Silicon carbide reinforced aluminum-based composite material and preparation method thereof

A composite material and reinforced aluminum-based technology, which is applied in the field of inorganic composite materials, can solve the problems of reducing the service life of the mold, growing silicon particles, and long heat preservation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

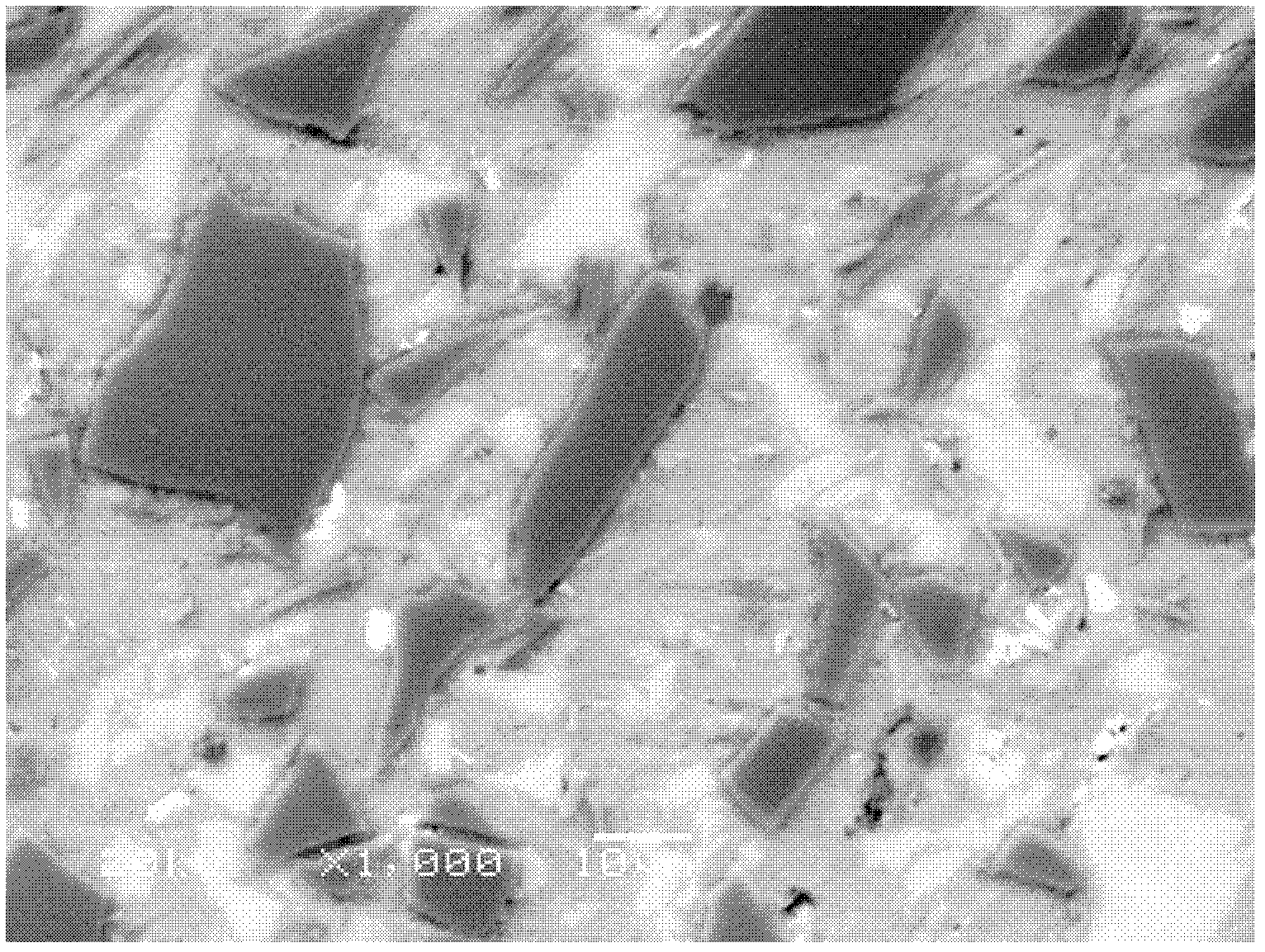

Image

Examples

Embodiment 1

[0027] The silicon carbide reinforced aluminum matrix composite material (SiCp / Al-30Si composite material) of this embodiment is compounded by SiC powder with a particle size of 325 mesh and Al-30Si alloy powder with a particle size of 500 mesh, and the volume fraction of silicon carbide powder is 20%. The amount is Al-30Si alloy powder.

[0028] The composite material of this embodiment is prepared in a vacuum brazing machine, and the steps are as follows:

[0029] 1) Mixing is performed on a planetary ball mill to obtain a mixed powder, wherein the ball-to-material ratio is 1:1, and the mixing time is 2 hours;

[0030] 2. Coat the inner surface of the mold cavity of the heat-resistant mold steel sintering mold with a release agent (75wt% graphite + 25wt% machine oil), put the mixed powder into the mold, put the mold into the vacuum brazing machine, and turn on the equipment. Vacuumize to 0.02Pa, and pre-press the mixed powder in the mold with a pressure of 40MPa;

[0031] ...

Embodiment 2

[0036] The silicon carbide reinforced aluminum matrix composite material (SiCp / Al-30Si composite material) of this embodiment is made of SiC powder with a particle size of 325 mesh and Al-30Si alloy powder with a particle size of 500 mesh. The volume fraction of silicon carbide powder is 23%. The amount is Al-30Si alloy powder.

[0037] The composite material of this embodiment is prepared in a vacuum brazing machine, and the steps are as follows:

[0038] 1. Perform mixing on a planetary ball mill to obtain mixed powder, wherein the ball-to-material ratio is 1:1, and the mixing time is 2.5 hours;

[0039] 2. Coat the inner surface of the mold cavity of the heat-resistant mold steel sintering mold with a release agent (75wt% graphite+25wt% machine oil), put the mixed powder into the mold, and put the mold into a vacuum brazing machine. Turn on the equipment, evacuate to 0.02Pa, and pre-press the mixed powder in the mold with a pressure of 40MPa;

[0040]3. Heat the mold in t...

Embodiment 3

[0045] The silicon carbide reinforced aluminum matrix composite material (SiCp / Al-30Si composite material) of this embodiment is made of SiC powder with a particle size of 325 mesh and Al-30Si alloy powder with a particle size of 500 mesh. The volume fraction of silicon carbide powder is 25%. The amount is Al-30Si alloy powder.

[0046] The composite material of this embodiment is prepared in a vacuum brazing machine, and the steps are as follows:

[0047] 1. Perform mixing on a planetary ball mill to obtain mixed powder, wherein the ball-to-material ratio is 1:1, and the mixing time is 3 hours;

[0048] 2. Coat the inner surface of the mold cavity of the heat-resistant mold steel sintering mold with a release agent (75wt% graphite+25wt% machine oil), put the mixed powder into the mold, and put the mold into a vacuum brazing machine. Turn on the equipment, evacuate to 0.01Pa, and pre-press the mixed powder in the mold with a pressure of 40MPa.

[0049] 3. Heat the mold in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com