Preparation method of high-throughput graphene oxide-cellulose acetate composite membrane

A cellulose acetate and graphene technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as uneven dispersion, and achieve the effects of simple process, improved performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

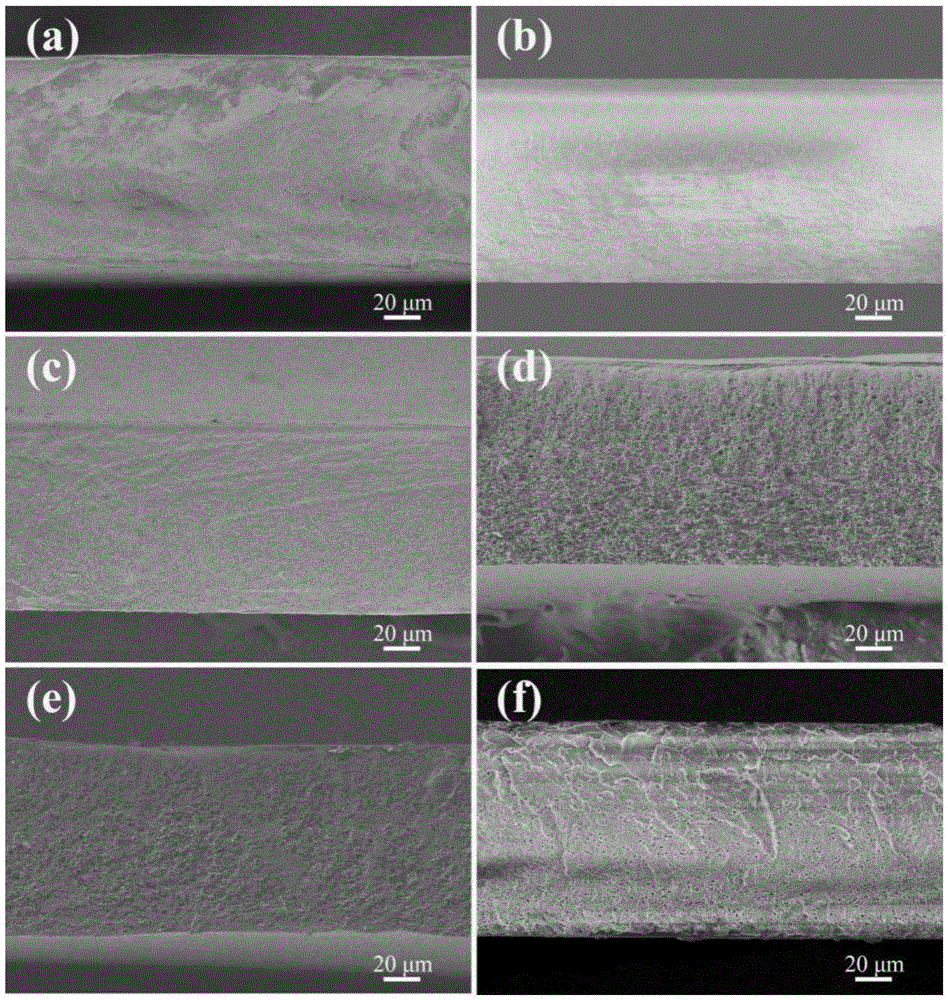

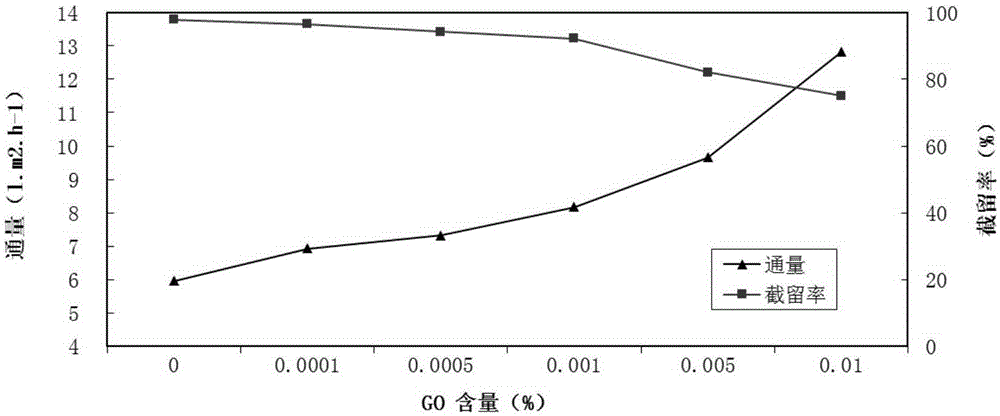

Image

Examples

Embodiment 1

[0031] 1) Preparation of graphene oxide powder:

[0032] Get 8g (325 order) natural flake graphite and 550ml mass concentration be 98% sulfuric acid after mixing uniformly, add 10.0g potassium nitrate, add 60g potassium permanganate rapidly in the water bath of 15 ℃, mix homogeneously. Then the temperature of the system was raised to 40°C, reacted for 3h, then added 300ml of water, and simultaneously the system was heated to 80°C for 30min, then the excess potassium permanganate was reduced with 500ml of distilled water and 100ml of hydrogen peroxide (30wt%), and centrifugally washed to The pH is 5, diluted to a certain concentration, 100kHz ultrasonic for 2 hours to obtain a graphene oxide aqueous solution, and freeze-dried to obtain a graphene oxide powder.

[0033] 2) Preparation of graphene oxide / formamide solution:

[0034] Disperse the powder of 1) in formamide to form a 0.1 g / L graphene oxide suspension, and sonicate at 40 kHz for 0.5 h to obtain a uniform graphene oxi...

Embodiment 2

[0042] 1) Preparation of graphene oxide / formamide solution:

[0043] The graphene oxide powder was dispersed in formamide to prepare a 1 g / L graphene oxide suspension, and ultrasonicated at 100 kHz for 4 hours to obtain a uniform graphene oxide / formamide solution.

[0044] 2) Configuration of casting solution

[0045] Add cellulose acetate and acetone into the dissolving tank, after fully stirring, add the solution of 2) and formamide into the dissolving tank, and control the weight percentage of the substance in the casting solution to be 15% of cellulose acetate, 69.9995% of acetone, and graphite oxide Alkenes 0.0005%, formamide 15%. Dissolve under mechanical stirring at 100rmp / min for 24h.

[0046] 3) Degassing treatment

[0047] The casting solution was protected from light, sonicated at 100kHz for 2h, and then placed at 10°C to remove residual air bubbles.

[0048] 4) Preparation of composite membrane

[0049] After scraping the film, the casting solution was volatil...

Embodiment 3

[0051] In embodiment 2, cellulose acetate and acetone are added in the dissolving tank, and after fully stirring, the solution of 2) and formamide are added in the dissolving tank, and the weight percentage of substances in the casting solution is controlled to be 30% of cellulose acetate, acetone 59.999%, graphene oxide 0.001%, formamide 10%. Other conditions remain unchanged to obtain graphene oxide / cellulose acetate composite membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com