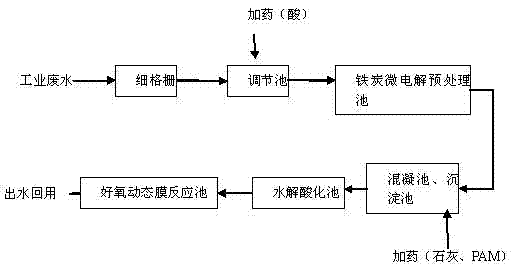

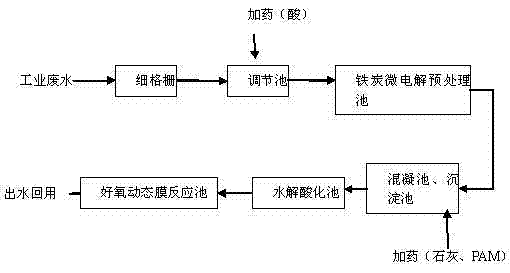

Iron-carbon micro-electrolysis-dynamic membrane wastewater deep treatment process

A technology of iron-carbon micro-electrolysis and treatment process, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Agglomeration and other problems can be achieved to improve the removal effect, improve the filtration flux, and achieve the effect of long operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Printing and dyeing wastewater treatment

[0029] During the implementation process, it was carried out in a printing and dyeing factory. The water quality of the inflow and outflow of the experiment is shown in Table 1.

[0030]

[0031] Table 1 Process inlet and outlet water quality

[0032] project COD (mg / L) pH Chroma (times) Ammonia nitrogen (mg / L) Total phosphorus (mg / L) Conditioning pond raw water 426-580 7.5-8.0 800-1000 30-40 4-7 Micro-electrolysis pretreatment of effluent 158-207 7.3-8 20 12-14 0.3-0.8 Aerobic dynamic membrane effluent <50

8.02-8.09 <15

1.8-3.6 0.2-0.45

[0033] (1) Wastewater iron-carbon micro-electrolysis pretreatment

[0034] Use waste sulfuric acid to adjust the pH value of the raw wastewater to 5-6, enter the reaction tank filled with iron-carbon fillers and perform aeration, the dissolved oxygen is 2-3mg / L, and the residence time is 1.5h. After pretreatment, adjust the pH valu...

Embodiment 2

[0048] Coking wastewater treatment

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com