Patents

Literature

597results about How to "No manual" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

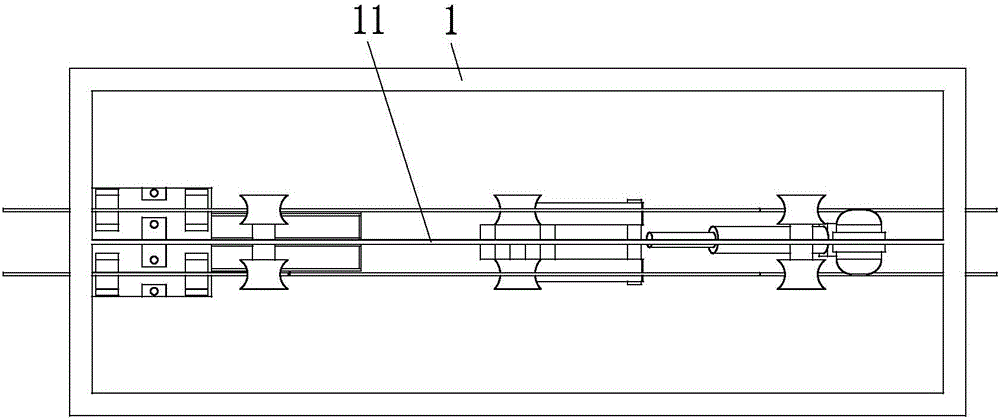

Continuous type alloy steel heat treatment line

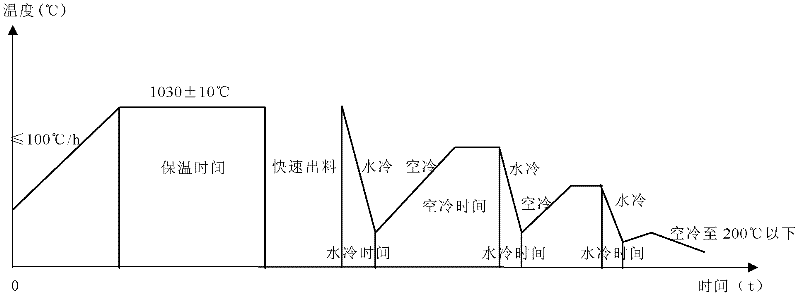

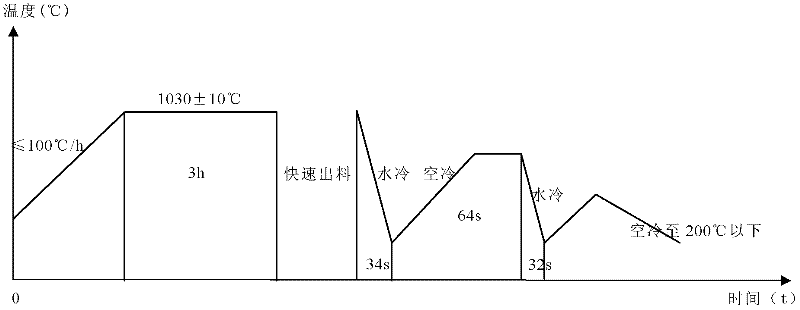

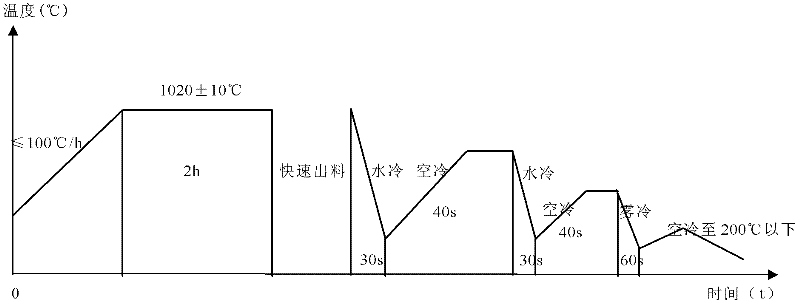

The invention discloses a continuous type alloy steel heat treatment line, solving the problem existing in small-section ultra-long material workpiece heat treatment. The continuous type alloy steel heat treatment line is formed by connecting a continuous type roller hearth heating furnace, a roller hearth type quenching groove and electric heating continuous type roller hearth furnace in series.The heat treatment process comprises the following steps of: carrying out austenitization heating on a workpiece in the continuous type roller hearth heating furnace, rapidly discharging after reaching the process time and then entering into the roller hearth type quenching groove; automatically generating a non-continuous water cold process according to the chemical components and different standards of the workpiece, and rapidly cooling through an immersion or spray mode; and tempering the workpiece which is cooled to room temperature according to the process requirement. The continuous type alloy steel heat treatment line has the advantages that: 1, the quenching, solid solution and normalizing continuous heat treatment of the small-section ultra-long material workpiece are achieved, and the heat treatment is completed on roller beds which are located on the same height and axis; 2, a quenching medium is stable in the rising process, and the workpiece can be simultaneously cooled in the length direction; and 3, fire danger and lamp black pollution are precluded by adopting non-continuous water quenching.

Owner:FUSHUN SPECIAL STEEL SHARES

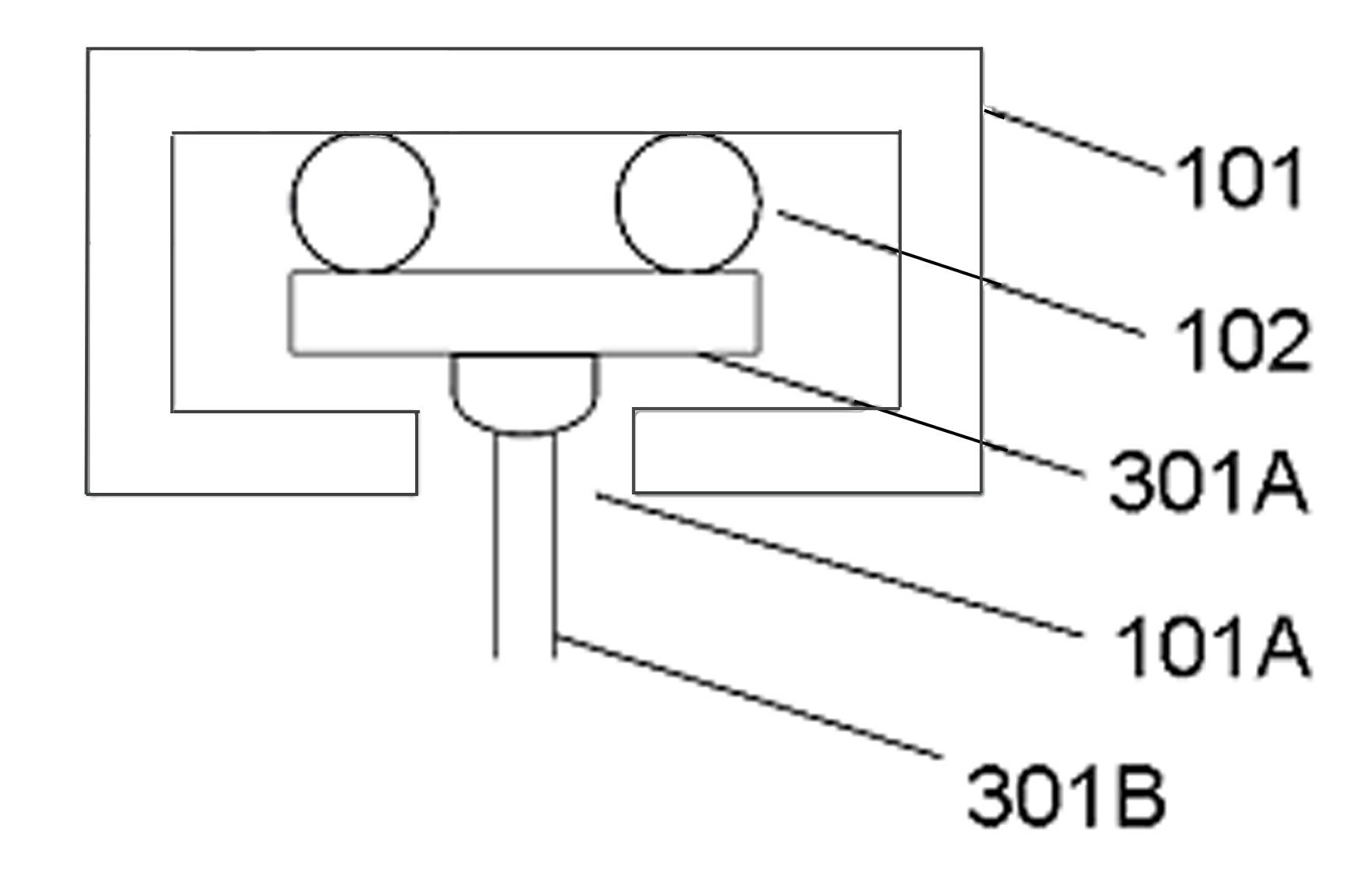

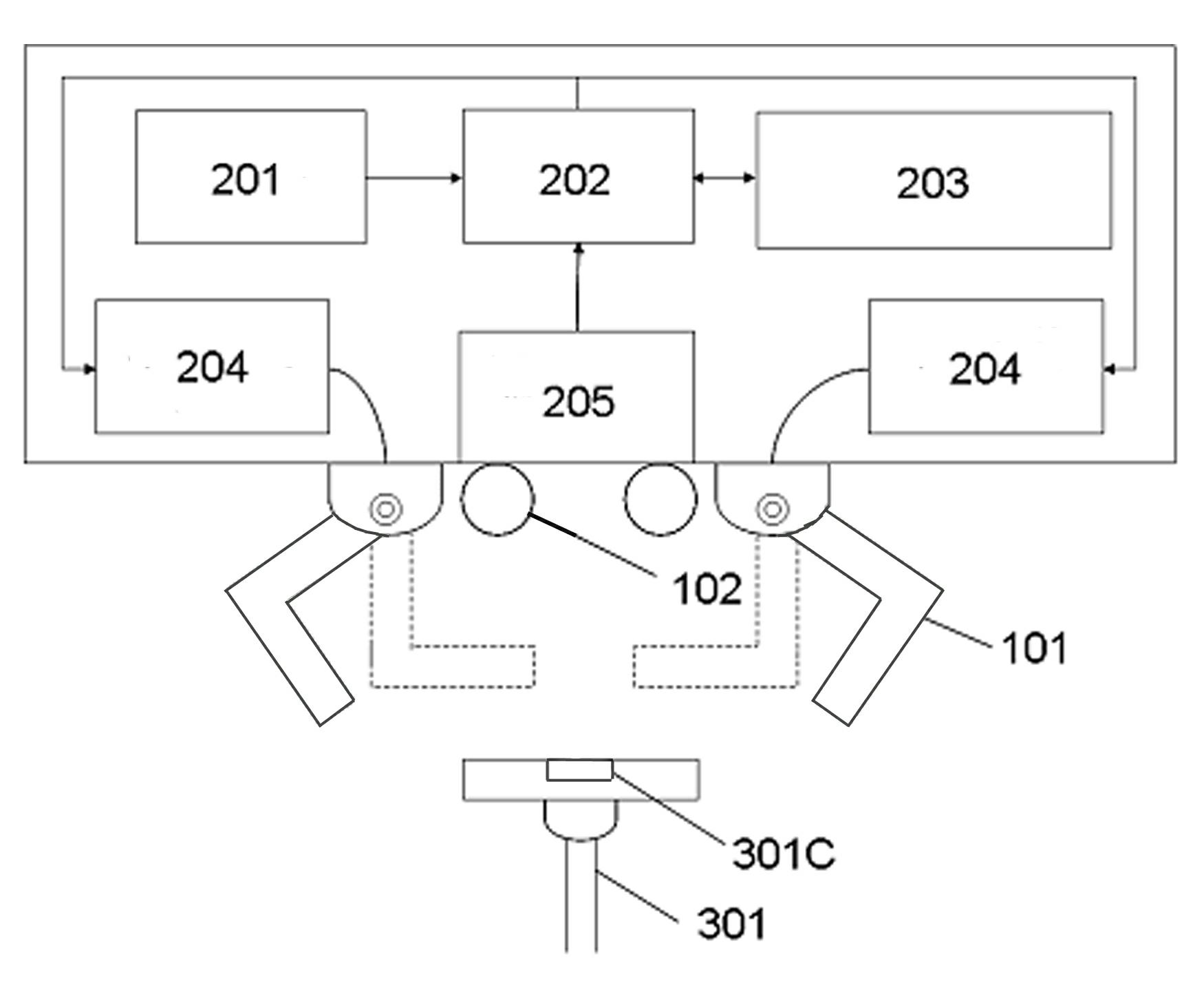

Midway charging system for electric vehicle

InactiveCN102593899ASolve charging problemsConducive to the promotion of generalBatteries circuit arrangementsElectric powerPower gridCharging station

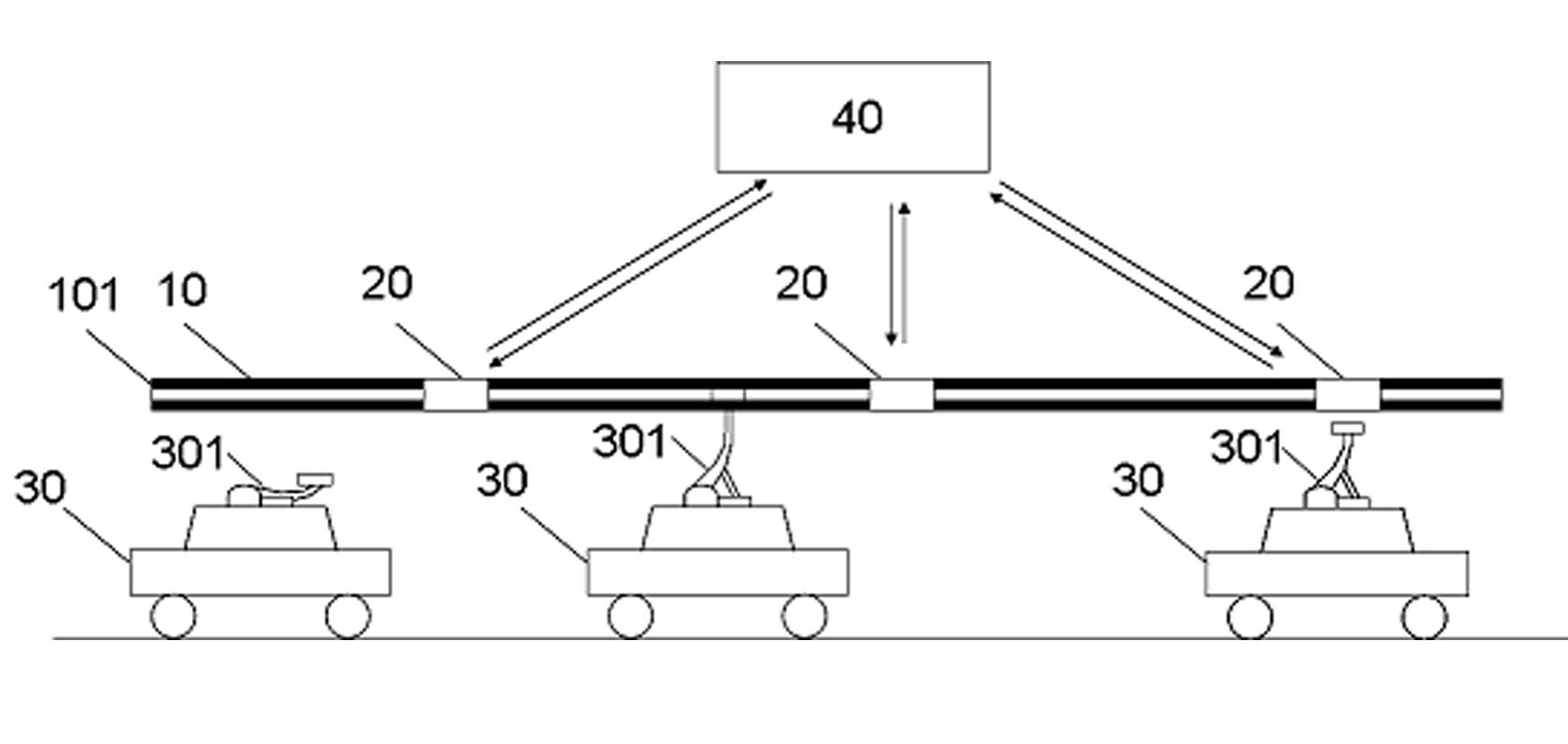

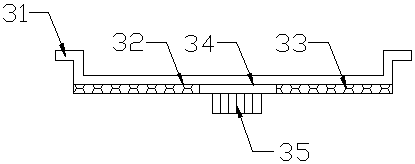

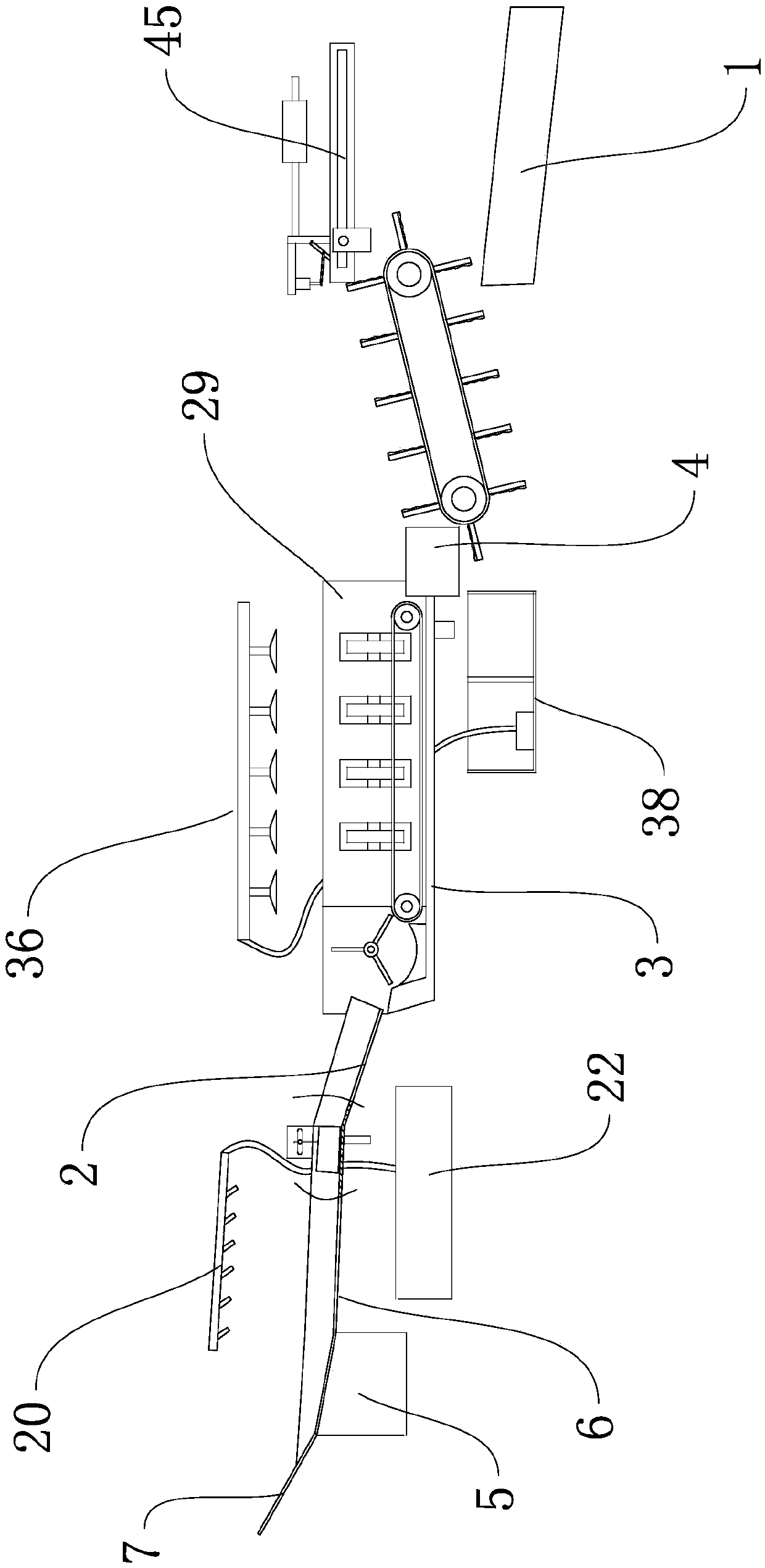

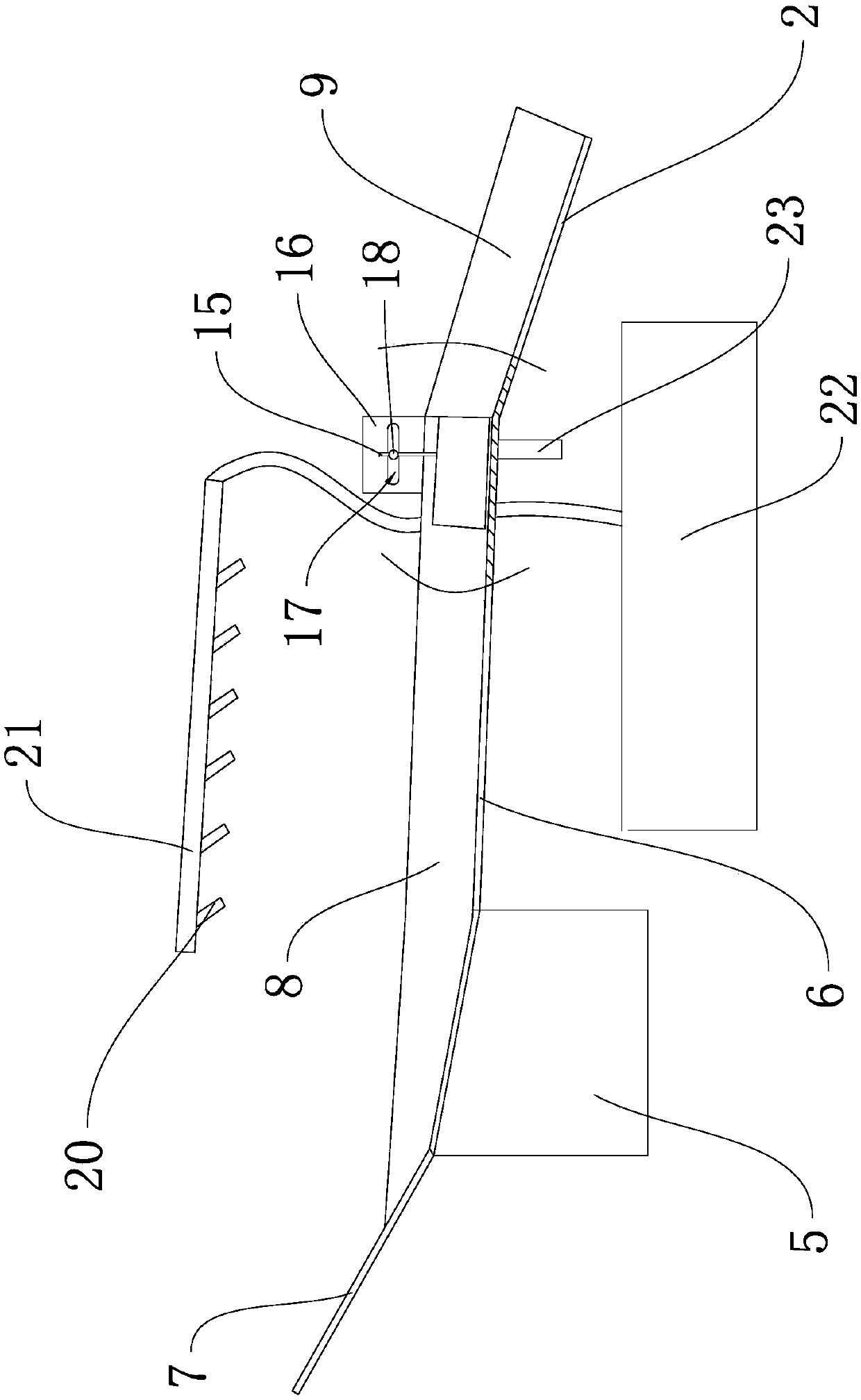

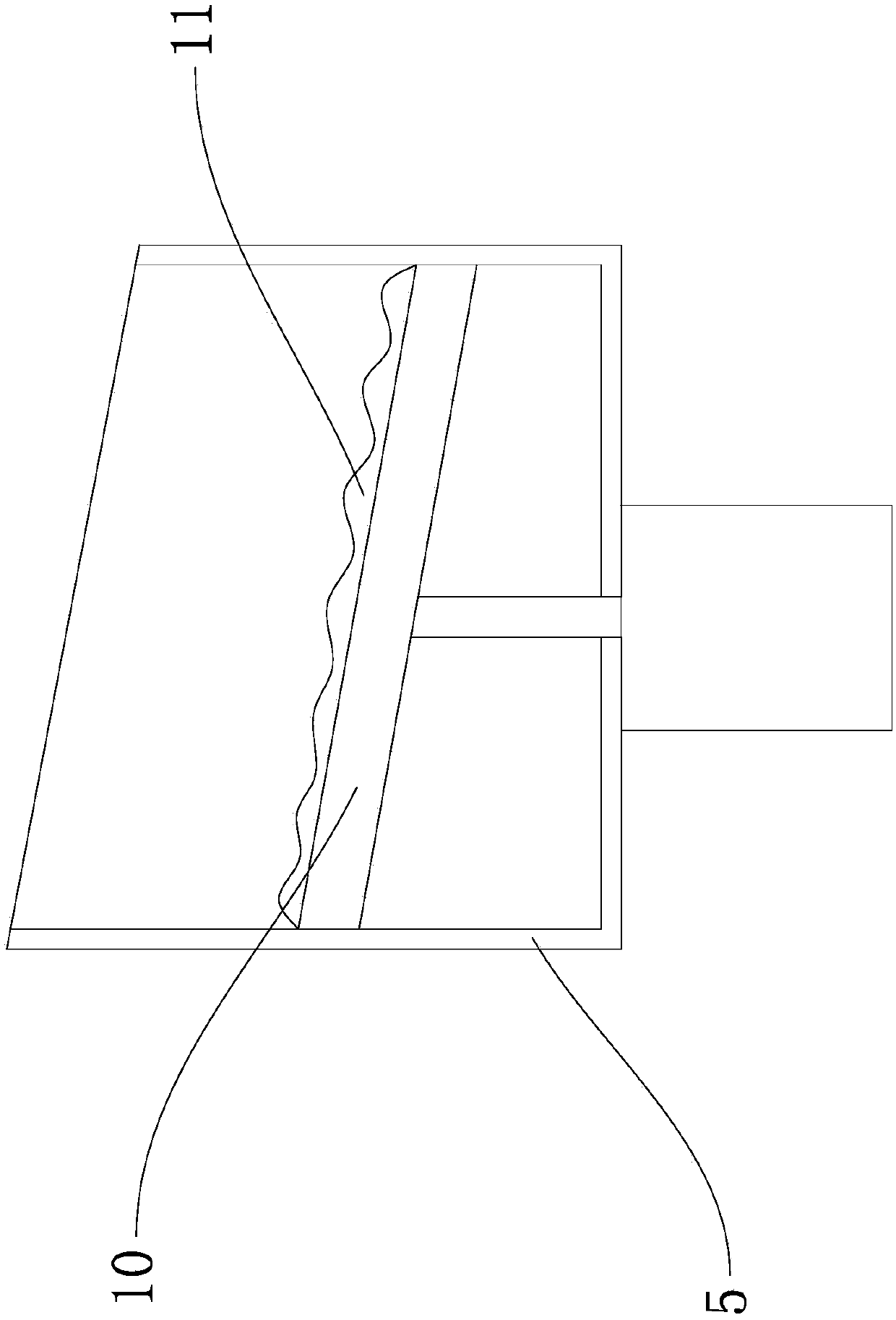

The invention provides a midway charging system for an electric vehicle. The electric vehicle is provided with a pantograph (301), a charging grid (10) is arranged along a road, and an insulating protection shell (101) is arranged on an outer layer of the charging grid (10); base stations (20) are arranged at certain intervals in the charging grid (10); when the pantograph (301) enters a preset range of one of the base stations (20), the base station (20) acquires the identification information of the electric vehicle (30) through near-field communication and remotely transmits the identification information to a management center (40), and the management center (40) authenticates the identification information; and under the condition that the identification information passes authentication, the management center (40) remotely controls the base station (20) to open the insulating protection shell (101) to allow the pantograph (301) to be contacted with the charging grid (10) for charging the electric vehicle, and the management center (40) performs billing and management. By adoption of the midway charging system for the electric vehicle, timely and convenient electric energy supplementation of the electric vehicle is ensured, the construction cost of a charging station is reduced, and the problem about charging of the electric vehicle in the prior art is fundamentally solved.

Owner:BEIJING UNION UNIVERSITY

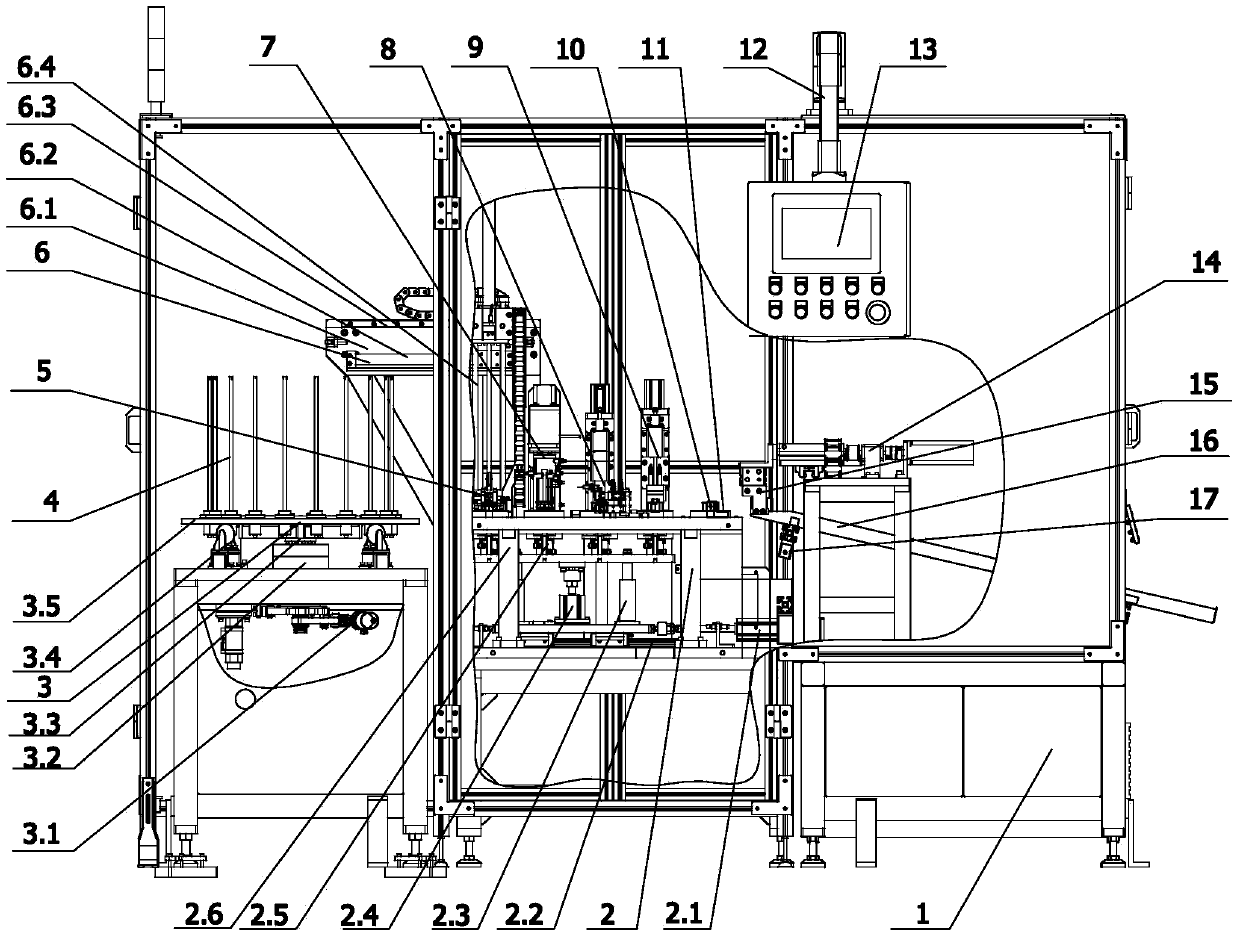

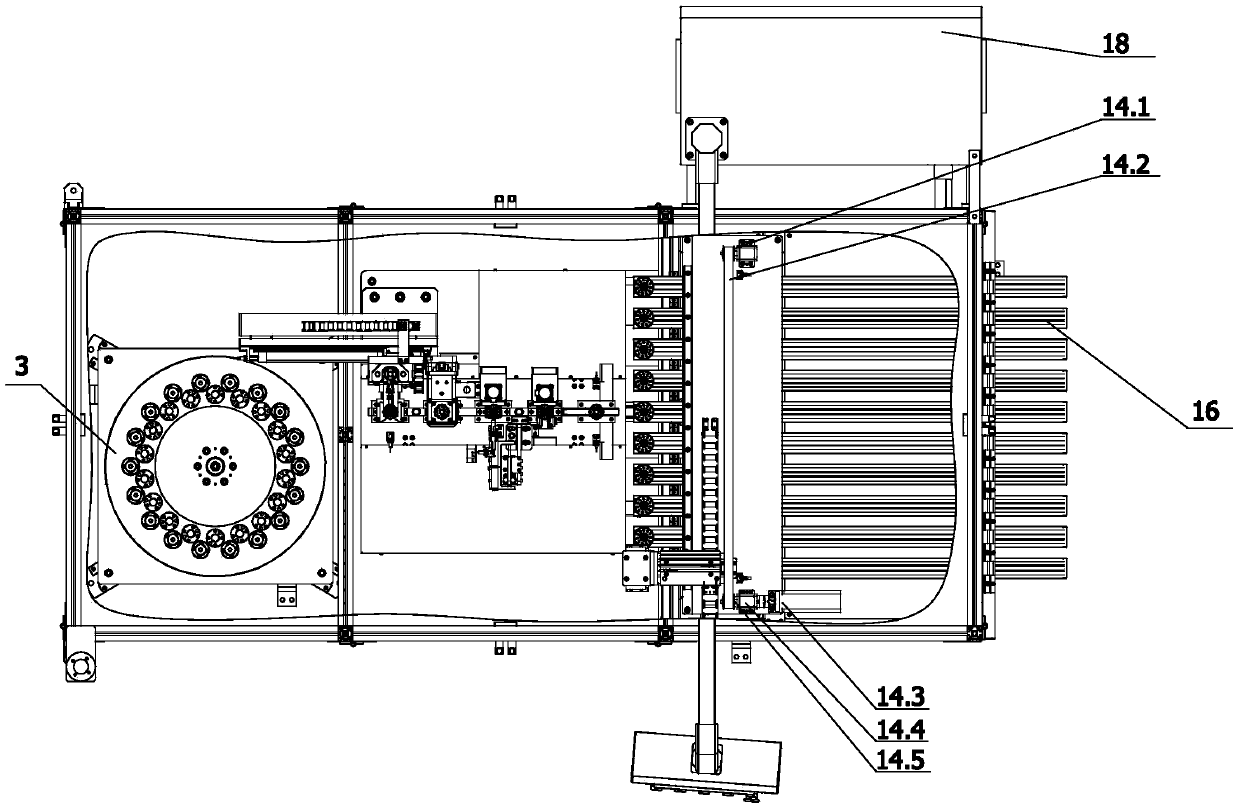

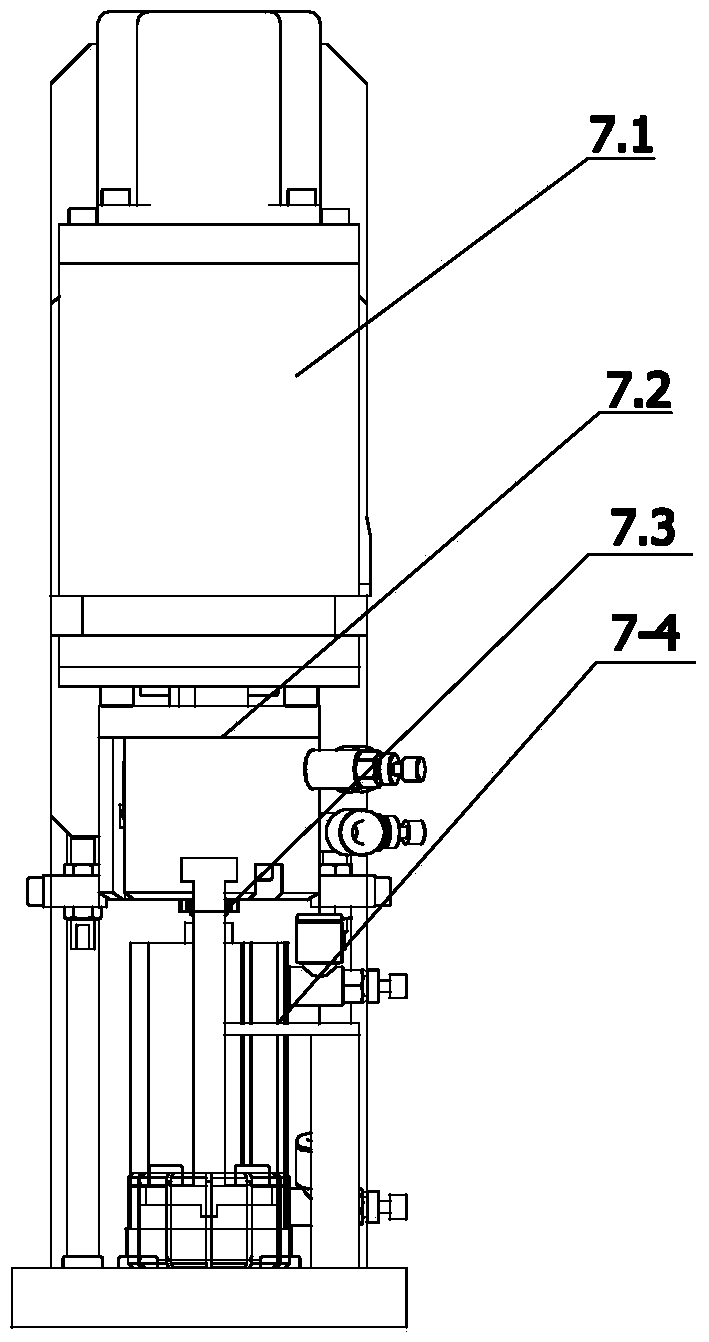

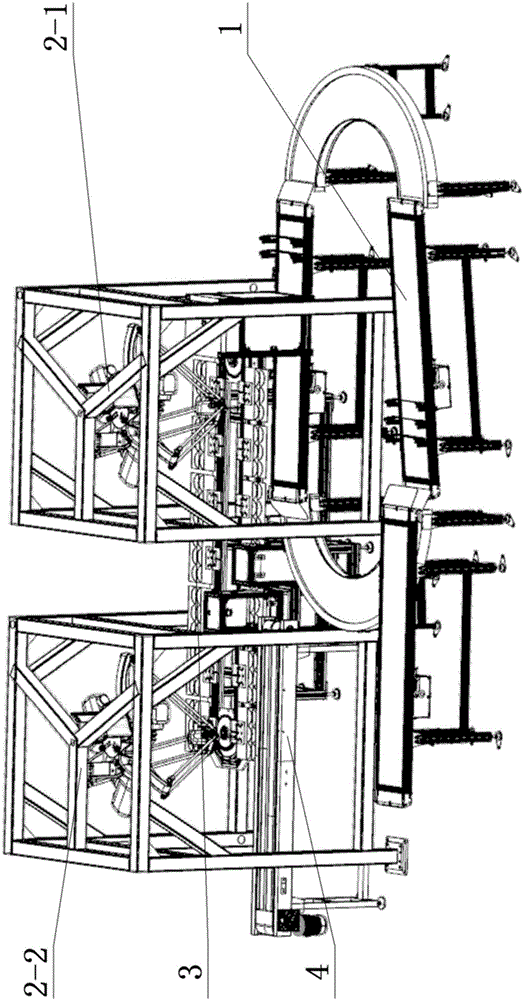

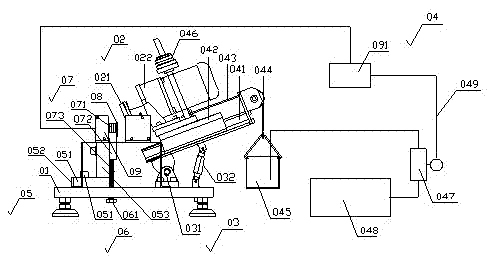

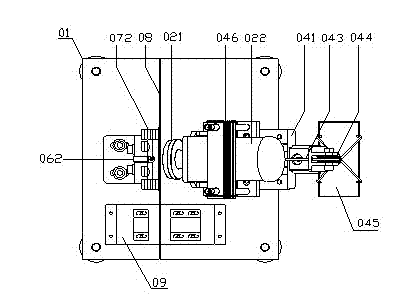

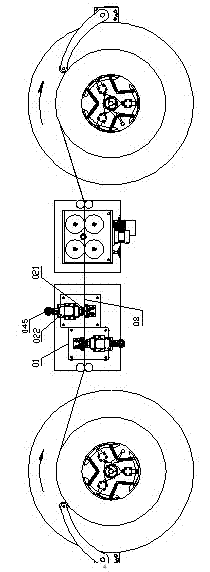

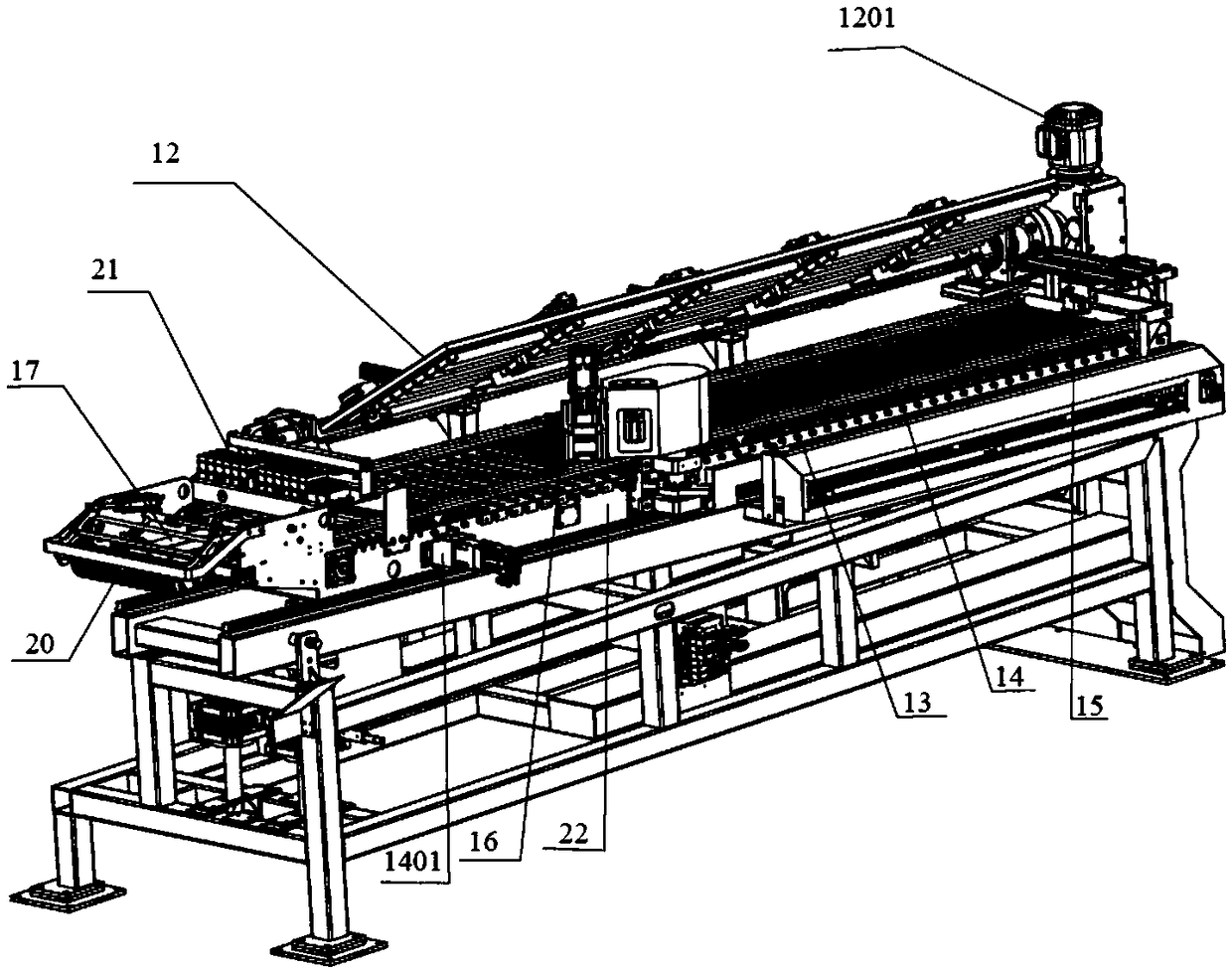

Full-automatic rotor measuring machine

ActiveCN103471542ARealize automatic crawlingRealize group storageMeasurement devicesGroove widthEngineering

The invention relates to a full-automatic rotor measuring machine, in particular to a measuring machine which can achieve measuring and grouping workpieces of the same specification in the same position and different groups in the production process of a rotor of an automobile steering vane pump according to the thicknesses and the groove widths, and the measuring machine has the functions of automatically achieving measuring and grouping of the workpieces. The measuring machine comprises a rack, a feeding stepping mechanism, a feeding stepping rotary material disc, feeding rods, a feeding mechanical arm, a material moving mechanism, a rotating positioning mechanism, a groove width measuring mechanism, a thickness measuring mechanism, an optical fiber sensor, a discharging station, an alarm light, an operation box, a servo motor movable grouping mechanism, a discharging mechanical arm, a gravity material channel, a alarm switch for the full state of material and an electronic control cabinet. The feeding stepping rotary material disc is arranged on the left portion of the rack, and the multiple feeding rods are connected to the feeding stepping rotary material disc. The full-automatic rotor measuring machine achieves automatic grabbing, automatic material moving, automatic recognizing and automatic storing in groups of the workpieces and automatically achieves measuring and grouping of the workpieces.

Owner:WUXI MEASURE MACHINE MFR

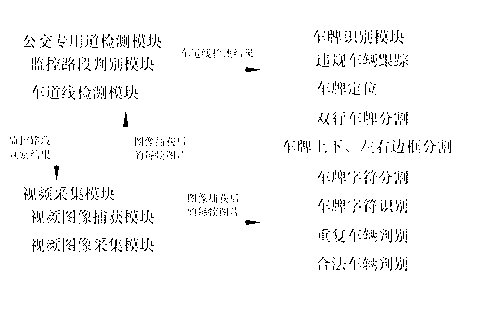

Snapshot system for bus lane

InactiveCN103268703ASolve the problem of multiple unreasonable dataAdequate basis for law enforcementDetection of traffic movementDigital videoVehicle detection

The invention relates to the field of traffic monitoring, in particular to a snapshot system for a bus lane. According to the snapshot system for the bus lane, firstly, whether a road segment is the bus lane and whether the present time is within a traffic control time are determined according to GPS data sent by a GPS positioning device and the traffic control time, and video capture is conducted on the front end or the rear end of a bus through high-definition cameras, each analog video signal is converted into a digital video signal. Secondly, vehicle detection is conducted within a detected lane line on each frame of an image which is captured, a vehicle is traced, and images are stored to be used as a snapshot result. Thirdly, license plate location is conducted on the snapshot images, double-line license plate distinguish and separation, license plate character segmentation, and license plate character recognition are conducted, whether the vehicle is repeatedly detected is determined according to a recognition result, whether the vehicle is an illegal vehicle is judged according to a legal license plate base if the vehicle is not detected repeatedly, and three snapshot images which are captured are stored and the recognition result are stored and the recognition result is sent to a background data processing subsystem if the vehicle is illegal.

Owner:智达信科技术股份有限公司

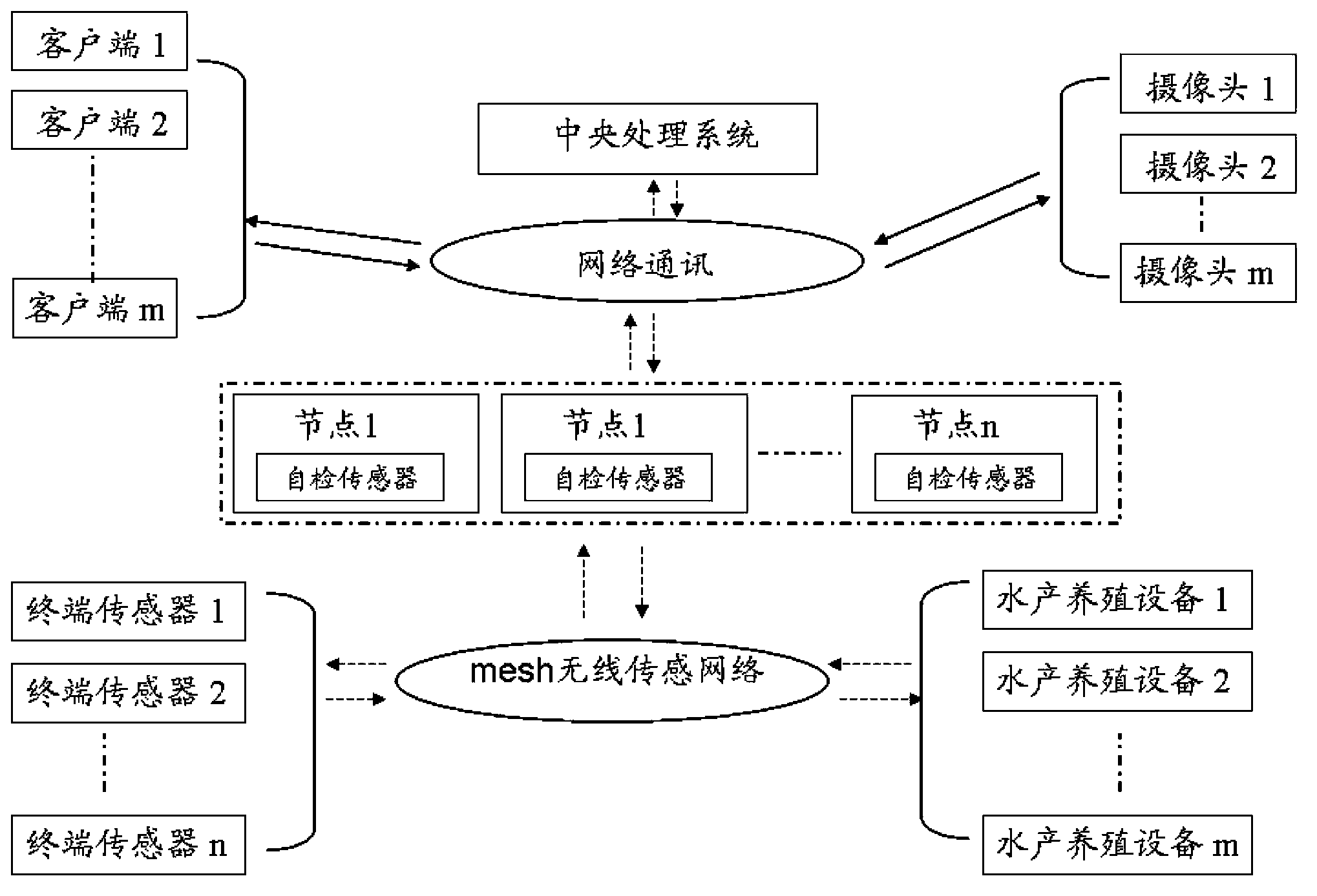

Aquaculture intelligence control system

InactiveCN103823415AEnsure stabilityRealize automatic operationTotal factory controlProgramme total factory controlWireless mesh networkControl system

The invention relates to an aquaculture intelligence control system. The system comprises: a terminal sensor, a central processing system and an aquaculture device which perform information data interaction based on a wireless sensing network. The terminal sensor monitors aquaculture environment and transmits acquired environment monitoring data to the central processing system via the wireless sensing network; and the central processing system, after receiving the environment monitoring data, according to a preset condition, determines whether to adjust the working parameters of the corresponding aquaculture device so as to enable the aquaculture environment to accord with aquaculture requirements such that the utilization rate of the aquaculture device and the working efficiency of aquaculture staff are greatly improved.

Owner:ACEINNA TRANSDUCER SYST CO LTD

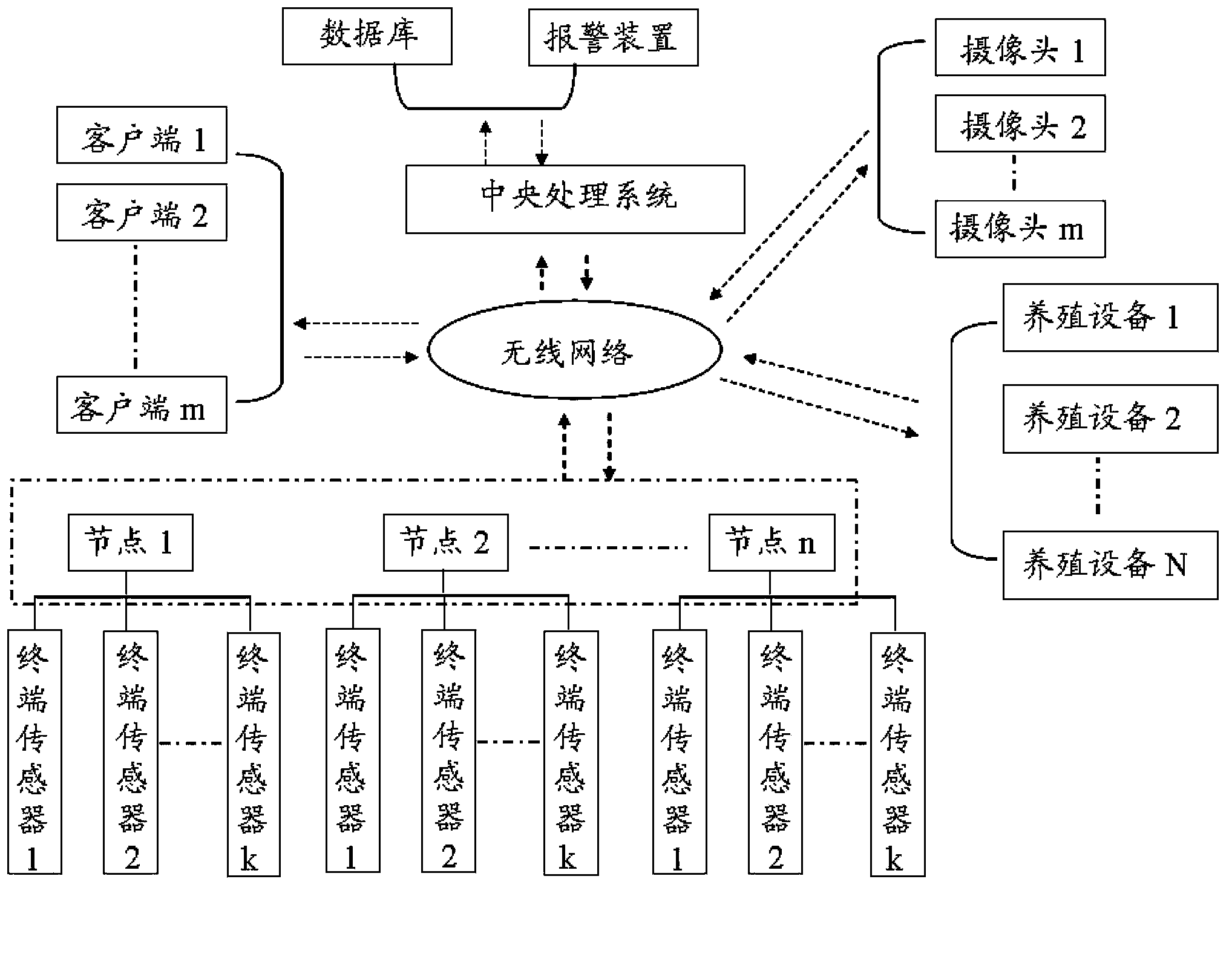

Intelligent cultivation system of Cordyceps sinensis

ActiveCN103814752ARealize automatic operationNo manualCultivating equipmentsHorticultureWireless mesh networkComputer terminal

The invention relates to an intelligent cultivation system of Cordyceps sinensis. The intelligent cultivation system comprises terminal sensors based on wireless network communicating interactive information data, a central processing system and cultivation equipment. The terminal sensors are integrated in system nodes, are used for monitoring cultivation environment of the Cordyceps sinensis, and transmit acquired environmental factor monitoring data to the central processing system through a wireless net via the nodes. The central processing system processes received environmental factor data and judges whether or not operating parameters of corresponding cultivation equipment are required to control and adjust; accordingly, the cultivation environment is adjusted to meet the cultivation requirements.

Owner:ACEINNA TRANSDUCER SYST CO LTD

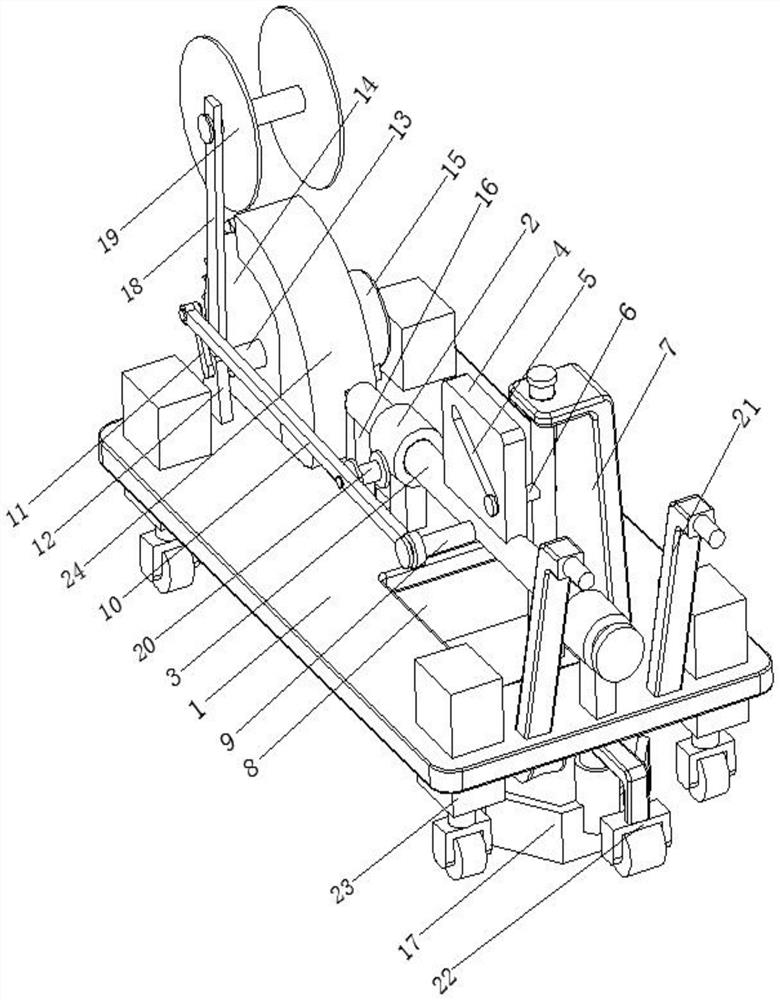

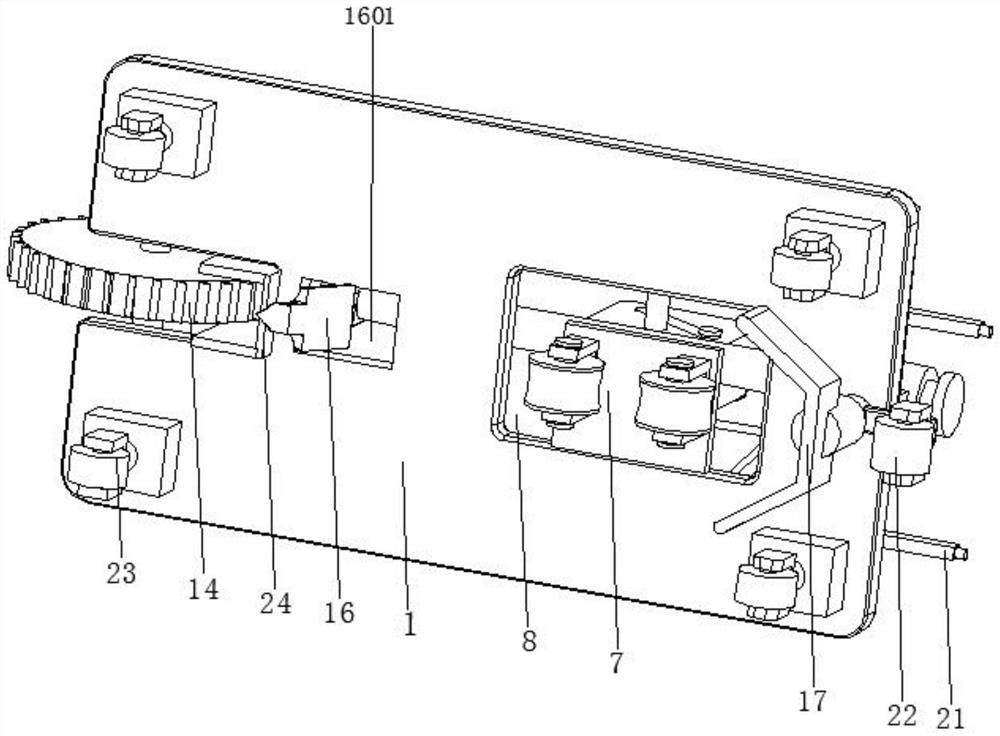

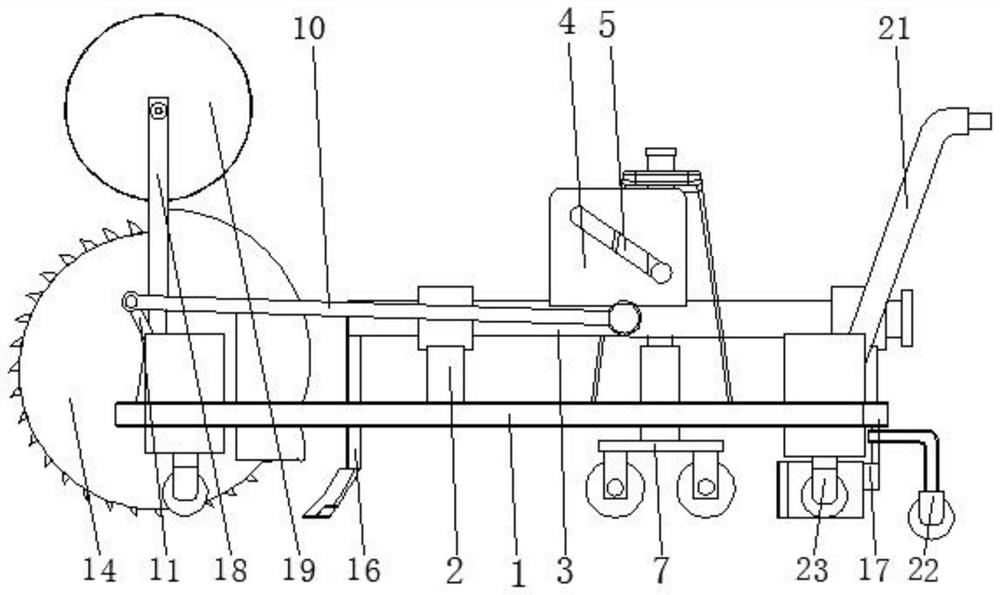

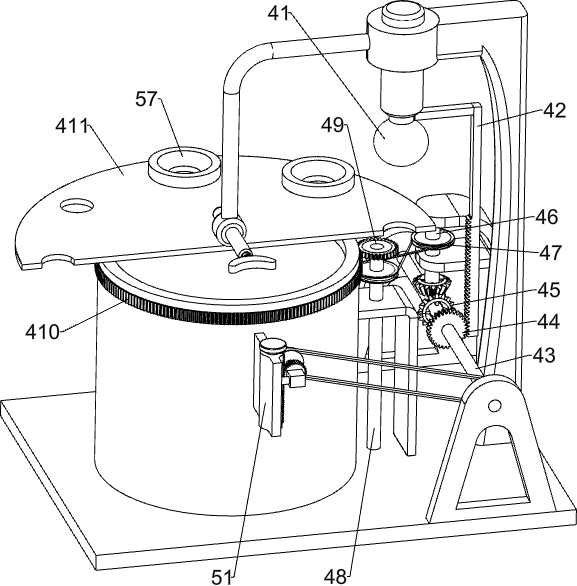

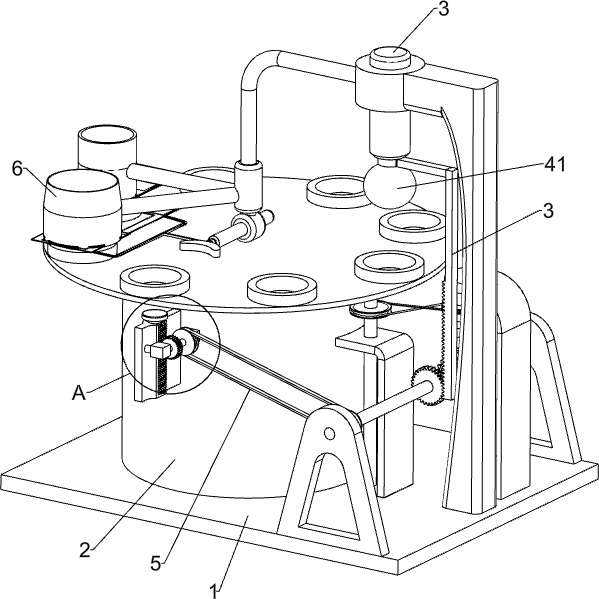

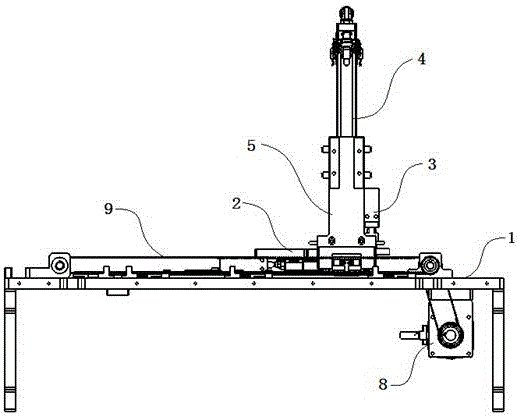

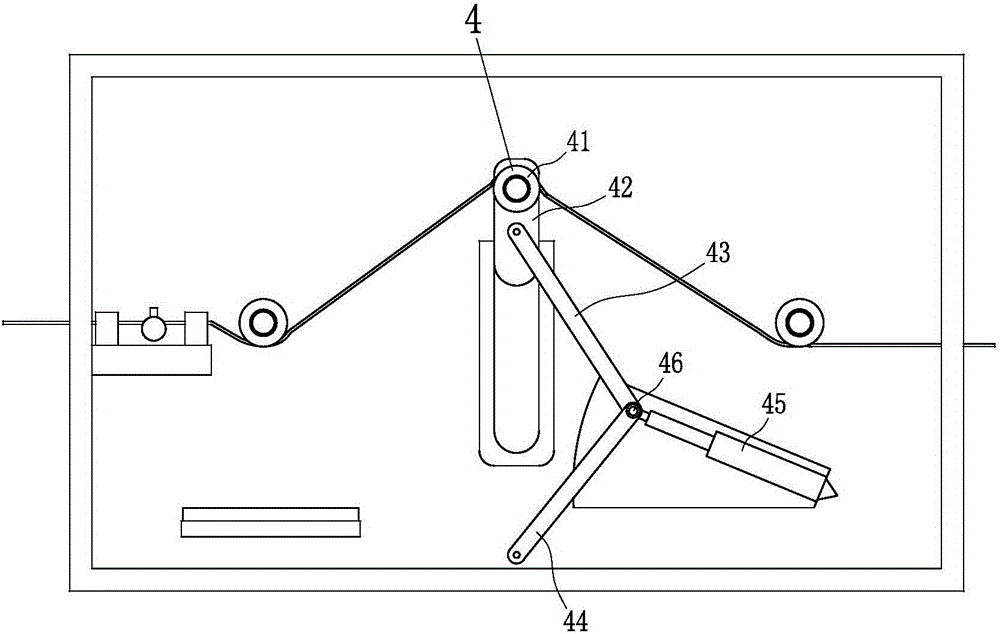

Automatic cable laying machine

InactiveCN112195993ARealize the function of automatic slottingNo manualSoil-shifting machines/dredgersApparatus for laying cablesStructural engineeringMechanical engineering

The invention discloses an automatic cable laying machine. The automatic cable laying machine comprises a bottom plate, wherein a linear inclined sliding hole is formed in the surface of a rectangularblock; a connecting sliding rod is slidably connected to the surface of the rectangular block and is located in the linear inclined sliding hole; a cable pressing device is arranged on one side of the top of the bottom plate and is located at one end of the connecting sliding rod; a grooving rotary disc is fixedly connected to the center of the surface of a rotary shaft; a digging device is fixedly connected to the position, close to the grooving rotary disc, of one end of the sliding rod; a burying device is fixedly connected to the position, away from the grooving rotary disc, of the bottomof the bottom plate; and a compacting wheel is fixedly connected to the position, close to the bottom of the bottom plate, of the top of the surface of the burying device. The invention relates to the technical field of cable laying. According to the automatic cable laying machine, the effect of integrating grooving, cable laying, burying and compacting is achieved, the amount of manual labor isreduced, the time and the labor are saved, the integration of grooving, cable laying, burying and compacting is achieved, and the working efficiency and the using performance are improved.

Owner:韩爱强

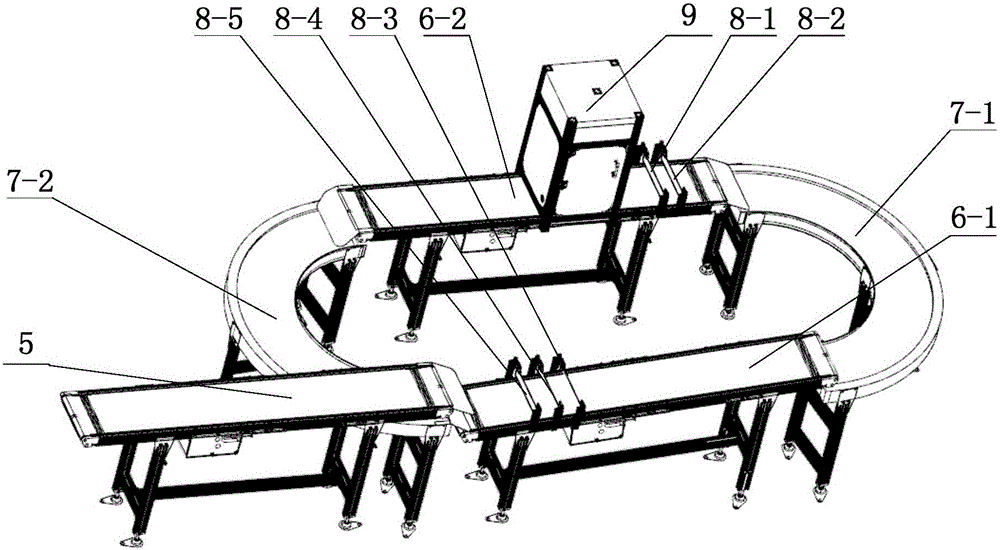

Product detecting and sorting system

ActiveCN105858197ASave human resourcesInspection speed and product sorting speed increaseConveyorsSortingManipulatorEngineering

The invention discloses a product detecting and sorting system which comprises an annular feed line, a first grabbing mechanical hand, a second grabbing mechanical hand, an annular detecting line and a finished product conveying belt. The first grabbing mechanical hand and the second grabbing mechanical hand are completely the same in structure. The annular detecting line is arranged on one side of the annular feed line. The first grabbing mechanical hand is arranged above the annular feed line and the annular detecting line and used for grabbing products on the annular feed line to the annular detecting line. The finished product conveying belt is arranged on one side of the annular detecting line. The second grabbing mechanical hand is arranged above the annular detecting line and the finished product conveying belt and used for grabbing products on the annular detecting line to the finished product conveying belt. By means of the full-automatic product detecting and sorting system, full automation is achieved, no manpower is needed, labor resources are saved, detecting speed and product sorting speed are greatly increased, production efficiency is greatly improved, accuracy is greatly improved, and the overall quality level of products can be improved.

Owner:JIANGSU RELAX AUTOMATION TECH CO LTD

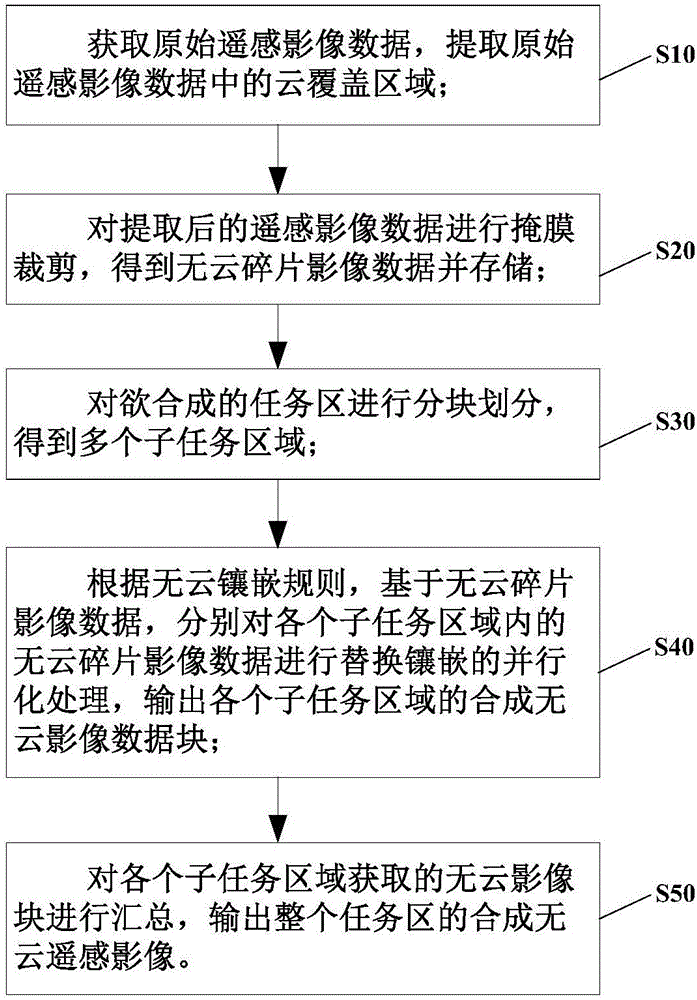

High-performance remote sensing image synthesis method and device

ActiveCN106846285AImprove image utilizationReduce data redundancyImage enhancementImage analysisCloud coverImage synthesis

The invention discloses a high-performance remote sensing image synthesis method. The method comprises the steps that original remote sensing image data is acquired, and a cloud covered area in the original remote sensing image data is extracted; mask clipping is performed on the remote sensing image data obtained after extraction, and cloudless fragment image data is obtained and stored; a task area to be synthesized is divided into blocks to obtain multiple subtask areas; the cloudless fragment image data in the subtask areas is subjected to substitutive inlaying parallelization processing according to cloudless inlaying rules, and synthesized cloudless image data blocks in all the subtask areas are output; and the cloudless image data blocks acquired from all the subtask areas are gathered to output a synthesized cloudless remote sensing image of the whole task area. According to the method, only a cloudless fragment image is stored, so that the data storage volume is lowered; substitutive inlaying processing is performed according to areas in a multithread parallel mode, thus, efficiency is improved, and a large-range cloudless inlaid image can be acquired; by means of local histogram matching, the problem of hue inconsistency is eliminated while hue adjustment is guaranteed.

Owner:SUZHOU ZHONGKE IMAGE SKY REMOTE SENSING TECH CO LTD +1

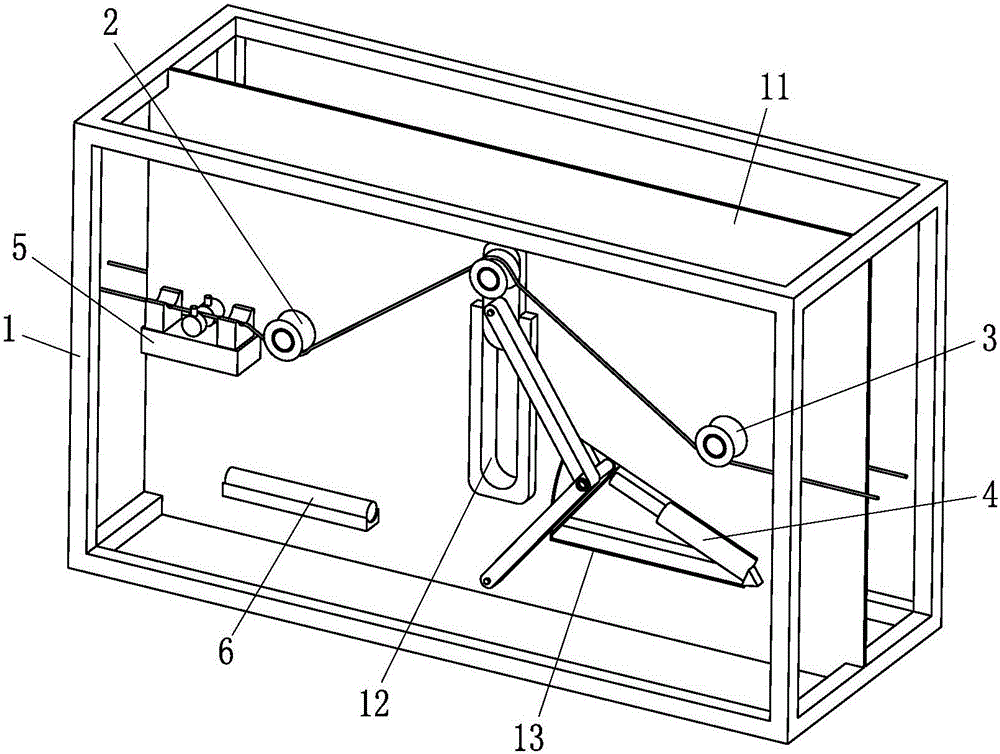

All-dimensional computer surface ash removing machine

ActiveCN105817435ARealize cleaningRealize sponge wipeCleaning using toolsLiquid-crystal displaySlide plate

The invention relates to the field of notebook computers, in particular to an all-dimensional computer surface ash removing machine. The all-dimensional computer surface ash removing machine comprises a body mechanism, a keyboard cleaning device, an advancing mechanism and a screen cleaning device. The body mechanism comprises a left side plate, a right side plate, four supporting air cylinders and two rodless air cylinders; the keyboard cleaning device comprises a sliding plate, front and back screws, front and back motors, a moving plate, a keyboard cleaning motor, a keyboard cleaning machine, a hairbrush, a keyboard cleaning air cylinder and a dirty removing sponge; and the screen cleaning device comprises a fixed plate, left and right screws, left and right motors, a screen cleaning block, a screen cleaning air cylinder, a rotary supporting air cylinder and a screen cleaning sponge. By means of the all-dimensional computer surface ash removing machine, a computer keyboard can be subject to automatic hairbrush cleaning and sponge wiping; in addition, automatic cleaning of a liquid crystal display can be achieved, the automatic degree is high, manual work is not needed, the structural design is ingenious, and the manpower is saved.

Owner:江苏弘汉生物科技有限公司

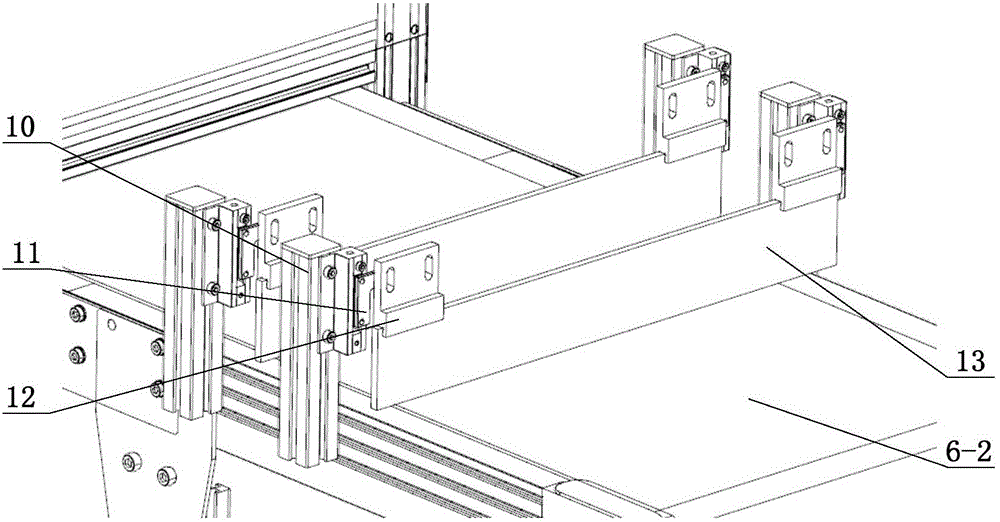

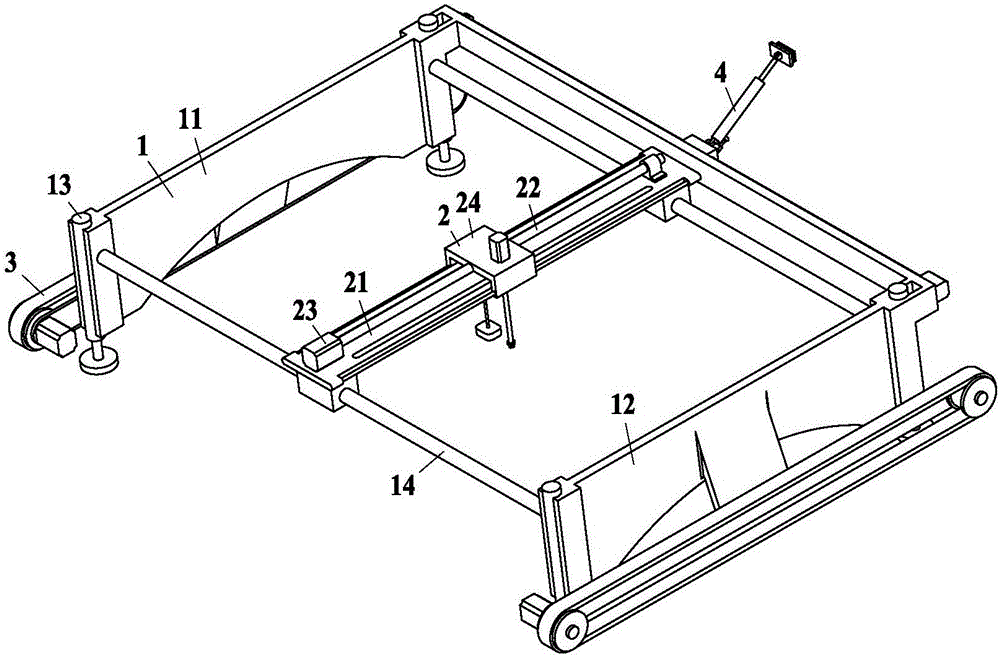

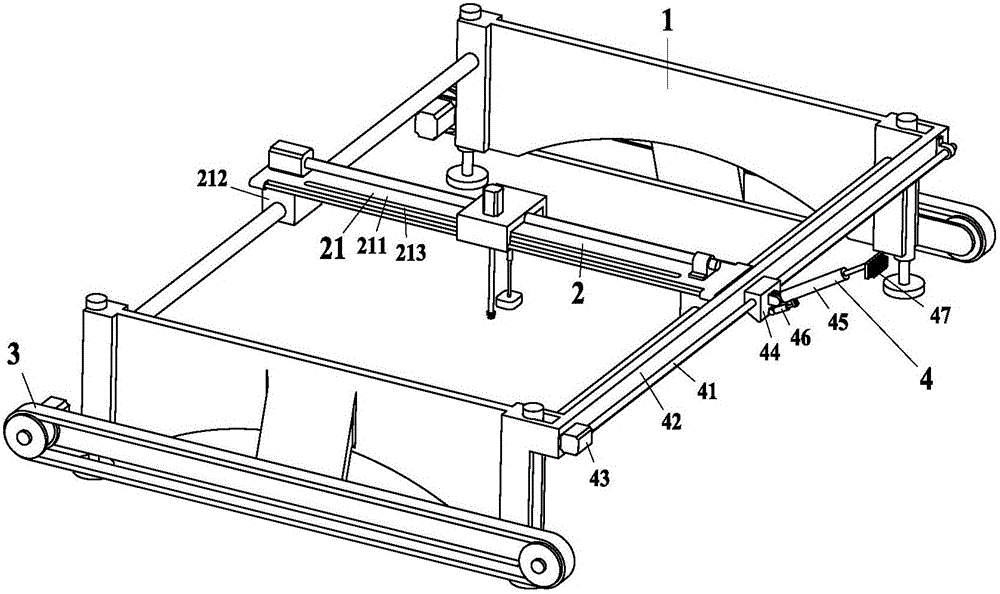

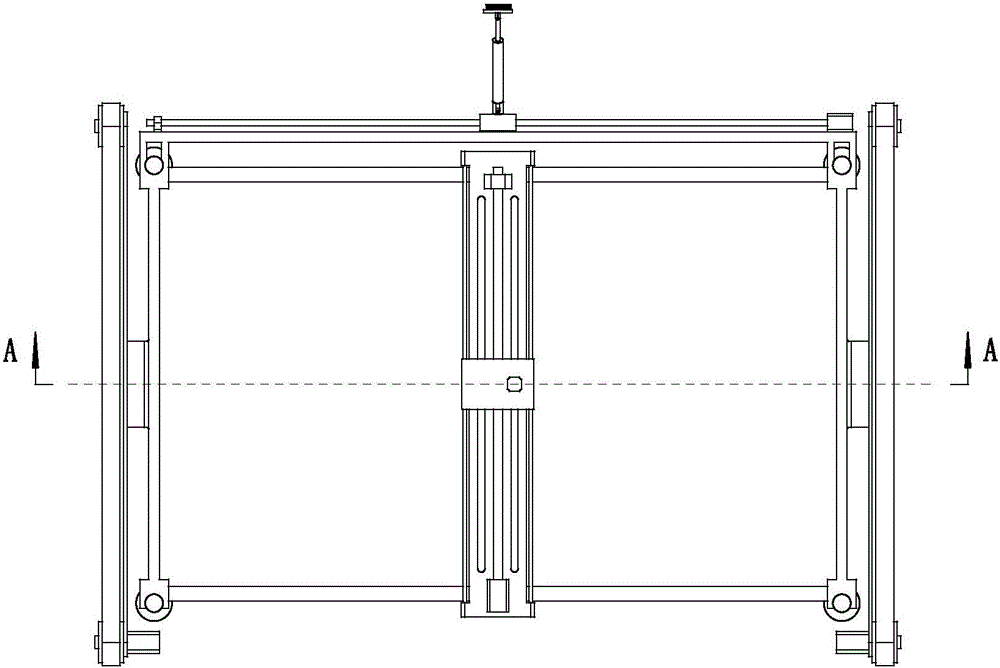

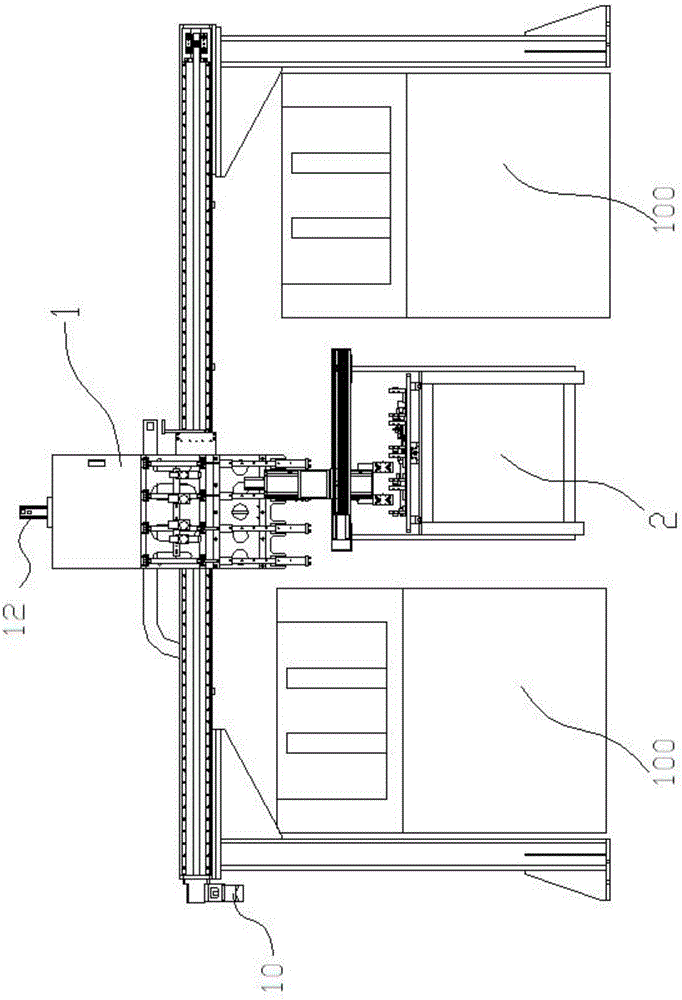

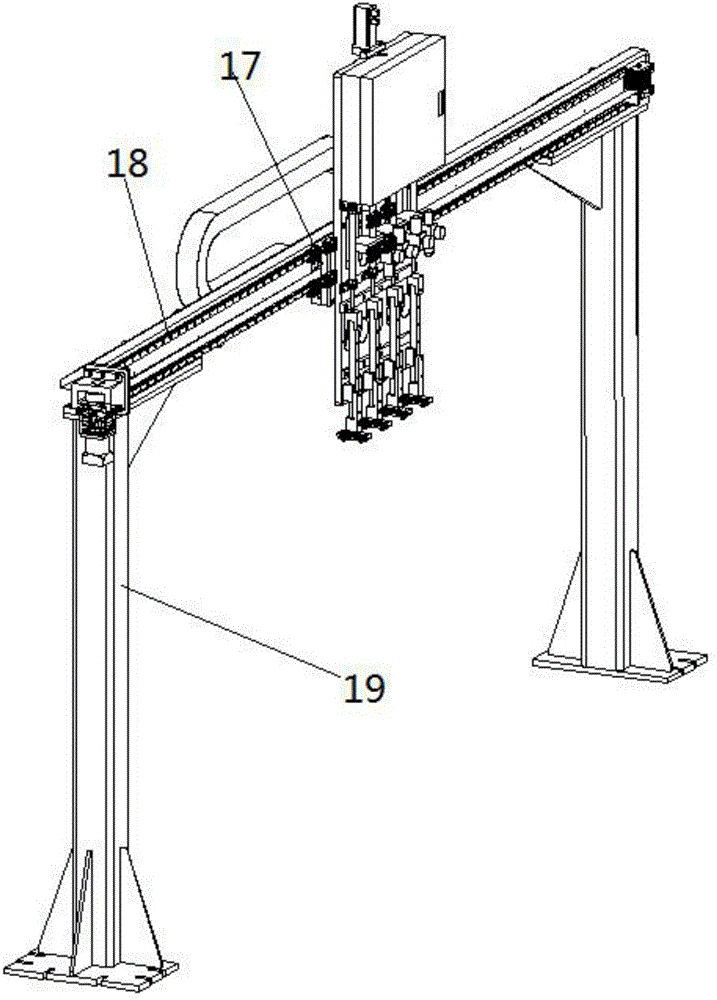

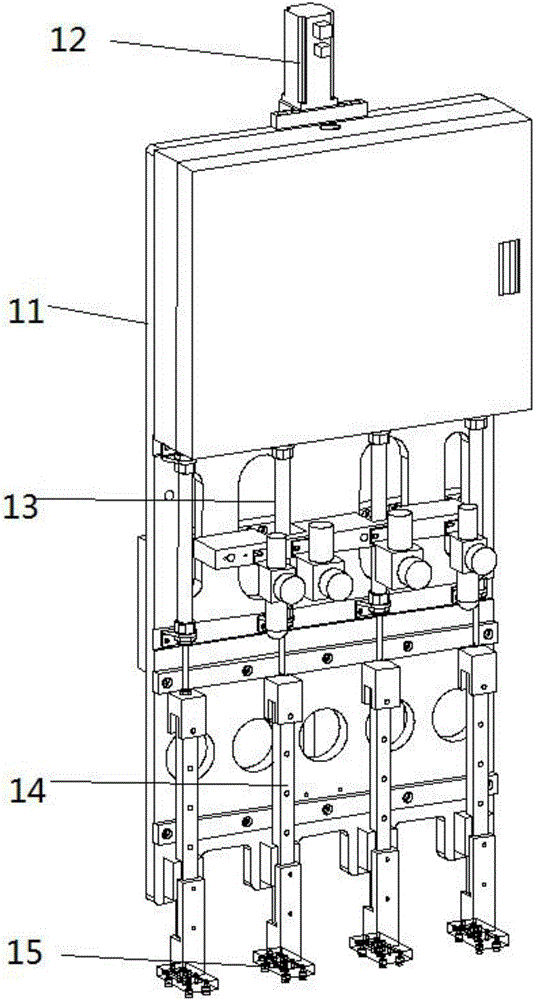

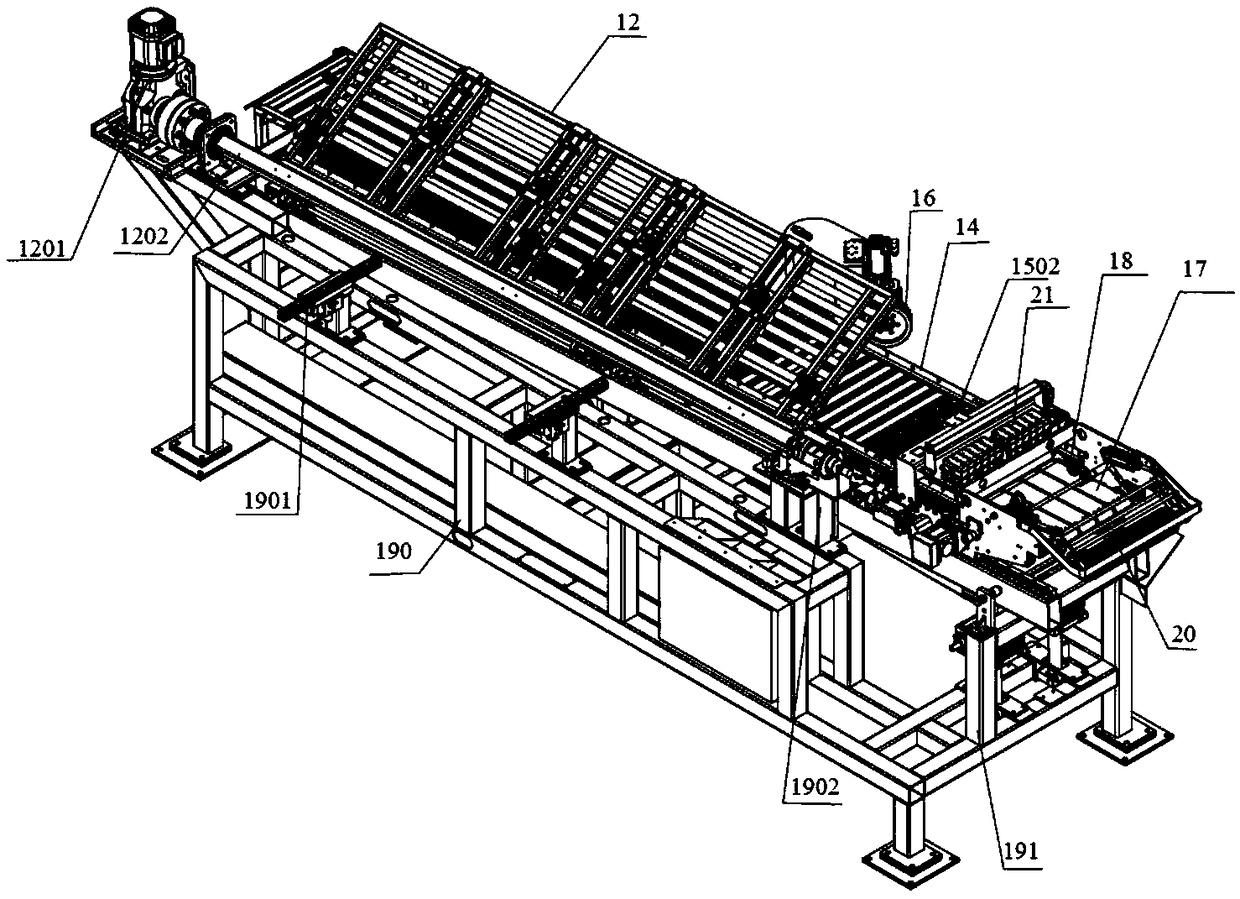

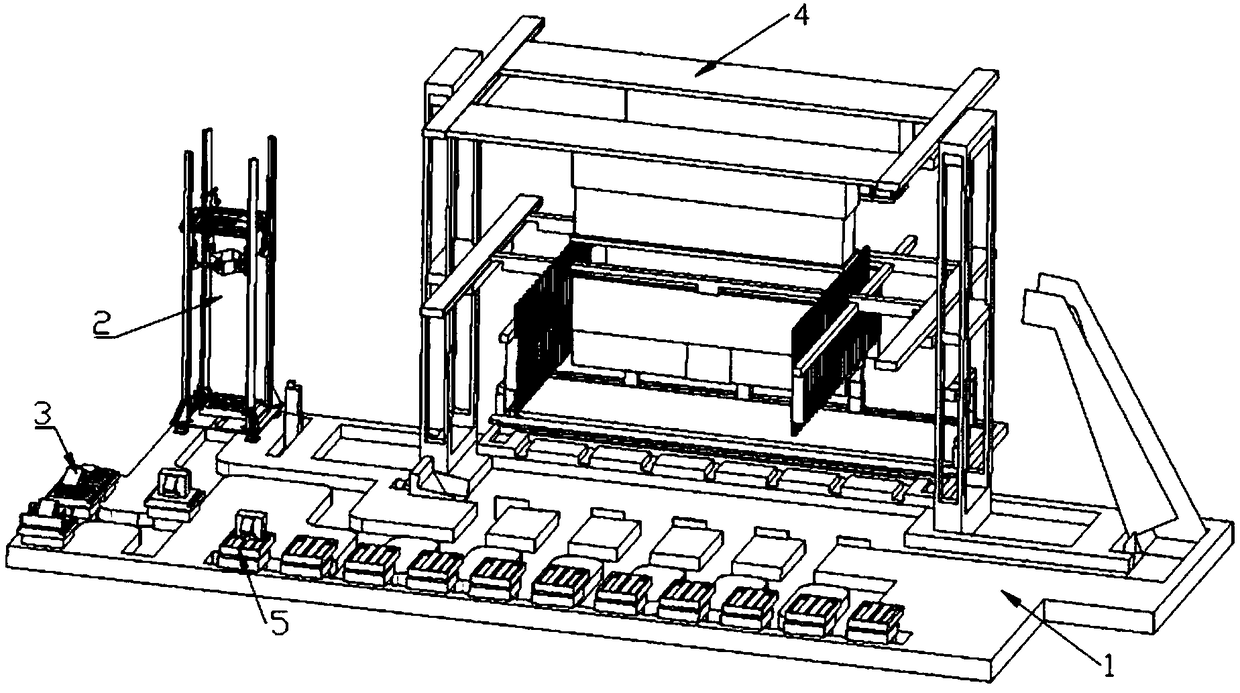

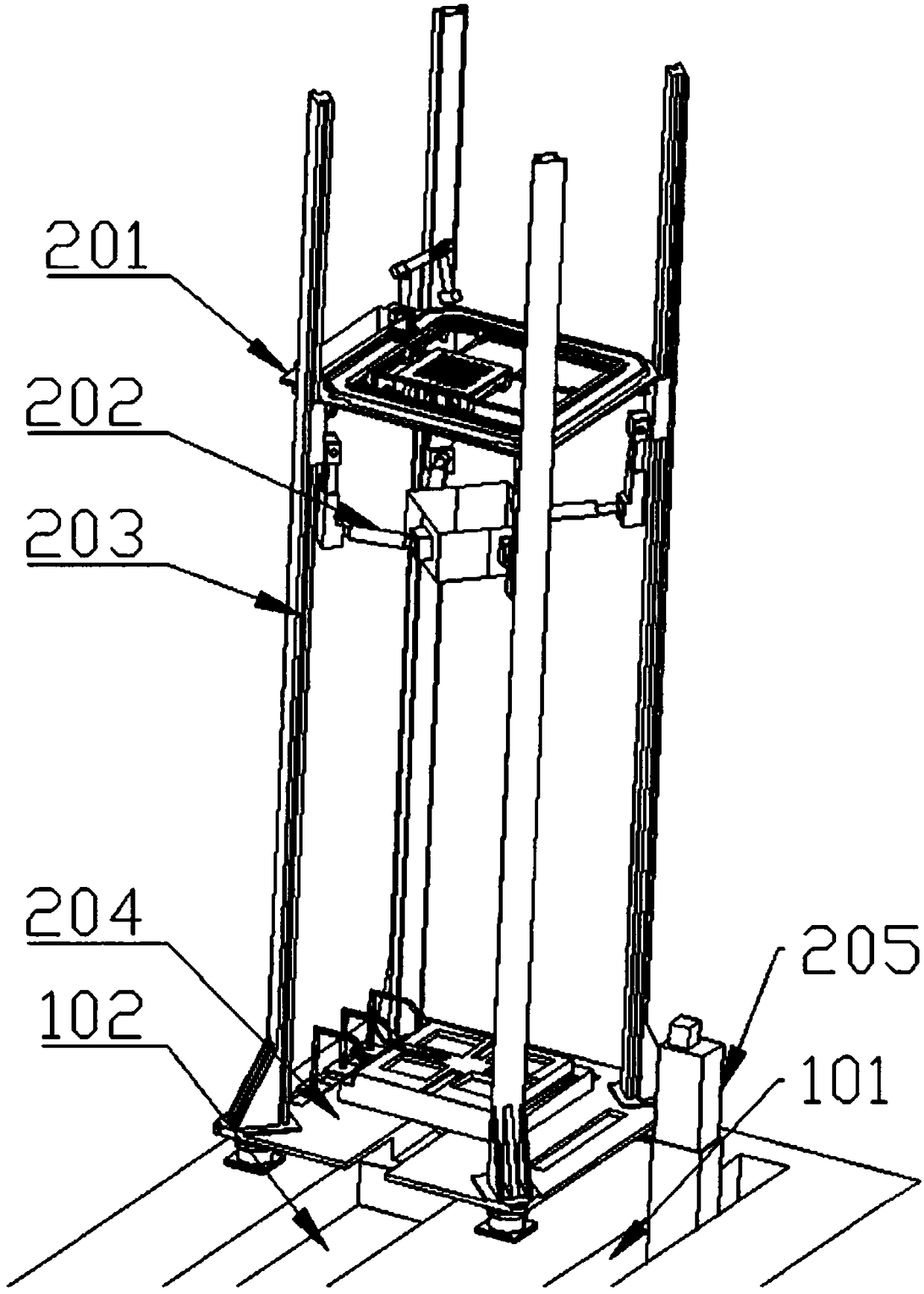

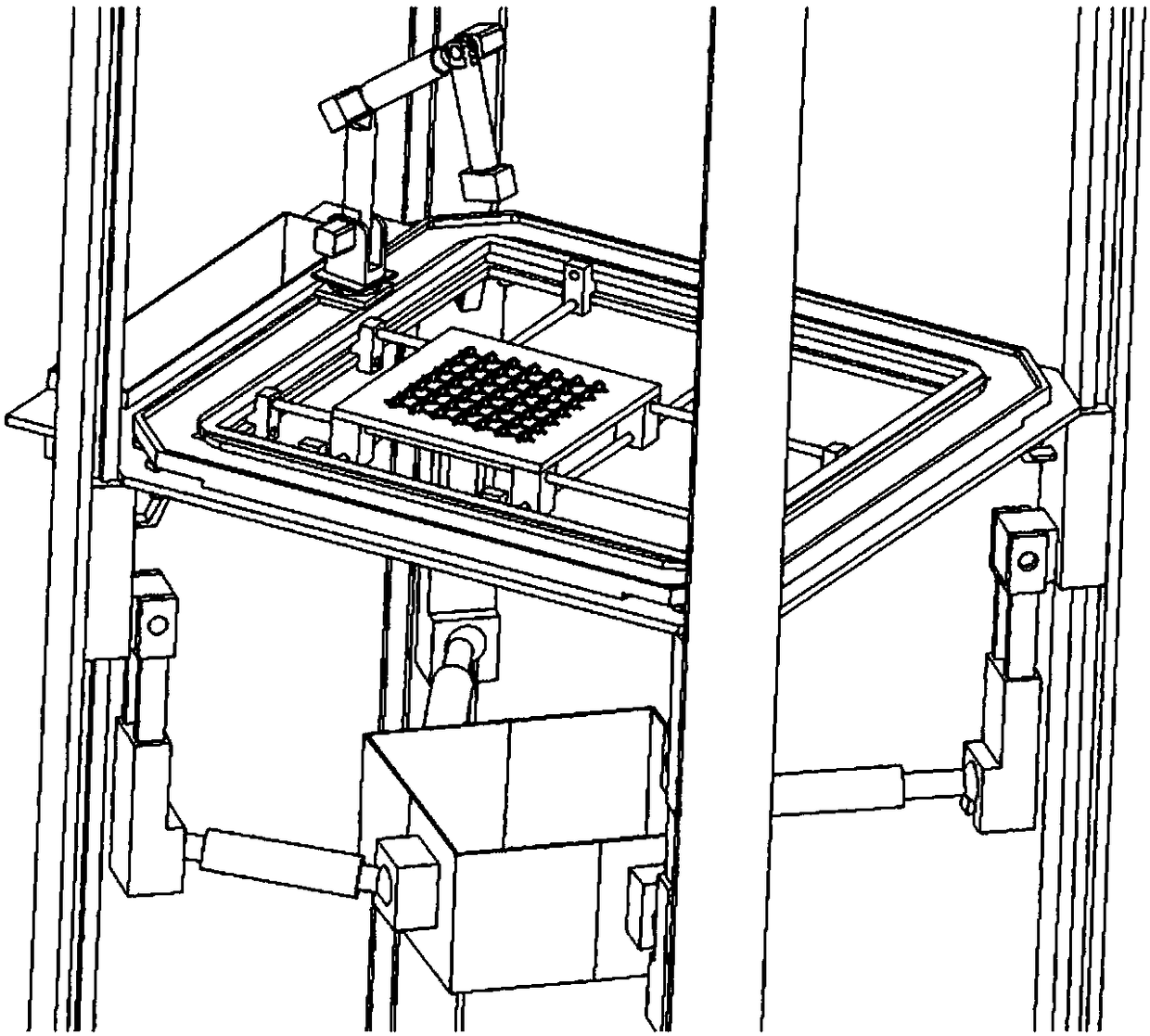

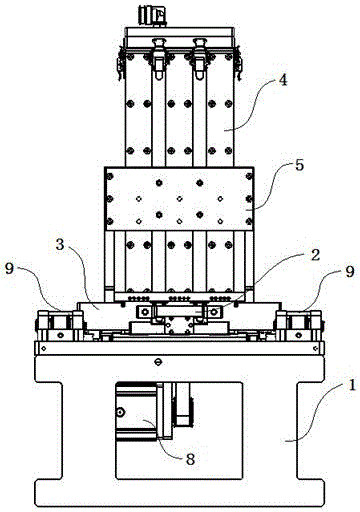

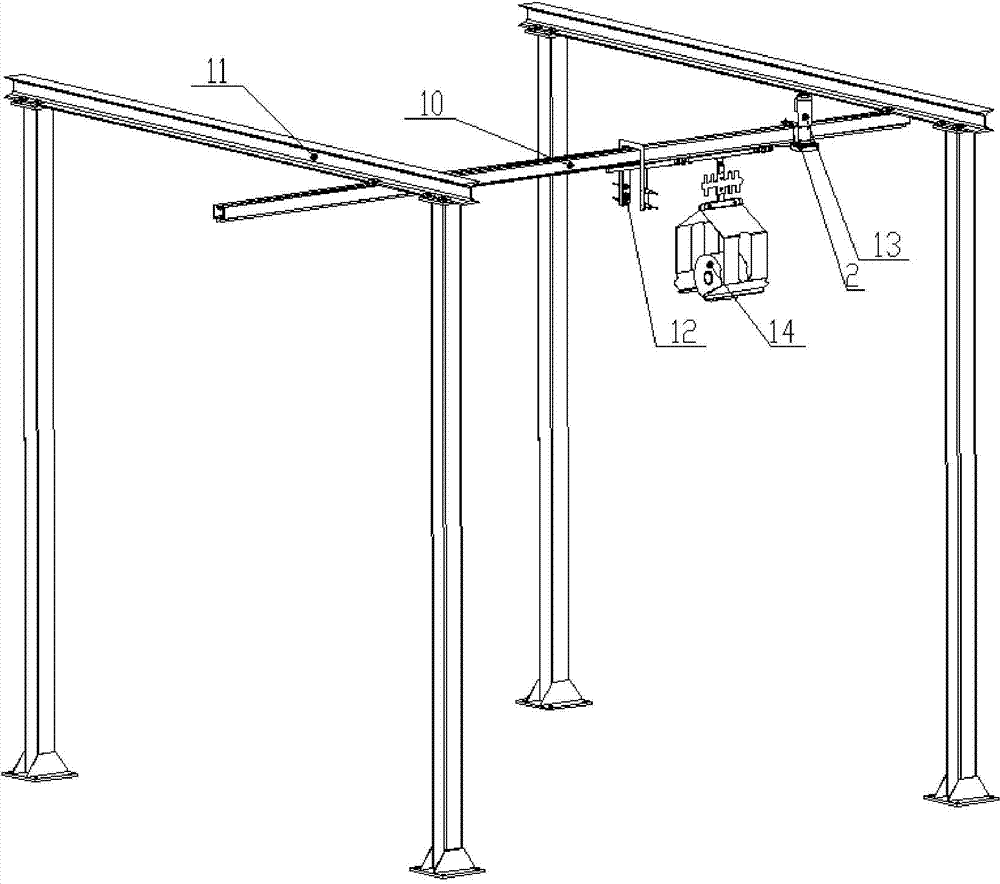

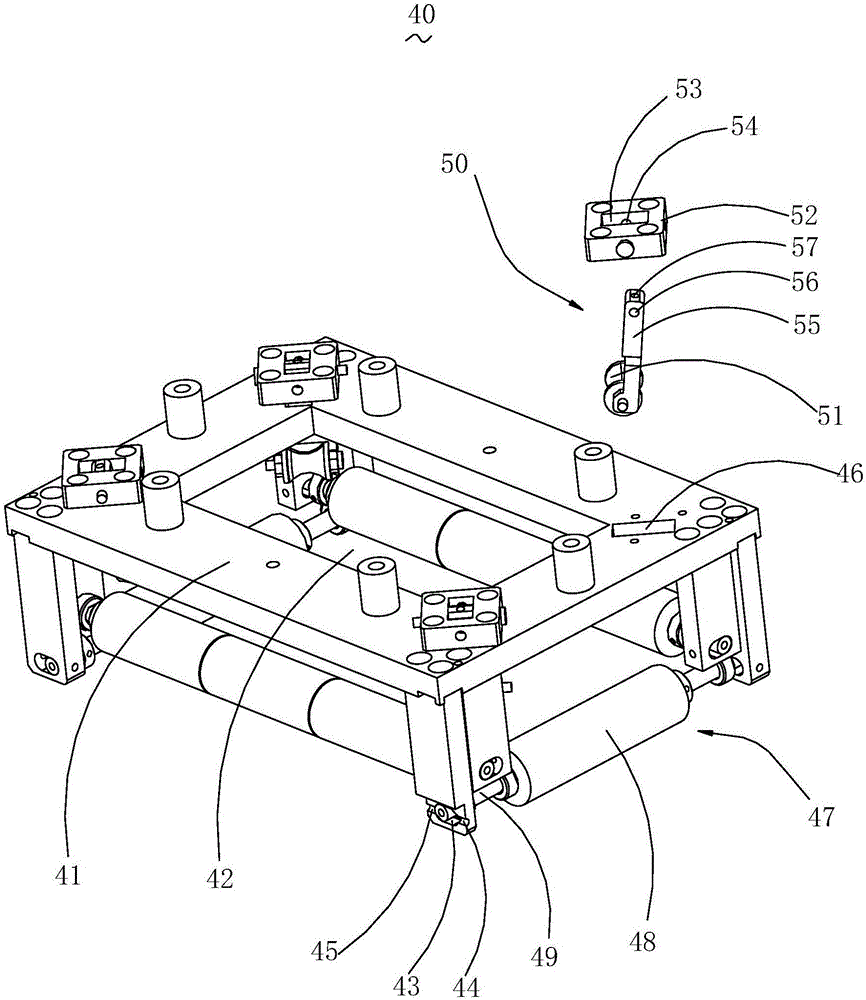

Full-automatic feeding and discharging equipment for engraving and milling machine

ActiveCN106081619APrecise loading and unloadingPrecise positioningCharge manipulationConveyor partsEngravingSlide plate

The invention discloses a full-automatic feeding and discharging device for a engraving and milling machine. The full-automatic feeding and discharging device equipment comprises a manipulator device and a storage bin device. The manipulator device comprises a fixed portal fixing frame which comprises a left stand column, a right stand column and a cross beam mounted at the top ends of the left stand column and the right stand column. A transverse guide rail, which is arranged in the transverse direction, is fixedly mounted on the cross beam. A transverse sliding seat, which can slide in the transverse direction, is arranged on the transverse guide rail. A transverse driving mechanism, which drives the transverse sliding seat, is mounted at one end of the transverse guide rail. A longitudinal sliding seat, which can slide in the longitudinal direction, is arranged on the transverse sliding seat. The storage bin device comprises a machine table. A Y-axis sliding plate, which can slide in the Y-axis direction, is arranged on the machine table, and is driven by a Y-axis motor mounted on the machine table. Multiple groups of discharging and clamping units, which are parallely arranged at an equal interval, are mounted on the Y-axis sliding plate. The full-automatic feeding and discharging device is suitable for the engraving and milling machine is particularly suitable for machining mobile phone glass, and can realize full-automatic and accurate feeding and discharging, manpower is not required, the labor cost is reduced greatly, and besides, compared with a general manipulator, the full-automatic feeding and discharging device is more stable in structure, and more accurate in positioning.

Owner:东莞市小智人机器人有限公司

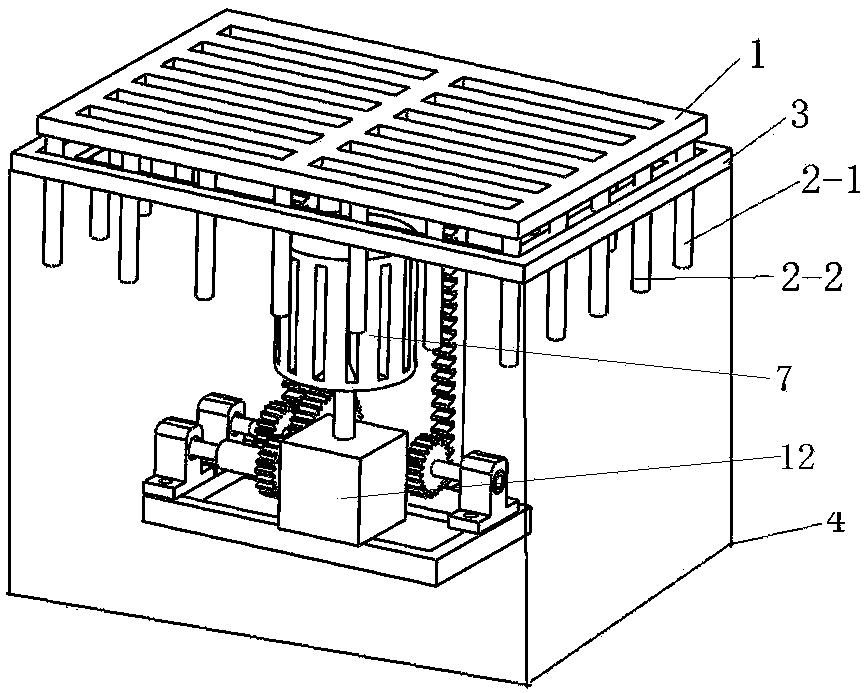

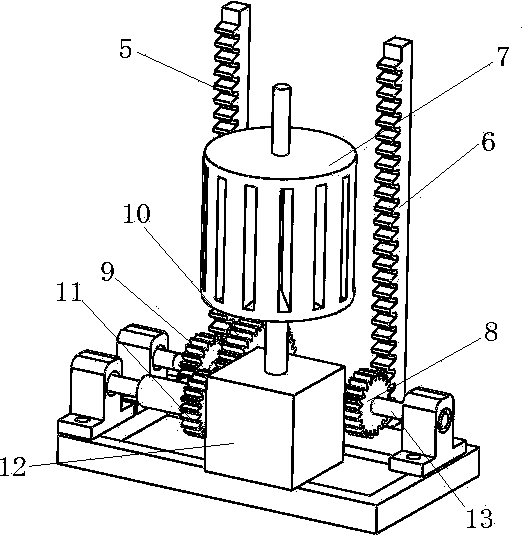

Flood control water drainage well cover system

InactiveCN104343178AImprove drainage capacityPrevent fallingSewerage structuresLifting devicesWater wheelDrive shaft

The invention discloses a water well cover system and belongs to the field of municipal and water drainage equipment. The flood control water drainage well cover system comprises a well cover with a water drainage opening, a water wheel is arranged below the water drainage opening of the well cover, a rack a and a rack b are fixedly arranged on both ends of the well cover in the vertical direction, a rotating shaft of the water wheel is connected to the input of a reducer, a gear c is arranged at the output of the reducer, a horizontal drive shaft is arranged, the middle portion and both ends of the drive shaft are respectively provided with a gear d, a gear a and a gear b, the gear d at the middle portion of the drive shaft is meshed with the gear c arranged at the output of the reducer, and the gear a and the gear b at both ends are respectively meshed with the rack a and the rack b fixedly arranged on the well cover. The flood control water drainage well cover system is applicable to a water drainage well for flood discharge or water drainage and can effectively improve the drainage capability of the water drainage well and reduce the probability of poor flood discharge of a city or other parts.

Owner:河南省安阳县星火工业技术研究所

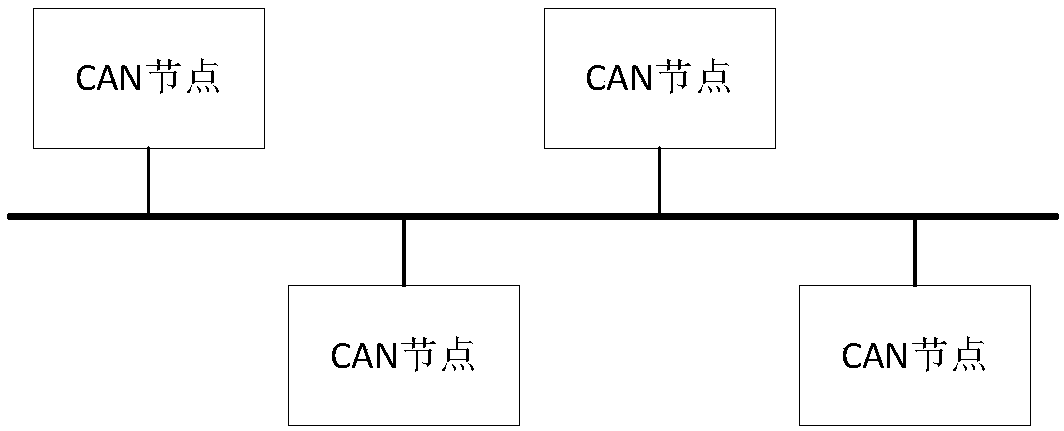

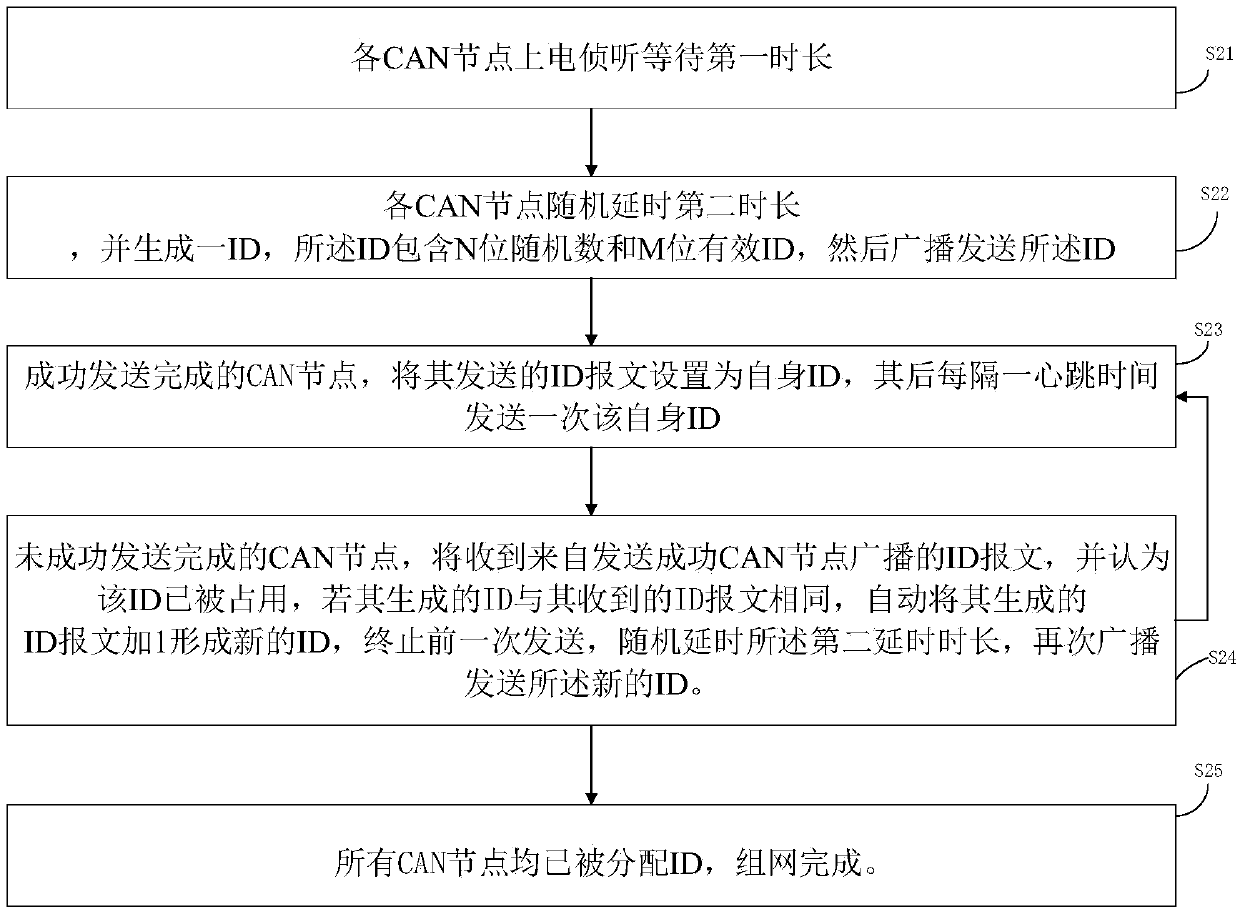

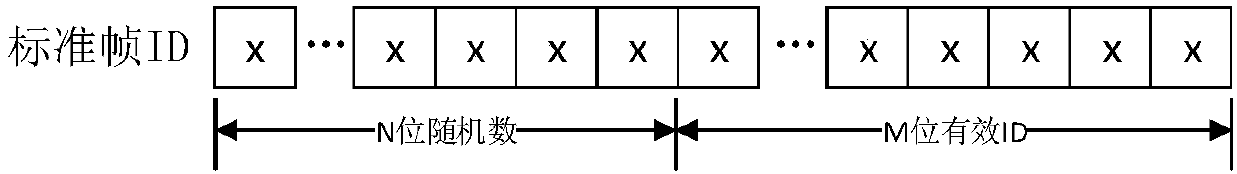

CAN bus-based multi-node automatic networking method

ActiveCN107786405ARealize dynamic increase and decreaseImplement ID assignmentBus networksElectricityBroadcasting

The invention discloses a CAN bus-based multi-node automatic networking method. A CAN node is electrified to intercept and wait for a first duration, randomly postpones for a second duration and obtains an ID, and then, sends the ID through broadcasting. The CAN node successfully sending the ID through broadcasting sets the sent ID as an own ID, and then, sends the own ID one time at each heartbeat time. The node which cannot successfully send the ID receives an ID message broadcasted by the CAN node successfully sending the ID, and considers that the ID is occupied, adds 1 to the ID to form anew ID, stops last sending, randomly postpones for the second duration, and sends the new ID message again through broadcasting. By analogy, until all the CAN nodes are allocated with the ID. The automatic networking method provided by the invention aims at applications where multiple machines are connected in parallel and a plurality of nodes are on the bus, through an automatic networking algorithm, realizes ID allocation and dynamic increase and decrease of nodes, and has no need of any artificial or external intervention.

Owner:FSP POWERLAND TECH

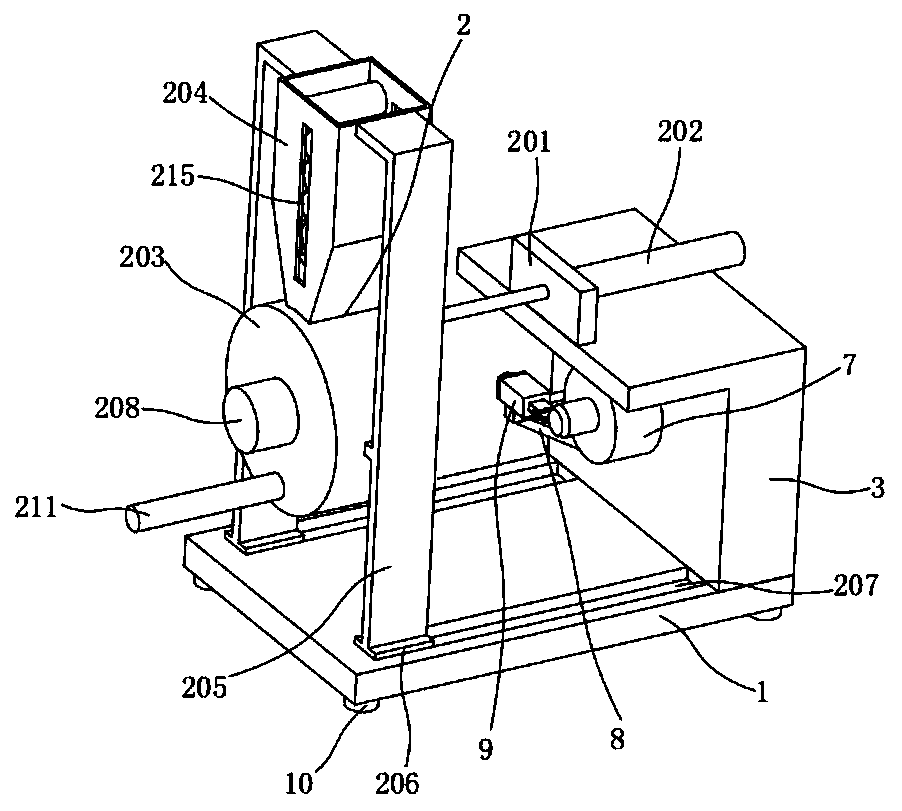

Cutter belt processing device and processing method thereof

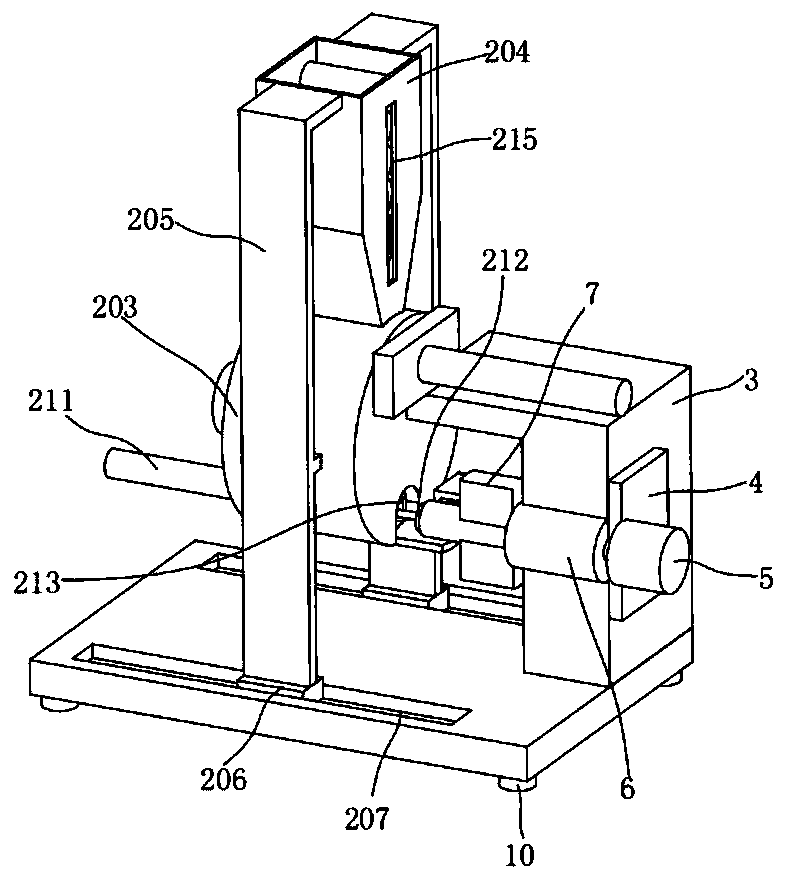

ActiveCN103358188ASolve the difficult problem of precise automatic feedingHigh precision grinding made easyGrinding drivesOther manufacturing equipments/toolsVertical planeDynamic positioning

A cutter belt processing device comprises a constant angle constant-pressure automatic compensating and feeding device and a dynamic positioning assembly, wherein the constant angle constant-pressure automatic compensating and feeding device and the dynamic positioning assembly are fixedly arranged on a base plate. The constant angle constant-pressure automatic compensating and feeding device comprises a grinder, an angle adjuster and a compensating feeder, wherein the grinder is arranged above the base plate through the angle adjuster, the grinder can rotate in a vertical plane above the base plate, and the compensating feeder is arranged on the grinder. The cutter belt processing device is strong in maneuverability, easy and convenient in angle adjusting and capable of meeting technological requirements for producing high-accuracy cutter belts, enables high-accuracy grinding of blades of the cutter belts to be easy and controllable, does not need manual or other types of intervention during service life of a grinding wheel, is high in dynamic positioning stability, cannot damage blades or abrade cutter bodies, guarantees technology and control stability of a cutter belt manufacturing process, avoids the time for replacing the positioning assembly when product specification needs to be changed and greatly reduces the preparation time for changing product specification.

Owner:SHANGHAI XINPENG PRINTING EQUIP

Egg tart making device

Owner:衡阳市南北特食品有限公司

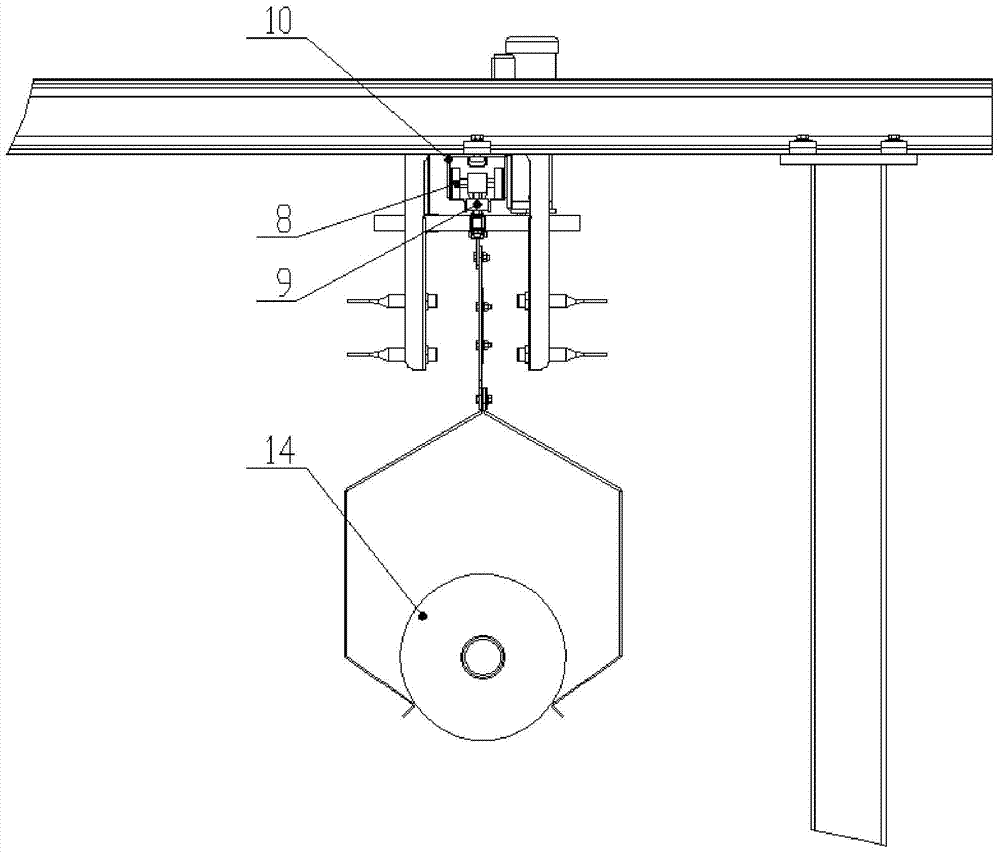

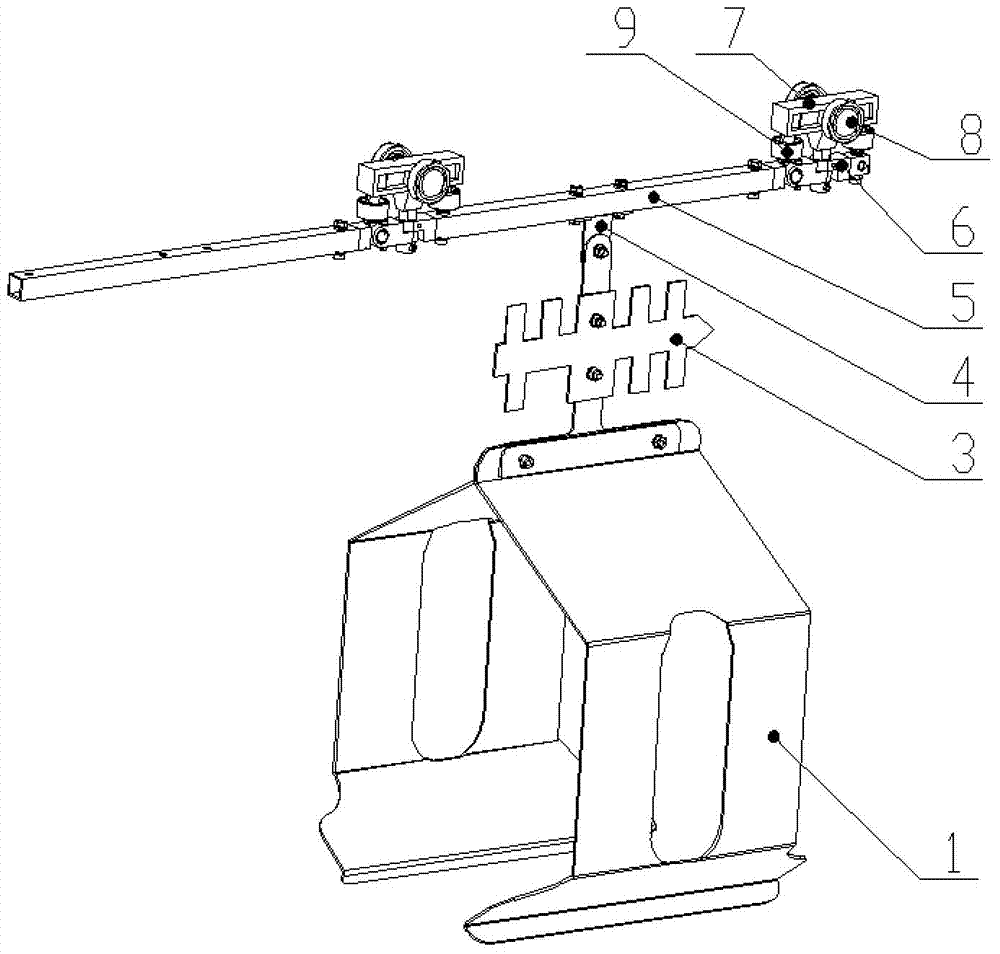

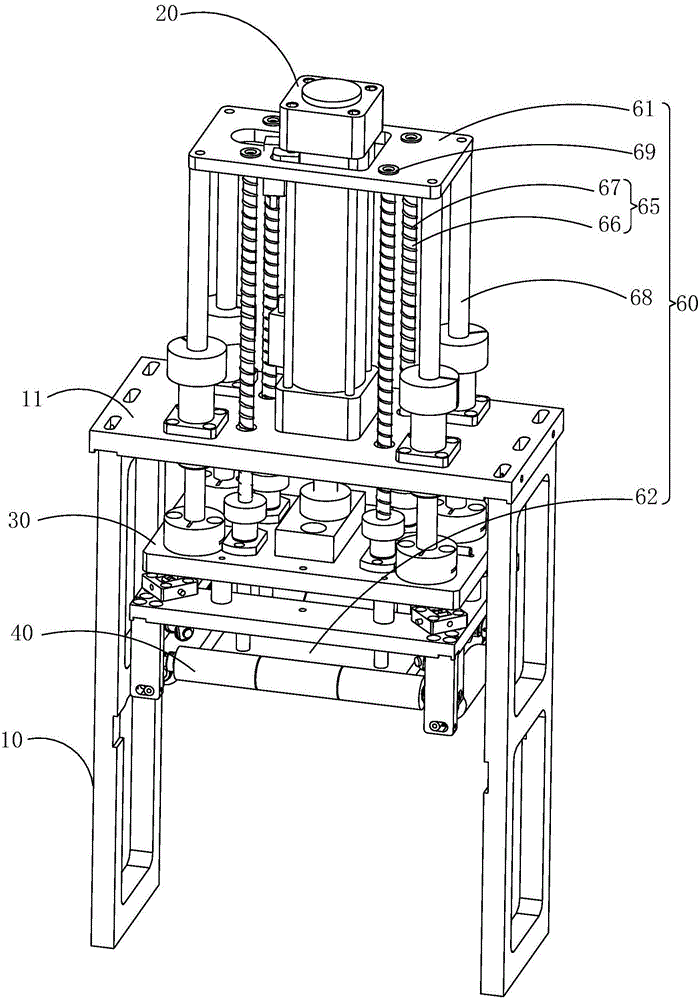

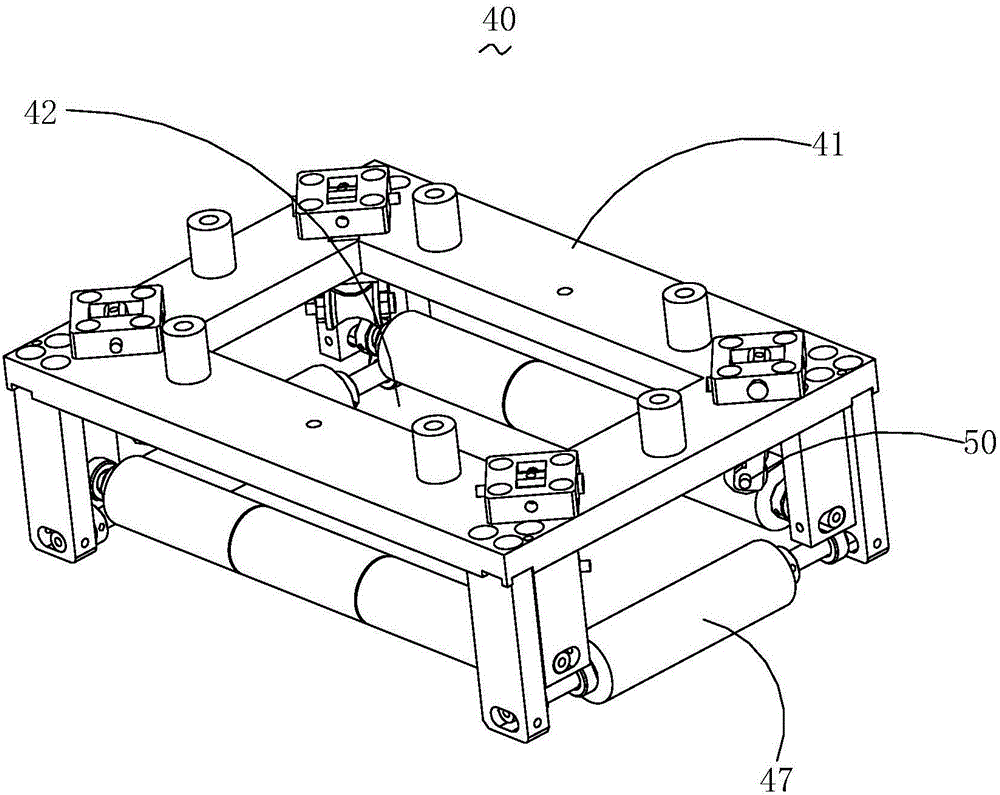

Automatic tire tread supply system

ActiveCN108790229AGood centering effectThe test result is accuratePlastic recyclingTyresTreadAutomotive engineering

The invention provides an automatic tire tread supply system. The automatic tire tread supply system comprises a shutter trolley, a grabbing device, a supply device and a PLC. Tire treads on the shutter trolley are transferred to the supply device through the grabbing device and then attached to a belt bundle drum, and the shutter trolley, the grabbing device and the supply device are in signal connection with the PLC.

Owner:HANGZHOU CHAOYANG RUBBER

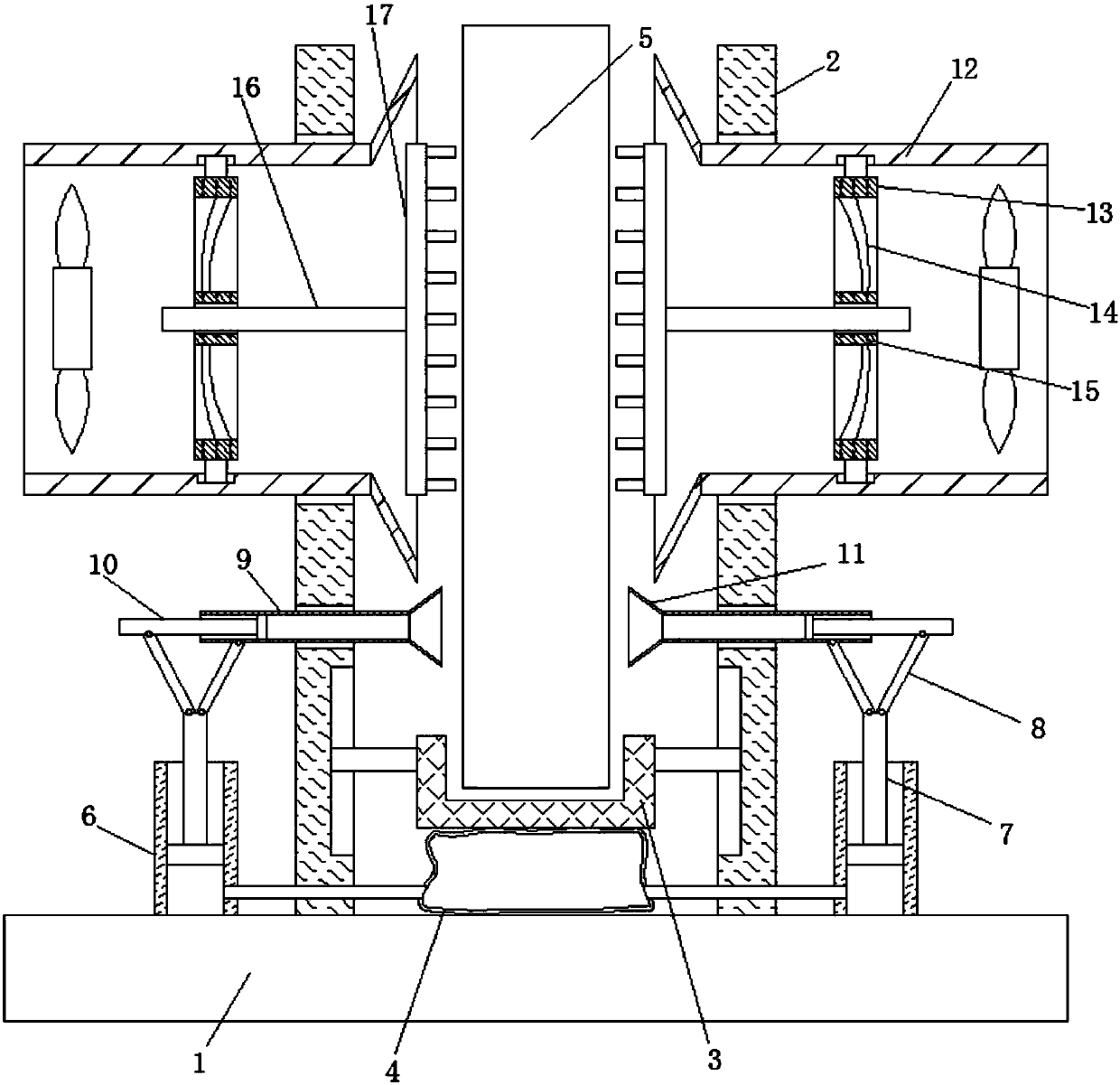

Top coal gangue interface recognition test system

ActiveCN108534975AStrong expandabilitySave spaceVibration testingShock testingDrop impactPilot system

The invention relates to a top coal gangue interface recognition test system comprising a base, a coal gangue particle impact vibration test device, a simulating coal flow coal gangue drop impact testdevice. The coal gangue particle impact vibration test device comprises a vibration table device, a bracket assembly, a coal release device and a high-speed camera component. The coal release devicereleases the coal gangue particles to the vibration table device. The high-speed camera component obtains instantaneous image information that the coal gangue particles drop on the vibration table device. The simulating coal flow coal gangue drop impact test device includes a simulating coal flow drop device, a coal gangue transport device, a coal shovel device and a top coal hydraulic support working group. Subsequently, a simulating coal pressure loading device and coal flow buckle device perform a simulating coal flow coal gangue drop impact test on the top coal hydraulic support working group. The test system can realize the vibration plate test of single-particle, multi-particle, group-particle coal gangue impact simulation, can also simulate the actual drop of the top coal, and can effectively obtain the data of the top coal drop test.

Owner:SHANDONG UNIV OF SCI & TECH

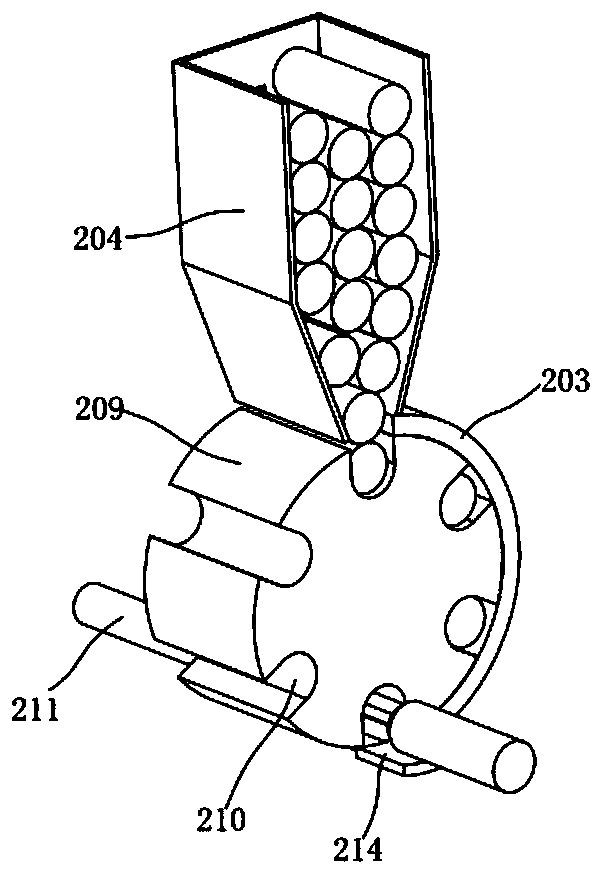

Magnet assembling mechanism

ActiveCN106041465AEasy to processEasy maintenanceMetal working apparatusProduction lineElectric machinery

The invention discloses a magnet assembling mechanism. The magnet assembling mechanism comprises an assembling working table, a conveying mechanism, a separating mechanism, a filling mechanism, a rapid disassembling magazine, a magazine holding mechanism and a tray, wherein a carrier plate used for placing the tray is arranged in the center of the table surface of the assembling working table; the conveying mechanism comprises two conveyor belts driven by a motor, and the two conveyor belts are separately arranged on the table surface, on the left and right sides of the carrier plate, of the assembling working table; and the filling mechanism is arranged on the two conveyor belts, the separating mechanism is arranged at the front part of the filling mechanism, the magazine holding mechanism is arranged at the upper part of the filling mechanism, and the rapid disassembling magazine is perpendicularly plugged on the magazine holding mechanism. The mechanism has the advantages of being simple to machine, simple to maintain, rapid to disassemble and assemble, low in cost, high in efficiency and the like, can be widely applied to various mobile phone production lines, and has advantages over the existing structures on the market in machining, assembly and later maintenance due to novel structural design and magnet assembling mode.

Owner:苏州茂特斯自动化设备有限公司

Automatic equipment for cleaning and maintenance of computer hardware

InactiveCN107755359AImprove ash removal efficiencyHigh degree of automationCleaning using toolsCleaning using gasesPistonEngineering

The invention relates to the technical field of computers, in particular to automatic equipment for cleaning and maintenance of computer hardware. The automatic equipment is characterized in that a computer hardware body is clamped at the upper end of a U-shaped clamp plate, two hoses symmetrically penetrate the side wall of an air bag, first T-shaped pistons located above the hoses are in movableinserting connection with the inner walls of cylinders, a sleeve is in movable inserting connection with each vertical plate, opposite ends of the two sleeves are connected with suckers correspondingly, a second T-shaped piston is in movable inserting connection with the inner wall of the end, away from the corresponding sucker, of each sleeve, the other end of each T-shaped piston penetrates thecorresponding sleeve to reach the outside of the corresponding sleeve, the other end of one of straight bars is hinged to the lower end of the corresponding sleeve, dust-proof tubes located above thesleeves are in fixed inserting connection with the vertical plates, and an induced draft fan is mounted in each dust-proof tube. The automatic equipment has the characteristics of simple structure, good dust-proof effect, high degree of automation and the like, and has very high practicability.

Owner:CHENGDU CHUANGNIAN TECH CO LTD

Equipment for adjusting relaxation degree of copper wires for cables

InactiveCN106044384ASimple equipment structureEasy to operateFilament handlingFunction indicatorsCopper wireEngineering

The invention relates to the field of cable equipment, in particular to equipment for adjusting relaxation degree of copper wires for cables. The equipment comprises a frame, a first guide wheel, a second guide wheel, a tensioning device, a tension sensor and an LED lamp, wherein the tensioning device is positioned on the right side of the frame; the tension sensor is positioned on the left side of the frame; the tensioning device comprises a pair of tensioning wheels, a sliding block, a pair of first connecting rods, a pair of second connecting rods and a tensioning cylinder; an LED lamp is mounted on a partition. The tensioning cylinder stretches and retracts to drive the tensioning wheels to slide so as to adjust tensioning of the copper wires in a wiredrawing process. The equipment is simple in structure and convenient to operate, and manual operation is not required. In addition, the equipment can simultaneously tension two copper wires, can adapt to the condition of simultaneous wire drawing of the two copper wires, is high in adaptability, and has high practical value.

Owner:安庆潜江电缆有限公司

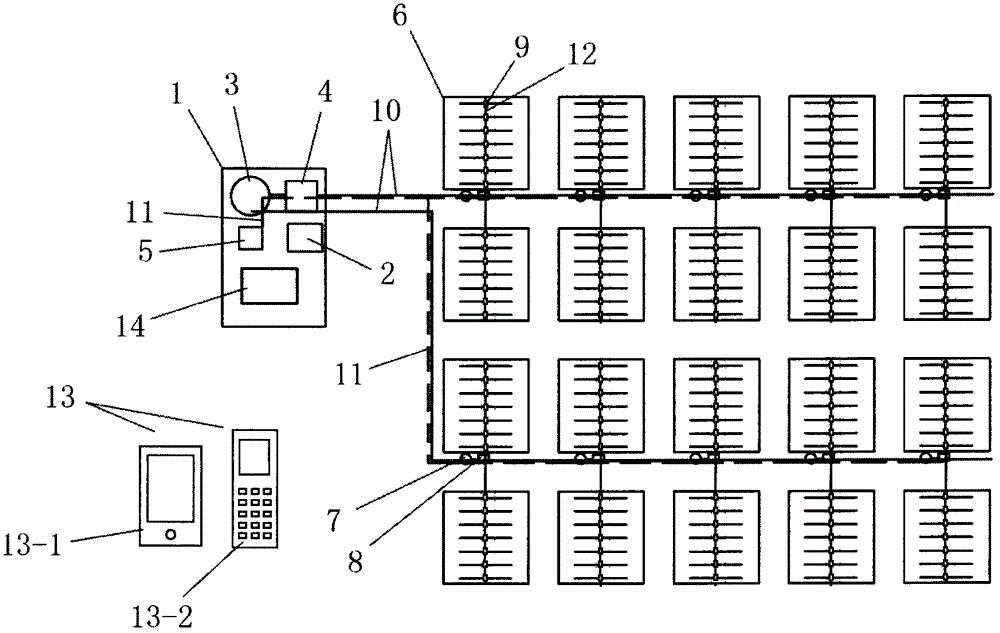

Intelligent liquid cloud feeding system for large livestock farm

InactiveCN106069842AFully intelligent operationNo manualAnimal feeding devicesAvicultureLivestockManufacturing engineering

The invention discloses an intelligent liquid cloud feeding system for a large livestock farm. The system comprises a stock bin and pig houses. The stock bin is internally provided with an intelligent central control room, a fully-intelligent matching and constant-temperature stirring tank, a fully-intelligent power main machine and a screw type air compressor. Each pig house is internally provided with distributed material conveying pipelines provided with intelligent discharge terminals. A distributed material stirring tank and a distributed material conveyer are arranged outside each pig house. The screw type air compressor is connected with distributed material stirring tanks through compressed air pipelines. The fully-intelligent matching and constant-temperature stirring tank is connected with the fully-intelligent power main machine and connected with the distributed material stirring tanks through main material conveying pipelines. The feeding system comprises an intelligent control terminal, and the intelligent central control room is provided with an intelligent control receiving device which is in wireless communication with the intelligent control terminal. Compared with the prior art, fully-automatic operation is achieved, and manual work is not needed; manual transport and vehicle transport cost is reduced; timed, quantitative and precise feeding is achieved, and feed cost is reduced.

Owner:河南瑞昂畜牧科技有限公司

Solid shaft chamfering device

ActiveCN110948051AReduce workloadRealize automatic feeding processFeeding apparatusMetal working apparatusControl engineeringManual handling

The invention discloses a solid shaft chamfering device. The solid shaft chamfering device comprises an installation block, one side of the installation block is provided with an automatic feeding device, the end, away from the automatic feeding device, of the installation block is fixedly provided with a supporting block, a first installation plate is fixedly arranged in the middle of the rear side of the supporting block, and a first servo motor is fixedly arranged on the first installation plate. The end of an output shaft of the first servo motor is fixedly provided with a rotary shaft, the rotary shaft is rotationally connected with a supporting block through a bearing, a hydraulic chuck is fixedly arranged on the end portion of the end, away from the first servo motor, of the rotaryshaft, the hydraulic chuck is located at the front end of the outer side of the supporting block, an installation rack is arranged on one side of the hydraulic chuck, the installation rack is fixed tothe front side of the supporting block, and the installation rack is provided with a chambering mechanism. Automatic feeding and chamfering are conducted without manual operation, the working efficiency is high, and the labor cost is saved.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

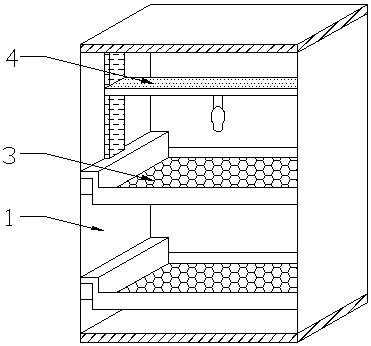

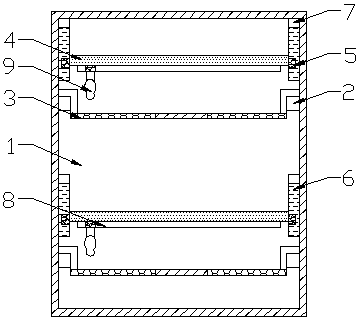

Air drying device for tea leaf processing

The invention discloses an air drying device for tea leaf processing. The air drying device for tea leaf processing comprises air drying chambers, tea leaf air drying trays and hot air blowers. A plurality of holding frames are installed on the two opposite sides inside the air drying chambers. The tea leaf air drying trays are installed on the holding frames. Each tea leaf air drying tray comprises a tray fixing frame and a tray bottom plate, wherein the tray fixing frame is installed on the corresponding holding frames. A transverse plate is installed inside each air drying chamber at the top of the corresponding tea leaf air drying tray. According to the air drying device for tea leaf processing, the hot air blowers move to achieve hot air drying of tea leaves on the tea leaf air dryingtrays, so that the tea leaves are heated uniformly, temperature balance and air flowing inside the air drying chambers can be facilitated, air drying efficiency is improved, and the air drying cost of the tea leaves is reduced; by vibrating the tray bottom plates, the gaps between the tea leaves on the tray bottom plates can be widened, the contact probability and contact area between hot air generated by the hot air blowers and the tea leaves at the bottoms of the tea air drying trays are increased, and thus the air drying uniformity and efficiency of the tea leaves are effectively improved,manual turning of the tea leaves is not needed, and the labor intensity of personnel is reduced.

Owner:龙岩市八仙岩茶业有限公司

Peeling and seed taking mechanism in snakegourd fruit processing production line

InactiveCN109549218AQuick and fully automatic peelingFast and fully automatic processingFruit stoningVegetable peelingProduction lineEngineering

The invention provides a peeling and seed taking mechanism in a snakegourd fruit processing production line, and belongs to the technical field of machines. The peeling and seed taking mechanism in snakegourd fruit processing production line comprises a machine frame, wherein a delivery tank for transporting processed snakegourd fruits out is fixedly arranged on the machine frame; the peeling andseed taking mechanism comprises a temporary storage box; the delivery tank is fixedly arranged on the machine frame, and is located below the peeling and seed taking mechanism; the peeling and seed taking mechanism also comprises a third drum, a fourth drum and a conveyer belt II; the third drum and the fourth drum are rotatably arranged on the machine frame; the conveyer belt II is arranged on the first drum and the fourth drum in a sleeving manner; the third drum is driven by a fifth motor to rotate; a plurality of material taking plates are arranged on the conveyer belt II in the equal distance; every two adjacent material taking plates form a placing region of the snakegourd fruits; and the material taking plates can extend into the temporary storage box. The peeling and seed taking mechanism disclosed by the invention has the advantage of being high in peeling and seed taking efficiency of the snakegourd fruits.

Owner:安徽省怡果生态科技有限公司

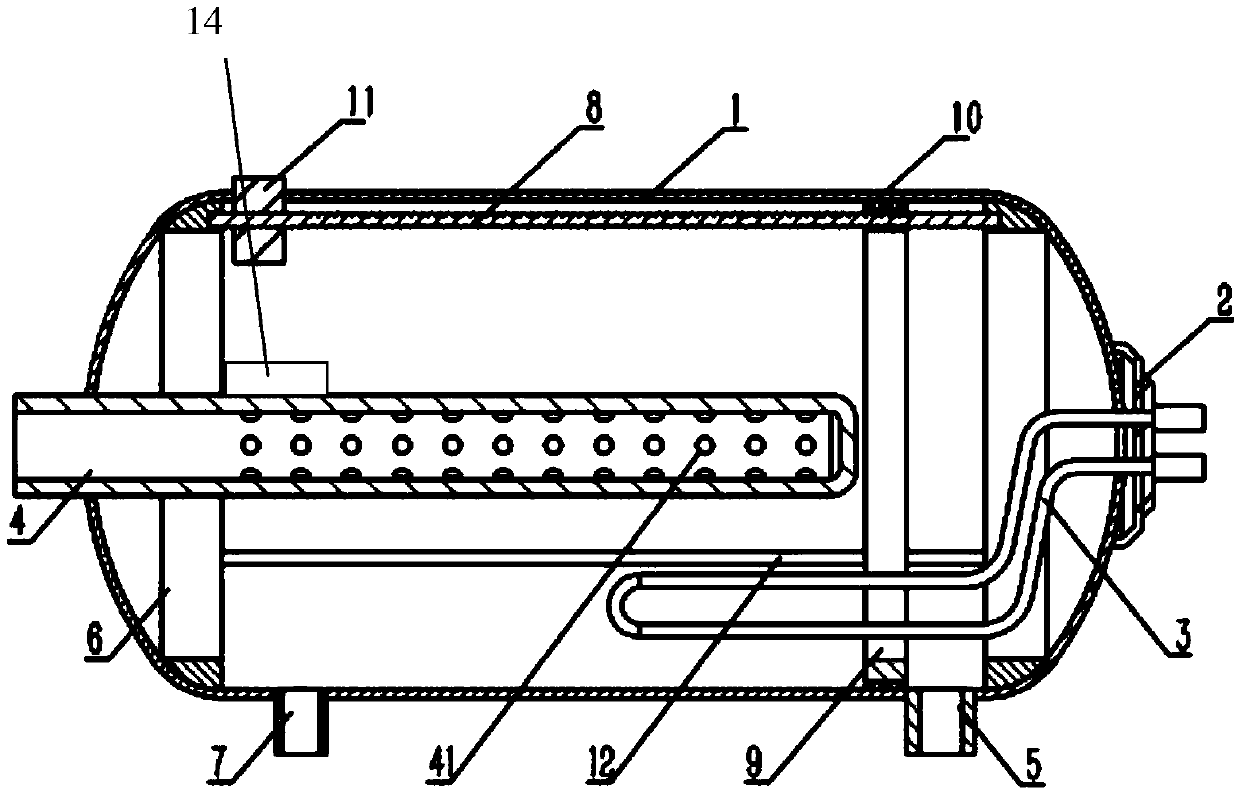

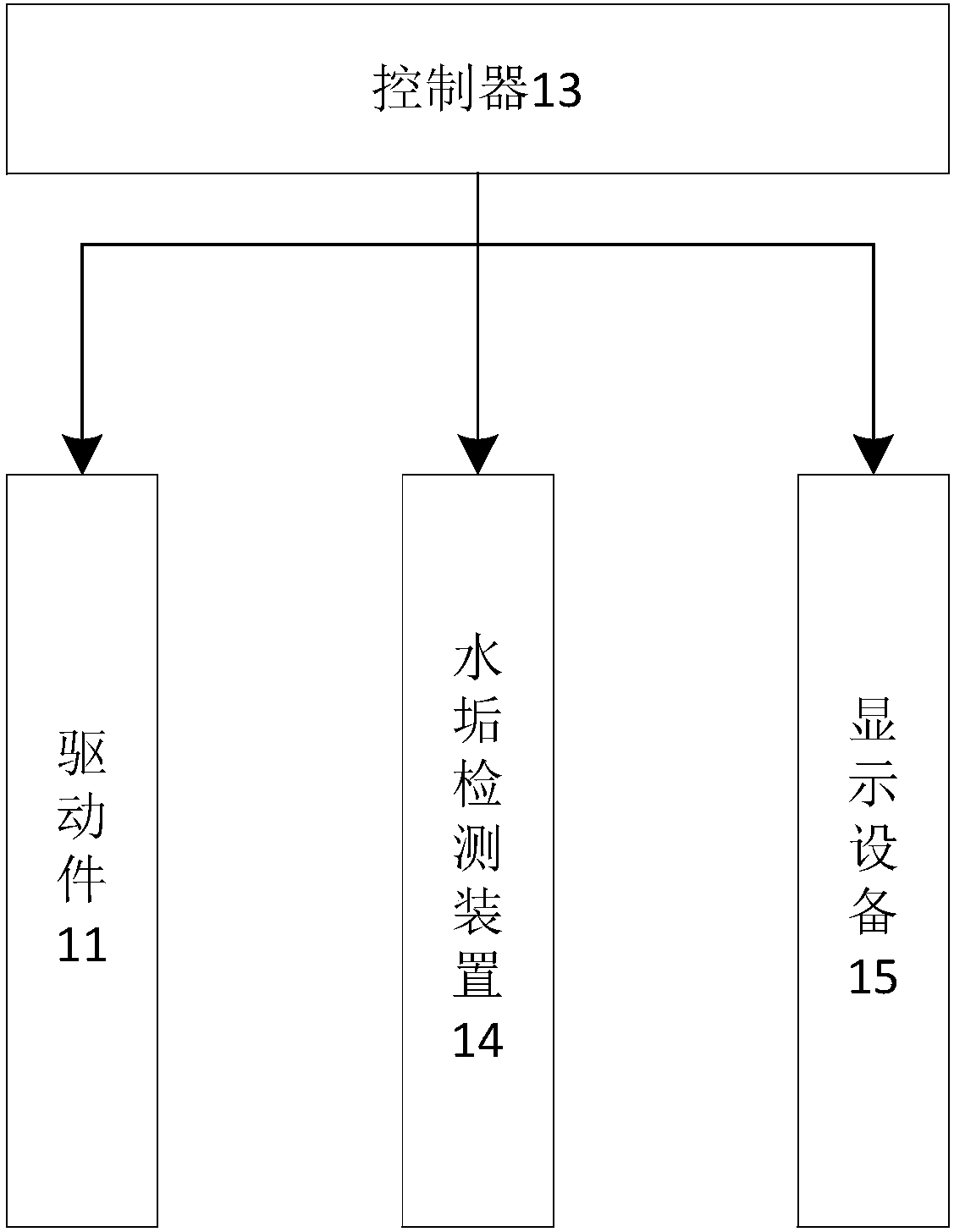

Water heater capable of automatically removing water scale and scale removal method

The invention provides a water heater comprising a water storage liner. A heating pipe is arranged in the water storage liner; a water inlet pipe with one end being closed is fixed to the other end ofthe water storage liner, and the closed end of the water inlet pipe is located in the water storage liner; water injection holes penetrating through the pipe wall of the water inlet pipe are formed in the position, in the water storage liner, of the outer wall of the water inlet pipe; an annular movable retainer ring is connected to a lead screw in a threaded mode; a plurality of flexible scrapers are fixed to the outer side wall of the movable retainer ring and abut against the inner side wall of the water storage liner in a pressed mode; a driving piece is fixed to one end of the lead screw; a sewage discharging pipe is fixed to the lower end of the water storage liner; the driving piece drives the lead screw under control of a controller to rotate; a water scale detection device is further arranged in the water storage liner and connected with the controller for detecting the thickness of water scale in the water storage liner in real time.

Owner:巨浪(苏州)热水器有限公司

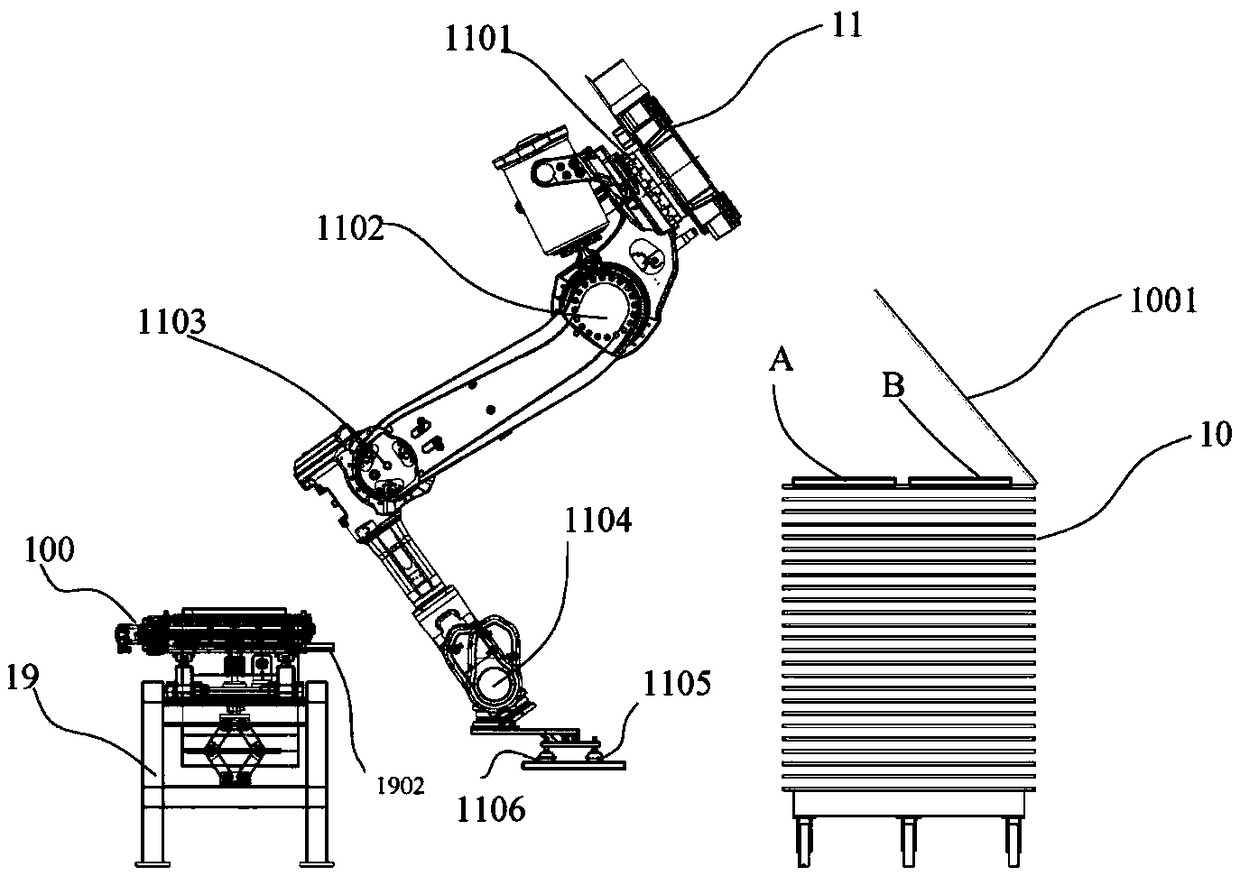

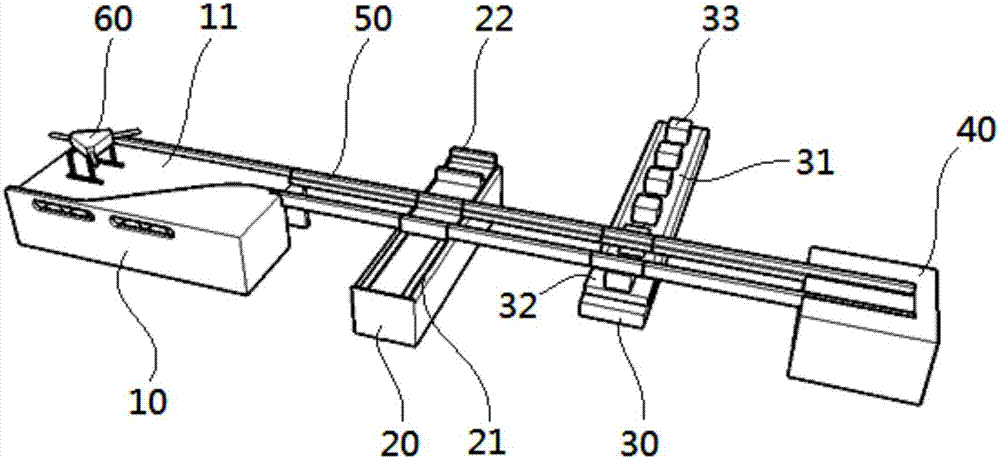

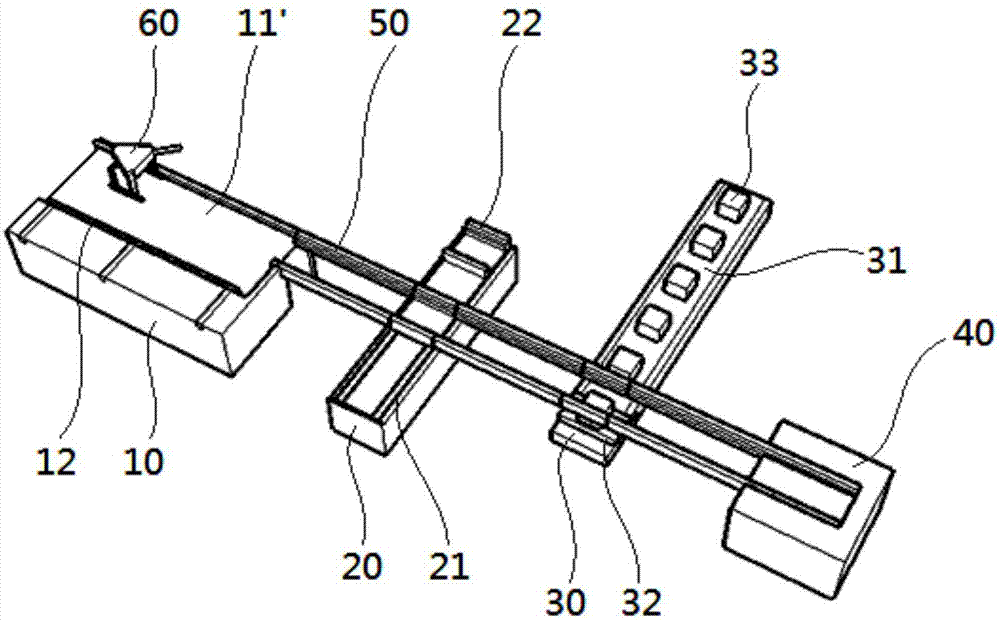

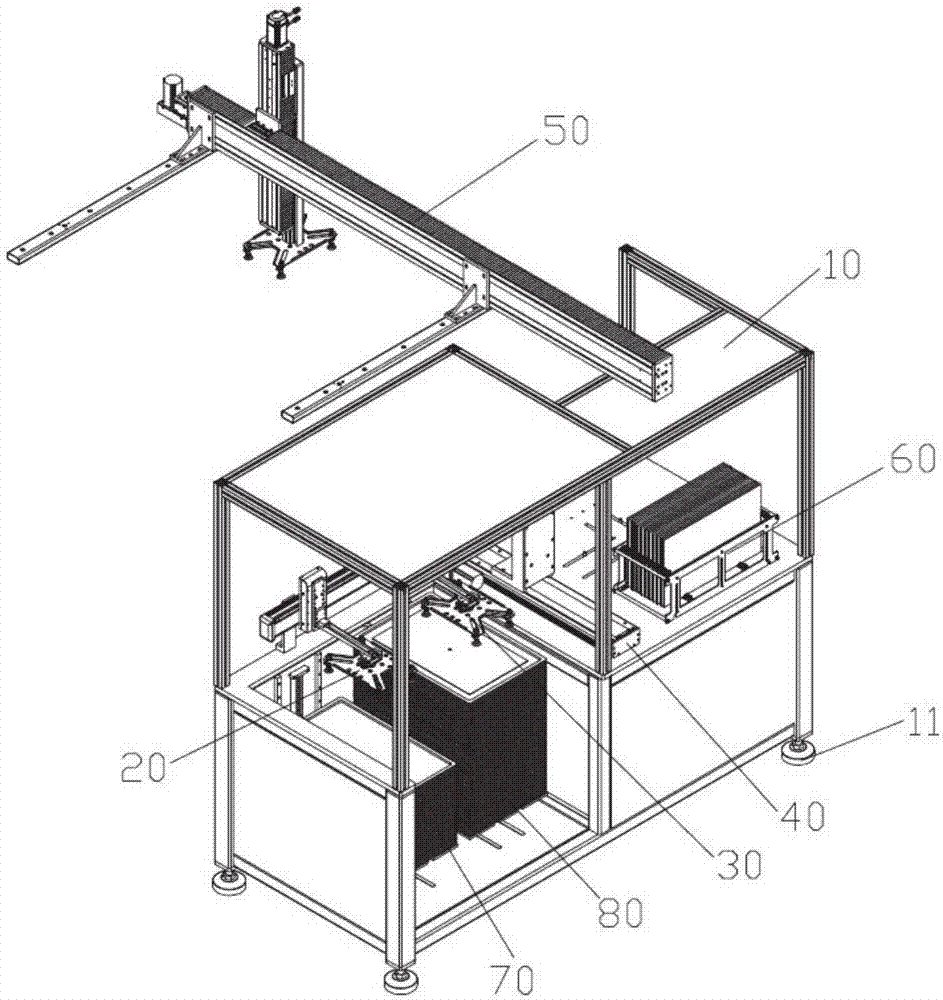

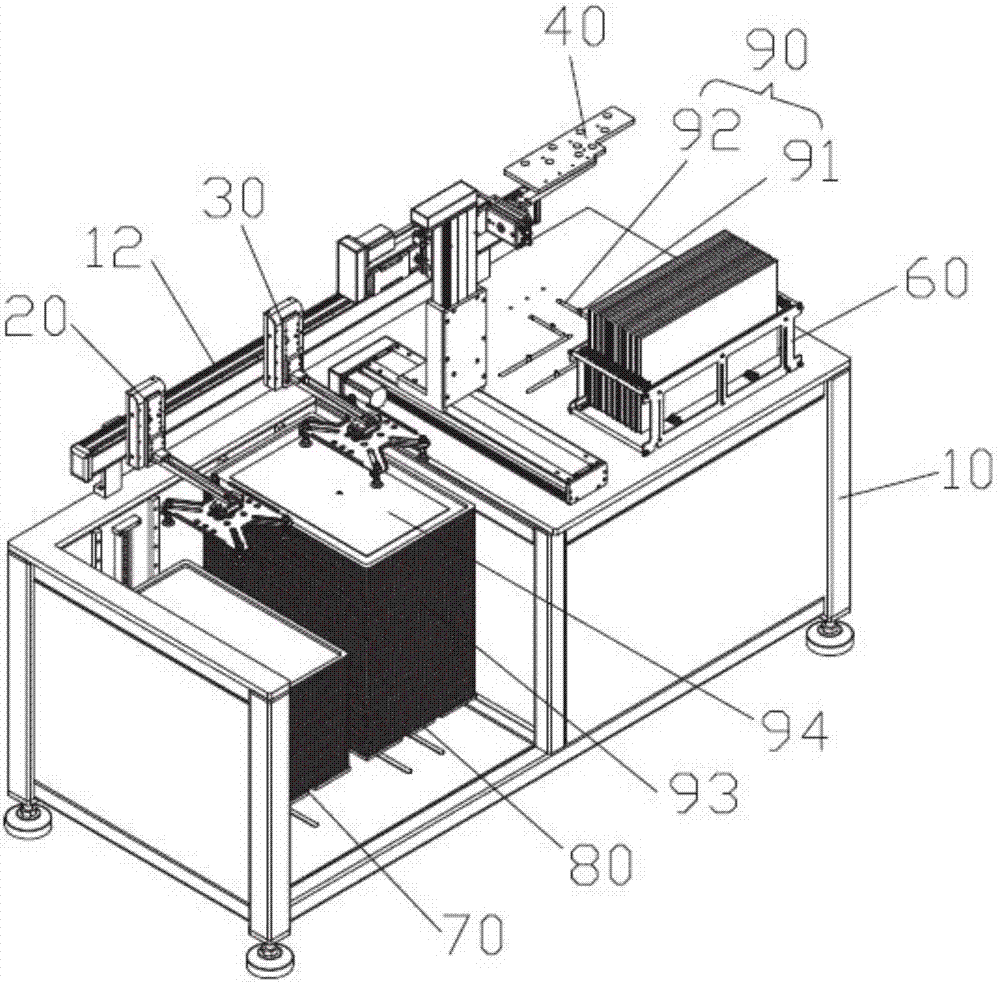

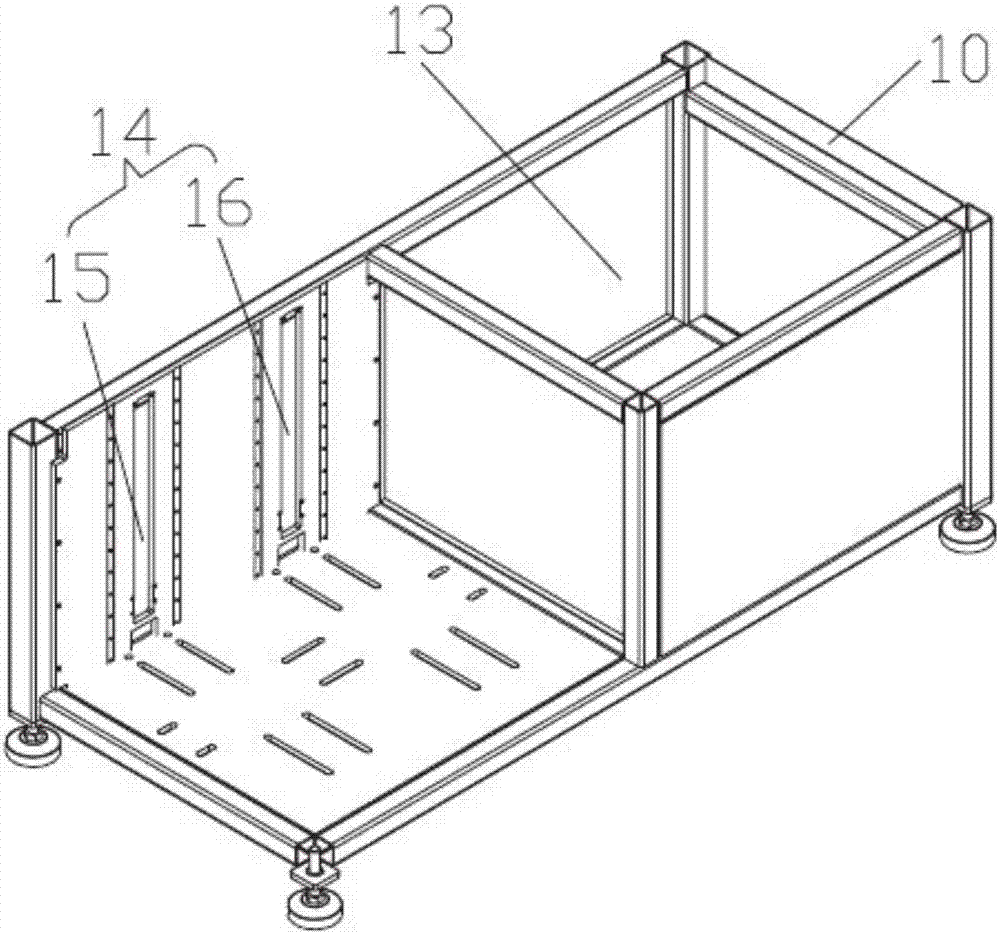

Unmanned aerial vehicle ground management system

The invention relates to an unmanned aerial vehicle ground management system comprising a landing platform (10), a ground service platform, a launching platform (40) and a first guide rail (50), wherein the first guide rail is used for connecting the landing platform, the ground service platform and the launching platform, so as to ensure that an unmanned aerial vehicle (60) moves along the first guide rail to the ground service platform to receive ground services after landing on the landing platform, and moves along the first guide rail to the launching platform to be ready to take off after receiving the ground services. According to the invention, by setting the first guide rail, the unmanned aerial vehicle can sequentially receive various services in the ground service platform along the first guide rail after landing on the landing platform, and reach the launching platform at last to get ready to take off; the first guide rail can guide a series of actions of the unmanned aerial vehicle on the ground; and the system can achieve high-degree automation, and autonomous operation in a whole course, and does not need manpower, so that the system can not only save the manpower, but also improve the efficiency and reduce the management cost, and is suitable for promotion and application.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Panel polishing device for square reading bookshelf production

InactiveCN111098217AAchieve contactAchieve separationGrinding carriagesPolishing machinesHydraulic cylinderPiston rod

The invention discloses a panel polishing device for square reading bookshelf production. The panel polishing device comprises a mounting frame, a hydraulic cylinder is fixed to one side of the mounting frame, a mounting box is fixed to the end of a piston rod of the hydraulic cylinder, the mounting box is slidably connected with the bottom end of the mounting frame through a linear rail, and a supporting mechanism is arranged on the mounting box; a first fixing block is fixed to one side of the top end of the mounting box, a steering mechanism is arranged on the first fixing block, a first clamping plate is arranged on the steering mechanism, and a second fixing block is fixed to the side, away from the first fixing block, of the mounting box; a jacking mechanism is arranged at the upperend of the second fixing block, and a second clamping plate is arranged on the jacking mechanism; and a panel is clamped between the first clamping plate and the second clamping plate, a supporting frame is fixed to the two sides of the middle of the mounting frame, a lifting mechanism is arranged on the supporting frame, a first servo motor is arranged on the lifting mechanism, and a grinding roller is fixed to an output shaft of the first servo motor. The panel polishing device has the advantages that automatic overturning and automatic polishing are achieved, and the working efficiency is high.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

Cone yarn fetching delivery wagon

PendingCN104843547AImprove production and transportation efficiencyLabor savingFilament handlingYarnEngineering

The invention discloses a cone yarn fetching delivery wagon. The cone yarn fetching delivery wagon comprises a rail, a driving device, a conveying mechanism, cone yarn holders, a marking card and a sensing identifying device; the rail crosses through the position where a cone yarn production process and a packaging process locate; the conveying mechanism is moved and positioned on the rail along the extending direction of the rail, and the driving device drives the conveying mechanism to move; several cone yarn holders are installed on the conveying mechanism, a holding space for stopping and storing the cone yarn is formed on the cone yarn holders; the marking card is installed on the cone yarn holder, and a mark corresponding to the cone yarn held by the cone yarn holders is arranged on the marking card; the sensing identifying device can identify the mark on the marking card and send it to a controller; the controller controls the movement of the driving device. The cone yarn fetching delivery wagon realizes the automatic conveying, variety identification, classified storage, and full-automatic operation of the cone yarn; besides, the cone yarn fetching delivery wagon improves the production and conveying efficiency, saves labor work, and avoids the classifying mistake.

Owner:苏州智尊智能科技有限公司

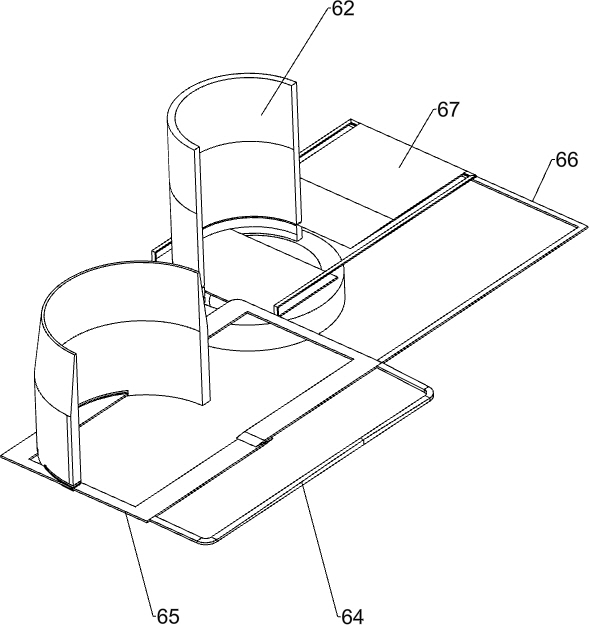

Automatic film-coating and edge-covering device

The invention discloses an automatic film-coating and edge-covering device. The automatic film-coating and edge-covering device comprises a rack with an installation plate, a cylinder fixed to the installation plate, a lower lifting plate connected with the output shaft of the cylinder, and an edge-covering mechanism and a shell-pressing mechanism which are connected with the lower lifting plate, wherein the edge-covering mechanism comprises a fixed frame connected with the lower lifting plate and four edge-pressing assemblies installed on the fixed frame; the fixed frame is provided with a mobile phone shell placement cavity; the edge-pressing assemblies are located at the four sides of the mobile phone shell placement cavity respectively; the shell-pressing mechanism comprises an upper lifting plate located at one side away from the lower lifting plate, of the installation plate, a shell-pressing element located in the mobile phone shell placement cavity, a plurality of slide rod assemblies connected with the upper lifting plate and the shell-pressing element, and a plurality of push rods connected with the upper lifting plate and the lower lifting plate; each slide rod assembly comprises a slide rod, an elastic element arranged on the slide rod in a sleeving manner, and a stop block located at one side away from the installation plate, of the upper lifting plate; and one end of each slide rod is connected with a press plate, and the other end of the slide rod penetrates through the upper lifting plate and then is connected with the corresponding stop block. The automatic film-coating and edge-covering device disclosed by the invention realizes simultaneous automatic edge-covering for the four edge parts of a mobile phone shell.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD +1

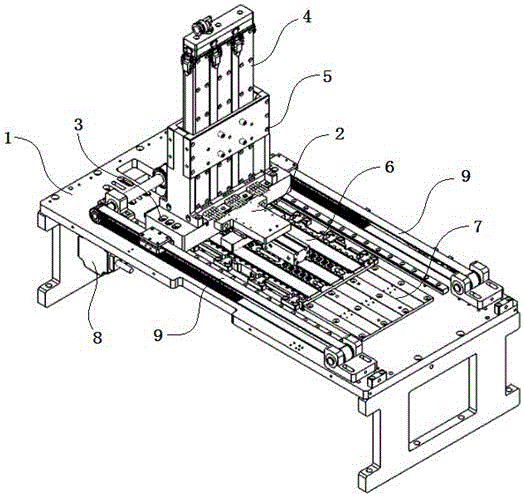

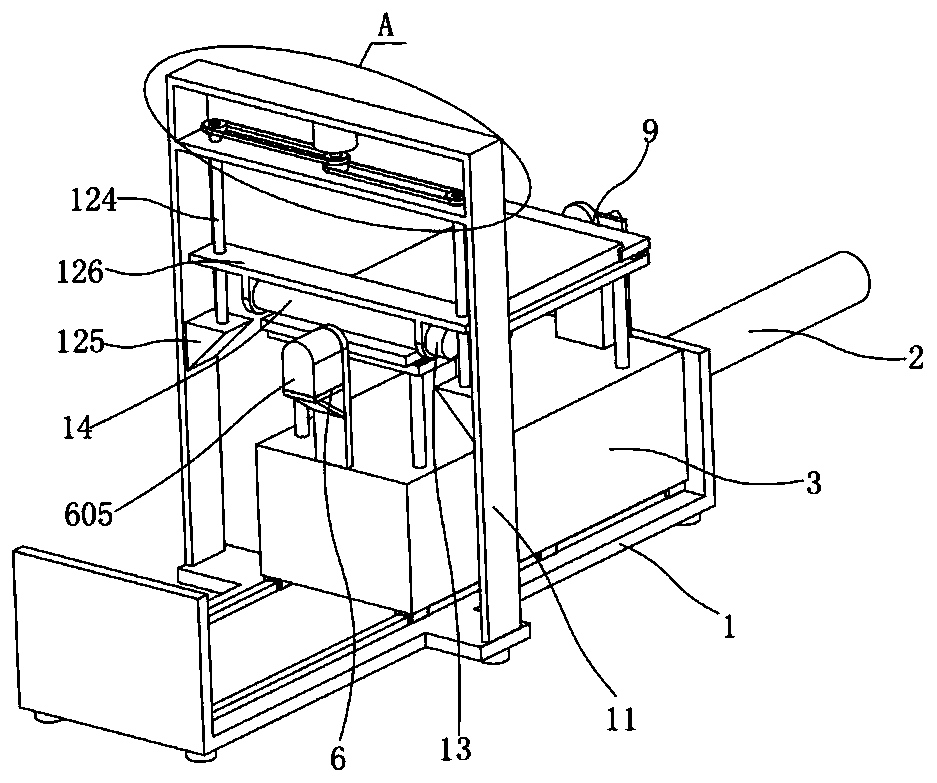

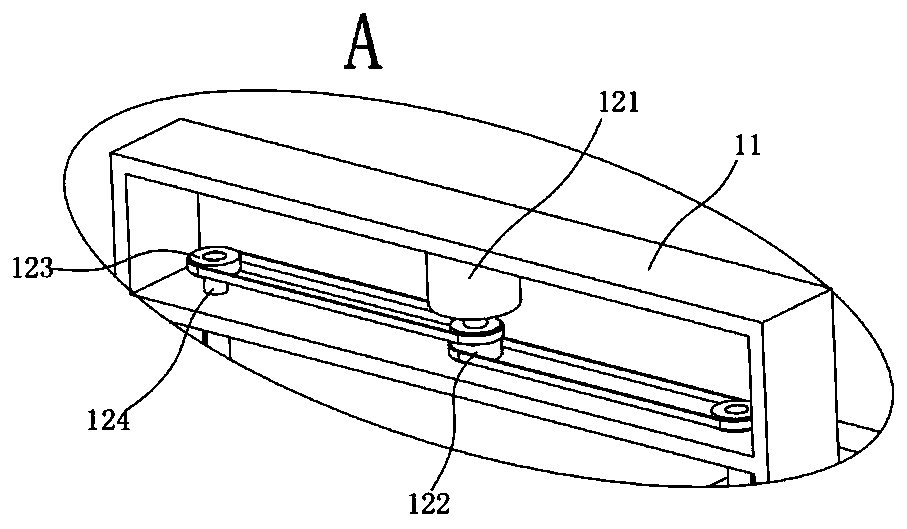

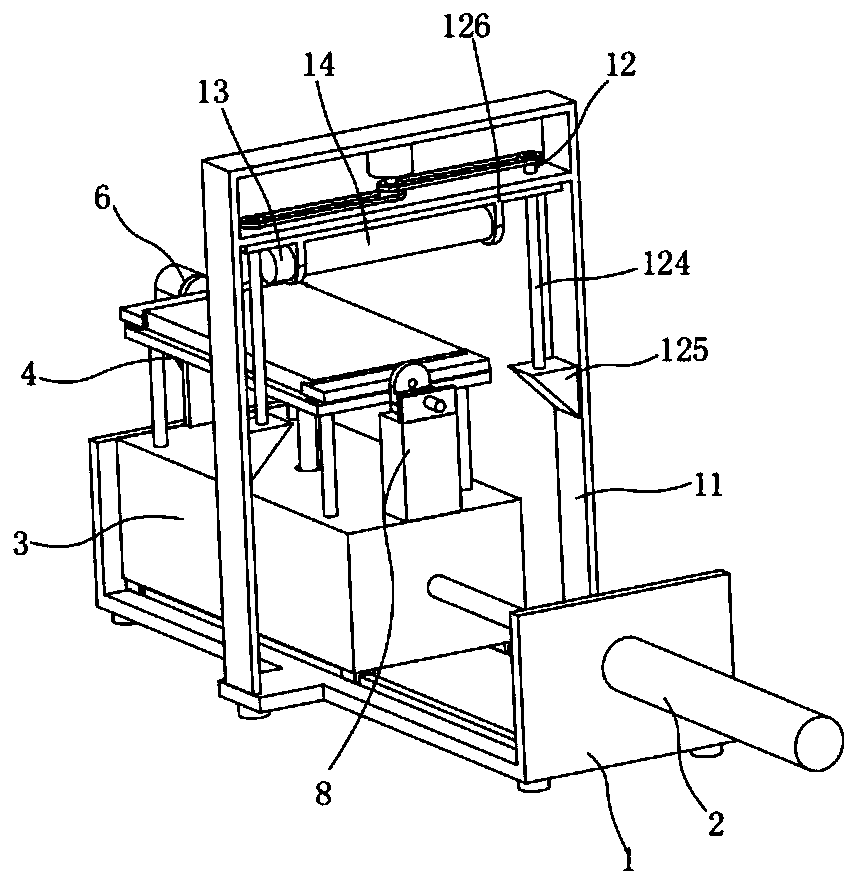

Automatic material loading equipment

PendingCN106976342APrecise loading and unloadingNo manualOther artistic work equipmentsManipulatorMachineManipulator

The invention discloses automatic material loading equipment. The automatic material loading equipment comprises a machine frame, a recycling manipulator, a positioning manipulator, a finished product manipulator and a material loading manipulator which is connected with a precise engraving machine; a positioning area is formed on the machine frame; after a workpiece on a material box is transferred to the positioning area by the positioning manipulator, the material box is taken away by the recycling manipulator; the workpiece is moved to the precise engraving machine for machining by the material loading manipulator; the workpiece which is machined on the material loading manipulator is taken out by the finished product manipulator. After the technical scheme is adopted, precise loading and unloading are realized without manpower, the labour cost is greatly reduced, and the automatic material loading equipment is suitable for batch production because the recycling manipulator, the positioning manipulator, the finished product manipulator and the material loading manipulator are arranged on the equipment.

Owner:深圳市宇瀚智慧装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com