Preparation method of novel fracturing propping agent-polymer sand

A technology of polymer and proppant, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling and mining, etc. It can solve the problems of low temperature resistance, low strength and complicated preparation process, and achieve high compressive strength, The preparation process is simple and the temperature resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

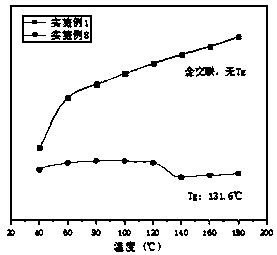

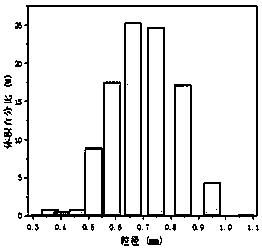

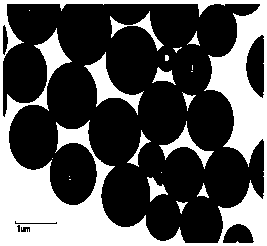

Embodiment 1

[0034] Add 2000mL of deionized water, 2.0g of tricalcium phosphate, and 2.0g of gelatin into a 5L reactor, and heat to 60°C while stirring. Add a mixture of 780.0g styrene, 220.0g divinylbenzene, 3.0g dibenzoyl peroxide, and 15.0g glycidyl methacrylate into the reactor, adjust the stirring rate to 120 rpm, and program the temperature to React at 75°C to 95°C for 8 hours. After the reaction, the materials were taken out, vacuum filtered, rinsed with deionized water for 3 times to obtain white microspheres, and the water was dried. Put the microspheres in a vacuum oven, raise the temperature to 195°C, keep the temperature for 60 minutes, and then cool to room temperature to obtain the polymer sand proppant.

Embodiment 2

[0036]Add 2000mL of deionized water, 1.5g of tricalcium phosphate, and 2.0g of polyvinyl alcohol into a 5L reactor, and heat to 60°C while stirring. Add 800.0g styrene, 200.0g divinylbenzene, 1.0g benzocyclobutene peroxide, 2.0g dibenzoyl peroxide, 10.0g glycidyl methacrylate and 10.0g glycidyl acrylate mixture In the reaction kettle, the stirring rate was adjusted to 115 rpm, and the temperature was programmed to rise to 75°C-95°C for 7 hours. After the reaction, the materials were taken out, vacuum filtered, rinsed with deionized water for 3 times to obtain white microspheres, and the water was dried. Put the microspheres in a vacuum oven, raise the temperature to 185°C, keep the temperature for 90 minutes, and then cool to room temperature to obtain the polymer sand proppant.

Embodiment 3

[0038] Add 2000mL of deionized water, 2.2g of talc powder, and 2.0g of polyvinyl alcohol into a 5L reactor, and heat to 60°C while stirring. Add a mixture of 750.0g styrene, 250.0g divinylbenzene, 2.2g dibenzoyl peroxide and 10.0g glycidyl acrylate into the reaction kettle, adjust the stirring rate to 120 rpm, and program the temperature to 75°C Reaction at ~95°C for 8h. After the reaction, the materials were taken out, vacuum filtered, rinsed with deionized water for 3 times to obtain white microspheres, and the water was dried. Put the microspheres in a vacuum oven, raise the temperature to 195°C, keep it warm for 50 minutes, and then cool down to room temperature to obtain a polymer sand proppant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com