Antibacterial oxidized graphene modified PVDF (polyvinylidene fluoride) hollow fibrous membrane and preparation method thereof

A graphene modification, fiber membrane technology, applied in chemical instruments and methods, oxidized water/sewage treatment, membranes, etc., can solve the problem of membrane water permeability and retention capacity decline, membrane pores narrowing and blocking, poor mechanical strength and other problems, to achieve the effect of improving sewage treatment efficiency, preventing reproduction and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

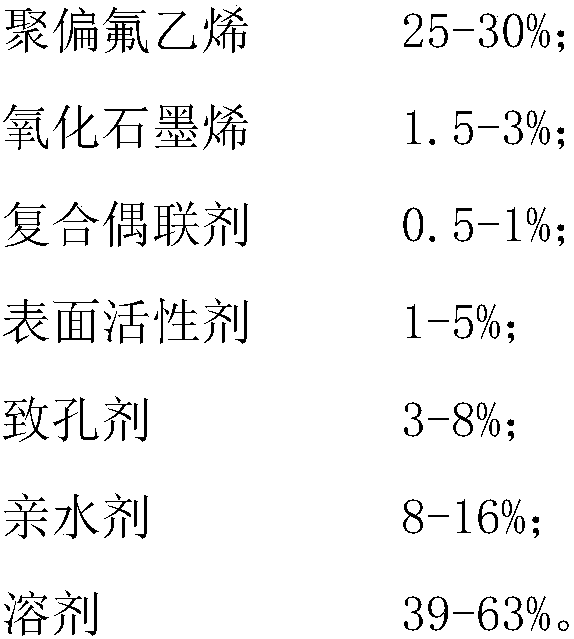

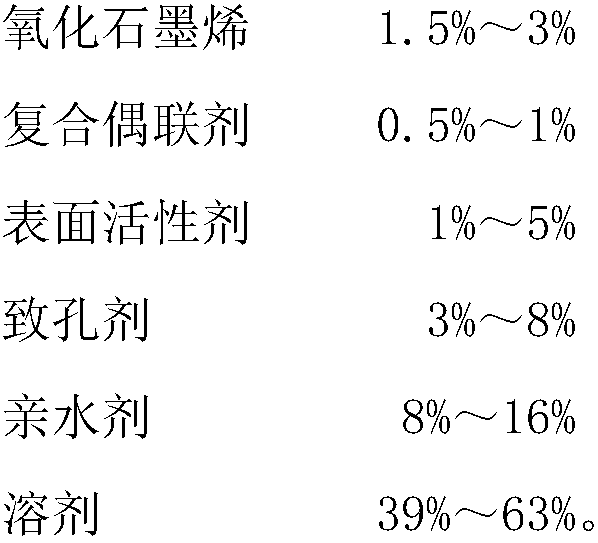

[0034] The preparation method of described antibacterial graphene oxide modified PVDF hollow fiber membrane, its specific steps are:

[0035] In order to effectively disperse graphene oxide in polyvinylidene fluoride and reduce costs, firstly dry graphene oxide in a vacuum oven at 60°C for 24 hours, then add composite coupling agent and polyvinylidene fluoride for high-speed mixing ;

[0036] The dry powder prepared above is added to a solution that is uniformly mixed and contains surfactants, porogens, hydrophilic agents, and solvents to make a spinning solution; the solution phase inversion process is used to prepare the hook knitting mesh tube lamination process. Graphene oxide modified PVDF hollow fiber membrane reinforced by woven mesh tube; in this way, graphene oxide can be effectively and evenly dispersed in polyvinylidene fluoride, and graphene oxide will not be agglomerated to cause failure or reduce effectiveness. Controlling the composition and temperature of the ...

Embodiment 1

[0039] Dry 1.5% graphene oxide in a vacuum oven at 60°C for 24 hours according to the mass ratio, then add 0.6% composite coupling agent and 28% polyvinylidene fluoride for high-speed mixing; add the dry powder prepared above to mix evenly and contain 2.5 % surface active agent, 4% porogen, 9% hydrophilic agent, 54.4% solvent solution to make spinning solution; the spinning solution is filtered into the spinning tank for defoaming, and the control defoaming temperature is 60 ℃, The time is 13h; Then the composite die mouth of the pressurized hollow fiber membrane is composited with the crochet mesh pipe (the composite is at 50 ℃, DMAc / H 2 O=70 / 30 (wt / wt) in the coagulation bath), and then separated and shaped by the coagulation tank to complete the preparation of the antibacterial graphene oxide modified PVDF hollow fiber membrane reinforced by the hook-woven mesh tube.

[0040] The outer diameter of the hollow fiber membrane obtained in this example is 1.3mm, the inner diamet...

Embodiment 2

[0042] Dry 2% graphene oxide in a vacuum oven at 60°C for 24 hours according to the mass ratio, then add 0.8% composite coupling agent and 26% polyvinylidene fluoride for high-speed mixing; add the dry powder prepared above to mix evenly and contain 4 % surface active agent, 6% porogen, 12% hydrophilic agent, 49.2% solvent solution to make spinning solution; the spinning solution is filtered into the spinning tank for defoaming, and the control defoaming temperature is 60 ℃, The time is 15h; Then the composite die mouth of the pressurized hollow fiber membrane is composited with the crochet mesh pipe (the composite is at 50 ℃, DMAc / H 2 O=70 / 30 (wt / wt) in the coagulation bath), and then separated and shaped by the coagulation tank to complete the preparation of the antibacterial graphene oxide modified PVDF hollow fiber membrane reinforced by the hook-woven mesh tube.

[0043] The hollow fiber membrane obtained in this example has an outer diameter of 1.3mm, an inner diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com