Patents

Literature

84results about How to "Implement automatic placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

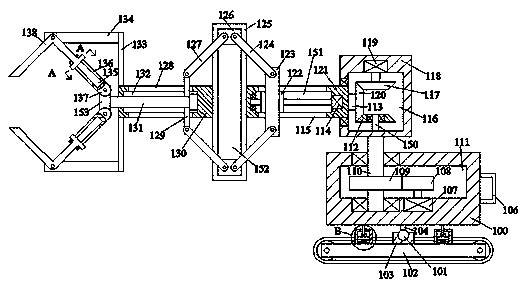

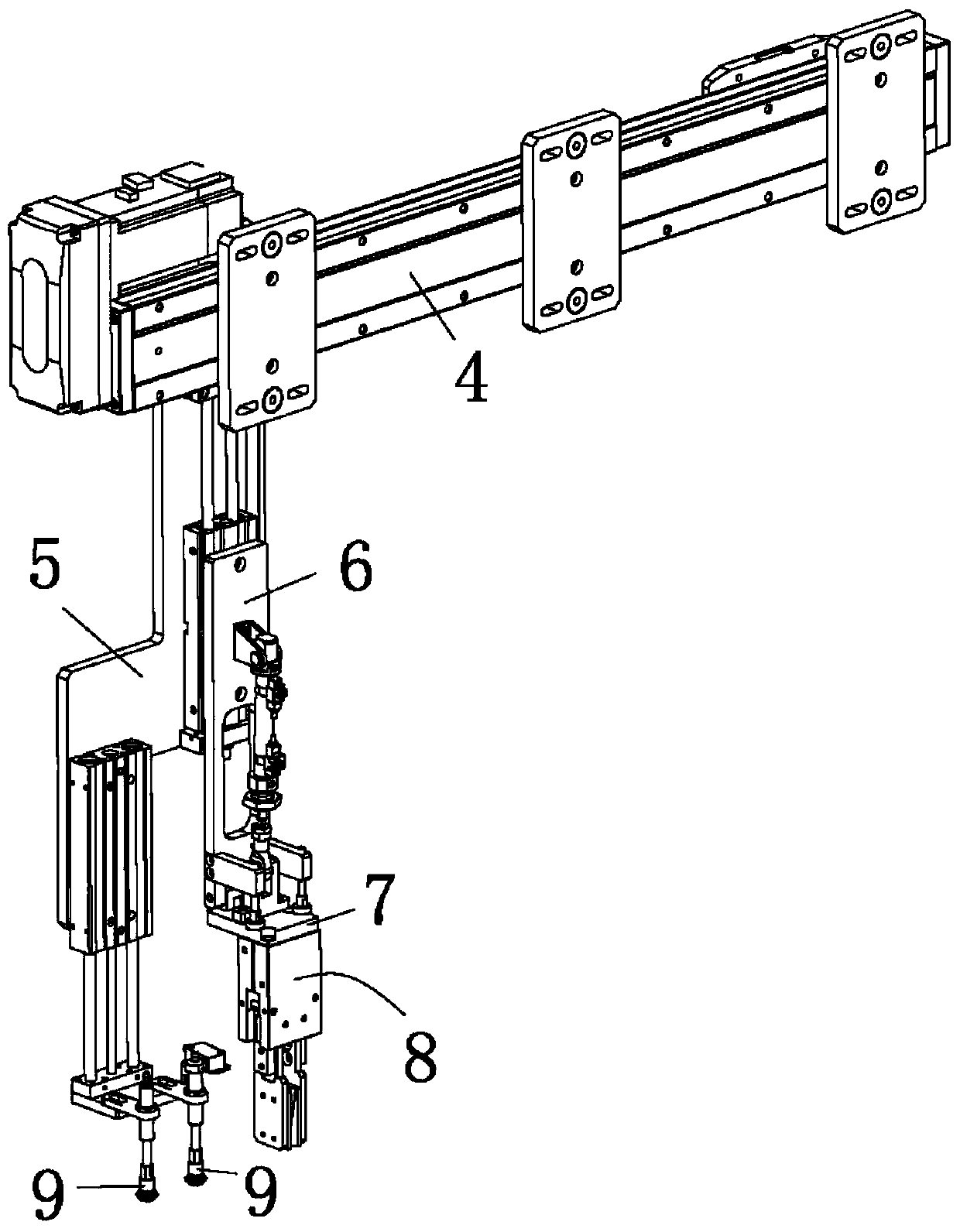

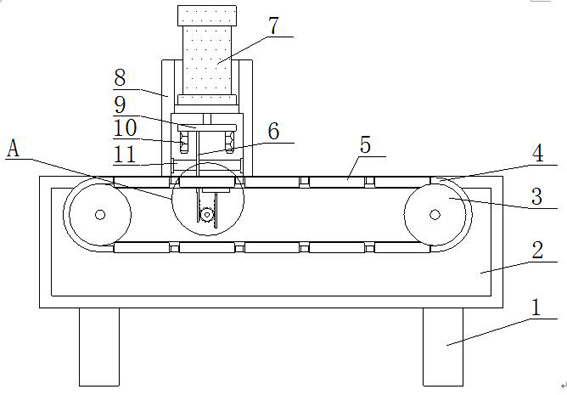

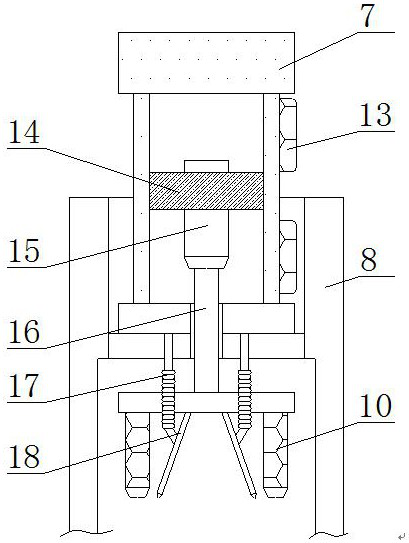

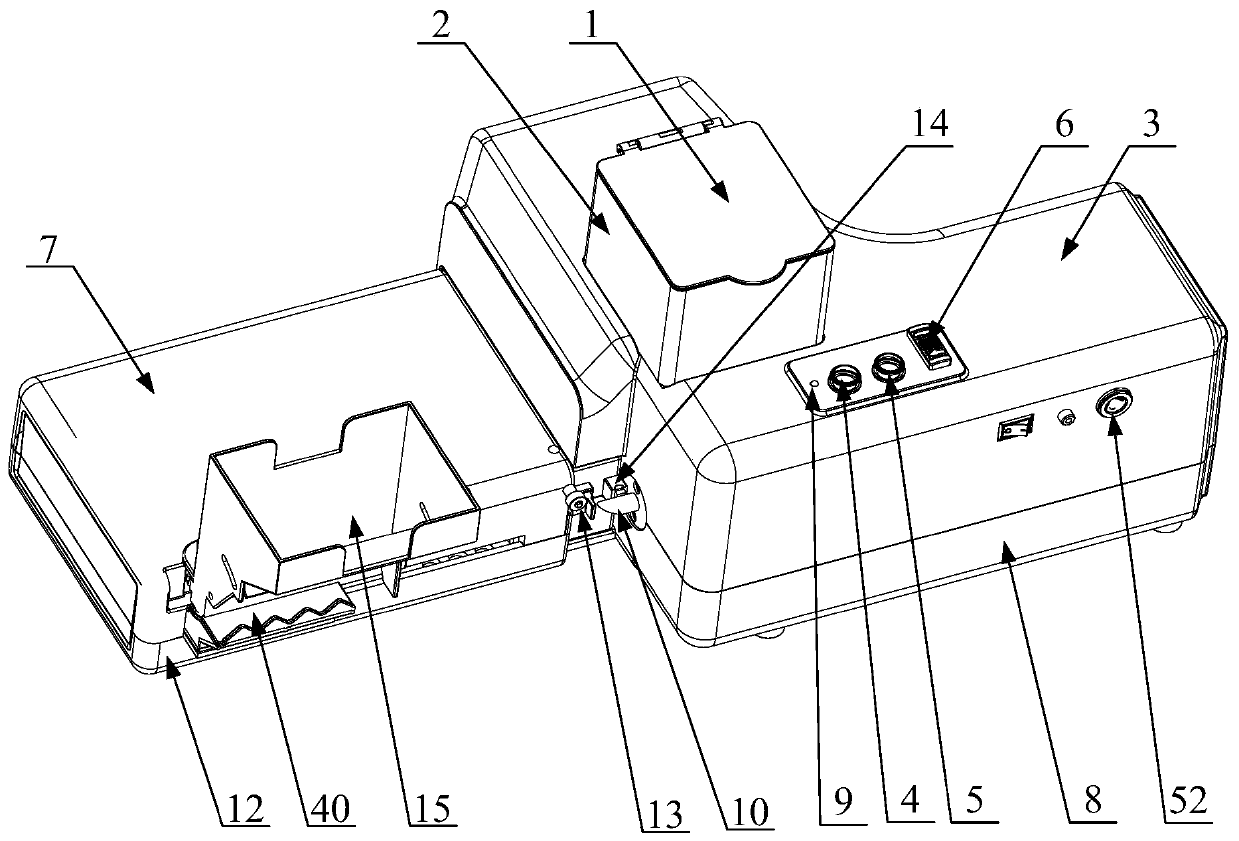

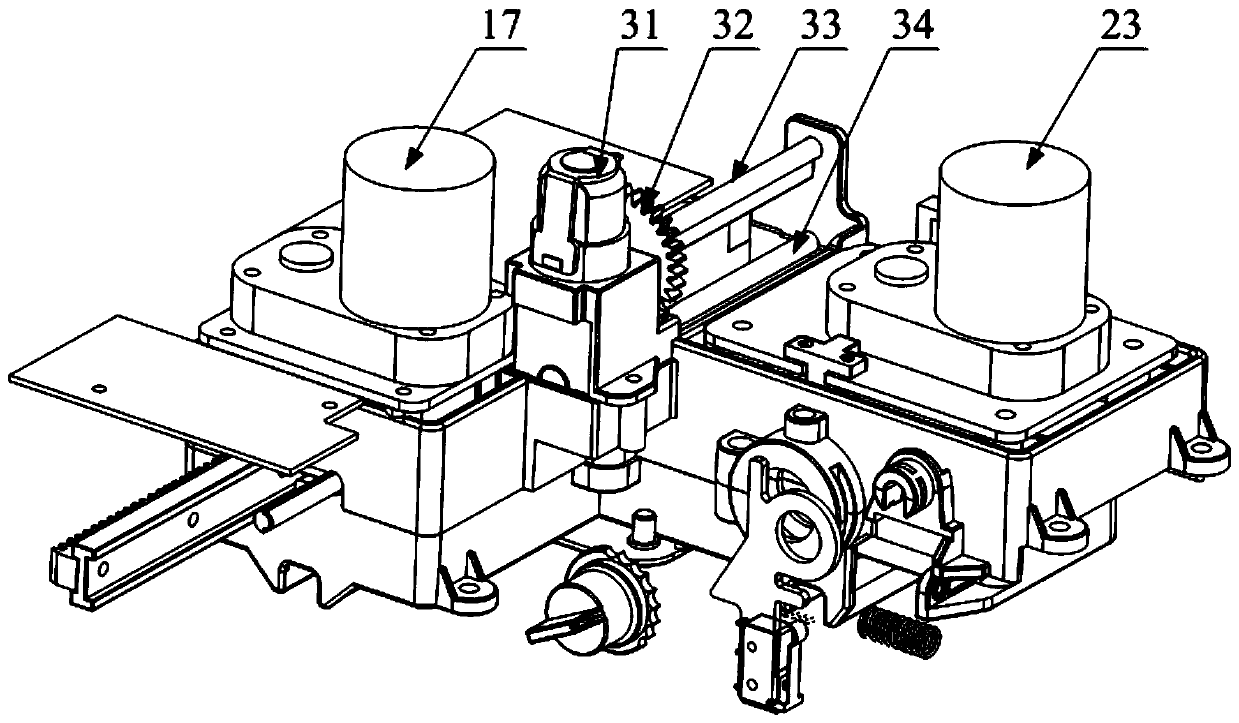

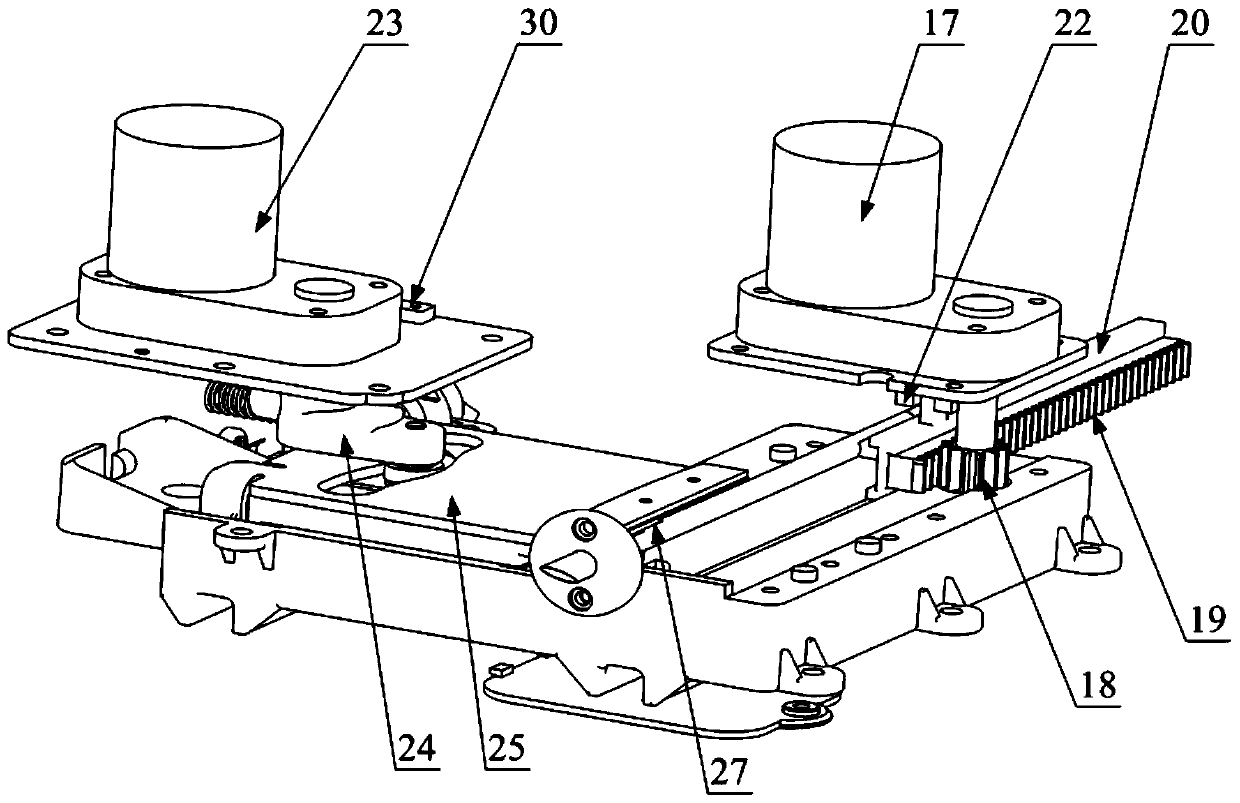

Assembly machine of breathable covers of disposable cell culture flasks

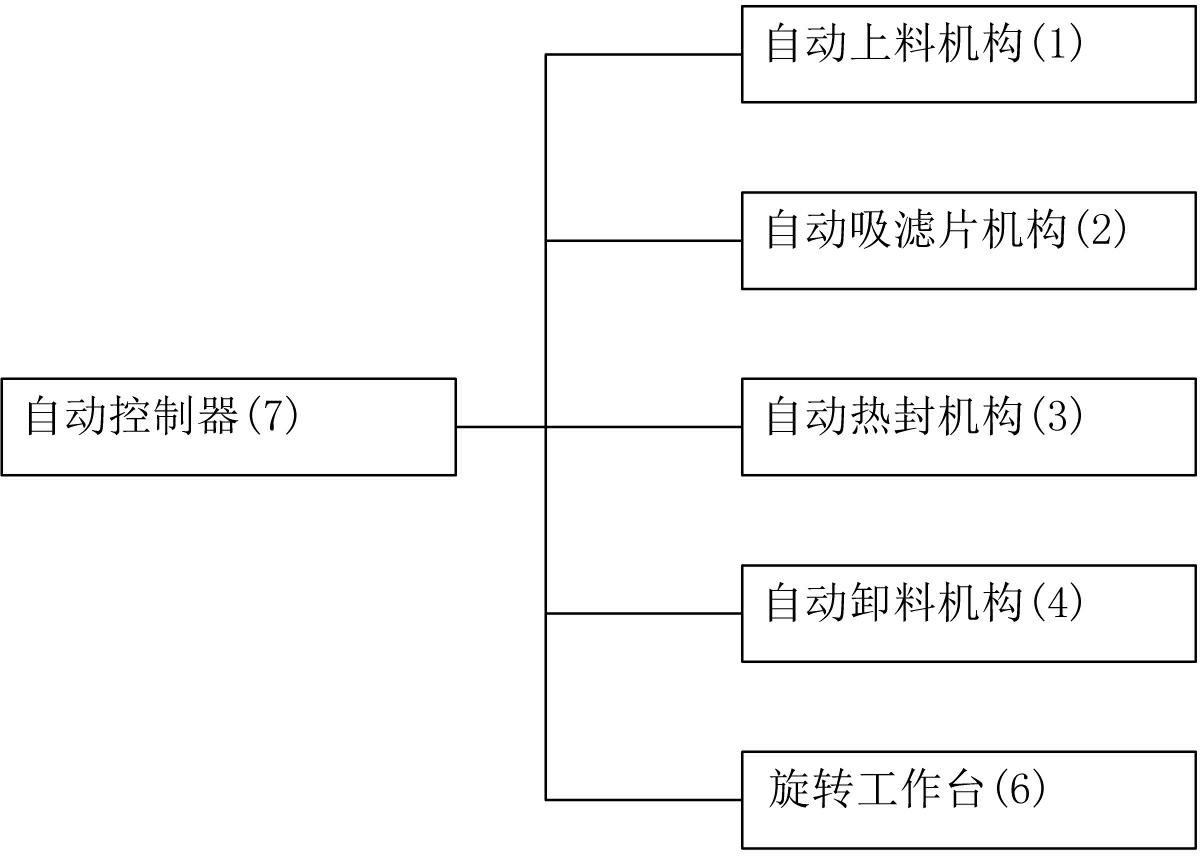

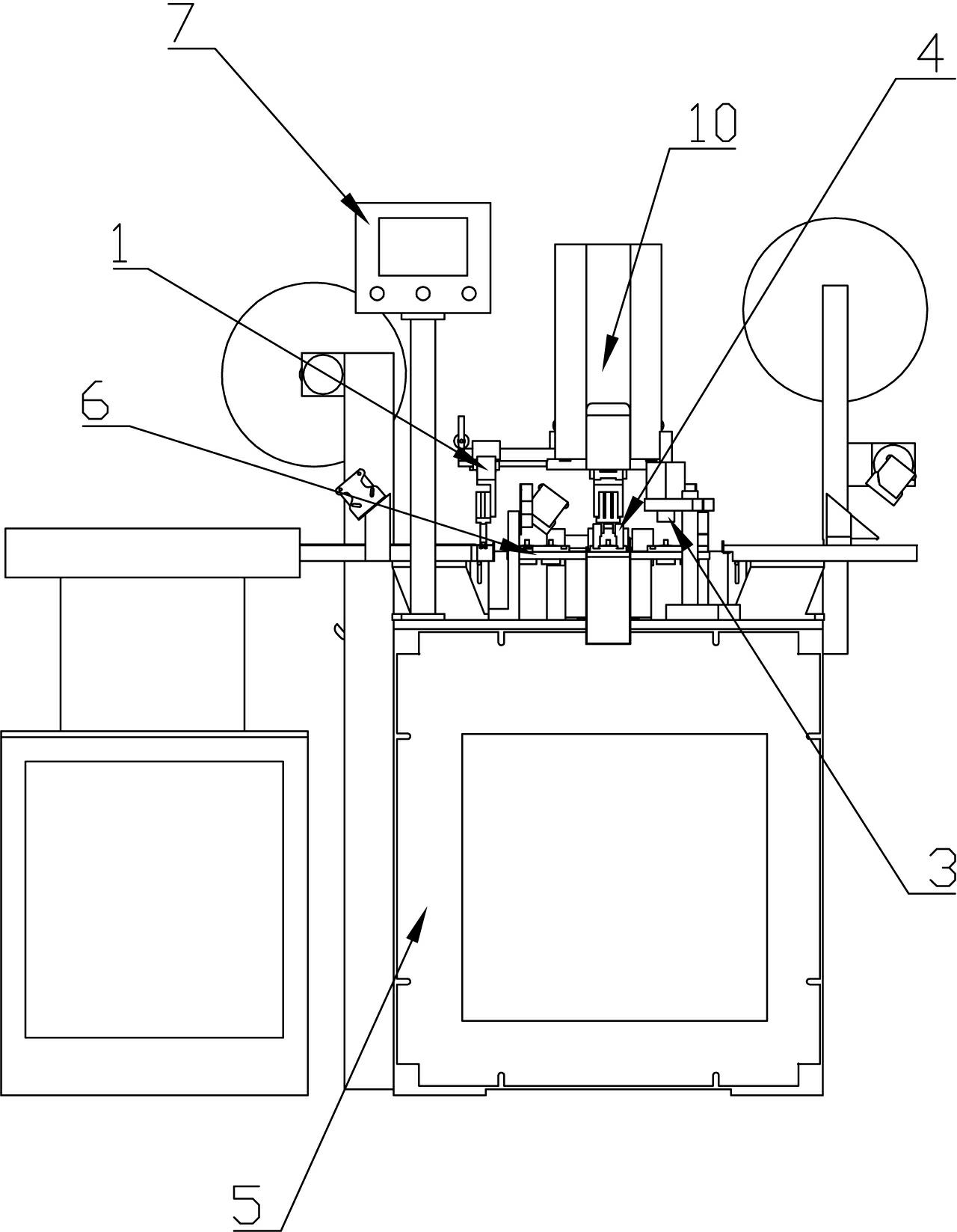

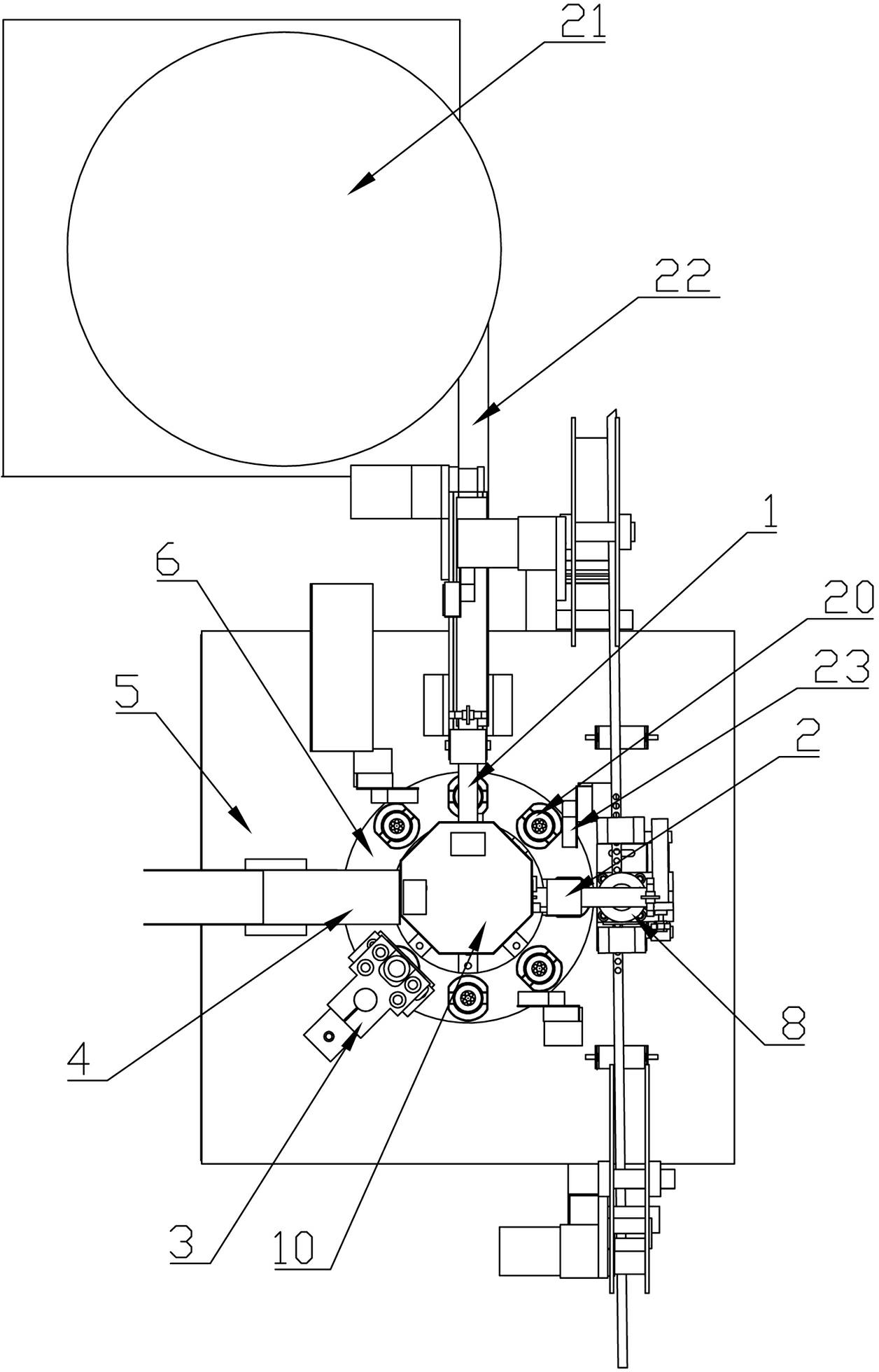

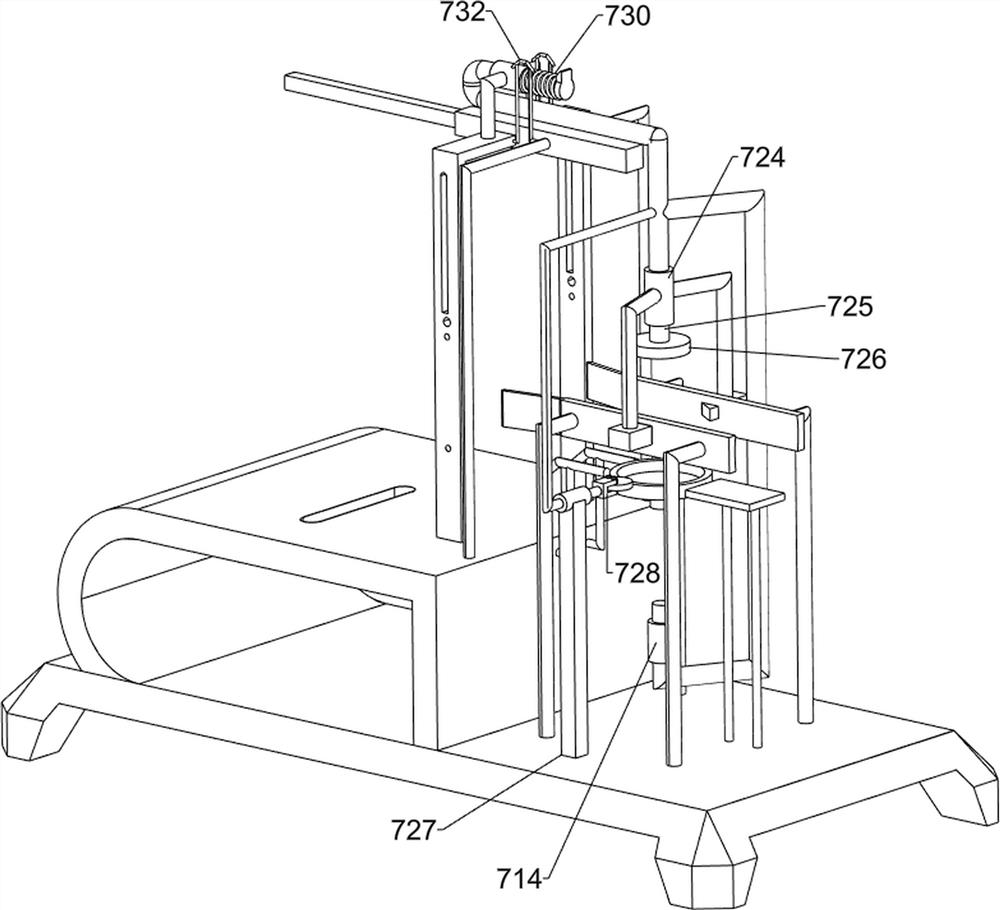

ActiveCN102528449AImplement automatic placementRealization of automatic heat sealingBiochemistry apparatusAssembly machinesAssembly machineAutomatic controller

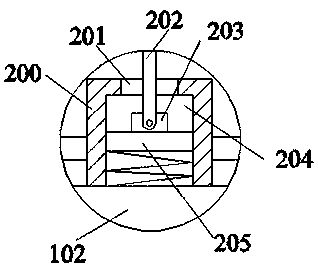

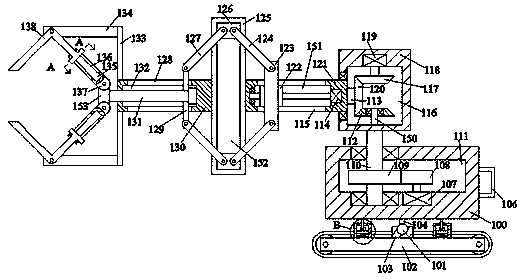

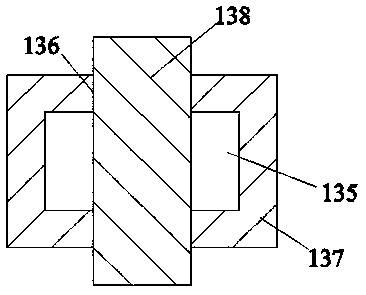

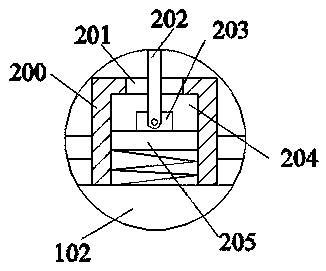

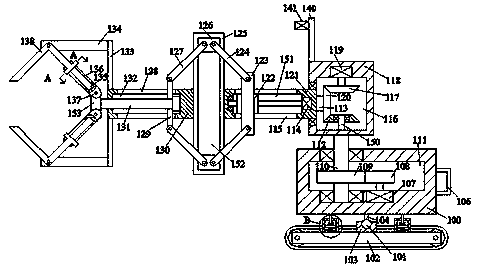

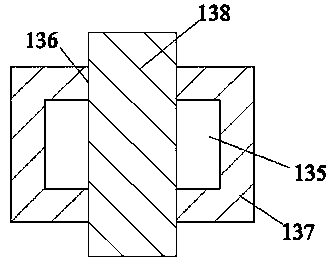

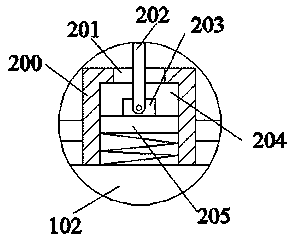

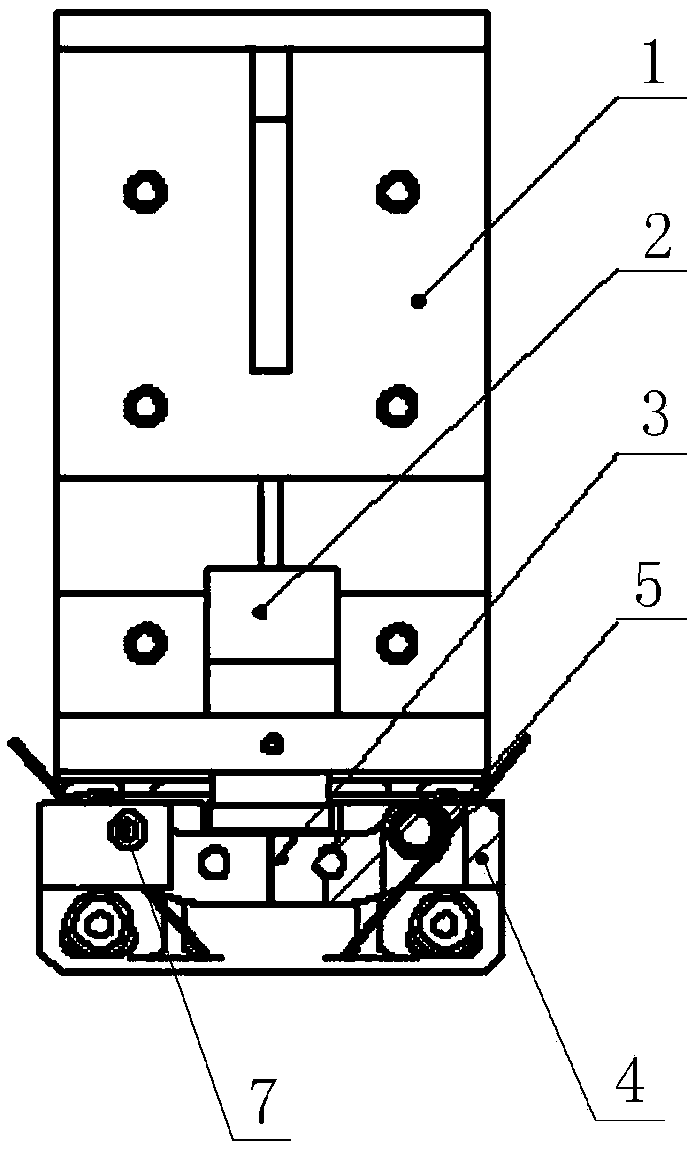

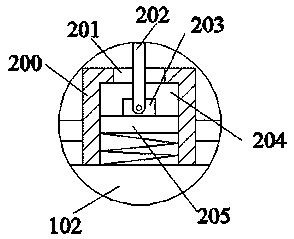

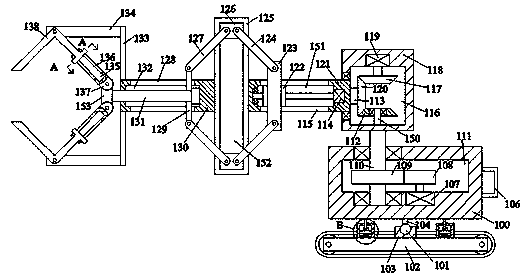

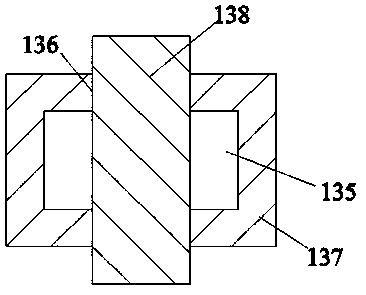

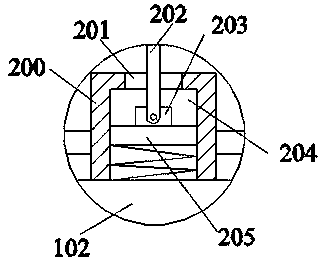

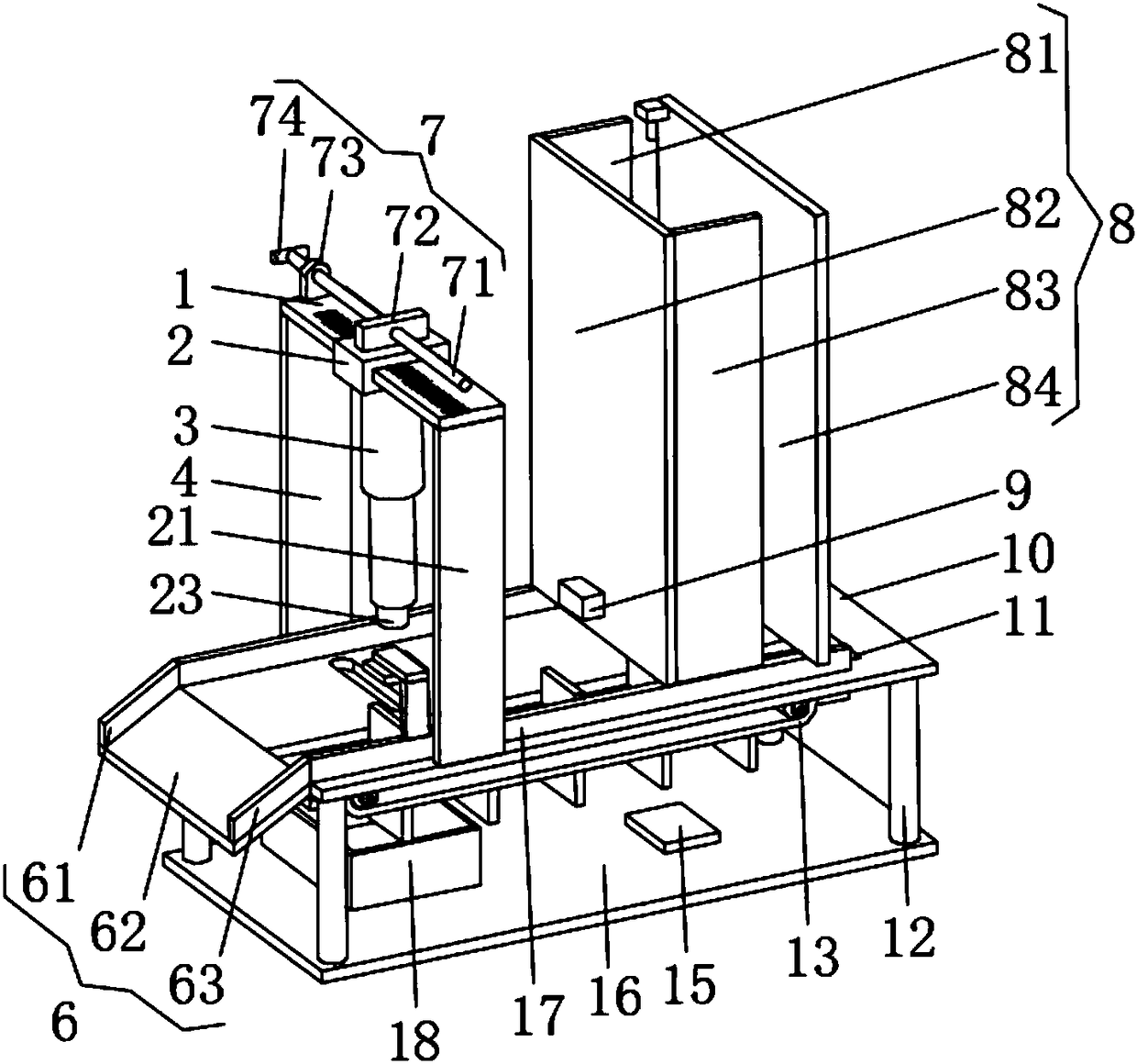

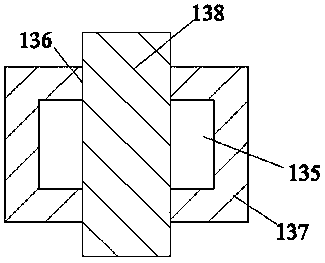

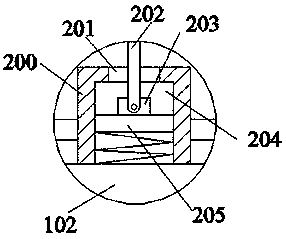

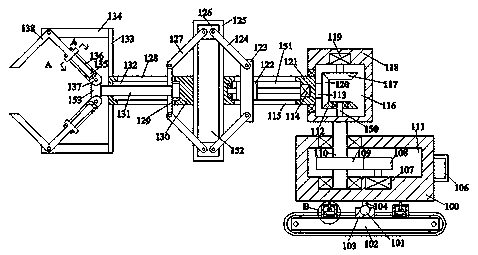

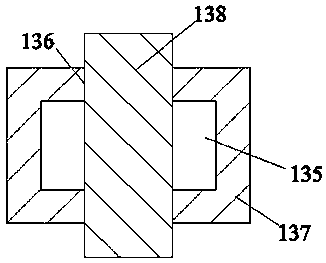

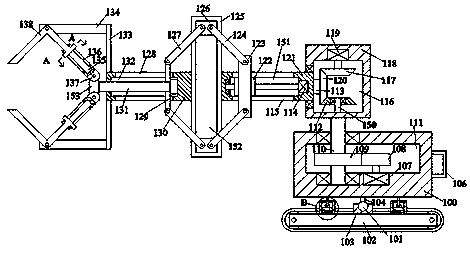

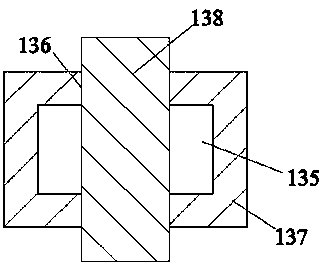

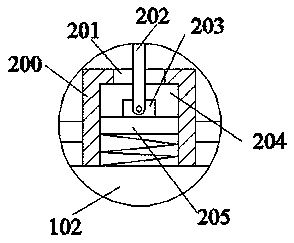

The invention discloses an assembly machine of breathable covers of disposable cell culture flasks, which comprises a bracket, an automatic controller and a rotary workbench, wherein the automatic controller and the rotary workbench are arranged on the bracket; an automatic feeding mechanism, an automatic filter-disc adsorbing mechanism, an automatic heat-sealing mechanism and an automatic discharging mechanism are arranged above the rotary workbench; and the automatic controller is electrically connected with the rotary workbench, and the automatic feeding mechanism, the automatic filter-disc adsorbing mechanism, the automatic heat-sealing mechanism and the automatic discharging mechanism arranged above the rotary workbench. The assembly machine can realize automatic feeding, automatic placing of filter discs of the breathable covers of the disposable cell culture flasks and automatic heat-sealing of the breathable covers of the disposable cell culture flasks and the filter discs and realize automatic production of the breathable covers of the disposable cell culture flasks through the automatic feeding mechanism, the automatic filter-disc adsorbing mechanism, the automatic heat-sealing mechanism, the automatic discharging mechanism and the automatic controller. The assembly machine is suitable for the automatic production of the breathable covers of the disposable cell culture flasks.

Owner:GUANGZHOU JET BIOFILTRATION CO LTD +1

Kettle bottom cover mounting device

Owner:黄志建

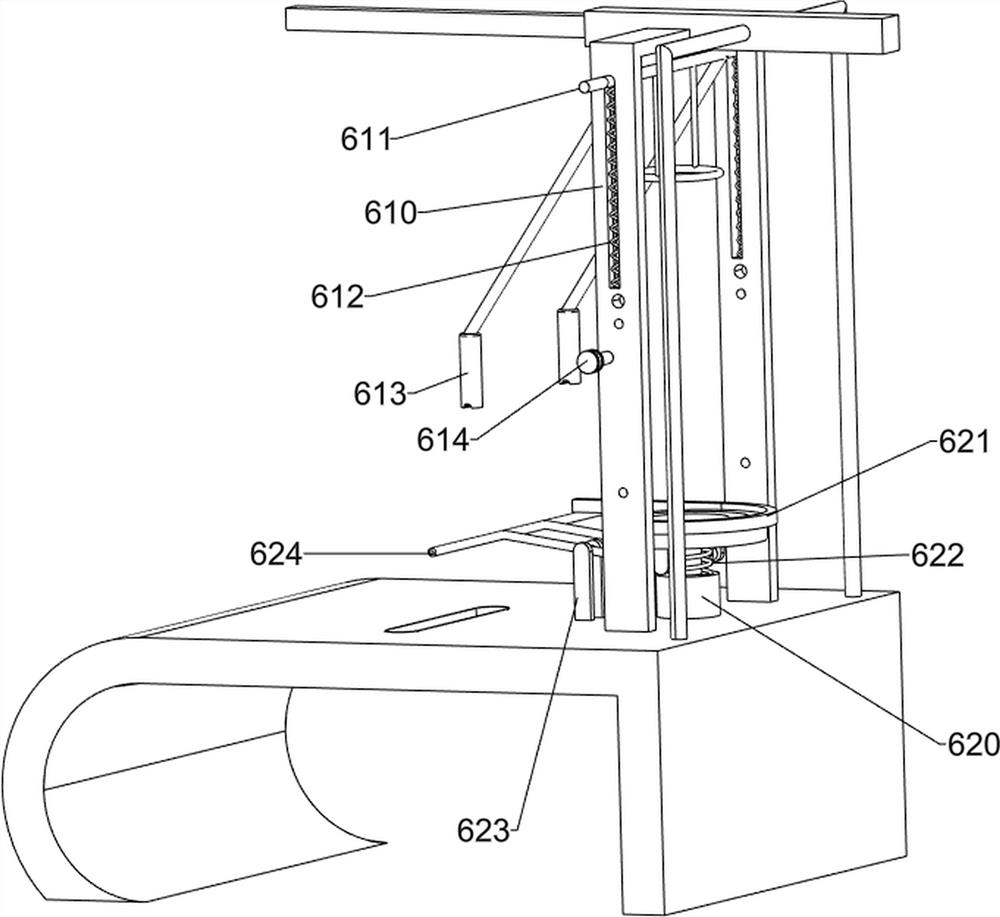

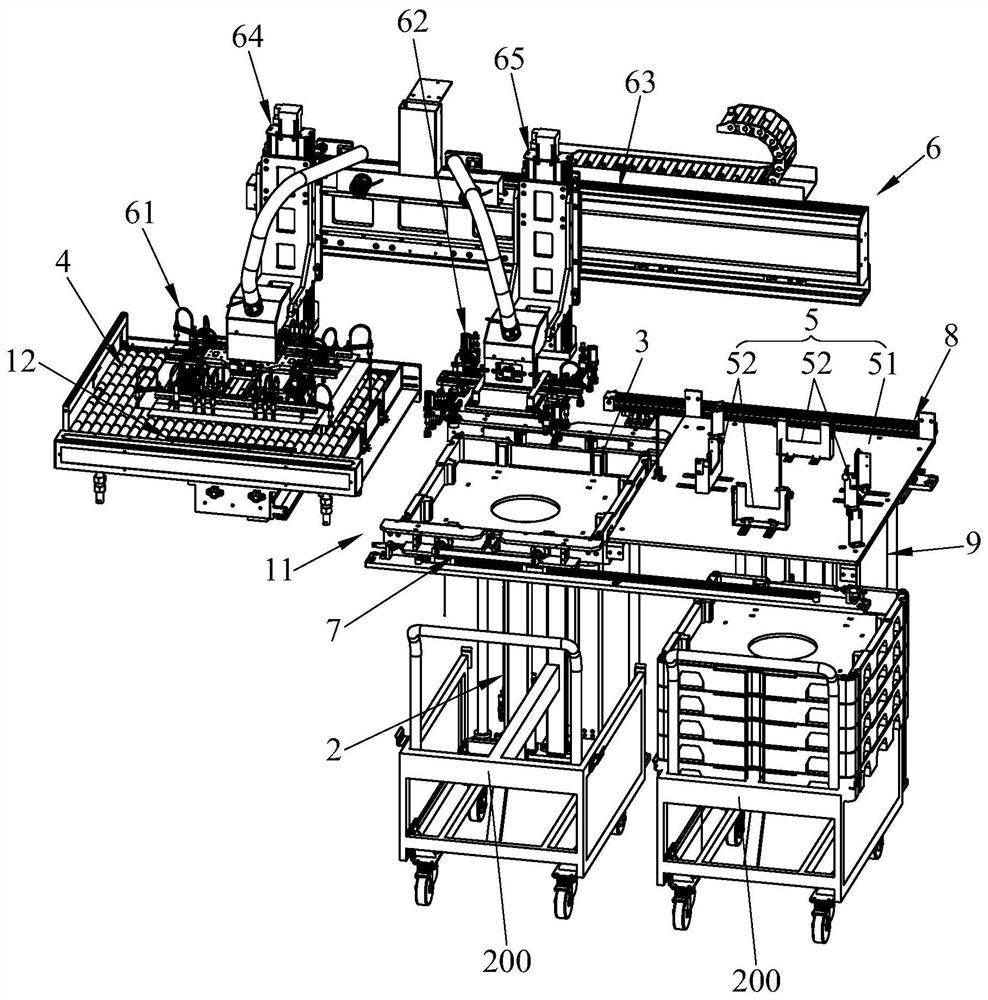

PCB partition paper collecting machine

PendingCN113264358AImplement automatic placementAvoid scratch damageStacking articlesDe-stacking articlesMechanical engineeringIndustrial engineering

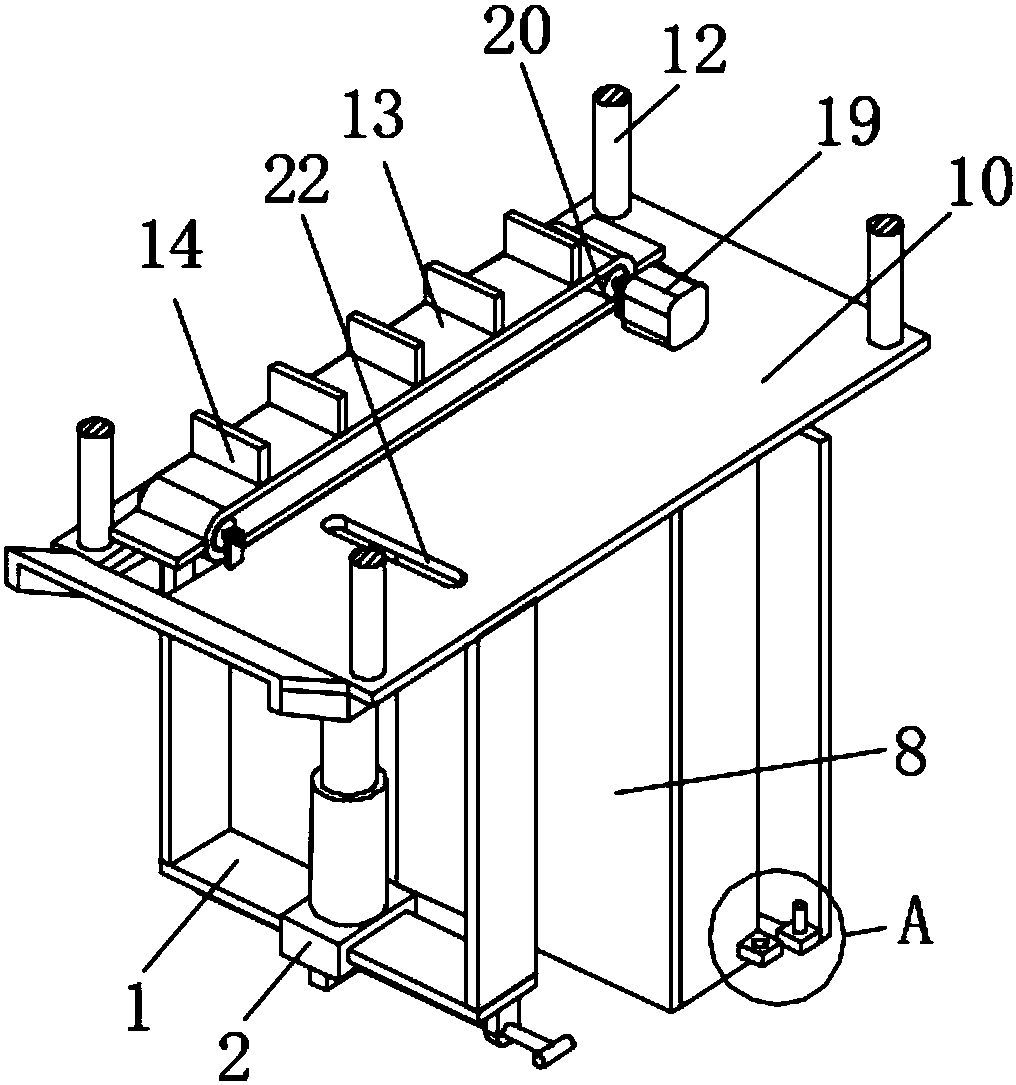

The invention provides a PCB partition paper collecting machine, which comprises a rack, a discharging driving mechanism, a material frame, a PCB conveying mechanism, a paper storage mechanism and a board collecting mechanical arm; a board collecting station is arranged on the rack; the material frame is arranged on the discharging driving mechanism and located on the board collecting station; the discharging driving mechanism can drive the material frame to move and leave the board collecting station; the PCB conveying mechanism is arranged on the rack and located on one side of the board collecting station; the paper storage mechanism is arranged on the rack and located on the other side of the board collecting station; and the board collecting mechanical arm is provided with a first material taking assembly and a second material taking assembly. The first material taking assembly and the second material taking assembly are driven by the board collecting mechanical arm to move together, so that the first material taking assembly sucks PCBs located on the PCB conveying mechanism, the second material taking assembly places sucked partition paper in the material frame, or the first material taking assembly places the sucked PCBs in the material frame, and the second material taking assembly sucks the partition paper located on the paper storage mechanism.

Owner:东莞思沃智能装备有限公司

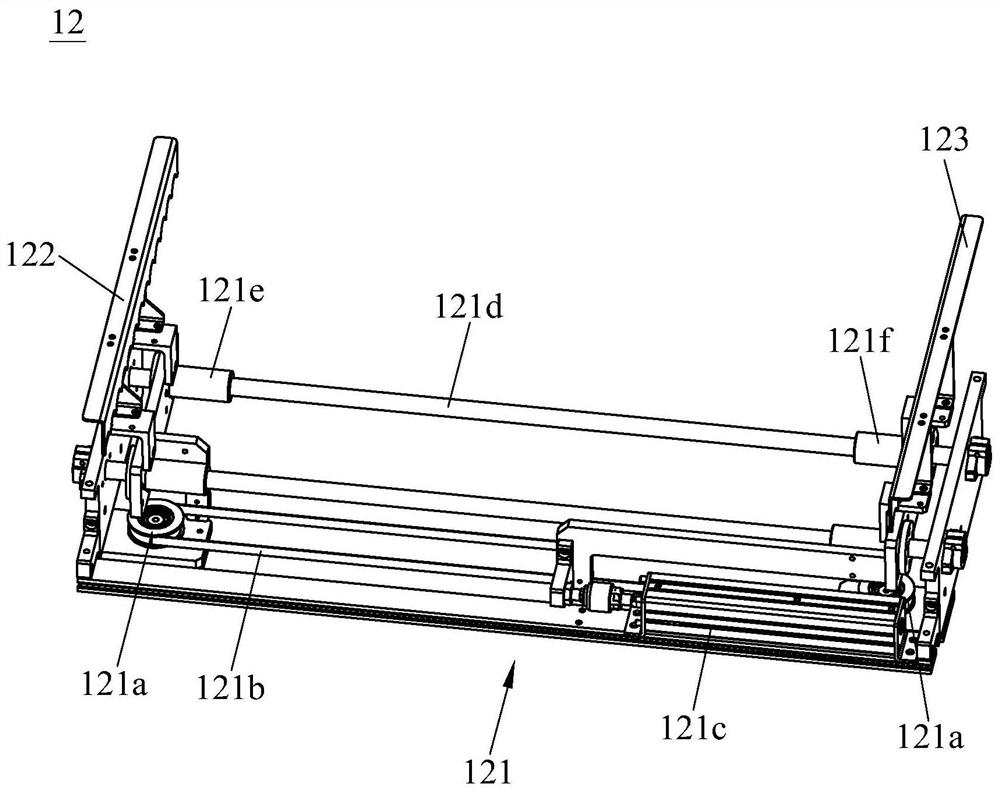

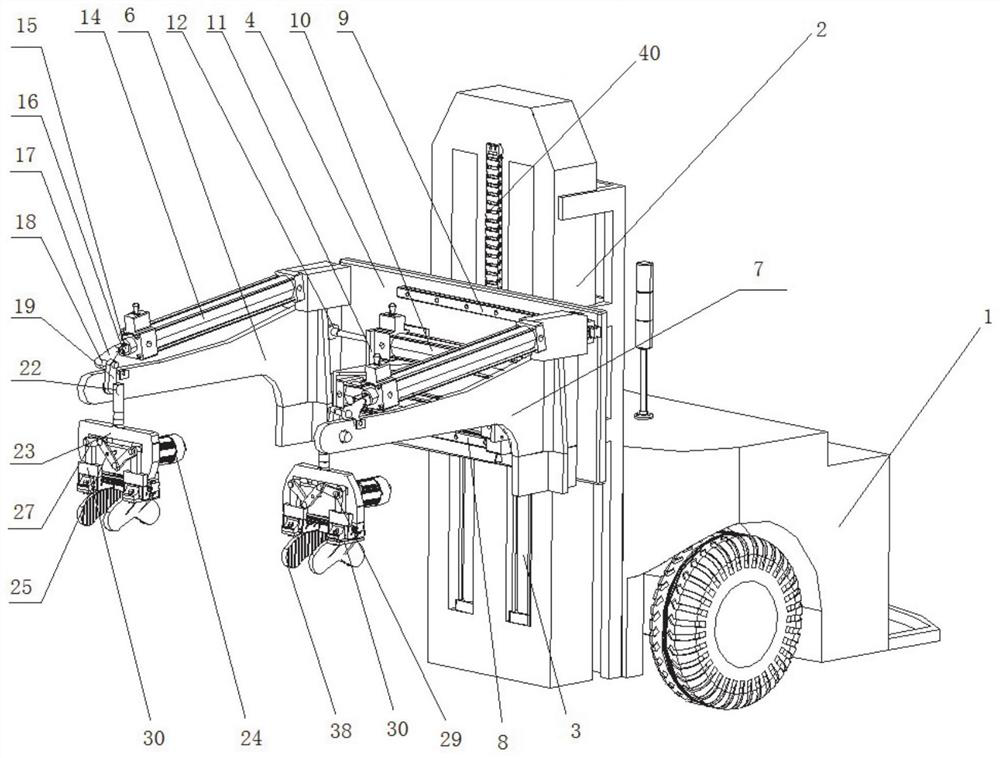

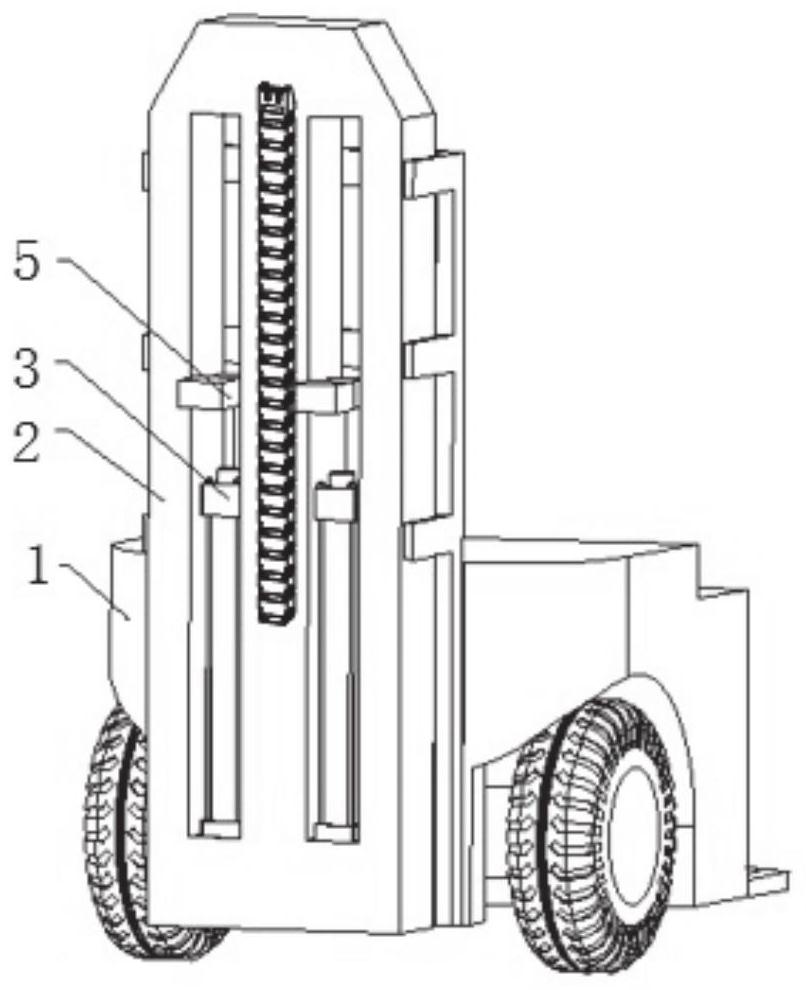

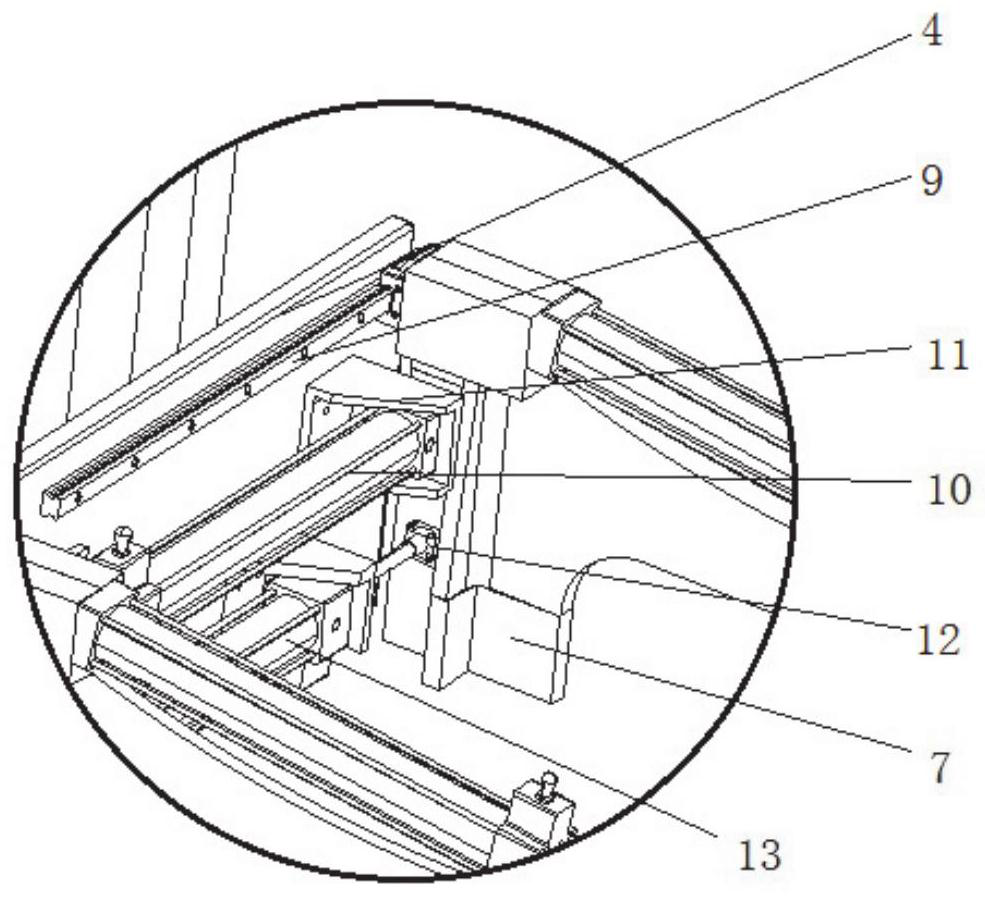

Automatic material frame clamping, overturning and transporting device and working method

PendingCN112408259AImplement automatic placementEasy to placeLifting devicesControl engineeringControl theory

Owner:山东大学日照智能制造研究院 +1

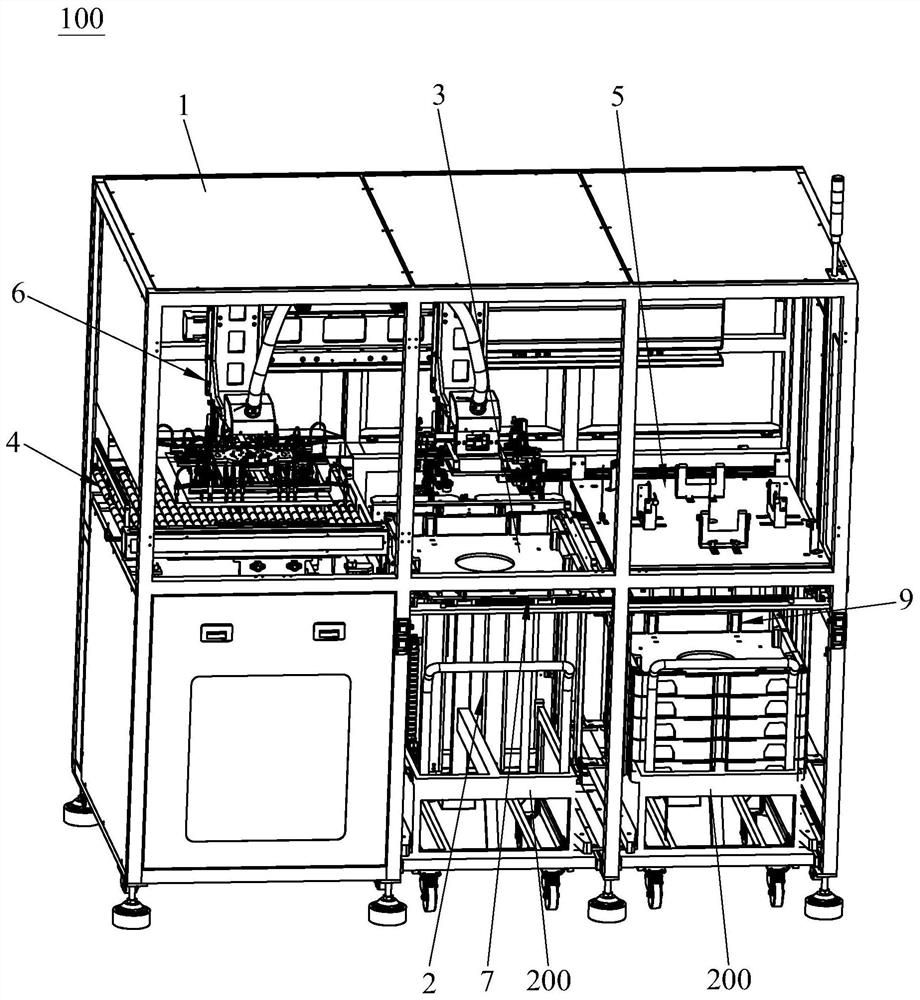

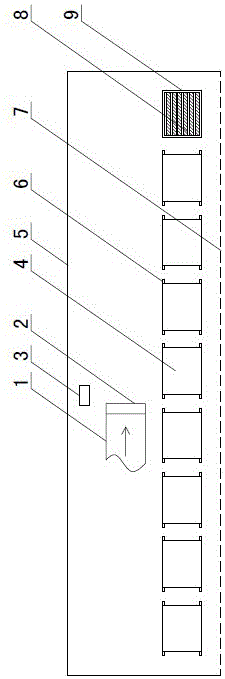

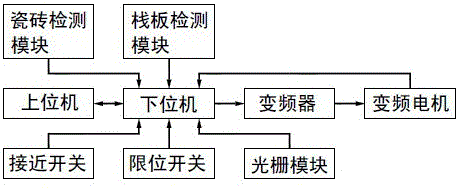

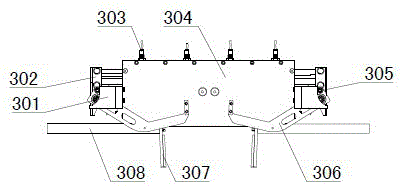

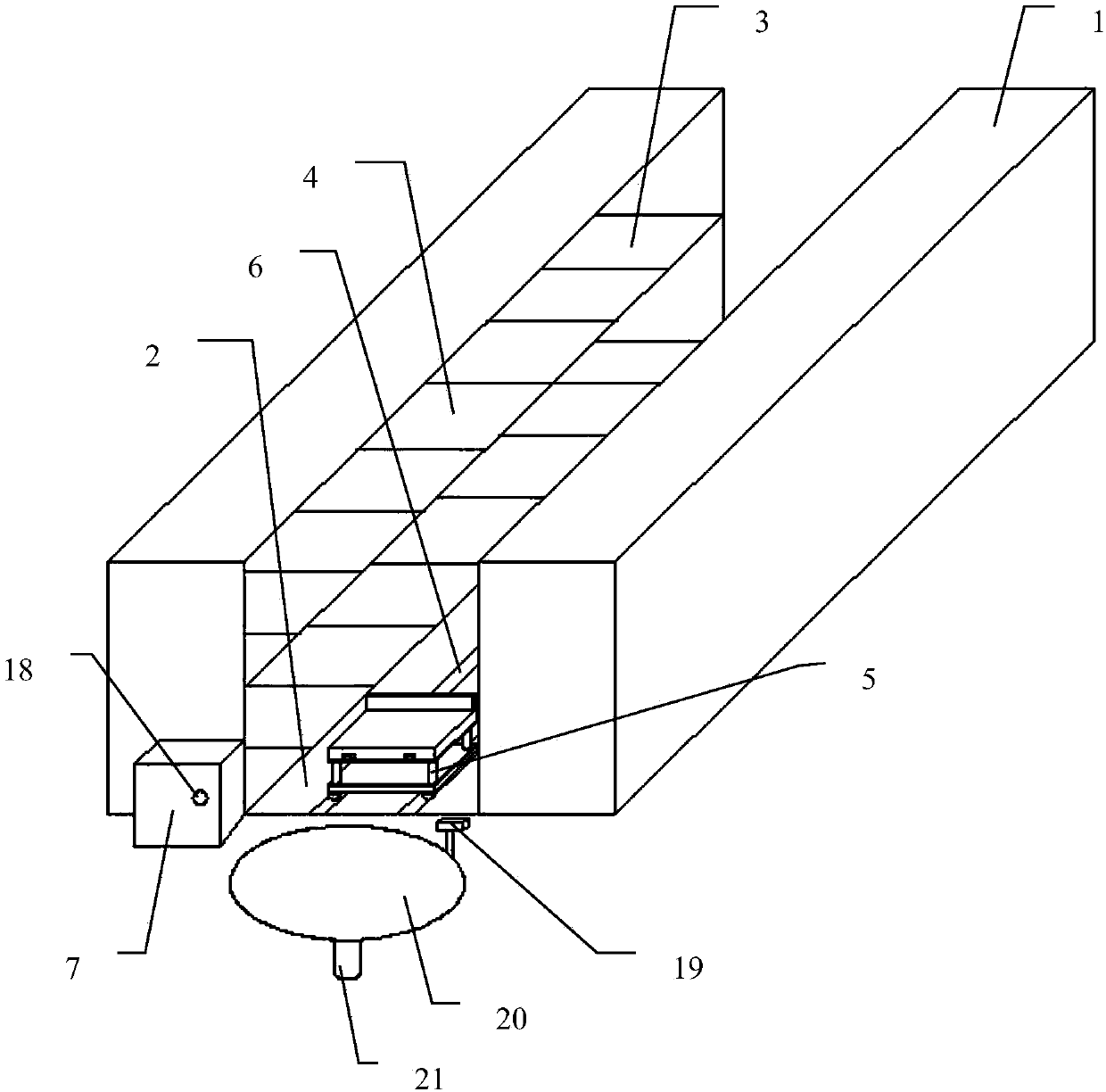

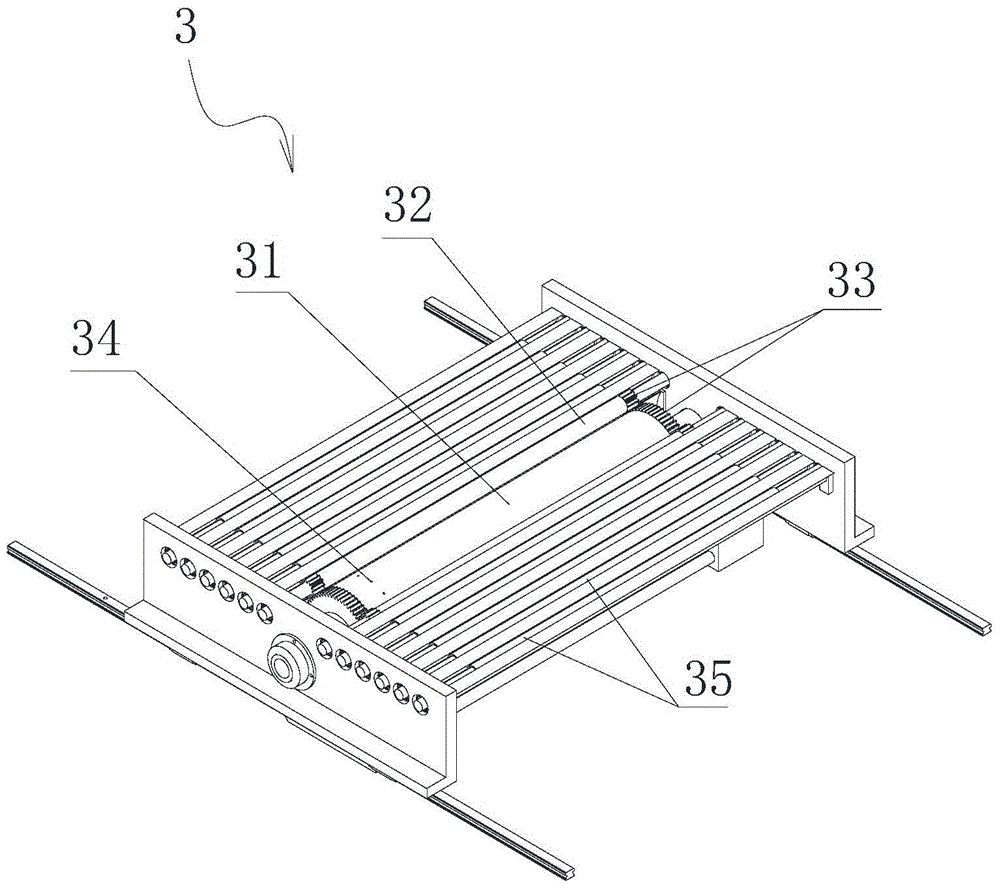

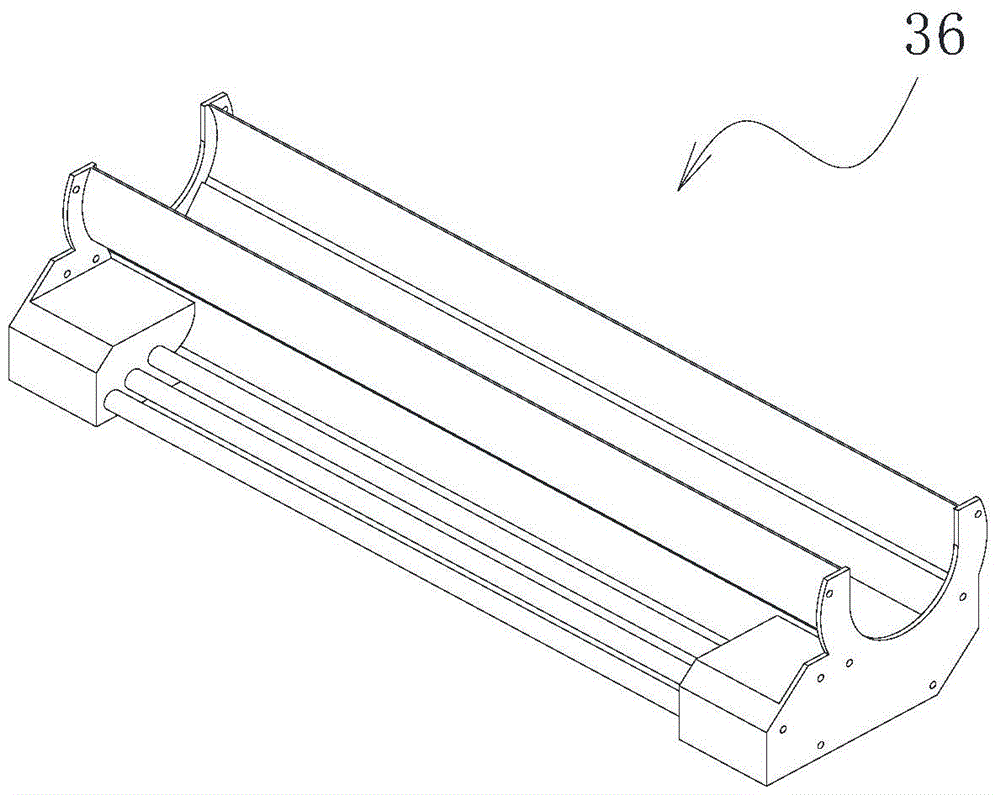

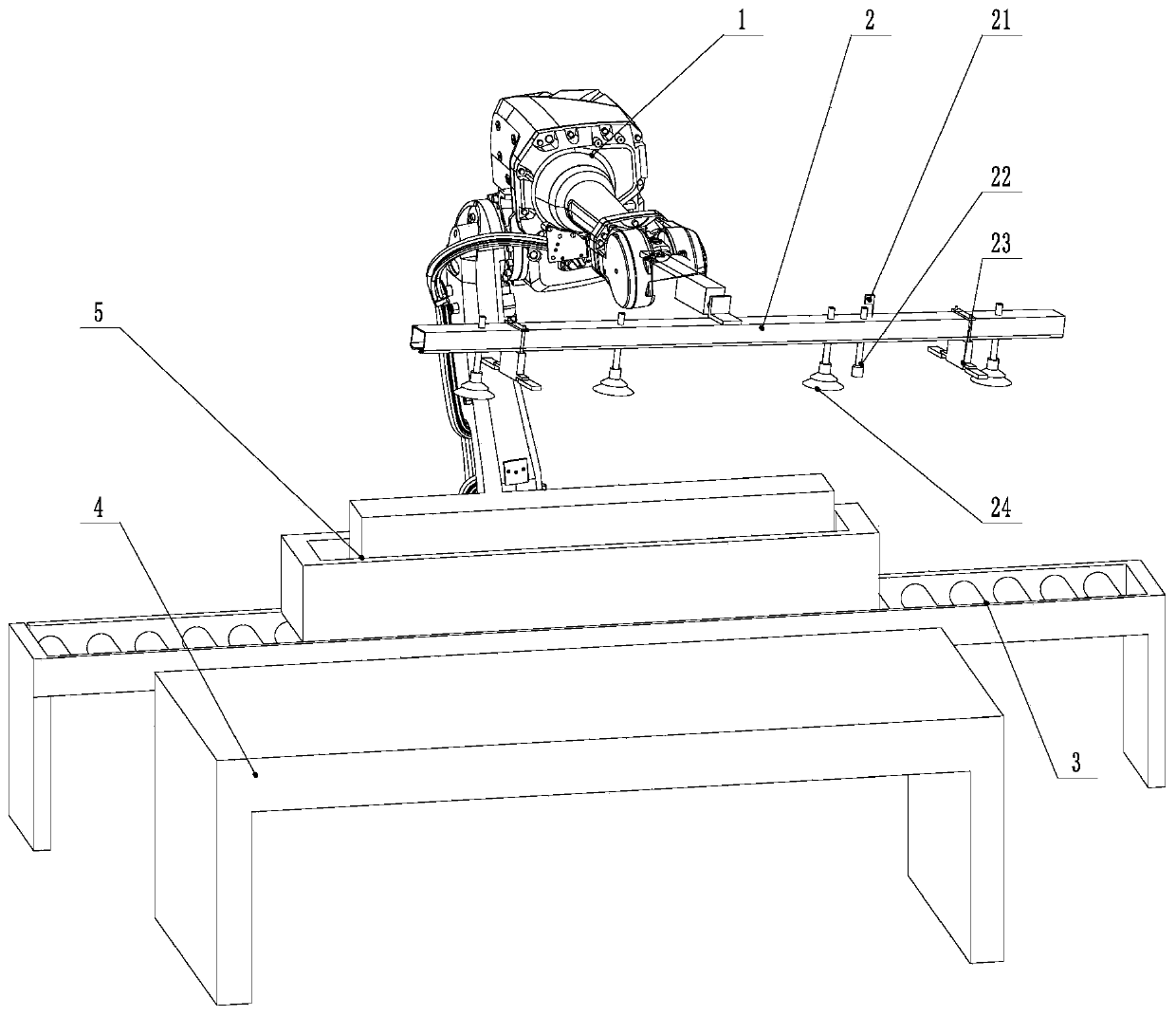

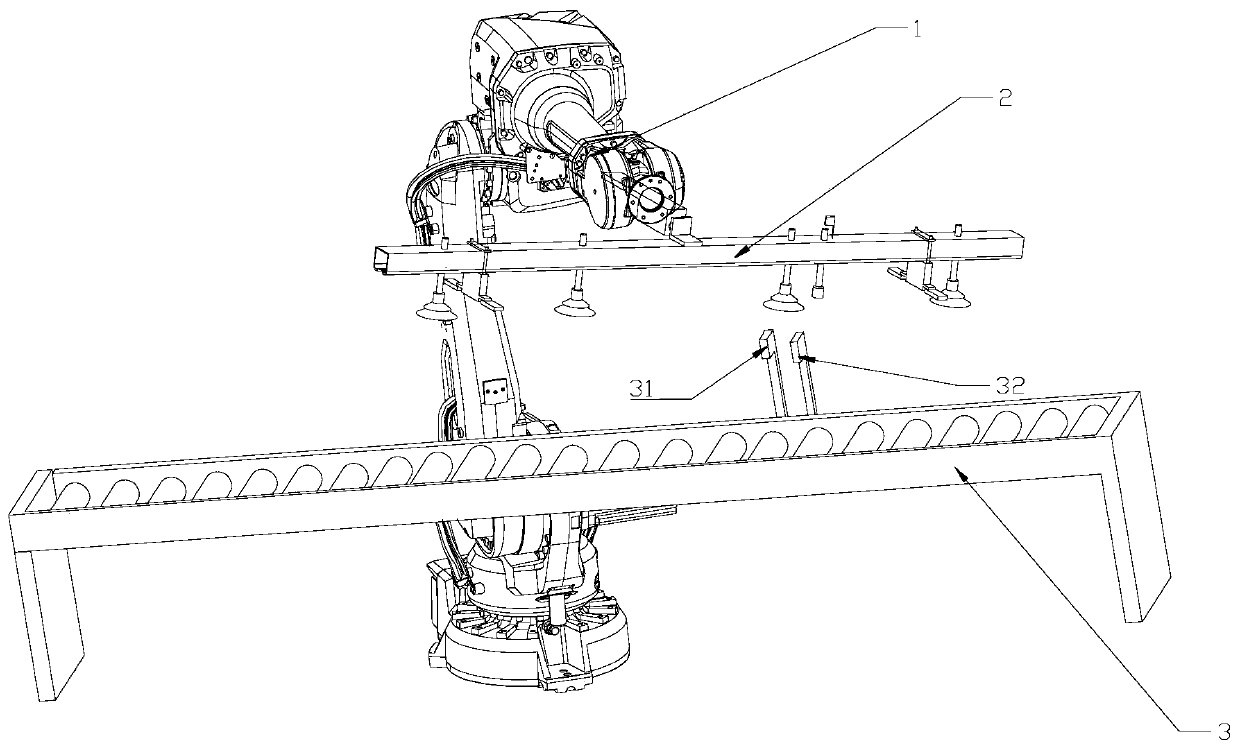

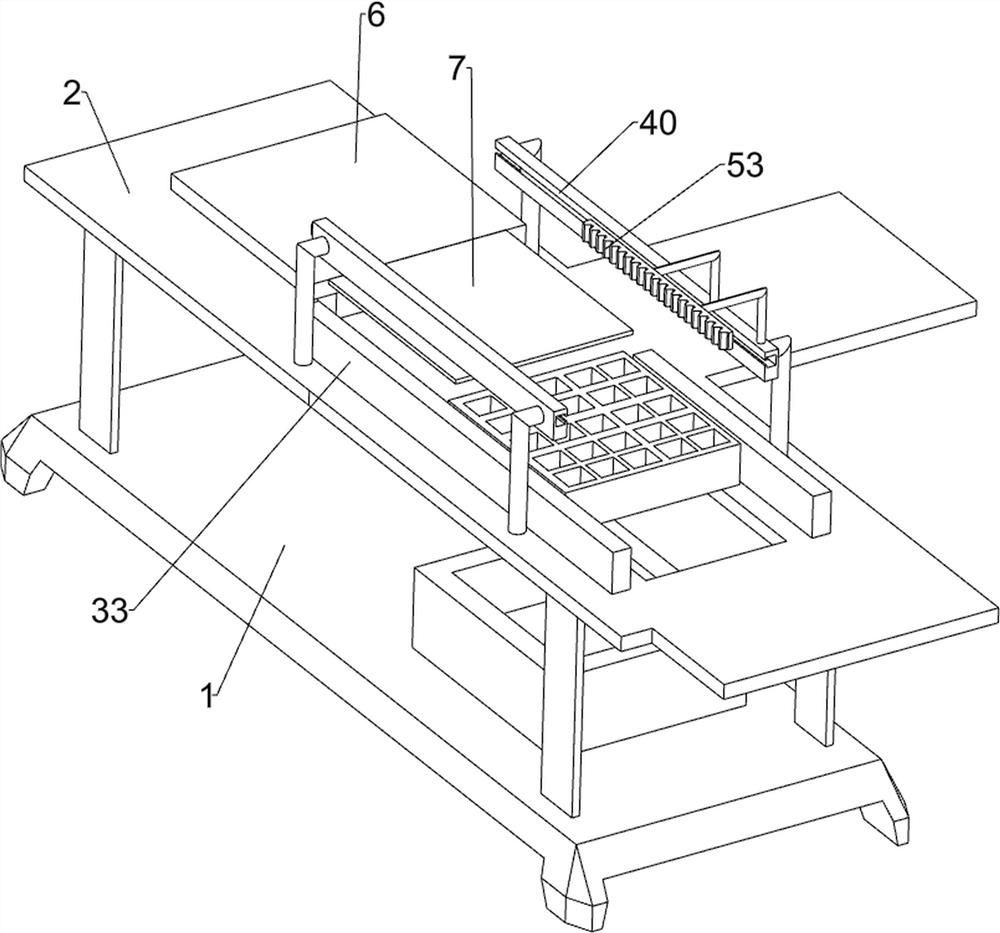

Multi-station ceramic tile transferring and stacking method and system based on pallets

ActiveCN106494900AImplement automatic placementAvoid a lot of waste of manpower and material resourcesStacking articlesDe-stacking articlesMaterial resourcesManipulator

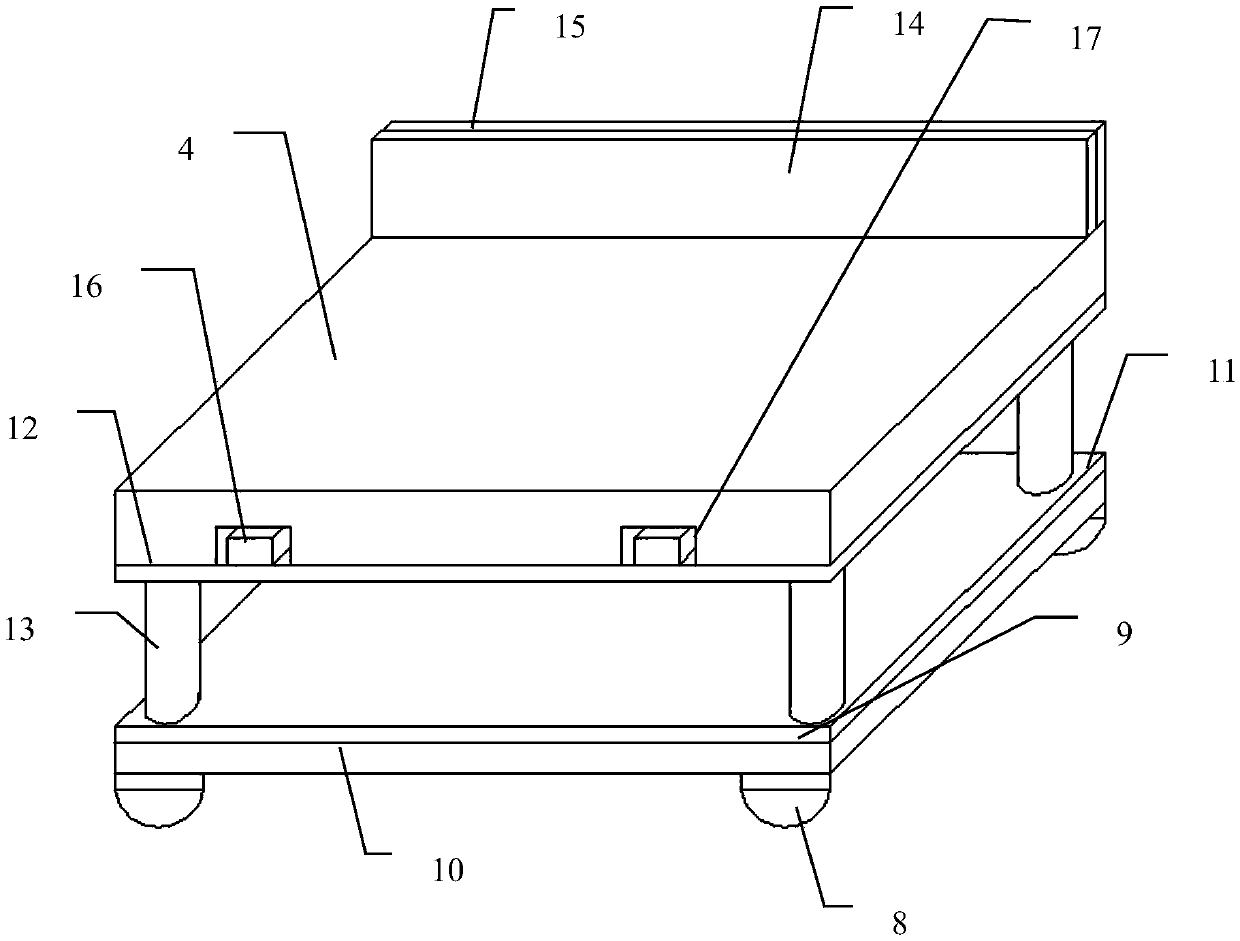

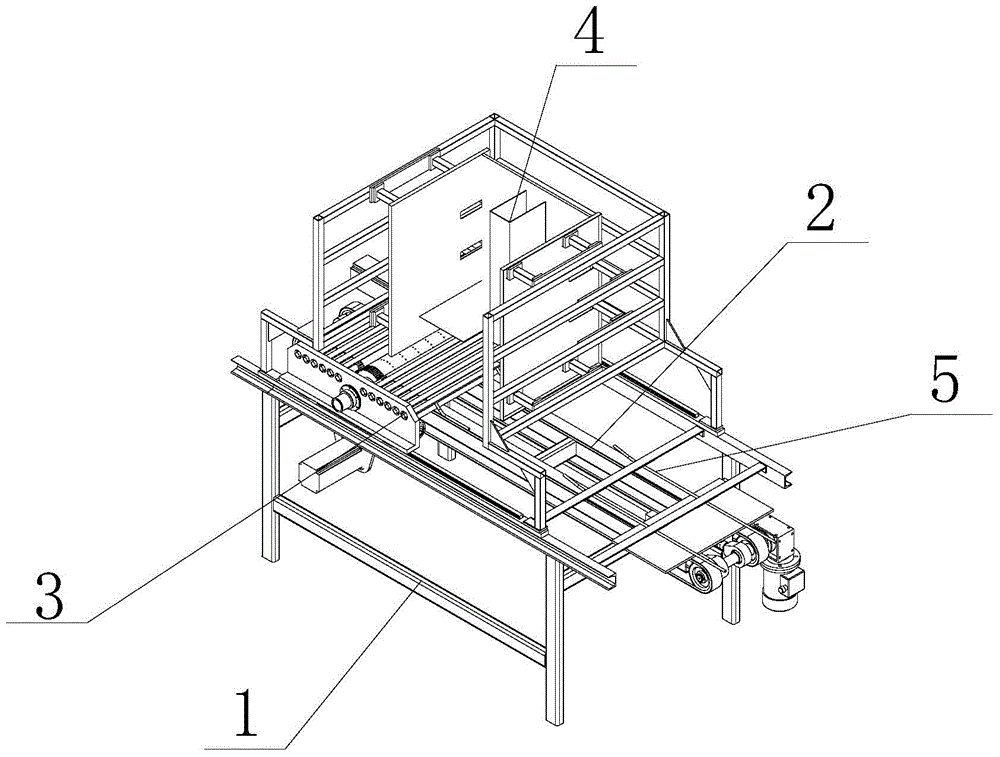

The invention provides a multi-station ceramic tile transferring and stacking method and system based on pallets, and belongs to the field of ceramic tile production equipment. The multi-station ceramic tile transferring and stacking system based on the pallets is characterized in that the system comprises a stacking work area which is defined by fences (5), a pallet storage station (9) and ceramic tile stacking stations (4) are arranged in the stacking work area, a conveying device (1) is arranged at the rear end of the stacking work area, a manipulator (3) is arranged above the stacking work area, a control cabinet is arranged outside the stacking work area, and a control unit is arranged in the control cabinet. Through the multi-station ceramic tile transferring and stacking system based on the pallets, automatic clamping and separated transferring and stacking of ceramic tiles of different grades are achieved, great waste of manpower resources and material resources is avoided, the probability of collision of products during manual transferring is avoided while the labor efficiency is greatly improved, and the appearances of the products are guaranteed.

Owner:山东爱而生智能科技有限公司

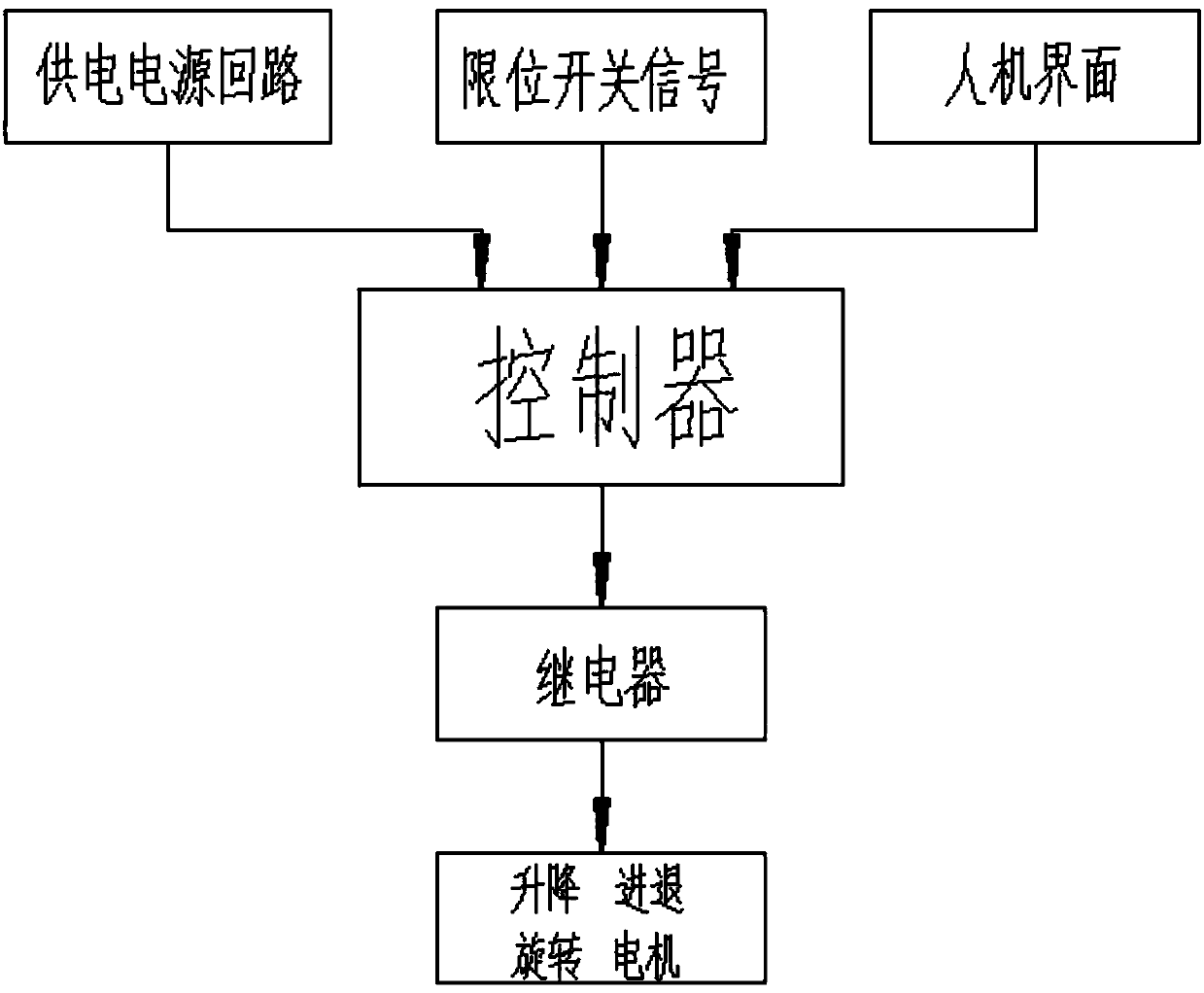

Automatic parking and taking intelligent stereo garage

InactiveCN107605212AImprove utilization efficiencyEasy to manageParkingsParking spaceAutomotive engineering

The invention discloses an automatic parking and taking intelligent stereo garage, which comprises a garage body, a plurality of car carrying plates, a support frame and a power system, wherein the garage body comprises a passage, a guide rail and parking spaces; the passage horizontally penetrates through the middle part of the garage body; the guide rail is arranged in the extending direction ofthe passage; the parking spaces are distributed at the two sides of the passage and are at least two layers; each car carrying plate corresponds to one parking space; the support frame supports the car carrying plates, can ascend, descend and rotate, and is arranged in a mode of sliding along the guide rail; and the power system drives the support frame to slide along the guide rail. Through thearrangement of the car carrying plates and the support frame, the goal that cars automatically go into or out of the garage can be achieved, so that the parking and the car taking by a user are more convenient and faster; the utilization of the garage is high; and the management is convenient.

Owner:肖博文

Novel mailbox device

InactiveCN108748070AImprove work coordinationIncrease flexibilityProgramme-controlled manipulatorGripping headsEngineeringBilateral symmetry

The invention discloses a novel mailbox device. The novel mailbox device comprises a first base, wherein a first linkage rod is fixedly arranged on the lower end surface of the first base, a ball is fixedly arranged on the lower end surface of the first linkage rod, a walking belt is arranged below the first base, a first fixed block is fixedly arranged on the upper end surface of the walking belt, the first fixed block and the ball are in rotating fit connection, first clamping blocks are fixedly arranged on the upper end surface of the walking belt in a bilateral symmetry manner, first sliding cavities with downward openings are fixedly arranged in the first clamping blocks, cavities are arranged in the upper end walls of the first sliding cavities in a communicating manner, the cavities communicate with the outer space, first sliding blocks are arranged in the first sliding cavities in a sliding manner, lugs are fixedly arranged on the upper end surfaces of the first sliding blocks, and first linkage arms are arranged on the front end surfaces of the lugs in a rotating manner. The device is simple in structure and convenient to use. The device adopting a claw type structure realizes the automatic placing and transporting of mailboxes without the direction participation of workers and effectively improves transporting convenience.

Owner:广州益为科技有限公司

Mailbox device

InactiveCN108861294AImprove work coordinationIncrease flexibilityManual conveyance devicesEngineeringMechanical engineering

Owner:广州益为科技有限公司

Improved mailbox device

InactiveCN108784255AImprove work coordinationIncrease flexibilityKitchen equipmentDomestic articlesEngineeringMechanical engineering

Owner:广州益为科技有限公司

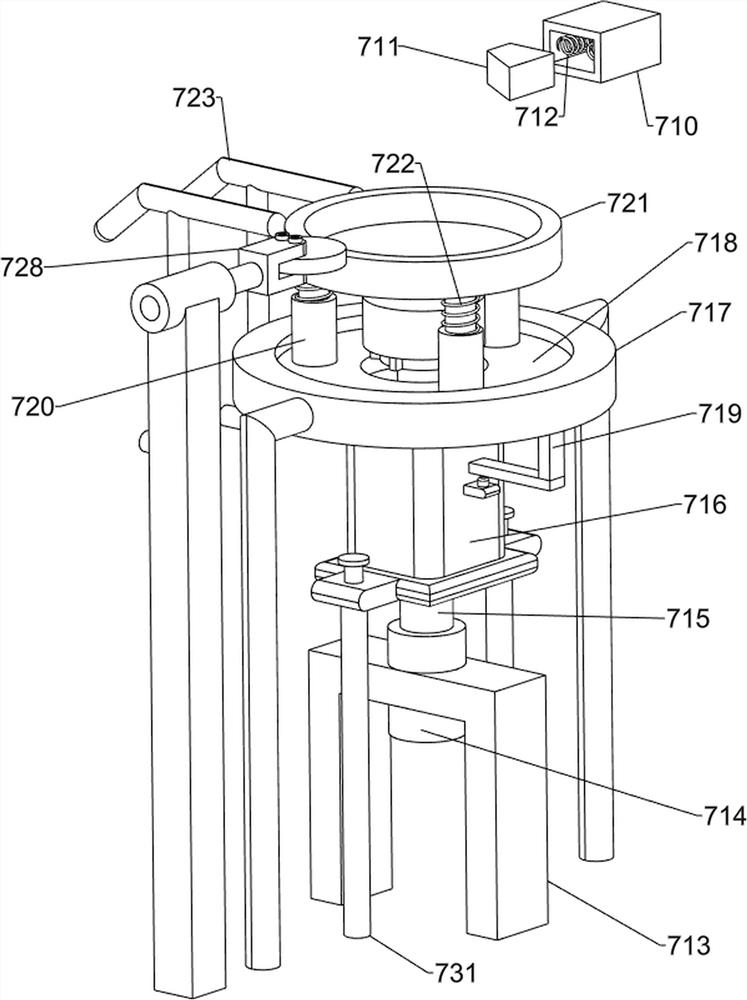

Pressing rivet screw automatic feeding device and system

PendingCN110757116ARealize automatic deliveryImplement automatic placementMetal working apparatusElectric controlPiston rod

The invention relates to a pressing rivet screw automatic feeding device. A material pipe seat is mounted on a mounting bracket, and a material guiding hole penetrating through the top surface to thebottom surface is formed in the material pipe seat; a material pushing cylinder is fixedly mounted at the bottom of the mounting bracket, the piston rod end of the material pushing cylinder is forwards connected with a flip plate bracket, and a piston rod of the material pushing cylinder extends and contracts to drive the flip plate bracket to move forwards and backwards and switch between a feeding station and a pressing rivet station; a feeding port is formed in the front part of the flip plate bracket, and when the flip plate bracket is located at the feeding station, the feeding port communicates with the lower end of the material guiding hole; and two symmetrically arranged flip plates are mounted in the feeding port, the flip plates are hinged to the two sides of the feeding port, and elastic reset pieces are arranged on the flip plates and the flip plate bracket. The invention further relates to a pressing rivet screw automatic feeding system. The pressing rivet screw automaticfeeding system comprises a pressing rivet machine frame and an electric control box, a pressing rivet operation position is arranged on the pressing rivet machine frame, and the pressing rivet screw automatic feeding device is mounted in the pressing rivet operation position. According to the pressing rivet screw automatic feeding device and system, automatic conveying of pressing rivet screws canbe realized, the working efficiency is improved, and the labor cost is saved.

Owner:江苏普莱斯特精密技术有限公司

Novel livestock breeding device

InactiveCN108925440AImprove work coordinationIncrease flexibilityAnimal feeding devicesLivestock breedingEngineering

The invention discloses a novel livestock breeding device. The novel livestock breeding device comprises a first base rack, wherein a first connecting arm is fixed on the lower end surface of the first base rack, a spherical body is fixed on the lower end surface of the first connecting arm, a driving chain belt is disposed below the first base rack, and a first fixing block is fixed on the upperend surface of the driving chain belt; the first fixing block is connected with the spherical body in a rotary and matched mode, first installation fixing blocks are arranged at the upper end surfaceof the driving chain belt symmetrically and fixedly, a first slide inlet cavity with a downward opening is fixedly formed in each first installation fixing block, and the upper end wall of a hole slotis provided with a hole slot in a communicating mode; the hole slot communicates with external space, a first slide inlet block is slidably disposed in each first slide inlet cavity, a convex plate is fixed on the upper end surface of each first slide inlet block, and a first joint column is rotatably disposed on the front end surface of each convex plate. The device has the advantages of a simple structure and convenient use, and a clamping claw-type structure is adopted by the device, so that automatic placement and transportation of feed are achieved without direct participation of personnel.

Owner:广州正辉科技有限公司

Garbage clearing device

InactiveCN108715342AImprove work coordinationImprove transmission stabilityManipulatorConveyor partsEngineeringCoupling

The invention discloses a garbage clearing device which comprises a first mounting frame. A first coupling shaft is fixedly arranged on the lower end face of the first mounting frame. A circular ballis fixedly arranged on the lower end face of the first coupling shaft. A traveling chain belt is arranged below the first mounting frame, and a first fixing block is fixedly arranged on the upper endface of the traveling chain belt. The first fixing block and the circular ball are connected in a rotating-fit mode, and first mounting frames which are symmetrical in the left-right direction are fixedly arranged on the upper end face of the traveling chain belt. First sliding cavities with downward openings are fixedly formed in the first mounting frames, and swing cavities are formed in the upper end walls of the first sliding cavities in a communicating mode and communicate with the external space. First sliding blocks are slidably arranged in the first sliding cavities, convex blocks arefixedly arranged on the upper end faces of the first sliding blocks, and first coupling rods are rotationally arranged on the front end faces of the convex blocks.

Owner:广州粤晟科技有限公司

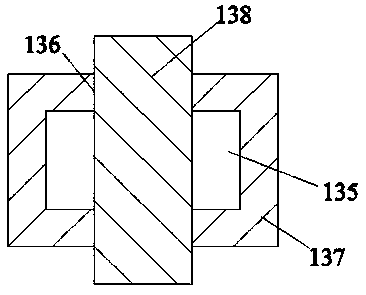

Punching device with high degree of automation for material fetching-placing mold

PendingCN108115043AImprove processing efficiencyImplement automatic placementPerforating toolsMetal-working feeding devicesPunchingAutomation

The invention discloses a punching device with high degree of automation for a material fetching-placing mold. The punching device comprises an upper plate, wherein clamping strips are symmetrically fixed on the front and rear sides of an upper surface of the upper plate; a blanking device is arranged at the right end of the upper surfaces of the clamping strips; through holes are formed in the upper surface of the upper plate along the left-right direction; left ends of the through holes are opened; two synchronizing wheels are arranged at positions, which correspond to the through holes, ofthe lower surface of the upper plate; a synchronous belt is arranged between the two synchronizing wheels; the upper surface of the synchronous belt and the upper surface of the upper plate are positioned on the same horizontal plane; and clamping plates are arranged on an outer side face of the synchronous belt in equal distance. The position of a slide block on a transverse plate is adjusted byworkers by virtue of an adjusting device, so that the punching position of the mold is conveniently adjusted; and a stepping motor enables the synchronous belt to drive the clamping plates to rotate anticlockwise, and the mold in the blanking device drops into a gap between two adjacent clamping plates, so that the mold is automatically placed. The machining efficiency of the punching device withhigh degree of automation for the material fetching-placing mold is improved.

Owner:南苗苗 +1

Logistics transportation equipment

InactiveCN108609063AImprove work coordinationImprove transmission stabilityEndless track vehiclesManipulatorLogistics managementFixed frame

The invention discloses logistics transportation equipment. The logistics transportation equipment comprises a first mounting and fixing frame; a first connecting arm is fixedly arranged on the lowerend face of the first mounting and fixing frame; a circular ball is fixedly arranged on the lower end face of the first connecting arm; a driving linkage belt is arranged below the first mounting andfixing frame; a first block is fixedly arranged on the upper end face of the driving linkage belt; the first block and the circular ball are connected in a rotating fit mode; first mounting and fixingblocks which are in bilateral symmetry are fixedly arranged on the upper end face of the driving linkage belt; first sliding cavities with downward openings are fixedly formed in the first mounting and fixing blocks; swing holes are formed in swing hole upper end walls in a mutually communicating mode; the swing holes communicate with the external space; first sliding blocks are slidably arrangedin the first sliding cavities, and flanges are fixedly arranged on the upper end faces of the first sliding blocks; and first connecting arms are rotatably arranged on the front end faces of the flanges. The logistics transportation equipment is simple in structure and convenient to use, and adopts a clamping-claw-type structure, and goods are automatically placed and transported without direct participation of personnel.

Owner:广州俊天科技有限公司

Livestock breeding device

InactiveCN108749942AImprove work coordinationImprove transmission stabilityEndless track vehiclesConveyor partsLivestock breedingEngineering

The invention discloses a livestock breeding device. The livestock breeding device comprises a first base frame, the lower end face of the first base frame is fixedly provided with a first connectingarm, the lower end face of the first connecting arm is fixedly provided with a ball body, a driving chain belt is arranged below the first base frame, the upper end face of the driving chain belt is fixedly provided with a first fixing block, and the first fixing block is rotatably and cooperatively connected with the ball body; the upper end face of the driving chain belt is fixedly provided withfirst mounting blocks which are symmetrical left and right, a first sliding cavity with an opening facing downwards is fixedly formed in each first mounting block, the upper end wall of each first sliding cavity is internally communicated with a hole groove, each hole groove is communicated with the external space, a first sliding block is slidingly arranged in each first sliding cavity, the upper end face of each first sliding block is fixedly provided with a convex plate, and the front end face of each convex plate is rotatably provided with a first linkage column. The device is simple in structure and convenient to use; the device adopts a claw-type structure, fodder is automatically placed and transported without the direct participation of personnel, and the transportation convenience is effectively improved.

Owner:广州正辉科技有限公司

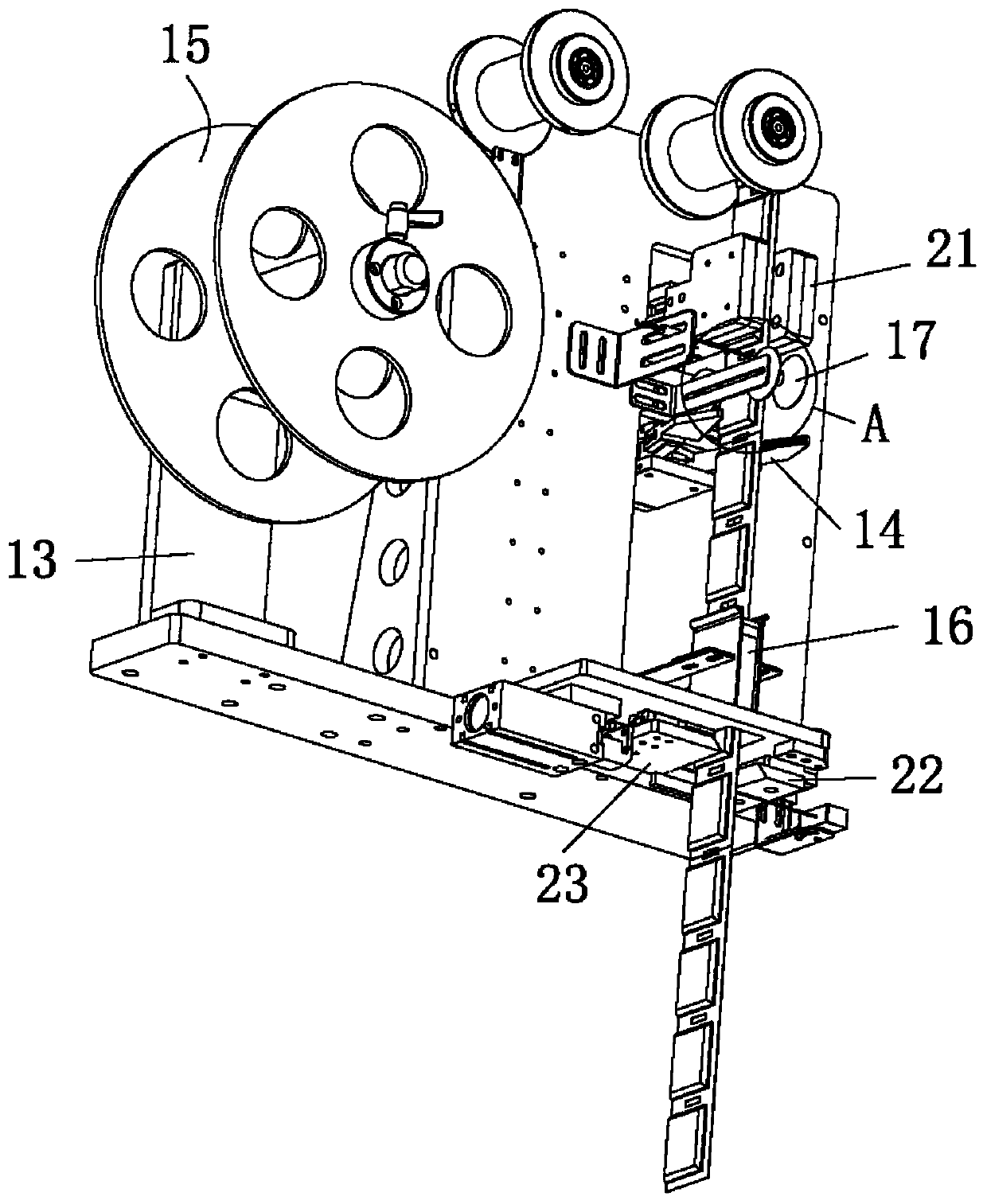

Paying-off device for copper wire cut-off device

InactiveCN105151887AImplement automatic placementIncrease productivityFilament handlingCopper wireEngineering

The invention discloses a paying-off device for a copper wire cut-off device. The paying-off device comprises a base. Vertical plates are arranged at the left end and the right end of the base. A paying-off wheel is arranged above the base. The left portion of a bottom plate is longitudinally provided with a threaded rod in a bearing connection manner. A rotation nut is fixed to the front end of the threaded rod. Positioning holes are evenly formed in the front end face of the rotation nut. A positioning plate is fixed to the front of the rotation nut and provided with a pin hole. The pin hole is internally provided with a positioning pin matched with the positioning holes. The right portion of the bottom plate is longitudinally provided with a guide rod in a bearing connection manner. A lower wedge-shaped block is arranged at the upper end of the bottom plate. An upper wedge-shaped block is arranged above the lower wedge-shaped block. A limiting plate is fixed to the upper end of the upper wedge-shaped block. A brake block is arranged above the limiting plate. A plurality of limiting columns perpendicular to the horizontal face are arranged at the bottom of the brake block and sleeved with springs. The paying-off device has the beneficial effects that the structural design is reasonable, the manufacturing cost is low, and using is convenient; and certain tensile force can be achieved while paying off is achieved.

Owner:ANHUI YUSHENG HAOHAN ELECTRONICS TECH

Novel logistics transportation equipment

InactiveCN108772820AImprove work coordinationImprove transmission stabilityProgramme-controlled manipulatorGripping headsFistLogistics management

The invention discloses a novel logistics transportation equipment. The equipment includes a first mounting frame; the lower end face of the first mounting frame is fixedly provided with a first linkarm; the lower end face of the first link arm is fixedly provided with a round ball; a driving link belt is arranged below the first mounting frame; the upper end face of the driving link belt is fixedly provided with a first block body; the first block body and the round ball are in rotation connection; the upper end face of the driving link belt is fixedly provided with first setting blocks which are in left and right symmetry; the first setting blocks are fixedly provided with fist slip cavities having openings facing downward; the insides of the upper walls of the fist slip cavities are provided with swing holes in an intercommunication manner; the swing holes and external space are in intercommunication; the first slip cavities are slidingly provided with first slip blocks; the upperend faces of the first slip blocks are fixedly provided with flanges; and the front end faces of the flanges are rotatably provided with first link arms. The equipment is simple in structure and convenient to use; and the equipment adopts a clamping claw-type structure, and thus, automatic placing and transporting of cargos can be realized without the direct involvement of personnel.

Owner:广州俊天科技有限公司

Automatic baffle device for packaging ceramic tiles

InactiveCN104477466ARealize automatic suctionImplement automatic placementPackagingStacking articlesMaterials sciencePlating efficiency

The invention discloses an automatic baffle device for packaging ceramic tiles, which comprises a rack, a delivery mechanism for to-be-isolated ceramic tiles, a suction plate device, a baffle storage device and a baffle blowing device. The delivery mechanism for to-be-isolated ceramic tiles is arranged on the rack. The suction plate device moves back and forth above the delivery mechanism for to-be-isolated ceramic tiles. The baffle storage device is installed above the suction plate device and is fixed relative to the position of the delivery mechanism for to-be-isolated ceramic tiles. A baffle position device is arranged above the delivery mechanism for to-be-isolated ceramic tiles and is mounted before the baffle storage device and the subsequent stacking procedure. The suction plate device comprises one big roller with suction holes and at least two small rollers. The big roller is arranged in the middle, and the small rollers are respectively arranged on the two sides of the big roller. The big roller and the small rollers are engaged via a gear set. When the suction plate device moves back and forth below the baffle storage device, the suction of corresponding baffles can be realized by controlling the big roller to rotate clockwise or anticlockwise. The suction plate efficiency is high.

Owner:广东科信达科技有限公司 +1

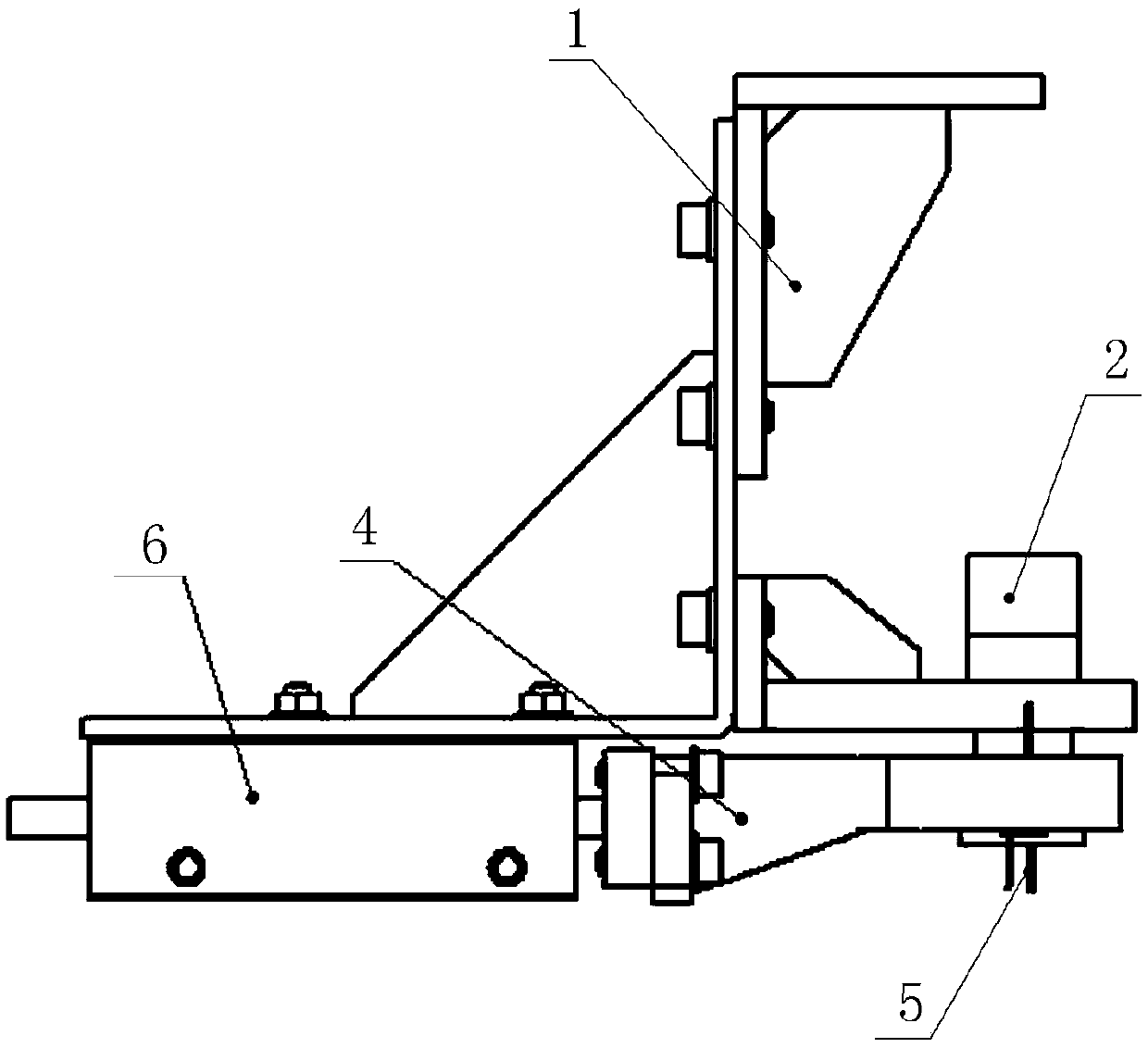

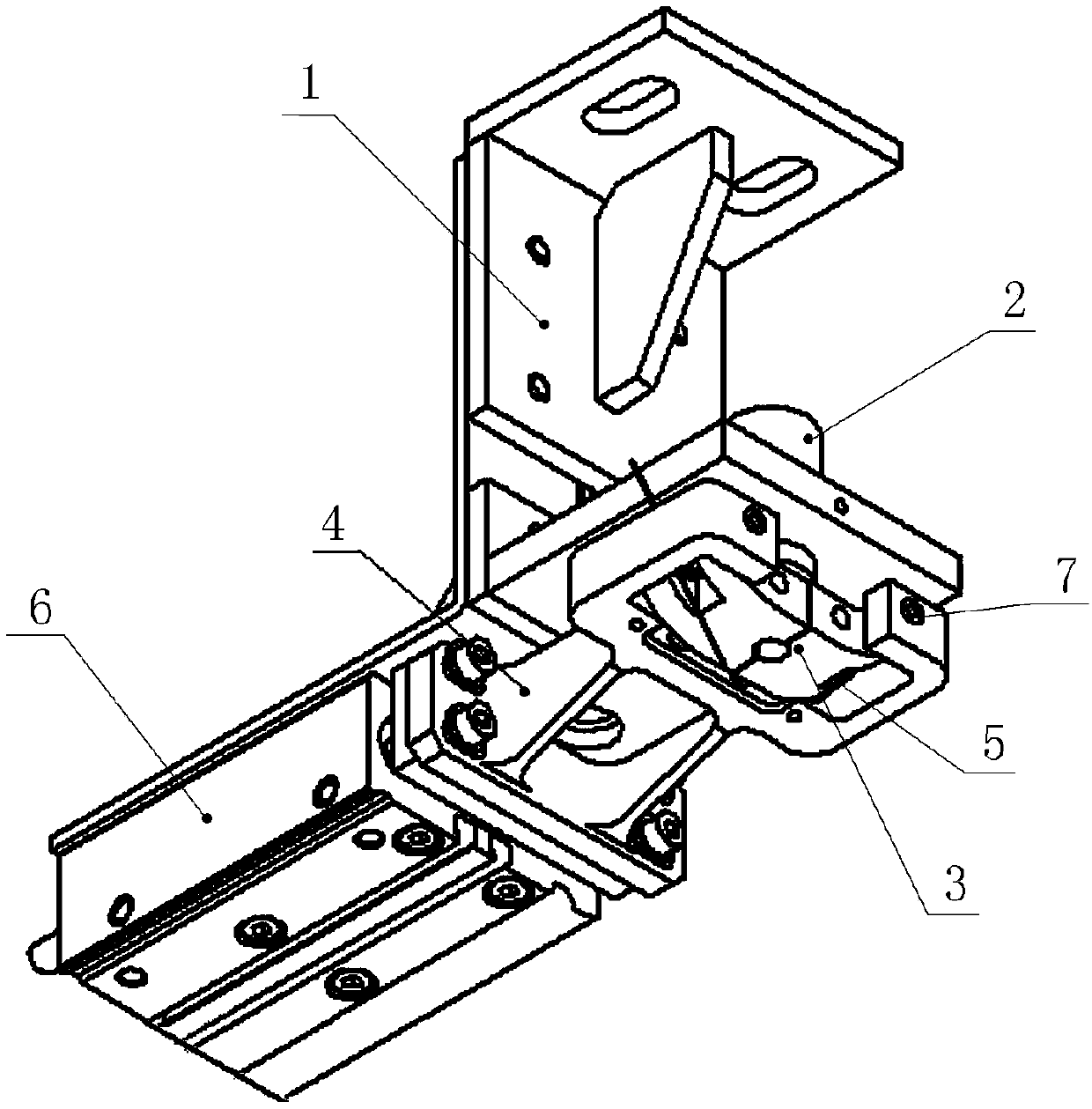

Clamp and laminating equipment

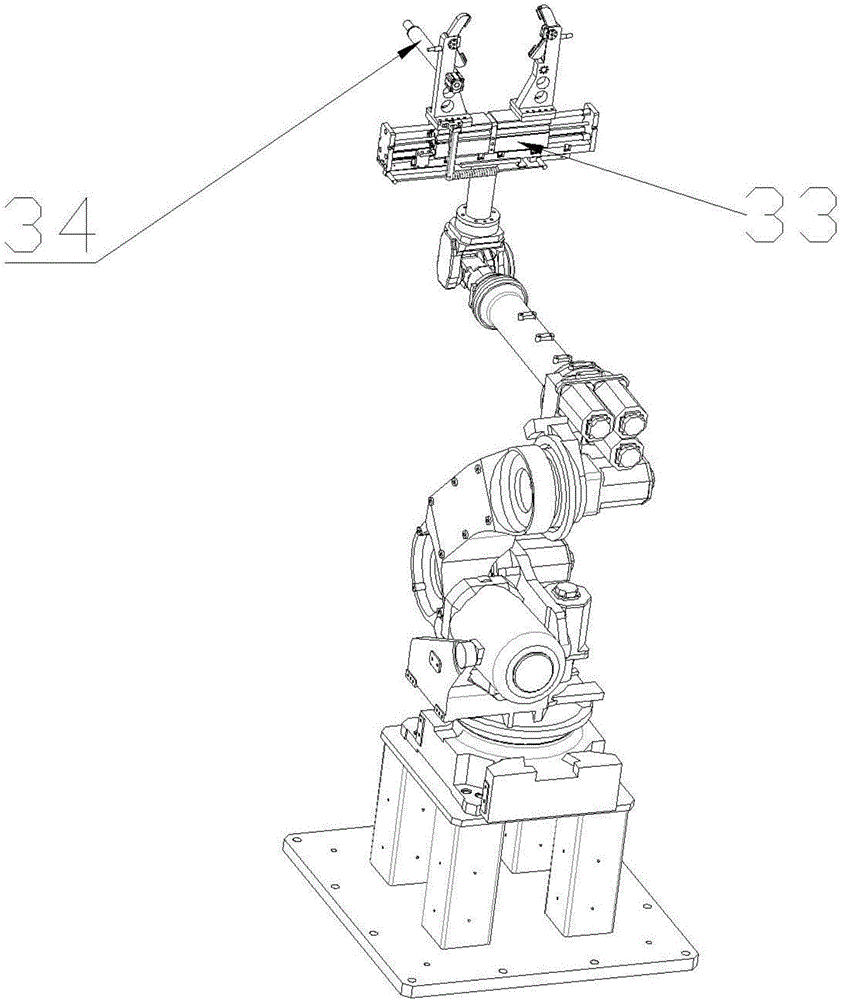

PendingCN111098329ARealize automatic laminationImplement automatic placementGripping headsRobot handPack material

The invention discloses a clamp which comprises a support. A fixing part is arranged on the upper surface of the support, an induction part is arranged on the support, and suction devices are arrangedon the two sides of the induction part, so that the suction devices grab packaging materials to wrap objects to be packaged. The invention also discloses laminating equipment which comprises a mechanical arm. The mechanical arm is connected with the clamp, a conveying component is arranged below the clamp, an object to be packaged is placed on the conveying component, a tooling table is arrangedon one side of the conveying component, and packaging materials are placed on the tooling table. According to the laminating equipment, automatic laminating of pearl cotton is realized by combining asmall-sized industrial six-axis robot with the cooperation of a lip suction disc and a finger clamping jaw, the suction disc is matched with a finger clamping jaw cylinder, and the problems that the pearl cotton is difficult to clamp and easily falls are solved. Meanwhile, automatic placement of the pearl cotton is realized, personnel investment is reduced, and product quality is improved.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

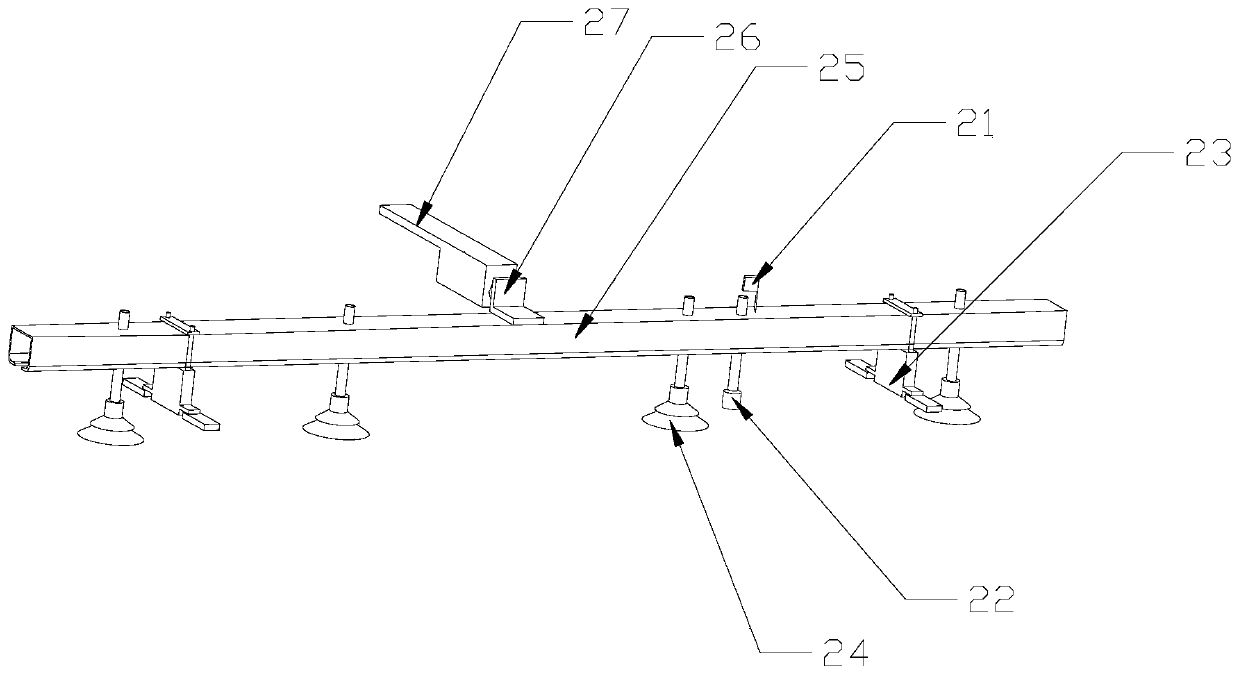

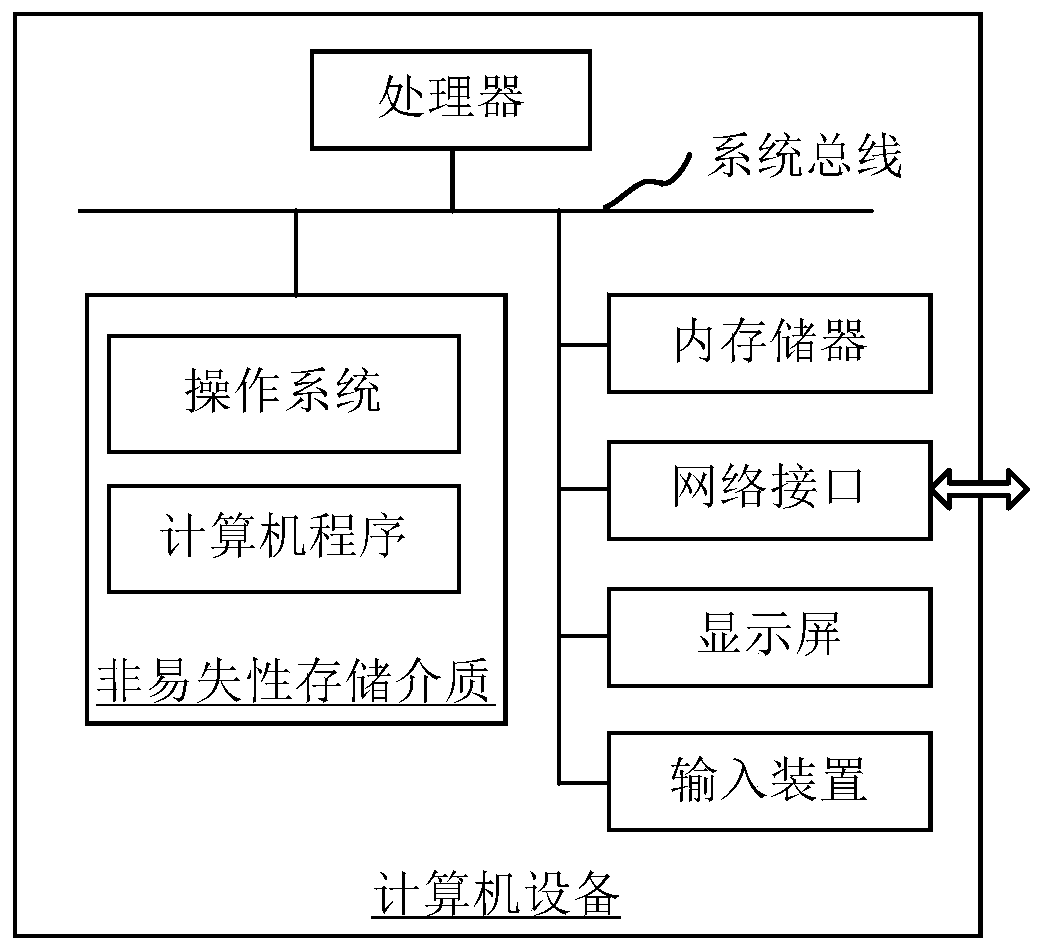

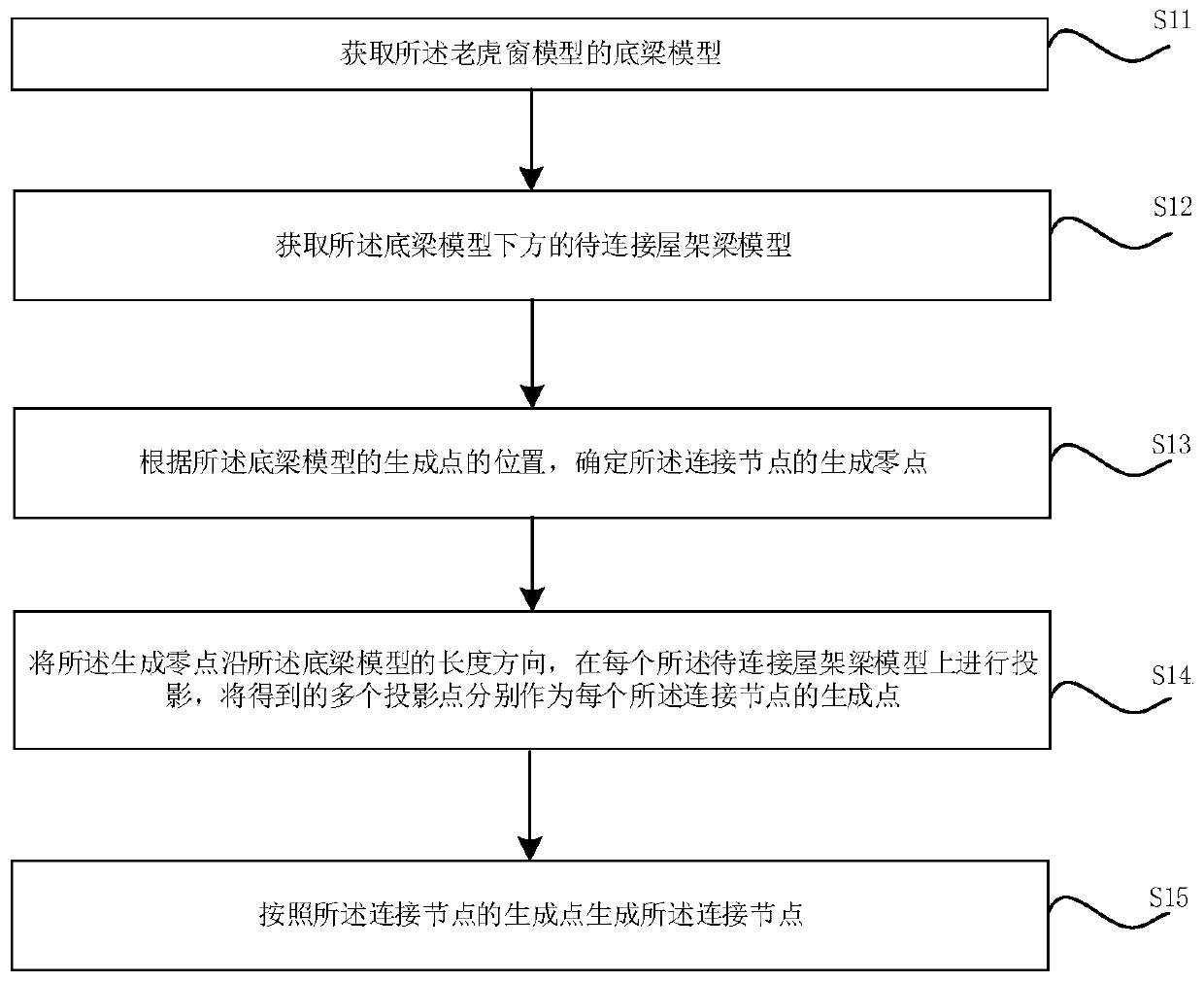

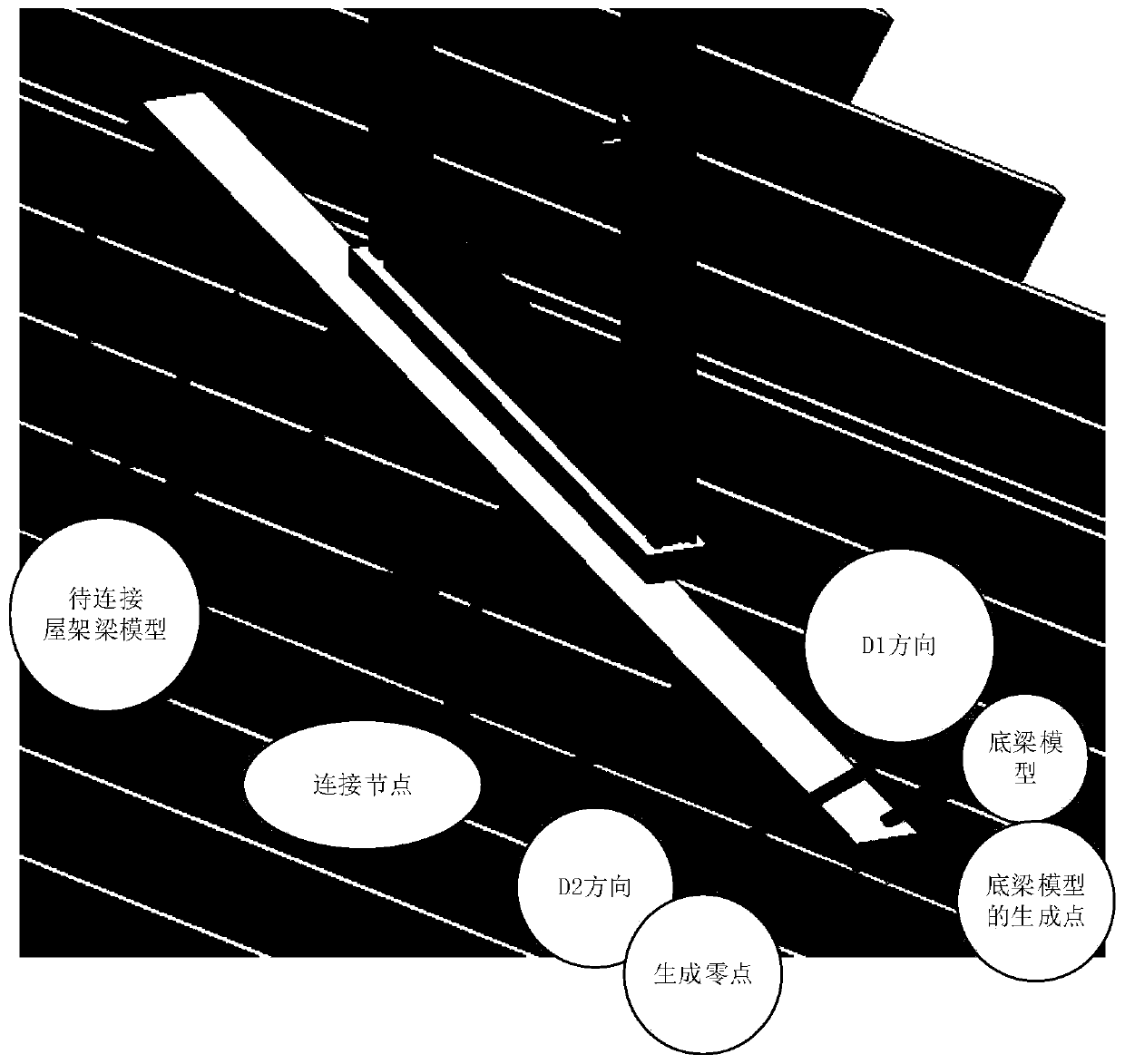

Method and product for placing connection nodes between tiger window model and roof truss beam model

ActiveCN110704898AImplement automatic placementImplementation inefficienciesGeometric CADDesign optimisation/simulationAlgorithmStructural engineering

The invention relates to a method and a product for placing a connection node between a tiger window model and a roof truss beam model. The method comprises the following steps: 1, ; obtaining a bottom beam model of the tiger window model and a to-be-connected roof truss beam model below the bottom beam model; the method comprises the steps of obtaining a plurality of to-be-connected roof truss beam models, determining generation zero points of connection nodes according to positions of generation points of the bottom beam models, then projecting the generation zero points on each to-be-connected roof truss beam model in the length direction of the bottom beam models, taking the obtained projection points as the generation points of each connection node, and finally generating the connection nodes according to the generation points of the connection nodes. According to the method, the placing difficulty of the connection node and the placing efficiency of the connection node are improved.

Owner:久瓴(江苏)数字智能科技有限公司

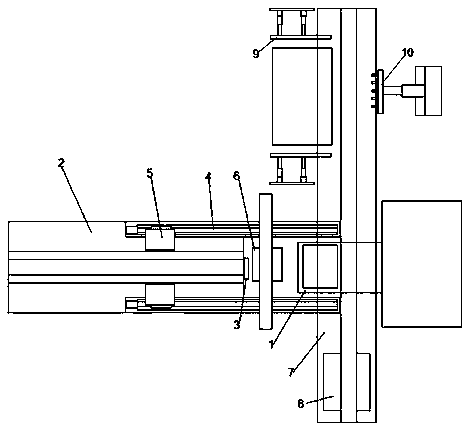

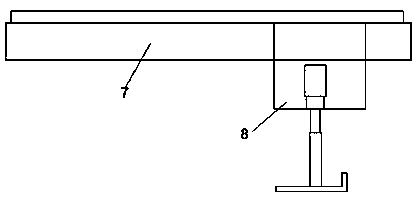

Suction craning transplanting device

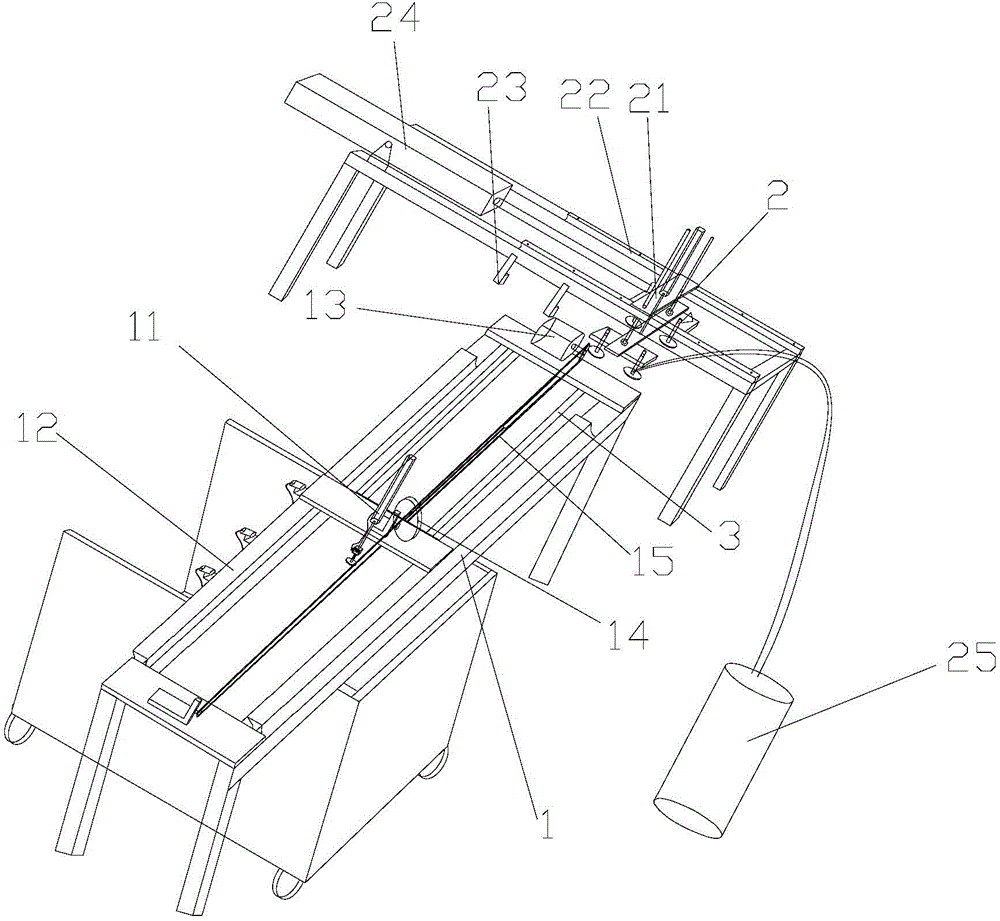

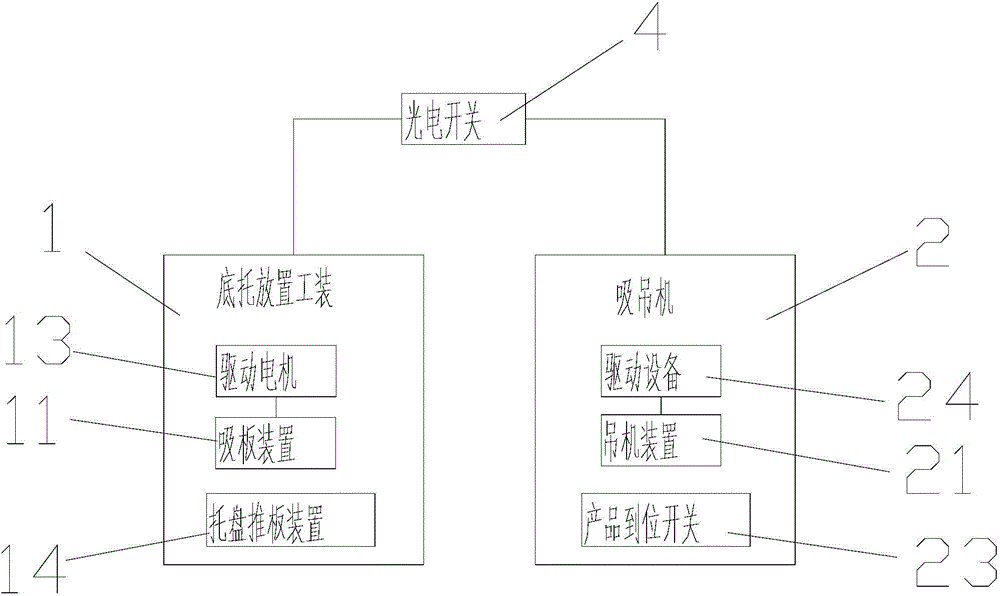

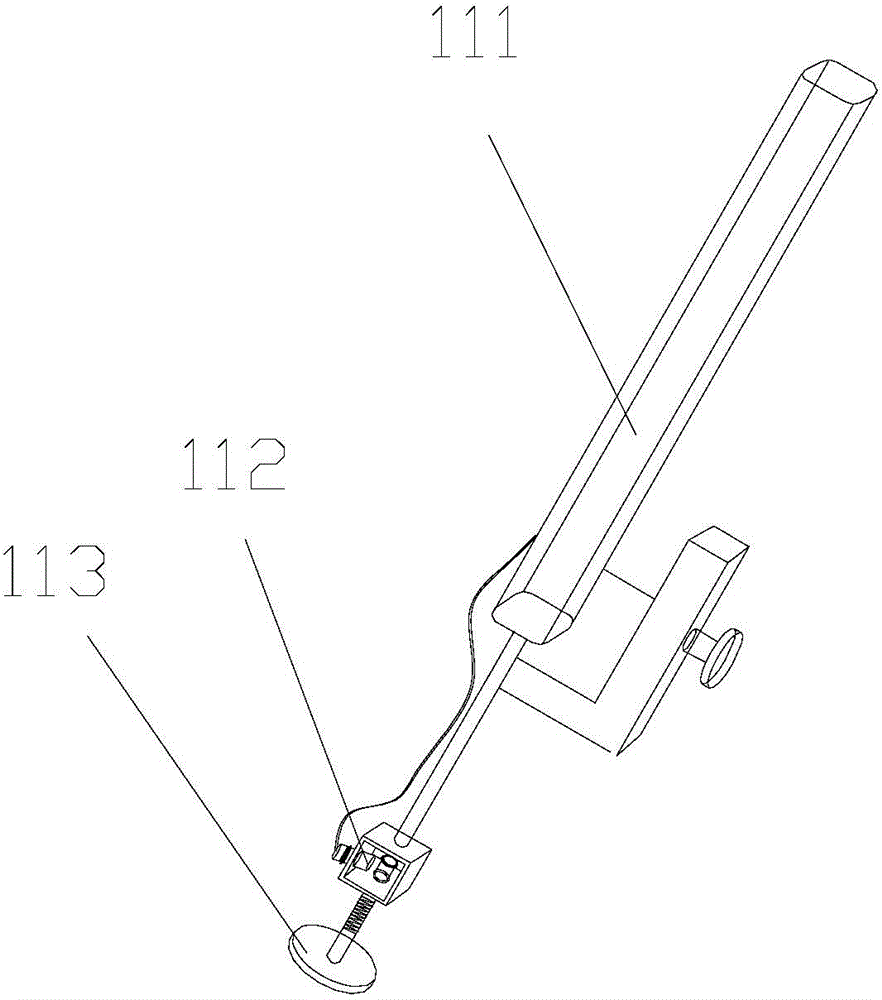

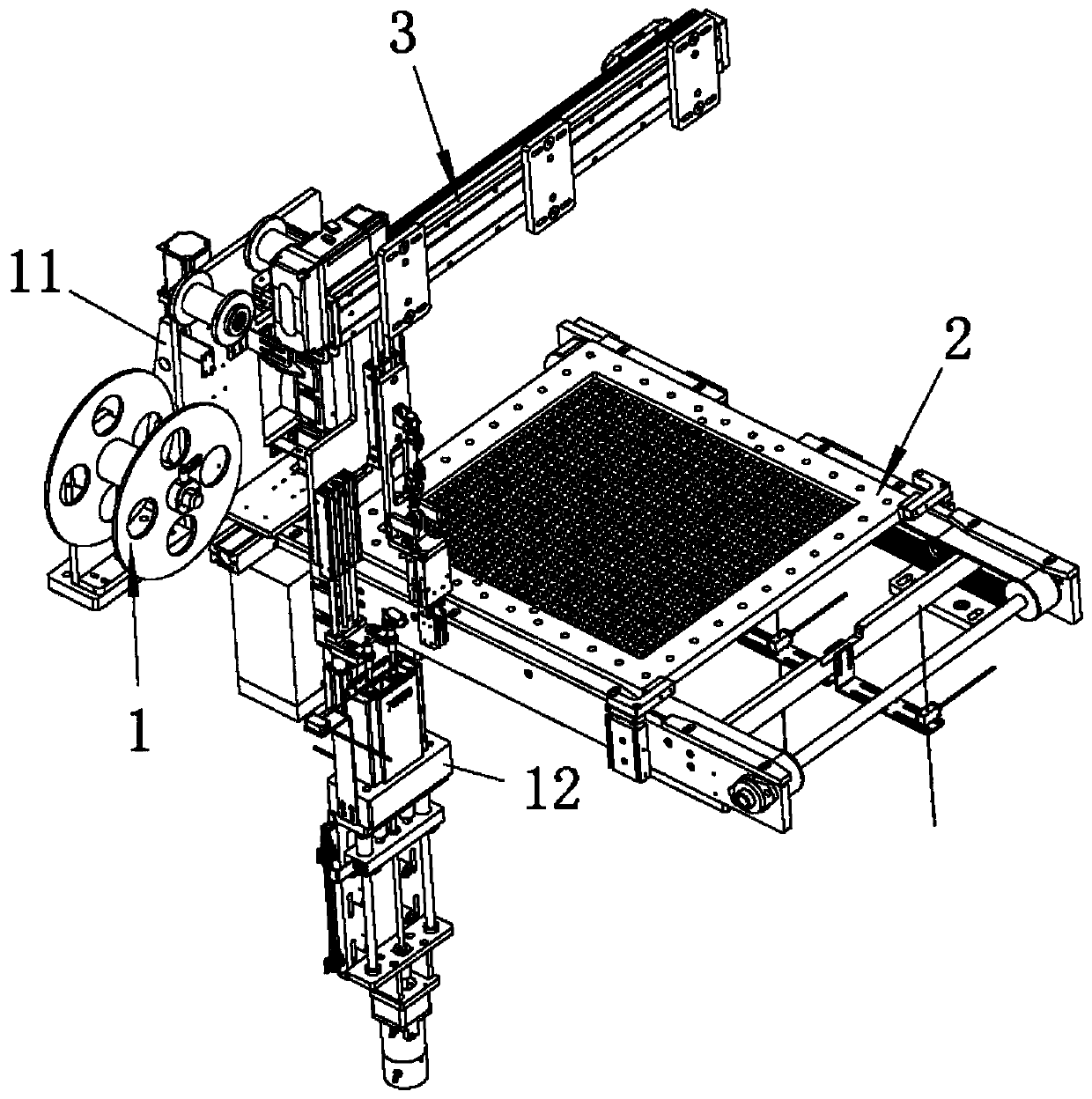

ActiveCN104692081ASimple structureReduce labor costsConveyorsControl devices for conveyorsEngineeringAssembly line

The invention provides a suction craning transplanting device which is used for moving a tray from a storage position to a preset position of an assembly line and assembling a machine body on the tray. The suction craning transplanting device comprises an optoelectronic switch, a mount placement tool and a suction crane, wherein the optoelectronic switch is respectively connected with the mount placement tool and the suction crane electrically, the optoelectronic switch senses the tray on the preset position of the assembly line and controls the mount placement tool and the suction crane to work according to the sensing information. The suction craning transplanting device is simple in structure, a mount is automatically placed, a whole machine is automatically transferred, so that the labor cost is saved, and the working efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Automatic auxiliary material placement device

PendingCN111409913AImplement automatic placementImprove placement efficiencyConveyorsPackagingControl engineeringTransfer mechanism

The invention relates to the technical field of automatic auxiliary material placement, and particularly discloses an automatic auxiliary material placement device which comprises a first feeding mechanism, a second feeding mechanism and a transferring mechanism. The transferring mechanism comprises a first support, a second support moving along the first support, a first driving piece used for driving the second support, a second driving piece arranged on the second support, a third support connected with the second driving piece, a fourth support rotationally arranged on the third support, athird driving piece used for driving the fourth support and a first cylinder clamp arranged on the fourth support and used for clamping auxiliary materials. In actual use, the first feeding mechanismsupplies the auxiliary materials automatically, the second feeding mechanism supplies circuit boards automatically, the transferring mechanism transfers the auxiliary materials supplied by the firstfeeding mechanism to the circuit boards supplied by the second feeding mechanism, automatic placement of the auxiliary materials is achieved, workers do not need to place the auxiliary materials manually, and the placement efficiency and the placement yield of the auxiliary materials are improved.

Owner:XUNDE MACHINERY DONGGUAN CO LTD

Automatic discharging mechanism for fully-automatic colored tile forming production line

PendingCN109650028AAccurate placementReduce labor intensityDischarging arrangementConveyor partsProduction lineCompression molding

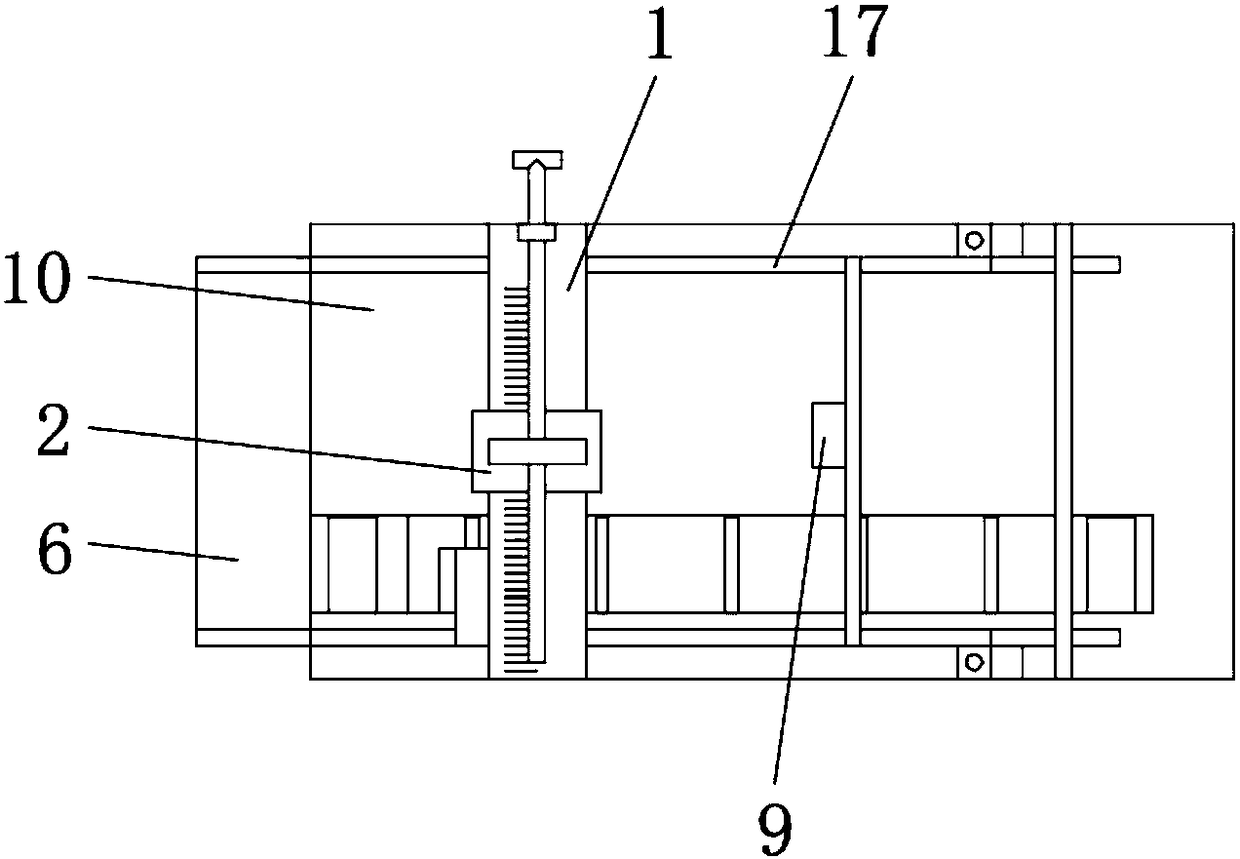

The invention discloses an automatic discharging mechanism for a fully-automatic colored tile forming production line. The automatic discharging mechanism comprises a rack and a sliding seat arrangedat the lower end of the rack, a mold placing seat is arranged on the sliding seat, a mold conveying device is arranged on the front side of the rack, a conveyor belt is arranged at the middle positionof the mold conveying device, a lifting mold stopping plate is arranged at the front end of the mold conveying device, a sliding groove with a wire rail is formed in the mold conveying device, a lifting seat with a top plate is arranged on a wire rail slider, a sensing area is arranged at the rear end of the lifting mold stopping plate, a spraying nozzle installing plate is arranged at the upperend of the sensing area, a guide rail bracket is arranged on the front side of the rack, a lifting and clamping mechanism is arranged on a guide rail, the two sides of the lower end of the placing area are provided with push plates, and the ground is provided with a pushing discharging device. The automatic discharging mechanism is simple in structure and reasonable in design, can ensure the precise mold placement position, can automatically place cement tiles obtained after compression molding on a placement frame, reduces the labor intensity of a worker and increases the production speed.

Owner:HAIAN TIANPENG MACHINERY MFG

Ultrasonic sponge mask production equipment

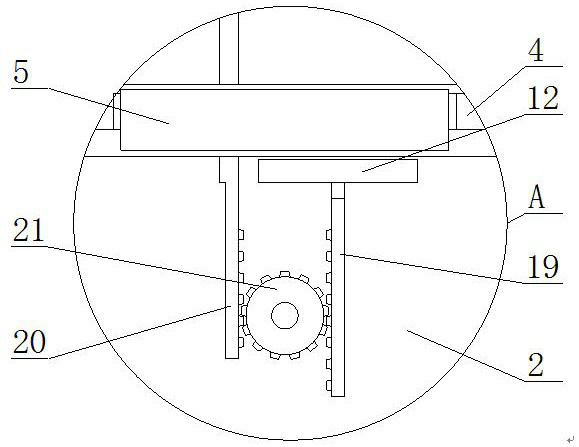

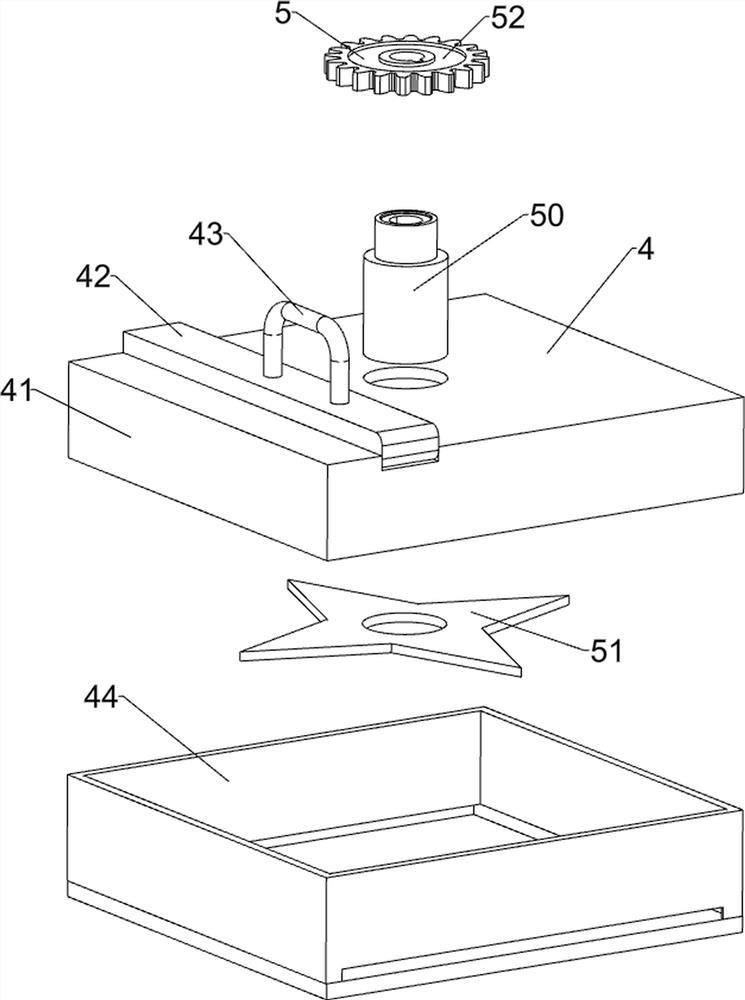

ActiveCN111660576AAdjustable distanceImplement automatic placementProtective garmentClothes making applicancesUltrasonic weldingGear wheel

The invention belongs to the technical field of mask production equipment, and discloses ultrasonic sponge mask production equipment. The ultrasonic sponge mask production equipment comprises a supporting frame, a device platform is fixedly mounted at the top of the supporting frame, and a conveying roller is fixedly mounted on the front of an inner cavity of the device platform. A conveyor belt is movably installed on the outer surface of the conveying roller, a supporting seat is fixedly installed on the top of the device platform and located at the top of the conveyor belt, a telescopic rodis fixedly installed on the inner side of the supporting seat, and the output end of the telescopic rod is fixedly connected with a ruler board. According to the ultrasonic sponge mask production equipment, through the coordination of a gear, a first rack, a second rack, a supporting disc, and a placement disc, when masks on the placement disc run to the lower part of an ultrasonic welding head,it is guaranteed that the supporting disc can lift the placing disc during the downward movement of an ultrasonic welding head, and the squeezing force between mask belts and the masks is relatively large

Owner:季广春

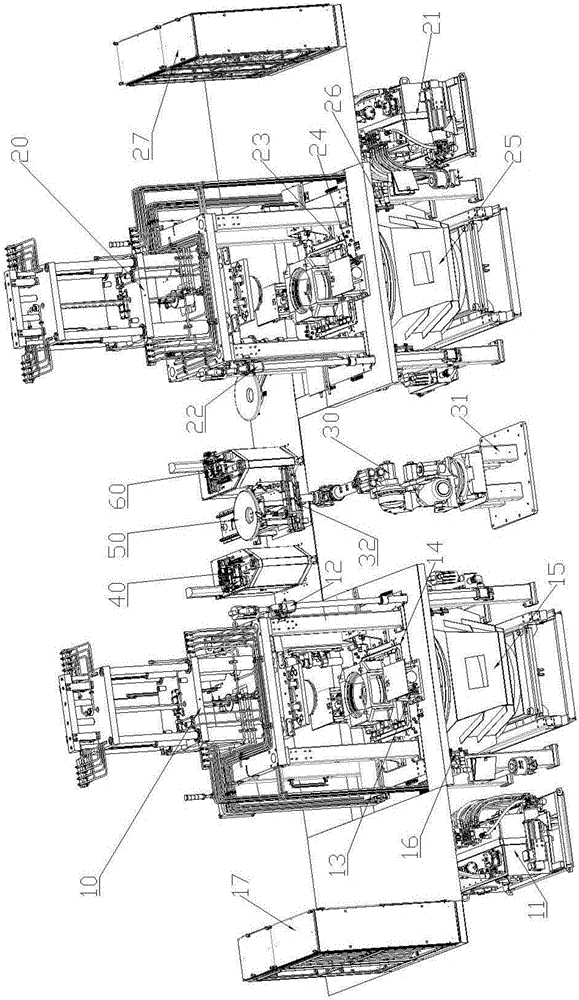

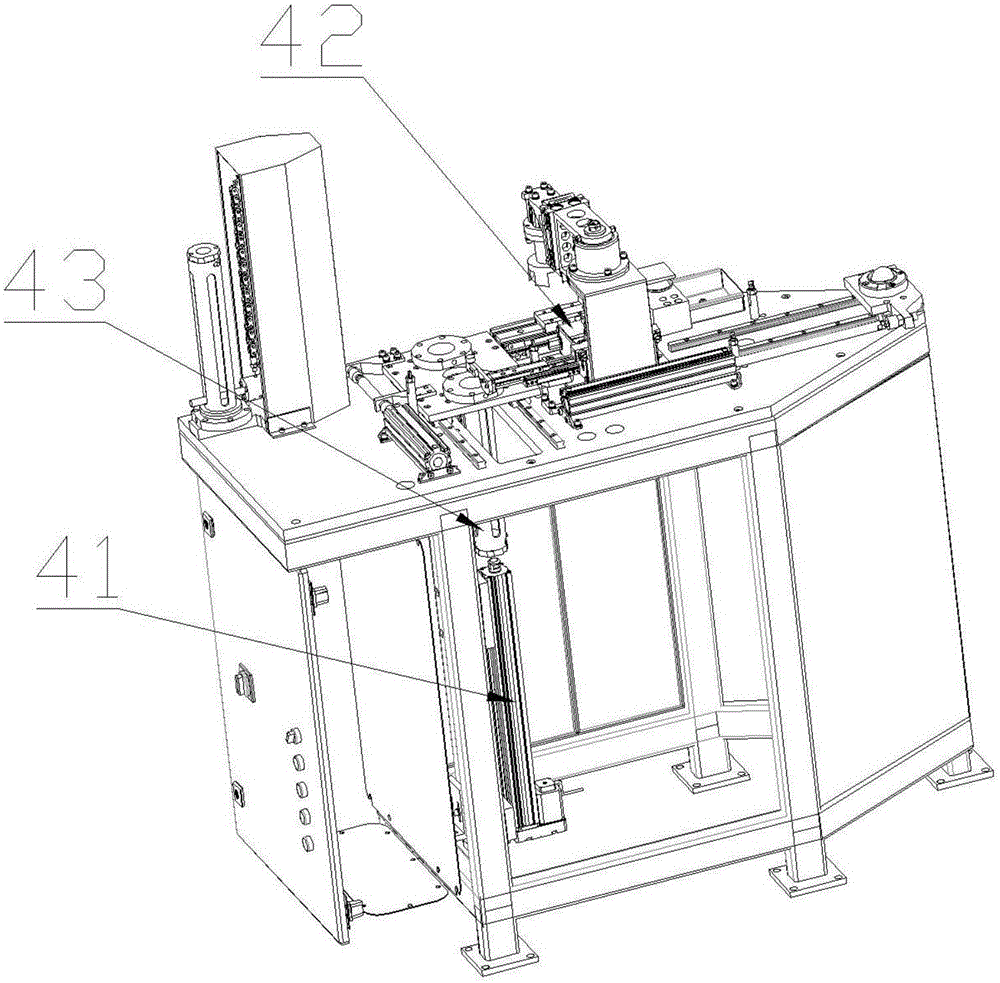

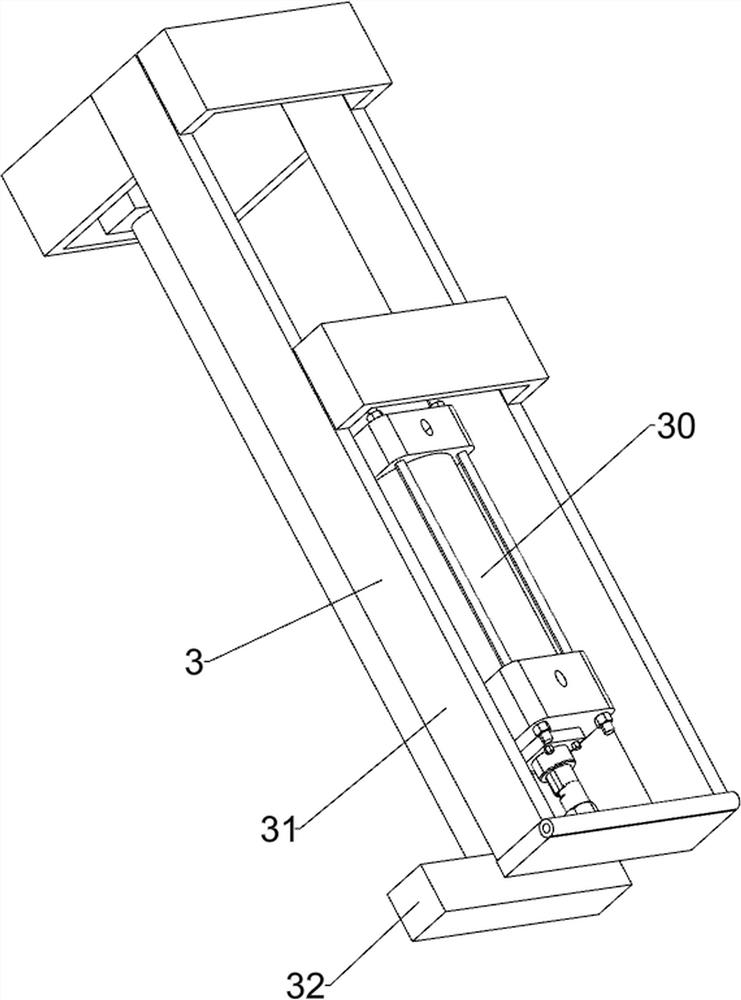

Low-pressure casting automation unit

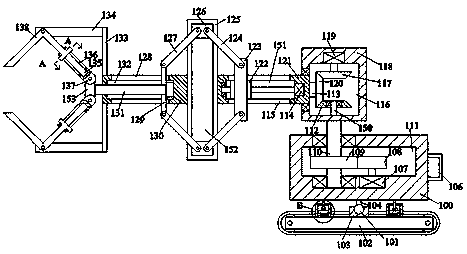

The invention discloses a low-pressure casting automation unit. The low-pressure casting automation unit is characterized by comprising at least one low-pressure casting machine and a six-degree-of-freedom robot; and the six-degree-of-freedom robot is provided with a tail end mechanism assembly, and the tail end mechanism assembly comprises a synchronization clamp and a filtering net suction mechanism installed on the synchronization clamp. The low-pressure casting automation unit equipment further comprises a filtering net supply mechanism, the filtering net supply mechanism comprises an electric actuator, an electric swing table and a net barrel, the electric actuator and the electric swing table gradually separate filtering nets in the net barrel one by one and transfer the filtering nets to the outlet position, the filtering nets are waiting for suction by the six-degree-of-freedom robot to the low-pressure casting machine, and therefore safe, energy-saving, unmanned and intelligent production of low-pressure casting is achieved.

Owner:QINHUANGDAO XINYUE INTELLIGENT EQUIP CO LTD

Automatic and uniform protective scrap placing equipment for egg packaging

ActiveCN112407470AAchieve automatic placementEvenly placedPackaging eggsUsing shock-absorbing mediaStructural engineeringScrap

The invention relates to protective scrap placing equipment, in particular to automatic and uniform protective scrap placing equipment for egg packaging. The technical problem to be solved by the invention is to provide the automatic and uniform protective scrap placing equipment for egg packaging, which is used for automatically and uniformly placing the protective scraps when eggs are packaged.The automatic and uniform protective scrap placing equipment for egg packaging comprises a bottom plate and a supporting table, wherein the top of the bottom plate is provided with the supporting table. The automatic and uniform protective scrap placing equipment for egg packaging further comprises a pushing mechanism, a moving mechanism, a fixing plate, a material ejecting plate and a collectingframe, wherein the pushing mechanism is arranged on the left side of the top of the supporting table; the moving mechanism is arranged on the right side of the top of the supporting table; the fixingplate is arranged on the left side of the top of the supporting table; the material ejecting plate is arranged on the upper part of the right side of the fixing plate; a discharging opening is formedin the right side of the supporting table; and a collecting frame is placed on the right side of the top of the bottom plate and is located below the discharging opening. The automatic and uniform protective scrap placing equipment for egg packaging provided by the invention achieves the effects that when eggs are packaged, protective scraps are automatically and uniformly placed.

Owner:利川市焕然农业发展有限公司

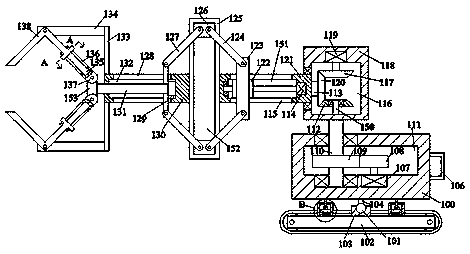

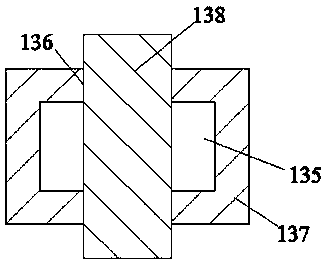

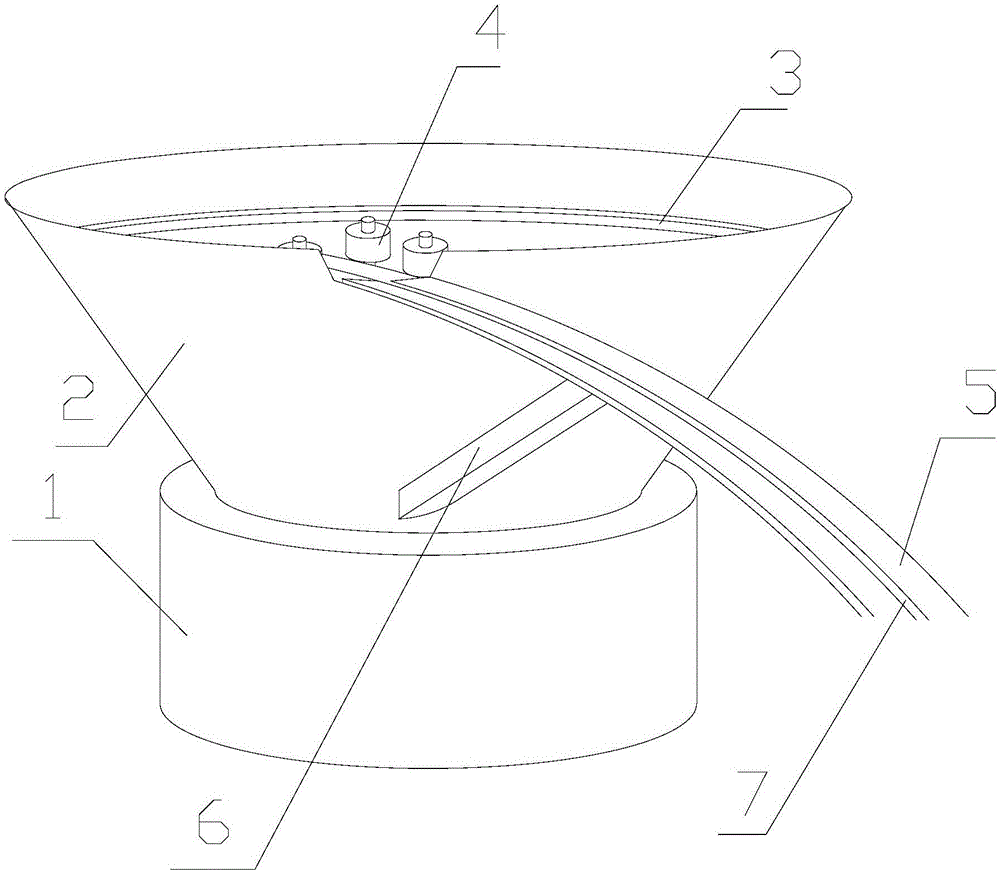

Feeding machine

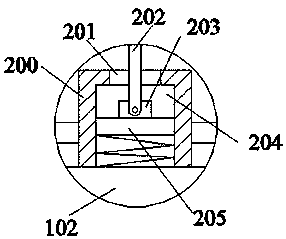

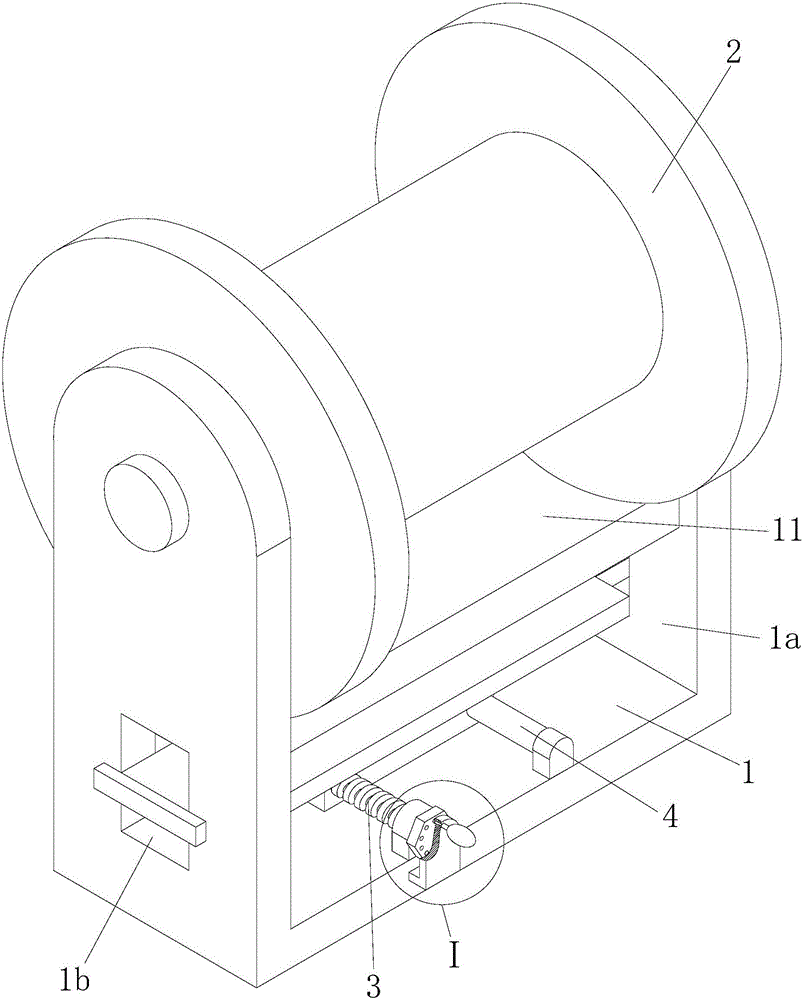

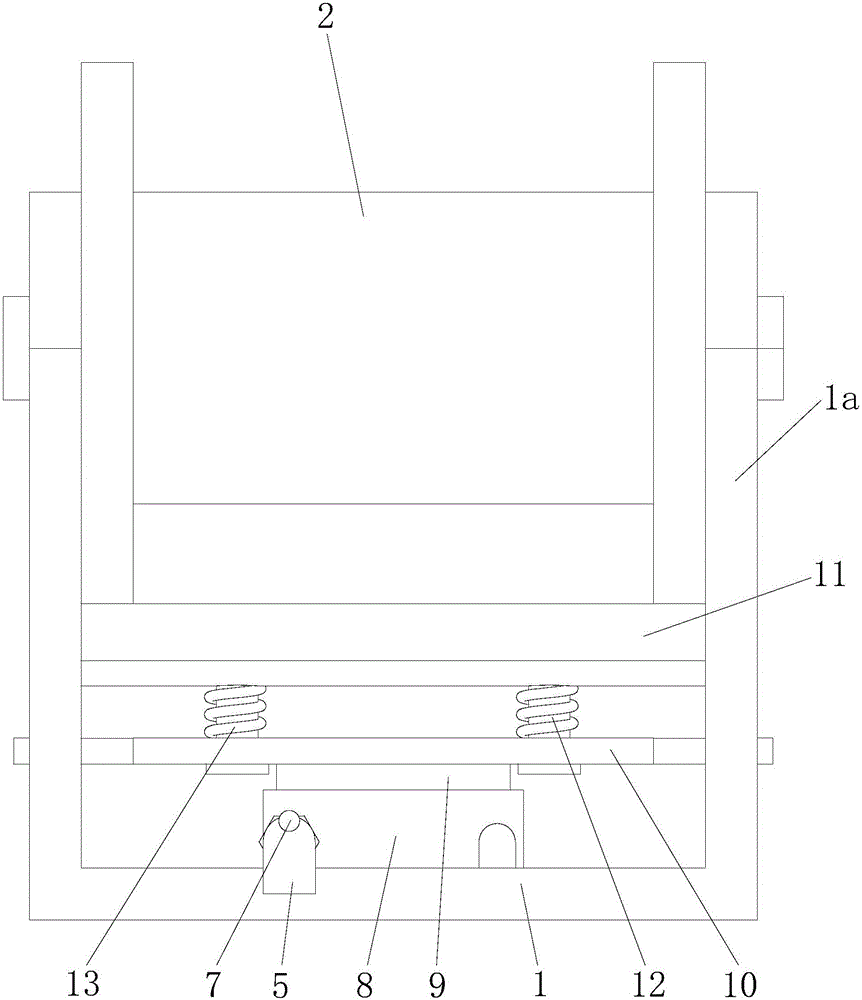

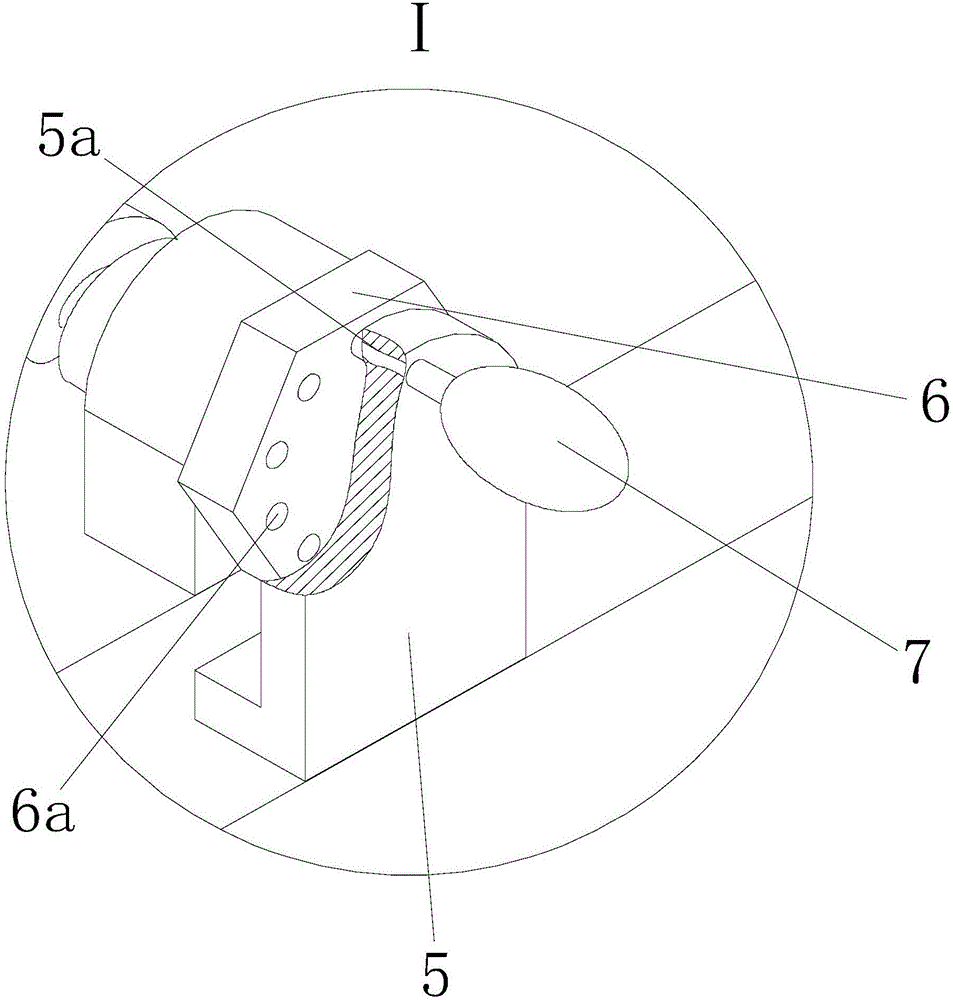

InactiveCN105035663ARealize transportationReduce transmission efficiencyJigging conveyorsConveyor partsPressure castingCasting mold

The invention discloses a feeding machine. The feeding machine comprises a vibration base (1), a material barrel (2), a spiral rail (3), a plurality of rotating wheels (4) and a feeding rail (5), wherein the vibration base (1) is arranged under the material barrel (2) in the vertical direction; the spiral rail (3) is arranged on the inner surface of the material barrel (2); one opening in one end of the spiral rail (3) is formed in the bottom surface of the material barrel (2); one opening in the other end of the spiral rail (3) is communicated with the feeding opening of the feeding rail (5); the feeding rail (5) penetrates through the material barrel (2) and is fixedly connected to the outer surface of the material barrel (2); the rotating wheels (4) are arranged on one side of the spiral rail (3); the lateral sides of the rotating wheels (4) face the spiral rail (3), and the rotating wheels (4) can freely rotate in the axial direction. The feeding machine solves the problem that in the prior art, when raw materials are placed on a pressure casting mold through manual work, the operation is inconvenient, and realizes the operation that raw materials are automatically conveyed on by one.

Owner:ANHUI JIANGWEI PRECISION IND

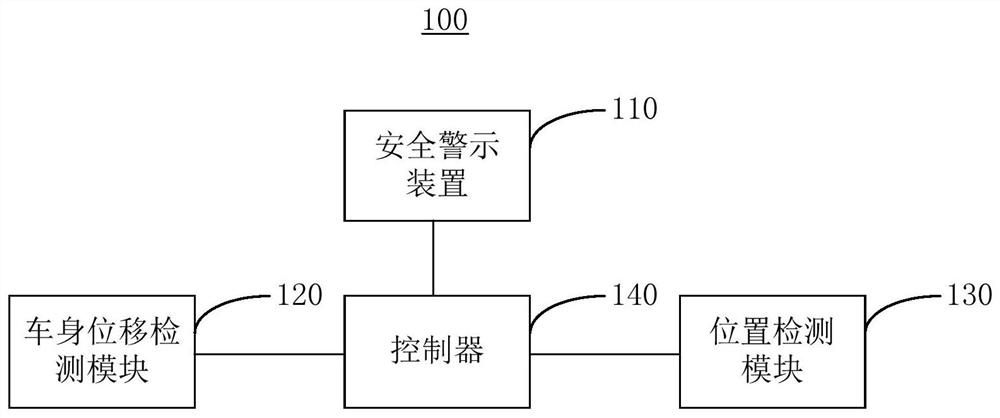

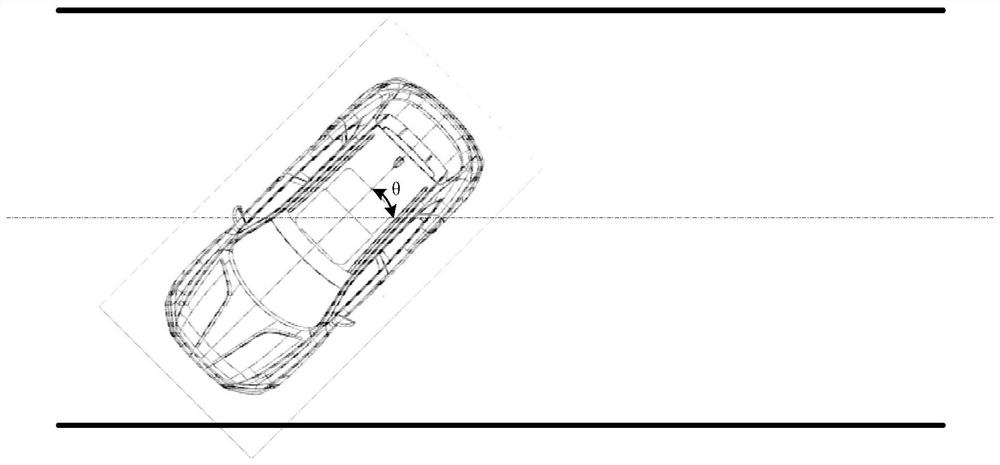

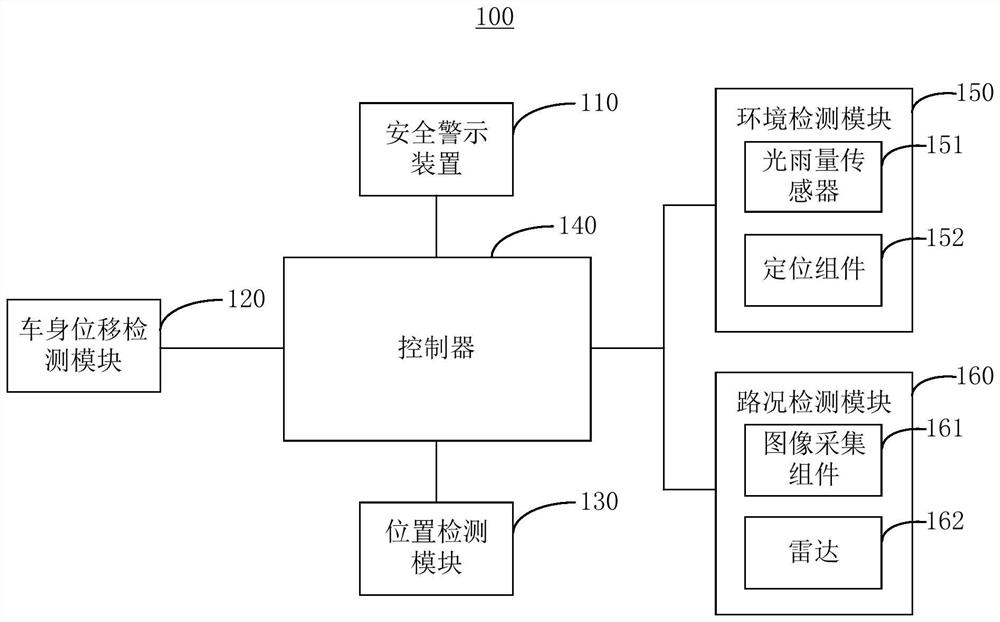

Safety warning system and vehicle

InactiveCN111688573AImplement automatic placementPortable emergency signal deviceRoad trafficReliability engineering

The invention relates to a safety warning system and a vehicle. The safety warning system comprises: a safety warning device, which is installed on the vehicle and can move; a vehicle body displacement detection module, which is used for acquiring deviation angle information of the vehicle; a position detection module, which is arranged on the safety warning device and used for acquiring positioninformation of the safety warning device in real time; a controller, which is respectively connected to the vehicle body displacement detection module and the position detection module and used for controlling separation of the safety warning device and the vehicle after receiving a preset placement instruction, determining the moving direction of the safety warning device according to the deviation angle information, and controlling the safety warning device to move to a set placing position according to the moving direction and the real-time position information of the safety warning device.By means of the technical scheme, the safety warning device can be automatically placed according to road traffic regulations, and compared with manual placement, the safety warning device is safer and more convenient.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

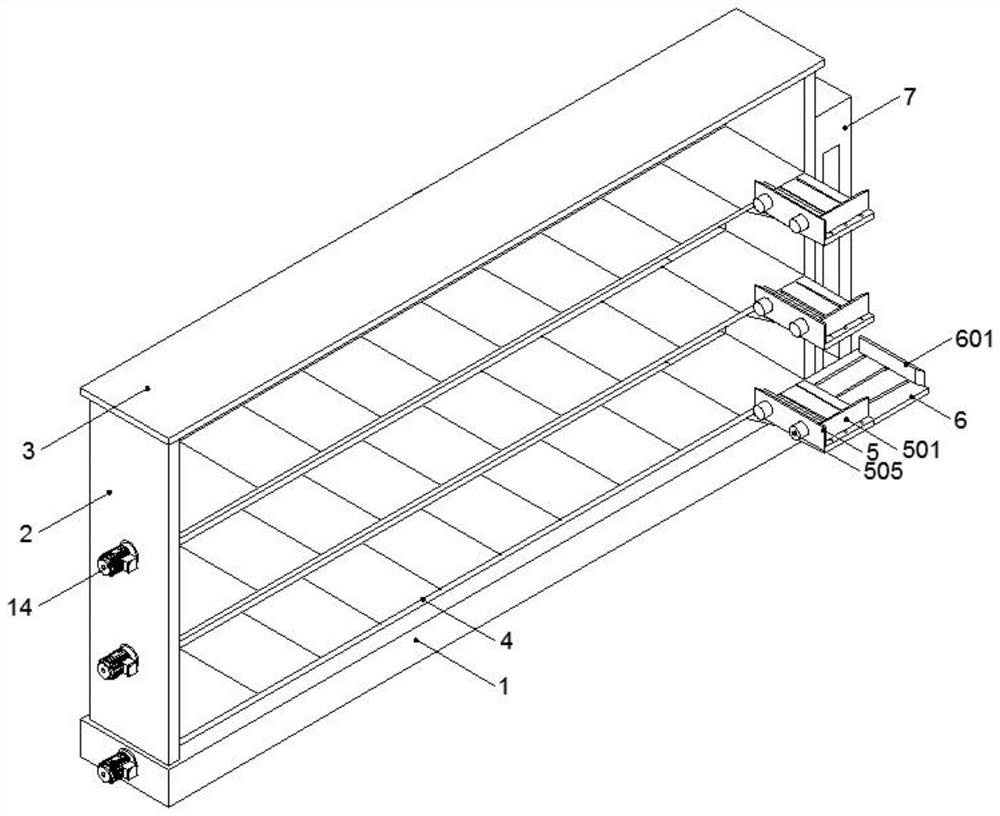

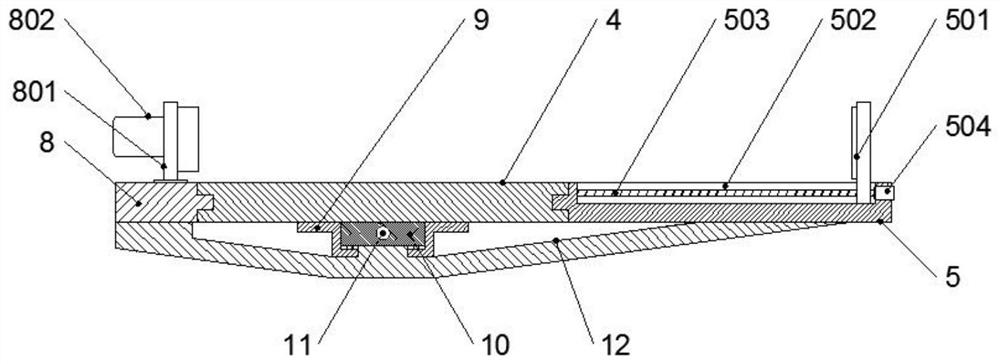

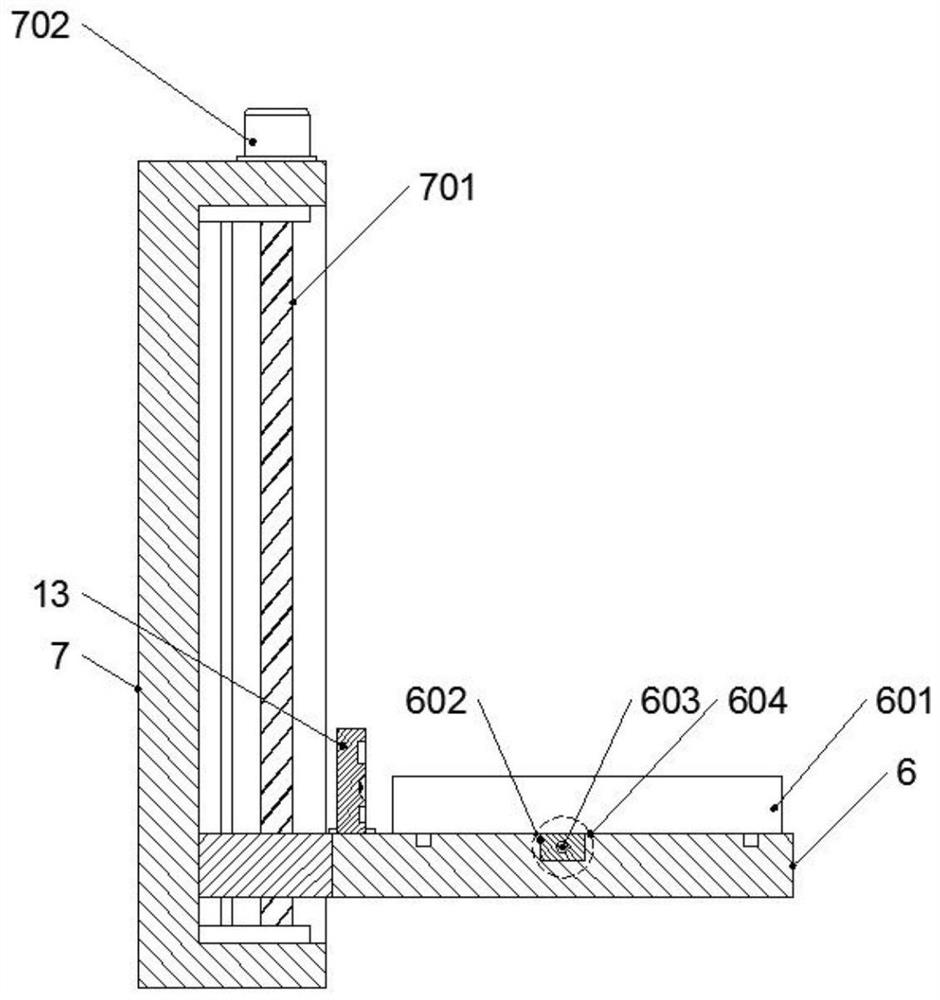

High-precision automatic goods shelf system special for stereoscopic warehouse

PendingCN112158502AImprove intelligenceImplement automatic placementStorage devicesStructural engineeringMechanical engineering

The invention discloses a high-precision automatic goods shelf system special for a stereoscopic warehouse. The high-precision automatic goods shelf system comprises a fixing base, supporting plates are vertically and fixedly connected to the left end and the right end of the upper end face of the fixing base, the top ends of the supporting plates are jointly connected with an upper fixing plate,multiple partition plates are arranged at the bottom of the upper fixing plate at equal intervals, the left ends and the right ends of the partition plates are fixedly connected with the supporting plates, feeding tables are arranged on one sides of the partition plates, first push plates are installed on the upper end faces of the feeding tables, the first push plates are perpendicular to the supporting plates, first sliding grooves are formed in the positions, close to the centers of the bottoms of the first push plates, of the feeding tables, first lead screws are fixedly installed in the first sliding grooves, sliding blocks are installed on the first lead screws, and the top ends of the sliding blocks are fixedly connected with the first push plates. The high-precision automatic goodsshelf system special for the stereoscopic warehouse is reasonable in structure, novel in design, easy to operate, capable of effectively improving the goods storage precision and intelligence of warehousing, and convenient to widely apply and popularize.

Owner:TIANJIN MASTER LOGISTICS EQUIP CO LTD

Filler

InactiveCN110447949AImplement autofillAchieve moldingDevices for heating/cooling reflex pointsCigarette manufactureFilling materialsReciprocating motion

The invention discloses a filler, comprising a filling portion and a paper tube portion, wherein the filling portion comprises a feeding system, a filling system, a discharging system and a filling portion rack, the paper tube portion comprises a paper tube box system, a paper tube docking system and a paper tube portion rack, the feeding system is used for automatic feeding, the filling system isused for automatically filling a filling material into a filling groove to realize automatic forming, the discharging system is used for pushing a formed material into a paper tube, the paper tube box system is used for automatically placing the paper tube in a paper tube groove, and the paper tube docking system is used for realizing the automatic docking of the paper tube and a docking tube through the reciprocating motion of the paper tube groove. The filler disclosed by the invention realizes the automatic filling and forming of the material, realizes the automatic docking of the paper tube, and does not require manual contact with the material and the paper tube in the whole process, thereby improving the automation degree of the filler and the processing efficiency of products.

Owner:亿都珩科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com