Cylindrical filtering water purifier

A water purifier, cylindrical technology, applied in the field of water purification, can solve problems such as loud noise, difficult production, poor filtration effect of membrane elements, etc., to achieve the goal of ensuring the filtration circulation effect, long-term high-efficiency filtration, and automatic cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

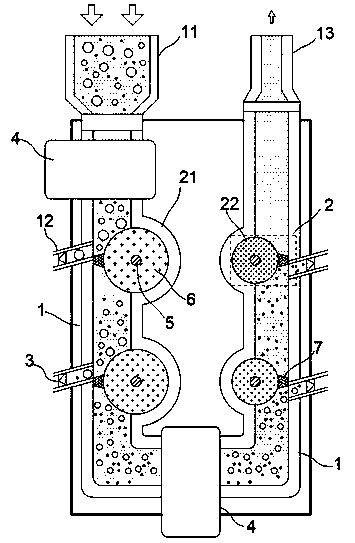

[0019] exist figure 1 In the shown embodiment, the cylindrical filter water purifier includes a cylindrical shell 1, a filter unit 2, a water inlet pipe 11, a drain pipe 12, and a water purification pipe 13; the water inlet pipe 11 is arranged at the front end of the cylindrical shell 1 , the clean water pipe 13 is arranged at the tail end of the cylinder shell 1; a normally closed pressure limiting valve 3 is arranged on the drain pipe 12; a booster pump 4 is arranged at the front end and the middle section of the cylinder shell 1;

[0020] The filter unit 2 includes a filter cavity 21, the filter cavity 21 is arranged on one side of the inner wall of the shell 1; a filter core 22 is arranged in the filter cavity 21, and the filter core 22 includes a rotating shaft 5 and a filter Cartridge 6; the two ends of the rotating shaft 5 are arranged in the inner wall of the cartridge case 1, and the filter cartridge 6 can rotate freely relative to the rotating shaft 5; during the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com