Patents

Literature

921 results about "Coke wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

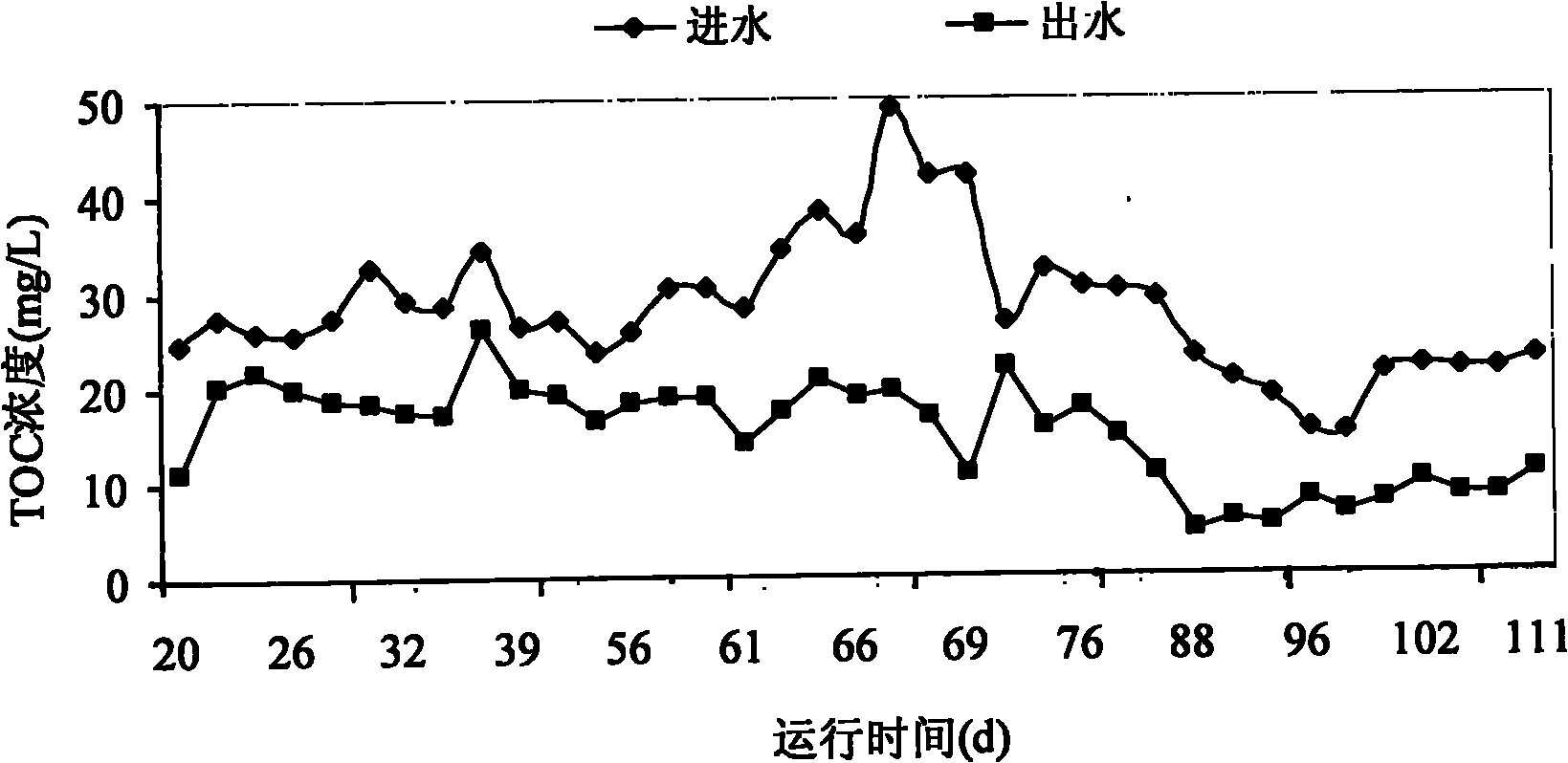

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

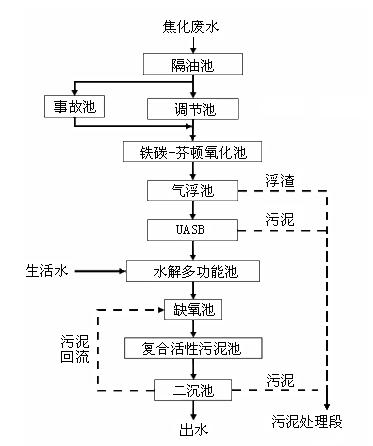

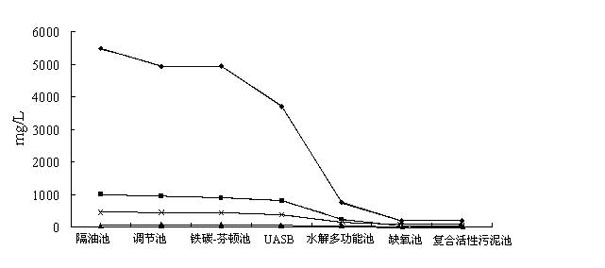

Method for treating coking wastewater

InactiveCN101781067AReduce CODPromotes electrochemical corrosionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeCyanide compound

The invention discloses a method for treating coking wastewater, which relates to the method for treating wastewater and aims to solve the problems that an activated sludge method for treating the coking wastewater has the disadvantage of relatively poorer effect on the removal of organic substances and the treated water is difficult to reach the secondary discharge standard of the Integrated Wastewater Discharge Standard (GB8978-96). The method comprises that: the coking wastewater is discharged after passing through an oil separation tank, an adjusting tank, an iron carbon-Fenton oxidation pond, an up-flow anaerobic sludge bed reactor, a multifunctional hydrolyzing pond, an anaerobic tank, a composite active sludge tank and a secondary sedimentation tank, wherein the coking wastewater can also pass through a floatation tank. The coking wastewater treated by the method of the invention has a pH value of 5 to 8 and the rate of removal of Cu2+ from the coking wastewater of 69 to 85 percent, contains 300 to 450mg / L phenol and less than 15mg / L cyanide and therefore reaches the secondary discharge standard of the Integrated Wastewater Discharge Standard (GB8978-96).

Owner:HARBIN INST OF TECH

Rhodococcus erythropolis and microbial inoculum and application thereof

ActiveCN101857846AReduce production and use costsStrong resistanceBacteriaWater contaminantsPetrochemicalCoking wastewater

The invention discloses a rhodococcus erythropolis (rhodococcus sp.) BZ-9 which is preserved in the China General Microbiological Culture Collection Center with the accession number of CGMCC No.3695. The invention also discloses a microbial inoculum, the active component of which is the rhodococcus erythropolis BZ-9. The rhodococcus erythropolis BZ-9 and the microbial inoculum thereof have high-efficient degradation performance on various toxic organic substances as well as high degradation ability even under the condition of chromium (VI), and are applicable to treatment on coking wastewater, tanning wastewater, printing and dying wastewater and other organic wastewater containing phenol, pyridine and other toxic organic substances produced in the process of the production of the petrochemical industry.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

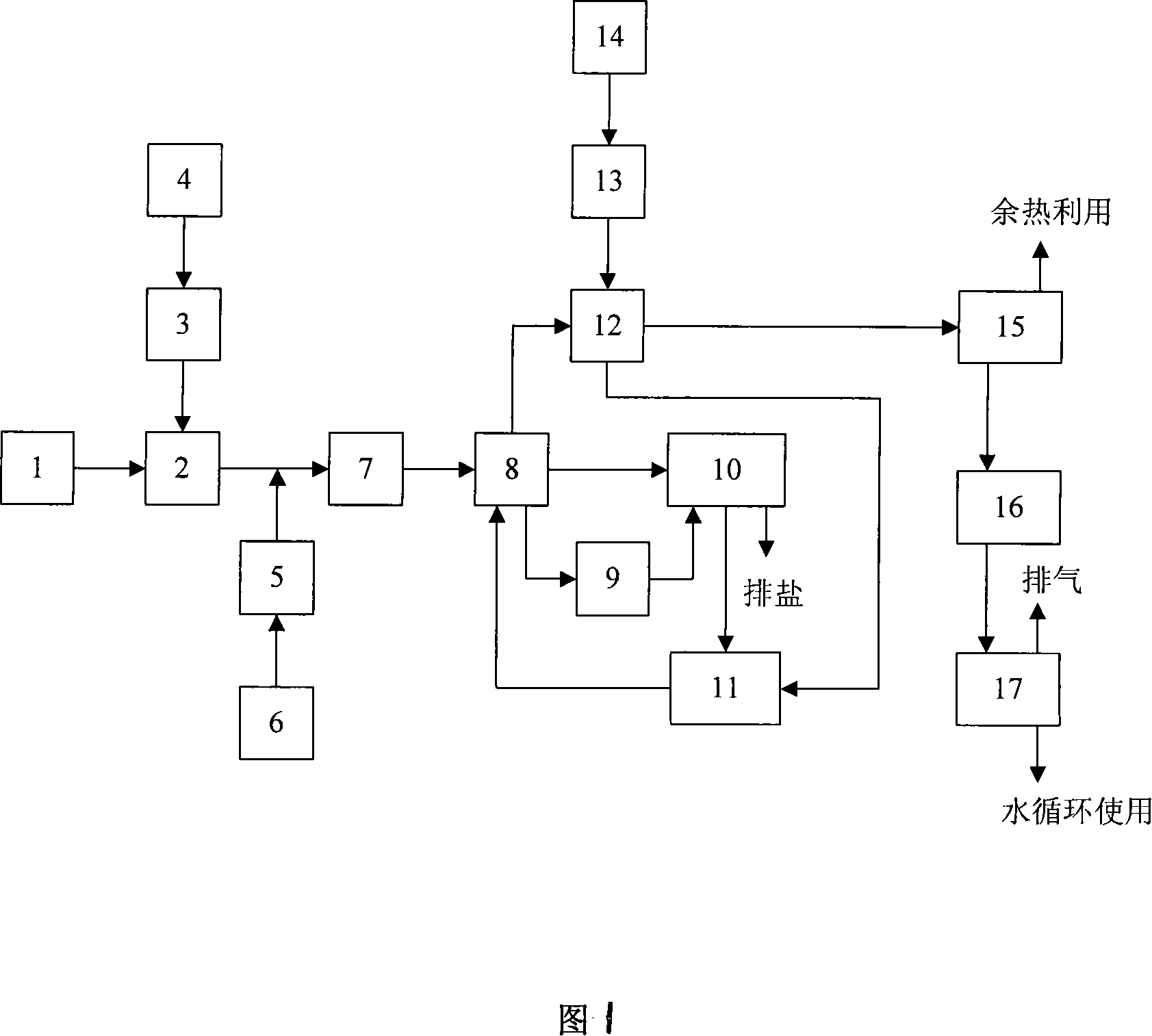

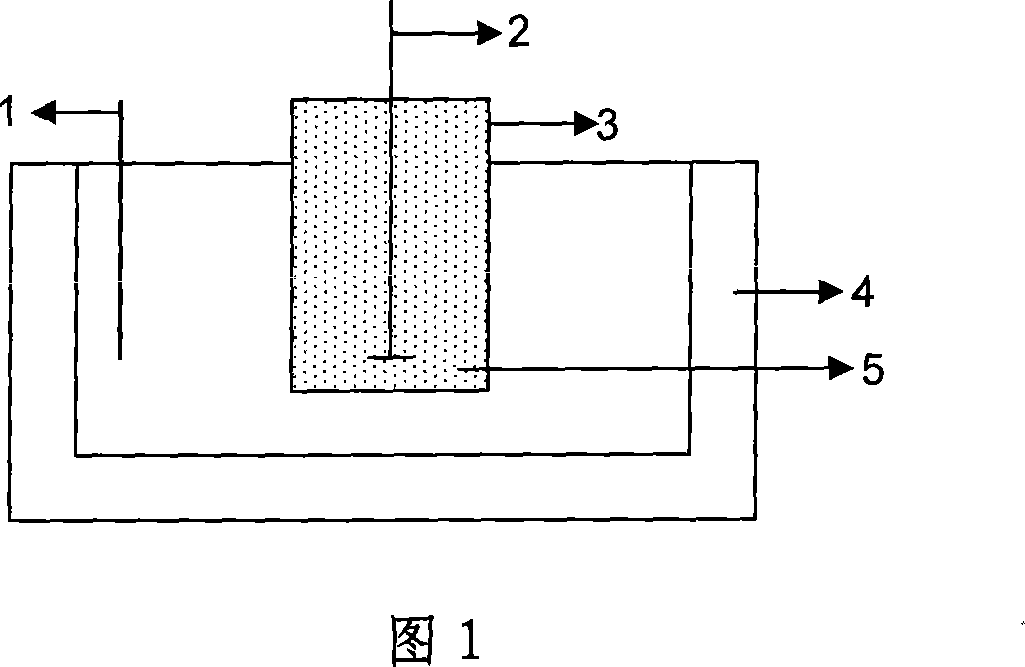

Technique for processing coking wastewater or organic wastewater by supercritical water oxidization technique

InactiveCN101209883AEmission reductionEfficient removalScale removal and water softeningMultistage water/sewage treatmentWater cyclingSolid particle

The invention relates to a process by adopting supercritical water oxidation technology to treat coking wastewater or organic wastewater. The invention is that: coking wastewater or organic wastewater is pretreated to obtain wastewater without solid granules; the wastewater is heated to 380-450 DEG C with a first interchanger and / or a supercritical boiler, and then enters demineralizing equipment to remove the salt in the wastewater by taking advantage of the property that supercritical inorganic matter is indissoluble; the wastewater after desalting is put in a reaction kettle to generate autothermal reaction with an heated and pressurized oxidant to obtain high-temperature gas-liquid mixture with higher temperature; the high-temperature gas-liquid mixture enters the first interchanger and acts as thermal medium to exchange heat with new coming coking wastewater or organic wastewater and then goes through a secondary interchanger to enter a cooler and is cooled to normal temperature, after pressure thereof is adjusted by a pressure regulation device, the high-temperature gas-liquid mixture enters a gas-liquid separator for separation, and then the air is discharged, while the liquid, namely the treated water is recycled. The organic contamination and oxidant are all dissolved in the wastewater; oxidation reaction is generated in homogeneous phase, in short reaction time, oxygenolysis of organic contamination is carried out quickly.

Owner:北京能泰高科环保技术有限公司

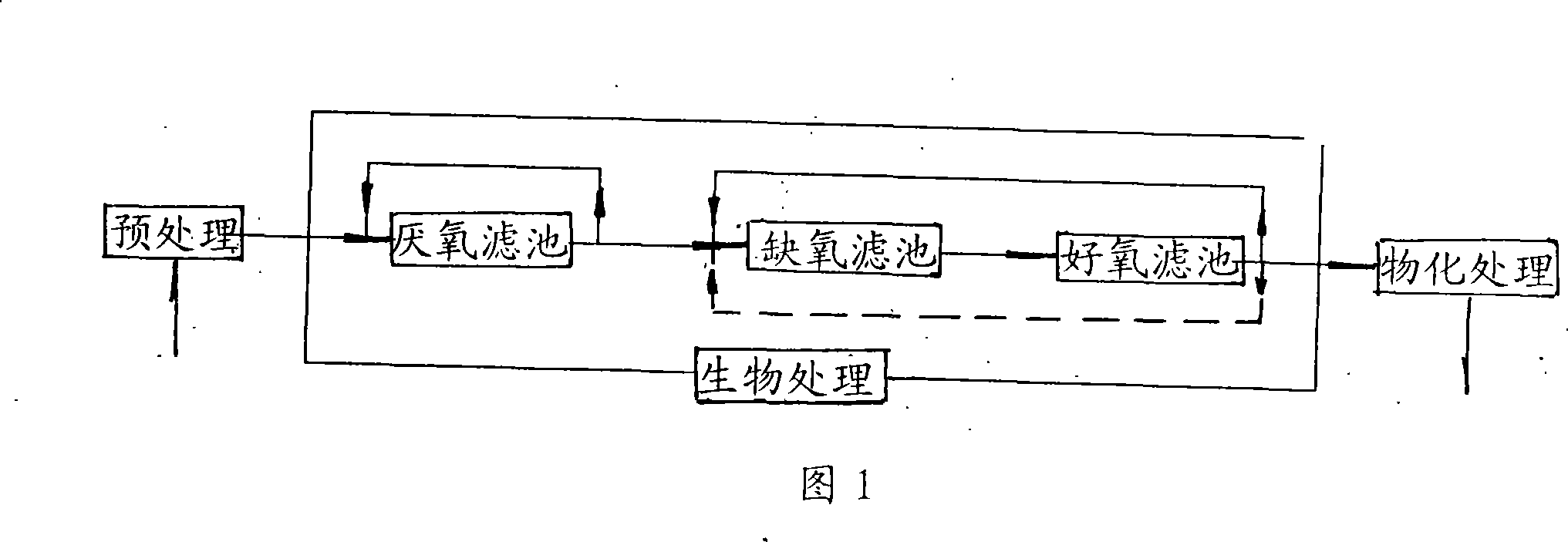

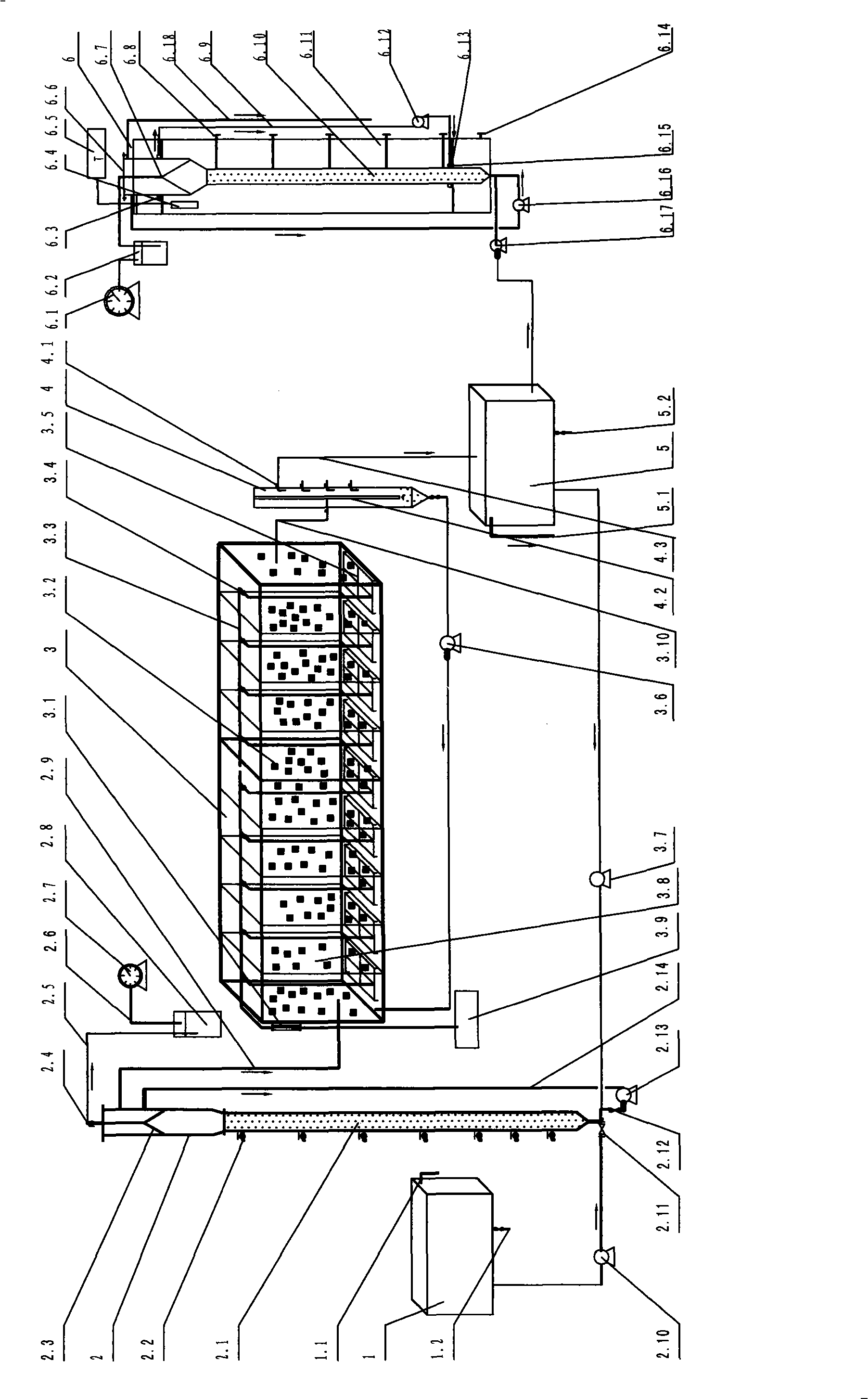

Biological treatment technique for coking waste water

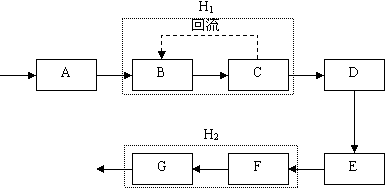

ActiveCN101215068AIncrease bioconcentrationHigh processing loadTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentRefluxRetention time

The invention discloses a technique of biological treatment for coking wastewater. The filter chamber is composed of a preprocessing part, a biological treatment part and a physical treatment part, wherein the biological treatment part is composed of an anaerobic ceramsite filter chamber, an anoxia ceramsite filter chamber and an aerobic ceramsite filter chamber which are connected in series, spherical ceramsite filtering materials or irregular-shape ceramsite filtering materials are all filled in the anaerobic ceramsite filter chamber, the anoxia ceramsite filter chamber and the aerobic ceramsite filter chamber as biofilm culturing filling and filtrating precoats, the anaerobic ceramsite filter chamber employs an internal reflux mode, a reversed flow mode is employed between the anoxia ceramsite filter chamber and the aerobic ceramsite filter chamber, the precoats in the filter chambers are respectively formed by ceramsite filtering materials with different thickness, the filter chambers employs backwash to exclude accumulated sludge and suspended substance in the filter chambers into flotation tanks of the preprocessing part, the anaerobic ceramsite filter chamber, an anoxia ceramsite filter chamber employs regular water scrubbing to drive macro-gas-bubble in the chambers. Compared with the prior art, the technique has the advantages of prolonging sluicing periodic time, stabilizing operational effect, improving treatment loading, thereby reducing retention time of waterpower, decreasing accommodation area and investment of pile plant.

Owner:北京嘉瑞环保股份有限公司

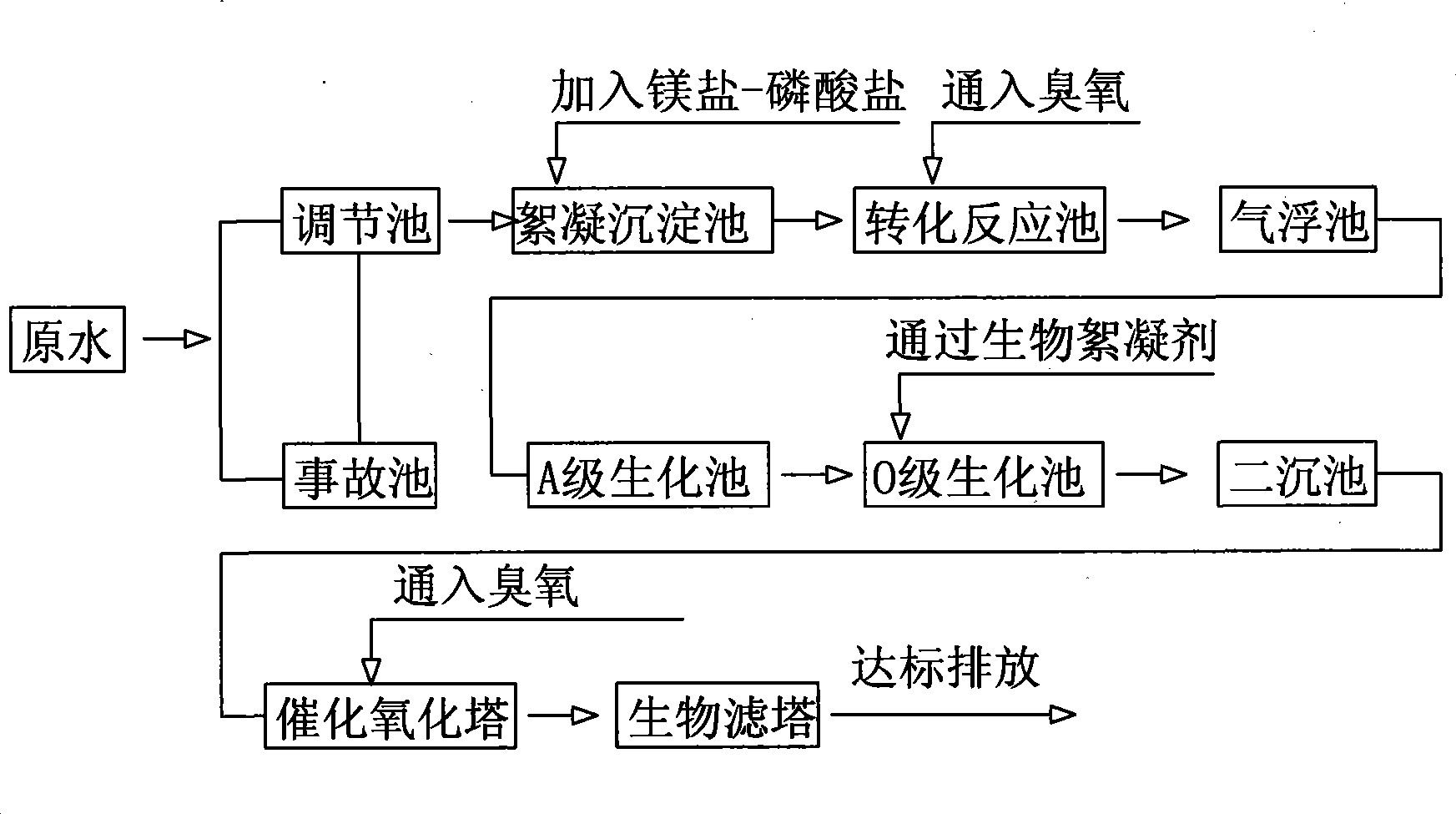

Novel process for treating coking waste water by charging activated sludge process

InactiveCN101417850AQuality improvementBulk volumeWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesActivated sludgeNitration

The utility model discloses a technology for treating coking wastewater by using a novel feeding activated sludge method, which comprises the following steps: biochemical treatment process is carried out on the pretreated wastewater, the coking wastewater first enters an A-grade biochemical pond to provide carbon sources for denitrification, and then the coking wastewater enters a 0-grade biochemical pond for carrying out oxidation and nitration under aerobic environment, the effluent water of the 0-grade biochemical pond enters a secondary sedimentation tank; the supernatant from the secondary sedimentation tank enters a subsequent-stage treatment system and one part of settling sludge refluxes and enters the A-grade biochemical pond and 0-grade biochemical pond; the other part of the settling sludge enters a sludge thickener. As flocculants are added into the biochemical pond, the ability of tolerating loads is greatly improved, and shock resistance is also greatly enhanced; the area of the biochemical reaction pond is reduced to 70 percent of the area of the reaction pond of traditional feeding activated sludge method, so investment costs are saved and operation costs are decreased; while the decolorizing ratio of the technology to coking wastewater, black liquor and chloromycetin wastewater can reach to more than 80 percent.

Owner:江苏百纳环境工程有限公司

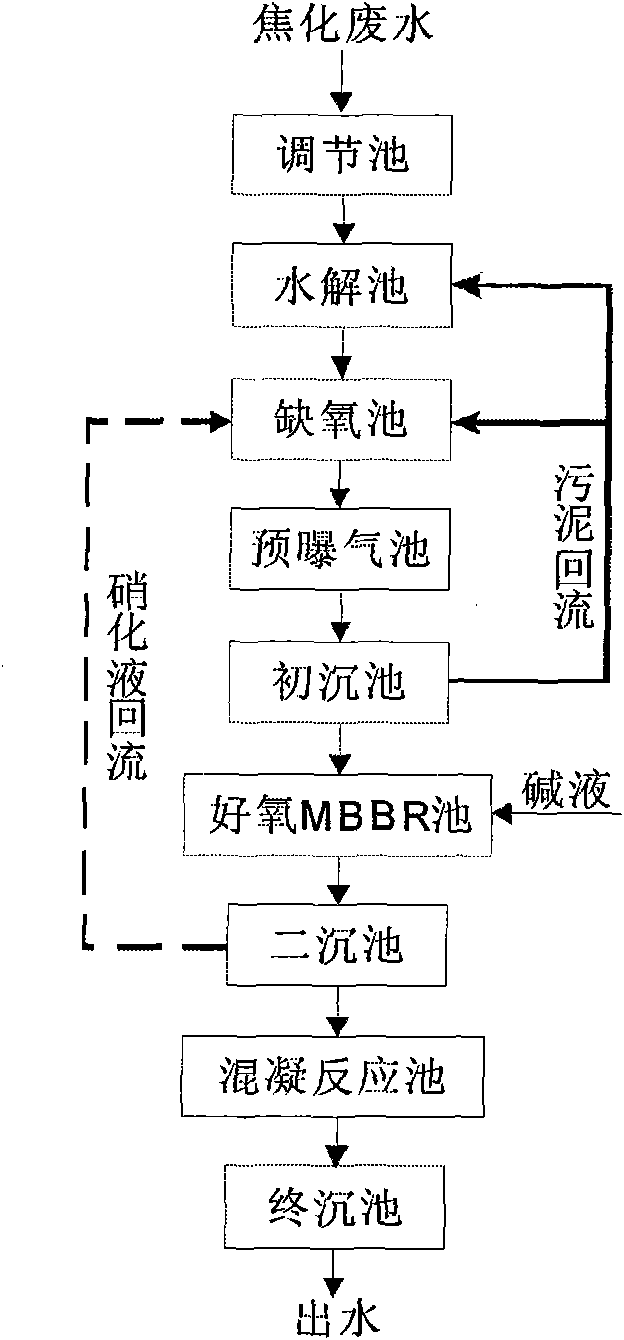

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

Apparatus and method for entire journey autotrophy denitrification of digested sludge dewatered liquid biomembrane

ActiveCN101293707AImprove nitrogen removal efficiencyReduce inhibitionTreatment with aerobic and anaerobic processesMonosodium glutamateToxic material

The invention relates to a biofilm full-rang autotrophic nitrogen removal device of digested sludge dehydrolysis liquid and a method thereof; wherein, the device is provided with a digested sludge dehydrolysis liquid pool, a pre-hypoxia denitrification pool, a short-range biofilm nitrification pool, a sedimentation pool, an intermediate pool and a biofilm anaerobic ammonia oxidation pool; the method consists of the following steps: 1. the pre-hypoxia denitrification pool and the short-range biofilm nitrification pool are started to operate; 2. the biofilm anaerobic ammonia oxidation pool is started; 3. the biofilm full-rang autotrophic nitrogen removal system of the digested sludge dehydrolysis liquid is operated in series. The device is suitable for biological nitrogen removal of wastewater containing high ammonia nitrogen, such as the digested sludge dehydrolysis liquid, late landfill percolate, coking wastewater, monosodium glutamate wastewater, etc. The device realizes efficient biological nitrogen removal of wastewater with high NH4<+>-N and low ratio of C / N, greatly decreases the construction and operation cost of nitrogen removal of wastewater, reduces alkalinity demand of the nitrification, runs stably, operates easily and has stronger shock resistance loading capability; meanwhile, the device is strongly adaptable to temperature fluctuation and toxic substances, which is easy to recover after being restrained.

Owner:BEIJING DRAINAGE GRP CO LTD +1

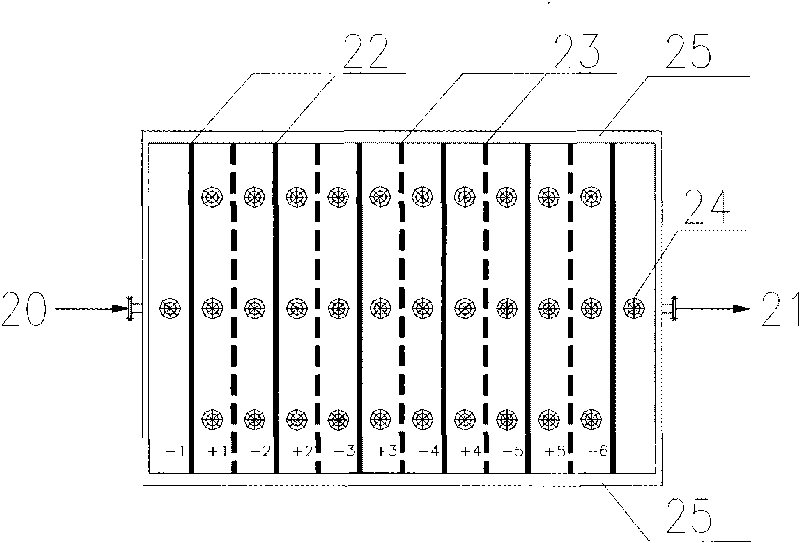

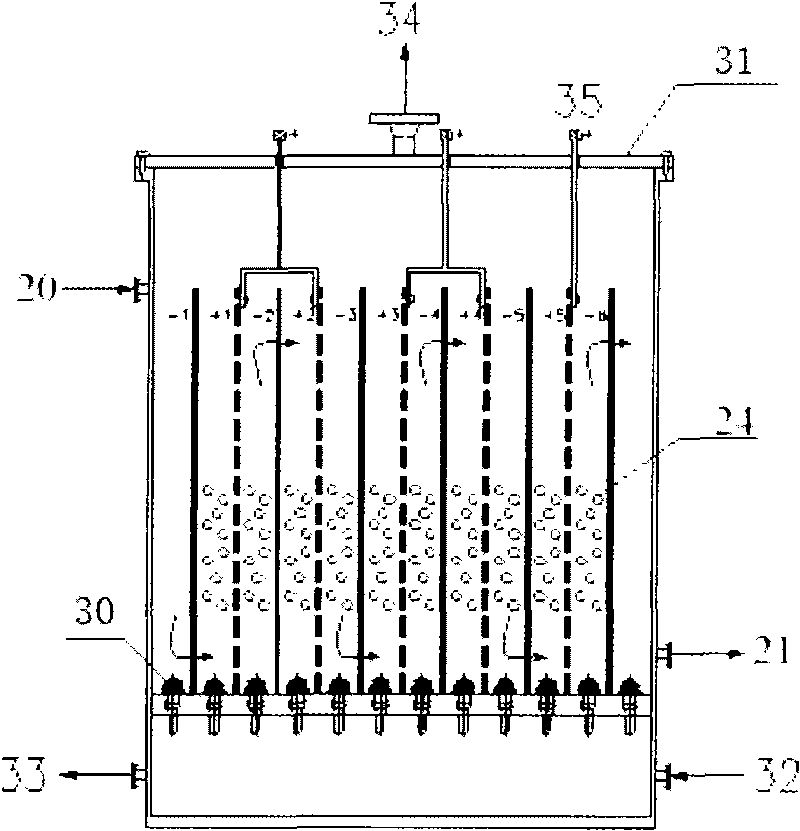

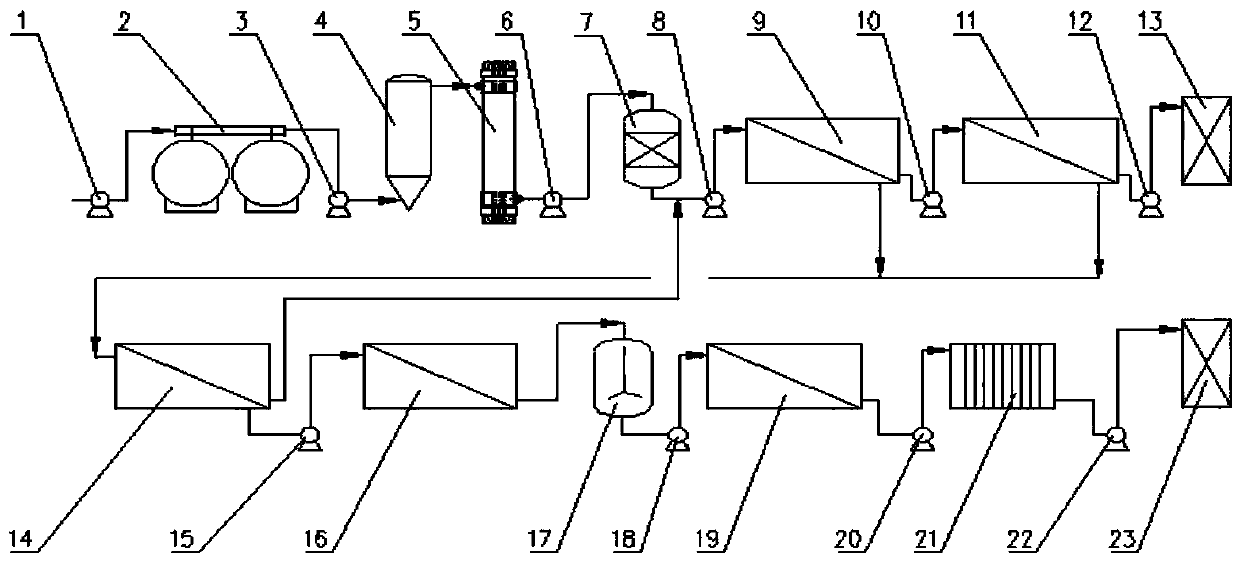

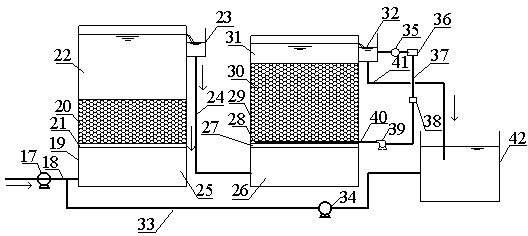

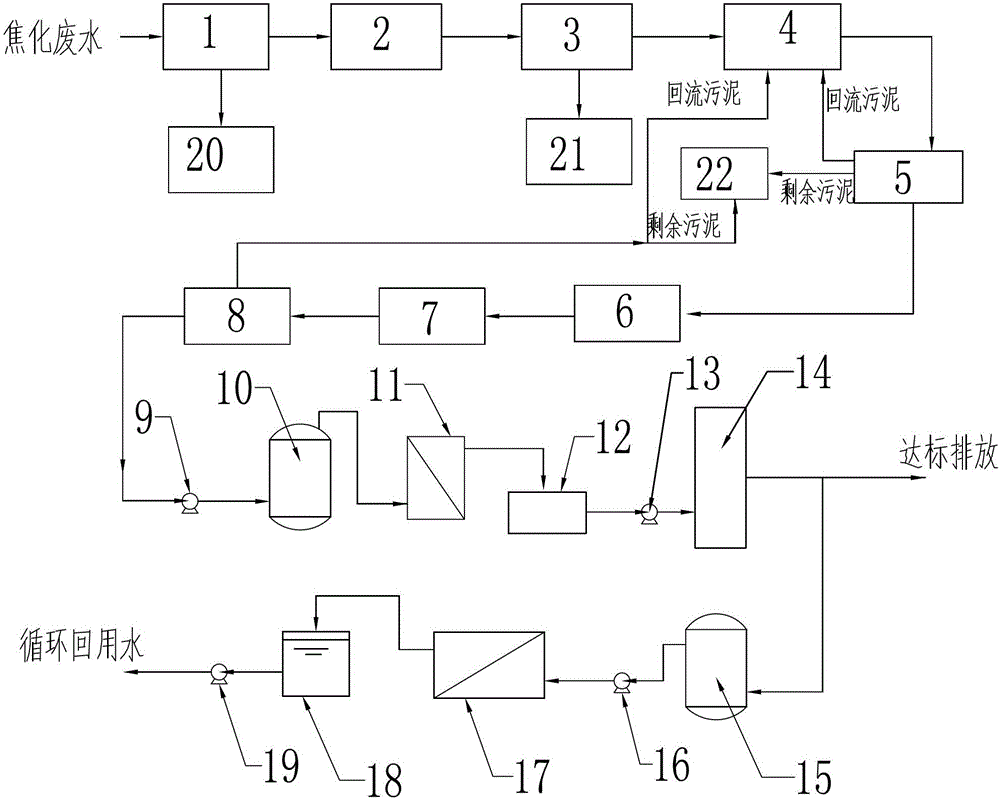

Coking wastewater deep treatment and reuse process and equipment thereof

InactiveCN101746923AGuaranteed uptimeImprove biodegradabilityGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisProcess equipmentSludge

The invention discloses a coking wastewater deep treatment and reuse process and equipment thereof, belonging to the technical field of environmental protection, and the main steps are as follows: dosing a coagulant in biochemical treatment water, then leading the biochemical treatment water to enter into a sedimentation tank, discharging sludge from a sludge hopper, leading treated water to enter into a three-dimensional electrode reactor, leading the outlet water after electro-oxidation treatment to enter into a biological filter tank, and leading the water after the treatment of the biological filter tank to enter into a follow-up ultrafiltration treatment; the ultrafiltration outlet water has two selections, one is to reuse the outlet water as the process water directly, the other one is to continuously pass through a reverse osmosis membrane system for treatment; and the coagulation and sedimentation tank, the process equipment of the three-dimensional electrode reactor, the biological filter tank, the ultrafiltration system and the reverse osmosis desalination system are adopted during the treatment process, thereby achieving the purposes of removing residual refractory organic matters, suspended impurities and salt in the waste water, reusing the outlet water, simultaneously leading the content of the organic matters in the reverse osmosis concentrated water not to exceed the national environmental protection standard, also reusing the concentrated water in occasions with less stringent requirements on the water quality and achieving the purpose of zero emission of the wastewater.

Owner:赵立功

Device for deep treatment and complete recovery of coking wastewater and application method thereof

InactiveCN101851046AHigh volume loadAchieve reuseWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesSeparation technologyEvaporation

The invention discloses a device for deep treatment and complete recovery of coking wastewater and an application method thereof. The device comprises a pretreatment system and a biochemical treatment system and is characterized in that an outlet of coking wastewater after pretreatment and biochemical treatment is connected with a membrane bioreactor; the water outlet of the membrane bioreactor is connected with an oxidation treatment component; the water outlet of the oxidation treatment system is connected with a reverse osmosis membrane treatment component; one water outlet of the reverse osmosis membrane treatment component is connected with a concentrated water evaporation and crystallization system; and the other water outlet of the reverse osmosis membrane treatment component is connected with a recycling water tank. The invention combines the technologies of biochemical treatment, oxidation, membrane separation and evaporation for deep treatment of the coking wastewater and realizes zero emissions. Therefore, the device and the application method are a novel treatment device and a novel application method for degradation of various pollutants in the coking wastewater and complete recovery of water after treatment.

Owner:吴静璇

Coking wastewater membrane concentration salt separation zero-emission treatment system and coking wastewater membrane concentration salt separation zero-emission treatment method

InactiveCN110734178AAvoid foulingGuaranteed uptimeSpecific water treatment objectivesChemical industryFiltrationReverse osmosis

The invention belongs to the technical field of water treatment, and particularly relates to a coking wastewater membrane concentration salt separation zero-emission treatment system and a coking wastewater membrane concentration salt separation zero-emission treatment method. The method comprises: coking wastewater pretreatment, wherein the coking wastewater pretreatment comprises full-automaticsand filtration, active carbon adsorption regeneration, ultra-filtration and softening; membrane salt separation and concentration treatment, wherein the membrane salt separation and concentration treatment comprises low-pressure nano-filtration, high-pressure nano-filtration, purification nano-filtration and reverse osmosis treatment; and concentration treatment, fluorine and silicon removal, electrodialysis concentration and evaporative crystallization, wherein an industrial-grade sodium chloride product with a purity of more than 92% is obtained, a sodium sulfate concentrated solution enters a freezing crystallization device to generate mirabilite, the mirabilite is heated and melted and then enters an evaporation crystallization, centrifugation and drying system, and an industrial-grade sodium sulfate product with a purity of more than 95% is obtained. According to the invention, with the system and the method, the zero discharge of coking wastewater is achieved, and the process technology is an innovative coking wastewater zero discharge process at home and abroad.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Method for removing coking waste water cyanide

InactiveCN101386437AHigh oxidation strengthImprove efficiencyWater contaminantsWaste water treatment from metallurgical processActivated carbonCyanide

The invention discloses a method for removing cyanides in coking wastewater, which effectively removes cyanides at various forms in wastewater mainly based on the oxidation of Fenton. The method also combines the adsorption of activated carbon and causes the concentration of the water to be lowered by the function of catalyzed oxidation available in the existence of hydrogen peroxide. The method has the advantages of low cost and can discharge water in accordance with the first grade discharge standard of China (less than 0.5mg / L).

Owner:EAST CHINA UNIV OF SCI & TECH

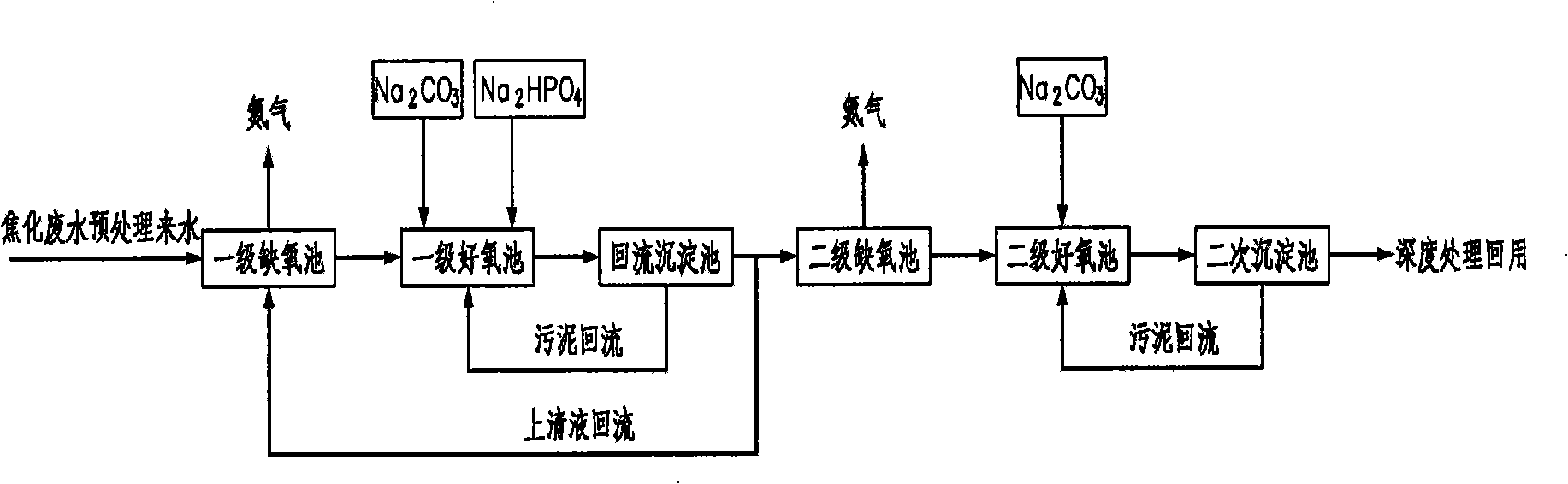

Coking wastewater biological denitrificaion treatment process

ActiveCN101514069AAchieve emissionsGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentOperational costsNitration

The invention relates to a coking wastewater biological denitrificaion treatment process, belonging to the technical field of environmental protection and wastewater processing, which is characterized in that the biological denitrificaion treatment process with A / O / A / O, namely, anoxia / oxic / anoxia / oxic as the core is adopted. The pretreated coking wastewater sequentially enters into a first-level anoxic tank, a first-level oxic tank, a reflow sedimentation tank, a second-level anoxic tank, a second-level oxic tank, a second-level sedimentation tank, short-range nitrification and denitrification biological denitrificaion treatment are carried out on the coking wastewater in the first-level anoxic tank and the first-level oxic tank, hydrolysis acidification and fine denitrification treatment are carried out on the coking wastewater in the second-level anoxic tank, and the second-level oxic tank realizes the full nitration reaction. The process method has stable operational effect, low operational cost, high denitrification percent, water-quality indexes such as CODCr, NH3-N and the like of water from the second-level sedimentation tank can simultaneously reach a first-level discharge standard in Integrated Wastewater Discharge Standard (GB8978-1996), and can be recycled and used by other users after advanced treatment, thus realizing the zero discharge of the coking wastewater.

Owner:BEIJING SHOUGANG INT ENG TECH

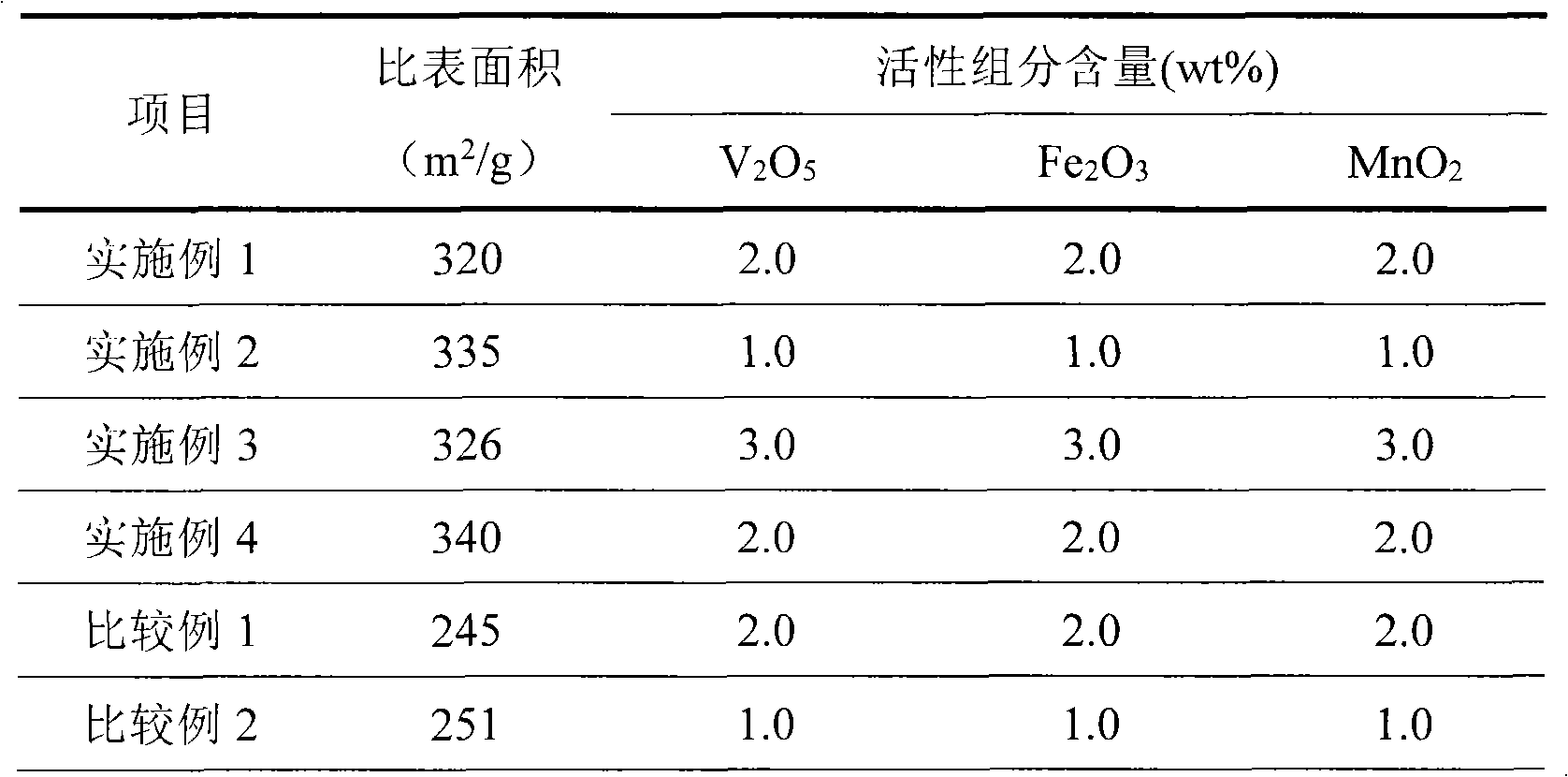

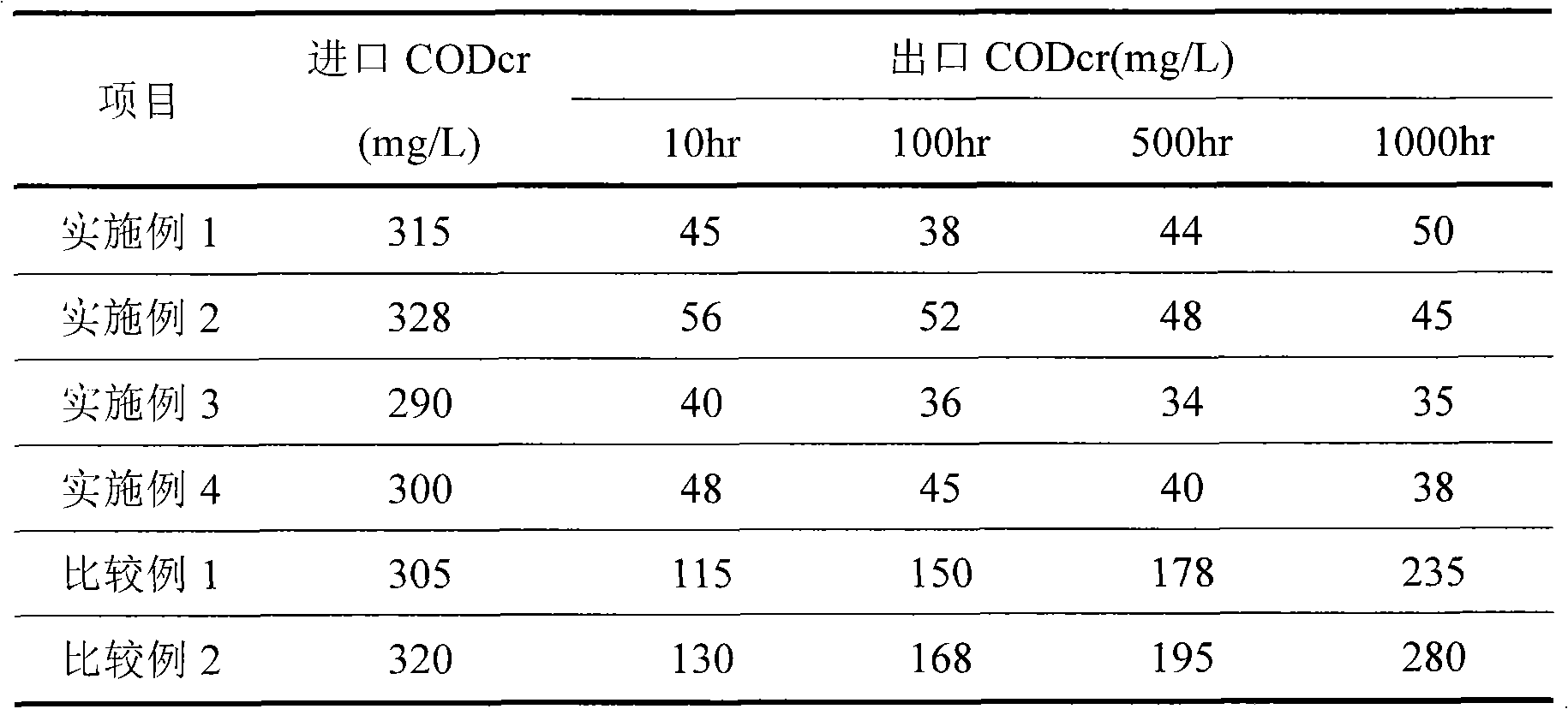

Method for preparing ozone catalytic oxidation catalyst for treating coking wastewater

ActiveCN102029165AEfficient removalSimple preparation stepsWater contaminantsWaste water treatment from metallurgical processAluminium hydroxideManganese

The invention discloses a method for preparing an ozone catalytic oxidation catalyst for treating coking wastewater, which is characterized in that: amorphous alumina is taken as carrier powder; and in the rolling granulating process, active ingredients, namely vanadium, iron and manganese are sprayed in a solution mode and are granulated, cured, dried and roasted to prepare a finished product catalyst. The catalyst is mainly used for removing nonbiodegradable organic pollutants from the coking wastewater. The amorphous alumina is prepared by quickly dehydrating industrial aluminum hydroxide at a high temperature, and has the specific surface area of 150 to 350m<2> / g, the total pore volume of 0.20 to 0.45ml / g and the average particle size of 1 to 80mu m. The active ingredients, namely the iron and the manganese in the mode of nitrate and the vanadium in the mode of ammonium metavanadate are added with water to be prepared into solution, and the spray amount of the solution is 2 to 50 percent based on the total mass of the amorphous alumina. The load capacity of the active ingredients, namely the iron, the manganese and the vanadium is 0.1 to 20.0 weight percent based on the total mass of the amorphous alumina.

Owner:CHINA NAT OFFSHORE OIL CORP +1

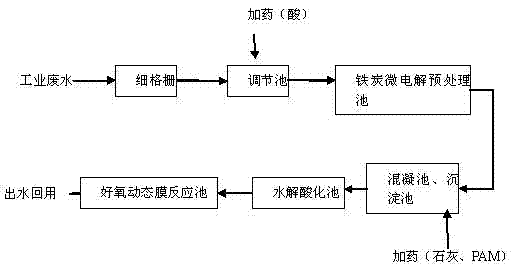

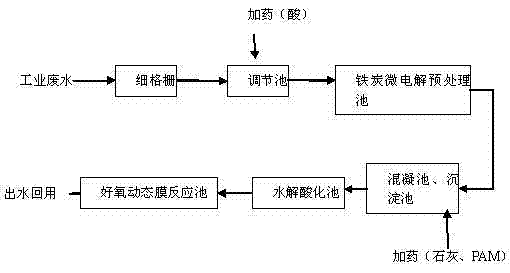

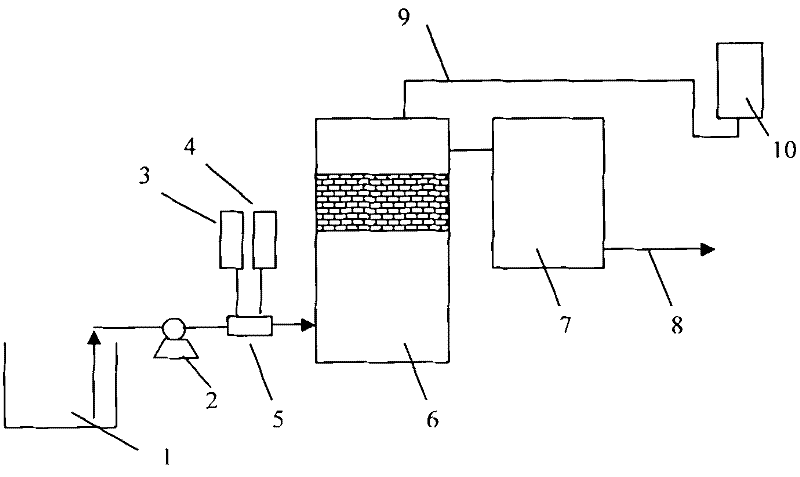

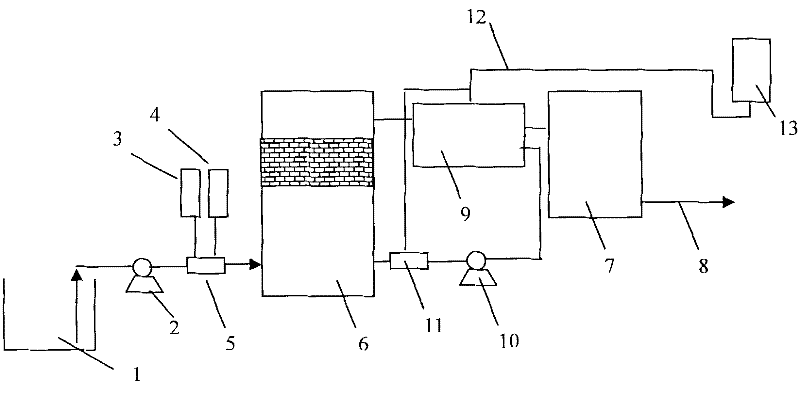

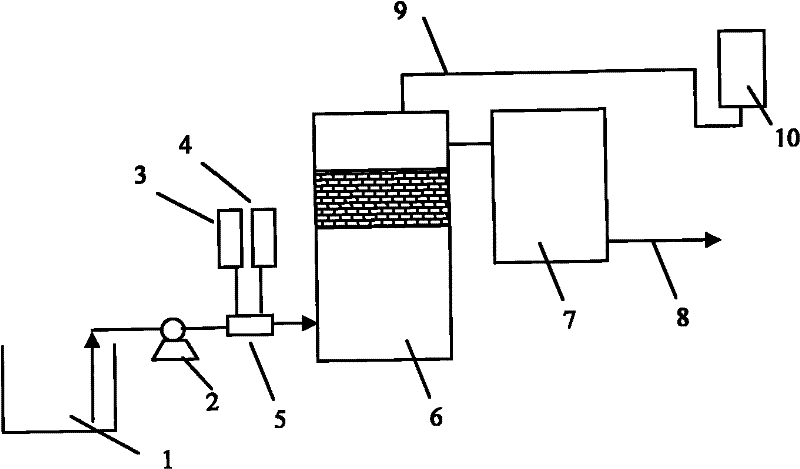

Iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process

ActiveCN102372401AStable water outputEasy to handleMultistage water/sewage treatmentSuspended particlesWater use

The invention relates to an iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process. The process comprises the following steps: pretreating pollutants in industrial wastewater by iron-carbon micro-electrolysis so as to remove partial pollutants and improve the biochemical performance of the wastewater; then, carrying out microorganism degradation by mainly using mixed liquids in a hydrolysis acidification pool and an aerobic dynamic membrane reaction pool so as to remove the pollutants; and finally, completing the solid-liquid separation and water discharge process of the mixed liquid with a dynamic membrane assembly. The invention aims at providing the iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process which is simple in process flow and efficient; the process can be effectively used for removing the difficultly-degradable organic substances in the industrial wastewater and improving the biochemical performance of the wastewater, and has obvious decoloring effect and good solid-liquid separation effect; the effluent is clear and does not contain suspended particles; and the process is suitable for standard-reaching discharge and deep treatment of various industrial wastewaters (such as dyeing and printing wastewater, pharmaceutical wastewater, heavy metal wastewater, coking wastewater, paper-making wastewater and the like), and the index of the quality of the treated effluent can meet the water quality standard of reused water.

Owner:TONGJI UNIV

Deep purification method of coking wastewater based on advanced ozone oxidation

InactiveCN102161537ANo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationPurification methodsChemical oxygen demand

The invention discloses a deep purification method of coking wastewater based on advanced ozone oxidation, belonging to the field of wastewater treatment, and particularly relating to a deep purification method for the effluent of the biochemical treatment facilities of coking plants. Aiming at the problem in the prior art, the invention provides a method for coupling homogeneous catalysis and non-homogeneous catalysis for ozone so as to realize deep purification of the effluent of the biochemical treatment facilities of coking wastewater. In the deep purification method, wastewater of which the pH value is 8-12 is subjected to homogeneous catalysis reaction in the presence of ozone and hydrogen peroxide; non-homogeneous catalysis is carried out in the presence of the non-homogeneous catalyst; thus, processed effluent COD (Chemical Oxygen Demand) is less than 100mg / L; and thus the processed effluent does not cause secondary pollution to environment.

Owner:王兵 +3

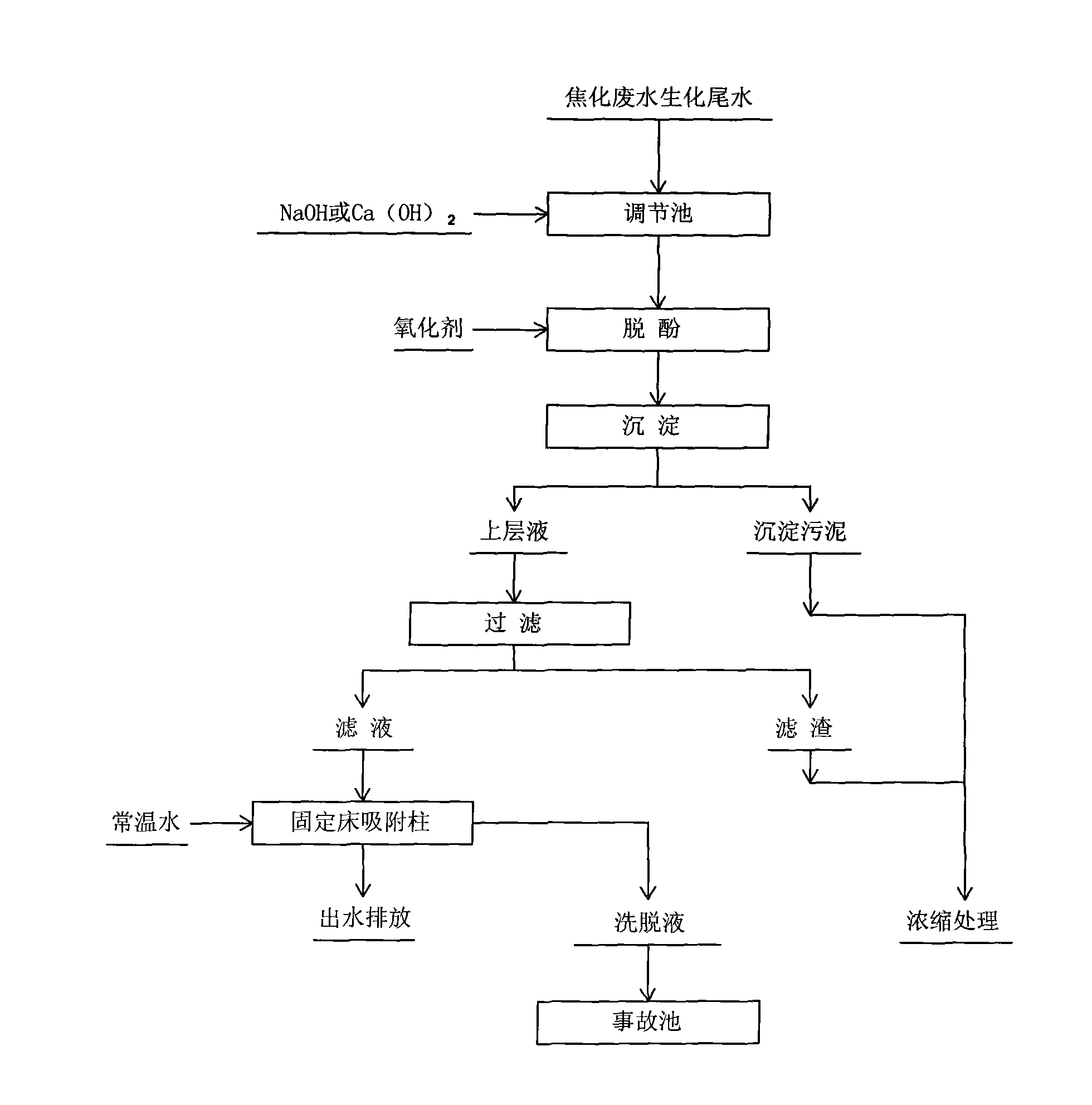

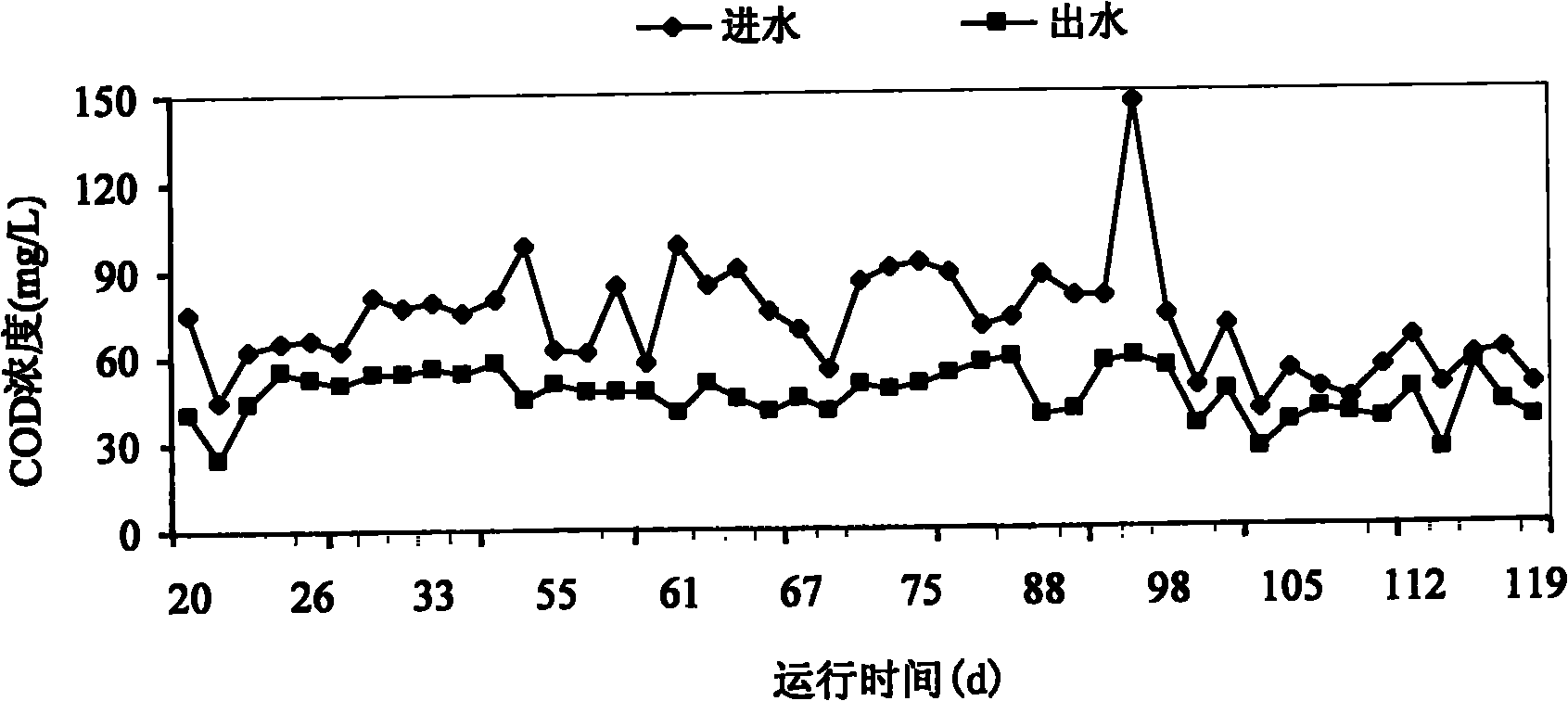

Advanced treatment method of biochemical tail water of coking wastewater

InactiveCN101514063ALow costReduce the content of phenol in the effluentWaste water treatment from metallurgical processMultistage water/sewage treatmentOrganic matterCoking wastewater

The invention discloses an advanced treatment method of biochemical tail water of coking wastewater. The method is characterized by regulating pH of the biochemical tail water of the coking wastewater in a regulation tank to 9-12 by alkaline matters, then adding high-efficiency oxidizing agent for oxidation treatment, precipitating and separating mixed solution, adsorbing filtrate; adsorbing trace organic matters in the wastewater on resin, reclaiming by water at normal temperature; COD of the wastewater reduces from 200mg / L to below 100mg / L after the treatment, chromaticity reduces from 100 folds to almost achromaticity, and other indexes meet Grade 1 standard of the national integrated sewage discharge standard.

Owner:HUNAN CHENZHOU QINXIN HIGH TECH GROUP

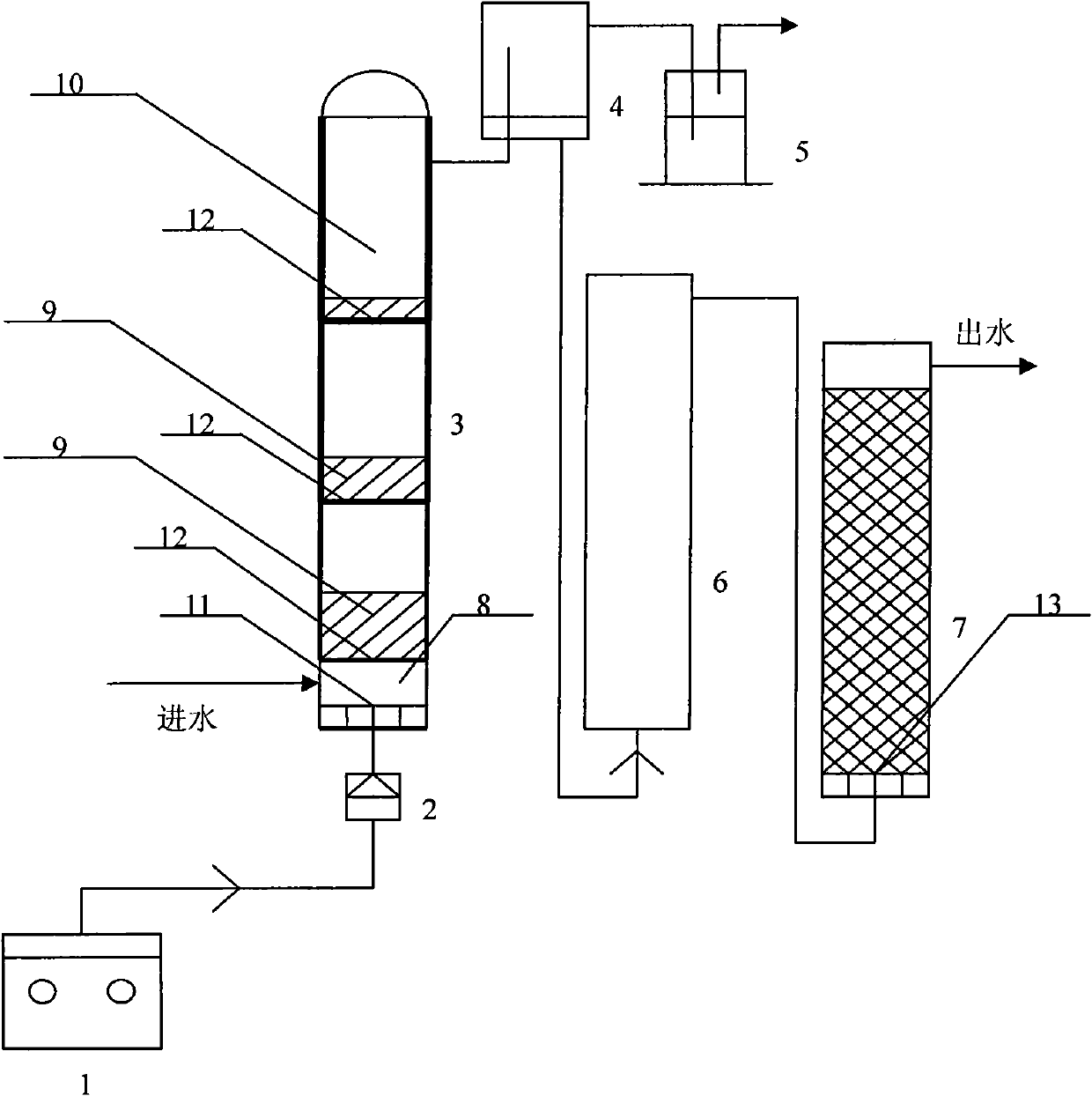

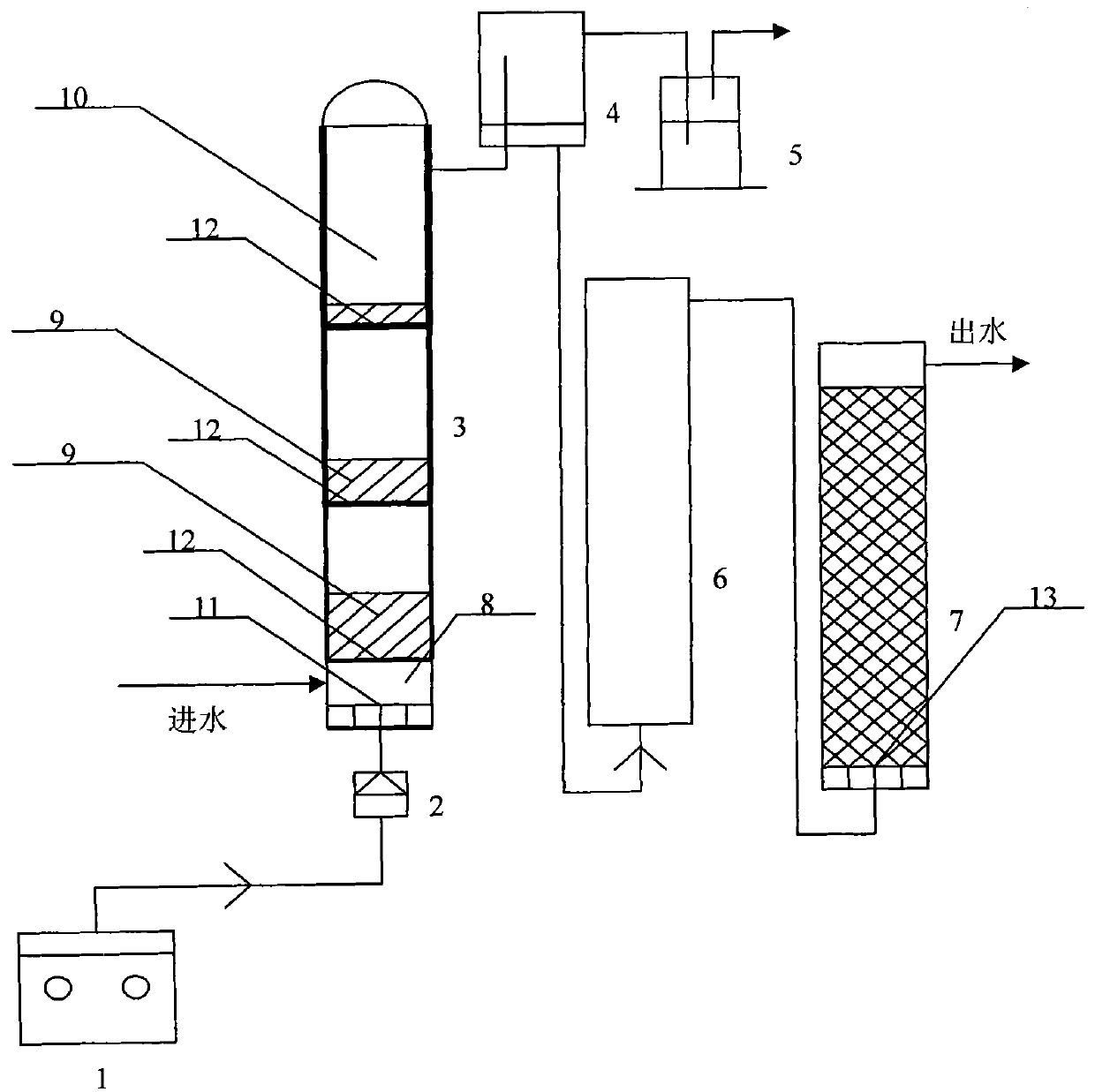

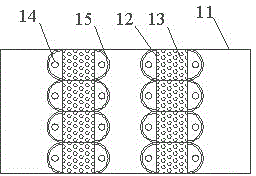

Advanced treatment system of coking wastewater

InactiveCN102001767AIncrease profitHigh removal rateMultistage water/sewage treatmentOzone generatorBiological activated carbon

The invention discloses an advanced treatment system of coking wastewater. The system mainly comprises an ozone generator, a catalytic ozonation reactor, a gas-liquid separation device, a bumper post, a biological activated carbon reactor and a tail gas absorption device, wherein the catalytic ozonation reactor has a three-section repeating structure; and each repeating structure section is divided to three subsections from bottom to top, namely an ozone absorption section, a catalyst bed layer and a catalytic reaction section. The three-section superimposing mode is utilized to intensify themass transfer function of ozone in the solution and increase the utilization rate of ozone; and the catalytic ozonation technology is adopted to increase the biochemical quality of coking wastewater,increase the treatment efficiency of the subsequent biological activated carbon technology and realize the aim of the high-efficiency advanced treatment of coking wastewater.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

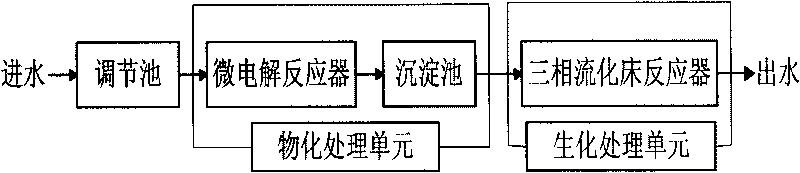

Process method for treating coking wastewater

InactiveCN101734826ALow densityReduce processing costsWaste water treatment from metallurgical processMultistage water/sewage treatmentVolatile phenolsActivated sludge

The invention discloses a process method for treating coking wastewater. The process method solves the technical problems that a micro-electrolysis method has hardening, channeling and narrow applicability of a pH range and a biochemical treatment process has long flow, large occupied area, poor impact load resistance and high expense. The method comprises a physical-chemical treatment unit consisting of a micro-electrolysis reactor and a settling tank; in the micro-electrolysis reactor, scrap iron, scrap copper and a lightweight blocky material are used as fillers; the pH of inlet water is between 2.0 and 6.0; the waterpower retention time is between 20 and 60 minutes; the method adopts air aeration; the method also comprises a filtering type inner circulating three-phase fluidized bed reactor biochemical treatment unit, and immobilized activated sludge balls are utilized to realize simultaneous denitrification and decarburization; the pH of inlet water is between 7.2 and 8.5; the concentration of dissolved oxygen is between 2 and 6mg / L; the temperature is between 28 and 32 DEG C; the waterpower retention time is between 20 and 40h; the COD of outlet water reaches secondary standard of integrated wastewater discharge standard; and volatile phenol, ammonia nitrogen and chroma reach primary standard of integrated wastewater discharge standard.

Owner:NANJING UNIV OF SCI & TECH

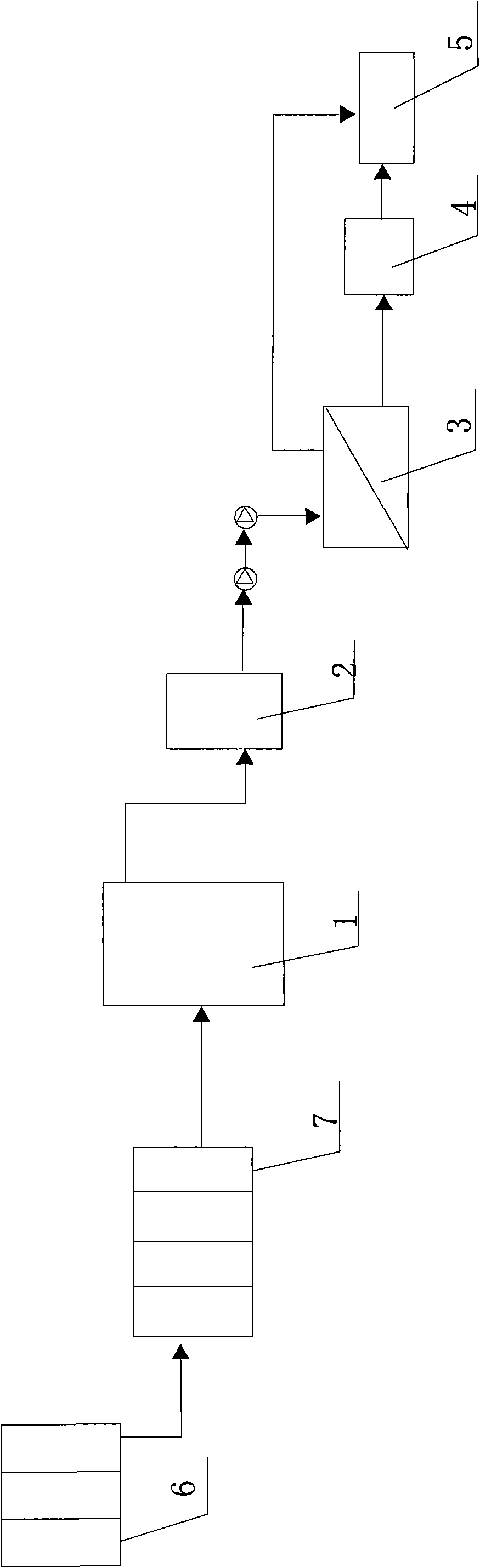

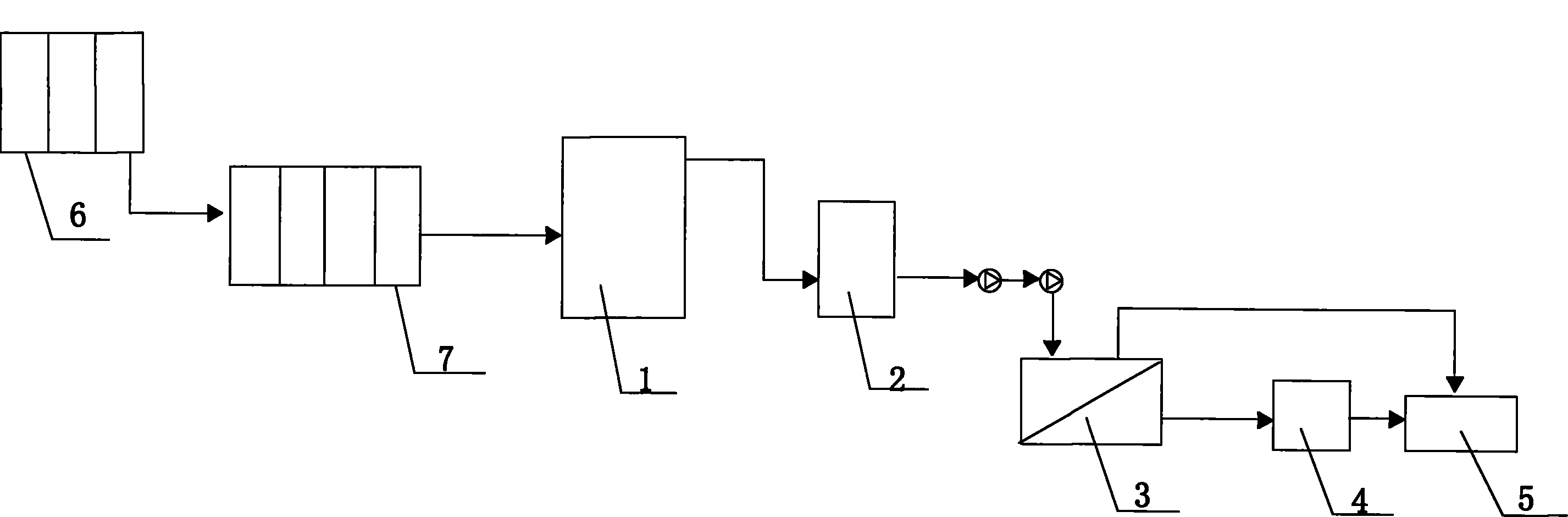

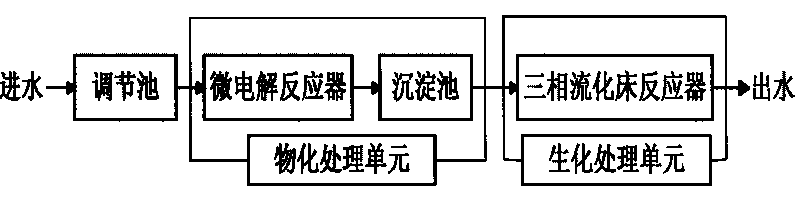

Advanced treatment and zero emission process for coking wastewater

ActiveCN104016547AReduce processingImprove BOD/COD valueMultistage water/sewage treatmentElectrolysisUltrafiltration

The invention relates to an advanced treatment and zero emission process for coking wastewater. The process comprises the following steps: performing ammonia stilling and dephenolizing on the coking wastewater, allowing the treated coking wastewater to enter a regulation pond, conveying the wastewater to an inner electrolysis intensified pretreatment system by using a pump, wherein the inner electrolysis intensified pretreatment system forms an anaerobic biofilter through iron carbon inner electrolysis fillers, and carrying out an iron carbon inner electrolysis reaction and a biological anaerobic reaction; and allowing the wastewater to sequentially enter an anoxic pool and an aerobic pool for carrying out an A / O biological reaction, then allowing the wastewater to enter a secondary sedimentation tank and a later coagulating basin, and further performing advanced treatment on the wastewater in a three-dimensional electrode reactor and an ultrafiltration reverse osmosis treatment system. The coked reverse osmosis concentrated water is treated in a concentrated water recycling system, and zero emission of the coking wastewater is achieved. The process has the aims that dilution water is not added in the conventional coking wastewater treatment process, the coking wastewater subjected to biochemical treatment is subjected to advanced treatment for recycling, and reduction, harmlessness and recycling of the coking wastewater are realized.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Method for decoloring burned waste water by using zero-valent iron/ultrasonic wave synergistic reaction

InactiveCN101234812AImprove biodegradabilityEasy to handleWater/sewage treatment with mechanical oscillationsWater/sewage treatment by reductionUltrasound - actionReaction temperature

The invention relates to environmental chemistry, in particular to a method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, which specifically comprises the following steps: wastewater and zero-valent iron chips / powders are added into a reactor; the pH value of the wastewater is adjusted to be 1 to 6; then stirring is carried out under the effect of the ultrasonic waves with the power of 150 to 200W; the reaction is lasted for 30 to 60 minutes; the wastewater is decolorized and COD is removed. During the process, the use amount of zero-valent iron in each liter of wastewater is 2 to 500g, and the reaction temperature is 10 to 80 DEG C. By applying the method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, the chromaticity of the coking wastewater can drop from 1,500 times to 140 times, and the removal efficiency can reach over 90 percent; in addition, after the synergetic effect of the zero-valent iron and ultrasonic waves, the removal efficiency of COD in the coking wastewater is higher than the efficiency under the signal effect of the zero-valent iron and the ultrasonic waves. The obtained BOD5 / COD is increased from 0.08 to 0.36, and the biodegradability of the wastewater is also increased remarkably.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

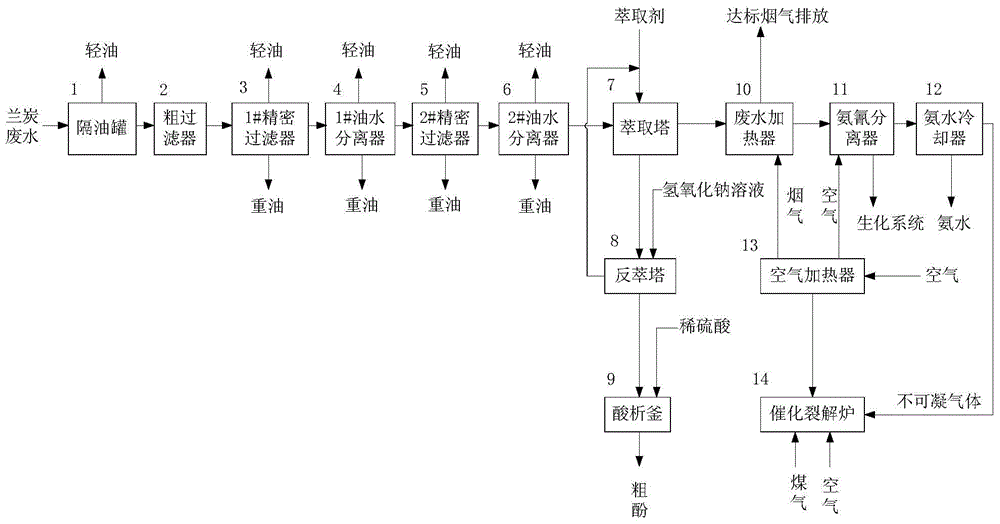

Technological method and device for semi-coke production wastewater resource utilization

ActiveCN104445815AImprove biodegradabilityImprove economic competitivenessOrganic chemistryOrganic compound preparationResource utilizationCoking wastewater

The invention discloses a technological method and device for semi-coke production wastewater resource utilization. The technological method comprises three steps, namely deep oil-water separation, high-efficiency complexing extraction dephenolization and ammonia stilling, to be specific, firstly, separating and recycling a part of coal tar from wastewater when the wastewater passes through an oil partitioning tank, recycling coal tar in a precision filter and an oil-water separator in sequence after discharged water passes through a coarse filter; feeding the oil-removed semi-coke wastewater and an extraction agent into an extraction tower for extraction and dephenolization, feeding the extract phase and a sodium hydroxide solution into a reverse extraction tower for countercurrent contact reverse extraction, feeding an obtained sodium phenolate solution into an acidification kettle, and adding sulfuric acid for acidification to obtain crude phenol; feeding dephenolized wastewater discharged from the bottom of the extraction tower into a wastewater heater, feeding into an ammonia cyanogen separator to be mixed with hot air from an air heater to remove ammonia after being heated by fume from the air heater, and feeding an ammonia-containing mixed gas discharged from the top of the ammonia-cyanogen separator into an ammonia water cooler for cooling to obtain ammonia water. By adopting the method and the device, precious resources such as coal tar, phenol and ammonia can be recycled from the semi-coke production wastewater resource, and the biodegradability of the semi-coke wastewater is improved.

Owner:陕西华祥能源科技集团有限公司

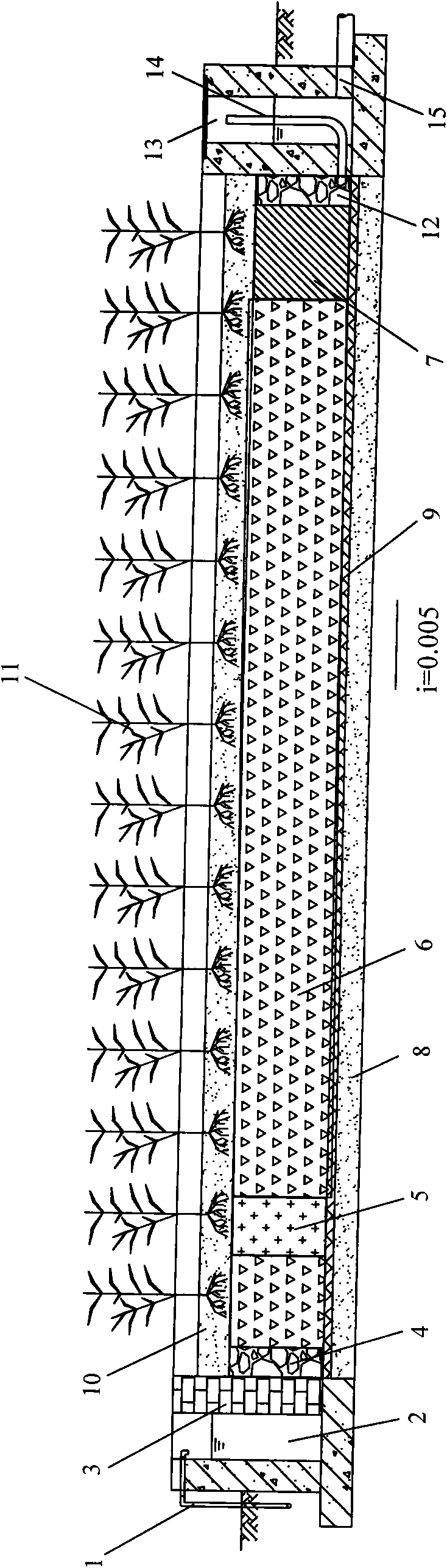

Artificial wetland with combined fillers and treating process thereof

ActiveCN102079579AGood at removingGood removal effectWater contaminantsWaste water treatment from metallurgical processConstructed wetlandTreatment effect

The invention provides an artificial wetland with combined fillers for the advanced treatment of the effluent coking wastewater of iron and steel enterprises, which sequentially comprises a water inlet area, a wetland processing unit area and a water outlet area, wherein the wetland processing unit area sequentially comprises a gravel filler section, an iron carbon filler section and a manganese sand filler section; and a soil covering layer and wetland plants are arranged on the surface of the wetland. By using iron carbon, manganese sand and gravels as combined fillers and using emerging plants (such as cattail, Scirpus tabernaemontani, Thalia dealbata, reed and the like) having large biomass, salinization resistance and high metal and organic substance adsorptive power as a composite plant bed, the invention forms a horizontal subsurface flow artificial wetland. Thus, when industrial waste water moves into the artificial wetland, pollutants can be removed on the basis of a series of physical, chemical and biological interaction among the fillers, plants and microorganisms. The process provided by the invention has high pollutant shock load resistance and good treatment effect. Besides, the outlet water is stable, and main indexes of the outlet water can meet the Reuse of Urban Recycling Water-Water Quality Standard for Industrial Uses (GB / T 19923-2005). Thus, the outlet water can be recycled as circulating cooling water for steel enterprises.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Coking wastewater treatment system and treatment method

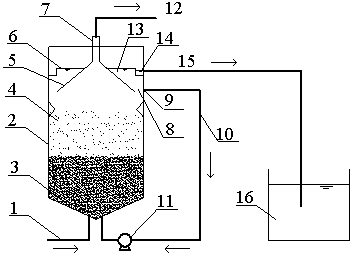

ActiveCN103880248AEfficient processing performanceLow running costMultistage water/sewage treatmentNitrationSmall footprint

The invention discloses a coking wastewater treatment system, including an upflow anaerobic sludge blanket reactor, an anoxic denitrification biofilter, an aerobic nitration biofilter, a multistage iron carbon micro-electrolysis coupling Fenton oxidation bed reactor, an aerobic nitration biofilter and an anoxic denitrification biofilter. A coking wastewater treatment method comprises the following steps of coking wastewater enters the upflow anaerobic sludge blanket reactor, the anoxic denitrification biofilter, the aerobic nitration biofilter, the multistage iron carbon micro-electrolysis coupling Fenton oxidation bed reactor, the aerobic nitration biofilter and the anoxic denitrification biofilter from a raw coking wastewater inlet pipe from bottom up, and is discharged. The coking wastewater treatment system disclosed by the invention has the advantages of being small in occupation area and low in energy consumption, having efficient wastewater treatment efficiency, reducing the operation cost of wastewater treatment, and being high in treatment load, low in energy consumption and small in sludge production yield.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Oxidization coagulant for treating coking wastewater

InactiveCN101734780AWide pH rangeGood removal effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationChemical oxygen demandAqueous solution

The invention discloses an oxidization coagulant for treating coking wastewater, which consists of two parts of an oxidization flocculant and a coagulant aid. The oxidization flocculant comprises the following components according to proportion by weight: 8-20% of flocculant polyferric sulfate, 0.1-2.0% of oxidant ferrate and the balance of water; and the coagulant aid is polyacrylamide aqueous solution. In the invention, the double functions of oxidization and flocculation are available, the removal rate of the coking wastewater CODcr (Chemical Oxygen Demand) can reach more than 70%, the draining water is clear, the colority is less than 80 times, the adding amount is little, and the cost is low, wherein the medicament cost of advanced treatment is only 0.5 RMB / ton; the condition is easy to control and the operation is convenient. The invention provides an economical and efficient method and powerful assurances for the draining standard of advanced treatment of the coking wastewater.

Owner:娄底市裕德科技有限公司

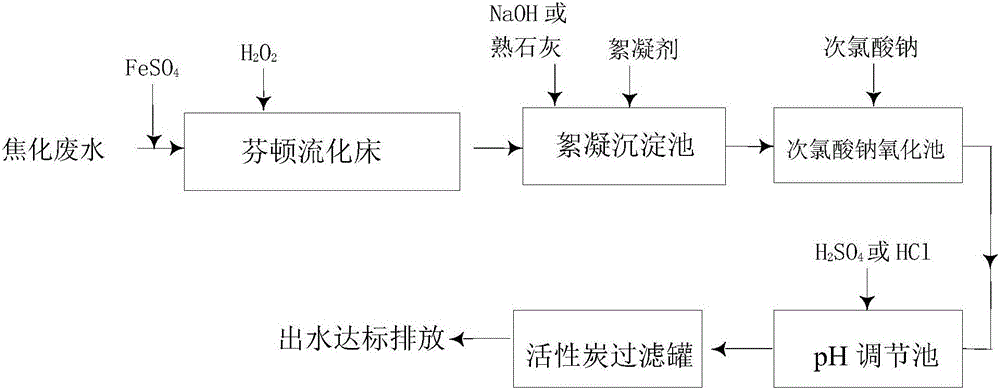

Method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide

ActiveCN106745961AGood effectImprove reaction efficiencyWater treatment compoundsWater contaminantsActivated carbon filtrationWater quality

The invention provides a method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide. The method comprises the following steps: 1) introducing the coking wastewater into a Fenton fluidized bed, and adding a mixed solution of ferrous sulfate, sulfuric acid and water into a solution; 2) adding hydrogen peroxide into the solution of the Fenton fluidized bed and sufficiently reacting; 3) leading out a reaction solution in the Fenton fluidized bed, adjusting the pH (Potential of Hydrogen) value of the reaction solution, adding a flocculating agent, and after precipitating, taking supernatant; 4) mixing the supernatant with sodium hypochlorite, and carrying out an oxidization reaction; and 5) adjusting the pH of the reaction solution, and carrying out adsorption treatment by active carbon to obtain a deeply treated water body. According to the method and the system, the Fenton fluidized bed, flocculation and sedimentation, sodium hypochlorite oxidization, and active carbon filtering and adsorption are effectively combined; the Fenton fluidized bed and the flocculation and sedimentation are carried out, residual cyanide in output water mainly exists in a CN<-> form, the oxidization efficiency of the sodium hypochlorite is higher, and the cyanide can be removed; and the adsorption effect of the active carbon is combined, so that the water concentration of the output water is lower.

Owner:CISDI ENG CO LTD

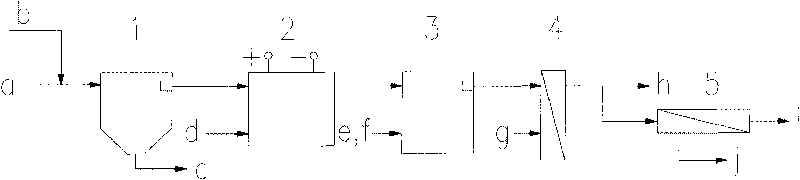

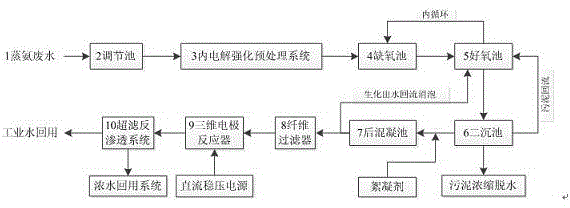

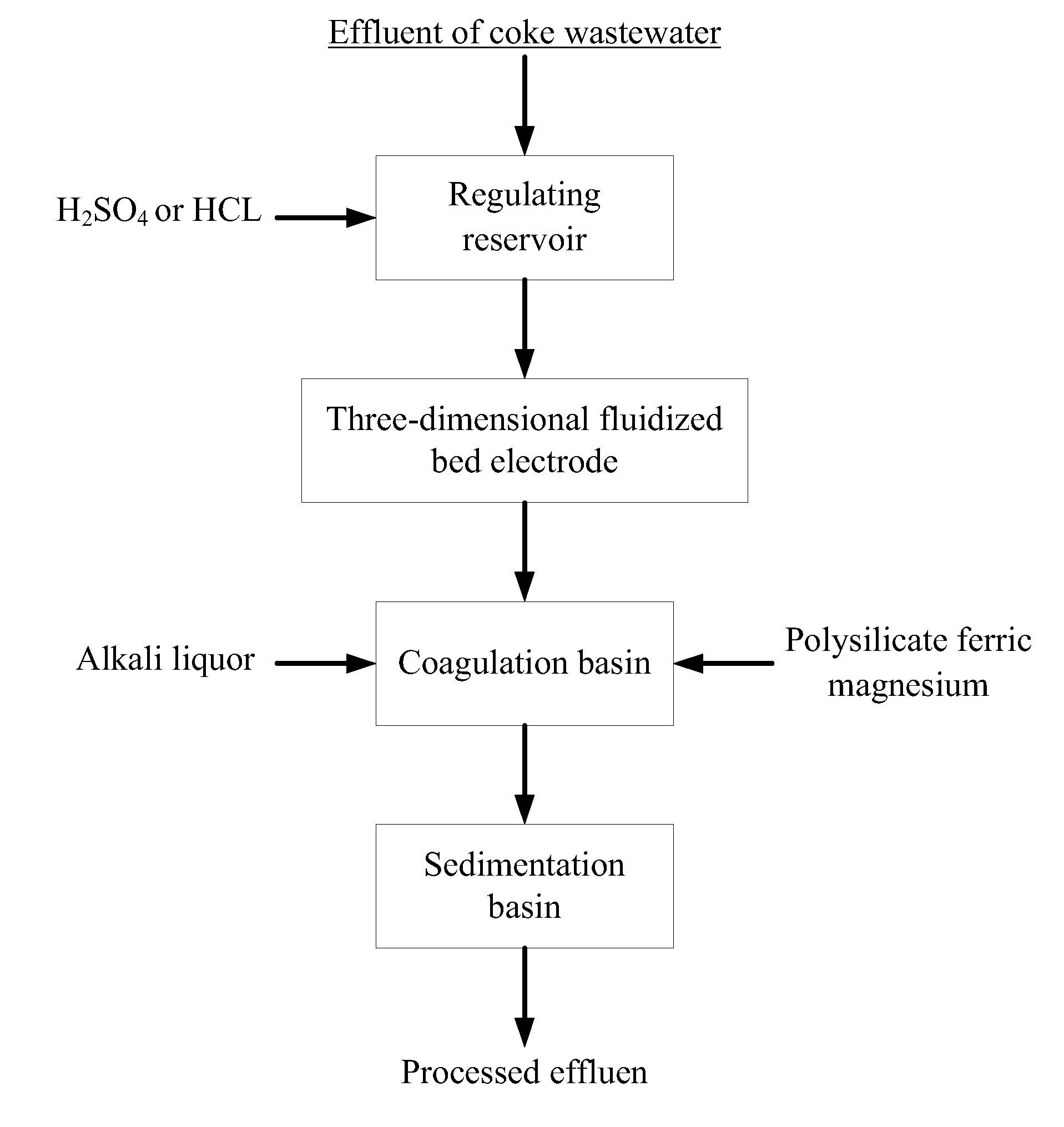

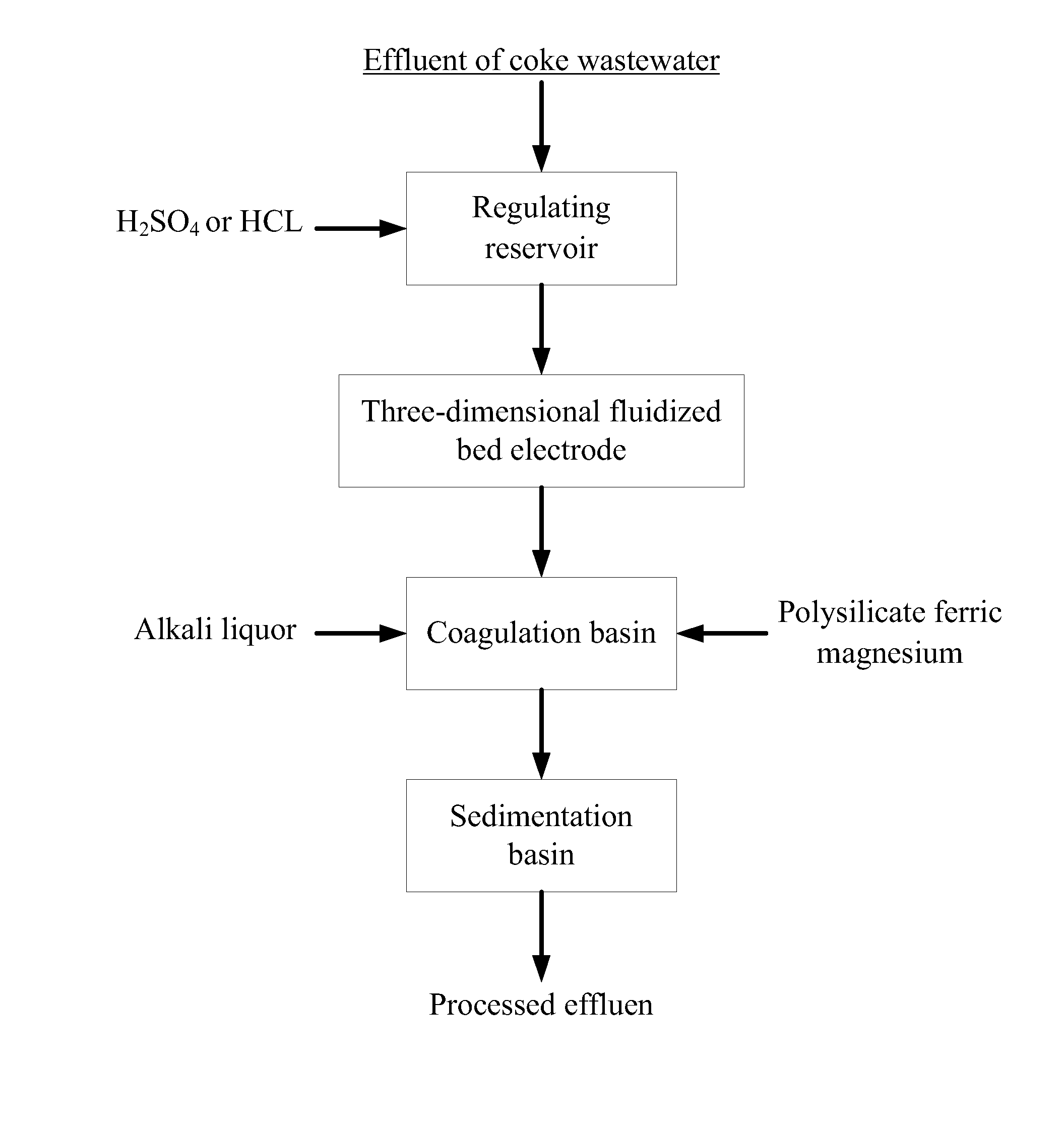

Method of treatment of coke wastewater

ActiveUS20120205317A1Reduce environmental pollutionLow costSedimentation separationMultistage water/sewage treatmentElectrolysisThree dimensional electrode

A method for treatment of coke wastewater, including (1) introducing wastewater into a regulating reservoir into which an acid liquor is added until the pH value of the wastewater ranges between about 5.5 and about 6.5; (2) introducing the wastewater into a three-dimensional electrode treatment device for electrolysis treatment; and (3) introducing the wastewater into a coagulation reaction tank into which an alkali liquor is added until the pH value of the wastewater ranges between 8 and 10, and as a coagulant polysilicate ferric magnesium is added into the wastewater for a hybrid reaction of between 5 and 15 mins; allowing the wastewater to flow into a sedimentation basin for plain sedimentation of between 4 and 6 hrs; and extracting a supernatant liquor to yield a processed effluent.

Owner:REN HONGQIANG +4

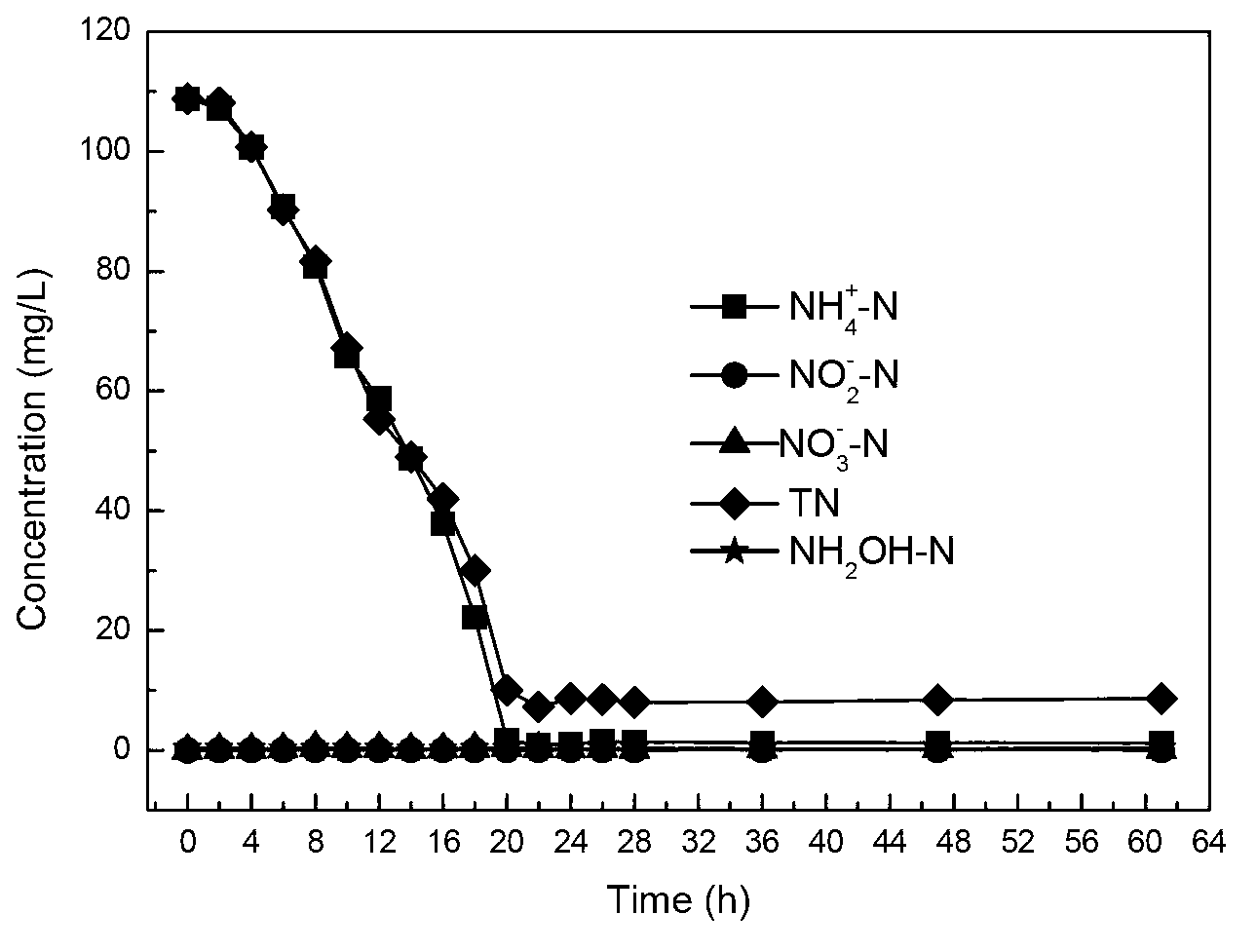

Heterotrophic nitrifying and aerobic denitrifying bacterium and culture and application thereof

InactiveCN103013872AImprove nitrogen removal efficiencyApplicable treatmentTreatment using aerobic processesBacteriaAcinetobacter speciesBacteroides

The invention relates to a heterotrophic nitrifying and aerobic denitrifying bacterium for efficient denitrification, and the culture and application of the heterotrophic nitrifying and aerobic denitrifying bacterium. The bacterium belongs to an acinetobacter species (Acinetobacter), with the name of Acinetobacter sp.Y1, the preservation registration number of CGMCC NO.6563, the preservation institution of China Microorganism Culture Preservation Management Council General Microbiological Center and the preservation time of September 14th, 2012. The bacterium is separated from activated sludge of coking wastewater, can not only quickly remove ammonia nitrogen, but also grow under the condition that nitrite and nitrate are taken as sole nitrogen sources, and effectively removes nitrite nitrogen and nitrate nitrogen, and can be applied to nitrogen-containing wastewater treatment.

Owner:TAIYUAN UNIV OF TECH

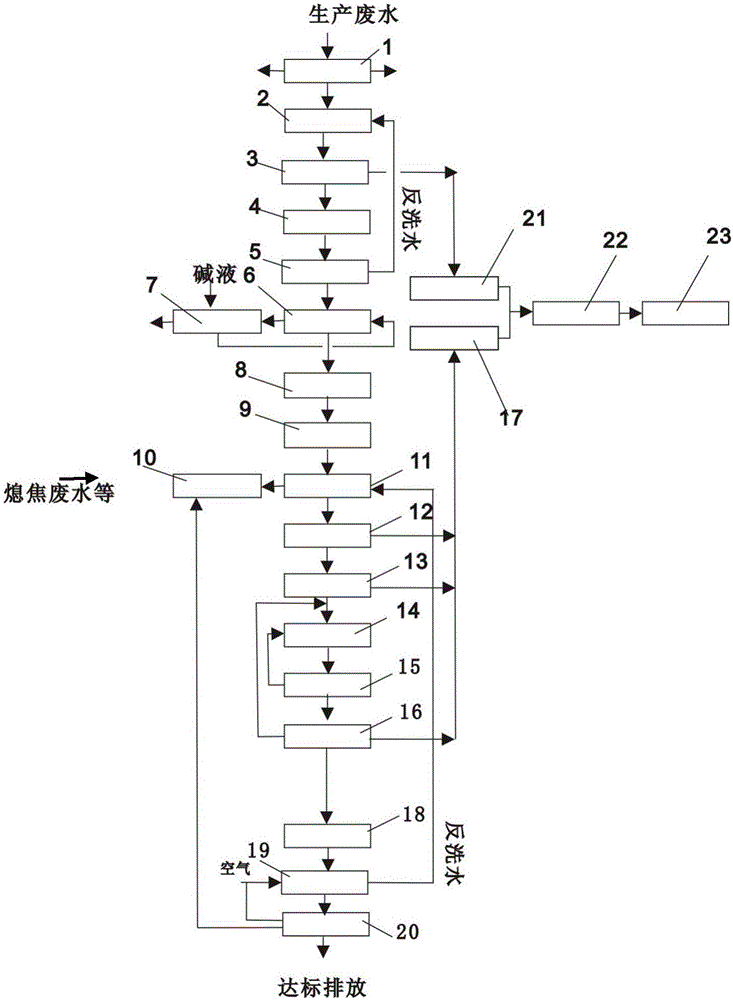

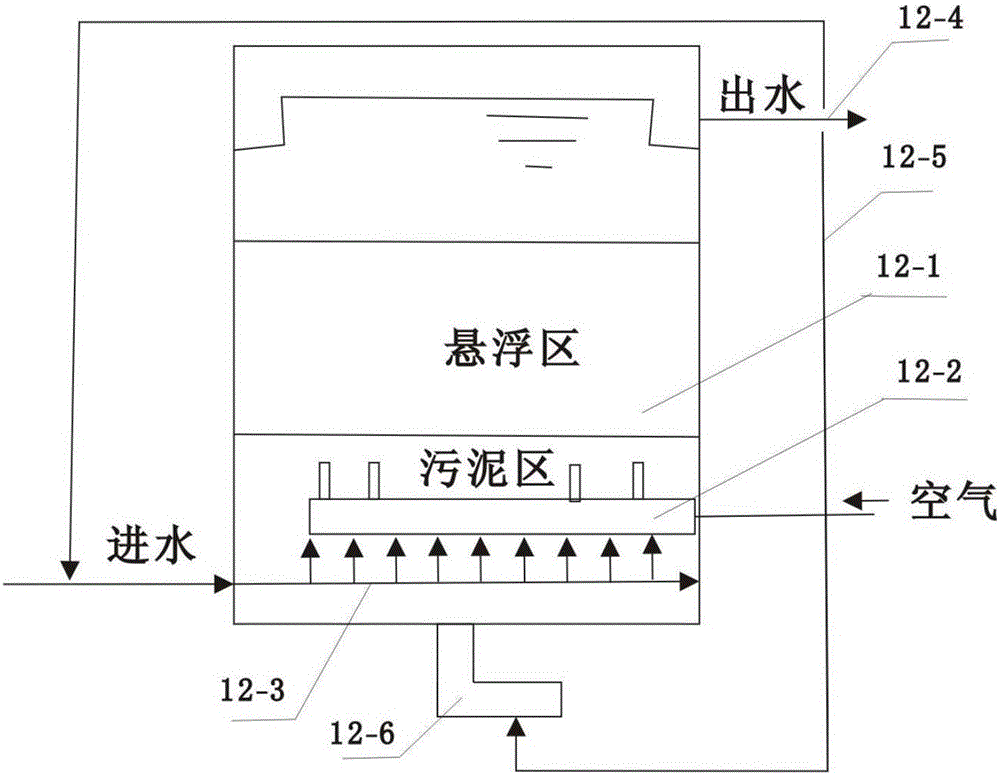

Semi-coke wastewater treatment method

ActiveCN105060628ASimple processLow construction costMultistage water/sewage treatmentWater dischargeEqualization

The invention discloses a semi-coke wastewater treatment method. A pretreatment process comprises the following steps: production wastewater goes through an oil separation sedimentation tank and undergoes oil-water separation, and obtained wastewater enters an equalization pool; the production wastewater in the equalization pool is pumped to a coagulation and air floatation machine and undergoes air floatation separation, and obtained production wastewater enters a first intermediate water pool; and production wastewater in the first intermediate water pool is pumped to a filtering system and is filtered, the obtained filtrate enters a phenol extraction system, and phenol extraction removed wastewater is pumped into an ammonia stripping tower in order to remove most free ammonia. A biochemical treatment process comprises the following steps: production wastewater obtained after removal of most of ammonia nitrogen through the ammonia stripping tower goes through a comprehensive equalization pool, obtained wastewater enters a hydrolysis-acidification pool, and wastewater from the hydrolysis-acidification pool enters an HABR compound anaerobic baffled reactor; and obtained wastewater enters an A / O treatment system, powdered active carbon is added to an aerobic tank in the A / O treatment system, wastewater discharged from the A / O treatment system enters a sedimentation tank, wastewater from the sedimentation tank goes through a third intermediate water pool, wastewater from the third intermediate water pool goes through an aeration bio-filter, and water discharged from the aeration bio-filter, reaching discharge standards, is discharged. The system has the advantages of simplicity, low cost and standard reaching discharge realization.

Owner:CHONGQING JIERUN TECH

Coking wastewater comprehensive treatment method and system thereof

InactiveCN102718363AGuaranteed uptimeSimple processWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisOxygenPre treatment

The invention discloses a coking wastewater comprehensive treatment method comprising the following steps of: pre-treatment, biochemical treatment and deep treatment. The deep treatment step comprises sequential steps of filtering, ultra-filtering, carrying out resin adsorption, re-filtering, and carrying out reverse osmosis. With the adoption of a coking wastewater comprehensive treatment system of the coking wastewater comprehensive treatment method, the pre-treatment step adopts a de-oiling pond, an adjusting pond and an air floating pond, which are connected in sequence; the biochemical treatment step adopts a primary aeration pond, a primary settling pond, an oxygen-poor pond, an aerobic pond and a secondary settling pond, which are connected in sequence; and the deep treatment step adopts a multi-medium filter, an ultra-filtering device, a resin adsorption column and a reverse osmosis device. The coking wastewater comprehensive treatment method has the beneficial effects that the method is stable to operate and has a simple process and good treating effects.

Owner:浙江晶泉水处理设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com