Water-based metal antirust paint and preparation method thereof

A kind of metal anti-rust, water-based technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor anti-corrosion performance, poor adhesion, high cost, achieve high adhesion, increase compactness, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of waterborne metal antirust paint, is prepared by following preparation method by following mass parts:

[0025] Mix 35 parts of pigment, 10.4 parts of corrosion inhibitor, 11 parts of filler, and 15 parts of deionized water, add 10 parts of silicone acrylic emulsion to the sand mill, add 0.1 part of dispersant, 0.15 parts of leveling agent, and start the sand mill Machine, grind for 2 hours at a speed of 200-400r / min, then transfer the ground and dispersed mixture to a high-speed mixer, add 0.2 parts of defoamer, 0.1 part of surfactant OP-10, and grind at 300-600r / min After stirring for 1 hour at the speed of rotation, reduce the speed to 200r / min, and add the remaining 10 parts of silicone acrylic emulsion, 3 parts of film-forming aids, 5 parts of adhesion promoter, and 0.05 parts of bactericide to adjust the viscosity to 80 -100KU / Stormer viscosity, stop the machine, filter and discharge the material, and then get the water-based metal antirust paint.

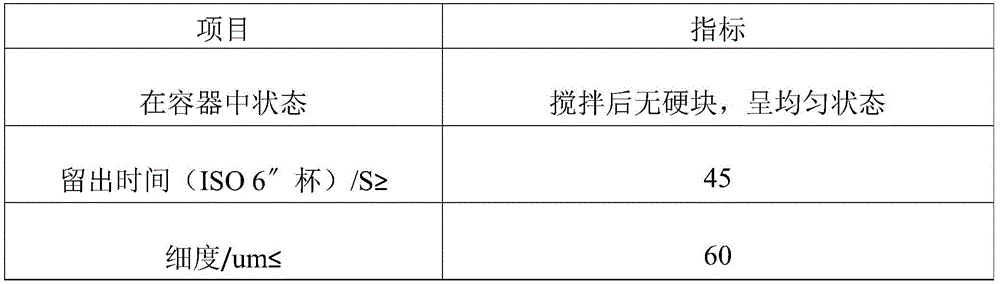

[002...

Embodiment 2

[0028] A kind of waterborne metal antirust paint, is prepared by following preparation method by following mass parts:

[0029] Mix 38.3 parts of pigment, 11.5 parts of corrosion inhibitor, 11.5 parts of filler, and 15.5 parts of deionized water, add 8.65 parts of silicone acrylic emulsion to the sand mill, add 0.1 part of dispersant, 0.15 parts of leveling agent at the same time, start the sand mill Machine, grind for 2 hours at a speed of 200-400r / min, then transfer the ground and dispersed mixture to a high-speed mixer, add 0.1 part of defoamer, 0.2 part of surfactant OP-10, and grind at 300-600r / min After stirring for 1 hour at the speed of rotation, reduce the speed to 200r / min, and add the remaining 8.65 parts of silicon acrylic emulsion, 1.5 parts of film-forming aid, 3.8 parts of adhesion promoter, and 0.05 parts of fungicide to adjust the viscosity to 80 -100KU / Stormer viscosity, stop the machine, filter and discharge the material, and then get the water-based metal a...

Embodiment 3

[0032] A kind of waterborne metal antirust paint, is prepared by following preparation method by following mass parts:

[0033] Mix 45 parts of pigments, 8 parts of corrosion inhibitors, 8 parts of fillers, and 10 parts of deionized water, add 12.5 parts of silicone acrylic emulsion to the sand mill, add 0.2 parts of dispersant, 0.15 parts of leveling agent, and start the sand mill Machine, grind for 2 hours at a speed of 200-400r / min, then transfer the ground and dispersed mixture to a high-speed mixer, add 0.2 parts of defoamer, 0.1 part of surfactant OP-10, and grind at 300-600r / min After stirring for 1 hour at the speed of rotation, reduce the speed to 200r / min, and add the remaining 12.5 parts of silicone acrylic emulsion, 1 part of film-forming aid, 2.3 parts of adhesion promoter, and 0.05 part of fungicide to adjust the viscosity to 80 -100KU / Stormer viscosity, stop the machine, filter and discharge the material, and then get the water-based metal antirust paint.

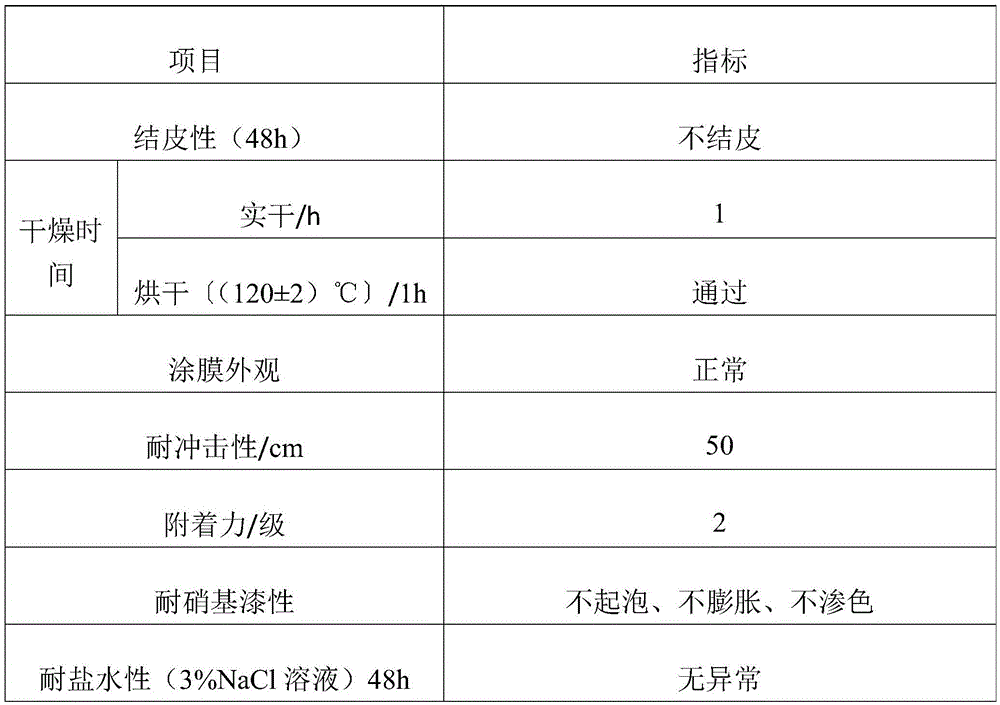

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com