Coking wastewater treating process with zero discharge

A technology for treating process and coking wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of cumbersome operation, lengthy process, complicated process, etc. The effect of convenient operation, operation and management, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

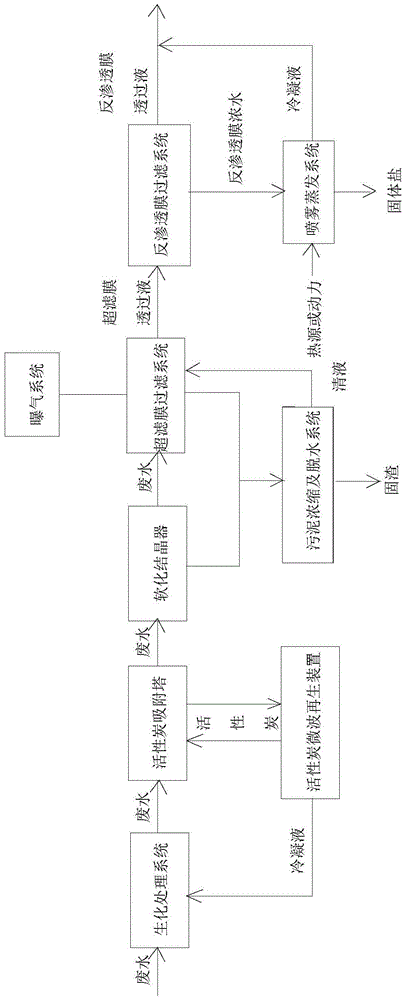

Image

Examples

Embodiment 1

[0035] Take the coking wastewater after ammonia distillation and oil removal as the raw water to be treated, the water volume is 100m 3 / h, the water quality of coking wastewater is shown in Table 1:

[0036] Table 1

[0037] project

[0038]The coking wastewater first enters the anaerobic reactor together with the return sludge from the sedimentation tank. Its main function is to release phosphorus and ammoniate some organic matter at the same time; the effluent from the anaerobic reactor enters the anoxic reactor for denitrification treatment. The nitrate nitrogen is sent from the aerobic reactor through internal circulation; the denitrified wastewater is introduced into the aerobic reactor, where COD / BOD removal, nitrification and phosphorus absorption are carried out, and a part of the mixed solution is refluxed to the anoxic reactor. Reactor; the effluent after the aerobic reaction is introduced into the sedimentation tank for mud-water separation, a part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com