Patents

Literature

753results about "Monocomponent halogenated hydrocarbon artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of porous fiber non-woven fabric

ActiveCN103981635AReduce melt viscosityReduce degradationFilament forming substance formingMelt spinning methodsDiluentNonwoven fabric

The invention relates to a preparation method of a porous fiber non-woven fabric. The aim of the preparation method is to improve the product performance of the conventional non-woven fabric, so that the non-woven fabric meets the requirements on high-precision and high-performance filter. The technical scheme is that the preparation method of the porous fiber non-woven fabric comprises the following steps in sequence: (1) uniformly mixing a polymer and a diluent to obtain a blend with 10 to 60 percent of polymer; (2) melting and extruding the blend in the step (1) by adopting a screw extruder granulator, and directly cooling and granulating in air; (3) producing master batches in the step (2) by melt-down equipment to obtain a primary non-woven fabric; (4) extracting to remove the diluent from the primary non-woven fabric in the step (3), performing pore-forming on fibers in the non-woven fabric, and drying to obtain the porous fiber non-wave fabric; (5) recovering mixed waste liquid of the diluent and an extraction agent for reuse.

Owner:浙江省轻工业品质量检验研究院

Fluoropolymer fine fiber

ActiveUS20090032475A1Advantageously employedHeat stableDispersed particle filtrationLiquid suspension thickening by filtrationPolymer scienceFiltration

A layer of fluoropolymer fine fiber can be made. The fine fiber can be made by electrospinning from a solvent or a solvent blend. The layers of the invention are useful in general filtration of fluid streams including gaseous and liquid streams. The fine fiber layers are also useful as hydrophobic filtration layers that can be used to separate water from a hydrocarbon stream.

Owner:DONALDSON CO INC

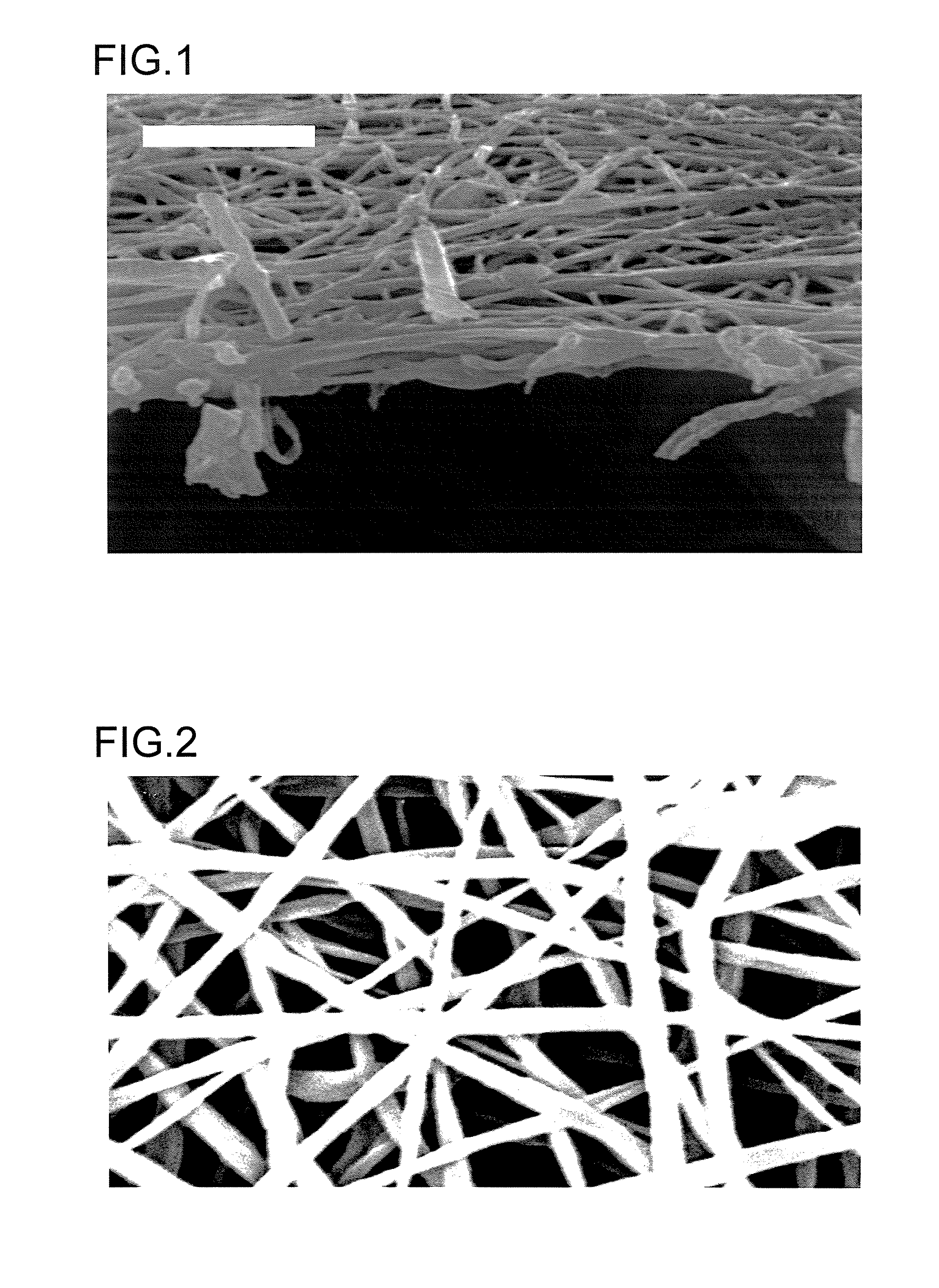

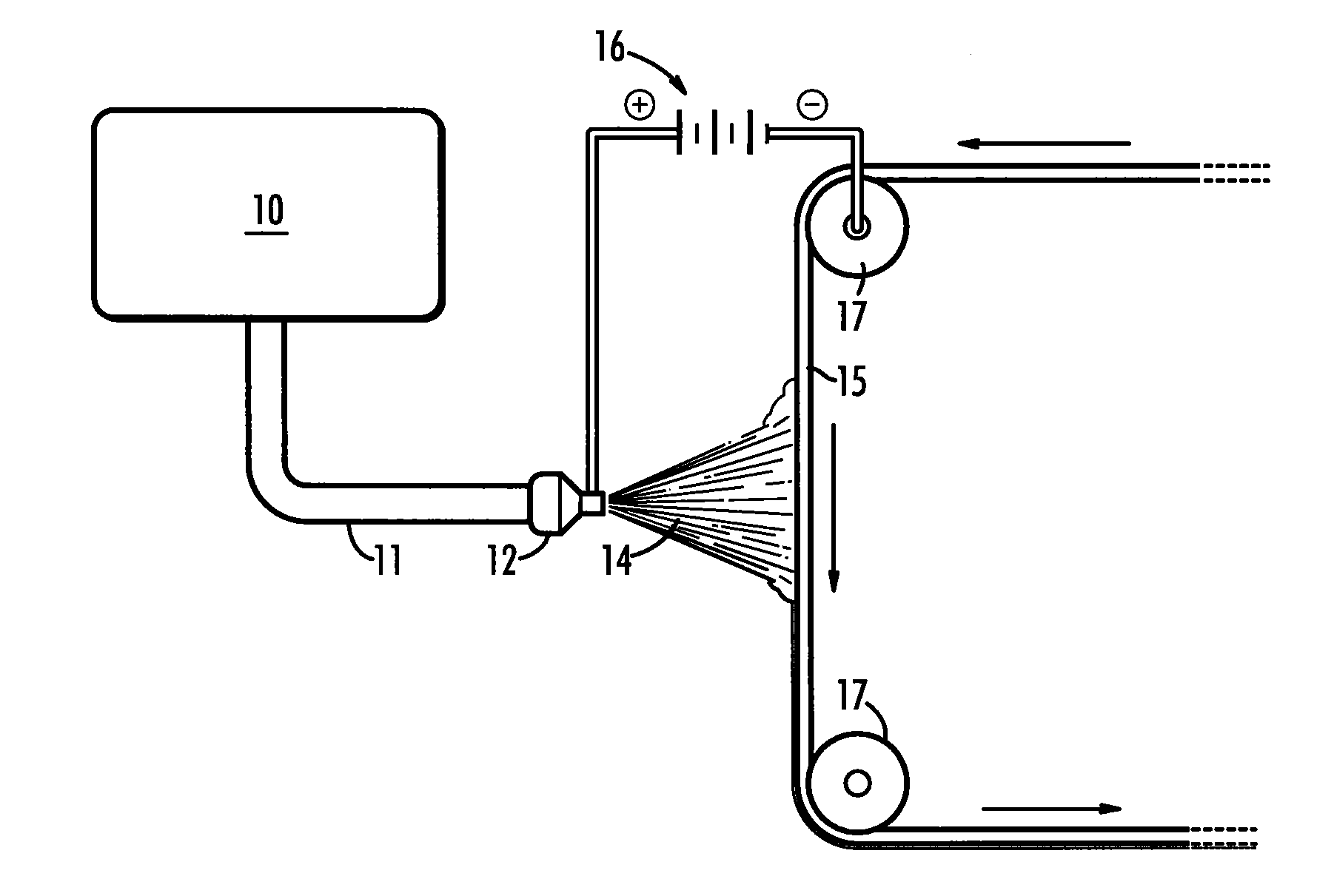

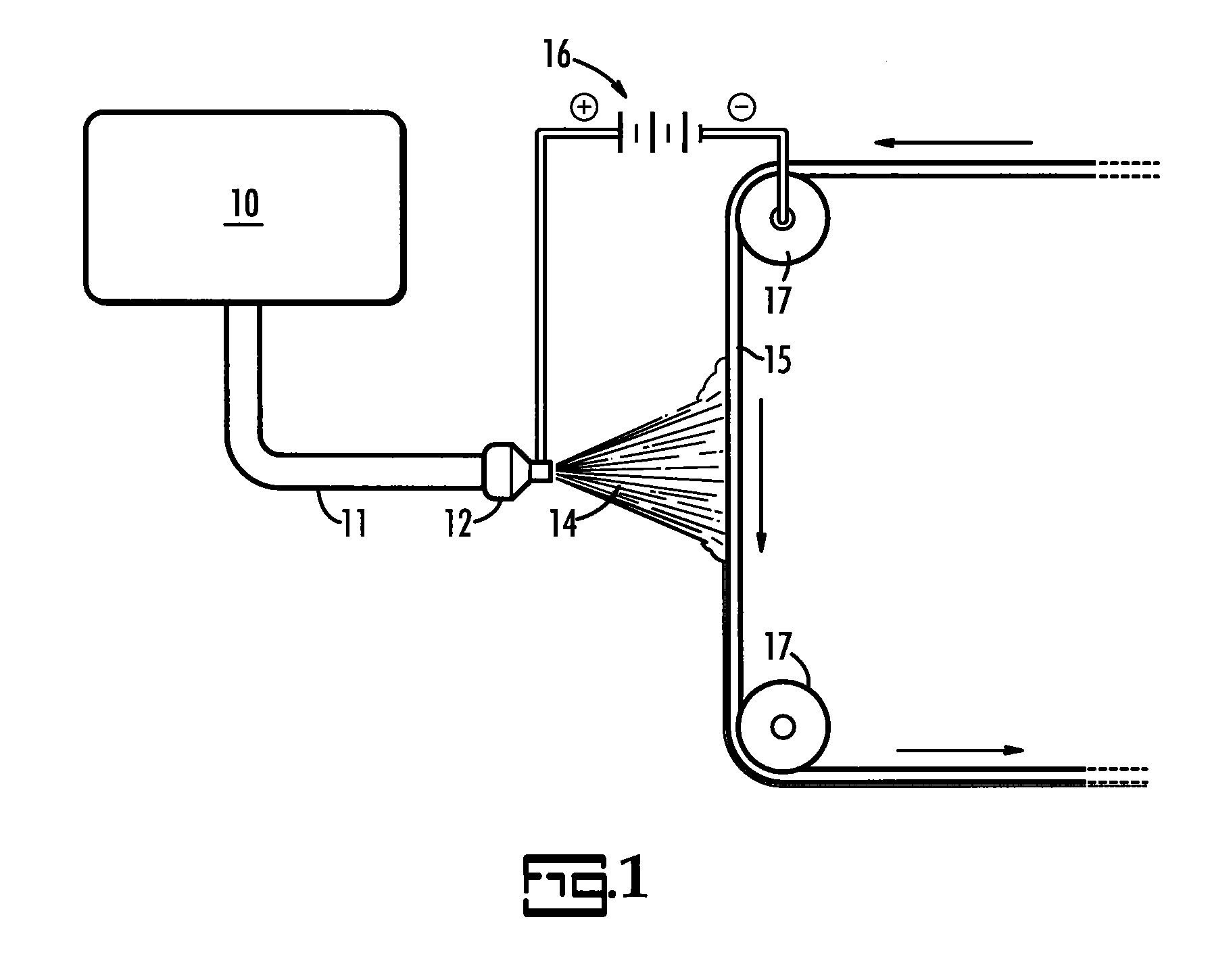

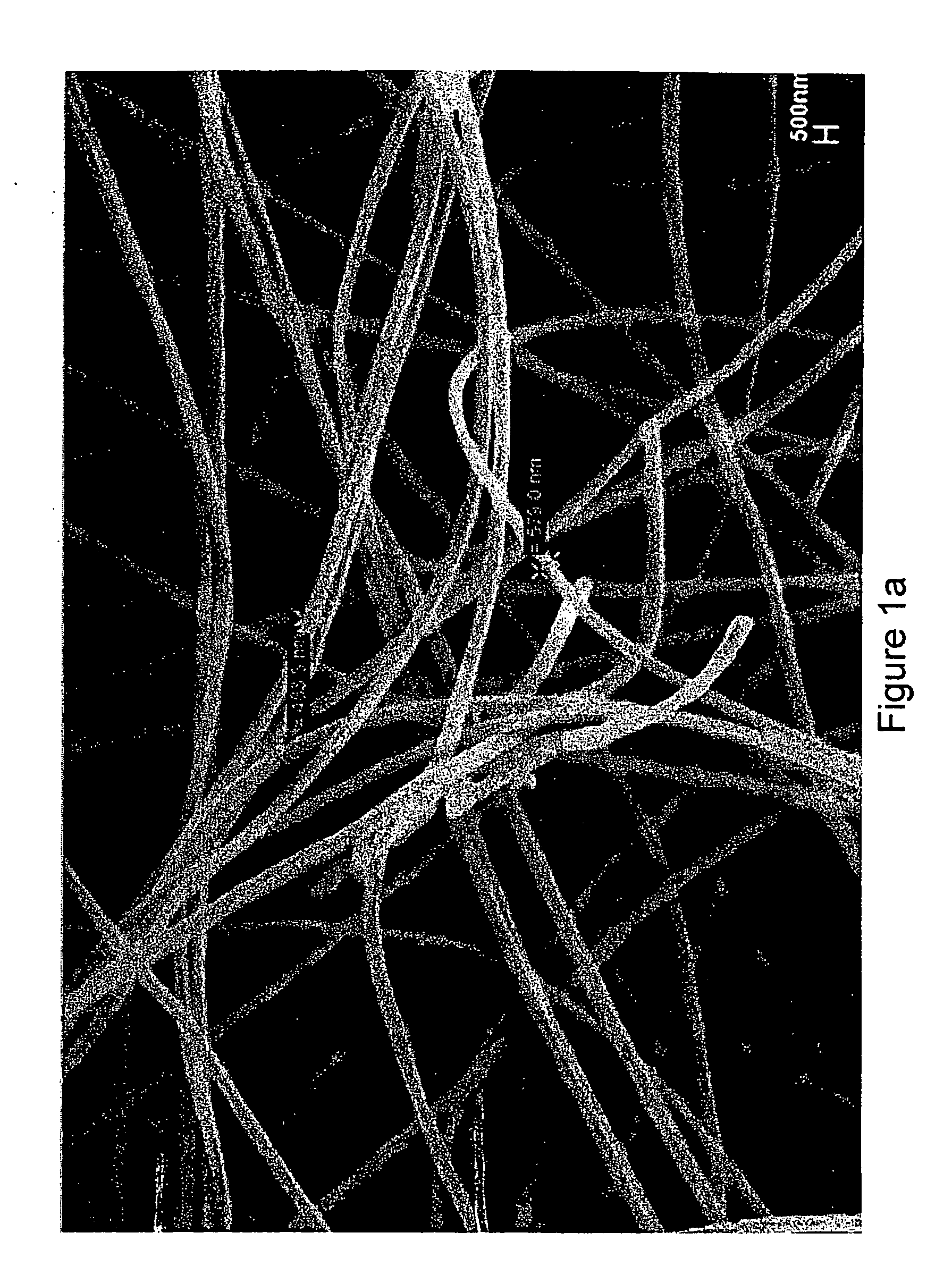

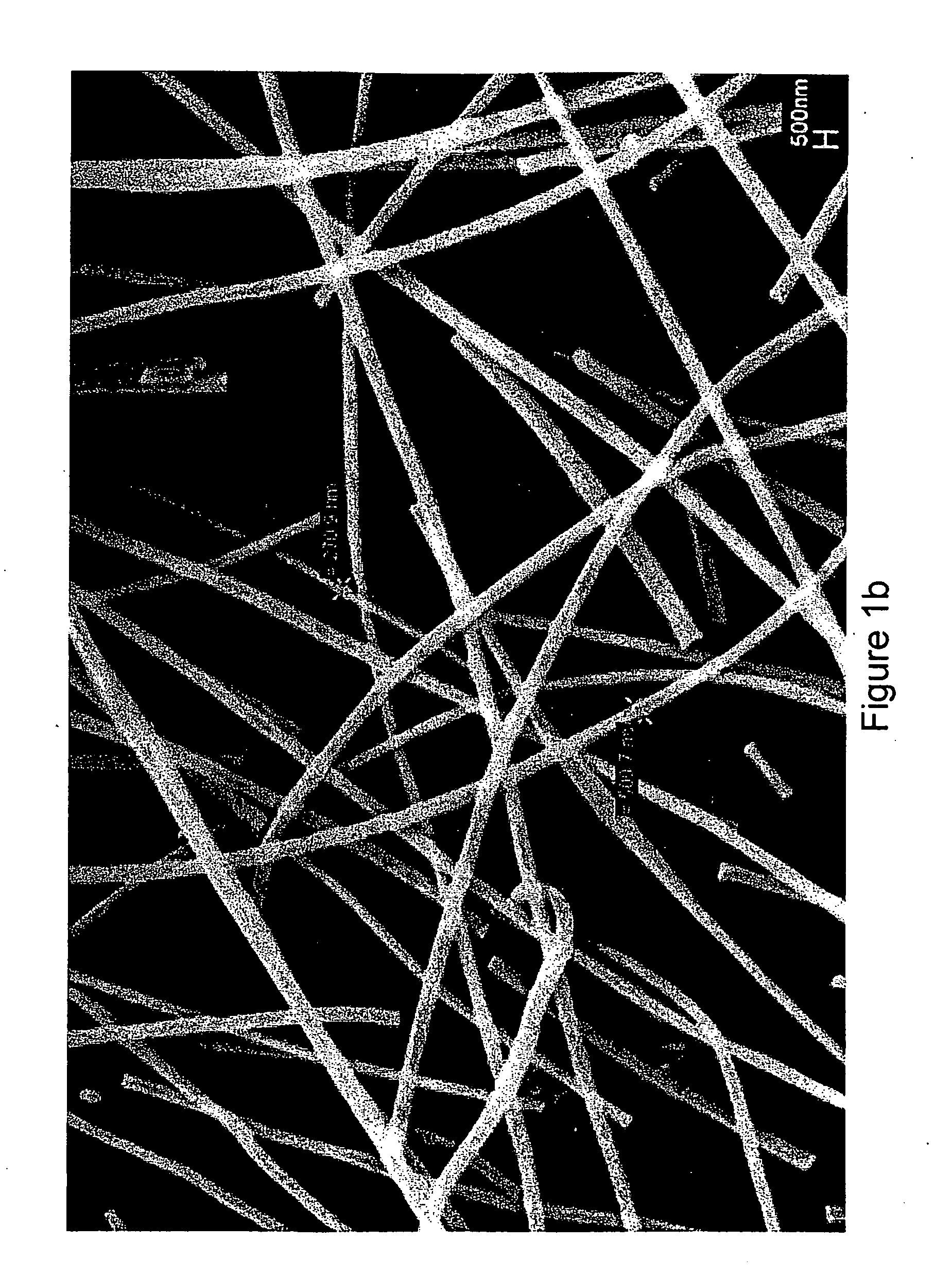

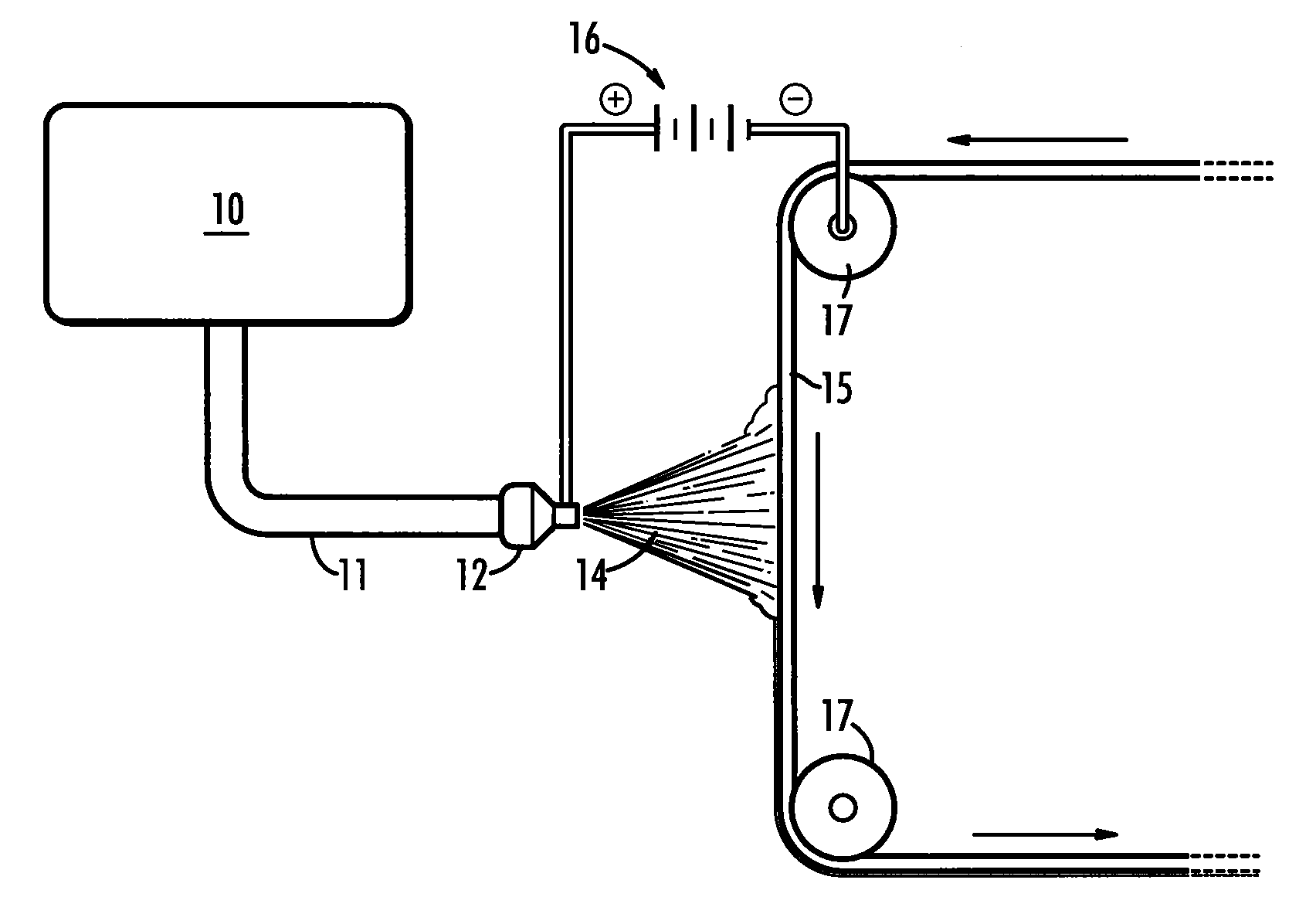

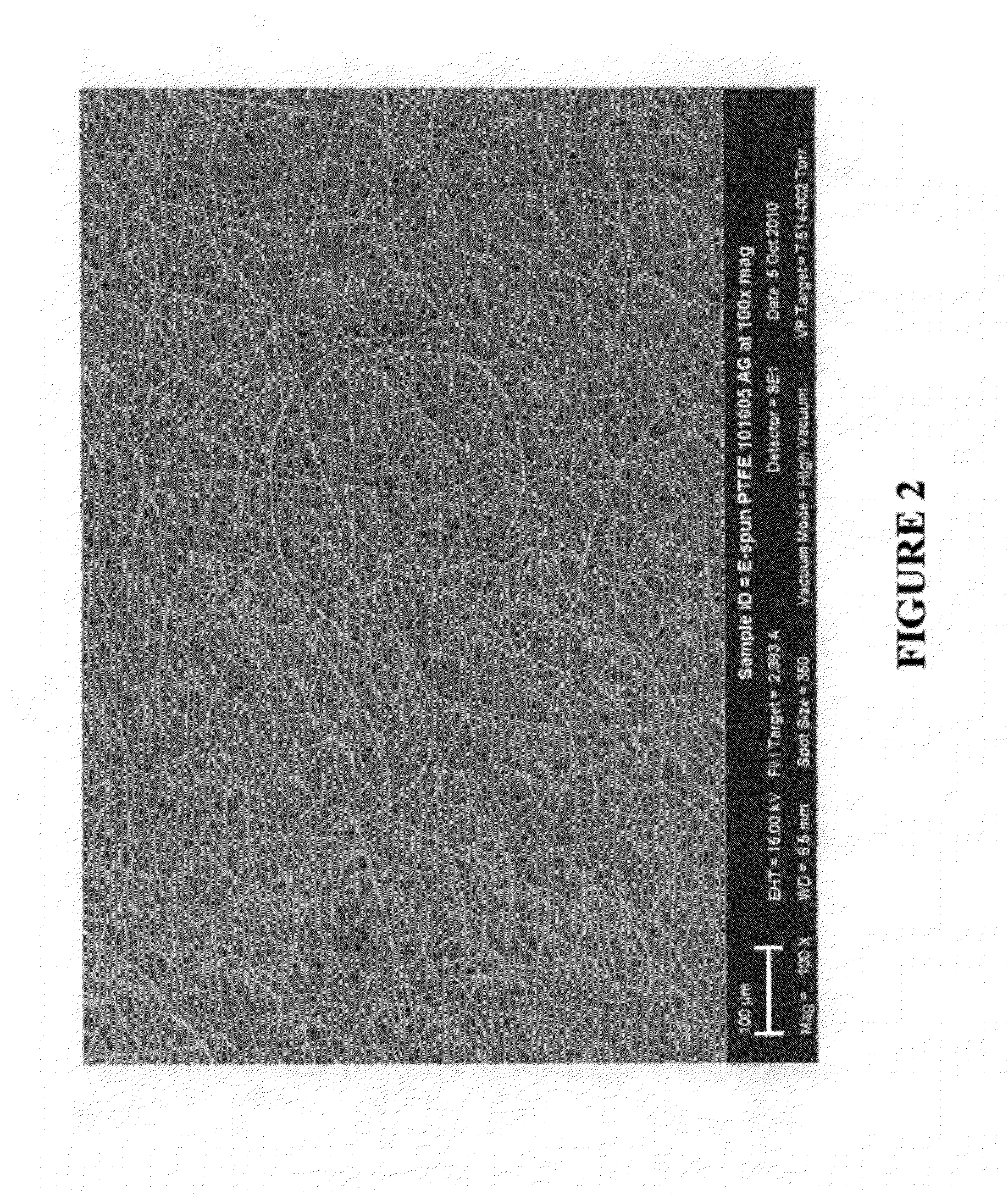

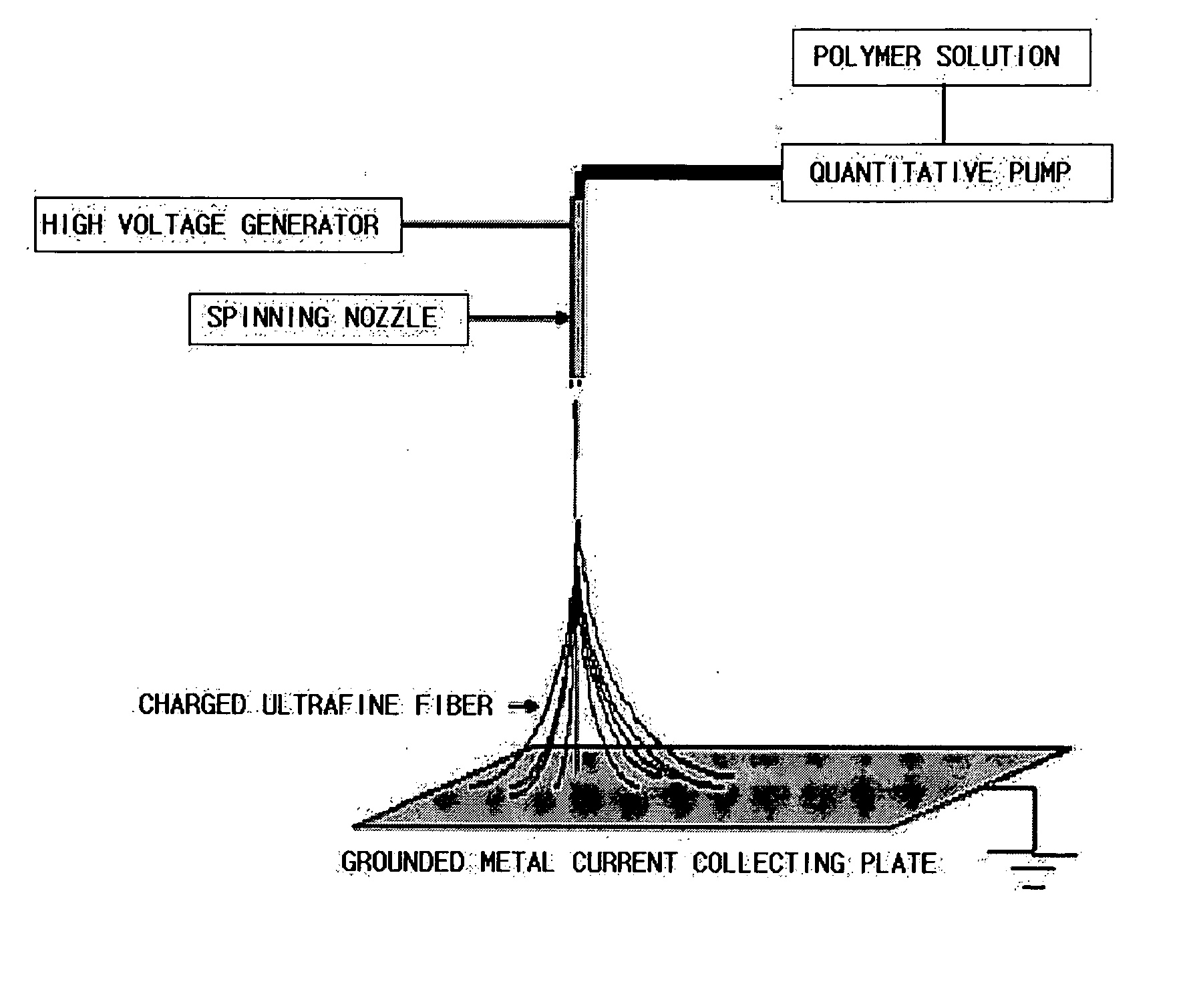

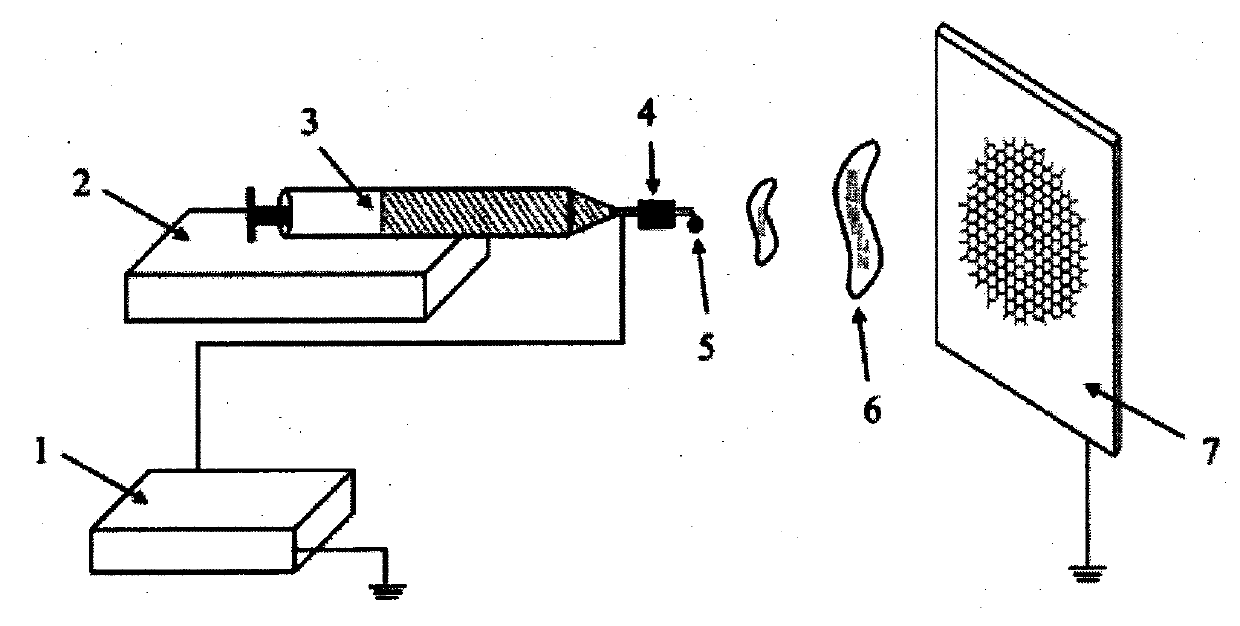

Electrospinning of PTFE with high viscosity materials

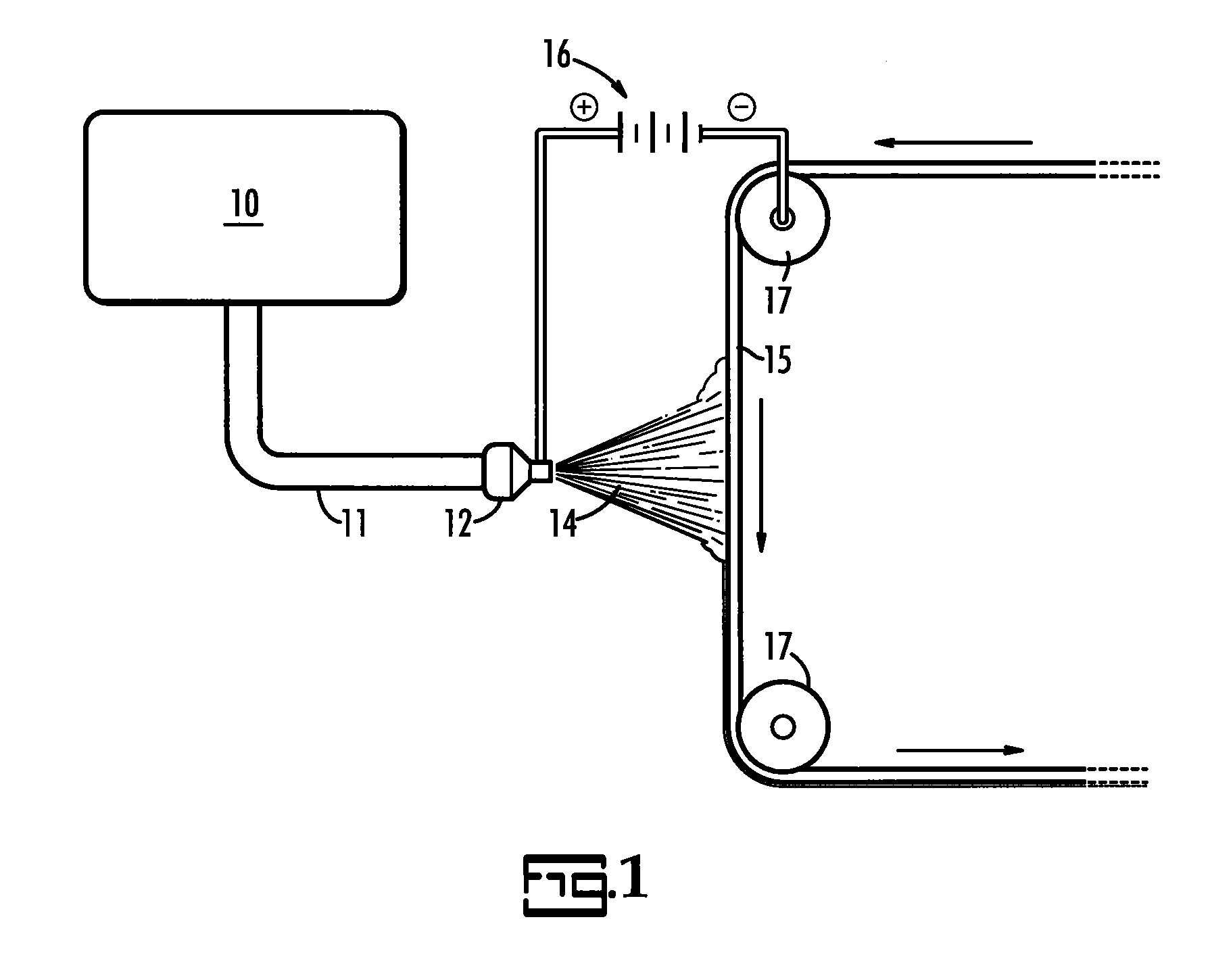

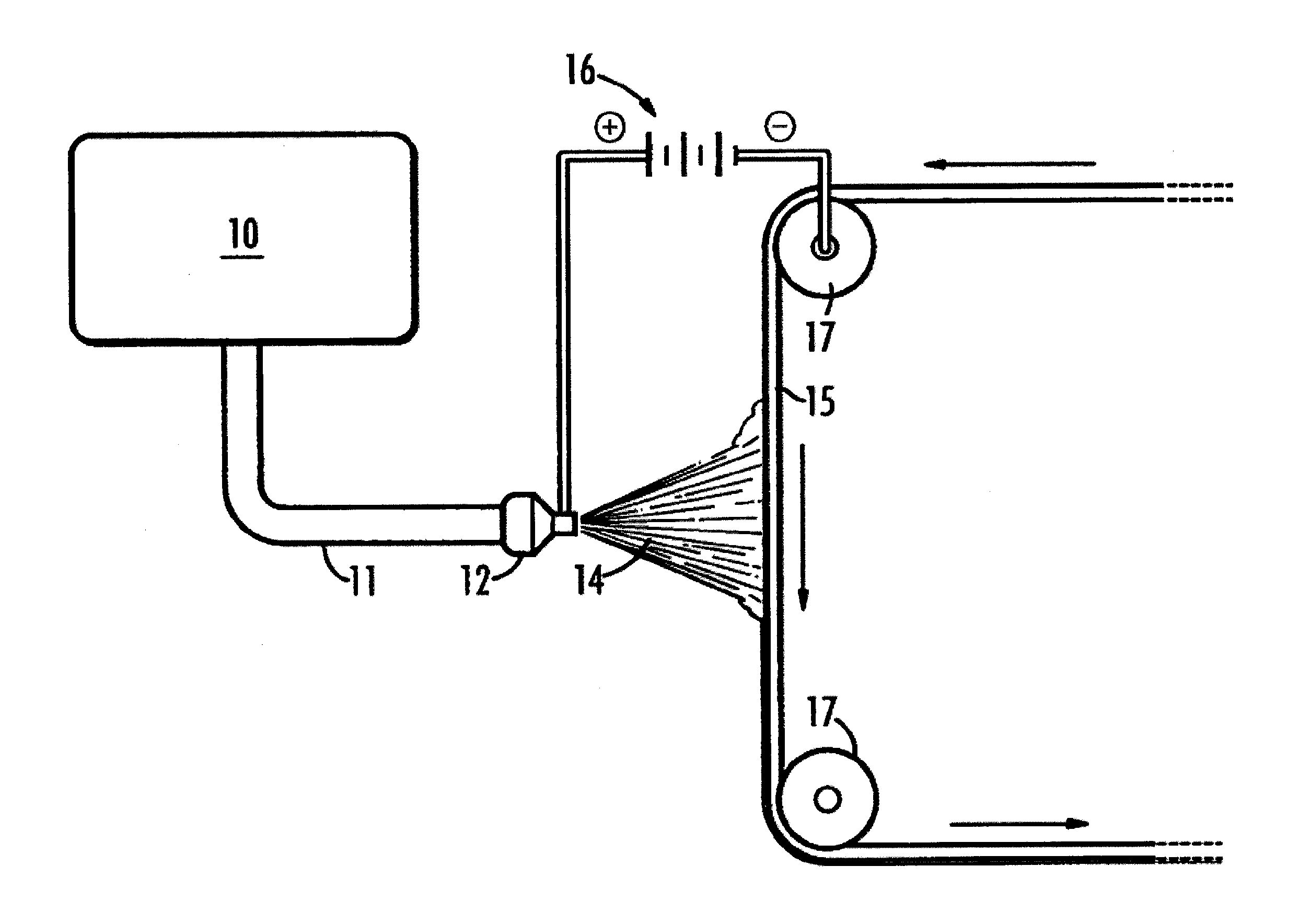

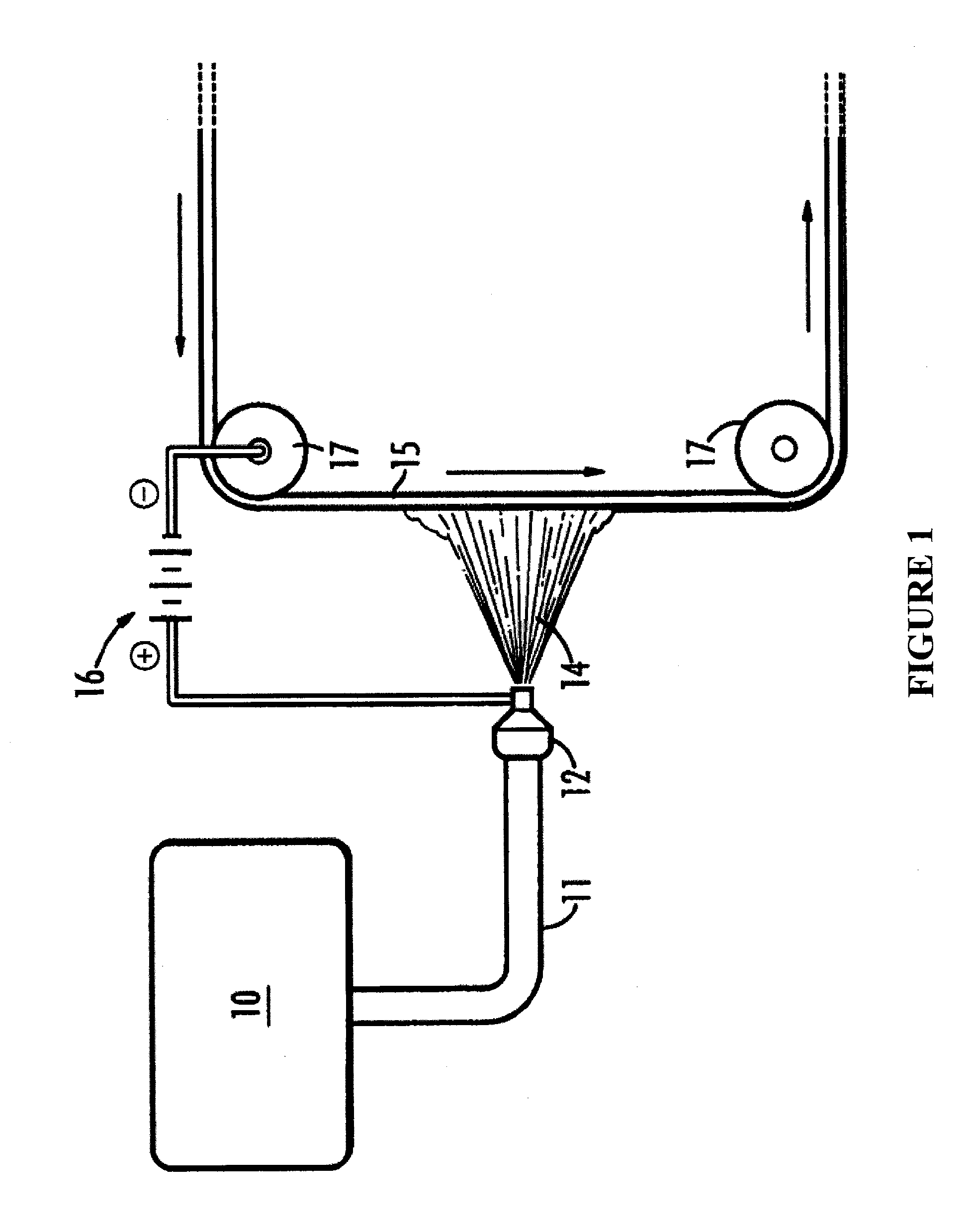

An improved process for forming a PTFE mat is described. The process includes providing a dispersion with PTFE, a fiberizing polymer and a solvent wherein said dispersion has a viscosity of at least 50,000 cP. An apparatus is provided which comprises a charge source and a target a distance from the charge source. A voltage source is provided which creates a first charge at the charge source and an opposing charge at the target. The dispersion is electrostatically charged by contact with the charge source. The electrostatically charged dispersion is collected on the target to form a mat precursor which is heated to remove the solvent and the fiberizing polymer thereby forming the PTFE mat.

Owner:ZEUS COMPANY INC

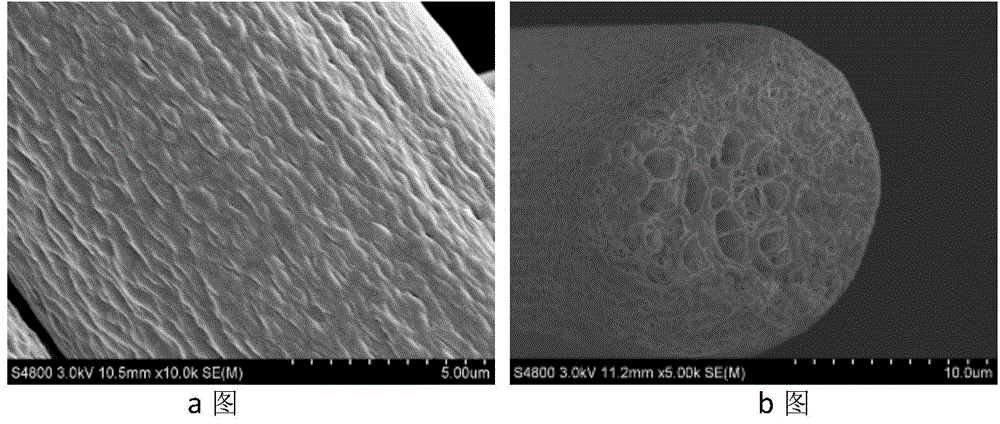

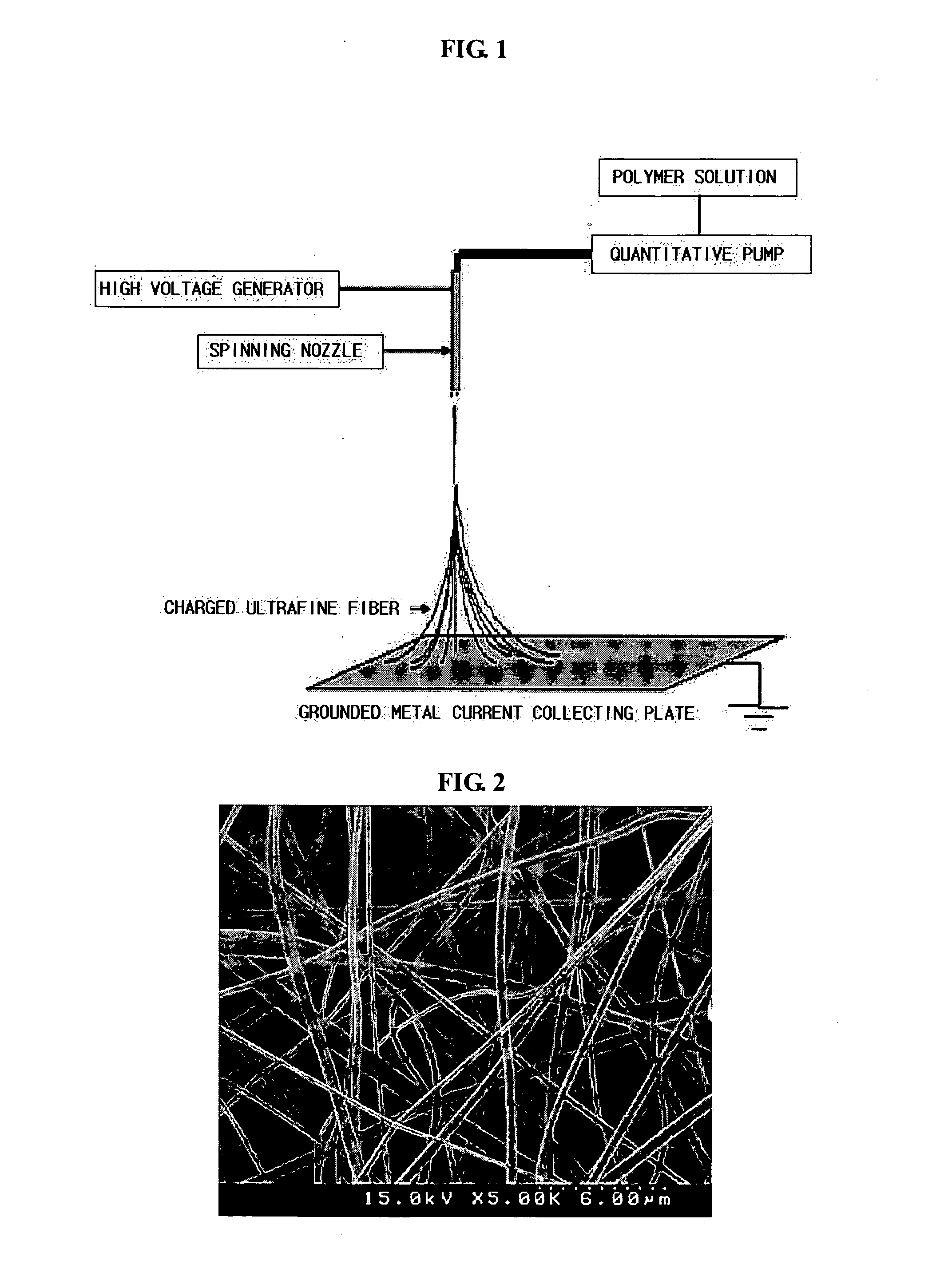

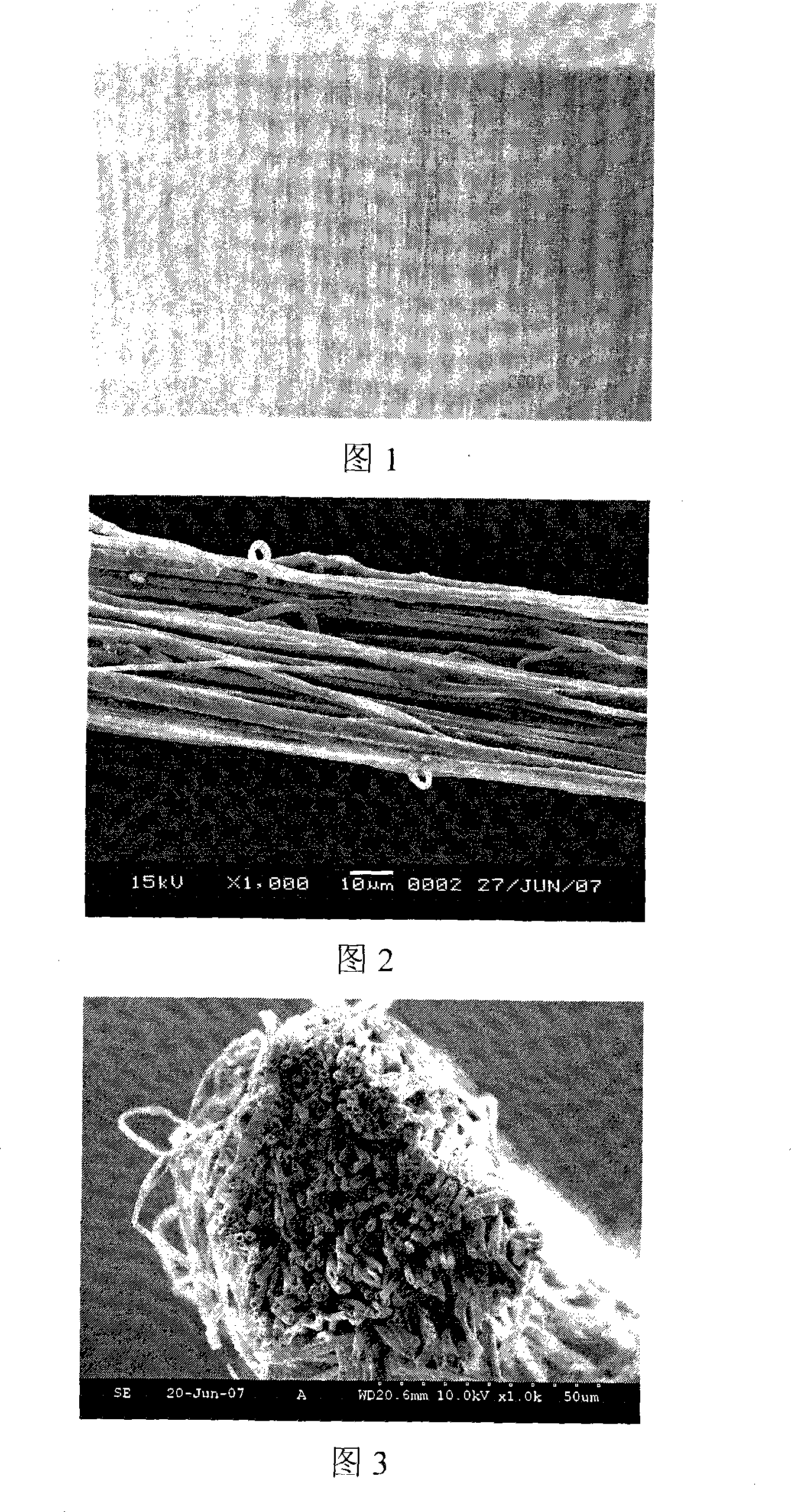

Method for preparing polytetrafluoroethylene superfine fiber

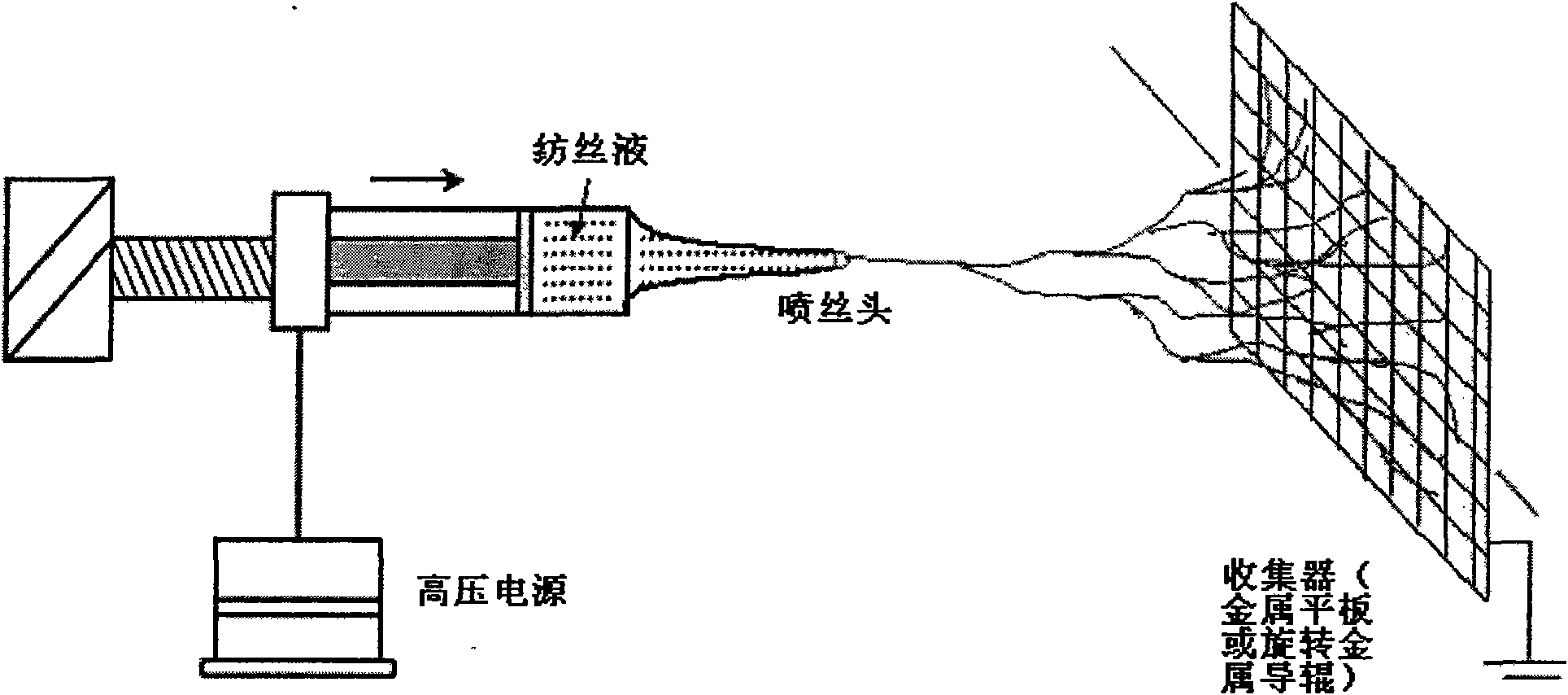

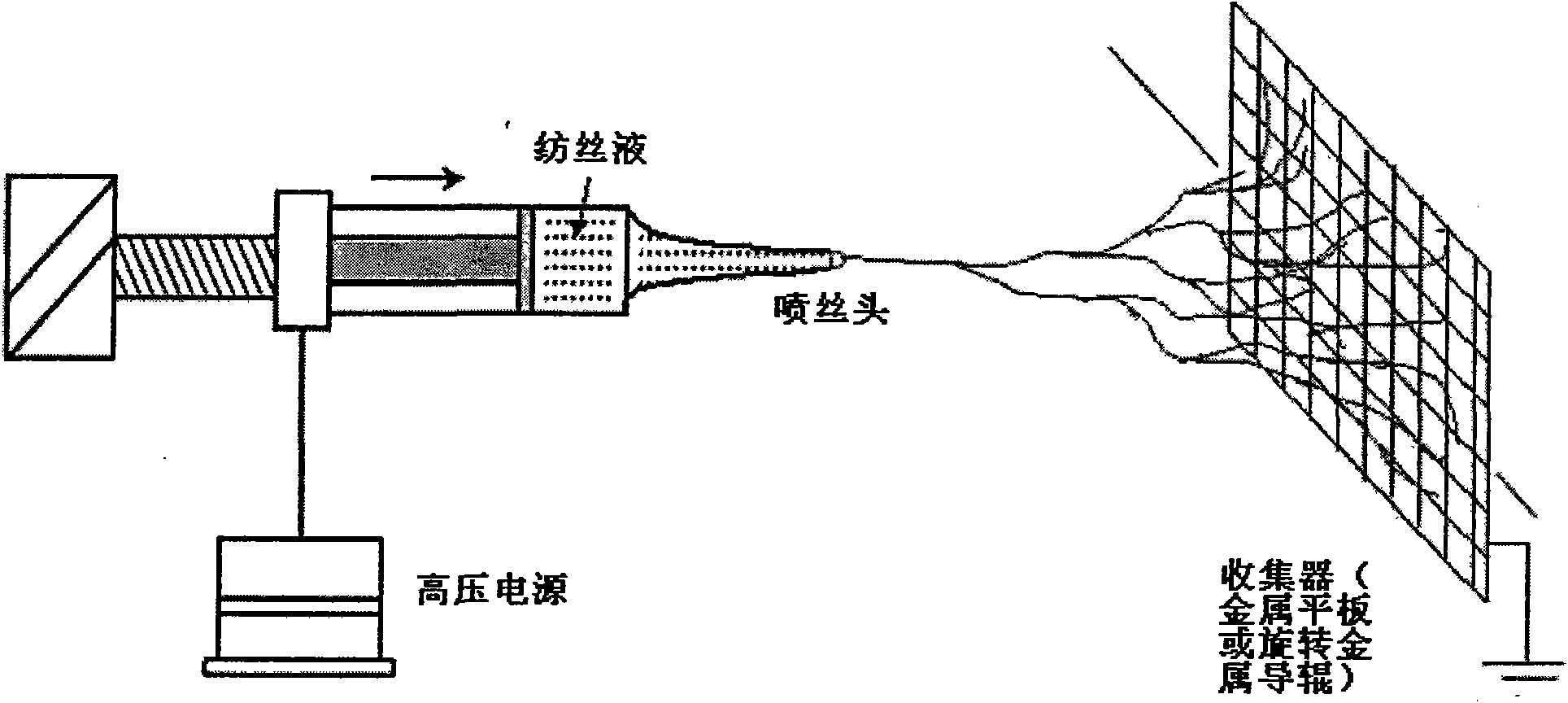

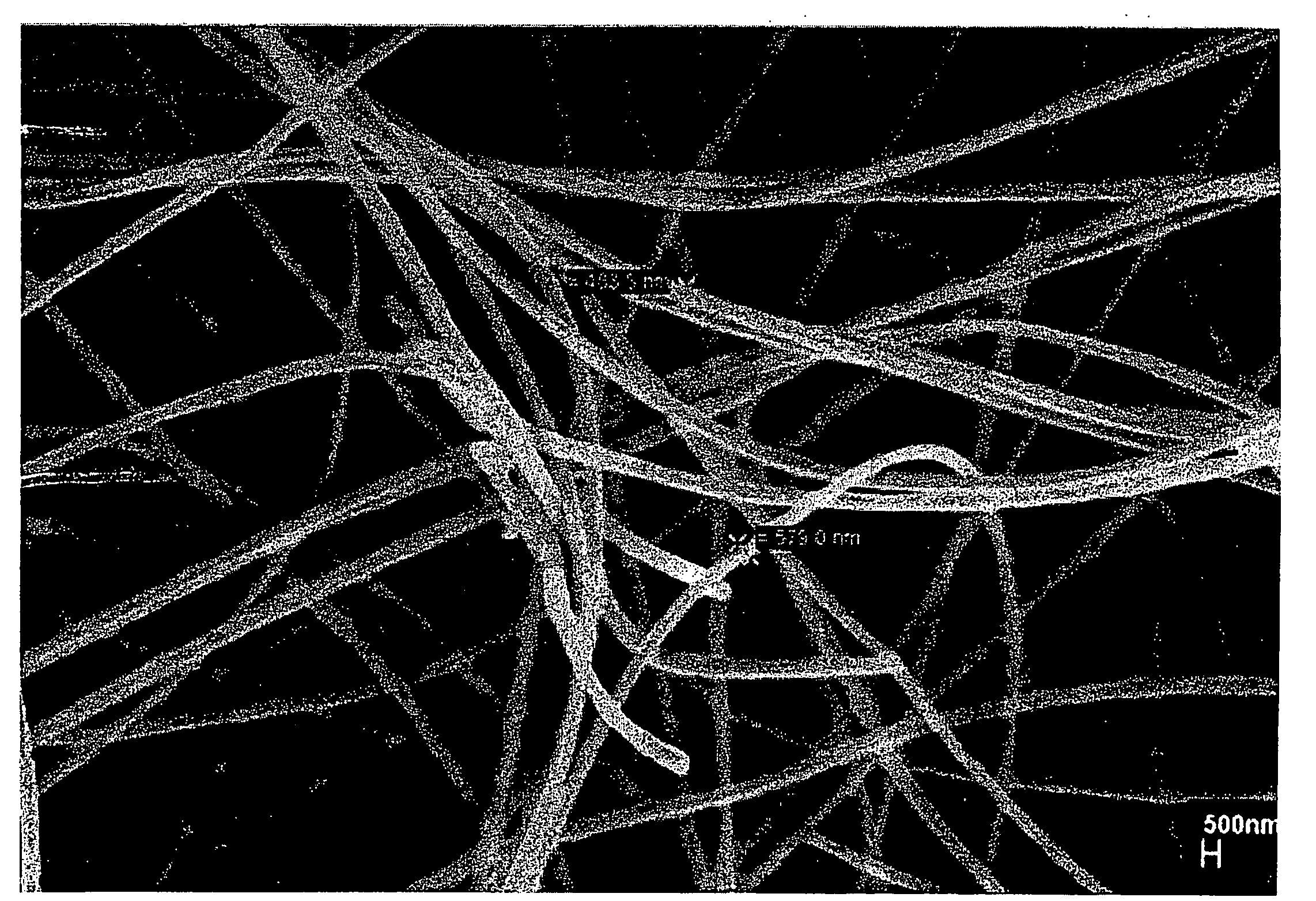

InactiveCN101994161AEasy to prepareArtificial filament washing/dryingFilament/thread formingFiberElectrospinning

The invention discloses a method for preparing a polytetrafluoroethylene superfine fiber, comprising the following steps of: firstly dissolving polyvinyl alcohol into water to prepare a polyvinyl alcohol solution, then evenly mixing the polyvinyl alcohol solution with polytetrafluoroethylene concentrated dispersion to prepare a spinning solution; then making the spinning solution into a polytetrafluoroethylene / polyvinyl alcohol superfine fiber by adopting an electrostatic spinning method; and finally, carrying out polyvinyl alcohol removal aftertreatment on the prepared polytetrafluoroethylene / polyvinyl alcohol superfine fiber to obtain the polytetrafluoroethylene superfine fiber. The prepared polytetrafluoroethylene superfine fiber is white or dark brown, and the diameter of the fiber is 30-2000nm.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

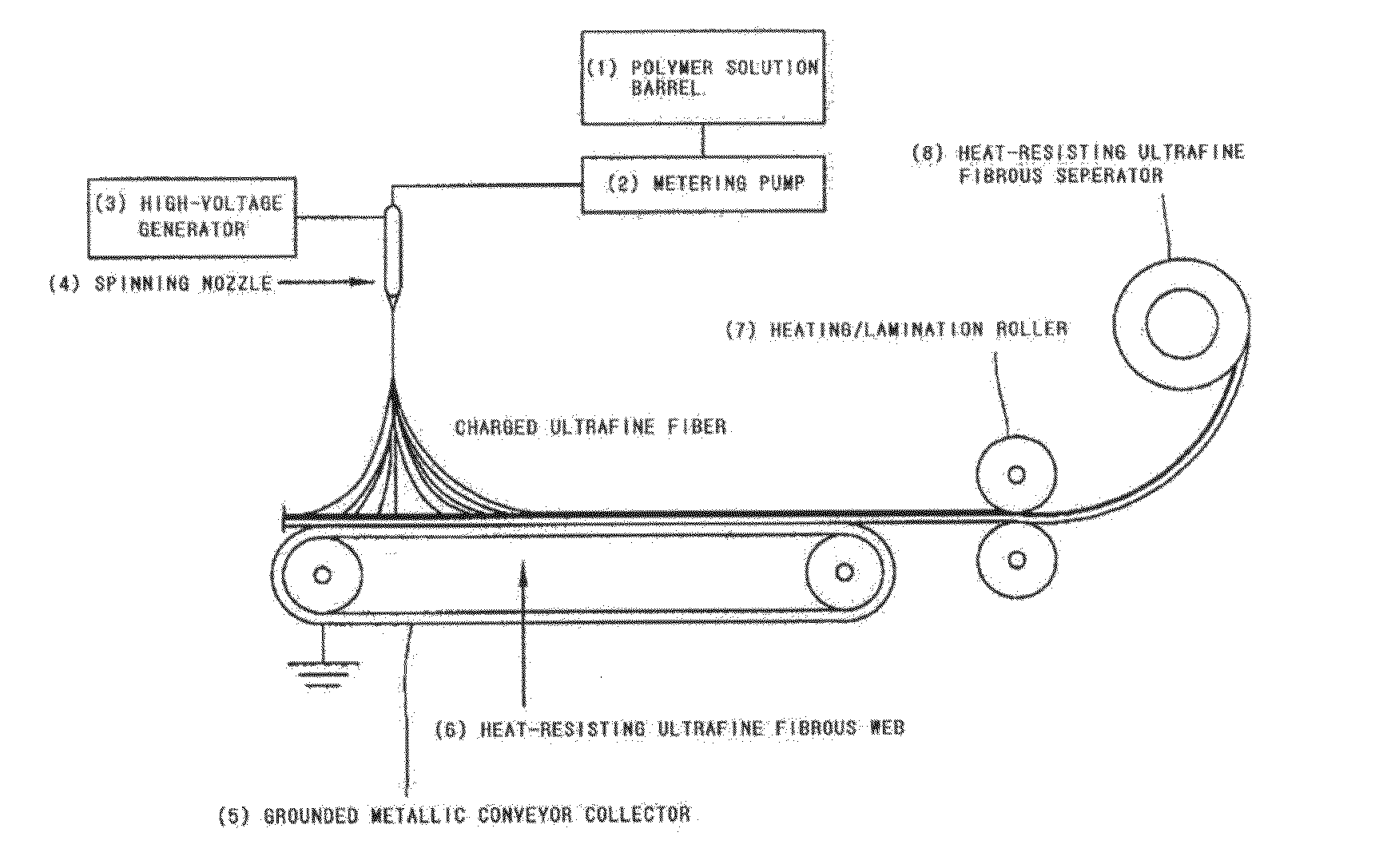

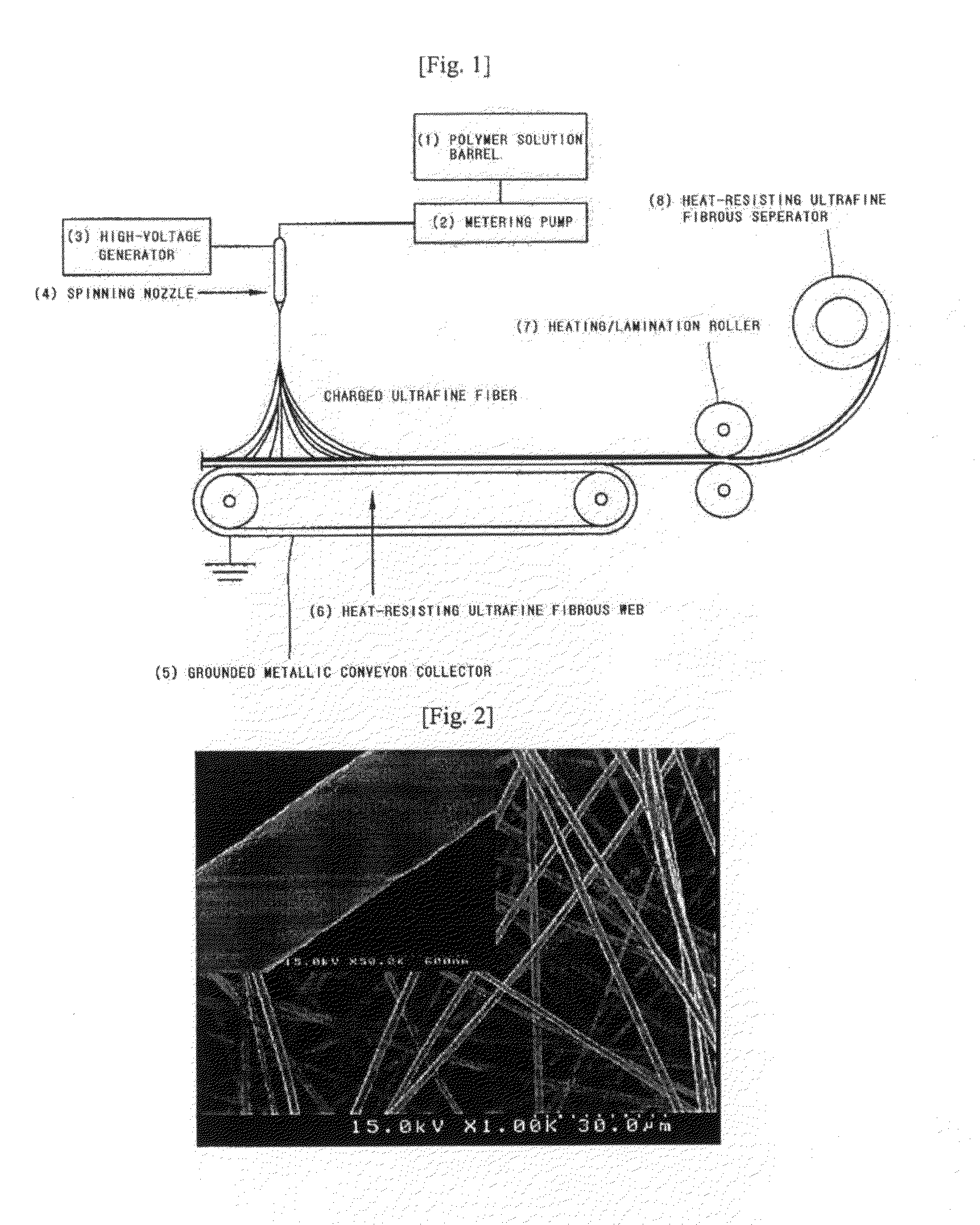

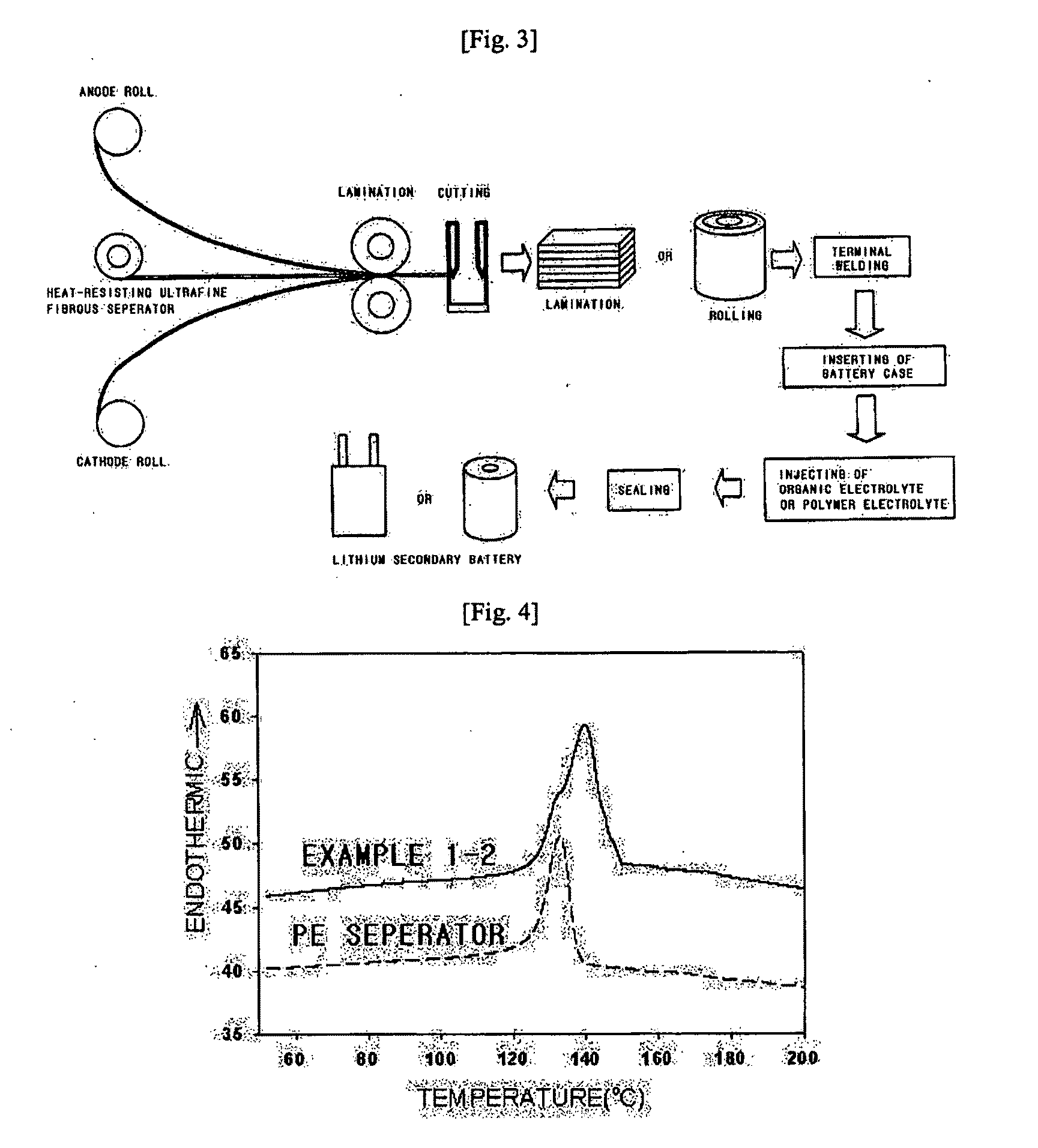

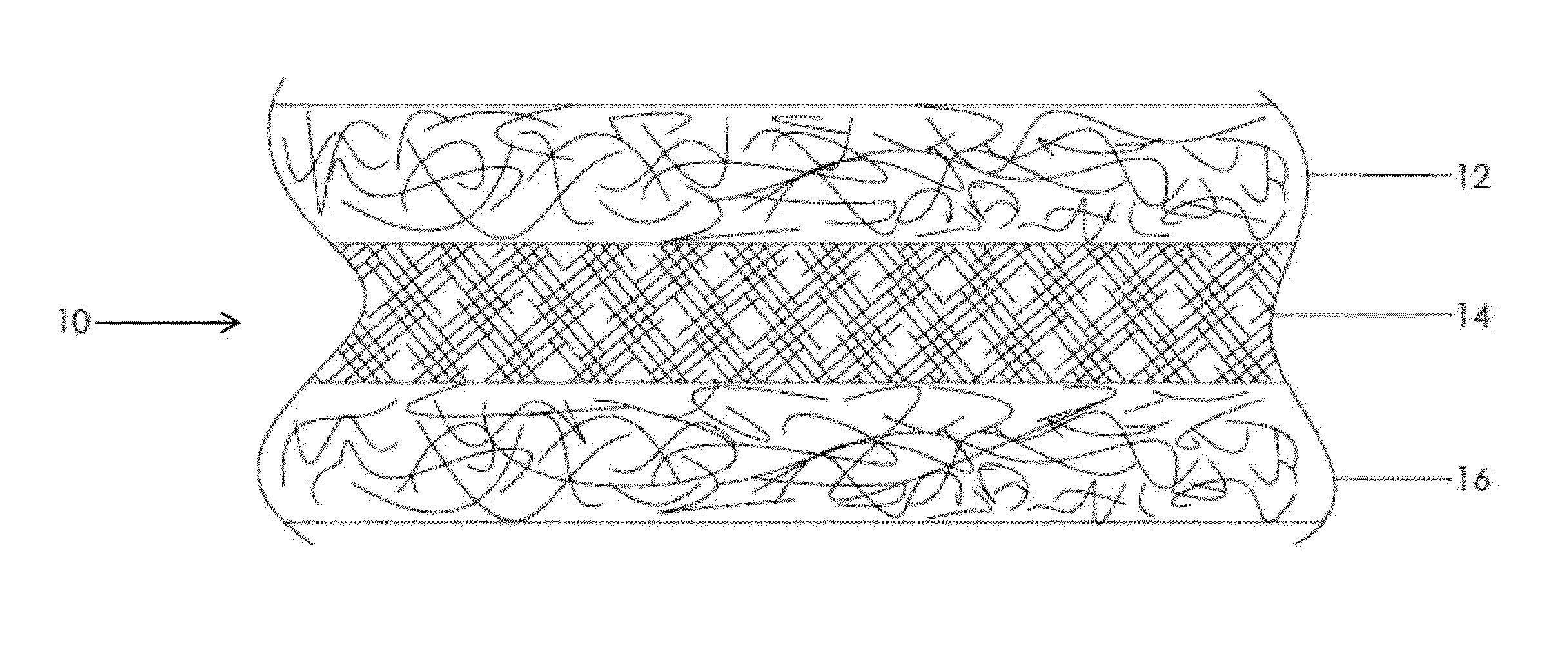

Heat resisting ultrafine fibrous separator and secondary battery using the same

ActiveUS20100233523A1Simple and easy processLow thermal contractionCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberPolymer science

A heat-resisting ultrafine fibrous separator of the present invention is prepared by an electrospinning process, formed of ultrafine fibers of heat-resisting polymer resin having a melting point more than 1800 C or not having the melting point, or ultrafine fibers of polymer resin capable of swelling in an electrolyte, together with the ultrafine fibers of heat-resisting polymer resin. Also, polyolefine fine particles providing a shutdown function are dispersed in the heat-resisting resin or the polymer resin capable of swelling in the electrolyte. The heat-resisting ultrafine fibrous separator of the present invention has the shutdown function, low thermal contraction, thermal endurance, excellent ionic conductivity and excellent adhesive property with an electrode, so a battery having excellent cycling characteristics, and having high-energy density and high capacity can be prepared.

Owner:KOREA INST OF SCI & TECH

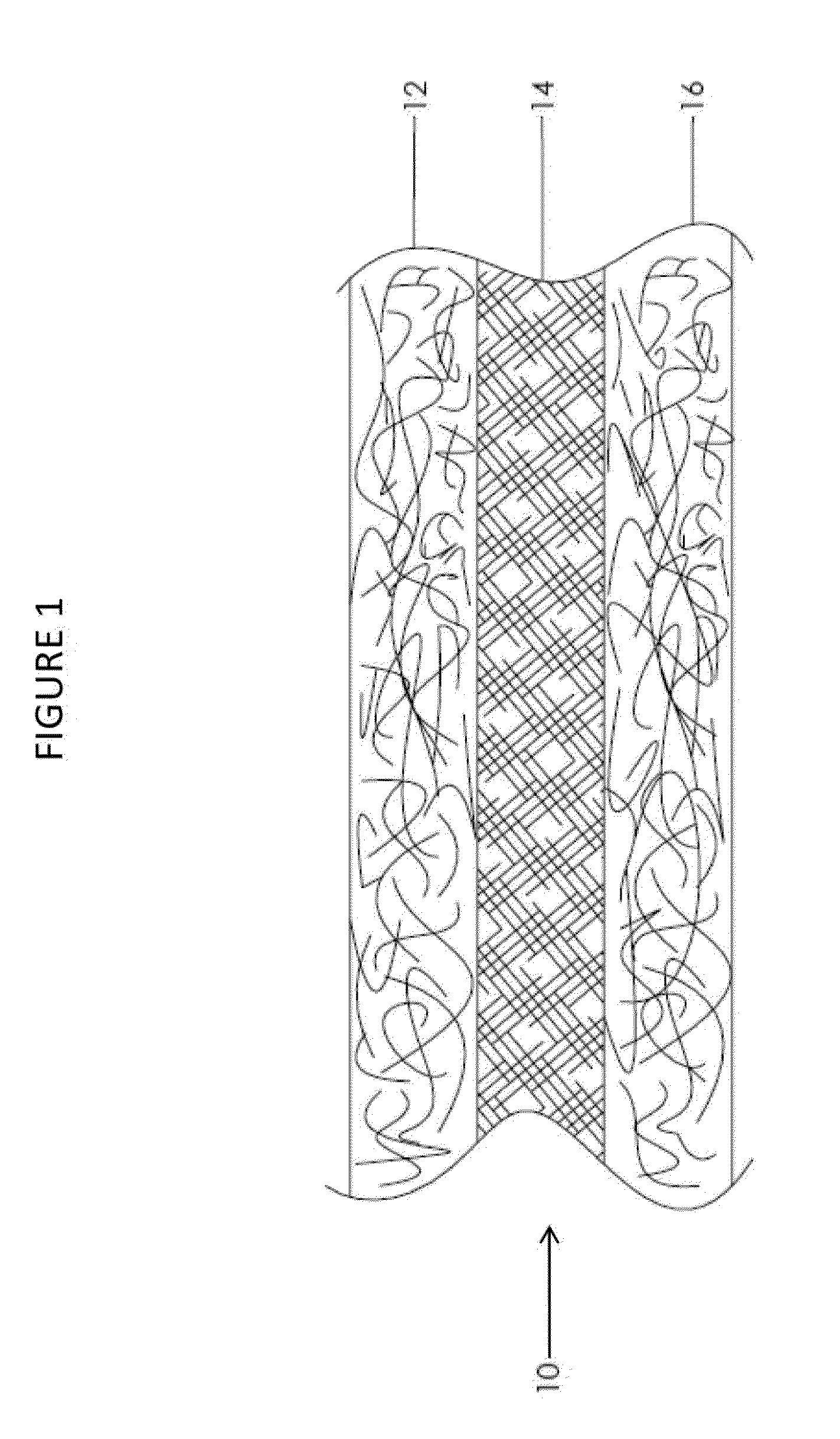

Composite prosthetic devices

The present disclosure provides composite prosthetic devices comprising two or more layers of electrospun polymers and methods of preparation thereof. In some embodiments, the two or more layers can be porous and in other embodiments, one or more components is nonporous. The composite prosthetic devices can comprise various materials and the properties of the prosthetic devices can be tailored for use in a range of different applications.

Owner:ZEUS INDUSTRIAL PRODUCTS INC

Heat-meltable fluororesin fibers

InactiveUS6479143B1Intermingling property can be enhancedEasy to produceSynthetic resin layered productsNon-woven fabricsFiberHot melt

To provide the heat-meltable fluorine-containing resin fiber having excellent intermingling property and various materials for fiber products obtained therefrom. The heat-meltable fluorine-containing resin such as ETFE having a branched structure is used solely or mixed to other fiber such as an electrically conductive fiber to be formed into a non-woven fabric.

Owner:DAIKIN IND LTD

Fibers and methods relating thereto

InactiveUS20090326128A1Monocomponent polyurethanes artificial filamentMaterial nanotechnologyFiberNanofiber

The present invention provides micro- and nanofibers made from polymers that comprise nanoparticles, such as carbon nanoparticles and inorganic nanoparticles, and methods of making such fibers.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

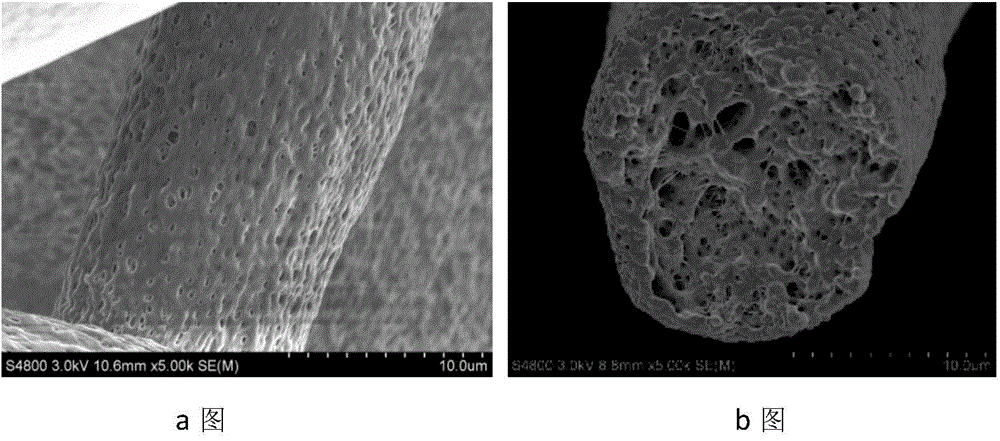

Method for producing hollow yarn film

InactiveUS20030107150A1Effect of shaking is smallHigh in resistance against marringWrappers shrinkageFilament/thread formingYarnFiltration

In a method for producing hollow fiber membranes which comprises melt kneading a mixture comprising polyvinylidene fluoride and an organic liquid or a mixture comprising polyvinylidene fluoride, an organic liquid and an inorganic fine powder, extruding the kneaded mixture to form hollow fibers, and extracting the organic liquid or the organic liquid and the inorganic fine powder from the hollow fibers, which includes the steps of drawing the hollow fibers before or after termination of the extraction and then shrinking the fibers. According to this method, it is possible to stably produce hollow fiber membranes having dense pores and having a high water permeation performance, excellent endurance and stain resistance, and which are suitable for filtration uses such as removal of turbidity of water.

Owner:ASAHI KASEI KK

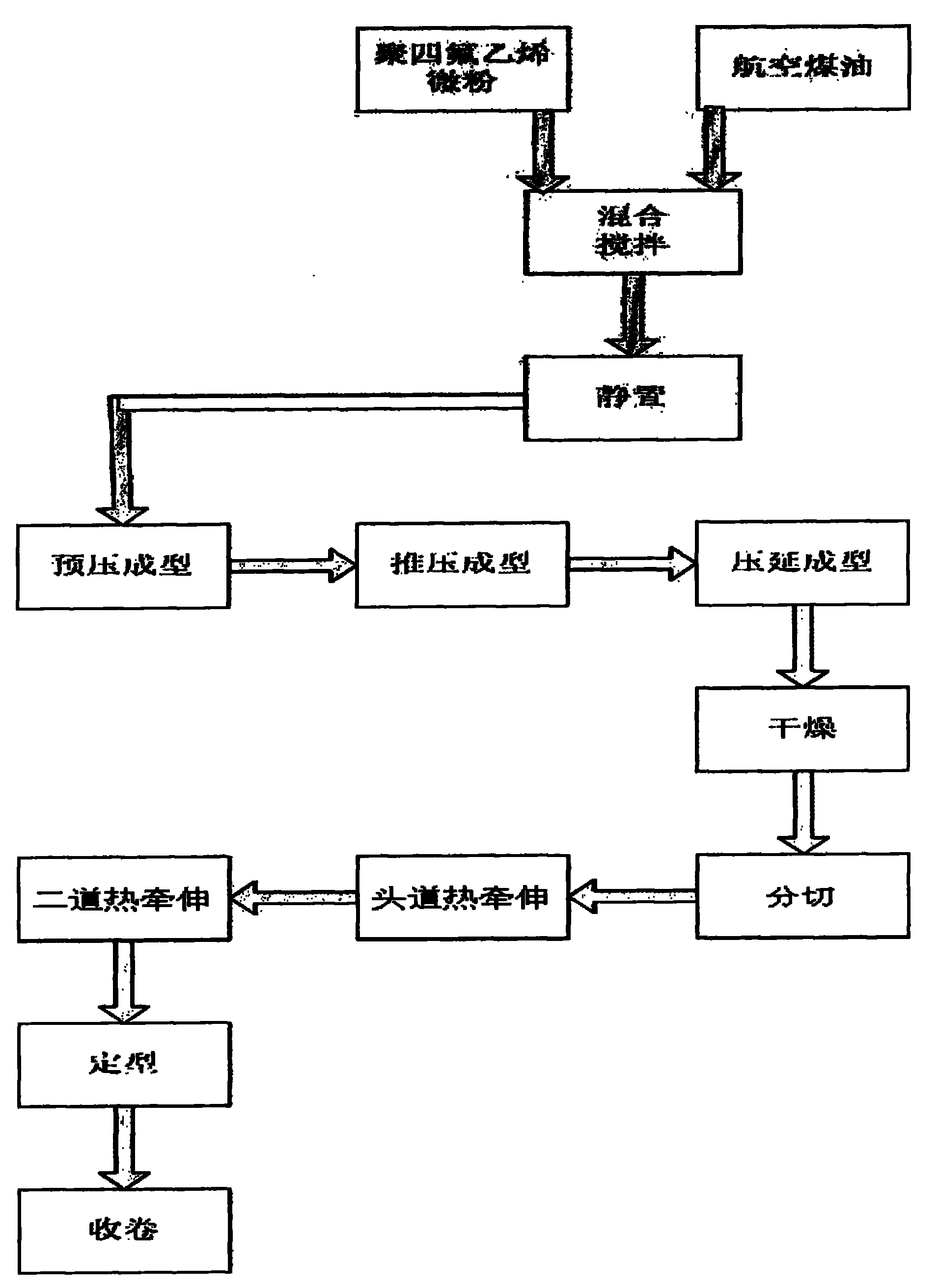

Manufacturing method of film split polytetrafluoroethylene fibers

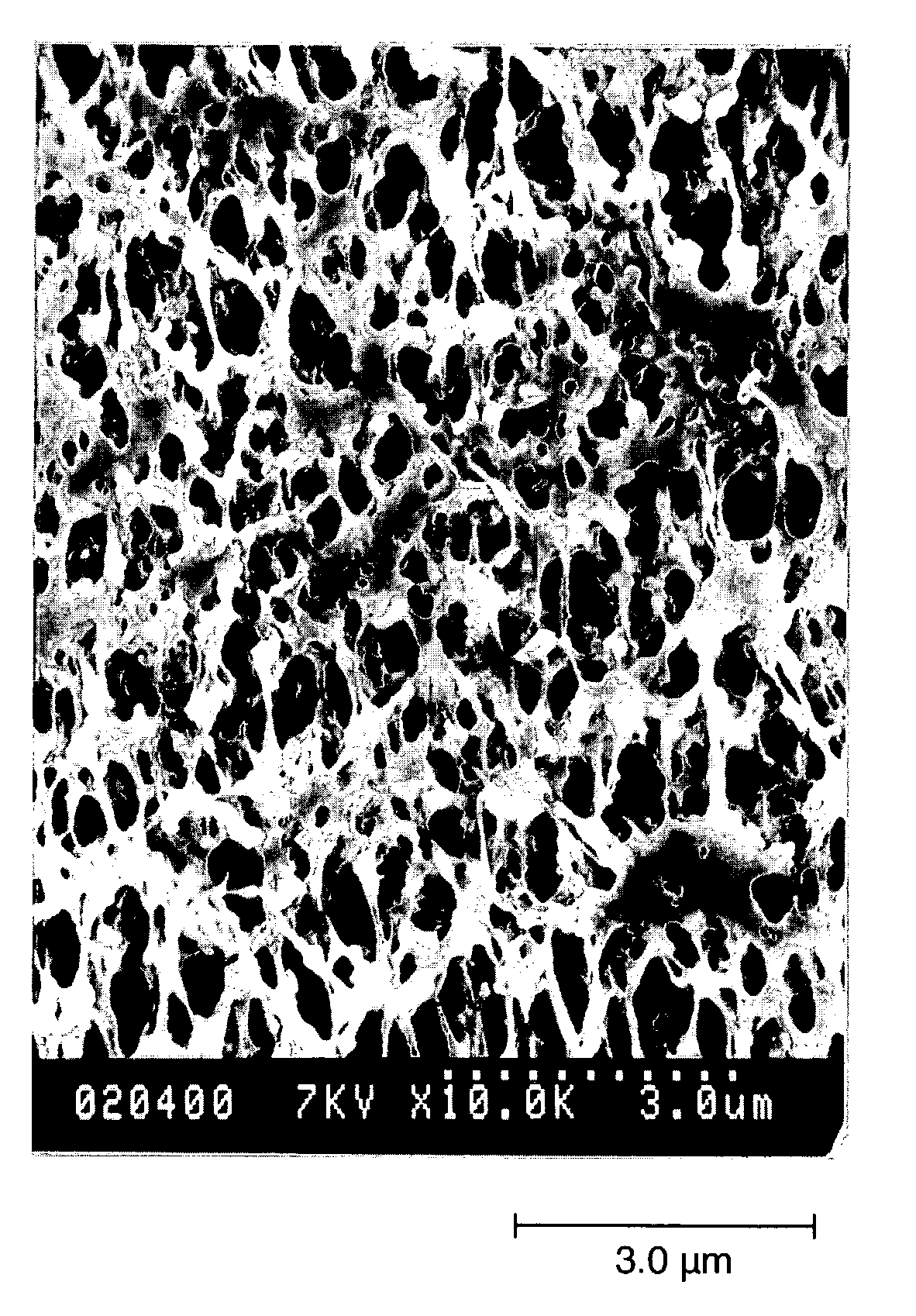

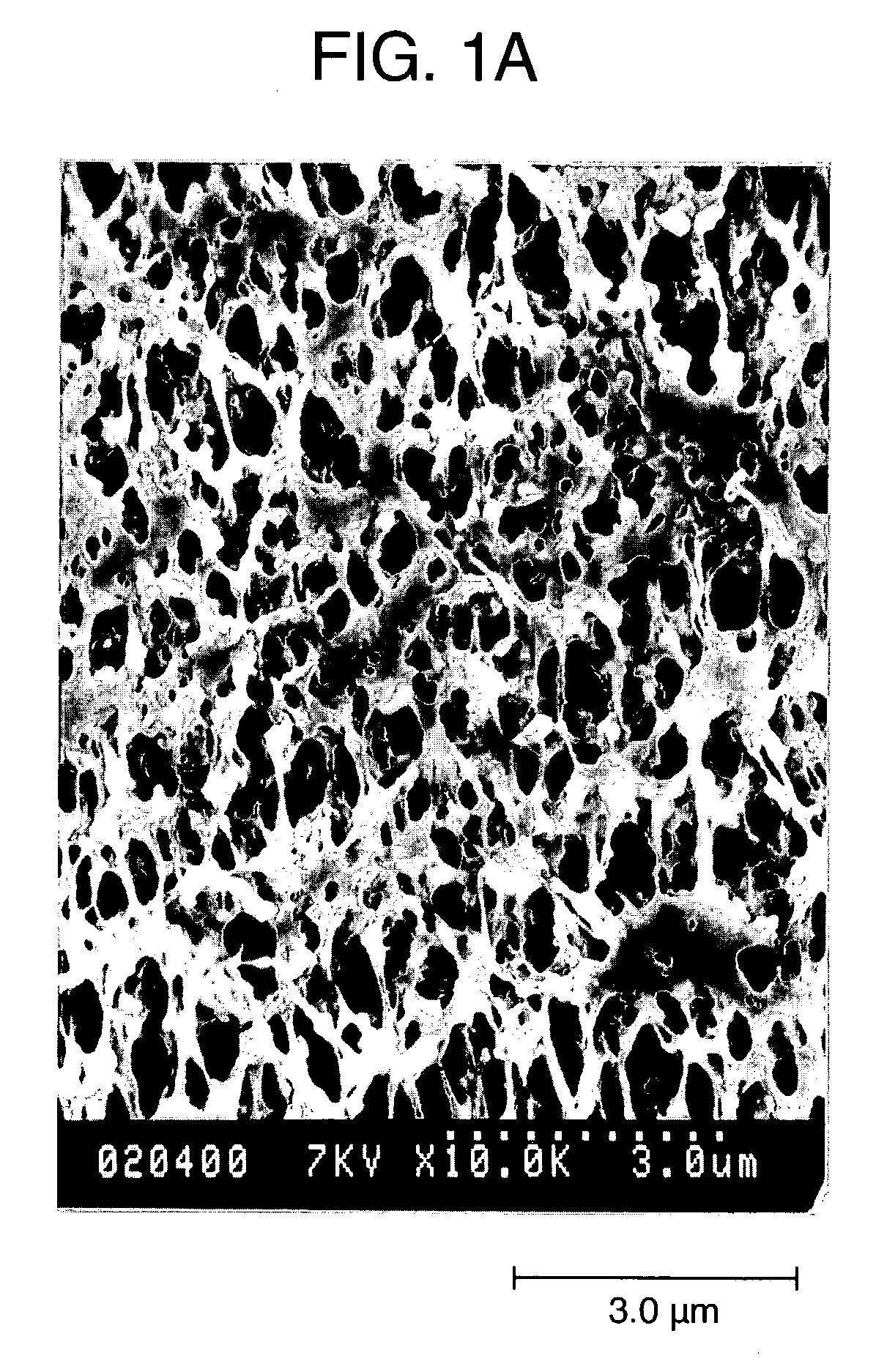

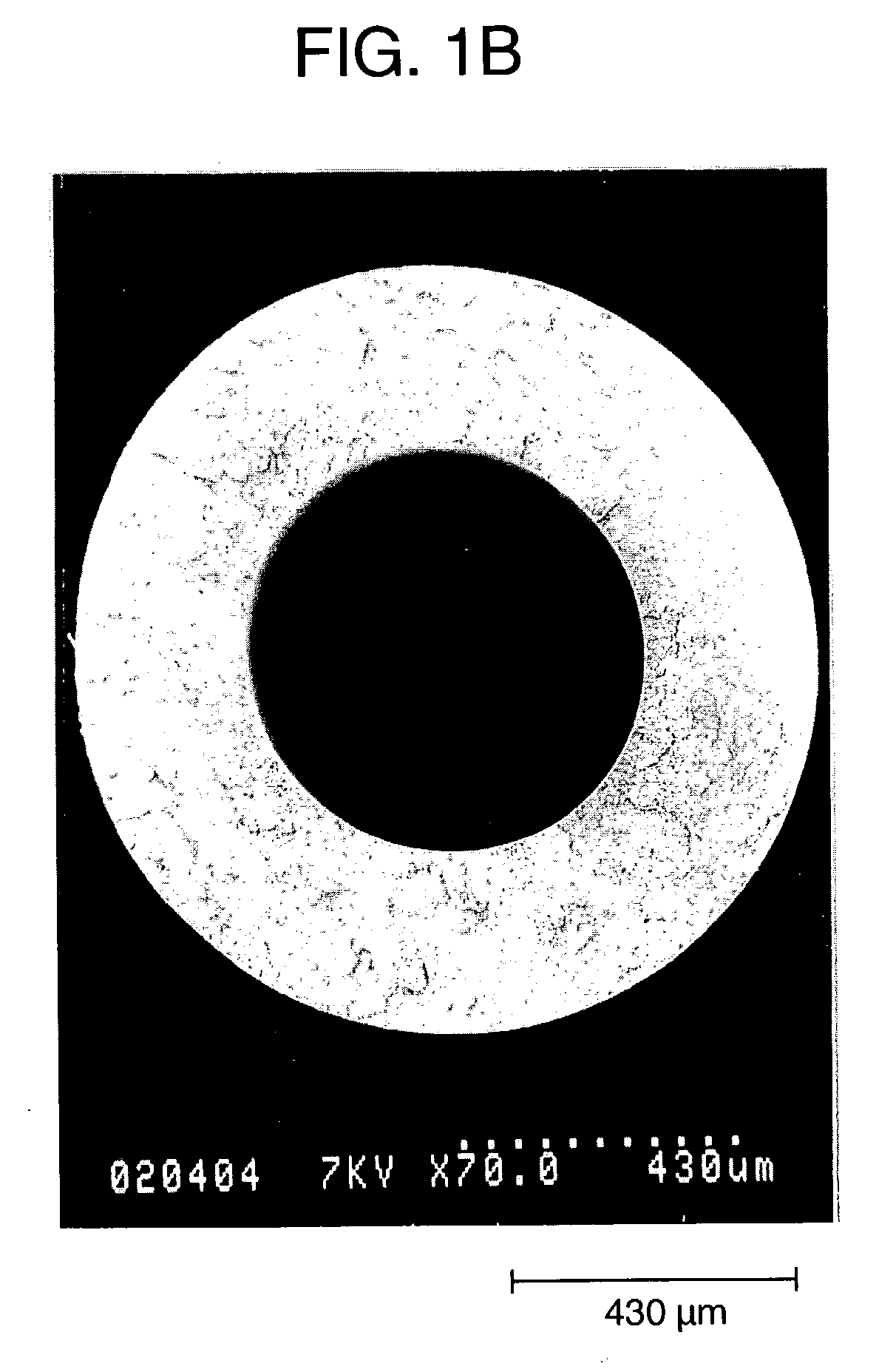

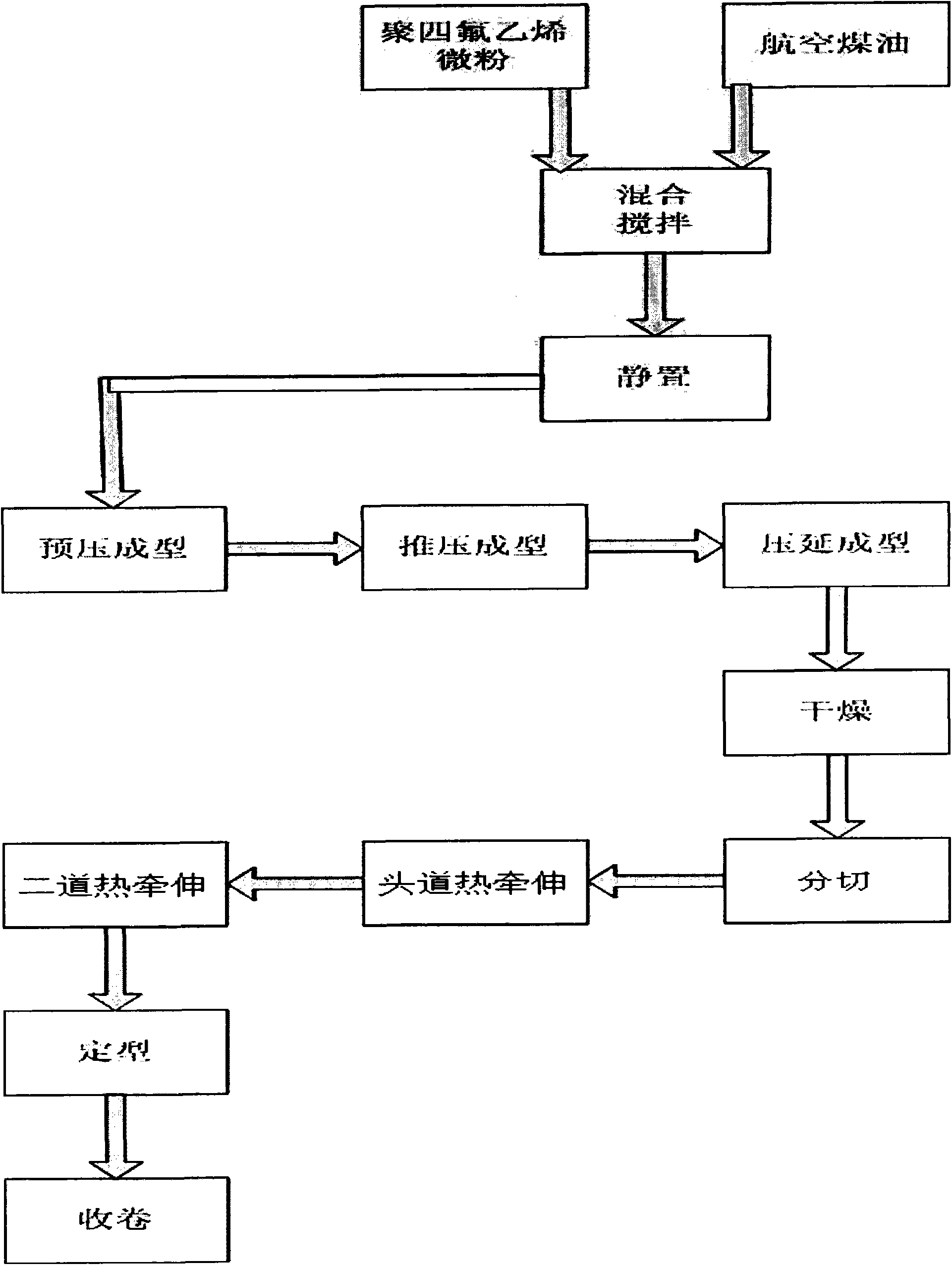

ActiveCN102051703AWell mixedWeight optimizationFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentPre compressionHigh intensity

The invention aims to provide a manufacturing method of film split polytetrafluoroethylene fibers with high intensity, high uniformity and low production cost. A process comprises the following steps of: mixing polytetrafluoroethylene micro-powder and a lubricant; stirring; standing; performing pre-compression molding; performing press molding; performing calendaring molding; drying; cutting; performing primary hot stretching; performing secondary hot stretching; performing heat shaping; and winding so as to obtain high-intensity polytetrafluoroethylene fibers. In the manufacturing process, temperatures during drying, cutting, primary hot stretching, secondary hot stretching and heat shaping rise in turn.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

Modacrylic Shrinkable Fiber and Method for Manufacturing The Same

A modacrylic shrinkable fiber according to the present invention is containing a polymer composition obtained by mixing 50 to 99 parts by weight of a polymer (A) containing 40 wt % to 80 wt % of acrylonitrile, 20 wt % to 60 wt % of a halogen-ontaining monomer and 0 wt % to 5 wt % of a sulfonic-acid-containing monomer, and 1 to 50 parts by weight of a polymer (B) containing 5 wt % to 70 wt % of acrylonitrile, 20 wt % to 94 wt % of an acrylic ester and 1 wt % to 40 wt % of a sulfonic-acid-containing monomer containing a methallylsulfonic acid or metal salts thereof or amine salts thereof, in which a total amount of the polymer (A) and the polymer (B) is 100 parts by weight. In this way, a modacrylic shrinkable fiber that has a favorable color development property after dyeing and a high shrinkage ratio even after dyeing is obtained.

Owner:KANEKA CORP

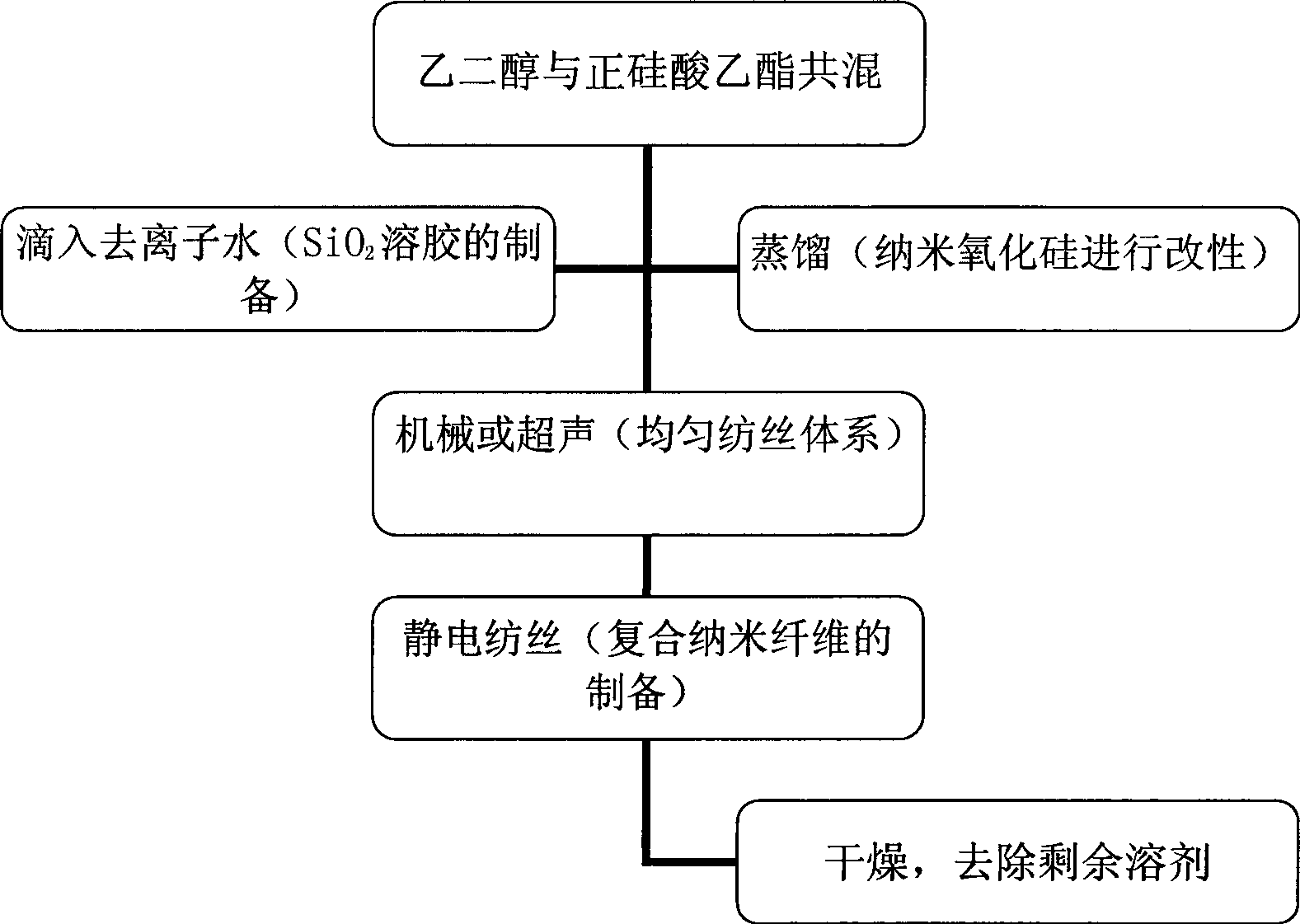

Preparation of silicon dioxide / polyvinylidene fluoride composite nano fiber film

InactiveCN101481855AHigh strengthImprove photoelectric performanceFilament/thread formingNon-woven fabricsLithium-ion batterySilicon dioxide

A preparation method of a silicon dioxide / polyvinylidene fluoride composite nano-fiber membrane relates to the technical fields of preparing modified nano-silicon dioxide by a sol-gel method, preparing a silicon dioxide / polyvinylidene fluoride nano-fiber membrane by an electrostatic spinning device and the like. The preparation method comprises the following steps: preparing the modified nano-silicon dioxide in virtue of a sol-gel principle by a one-step method; mixing the modified nano-silicon dioxide with the polyvinylidene fluoride; and preparing the composite nano-fiber by an electrostatic spinning technology. The preparation method helps relieve the disadvantages of low strength of the nano-fiber, long preparation flow of the modified nano-silicon dioxide, complex process and the like in the electrostatic spinning technology. The nano-fiber prepared by the method has the advantages of high strength, high machinability, short fiber diameter and uniform distribution and can be widely applied to a plurality of fields such as lithium ion battery diaphragm, filtering, biomedical material and the like.

Owner:JIANGNAN UNIV

Acrylic shrinkable fiber and method for production thereof

InactiveUS20070098982A1Low heat resistanceCompatibilityYarnThin material handlingPolymer scienceSpinning

An object of the present invention is to provide a dyeable acrylic shrinkable fiber that only slightly shrinks when dyed and has a high shrinkage percentage even after dyeing. By spinning an incompatible spinning solution, the above object can be achieved, and a dyeable acrylic shrinkable fiber that only slightly shrinks when dyed and has a high shrinkage percentage even after dyeing can be provided.

Owner:KANEKA CORP

Electrospinning of PTFE with high viscosity materials

An improved process for forming a PTFE mat is described. The process includes providing a dispersion with PTFE, a fiberizing polymer and a solvent wherein said dispersion has a viscosity of at least 50,000 cP. An apparatus is provided which comprises a charge source and a target a distance from the charge source. A voltage source is provided which creates a first charge at the charge source and an opposing charge at the target. The dispersion is electrostatically charged by contact with the charge source. The electrostatically charged dispersion is collected on the target to form a mat precursor which is heated to remove the solvent and the fiberizing polymer thereby forming the PTFE mat.

Owner:ZEUS COMPANY INC

Antimicrobial substrate

Owner:ZEUS COMPANY INC

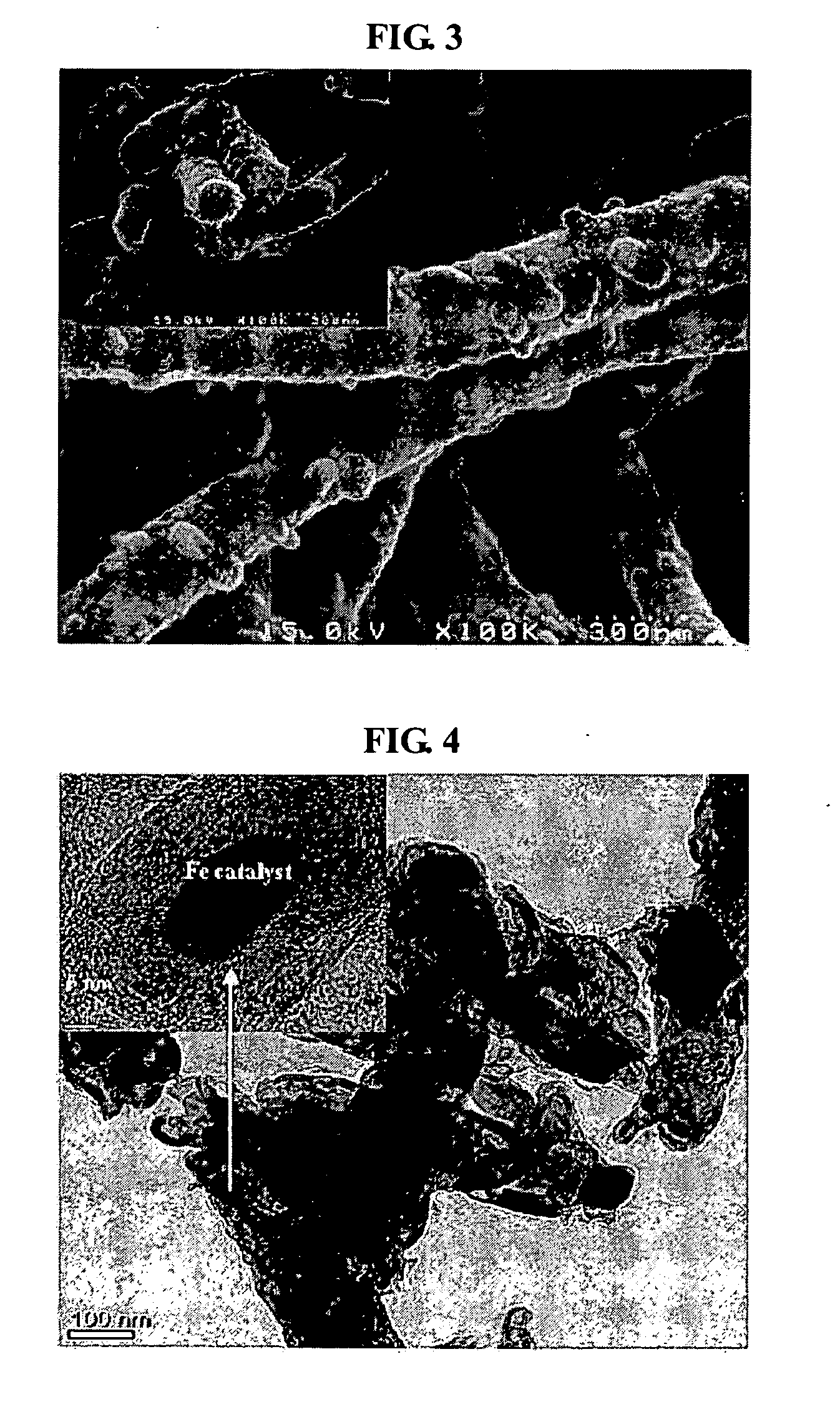

Ultrafine porous graphitic carbon fiber and preparation method thereof

ActiveUS20070134151A1Physical/chemical process catalystsElectric discharge heatingFiberCarbon fibers

The present invention discloses an ultrafine graphitic carbon fiber and a preparation method thereof. An ultrafine fiber having a diameter of 1 to 3000 nm is prepared by electrospinning a halogenated polymer solution containing a metal compound inducing graphitization. In carbonization, an ultrafine porous graphitic carbon fiber having a large specific surface area, micropores and macropores is prepared by the graphitization by a metal catalyst generated from the metal compound. The ultrafine carbon fiber can be used as a carbon material for storing hydrogen, an adsorbing material of biochemically noxious substances, an electrode material of a supercapacitor, a secondary cell and a fuel cell, and a catalyst carrier material.

Owner:KOREA INST OF SCI & TECH

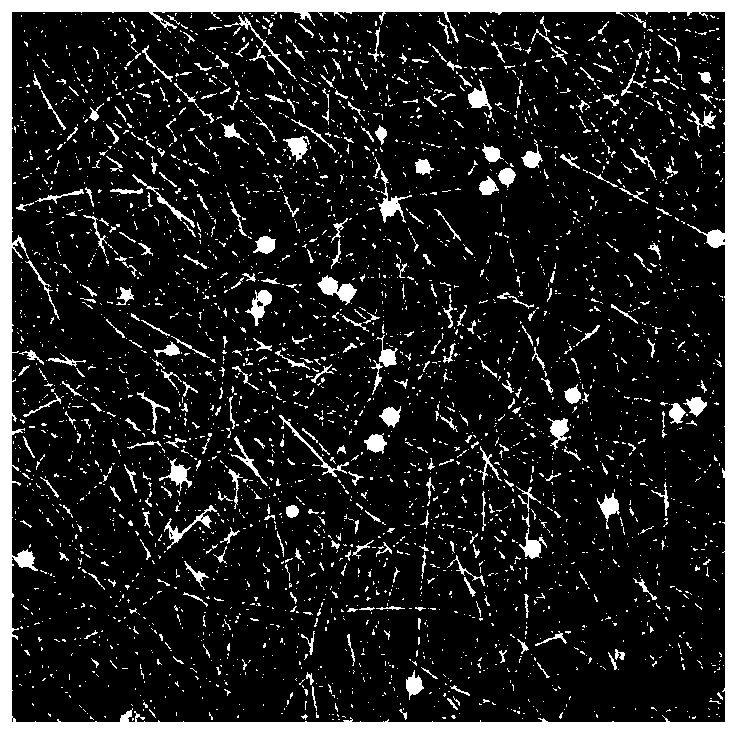

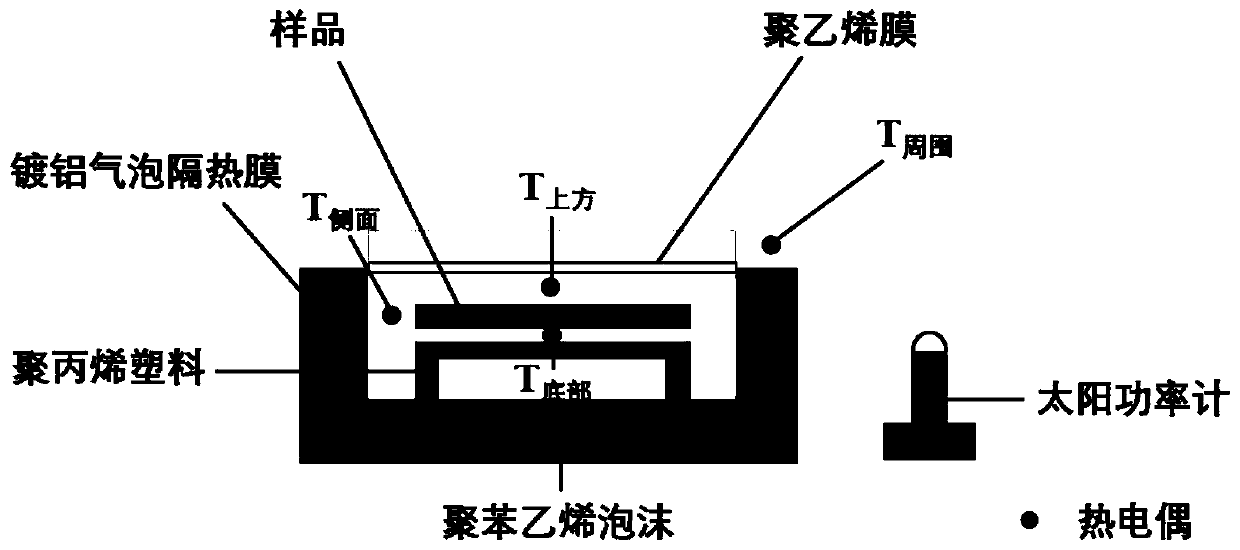

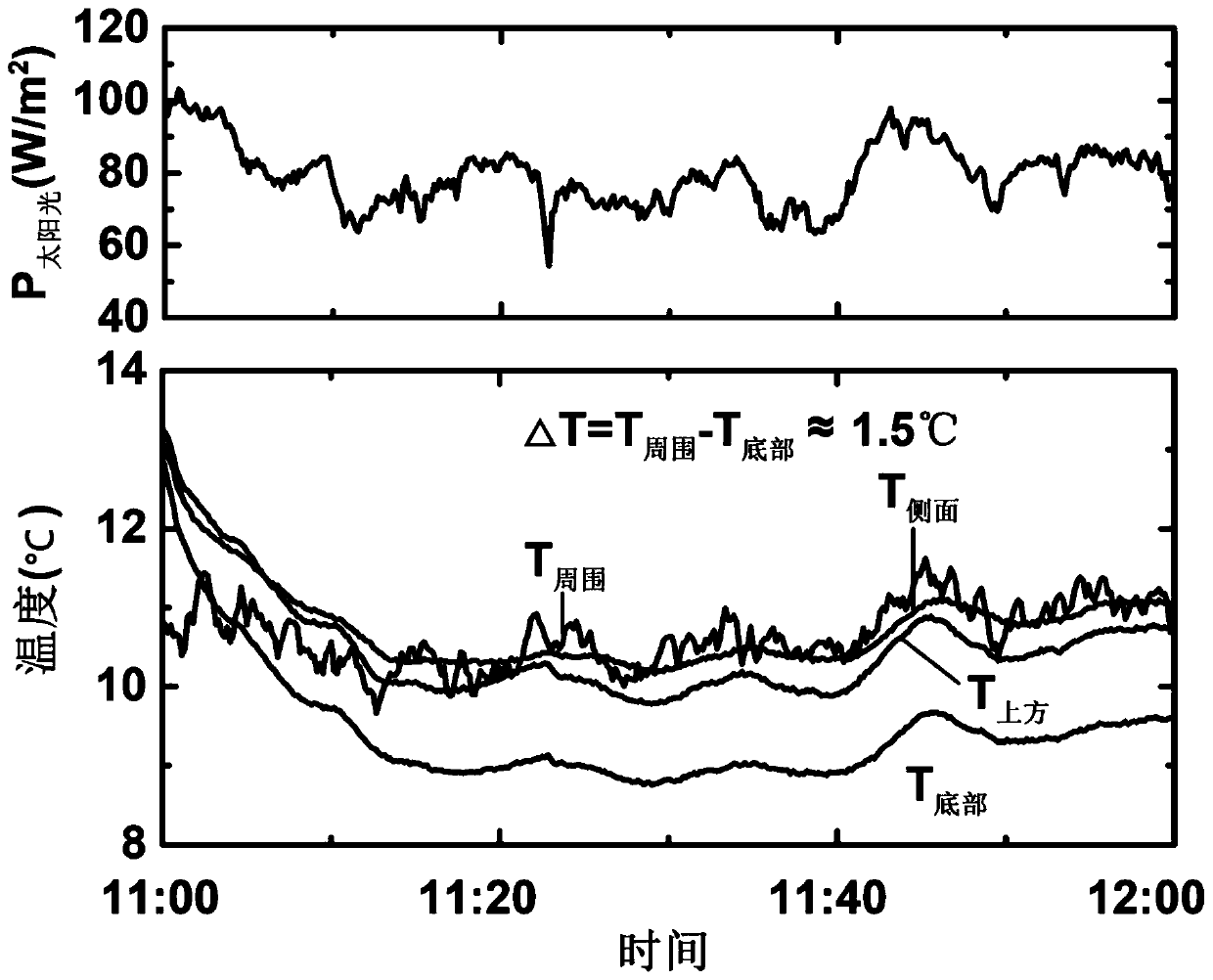

Radiation refrigeration fiber membrane and preparation method and application thereof

InactiveCN110042564AEnhanced radiationSimple structureNon-woven fabricsMonocomponent polyolefin artificial filamentFiberDispersity

The invention relates to a radiation refrigeration fiber membrane and a preparation method and application thereof. The fiber membrane comprises polymer fibers and radiation particles with high mono-dispersity, wherein the radiation particles with the high mono-dispersity are randomly dispersed among the polymer fibers. The preparation method comprises the steps of uniformly dispersing the radiation particles with the high mono-dispersity in a polymer solution and performing electrostatic spinning. The fiber membrane is simple in structure, has a great radiation refrigeration effect and can beused for cooling the human body.

Owner:DONGHUA UNIV

Preparation method for regularly electrostatic spinning hollow fibre

InactiveCN101144196ASimple manufacturing methodHollow filament manufactureArtificial filaments from cellulose derivativesHollow fibreFiber bundle

The present invention relates to a preparation method for regularized static electricity spinning hollow fiber, and the method comprises the procedures that: firstly, high molecular compound is dissolved in good solvent to be made into uniform solution; secondly, poor solvent is added to be dispensed into spinning raw liquid, and the volume ratio of the good solvent and the poor solvent is 10 / 1 to 1 / 3; thirdly, the spinning raw liquid is added into a container, is controlled and extruded by a micro-syringe pump, a jet opening is connected with a high voltage positive pole, a grounding microelectrode with the removable area of 0 to 100 mm 2 is taken as a negative pole, various parameters of static electricity spinning are adjusted, and the spinning raw liquid carries on the static electricity spinning; fourthly, the grounding microelectrode backwards and continuously moves, and a continuous regularized static electricity spinning hollow fiber bundle is obtained; fifthly, the continuous hollow fiber bundle obtains the regularized static electricity spinning hollow fiber through winding and collecting. The preparation method provided by the present invention is simple and feasible, and the obtained static electricity spinning hollow fiber has the potential application and the prospect in the fields such as nanowire devices, filtering materials, and composite reinforcing materials, etc.

Owner:DONGHUA UNIV

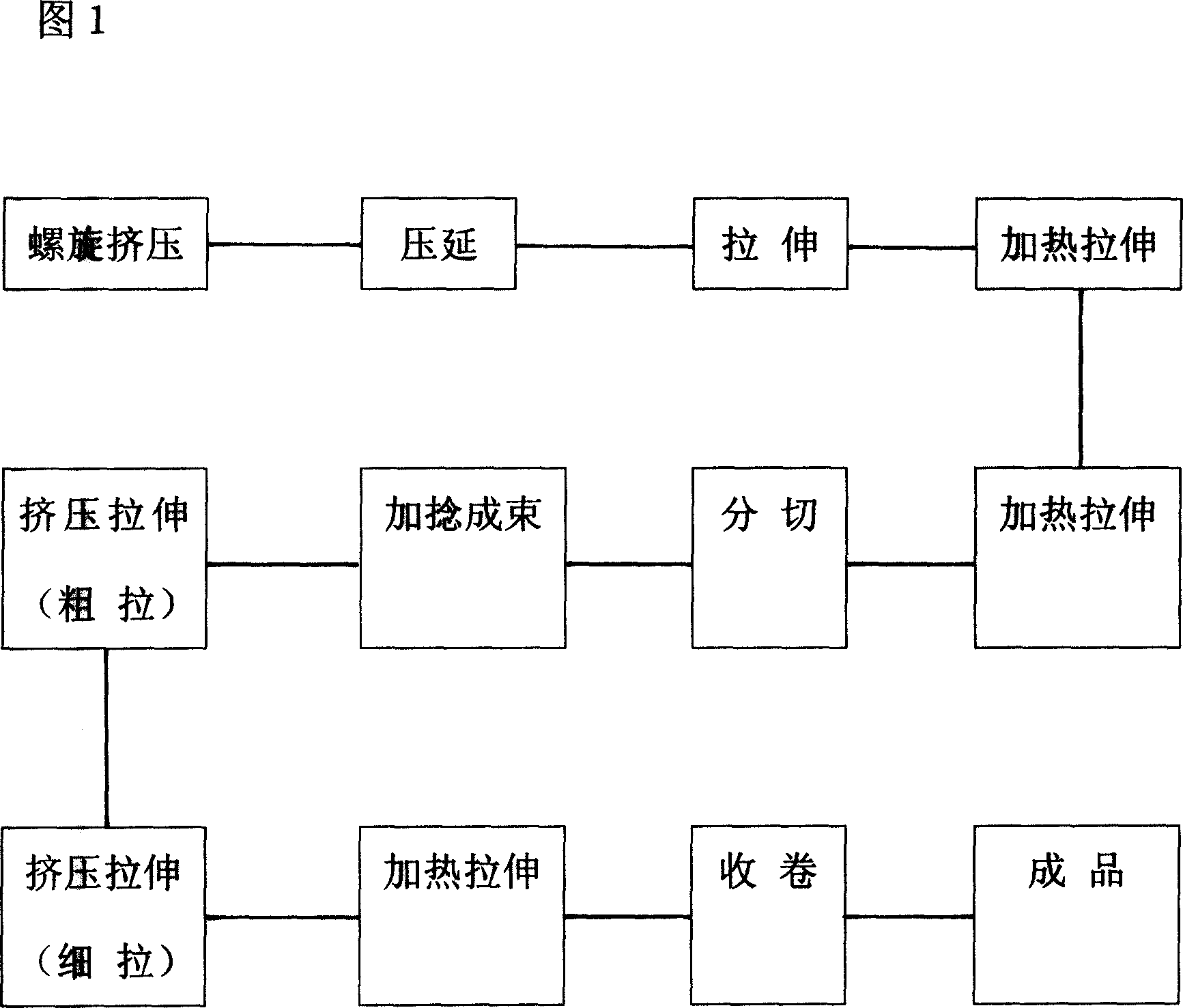

Method for producing polytef amosite

ActiveCN101074499AAchieve preparationExtended service lifeMelt spinning methodsMonocomponent halogenated hydrocarbon artificial filamentFiberProcess equipment

This invention provides one method for producing PTFE long fiber. The raw materials for this invention is 100% PTFE, the use of processing equipment includes spiral extrusion machine, calendar, stretching machine, heating tensile machine, Slitter, twisting machines, extrusion tensile machine, and roll-up. Firstly put the PTPE into spiral extruder and crash, secondly put into heating tensile machine to heat and stretch, do it once more, thirdly cut through slitter, twist into beam by twisting Machine, fourthly roughly stretch by squeeze tensile machine, and then stretch finely by squeeze tensile machine, finally put into heating tensile machine to heat and stretch, roll up by the roll-up machine, after which the production of PTFE long fiber is done. The PTFE long fiber in this invention can produce the monofilament long fiber and multi long fiber which can be used as the fabric filter substrate of bag filter as well as high-intensity industrial sewing thread which longer the durability of the filter bag for Teflon bag.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

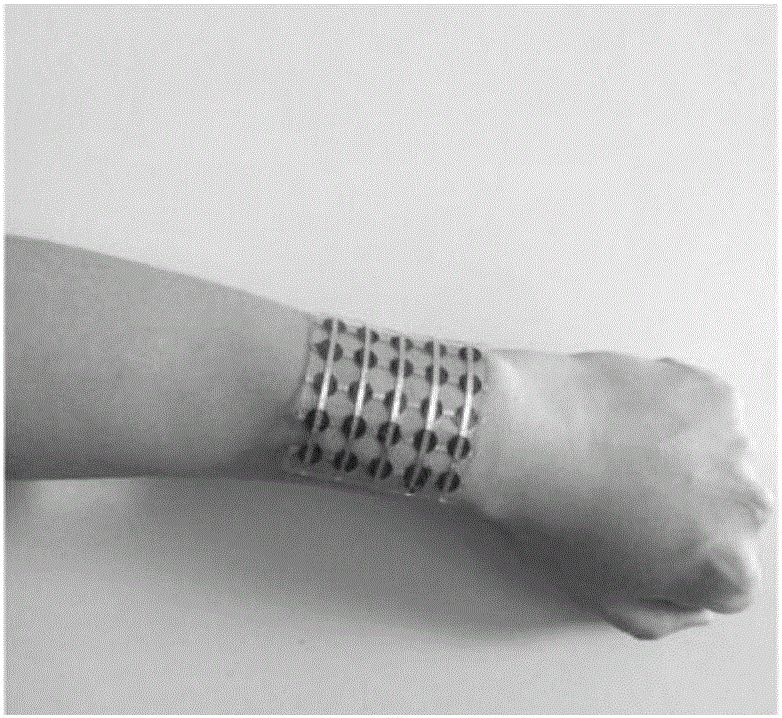

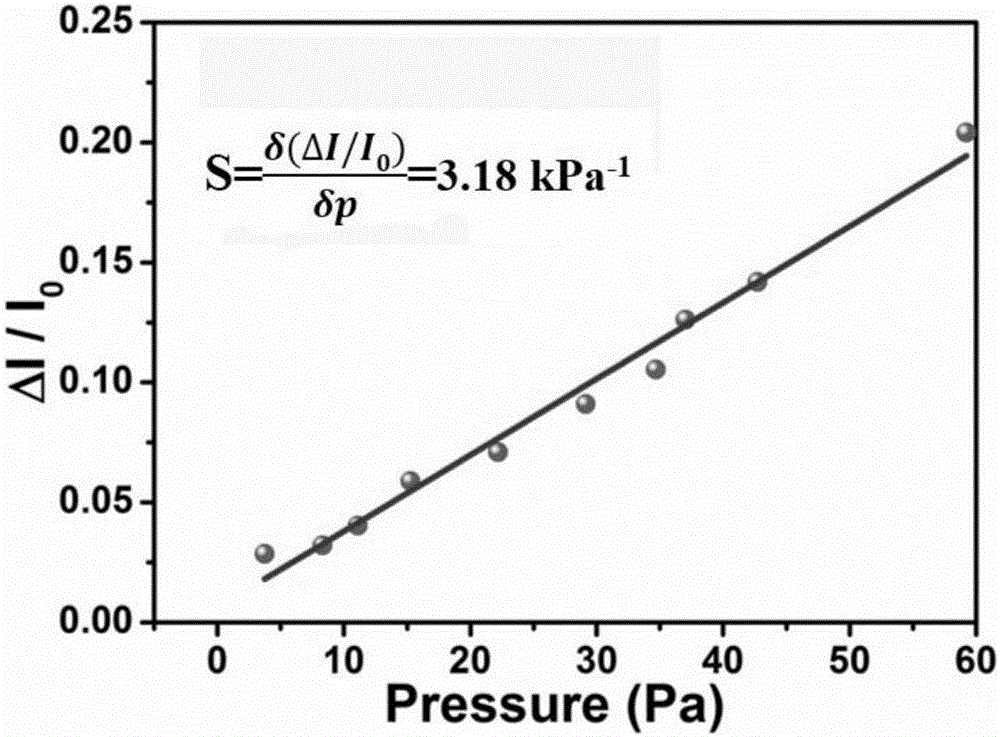

Development of flexible resistance type pressure transducer capable of being applied to human body pulse detection

InactiveCN105708425AThe preparation method is simple and environmentally friendlyLow costFibre treatmentCatheterFiberHuman body

The invention relates to a flexible resistance type pressure transducer which can be applied to human body pulse detection. Polymer micro-nano fibers prepared by adopting an electrospinning technique are taken as a framework, and graphene is taken as a conductive active layer and coats the outer layer of the framework, so that a sensitive layer of the transducer is formed; and then the sensitive layer is transferred onto a polydimethylsiloxane (PDMS) substrate, and finally another PDMS thin film covers a composite material for encapsulation, so that a device is formed. The device can be arbitrarily made into an n*m transducer array as required, so that the flexible resistance type pressure transducer is made. The flexible resistance type pressure transducer provided by the invention has extremely high sensitivity, extremely high response and restoration speed and stable response performance on a weak pressure and has good detectability on human body pulse.

Owner:姜凯 +1

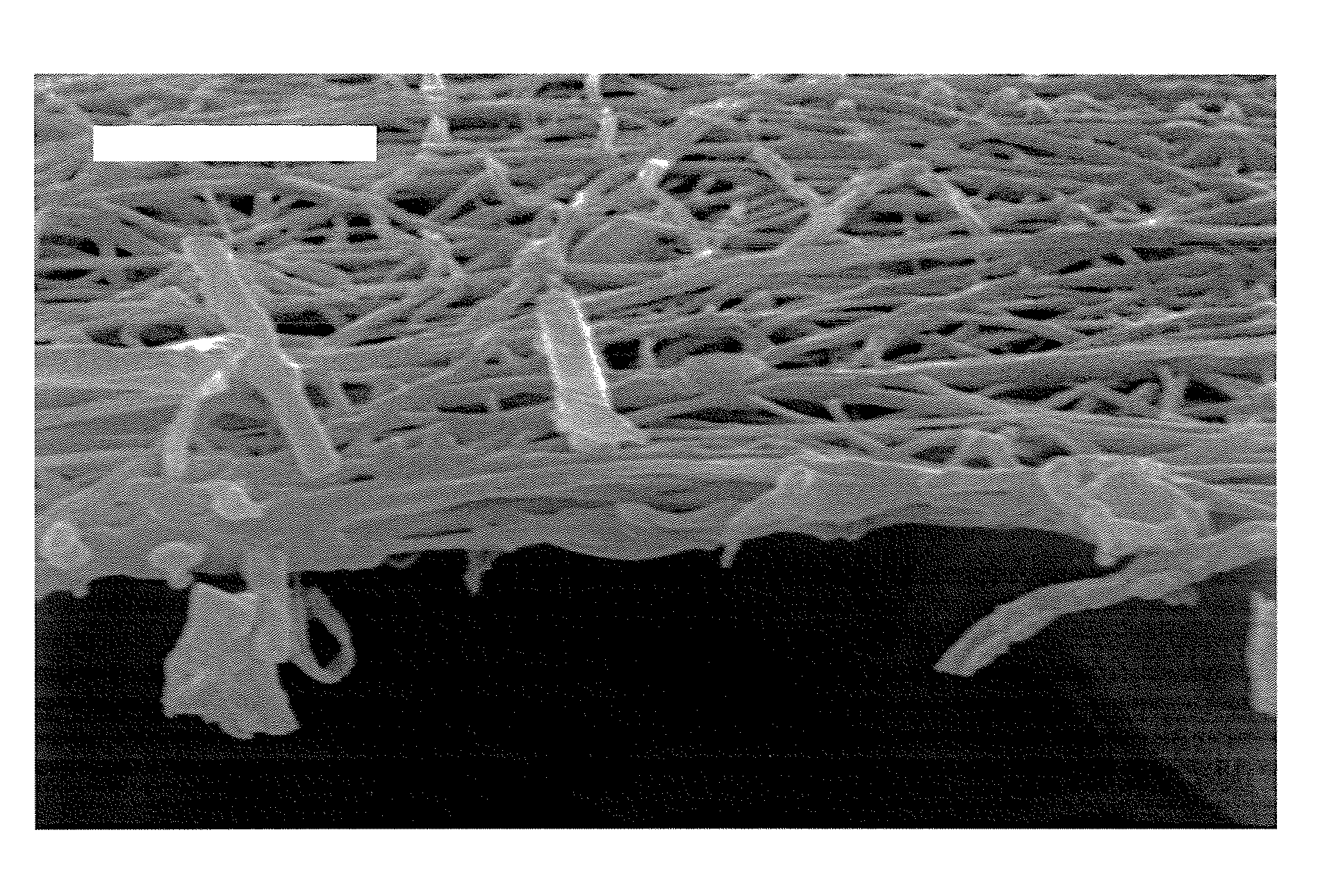

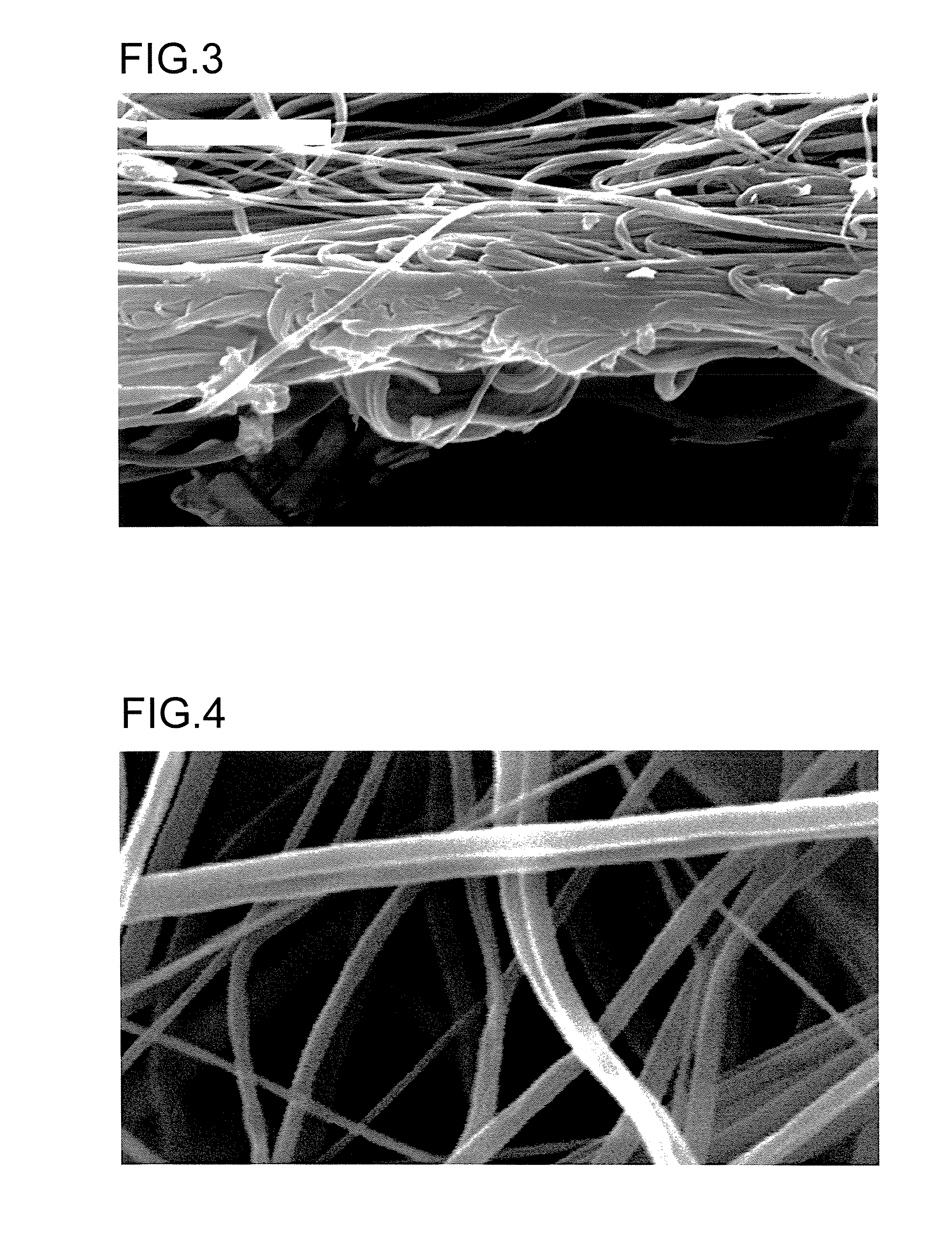

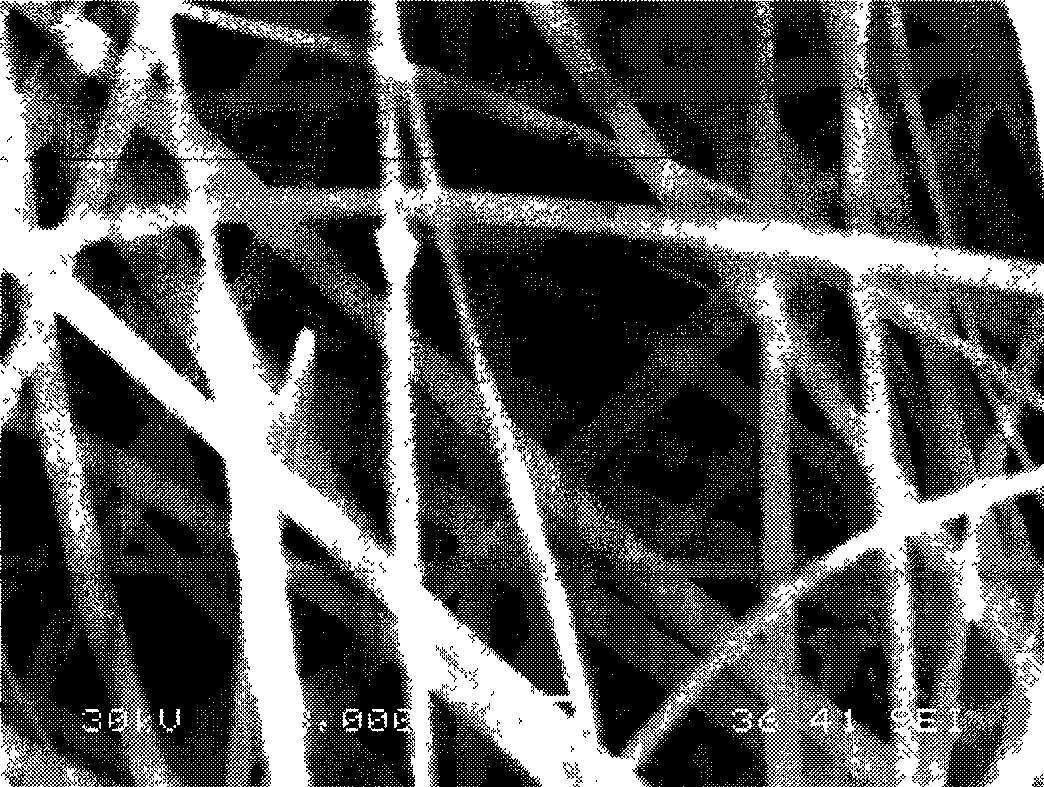

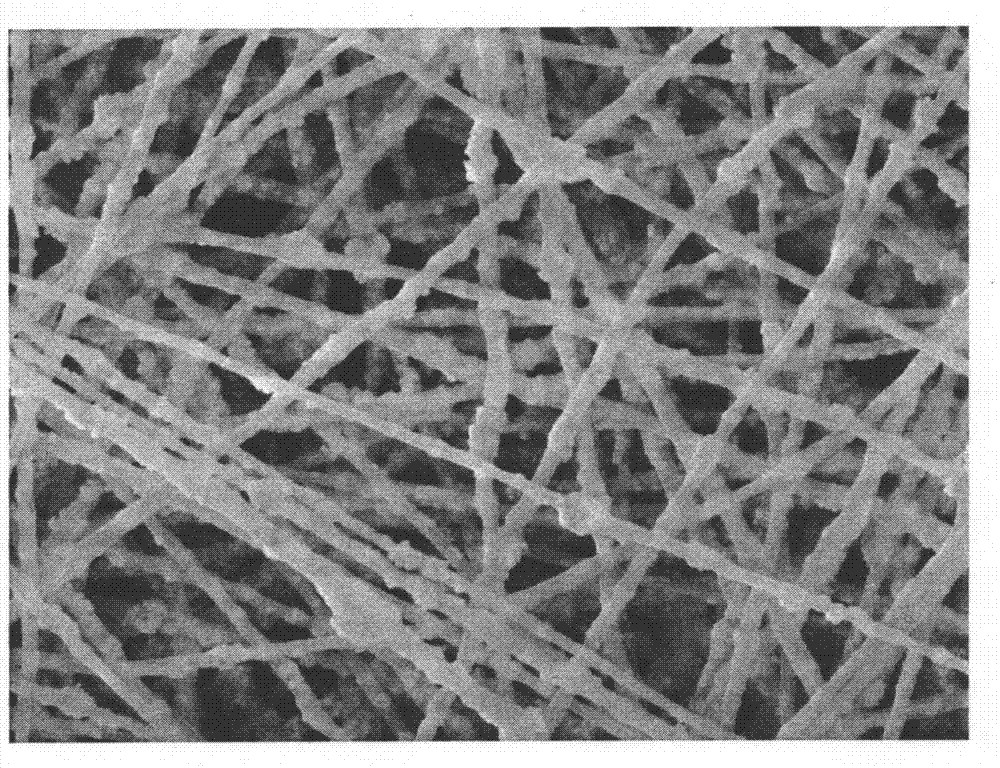

High-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and preparation method thereof

InactiveCN107557894AImprove throughputHigh porosityFatty/oily/floating substances removal devicesUltrasonic/sonic fibre treatmentFiberNanofiber

The invention discloses a high-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and a preparation method thereof. The preparation method comprises the following steps: a polymer solution is prepared from a selected polymer, a net is formed through electrostatic direct injection of the polymer solution, a spinneret vibrates in situ by the aid of external force inan electrostatic direct injection process to promote generation of charged droplets, the droplets are subjected to phase separation, and a uniform 2D net-shaped ultrafine nanofiber material is formedon the surface of a receiving substrate and is in a continuous and seamlessly stacked shape; then the obtained material is subjected to surface modification, and the 2D net-shaped ultrafine nanofiberoil-water separation material with selective surface and interface wetting property is obtained. The preparation process is simple, raw material limitations are few, and the net-shaped ultrafine nanofiber oil-water separation material has tiny meshes and good pore channel connectivity and has great application prospect in the fields of oil purification, oil-containing wastewater treatment and thelike.

Owner:DONGHUA UNIV

Composite nano fiber filtration material with photocatalysis/anti-bacterial functions and preparation method of filtration material

ActiveCN107497182AIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

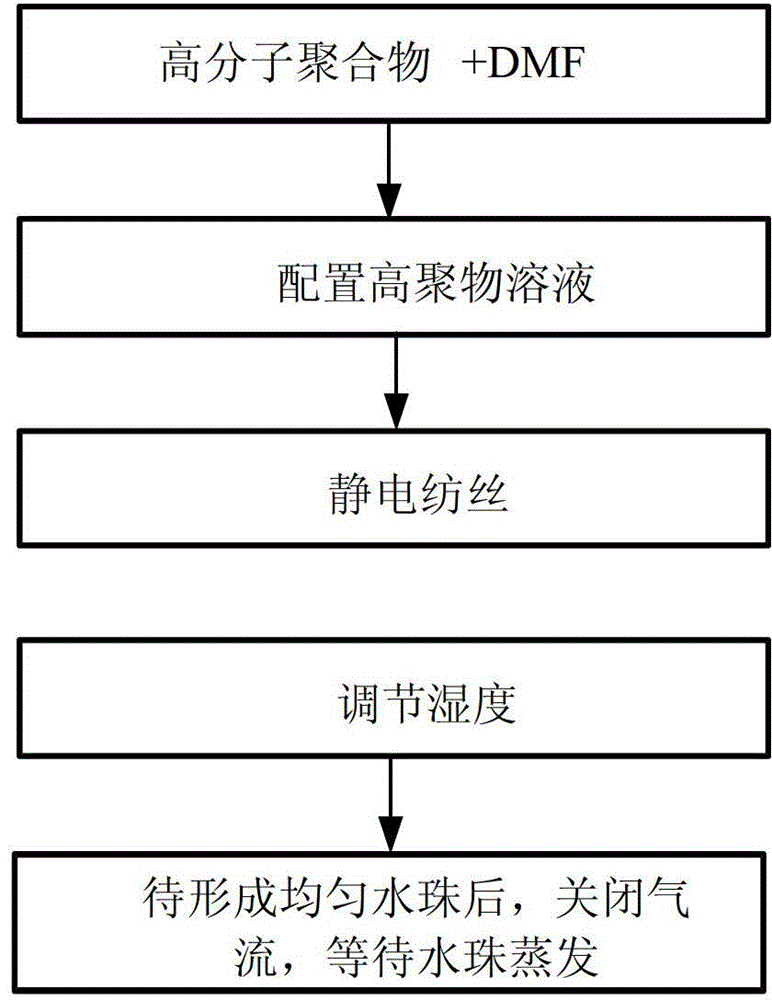

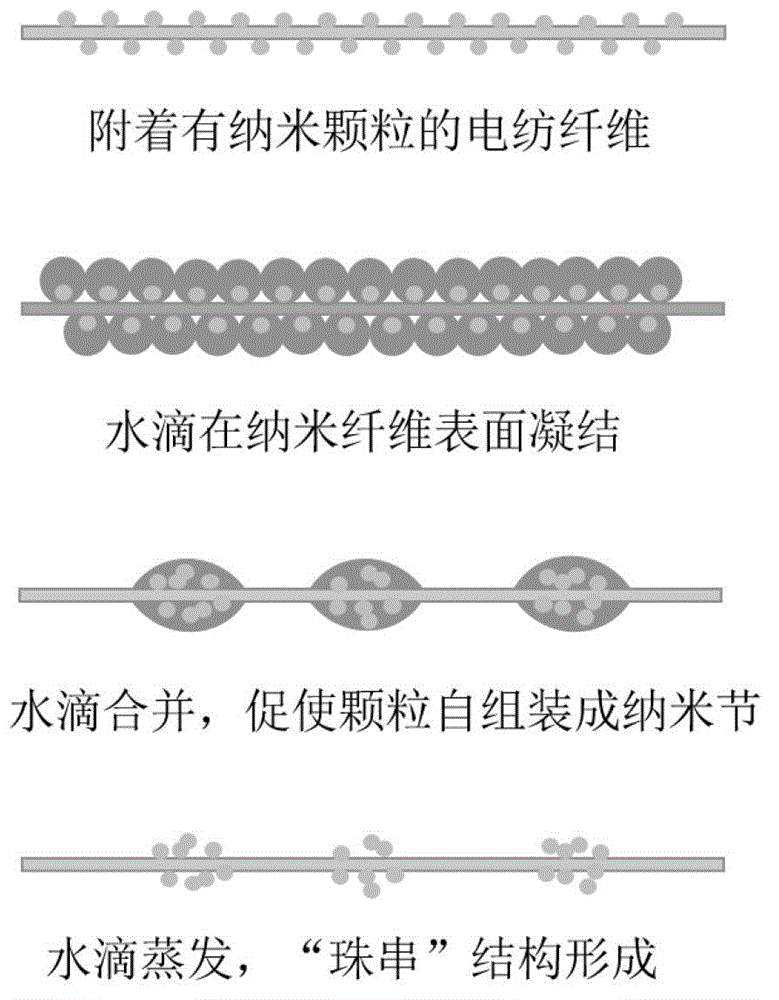

Preparation method for self-assembly of electrospinning rosary-like fibers

ActiveCN103334244AEasy to operateEasy to makeMonocomponent polyethers artificial filamentFilament/thread formingFiberOperability

The invention discloses a preparation method for the self-assembly of electrospinning rosary-like fibers, and belongs to the technical field of chemistry and material. By inspired by the situation that a cobweb can be assembled to a spindle structure in the wet environment respectively, a static electricity spinning device is utilized to prepare man-made fibers, and an aluminum bracket is used for receiving, so as to form the man-made fibers with the structure that nano-particles are adhered to surfaces; the man-made fibers are allowed to be assembled to the micron-sized ' rosary' structure respectively in the wet environment. According to the preparation method provided by the invention, the manufacturing process is simpler, the cost is lower, the operability is strong, and the method is suitable for mass productions; the respectively assembled fibers have stable quality and long practicability; the method can be used for collecting fresh water, reducing fog, solving the problem of serious water shortage in deserts and wastelands, and dispersing the steam around airports, street lamps, and signal lamps.

Owner:BEIHANG UNIV

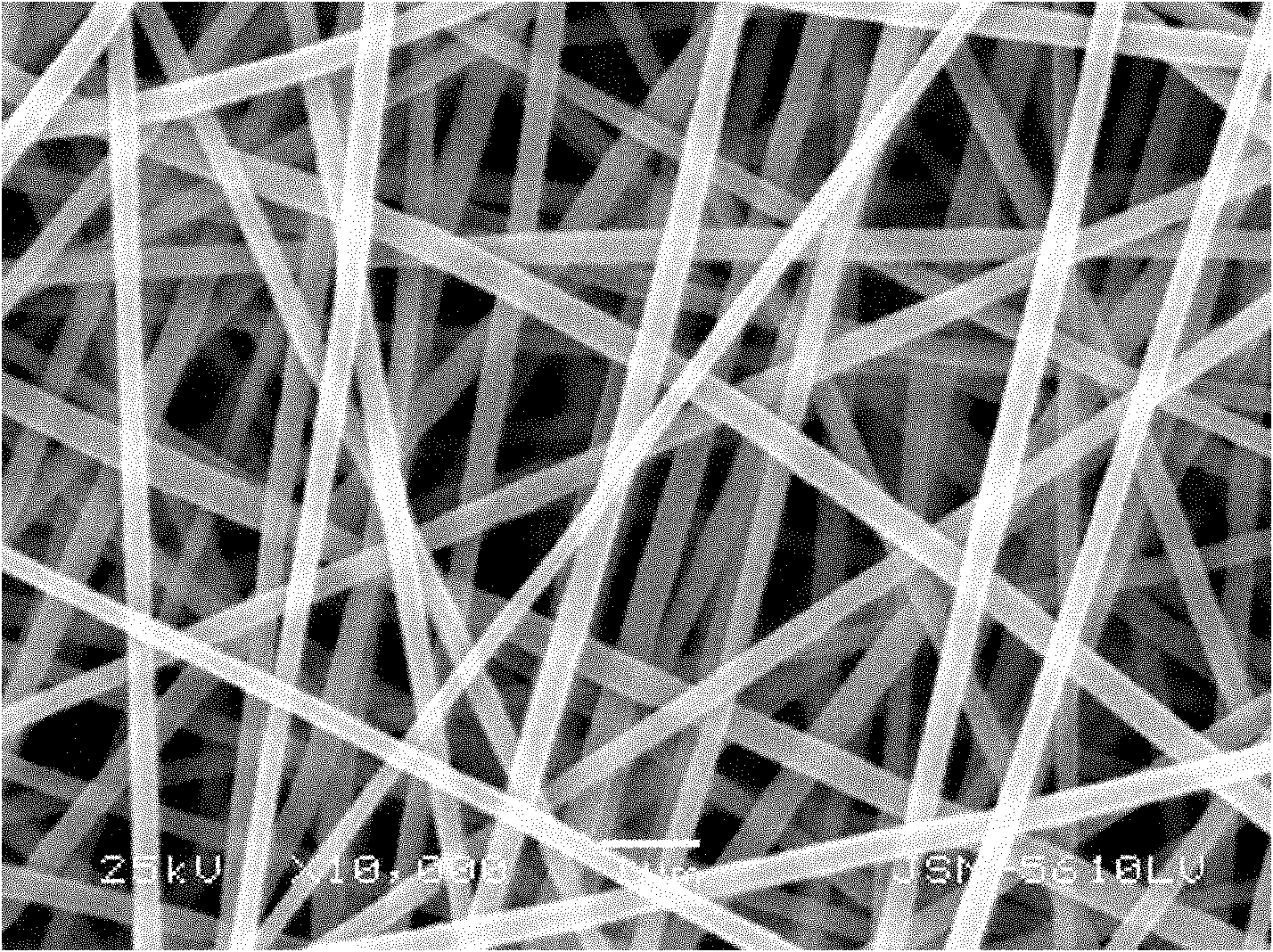

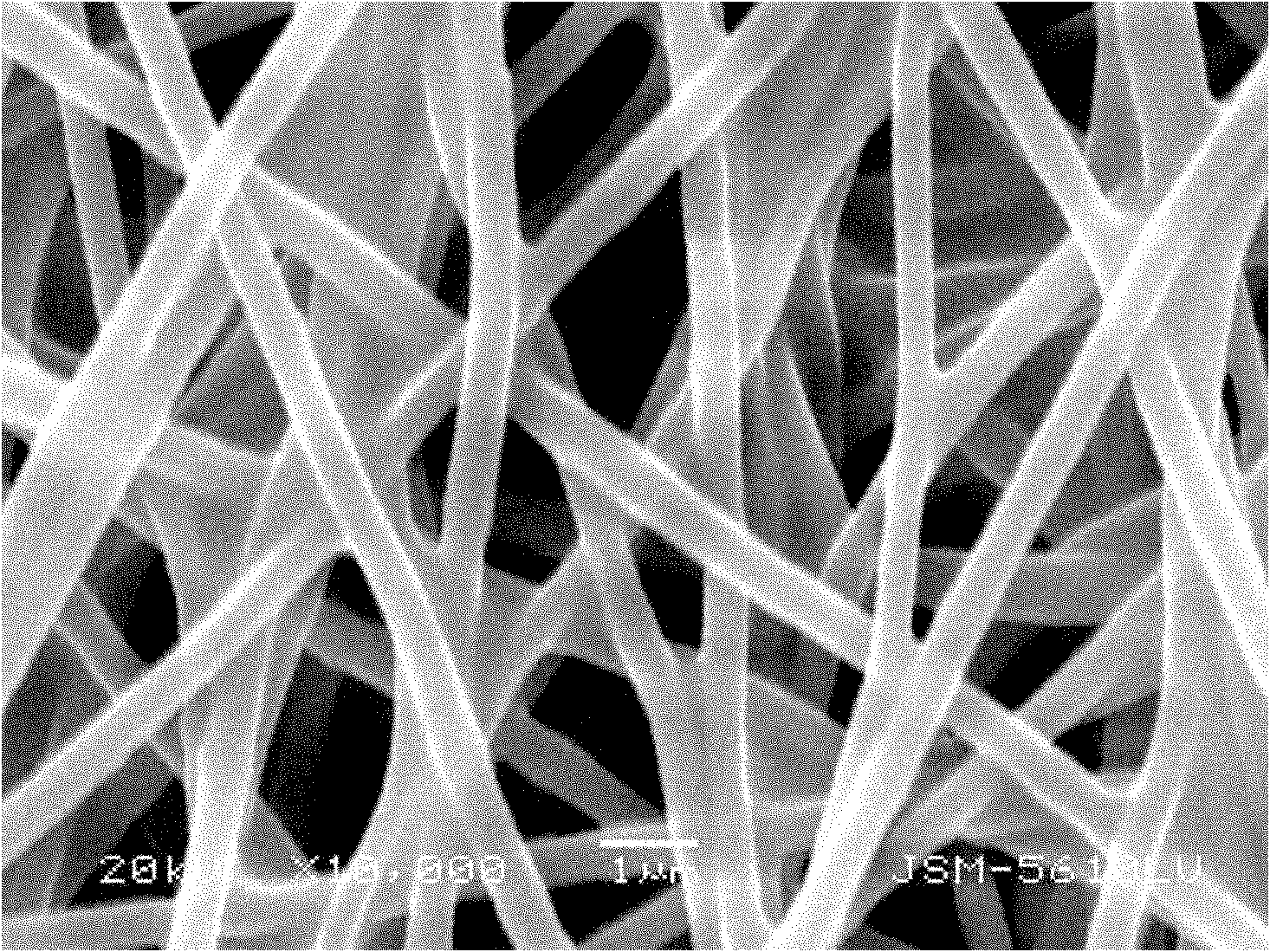

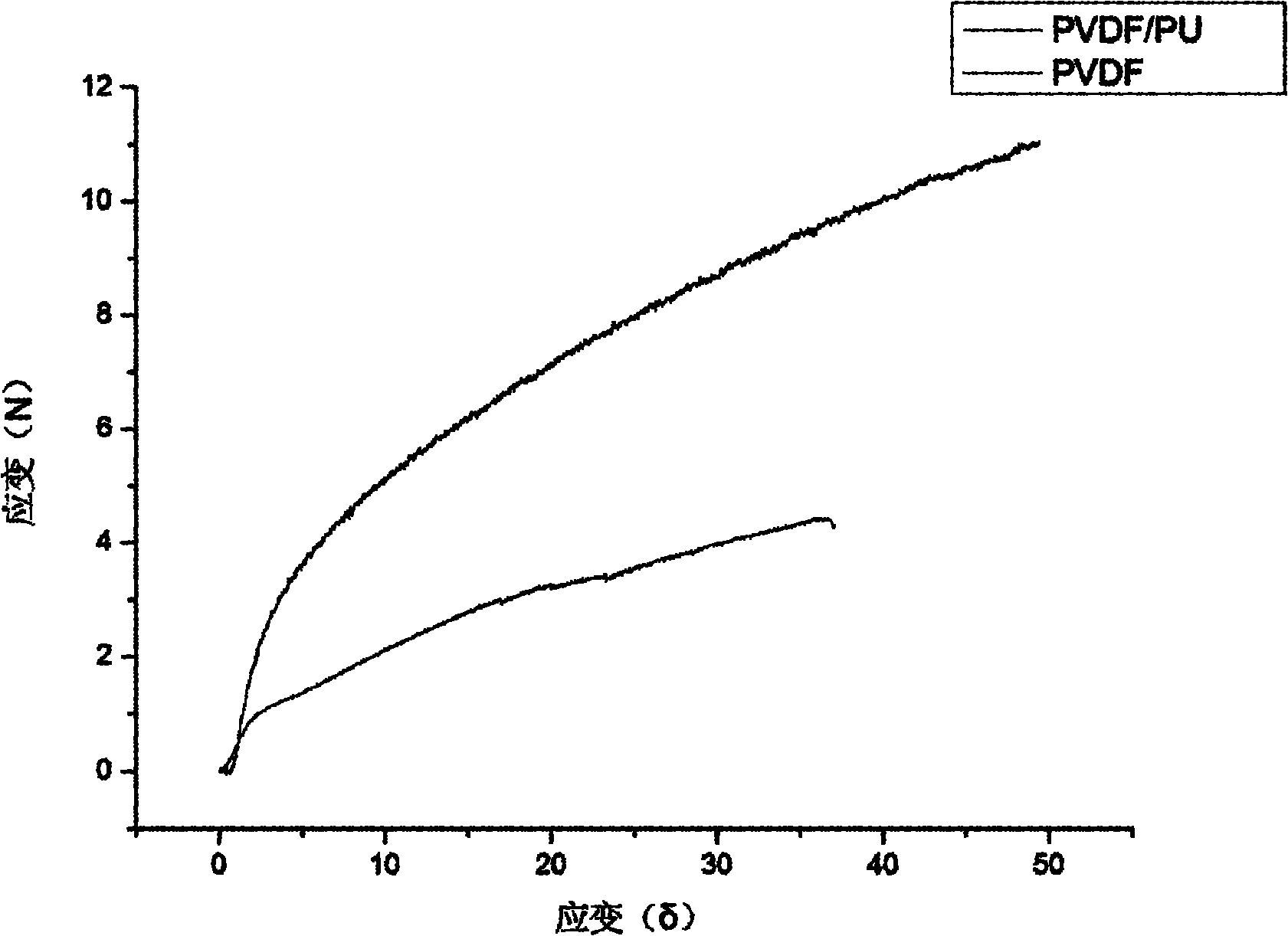

Reinforced nanofiber porous membrane and preparation method thereof

InactiveCN102140762AHigh porosityImprove wettabilityFibre typesCell component detailsFiberPolymer science

The invention relates to a reinforced nanofiber porous membrane and a preparation method thereof. The porous membrane is a two-component lithium ion battery diaphragm formed by compounding polymer resin with polyurethane, and has a semi-interpenetrating network structure, the porosity of 60 to 80 percent, and mechanical property which is 3 to 4 times higher than that of a polymer resin single-component porous membrane. The preparation method comprises the following steps of: preparing a polymer resin non-woven membrane by high-voltage electrostatic spinning, impregnating the non-woven membrane in solution of wet curing reaction polyurethane prepolymer with a high-reactivity isocyanate group, reacting -NCO in the polyurethane prepolymer with a -OH bond of water in air at room temperature to obtain the polyurethane through crosslinking and autopolymerization, so that nanofibers in the non-woven membrane are bonded to form a polymer resin and polyurethane two-component composite membrane, and the mechanical strength of the fiber membrane is greatly improved. The method is easy to operate, and the prepared non-woven membrane keeps the advantages of high porosity of a membrane prepared by an electrostatic spinning technology, and heat stability of the polymer resin, and has high ion permeability and affinity of electrolyte.

Owner:WUHAN UNIV OF TECH

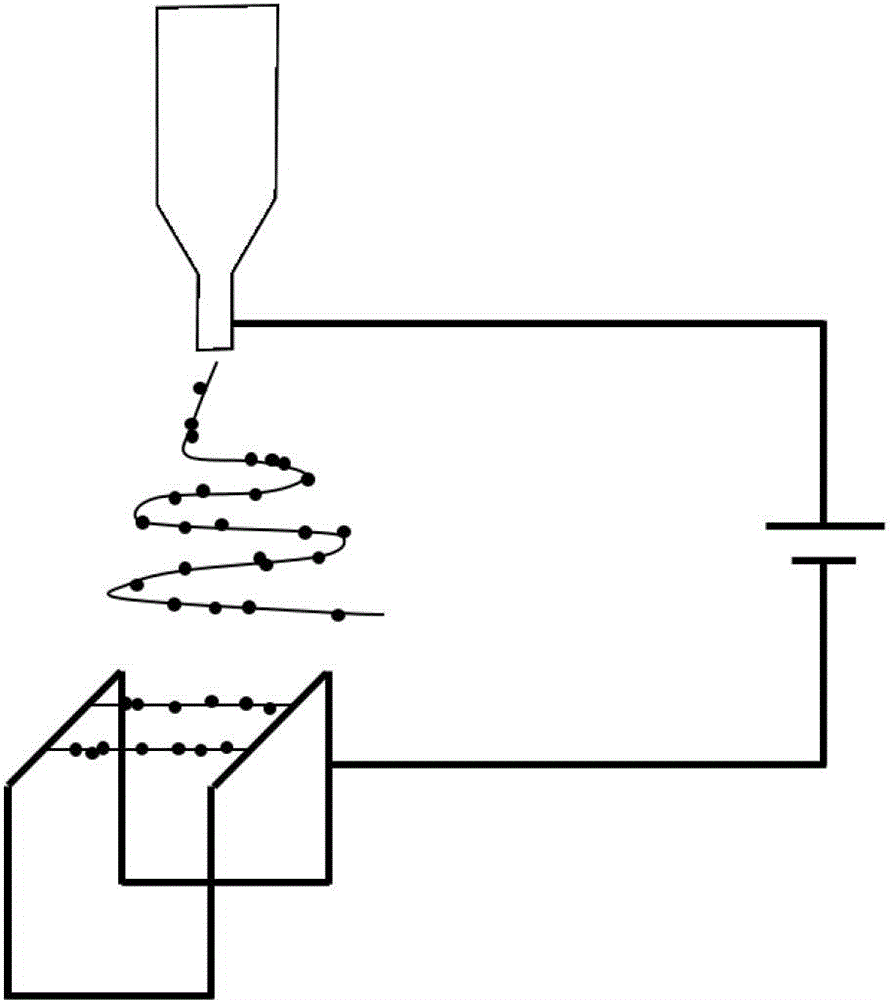

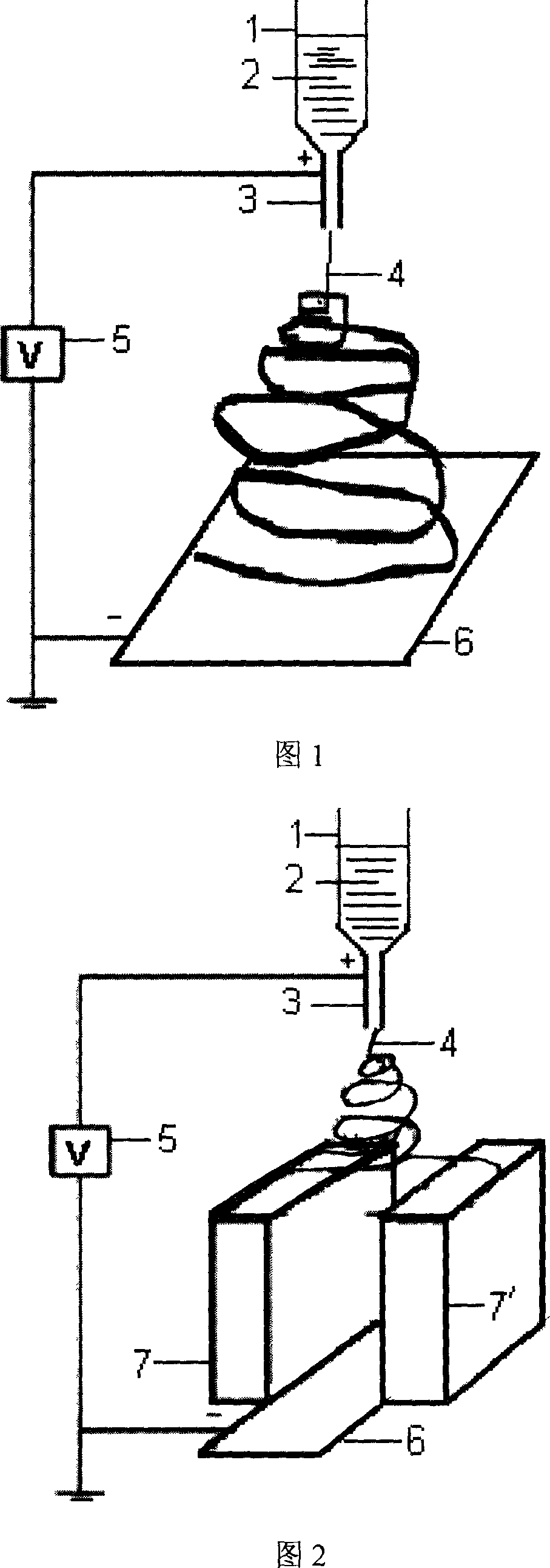

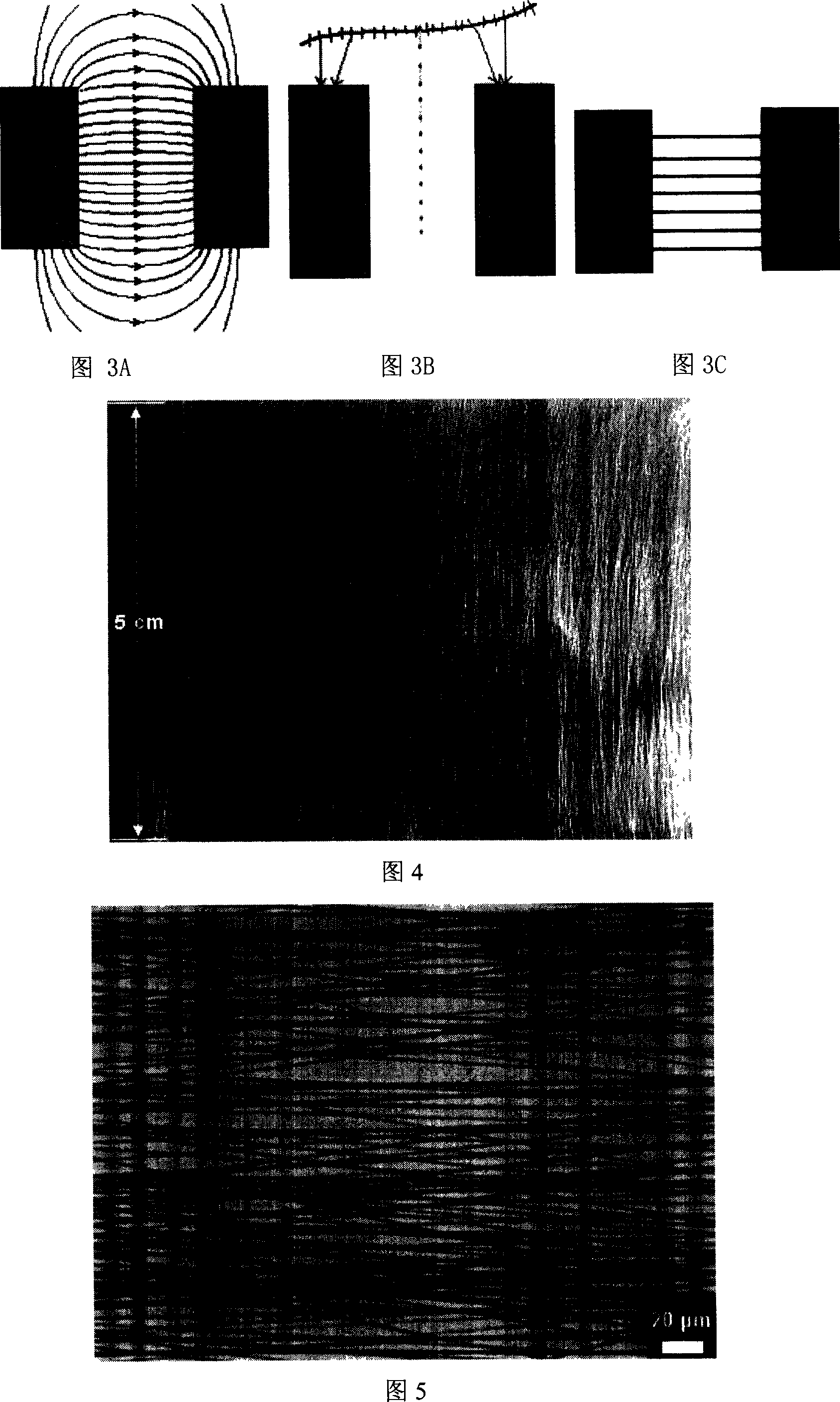

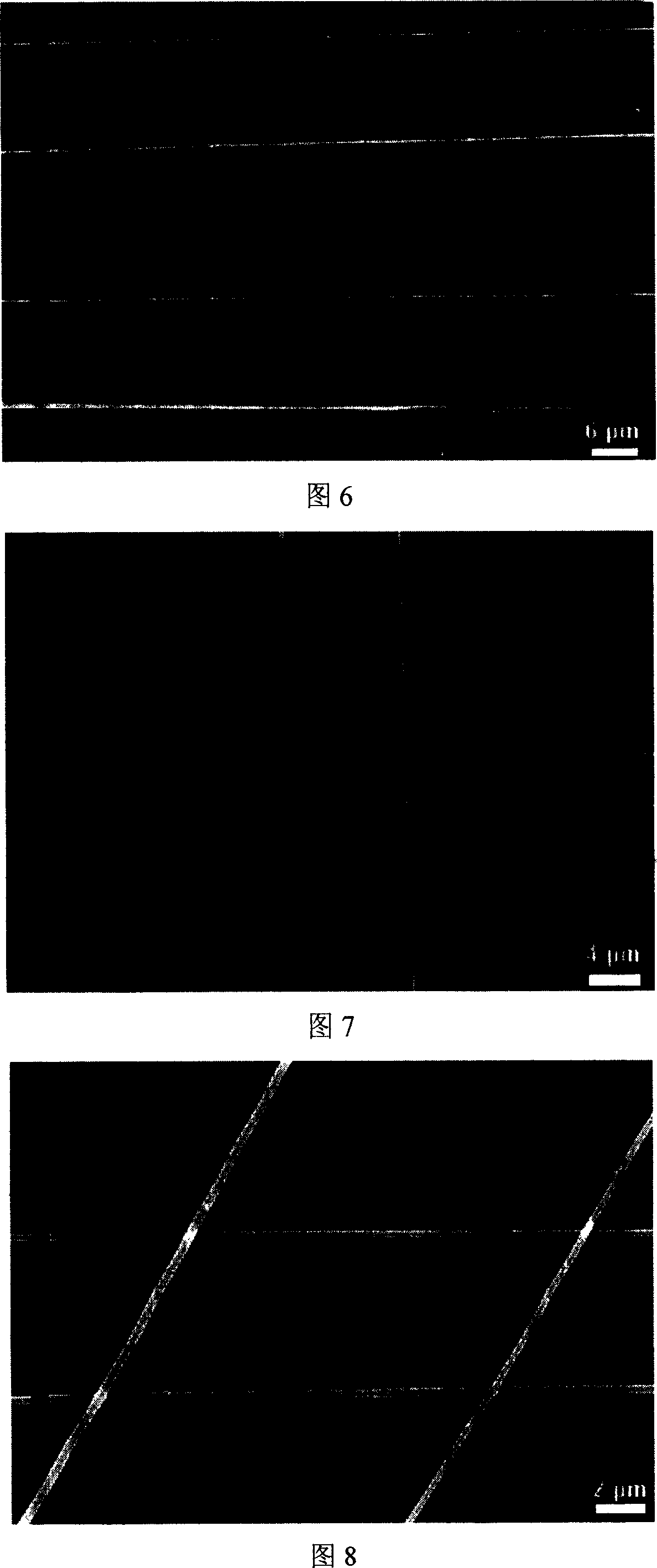

Device and method for preparing regular arranged macromolecular nano-fibre

The invention relates to an equipment for preparing polymer nanometer fiber with regular arrangement and the method. The equipment comprises a spraying silk tube for containing polymer solution. A spraying nozzle is sealed and assembled at the end of spraying silk tube. The nozzle is connected with the positive electrode of high pressure generator and is used as anticathode. An aluminum foil is connected with the negative electrode of high pressure generator and is used as cathode, which is grounded at the same time. The aluminum foil is set between a first permanence magnet and a second one. The nozzle is faced to the aluminum foil. The electrical spinning method controlled by magnet is that soluble macromolecules are put into the corresponding solvent and the concentration is adjusted, the polymer solution with good performance for spinning is confected; magnetic nanometer grains are put into the polymer solution and magnetized polymer solution is formed. In the electrical spinning equipment controlled by magnet, the magnetized polymer solution becomes micro-nano continuous fiber under the effect of electric field and at the same time fibers are arranged along the direction of magnetic line under the effect of external magnetic field to form micro-nano fiber material with parallel arrangement.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

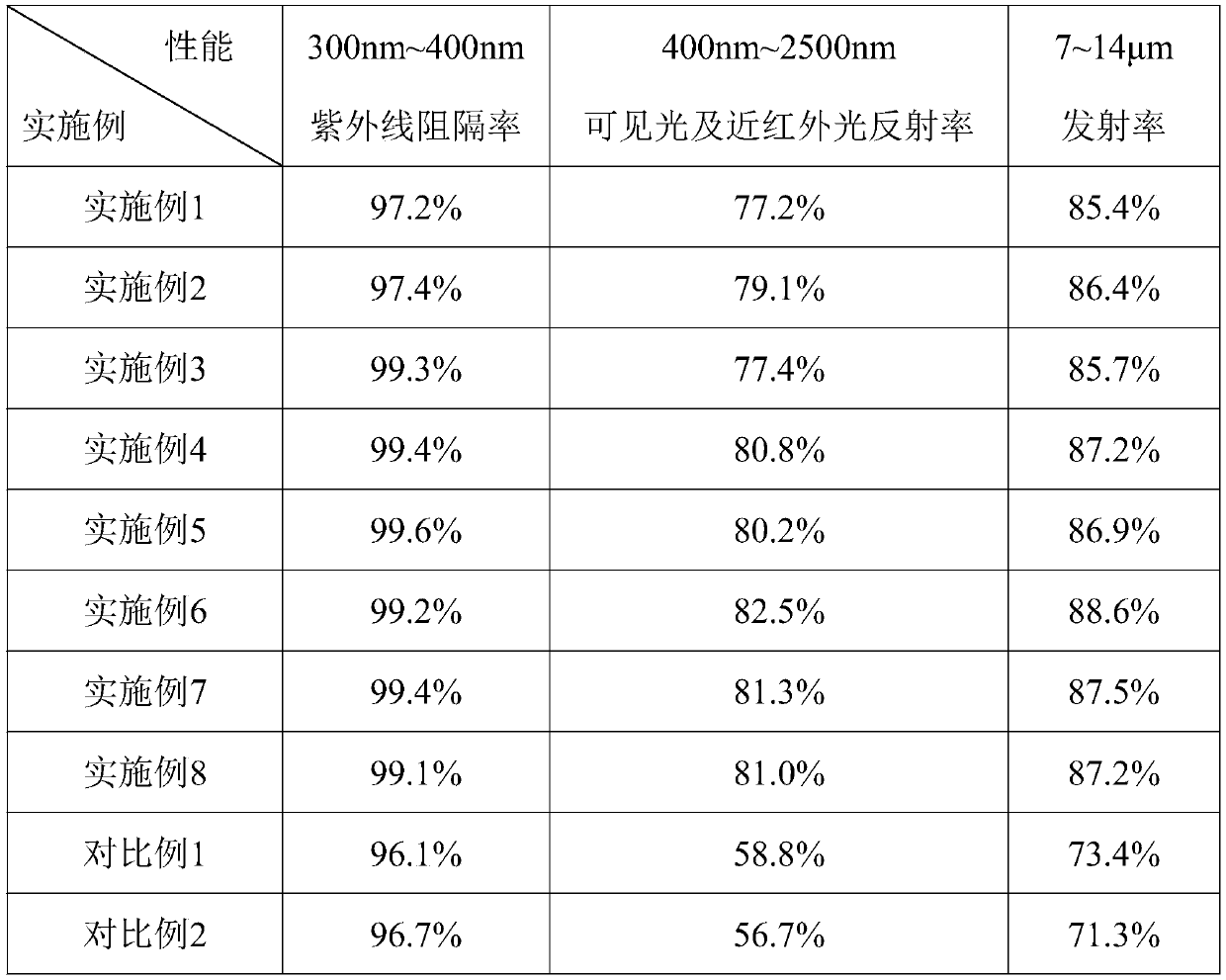

Radiation refrigeration fiber, preparation method thereof and application of fiber

ActiveCN110685031APerformance is not affectedGuaranteed breathableMonocomponent polyolefin artificial filamentYarnFiberEmissivity

The invention relates to a radiation refrigeration fiber, a preparation method thereof and an application of the fiber. The radiation refrigeration fiber comprises a base and functional fillers fixedly distributed in the base, the mass percent of the functional fillers in the radiation refrigeration fiber is 1%-17%, the linear density of the radiation refrigeration fiber is 0.3dtex-10dtex, the radiation refrigeration fiber can reflect visible light and near-infrared light, and heat is emitted by an atmospheric window in an infrared radiation mode. The visible light and near-infrared light reflectivity of a radiation refrigeration fabric prepared from the radiation refrigeration fiber is higher than or equal to 60%, and the emissivity of 7-14 micrometers is higher than or equal to 80%. Therefore, the radiation refrigeration fabric can be further used for preparing textile products such as clothes, curtains, tents, sunshades, hats, scarves, car covers and hoods with cooling requirements,comfort and breathability of the textile products are kept, cooling can be realized by the aid of the textile products, comfortable feeling is increased, energy consumption is omitted, energy is saved, and environments are protected.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD

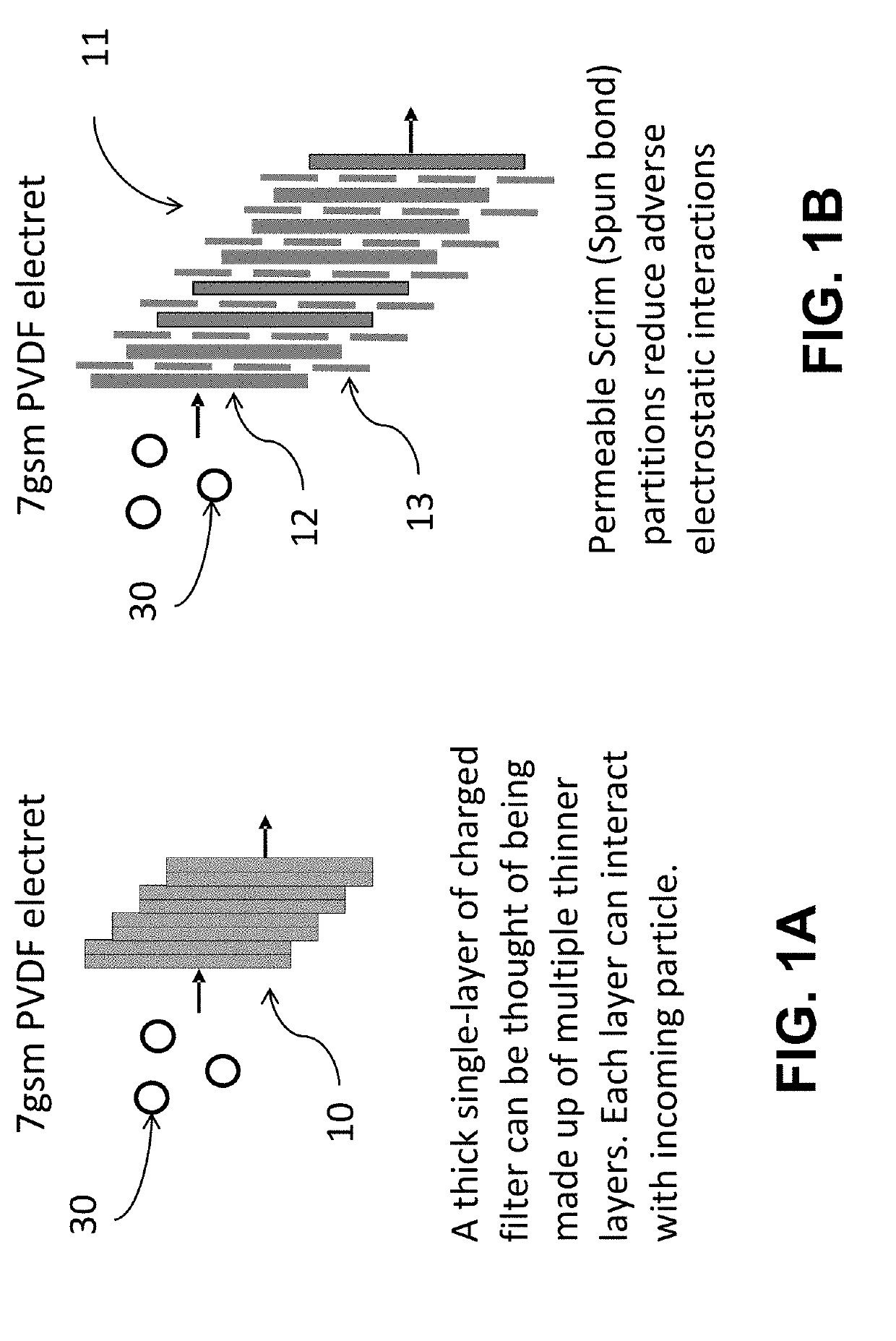

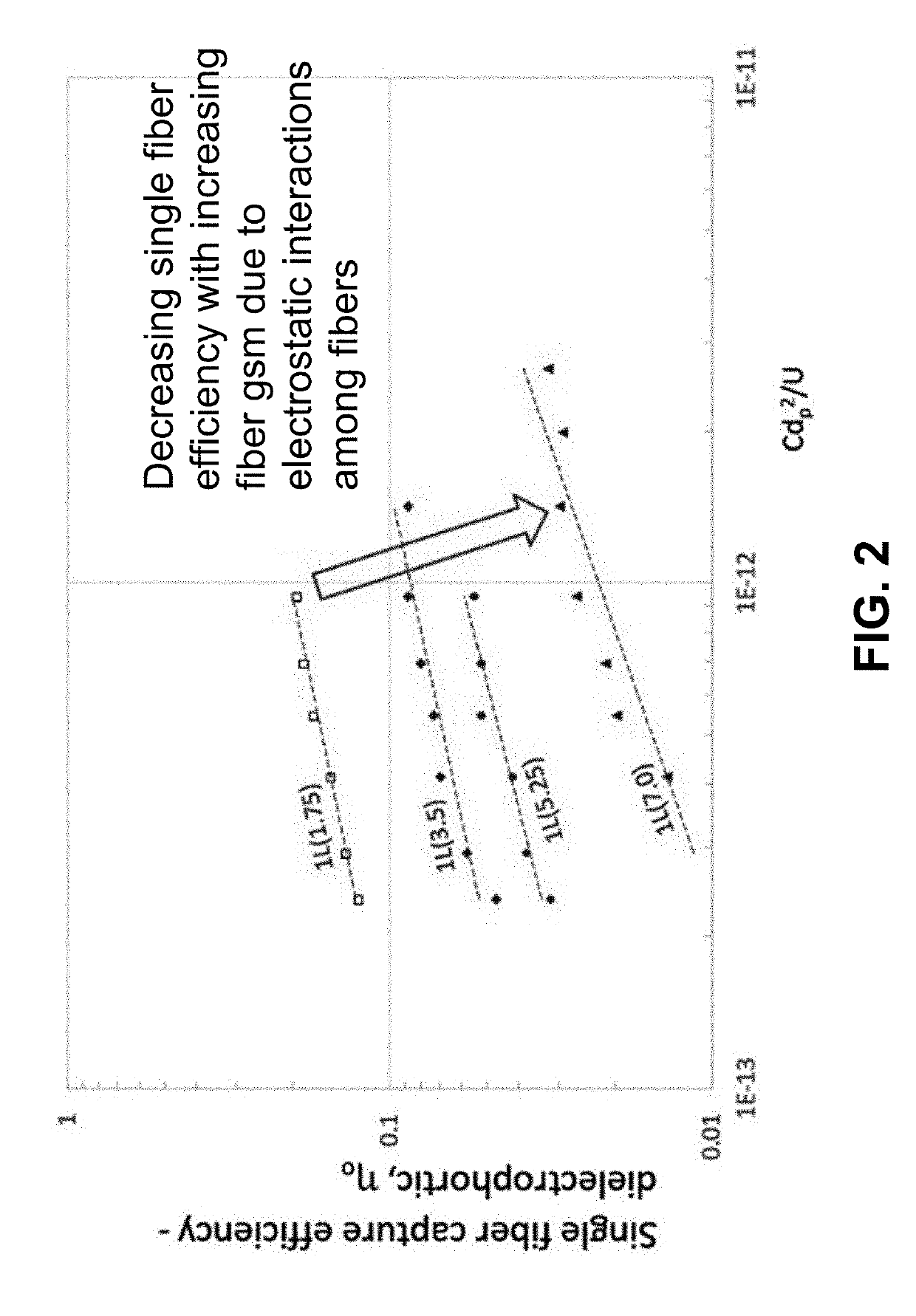

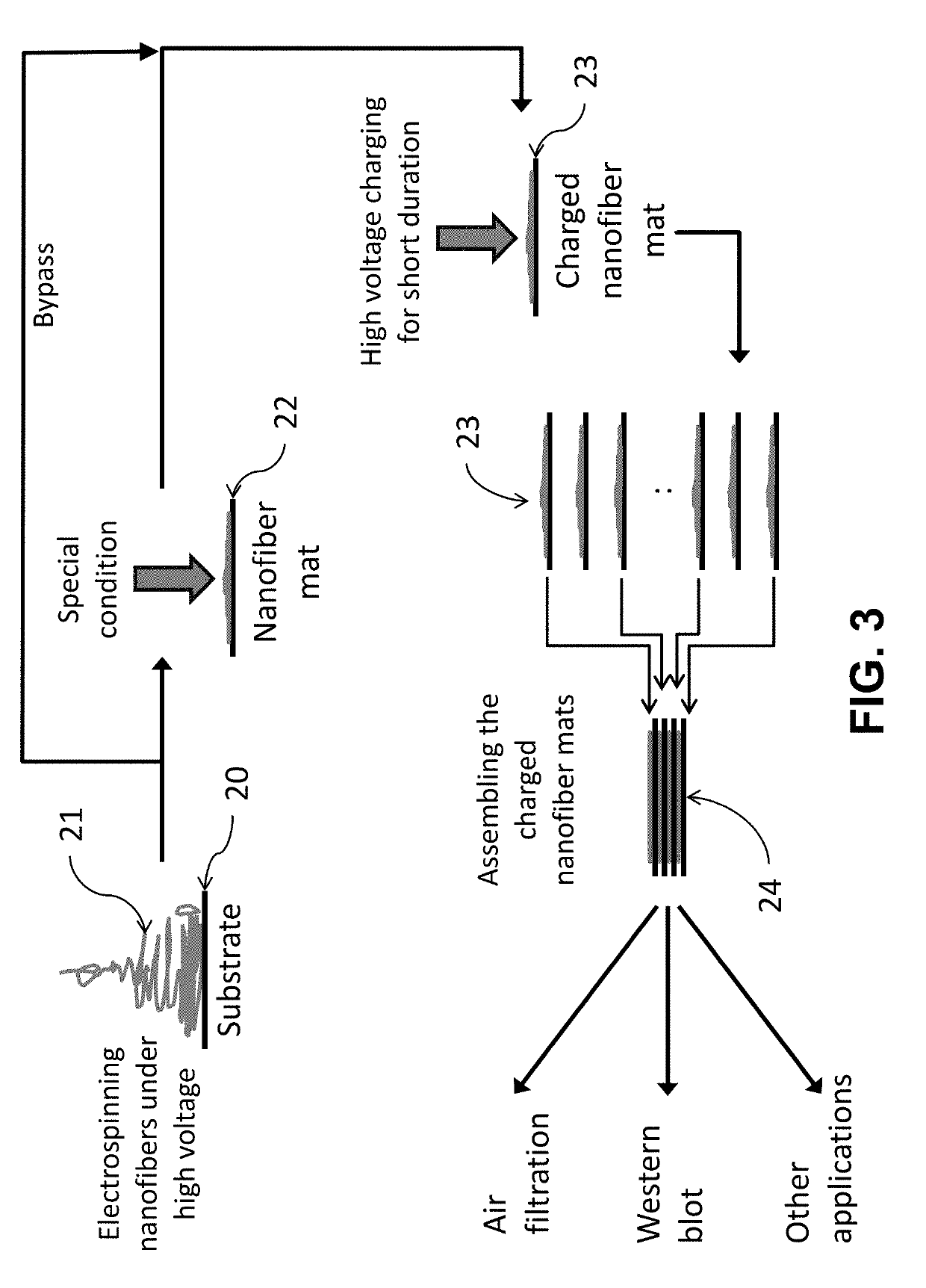

Electrostatically-charged Nanofiber Media and Fabrication Method Thereof

ActiveUS20190314746A1High filtration efficiencyLower overall pressure dropPhysical treatmentDispersed particle filtrationAir filtrationNanofiber

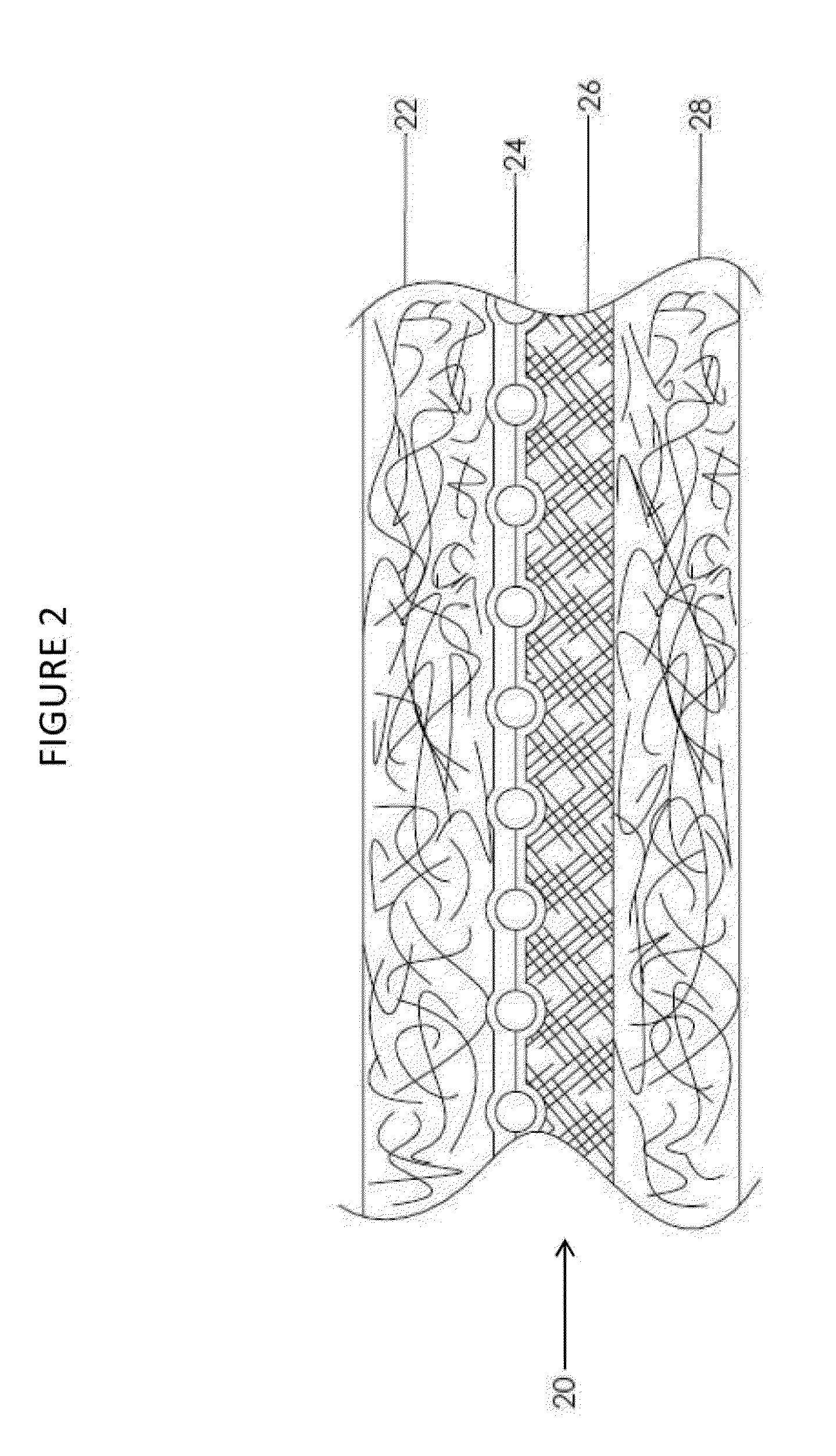

A charged multilayer nanofiber filter for air filtration and the fabrication method thereof is disclosed. The charged multilayer nanofiber filter has a plurality of charged nanofiber mats. Each of the plurality of charged nanofiber mats is obtained by charging nanofiber mats individually before assembling. The nanofiber mat comprises a nanofiber layer and a substrate layer. The plurality of charged nanofiber mats is assembled such that the nanofiber layers and the substrate layers are stacked together in an alternative manner. The charged multilayer nanofiber filter can be fabricated by electrospinning a polymer solution on the substrate layer to obtain a nanofiber mat, charging the nanofiber mat to obtain a charged nanofiber mat, and assembling a plurality of charged nanofiber mats to form the charged multilayer nanofiber filter.

Owner:THE HONG KONG POLYTECHNIC UNIV

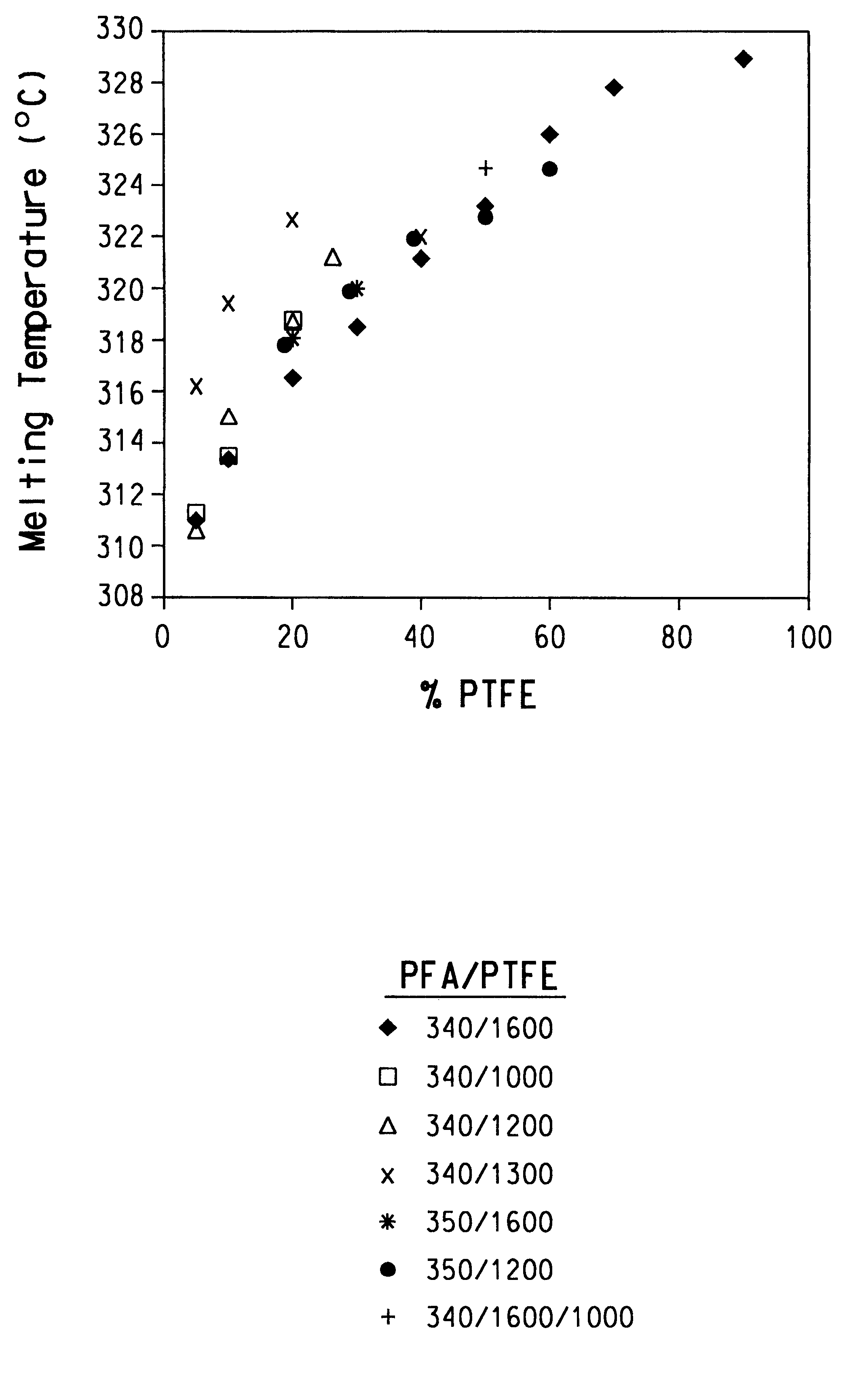

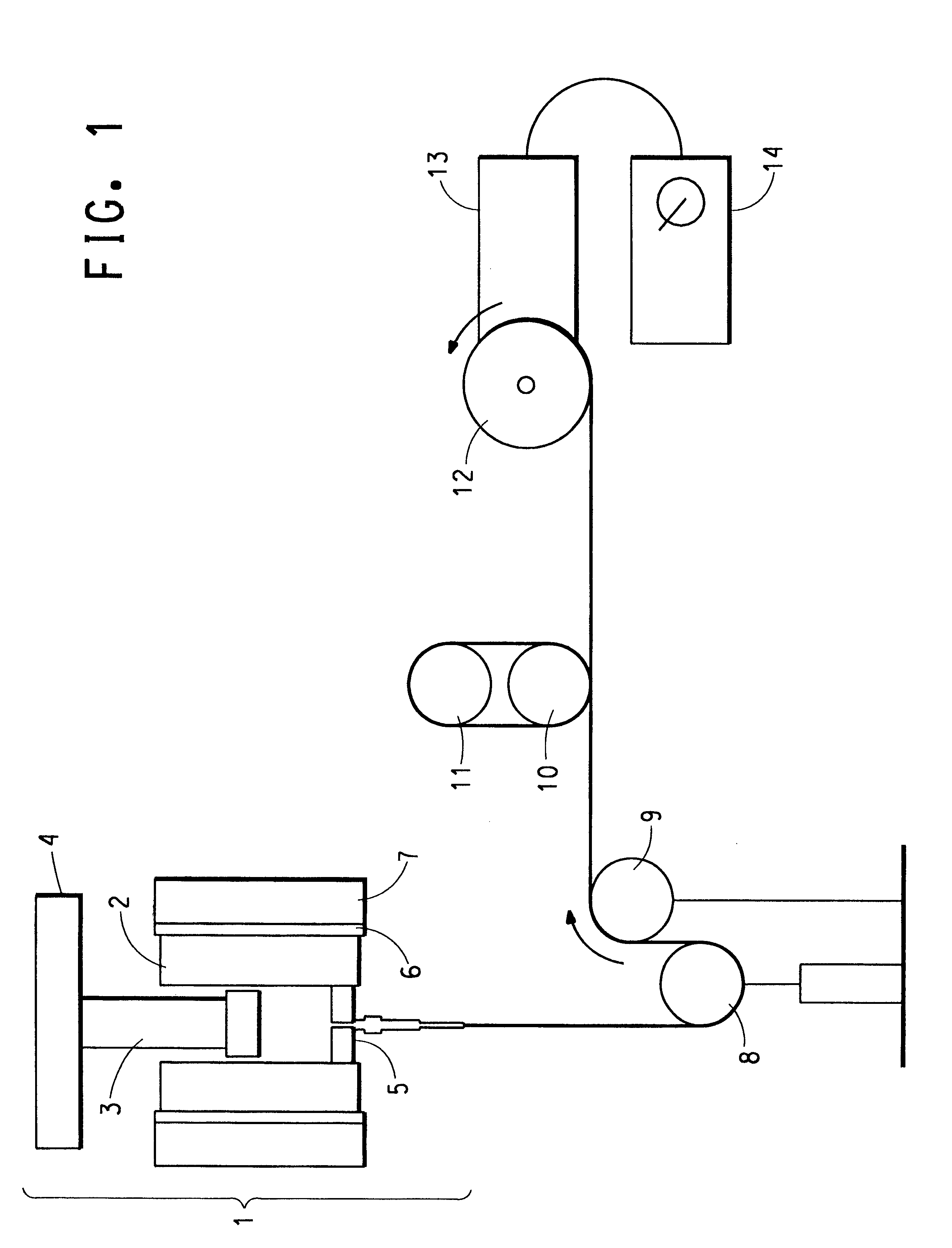

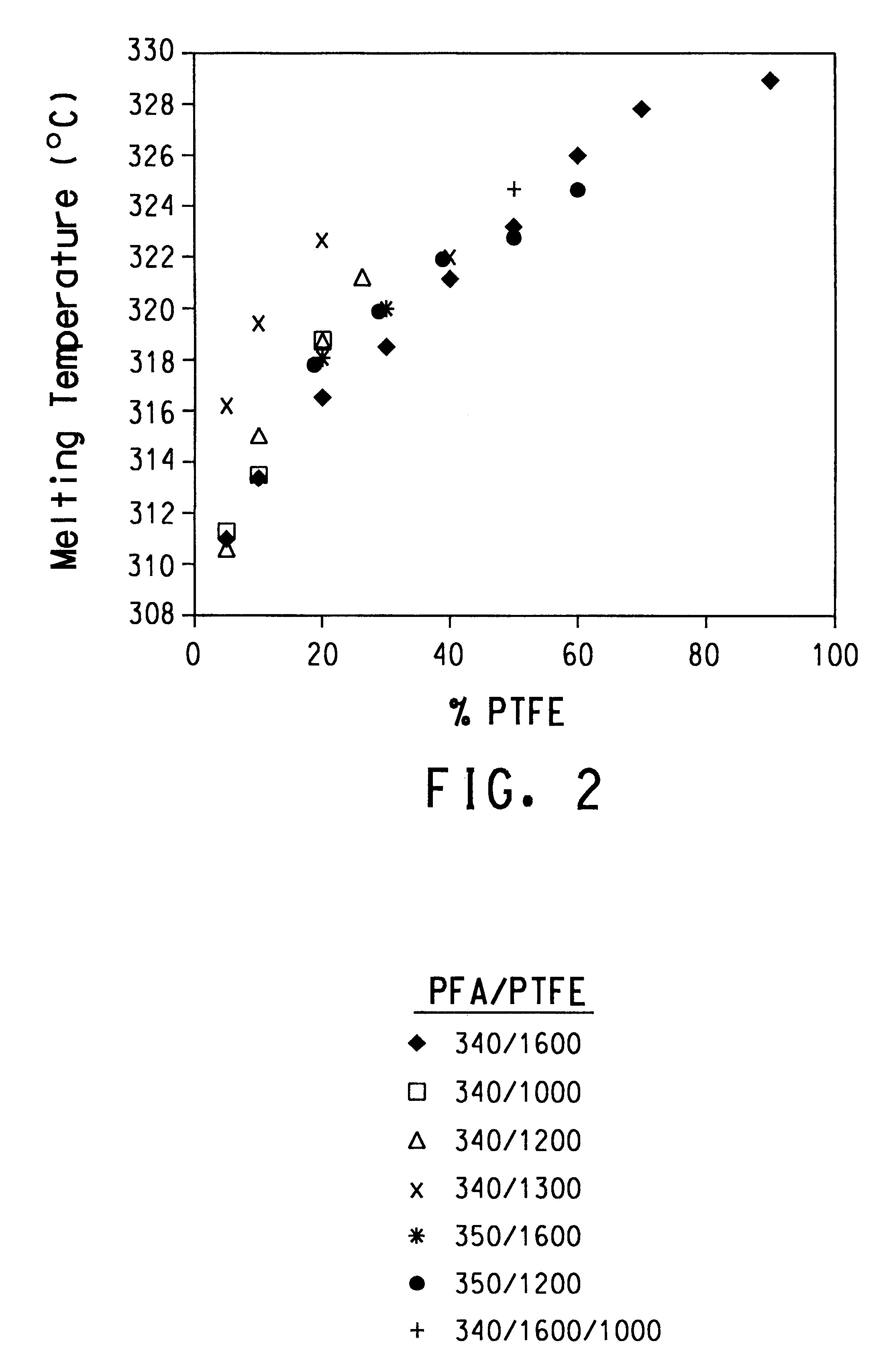

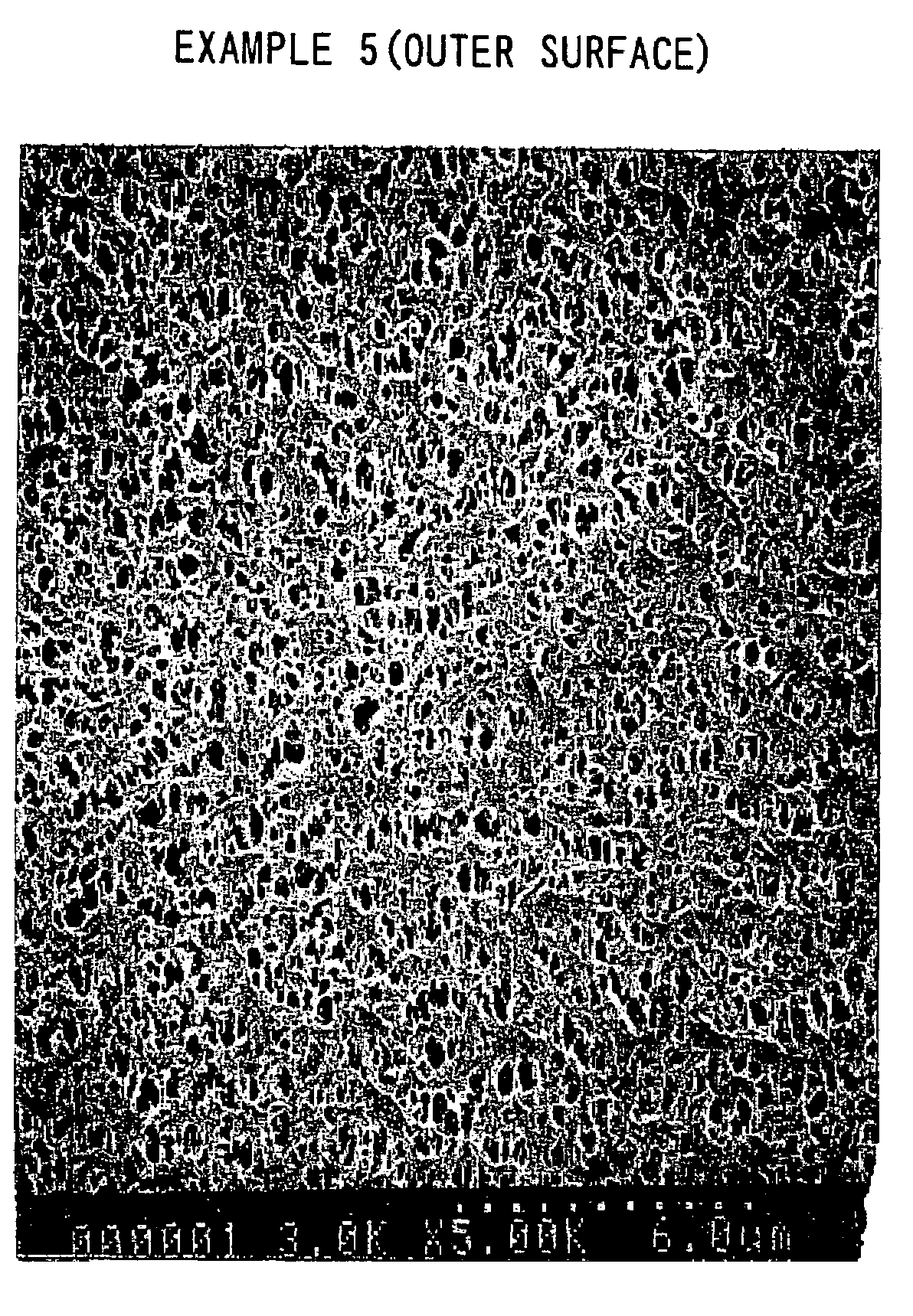

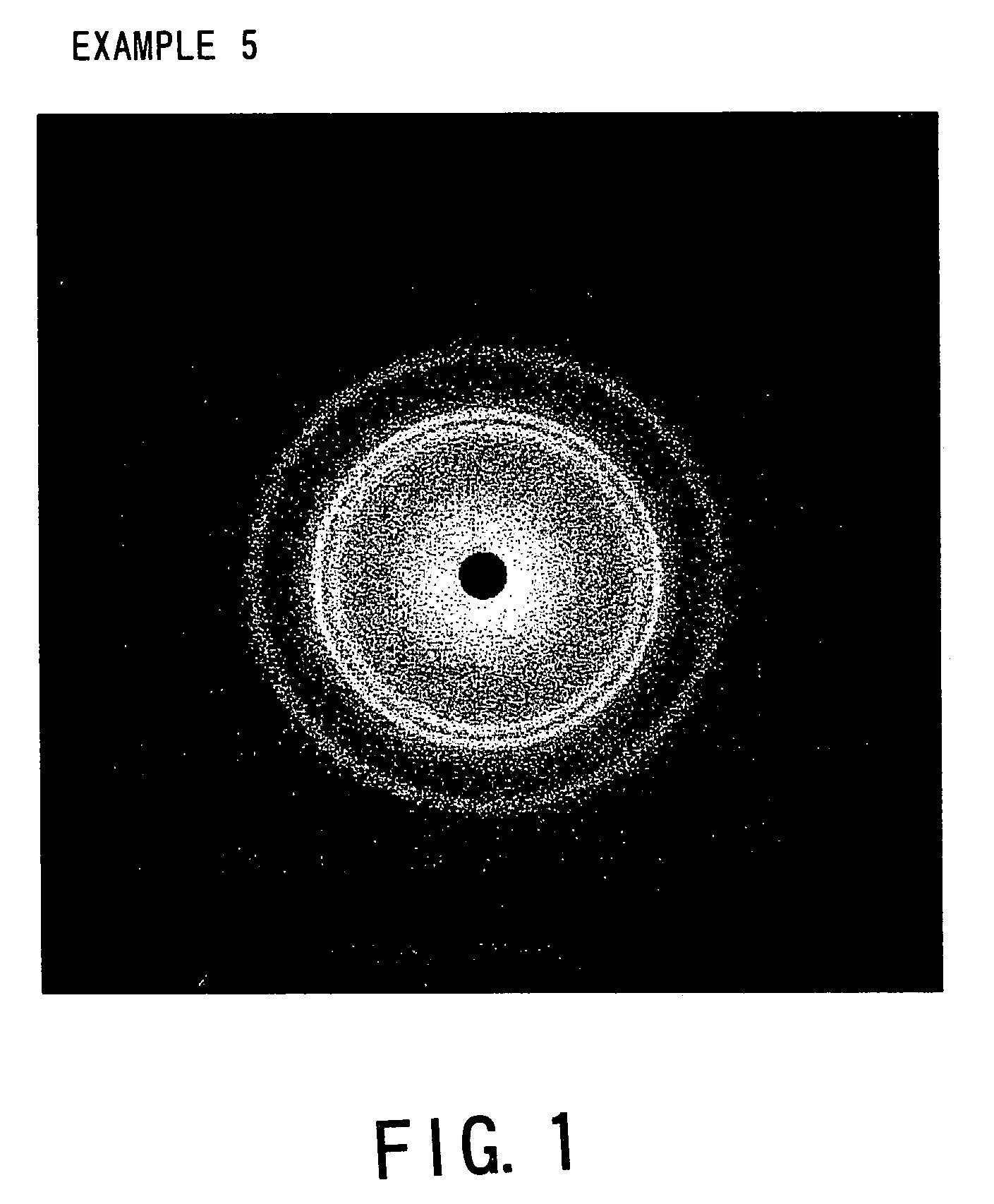

Melt spun fibers from blends of poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-perfluoro-alkylvinyl ether)

The present invention relates to melt spun fibers prepared from blends of poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-perfluoro-alkylvinyl ether).

Owner:EI DU PONT DE NEMOURS & CO

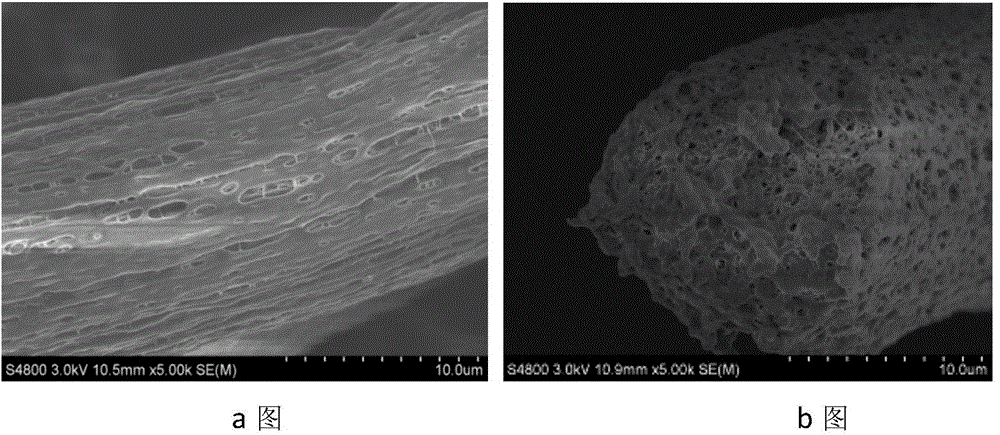

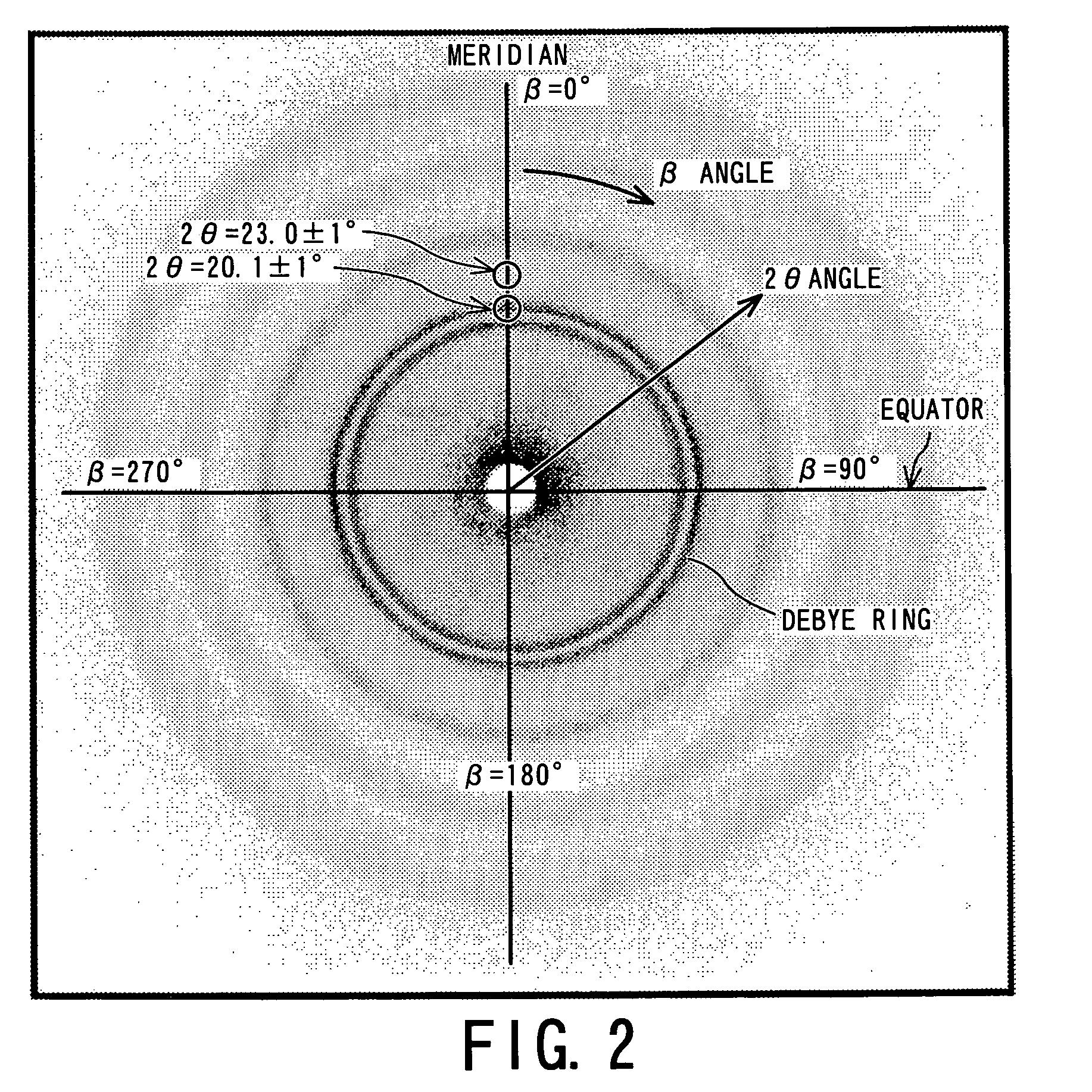

Porous membrane of vinylidene fluoride resin and process for producing the same

There is provided a porous membrane of vinylidene fluoride resin which has pores of appropriate size and distribution and also excellent mechanical strength represented by tensile strength and elongation at break and is useful as a microfiltration membrane or a separator for batteries. The porous membrane of vinylidene fluoride resin is characterized by the presence in mixture of a crystalline oriented portion and a crystalline non-oriented portion as confirmed by X-ray diffraction, and is produced by subjecting a melt-extruded composition obtained by mixing a vinylidene fluoride resin having a molecular weight distribution which is appropriately broad and high as a whole with a plasticizer and a good solvent for vinylidene fluoride resin, to cooling for solidification from one surface, extraction of the plasticizer and stretching.

Owner:KUREHA KAGAKU KOGYO KK

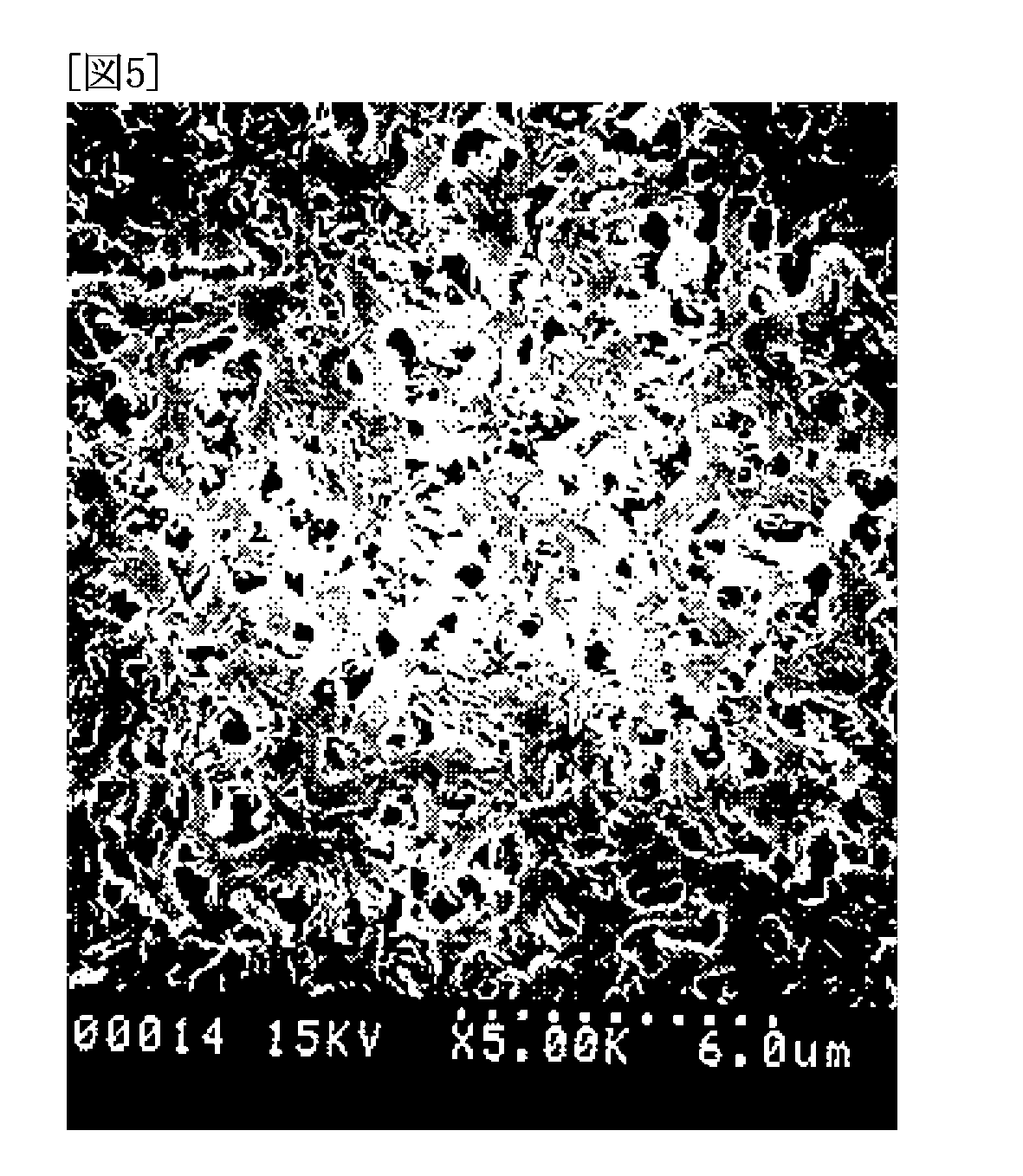

Polyvinylidene fluoride hollow yarn type microporous film and process for production of the same

InactiveUS20090283469A1Easy to separateImprove permeabilitySemi-permeable membranesMembranesYarnFiber

Problems: To provide a polyvinylidene fluoride microporous membrane which has high water permeability and separation performance and is excellent in mechanical and chemical strength; and a process for producing the film.Means for Solving Problems: An anisotropic polyvinylidene fluoride hollow fiber microporous membrane characterized in that the porosity of the cross-sectional bulk layer is higher than the membrane surface porosity of the outer layer and that in the cross section of the membrane, the dense microstructure of the outer surface changes substantially discontinuously into the coarse structure of the bulk layer. The microporous membrane can be produced by introducing by a dry-wet method a dope prepared by dissolving a polyvinylidene fluoride resin together with a water-soluble latent solvent at high temperature into a cooling bath consisting of water or a mixture thereof with a water-soluble latent solvent and subjecting the dope to membrane formation wherein the cross-sectional bulk layer is formed mainly by thermally-induced phase separation and the outer layer is formed mainly by nonsolvent-induced phase separation.

Owner:TOYO TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com