Method for extracting high-purity liquid neon

An extraction method and liquid neon technology, applied in the field of gas separation, can solve problems such as hidden dangers, consumption, unsafe equipment manufacturing and operation, etc., and achieve the effect of easy control and simple process

Active Publication Date: 2012-07-11

SHANGHAI QIYUAN GAS DEV

View PDF10 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method of using liquid nitrogen as a cold source to prepare neon first needs to consume the cooling capacity of liquid nitrogen provided by the outside world, and secondly, the neon-helium separation equipment is a high-pressure equipment, which brings unsafe hidden dangers to the manufacture and operation of the equipment.

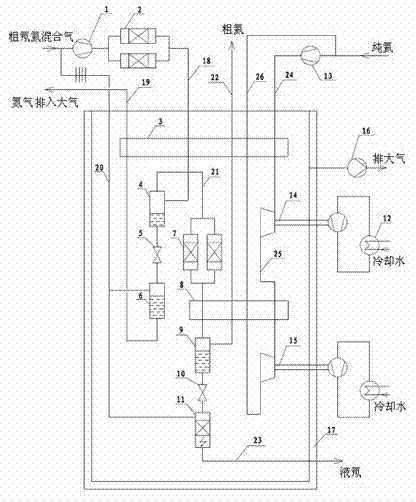

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

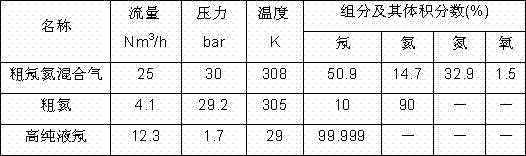

example 1

[0036] The condition that the present invention adopts of example 1 and each component data sheet:

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for extracting high-purity liquid neon. A closed refrigeration circulating system consisting of a double-helium turbine expansion engine is adopted so as to realize cold supply. The method particularly includes pressurizing raw material gas and cooling the raw material gas; removing impurities such as nitrogen, oxygen and the like in the raw material gas by the aid of a low-temperature condensation method and an adsorption method and then obtaining neon and helium gas mixture; continuing cooling the neon and helium gas mixture, separating neon from helium by the aid of a low-temperature rectification method; and obtaining the high-purity liquid neon. The closed refrigeration circulating system consisting of the double-helium turbine expansion engine meets cold requirement during extraction of the liquid neon.

Description

technical field [0001] The invention relates to a method for gas separation, in particular to a method for extracting high-purity liquid neon from helium-neon mixed gas. In particular, it relates to a low-pressure refrigeration cycle composed of a miniature high-speed gas bearing helium turboexpander, which provides the required cooling capacity for the separation process. Background technique [0002] Neon is an inert gas whose content in air is only 18.18×10 -6 However, with the development of science and technology, it has been widely used in various fields of industry as an important energy source. For example, in the electronics industry, neon gas can be used as a filling medium for neon lamps, high-voltage neon lamps, and counting tubes; it can be used in laser technology; because liquid neon has the advantages of low boiling point, it can be used as a low-temperature cold source between 26 and 40K Use; Neon can also be used in high-energy physics research. [0003]...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25J3/02

CPCF25J1/0005F25J1/004F25J1/0045F25J1/005F25J3/04642F25J2205/04F25J2205/60F25J2210/04F25J2215/32F25J2220/02F25J2230/30F25J2245/02F25J2270/16

Inventor 俞建曹月丛严寿鹏

Owner SHANGHAI QIYUAN GAS DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com