Polyimide resin-based structure wave-absorbing material reinforced by nickel cobaltate-silicon carbide fiber multi-scale reinforcement and preparation method thereof

A polyimide resin and silicon carbide fiber technology, which is applied in the field of wave-absorbing materials, can solve problems such as poor wave-absorbing performance and reduced mechanical properties, and achieve improved electrical conductivity, good high-temperature stability, and increased interface polarization capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the nickel cobaltate-silicon carbide fiber multi-scale reinforcement reinforced polyimide resin-based structural wave-absorbing material of the present invention, its specific steps:

[0035] Step 1, evenly brush the polyamic acid solution (the solid content of the polyimide is 40%) of the precursor of polyimide on the upper surface of the prepared multi-piece nickel cobaltate-silicon carbide fiber multi-scale reinforcement and the lower surface. The nickel cobaltate-silicon carbide fiber multi-scale reinforcement coated with polyamic acid is stacked neatly, generally 5 to 10 pieces, to obtain a prefabricated piece of polyimide resin-based structural wave-absorbing material. Put the prefabricated part of the polyimide resin-based structural wave-absorbing material into a vacuum oven, vacuumize the vacuum oven-hold pressure-release pressure to impregnate the nickel cobaltate-silicon carbide fiber multi-scale reinforcement, specifically Yes, eva...

Embodiment 1

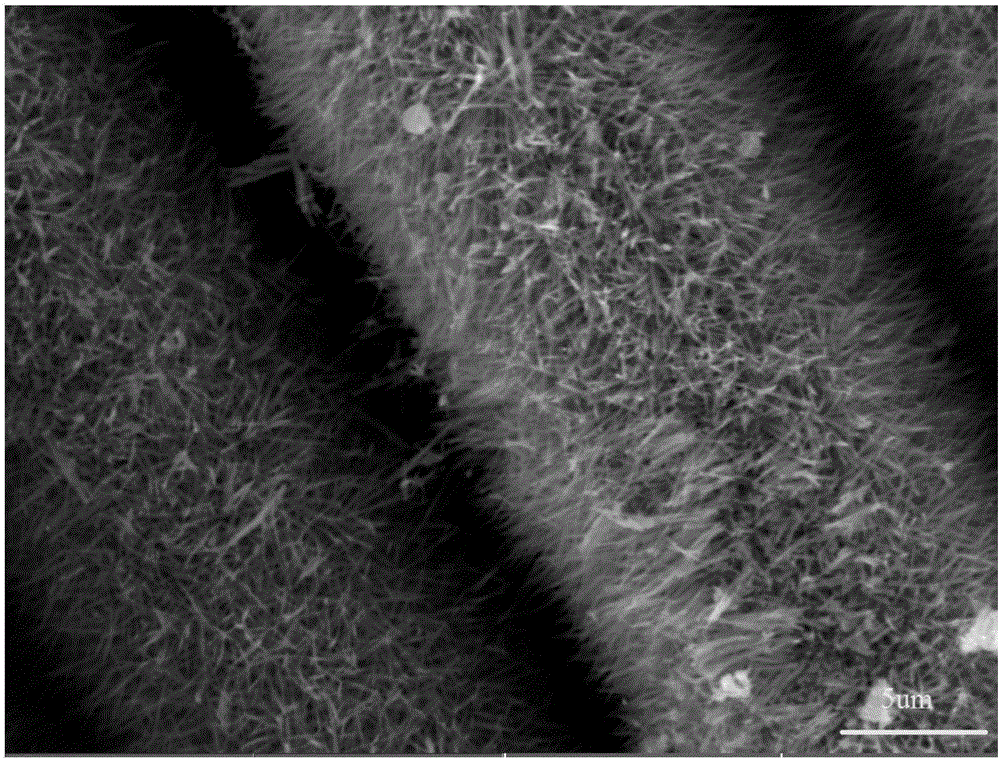

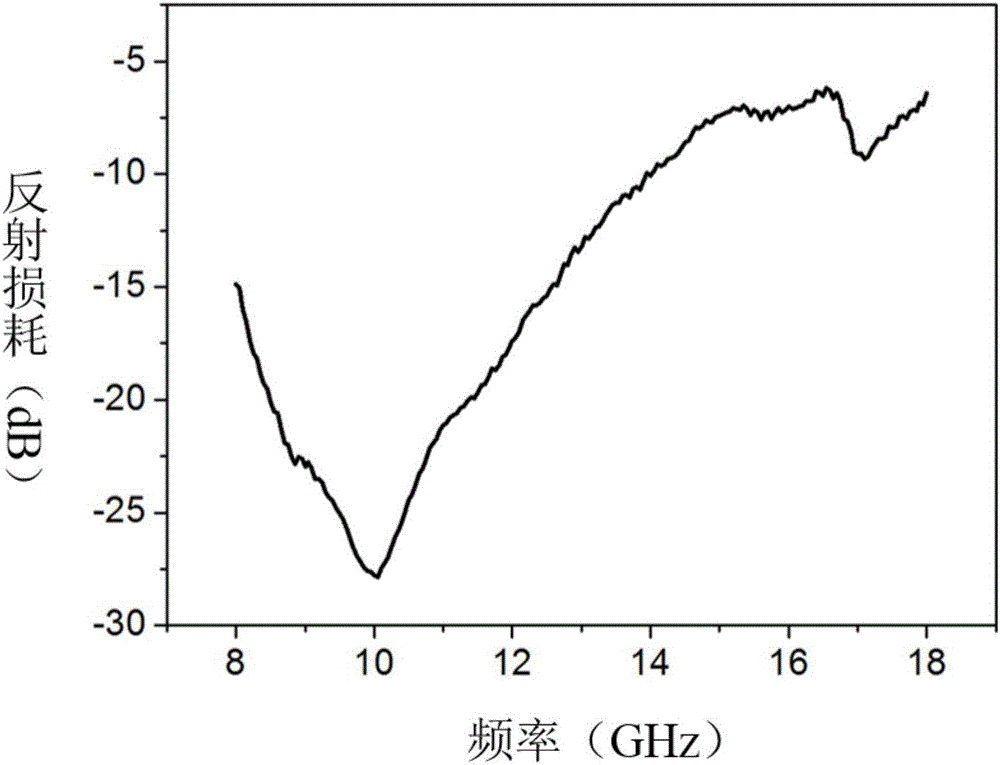

[0038] This embodiment is a nickel cobaltate-silicon carbide fiber multi-scale reinforcement reinforced polyimide resin-based structural wave-absorbing material, the polyimide resin-based structural wave-absorbing material The multi-scale reinforcement is the absorbent, and the polyimide resin is used as the matrix. The nickel cobaltate-silicon carbide fiber multi-scale reinforcement has a content of 40wt%, and the polyimide resin has a content of 60wt%.

[0039] This example also proposes a method for preparing the nickel cobaltate-silicon carbide fiber multi-scale reinforcement reinforced polyimide resin-based structure absorbing material, the specific process is:

[0040] Step 1. Put 6 pieces of silicon carbide fiber cloth cut to a suitable size, put them in acetone, wash them in an ultrasonic wave for 1 hour, and then dry them in an oven; the drying temperature is 80°C; the ultrasonic power is 100W. The size of silicon carbide fiber cloth is 35mm*45mm.

[0041] Step 2, s...

Embodiment 2

[0047] This embodiment is a nickel cobaltate-silicon carbide fiber multi-scale reinforcement reinforced polyimide resin-based structural wave-absorbing material, the polyimide resin-based structural wave-absorbing material The multi-scale reinforcement is the absorbent, and the polyimide resin is used as the matrix. The nickel cobaltate-silicon carbide fiber multi-scale reinforcement has a content of 40wt%, and the polyimide resin has a content of 60wt%.

[0048] This example also proposes a method for preparing the nickel cobaltate-silicon carbide fiber multi-scale reinforcement reinforced polyimide resin-based structure absorbing material, the specific process is:

[0049] Step 1. Put 7 pieces of silicon carbide fiber cloth cut to a suitable size, put them in acetone, wash them in an ultrasonic wave for 1 hour, and then dry them in an oven; the drying temperature is 80°C; the ultrasonic power is 100W. The size of silicon carbide fiber cloth is 35mm*45mm.

[0050] Step 2, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com