Halogen-free Tg resin composite and presoaked material and laminated board made by adopting same

A technology of resin composition and prepreg, which is applied in the direction of synthetic resin layered products, fabrics, thin material processing, etc., can solve the problems of affecting the performance of the board, easy to open the ring, and affect the cyanate ester ring-forming reaction, etc., to overcome Low heat resistance, low CTE, and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides a halogen-free high Tg resin composition, which contains components and parts by weight of organic solids:

[0018] (A) at least one cyanate and a prepolymer of cyanate, 10-50 parts by weight;

[0019] (B) at least one compound with a dihydrobenzoxazine ring, 10-50 parts by weight;

[0020] (C) 10 to 50 parts by weight of at least one bismaleimide resin

[0021] (D) at least one polyepoxide, 10-50 parts by weight;

[0022] (E) At least one phosphorus-containing flame retardant, 5-30 parts by weight.

[0023] Each component is described in detail below:

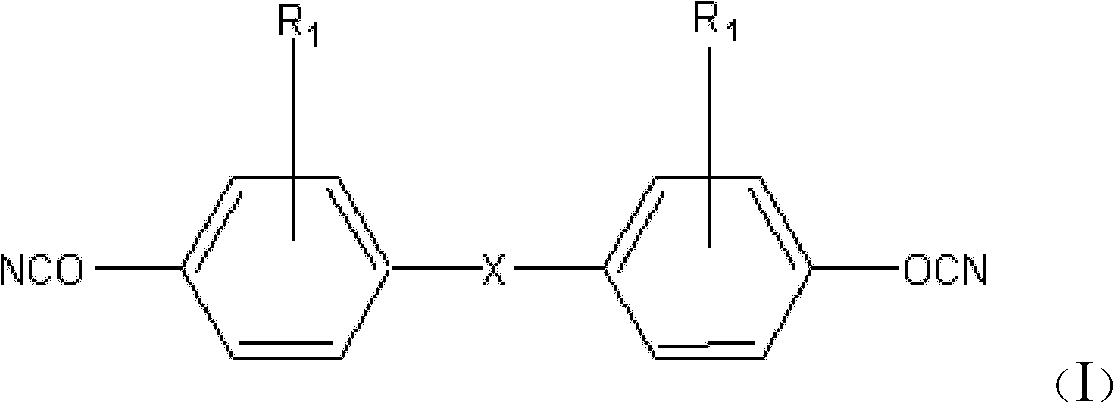

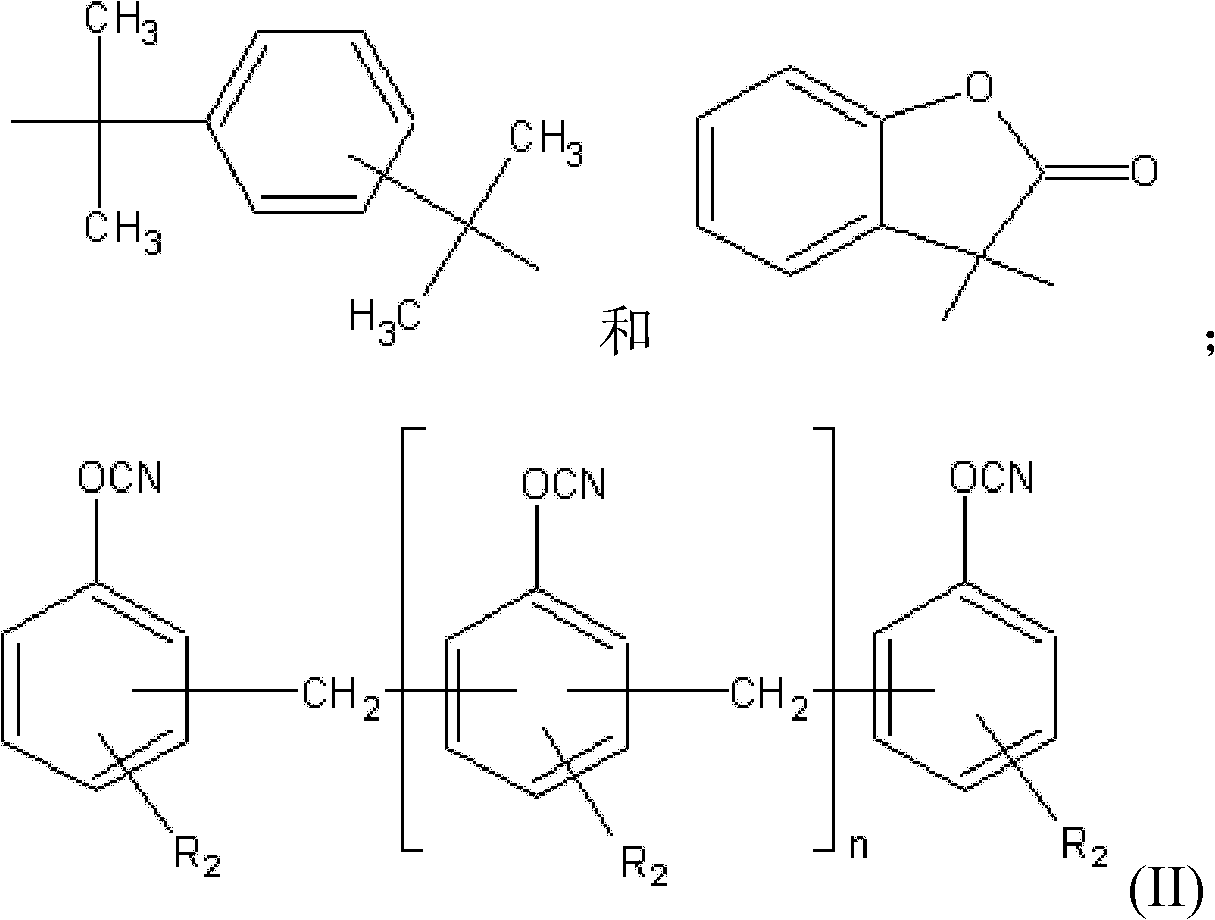

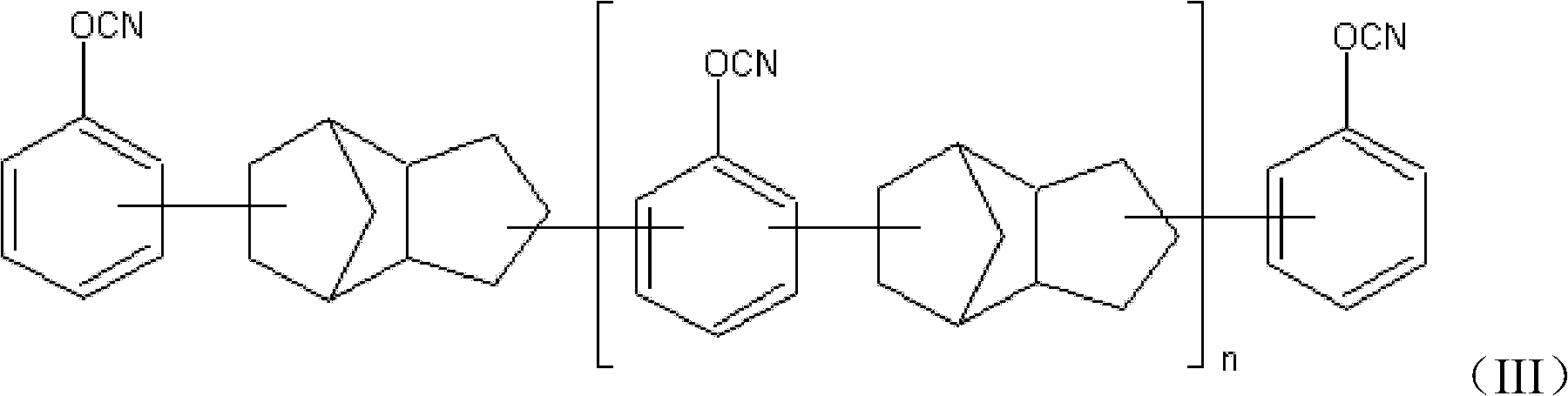

[0024] The component (A) in the present invention is cyanate and cyanate prepolymer, which can further improve the thermal and electrical properties of polymers and products. The prepolymer molecular structure formula of cyanate and cyanate is selected from the compound represented by general formula (I), (II), (III) and the prepolymer formed by one or more of the above-mentioned compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com