Egg tart making device

A technology for making devices and egg tarts, which is applied in baking, dough processing, food science, etc., can solve the problems of frequent manual operations, and achieve the effect of reducing manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

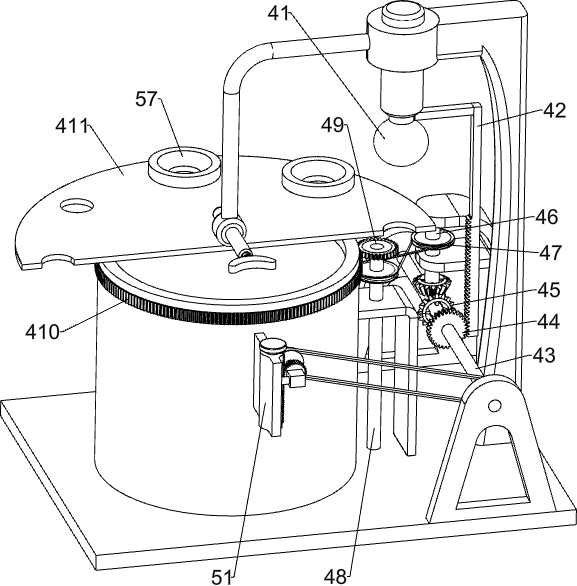

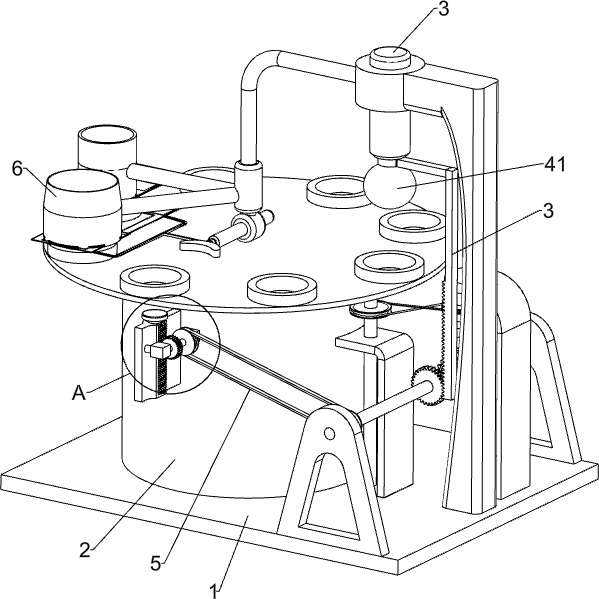

[0036] A kind of egg tart making device, such as figure 1 As shown, it includes a frame 1, a support cylinder 2, a first cylinder 3, a rotating mechanism 4 and a discharge mechanism 5. The bottom wall of the frame 1 is provided with a support cylinder 2, and the top of the frame 1 is provided with a first cylinder 3. A rotating mechanism 4 is arranged between the bottom wall of the frame 1, the support cylinder 2 and the first cylinder 3, and a discharge mechanism 5 is installed between the front side of the support cylinder 2 and the upper part of the frame 1, and the discharge mechanism 5 is connected with the rotation mechanism 4 .

[0037] When it is necessary to make egg tarts, the small disc and the dough are manually placed in the parts of the discharge mechanism 5, so that the small disc and the dough are located directly below the first cylinder 3, and then the telescopic rod of the first cylinder 3 is controlled to extend downward. Long, the parts of the rotating me...

Embodiment 2

[0039] Specifically, such as Figure 2-3 As shown, the rotating mechanism 4 includes a circular pressing block 41, an L-shaped rack 42, a first rotating shaft 43, a first gear 44, a straight bevel gear 45, a second rotating shaft 46, a reverse transmission device 47, and a third rotating shaft 48 , the first one-way gear 49, the second gear 410 and the rotating disk 411, the bottom of the telescopic rod of the first cylinder 3 is connected with a circular briquetting block 41, the bottom of the telescopic rod of the first cylinder 3 is provided with an L-shaped rack 42, and the frame 1 The right side of the bottom wall is rotatably provided with a first rotating shaft 43, the middle part of the first rotating shaft 43 is equipped with a first gear 44, the first gear 44 meshes with the L-shaped rack 42, and the right rear side of the frame 1 bottom wall is rotatably installed with The second rotating shaft 46, the second rotating shaft 46 bottom and the first rotating shaft 43 ...

Embodiment 3

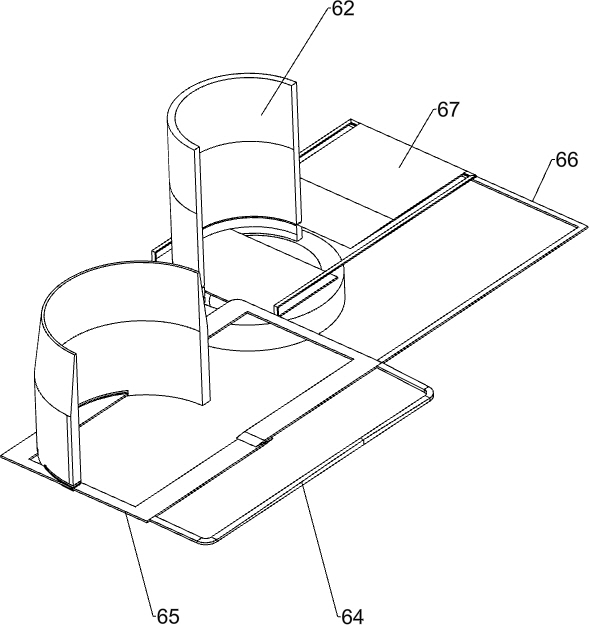

[0044] according to Figure 4-6 As shown, also includes a blanking mechanism 6, the blanking mechanism 6 includes a V-shaped connecting rod 61, a blanking frame 62, a first connecting rod 63, a U-shaped connecting rod 64, a first separating piece 65, a special-shaped connecting rod 66 and The second separating piece 67, the V-shaped connecting rod 61 is installed on the lower part of the L-shaped connecting rod 58, the end of the V-shaped connecting rod 61 is connected with the blanking frame 62, and the left part of the front side of the arc-shaped push rod 510 is provided with the first connecting rod 63 , the end of the first connecting rod 63 is provided with a U-shaped connecting rod 64, the left side of the U-shaped connecting rod 64 is equipped with a first separating piece 65, the rear side of the first separating piece 65 is provided with a special-shaped connecting rod 66, and the left side of the special-shaped connecting rod 66 A second separating sheet 67 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com