Production method of nano-silver/silica core-shell doped PVDF ultrafilter membrane

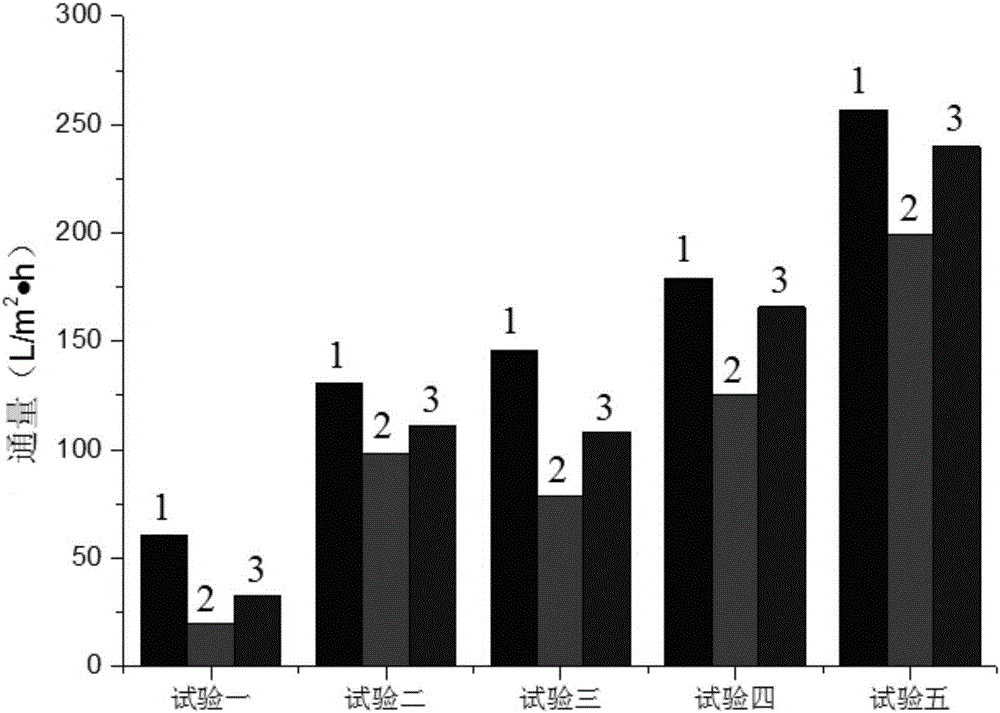

A silicon dioxide and nano-silver technology, applied in chemical instruments and methods, ultrafiltration, membranes, etc., can solve the problems of fast release rate, easy agglomeration of nano-silver, and insignificant enhancement of anti-pollution performance of PVDF ultrafiltration membranes. Achieve the effects of increased water flux and flux recovery rate, overcoming agglomeration, obvious bacteriostatic and anti-biological contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: this embodiment is a kind of preparation method of nano-silver / silicon dioxide core-shell doped PVDF ultrafiltration membrane, specifically completes according to the following steps:

[0030] 1. Preparation of PVDF solution: Mix PVDF powder with dispersing solvent I, then stir for 4h-6h at a stirring speed of 400r / min-600r / min and a temperature of 50°C-60°C to obtain a PVDF solution;

[0031] The mass ratio of PVDF powder described in step 1 and dispersion solvent I is 15:(70~100);

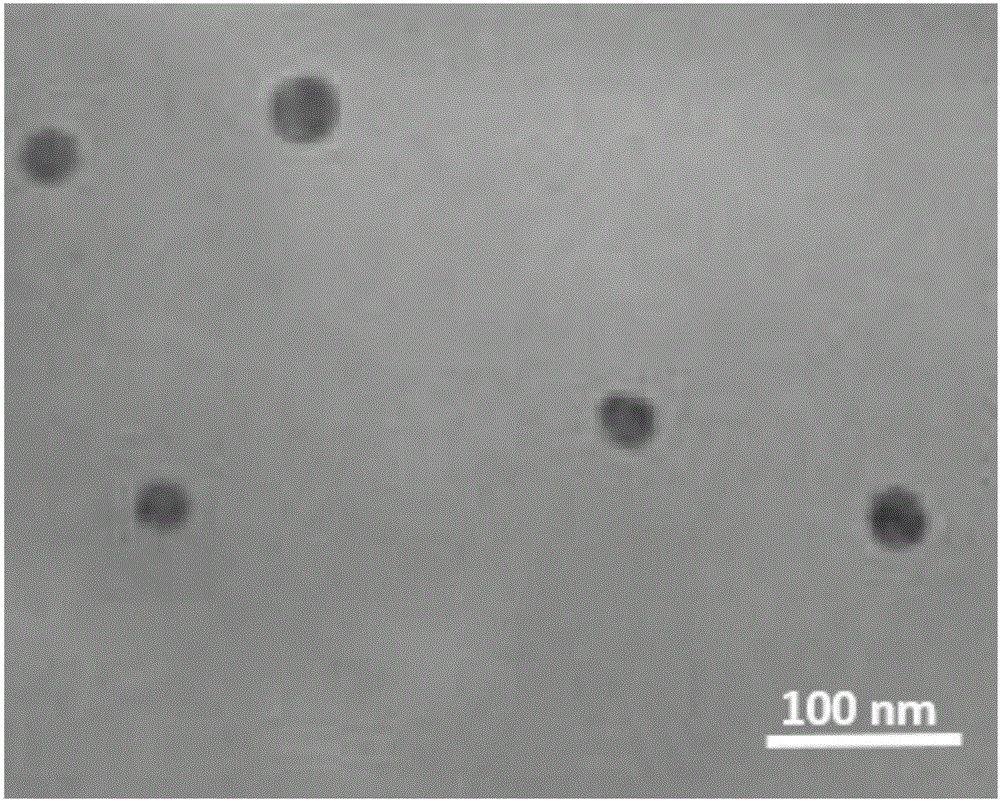

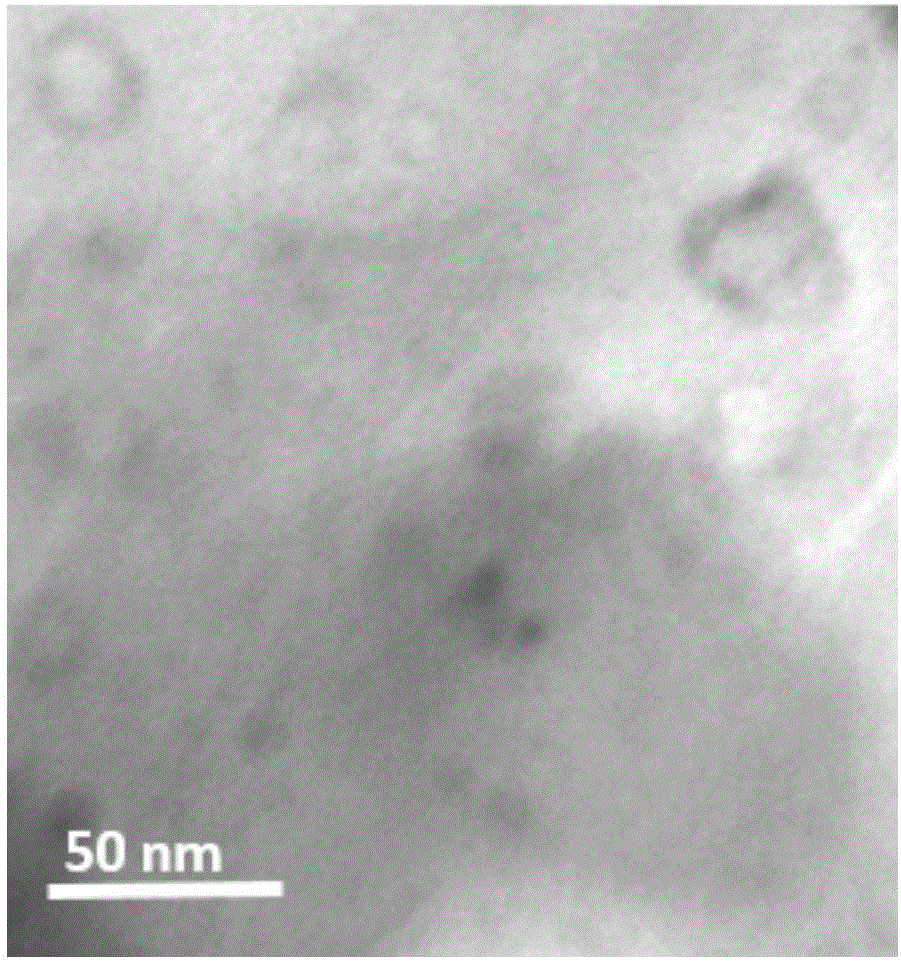

[0032] 2. Preparation of a mixed solution containing nano-silver / silica core-shell particles: the AgNO 3 Dissolve in dispersion solvent II, then add silane coupling agent, then stir and react at a temperature of 60°C to 156°C and cooling water reflux for 0.5h to 24h, then add a porogen, and then add a porogen at a temperature of 50°C to 60°C Stir and react at ℃ for 4h-6h to obtain a mixed solution containing nano-silver / silicon dioxide core-shell particles;

[00...

specific Embodiment approach 2

[0048] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the dispersion solvent I described in step one is N,N-dimethylformamide, 1-methyl-2-pyrrolidone, 1-vinyl -2-pyrrolidone or N,N-dimethylacetamide. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dispersion solvent II described in step two is N,N-dimethylformamide, 1-methyl-2-pyrrolidone, 1-vinyl-2-pyrrolidone or N,N-dimethylacetamide. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com