Patents

Literature

520 results about "Yttrium aluminium garnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

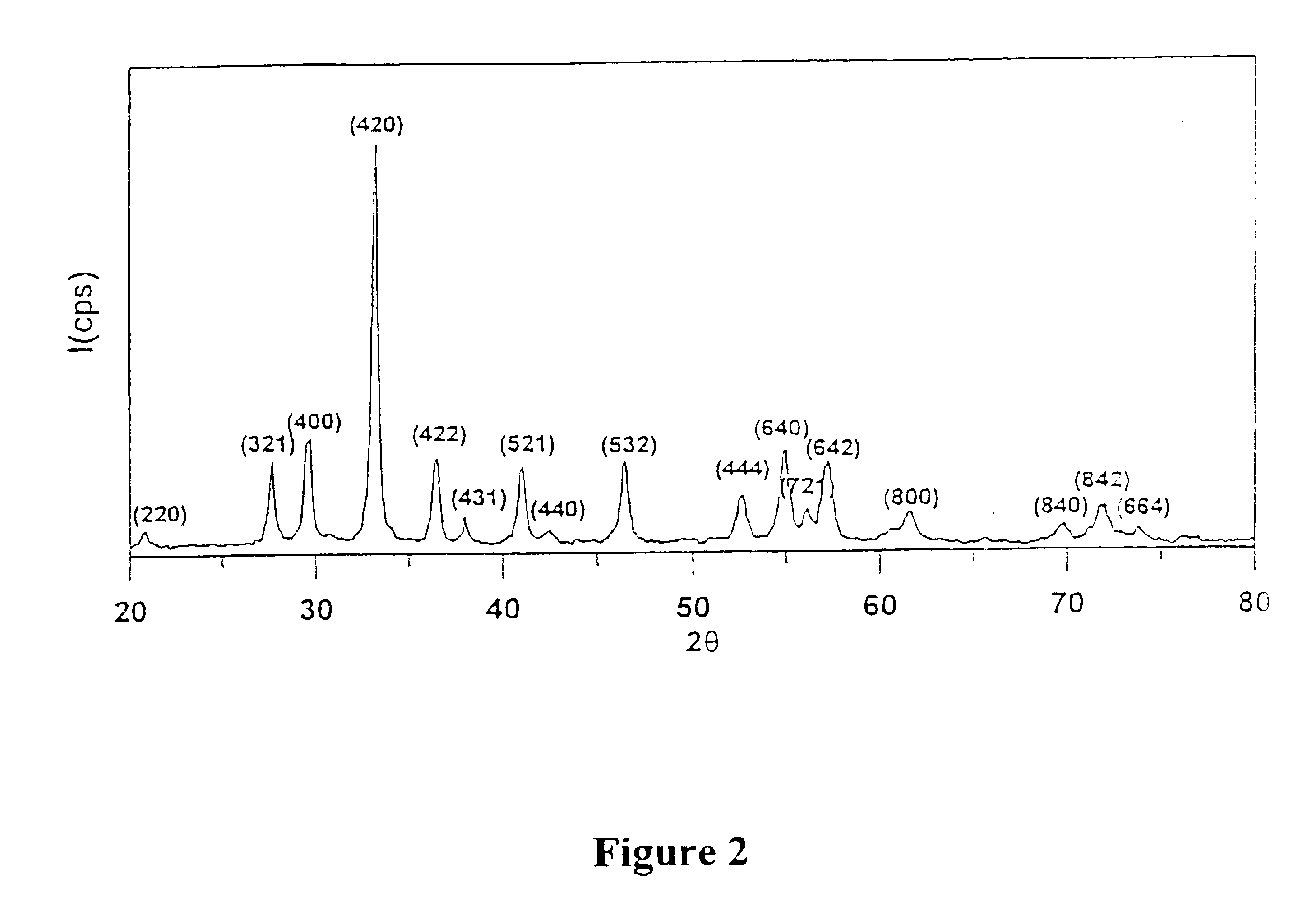

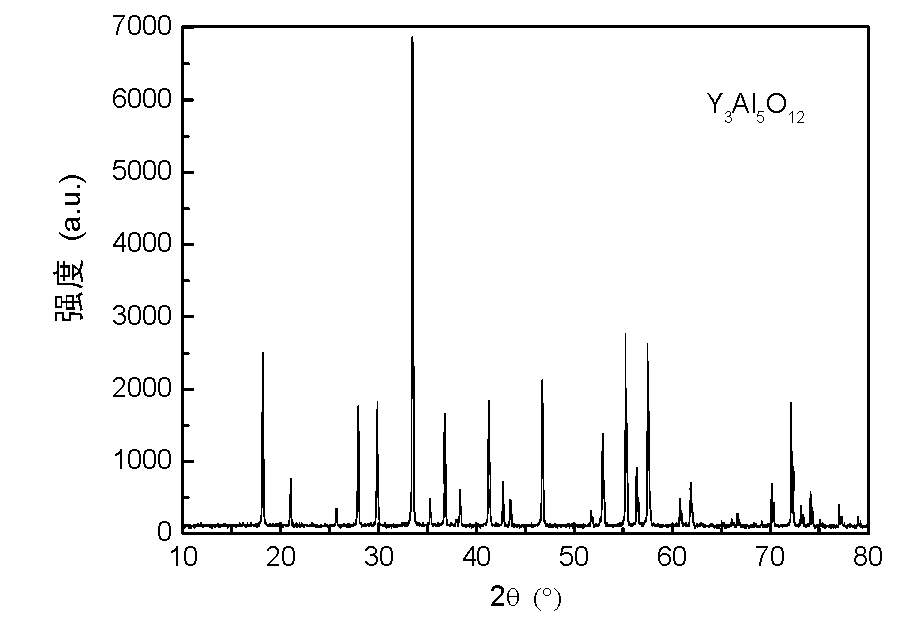

Yttrium aluminum garnet (YAG, Y₃Al₅O₁₂) is a synthetic crystalline material of the garnet group. It is a cubic yttrium aluminum oxide phase, with other examples being YAlO₃ in a hexagonal or an orthorhombic, perovskite-like form, and the monoclinic Y₄Al₂O₉.

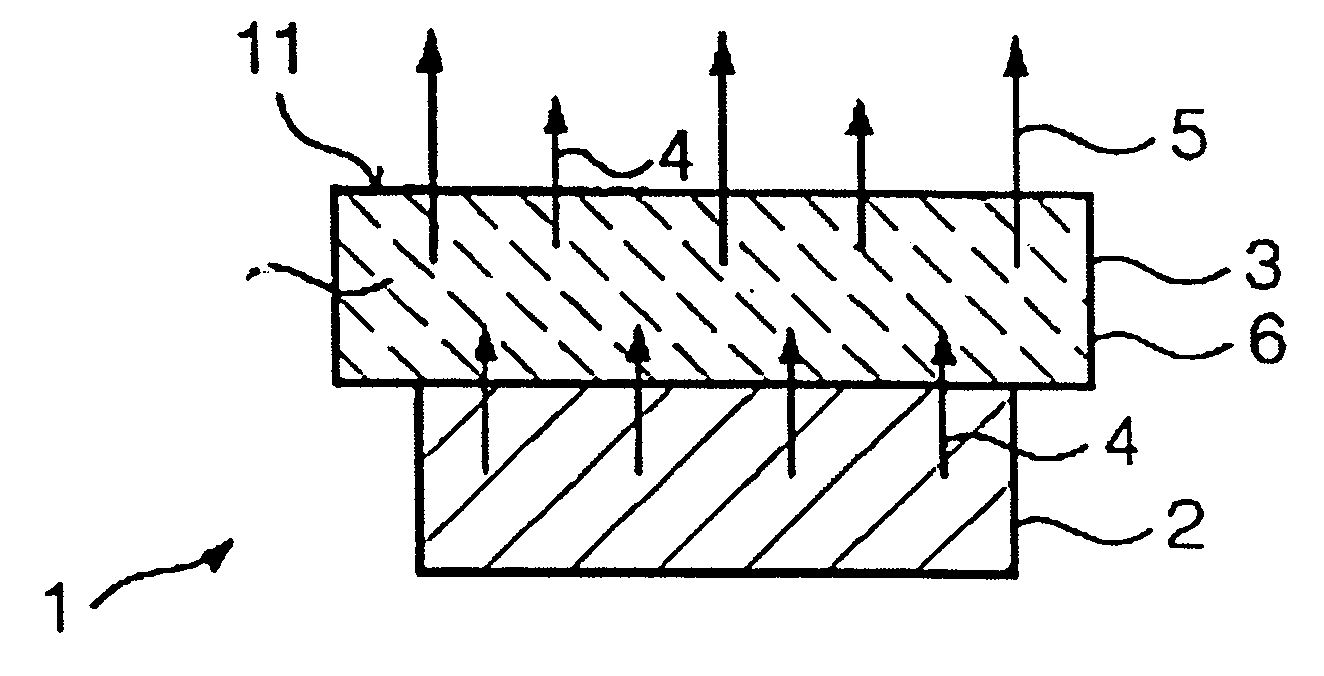

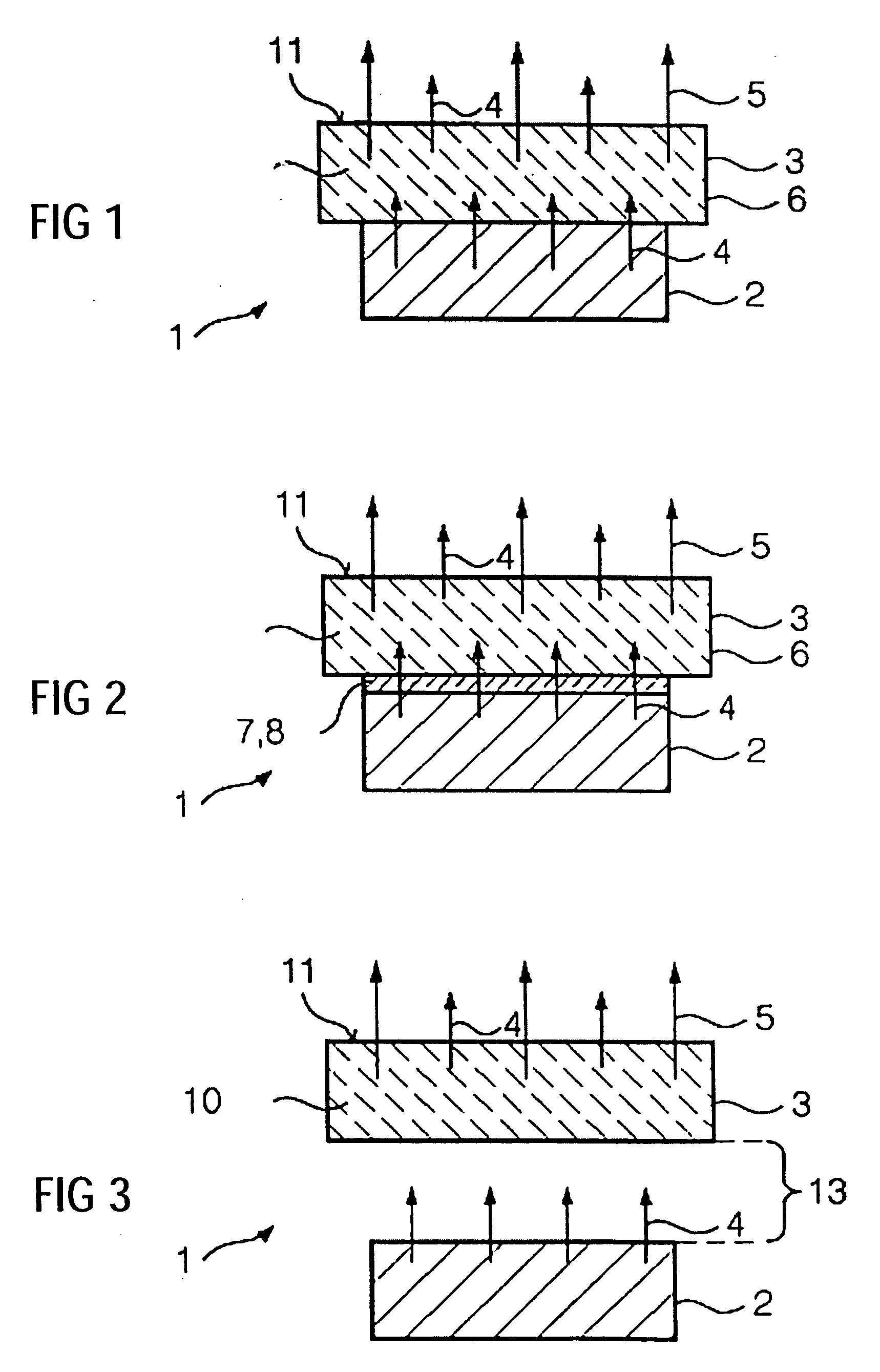

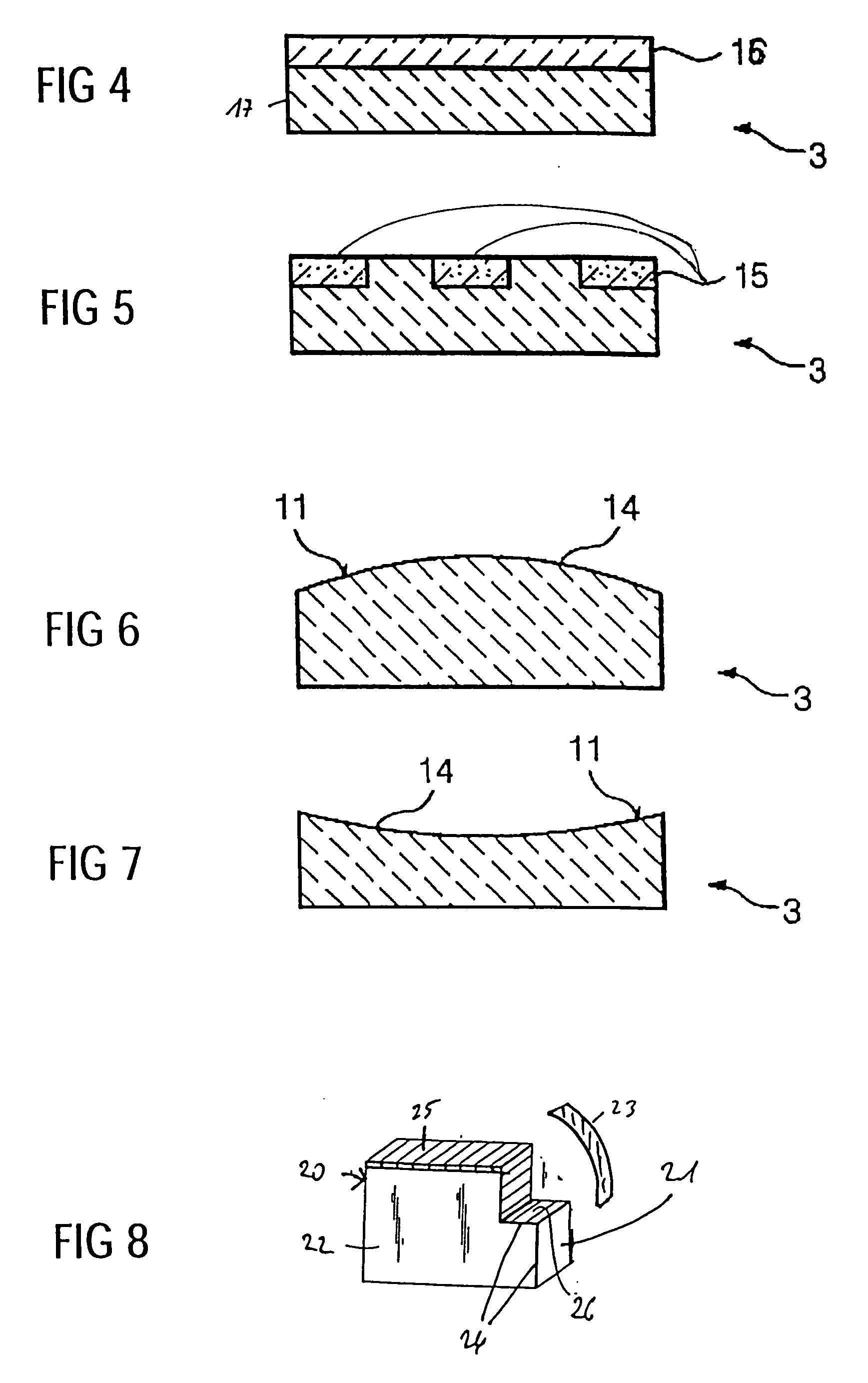

Light source having an LED and a luminescence conversion body and method for producing the luminescence conversion body

ActiveUS20040145308A1Efficient luminescence conversionDischarge tube luminescnet screensLamp detailsDopantSecondary radiation

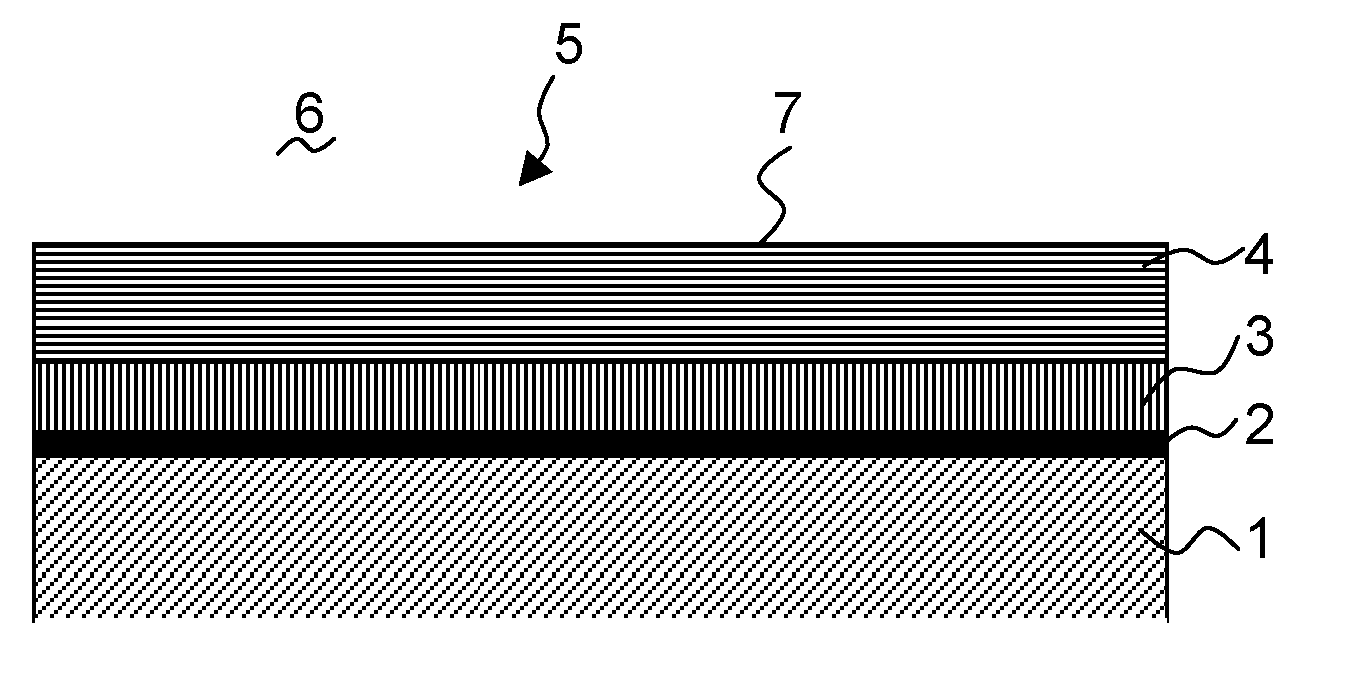

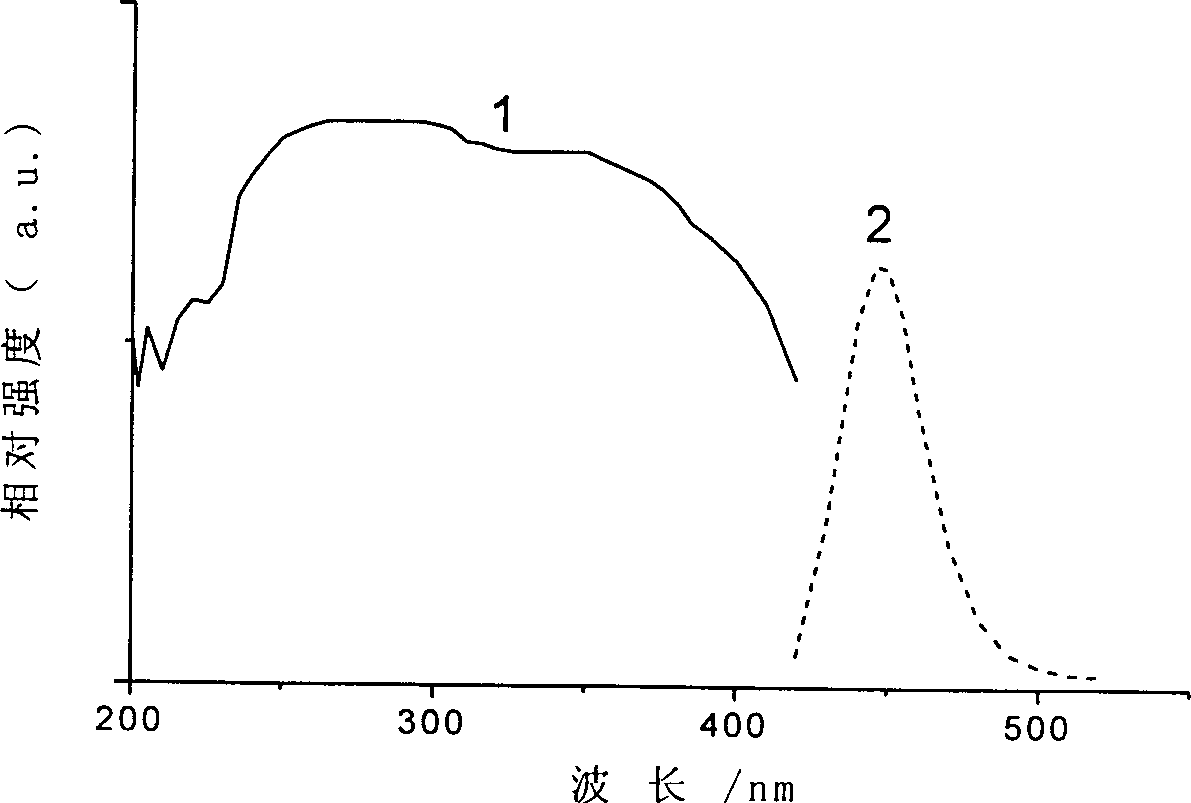

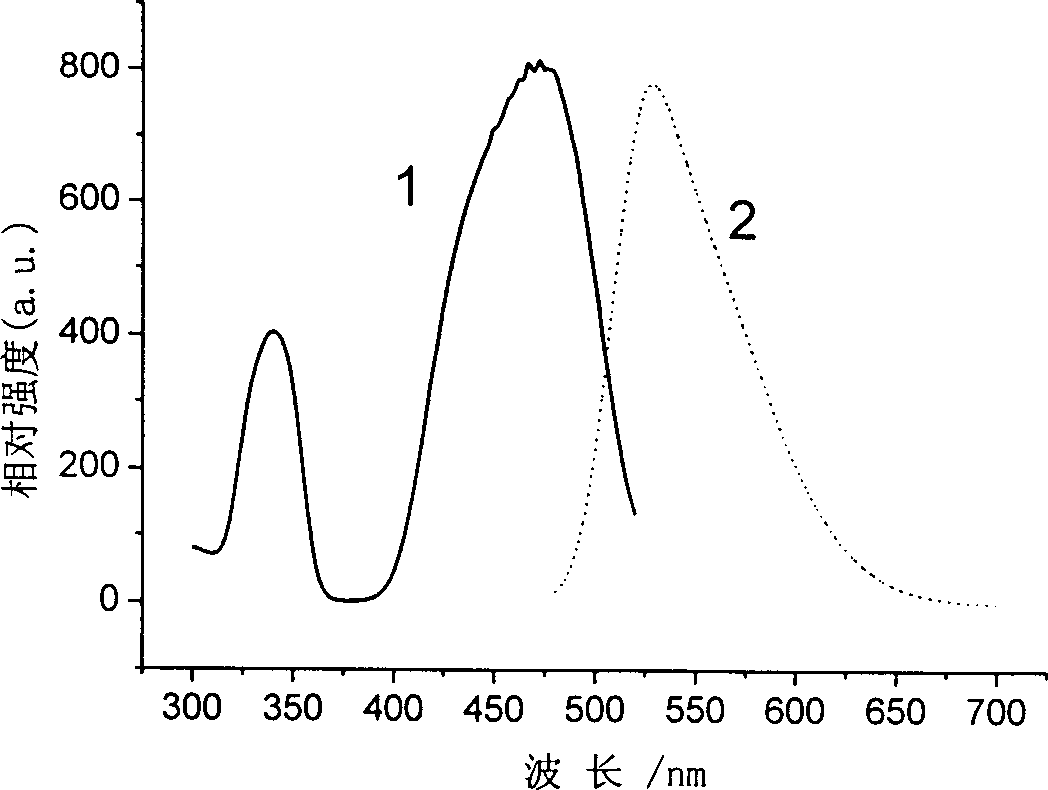

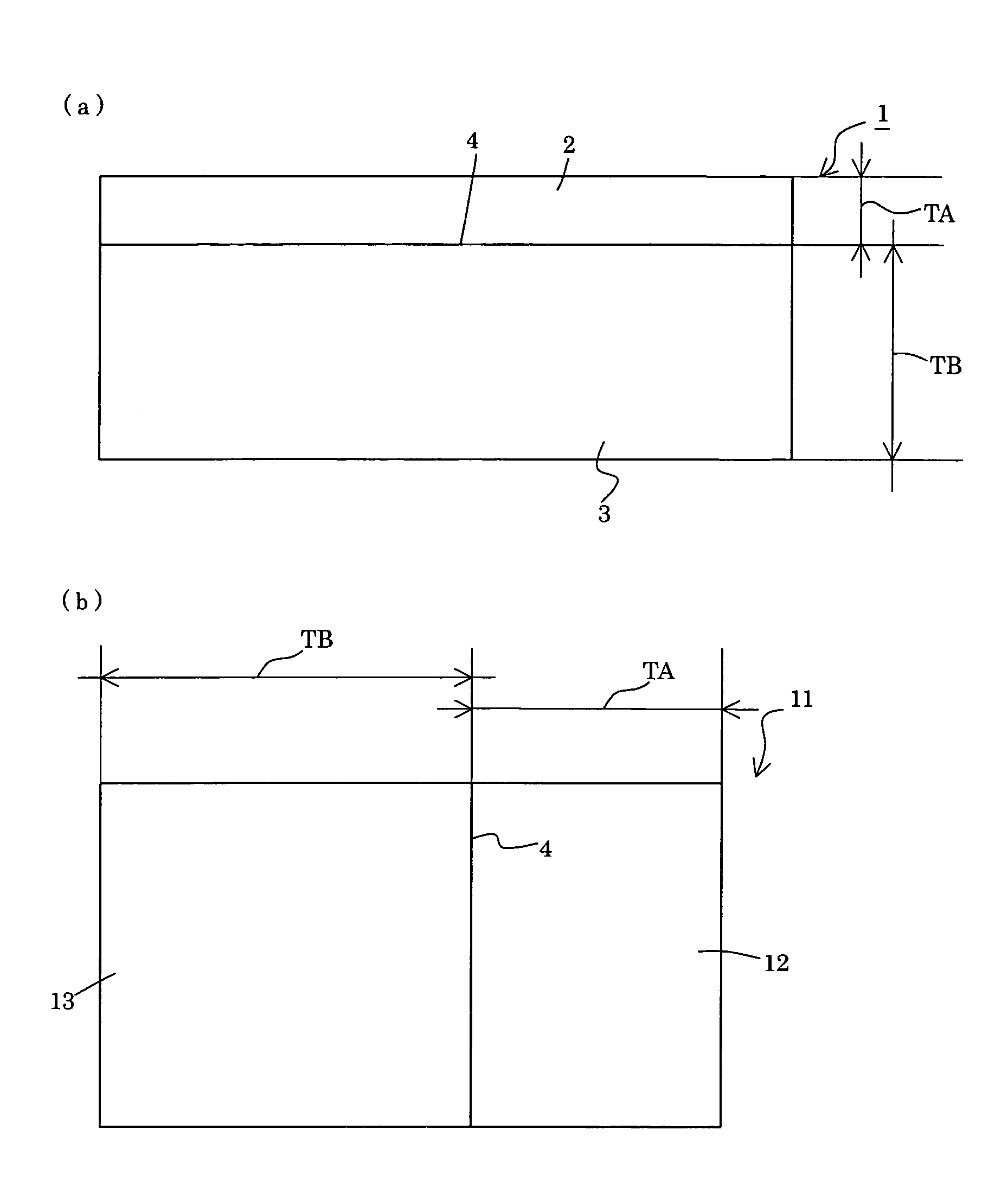

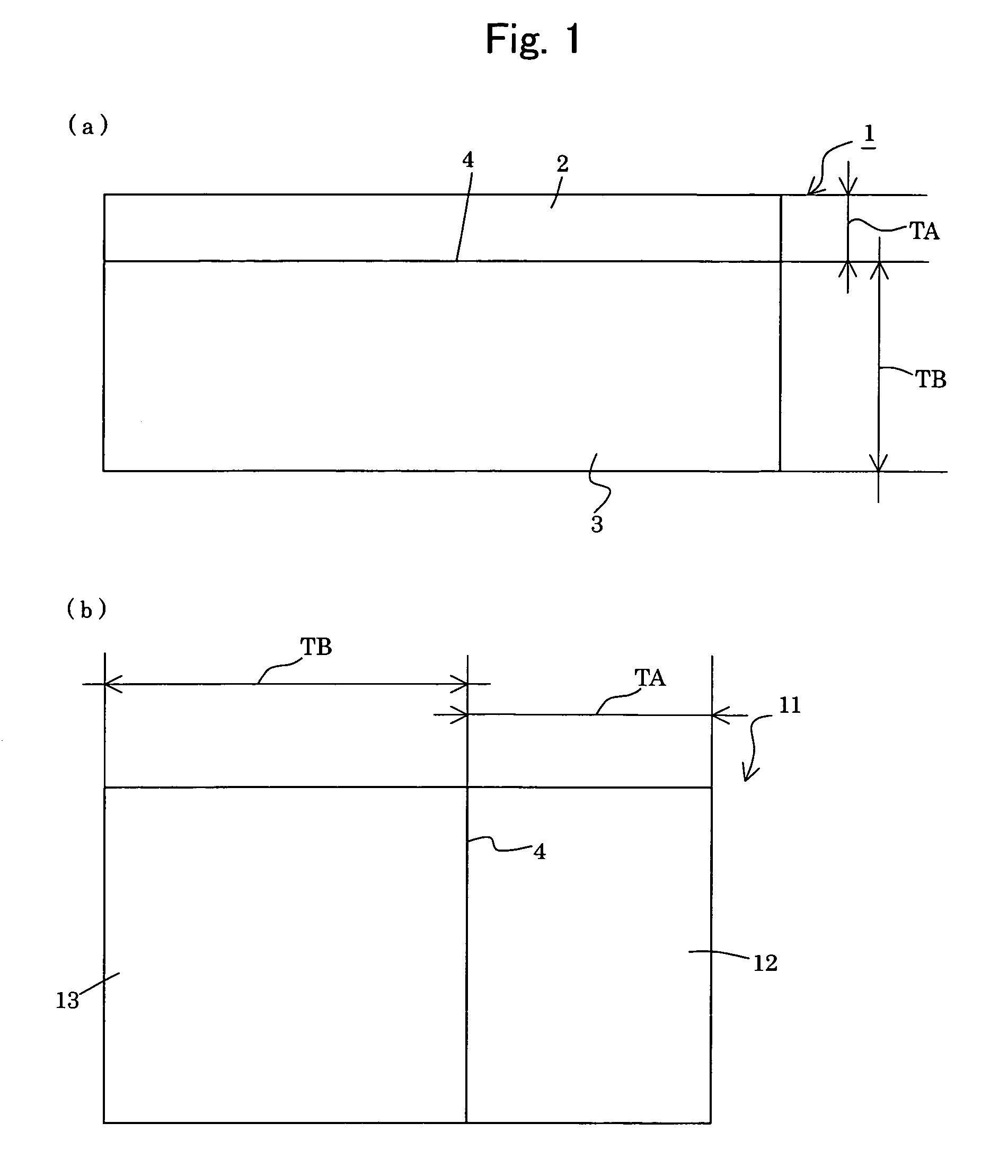

The invention relates to a light source (1), having at least one LED (2) for emitting a primary radiation (4) and at least one luminescence conversion body (3) having at least one luminescent material for converting the primary radiation (4) into a secondary radiation (5). The luminescence conversion body is a polycrystalline ceramic body. The LED is based on GaInN and emits blue primary radiation. The ceramic body comprises for example a luminescent material based on a cerium-doped yttrium aluminum garnet. This luminescent material emits yellow secondary radiation. Blue primary radiation and yellow secondary radiation penetrate through the luminescence conversion body and are perceived as white light by the observer. In order to produce the luminescence conversion body, provision is made of a polycrystalline ceramic body which is united with a solution of a dopant. By means of a thermal treatment, the dopant (activator) diffuses into the ceramic body, the luminescent material being formed.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

Ceramic material resistant to halogen plasma and member utilizing the same

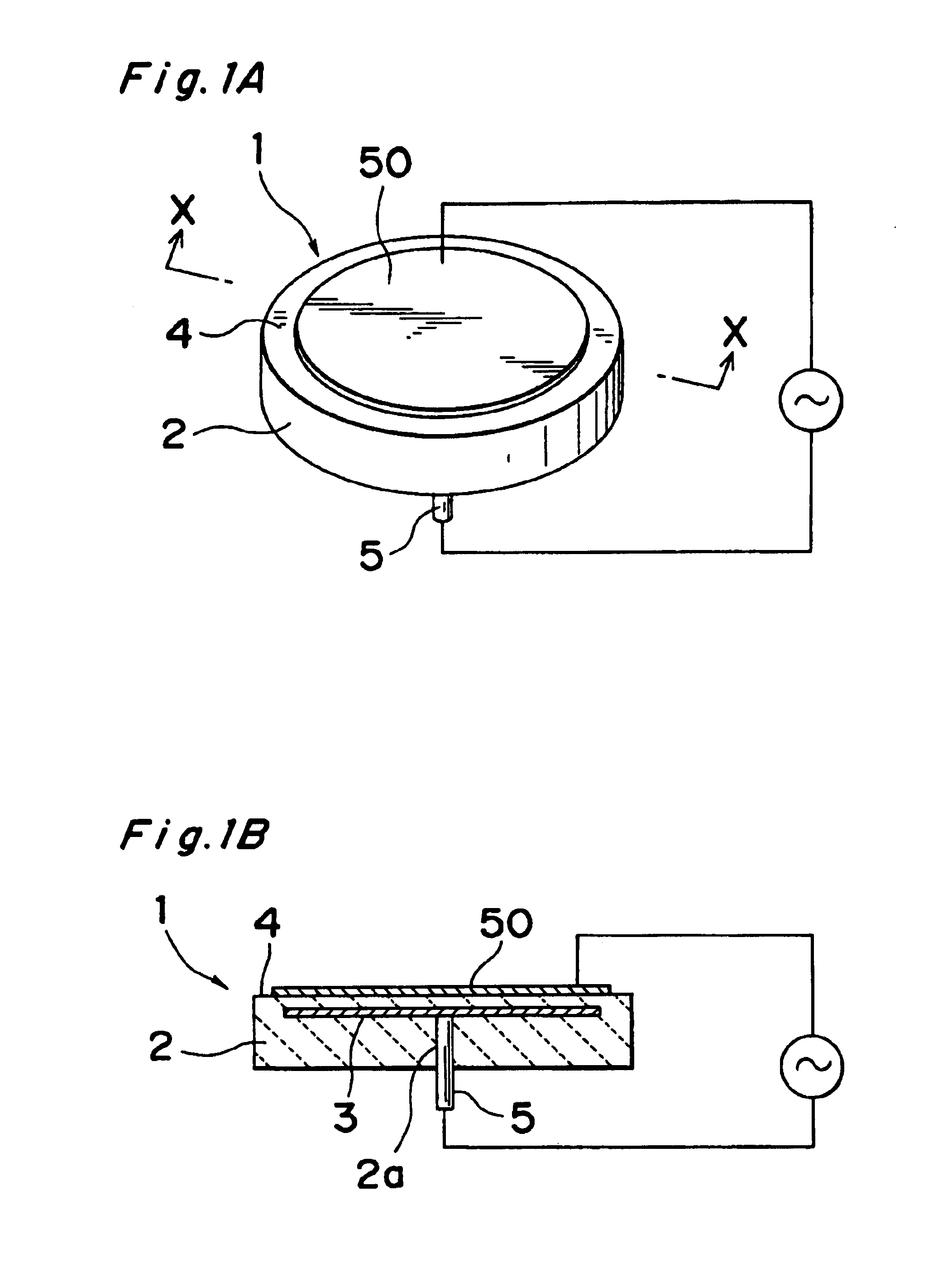

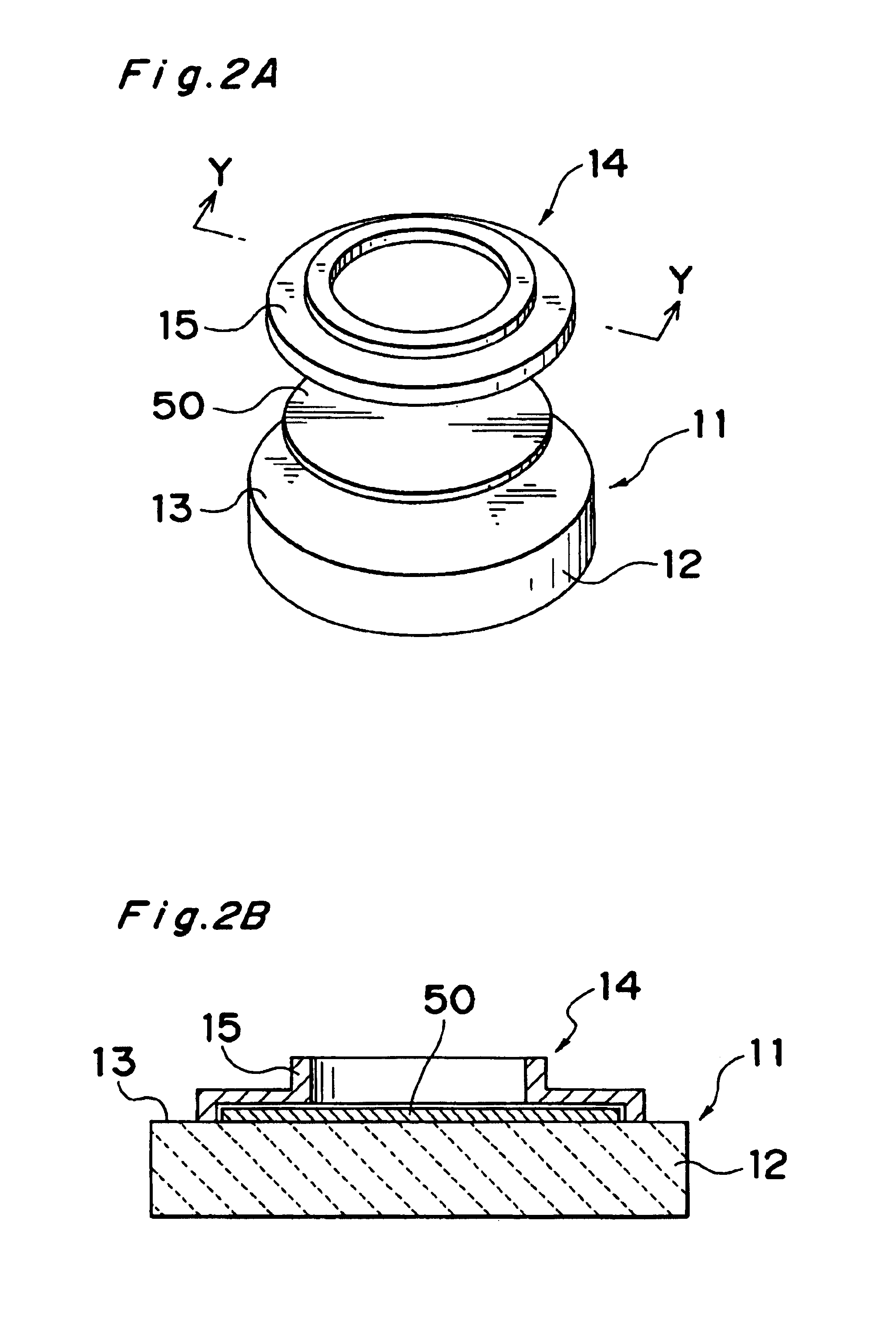

InactiveUS6916559B2Improve the immunityRecord information storageLight beam reproducingPorosityHalogen

A member used within a plasma processing apparatus and exposed to a plasma of a halogen gas such as BCl3 or Cl2 is formed from a sintered body of metals of Group IIIa of Periodic Table such as Y, La, Ce, Nd and Dy, and Al and / or Si, for example, 3Y2O3.5Al2O3, 2Y2O3.Al2O3, Y2O3.Al2O3 or disilicate or monosilicate, and in particular, in this sintered body, the content of impurity metals of Group IIa of Periodic Table contained in the sintered body is controlled to be 0.15 wt % or more in total. Specifically, for this member, an yttrium-aluminum-garnet sintered body having a porosity of 3% or less and also having a surface roughness of 1 μm or less in center line average roughness Ra is utilized.

Owner:KYOCERA CORP

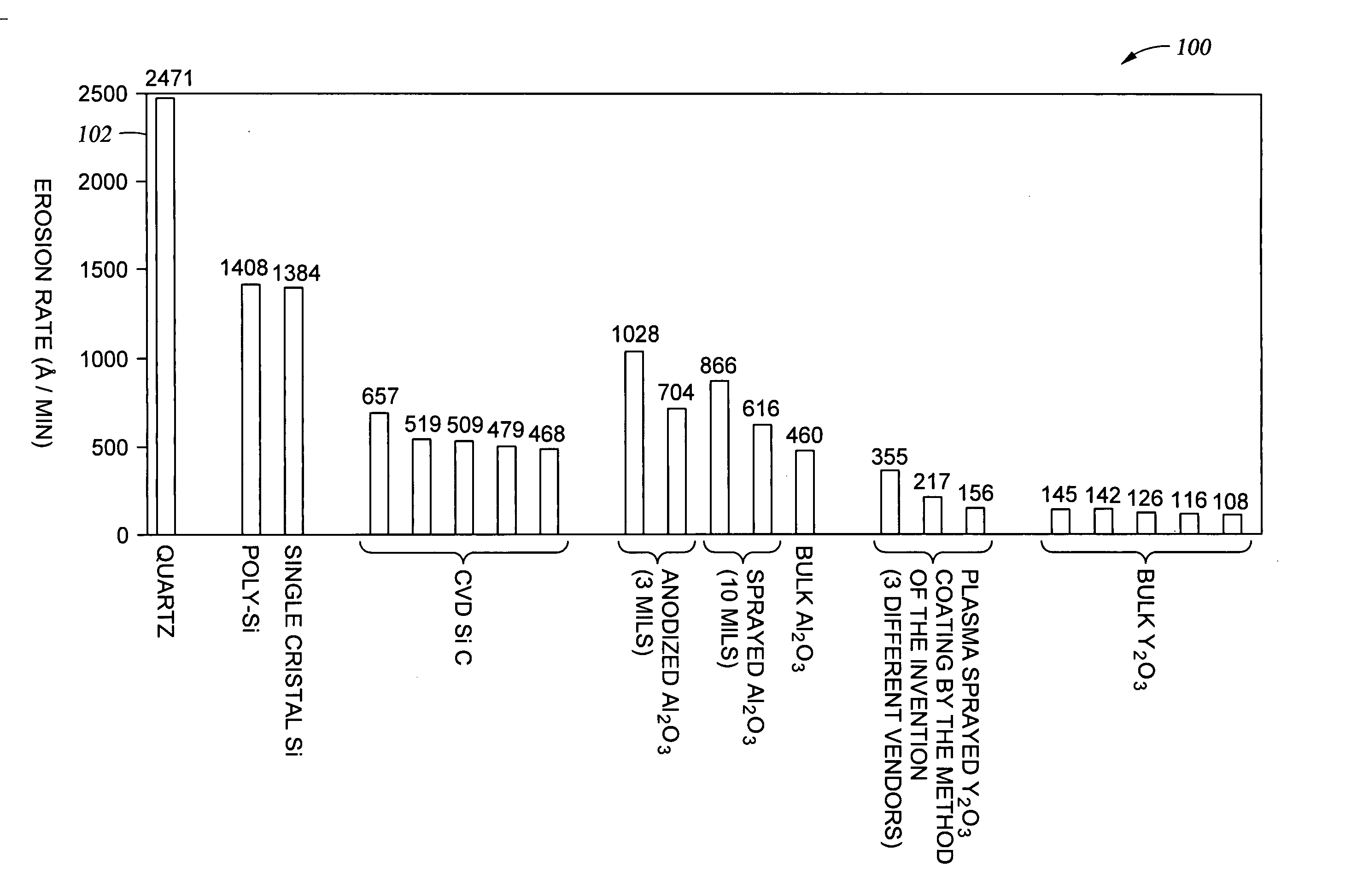

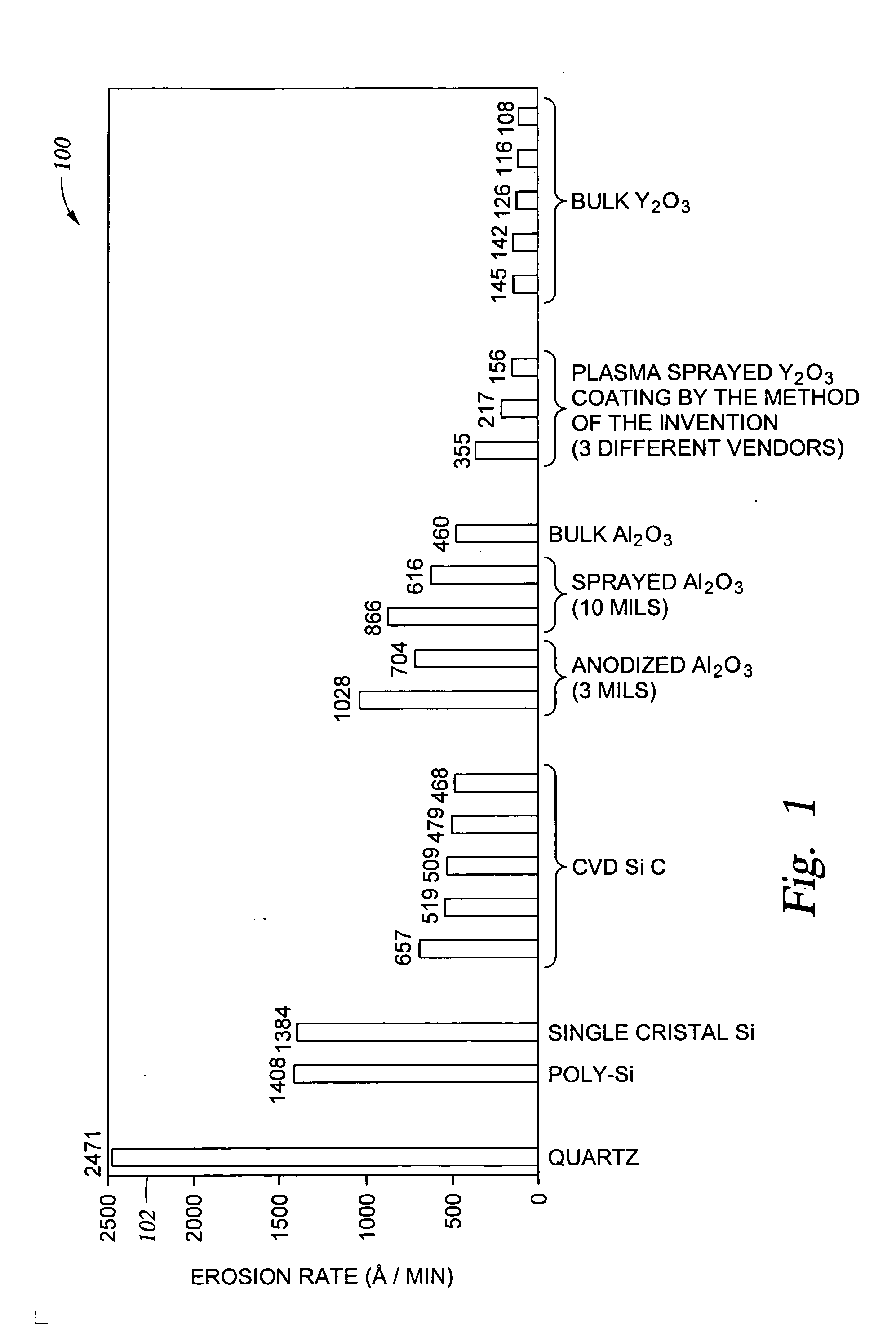

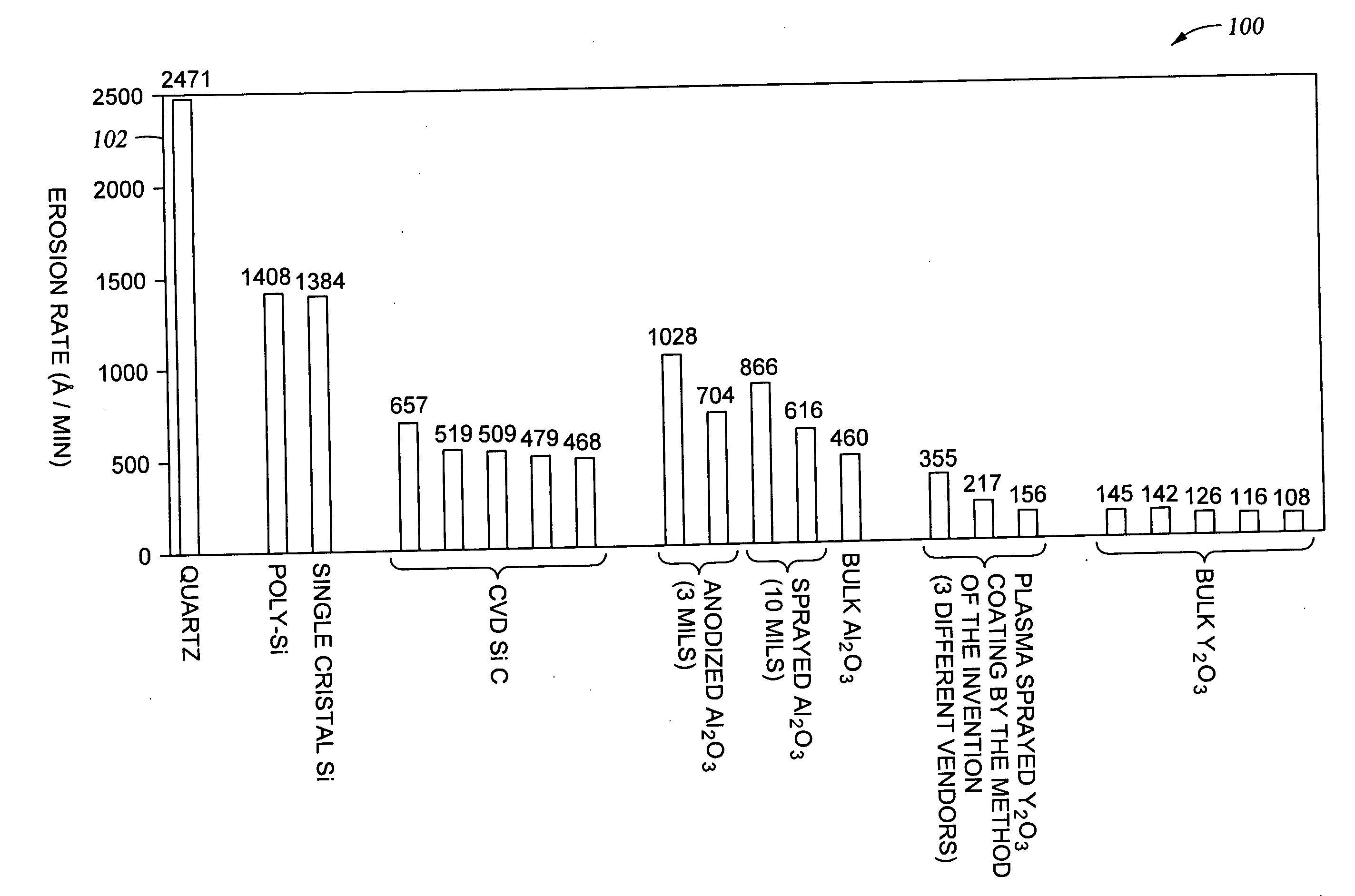

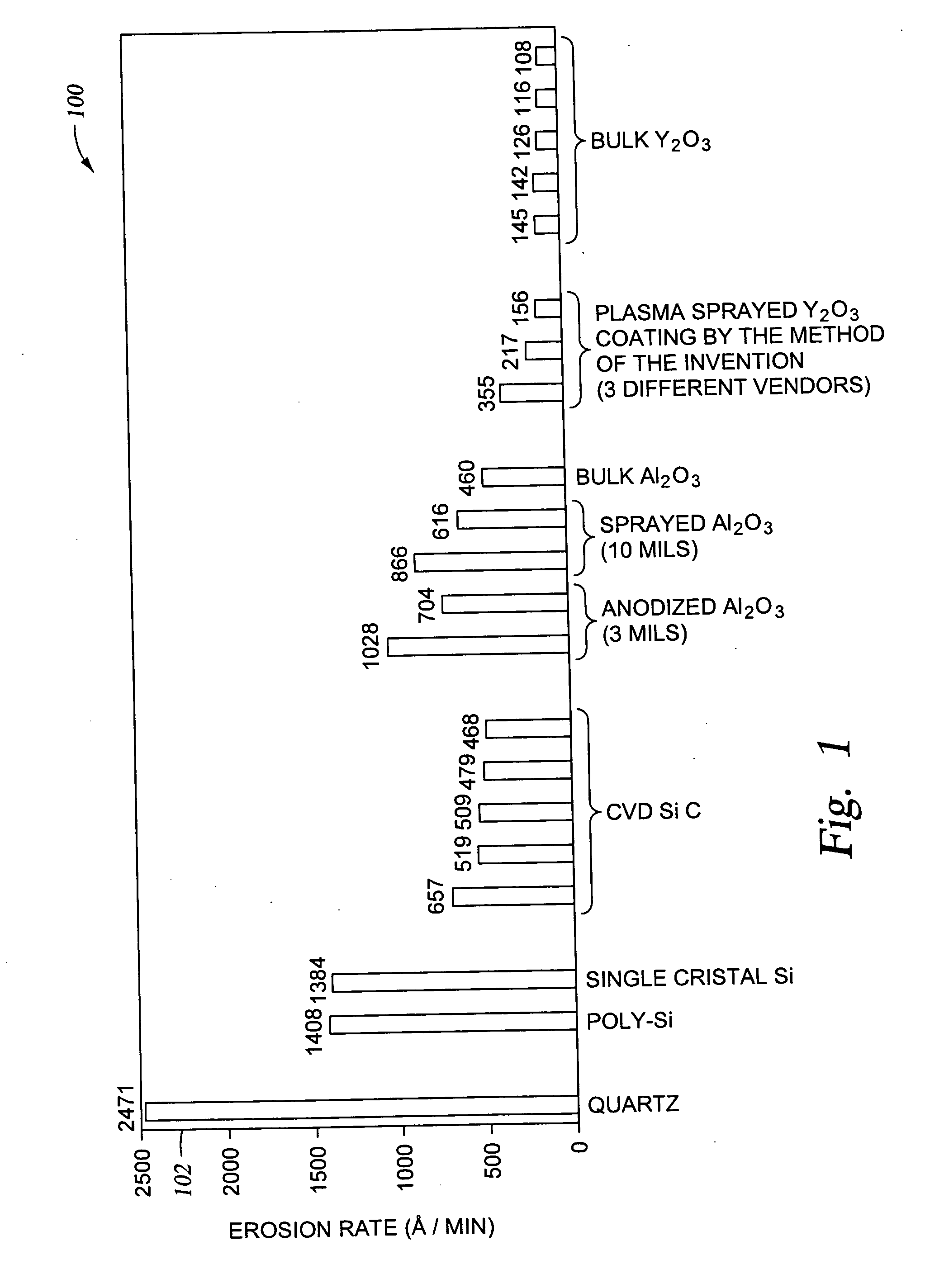

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

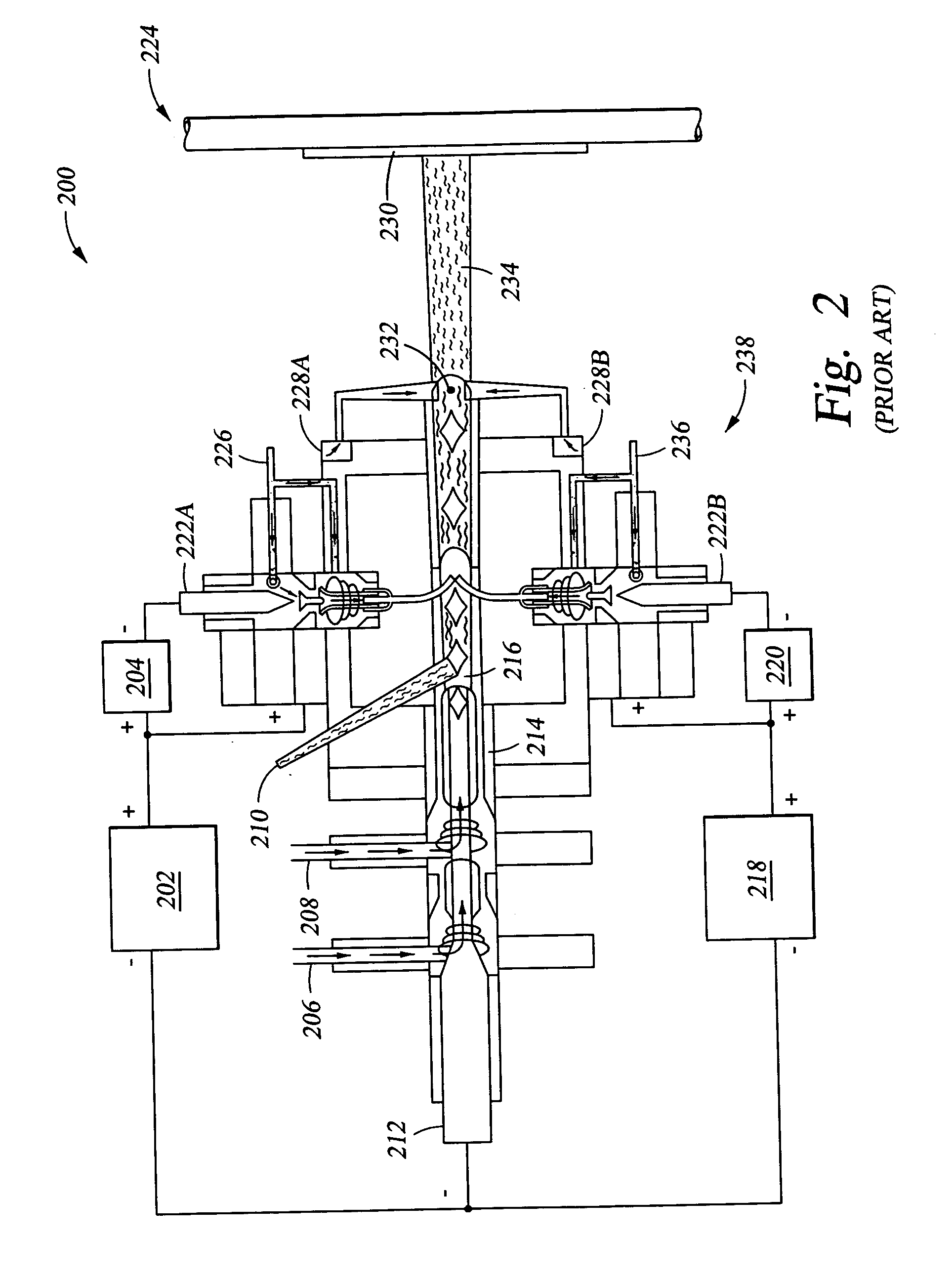

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

Erosion-resistant components for plasma process chambers

An erosion-resistant article for use as a component in plasma process chamber. The erosion-resistant article comprises a support and an oxide coating comprising yttrium, which is disposed over the support. The support and the oxide coating preferably have material compositions that differ from one another in coefficient of thermal expansion by no more than 5x10<-6> / K. Preferred oxide coating compositions include yttria and yttrium aluminum garnet. Preferred supports include alumina supports and aluminum-silicon carbide supports.

Owner:APPLIED MATERIALS INC

Transparent polycrystalline yttrium aluminum garnet

A transparent polycrystalline yttrium aluminum garnet (YAG) ceramic is described wherein the ceramic is colorless and transparent in both as-sintered and post-sinter, air-fired states which makes it highly desirable for lamp applications. The transparent YAG ceramic is co-doped with an amount of MgO and an amount of ZrO2 wherein the weight ratio of MgO to ZrO2 is from about 1.5:1 to 3:1.

Owner:OSRAM SYLVANIA INC

Inorganic optical taggant and method of making

InactiveUS6899827B2Overcomes shortcomingDesired performanceCell electrodesMachines/enginesExplosive AgentsTitanium oxide

Owner:UT BATTELLE LLC

Thermal barrier coating system, components coated therewith and method for applying a thermal barrier coating system to components

A thermal barrier coating system on a base material includes a bond coat layer with a lower face in direct contact with the base material and an upper face, a first ceramic layer in direct contact with the upper face of the bond coating layer and a second ceramic layer disposed on an outermost surface of the coating system and configured to be exposed to hot gas. The first ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of yttria-stabilized zirconia with a yttria content in a range of 6-8 wt-%, YTaO4 doped zirconia, and titania doped zirconia. The second ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of YTaO4 doped zirconia, titania doped zirconia, scandia stabilized zirconia, ceria containing perovskite material, yttrium aluminium garnet material, Monazite material, and spinel material. A material of the second ceramic layer is different from a material of the first ceramic layer.

Owner:ANSALDO ENERGIA SWITZERLAND AG

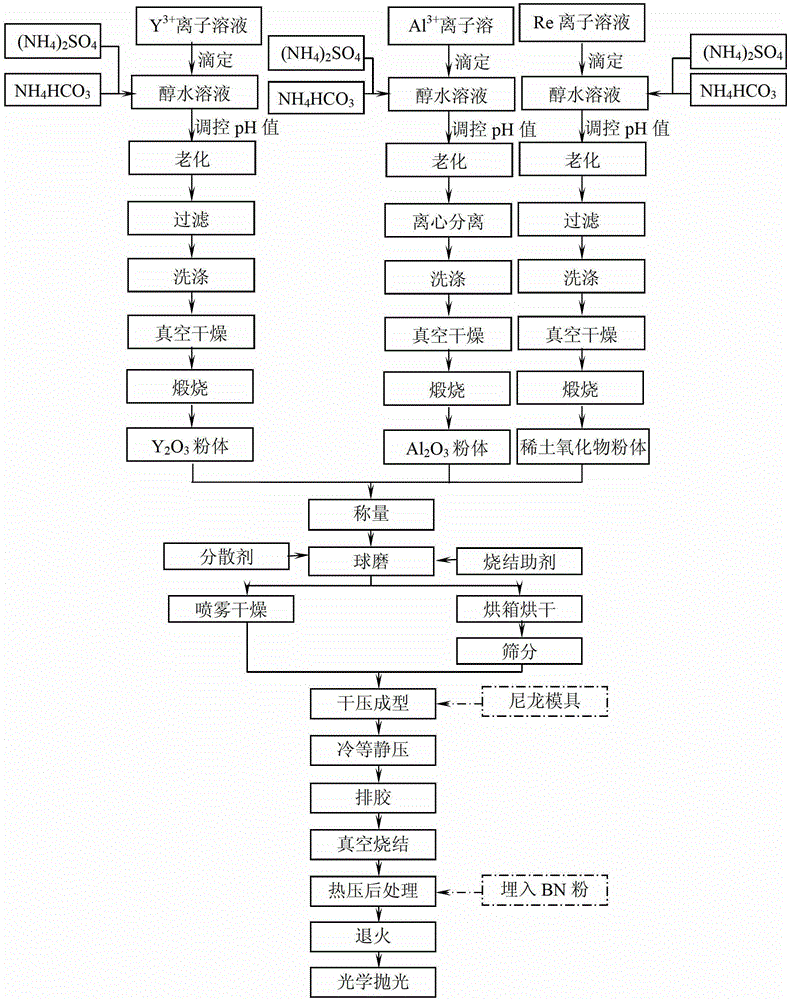

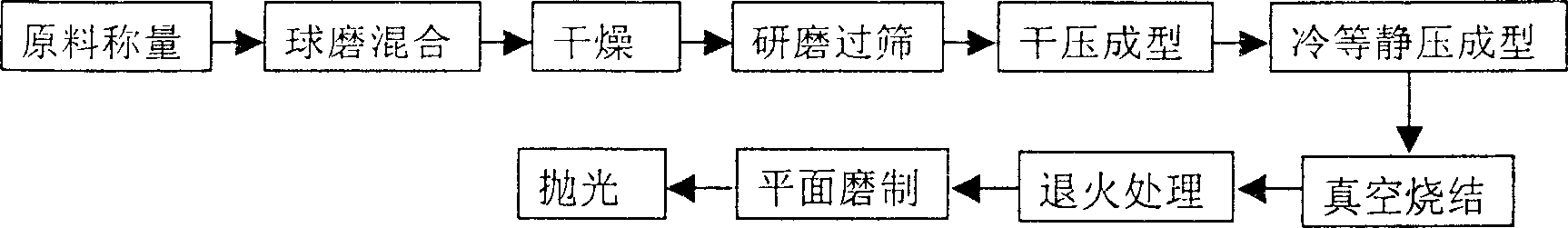

Method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic

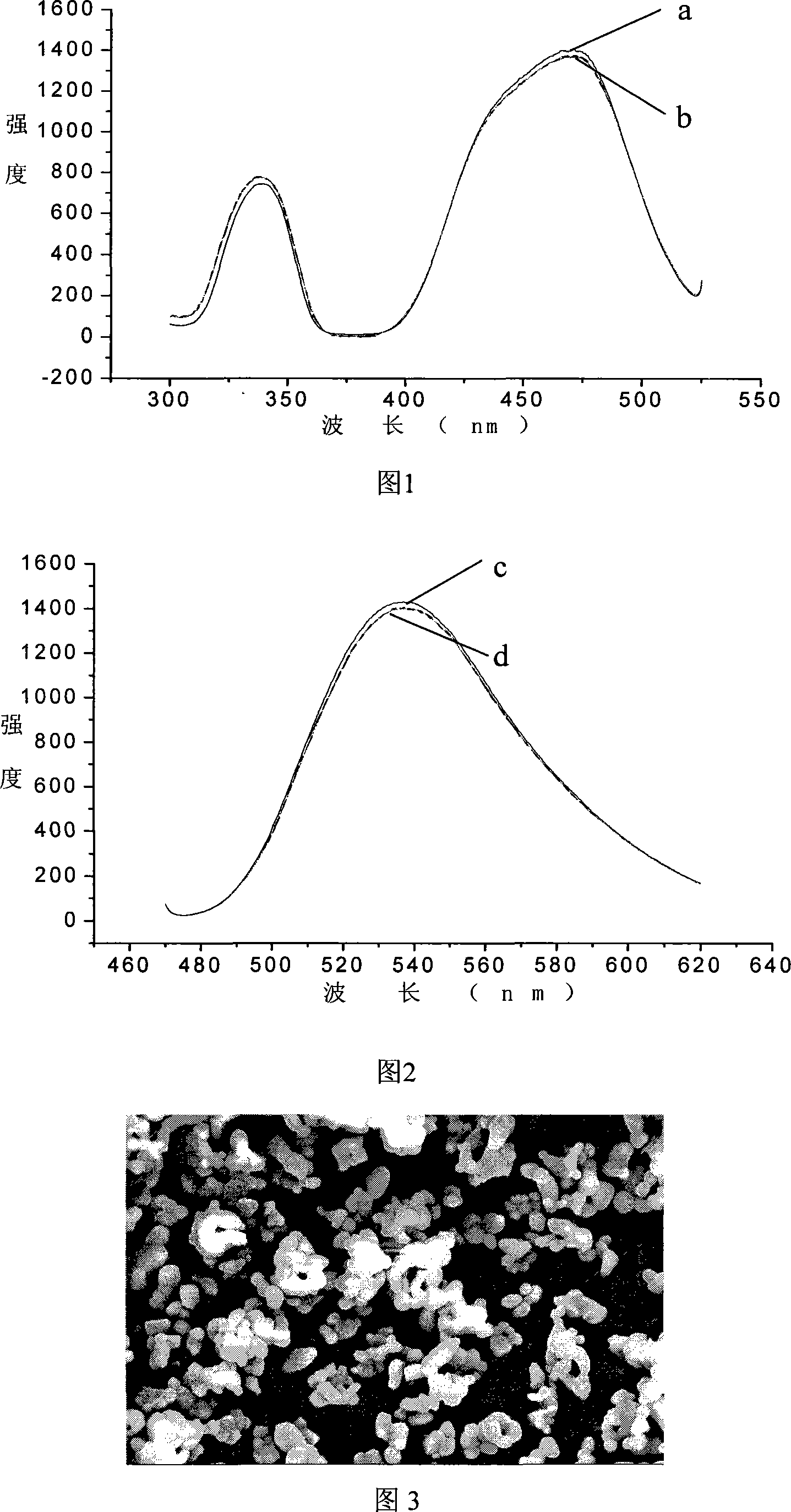

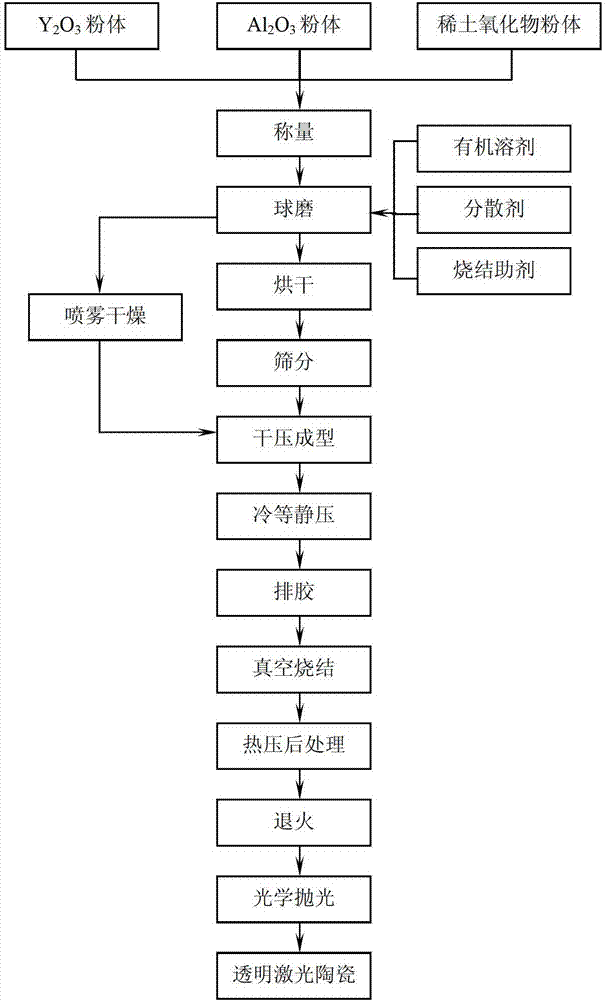

ActiveCN101985397AHigh linear transmittanceImprove mechanical propertiesRare-earth elementSpray Granulation

The invention relates to a method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic. In the invention, high-transparency polycrystalline ceramic is prepared by using commercial powdered Y2O3, Al2O3 and Re2O3, of which the purities are over 99.9 percent, as main raw materials and by spray granulation dry pressing molding process and vacuum reaction and sintering, wherein the Re may be one or several of trivalent rare earth elements such as Nd<3+>, Yb<3+>, Cr<3+>, Er<3+>, Ce<3+>, Sm<3+> and Eu<3+>; MgO or CaO or tetraethyl orthosilicate (TEOS) or SiO2 is used as a sintering assistant; a certain amount of bonding agent, plasticizer and dispersant is added; the oxides, sintering assistant and additive are mixed and added into a liquid medium, and the mixture is ball-milled and mixed for 0.5 to 100 hours; after the powder materials are mixed uniformly, the powder is made into spherical or approximately spherical grains; blanks formed by drying pressing isostatic forming are degreased; sintering the blanks in a vacuum sintering furnace; and annealing after sintering. The transmissivity at a laser wavelength of the rare earth-doped yttrium aluminum garnet transparent ceramic prepared by the method is more than or equal to 77 percent.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

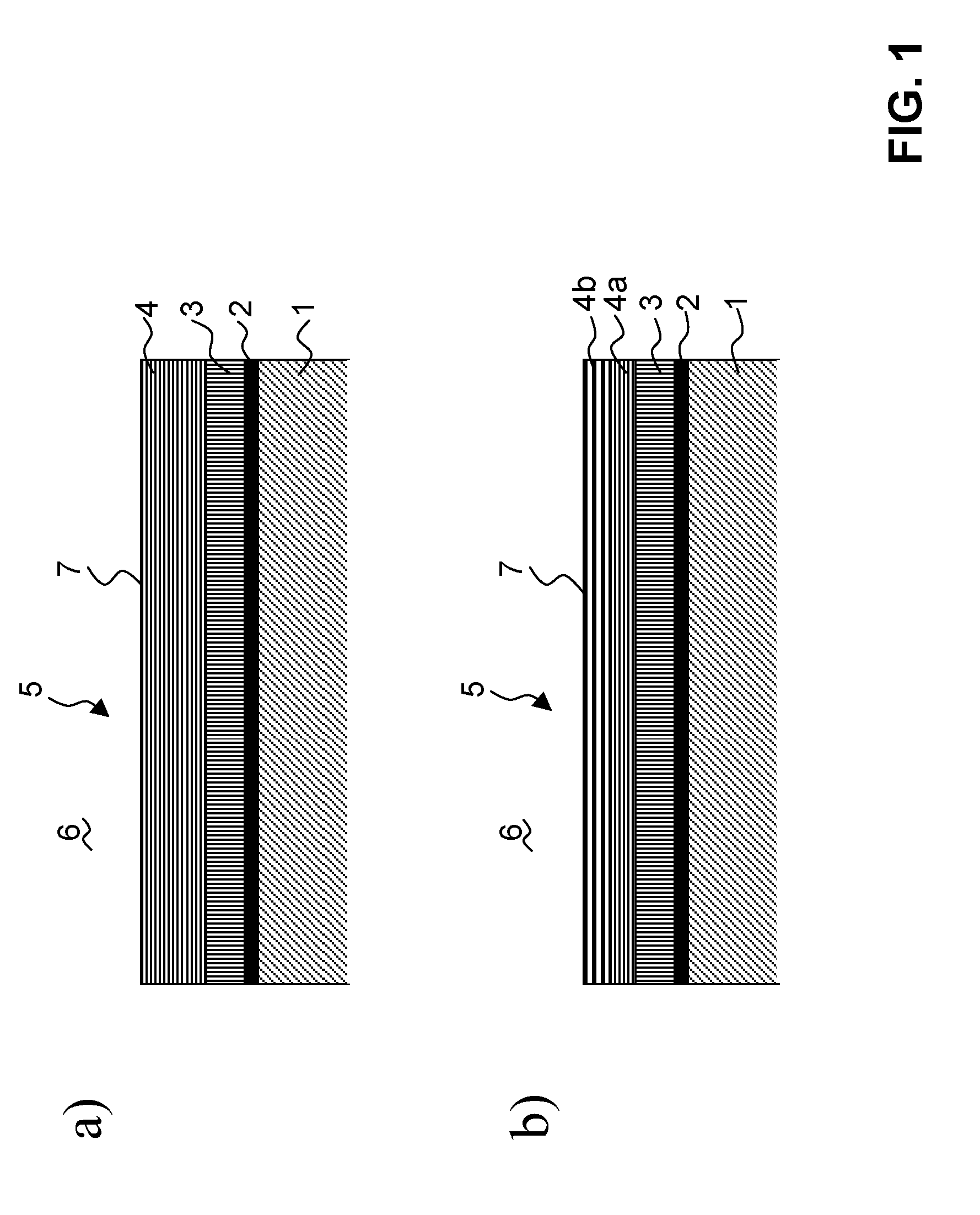

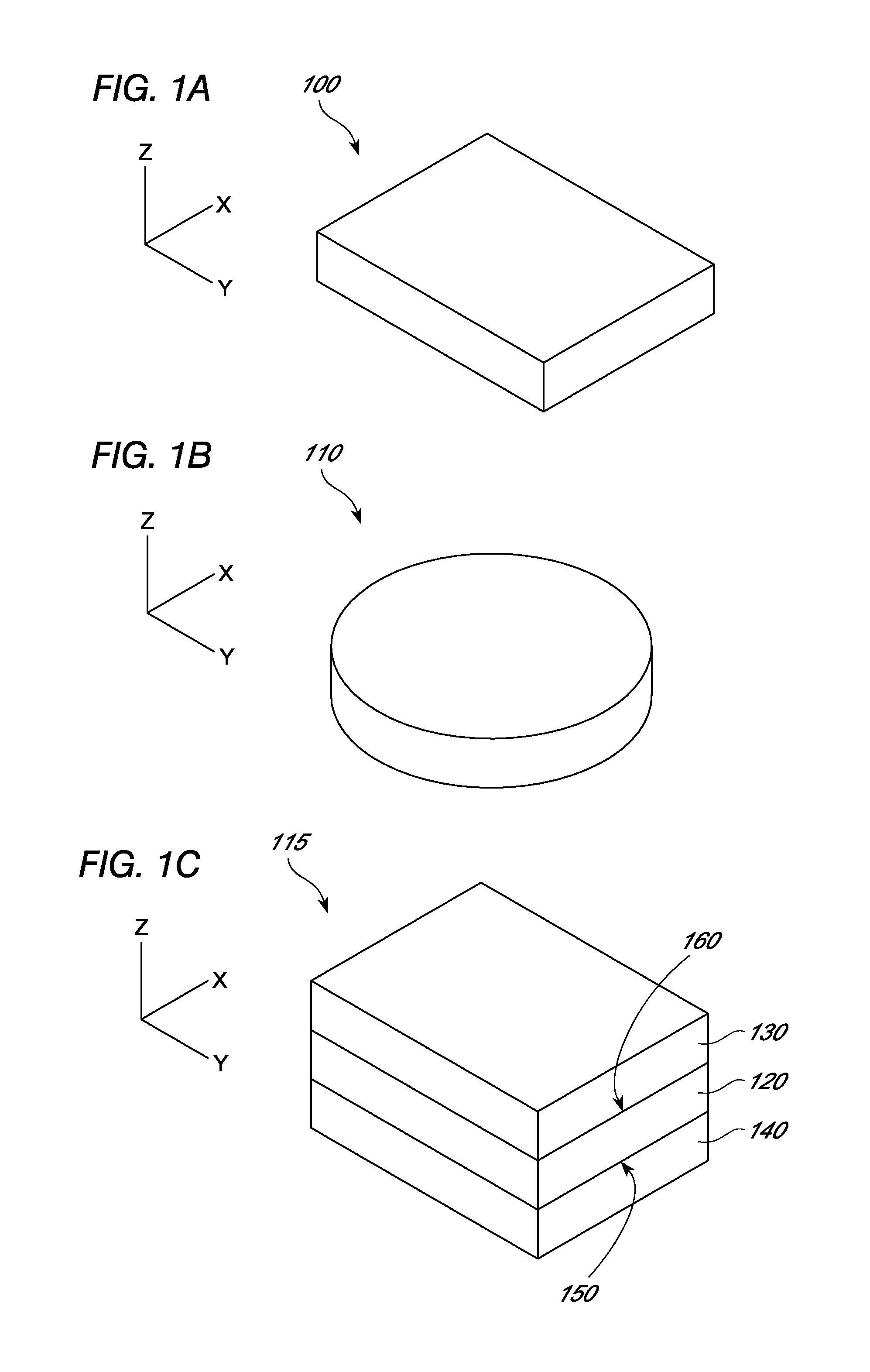

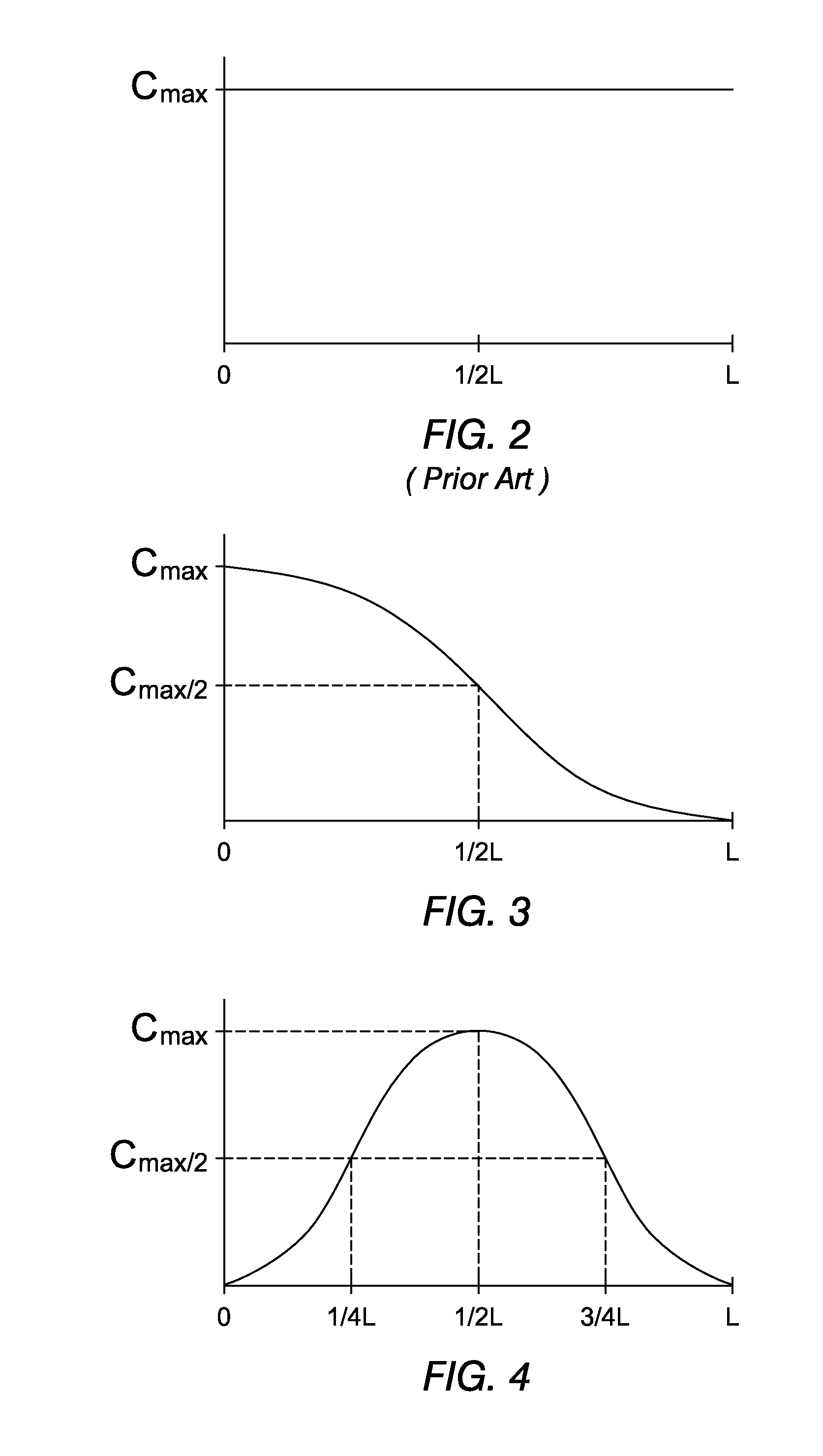

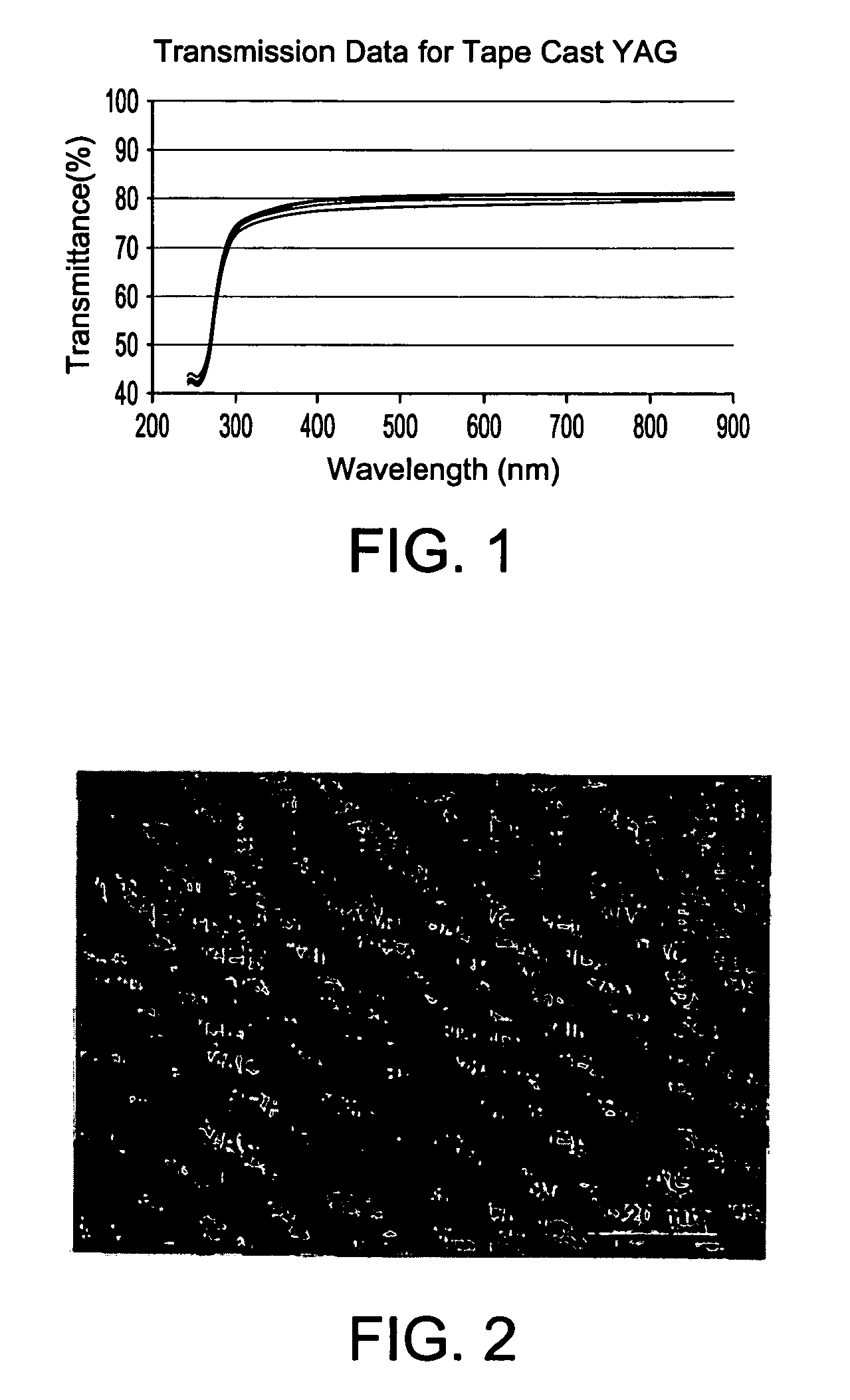

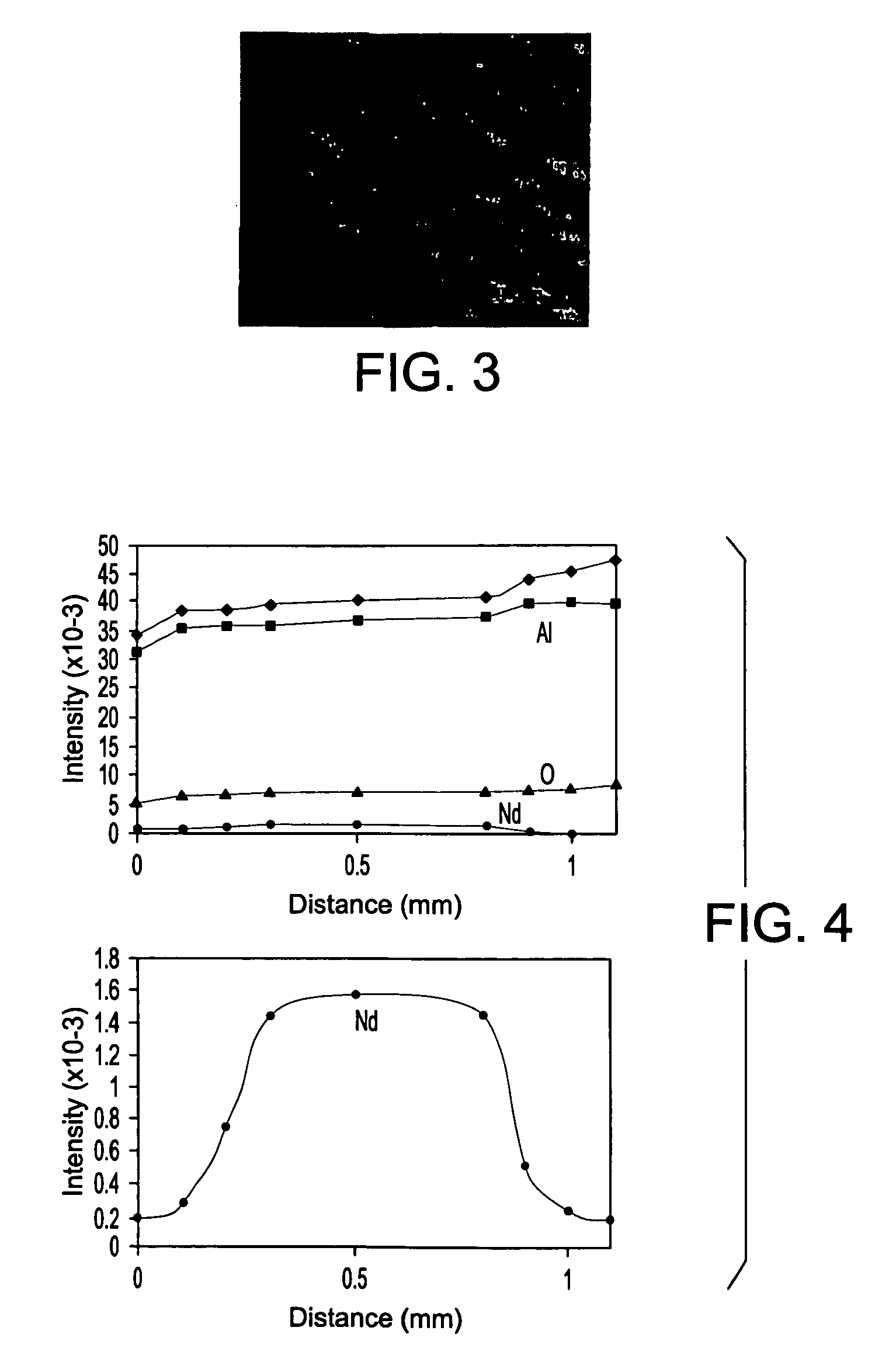

Emissive ceramic materials having a dopant concentration gradient and methods of making and using the same

Disclosed herein are emissive ceramic materials having a dopant concentration gradient along a thickness of a yttrium aluminum garnet (YAG) region. The dopant concentration gradient may include a maximum dopant concentration, a half-maximum dopant concentration, and a slope at or near the half-maximum dopant concentration. The emissive ceramics may, in some embodiments, exhibit high internal quantum efficiencies (IQE). The emissive ceramics may, in some embodiments, include porous regions. Also disclosed herein are methods of make the emissive ceramic by sintering an assembly having doped and non-doped layers.

Owner:SCHOTT AG

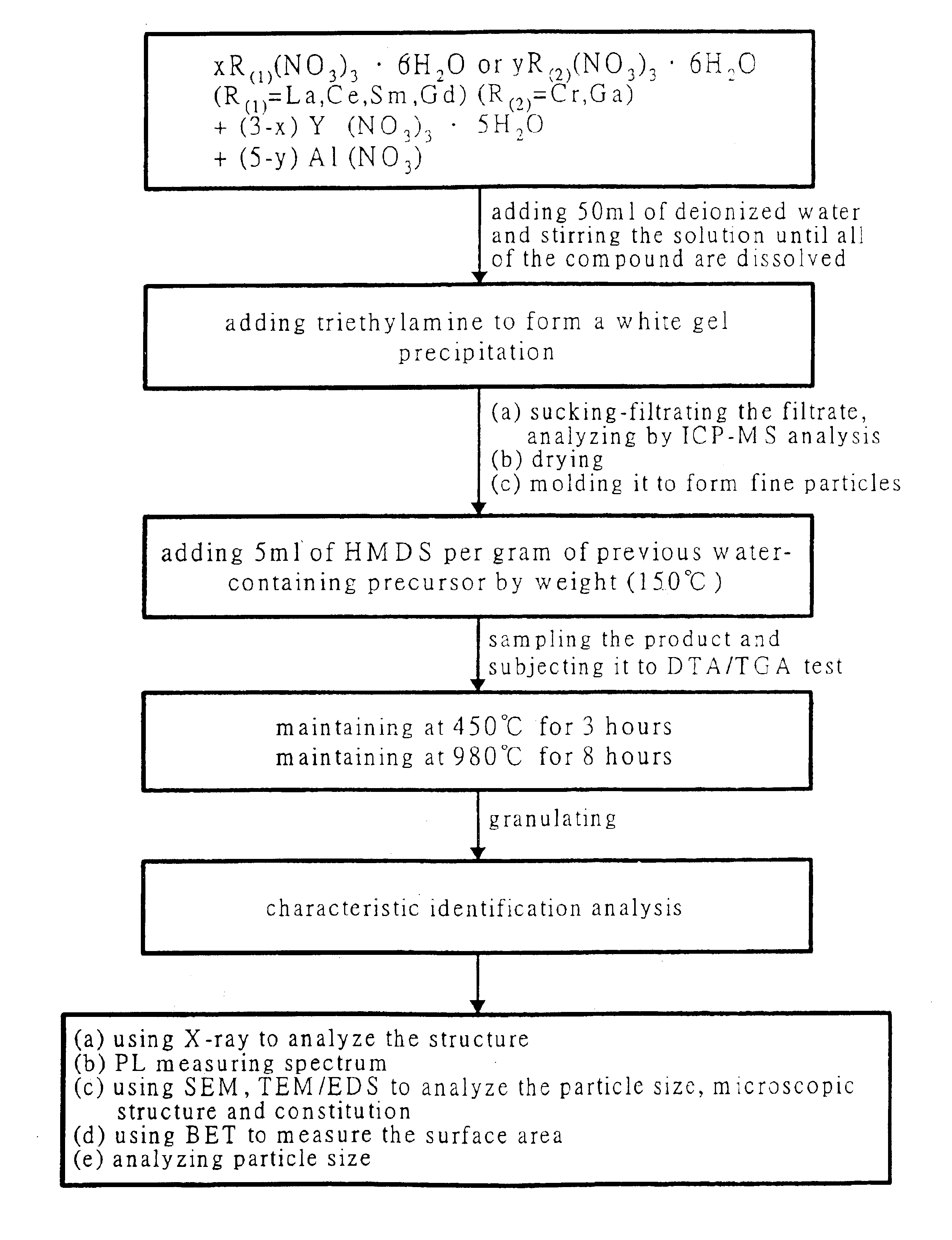

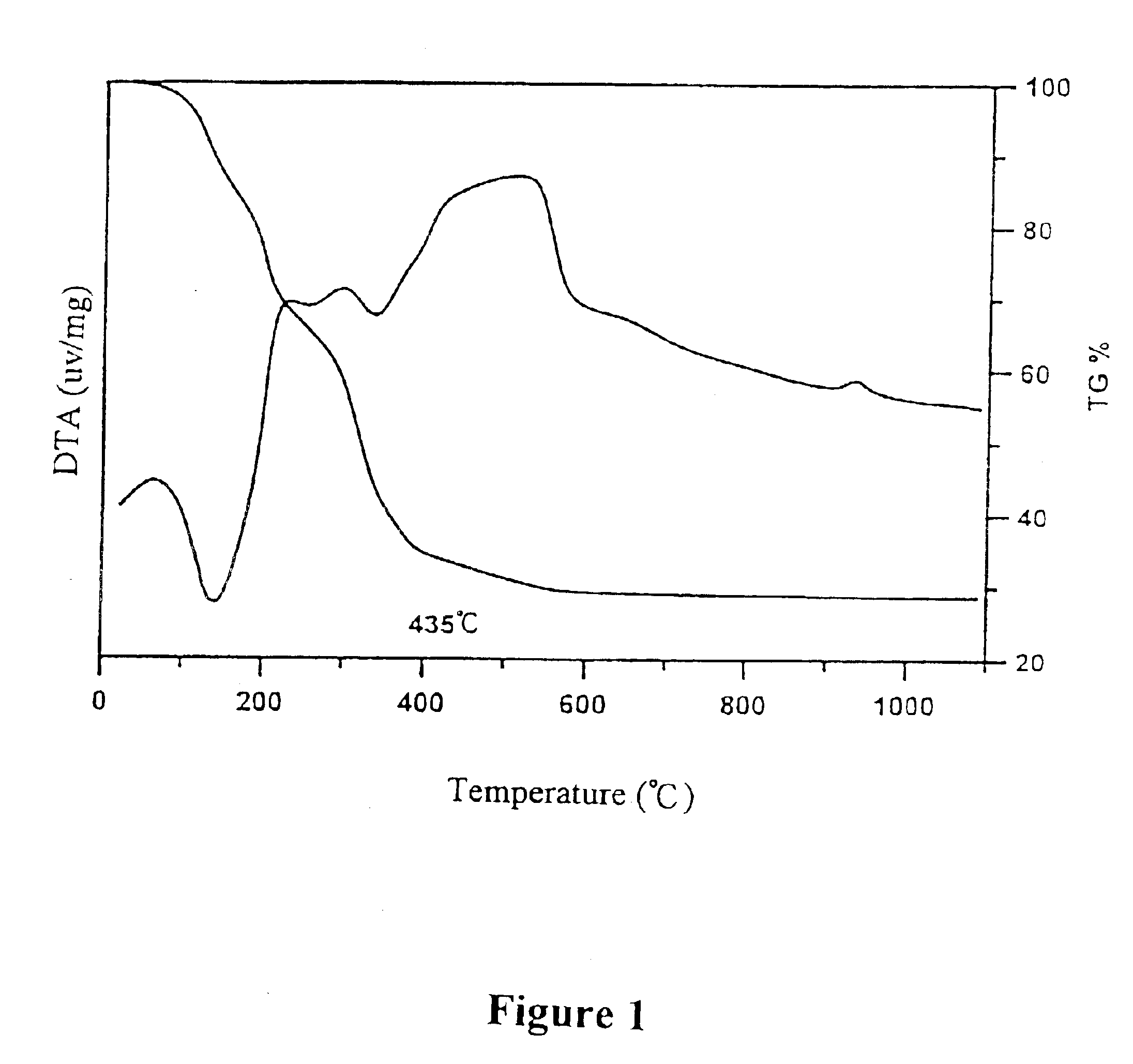

Process for producing nanoscale yttrium aluminum garnet (YAG) fluorescent powders

The present invention pertains to a process for synthesizing nano-scale yttrium aluminum garnet (YAG) fluorescent powders having formula (I):(Y3−xR1x)(Al5−yR2y)O12 (I)wherein R1 and R2 are independently selected from the elements consisting of rare earth metals and transition metals, and each of x and y is independently a value between 0 and 1.5, where the process comprises the steps:(a) forming an aqueous solution comprising rare earth metal ions, transition metal ions, yttrium ion and aluminum ion;(b) adding a precipitating agent to the aqueous solution of step (a) in an amount sufficient to allow the rare earth metal ions, transition metal ions, yttrium ion and aluminum ion comprised in the aqueous solution to substantially complex with the depositing agent;(c) drying the gel of step (b) to obtain a dried gel;(d) adding a dehydroxying compound to the dried gel of step (c) and subjecting it to a further drying step; and(e) sintering the product of step (d) at a temperature between 700 and 1400° C. to obtain the nano-scale yttrium aluminum garnet fluorescent powders of formula (I).

Owner:NAT CHENG KUNG UNIV

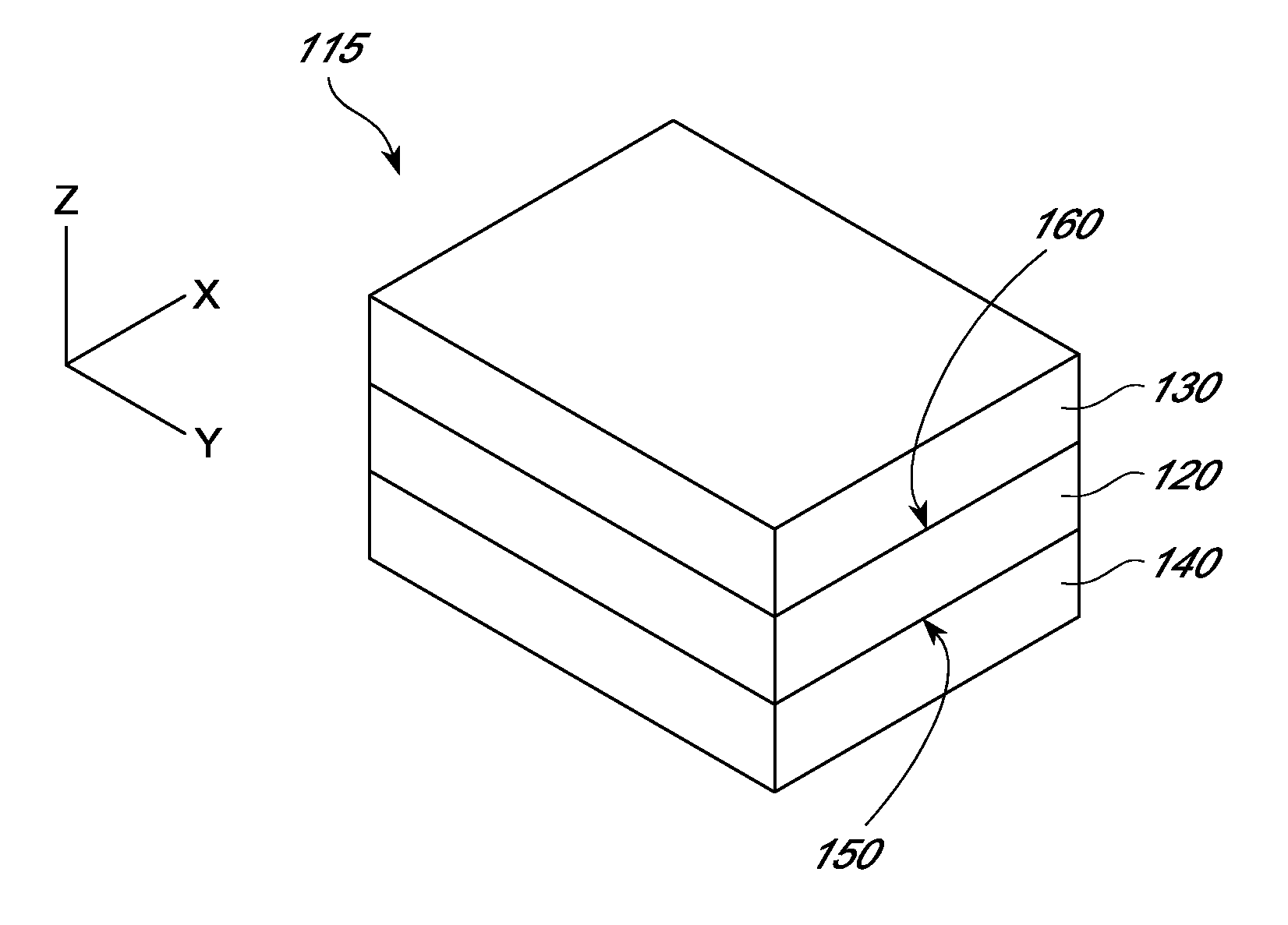

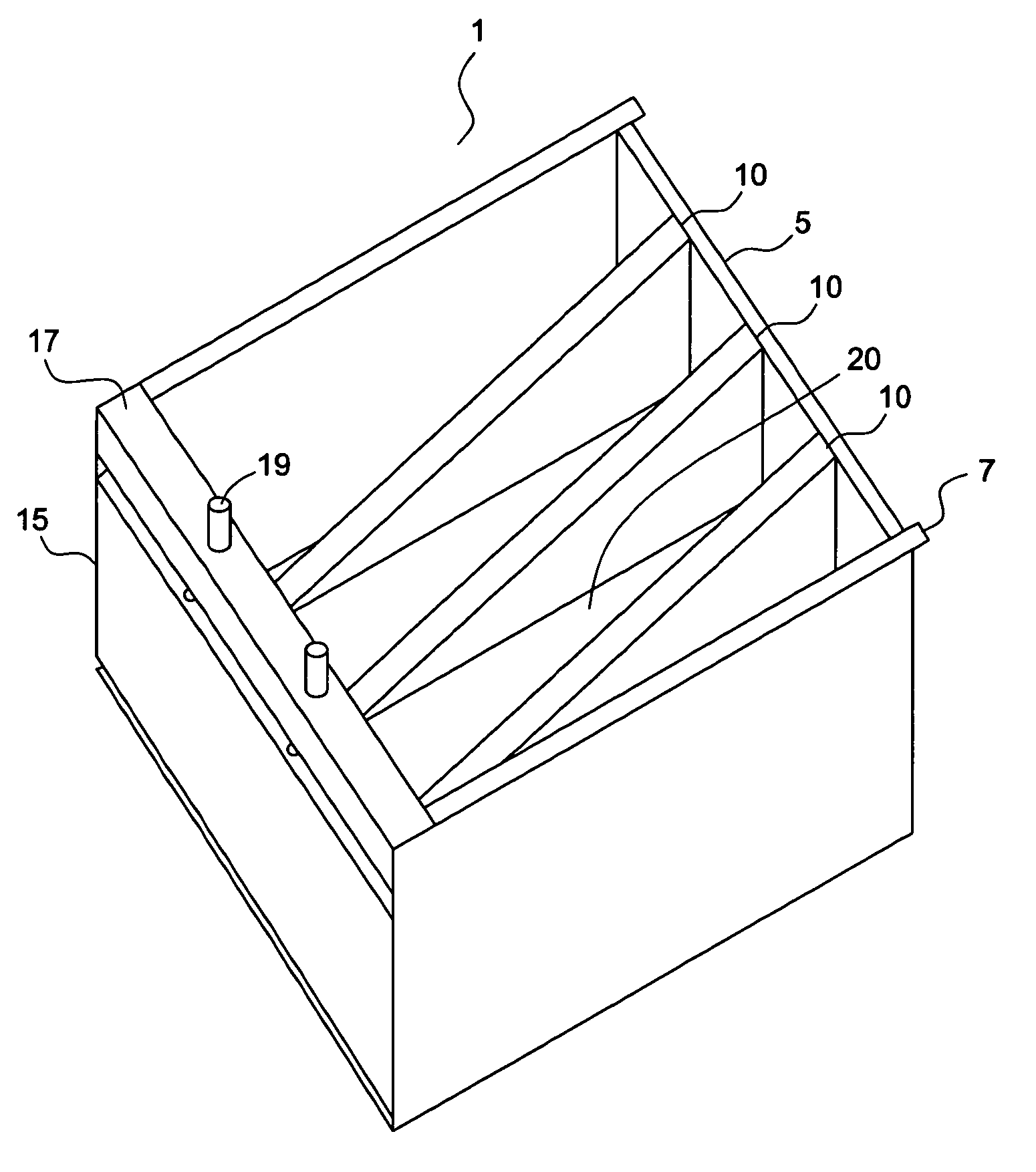

Method for manufacture of transparent ceramics

The disclosed invention relates to a method of manufacture of transparent ceramics such as yttrium aluminum garnet by tape casting. The method entails forming a mixture of ceramic oxide, dispersant and organic solvent, milling the mixture to produce a first slurry, mixing the first slurry with an organic binder and a plasticizer to form a treated slurry, milling the treated slurry to produce milled slurry, tape casting the milled slurry to produce cast tape, drying the cast tape to produce dried tape, stacking portions of dried tape to form an assembly, compressing the assembly to produce a preform, heating the preform to produce a green preform, and sintering the green preform to produce transparent yttrium aluminum garnet. The method may be used to produce a unitary ceramic product having differing transparent sections as well as transparent ceramic product having a dopant gradient across a portion of the thickness of the product.

Owner:PENN STATE RES FOUND

Method for preparing cerium-activated yttrium aluminium garnet fluorescent powder

The invention relates to a preparation method of yttrium aluminum garnet phosphor activated by cerium and a phosphor. The invention provides a generalized preparation method of yttrium aluminum garnet phosphor activated by cerium. A chemical formula is Y3-x-y-zRyAl5-mGamO12: Cex, R'z. The preparation method comprises the steps of: preparation of metal ions solutions, preparation of precipitant solutions, preparation of metal ions precipitants, addition of flux and solid phase reaction, sintering, grinding powders sintered under high temperature, pickling, alkali washing, water washing and drying, then the target product YAG:Ce phosphor, which has high luminous intensity, low agglomeration degree without ball milling, proper powder size and narrow particle size distribution, is obtained; besides, the phosphor has low agglomeration degree after being treaded under high temperature, and the phosphor can be packed and sealed without ball milling and can maximize the excellent optical property.

Owner:XIAMEN UNIV

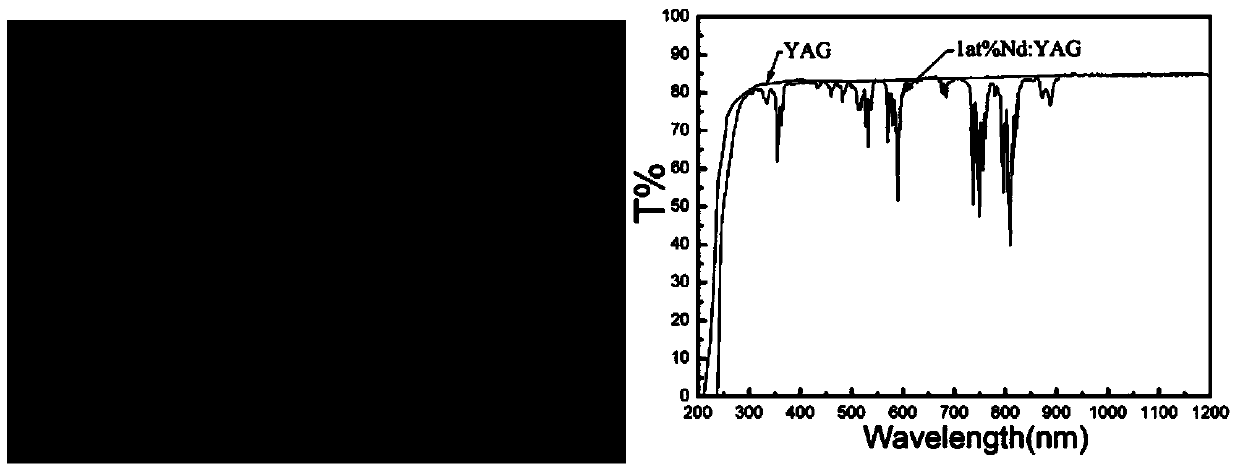

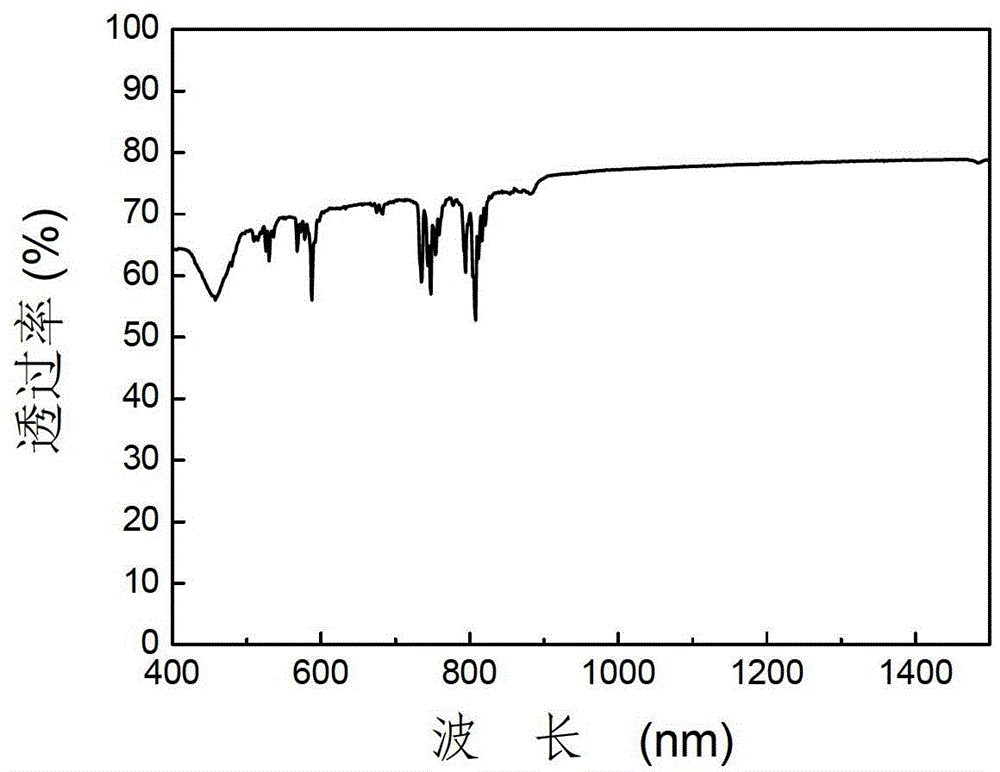

Method for preparing rare earth ion-doped yttrium aluminum garnet (Re: YAG) transparent laser ceramic by using hot-pressing post treatment

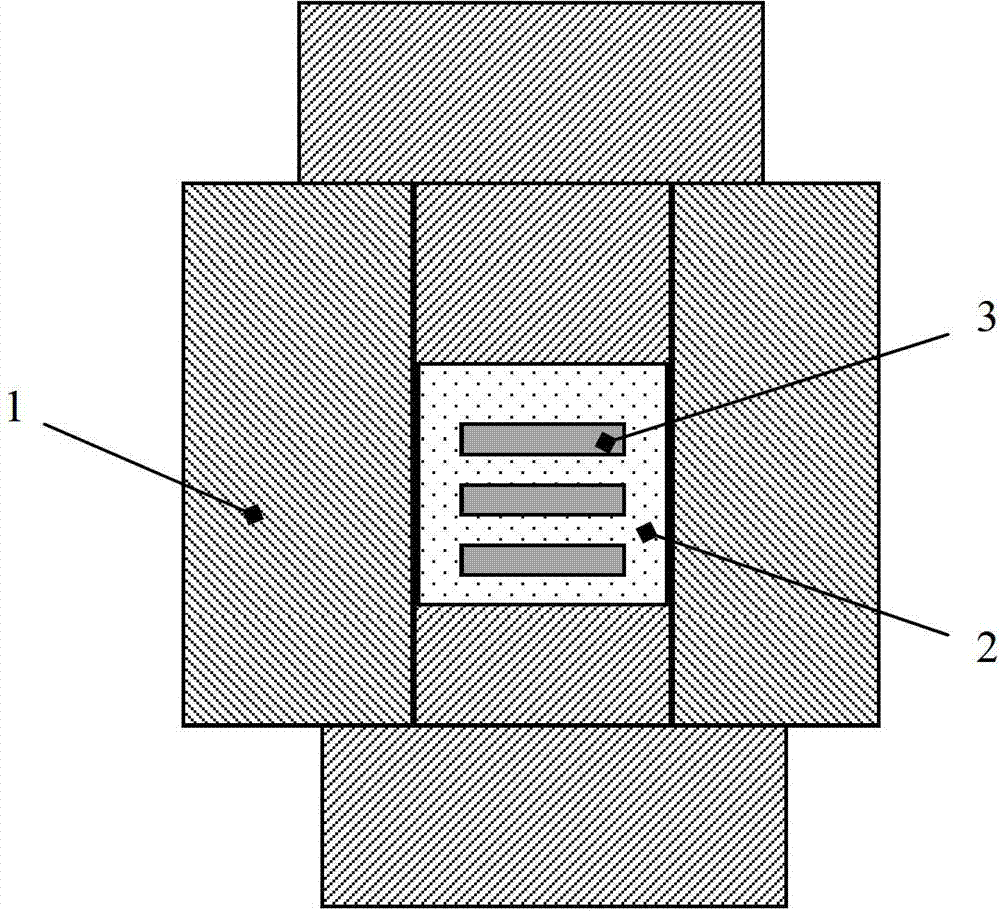

ActiveCN102924073AOvercoming low driving force for sinteringDegree of overcomingRare earth ionsControllability

The invention discloses a method for preparing rare earth ion-doped yttrium-aluminum garnet (Re: YAG) transparent laser ceramic by using hot-pressing post treatment. The method comprises the steps of using oxide powder as a raw material, mixing with a ball mill, drying, forming, performing cold isotactic processing to obtain a ceramic biscuits, then dumping, and carrying out vacuum sintering to obtain the Re: YAG ceramic; and performing powder-embedded hot pressing, annealing and optically polishing on the Re: YAG ceramic to obtain the final Re: YAG transparent laser ceramic. The method provided by the invention has the advantages of strong controllability and repeatability, and low cost, and the Re: YAG transparent ceramic prepared by the method provided by the invention has high transmittance.

Owner:北京雷生强式科技有限责任公司

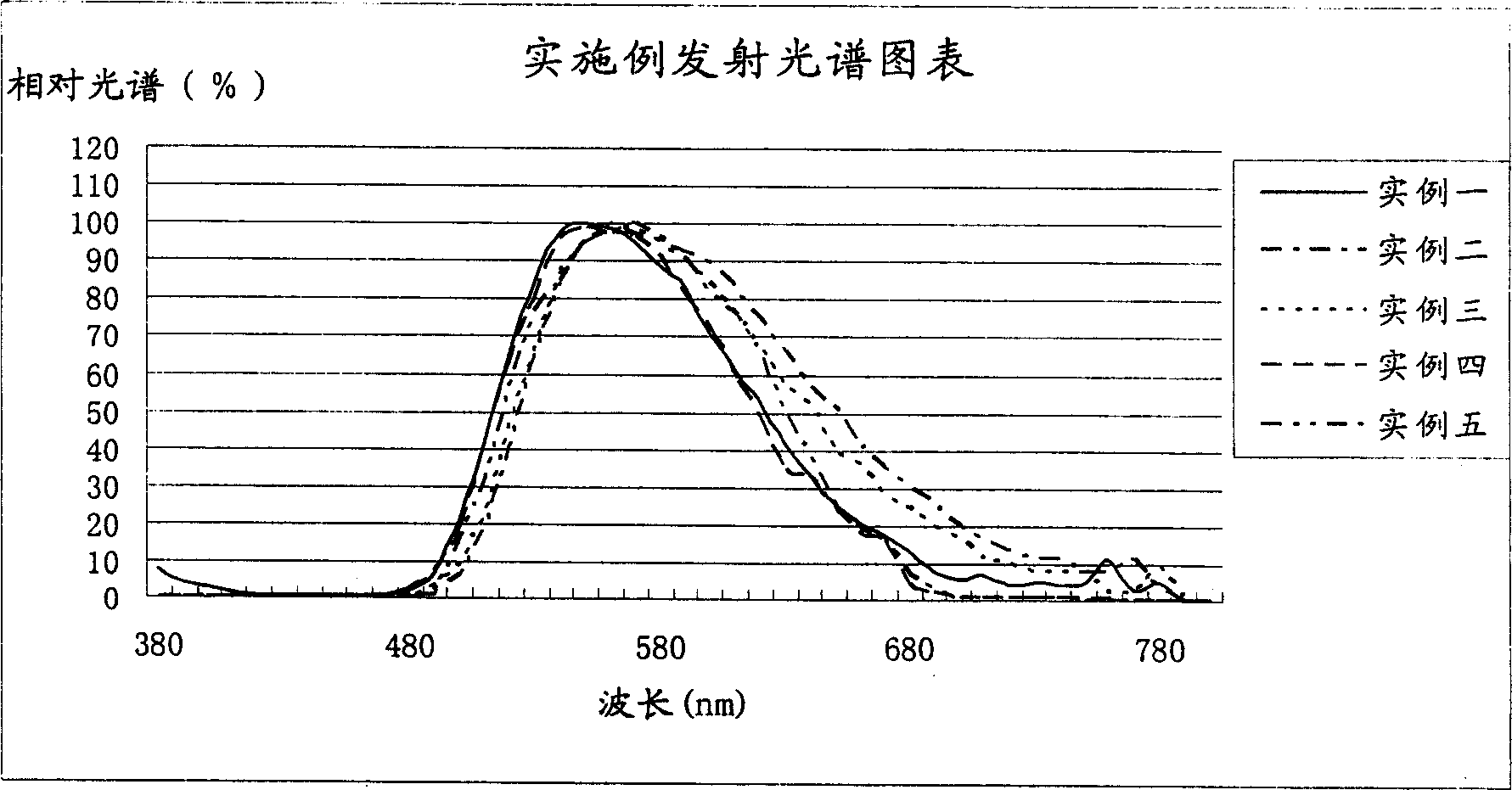

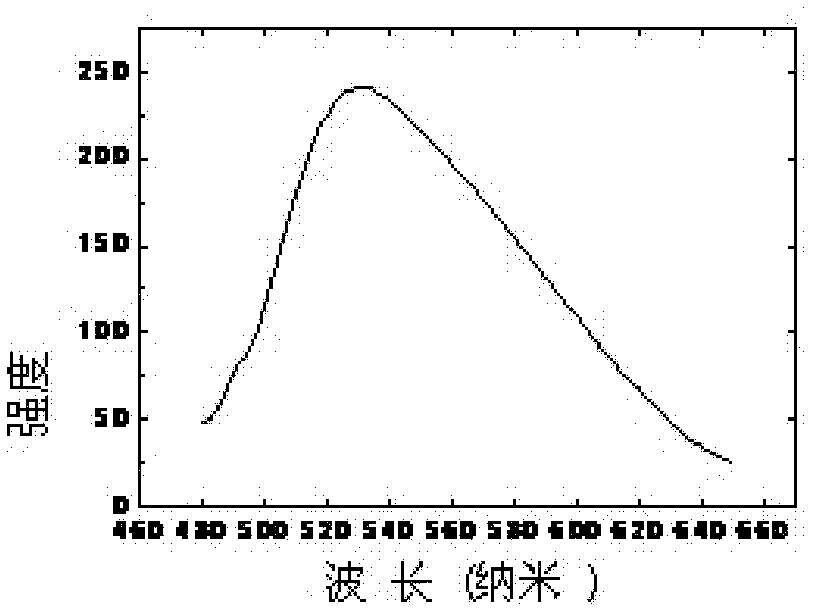

Synthesis of YAG luminescent material for white LED

InactiveCN1818016AImprove luminous brightnessLow attenuation characteristicsGas discharge lamp usageLuminescent compositionsLithium chlorideRare earth

Synthesis of yttrium aluminum garnet luminescent material for white light LED is carried out by proportioning by chemical component formula (Y1-x-yMyCex) 3Al5O12, weighing raw material, mixing with flux additive, putting into corundum crucible, firing in oxidation atmosphere furnace, crushing, mesh screening, acid washing by dilute nitric acid solution to indifference, extraction filtering, drying powders, firing the powder at reduction atmosphere, and screen grading to obtain the final product. It uses two kinds or above of boric acid, barium fluoride, strontium fluoride, lithium chloride or lithium fluoride as composite flux and mixes with other rare earth or metal oxide. It has excellent single crystal particular growth, powder fluidity, better brightness and low decrement.

Owner:常熟市江南荧光材料有限公司

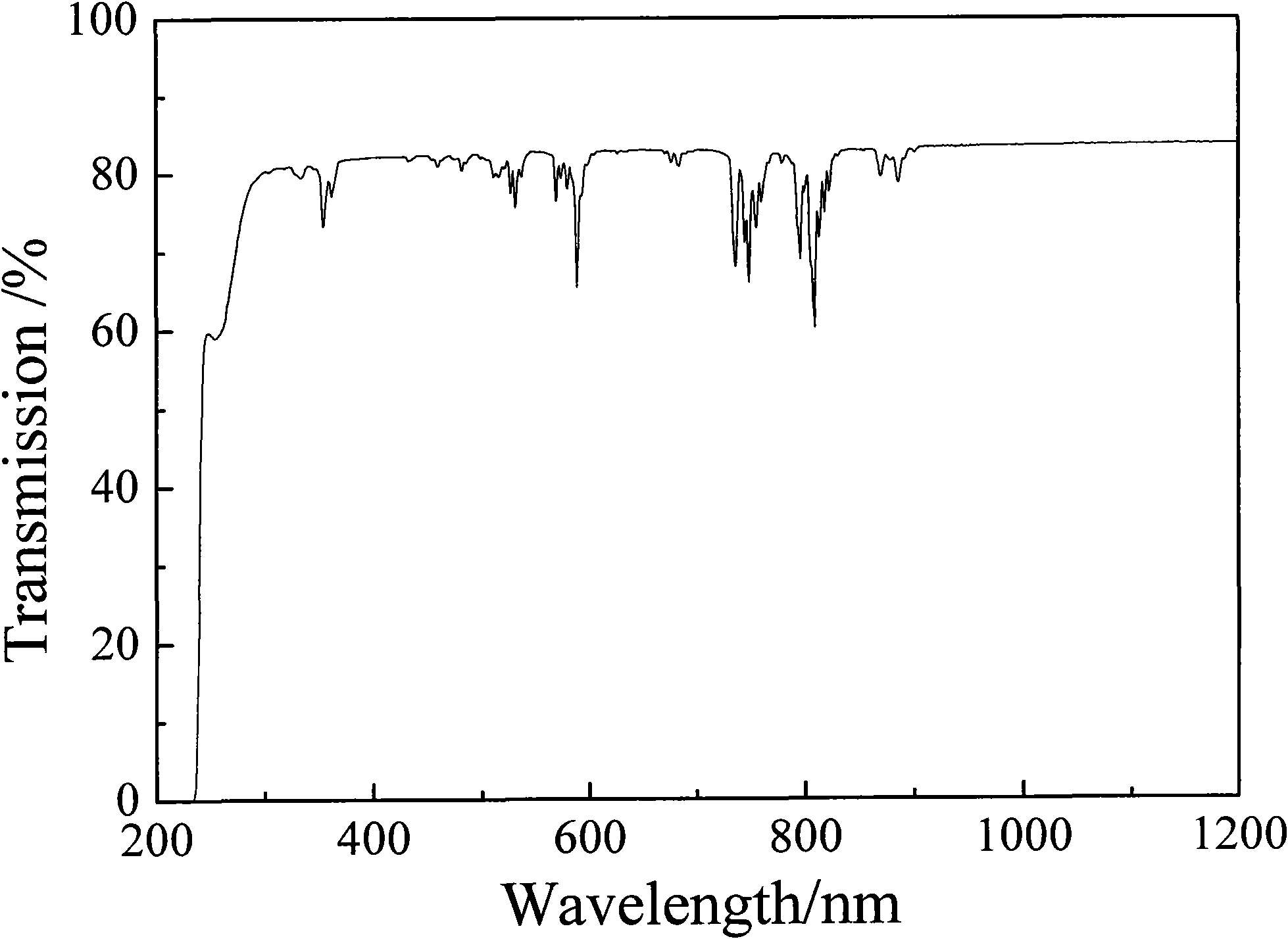

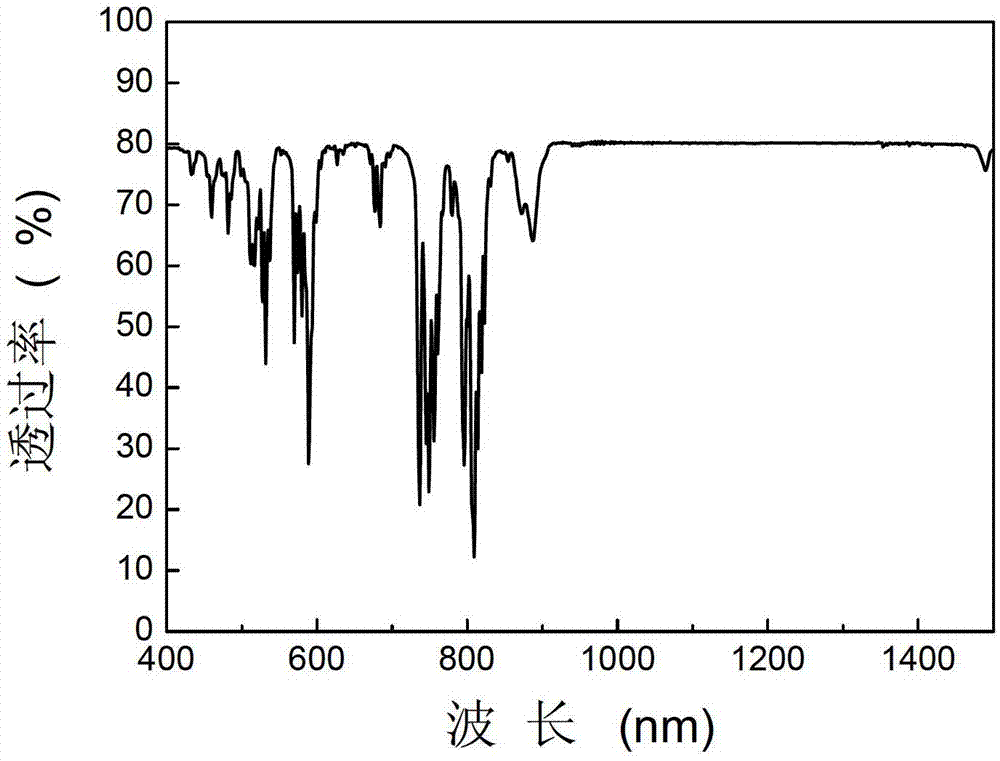

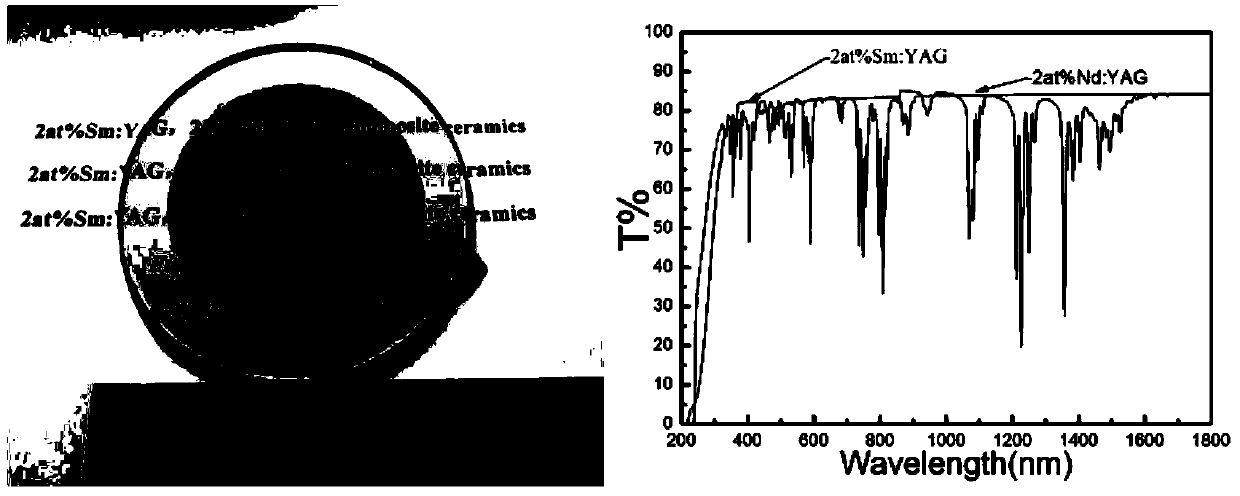

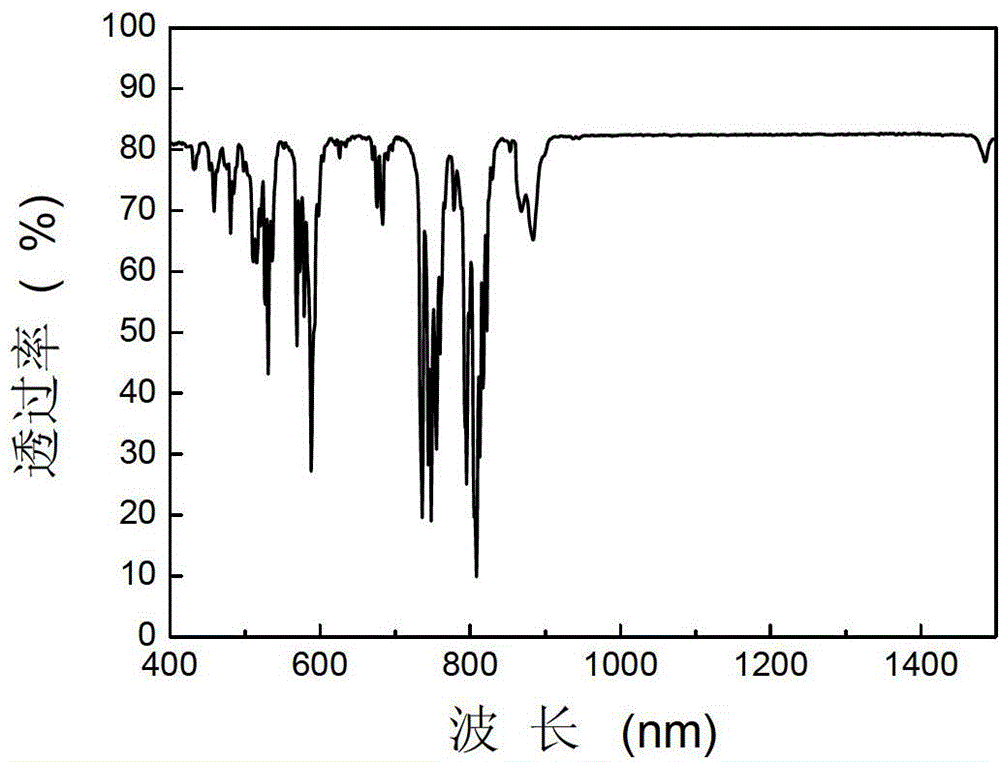

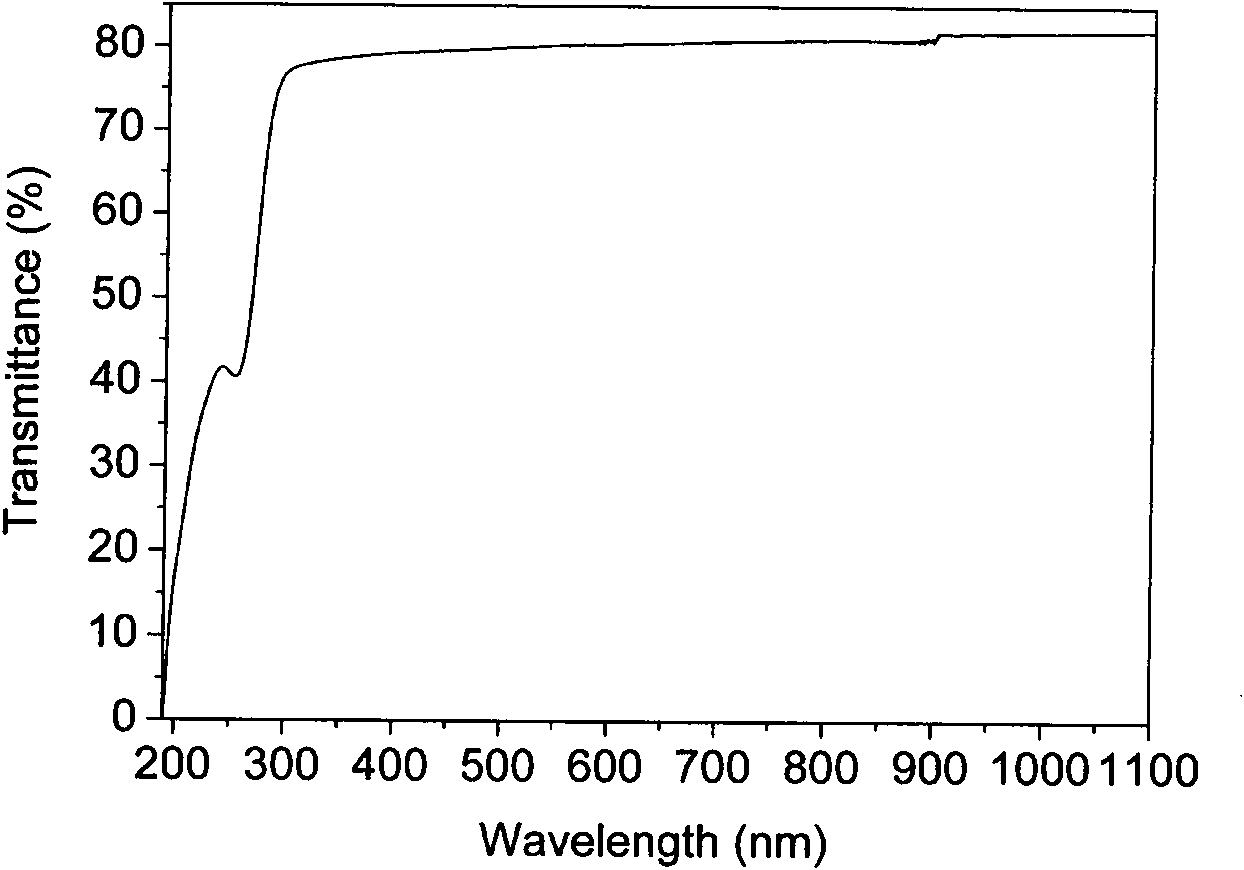

Method for preparing yttrium aluminium garnet transparent ceramic with composite structure

The invention provides a method for preparing yttrium aluminium garnet (YAG) transparent ceramic with a composite structure. The method comprises the following steps: by using Re:YAG powder and high-purity Y2O3, Al2O3 and Re2O3 as raw materials, adding a certain amount of dispersing agent, binder, plasticizer and defoaming agent to mix slurry in a ball-milling manner; preparing different doped and bound composite structures of ceramic biscuits, such as Sm:YAG / Nd:YAG, Cr:YAG / Yb:YAG and YAG / Nd:YAG, different multi-segment doped Re:YAG ceramic biscuits, such as YAG / Cr:YAG / Nd:YAG / YAG, a core-shell structured composite ceramic biscuit, and a layered composite structure of transparent ceramic biscuit in a vacuum pressure slip casting manner. Different composite structures of Re:YAG transparent ceramics are obtained by the following processing steps: biscuit degreasing, vacuum sintering, hot isostatic pressing sintering, annealing and the like. The linear transmittance of the transparent ceramic after being polished at double sides in a visible near infrared region can be up to over 80%.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

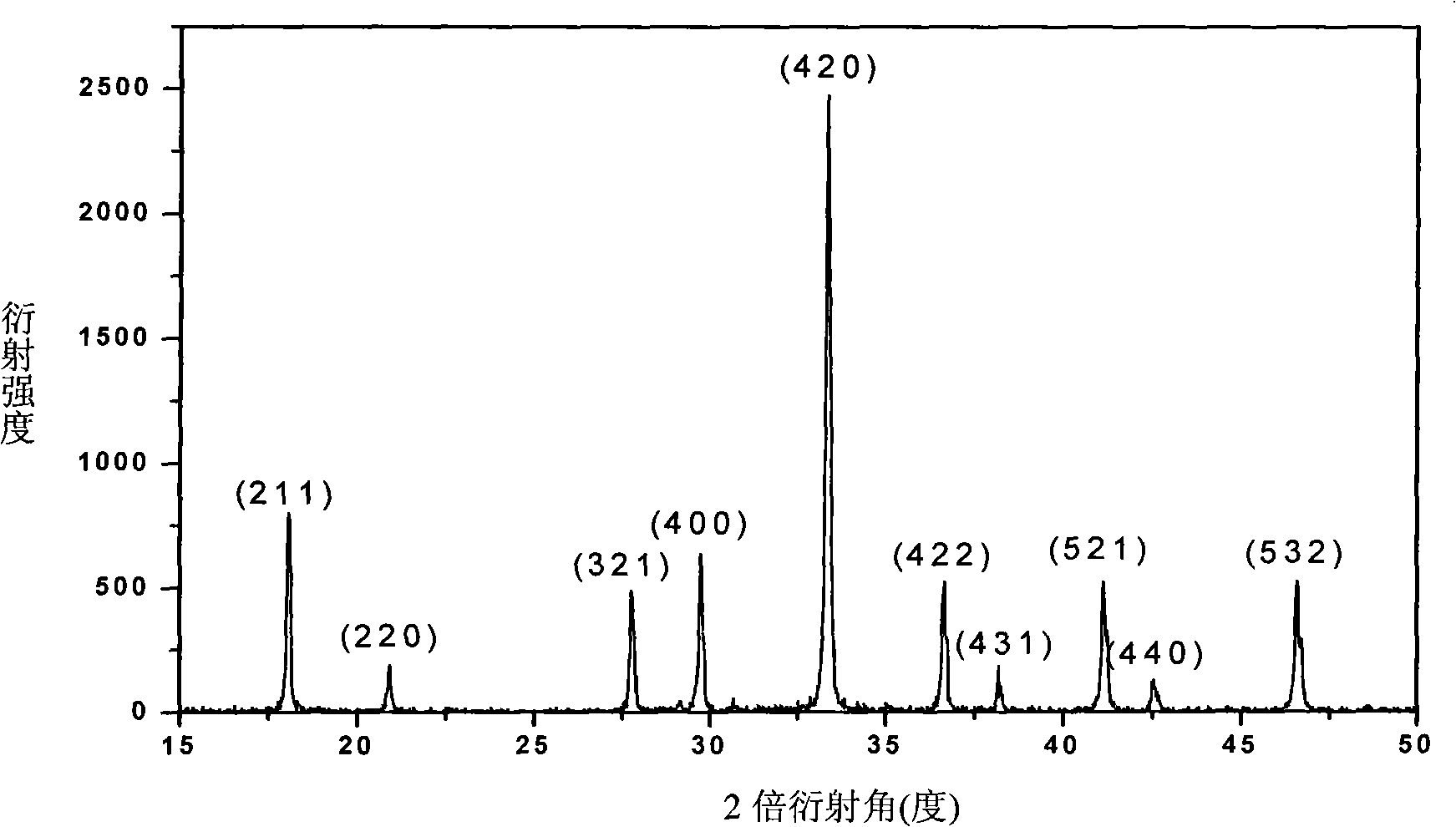

Preparation method of yttrium aluminium garnet doped transparent laser ceramics

The invention discloses a preparation method of yttrium aluminium garnet doped transparent laser ceramics. The method includes using an alcohol-aqueous system stepping chemical co-precipitation method to firstly prepare high-dispersity and high-activity nanometer Y2O3 oxide powders, Al2O3 oxide powders and rare earth (Re) oxide powders, weighing raw materials of the powders according to a stoichiometric ratio of Y<3-x>RexAl5O12 when the powders are prepared, placing the powders, sintering aids, dispersing agents and absolute ethyl alcohol into a ball-milling tank for ball milling, drying ball-milling mixing slurries into powders, forming the powders into green bodies with certain shapes by dry pressing, and then subjecting the green bodies to isostatic cool pressing to obtain ceramic biscuits. The ceramic biscuits are subjected to binder removing, vacuum sintering, powder-burying hot-pressing post-processing, annealing and optical polishing to obtain Re:YAG transparent ceramics. The preparation method has the advantages of being controllable, high in repeatability, low in cost and high in transmittance.

Owner:北京雷生强式科技有限责任公司

Method for preparing rare earth-doped yag nano-powder by partial liquid phase precipitation method

ActiveCN101302019AEvenly dopedEvenly distributedRare earth metal compoundsAluminium oxides/hydroxidesRare-earth elementMetallurgy

The invention relates to a method for preparing a rare earth doped yttrium aluminum garnet nanometer powder body by a partial liquid phase precipitation method. Y(NO3)3 and Al2O3 are used to synthesize the yttrium aluminum garnet nanometer powder body; and Nd, Yb, Cr and other rare earth elements are used for ion doping. Ammonium oxalate, NH4HCO3 or urea is adopted as a precipitant. Sediment is aged, fully washed, dried and calcined for 15 to 120 minutes at a temperature of between 1000 and 1600 DEG C under the aerobic condition, thereby acquiring the rare earth doped YAG powder body with a grain diameter between 80 to 200 nm. The method can realize the uniform doping of the rare earth elements, also avoid forming a colloidal substance which is unfavorable for washing, and prepare the rare earth doped YAG nanometer powder body material in high efficiency.

Owner:SHANDONG UNIV

Sintered polycrystalline yttrium aluminum garnet and use thereof in optical devices

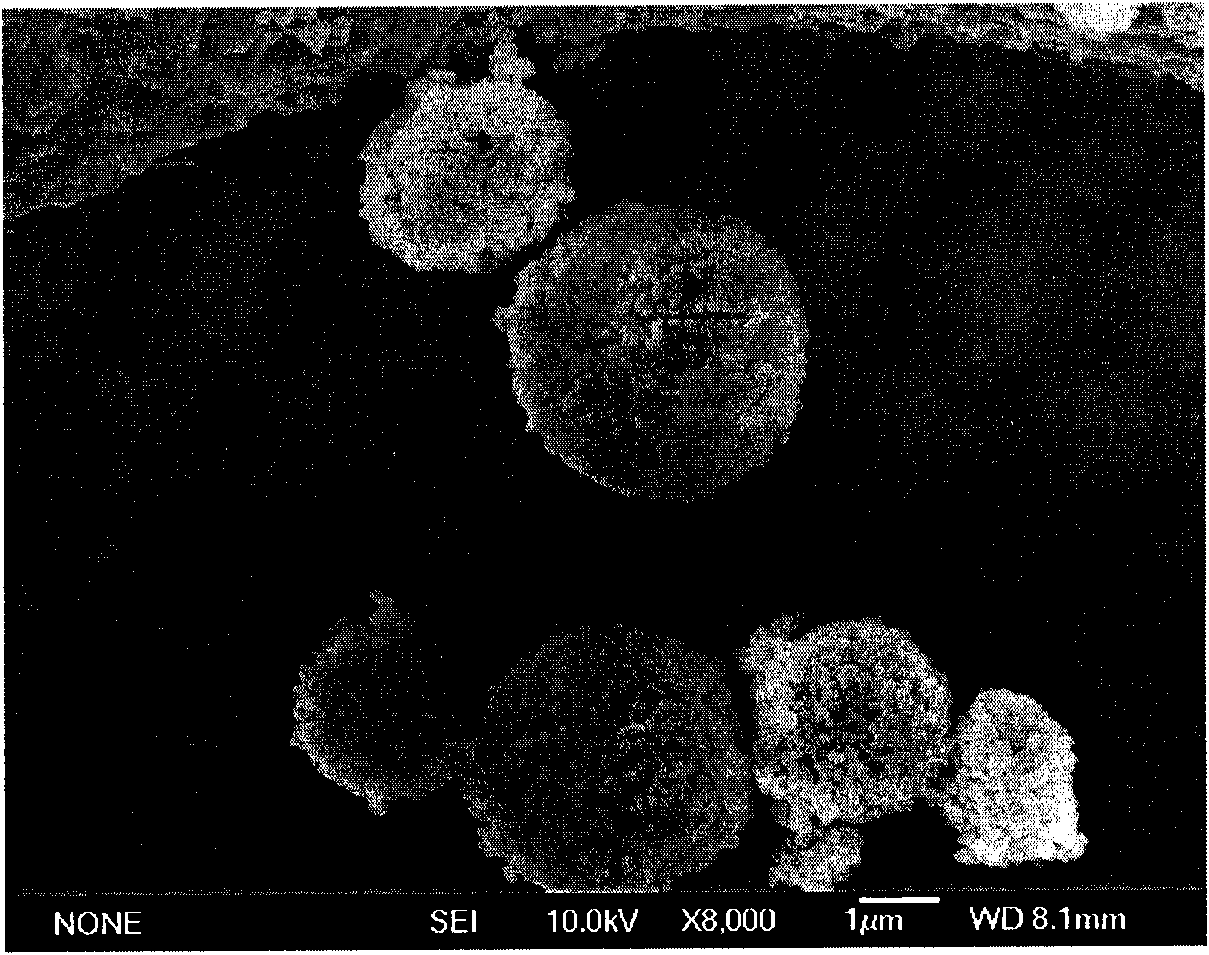

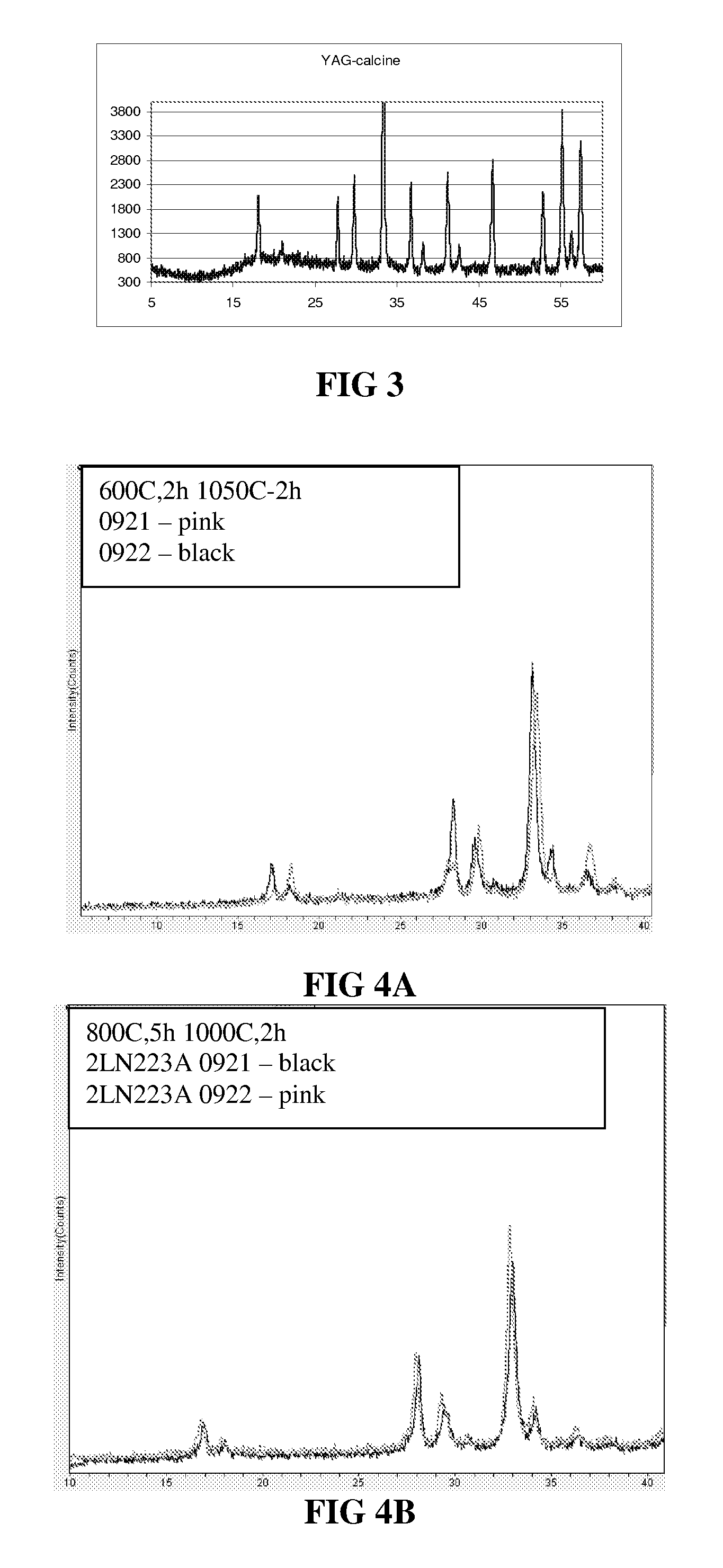

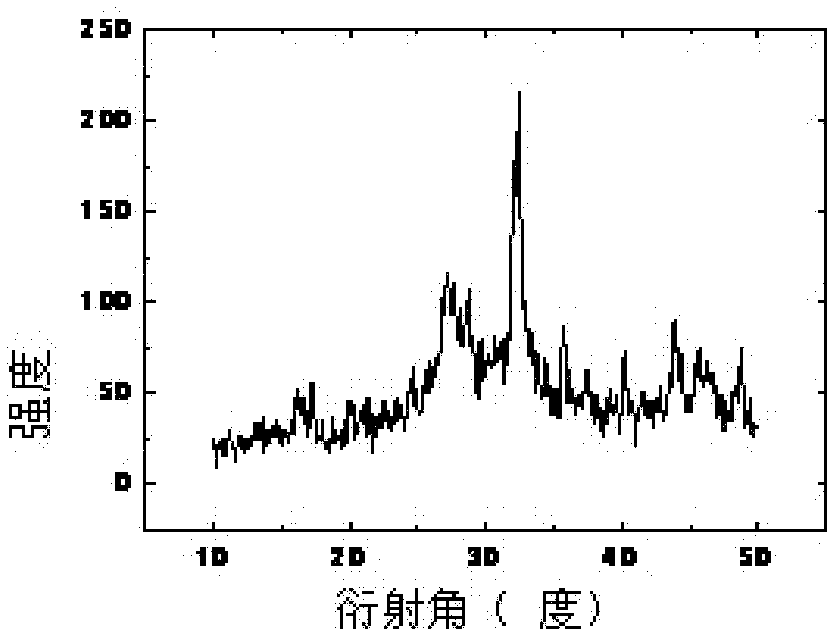

InactiveUS20100048378A1Improve the level ofControl loadMaterial nanotechnologyRare earth metal compoundsCelsius DegreeYttrium

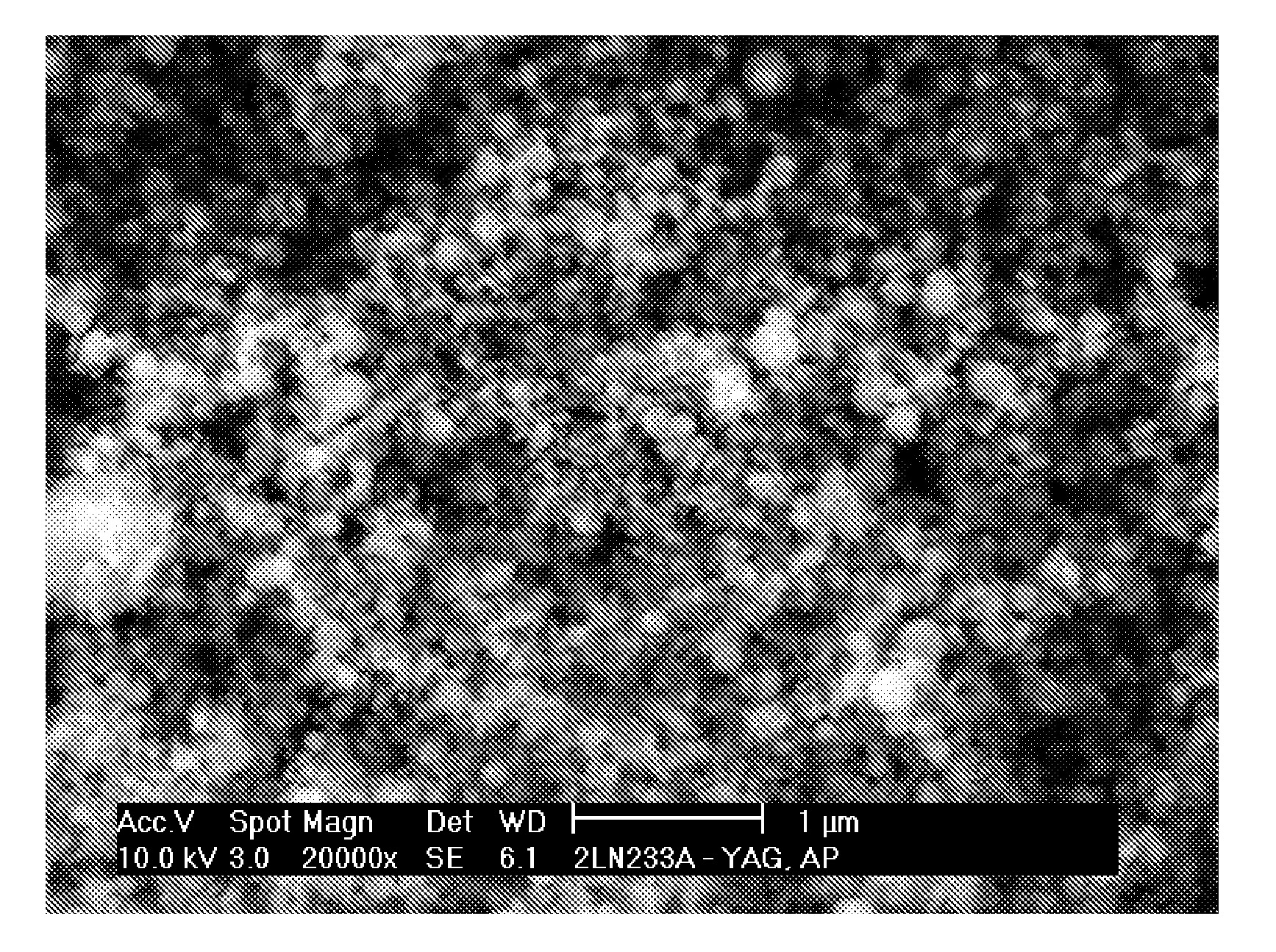

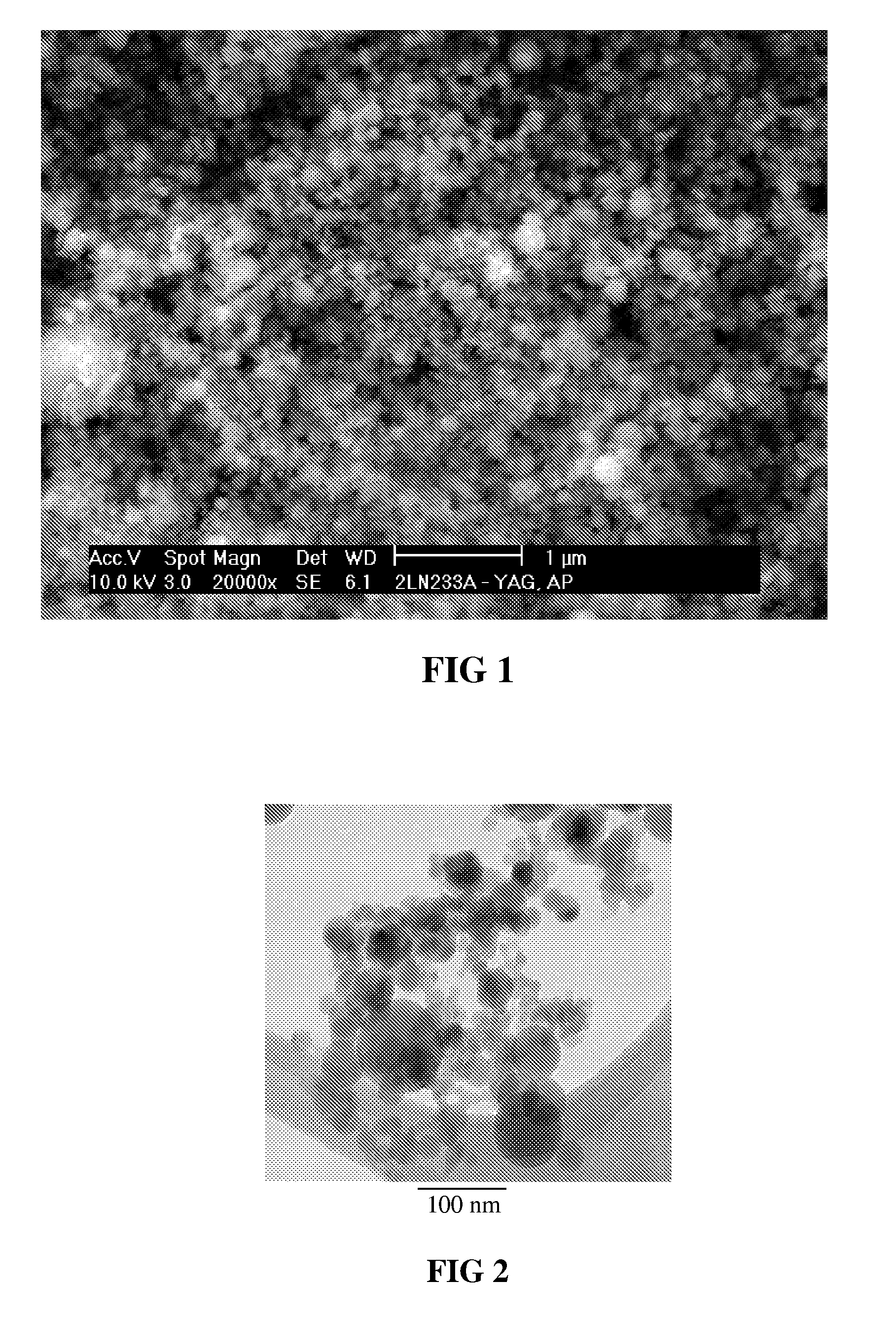

A transparent yttrium aluminum garnet precursor composition is provided that includes a plurality of calcined particles of yttrium aluminum oxide having a mean particle domain size of between 10 and 200 nanometers and a predominant hexagonal crystal structure. High levels of YAG transparency are obtained for large YAG articles through control of the aluminum:yttrium atomic ratio to 1:06±0.001 and limiting impurity loadings to less than 100 ppm. The composition is calcined at a temperature between 700° Celsius and 900° Celsius to remove organic additives to yield a predominant metastable hexagonal phase yttrium aluminum oxide nanoparticulate having an atomic ratio of aluminum: yttrium of 1:0.6±0.001. With dispersion in an organic binder and a translucent YAG article is formed having a transmittance at a wavelength of 1064 nanometers of greater than 75%. The translucent YAG article is characterized by an average domain size of less than 1 micron and having a density of at least 99% and inclusions present at less than 2 surface area percent. The ability of a batch of yttrium aluminum oxide nanoparticles to serve as a transparent YAG precursor includes collecting an X-ray fluorescence spectrum from a plurality of aluminum oxide nanoparticles having a predominant crystal structure other than garnet to yield an A1:Y raw integrated peak intensity ratio. The nanoparticles are sintered to yield a predominant garnet phase and a secondary phase and optionally isostatic pressing during sintering. By using only precursor nanoparticles with a standard deviation of ±0.003 in the peak ratio exceptionally high transparency YAG is reproducibly produced.

Owner:NANOCEROX

Microcrystalline glass containing rare earth mixing yttrium aluminum garnet (YAG) phase and preparation method thereof

The invention discloses microcrystalline glass containing rare earth mixing yttrium aluminum garnet (YAG) phase and a preparation method thereof. A glass matrix material uses SiO2, B2O3, Na2O, BaO, K2O, ZnO, CaO and Li2O as raw materials and is obtained by melting and fusing, a general form of yttrium aluminum pomegranate stone microcrystal materials containing the rare earth is (Y1-XLnX)3A15O12, Ln is Ce, Eu or Nd, X=0.03-0.08, and the glass matrix material and the yttrium aluminum pomegranate stone microcrystal materials containing the rare earth are melted and fused according to the weight ratio of 95:4-6. The microcrystalline glass containing the rare earth mixing the YAG phase is obtained by annealing. The microcrystalline glass is semi-transparent, the microcrystalline glass containing the rare earth mixing the YAG phase is small in crystal particle, the microcrystalline glass is good in dispersibility of rare earth mixed YAG phase crystal, rare earth ion basically enters YAG crystal lattices, and the rare earth ion is also good in dispersibility, so that the microcrystalline glass is excellent in optical property and strong in fluorescence, and can be obtained through a two-step fusion method, melting and fusing temperature is low and lower than 100 DEG C, requirements of a preparation process are low, production cost is low, and the microcrystal materials are good in uniformity.

Owner:NINGBO UNIV

Cleaning method used in removing contaminants from the surface of an oxide or fluoride comprising a group III B metal

InactiveUS20070134416A1Excellent plasma corrosion-resistanceHigh coating densityAfter-treatment apparatusMolten spray coatingCleaning methodsAluminum substrate

Disclosed herein is a cleaning method useful in removing contaminants from a surface of a coating which comprises an oxide or fluoride of a Group III B metal. Typically the coating overlies an aluminum substrate which is present as part of a semiconductor processing apparatus. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3.

Owner:APPLIED MATERIALS INC

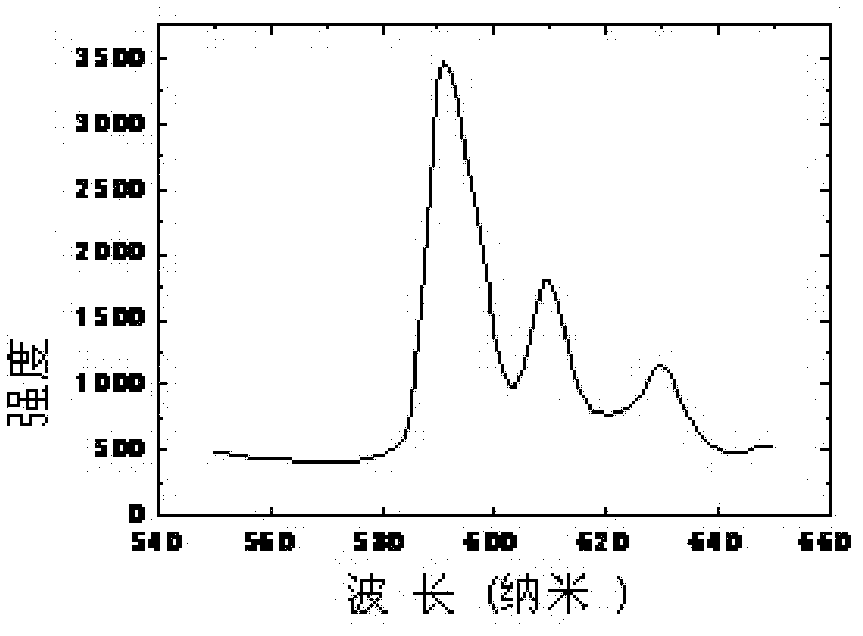

Luminescent powder of light emitting diode for semiconductor white light illumination, and preparation method thereof

InactiveCN1687307AChange the number of molesHigh emission intensitySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceAcid washing

The present invention relates to a semiconductor illumination white light emitting diode fluorescence powder and its preparation method. Said fluorescence powder is yttrium aluminium garnet fluorescence powder activated by cerium. Said invention also provides its chemical molecular formula. Its preparation method includes the following steps: selecting raw material whose purity is 4-5 N and grain size is 1-2 micrometers, preparing precursor body, adding fusing agent which is selected from BaF2+H3BO3, after the fluorescence powder is synthesized, making after-treatment, acid-washing, alkali-washing, water-washing, pulverizing, sieving and finished product detection, its lumen efficiency can be up to 33-401 m / w.

Owner:王锦高

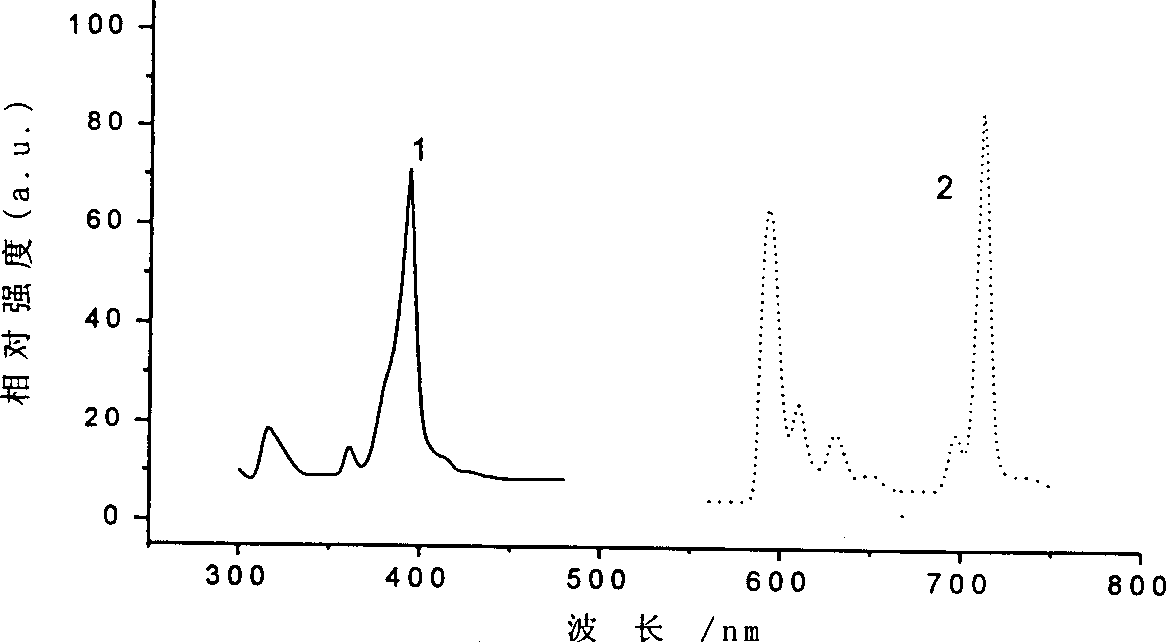

Three-primary-colour fluorescent powder stimulated by purple-light LED and its synthesizing process

InactiveCN1397625ASolve difficult technical problemsGas discharge lamp usageLuminescent compositionsCeriumStrontium

A three-primary-color fluorescent powder excited by violet-light LED is composed of the red powder whose emission peak is in red light region, the blue powder whose emission peak is in blue light region and the green powder whose emission peak is in green light region, and can emit white light under excitation of violet-light LED. It is prepared through high-temp solid-phase reaction to prepare red powder (3-valence Eu activated YAG), blue powder (2-valence Eu activated strontium / calcium chlorophosphate) and green powder (Ce activated YAG), and mxing in Wt. ratio of (0.5-2):(0.7-2.3):(2-5).

Owner:PEKING UNIV

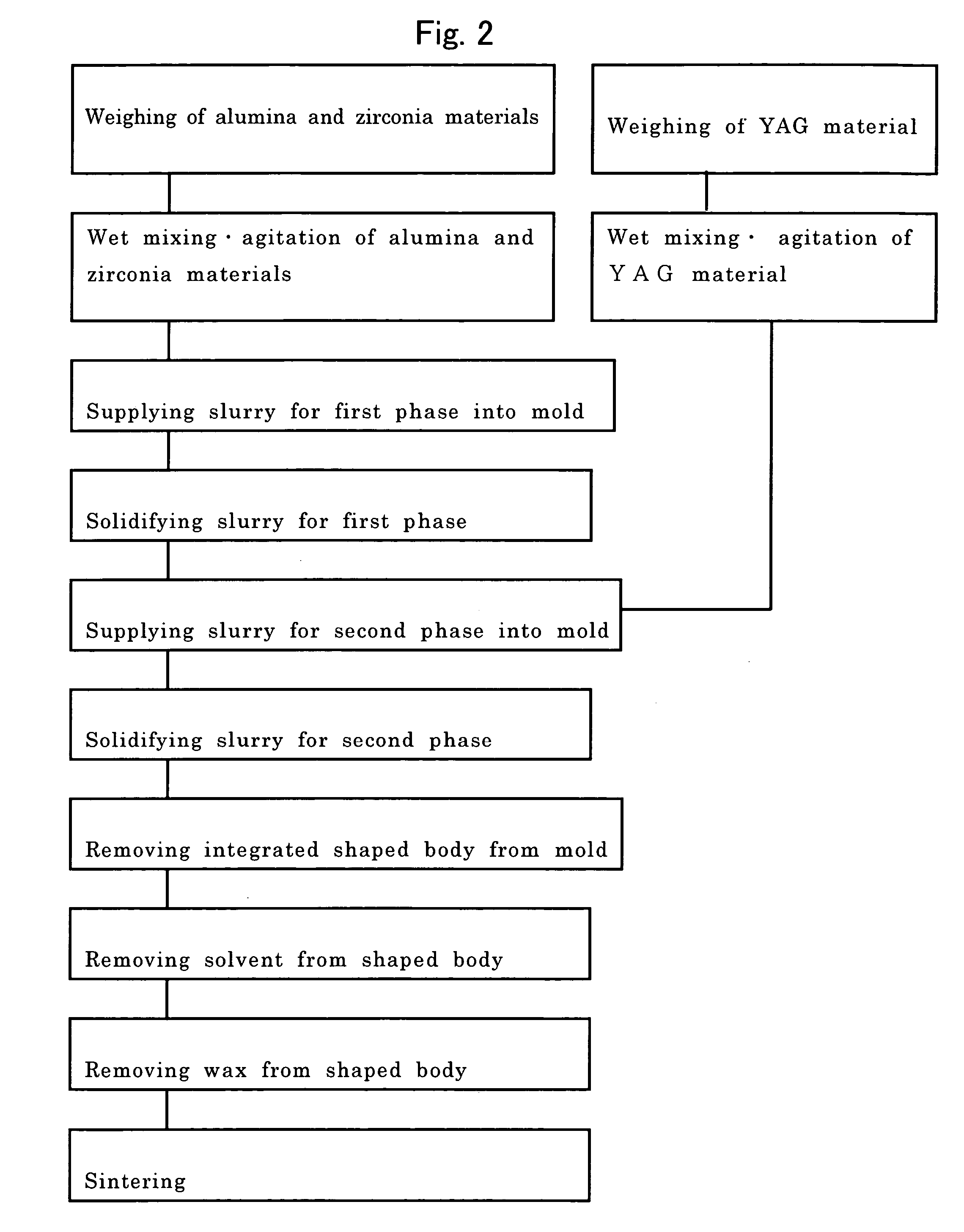

Integrated sintered bodies and a method of producing the same

ActiveUS7226673B2Improve production yieldReduce morbidityCeramic shaping apparatusCeramic layered productsYttriumYttrium aluminium garnet

An integrated sintered body is provided having at least a first phase and a second phase. The first phase includes alumina as a main component, and the alumina contains a total amount of 12 weight percent or more and 50 weight percent or less of one or more of stabilized zirconia and partially stabilized zirconia. The second phase contains yttrium-aluminum garnet as a main component.

Owner:NGK INSULATORS LTD

Yttrium aluminum garnet powders and processing

Methods of producing doped and undoped yttrium aluminum garnet and yttrium aluminum perovskite containing powders and the powders produced thereby are provided. Additionally, methods of forming doped and undoped polycrystalline yttrium aluminum garnet having a mean grain size of between about 1 μm to about 3 μm and the yttrium aluminum garnet produced thereby are provided. The doped and undoped polycrystalline yttrium aluminum garnet may be formed by sintering a compact and subsequently hot isostatically pressing the compact.

Owner:RAO UES

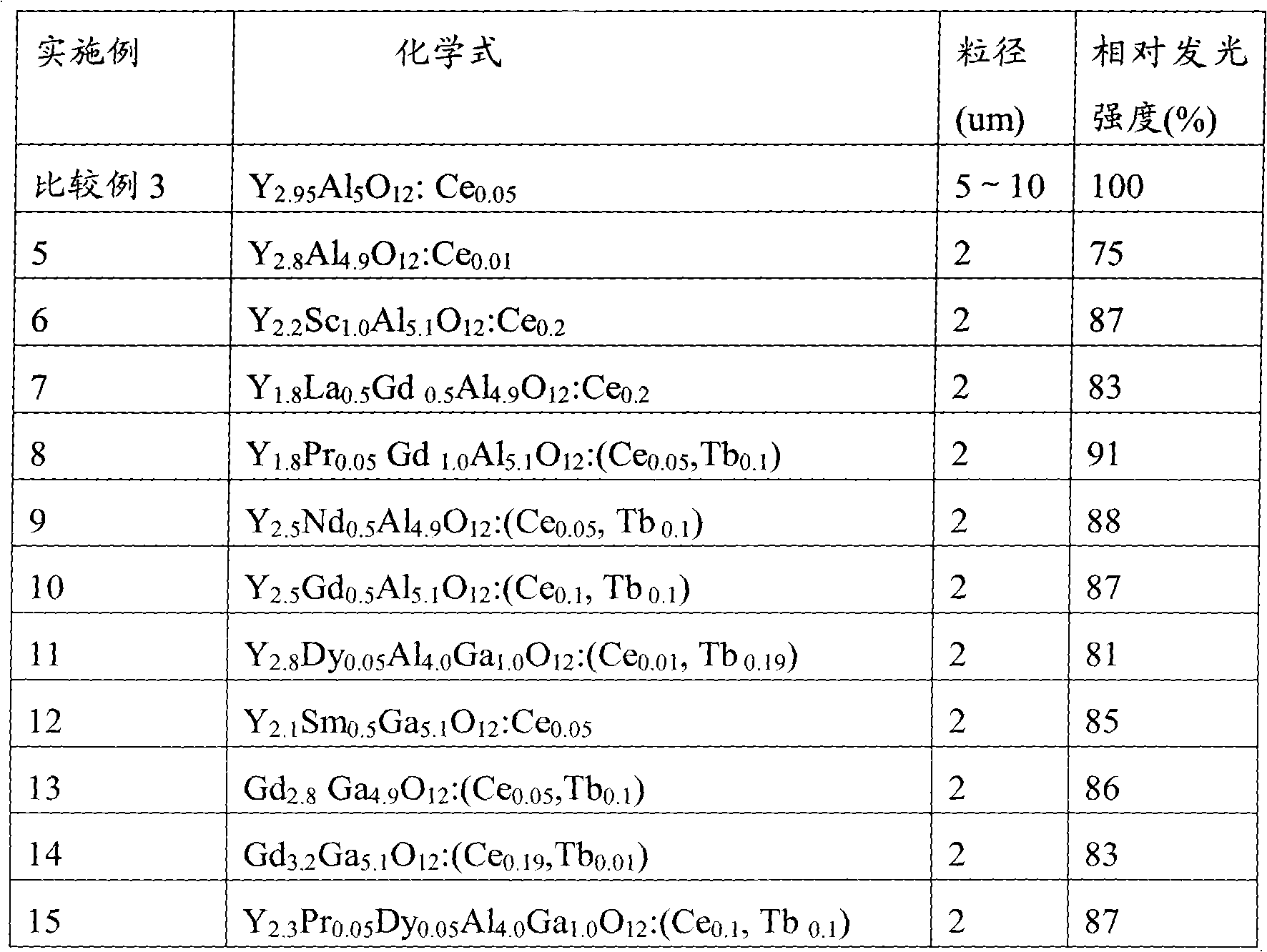

Coprecipitation preparation method of rare earth-doped yttrium aluminium garnet fluorescent powder

InactiveCN102079975AUniform particle sizeUniform particle size distributionLuminescent compositionsCeriumLuminescence

The invention provides a coprecipitation preparation method of rare earth-doped yttrium aluminium garnet fluorescent powder. The chemical formula of the fluorescent powder is LnaMbO12:Rx,R'y, wherein Ln is at least one of Sc, Y, Pr, Nd, Gd, Dy and Sm; a is more than or equal to 2.8 and less than or equal to 3.2; M is at least one of Al and Ga, and b is more than or equal to 4.9 and less than or equal to 5.1; R is at least one of Ce and Tb, and x is more than or equal to 0.01 and less than or equal to 0.2; and R' is at least one of Pr and Dy, and y is more than or equal to 0 and less than or equal to 0.1. The coprecipitation preparation method comprises the following steps: preparing a metal ion mixed liquid and preparing nano doped cerium yttrium aluminium garnet crystal seeds; adding the crystal seeds and a dispersing agent to a precipitator, thus obtaining a mixed solution; dropwise adding the metal ion mixed liquid into the mixed solution so as to obtain an intermediate product, and carrying out water washing, alcohol leaching and drying on the intermediate product; adding a fluxing agent in the intermediate product, and then roasting under the reducing atmosphere; and carrying out gas stream smashing, impurity removal, drying and grading on a product of roasting, thus obtaining the rare earth-doped yttrium aluminium garnet fluorescent powder. The shape of the product is regular, the particle diameter (d50) of the product is 1-10 mu, and the product has the advantages of stable property and good luminescence performance, and can be effectively excitated by blue light.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing yttrium aluminum garnet based transparent ceramic by slip casting

The invention discloses a method for preparing a yttrium aluminum garnet (YAG) based transparent ceramic by slip casting. The method comprises the following steps: performing ball-milling and mixing on oxide ceramic powder, a sintering adjuvant, a nonaqueous solvent and a dispersant; adding an adhesive, a plasticizer and a defoaming agent; and preparing a nonaqueous based slurry through ball-milling and mixing, wherein the slurry consists of the following components in percentage by mass: 40 to 70 percent of oxide ceramic powder, 0.01 to 1 percent of sintering adjuvant, 0.005 to 2.5 percent of dispersant, 0.01 to 5 percent of adhesive, 0.01 to 3 percent of plasticizer, 0.005 to 0.5 percent of defoaming agent, and the balance of the nonaqueous solvent; and preparing a ceramic block from the slurry through slip casting, preparing a ceramic biscuit by adopting a two-step drying method, and preparing the transparent ceramic through vacuum sintering. The method adopts the slip casting, is particularly suitable for preparing the ceramic sample with complicated shape, large size and composite structure, and greatly widens the preparation means of the transparent ceramic.

Owner:中国科学院上海硅酸盐研究所苏州研究院

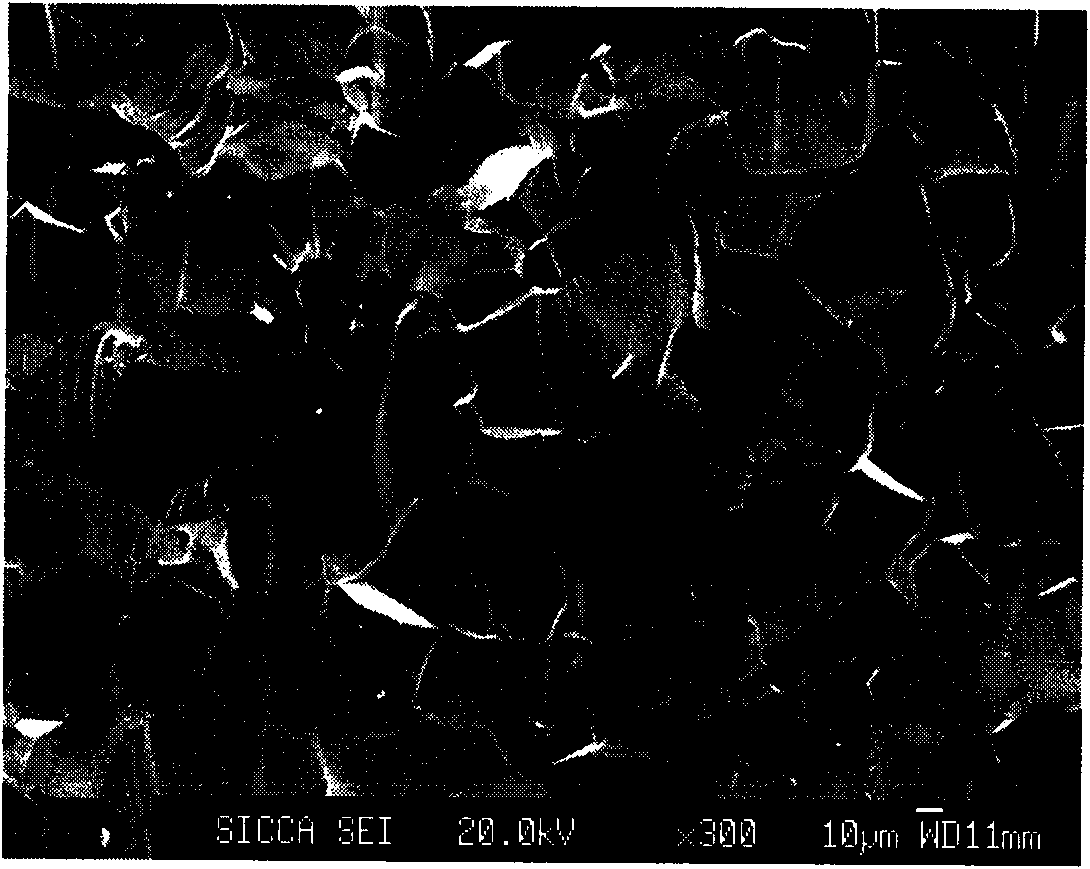

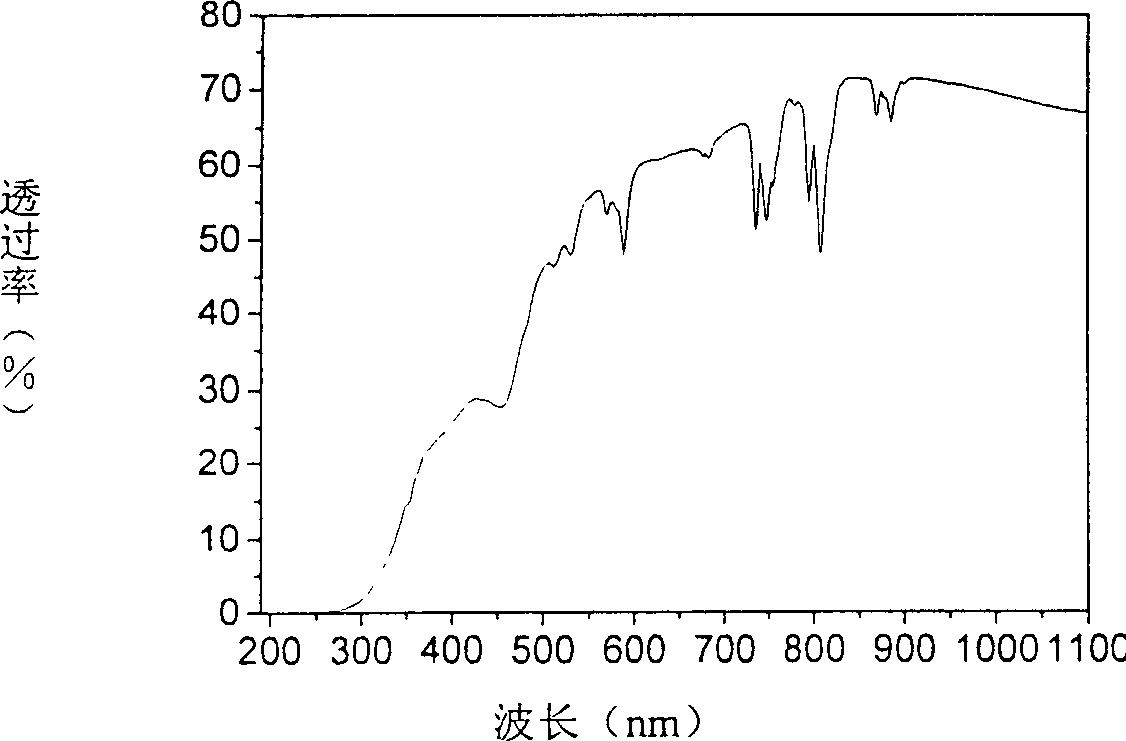

Transparent ceramic material of dual adulterated yttruim aluminum garnet, and prepartion method

This invention relates to a method for preparing double-doped YAG transparent ceramic material. For Cr4+- and Nd3+-doped system, Tthe doping amount of Cr4+ is 0.02-0.5 at%, while that of Nd3+ is 0.4-4.0 at%. For Cr4+- and Yb3+-doped system, the doping amount of Cr4+ is 0.01-0.5 at%, while that of Yb3+ is 5-30 at%. The method comprises: evenly mixing the powdery raw materials, performing dry pressing and cold static pressing, sintering in a vacuum furnace, and annealing. The light transmittance of the double-doped YAG transparent ceramic material is higher than 70%, and can be used as the working substance of self-regulating Q solid laser.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method of preparing yttrium aluminium garnet fluorescent powder

ActiveCN101012376ASolve pollutionGuaranteed uniformityLuminescent compositionsNitrateLiquid temperature

The invention discloses a making method of fluorescent powder of yttrium aluminium garnet, which comprises the following steps: allocating certain quantity of alumina powder, yttrium nitrate, cerous nitrate and gadolinium nitrate into sediment mother liquid; allocating sediment agent solution through at least one of NaOH, NH3.H2O or NH3HCO3; maintaining sediment mother liquid temperature between 10 and 70 deg.c; stirring evenly; adding sediment agent solution into sediment mother liquid; stopping adding sediment agent when pH value is 6.8-11; insulating and stirring; separating solid from liquid of sediment mother liquid; washing solid through clean water; drying; adding fluoride in the powder as reacting adjuvant; placing blended powder into high-temperature stove; heating protected by gas; cooling; obtaining sintered fluorescent powder bulk; grinding; sieving; obtaining the product.

Owner:JIANGSU BREE OPTRONICS CO LTD +1

Method for preparing yttrium aluminum garnet-based transparent ceramic through aqueous tape casting

The invention provides a method for preparing yttrium aluminum garnet-based transparent ceramic through aqueous tape casting. The method comprises steps: preparing a slurry of the yttrium aluminum garnet-based transparent ceramic and a casting film by adopting water as a solvent through adopting an aqueous tape casting technology; processing the casting film to form diaphragms having different shapes as needed; carrying out lamination treatment of the diaphragms at a lamination temperature of 75-95DEG C under a lamination pressure of 40-120MPa to obtain a biscuit; and carrying out degumming treatment and cold isostatic pressing treatment of the biscuit, and sintering to obtain the yttrium aluminum garnet-based transparent ceramic. The method has a good environmental compatibility, and the transparent ceramic can be obtained through the method.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing neodymium-doped yttrium aluminum garnet micro/nano powder by spray freeze-drying

InactiveCN102173775AEvenly dopedEfficient preparationDrying solid materials without heatFreeze-dryingRare earth

The invention discloses a method for preparing neodymium-doped yttrium aluminum garnet micro / nano powder by spray freeze-drying, which comprises the following steps: dissolving soluble salts of yttrium, aluminum and neodymium, which are used as raw materials; mixing the raw materials according to the stoichiometric proportion; and by using ammonia water or acetic acid as a pH regulator and the mixture of liquid nitrogen and liquid ethane as a freezing agent, granulating by spray freeze-drying, and calcining to obtain the uniform neodymium-doped yttrium aluminum garnet micro / nano powder. The method disclosed by the invention is simple, has the advantage of low cost, and can be used for scale-up production of the raw material of rare-earth-doped transparent ceramics.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com