Method for purifying magnesium alloy melt

A magnesium alloy and melt technology, which is applied in the field of magnesium alloy melt purification, can solve problems such as changes in alloy composition and unsatisfactory removal of inclusions, etc., and achieves the effects of low cost, favorable for popularization and application, and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

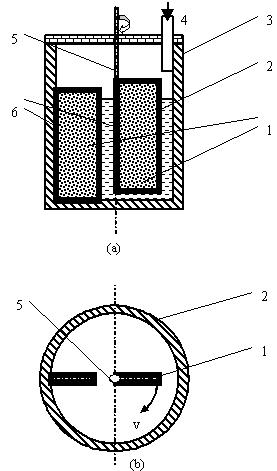

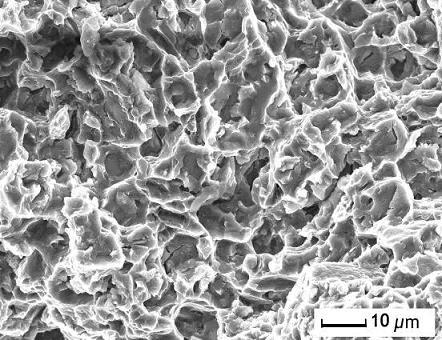

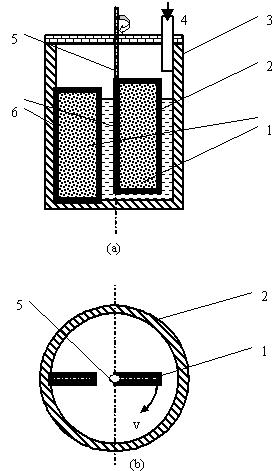

[0022] Example 1

[0023] The magnesium alloy to be smelted is AZ91 alloy, the crucible used is iron, the inner diameter is 200mm, the height is 200mm, and the protective gas is argon; the foam ceramic block used is ZrO 2 As the basic material, the size is 160mm×85mm×12mm, the average pore size is 0.8mm, and the porosity is 65%. It is a square structural frame made of heat-resistant steel with an inner size of 155mm×90 mm×15 mm, and the frame is 4mm thick. Heat-resistant steel plate, the width of the frame is 5mm, and the middle is an open structure. The movement of the foam ceramic sheet or block placed in the frame is restricted by the buckle locking mechanism on the frame to prevent the foam ceramic from floating and falling off from the frame; two Pieces of ceramic foam were inserted into two frames painted with CaO coating, and the frame and ceramic foam were preheated at 400℃±20℃ for 30min, and then slowly added together with the frame at a speed of 20mm / s to melt to 750℃ ...

Example Embodiment

[0024] Example 2

[0025] The melting alloy is AM60 alloy, the crucible used is iron, the inner diameter is 150mm, the height is 200mm, and the protective gas is argon; the ceramic block used is based on MgO, the size is 150mm×65mm×10mm, the average pore size is 0.9mm, The rate is 70%. A square structural frame with an inner size of 145mm×70 mm×13 mm made of heat-resistant steel, the frame is made of heat-resistant steel with a thickness of 3mm, the frame width is 5mm, and the middle is an open structure. The foam ceramic sheet or foam placed in the frame The movement of the blocks is restricted by the buckle-type locking mechanism on the frame to prevent the foam ceramics from floating and falling off from the frame; the two foam ceramics are inserted into the two frames painted with CaO paint, and the frame and the foam ceramics are together After preheating at 400℃±20℃ for 50min, and then slowly adding with the frame to the AM60 alloy melt melted to 740℃ at a speed of 30mm / s...

Example Embodiment

[0026] Example 3

[0027] The melting alloy is ZK60 alloy, the crucible used is iron, the inner diameter is 280mm, the height is 300 mm, and the shielding gas is argon; the ceramic block used is based on MgO, and the size is 230mm×125mm×15mm. The average pore size is 0.6mm. The rate is 75%. A square structural frame with an inner size of 225mm×120mm×18mm made of heat-resistant steel, the frame is made of heat-resistant steel plate with a thickness of 5mm, and the width of the frame is 5mm. The two larger sides are crossed with stiffeners. The width is 10mm and the thickness is 3mm. It is welded to the frame. The rest is an open structure. The foam ceramic sheet or block placed in the frame is restricted by the buckle locking mechanism on the frame to prevent the foam ceramic from floating up and out of the frame. Fall off. Two pieces of ceramic foam were inserted into the two frames painted with CaO coating, and the frame and ceramic foam were preheated at 400℃±20℃ for 40min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com