Method for preparing polymer porous nanofiber through mixed phase separation

A nanofiber, polymer technology, applied in the direction of single-component synthetic polymer rayon, chemical post-treatment of synthetic polymer rayon, rayon made of cellulose derivatives, etc. High requirements, limited range of polymer selection, etc., to achieve the effect of wide application range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

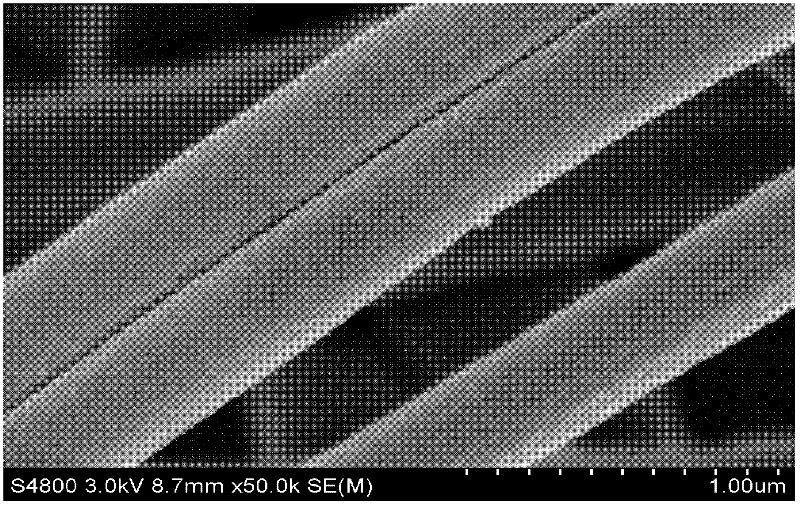

Embodiment 1

[0024] Select ethylene glycol as the additive, N,N-dimethylacetamide as the solvent, the mass ratio of the additive to the solvent is 1:4, the mass ratio of polyvinylidene fluoride to the solvent is 1:5, mix in a round bottom flask Evenly, heat to 90°C, stir well until the mixed system becomes a homogeneous solution, then let it stand for defoaming. Then the solution was electrospun under the condition of spinning voltage of 20kV, micro injection pump flow rate of 0.5mL / h, and spinning distance of 11cm, and the obtained fibers were received in an ice-water bath. Soak the obtained nanofibers in ethanol at 0°C for 60 minutes, extract ethylene glycol and N,N-dimethylacetamide, then soak them in n-hexane for 30 minutes, replace the ethanol, and then vacuum-dry the nanofibers at 30°C for 6 Hours, polyvinylidene fluoride porous nanofibers were obtained. The average diameter of the fiber is about 450nm, and the pore size ranges from 30 to 70nm.

[0025] The above PVDF porous nanofi...

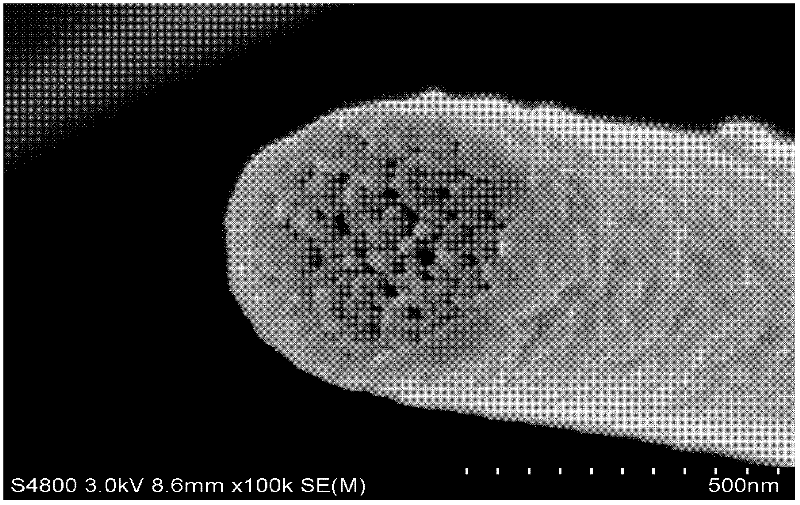

Embodiment 2

[0030] Select dimethyl sulfoxide as additive, N,N-dimethylformamide as solvent, the mass ratio of additive to solvent is 1:1, the mass ratio of polyacrylonitrile to solvent is 1:3, in a round bottom flask Mix evenly, heat to 90°C, stir well until the mixed system becomes a homogeneous solution, then let it stand for defoaming. Then the solution was electrospun under the conditions of a spinning voltage of 16kV, a flow rate of a micro-syringe pump of 0.7mL / h, and a spinning distance of 5cm, and the obtained fibers were received in an ice-water bath. Soak the obtained fibers in ethanol at 0°C for 30 minutes, extract dimethyl sulfoxide and N,N-dimethylformamide, soak them in n-hexane for 20 minutes, replace the ethanol, and then vacuumize the nanofibers at 40°C Dry for 8 hours to remove n-hexane to obtain polyacrylonitrile porous nanofibers. The average diameter of the nanofiber is about 450nm, and the pore diameter ranges from 20 to 120nm.

[0031] The above polyacrylonitrile ...

Embodiment 3

[0033] Select dimethyl sulfone as additive, N,N-dimethylformamide as solvent, the mass ratio of additive to solvent is 1:1, the mass ratio of polyacrylonitrile to solvent is 1:4, mix in a round bottom flask Evenly, heat to 90°C, stir well until the mixed system becomes a homogeneous solution, then let it stand for defoaming. Then the solution was electrospun under the conditions of a spinning voltage of 10 kV, a flow rate of a micro-syringe pump of 0.5 mL / h, and a spinning distance of 7 cm, and the obtained fibers were received in a water bath at 10° C. Soak the obtained fibers in ethanol at 10°C for 30min, extract dimethyl sulfone and N,N-dimethylformamide, then soak in n-hexane for 15min, replace the ethanol, and then vacuum-dry the nanofibers at 30°C The n-hexane was removed for 8 hours to obtain polyacrylonitrile porous nanofibers. The average diameter of the nanofiber is about 700nm, and the pore diameter ranges from 1 to 120nm.

[0034] The above-mentioned PAN porous n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com