Patents

Literature

311results about How to "Achieve molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

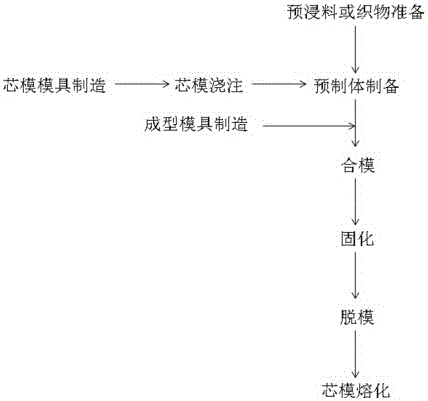

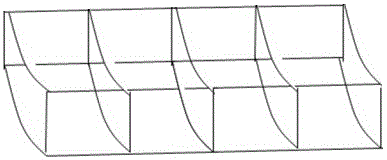

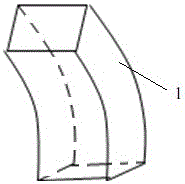

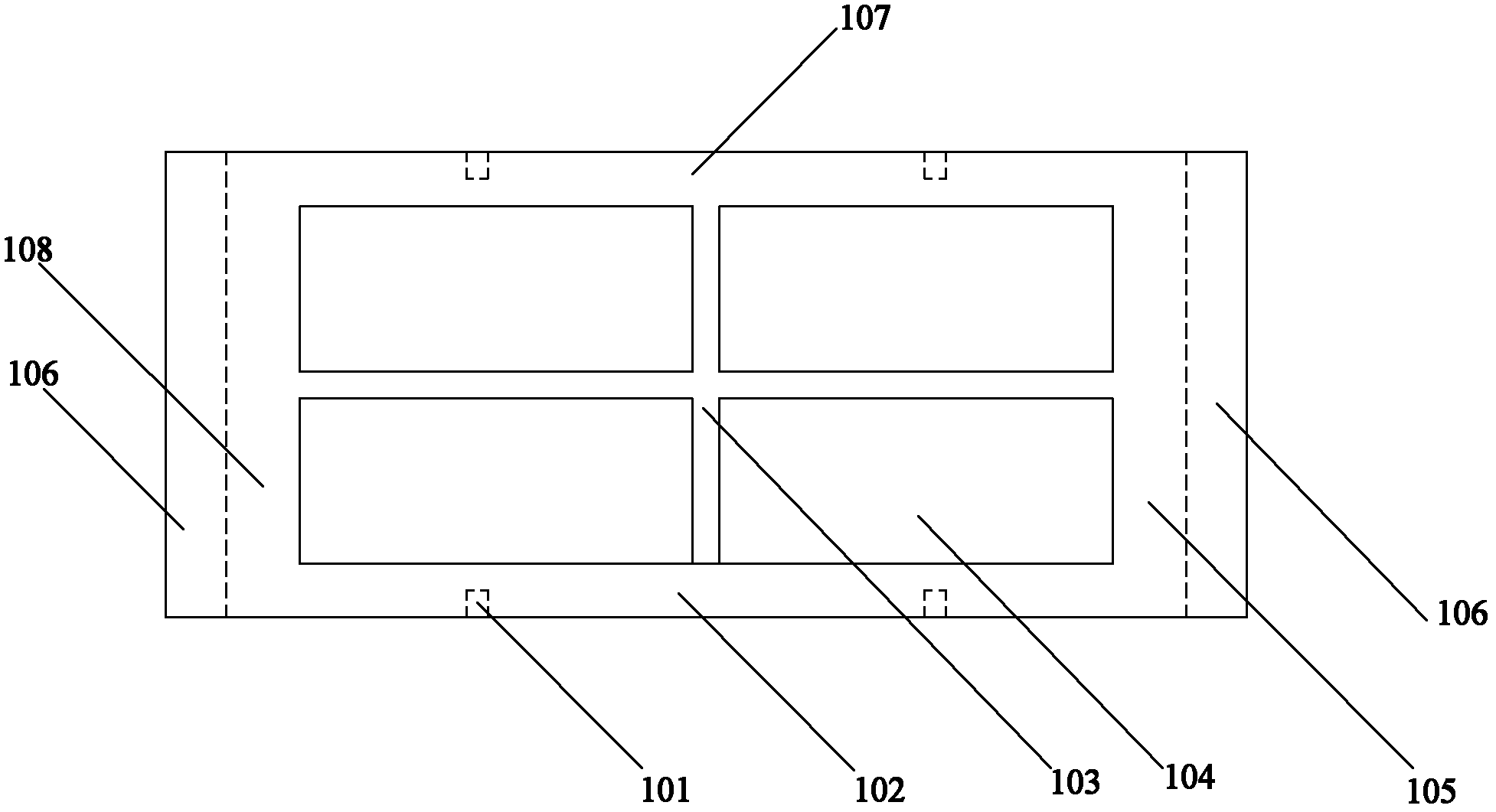

Integral forming technology for hollow multi-cavity special-shaped surface composite material complex structural member

The invention provides an integral forming technology for a hollow multi-cavity special-shaped surface composite material complex structural member. The technology includes the steps that low-melting-point alloy is subjected to low-pressure casting, and a fusibility mold core is obtained to serve as a mandrel; the prepreg or fabric is laid on the outer surface of the mandrel of the fusibility mold core to be made into a prefabricated part; and after the mandrel with the prefabricated part and an outer mold body of a workpiece mold are subjected to die assembly solidification, a composite material grating workpiece with the fusibility low-melting-point alloy mandrel is placed into a drying box, and accordingly a qualified composite material grating is obtained after fusion. The integral forming technology for the hollow multi-cavity special-shaped surface composite material complex structural member solves the integral forming problem of the hollow multi-cavity composite material complex structural member with the complex inner contour and curvature, the low-melting-point alloy is used for preparing the mandrel, the cost is much lower than that of a metal mandrel, the manufacturing cycle is short, efficiency can be improved, the processing difficulty and technique implementation difficulty are low, and demolding can be performed easily.

Owner:HENGSHEN

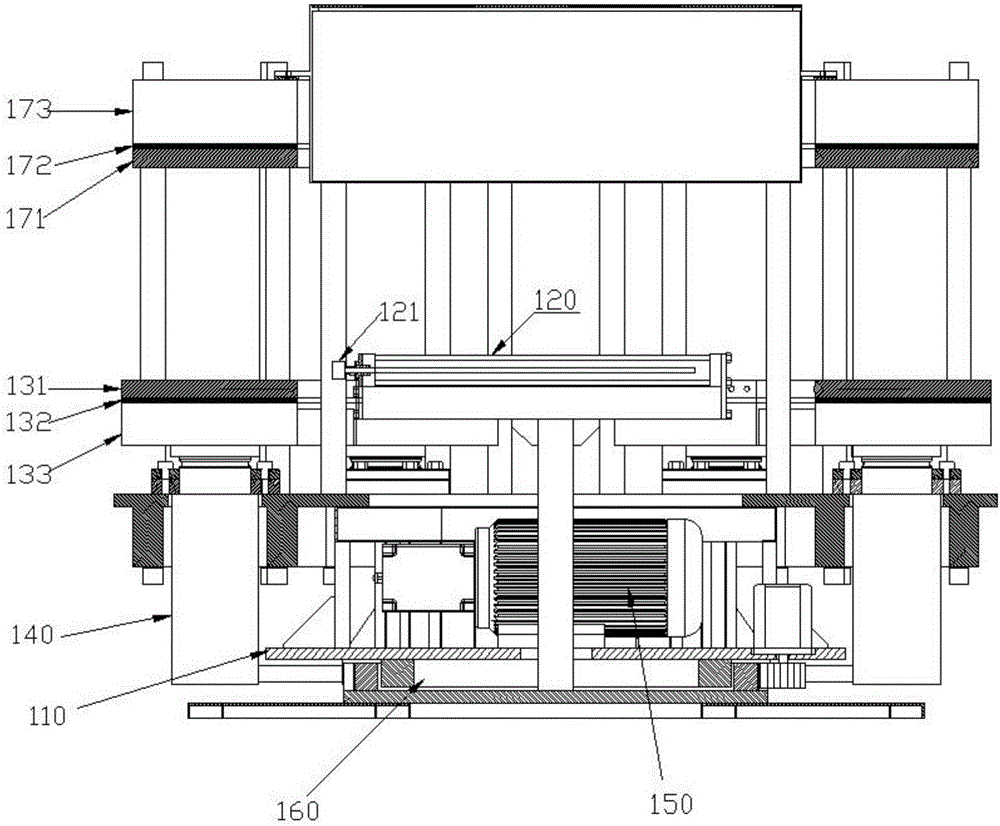

Brick molding device and molding equipment

The invention discloses a brick molding device which comprises a mold pressing device and a mold receiving device, the same guiding device is adopted in the vertical moving process of the mold pressing device and the mold receiving device, a mold placing area is arranged on the mold receiving device, supporting arms are arranged on two sides of the mold placing area, and a mold locating device is further arranged on the mold receiving device. The invention further discloses equipment provided with the brick molding device. Functions of receiving, locating, pressing and drawing of molds can be achieved by arranging only one mold receiving device so that the mold receiving device can be matched with the structures of a groove and a locating hole of the brick molding mold, operation is convenient, structure is simple, and production efficiency is improved.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

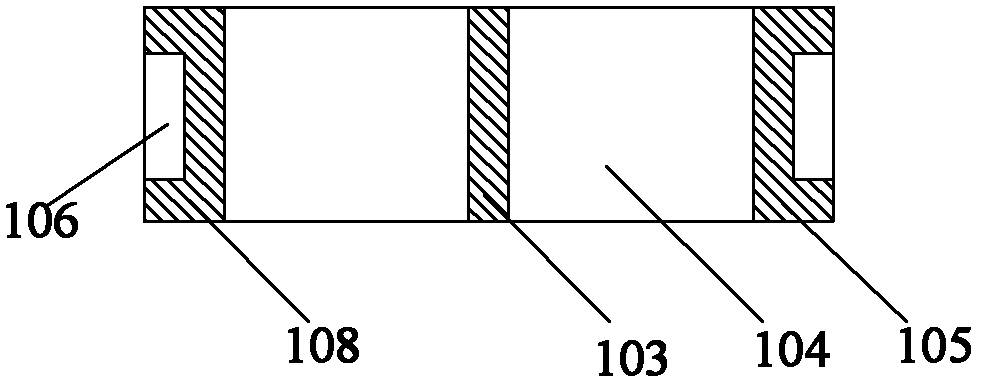

High-unwinding-tension spandex oil preparation

The invention discloses a high-unwinding-tension spandex oil preparation, which comprises the following components: 40-90% of mineral oil, 5-60% of dimethyl silicone oil, 1-10% of functional modified silicone oil and 3-15% of high-carbon isomerized fatty alcohol, and the sum of content percentages is 100% by total weight. The oil preparation disclosed by the invention is mainly applied to dry spinning, and has an outstanding characteristic that fibers both have a moderate astringent sliding degree so as to facilitate the forming of the fibers, and have an extremely good lasting barrier property so as to prevent inner-layer yarn bundles from being adhered, namely, the fibers are slidable but astringent, and astringent but non-stick, so that the astringent sliding degrees between fibers are kept, and the friction among fibers and metals is reduced, therefore, good astringent sliding property, permeability, antistatic property and unwinding property can be given to fibers, and then the perfect unification of forming and unwinding is achieved.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

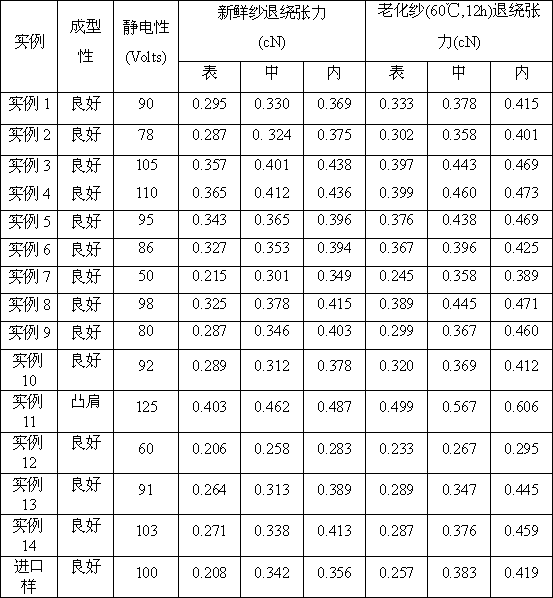

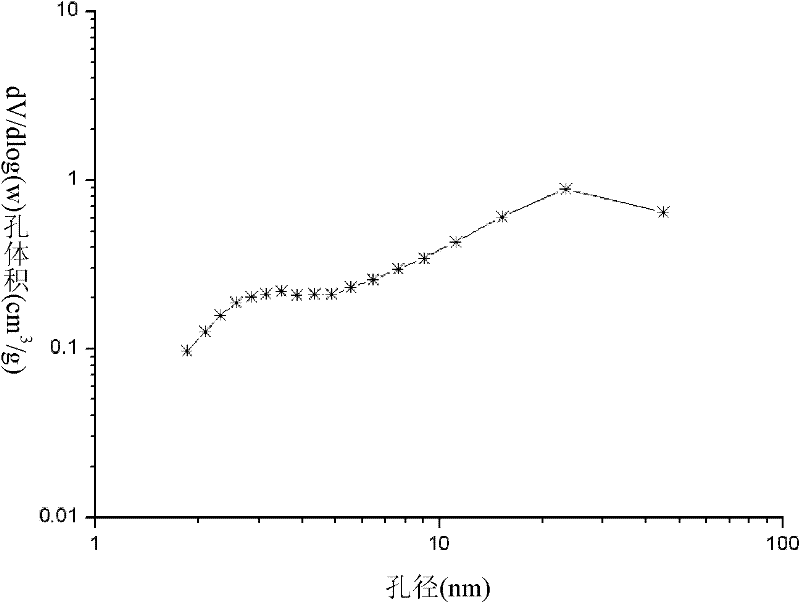

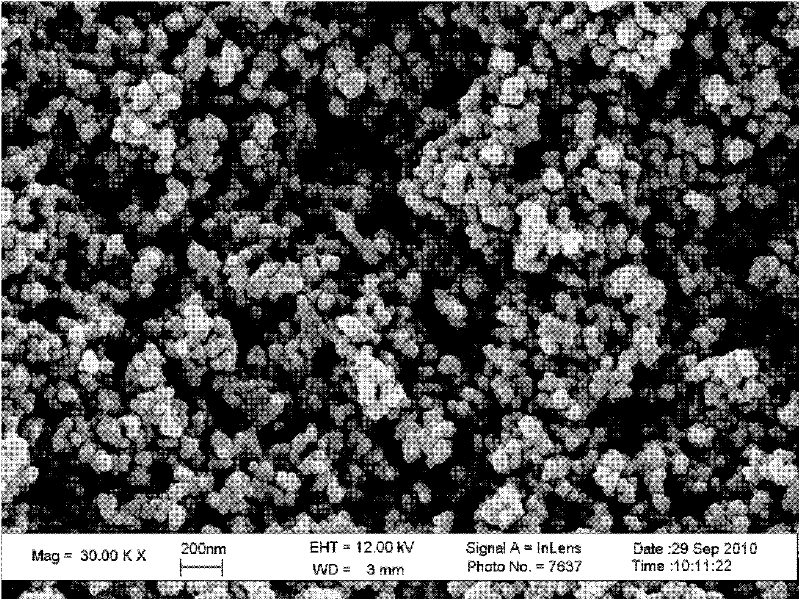

Preparation method of block high temperature resistant silicon-charcoal composite aerogel material

ActiveCN102351506AThe process is simple and easy to controlSimple and fast operationSupercritical dryingPolymer science

The invention a preparation method of a block high temperature (>=1000 DEG C) resistant silicon-charcoal composite aerogel material. According to the invention, reactants of resorcinol, formaldehyde, 3-amino propyl triethoxysilane, a hydrolysis agent of deionized water and a solvent of alcohols are prepared into wet gel through a one-step sol-gel reaction under effect of a basic catalyst. The wetgel is treated with ageing, solvent displacement, supercritical drying and high temperature heat treatment to obtain the block high temperature resistant silicon-charcoal composite aerogel. The preparation method of the invention has simple technology and good controllability. The silicon-charcoal composite aerogel prepared by the method of the invention overcomes defects of weak high temperature resistance and uneasy moulding due to low strength of aerogel; and the prepared aerogel can be used at a high temperature higher than 1000 DEG C for a long time and has characteristics of low density, large specific surface area, large pore volume, high strength and high temperature resistance.

Owner:NANJING UNIV OF TECH

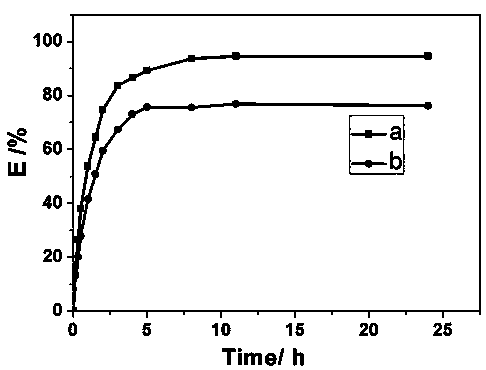

Cellulose/tannin hydrogel and preparation method thereof

The invention belongs to the technical field of materials and provides cellulose / tannin hydrogel. The cellulose / tannin hydrogel is a product which is obtained by adding a cross-linking agent into a mixed liquid of tannin and cellulose to perform cross-linking and immobilization reaction. A preparation method of the cellulose / tannin hydrogel comprises the following steps: (1) dissolving the cellulose into a solvent which consists of urea, alkaline and water or thiourea, alkaline and water at a low temperature to obtain a cellulose liquid; (2) adding tannin into the cellulose liquid to obtain a mixture I, putting the mixture I into an ice bath for ultrasonically dispersing uniformly to obtain a mixed liquid of tannin and cellulose; and (3) adding the cross-linking agent into the mixed liquid obtained in the step (2) and performing cross-linking and immobilization reaction at the same time to obtain the cellulose / tannin hydrogel. According to the cellulose / tannin hydrogel and the preparation method of the cellulose / tannin hydrogel disclosed by the invention, the cellulose is taken as an immobilization carrier, and tannin, especially condensed tannin with relatively good stability is fixed to the cellulose by adopting a homogeneous reaction way, so that the tannin is immobilized and processed into material so as to obtain a gel adsorbent with good performance, and thus, the cellulose / tannin hydrogel can be widely applied to water treatment.

Owner:ZHENGZHOU UNIV

Three-dimensional printing method

ActiveCN105711094ABroaden your optionsAchieve stabilityAdditive manufacturing apparatusResin matrixEngineering

The invention discloses a three-dimensional printing method, wherein a melt enters a three-dimensional printing device to print a finished product. The three-dimension printing device comprises a three-dimensional moving mechanism, a working platform mechanism and a computer control and driving system; the melt is made from a modified nylon material formed by a nylon resin matrix and a tackifying nucleating agent; the tackifying nucleating agent is prepared by compounding of ion liquid and nano carbon filler; and the ion liquid is formed by anions and cations, wherein the anions are alkyl imidazole ions. The device disclosed by the invention has the advantages of being simple and compact in structure, high in automation degree, easy to control, high in precision, high in efficiency and high in adaptability; the modified nylon material provided by the invention can effectively avoid edge warping during 3D printing; and a finally printed product has the advantages of being excellent in mechanical property, good in dimension stability, smooth in surface, low in cost and the like.

Owner:DONGHUA UNIV

Aluminum-silicon alloy seamless flux-cored wire for brazing as well as preparation and application

InactiveCN103551757AAchieve moldingWelding Welding RealizationWelding/cutting media/materialsWelding/soldering/cutting articlesSilicon alloySoldering

The invention provides an aluminum-silicon alloy seamless flux-cored wire for brazing as well as preparation and an application and belongs to the technical field of flux-cored wires. The aluminum-silicon alloy seamless flux-cored wire for brazing takes an aluminum-silicon alloy as an outer skin and takes a flux core as a soldering flux. The preparation comprises the following steps: preparing an outer-skin aluminum-silicon alloy strip by procedures of non-vacuum smelting, extrusion, rolling and annealing; rolling and closing the strip by a pressing roller to form a hollow welding rod with an O-shaped section and cladding flux core powder into the welding rod to prepare a seamless flux-cored wire blank with the diameter range of phi3.8mm-phi4.4mm; and then carrying out drawing and annealing processes to reduce the diameter to phi1.0mm and above. The aluminum-silicon alloy seamless flux-cored wire for brazing provided by the invention has the advantages that a brazing flux is carried and does not need to be added manually, and the automatic welding of brazing can be realized.

Owner:BEIJING UNIV OF TECH +1

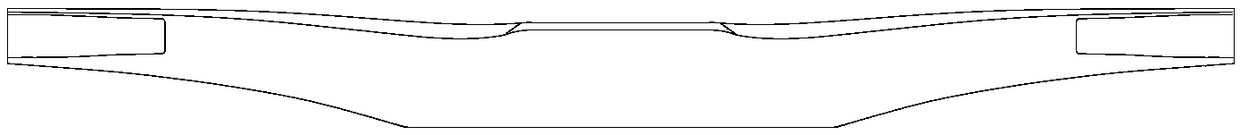

Manufacturing method of non-isometric closed square tube shaped carbon fiber beam structural workpiece of unmanned aerial vehicle

ActiveCN108943769ASolve structural layout optimization problemsSolve layout optimization problemsDomestic articlesFiberManufacturing engineering

The invention relates to a manufacturing method of a non-isometric closed square tube shaped carbon fiber beam structural workpiece of an unmanned aerial vehicle. The manufacturing method comprises the following steps: manufacturing a mold; then manufacturing rigid false body in the mold; then manufacturing an air bag core membrane in the rigid false body; and finally, removing the rigid false body, paving a prepreg between the mold and the air bag core membrane and carrying out vacuumizing, vacuum pre-compacting, process combining and curing to obtain a product. The integral forming tool is simplified effectively, the forming process is simplified, and the integrally formed product is reliable in performance and stable in dimension.

Owner:XIAN AISHENG TECH GRP +1

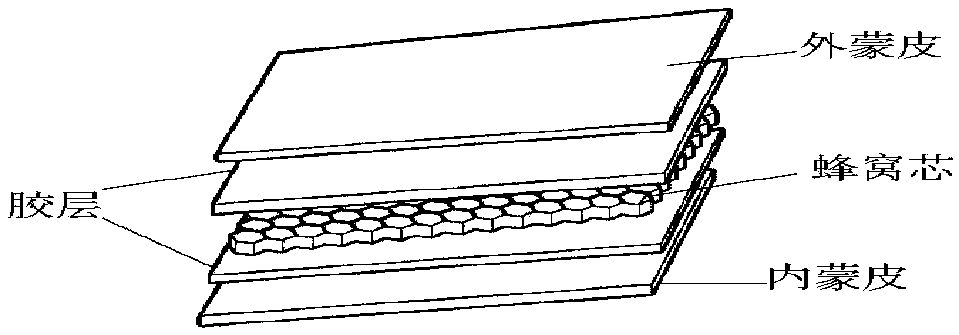

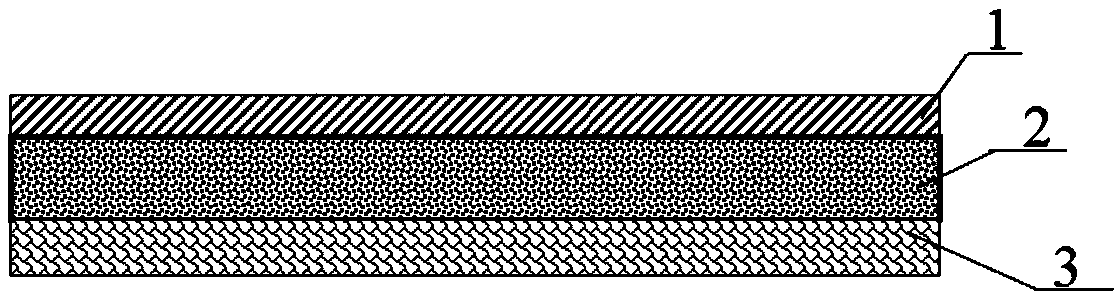

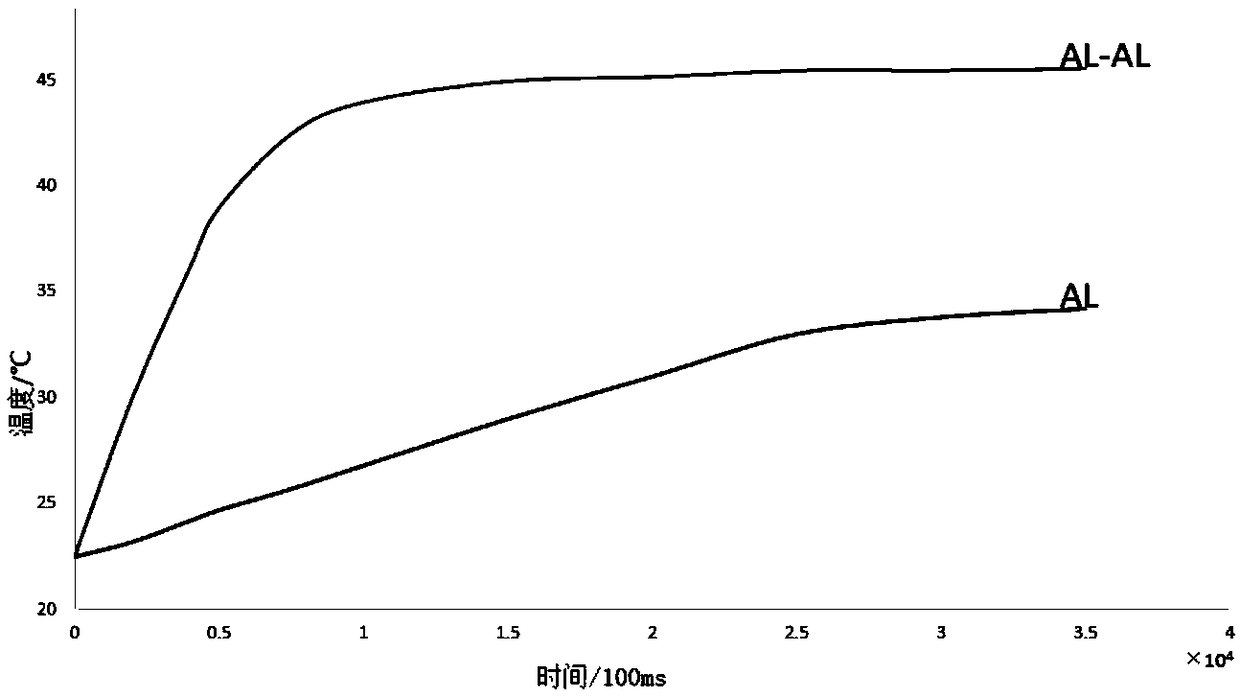

Light epoxy foam-based sandwich plate and preparation method thereof

InactiveCN108705829AGood noise reduction performanceGood adhesionSynthetic resin layered productsGlass/slag layered productsThermal insulationFire retardant

The invention relates to a light epoxy foam-based sandwich plate. The plate comprises an exterior panel, an epoxy foam core and an inner skin from outside to inside in sequence, and the epoxy foam core is formed by foaming an epoxy foam-based composite material which is prepared from a two-component system with a component A and a component B at the weight ratio being 100:(30-80), wherein the component A is prepared from 100 parts of epoxy resin, 5-20 parts of flame retardant, 1-10 parts of foaming agent and 0.5-1.5 parts of coupling agent, and the component B is prepared from 1-100 parts of curing agent, 1-10 parts of foaming agent, 0.5-5 parts of flame retardant and 1-10 parts of curing accelerator. Accordingly, the plate is prepared through a secondary on-site foaming process method, byconducting foaming after placing is conducted for 4-24 h at room temperature, reacting is conducted for 1-3 h at 110-140 DEG C, and secondary foaming and curing molding are conducted. Accordingly, integrated completion of filling, encapsulation and bonding can be achieved, the epoxy foam-based sandwich plate is easy to mold and is not limited by the sandwich plate shape and type, the thermal insulation, sound insulation and flame retardant properties are achieved while weight lightening is achieved, no toxic gas is generated in the case of fire, the good environmental-friendly performance isachieved, and the plate can be used for densely populated places.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

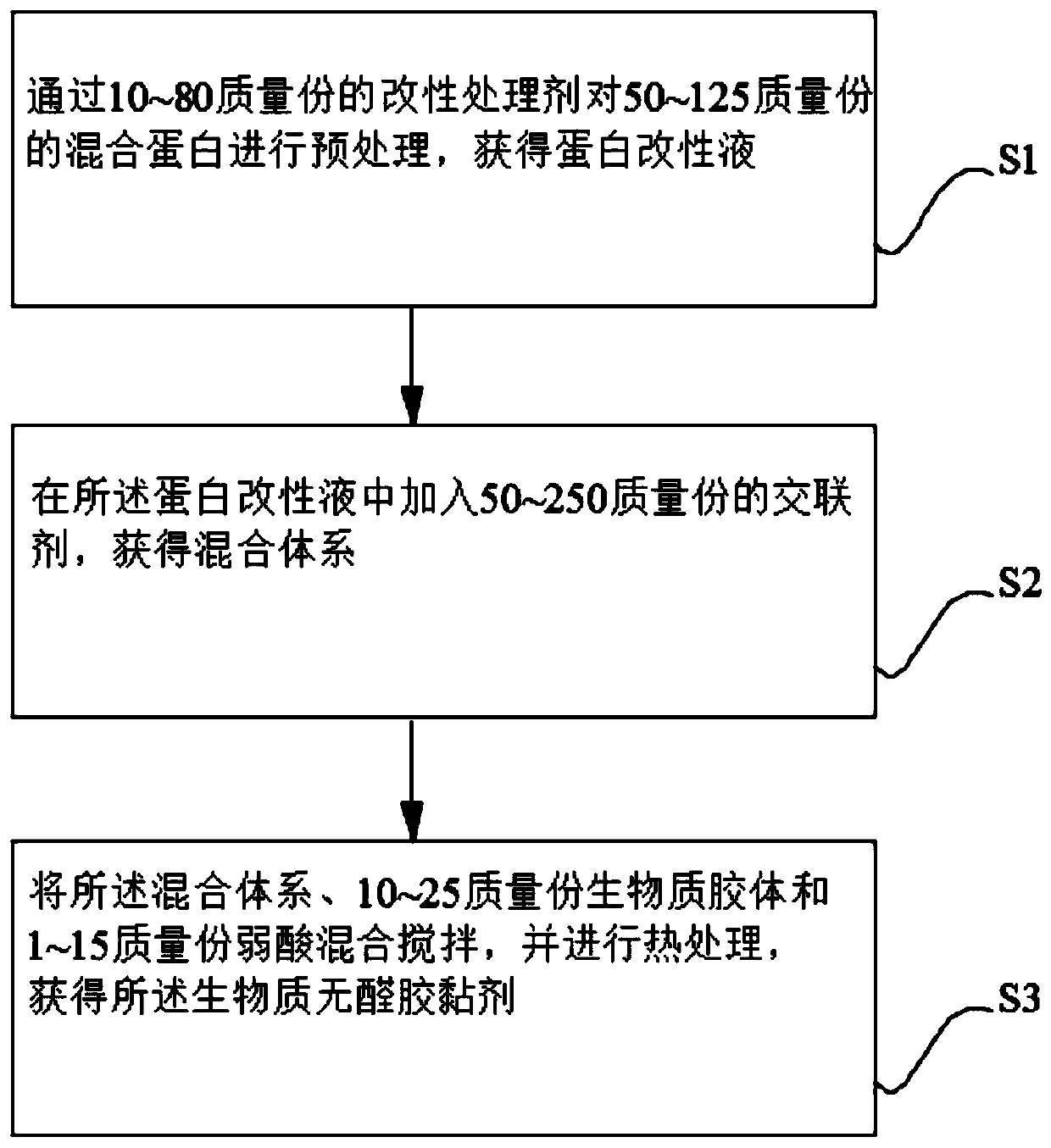

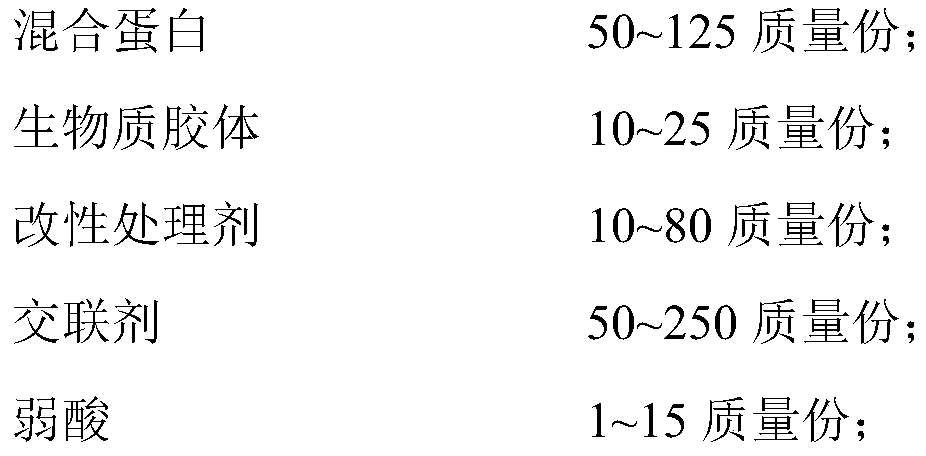

Biomass formaldehyde-free adhesive for artificial board and preparation method thereof

ActiveCN110922941AStable structureAchieve stabilizationProtein adhesivesPolyureas/polyurethane adhesivesAdhesiveCross linker

The invention discloses a biomass formaldehyde-free adhesive for an artificial board and a preparation method thereof. The biomass formaldehyde-free adhesive comprises mixed protein, biomass colloid,a modification treatment agent, a cross-linking agent, weak acid and the like. The biomass formaldehyde-free adhesive has the advantages of zero formaldehyde, high bonding strength, good water resistance, good anti-mildew effect, easiness in sizing and the like.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Thermoplastic composite solid propellant and preparation method thereof

ActiveCN107867962AAchieve moldingImprove securityNon-explosive fillers/gelling/thickening agentsAmmonium perchlorate explosive compositionsInherent safetyPlasticizer

The invention provides a thermoplastic composite solid propellant applicable to a solid booster. The thermoplastic composite solid propellant is prepared from components in percentage by mass as follows: 55%-70% of an oxidant, 10%-20% of a thermoplastic resin adhesive, 10%-20% of a plasticizer, 5%-20% of metal fuel and 3%-8% of auxiliaries. According to the prepared thermoplastic composite solid propellant, relative independence of mixing and pouring, integrated formation of the propellant and secondary formation of engine charge can be realized according to temperature adjustment, and melt mixing and formation of the thermoplastic propellant can be realized at relatively low temperature lower than 90 DEG C, so that inherent safety of preparation of the thermoplastic propellant is greatlyimproved; compared with a traditional thermosetting propellant, crosslinking curing process is omitted, technological process is shortened, recovery and repeated processing of waste products can be realized, and production cost is reduced. The thermoplastic propellant is prepared with a hot melt mixing-cooling formation technology, and application of components absorbing moisture easily in the propellant is realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

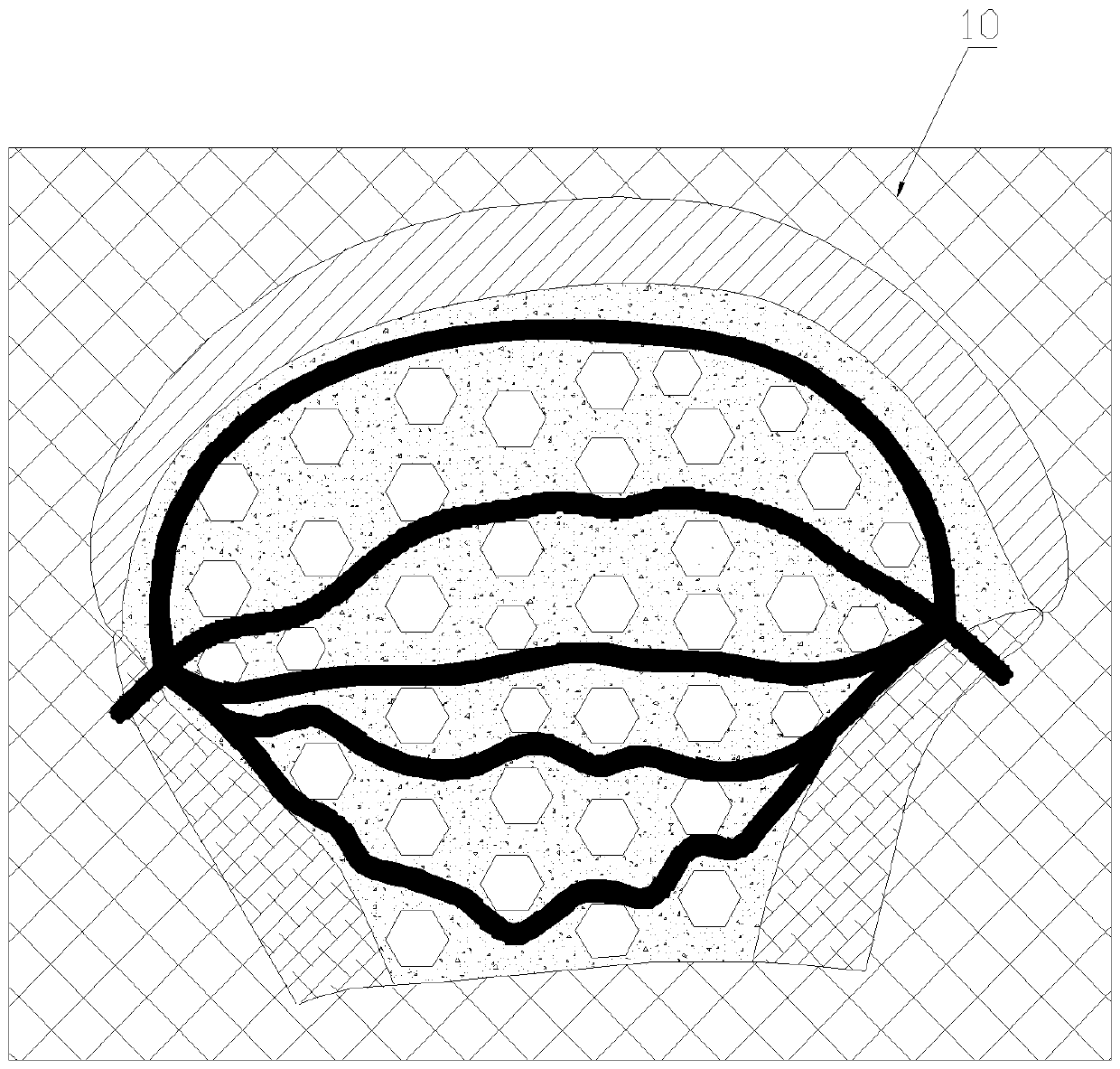

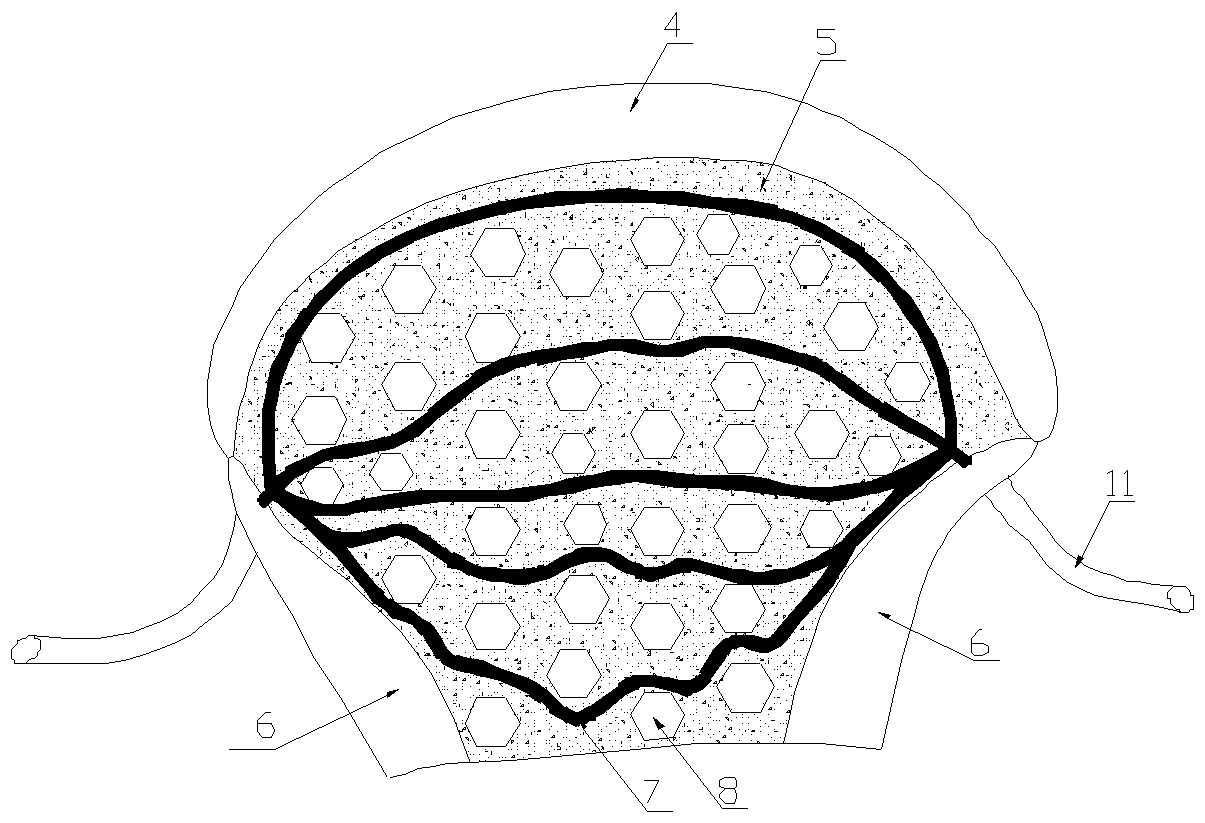

Cartilage-bone-marrow composite tissue structure based on 3D living cell printing and method of cartilage-bone-marrow composite tissue structure

ActiveCN110302428APrevent collapseGuaranteed stabilityAdditive manufacturing apparatusTissue regenerationCartilage boneTissue engineered

The invention discloses a cartilage-bone-marrow composite tissue structure based on 3D living cell printing and a method of the cartilage-bone-marrow composite tissue structure. Biological informationof bone tissue is collected and input into a computer for biomimetic modeling, and bio-ink suitable for cells such as cartilage, osteogenesis, mesenchymal stem, vascular endothelium, etc., is prepared; hard materials for printing dense bone area are prepared; various casting agent is prepared; living cells are inoculated into corresponding bio-ink at a certain density; and various types of printing ink are loaded into a printer bin correspondingly, 3D printing is carried out after setting printing parameters, and printed bone tissue is cultured in a tissue engineering bionic incubator. Aftera certain time, the method of temperature control or enzyme control or light control is used to remove casting agent materials at different times, artificial blood vessels are grafted on the outside of the cartilage-bone-marrow composite tissue, and continuous circulation perfusion cultivation is carried out in the tissue engineering biomimetic incubator, so as to achieve the pre-maturation of printed tissue, and the long-term survival and biological function of 3D printing bone tissue can be realized.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Low-melting-point thermoplastic solid propellant and preparation method thereof

ActiveCN108147934ARealize complementary advantagesImprove mechanical propertiesNon-explosive/non-thermic compositionsPressure gas generationElastomerPlasticizer

The invention relates to a low-melting-point thermoplastic solid propellant and a preparation method thereof, and belongs to the technical field of composite solid propellants. The propellant is prepared from the following components by mass percent: 55%-70% of oxidant, 10%-20% of thermoplastic elastomer binder, 10%-20% of plasticizer, 5%-20% of metal fuels and 3%-8% of auxiliaries. The prepared low-melting-point thermoplastic solid propellant has the advantages that melting mixing and forming of the thermoplastic propellant at a relatively low temperature lower than 95 DEG C can be realized,process safety of thermoplastic propellant preparation is greatly improved, a curing and cross-linking process in comparison with a thermoplastic propellant is cut out, process flow is shortened, production efficiency is improved, production cost is reduced and repeated processing of waste products can be realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

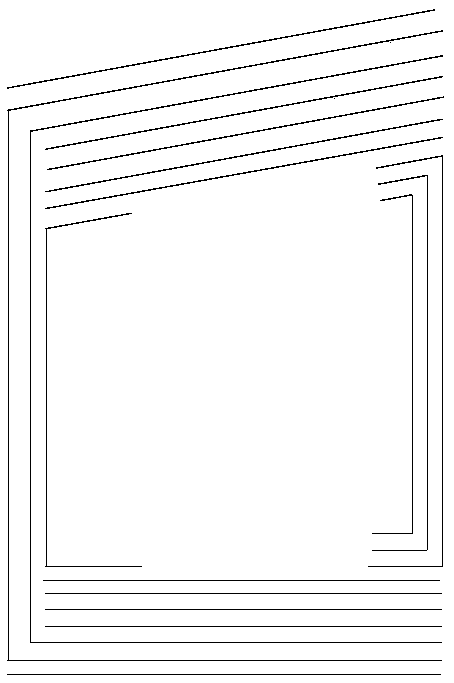

Novel method for molding resin base composite material by sewing/resin film infusion

ActiveCN103909660AConducive to specificationSuitable for engineering productionResin-Based CompositeEngineering production

The invention belongs to a resin base composite material liquid molding technology and relates to a novel method for molding a resin base composite material by sewing / resin film infusion (RFI). According to the novel method, a resin film is arranged between fabric paving layers of a non-sewing region of a fiber enhanced pre-molded body; a resin film is arranged on the upper part of a sewing region. According to the novel method, a traditional manner of a single resin film in a traditional resin film infusion molding process is changed and different resin arranging manners are adopted aiming at the sewing region and the non-sewing region of a sewing structure so as to meet the requirements on a sewing process of the sewing region and conveniently carry out resin flow control of an RFI process; the novel method is good for sewing / RFI molding of a complicated structure and the RFI molding of more structures, even non-opening structures can be realized; the process stability is improved and the requirements on engineering production are adapted.

Owner:AVIC COMPOSITES

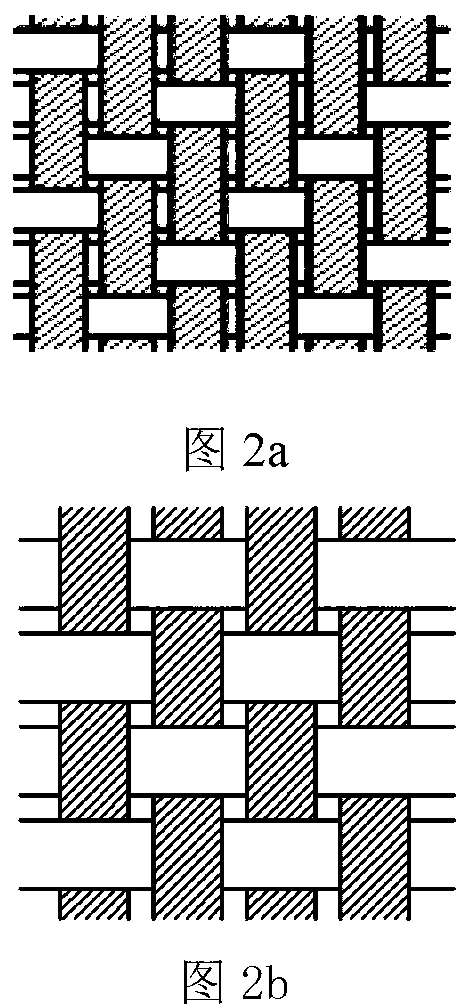

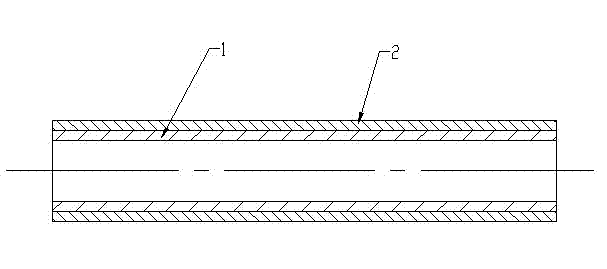

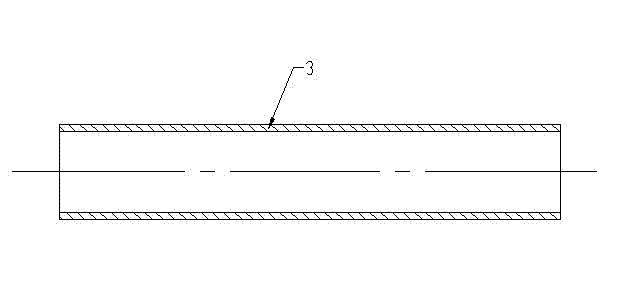

Woven 2D+2.5D profiling fabric composite fabric and forming method thereof

ActiveCN103266391AIncrease the level of detailEasy to meet thickness requirementsWoven fabricsDamage toleranceStructural unit

The invention provides woven 2D+2.5D profiling fabric composite fabric and a forming method thereof. The fabric is formed by combining one or two 2D structural unit sets with n layers and a 2.5D structural unit set with m layers. When the number of the 2D structural unit set is one, the 2D structural unit set serves as an outer layer, and the 2.5 structural unit set serves as an inner layer. When the number of the 2D structural unit sets is two, the 2.5D structural unit set serves as a middle layer, and the 2D structural unit sets serve as both the inner layer and the outer layer. From inside to outside, the outer diameter of each layer of the unit set is the same as the inner diameter of a layer of the unit set on the outer side of the unit set. The forming method of the woven 2D+2.5D profiling fabric composite fabric includes: 1) 2D and 2.5D profiling fabric is woven by adopting a plane profiling weaving mode; and 2) after the two kinds of structural unit sets are formed independently, cover die shaping is performed by a core mold according to sizes of the inner diameters of the unit sets. The woven 2D+2.5D profiling fabric composite fabric is rapid in forming, low in cost and good in evenness, can be applied to forming of variable cross-section fabric and forming of cylindrical fabric, and is high in damage tolerance, resistant to impact, resistant to delamination and anti-fatigue.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

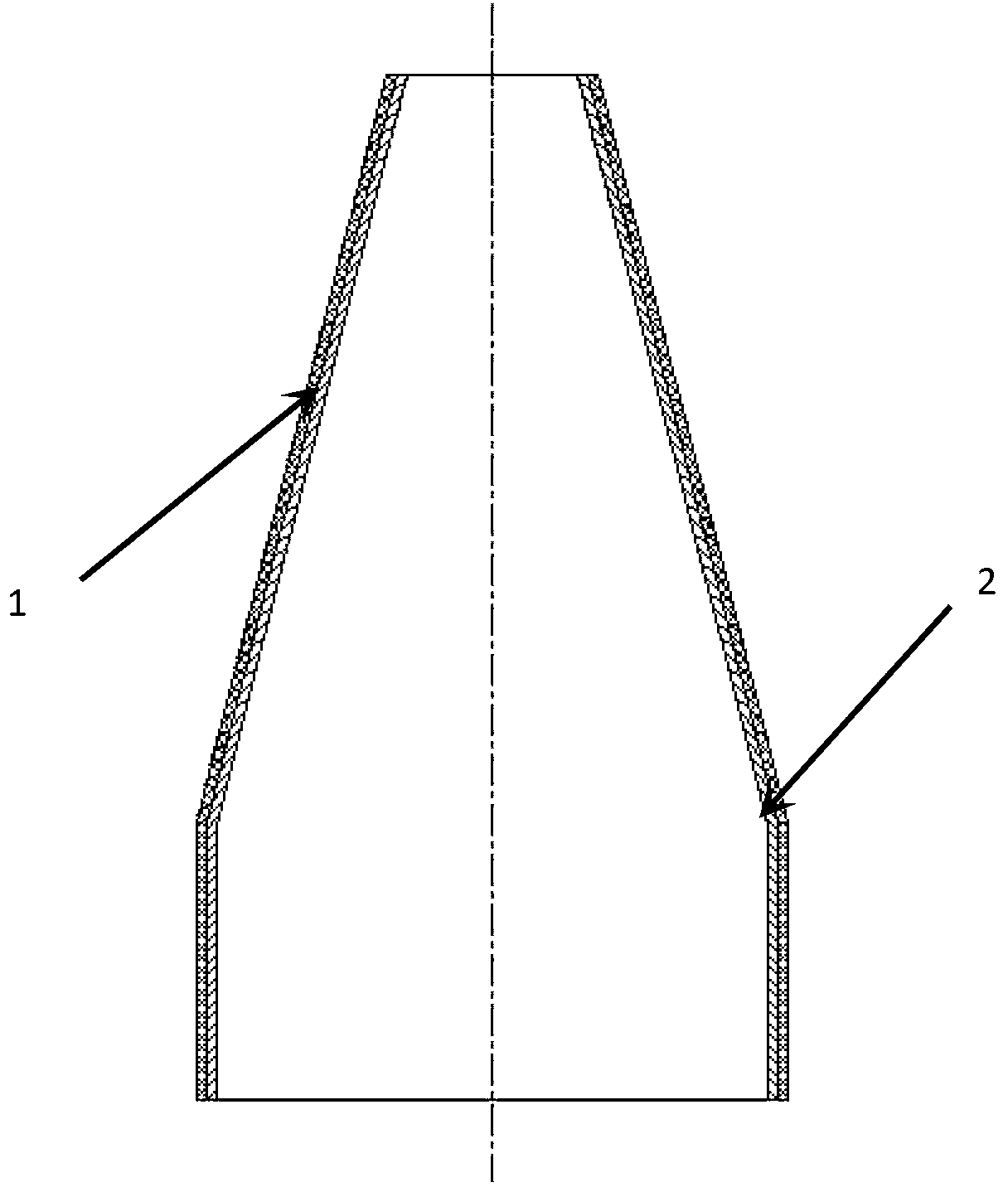

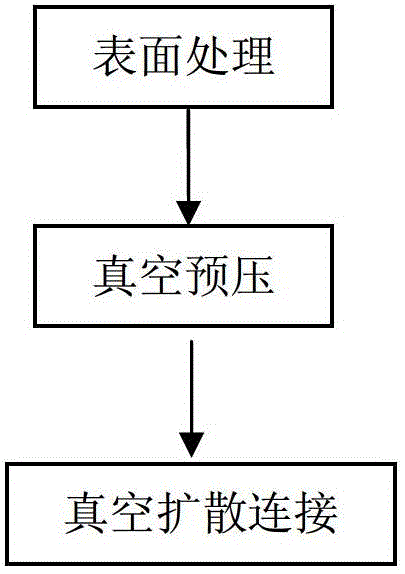

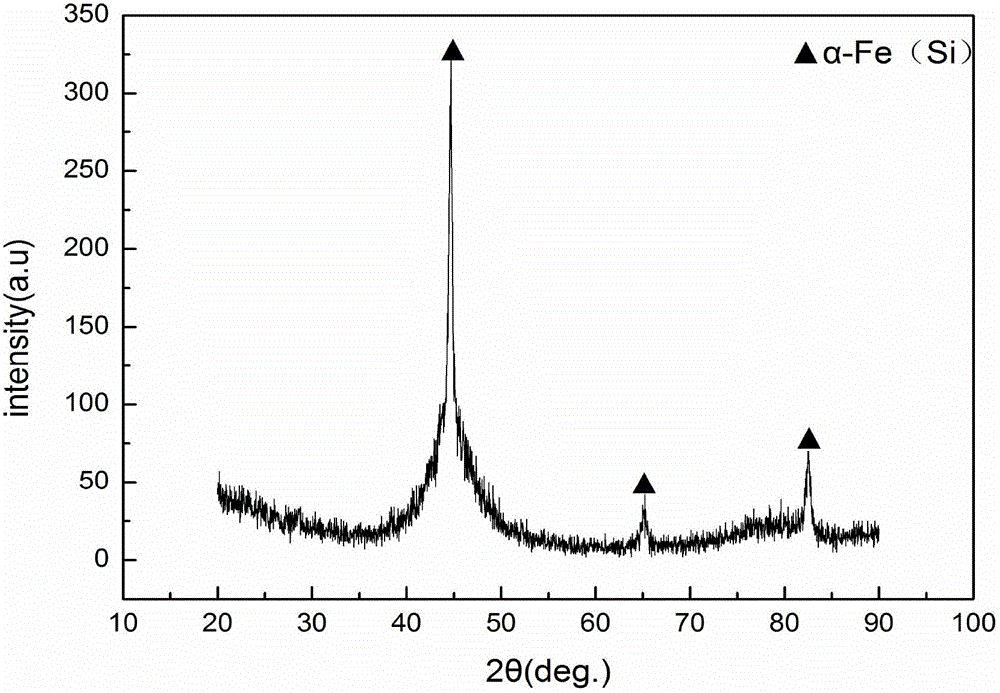

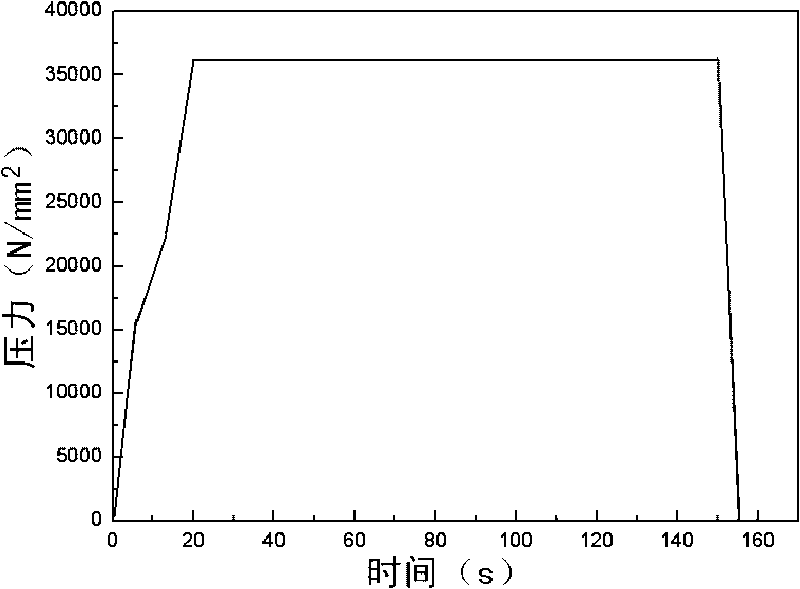

Fe-Si-B amorphous alloy-copper laminated composite material and preparation method thereof

ActiveCN102873938ATroubleshoot Diffusion Join Forming IssuesEnable connectivityLaminationLamination apparatusSuper coolingSurface oxidation

The invention provides a Fe-Si-B amorphous alloy-copper laminated composite material and a preparation method thereof. A vacuum diffusion connection testing machine is used, and Fe-Si-B amorphous alloy and copper are welded to form the laminated composite material through a diffusion welding method. In preparation, at super-cooled liquid-phase region temperature of the amorphous alloy, plastic deformation is performed on the amorphous alloy and the copper through pressure effect, connection surface oxidation films are removed, fresh surfaces of the amorphous alloy and the copper are contacted tightly, connection interface diffusion process is promoted through thermal insulation and pressure maintaining simultaneously, and an iron-based amorphous-copper laminated composite material of a large size is prepared under the precondition that crystallization of the amorphous alloy is avoided. By adopting the technical scheme, process parameters are controlled strictly and accurately, and the large-size composite material with good connection performance and broadband shielding performance is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

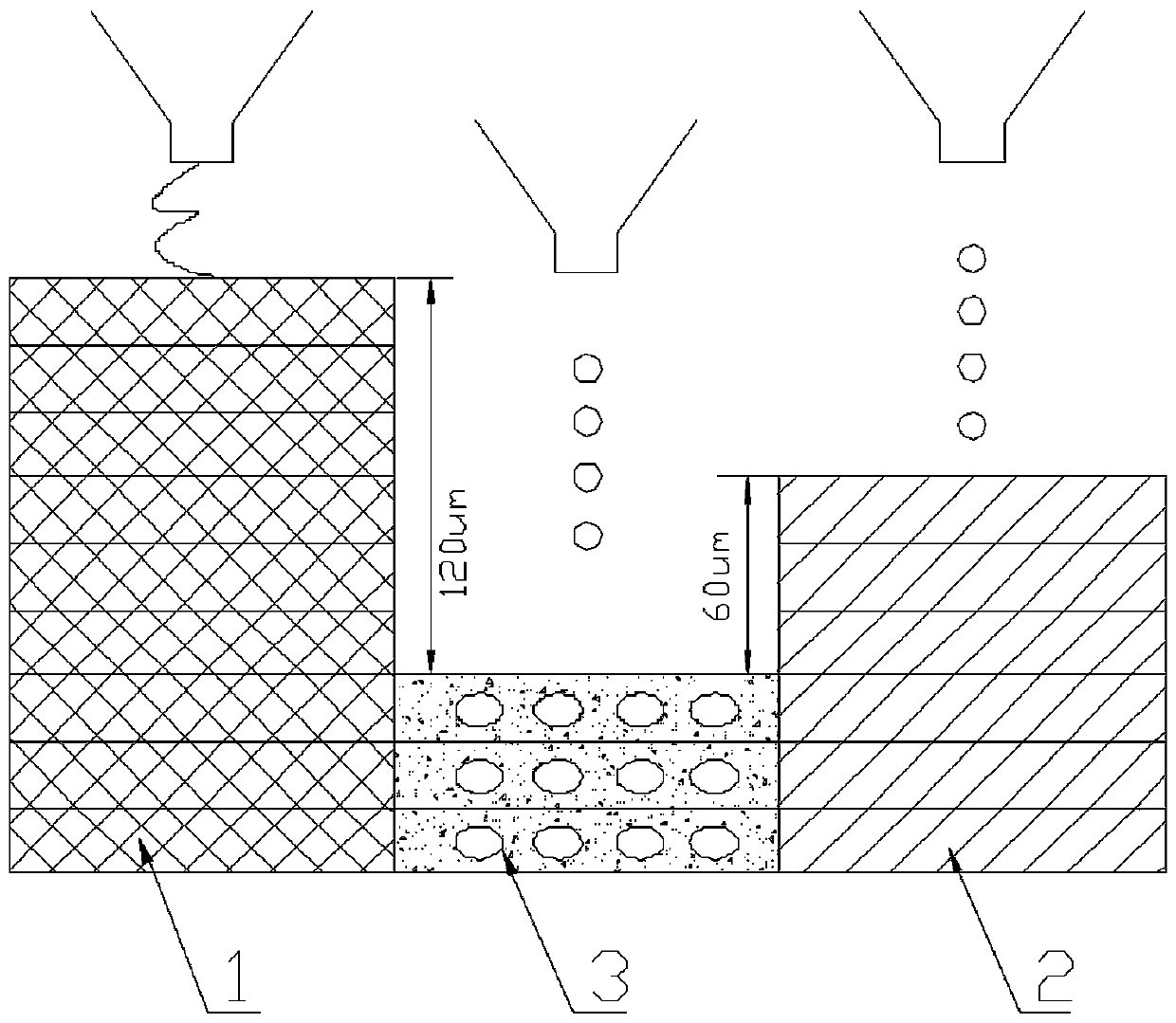

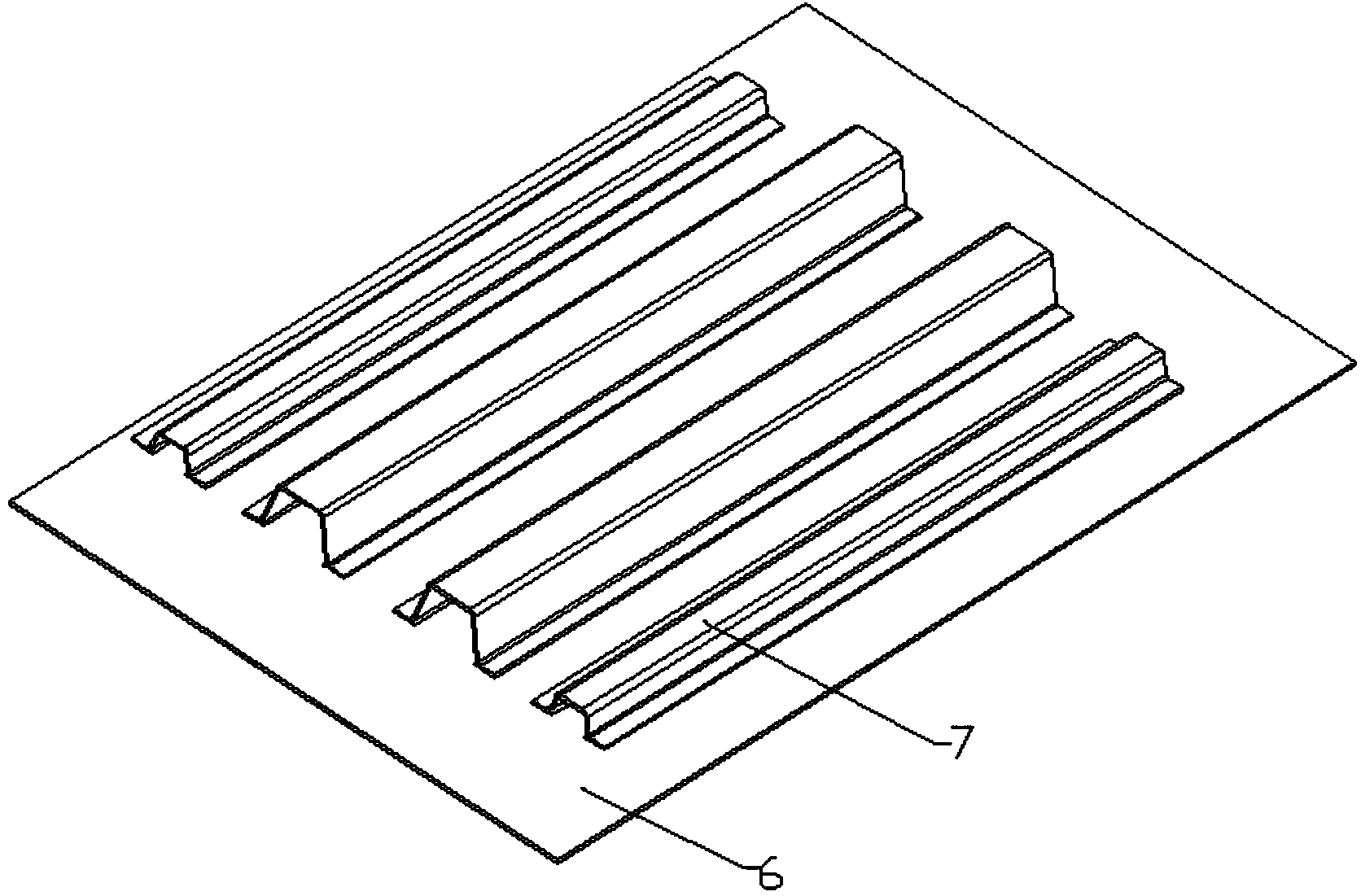

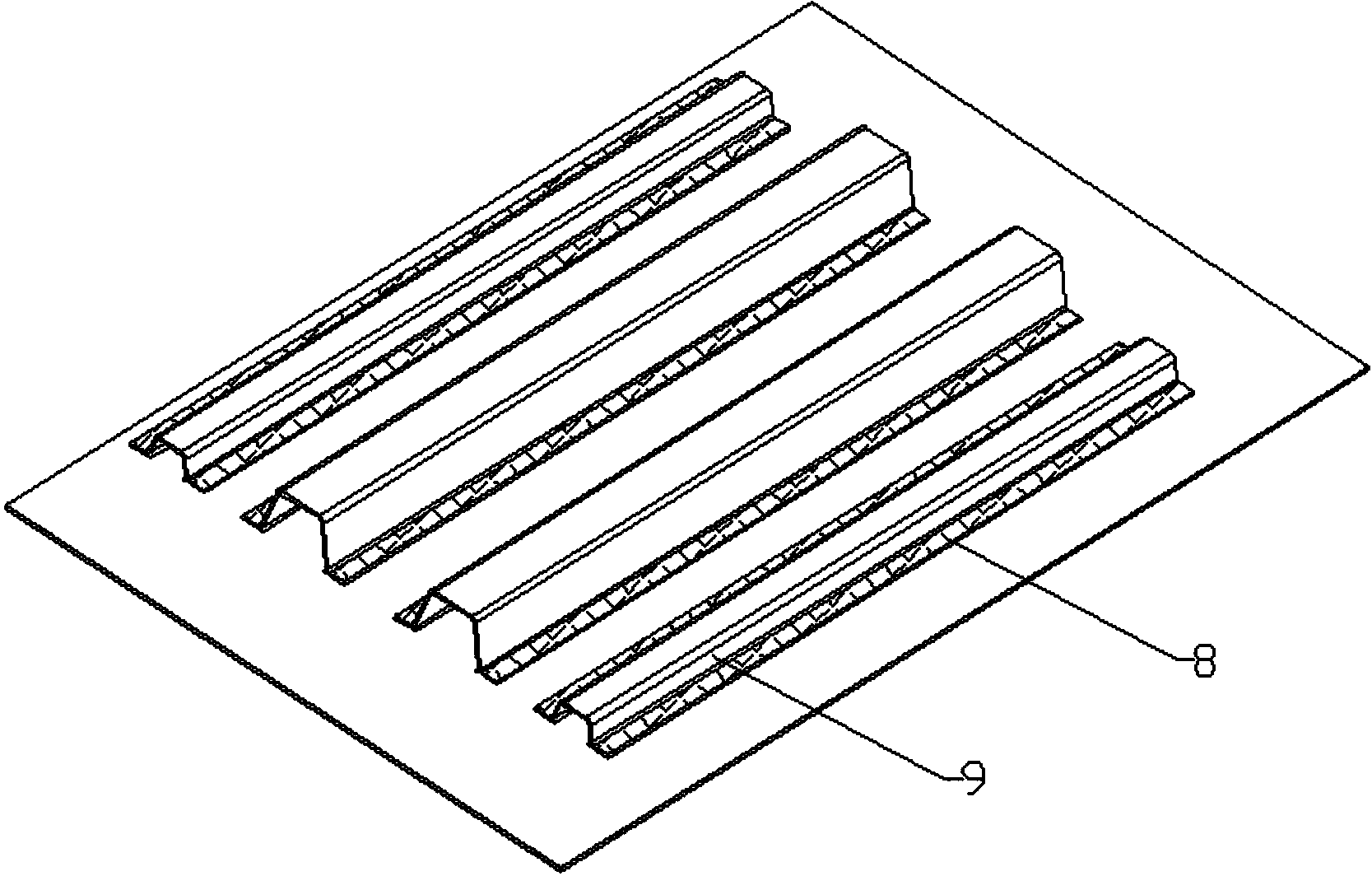

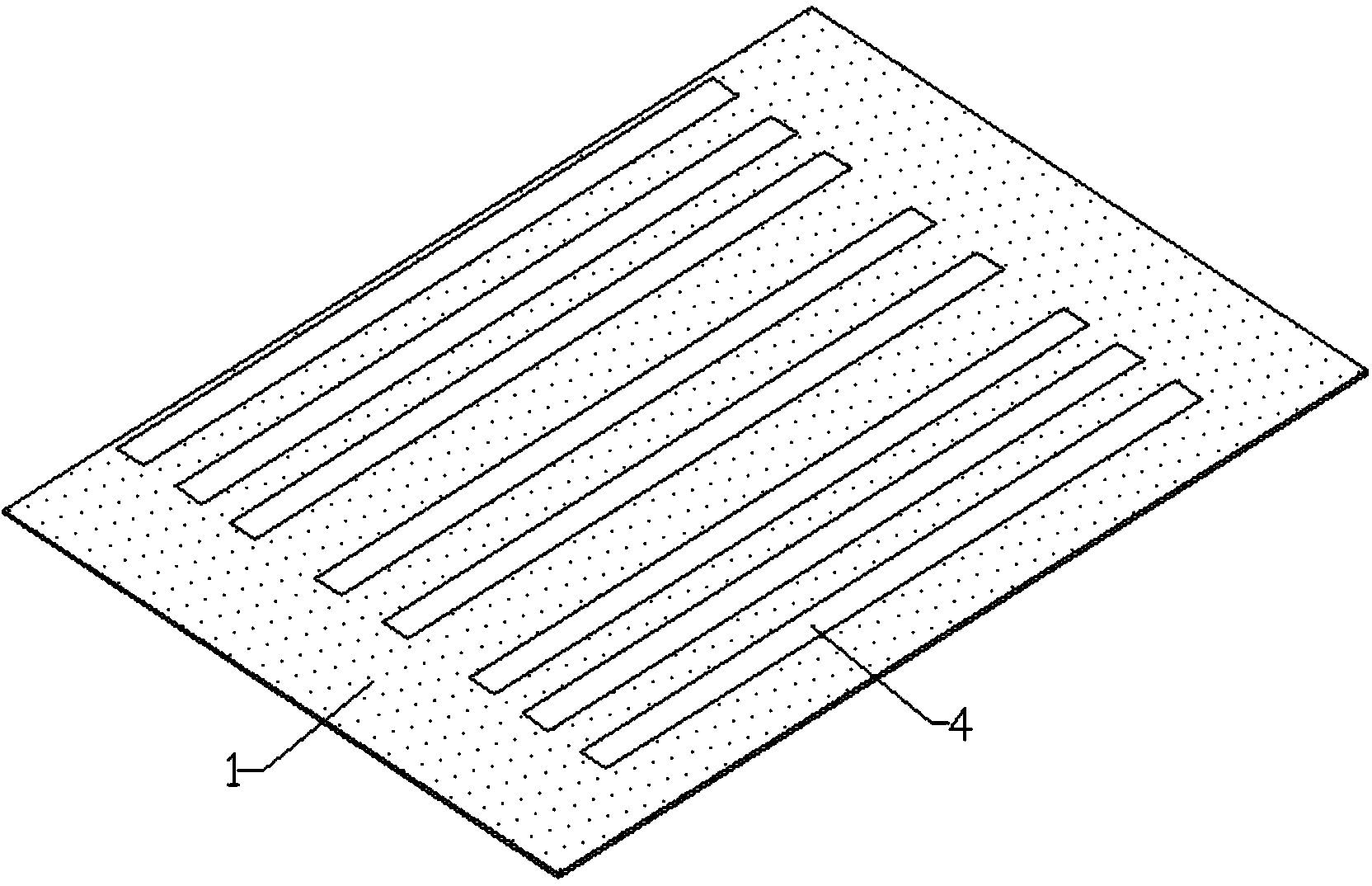

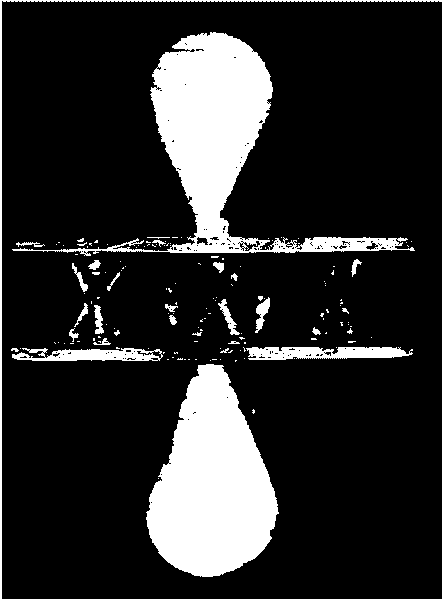

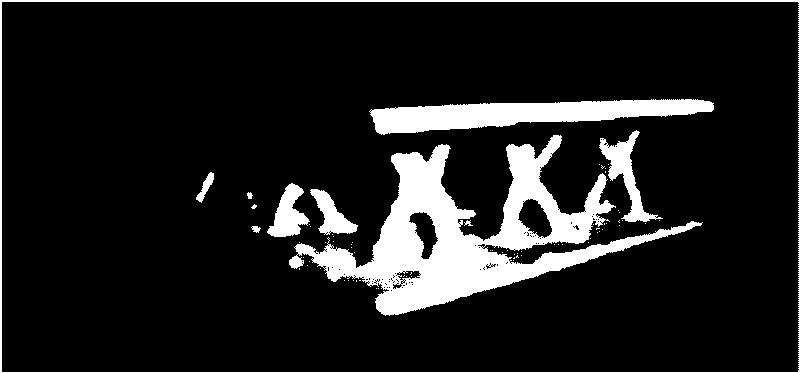

Low pressure casting method for lattice sandwich plate

InactiveCN101700568AAchieve preparationHigh bonding strengthFoundry mouldsFoundry coresWaxPressure casting

The invention discloses a low pressure casting method for a lattice sandwich plate and relates to a method for manufacturing the lattice sandwich plate. The invention solves the problems, such as difficult complete formation and high defect rate of the lattice sandwich plate resulted from the current manufacturing methods. The method according to the invention comprises the steps: producing a wax pattern, pasting and drying the surface, the adjacent surface and the back of the wax pattern; heating and demoulding the wax pattern to obtain the profile shell of the lattice sandwich plate; and in the end, obtaining the lattice sandwich plate by lifting, filling and pressure maintaining with a low pressure casting machine. The method combines investment pattern precision casing technique, rapid prototyping manufacturing technique with low pressure casing technique so as to result in the lattice sandwich plate with complete formation and low defect rate.

Owner:HARBIN INST OF TECH

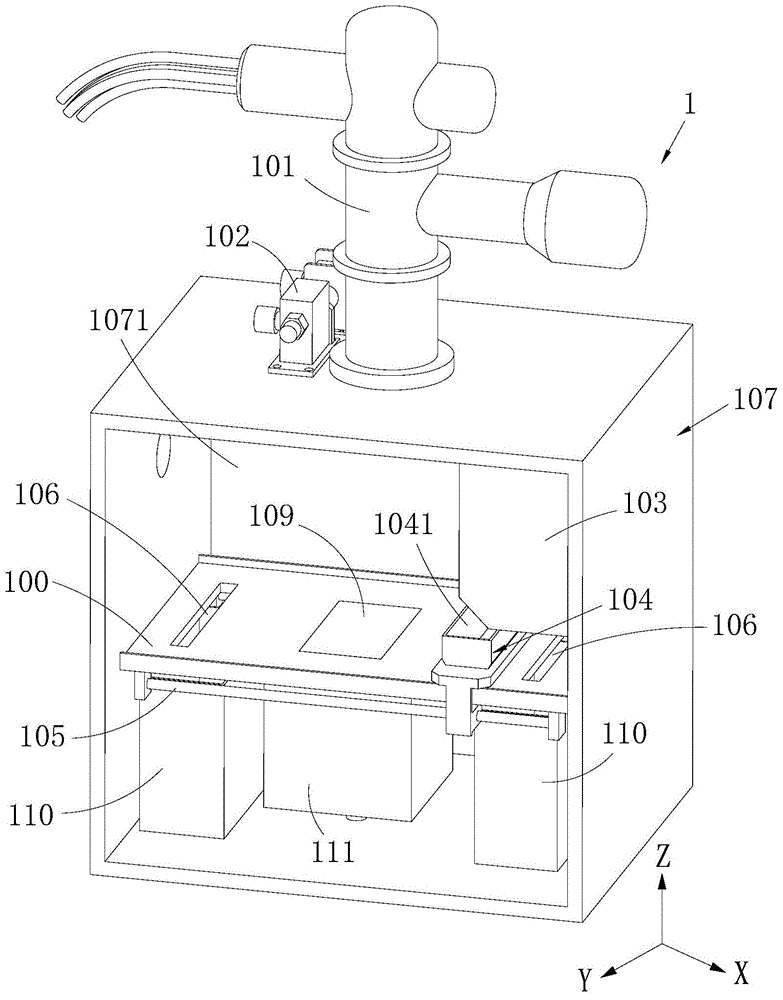

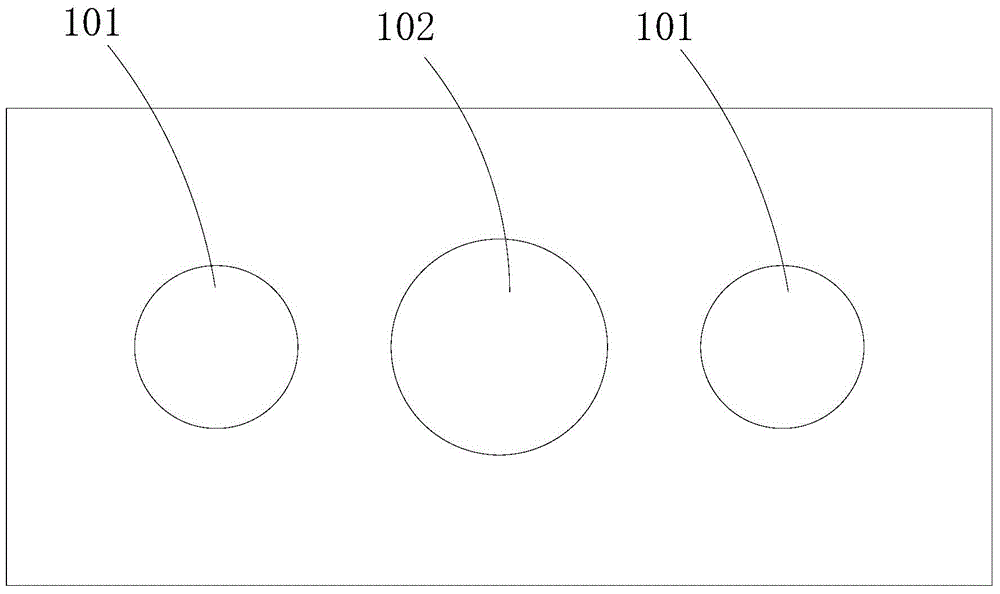

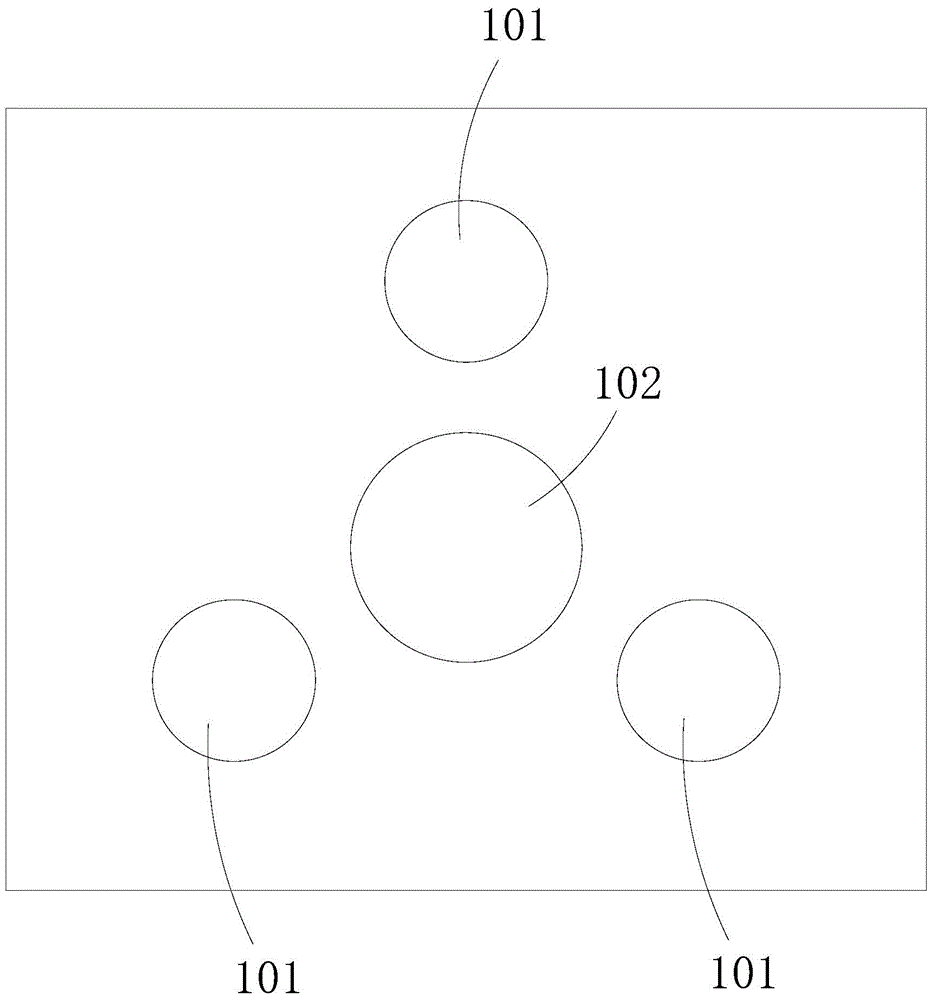

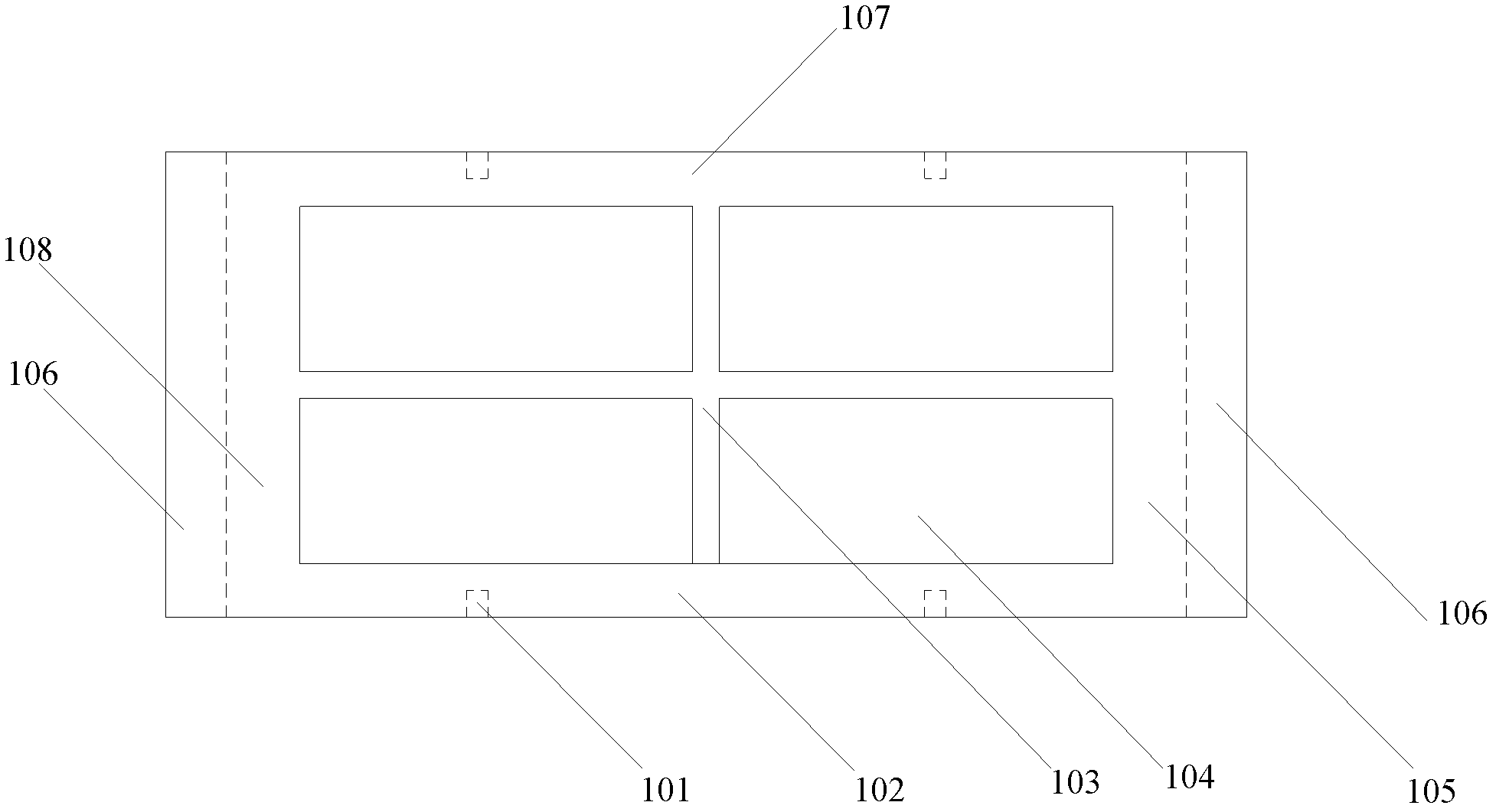

Multi-electron-beam fusing and milling composite 3D printing device

InactiveCN104526359AAvoid clamping difficultiesBroad application spaceOther manufacturing equipments/toolsMachining processEngineering

The invention relates to the technical field of 3D printing devices, and discloses a multi-electron-beam fusing and milling composite 3D printing device which comprises a base. A machining platform is arranged on the base which is provided with a powder laying structure. A plurality of electron beam transmitting structures and milling heads are arranged on the machining platform. The electron beam transmitting structures are arranged outside the milling heads in a surrounding mode at intervals and transmit electron beams to fuse different areas of a metal powder layer so as to form a plurality of single-layer or multi-layer approximate bodies. The milling heads mill the single-layer or multi-layer approximate bodies respectively. By means of the 3D printing device, the removal type machining process with laser milling as the main part and the incremental laminated manufacturing process with electron beam fusing 3D printing as the main part are integrated, and the deflects of the size and shape of the 3D printing technology are overcome; for large-size parts, the electron beams fuse different areas, milling is then conducted through the milling heads, and parts can be formed in any large sizes.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

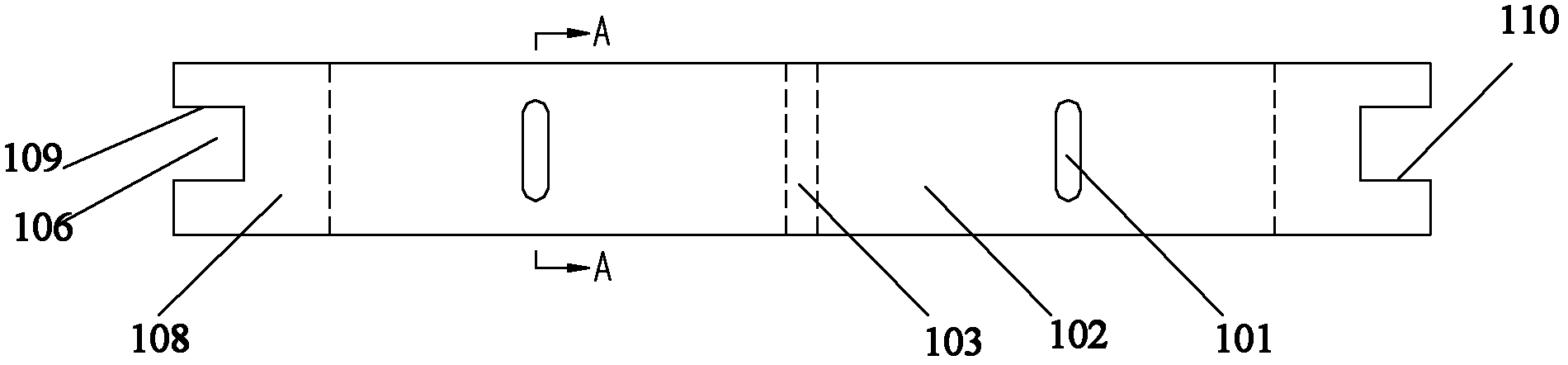

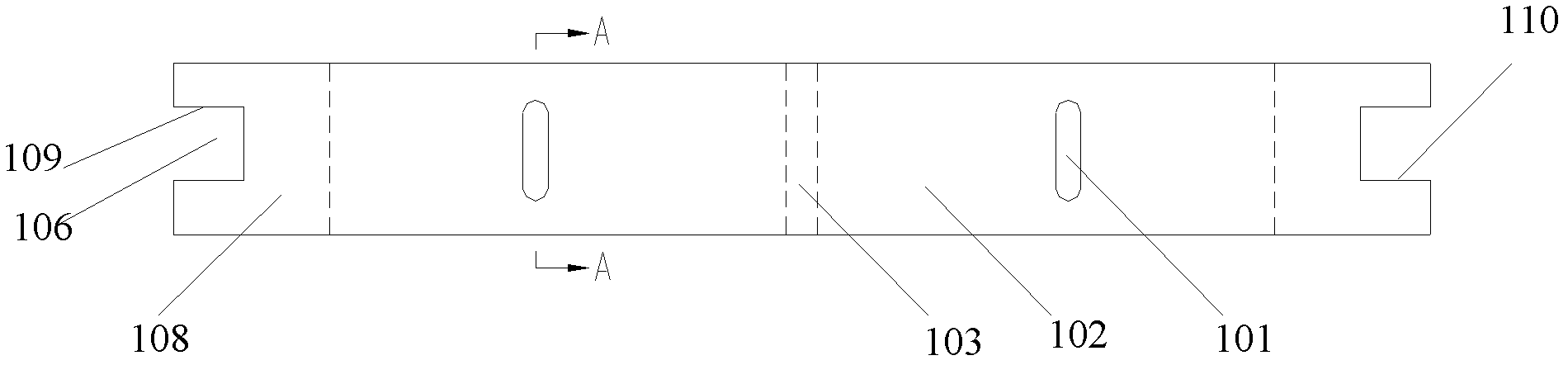

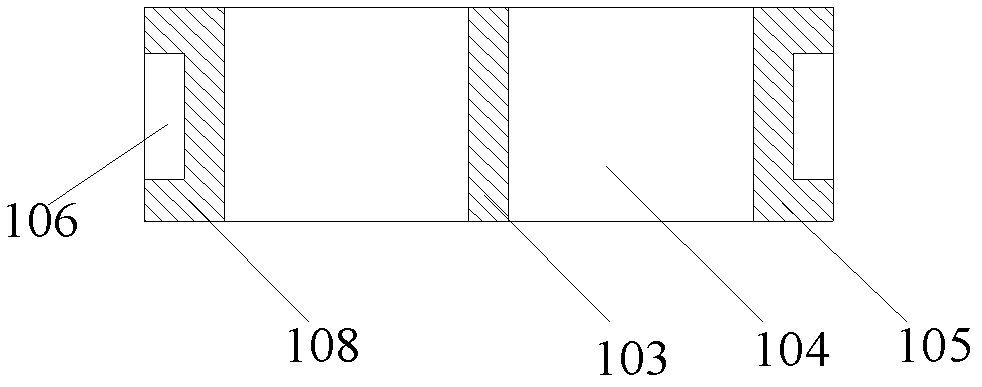

Forming process of brick in composite structure

ActiveCN103171045ALarge operating spaceHigh strengthMouldsCeramic shaping plantsComposite structureForming processes

The invention discloses a forming process of a brick in a composite structure. The forming process includes the steps that a mold frame supporting plate is conveyed to first forming equipment by a first continuous conveying device, the mold frame supporting plate is pressed to be a mold frame on the first forming equipment, and after material distribution and pre-pressing, the mold frame is sent to a second material distribution machine and second forming equipment to complete second material distribution and pressing. According to the forming process, different brick courses are formed on the different forming equipment, and pollution between materials in different layers is thereby avoided.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

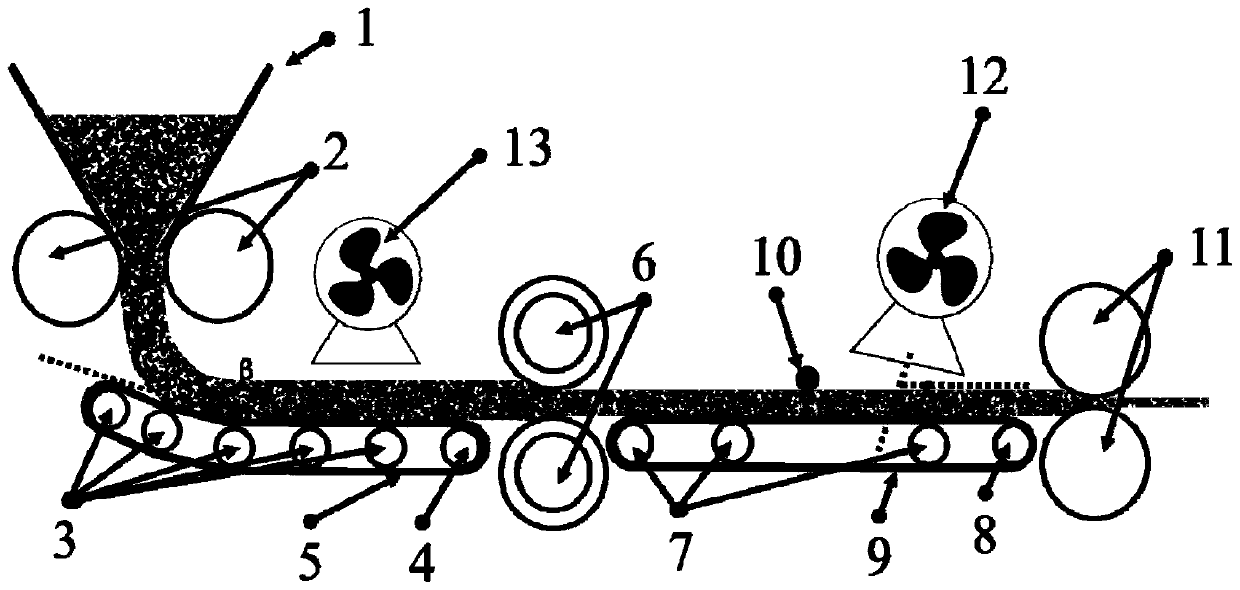

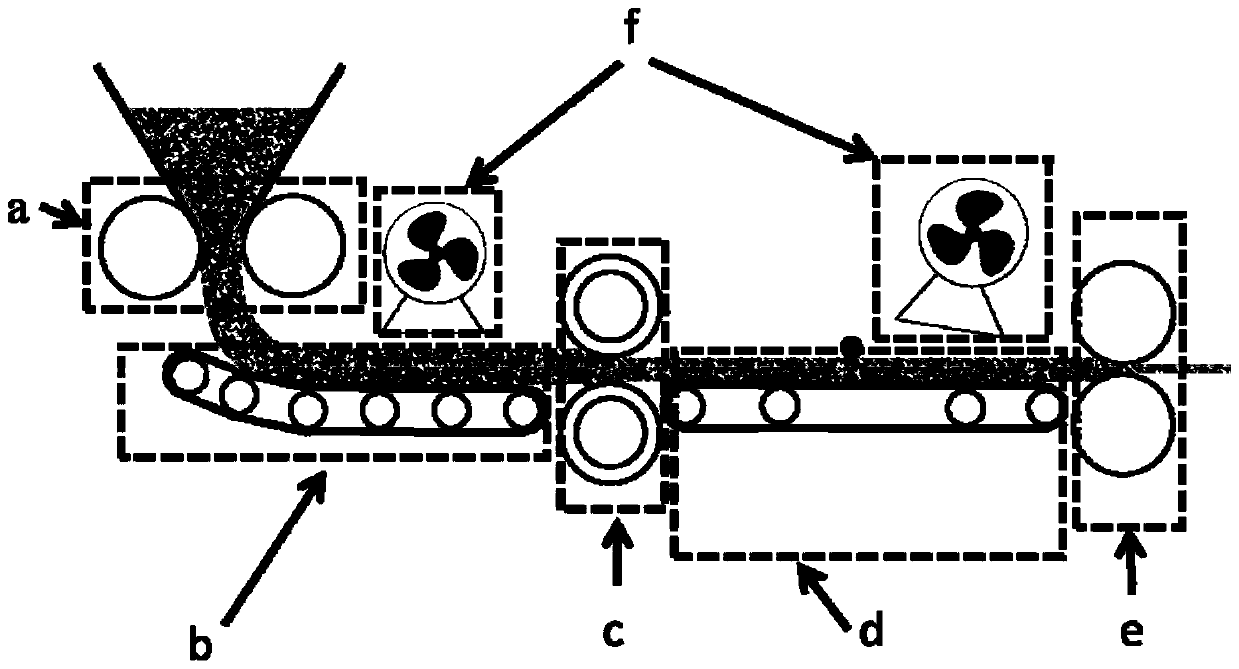

Preparation process for graphene conductive film

ActiveCN109801758AEnables continuous productionAvoid mixing disperse-pulp-coatConductive layers on insulating-supportsCable/conductor manufacturePolymer scienceTransfer procedure

The invention provides a preparation process of a graphene conductive film. The preparation process is of simplicity and has high efficiency. According to the preparation process, a dry preparation process is adopted. The dry preparation process includes the following steps that: a graphene-based conductive functional agent, a binder dispersion, and an auxiliary are thoroughly mixed so as to forma semi-dry slurry; and the semi-dry slurry is subjected to a vertical rolling procedure a, a guide traction procedure b, a thermal rolling procedure c, a transfer procedure d, a cold rolling proceduree and a blowing procedure f, so that a graphene conductive film is obtained. With the preparation process of the invention adopted, the continuous preparation of the graphene conductive film is realized, process steps such as mixing and dispersing, slurrying and coating are avoided; and the procedures are optimized, and efficiency can be improved, and therefore, costs can be saved, high-speed non-stop preparation is realized, and a process flow is simplified.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Technology for manufacturing hard alloy thin-wall shaft sleeve

The invention relates to a technology for manufacturing a hard alloy thin-wall shaft sleeve, which comprises the following processes of: A, parison machining: taking a circular steel tube or a taper steel tube as a shaft sleeve parison and trimming a size of an excircle; B, spray-welding: spray-welding a hard alloy material on the external surface of the shaft sleeve parison to form an even spray-welded layer; C, external surface machining: turning or grinding a size of an excircle of the spray-welded layer; and D, internal surface machining: cutting to remove the shaft sleeve parison by using a turning or grinding method, so as to form the hard alloy shaft sleeve. The technology for manufacturing the hard alloy thin-wall shaft sleeve, provided by the invention, is a manufacturing method which comprises the following steps of: firstly spray-welding the hard alloy material on the external surface of the shaft sleeve parison and then cutting to remove the shaft sleeve parison, so as to form the hard alloy shaft sleeve, so that the molding of small-bore thin-wall hard alloy shaft sleeves is realized, and the technical difficult problem that the small-bore thin-wall hard alloy shaft sleeves are difficult to be manufactured through a powder metallurgy molding and double-surface spray-welding method currently is solved.

Owner:自贡市巨光硬面材料科技有限公司

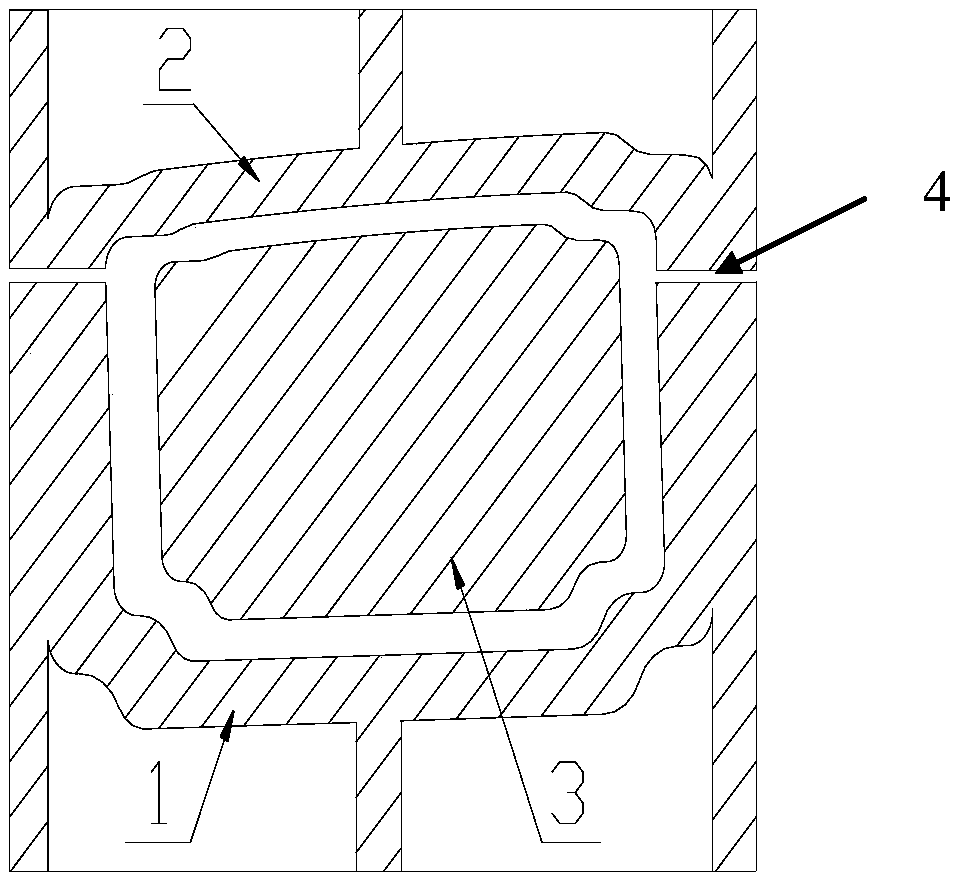

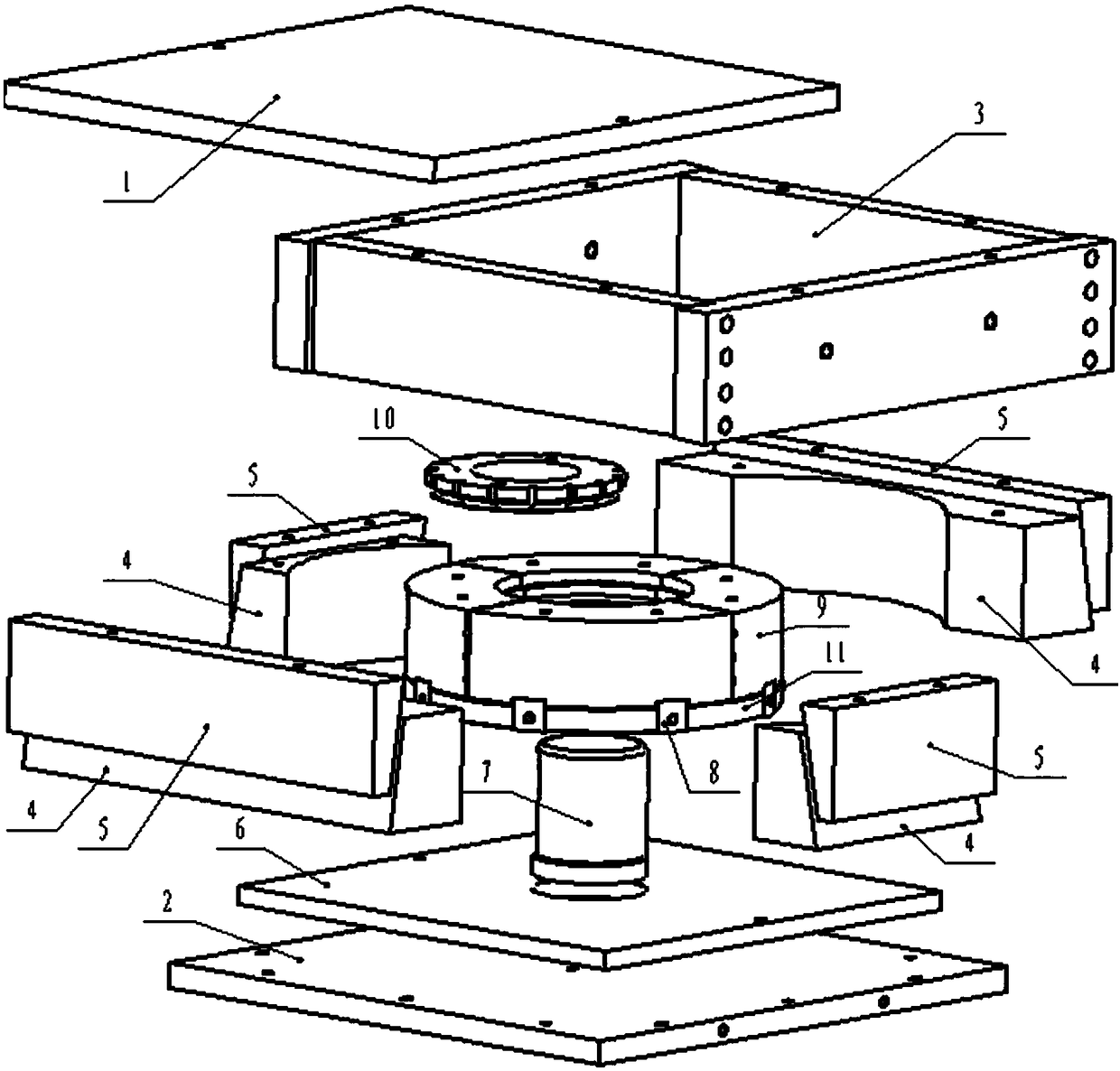

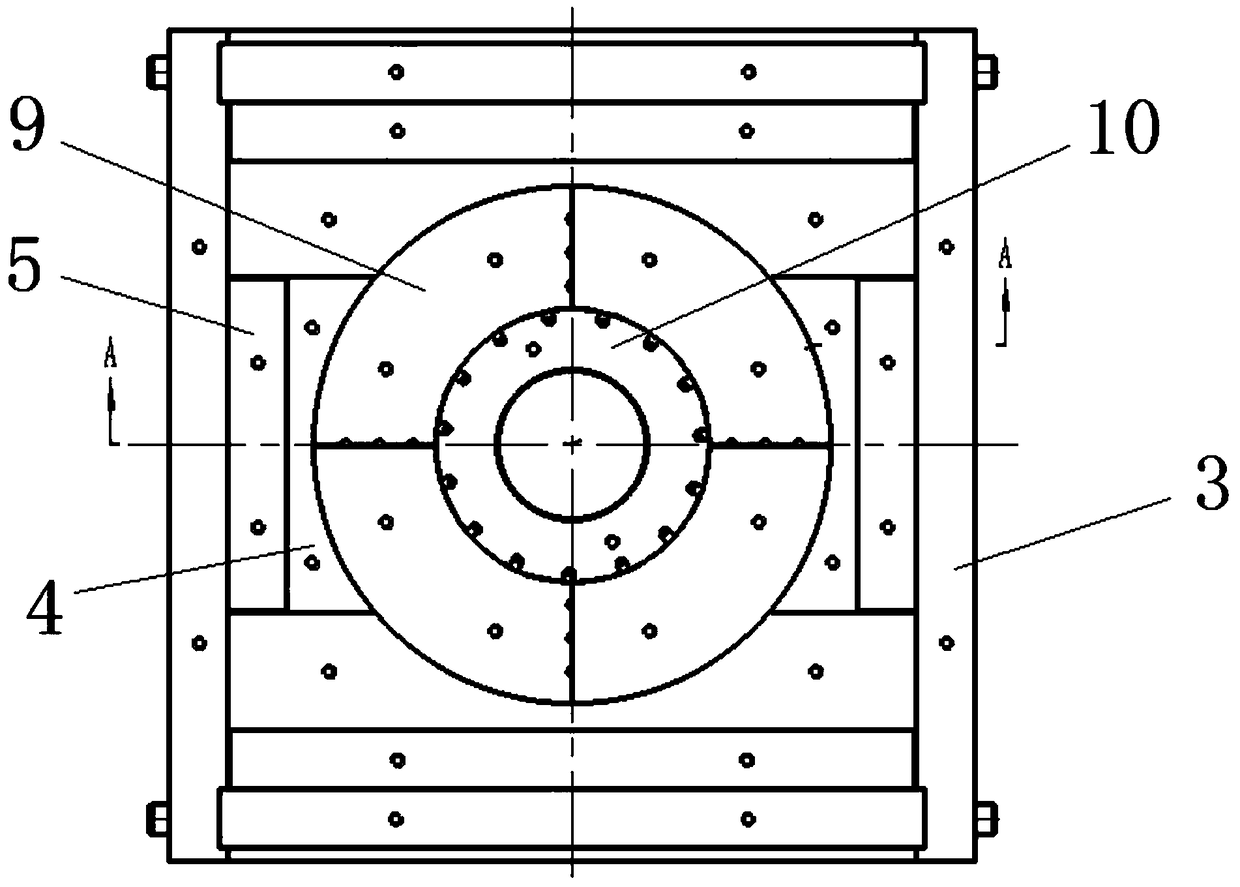

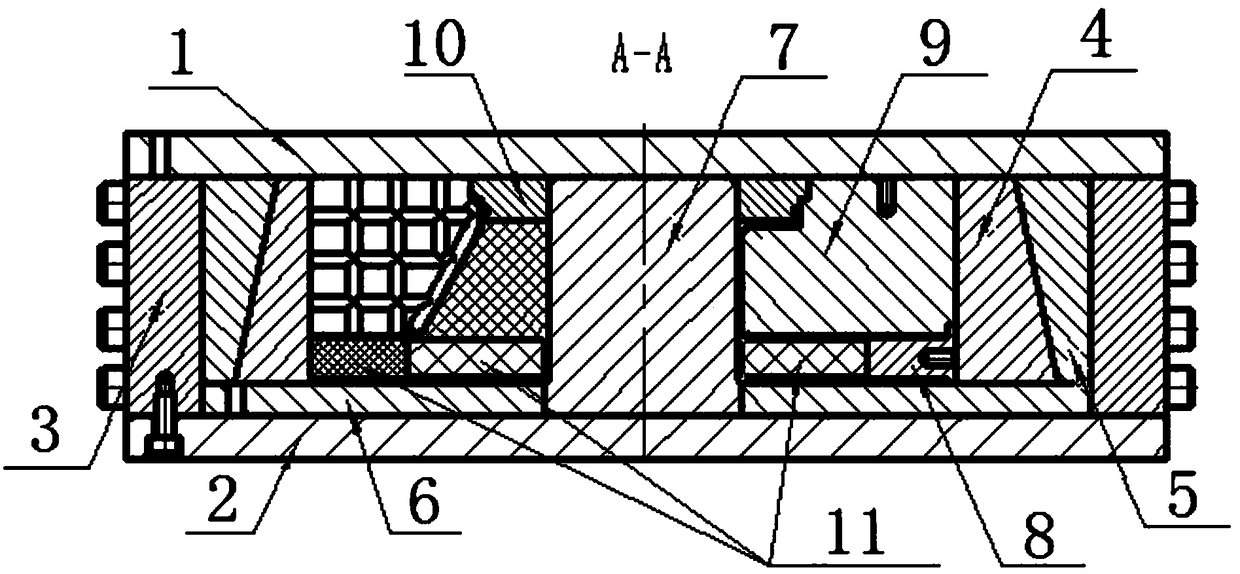

Molding die for the satellite reflector composite center fixing ring

The invention discloses a molding die for a satellite reflector composite center fixing ring, comprising: a die sleeve assembly, wherein a storage space is arranged in the die sleeve assembly; a positioning component, wherein the positioning component is disposed in the storage space; a wedge assembly, wherein the wedge assembly is disposed in the storage space and around the positioning component. The positioning component includes: a core disposed at the bottom of the storage space; first splicing block units, the first splicing block units sleeving the outer side of the core; second splicing block units, the second splicing block units being disposed on the outer side of the core and on the first splicing block units; and a pressure plate, the pressure plate sleeving the outer side of the core. Compared with the prior art, the present invention has the following advantages of: 1, improving the feasibility of the center fixing ring; 2, realizing the integral molding of complex ribs of multi-layer flanges; and 3, achieving an effective weight loss.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

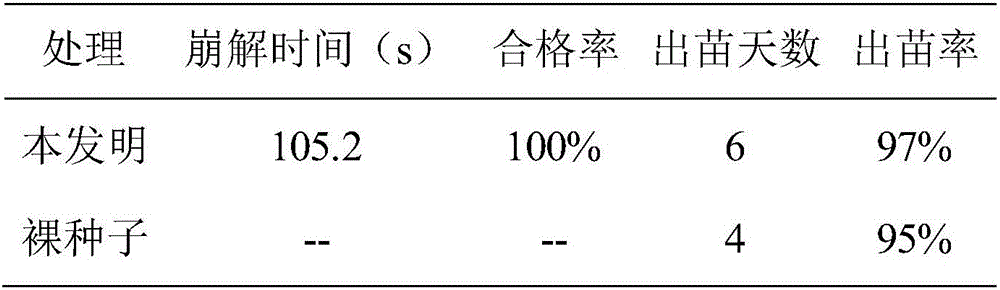

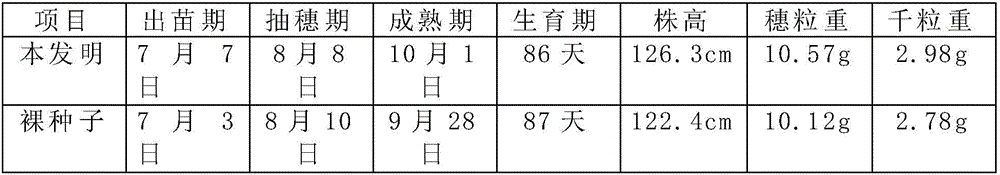

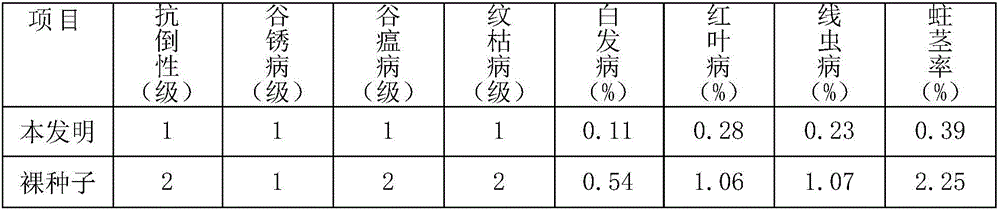

Millet granule processing method

ActiveCN105766139AReduce harmThe particle number is accurate and flexibleSeed coating/dressingSowing

The invention relates to a millet granule processing method, and belongs to the technical field of millet sowing. Millet seeds for sowing are pelleted, each millet seed is coated, 5-8 coated millet seeds are combined together to form seed balls, the seed balls are coated to obtain formed millet granules, and then a sower is used for sowing and planting. By means of the mode of sowing millet granules, sowing is convenient, seed mobility is good, the emergence rate is large, seedling heights are uniform, and later-stage maintenance is easy.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

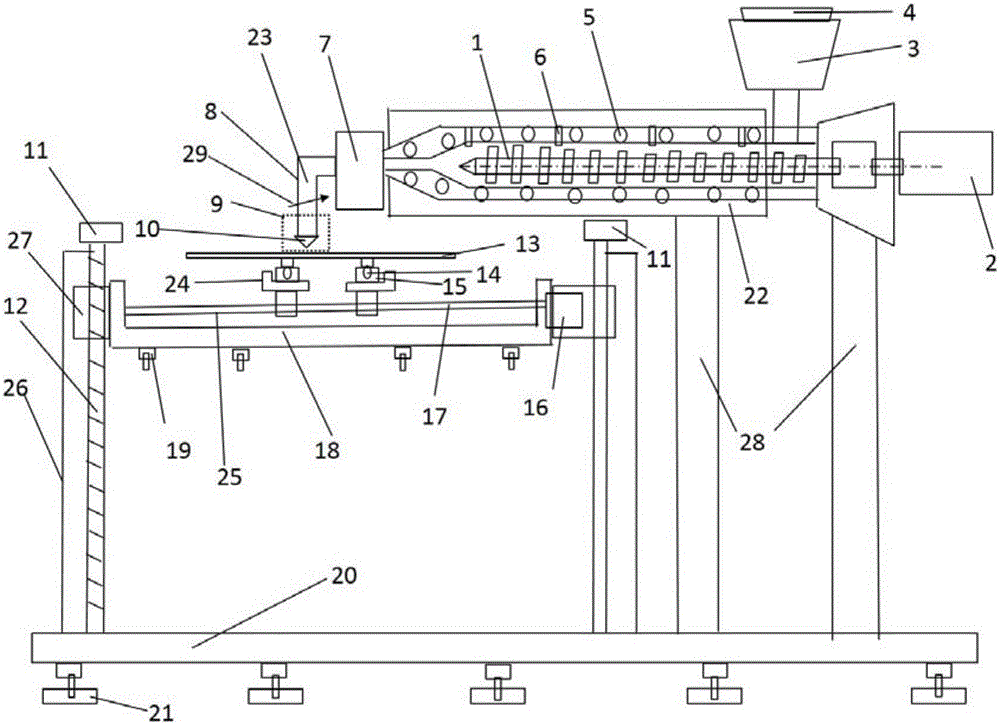

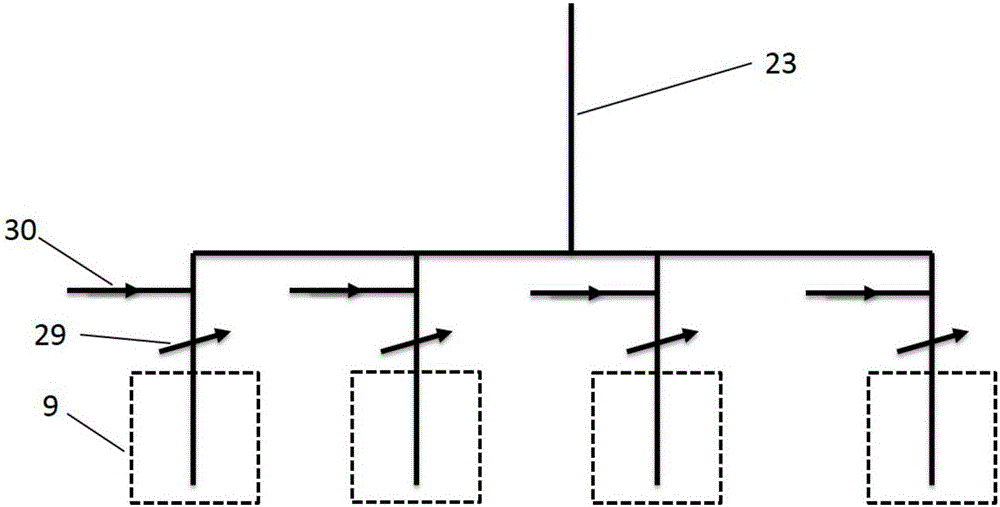

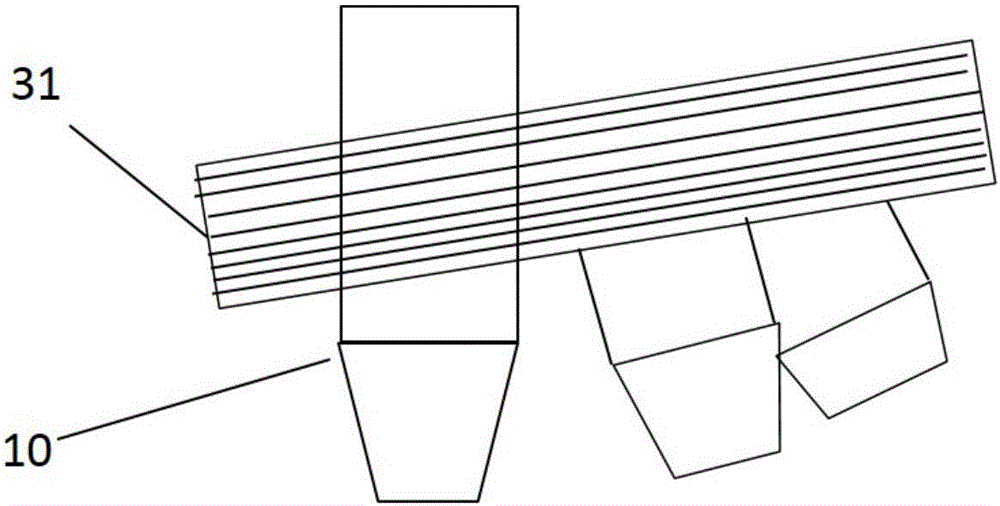

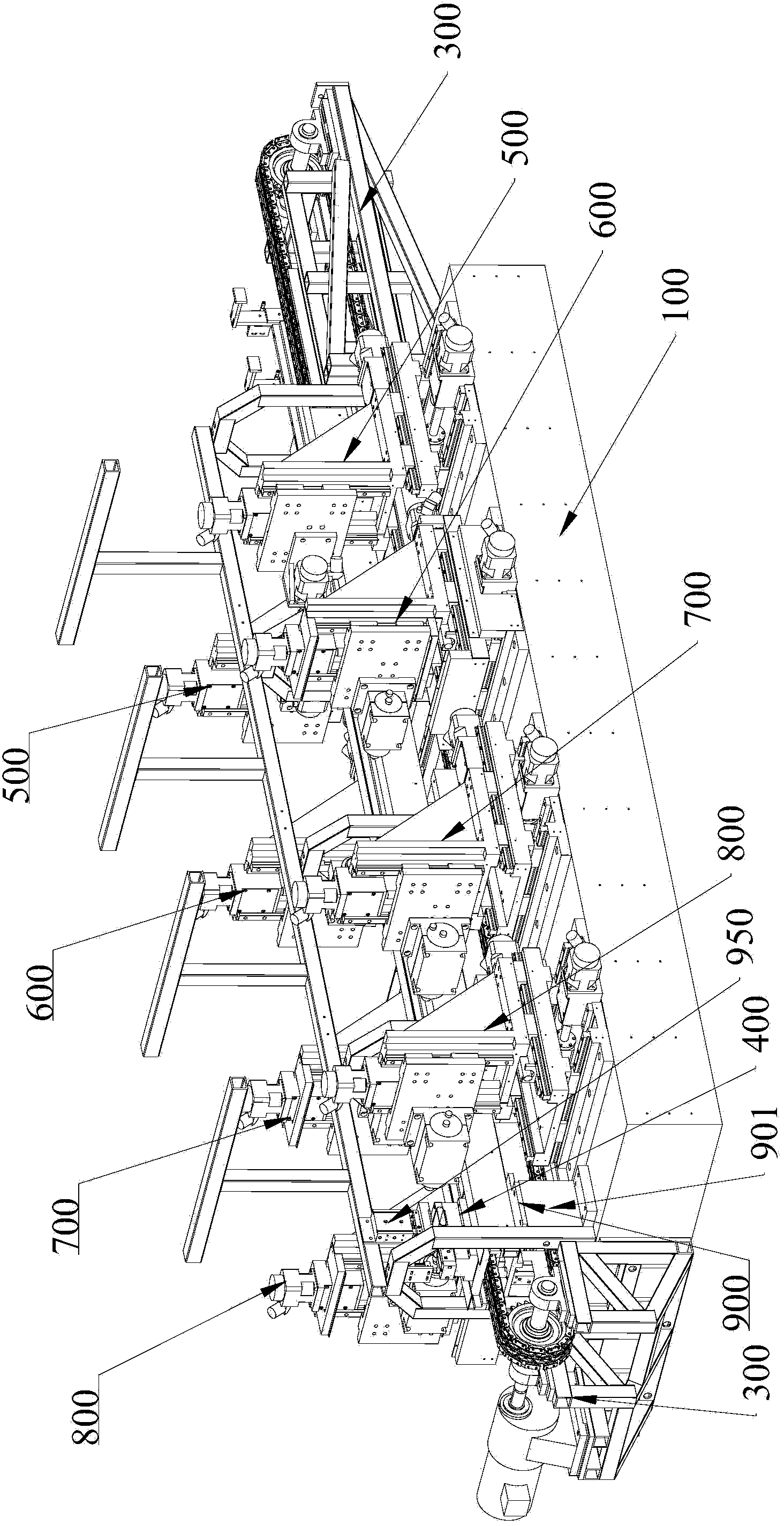

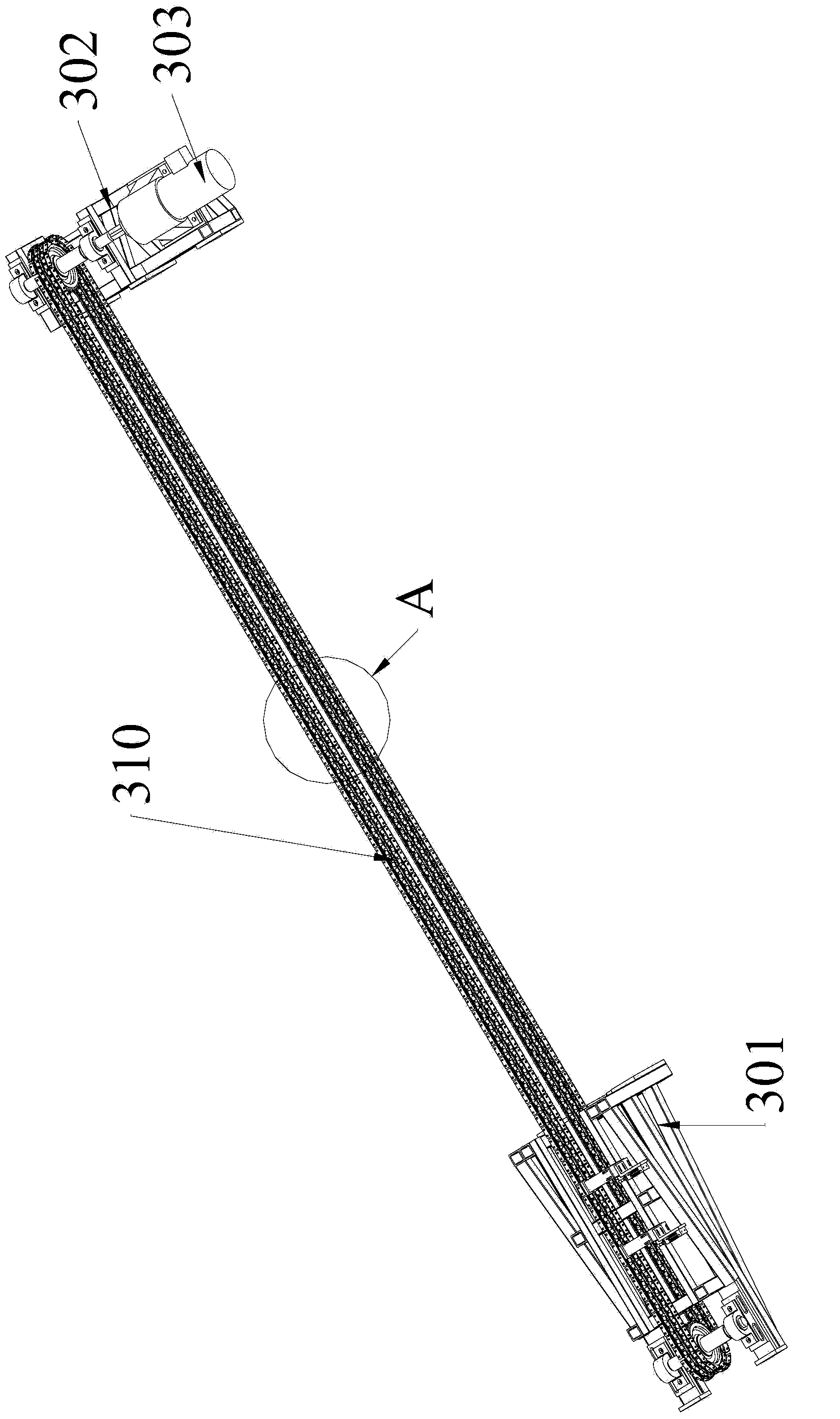

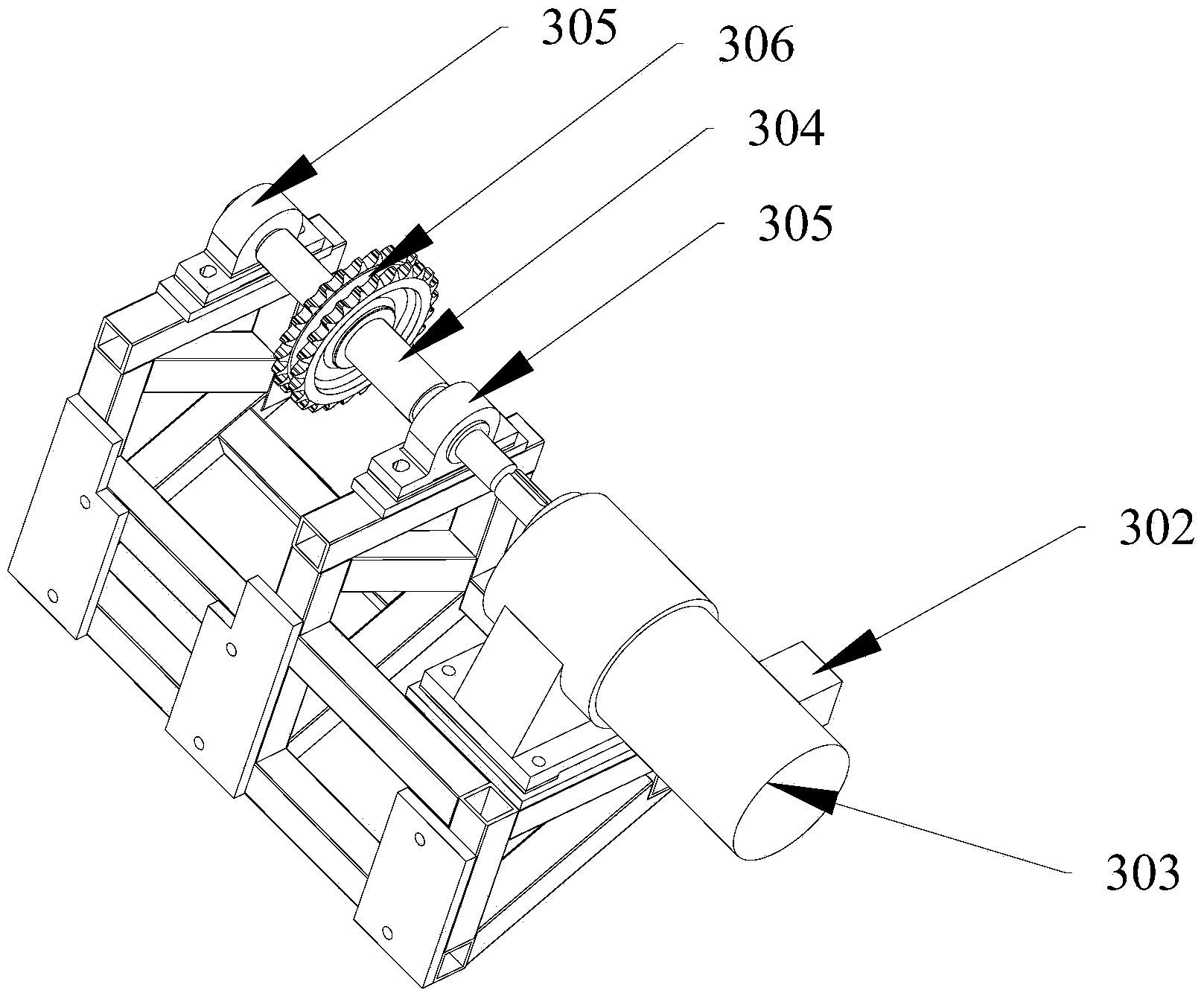

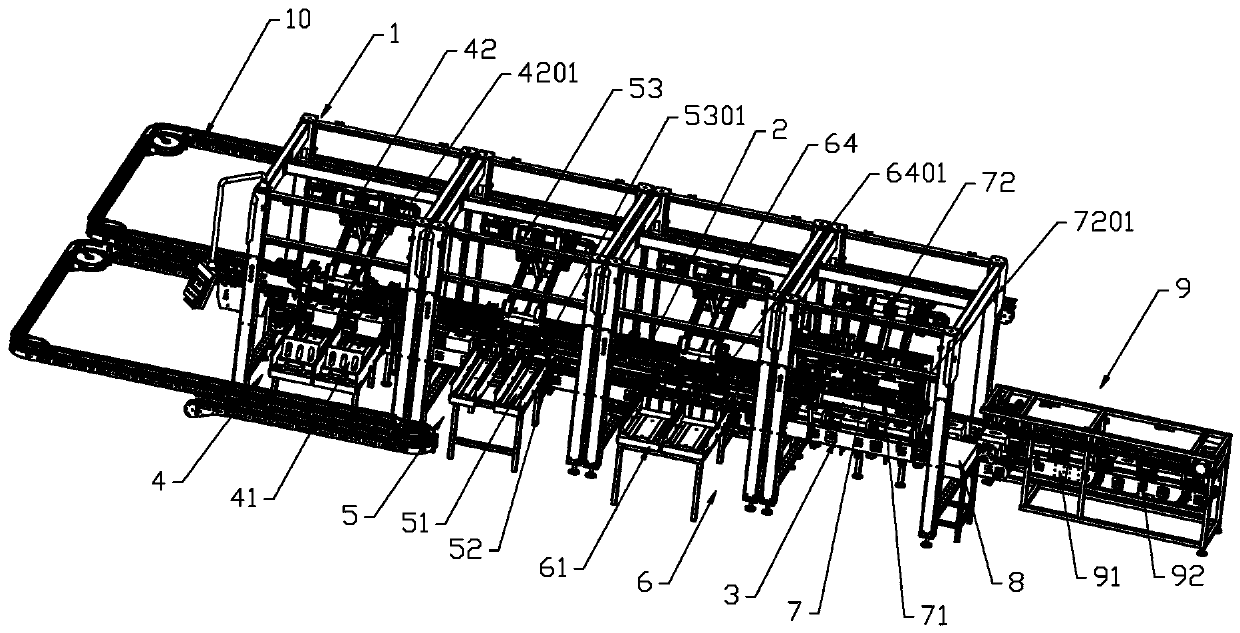

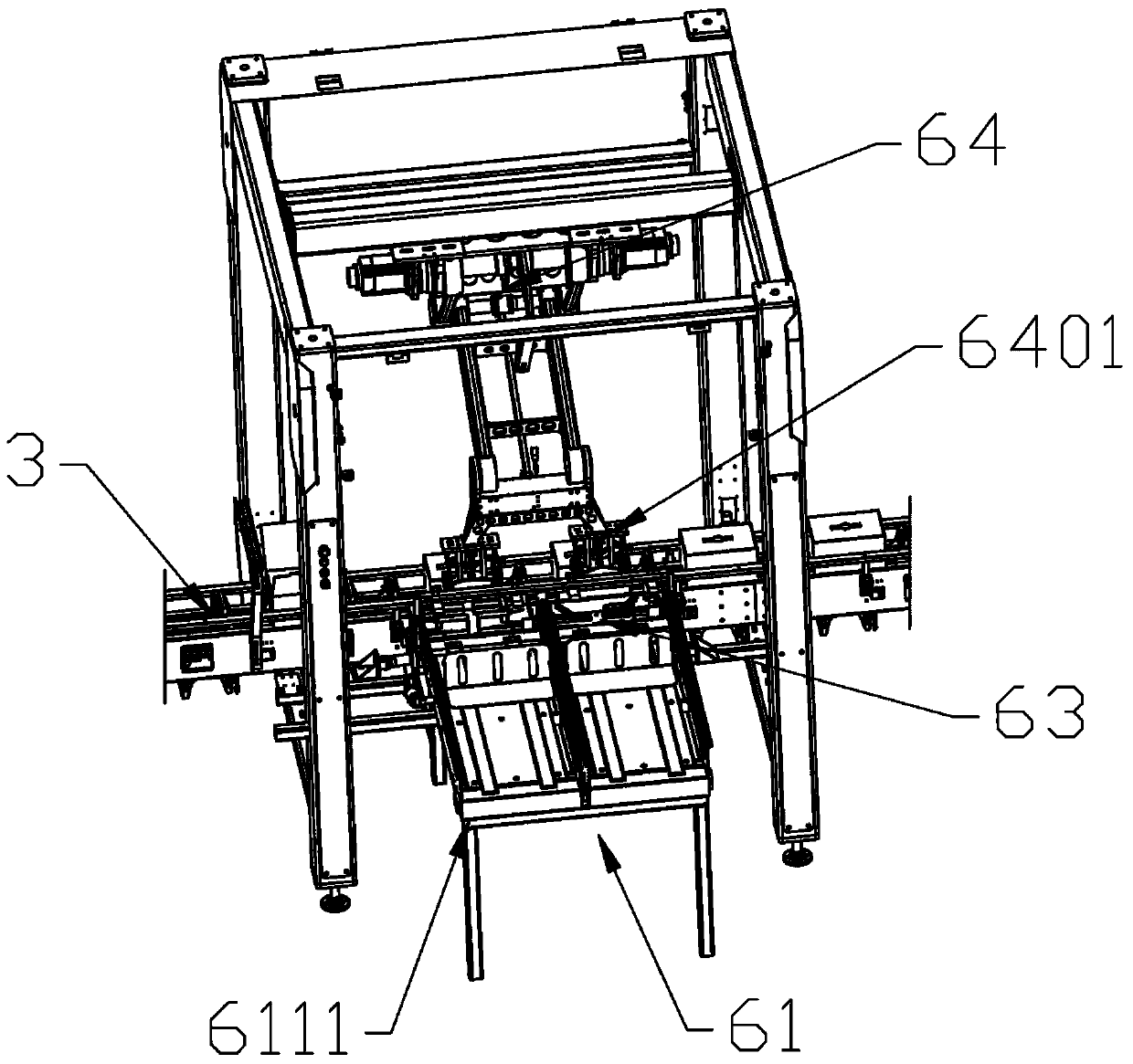

Four-station dual-end process automation production line

ActiveCN104384938AAchieve moldingImprove processing efficiencyOther manufacturing equipments/toolsMetal working apparatusProduction lineEngineering

The invention discloses a four-station dual-end process automation production line which comprises a rough milling station, a fine milling station, a drilling station and a tapping station which are formed by two tri-axial linkage rough milling mechanisms, two tri-axial linkage fine milling mechanisms, two tri-axial linkage drilling mechanisms and two tri-axial linkage tapping mechanisms, wherein the two tri-axial linkage rough milling mechanism, the two tri-axial linkage fine milling mechanisms, the two tri-axial linkage drilling mechanisms and the two tri-axial linkage tapping mechanisms are respectively positioned on two sides of a chain, so that two end surfaces of a workpiece can be simultaneously processed by two processing mechanisms at each station; the production line also comprises multiple fixture devices used for clamping the workpiece, and the workpiece is conveyed to the four stations by a chain of a fixture circulating device. After the fixture devices sequentially pass the four stations, processing of the workpiece is finished, so that the four-station dual-end process automation production line is capable of realizing molding of the workpiece only by virtue of once positioning, thus improving the working efficiency and improving the processing precision.

Owner:北京海普瑞森超精密技术有限公司

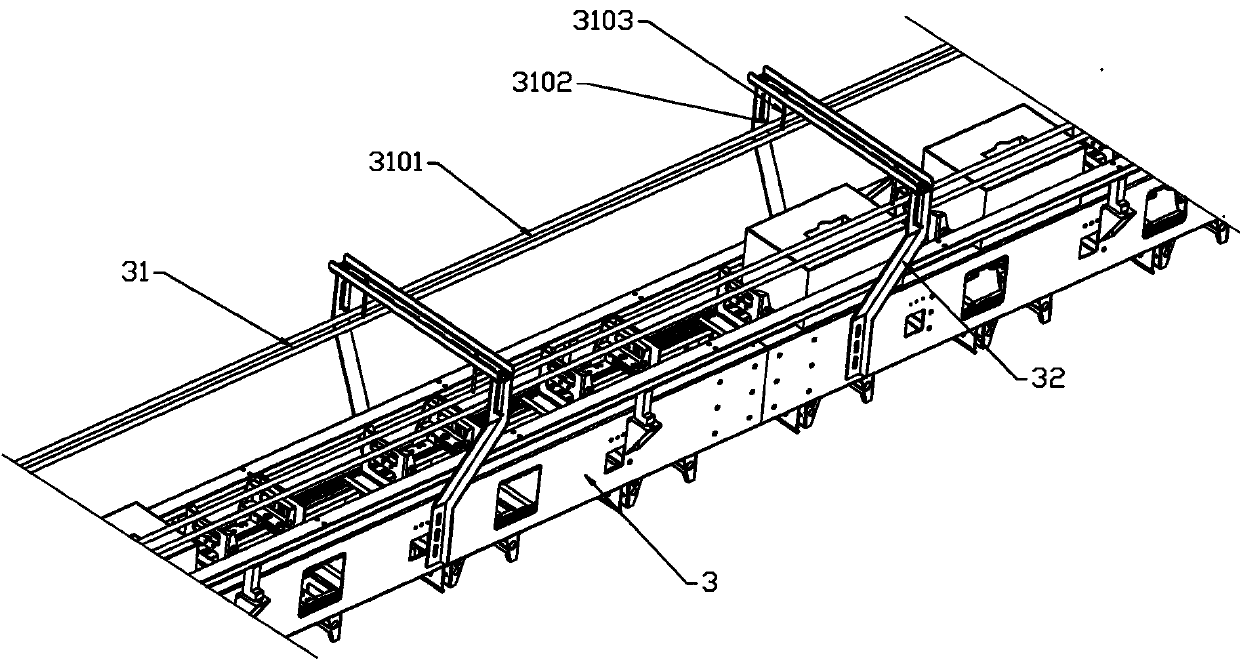

Modular flexible packaging system for liquid packages

PendingCN107826327AWide range of applicationsStrong compatibilityPackagingPhysicsMechanical engineering

The invention discloses a modular flexible packaging system for liquid packages. The modular flexible packaging system comprises a rack (1), wherein a liquid package splitting conveying line (2) and apackaging box conveying line (3) are arranged in an inner cavity of the rack (1) in parallel, an integration platform (7) is arranged on the tail end of the liquid package splitting conveying line (2), a packaging box module (4), a partition module (6), an integration box loading module (7) and a box pushing module (8) are arranged in sequence in the operating direction of the packaging box conveying line (3), the packaging box module (4) is used for supplying packaging boxes, the partition module (6) is used for supplying partitions put in the packaging boxes, the integration box loading module (7) is used for integrating the liquid packages and then grabbing the liquid packages so as to be put in the packaging boxes, and the box pushing module (8) is used for pushing the packaging boxesloaded with the liquid packages to a box sealing conveying line (91) of a box sealing module (9), so that box sealing is completed by a box sealing mechanism (92). According to the modular structureof the modular flexible packaging system, different liquid packages can be packaged only by replacing different tools and fixtures.

Owner:苏州澳昆智能机器人技术有限公司

Flexible electrode film and preparation method and application thereof

ActiveCN110098374AGreat suctionImprove liquid retention capacityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSulfurActive component

The invention discloses a flexible electrode film and a preparation method and an application thereof. The film comprises a carbon fluoride supported sulfur composite material, carbon nanotubes and abinder. The mass ratio of the carbon fluoride supported sulfur composite material to the carbon nanotubes to the binder is (5-12): (0.8-1.2): (0.8-1.2). After hot pressing of the film, a self-supporting flexible cathode is obtained. A preparation method combining atmospheric-pressure low-temperature drying and high-temperature short-time hot pressing is adopted, which can cause secondary melting expansion of sulfur, reduce the resistance of the electrode and achieve the effects of film formation, flexibility improvement and reduction in sulfur loss of active components. The electrode has a compact structure, excellent flexibility and good conductivity.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

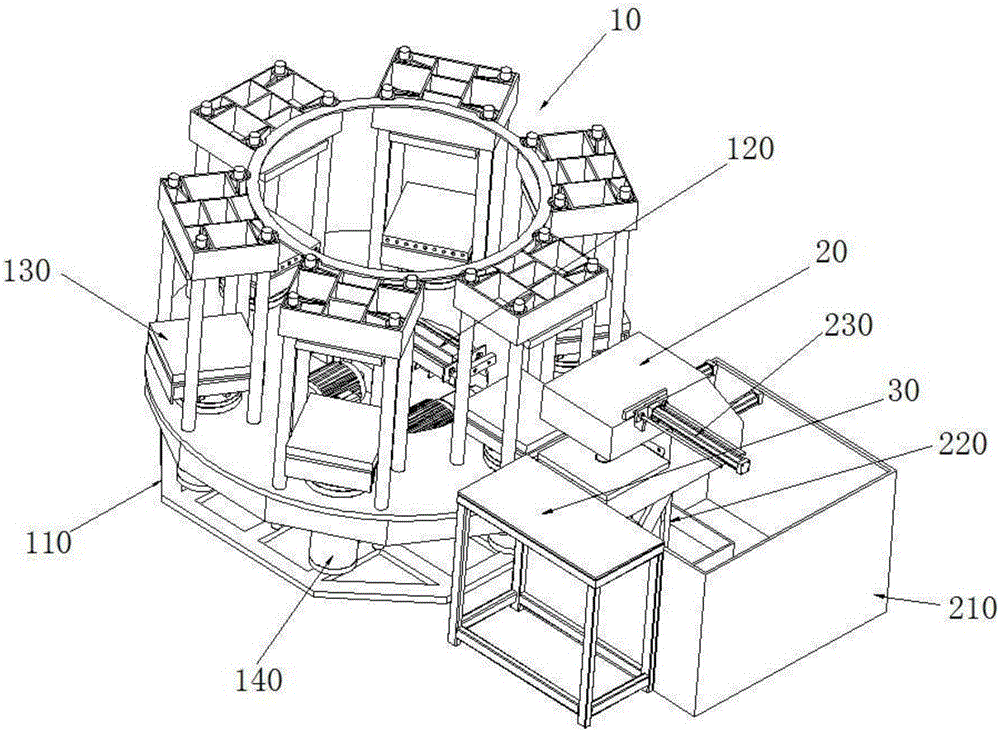

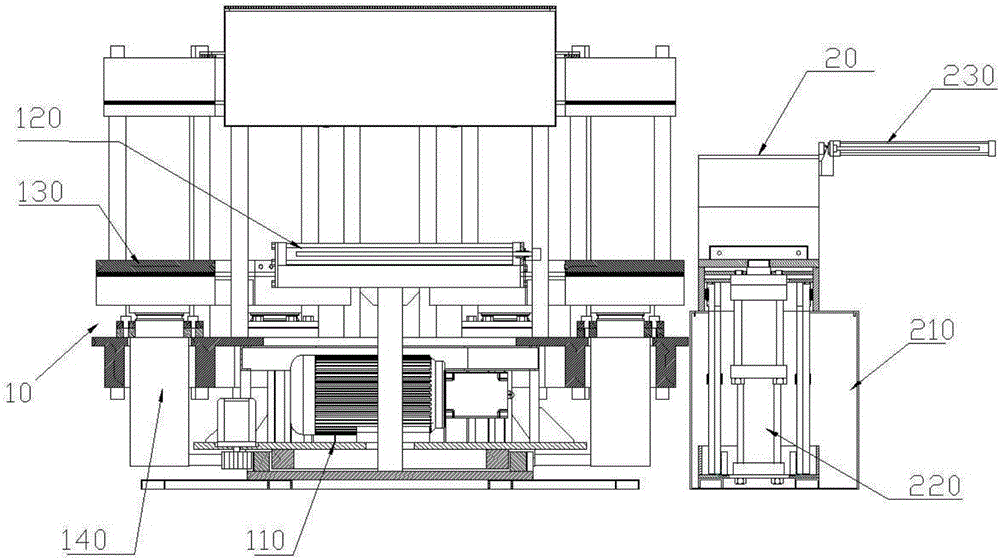

EVA cold/hot forming machine and forming method of cold/hot forming machine

The invention discloses an EVA cold / hot forming machine. The machine comprises a hot forming machine and a cold forming machine; the hot forming machine includes a rotating base capable of intermittently rotating by 360 degrees; n stations are annularly arranged on the rotating base; a first mold pushing mechanism is arranged in the center of the rotating base; a movable end of the first mold pushing mechanism is aligned to a mold placing position on the first station; each station is provided with a heating part and a first hydraulic cylinder; the cold forming machine includes a cooling liquid box and a lifting mechanism arranged in the cooling liquid box; the lifting mechanism is near the first station, and is provided with a second mold pushing mechanism; and the moving directions of the second mold pushing mechanism and the first mold pushing mechanism are positioned on the same straight line or in parallel for pushing molds to be heated on the lifting mechanism to the heating parts. The EVA cold / hot forming machine is simple and compact in structure, is combined only by the cold forming machine and the hot forming machine, and can finish work of multiple stations only by one operator standing in one station.

Owner:东莞市昌亿复合材料机械科技有限公司

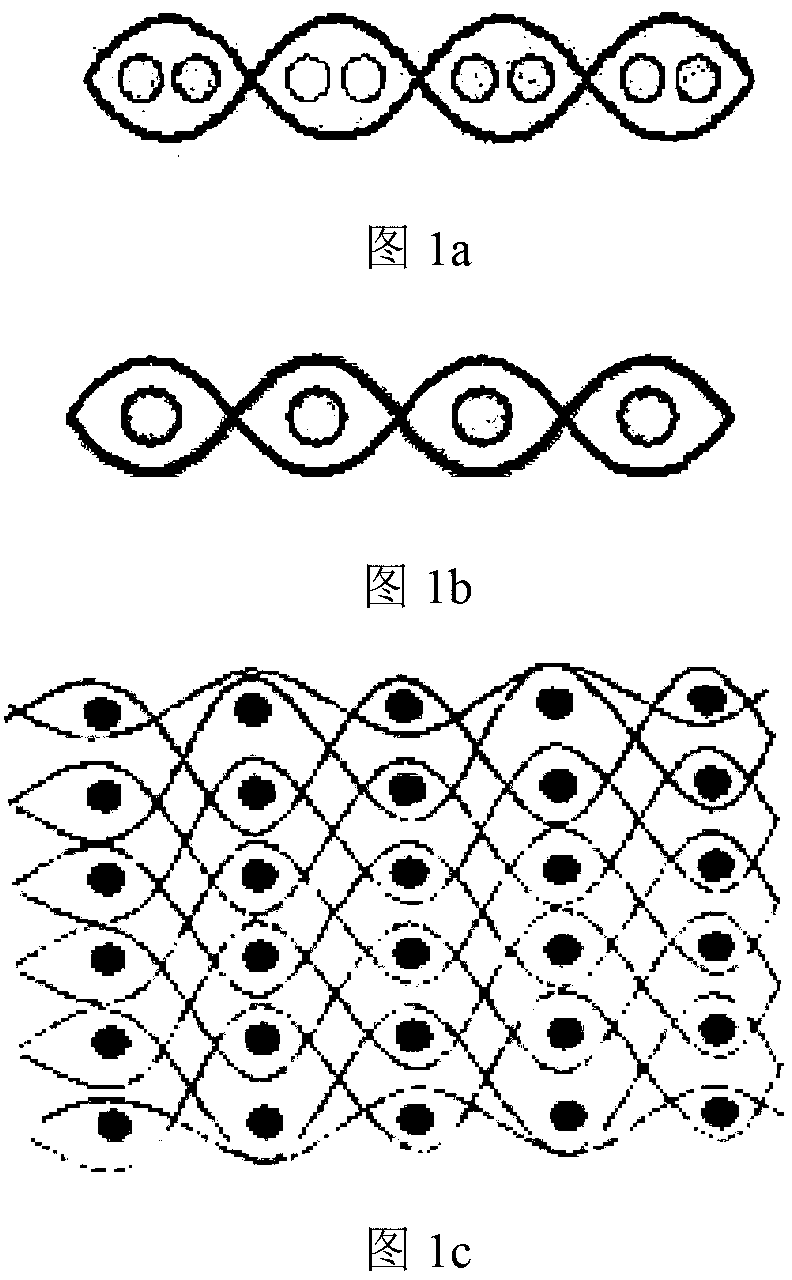

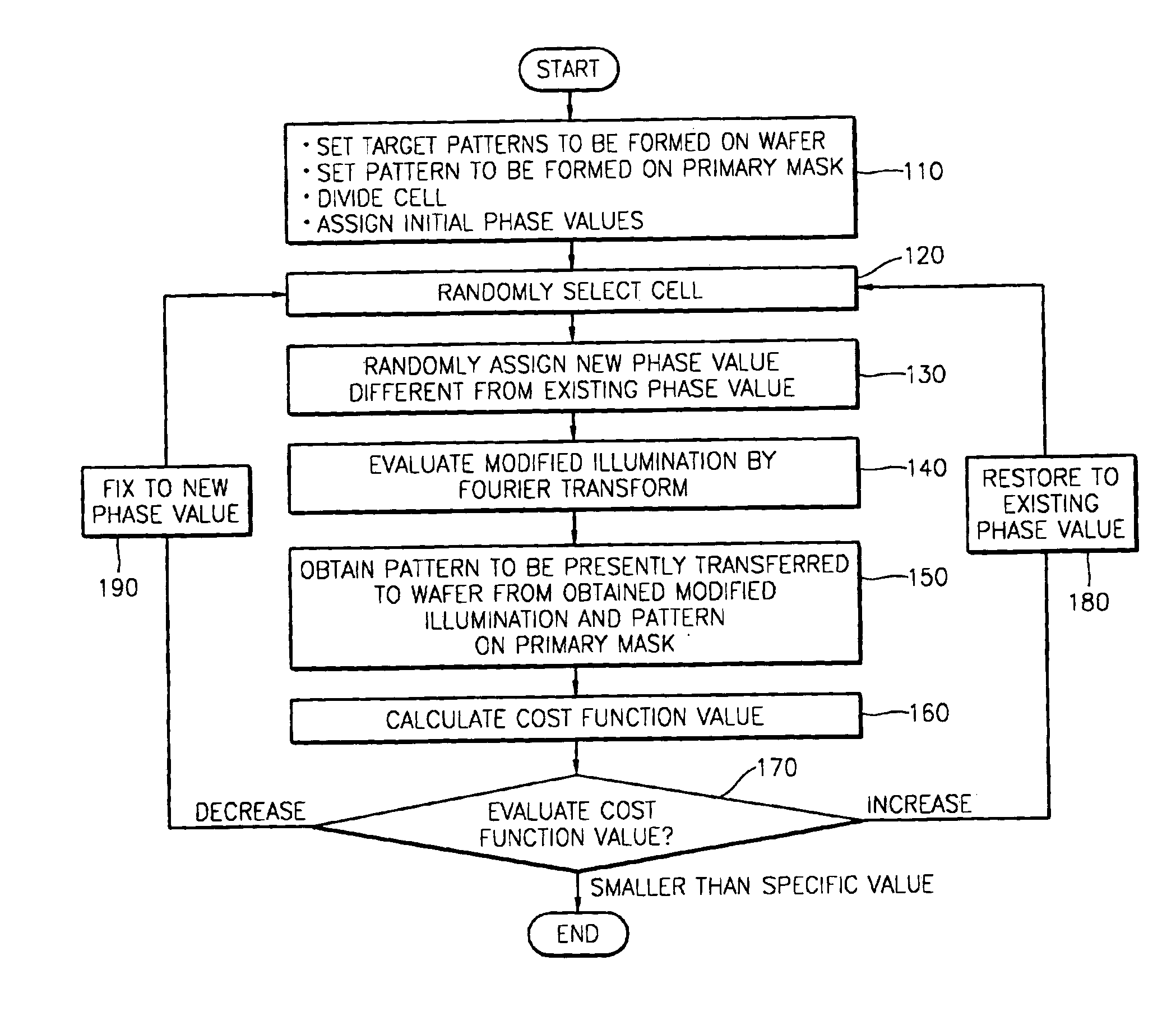

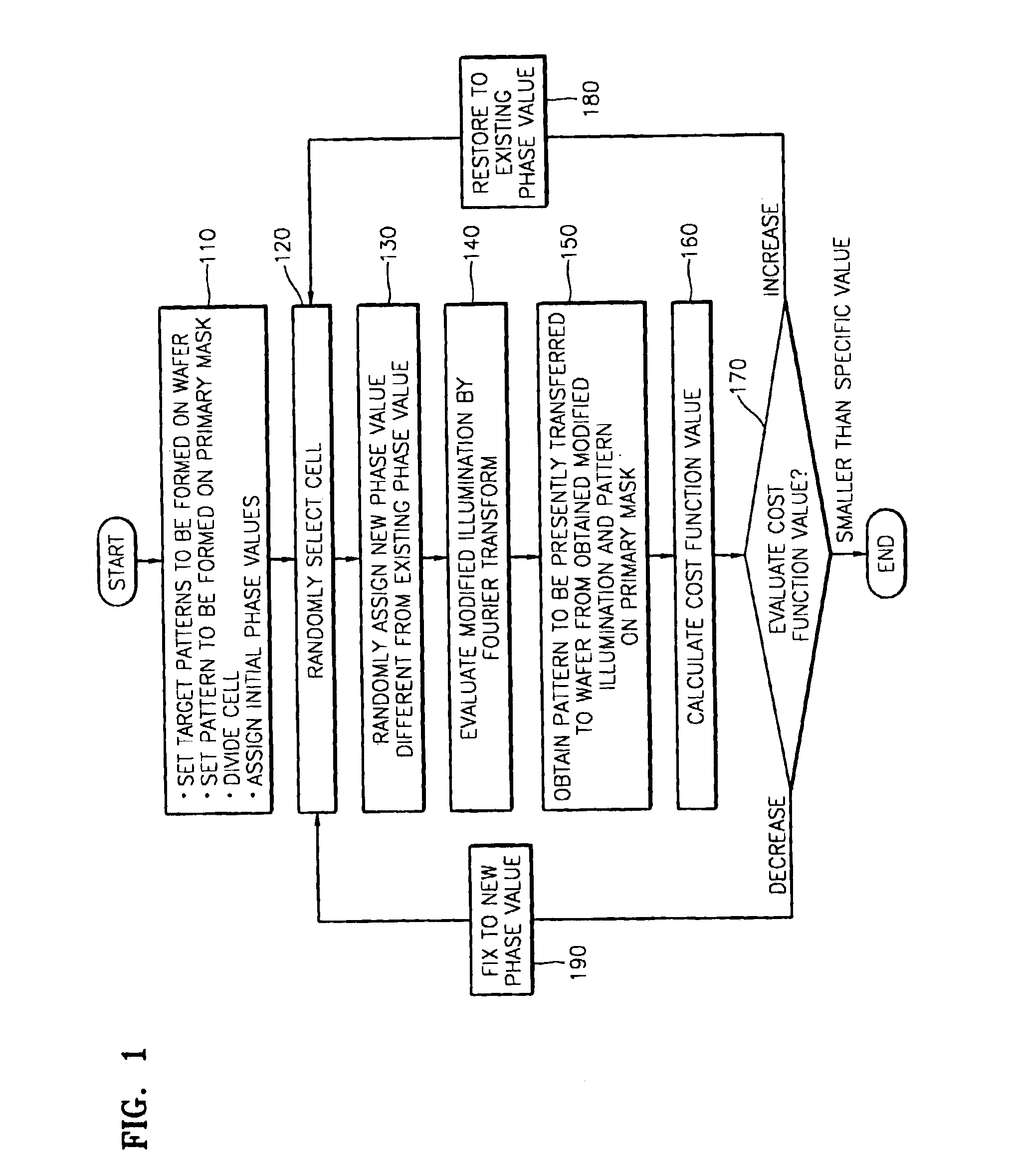

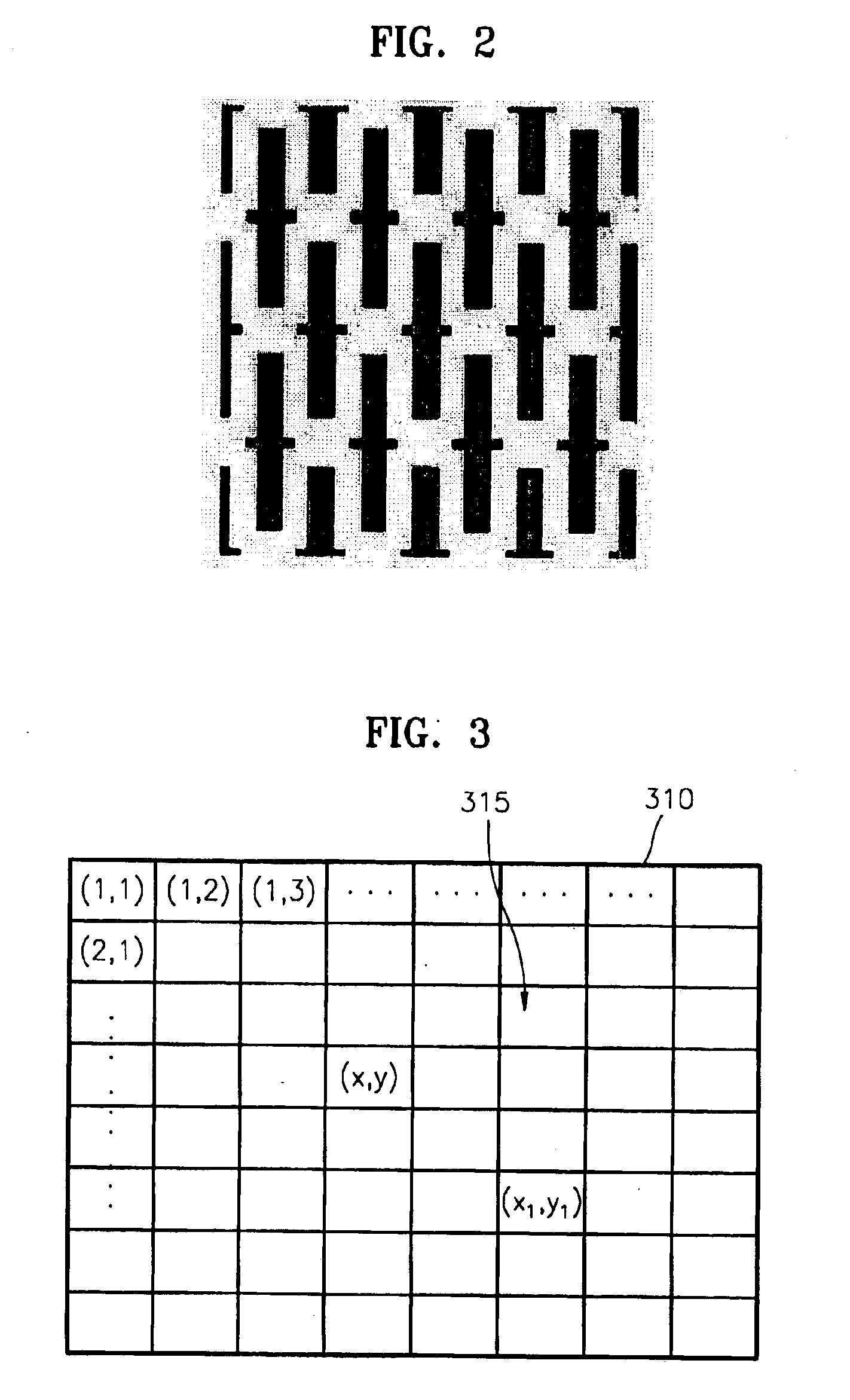

Method of designing phase grating pattern providing modified illumination optimum for producing a target pattern and method of manufacturing a photo mask system comprising the phase grating pattern

InactiveUS6911286B2High resolutionAdd depthSemiconductor/solid-state device manufacturingDiffraction gratingsPhase gratingDesign phase

A method of designing a phase grating pattern provides a modified form of illumination for a main mask, optimum for producing one or more target patterns on a wafer in a photolithographic process. Once the target pattern(s) to be formed on the wafer are decided, an area to be occupied by at least a portion of the phase grating is divided into a plurality of subcells, initial phase values are assigned to each of the subcells, and one of the subcells is randomly selected and the phase value last assigned thereto is changed, and the process is repeated. The process is in an iteration that changes the arrangement of the phase values assigned to the subcells until they converge on one which will provide the design for a phase grating which will produce a modified form of illumination optimum for use in forming the target pattern(s) on the wafer.

Owner:SAMSUNG ELECTRONICS CO LTD

Pitch-free bonding cathode carbon block material for aluminium electrolysis cell and production method of pitch-free bonding cathode carbon block material

InactiveCN103387221AHarm reductionRealize mixing at room temperatureCarbon preparation/purificationAluminium electrolysisRoom temperature

The invention discloses a pitch-free bonding cathode carbon block material for an aluminium electrolysis cell and a production method of the pitch-free bonding cathode carbon block material. The production method of the pitch-free bonding cathode carbon block material comprises the following steps: carrying out dry blending on 60%-98% of calcined coke with different grains and 2%-50% of artificial graphite in weight percentage until the mixture is uniform, then adding 7%-13% of modified phenolic resin in weight percentage, carrying out wet mixing until the mixture is uniform and then discharging; ageing the wetly mixed material for 24-48 hours at room temperature and then placing the aged material into a normal-temperature moulding die for vibration moulding, or directly placing the wetly mixed material into the moulding die for moulding without aging; and carrying out roasting, machining and the like, so that the finished cathode carbon block product is obtained. The production method of the pitch-free bonding cathode carbon block material has the advantages that modified phenolic resin is adopted as a bonding agent, so that harm to a human body and environment pollution caused by a pitch bonding agent in the prior art are alleviated; the production method of the pitch-free bonding cathode carbon block material realizes that material mixing and moulding operation are carried out at room temperature; the cathode carbon block produced by the production method has the characteristics of high strength, good thermal conductivity, high electrical conductivity and molten salt corrosion resistance, and the service life of the aluminium electrolysis cell with the cathode carbon block can be effectively prolonged.

Owner:DONGE COUNTY LUXI METALLURGY REFRACTORY MATERIALCO LTD

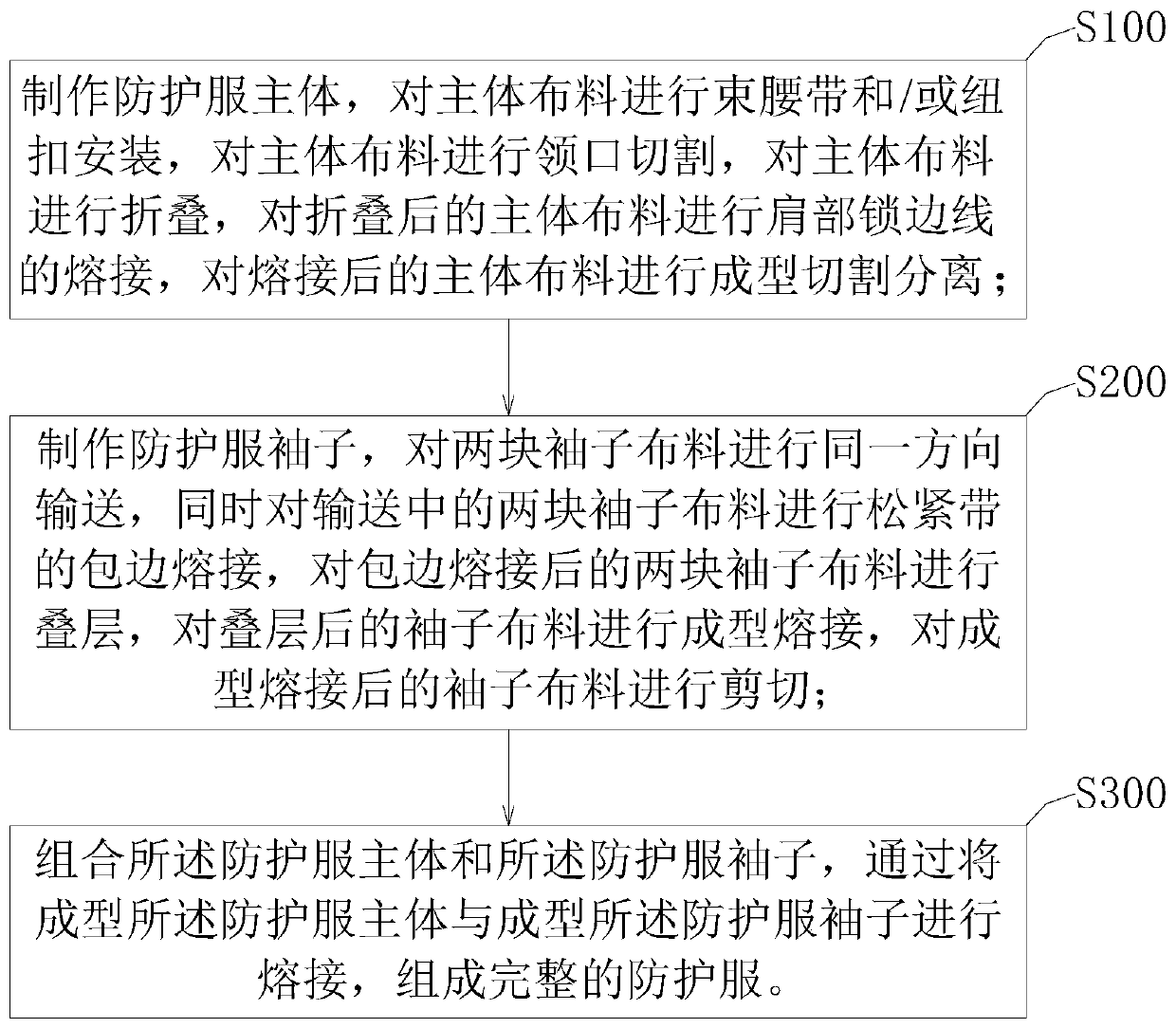

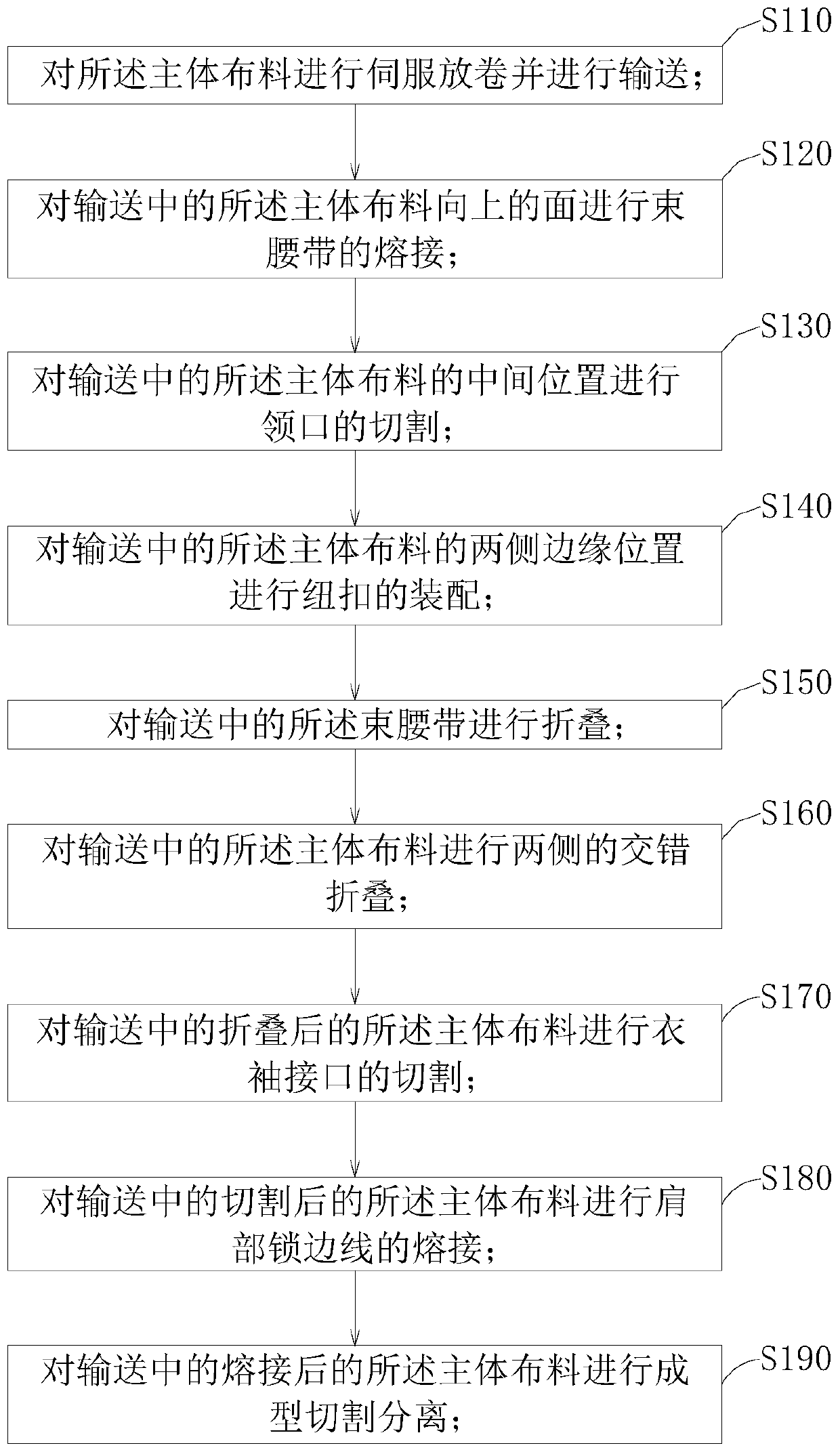

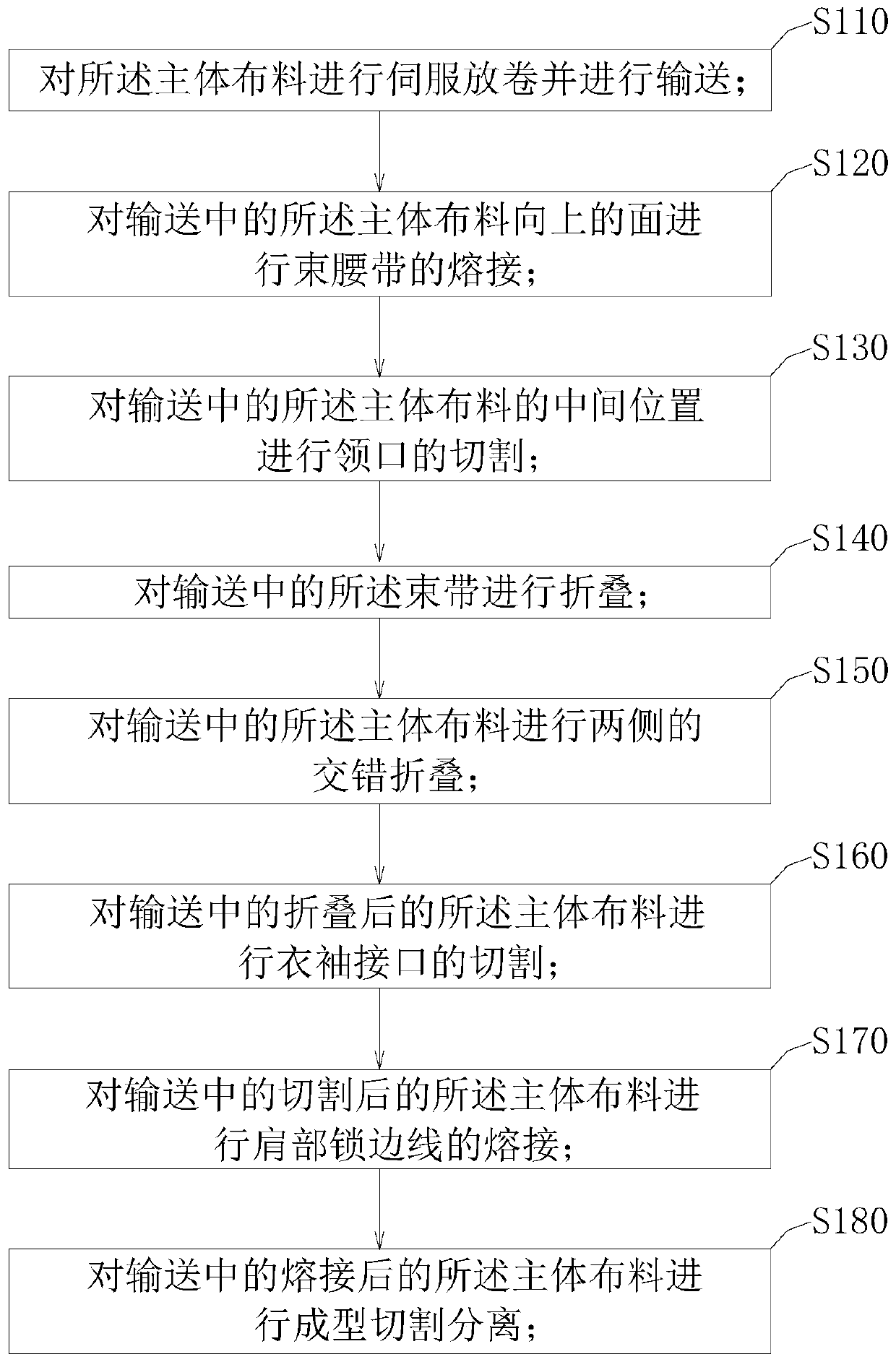

Production method of protective clothing

ActiveCN110897234AStable deliveryAchieve moldingGarment beltsProtective garmentWaste materialIndustrial engineering

The invention belongs to the technical field of medical protective clothing production, in particular to a production method of protective clothing. The production method comprises the following steps: manufacturing a protective clothing main body, conducting waistband and / or button installation on main body cloth, conducting neckline cutting on the main body cloth, folding the main body cloth, conducting shoulder locking line welding on the folded main body cloth, and conducting forming, cutting and separating on the welded main body cloth; manufacturing sleeves of protective clothing, meanwhile, enabling the first sleeve cloth and the second sleeve cloth which are conveyed to be subjected to covered edge welding of the elastic band; and laminating the first sleeve cloth and the second sleeve cloth which are subjected to edge covering and welding, carrying out forming and welding on the laminated first sleeve cloth and second sleeve cloth, and shearing the formed and welded first sleeve cloth and second sleeve cloth; the protective clothing body and the protective clothing sleeves are combined. The production method of protective clothing can be matched with related equipment forproduction to achieve the effect of automatic production, so that the production efficiency is improved, and waste materials are reduced.

Owner:东莞快裕达自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com