Cleaning method used in removing contaminants from the surface of an oxide or fluoride comprising a group III B metal

a cleaning method and fluoride technology, applied in the direction of superimposed coating process, crystal growth process, transportation and packaging, etc., can solve the problems of insufficient corrosion resistance, insufficient useful in preventing, and insufficient compression of coating, etc., to achieve excellent plasma corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As a preface to the detailed description, it should be noted that, as used in this specification and the appended claims, the singular forms “a”, “an”, and “the” include plural referents, unless the context clearly dictates otherwise.

[0041] Disclosed herein is a method of applying a plasma-resistant coating on an aluminum or an aluminum alloy substrate. The present method is particularly useful for applying a plasma-resistant coating to a substrate which comprises an aluminum alloy of the 2000 series or the 5000 through 7000 Series. Because of its greater malleability, 2000 series aluminum is particularly preferred when fabricating parts and components having complex shapes.

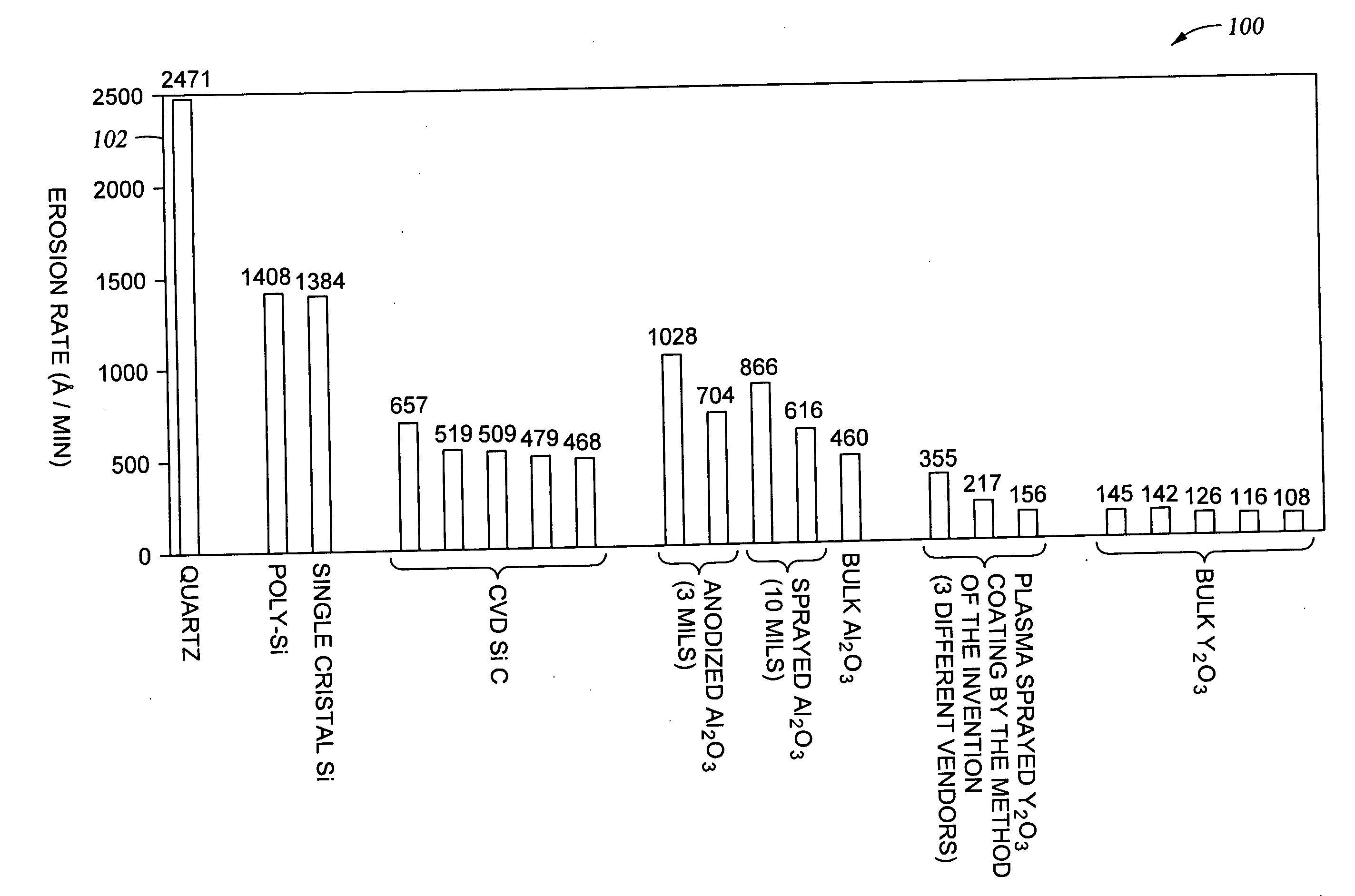

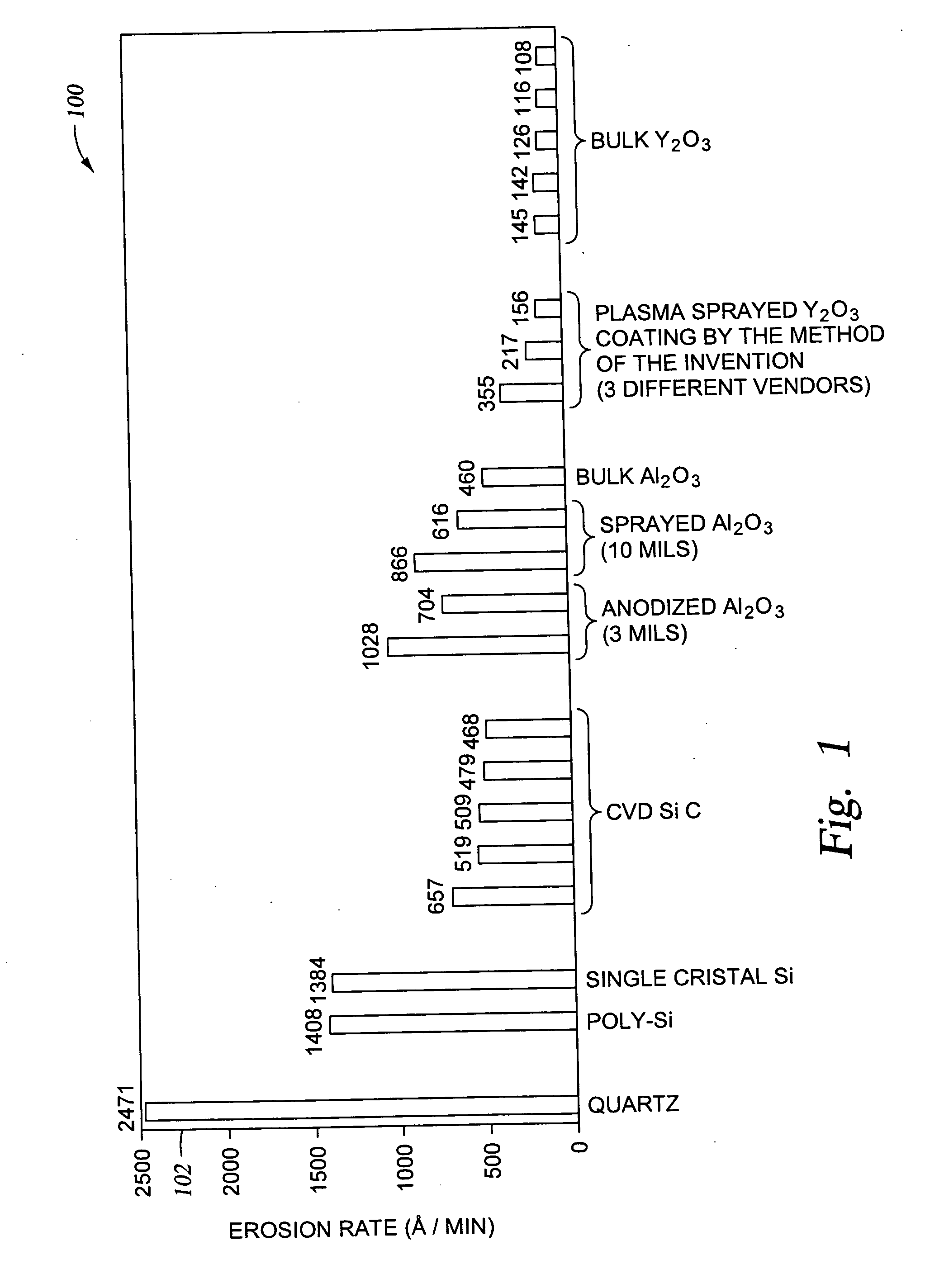

[0042] The plasma-resistant coating comprises an oxide of Y, Sc, La, Ce, Eu, Dy, or the like, or a fluoride of one of these metals, or yttrium-aluminum-garnet (YAG). An aluminum alloy coated with the coating of the invention applied by the method of the inventions shows excellent plasma corrosion-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time period | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com