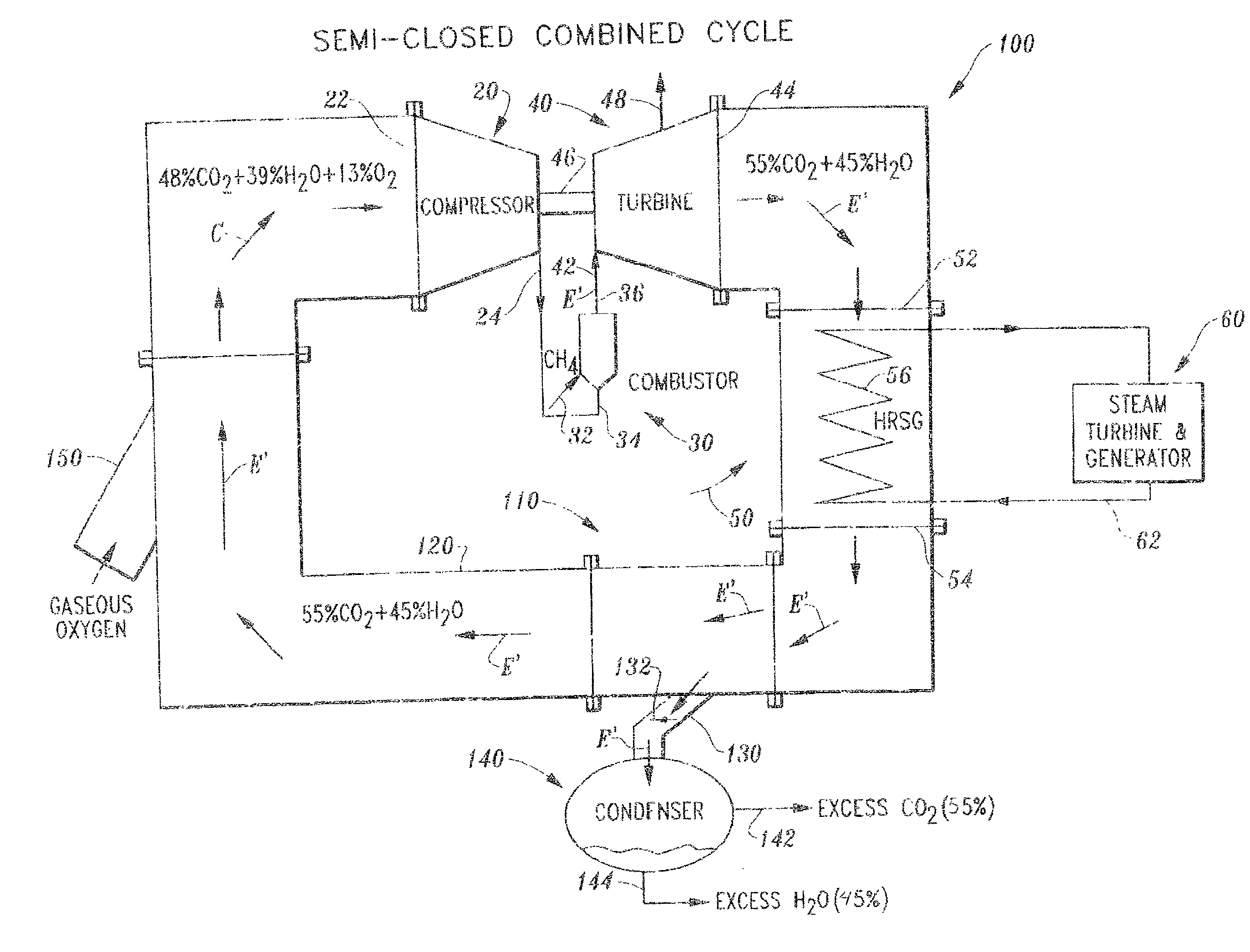

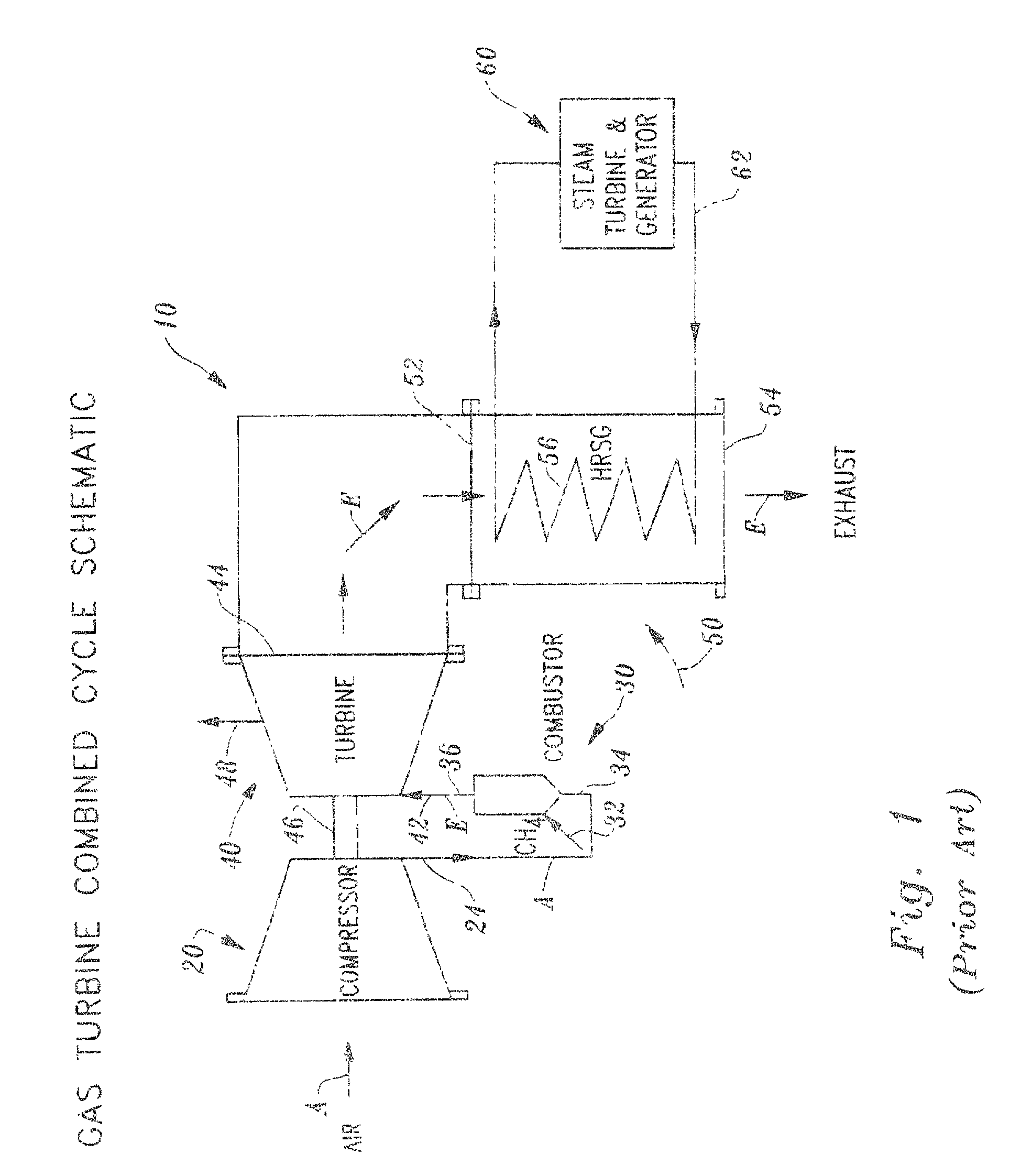

A semi-closed combined cycle power system 100 is provided which can also convert an open combined cycle gas turbine 10 into a non-polluting zero emissions power system. The prior art open combined cycle gas turbine 10 includes a compressor 20 which compresses air A' and combusts the air A' with a fuel, such as natural gas. The products of combustion and the remaining portions of the air form the exhaust E' which is expanded through the turbine 40. The turbine 40 drives the compressor 20 and outputs power. The exhaust E' exits the turbine 40 and then can optionally be routed through a heat recovery steam generator 50 to function as a combined cycle. According to this invention, the exhaust E' is not emitted into the atmosphere, but rather is routed to a divider 110. The divider 110 includes two outlets for the exhaust E' including a return duct 120 and a separation duct 130 which both receive a portion of the exhaust E'. The return duct 120 routes a portion of the exhaust E' back to the compressor 20. Before reaching the compressor 20, an oxygen duct 150 adds additional oxygen to the exhaust E' to form a gas mixture C which includes CO2 and steam from the exhaust E' and oxygen from the oxygen duct 150. This gas mixture C has characteristics which mimic those of air, so that the compressor 20 need not be modified to effectively compress the gas mixture C. The gas mixture C is compressed within the compressor 20 and routed to the combustor 30 where the fuel combusts with the oxygen of the gas mixture C' and produces exhaust E' which is substantially entirely CO2 and steam. This exhaust E' is routed through the turbine 40 and expanded to drive the compressor 20 and output power. The exhaust E' exits the turbine 40 and is routed back to the divider 110, preferably by way of a heat recovery steam generator 50 or other heat removal device, so that the semi-closed cycle operates as a combined cycle power system 100. The divider 110 directs a portion of the exhaust E' to a separation duct 130 which leads to a condenser 140. In the condenser 140 the exhaust E' is separated by condensation of the steam / water portion of the exhaust and removal of the remaining CO2 as gas from the condenser 140. The only exhaust from the semi-closed power system 100 is water and CO2 from the condenser. The CO2 exhaust is substantially pure and ready for appropriate further handling and disposal. Hence, no pollutants are emitted from the semi-closed power system 100. The return duct 120 can

Owner:CLEAN ENERGY SYST

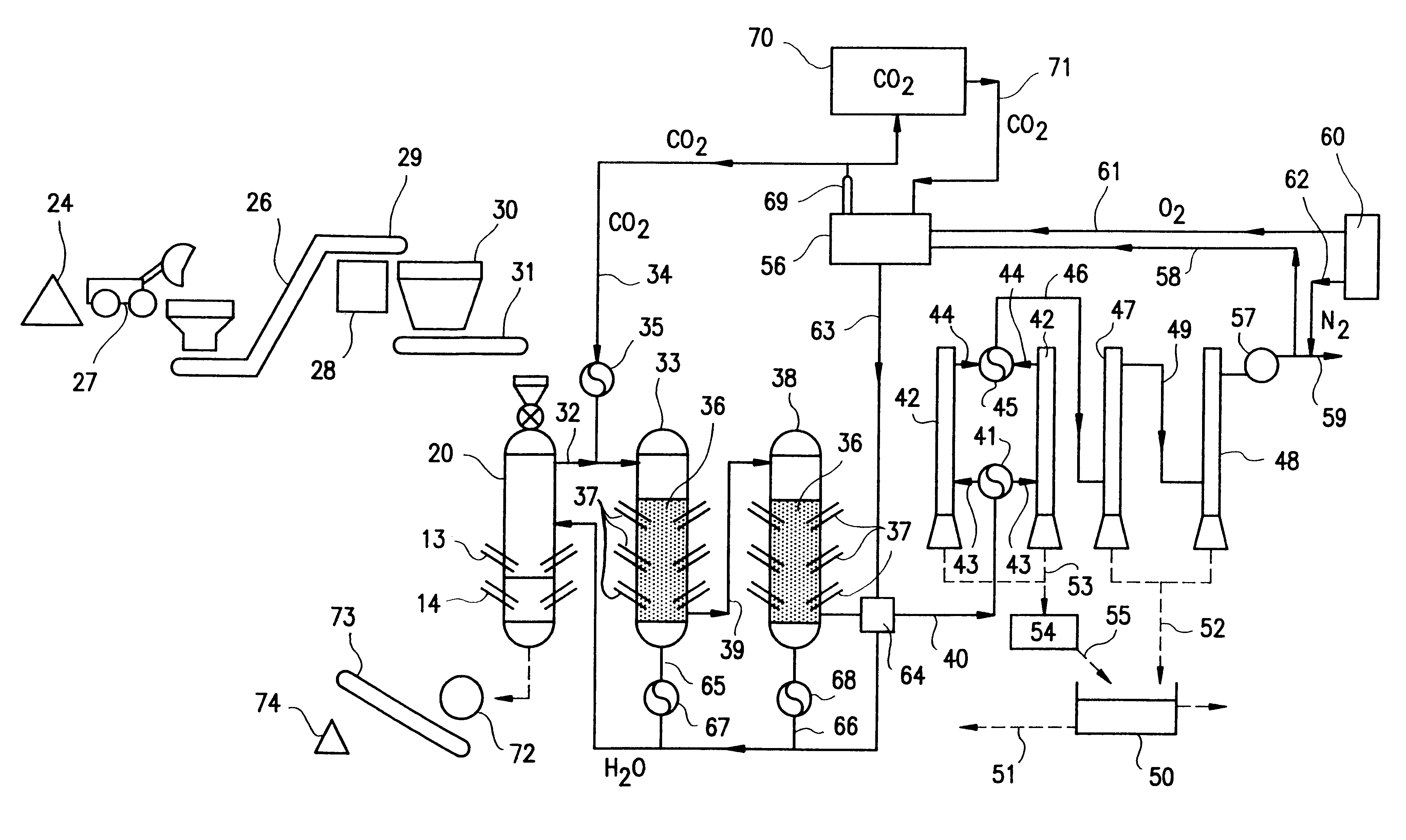

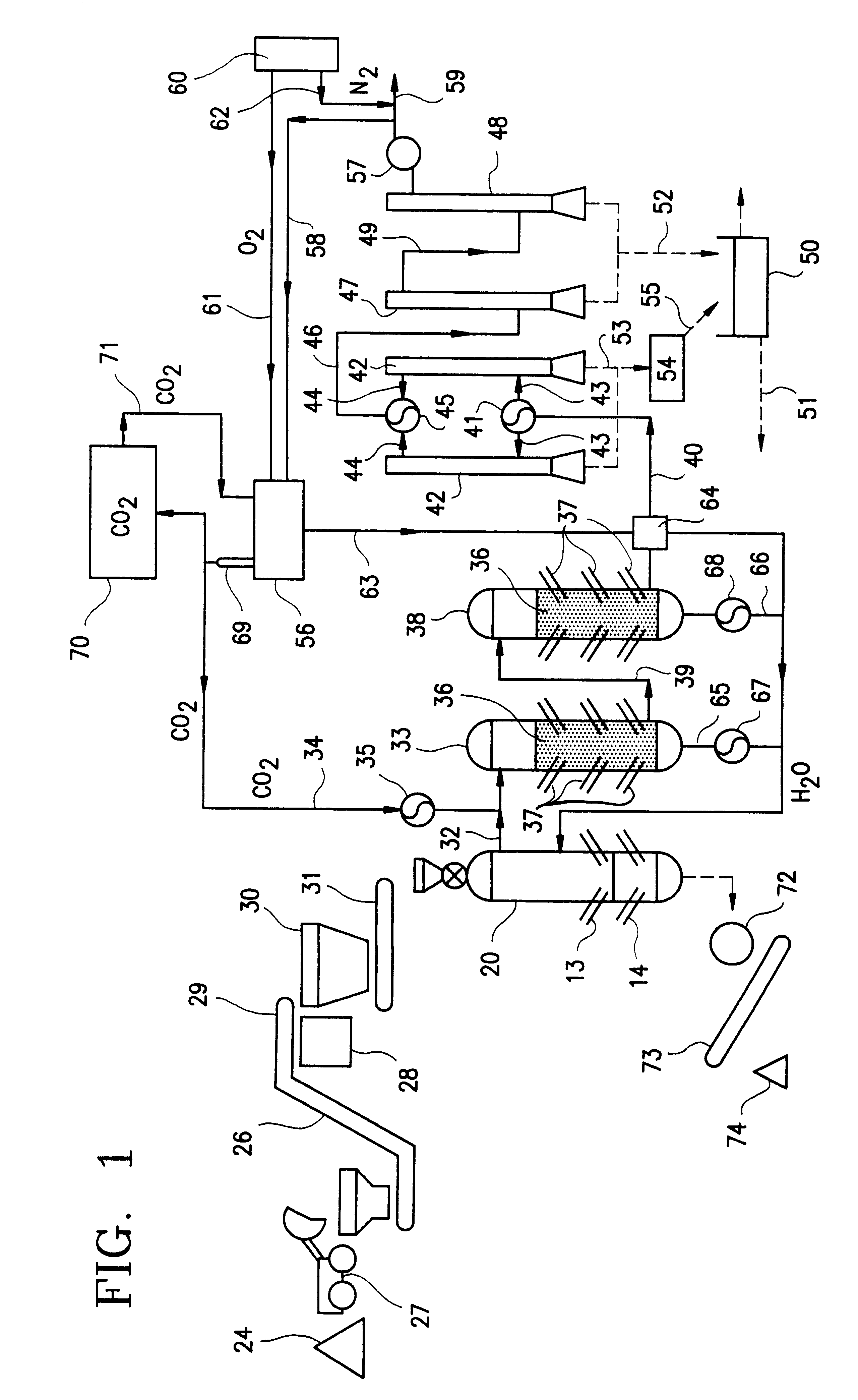

Synthesis gas production and power generation with zero emissions

InactiveUS6333015B1Avoid water pollutionEliminate needElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS GLORIA B

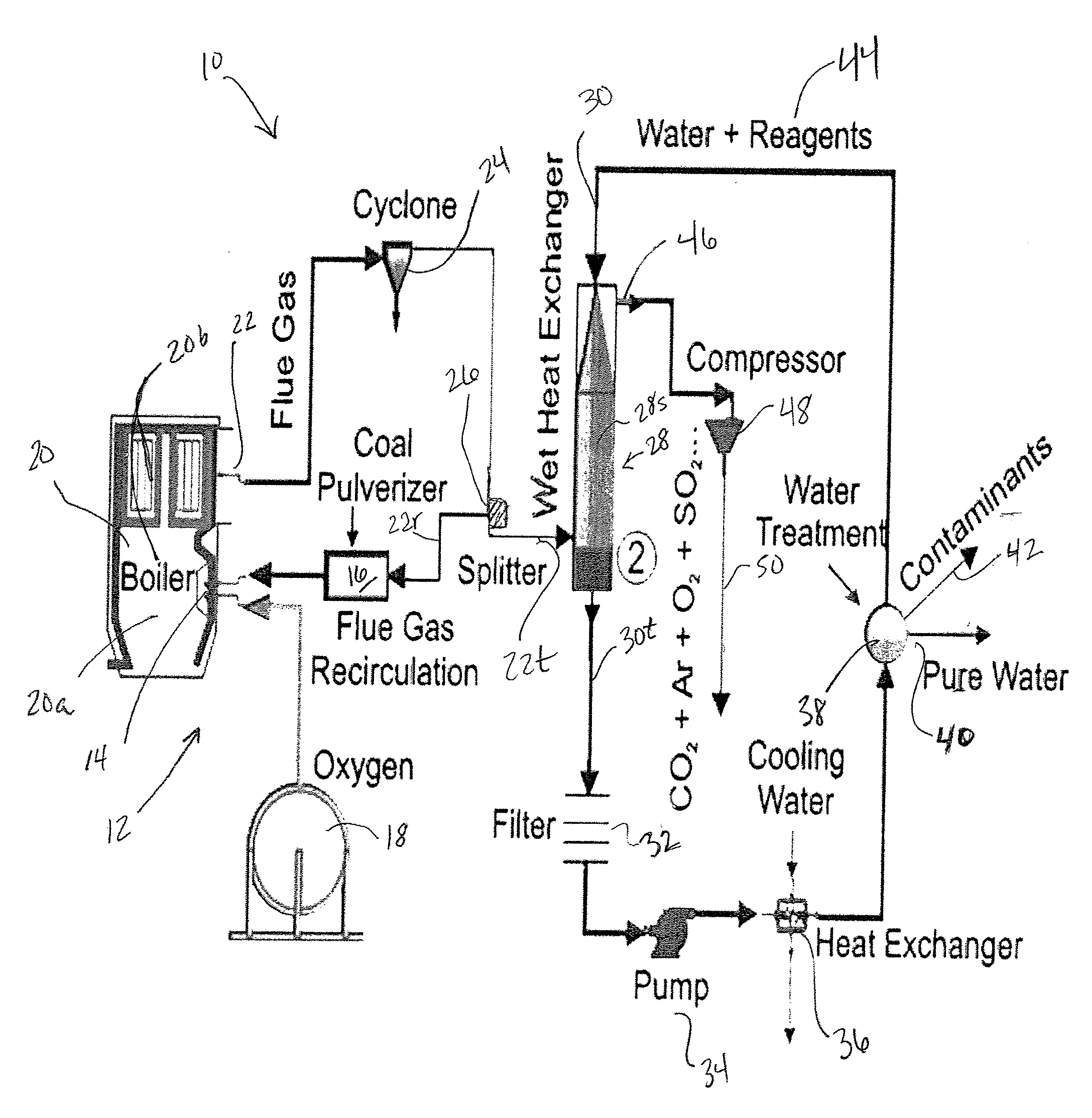

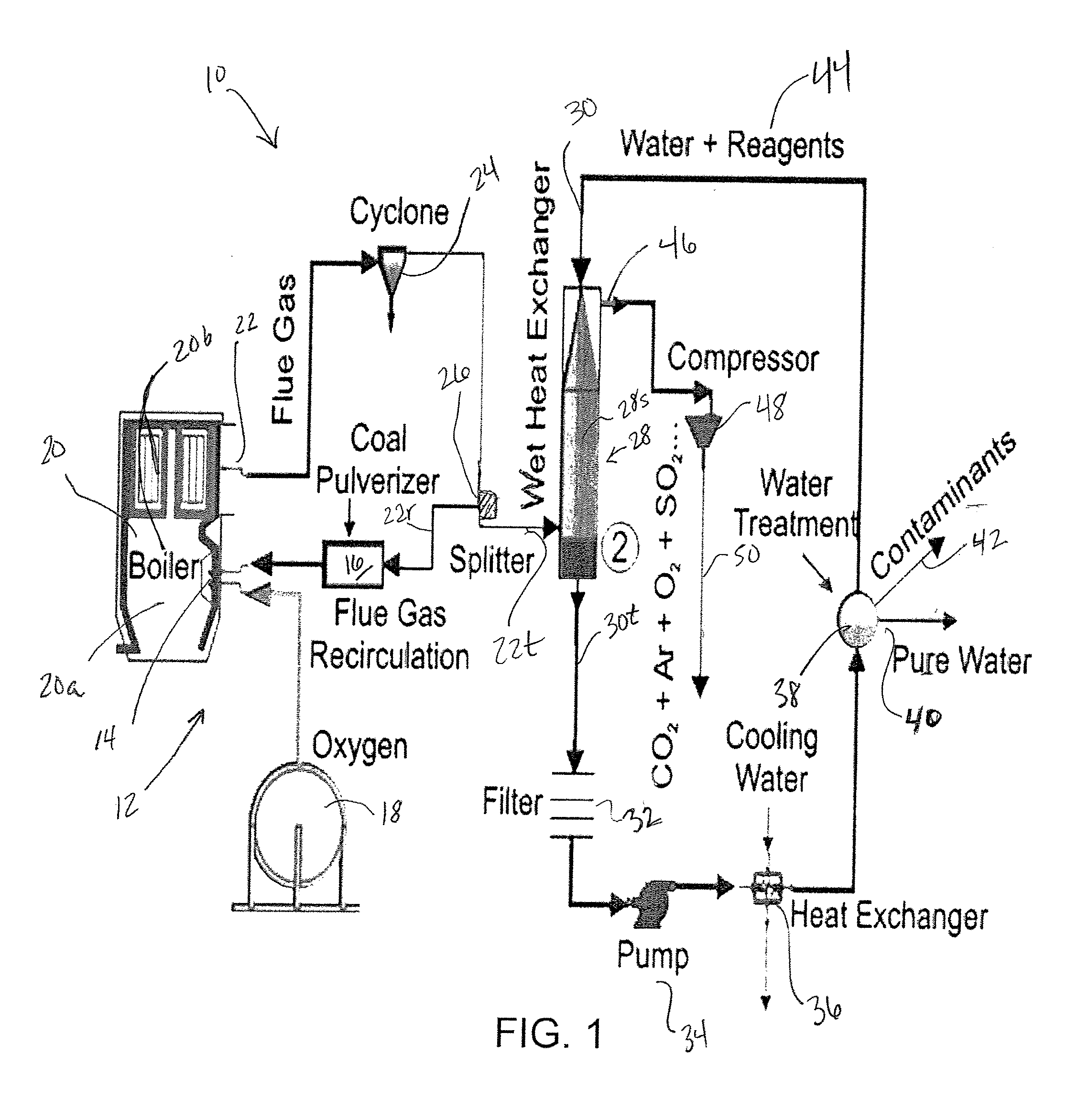

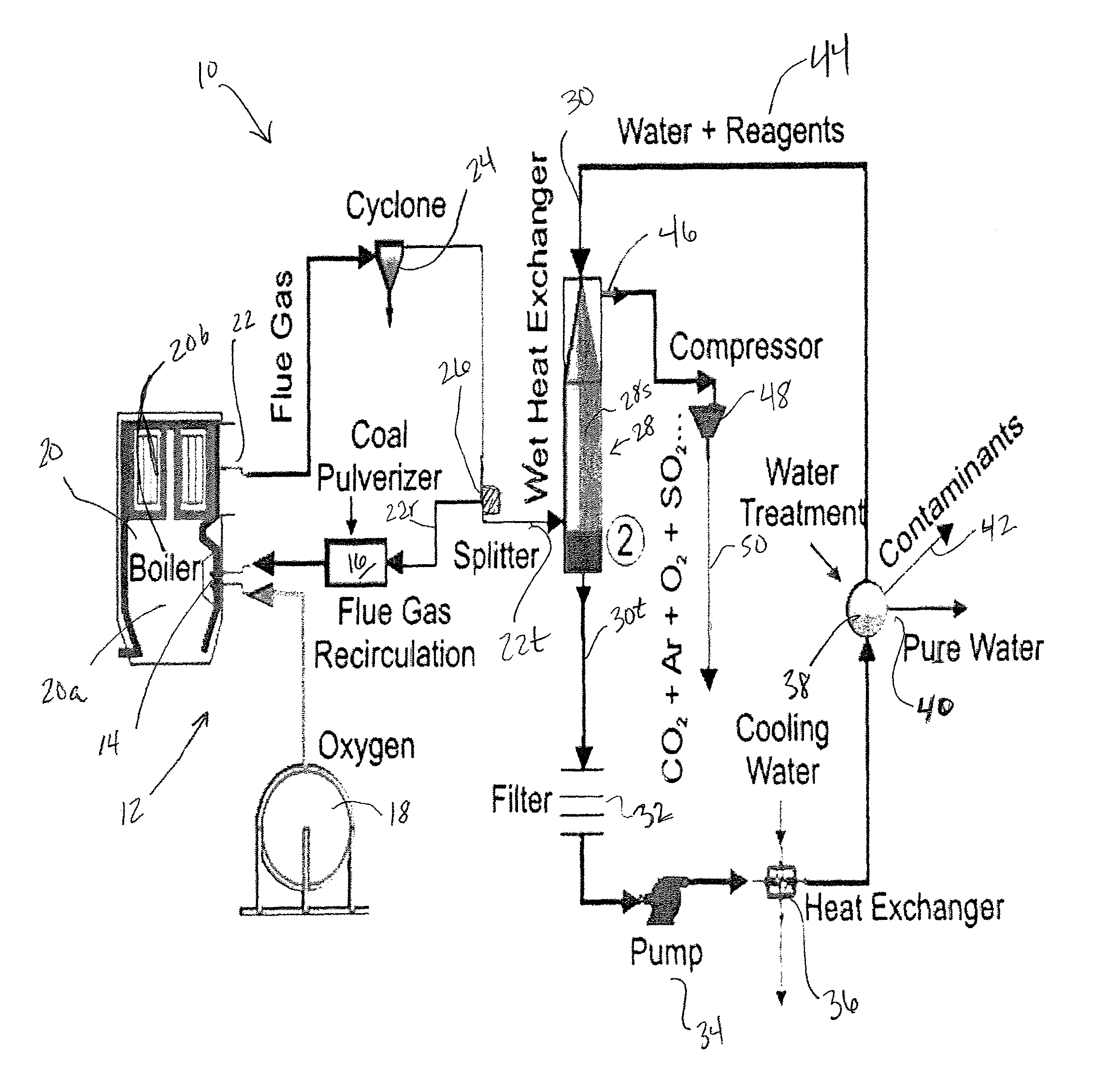

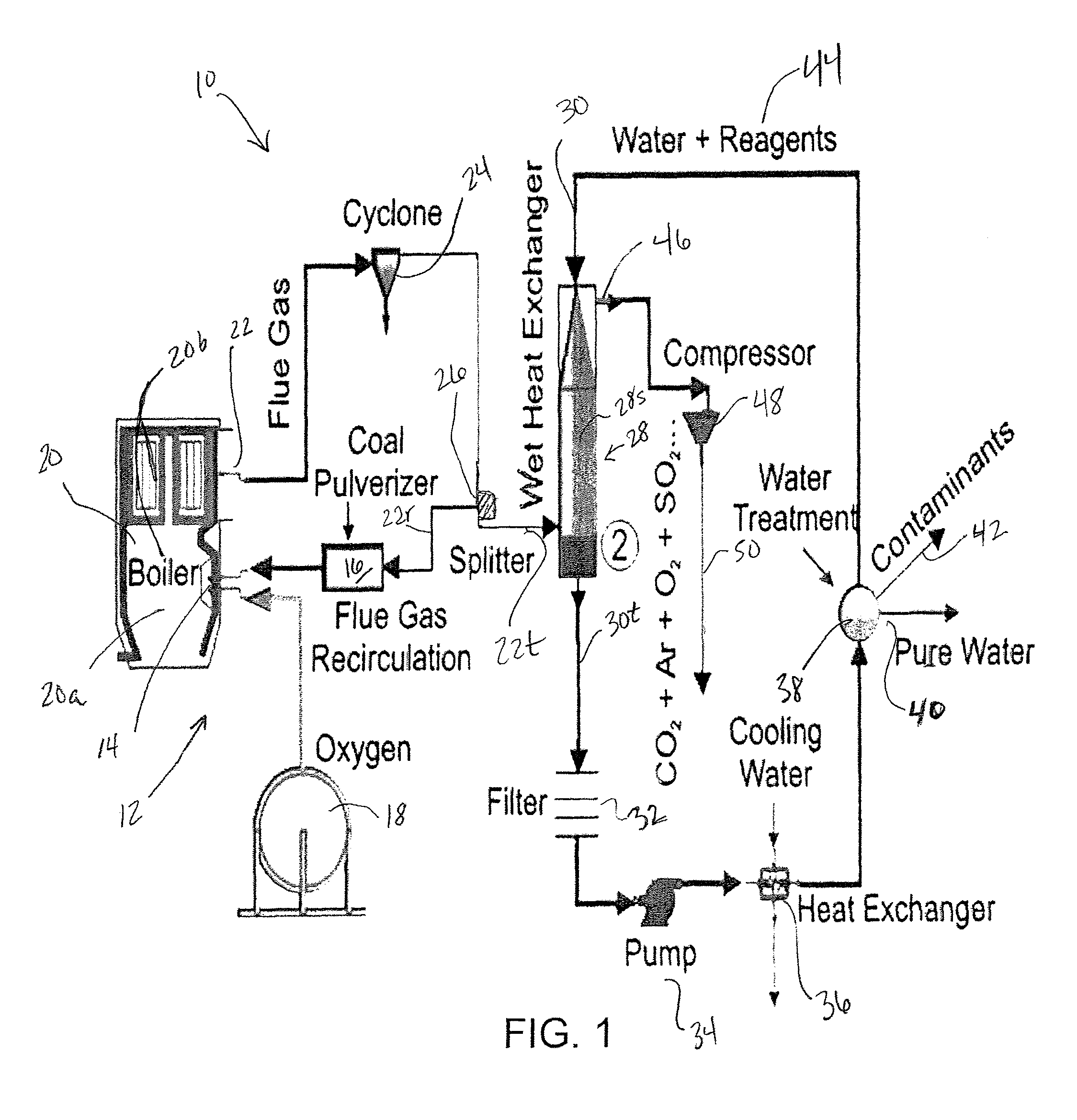

Integrated capture of fossil fuel gas pollutants including co2 with energy recovery

ActiveUS20080016868A1Increase costMaximum recoveryUsing liquid separation agentEmission preventionParticulatesEnergy recovery

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

Integrated capture of fossil fuel gas pollutants including CO2 with energy recovery

ActiveUS8038773B2Maximum recoveryUsing liquid separation agentEmission preventionParticulatesAtmospheric air

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

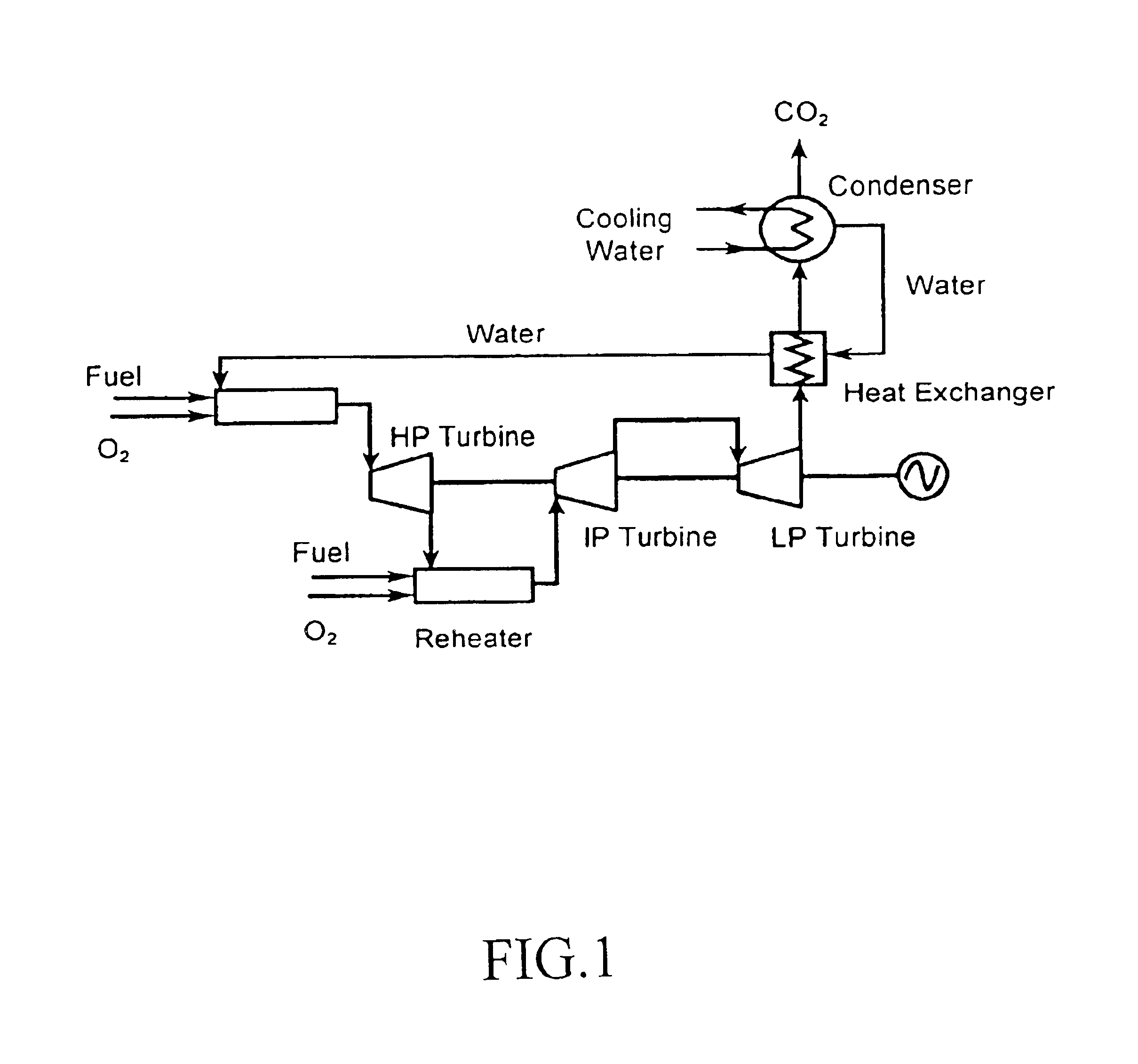

Optimized power generation system comprising an oxygen-fired combustor integrated with an air separation unit

InactiveUS6871502B2Maximize efficiencyImprove efficiencySolidificationLiquefactionHigh pressureCycle efficiency

A novel power generation system, more specifically an integrated power generation and air separation system and an integrated power generation and air separation process is provided. A key component of the system and process is an oxygen-fired combustor designed for gas turbine operating pressures. The combustor produces a high-temperature gas stream that enters one or more heat exchangers to generate / heat steam, and then enters one or more turbines to generate power. The steam from the heat exchanger drives one or more steam turbines to generate power, and the discharged steam is admitted to the combustor. To maximize cycle efficiency, steam extraction and reheat is incorporated in the process. Additional power is generated from a high-pressure nitrogen stream produced by an air separation unit (ASU). This process has the potential to attain high cycle efficiencies with zero emissions, while utilizing existing or near-term steam turbines, and moderate-pressure combustion systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

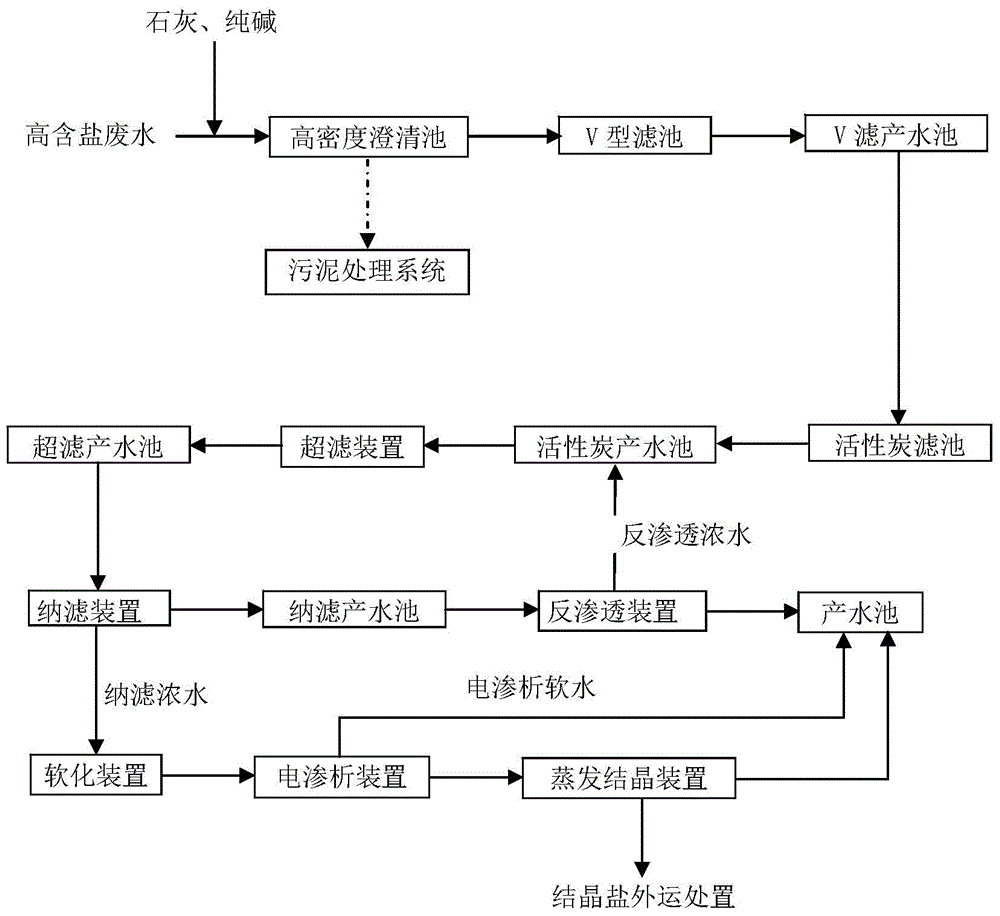

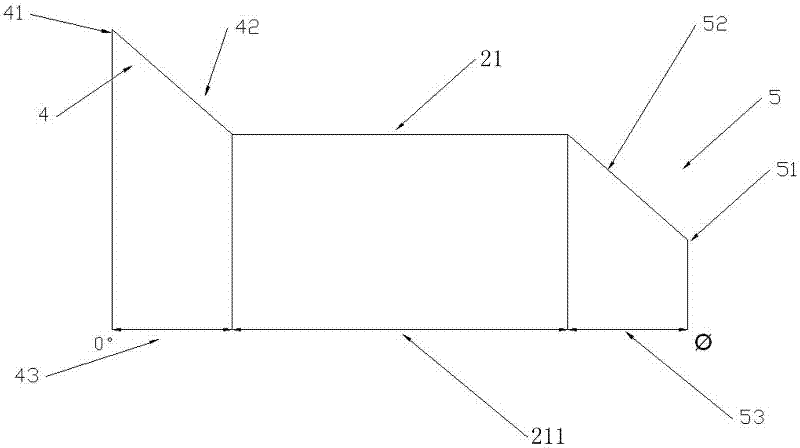

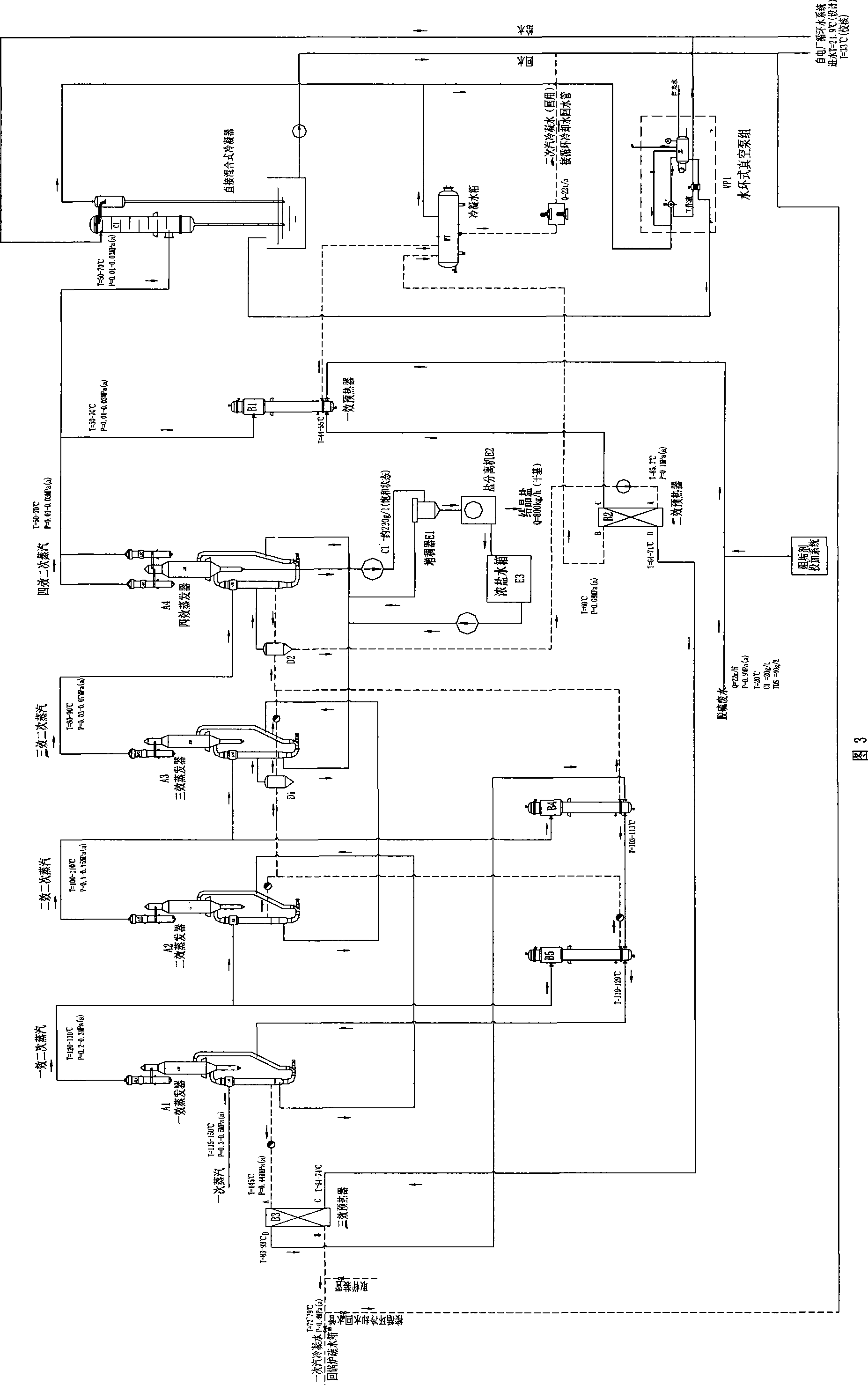

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

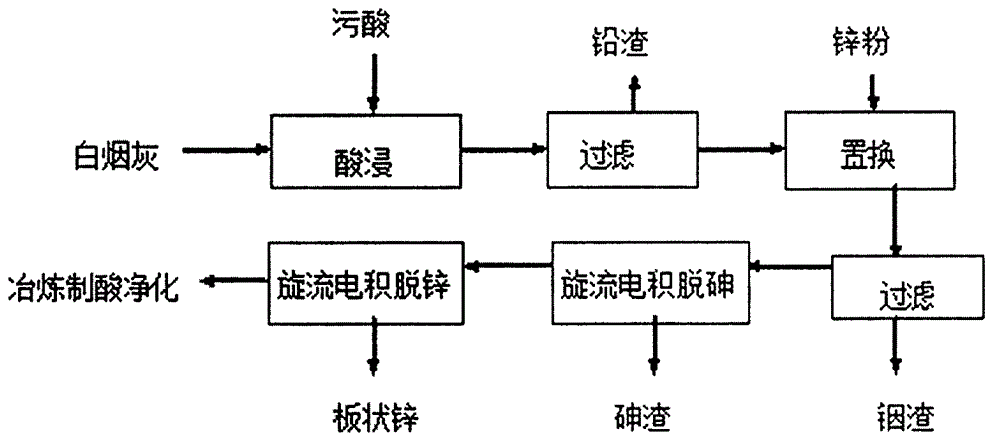

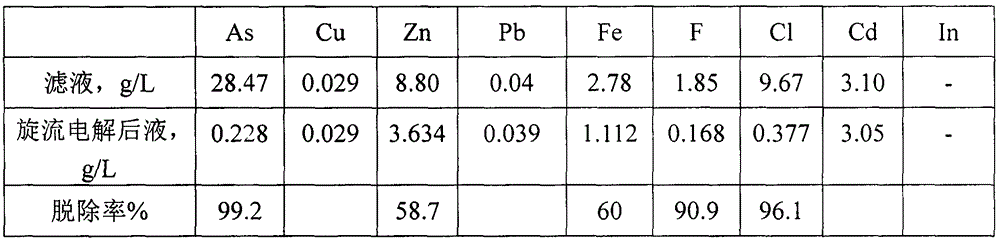

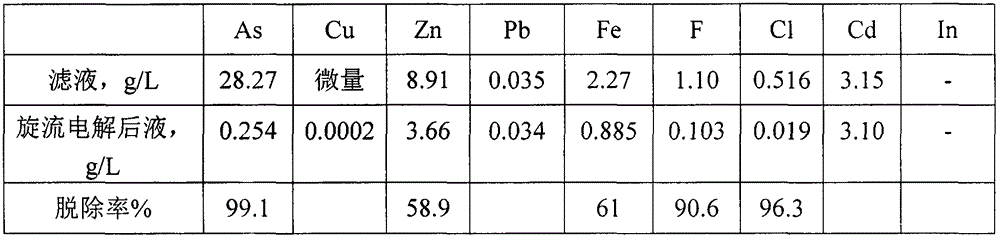

Method of recycling valuable metals from arsenic-containing soot

The invention relates to a method of recycling valuable metals from arsenic-containing soot. The method comprises the following steps: (1) mixing acidic wastewater with white soot, controlling the pH value to 2.5-3.0, performing acid leaching at a temperature of 70-80 DEG C, and filtering to obtain leachate and lead slag; (2) replacing indium for the leachate by using zinc powder, and filtering to obtain indium slag; (3) performing rotational-flow electrodeposition arsenic removal and zinc removal on filtrate in sequence to obtain arsenic slag and zinc slag. The method disclosed by the invention can be used for purifying the acidic wastewater to reach a condition for recycling the acidic wastewater to a smelting acid manufacturing and purifying section, so that the treated acidic wastewater can be directly returned to the acid manufacturing and purifying section, and therefore, the gypsum slag is completely removed to truly achieve the purpose of zero emission. Meanwhile, the method disclosed by the invention can also be used for achieving the treatment of white soot and recycling the valuable metals, so that environmental protection and resource comprehensive utilization are achieved.

Owner:五矿铜业(湖南)有限公司 +3

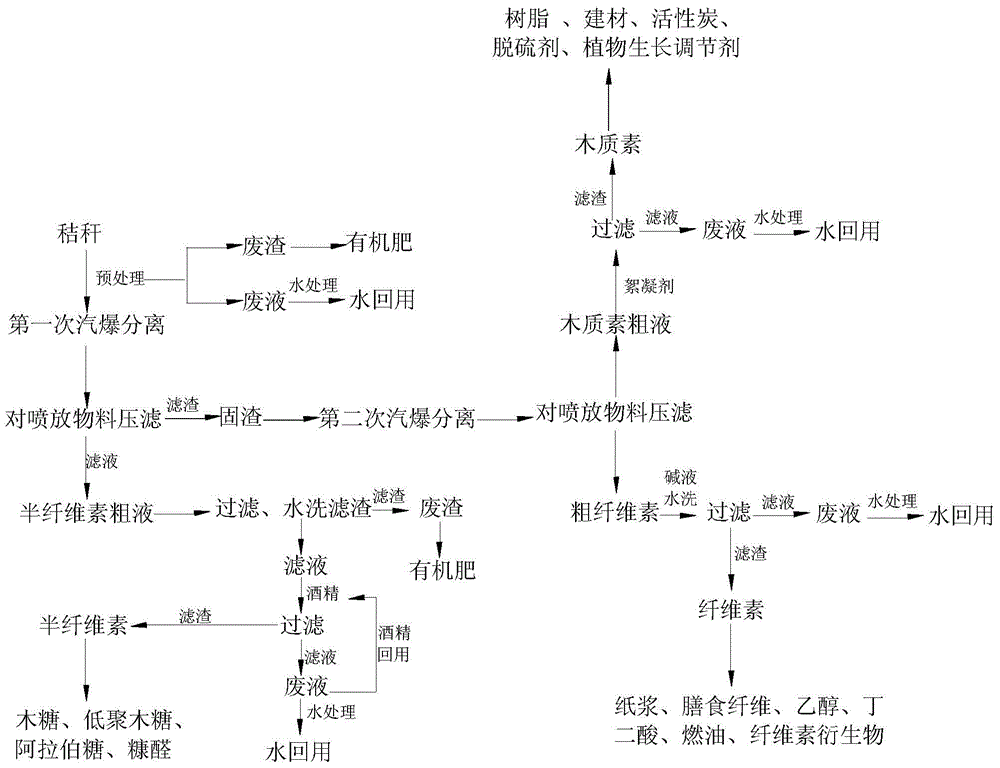

Straw component separation and straw component full utilization method

ActiveCN104404803AAchieve separationEasy to separateRaw material divisionSeparation technologyWastewater

The invention discloses a straw component separation and straw component full utilization method, and relates to the technical field of straw comprehensive utilization. According to the method, straws are subjected to a steam explosion treatment, such that hemicellulose is first separated; and the rest of the material after hemicellulose extraction is subjected to steam explosion treatment again, such that the separation of cellulose and lignin is realized. The method has the advantages of simple process, environment-friendliness, low cost, and thorough separation of hemicellulose, cellulose and lignin. With the method provided by the invention, an environment-friendly separation technology of cellulose and lignin is realized for the first time internationally, and a basis is provided for full-element, high-added-value and comprehensive utilization of straws. On the basis, products with higher added values can be derived or generated. With the production process provided by the invention, all wastewater is treated and is completely recycled, and all waste residue is used for producing organic fertilizers, such that straws are thoroughly utilized, and straw component full utilization is realized. Also, zero emission and zero pollution are realized, such that the difficulty of straw comprehensive utilization is solved.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

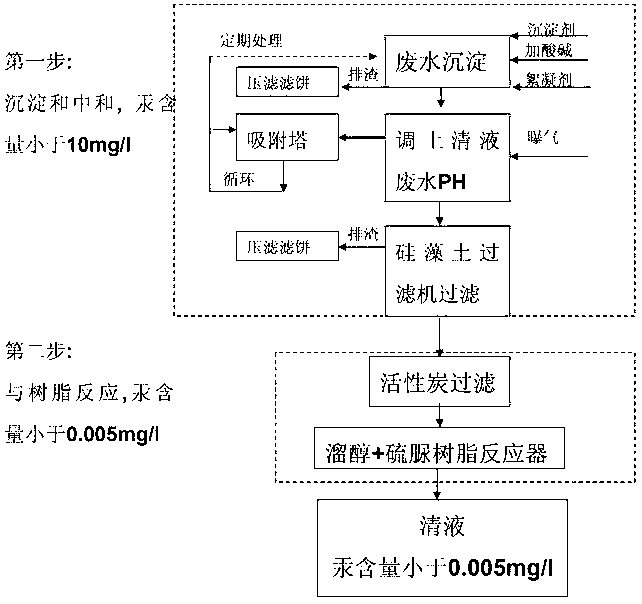

Method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through two-step process

InactiveCN102936070AEnsuring a circular economyImprove processing efficiencyMultistage water/sewage treatmentNature of treatment waterSlagGas phase

The invention discloses a method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through a two-step process. The method comprises the following steps of: firstly, completing primary removal of mercury, copper, ferrous and ferric iron, cadmium, zinc, manganese, lead and suspending impurities of above 10mg / l by using a precipitator and a flocculating agent, regulating PH to 6-8 and then adding the flocculating agent and stirring for 30 minutes, standing for above 1 hour, discharging slag and aerating, absorbing mercury carried away by a gas phase through a sulfide adsorber, purifying water by using a plate type kieselguhr filter, removing residual suspended matters; and 2, carrying out complete reaction on the mercury in the wastewater by using an active carbon and a mercaptan and thiourea resin combining method again for being removed, and finally reaching the standard that the content of the mercury is less than 0.005mg / l. The treated wastewater can be recycled to salt melting or an acetylene generator, so that zero emission of the treated wastewater is achieved; and the mercury-containing waste acid water of hydrochloric acid desorption in the industry of chlor-alkali can be treated, the consumption of acid is reduced, and the great popularization significance is achieved in the industry of chlor-alkali.

Owner:赵建军

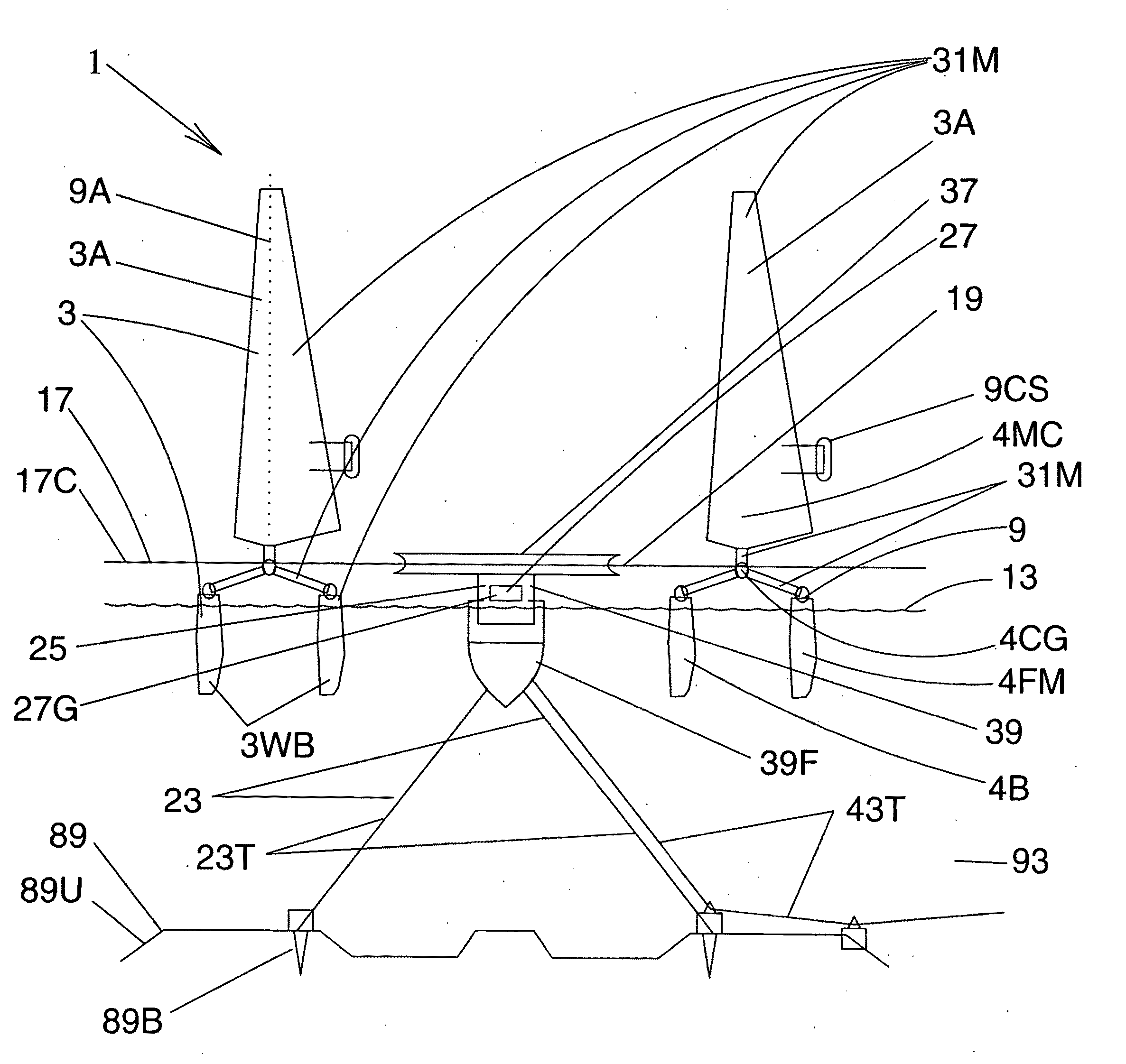

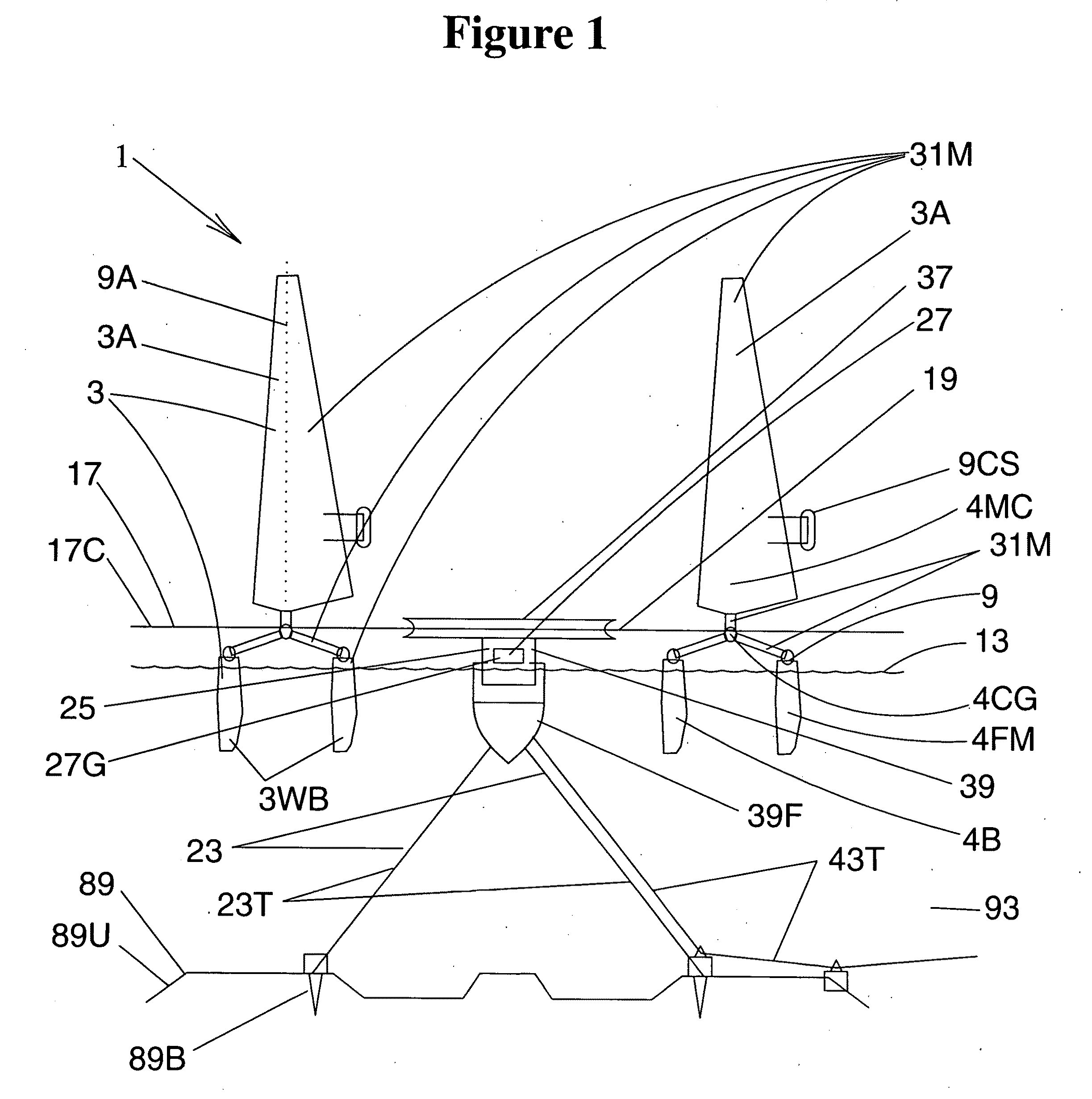

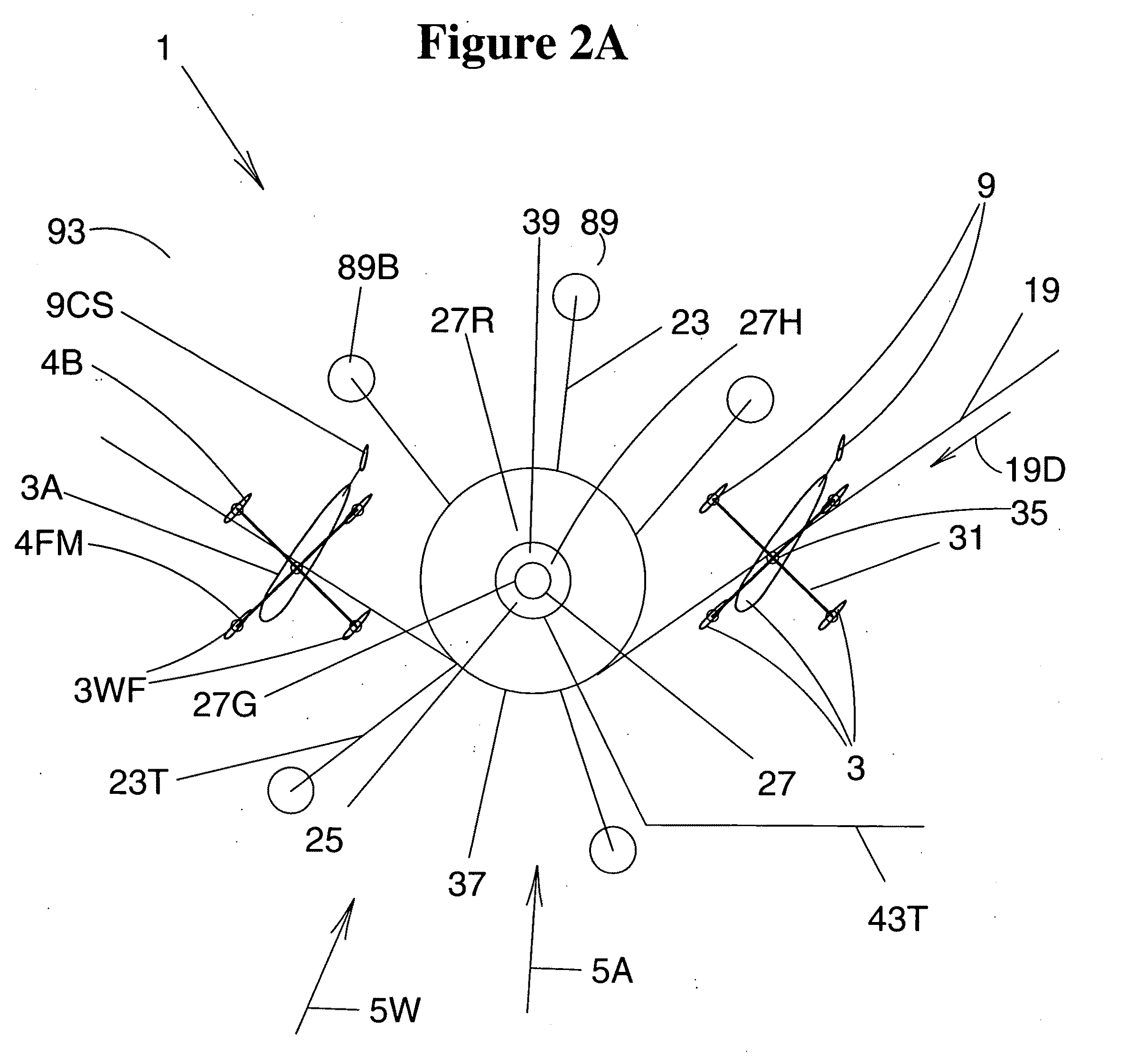

Fluid-dynamic renewable energy harvesting system

ActiveUS20090127861A1Efficiently energy needArtificial islandsWind motor combinationsCollection systemEngineering

The invention provides a fluid-dynamic renewable energy harvesting system which includes fluid-foil means for interfacing with a fluid current such as a water current or wind or both, and which includes energy harvesting means utilizing fluid current driven periodic motion of the fluid-foil means for capturing fluid-dynamic renewable energy and converting it into usable energy in a desired form such as electricity. The invention provides devices, methods and systems for harvesting renewable energy for small-scale, medium-scale and large-scale applications, to provide real and substantial benefits towards efficiently fulfilling energy needs while also more broadly serving humanity and our global environment. The various embodiments of the invention provide energy with zero consumption of fossil fuels and zero emissions of greenhouse gases, and some selectively sited embodiments can beneficially counter global warming induced ice melting.

Owner:RIC ENTERPRISES

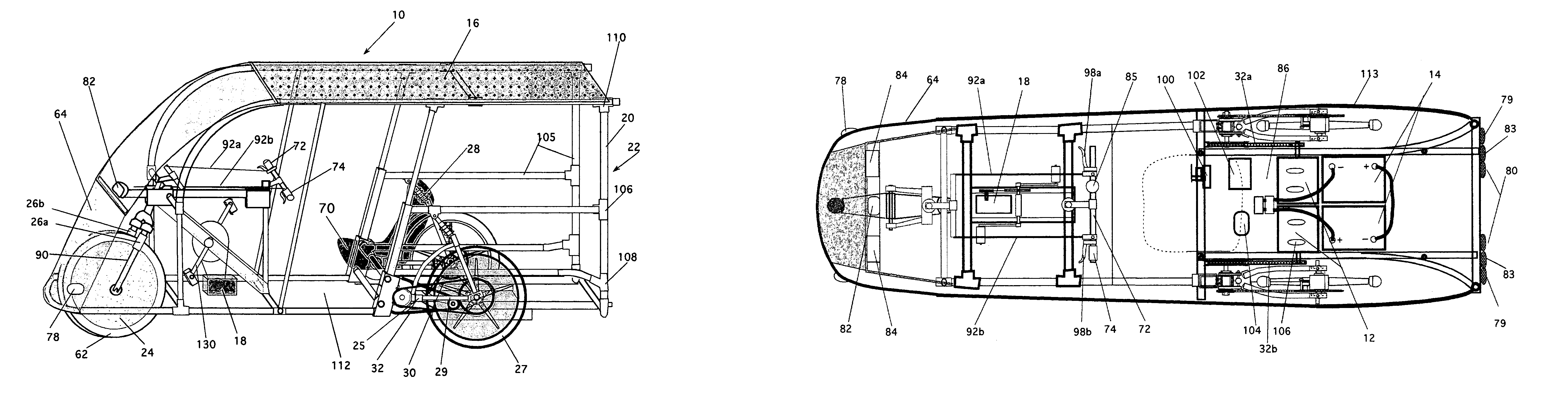

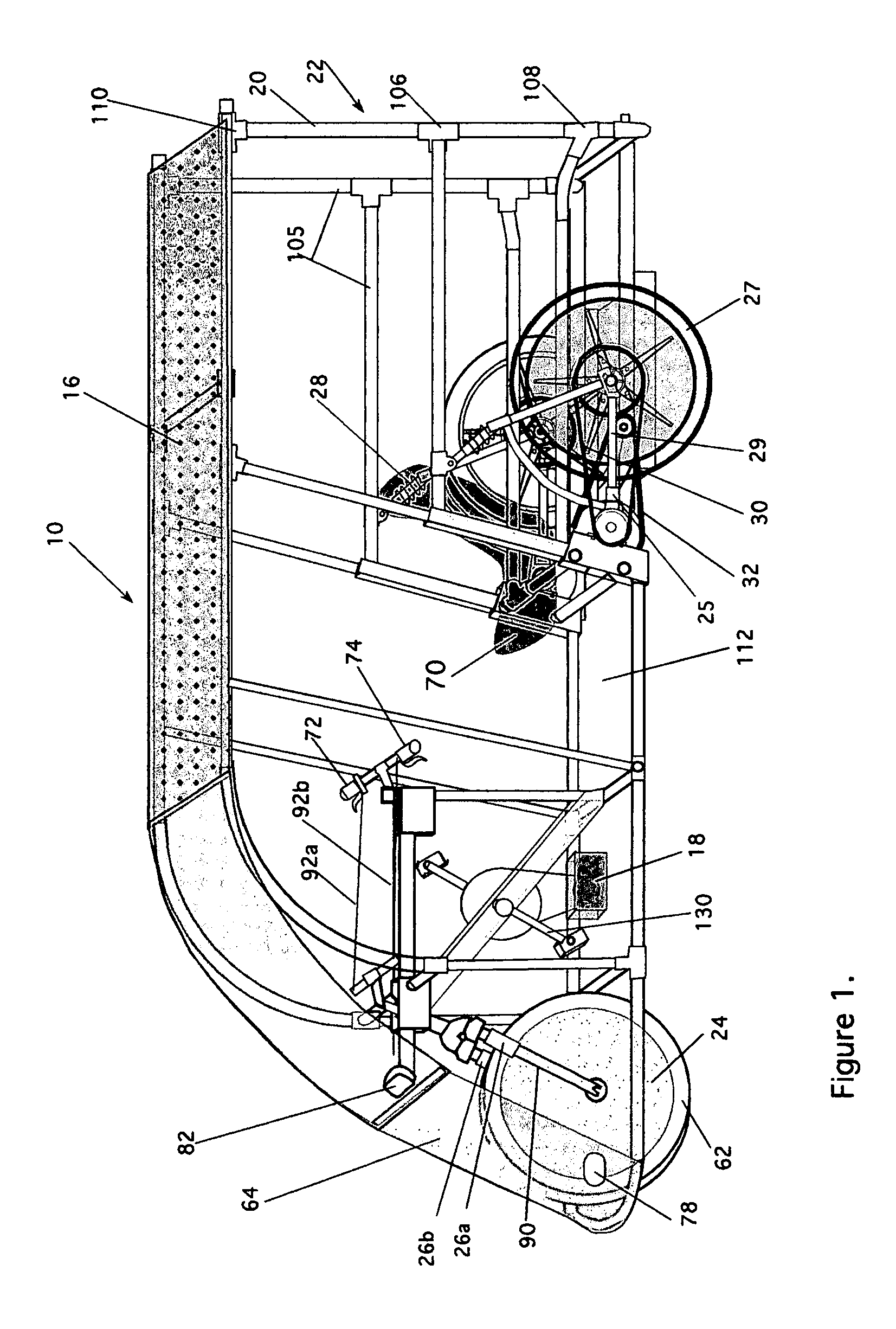

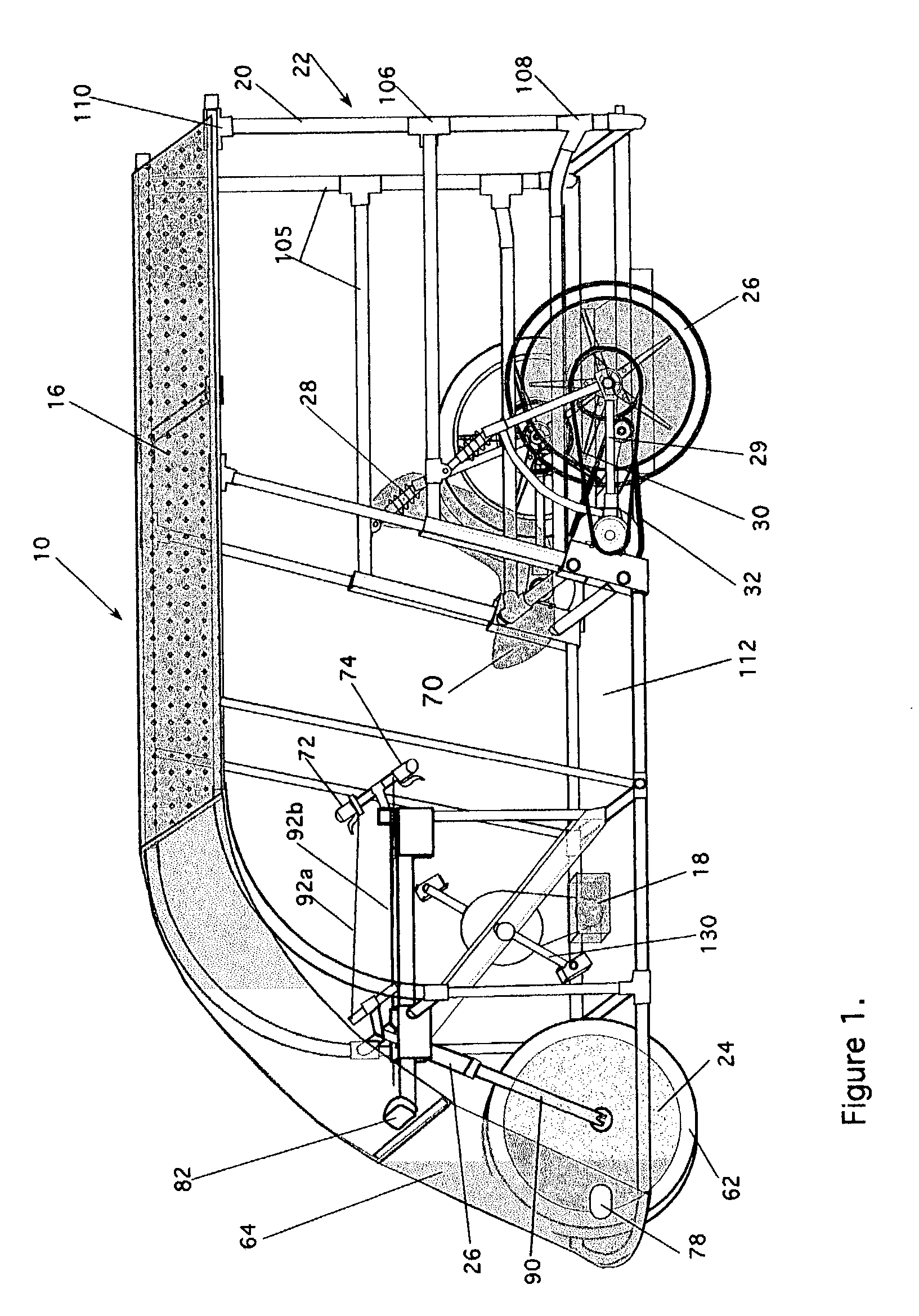

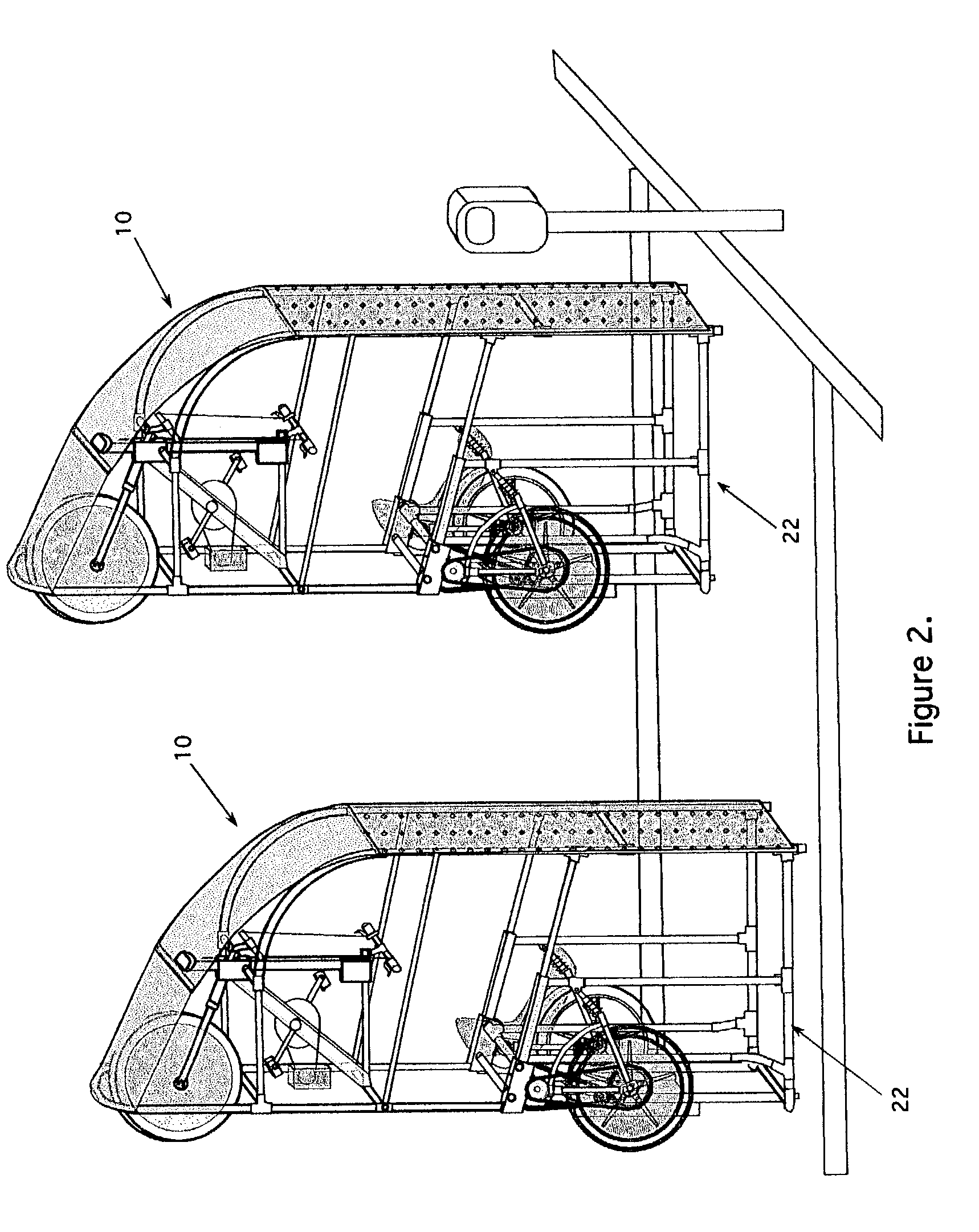

Combination pedal/motor driven tricycle

InactiveUS7017685B2Eliminate needReduce needAuxillary drivesElectric devicesBattery chargeMotor drive

A zero-emissions electric three-wheeled, enclosed scooter with two 1 hp motors driven from batteries charged by solar panels and a pedal-driven generator; also incorporating an innovative rear wheel drive and suspension system and a tilt capability to reduce parking space requirement to approximately one quarter of that of a conventional automobile.

Owner:SCHOENBERG ANDREW

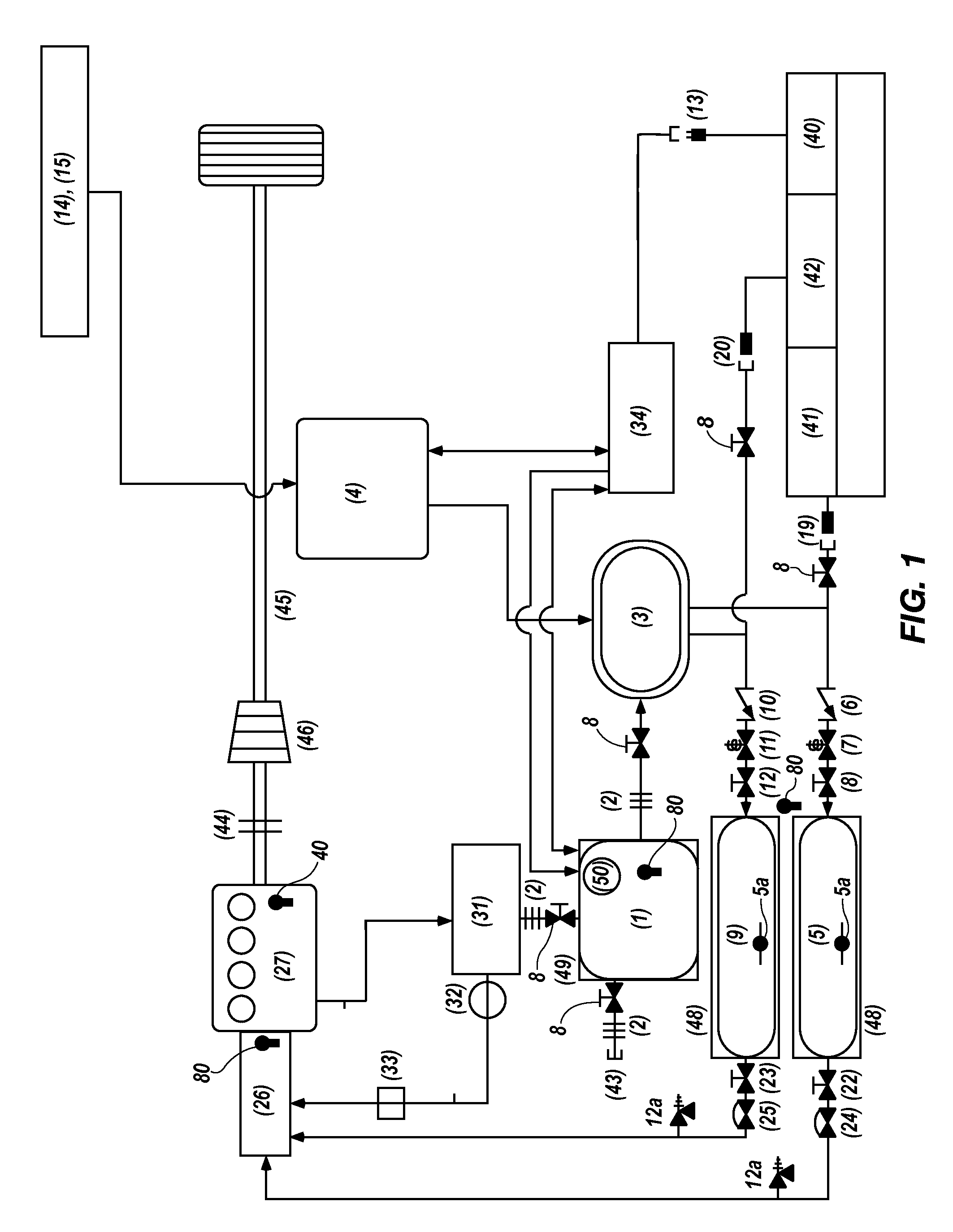

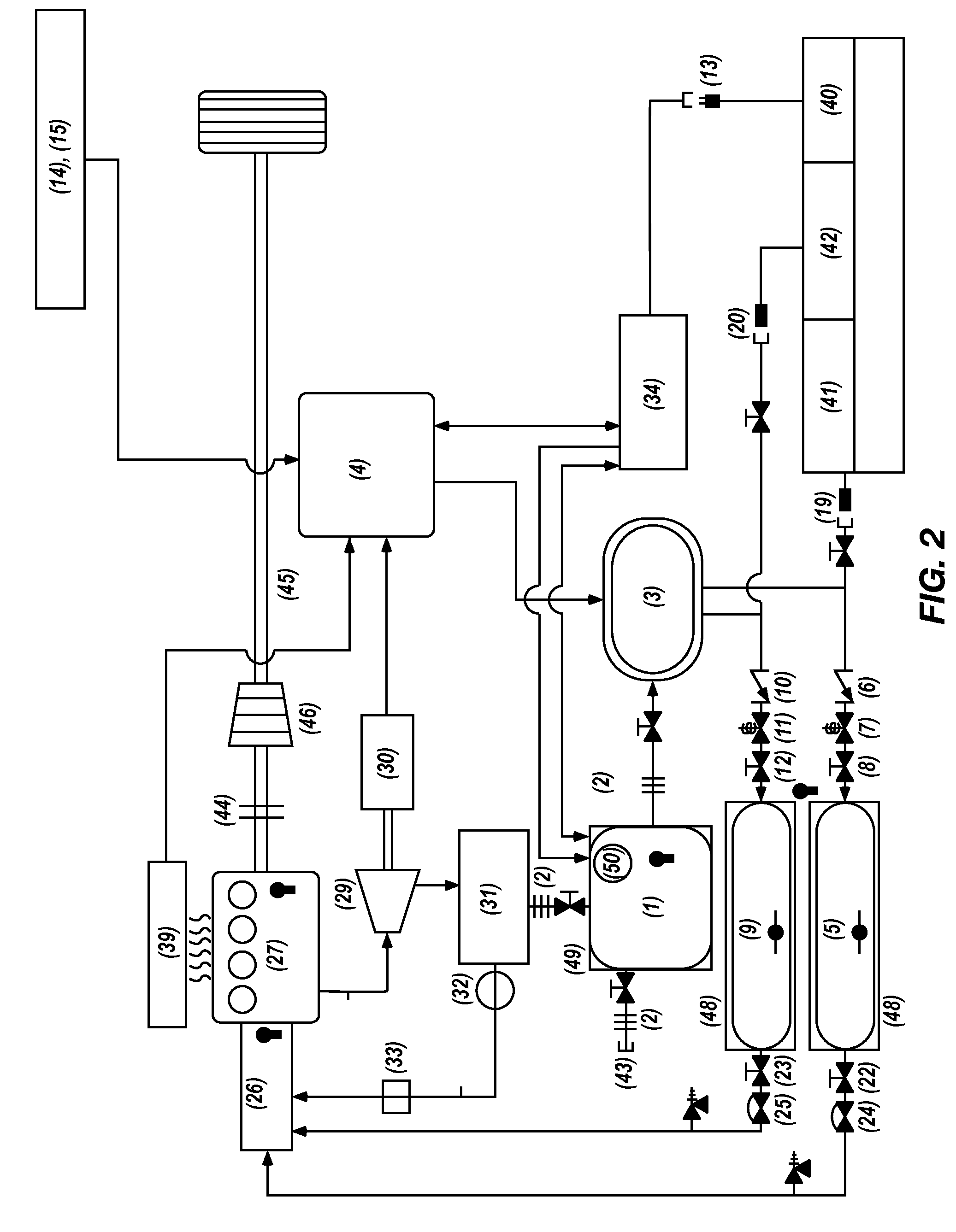

Partially Self-Refueling Zero Emissions System

ActiveUS20090260363A1Good effectReciprocating combination enginesPiezoelectric/electrostriction/magnetostriction machinesExternal combustion engineOn board

A method and device to optimize the cumulative beneficial effect of harvesting all available forms of lost energy, including energy that is lost while a vehicle is in motion (e.g., kinetic, inertia, friction, thermodynamic, and aerodynamic losses). The cumulative energy that is recovered is converted to electrical energy which powers the on-board electrolyzer to produce more hydrogen and oxygen while the system is in operation and stationary. Stationary, passive means of energy, solar, wind, hydro, etc. will also be available to power the electrolyzer. The system also contemplates utilizing passive means of energy to power a non-mobile system which incorporates an internal or external combustion engine in place of a fuel cell.

Owner:MORIARTY DONALD E

Recovery processing method of silicon slice cut waste mortar

The invention relates to a recovery processing method of silicon slice cut waste mortar, comprising the following steps: (1) separating solid-liquid components in the silicon slice cut waste mortar; (2) further recovering the remained cutting liquid component in a solid; (3) separating silicon powder and silicon carbide through water flow flotation; (4) recovering the silicon powder; (5) recovering the silicon carbide; (6) coarsely filtering, finely filtering, decoloring, vacuum distilling and dehydrating the recovered cutting liquid, and adding component with corresponding amount for secondary filter. The method can get various recovered products, such as silicon carbide micro powder, cutting liquid and silicon powder, has high recovery rate and recovery profit and can save the cost of the mortar by at least 40 percent; meanwhile, the invention effectively solves the problem of possible secondary pollution caused by single recovery; the cutting function of recovered and treated silicon carbide micro powder is recovered again, thereby changing waste into wealth, realizing the resource reutilization in true sense, and promoting the development of recycling economy; and the method basically realizes the zero emission of waste liquid by reutilizing the treated waste water after combining a sewage treatment process, thereby being beneficial to environment protection.

Owner:HENAN XINDAXIN SCI & TECH

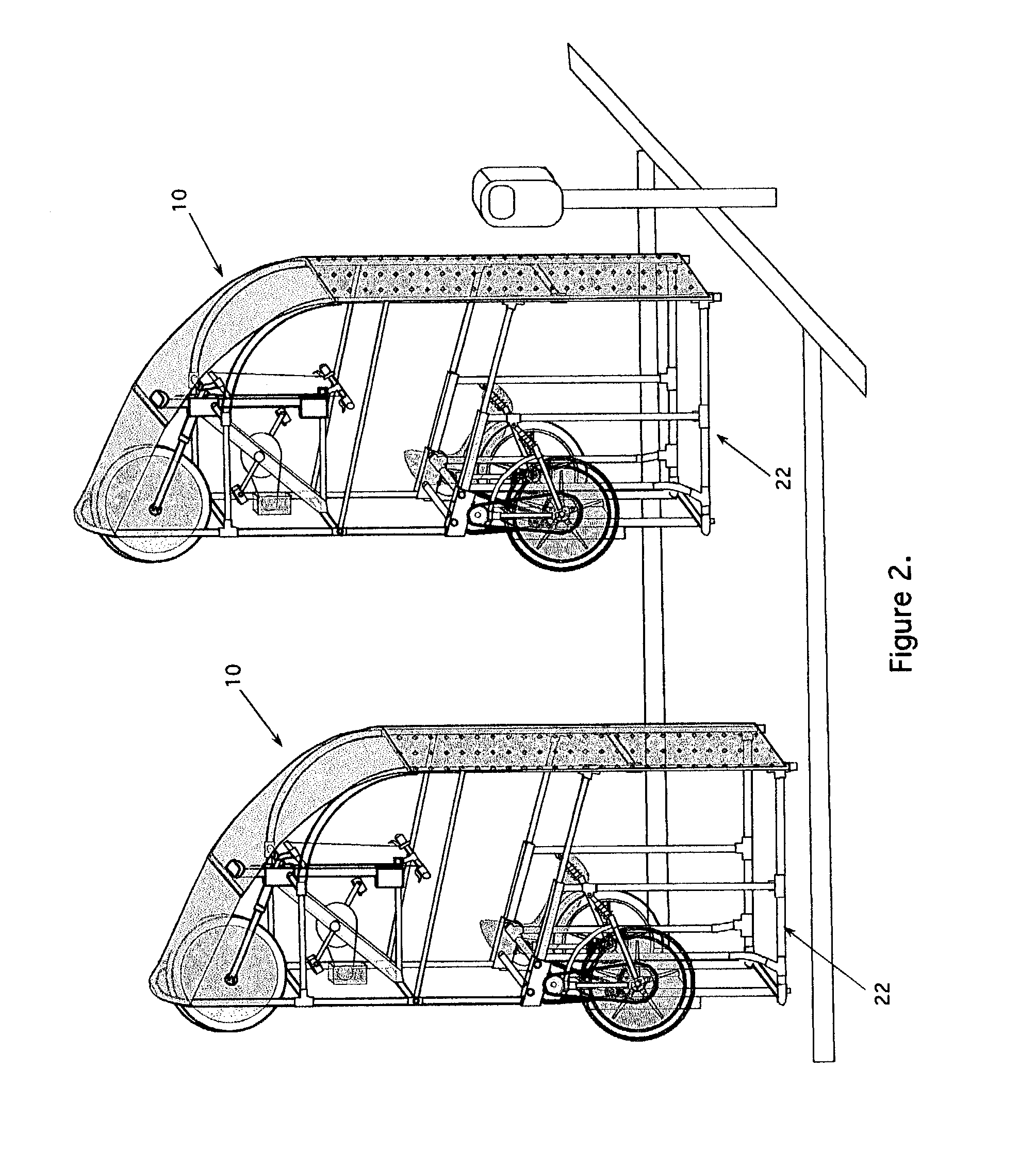

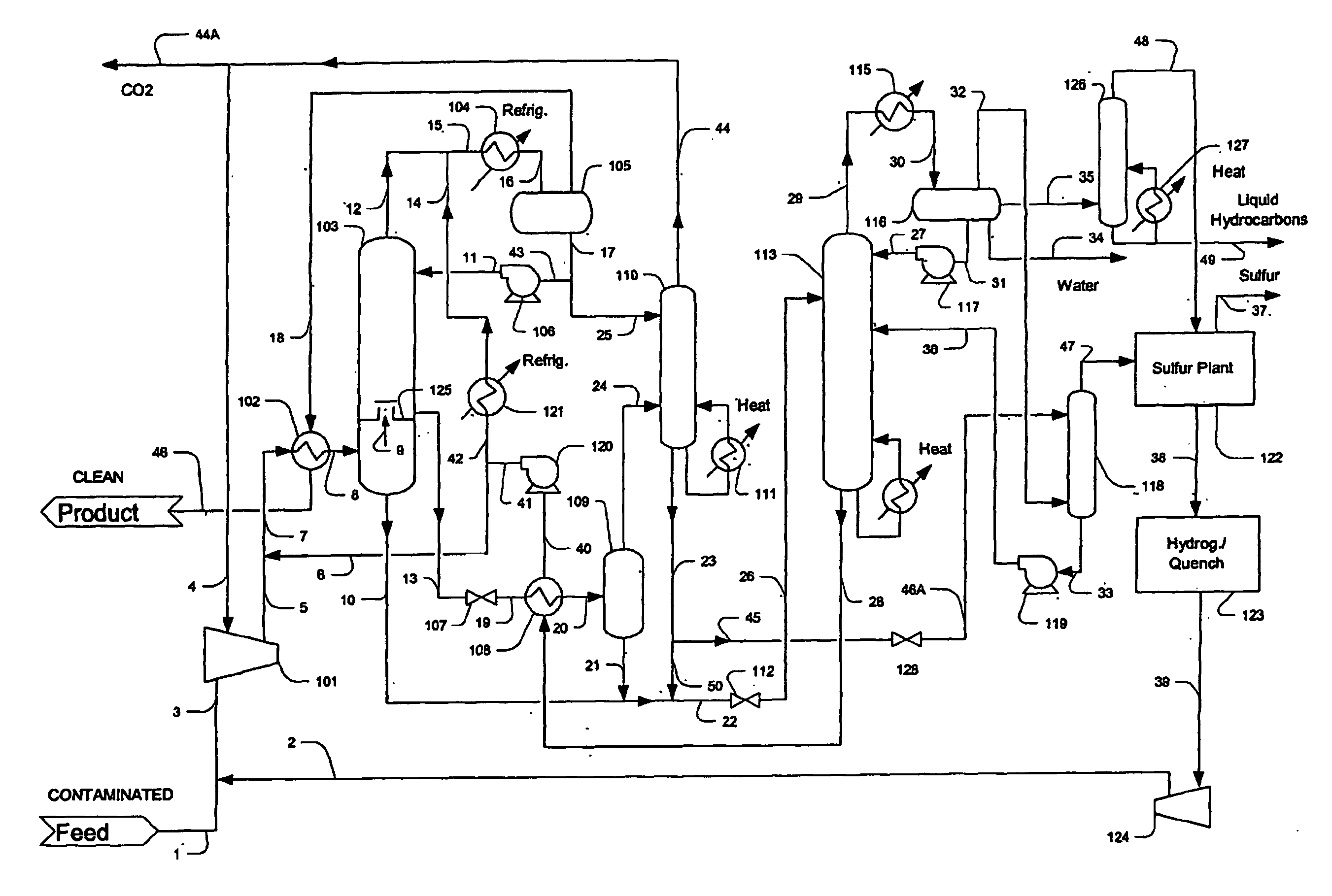

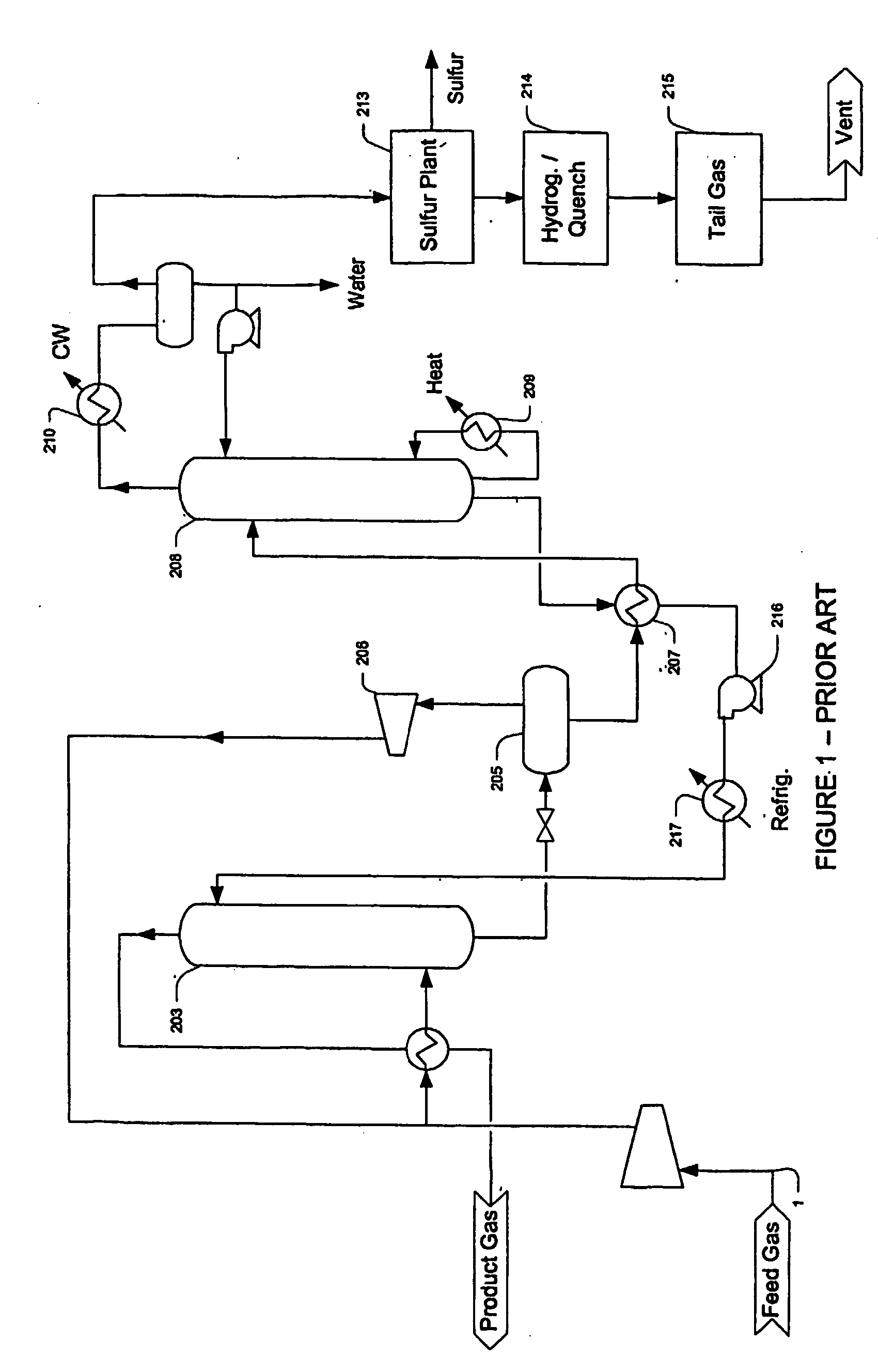

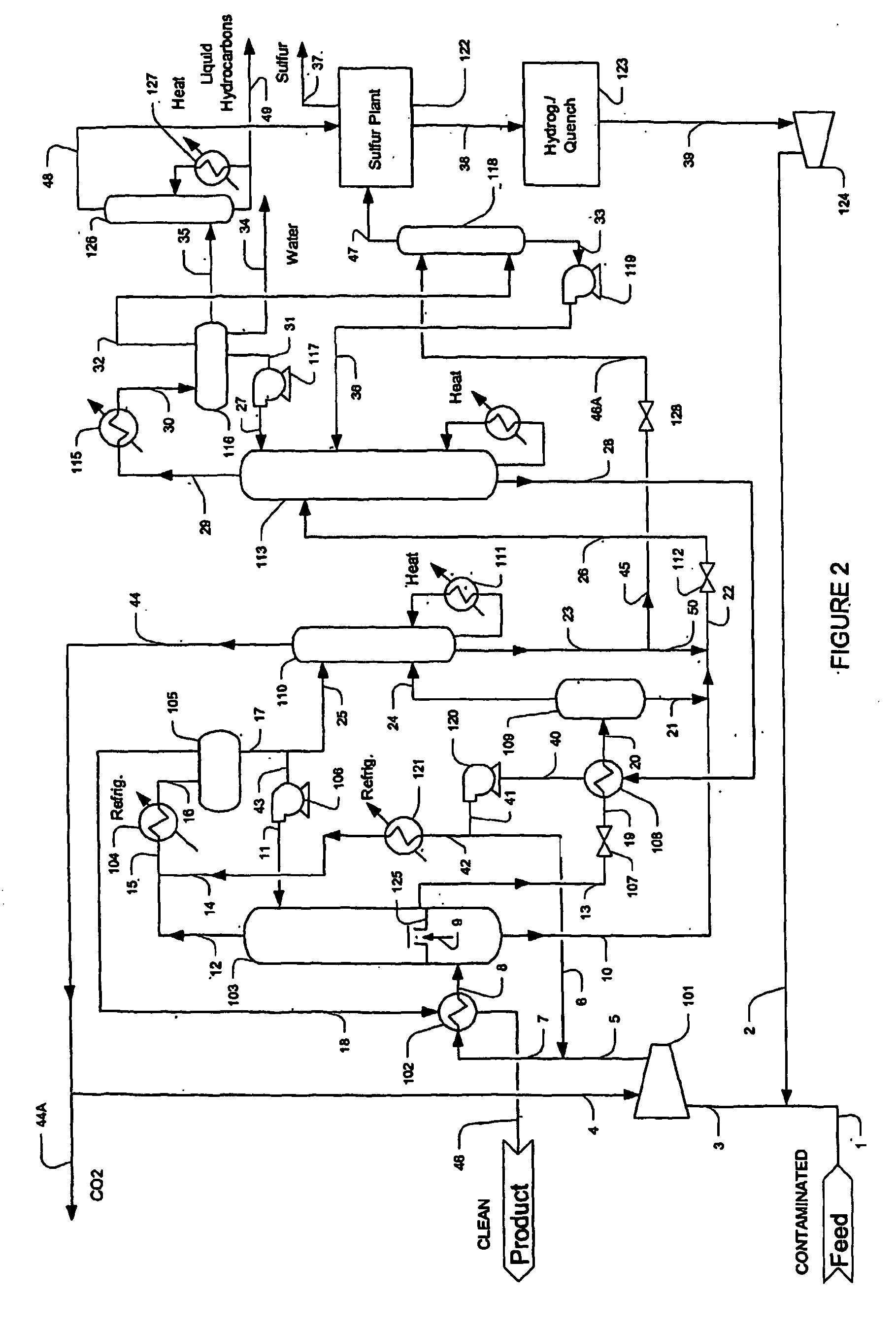

Configurations and methods for acid gas and contaminant removal with near zero emission

InactiveUS20060150812A1Reduce temperature riseEnhance selective absorptionProductsLiquid degasificationWaste streamHydrocotyle bowlesioides

A gas (1) comprising hydrogen sulfide, carbon dioxide, and hydrocarbon contaminants is treated in a plant (FIG. 2) in a configuration in which waste streams are recycled to extinction. In especially preferred aspects of contemplated methods and configurations, hydrogen sulfide and other sulfurous components are converted to a sulfur product (37), carbon dioxide (44A) is separated at a purity sufficient for enhanced oil recovery or sale, and hydrocarbon contaminants are purified to a marketable hydrocarbon product (49).

Owner:FLUOR TECH CORP

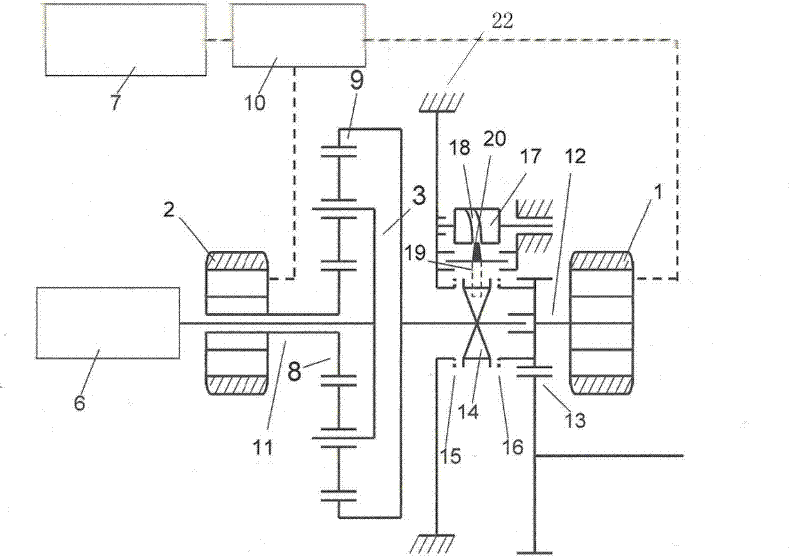

Extended range hybrid electric vehicle power system with modes switched by synchronizer

InactiveCN102303517ASimple structureLow costGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machinery

The invention aims to provide an extended range hybrid electric vehicle power system with modes switched by a synchronizer. The system comprises a first motor and a second motor, an engine, a planetary gear train, the synchronizer, a fixed canine tooth ring which is fixedly connected with a box, a shaft gear canine tooth ring which is fixedly connected with a gear of an output shaft of the first motor, and a battery and an inverter; the engine is connected with a planet carrier of the planetary gear train; the second motor is connected with a sun gear of the planetary gear train through a sleeve; annular internal gears of the planetary gear train can be fixed on the box through the synchronizer and can also be connected with the output shaft of the first motor through the synchronizer, and the output shaft of the first motor is connected with a main change gear; the synchronizer is positioned between the fixed canine tooth ring and the shaft gear canine tooth ring; the annular internal gears of the planetary gear train are connected with a shaft sleeve spline of the synchronizer; the extended range hybrid electric vehicle power system can run in a pure motor-driven way to realize zero oil consumption and emission, and if the extended range hybrid electric vehicle power system needs to run for a long distance, the extended range hybrid electric vehicle system can run in an extended range mode, and the motor controls the position of the synchronizer to realize mode switching.

Owner:苏州安远新能源动力有限公司

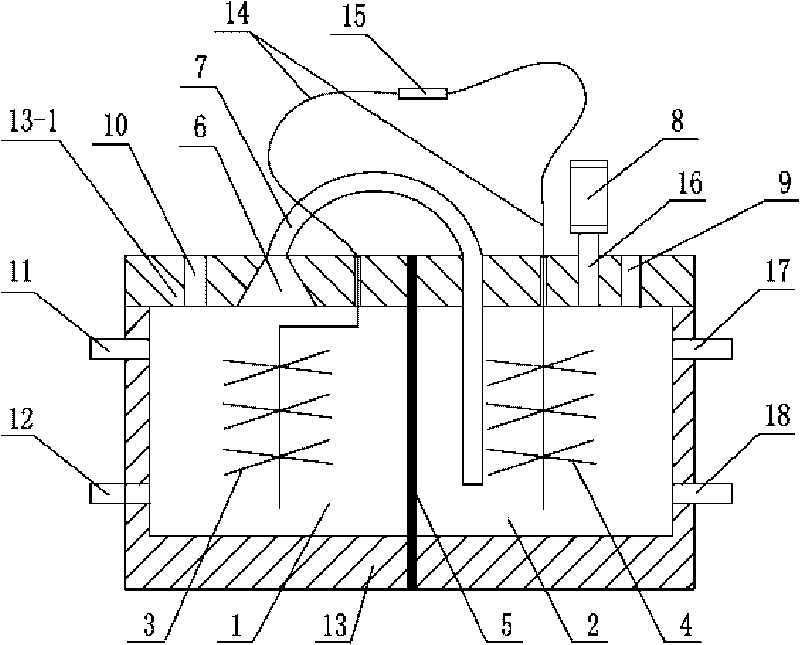

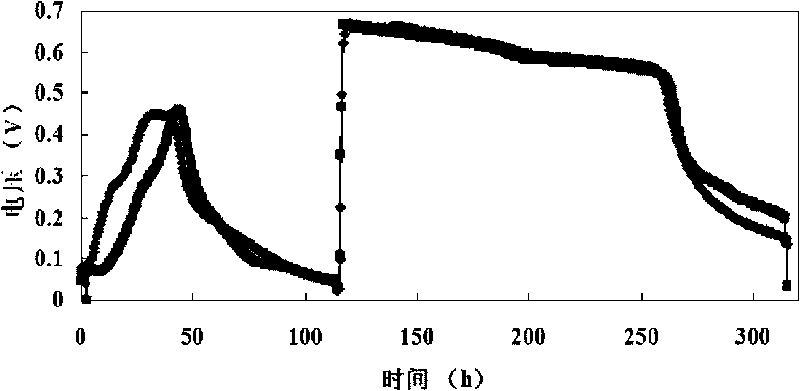

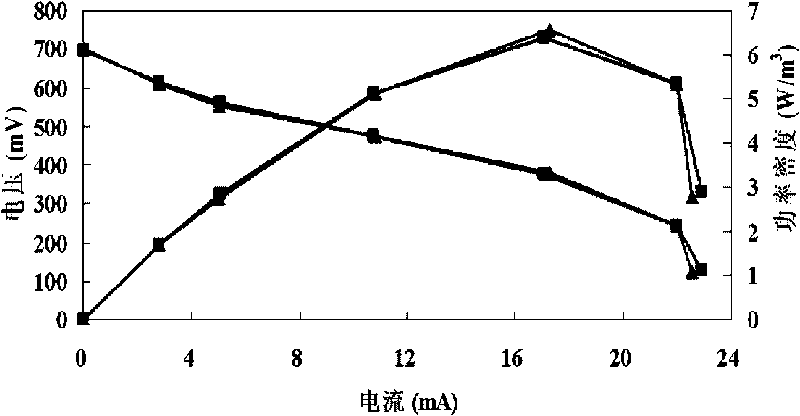

Double-chamber alga microbial fuel cell and method thereof for treating waste water and realizing zero carbon emission

ActiveCN101719555AAchieving zero emissionsAchieving zero carbon emissionsCell electrodesBiochemical fuel cellsPhotosynthesisZero emission

The invention discloses a double-chamber alga microbial fuel cell and a method thereof for treating waste water and realizing zero carbon emission, which relates to a microbial fuel cell and a method for treating waste water. The invention solves the problem that the traditional microbial fuel cell can generate a large amount of CO2 in the process of treating waste water. In the invention, a cation exchange membrane is vertically arranged in a box body of a reactor; an anode chamber and a cathode chamber are formed in the box body of the reactor; an anode is arranged in the anode chamber; a cathode is arranged in the cathode chamber; leads are connected with the anode and the cathode; one end of a gas duct is hermetically connected with a gas collecting chamber, and the other end of the gas duct is arranged at the bottom of the cathode chamber; and a gas collecting device is hermetically installed at a gas outlet. The method comprises the following steps: (1) starting the reactor; and (2) introducing the waste water into the cathode chamber and the anode chamber, catabolizing organic matters by microbes at room temperature, simultaneously obtaining electrical energy, and introducing the CO2 generated in the anode chamber into the cathode chamber to be used by the alga at the cathode for photosynthesis. The invention realizes zero emission of CO2 and simultaneously can recover electrical energy, thereby really changing waste into resources.

Owner:HARBIN INST OF TECH

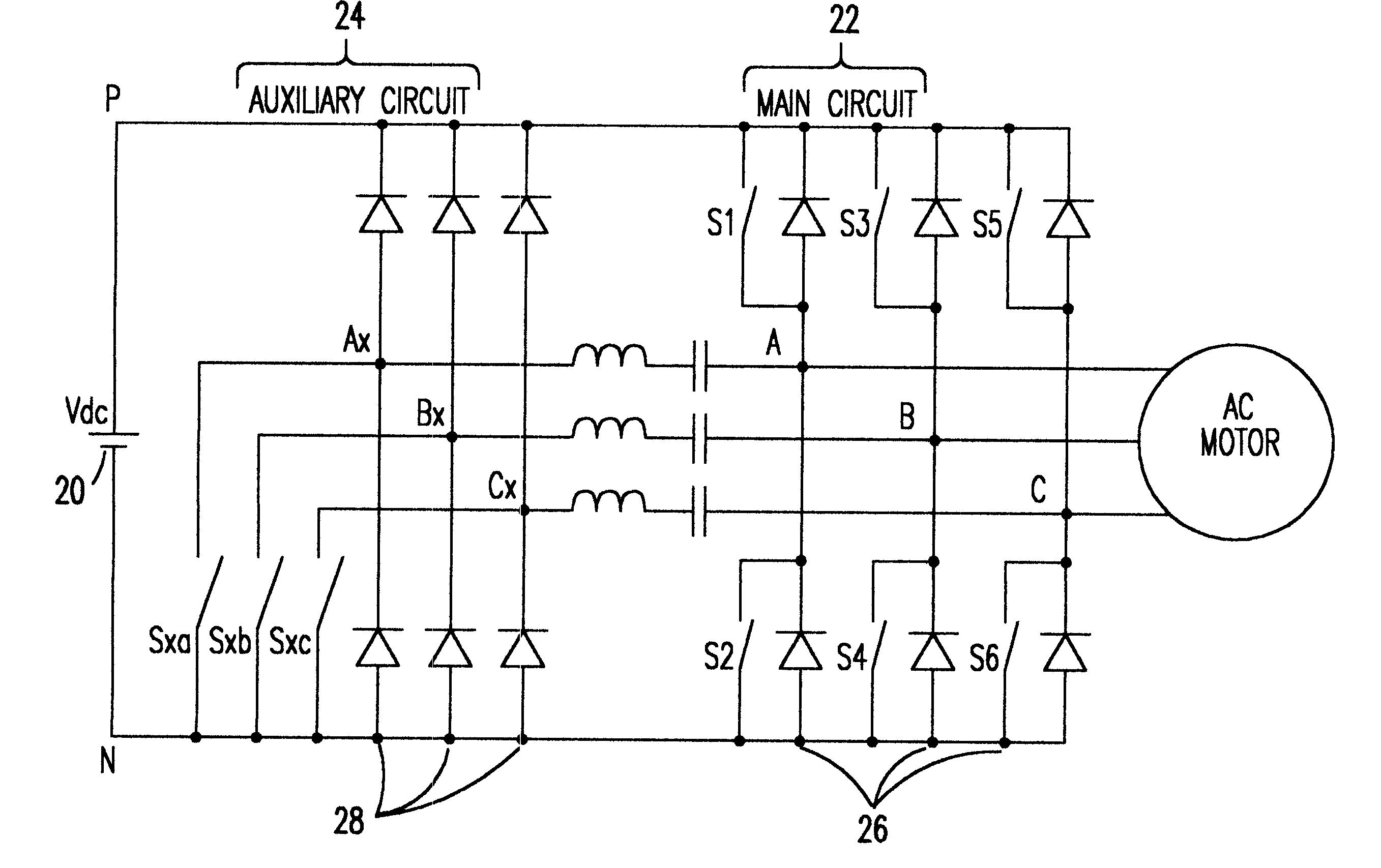

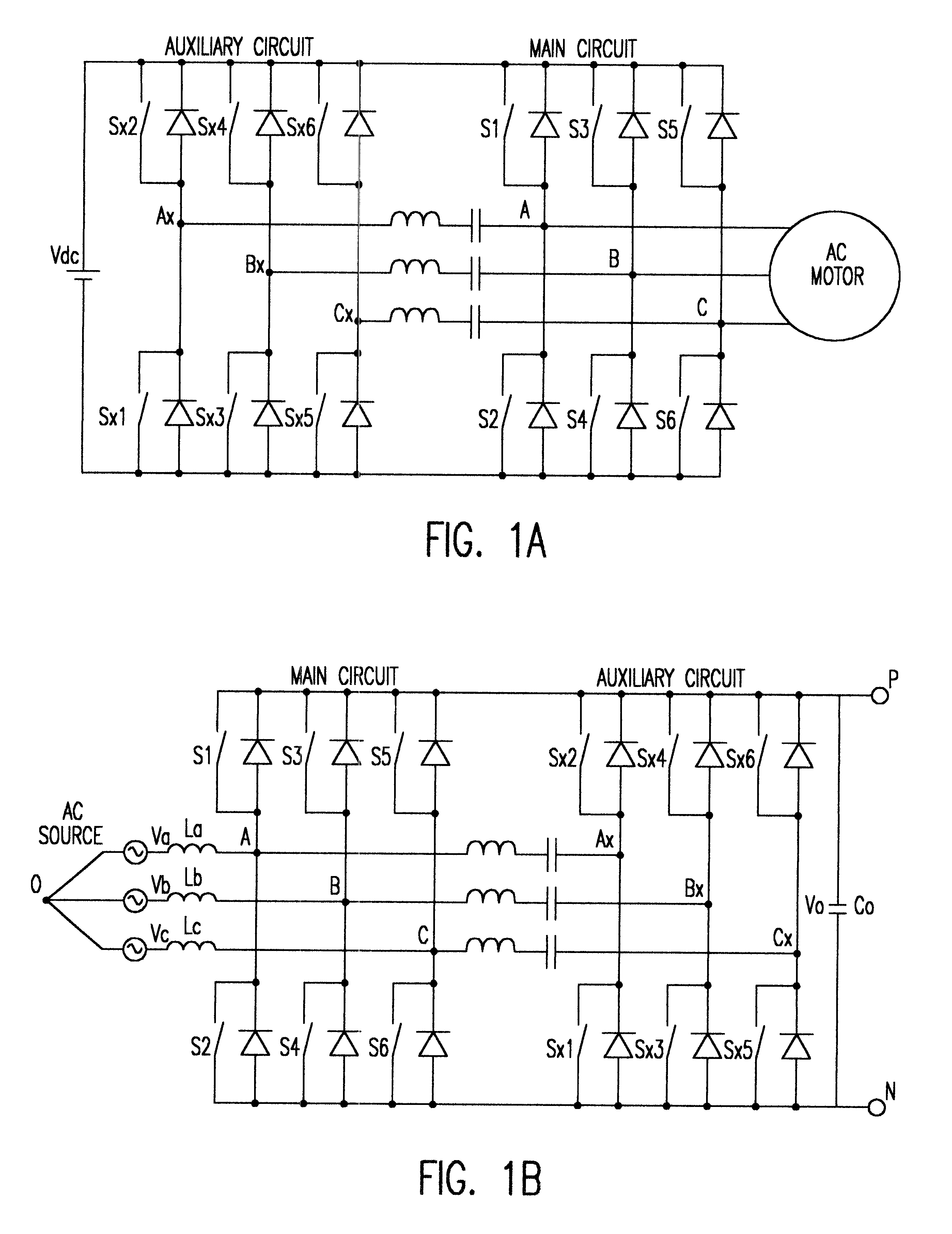

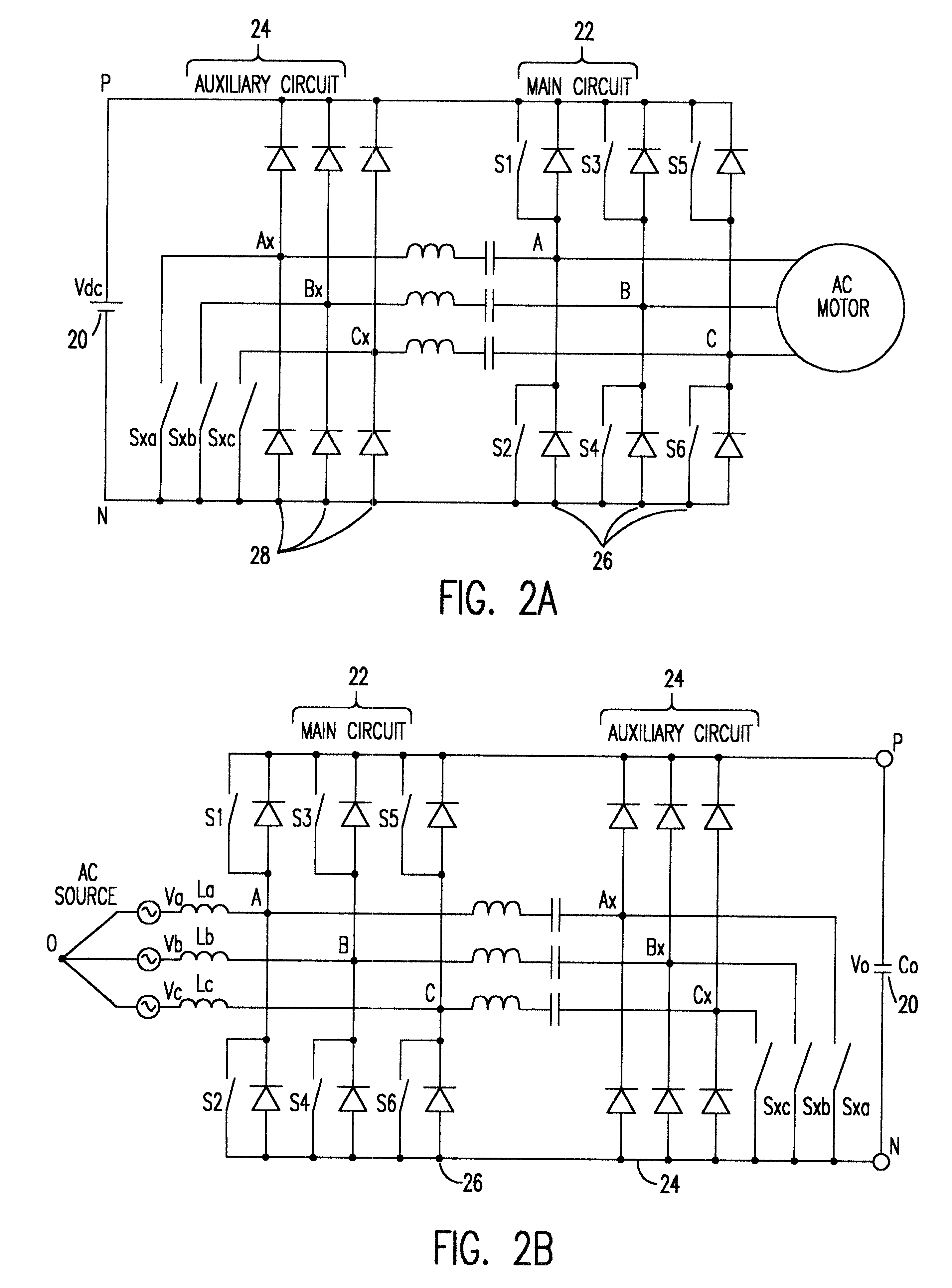

Three-phase zero-current-transition (ZCT) inverters and rectifiers with three auxiliary switches

InactiveUS6337801B2Dc-ac conversion without reversalConversion with reversalSoft switchingCombustion

Zero current transition (ZCT) topologies are presented for three-phase inverters and rectifiers. Such devices are used for example in AC adjustable speed drives for so-called zero-emission vehicles (i.e., electric and hybrid combustion / electric automobiles). Compared to existing three-phase ZCT techniques, the number of auxiliary switches is reduced from six to three, while not altering the necessary device rating. Correspondingly, the number of gate-drivers for the auxiliary switches is also reduced to three. Meanwhile, the merits of the existing three-phase ZCT techniques are still retained, i.e., all the main switches and the auxiliary switches are turned on and turned off under zero-current conditions, and the independent commutation for each main switch is achieved. The desired soft-switching features are achieved. Therefore, this invention will contribute to more cost-effective, reliable, and efficient high-performance three-phase inverters and rectifiers.

Owner:VIRGINIA TECH INTPROP INC

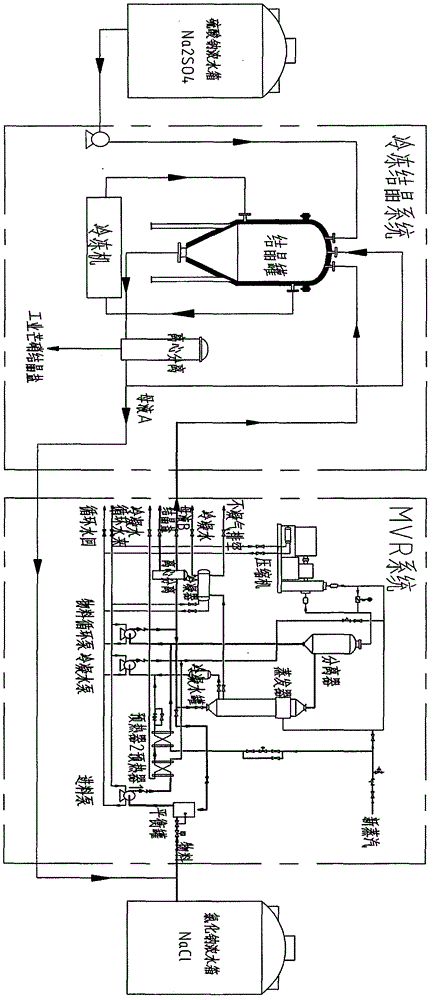

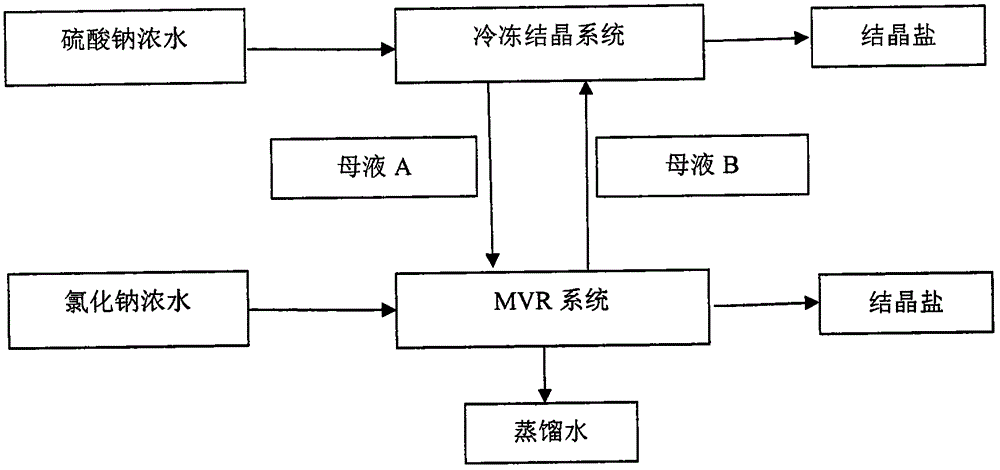

Crystallization treatment method and device of high salt wastewater

ActiveCN104692575AHigh energy consumptionHigh operating costsAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentResource utilizationWastewater

The invention relates to a crystallization treatment method and device of high salt wastewater and belongs to the technical field of water treatment. The method is characterized in that after sodium sulfate concentrated water is treated by a freezing crystallization system, generated mother liquor A enters into an MVR system for evaporative crystallization; after sodium chloride concentrated water is treated by the MVR system, generated mother liquor B enters into a freezing crystallization system for freezing crystallization, and the mother liquor can be treated in a circulation overlapping manner; a drain outlet of the MVR system of the device is connected with a liquid inlet of a crystallization tank in the freezing crystallization system through a pipeline and the drain outlet of the freezing crystallization system is connected with a liquid inlet pipe of the MVR evaporative crystallization system. The method has the advantages that the mother liquor is treated by a freezing crystallization technology and an MVR evaporation crystallization technology in a circulation overlapping manner, so that the problems of zero emission and resource utilization are solved, and therefore, the energy consumption is effectively reduced and the operating cost is lowered.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Energy utilization method of carbon dioxide zero-emission type organic waste

ActiveCN101914572AReduce the cost of trainingAvoid emissionsBio-organic fraction processingInternal combustion piston enginesNew energySludge

The invention provides an energy utilization method of carbon dioxide zero-emission type organic wastes, comprising the following steps of: (1) collecting and pretreating raw materials; (2) preparing hydrogen by anaerobic fermentation and purifying hydrogen; (3) fermenting methane and generating power by the methane; (4) treating biogas slurry and fixing carbon dioxide with microalgae; (5) processing biogas residues and planting energy grass; and (6) recycling afterheat. The method is suitable for treating various types of organic wastes, can be used for treating agricultural organic wastes, industrial organic wastes, domestic organic garbage, mud, and the like and the industries of developing new energy, and the like. The method can carry out a concrete application example of cyclic economy, eliminates environmental pollution, obtains clean energy at the same time, has no greenhouse gas emission in the process and can realize three effects of treating wastes, generating renewable clean energy and reducing carbon dioxide emission.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

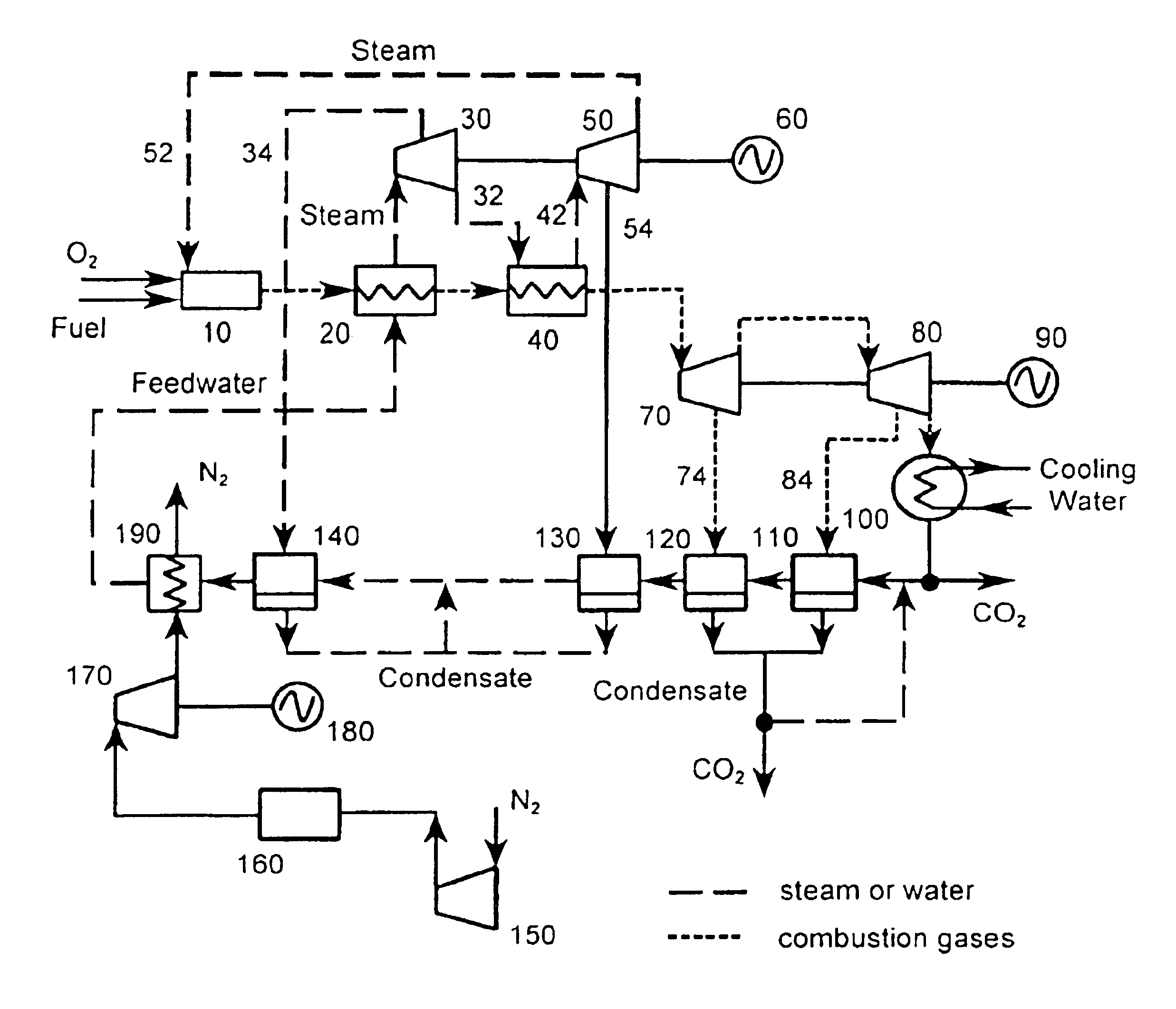

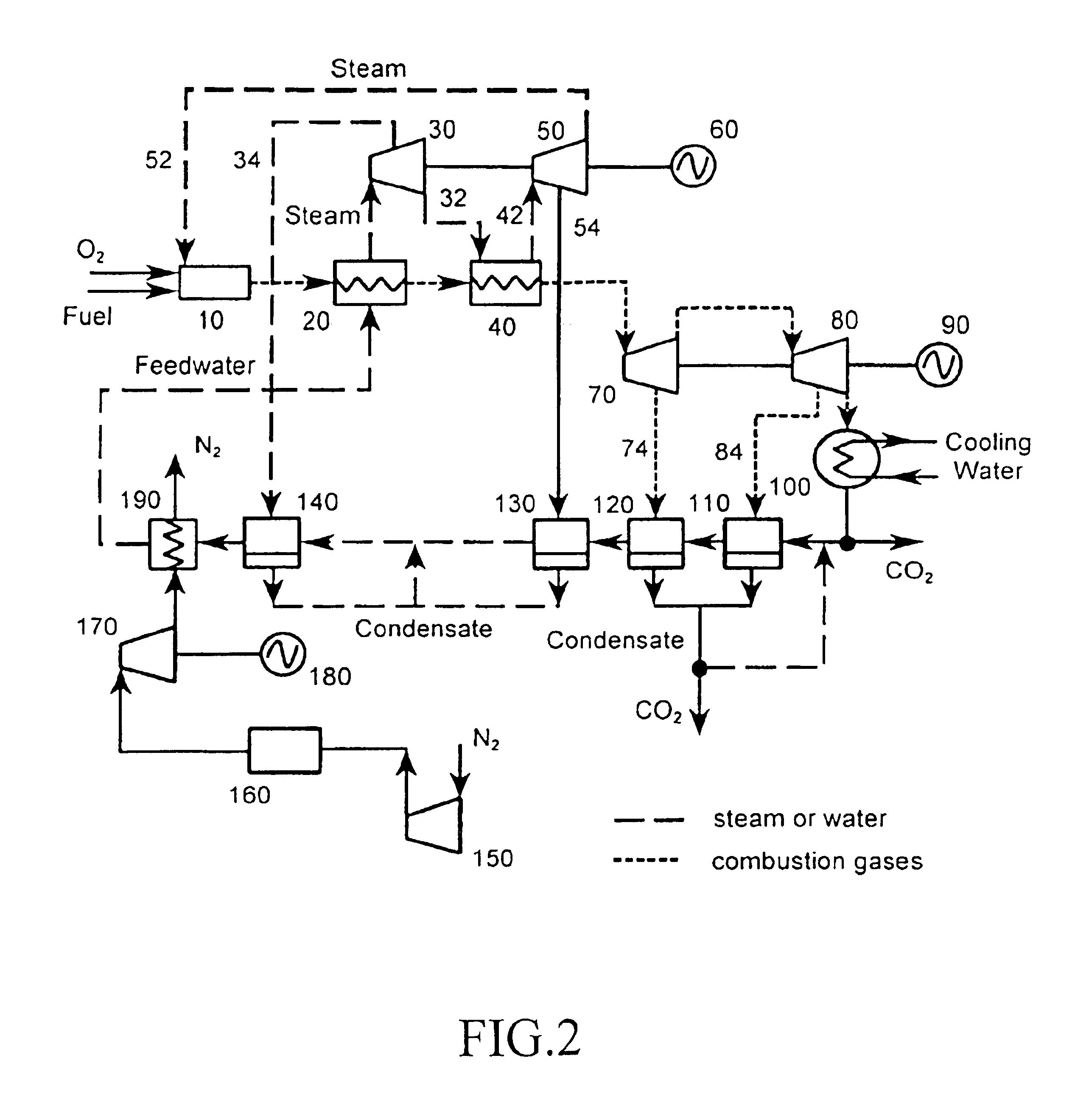

Zero emissions closed rankine cycle power system

InactiveUS20070204620A1Minimal modificationSolidificationLiquefactionAtmospheric emissionsWorking fluid

A fuel combustion power generation system is provided operating as a closed loop Rankine cycle and with zero atmospheric emissions. The fuel is combusted with oxygen in a combustor to generate high temperature products of combustion. The products of combustion are routed to a first side of a heat exchanger. A second side of the heat exchanger has a working fluid of the closed loop Rankine cycle passed therethrough to boil the working fluid into a gas. The working fluid is then expanded, condensed back to a liquid and pumped back to high pressure for return to the heat exchanger the products of combustion enter a condenser, where gases are collected and liquids recirculated or released. The products of combustion can be expanded upstream of the heat exchanger. The fuel can be a gaseous fuel or a solid or liquid fuel, such as coal or biomass, with gasification before combustion.

Owner:CLEAN ENERGY SYST

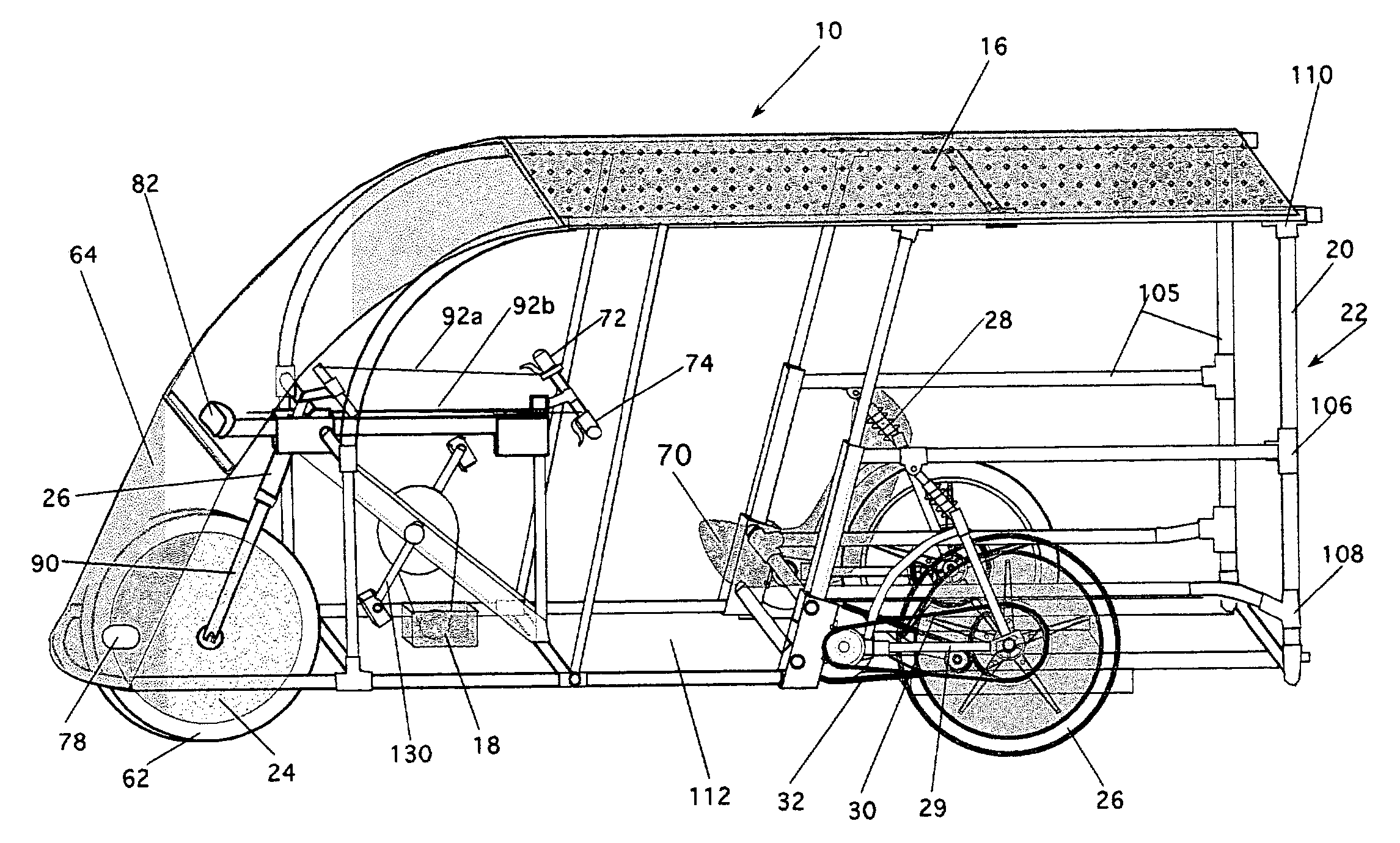

Combination pedal/motor driven tricycle

ActiveUS20030217874A1Increasing vehicle rangeIncrease rangeAuxillary drivesElectric devicesElectrical batterySolar battery

A zero-emissions electric three-wheeled, enclosed scooter with two 1 hp motors driven from batteries charged by solar panels and a pedal-driven generator; also incorporating an innovative rear wheel drive and suspension system and a tilt capability to reduce parking space requirement to approximately one quarter of that of a conventional automobile.

Owner:SCHOENBERG ANDREW

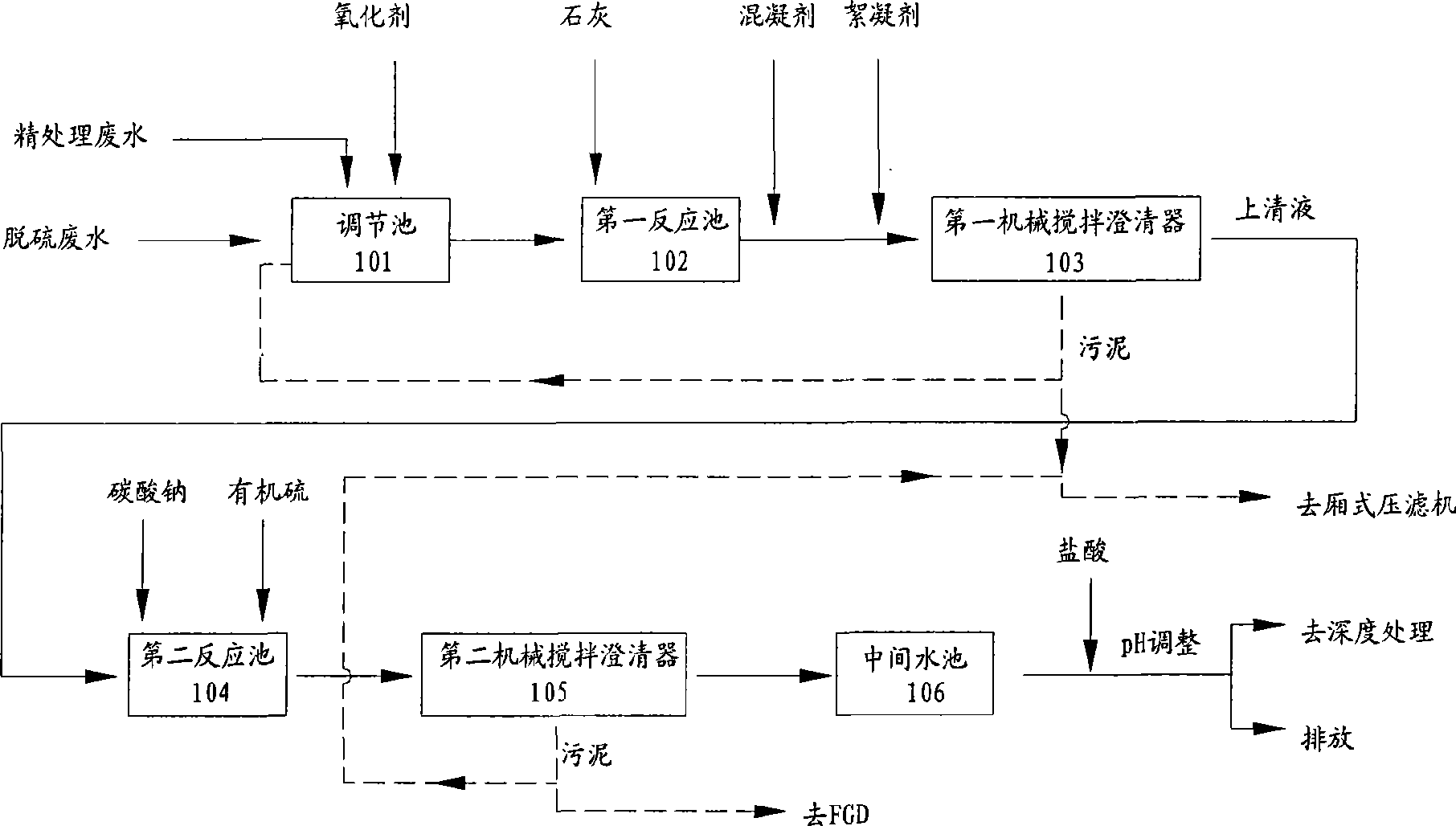

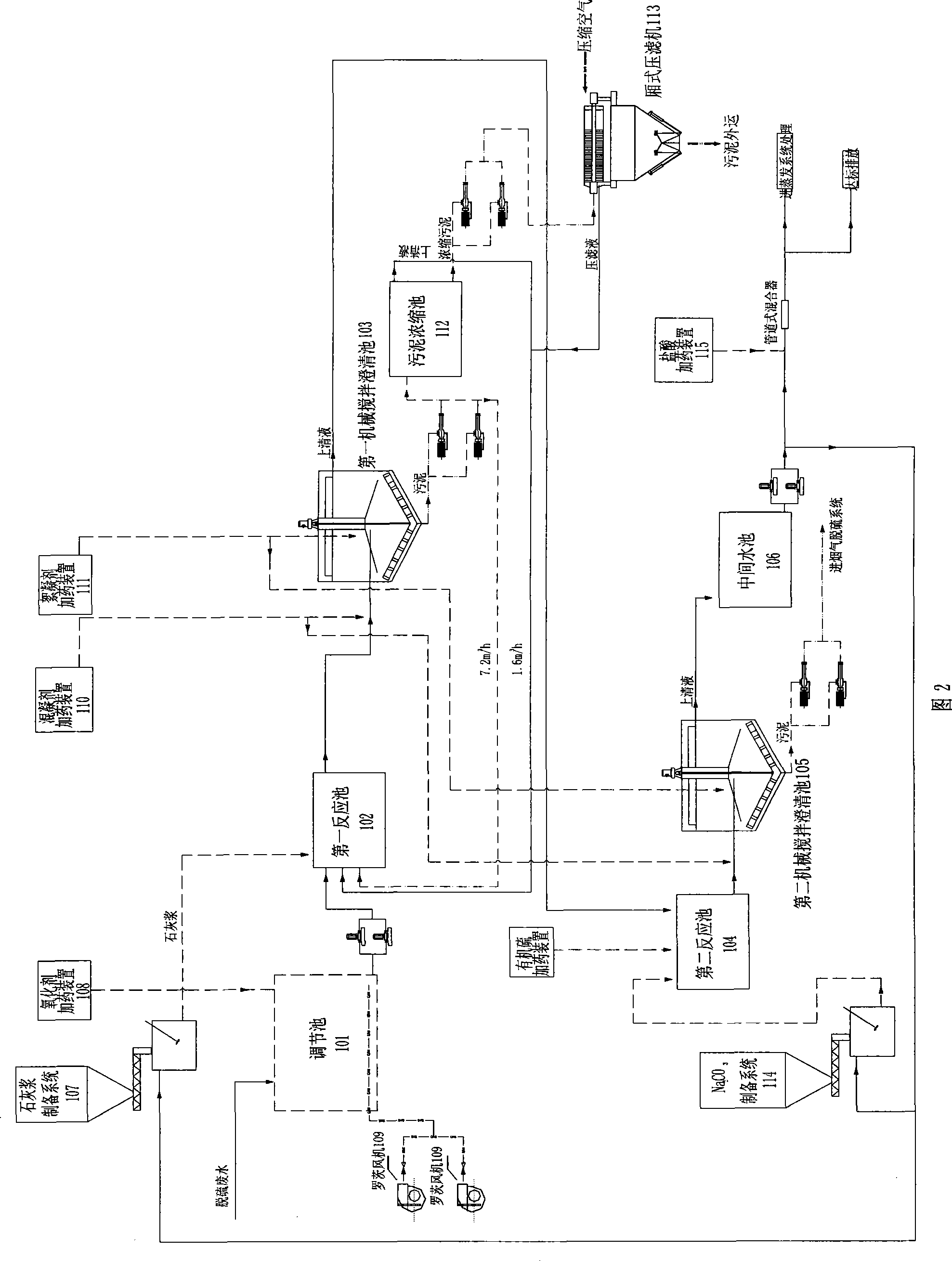

Process and system for treating electric power plant waste water

ActiveCN101456635AEasy to reuseEfficient removalMultistage water/sewage treatmentWater/sewage treatment by neutralisationSolubilityZero emission

The invention relates to a method for treating waste water from a power plant and a system for realizing the same. The system comprises a pre-treatment system and an evaporative crystallizing system which are connected with each other; the pre-treatment system is connected to the waste water from the power plant, the majority of SS, heavy metals, Mg<2+>, F<-> and sulfate radicals in the waste water from the power plant are removed by coagulating sedimentation, and organic pollutants and ammonia nitrogen are also removed; the CaSO4 content in the waste water is adjusted to be far less than saturated concentration of the CaSO4, and the pH value is adjusted back to make partial CO3<2-> converted into HCO3<->; and the waste water treated by the pre-treatment system flows in the evaporative crystallizing system, by evaporation concentration, the dissolved solids in the waste water reach and exceed the saturated concentration to form salt crystal, and the solid-liquid separation is performed. The method has the advantages of effectively removing suspended matters, organic matters, fluorine and heavy metals in the waste water from the power plant, removing dissolved salt such as Ca<2+>, Mg<2+>, Cl<->, SO4<2-> and the like which can not be removed by the prior method for treating the waste water from the power plant, and basically meeting zero emission, and the treated waste water can be reutilized.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

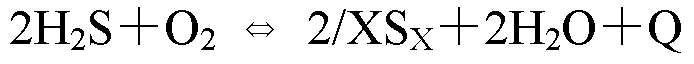

Zero-emission sulfur recovery technology combined with low-temperature methanol washing acid gas treatment

InactiveCN102631827ALow temperature methanol washing process has no effectThe process is not affectedDispersed particle separationClosed loopTower

The invention belongs to the technical field of sulfur recovery and particularly relates to a zero-emission sulfur recovery technology combined with low-temperature methanol washing acid gas treatment. In the zero-emission sulfur recovery technology, a low-temperature methanol washing acid gas treatment unit and a Claus sulfur recovery unit are set to a closed loop. The zero-emission sulfur recovery technology comprises the following steps: firstly, acid gas emitted from low-temperature methanol washing is subjected to sulfur production and recovery by the Claus sulfur recovery unit; sulfur production tail gas enters a low-temperature methanol washing unit after being subjected to hydrogenation reduction, cooling and compression; H2S in the tail gas is absorbed by low-temperature methanol and waste gas is exhausted from the top of a tower; methanol at the bottom of a hydrogen sulfide removal tower enters a methanol thermal regeneration tower; concentrated H2S acid gas is obtained at the top of the tower; and the concentrated H2S acid gas together with the H2S-containing acid gas produced in low-temperature methanol washing enters the Claus sulfur recovery unit for sulfur production. The zero-emission sulfur recovery technology is free of limitation by balance absorption of amine-method tail gas treatment, can obtain theoretic 100% sulfur recovery rate and has remarkable economical and environmental benefits; and the process is shortened greatly and the construction investment, operating cost and energy consumption are reduced by over 30%.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

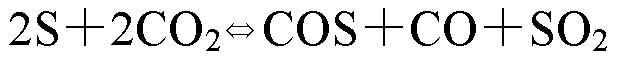

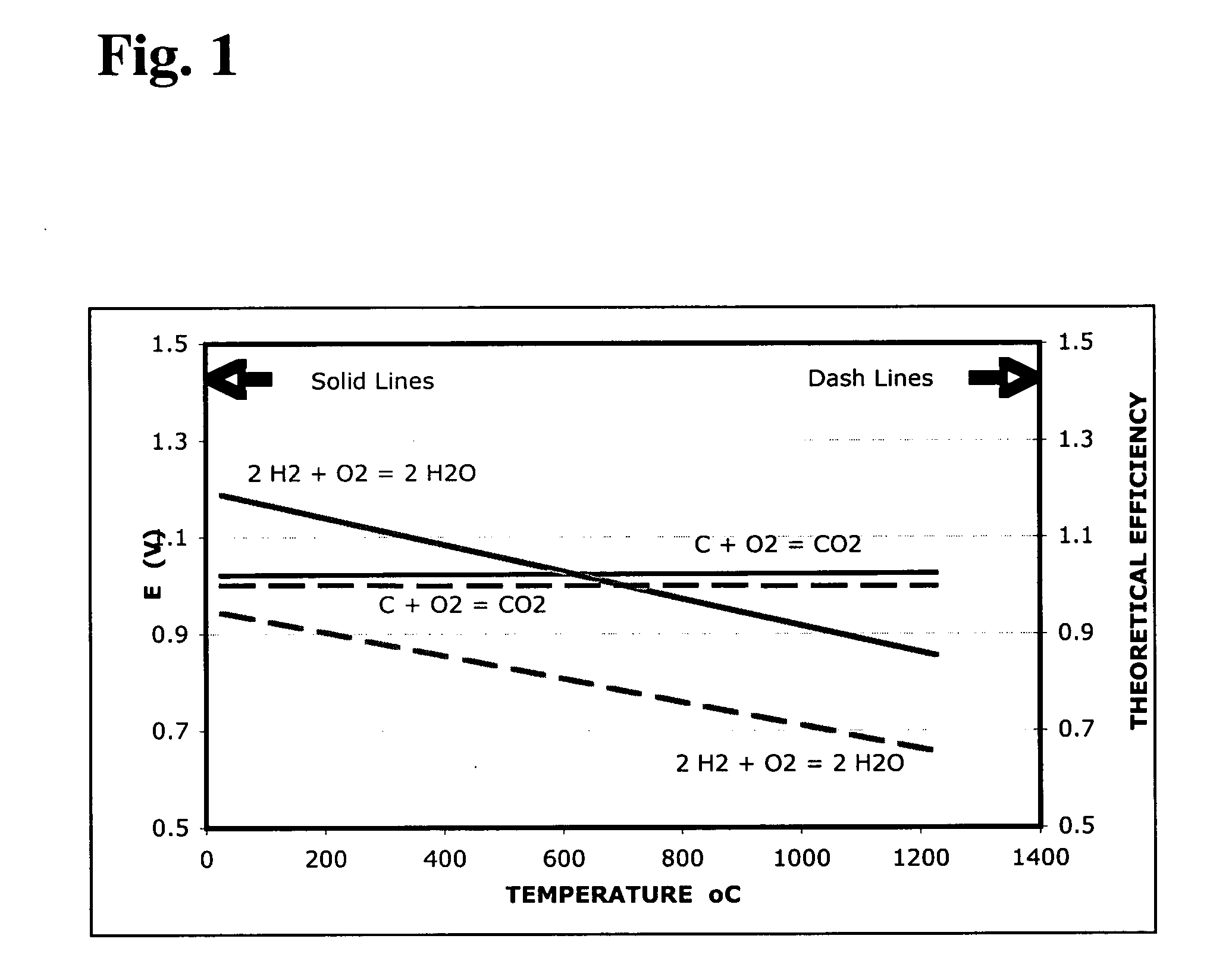

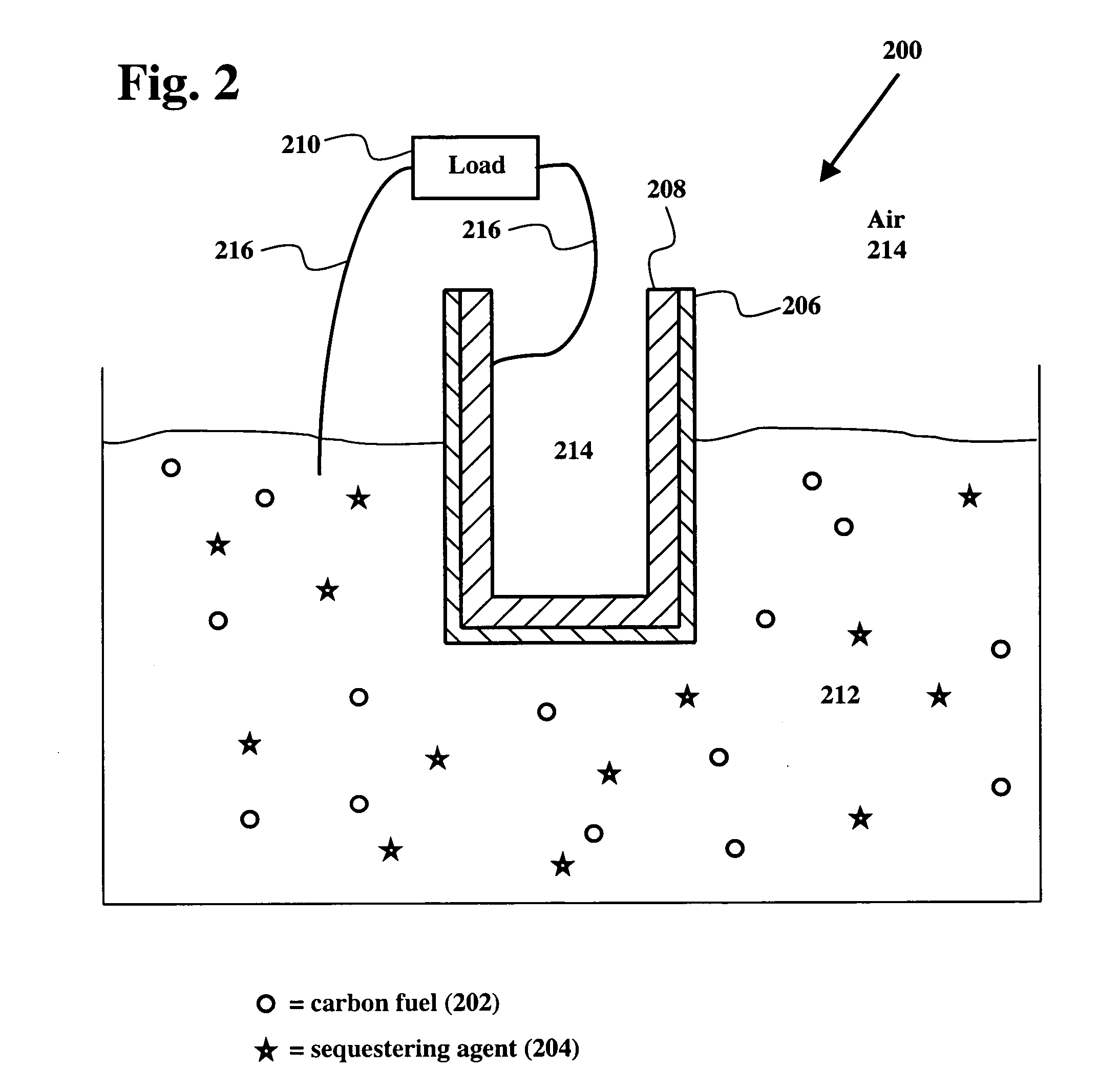

Direct carbon fuel cell with molten anode

This invention discloses a method of converting carbon-containing materials directly to electrical energy without the need for intermediate processing steps. An embodiment comprises the use of a conductive molten medium with dispersed particles of carbon material as the anode in a fuel cell with a solid oxide electrolyte which enables conversion of carbon-containing materials (such as pulverized coal, charcoal, peat, coke, char, petroleum coke, oil sand, tar sand, waste plastics, biomass, and carbon produced by pyrolysis of carbonaceous substance) directly into electrical energy in a single step process. The anode optionally may have a dispersed second solid phase that getters CO2 and SO2 gases that are produced during the anodic reaction. Hence, this invention facilitates near-zero emissions and dramatically reduces the release of environmentally harmful emissions. More importantly, this direct route to electrical energy eliminates Carnot cycle constraints and offers high thermodynamic efficiency.

Owner:DIRECT CARBON TECH

Production process for tail gas catalytic reducer

ActiveCN101811065AAvoid pollutionGuaranteed stabilityInternal combustion piston enginesOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeProcess engineering

The invention relates to a production process for a tail gas catalytic reducer, in particular a production process for a tail gas catalytic reducer of vehicles, and belongs to the technical field of chemical engineering. In the production process, the continuous filtration and ion exchange technology is adopted; attributes of different impurities of the traditional urea are utilized; through continuous purification and exchange adsorption of metallic and nonmetallic ions, the common urea is subjected to vehicle-grade purification, so that the common urea is prepared into the high-purificationtail gas catalytic reducer through trough-type continuous purification and ion exchange process to ensure normal work of an SCR system. Compared with the traditional crystallization process, the production process has the advantages that: the innovative process method is adopted, chemical agents are not needed, zero emission is achieved, the production is continuous and the operation is simple. On the premise of ensuring low cost, energy conservation and environmental protection, the tail gas catalytic reducer, namely AUS32, with stable quality can be produced, and a foundation for supplying raw materials is laid for wide-range promotion of the domestic SCR system.

Owner:KELAS ENVIRONMENTAL PROTECTION TECH CO LTD

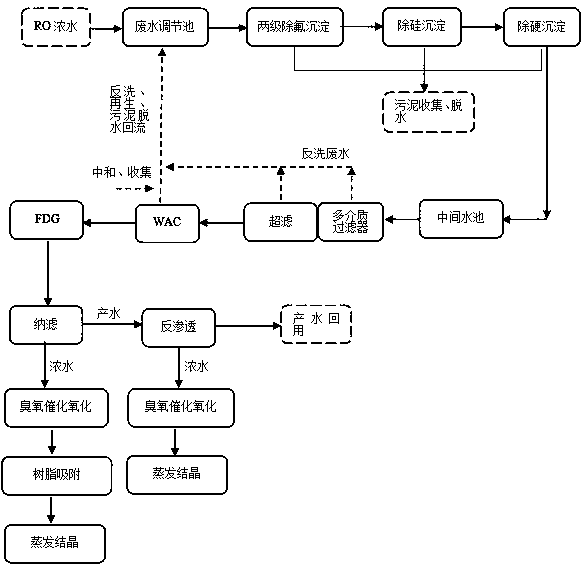

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

Water-soluble discharging medium compound for electrospark wire-electrode cutting

The invention discloses a water-solubility discharging dielectric combination for electrospark wire electrode cutting, comprising the following components: 20 to 46 percent weight of polyalkyl glycol and / or polyatomic alcohol, 2 to 8 percent weight of alkylol amine, 26 to 40 percent weight of water-solubility anti-rust agent, 2 to 4 percent weight of non-ionic surface active agent, 3 to 6 percent weight of anionic surface active agent, 1 to 2 percent weight of thickening agent solution, 0.2 to 1.0 percent weight of anti-foam agent, 0.01 to 0.04 percent weight of copper alloy corrosion inhibitor, 0.2 to 0.5 percent weight of mildew inhibitor, 0.5 to 1.0 percent weight of water quality stabilizing agent and equilibrium amount of distilled water; moreover, all components are simply mixed to obtain the combination. The combination can be used for a long time with zero emission or little emission; meanwhile, the invention does not cause pollution, toxin and harm to work environment and the nature and is nonirritating to human body.

Owner:BEIJING DONGXING LUBRICANT CO LTD

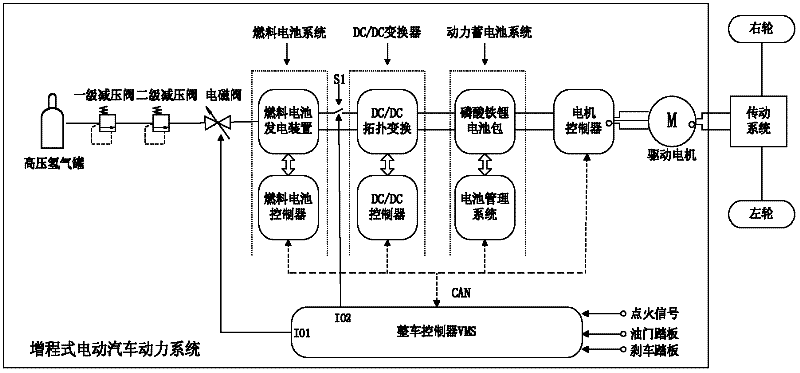

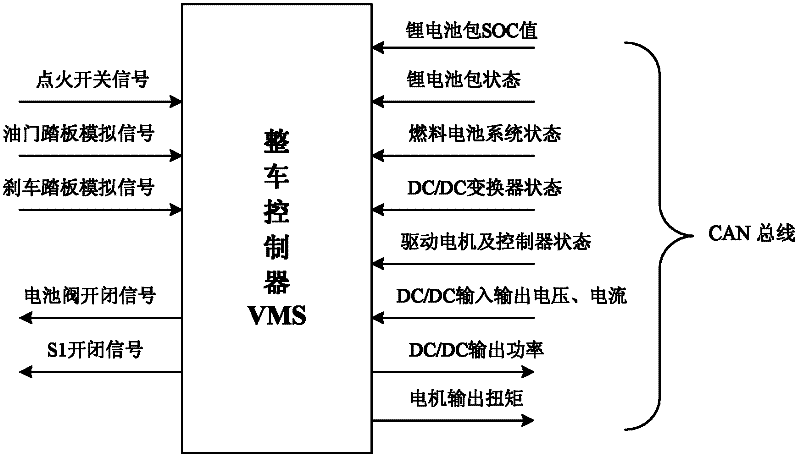

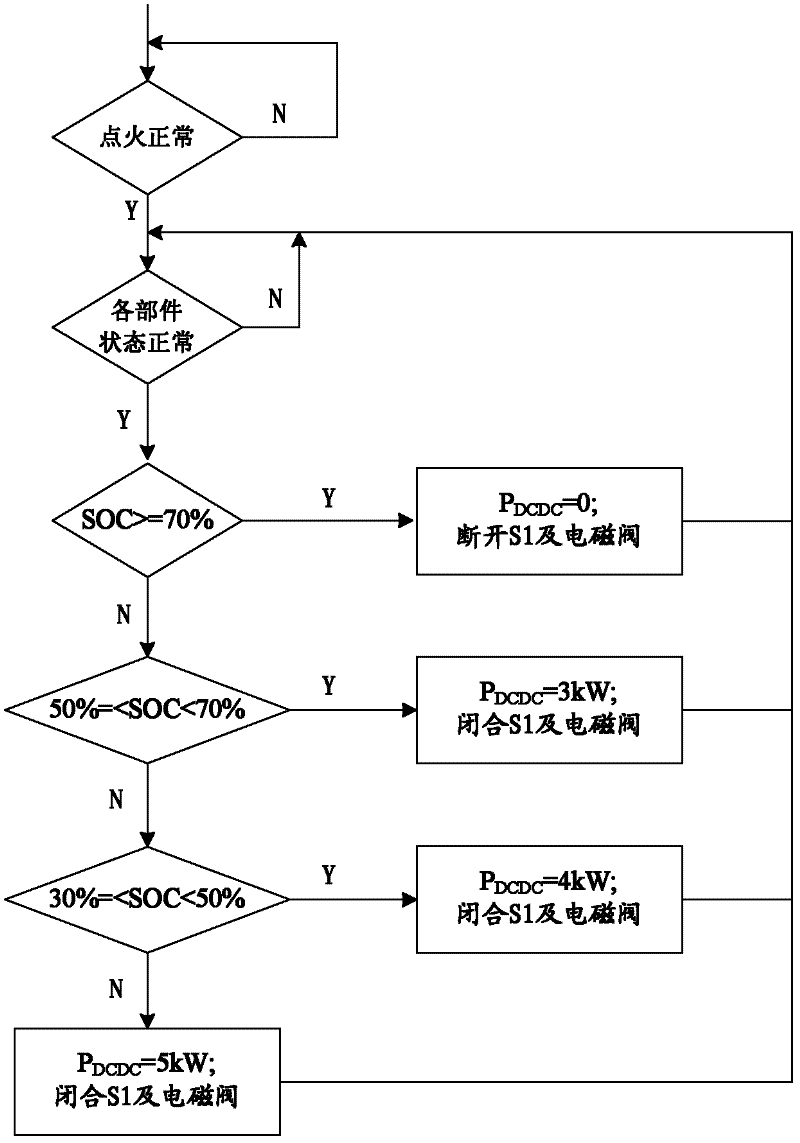

Extended range type electric vehicle power system based on fuel battery and control method for extended range type electric vehicle power system

ActiveCN102358201AIncrease mileageSolve the lack of energy storageVehicular energy storageElectric propulsionDrive motorInternal combustion engine

The invention discloses an extended range type electric vehicle power system based on a fuel battery and a control method for the extended range type electric vehicle power system. The output end of a fuel battery system with a hydrogen pot is connected with an input of a direct current / direct current (DC / DC) transformer through a controllable relay S1; an output of the DC / DC transformer is connected with a lithium iron phosphate power battery pack; the lithium iron phosphate power battery pack is connected with the high voltage input end of a motor controller; the three-phase output end of the motor controller is connected with a driving motor; a whole vehicle controller VMS directly controls an electromagnetic valve for managing hydrogen output and the relay S1 through an input / output (I / O) port, and communicates with the fuel battery system, the DC / DC transformer, a battery management system and the motor controller through controller area network (CAN) buses so as to control a motor to drive the whole vehicle to run and manage the whole power system. The fuel battery system with the hydrogen pot is used as a vehicle-mounted charger for the lithium iron phosphate power battery pack; and a scheme of a vehicle-mounted range extender of an electric vehicle can be provided. The efficiency of the fuel battery system serving as the vehicle-mounted range extender is higher than that of an internal combustion engine; furthermore, the noise is low, and zero emission and zero pollution are realized.

Owner:武汉海亿新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com