Patents

Literature

918results about How to "Play a filtering role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated internal circulation type denitrification and decarburization bio-membrane reactor and operating method thereof

InactiveCN102659244AEfficient removalEfficient nitrogen and carbon removalTreatment with aerobic and anaerobic processesSludgeMembrane reactor

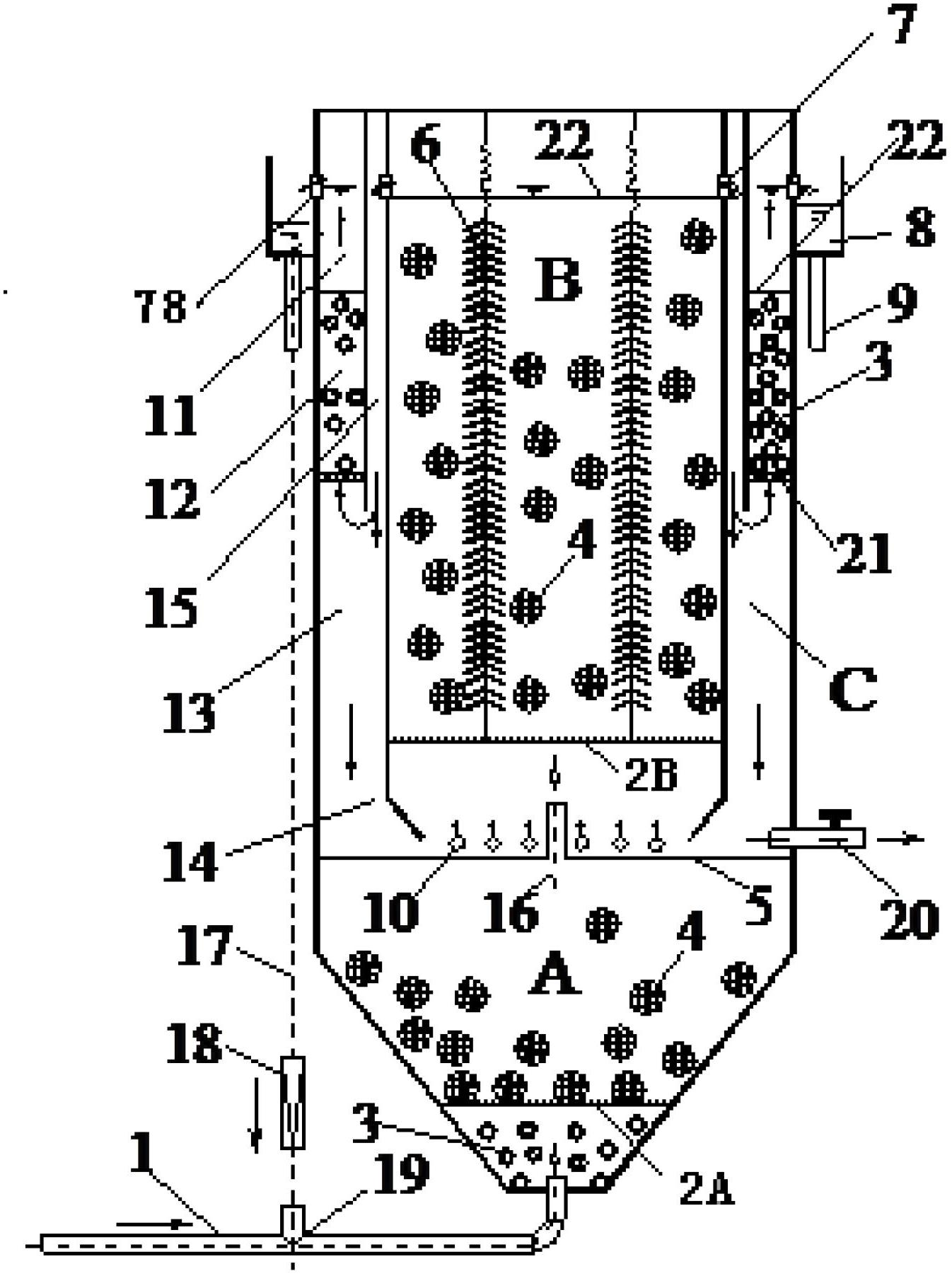

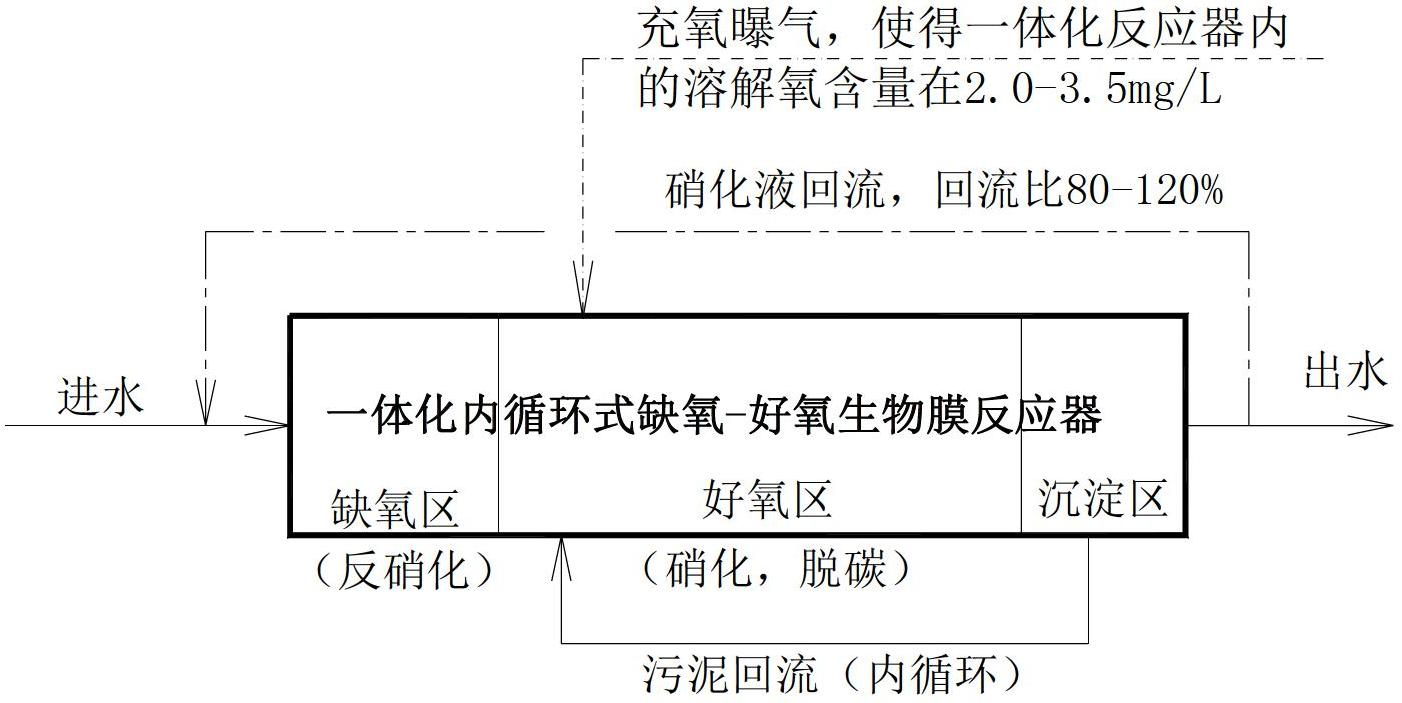

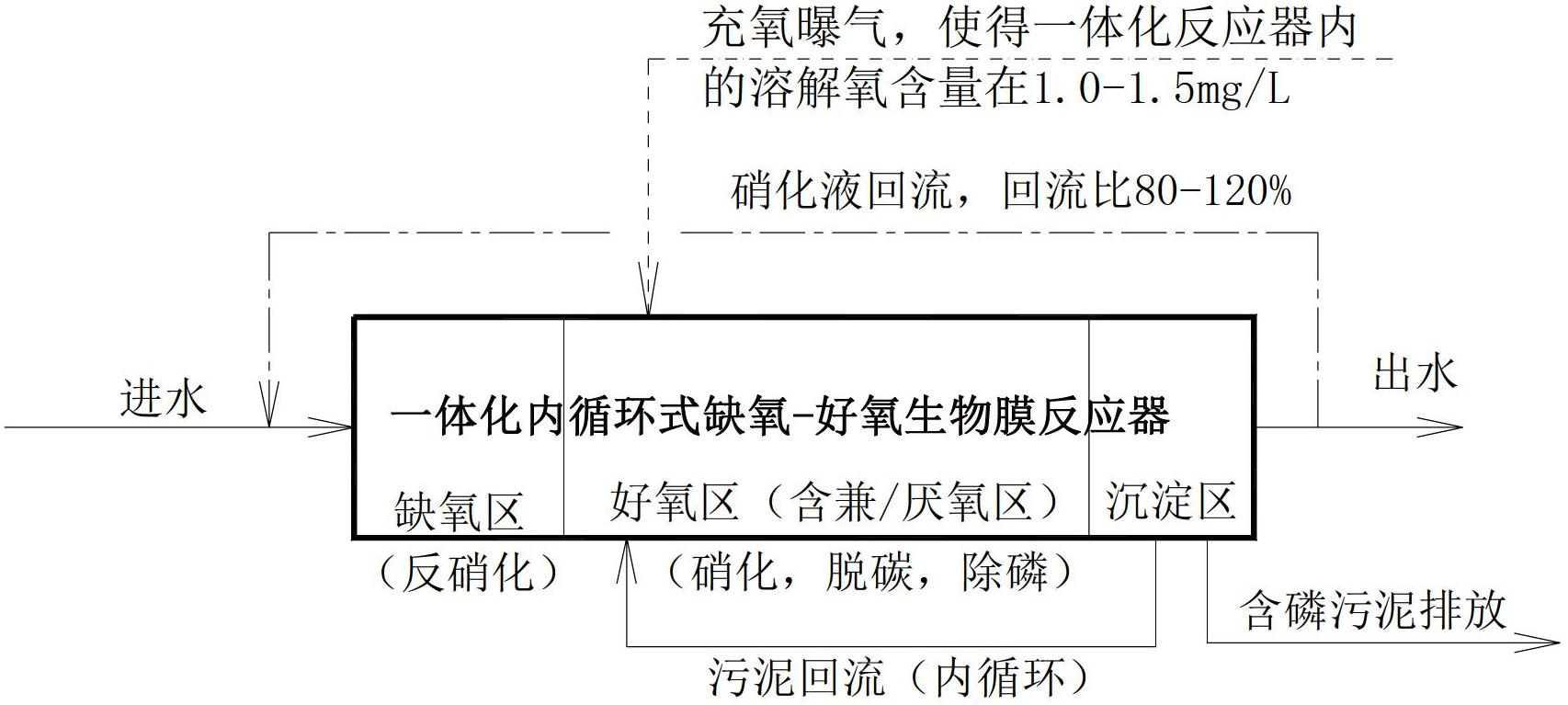

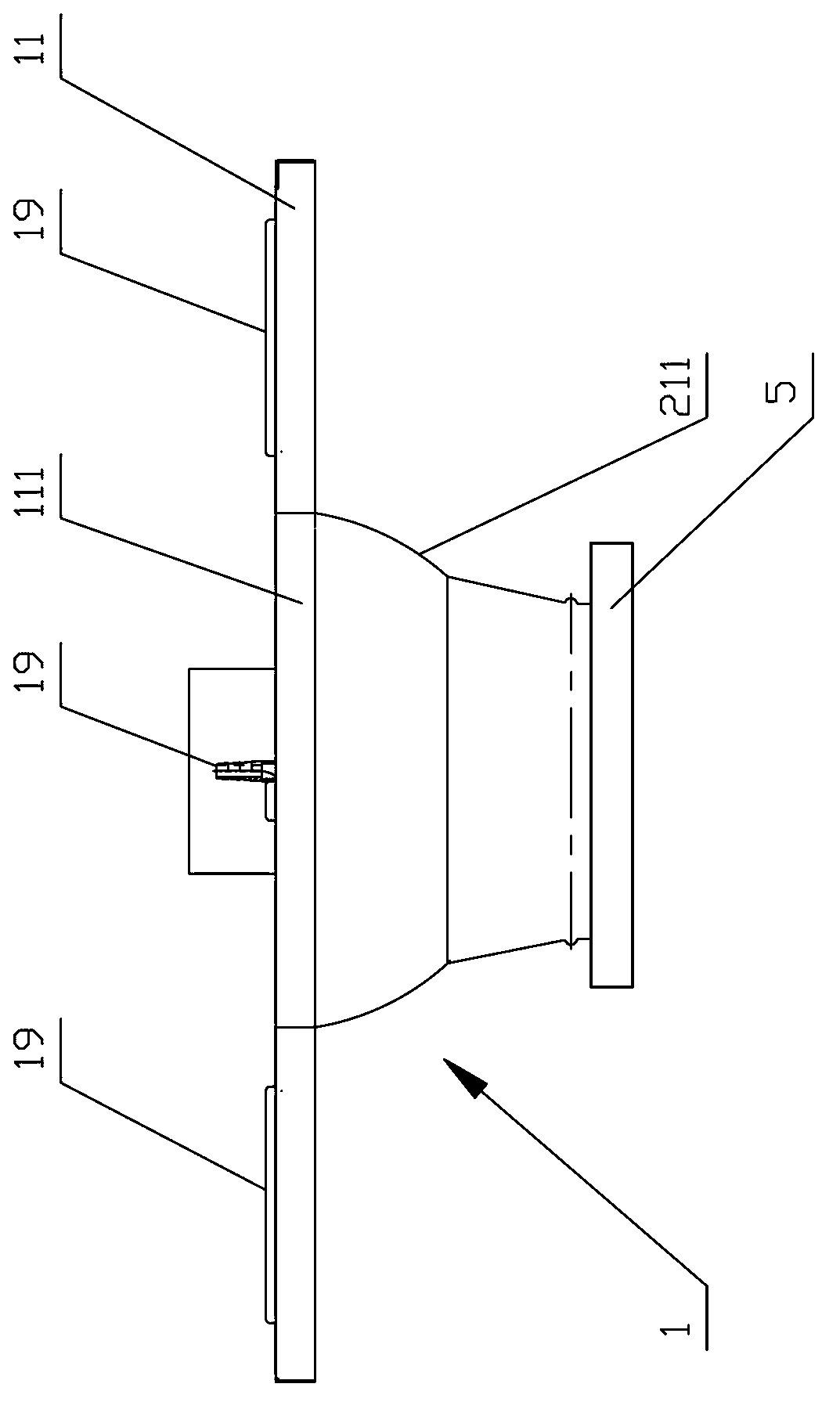

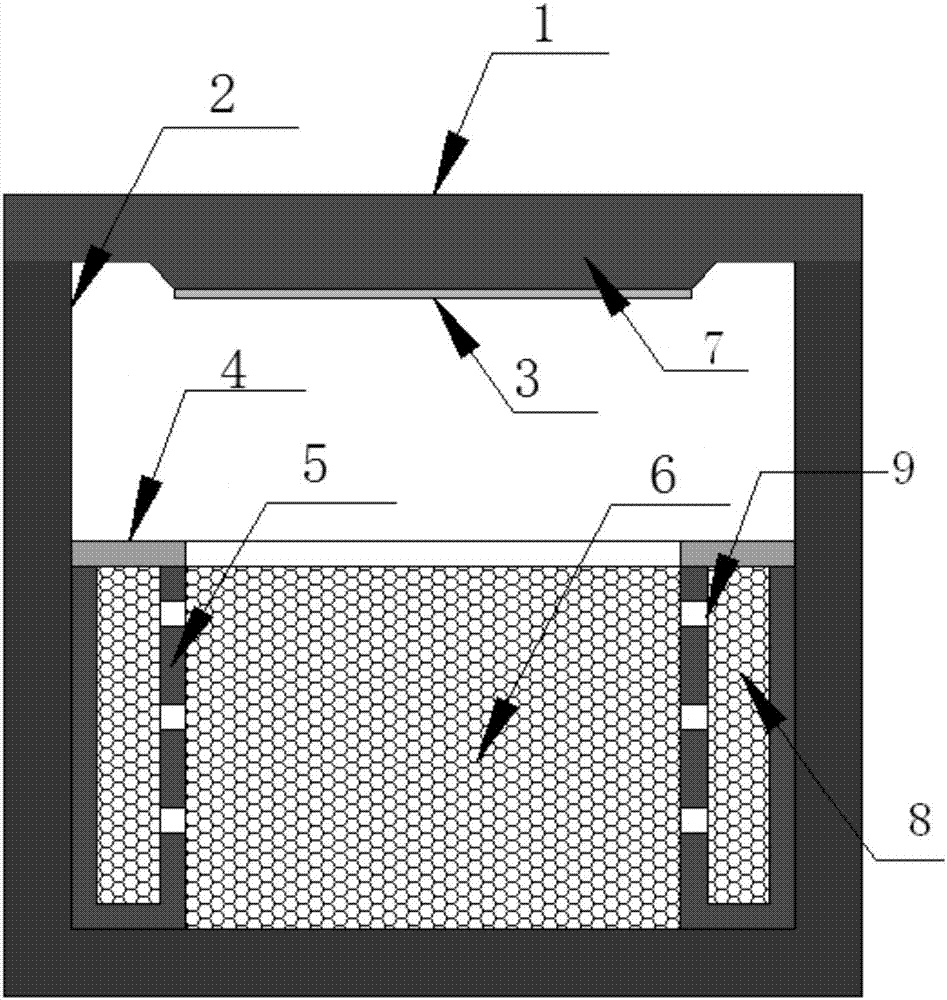

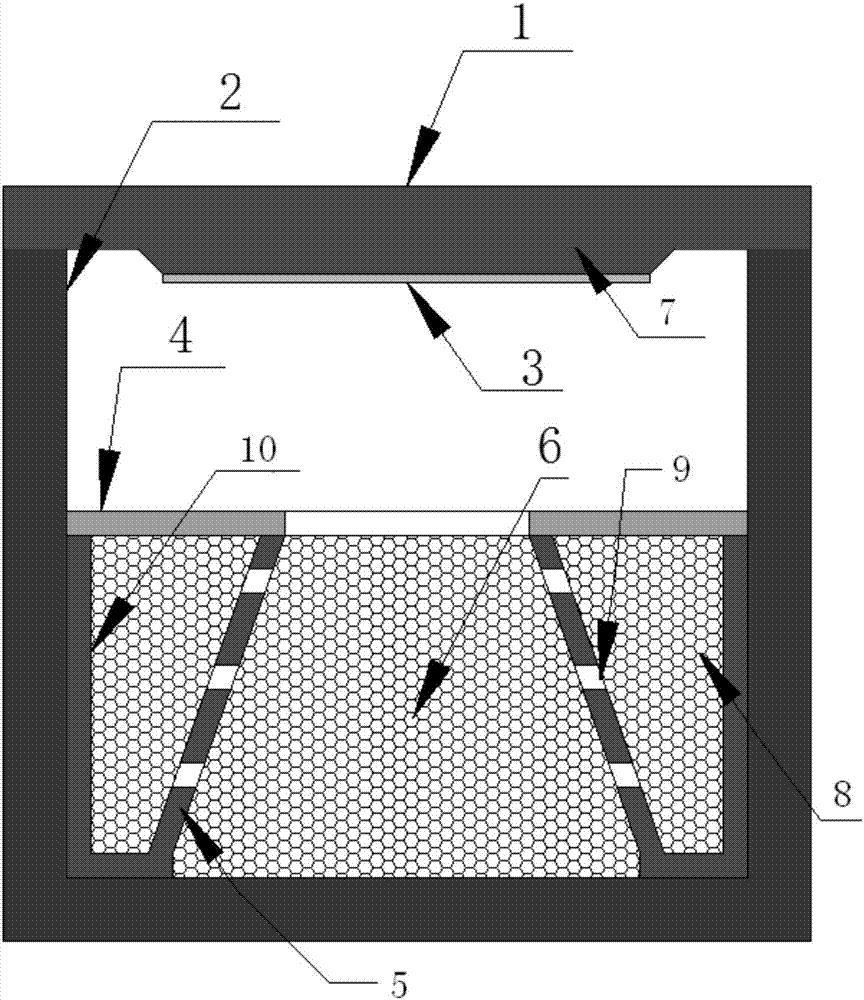

The invention provides an integrated internal circulation type denitrification and decarburization bio-membrane reactor and an operating method thereof. The main body of the reactor consists of an anoxic zone on the lower part, an aerobic zone on the upper part and a settling zone on the periphery of the aerobic zone; a composite filler is filled in the anoxic zone, and a water inlet pipe is communicated with the bottom of the anoxic zone; the aerobic zone is partitioned into a filler zone for adding a carrier on the upper part and a mud-water mixing zone on the lower part by adopting an orifice plate, the anoxic zone and the aerobic zone are partitioned through an impermeable partition plate, and a plurality of aeration pipes are arranged at the bottom of the aerobic zone and provided with air inlet pores; and the settling zone consists of three parts, namely a clean water zone, a contact settling zone and a sludge returning zone which are sequentially arranged from top to bottom, wherein the bottom of the sludge returning zone is provided with a sludge returning seam and communicated with the bottom of the aerobic zone. The reactor realizes zero power consumption in sludge returning, and is compact in structure; and a back flushing system is not required in the contact settling zone, and additional agents and carbon sources are not required, so that the reactor is low in running cost.

Owner:SUZHOU UNIV OF SCI & TECH

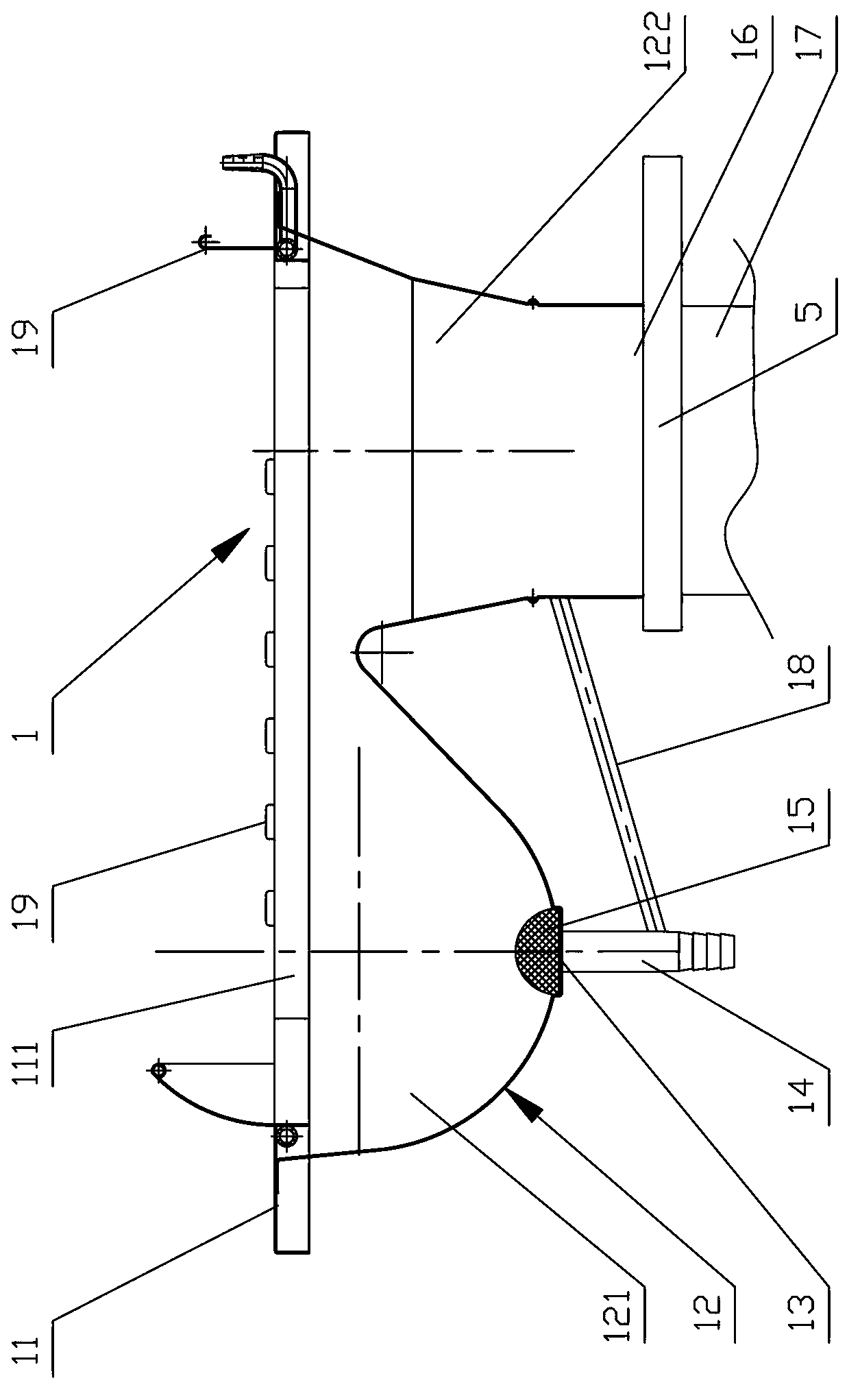

Solid-liquid separation toilet bowl and solid-liquid separation treatment system

InactiveCN102836866AReduce the possibility of mixingIncrease the amount of separationSolid waste disposalExcrement fertilisersUrine collectionEngineering

The invention provides a solid-liquid separation toilet bowl and a solid-liquid separation treatment system comprising the solid-liquid separation toilet bowl. The solid-liquid separation toilet bowl comprises a panel and a toilet bowl body, wherein the middle part of the panel is provided with a seat hole; the toilet bowl body is provided with a urine collection cavity and an excrement collection cavity; and the urine collection cavity and the excrement collection cavity are arranged with one in front of the other in longitudinal direction of the panel, are positioned below the seat hole and are opposite to the seat hole. Through the urine collection cavity and the excrement collection cavity formed in the toilet bowl body and by arranging the urine collection cavity and the excrement collection cavity with one in front of the other in the longitudinal direction of the panel, the urine collection cavity arranged at the front end is used for collecting urine, the excrement collection cavity arranged at the rear end is used for collecting the excrement, so that the urine and the excrement are effectively prevented from being mixed in the toilet bowl body; and thus, separation and recovery of the urine and the excrement are realized, further recycling of the excrement and the urine is realized respectively, and premise is provided for realizing the value of full utilization of the excrement and the urine.

Owner:张少岩 +2

Facility for automatically collecting waste liquid in volumetric flasks

InactiveCN102745636AEasy to operateSimple structureTight-fitting lid removalThreaded caps removalLiquid wasteMaterial resources

The invention discloses facility for automatically collecting waste liquid in volumetric flasks. The technical scheme of the facility includes that the facility for automatically collecting waste liquid comprises a fixing device, a power transmission device, a single-shaft robot, a transportation device and a rotary fixture. A container containing waste liquid is arranged on the fixing device, the fixing device on a conveyor is driven by a motor to be conveyed to an operation table, a cover of the container is unscrewed and placed in a cover collecting disc by a manipulator, the fixing device is transported to the rotary fixture above a waste liquid collecting barrel by a sucker, is fixed in a fixed sleeve, is turned and shaken by a rotating cylinder so that the waste liquid can be poured out, and finally is transported to the conveyor to be moved out of the operation table. The facility for automatically collecting waste liquid is simple in structure, convenient to operate, labor-saving, material-resource-saving, time-saving, safe, quick, high-efficient and automatic. Frequent working procedures are avoided.

Owner:CENT TESTING INT GRP CO LTD

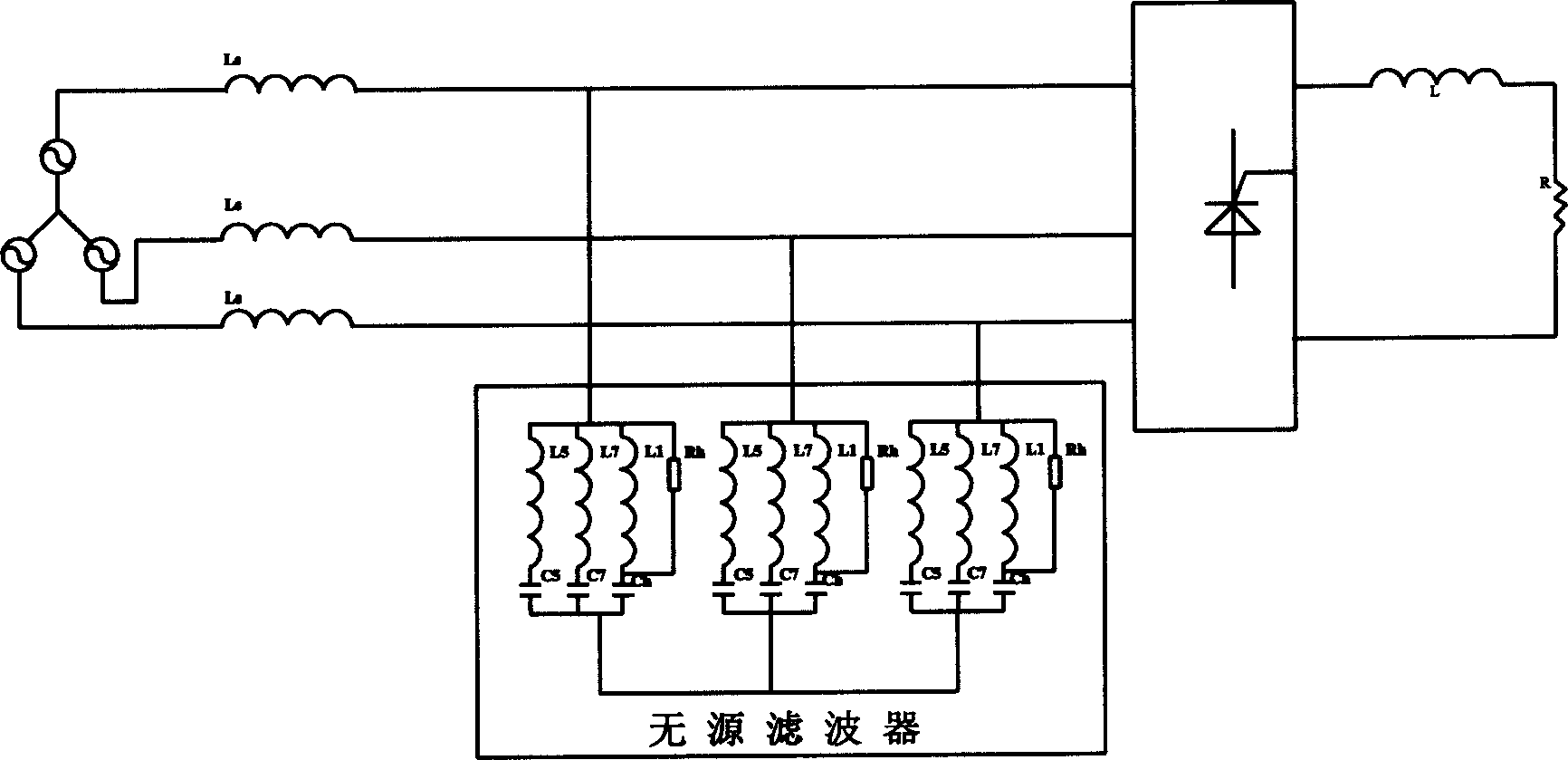

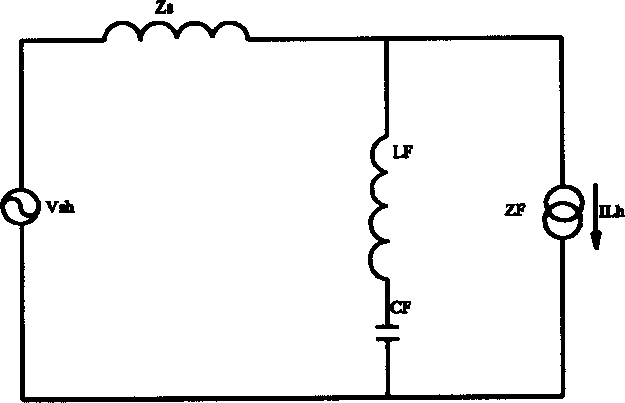

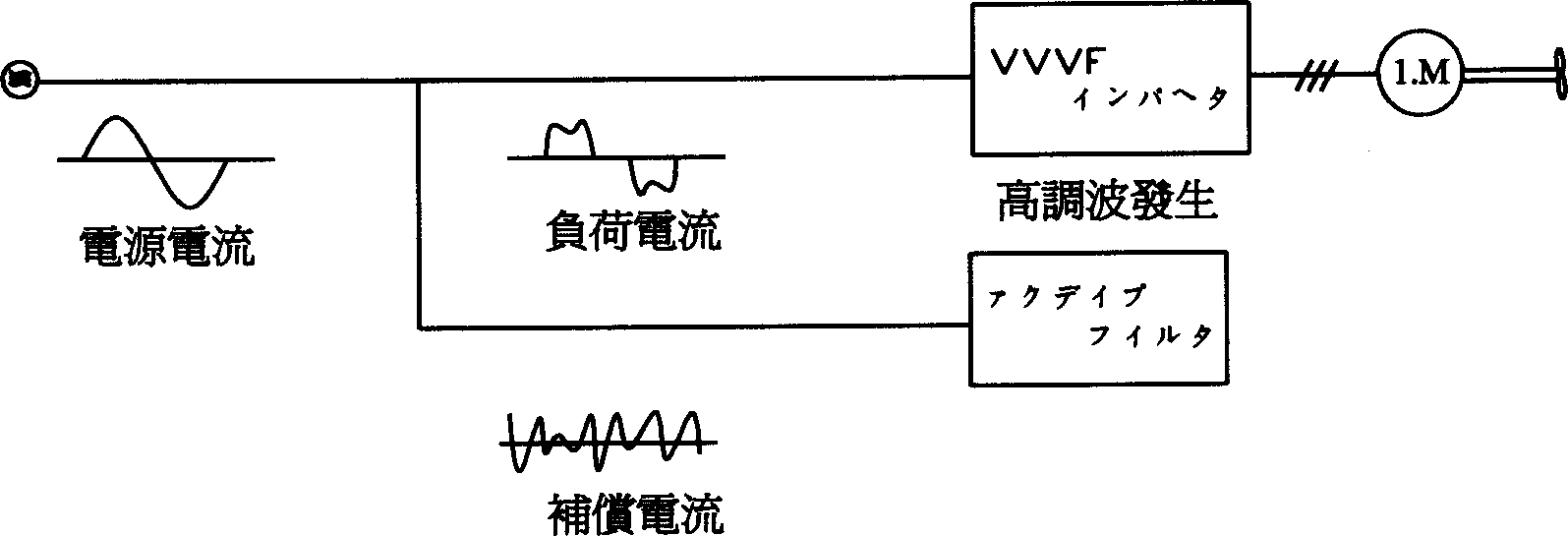

Synthetized compensation device in electric power system and synthetized compensation method

InactiveCN1540831AReduce the difficulty of detectionReduce capacityReactive power adjustment/elimination/compensationReactive power compensationDigital signal processingElectric power system

The device includes voltage detection unit at net side, current detection unit at net side, device of picking-up fundamental current at load side, digital signal processor DSP and control system based on DSP, generator of pulse-width modulation, inverter and LC filter. Structure and control method of combining unsmoothed nonlinear control with observer of expanding state are utilized in the invention. Output, derivative and unknown internal and external interference are observed through observer of expanding state. Harmonic opposite phase compensation is converted to tracking of ideal sine signal. Wattless dynamic compensation is realized through voltage-controlled reactor so as to reduce capacity of inverter to minimum and play filtering action. The invention integrates active filtering, passive filtering and wattless dynamic compensation.

Owner:SOUTH CHINA UNIV OF TECH

Novel crucible capable of reducing inclusions in silicon carbide single crystals and method for growing single crystals by using crucible

ActiveCN107059130AAvoid transmissionPlay a filtering rolePolycrystalline material growthFrom condensed vaporsCrucibleGas phase

The invention relates to a novel crucible capable of reducing inclusions in silicon carbide single crystals and a method for growing single crystals by using the crucible. The novel crucible comprises an outer crucible and a crucible cover, wherein an inner crucible is arranged in the outer crucible; the inner crucible comprises a bottom and a side wall; the side wall is a double-layer side wall; the double-layer side wall comprises an inner wall and an outer wall; small holes penetrating through the inner wall are formed in the inner wall; an annular end cover for sealing an interlayer between the inner wall and the outer wall is arranged at the upper end opening of the double-layer side wall. The inner crucible of the crucible closes SiC powder, which is located at a high temperature position and is easy to carbonize, in the interlayer between the inner wall and the outer wall of the inner crucible, so that powdered carbonized tiny carbon particles cannot be transported to the surfaces of seed crystals; meanwhile, powder in an inner cavity achieves a filter effect on a pyrolytic gas phase in the interlayer, so that the carbon particles are prevented from being transmitted to the surfaces of the SiC single crystals; therefore, carbon inclusions in the SiC single crystals are greatly reduced, and even in the SiC single crystals with the thickness of 20 mm, still no carbon inclusions are generated.

Owner:SHANDONG UNIV

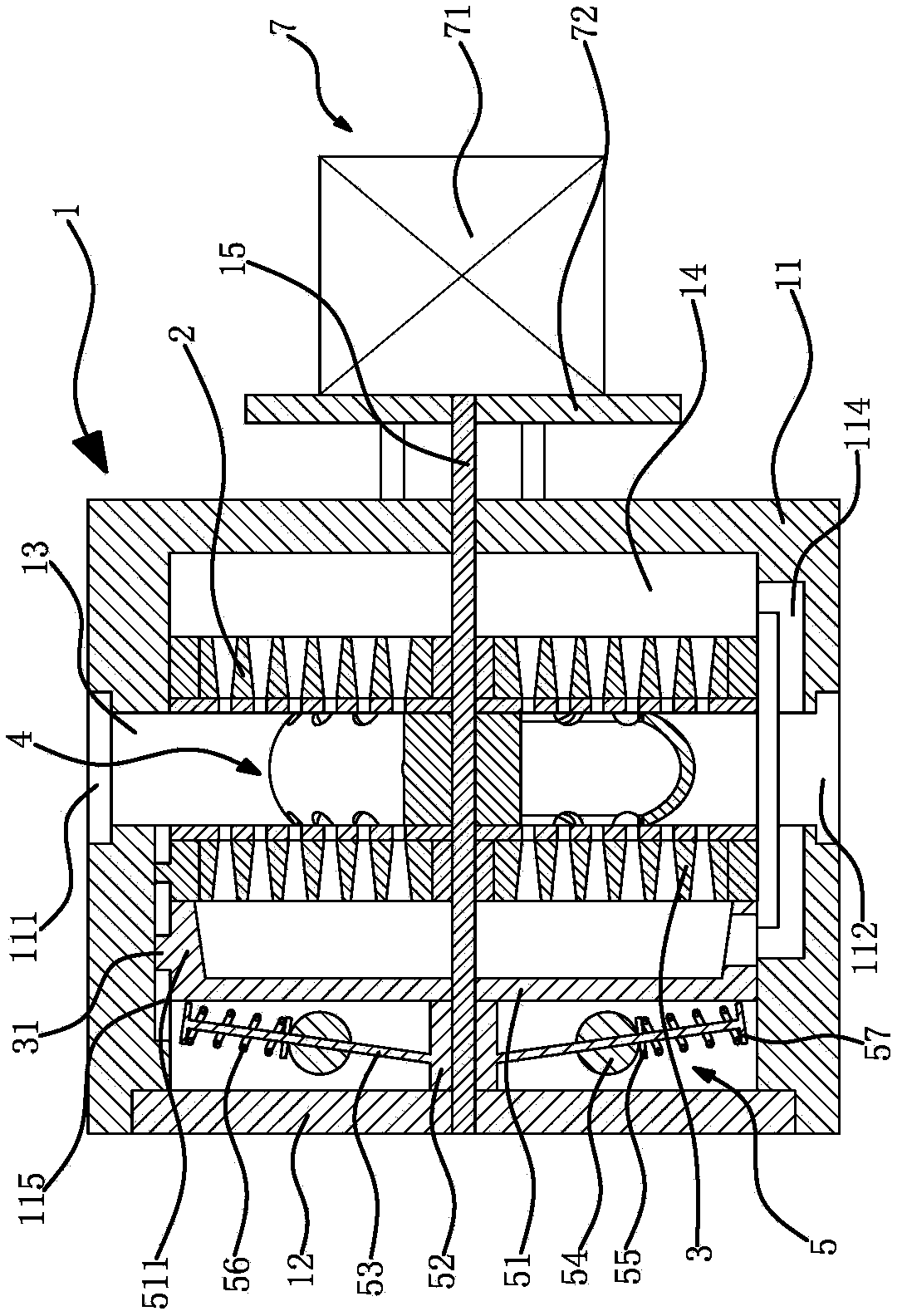

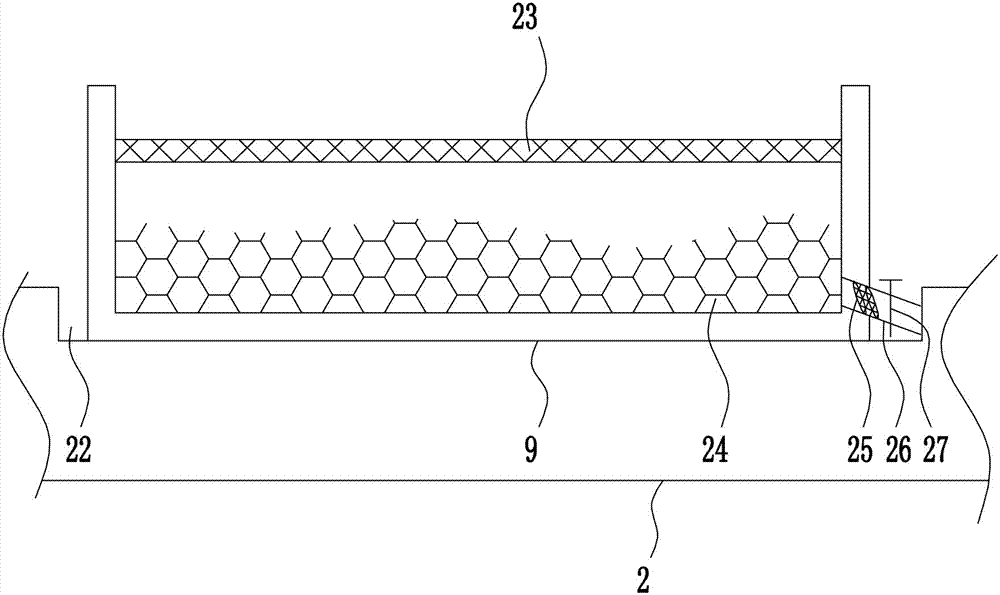

Integrated sewage treatment device with high efficiency and low consumption and treatment method

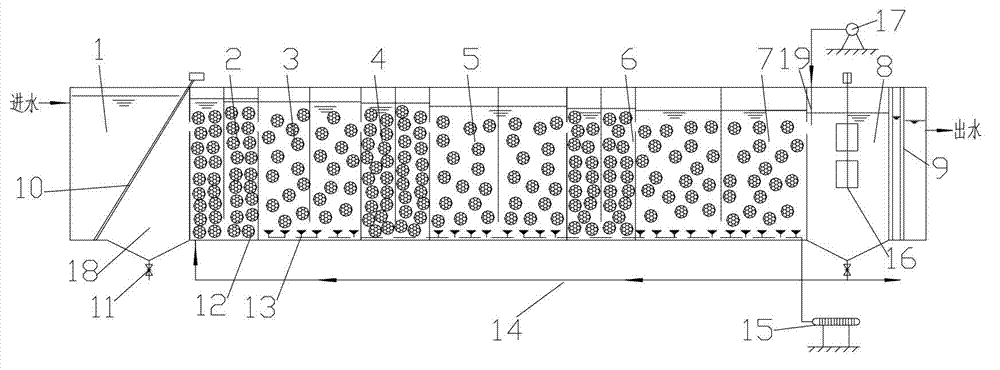

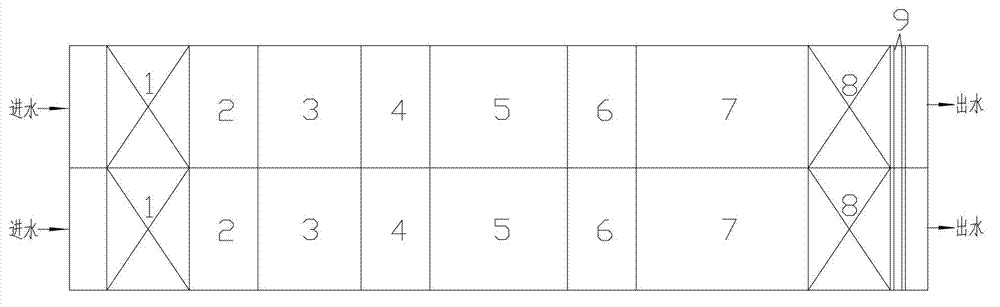

The invention relates to an integrated sewage treatment device with high efficiency and low consumption and a treatment method, and belongs to the field of sewage treatment. The integrated sewage treatment device comprises a pretreatment unit, a multi-oxidation-deoxidation environment coupling biological reaction pond unit and a deep treatment unit sequentially connected. The multi-oxidation-deoxidation environment coupling biological reaction pond unit adopts a three-stage anoxia-aerobiotic alternating reaction pond filled with a circular composite glass ball porous microbial carrier. The deep treatment unit comprises a filter cloth dynamic film biological reaction pond and first and second dynamic films. Sewage is treated through the devices sequentially. The device provided by the invention cannot only remove carbon containing organic matters, but also has good nitrogen and phosphorus removal capacity.

Owner:BEIJING UNIV OF TECH

Method for cultivating edible fungi

The invention discloses a method for cultivating edible fungi, which comprises the following steps: using mulberry branches as the raw material to prepare cone-shaped particle and drying the corn-shaped particle; putting the dried mulberry branch particle into nutrient solution to be immersed until the nutrient solution is totally absorbed, wherein 100 parts by weight of dried mulberry branch particle is taken as the reference, and the weight proportion of the nutrient solution is that 170 to 277 parts of water, 13 to 18 parts of corn meal, 0.3 to 0.5 part of sucrose and 0.1 to 0.3 part of calcined lime; uniformly mixing the immersed mulberry branch particle with a fungi culture medium determined according to the type of the edible fungi, filling the mixture into a fungi bag or a fungi bottle, sterilizing, cooling, inoculating and cultivating the fungi; after hypha overgrows the whole fungi bag or the fungi bottle for 7 days, taking out the mulberry branch particle and inserting the mulberry branch particle into a fungi stick; and carrying out conventional treatment according to the type of the cultivated edible fungi after inoculating to obtain the edible fungi. The method does not need to use the device to punch and has simple and convenient operation, low production cost and low mixed bacterium infection rate. The harvest time of the edible fungi of the method is longer 20 to 30 days than that in the prior art.

Owner:桂林宏旺菌业股份有限公司

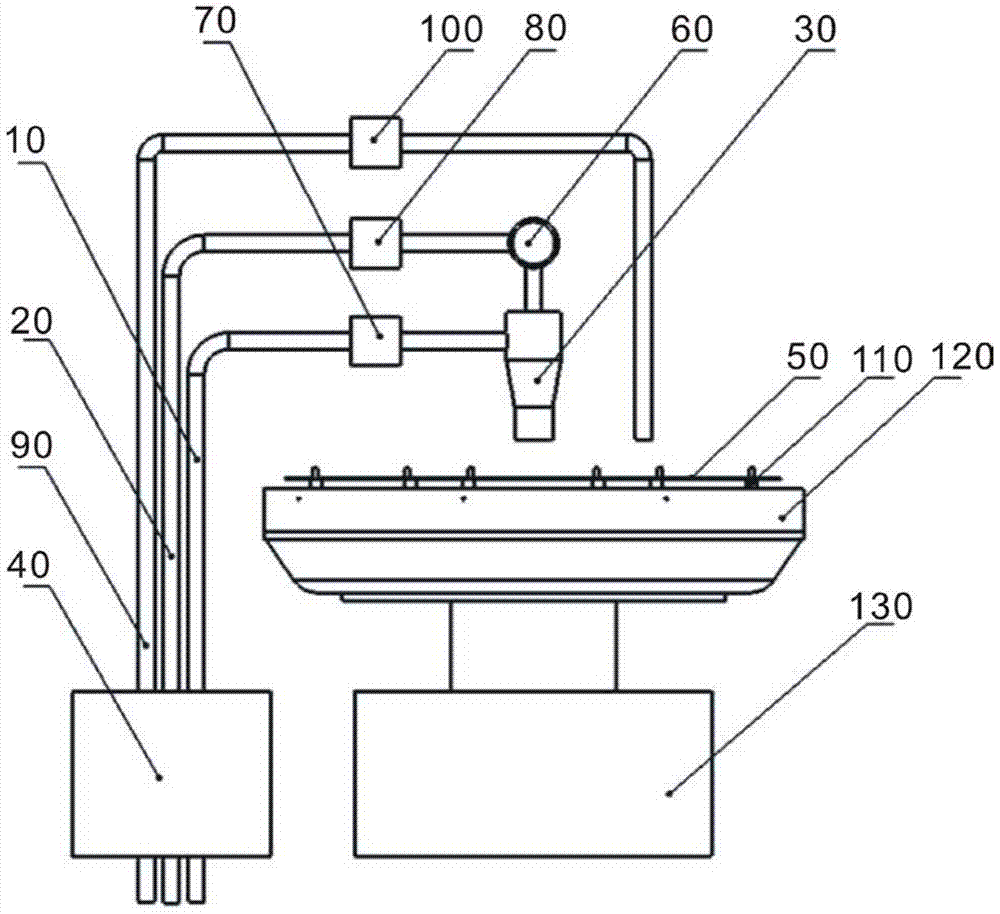

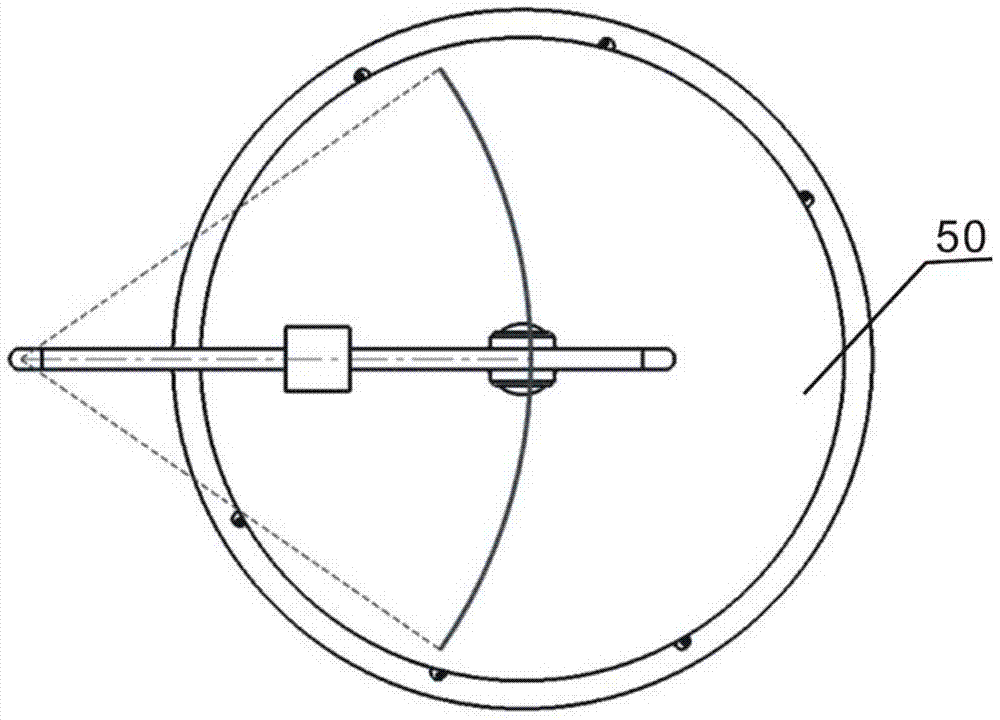

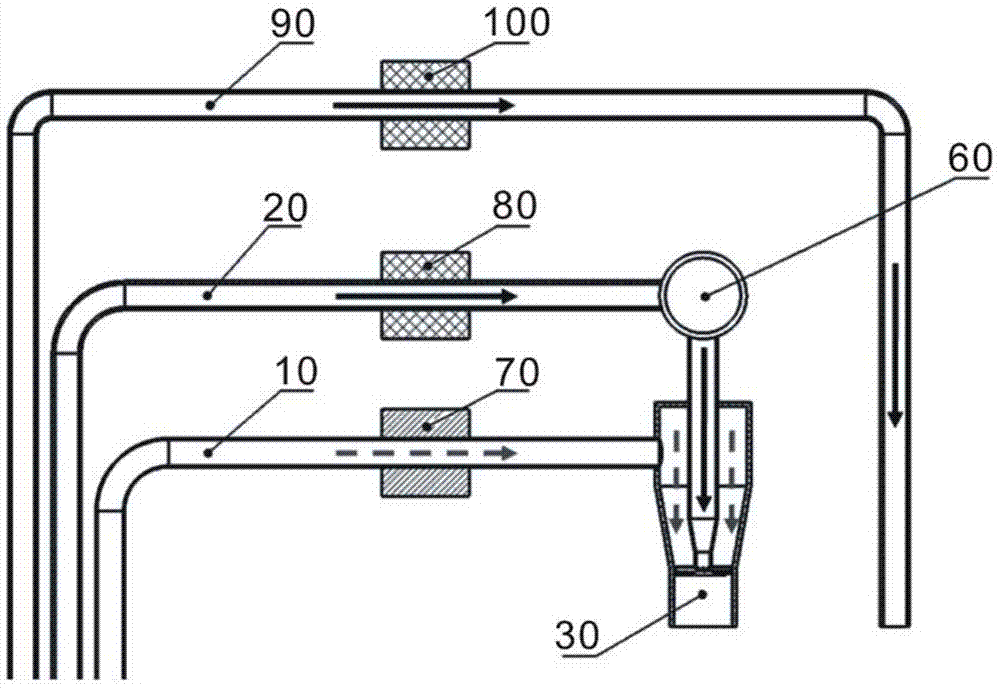

Gas-liquid two-phase atomization cleaning device and cleaning method

ActiveCN104841660AFacilitate deliveryImprove efficiencyCleaning using liquidsGas pipelineProduct gas

The invention provides a gas-liquid two-phase atomization cleaning device and relates to the technical field of the semiconductor chip technology. The gas-liquid two-phase atomization cleaning device comprises a gas pipeline, a liquid pipeline and a gas-liquid two-phase atomization nozzle, one end of the gas pipeline and one end of the liquid pipeline are arranged on a swing arm while the other end of the gas pipeline and the other end of the liquid pipeline are communicated with the gas-liquid two-phase atomization nozzle to form atomization particles, and the swing arm drives the gas-liquid two-phase nozzle to reciprocate in a circular arc manner between the edge and the center of a wafer. High-speed liquid flow and high-speed gas flow are sufficiently acted through a gas-liquid two-phase atomization nozzle structure, superfine atomized droplets uniform in particle size are formed by adjusting gas flow rate and liquid flow rate of small flow rate, the superfine atomized droplets are sprayed on the surface of the wafer after being accelerated through the high-speed gas flow, and cleaning is completed. By the arrangement, transferring of impurities in troughs to a main flow body is promoted, efficiency in cleaning is improved, cleaning effect is improved, and damage to the surface structure of the wafer is reduced due to small quality of the atomization particles.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

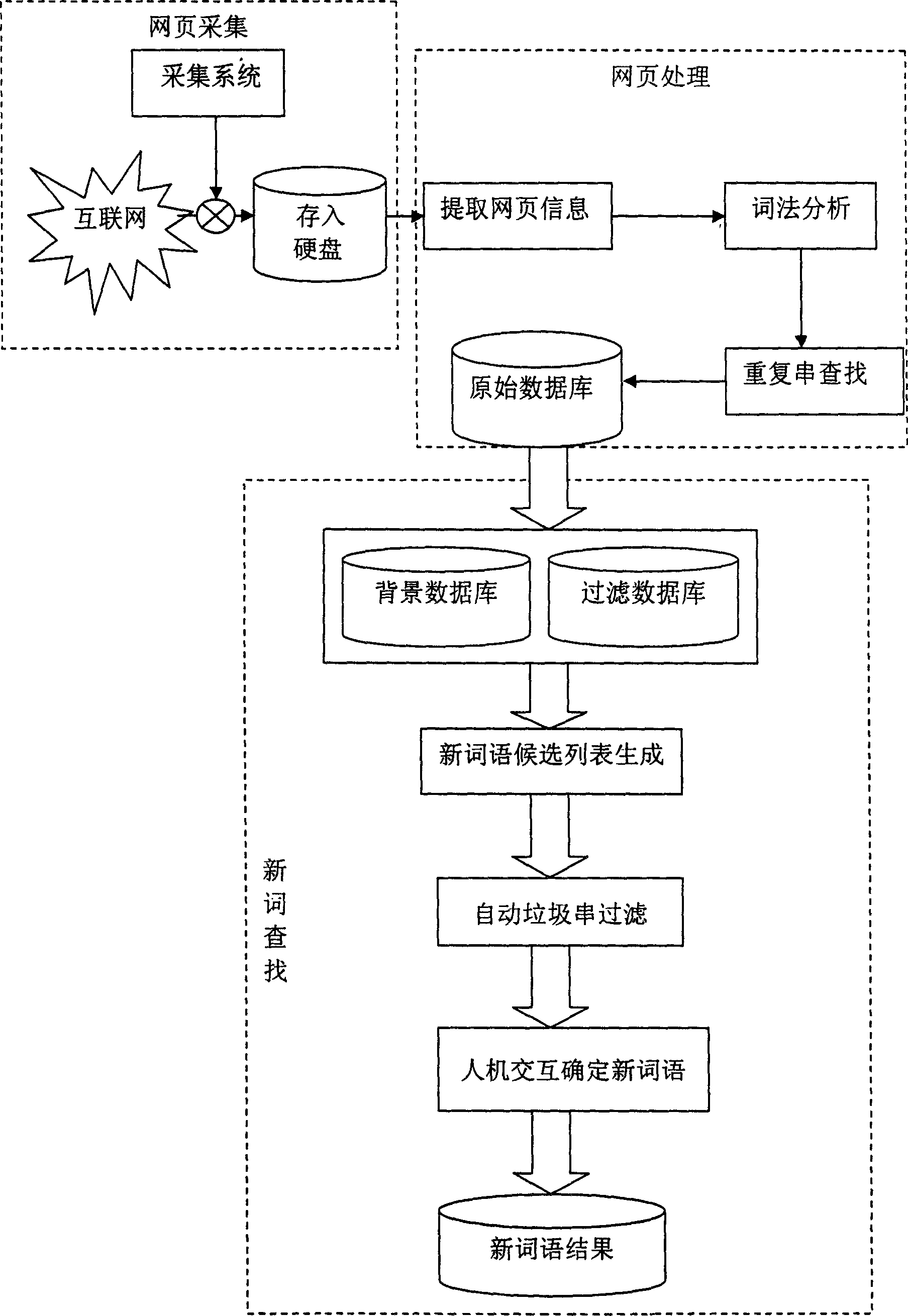

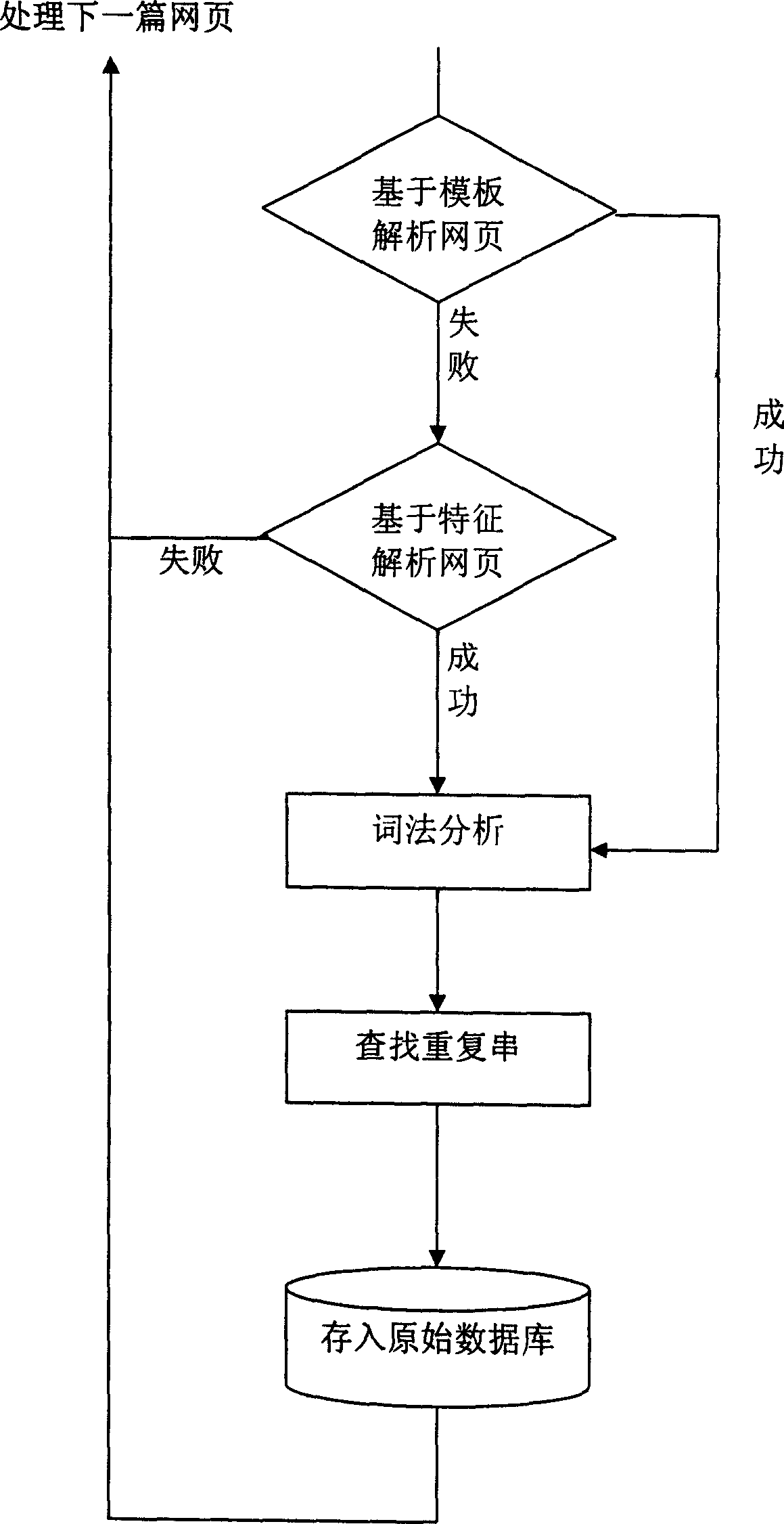

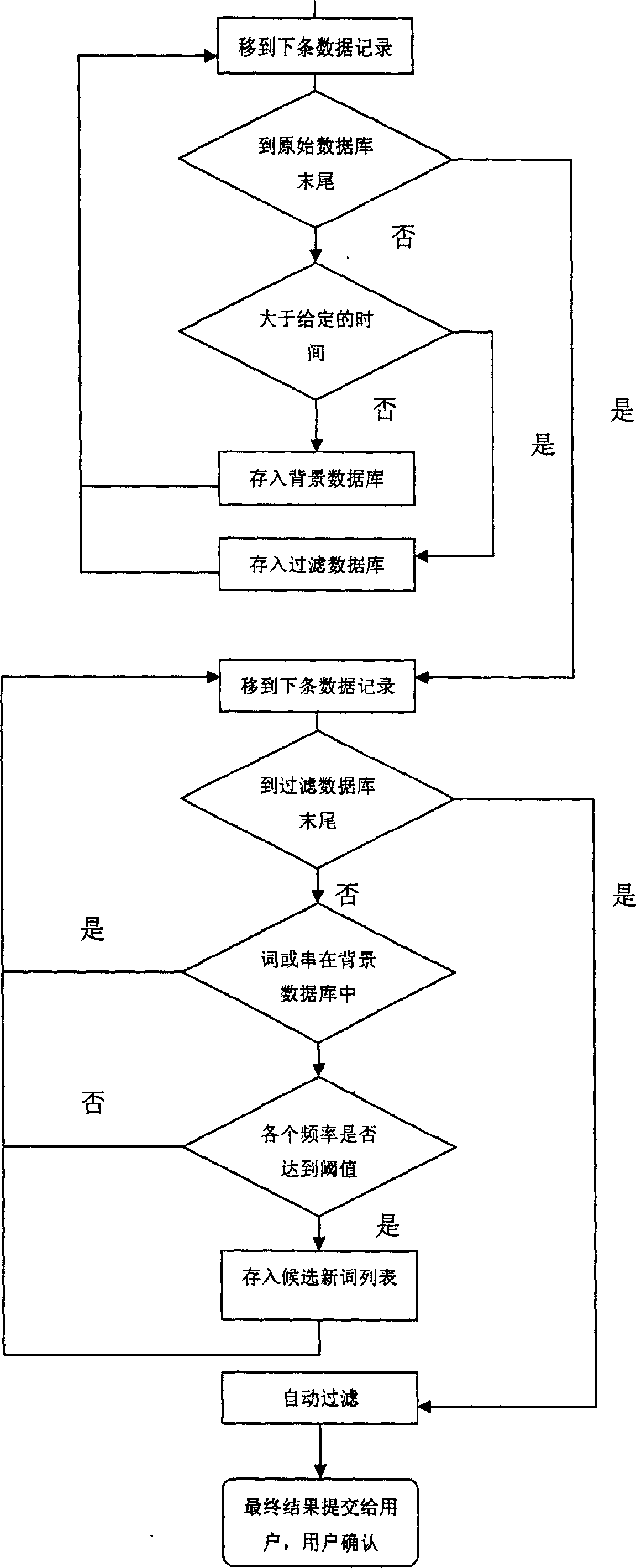

Chinese new word and expression detecting method and its detecting system

ActiveCN1641634APlay a filtering roleImprove timelinessSpecial data processing applicationsInformation retrievalSetting time

The invention relates to a Chinese character new phrase checking method and the checking system. It is based on Internet Chinese character new phrase auto-checking method. It includes page collection, page information process and new phrase searching, and making the most of the time information of page collected from Internet. Separating the time information and content drawn from page and searching the repeating string on the base of the separation, saves into original database. The original database is separated into before setting time database and after setting time database. Comparing the two databases, the new phrase selected list would be gained. Then, the final result should be affirmed. The invention would search new plural characters phrase and new phrase combined by plural characters without length limited and structure. And the rubbish strings would be filtered by the phrase construction rule. It has the feature of high time effect.

Owner:HUAWEI TECH CO LTD

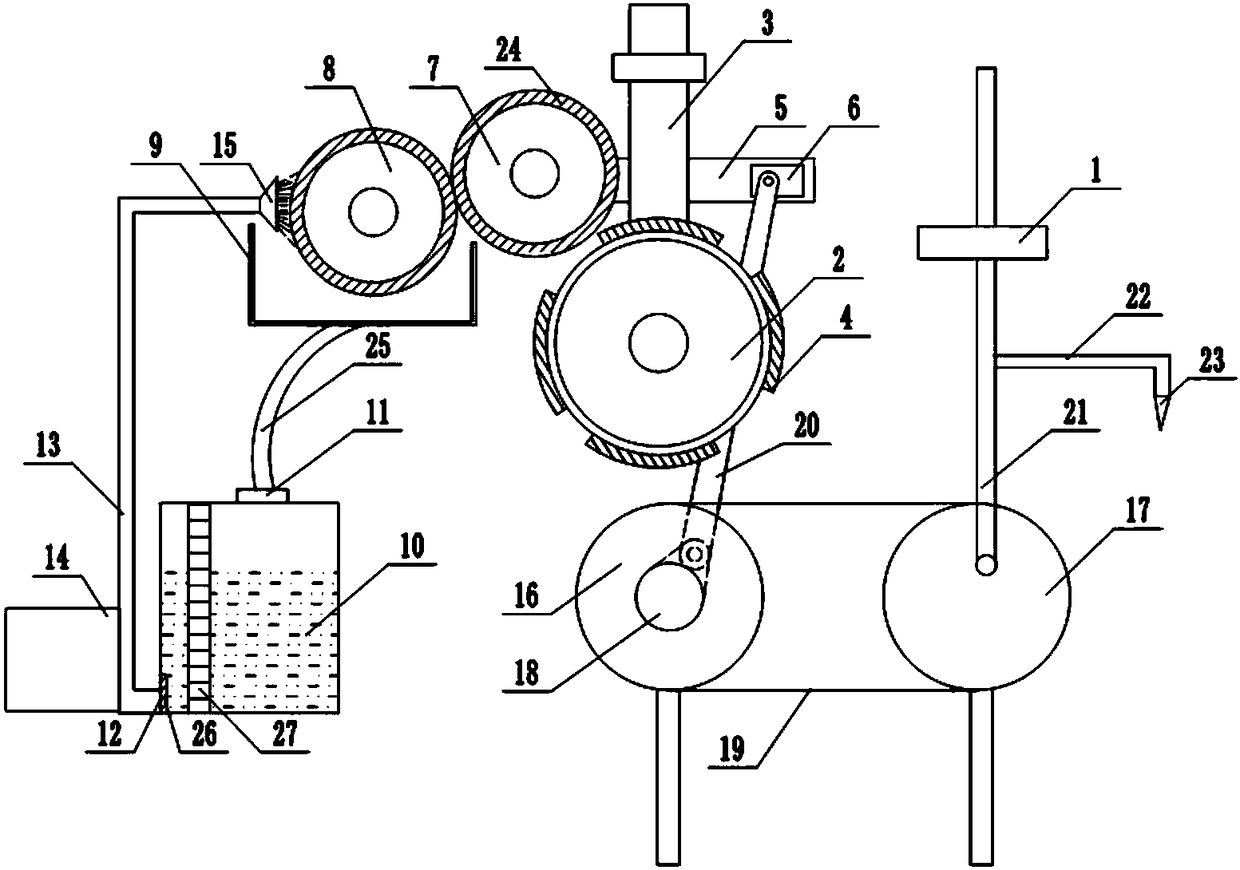

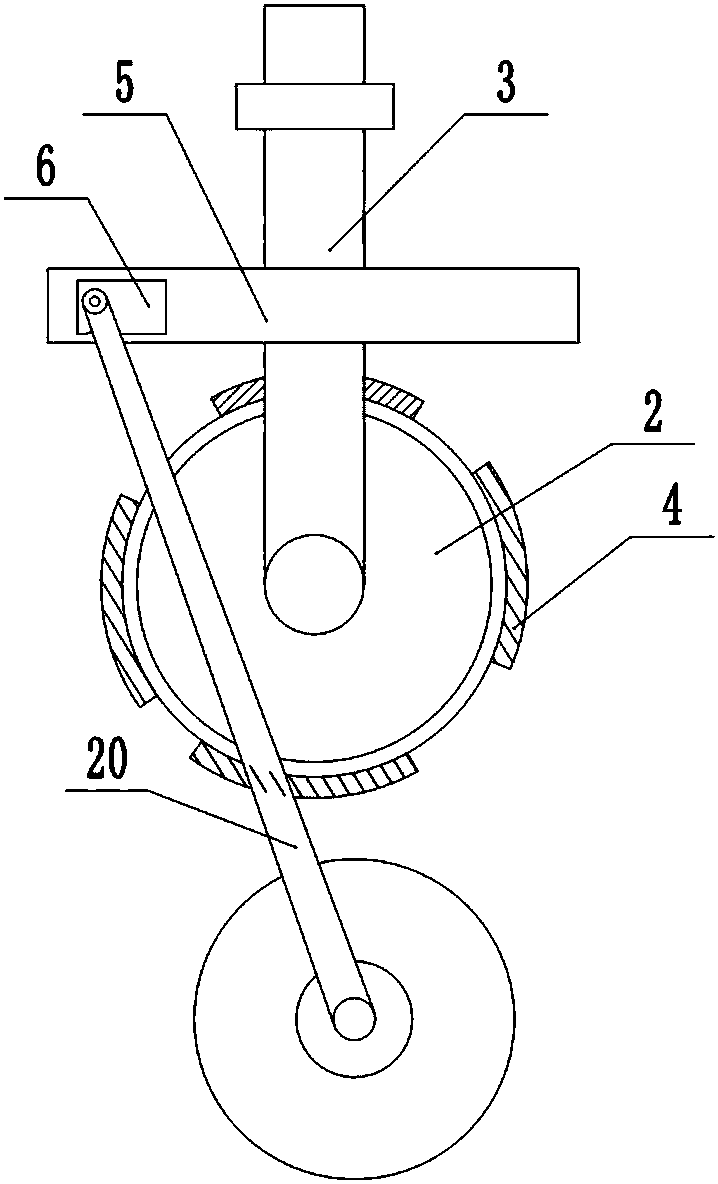

Paperboard printing device

InactiveCN108215475AAvoid dripping problemsHigh degree of automationInking apparatusRotary pressesDrive wheelDrive shaft

The invention relates to a paperboard printing device. The paperboard printing device comprises a machine frame, a printing roller and a sliding rod; the printing roller is connected with a first motor; one end of the printing roller is connected to the sliding rod; printing plates are arranged at the other end of the printing roller; the sliding rod is connected to the machine frame in a slidingmode; a sliding groove is fixedly connected to the sliding rod; a sliding block is connected in the sliding groove in a sliding mode; an ink feeding mechanism is arranged on one side of the printing roller and comprises a first ink roller and a second ink roller; the printing roller, the first ink roller and the second ink roller abut against one another in sequence; an ink tank is arranged belowthe second ink roller; an ink barrel is arranged below the ink tank; an ink feeding pipe is arranged on the ink barrel; a spray head is arranged at one end of the ink feeding pipe; a conveying mechanism is arranged below the printing roller and comprises a driving wheel, a driven wheel and a conveying belt; a driving shaft is arranged in the center of the driving wheel; an extension end is arranged on the driving shaft of the driving wheel; the extension end is connected with a push rod in a rotating mode; and the other end of the push rod is hinged to the slide block. According to the paperboard printing device, the problem of ink dripping caused by excessive ink coating in the paperboard printing process can be solved.

Owner:重庆市琦缘包装有限公司

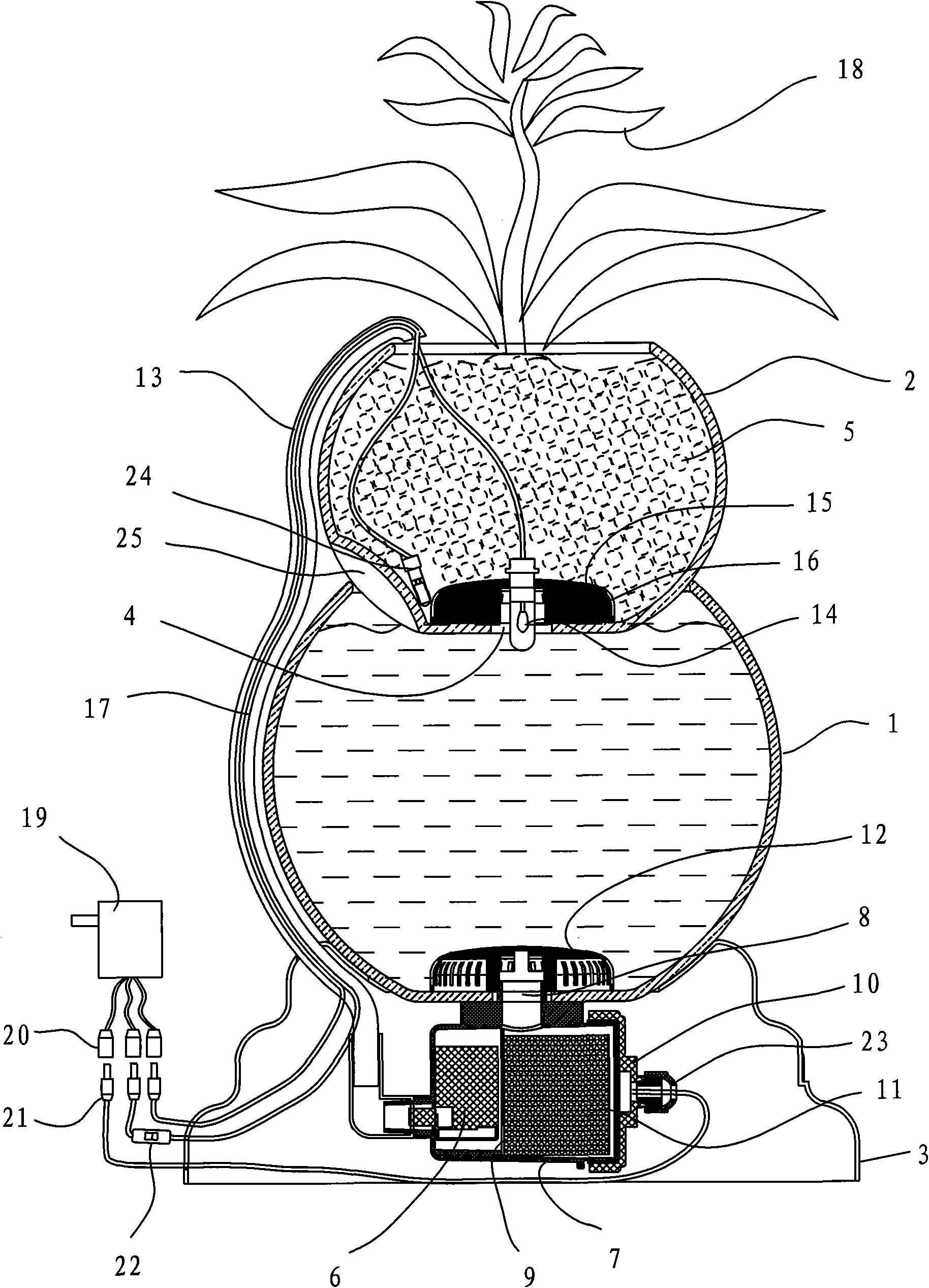

Vase fish tank

InactiveCN101558751AGood choice varietyStrong perceptionPisciculture and aquariaAgriculture gas emission reductionEngineeringCirculating pump

The invention discloses a vase fish tank which comprises a fish tank and a vase, wherein the vase is arranged above the fish tank, the bottom of the vase is provided with a through hole communicated with an inner cavity of the fish tank, the inner part of the vase is provided with ice soilless nutrient body, the fish tank is arranged on a fish tank base internally provided with a circulating water pump, the bottom of the fish tank is provided with a water outlet communicated with the inner cavity of the fish tank and the circulating pump, and an outlet pipe of the circulating pump extends outside an opening of the vase from the outside of the vase. The vase and the fish tank can be placed in an overlapping way, i.e. plant landscape is arranged in the vase and water landscape is arranged in the fish tank, therefore, the vase fish tank can be used for planting various plants including land plant so as to have good selection variety; solid material produced by the water plant can be used as nutrient source of the plant, so the vase fish tank is easy to build and maintain natural balance, and has strong ornamentation effect because of strong integral sight and special model.

Owner:GUANGDONG ZHENHUA ELECTRICAL APPLIANCE CO LTD

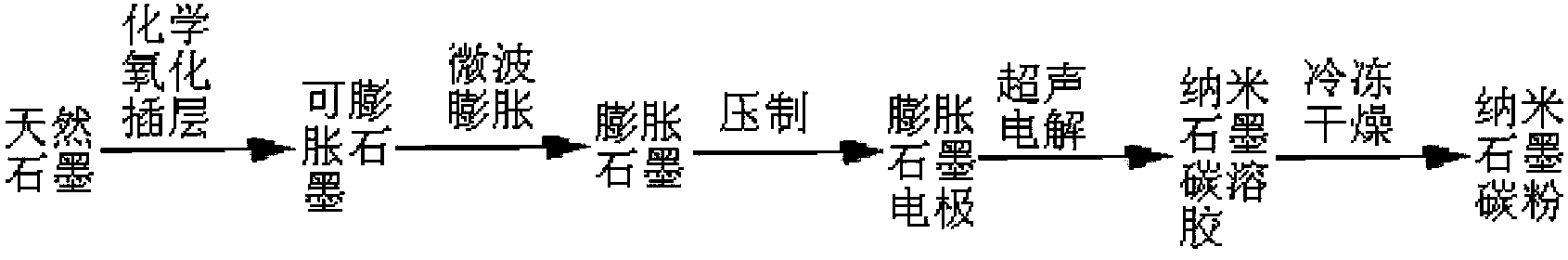

Preparation method of nano-graphite carbon powder

ActiveCN103395777AImprove electrolysis efficiencyShorten electrolysis timeMaterial nanotechnologyGraphiteElectrolysisFreeze-drying

The invention relates to a preparation method of nano-graphite carbon powder. The method comprises the steps of: (1) preparing expansible graphite by a chemical oxidation intercalation process; (2) preparing expanded graphite by a microwave process; (3) pressing the expanded graphite into a expanded graphite sheet, putting it into a microporous filter membrane sieving assembly, conducting pressing and sealing, then placing the assembly at the anode and cathode of an electrolytic bath, taking a chlorate solution as an electrolyte solution, carrying out ultrasonic electrolysis at a temperature below 60DEG C, controlling the electrolytic current at 5-18A / cm<2>, the voltage at 6-20V, the ultrasonic oscillation power at 200-600W, and the frequency at 20-40kHz, inverting the anode and the cathode at an interval of 8-15min, completing electrolysis when the concentration of sol in the electrolytic bath is 2-5%, thus obtaining nano-graphite carbon sol; and (4) adding ammonium sulphate into the nano-graphite carbon sol till the mass concentration of ammonium sulfate reaches 5-8%, stirring them uniformly, then performing freeze drying, thus obtaining the nano-graphite carbon powder. The method has the advantages of mild reaction condition and high speed, thus being suitable for industrialized mass production.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

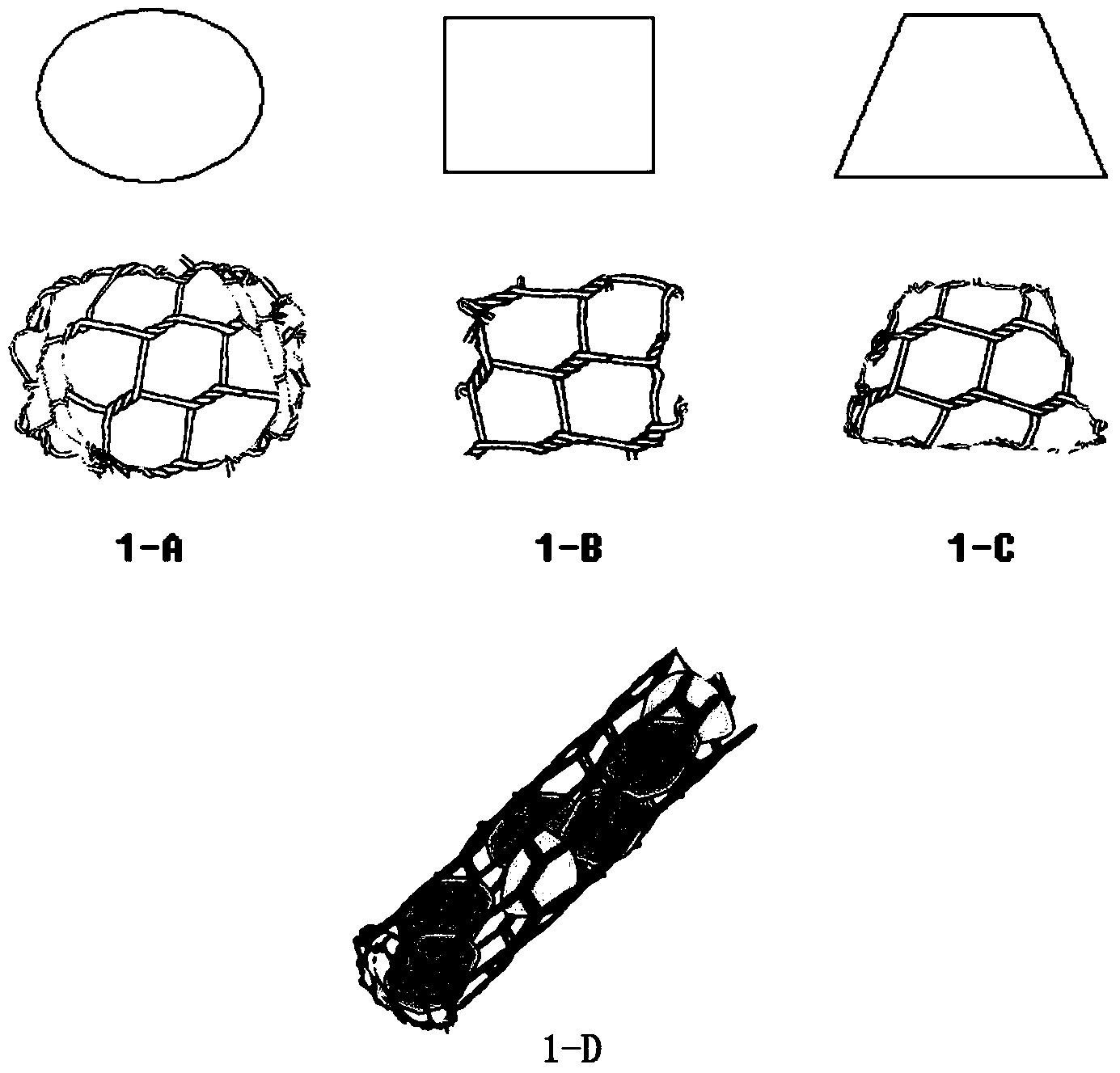

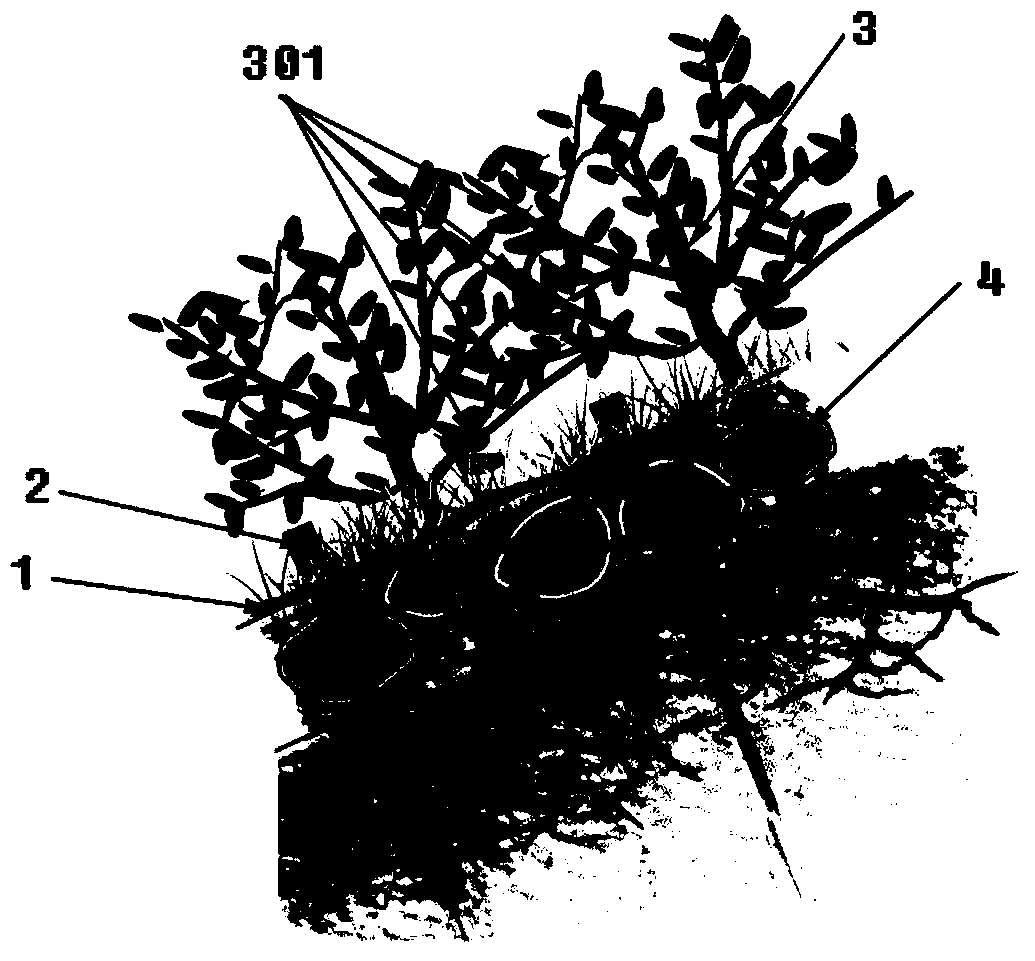

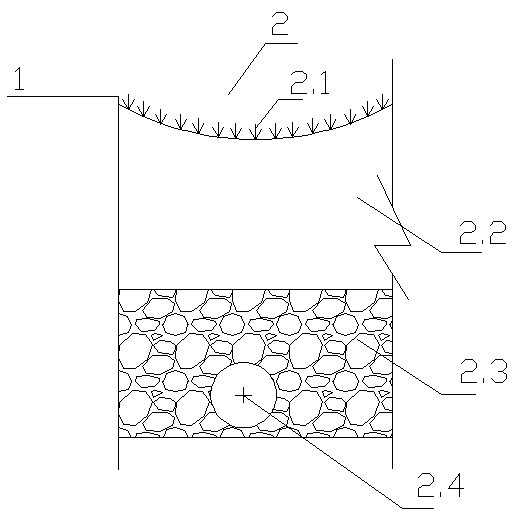

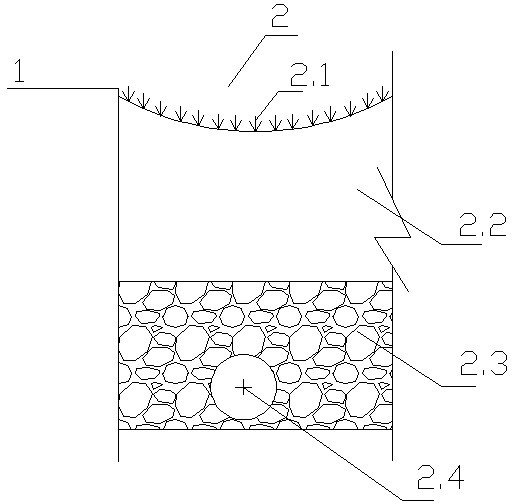

Method for ecological management of hedgerow riverbank revetment

ActiveCN103643654AImprove the landscape effectFully woundCoastlines protectionHorticultureBuffer stripAquatic animal

The invention relates to a method for ecological management of a hedgerow riverbank revetment. The method comprises the steps as follows: ecological gabion revetment grooving, gabion box laying, hedgerow shrub planting, pebble backfilling, shrub grafting and the like. According to the method, a method for fixing gabions through hedgerows formed with a coordinal plant grafting technology is fully used, the revetment is more stable in structure, the water erosion resistance of the revetment is enhanced, and meanwhile, riverbank buffer zones consisting of flooding-resistant shrubs, ground cover herbage and gabion filler can play an important role in filtering non-point source pollutants entering a water body; a richer habitat is provided for aquatic animals and plants by gap structures formed by ecological gabions, so that the stability of a river ecological system is maintained; and the landscape effect of the riverbank revetment can be further improved by planting of shrub vegetation.

Owner:金辛(海南)科技有限公司

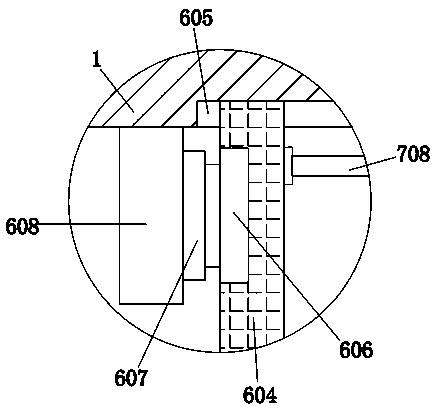

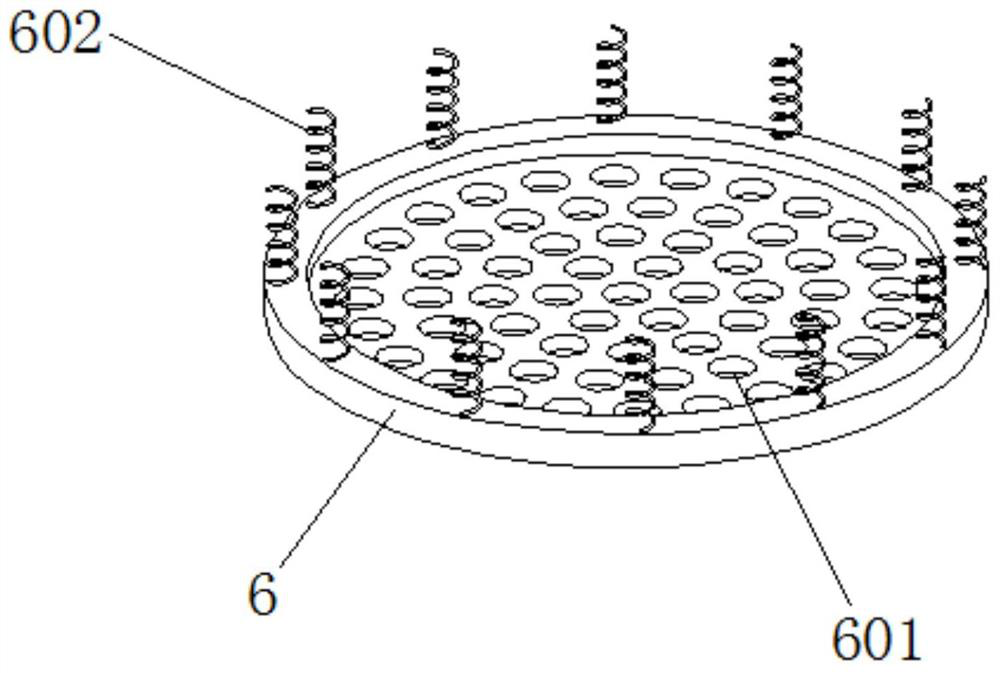

Double-plate type filter without replacing filter screen

The invention provides a double-plate type filter without replacing a filter screen, belonging to the technical field of melt filter equipment, and aiming at solving the problem that when the existing filter is used, the service life of a filter plate is shortened. The double-plate type filter without replacing the filter screen comprises a shell; a rotating shaft is rotatably arranged in the shell in a penetrating way; the peripheral wall of the shell is respectively provided with a feeding hole and a discharge hole; a fixed filter tray is fixedly connected in the shell; the inner circumference wall of the shell is connected with a movable filter tray in a sliding way along the axial direction of the shell; a scraper is fixedly connected in a feeding cavity of the rotating shaft; a cutting edge of the scraper respectively leans against the sides of the fixed filter tray and the movable filter tray; a hold-down mechanism is also arranged in the shell; the circumference wall of the shell is also provided with an impurity discharge hole which is connected with a transmission mechanism. After the double-plate type filter without replacing the filter screen is used, the service lives of the filter trays are prolonged, and the filtering quality and the filtering efficiency are improved.

Owner:ZHEJIANG LEENY TECH

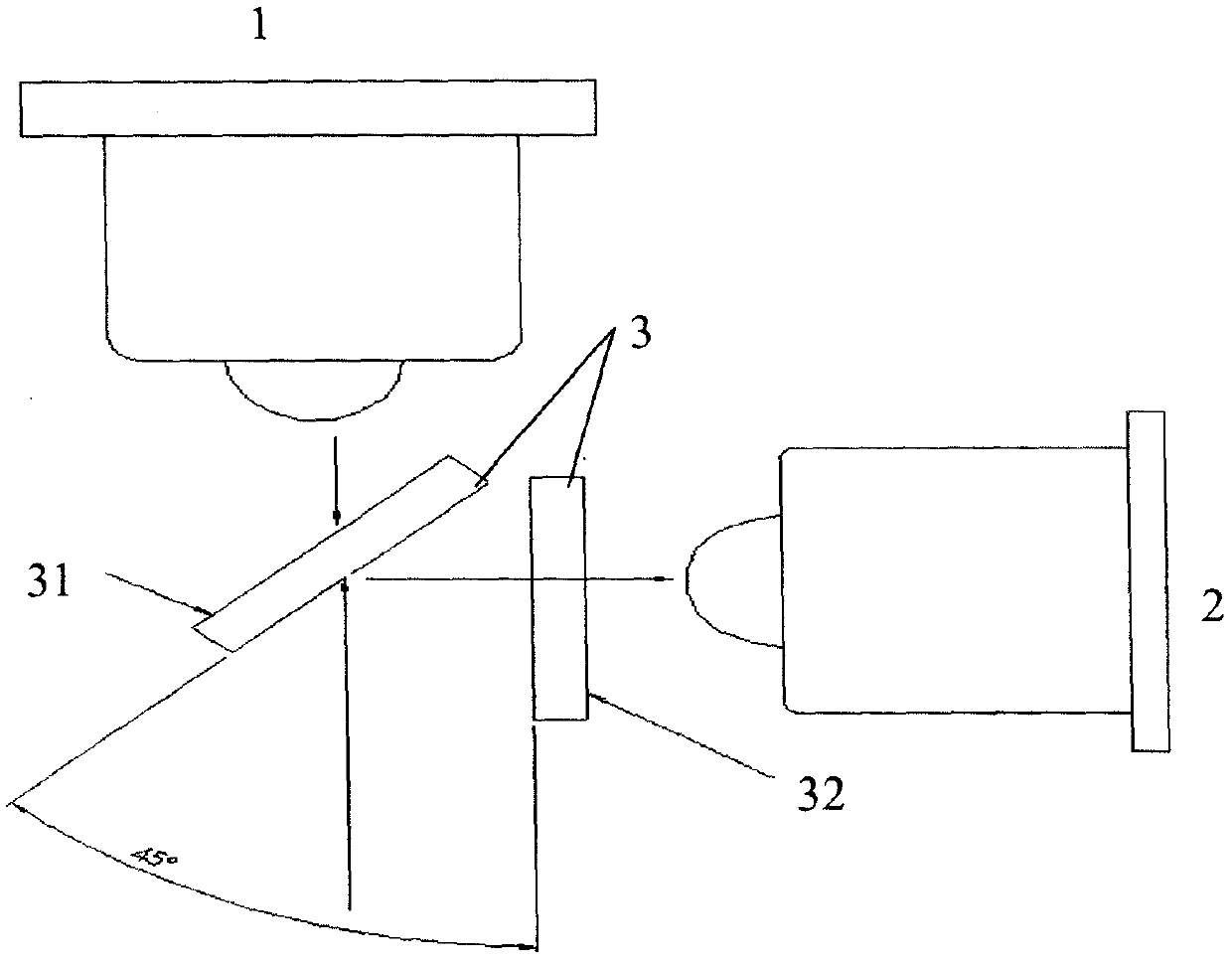

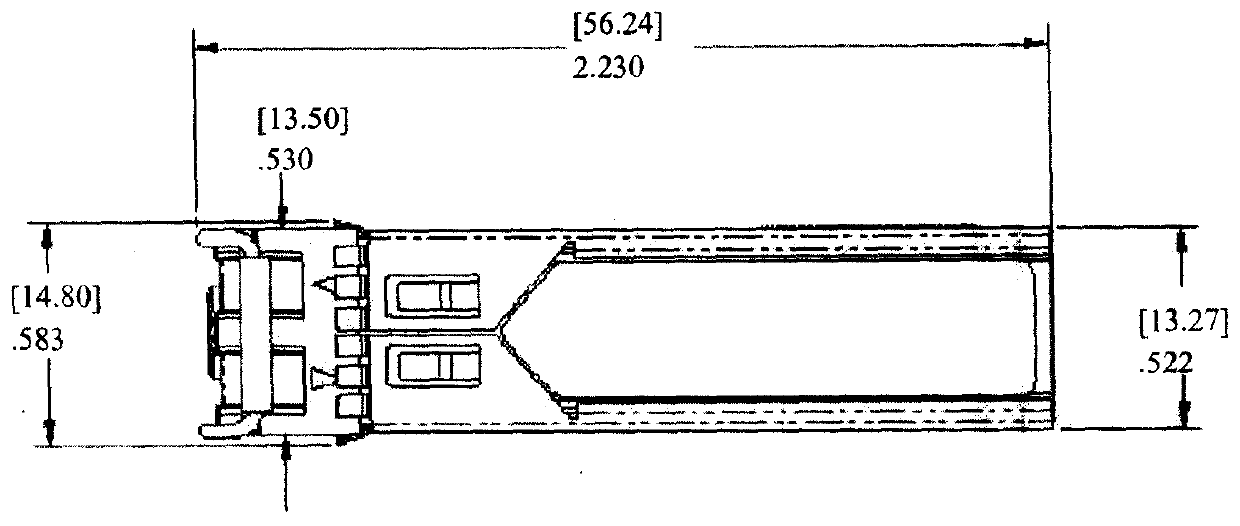

Photoelectric receiver-transmitter integrated module assembly of mono-optical fibre two-way

InactiveCN101030817AIncrease laser powerHigh sensitivityFibre transmissionElectromagnetic transceiversOptical pathOptoelectronics

Owner:深圳市华润通光电股份有限公司

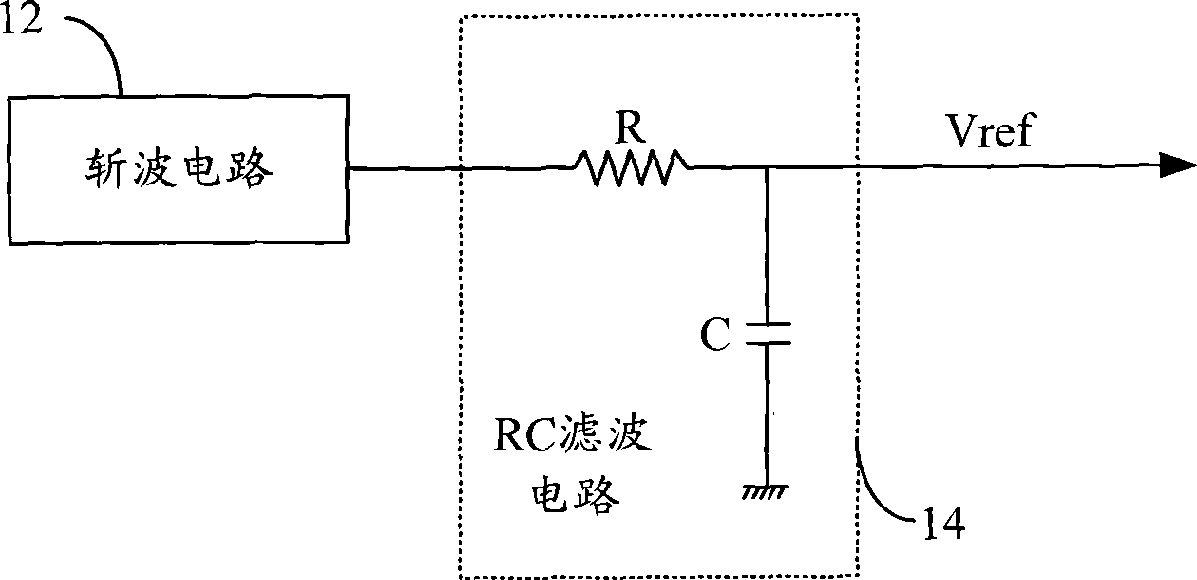

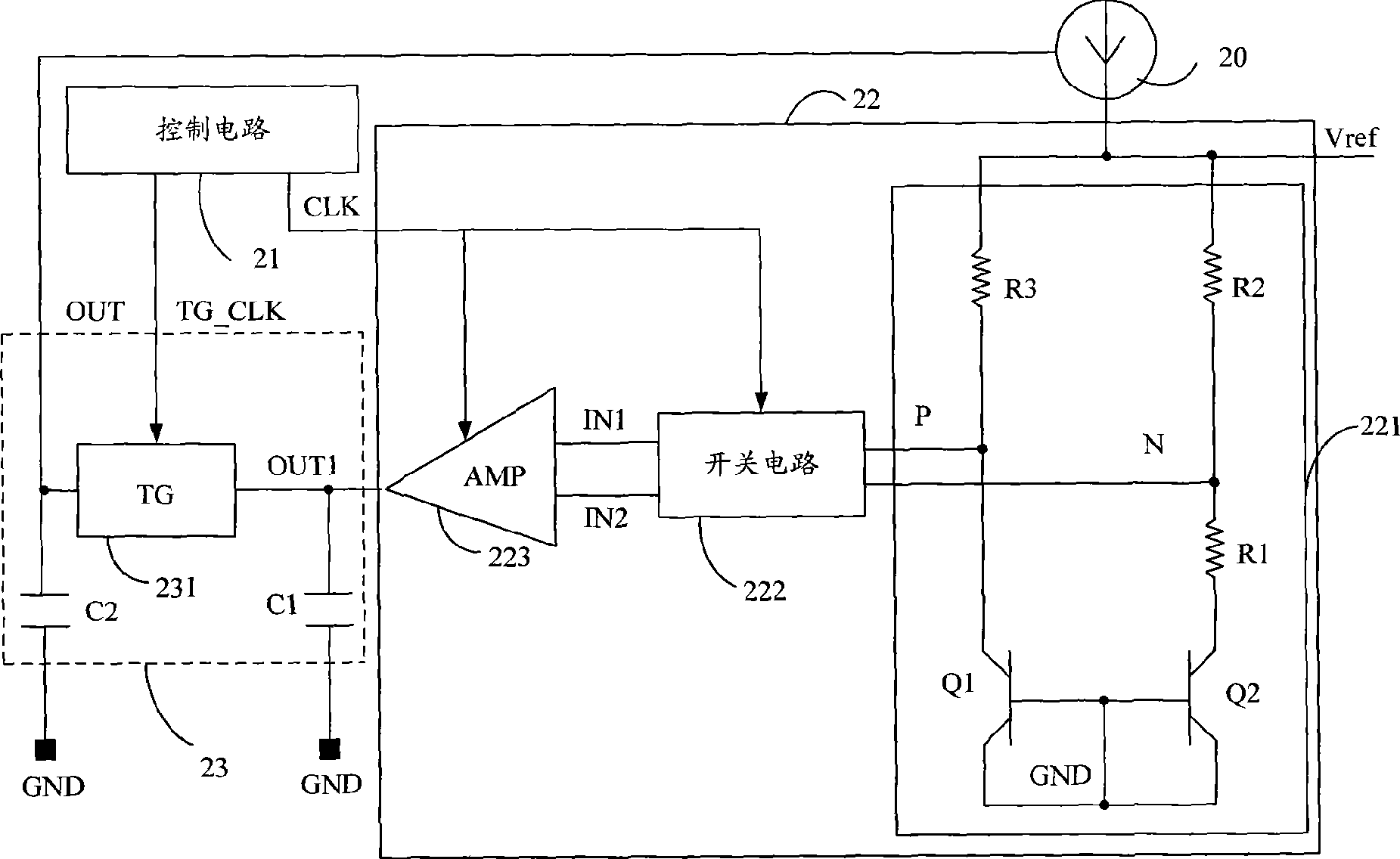

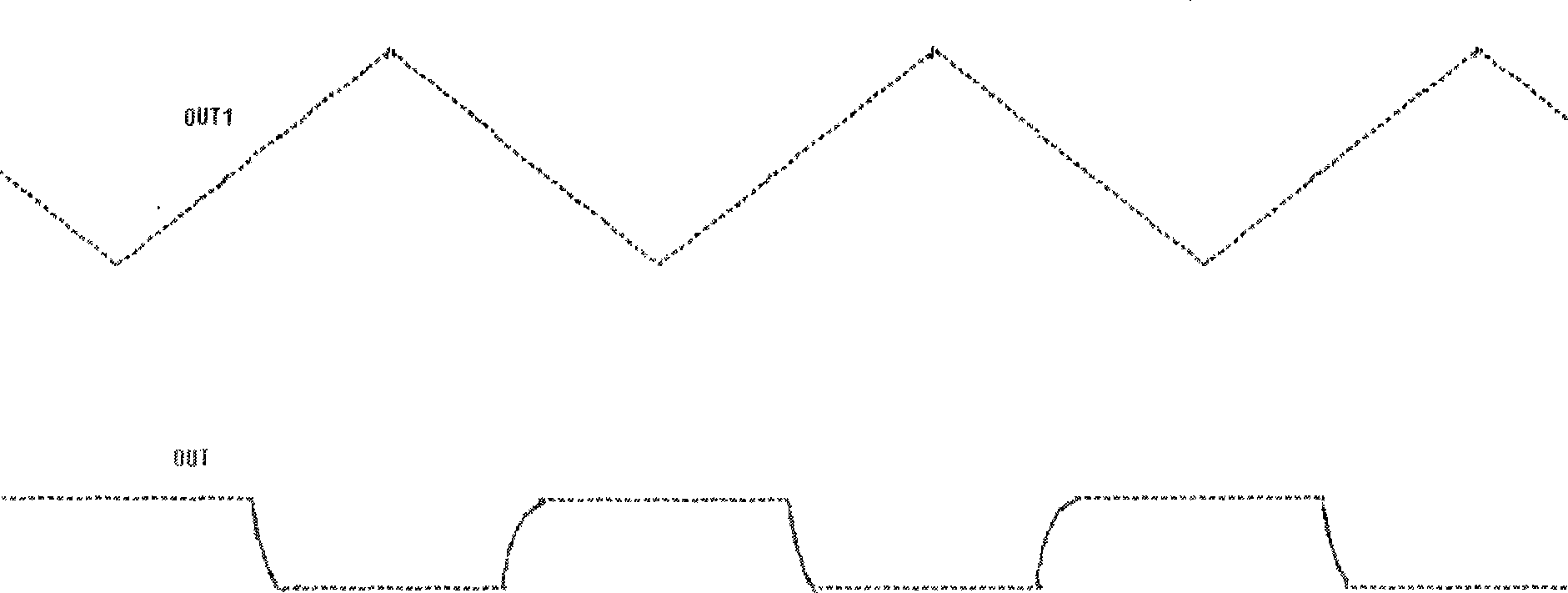

Band-gap reference voltage circuit

InactiveCN101458540ASimple structureOvercoming Difficult Integration ProblemsElectric variable regulationCapacitanceEngineering

The invention discloses a band gap basic voltage circuit that uses a combined circuit of TG switch and capacitance for displacing RC filter circuit in existing band gap basic voltage circuit, and controls output voltage ripples by controlling turn-on time of TG switch for realizing filtering of voltage signal, accordingly, larger R or C is not needed and can overcome problem that RC filter circuit is difficult to integration, and the combined circuit of TG switch and capacitance has simple structure. A chopper circuit has higher switch frequency, and can act on filtering, increase stability of basic voltage further.

Owner:SUNPLUS TECH CO LTD +1

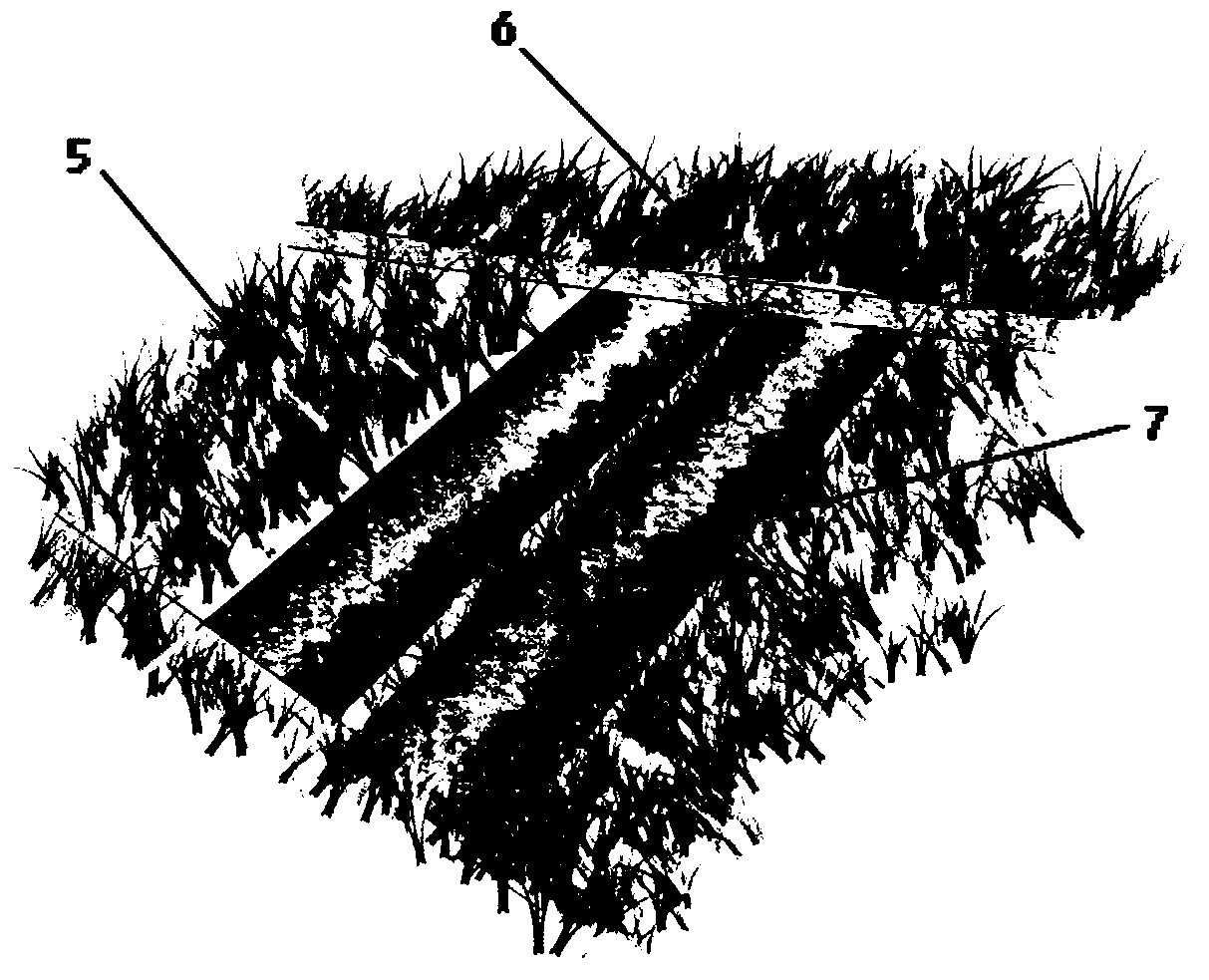

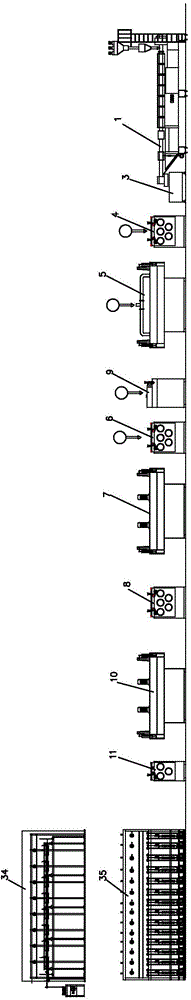

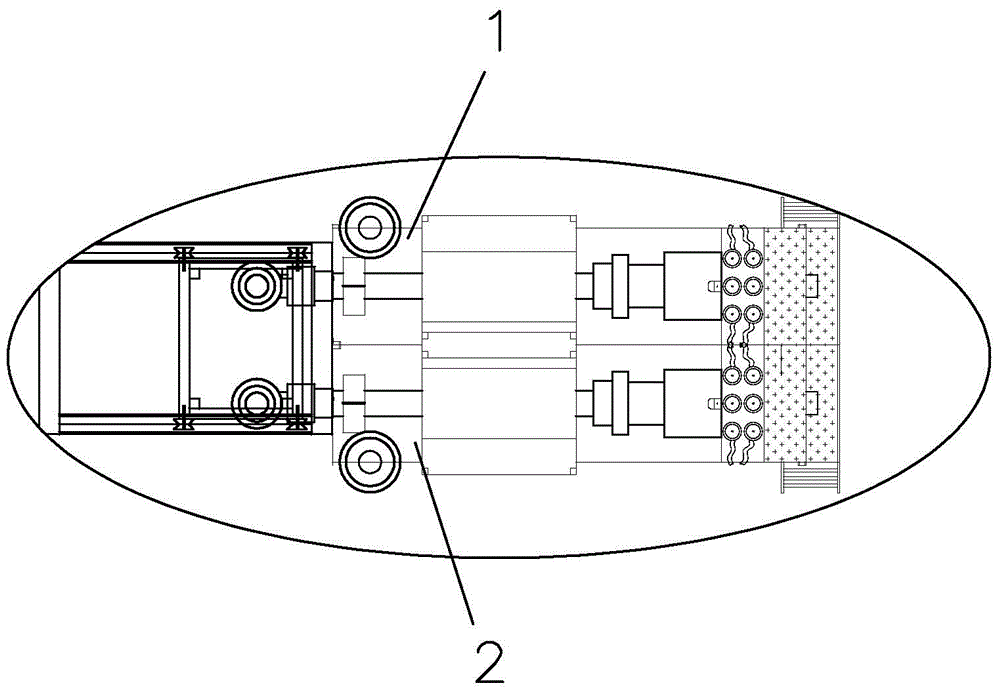

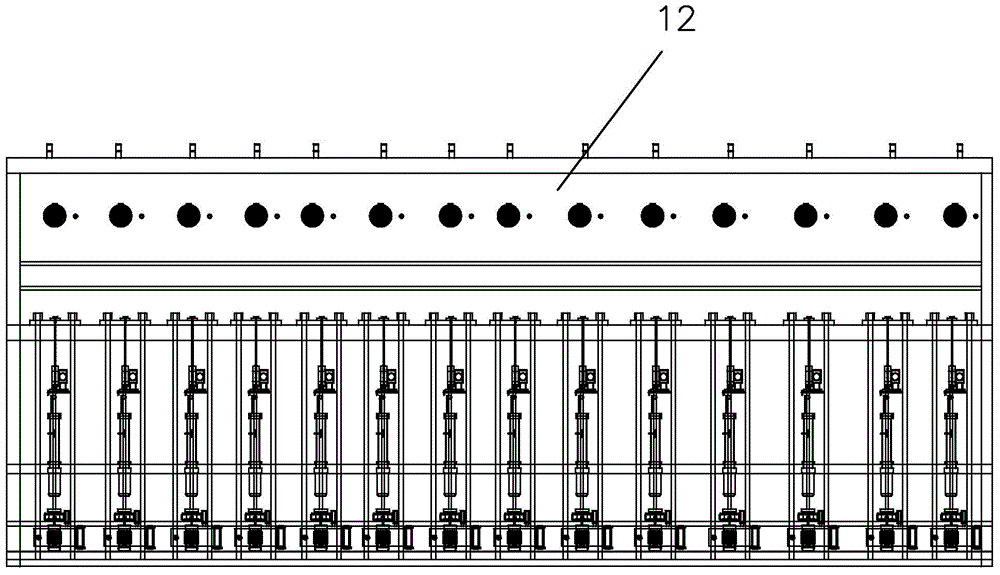

Lawn rayon production line and production method

ActiveCN104862792ASingle screw speed adjustment rangeRealize stepless speed regulationArtificial thread manufacturing machinesMelt spinning methodsProduction lineProcess time

The invention discloses a lawn rayon production line and production method. The lawn rayon production line comprises monofilament production equipment, after finishing equipment and a plying and twisting unit which are installed in sequence; two extruders of the monofilament production equipment of the lawn rayon production line are arranged in parallel and can produce monofilament with different colors and different types; the plying and twisting equipment conducts plying and twisting on the monofilament produced through the production line and monofilament which needs to be twisted, rewinding does not need to be conducted repeatedly, the process time and the workshop space are saved, requirements for plying and twisting production of two or more monofilament are met, and the production efficiency is greatly improved.

Owner:QINGDAO QINGHE ARTIFICIAL TURF

Industrial dust treatment device with multi-stage dust removal function

InactiveCN108568185AIncrease humidityAvoid cloggingCombination devicesEnvironmental resistanceWater storage tank

The invention relates to the technical field of environmental protection, in particular to an industrial dust treatment device with multi-stage dust removal function. The industrial dust treatment device comprises a device body, wherein a door body is arranged at both ends of the device body, a fixed rod, a motor I, a sliding rod, fixed plates, a filter net I and a heater are fixed in the device body, an induced draft fan is fixed on the fixed rod, a turntable is fixed on a rotating shaft I of the motor I, a connecting rod I is fixed on the turntable, a slider is connected with the sliding rodin a sliding manner and is connected with the connecting rod I by a connecting rod II, a brush I is fixed on the side wall of the slider, the fixed plates are symmetrically arranged on the top and bottom of the device body, a filter net II is fixed between the two fixed plates, a water storage tank and a motor II are fixed on the top of the device body, a brush II is fixed on a rotating shaft IIof the motor II, and a dust door is arranged at the bottom of the device body. In the industrial dust treatment device provided by the invention, a filter net cage is convenient to clean, and throughthe multi-stage dust removal structure, the dust treatment quality is greatly improved.

Owner:浙江格扬热工装备科技有限公司

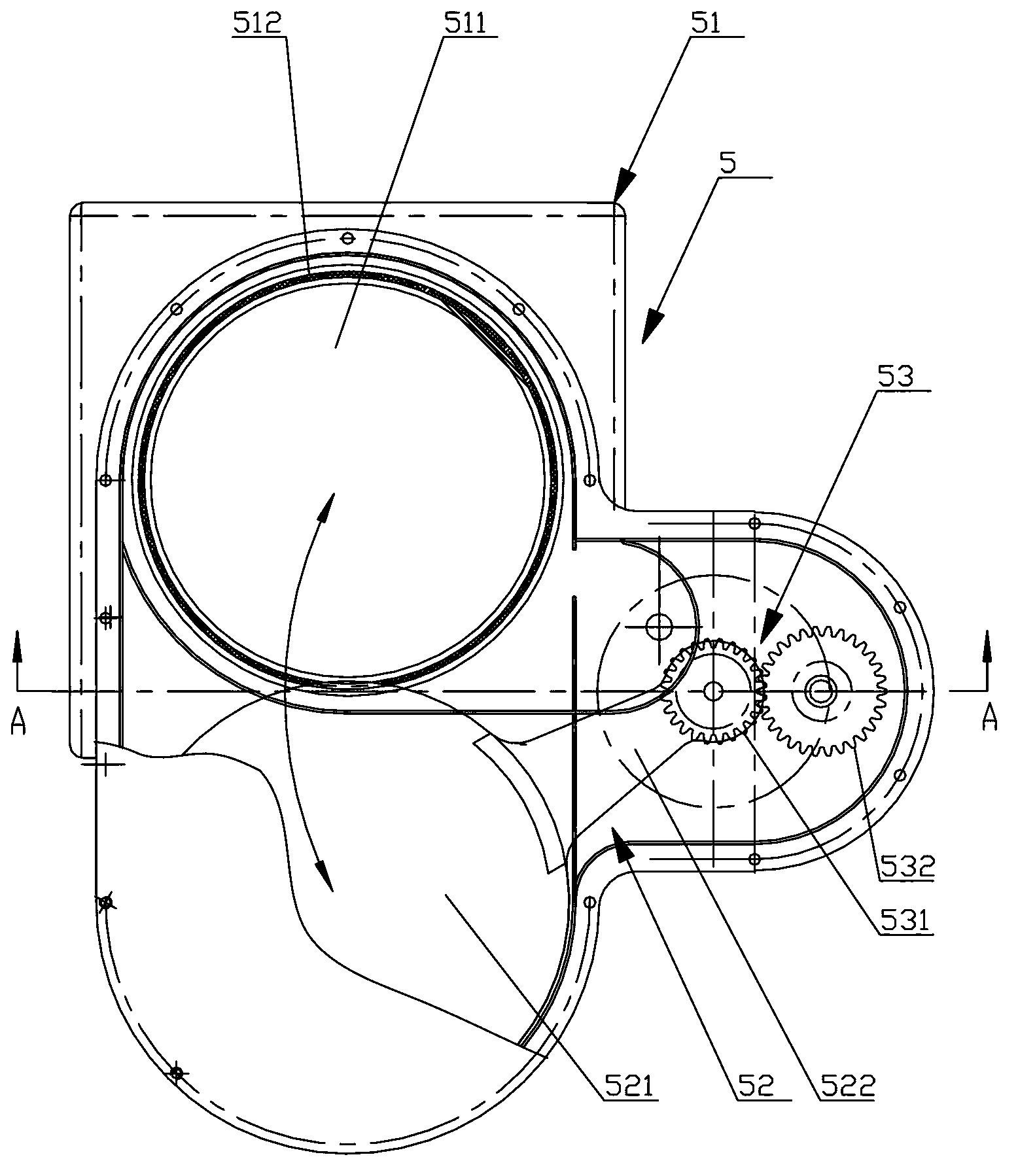

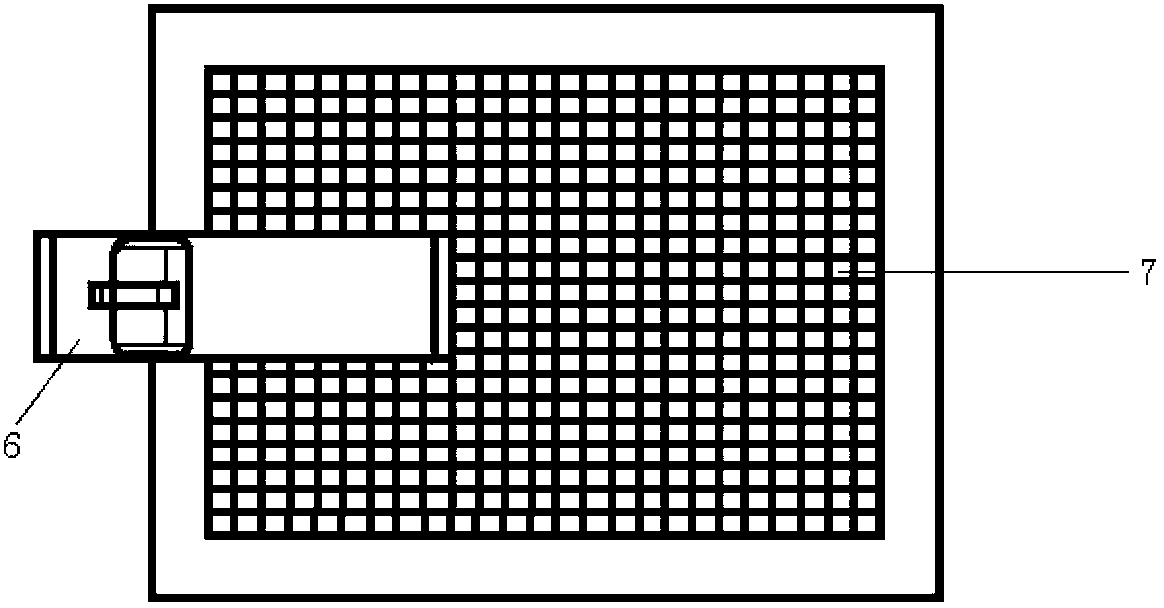

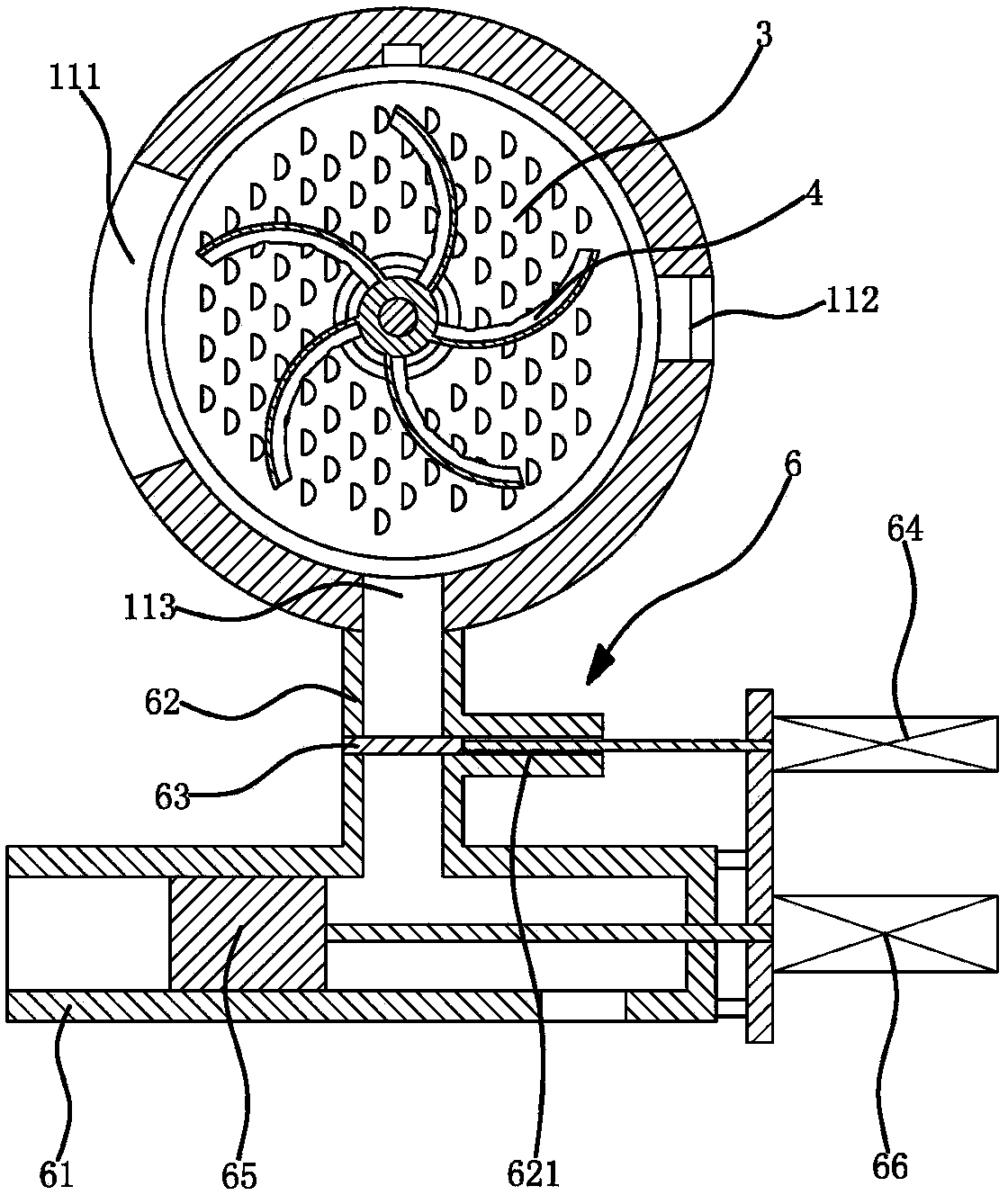

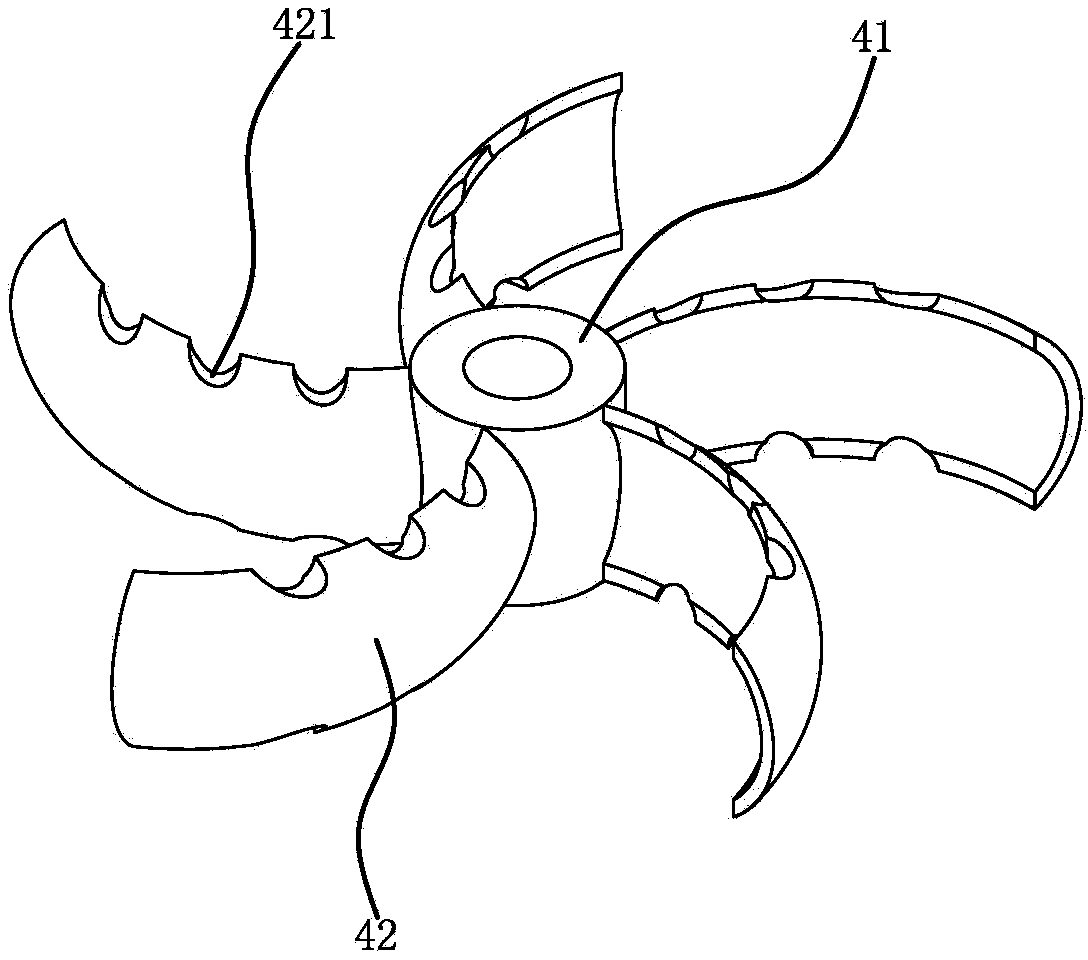

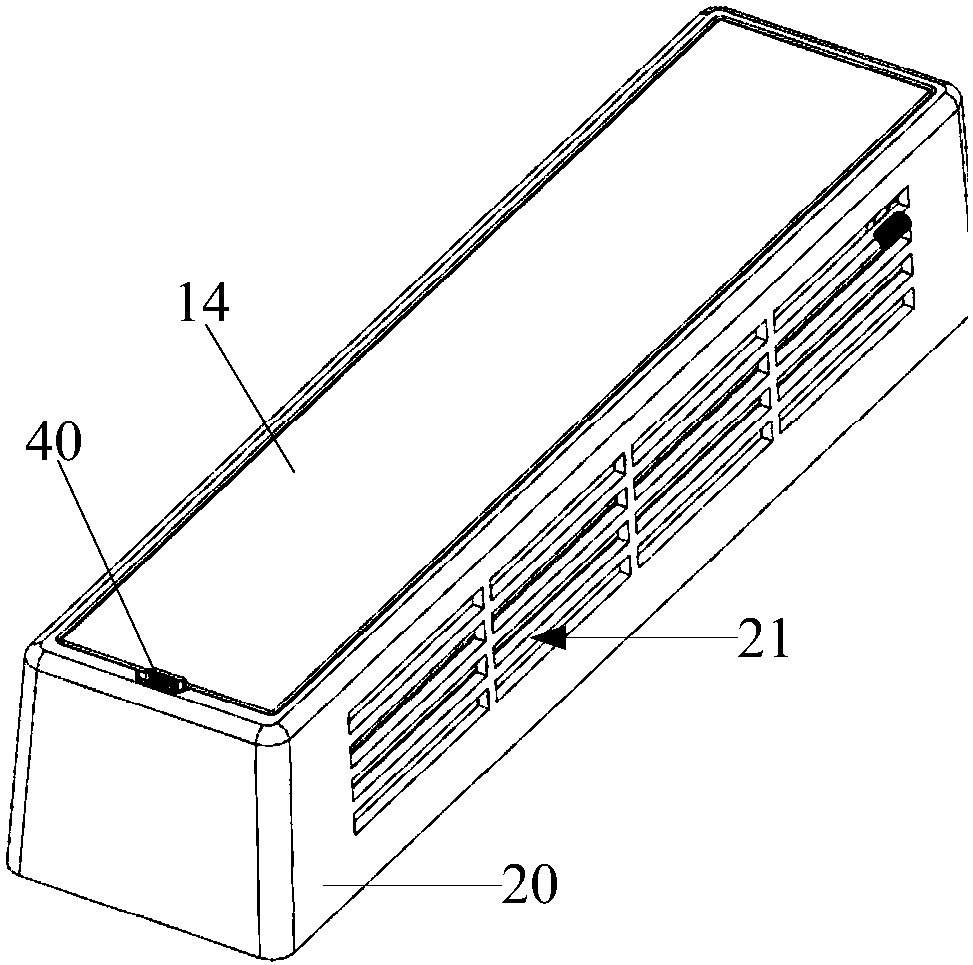

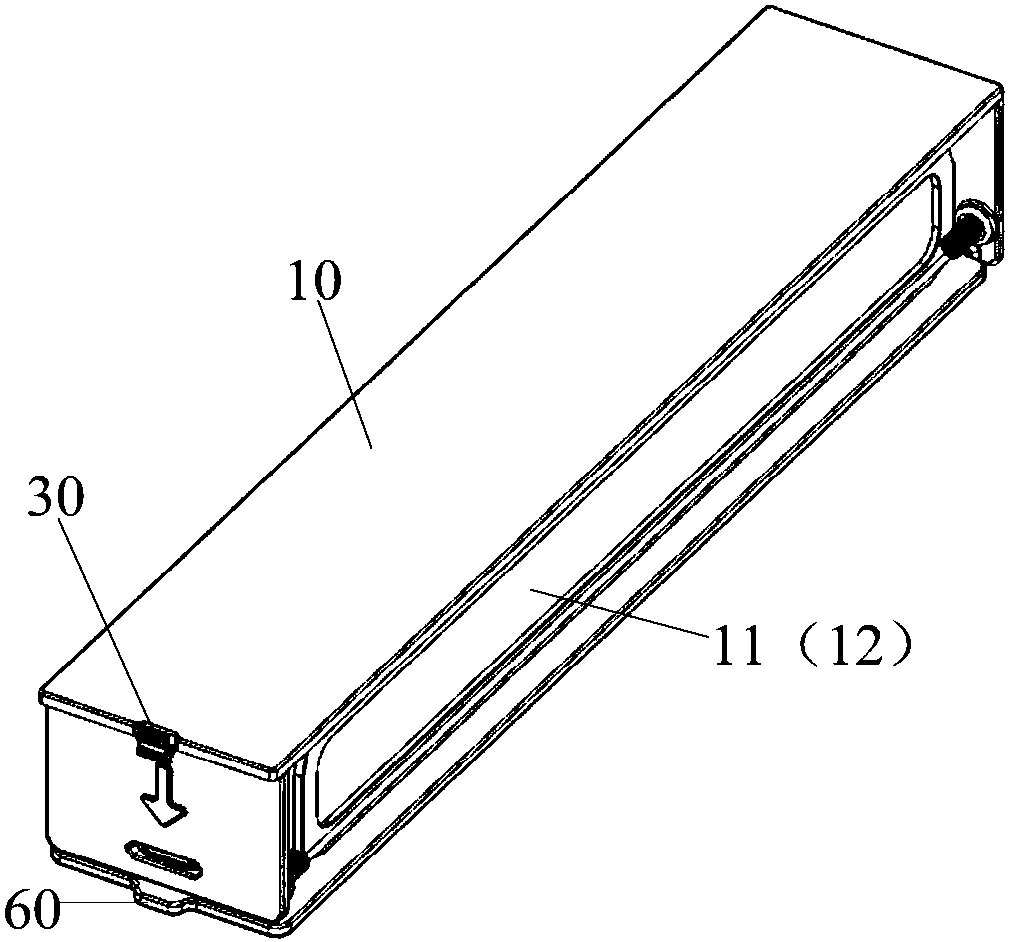

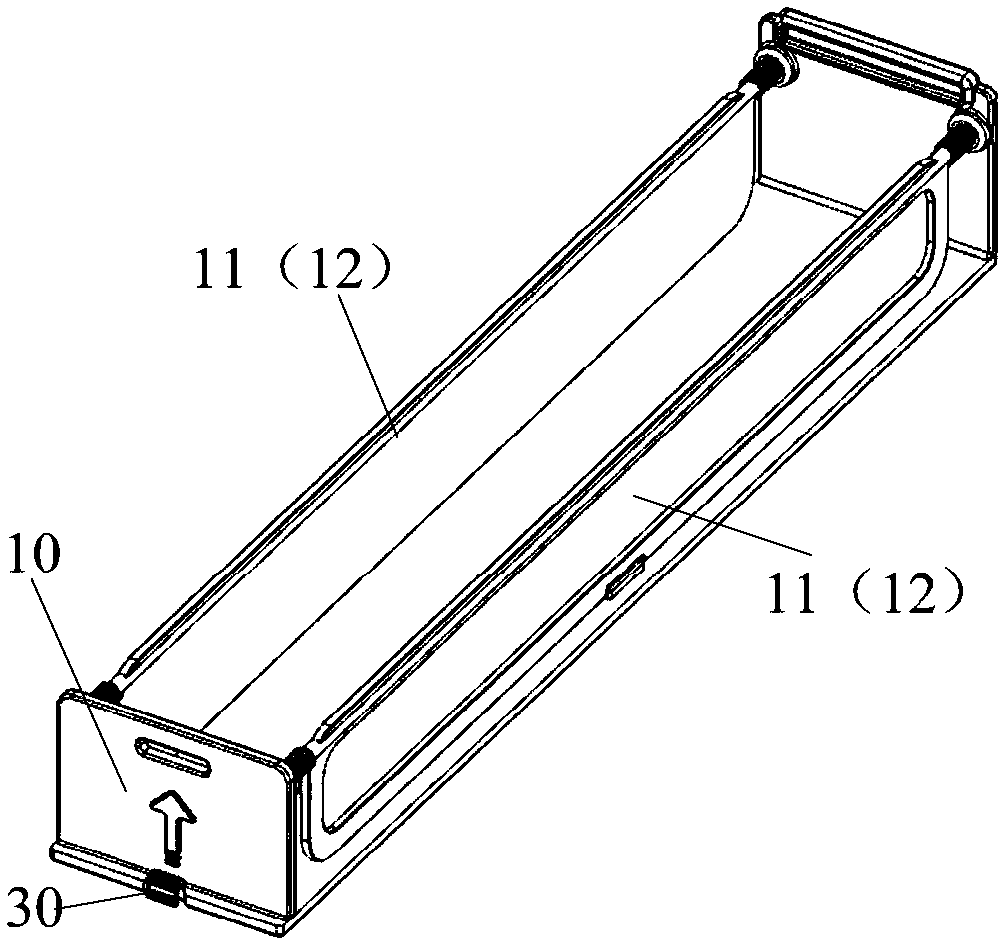

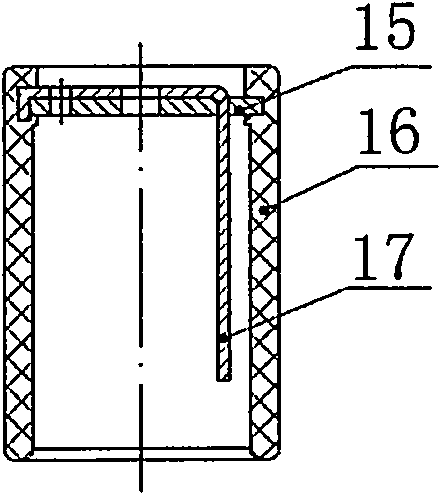

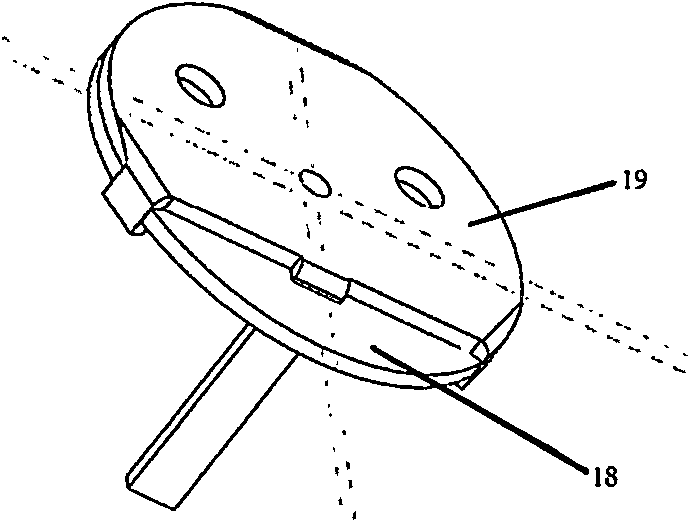

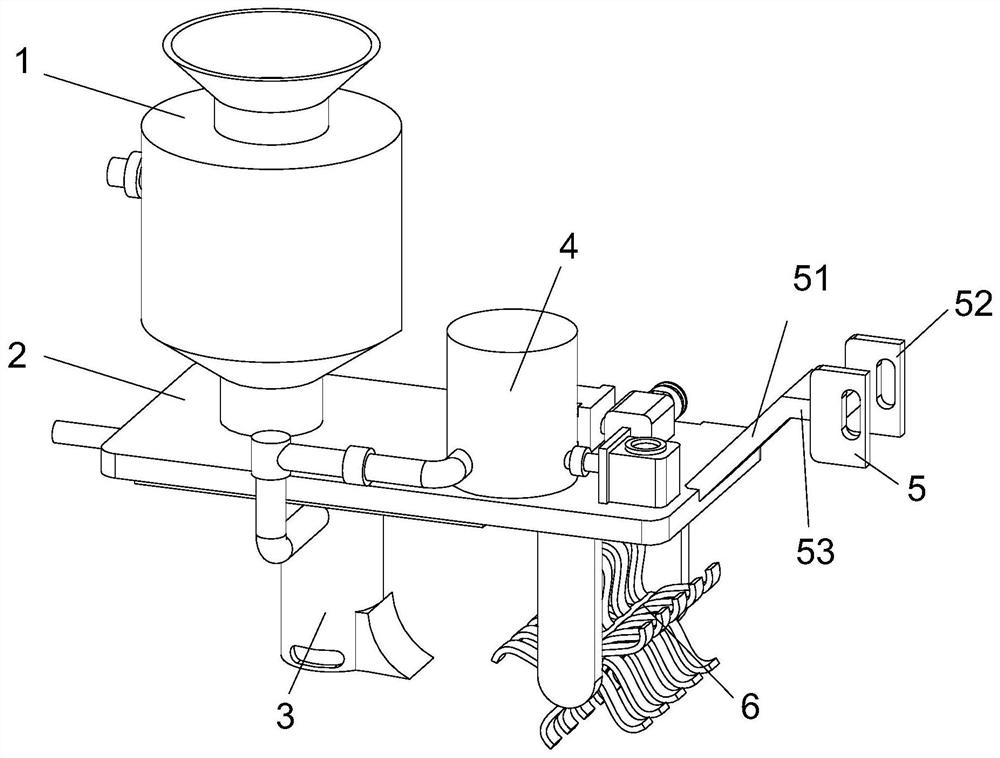

Filtering and lifting device and roller washing machine

ActiveCN108193444AFully washedPlay a filtering roleOther washing machinesTextiles and paperWater flowPulp and paper industry

The invention provides a filtering and lifting device and a roller washing machine, and relates to the technical field of household appliances. The problem that a roller washing machine is poor in washing effect in the prior art is solved. The filtering and lifting device comprises a shell with an inner cavity. The two opposite sides in the water flow passing direction of the shell are each provided with a water passing hole. A baffle is arranged beside each water passing hole. At least part of the area of the side face of each water passing hole and / or the corresponding baffle on the shell isprovided with a filtering structure. The baffles are pushed by water flow to swing toward the inner side of the shell so as to completely expose the water passing holes, and the baffles are pushed bywater flow to swing towards the outer side of the shell so as to cover the water passing holes, so water flows out of the inner cavity of the shell through the filtering structure. The filtering andlifting device is applied to the roller washing machine and used for filtering away hair and other sundries in an inner tub, and the washing effect of the roller washing machine is improved.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

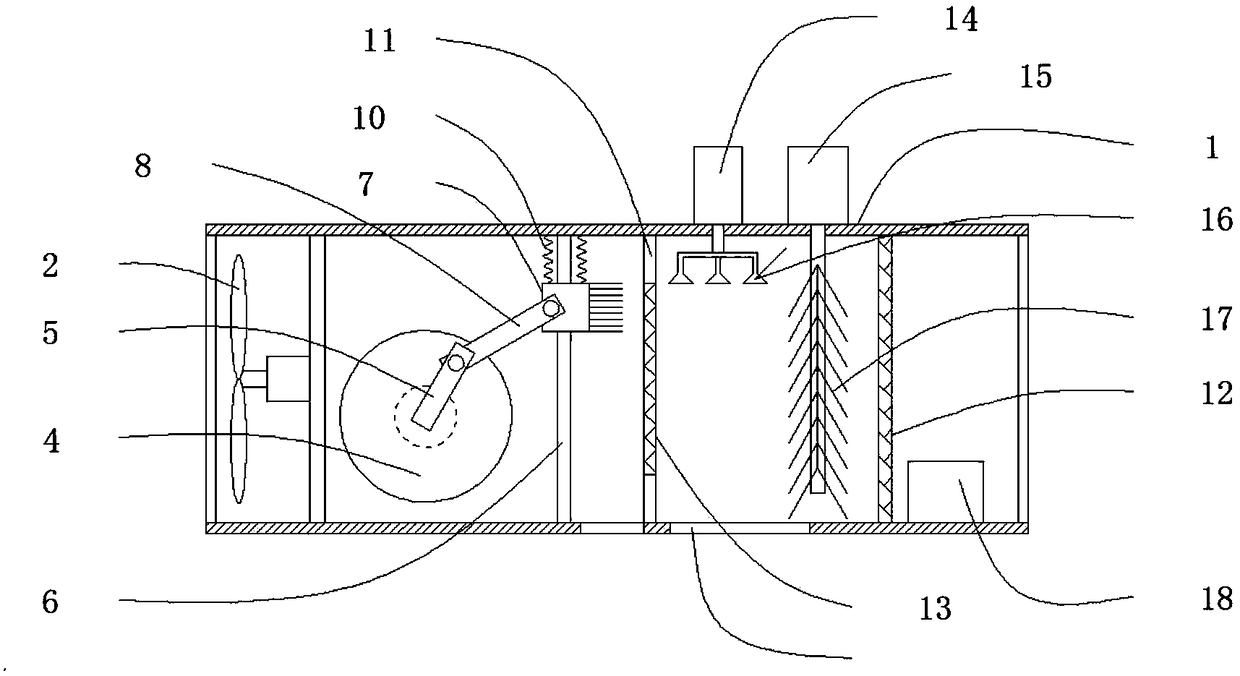

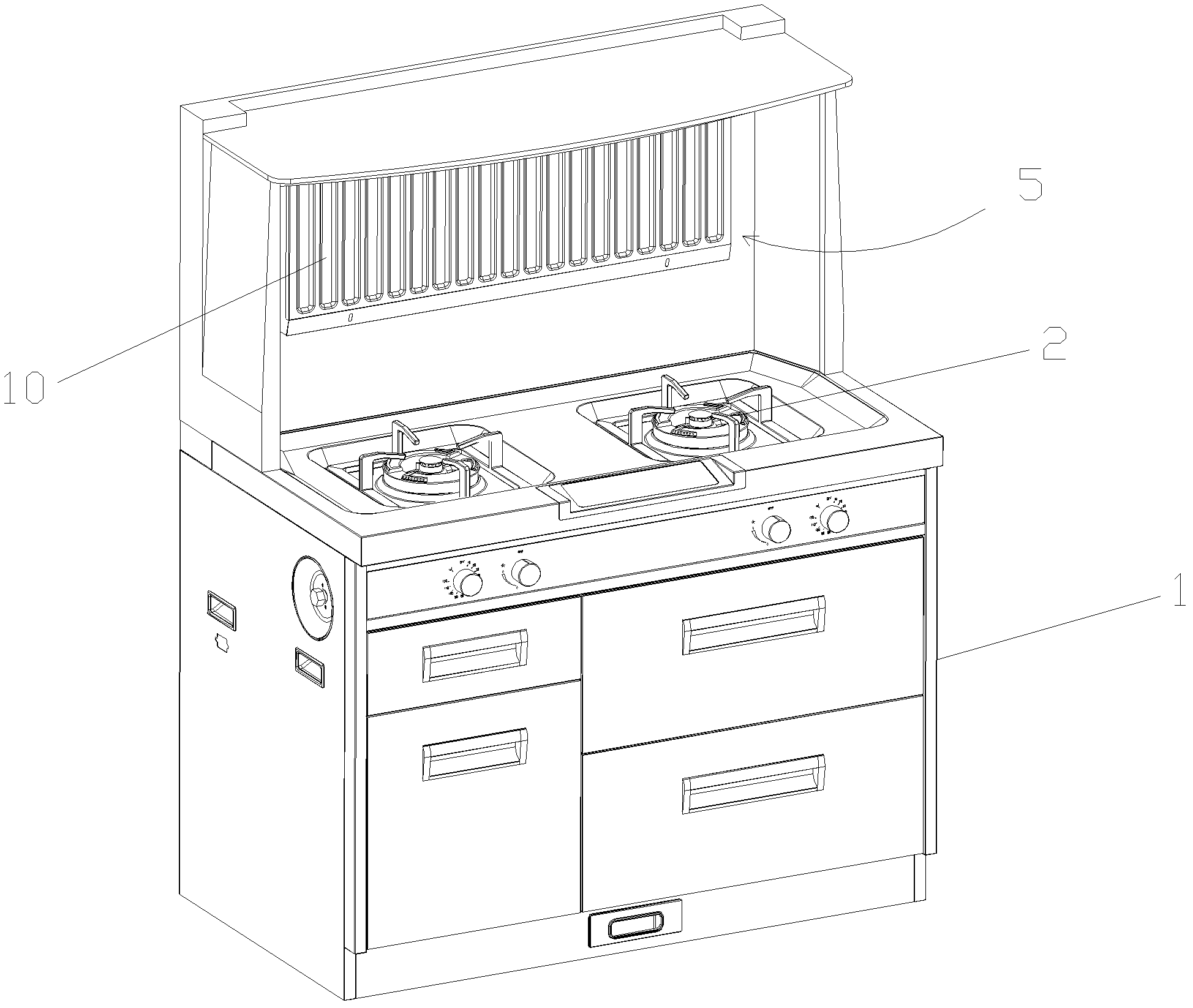

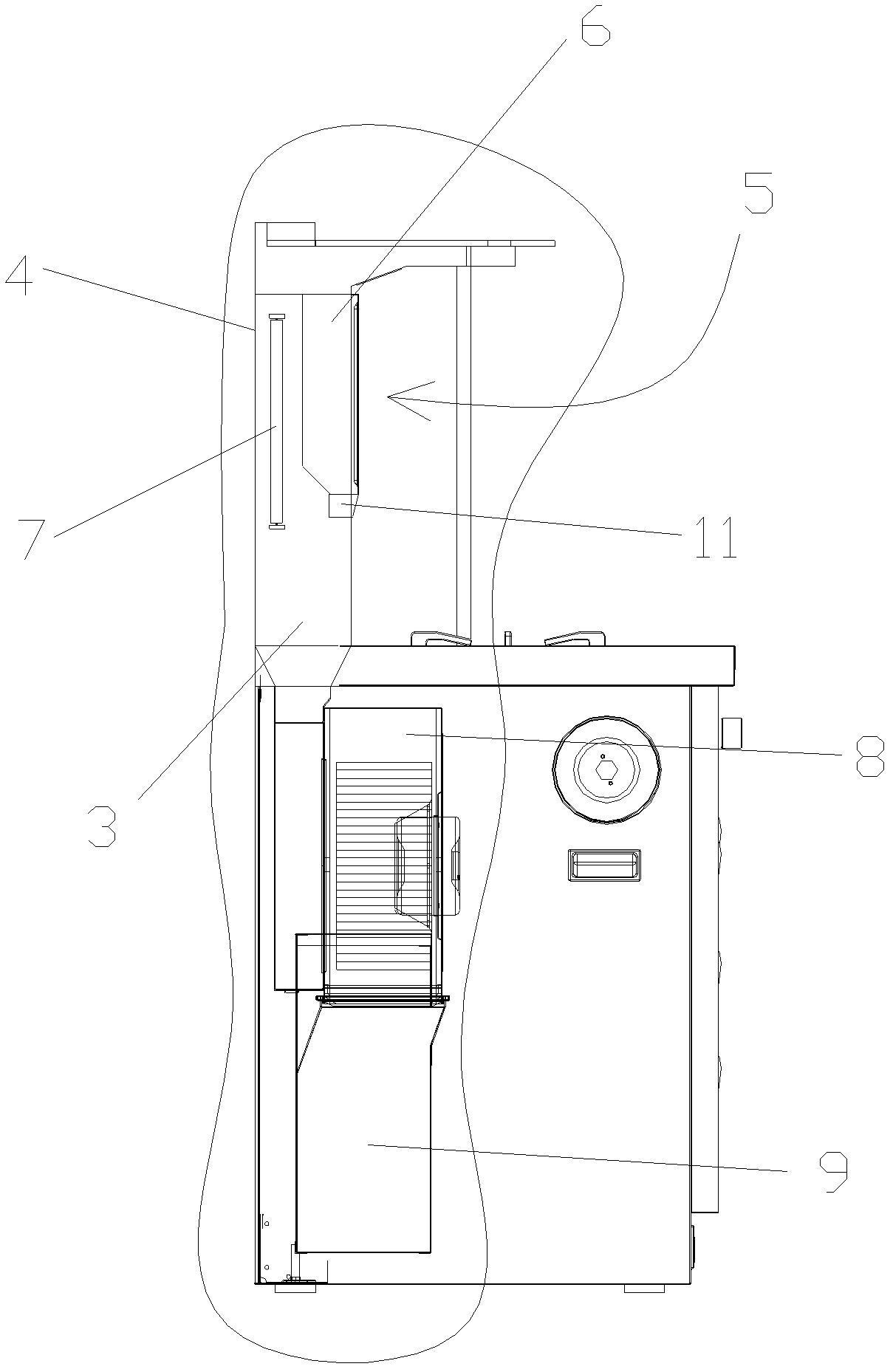

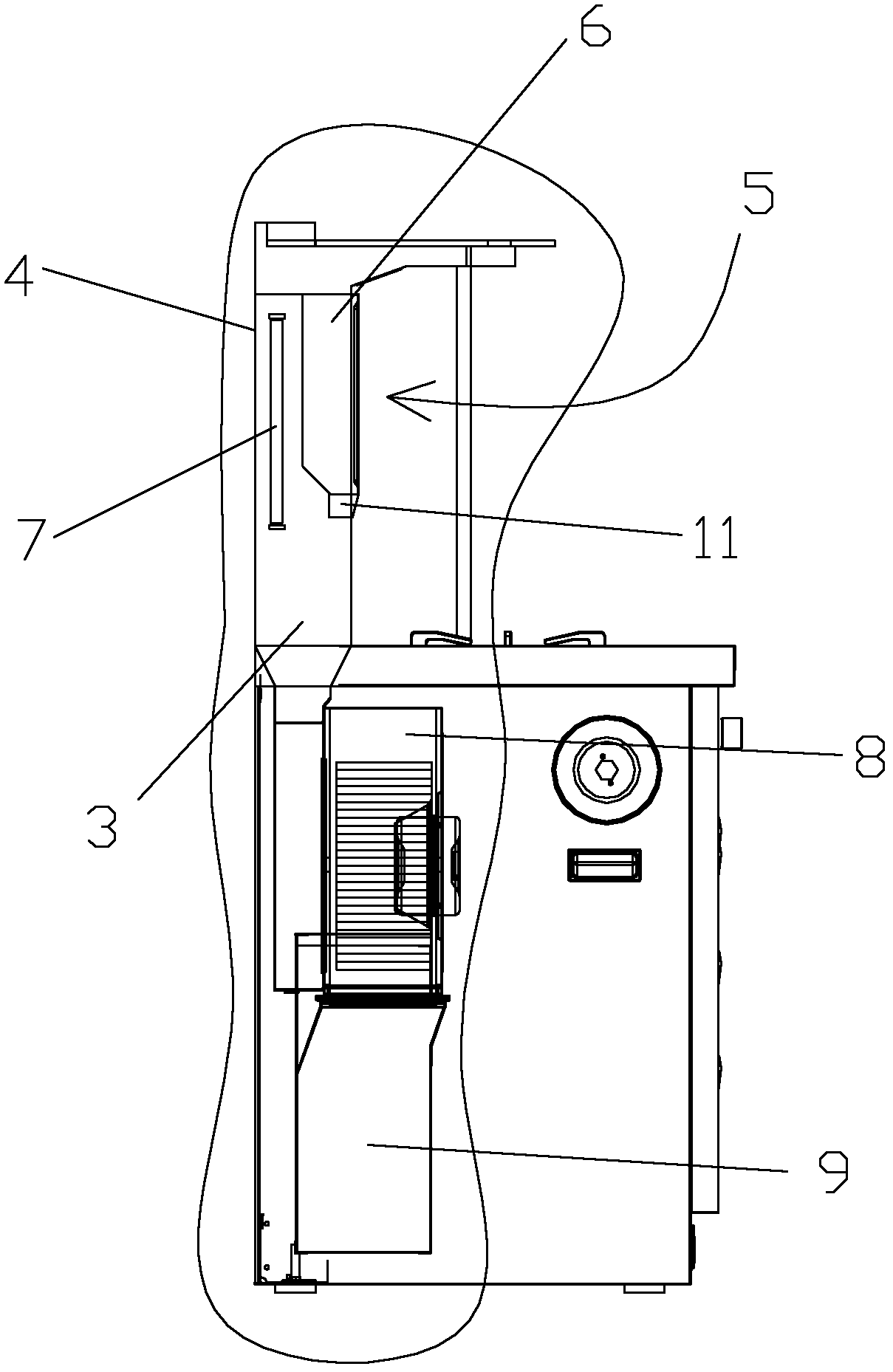

Inner circulation purifying type environmental protection integrated stove

InactiveCN102434900AEfficient purificationPromote decompositionDomestic stoves or rangesLighting and heating apparatusFuel tankEngineering

The invention provides an inner circulation purifying type environmental protection integrated stove which solves the technical problem that fume needs to be exhausted out of a room because the current integrated stove has a poor fume purifying effect. The inner circulation purifying type environmental protection integrated stove comprises a stove body, a stove assembly and a fume purifying channel assembly, wherein the fume purifying channel assembly comprises an air inlet box which is connected with the stove body and is arranged on the rear of the stove body. The inner circulation purifying type environmental protection integrated stove is characterized in that an air inlet is arranged on a front side plate of the air inlet box; the rear of the air inlet is provided with an oil filter box; a first purifying device which is arranged behind the oil filter box is arranged on a rear side plate of the air inlet box; a fan assembly is installed at the downstream of the first purifying device; a second purifying device is installed at the downstream of the fan assembly; and the stove body is provided with a release opening which is communicated with the fume purifying channel assembly. According to the inner circulation purifying type environmental protection integrated stove, the purifying function is maximized so that the fume sucked by the integrated stove is converted into fresh air to form inner circulation in the room after being purified; and the fume does not need to be exhausted out of the room, and thereby, the installation is convenient, and the limitation performance of the installation location of the integrated stove is removed.

Owner:ZHEJIANG SANFER ELECTRIC

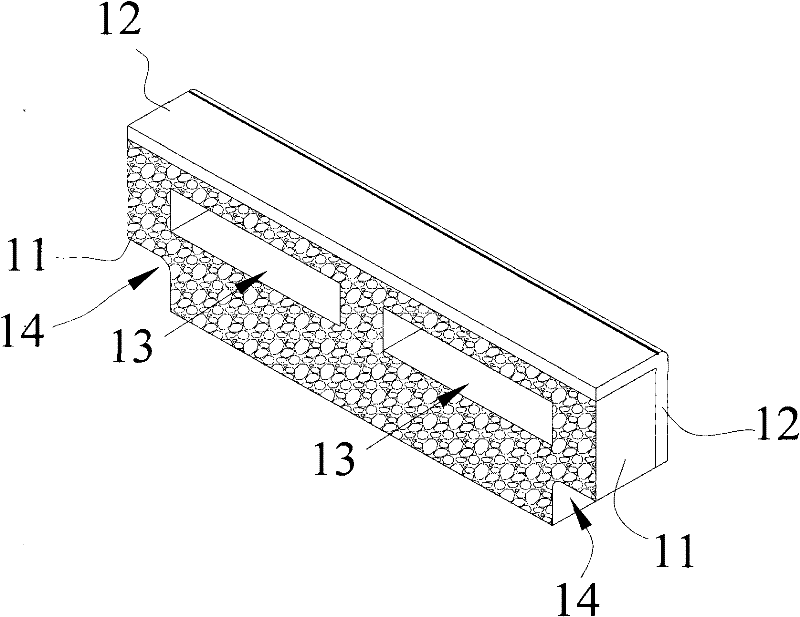

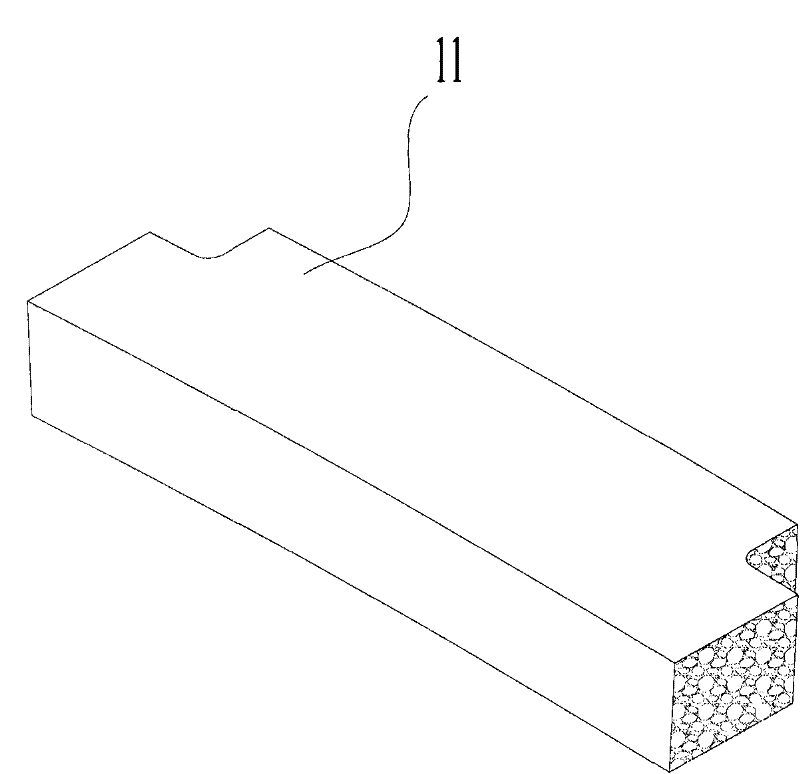

A kind of curb stone and its preparation method and road including the curb stone

ActiveCN102261029AImprove drainage efficiencyGood aesthetic effectPaving gutters/kerbsCeramic shaping apparatusSurface layerPorosity

The invention relates to a kerb and a preparation method thereof. The kerb is made of a water-permeability material and comprises a base body and a surface layer covered on the base body, wherein the porosity of the surface layer is more than that of the base body; and the average aperture of holes in the surface layer is less than that of the holes in the base body. A road comprises a road surface and kerbs positioned on at least one side of the road surface, wherein the kerbs are the kerbs provided by the invention; and the sides, covered by the surface layer, of kerbs face the road surface. According to the kerb provided by the invention, the preparation method thereof and the road comprising the kerb, the kerb is made of the water-permeability material, so the drainage efficiency of the kerb is improved. In addition, the surface layer with small porosity is finer than the base with big porosity, so that the appearance of the traditional kerb is provided.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

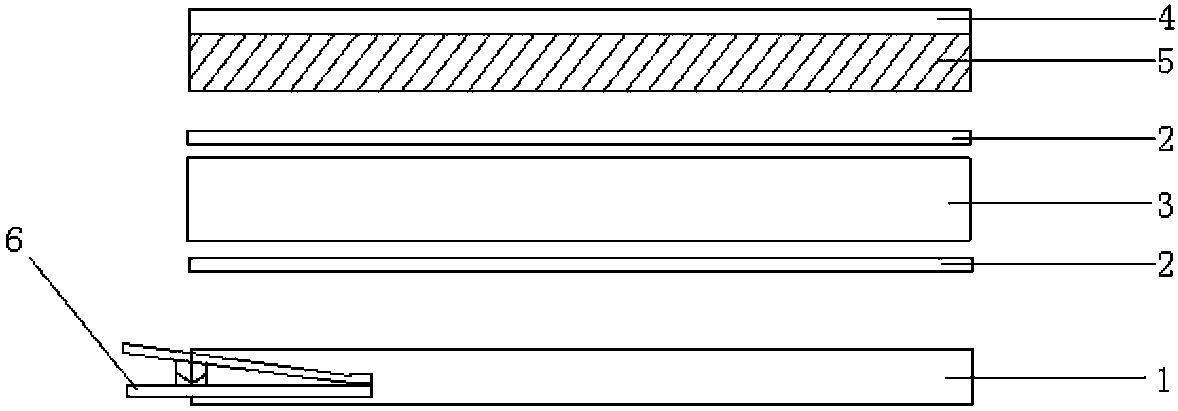

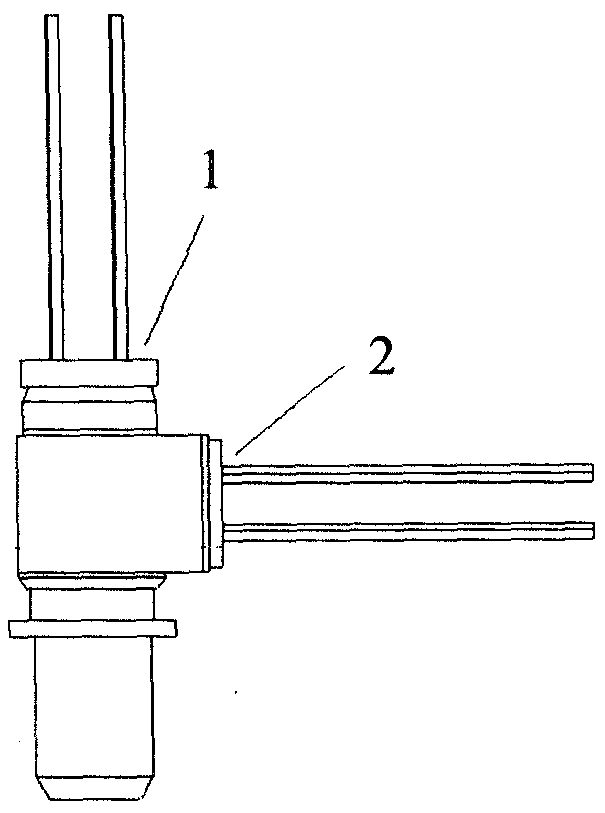

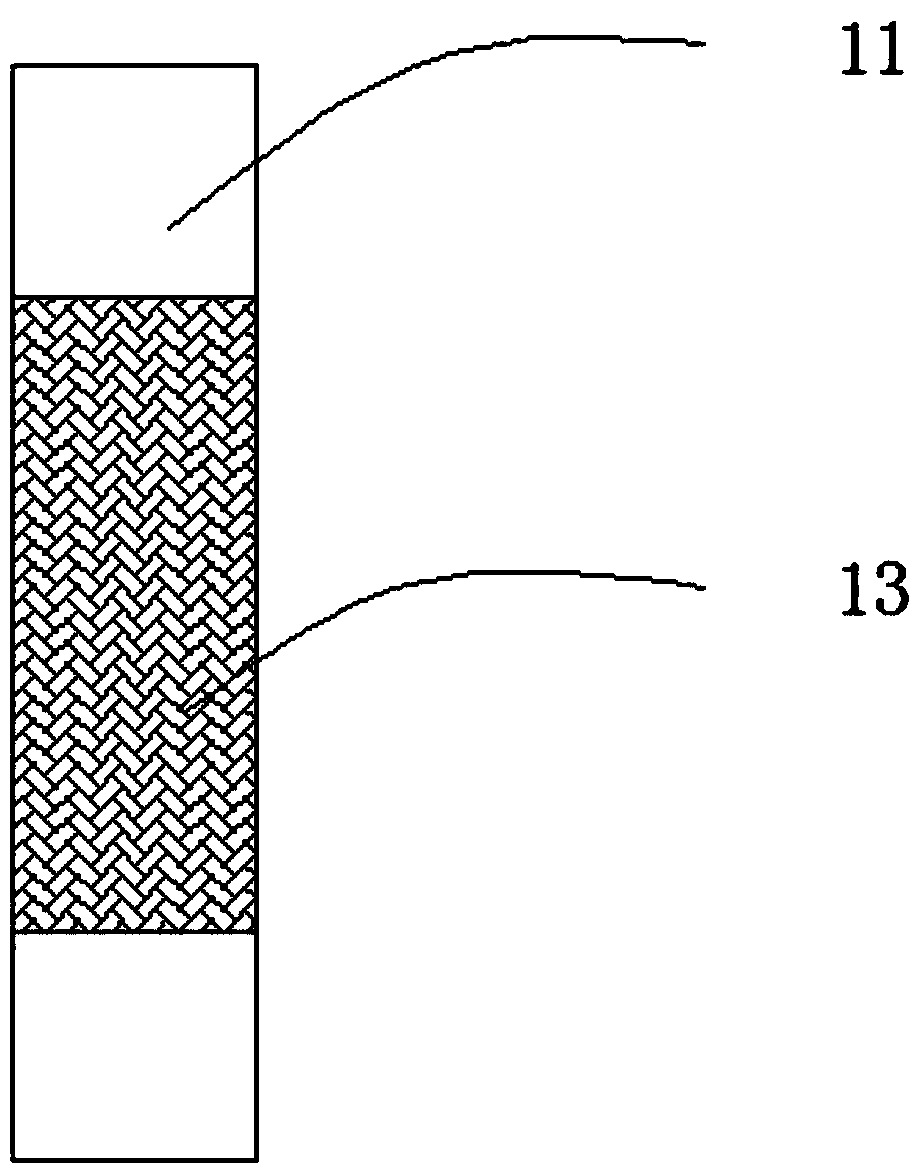

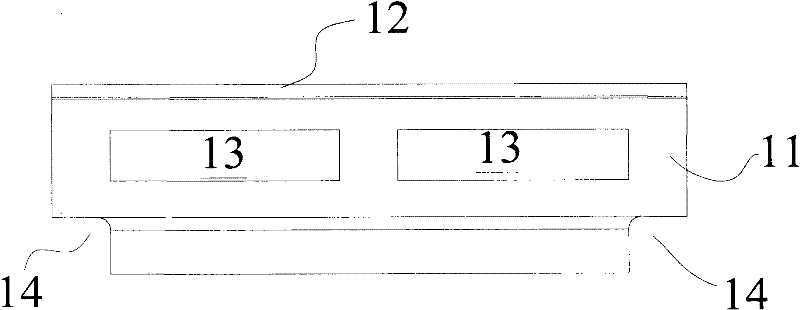

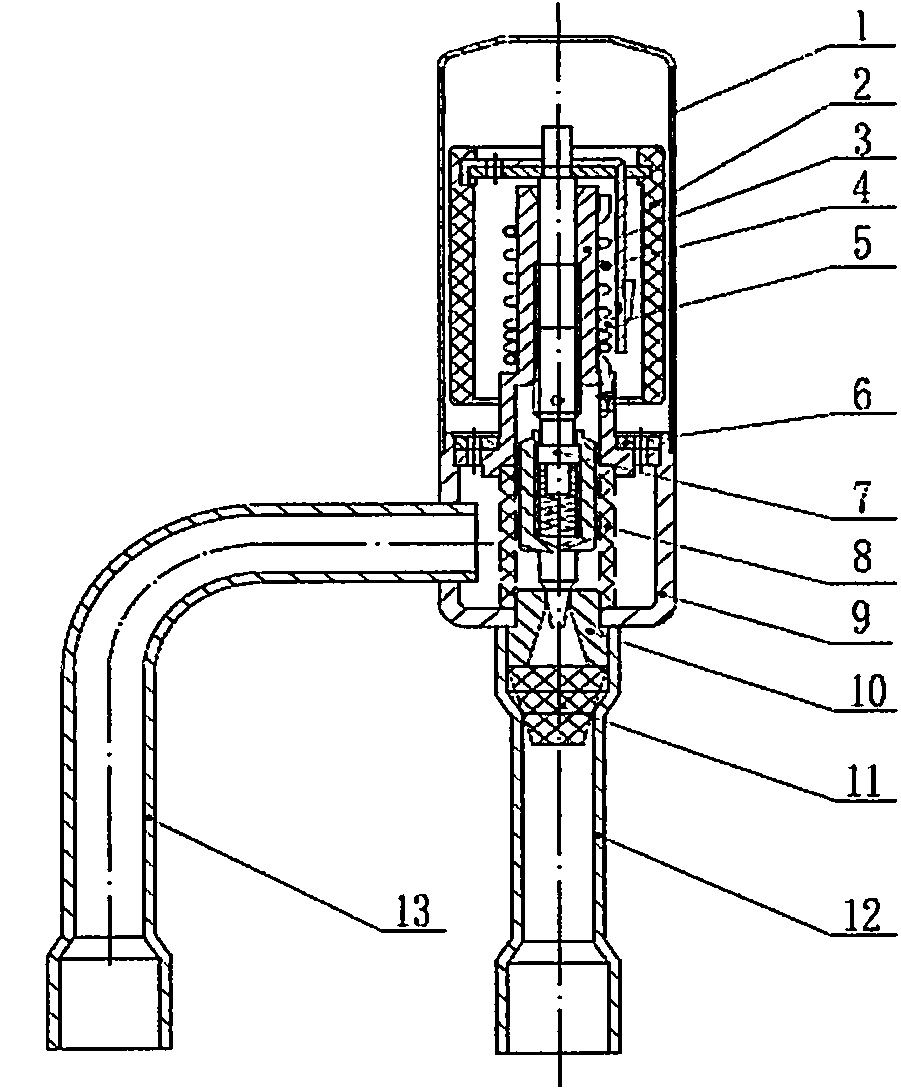

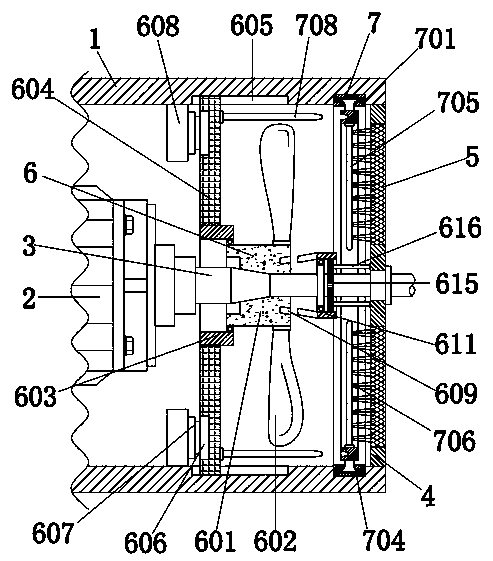

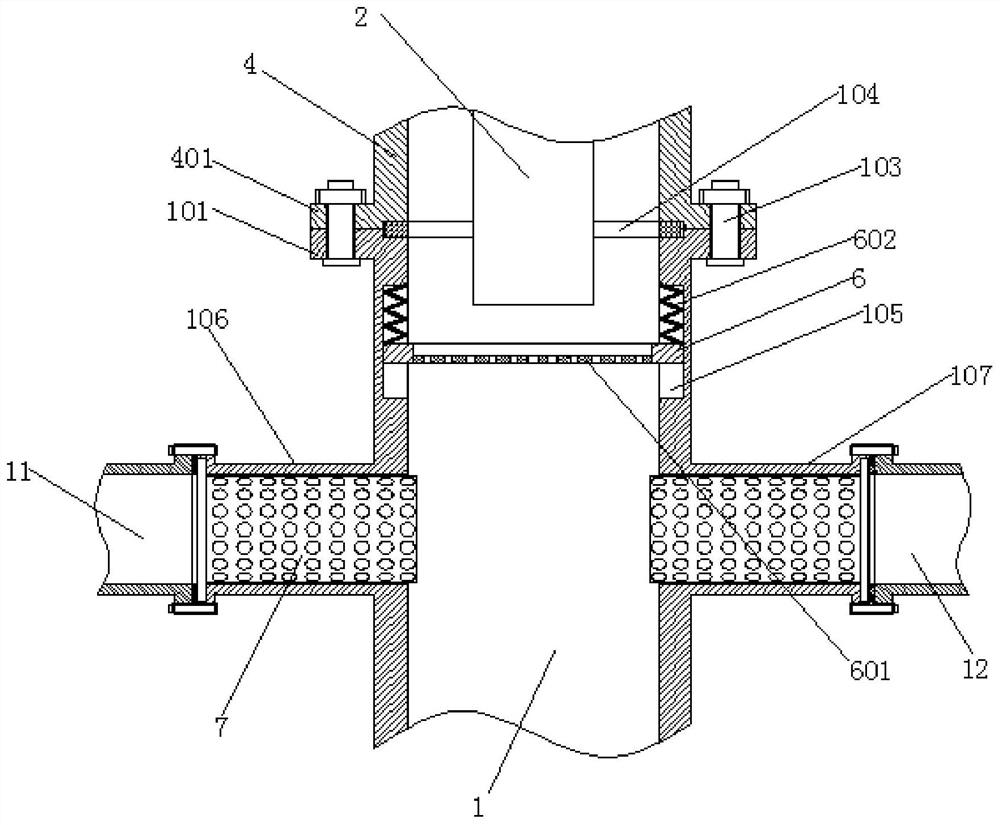

Electronic expansion valve

InactiveCN103994231AEasy injection moldingReduce thicknessOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringEqualization

The invention discloses an electronic expansion valve which comprises a valve cover (1), a magnet rotor assembly (2), a screw sleeve (3), a check ring guide rail (4), a check ring (5), a screw sleeve pressing plate (6), a valve needle assembly (7), a flow equalization device (8), a valve body (9), a valve deck (10), a filter screen (11), a lead-out pipe (12) and a lead-in pipe (13). The magnet rotor assembly (2) is arranged in the expansion valve, the upper end of the valve needle assembly (7) penetrates through and is welded together with a central hole of the magnet rotor assembly (2), the valve needle assembly (7) is sleeved with the screw sleeve (3) and can only do axial movement, and the screw sleeve (3) is embedded in and presses the flow equalization device (8). By means of the electronic expansion valve, the magnet rotor installation and fixation procedures can be reduced, machining cost can be reduced, impact which is exerted on a valve needle by flow can be effectively reduced, noise can be effectively lowered, and a valve opening can be effectively protected. By means of the electronic expansion valve, reliability and stability can be improved, the service life can be prolonged, and noise in the valve can be effectively lowered.

Owner:吴俊云

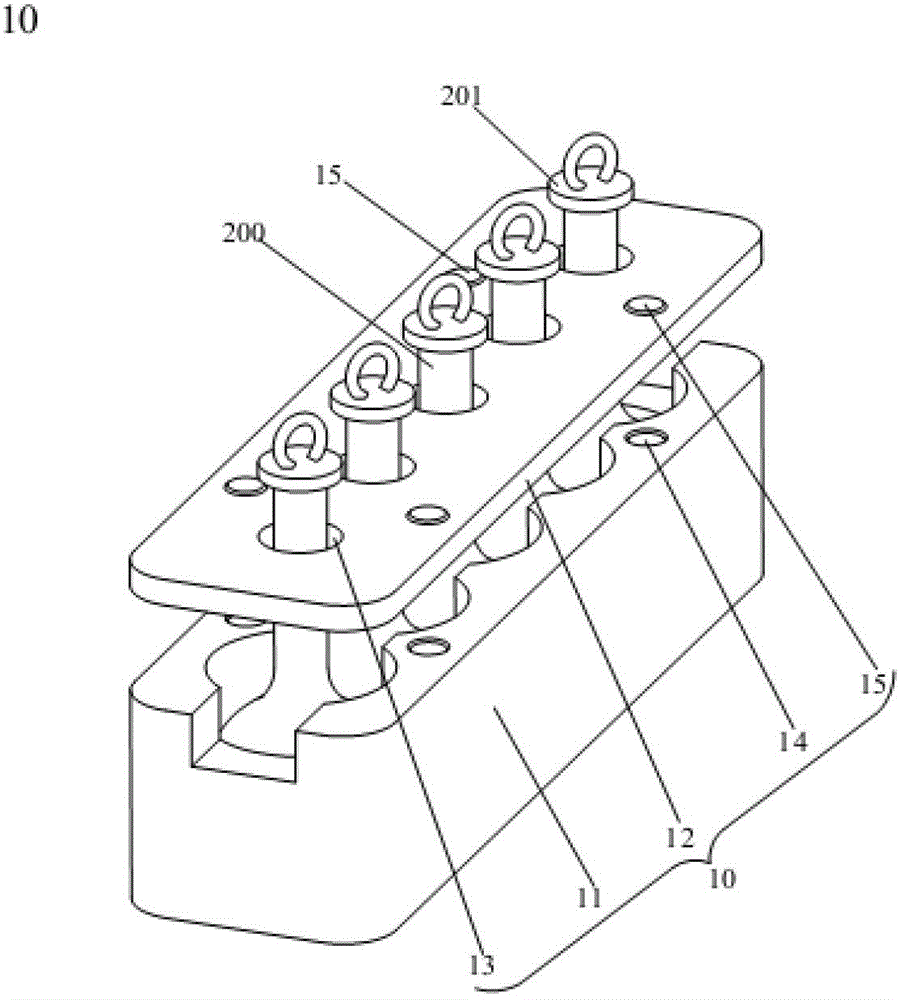

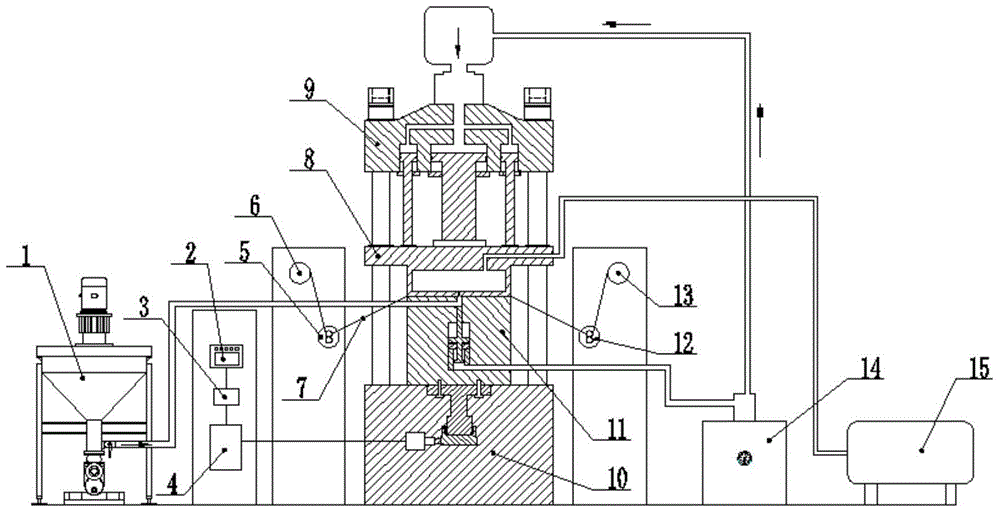

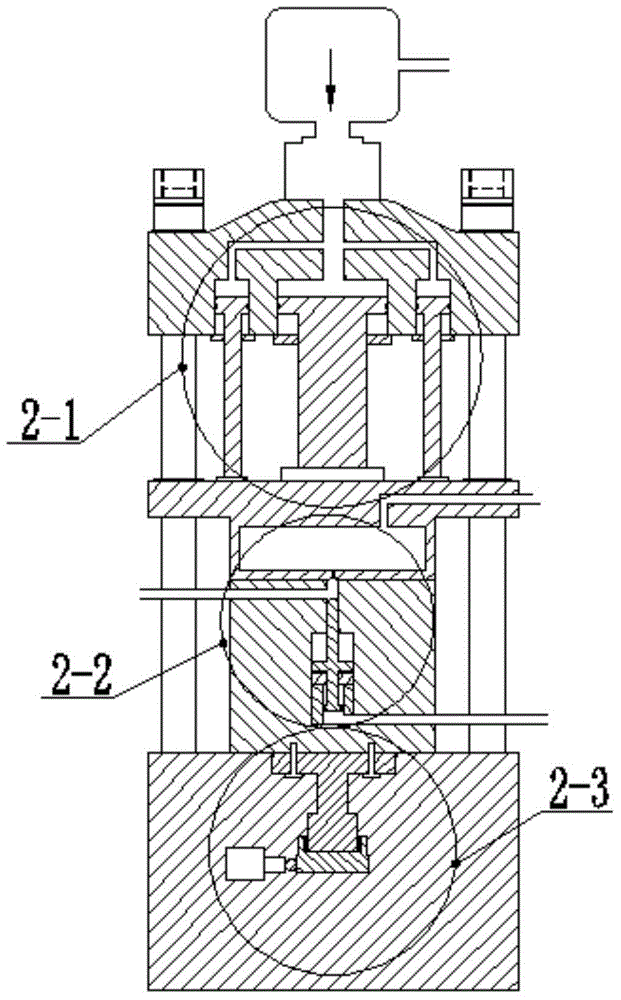

Downward-pushing magnetic material wet forming hydraulic machine and use method thereof

The invention discloses a downward-pushing magnetic material wet molding hydraulic machine and a use method thereof and belongs to the magnetic material wet forming field. The downward-pushing magnetic material wet molding hydraulic machine comprises a downward-pushing pressing structure. The downward-pushing magnetic material wet molding hydraulic machine further comprises a mechanical limiting structure, a packing structure, a blank fetching system, a double-oil cylinder balance system and a mould surface cleaning system; the downward-pushing pressing structure comprises an upper mould seat, a pushing rod, a large-bore oil cylinder, a fixing mould frame and a lower mould hydraulic cylinder, wherein the upper mould seat is driven by the large-bore oil cylinder, the pushing rod is located in the fixing mould frame, and the fixing mould frame is connected with the lower mould hydraulic cylinder, the large-bore oil cylinder and the lower mould hydraulic cylinder are both communicated with a hydraulic station; the mechanical limiting structure includes a horizontal mechanical limiting structure and a longitudinal mechanical limiting structure; the horizontal mechanical limiting structure comprises the pushing rod and the fixing mould frame; a fixing mould cavity is arranged in the fixing mould frame; the pushing rod is located in the fixing mould cavity in the fixing mould frame; and the longitudinal mechanical limiting structure includes a servo motor A and a transmission mechanism. With the downward-pushing magnetic material wet molding hydraulic machine and the use method thereof adopted, product formation error is small, and the pollution source of slurry to hydraulic oil can be eliminated.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

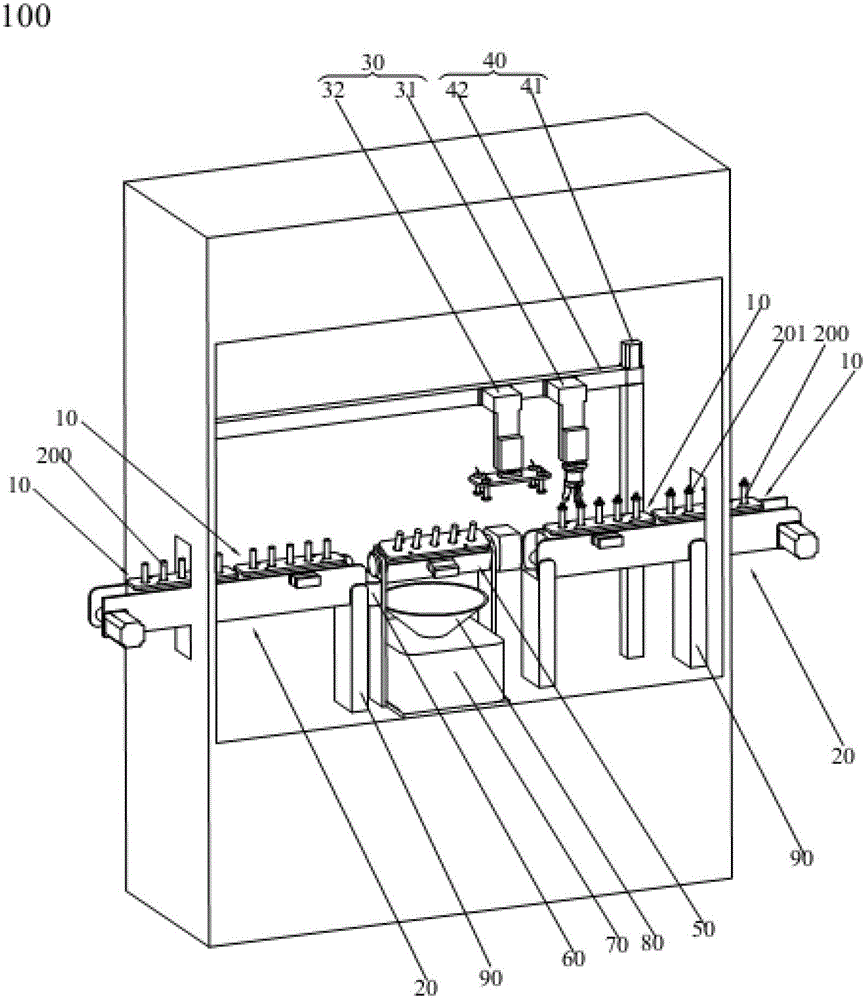

Integration station and cleaning robot system

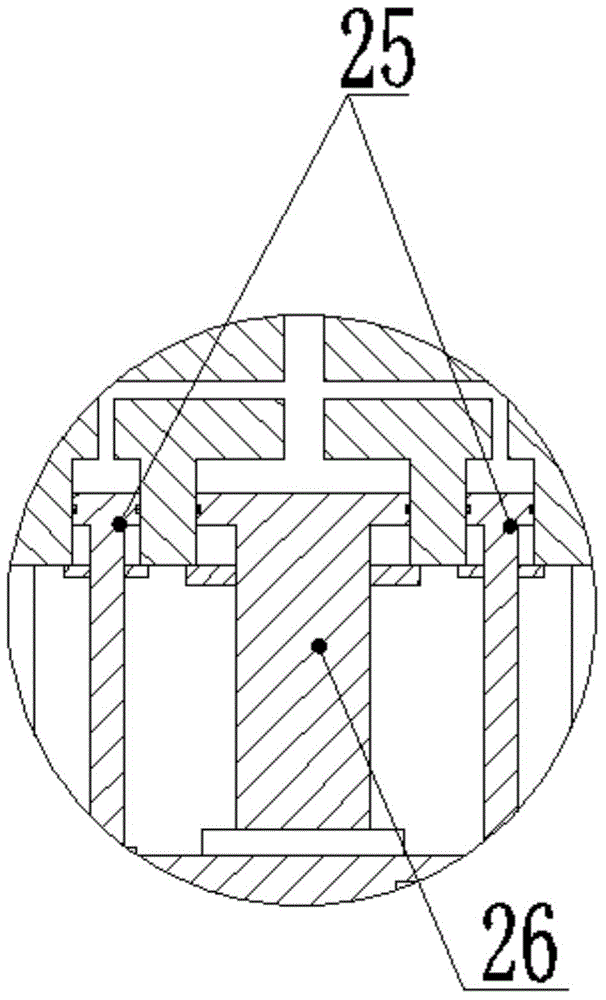

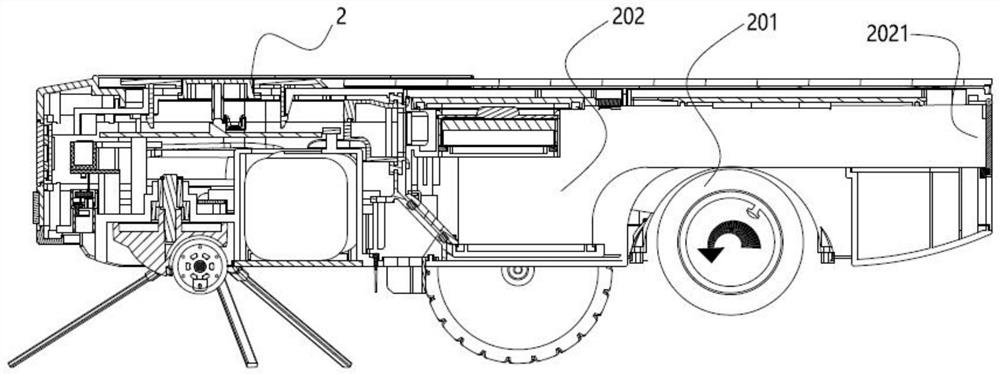

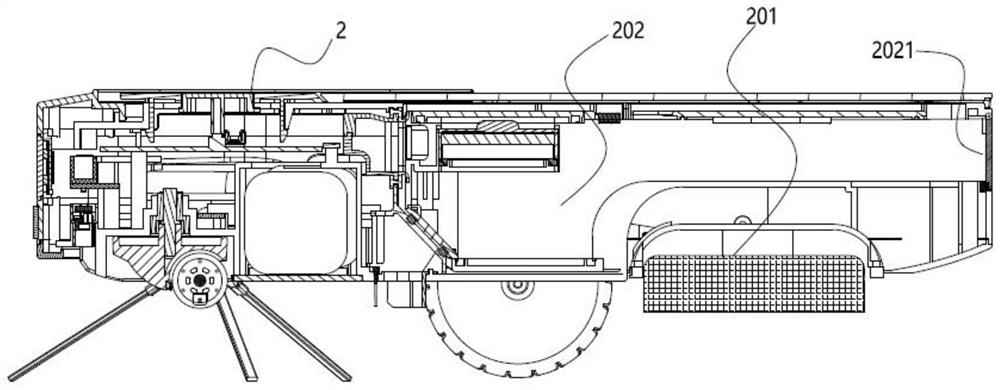

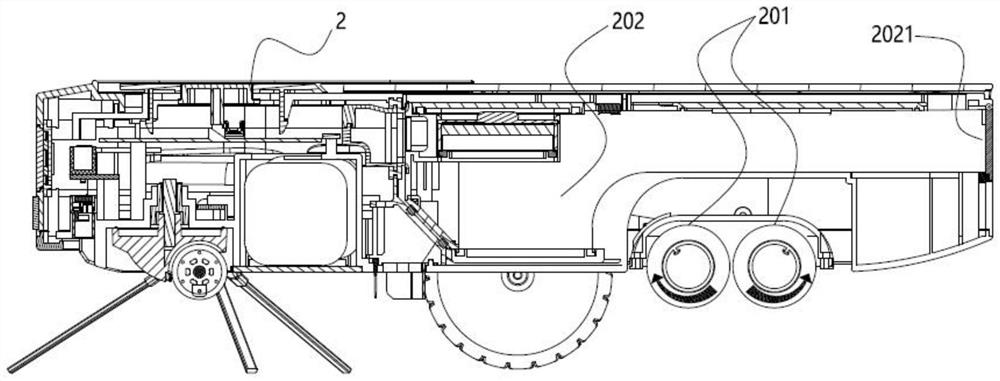

PendingCN112263191ATo achieve a mixed filter effectPlay a mixed filter effectCarpet cleanersUsing liquid separation agentRobotic systemsSuction force

The invention provide an integration station and a cleaning robot system. The integration station is provided with a cleaning area, and the cleaning area is used for cleaning the cleaning parts; the integration station comprises a dirt collecting box, and the dirt collecting box is used for collecting garbage particles and collecting cleaning liquid in the cleaning area; the integration station further comprises a power mechanism, and the power mechanism is connected with the dirt collecting box and generates suction force of airflow. When the power mechanism works, garbage particles in the cleaning robot enter the dirt collecting box to be collected, and / or cleaning liquid in the cleaning area enters the dirt collecting box to be collected. A dirt collecting channel is formed in the dirtcollecting box, and garbage particles can pass through the dirt collecting channel, enter the dirt collecting box and are mixed with cleaning liquid in the dirt collecting box. The cleaning robot system comprises a cleaning robot and the integration station. According to the scheme, the problems of complex base station mechanism, poor experience effect, high base station construction and maintenance cost and serious dust raising caused by the fact that a disposable cloth bag or a multi-step hierarchical filtering structure is arranged for a filtering system in an existing base station are solved.

Owner:杭州匠龙机器人科技有限公司

Green belt for roads

InactiveCN102487695AReserved functionEfficient purificationWatering devicesCultivating equipmentsPondingWater filter

The invention relates to improvement of a green belt for roads and is characterized in that the surface of the green belt is lower than a road surface. The quickly seeping green belt is composed of a greening vegetation layer, a permeable soil layer and a grit layer which are sequentially arranged from top to bottom, and a permeable drain pipe is arranged in the grit layer. Accordingly, the green belt has the greening function and filtering and quick draining functions simultaneously and solves the problem of water gathering on the road surface when it rains. Besides, rain water which is drained and seeps to the underground is purified water filtered by vegetation, soil and grit. In addition, the green belt further expands rain water absorbing area and can collect more rain water to supplement underground water. Therefore, the green belt for roads effectively overcomes the insurmountable shortcomings of a design method of an existing green belt higher than the ground, and has a novel function which a green belt in the prior art cannot have.

Owner:WUXI MUNICIPAL DESIGN INST

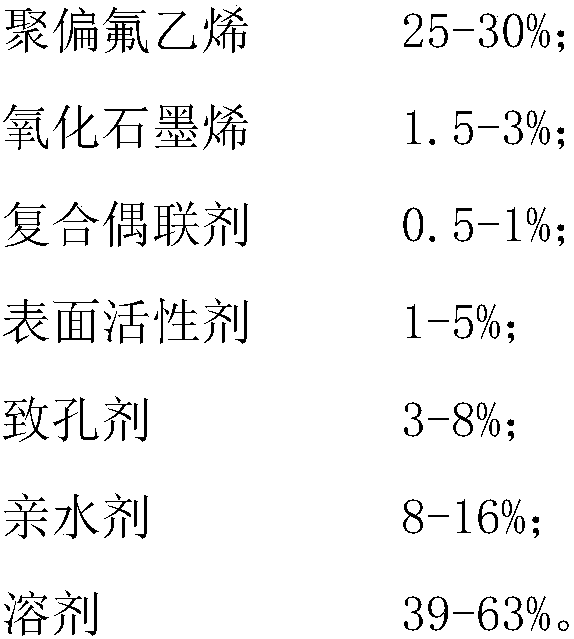

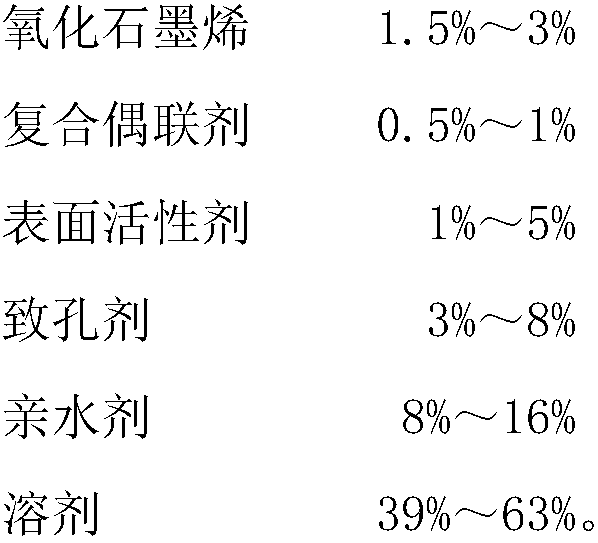

Antibacterial oxidized graphene modified PVDF (polyvinylidene fluoride) hollow fibrous membrane and preparation method thereof

InactiveCN108786495APlay a filtering rolePromote oxidative degradationSemi-permeable membranesMembranesPorosityFiber

The invention relates to an antibacterial oxidized graphene modified PVDF hollow fibrous membrane and a preparation method thereof. The antibacterial oxidized graphene modified PVDF hollow fibrous membrane is prepared from the following ingredients: polyvinylidene fluoride, oxidized graphene, a composite coupling agent, a surface active agent, a pore forming agent, a hydrophilic agent and a solvent. The preparation method comprises the steps that after oxidized graphene is subjected to vacuum drying, the composite coupling agent and polyvinylidene fluoride are added and mixed, and a dry powdery material is prepared; the dry powdery material is added into a mixed solution which is formed through blending of the surface active agent, the pore forming agent, the hydrophilic agent and the solvent to prepare spinning liquid, and the spinning liquid is subjected to membrane preparation through a solution spinning method technology and a membrane complexing technology. The prepared hollow fibrous membrane has the advantages that the porosity is high, the pores are distributed evenly and easy to control, the chemical property is stable, and the membrane has the catalytic and antibacterialfunctions, the membrane can achieve the effects of accelerating oxygenolysis of pollutants and preventing bacteria from proliferating on the surface of the membrane in the wastewater treatment process, and accordingly the anti-pollution property and the filtering effect of the membrane are improved.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

New energy automobile efficient motor with blowback self-cleaning function

ActiveCN111446817AWith back blowing self-cleaning functionImprove cleaning operationsDispersed particle filtrationTransportation and packagingElectric machineNew energy

The invention discloses a new energy automobile efficient motor with a blowback self-cleaning function. The motor comprises a case, a motor and an output shaft. The motor is installed in the case, anoutput shaft is arranged on a right side of the motor, a baffle is fixedly connected to the right side of the case, a plurality of filter holes are machined in an outer side surface of the baffle, anda heat dissipation mechanism is arranged on an outer wall of the output shaft. By using the new energy automobile efficient motor with the blowback self-cleaning function, through cooperation of thecase, the motor, the output shaft, the baffle, the filter holes and the heat dissipation mechanism, an operator controls an electromagnet so as to change a magnetic pole on a right surface of the electromagnet; and a circular slope groove abuts against an arc-shaped plate so that rotating directions of a circular block and a fan are opposite, air in the case is blown out towards the right side, back blowing operation can be performed on the filter holes, dust around the filter holes can be cleaned, manual bare-handed cleaning operation is not needed in a period, and convenience can be providedfor a user.

Owner:江西德尔盛汽车电机有限公司

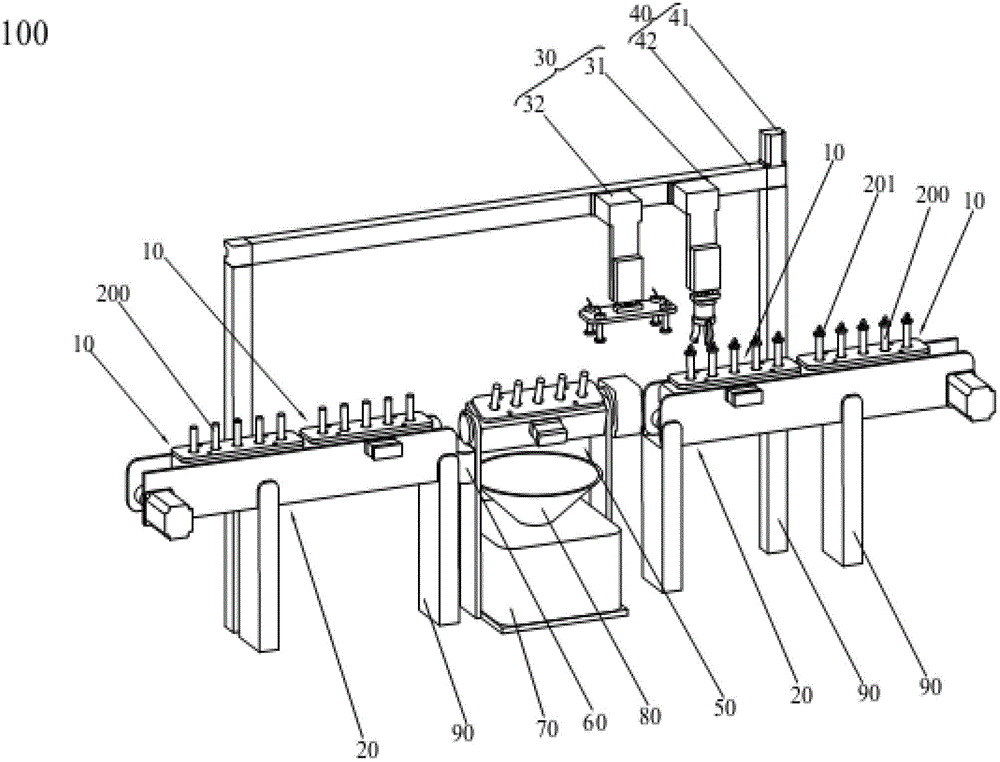

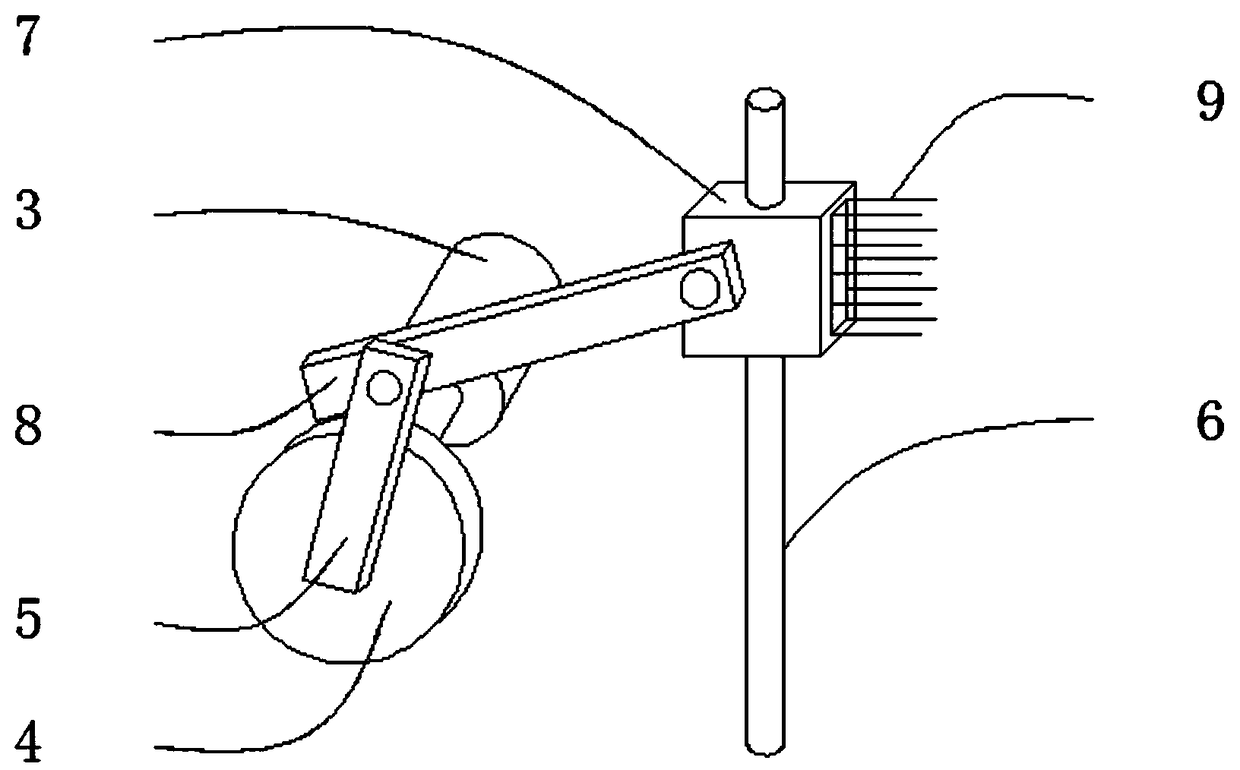

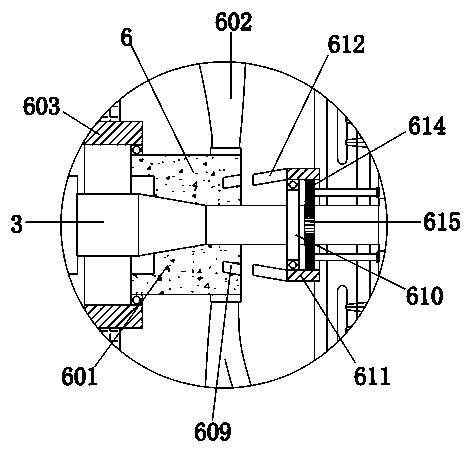

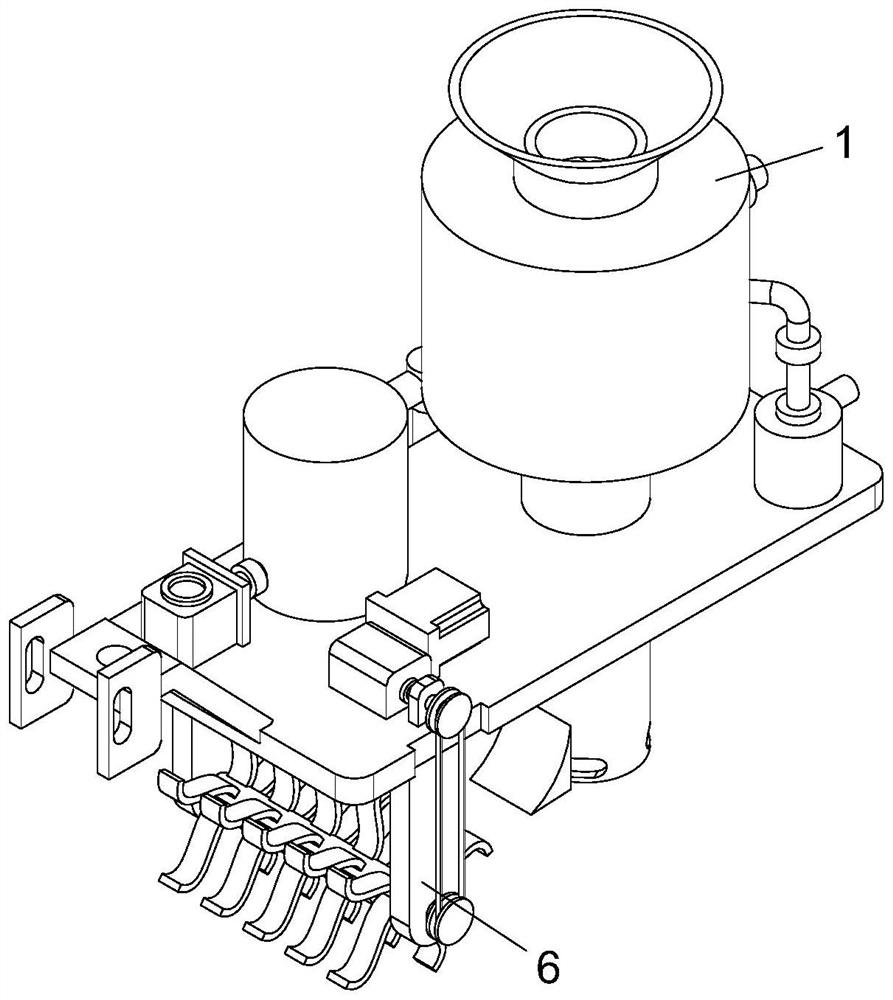

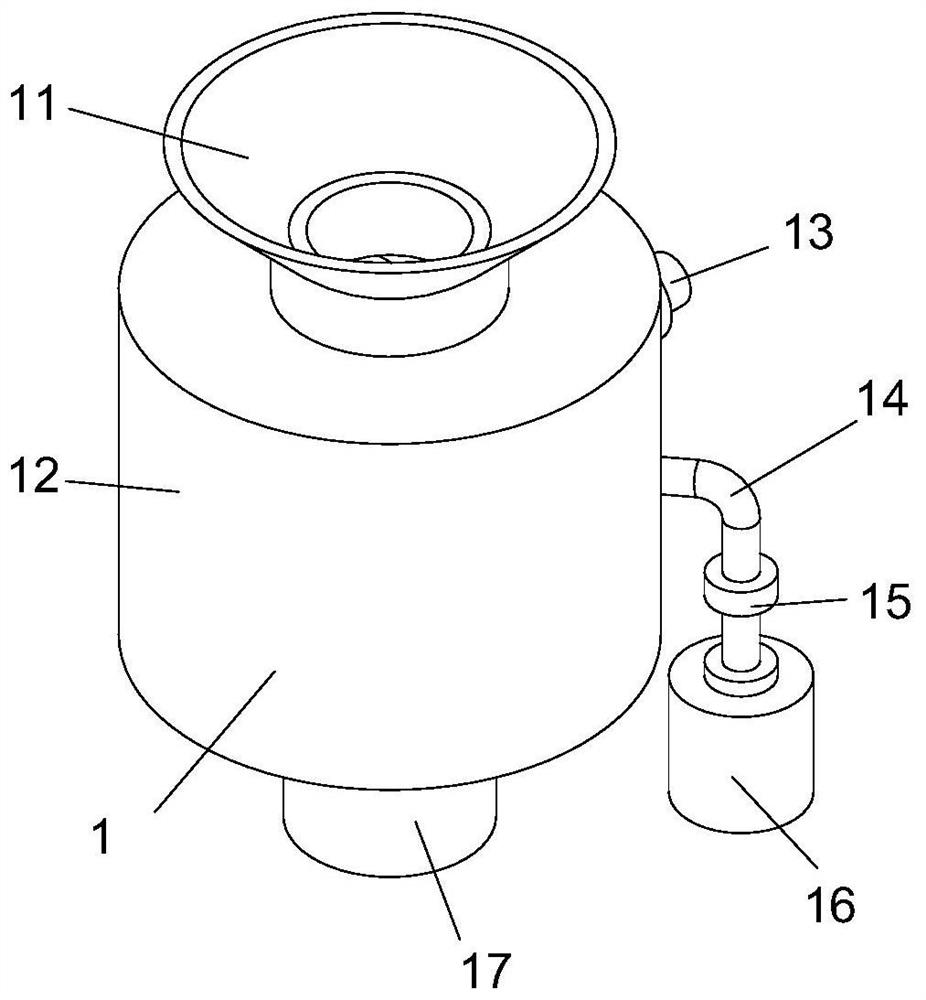

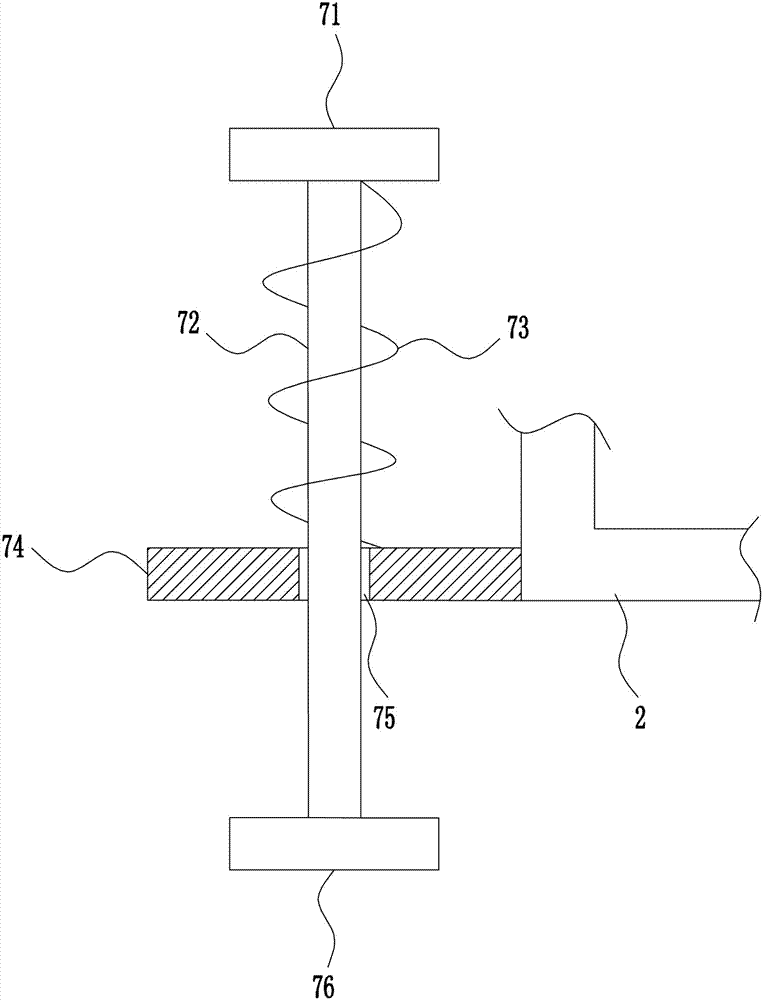

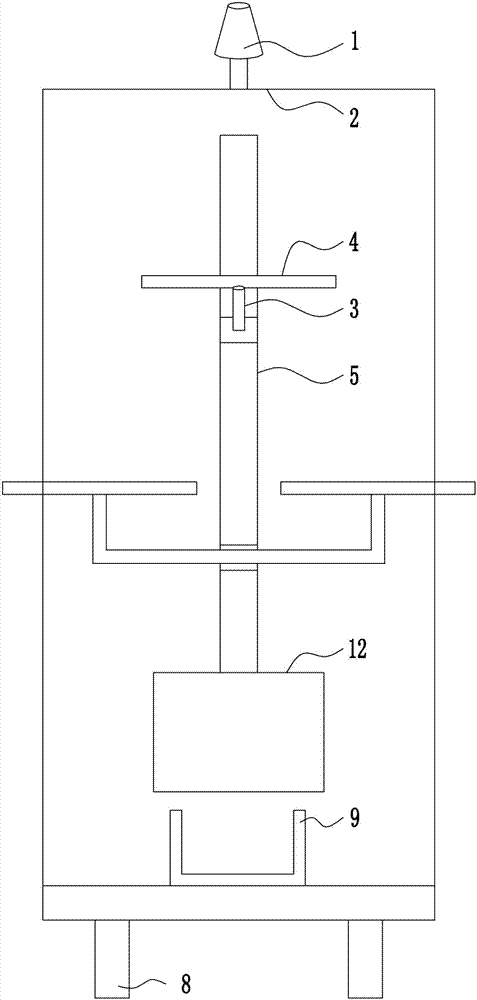

Automatic fertilizing device for farmland soil improvement

InactiveCN113016307APlay a filtering roleAvoid enteringSoil lifting machinesSpadesAgricultural engineeringMechanical engineering

The invention relates to the technical field of agricultural machinery, in particular to an automatic fertilizing device for farmland soil improvement. The automatic fertilizing device for farmland soil improvement comprises a mounting plate, a connecting structure through which an automatic fertilizing device is connected with an external driving machine, a rotary tillage mechanism connected with the mounting plate and used for loosening soil, a fertilizer storage mechanism connected with the mounting plate, a discharging mechanism connected with the mounting plate, and used for unidirectionally and uniformly discharging fertilizers in the fertilizer storage mechanism to a fertilizing pipe mechanism, the fertilizing pipe mechanism used for spreading the fertilizers, and an air gun mechanism connected with the mounting plate, wherein an air outlet of the air gun mechanism is communicated with the fertilizing pipe mechanism, and compressed air is regularly or controllably introduced into the fertilizing pipe mechanism through the air gun mechanism. The automatic fertilizing device for farmland soil improvement provided by the invention has the advantages of high fertilization efficiency, uniform fertilization and good fertilization effect.

Owner:马边青山莲农业科技开发有限公司

Cosmetic try-out display device for marketing

The invention relates to a cosmetic try-out display device, in particular to a cosmetic try-out display device for marketing. The invention is aimed at solving the technical problem of providing a cosmetic try-out display device for marketing. In order to solve the technical problem above, the invention provides the cosmetic try-out display device for marketing, wherein the device includes a flashlight, a holder, a support rod, a tray, a lifting gear, a storage battery, a fixed device and the like; the bottom of the holder is provided with rolling wheels, and the top of the holder is provided with the flashlight, and meanwhile, the interior rear wall of the holder is provided with the lifting gear and a water storage box; the lifting gear is positioned above the water storage box, and the front side of the lifting gear is connected with the support rod, the upper end of which is rotatably connected with the tray which is provided with annular grooves in different radii. The cosmetic try-out display device has the advantages of managing to focusing customers' attention, better catching customers' eyes, providing an obvious marketing effect, and appropriately disposing liquid waste after cleaning cosmetic samples used by customers.

Owner:泰安市会达百货有限公司

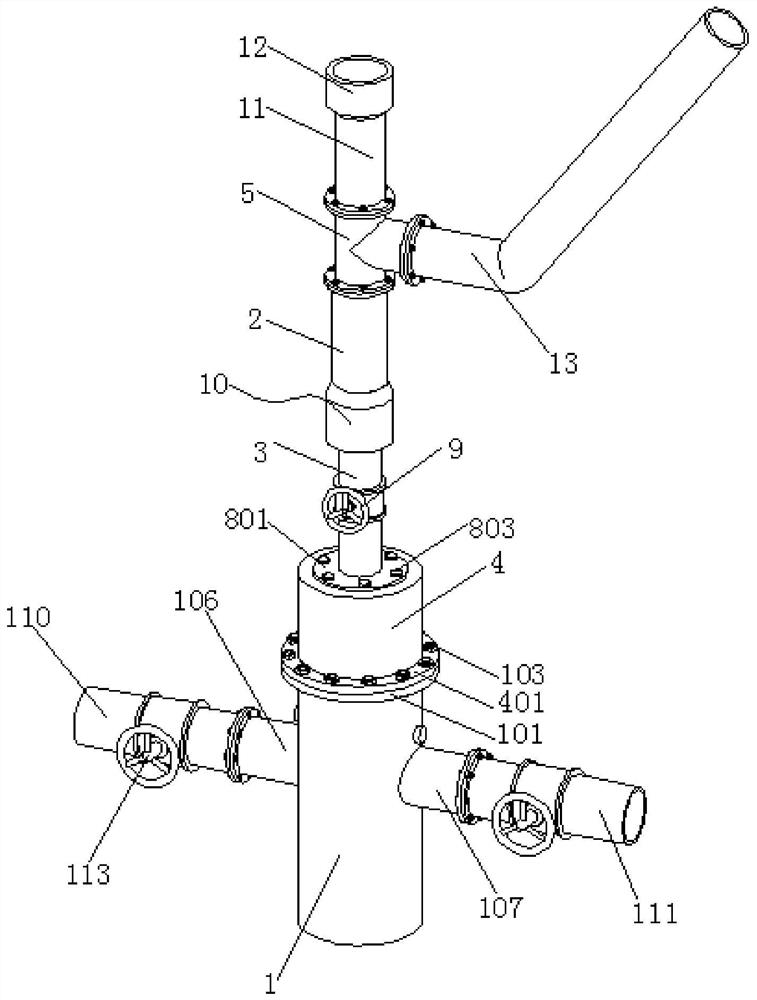

Sand prevention and filling integrated wellhead device

InactiveCN112065315AAvoid cloggingDoes not affect oil outputFluid removalSealing/packingMechanical engineeringWellhead

The invention relates to the technical field of oil exploitation equipment, and particularly relates to a sand prevention and filling integrated wellhead device. The sand prevention and filling integrated wellhead device comprises a wellhead body, an upper central pipe, a lower central pipe, a wellhead connecting cover body and a pipeline connecting tee joint, wherein the upper end face of the wellhead body is connected with a wellhead flange; a first sealing ring groove is formed in the inner side face of the wellhead flange; a cover body flange is arranged at an opening in the lower end of the wellhead connecting cover body; and the wellhead flange and the cover body flange are connected in a fastened mode through bolts. The sand prevention and filling integrated wellhead device has better pressure-resistant rotating and sliding effects, can turn flexibly and is resistant to impact, vibration and high temperature and high pressure; an annular screen frame is arranged at the upper endof the wellhead body, a sand prevention screen is arranged on the annular screen frame and can filter sand mixed in gushing liquid, and thus the sand prevention effect is achieved; and in addition, the annular screen frame vibrates up and down in the construction process, the sand prevention screen can be effectively prevented from being blocked by the sand, and the oil outlet amount of the sandprevention screen is not affected.

Owner:东营市正能石油科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com