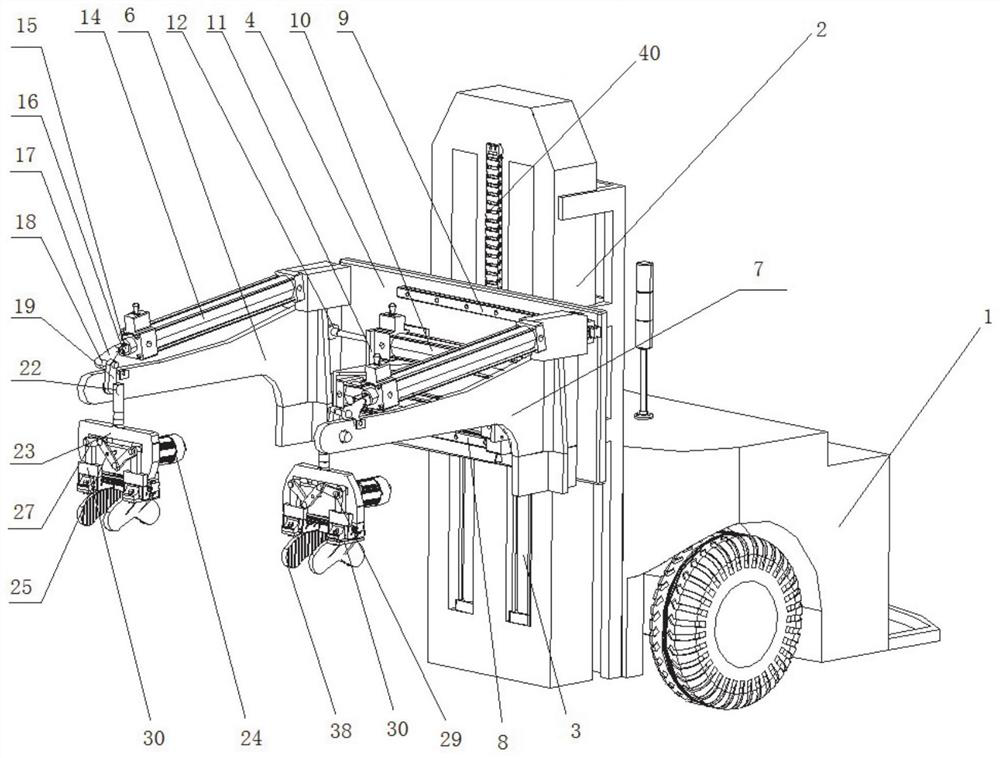

Automatic material frame clamping, overturning and transporting device and working method

A technology of transportation device and material frame, which is applied in the direction of lifting device, etc., can solve the problems of time-consuming and labor-intensive, heavy metal parts, affecting processing efficiency, etc., and achieve the effect of high fixing strength, reducing labor intensity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

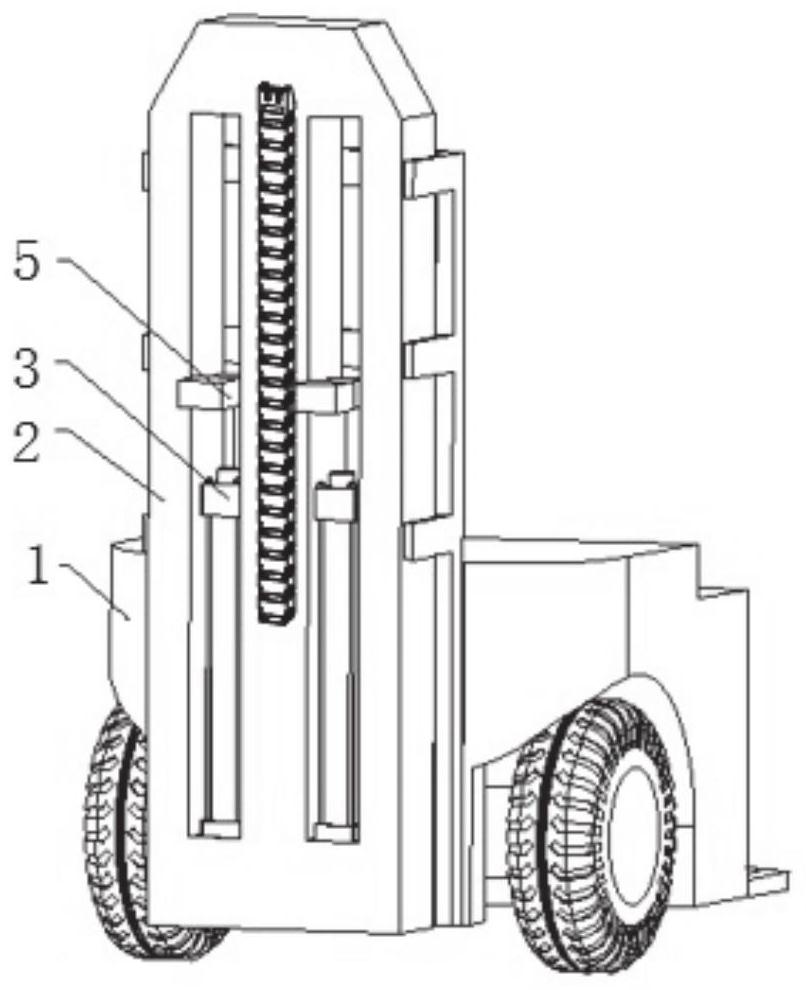

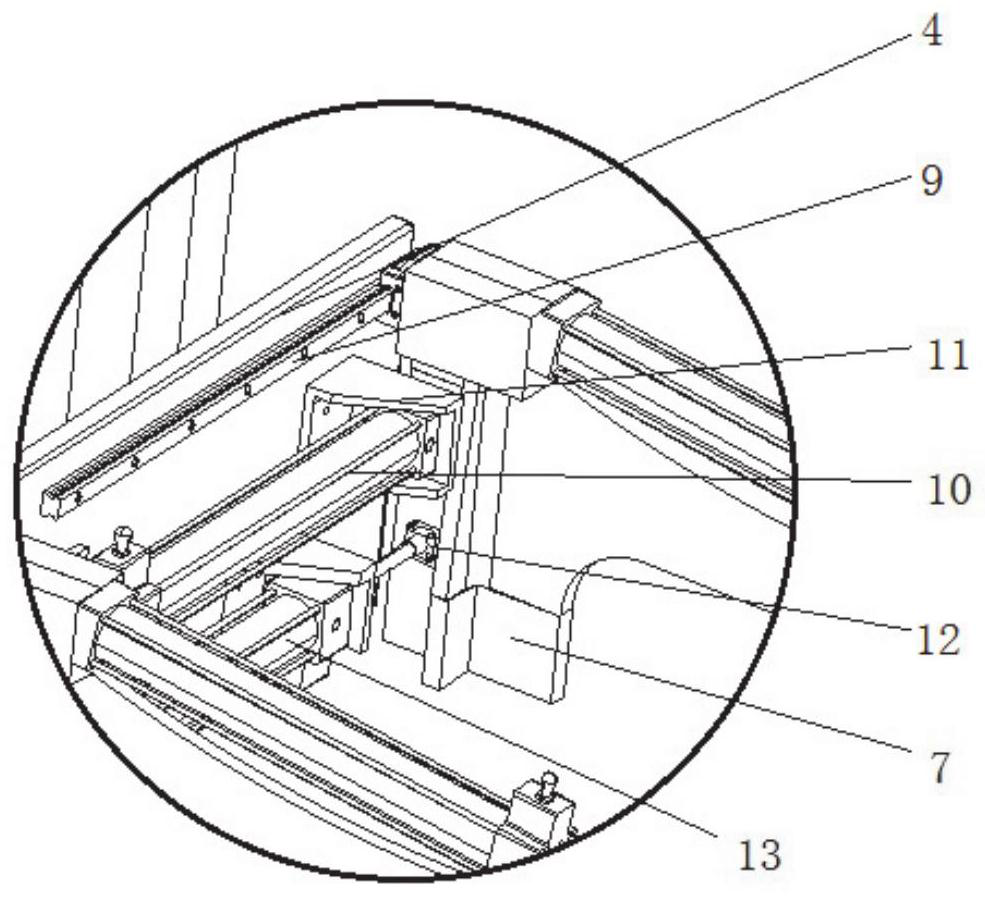

Method used

Image

Examples

Embodiment 2

[0062] This embodiment discloses the working method of the material frame automatic clamping and flipping transportation device described in Embodiment 1: the flipping drives the cylinder to work, the first splint and the second splint are pre-adjusted to the vertical setting, and the AGV automatically guides the vehicle to move to the setting. At a certain reclaiming position, the lifting cylinder works to drive the lifting backboard to rise to the set height, then the AGV automatically guides the vehicle to move, the first horizontal driving cylinder and the second horizontal driving cylinder work, and adjust the first fixing part and the second fixing part The position makes the two clamping mechanisms adapt to the width of the material frame, and the lifting cylinder works to drive the lifting backplane down, so that the two side frames of the material frame are located between the first splint and the second splint of the two clamping mechanisms. The stepping motor works t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com