Patents

Literature

176 results about "Immersion precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

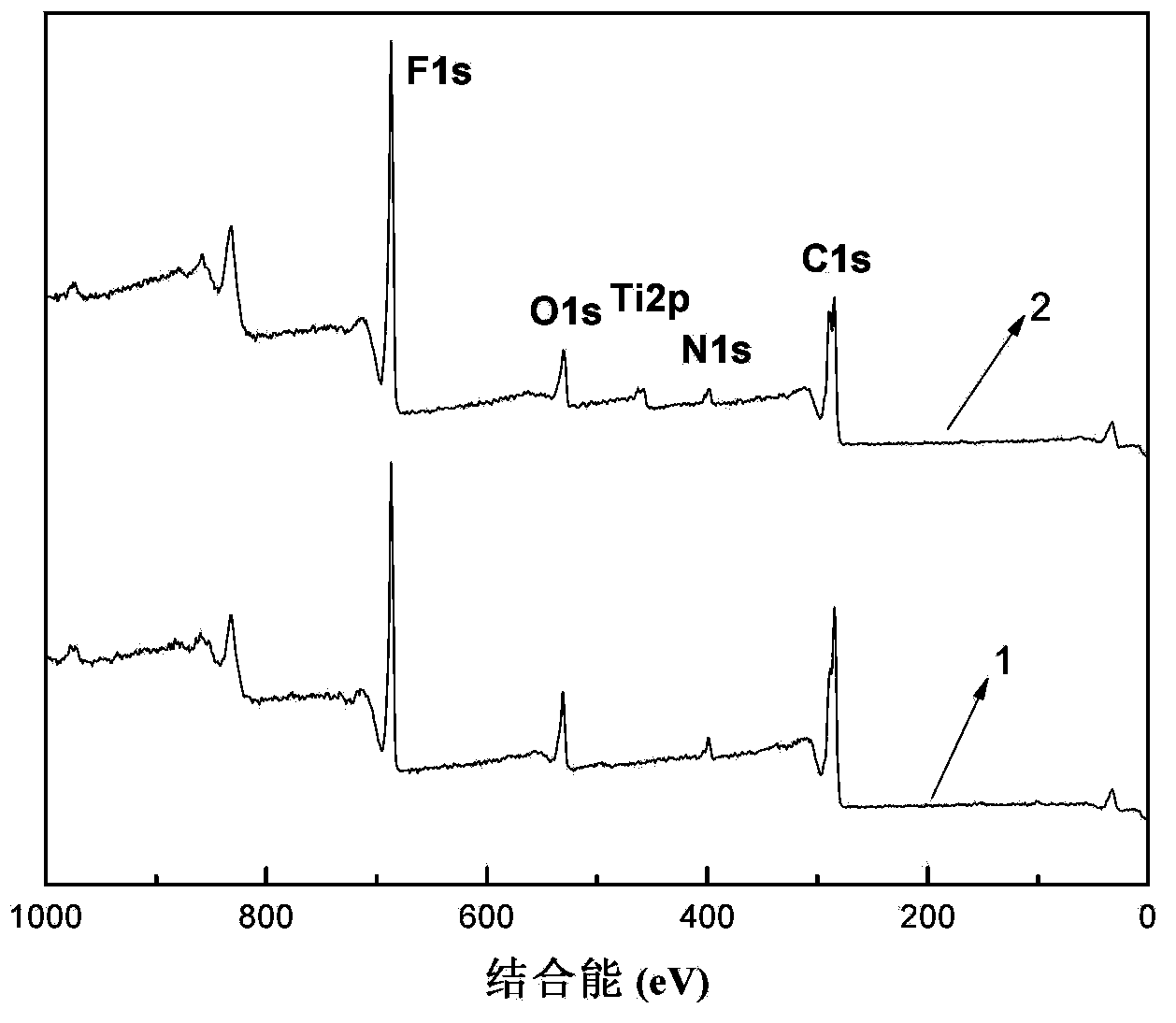

Preparation method of high-performance PVDF composite ultrafiltration membrane with surface loaded with TiO2 thin membrane

InactiveCN103394294AImprove stabilityEasy to manufactureSemi-permeable membranesThin membraneRejection rate

A preparation method of a high-performance PVDF composite ultrafiltration membrane with the surface loaded with a TiO2 thin membrane is provided. The invention is used for solving the problems of complex process, high membrane preparing cost, and difficult industrialized production existing in a conventional method for improving membrane hydrophilicity so as to improve membrane flux, anti-fouling performance and the like. The preparation method comprises the steps: 1, preparing a PVDF polymer membrane casting solution, and preparing an ultrafiltration basement membrane by an immersion-precipitation method; 2, preparing an auxiliary agent solution; 3, soaking the basement membrane in the auxiliary agent solution, taking out and swashing with water, and soaking in deionized water; 4, preparing a titania precursor solution; 5, immersing the basement membrane in the titania precursor solution, hydrolyzing a precursor, taking out and swashing with water, and thereby obtaining the high-performance ultrafiltration membrane with the surface firmly loaded with the TiO2 thin membrane. The method of the invention has the advantages of simple operation and low cost; and the obtained ultrafiltration membrane has large permeation flux, high rejection rate, strong hydrophilicity and outstanding anti-fouling performance. The preparation method is used for the membrane processing field.

Owner:HARBIN INST OF TECH

TiO2/C hybrid aerogel modified polyvinylidene fluoride membrane and preparation method thereof

The invention provides a TiO2 / C hybrid aerogel modified polyvinylidene fluoride membrane. The TiO2 / C hybrid aerogel modified polyvinylidene fluoride membrane consists of PVDF, a pore-foaming agent, TiO2 / C hybrid aerogel and an organic solvent. The invention also provides a preparation method of the TiO2 / C hybrid aerogel modified polyvinylidene fluoride membrane. The method comprises the steps of preparing membrane casting solution firstly, mechanically stirring the membrane casting solution in a thermostat water bath to fully dissolve PVDF, standing and defoaming the membrane casting solution for membrane scraping, scraping the membrane casting solution on a glass plate by a glass rod to form a membrane, exposing the glass plate in air, soaking the glass plate in coagulating bath to form the membrane by immersion precipitation phase inversion, soaking the prepared membrane in distilled water for 5-8 days, taking out and airing to obtain the membrane. According to the TiO2 / C hybrid aerogel modified polyvinylidene fluoride membrane, the TiO2 / C hydrophilic composite material is added on the surface of the PVDF ultrafiltration membrane, so that the hydrophilcity of the PVDF ultrafiltration membrane is effectively improved, the energy consumption is greatly reduced, the TiO2 / C can be adopted for photocatalytic degradation of organic matters and the service life of the membrane is prolonged.

Owner:SHANGHAI INST OF TECH

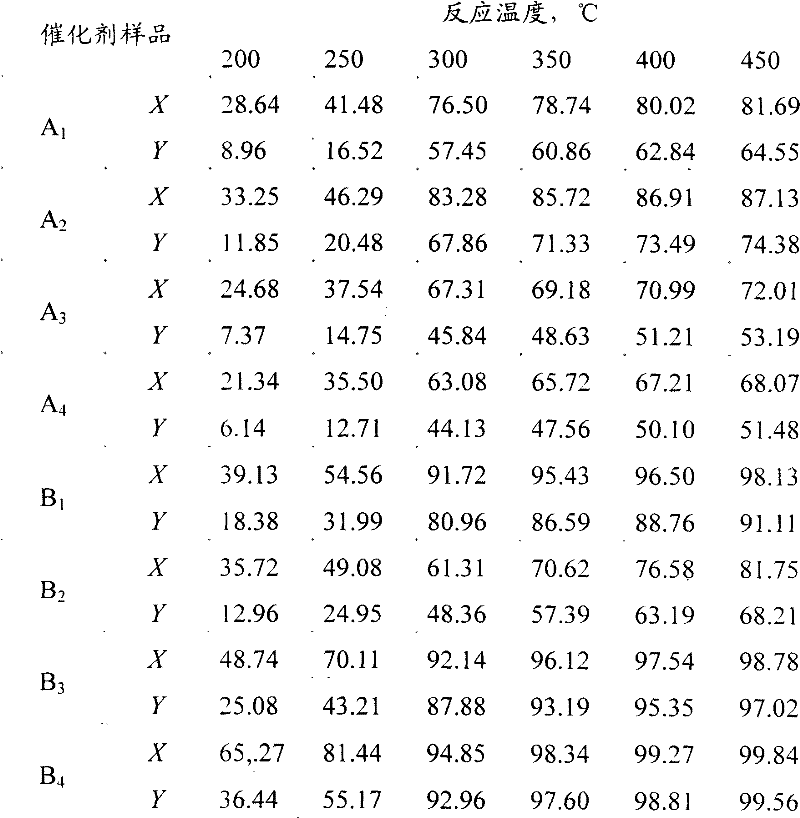

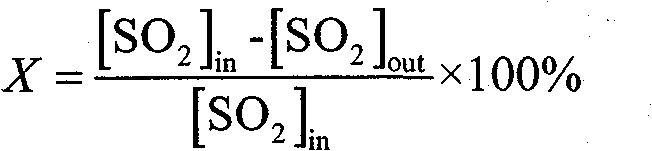

Preparation of activated carbon-based catalyst used for selective reduction desulphurization of flue gas

ActiveCN102357364AImprove activity stabilityGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoalPollution

Belonging to the technical field of sulfur recovery, the invention relates to a catalyst for selective reduction desulphurization, its preparation method and application. The catalyst is characterized in that: a catalyst active component is loaded on a carrier by means of an isometric immersion method, a multiple immersion method and an immersion precipitation method so as to obtain the catalyst; the catalyst carrier consists of coconut-shell activated carbon, fruit-shell activated carbon and coal-based activated carbon; the oxidation modifier of the catalyst carrier is one or a mixture of any of chloric acid, nitric acid, hydrogen peroxide or concentrated sulfuric acid; the active component of the catalyst is one or a mixture of any of CuO, NiO, Fe2O3, ZnO, Cr2O3, Co2O3, MnO2, and V2O5. The desulfurizer of the invention employs a selective reduction desulphurization technology to convert SO2 in flue gas into elemental sulfur. The preparation technology of the catalyst has the advantages of simplicity, easy control, low cost and long service life. Adoption of the activated carbon-based catalyst prepared in the invention for selective reduction desulphurization not only realizes high efficiency SO2 conversion rate and sulfur selectivity, but also effectively prevents secondary pollution.

Owner:SHANDONG QINGYUAN GROUP CO LTD

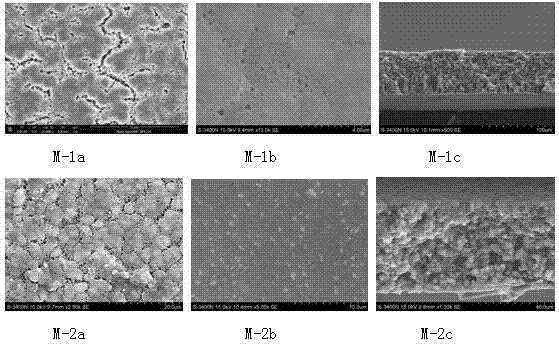

Method for preparing composite flat ultrafiltration membrane

The invention discloses a method for preparing a composite flat ultrafiltration membrane. According to the invention, immersion-precipitation phase transformation method is used in the preparation method, a supporting layer used herein is a PET fiber braided fabric, and a high-molecular polymer casting solution is coated on the supporting layer. The preparation method comprises the following steps: (1) mixing high-molecular polymer, organic solvent, and additives in proportion to prepare a homogeneous casting solution; (2) putting the PET fiber braided fabric in an NaOH solution with a certain concentration, and removing residual oil stains and dirt on the fabric; (3) carrying out surface modification on the PET fiber braided fabric; and (4) uniformly coating the casting solution obtainedby the step (1) on the surface of the modified fiber braided fabric, then putting the coated fiber braided fabric in a gel bath to carry out phase-inversion film forming to obtain the composite flat ultrafiltration membrane which has the advantages of high flux, high strength, pollution resistance, and hydrophilicity, wherein the supporting layer and the coating layer are not easy to be separated.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

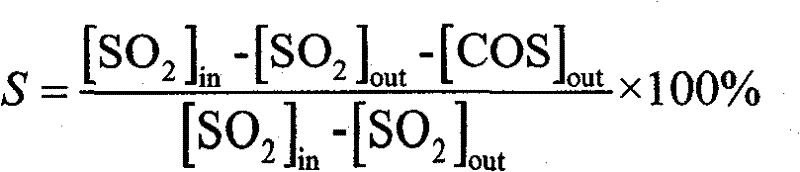

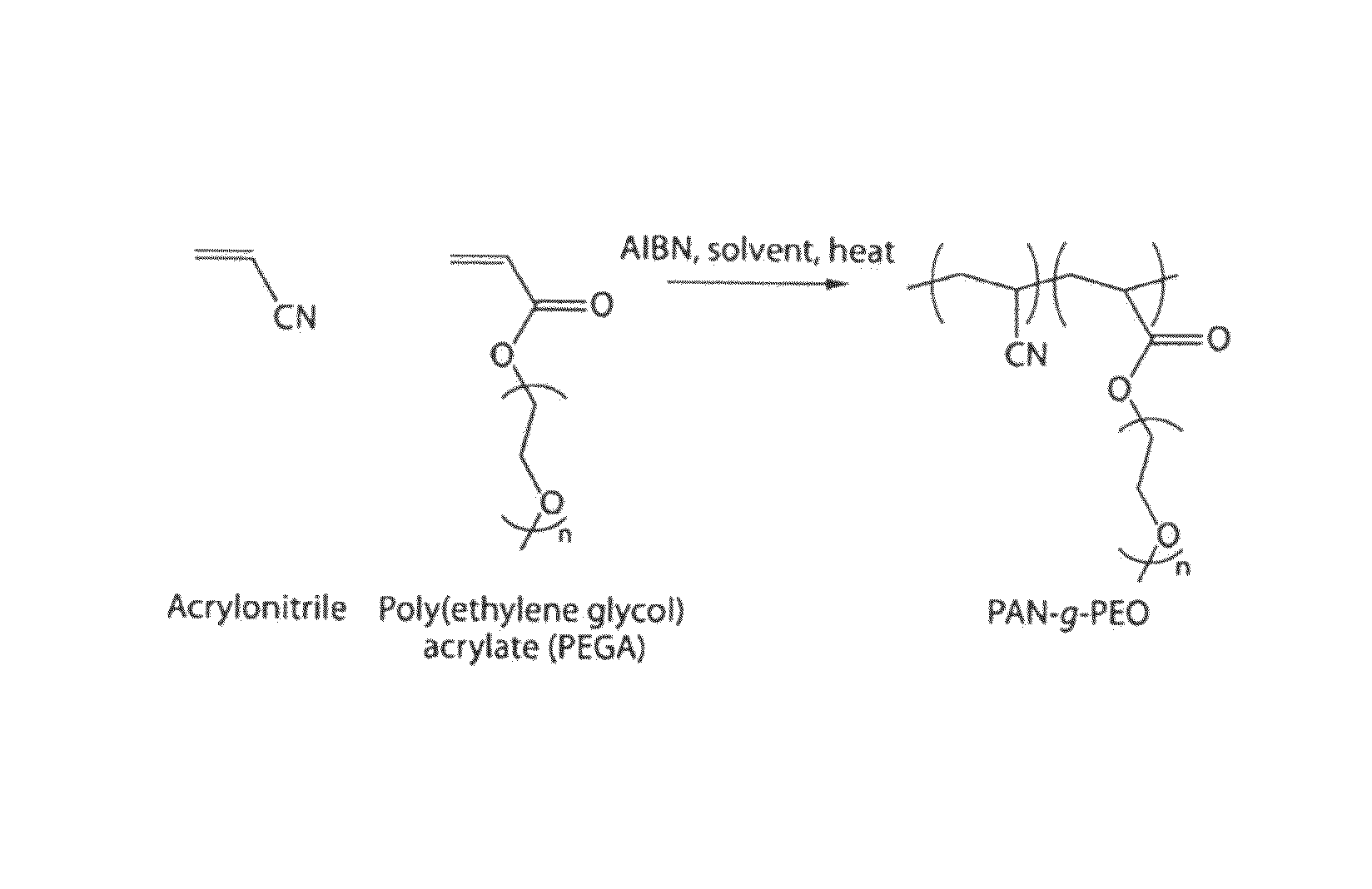

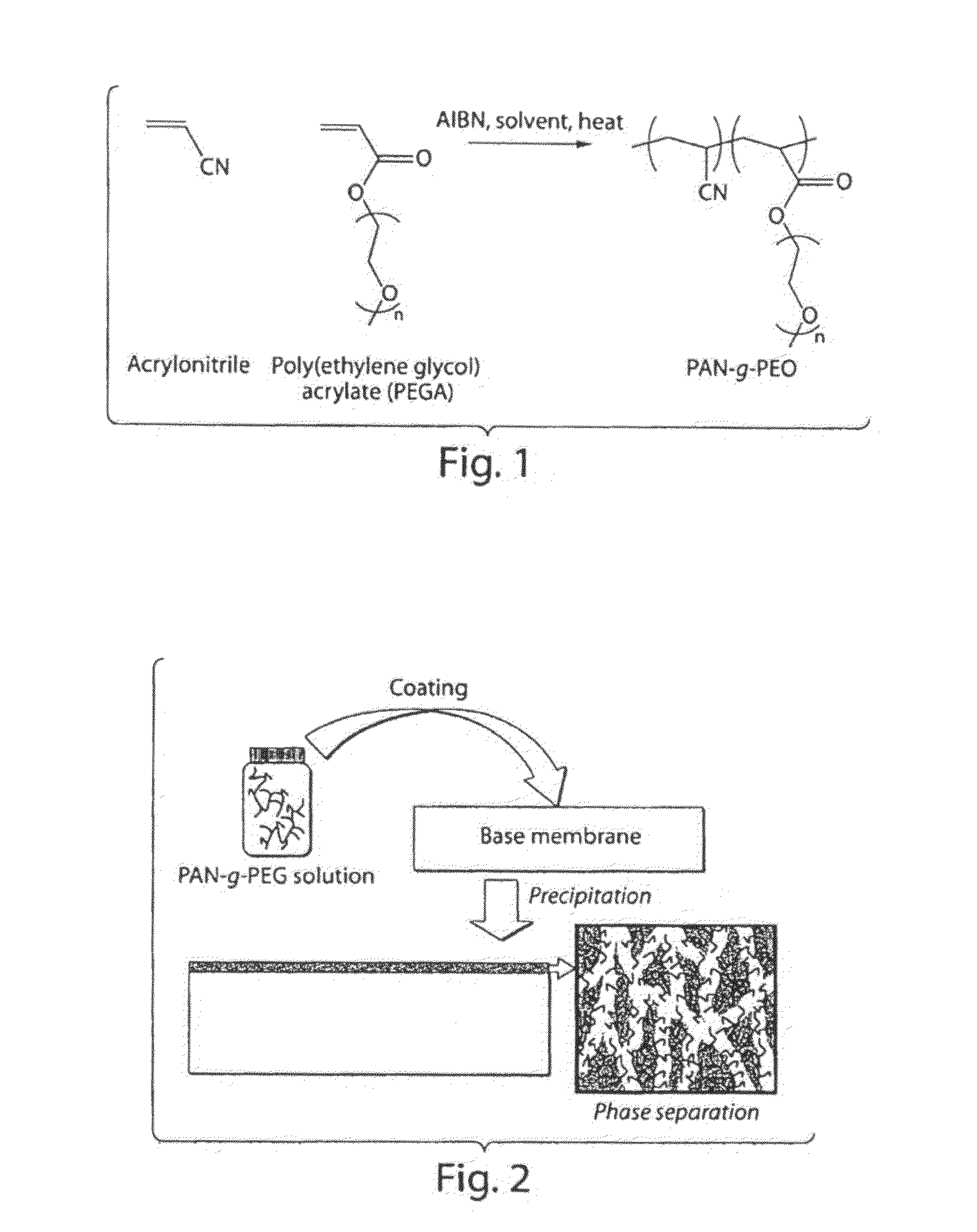

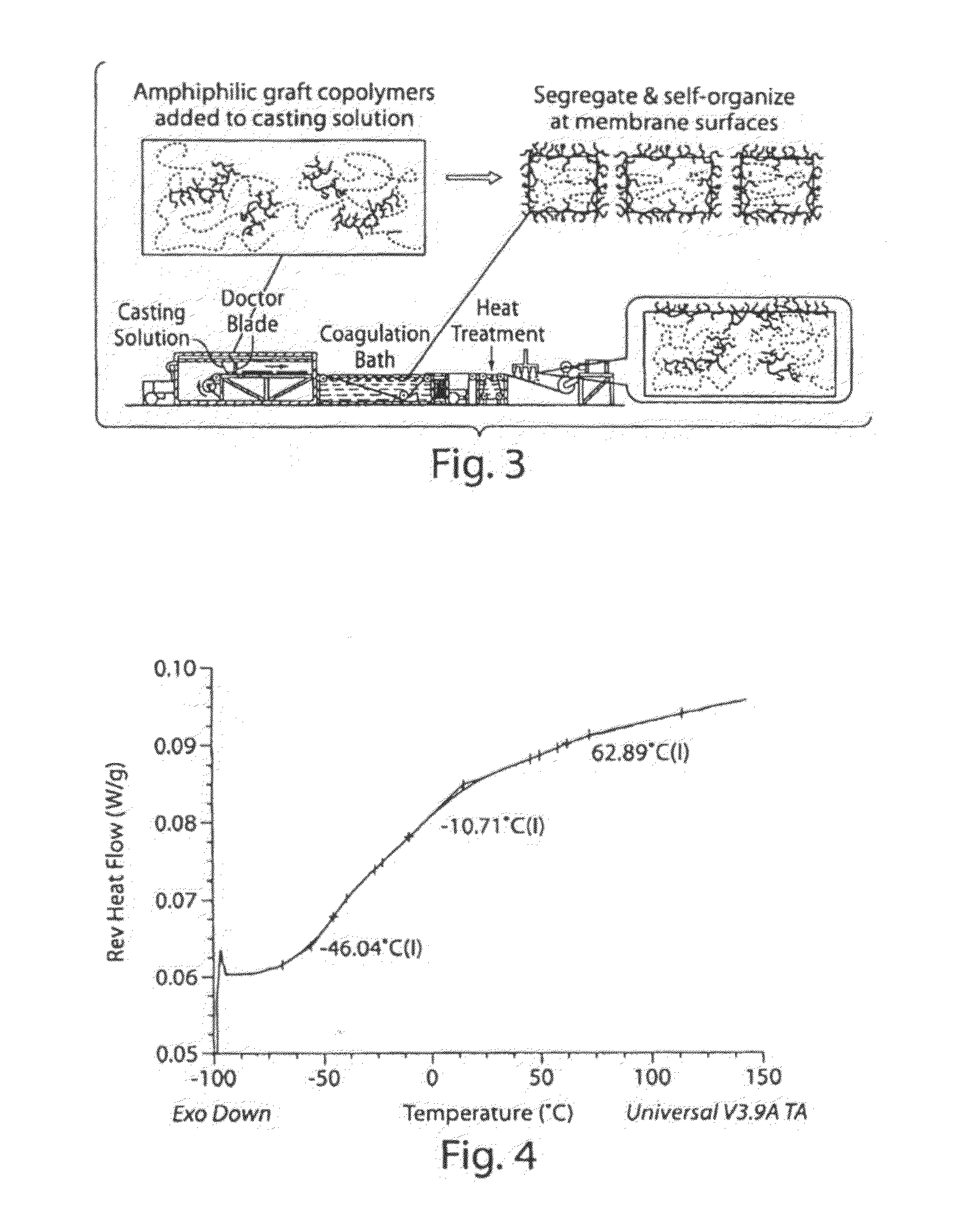

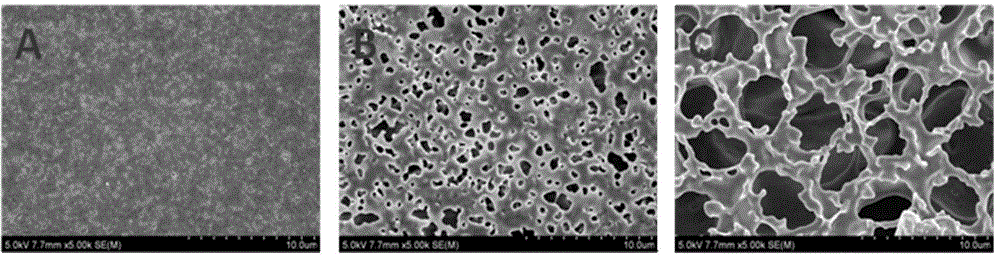

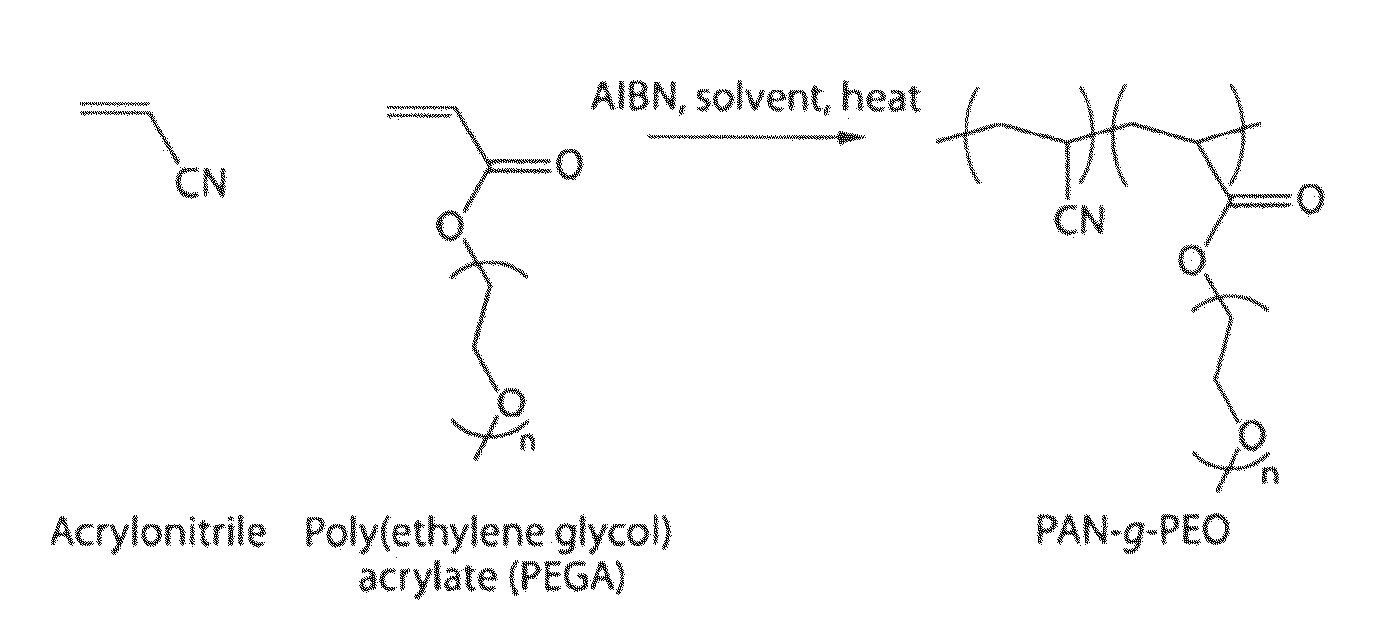

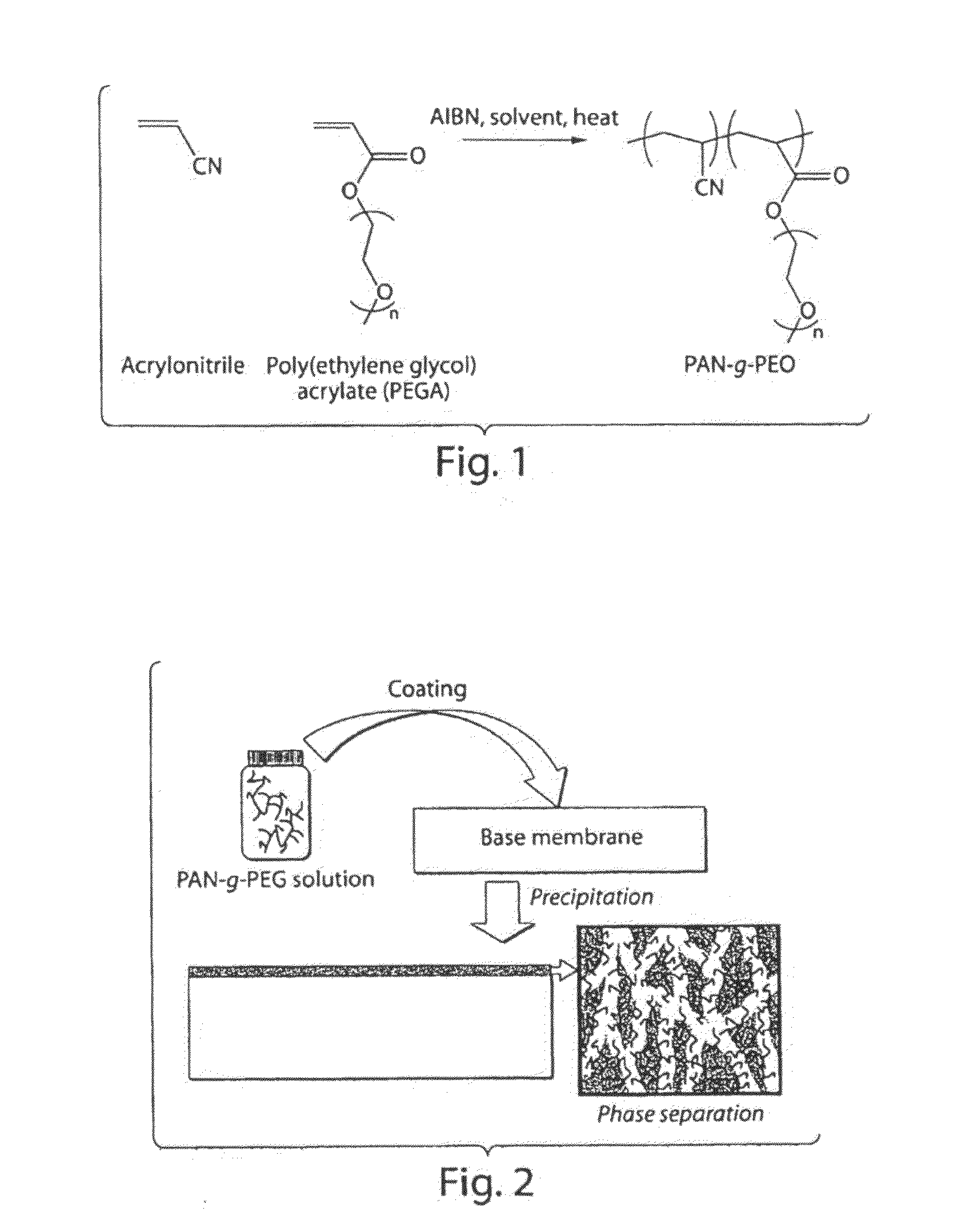

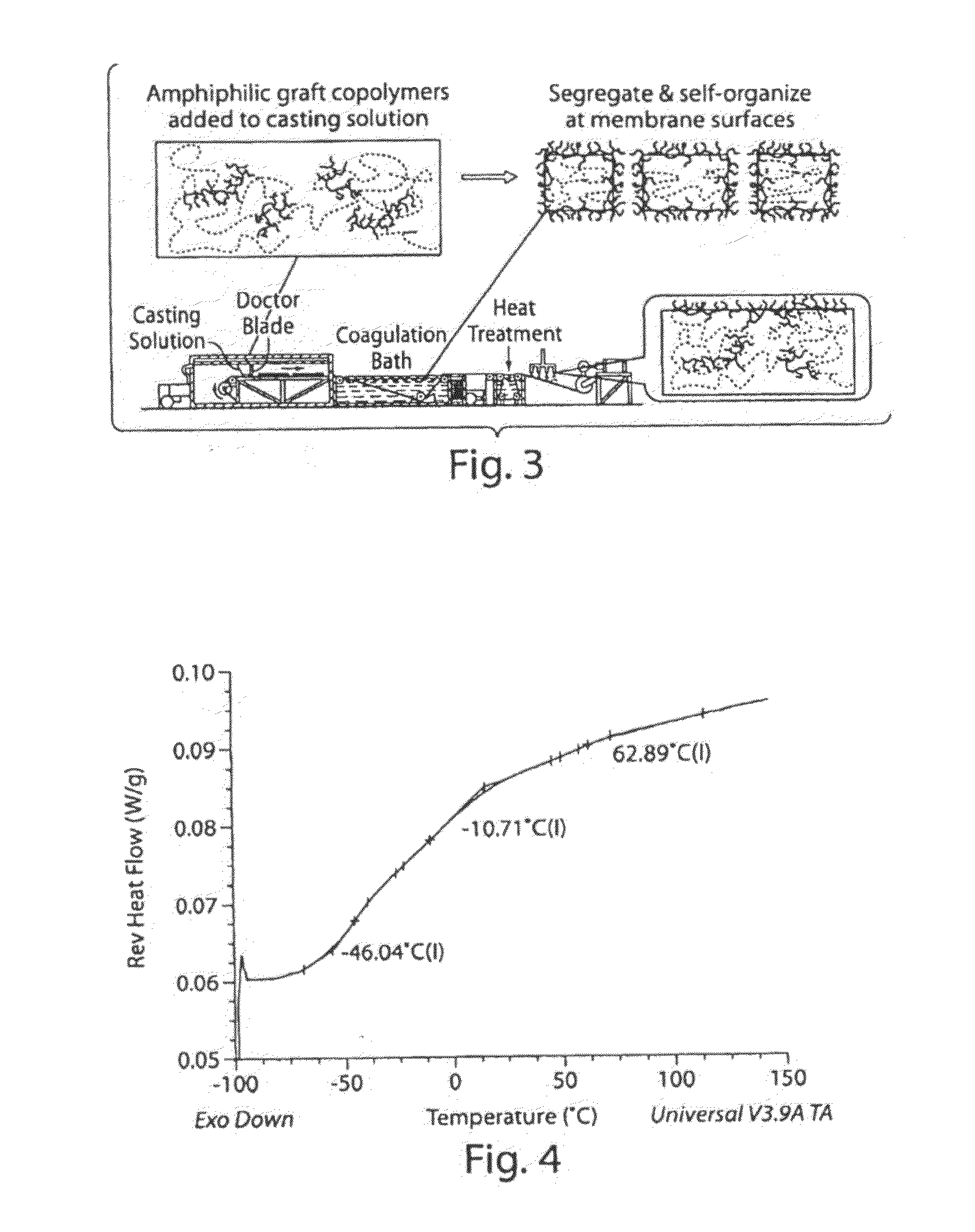

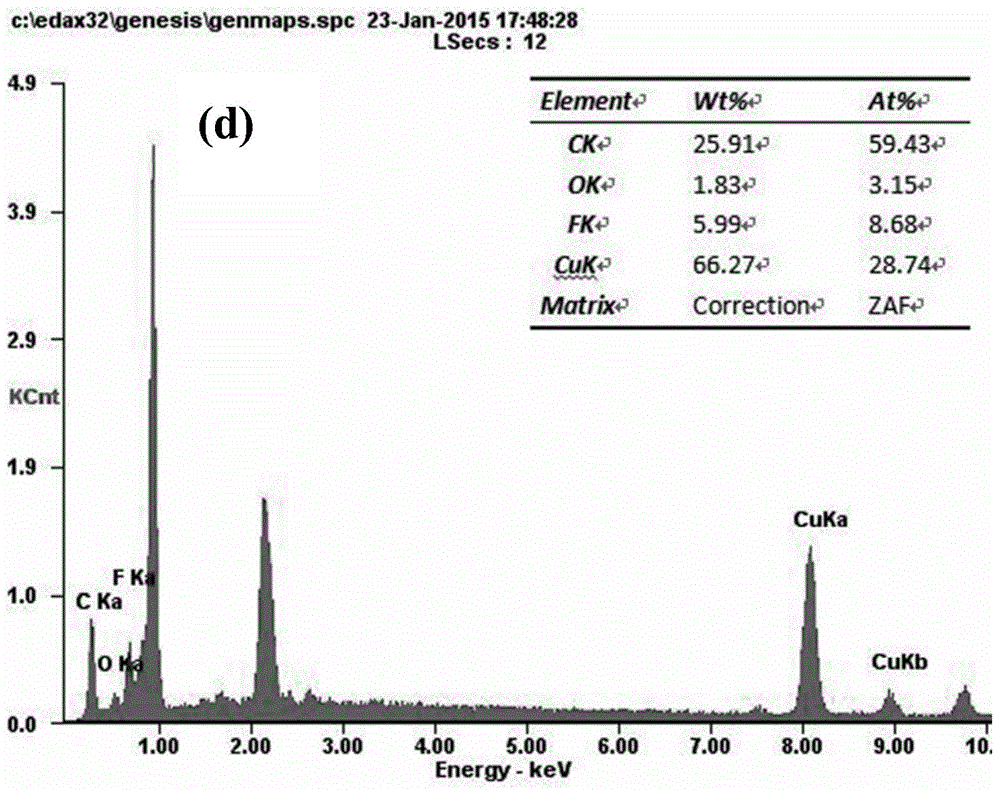

Fouling resistant membranes formed with polyacrylonitrile graft copolymers

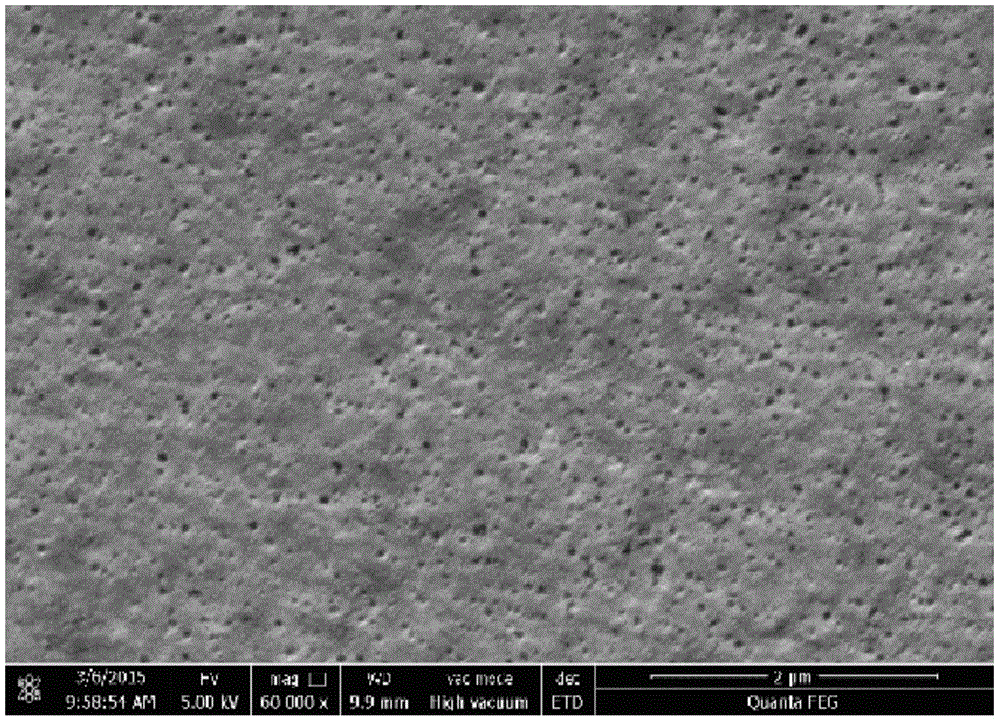

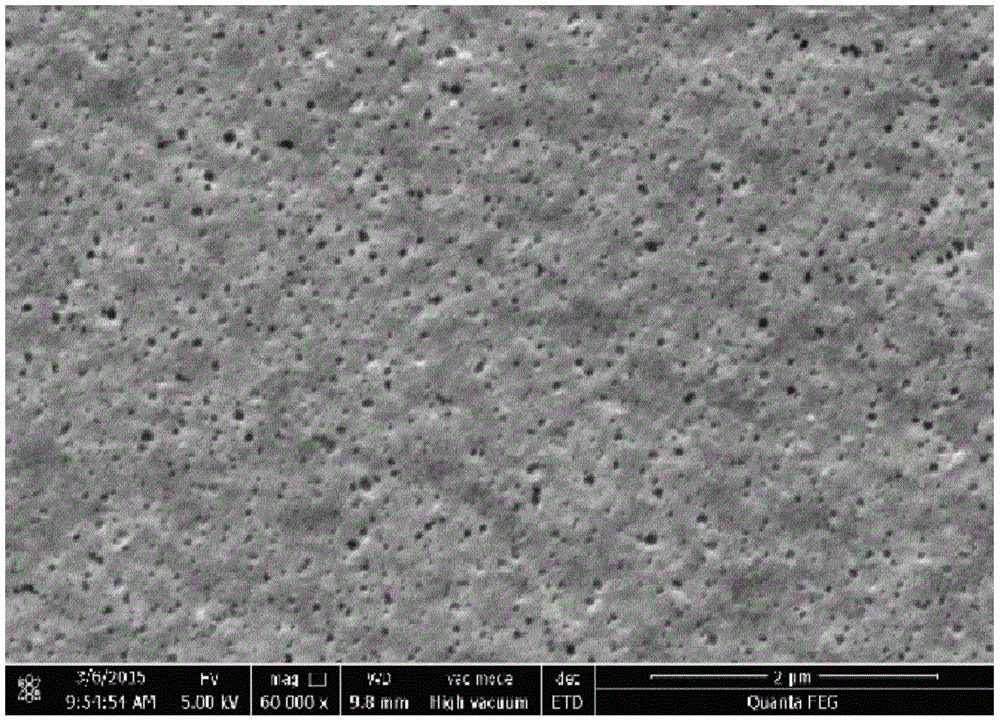

The present application is generally directed towards polyacrylonitrile- (PAN-) based, amphophilic graft copolymers, for example, for the production of membranes for liquid filtration. In one aspect, the present invention provides systems and methods for preparing high flux, fouling resistant nanofiltration membranes whose pore size can be readily tuned. In some cases, microphase separation of a graft copolymer comprising a backbone comprising polyacrylonitrile (PAN) and hydrophilic side-chains is used. In some cases, nanochannels of tunable width are formed, which may give the membrane permselective properties and / or anti-fouling character. In some cases, a copolymer may be used as an additive in the immersion precipitation casting of ultrafiltration or microfiltration membranes. In certain instances, the additive can segregate to the membrane exterior and / or pore surfaces, e.g., due to favorable interactions between the hydrophilic side chains and the surrounding environment, which may create a surface that resists fouling, e.g., by biological molecules.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY +1

Preparation method of super-hydrophilic polymer membrane with demulsification function

ActiveCN109316981AWith demulsification functionMembranesSemi-permeable membranesTetrafluoroethyleneDemulsifier

The invention provides a preparation method of a super-hydrophilic polymer membrane with a demulsification function. Specifically, polyvinylidene fluoride (PVDF) or polypropylene (PP) or poly-tetrafluoroethylene (PTFE) is used as a base membrane material and blended with a styrene-maleic anhydride copolymer (SMA) to prepare a membrane casting solution, a PVDF / SMA hyperfiltration membrane is prepared by adopting an immersion precipitation phase inversion method, a hyperbranched polyether demulsifier is conjugated to the surface of the polymer membrane by utilizing a chemical reaction between anhydride on the surface of the membrane and a terminal hydroxyl group of the hyperbranched polyether demulsifier, and thus the demulsification effect, hydrophily, water flux and the retention rate of the modified membrane are all improved, efficient oil-water separation is achieved, membrane pollution is lowered, and the service life of the membrane is prolonged.

Owner:TIANJIN POLYTECHNIC UNIV

Method for synchronously preparing hollow fiber compound nanofiltration membrane through immersion precipitation phase inversion/interface crosslinking

InactiveCN102836644AThickness is easy to controlEasy to control uniformitySemi-permeable membranesFiberOrganic solvent

The invention discloses a method for synchronously preparing a hollow fiber compound nanofiltration membrane through immersion precipitation phase inversion / interface crosslinking. The method comprises the following steps of: mixing a polymer, a pore diameter regulator and crosslinking agent with an organic solvent, and dissolving into a uniform solution at the temperature of 30-70 DEG C to obtain a membrane casting liquid; (2) dissolving a crosslinking prepolymer into water at the temperature of 20-60 DEG C to obtain 1-15g / L of solution, i.e., a core liquid; and (3) extruding the membrane casting liquid and the core liquid into a tubular liquid membrane under the pressure of 0.1-0.3MPa and at the spinning speed of 10-40 meters per minute, introducing into a coagulation bath of 26-60 DEG C through an air gap of 0-20 centimeters, and soaking and cleaning with water to obtain a hollow fiber compound nanofiltration membrane. Compared with the existing nanofiltration membrane preparation technology, the method has the advantages that: molding and interface crosslinking of a base membrane of the hollow fiber compound nanofiltration membrane are finished synchronously in the method, a nanofiltration compound layer is stable and has high controllability, the using amount of the polymer is saved, a process is simple, and clean production can be realized.

Owner:ZHEJIANG UNIV

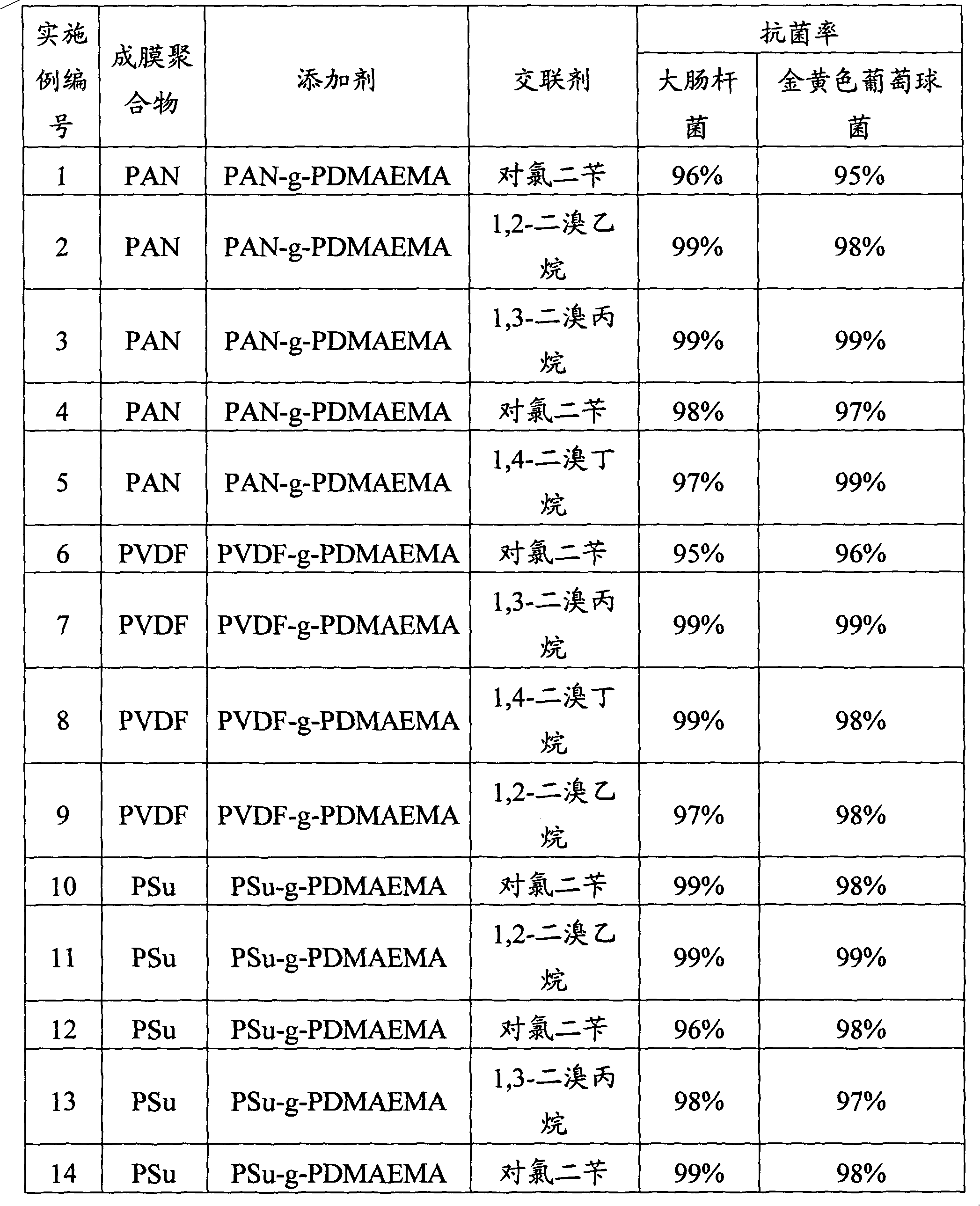

Preparation method of high-efficiency compound antibacterial separation membrane

InactiveCN101934203APromote enrichmentAvoid churnSemi-permeable membranesPhase conversionAqueous solution

The invention discloses a preparation method of a high-efficiency compound antibacterial separation membrane, comprising the following steps: (1) preparing a membrane forming polymer and additive into membrane casting liquid, and adopting an immersion precipitation phase conversion method to prepare a polymer separation membrane; (2) carrying out annealing treatment on the polymer separation membrane; (3) successively dipping the annealing treatment polymer separation membrane into silver nitrate aqueous solution and sodium borohydride aqueous solution to obtain a polymer separation membrane the surface of which adsorbs silver nano particles; (4) dipping the polymer separation membrane the surface of which adsorbs the silver nano particles into crosslinker solution; carrying out quaternization and in situ crosslinking reaction; and drying to obtain the compound antibacterial separation membrane. The method is easy and simple to realize, and the prepared compound antibacterial separation membrane is stable and durable and has high antibacterial efficiency and obvious antibacterial effect.

Owner:ZHEJIANG UNIV

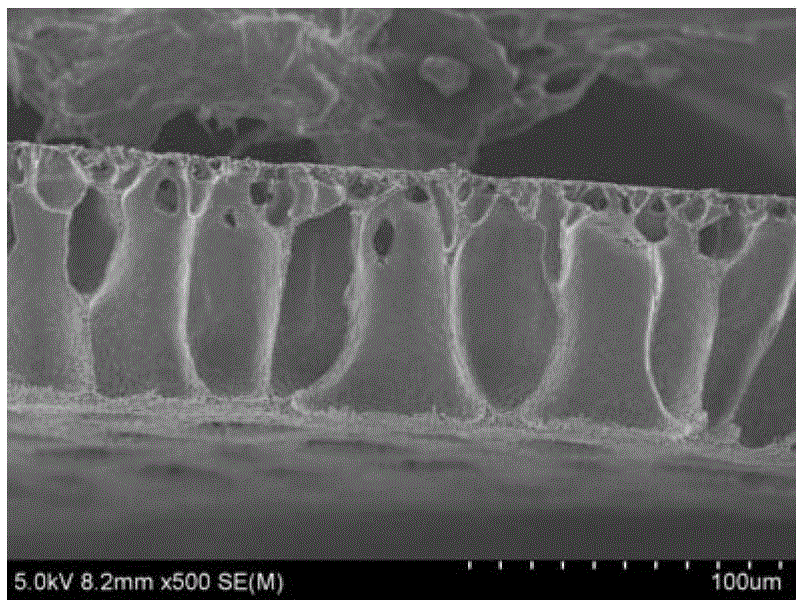

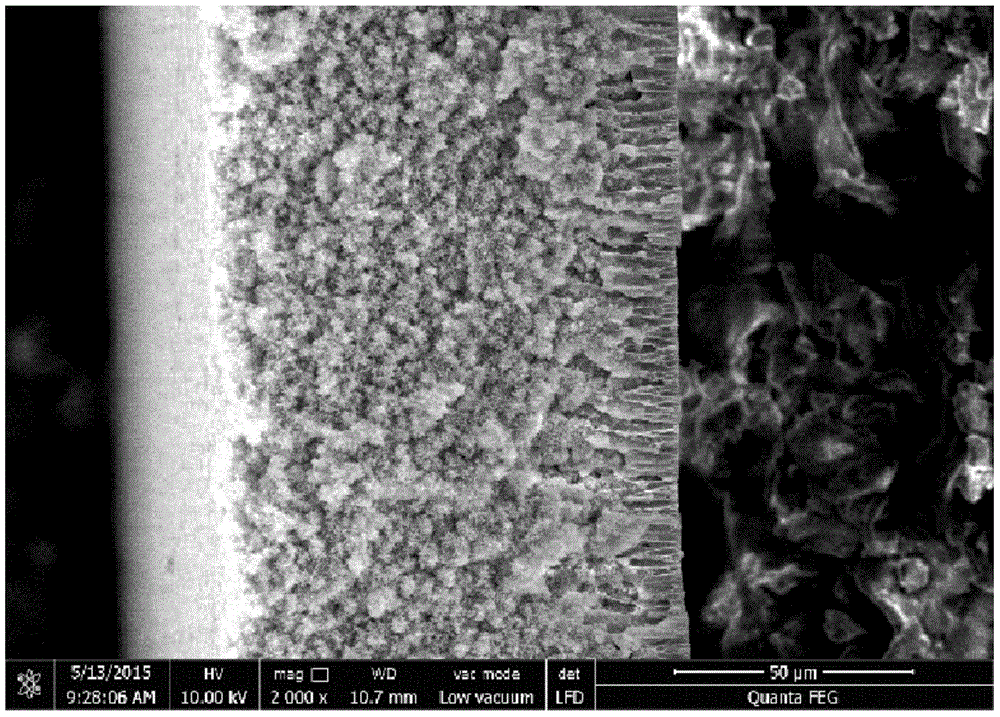

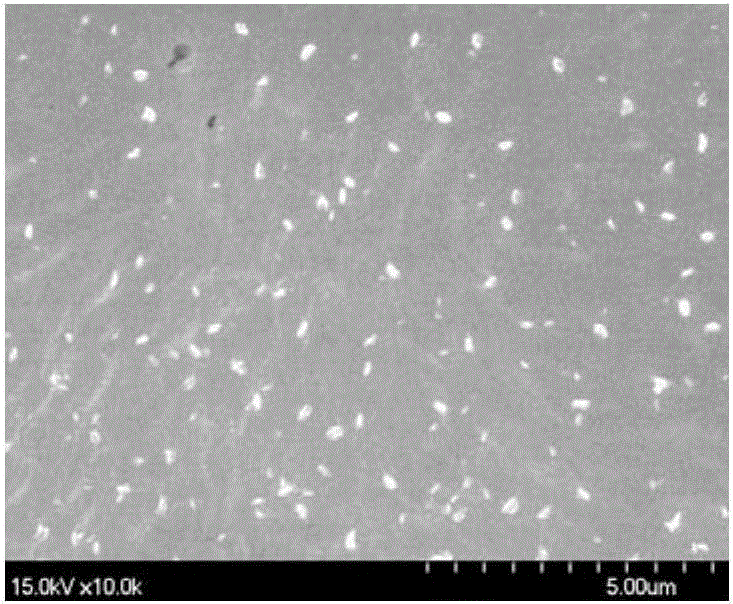

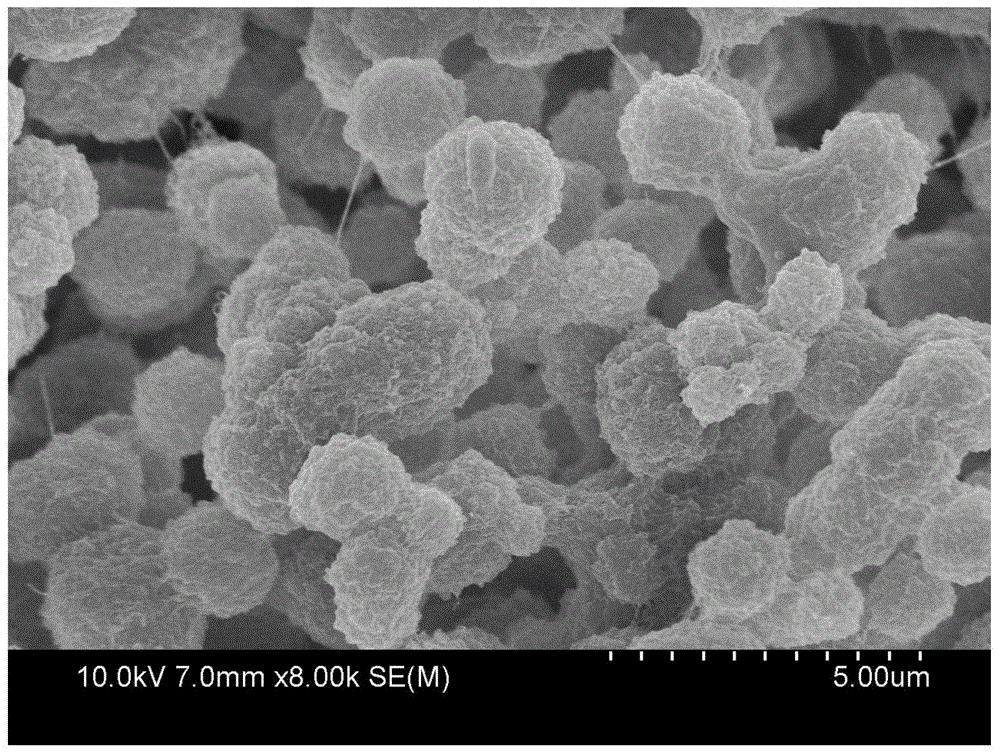

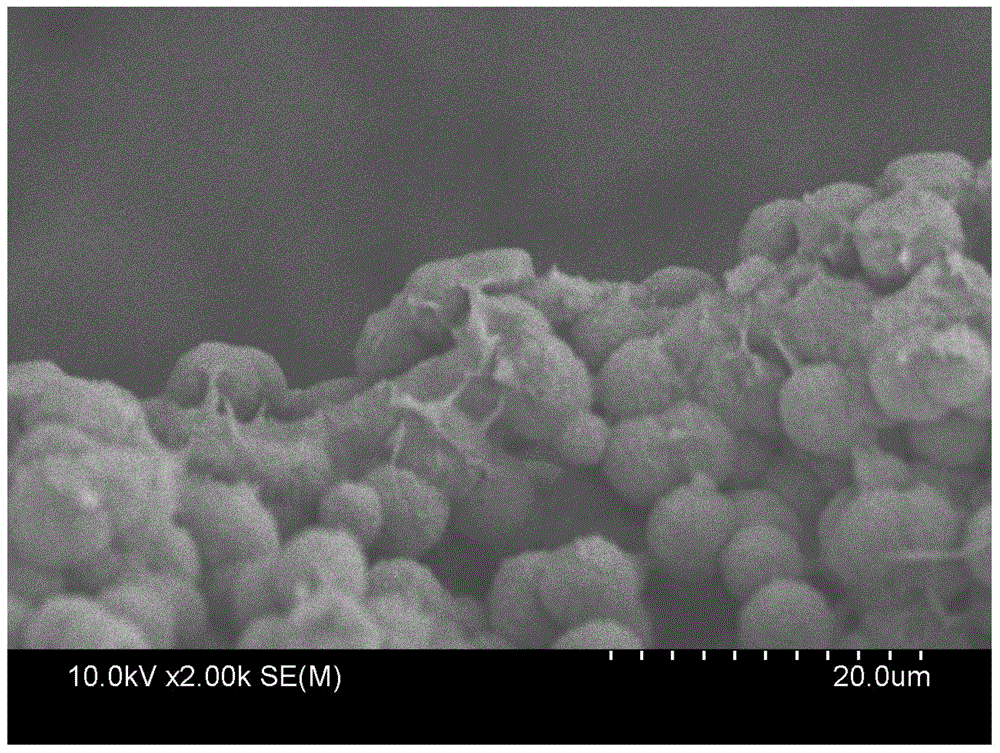

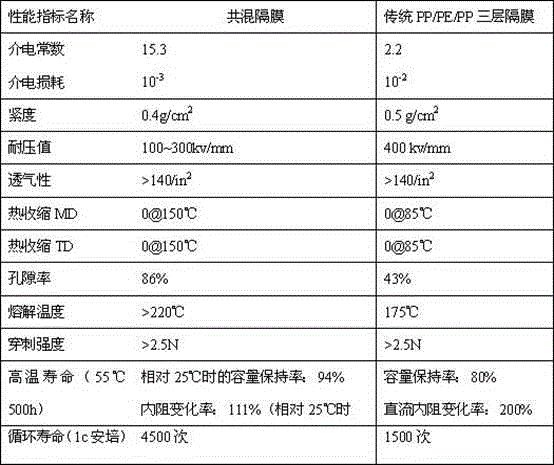

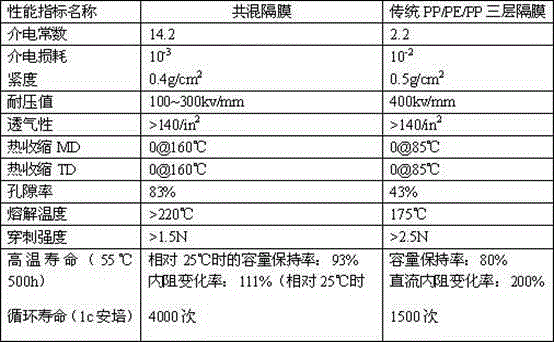

Preparation method of large-rate discharge porous diaphragm material and application of material

The invention relates to the film material field, and especially relates to a preparation method of a large-rate discharge porous diaphragm material and an application of the material. The preparation method of the large-rate discharge porous diaphragm material comprises the following steps: preparing a porous film through utilizing polyvinylidene fluoride (PVDF) or poly(vinylidene fluoride-co-hexafluoropropene) (PVDF-HFP) by adopting an immersion precipitation method or a thermotropic phase separation method; and carrying out post-treatment of the surface of the prepared PVDF or PVDF-HFP porous film through an ion technology to form a nano-micro hole controllable high-hole-ratio porous diaphragm having fingerlike tunnels penetrating to the bottom. The morphology of the porous film prepared in the invention is composed of a uniform nano / micro hole surface layer, thumb-like tunnels and a sponge hole bottom layer, and the porous film having the above structure provides an enough space for accommodating an electrolyte, so the tunnels are full of the electrolyte, the electrolyte and the PVDF form a gel electrolyte in a largest area mode, and the accommodating capability of the porous diaphragm to the electrolyte is increased.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Easy-to-wash PVDF (polyvinylidene fluoride) ultrafiltration membrane and preparation method thereof

ActiveCN104971632ASimple structureHigh strengthSemi-permeable membranesPeptide preparation methodsPolymer sciencePolyethylene glycol

The invention discloses an easy-to-wash PVDF (polyvinylidene fluoride) ultrafiltration membrane and a preparation method thereof. The preparation method comprises the following steps: with triethyl phosphate as a solvent, ultrasonically dispersing a certain amount of poly N-isopropylacrylamide modified attapulgite in the solvent, adding PVDF powder and stirring violently till the PVDF powder is dissolved, adding a pore-foaming agent, namely polyethylene glycol, and uniformly stirring, and finally standing for defoaming to obtain a membrane casting solution; with water as a coagulating bath, preparing the ultrafiltration membrane by using an immersion precipitation phase conversion method. By introducing the poly N-isopropylacrylamide modified attapulgite into the PVDF ultrafiltration membrane, the unique nano-fiber structure of the attapulgite and the three-dimensional net structure formed by PVDF can be used to effectively improve the structure and strength of a pure PVDF ultrafiltration membrane, and the high hydrophilicity of the attapulgite is used to improve the permeability and hydrophilicity of the membrane; meanwhile, the ultrafiltration membrane also has the temperature sensitivity of poly N-isopropylacrylamide, and anti-pollution and easy-to-wash properties are realized.

Owner:HUAIYIN TEACHERS COLLEGE

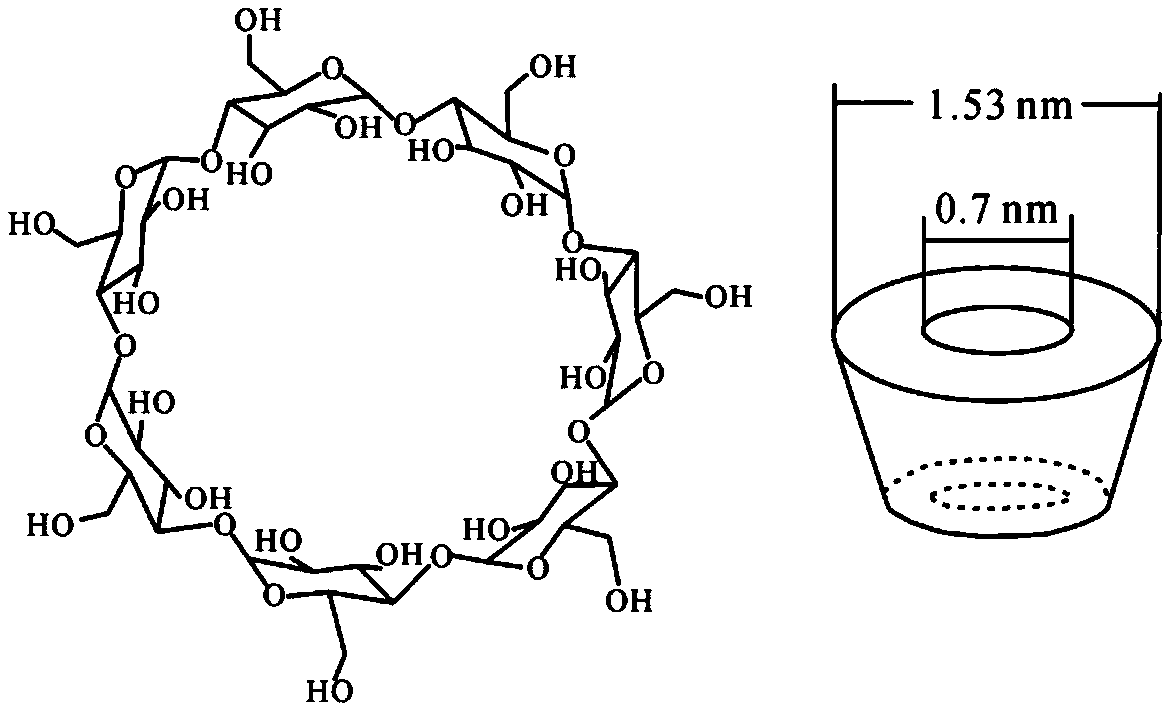

Preparation method of composite membrane for efficiently filtering micro-pollutants in water

ActiveCN109173746AImprove hydrophilicityImprove stabilitySemi-permeable membranesMembranesCross-linkWater quality

The invention discloses a preparation method of a composite membrane for efficiently filtering micro-pollutants in water. The preparation method comprises: dissolving functionalized beta-cyclodextrinas a film forming additive, a film forming polymer, a pore forming agent and a cross-linking agent in a solvent according to a set ratio to prepare a film casting solution, and preparing the compositemembrane capable of efficiently filtering organic micro-pollutants by using an immersion precipitation phase transformation method through the moderate in-situ cross-linking of the functionalized beta-cyclodextrin in the film casting solution. According to the present invention, the composite membrane maintains the high water permeability, has the high removal rate on micro-contaminants in water,can remove planktons, algae, bacteria, proteins, colloids, viruses and other pollutants through filtering, and can remove antibiotics, hormones, plasticizers and other organic small molecule micro-pollutants through adsorption; the preparation process is simple, controllable and low in cost; and the composite membrane can be widely used in household water purification, sewage treatment, water purification and other separation fields, is the efficient and stable water treatment material, and has wide application value.

Owner:ZHEJIANG UNIV

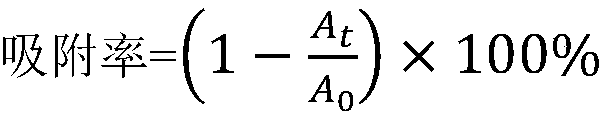

Nano-silver/graphene/polyvinylidene fluoride hybrid ultrafiltration membrane and preparation method thereof

ActiveCN105214511AEasy to manufactureAvoid uneven loadSemi-permeable membranesUltrafiltrationPolyethylene glycol

The invention discloses a nano-silver / graphene / polyvinylidene fluoride hybrid ultrafiltration membrane and a preparation method thereof. The method comprises the steps of: (1) subjecting graphene oxide and polyethylene glycol to ultrasonic dispersion in N, N-dimethylacetamide to obtain a solution A; dissolving AgNO3 and polyethylene glycol in N, N-dimethylacetamide to obtain a solution B; (2) mixing the solution A and the solution B evenly in proportion to obtain a nano-silver / graphene compound solution; (3) dissolving polyvinylidene fluoride in the obtained nano-silver / graphene compound solution, and carrying out standing defoaming to obtain a membrane casting solution; and (4) preparing the membrane casting solution into the nano-silver / graphene / polyvinylidene fluoride hybrid ultrafiltration membrane by an immersion precipitation phase inversion process. With the preparation method, nano-silver particles can be uniformly loaded on graphene, also the nano-silver / graphene compound can be uniformly dispersed in the polyvinylidene fluoride hybrid ultrafiltration membrane, and the prepared hybrid ultrafiltration membrane has good antibacterial and anti-pollution performance.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Hydrophilic PVDF (Polyvinylidene Fluoride) composite ultrafiltration membrane and preparation method thereof

ActiveCN103394295AImprove hydrophilicityImprove hydrophilic abilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEpoxyPhase conversion

The invention discloses a hydrophilic PVDF (Polyvinylidene Fluoride) composite ultrafiltration membrane and a preparation method thereof, relates to membranes and preparation methods thereof and particularly relates to PVDF composite ultrafiltration membranes and preparation methods thereof. The hydrophilic PVDF composite ultrafiltration membrane and the preparation method thereof are used for solving the problem that the service lives of the existing PVDF ultrafiltration membranes are shortened because contaminants of protein and the like are easily adsorbed to the surfaces of the existing PVDF ultrafiltration membranes caused by the fact that the existing PVDF ultrafiltration membranes are strong in hydrophobicity and weak in contamination resistance. The hydrophilic PVDF composite ultrafiltration membrane disclosed by the invention is prepared through blending PVDF, a dopa assistant and a reaction product of end-epoxy PEO (Polyoxyethylene). The preparation method comprises the steps of dissolving the dopa assistant into a solvent, adding end-epoxy PEO so as to obtain a mixed solution, then adding PVDF powder in the mixed solution so as to obtain a blended membrane casting solution, standing the blended membrane casting solution until no bubbles exist, uniformly coating the blended membrane casting solution on a glass plate by using a scraping cutter, and obtaining the hydrophilic PVDF composite ultrafiltration membrane by using an immersion precipitation phase conversion method. The preparation method can be used for preparing the hydrophilic PVDF composite ultrafiltration membrane.

Owner:HARBIN INST OF TECH

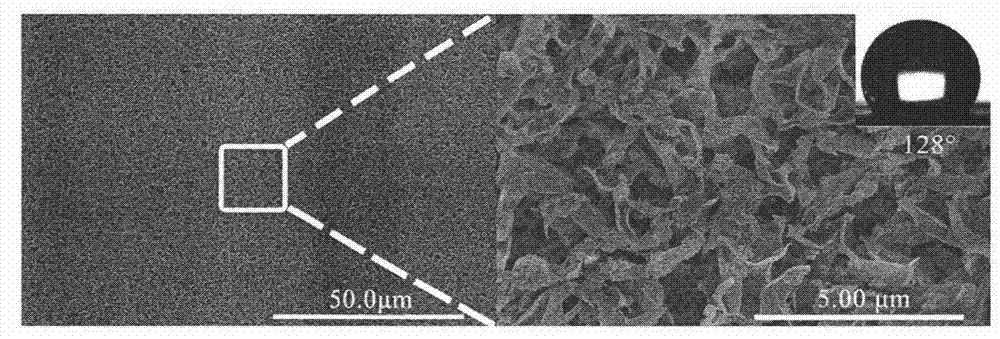

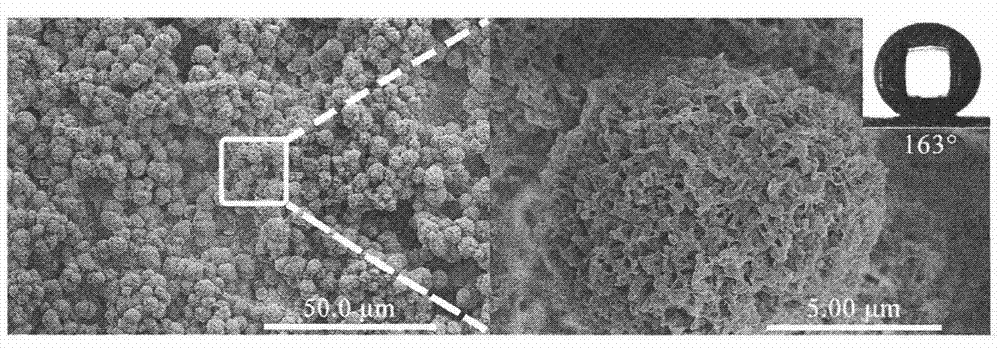

Polyvinylidene fluoride super-hydrophobic self-cleaning coating and preparation method thereof

InactiveCN104774511AEasy to prepareEasy to operateCoatingsPhysical chemistryPolyvinylidene difluoride

Owner:TIANJIN POLYTECHNIC UNIV

A preparation method of poly(m-phenylene isophthalamide) hollow fiber nanofiltration membrane

The invention relates to a preparation method of poly(m-phenylene isophthalamide) hollow fiber nanofiltration membrane. Poly(m-phenylene isophthalamide) is adopted as raw material, sufficiently mixed with organic solvent and additive, to obtain homogeneous spinning stock solution, the spinning stock solution is prepared into the hollow fiber nanofiltration membrane by use of immersion precipitation phase inversion method. In the spinning stock solution, the content of the poly(m-phenylene isophthalamide) is of 10%-25%, the content of the organic solvent is of 50%-70%, and the content of the additive is of 8%-25%. The prepared hollow fiber nanofiltration membrane has the outside diameter of 0.8-2.5mm, the inside diameter of 0.5-2.0mm, the pore size distributed in 2-30 nm, the tensile strength up to 8-15 MPa, and the breaking elongation in the range of 90%-160%. At 25 DEG C., under the operating pressure of 0.5 MPa, in the membrane treatment experimental study with 500 mg / L Na2SO4 water solution as study system, the water flux is up to 32-85 L / m2.h, and the interception rate for Na2SO4 is up to 50%-95%. The process is easy to operate, the film-forming process is simple, and the membrane has excellent mechanical property, high water flux, and wide application prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

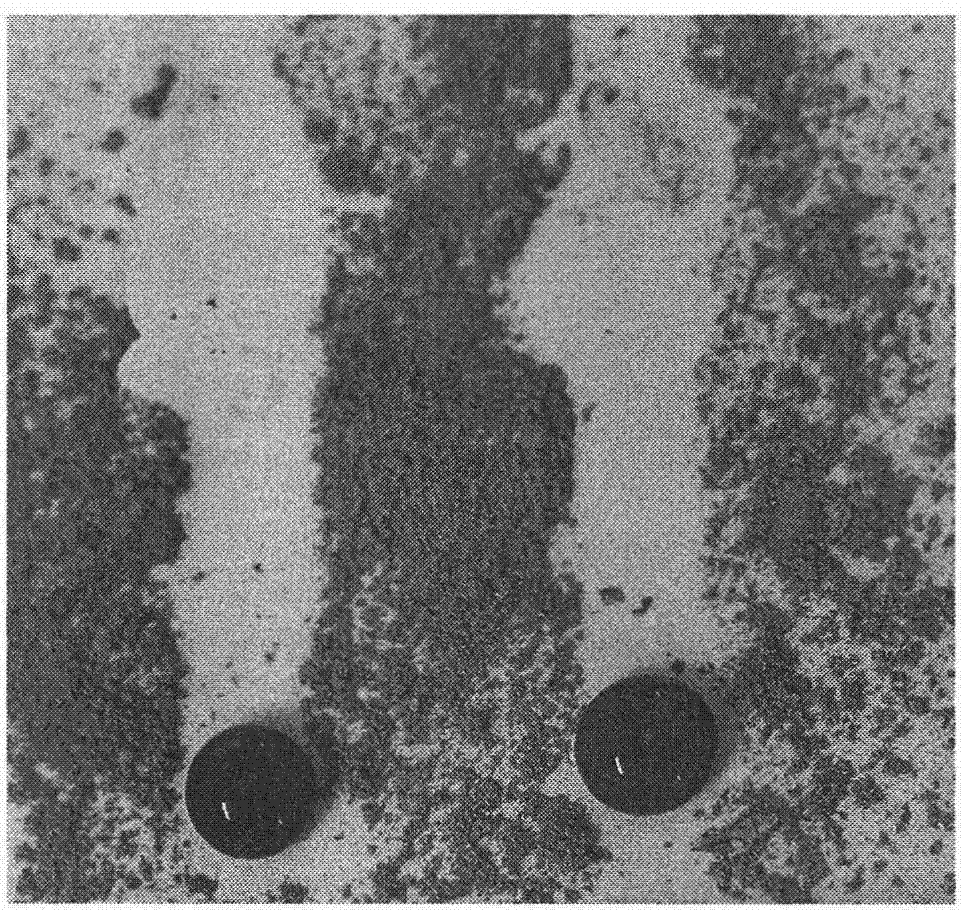

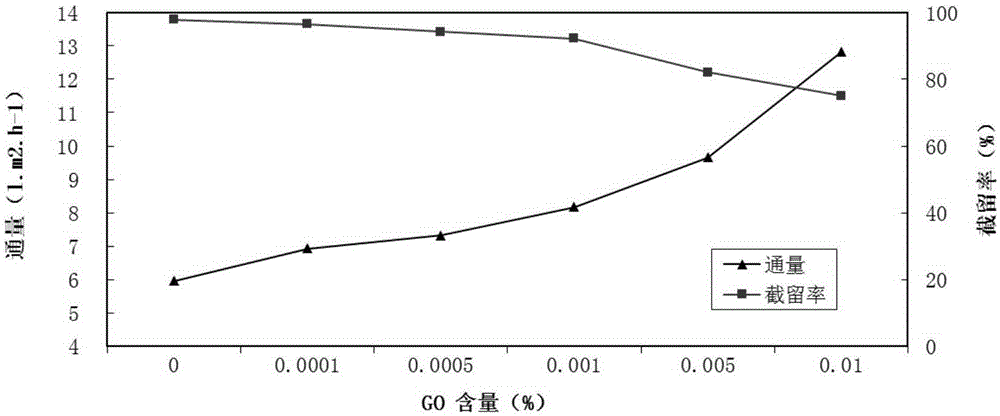

Preparation method of high-throughput graphene oxide-cellulose acetate composite membrane

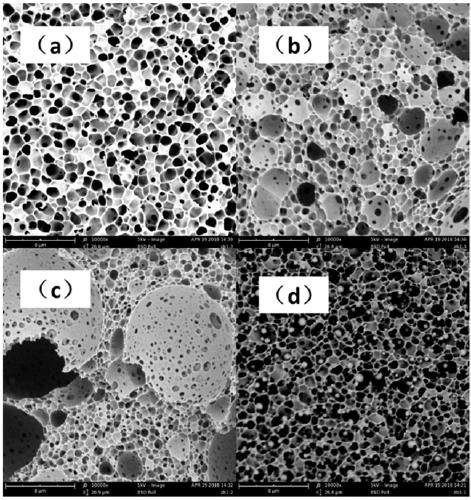

ActiveCN105169964AOvercome reunionOvercome uniformity issuesSemi-permeable membranesMicro structureIndustrial waste water

The invention discloses a preparation method of a high-throughput graphene oxide-cellulose acetate composite membrane which is prepared with an immersion precipitation phase inversion process. A casting membrane solution comprises components in mass of the casting membrane solution respectively of 15%-30% of cellulose acetate, 0.0001%-0.01% of graphene oxide, 10%-35% of formamide and 35%-70% of acetone. Single layer graphene oxide has the advantages of large specific surface area and high absorbability, the micro-structure of the membrane can be finely adjusted, and the membrane performance is improved. The prepared high-throughput graphene oxide-cellulose acetate composite membrane has a great application value and potential. Experiments prove that compared with a pure cellulose acetate membrane, the throughput of the high-throughput graphene oxide-cellulose acetate composite membrane is improved by 220%, the operating pressure can be reduced greatly, energy consumption is saved, and the high-throughput graphene oxide-cellulose acetate composite membrane has a better application in the fields of heavy-metal ion removal, industrial waste water treatment and seawater desalination and the like.

Owner:NANJING UNIV OF TECH

Polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film and preparation method thereof

ActiveCN104307387AImprove performanceHigh mechanical strengthSemi-permeable membranesComposite filmDistillation

The invention discloses a method for preparing a polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film. According to the method, the surface of a non-woven fabric is respectively coated with a porous supporting layer and a super-hydrophobic layer in a blade coating manner by adopting an immersion-precipitation phase transformation method, and the size of the pore diameter of a composite film is controlled by virtue of the porous supporting layer. According to the polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film, six fluorine atoms in the structure unit show high hydrophobic performance, and the super-hydrophobic layer is formed on the surface of the porous supporting layer by delayed phase transformation. The method is simple to operate, low in manufacture cost and easy to industrialize; the super-hydrophobic composite film has a water contact angle of 153+ / -3 degrees, a rolling angle of 3+ / -1 degrees and pore diameter of 0.05-2 microns, is stable in performance and high in mechanical strength, shows excellent super-hydrophobic performance and self-cleaning function, and can be used in liquid degassing, defoaming, film distillation and other industries.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

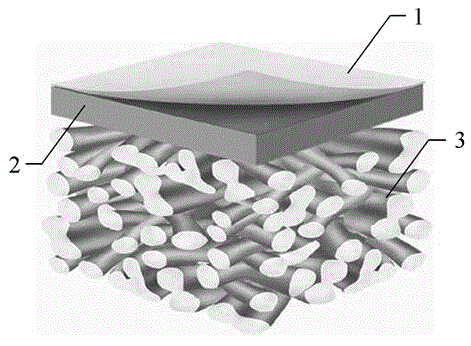

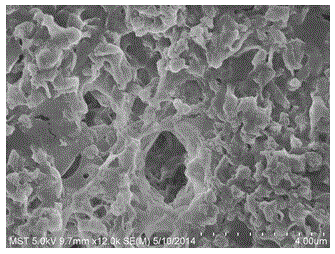

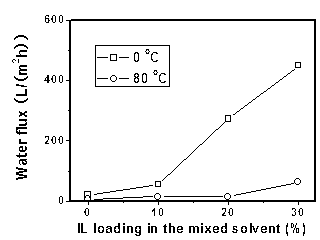

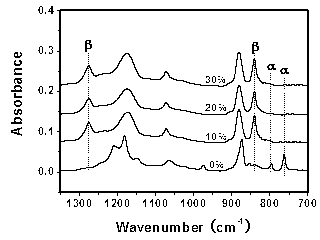

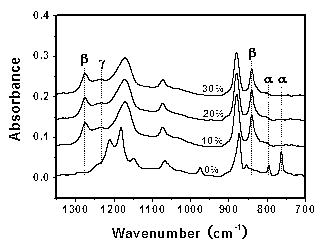

Piezoelectric polyvinylidene fluoride porous membrane and preparation method thereof

InactiveCN103252174AHigh strengthIncrease water fluxSemi-permeable membranesPhysical chemistryPorous membrane

The invention discloses a piezoelectric polyvinylidene fluoride porous membrane and a preparation method thereof. The piezoelectric polyvinylidene fluoride porous membrane is characterized by being prepared by dissolving polyvinylidene fluoride into a mixed solution of N,N-dimethyl formamide and an ionic liquid by using an immersion-precipitation method, wherein the w / v concentration of the polyvinylidene fluoride in the mixed solution is 10-20%, the volume ratio of the N,N-dimethyl formamide in the mixed solution is 60-95%, and the volume ratio of the ionic liquid is 5-40%. The piezoelectric polyvinylidene fluoride porous membrane provided by the invention has excellent water flux and meets the requirement for the performance of an industrial separation membrane; and meanwhile, the prepared polyvinylidene fluoride porous membrane is a beta crystal with a piezoelectric effect and can vibrate under a low alternating electric field, so that the antipollution capability of the separation membrane can be further improved, and the separation efficiency of the membrane can be further increased.

Owner:EAST CHINA UNIV OF TECH

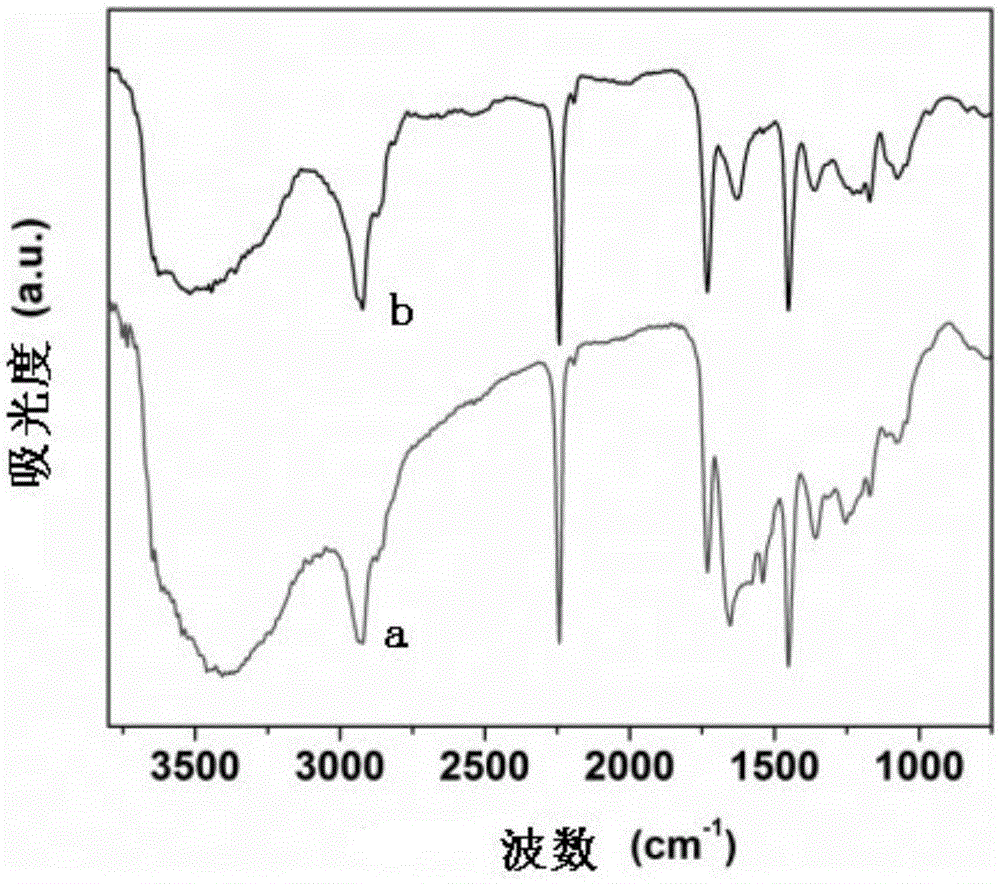

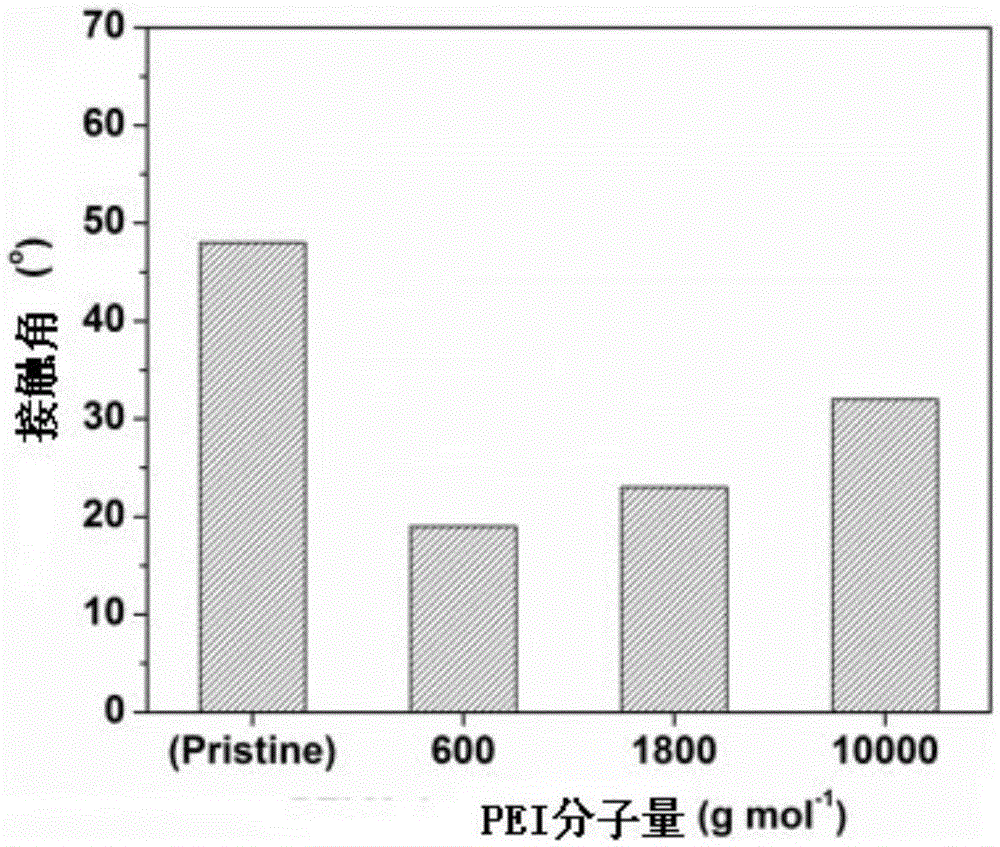

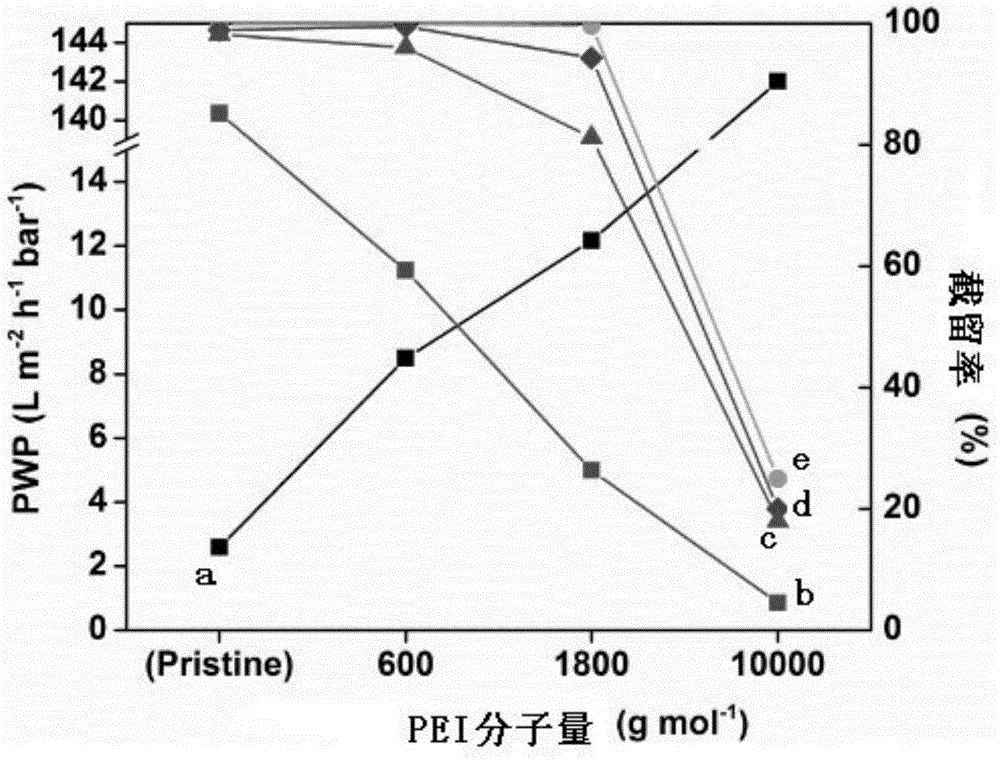

Method for preparing nanofiltration membrane by collectively coating pyrocatechol and polyethyleneimine

InactiveCN105289336AImprove performanceStable structureSemi-permeable membranesPhase conversionInorganic salts

The present invention relates to a method for preparing a nanofiltration membrane by collectively coating pyrocatechol and polyethyleneimine. The method provided by the present invention aims to solve the problem that the existing preparation nanofiltration membrane industry is complex and unstable in performance and structure. The method comprises the steps of: preparing a polymeric solution, adding a pore-foaming agent, then forming a membrane by using an immersion precipitation phase conversion method and washing the membrane by deionized water to obtain a polymeric initial membrane; preparing a buffer solution and then adding pyrocatechol to obtain a pyrocatechol solution; then adding polytheneimine to obtain a mixed solution B; and and putting the polymer initial membrane into the mixed solution B to leave the membrane to stand so as to obtain the nanofiltration membrane. The nanofiltration membrane prepared by the method provided by the present invention has the advantages that the hydrophilicity is enhanced significantly, the permeation flux is great, and the retention rate of small molecules and inorganic salt is high and the like. Meanwhile, the method is simple in operation and low in cost. The method provided by the present invention is applied to the field of nanofiltration membrane preparation.

Owner:HARBIN INST OF TECH

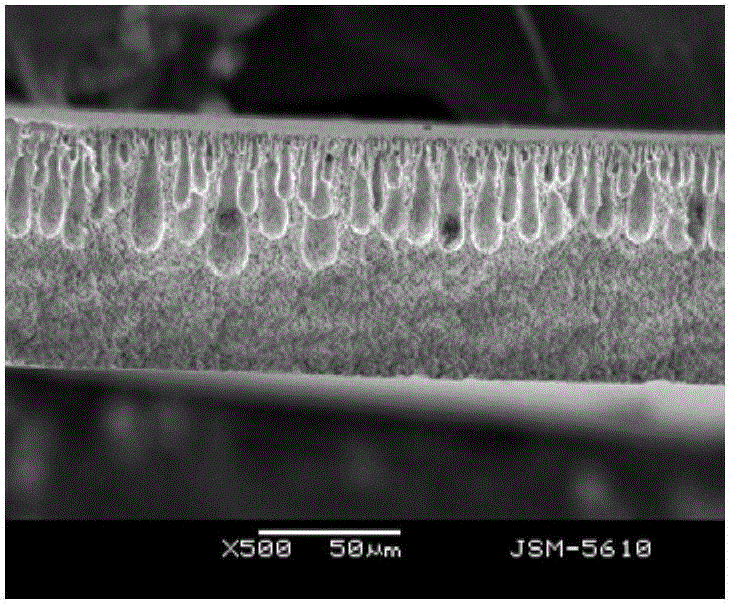

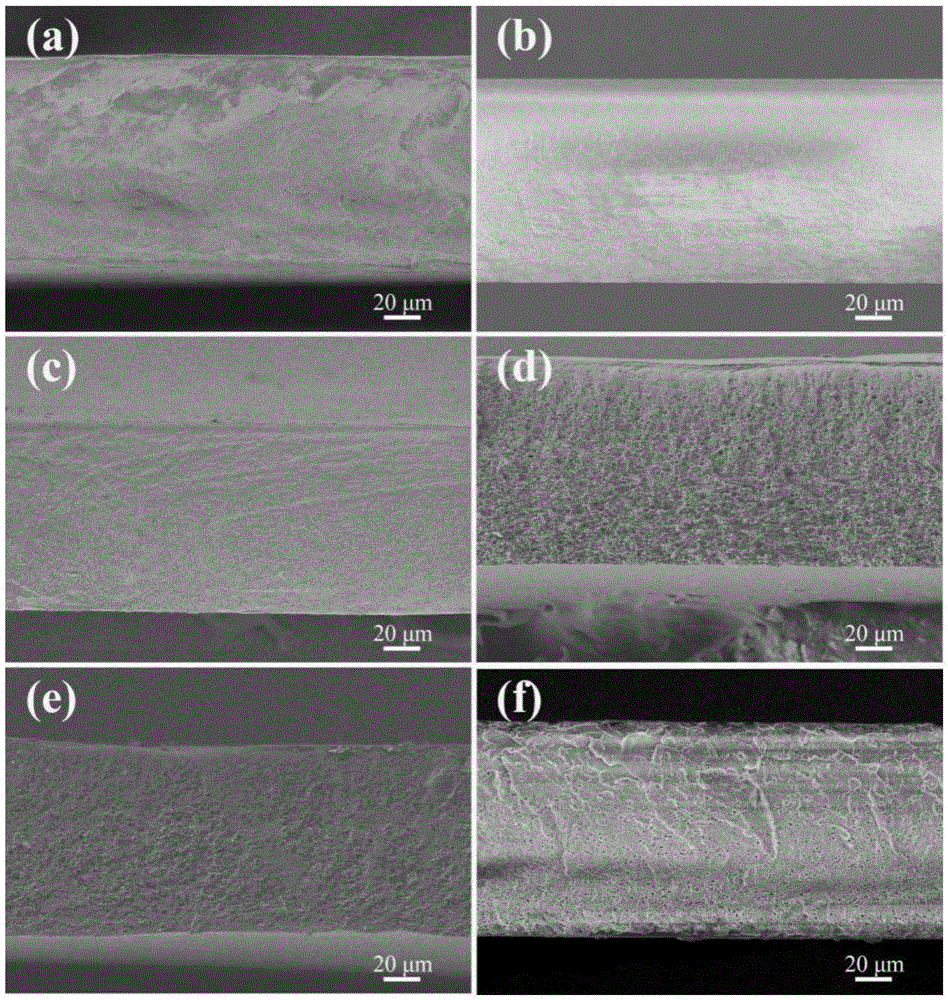

Preparation method of polyester fiber braided tube enhanced type composite hollow fiber forward osmotic membrane

ActiveCN106731901ATightly boundSolve the problems of easy falling off and complicated multi-program film making processMembranesSemi-permeable membranesWater bathsFiber

The invention discloses a preparation method of a polyester fiber braided tube enhanced type composite hollow fiber forward osmotic membrane. The preparation method comprises the following steps of confecting a polymer, an organic additive, an inorganic additive and an organic solvent to be homogeneous membrane casting liquid according to a proportion; uniformly coating the membrane casting liquid on the outer wall and an internal pore canal of a polyester fiber braided tube, so as to obtain a braided tube of which the inner wall and the outer wall are coated with membranes; making the membrane coated braided tube pass a certain air residence time and then enter a coagulation bath to carry out phase-inversion membrane formation; soaking a primarily formed membrane in deionized water to remove the residual organic solvent, soaking the primarily formed membrane in a hot water bath, finally, soaking the primarily formed membrane in a glycerol aqueous solution, and then taking out and airing the primarily formed membrane, so that the polyester fiber braided tube enhanced type composite hollow fiber forward osmotic membrane is made. According to the preparation method, polymer membrane casting liquid is coated on the inner wall and the outer wall of the braided tube in a one-step manner by adopting an immersion precipitation phase inversion method to obtain a high-strength composite hollow fiber forward osmotic membrane; the film making process is simple; the water flux, the selectivity, the hydrophilism, the performance stability and the service life of a membrane are improved by an organic and inorganic blending membrane making method.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of pervaporation composite membrane filled with hydrophobically modified nano calcium carbonate

The invention discloses a preparation method of a pervaporation composite membrane filled with hydrophobically modified nano calcium carbonate. The preparation method of the pervaporation composite membrane filled with hydrophobically modified nano calcium carbonate comprises the following steps: (1) adding dried nano calcium carbonate into oleic acid, stirring for reacting, then repeatedly washing with hexane for removing excess oleic acid,, drying in vacuum, and grinding so as to obtain hydrophobically modified nano calcium carbonate; (2) mixing dried polyvinylidene fluoride with hydrophobically modified nano calcium carbonate, subsequently adding the mixture into dimethylacetamide, carrying out ultrasonic dispersion, stirring, filtering, standing and defoaming, and subsequently pouring the obtained liquid on a polyester non-woven fabric for scraping a membrane so as to obtain a modified polyvinylidene fluoride base membrane by using an immersion precipitation phase inversion method; and (3) dissolving polydimethylsiloxane in n-hexane, adding hydrophobically modified nano calcium carbonate, carrying out ultrasonic dispersion, adding a cross-linking agent and a catalyst, stirring for reacting, centrifuging and dedoaming, subsequently pouring the obtained liquid on the polyvinylidene fluoride base membrane for scraping the membrane, airing and drying the membrane in vacuum to prepare the pervaporation composite membrane. The composite membrane prepared by the method is simple in process and low in cost, and moreover, the selectivity and the flux of the composite membrane on alcohol are improved.

Owner:宣城市红兴碳酸钙有限公司

Fouling Resistant Membranes Formed with Polyacrylonitrile Graft Copolymers

The present application is generally directed towards polyacrylonitrile— (PAN—) based, amphophilic graft copolymers, for example, for the production of membranes for liquid filtration. In one aspect, the present invention provides systems and methods for preparing high flux, fouling resistant nanofiltration membranes whose pore size can be readily tuned. In some cases, microphase separation of a graft copolymer comprising a backbone comprising polyacrylonitrile (PAN) and hydrophilic side-chains is used. In some cases, nanochannels of tunable width are formed, which may give the membrane permselective properties and / or anti-fouling character. In some cases, a copoylmer may be used as an additive in the immersion precipitation casting of ultrafiltration or microfiltration membranes. In certain instances, the additive can segregate to the membrane exterior and / or pore surfaces, e.g., due to favorable interactions between the hydrophilic side chains and the surrounding environment, which may create a surface that resists fouling, e.g., by biological molecules.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY +1

Preparation method of composite separation membrane

ActiveCN104984665AImprove hydrophobicityImprove pollutionSemi-permeable membranesNon solventVacuum pumping

The invention discloses a preparation method of a composite separation membrane. The method includes the steps of: 1) taking a crystalline polymer as the film-forming polymer, preparing a base membrane by a solvent-non solvent vapor double diffusion induced phase transformation method or immersion precipitation method; 2) cleaning the base membrane, and then conducting hole preserving drying; and 3) firstly placing the dried base membrane on a sample stage in a magnetron sputtering process sputtering chamber, conducting vacuum pumping, then introducing argon as the sputtering gas, using an inorganic substance as the target, and sputtering the inorganic substance to the base membrane surface and into the holes through magnetron sputtering, thus obtaining the composite separation membrane. The preparation method sputters a layer of inorganic substance on the polymer membrane surface and in the membrane holes by mean of the magnetron sputtering technology, and significantly improves the hydrophobicity and anti-fouling property of the polymer membrane.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of lithium ion battery diaphragm

InactiveCN104953071AImproved magnification performanceImprove cycle performanceCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityPolymer science

The invention relates to a preparation method of a lithium ion battery diaphragm. The preparation method comprises the following steps: (1) preparing a graphene nanosheet dispersion liquid of which the concentration is lower than or equal to 0.1 g / L; (2) preparing polymer particles of which the particle diameters are smaller than or equal to 600 nm; (3) uniformly mixing the polymer particles, the graphene nanosheet dispersion liquid and a polymer to prepare a polymer, polymer particle and graphene co-mixed casting solution; (4) treating the casting solution according to an immersion precipitation method, so as to obtain a polymer, polymer particle and graphene lithium ion battery diaphragm. The diaphragm prepared according to the preparation method is suitable for different battery material systems, is 4.6V or higher in decomposition voltage, and has the advantages that the porosity rate and the ionic conductivity are respectively 30 percent and 50 percent or higher than those of a pure polymer diaphragm, the puncture strength is improved by 46 percent, and all the service performances are superior.

Owner:CENT SOUTH UNIV

Hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and preparation method thereof

ActiveCN102512997AImprove connectivityHigh porosityUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberHollow fibre

The invention discloses a novel hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and a preparation method thereof. According to the invention, hydrophilic polyethersulfone with cardo (PES-C) and hydrophilic polyvinylpyrrolidone (PVP) with a high molecular weight are blended, and a flat or hollow fiber ultrafiltration membrane is prepared by using an immersion-precipitation process or a dry / wet phase inversion process; and then the PES-C / PVP alloy ultrafiltration membrane with permanent hydrophilicity is prepared through hydrophilic long-lasting aftertreatment. The preparation method provided in the invention is simple, convenient, highly efficient and economy and is favorable for realization of industrial application. The prepared ultrafiltration membrane has good high temperature resistance, chemical solvent resistance, acidic and alkaline corrosion resistance and osmotic separation performance and excellent anti-pollution ability and can be used in the fields of purification of water quality, treatment of industrial waste water, recycling of domestic sewage, purification and separation of biological medicine products, etc.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

Ag@NH2-MIL-125/polyarylether sulfone hybrid dense reactive ultrafiltration membrane and preparation method thereof

ActiveCN109603589AExcellent sunlight-induced self-cleaning and anti-pollution capabilitiesEnhanced photocatalytic aging resistanceUltrafiltrationUltrafiltrationSeparation technology

The invention provides an Ag@NH2-MIL-125 / polyarylether sulfone hybrid dense reactive ultrafiltration membrane and a preparation method thereof, and belongs to the technical field of polymer materials.The method comprises the following steps of: firstly, preparing a sunlight-responsive photocatalytic material Ag@NH2-MIL-125; and then introducing the photocatalytic material into a polyarylether sulfone molecular chain structure through molecular design and chemical bond action to synthesize the Ag@NH2-MIL-125 / polyarylether sulfone hybrid material, and preparing a dense reactive ultrafiltrationmembrane by using an immersion precipitation phase conversion method. The ultrafiltration membrane shows excellent separation performance and high-efficiency sunlight response self-cleaning capabilityin the treatment process of dye wastewater, and has important significance and wide application prospect in the technical field of water treatment membrane separation.

Owner:NORTHEAST NORMAL UNIVERSITY

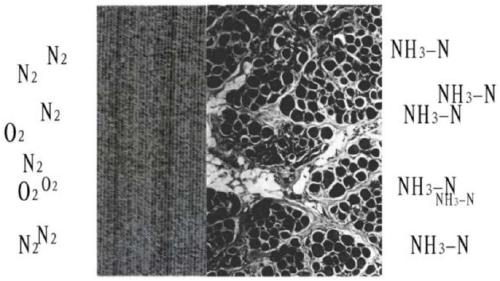

Fiber tube reinforced hollow fiber composite biofilm as well as preparation method and application thereof

InactiveCN110180403AHigh porosityHigh separation precisionSemi-permeable membranesMembranesFiberHollow fibre

The invention discloses a fiber tube reinforced hollow fiber composite biofilm as well as a preparation method and application thereof. According to the invention, a coating-immersion precipitation phase transformation method is adopted for utilizing a composite film spinning device to coat a braided tube by a casting solution liquid to prepare the fiber tube reinforced hollow fiber composite biofilm with high strength and high flux. The product provided by the invention has a large specific surface area, in particular, the specific surface area of the oxygen permeable film can be as high as 5108 m<2> / m<3>; the film is used as a carrier, a sufficient adhesion area can be provided for growth of microorganisms in a smaller space, so that a concentration of the microorganisms in the unit space is greatly improved, the treatment capacity per unit volume can be improved, and the aeration efficiency is high; the film has the characteristics of selective ventilation, and the oxygen absorptioncapacity is multiple times that of conventional equipment; and the product has the high-efficiency oxygen separation characteristic, so that the microorganisms are attached to the surface of the biofilm to form a biotic community to naturally form a stable ecosystem, the efficiency of biological absorption of water pollutants is accelerated, and the black odor problem can be thoroughly solved.

Owner:SUZHOU BEST COLOR ENVIRONMENTAL PROTECTION NANOTECH CO LTD

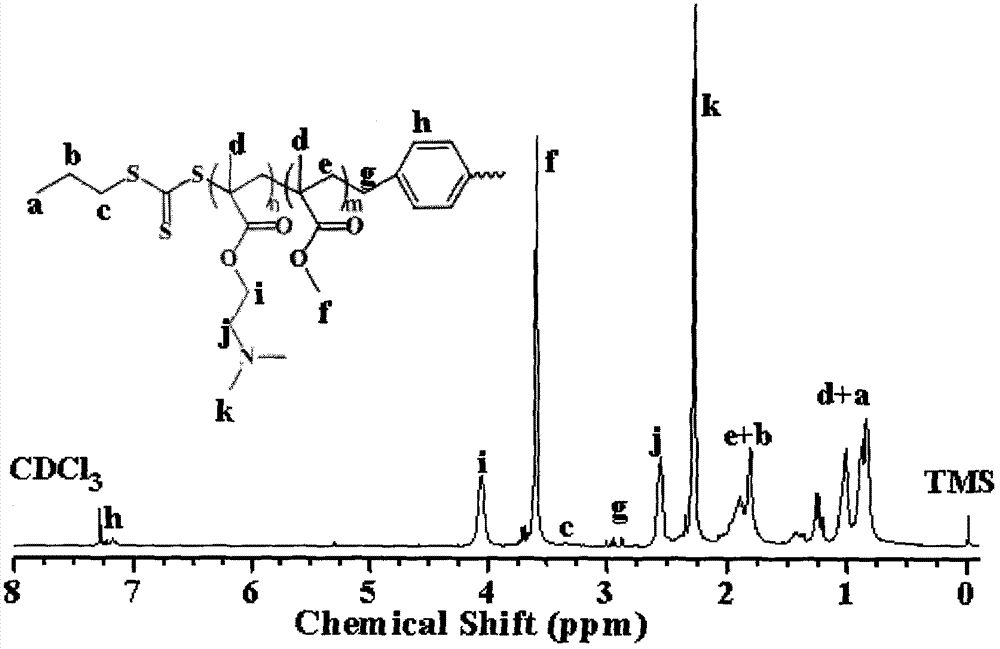

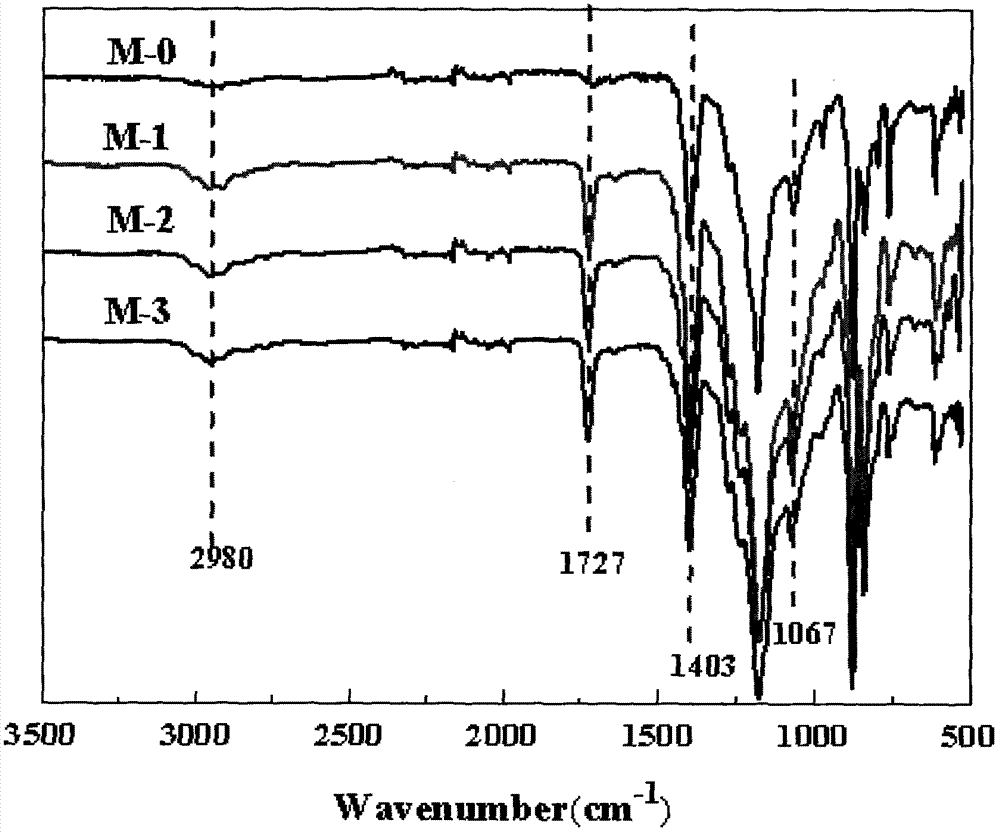

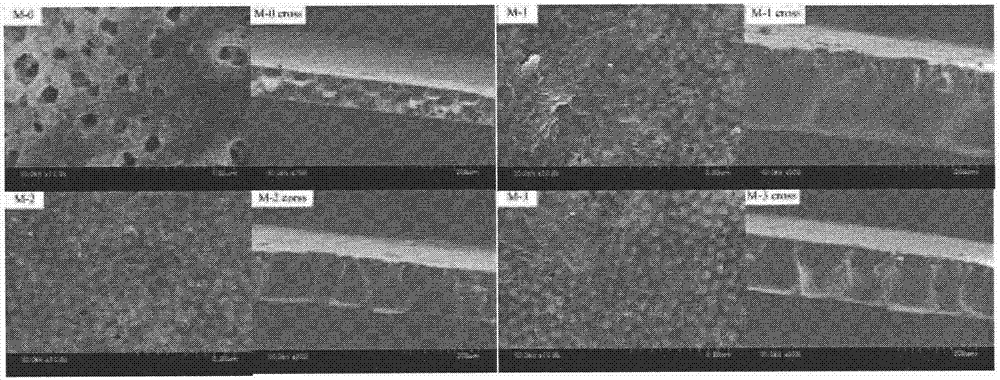

Preparation method for amphipathic triblock copolymer modified polyvinylidene fluoride membrane

InactiveCN107486043AExtended service lifeImprove stabilitySemi-permeable membranesEthyl esterPolyvinylidene difluoride

The invention provides a preparation method for an amphipathic triblock copolymer modified polyvinylidene fluoride membrane. According to the preparation method, methyl methacrylate (MMA) and methacrylic acid-N,N-dimethylamino ethyl ester (DMAEMA) are utilized as a polymerization monomer, two amphipathic segmented copolymers of ABA type (PDMAEMA-b-PMMA-b-PDMAEMA, PDMD) and BAB type (PMMA-b-PDMAEMA-b-PMMA, PMDM) can be prepared by two-step reversible addition-fragmentation chain transfer (RAFT) free radical polymerization, the two amphipathic segmented copolymers have different topological structures, and the structures are controllable, the two amphipathic segmented copolymers are utilized as blending modifiers to prepare the amphipathic triblock copolymer modified polyvinylidene fluoride membrane by an inversion method of immersion precipitation phase. PMMA chain sections in the modifiers prepared by the preparation method disclosed by the invention have good compatibility with PVDF, so that the modifiers have good stability in the membrane and are not prone to losing; the PDMAEMA chain sections are enriched on the surface to improve hydrophilia of the membrane. Compared with a pure membrane, surface hydrophilicity and water flux of the amphipathic triblock copolymer modified polyvinylidene fluoride (PVDF) membrane prepared by the preparation method disclosed by the invention are obviously improved.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation for silicone hydride modified zeolite filled silicon rubber compound film

InactiveCN101318111ASimple production processReduce manufacturing costSemi-permeable membranesSeparation factorPolyester

The invention relates to a method for preparing a silicone rubber composite membrane filled with silane-modified zeolite and pertains to the technical field of the separation of pervaporation membrane. The method includes the steps that of scraping a polyester non-woven fabric layer by using polyvinylidene fluoride (PVDF) solution, and a PVDF porous basement membrane is obtained by applying the immersion precipitation phase inversion process; after MFI-type zeolite is modified by various alkoxy silanes or chlorosilanes, a membrane liquid which contains MFI-type zeolite, polydimethylsiloxane (PDMS), a crossing linking agent and a catalyst is prepared; the scraping is carried out on the PVDF porous basement membrane, and the scrapped membrane is air-dried at room temperature to ensure that the crossing linking is complete. The prior PDMS membrane which is not filled with zeolite has poorer performance of separating the ethanol water, and has separately lower separation factor and permeation flux. The silicone rubber composite membrane filled with silane modified zeolite obtained in the method has excellent ethanol permselective performance. When the mass ratio of silane modified zeolite to PDMS ranges from 50 to 100, the separation factor Alpha is equal to 19.9, and the permeation flux J is equal to 66.3g / m2h((EtOH) is equal to 5wt percent, 40 DEG C).

Owner:TSINGHUA UNIV

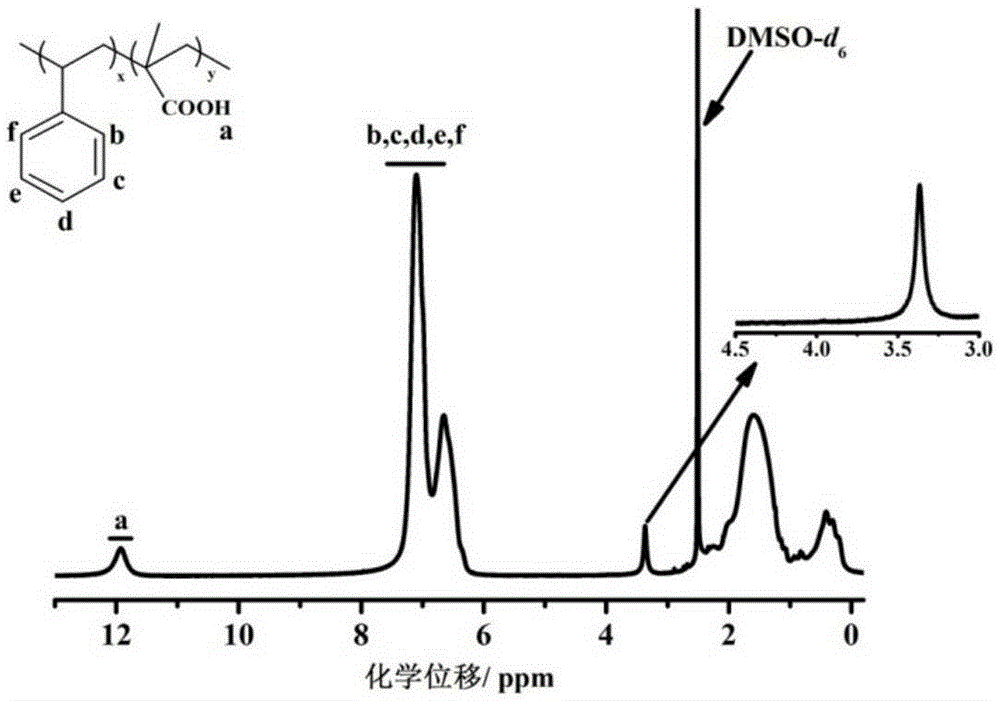

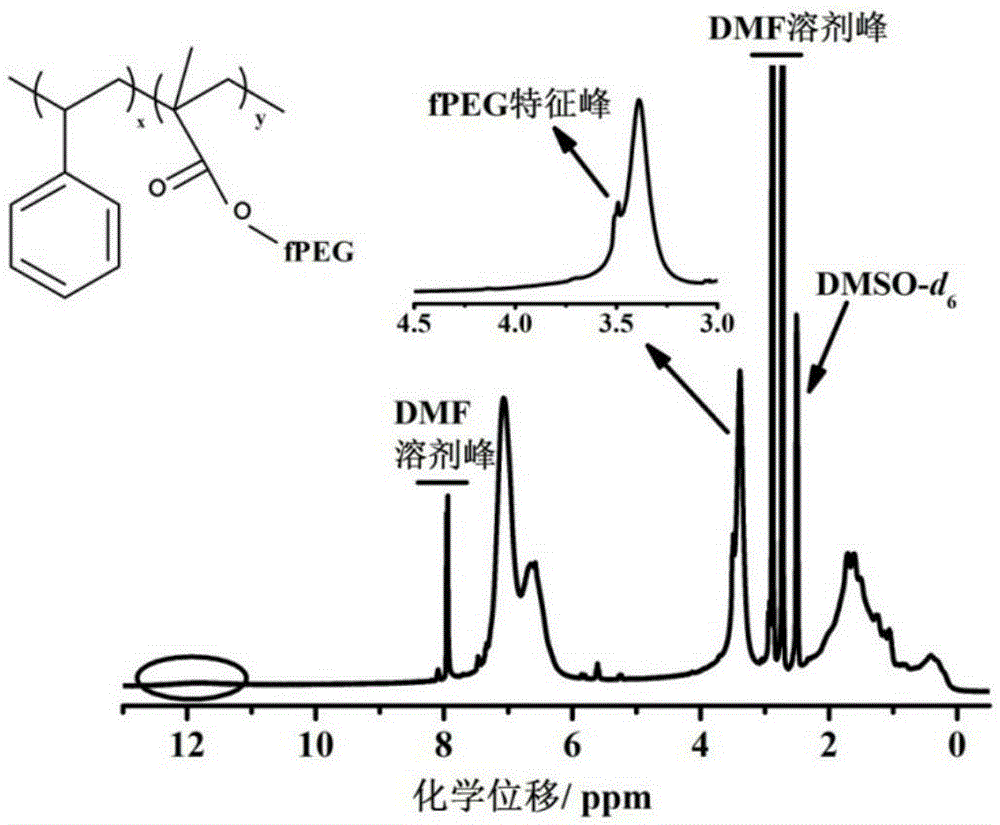

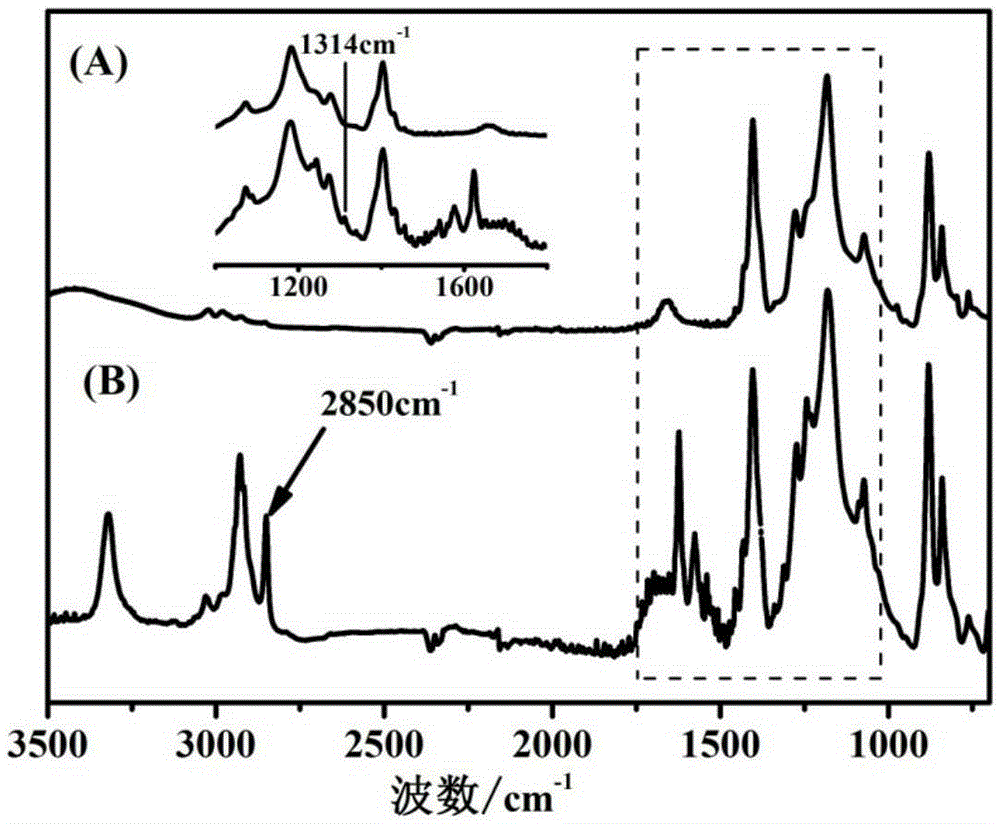

Amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane and preparation method thereof

ActiveCN105289331AControllable structureImprove stabilitySemi-permeable membranesPolymer scienceUltrafiltration

The invention provides an amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane and a preparation method thereof. PS(x)MAA(y)-g-fPEG(z) is used as an additive for modifying PVDF to obtain the amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane. The amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane is prepared by adopting an immersion precipitation phase inversion method, the modified membrane can keep long-time stability. According to the method, the adopted additive is prepared by simple free radical polymerization and normal temperature esterification reaction, the operation is simple, the use rang is wide, and compared with the prior art, the method is few in operation steps, simple and convenient to operate, low in cost and easy to implement in commercial production; as a PS chain section in the additive-PS(x)MAA(y)-g-fPEG(z) has good compatibility with PVDF, the modified membrane is relatively stable in the using process and not liable to disappear; an MAA(y) chain section in the additive-PS(x)MAA(y)-g-fPEG(z) is enriched on the surface of the PVDF, so that the hydrophily of the modified PVDF membrane is good, the contact angle of the membrane with water is small, the water drop seepage velocity is high, and tight contact of pollutants on the surface of the membrane is prevented.

Owner:SUZHOU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com