Method for preparing metallic nickel nano-wire

A nickel nanowire and nanowire technology, which is applied in the field of chemical preparation of metal nickel nanowires, can solve the problems of complex preparation process, few products, complicated experimental equipment, etc., and achieve the effects of low preparation cost, short cycle and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of reaction precursor solution:

[0032] Prepare a solution in the following proportions with a mixed solution of water and ethanol at a mass ratio of 1:1.

[0033] NiSO 4 0.006mol / L

[0034] NaOH 1mol / L

[0035] Add 85% (w / w) aqueous solution of hydrazine hydrate to the prepared solution at a volume ratio of 1:0.6, stir and react at room temperature, and the reaction time is 5 minutes;

[0036] 2. Preparation of nickel nanowires:

[0037] ① Place the reaction precursor solution prepared by the above method in an external uniform magnetic field of 0.37T;

[0038] ② Heating to 50°C;

[0039] ③React for 30 minutes until the reaction is complete;

[0040] ④ Separate the solution and nickel nanowires with a magnetic field;

[0041] ⑤ Wash the nickel nanowires twice with deionized water, and then wash the nickel nanowires twice with absolute ethanol or acetone;

[0042] ⑥ dry collection.

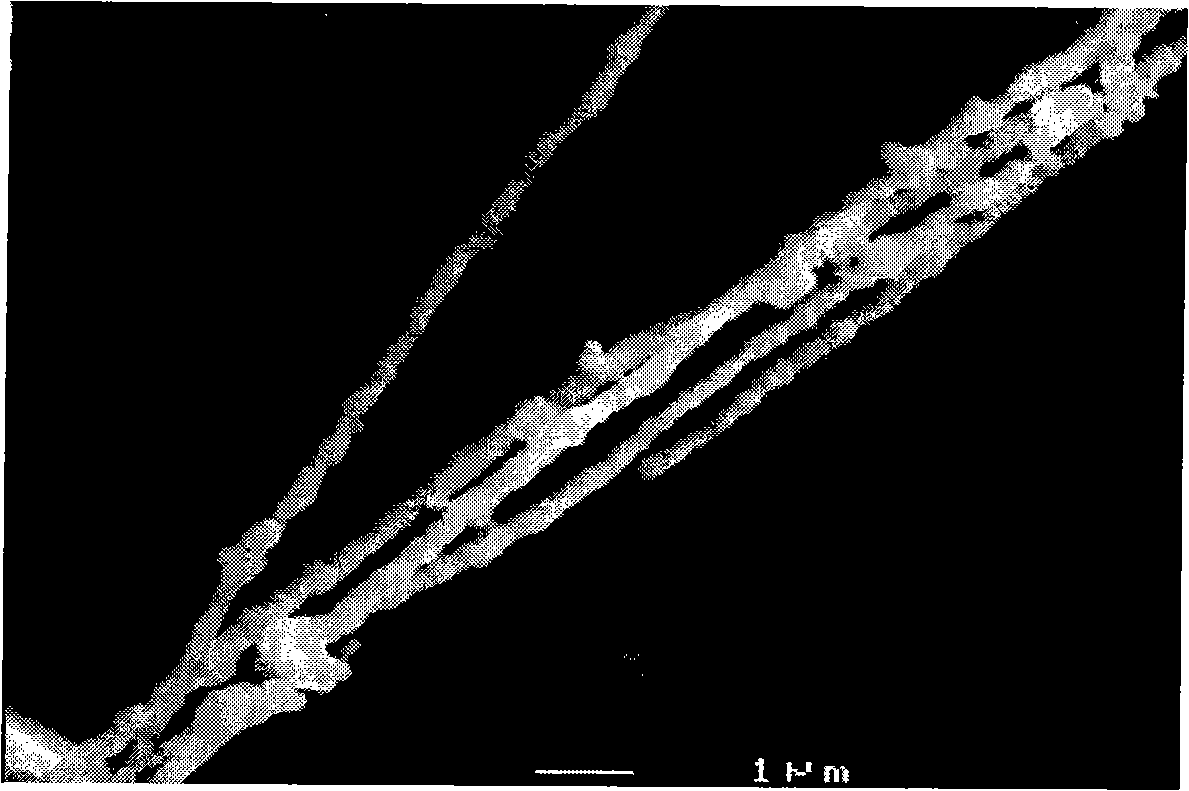

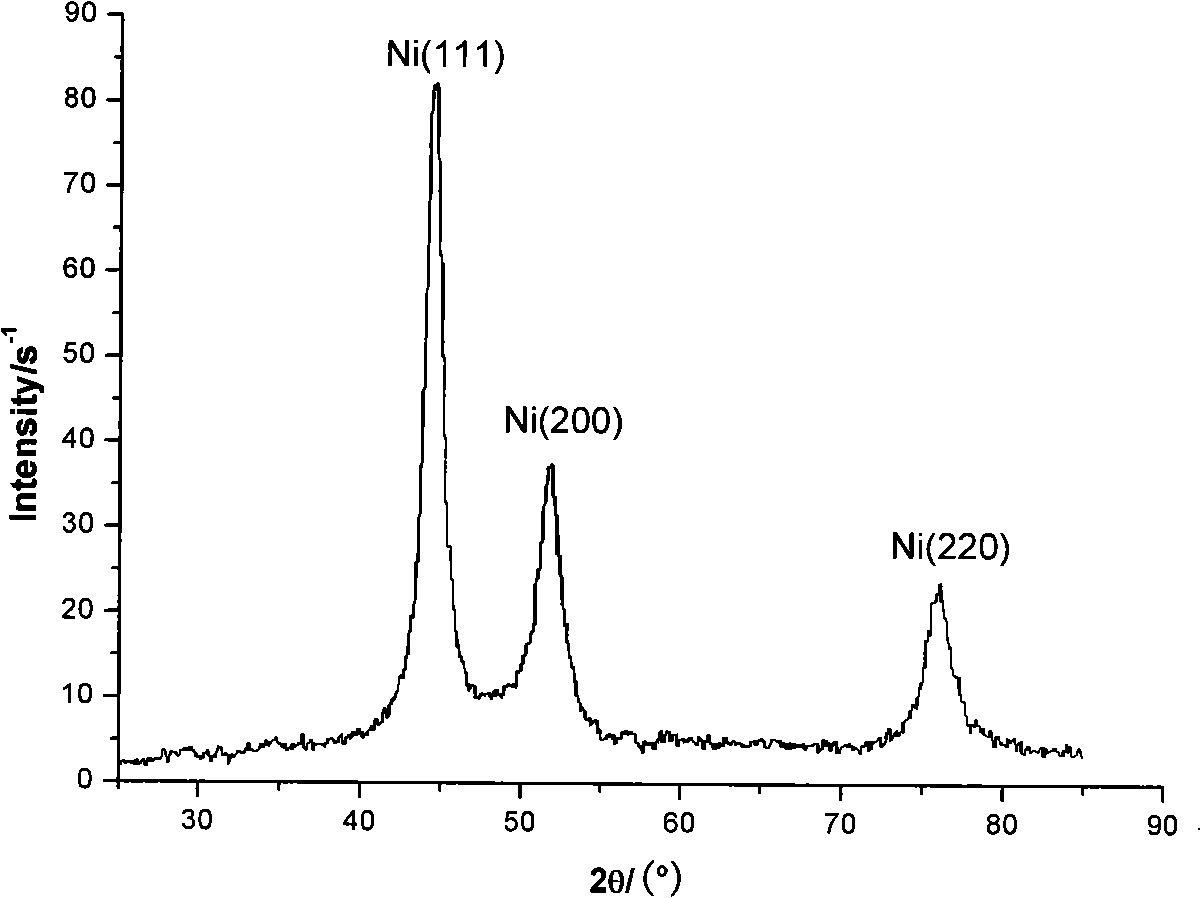

[0043] Nickel nanopowder with an average length of 69 μm, ...

Embodiment 2

[0045] 1. Preparation of reaction precursor solution:

[0046] Prepare a solution in the following proportions with a mixed solution of water and ethanol at a mass ratio of 1:0.

[0047] Ni(CH 3 COO) 2 0.006mol / L

[0048] NaOH 0.1mol / L

[0049] Add 85% (w / w) aqueous solution of hydrazine hydrate to the prepared solution at a volume ratio of 1:0.6, stir and react at room temperature, and the reaction time is 10 minutes;

[0050] 2. Preparation of nickel nanowires:

[0051] ① Place the reaction precursor solution prepared by the above method in an applied uniform magnetic field of 0.52T;

[0052] ② Heating to 85°C;

[0053] ③React for 60 minutes until the reaction is complete;

[0054] ④ Separate the solution and nickel nanowires with a magnetic field;

[0055] ⑤ Wash the nickel nanowires twice with deionized water, and then wash the nickel nanowires twice with absolute ethanol or acetone;

[0056] ⑥ dry collection.

[0057] Nickel nanowires with an average length ...

Embodiment 3

[0059] 1. Preparation of reaction precursor solution:

[0060] Prepare a solution in the following proportions with a mixed solution of water and ethanol at a mass ratio of 1:1.

[0061] Ni(NO 3 ) 2 0.006mol / L

[0062] NaOH 1mol / L

[0063] Add 85% (w / w) aqueous solution of hydrazine hydrate to the prepared solution at a volume ratio of 1:0.4, stir and react at room temperature, and the reaction time is 7 minutes;

[0064] 2. Preparation of nickel nanowires:

[0065] ① Place the reaction precursor solution prepared by the above method in an applied uniform magnetic field of 0.52T;

[0066] ② Heating to 60°C;

[0067] ③React for 15 minutes until the reaction is complete;

[0068] ④ Separate the solution and nickel nanowires with a magnetic field;

[0069] ⑤ Wash the nickel nanowires with deionized water for 3 times, and then wash the nickel nanowires with absolute ethanol or acetone for 3 times;

[0070]⑥ dry collection.

[0071] Nickel nanowires with an average l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com