Modular flexible packaging system for liquid packages

A flexible packaging and modular technology, applied in packaging and other directions, can solve the problems of lack of modular structure, etc., and achieve the effect of being suitable for popularization and use, strong compatibility, and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

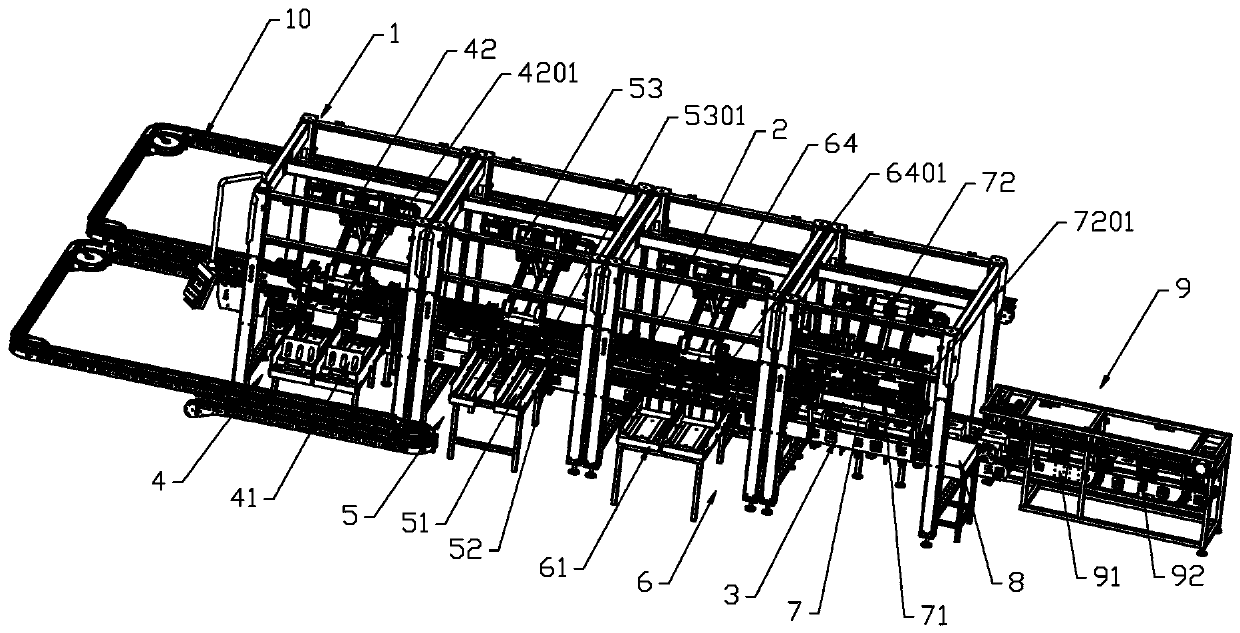

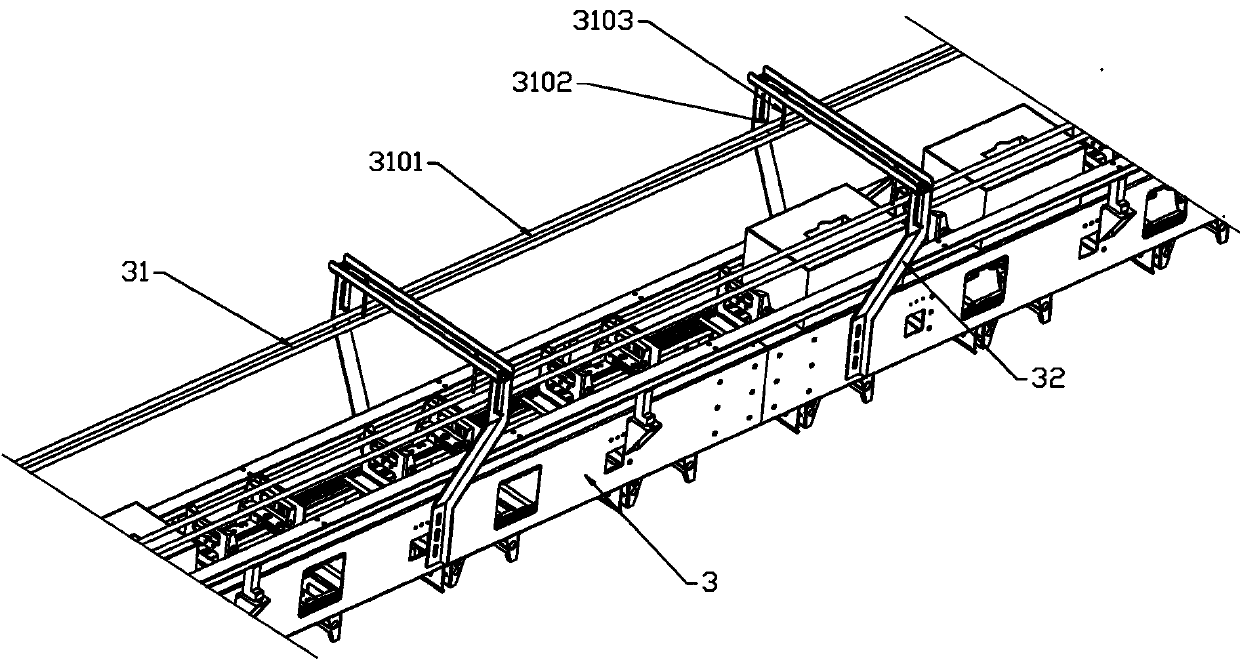

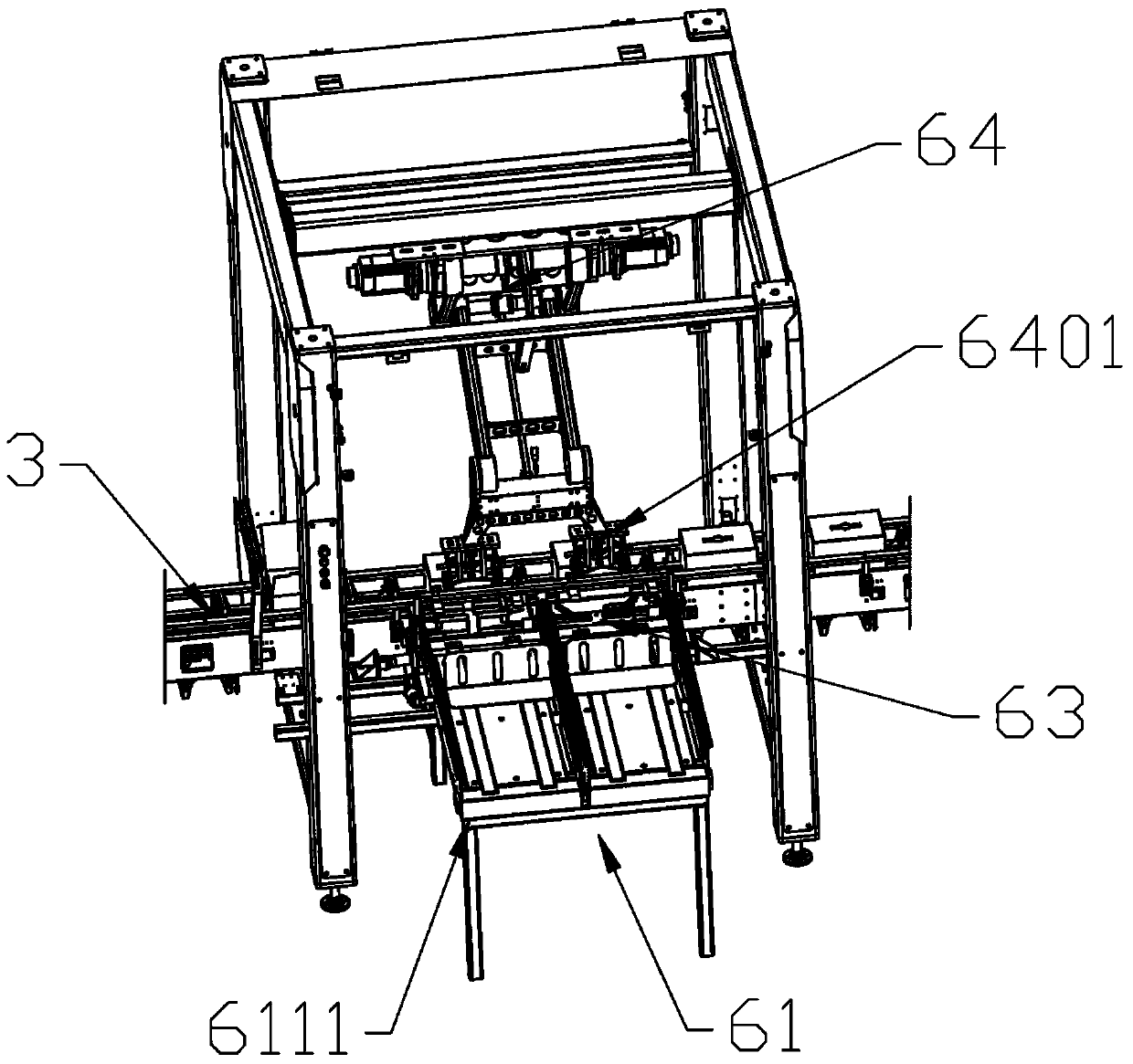

[0042] like Figure 1-8 Shown: a modular liquid package flexible packaging system, including a frame 1, in the inner cavity formed by the frame 1, a liquid package lane conveying line 2 and a packing case conveying line 3 are arranged in parallel, and the liquid package divides into lanes The front end of the conveying line 2 can at least receive the supply of liquid packs from two liquid pack conveying lines 10, and the tail end of the liquid pack conveying line 2 is provided with an integration platform 71, and packing boxes are sequentially arranged along the running direction of the packing case conveying line 3 Module 4, clapboard module 6, integrated packing module 7 and box pushing module 8, packing case module 4 is used for packing case conveying line 3 to provide packing case and can place the opened packing case in packing case On the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com