Method for producing polytef amosite

A technology of polytetrafluoroethylene and its manufacturing method, which is applied in the field of fiber manufacturing, can solve problems such as difficulty in processing, difficulty in becoming a raw material for a bag filter bag, difficulty in making polytetrafluoroethylene fibers, etc., and achieve a good service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

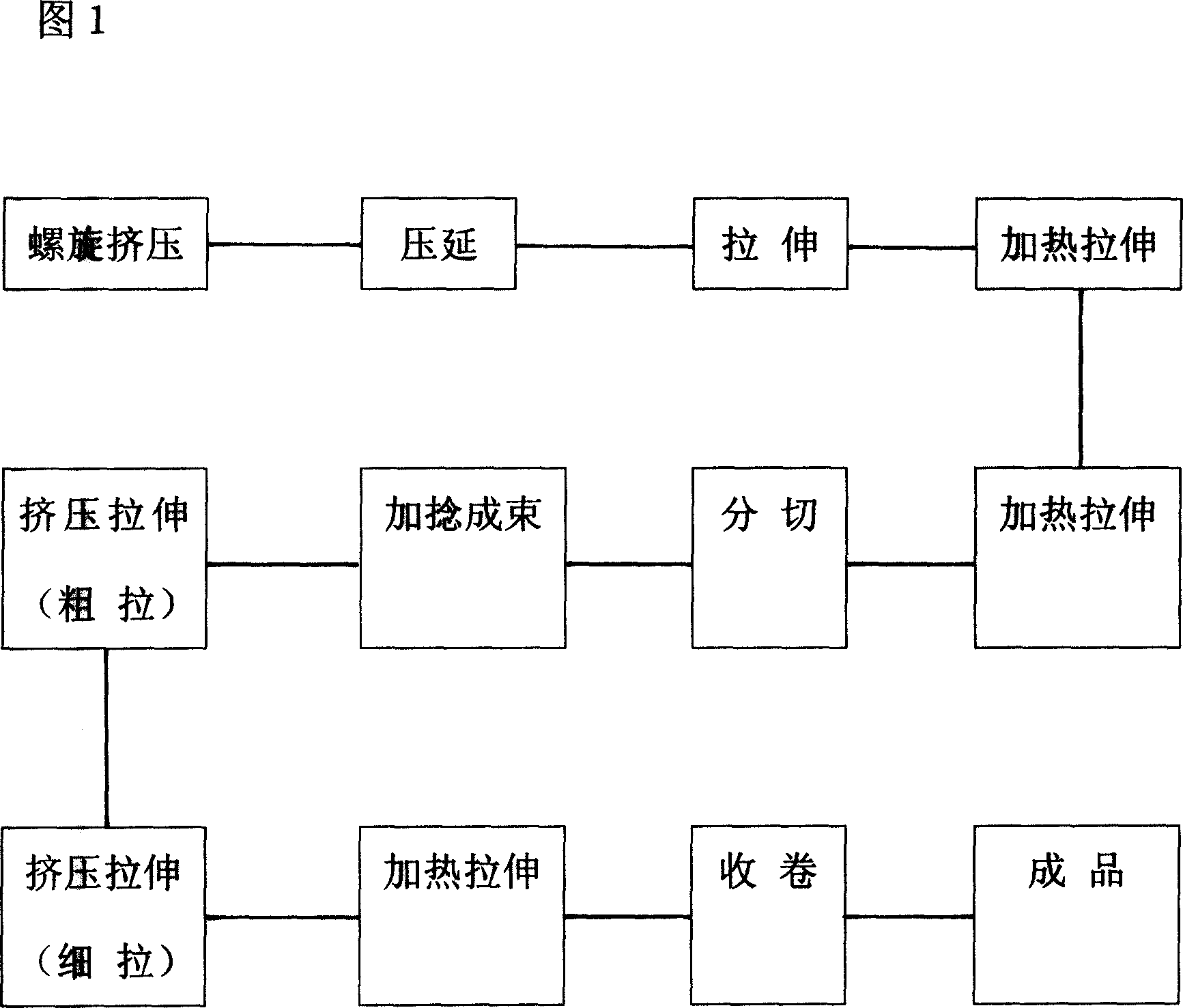

[0011] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] Referring to Fig. 1, the steps of the manufacture method of a kind of polytetrafluoroethylene long fiber of the present invention are as follows:

[0013] 1. Put 100% polytetrafluoroethylene into the screw extruder for extrusion. The working temperature of the screw extruder is 325-420°C and the speed is 3-100r / min;

[0014] 2. After passing through the screw extruder, it enters the calender for calendering. The working temperature of the calender is 10-50°C and the line speed is 0.5-1m / min;

[0015] 3. After entering the stretching machine for stretching, the working temperature of the stretching machine is 10-50°C, and the line speed is 0.3-1.2m / min;

[0016] 4. Then enter the heating and stretching machine for heating and stretching. The working temperature of the heating and stretching machine is 130-190°C and the line speed is 0.4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com