Method for preparing hydrophobic silica aerogel

一种二氧化硅、疏水性的技术,应用在二氧化硅、氧化硅、气凝胶制备等方向,能够解决低导热性、热传导率增加等问题,达到高疏水性、高经济性、改善物理性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The step 1 of preparing hydrophobic silica airgel according to one embodiment of the present invention is preparing hydrophobic silica wet gel.

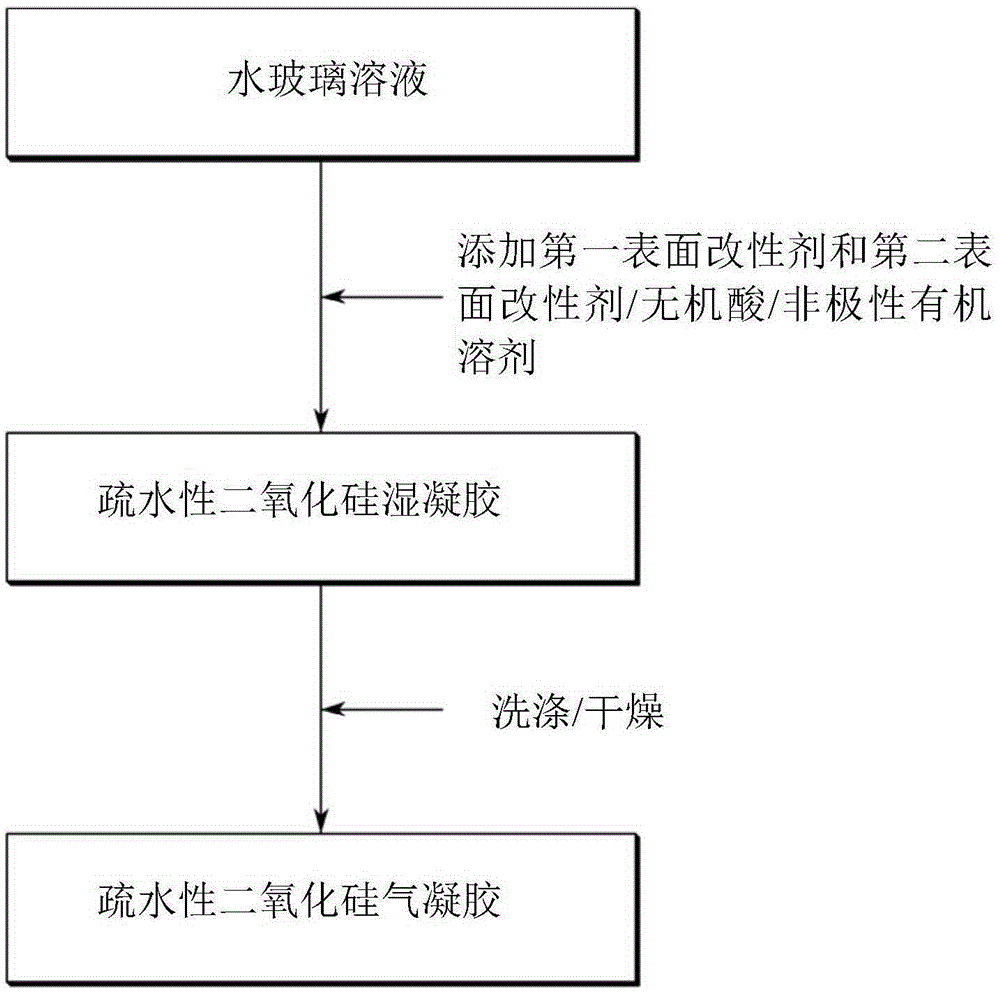

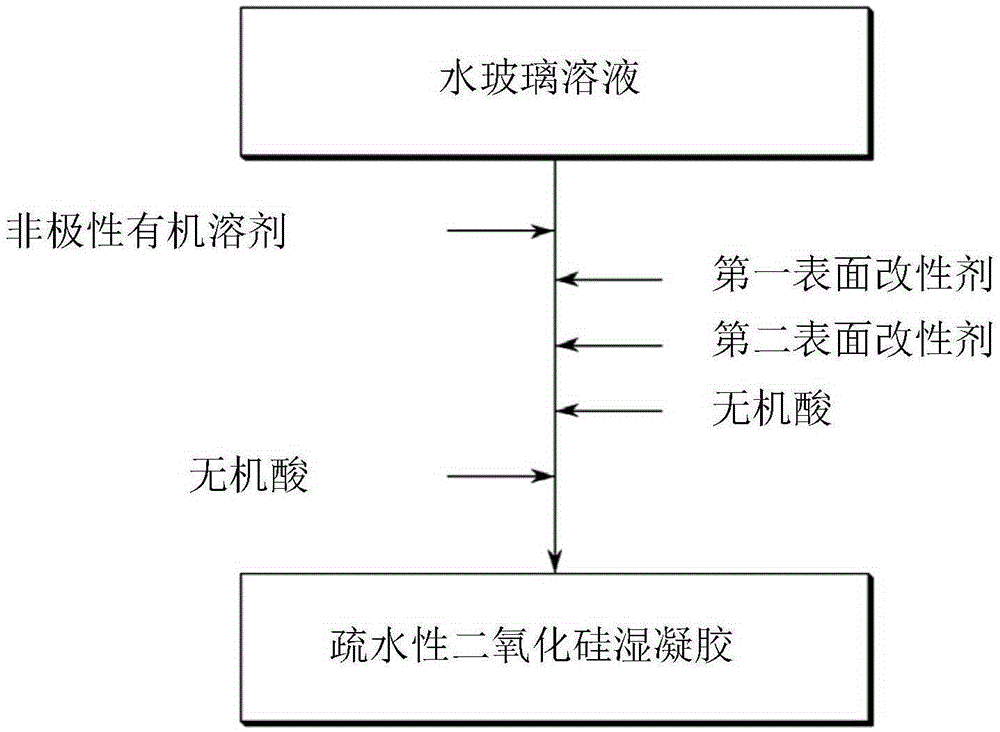

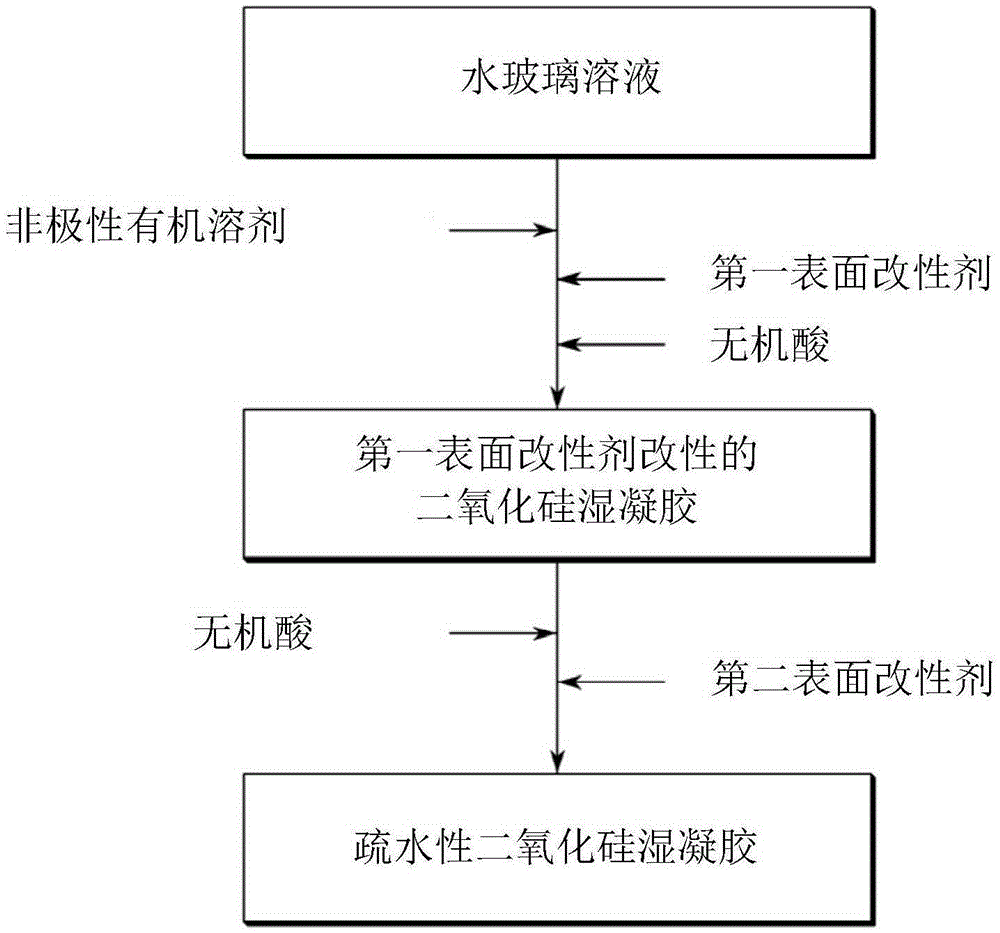

[0042] Specifically, a hydrophobic silica wet gel can be prepared by adding a first surface modifier and a second surface modifier, a non-polar organic solvent, and an inorganic acid to a water glass solution, and reacting In this case, an ion exchange resin may further be selectively used.

[0043] For example, the hydrophobic silica wet gel may be prepared by various methods according to the order of adding the above compounds.

[0044] Figures 2A to 2Dare block diagrams respectively showing various methods (methods A to D) for preparing a hydrophobic wet gel during the preparation of a hydrophobic silica airgel according to an embodiment of the present invention. Figures 2A to 2D These are merely examples for describing the present invention, and the scope of the present invention is not limited thereto. Below, will re...

Embodiment 1-1

[0161] Add 120ml of hexane to the water glass solution (comprising 4.35wt% of silicon dioxide) of 100g (about 100ml), and raise the temperature to 50°C to prepare the water glass-non- Polar organic solvent layer separation composition. Thereto, 6 ml of hexamethyldisilazane and 3.6 ml of nitric acid were sequentially added and stirred to obtain a wet gel (pH 7 to 8) modified by the first surface modifier. After 5 minutes, 0.5 ml of nitric acid was further added to the obtained wet gel modified by the first surface modifier, and after 10 minutes, 2.5 ml of methyltrimethoxysilane hydrated at 50 wt % was added , stirred for 3 hours, and reacted to obtain a hydrophobic silica wet gel. In this case, hydrated methyltrimethoxysilane was prepared by mixing 10 g of methyltrimethoxysilane and 10 g of distilled water and stirring for 20 hours.

[0162] The aqueous layer separated from the obtained hydrophobic silica wet gel was removed, and washed by adding 120 ml of hexane. Repeat the...

Embodiment 1-2

[0164] A hydrophobic silica airgel was obtained in the same manner as in Example 1-1 except for adding 1.1 ml of hydrated methyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com