Fluidized bed process and device for preparing methane by synthetic gas

A fluidized bed and synthesis gas technology, applied in chemical instruments and methods, organic chemistry, hydrocarbon production from carbon oxides, etc., can solve the problem that it is difficult to remove the heat of reaction and control the bed temperature in a fixed bed, and cannot produce high-quality Problems such as excessive steam and inability to scale up the reactor industrially, etc., to achieve long continuous operation time, remarkable heat removal ability, and good heat removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

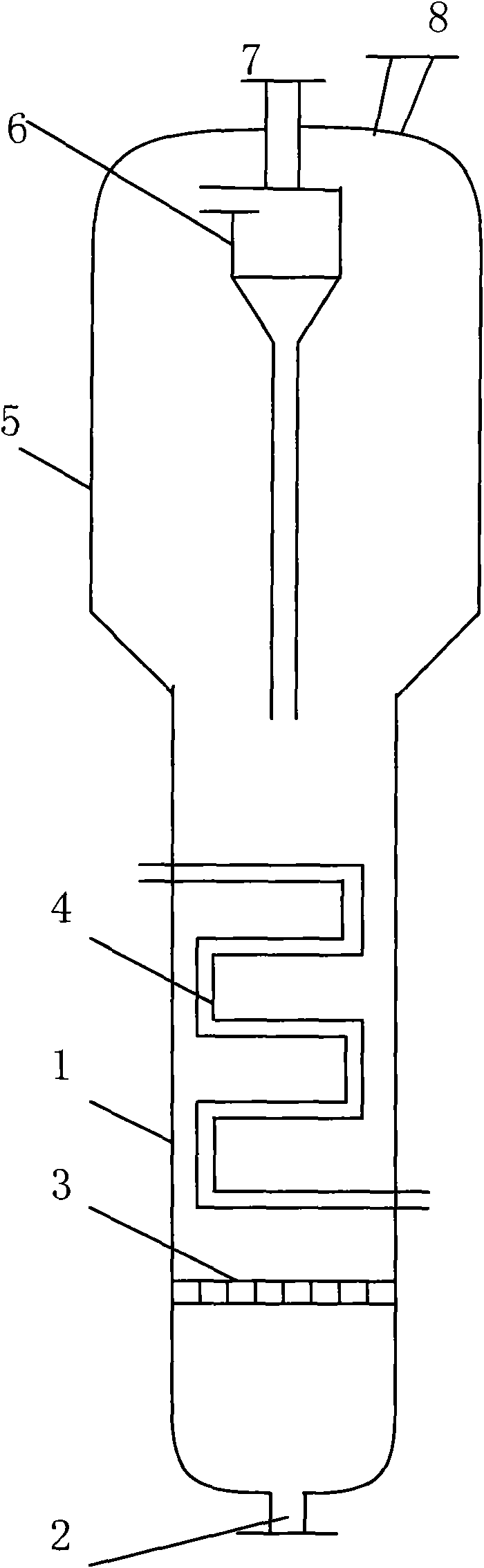

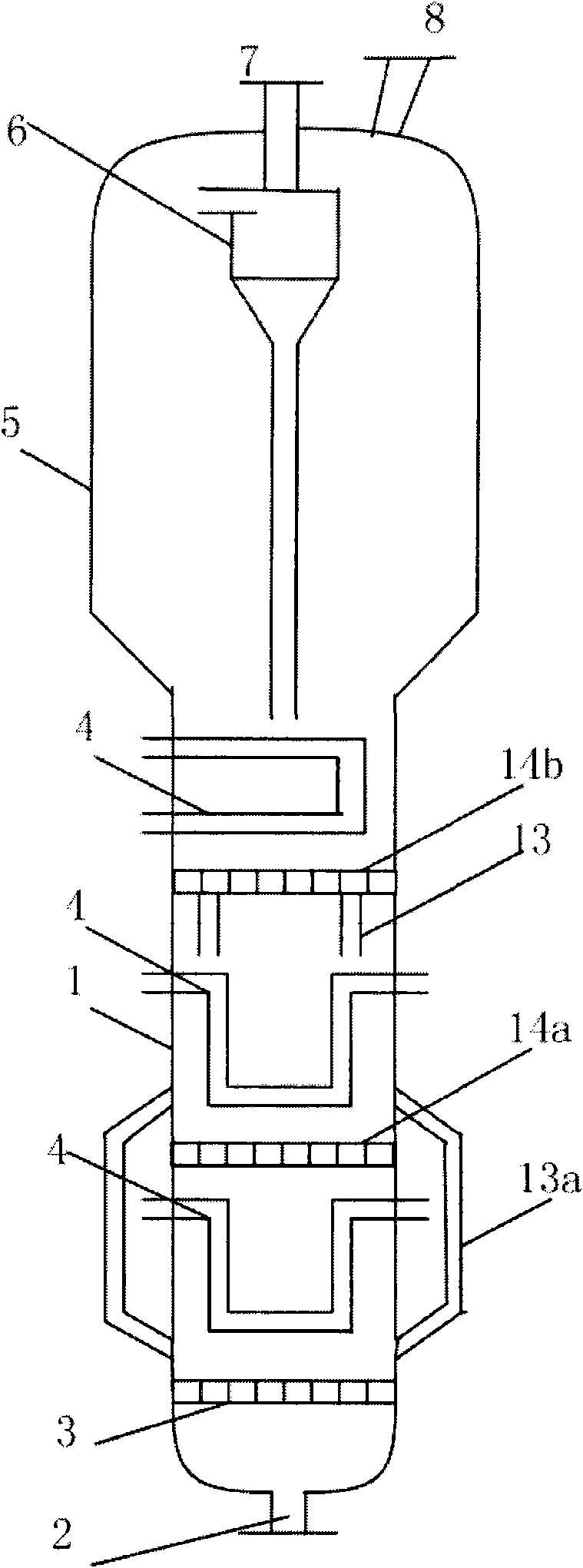

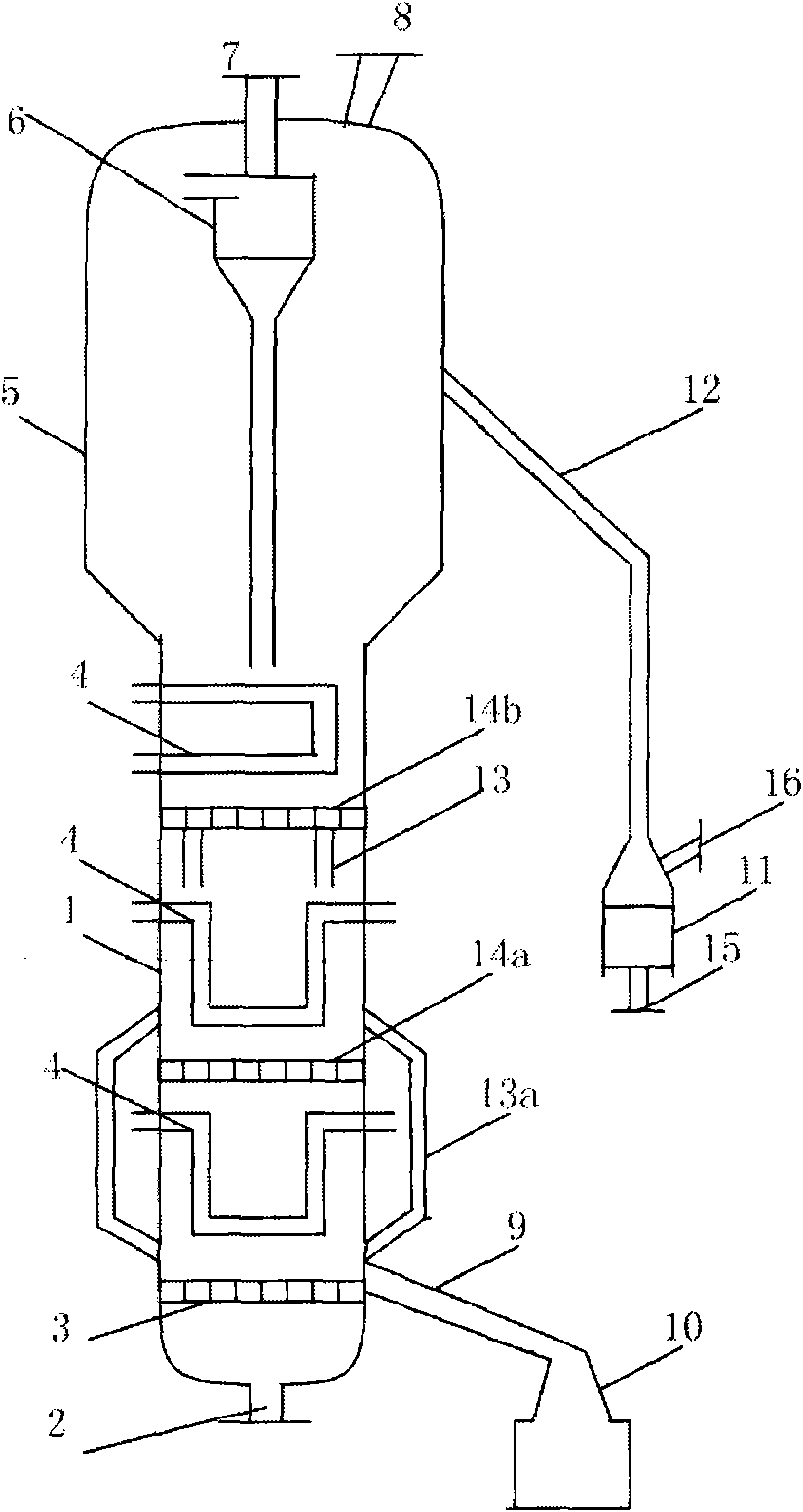

[0036] The fluidized bed process and device for producing methane from synthesis gas according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0037] In the first embodiment, in order to realize the fluidized bed process of syngas to methane of the present invention, the present invention provides a fluidized bed device for syngas to methane, such as figure 1 shown. The fluidized bed device includes a fluidized bed reactor cylinder 1, a feed gas inlet 2 and a gas distributor 3 located at the bottom of the fluidized bed reactor cylinder, an expansion section 5 located at the upper part of the fluidized bed reactor, and an expansion section located at the expansion section The cyclone separator 6 inside, the gas outlet 7 and the catalyst feeding port 8 at the top of the enlarged section, and the heat exchange member 4 arranged inside or outside the fluidized bed reactor cylinder. The gas distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com