Patents

Literature

349results about How to "Eliminate fire hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

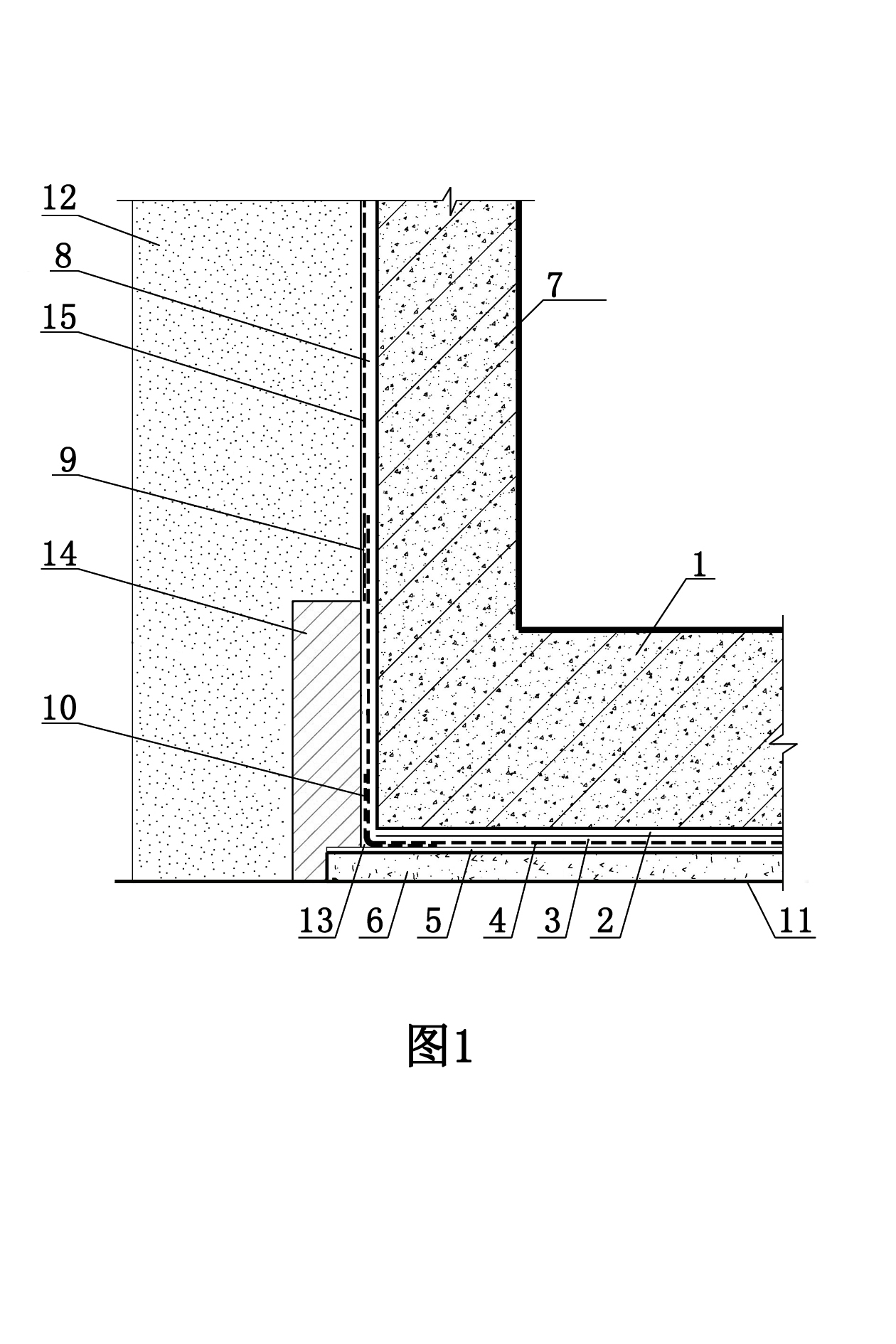

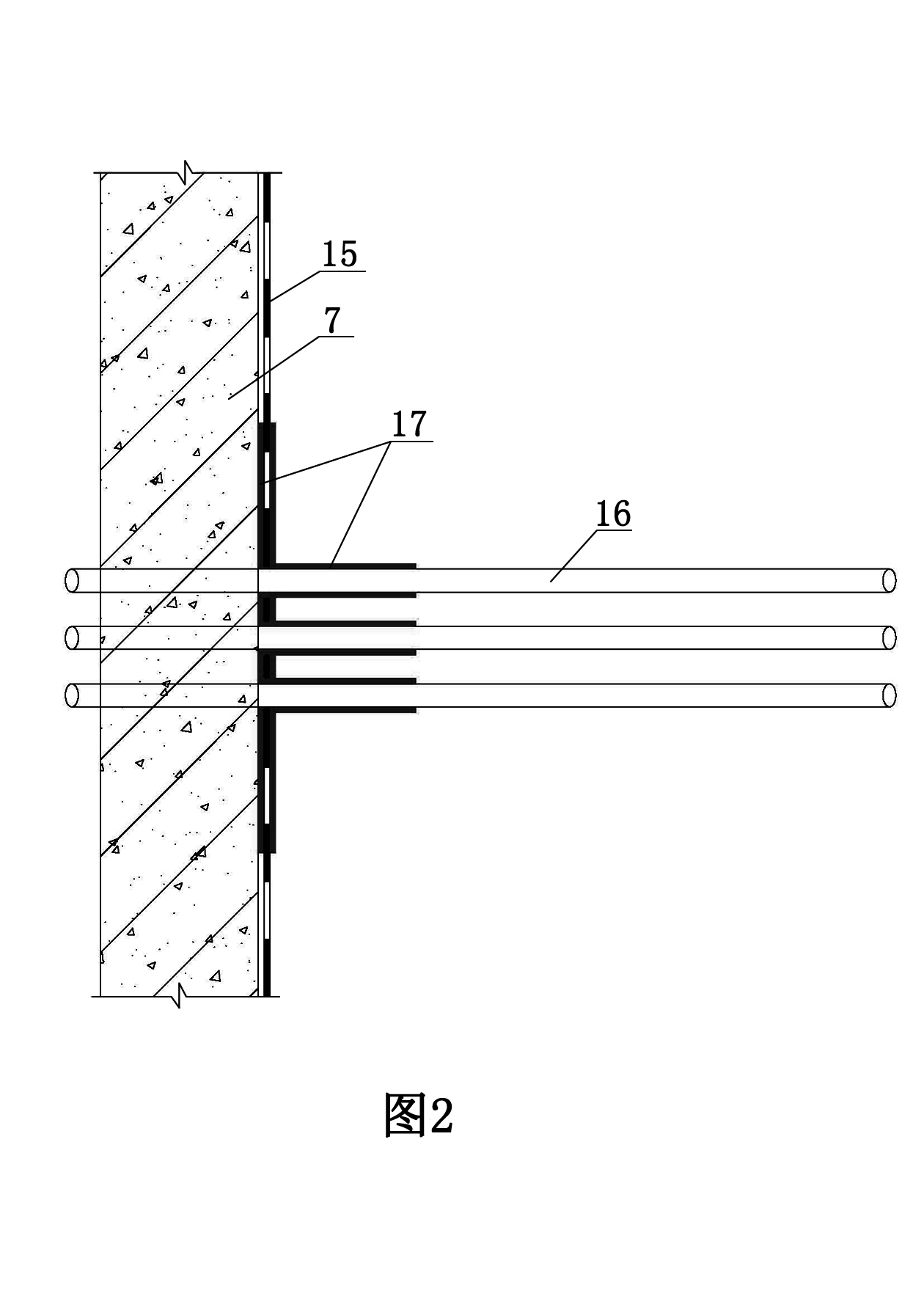

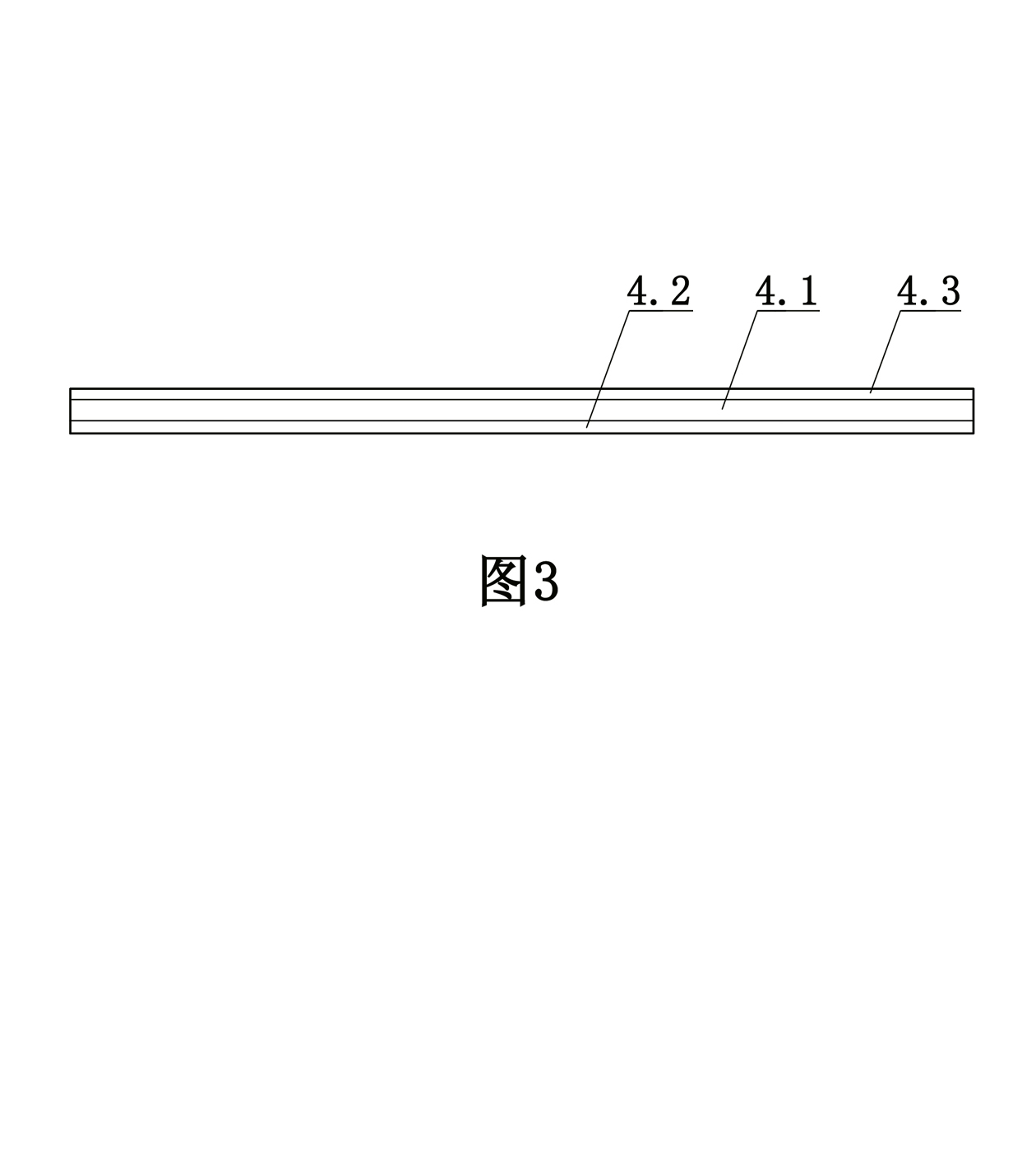

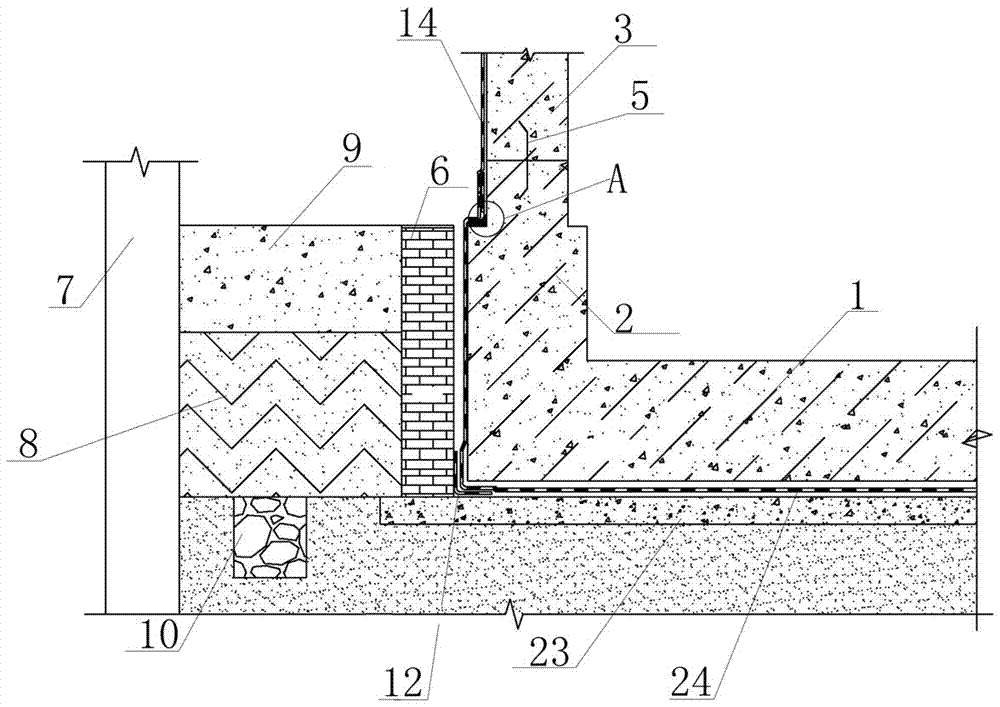

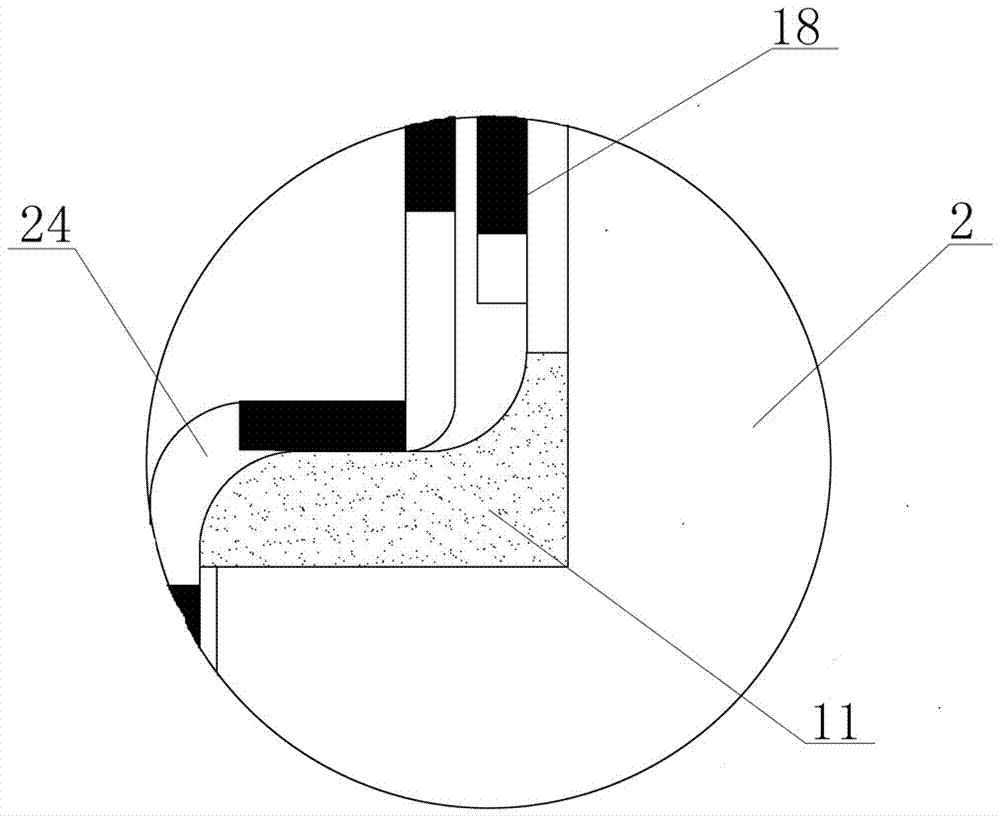

Waterproof system for basement bottom board and wall surface and construction method thereof

InactiveCN101914927AReduce weightHigh tensile strengthArtificial islandsBuild-up roofsBasementBituminous waterproofing

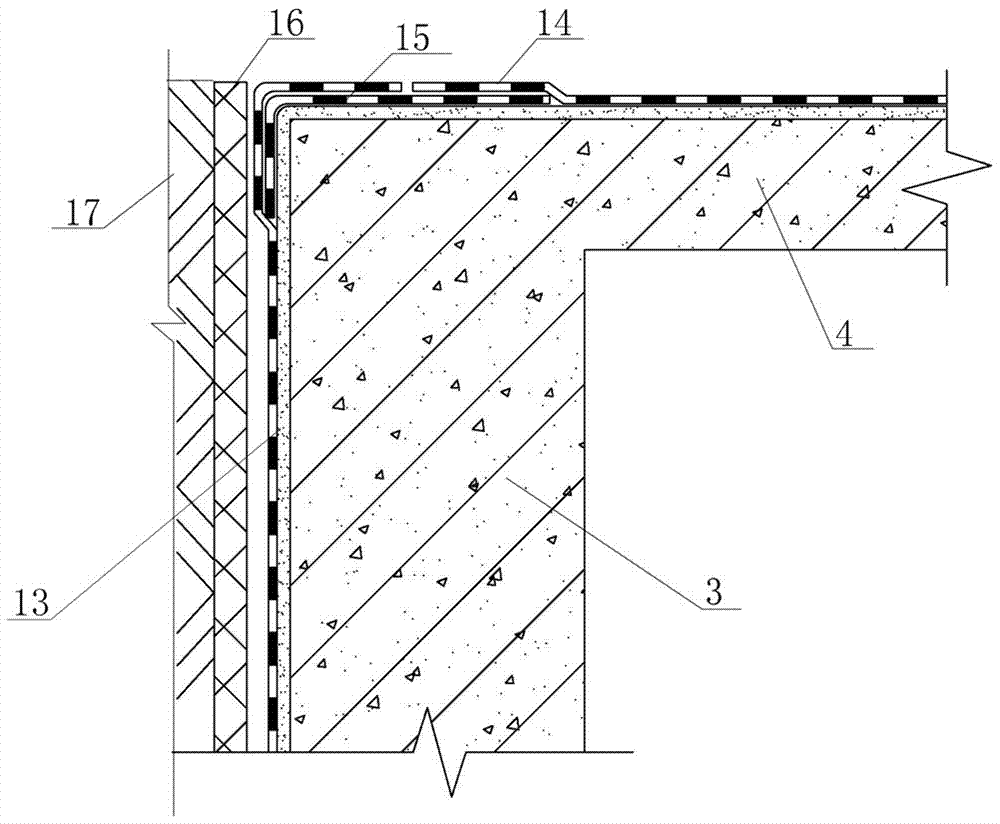

The invention relates to a waterproof system for a basement bottom board and a wall surface and a construction method thereof. The construction method comprises the steps of: horizontally spreading and pasting a self-adhesive rubber bituminous waterproof sheet material on a concrete base layer, and building up a brick permanent protection wall outside a preset position of a basement wall surface, wherein the bottom of the brick permanent protection wall is vertically connected with the concrete base layer, the self-adhesive rubber bituminous waterproof sheet material spreads over corners of the basement wall surface and then is upward folded to be spread and pasted on the water attaining surface of the brick permanent protection wall, then the self-adhesive rubber bituminous waterproof sheet material is lapped with another self-adhesive rubber bituminous waterproof sheet material pasted above the brick permanent protection wall, a self-adhesive rubber bituminous waterproof sheet material is pasted on an outer vertical surface of the basement wall surface. The construction method has the advantages of strong construction continuity, fast speed, good construction environment, low cost and the like, eliminates the hidden danger of fire since the heating is avoided in the construction process, is safe and reliable, completely changes and improves the traditional waterproof construction environments and the waterproof construction technology. The waterproof system can be widely applied in basements, underground structures and roofs.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Method for manufacturing foamed synthetic leather based on water-based resin and TPU (Thermoplastic Polyurethane) resin

ActiveCN103696274AEliminate pollutionSave resourcesLamination ancillary operationsLaminationOrganic solventThermoplastic polyurethane

The invention discloses a method for manufacturing foamed synthetic leather based on water-based resin and TPU (Thermoplastic Polyurethane) resin. The manufacturing method comprises the following steps: using water-based polyurethane as a facial layer and a surface treatment layer, using TPU resin as a foaming layer, using a water-based cement as a bonding layer, and obtaining the environment-friendly foamed synthetic leather through a coating transfer process. The method has the advantages that organic pollutants are thoroughly eliminated from the source, organic solvent resources are saved, potential safety hazard is eliminated, and the work environment of workers is improved. The VOC (volatile organic compound) content of a finished leather product is lower than 5 mg / kg. The foamed synthetic leather is ecological environmental friendly and meets European ecological foamed synthetic leather requirements, and the other properties of the leather can also reach or superior to the properties of solvent products.

Owner:SICHUAN UNIV

Water-soluble discharging medium compound for electrospark wire-electrode cutting

The invention discloses a water-solubility discharging dielectric combination for electrospark wire electrode cutting, comprising the following components: 20 to 46 percent weight of polyalkyl glycol and / or polyatomic alcohol, 2 to 8 percent weight of alkylol amine, 26 to 40 percent weight of water-solubility anti-rust agent, 2 to 4 percent weight of non-ionic surface active agent, 3 to 6 percent weight of anionic surface active agent, 1 to 2 percent weight of thickening agent solution, 0.2 to 1.0 percent weight of anti-foam agent, 0.01 to 0.04 percent weight of copper alloy corrosion inhibitor, 0.2 to 0.5 percent weight of mildew inhibitor, 0.5 to 1.0 percent weight of water quality stabilizing agent and equilibrium amount of distilled water; moreover, all components are simply mixed to obtain the combination. The combination can be used for a long time with zero emission or little emission; meanwhile, the invention does not cause pollution, toxin and harm to work environment and the nature and is nonirritating to human body.

Owner:BEIJING DONGXING LUBRICANT CO LTD

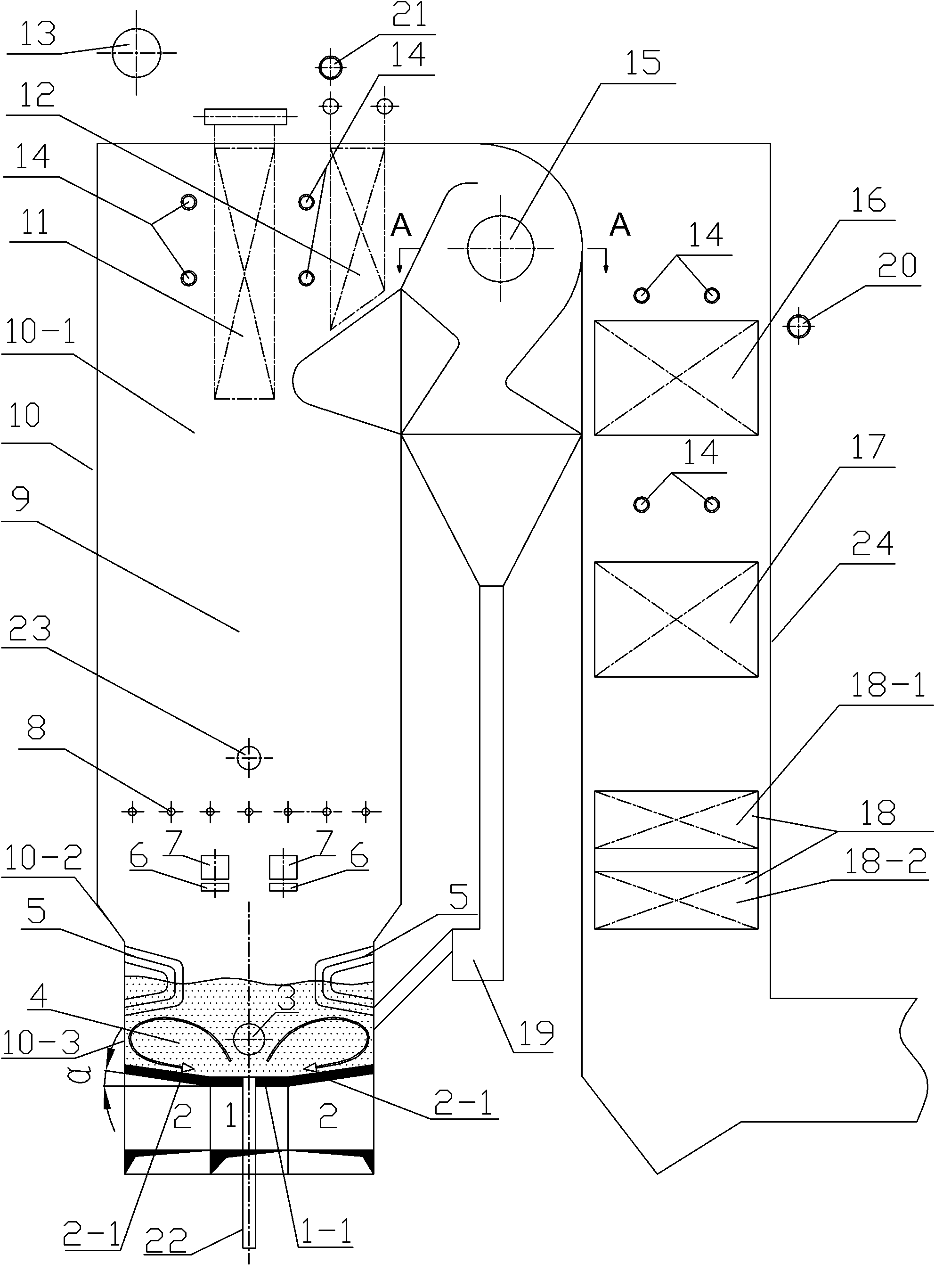

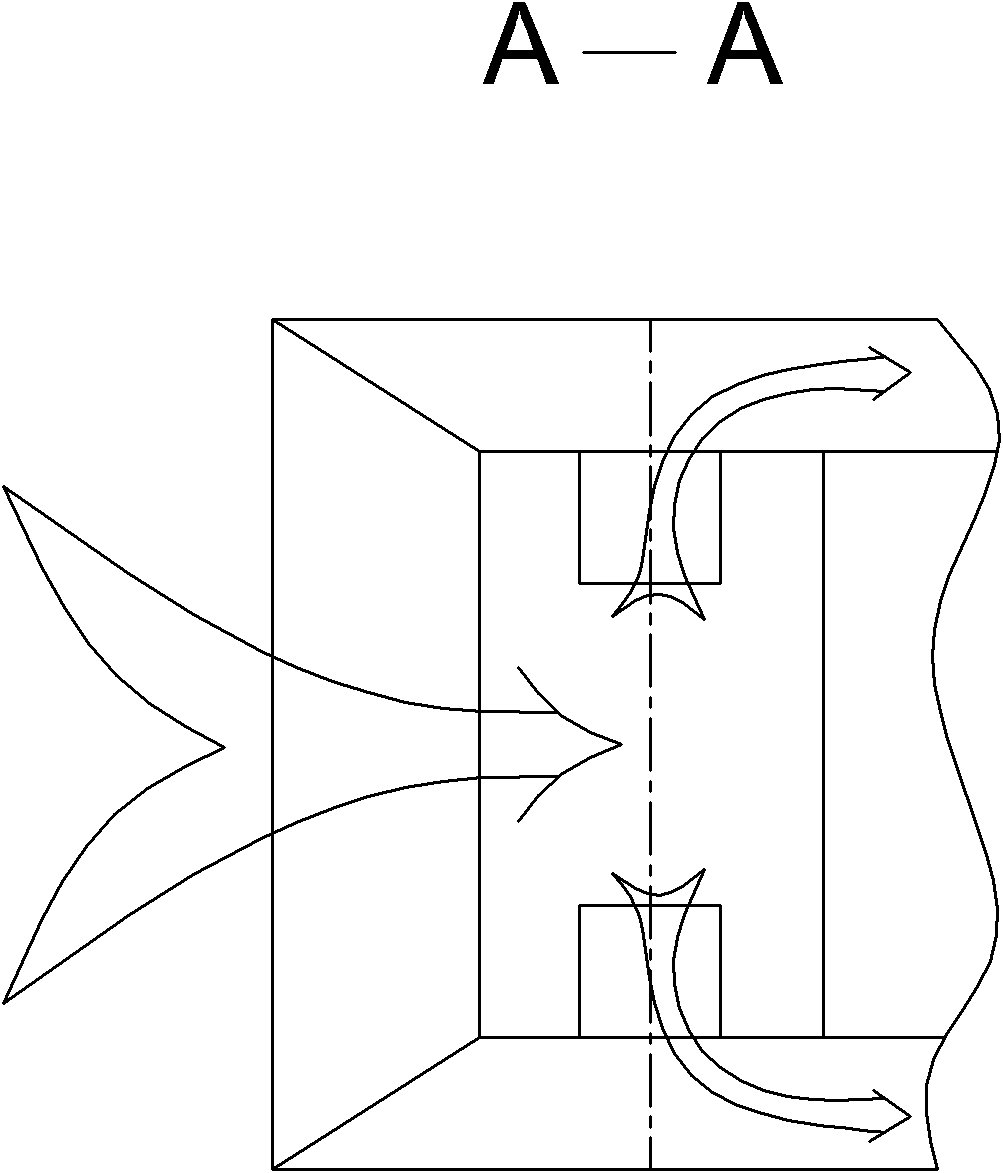

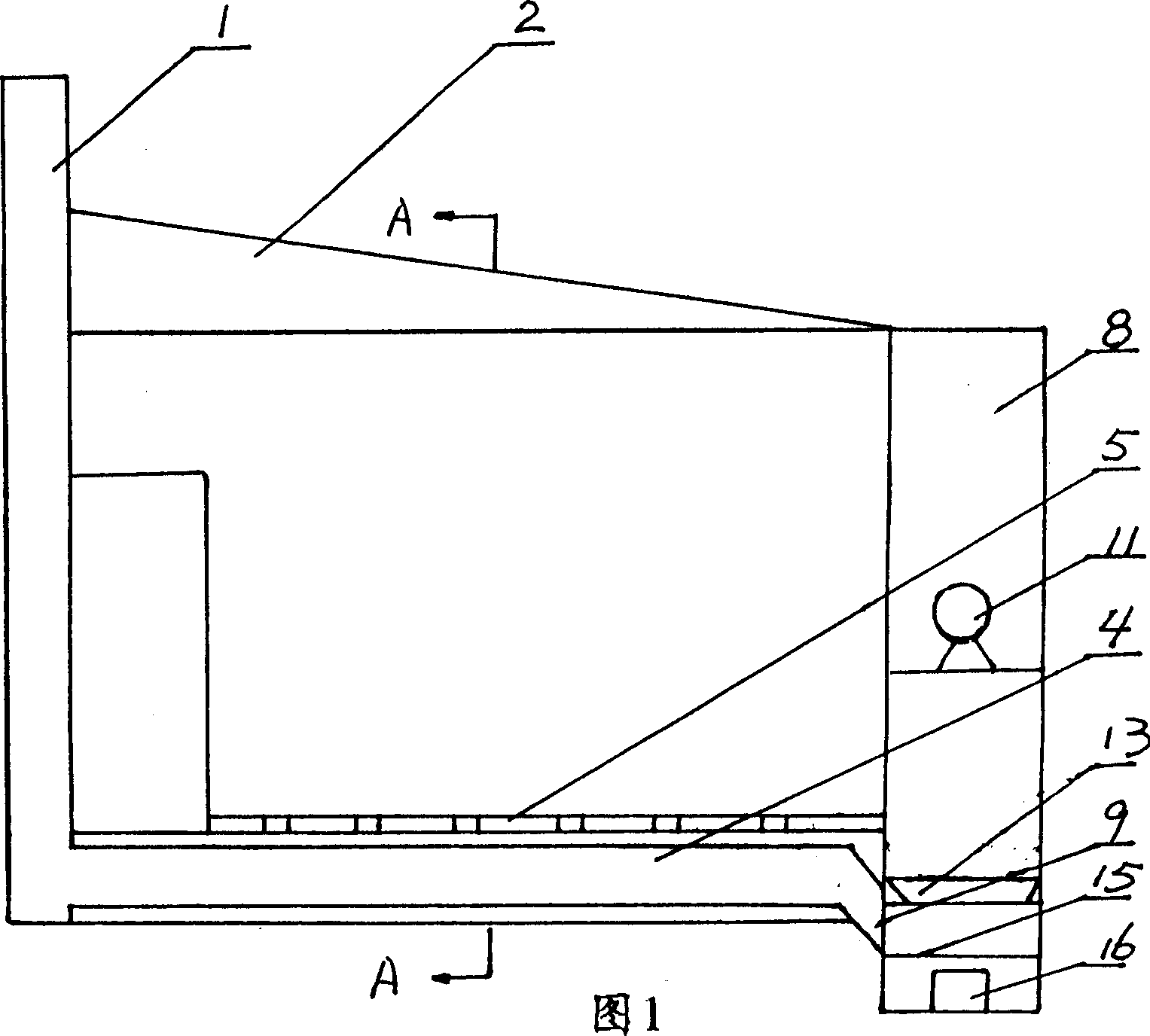

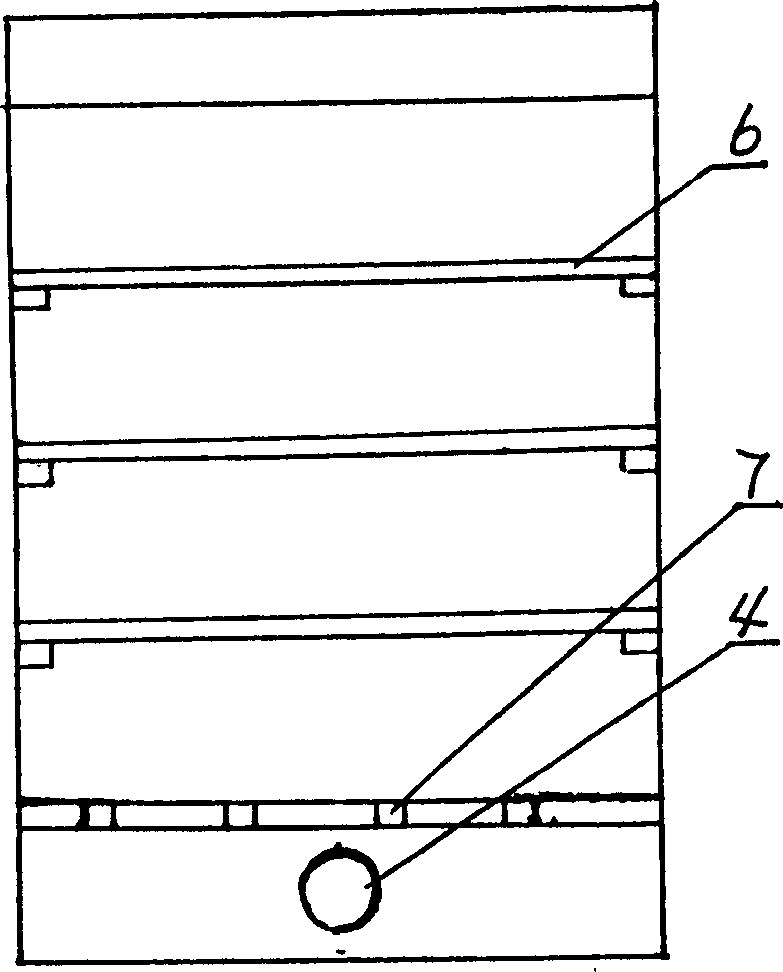

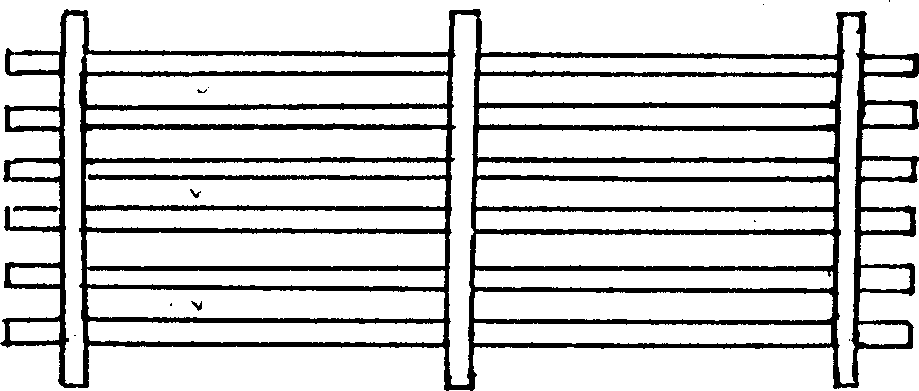

Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

InactiveCN101949535AProlonged combustion residence timeSolve cokingFluidized bed combustionApparatus for fluidised bed combustionCombustionLow speed

The invention relates to a low-ratio biomass circulating fluidized bed boiler and a combustion method thereof, relating to a circulating fluidized bed boiler and a combustion method thereof and solving the problems of difficult feeding, grate slagging, bed material coking, tempering and output reduction, and the like existing in the operation of traditional grate furnaces and circulating fluidized bed boilers. A middle air chamber corresponds to the middle of a dense-phase area at the lower part, lateral grid plates are arranged between a lateral air chamber and the dense-phase area at the lower part, and a medium-temperature steam-cooled cyclone separator is arranged at the joint between a flue shaft at the tail part and a health outlet of a boiler body, respectively communicated with the flue shaft and the health outlet and communicated with the dense-phase area at the lower part through a material returner. The method adopts a negative-pressure feeding manner so that the fluidization air velocity of a high-speed area of the dense-phase area at the lower part is 4-5 m / s, the fluidization air velocity of a low-speed area is 1.5-2.0 m / s, the temperature of the dense-phase area at the lower part is 650-780 DEG C, and the material circulation ratio is below 10. The invention is suitable for the biomass circulating fluidized bed boiler for an electric power plant.

Owner:湖南博茂节能环保科技有限公司

Method for manufacturing environment-friendly semi-polyurethane leather

InactiveCN102433765ASoft touchFeel comfortableSynthetic resin layered productsTextiles and paperEnvironmental resistanceWater based

The invention discloses a method for manufacturing environment-friendly semi-polyurethane leather. The method is characterized in that: polyvinyl chloride (PVC) is taken as a foam layer, water-base cement is taken as an adhesive layer, and the environment-friendly semi-polyurethane (PU) leather is prepared by a transfer coating method. Water-borne polyurethane replaces the traditional solvent-type polyurethane to serve as a surface layer, a surface treatment layer and an adhesive layer of the semi-polyurethane leather, organic pollution is eliminated from the source, organic solvent resourcesare saved, potential safety hazards are eliminated, and the working environment of workers is improved. The content of volatile organic compounds (VOC) of the finished leather is less than 5mg / kg (ofleather), the finished leather is eco-friendly and meets the requirement of ecological semi-PU leather, and other performance of the finished leather is equal to or superior to that of a solvent-typeproduct.

Owner:SICHUAN UNIV

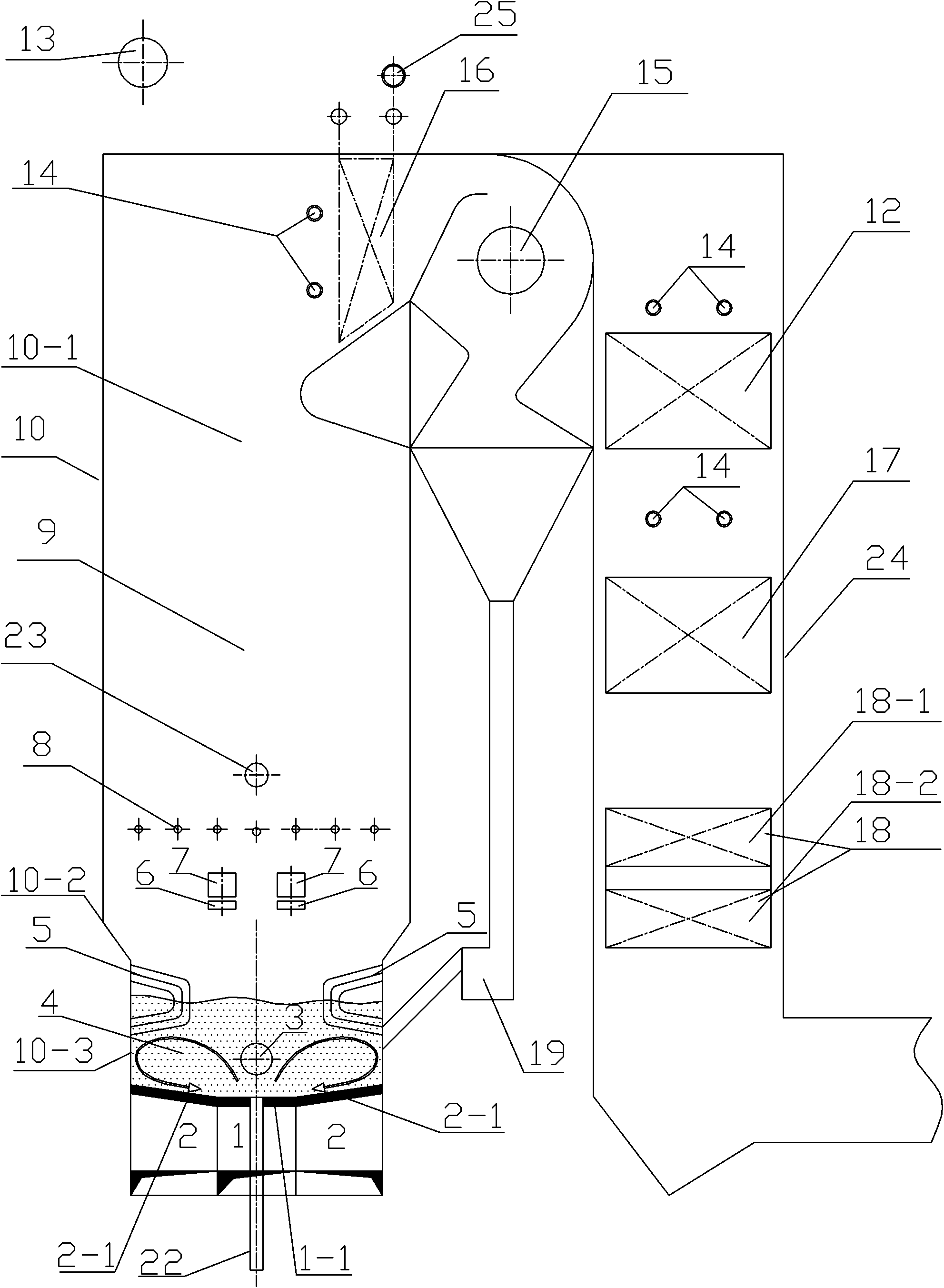

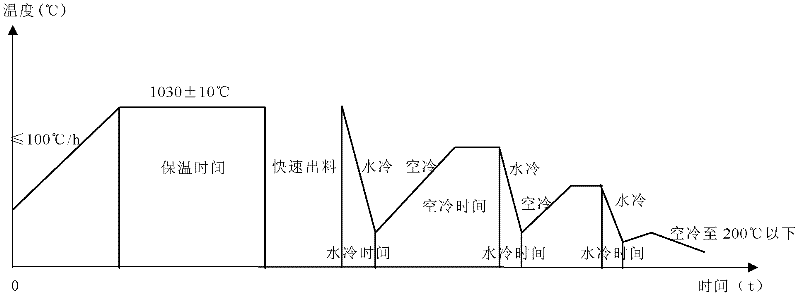

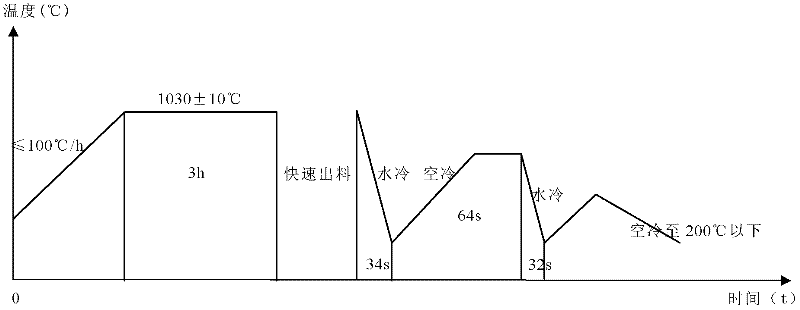

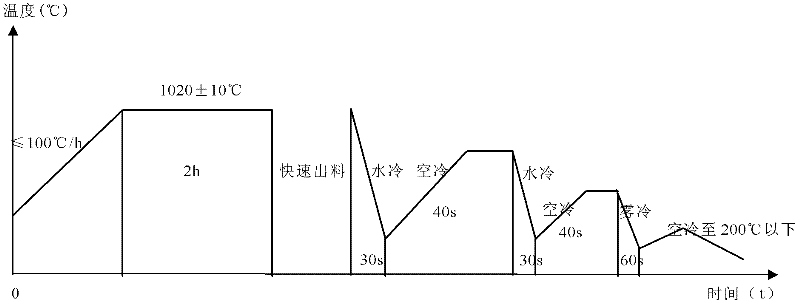

Continuous type alloy steel heat treatment line

The invention discloses a continuous type alloy steel heat treatment line, solving the problem existing in small-section ultra-long material workpiece heat treatment. The continuous type alloy steel heat treatment line is formed by connecting a continuous type roller hearth heating furnace, a roller hearth type quenching groove and electric heating continuous type roller hearth furnace in series.The heat treatment process comprises the following steps of: carrying out austenitization heating on a workpiece in the continuous type roller hearth heating furnace, rapidly discharging after reaching the process time and then entering into the roller hearth type quenching groove; automatically generating a non-continuous water cold process according to the chemical components and different standards of the workpiece, and rapidly cooling through an immersion or spray mode; and tempering the workpiece which is cooled to room temperature according to the process requirement. The continuous type alloy steel heat treatment line has the advantages that: 1, the quenching, solid solution and normalizing continuous heat treatment of the small-section ultra-long material workpiece are achieved, and the heat treatment is completed on roller beds which are located on the same height and axis; 2, a quenching medium is stable in the rising process, and the workpiece can be simultaneously cooled in the length direction; and 3, fire danger and lamp black pollution are precluded by adopting non-continuous water quenching.

Owner:FUSHUN SPECIAL STEEL SHARES

Defrosting control method for refrigerator

ActiveCN102954666AReduce consumptionPrevent poor defrostingLighting and heating apparatusDefrostingElectricityEngineering

The invention relates to a defrosting control method for a refrigerator, comprising the following steps of: determining to obtain a defrosting mode; confirming whether the defrosting start condition is met; and defrosting until the defrosting condition is met. Different defrosting control modes are executed according to different external conditions, and the defrosting cycle is determined according to the number of times of door opening after the end of first defrosting after power-on, accordingly, the poor defrosting can be prevented, and the energy consumed by unnecessary defrosting operation can also be reduced.

Owner:GUANGDONG HOMA REFRIGERATOR CO LTD

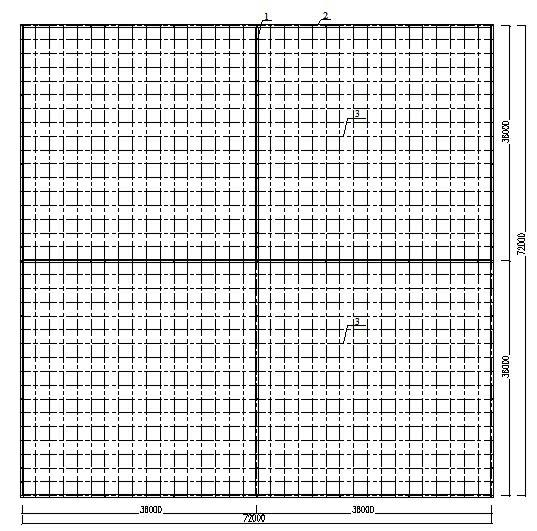

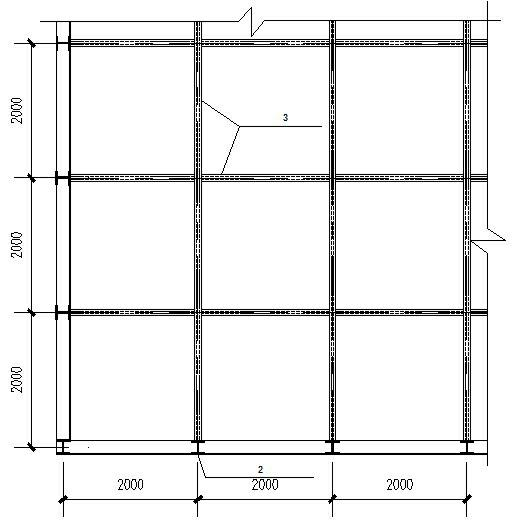

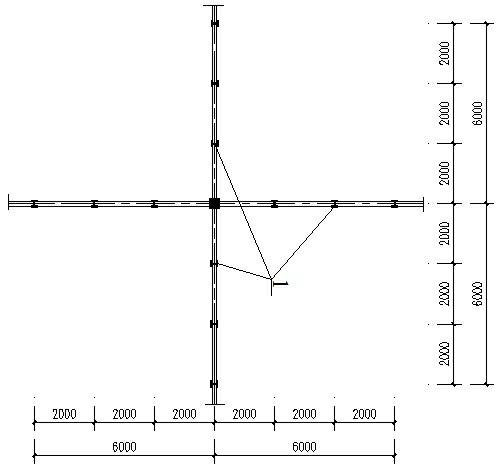

Assembled monolithic multilayer long-span bidirectional multi-span building with space steel grid box-type structures

InactiveCN102635163AEliminate fire hazardsShorten the construction scheduleWallsFloorsLateral stiffnessLong span

The invention discloses an assembled monolithic multilayer long-span bidirectional multi-span building with space steel grid box-type structures, which is characterized in that each layer of ground steel structural framework is formed into a single space steel grid box-type structure by a central cross-shaped single-layer steel grid wall frame, a surrounding single-layer steel grid-type outer wall frame and a top steel open-web sandwich plate floor frame, and the steel grid wall frames are respectively connected by small-sized assembly units prefabricated in a factory at the construction site by using high-strength bolts; all layers of single space steel grid box-type structures are upwards superposed layer by layer to form a superposed single barrel box-type structure; and four multilayer superposed single barrel box-type structures are connected with each other at the floor to form an assembled monolithic multilayer long-span bidirectional multi-span barrel bundle with the space steel grid box-type structures. According to the building disclosed by the invention, welding operations are not needed at the construction site, so that the fire hidden danger is eliminated. Compared with traditional steel framework structures, the construction cost of the steel structure is reduced by 15-20 percent, the construction progress is shortened by at least 1 / 3, and the resist lateral stiffness is increased by at least twice.

Owner:唐山建华检测股份有限公司 +6

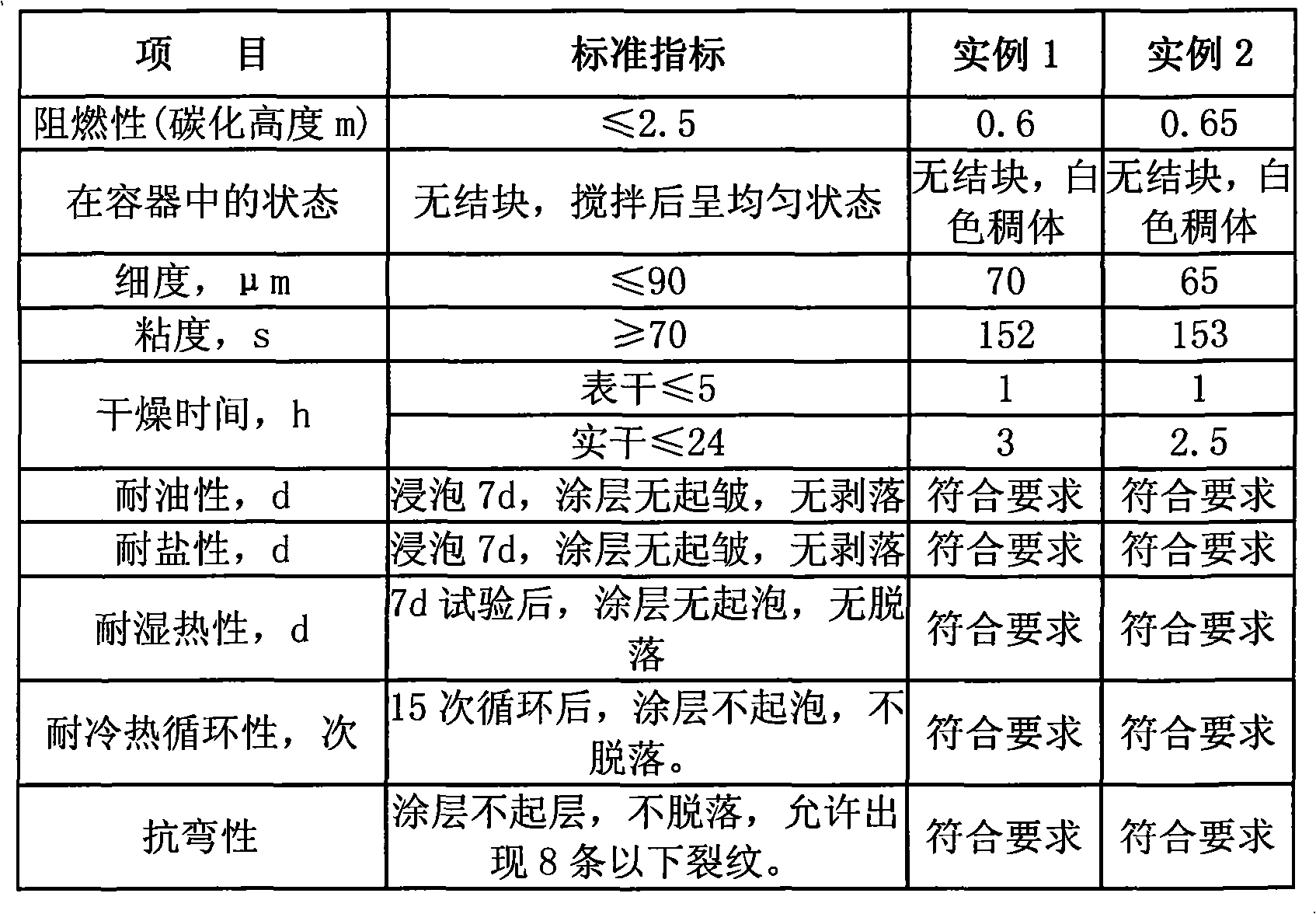

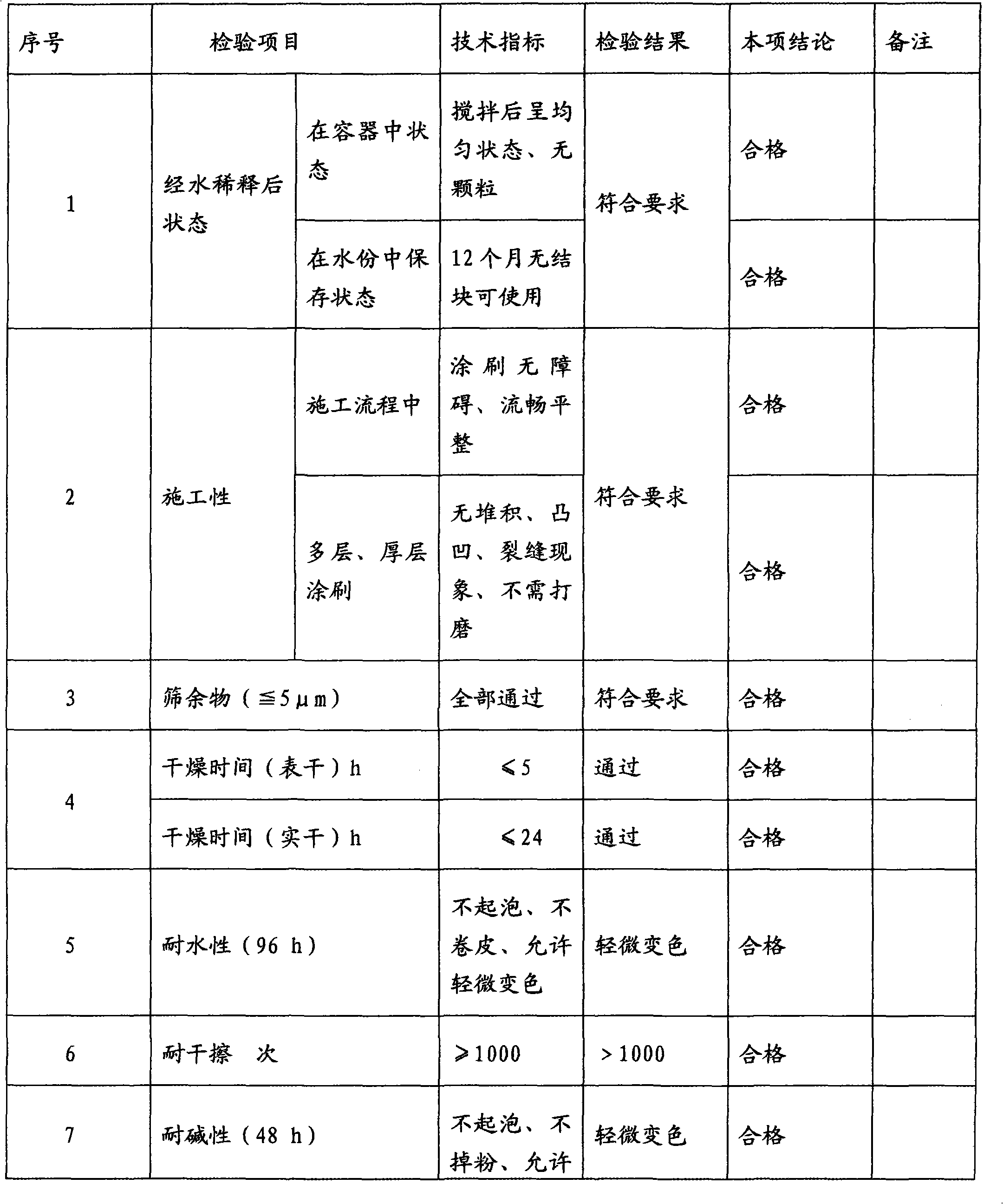

Environment-friendly cable fireproof paint and manufacturing method thereof

InactiveCN101654579AEliminate fire hazardsHarm reductionFireproof paintsInsulated cablesWater basedFire risk

The invention relates to a manufacturing method of fireproof paint, in particular to environment-friendly cable fireproof paint and a manufacturing method thereof. The environment-friendly cable fireproof paint comprises the following initial raw materials in parts by weight: 1-50 parts of water, 10-90 parts of elastic acrylic based emulsion, 1-10 parts of stuffing, 10-90 parts of flame retardant,1-10 parts of melamine, 1-10 parts of rutile type titanium pigment, 1-10 parts of dipentaerythritol, 1-10 parts of thixotropic agent and 1-10 parts of thickening agent. The environment-friendly cablefireproof paint is water-based fireproof paint, has the advantages of no halogen, innocuity, no corrosion, safety, environmental protection, high-effective flame retardance, volume increase in case of fire, convenient construction and the like, radically eliminates the fire risks due to the solvent volatilization of solvent type paint in production and construction, and reduces the harm to peopleand the pollution to environment caused by harmful organic solvents.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

New-type tobacco flue-curing room and the tobacco flue-curing process

InactiveCN1403035ACompatible with growth physiological characteristicsSelection quality improvementTobacco preparationThree stageSmall footprint

Owner:刘志峰

Heat-preserving material for outer wall

The present invention discloses a heat-preserving material for an outer wall which comprises the following raw materials in parts by weight: 45-55 parts of coal ash silicate cement, 15-20 parts of white floating beads, 1.5-2 parts of nano TiO2, 0.5-1.2 parts of ceramic cotton fiber, 5-10 parts of aluminium silicate fiber cotton, 0.2-0.6 part of a water repellent, 3-7 parts of an elastic emulsion, 6-9 parts of swelled vitrified microbead heat-preserving slurry, 3.5-4.5 parts of polypropylene fiber, 2-5 parts of an inorganic nano coating, 0.05-0.1 part of foam filaments, 0.05-0.1 part of bamboo fiber and 10-15 parts of a flame retardant. The heat-preserving material for the outer wall has the characteristics of good heat preservation, thermal insulation, sound insulation, self-cleaning, ray resistance, water resistance, energy conservation and environment protection and high strength.

Owner:NANYANG INST OF TECH

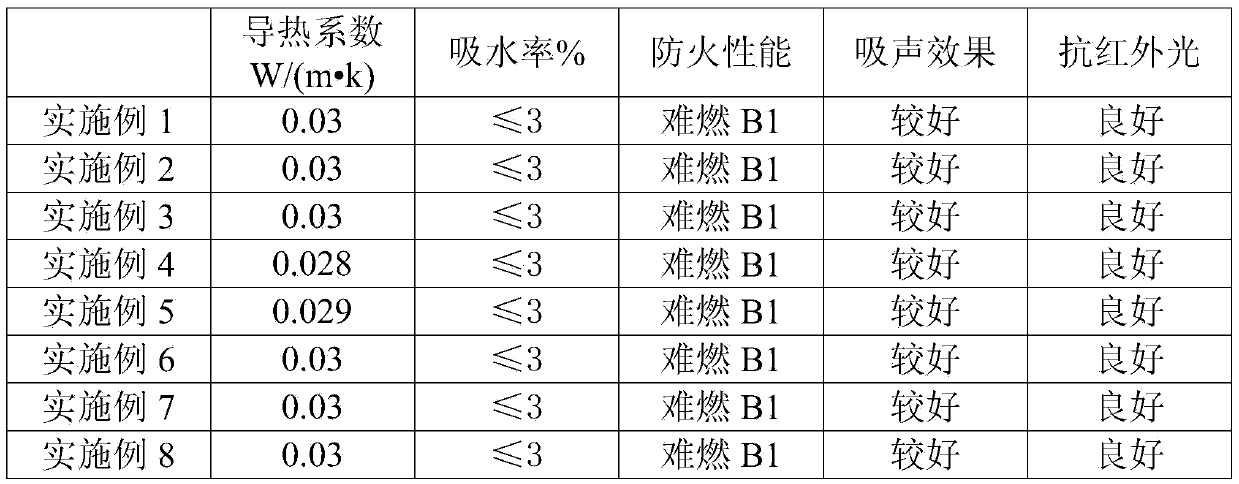

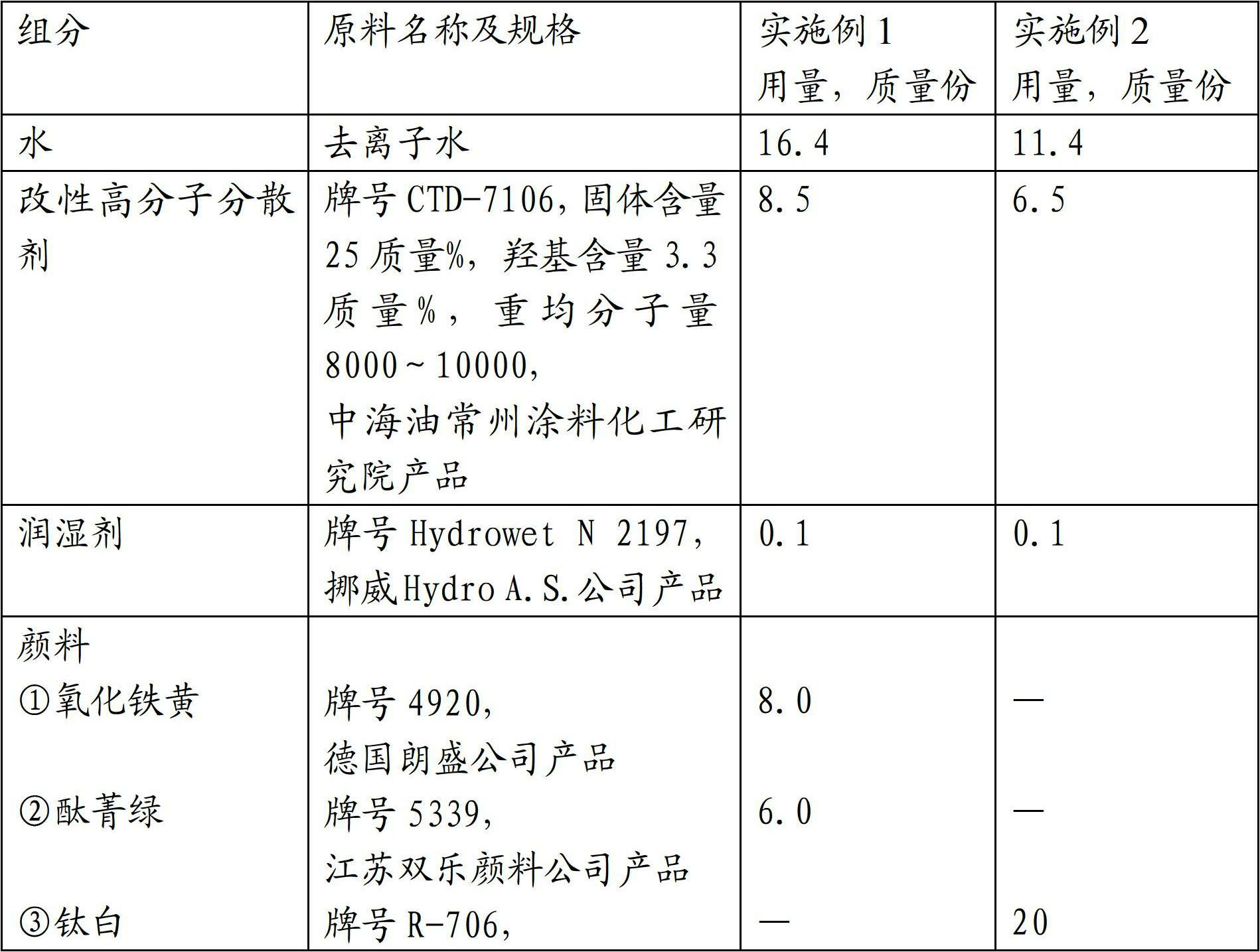

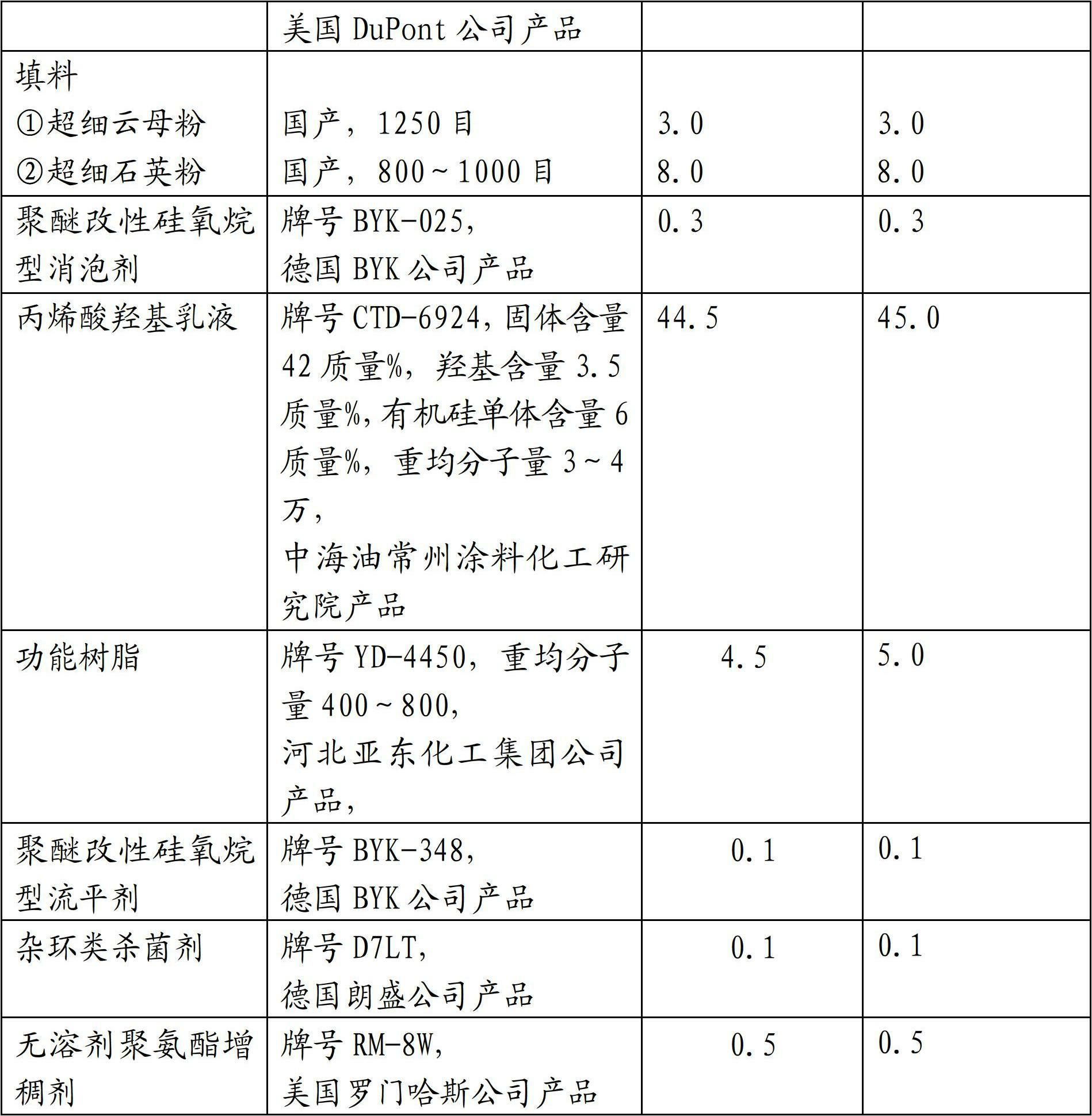

Environment-friendly water-based double-component polyurethane floor coating

ActiveCN102634273AImprove performanceImprove adhesionPolyurea/polyurethane coatingsWater basedMass ratio

The invention relates to an environment-friendly water-based double-component polyurethane floor coating. A component I is water-based aliphatic isocyanate containing 100% by mass of solid content, a component II comprises the following components by weight parts: 10-18 parts of water, 4-10 parts of modified polymeric dispersant, 0.1-0.3 parts of non-ionic and / or anionic wetting agent, 2-20 parts of pigment, 3-15 parts of filler, 40-70 parts of acrylic hydroxyl emulsion, 3-6 parts of functional resin, 0.1-0.5 parts of polyether modified siloxane defoamer, 0.1-0.3 parts of polyether modified siloxane flatting agent, 0.1-0.3 parts of heterocyclic fungicide and 0.2-1.0 part of solvent-free polyurethane thickening agent. When the floor coating is used, the component I and the component II are mixed according to the mass ratio of the component I to the component II being 1:(5-6). According to the coating, all the performances of the coating completely meet the requirements of solvent-based floor coating, the artificial aging resistance is excellent, and the volatile organic compound content in the water-based double-component polyurethane floor coating is obviously lower than that of single-component water-based polyurethane floor coating, and the environmental requirement is met.

Owner:CHINA NAT OFFSHORE OIL CORP +3

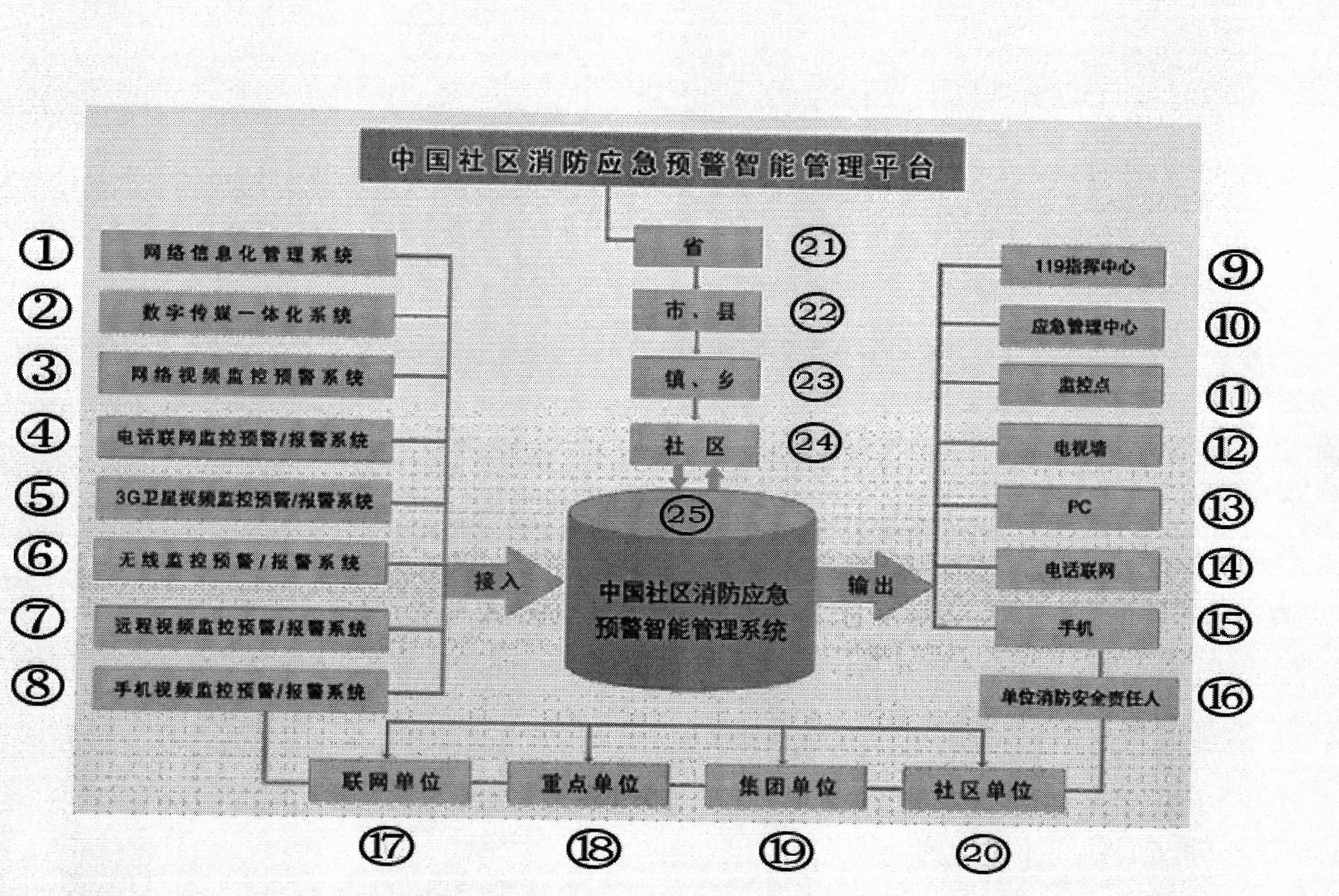

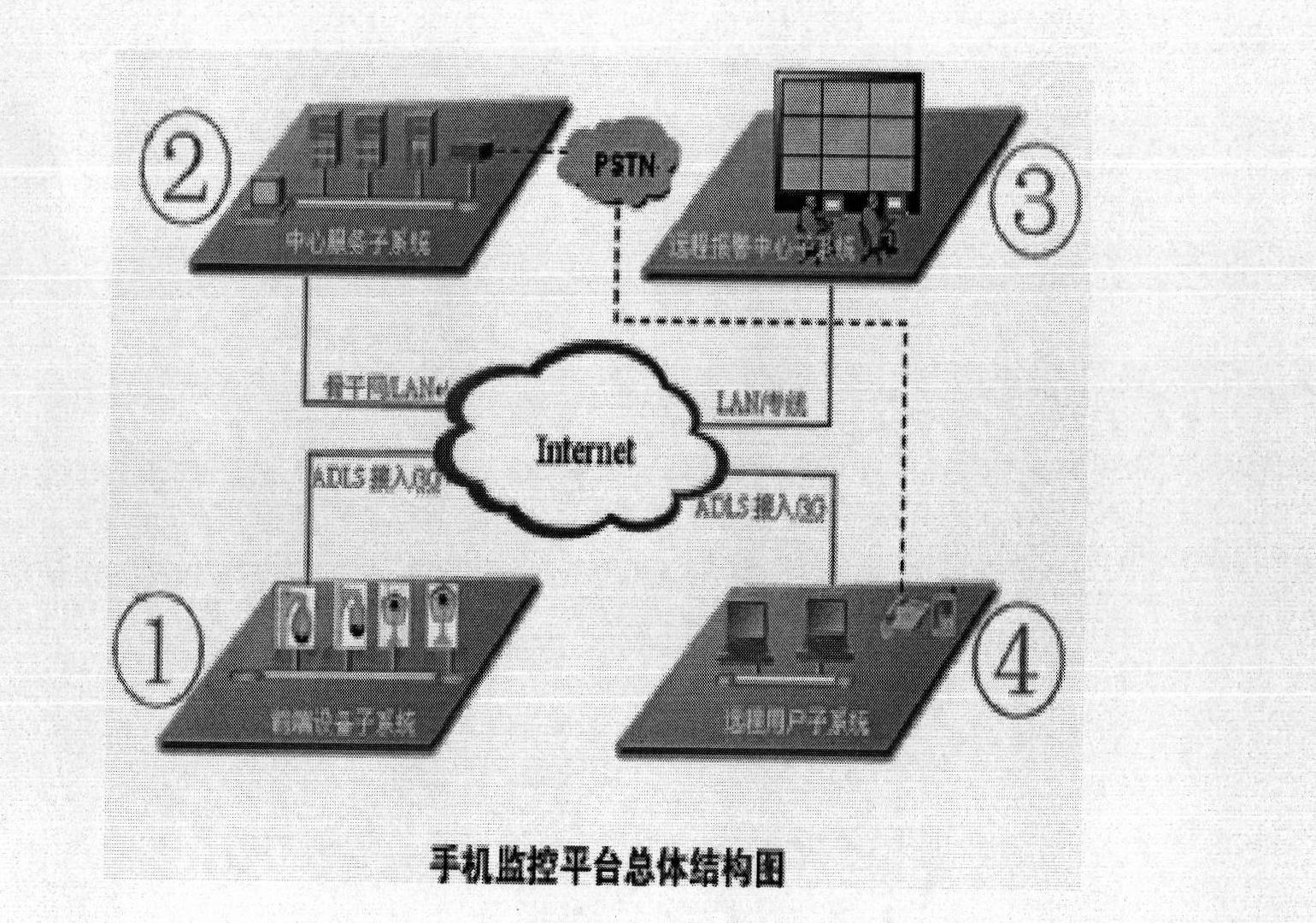

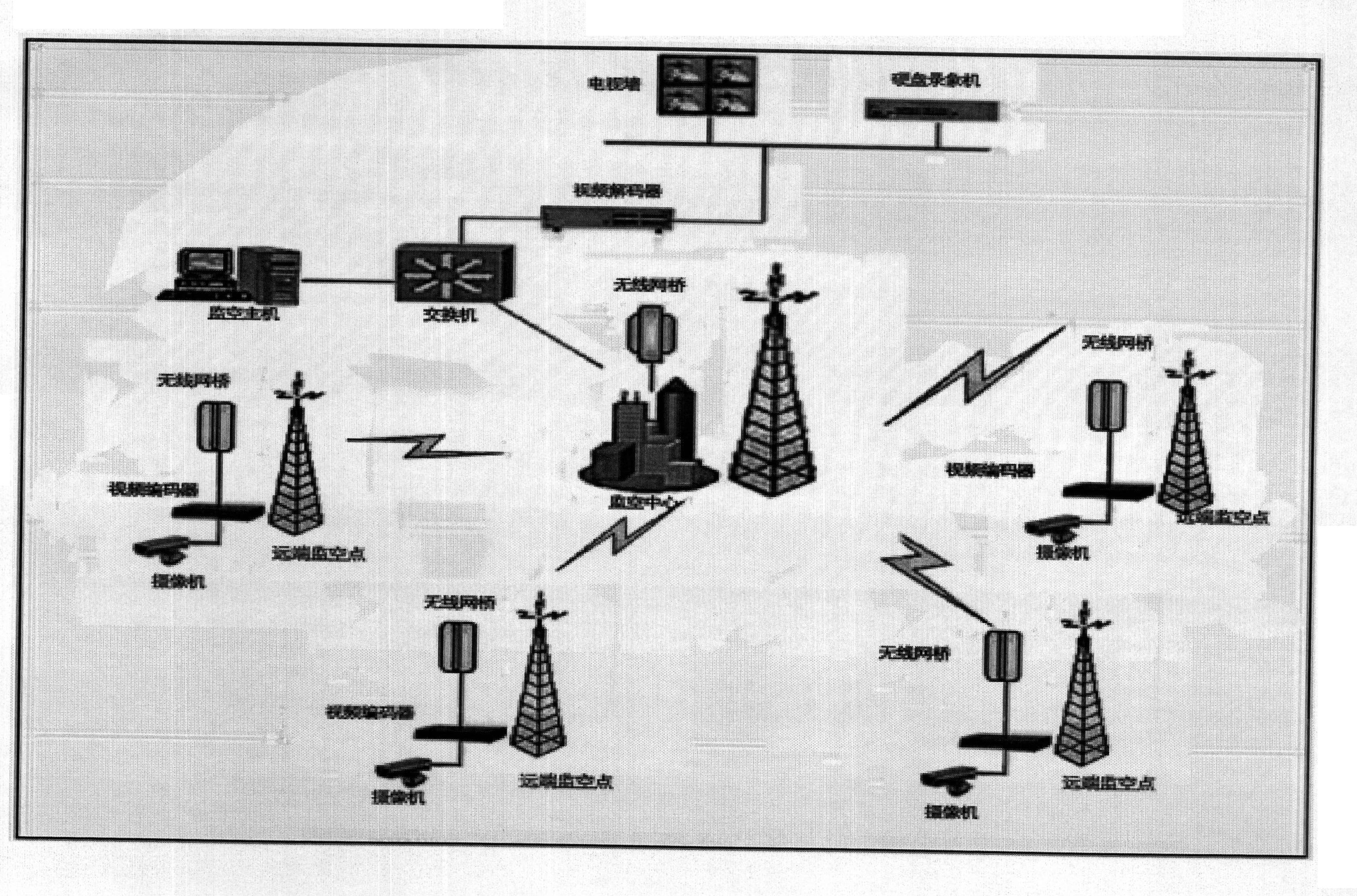

Fire-fighting early-warning monitoring and intelligent management system based on internet

InactiveCN101998166AImprove reliabilityReduce false alarm rateTelevision conference systemsRegistering/indicating working of machinesVideo monitoringArea network

The invention relates to a fire-fighting early-warning monitoring and intelligent management system based on an internet. The system integrates functions of eight kinds of software, comprising telephone networking early-warning software, wire video monitoring early-warning software, wireless video monitoring early-warning software, mobile video monitoring early-warning software, satellite video monitoring early-warning software, video on demand software, video session software, live video software, and the like, and the functions can be used independently or integratedly by users. The system can perform large-area networking management on fire alarm systems in buildings, and can realize effective monitoring and quick alarm. The system guarantees the normal operation of the fire alarm systems and fire safety facilities, improves the reliability of the fire alarm systems, and reduces the rate of false alarm. Moreover, through the equipment operating data and alarm information of the fire early-warning monitoring intelligent alarm system based on the internet, the developing process of intelligence and networking of city fire management is accelerated, and thus, the integral technology level and the comprehensive capability of fire prevention and reduction are enhanced.

Owner:北京中海锦安高科技有限公司

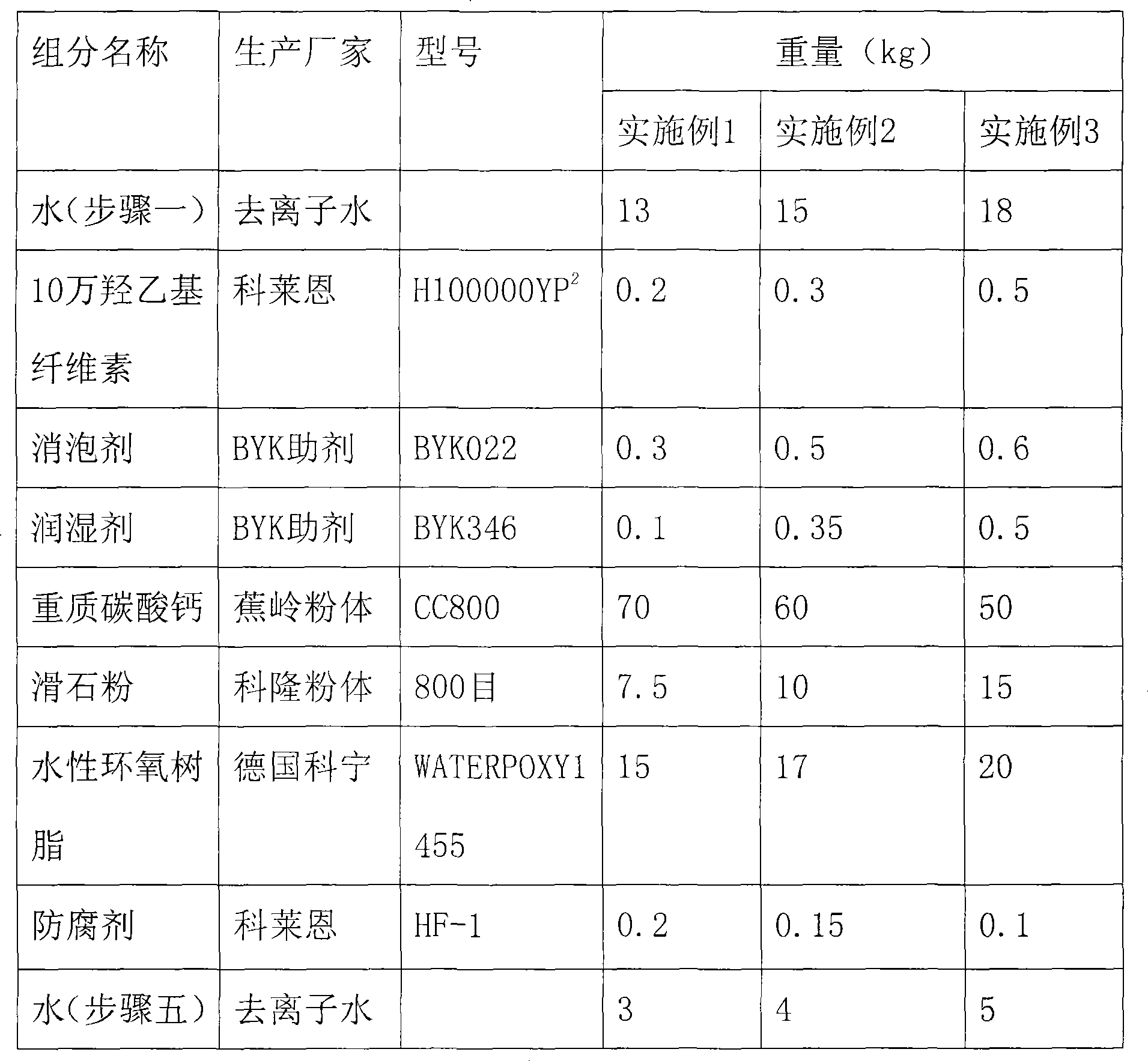

Aqueous epoxy putty, and preparation and use method thereof

The invention relates to an aqueous epoxy putty and a preparation method thereof. The preparation method comprises the following steps: 1. 13 to 18 weight portions of water is added with 0.2 to 0.5 weight portion of thickening agent under the stirring at the speed of 500 to 800 revolutions / minutes, is stirred and is fully dissolved; 2. 0.3 to 0.6 weight portion of a defoaming agent and 0.1 to 0.5 weight portion of wetting agent are sequentially added into the mixture and are evenly stirred; 3. 50 to 70 weight portions of powdered whiting and 7.5 to 15 weight portions of talcum powder are added into the mixture; under the rotational speed of 500 to 800 revolutions / minute, all composition are mixed; and if water is too little to stir the compositions evenly, 3 to 5 weight portions of an aqueous epoxy resin is added into the mixture, is stirred for 5 to 8 minutes till the fineness is between 30 and 40 microns at the rotational speed of 1,200 to1,500 revolutions / minute; 4. at the middle rotational speed, the residual amount of the aqueous epoxy resin is fully replenished to 15 to 20 weight portions totally and is evenly stirred; and 5. the mixture is continuously added with 0.1 to 0.2 weight portion of antiseptic and 3 to 5 weight portions of water, is stirred for 7 to 19 minutes at low speed, and is filtered to obtain the aqueous epoxy putty. According to weight ratio of 6 to 4, an aqueous epoxy curing agent and water are mixed to obtain a special matched curing agent; and according to weight ratio of 20 to 1, the aqueous epoxy putty and the curing agent are mixed for use. The aqueous epoxy putty can solve the problem that oily paint dissolves a polystyrene plate due to the fact that an aqueous epoxy primer is leaked to paint or the thickness of the painted primer does not meet the requirement, and can well decorate and protect a coating layer.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

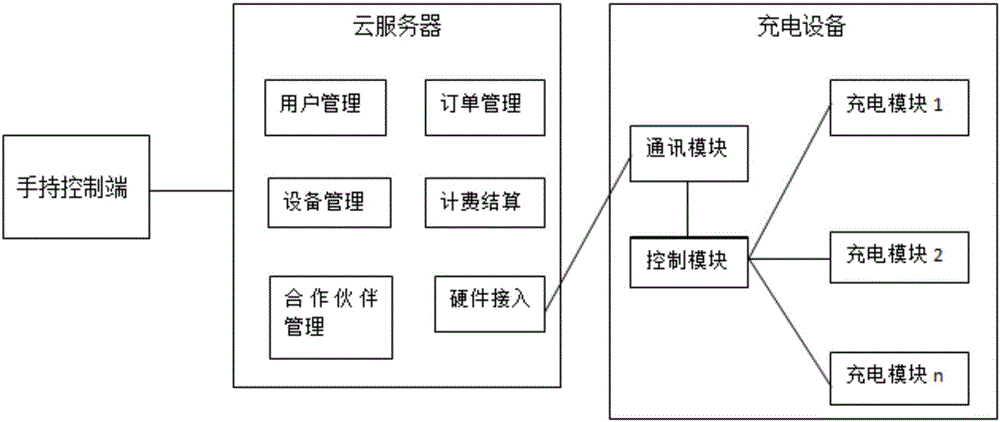

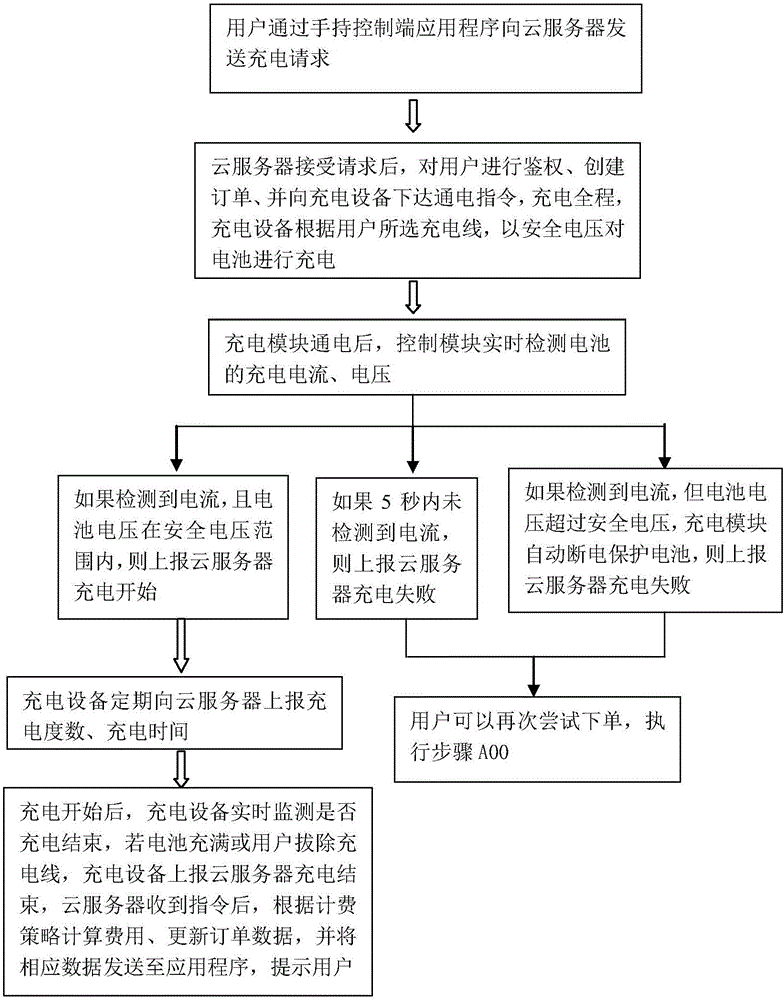

Electric bicycle self-service charging system and method

InactiveCN106230039AImprove securityMeet the use requirementsCharging stationsElectric powerHand heldTime cost

Owner:深圳市绿色星球互联新能源科技有限公司

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

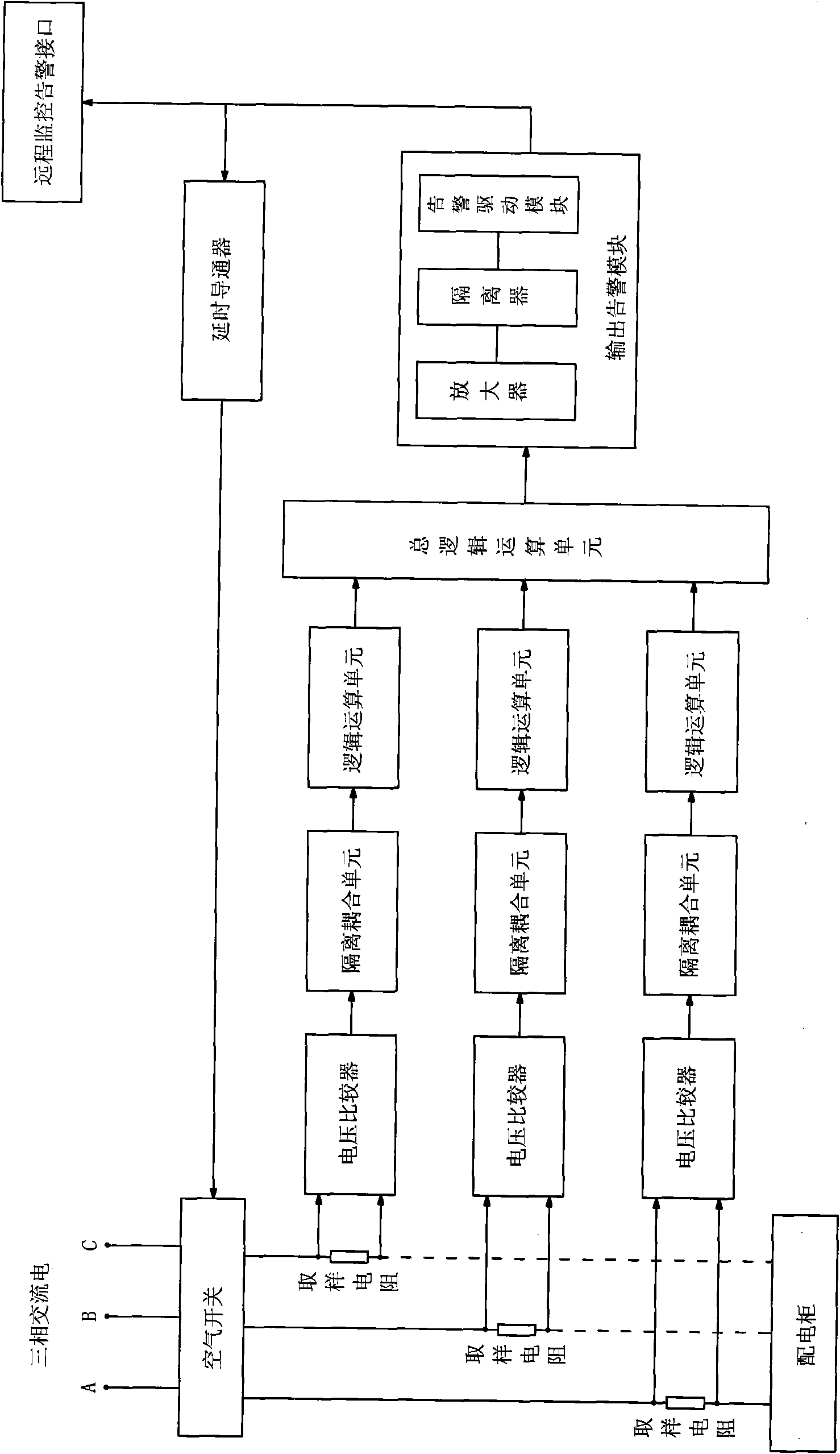

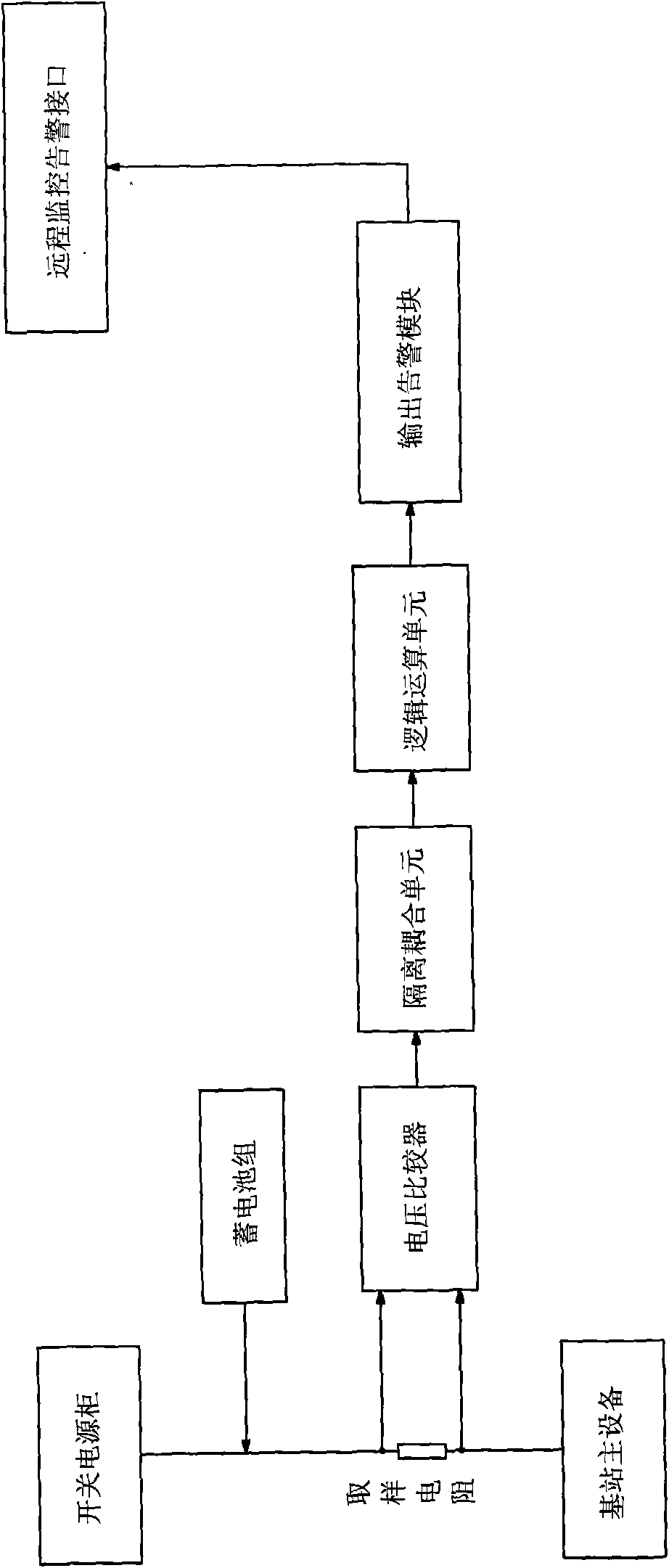

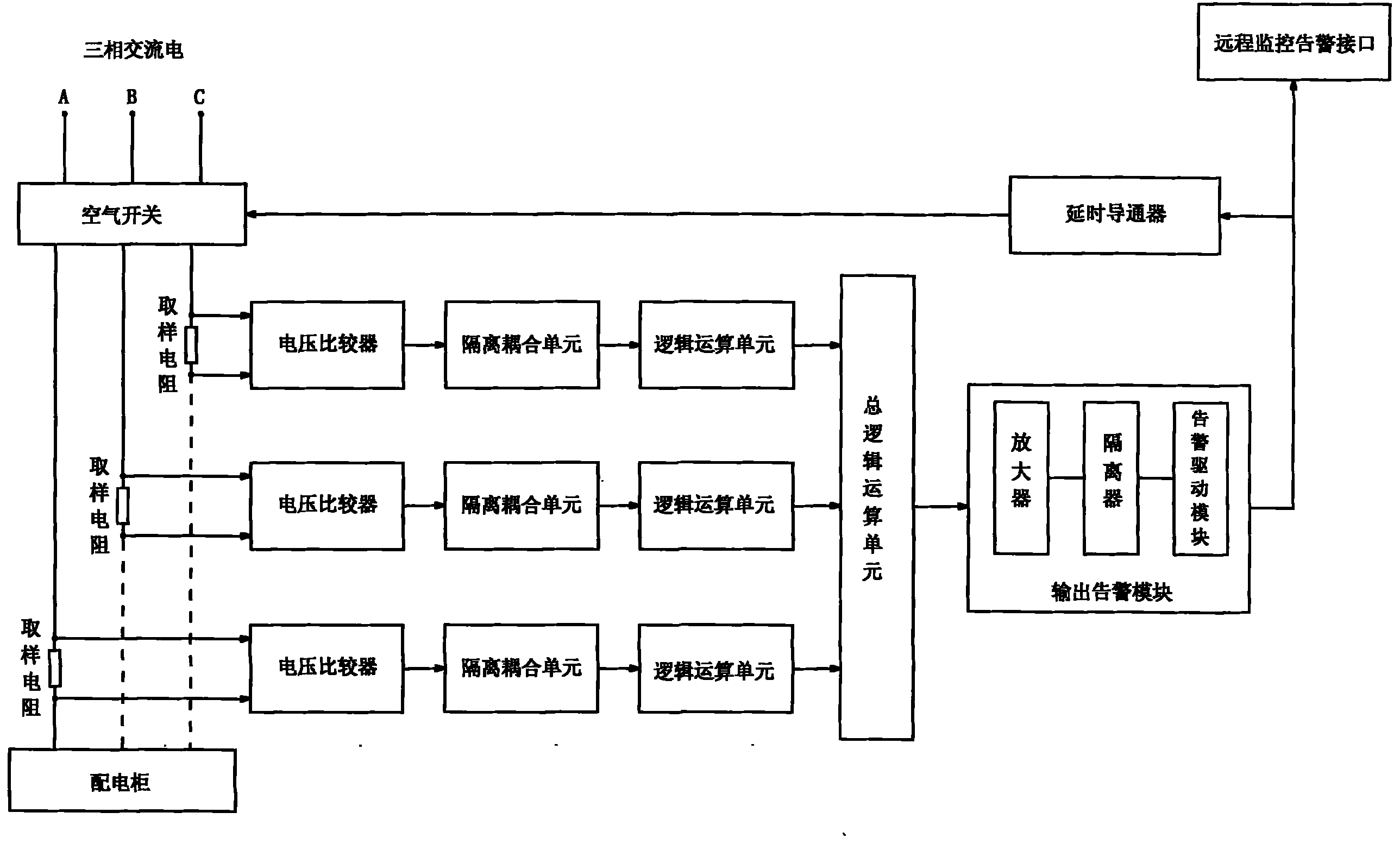

Fireproofing pre-warning monitoring method for unmanned base station and system thereof

InactiveCN101853554AEliminate fire hazardsCurrent/voltage measurementFire alarm electric actuationFire hazardLoad following power plant

The invention discloses a fireproof pre-warning monitoring method for an unmanned base station and a system thereof. In the method, threshold values of a sample resistor and a voltage comparator are compared by two sets of power supply abnormal change monitoring circuits so as to obtain whether the power supply has abnormal changes and determine whether to warn or not. The method and the system first detect electric load increase, fire strike and jump spark on alternating current commercial 380V or 220V power supply, and secondly detect load increase (unknown increase) and direct current power supply short-circuit and fire strike on direct current 48V or 24V power supply which is outputted by a switch power supply cabinet for master equipment, so that the portent of a fire disaster in the equipment room of the base station can be found in advance, alternating current power supply can be automatically cut off in time, technicians can be dispatched for checking in the station in time, and fire hazards can be eliminated.

Owner:卢代高

Preparation method of aluminum silver paste

The invention discloses a preparation method of aluminum silver paste. The preparation method comprises the following steps of: putting aluminum powder with stipulated particle size, grinding aid and liquid nitrogen into a vibrating mill which is heat-insulation under the state of bearing the pressure intensity of 6MPa according to certain proportion; grinding for 3-6 hours; vibrating and grinding into a mixture of liquid nitrogen and sheet-shaped aluminum powder; injecting a solid and liquid mixture into a vortrap at high flowing speed through a pump, wherein the mixture (of liquid nitrogen and sheet-shaped aluminum powder) which does not achieve the fine degree returns to the vibrating mill and is grinded continuously; inputting the sheet-shaped aluminum powder with the mass percentage less than 10% of the liquid nitrogen into a stirring container with certain pressure intensity and temperature; injecting solvents and aids required to be mixed in according to proportion; and then stirring and mixing uniformly; and gasifying and discharging the liquid nitrogen, thereby obtaining the aluminum silver paste product in the stirring container. The preparation method of the aluminum silver paste provided by the invention has the advantages that the aluminum silver paste is produced continuously in the liquid nitrogen protection atmosphere, so that the fire disaster hazard of the production process is eliminated; and aluminum powder is grinded by adopting the vibrating mill with high efficiency, and the vibrating mill can save 2 / 3 of time compared with a ball mill under the same specification and yield, the solvent damage and solvent oil abandoning are avoided, and no pollutant is discharged.

Owner:HEFEI SUNRISE PIGMENTS

Water-based inorganic synthetic fluid coat, preparation method thereof and use method thereof

InactiveCN101899232AEasy to do it yourselfChange the professional single construction methodCoatingsWater basedCalcite

The invention discloses a water-based inorganic synthetic fluid coat. Calcite powder, heavy calcium carbonate powder, light calcium carbonate powder and sierozem powder are taken as the base material; and powdery mixture of water-soluble methylcellulose, ethyecellulose and hydroxypropyl methyl cellulose is taken as the filling material of the water-soluble glue of the solid powder. The water-based inorganic synthetic fluid coat is characterized in that the base mailer thereof further comprises anatase white powder, mica powder and wollastonite. The filling material of the water-based inorganic synthetic fluid coat further comprises hydroxypropyl methyl cellulose, polyacrylamide and water-based nanometer material. The invention has the benefit effects of changing the professional and single construction mode, being convenient for 'DIY' self-actuated operation of the user, adjusting the diversified structure of the product, improving the synthesis function of the product, and being good for 'environmental protection' and 'functionality'.

Owner:赵应征

Incombustion composite plastic and preparation process thereof

The invention is a fire-retardant composite plastic and making method, which comprising basal material PVC, fillings light CaCO3, ultrafine asbestos powder, antishock modifier CPE, processing modifier ACR, surface processing agent stearic acid, heat stabilizers tribasic calcium stearate, and lead stearate, photostabilizer titanium pigment, and permanent flame retardant tri(2,3-dichloropropyl) phosphate, proportionally, adding them in a hot-mix kneading machine for mechanically commixing modification, then discharging them into a cold mixer to cool to normal temperature, and obtaining the product. It has the advantages of reasonable mixing of raw materials, and simple and convenient preparing process.

Owner:王志勇

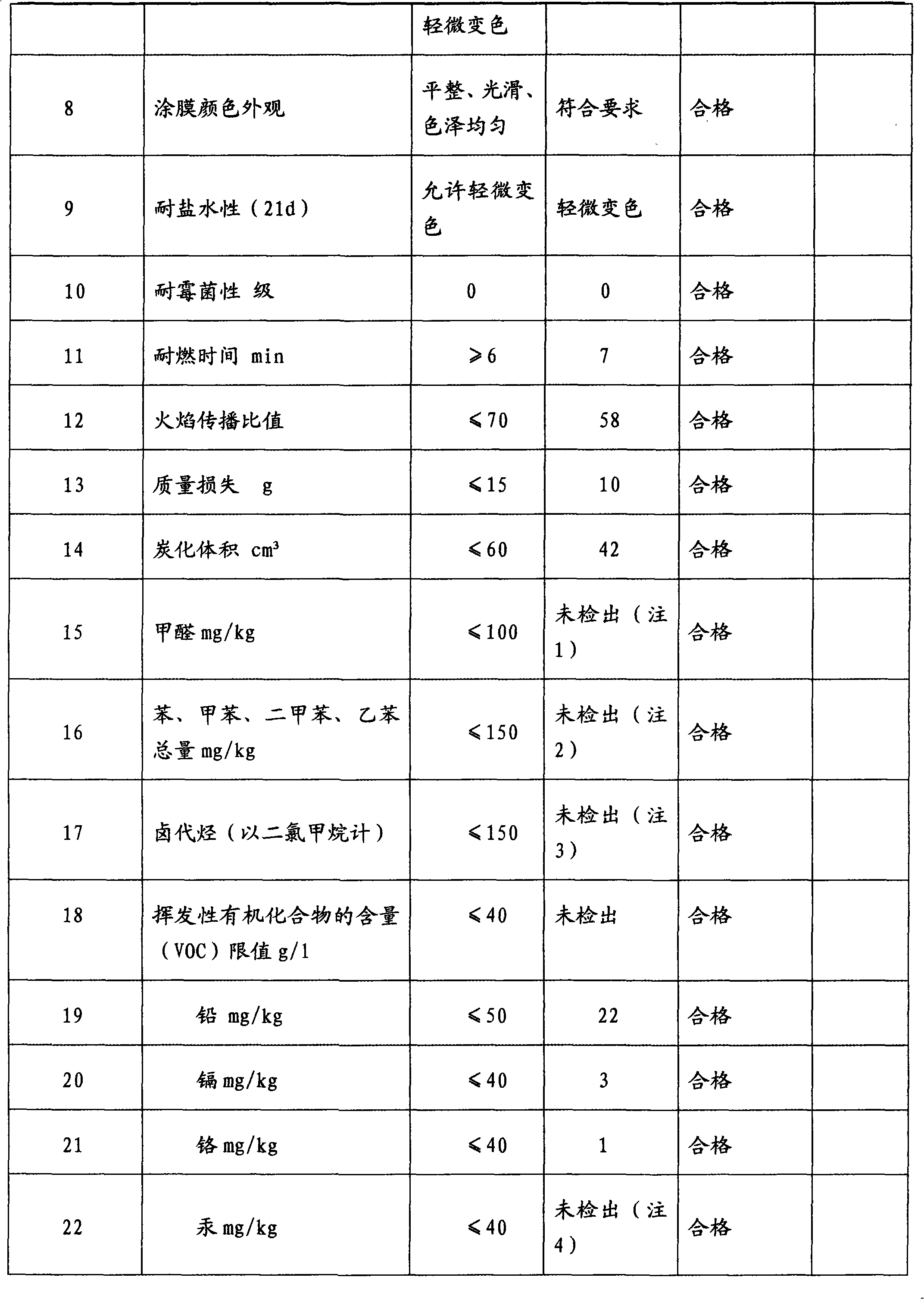

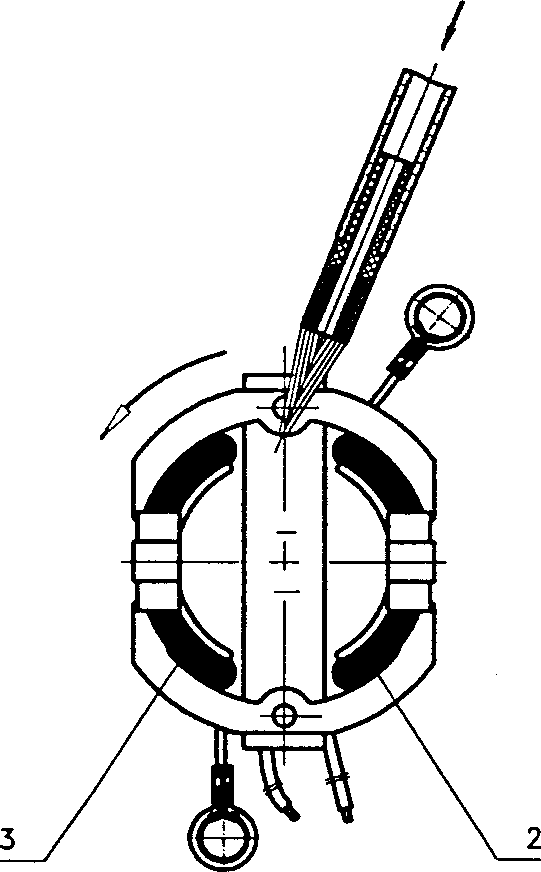

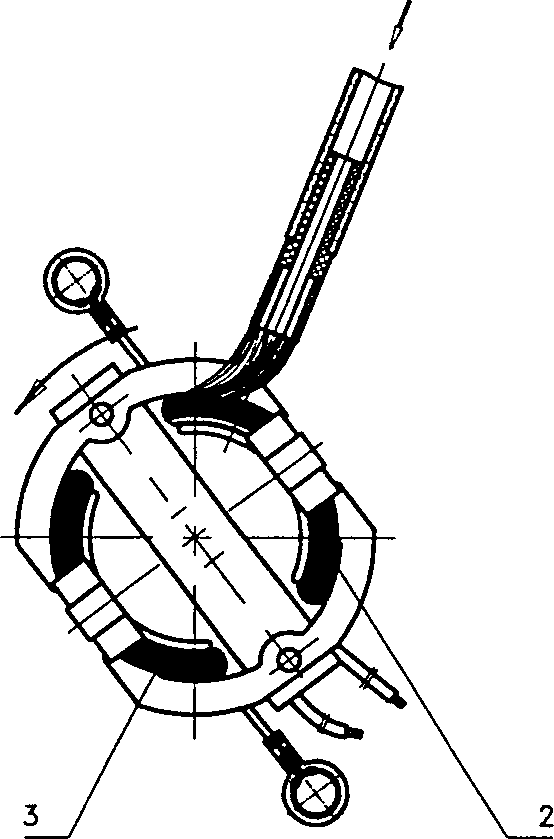

Stator resin trickling technique and resin trickling device

InactiveCN1485967ALow costReduce pollutionManufacturing dynamo-electric machinesManufacturing cost reductionStator coil

The invention refers to a stator paint dropping technique and paint-dropping device. The method: only when the paint dropping heat contacts the stator coil, the insulating paint can be output to droppaint; the paint-dropping device is composed of clamp, paint dropping head, elastic collet, active bracket and vernier bracket. The paint dropping head has the ability to store paint and adopts contact-type and intermittent paint dropping.

Owner:上海电动工具研究所(集团)有限公司

Basement water-proof structure and construction method for basement outer wall water-proof structure thereof

PendingCN107190783AImprove the weak bondEffective waterproof barrierProtective foundationGasketsBasementEconomic benefits

Provided are a basement water-proof structure and a construction method for a basement outer wall water-proof structure thereof. A basement comprises a basic bottom plate, a basement wall body and a basement top plate. Wall bushings are formed in the basement wall body. The basement wall body comprises a guiding wall and a basement outer wall. Construction joints between the guiding wall and the basement outer wall are connected and fixed through water-stop steel plates. A concrete gel layer and a cross film water-proof layer are arranged at the periphery, from inside to outside in sequence, of the basement outer wall and the basement top plate. A second additional cross film water-proof layer is arranged in the portion, located at the inside corner position between the wall bushings and the basement wall body, of the cross film water-proof layer. The tail ends of the cross film water-proof layer and the second additional cross film water-proof layer are fixed to the wall bushings through metal hoops, and are sealed by applying polyurethane. The basement water-proof structure and the construction method for the basement outer wall water-proof structure have the characteristics of being safe and applicable, have good popularization and use value, and can generate good economic benefits after being widely popularized and applied.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

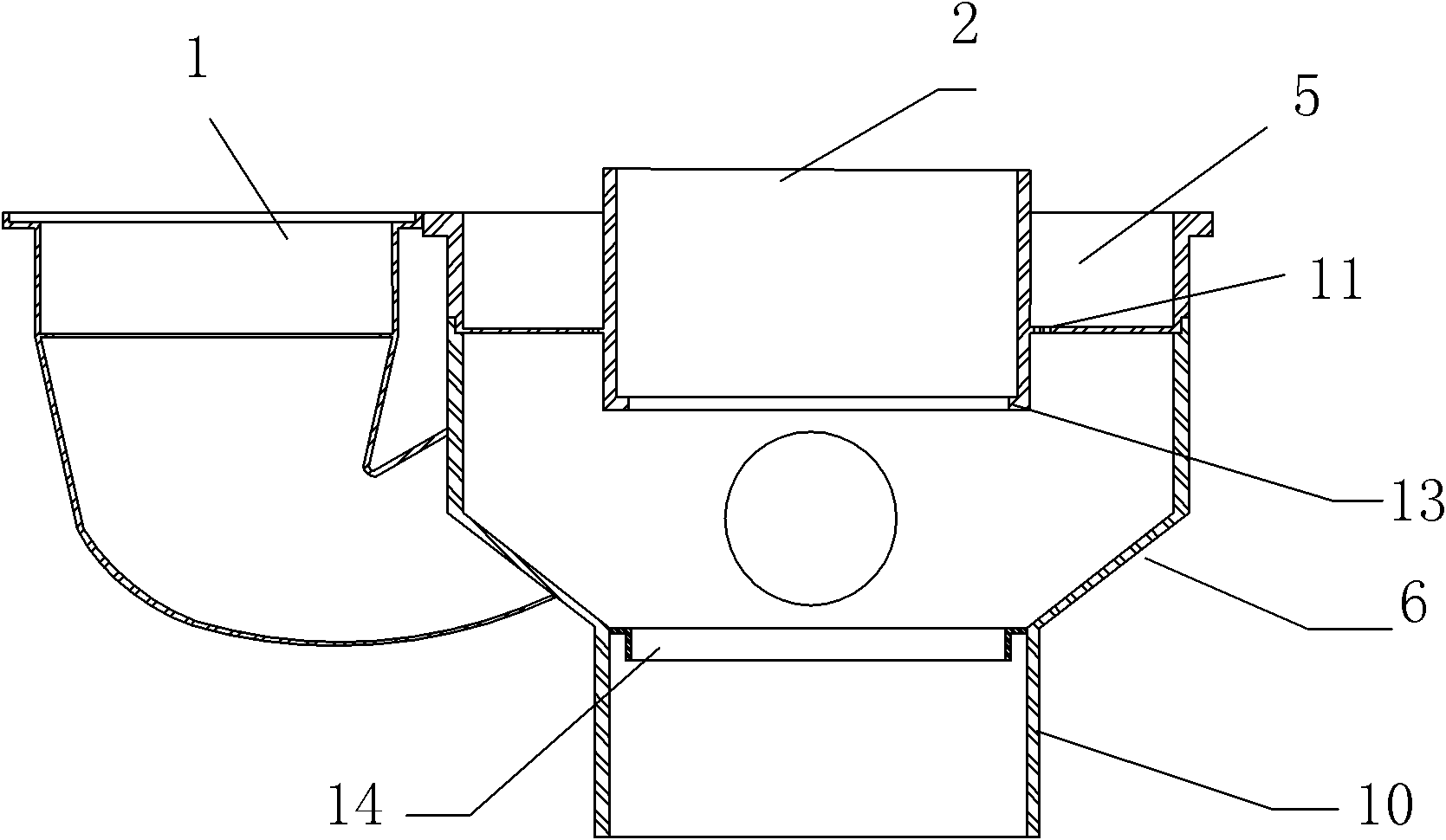

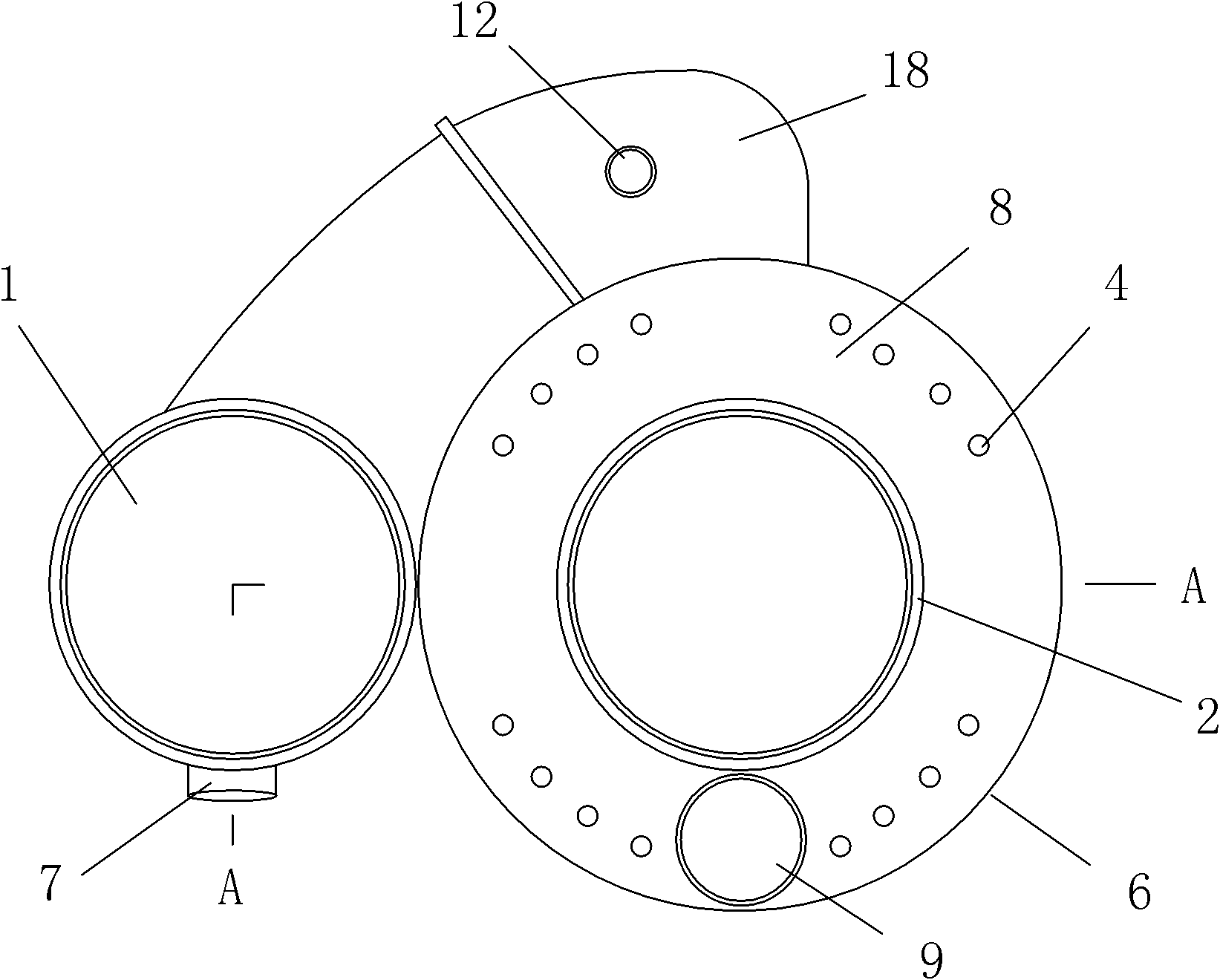

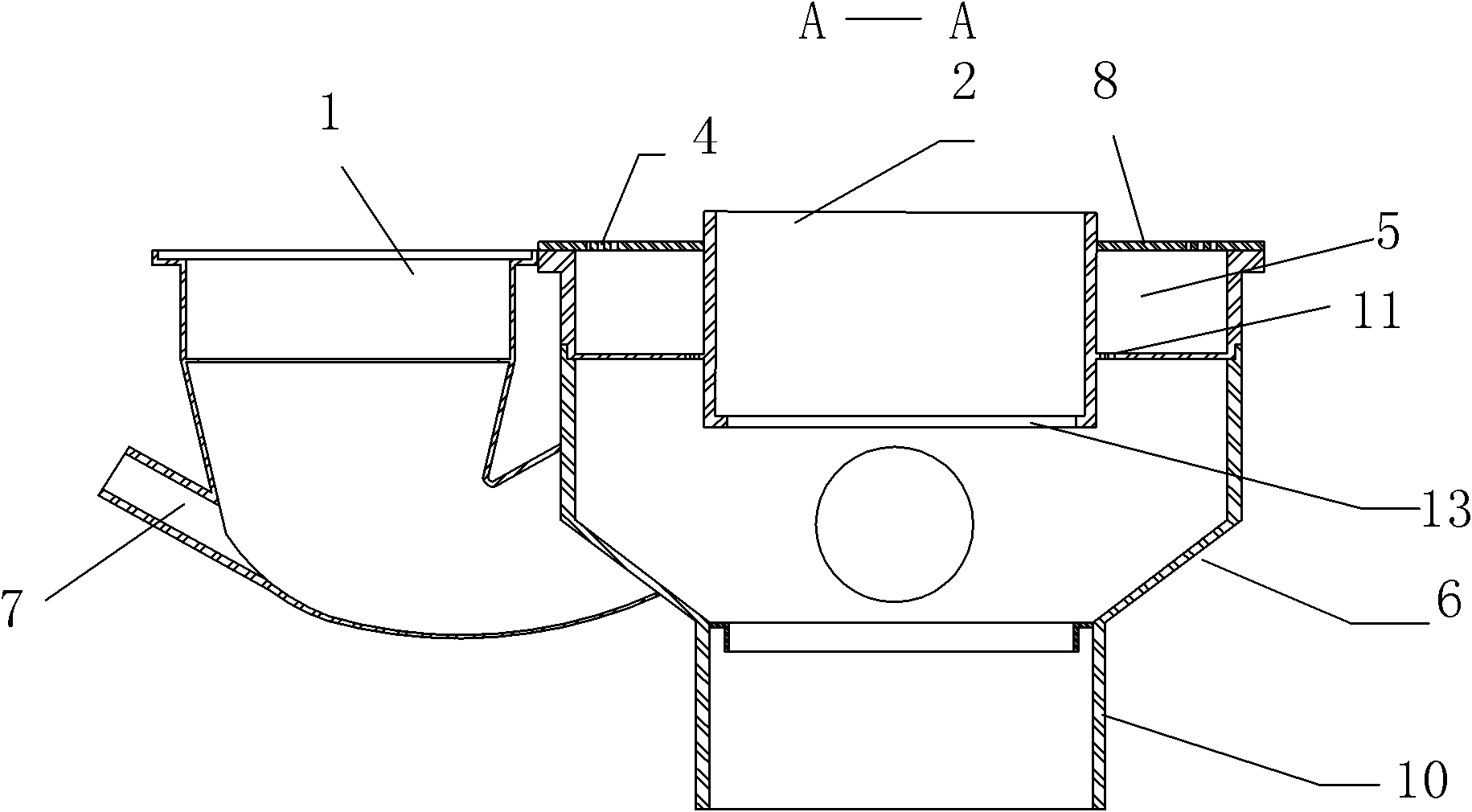

Combined drainage device

The invention discloses a combined drainage device, which comprises a water leakage device (6), wherein the water leakage device (6) is provided with main building siamese and a water collection tank (5); and a drain trap (1) is connected to the water leakage device (6) and is communicated with the main building siamese to form a whole. The combined drainage device is a drainage system, which can integrate the drain traps of a plurality of sanitary fixtures and floor drains in kitchens and toilets into a main water seal device and randomly realize serial connection and parallel connection, and is convenient to arrange and scientific, rational and humanized; positions of the sanitary fixtures, the floor drains and bath facilities in decoration can be randomly determined by users, and are not limited by the positions of the siameses; and the combined drainage device has the characteristics of simple structure, convenient and fast mounting, capability of saving the construction cost of developers, benefits to the state and citizens, low manufacture cost, vast market prospect, and high economic value and application value.

Owner:张超

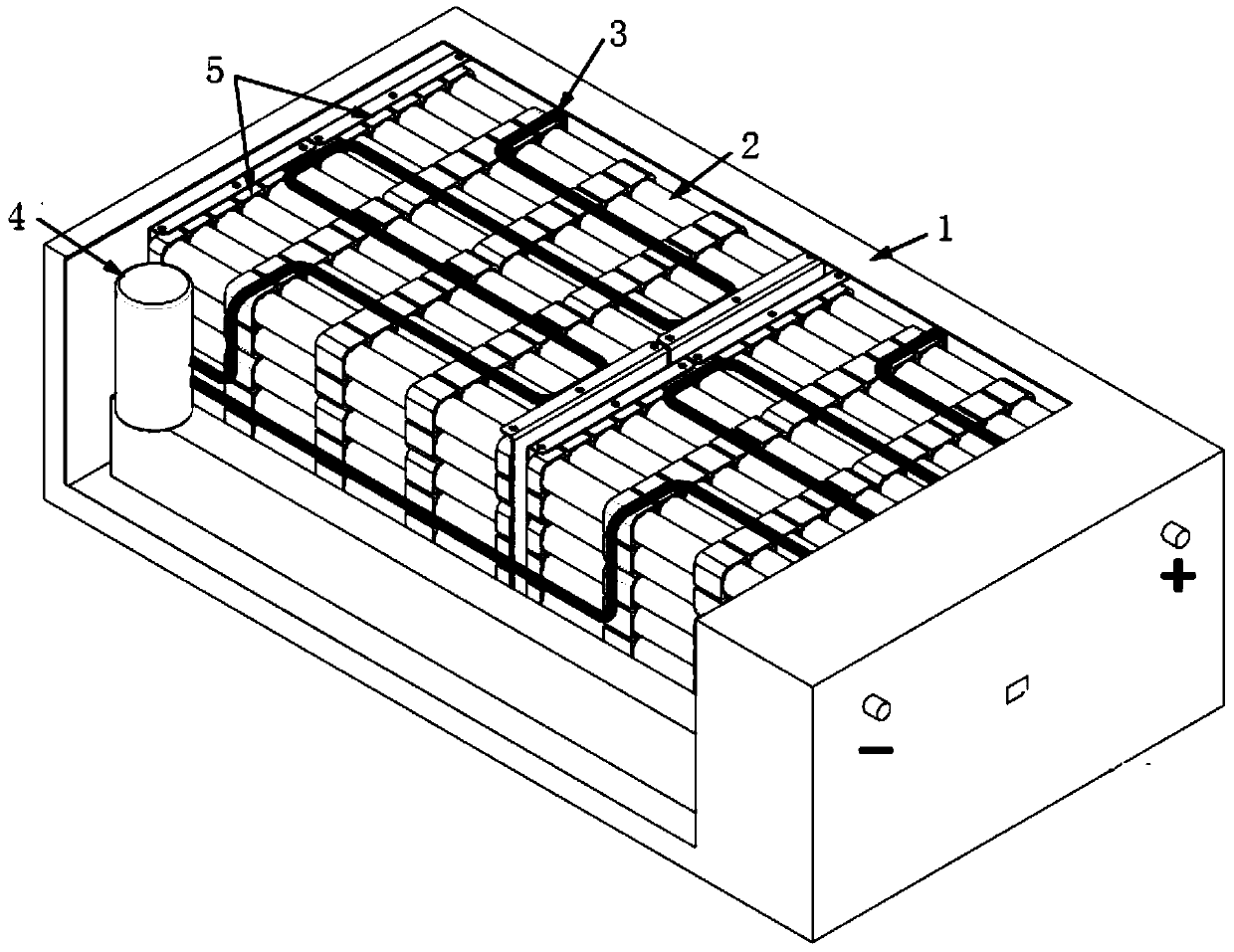

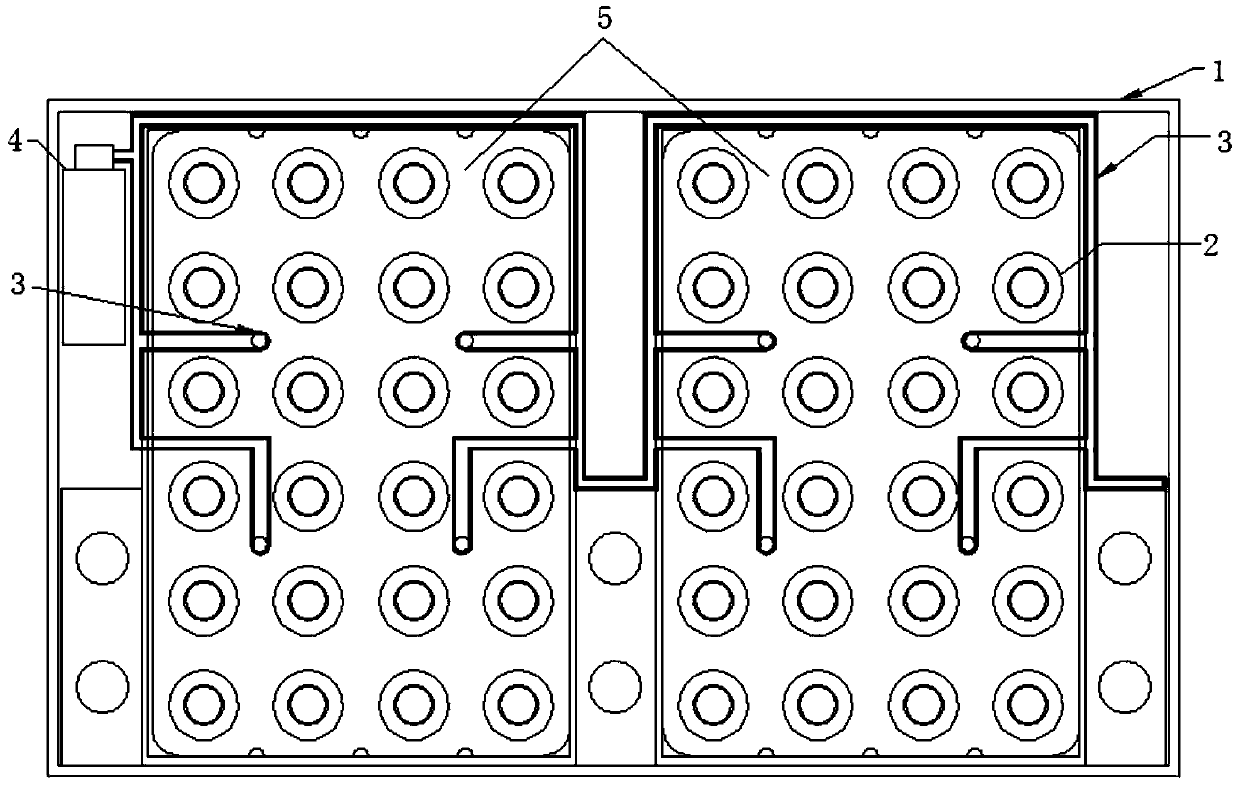

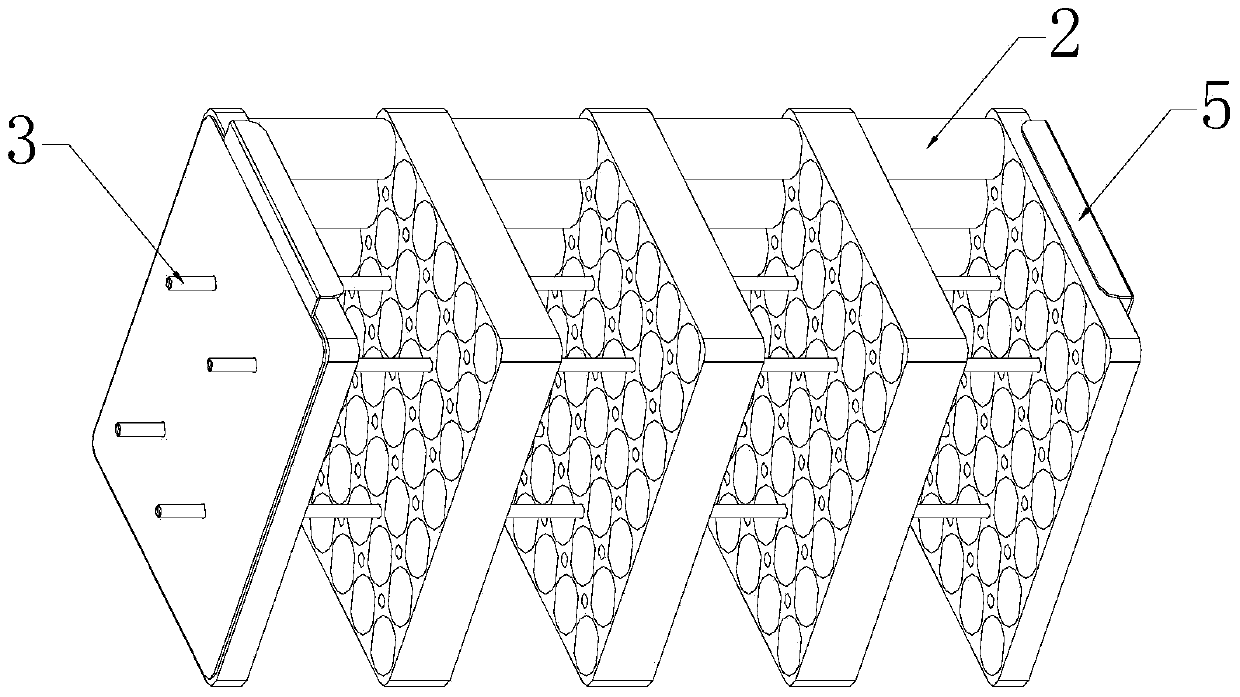

Safe battery pack

InactiveCN104091904AImprove reliabilityImprove securityBattery isolationFire rescueFire extinguisherEngineering

The invention relates to a safe battery pack, which includes a safe battery pack shell. A plurality of battery sets in series-parallel connection are installed in the safe battery pack shell. The battery set is formed by series-parallel connection of multiple cylindrical single batteries. A fire detection and extinguishing device is mounted in the battery pack shell, and consists of a fire detection tube and an extinguisher. The fire detection tube is mounted in the gaps formed by the adjacent cylindrical single batteries, and is in connection with the extinguisher. The safe battery pack provided by the invention not only can put out a fire quickly after outbreak of the fire, but also can eliminate hidden fire outbreak dangers before sudden change of temperature and fire outbreak, and has the characteristics of good fire extinguishing effect, high fire extinguishing efficiency, high reliability and high safety performance.

Owner:SUZHOU ANKAO ENERGY

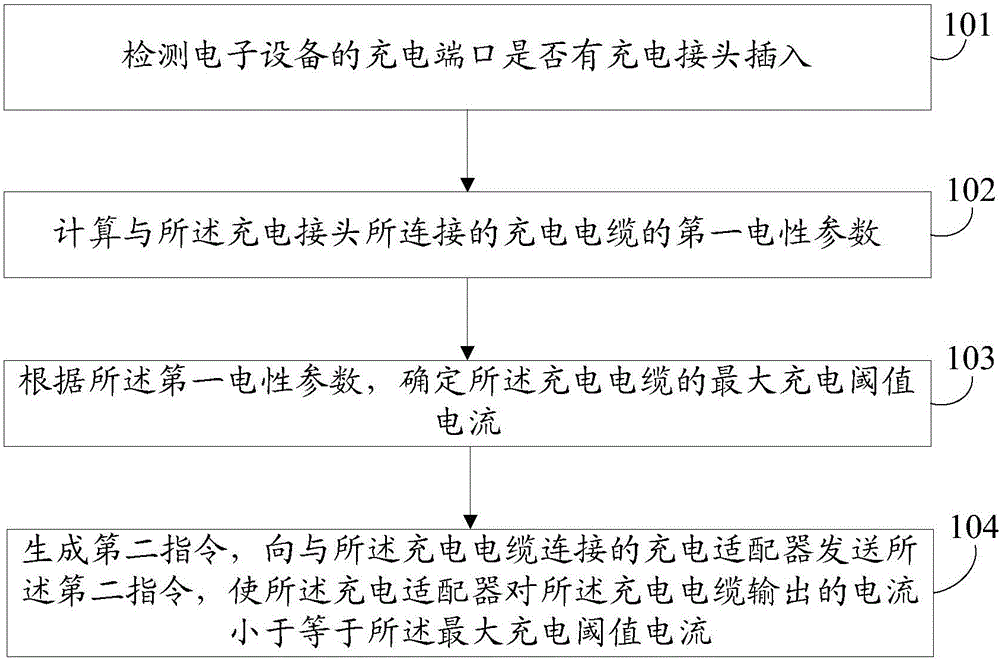

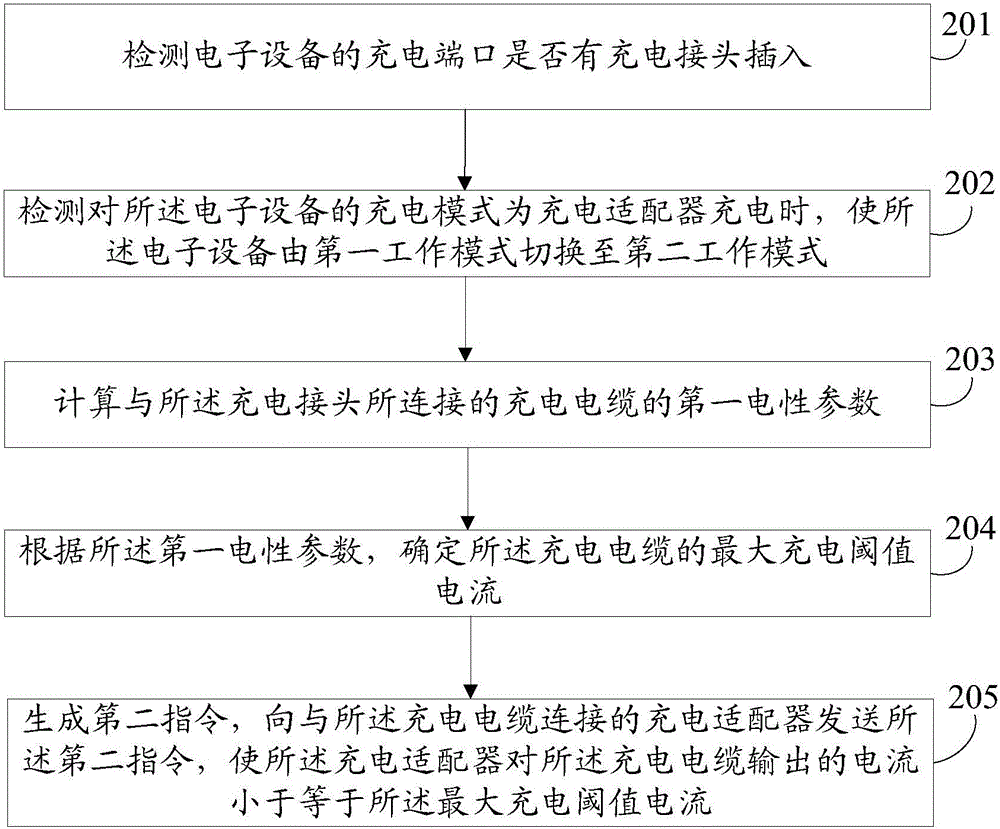

Method for reducing heating of charging cable, and electronic device

InactiveCN105914807AOverheating will not causeLimit heating temperatureBatteries circuit arrangementsElectric powerElectric equipmentThreshold current

Owner:LENOVO (BEIJING) LTD

Reflective insulation energy-saving coating for external surface of building

InactiveCN102352147ASimple manufacturing processEasy to process and produce on a large scaleReflecting/signal paintsInsulation systemRutile

The invention relates to a reflective insulation energy-saving coating for the external surface of a building. The coating is characterized by comprising the following components in percentage by weight: 15 to 45 percent of deionized water, 0.5 to 5 percent of dispersing agent, 16 to 36 percent of rutile type titanium dioxide, 3 to 35 percent of insulation powder, 0.1 to 3.5 percent of wetting agent, 0.5 to 2 percent of auxiliary film forming anti-freezing aid, 1.5 to 7.8 percent of film forming aid, 0.1 to 1.8 percent of antifoaming agent and 0.5 to 2.5 percent of thickening agent. The reflective insulation energy-saving coating for the external surface of the building effectively resists radiation of heat energy produced by sunlight and is an energy-saving and environment-friendly product; meanwhile, the preparation process flow for the coating is simple, complex equipment is not needed, large-scale processing production is easy to implement, the preparation process is environment-friendly, the conventional insulation system can be partially or completely replaced through thermal performance design calculation, and the potential fire hazard of an external wall insulation system is eliminated.

Owner:廖兴旺

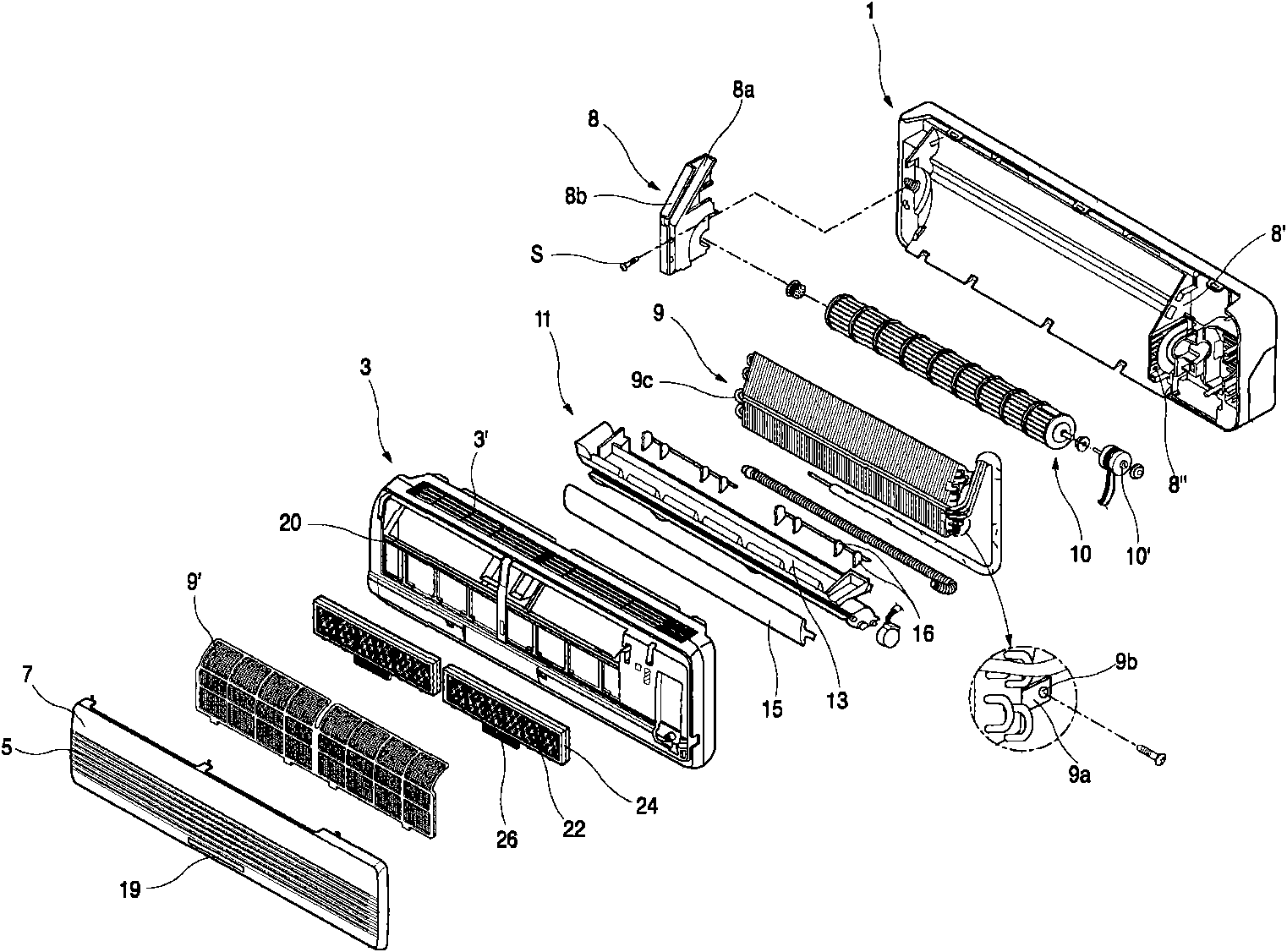

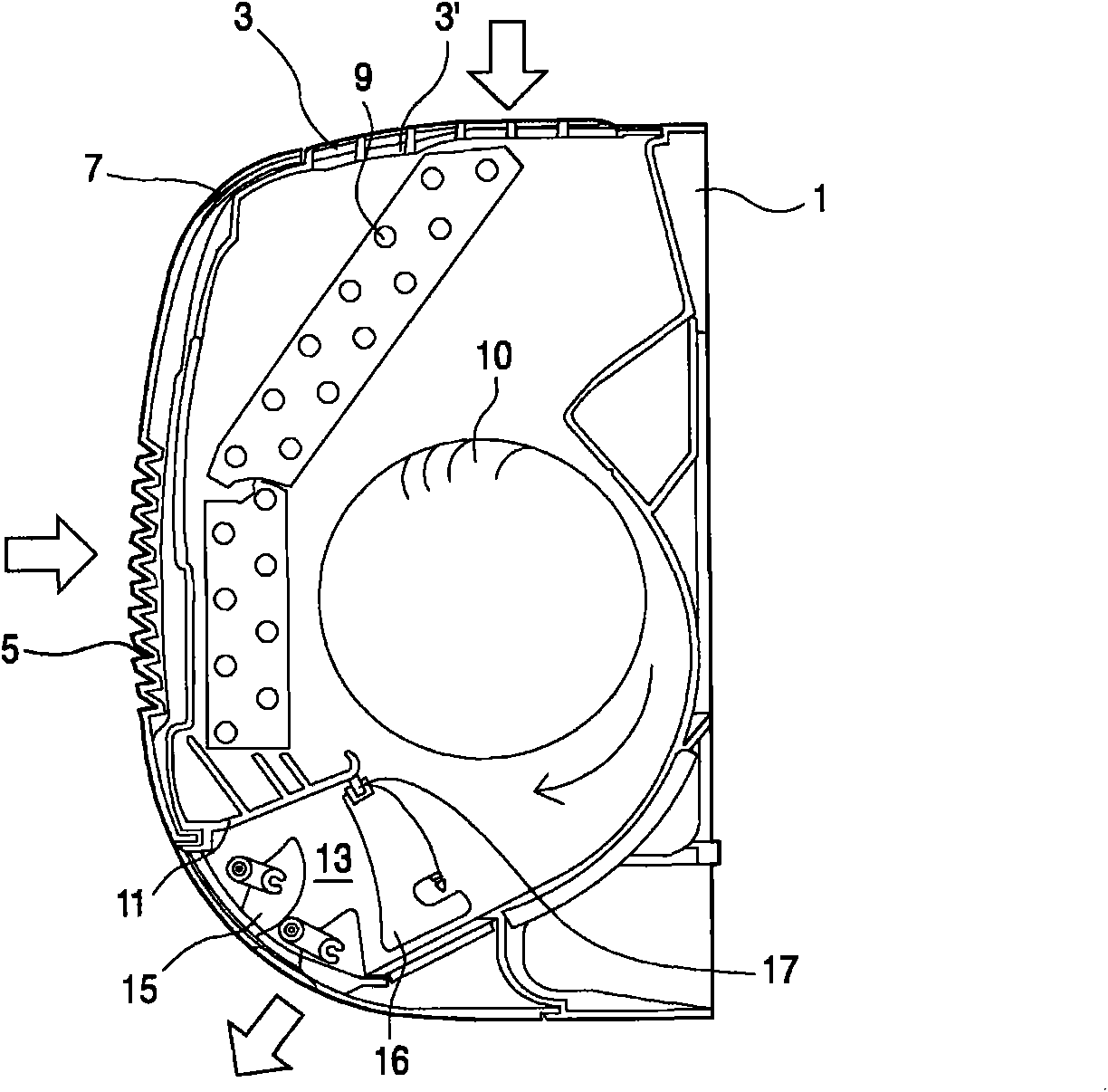

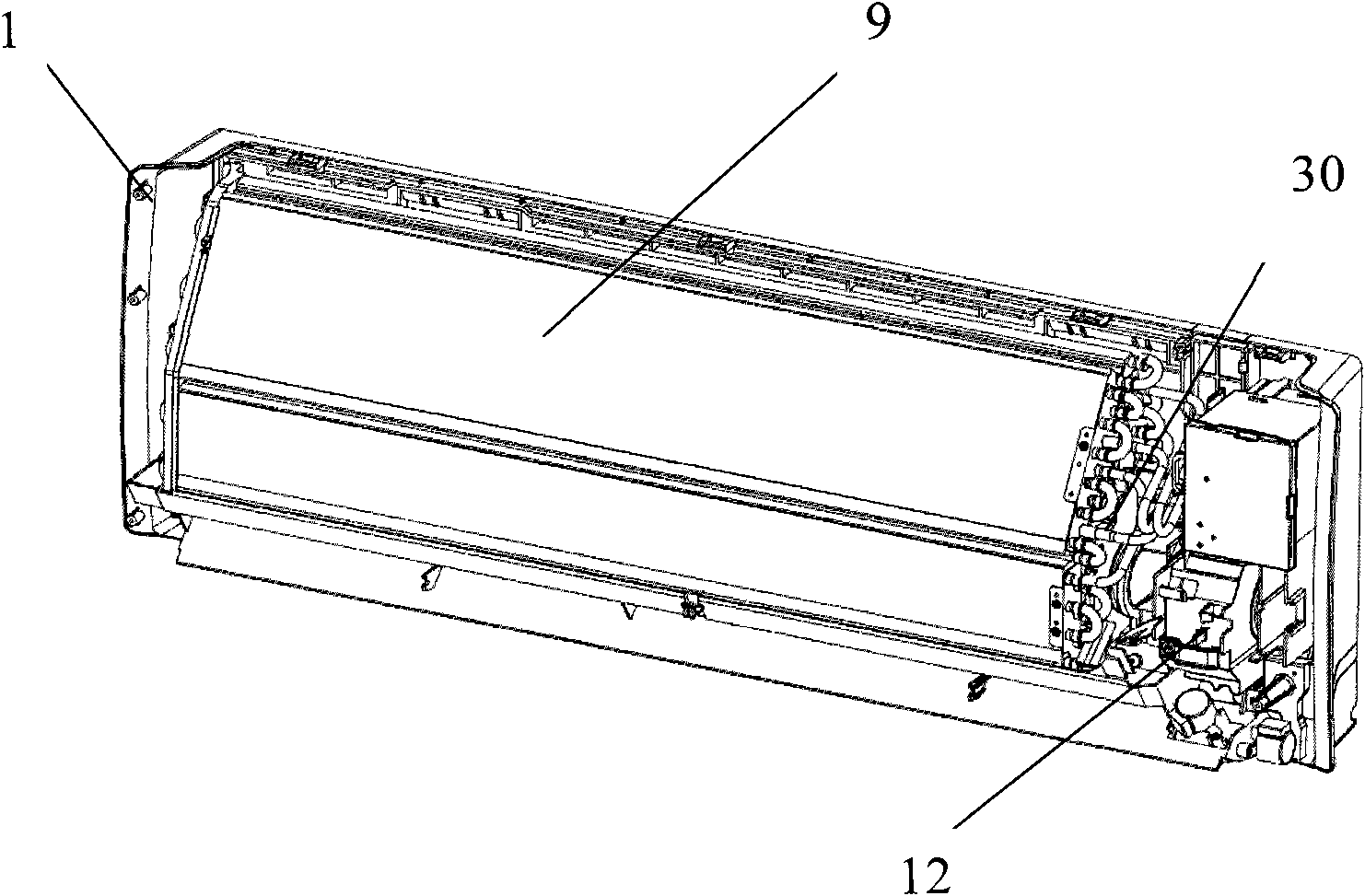

Split wall-mounted type air-conditioner indoor room

InactiveCN102313348AAvoid direct contactEliminate fire hazardsCondensate preventionNoise suppressionAppliance componentEngineering

The invention discloses a split wall-mounted type air-conditioner indoor room, which comprises a main surrounding frame, a front-surface framework, a heat exchanger and a control box, wherein the front-surface framework is positioned on the main surrounding frame, the heat exchanger is arranged behind the front-surface framework, the control box is positioned on the lateral surface of the heat exchanger, and a heat-exchanger cooling-medium pipe cover for preventing the condensed water of a cooling-medium pipe from dropping onto the control box is sleeved on the cooling-medium pipe on the end surface of the heat exchanger positioned between the heat exchanger and the control box. A control-box cover is formed by being integrated with the heat-exchanger cooling-medium pipe cover, a baffle plate is formed between the heat-exchanger cooling-medium pipe cover and the control-box cover, and the heat-exchanger cooling-medium pipe cover and the control-box cover are divided into respectively-independent cavity bodies through the baffle plate. Through the split wall-mounted type air-conditioner indoor room, the hidden fire danger of air-conditioner operation is eliminated: through the use of the heat-exchanger cooling-medium pipe cover, the condensed water on the surface of the cooling-medium pipe can not flow onto electrical-appliance components, such the control box and the like. The direct contact of a heat-exchanger fin and the main surrounding frame is avoided, and the severe phenomena of icing and the like are prevented from being caused.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Waterborne nano coil coating and preparation method thereof

The invention belongs to a waterborne nano coil coating and a preparation method thereof. Firstly, an inorganic material with no toxic property, foreign smell and combustion characteristic is used as a basic powder material of a coil coating, a waterborne acrylic emulsion, waterborne epoxy resin, water-soluble functional auxiliaries and other film forming matters are compounded, updated and modified by using a nanotechnology and nano materials, and gaps of large micro materials in a coating structure are filled by using various nano powder materials after the hydration of the coil coating is effectively finished, so that the coating generates a coating function enhancing effect under the synergistic action of multi-effect combination of the nano materials and micro materials, the defect that the performance of the waterborne coil coating prepared by a micrometer technology is lowered is overcome effectively, and the technical performance of the waterborne coil coating is remarkably enhanced. By using the waterborne nano coil coating and the preparation method thereof, the production efficiency is increased, the fire risks and industrial pollution of the traditional solvent type coil coating are eliminated, and meanwhile, the aim of safe, environment-friendly, low-consumption and efficient production is achieved.

Owner:北京中科捷达纳米应用科技有限公司

Preparation method of aromatic high solid content water-borne polyurethane

The invention discloses a preparation method of aromatic high solid content water-borne polyurethane. The water-borne polyurethane which can be used for manufacturing synthetic leather and has aromatic high solid content of more than or equal to 50 % is obtained by using aromatic isocyanate as the raw material and adopting an interpenetrating network technology, a blocking technology and a post-crosslinking technology. The preparation method comprises the following steps: firstly, preparing water-borne polyurethane A comprising an active end group -NH2; then dispersing a polyurethane prepolymer B sealed by a -NCO end group in the polyurethane A, wherein due to small relative molecular mass and low body viscosity of the polyurethane B, the polyurethane B is very easy to disperse in the polyurethane A; and carrying out molecular-level compounding and interpenetrating on the polyurethane A and the polyurethane B to obtain high solid content water-borne polyurethane resin with concentration of more than or equal to 50 %. The molecular design and synthesis method provided by the invention not only breaks through the bottleneck on a aromatic high solid content water-borne polyurethane preparation technology and reduces cost, but also meets the requirements for technically reducing energy consumption and improving drying speed and physical property of a coating.

Owner:浙江德美博士达高分子材料有限公司

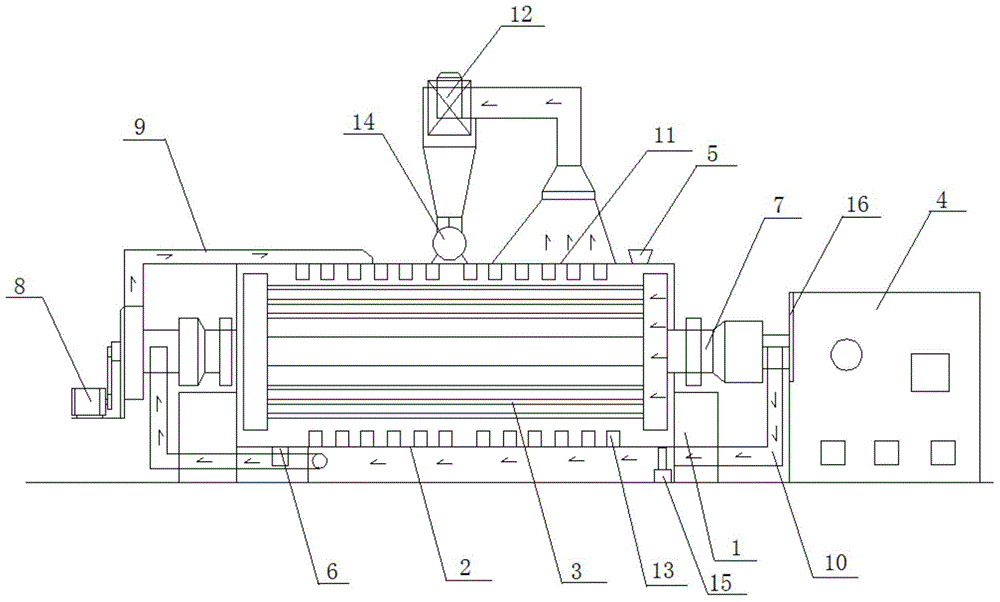

Heat conducting pipe type wet material dryer and drying method thereof

InactiveCN105115265AImprove drying efficiencyEliminate fire hazardsDrying gas arrangementsDrying machines with non-progressive movementsHeat conductingWater vapor

The invention discloses a heat conducting pipe type wet material dryer which comprises a support. A heating drum is arranged on the support, rotatable heat conducting pipes are arranged in the heating drum, and scraper plates are arranged on the peripheral heat conducting pipes. The whole support is obliquely arranged, the higher end of the heating drum of the dryer is connected with a hot blast furnace, the end, close to the hot blast furnace, of the heating drum is provided with a feeding inlet, and the other end of the heating drum is provided with a dried material discharging outlet. The heat conducting pipes are communicated with the hot blast furnace through a first pipeline. High-temperature hot air generated by the hot blast furnace flows through the heat conducting pipes, wet materials to be dried are completely isolated from the high-temperature hot air, and therefore the potential hazard of fires of the materials is eliminated; the wet materials to be dried enter from the high-temperature end close to the hot blast furnace, vapor outlets are formed in the high-temperature end, and when the wet materials enter the high-temperature end, a large amount of generated vapor is directly exhausted from the vapor outlets through a vapor exhaust fan and a cyclone separator; the vapor exhausting effect is good, the material drying effect is good, and the drying efficiency is high.

Owner:宜兴市凯世达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com