Sand prevention and filling integrated wellhead device

A wellhead device and body technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and mining, etc., can solve problems such as heavy workload, frequent construction, and potential safety hazards in construction, and achieve good pressure-resistant rotation and sliding effects , reduce construction risk, excellent filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

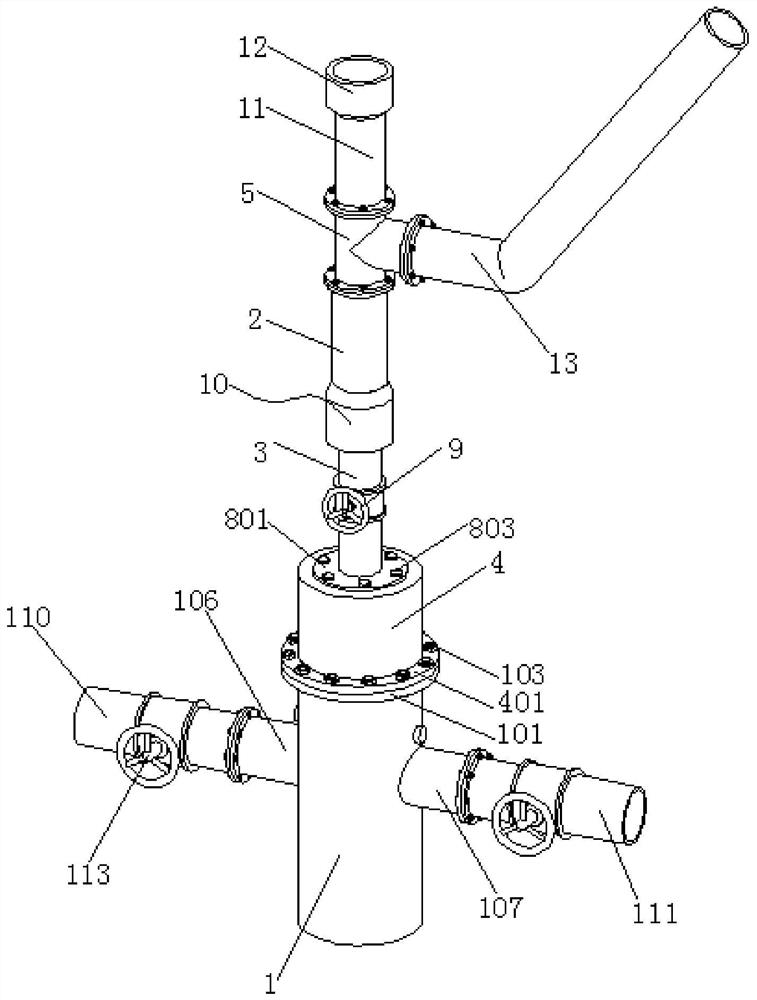

[0039] This Example 1 introduces an integrated wellhead device for sand control and filling, refer to the attached figure 1 , its main structure includes a wellhead body 1, an upper center pipe 2, a lower center pipe 3, a wellhead connection cover 4 and a pipe connection tee 5.

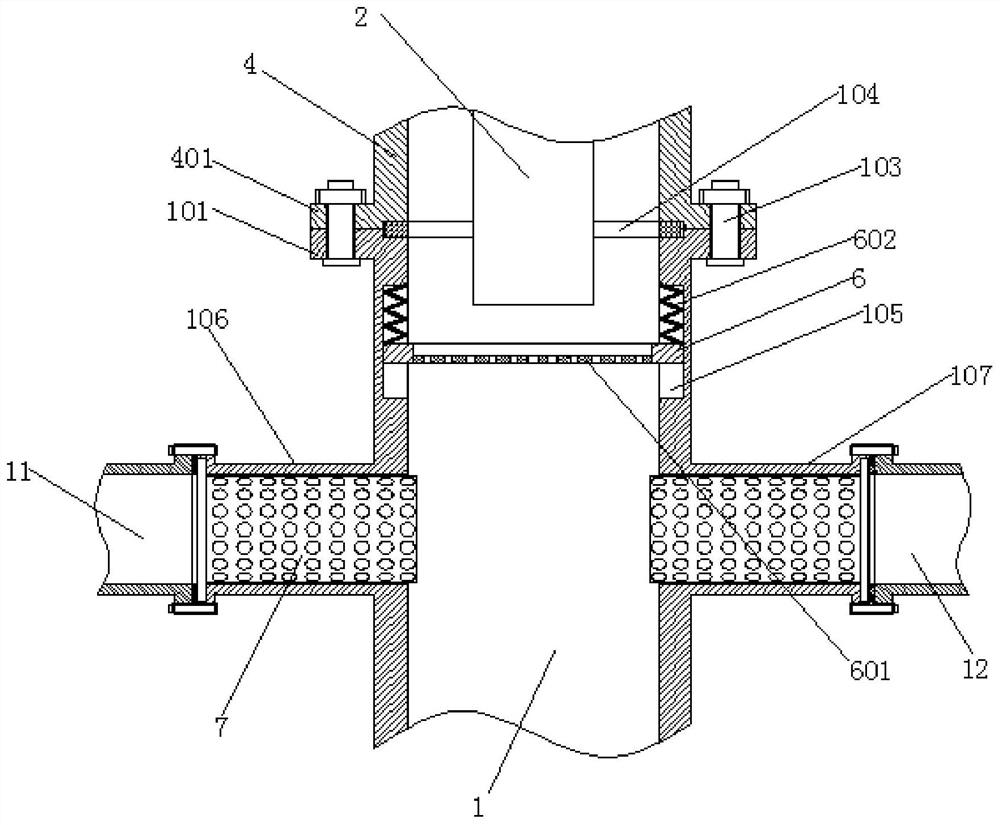

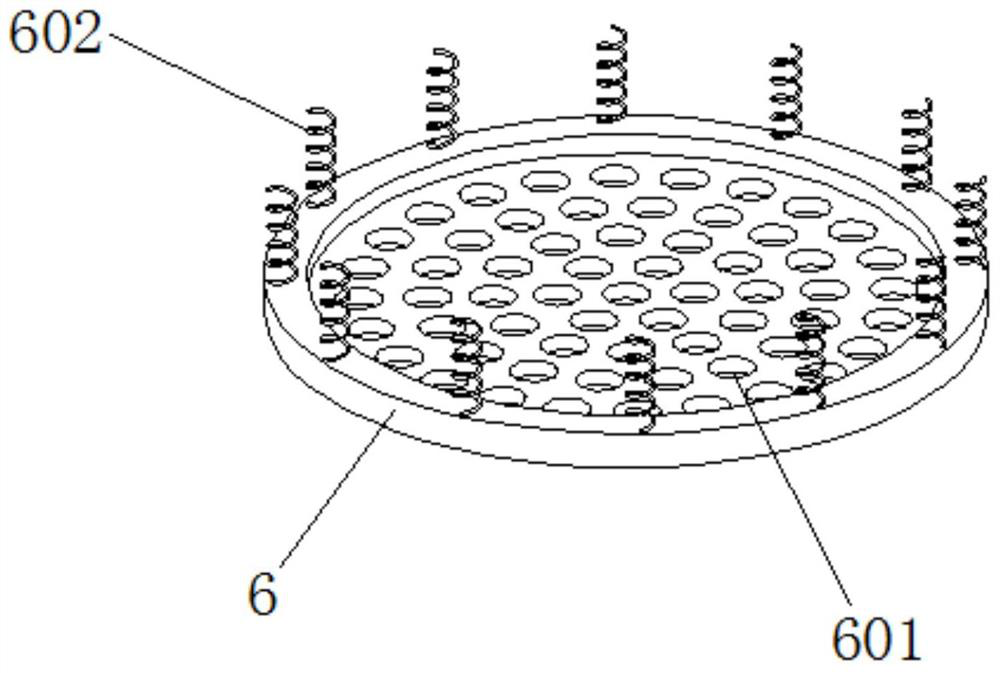

[0040] Reference attached figure 2 And attached Figure 4 The upper end surface of the wellhead body 1 is connected with a wellhead flange 101, the inner surface of the wellhead flange 101 is provided with a first sealing ring groove 102, and the lower end opening of the wellhead connection cover body 4 is provided with a cover body flange 401, the cover body method The inner surface of the flange 401 is provided with a second sealing ring groove 402 corresponding to the first sealing ring groove 102. The wellhead flange 101 and the housing body flange 401 are tightly connected by bolts 103, and the first sealing ring is recessed. A large rubber sealing ring 104 is arranged between the groove 102 a...

Embodiment 2

[0046] This embodiment 2 introduces the improved integrated wellhead device for sand control and packing based on the embodiment 1.

[0047] First of all, the similarities between Embodiment 2 and Embodiment 1 will not be described again here, and the differences of Embodiment 2 will be described in detail below:

[0048] First, referring to the accompanying drawings, 8 and attached Figure 9 , in this embodiment 2, it is not a direct sleeve pipe, the entire rotating connecting pipe assembly 10 includes a rotating sleeve joint 14, the rotating sleeve joint 14 is integrally connected with the lower end of the upper central pipe 2, and the upper end of the inner wall of the rotating sleeve joint 14 A swivel bearing 15 is provided, and the top outer wall of the lower center tube 3 is welded to the inner cavity of the swivel bearing 15 , and a retaining ring 16 is arranged in the gap between the swivel sleeve joint 14 and the lower central tube 3 . Further, the top end of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com