Thermal-spalling acrylic ester pressure-sensitive adhesive, adhesive tape and preparation method thereof

A technology of pressure-sensitive adhesive tapes and pressure-sensitive adhesives, applied in the field of pressure-sensitive adhesives, can solve the problems of low foaming temperature, high price and cost, difficulty in meeting low-temperature viscosity requirements, etc., and achieve good application prospects and good adhesion and thermal peelability, good temperature resistance and peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

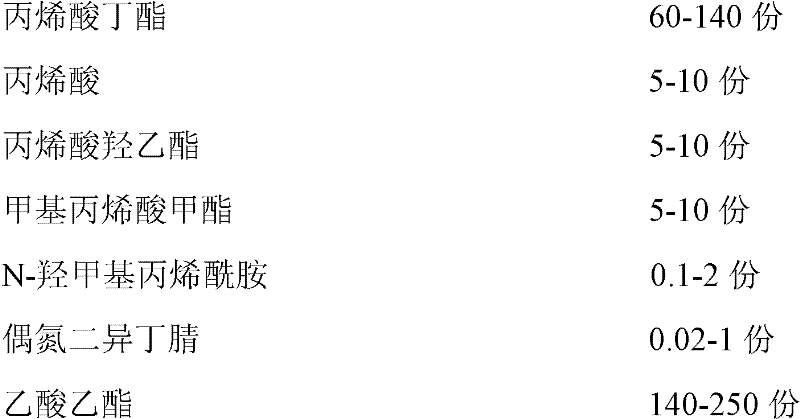

[0024] A heat-peelable acrylate pressure-sensitive adhesive, which is polymerized from the following components by weight:

[0025]

[0026] First, dissolve N-methylolacrylamide in acrylic acid, stir well to make it dissolve evenly, and dissolve 0.18 parts of azobisisobutyronitrile in 95 parts of ethyl acetate, and mix the two solutions after the dissolution is complete. mix. Then add the above-mentioned isooctyl acrylate, butyl acrylate, hydroxyethyl acrylate and methyl methacrylate and mix well.

[0027] Add 40 parts of ethyl acetate into the reactor and raise the temperature to 75°C. After the reflux is stable, start to slowly add 1 / 2 of the above-mentioned monomer mixture solution dropwise, and finish adding dropwise in 1 hour, and control the reaction temperature at 78-80°C ; Add 20 parts of ethyl acetate with 0.045 parts of azobisisobutyronitrile dropwise, drop it within 10 minutes, and keep it warm for 1 hour; For 2.5 hours, the reaction temperature was controlled ...

Embodiment 2

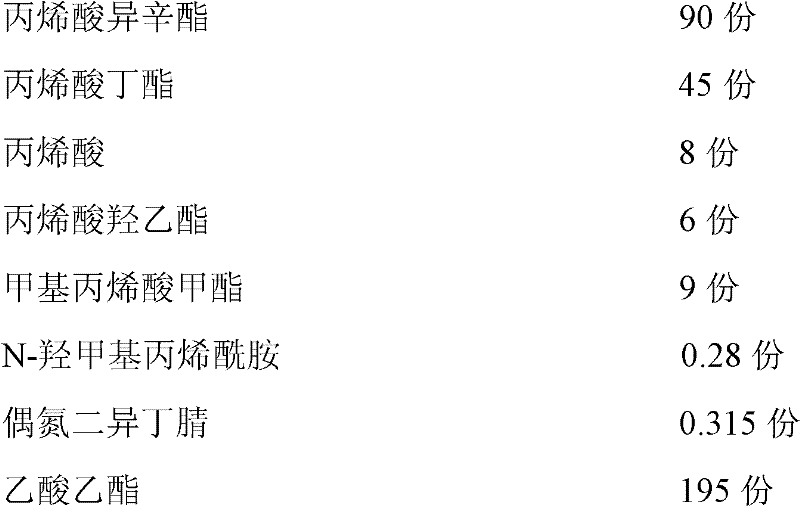

[0036] A heat-peelable acrylate pressure-sensitive adhesive, which is polymerized from the following components by weight:

[0037]

[0038] First, dissolve N-methylolacrylamide in acrylic acid, stir well to make it dissolve evenly, and dissolve 0.18 parts of azobisisobutyronitrile in 95 parts of ethyl acetate, and mix the two solutions after the dissolution is complete. mix. Then add the above-mentioned isooctyl acrylate, butyl acrylate, hydroxyethyl acrylate and methyl methacrylate and mix well.

[0039] Add 40 parts of ethyl acetate into the reactor and raise the temperature to 75°C. After the reflux is stable, start to slowly add 1 / 2 of the above-mentioned monomer mixture solution dropwise, and finish adding dropwise in 1 hour, and control the reaction temperature at 78-80°C ; Add 20 parts of ethyl acetate with 0.045 parts of azobisisobutyronitrile dropwise, drop it within 10 minutes, and keep it warm for 1 hour; For 2.5 hours, the reaction temperature was controlled ...

Embodiment 3

[0044] A heat-peelable acrylate pressure-sensitive adhesive, which is polymerized from the following components by weight:

[0045]

[0046]

[0047] First, dissolve N-methylolacrylamide in acrylic acid, stir well to make it dissolve evenly, and dissolve 0.18 parts of azobisisobutyronitrile in 95 parts of ethyl acetate, and mix the two after the dissolution is complete. liquid mix. Then add the above-mentioned isooctyl acrylate, butyl acrylate, hydroxyethyl acrylate and methyl methacrylate and mix well.

[0048] Add 40 parts of ethyl acetate into the reactor and raise the temperature to 75°C. After the reflux is stable, start to add 1 / 2 of the above monomer mixture dropwise at a constant speed, and finish adding dropwise in 1 hour, and control the reaction temperature at 78-80°C ; Add 20 parts of ethyl acetate with 0.045 parts of azobisisobutyronitrile dropwise, drop it within 10 minutes, and keep it warm for 1 hour; For 2.5 hours, the reaction temperature was controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com