Patents

Literature

336results about How to "Low dielectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

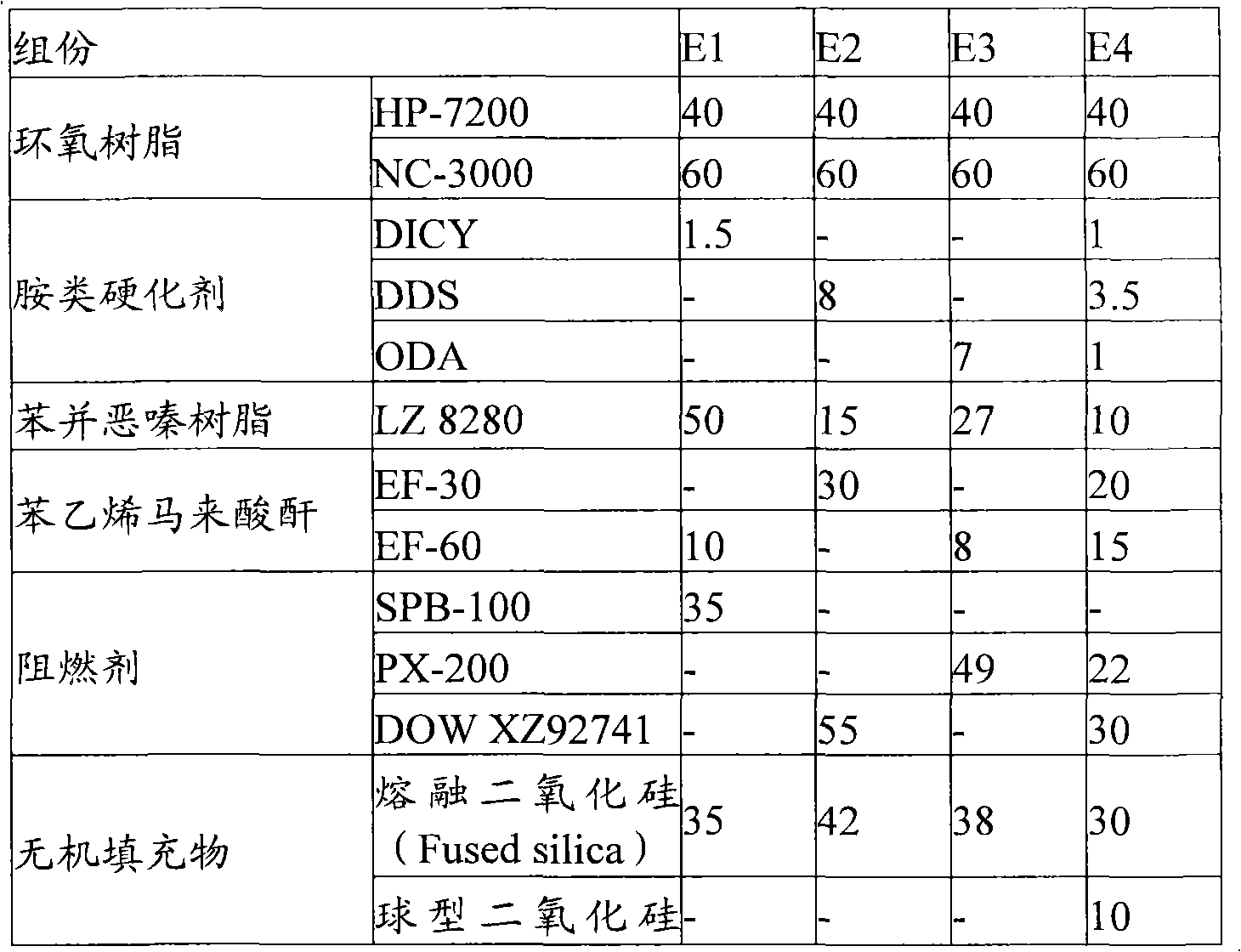

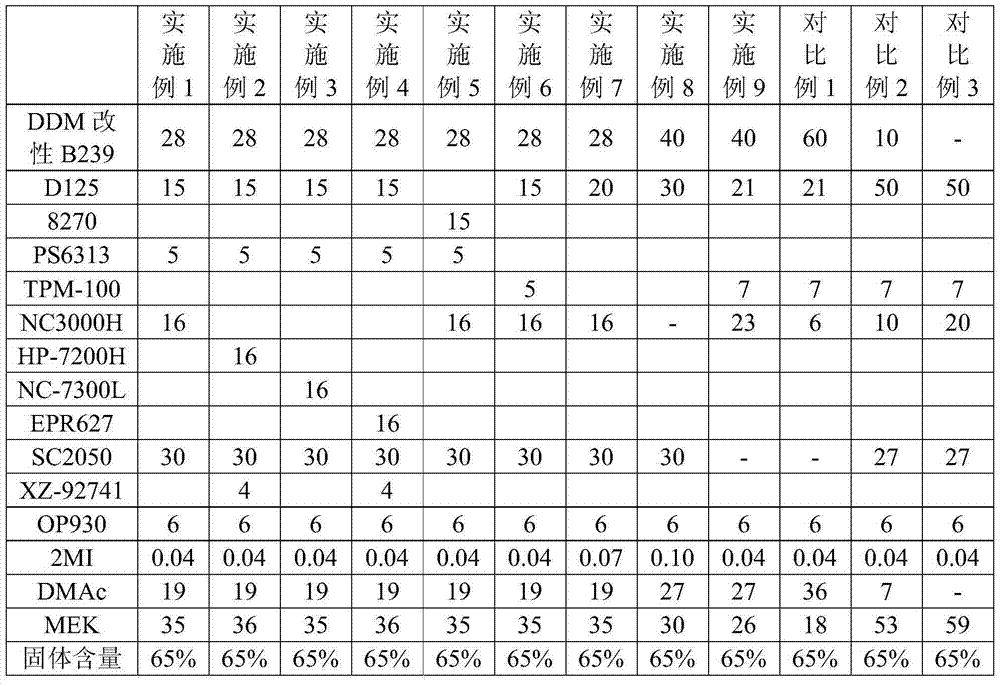

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

Thermosetting Resin Composition and Application Thereof

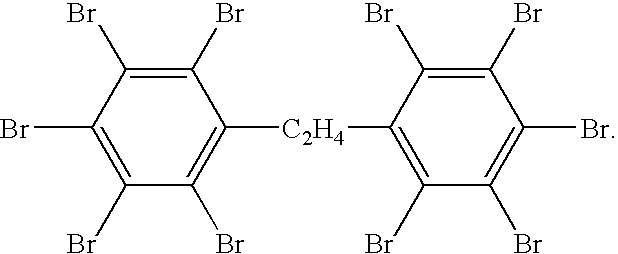

InactiveUS20100240811A1Excellent dielectric propertiesIncrease thermal resistanceBiocideOrganic chemistryTetrabromobisphenol ASolvent

The present invention discloses a thermosetting resin composition including: a bi-functional or multi-functional epoxy resin, a SMA uses as a curing agent, an allyl phenol such as diallyl bisphenol A used as a co-curing agent and a toughening agent a low-bromine or high-bromine BPA epoxy resin or tetrabromobispheno A (TBBPA or TBBA) uses as a flame retardant agent, and an appropriate solvent. After the resin composition of the invention is cured, the resin composition has lower dielectric property and better thermal reliability and tenacity. A copper clad laminate made of an enhanced material such as glass fiber has lower dielectric constant (Dk) and loss tangent (Df), high Tg, high thermal decomposition temperature (Td), better tenacity and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs or applied as a molding resin material for contraction, automobile and air navigation.

Owner:ITEQ DONGGUAN +1

Halogen-free resin composition as well as copper foil substrate and printed circuit board applying same

ActiveCN103013110AWith flame retardant functionWon't happenCircuit susbtrate materialsSheet filmCopper foil

The invention provides a halogen-free resin composition which comprises (A) 100 parts of cyanate ester resin, (B) 5-50 parts of styrene maleic anhydride, (C), 5-100 parts of polyphenyl ether resin, (D) 5-100 parts of maleimide resin, (E) 10-150 parts of nitrogenous compound, and (F) 10-1000 parts of inorganic filler. As the composition comprises components in special proportion, the halogen-free resin composition is low in dielectric constant, low in dielectric loss, high in heat resistance and high in flame resistance. The halogen-free resin composition can be prepared as a semi-cured film or a resin film, so that the composition can be applied to a copper foil substrate and a printed circuit board.

Owner:ELITE MATERIAL

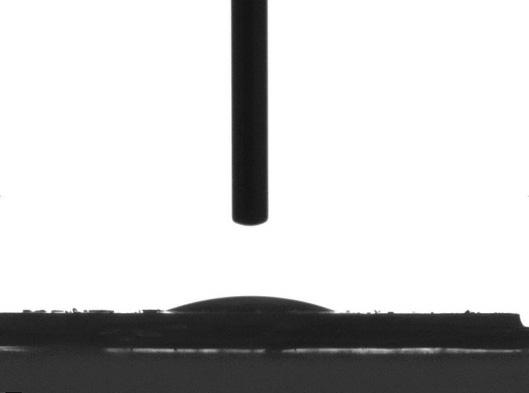

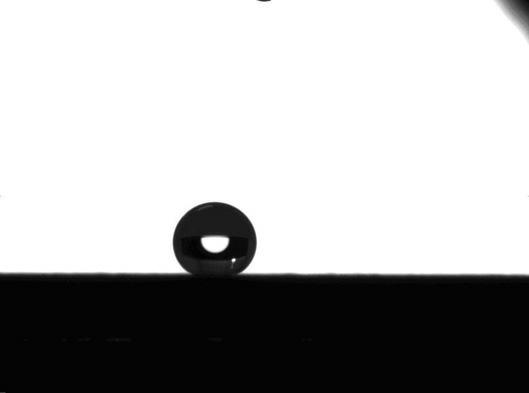

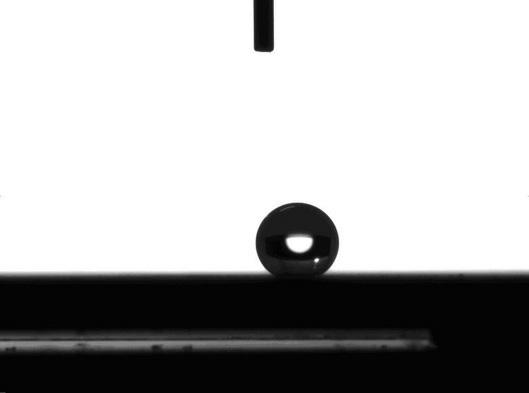

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Thermosetting resin composition and use thereof

The present invention discloses a thermosetting resin composition comprising: a bifunctional or multifunctional epoxy resin, a styrene-maleic anhydride (SMA) copolymer with a styrene / maleic anhydride molar ratio of 5-12:1 as a curing agent, a BPA epoxy resin with a low or high bromine content or tetrabromobisphenol A as a flame retardant agent, an accelerator and a solvent. The cured resin composition of the invention has a very low dielectric property, improved thermal reliability and better toughness. A copper clad laminate made of the resin composition and a reinforced material such as glass fiber cloth has a very low dielectric constant and dissipation factor, high Td, better toughness and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs and also applied to the common use of epoxy resins, such as molding resins, and composite materials for construction, automobiles and aviation.

Owner:ITEQ DONGGUAN +1

Epoxy resin composition and high-frequency circuit board manufactured thereby

InactiveCN102504201AExcellent dielectric propertiesLow dielectric propertiesCircuit susbtrate materialsSolid componentCopper foil

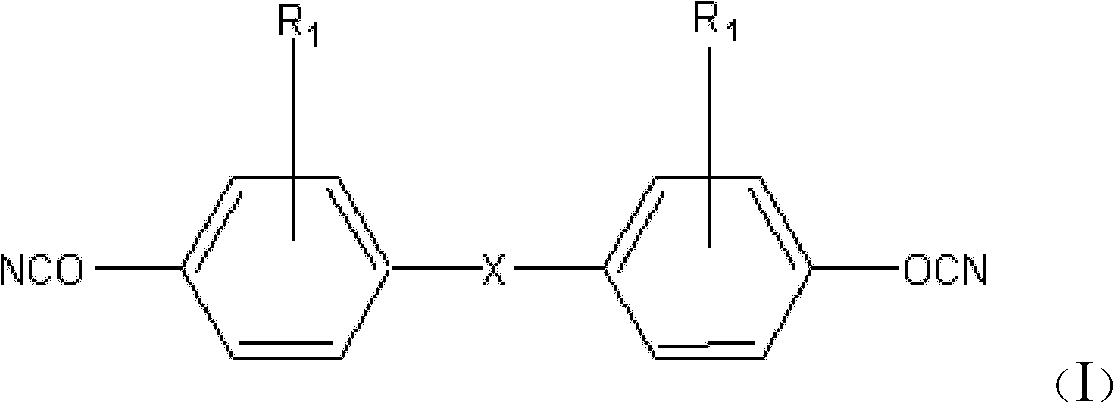

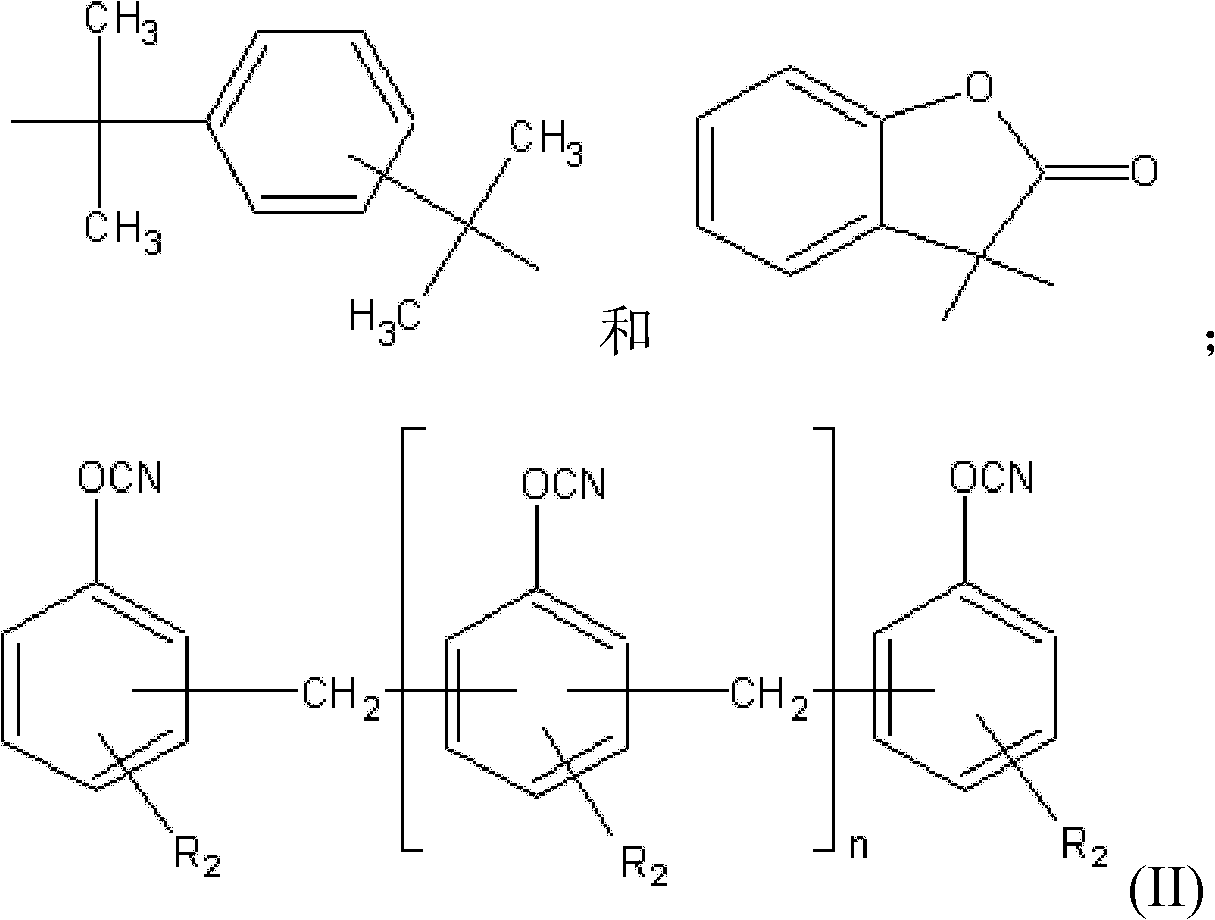

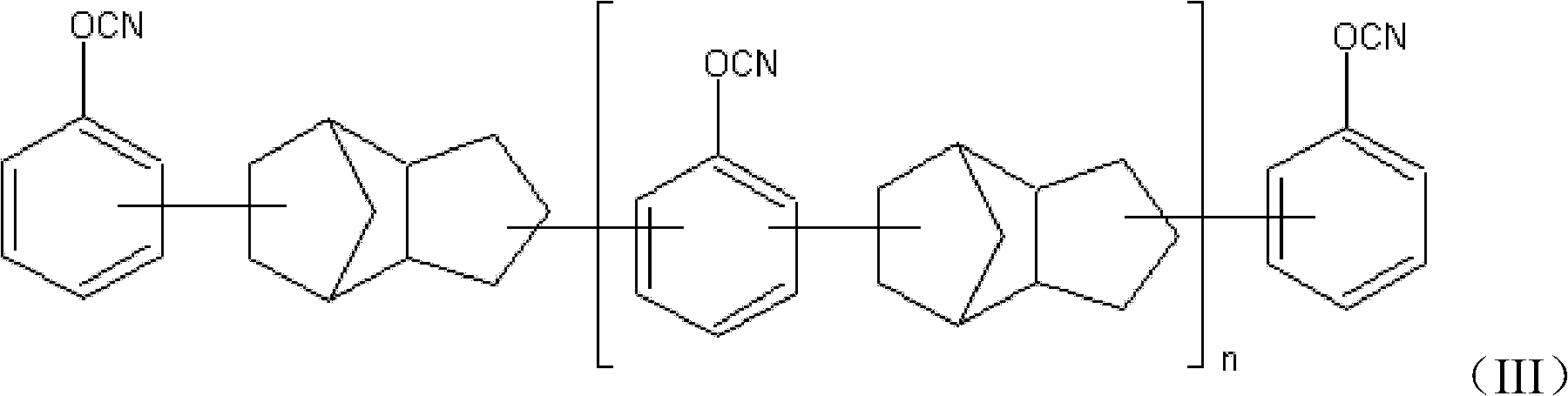

The invention relates to an epoxy resin composition and a high-frequency circuit board manufactured thereby. The epoxy resin composition comprises the following solid components: (A) cyanate compound or prepolymer thereof, wherein the molecule of the cyanate compound contains at least two cyanato groups; (B) active ester; and (C) epoxy resin containing a naphthol structure; calculated in solid component in parts by weight, the total amount of the component (A), i.e. the cyanate compound containing at least two cyanato groups in the molecule thereof or the prepolymer thereof, and the component (B), i.e. active ester, is 10-70 parts by weight, and the amount of the component (C), i.e. epoxy resin containing naphthol structure, is 30-90 parts by weight, wherein the weight ratio of the component (A), i.e. the cyanate compound containing at least two cyanato groups in the molecule thereof or the prepolymer thereof, to the component (B), i.e. active ester, is (0.2-5):1. The high-frequency circuit board manufactured by using the epoxy resin composition of the invention comprises a plurality of layers of prepregs which are overlapped mutually, and copper foils which are compressed on the two sides respectively; and each of the plurality of layers of prepregs comprises a base material and the epoxy resin composition which is adhered to the base material through impregnation and drying.

Owner:GUANGDONG SHENGYI SCI TECH

Thermosetting resin composition and use

InactiveCN101481490AImprove heat resistanceExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsGlass fiberTetrabromobisphenol A

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

Halogen-free Tg resin composite and presoaked material and laminated board made by adopting same

ActiveCN102134375AExcellent dielectric propertiesLow dielectric propertiesPrinted circuit aspectsSynthetic resin layered productsVitrificationPhosphonium

The invention relates to a halogen-free Tg resin composite and a presoaked material and a laminated board made by adopting the composite. Counted by part by weight of organic solid matters, the halogen-free high-Tg resin composite contains the following components according to part by weight: (A) 10 to 50 parts by weight of cyanate resin; (B) 10 to 50 parts by weight of at least one compound withdihydro-benzoxazine ring; (C) 10 to 50 parts by weight of at least one kind of bismaleimides resin; (D) 10 to 50 parts by weight of at least one kind of poly-epoxy compound; and (E) 5 to 30 parts by weight of at least one kind phosphonium flame retardant. The halogen-free high-Tg resin composite has the performances of low water absorption, low CTE (coefficient of thermal expansion), high Tg, good dielectric property and the like, and the presoaked material and laminated board made by adopting the composite has the characteristics of high vitrification transition temperature, low CTE, low dielectric constant, low water absorption, high thermal resistance and the like, thus being application to multi-layer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

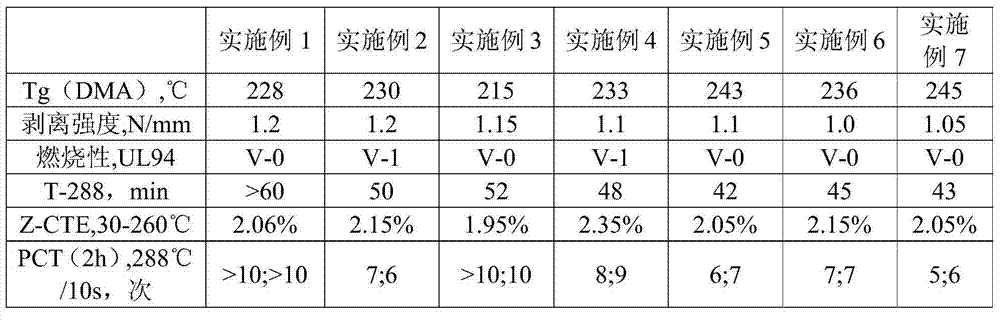

Resin composition, prepreg using resin composition and laminate

ActiveCN104725781AHigh TgLow CTESynthetic resin layered productsCircuit susbtrate materialsDielectric lossElastic modulus

The invention belongs to the technical field of copper clad laminates and particularly relates to a resin composition, prepreg using the resin composition and a laminate. The resin composition contains the ingredients in percentage by weight: 15-55% of amine modified bismaleimide (BMI), 10-45% of benzoxazine resin and 0-75% of epoxy resin. According to the resin composition, through further reaction of benzoxazine (BOZ) and amine modified bismaleimide (BMI), performance advantages of two kinds of high-performance resin, namely BMI and BOZ, are excellently exerted, so that the prepreg and the copper clad laminates, manufactured from the resin composition, have the properties of high Tg, relatively high peeling strength, relatively low CTE, relatively low water absorbing capacity, relatively low dielectric loss, relatively high elastic modulus high-temperature retention rate, relatively good resistance to hot and damp and the like, and reach a flame-retardant level UL94-V0.

Owner:GUANGDONG SHENGYI SCI TECH

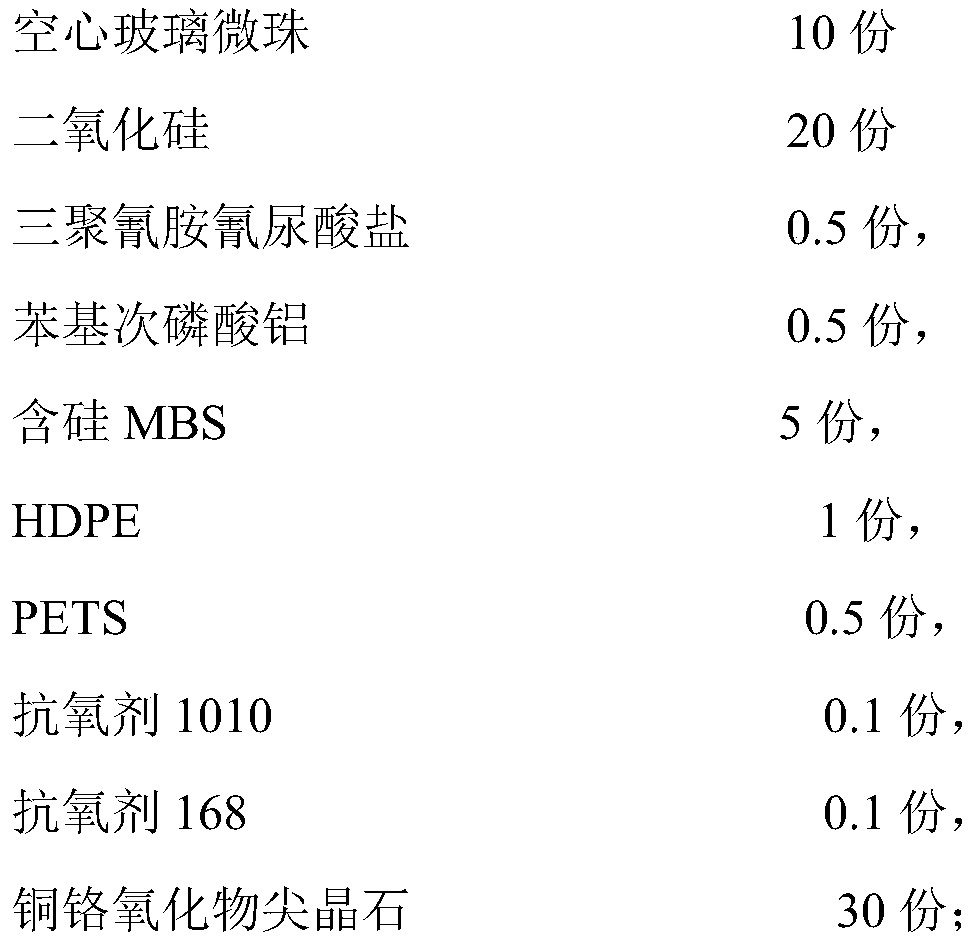

Low-dielectric laser direct structuring composite material suitable for 5G communication and preparation method thereof

ActiveCN110655792ALow dielectric constantHigh heat distortion temperatureChemical platingFire retardant

The invention relates to a low-dielectric laser direct structuring composite material suitable for 5G communication. The composite material is composed of the following components in parts by weight:52 to 86 parts of base resin, 0 to 30 parts of glass fibers, 10 to 30 parts of a filling agent, 1 to 9 parts of a flame retardant, 4 to 15 parts of a toughening agent, 0.1 to 1 part of a lubricating agent, 0.2 to 1 part of an antioxidant and 10 to 30 parts of a laser sensitive additive. A preparation method of the composite material comprises the steps that a twin-screw extruder is used for processing, the melt extrusion temperature is 250-380 DEG C, and the screw rotating speed is 150-300 rpm / min. The composite material has low dielectric property, so that improvement of the transmission speed of 5G communication millimeter wave signals is facilitated, the signal delay is reduced, and the signal loss is reduced; the composite material has the LDS processing capacity, can be rapidly prepared in a small size and a large number, can be subjected to batch laser etching and chemical plating to form a metal connecting circuit, and is an optimal solution of a 5G plastic antenna oscillator material.

Owner:中广核高新核材科技(苏州)有限公司

Vinylbenzyl-etherified-dopo compound resin composition and preparation and application thereof

The present invention belongs to the technical field of a resin having low dielectric properties, and presents a vinylbenzyl-etherified-DOPO compound resin composition and a preparation method and application thereof. The composition includes a vinylbenzyl-etherified-DOPO compound resin and a vinyl-terminated polyphenylene ether resin. The DOPO resin is vinylbenzyl etherified in the present invention, thus obtaining a vinylbenzyl-etherified-DOPO compound resin having low dielectric properties, and there are no hydroxyl group on itself, no hydroxyl function group will be generated during the cross-linking reaction; and the vinylbenzyl-etherified-DOPO compound resin contains phosphorus atoms, and has flame retardancy. The prepared vinylbenzyl-etherified-DOPO compound resin and the hydroxyl-free, low dielectric vinyl-terminated polyphenylene ether resin are combined in the present invention, thus obtaining a resin composition having low dielectric constant and low dielectric loss tangent, which can achieve excellent dielectric properties and flame retardancy when applying to the metal laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

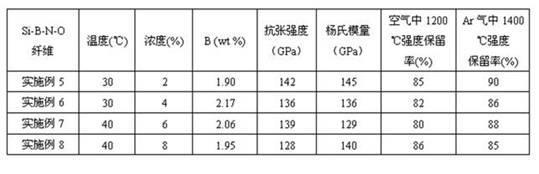

Method for continuously preparing Si-B-N-O fiber by using PCS (Polycarbosilane) fiber

The invention discloses a method for continuously preparing an Si-B-N-O fiber by using a PCS fiber, which comprises the following steps of: after air curing treatment is carried out on the PCS fiber, firstly carrying out nitrogen treatment on a PCS curing fiber and then carrying out boronization treatment or firstly carrying out the boronization treatment and then carrying out the nitrogen treatment; then sintering the PCS curing fiber after the nitrogen treatment and the boronization treatment under the high temperature condition of 1200-1400 DEG C under the protection of high-purity N2 gas or argon atmosphere to prepare the Si-B-N-O fiber. Compared with an Si-N-O fiber, the prepared Si-B-N-O fiber has better temperature resistance, lower dielectric performance and simpler preparation process and is easy to realize industrialized batch preparation.

Owner:NAT UNIV OF DEFENSE TECH

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

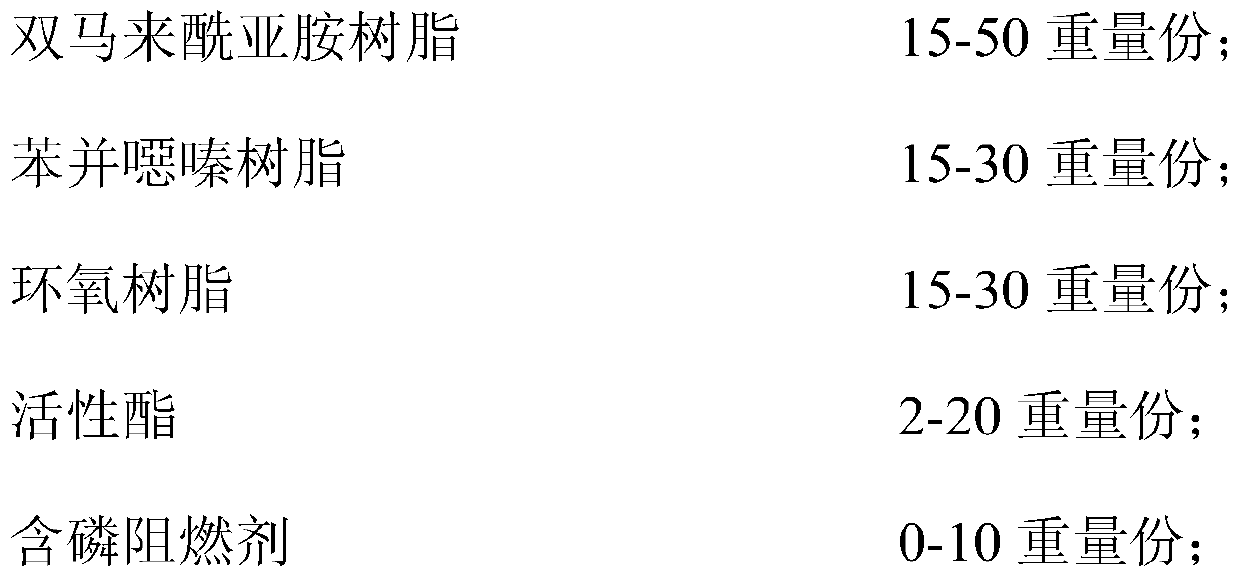

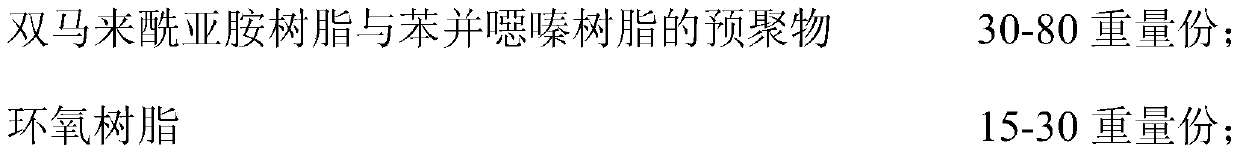

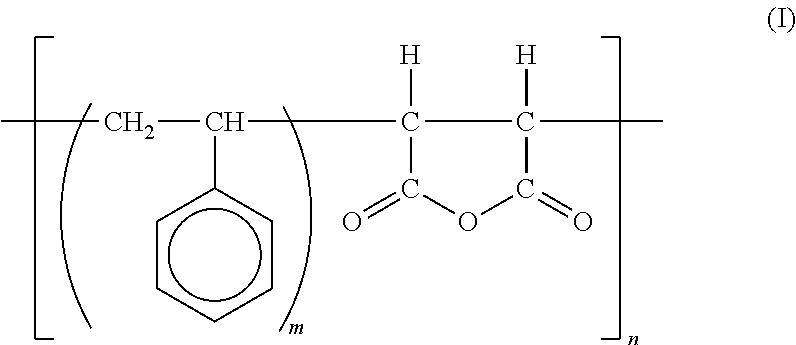

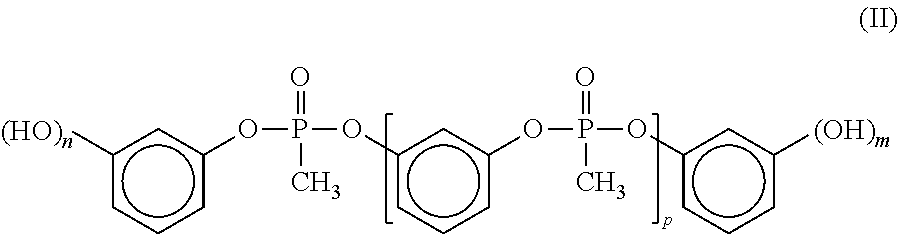

Thermosetting resin composition, prepreg comprising same, metal-foil-coated laminate and printed circuit board

ActiveCN109825081AHigh glass transition temperatureImprove heat resistancePrinted circuit aspectsSynthetic resin layered productsBenzoxazoleEpoxy

Owner:GUANGDONG SHENGYI SCI TECH

Halogen-free flame-retardant epoxy resin composition, and prepreg and printed circuit board using the same

ActiveUS20110278052A1Easy to processImprove toughnessPlastic/resin/waxes insulatorsPrinted circuitsEpoxyPrinted circuit board

Disclosed is a halogen-free flame-retardant epoxy resin composition for printed circuit board, which includes (A) a halogen-free epoxy resin; (B) a copolymer of styrene and maleic anhydride used as a first curing agent; (C) poly(1,3-phenylene methylphosphonate) used as a second curing agent; (D) a curing accelerator; and (E) an inorganic filler.

Owner:TAIWAN POWDER TECH CO LTD

Piezoelectric ceramic material and preparation method thereof

The invention discloses a piezoelectric ceramic material, the chemical formula of the material is as follows: Pb1.05-dSrdZrxTiyO3 + amol% La2O3 + bmol% M + cmol% SiO2, wherein, d is more than or equal to 0 and less than or equal to 0.03, x + y = 1, a is more than or equal to 0 and less than or equal to 5, b is more than or equal to 0 and less than or equal to 5, c is more than or equal to 0 and less than or equal to 1, M presents LiNbO3 or Nb2O5. The invention also discloses the preparation method of the piezoelectric ceramic material. Compared with the prior art, the advantages of the invention are as follows: replacement of doping in the PZT piezoelectric ceramic is conducted, and the preparation process which is suitable for the piezoelectric ceramic material is selected creatively, which leads the Curie point of the piezoelectric ceramic material to be greatly increased, the piezoelectric property and the dielectric property are excellent, under high temperature of 270 degrees C., the piezoelectric property and the dielectric property of the piezoelectric ceramic material is decreased very little, and the invention can be used for SMD piezoelectric ceramic buzzer.

Owner:NINGBO KEPO ELECTRONICS

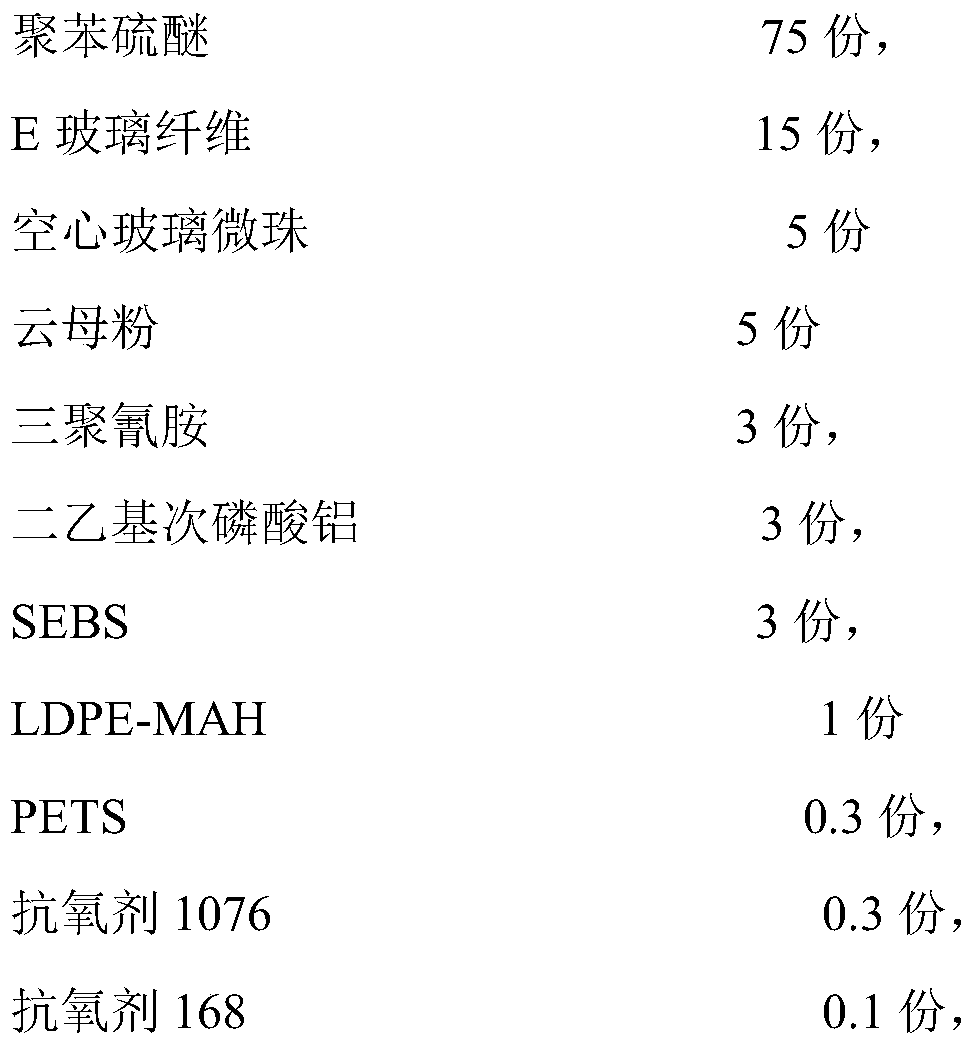

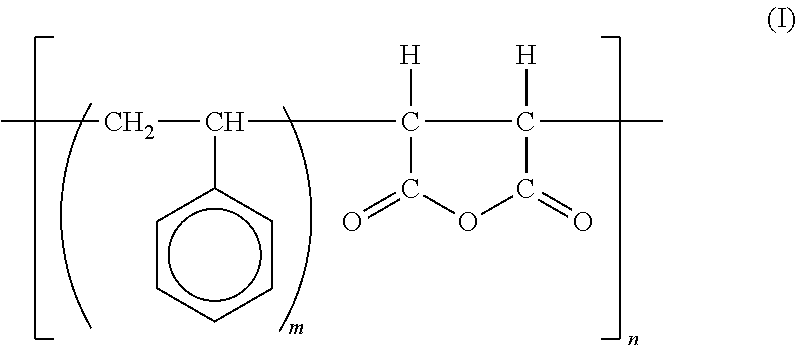

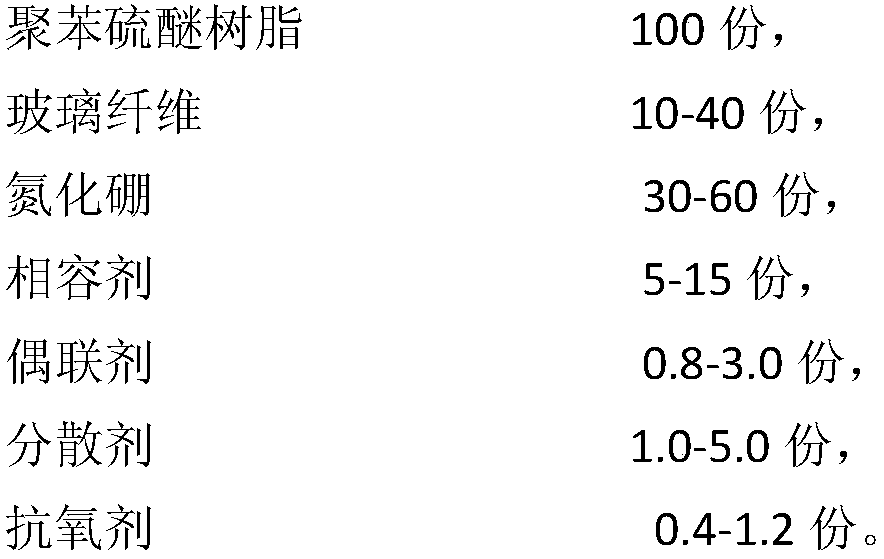

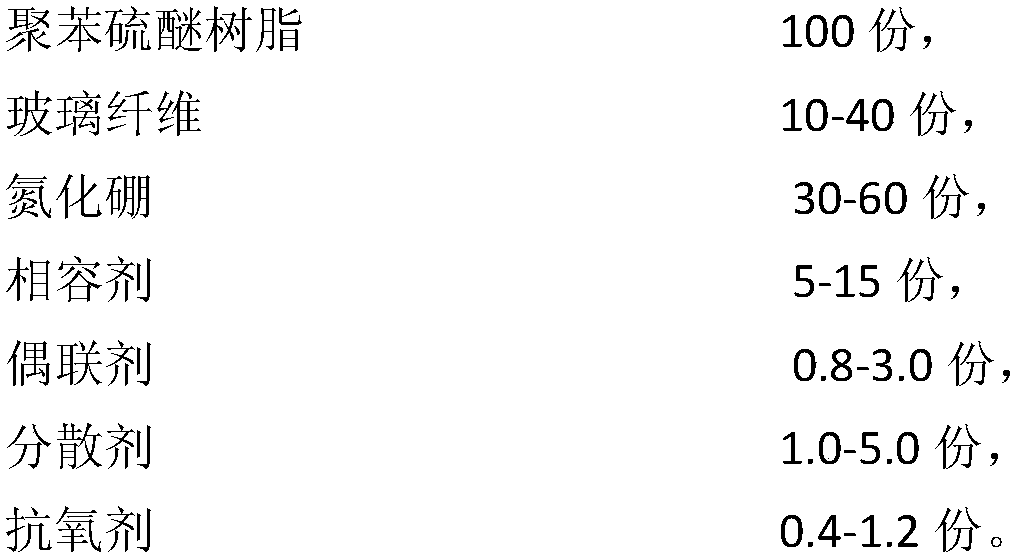

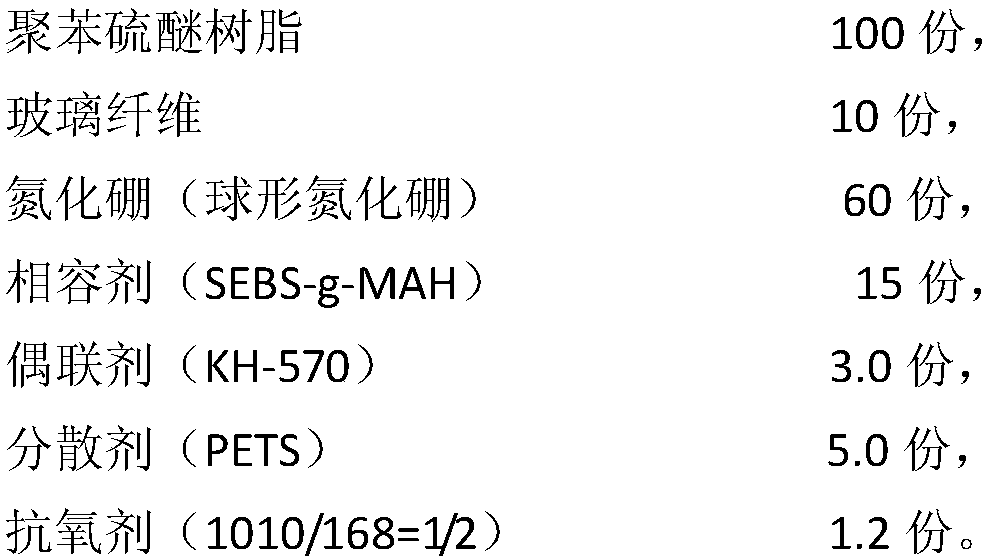

High-thermal-conductivity low-dielectric-loss polyphenylene sulfide composite and preparation method thereof

InactiveCN108165010AHigh thermal conductivityLow dielectric lossHeat-exchange elementsGlass fiberDielectric loss

The invention provides a high-thermal-conductivity low-dielectric-loss polyphenylene sulfide composite and a preparation method thereof. The composite comprises 100 parts of polyphenylene sulfide resin, 10 to 40 parts of glass fibers, 30 to 60 parts of boron nitride, 5 to 15 parts of a compatilizer, 0.8 to 3.0 parts of a coupling agent, 1.0 to 5.0 parts of a dispersant and 0.4 to 1.2 parts of an anti-oxidant. The preparation method comprises the following steps: mixing boron nitride with the coupling agent so as to obtain a first mixture, adding the dispersant into the first mixture and carrying out mixing so as to obtain a second mixture; and mixing the polyphenylene sulfide resin, the compatilizer and the anti-oxidant, adding the obtained mixture into a screw extruder from a main feed inlet, adding the second mixture into the screw extruder from a lateral feed inlet, adding the glass fibers into the screw extruder from a glass fiber feeding inlet, and carrying out extrusion granulation via the screw extruder so as to obtain the polyphenylene sulfide composite in the form of granules. The polyphenylene sulfide composite provided by the invention has the advantages of high heat conduction coefficient and low dielectric loss and is applicable to the field of electrocommunication.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

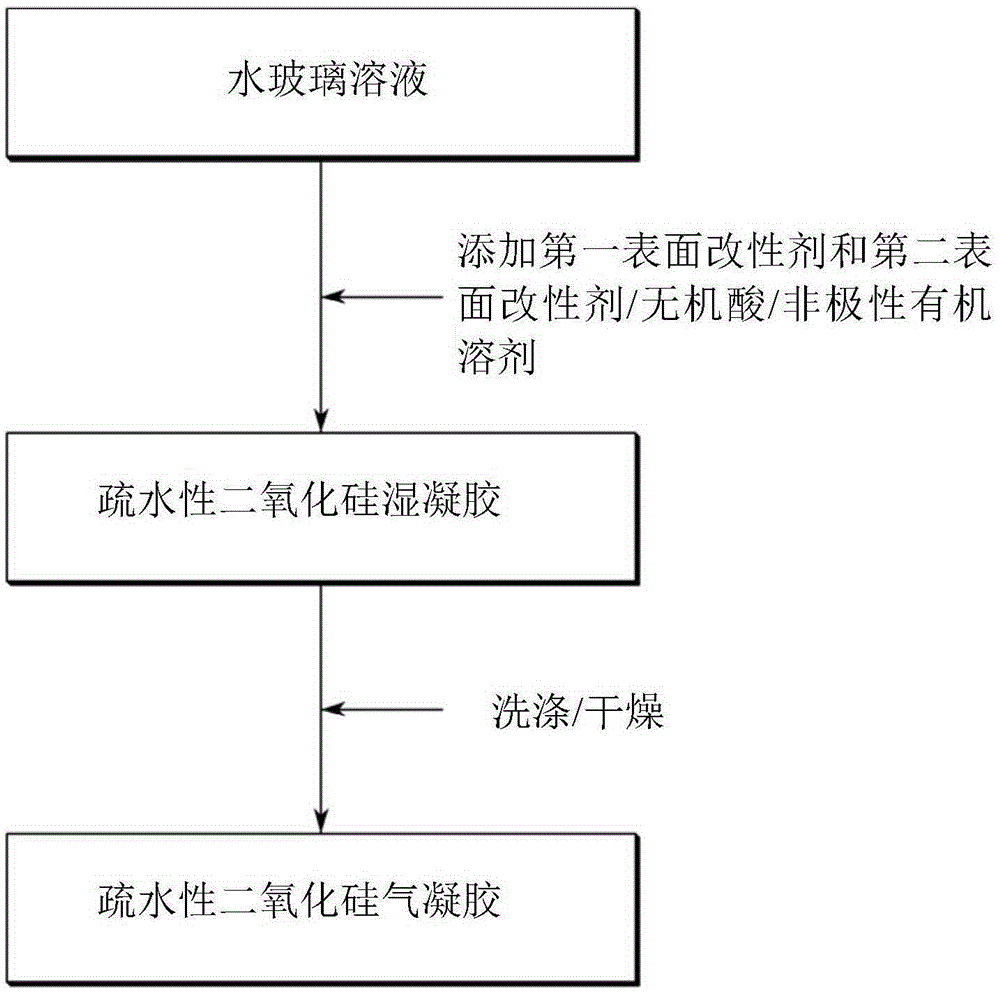

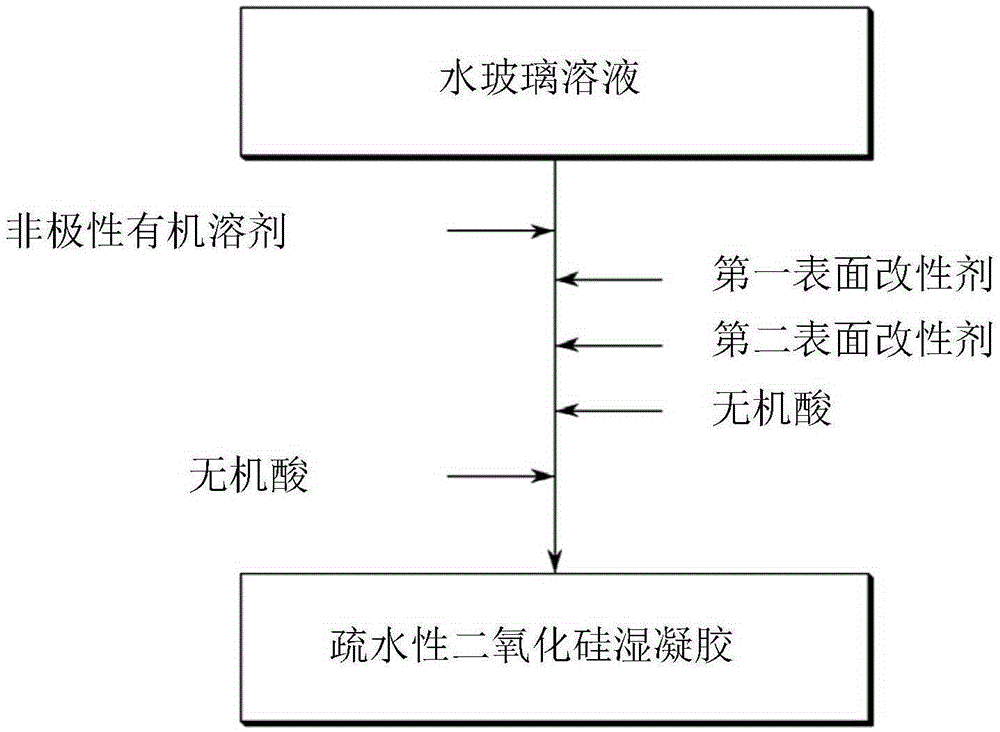

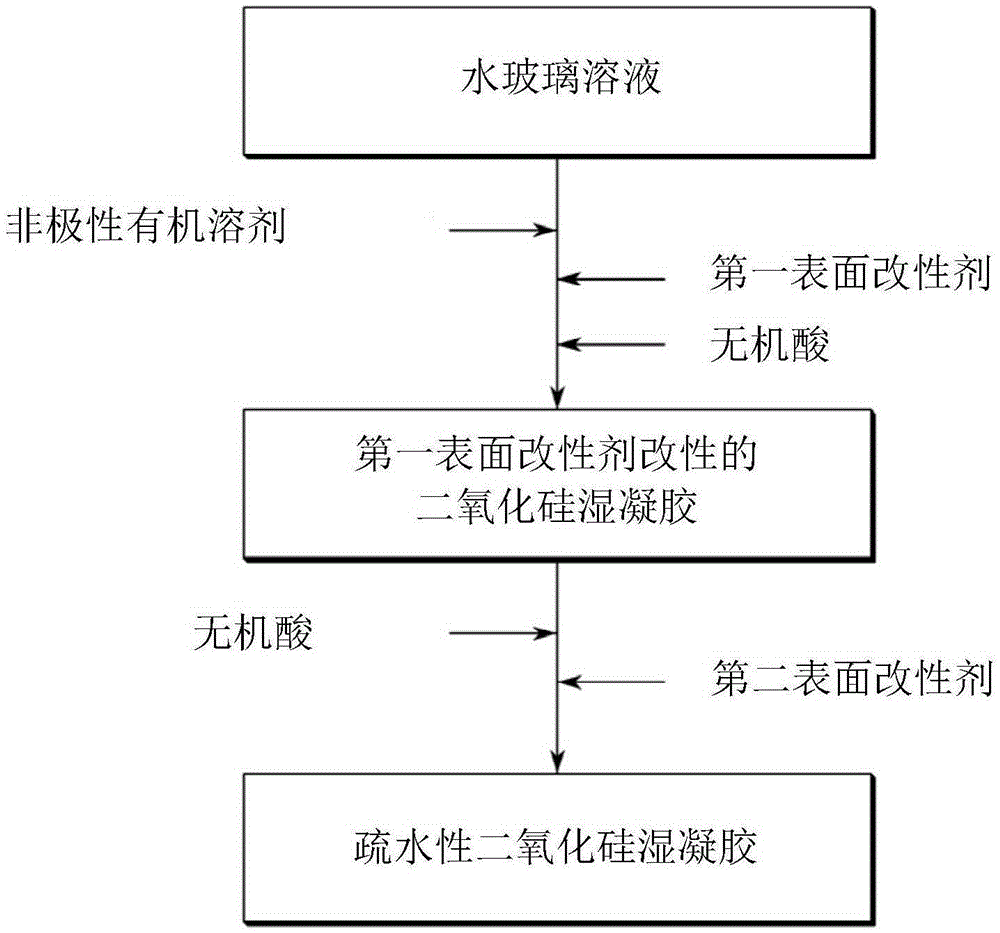

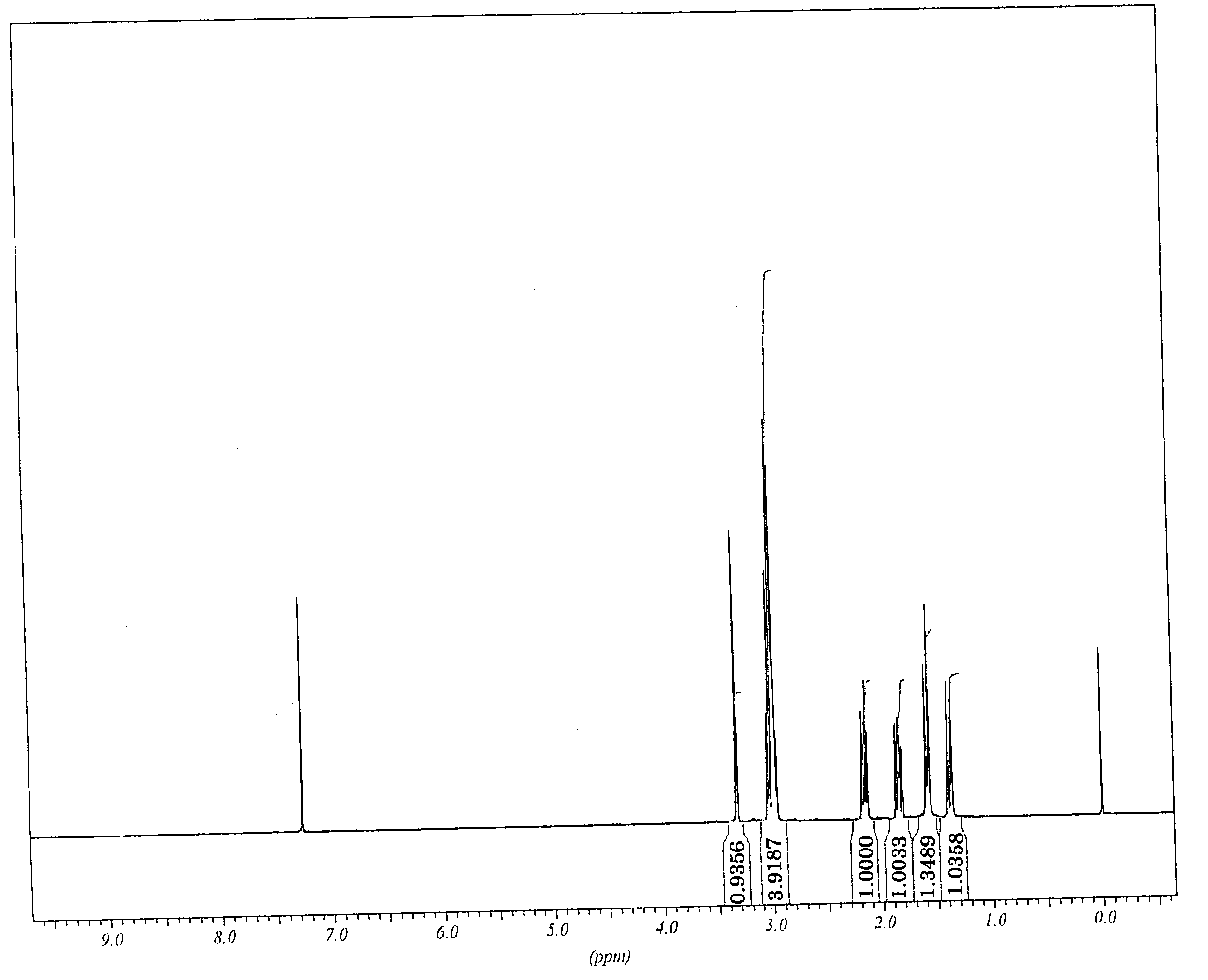

Method for preparing hydrophobic silica aerogel

ActiveCN105377759ALow modification effectImprove hydrophobicitySilicaAerogel preparationPolymer scienceCombined use

The present invention provides: a method for preparing a hydrophobic silica aerogel by using a first surface modifier and a second surface modifier in combination; and a hydrophobic silica aerogel prepared by using the same. A hydrophobic silica aerogel having excellent physical properties and pore properties and high hydrophobicity can be effectively prepared by the preparation method according to the present invention.

Owner:LG CHEM LTD

Positive-type radiation-sensitive composition, cured film, interlayer insulating film, method of forming interlayer insulating film, display device, and siloxane polymer for forming interlayer insulating film

ActiveUS20110008730A1High radiation sensitivityLow dielectricityDiazo compound compositionsPhotomechanical exposure apparatusChemistryQuinone

Owner:JSR CORPORATIOON

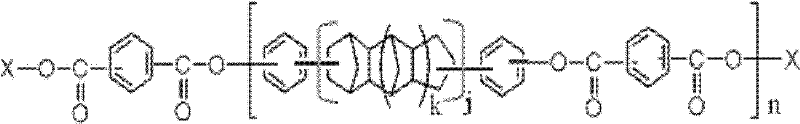

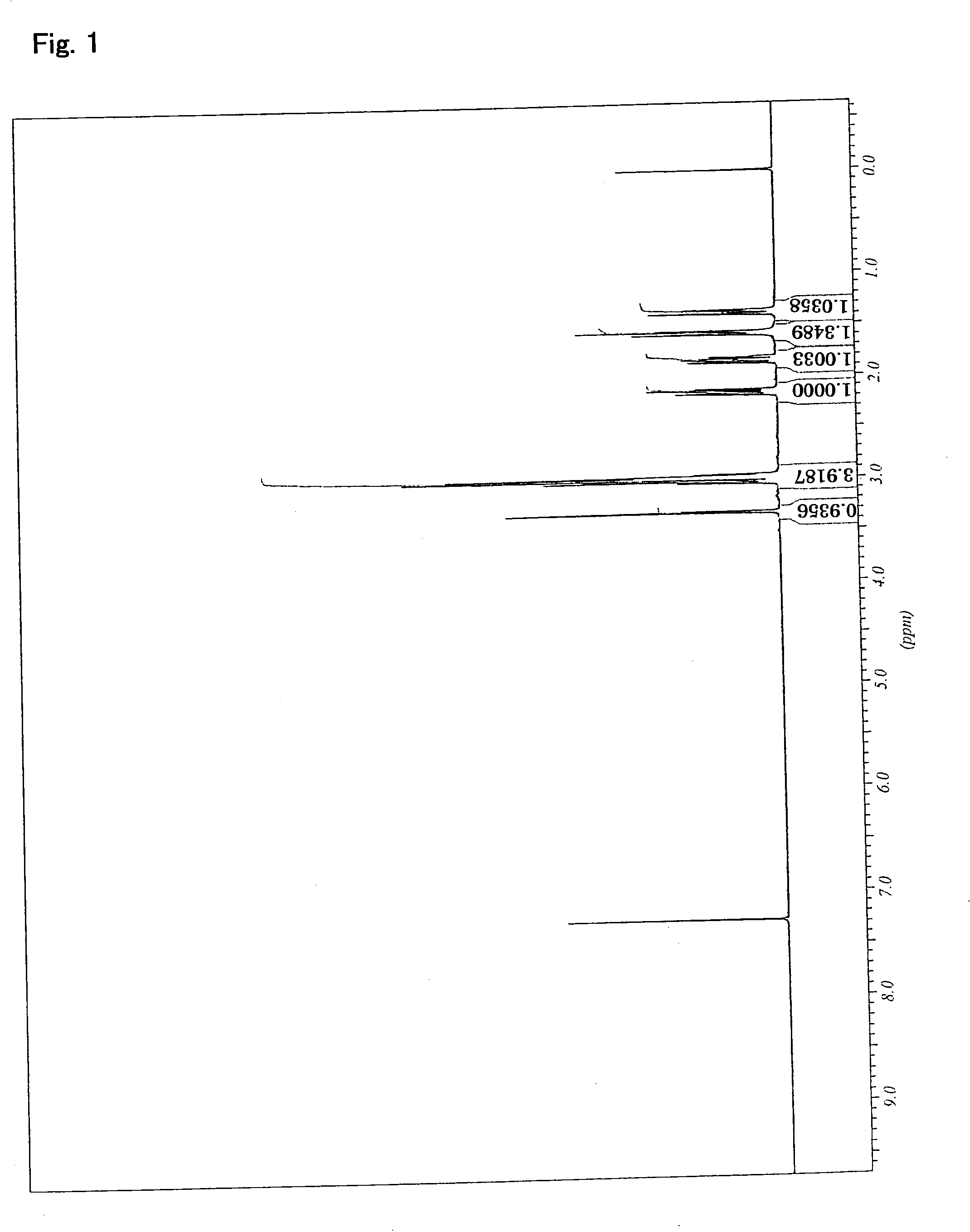

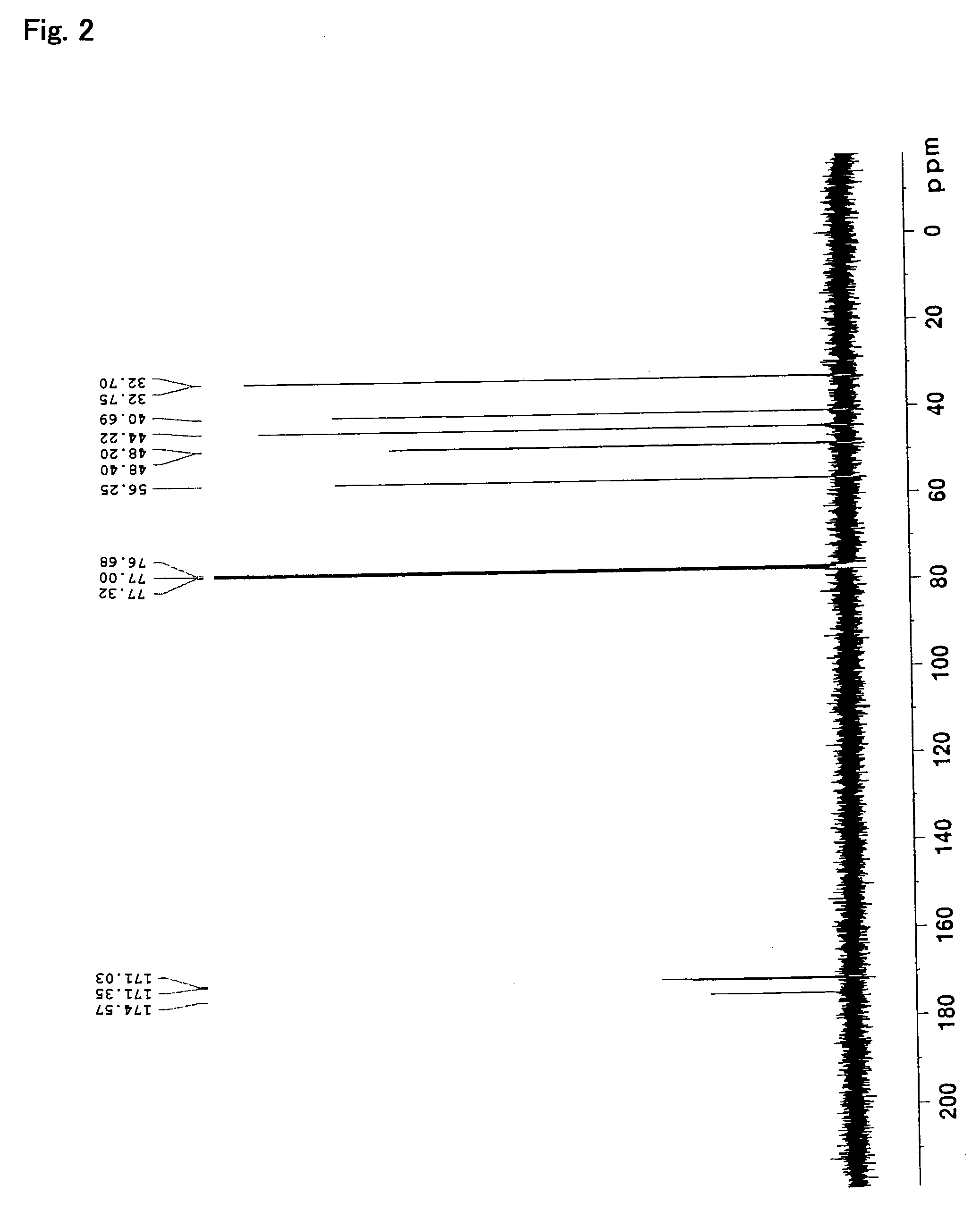

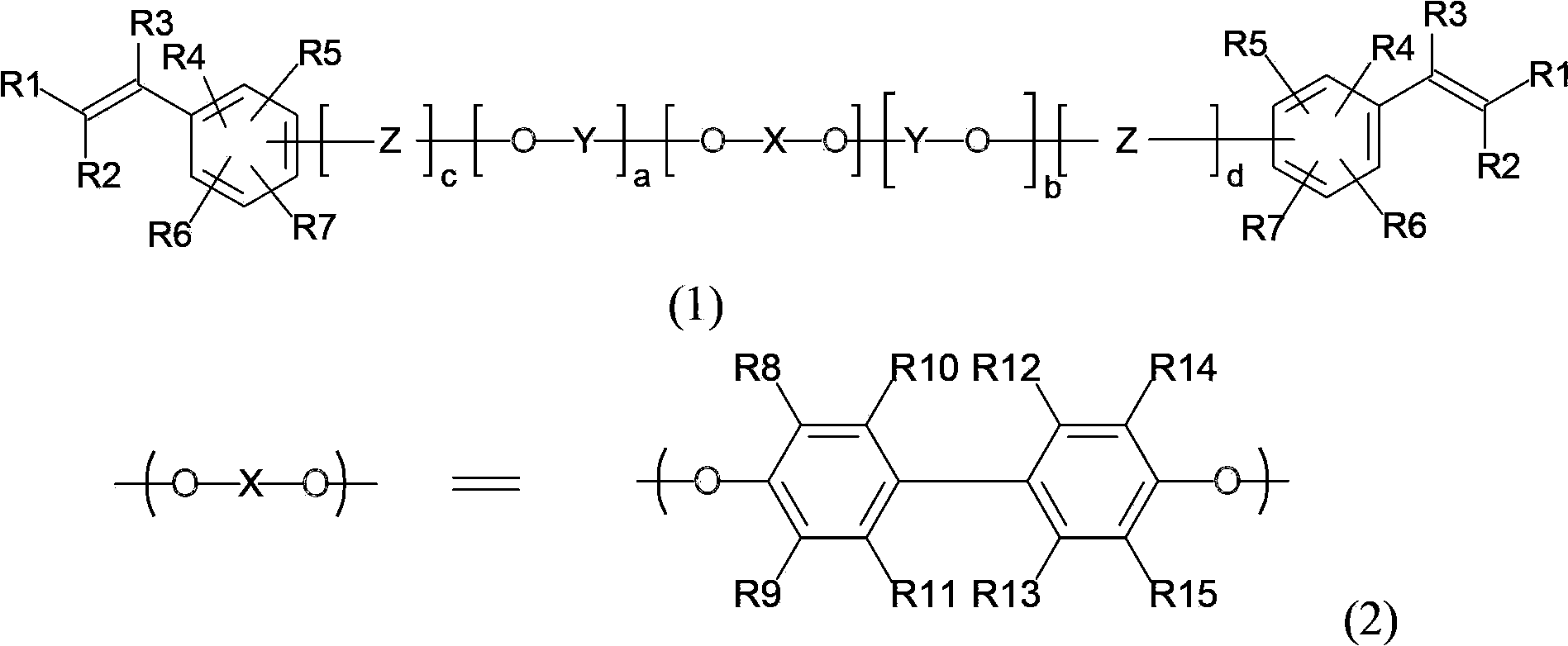

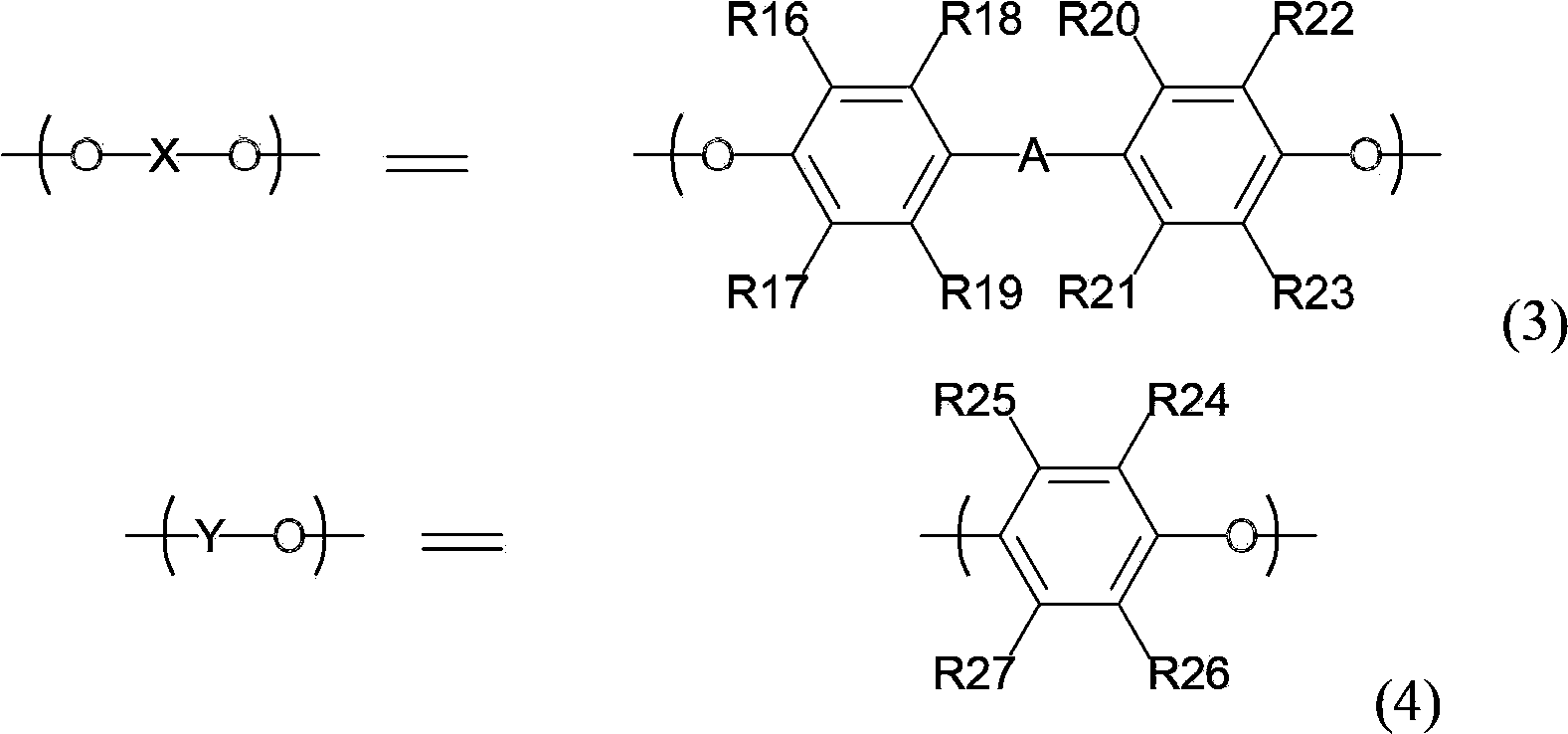

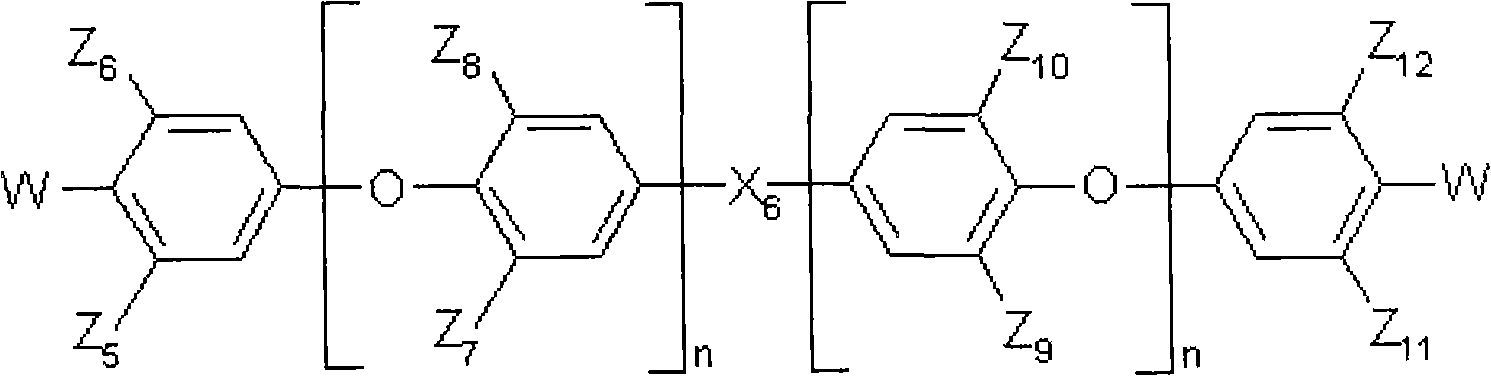

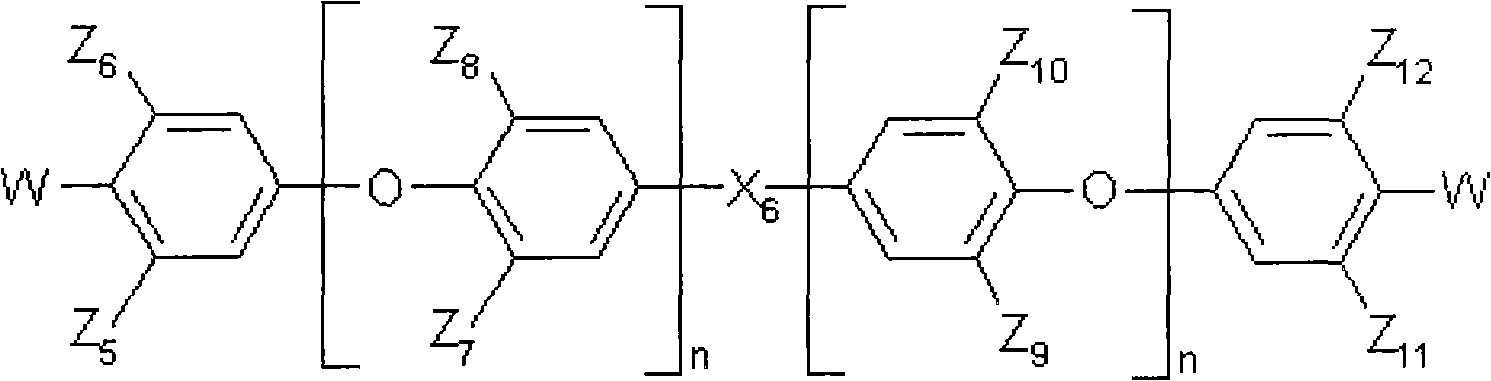

Tetracarboxylic acid compound, polyimide thereof, and production method thereof

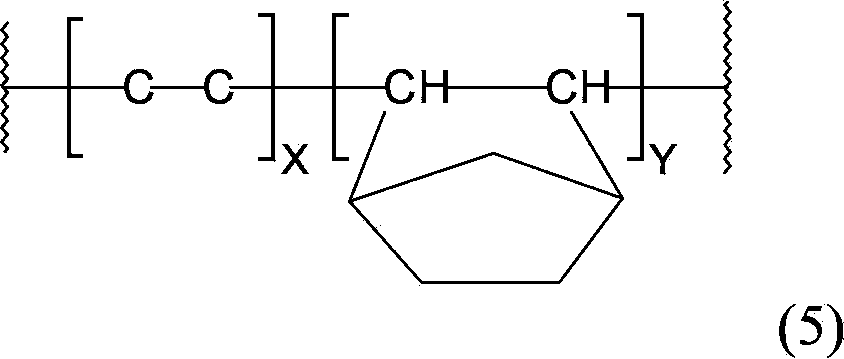

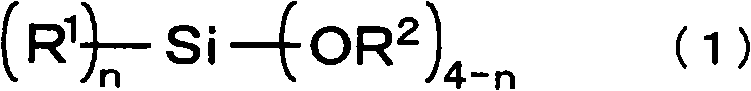

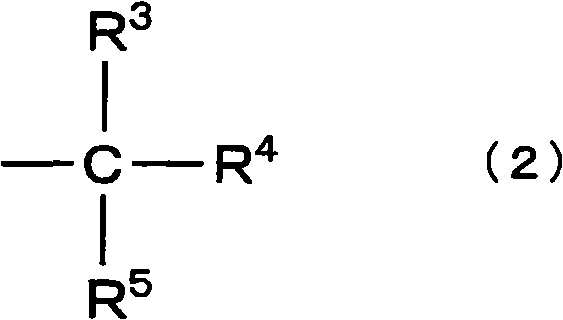

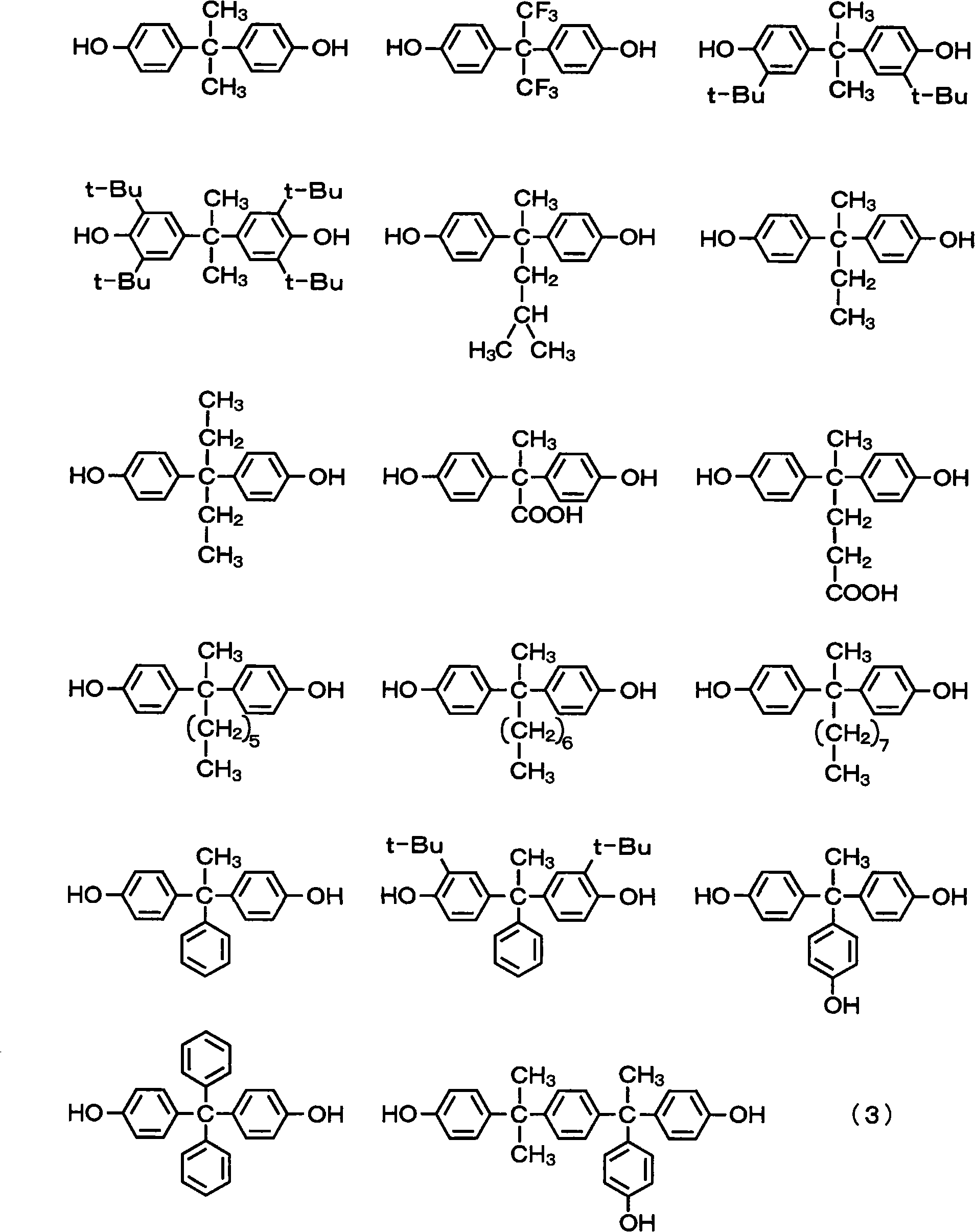

InactiveUS20090182114A1Maintain good propertiesHigh transparencyOrganic chemistrySynthetic resin layered productsPolyesterThermal dilatation

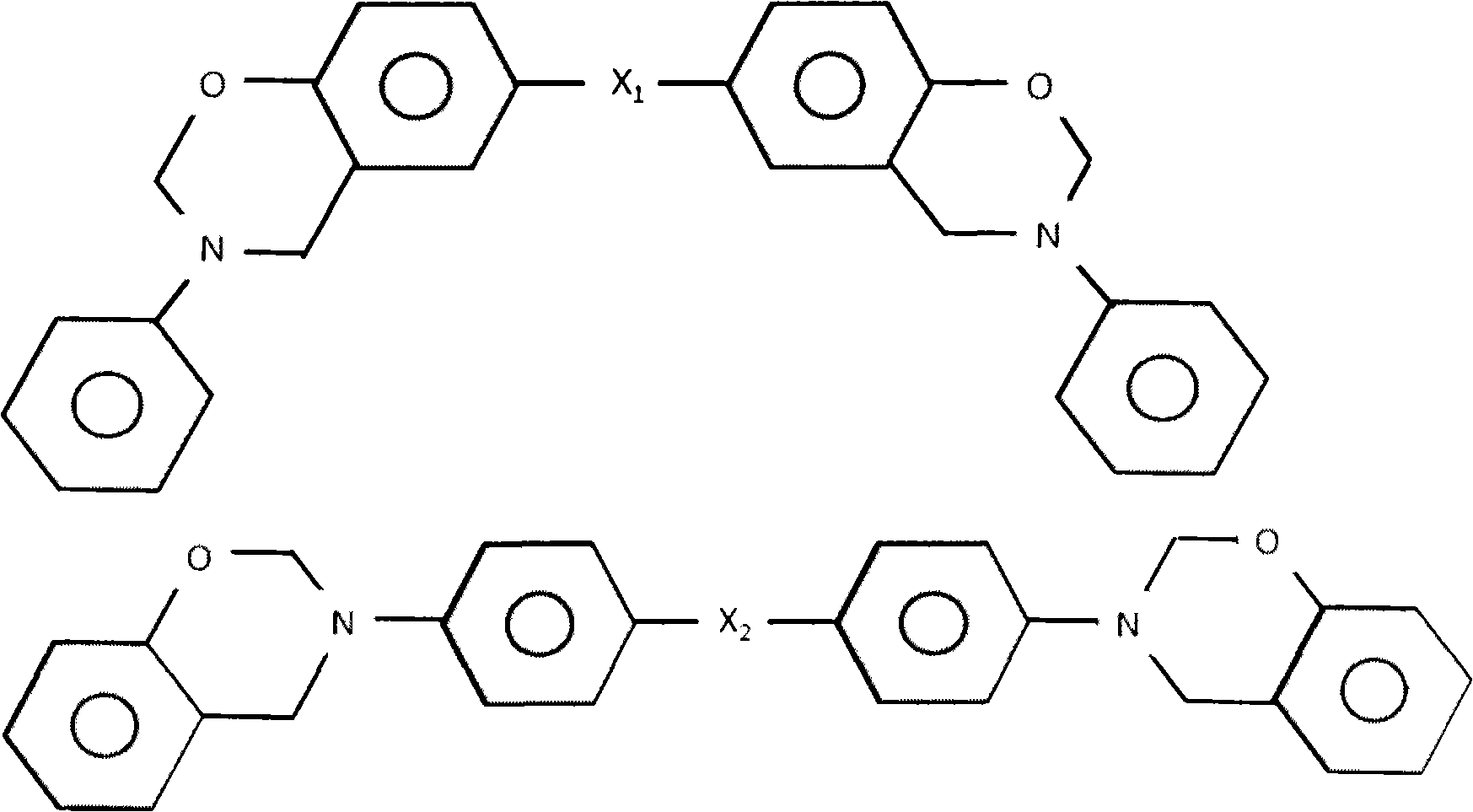

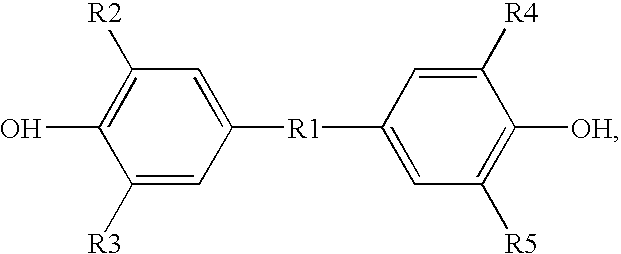

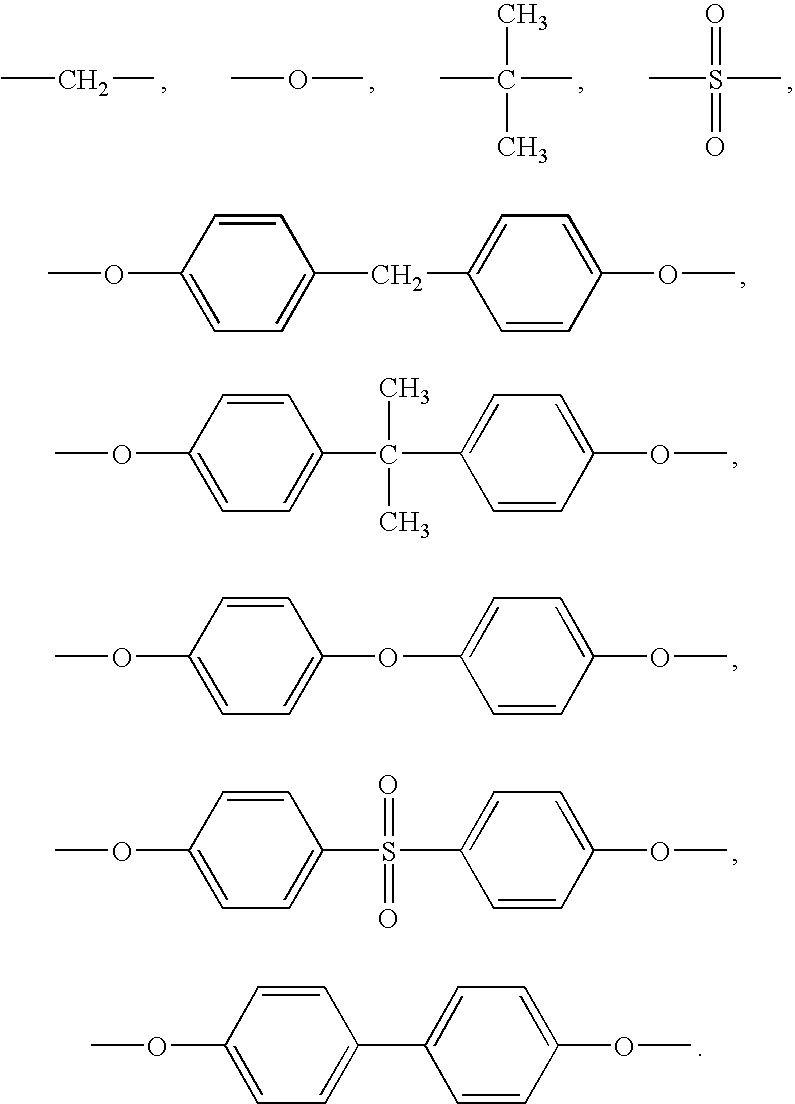

Disclosed is a novel tetracarboxylic acid compound having excellent characteristics such as high transparency, low dielectric property, low water absorption, low thermal expansion, solvent solubility and etching characteristics, while exhibiting high heat resistance at the same time. This tetracarboxylic acid compound is useful as a raw material monomer for producing a polyesterimide or a polyamideimide. Specifically disclosed is a tetracarboxylic acid compound represented by the general formula (1) or (2) below.In the formulae, A represents a divalent group; X1, X2 and X3 respectively represent a hydrogen atom or the like; R1, R2, R3 and R4 respectively represent a carboxyl group or an acid anhydride group; n represents 1 or 2; and ring B represents a cyclic group.

Owner:MITSUBISHI CHEM CORP

Low dielectric resin composite and copper foil base plate applying composite as well as printed circuit board

ActiveCN103509329AHigh mechanical strengthLow dielectric propertiesMaterial nanotechnologyPrinted circuit aspectsElectricityHeat resistance

The invention provides a resin composite which comprises the following components in parts by weight: (A) 100 parts of terminal styryl polyphenylene oxide resin, (B) 5-75 parts of olefin copolymers and (C) 1-150 parts of polyphenyl ether functional group containing cyanate ester resin. The resin composite provided by the invention can achieve the characteristics of low dielectric constant, low dielectric loss and high heat resistance by containing specific components and proportions; the resin composite provided by the invention can be prepared into a semi-solidified colloidal film or a resin film, thereby achieving the purpose of being applied to a copper foil base plate and a printed circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Positive type radiation-sensitive composition, cured film, interlayer insulating film, method for forming method interlayer insulating film, display element and siloxane polymer

ActiveCN101937172AExcellent mechanical propertiesExcellent electrical propertiesSemiconductor/solid-state device detailsSolid-state devicesSilane compoundsQuinone

The present invention relates to a positive-type radiation-sensitive composition, a cured film, an interlayer insulating film, a method for forming the interlayer insulating film, a display element and a siloxane polymer. The invention provides a polysiloxane series positive-type radiation-sensitive composition having high compatibility with a quinone diazide compound and capable of forming the interlayer insulating film having excellent corrosion inhibitor stripping liquid resistance in an ITO film etching step. The composition contains (A) a siloxane polymer, and (B) a quinone diazide compound, in which the content of aryl groups relative to Si atoms in the siloxane polymer (A) is greater than 60% by mole and no greater than 95% by mole. The (A) siloxane polymer is a hydrolytic condensation containing a hydrolytic silane compound represented by formula (1).

Owner:JSR CORPORATIOON

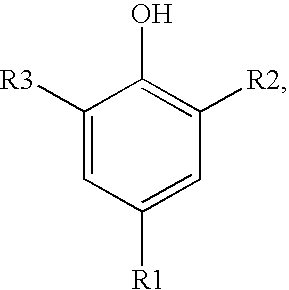

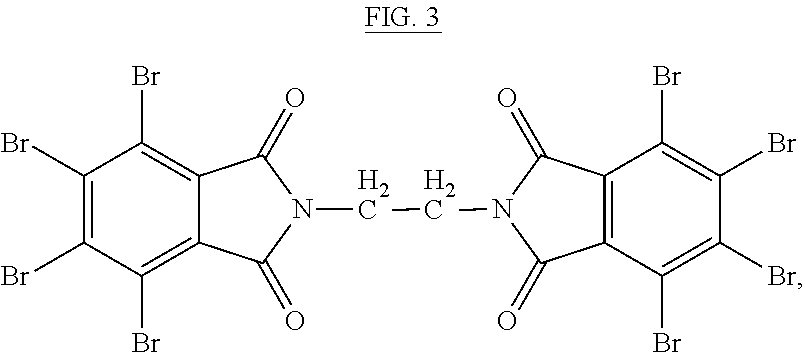

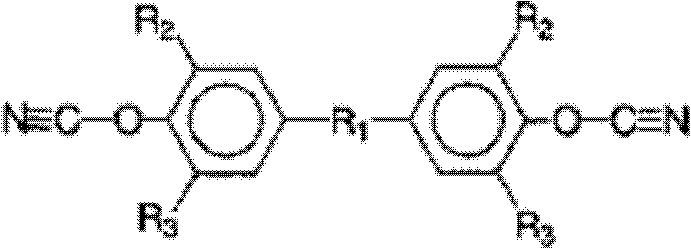

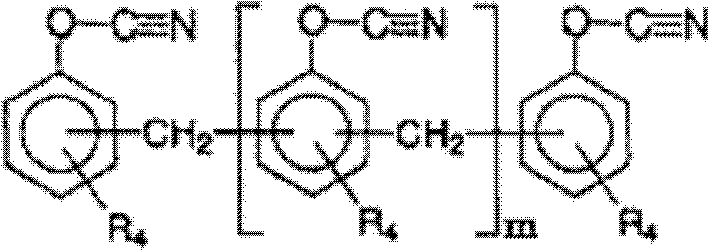

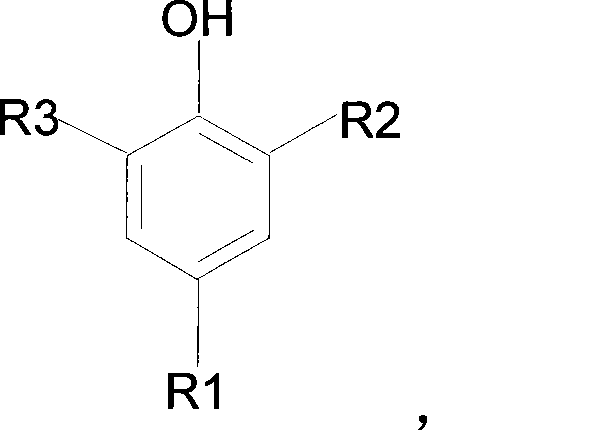

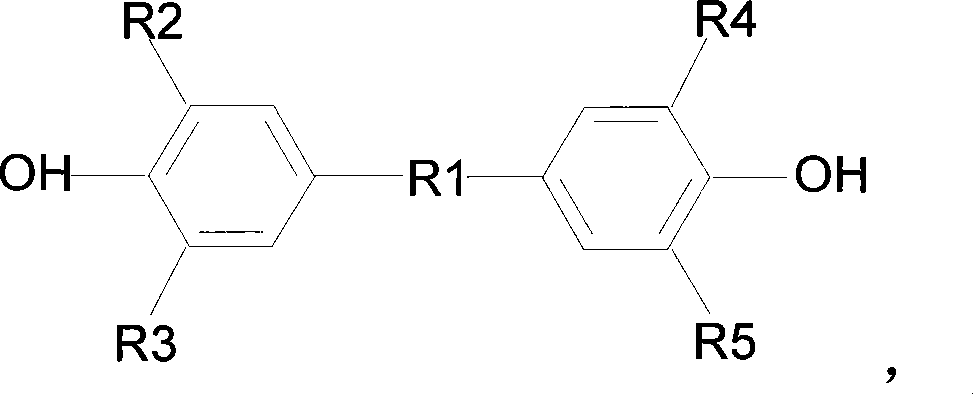

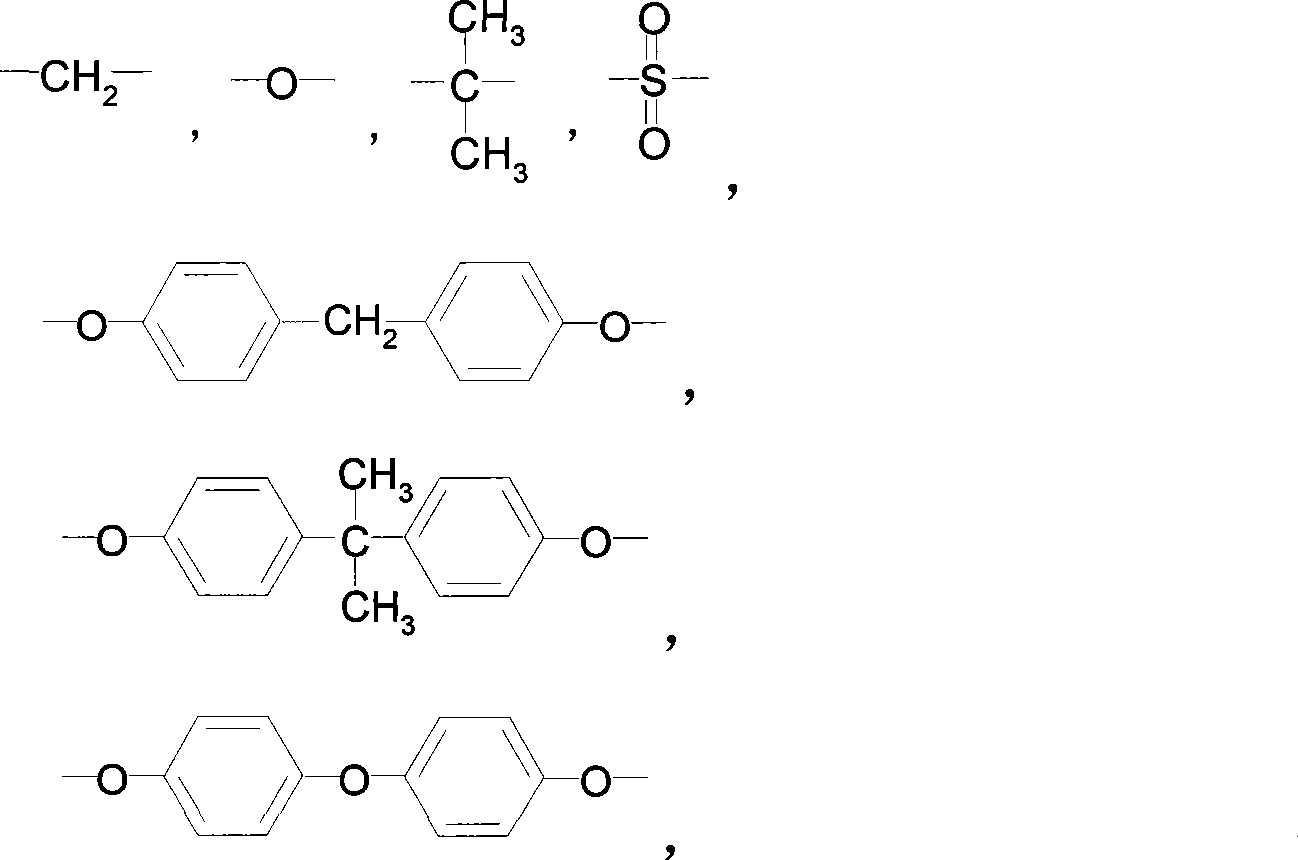

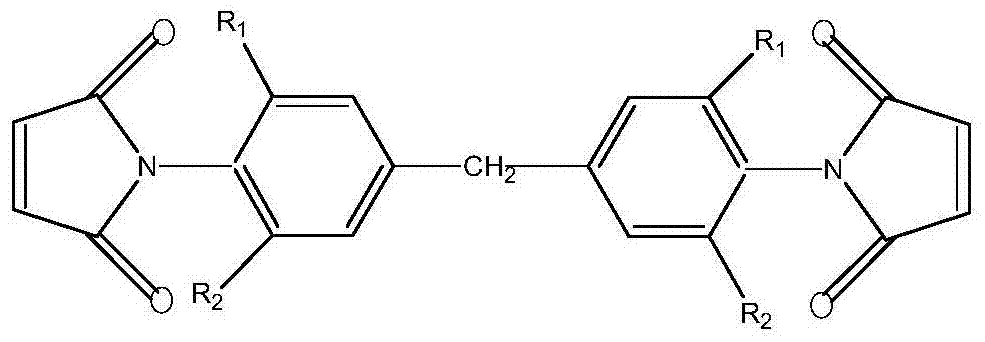

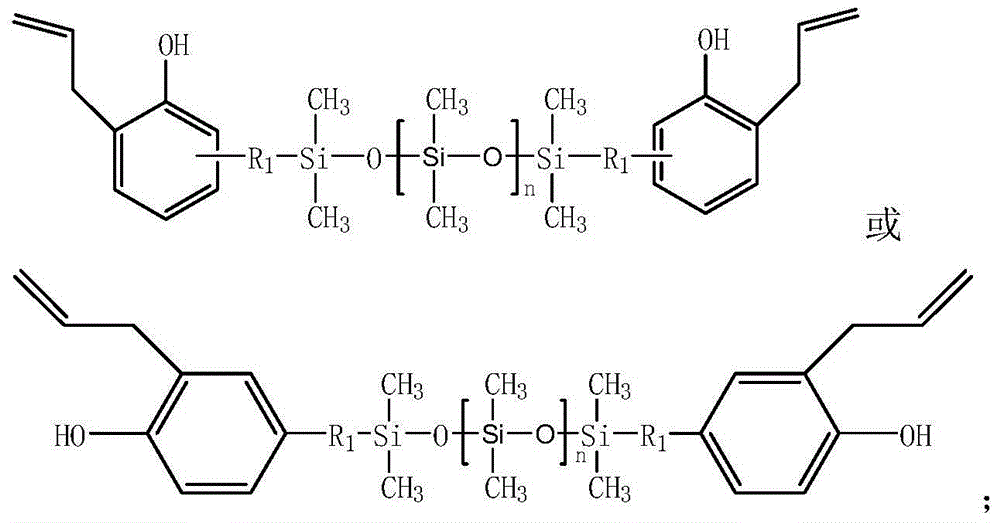

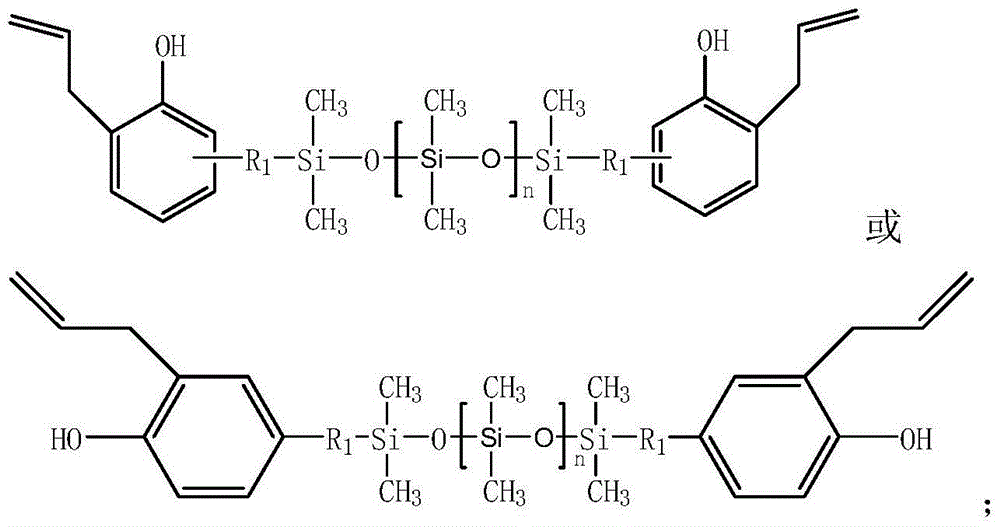

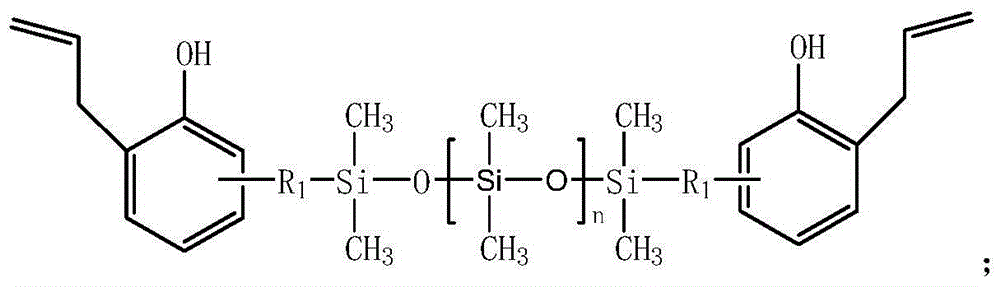

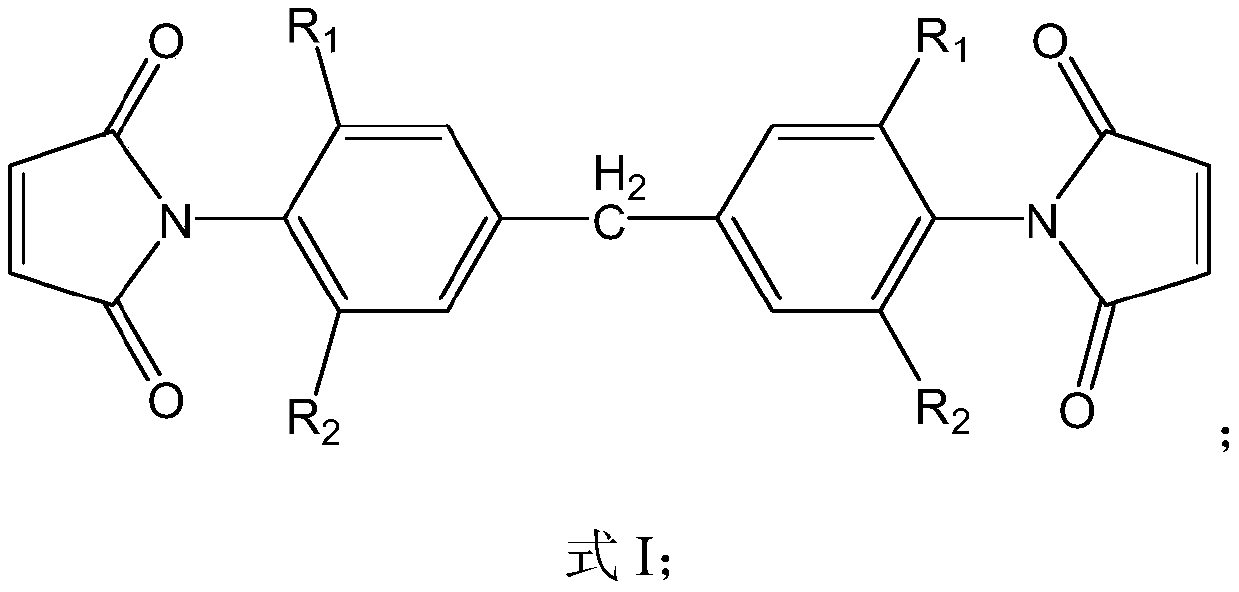

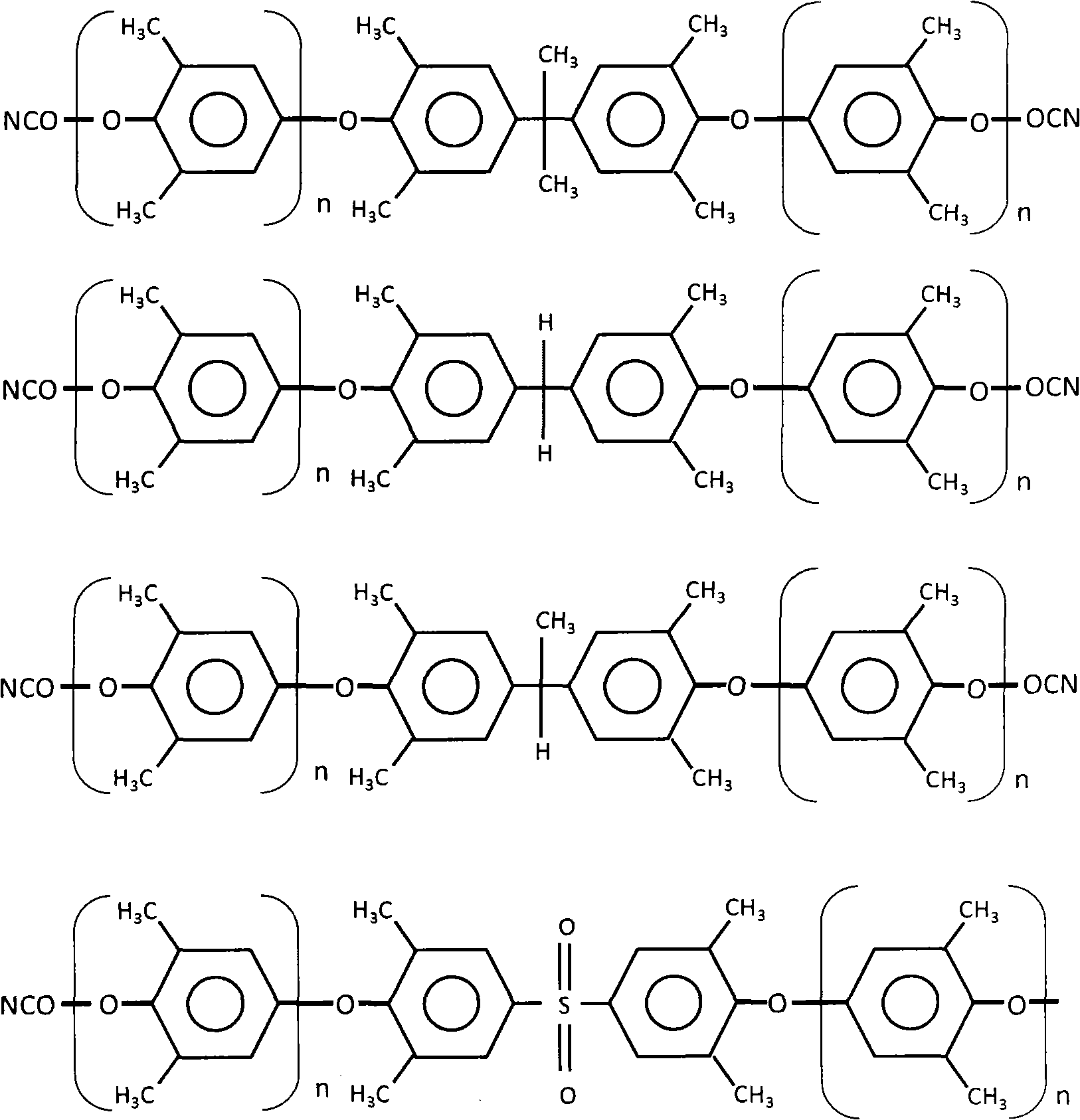

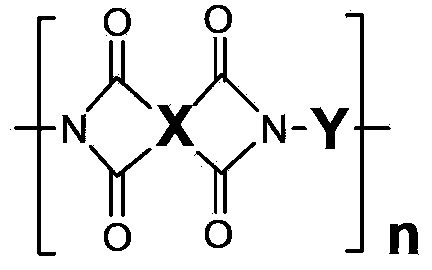

Bismaleamic acid, bismaleimide and cured product thereof

InactiveCN101602704ALow dielectric propertiesImprove solubilityOrganic compound preparationCarboxylic acid amides preparationSolubilityOligomer

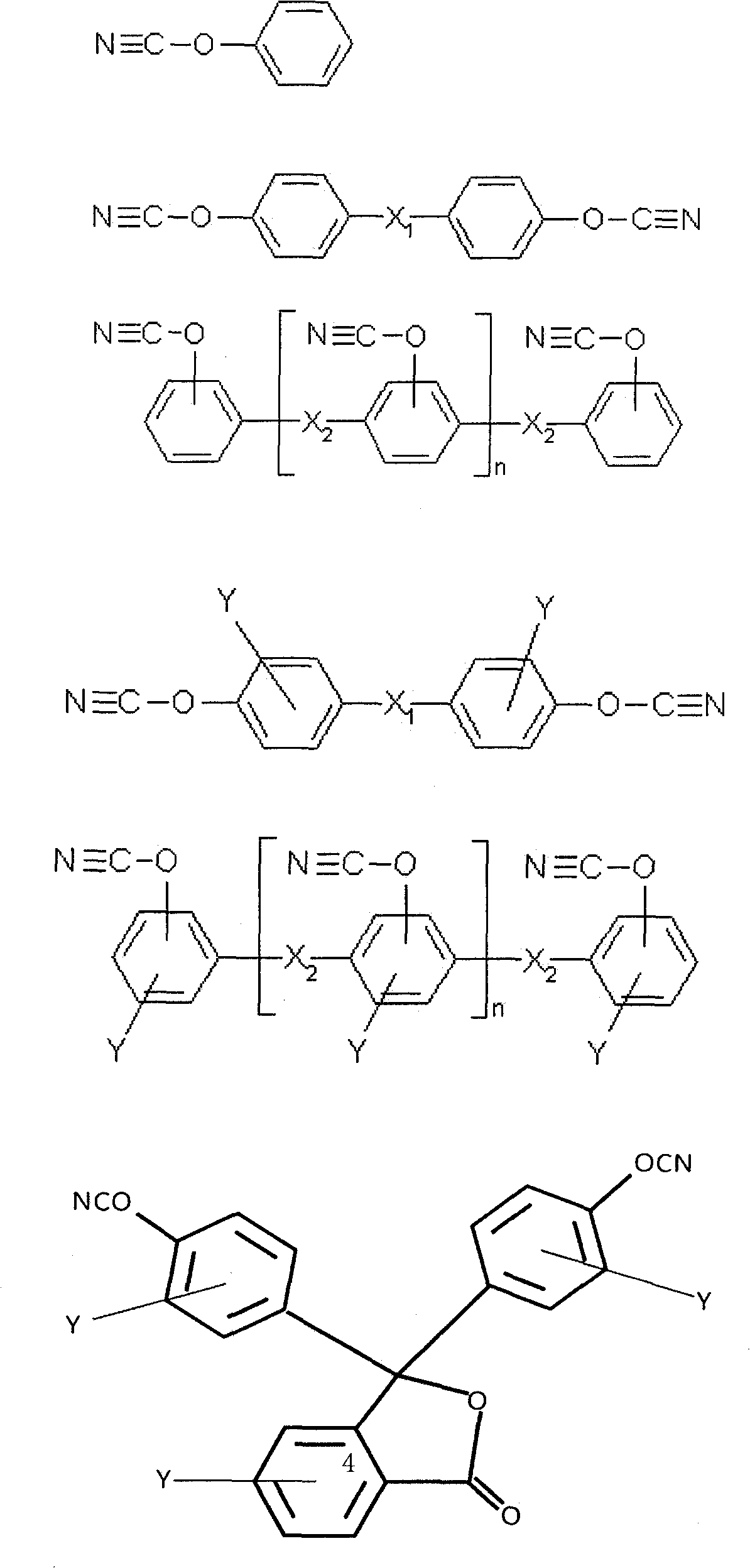

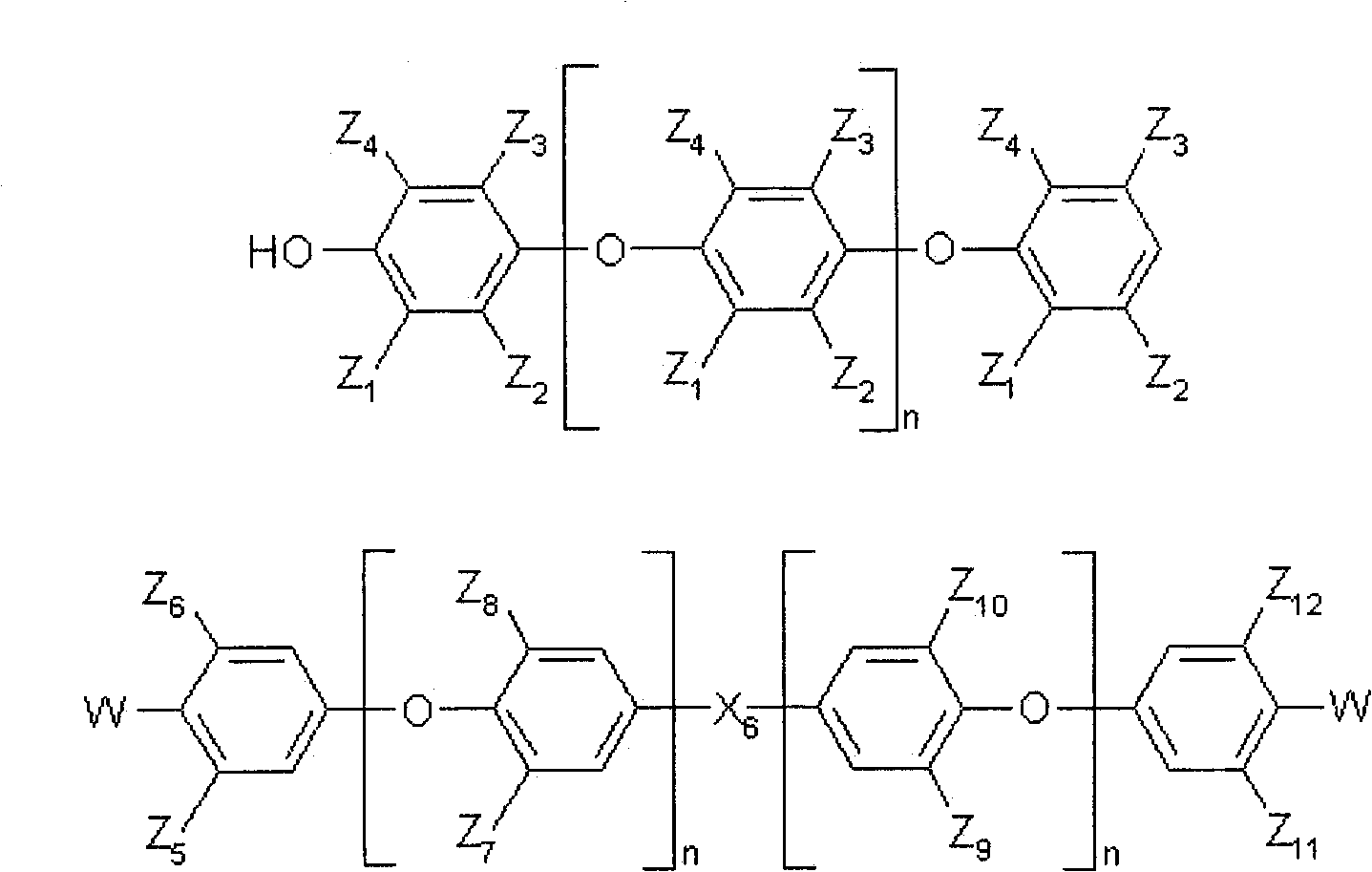

The invention provides bismaleamic acid, bismaleimide and cured product thereof. Particularly, the invention provides a bismaleimide having high heat resistance, a low dielectric constant, a low water absorption coefficient and excellent solvent solubility, a bismaleamic acid capable of generating the above bismaleimide, a cured resin composition containing the above bismaleimide and a cured product obtained by curing the above resin composition. Bismaleamic acid, bismaleimide, the cured resin composition containing the bismaleimide and the cured product obtained by curing the resin composition are obtained by reaction between diamine of bifunctional phenylene ether oligomer and maleic anhydride, wherein the diamine of bifunctional phenylene ether oligomer is obtained by introducing aromatic amino into two terminals of the bifunctional phenylene ether oligomer.

Owner:MITSUBISHI GAS CHEM CO INC

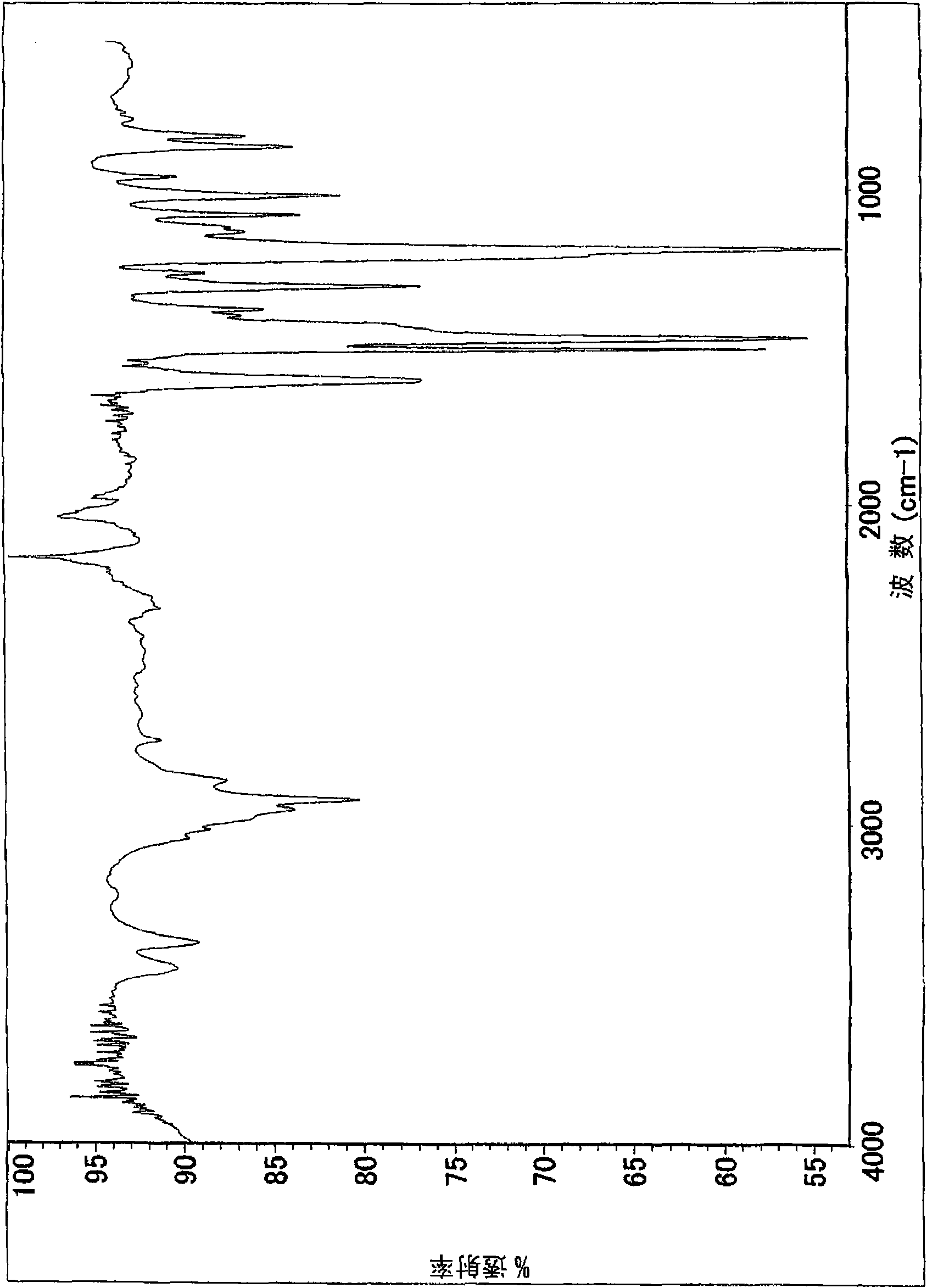

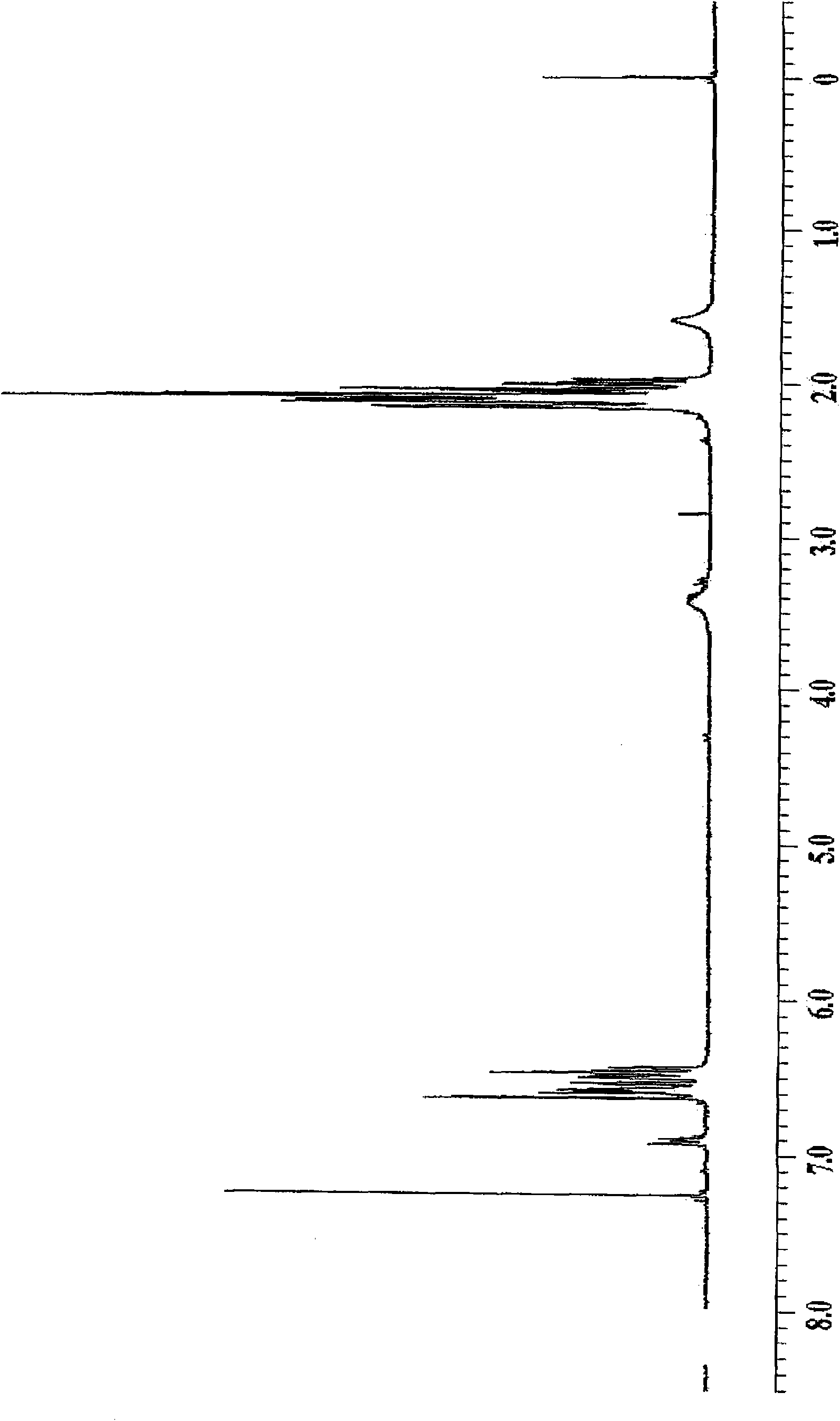

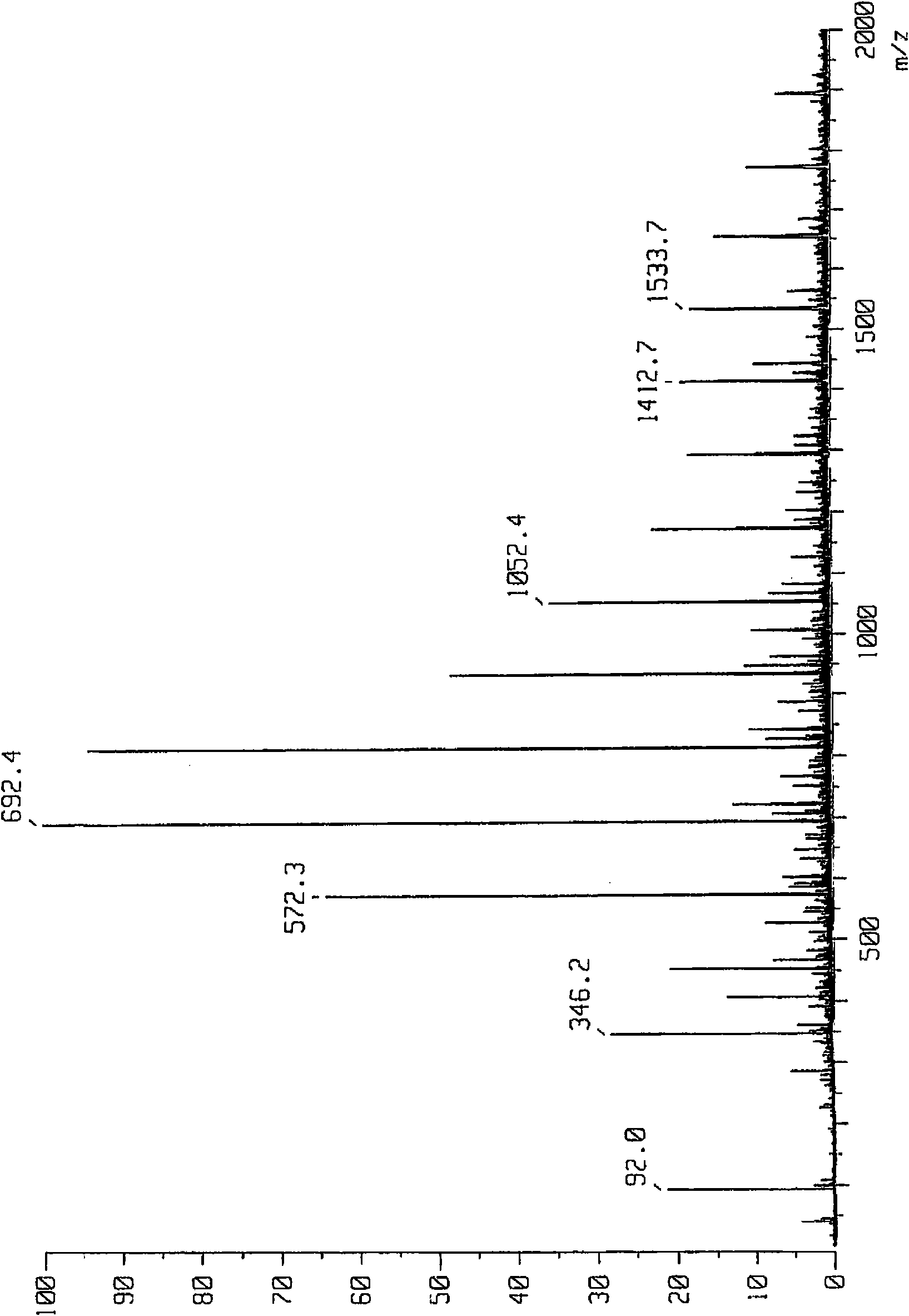

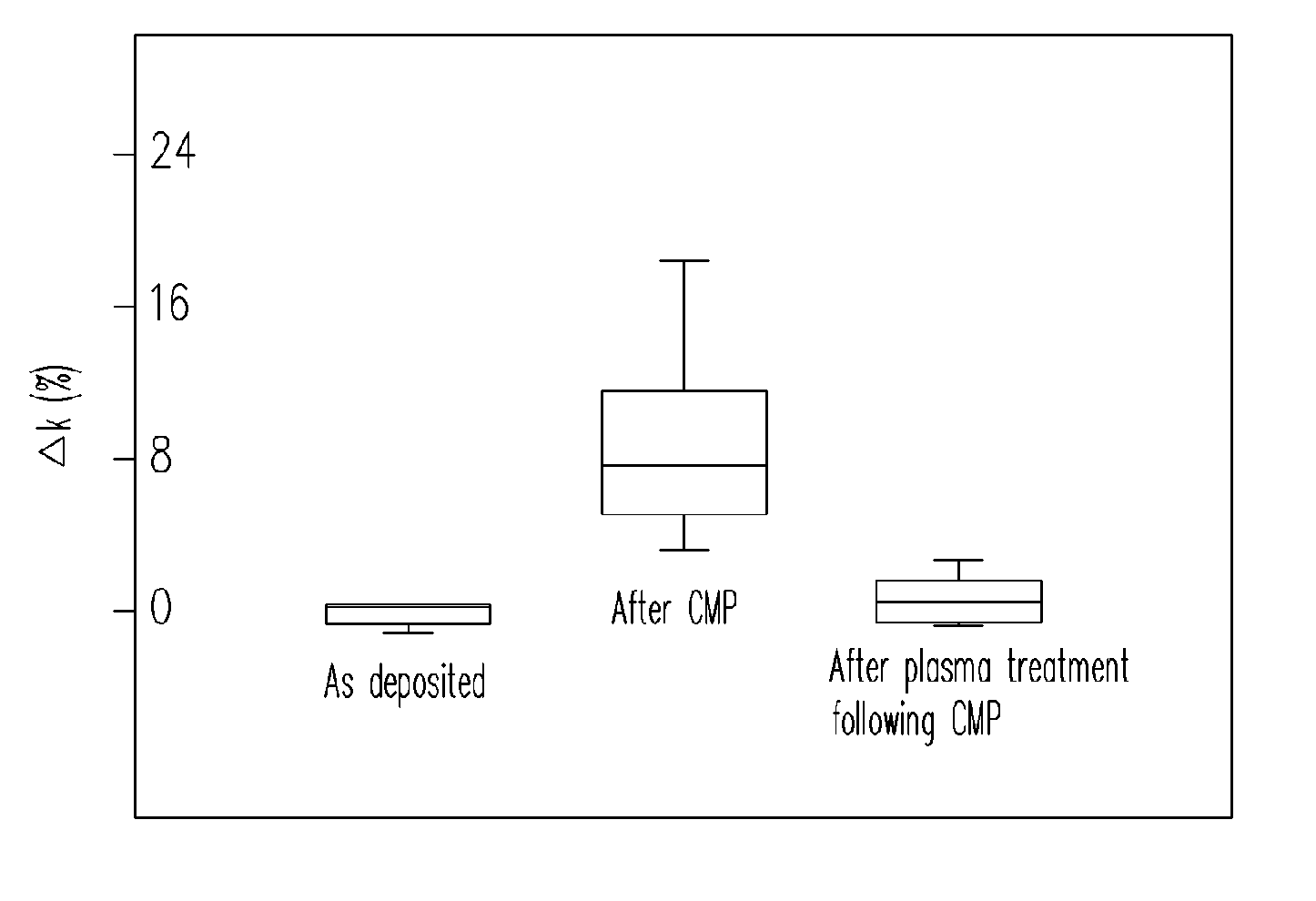

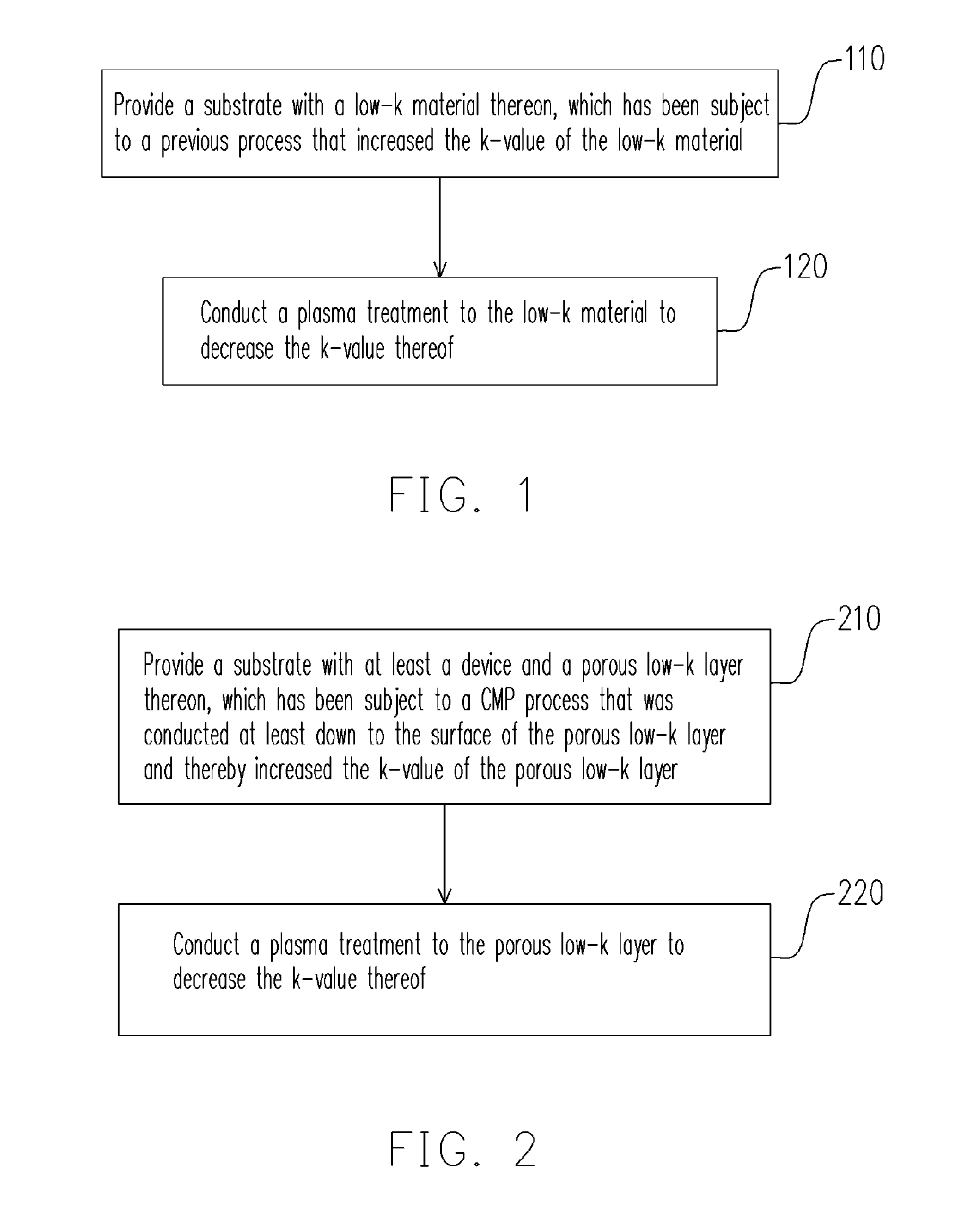

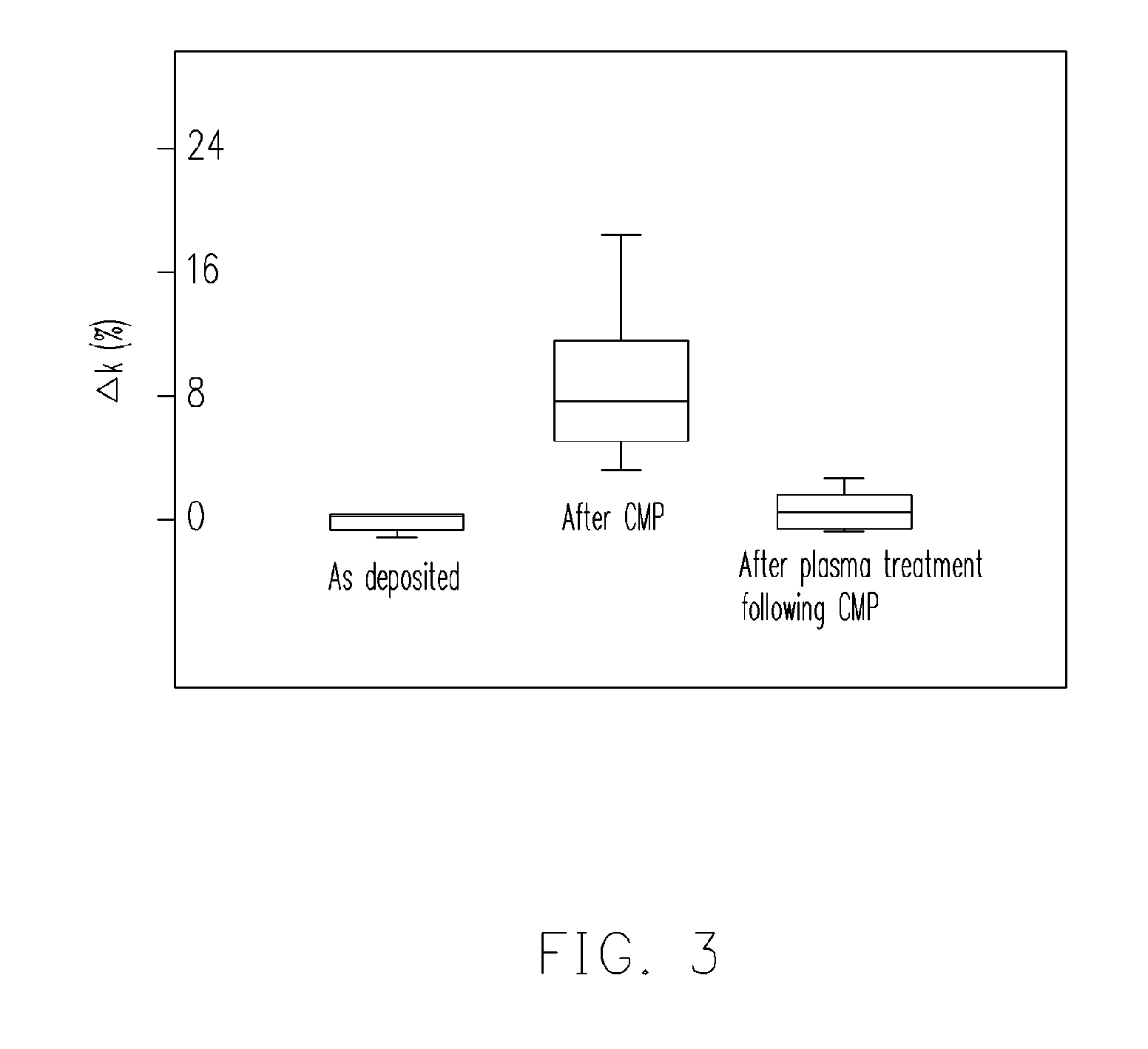

Method of restoring low-k material or porous low-k layer

InactiveUS20070077751A1Lower the k-value of the low-k materialLower the k-value of the porous low-k layerSemiconductor/solid-state device manufacturingPlasma treatmentComposite material

A method of restoring a low-k material is described, applied to a substrate with a low-k material thereon, wherein the substrate has been subject to a previous process that raised the k-value of the low-k material. The method includes performing a plasma treatment to the low-k material to decrease the k-value thereof.

Owner:UNITED MICROELECTRONICS CORP

Epoxy resin composition and low dielectric constant insulating material employing same

ActiveCN103131130ALow dielectric propertiesLow heat resistanceSynthetic resin layered productsCircuit susbtrate materialsCopper foilStyrene maleic anhydride

The invention provides an epoxy resin composition, comprising (A) 100 parts by weight of the epoxy resin; (B) 20-100 parts by weight of a cyanate ester resin containing a polyphenylene oxide structure; (C) 10-50 parts by weight of a styrene-maleic anhydride (SMA) copolymer; (D) 5-50 parts by weight of a maleimide resins, and optionally at least one of the following components of (E) an inorganic filler, (F) a catalyst, (G) a phenolic resin, (H) a flame retardant and (I) an adhesion agent. The epoxy resin composition contains specific components and proportions to achieve low dielectric constant, low-dielectric loss, high glass-transition temperature and no halogen; the printed circuit board can be made into a half-cured film or a resin film, and further the object of applying the epoxy resin composition to copper foil substrates and printed circuit boards can be reached.

Owner:ELITE MATERIAL

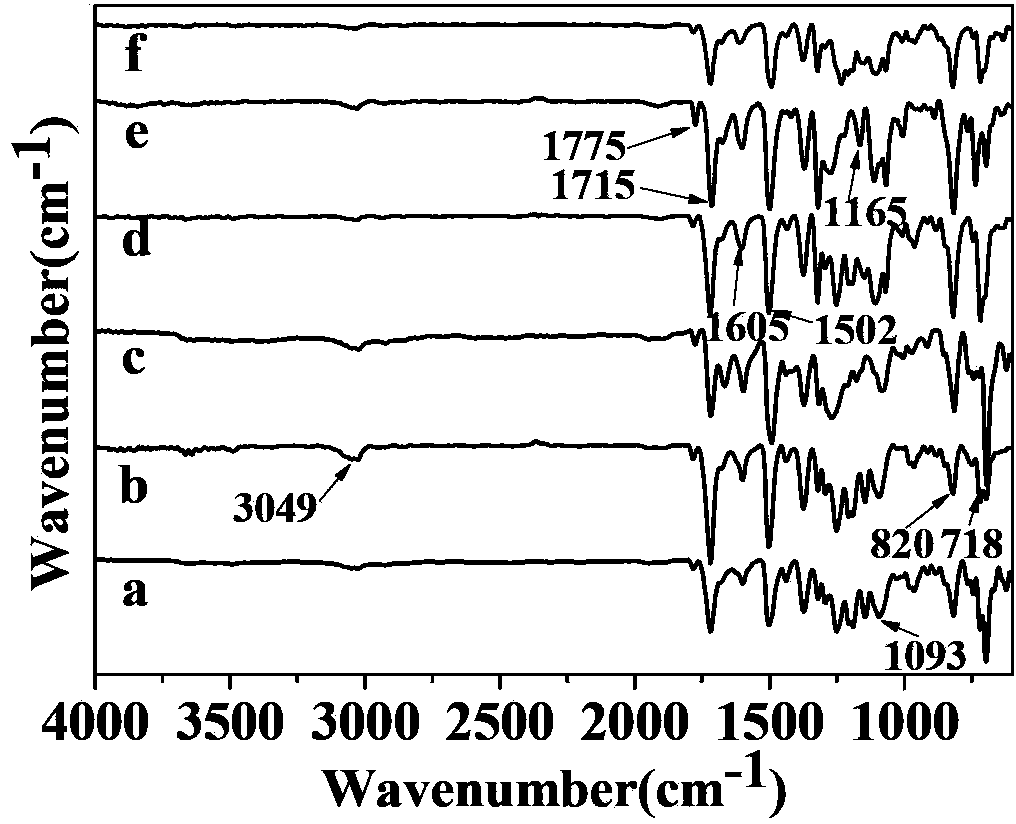

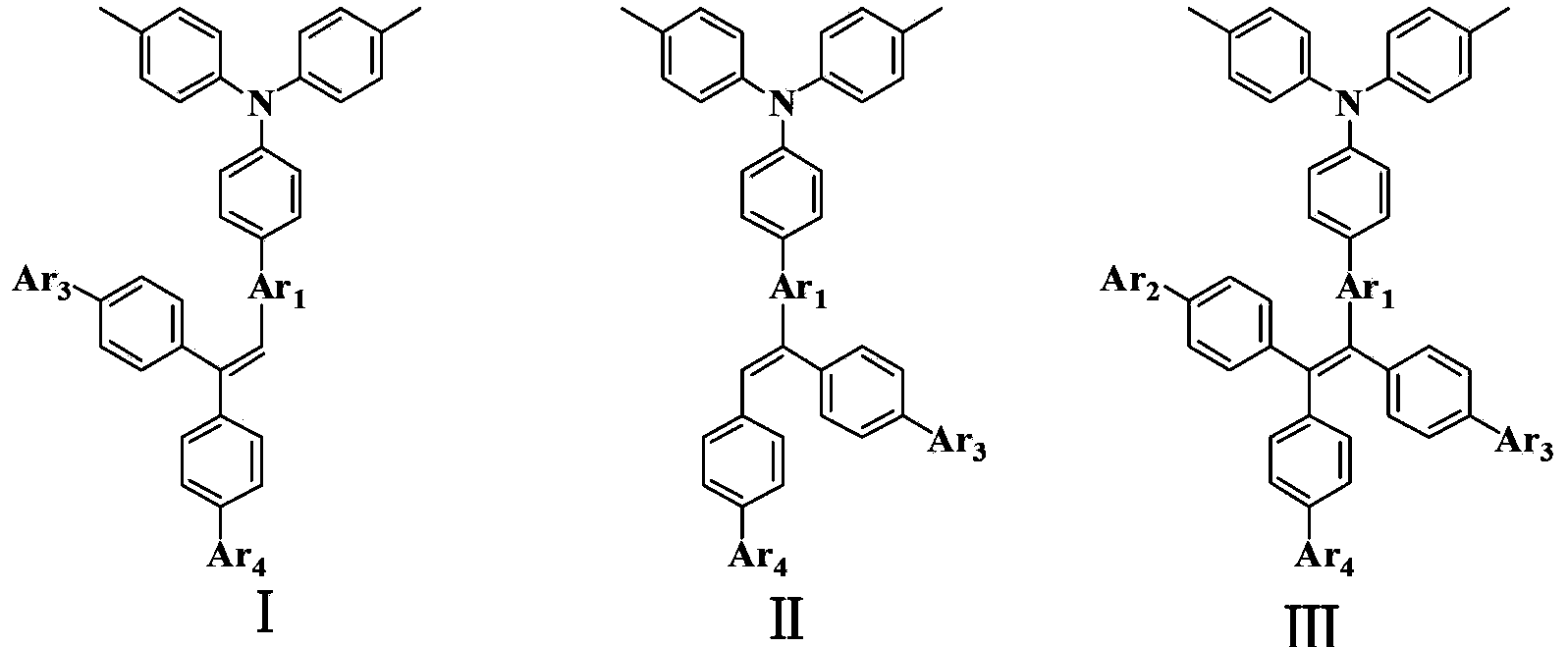

Polyimide with low dielectric properties, and preparation method and application thereof

The invention discloses polyimide with low dielectric properties, and a preparation method and an application thereof. The polyimide provided by the invention is prepared through an imidization method by using the raw materials of aromatic diamine comprising triphenylamine and with large side group comprising triphenylethylene / tetraphenylethylene, and various tetra-dianhydrides. The polyimide provided by the invention has ultra-low dielectric constant, relatively low dielectric loss, excellent solubility, relatively high glass transition temperature, relatively high thermal stability, excellent mechanical performances, excellent photo-luminescent performance, and the like. The synthesis method of the polyimide is simple and diverse, and is suitable for industrial productions. The polyimide provided by the invention can be used for preparing low dielectric materials, and can be widely applied in high-tech industry fields such as electronics, microelectronics, information, luminescent materials, aeronautics and astronautics, and specially very large scale integrated circuits.

Owner:SUN YAT SEN UNIV

High-frequency resin composition as well as semi-cured sheet and laminated board manufactured by high-frequency resin composition

ActiveCN103232705AReduce the temperatureReduce heatSynthetic resin layered productsMetal layered productsDielectric lossBottle

The invention discloses a high-frequency resin composition. The high-frequency resin composition comprises the following components in parts by weight: (a), 15-80 parts of anhydride-modified benzoxazine resin prepolymer, (b),10-60 parts of halogen-free epoxy resins, (c), 5-40 parts of fire retardant, (d), 0.001-2 parts of accelerant and (e), 0-70 parts of inorganic fillers, wherein the number-average molecular weight of the anhydride-modified benzoxazine resin prepolymer is 400-20000. The preparation method of the anhydride-modified benzoxazine resin prepolymer comprises the following steps of: getting and placing benzoxazine and anhydride compounds in a reaction bottle, heating up to 60 DEG C to 200 DEG C, adding a catalyst which is 0%-2% of the total weight of the reactants, and reacting for 10minutes-150minutes to obtain uniform and transparent anhydride-modified benzoxazine resin prepolymer. According to the high-frequency resin composition as well as a semi-cured sheet and a laminated board manufactured by the high-frequency resin composition, the anhydride-modified benzoxazine resin prepolymer is used for lowering concentration of hydroxyl groups generated by the epoxy resin curing process by the anhydride, so that the content of benzene ring is relatively improved, and the dielectric constant and the dielectric loss of the product are greatly lowered.

Owner:SHENGYI TECH SUZHOU

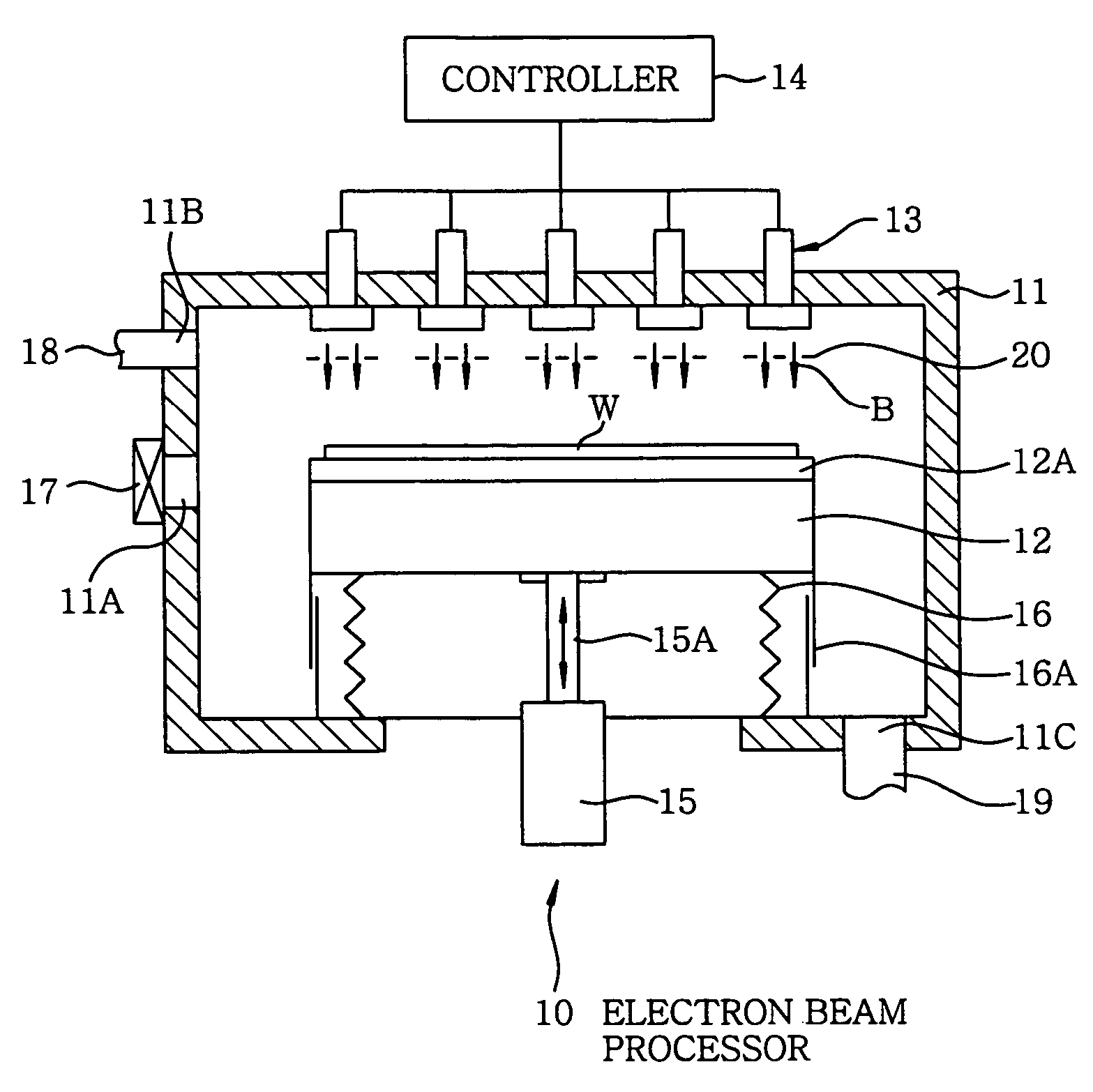

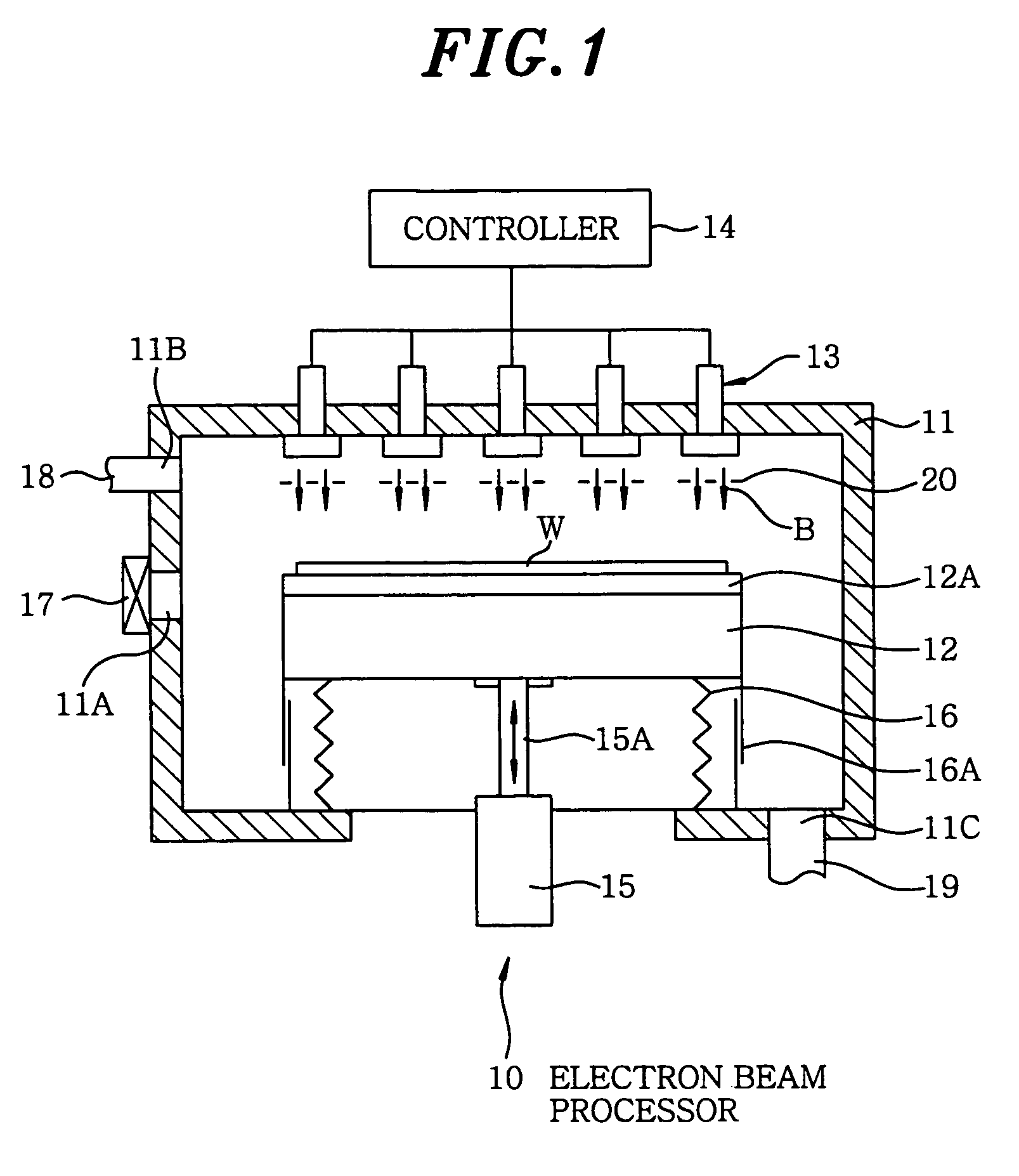

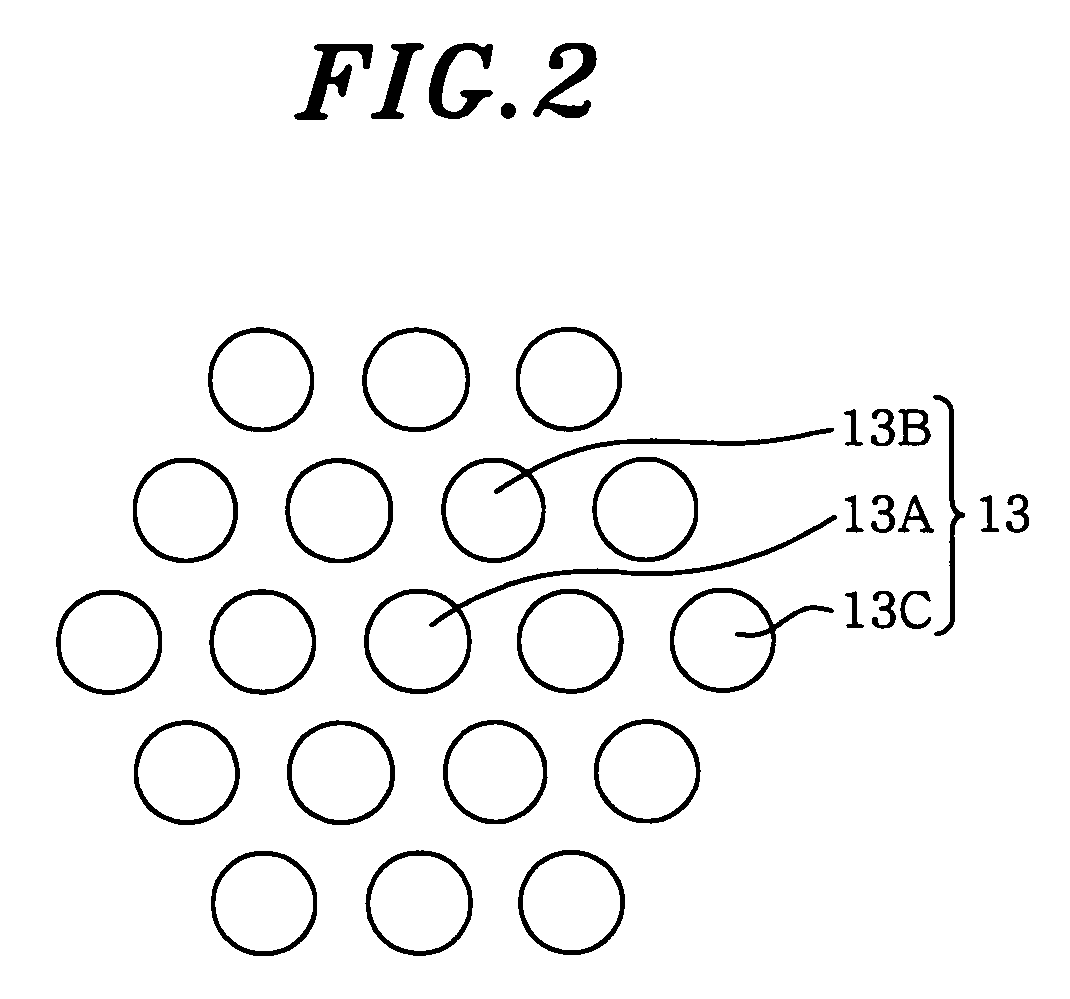

Method and apparatus for reforming laminated films and laminated films manufactured thereby

InactiveUS20050212179A1Improve throughputImprove interlayer strengthElectric discharge tubesSemiconductor/solid-state device manufacturingBeam tubeEngineering

There is provided a method for reforming laminated films, which simultaneously reforms a plurality of laminated films by irradiating electron beams on the laminated films. The method for reforming laminated films includes the steps of forming a lower film by coating a first low dielectric material in liquid form on a surface of a substrate; forming an upper film by coating a second low dielectric material in liquid form on the lower film; and irradiating electron beams on the lower and upper film. A laminated film manufacturing system includes a mounting table for mounting thereon a substrate on which the laminated films are formed; and an electron beam unit having a plurality of electron beam tubes for irradiating electron beams on the laminated films to thereby simultaneously reform the films.

Owner:TOKYO ELECTRON LTD

Hollow polymer particle and its preparing method, paper coating composition, coating paper and mfg. method

InactiveCN1477134AImprove the hollow rateGood spreadabilityCoated paper substrateCoatingsPolymer scienceEmulsion polymerization

The present invention provides a kind of hollow polymer granules with good balancing property, for example gloss and coating strength and production method of said granules, paper coating composite by using said granules and coated paper. The hollow polymer granules can be obtained by using the following raw materials and processes: emulsion polymerization containing unsaturated carboxylic acid and free radical polymerizable monomer which can be copolymerized with unsaturated carboxylic acid, preparation of polymer granules, preparing core-shell polymer granules, regulating pH value of dispersion containing said core-shell polymer granules to above 7 and polymerizing unreacted monomer.

Owner:JSR CORPORATIOON

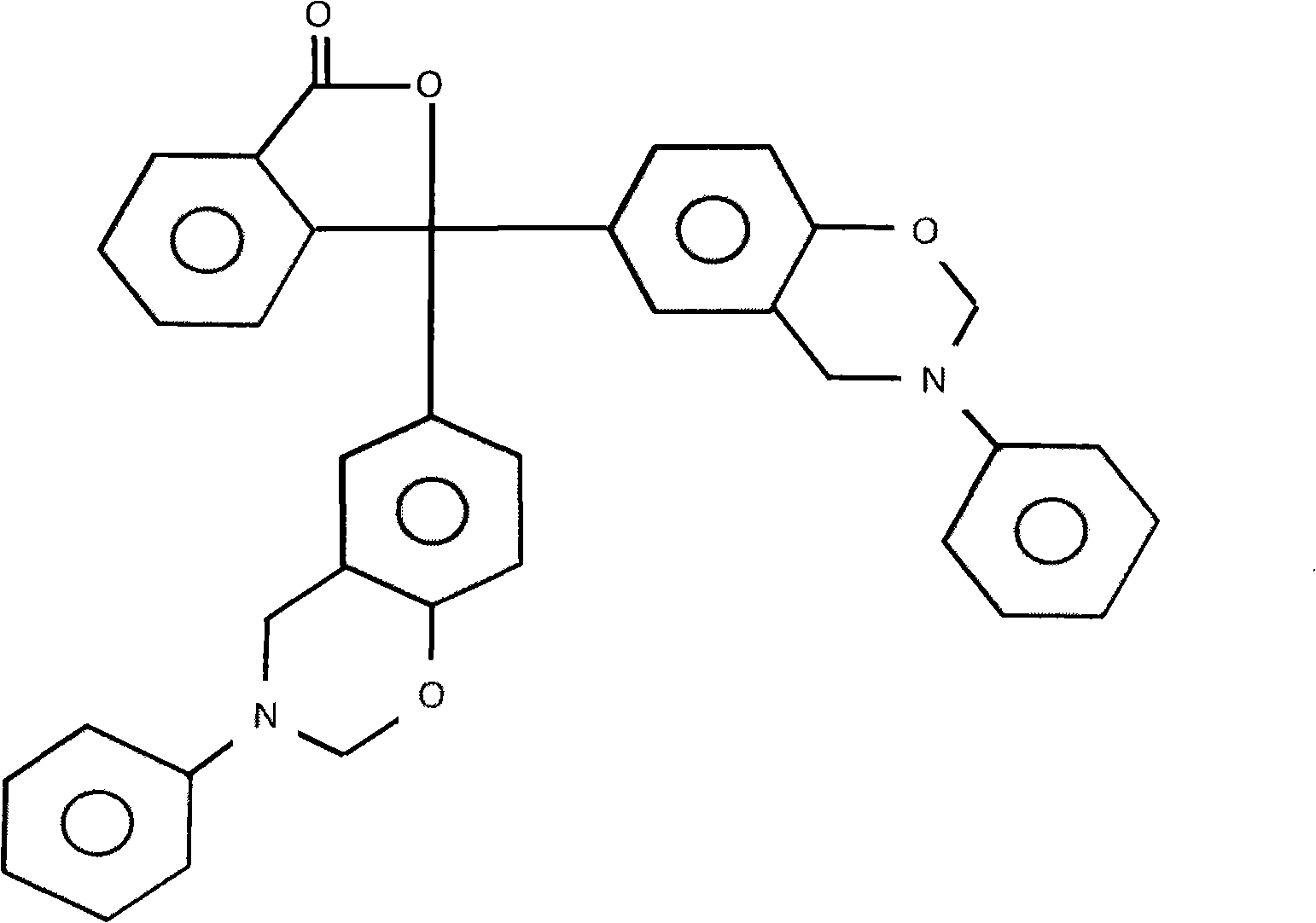

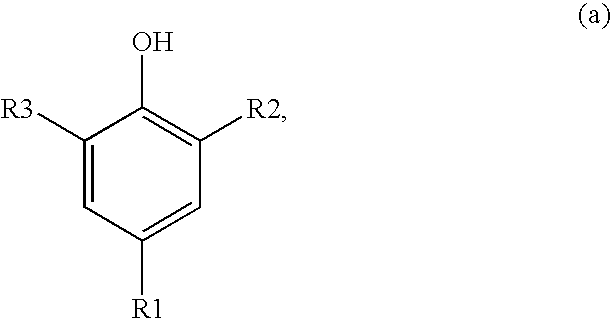

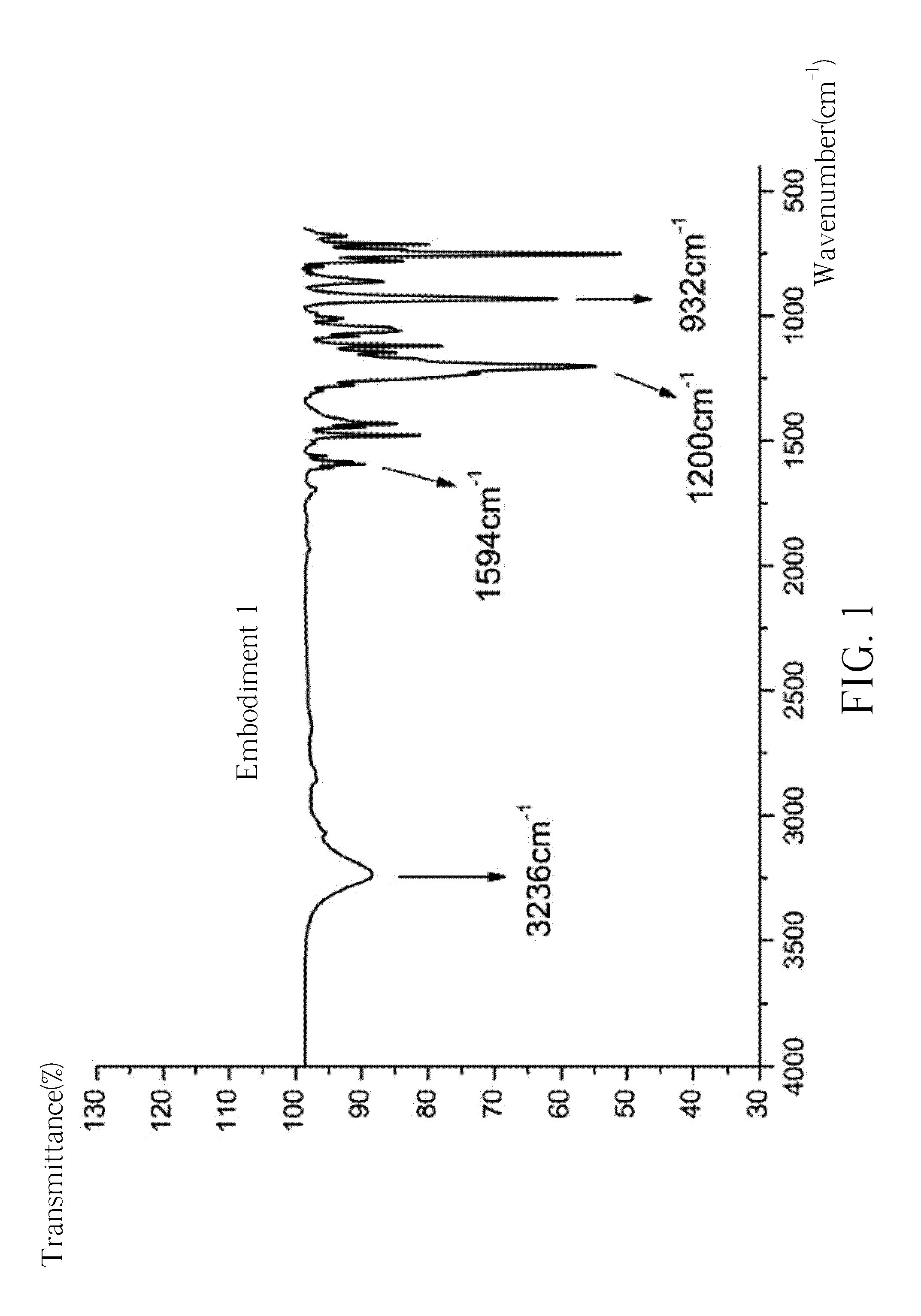

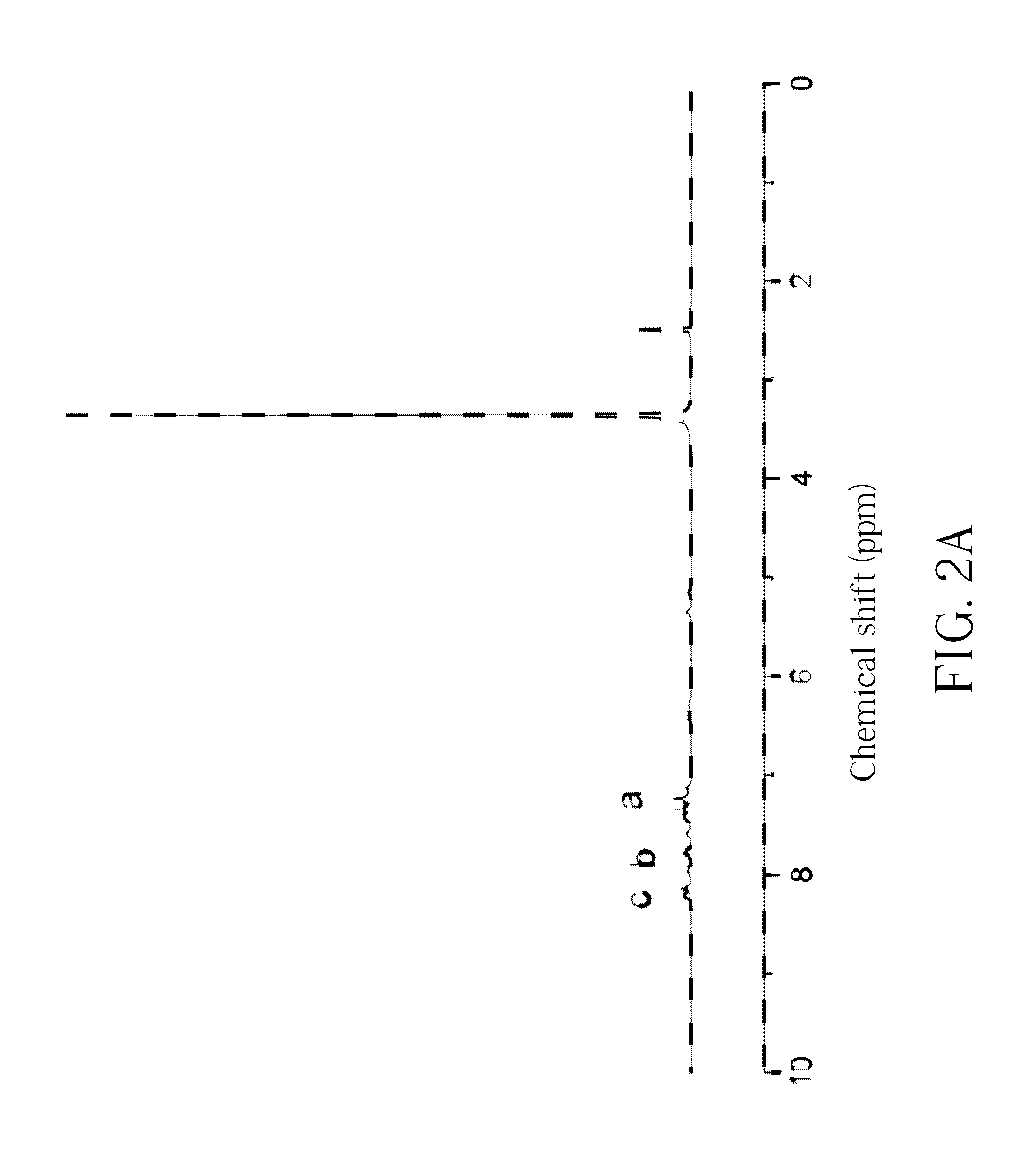

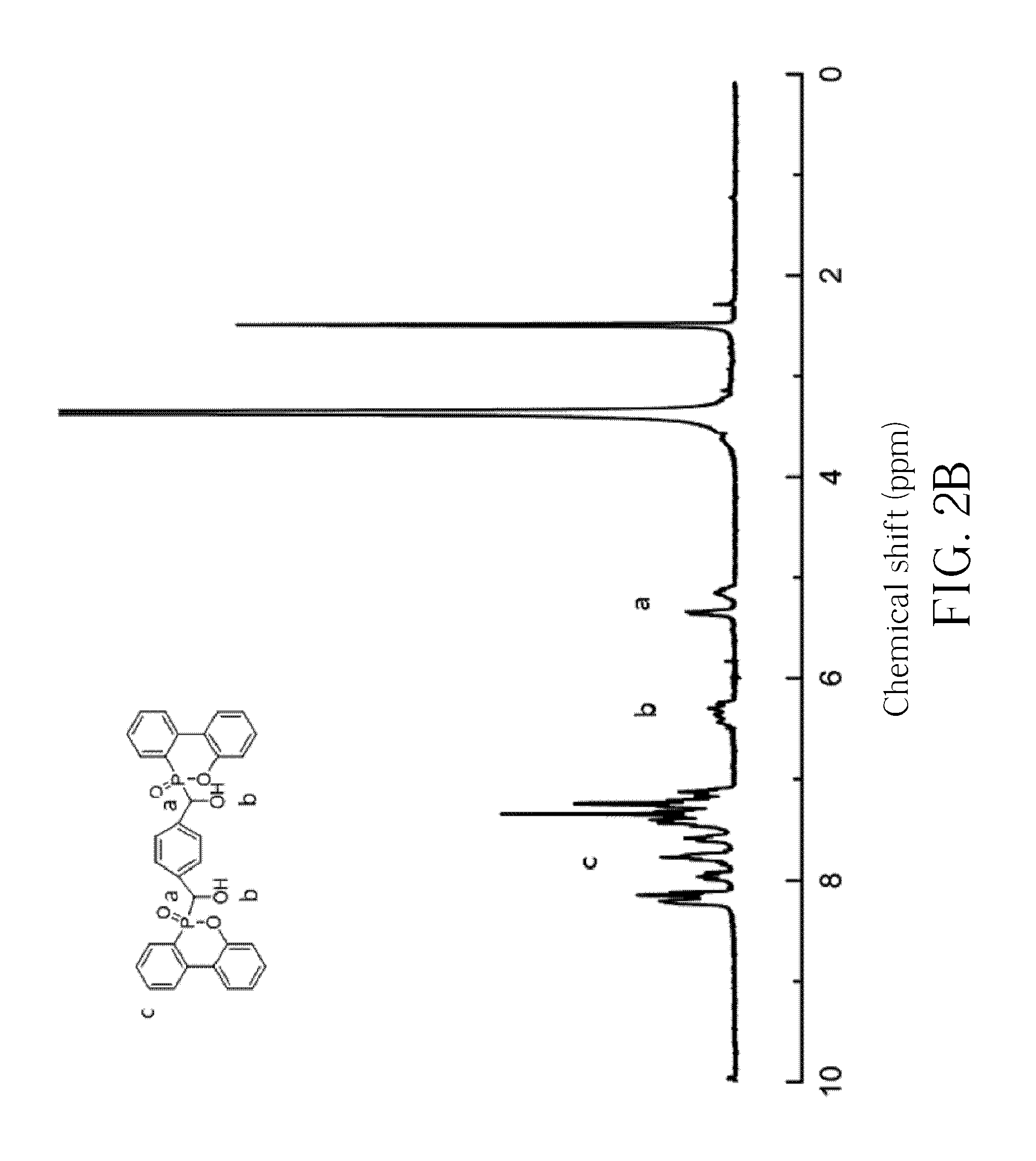

Phosphaphenanthrene-based compound and related preparation method and application

ActiveUS20170022228A1Reduction factorLow thermal expansionGroup 5/15 element organic compoundsPolymer sciencePrinted circuit board

Provided is a phosphaphenanthrene-based compound represented by the following chemical structure:The phosphaphenanthrene-based compound can be added in a resin composition and made into a prepreg or resin film. The prepreg or resin film made from such resin composition has low coefficient of thermal expansion, low dielectric constant and dissipation factor, and flame retardancy, thereby being suitable for copper-clad laminate or printed circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com