Patents

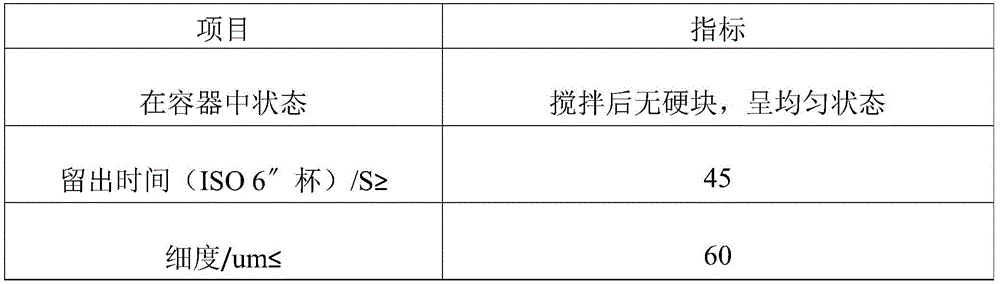

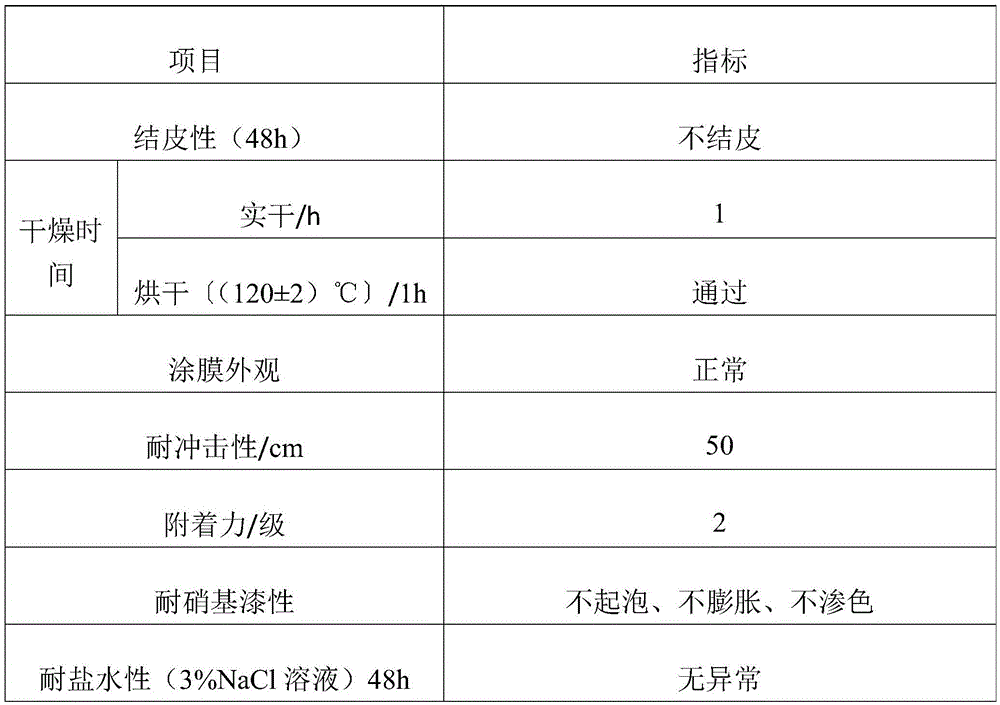

Literature

544results about How to "Increase drying speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

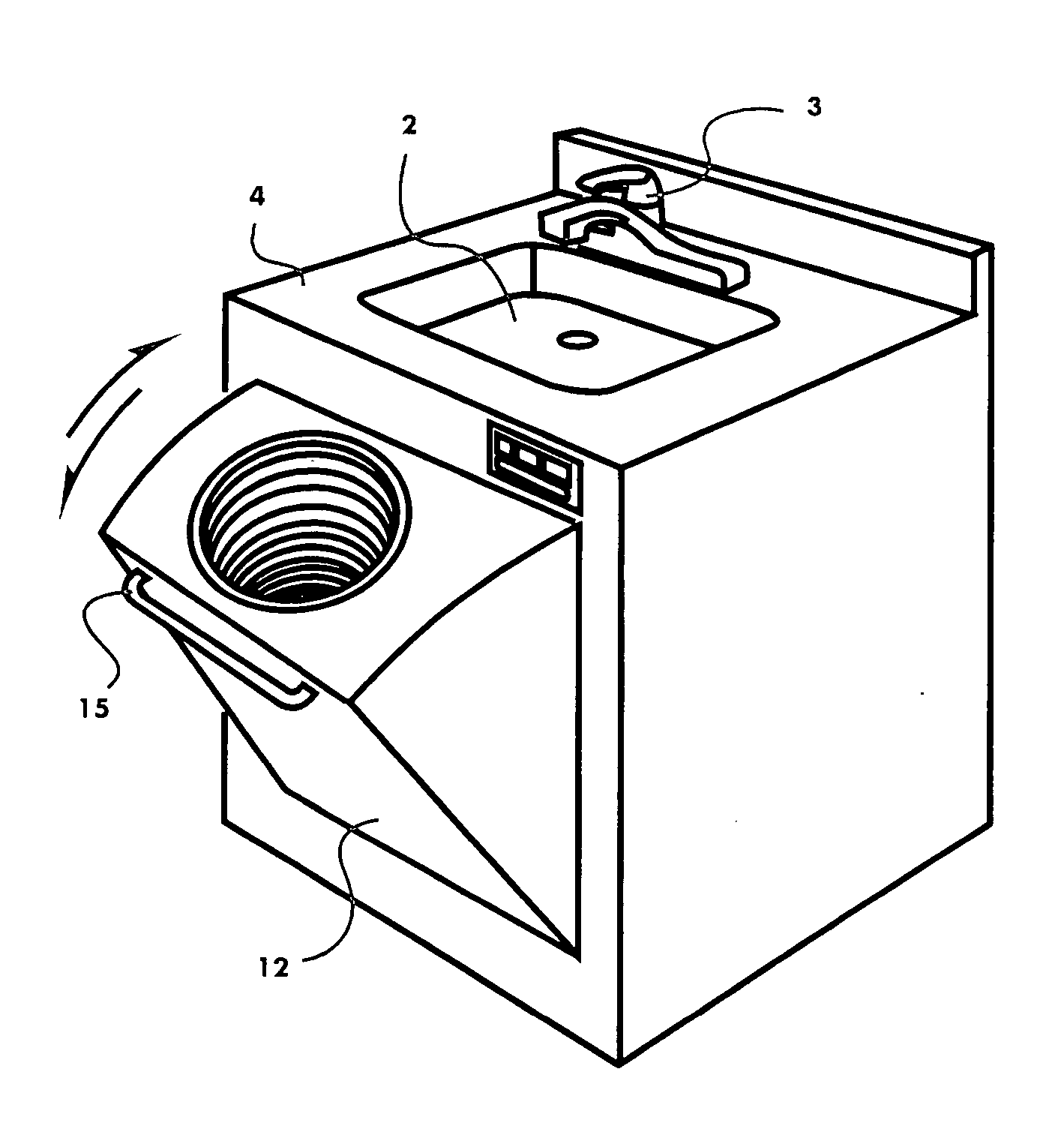

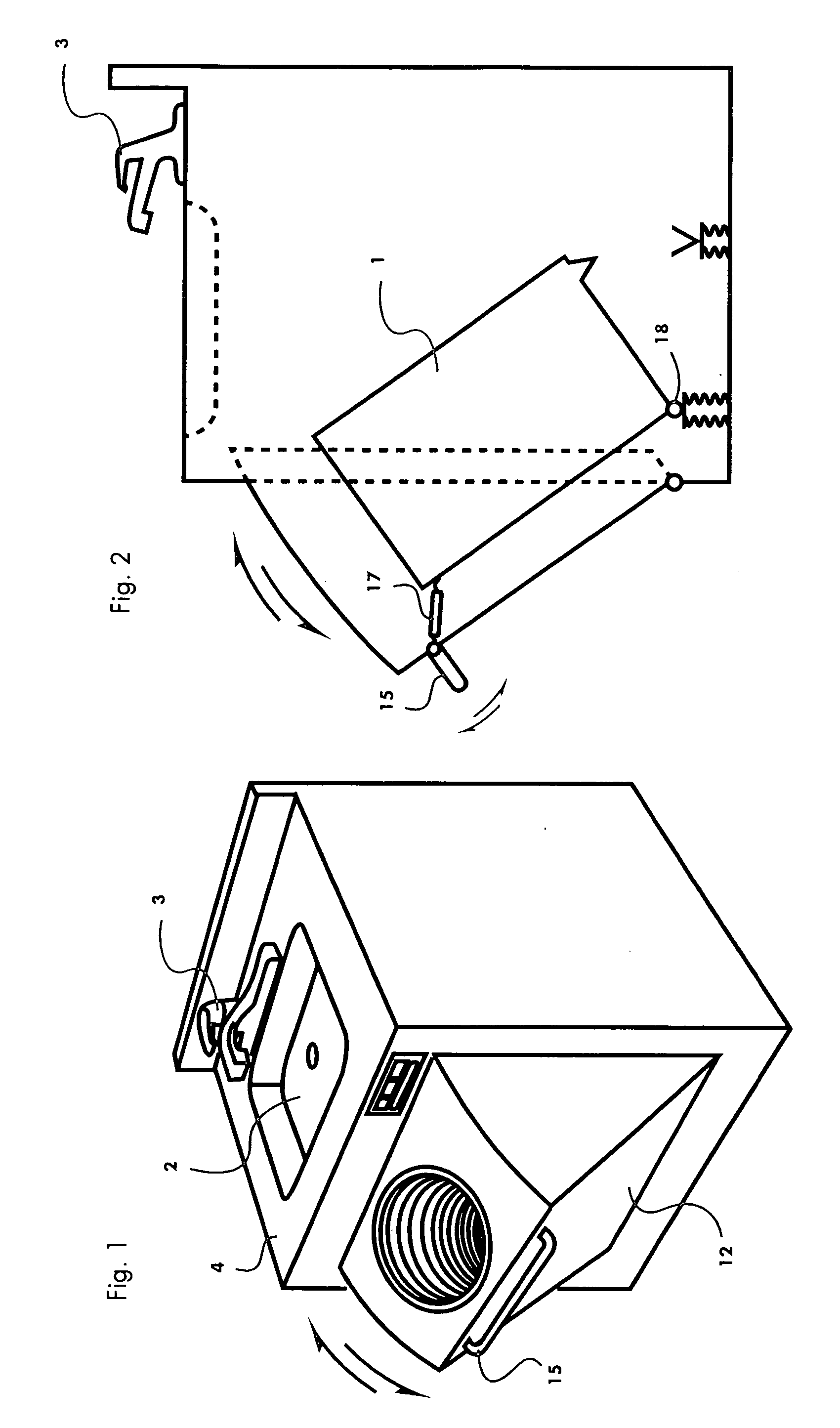

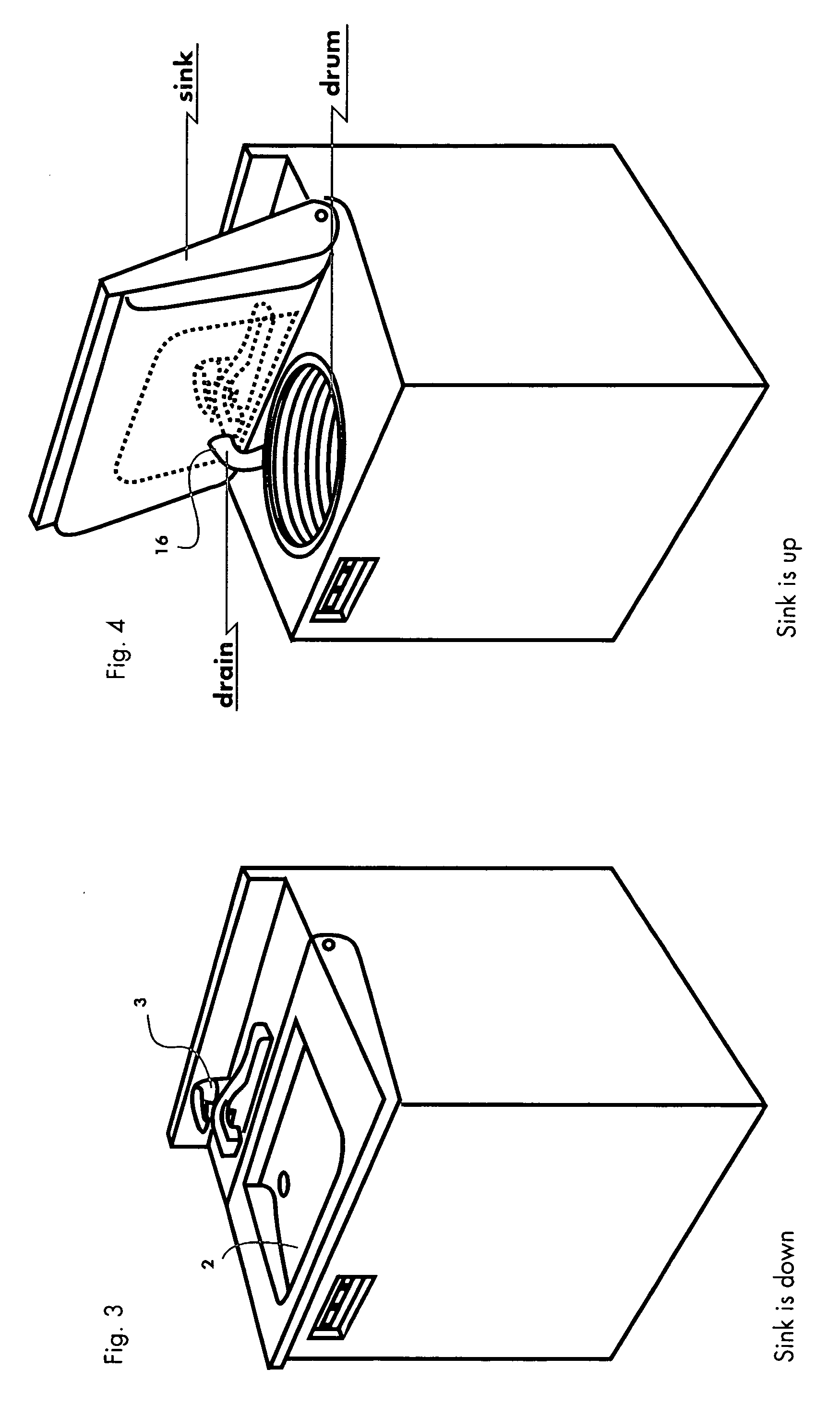

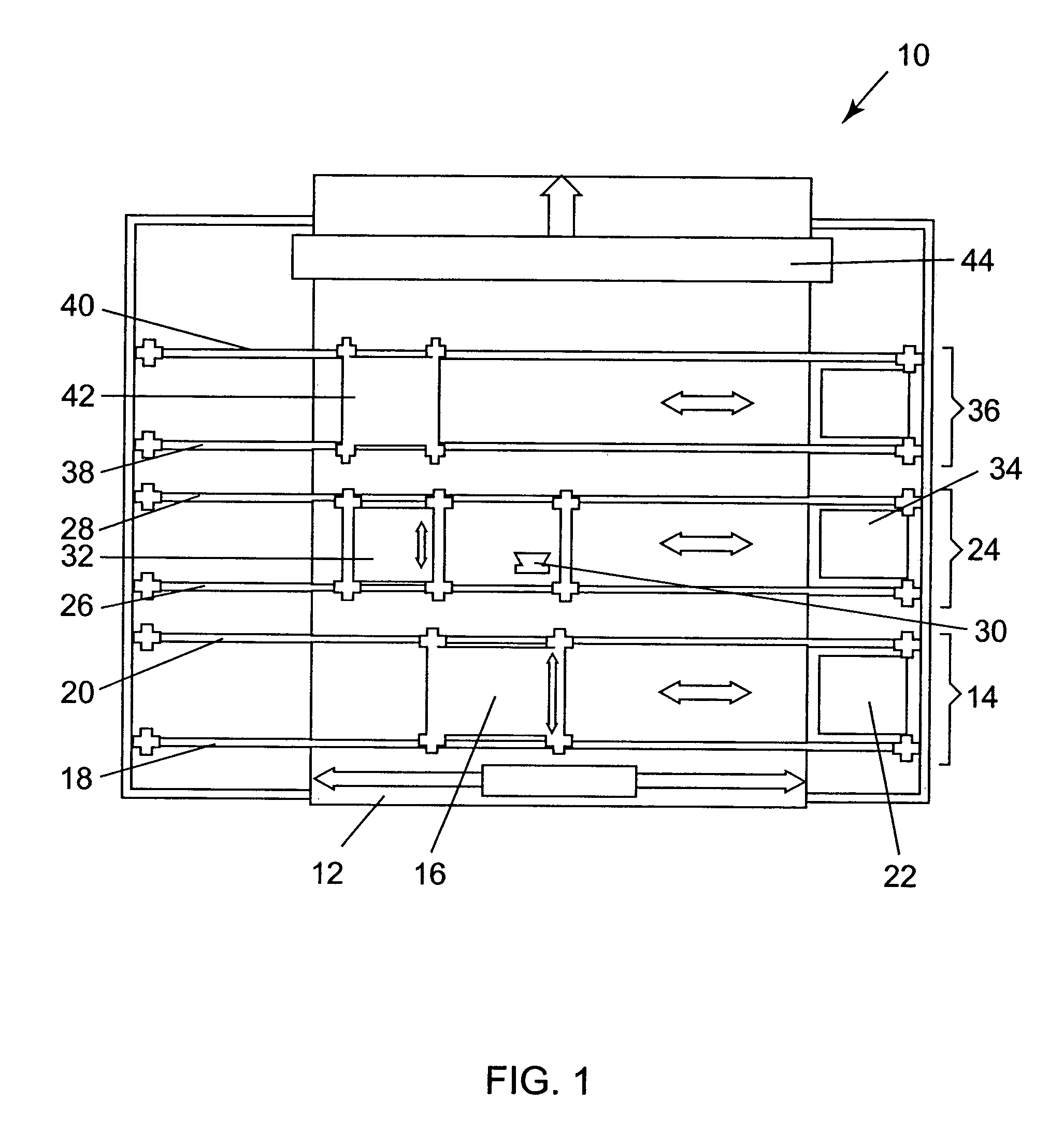

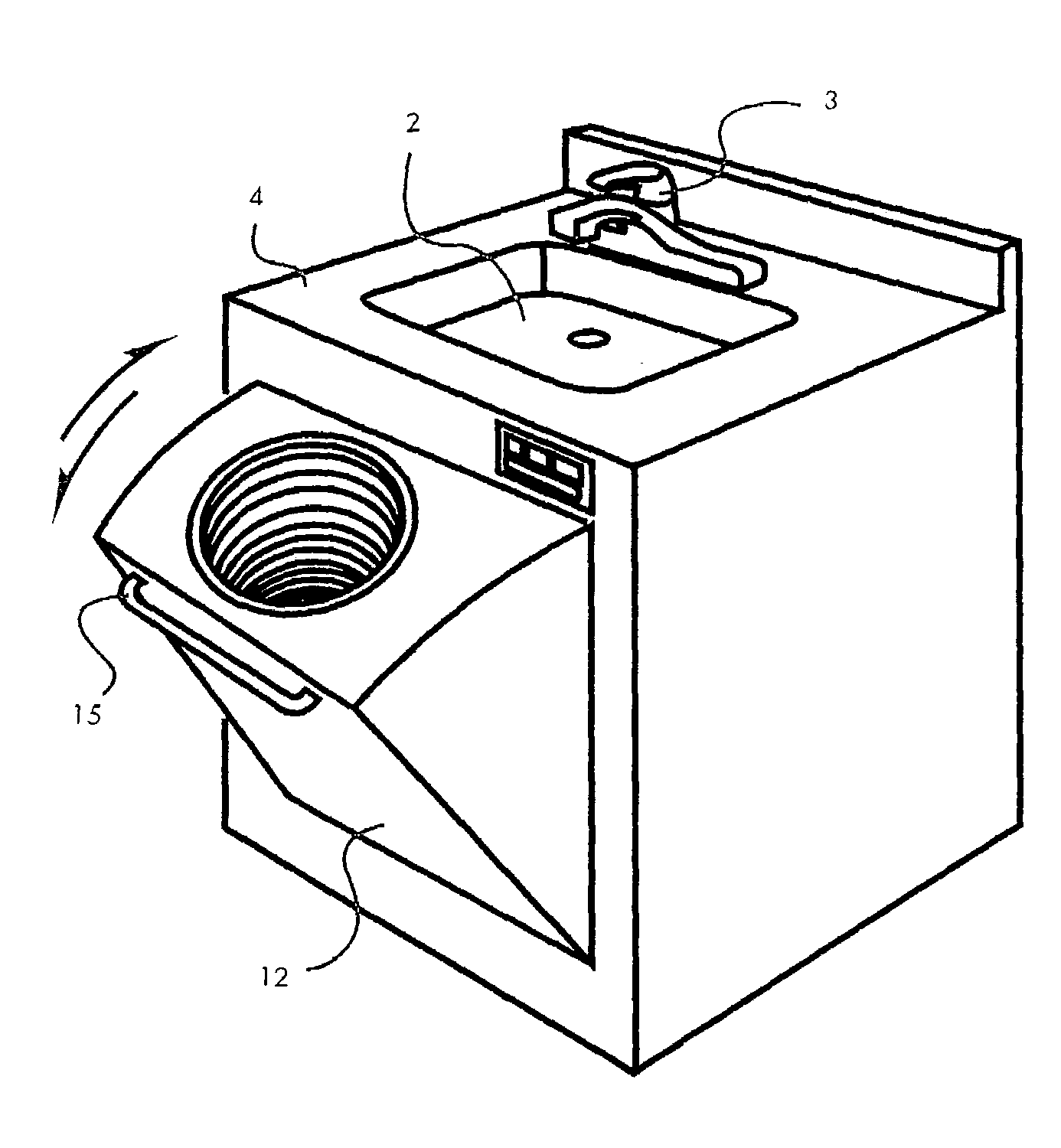

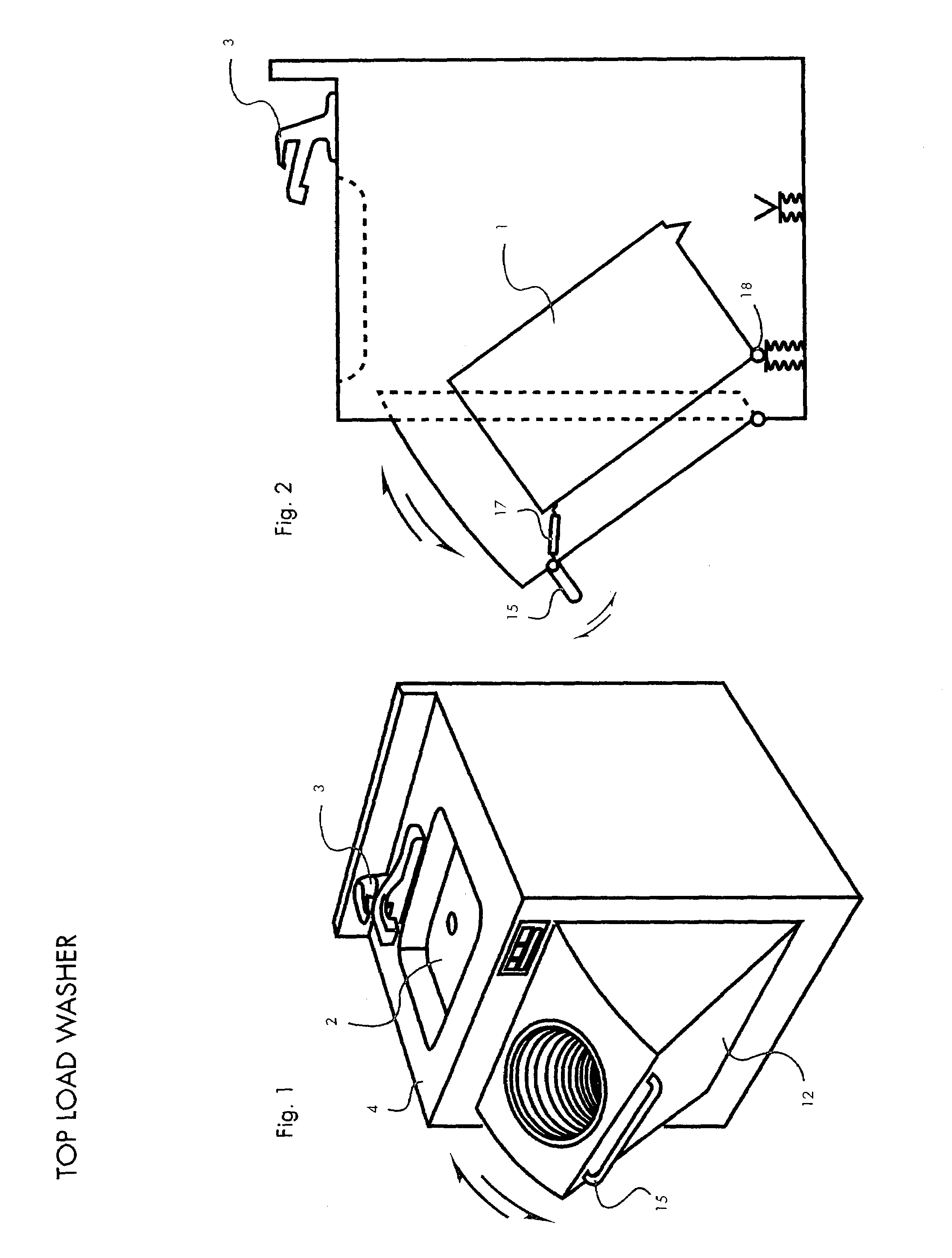

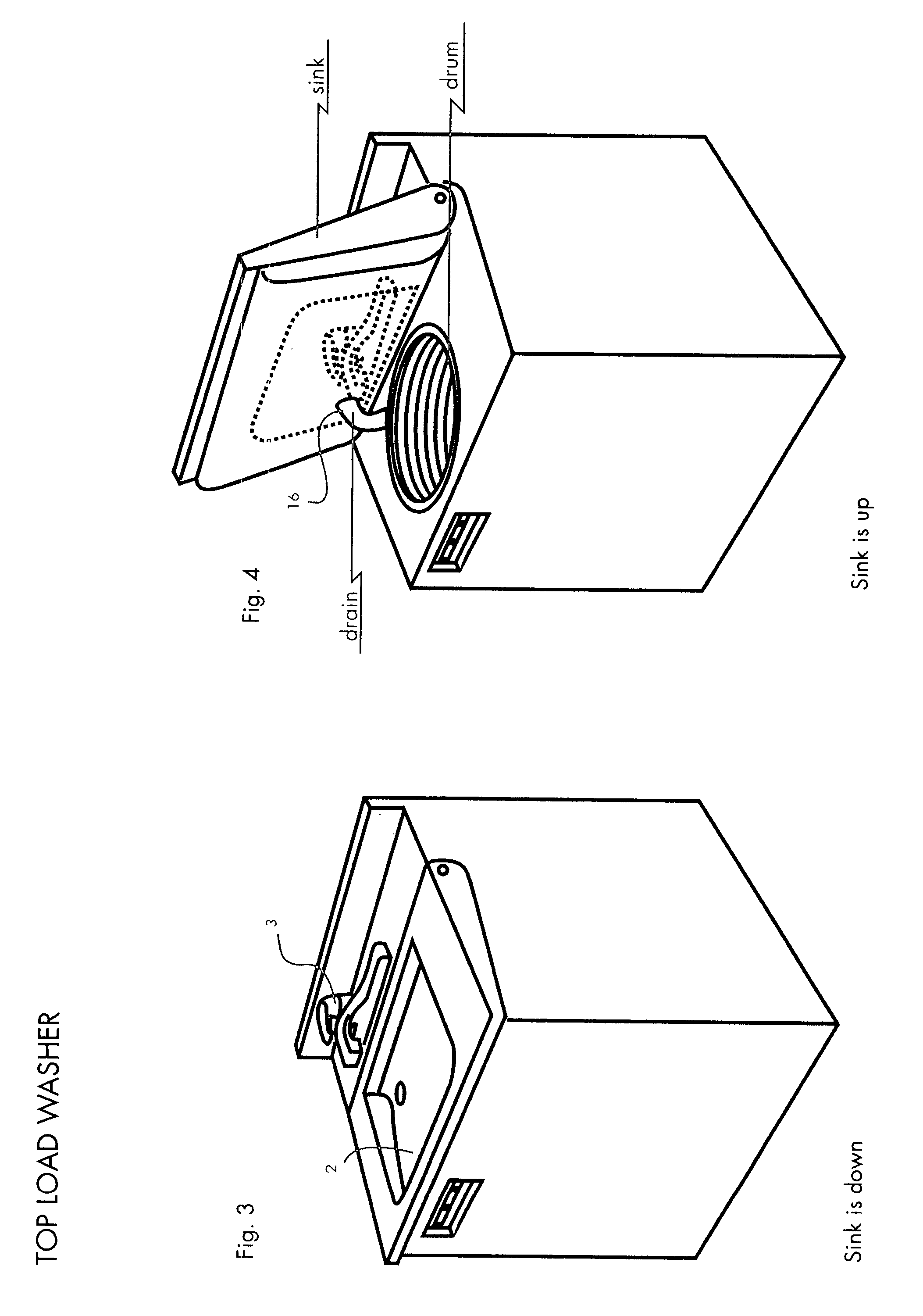

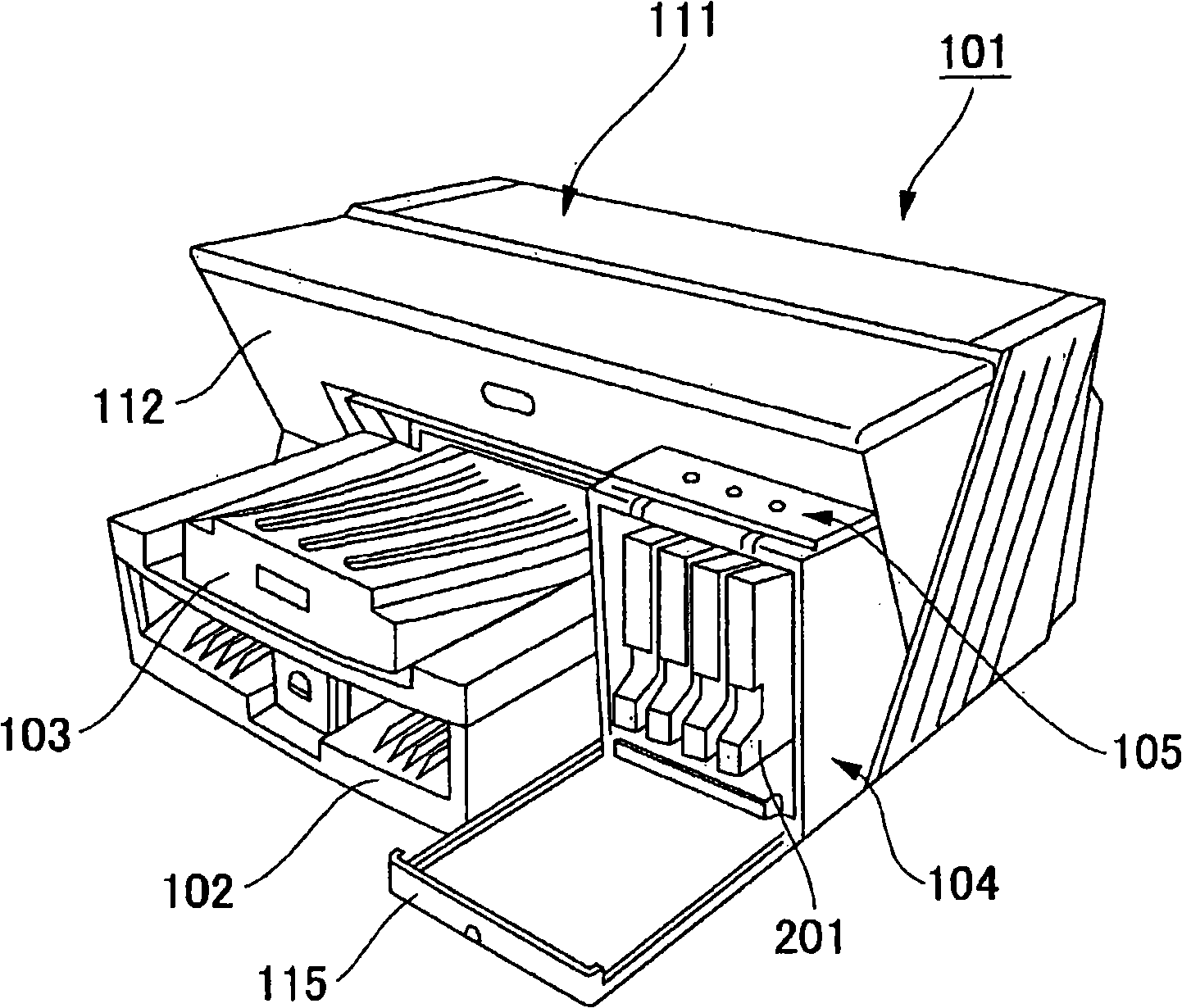

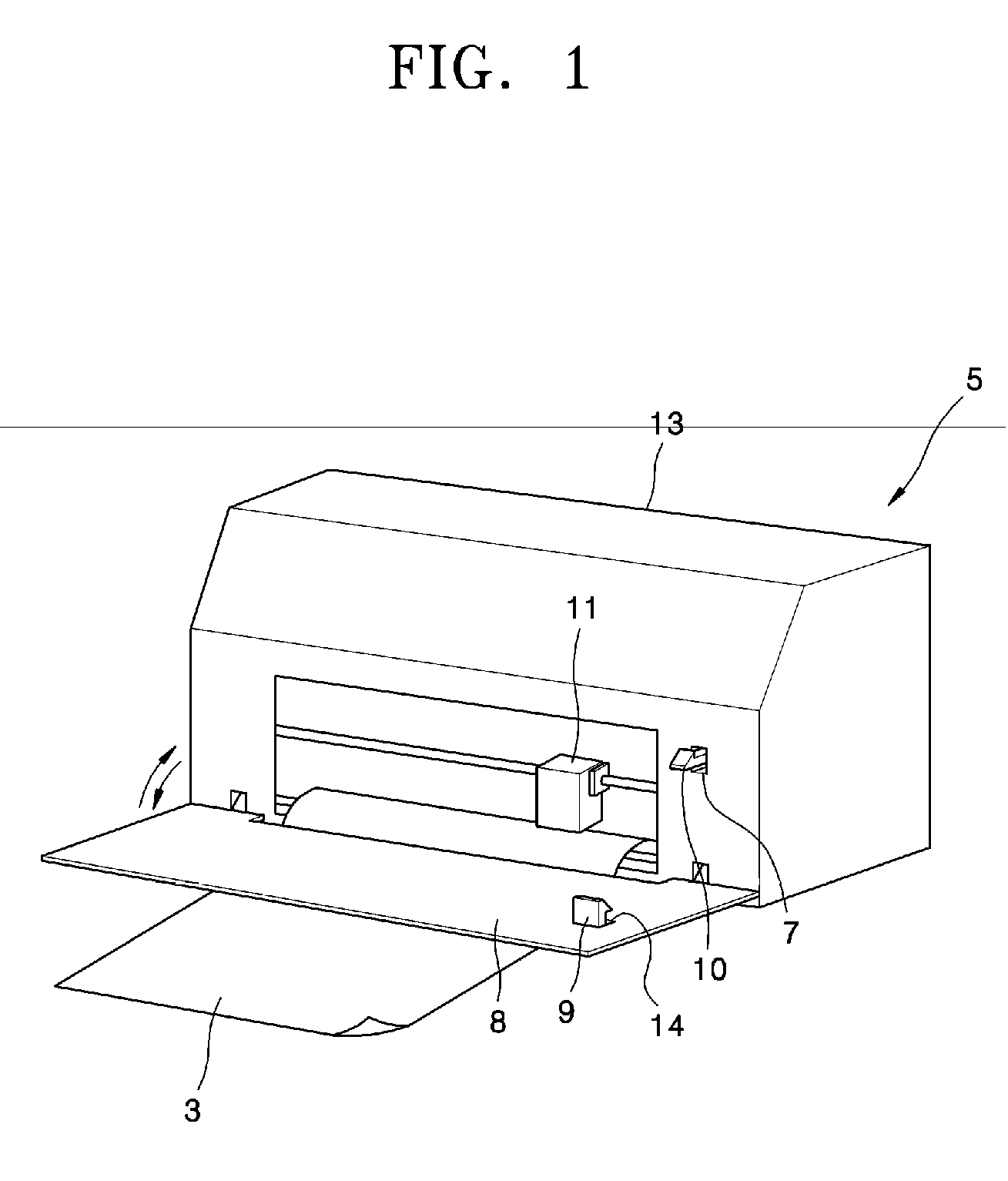

Top-load sink/laundry combo

InactiveUS20050056059A1Increase drying speedAvoid great wasteOther washing machinesControl devices for washing apparatusLaundryMobile home / trailer

An automatic washing machine including a drum, a sink, connection means for water and waste line, which are assembled in one integrated unit. It looks like a vanity with a built-in laundry machine and could be installed in any bathroom, kitchen or any utility room, mobile home, RV or even a boat having standard provision for sink connection. It could replace any existing standard sink giving customer an additional laundry capability.

Owner:HAIER AMERICA TRADING

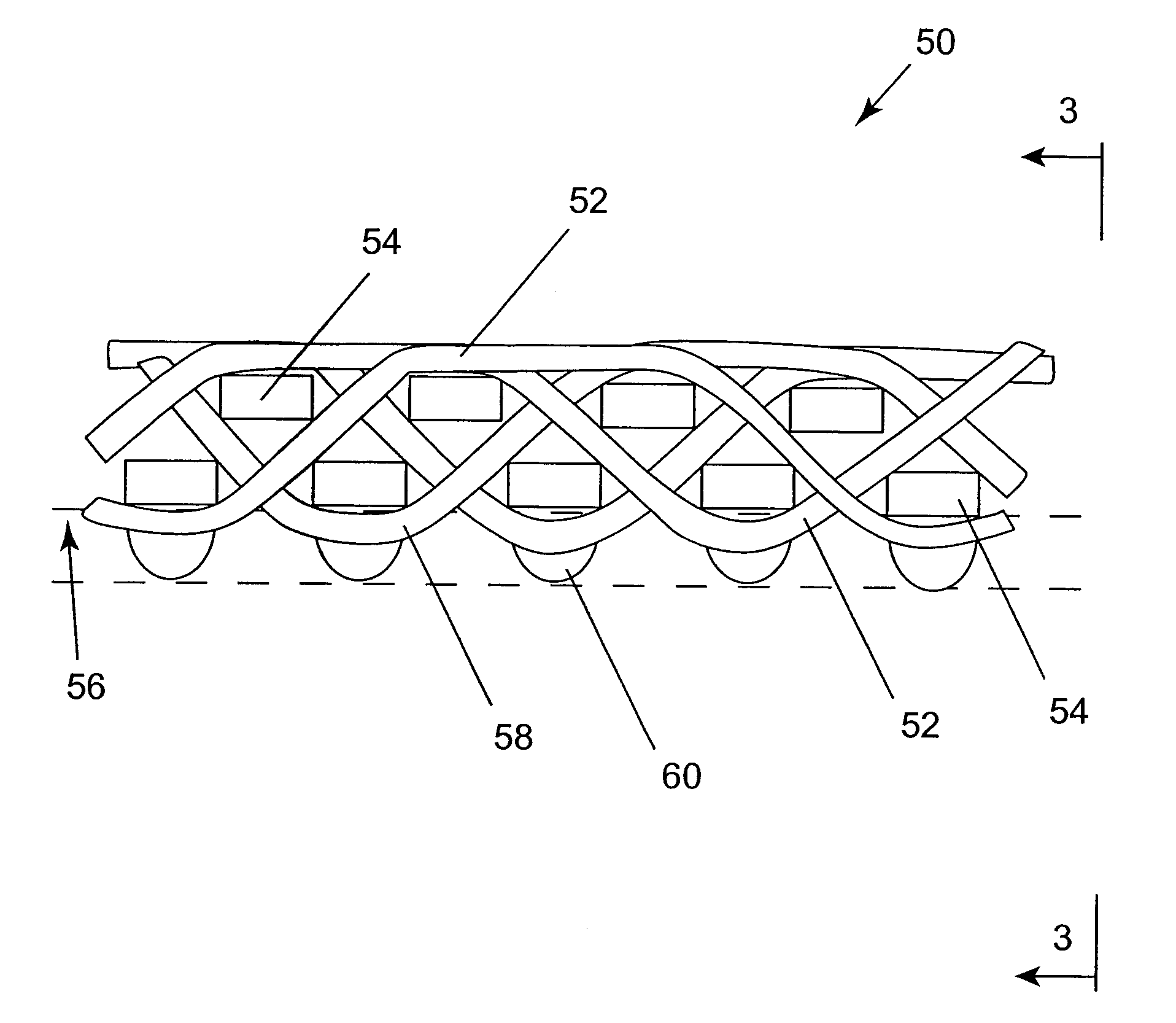

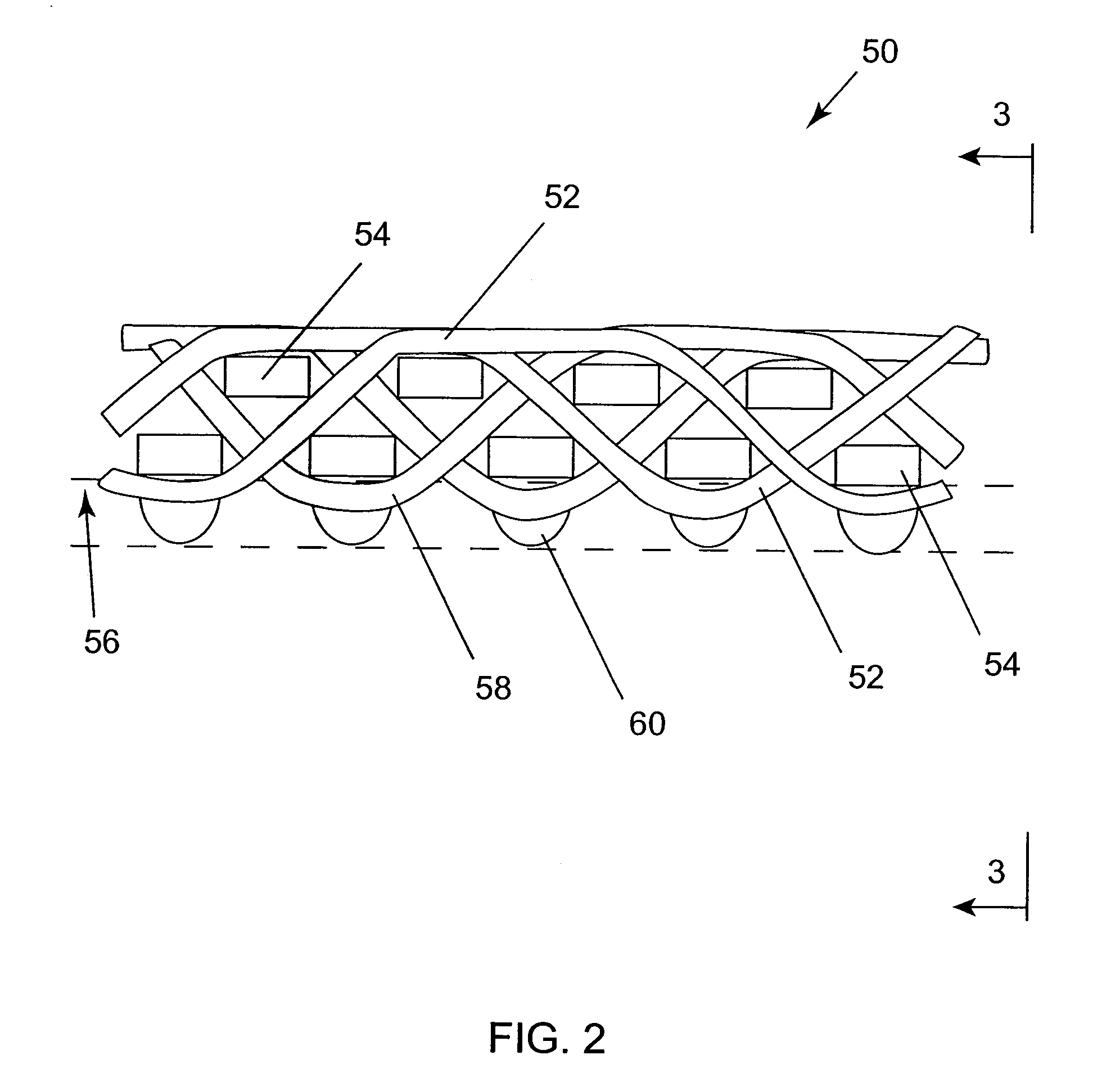

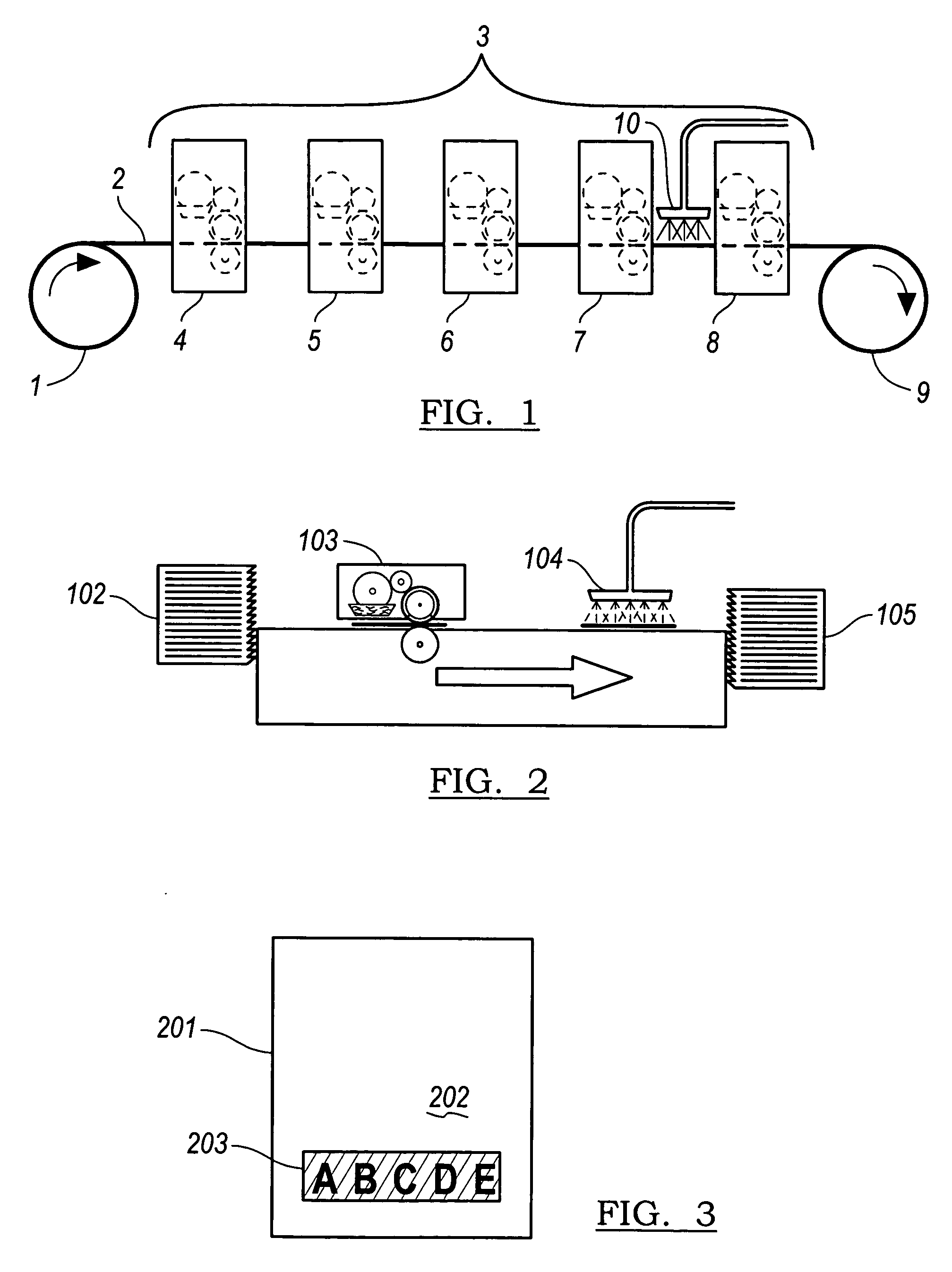

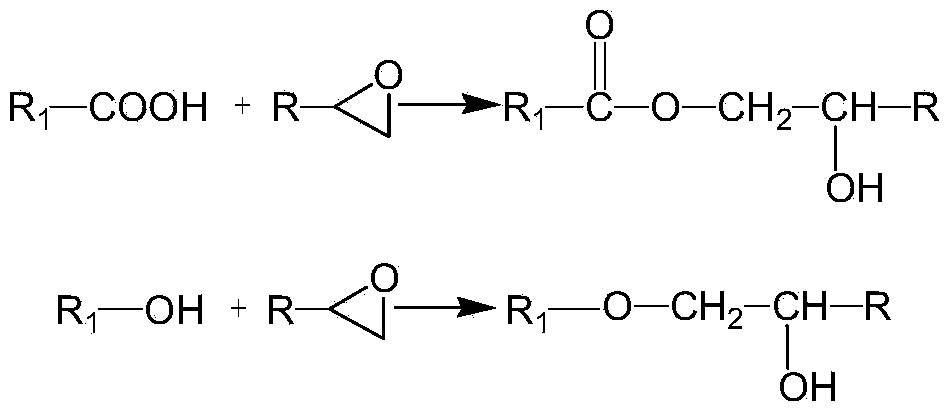

Method of fabrication of a dryer fabric and a dryer fabric with backside venting for improved sheet stability

InactiveUS7005043B2Reduce decreaseSimpler and less-costly to manufacture and seamNon-fibrous pulp additionNatural cellulose pulp/paperYarnPolymer resin

A method of manufacturing and a papermaker's or industrial fabric, such as a dryer fabric for the dryer section of a paper machine, includes the application of a polymeric resin material onto preselected locations on the backside of a base substrate using a piezojet array which deposits the polymeric resin material in droplets having an average diameter of 10μ (10 microns) or more to build up discrete, discontinuous deposits of the polymeric resin material having a height of about 0.5 mm at the preselected locations. The preselected locations may be the knuckles formed by the interweaving of the yarns making up the fabric. The purpose of the deposits is to separate the backside of the dryer fabric from a surface, such as that of a dryer cylinder or turning roll, to enable air trapped between the dryer fabric and the surface to escape in lengthwise and crosswise directions parallel to the surface, instead of being forced through the fabric, possibly causing “drop off”. The polymeric resin material is set by means appropriate to its composition, and, optionally, and, if necessary, may be abraded to provide the deposits with a uniform height above the surface plane of the base substrate.

Owner:ALBANY INT CORP

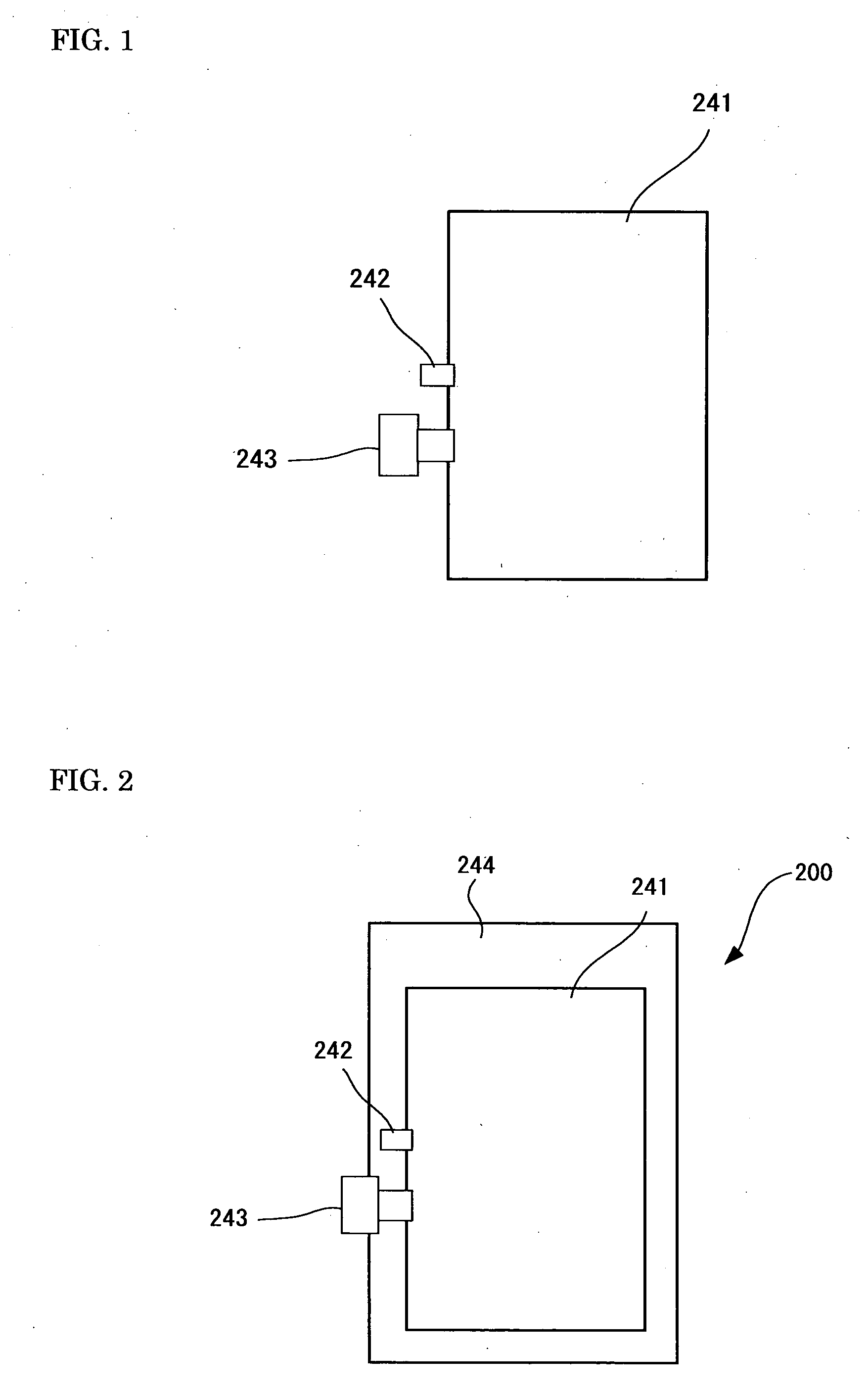

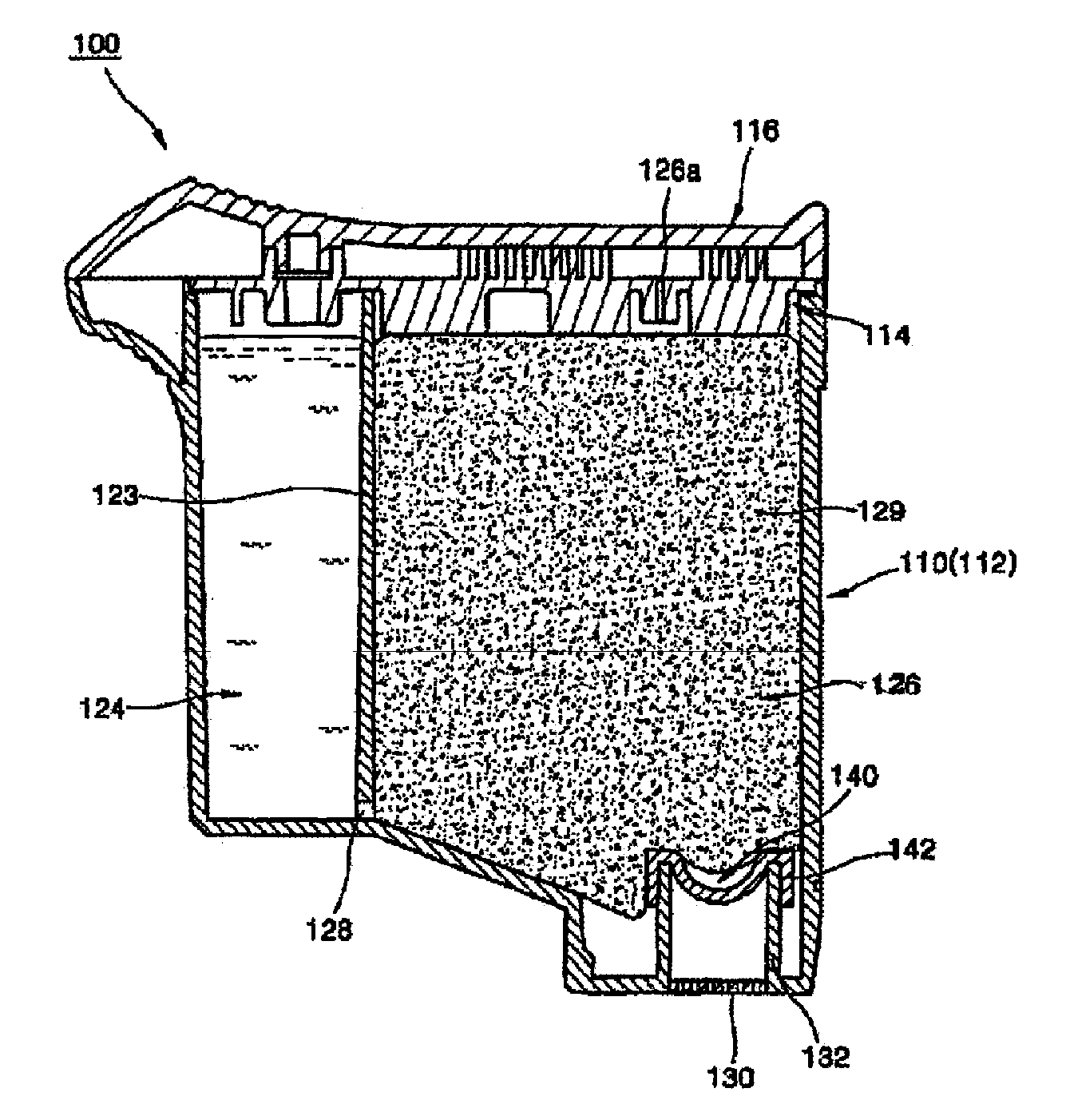

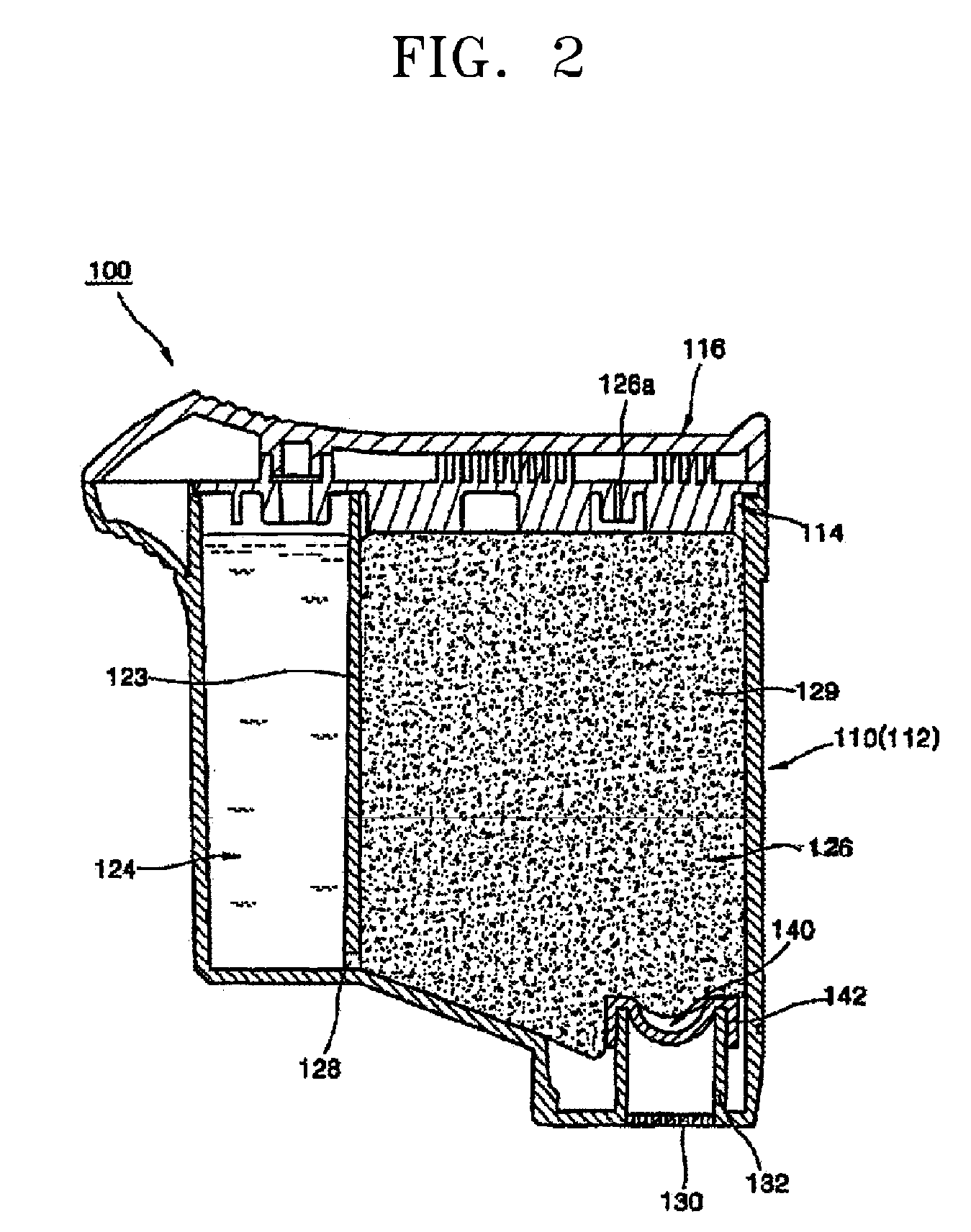

Recording Ink, Ink/Media Set, Ink Cartridge, Inkjet Recording Method and Inkjet Recording Apparatus

ActiveUS20080233363A1Avoid it happening againHigh image densityDecorative surface effectsLayered productsParticulatesWater dispersible

To provide a recording ink which contains at least a water-dispersible colorant, a water-dispersible resin, a wetting agent, a surfactant and water, wherein the content of the wetting agent in the recording ink is in the range of from 20% by mass to 35% by mass, the total solid content of the water-dispersible colorant and the water-dispersible resin in the recording ink is in the range of from 12% by mass to 40% by mass, the water-dispersible resin contains fluorine resin particulates, and the ratio A:B, where A is the solid content of the water-dispersible resin in the recording ink and B is the solid content of a pigment contained in the water-dispersible colorant in the recording ink, is in the range of 0.5 to 8.

Owner:RICOH KK

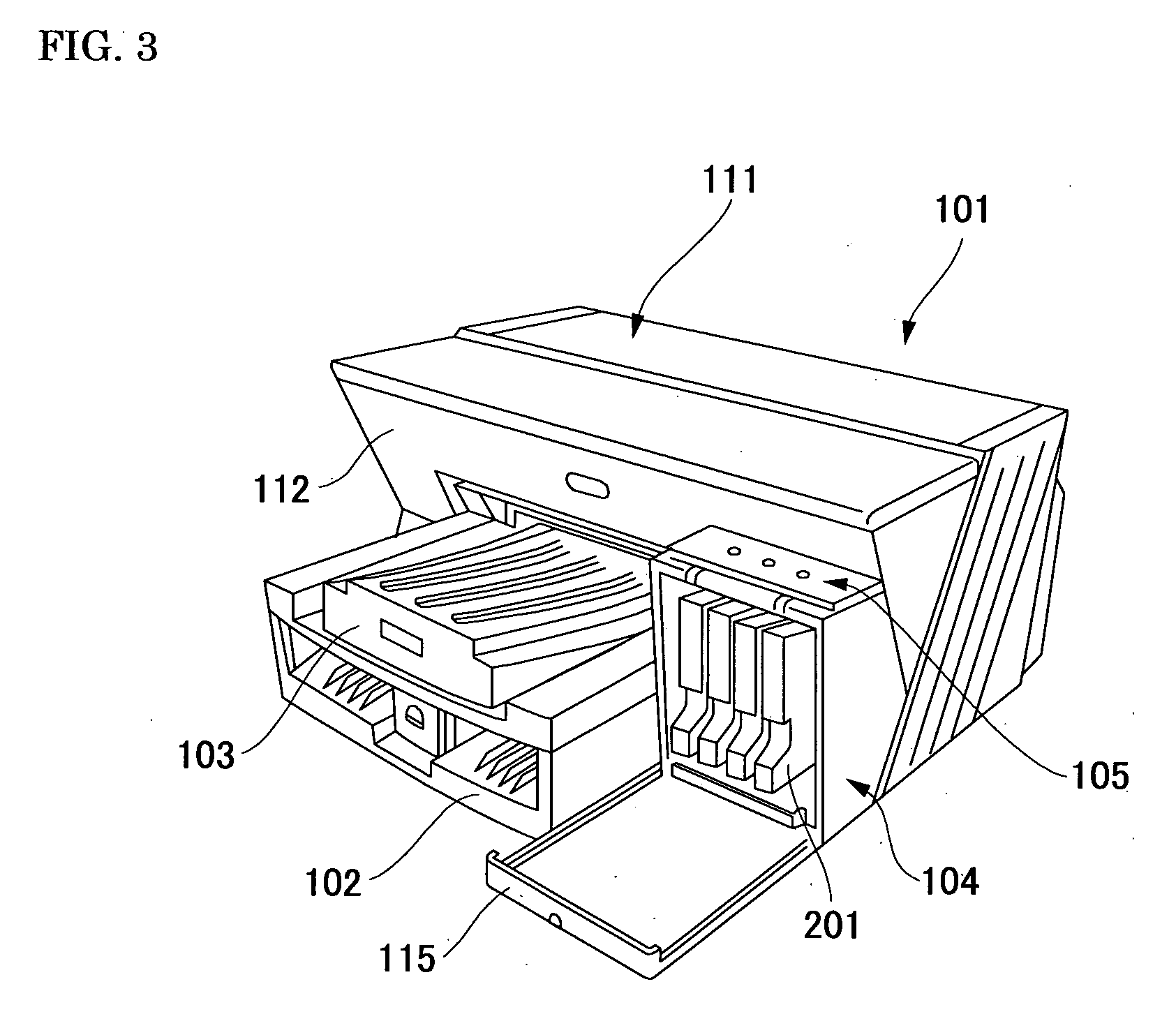

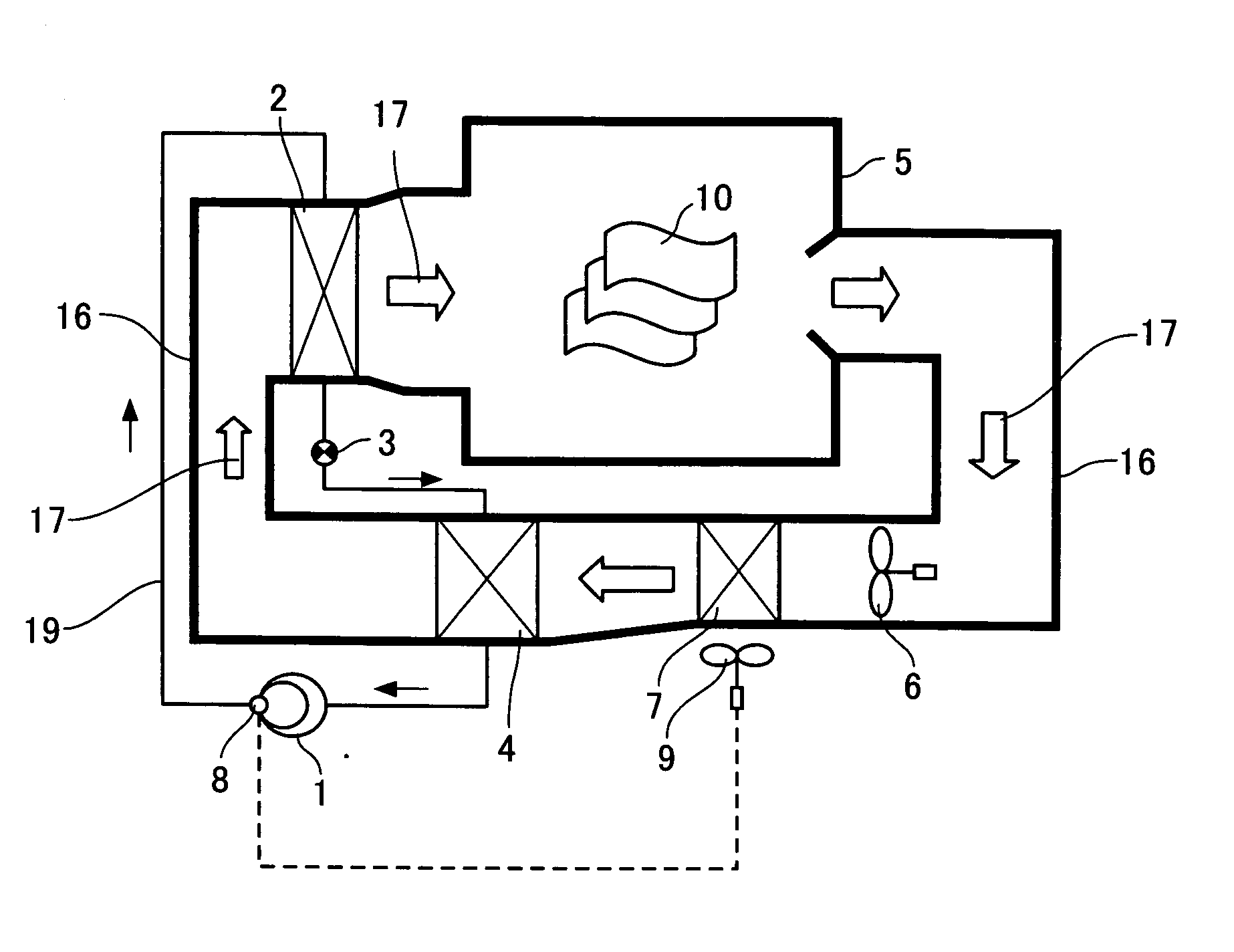

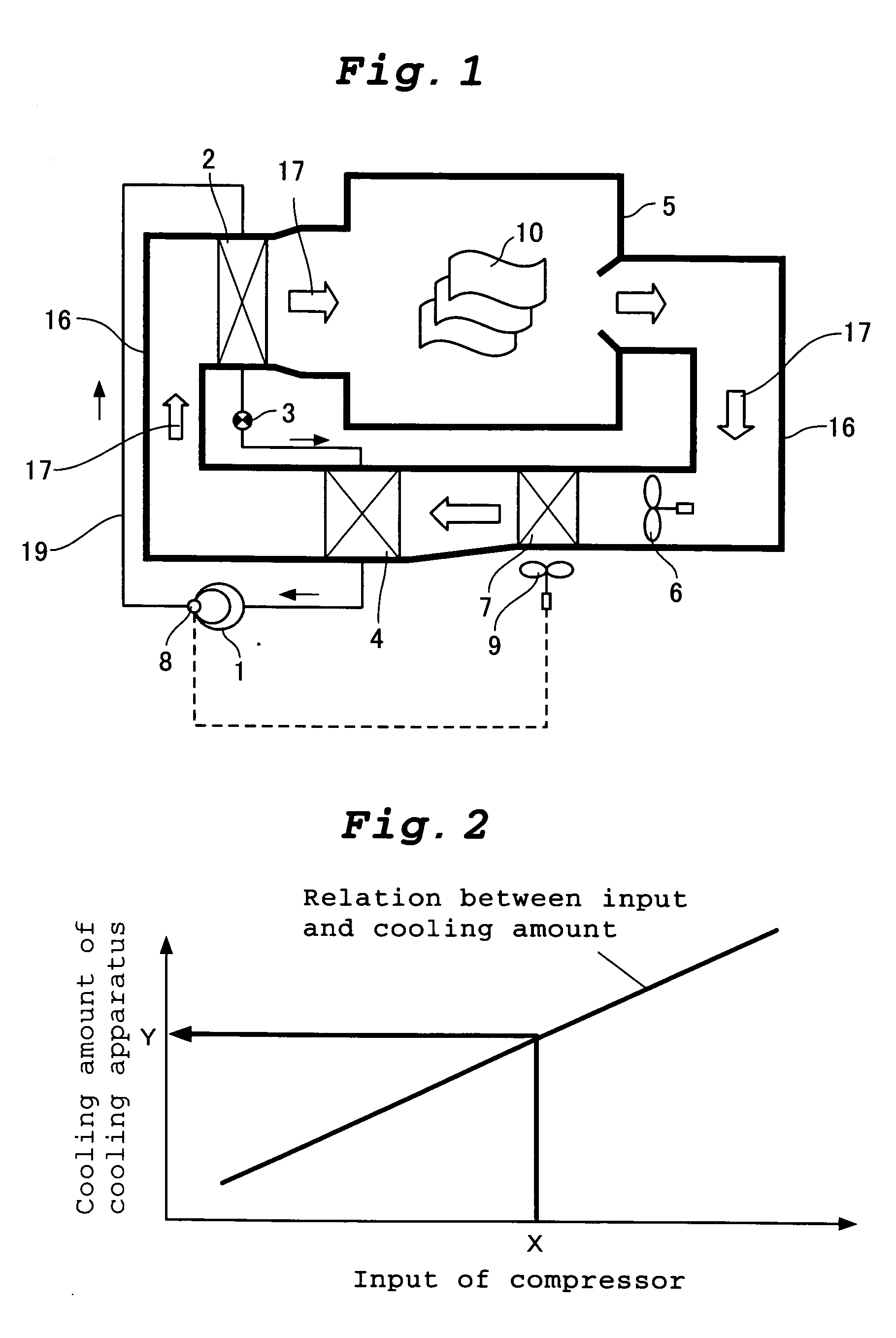

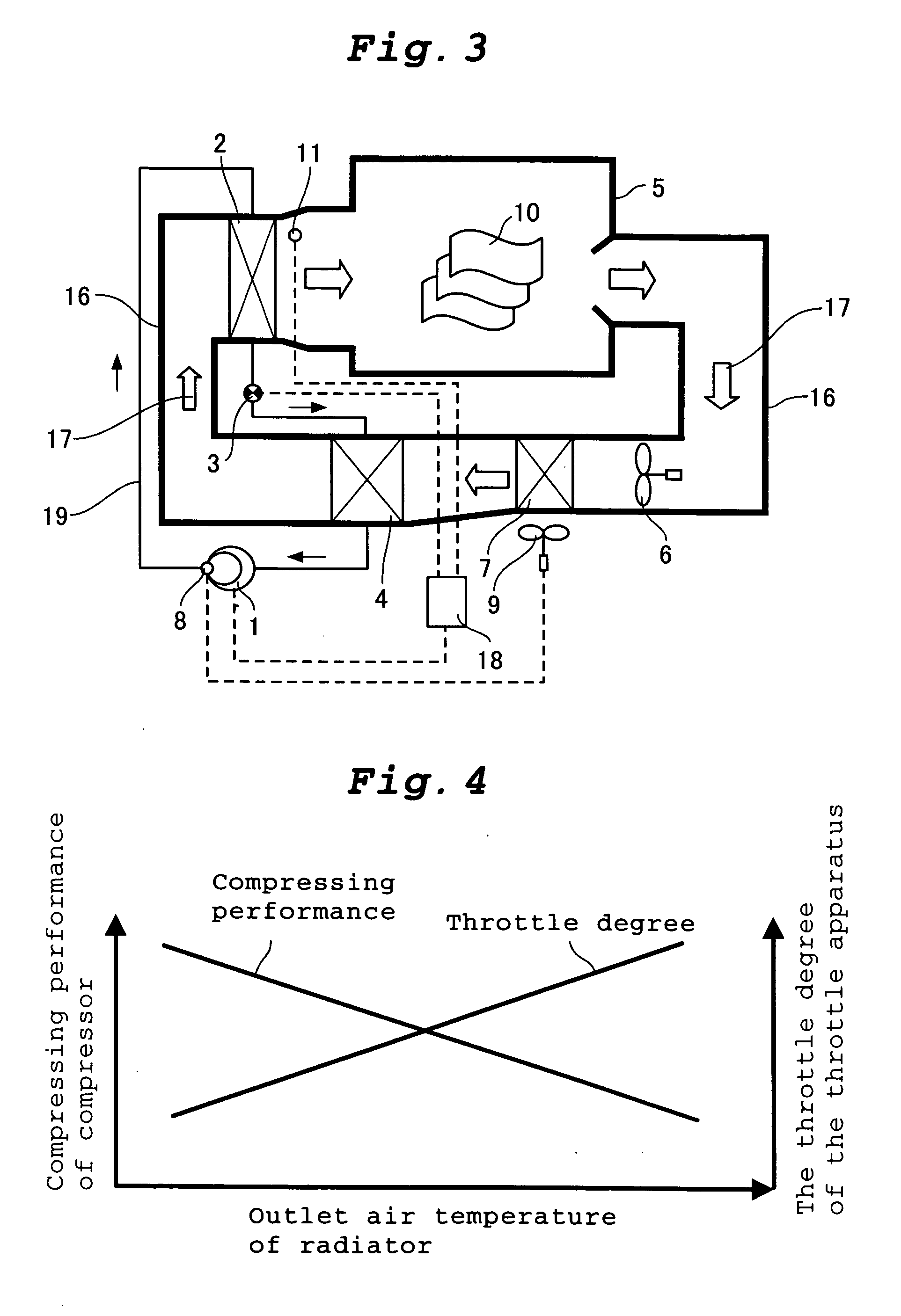

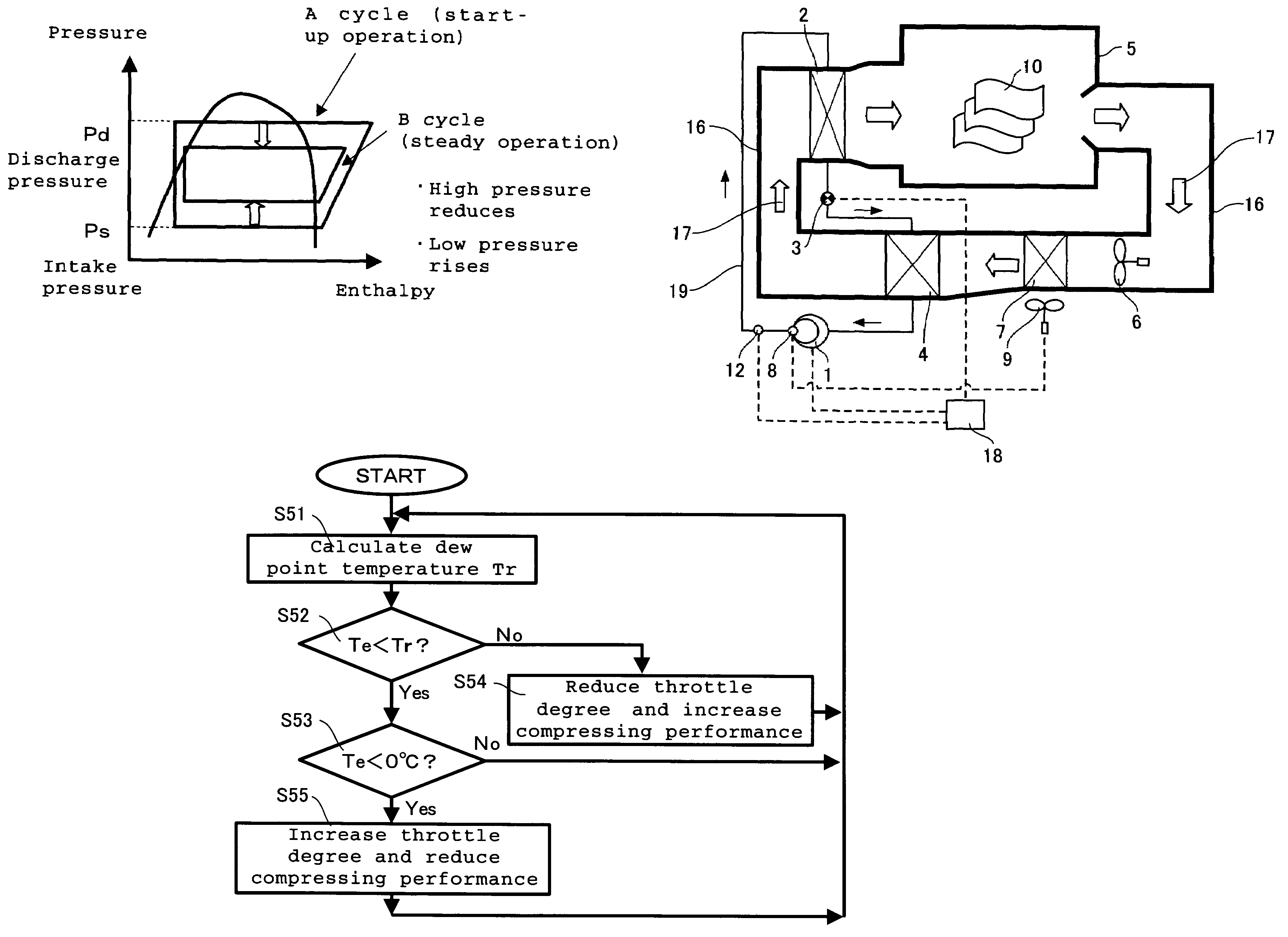

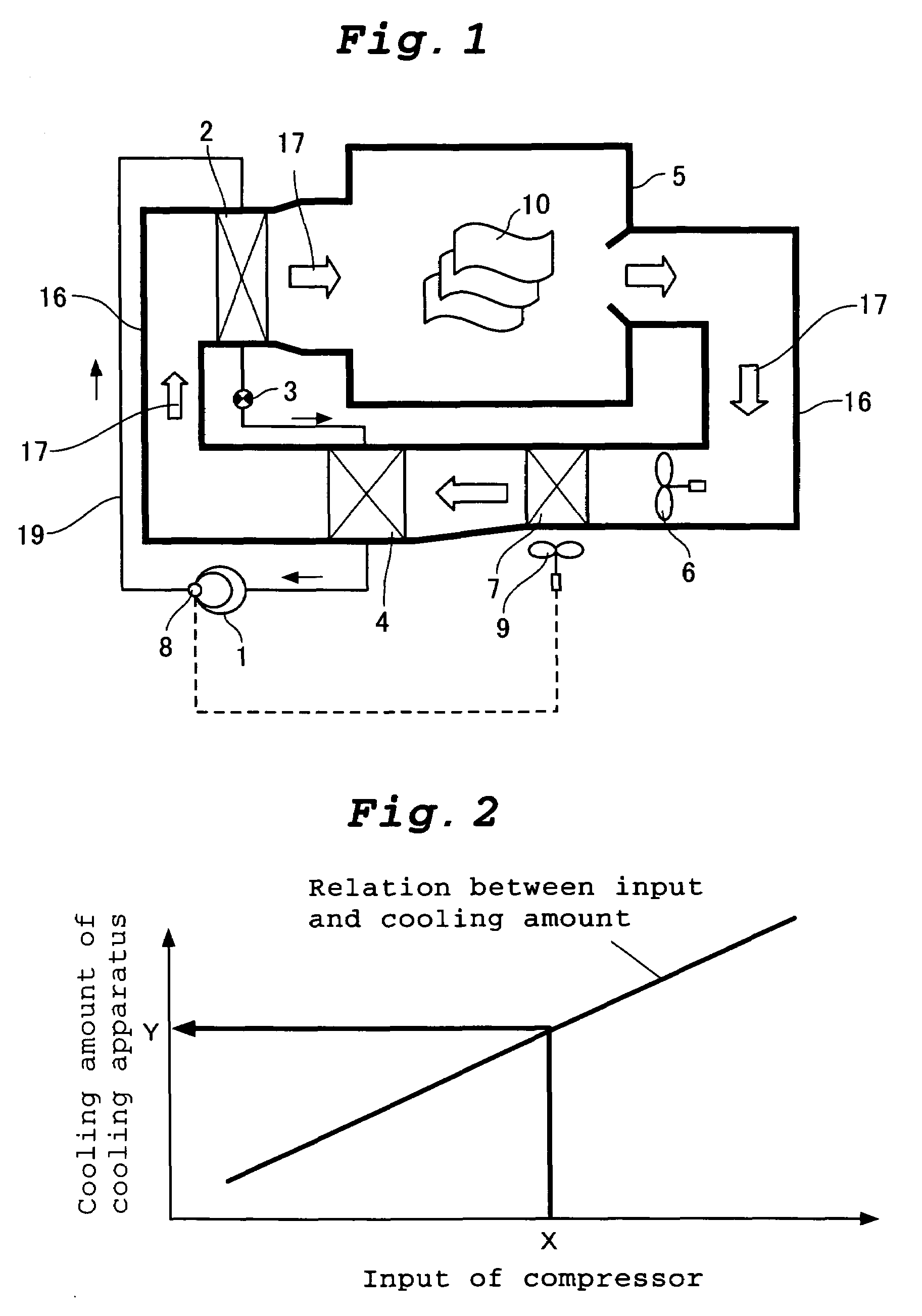

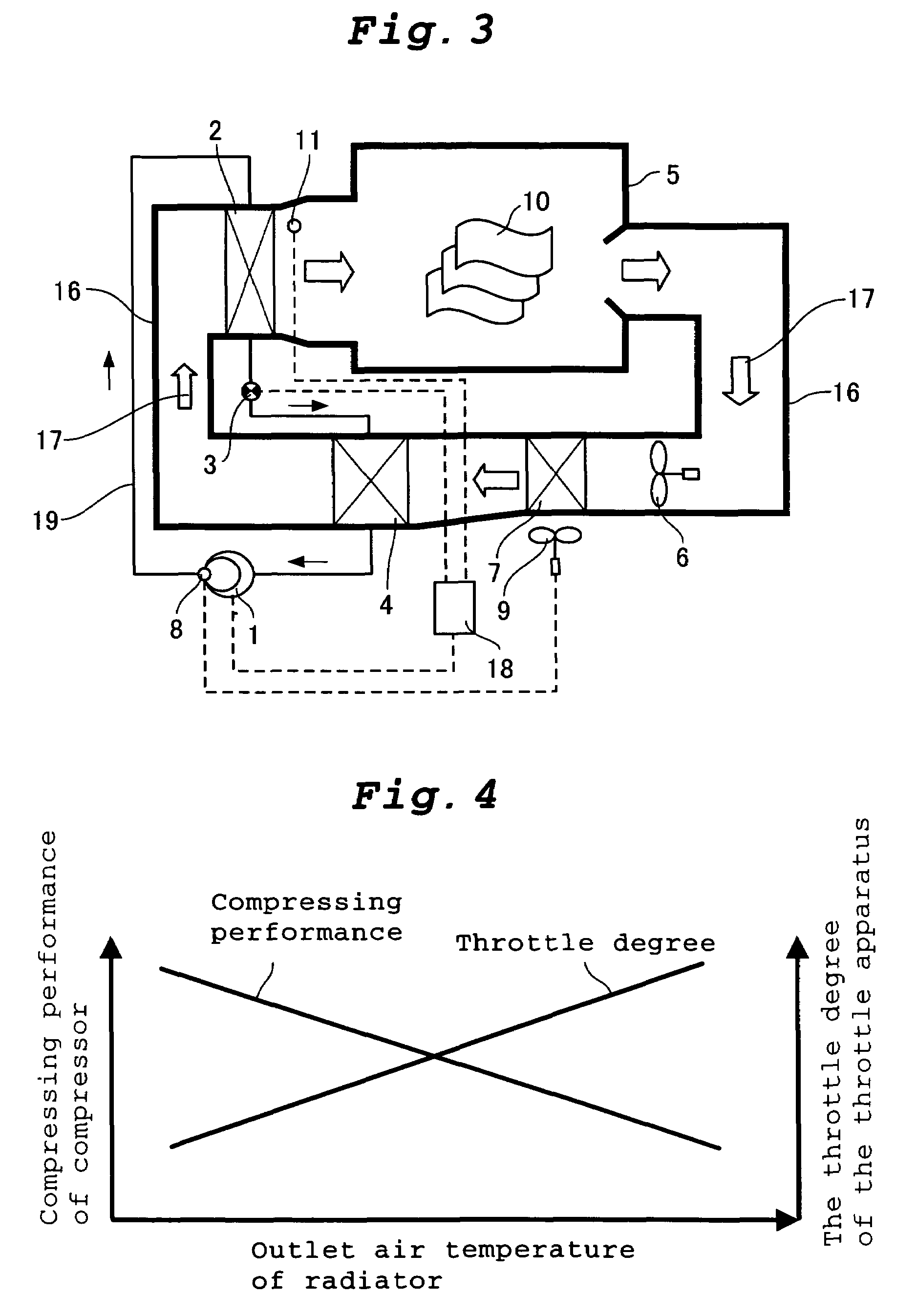

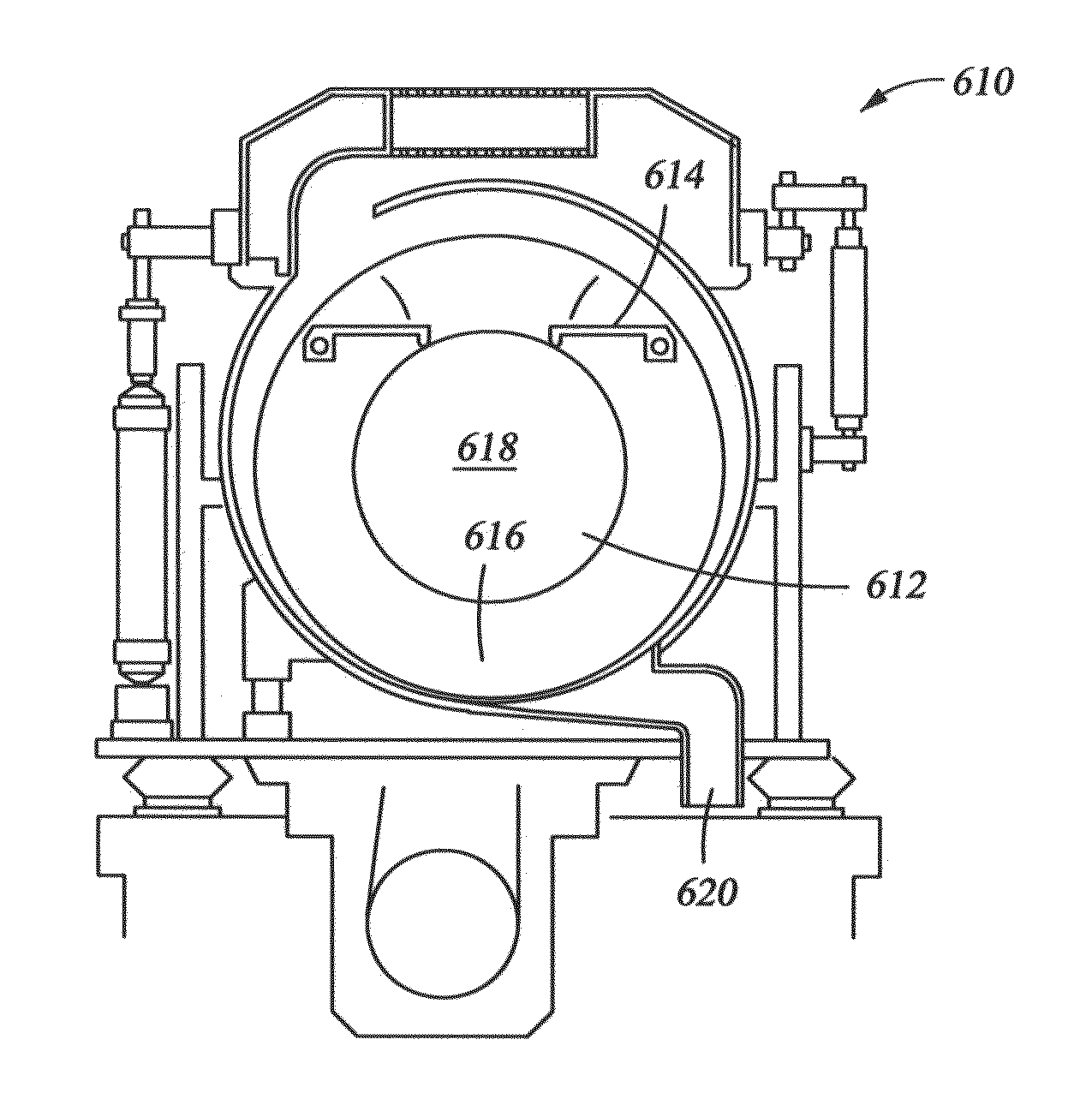

Drying device and method of operation therefor

InactiveUS20050217133A1High reliabilityIncrease drying speedDrying solid materials with heatCompression machinesRefrigerantEvaporator

A drying apparatus comprising a heat pump apparatus in which a refrigerant circulates through a compressor, a radiator, a throttle apparatus and an evaporator in this order, in which air heated by the radiator is introduced into a dry chamber, the air coming out from the dry chamber is cooled by a cooling apparatus, the air cooled by the cooling apparatus is dehumidified by the evaporator, and the air dehumidified by the evaporator is again heated by the radiator, wherein the drying apparatus further comprises compressor input detecting means for detecting input of the compressor, and cooling quantity control means for controlling a cooling quantity of the cooling apparatus using a value detected by the compressor input detecting means.

Owner:PANASONIC CORP

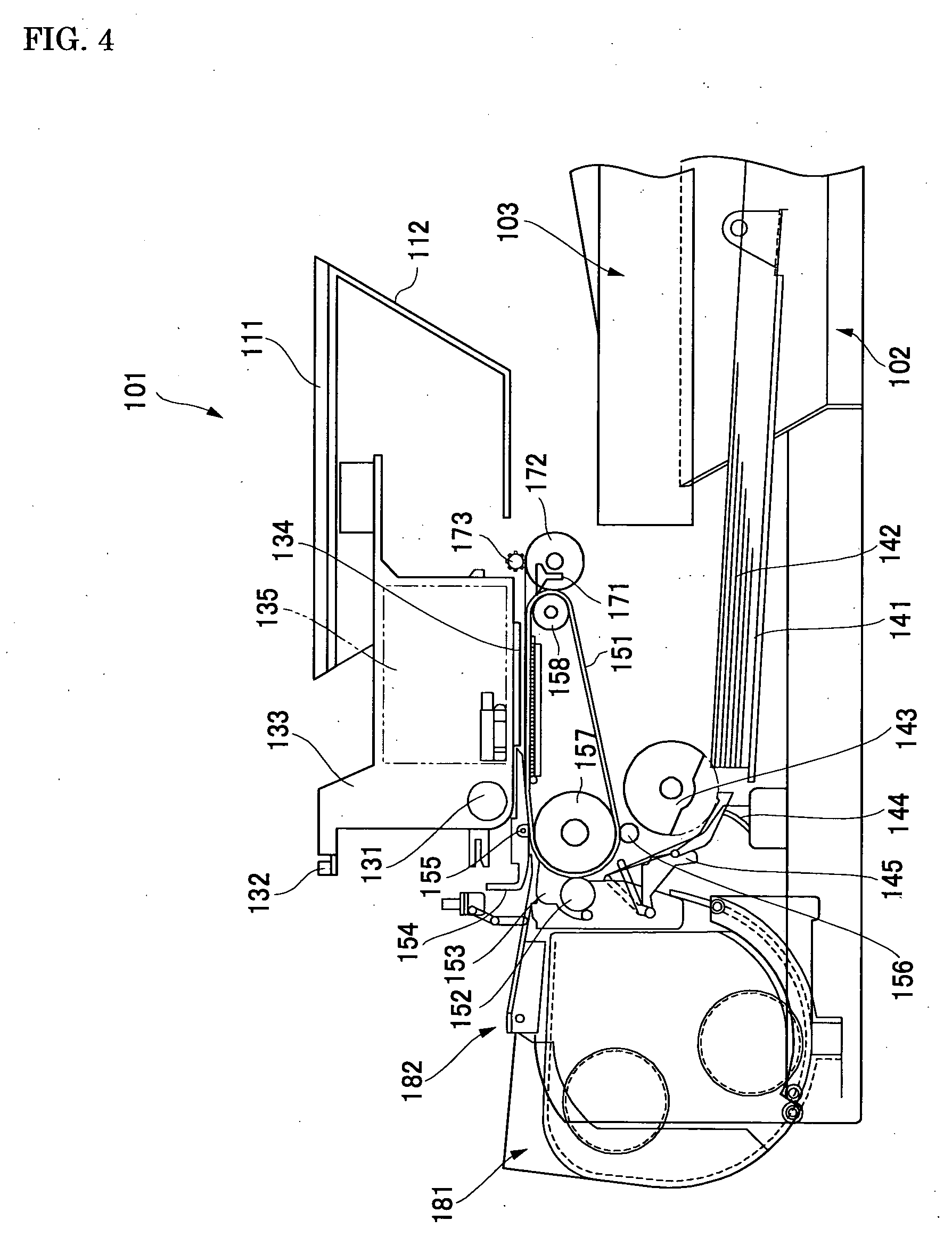

Top-load sink/laundry combo

InactiveUS7296443B2Increase drying speedReduce vibrationOther washing machinesKitchen cabinetsLaundryMobile home / trailer

An automatic washing machine including a drum, a sink, connection means for water and drain line, which are assembled in one integrated unit. It looks like a vanity with a built-in laundry machine and could be installed in any bathroom, kitchen or any utility room, mobile home, RV or even a boat having standard provision for sink connection. It could replace any existing standard sink giving customer an additional laundry capability.

Owner:HAIER AMERICA TRADING

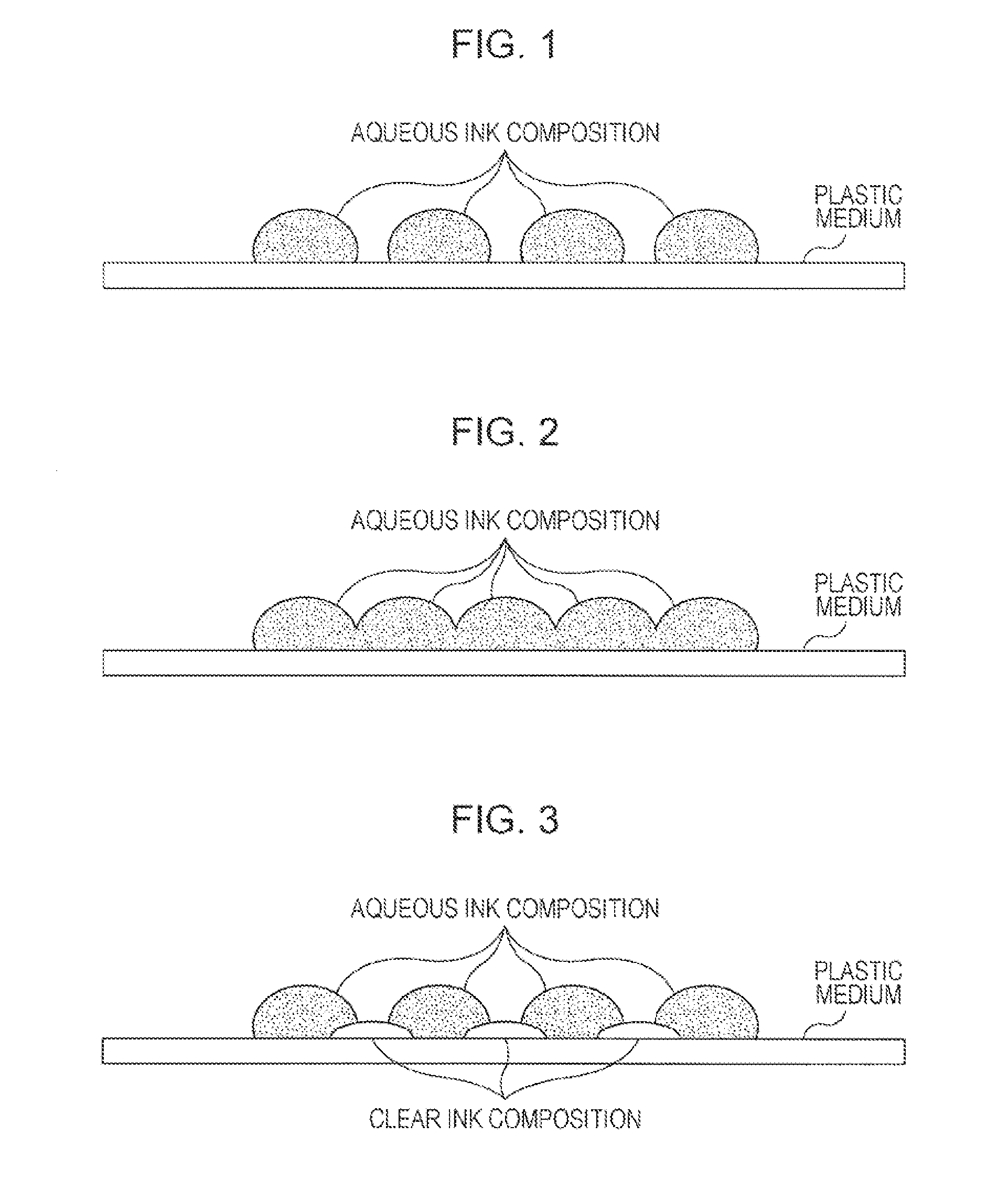

System and method for ink jet printing of water-based inks using aesthetically pleasing ink-receptive coatings

InactiveUS20060075916A1Promote absorptionDrop spreadCoatingsOther printing apparatusWater basedEngineering

A system and method for printing aqueous ink jet ink in selected areas of nonabsorbent and semi-nonabsorbent substrates includes applying an ink-receptive coating having an aesthetically pleasing appearance in the selected areas, for example with printing station having a printing and drying unit for applying the ink-receptive coating in the desired area or areas of the substrate and then drying the coating, and printing an aqueous ink jet ink in the coated area with a CIJ, TIJ, pr PIJ printer. Variable print may be printed with the ink jet ink in a high speed process.

Owner:ELECTRONICS FOR IMAGING

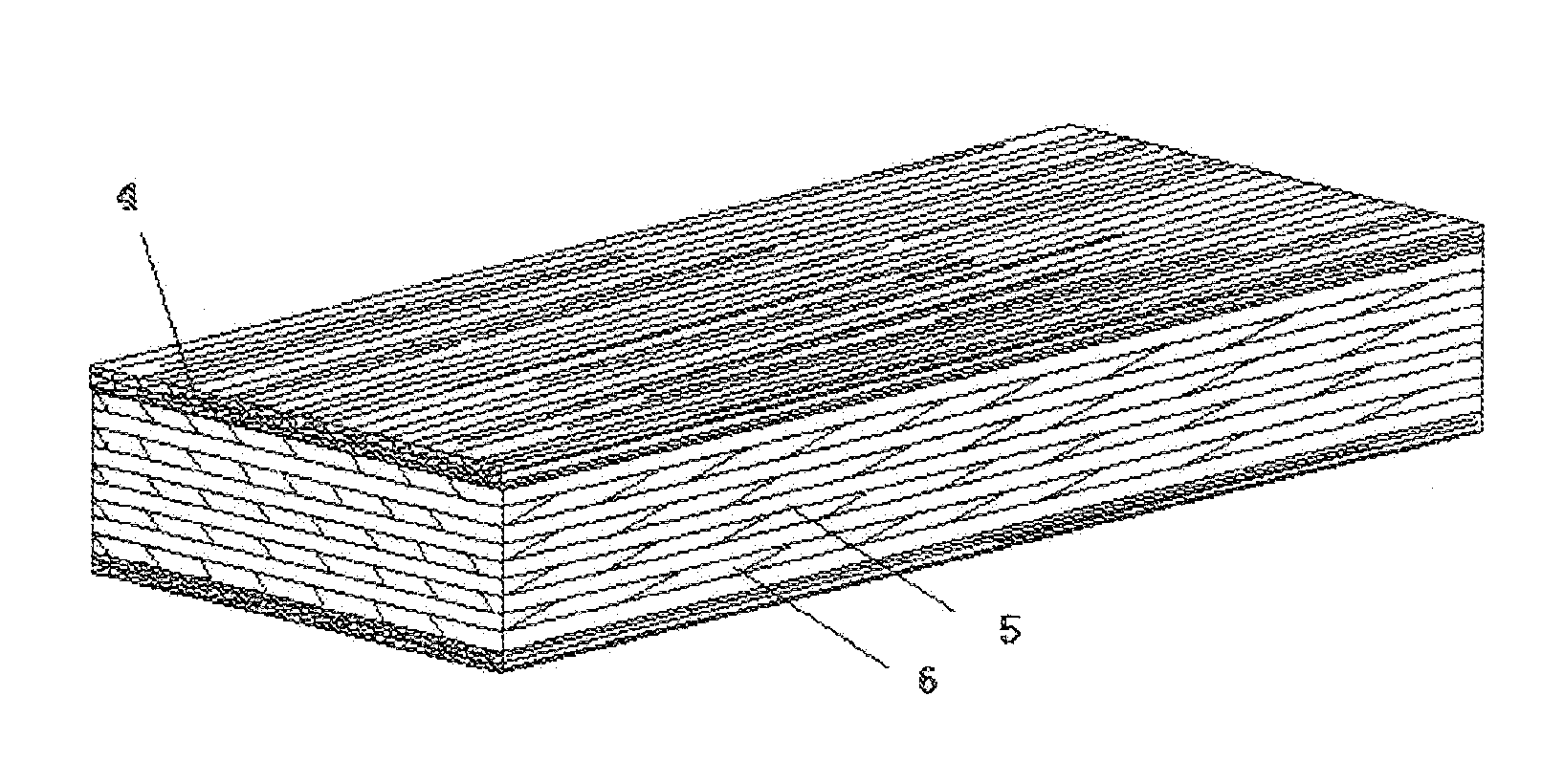

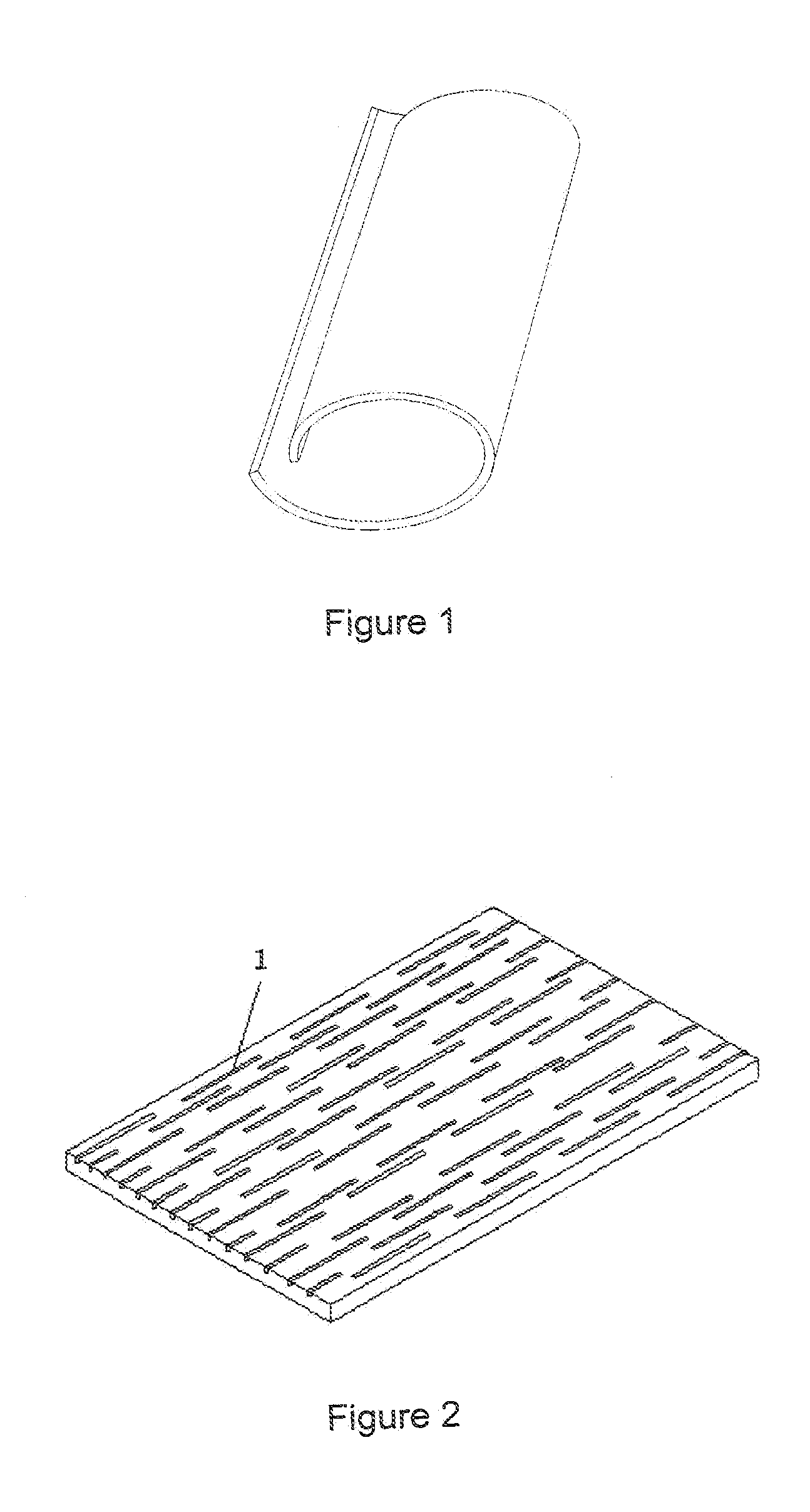

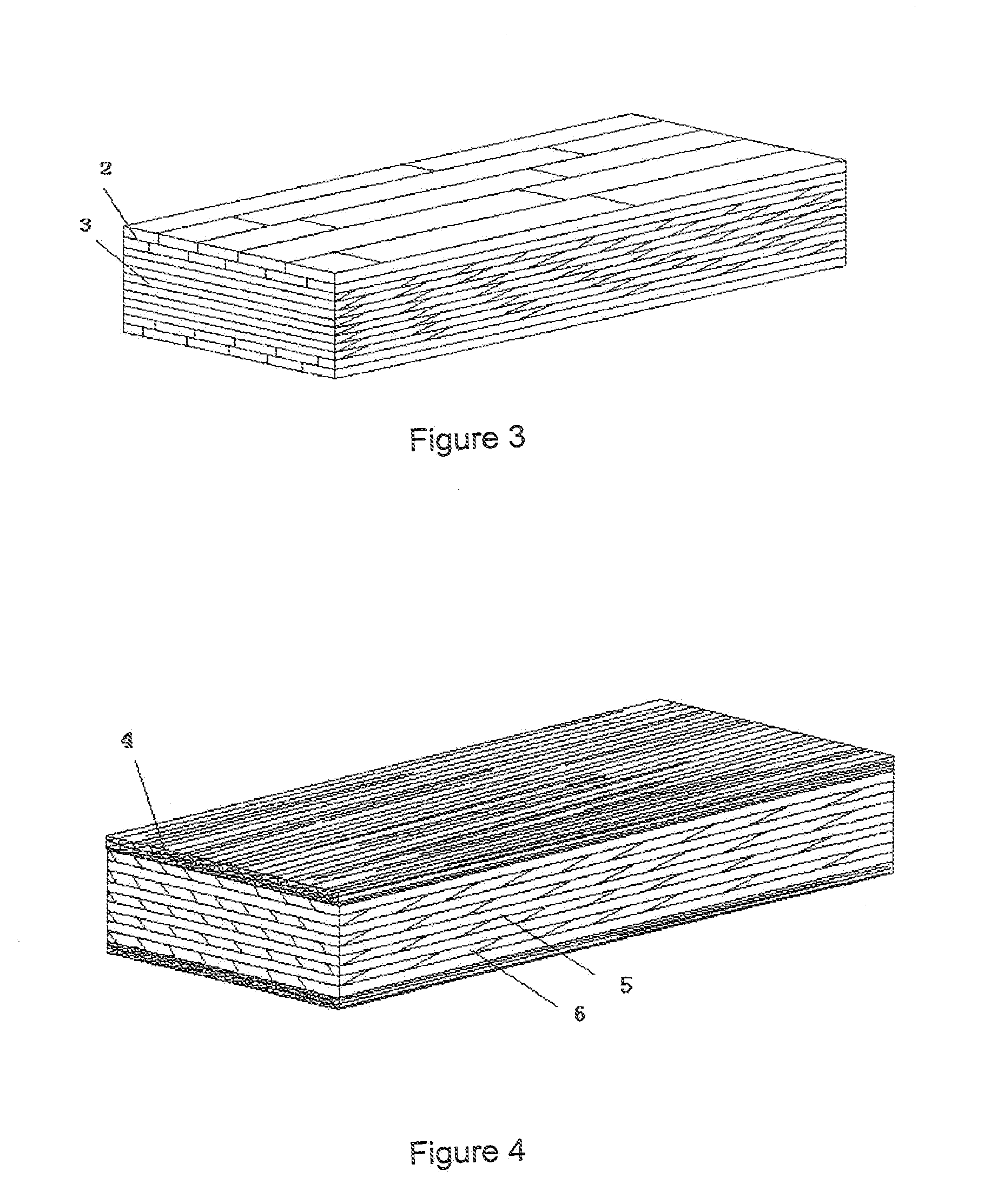

Ultra thick bamboo-wood composite panel, ultra thick solid wood composite panel and manufacturing methods thereof

InactiveUS20110274872A1Improve technologyLess amountWood veneer joiningPlant material mechanical workingLine segmentSolid wood

The present invention provides ultra-thick bamboo / wood and solid wood composite panels, comprising core board, surface board and back board; said core board is composed of ultra-thick peeling veneers with the thickness of 6 to 12 mm, both said surface board and back board are made of bamboo or wood; said core board comprises several layers of said ultra-thick veneers, and the veneers of contiguous layer are assembled with parallel structure; glue layer is arranged between contiguous said veneers, the adhesive in the glue layer is the aqueous macromolecule isocyanate adhesive; said ultra-thick veneers of the core layer are the veneers with stress degradation treatment, i.e., punctate or line segment cracks are formed along the grain of said veneer loose side in each layer. The glue spread amounts of said composite panels are obviously less than that of the existing composite panels with the same thickness, and the composite panels are without warping or deformation. The present invention also provides the manufacturing method of the above composite panels.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Ink jet recording method and recorded matter

ActiveUS20110234683A1Good rubbing fastnessHigh color reproductionDecorative surface effectsLayered productsPolymer chemistryColoring agents

Owner:SEIKO EPSON CORP

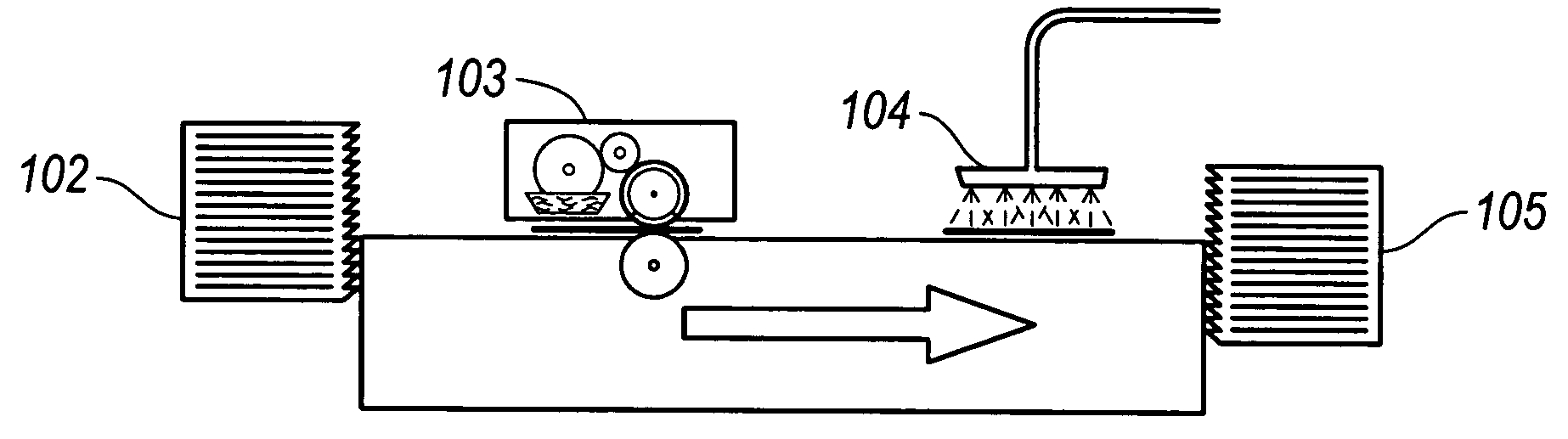

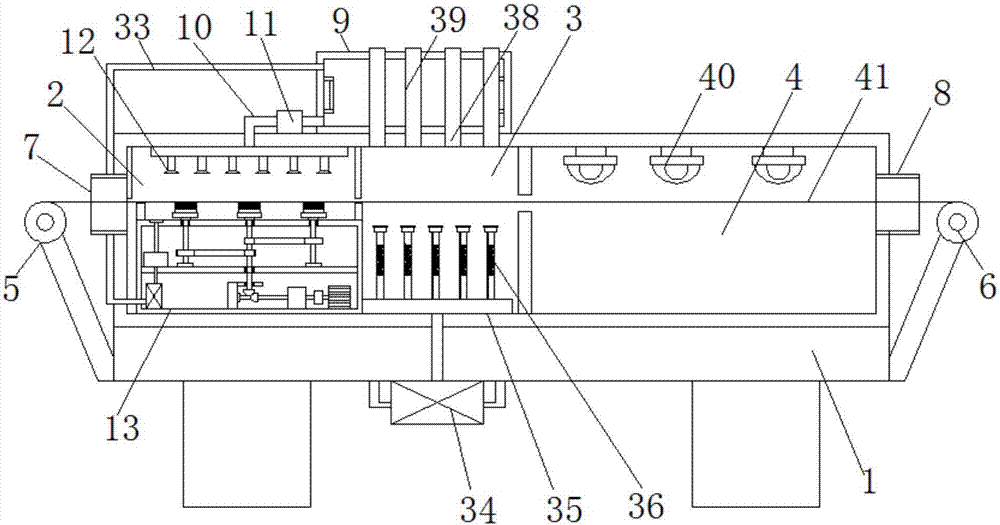

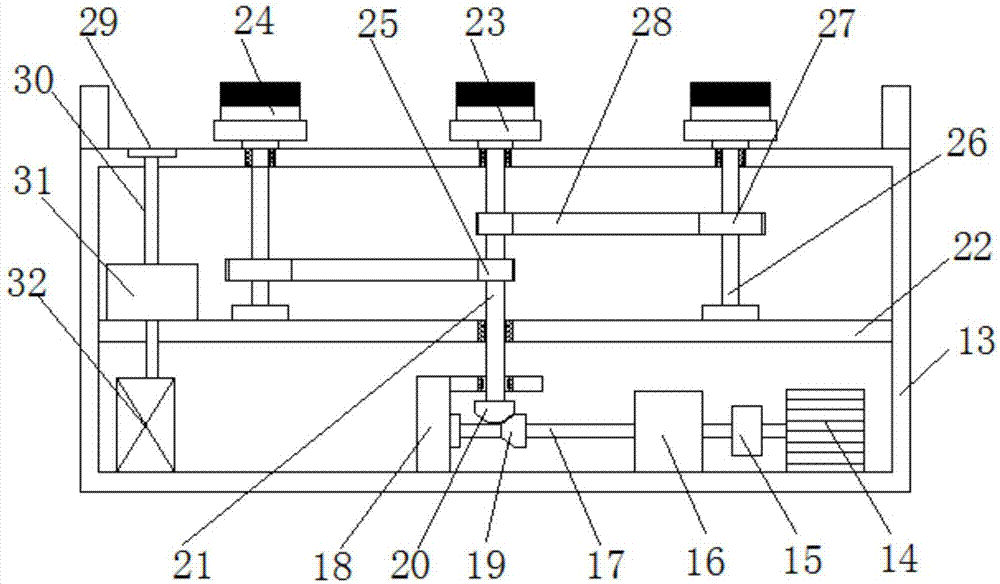

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

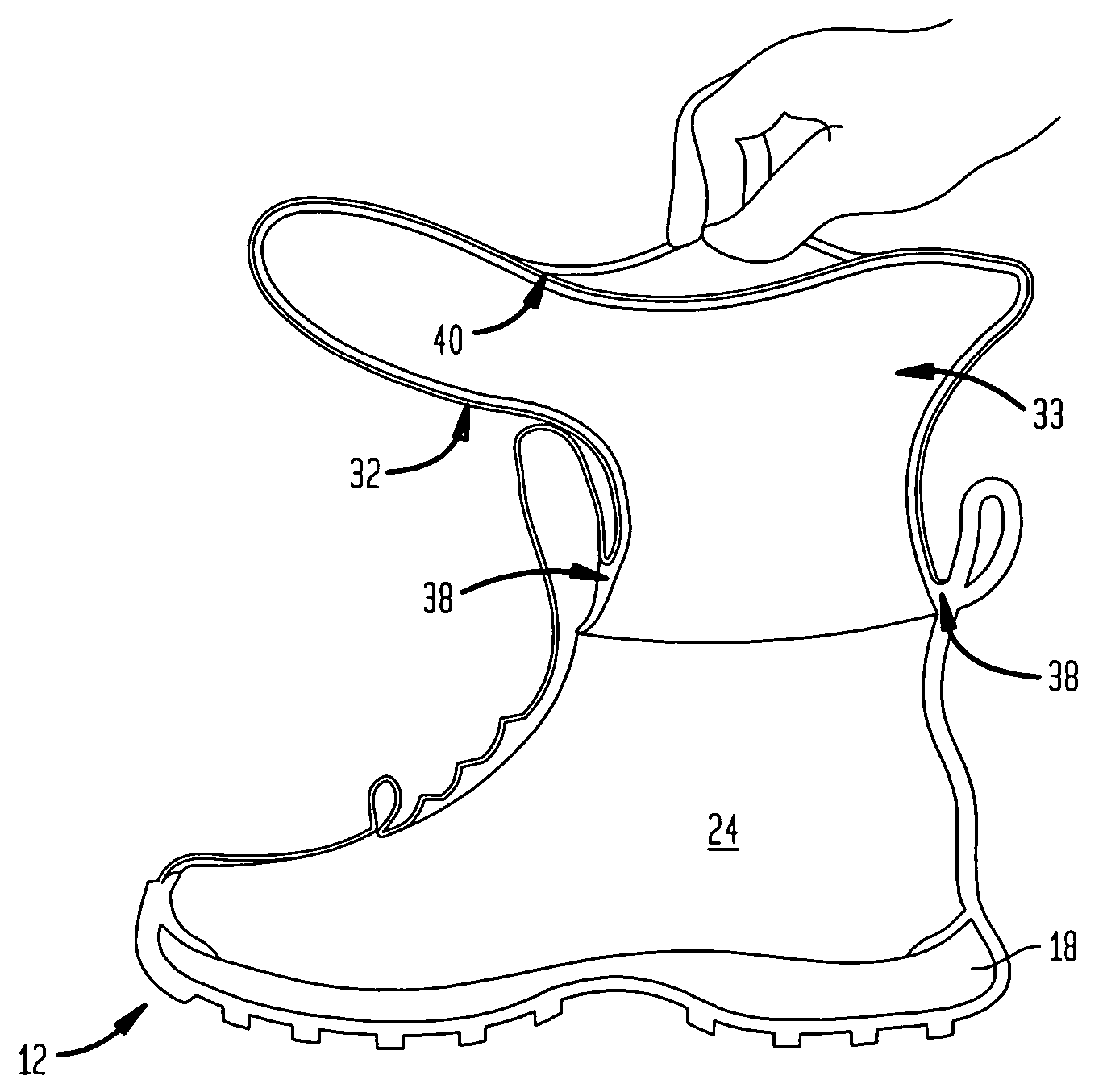

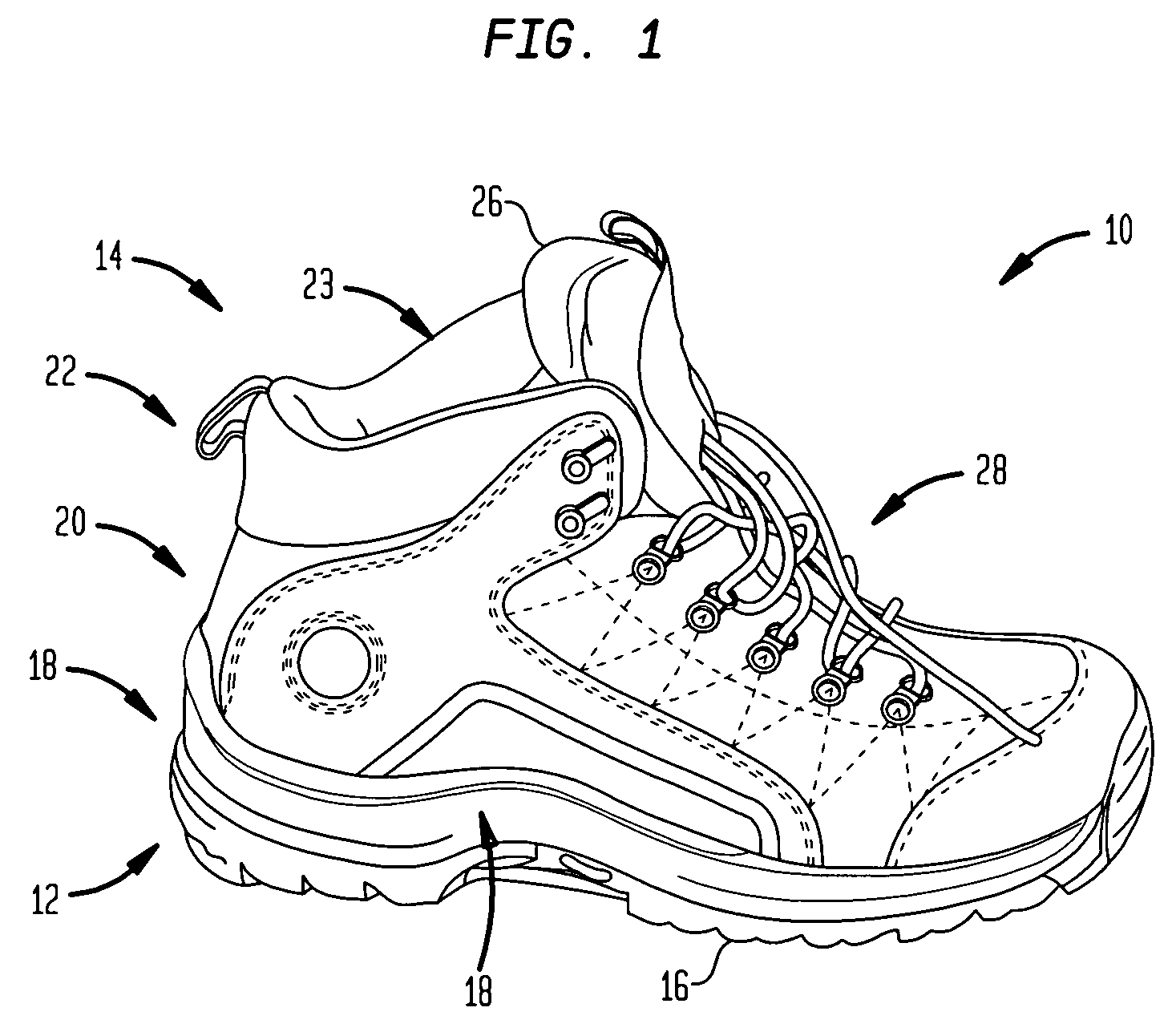

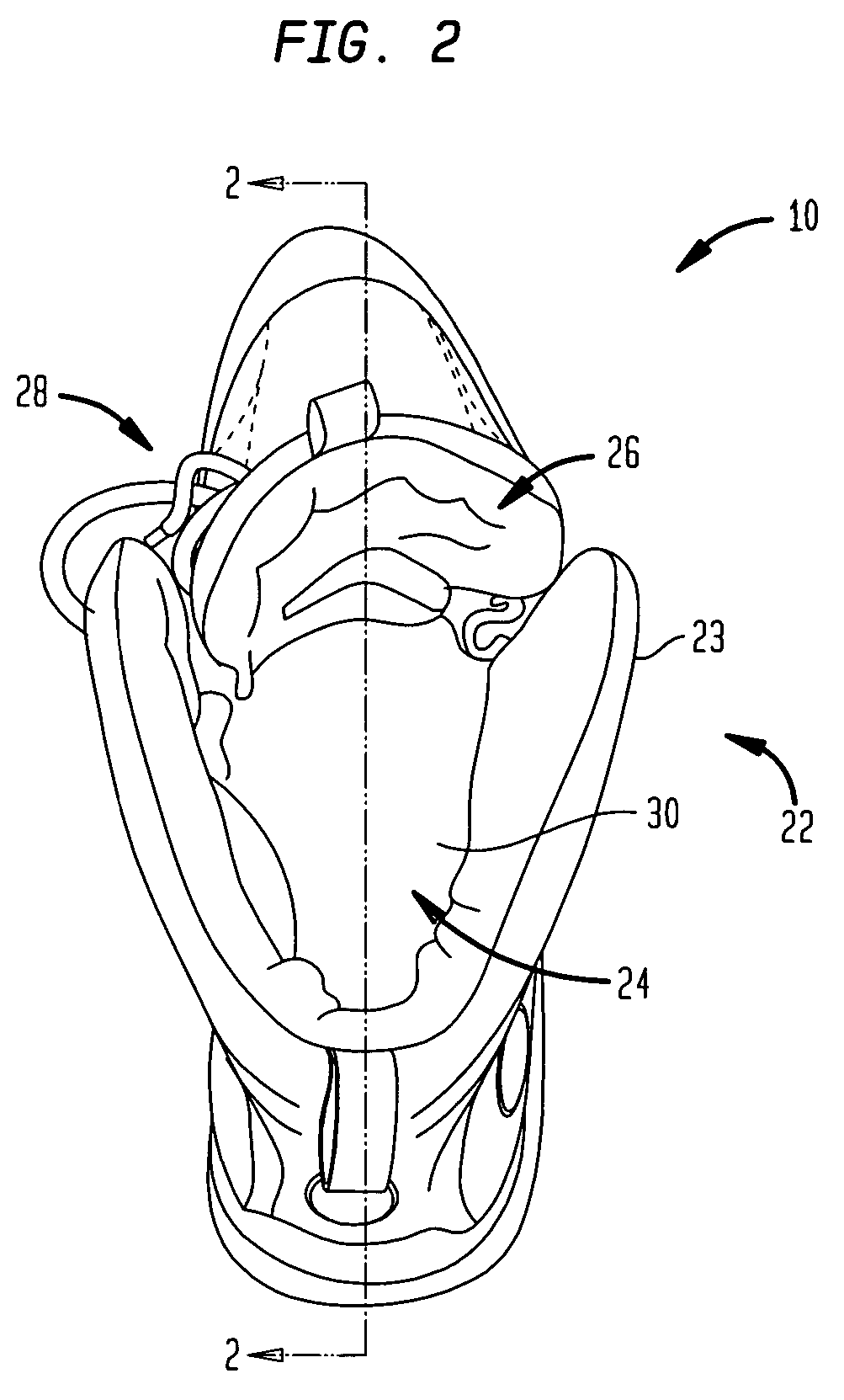

Removable or reversible lining for footwear

Owner:THE TIMBERLAND COMPANY

Drying device and method of operation therefor

InactiveUS7191543B2Increase drying speedReduce the amount of solutionDrying solid materials with heatCompression machinesComing outEngineering

Owner:PANASONIC CORP

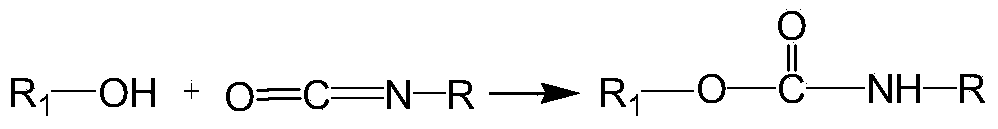

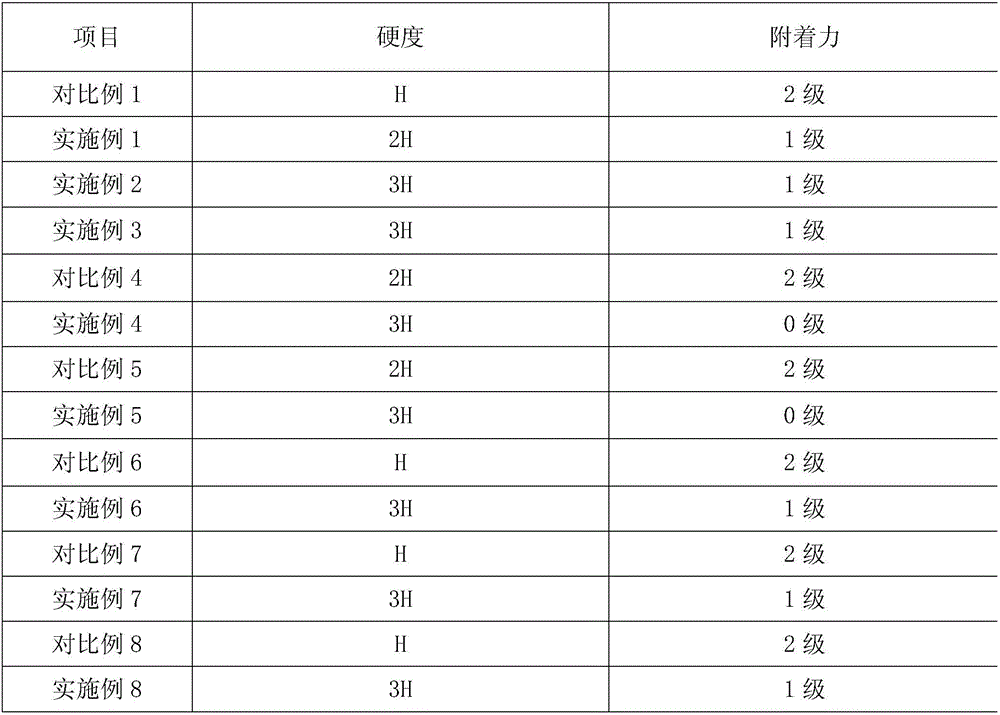

Aqueous two-component wood varnish and application thereof

The invention discloses an aqueous two-component wood varnish and application thereof. The aqueous two-component wood varnish mainly comprises a main agent and a curing agent. The main agent comprises the following components in percentage by mass: 60-80% of emulsion containing hydroxyl polymer, large than 0 and less than or equal to 6% of polycarbodiimide cross-linking agent. The curing agent mainly comprises the following component in percentage by mass: 80-85% of water dispersible polyisocyanate. By adopting double cross-linking, a varnish film with sensory effect and final performance better than that of a one-component aqueous self-crosslinking paint and an ordinary two-component aqueous paint is obtained; the varnish has the advantages of quick varnish film drying speed, quick performance improving speed, excellent varnish film performance and small dosage of aqueous isocyanate. The aqueous two-component aqueous varnish can be used as surface paint in match with the one-component priming paint which is excellent in initial water resisting property and quick in hardness improvement, thereby achieving the coating effect and performance of the conventional two-component aqueous paint at lower cost.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

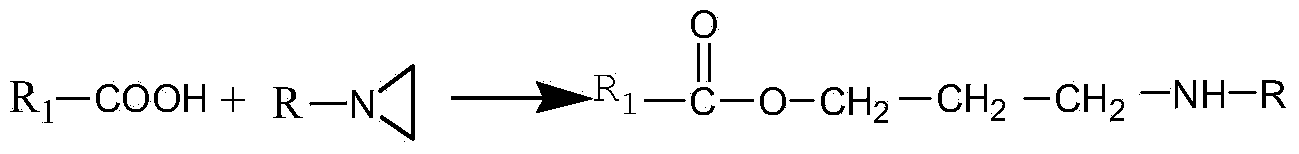

Latex compositions having improved drying speed

Disclosed are modified latexes having improved drying speed, comprising a polymer having one or more pendant side chains, such side chain comprising the product of the reaction between a mono- or poly-functional group capable of reacting with an acid or hydroxyl unit, and such units present on the precursor polymer. Such modified latexes are storage-stable one-pack compositions useful alone or in combination in coating applications, or as adhesives, sizing agents, composites, impregnants, castings, caulks, and non-woven binders. Also disclosed is a method for providing a crosslinked protective coating on a substrate, comprising the steps of: applying a coating of the composition of the present invention to the substrate; and allowing the composition to cure at ambient temperature or greater, or applying radiation to the composition to effect curing.

Owner:ROHM & HAAS CO

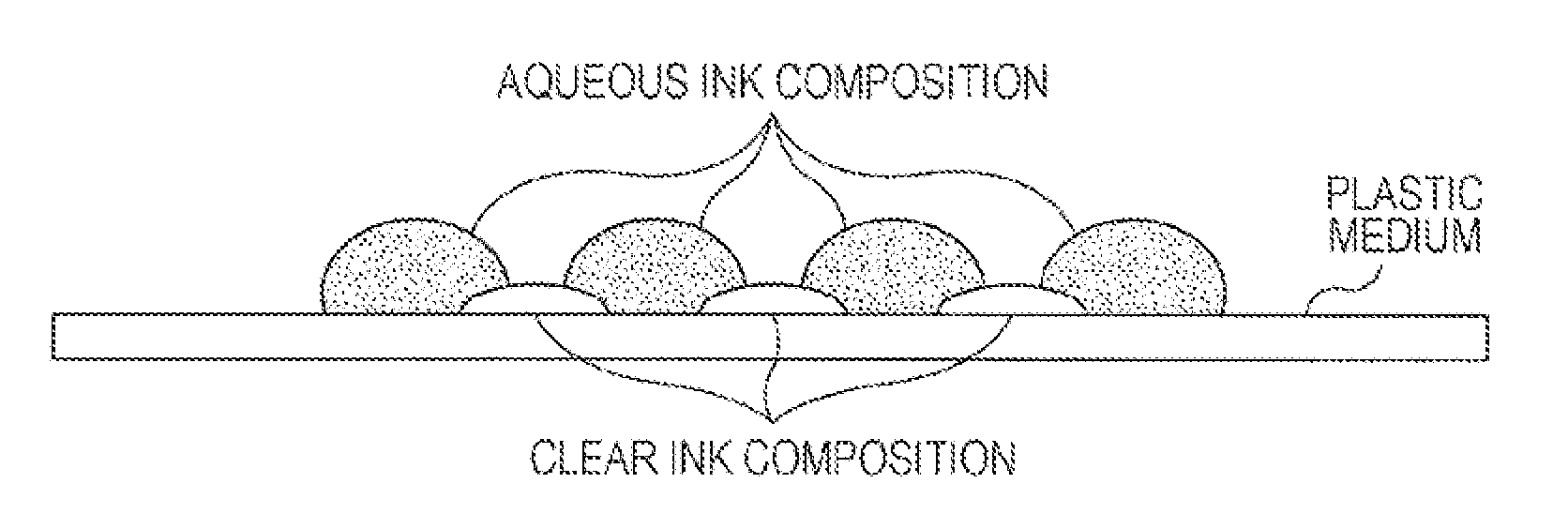

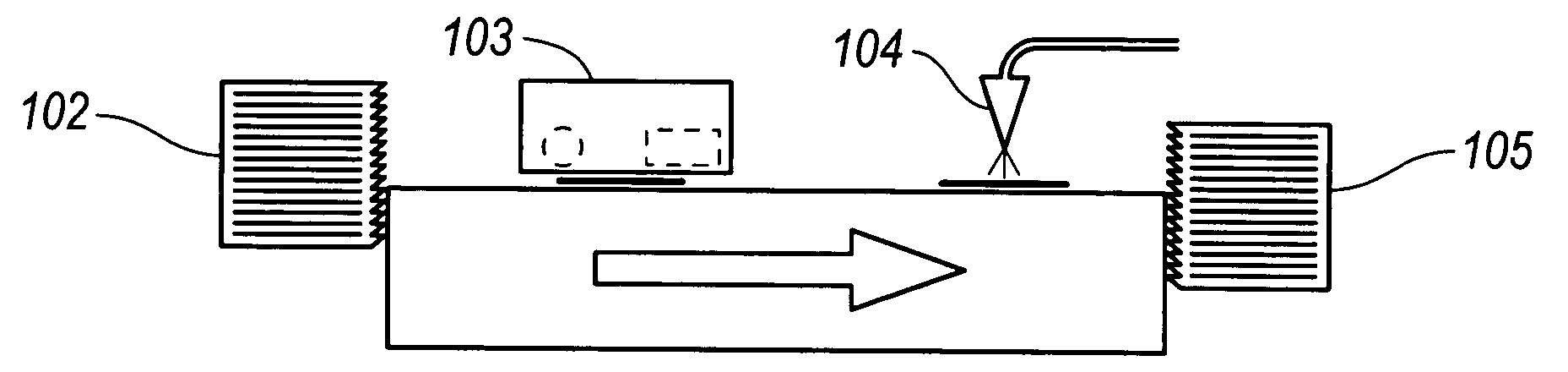

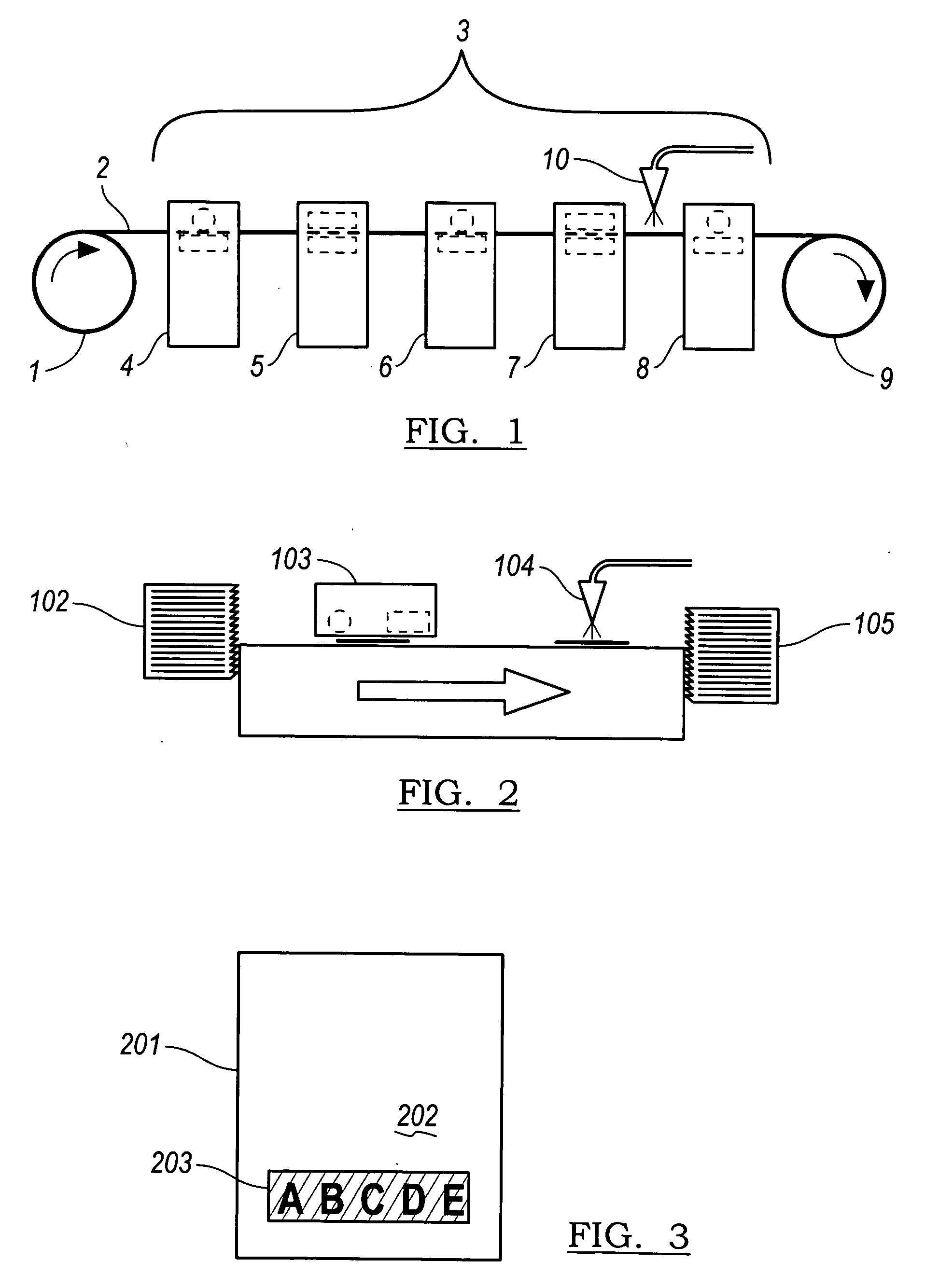

System and method for ink jet printing of water-based inks using ink-receptive coating

InactiveUS20060077244A1Promote absorptionDrop spreadOther printing apparatusDuplicating/marking methodsWater basedInk printer

A system and method for printing aqueous ink jet ink in selected areas of nonabsorbent and semi-nonabsorbent substrates includes applying an ink-receptive coating in the selected areas, for example with printing station having a printing and drying unit for applying the ink-receptive coating in the desired area or areas of the substrate and then drying the coating, and printing an aqueous ink jet ink in the coated area with an ink jet printer. Variable print maybe printed with the in jet ink in a high speed process.

Owner:ELECTRONICS FOR IMAGING

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

Pulp molding machine, pulp molding process and paper-shaped article made thereby

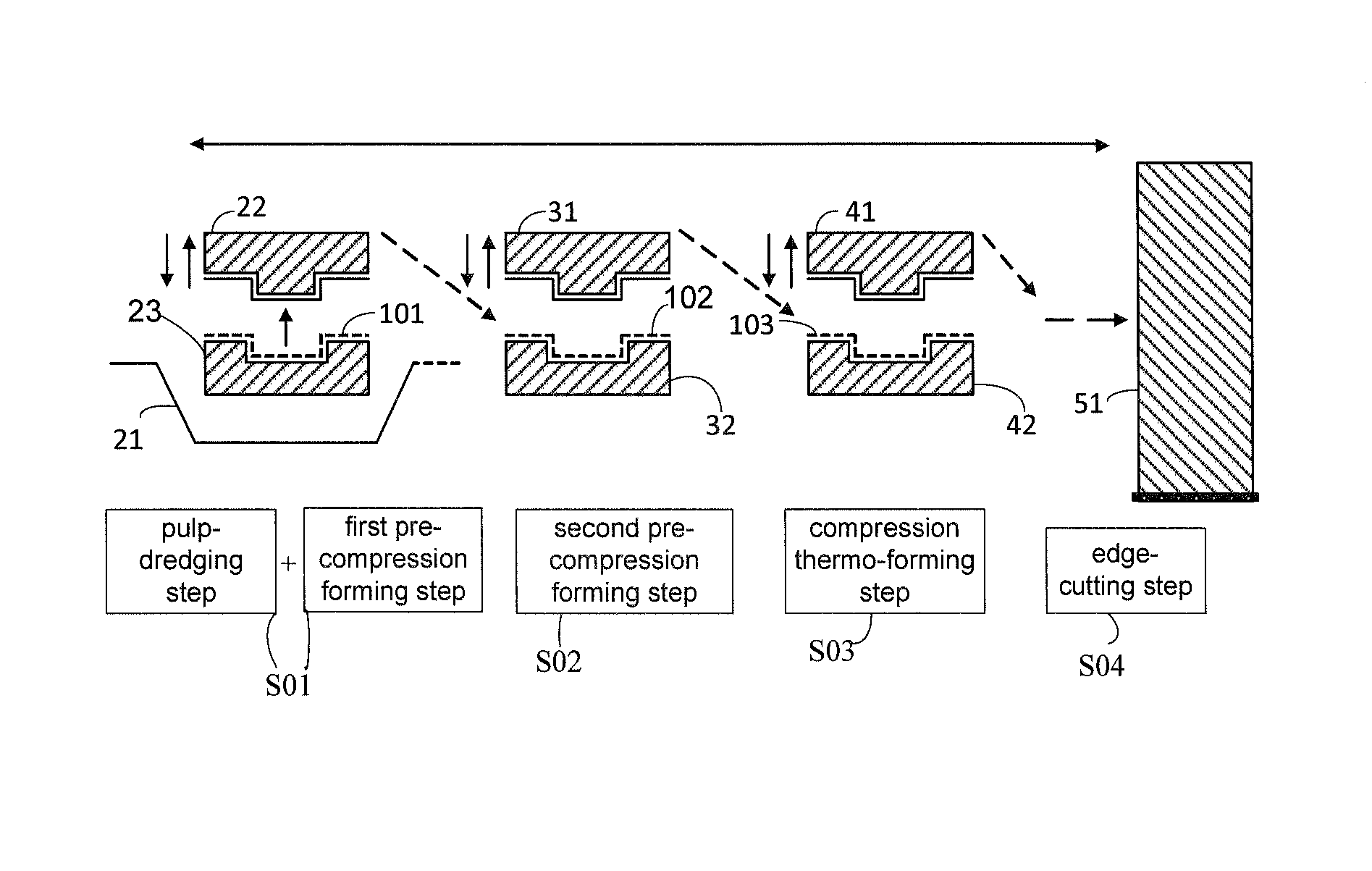

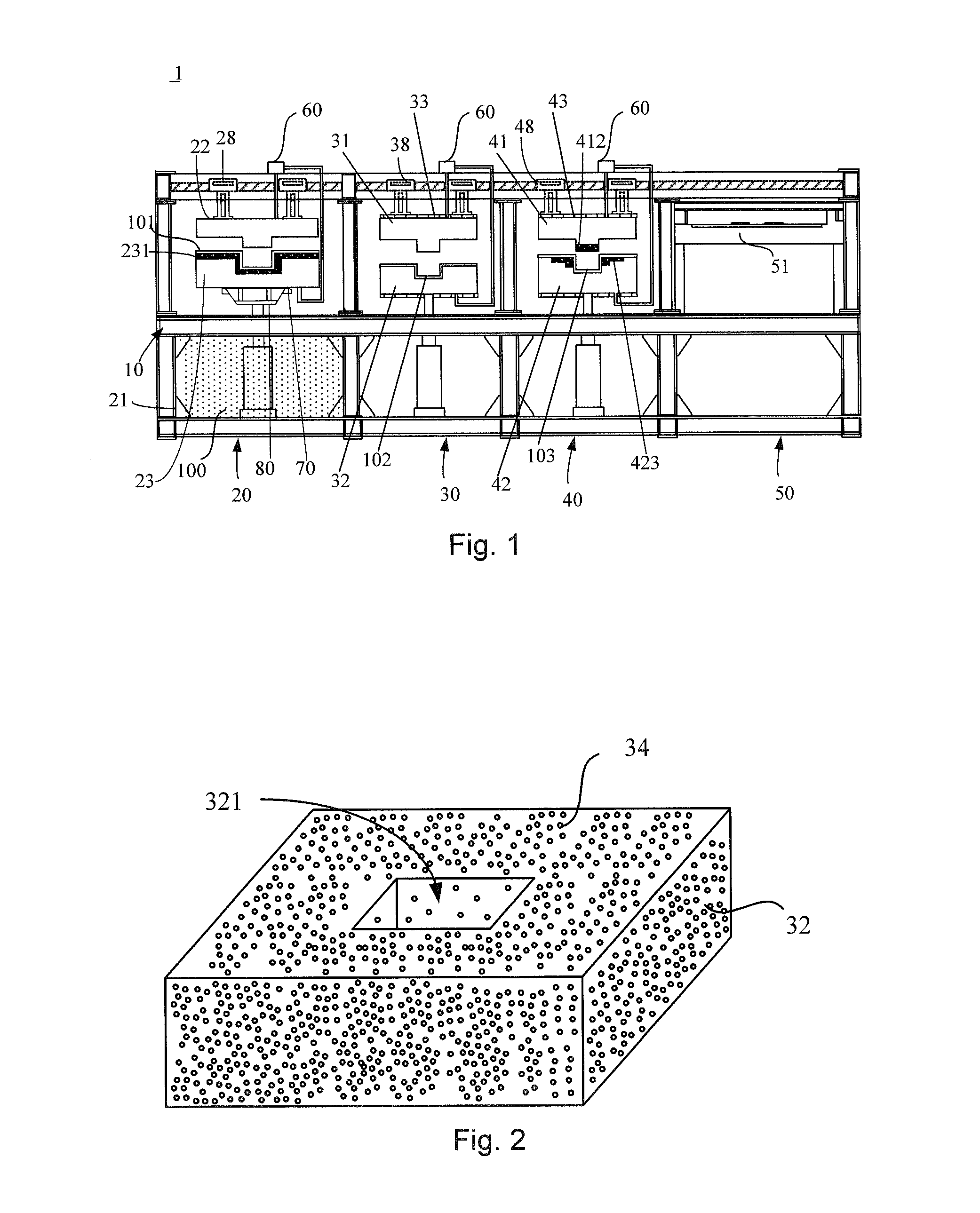

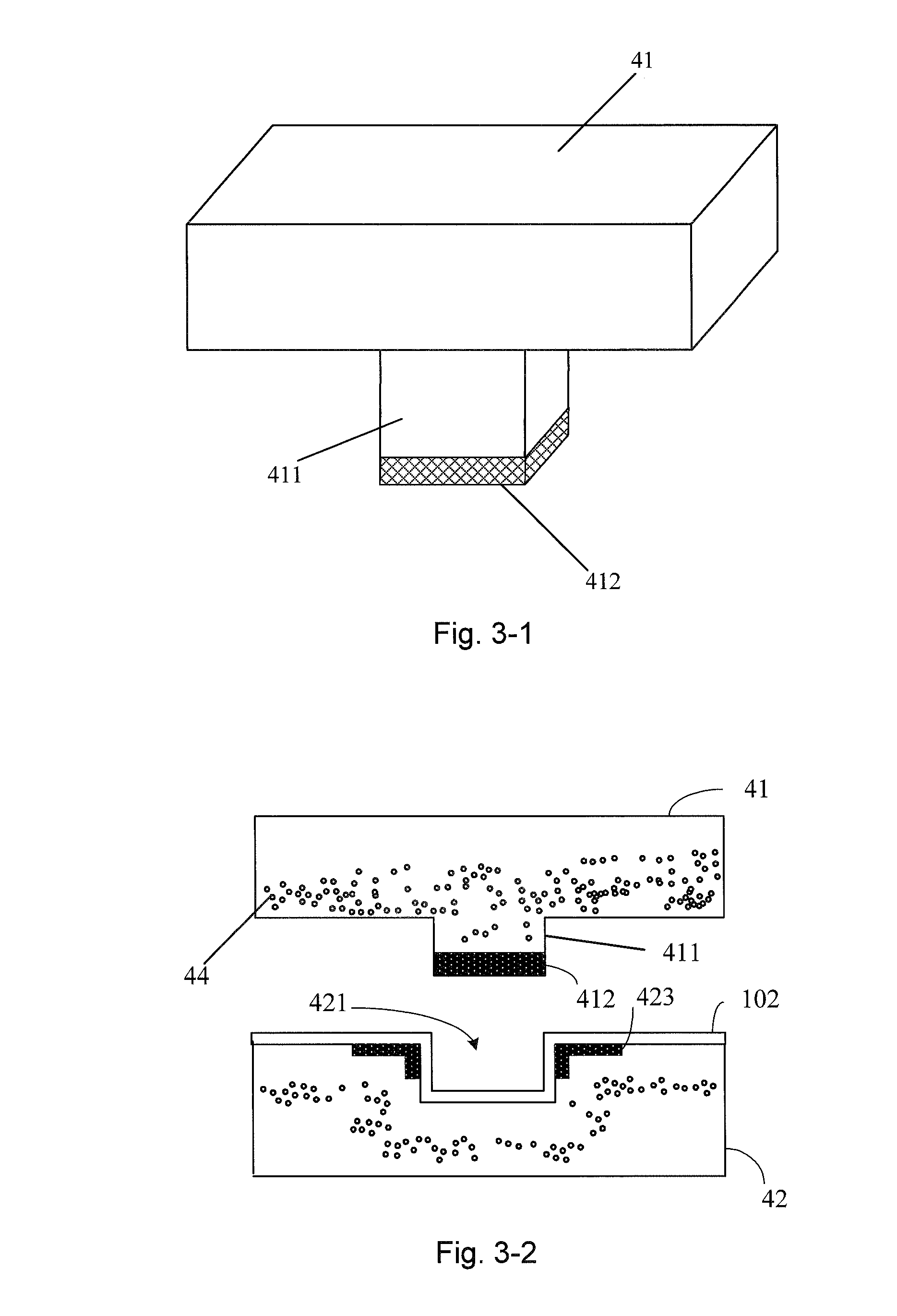

ActiveUS20160168801A1Shorten production timeReduce contentFibreboardPaper-making machinesMolding machineShell molding

A pulp molding machine, a pulp molding process and a paper-shaped article made thereby are provided. The pulp molding machine comprises a pulp-dredging stage, a first pre-compression forming sub-stage, a second pre-compression stage, a compression thermo-forming stage and an edge-cutting stage. The pulp molding process comprises the steps of a pulp-dredging step, a first pre-compression forming step, a second pre-compression forming step, a compression thermo-forming step and an edge-cutting step. The pulp molding machine the pulp molding process can drain off water or vapor from a wet pulp more efficiently and shorten the cycle time of the pulp molding process due to the extra pre-compression sub-stage. The paper-shaped article made thereby has a greater smoothness and structural strength than conventional paper-shaped product.

Owner:GOLDEN ARROW PRINTING

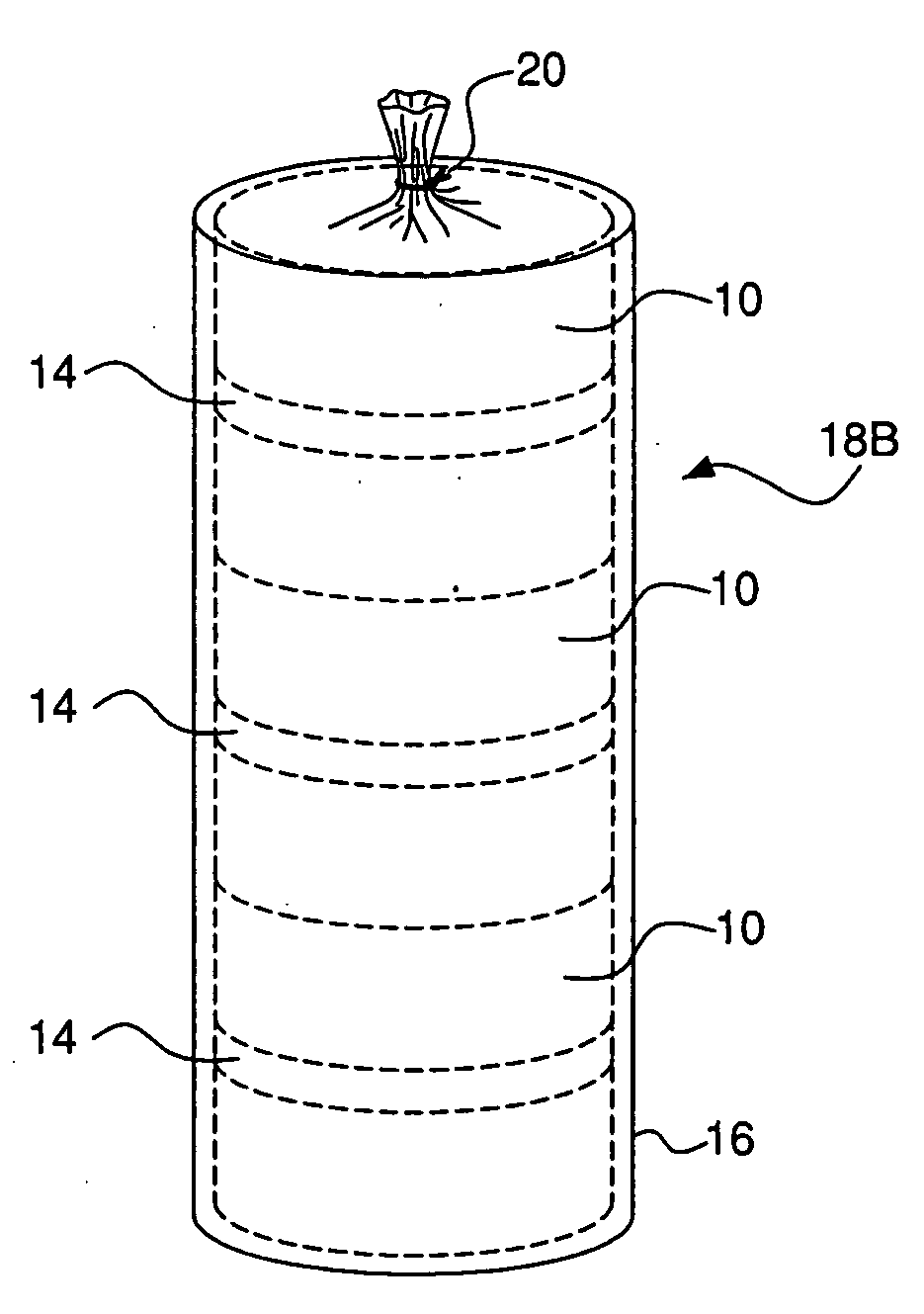

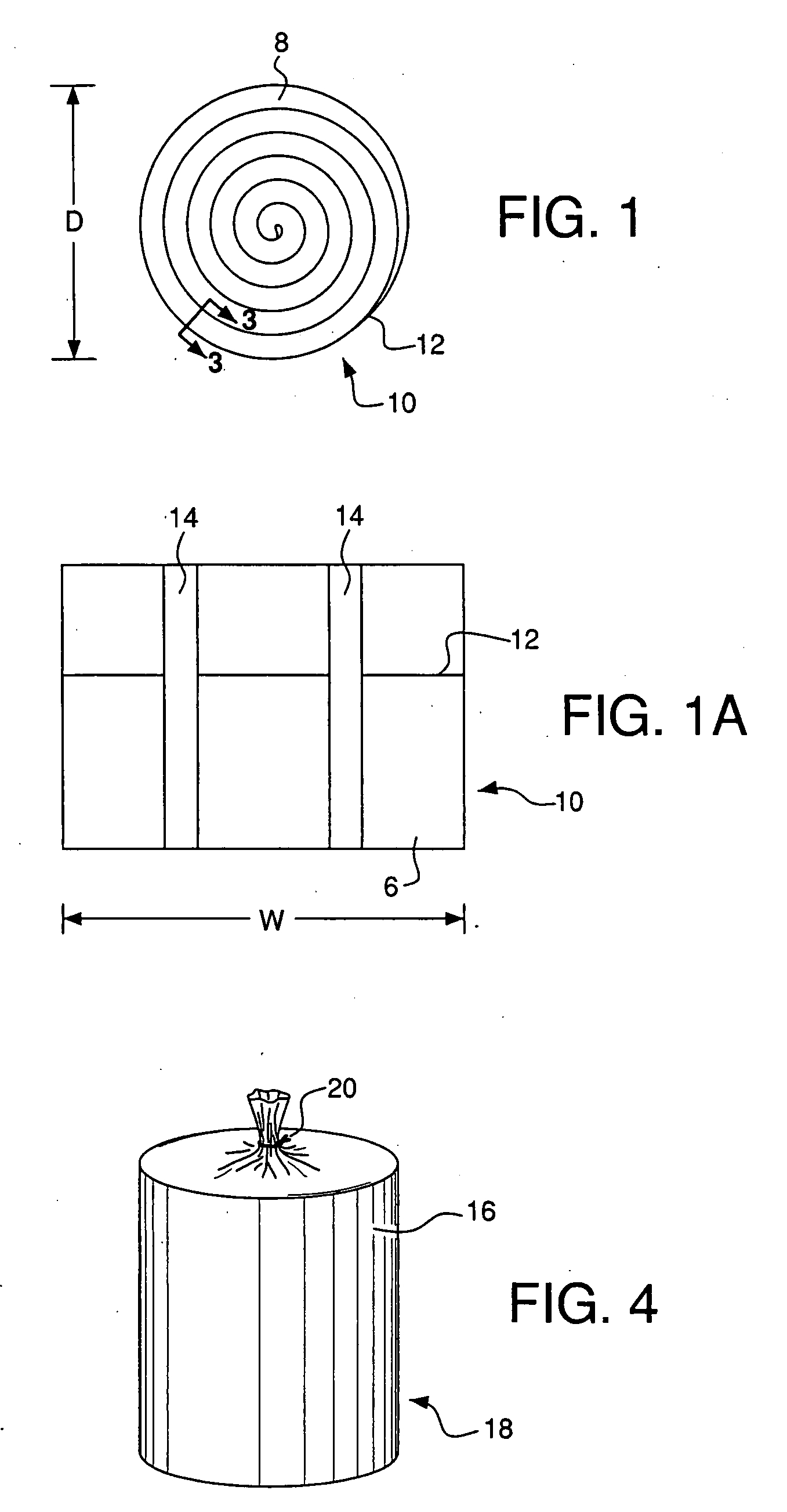

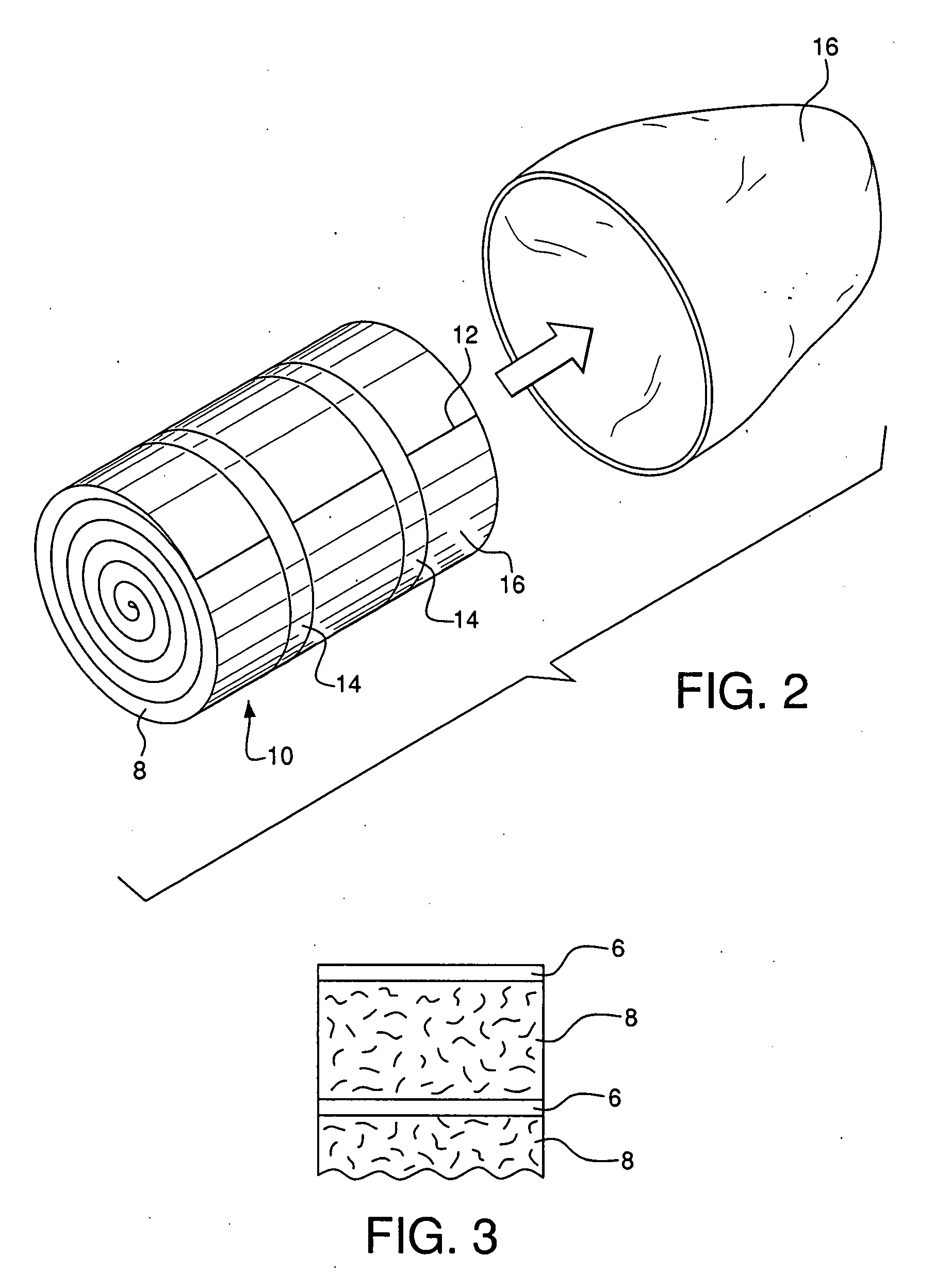

Packaging for insulation products

InactiveUS20080115460A1Increase drying speedControl odorEnvelopes/bags making machineryWrappersEngineering

Owner:CERTAINTEED CORP

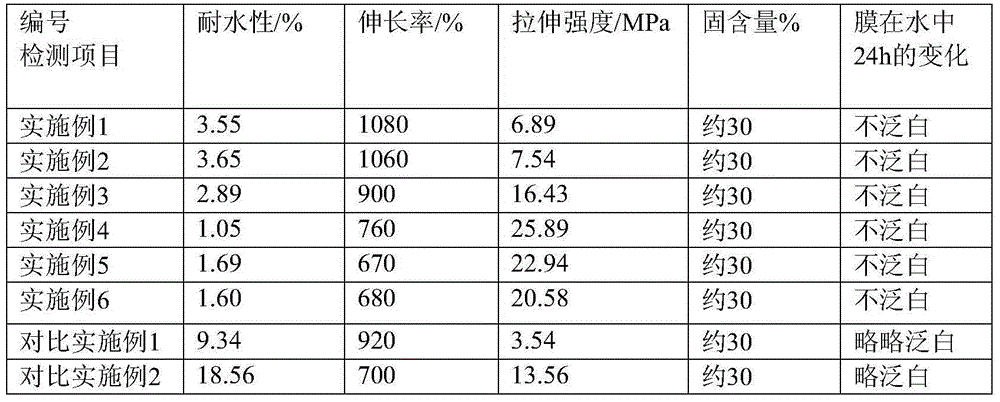

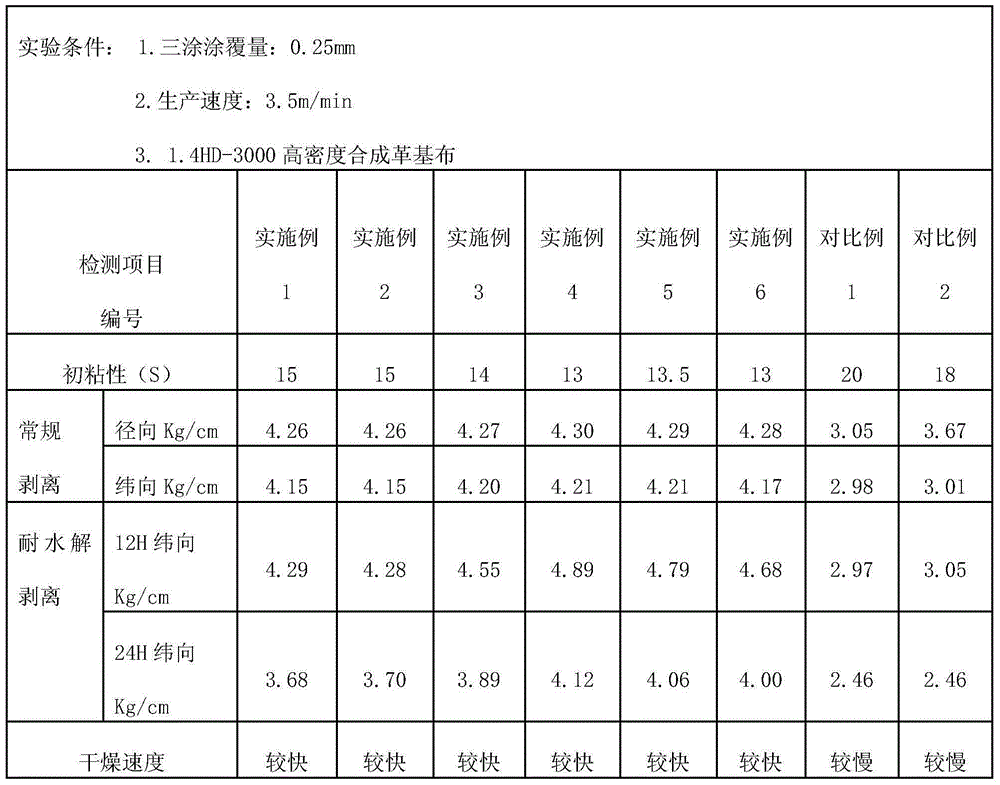

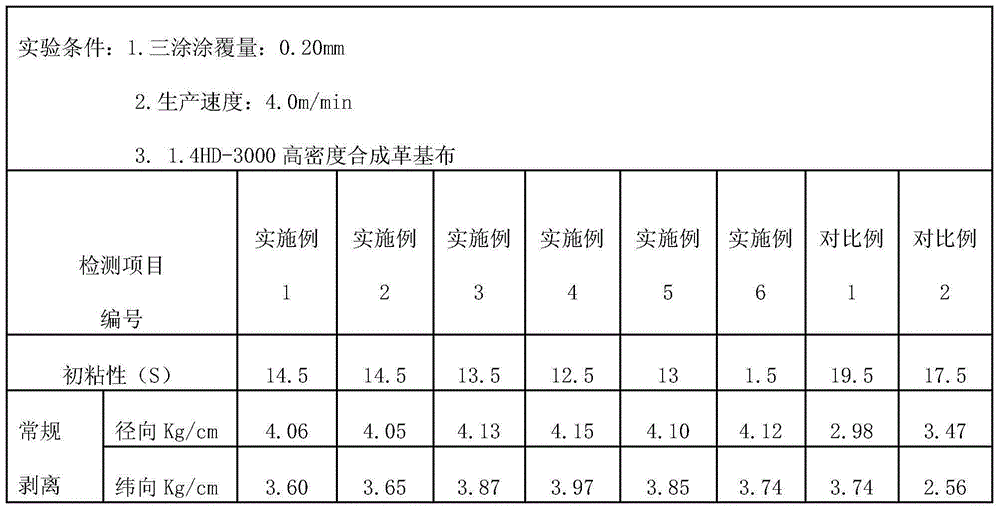

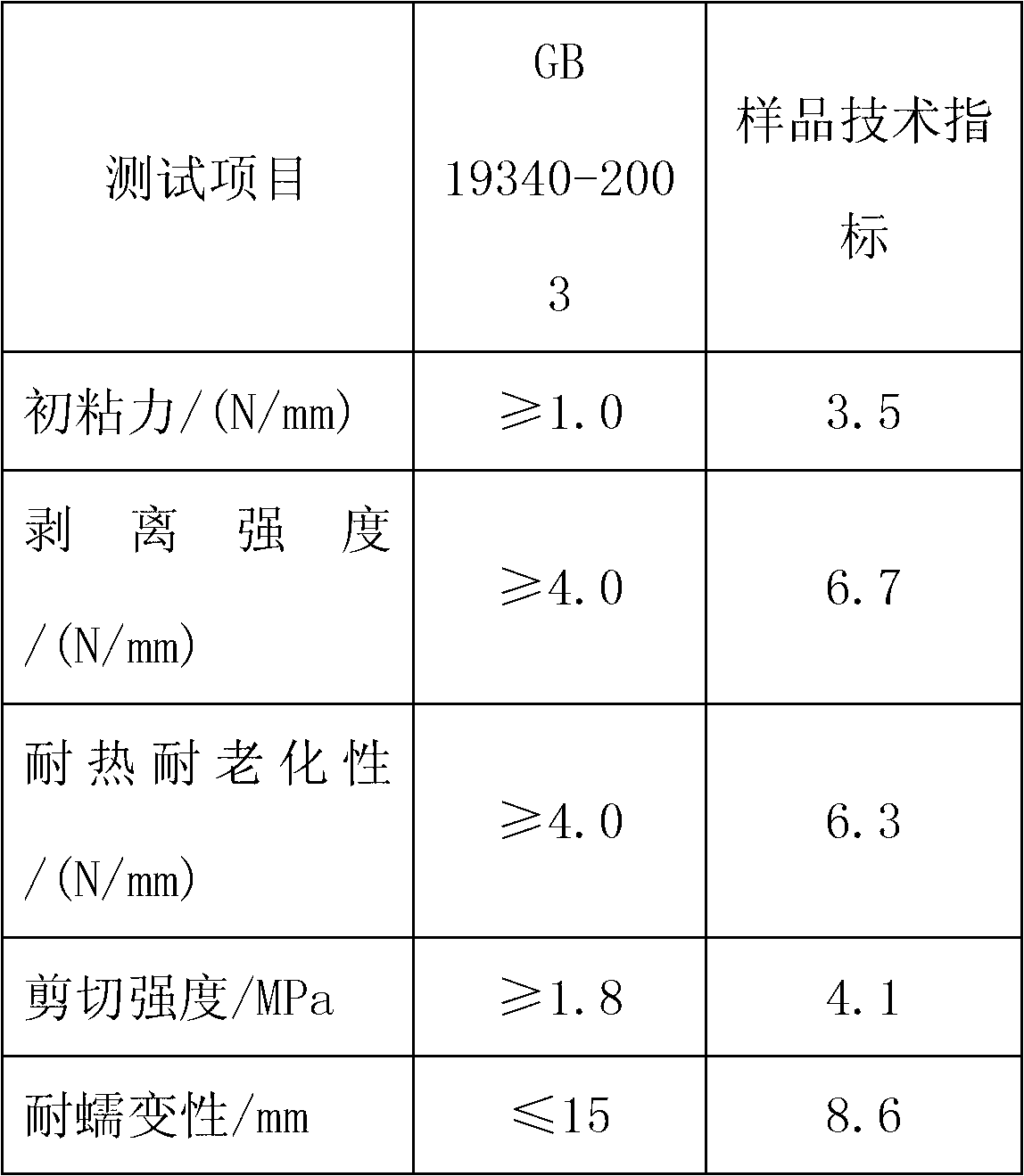

Synthetic leather binding agent and preparation method thereof

ActiveCN105062403AGood light fastnessImprove initial tack performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAlcohol

The invention provides a synthetic leather binding agent and a preparation method thereof. The synthetic leather binding agent is mainly prepared from polyhydric alcohol, diisocyanate, catalysts, epoxy resin and the like. According to the synthetic leather binding agent and the preparation method thereof, chemical modification is conducted on waterborne polyurethane through the epoxy resin, the high degree of branching of the epoxy resin is introduced into a main chain of polyurethane, and the initial adhesion, the peel strength, the drying rate and the water resistance of a dispersion liquid film are improved. The synthetic leather binding agent prepared through the method has good environment protectability. Dispersion liquid has the advantages of being high in initial adhesion, good in peel strength, high in drying rate and excellent in water resistance. Meanwhile, the good levelling property and spreadability are achieved. The using condition of the synthetic leather binding agent is met.

Owner:SHANDONG TIANQING TECH DEV

High-solid-content aqueous adhesive for shoes and preparation method thereof

InactiveCN102827570AHigh solid contentIncrease drying speedMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesAdhesiveSolid content

The invention discloses a high-solid-content aqueous adhesive for shoes and a preparation method thereof. The aqueous adhesive is prepared from an aqueous resin and a deionized water-emulsified polyurethane prepolymer, wherein the polyurethane prepolymer is synthesized from isocyanate, polylol, a hydrophilic chain extender, a crosslinking agent and a neutralizing agent. The preparation method comprises the following steps of: preparing a polyurethane prepolymer through pre-polymerizing and neutralizing processes; and preparing the aqueous adhesive for a high-solid-content shoe by using an aqueous resin in cooperation with deionized water emulsification. The aqueous adhesive for shoes disclosed by the invention has the advantages of high solid content, low cost, excellent performance and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Compositions and Methods to Improve the Setting Properties and Rub Resistance of Printing Inks

ActiveUS20130324653A1Easy to processQuick set upLiquid surface applicatorsInksPolymer sciencePrinting ink

Provided are high viscosity essentially non-aqueous dispersions containing acrylic core / shell polymer particles in a non-aqueous solvent; sheetfed, heatset and coldset lithographic ink compositions containing the dispersions; and methods of printing with ink containing the dispersions to improve the setting and drying properties and rub resistance of sheet fed offset, heatset and coldset lithographic inks. The lithographic inks containing the dispersions set quickly enough to allow processing of printed sheets soon after printing.

Owner:SUN CHEM CORP

Aqueous double-component polyurethane varnish and preparation method of aqueous double-component polyurethane varnish

The invention discloses an aqueous double-component polyurethane varnish and a preparation method of the aqueous double-component polyurethane varnish. The raw material formula of the aqueous double-component polyurethane varnish is composed of a component 1 and a component 2, wherein the component 1 comprises the following components: 55-65% of hydroxy polyurethane dispersion, 15-18% of water, 0.2-0.5% of acetobutyryl cellulose flatting agent, 0.5-0.8% of flowing deformation auxiliary agent, 0.5-0.8% of nano silica particle, 0.1-0.3% of defoamer, 0.3-0.5% of defoaming agent, 0.1-0.3% of thickener, 0.4-0.6% of film-forming auxiliary agent, 0.2-0.5% of aqueous drier and 0.5-1.5% of teflon wax; and the component 2 comprises 15-20% of polyisocyanate and 1-3% of degassing solvent. The aqueousdouble-component polyurethane varnish has the characteristics of fast drying speed and good leveling property, is not easy to generate bubbles, is easy to store, and can endow a varnish film with high hardness and high anti-scratching property.

Owner:HUIZHOU CHANGRUNFA PAINT

Pigment dispersion and recording ink, and ink cartridge, ink jet recording method, and ink jet recording device

InactiveCN101360799AHigh image densityHigh color saturationDuplicating/marking methodsInksWater dispersiblePolymer science

A pigment dispersion is provided that comprises a pigment, a pigment dispersant, a polymer dispersion stabilizer and water, wherein the polymer dispersion stabilizer is an alpha-olefin / maleic anhydride copolymer expressed by the formula (1) below. A recording ink is also provided that comprises the pigment dispersion, a surfactant, a water-dispersible resin, a humectant and water. in the structural formula (1), R represents an alkyl group and n is an integer of 30 to 100.

Owner:RICOH KK

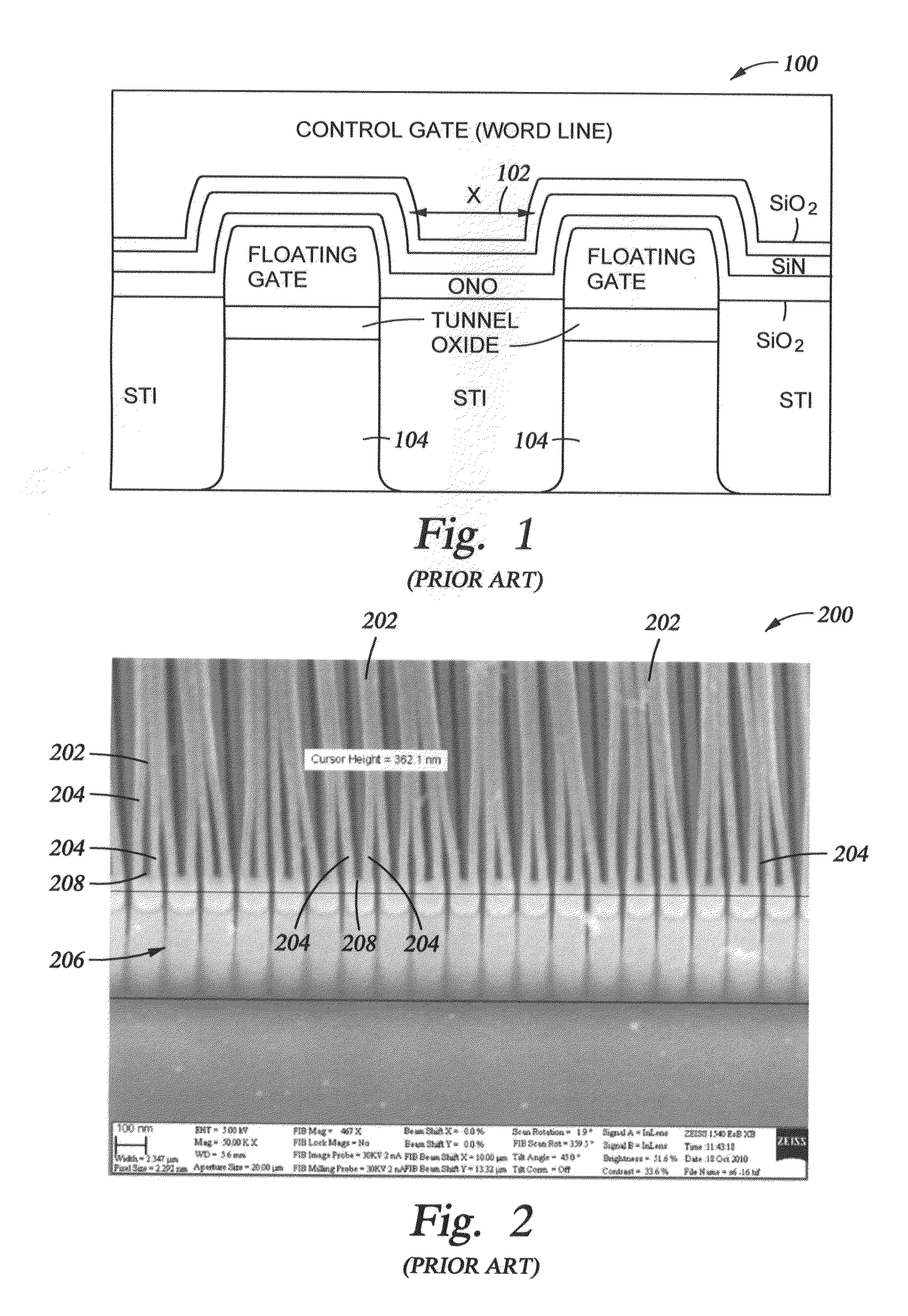

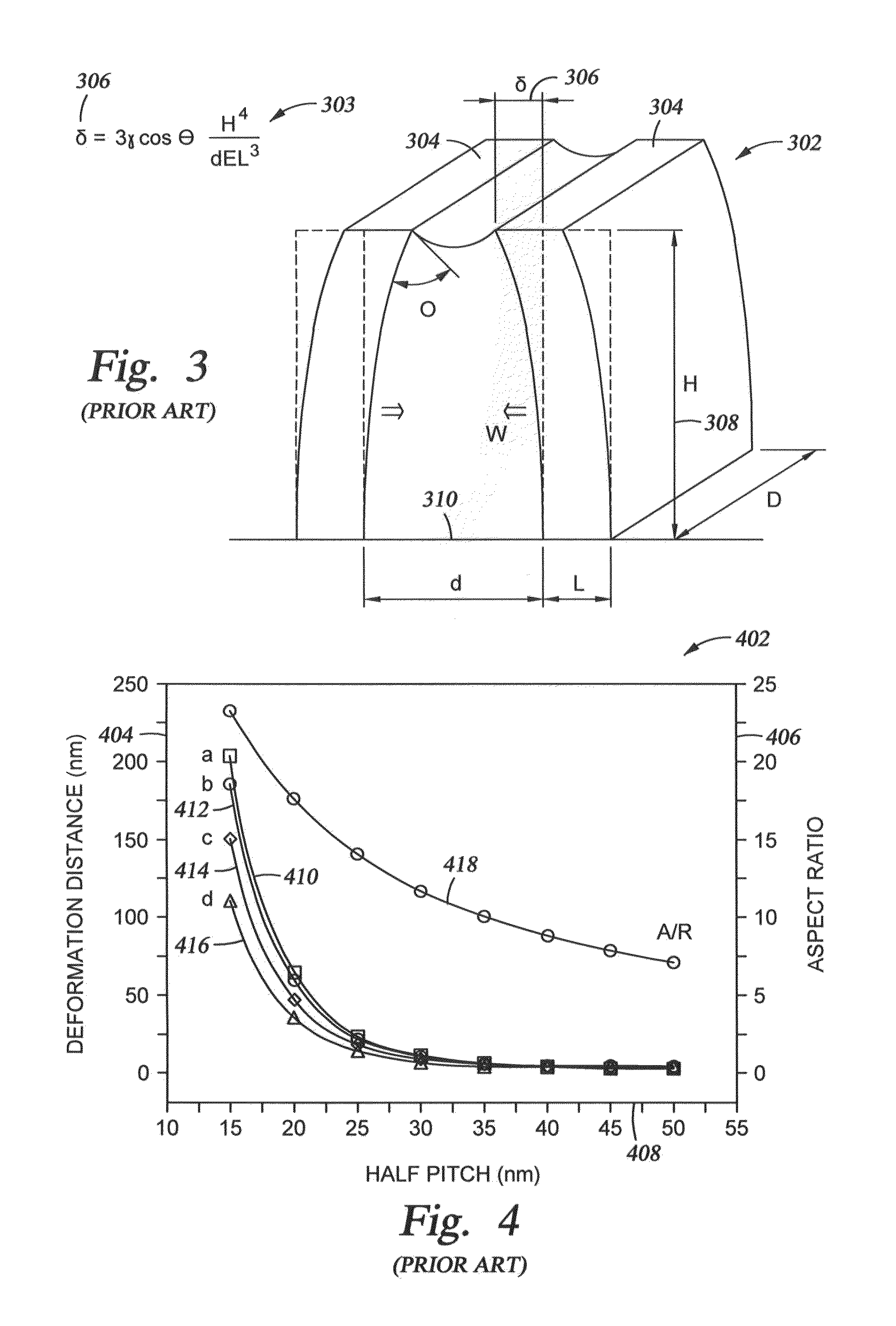

Stiction-free drying of high aspect ratio devices

InactiveUS20130081301A1Shorten the time periodNot to damageDrying solid materials with heatSolid-state devicesAspect ratioSurface tension

A method of removing a water-comprising rinse / cleaning material from the surface of a device which includes high aspect ratio features (an aspect ratio of 5 or greater) where sidewalls of the feature are separated by 50 nm or less without causing stiction between the feature sidewall surfaces. The method relies on the use of a low surface tension drying liquid which also exhibits a high evaporation rate. The method also relies on a technique by which the drying liquid is applied. Increasing the evaporation rate of the drying liquid and application of the drying liquid in the form of a vapor helps to eliminate stiction.

Owner:APPLIED MATERIALS INC

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Anti-yellowing waterborne polyurethane emulsion with high glue film hardness and preparation method of anti-yellowing waterborne polyurethane emulsion

ActiveCN105885666APrevent crystallizationIncrease drying speedPolyurea/polyurethane coatingsEmulsionPolyol

The invention provides an anti-yellowing waterborne polyurethane emulsion with high glue film hardness. The anti-yellowing waterborne polyurethane emulsion is prepared from raw materials in parts by weight as follows: 60 parts of carbon dioxide copolymer polyols, 1-10 parts of a hydrophilic chain extender, 20-60 parts of aliphatic diisocyanate, 0.01-1 part of a catalyst, 0-10 parts of a non-hydrophilic chain extender, 100-300 parts of deionized water, 0.1-5 parts of a chain-extending crosslinking agent and 5-40 parts of a polyacrylate emulsion. The invention further provides a preparation method of the anti-yellowing waterborne polyurethane emulsion with high glue film hardness. The waterborne polyurethane emulsion is prepared from basic raw materials including carbon dioxide copolymer polyols and aliphatic diisocyanate through composite modification under the action of the polyacrylate emulsion and has higher glue film hardness and a higher anti-yellowing property.

Owner:GUANGDONG UNIV OF TECH

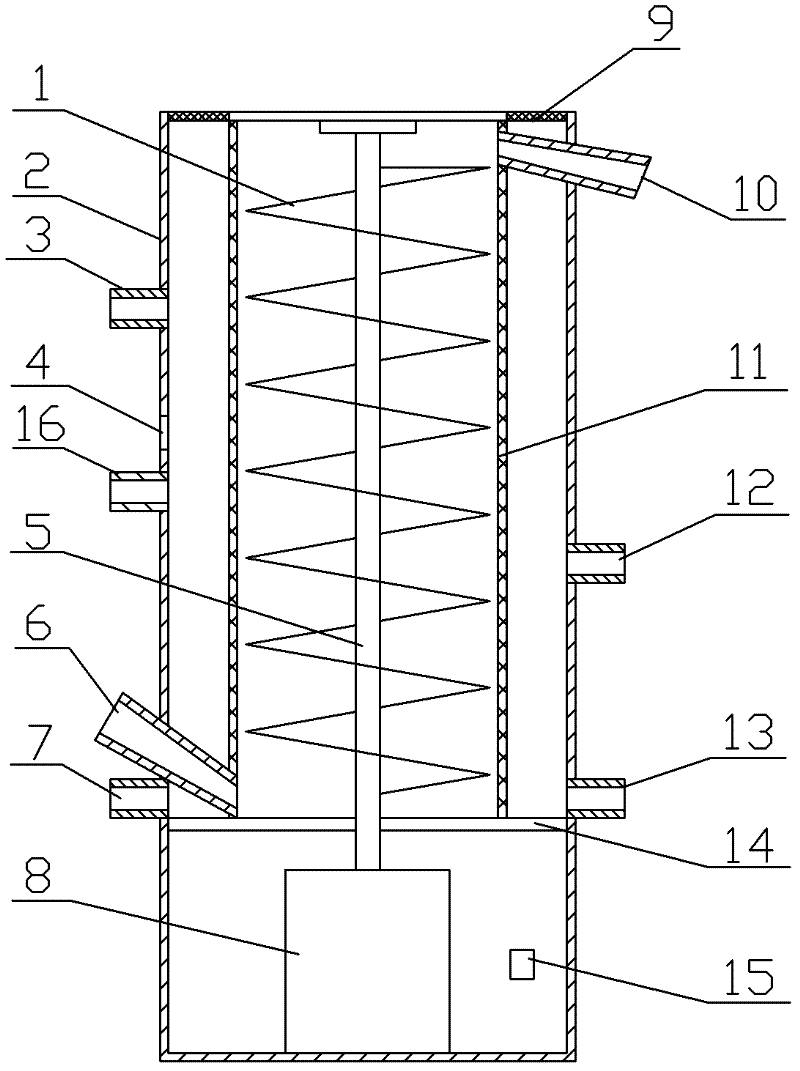

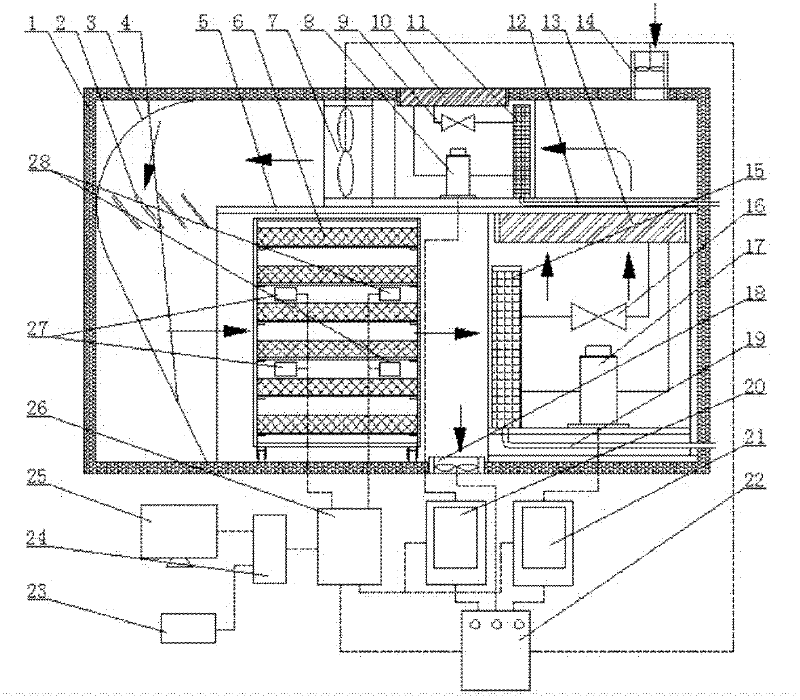

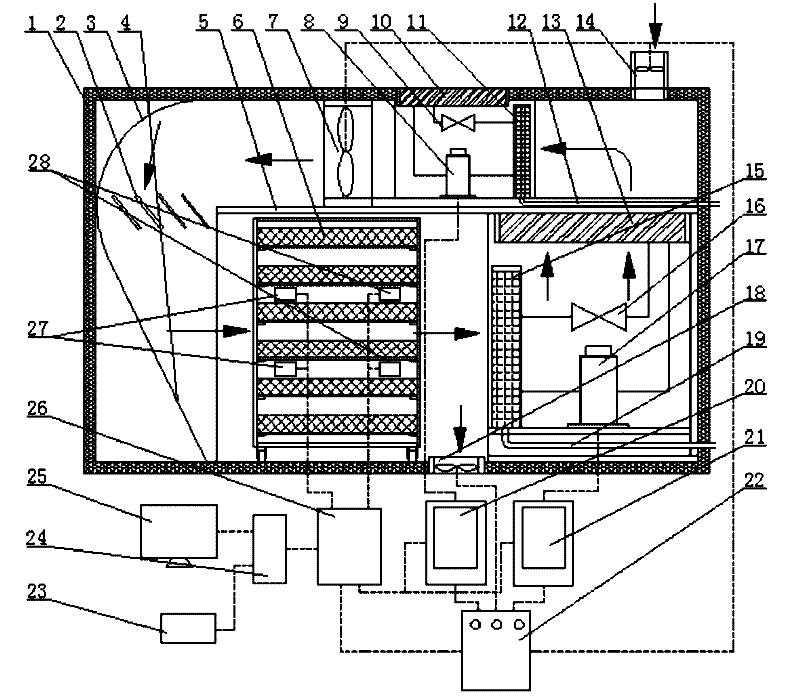

Push type medicinal materials drier

InactiveCN102393131ADry comprehensiveLarge drying capacityDrying solid materials with heatDrying gas arrangementsAgricultural engineeringLower upper

The invention discloses a push type medicinal materials drier which belongs to a drier. The structure comprises a shell, a mesh-typed sleeve, a speed-regulating motor, a spiral boosting piece and a hot wind inlet. Wherein a partition plate is arranged in the shell, the mesh-typed sleeve is arranged on the upper part of the partition plate, the speed-regulating motor is arranged at the lower part of the partition plate, a rotating shaft connected with the speed-regulating motor penetrates through the partition plate and is arranged in the mesh-typed sleeve, the spiral boosting piece is arranged on the rotating shaft, a speed-regulating switch connected with the speed-regulating motor is arranged on the shell, a material feeding opening and a material discharging opening are respectively arranged at the lower part and the upper part of the mesh-typed sleeve, a hot wind inlet and a viewing port are respectively arranged on the shell at the upper part of the partition plate, a primary dehumidification port is arranged on the side wall of the shell, and a moisture removing port is arranged on top of the shell. The push type medicinal materials drier has the characteristics that: weather effect can be avoided when the drier is dried, machining can be carried out at any time, drying quantity is large, whole area of the medicinal materials can be comprehensively contacted by hot wind, medicinal materials heating is comprehensive, drying speed is increased, and the like.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Inkjet composition, ink cartridge comprising the same, and inkjet recording apparatus comprising the same

InactiveUS20070002111A1Good storage stabilityIncrease drying speedMeasurement apparatus componentsDuplicating/marking methodsSolubilityBoiling point

An ink composition including a colorant, a cyclic amide compound, a cyclic dicarbonyl compound, and water, an ink cartridge including the same, and an inkjet recording apparatus including the same. The ink composition maintains high solubility and stability of a colorant, even when used in small amounts, thereby enhancing not only a storage stability but also a fusing property of the ink composition on a print medium, and thus reinfroces a rubbing resistance of the ink composition on the print medium. The ink composition is easily dried on the print medium, and thus bleeding between colors is minimized, thereby improving printed image quality because little or solvent having a high boiling point is used in the ink composition.

Owner:S PRINTING SOLUTION CO LTD

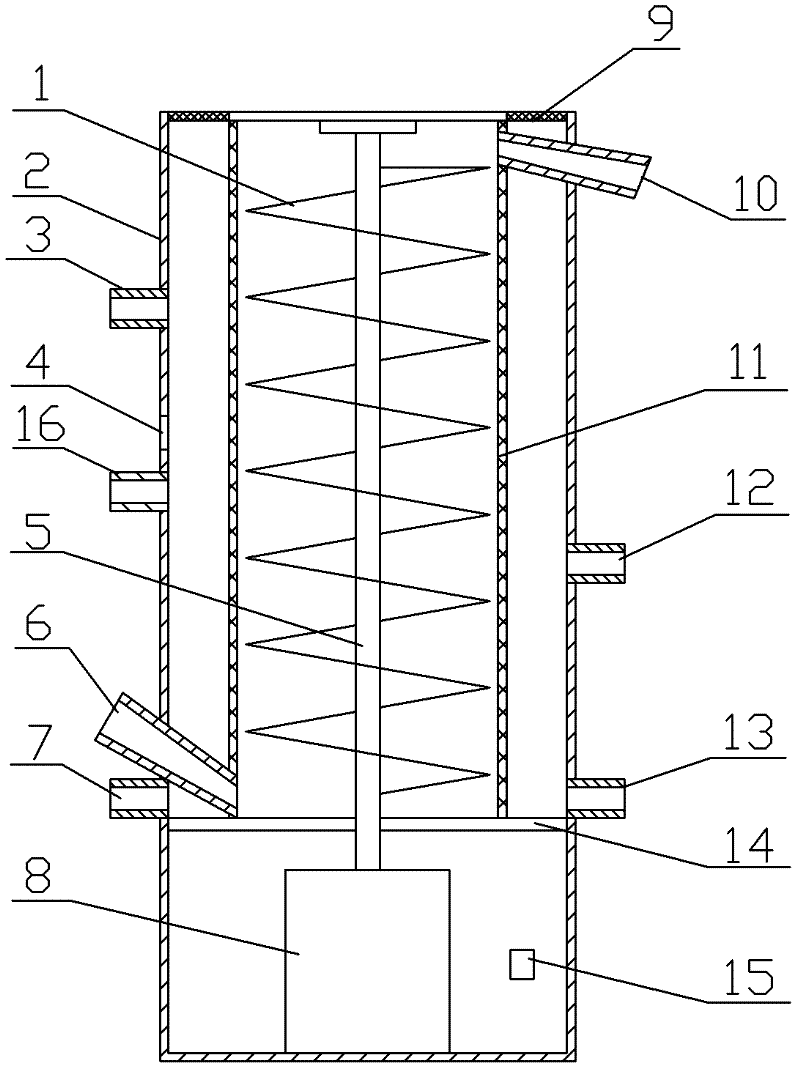

Heat pump drying device

InactiveCN102410709AFast high temperature dryingHigh quality low temperature dryingDrying gas arrangementsDrying solid materialsControl systemProcess engineering

The invention discloses a heat pump drying device, which comprises a drying box and a control system, wherein the drying box comprises a shell and an air inlet fan, a dehumidifying heat pump, a main fan, a material shelf, an air outlet fan and a heating heat pump which are arranged in the shell; when an air inlet and an air outlet are closed, the dehumidifying heat pump, the main fan, the material shelf, the heating heat pump and the dehumidifying pump are communicated in sequence, and a circulating path of a drying medium is formed in the shell; when the air inlet and the air outlet are opened, the air outlet, the dehumidifying heat pump, the main fan, the material shelf and the air outlet are communicated in sequence to form a one-way circulating path of the drying medium; and an air path between the main fan and the material shelf is arc-shaped, and an inclined air deflector is arranged in the air path. The heat pump drying device can not only realize high-temperature drying but also realize low-temperature drying and can meet temperature and humidify requirements of the same product at different drying stages; and the air path for communicating the main fan with the material shelf and the air deflector is improved, therefore airflow vortex is reduced, and drying quality and speed are increased.

Owner:SOUTH CHINA UNIV OF TECH

Water-based metal antirust paint and preparation method thereof

InactiveCN105602382AImprove densification performanceImprove shielding effectAnti-corrosive paintsWater basedEmulsion

The invention discloses water-based metal antirust paint. The water-based metal antirust paint is prepared from, by mass, 35-45 parts of pigment, 8-15 parts of filler, 8-15 parts of corrosion inhibitors, 10-20 parts of deionized water, 15-25 parts of silicone acrylic emulsion, 0.1-0.2 part of a dispersing agent, 0.1-0.2 part of a flatting agent, 2-5 parts of an adhesive force promoting agent, 1-3 parts of film-forming aiding agent, 0.1-0.3 part of surfactant OP-10, 0.1-0.2 part of a defoaming agent and 0.05-0.1 part of bacteriacide. The invention further discloses a preparation method of the water-based metal antirust paint. The water-based metal antirust paint solves the problems that water-based metal antirust paint used in the current market is poor in corrosion resistance and adhesive force, slow in drying, poor in early-stage water resistance and high in cost.

Owner:JINAN GUANGDA CASTING MATERIAL CO LTD

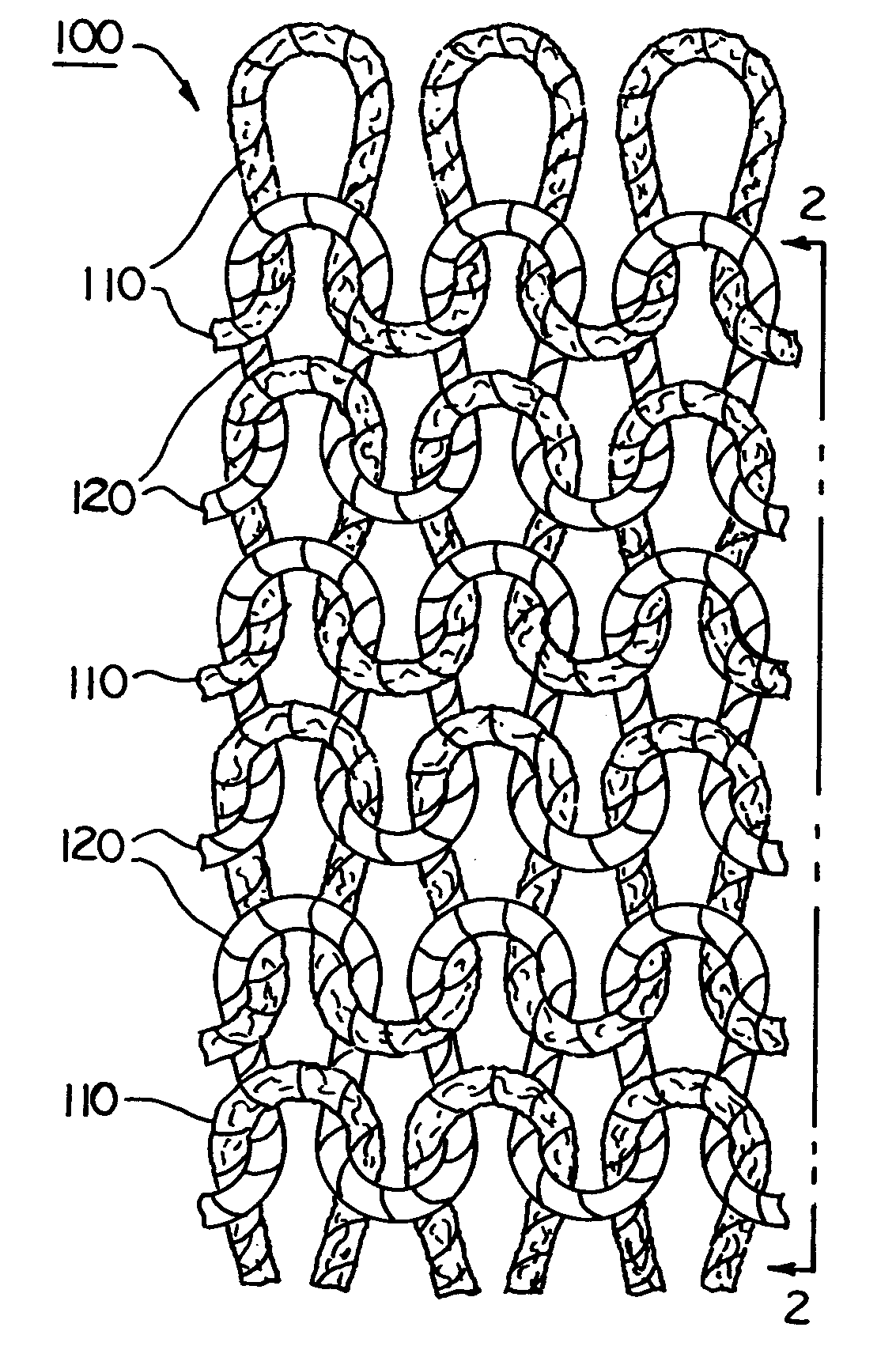

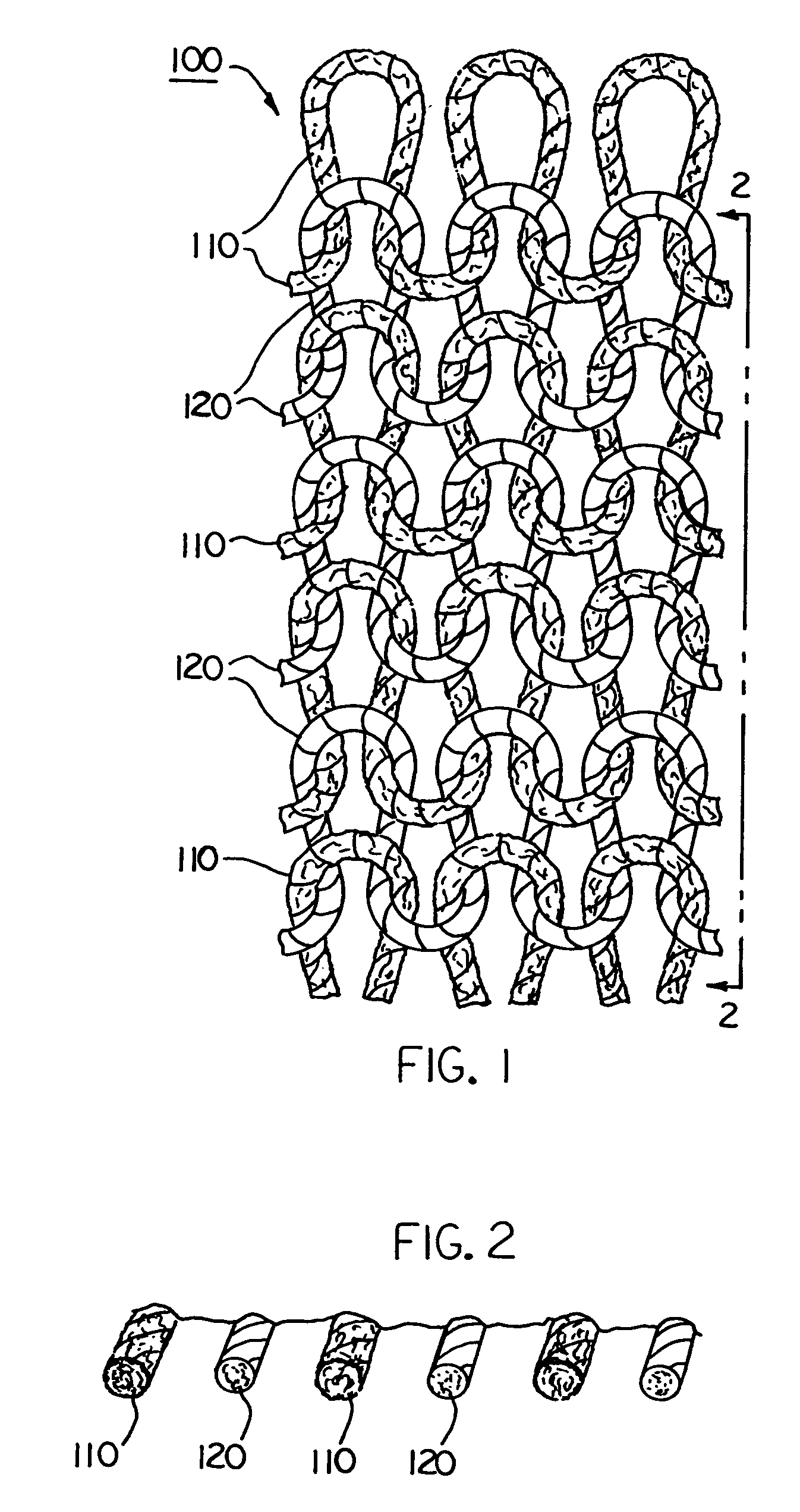

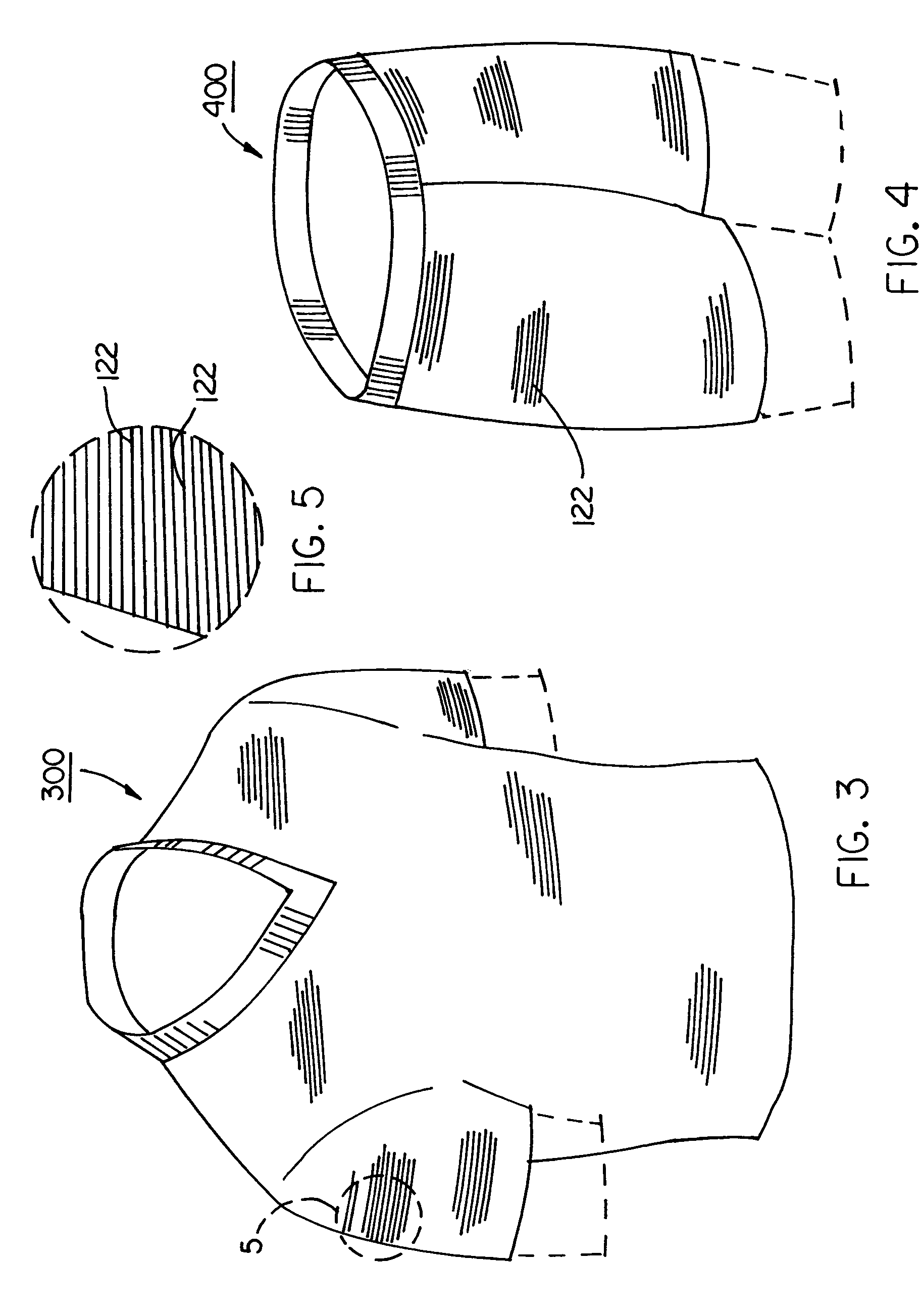

Knitted fabric construction with improved moisture management

ActiveUS6986270B2Good moisture managementTransportation is highLiquid transferring devicesCircular knitting machinesYarnMoisture management

A knitted fabric having moisture management properties. The fabric is formed from filamentary yarns and spun yarns, both the filamentary and spun yarns having substantially the same weight per unit of length. The fabric is knitted with so that the courses alternate between a filamentary yarn and a spun yarn.

Owner:HBI BRANDED APPAREL ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com