Patents

Literature

104results about How to "High degree of sphericity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

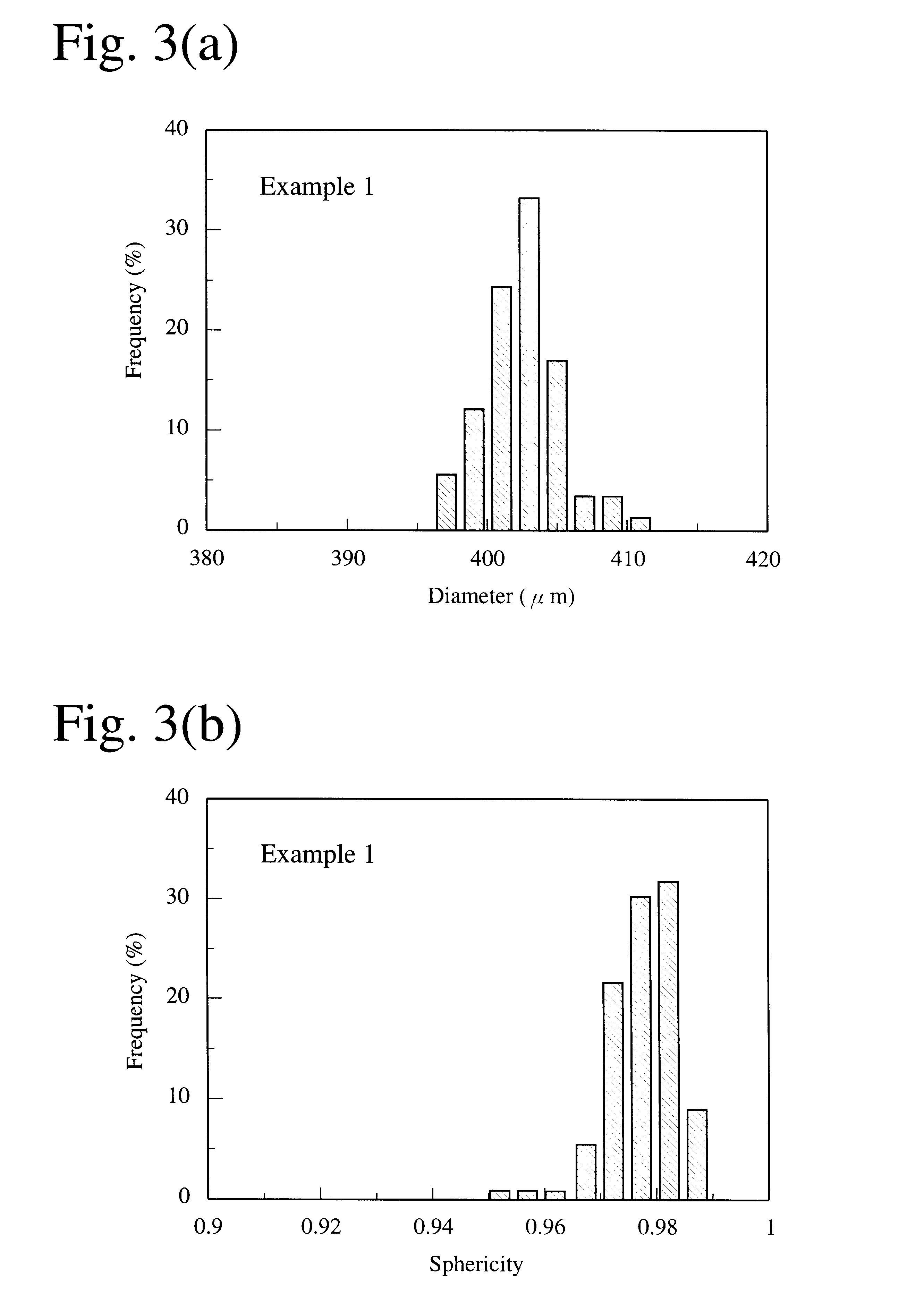

Solder ball and method for producing same

InactiveUS6517602B2High degree of sphericityNarrow distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass % of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

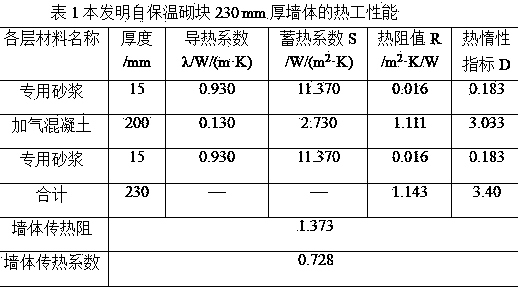

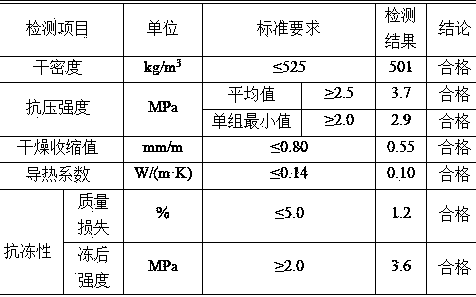

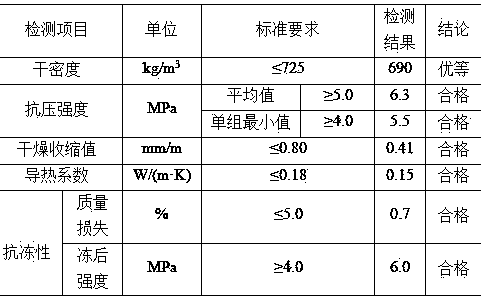

Self-heat-insulating fly ash autoclaved aerated concrete block and preparation method thereof

The invention relates to a self-heat-insulating fly ash autoclaved aerated concrete block which comprises the following components in parts by weight: 1400-2200kg of fly ash, 330-400kg of cement, 390-550kg of quicklime, 100-200kg of white lime, 50-100kg of desulfurized gypsum, 255-420kg of block waste, 2.15-2.90kg of aluminum powder paste and 0.20-0.50kg of foam stabilizer. According to the invention, the fly ash, desulfurized gypsum and excessive cut waste from a power plant are fully utilized, and meanwhile, the Level B04, Level B05, Level B06 and Level B07 self-heat-insulating fly ash aerated concrete blocks can be prepared. The block products contain a large amount of micro and macro pores, and are uniform in pore size, low in heat conductivity coefficient and favorable in self-heat-insulating property.

Owner:HENAN XIAN NEW BUILDING MATERIALS

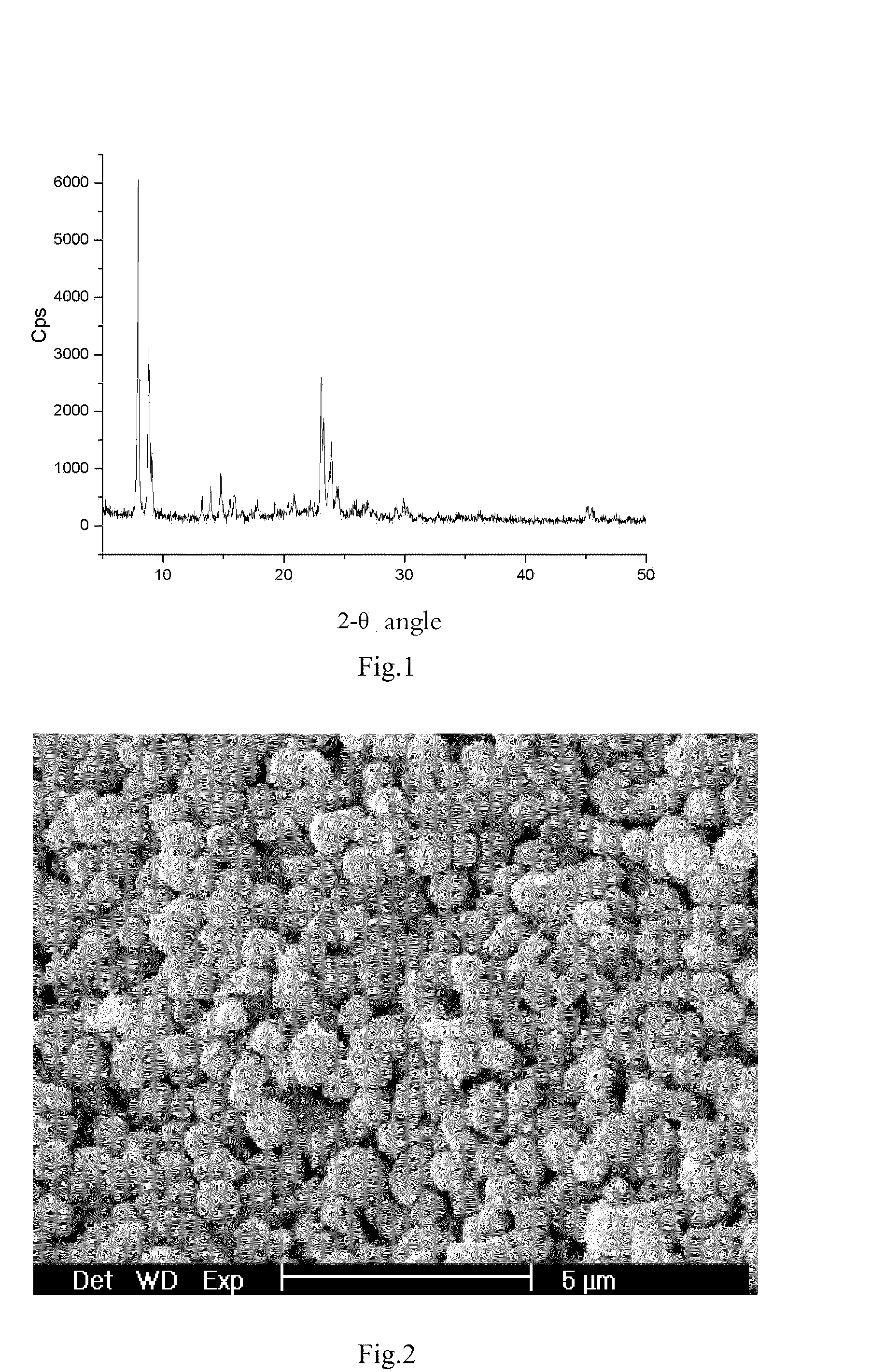

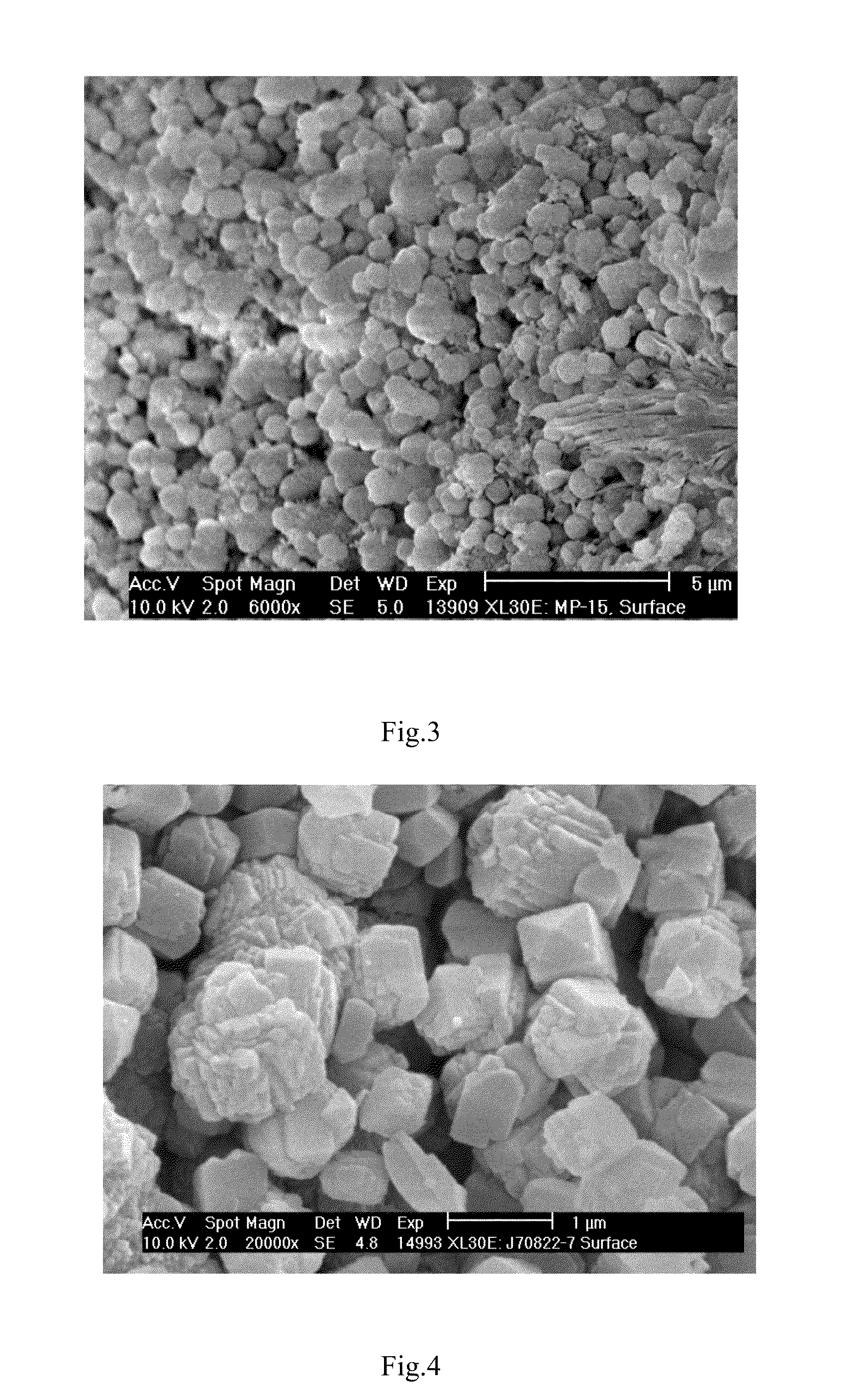

Binderless Molecular Sieve Catalyst and a Preparation Method Thereof

ActiveUS20130225397A1High activityGreat pore volumeAluminium compoundsMolecular sieve catalystsLow activityMolecular sieve

The present invention relate to a binderless molecular sieve catalyst and a process for preparing the same, which are mainly useful for solving the problems of the current catalysts, such as lower activity, less pore volume and worse diffusivity. The present invention relates to a novel binderless molecular sieve catalyst, comprising, based on the weight of the catalyst, 90-100 wt. % of a molecular sieve, 0-10 wt. % of a binder, and 0-10 wt. % of an anti-wear agent, wherein said catalyst has a pore volume of 0.1-0.5 ml / g, an average pore diameter of 50-100 nm, and a porosity of 20-40%; the anti-wear agent is selected from the rod or needle-like inorganic materials having a length / diameter ratio of 2-20. Said catalyst has the advantages of higher activity, greater pore volume, larger average pore diameter and porosity, and better diffusivity, and well solves said problems and can be used for the industrial preparation of binderless molecular sieve catalysts.

Owner:CHINA PETROCHEMICAL CORP +1

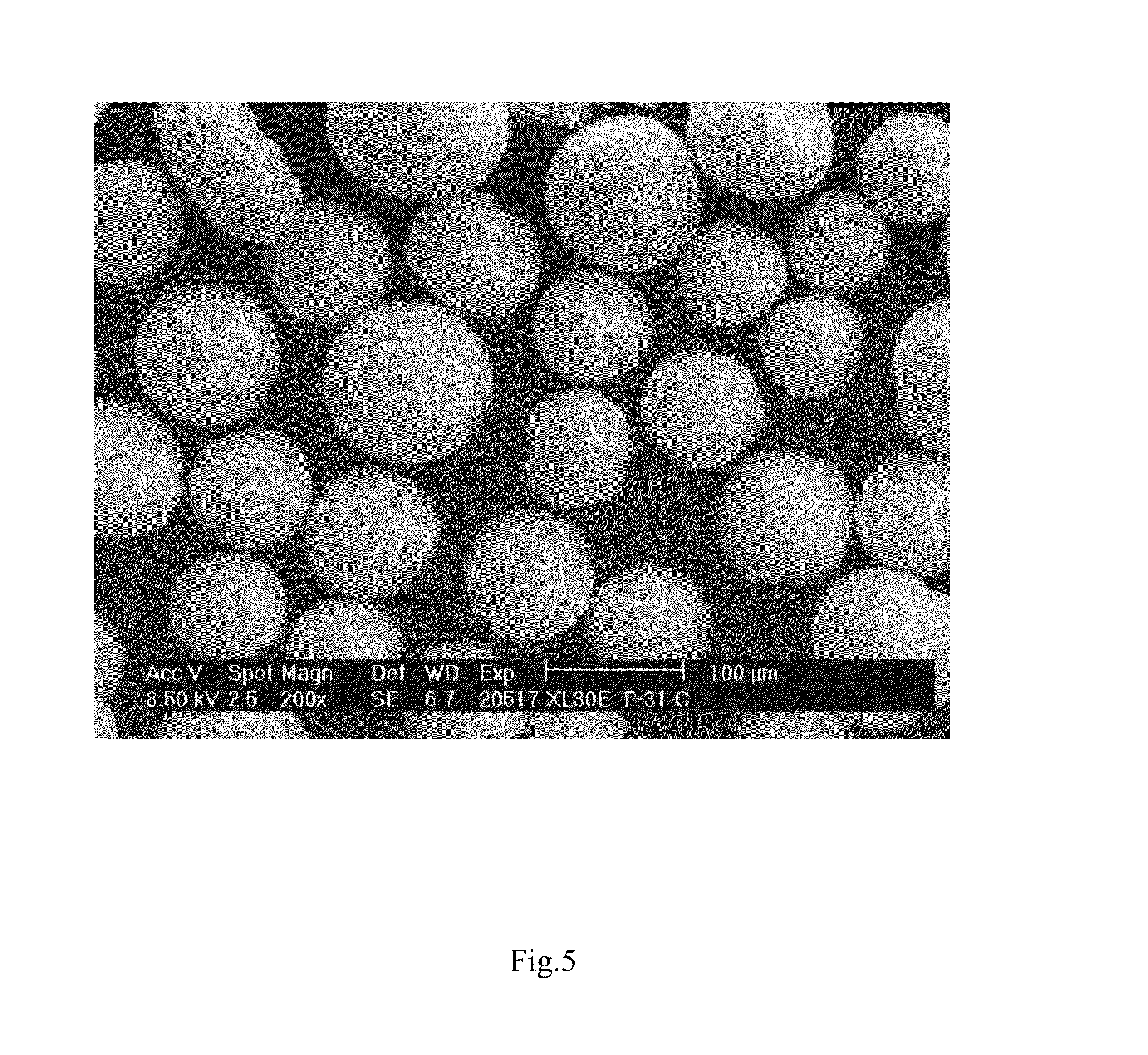

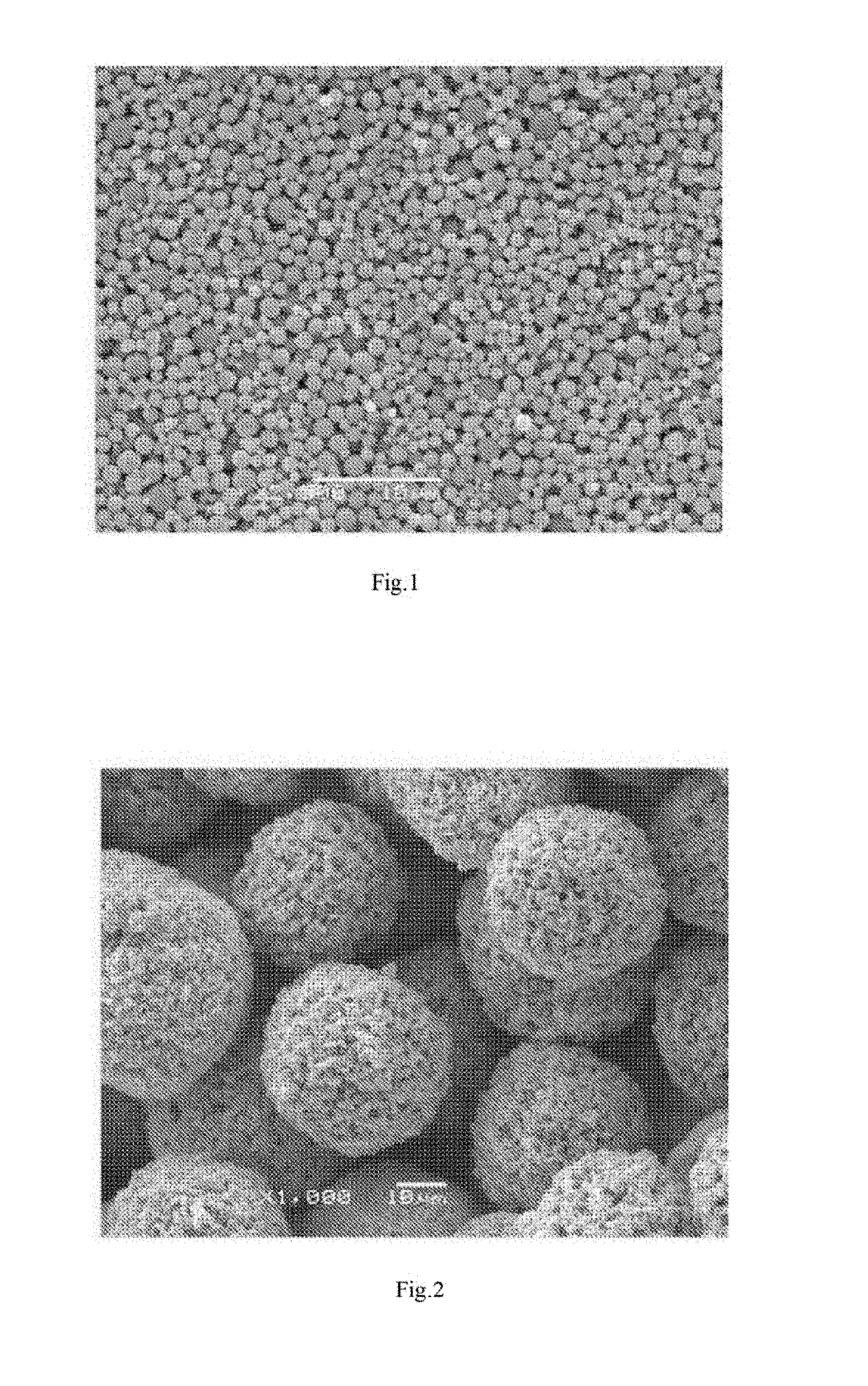

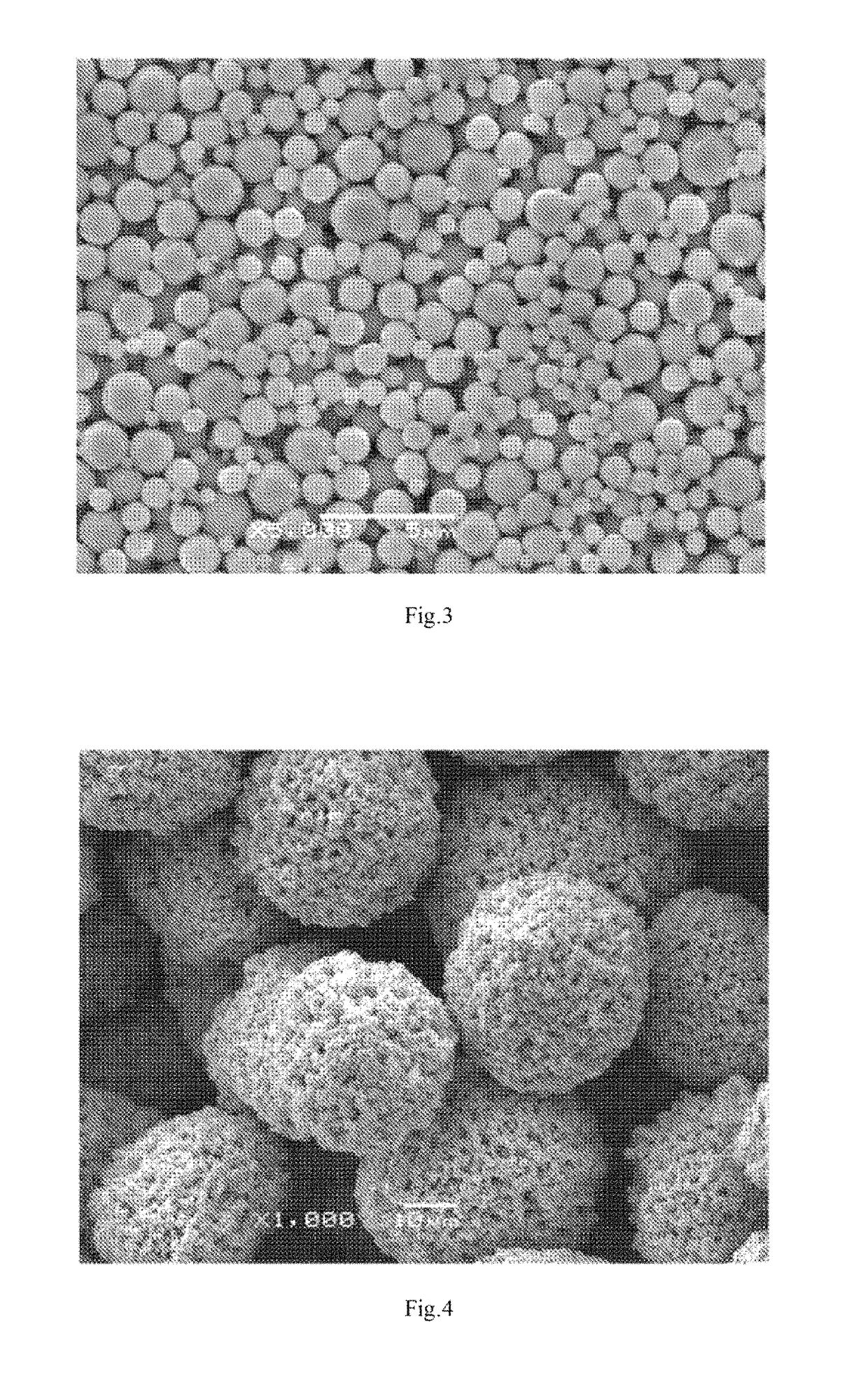

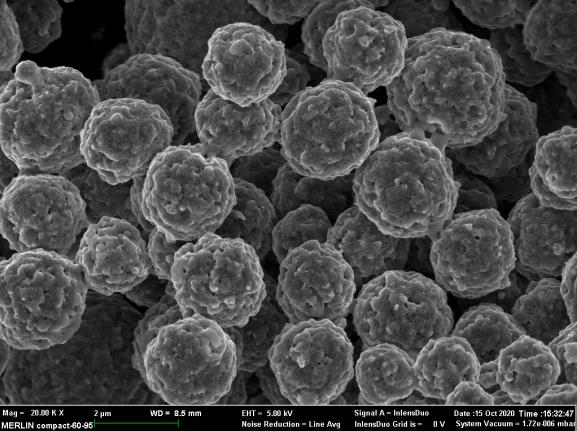

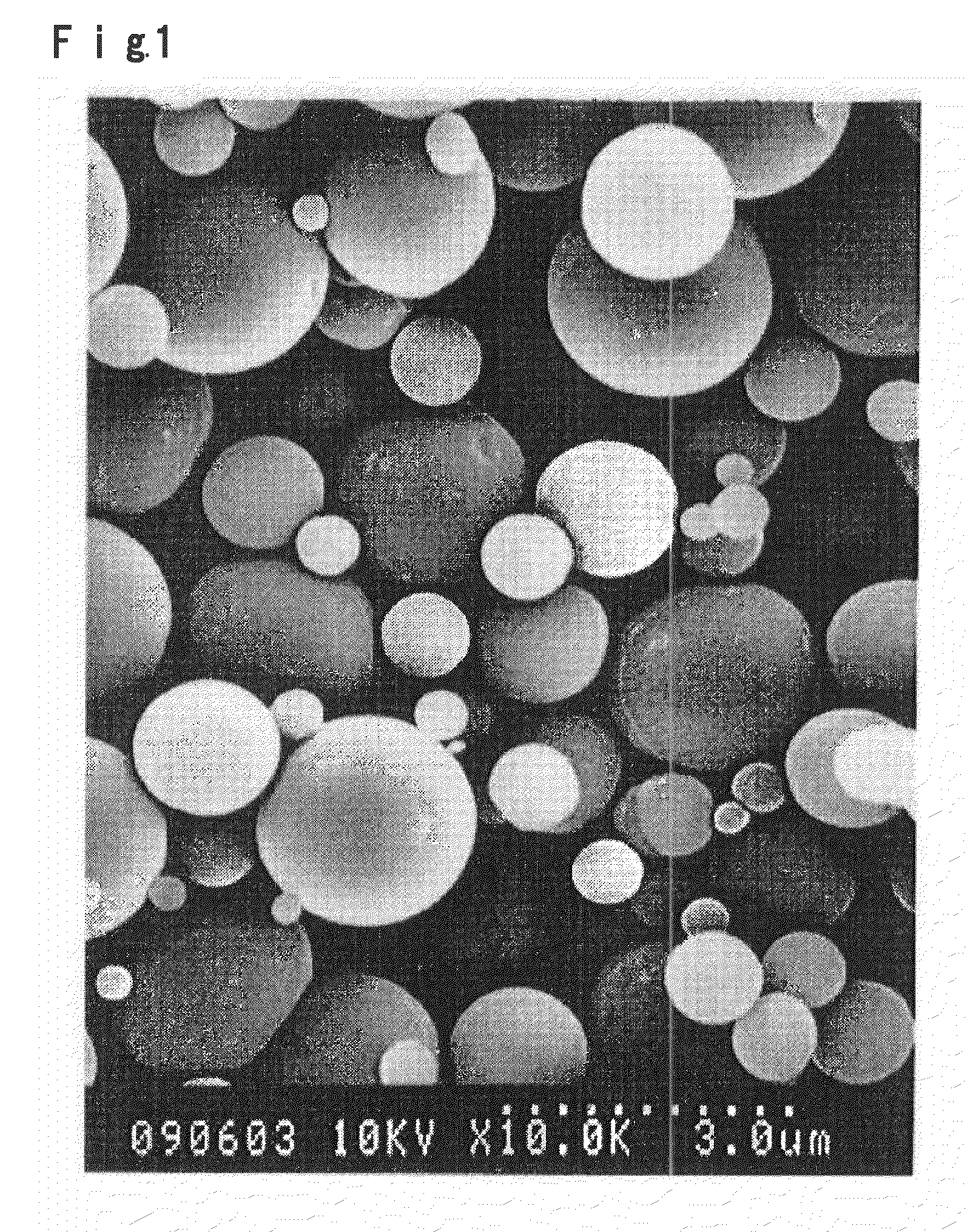

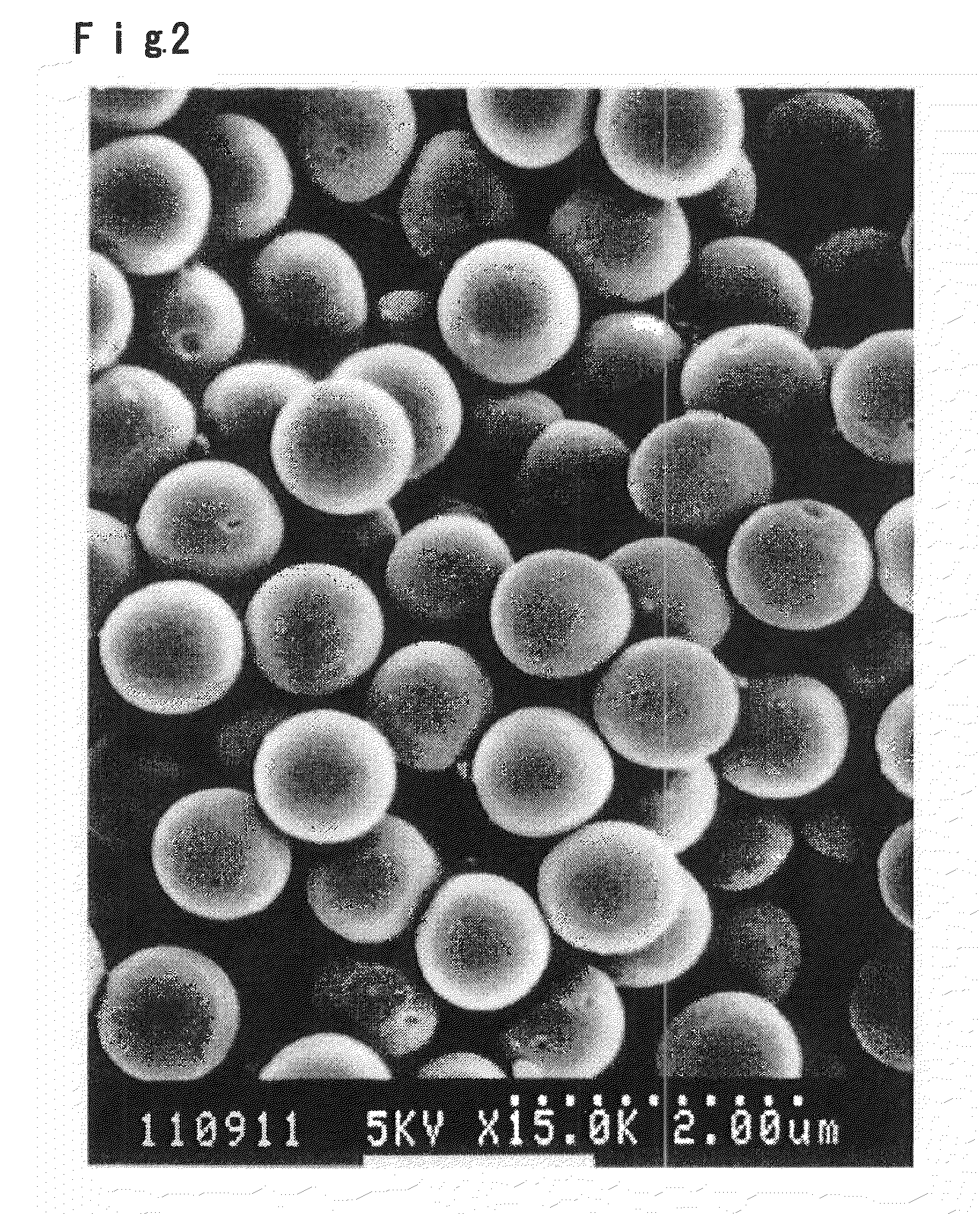

Metal powder for 3D printers and preparation method for metal powder

ActiveUS20170008082A1High sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingMetal particle3d printer

The invention discloses metal powder for a 3D printer. The metal powder for 3D printers is 10-50-micron metal powder made by agglomerating many submicron order metal particles through a granulating process. As the metal powder is combined by submicron order metal particles, the metal powder is low in melting point and high in melting speed, so that the printing speed of the metal 3D printer can be increased and the precision of a printing member can be improved. Meanwhile, the average grain size of the metal powder is equivalent to existing atomized metal powder for 3D printers, and the metal powder has good dispersibility and conveying property, and can be suitable for existing 3D printer equipment.

Owner:JIANGSU BOQIAN NEW MATERIALS

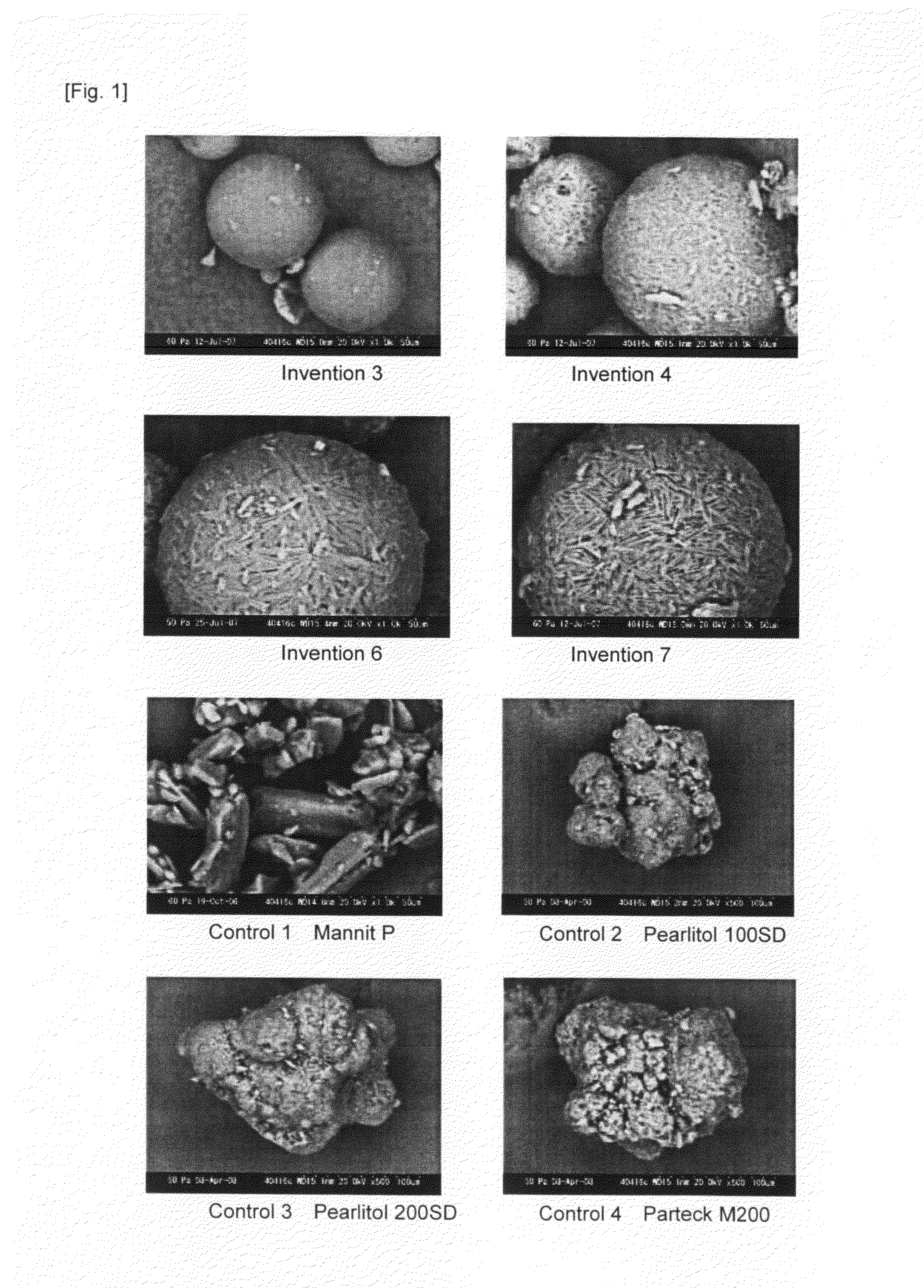

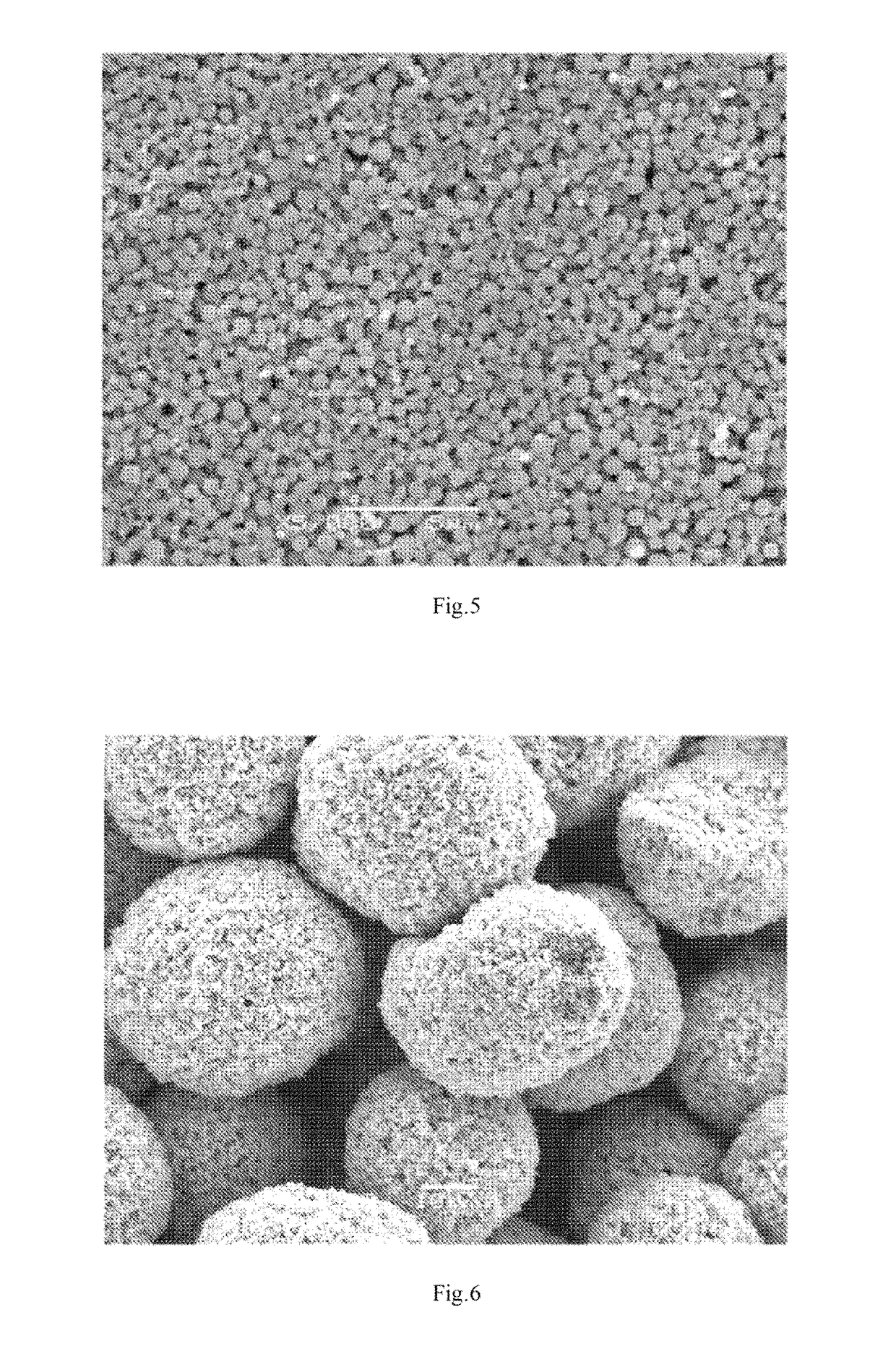

Spherical particle of crystalline mannitol

InactiveUS20100167052A1Improve liquidityHigh oil absorptionPowder deliverySynthetic resin layered productsMANNITOL/SORBITOLHardness

[Summary][Problems] To provide extremely-spherical-three-dimensional-shaped particles of crystalline mannitol containing large hollows and gaps inside.[Solution] Spherical particles of crystalline mannitol made by spray drying, extremely spherical (having an aspect ratio of 1.0 to 1.2), high oil absorption rates according to test method A, wherein powder has a mean particle diameter of 15 to 165 μm, a loose bulk density of 0.35 to 0.60 and an angle of repose of 30 to 50 degrees, and has a hardness of 7 to 20 kgf, when directly compressed.

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Metal powder for 3D printers and preparation method for metal powder

ActiveUS10065240B2Stable structureHigh degree of sphericityAdditive manufacturing apparatusTransportation and packagingMetal particleMetal powder

The invention discloses metal powder for a 3D printer. The metal powder for 3D printers is 10-50-micron metal powder made by agglomerating many submicron order metal particles through a granulating process. As the metal powder is combined by submicron order metal particles, the metal powder is low in melting point and high in melting speed, so that the printing speed of the metal 3D printer can be increased and the precision of a printing member can be improved. Meanwhile, the average grain size of the metal powder is equivalent to existing atomized metal powder for 3D printers, and the metal powder has good dispersibility and conveying property, and can be suitable for existing 3D printer equipment.

Owner:JIANGSU BOQIAN NEW MATERIALS

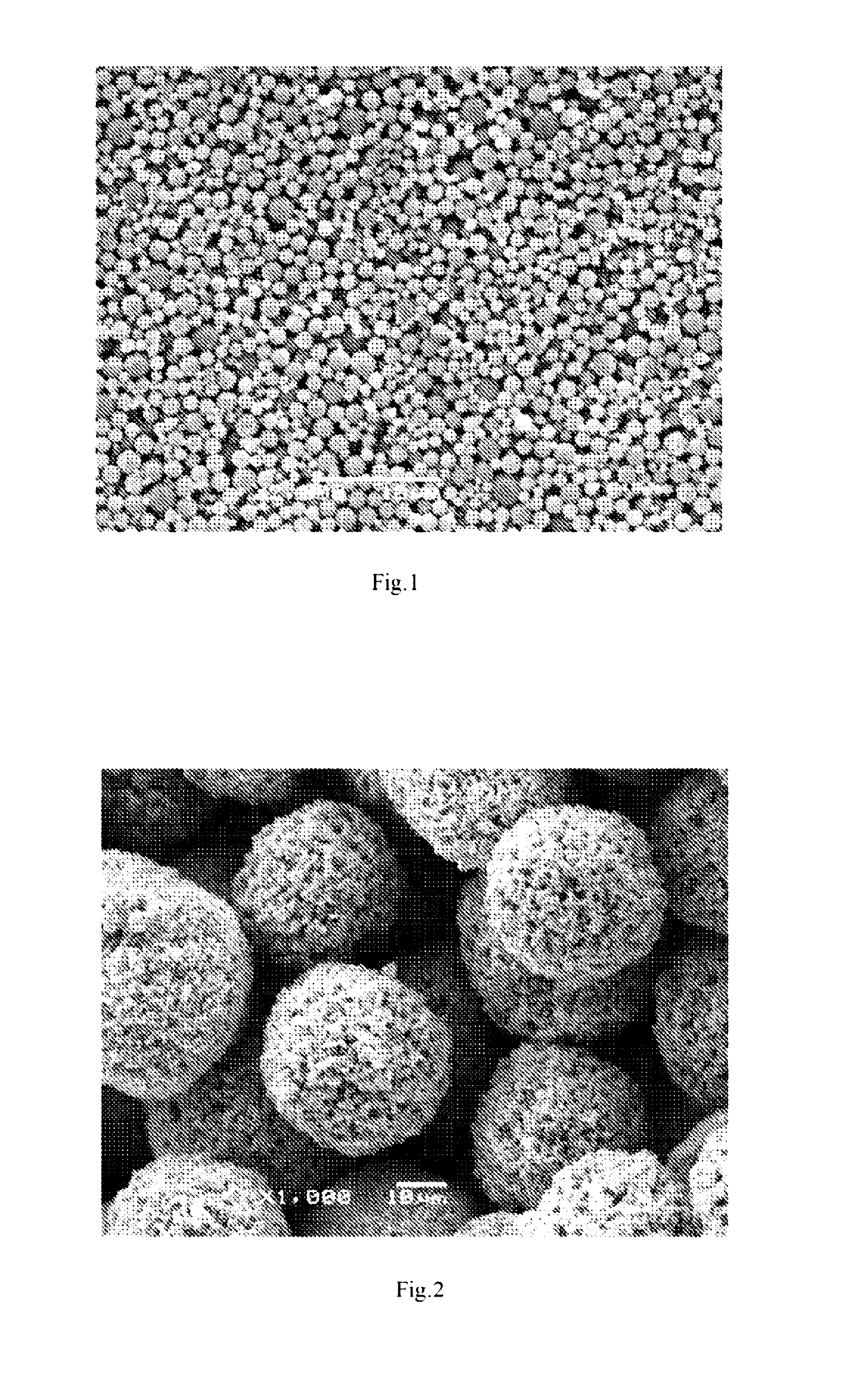

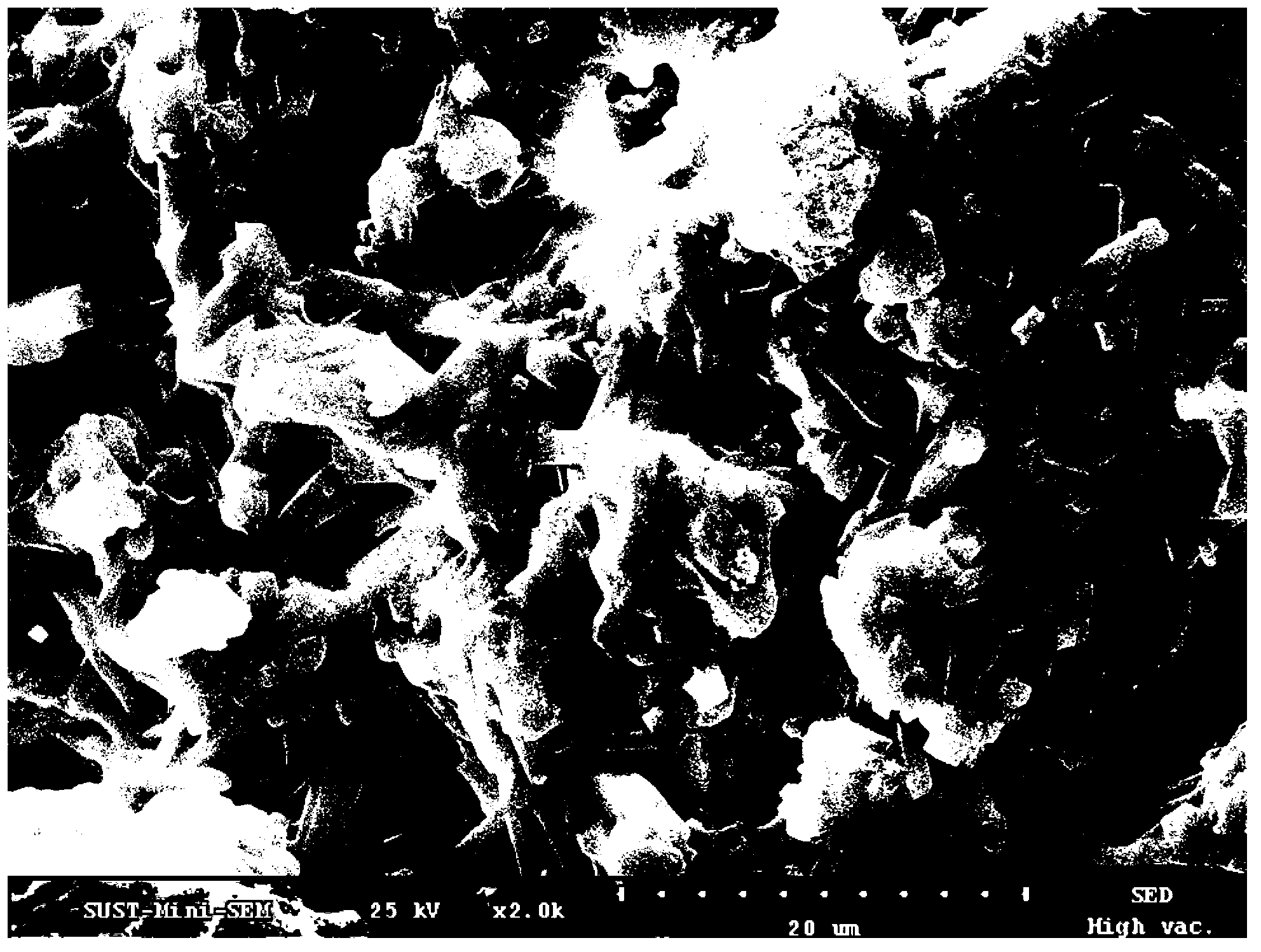

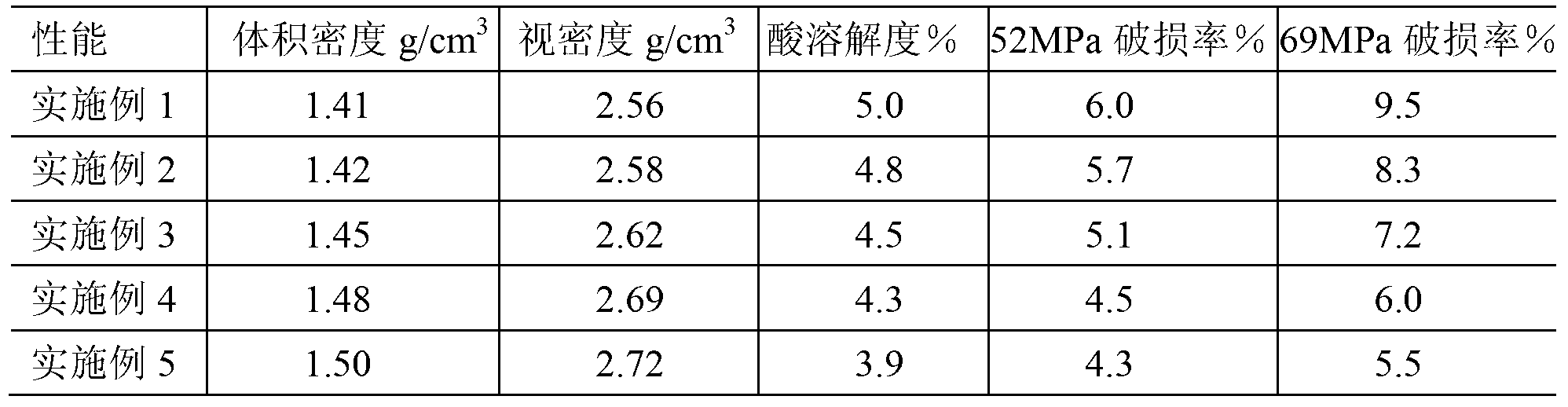

Method for preparing fracturing propping agent special for shale gas from fly ash

InactiveCN103288420AEvenly mixedReduce energy consumptionCeramic materials productionClaywaresOil shale gasTemperature resistance

The invention relates to a method for preparing a fracturing propping agent special for shale gas from fly ash. The method comprises the following steps of: performing wet grinding on the fly ash, kaolinite, a high-activity compound sintering aid and a small amount of industrial coke to form mixed slurry in a ball mill; performing primary granulation on the mixed slurry in a fluidized bed spray granulator; performing secondary granulation by using powdered coal slurry formed by wet grinding of coke as coating liquid; putting balled granules into a crucible; and putting the crucible into an electric furnace for ultralow temperature self-propagating sintering, cooling naturally and then taking the crucible out of the electric furnace to obtain the fracturing propping agent special for shale gas. By adopting the method, the raw material has a wide source, the temperature of the self-propagating sintering is low, the sintering period is short, energy resources are saved, a low-carbon environmental protection effect is achieved, and the comprehensive performance of the product is improved; a shaping method adopted in the method is low in energy consumption, the production process is simple and easy to control, and the product quality is stable; and the prepared propping agent is low in density and high in strength, has excellent characteristics of high-temperature resistance and corrosion resistance, and can provide a fracturing material with better performance for medium and deep layer shale gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

Aluminum powder for 3D (three-dimensional) printing and preparation method of aluminum powder

ActiveCN104668552ALower melting temperatureEvenly meltedTransportation and packagingMetal-working apparatus3D printingAluminium oxides

The invention provides aluminum powder for 3D (three-dimensional) printing. In the aluminum powder, white carbon black serves as a carrier. A preparation method of the aluminum powder comprises the following steps of fusing aluminum at the temperature of 680 DEG C in a vacuum environment; staying the fused aluminum in gaps of the white carbon black; and performing argon protecting grinding on the fused aluminum to form spherical aluminum powder of which the average grain diameter is 50-100 nanometers and the degree of sphericity is above 0.75. Monomers wrap the surface of the aluminum powder in a gathered manner, so that the oxygen content of the spherical aluminum powder is reduced; and influences of aluminum oxide on fusion of the aluminum are avoided, the fusing temperature of the obtained aluminum powder is low, the aluminum powder is fused uniformly, tissues in metal are uniform when the aluminum powder is used for 3D printing, the forming precision of products is improved, and the aluminum powder can be used for preparing precise metal products of complicated components.

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

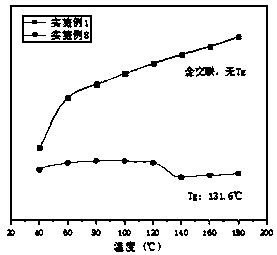

Spherical polyphenylene sulfide powdery material for 3D printing and preparation method of spherical polyphenylene sulfide powdery material

The invention provides a spherical polyphenylene sulfide powdery material for 3D printing. According to the material, nano mica powder is dispersed in polyphenylene sulfide and has quick meltbility and flowability. The invention further provides a preparation method of the spherical polyphenylene sulfide powdery material for 3D printing. The spherical polyphenylene sulfide powdery material with high sphericity is obtained through crushing and spheroidizing. Powdery polyphenylene sulfide is subjected to surface softening and pelletizing through high-temperature air flow under the action of a crosslinking agent, and the spherical polyphenylene sulfide powdery material with high sphericity is obtained. With the introduction of nano mica powder, the spherical polyphenylene sulfide material can be quickly and uniformly heated and melted and is suitable for the field of quick forming during 3D printing.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

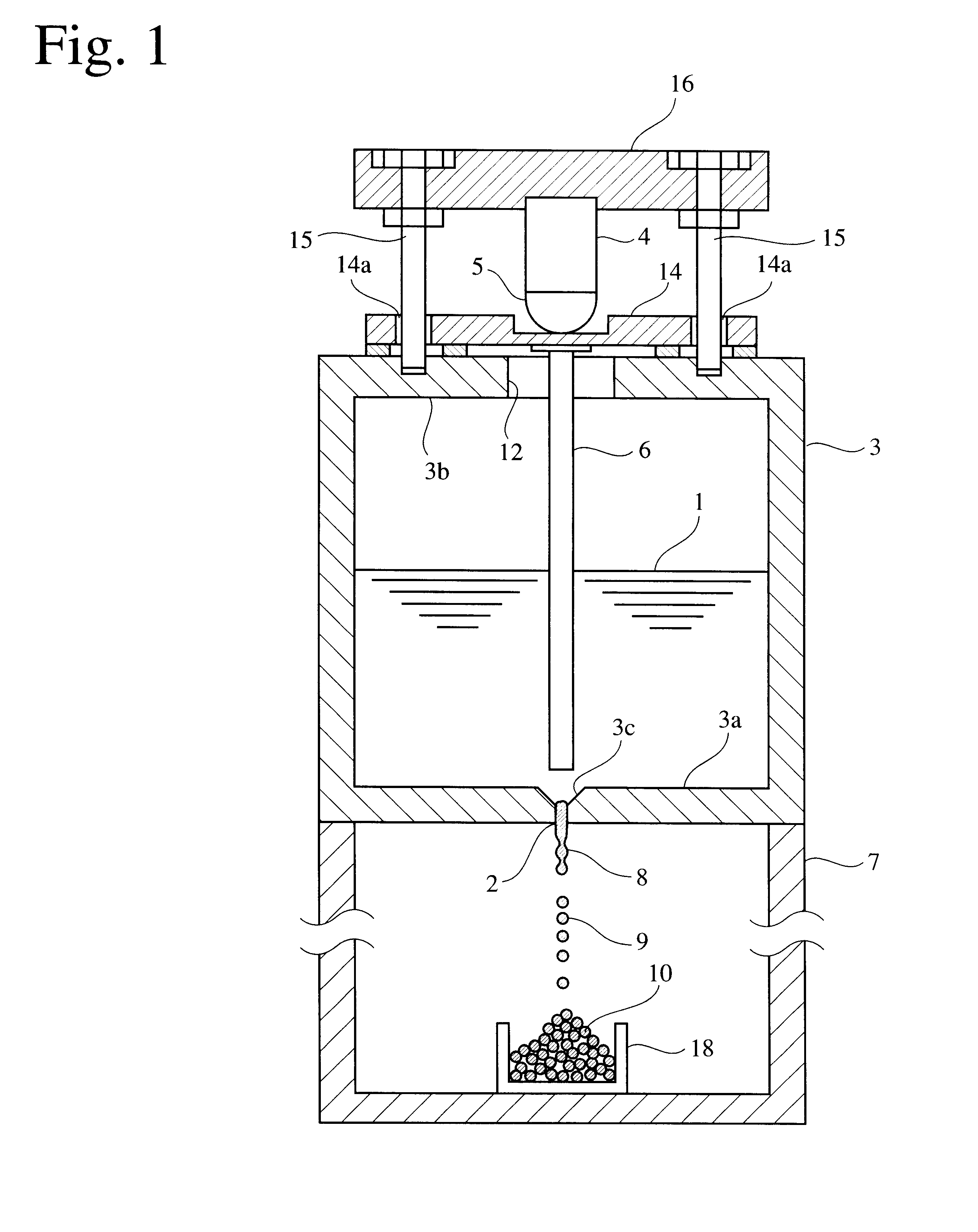

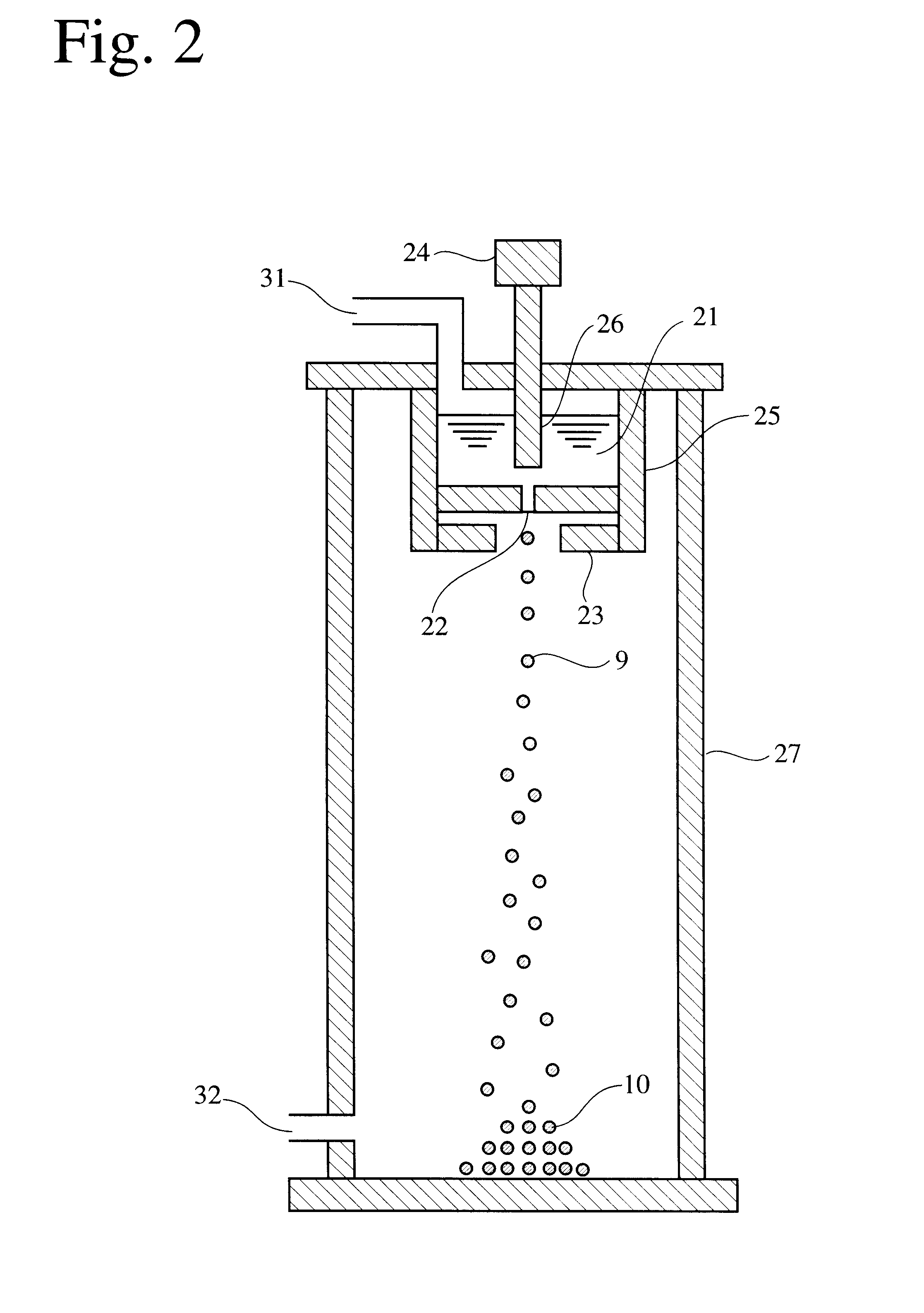

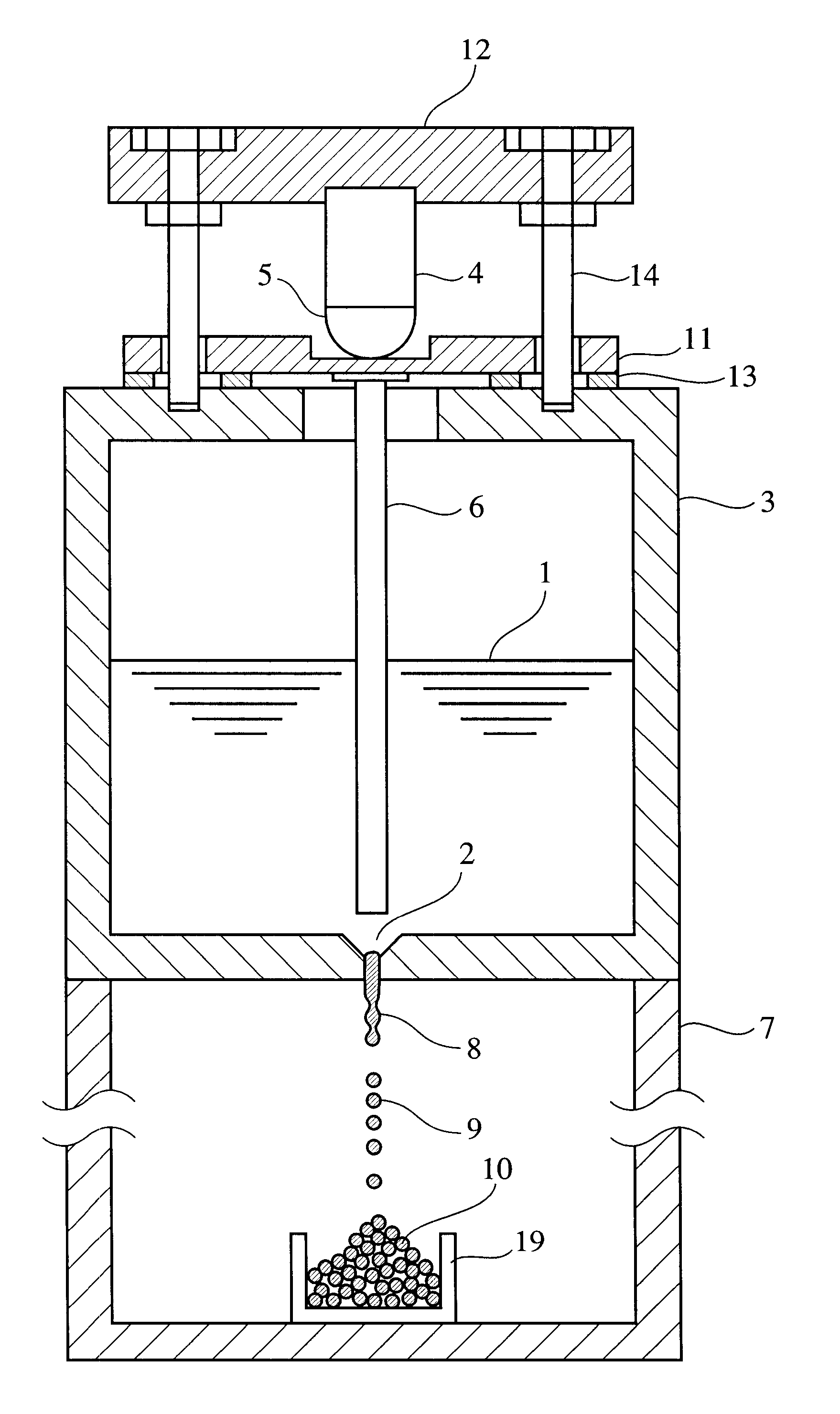

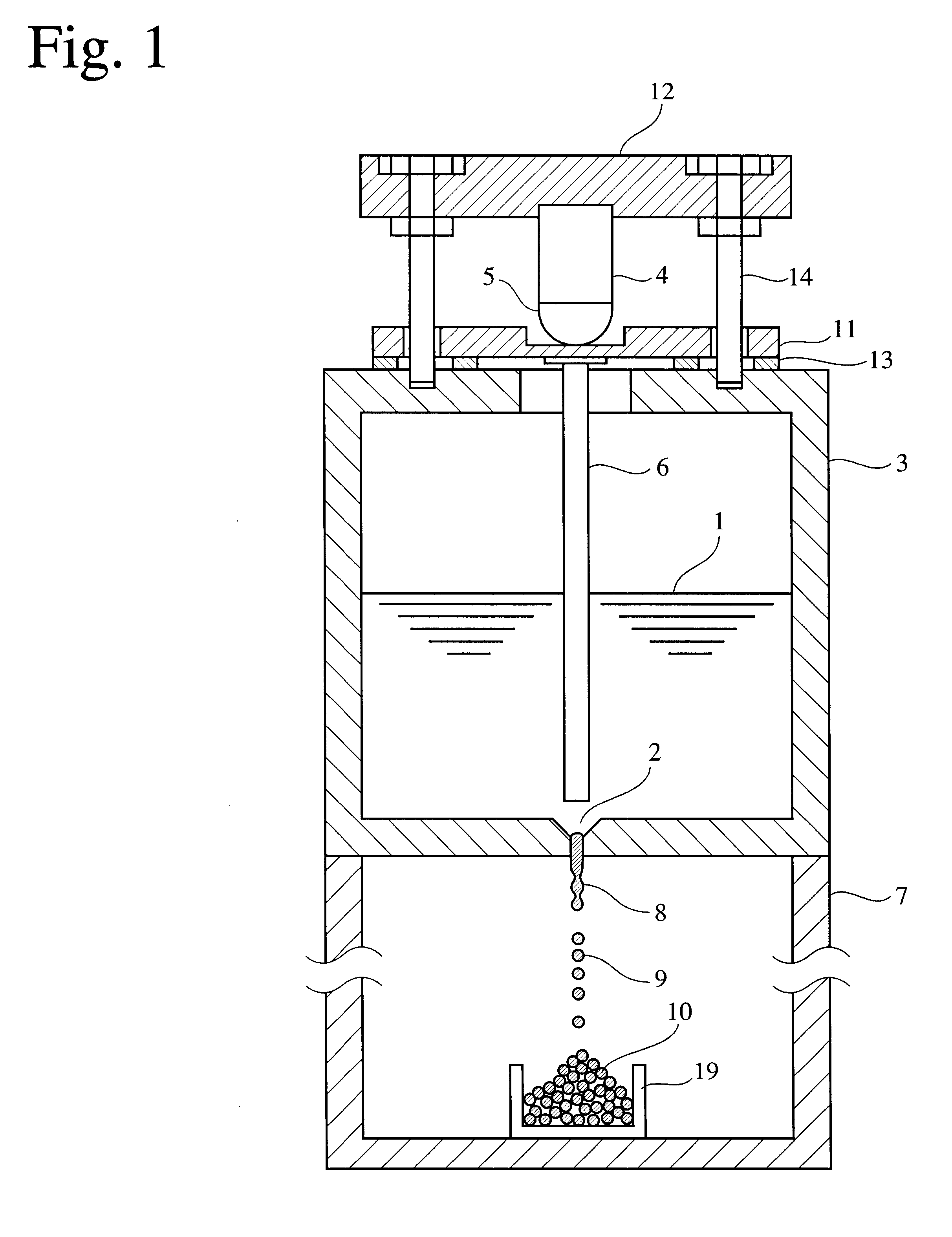

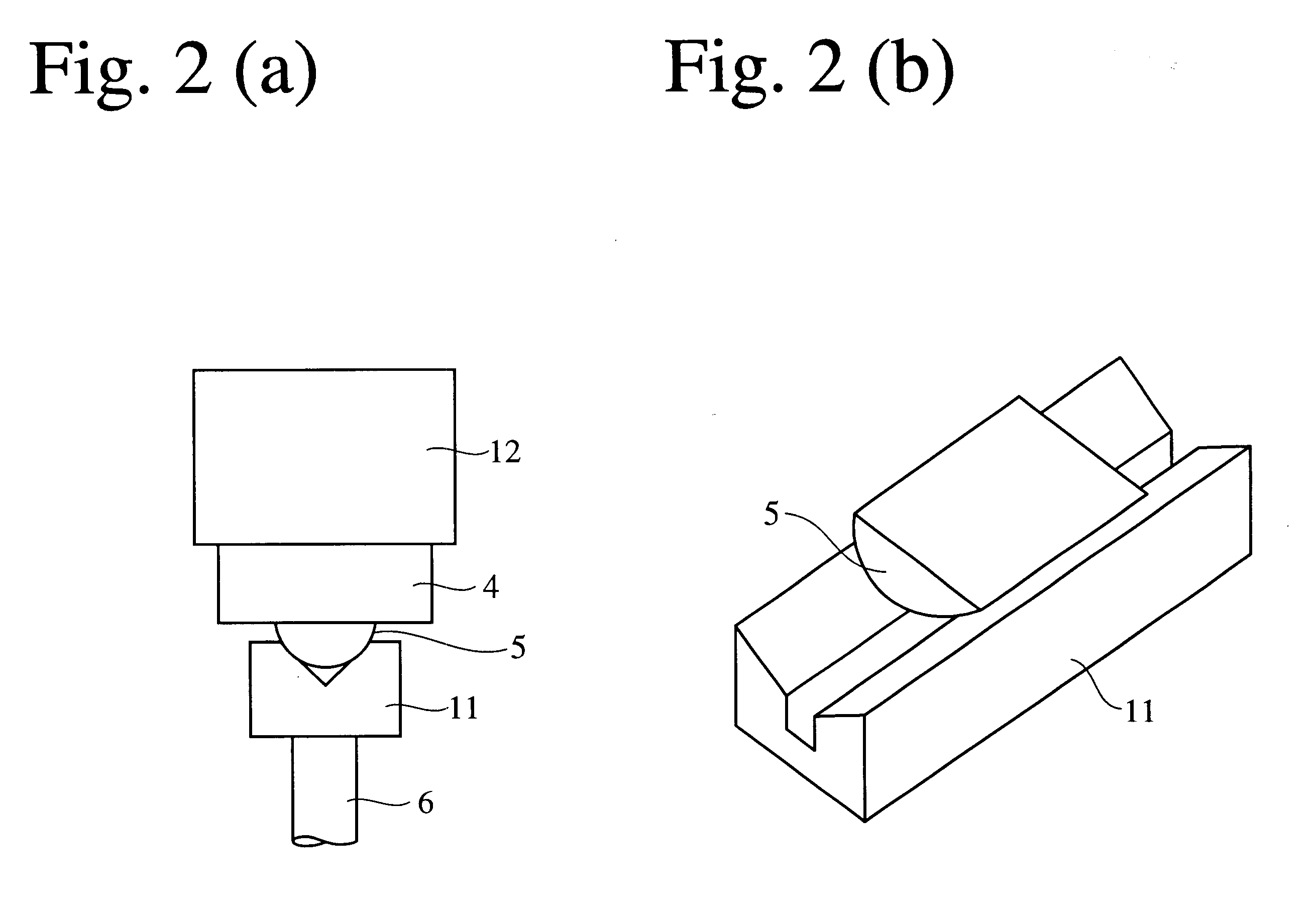

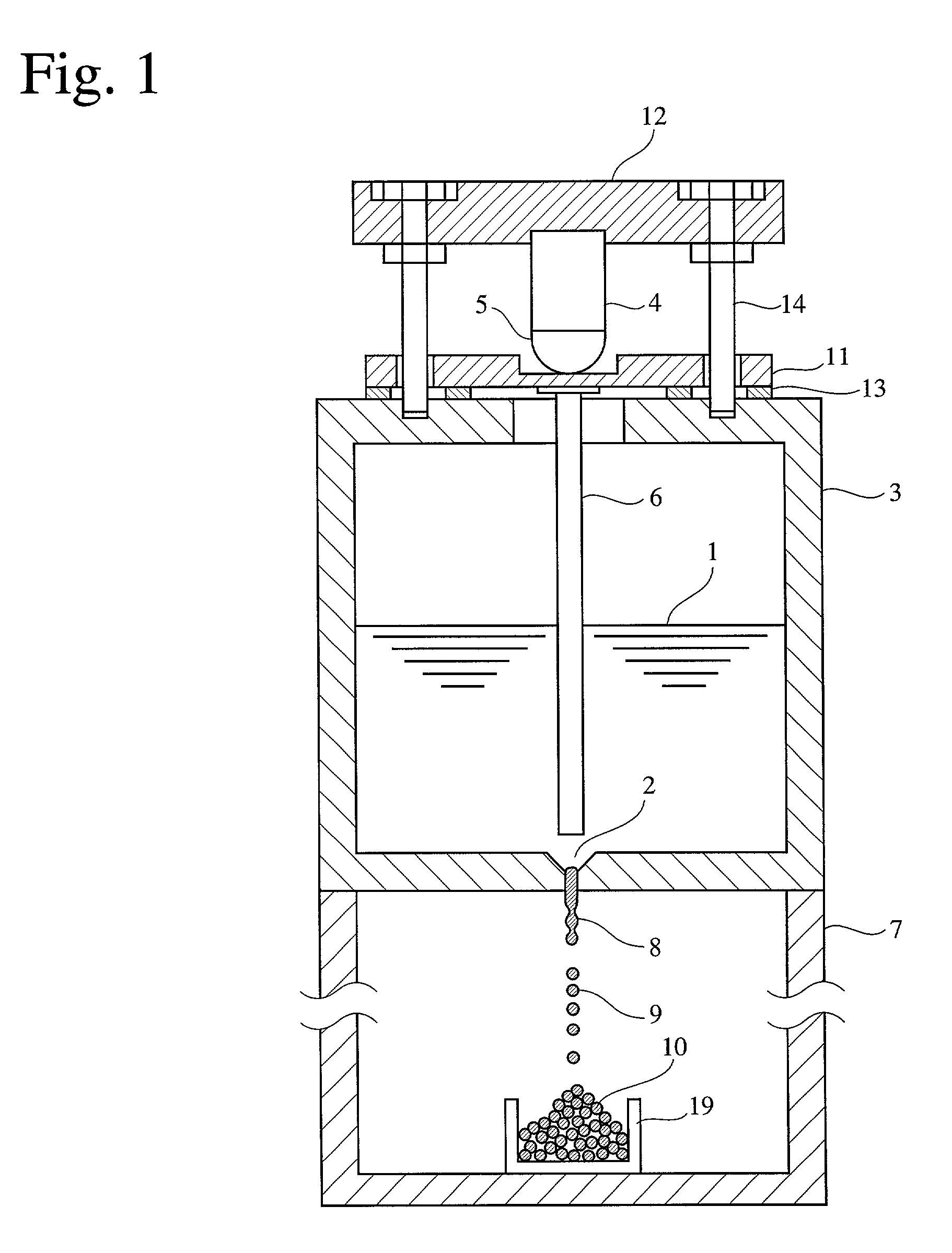

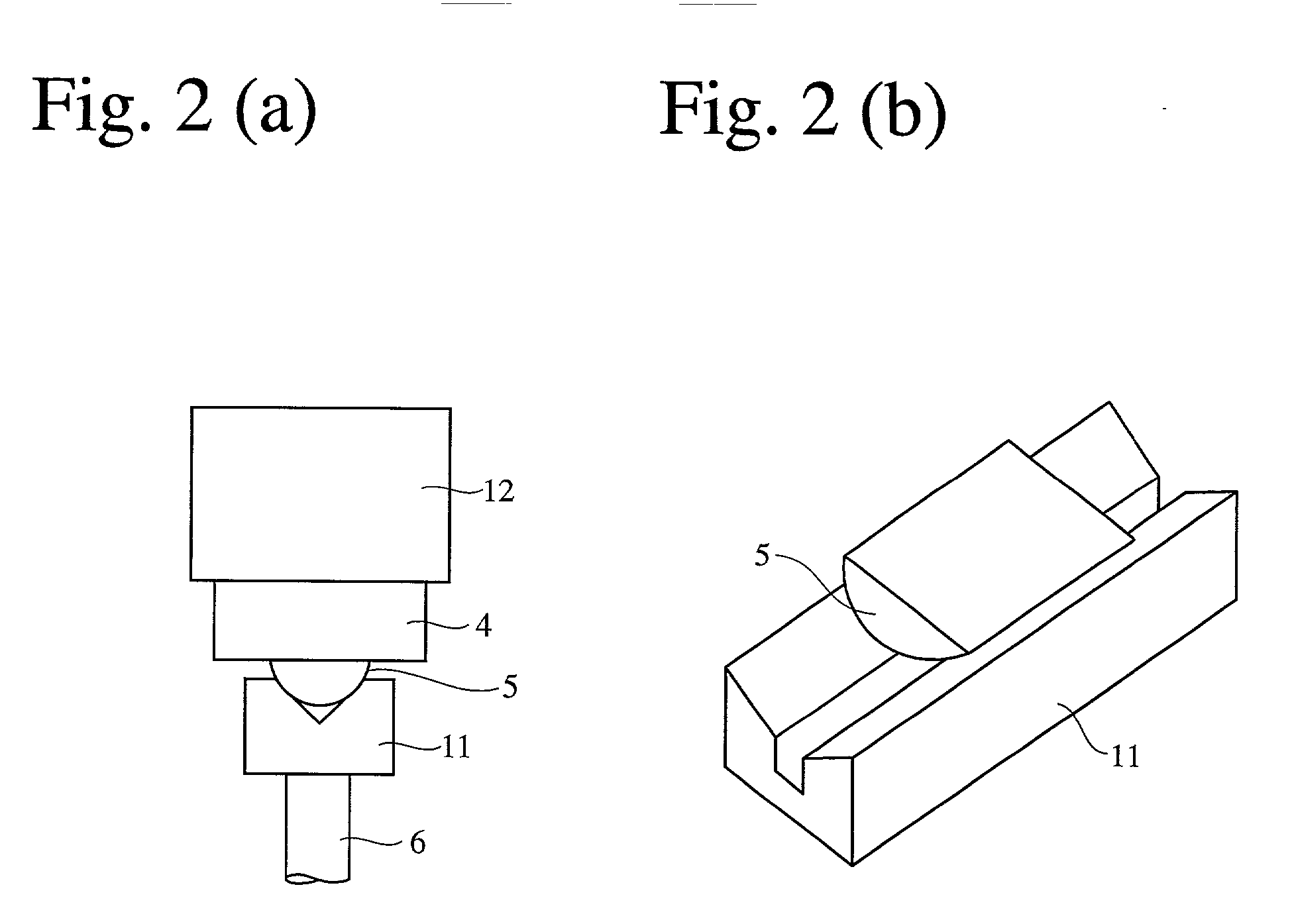

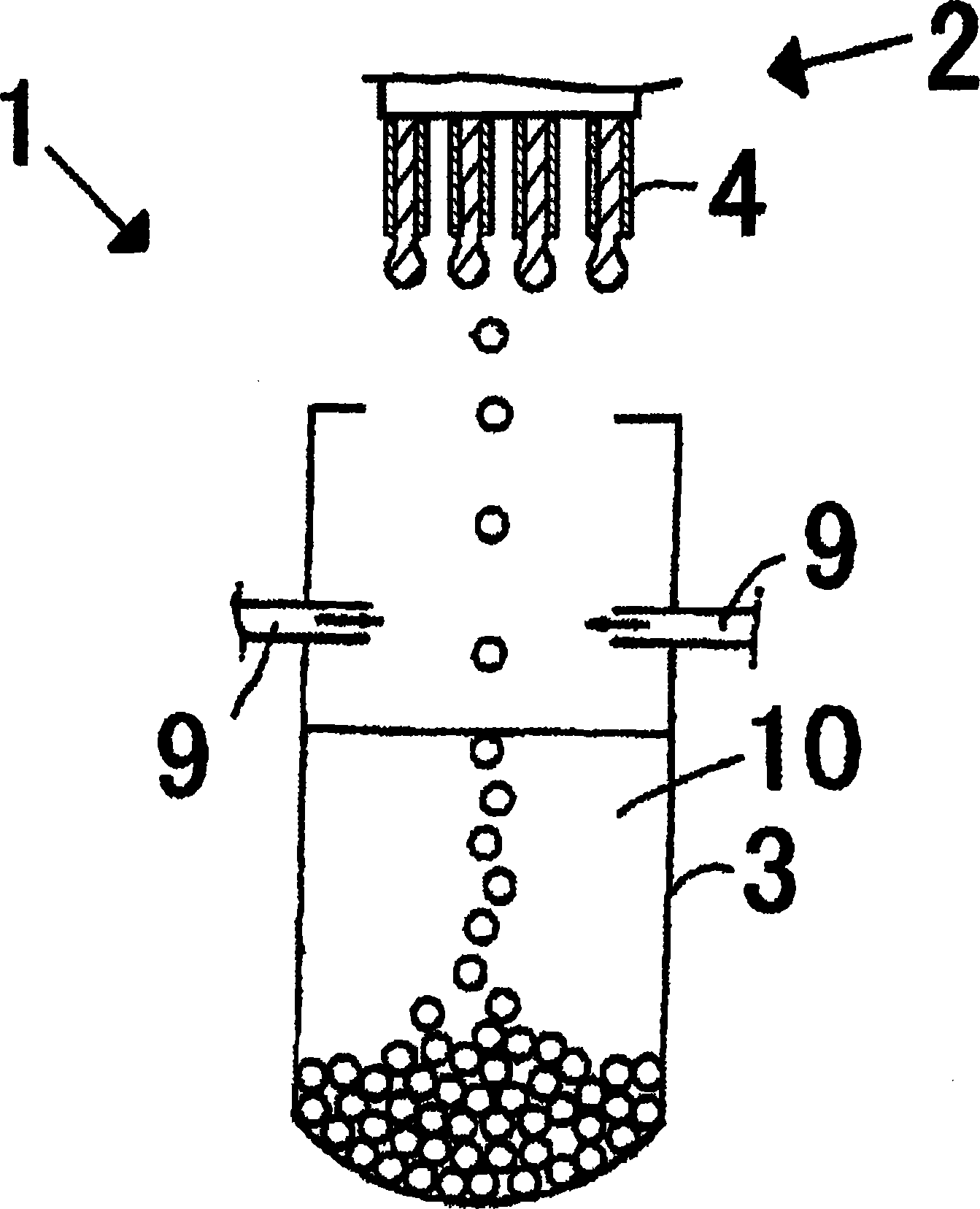

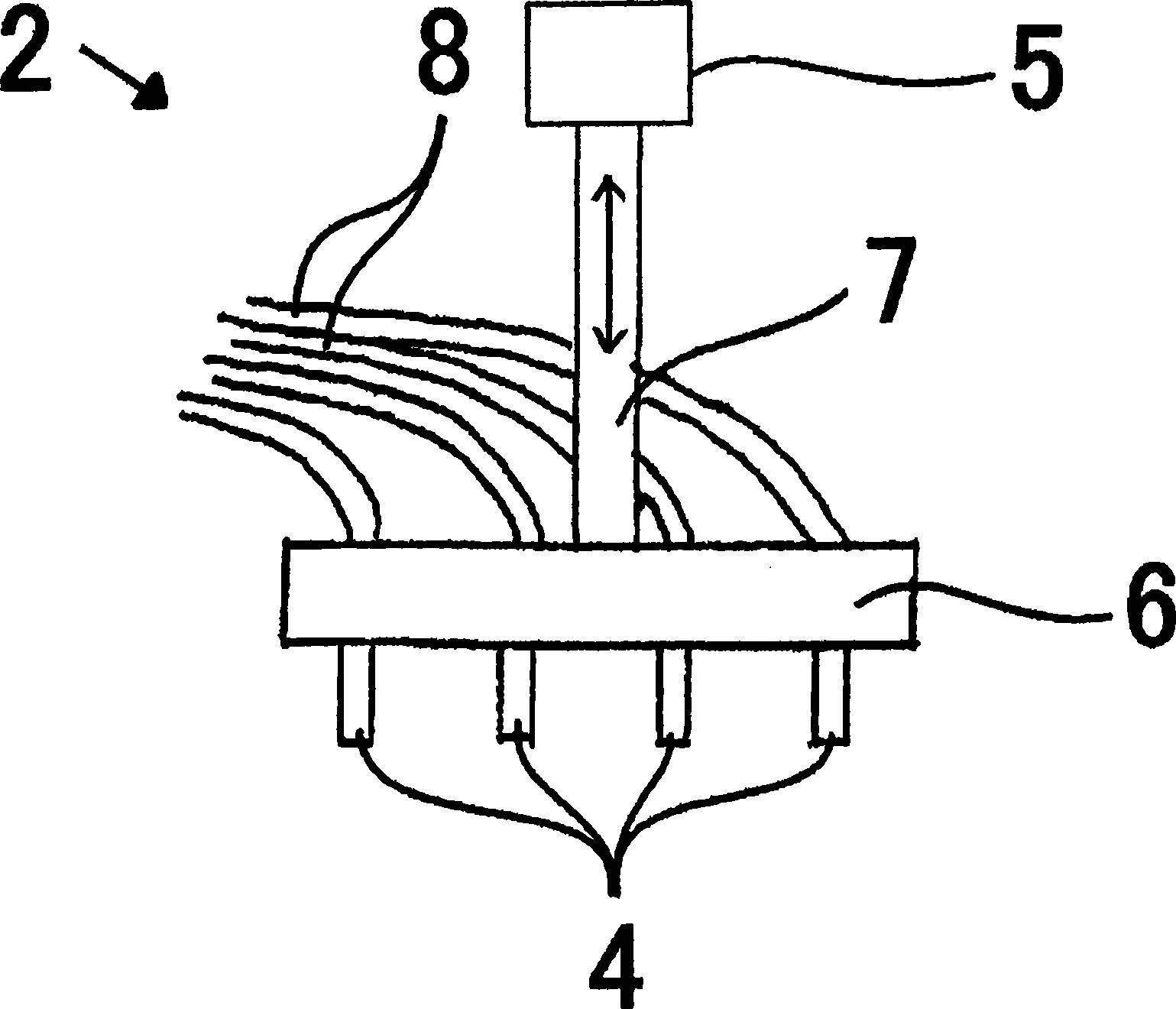

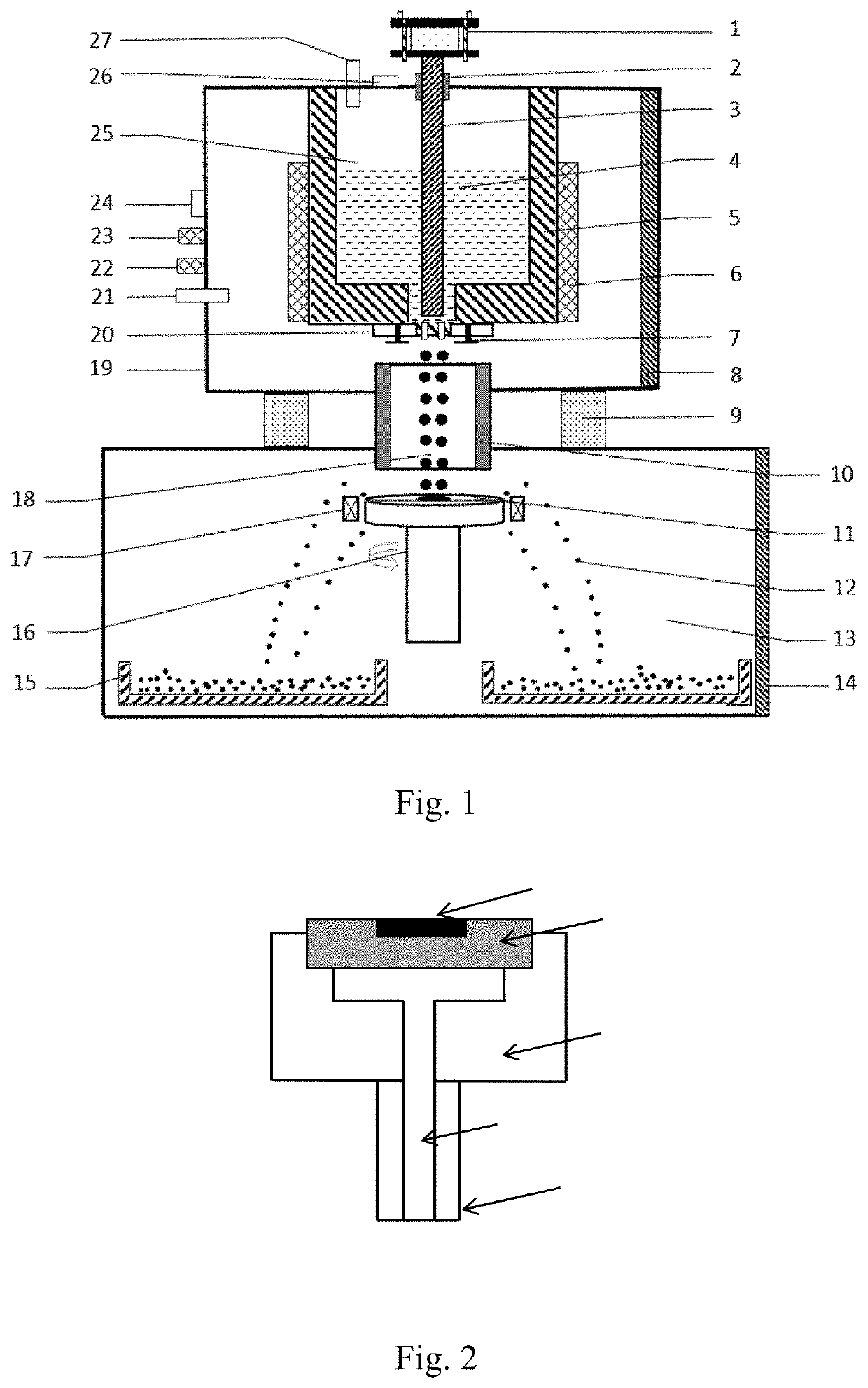

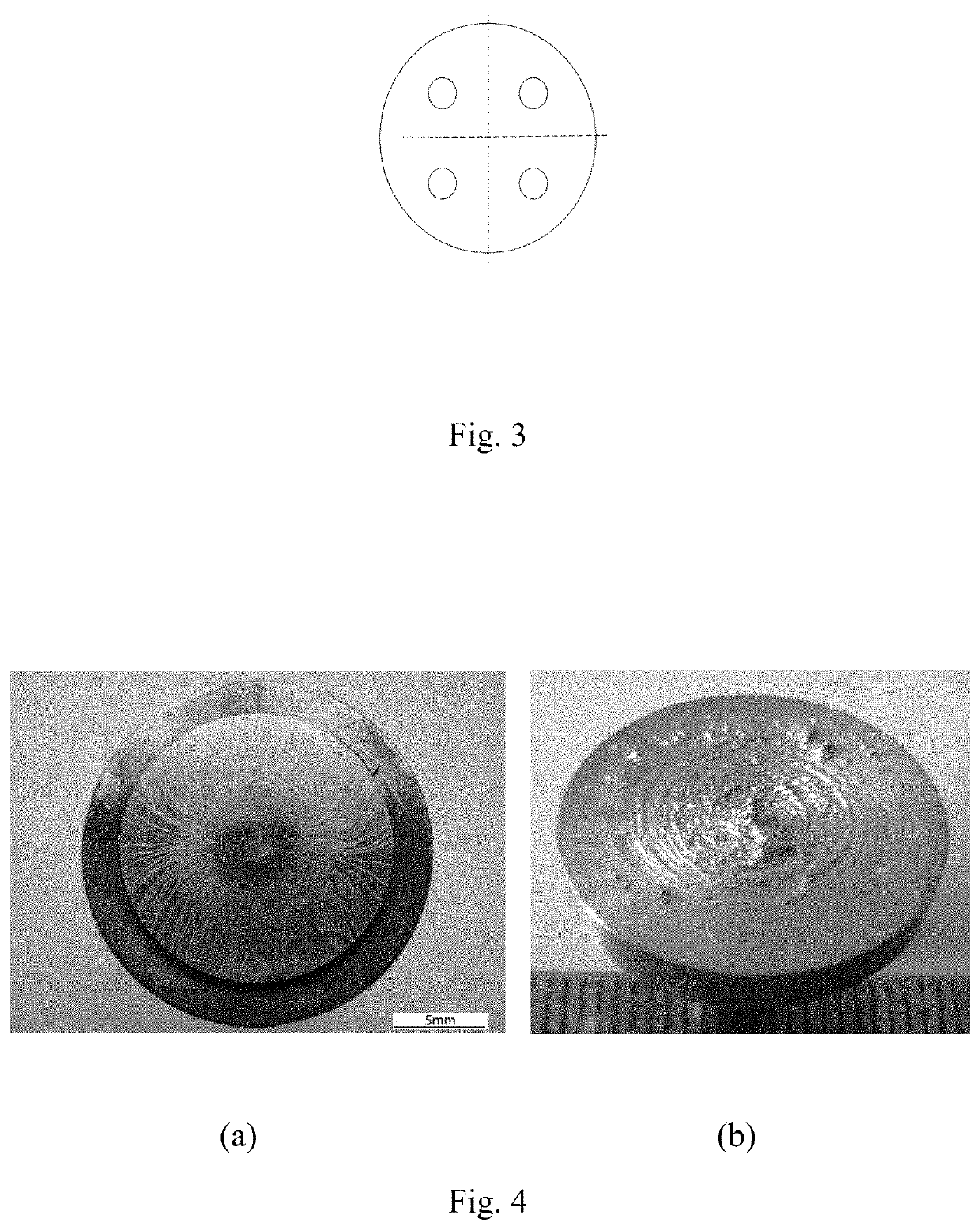

Apparatus for producing fine metal balls

InactiveUS6554166B2High degree of sphericityStable productionMelt-holding vesselsBlast furnace componentsCrucibleMaterials science

An apparatus for producing fine metal balls comprising a crucible 3 for holding a metal melt and equipped with orifices 2 for ejecting the metal melt; a vibration rod 6 for giving vibration to the melt 1 held in the crucible 3; a vibrator 4 for giving vibration to the vibration rod 6; a means 5 for transmitting the vibration of the vibrator 4 to the vibration rod 6; and a chamber 7 in which melt droplets 9 ejected through the orifices 2 are solidified while dropping, the vibration-transmitting means 5 having one end in contact with the vibrator 4 and the other end abutting a support member 11 connected to the vibration rod 6; the vibration-transmitting means 5 having a cross section decreasing as it nears the support member 11.

Owner:HITACHI METALS LTD

Porous silicon

InactiveUS20130034714A1High pore volumeImprove solubilityCosmetic preparationsPaper/cardboard articlesMaterials sciencePorous silicon

Owner:PSIMEDICA

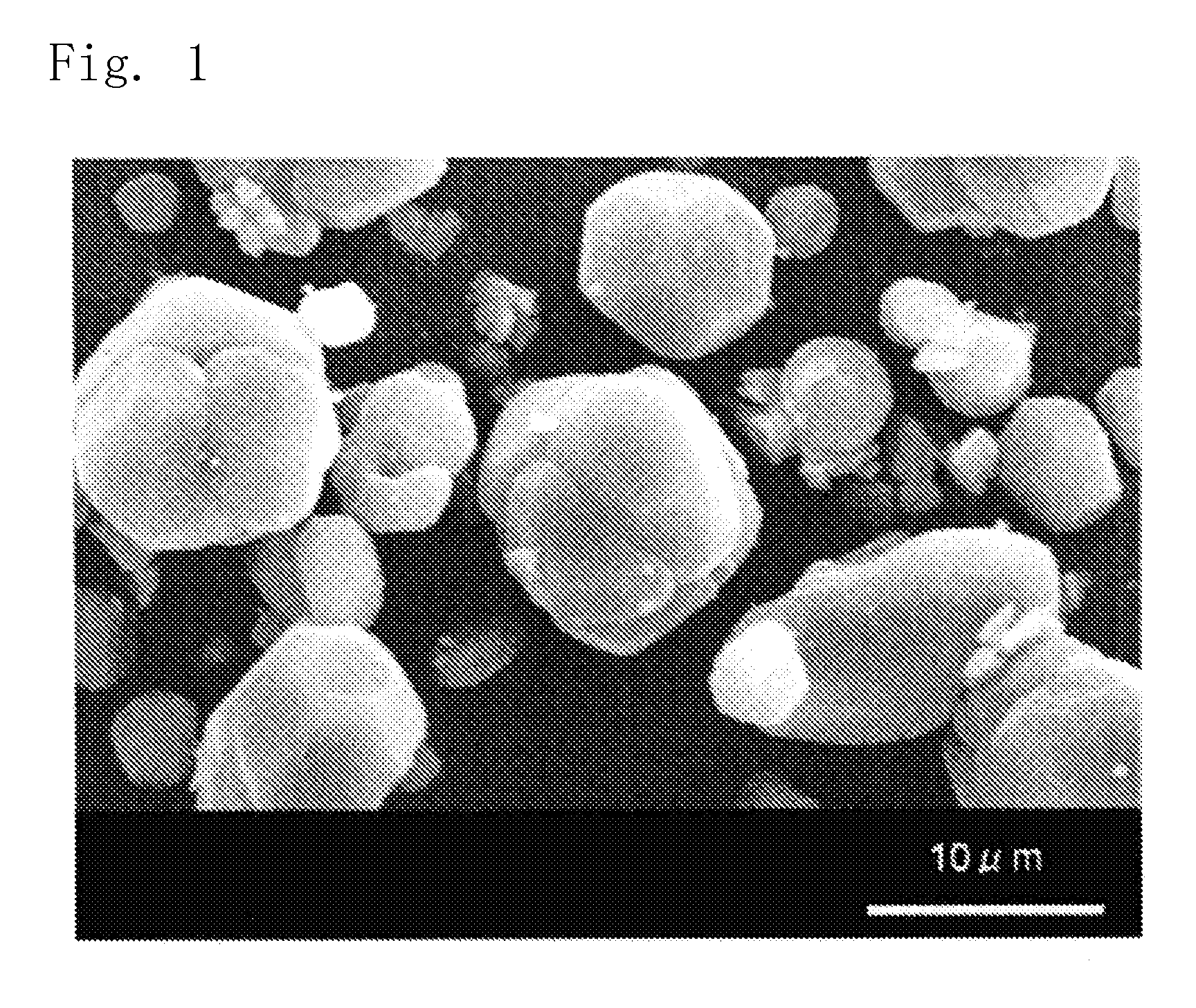

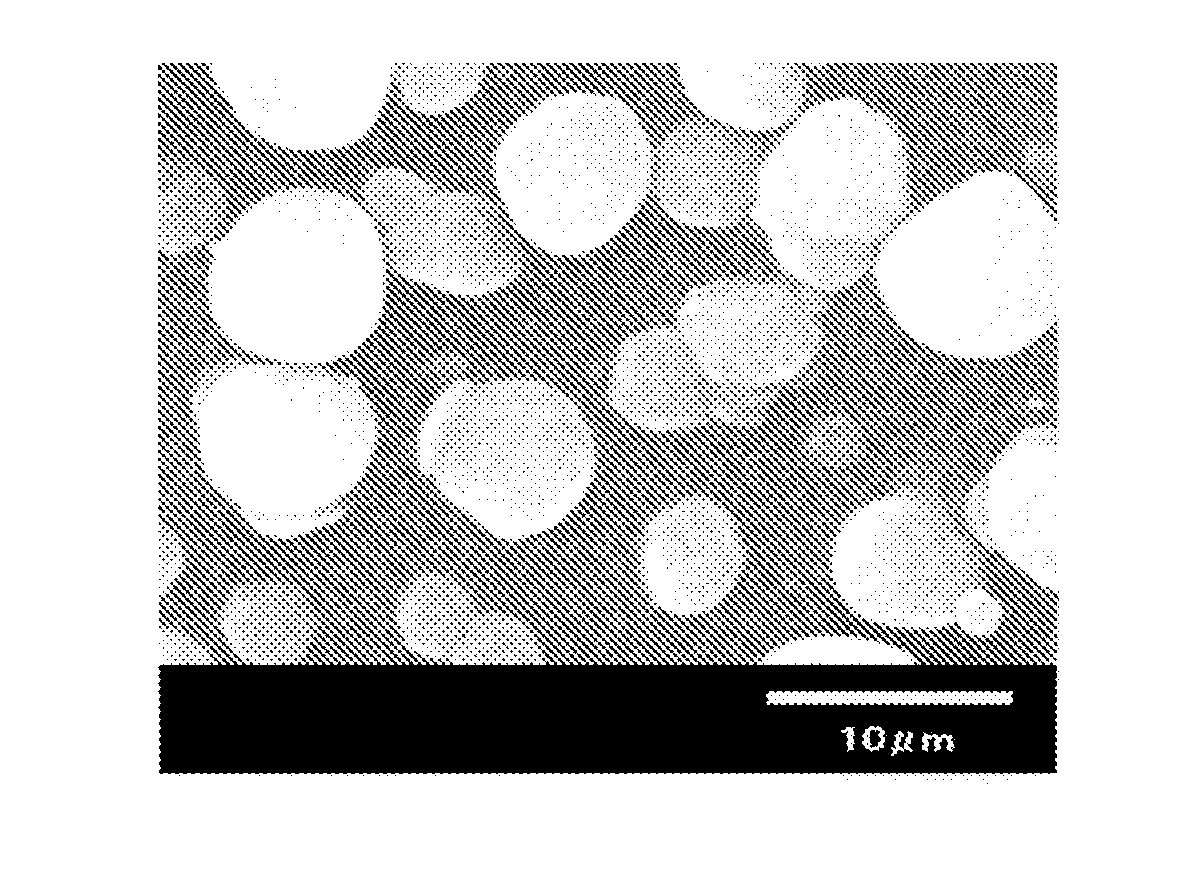

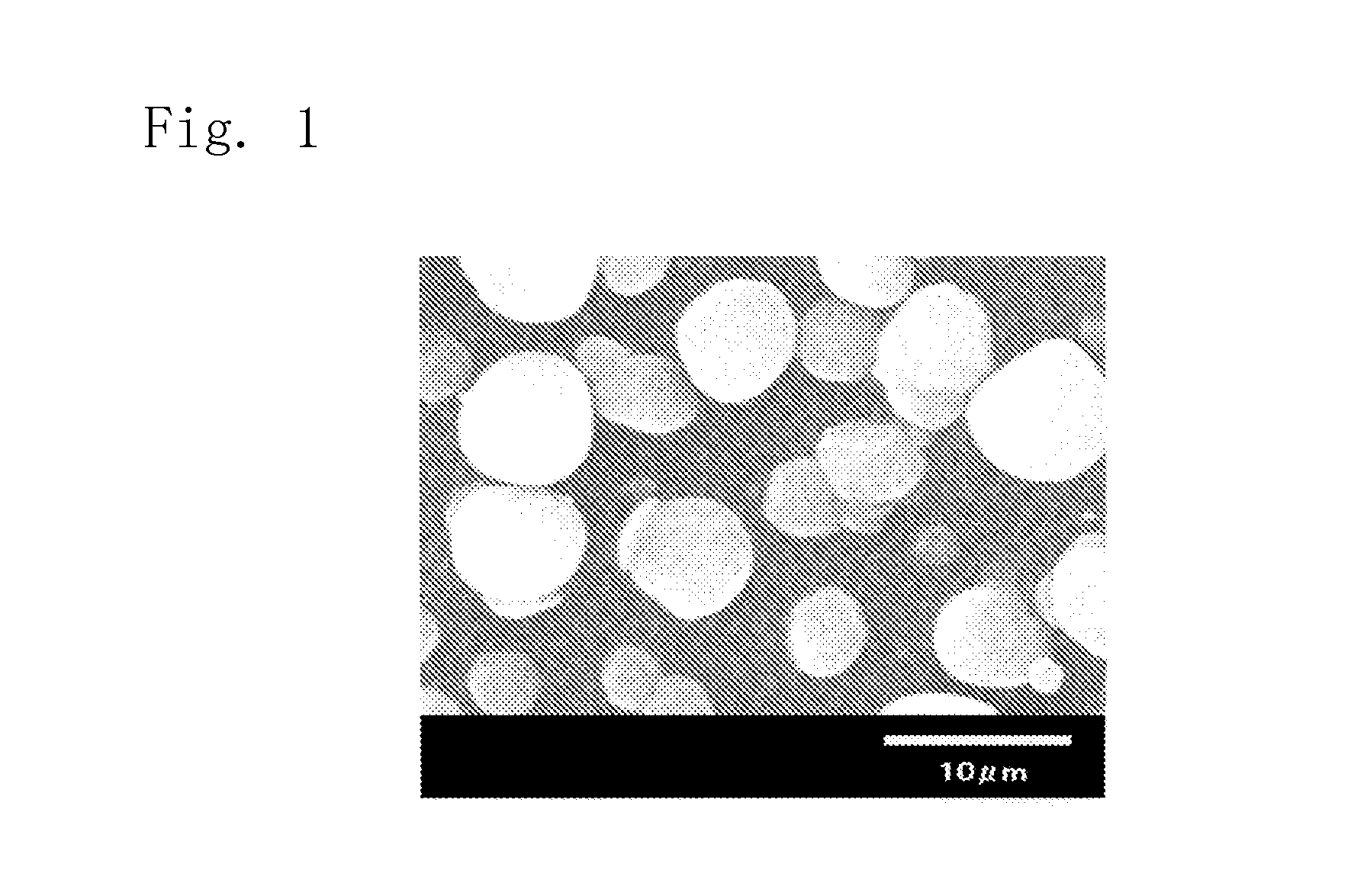

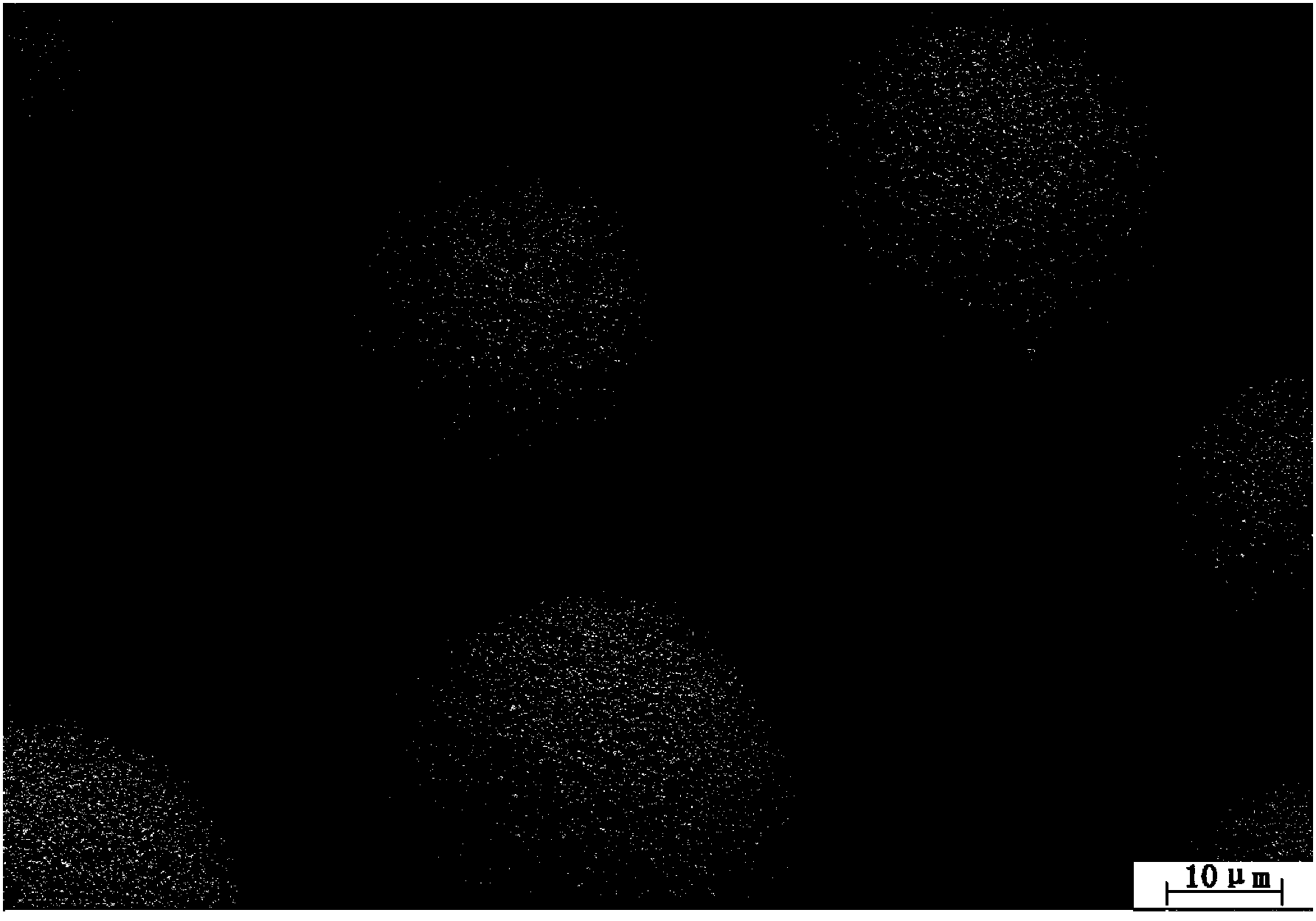

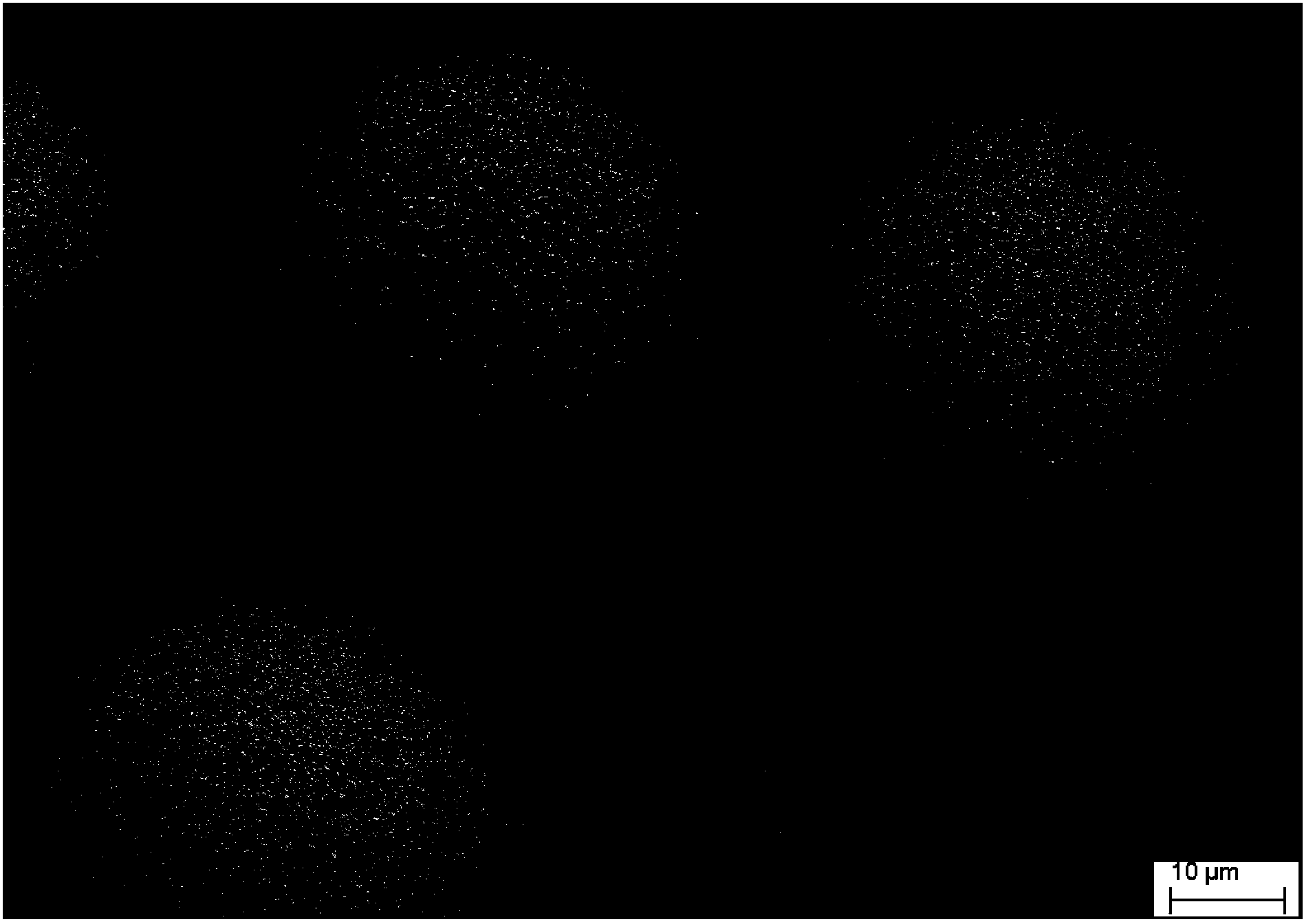

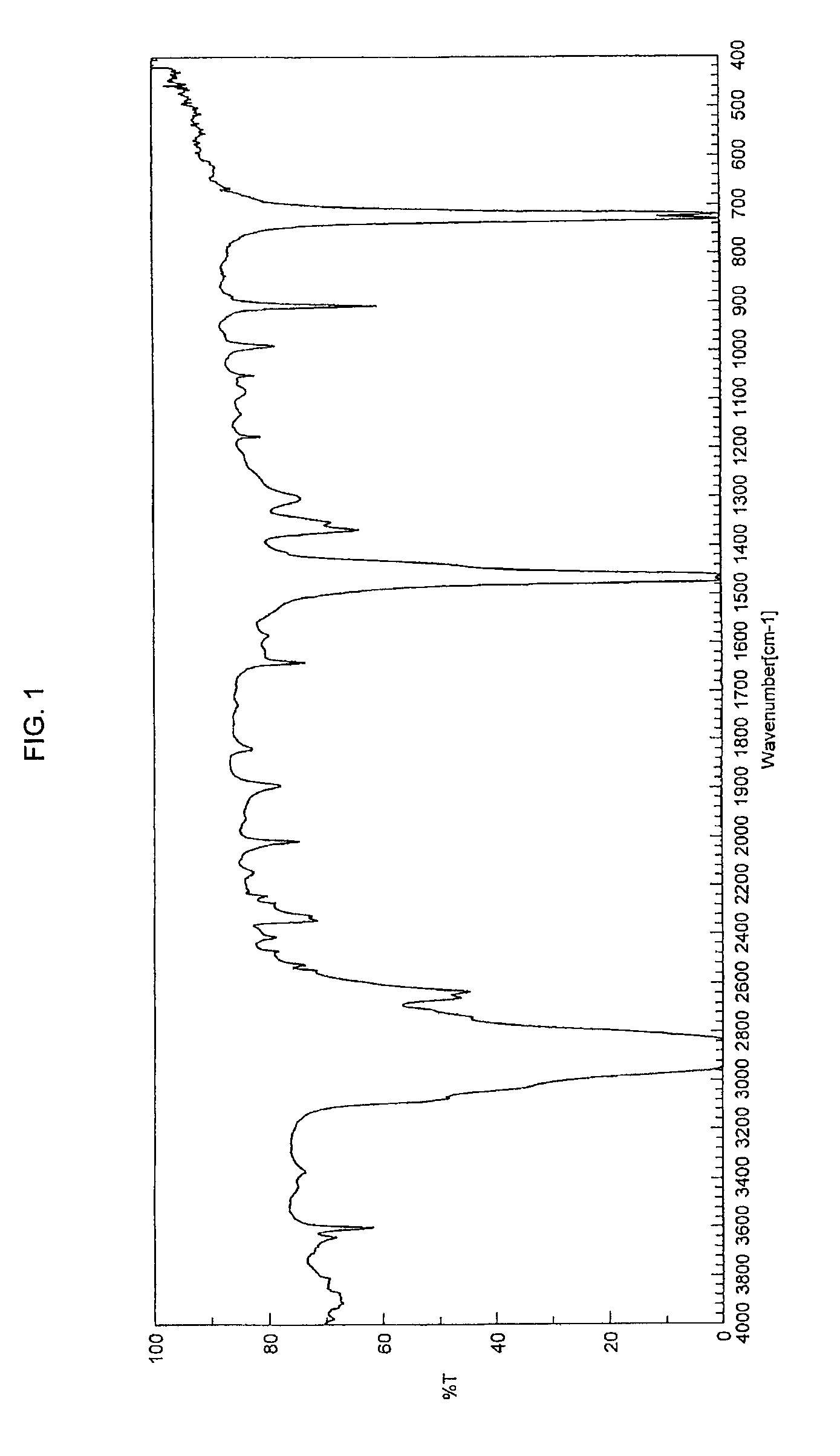

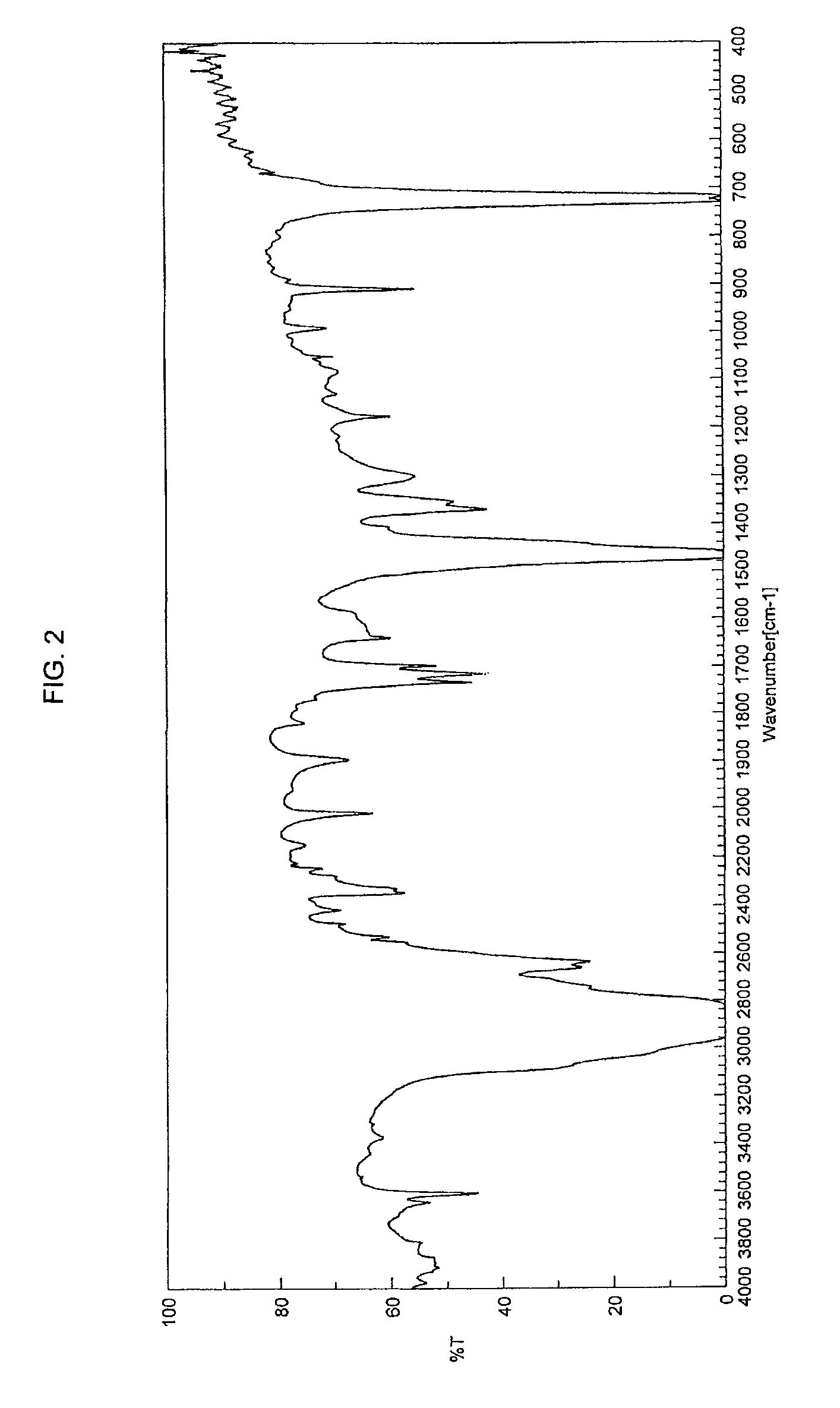

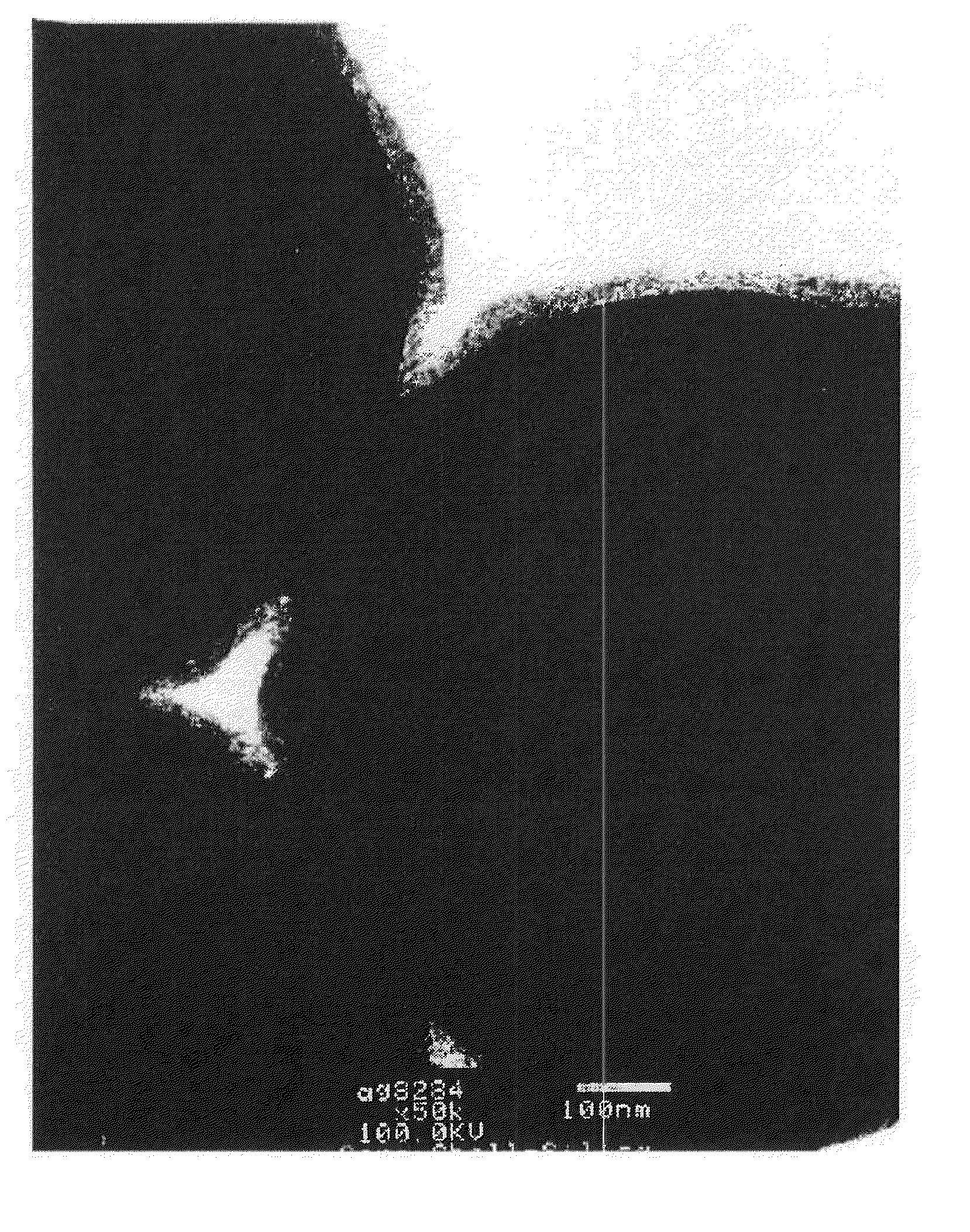

Aluminum nitride powder and method of producing the same

ActiveUS20130244036A1High degree of sphericityIncrease production capacityNitrogen compoundsSynthetic resin layered productsHydrated aluminaRare earth

[Problem] To provide a method of producing aluminum nitride that has high conducting property and can be excellently filled and is useful as a filler for heat-radiating materials, and an aluminum nitride powder obtained by the same method.[Means for Solution] An aluminum nitride powder is produced by reducing and nitriding:an alumina powder or a hydrated alumina powder having a primary grain size of 0.001 to 6 μm; anda powder of a compound containing a rare earth metal element and having an average grain size in a range of 2 μm to 80 μm, the average grain size being not less than 6 times as great as the primary grain size of the alumina powder or the hydrated alumina powder;in the presence of a carbon powder at a temperature of 1620° C. to 1900° C. for not less than 2 hours.

Owner:TOKUYAMA CORP

Production of fine spherical thermoplastic resin particles

InactiveUS20060269749A1Reduce loadEasy to carryLiquid surface applicatorsSynthetic resin layered productsWater insolubleWater soluble

Fine spherical thermoplastic resin particles are produced by preparing a resin composition including a matrix of a water-soluble material, and fine particles of a water-insoluble thermoplastic resin dispersed in the matrix, the fine particles and the matrix each being melted or softened in the resin composition; cooling and solidifying the resin composition under such conditions that the resin composition does not undergo deformation due to stress; and removing the water-soluble material by washing with water to thereby yield fine spherical particles containing the water-insoluble thermoplastic resin. This method has wide applicability, applies less loads on the environment, does not require special devices, can be easily conducted, and can efficiently produce such particles. The resulting particles are highly spherical.

Owner:DAICEL EVONIK LTD

Apparatus for producing fine metal balls

InactiveUS20020056950A1High degree of sphericityStable productionMelt-holding vesselsBlast furnace componentsCrucibleMaterials science

An apparatus for producing fine metal balls comprising a crucible 3 for holding a metal melt and equipped with orifices 2 for ejecting the metal melt; a vibration rod 6 for giving vibration to the melt 1 held in the crucible 3; a vibrator 4 for giving vibration to the vibration rod 6; a means 5 for transmitting the vibration of the vibrator 4 to the vibration rod 6; and a chamber 7 in which melt droplets 9 ejected through the orifices 2 are solidified while dropping, the vibration-transmitting means 5 having one end in contact with the vibrator 4 and the other end abutting a support member 11 connected to the vibration rod 6; the vibration-transmitting means 5 having a cross section decreasing as it nears the support member 11.

Owner:HITACHI METALS LTD

Spherical aluminum nitride powder

ActiveUS20130164534A1High degree of sphericityFlat surfaceNitrogen compoundsSynthetic resin layered productsOxygen contentThermal conductivity

[Problems]To provide a spherical aluminum nitride powder that features high thermal conductivity and filling property, and that is useful as a filler for a heat radiating material, and a method of producing the same.[Means for Solution]A spherical aluminum nitride powder comprising aluminum nitride particles having an average particle diameter of 3 to 30 μm, a sphericalness of not less than 0.75, and an oxygen content of not more than 1% by weight wherein, when the average particle diameter is d (μm), the specific surface area S (m2 / g) satisfies the following formula (1),(1.84 / d)≦S≦(1.84 / d+0.5) (1)

Owner:TOKUYAMA CORP

Spherical composite composition and process for producing spherical composite composition

InactiveUS20060278843A1High sphericityHigh degree of sphericityInorganic material magnetismDevelopersProduction rateAqueous medium

Owner:MITSUI CHEM INC

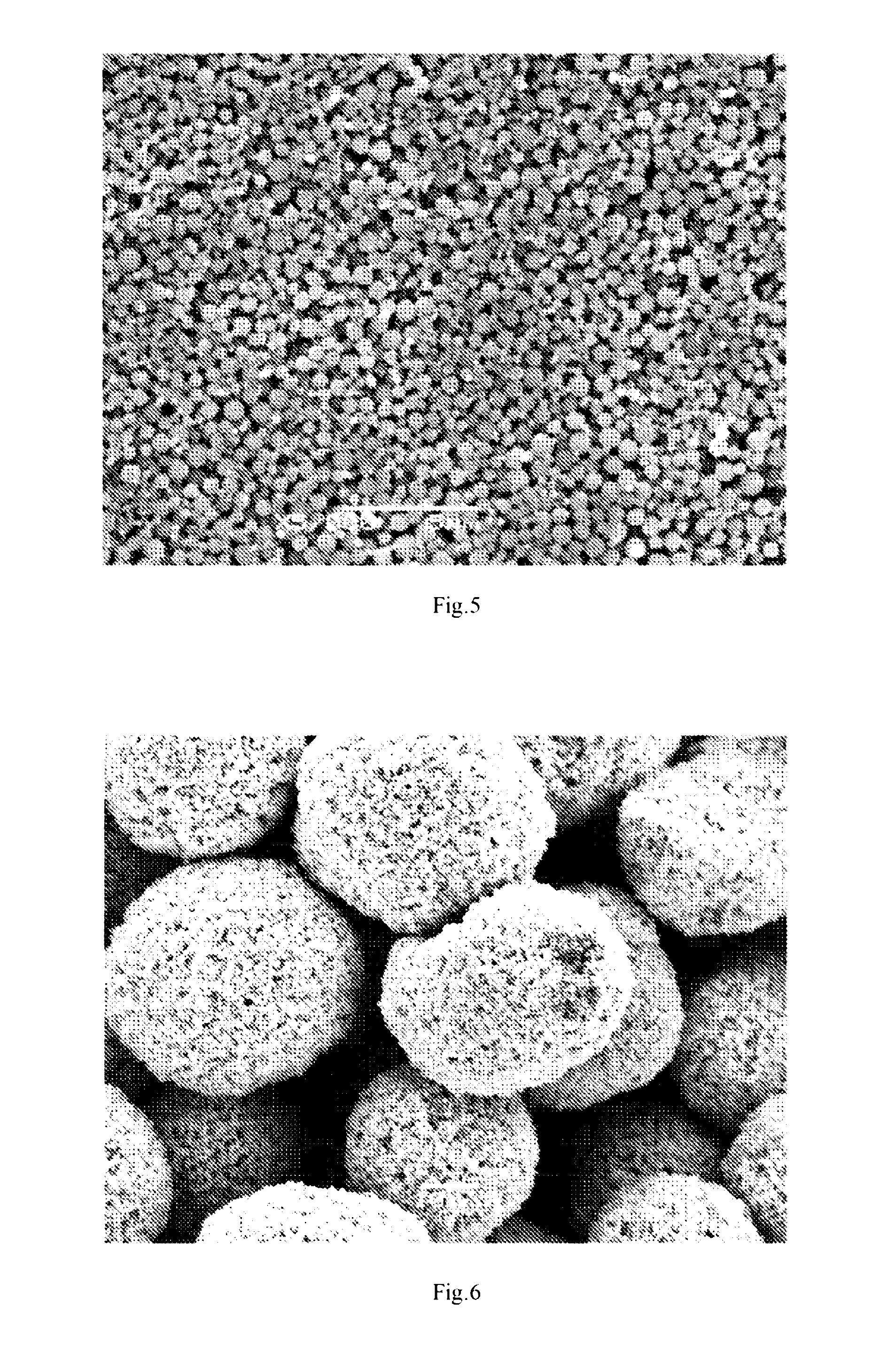

Plasma-etching-resistant granulated yttrium oxide for hot spraying and preparation method thereof

The invention belongs to the technical field of hot spraying, and particularly relates to plasma-etching-resistant granulated yttrium oxide for hot spraying and a preparation method thereof. The preparation method of the plasma-etching-resistant granulated yttrium oxide for hot spraying comprises the following steps: preparing nano or ultrafine yttrium oxide powder and deionized water or an organic solution into a paste, performing depolymerization and reduction, adding surface activity activator into the paste for preparation, and performing hot expansion balling and high-temperature densification treatment to obtain the granulated yttrium oxide for hot spraying. According to the invention, the surface activity activator is added into the paste before hot expansion balling, so that the prepared granulated yttrium oxide for hot spraying is favorable in spherical degree, and the high-spherical-degree favorable-flowability high-density granulated yttrium oxide for hot spraying can be obtained without later spheroidization, thereby achieving favorable flowability during hot spraying, ensuring that the supply of the granulated yttrium oxide for hot spraying is more stable, and providing a guarantee for obtaining a hot spray coating having a uniform thickness.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

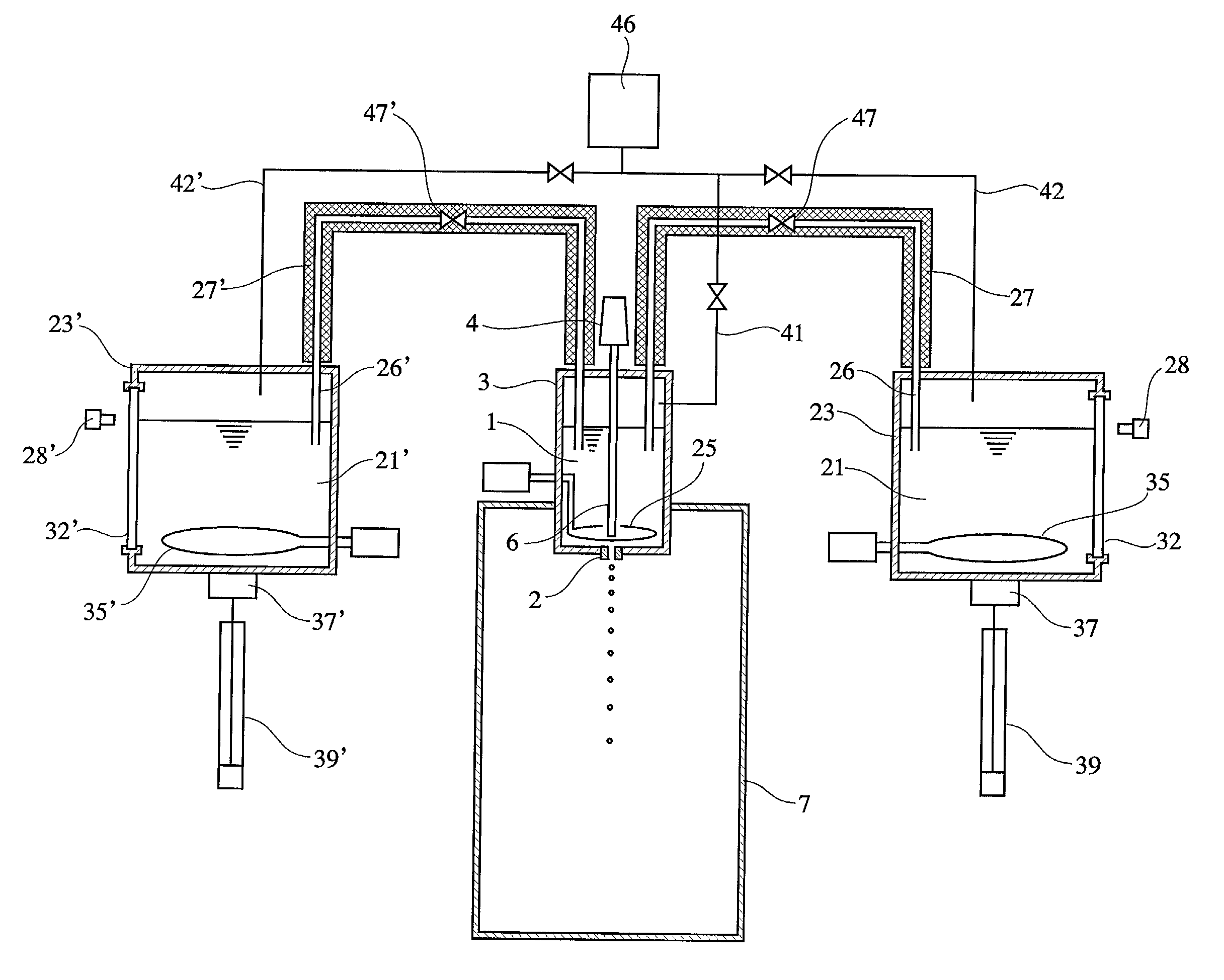

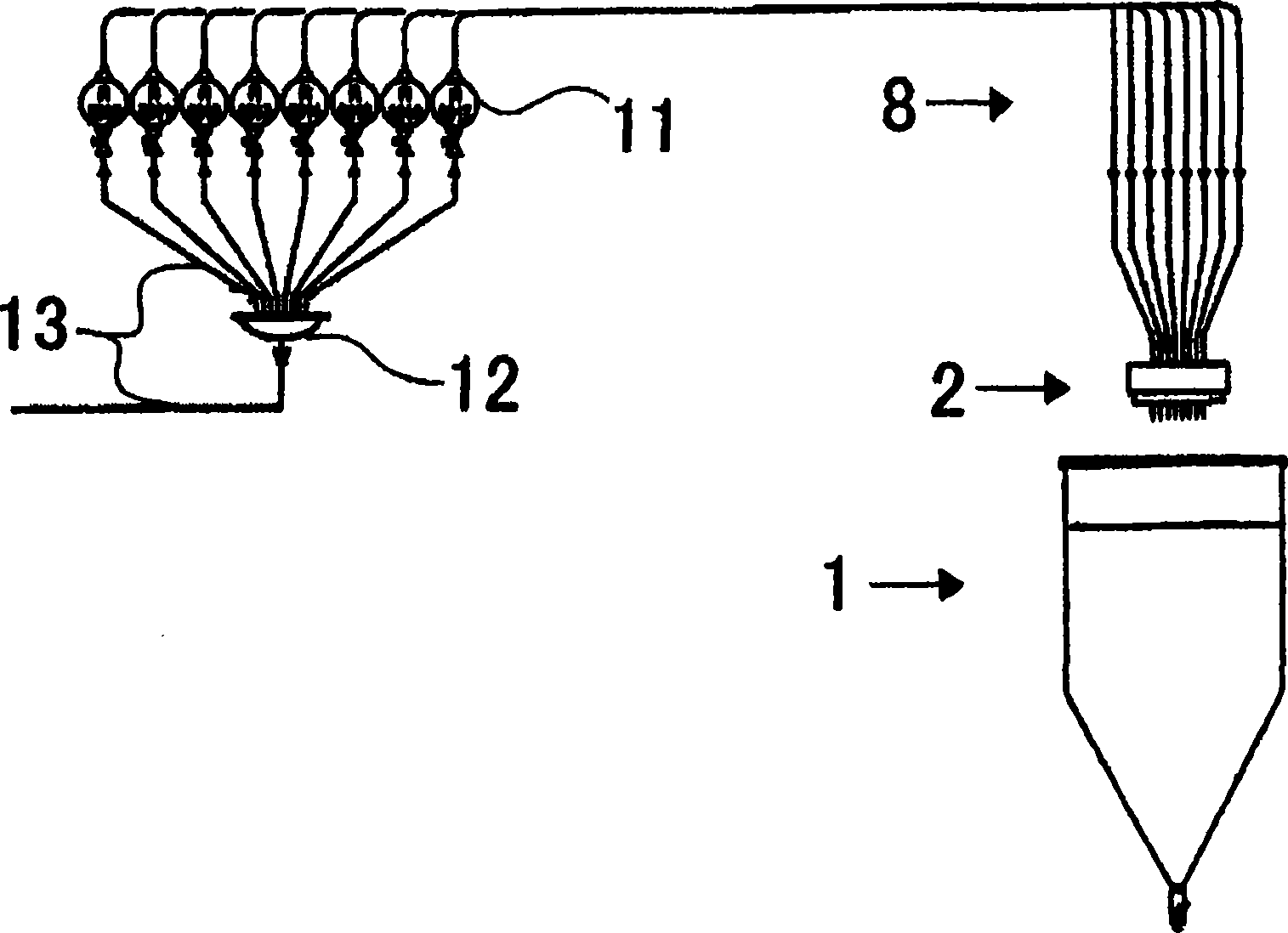

Dropping nozzle device, device for recovering dropping undiluted solution, device for supplying dropping undiluted solution, device for solidifying surface of droplet, device for circulating aqueous a

InactiveCN1867516AEasy to manufactureHigh degree of sphericityNuclear energy generationReactors manufactureEngineeringAmmonium diuranate

The object of the present invention is to provide the following devices: a dripping nozzle device that forms substantially spherical ADU particles, a dripping stock solution recovery device that prepares a homogeneous dripping stock solution, a dripping stock solution supply device that can drop liquid droplets of a uniform volume, and even liquid droplets Droplet surface solidification device that does not deform when it collides with the surface of ammonia solution when dropped, ammonia solution circulation device that can fully turn uranyl nitrate into ADU from the center of the droplet, and ADU with good sphericity The ADU particle manufacturing device for particles, the dripping nozzle device has an exciter that vibrates multiple nozzles at the same time, the dripping stock solution recovery device recovers the bottom fine stock solution in the nozzle and mixes it into the dripping stock solution, and the dripping stock solution supply device has a mechanism for falling The light irradiation mechanism that irradiates the droplet of the original solution with light, the droplet surface curing device sprays ammonia gas toward the drop path of the droplet of the original solution dripped from the nozzle, and the ammonia solution circulation device can make the droplets in the ammonia solution storage tank The ammonium diuranate particle manufacturing device uses the above-mentioned device for ascending flow in the ammonia solution in the interior.

Owner:NUCLEAR FUEL INDS

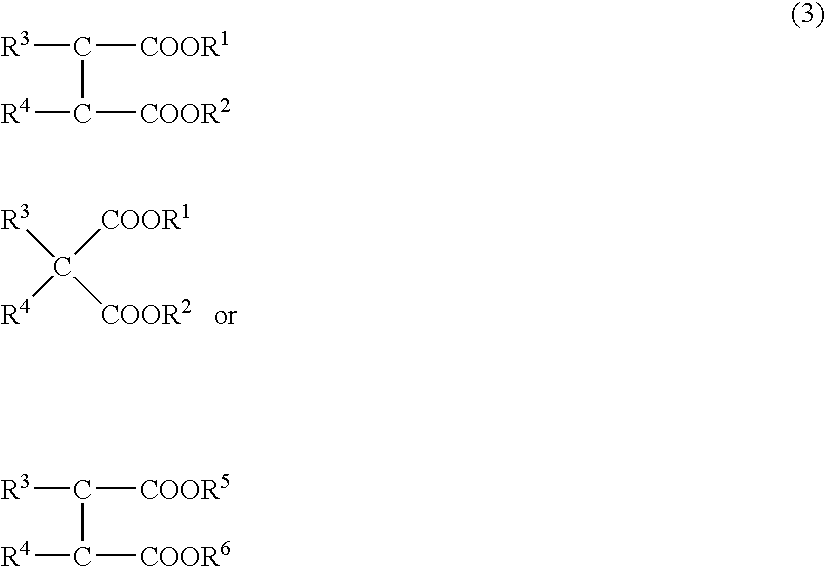

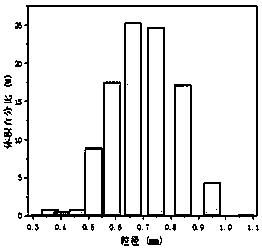

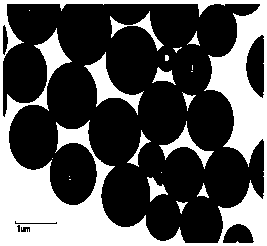

Ethylene-based polymer microparticles, functional group-containing ethylene-based polymer microparticles, and catalyst carriers for manufacture thereof

ActiveUS7601423B2Small particle sizeHigh degree of sphericitySynthetic resin layered productsCellulosic plastic layered productsPolymer sciencePtru catalyst

Ethylene-based copolymer microparticles and functional group-containing ethylene-based copolymer microparticles that have particle diameter smaller than that of conventional polyethylene fine-particles, no inter-particle agglomeration, very narrow particle size distribution, and high sphericity are provided, in which requirements (A) to (E): (A) The intrinsic viscosity [η] measured in decalin at 135° C. is in the range of 0.1 to 50 dl / g, (B) at least 95 wt % or more of particles pass through a mesh screen with an opening of 37 μm, (C) the median diameter (d50) measured by laser diffraction scattering is 3 μm≦d50≦25 μm, (D) the circularity coefficient is 0.85 or more, and (E) the variation coefficient of particle diameter (Cv) is 20% or less. Non-agglomerated spherical magnesium-containing microparticles used as magnesium-containing carrier component for olefin-polymerization catalysts that can manufacture the above microparticles are also provided.

Owner:MITSUI CHEM INC

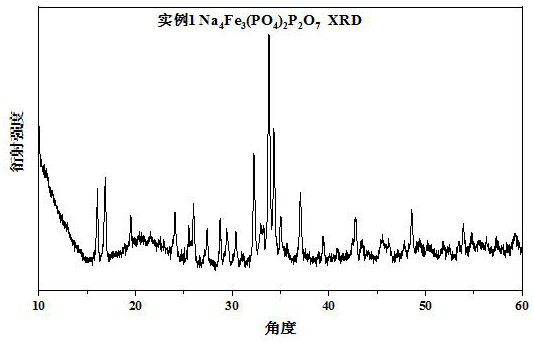

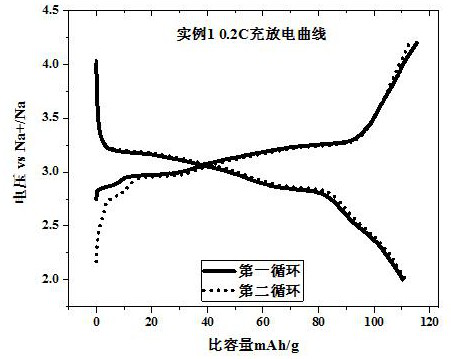

Method for preparing Na4Fe3 (PO4) 2 (P2O7) by homogeneous phase method and application

InactiveCN113060713AEvenly dispersedHigh puritySecondary cellsPositive electrodesMicro nanoElectrical battery

The invention discloses a method for preparing Na4Fe3 (PO4) 2 (P2O7) by a homogeneous method and an application, and the preparation method comprises the following steps: mixing a carbon source, an iron source, a sodium source and a phosphorus source according to a certain stoichiometric ratio, adding an organic solvent, and sanding to form a homogeneous dispersion system; and carrying out spray drying to obtain a precursor, and sintering the precursor in an inert atmosphere to obtain Na4Fe3 (PO4)2(P2O7) powder. According to the method, the agglomeration phenomenon of the Na4Fe3 (PO4) 2 (P2O7) micro-nano powder can be remarkably improved, the morphology and the electrical performance of the powder are improved, the used organic solvent can be recycled through a cooling system for secondary utilization, the latent heat of vaporization of the organic solvent is far lower than that of water, and the heating power consumption is reduced. Compared with the existing transition metal oxide, Prussian blue and vanadium-based polyanionic compound positive electrode materials, the Na4Fe3 (PO4) 2 (P2O7) positive electrode material prepared by the invention is lower in cost, better in cycling stability, green and pollution-free, and can provide an ideal positive electrode for a commercial sodium ion battery.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Method for producing support agent for petroleum well by using quartz tail sand

The invention discloses a method for producing a support agent for a petroleum well by using quartz tail sand, and relates to the technical field of quartz sand production. Through a series of steps of water washing, mechanical wiping deironing, flotation deironing, dry washing cleaning, primary grading, secondary grading, resin coating and bag charging, the quartz tail sand is successfully processed into the support agent for the petroleum well; the problems that the quartz sand has insufficient sphericity and hardness and cannot be widely applied to the support agent for the petroleum well in the prior art can be solved.

Owner:SICHUAN NANLIAN MINING CO LTD

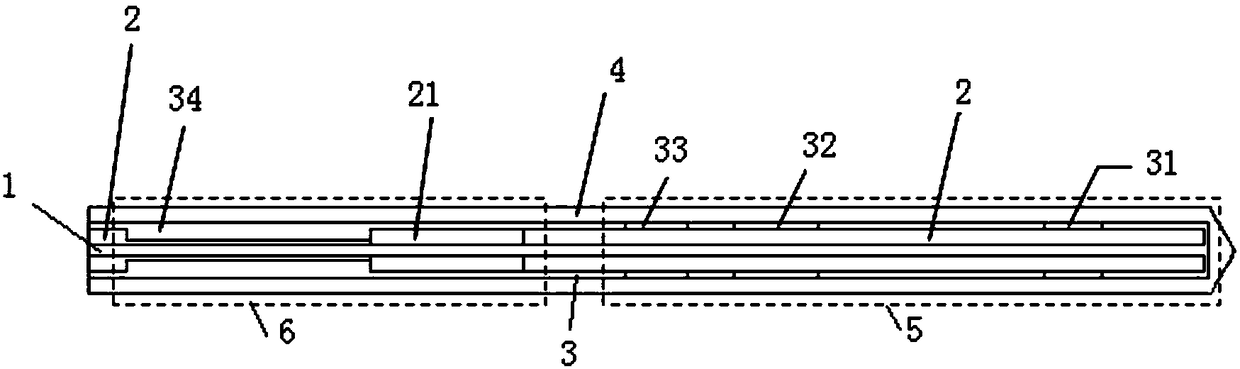

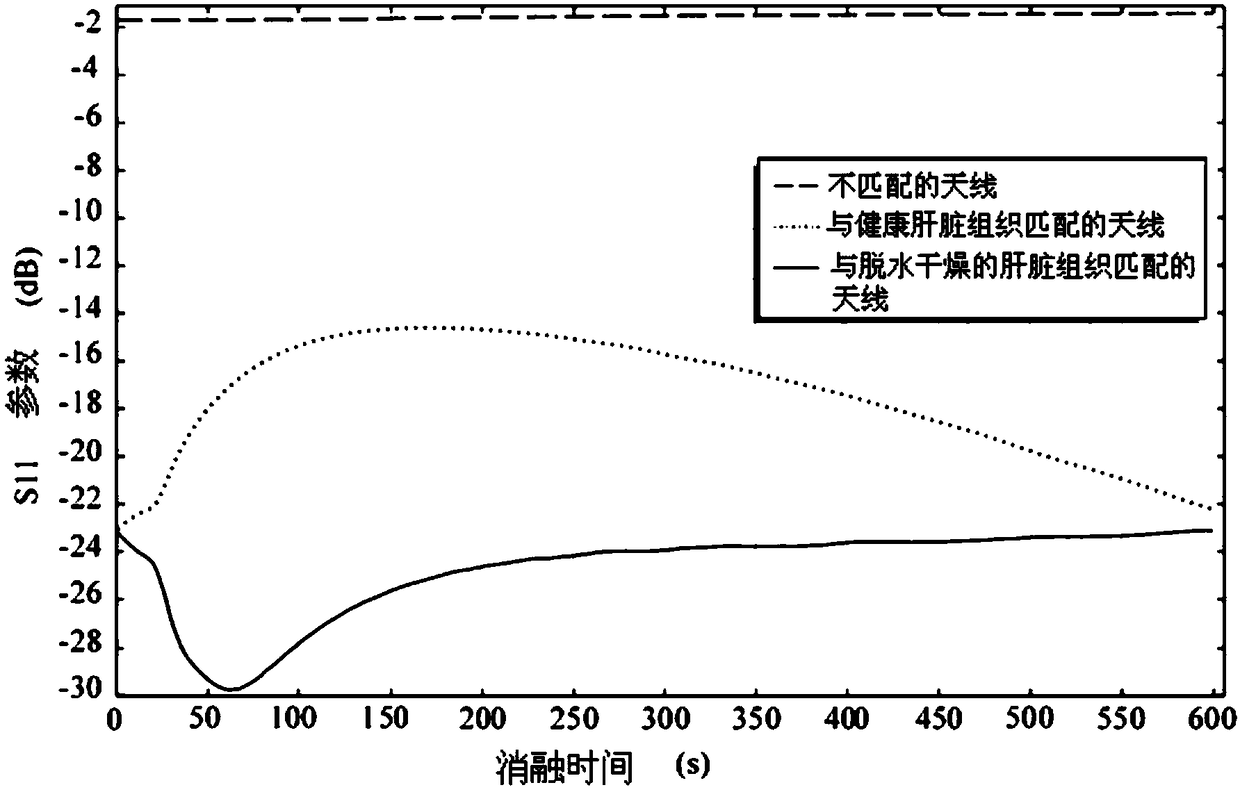

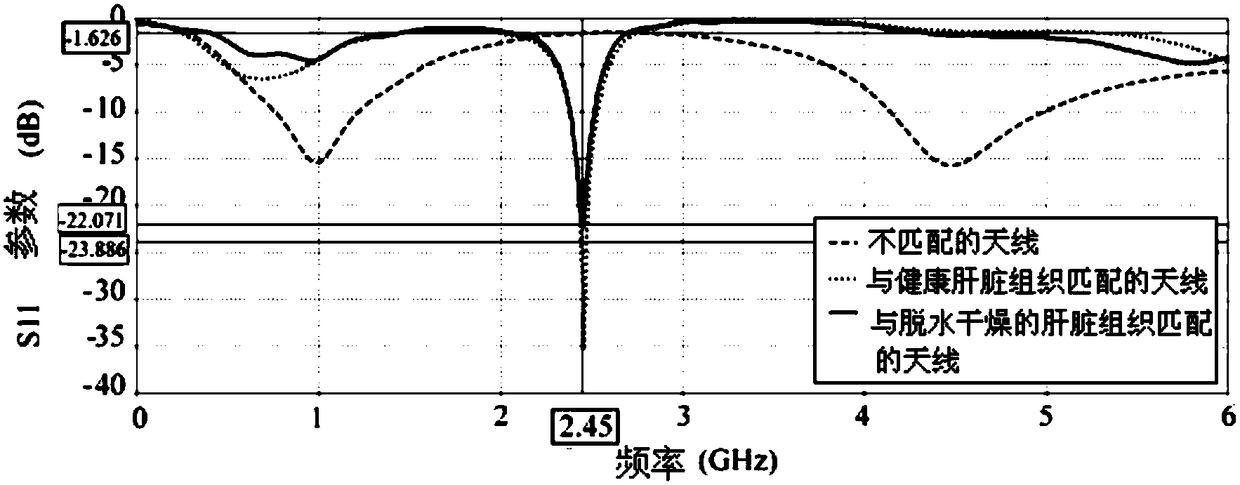

Microwave ablation antenna

InactiveCN108652738AReduce feverFacilitate depositionSurgical needlesSurgical instruments using microwavesLongest DiameterEngineering

The invention provides a microwave ablation antenna. The antenna is provided with an antenna body, the antenna body comprises an inner conductor, and the outer side of the inner conductor is sequentially covered with a dielectric, an outer conductor and a shell; the antenna body extends in the axial direction, one end of the antenna body is used for being connected with a coaxial cable, the otherend of the antenna body is an antenna tail end, and the portions, at the antenna tail end, of the outer conductor and the inner conductor protrude out of the dielectric and are welded to each other; three gaps are girdled in the portion, close to the antenna tail end, of the outer conductor; the dielectric in the middle of the antenna body is axially and sequentially provided with a dielectric hollowed-out section and a thickened outer conductor extending inwards from the outer conductor. According to the microwave ablation antenna, the large ablation long diameter and ablation sphericity areobtained through a three gap joint, the ablation radius is increased through the cooperation with a pi matching joint, the comet tail effect can be well eliminated under the condition of not increasing the diameter of the antenna, the ablation sphericity is increased, the sphericity of an ablation area cannot be significantly reduced even if the microwave power is increased, and the large-range high-sphericity ablation area can be formed.

Owner:EAST CHINA UNIV OF SCI & TECH

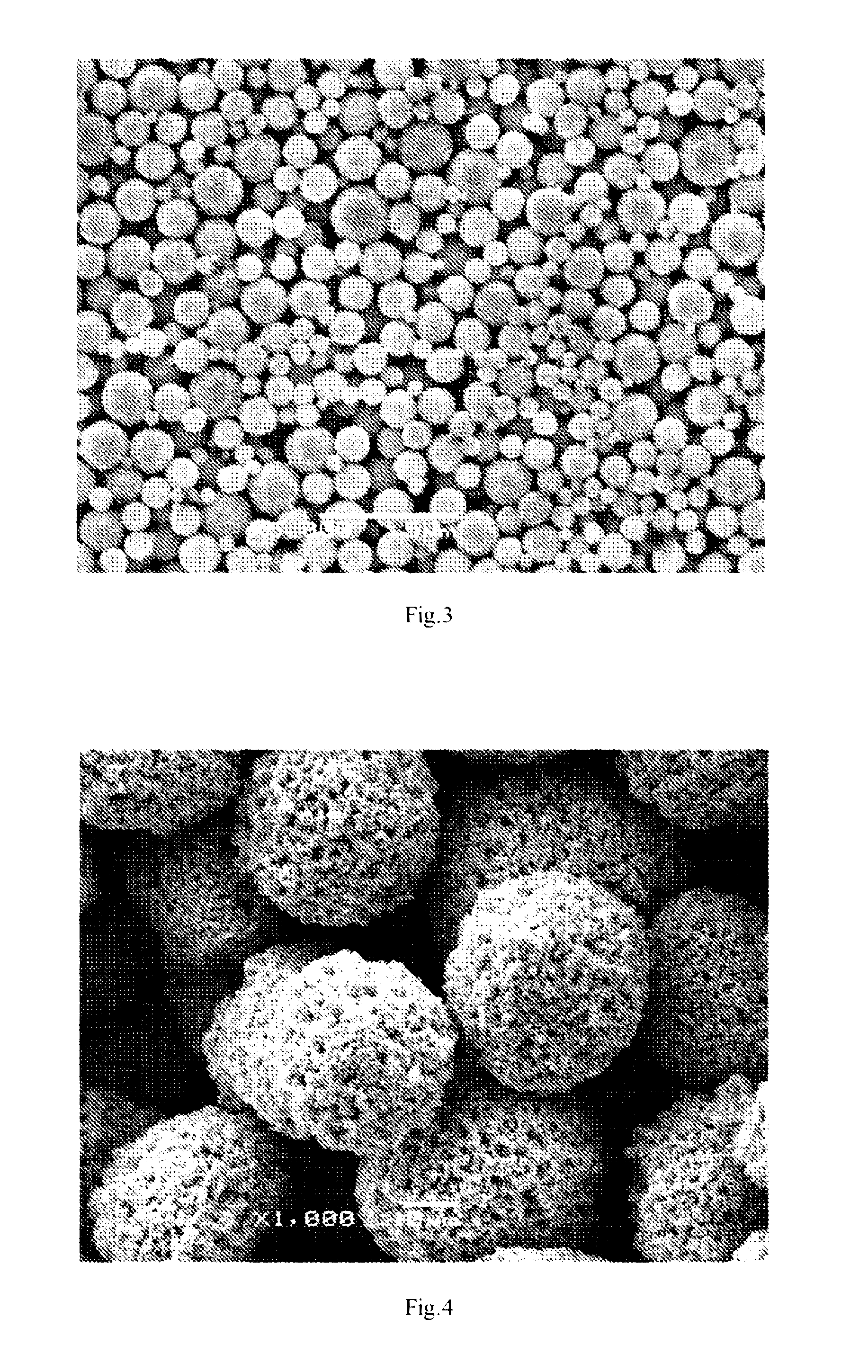

Preparation method of novel fracturing propping agent-polymer sand

InactiveCN110713825AImprove temperature resistanceIncrease crosslink densityFluid removalDrilling compositionPolymer scienceMicrosphere

The invention provides a preparation technology of novel fracturing propping agent-polymer sand. The preparation method comprises the following steps: 1) adding styrene, divinyl benzene, a latent active monomer and an initiator into water filled with an organic / inorganic dispersant, stirring the components, heating the mixture to 70-100 DEG C, carrying out suspension polymerization reaction for 4-12 hours, and filtering, washing and drying a reaction product to obtain an intermediate product polymer microsphere; and 2) carrying out a thermal cross-linking reaction for 10-120 min at a temperature of 180-230 DEG C. The organic proppant polymer sand has the characteristics that 1) the organic proppant polymer sand is high in compressive strength at high temperature, good in temperature resistance and not easy to break; 2) a flexible latent active monomer is introduced into a molecular chain to improve the toughness and crosslinking degree of the product and reduce the dosage of a crosslinking agent, and 3) the product not only has the advantages of simple preparation and use of an organic proppant, but also has the characteristics of high temperature resistance and high strength of aninorganic proppant, and obviously improves the flow conductivity of fracturing exploitation of oil and gas fields.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing non-porous core-porous shell silica

InactiveUS7976812B2High degree of sphericityNarrow particle size distributionPigmenting treatmentLiquid surface applicatorsAlcoholSilicon dioxide

A core-shell silica having a high sphericity and a narrow particle distribution and a method for easily producing the core-shell silica which includes dispersing substantially non-porous silica core particles having a sphericity of at least 0.8 and a coefficient of variation of at most 0.2 in a dispersion medium containing an alcohol and water in the presence of a surfactant to prepare a dispersion; adding a silica material to the dispersion and reacting the silica material under a condition of pH of from 8 to 13 to form a shell precursor containing silica and the surfactant on the surface of each silica core particle; and removing the surfactant from the shell precursor to form a porous shell.

Owner:ASAHI GLASS CO LTD

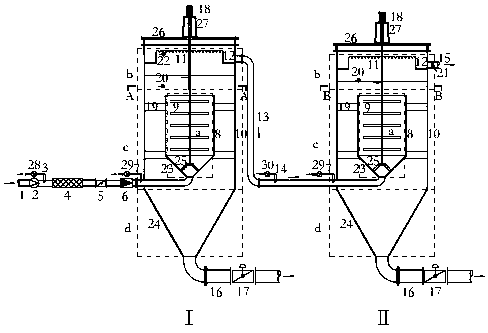

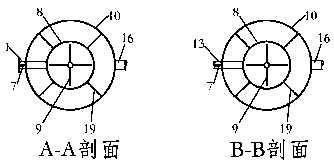

Apparatus and method for preparing spherical metal powder based on one-by-one atomization method for uniform droplets

ActiveUS20210308764A1Reduce heat transferPromote disseminationAdditive manufacturing apparatusTransportation and packagingCrucibleMetal powder

An apparatus includes a housing, a crucible disposed in the housing, and a collection bin. A turnplate disposed in a powder collection area is of an inlaid structure. A concentric circular groove is provided on the atomization plane. An air hole is provided in the turnplate. The present invention combines the pulsated orifice ejection method and the centrifugal atomization method, in cooperation with the turnplate structure and subjecting the turnplate surface to induction heating, so that a metal liquid is allowed to break through the split mode of traditional molten metal, achieves a fibrous split mode that can be implemented only when an atomizing medium is an aqueous or organic solution, and prepares a high-melting-point metal powder that meets requirements, and has a controllable particle size, high sphericity, no satellite droplets, and good flowability and spreadability, and is suitable for industrial production.

Owner:WANG XIAOMING +12

Degreasing wastewater treatment device and process

InactiveCN108191117AImprove uniformityHigh floc densityMultistage water/sewage treatmentTreatment involving sedimentationFlocculationSludge

The invention discloses a degreasing wastewater treatment process. The process takes loading flocculation as a core, and a produced floc structure is compact, has small content of void water and is high in settling speed, good in uniformity, high in shear resistance and applicable to treatment of degreasing wastewater. Raw water enters a loading flocculation area in main equipment under pressure for flocculation, then, floc enters a settling area and a sludge concentration area, and clear water enters a clarification area, is discharged through a triangular weir and an annular collecting channel and enters a secondary reaction tank for secondary treatment. During process operation, the floc can form a suspension layer nearby a water outlet of the flocculation area under the action of gravity and rising hydraulic power, small floc and part of soluble organic matter can be removed. According to the process, loading flocculation, settlement, clarification, sludge concentration and other process units are integrated, and the integration of the main equipment is improved. The process is high in automation degree, wide in application range, low in capital construction investment and operation cost, small in floor area and simple to operate.

Owner:UNIV OF JINAN

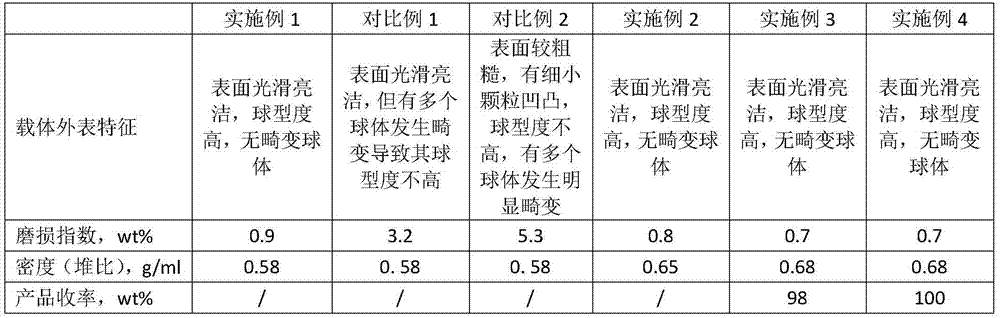

Preparation method of spherical aluminum oxide

ActiveCN106892648AHigh degree of sphericitySmooth and wear-resistant surfaceOther chemical processesAlkali metal oxides/hydroxidesPelletizingSmooth surface

The invention relates to a preparation method of spherical aluminum oxide. The method comprises the following steps: mixing pseudoboehmite powder and a forming aid, adding acid-containing deionized water, kneading, and extruding to obtain a strip plastic; putting the strip plastic in a balling device on the premise of no adhesion of the strip plastic surface to implement strip breaking and rolling granulation, spraying a misty liquid drop wetting agent while keeping the granules rotating, wetting the granule surfaces on the premise of no adhesion of the granules, stopping spraying, continuing rotation until the granules become spherical granules with smooth surfaces, changing cold air in the balling device into hot air, drying to harden the spherical granule surfaces, and stopping the rolling granulation; and drying the spherical granules, and roasting to finally obtain the aluminum oxide spherical carrier. The method solves the problems of unsmooth surface, poor sphericity and poor wear resistance in the balls prepared by the original process, and has the advantages of low preparation cost and no pollution in the preparation process.

Owner:PETROCHINA CO LTD

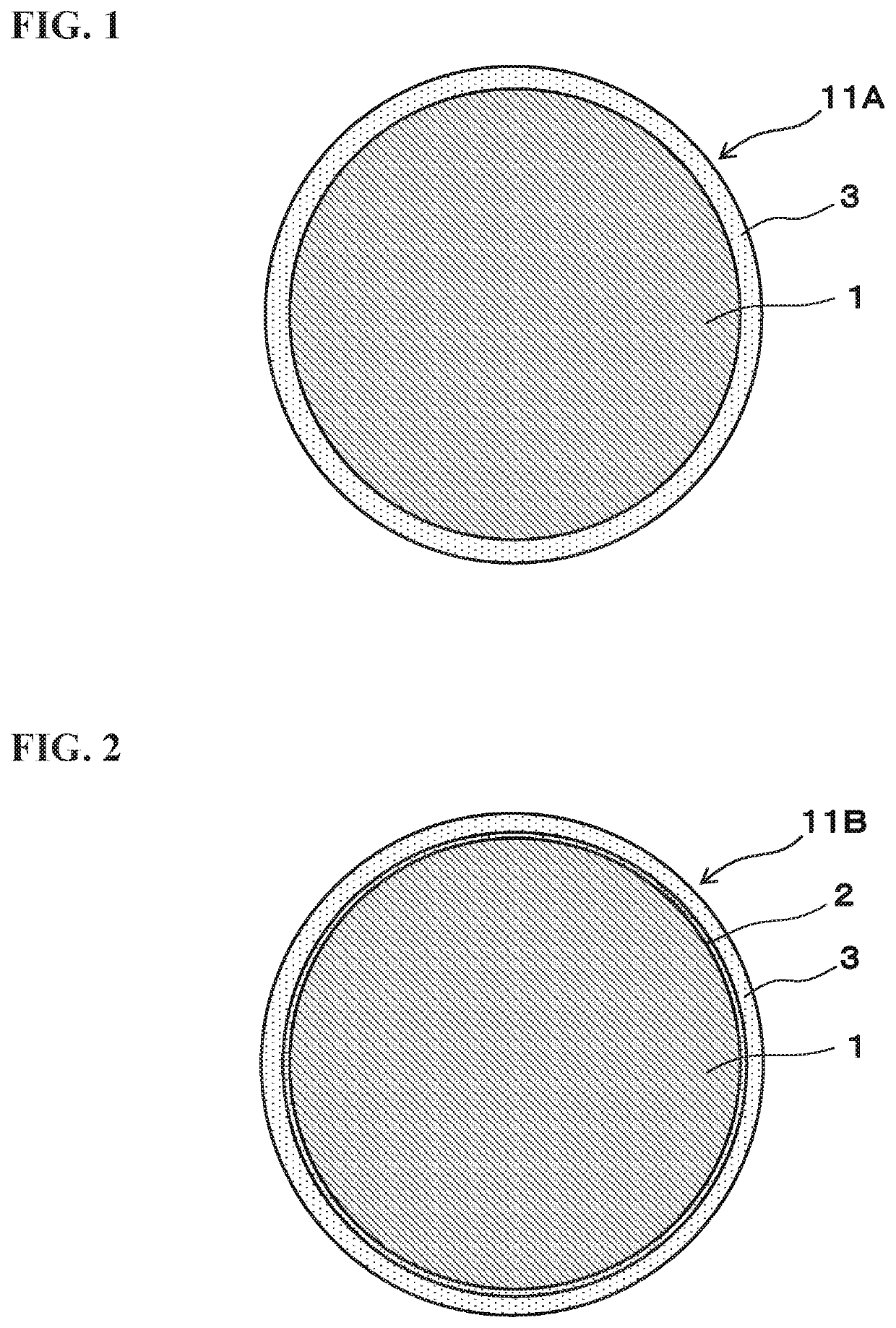

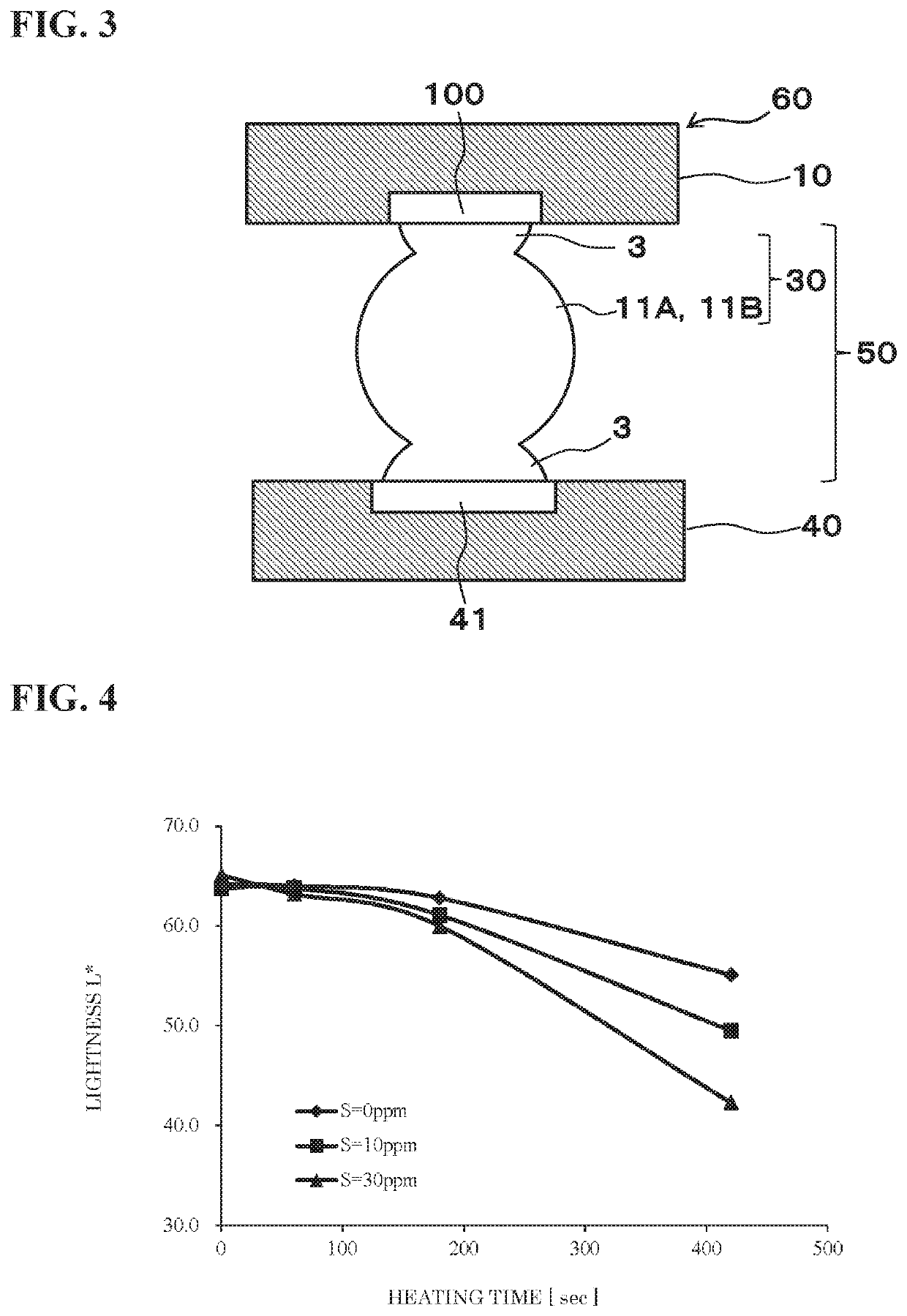

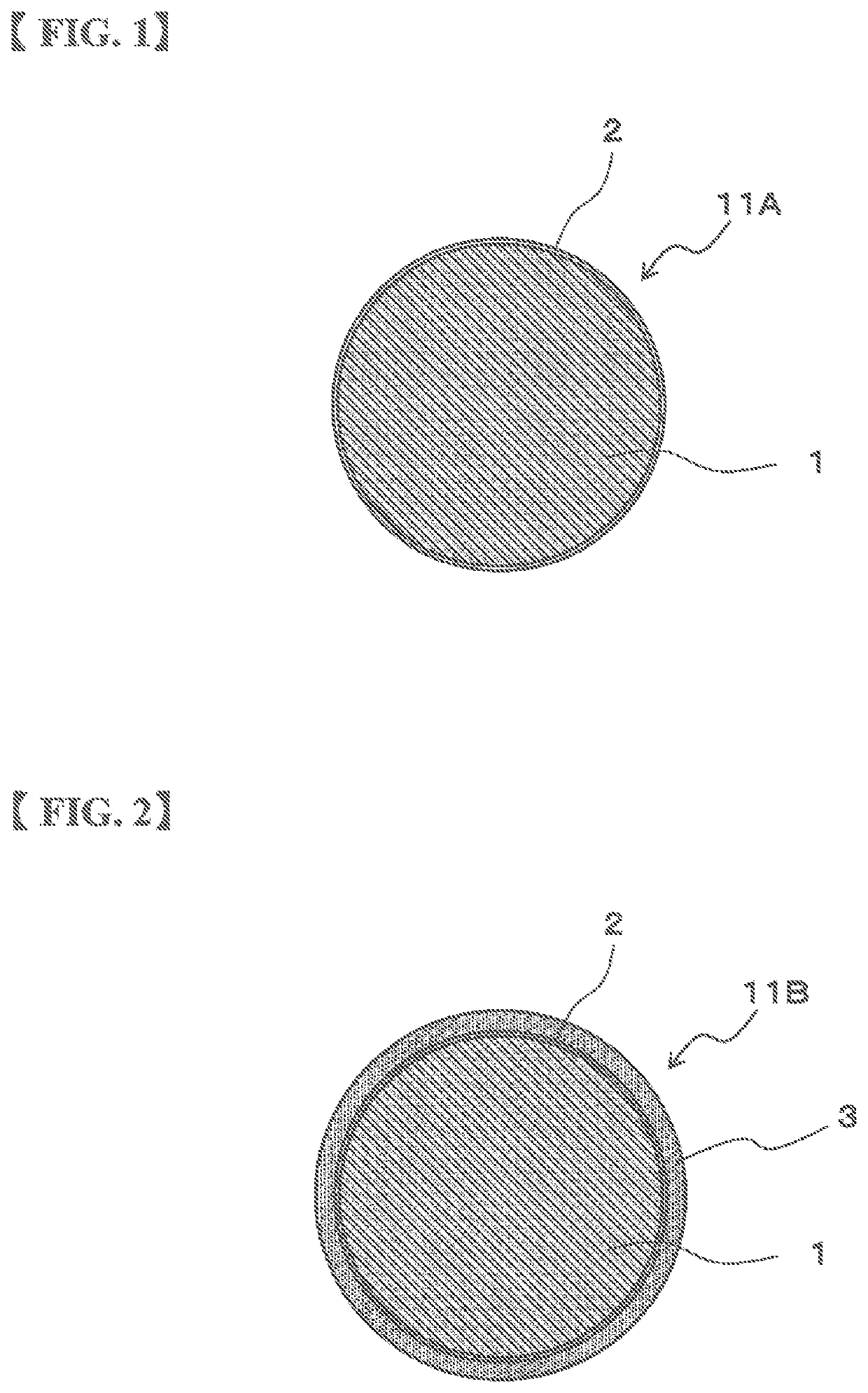

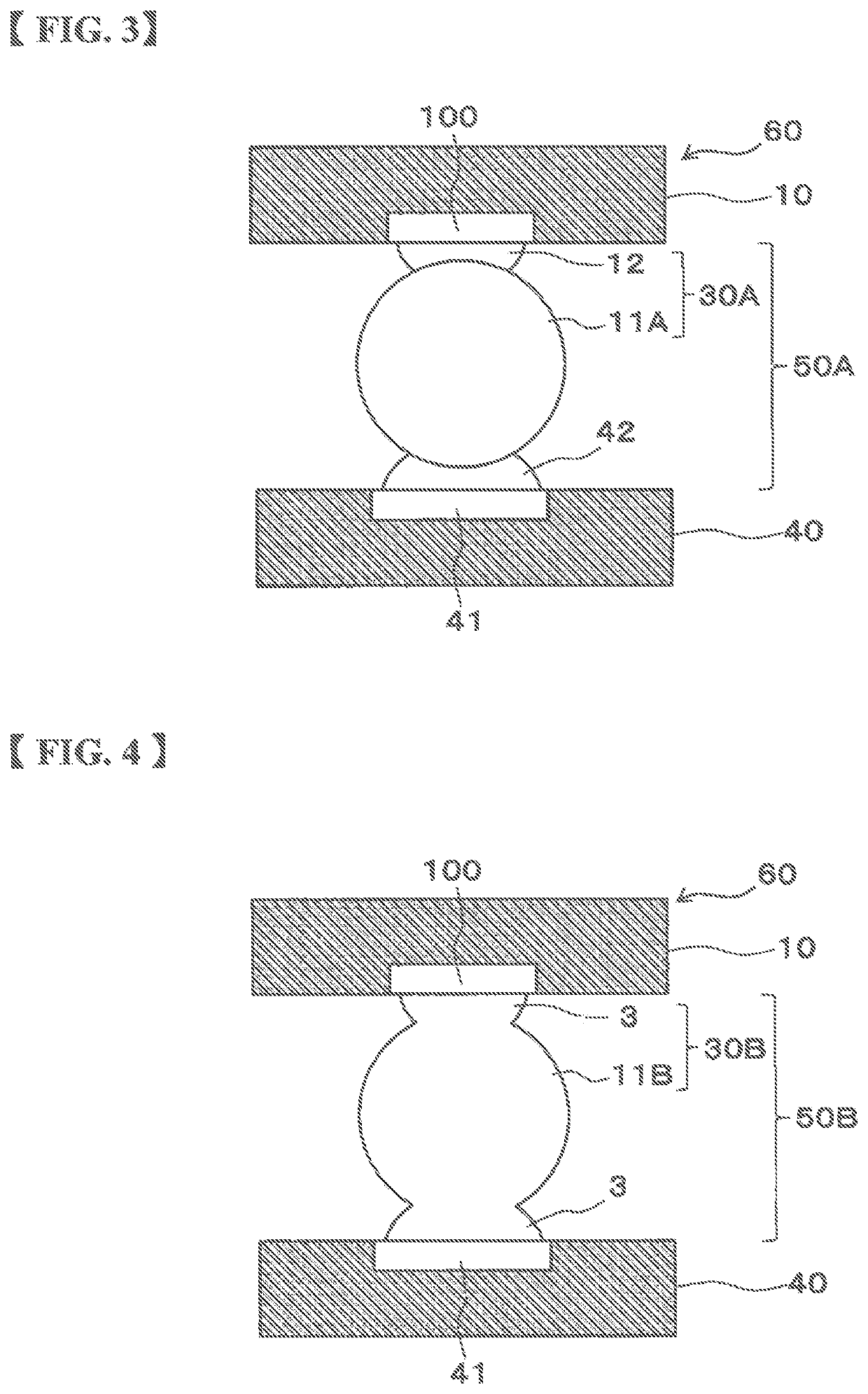

Cu Core Ball, Solder Joint, Solder Paste and Formed Solder

InactiveUS20190376161A1High degree of sphericityReduce hardnessPrinted circuit assemblingFinal product manufactureCopperSolder paste

A Cu core ball contains a Cu ball and at least one metal layer for covering a surface of the Cu ball. The metal layer is made of at least one element selected from the group of Ni, Co, Fe and Pd. The Cu ball contains at least one element selected from a group of Fe, Ag and Ni in a total amount of 5.0 ppm by mass or more to 50.0 ppm by mass or lower, S in an amount of 0 ppm by mass or more to 1.0 ppm by mass or lower, P in an amount of 0 ppm by mass or more to less than 3.0 ppm by mass, and remainder of Cu and inevitable impurities. The Cu ball contains purity which is 99.995% by mass or higher to 99.9995% by mass or lower, and sphericity which is 0.95 or higher.

Owner:SENJU METAL IND CO LTD

Cu Core Ball, Solder Joint, Solder Paste and Formed Solder

ActiveUS20190375054A1High degree of sphericityImprove impact resistanceSemiconductor/solid-state device detailsSolid-state devicesSolder pasteImpurity

The Cu core ball contains a Cu ball and one or more metal layer for covering a surface of the Cu ball, each layer including one or more element selected from Ni, Co, Fe and Pd. The Cu ball contains at least one element selected from Fe, Ag, and Ni in a total amount of 5.0 or more to 50.0 ppm by mass or lower, S in an amount of 0 ppm by mass or more to 1.0 ppm by mass or lower, P in an amount of 0 ppm by mass or more to less than 3.0 ppm by mass, and remainder of Cu and inevitable impurities. The Cu ball contains purity which is 99.995% by mass or higher and 99.9995% or lower, sphericity which is 0.95 or higher and a diameter of 1 μm or more to 1000 μm or lower.

Owner:SENJU METAL IND CO LTD

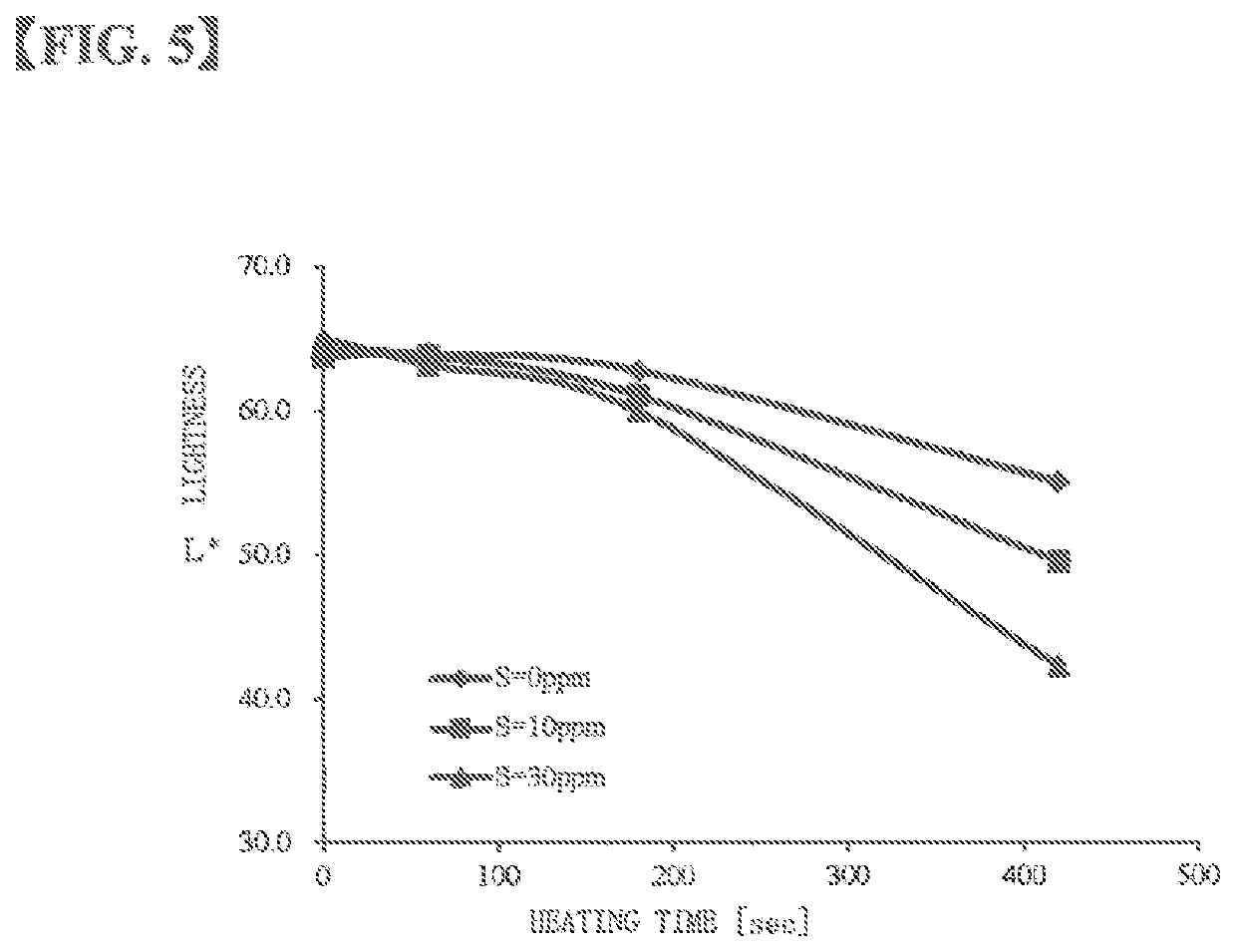

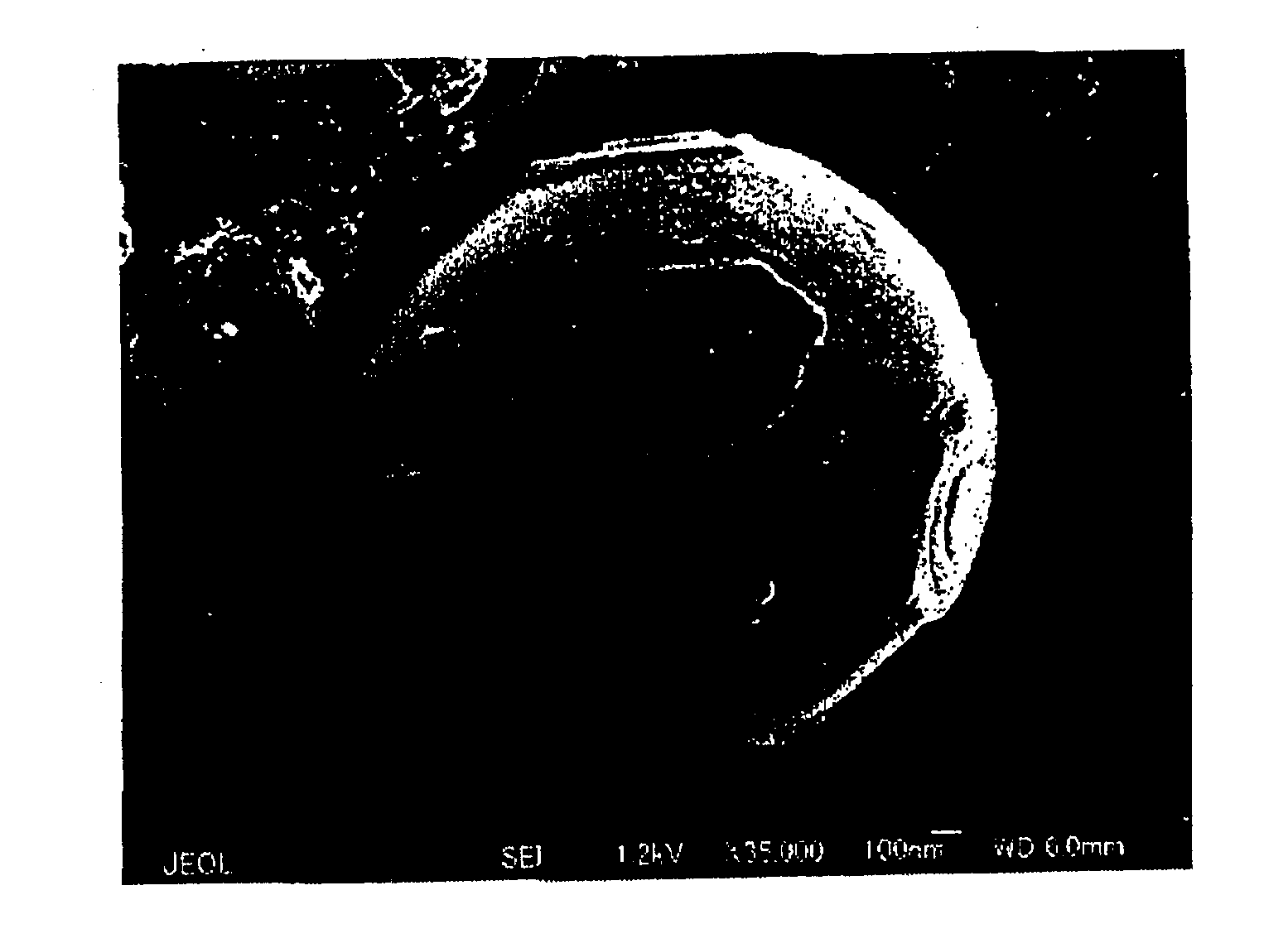

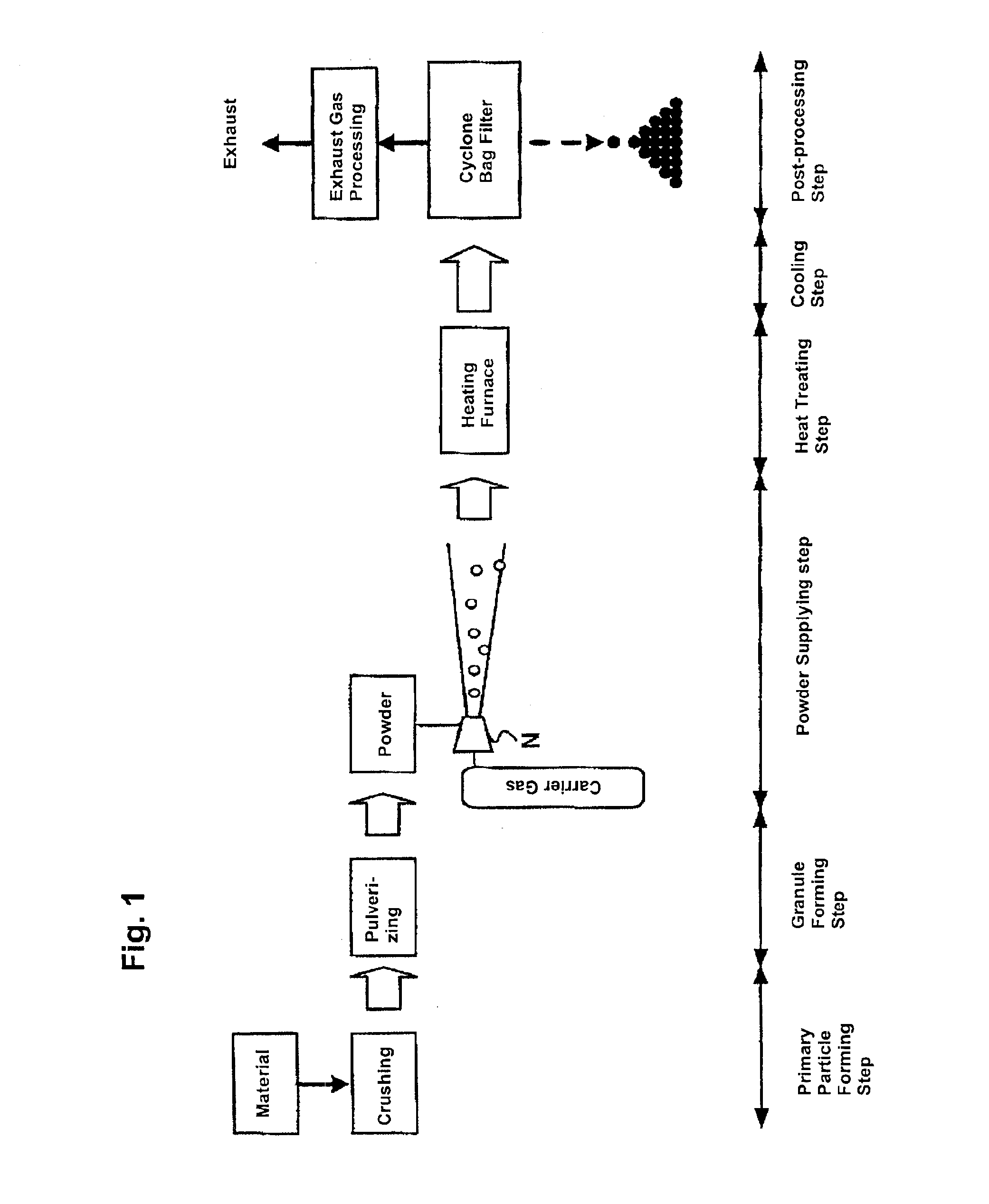

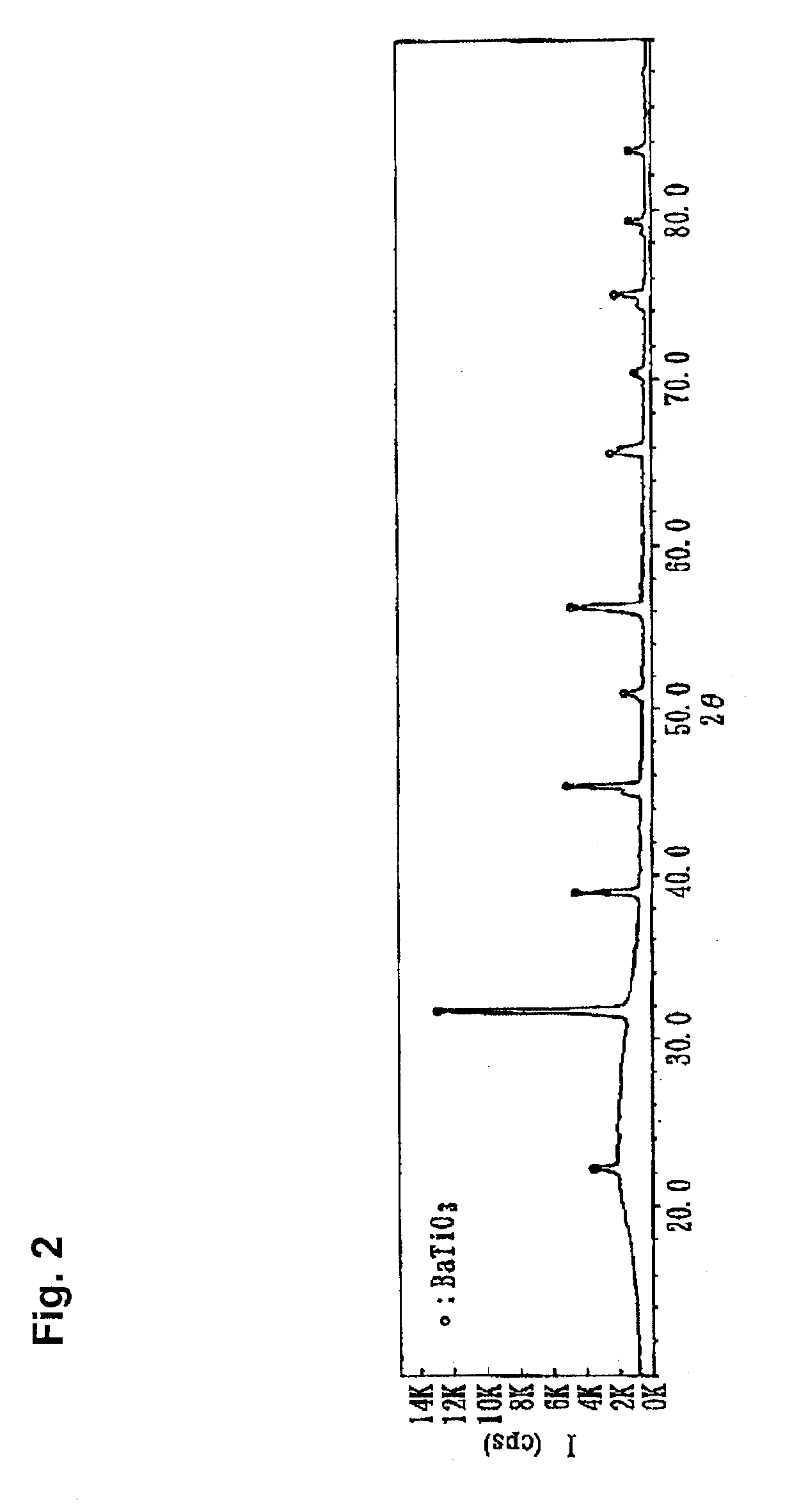

Method for manufacturing single crystal ceramic powder, and single crystal ceramic powder, composite material, and electronic element

InactiveUS6872251B2Excellent spherical characteristicSmall particle sizeBy zone-melting liquidsSolid-state devicesSingle crystalElectronic component

A method for manufacturing single crystal ceramic powder is provided. The method includes a powder supply step for supplying powder consisting essentially of ceramic ingredients to a heat treatment area with a carrier gas, a heat treatment step for heating the powder supplied to the heat treatment area at temperatures required for single-crystallization of the powder to form a product, and a cooling step for cooling the product obtained in the heat treatment step to form single crystal ceramic powder. The method provides single crystal ceramic powder consisting of particles with a very small particle size and a sphericity being 0.9 or higher.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com