Patents

Literature

258results about How to "Extended operating temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

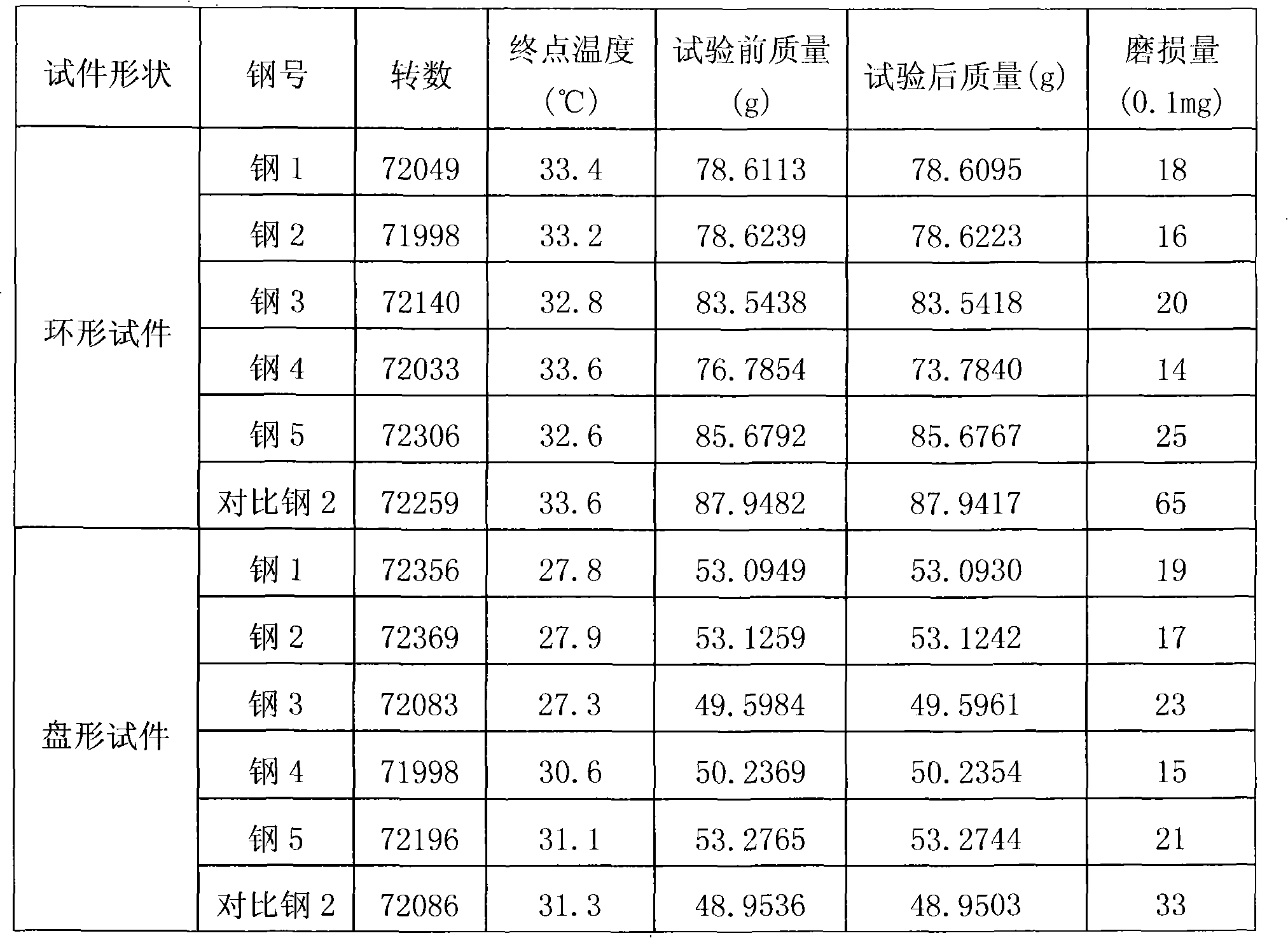

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

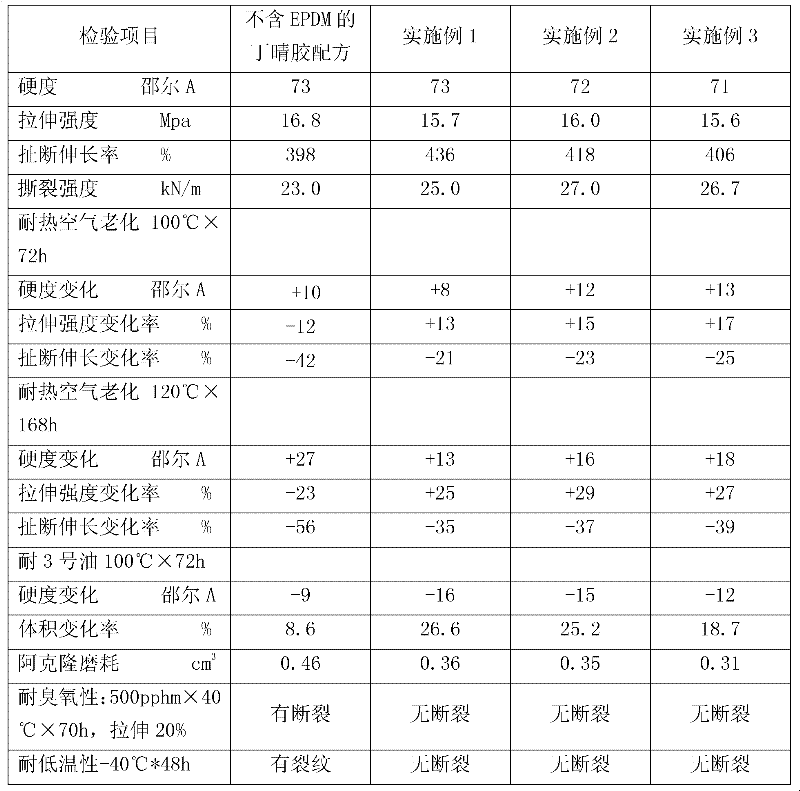

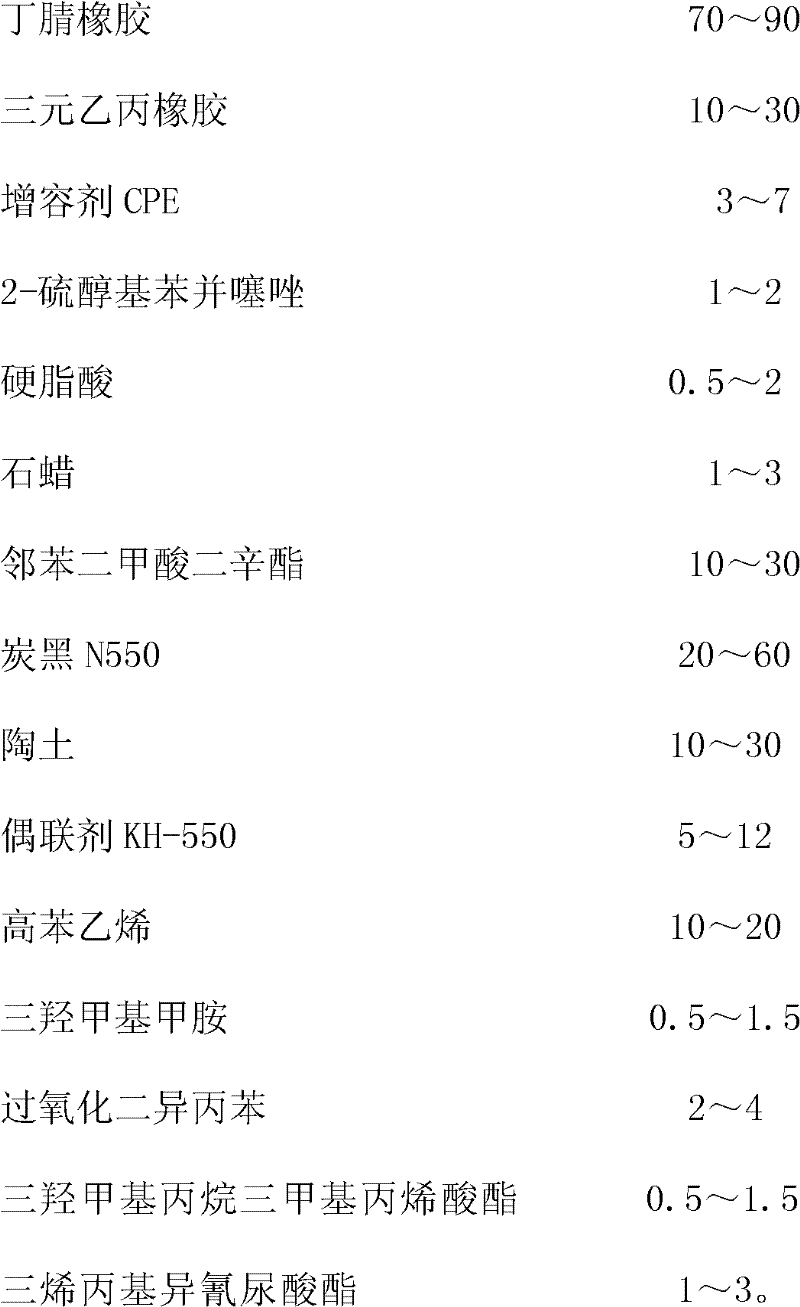

Nitrile/EPDM for ozone and low temperature resistant seals

The invention relates to a nitrile rubber / ethylene-propylene-diene rubber used for an ozone resistant and low temperature resistant sealing ring. The rubber comprises the following components of: a nitrile rubber, an ethylene-propylene-diene rubber, a compatibilizer CPE, an anti-aging agent MB, stearic acid, paraffin wax, a plasticizer DOP, carbon block N550, pottery clay, a coupling agent KH-550, high styrene, a neutralizer TRA, a cross-linking agent DCP, a cross-linking aid TMPTMA and a cross-linking aid TAIC, wherein the nitrile rubber and the ethylene-propylene-diene rubber are used together to make up deficiencies of each other so that the poor ozone resistance, poor low temperature resistance and narrower heat resistant temperature range of the nitrile rubber can be improved and theuse temperature range of the product can be also expanded. After a small quantity of EPDMs (Ethylene-Propylene-Diene Monomers) are added to the nitrile rubber, the ozone resistance, the low temperature resistance and the heat resistance of the blended rubber product can be improved; meanwhile, the rubber product obtains wider use temperature range, better process performance and lower raw material and production cost while being compared with the nitrile rubber and the chloroprene rubber; and the requirements on the performance of domestic parts are satisfied.

Owner:TIANJIN PENGYI GRP CO LTD

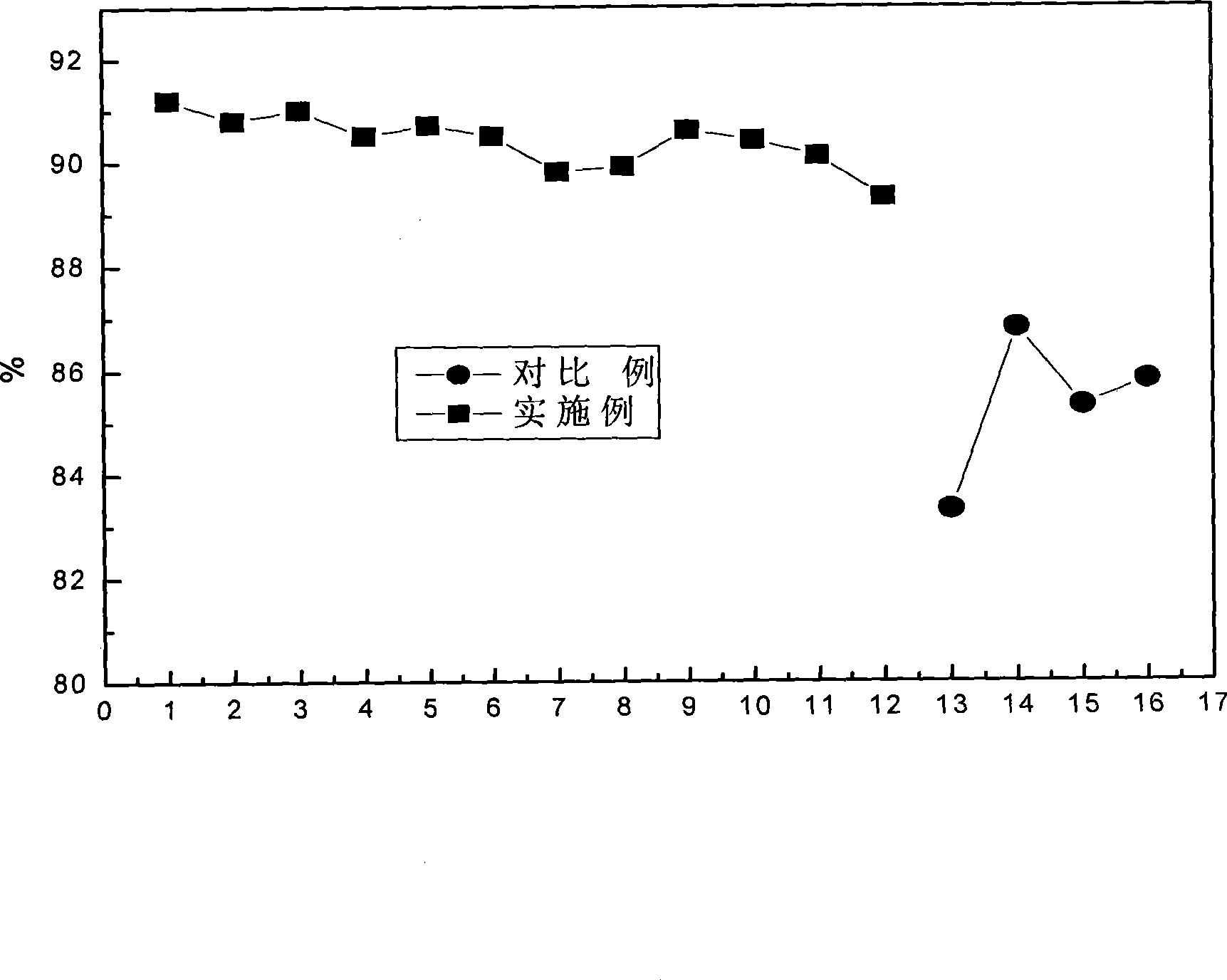

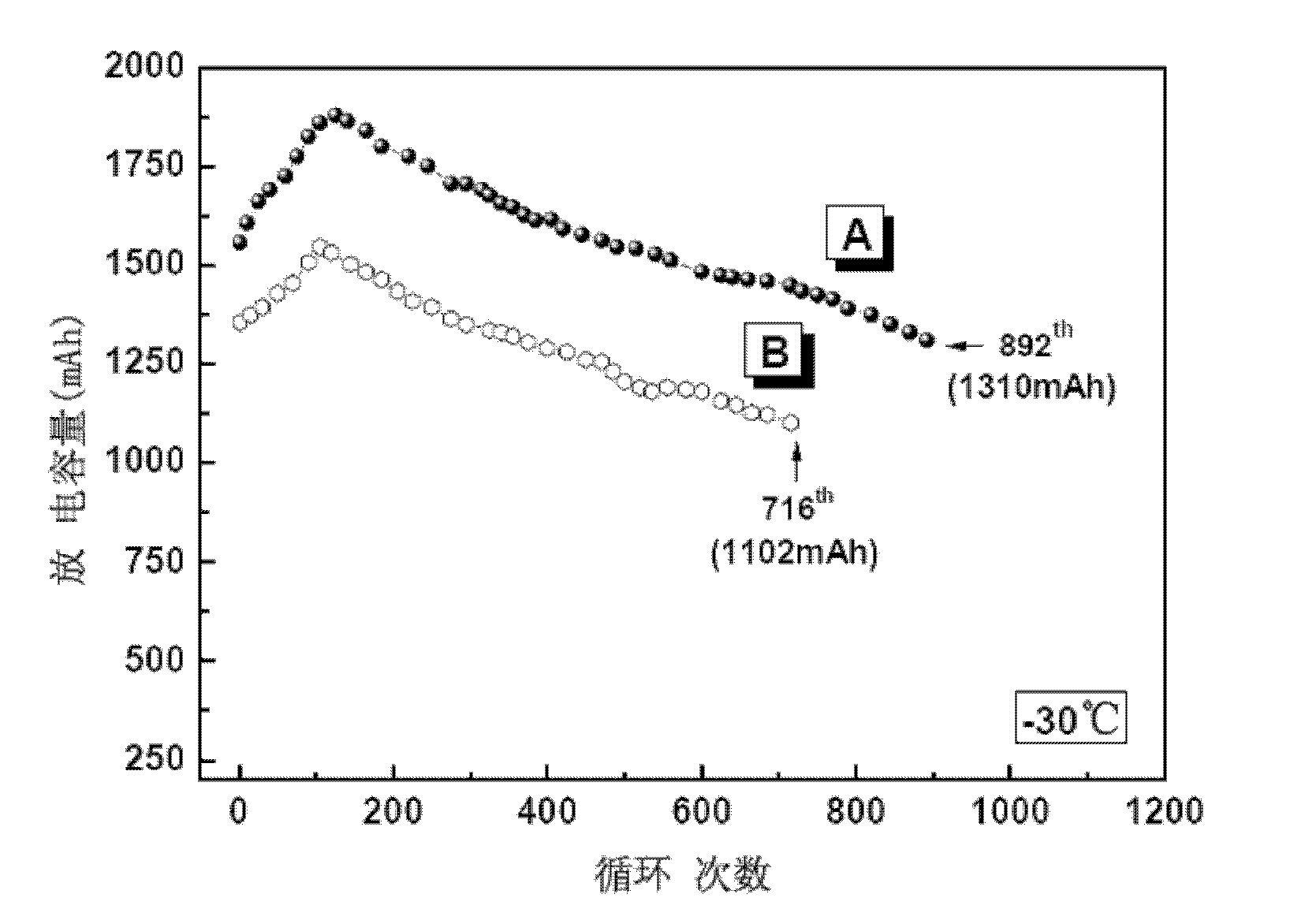

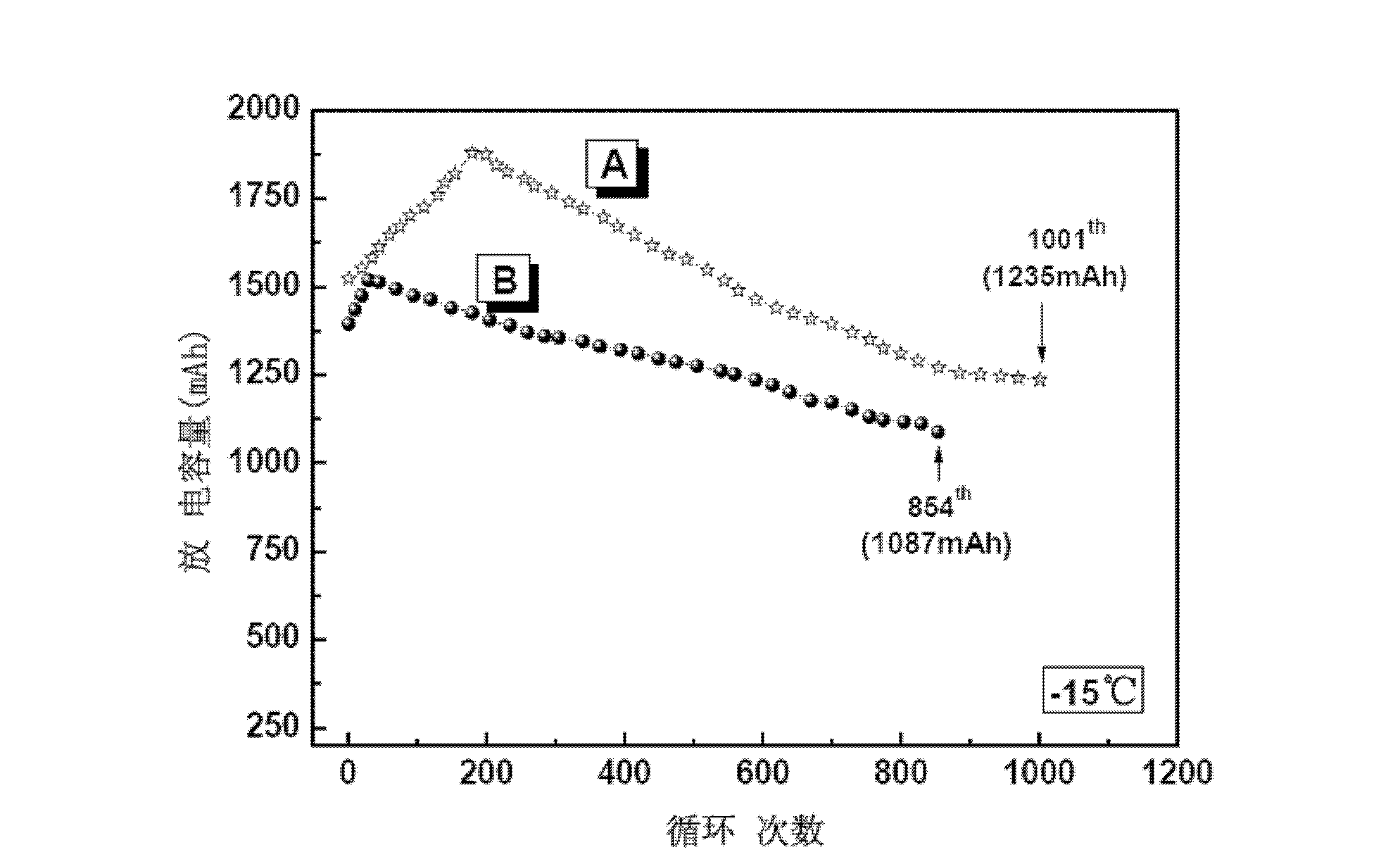

Lithium ion secondary battery using lithium iron phosphate as anode material with overall consideration of high and low temperature performance

InactiveCN101394008AExtended operating temperature rangeWide temperature rangeSecondary cellsPhosphateEthyl butyrate

The invention discloses an aqueous electrolyte solution of a secondary lithium ion battery with ferric phosphate considering as the positive material and with both the high temperature performance and the low temperature performance. The aqueous electrolyte solution comprises LiPF6 lithium salt, an organic solvent and a film-forming additive, and is characterized in that the electrolyte solution further comprises high temperature additive; the organic solvent is composed of one or a plurality of carbonic esters and one or more carboxylic esters with low melting point and high boiling point. The carboxylic esters with low melting point and high boiling point are selected from one or a combination of methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate. The high temperature additive is 1, 3- propane sultone and 1, 4- butane sultone. The electrolyte solution is used for maintaining both the circulation performance in a high temperature state and the low temperature laying performance of the secondary lithium ion battery with the ferric phosphate lithium as the positive material.

Owner:GUANGZHOU TINCI MATERIALS TECH

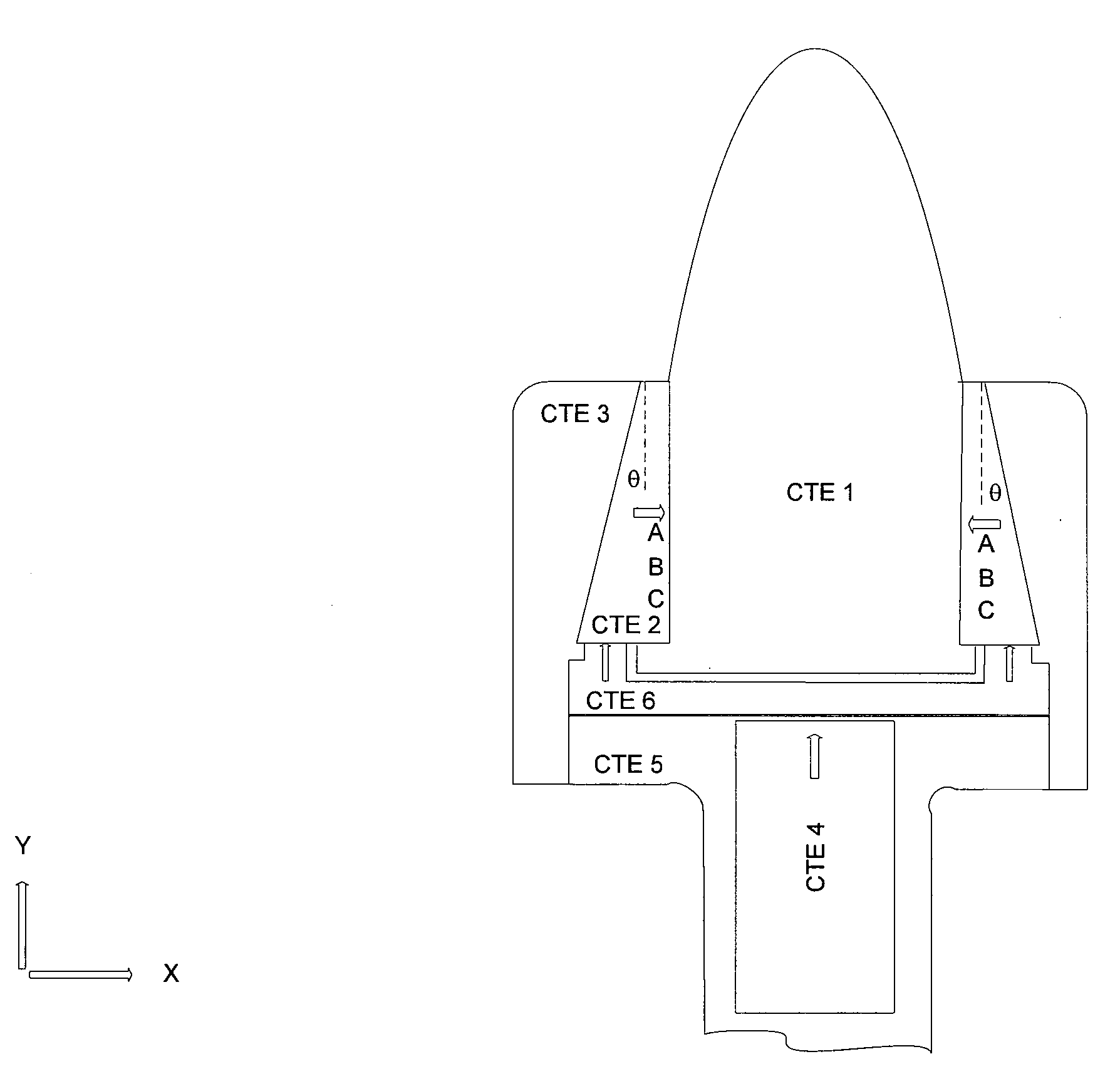

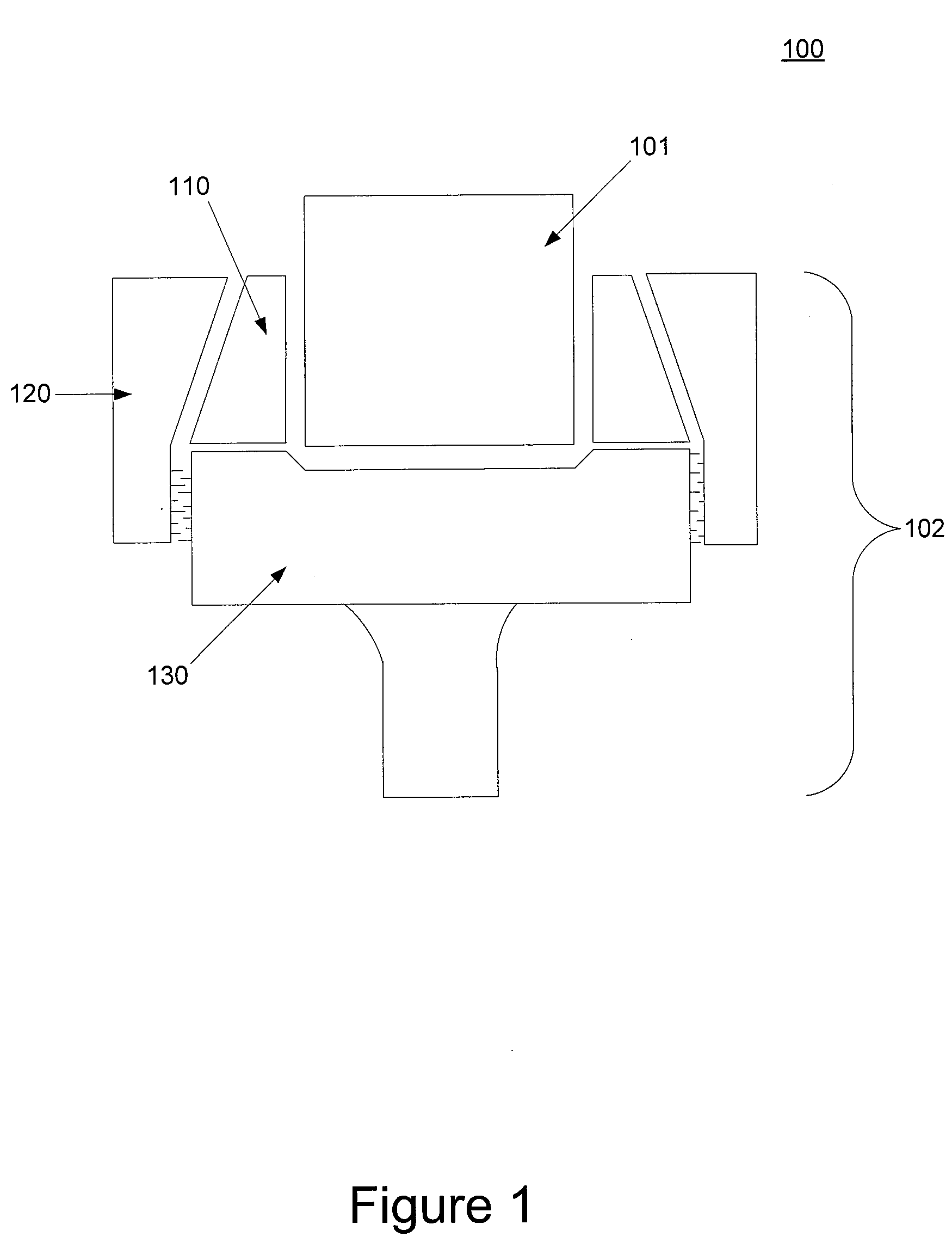

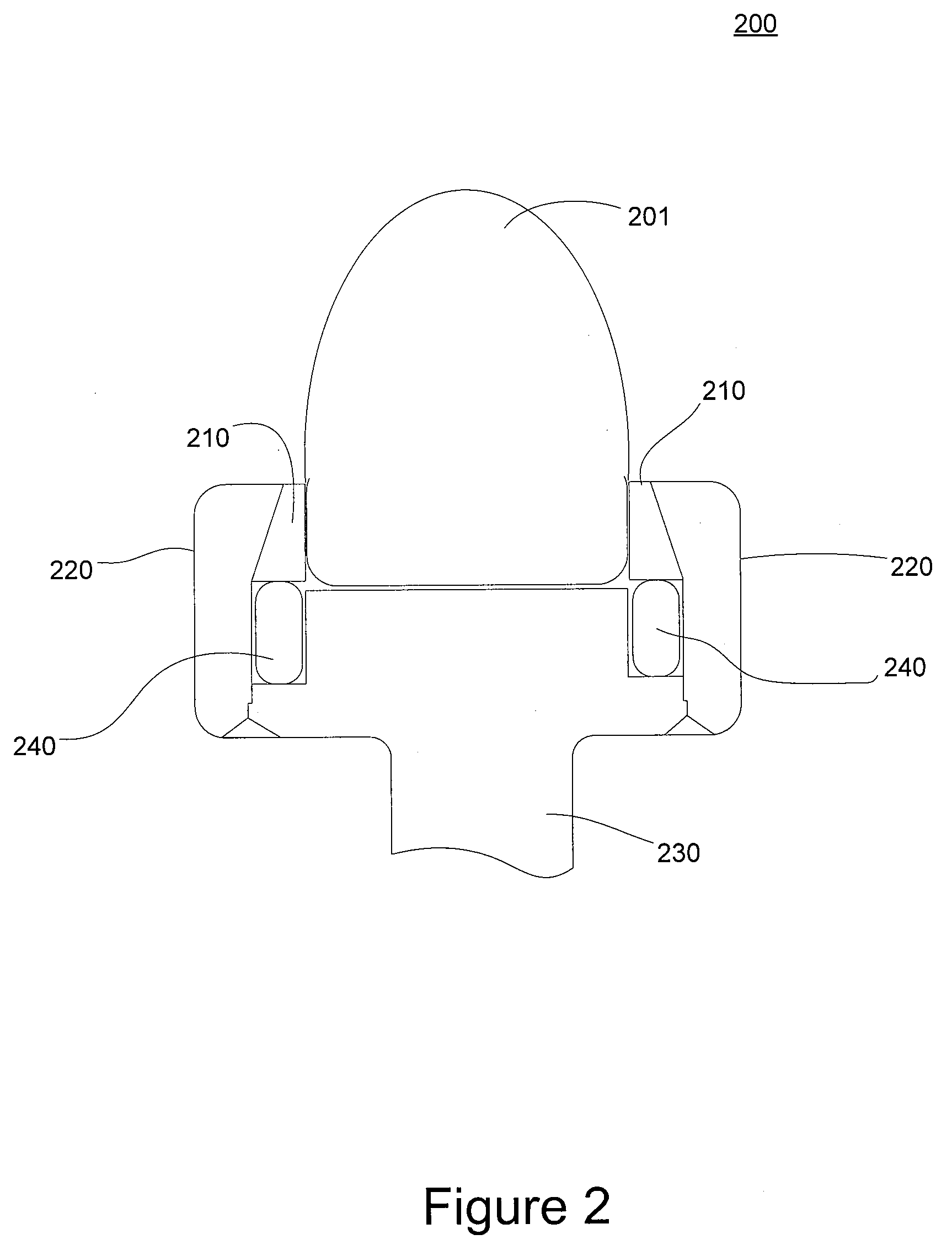

Dissimilar material retention

InactiveUS20100140530A1Extended operating temperature rangeLift valveValve member-seat contactsEngineeringCollet

In accordance with various aspects of the present invention, methods and apparatuses for designing and configuring dissimilar material retention, specifically a valve plug assembly, are disclosed. The methods and apparatuses enable the application of a wider range of materials in a valve plug assembly than previous valve plug assemblies, and also increase the operational temperature range of the valve plug assembly. In an exemplary embodiment, a valve plug assembly comprises a plug head, a collet surrounding the plug head, a plug base adjacent to the collet, and a retainer surrounding the tapered outside surface of the collet and the plug base, where the plug head extends past the collet and the retainer. The valve plug assembly is configured to create an interference fit of the various components.

Owner:CALDERA ENG

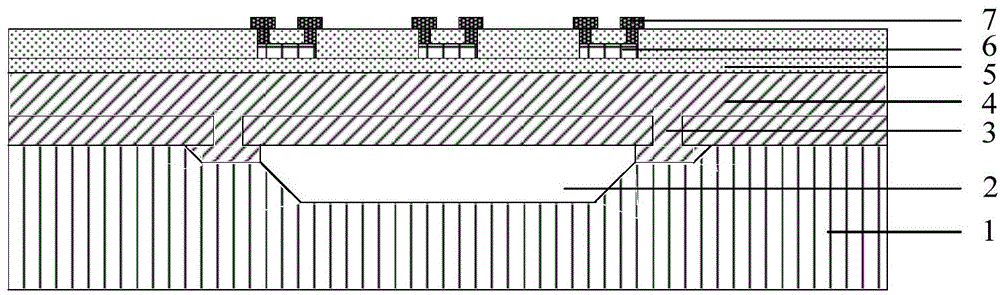

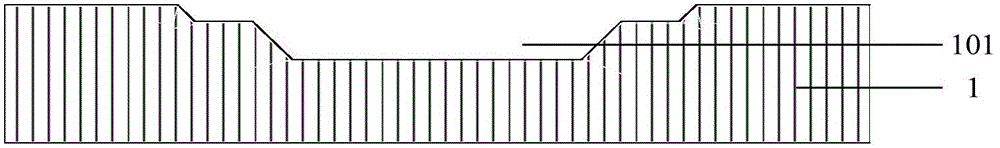

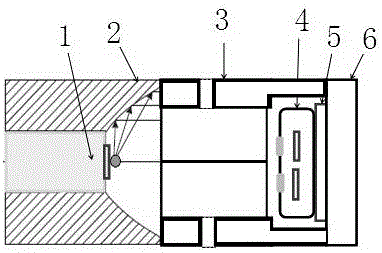

MEMS pressure sensor chip based on SOI technology and manufacturing method thereof

ActiveCN103604538AEasy to integrateEasy to miniaturizeDecorative surface effectsForce measurementHysteresisMems pressure sensor

The invention discloses an MEMS pressure sensor chip based on an SOI technology and a manufacturing method of the MEMS pressure sensor chip. The MEMS pressure sensor chip is suitable for absolute pressure measurement and comprises a monocrystalline silicon substrate. A flat elastic membrane is arranged on a groove of the monocrystalline silicon substrate. The edge of the elastic membrane is provided with corrosion holes. The elastic membrane and the groove of the silicon substrate form an airtight cavity. Four monocrystalline silicon strain resistors are arranged on the elastic membrane. All the monocrystalline silicon strain resistors are isolated from one another through insulating media, and the monocrystalline silicon strain resistors are also isolated from the elastic membrane through insulating media. The four strain resistors are connected through metal wires to form a Wheatstone bridge so as to convert pressure into a voltage and output the voltage. The MEMS pressure sensor chip has the advantages of being small in size, good in repeatability and hysteresis, high in sensitivity, wide in operating temperature range, and the like; besides, the manufacturing technique is compatible with the integrated circuit technique.

Owner:SHENYANG POLYTECHNIC UNIV

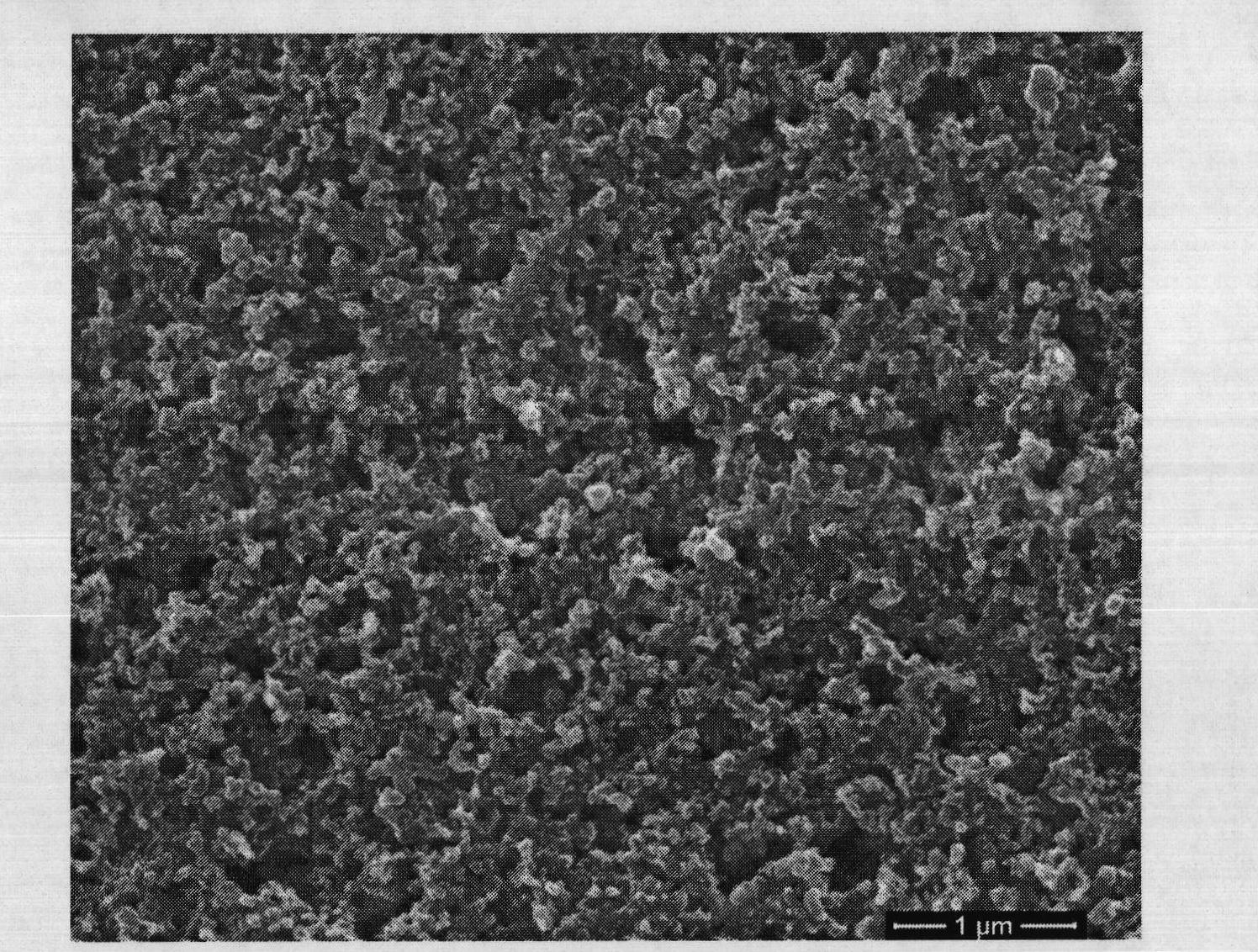

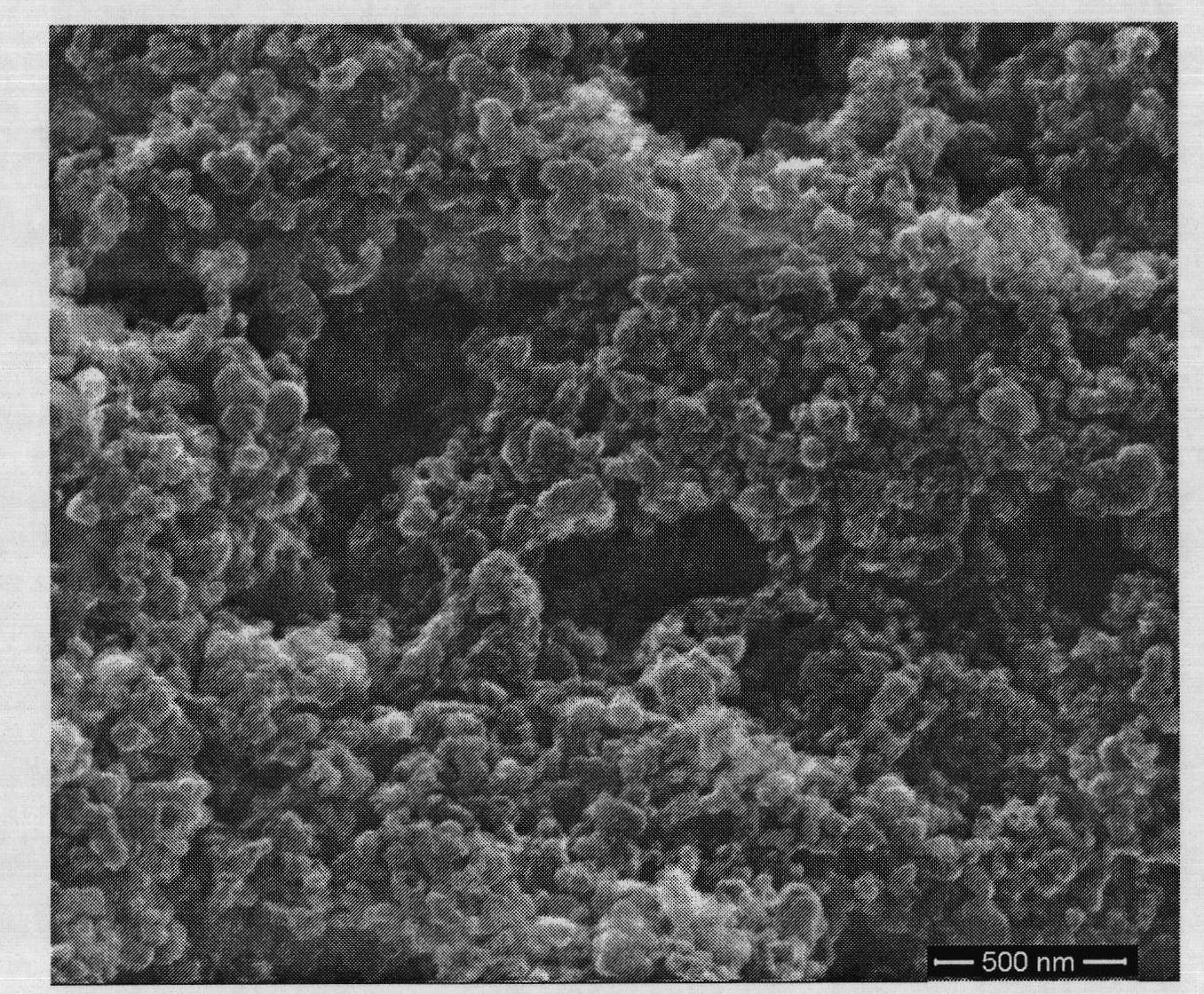

Carbon/aluminum composite cathode foil for solid aluminum electrolytic capacitor and preparation method thereof

InactiveCN101923961AImprove bindingExtended service lifeSolid electrolytic capacitorsCapacitanceElectrolysis

The invention relates to a carbon / aluminum composite cathode foil for a solid aluminum electrolytic capacitor and a preparation method thereof. The technical scheme is as follows: carrying out proportioning according to that the weight ratio of conductive carbon black: dispersant: organic binder: solvent is 1: (0.0001-0.05): (0.01-1): (10-1000), firstly mixing the conductive carbon black, the dispersant and the organic binder, further adding the solvent, uniformly stirring and mixing, and preparing into slurry; uniformly coating the prepared slurry on the surface of an aluminum foil after pretreatment, then placing the aluminum foil coated with the slurry into a vacuum furnace, keeping the temperature for 1-40h under the conditions that the vacuum degree is 10-4-10-1Pa and the temperature is 300-660 DEG C, naturally cooling to room temperature in the vacuum furnace, and directly preparing the carbon / aluminum composite foil for the solid aluminum electrolytic capacitor or preparing the carbon / aluminum composite foil for the solid aluminum electrolytic capacitor after activation treatment. The process is simple and the preparation process is safe and environment-friendly; and the prepared product has the characteristics of high specific capacitance, good stability, high carbon / aluminum interfacial binding force and long service life.

Owner:WUHAN UNIV OF SCI & TECH

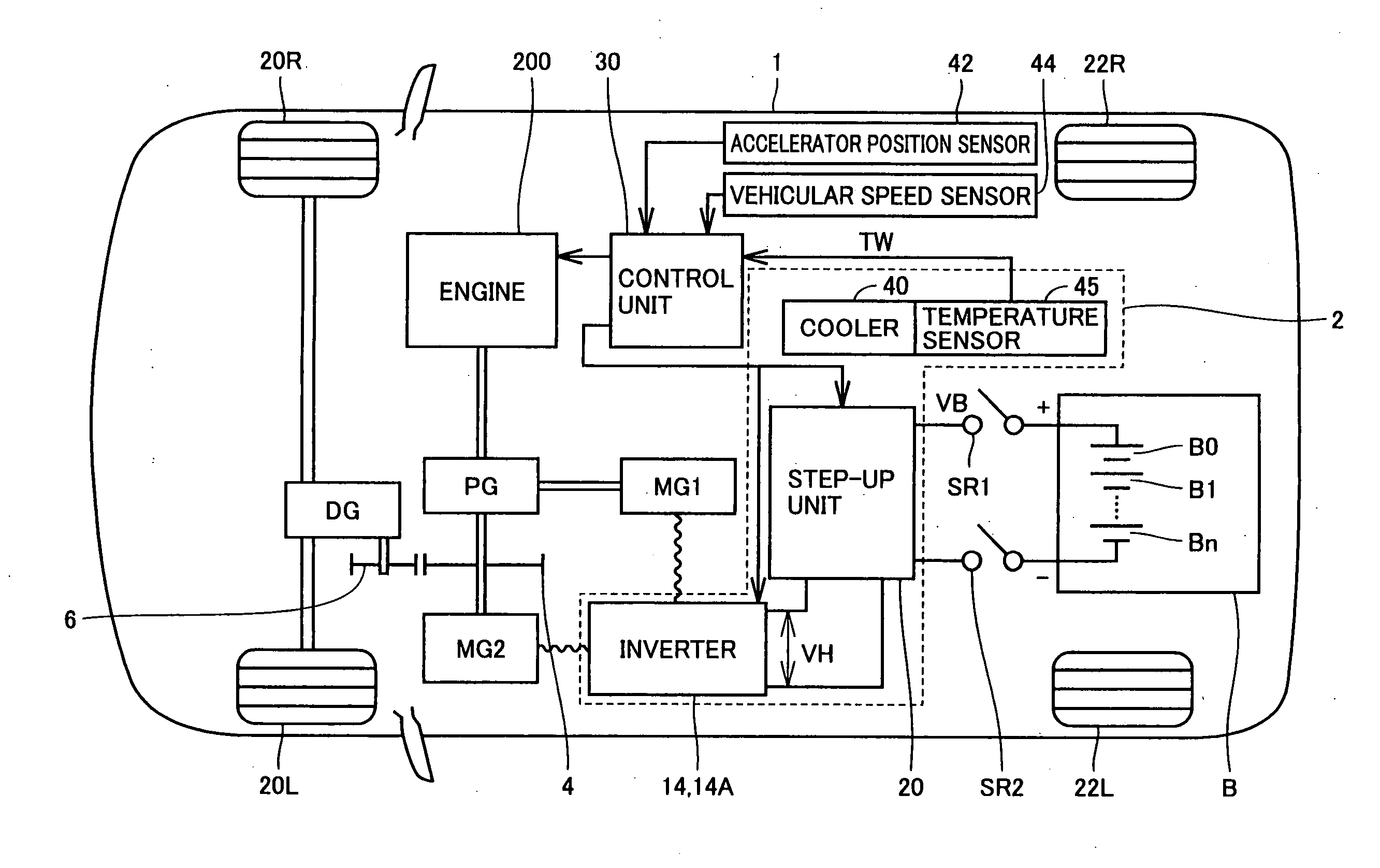

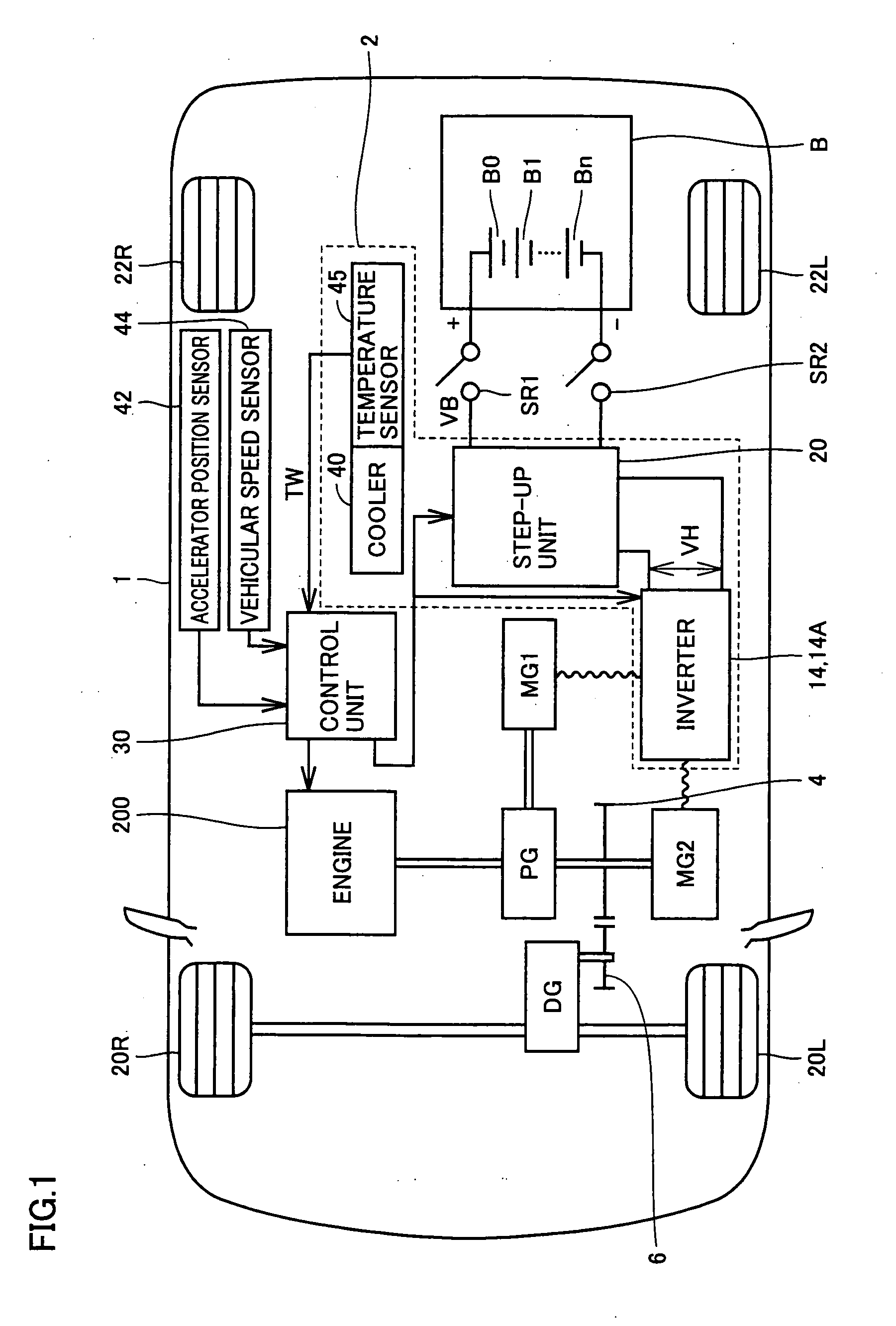

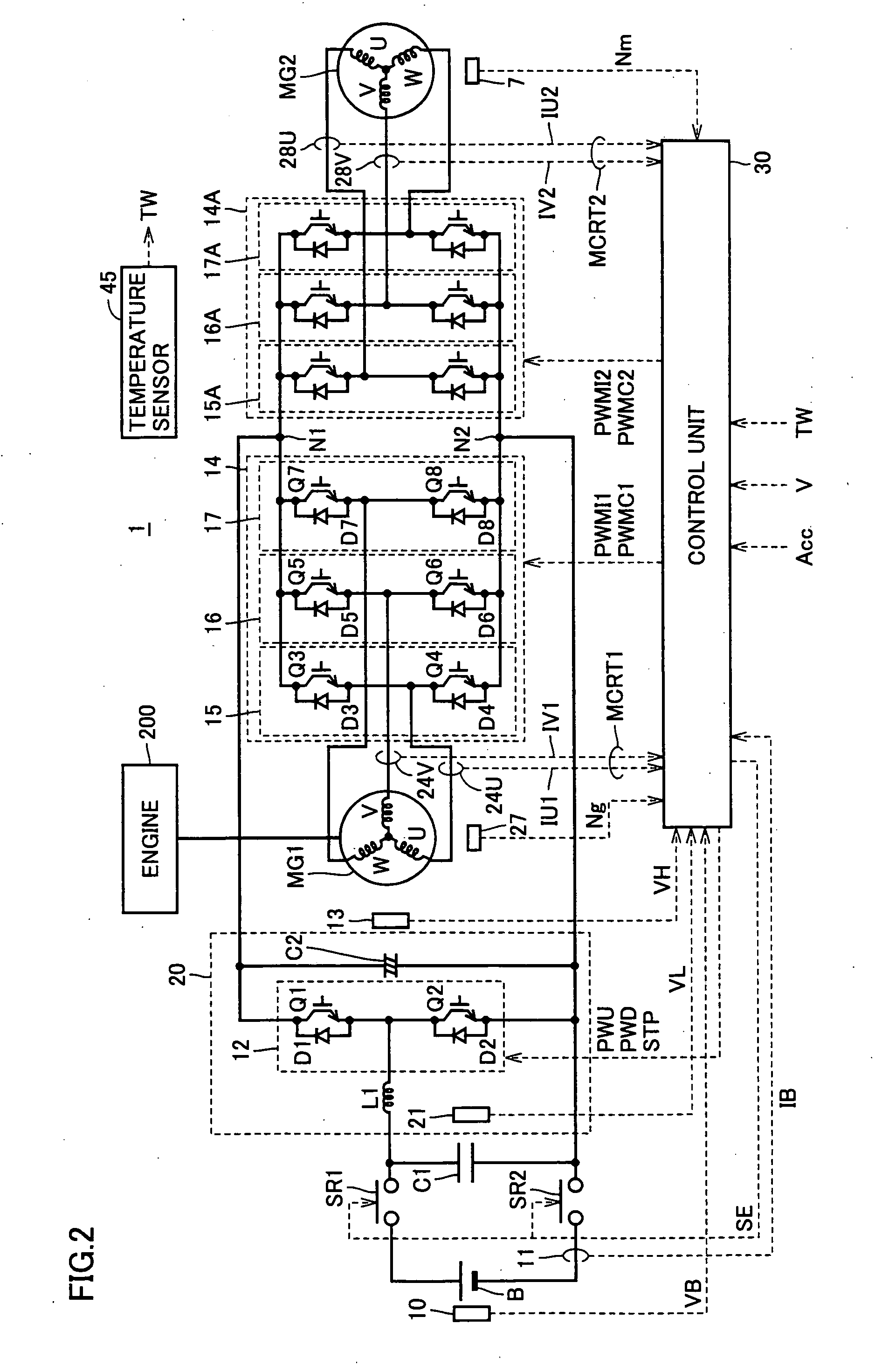

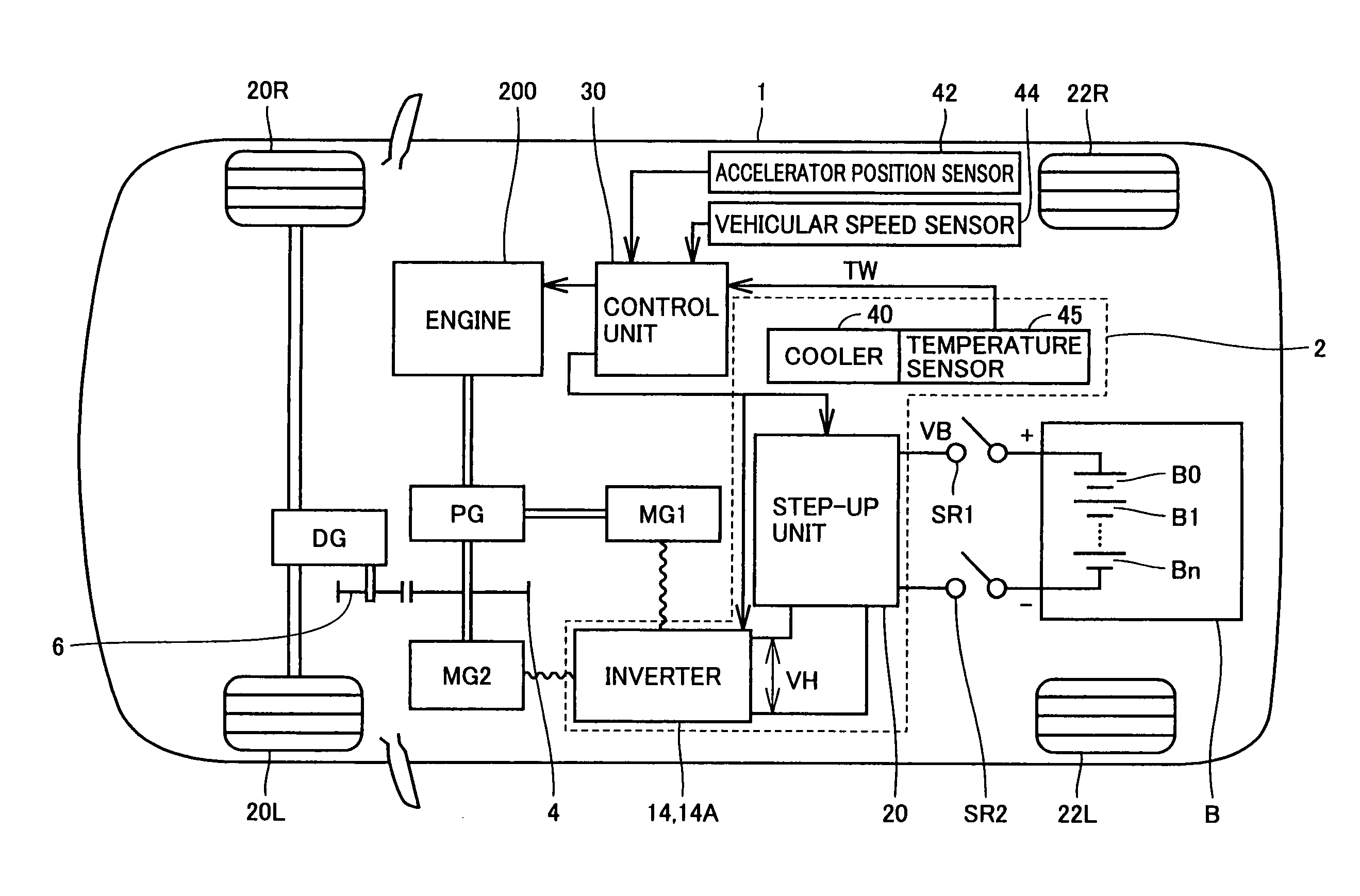

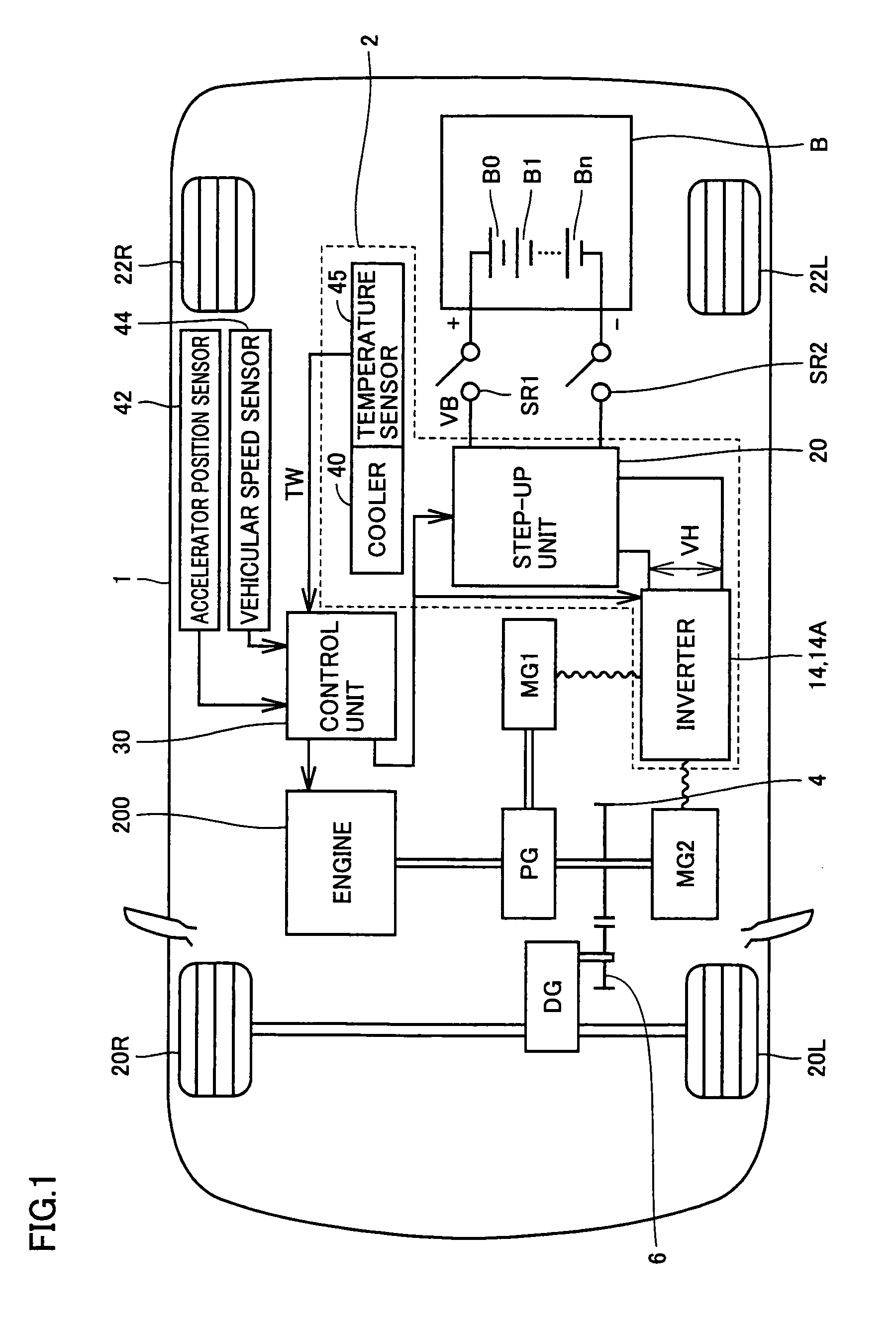

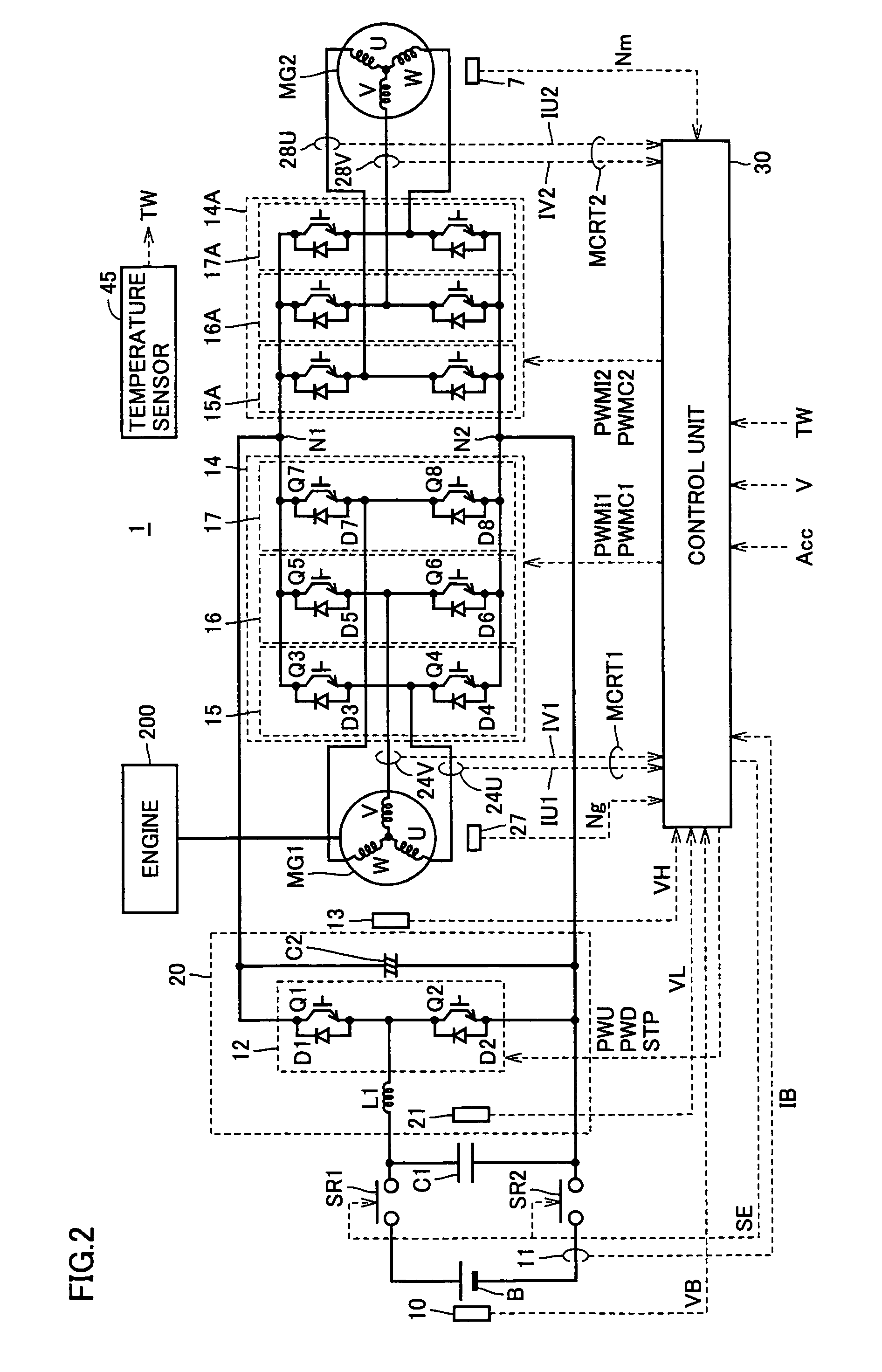

Control apparatus for load device, and vehicle

ActiveUS20100045103A1Extended operating temperature rangeExtended temperature rangeAC motor controlBoards/switchyards circuit arrangementsPower inverterEngineering

A control apparatus for a load device mounted on a vehicle is provided with: a temperature sensor detecting a temperature of an inverter; a voltage sensor detecting an applied voltage of the inverter; and a control unit operating the inverter in a case where the applied voltage is a predetermined upper limit value or lower whereas stopping the inverter in a case where the applied voltage is higher than the upper limit value based on a voltage detection result by the voltage sensor. The control unit sets the upper limit value based on temperature dependency of a withstand voltage of an IGBT element included in the inverter and a temperature detection result by the temperature sensor.

Owner:DENSO CORP

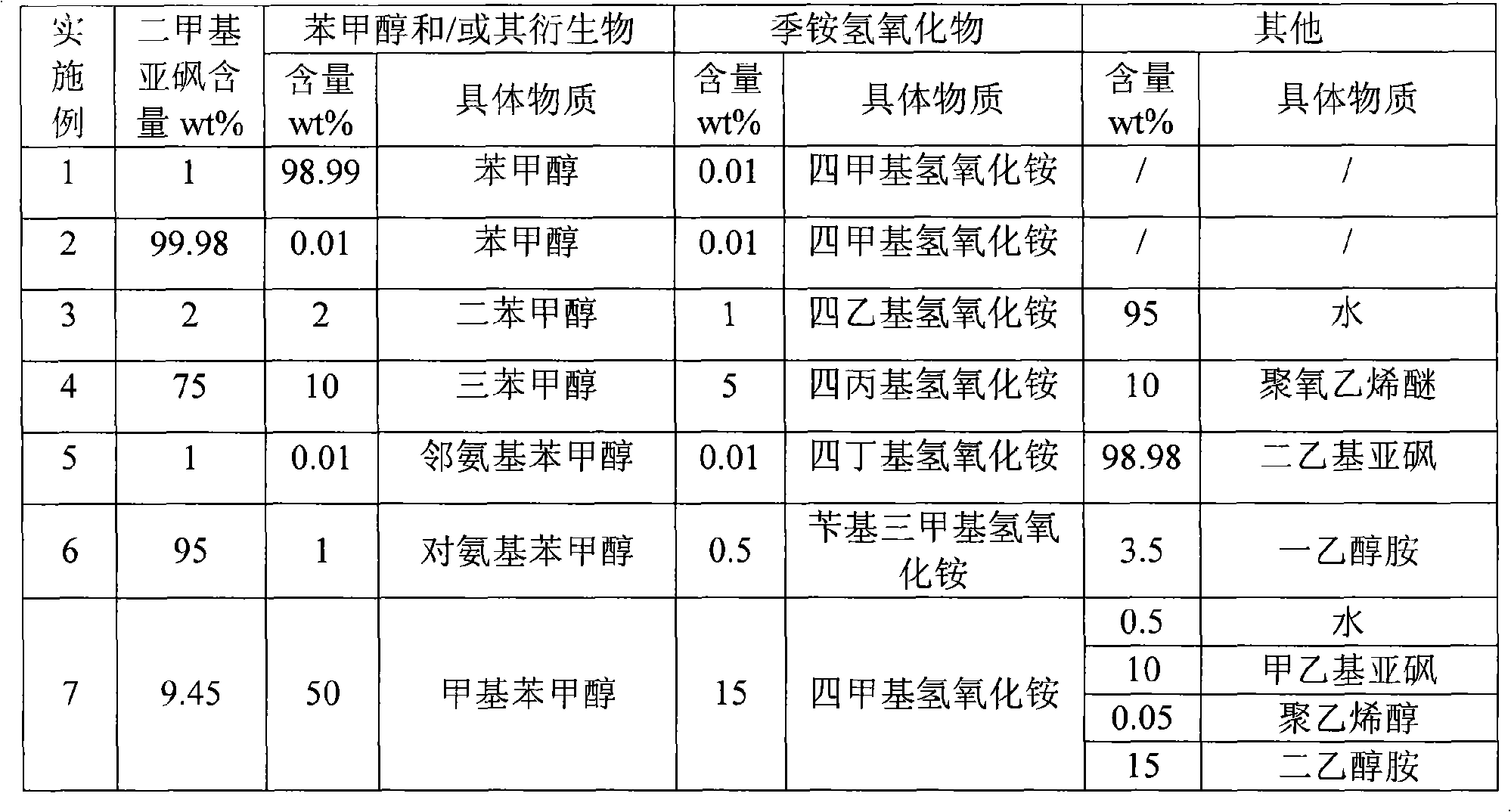

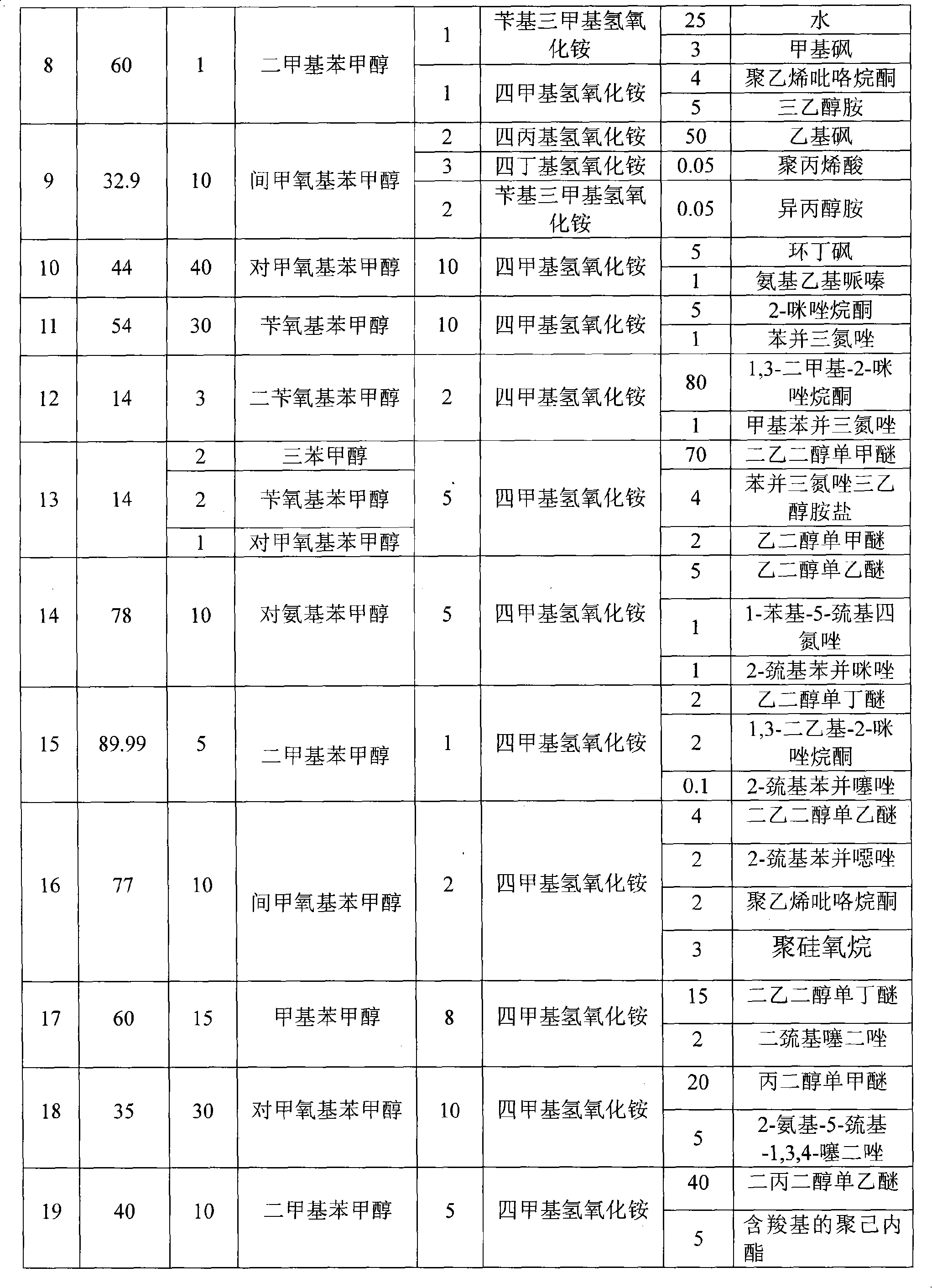

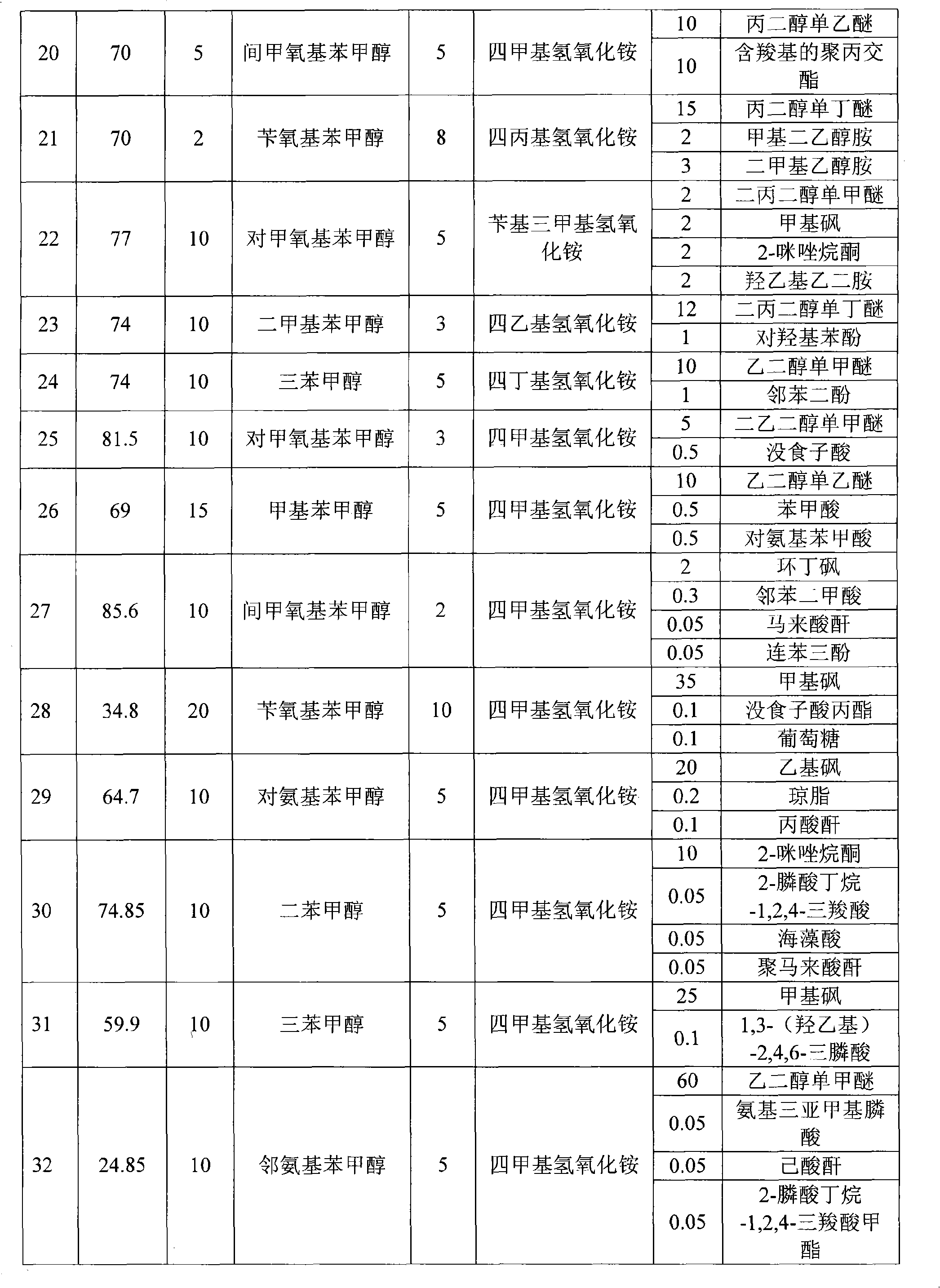

Low etching photoresist cleaning agent

InactiveCN101286016AGood application prospectExtended operating temperature rangeNon-surface-active detergent compositionsPhotosensitive material processingDielectric substrateAmmonium hydroxide

The invention discloses a low etching photoresist cleaning agent, comprising benzyl alcohol and / or ramification of the benzyl alcohol, quaternary ammonium hydroxide and dimethyl sulfoxide. The cleaning agent of the invention can be used for removing photoresist (light resistance) and other residues on metals, metal alloys or dielectric substrates, has low etching speed on metals such as SiO2, copper, etc. and low-k material, and has excellent application prospect in micro-electron fields such as semiconductor wafer cleaning, etc.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

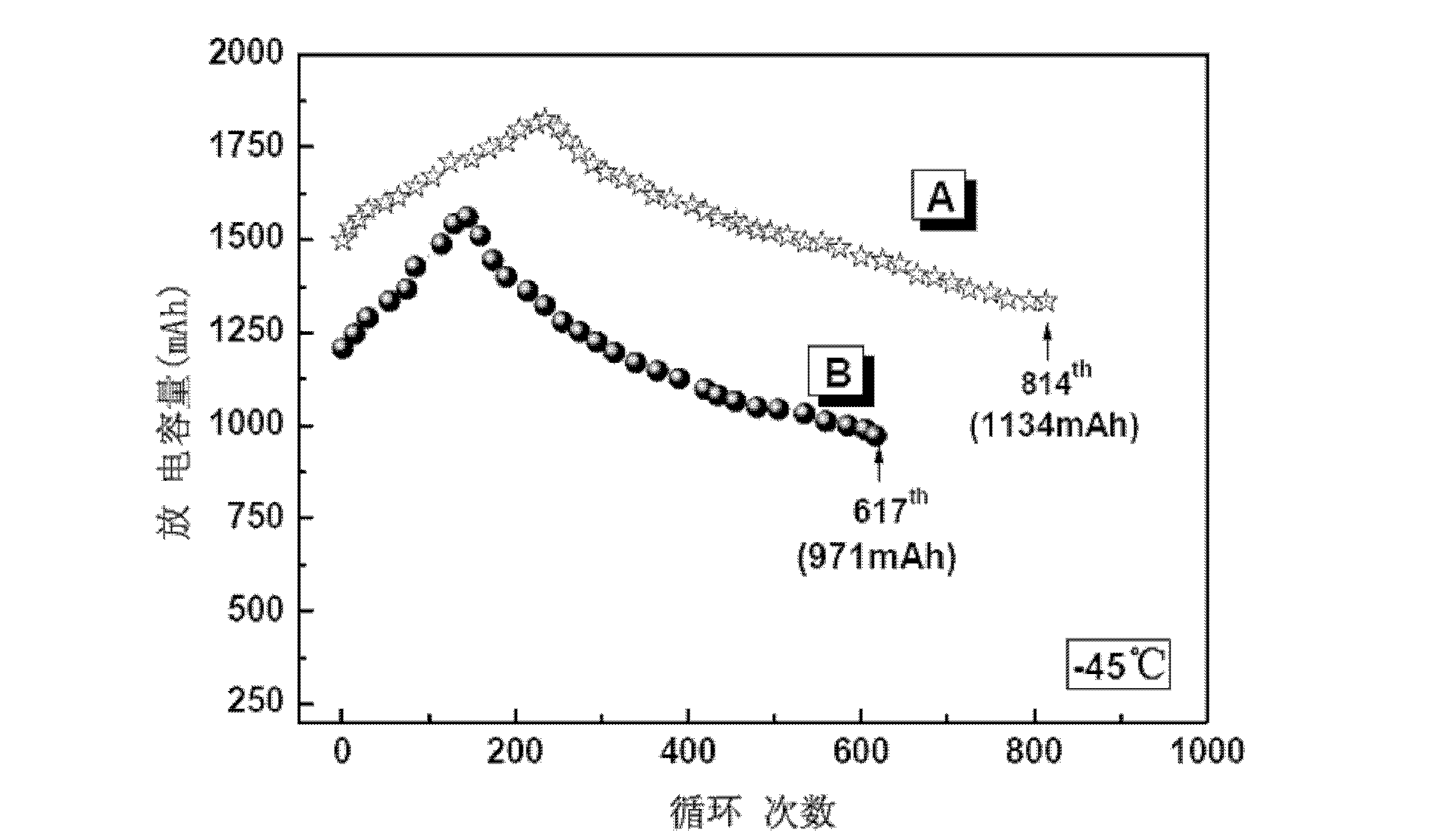

Electrolyte for lithium ion battery and preparation method thereof

ActiveCN102637901AGood effectImprove charge and discharge efficiencySecondary cellsLithium oxideLithium hydroxide

The invention discloses an electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte consists of a main electrolyte, an electrolyte additive, a main solvent and a solvent additive. The preparation method comprises the following steps of: A. under the condition of vacuum or inert gas protection, respectively mixing the main solvent and the solvent additive with a drying agent (lithium oxide) which is dried to be at constant weight in advance, and mixing and filtering to remove the lithium oxide and lithium hydroxide sediment; B. uniformly mixing the dried main solvent and the dried solvent additive from the step A; and C. adding a main electrolyte mixture and an electrolyte additive into the solvent mixed in the step B, and agitating and dissolving under the vacuum and inert gas protection to prepare a solution with the mass mol concentration of the main electrolyte of 0.5-1.5 M. The electrolyte has the advantages of abundant resources, low price and no toxin, effectively improves the work temperature range of the battery and effectively prolongs the circulating service life of the battery, so that various types of the lithium ion batteries are manufactured; and the electrolyte is particularly suitable for manufacturing a lithium ion power battery with high power capacity and high multiplying power charging and discharging capacity.

Owner:广州云通锂电池股份有限公司

Control apparatus for load device, and vehicle

ActiveUS7952236B2Extended operating temperature rangeExtended temperature rangeAC motor controlBoards/switchyards circuit arrangementsPower inverterEngineering

A control apparatus for a load device mounted on a vehicle is provided with: a temperature sensor detecting a temperature of an inverter; a voltage sensor detecting an applied voltage of the inverter; and a control unit operating the inverter in a case where the applied voltage is a predetermined upper limit value or lower whereas stopping the inverter in a case where the applied voltage is higher than the upper limit value based on a voltage detection result by the voltage sensor. The control unit sets the upper limit value based on temperature dependency of a withstand voltage of an IGBT element included in the inverter and a temperature detection result by the temperature sensor.

Owner:DENSO CORP

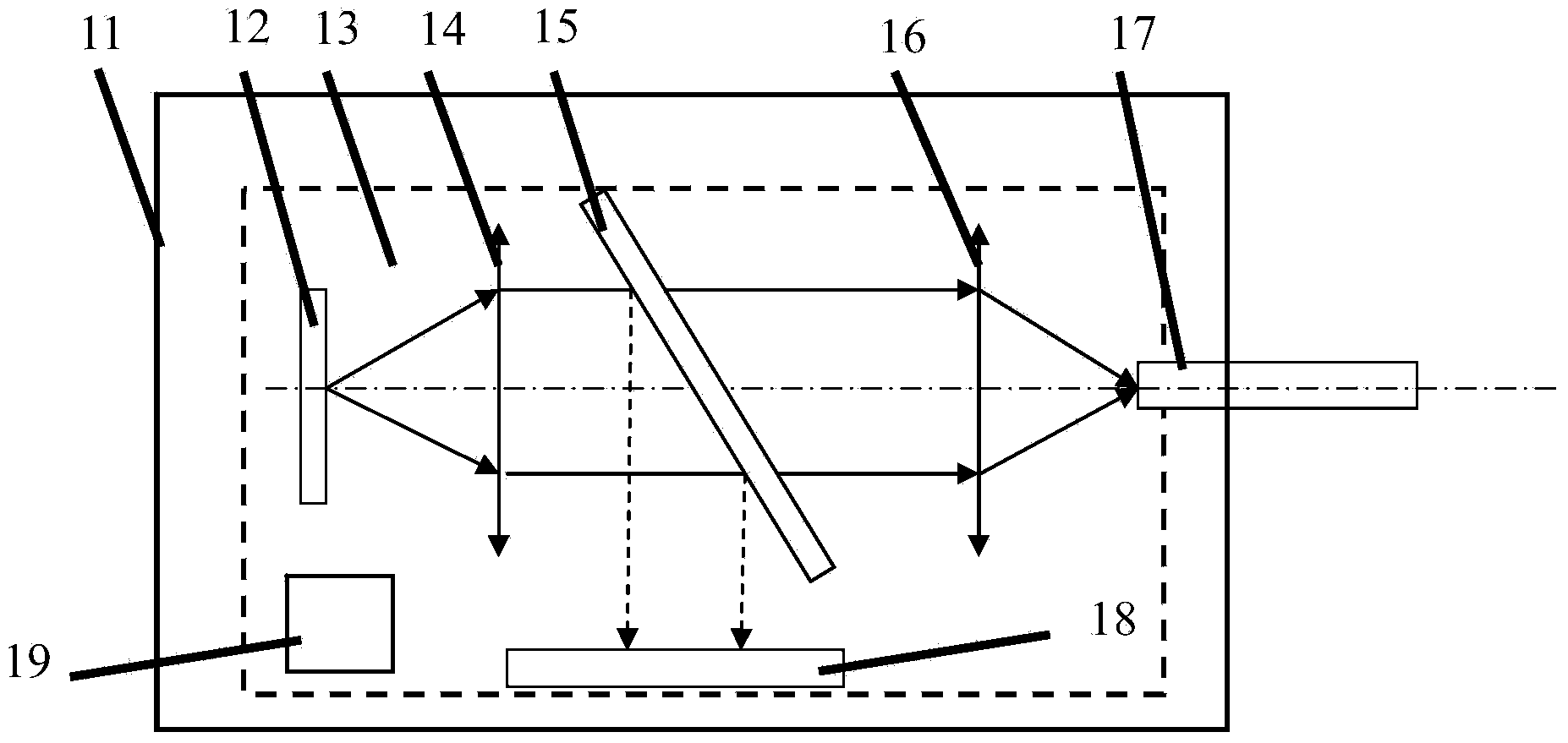

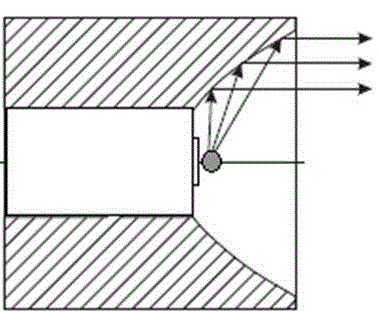

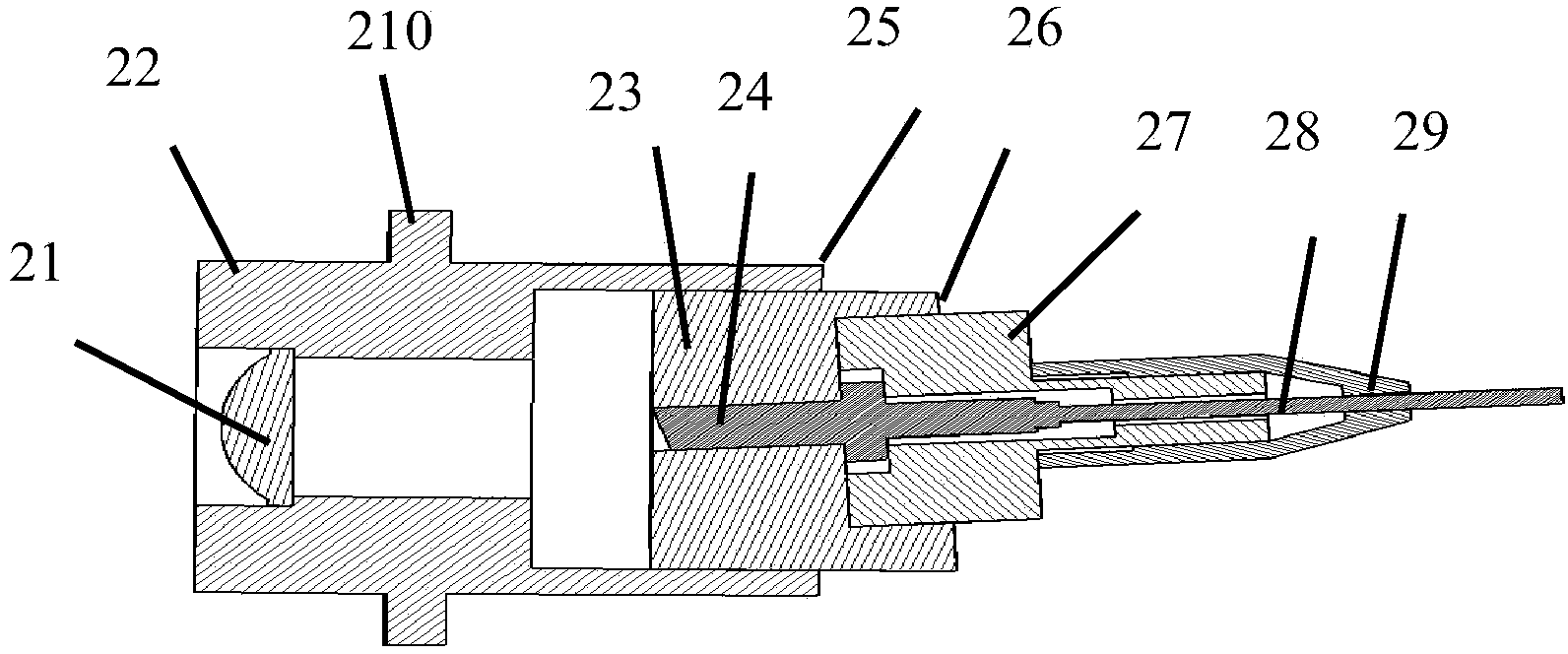

Optical fiber coupling vertical-cavity surface emitting laser with power monitoring function

InactiveCN103887708AAvoid pollutionExtended operating temperature rangeLaser detailsCoupling light guidesVertical-cavity surface-emitting laserEffect light

Provided is an optical fiber coupling vertical-cavity surface emitting laser with a power monitoring function. The laser comprises a laser shell, a semiconductor refrigerator, a vertical-cavity surface emitting laser body, a collimating lens, a lighting distributing plate, a coupling lens, a detector and an optical fiber assembly. The laser has the advantages of having the power monitoring function, being high in temperature stability and reliability, truly achieving all-metal hermetic sealing and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

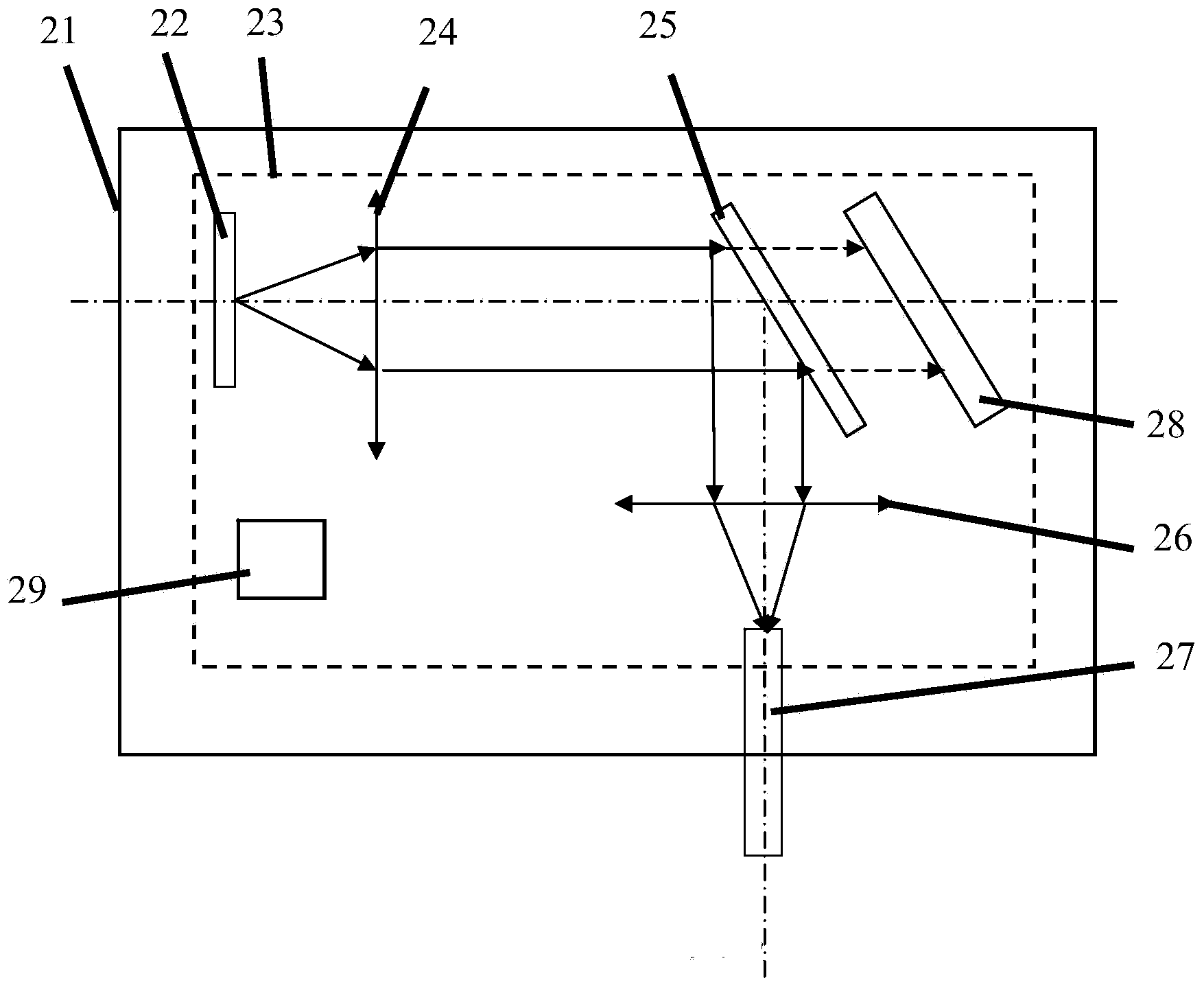

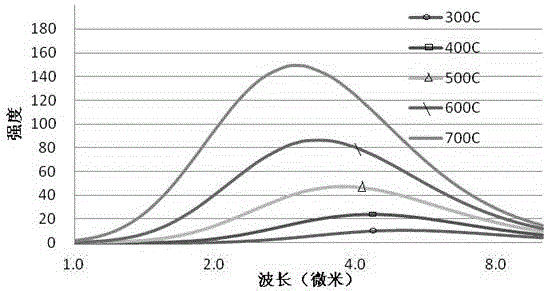

Measuring method and device for MWD (measurement-while-drilling) spectrometer used for measuring oil gas components

InactiveCN105156092AAvoid missingFast analysisSurveyColor/spectral properties measurementsThermopileTransmission technology

The invention relates to a measuring method and device for an MWD (measurement-while-drilling) spectrometer used for measuring oil gas components. The MWD spectrometer device comprises a parabolic mirror used for collimating a luminous point of a light source, and is characterized in that a sampling air chamber, a reference air chamber and a detector with four channels and four independent thermopiles are arranged at the back of the mirror, each channel is equipped with a filter plate and a transmission window, and the detector is installed on a semiconductor chilling plate. The MWD spectrometer device is advantaged in that the analysis speed is fast, the analysis cost is low, and the reappearance of the test results is good; the device can carry out on-line analysis by means of a current mature downhole signal transmission technology; the size is small, especially the cross section is small, and the device can be integrated into an MWD device conveniently; the power dissipation is low, the driving current of a novel infrared radiation light source is approximately 100mA, taking regard of pulse width modulation the duty ratio of which is 20-50%, the actual power is lower.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Vacuum infiltration preparation process for titanium-coated diamond/SiC composite material

InactiveCN108165792AEnhanced interface bindingImprove mechanical propertiesTransportation and packagingMetal-working apparatusChemical reactionGraphite

The invention relates to a vacuum infiltration preparation process for a titanium-coated diamond / SiC composite material, wherein interface bonding property between silicon and diamond in the compositematerial is strengthened in a mode of coating the diamond with titanium. The vacuum infiltration preparation process comprises the following steps of: mixing diamond and titanium powder in proportion, sintering and plating under vacuum or inert gas atmosphere to form a silicon carbide layer on a diamond surface, thereby preparing titanium-coated diamond particles; uniformly mixing titanium-coateddiamond, silicon powder, graphite and an organic binder to obtain a mixture, pressing the mixture into a porous preformed blank body which has a regular shape and is made of a composite material, degreasing the preformed blank body, and performing liquid silicon infiltration on the degreased porous blank body in a vacuum infiltration furnace for enabling the porous blank body to be completely compact. In the infiltration process, TiC reacts with Si to generate SiC and Ti2SIC3, so that formation of SIC is quickened while TiC is used as an intermediate phase in comparison with a mode that Si and diamond directly react to generate an interface phase of silicon carbide, generation difficulty of SiC is reduced and SiC content is increased; and moreover, integral strength of the material is improved through interface bonding, formed by chemical reaction, between diamond and silicon.

Owner:北京科技大学广州新材料研究院

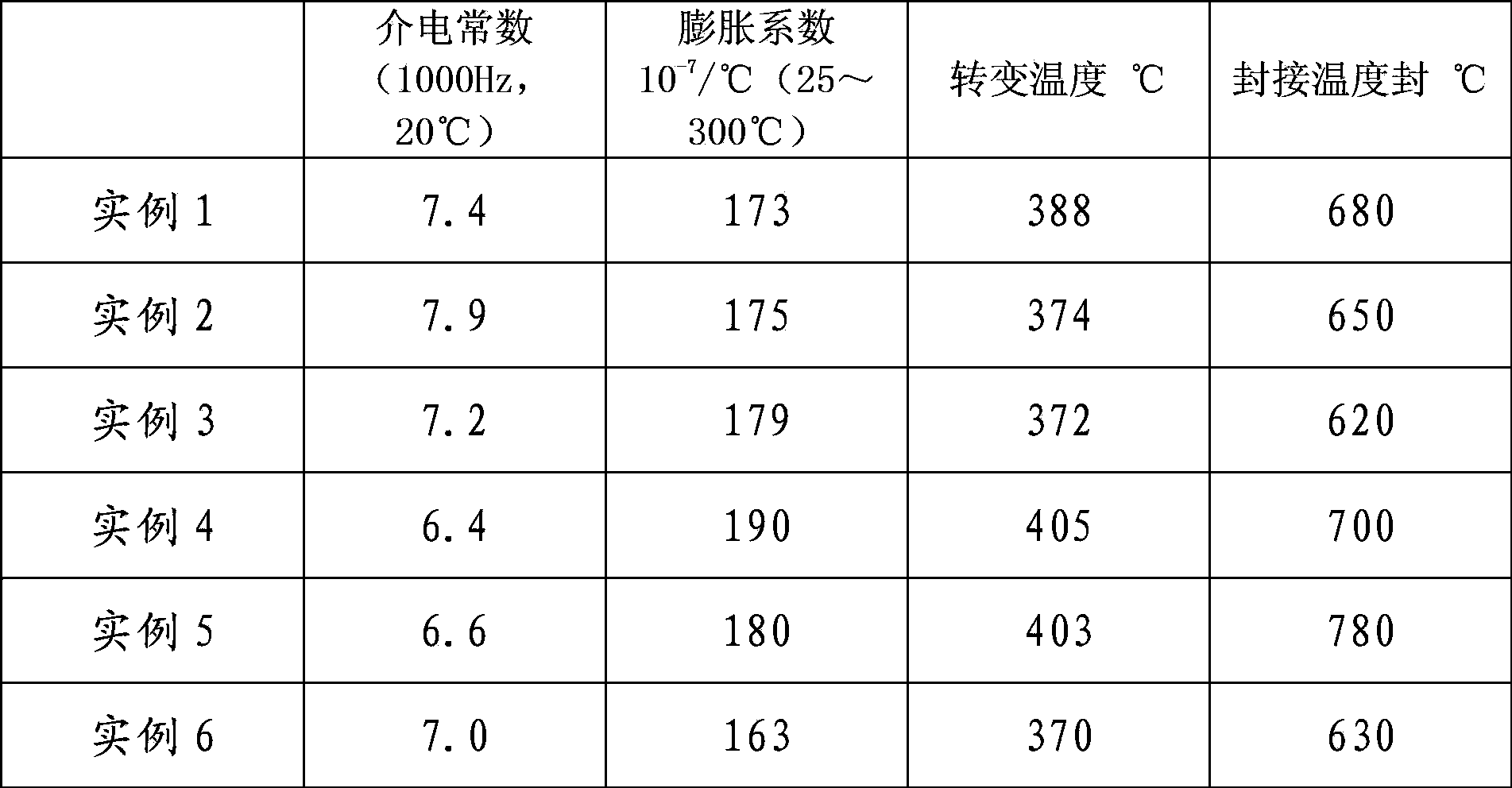

Preparation method and application of high expansion coefficient copper sealing glass powder

ActiveCN103880290AHigh expansion coefficientImprove mechanical propertiesCouplings bases/casesThermal insulationHigh resistivity

The invention relates to a preparation method and an application of high expansion coefficient copper sealing glass powder, wherein the technical difficult problems of high cost, long production period, high use environment requirements and the like of the existing copper seal electrical connector are solved. The high expansion coefficient copper sealing glass powder adopts a phosphate glass system and comprises the following components by mole: 45-65% of P205, 10-15% of B203, 4-15% of Al2O3, 5-20% of Na2O, 8-22% of K2O, and 0-12% of PbO+BaO+CaO+MgO. The application comprises: carrying out mixing, heating, stirring, molding, drying and other steps on the glass powder and a paraffin thin sheet, assembling a sealing copper shell and a glass billet, placing on a graphite mold, placing into a nitrogen atmosphere furnace or vacuum furnace, carrying out thermal insulation for 30 min at a temperature of 600-780 DEG C, and cooling to a room temperature to obtain the electrical connector with characteristics of high temperature resistance, high resistivity and high air-tightness. According to the present invention, the glass powder can match to the copper alloy shell expansion coefficient, the produced copper alloy electrical connector can achieve good electrical property, the preparation method is suitable for industrial production, and the economic benefits can be increased.

Owner:LIAONING SILICATE RES INST

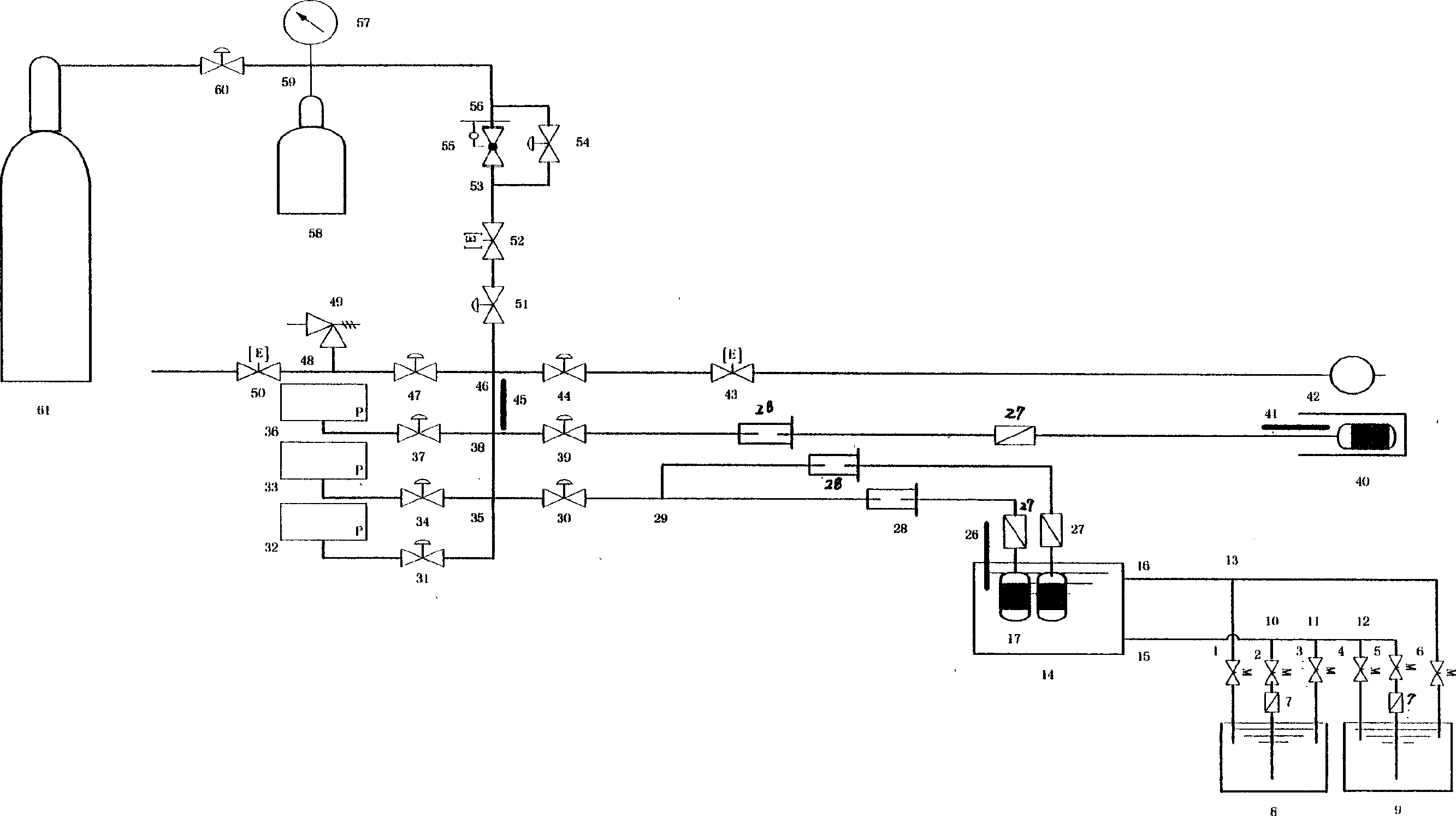

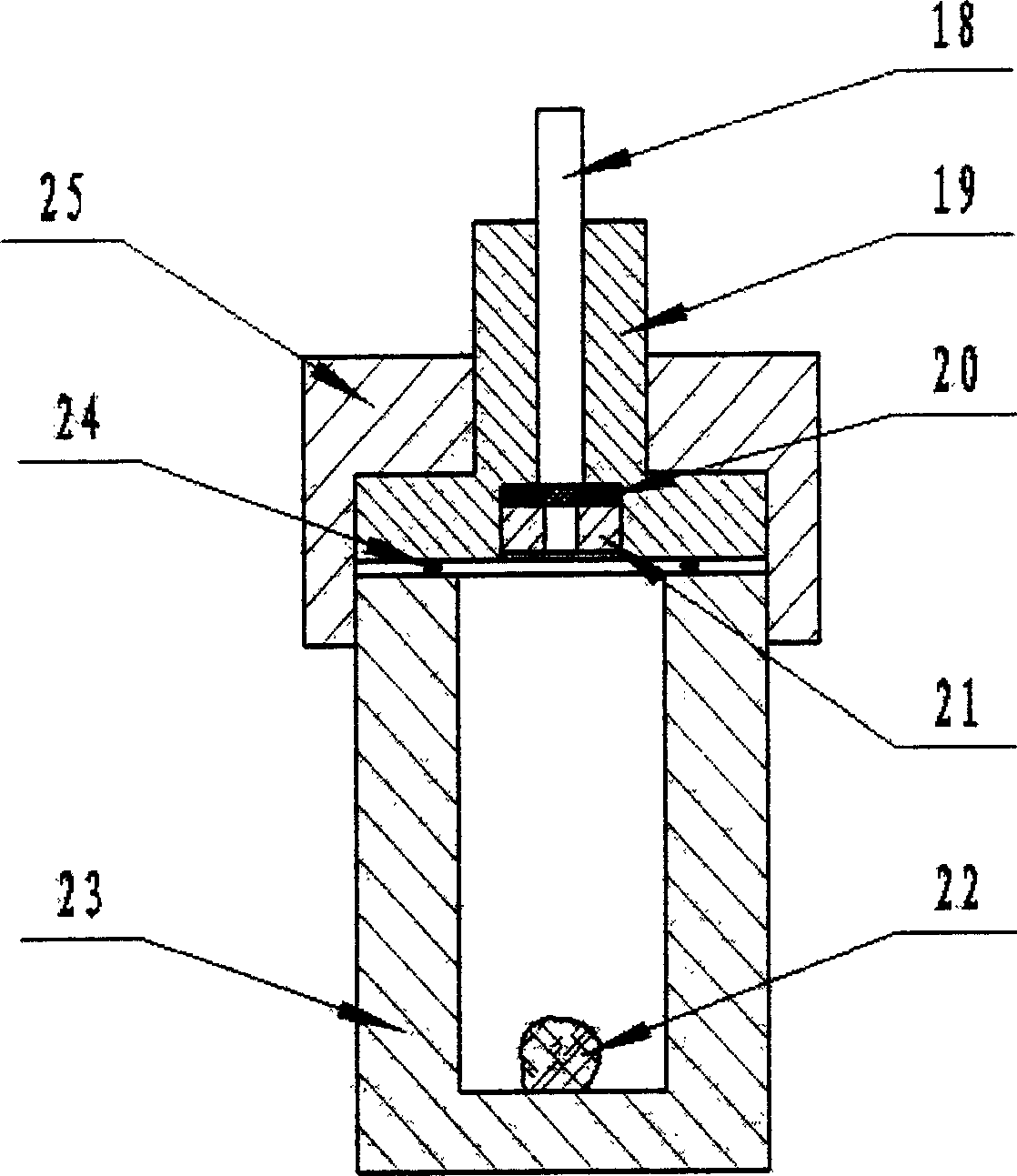

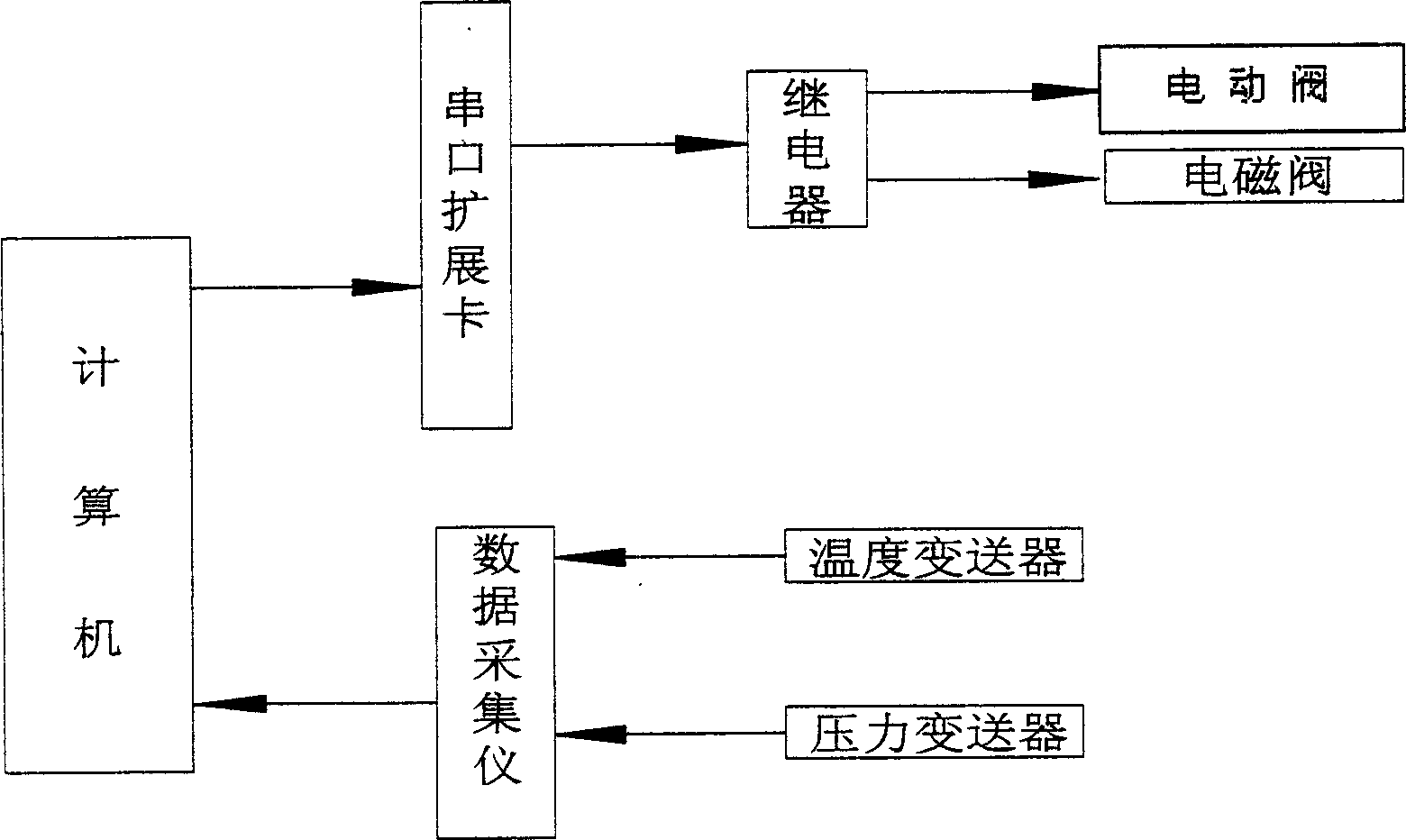

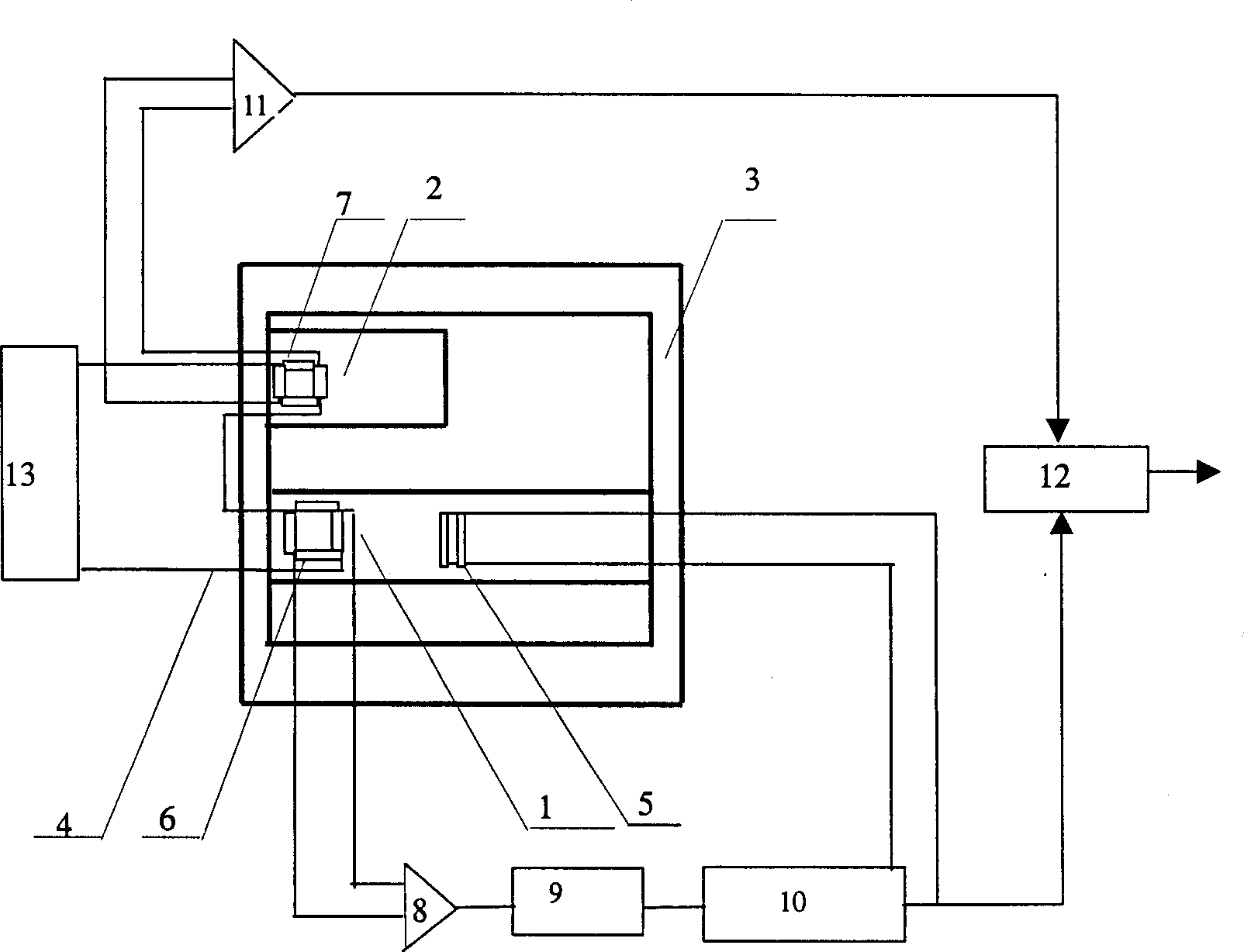

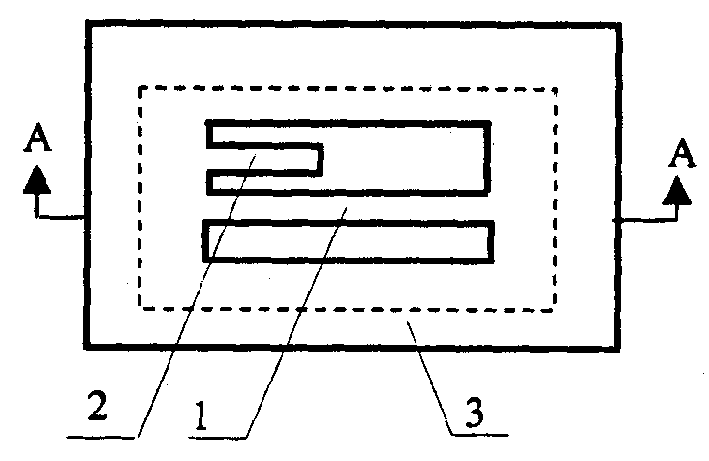

Hydrogen storage alloy performance integrated experimental appts

InactiveCN1601281AHigh degree of automationAutomatic Control RunabilityChemical methods analysisNuclear engineeringControl system

The invention relates to a material testing equipment, in particular, it relates to a hydrogen storage alloy testing equipment. It is formed from reaction chamber, hydrogen gas circulation system and liquor circulation system, in which between reaction chamber and hydrogen gas circulation system a quick joint is used to implement closed connection, the hydrogen gas circulation system can make the hydrogen gas be continuously circulated between the reaction chamber and hydrogen gas circulation system, and said liquid circulation system can make the constant temperature liquids with different temperatures be alternatively circulated between the opened container and oil bath so as to make the hydrogen storage alloy implement alternative circulation of absorbing and releasing hydrogen. In the course of hydrogen gas and liquid circulation the control and data acquisition system can be used for acquiring and processing data, and outputting signal to control system to make test.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

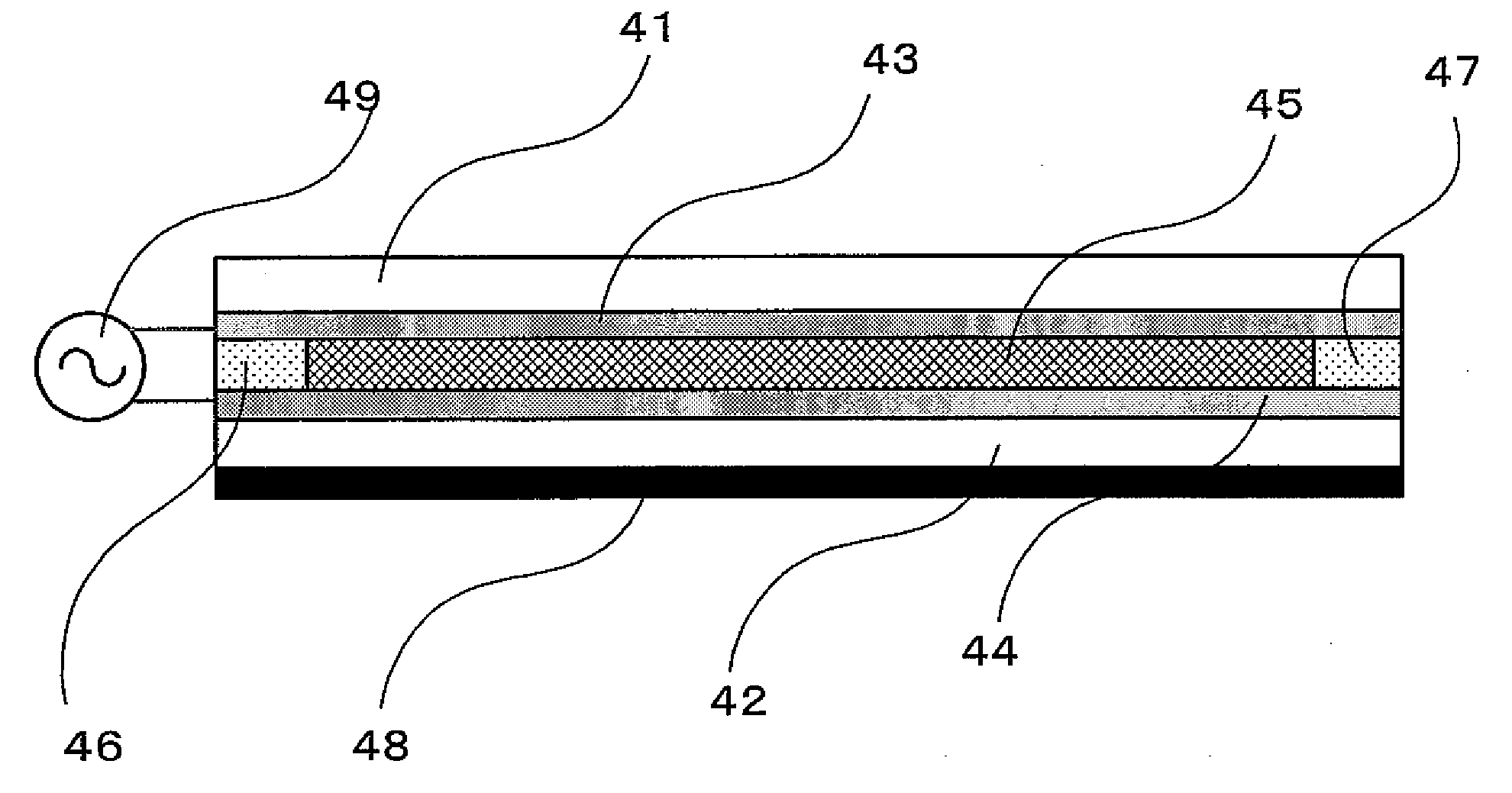

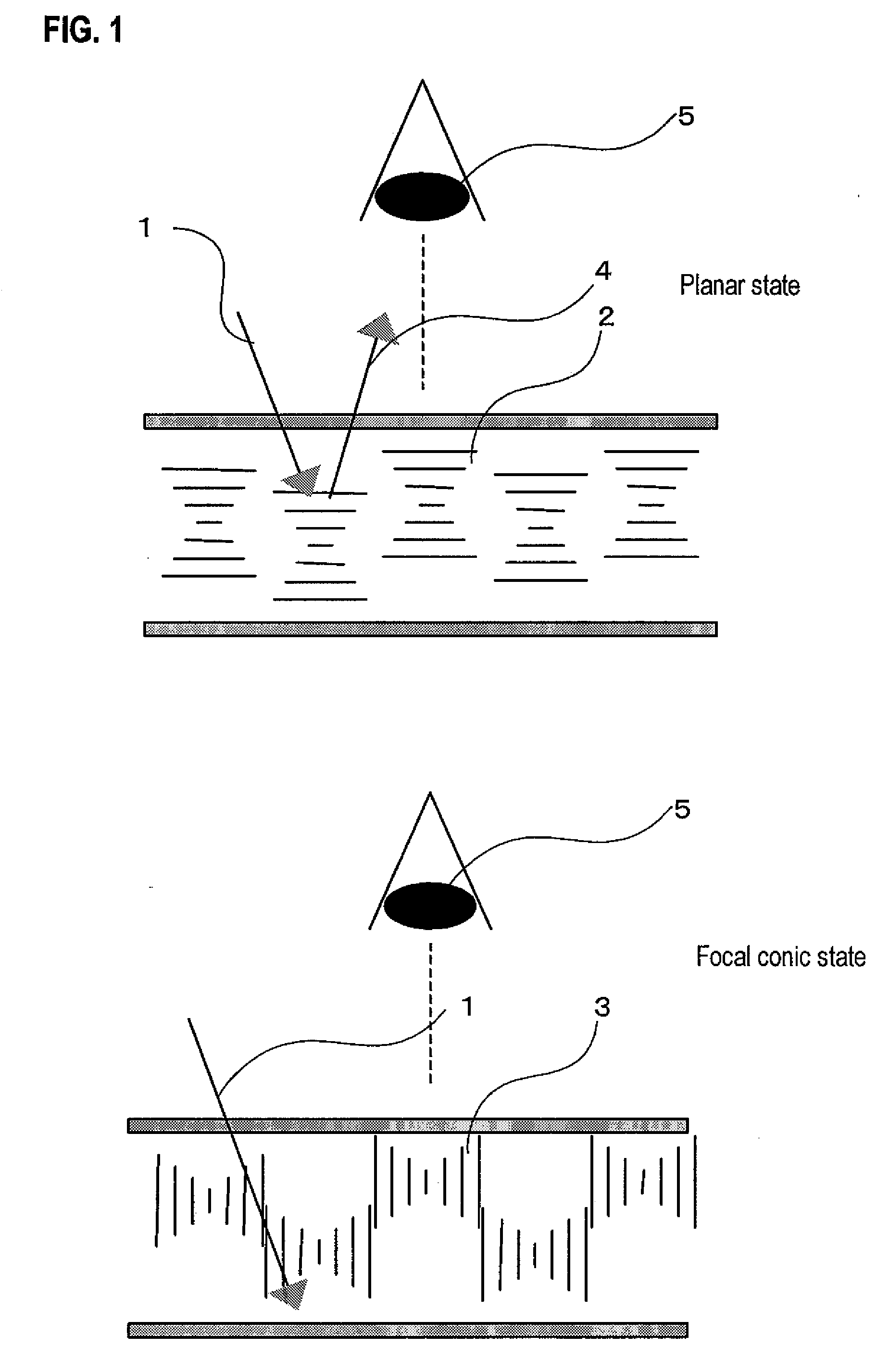

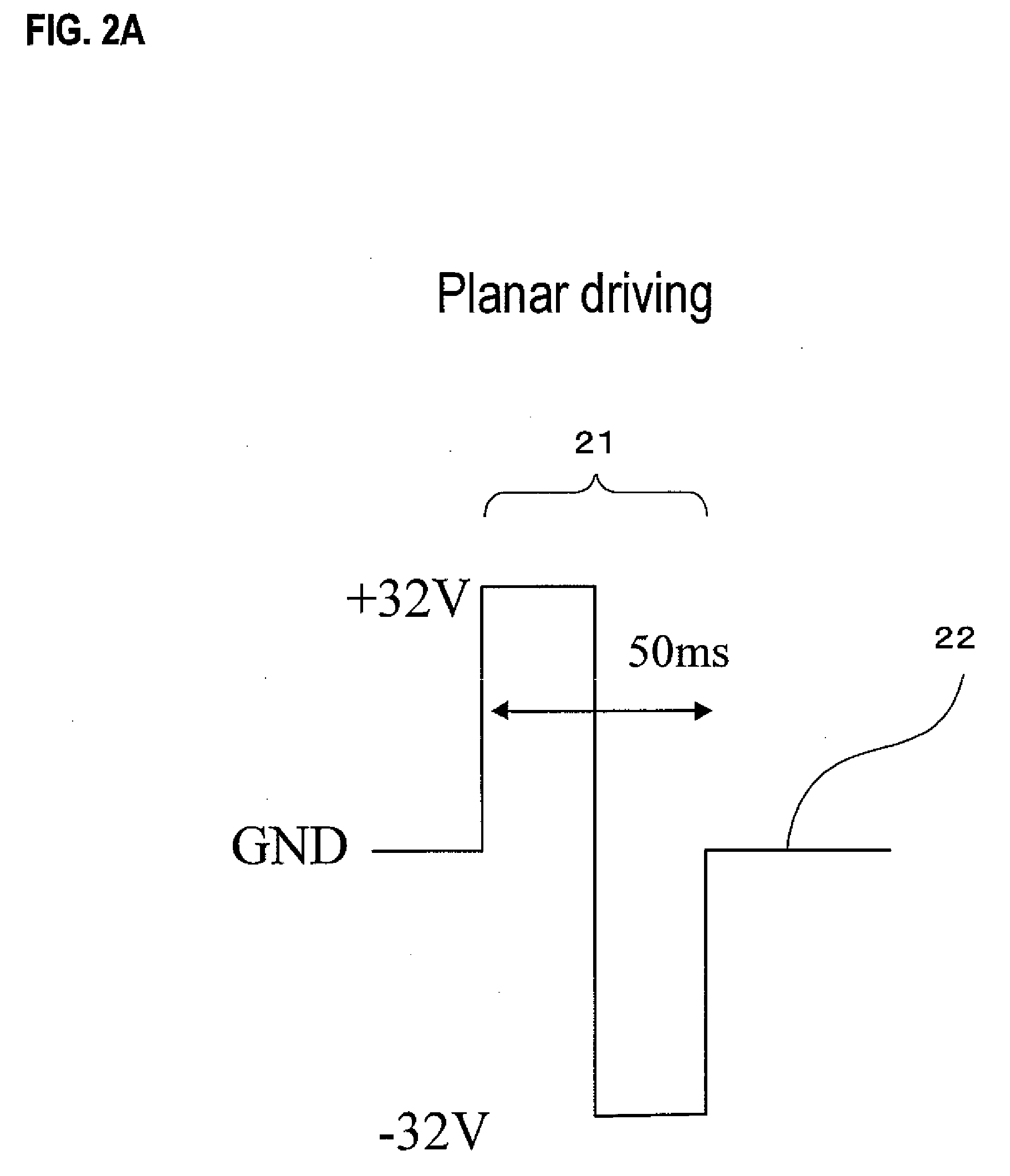

Liquid crystal display element

ActiveUS20070285611A1Reduce the driving voltageExtended operating temperature rangeLiquid crystal compositionsNon-linear opticsDielectric anisotropyOperating temperature range

A liquid crystal display element according to the present invention includes one or more sets of combinations of a pair of substrates, a liquid crystal layer composed of a liquid crystal composition indicating a cholesteric phase and disposed between the pair of substrates, and at least one layer of insulating thin film to insulate the liquid crystal layer from an electrode, wherein: the insulating thin film has an electrostatic capacity of not more than 10 μF; the liquid crystal layer has a layer thickness in the range of 2 to 5 μm; and the liquid crystal composition has a dielectric anisotropy in the range of 20 to 50. The present invention can realize at least one of lowered driving voltage, enlarged operating temperature range, decrease in electric power consumption and wide display maintaining temperature range, in a liquid crystal display element having a semi-permanent display maintaining function (memory function).

Owner:IRIS OPTRONICS INC

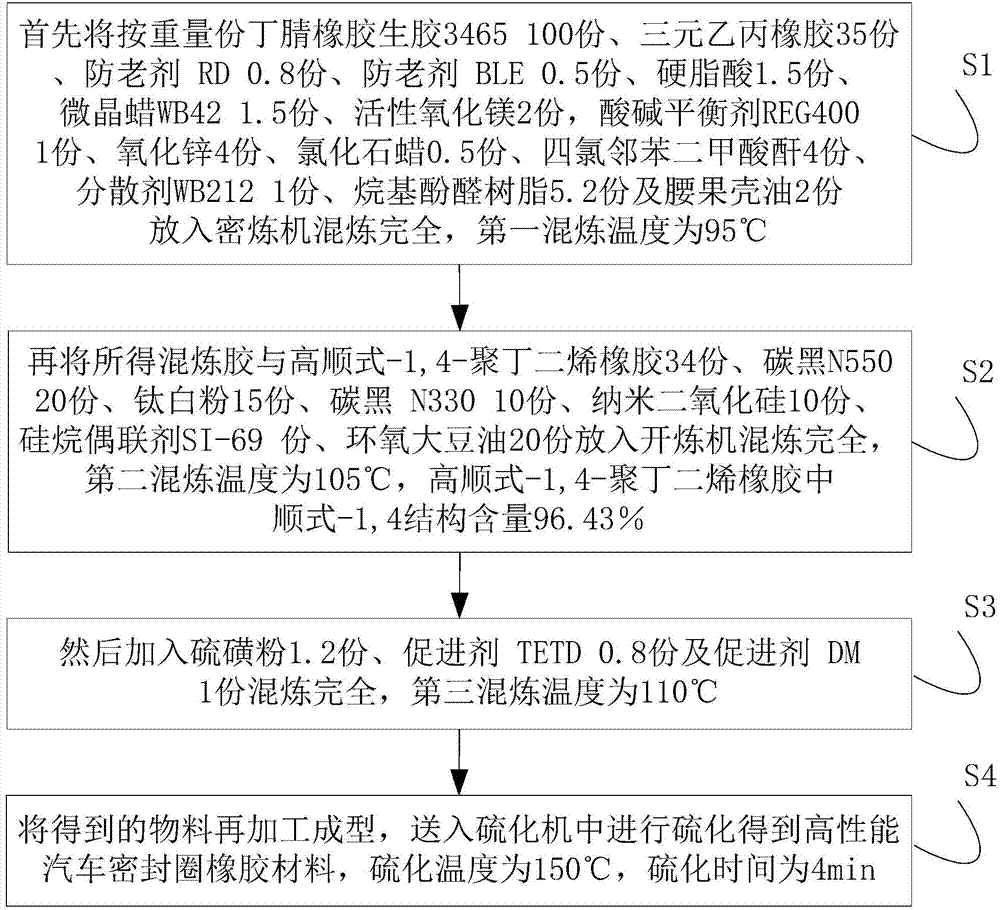

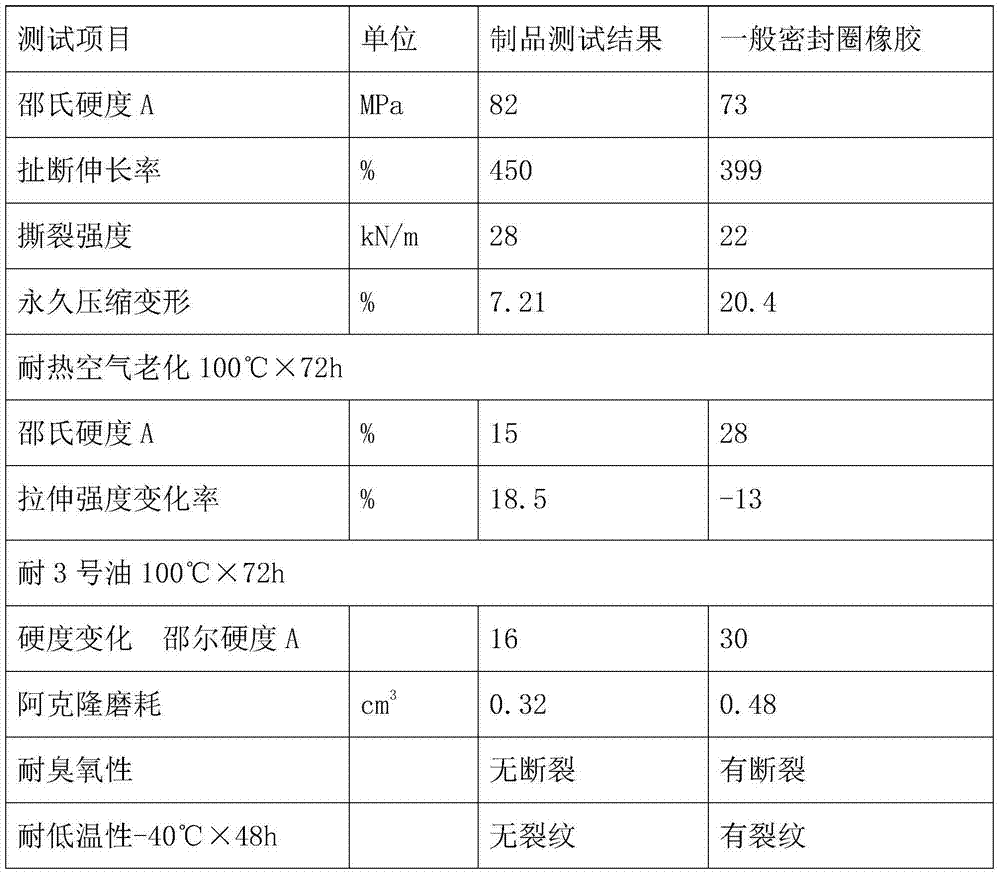

High-performance automobile seal ring rubber material and preparation technique thereof

The invention discloses a high-performance automobile seal ring rubber material which is prepared from the following raw materials in parts by weight: unvulcanized nitrile-butadiene rubber 3465, high cis-1,4-polybutadiene rubber, ethylene propylene diene monomer rubber, anti-aging agent RD, anti-aging agent BLE, stearic acid, sulfur powder, microcrystalline wax WB42, activator magnesium oxide, acid-base balancing agent PEG 400, zinc oxide, chlorinated paraffin, tetrachlorophthalic acid anhydride, dispersing agent WB212, alkyl phenol aldehyde resin, rubber plastizing agent cashew nut shell oil, carbon black N550, titanium white, carbon black N330, nano silicon dioxide, silane coupling agent Si-96, epoxy soybean oil, accelerator TETD (tetraethyl thiuram disulfide) and accelerator DM. The invention also discloses a preparation technique of the high-performance automobile seal ring rubber material. The high-performance automobile seal ring rubber material has the advantages of excellent abrasion resistance, excellent aging resistance, excellent high / low temperature resistance, high hardness, favorable tear resistance, favorable processability and low cost.

Owner:安徽宁国尚鼎橡塑制品有限公司

Improved polyvinyl chloride granula for cable

InactiveCN1962744AExtended operating temperature rangeSatisfy frequent transfer useInsulated cablesInsulated conductorsAcetic acidUltraviolet

The invention discloses a polychloroethylene cable material for torrid zone and frigid zone, which comprises the following parts: 40-70%wt polychloroethylene resin and 30-60%wt ethylene-acetic acid ethyenyl ester copolymer composition or 70-95%wt vinyl chloride and 5-30%wt maleate copolymer, 20-35%wt dioctyl sebacate and or adipate dioctyl plasticizer, 0.3-1.6%wt ultraviolet adsorbent and 0.5-2.0%wt anti-fungus agent. The temperature scale of cable material is -50+80 Deg C, which is fit for frequent transmitting utility.

Owner:WUXI HUANCABLE

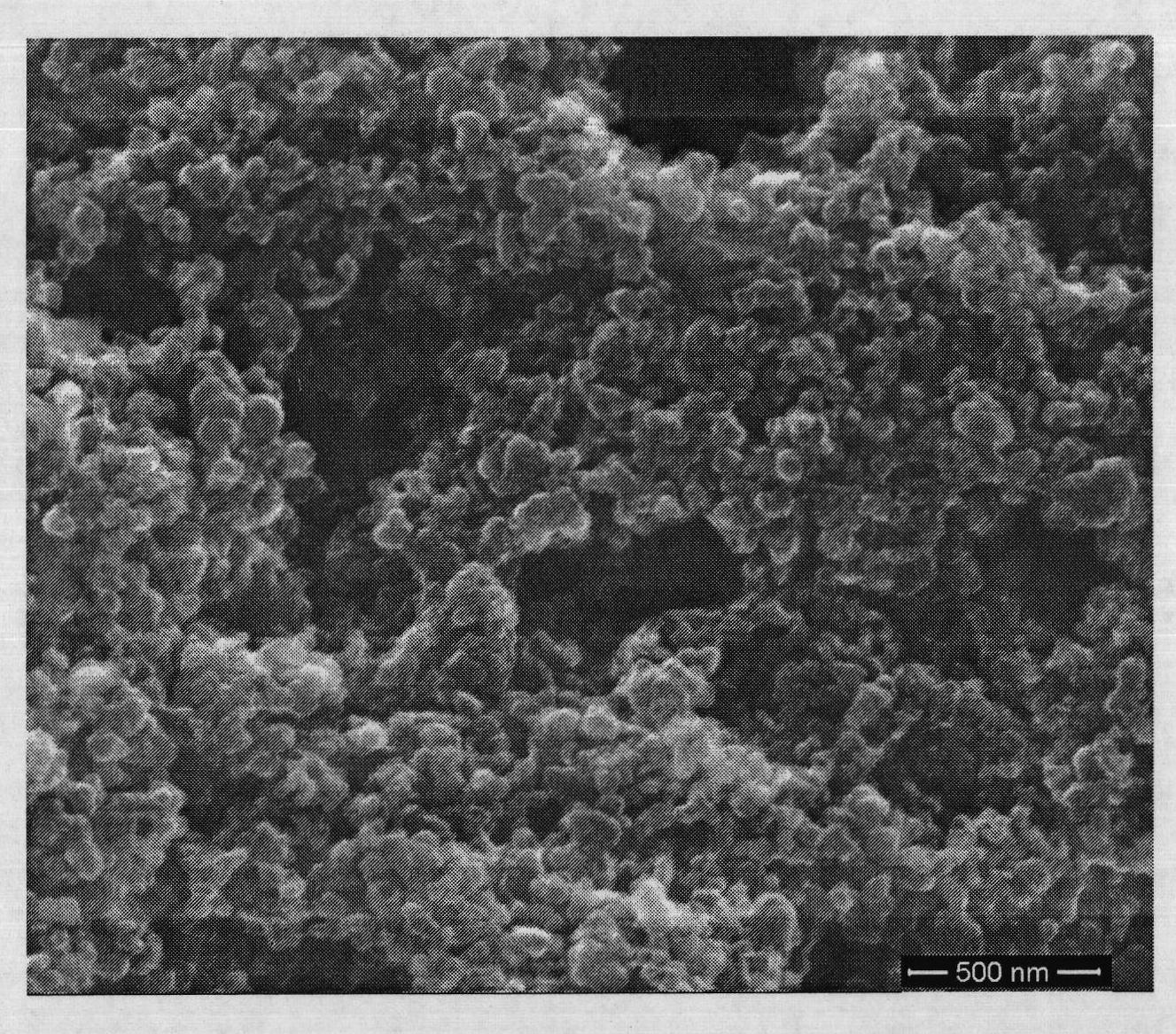

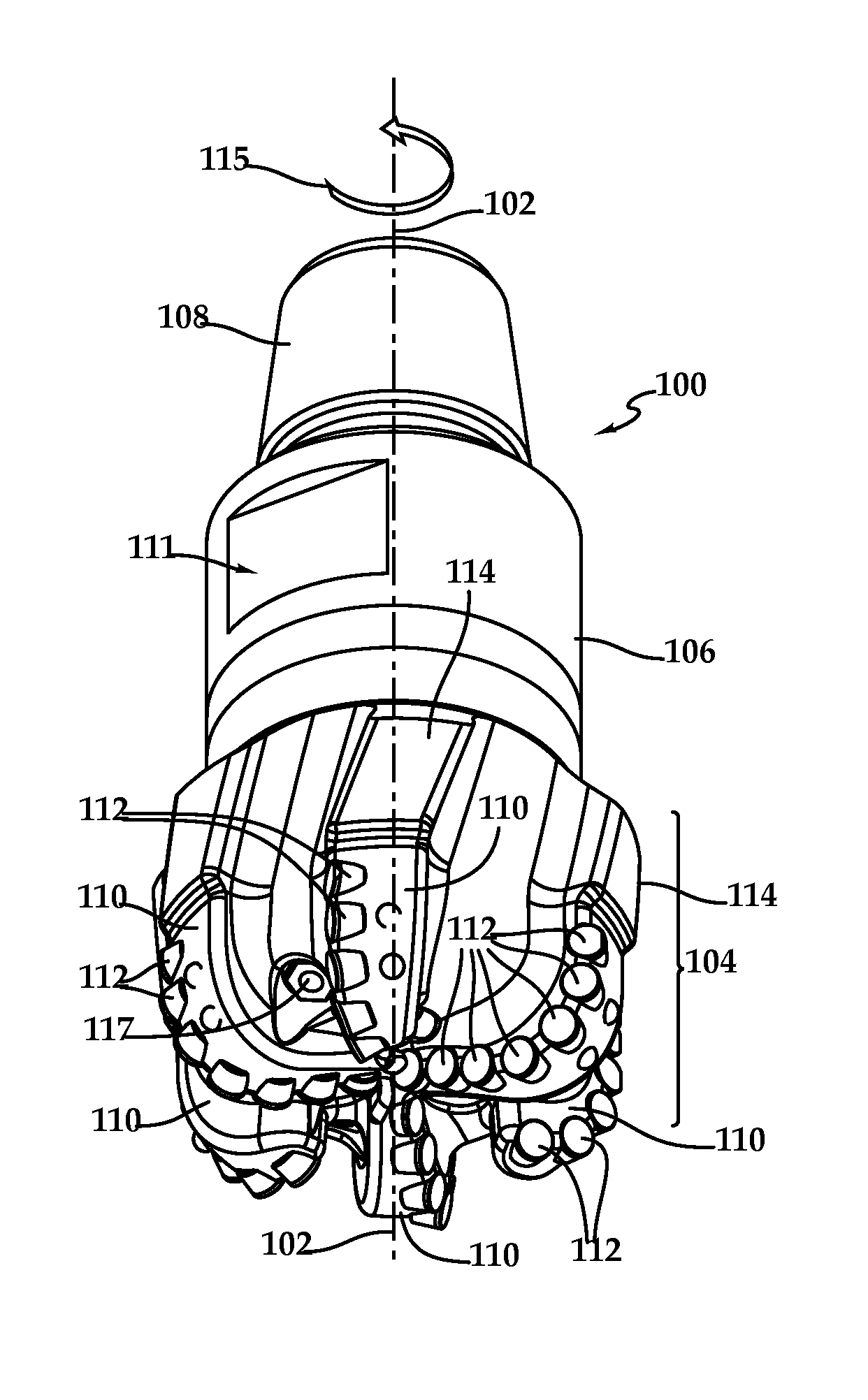

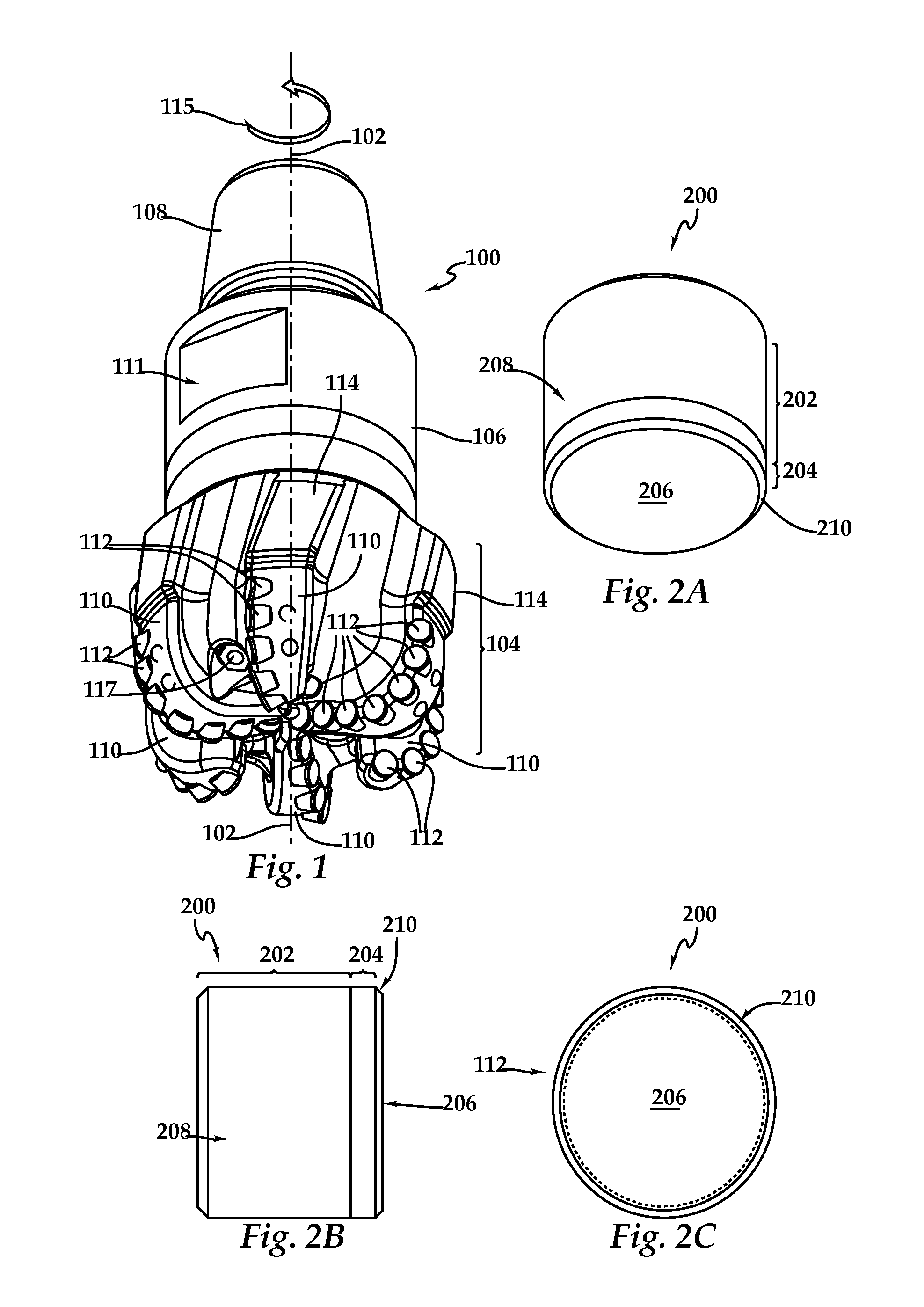

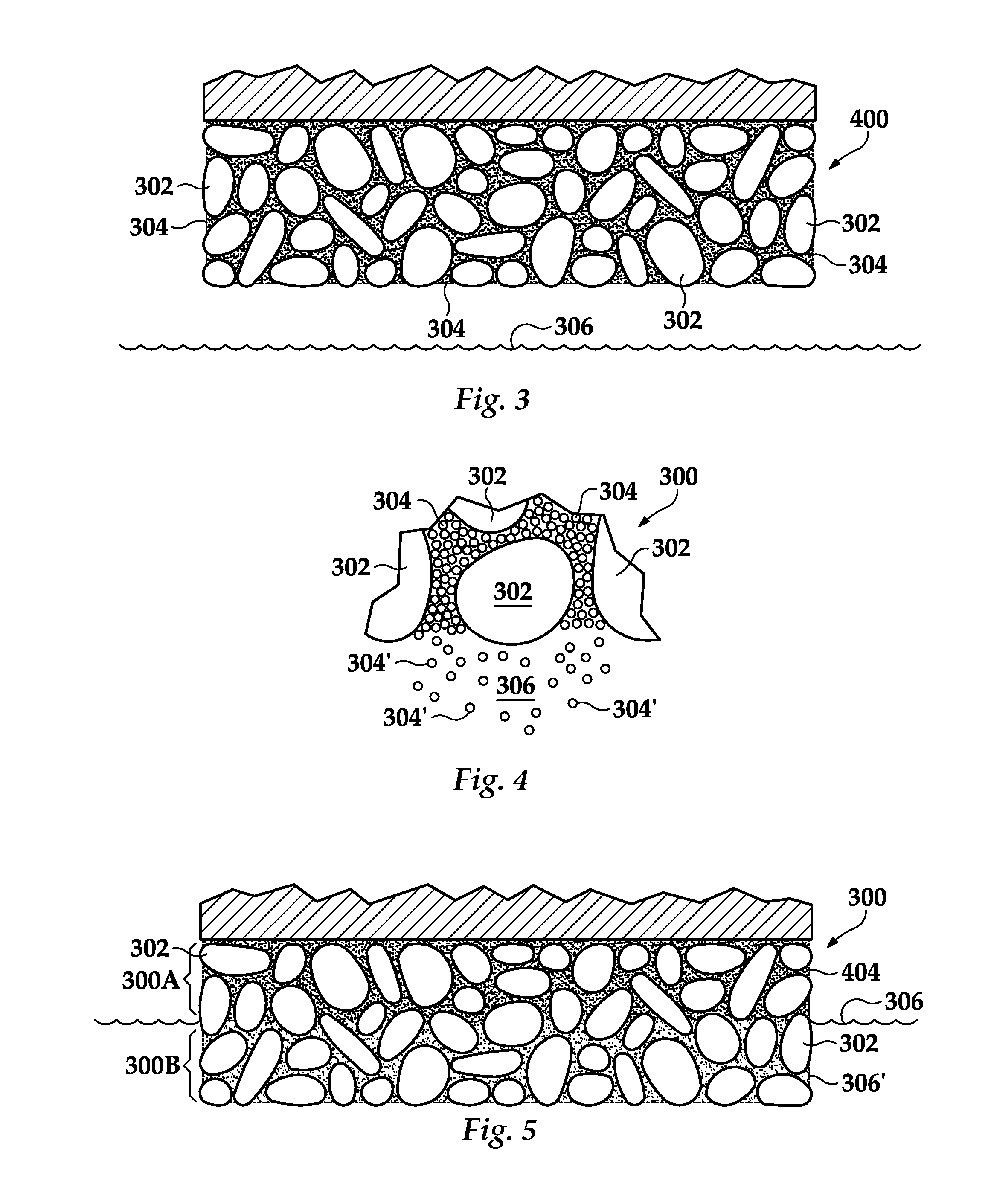

PCD Elements And Process For Making The Same

InactiveUS20140360791A1Extended operating temperature rangeReduce processing costsPigmenting treatmentDrill bitsPolycrystalline diamondSolvent

Catalyst in a sintered polycrystalline diamond (PCD) structure is dissolved in at least a portion of the structure by a liquid solvent metal. The structure is infused with the heated solvent and the solvent infiltrates interstitial spaces between consolidated diamond grains to contact residual catalyst from the sintering process. The dissolved catalyst passes to the bulk solvent and the solvent replaces the catalyst in the interstitial spaces.

Owner:ULTERRA DRILLING TECH LP

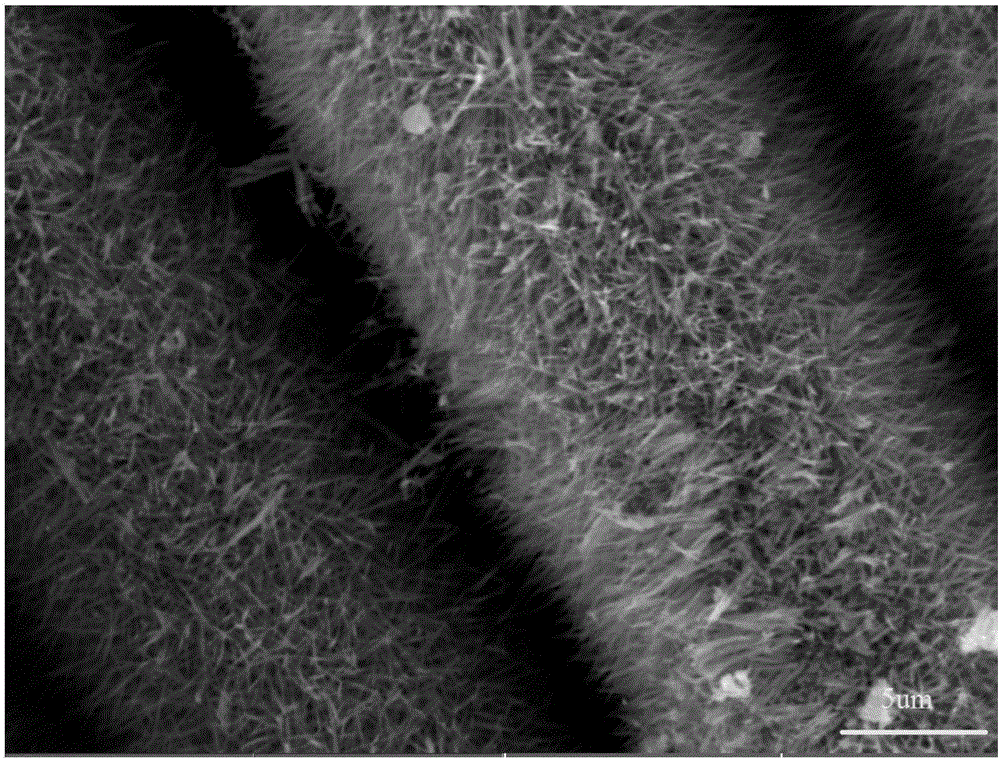

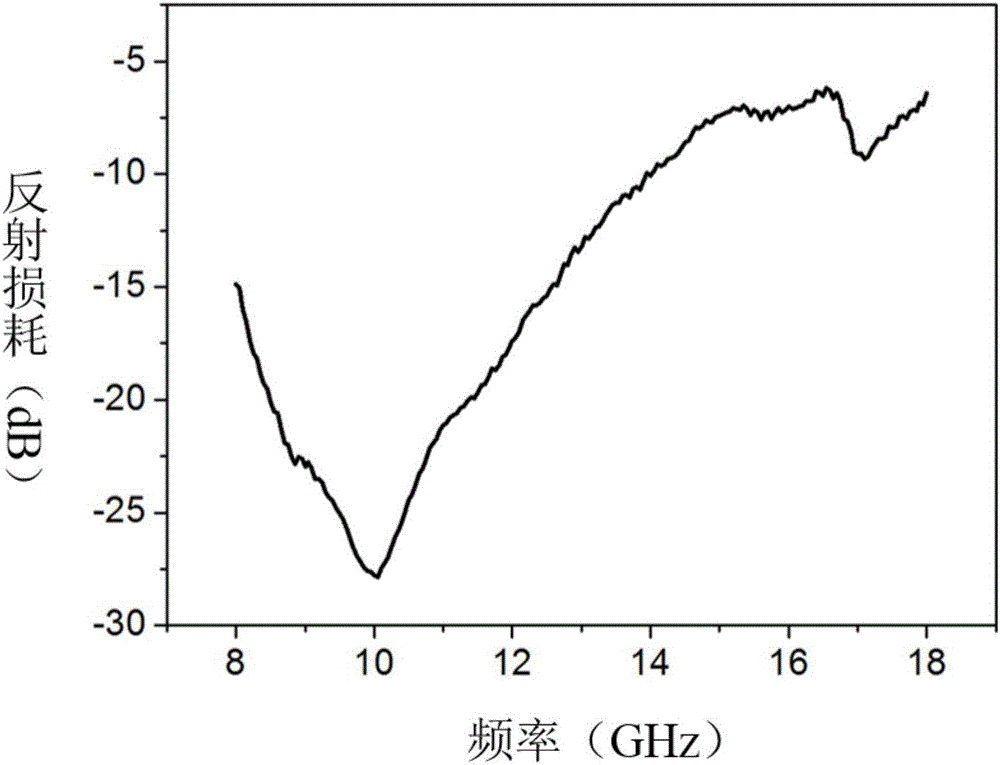

Polyimide resin-based structure wave-absorbing material reinforced by nickel cobaltate-silicon carbide fiber multi-scale reinforcement and preparation method thereof

ActiveCN107177053AExcellent dielectric propertiesIncreased interfacial polarization capabilityOther chemical processesNitrateCobalt

The invention relates to a polyimide resin-based structure wave-absorbing material reinforced by nickel cobaltate-silicon carbide fiber multi-scale reinforcement and a preparation method thereof; the preparation method comprises: adding degummed dried silicon carbide fiber cloth in solution A to carry out hydrothermal reaction, taking out the silicon carbide fiber cloth after reacting, and annealing to obtain nickel cobaltate-silicon carbide fiber multi-scale reinforcement, wherein the solution A is made by adding cobalt nitrate, nickel nitrate and urea in water and stirring well; brushing polyamide acid solution evenly to the outer surface of the nickel cobaltate-silicon carbide fiber multi-scale reinforcement, and stacking neatly to obtain a preform; subjecting the preform to a multiple repeat process of vacuumizing, pressure holding, and relief, and performing mold pressing to obtain the polyimide resin-based structure wave-absorbing material reinforced by nickel cobaltate-silicon carbide fiber multi-scale reinforcement. Nickel cobaltate is grown on the surface of silicon carbide fiber, interfacial polarizing capacity and electrical conductivity of the composite are improved, and good wave-absorbing performance and mechanical properties are achieved.

Owner:SHAANXI UNIV OF SCI & TECH

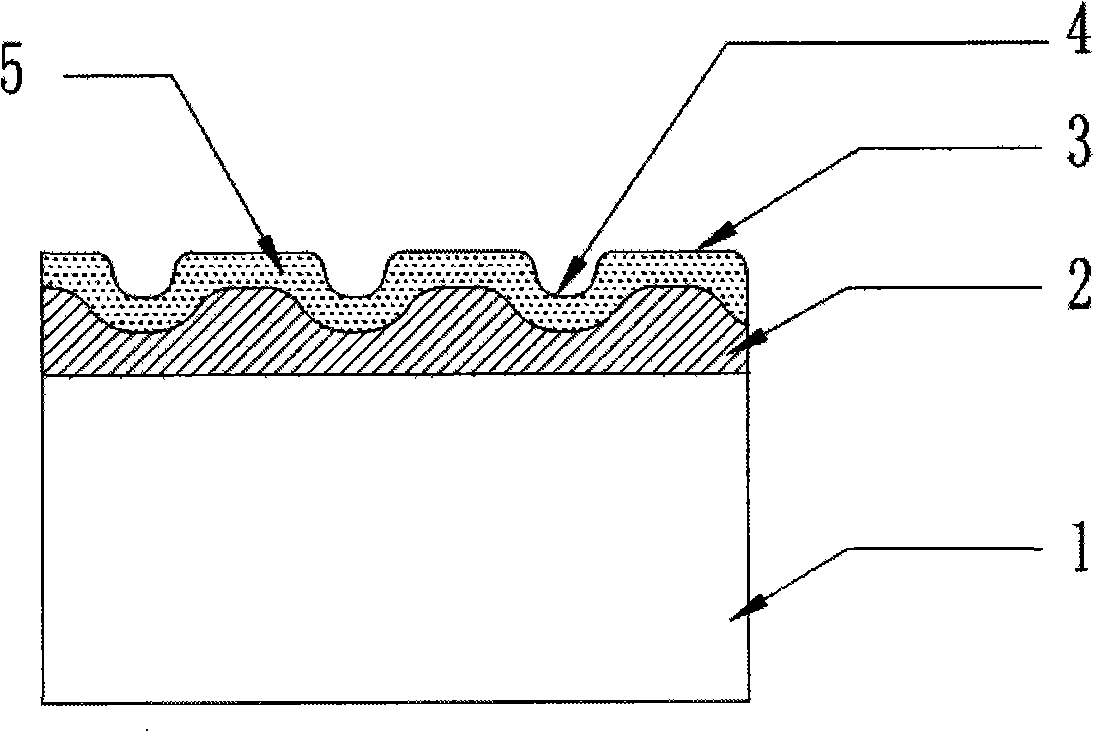

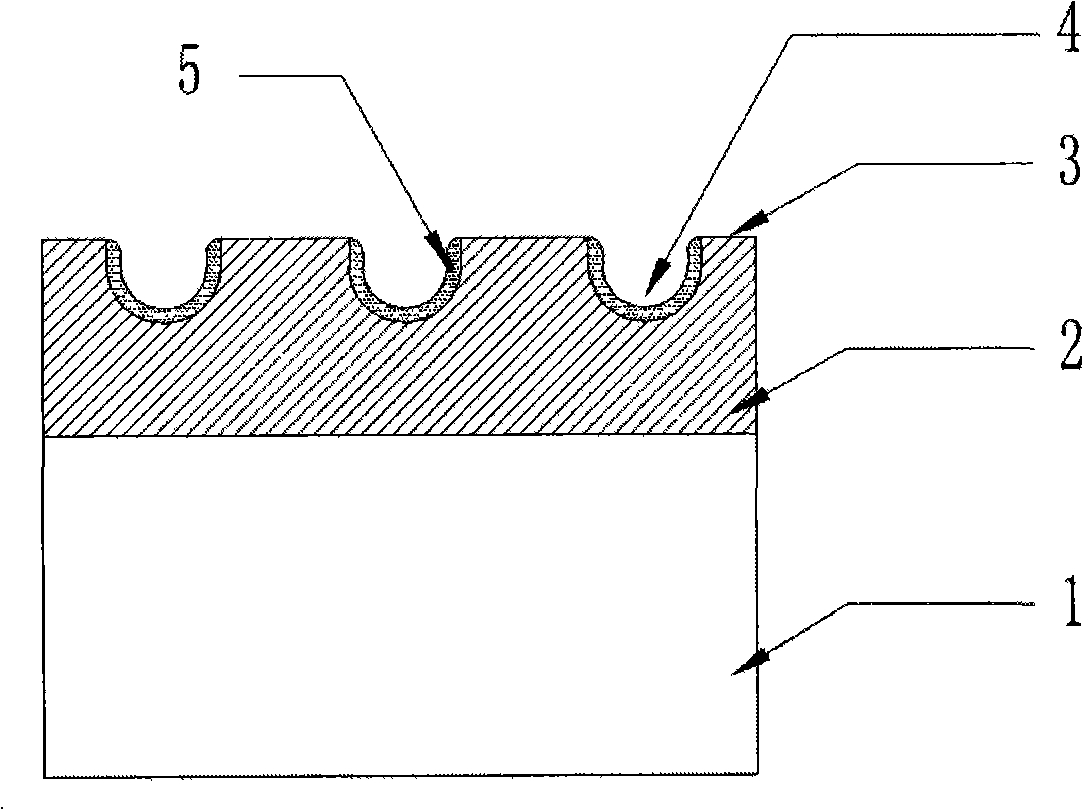

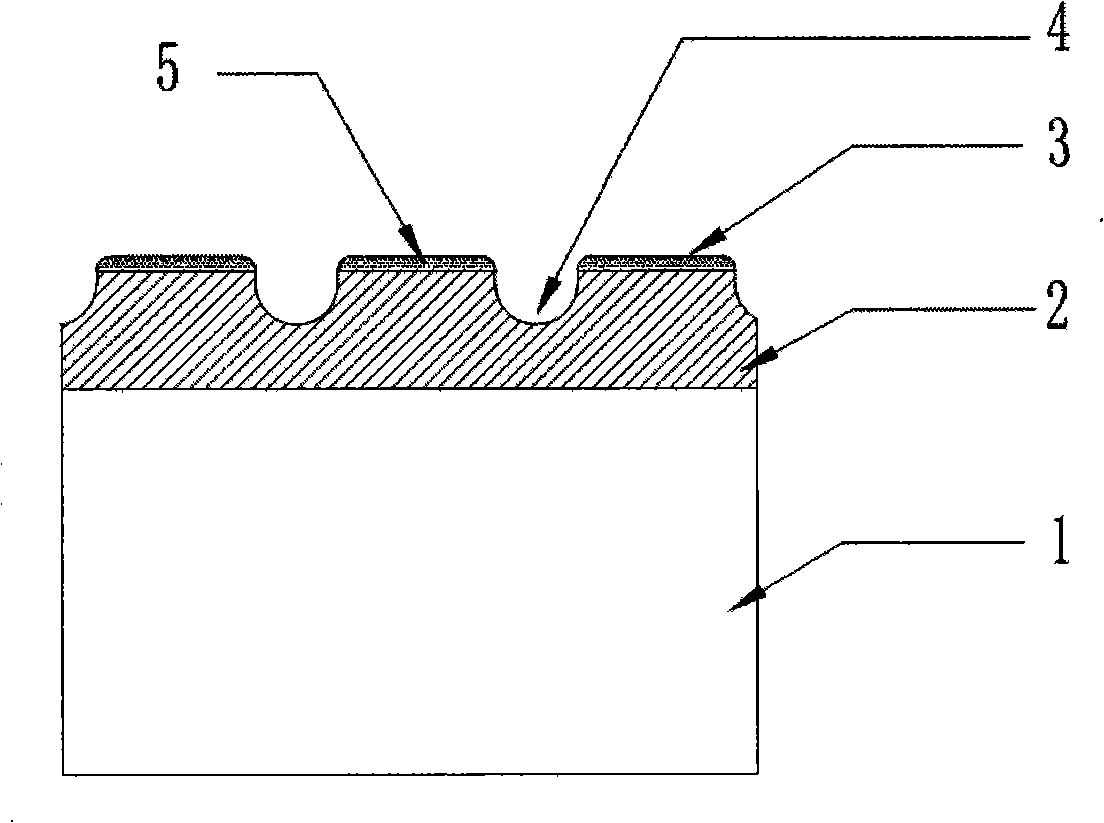

Polycrystal diamond hard alloy complex sheet of surface groove with lack Co area

The invention discloses a carbide composite tablet of polycrystalline diamond with Co deficient areas and a grooved surface, which includes a carbide layer and a polycrystalline diamond layer; the carbide layer consists of a carbide (usually adopting tungsten carbide: WC) and a bonding agent (usually adopting Co), and a polycrystalline diamond layer consists of a diamond and a catalytic binder (usually adopting Co). The surface of the diamond is engraved with grooves, wherein, the engraved grooves divide the diamond layer into a plurality of platforms. Through the process of removing Co, Co deficient areas are formed on the engraved grooves or the platforms of the polycrystalline diamond layer or on both. The carbide composite tablet of polycrystalline diamond of the invention is increased by 1-2 times in abrasion ratio; under the same size of impact force, the break-off area of the diamond layer can be reduced by 50 to 80 percent, and the composite tablet of the invention can greatly improve the use temperature of carbide composite tablet of polycrystalline diamond, and the use temperature can be improved to at least 100 DEG C, thus enlarging the scope of use temperature and enabling the composite tablet to be used under higher abrasion speed.

Owner:河南四方超硬材料有限公司

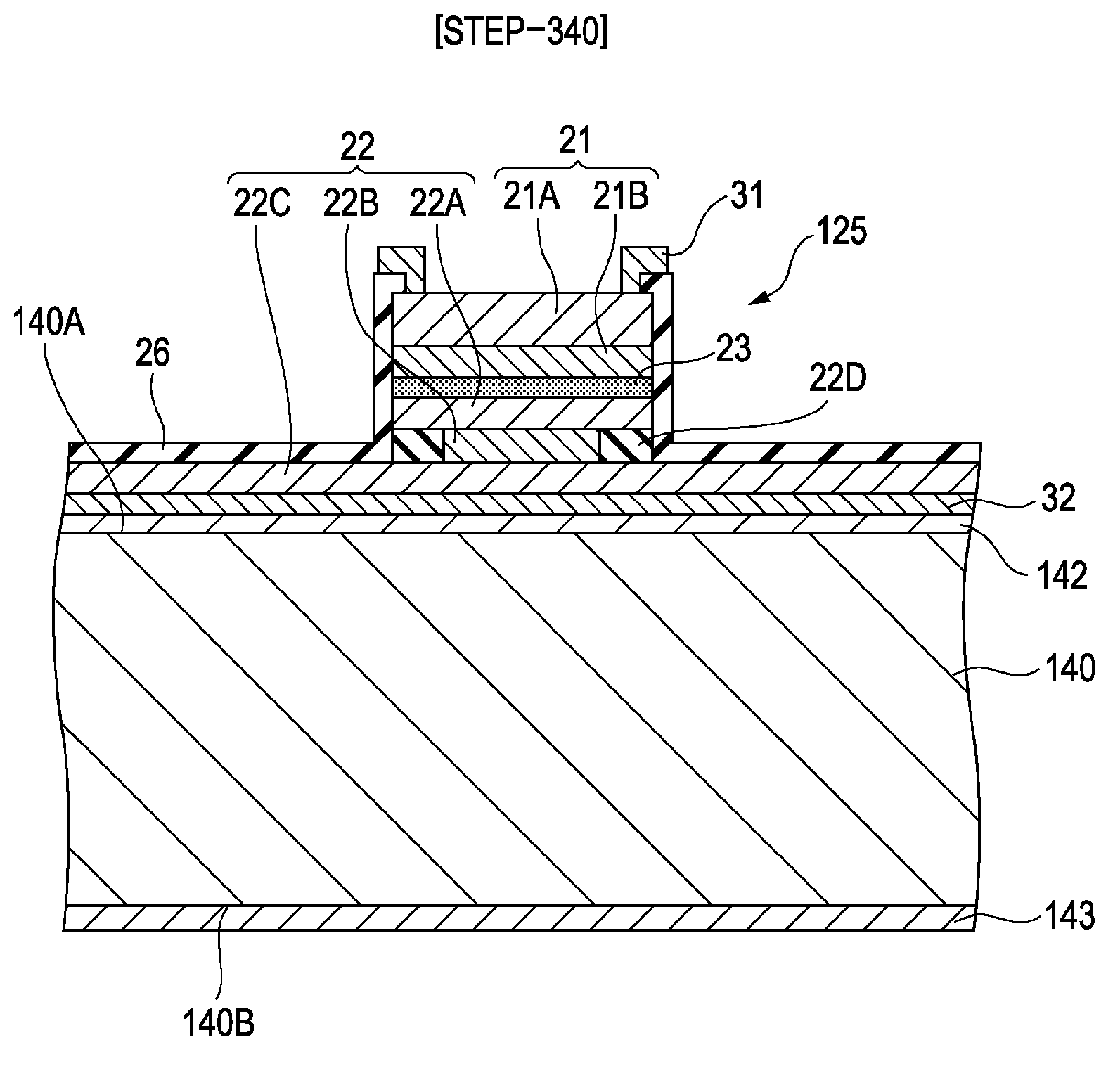

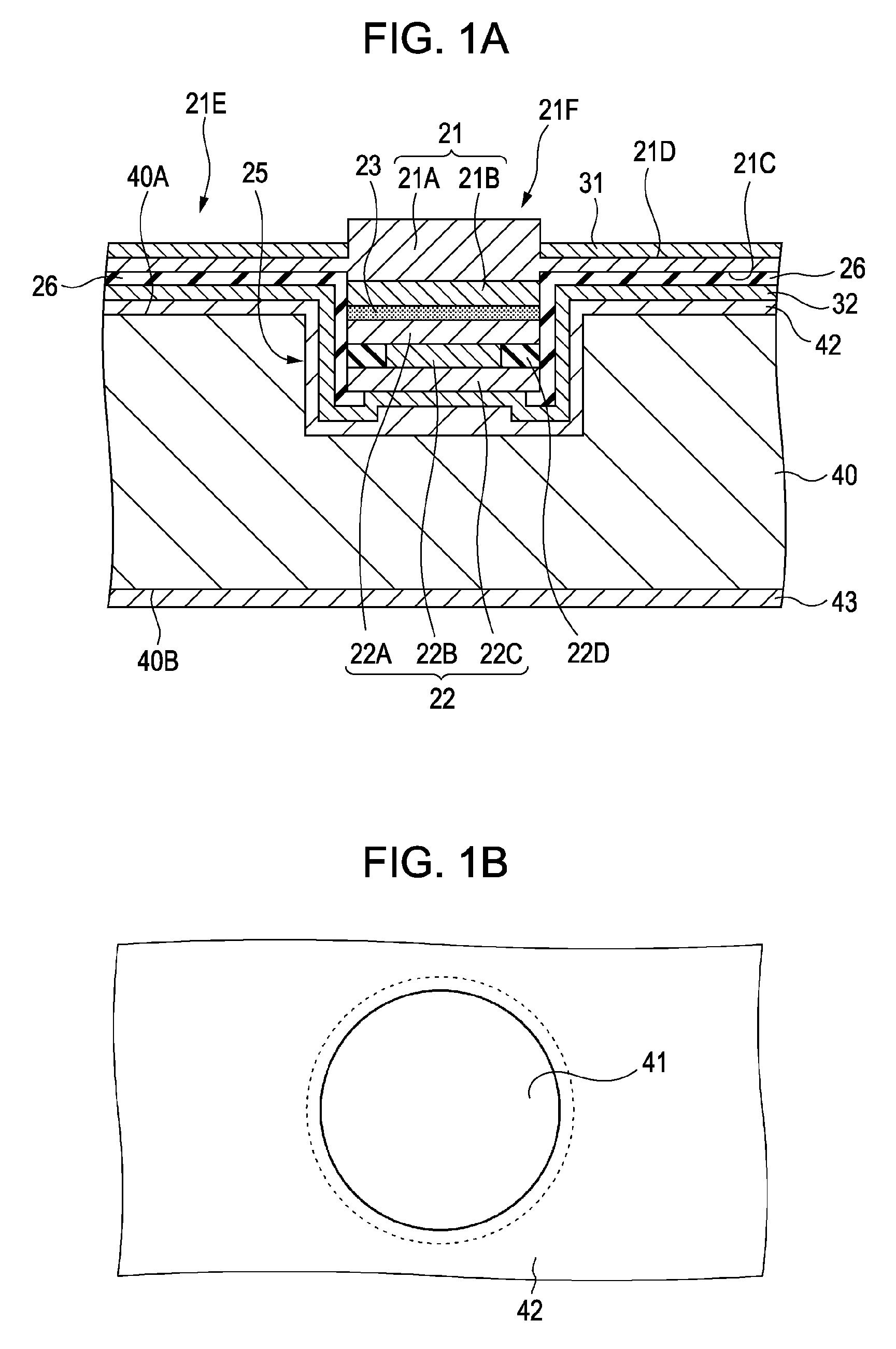

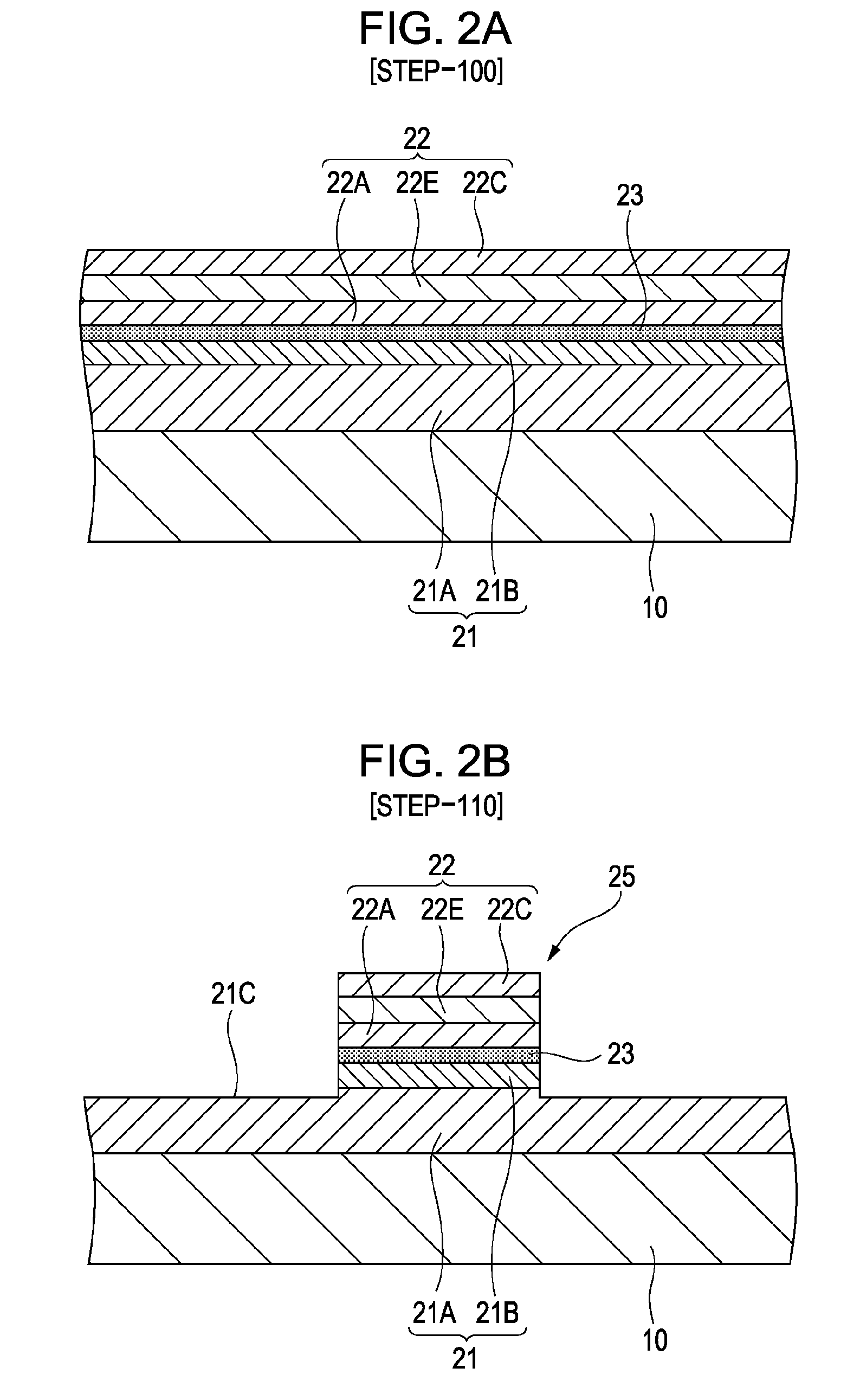

Light-emitting element assembly and method for manufacturing the same

ActiveUS20090168825A1Emission Reduction EfficiencyExtended operating temperature rangeLaser detailsSolid-state devicesConductive materialsEngineering

A light-emitting element assembly includes a support substrate having a first surface, a second surface facing the first surface, a recessed portion, and a conductive material layer formed over the first surface and the inner surface of the recessed portion, and a light-emitting element. The light-emitting element has a laminated structure including a first compound semiconductor layer, a light-emitting portion, and a second compound semiconductor layer, at least the second compound semiconductor layer and the light-emitting portion constituting a mesa structure. The light-emitting element further includes an insulating layer formed, a second electrode, and a first electrode. The mesa structure is placed in the recessed portion so that the conductive material layer and the second electrode are in at least partial contact with each other, and light emitted from the light-emitting portion is emitted from the second surface side of the first compound semiconductor layer.

Owner:SONY CORP

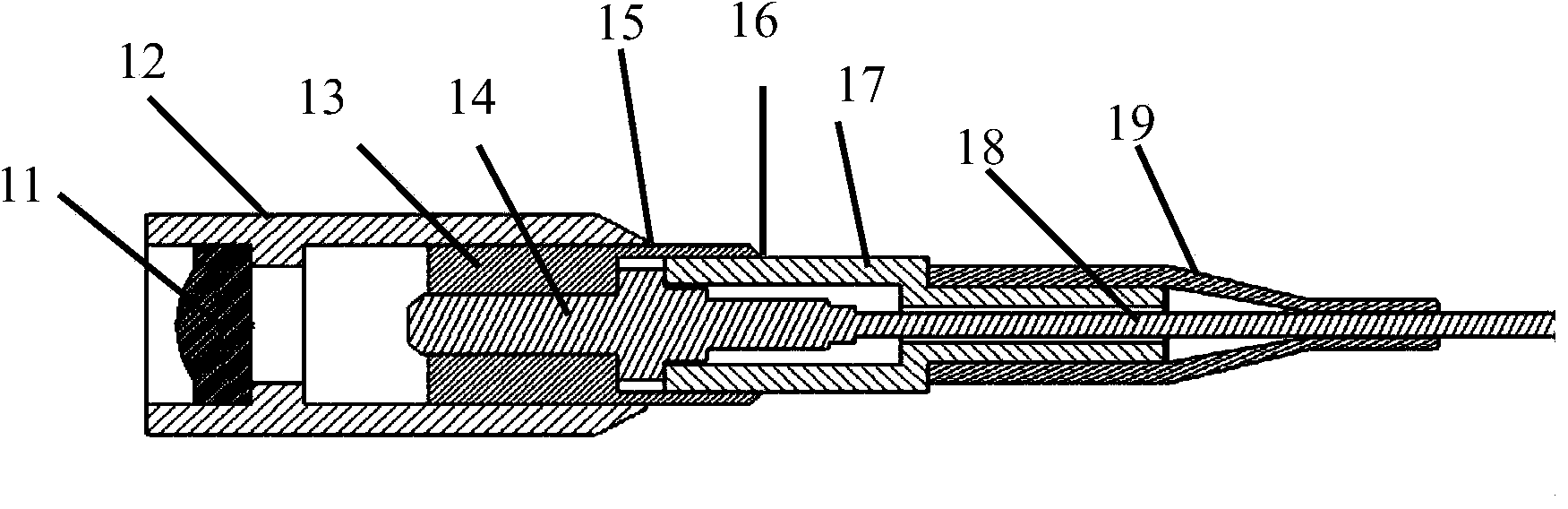

Optical fiber collimator

ActiveCN103901546AAvoid pollutionExtended operating temperature rangeCoupling light guidesHigh power lasersMechanical stability

The invention relates to an optical fiber collimator which comprises optical fibers, an optical fiber inserting core, an optical fiber inserting core fixing piece, an optical fiber inserting core fastener, a collimating lens, a collimator structure piece and a tail protection sleeve. The optical fiber collimator has the advantages that the optical fiber inserting core is fixed through machines in a welding reinforcing mode; meanwhile, the optical fiber inserting core fixing piece is fixed with the laser welding technology, the reliability of the optical fiber collimator is improved, the end faces of the optical fibers are slope end faces, feedback of high-power lasers can be avoided, and when polarization maintaining optical fibers are used, the polarization direction of the optical fiber collimator has the good coincidence. The optical fiber collimator has the advantages of being convenient to install and debug, high in temperature stability, high in mechanical stability and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

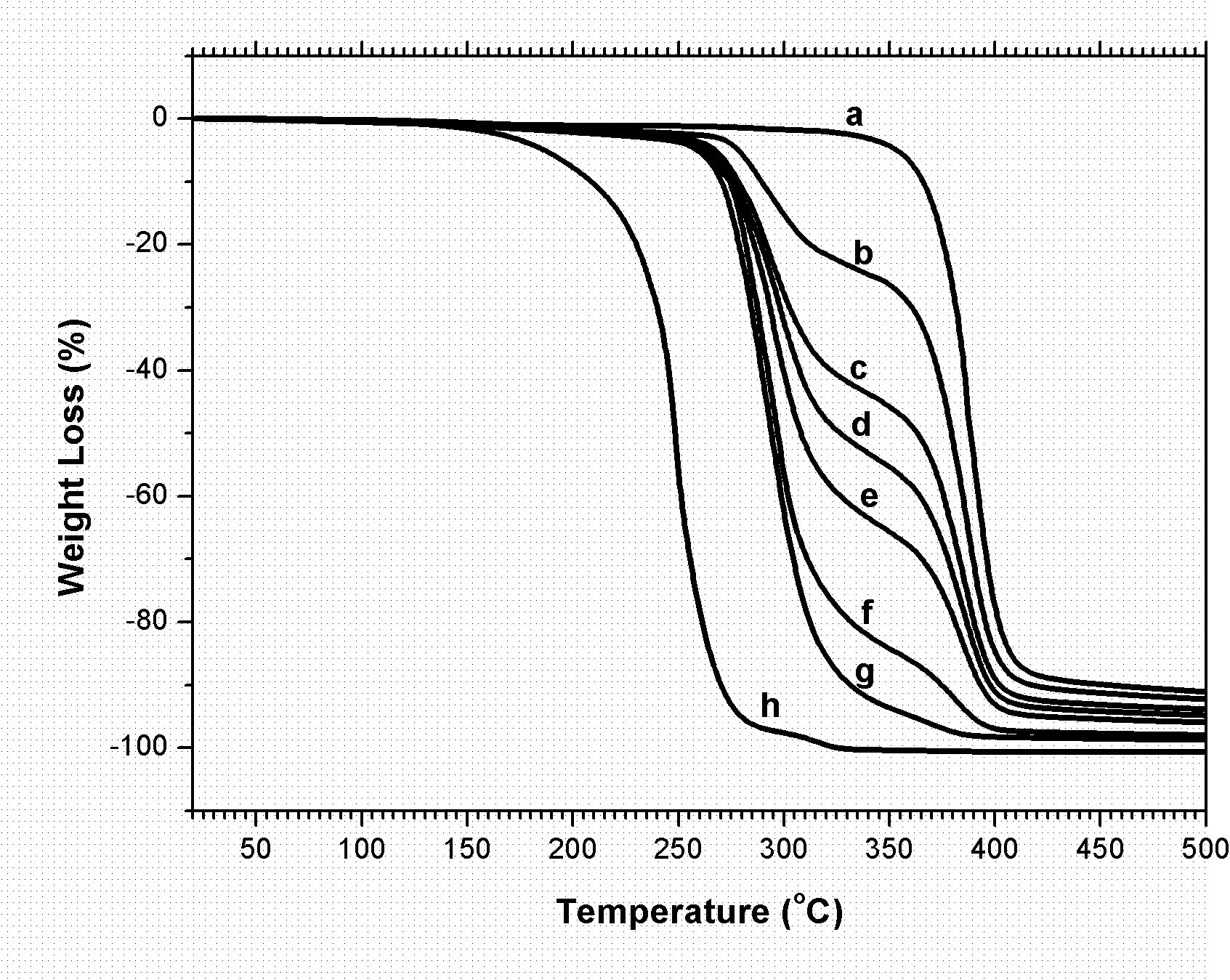

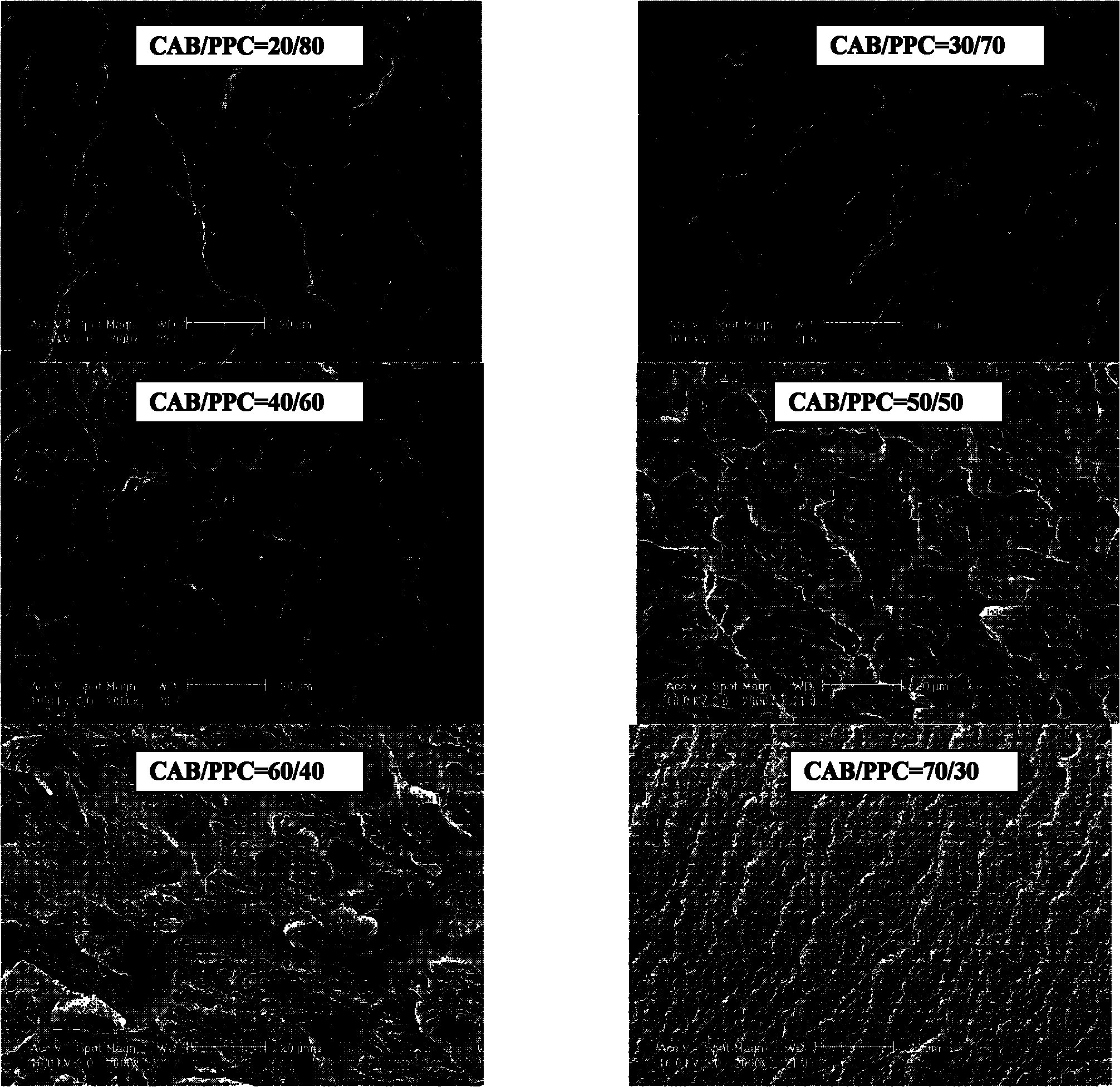

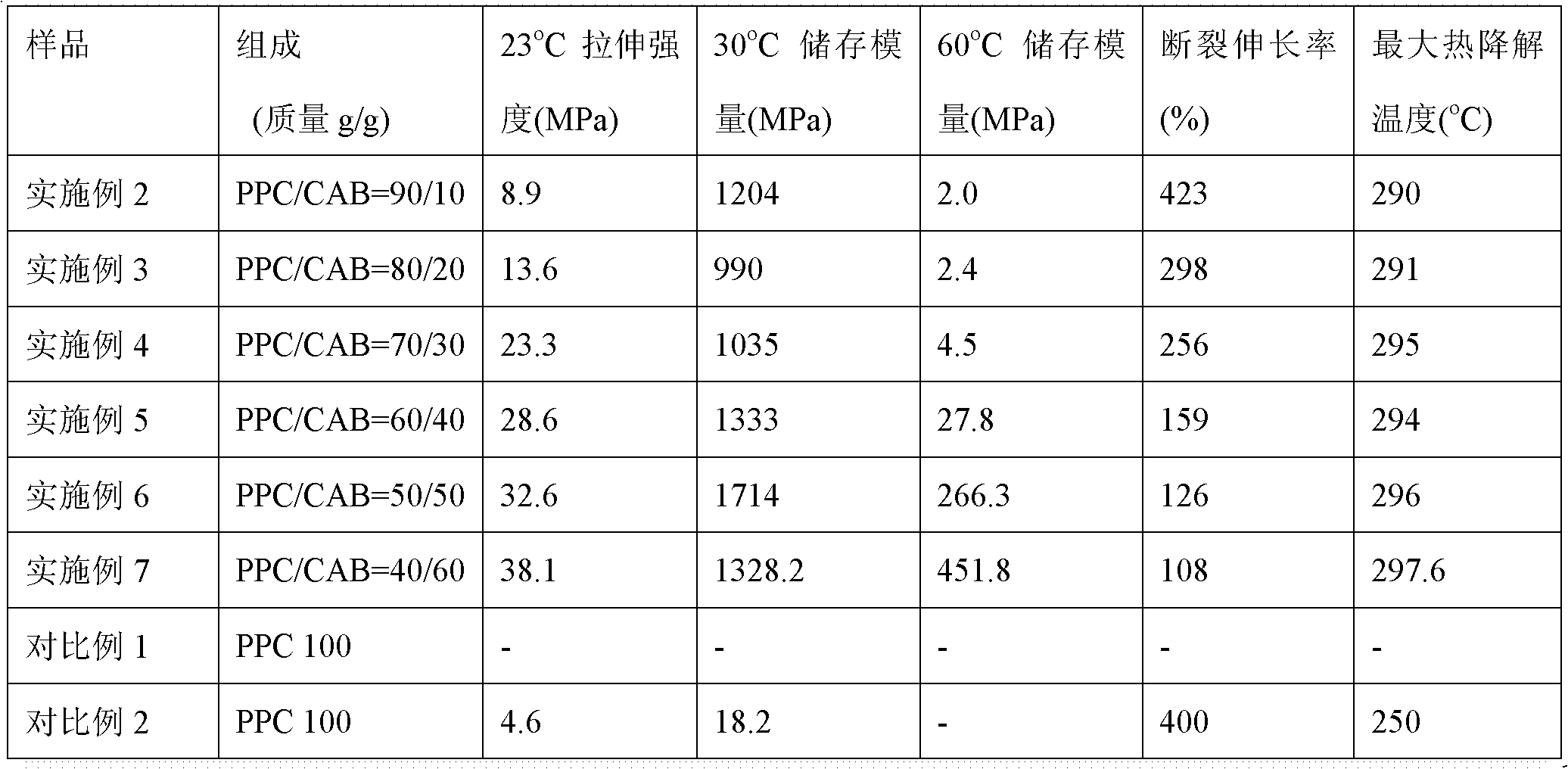

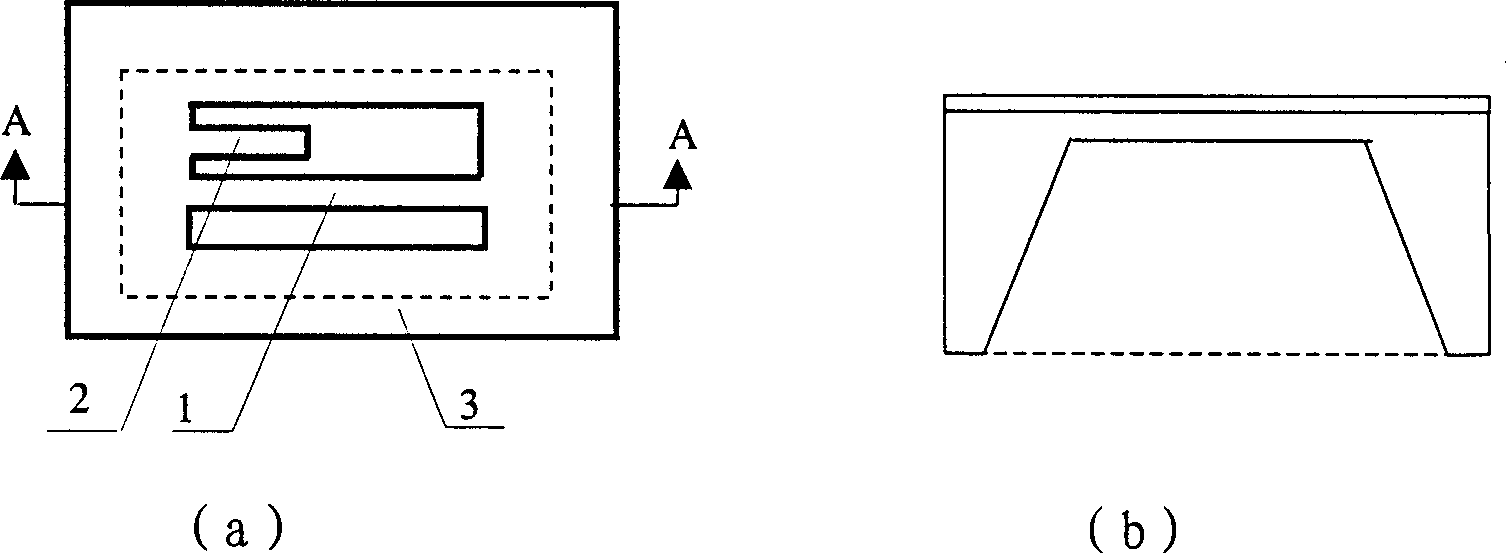

Aliphatic polycarbonate alloy material

ActiveCN102153849ALow dependence on petrochemical resourcesReduce light transmittanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCelluloseAlloy

The invention discloses an aliphatic polycarbonate alloy material which is obtained by the following main steps: evenly mixing aliphatic polycarbonate and esterified cellulose, and then directly adding the mixture into a melting mixing device for melt blending. Based on the aliphatic polycarbonate and esterified cellulose, the mass fraction of the aliphatic polycarbonate is 5-95%, the mass fraction of the esterified cellulose is 5-95%, and the aliphatic polycarbonate is a copolymer of carbon dioxide and epoxide. By using the aliphatic polycarbonate alloy material, the mechanical property of the aliphatic polycarbonate material is greatly improved, the applicable temperature range of the aliphatic polycarbonate material is broadened, and the thermal degradation temperature of the aliphaticpolycarbonate material is improved.

Owner:南通九思医疗器械有限公司

Frequency output type micromechanical dual-beam resonator with autoamtic temp compensation

InactiveCN1381710ASmall temperature coefficientExtended operating temperature rangeConverting sensor outputCross sensitivityDual beam

A frequency output type micromechanial dual-beam resonator with automatic temp. compensation function is composed of Si / SiO2 microbridge resonator and dual-layer microcantilever Si / SiO2 thermosensitive elements, which are made on a single chip. The output signal of said thermosensitive element can automatically compensate the influence of temp. to cross sensitivity of resonant frequency of microbridge resonator, so reducing the resonant frequency temp. coefficient of microbridge resonator and windening the working temp. range.

Owner:XI AN JIAOTONG UNIV

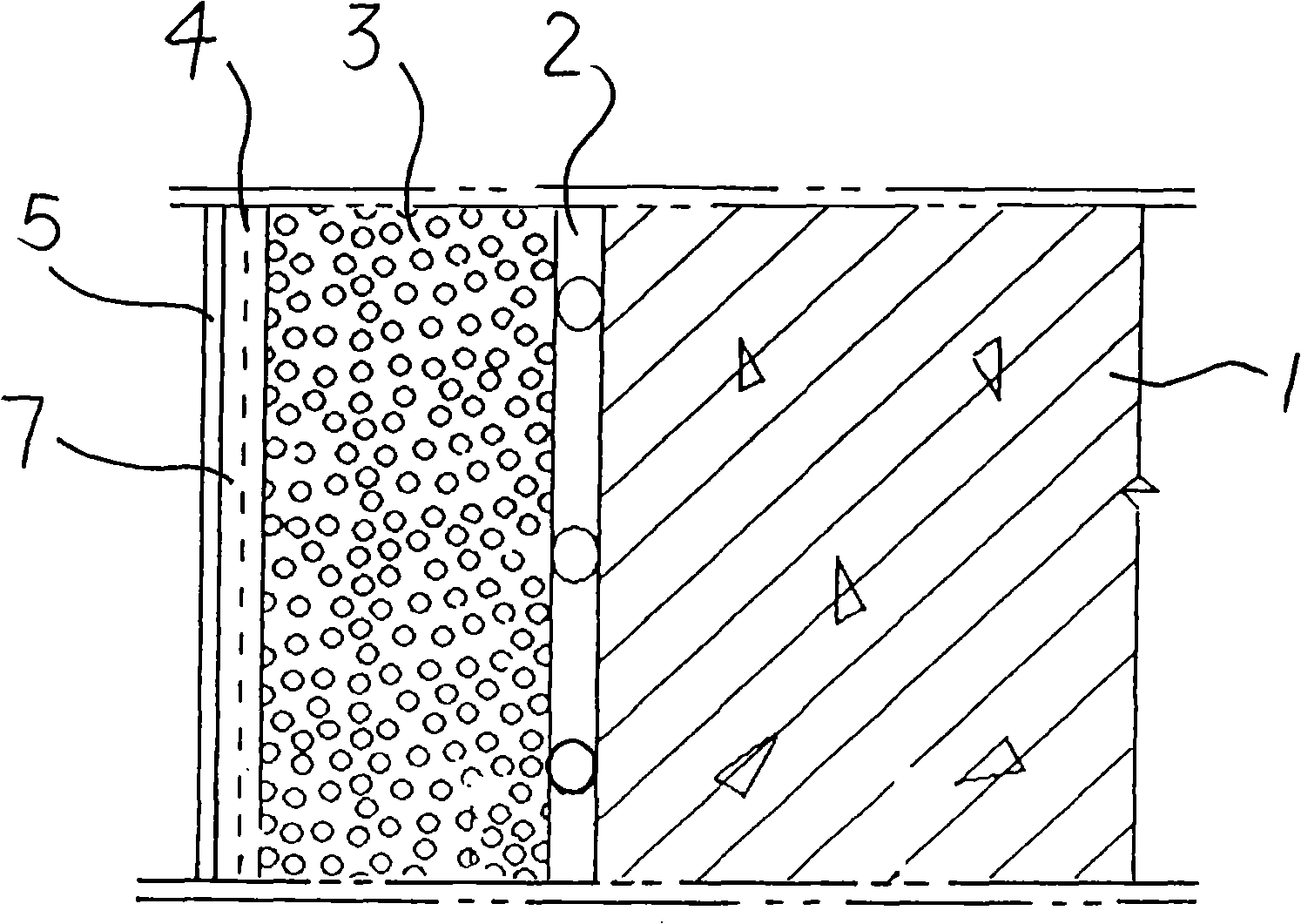

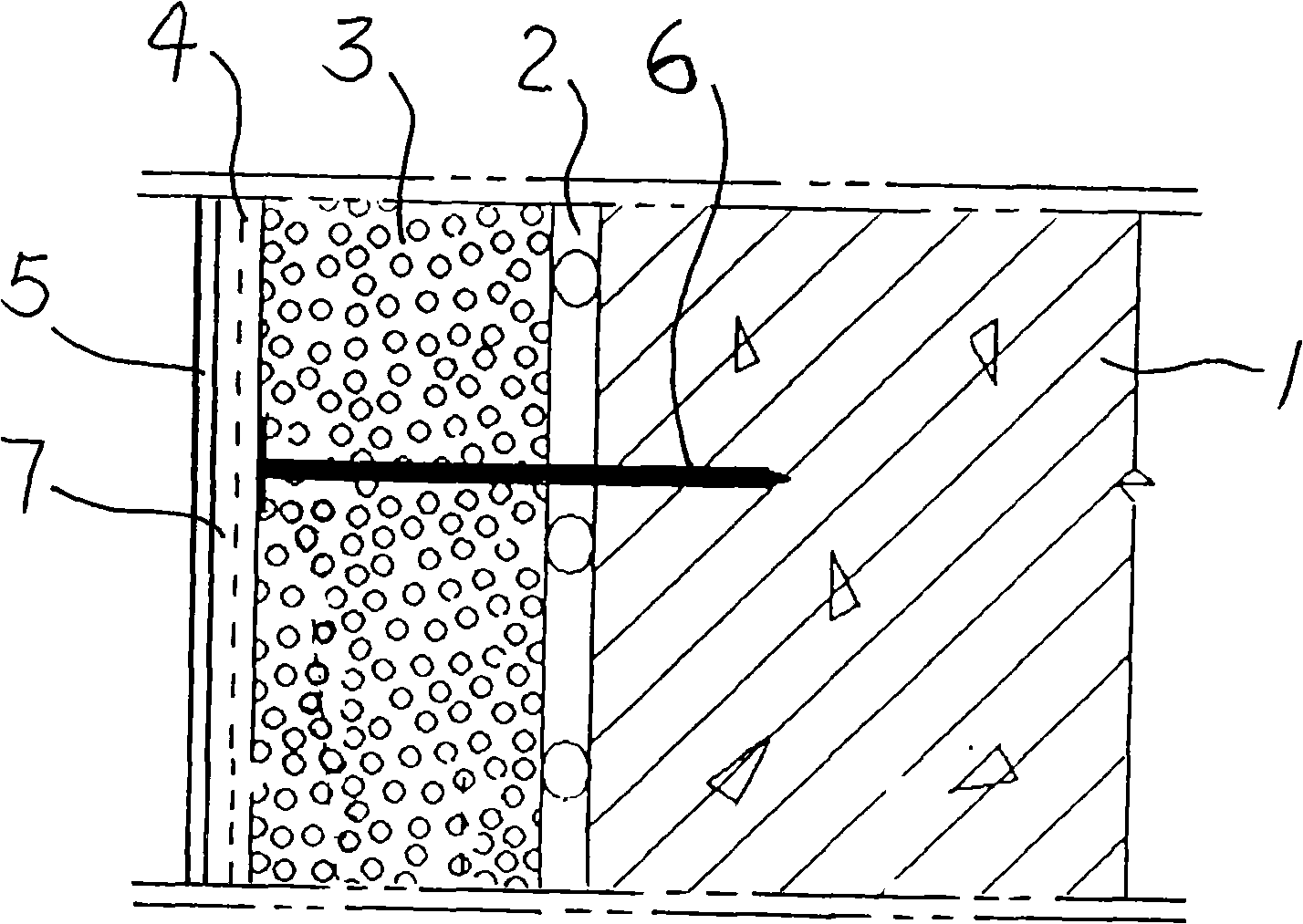

Construction method of building wall

The invention relates to the building construction technical field, in particular to a construction method which is suitable for various industrial and civil building walling having the requirement of energy conservation in a large part of China under different climate conditions. The construction method comprises the following steps that: a bonding agent is used for bonding an insulation board on the walling; mortar is coated on the insulation board and a piece of medium-alkali mesh cloth is wrapped in the mortar; and coating is plastered on the mortar, and the insulation board is a foam glass insulation board. The construction method effectively utilizes waste resources, reduces the environmental pollution, improves the utilization rate of energy, not only solves the problems of cracking and hollowing of the building walling but also improves the heat-insulating property, guarantees the elegant appearance of a veneer of the building walling, prevents the occurrence of a fire disaster, and protects the life and property safety of people.

Owner:上海永丽节能墙体材料有限公司

Electrical contact-making system

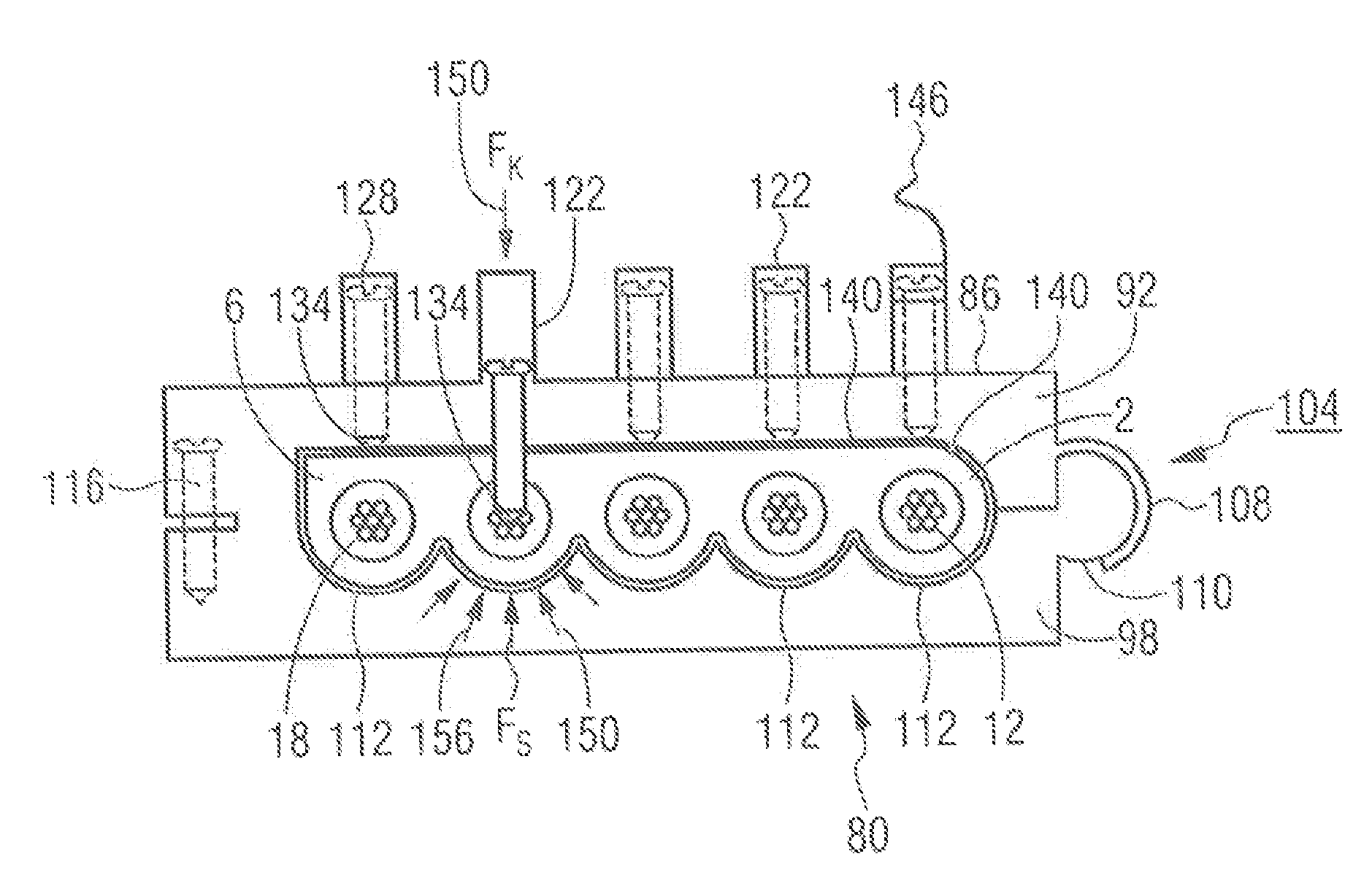

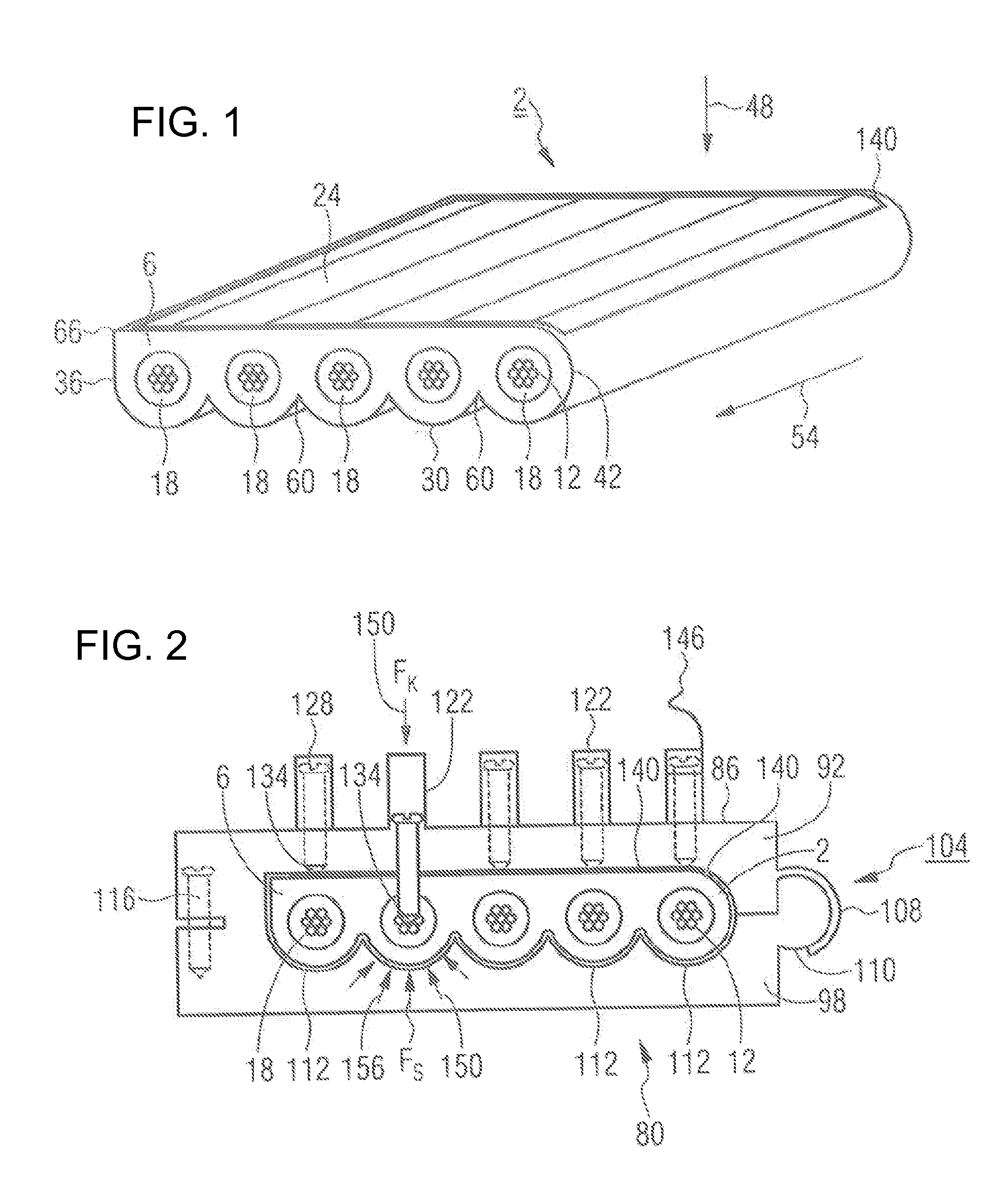

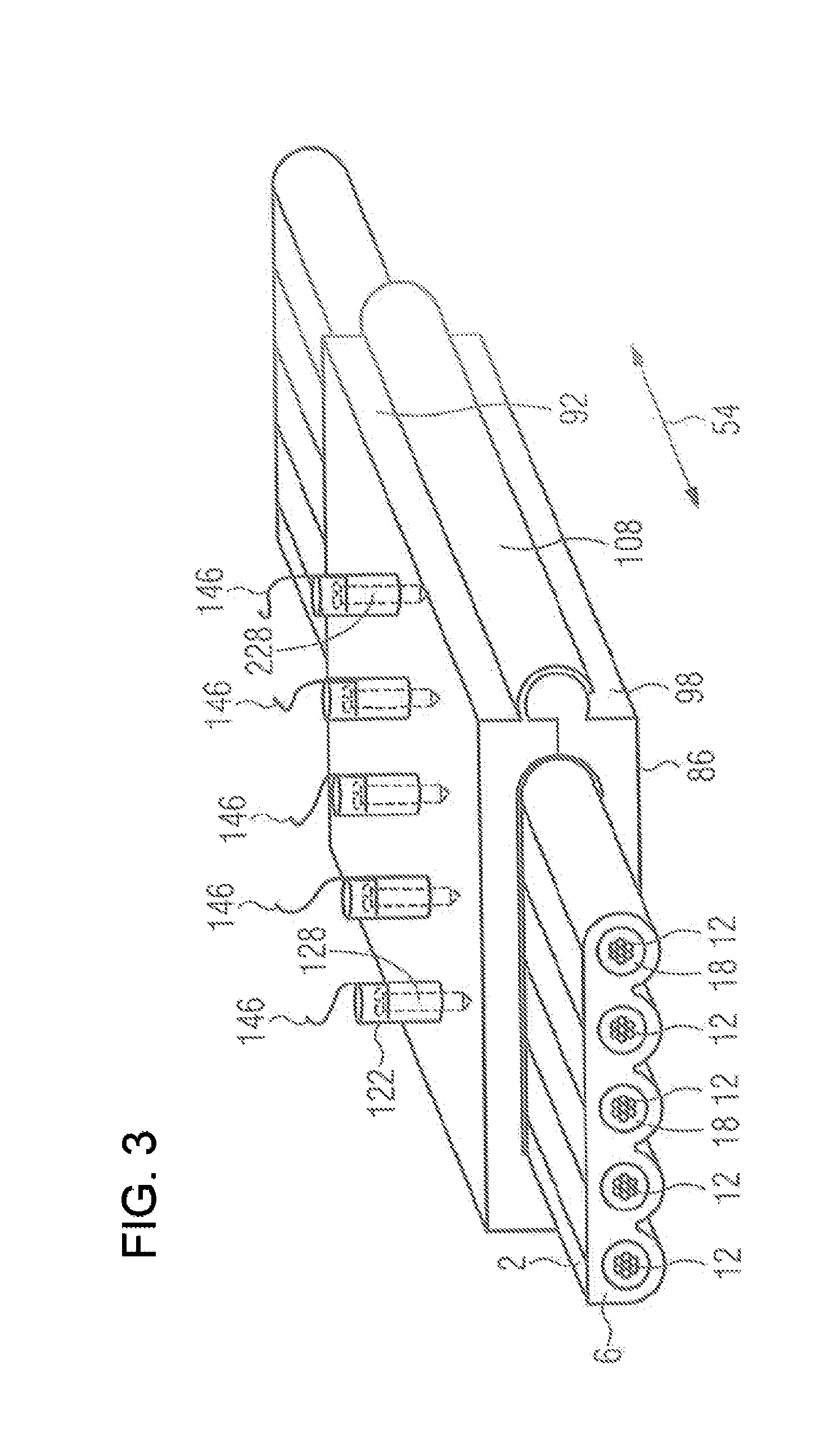

ActiveUS20140235094A1Extended operating temperature rangeImprove impermeabilityCoupling device detailsInsulated cablesRibbon cableElectrical contacts

An electrical contact-making system includes a flat ribbon cable with a sheath which has a planar top sheath face, a core plane containing electrical cores and a bottom sheath face with constricted portions which are parallel to the cores and are each disposed between two of the cores. A tapping collar makes electrical contact with the cores. A peripheral sealing strip encloses a rectangular contact-making region and is disposed on a bottom face of the top part of the tapping collar facing the top sheath face of the flat ribbon cable.

Owner:WIELAND ELECTRIC

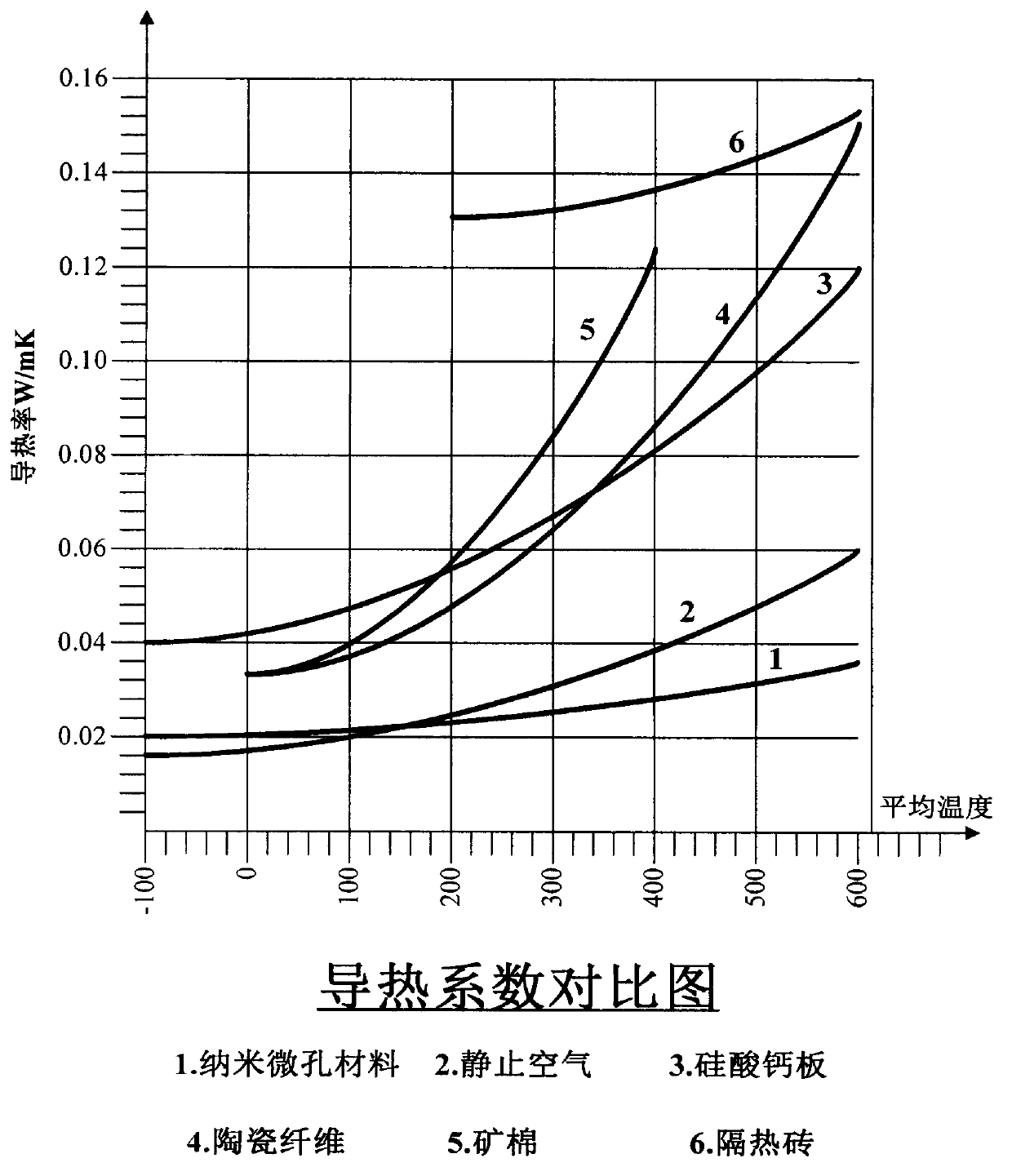

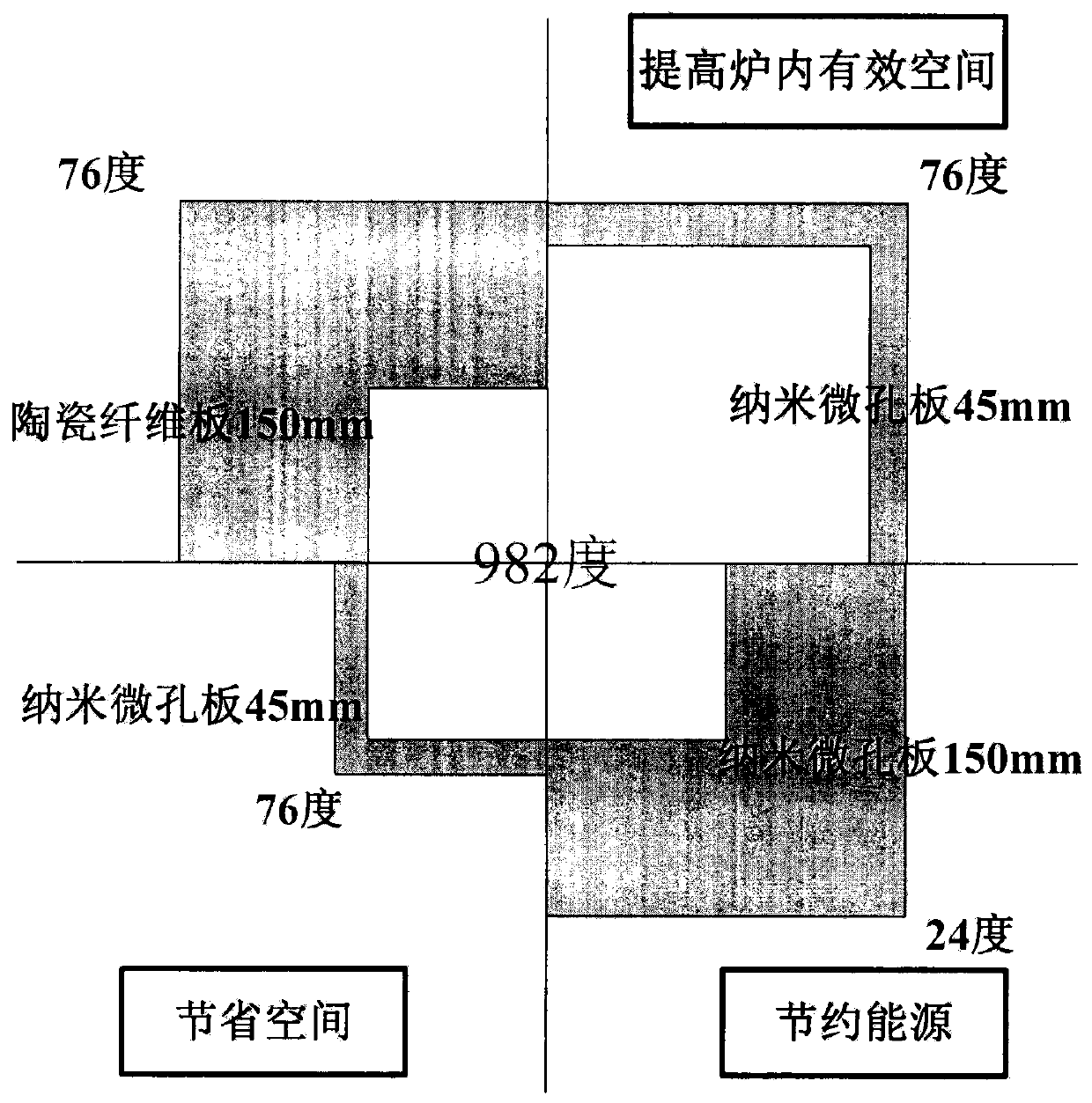

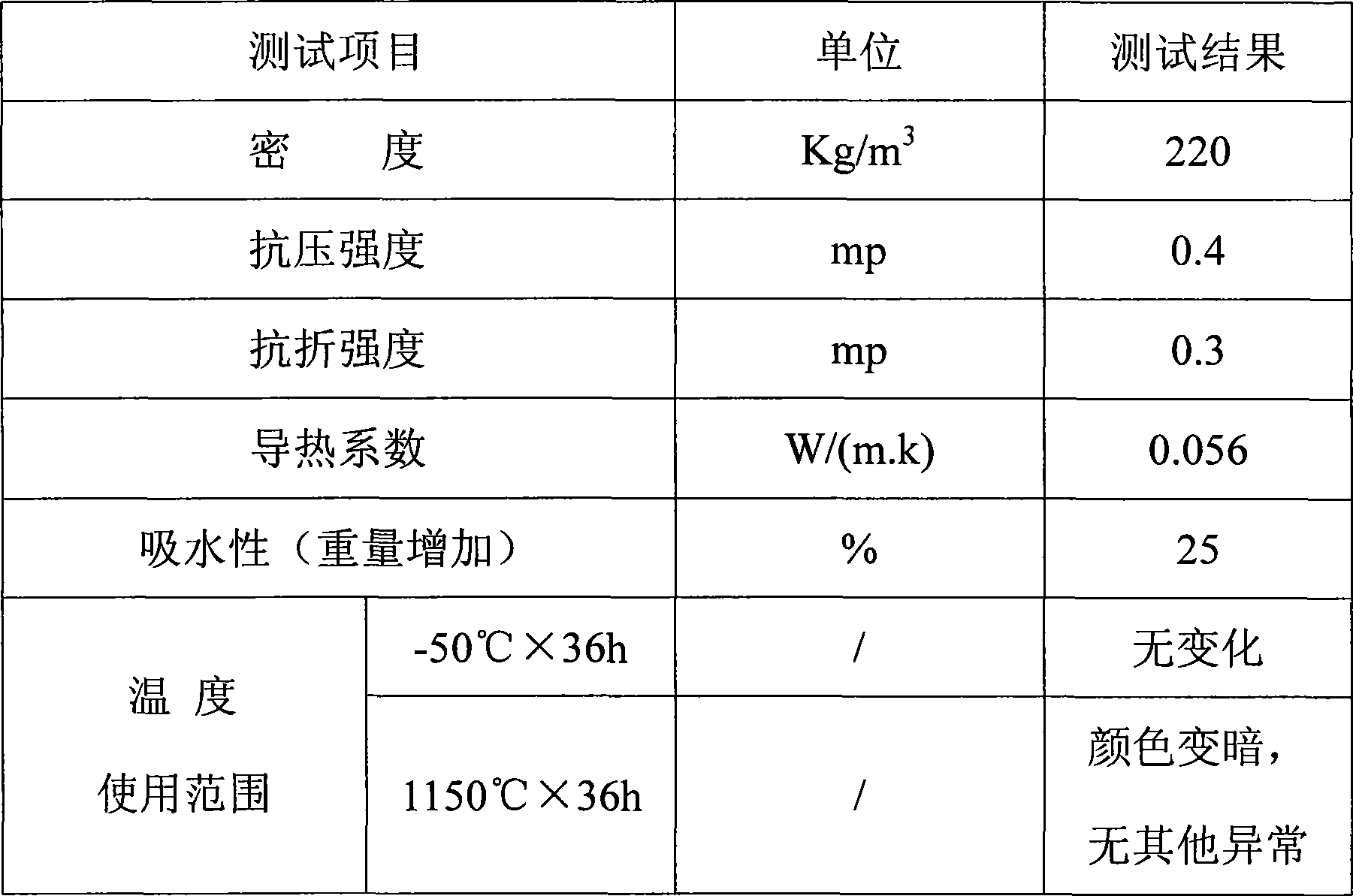

Nanometer micropore thermal insulation plate and manufacturing method thereof

InactiveCN103964813AExtended operating temperature rangeLow thermal conductivityGlass fiberThermal insulation

The present invention discloses a nanometer micropore thermal insulation plate, which comprises silica with a particle size range of 5-20 nm, silicon carbide with a particle size range of 2-12 m, zirconium silicate with a particle size range of 2-15 m, and high silica glass fibers with a diameter range of 5-15 m. The present invention further provides a manufacturing method for the nanometer micropore thermal insulation plate. With the nanometer micropore thermal insulation plate, the use temperature range of the materials is increased, and the low thermal conductivity of the materials is maintained.

Owner:上海依南新材料有限公司

Expansion vitrification micro-bead thermal insulation pipe case and production method thereof

ActiveCN101498395ALow thermal conductivityImprove thermal insulationThermal insulationAmide/imide polymer adhesivesVitrificationAntioxidant

The invention discloses an environment-friendly nonflammable insulating pipe casing with good insulating effect and light volume weight. The insulating pipe casing is produced in such a way that mixed materials are molded into insulating pipe casings with different calibers and different thickness, and the insulating pipe casings are dried and then directly used for the insulation of pipelines. The environment-friendly nonflammable insulating pipe casing is constructed simply and conveniently and has good insulation effect. The insulating pipe casing includes the following components by weight percent: 10 to 15 percent of expansion vitrified beads, 12 to 15 percent of brucite, 10 to 12 percent of attapulgite, 10 to 13 percent of casi powders, 0.1 to 0.15 percent of binders, 0.2 to 0.3 percent of latex, 45 to 54 percent of water, 0.01 to 0.02 percent of antioxidants, 3 to 5 percent of aluminum silicate wool, and 0.1 to 0.3 percent of infrared reflective paints.

Owner:江苏华伟佳建材科技有限公司

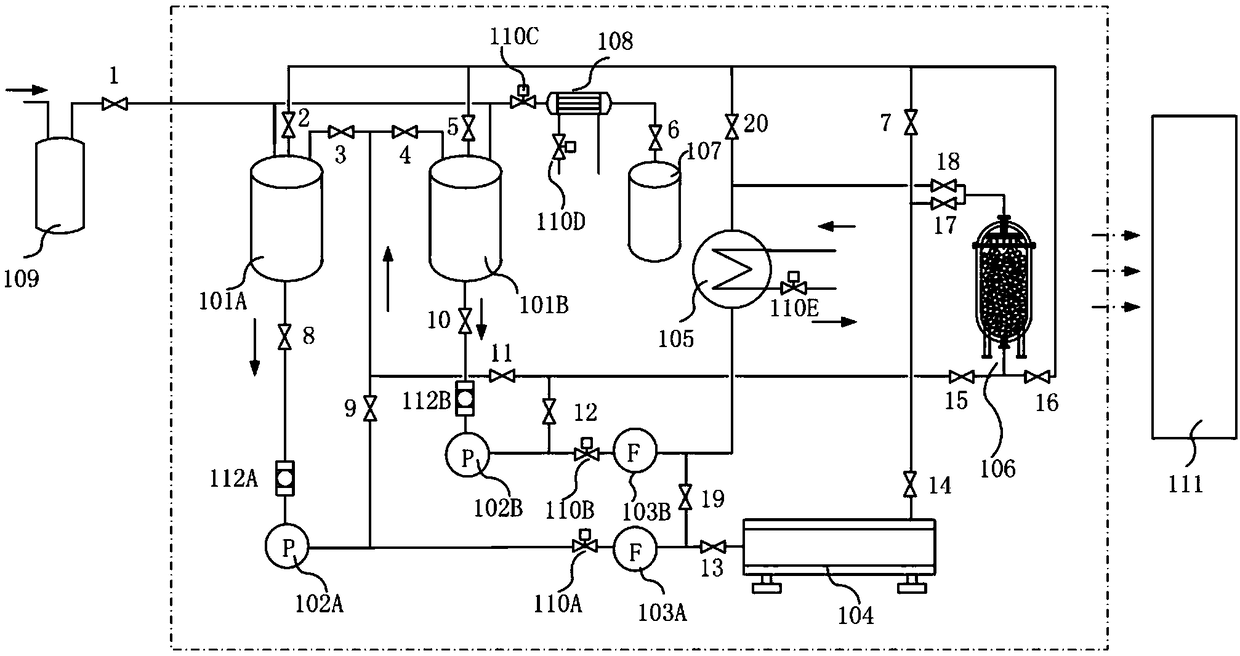

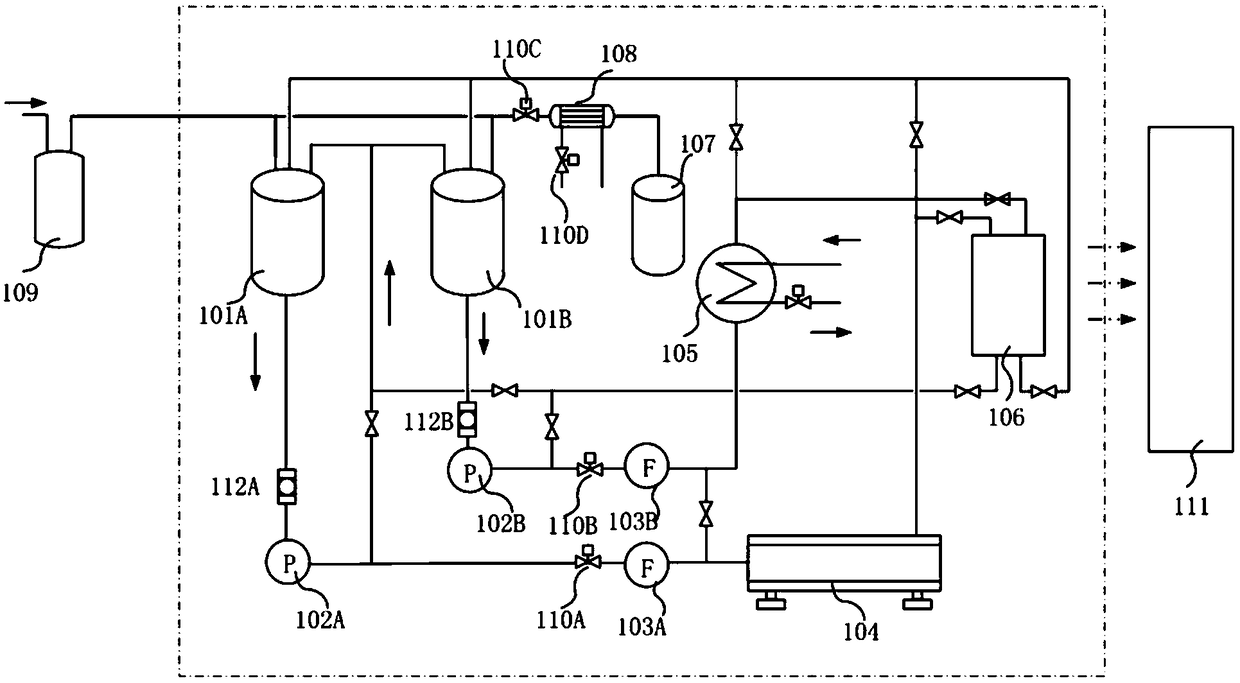

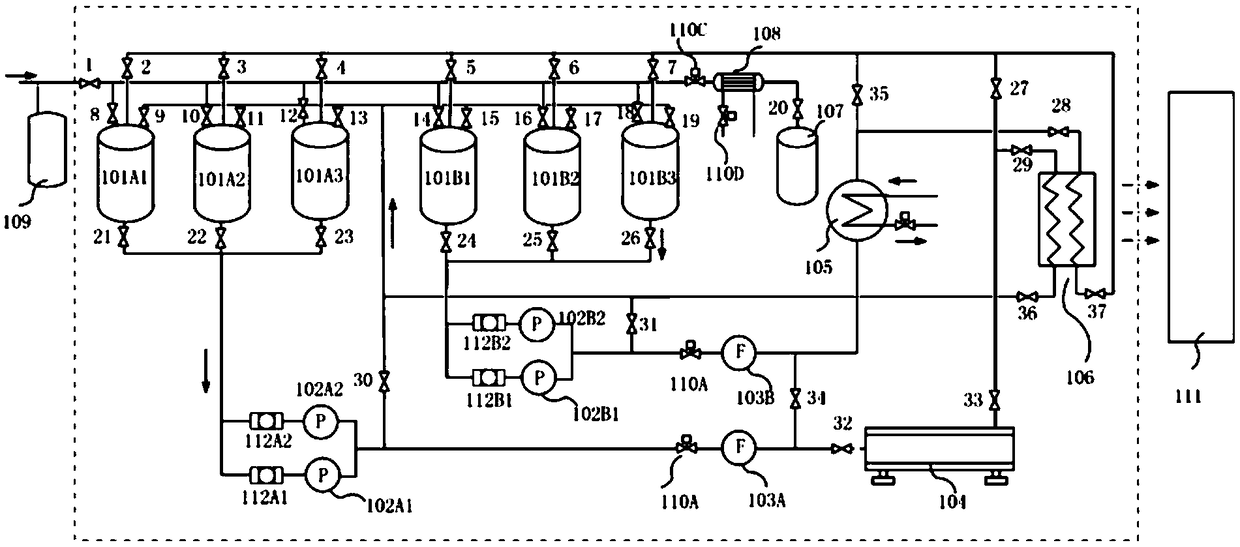

Heat performance test system

ActiveCN108918175AExtended operating temperature rangeWide power rangeStructural/machines measurementControl systemEngineering

The invention discloses a heat performance test system, which can perform test experiment and performance estimation on the heat storage / release performance of a heat storage device with high power and a wide temperature range and the heat exchange performance of a large-sized heat exchanger. The system consists of a test and control system, a heat energy production and storage system, a pressurestabilizing system, a tested device assembly, a pump valve assembly and the like, and can implement a test under a relatively wide temperature and pressure range. The system can also simulate outputting of unstable heat energy such as regenerable energy and implement a performance test and an operation strategy research on a large-scale medium and high-temperature heat storage device array, and can meet work such as a research and development test on key components of a compressed air energy storage system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com