Process for preparing yttrium aluminum garnet

A technology of yttrium aluminum garnet and aluminum nitrate, which is applied in the field of preparation technology of yttrium aluminum garnet, can solve problems such as difficulty in industrialization of optical properties, and achieve the effects of being beneficial to industrialization, saving energy and overcoming agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

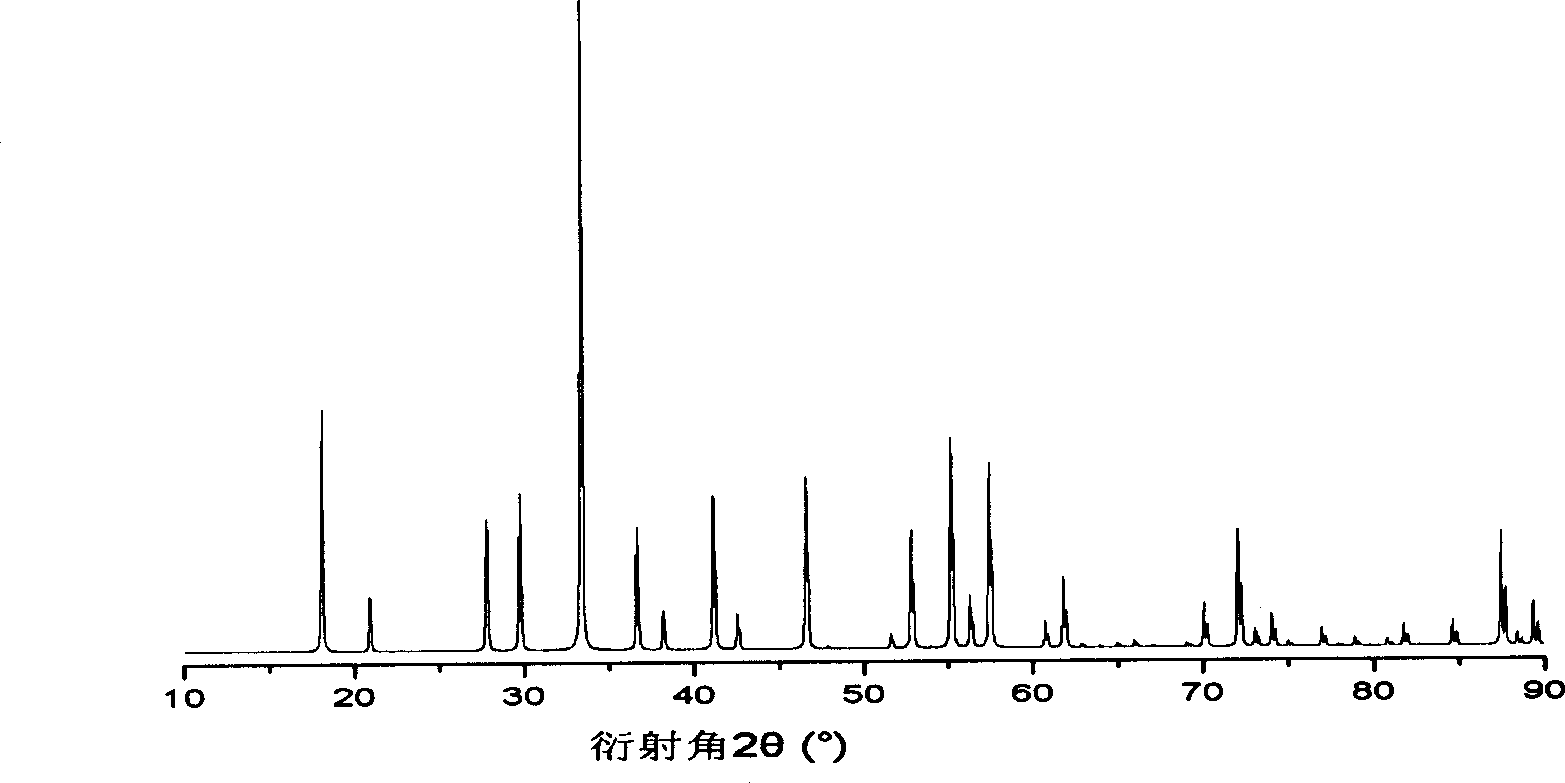

[0036] 1. Pure YAG

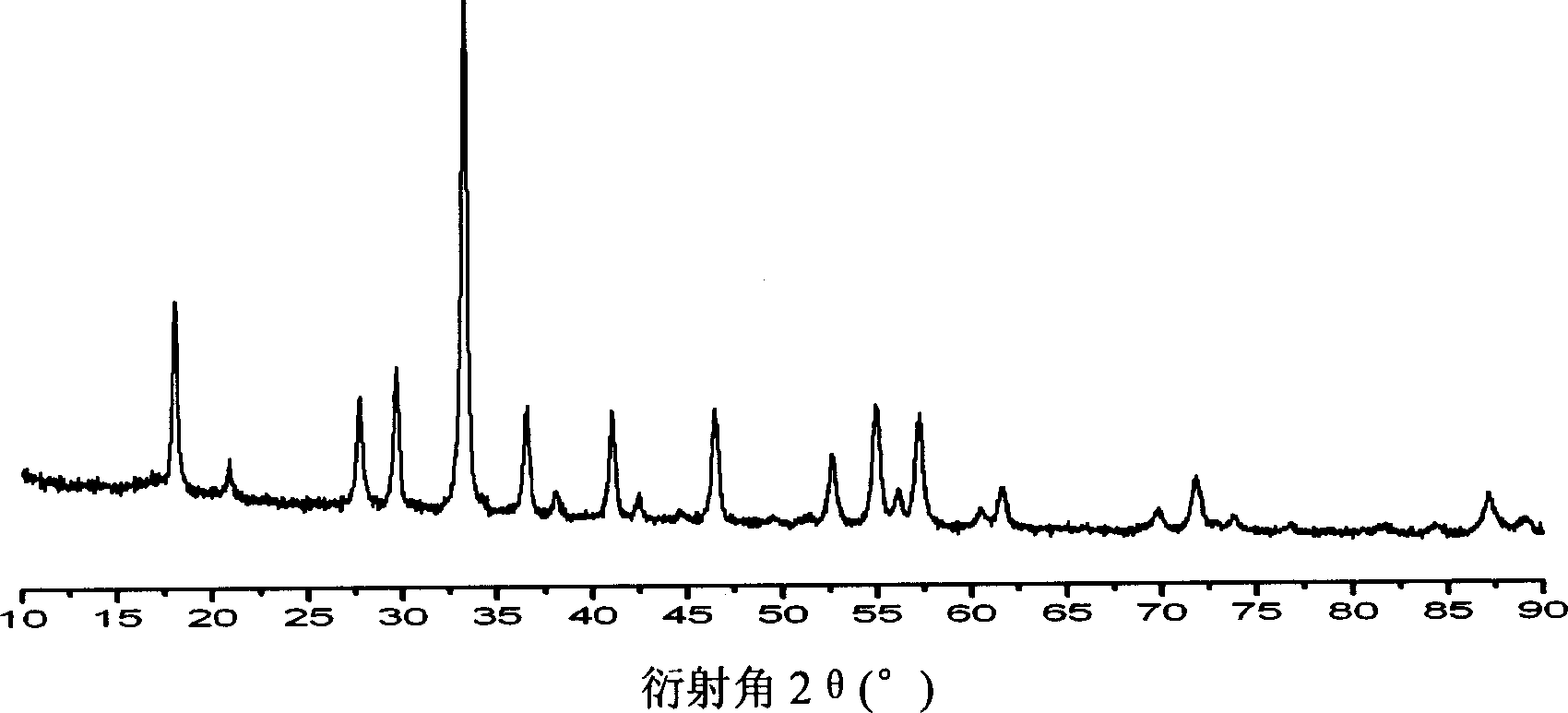

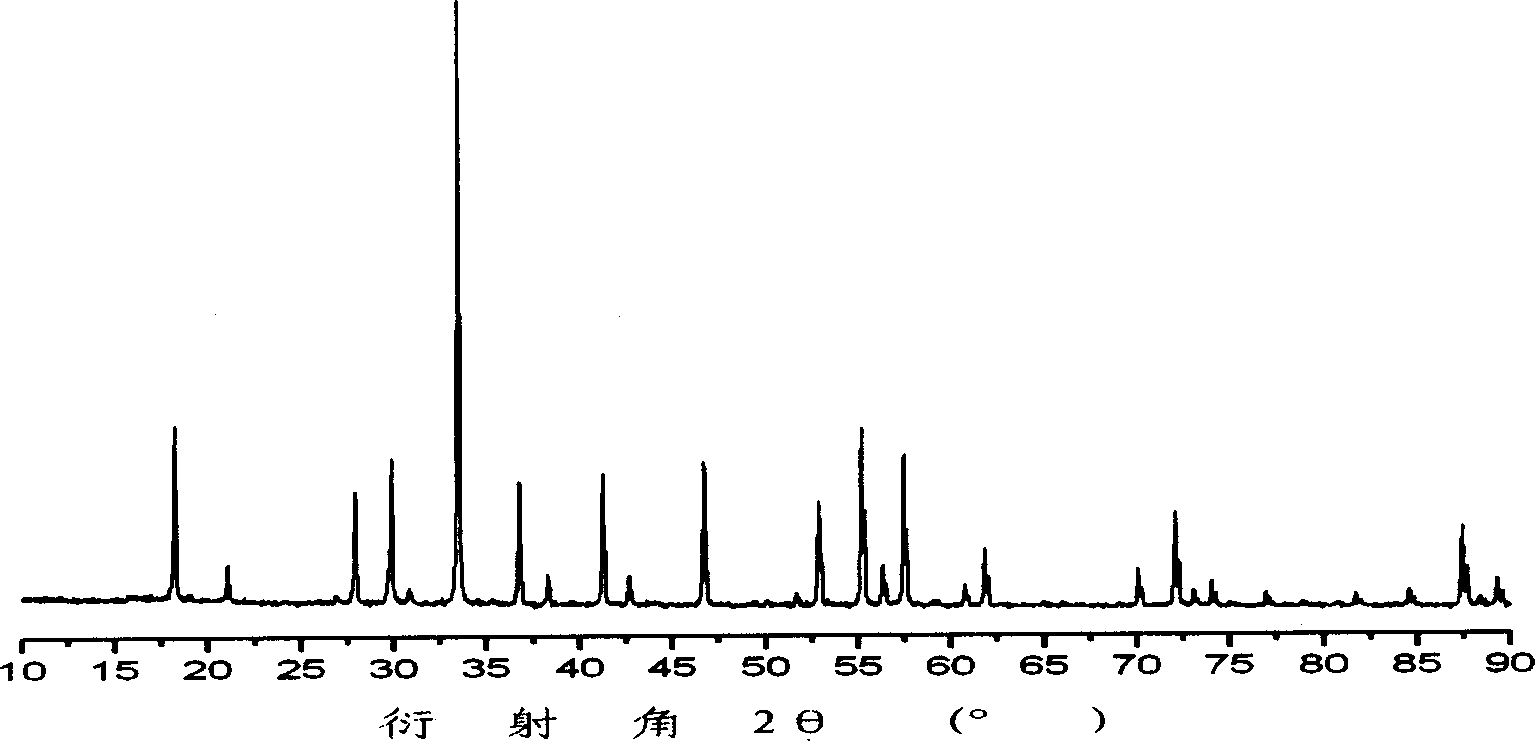

[0037] Add 61.31g of yttrium nitrate, 100g of aluminum nitrate and 269.60g of citric acid into 860g of deionized water, stir to dissolve, and adjust the pH value to pH=7 with ammonia water. Add 207.25g of acrylamide and 17.27g of N,N-methylenebisacrylamide after 10 minutes in a water bath at 70°C, and add 0.80g of tetraethylethylenediamine and 26.60g of 3% hydrogen peroxide after keeping warm in a 75°C water bath for 20 minutes Aqueous solution, keep warm in a 75°C water bath until it turns into a white gel. Keep the gel prepared above at 700°C for 3 hours to burn all the water and organic matter to obtain a white powder. The pure phase YAG powder can be obtained by keeping the obtained white powder at 850° C. for 1 hour, and the YAG nano powder with good crystal phase and good luminescent performance can be obtained by keeping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com